Patents

Literature

78 results about "Globular shaped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-assembled photonic crystals and methods for manufacturing same

InactiveUS6858079B2Well formedImprove assembly strengthFrom gel stateMaterial nanotechnologyPhotonic crystalGlobular shaped

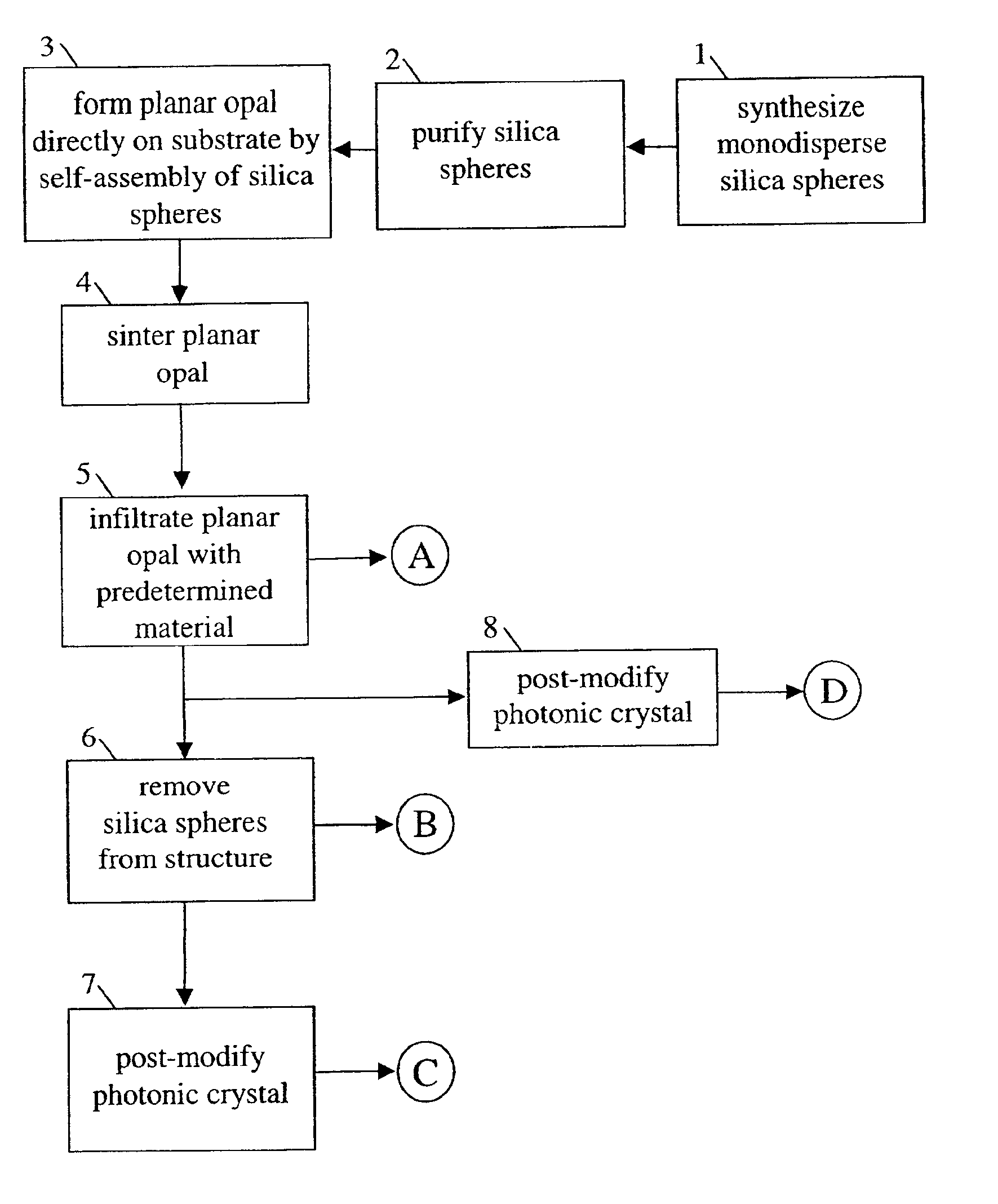

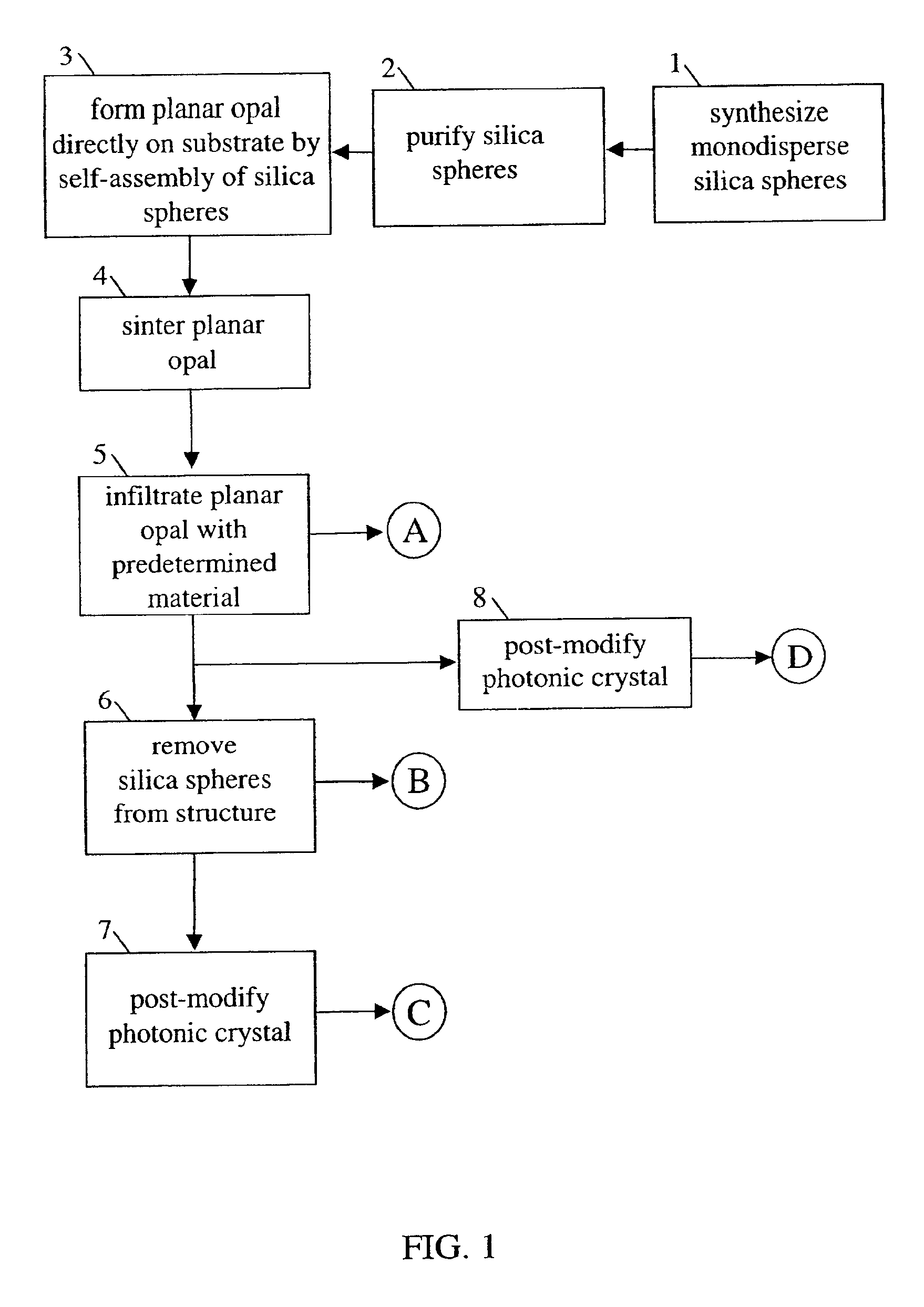

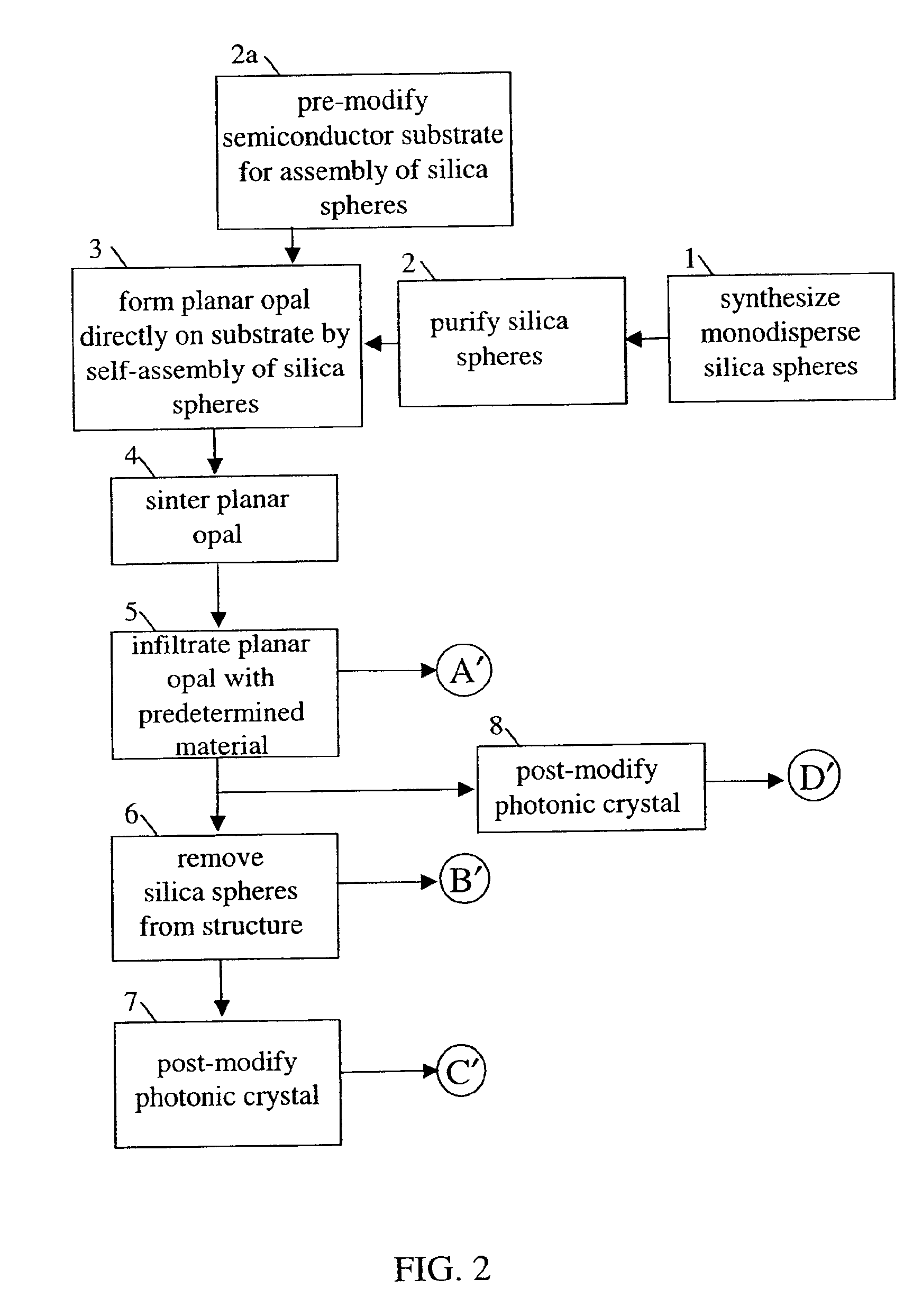

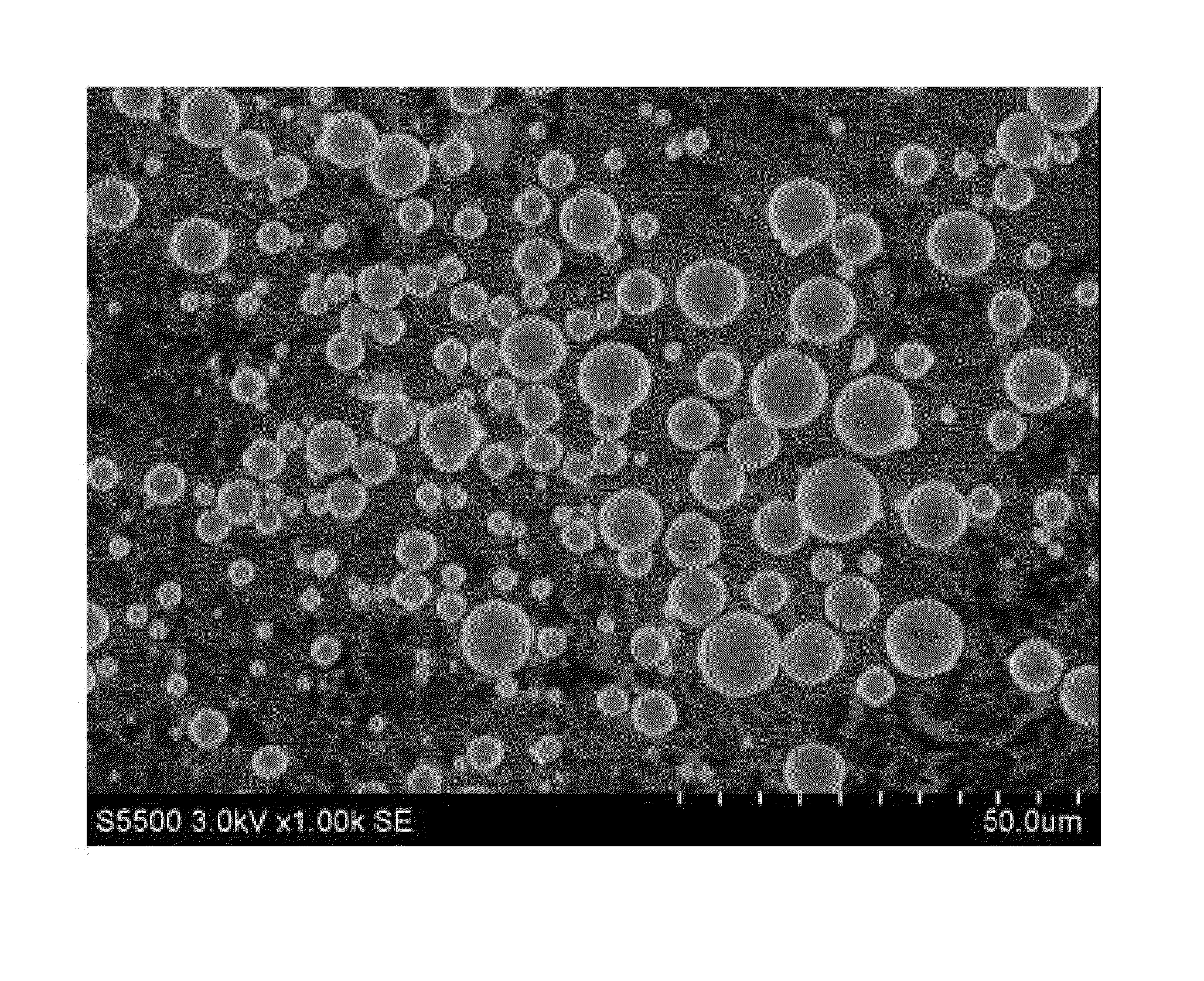

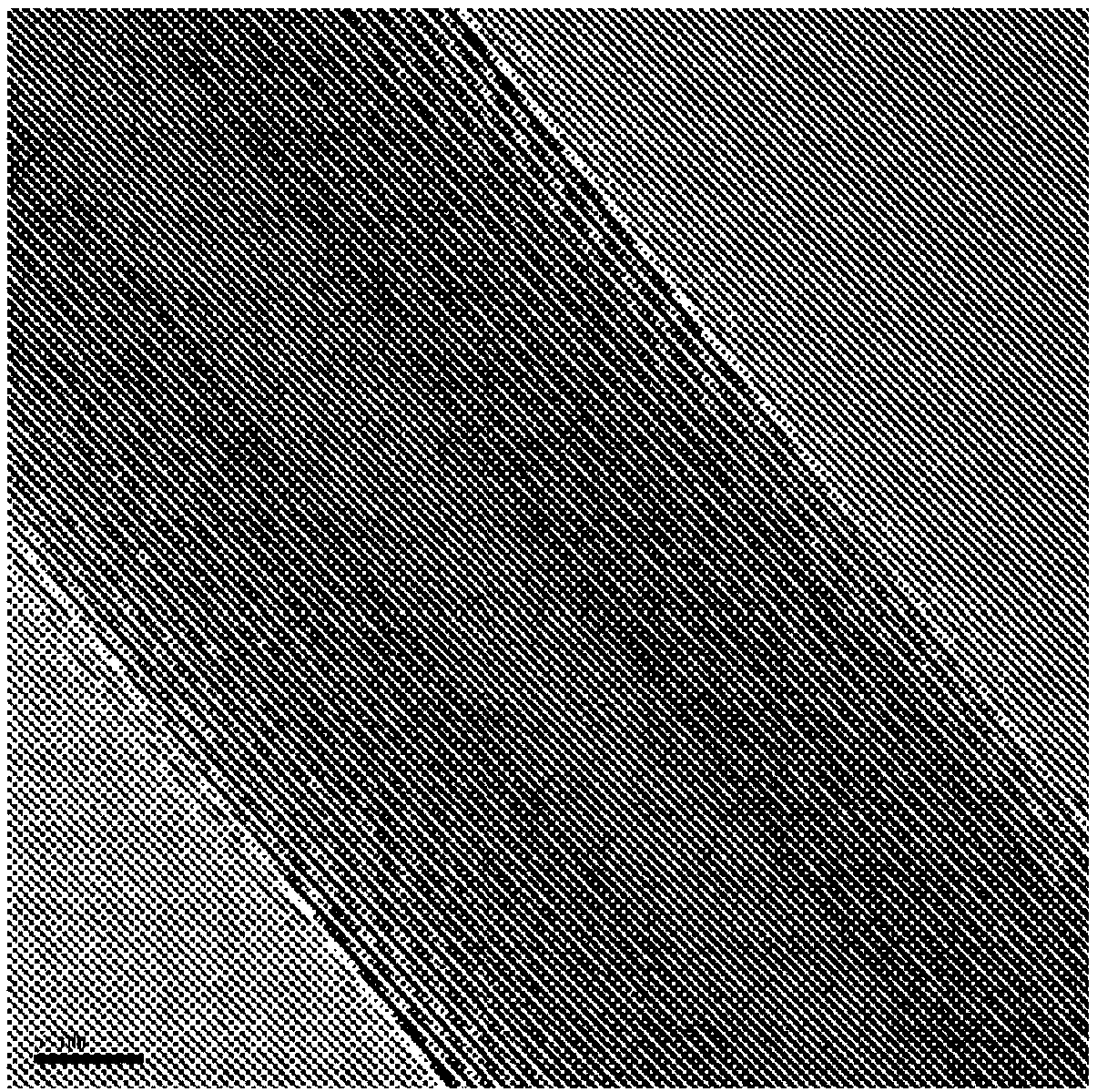

Self-assembled photonic crystals, including large sphere planar opals, infiltrated planar opals and inverted planar opals, as well as methods for manufacturing same are provided. Large sphere planar opals are manufactured according to a method comprising the steps of: synthesizing monodisperse silica spheres, wherein each of the silica spheres has a diameter greater than or equal to about 400 nanometers; purifying the silica spheres; and self-assembling the silica spheres into a plurality of ordered, planar layers on a substrate. Infiltrated planar opals may also be manufactured by further processing the large sphere planar opal by sintering the planar opal and infiltrating the planar opal with a predetermined material. Inverted planar opals may further be manufactured by removing the silica spheres from the infiltrated planar opal. Various modifications to the substrate and planar opal are also provided to enhance the properties of these photonic crystals.

Owner:NEC CORP

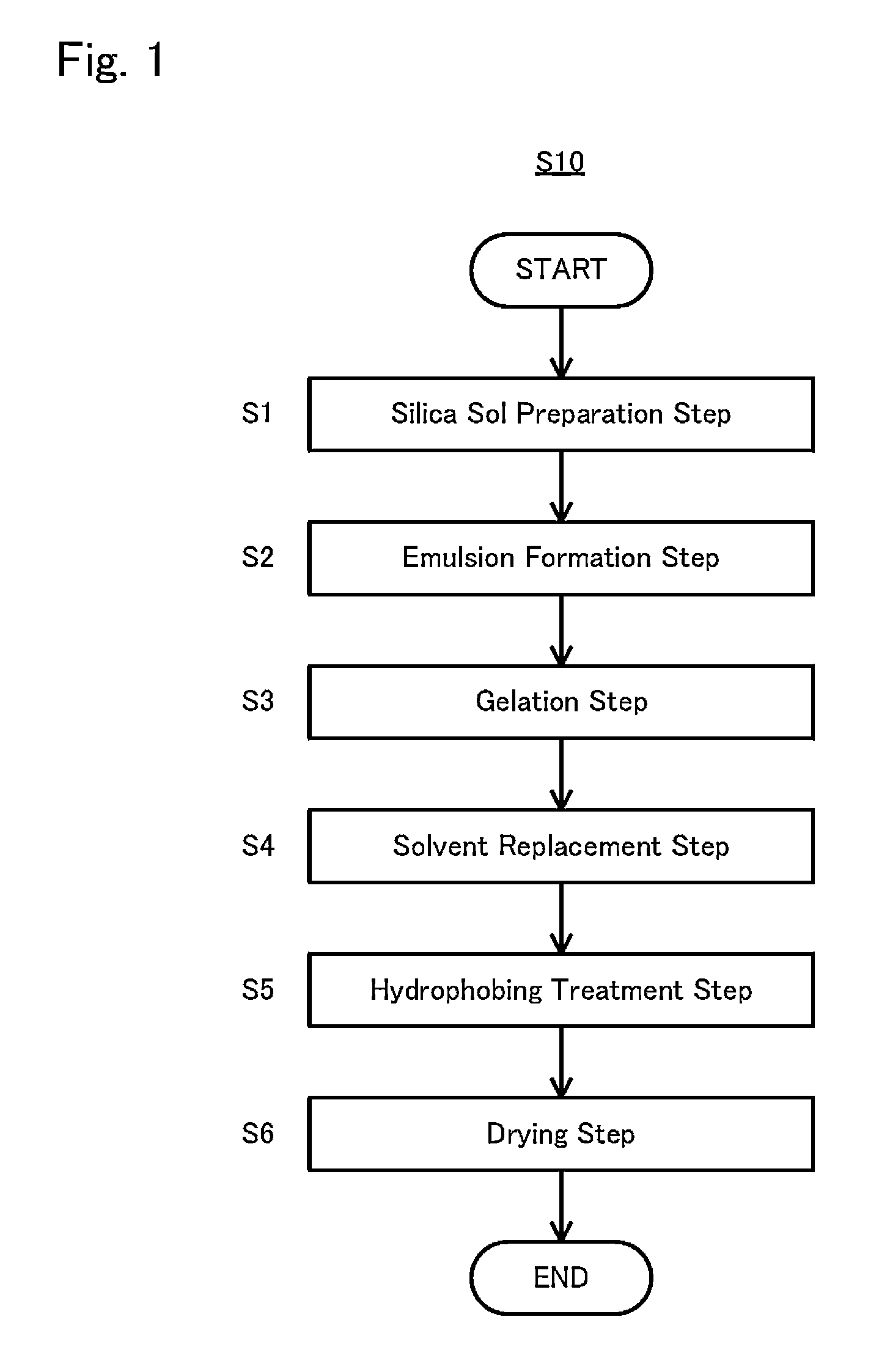

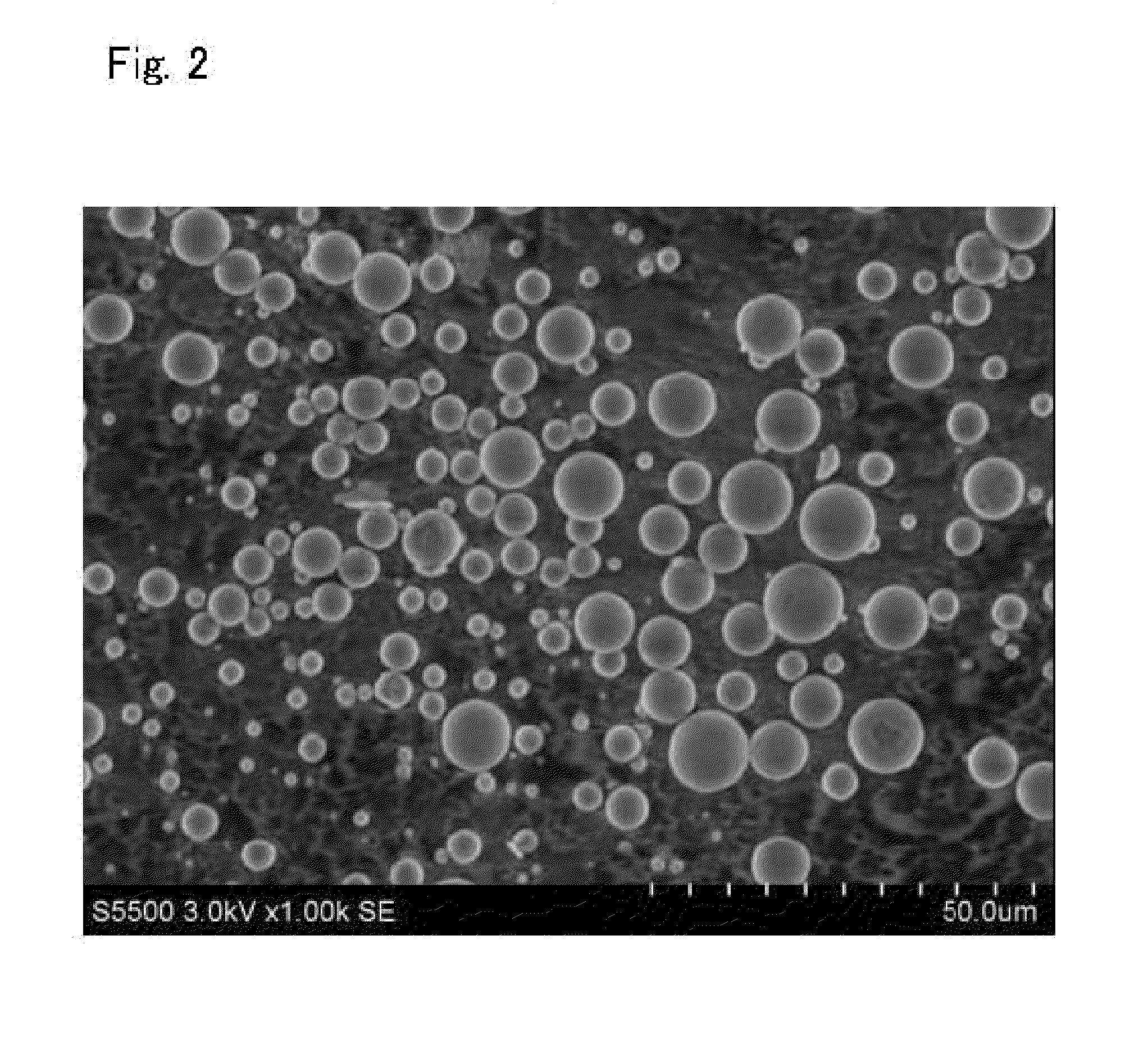

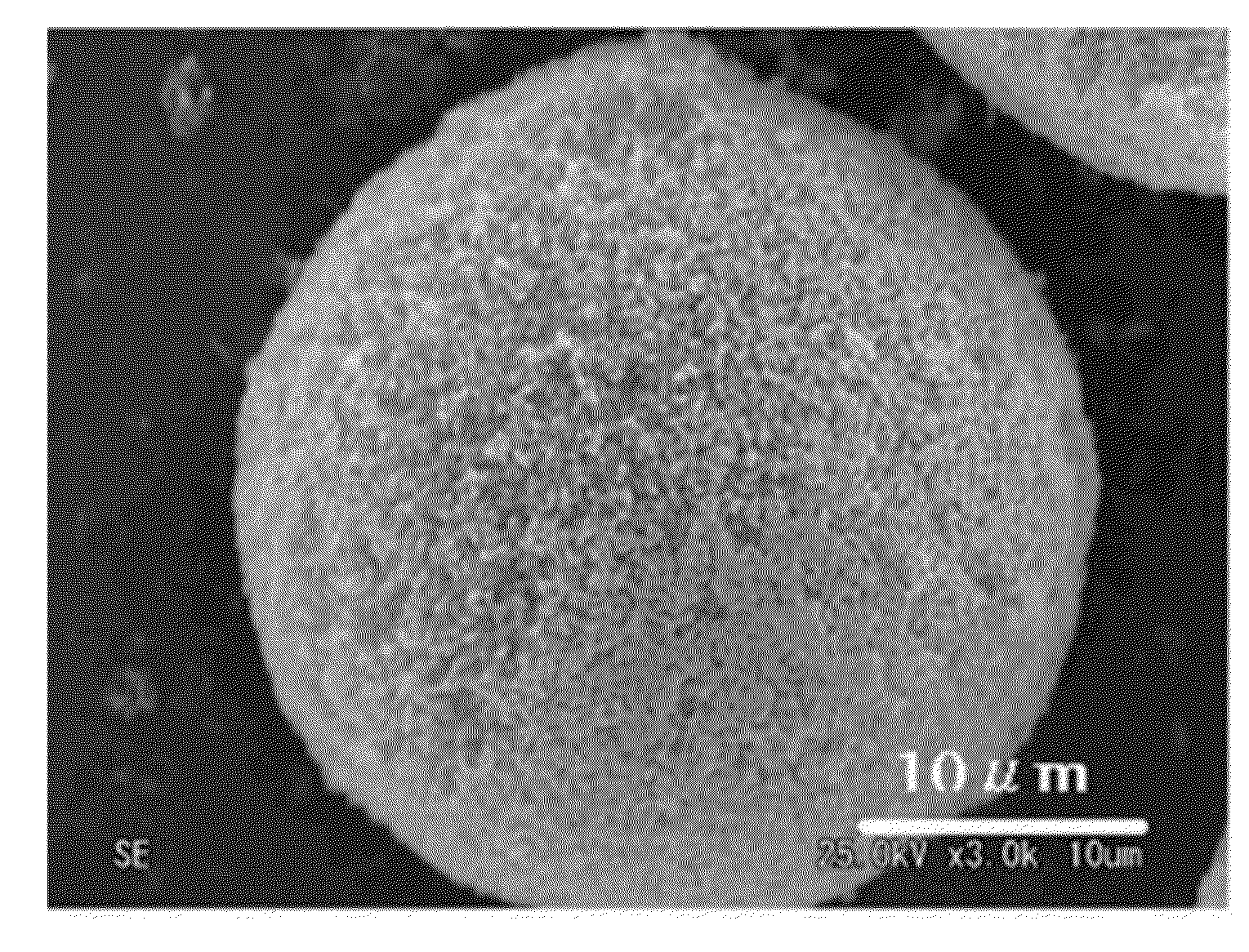

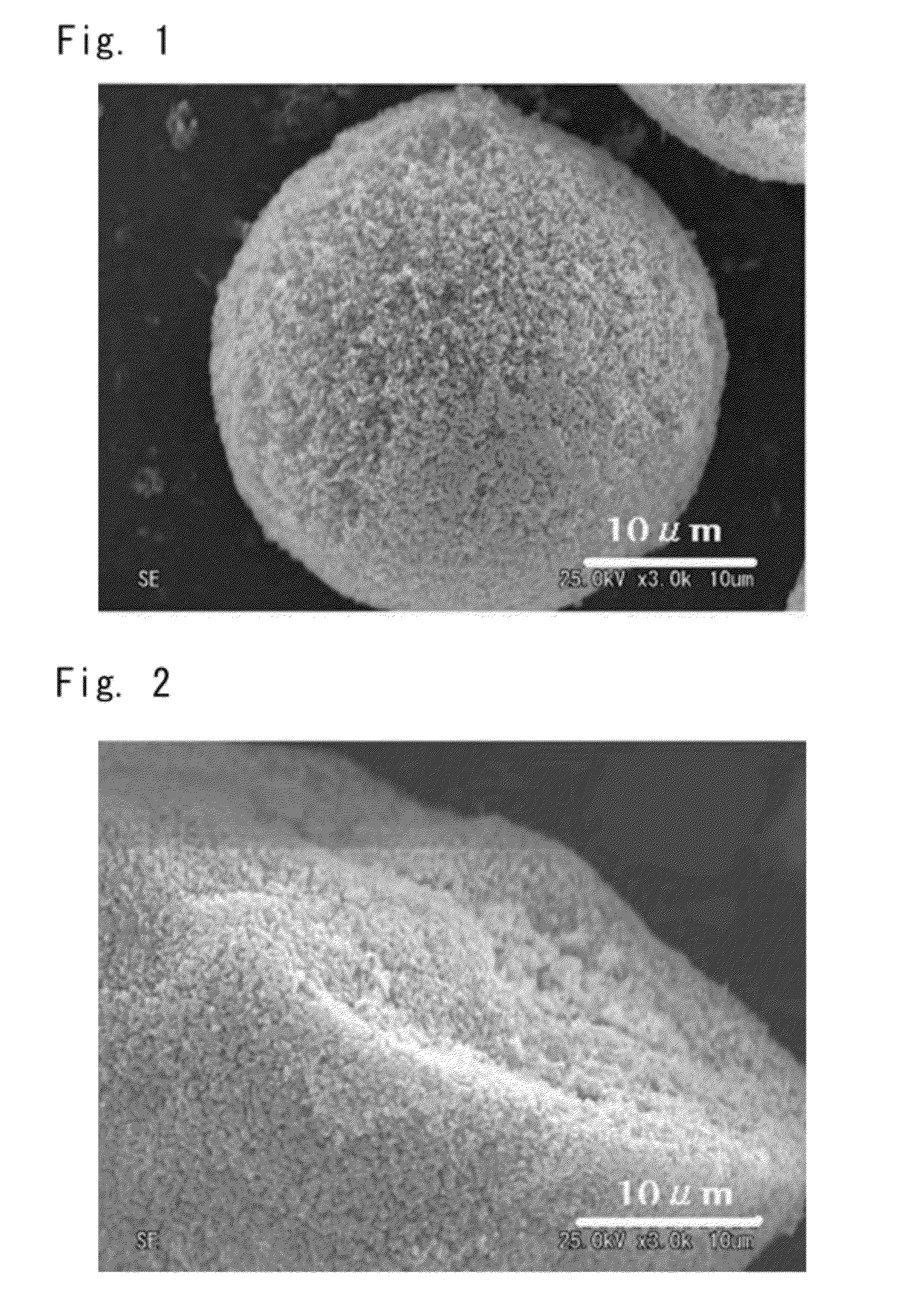

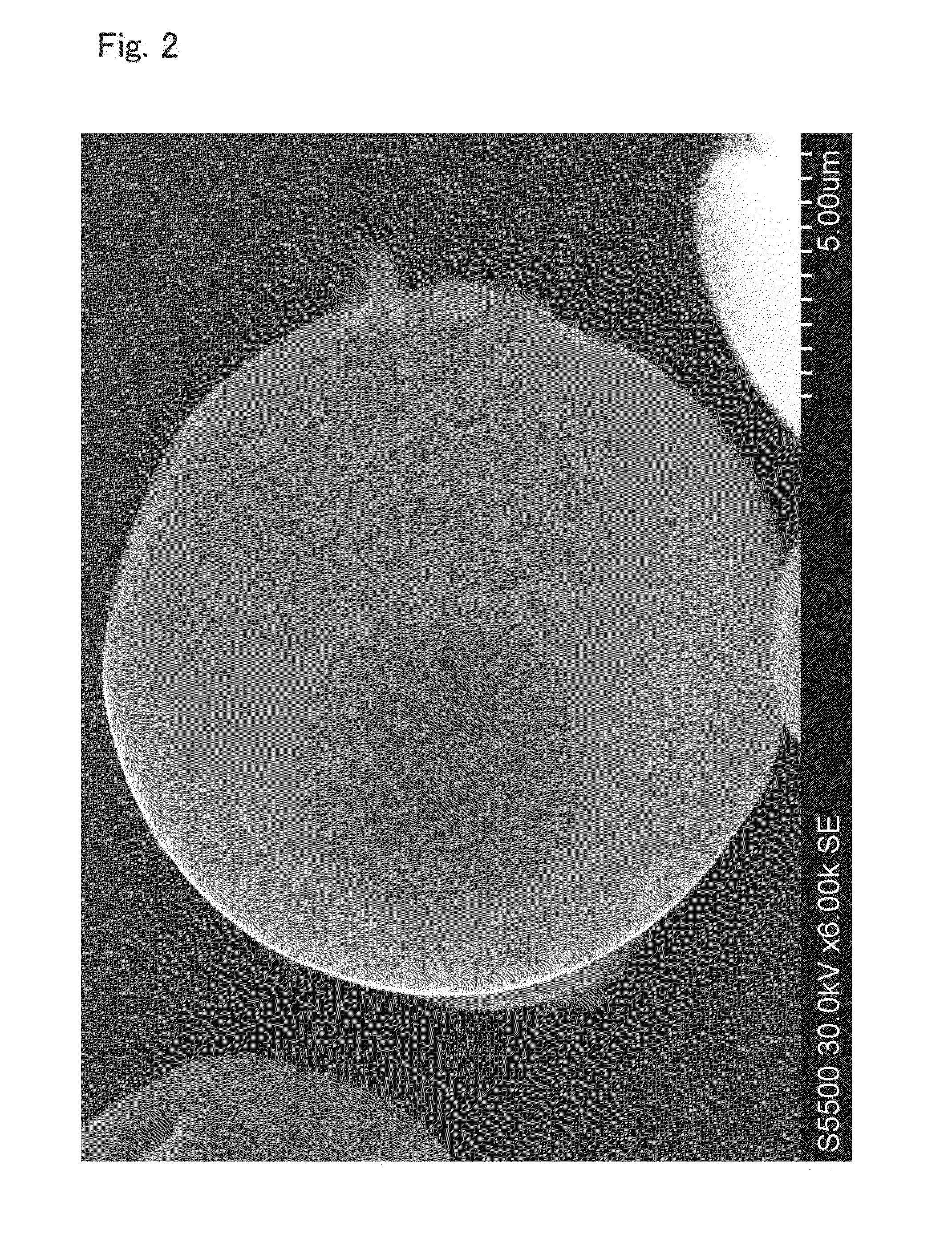

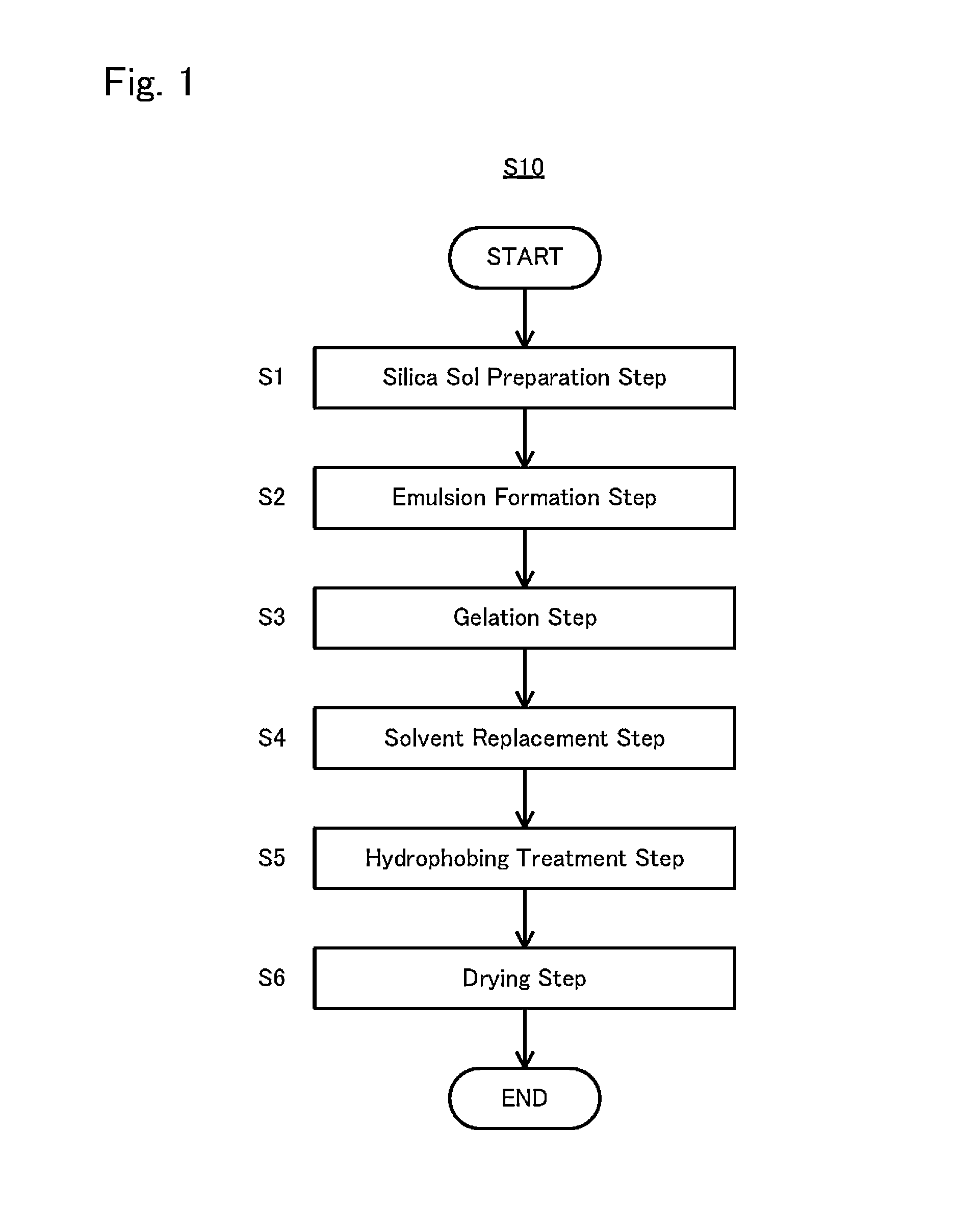

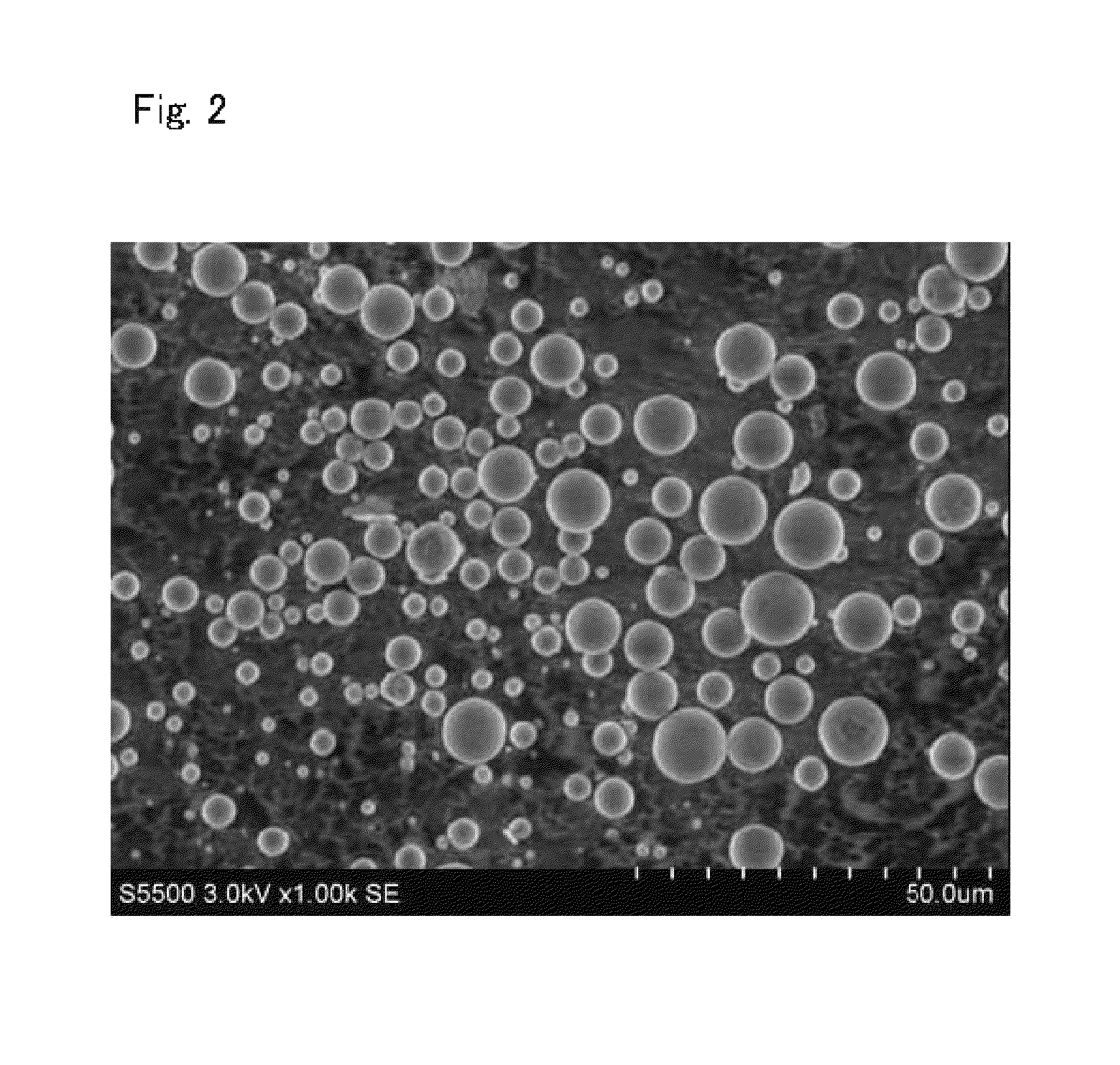

Aeogel and method for manufacture thereof

ActiveUS20130189521A1Efficient productionGood heat insulationSilicaSynthetic resin layered productsEmulsionThermal insulation

An aerogel with excellent thermal insulation performance, average particle size of 1 to 20 μm and globular shape; and a method of manufacturing it efficiently, is provided. The aerogel has specific surface area by BET method of 400 to 1000 m2 / g; pore volume and peak pore radius by BJH method of 3 to 8 mL / g and 10 to 30 nm, respectively; average particle size and average circularity by image analysis method of 1 to 20 μm and no less than 0.8, respectively. The method includes the steps of: preparing an aqueous silica sol; dispersing the sol into a hydrophobic solvent, thereby forming a W / O emulsion; causing gelation of the sol, thereby converting the emulsion into a dispersion of a gel; replacing water in the gel with a solvent having a small surface tension; treating the gel with a hydrophobing agent; and removing the solvent used in the solvent replacement.

Owner:TOKUYAMA CORP

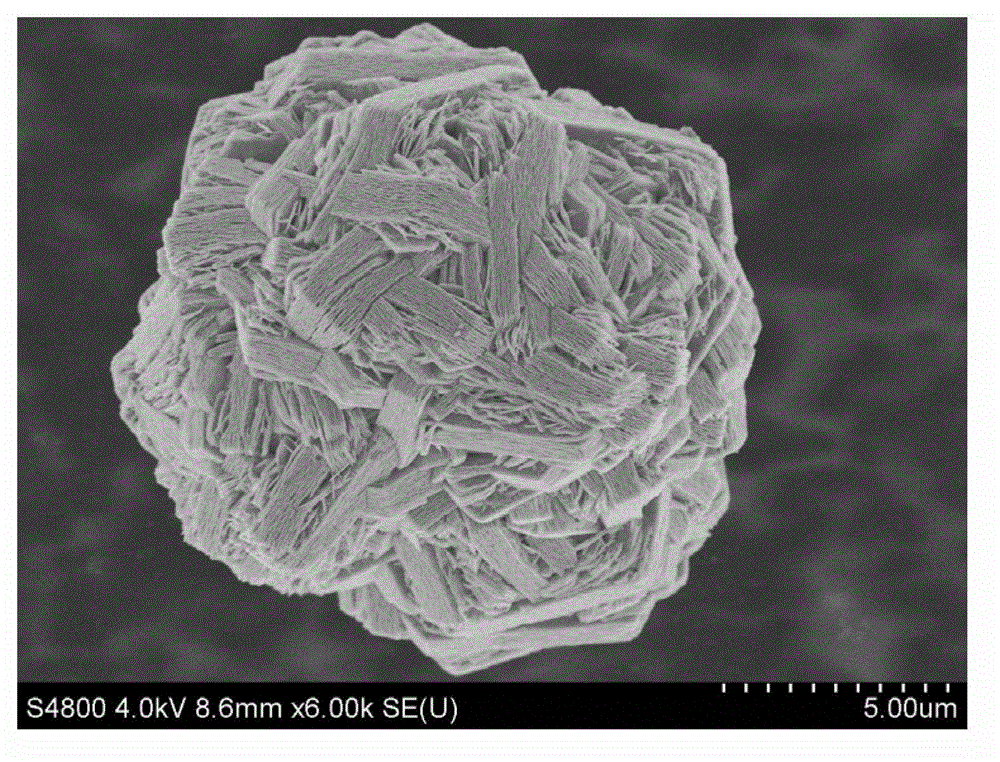

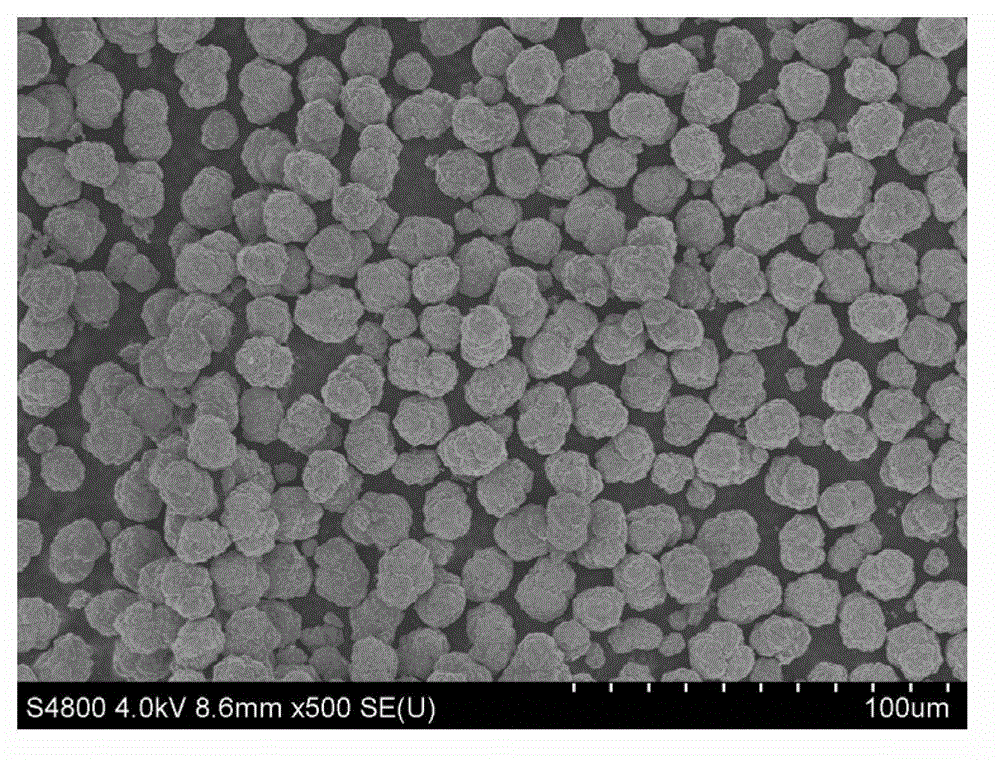

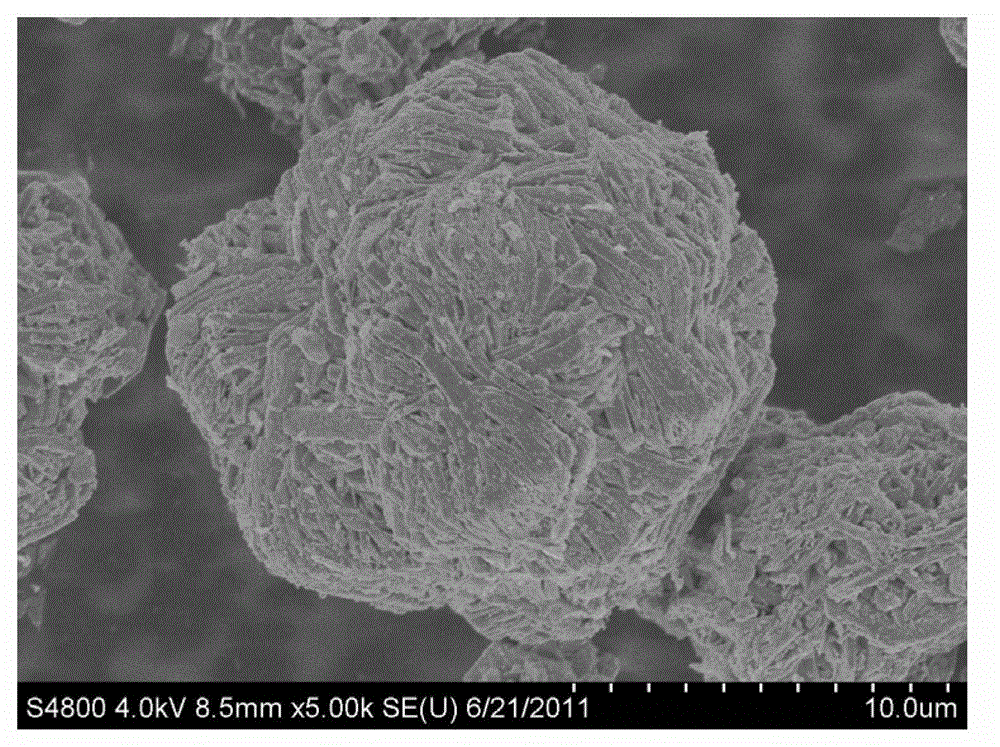

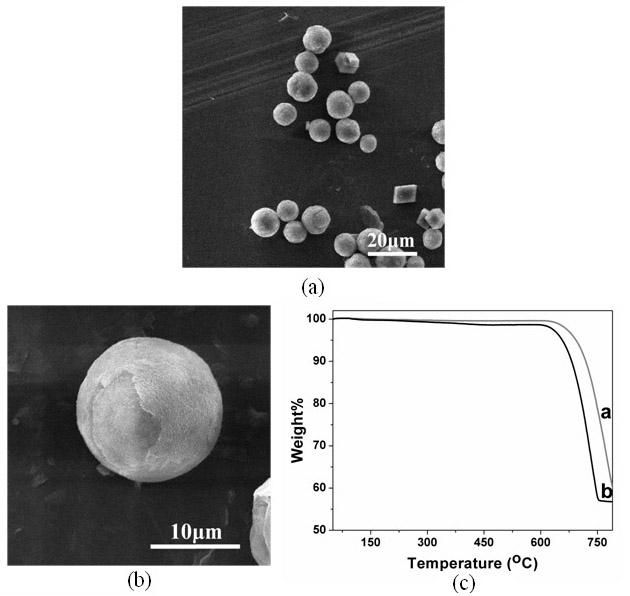

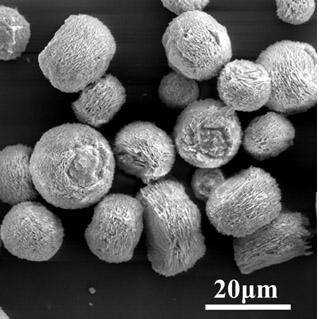

Nickel cobalt manganese hydroxide precursor and preparation method thereof

ActiveCN102916177AUniform particlesParticles have good fluidityCell electrodesNickel saltGlobular shaped

The invention provides a nickel cobalt manganese hydroxide precursor represented by a general formula (I). The hydroxide precursor is an orderly accumulated sphere with a page-like structure composed of a plurality of layers of sheets. The invention further provides a preparation method of the nickel cobalt manganese hydroxide precursor. In the process of preparing the nickel cobalt manganese hydroxide precursor, a sodium hydroxide solution, an ammonia water solution and a mixed solution of nickel salt, cobalt salt and manganese salt are reacted; and the nickel cobalt manganese hydroxide precursor which is the orderly accumulated sphere with the page-like structure is obtained by controlling pH and the amount of the ammonia water solution in the reaction process and adding an additive for adjusting particle morphology in the reaction process at the same time. The experimental results show that the nickel cobalt manganese hydroxide precursor prepared by the invention has better spherical morphology, uniform particle and good particle mobility; therefore, the nickel cobalt manganese hydroxide precursor is beneficial to diffusing lithium ion in the subsequent sintering process.

Owner:宁波富理电池材料科技有限公司

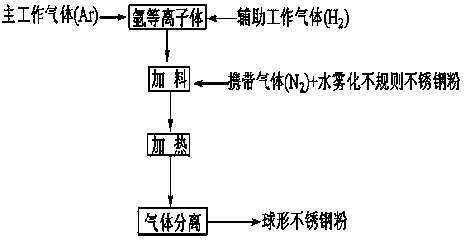

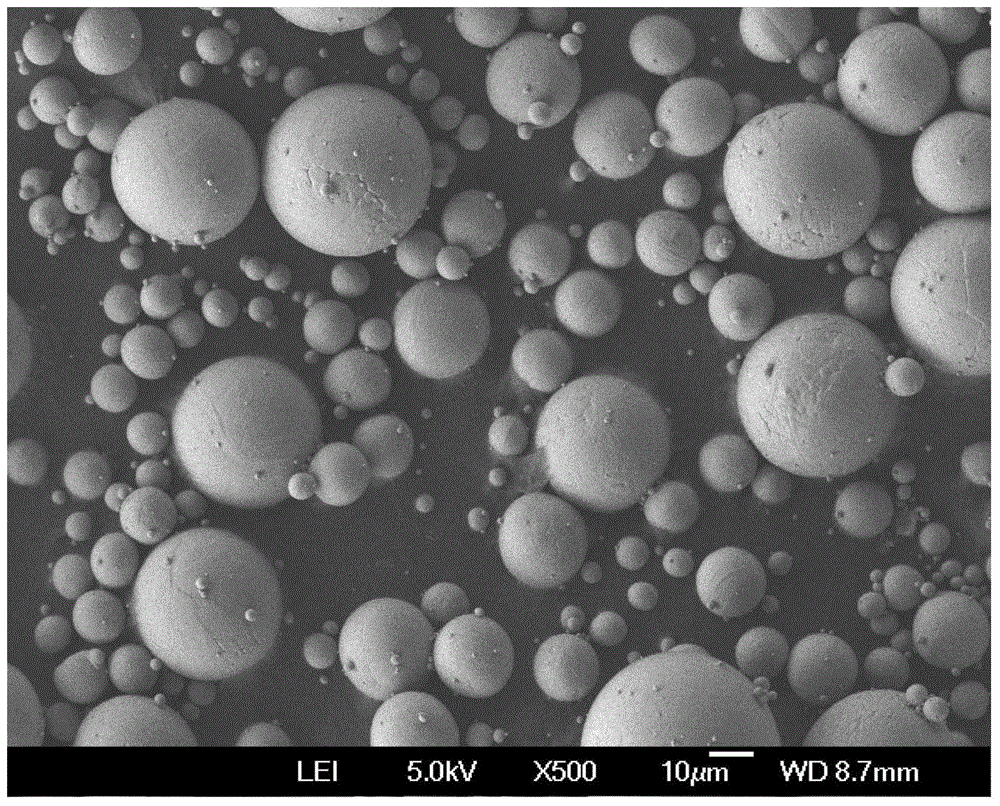

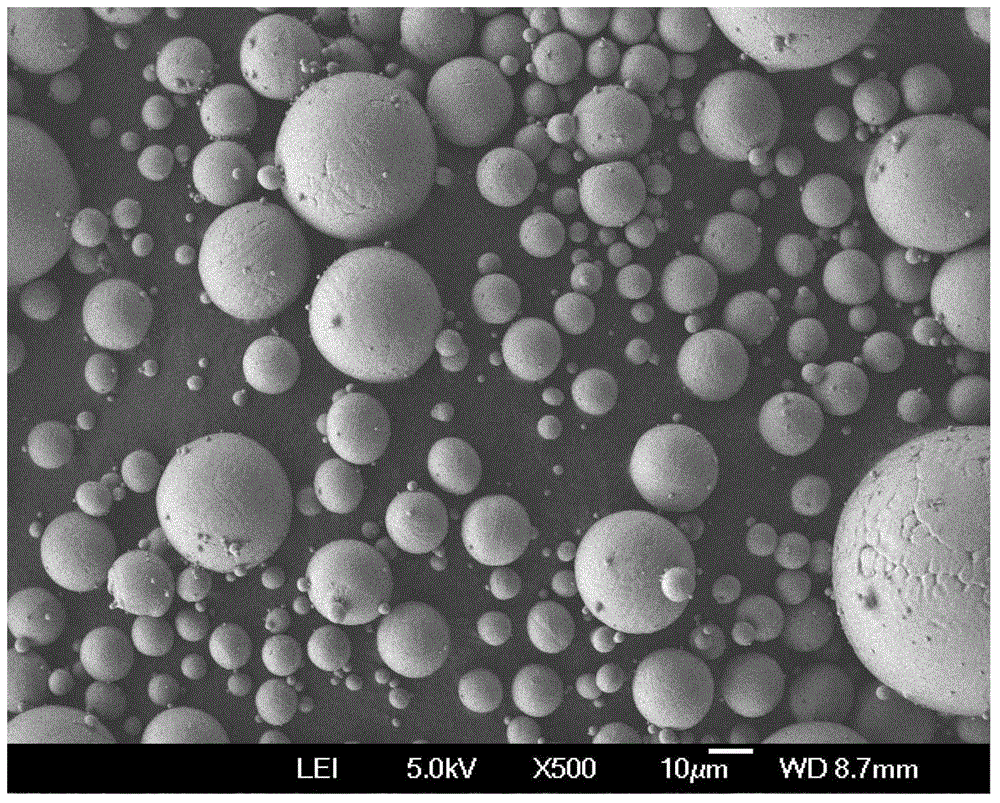

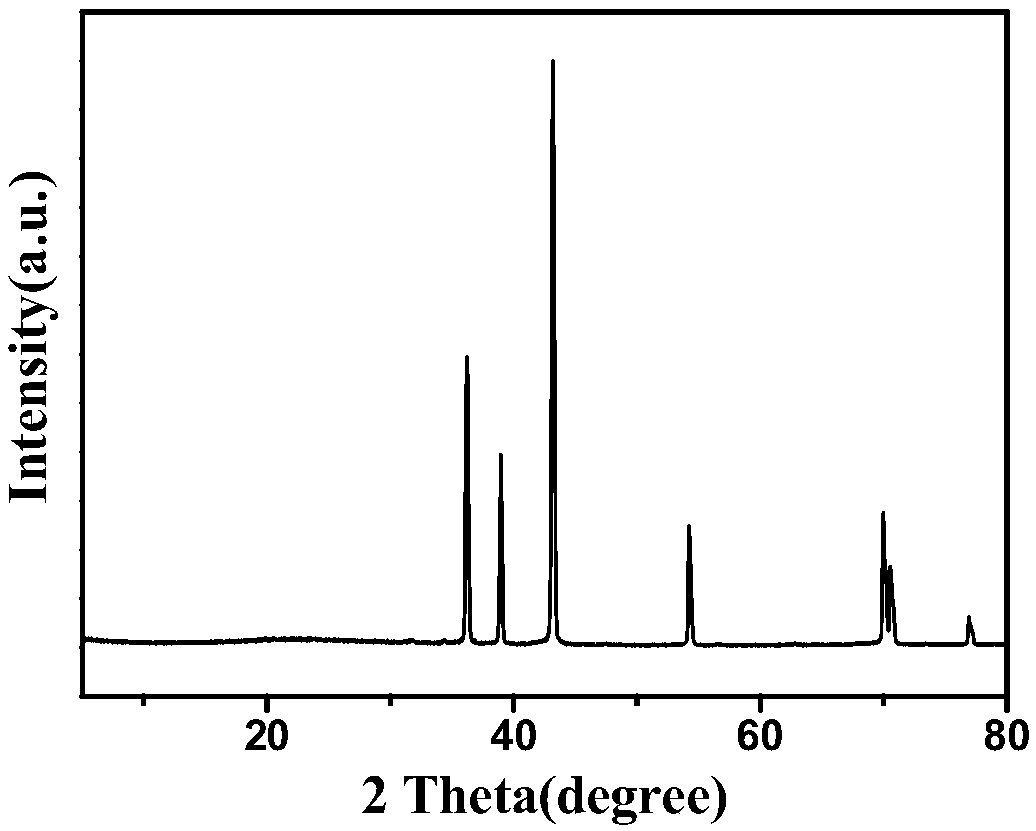

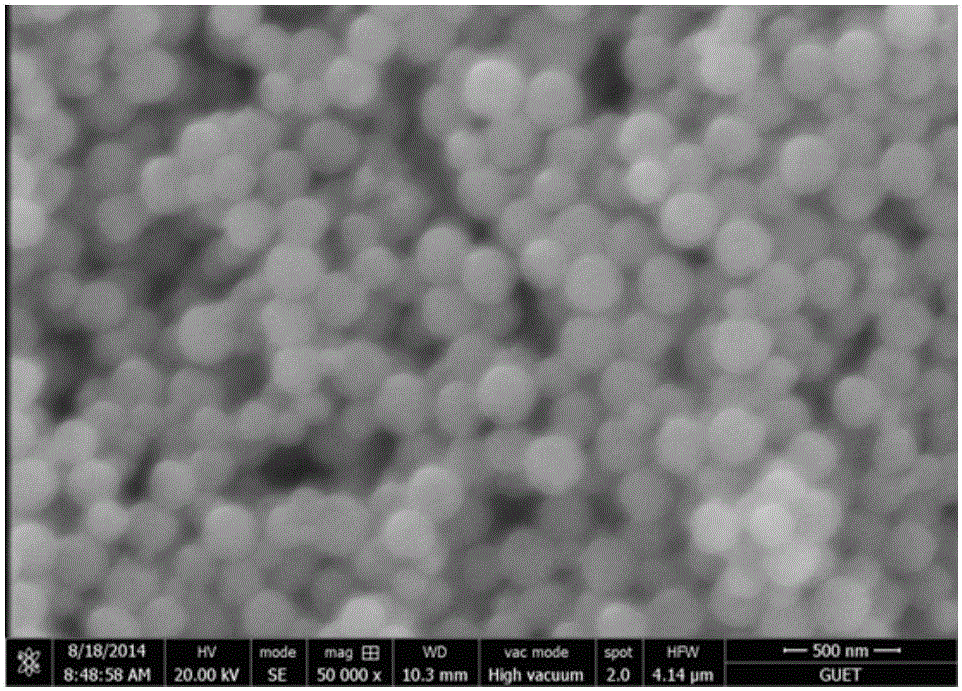

Preparation method for superfine spherical stainless steel powder

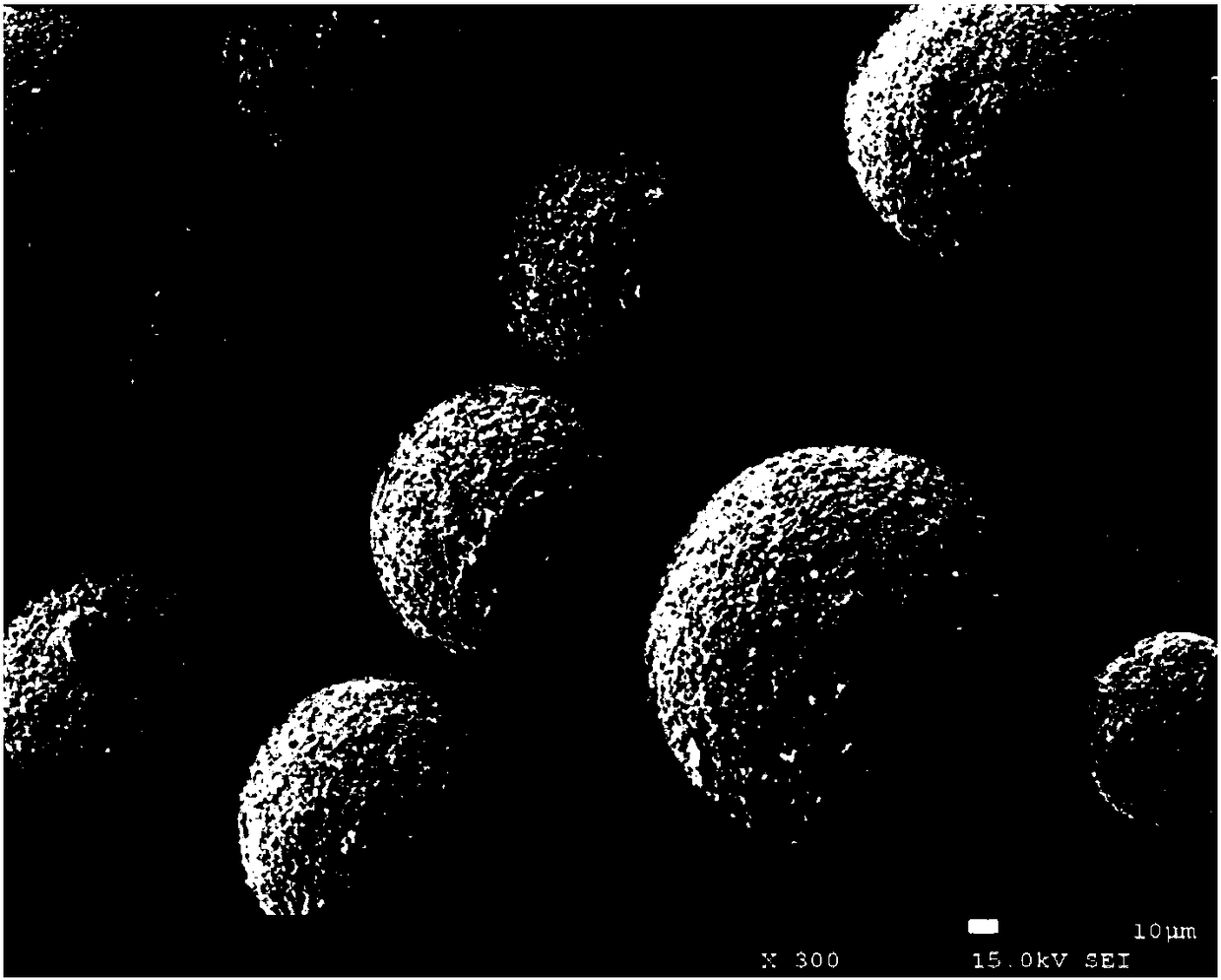

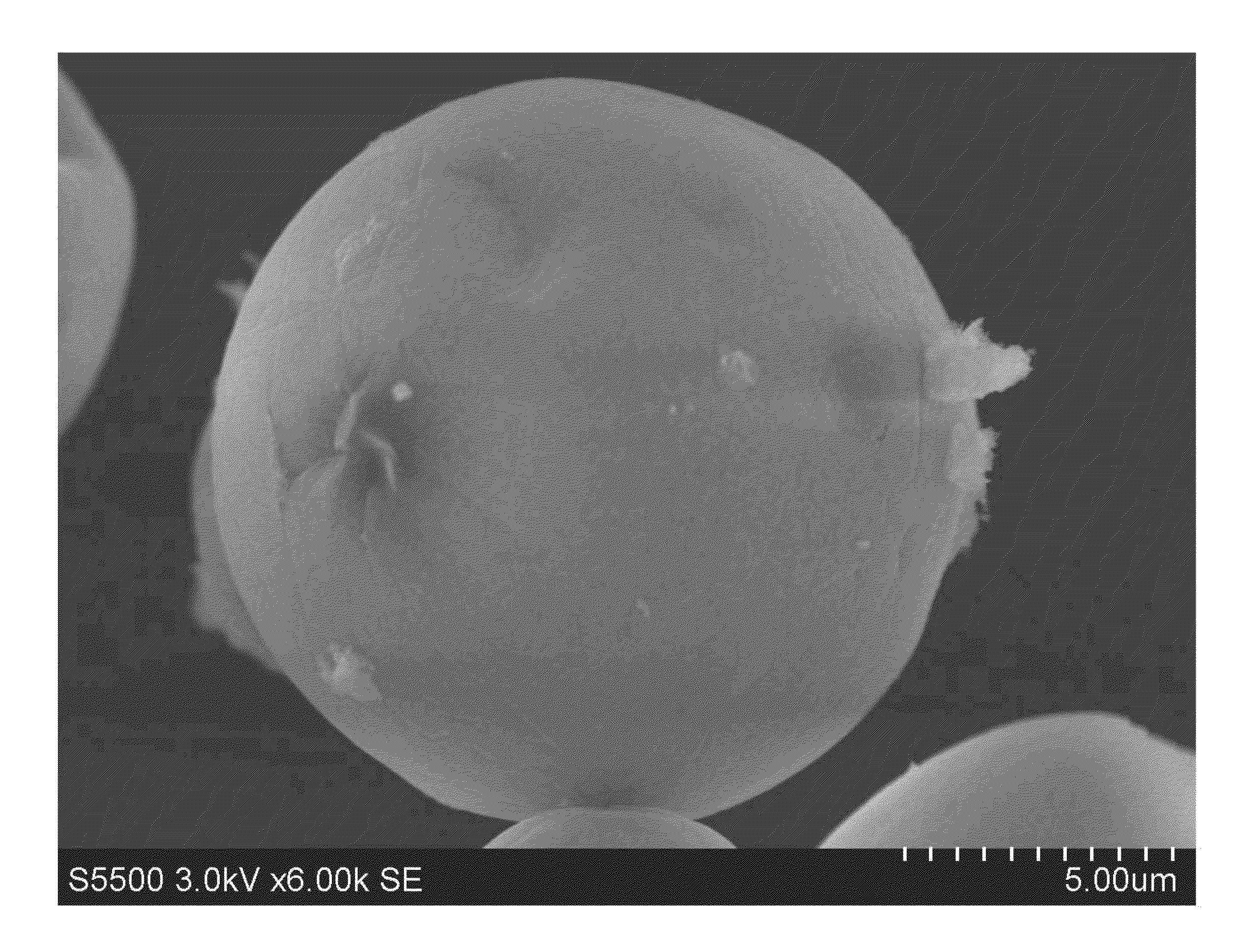

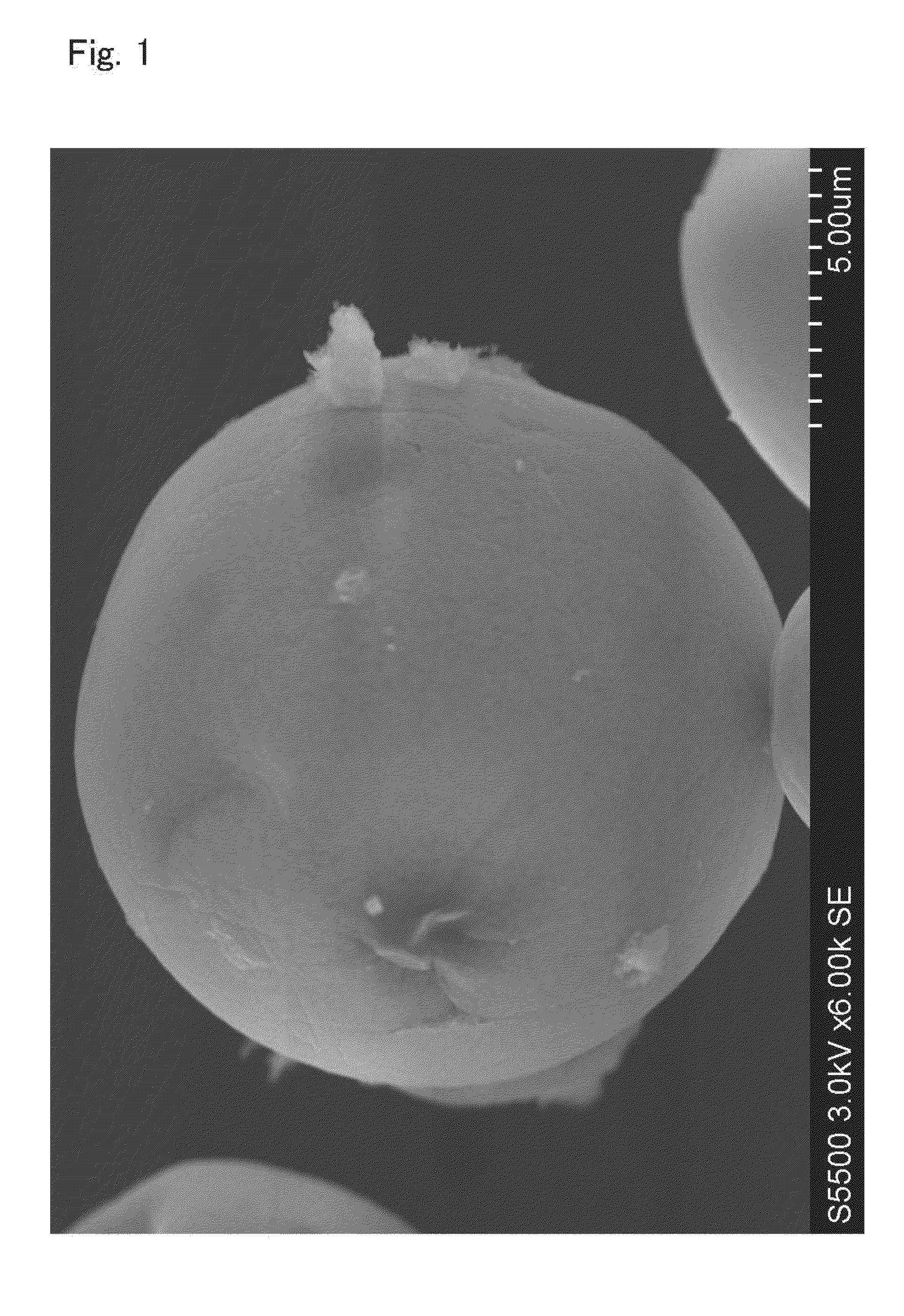

The invention relates to a stainless steel powder preparation method for metal powder injection molding, in particular to a method for preparing superfine spherical stainless steel powder by plasma spherifying. Stable argon plasmas are constructed, and plasma parameters are adjusted, so that a water-atomized irregular stainless steel powder raw material is heated, and is separated to obtain the superfine spherical stainless steel powder after being cooled and cured, and compared with the original water-atomized irregular stainless steel powder raw material, spherified stainless steel powder has higher flowability, tap density and purity. According to the method, the problems of poor flowability, low apparent density, low operational performance and the like caused by irregular shapes such as a flake shape, a strip shape and a branch shape in the conventional water-atomized stainless steel powder are solved, the quality of the stainless steel powder and the performance of a stainless steel product are improved, the added value and the market competitiveness of the water-atomized stainless steel powder are improved, and the method is low in cost.

Owner:JIANGXI YUEAN SUPERFINE METAL

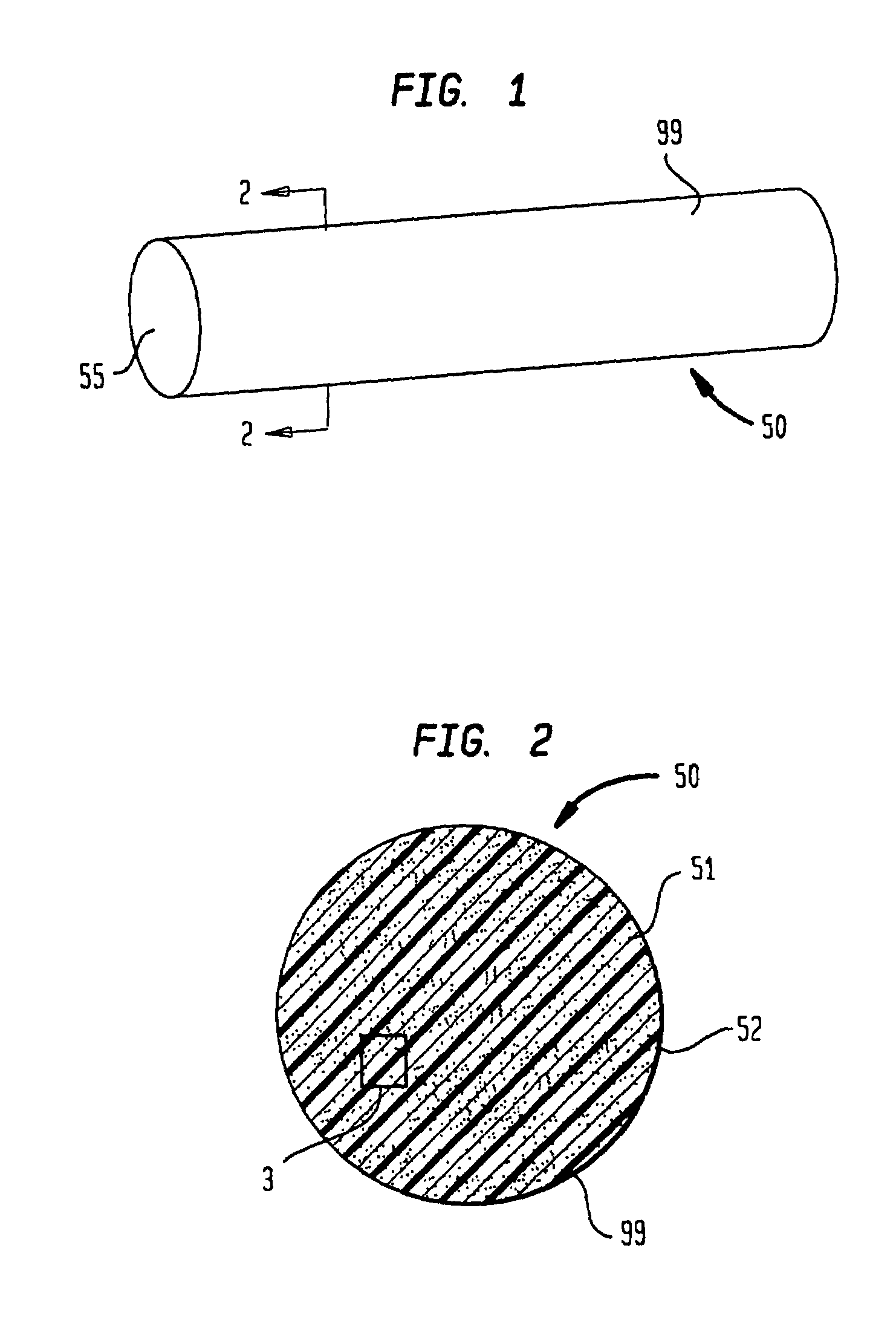

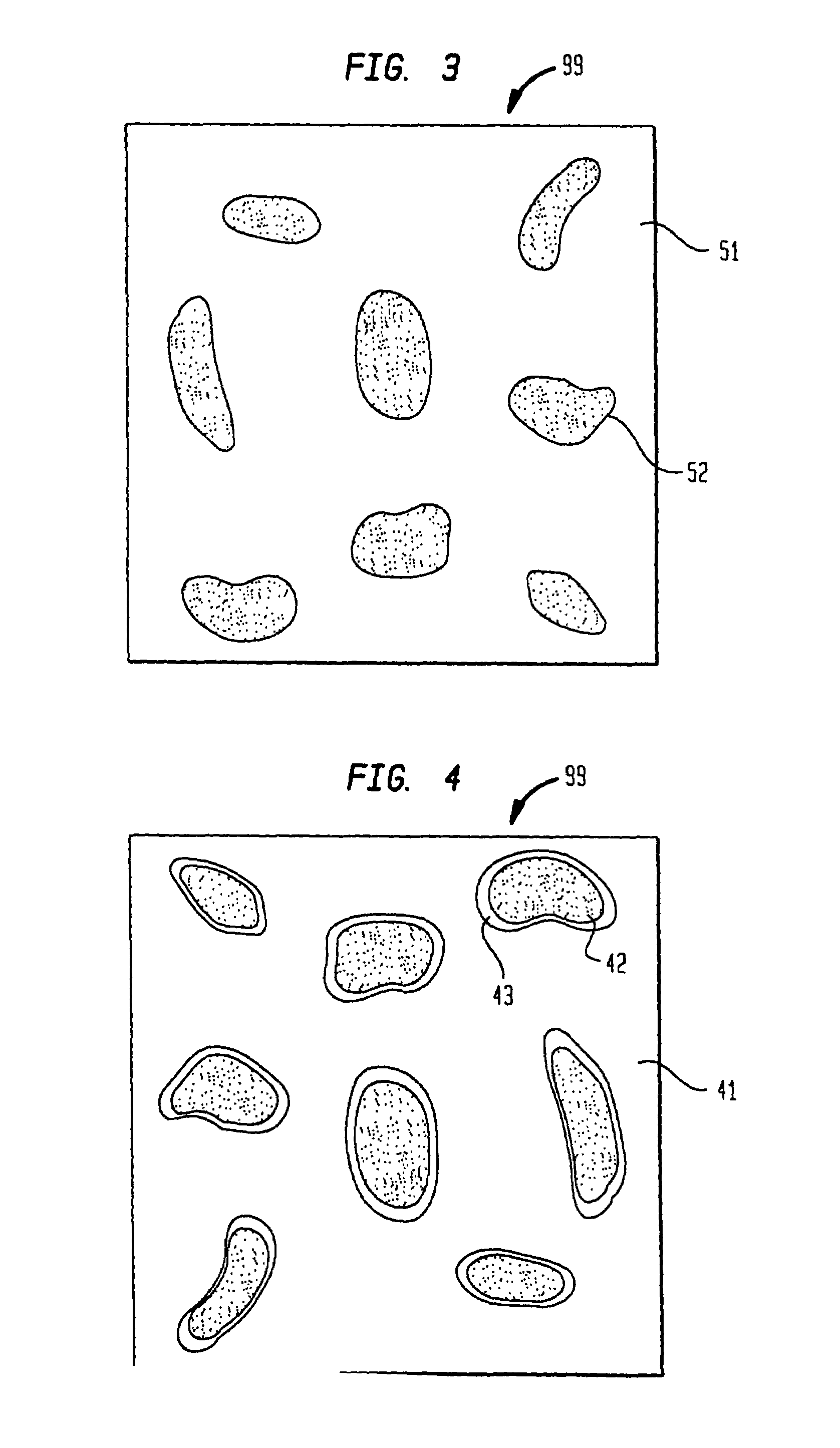

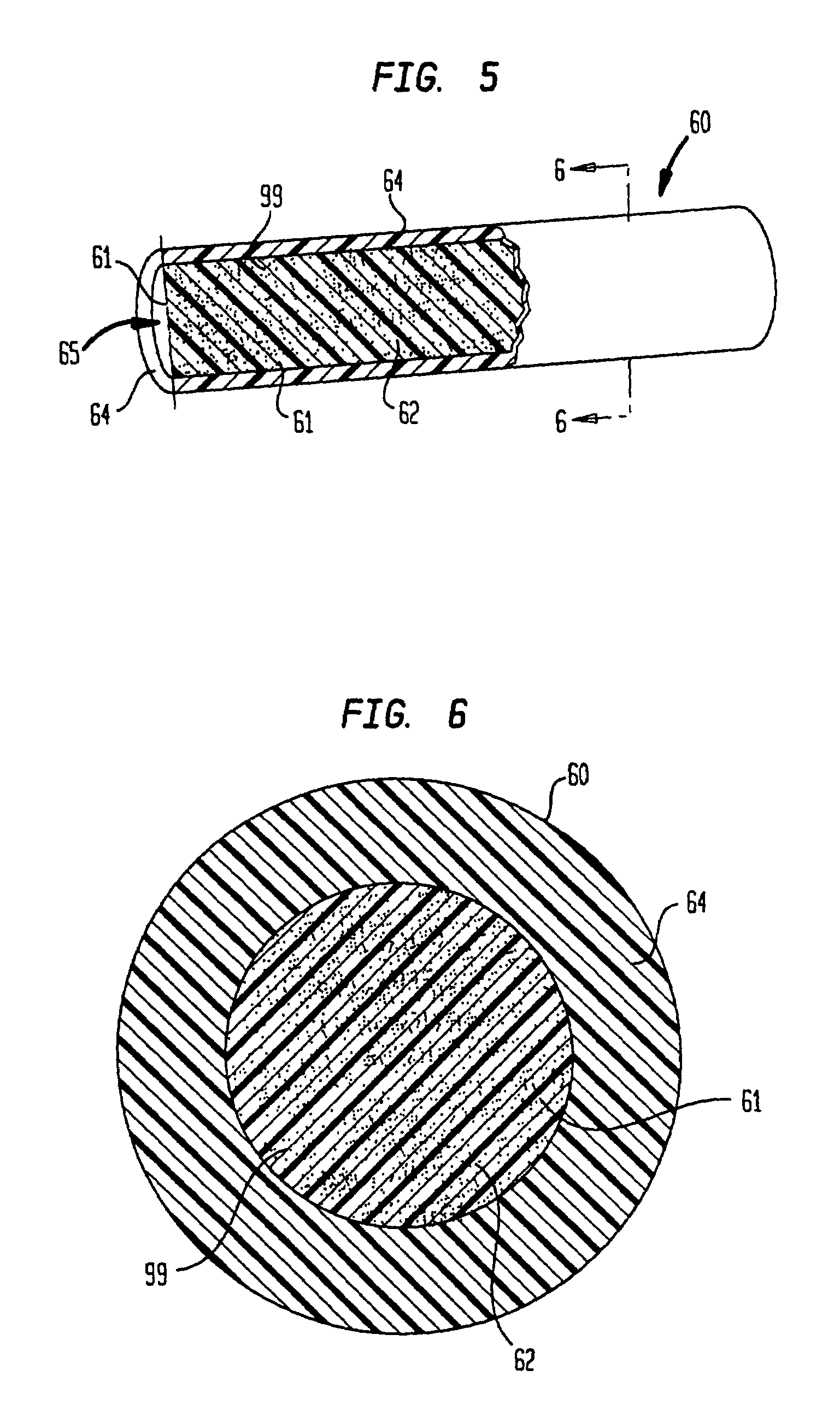

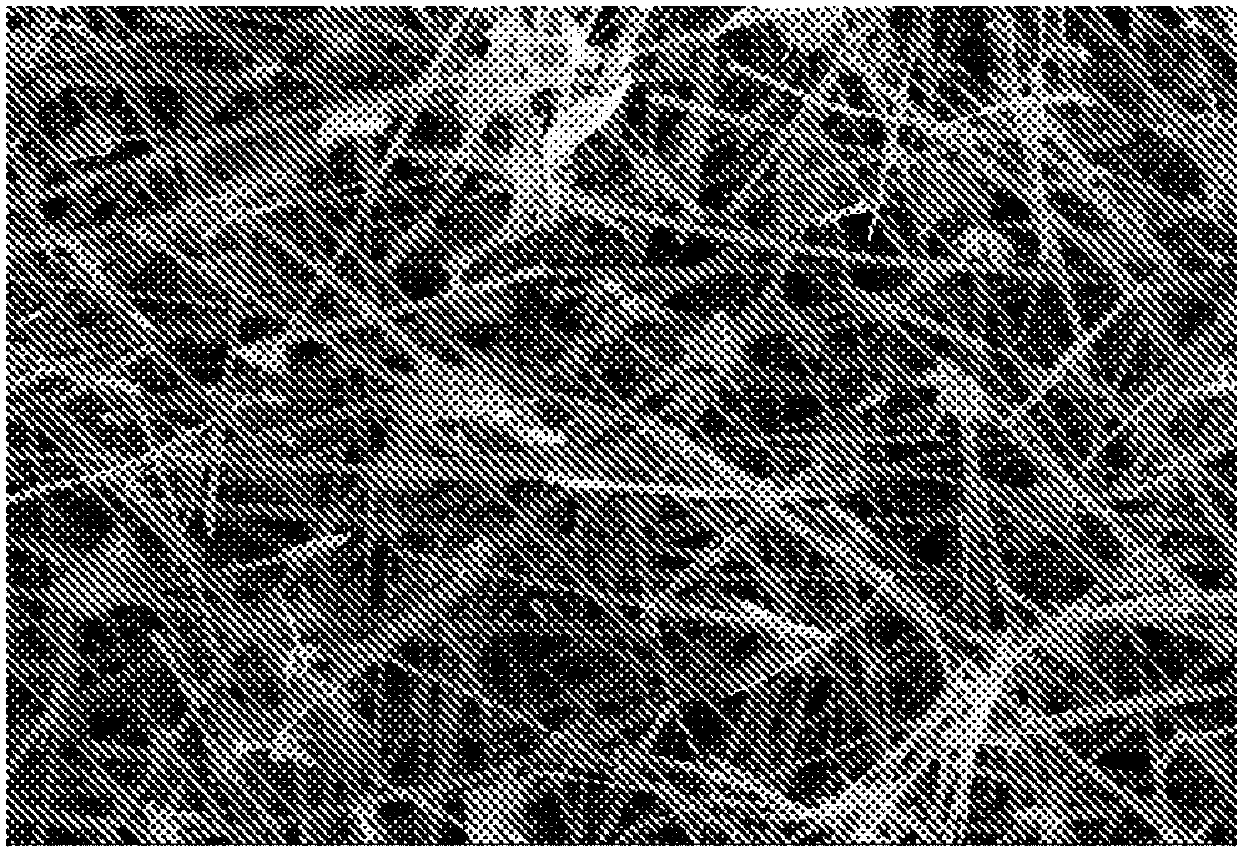

Polymeric-matrix brachytherapy sources

InactiveUS6986880B2Simply and inexpensivelyDegree of flexibilityRadioactive preparation formsRadioactive sourcesGlobular shapedBrachytherapy source

Therapeutic sources for use in the practice of brachytherapy comprise a radioactive composite that includes (a) a polymeric matrix and (b) a radioactive powder, e.g. Pd-103 or I-125, consisting essentially of very fine radioactive particles that are randomly and essentially uniformly dispersed within the polymeric matrix. The composite may be in the shape of one or more solid cylindrical rods surrounded by a non-radioactive sleeve. Alternatively it may be a hollow rod, suture, film, sheet, or microspheroidal particles. The composite may be shaped by molding, extrusion or other methods, may be made with a flexibility suitable to its intended use or may be encapsulated in a metallic capsule.

Owner:INT BRACHYTHERAPY

Metal alloy composites

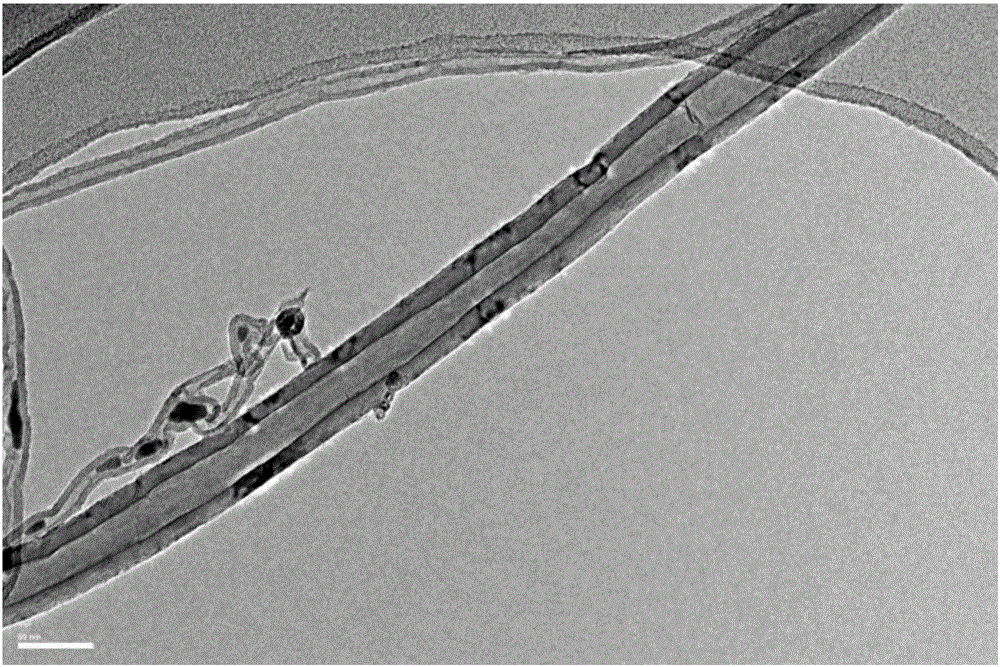

This invention relates to metal composites and to metal-alloy composites. Metal-alloy composites of this invention comprise a metal alloy and layered inorganic nanostructures or nanoparticles such asnanotubes, nanoscrolls, spherical or quasi-spherical nanoparticles, nano- platelets or combinations thereof. Methods of producing the metal composites and the metal-alloy composites are demonstrated.The layered inorganic nanostructure serves as a strengthening phase. The layered inorganic nanostructure provides reinforcement to the metal alloy.

Owner:YEDA RES & DEV CO LTD +1

Coating Compositions With Anticorrosion Properties

InactiveUS20120091397A1Improve corrosion resistanceEasy to manufactureLiquid surface applicatorsOther chemical processesAlkaline earth metalNano size

Anticorrosive coating compositions as disclosed comprise a binding polymer and an aluminum phosphate corrosion inhibiting pigment dispersed therein. The coating composition comprises up to 25 percent by weight aluminum phosphate. The binding polymer can include solvent-borne polymers, water-borne polymers, solventless polymers, and combinations thereof. The aluminum phosphate is made by sol gel process of combining an aluminum salt with phosphoric acid and a base material. Aluminum phosphate colloidal particles are nanometer sized, and aggregate to form substantially spherical particles. The coating composition provides a controlled delivery of phosphate anions of 100 to 1,500 ppm, depending on post-formation treatment of the aluminum phosphate, and has a total solubles content of less than 1500 ppm, The amorphous aluminum phosphate is free of alkali metals and alkaline earth metals, and has a water adsorption potential of up to about 25 percent by weight water when present in a cured film.

Owner:BUNGE AMORPHIC SOLUTIONS

Process for producing spherical aluminum nitride powder and spherical aluminum nitride powder produced by the same process

ActiveUS20120258310A1Efficient productionLarge particle sizeNitrogen compoundsSynthetic resin layered productsAlumina hydrateGlobular shaped

[Problems] To provide a process capable of efficiently producing a spherical aluminum nitride powder having a size most suited for use as a filler, and having a high sphericalness and a large particle strength.[Means for Solution] A spherical aluminum nitride powder is produced by using a spherical granulated product of an alumina powder or an alumina hydrate powder as a starting material, and feeding the spherical granulated product to the step of reductive nitrogenation so as to be reductively nitrogenated.

Owner:TOKUYAMA CORP

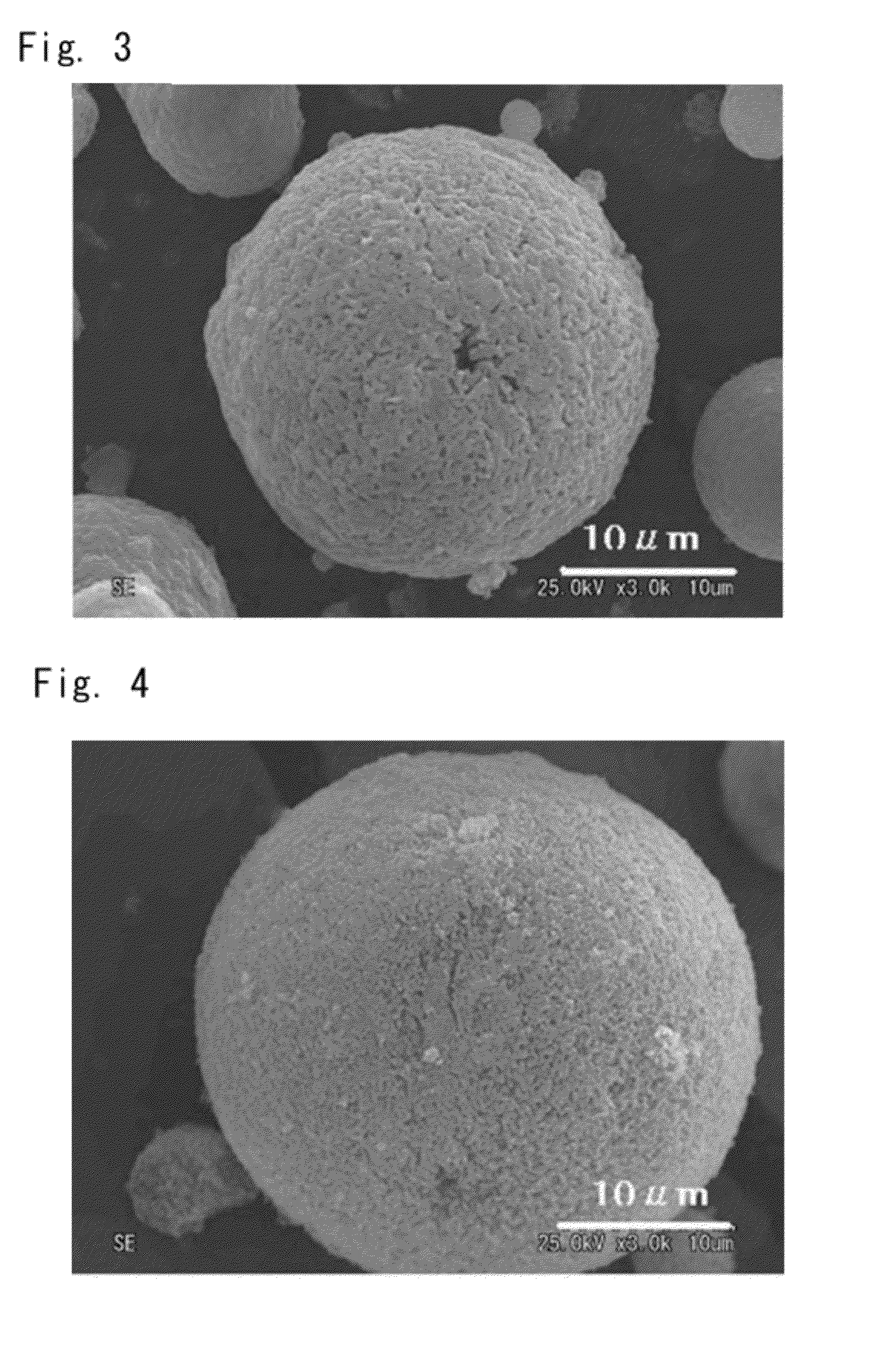

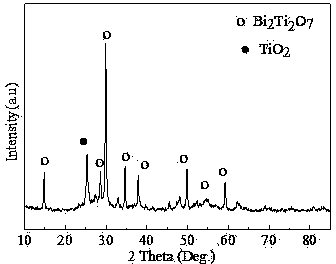

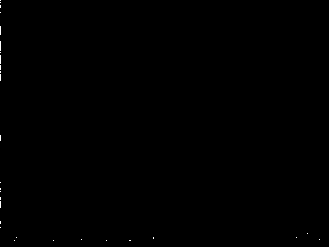

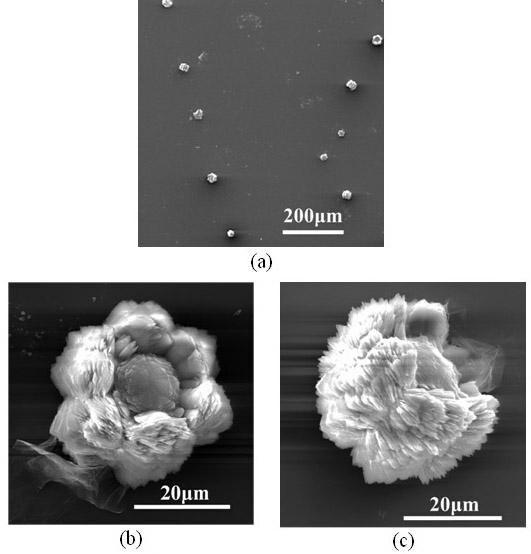

Method for preparing pure phase bismuth titanate and titanium oxide composite material by using alcohol heat method

ActiveCN104069848ALow costSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsTemperature controlAlcohol

The invention discloses a method for preparing a pure phase bismuth titanate and titanium oxide composite material by using an alcohol heat method. The method comprises the following steps: adding a bismuth nitrate solid in a mixed solvent of glycerin and ethyl alcohol the volume ratios being (0.05-0.2) to 1, fully dissolving the bismuth nitrate solid in the mixed solvent, dropwise adding tetrabutyl titanate in the solution, stirring and carrying out ultrasonic treatment on the solution, transferring the mixed solution in a reaction kettle, arranging the reaction kettle in a 110-150 DEG C constant temperature oven and reacting for 18-24h, cooling, filtering and drying a mixture in the reaction kettle, burning the mixture in a procedure temperature control furnace for 1-3h under 500-600 DEG C, and preparing the pure phase bismuth titanate and titanium oxide composite material. The method provided by the invention has the advantages that the bismuth titanate and titanium oxide composite material with different types and shapes are obtained by controlling, bismuth titanate comprises a pure phase Bi4Ti3O12, Bi2Ti2O7 or Bi2TiO32, and the shape of the composite material comprises a globular shape, a petal shape, a three-dimensional layer shape and a piece shape and the like.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of fine particle size and low oxygen spherical titanium and titanium alloy powder

The invention provides a preparation method of fine particle size and low oxygen spherical titanium and titanium alloy powder. The preparation method comprises the following steps: forming molten titanium and titanium alloy liquid drops by adopting arc melting wires, then crushing the metal liquid drops into superfine fog drops by using supersonic speed airflows, and condensing the metal fog drops into the spherical titanium and titanium alloy powder under the surface tension effect of the fog drops. By adopting the arc melting wires, the spherical titanium and titanium alloy powder is prepared in a high-purity argon or helium spray atomization technology, so that the preparation method is short in technological process and low in energy consumption; moreover, the powder preparation process of melting and atomizing raw materials is carried out under the protection of an inert atmosphere, so that the high-activity titanium and titanium alloy powder can be effectively prevented from being polluted, and low oxygen and high purity of the prepared powder are guaranteed; in addition, the molten titanium and titanium alloy liquid drops are sufficiently atomized through three paths of supersonic speed airflows, so that the prepared powder is fine in particle size and higher in yield and has a higher practical value.

Owner:陕西维克德科技开发有限公司

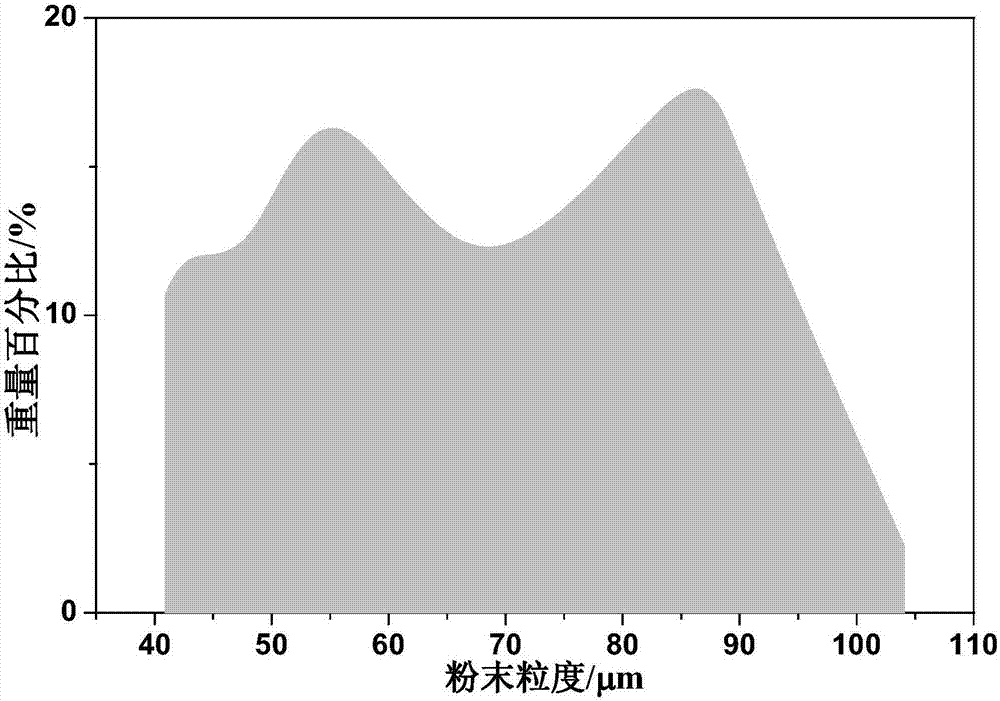

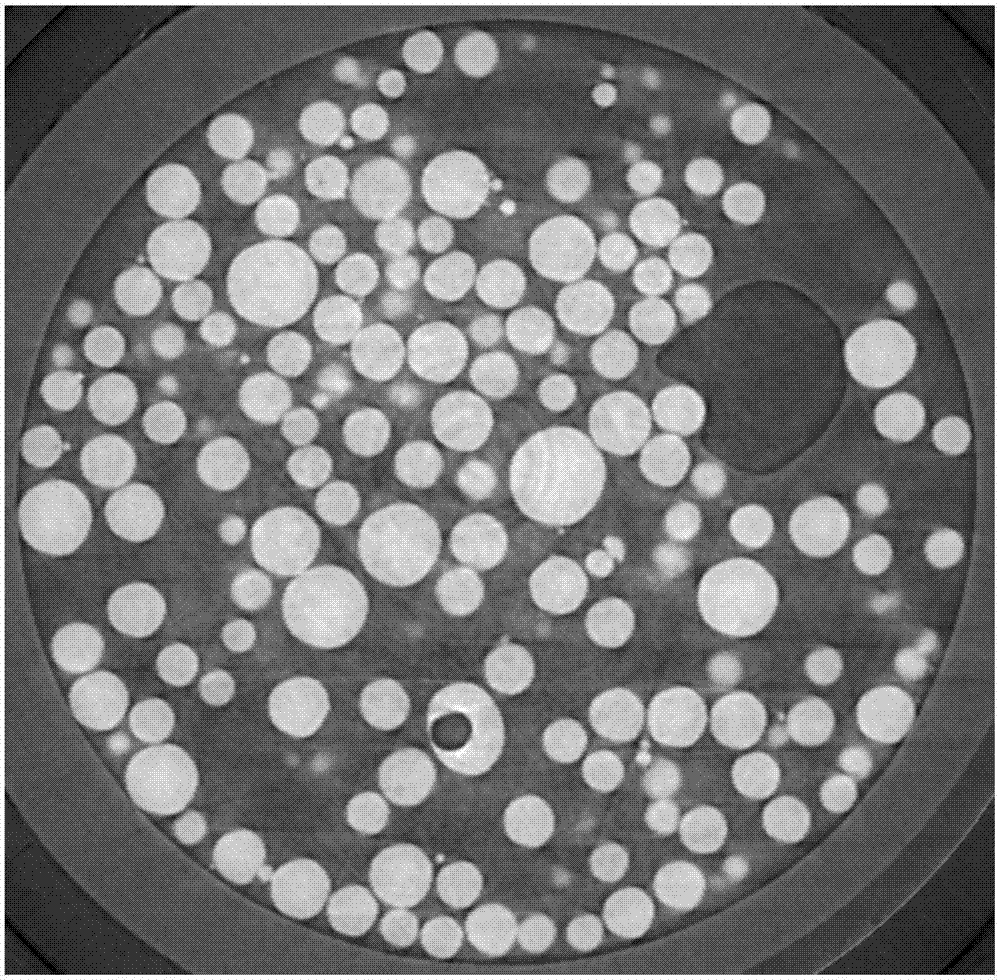

Method for preparing titanium based spherical powder with reduced particle size through gas atomization

ActiveCN107498059AGood physical propertiesLarge particle sizeTransportation and packagingMetal-working apparatusCrucibleGlobular shaped

The invention discloses a method for preparing titanium based spherical powder with reduced particle size through gas atomization. The method comprises steps as follows: step one, a titanium based raw material and a tin material are placed in a smelting crucible, and the smelting crucible is put in a smelting chamber of a vacuum induction melting gas atomization equipment for vacuum induction melting; step two, after the titanium based raw material and the tin material are melted through vacuum induction melting, argon is introduced for protection, a graphite diversion pipe located at the bottom of the smelting crucible is heated, a melted liquid produced after melting of the titanium based raw material and the tin material freely falls into an atomization chamber through the graphite diversion pipe and subjected to vacuum induction melting gas atomization treatment, atomized powder is obtained, and titanium based spherical powder is obtained from a collecting tank. According to the method, tin is introduced into the titanium raw material or a titanium alloy raw material for reducing viscosity of the melted liquid obtained after smelting, so that the raw materials are easy to break during gas atomization, the particle size of the prepared powder becomes small, wherein the yield of the powder with the particle size smaller than 45 mu m in the titanium based spherical powder is not lower than 28%, pores in the powder are reduced, and the amount of hollow powder is reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Coating spraying and 3D printing cermet material based on TiCN-MxC-Co and preparation method of coating spraying and 3D printing cermet material based on TiCN-MxC-Co

ActiveCN108213411AReduce composition segregationUniform microstructureAdditive manufacturing apparatusMolten spray coatingSpray GranulationCarbide

The invention disclose a coating spraying and 3D printing cermet material based on TiCN-MxC-Co and a preparation method of the coating spraying and 3D printing cermet material based on TiCN-MxC-Co. The cermet material is spherical powder and comprises TiCN-MxC-Co and at least one selected from Ni, Mo and Fe, wherein, by mass percentage, 20-94% of TiCN, 1-40% of MxC and 5-40% of Co and at least oneselected from Ni, Mo and Fe are included, and carbide MxC is at least one of WC, MoC, Mo2C, TaC, Cr3C2, NbC, VC and ZrC. The material is prepared through the steps of mixing, drying, powder spheroidization and sintering, wherein powder spheroidization can be carried out by the adoption of a roller spheroidization method or a radio frequency plasma spheroidization method or a spray granulation spheroidization method and the like. The cermet material can be used as a coating material to improve the bonding force between the coating and a substrate and can be used as a 3D printing material to improve the quality of 3D printing products.

Owner:成都锦钛精工科技有限公司

Method for preparing vanadium-nitrogen alloy

ActiveUS20140037530A1Low production costIncrease productivityNitrogen-metal/silicon/boron binary compoundsIncreasing energy efficiencyGlobular shapedNitrogen

A method for preparing vanadium-nitrogen alloy, the method including: 1) mixing and pressing a vanadium-containing compound, an agglutinant, and a carbon-premixed reducing agent to yield a spherical raw material, and air drying the spherical raw material; and 2) mixing the spherical raw material with a granular carbonaceous reducing agent to yield a mixture, and continually feeding the mixture into a shaft kiln of a medium frequency induction furnace, purging the shaft kiln with pure nitrogen and maintaining a furnace pressure at between 0.01 and 0.03 mPa, drying the mixture at a temperature of between 100 and 600° C., carbonizing and nitriding at a temperature of between 900 and 1350° C., cooling the resulting product to less than 100° C., and discharging the product.

Owner:ZHENG JIANWEI

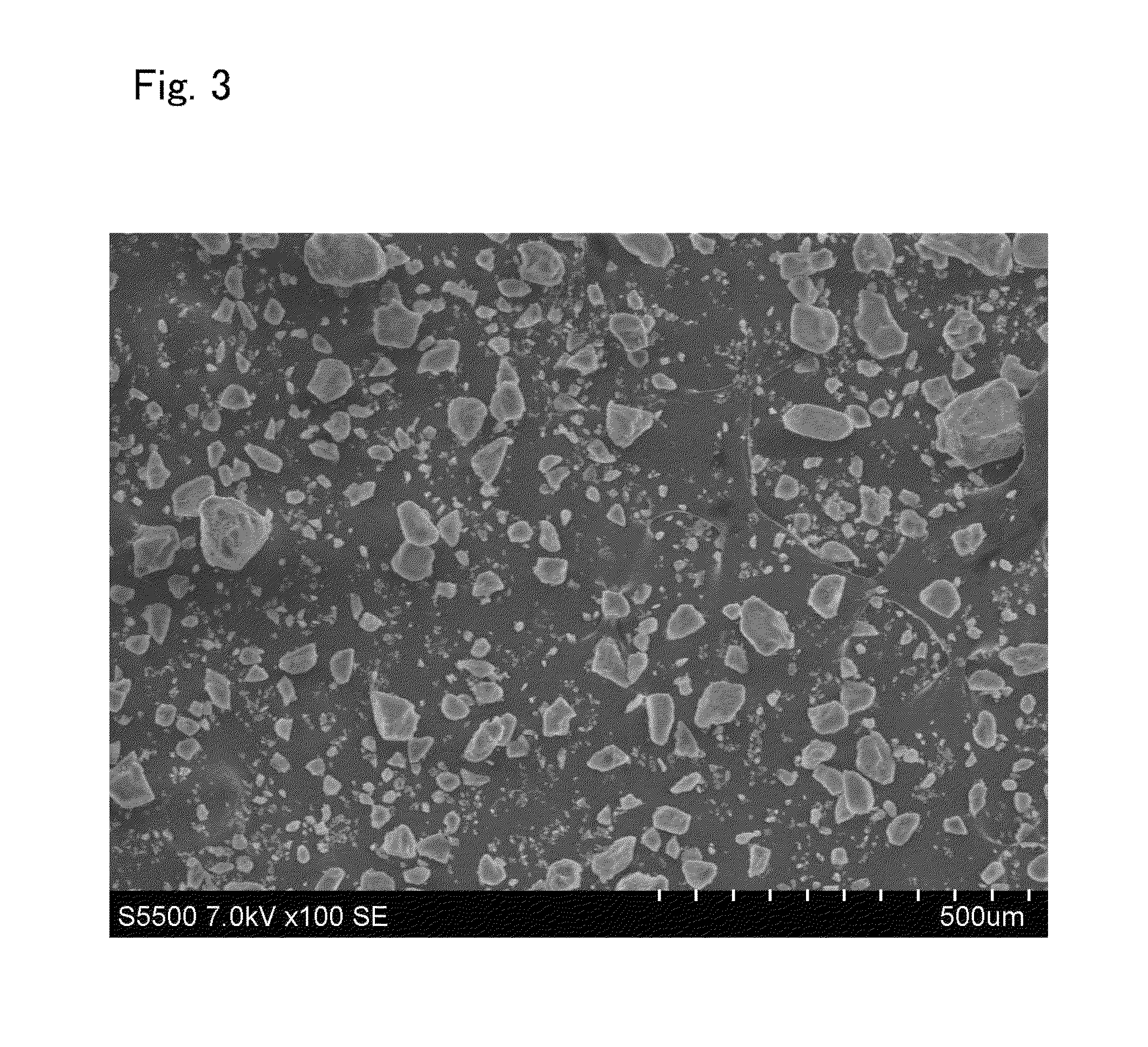

Metal oxide powder and method for manufacture thereof

ActiveUS20140057111A1Improve insulation effectIncrease surface areaOxygen/ozone/oxide/hydroxideSilicaDensity reductionEmulsion

The present invention provides a globular-shaped metal oxide powder with excellent thermal insulation performance and reduced bulk density, and a method of manufacture thereof, wherein the metal oxide powder has globular independent particles as the main component, and has BET specific surface area of 400 to 1000 m2 / g, BJH pore volume of 2 to 8 mL / g, and oil absorption of no less than 250 mL / 100g. The present invention also provides a method for manufacturing the hollow and globular shaped metal oxide powder including the step of forming an O / W / O emulsion.

Owner:TOKUYAMA CORP

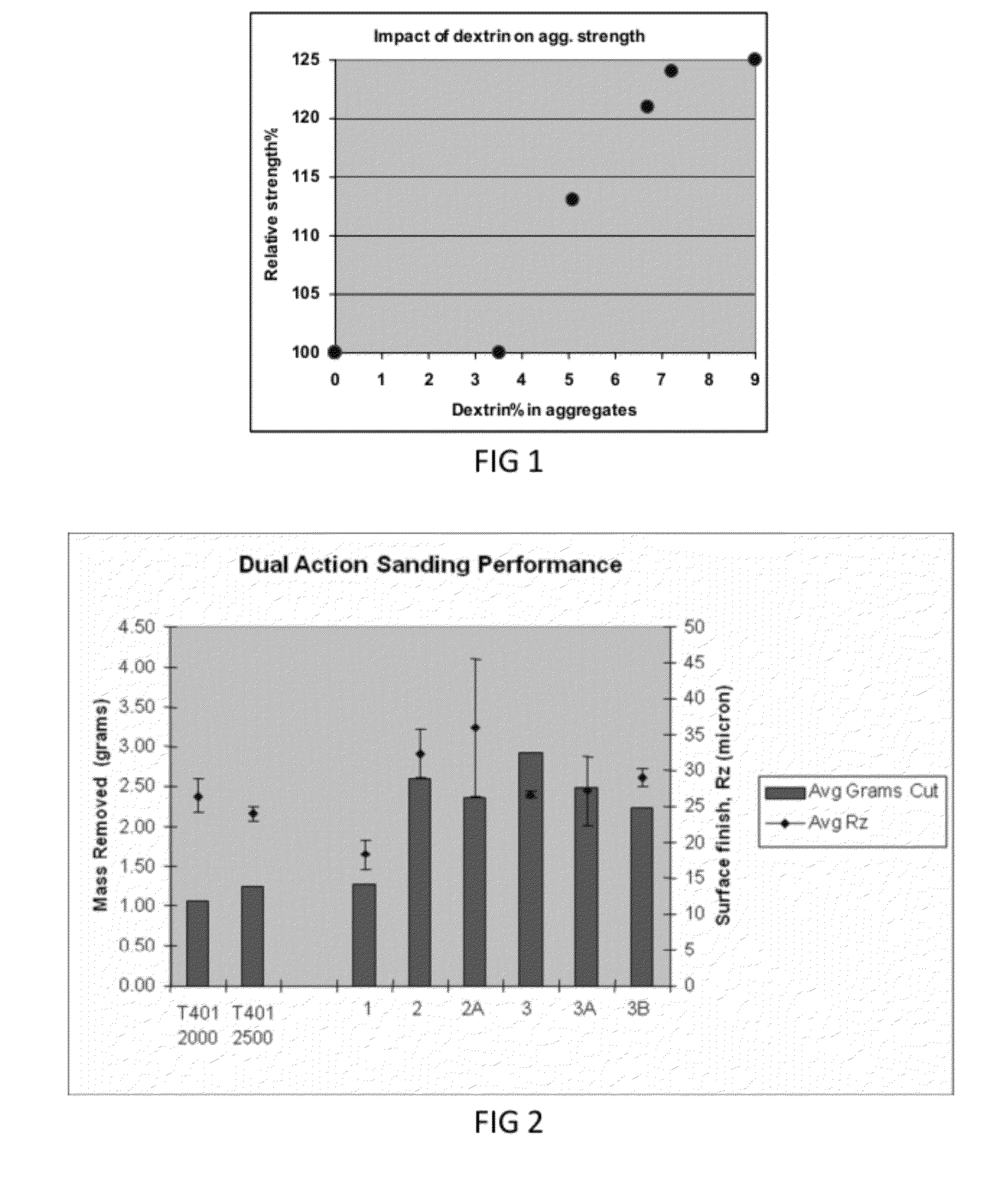

Coated abrasive aggregates and products containg same

Owner:SAINT GOBAIN ABRASIVES INC +1

Casting sand core composition

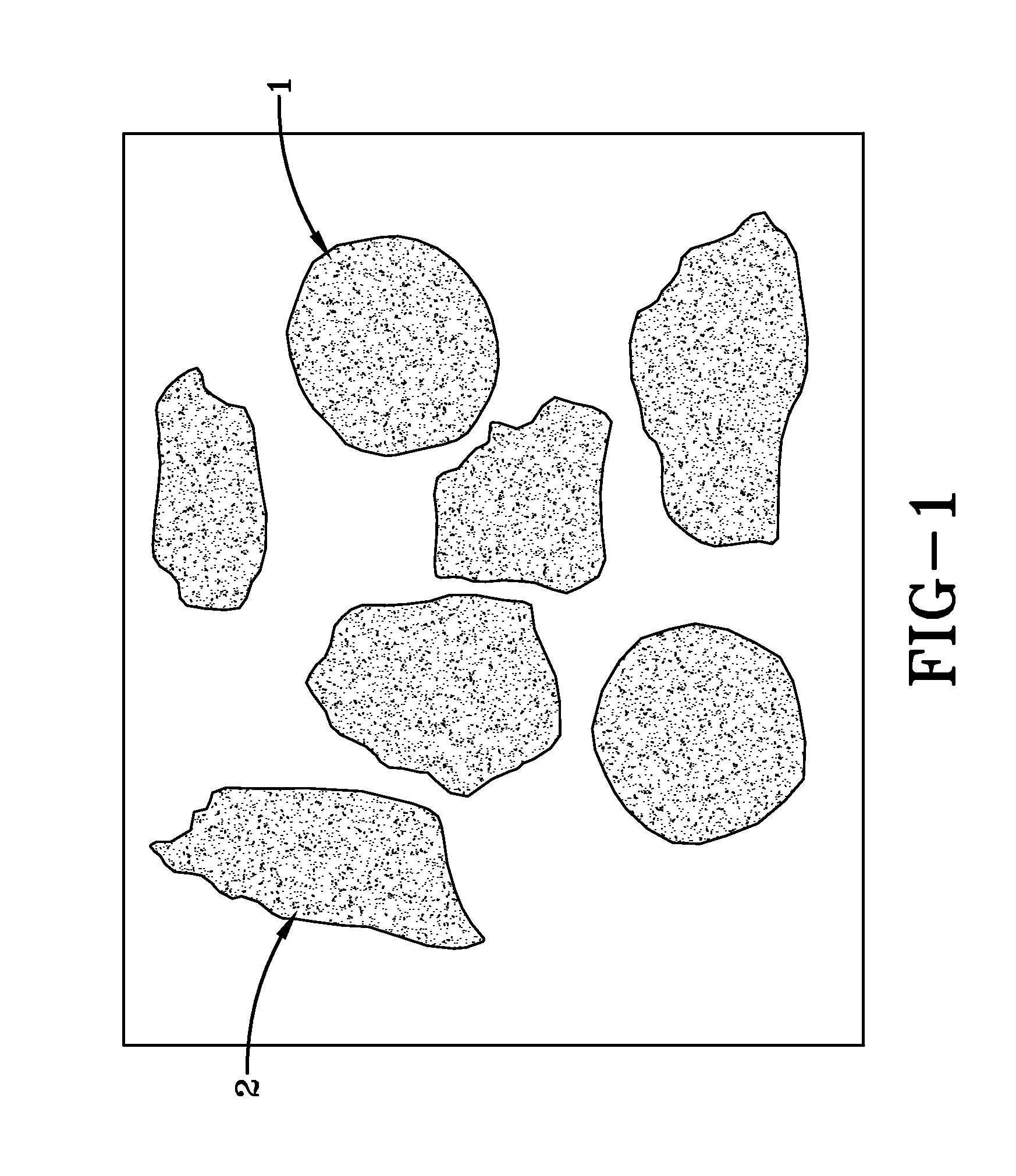

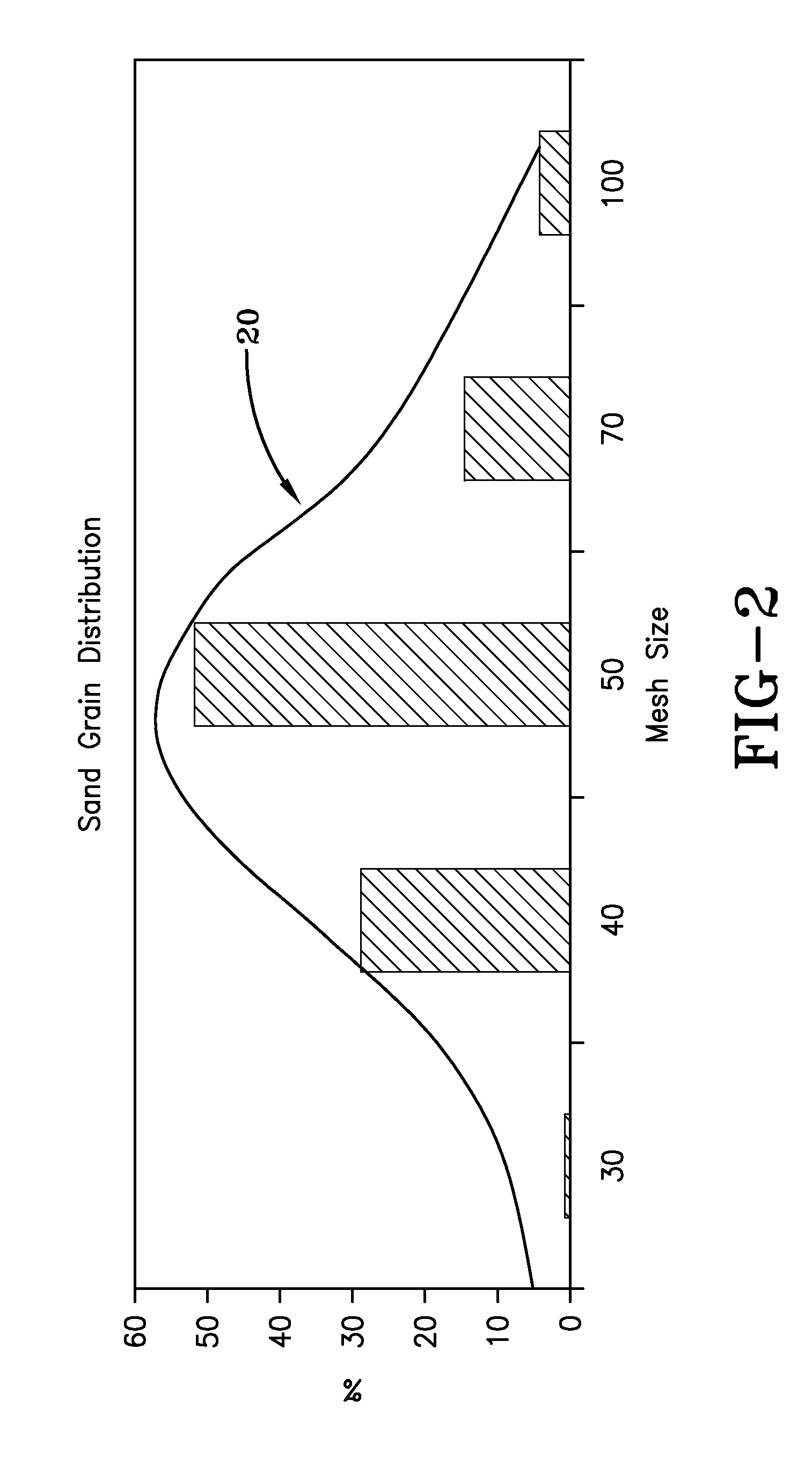

ActiveUS20120118200A1Improve liquidityHigh strengthCeramic shaping liningsGlobular shapedMaterials science

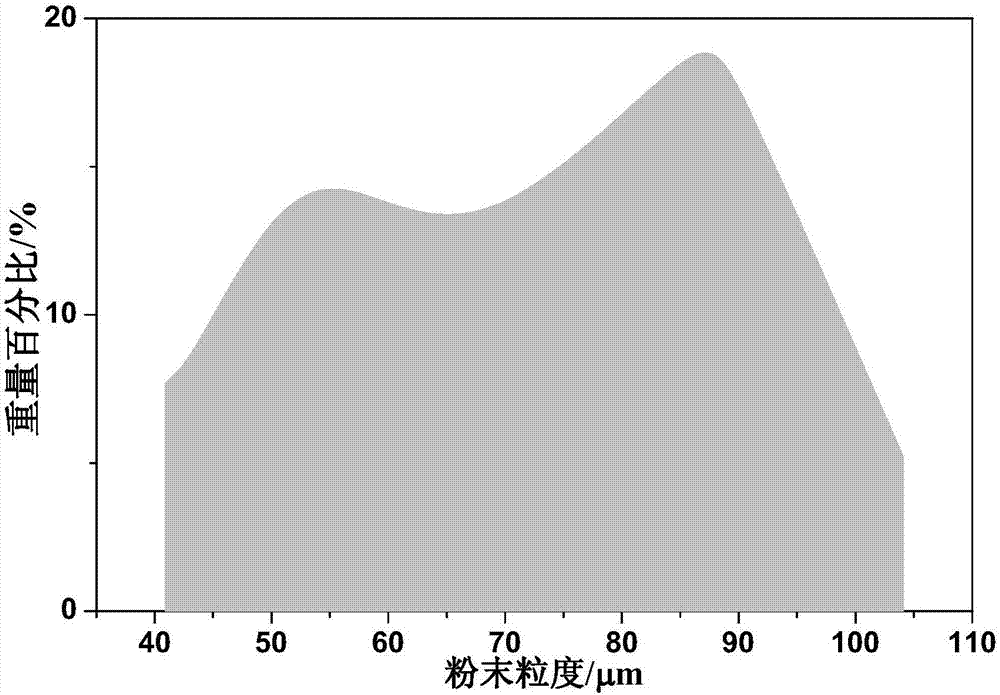

A casting process sand core composition including sand particles (grains) and a binder material. Both substantially spherical sand grains and substantially non-spherical grains may be present. The size of the sand grains is preferably held within a preselected and controlled range, and the size distribution by weight percentage of the sand grains within the grain size range is also controlled. The present invention also contemplates methods of making a sand core from such a composition, and methods of making a casting with a die that uses a sand core made from such a composition.

Owner:HONDA MOTOR CO LTD

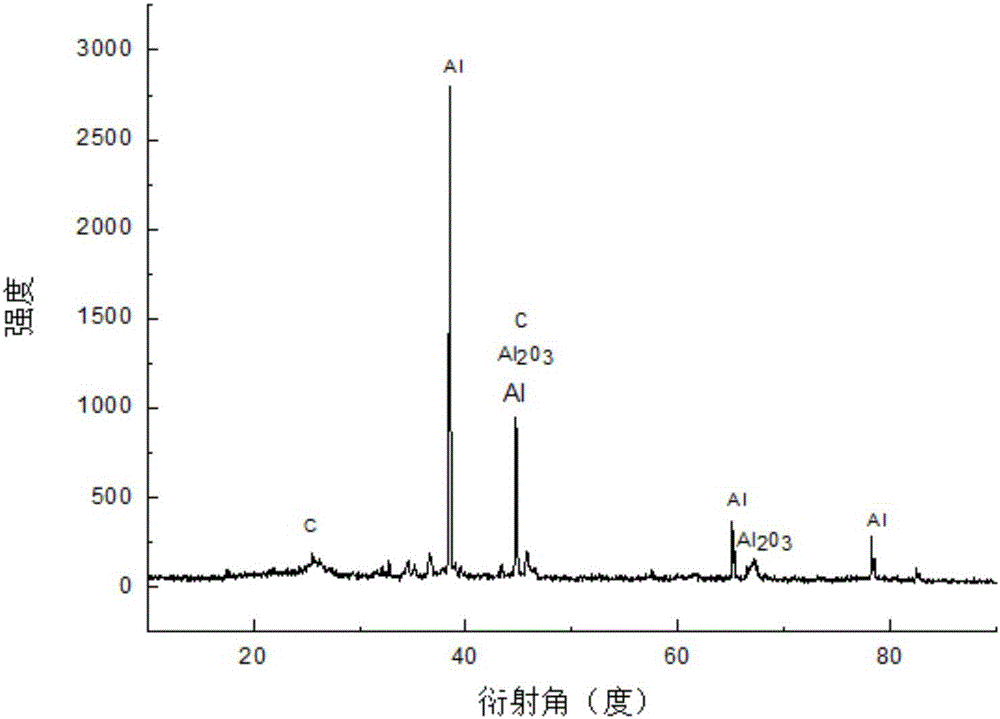

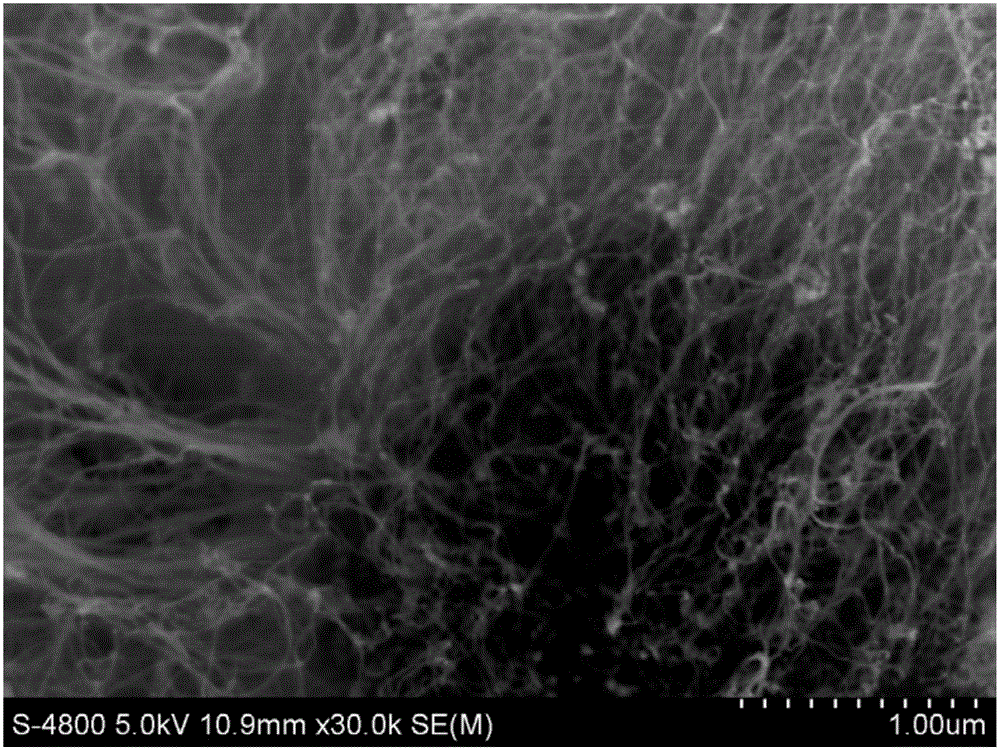

Preparation method for carbon nanotube-alumina mixed reinforced magnesium aluminum alloy composite

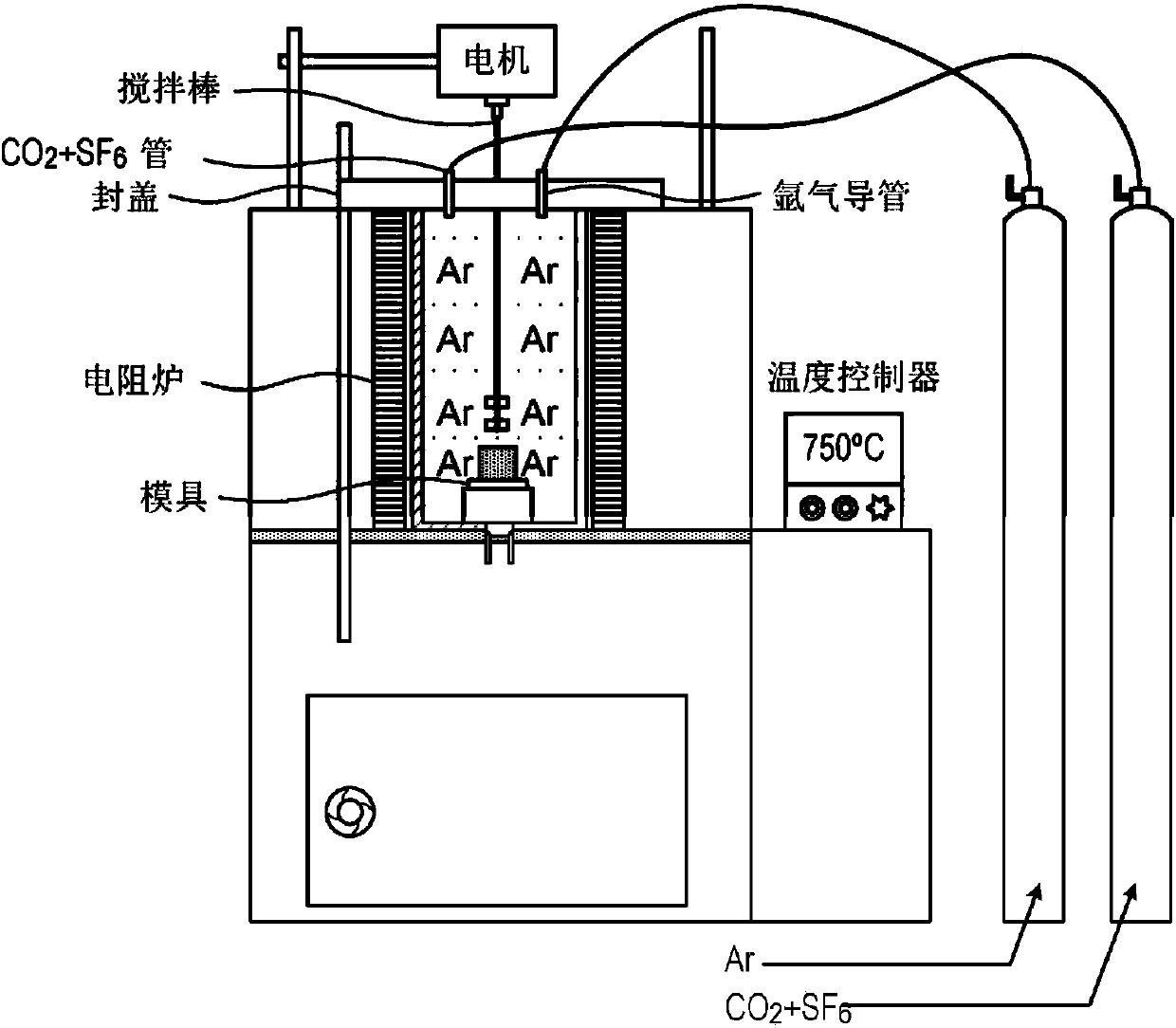

InactiveCN106498225AHighlight substantive featuresImprove mechanical propertiesMaterial nanotechnologyChemical vapor deposition coatingCarbon nanotubeGlobular shaped

Owner:HEBEI UNIV OF TECH

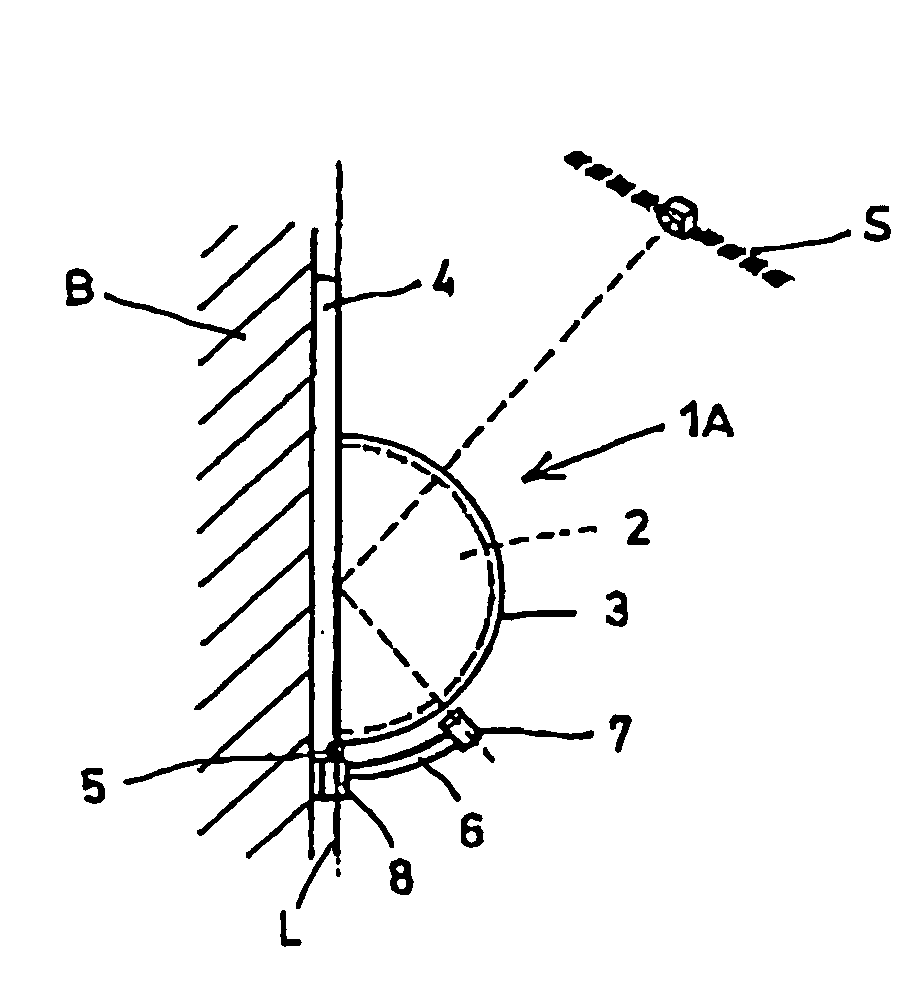

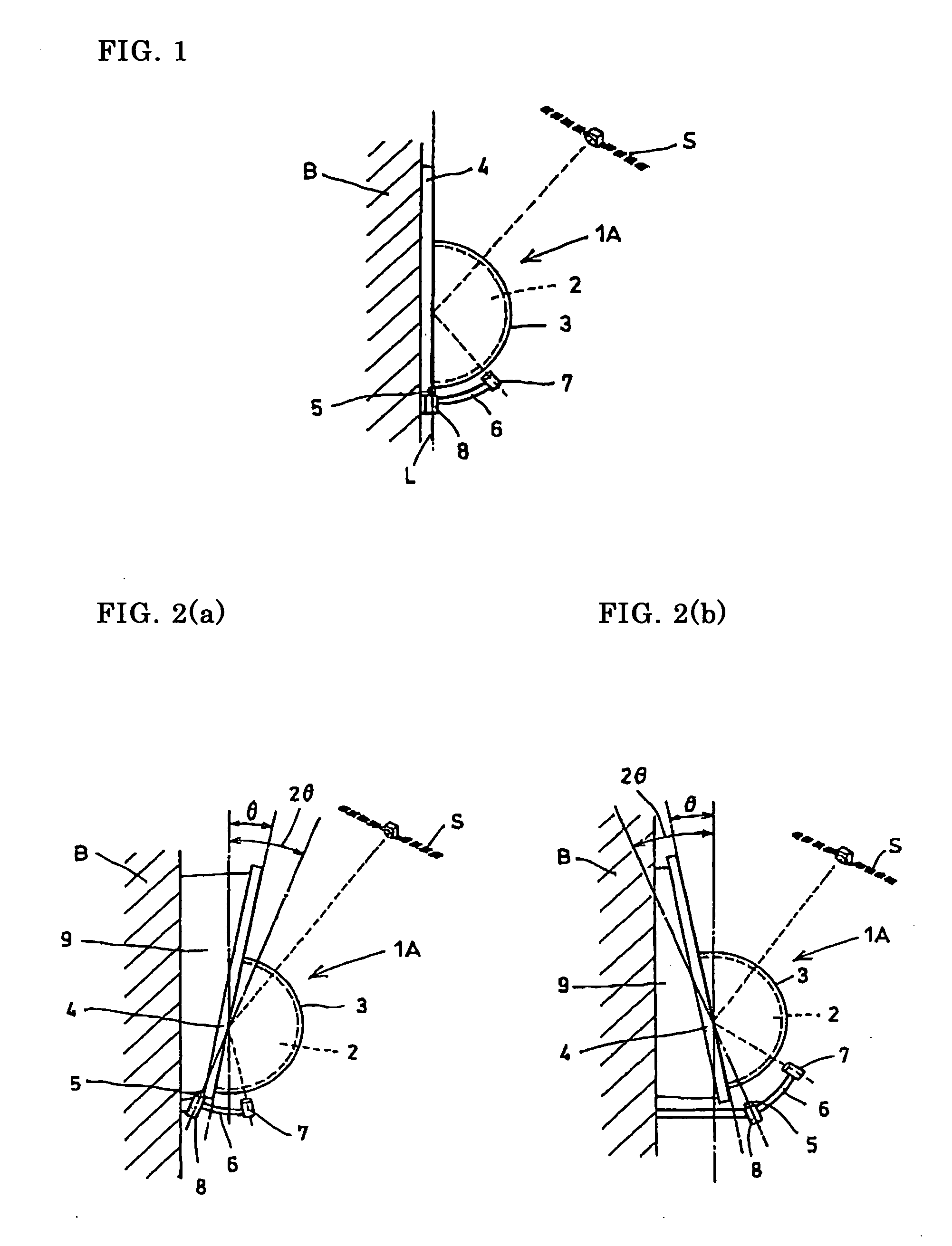

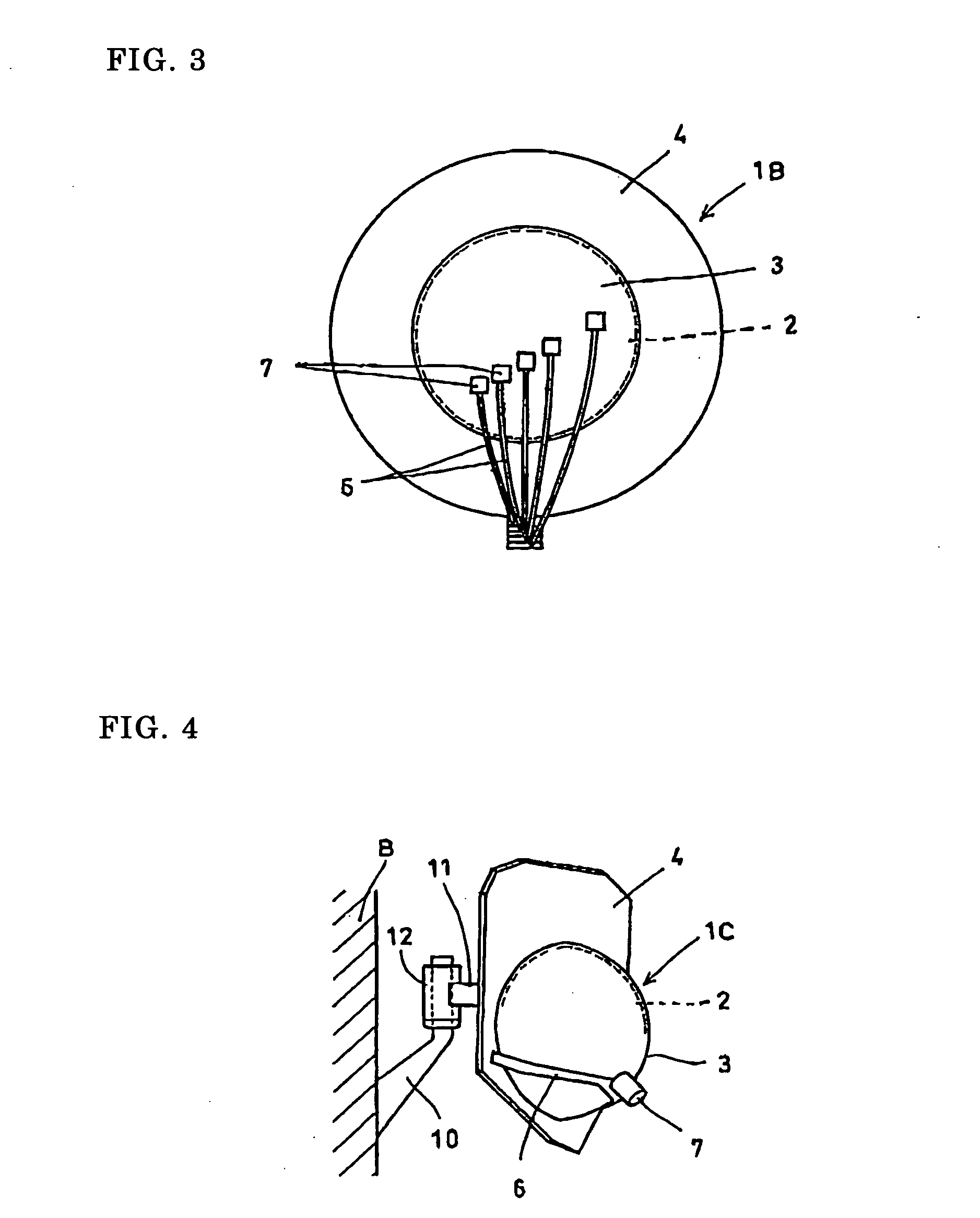

Radiowave lens antenna device

Lens antenna equipment including a hemispherical Luneberg lens made of dielectric, a reflector which has a size larger than the lens diameter and which is to be provided on a face equivalent to a cross-section made by halving a globular shape of the lens, a primary feed to be arranged at a focus part of the lens, and an arm for holding the primary feed, all of which are unitarily assembled together, wherein the holder of the arm can be turned about an axis that is a perpendicular line passing the center of the lens when the reflector is attached to its installation position in a substantially perpendicular manner with respect to the ground surface, and wherein the primary feed can be moved along the surface of the lens, on a plane that is perpendicular to the axis passing the center of the lens, and on a semicircle centering the axis.

Owner:SUMITOMO ELECTRIC IND LTD

Spherical alumina carrier and preparation method and application thereof

ActiveCN110404591AGel tightlyTight after gellingCatalyst carriersCatalyst activation/preparationWater vaporGlobular shaped

The invention provides a preparation method of a spherical alumina carrier, and belongs to the technical field of catalysts. The preparation method comprises the steps that 1) pseudo-boehmite is addedinto water, and after a gelatinizing agent is added, the pseudo-boehmite is acidized into sol; 2) the sol is dropped into an oil ammonia column device, formed and aged; 3) aged gel balls are flushedwith deionized water, dried and roasted to obtain the spherical alumina carrier. The preparation method of the spherical alumina carrier has the advantages that the large-pore-volume pseudo-boehmite is used for gelatinization, and the particle diameters of sol particles are controlled, so that the sol is more compact after being gelatinized in an ammonium hydroxide phase, and the mechanical strength of the alumina carrier is improved. The gel balls are dried in the air containing water vapor so that the abrasive resistance of the finished alumina carrier product can be improved, and the abrasion is reduced; the appropriate gelatinizing agent is added, and ammonium nitrate and alcohol are added into the ammonium hydroxide phase, so that sol globules are rapidly gelatinized and solidified inthe ammonium hydroxide phase, the height of an ammonium hydroxide layer is reduced, and the use amount of ammonium hydroxide is reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Three-dimensional zinc/carbon composite material for zinc-based battery and preparation method of three-dimensional zinc/carbon composite material

InactiveCN107681129AEasy to prepareShort timeCell electrodesNickel accumulatorsCarbon compositesGlobular shaped

The invention provides a three-dimensional zinc / carbon composite material for a zinc-based battery. The three-dimensional zinc / carbon composite material comprises a carbon conducting network of a three-dimensional multistage structure and zinc and / or zinc oxide loaded on the carbon conducting network, wherein the mass ratio of the zinc and / or the zinc oxide is 50-95%; the three-dimensional carbonconducting network is obtained through carbonization treatment of a polymer and has a macroporous, mesoporous and microporous pore structure; the shapes and forms of the zinc and the zinc oxide loadedon the three-dimensional carbon conducting network are one or more of a globular shape, a rod shape and a needle shape independently; and the sizes of the zinc and the zinc oxide are 10nm to 20 microns. The invention further provides a preparation method of the composite material. The three-dimensional zinc / carbon composite material provided by the invention has an ordered porous structure and high conductivity, has excellent electrochemical properties and cycle stability when used as a negative electrode of a nickel-zinc battery, and can be widely applied to the fields of various portable electronic devices, electric vehicles and aerospace.

Owner:BEIHANG UNIV

Preparation method of spherical yttrium oxide powder

InactiveCN106082296AReduce energy consumptionIncrease productivityRare earth metal oxides/hydroxidesAlcoholWater volume

The invention relates to a preparation method of spherical yttrium oxide powder, and relate to a preparation method of yttrium oxide powder. The method comprises the following steps: adding a surfactant in an aqueous solution containing yttrium salt and a precipitating agent to prepare a reaction solution, wherein the yttrium salt concentration in the reaction solution is 0.05-0.1 mol.L<-1>, employing a homogeneous precipitation method to prepare a yttrium oxide precursor precipitate, after solid-liquid separating, respectively washing the precipitate by water and small molecular alcohol, processing precipitate suspending liquid by using ultrasonic dispersion, separating the suspending liquid, drying the material, and calcining the material to obtain the yttrium oxide powder composed by submicron spherical particles. The yttrium salt solution with concentration of 0.05-0.1 mol.L<-1> is taken as a reaction solution, production efficiency of yttrium oxide is obviously increased, precipitating agent amount is obviously reduced, production cost is reduced, waste water volume is reduced, and the method is in favor of the protection environment, has simple process, and is convenient for popularization and usage.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

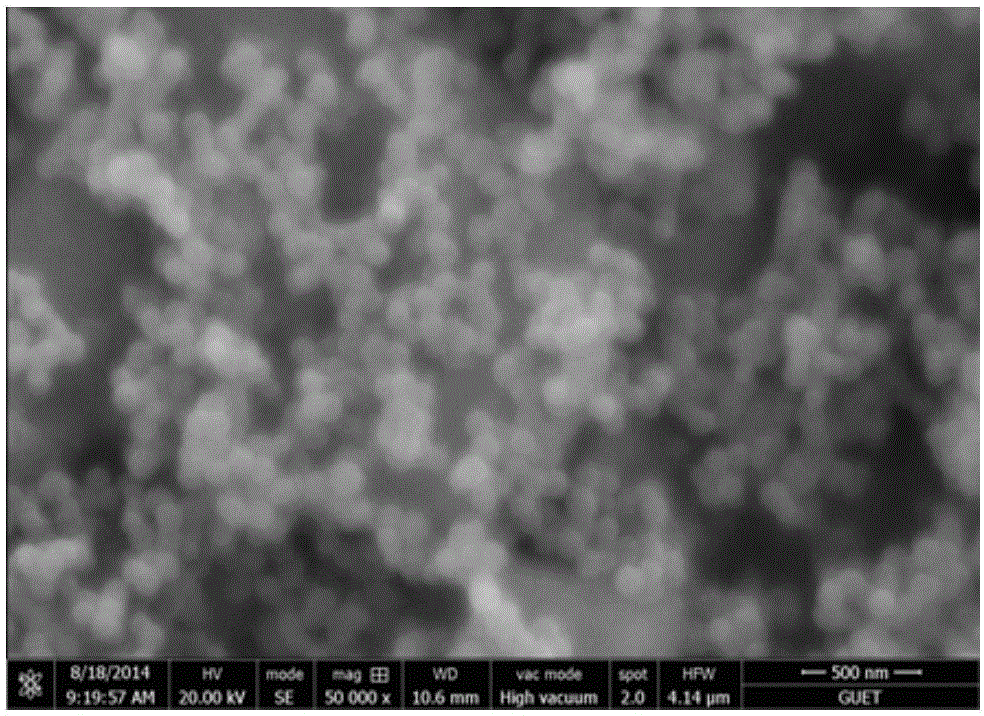

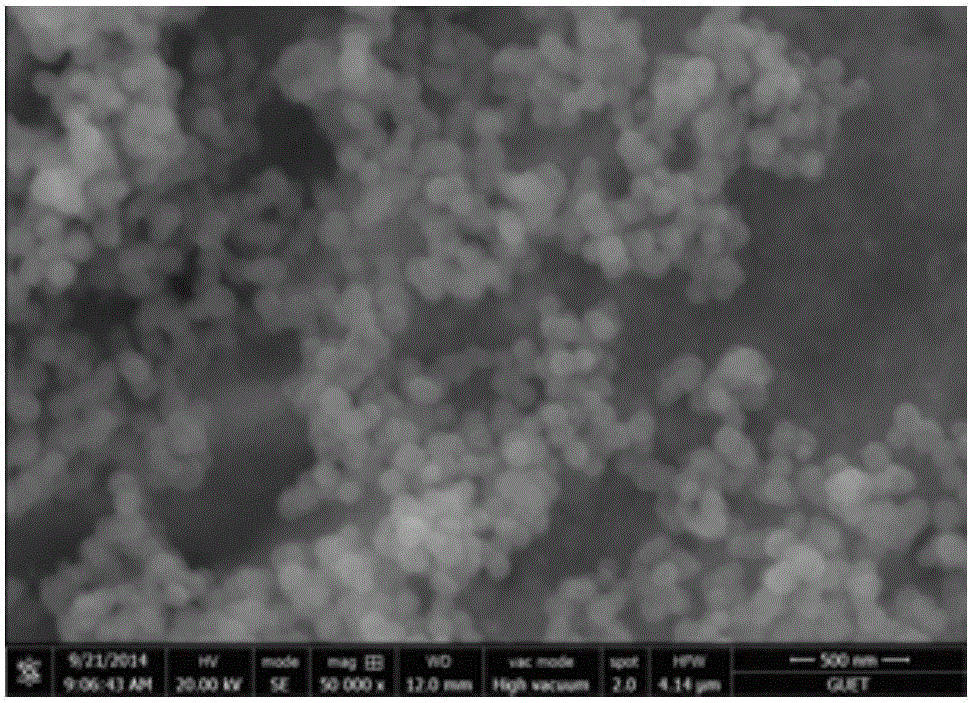

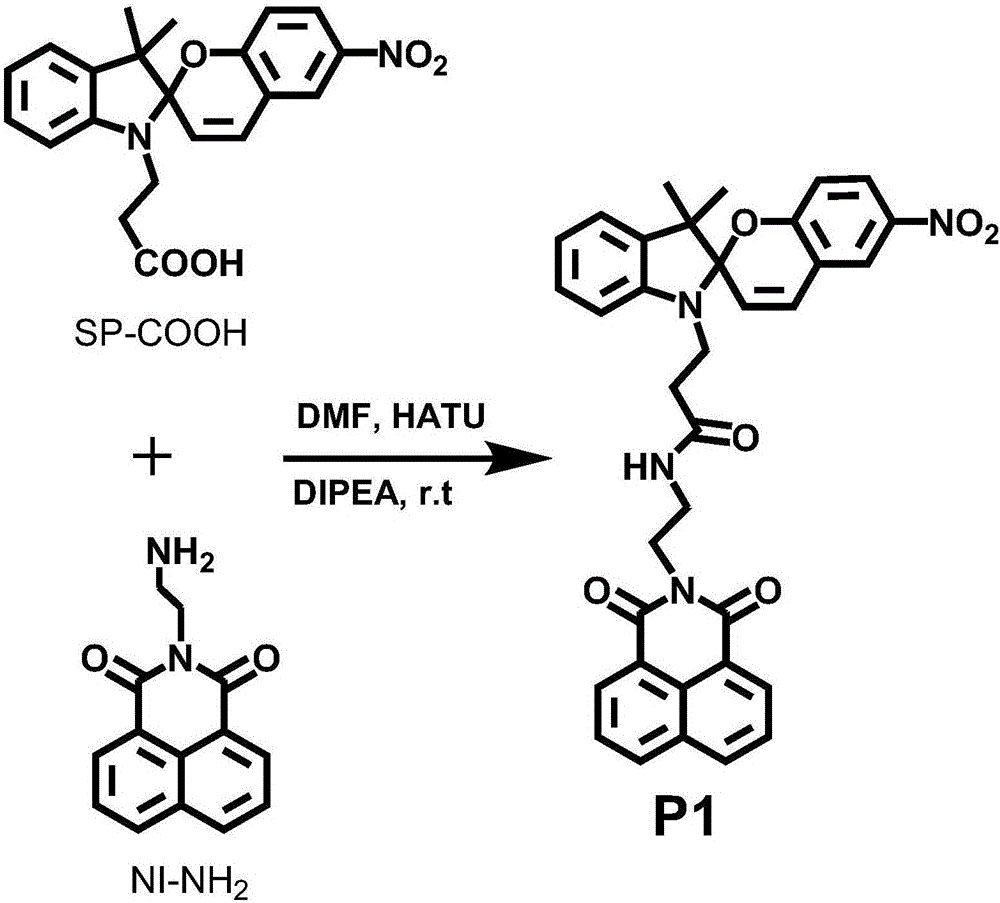

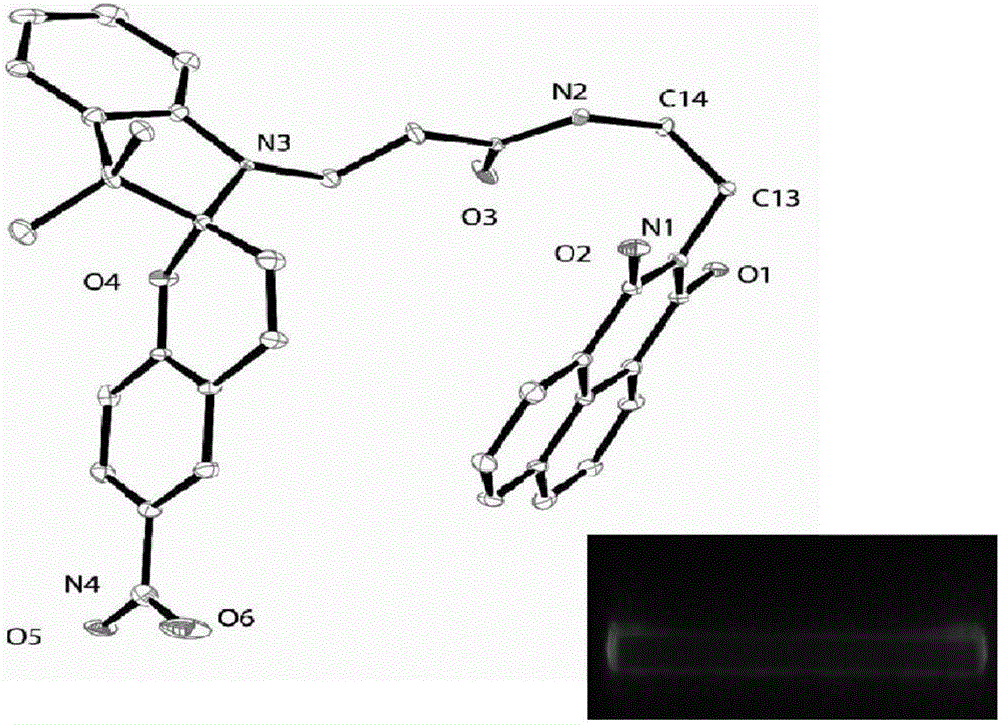

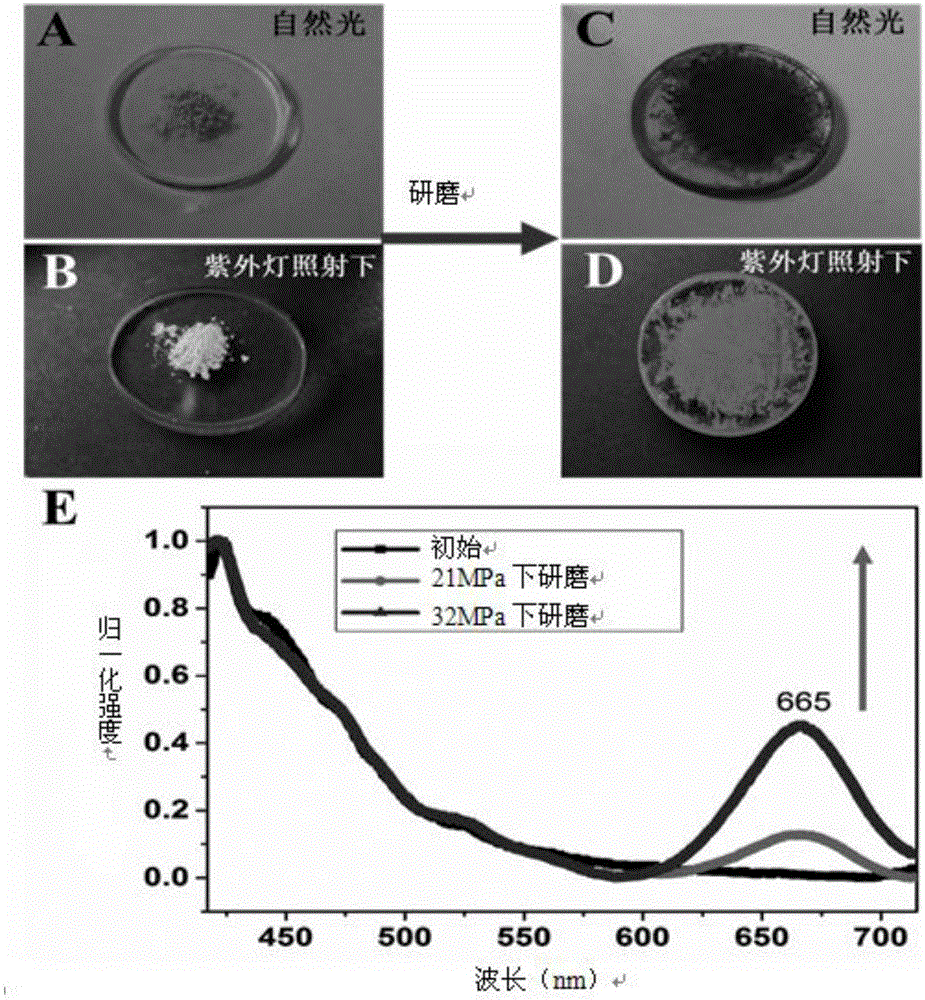

Power and light dual responses type self-assembly body based on dual fluorophore and preparing method thereof

ActiveCN106397450AControllable change of molecular assembly morphologyHigh crystallinityOrganic chemistryTenebresent compositionsDual responseGlobular shaped

The invention relates to a power and light dual responses type self-assembly body based on dual flurophore and a preparing method thereof. By using spiropyrane and naphthalimides of the dual fluorophore, a molecular self-assembly body of which the morphology of molecular self-assembly can be adjusted and controlled is obtained through amidation. The molecular self-assembly body can be a power-induced fluorescent color material and has the advantages of being easy to erase, being able to return to an original state through a way of heating, and having good repeatability. Meanwhile, the self-assembly body has a light-induced fluorescent color performance, and the fluorescent maximum emission wavelength of the self-assembly body under the stimulation of mechanical force has a certain degree of red shift compared with light-induced fluorescent maximum emission wavelength, thus under the effect of the mechanical force, the assembly morphology of the self-assembly body can achieve the transformation from a fibrous shape to a globular shape. The self-assembly body is simple and convenient in preparing method, and can promote the applications of power-induced fluorescent color materials in practice.

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of calcium carbonate particle

InactiveCN102275966AUnique structureUniform sizeCalcium/strontium/barium carbonatesInorganic saltsGlobular shaped

The invention belongs to the technical field of inorganic salt materials, and specially relates to a preparation method of calcium carbonate particulates. The method comprises the following steps of adding 0.001 to 2 mol / L of a calcium salt into an 0.0005 to 1 g / L of additive solution to obtain a mixed solution, standing, adjusting a pH value of the mixed solution to a pH value of 5 to 12, through adopting different carbonate sources and corresponding different concentrations, carrying out a reaction at a temperature of 10 to 60 DEG C in an inclosed system for 10 minutes to 30 days, separating a product obtained by the previous step, and drying to obtain a desired product. Calcium carbonate particulates prepared by the method have different sizes which are in a range of 0.1 to 50 micrometers, different shapes such as a hexagonal petal shape and a globular shape, and high thermal stability. The method has the advantages of wide raw material source, low price, simple process, good operability, low pollution of adopted solvents, no toxic effect, good conformity with green chemistry requirements, and great potential for large-scale production.

Owner:FUDAN UNIV

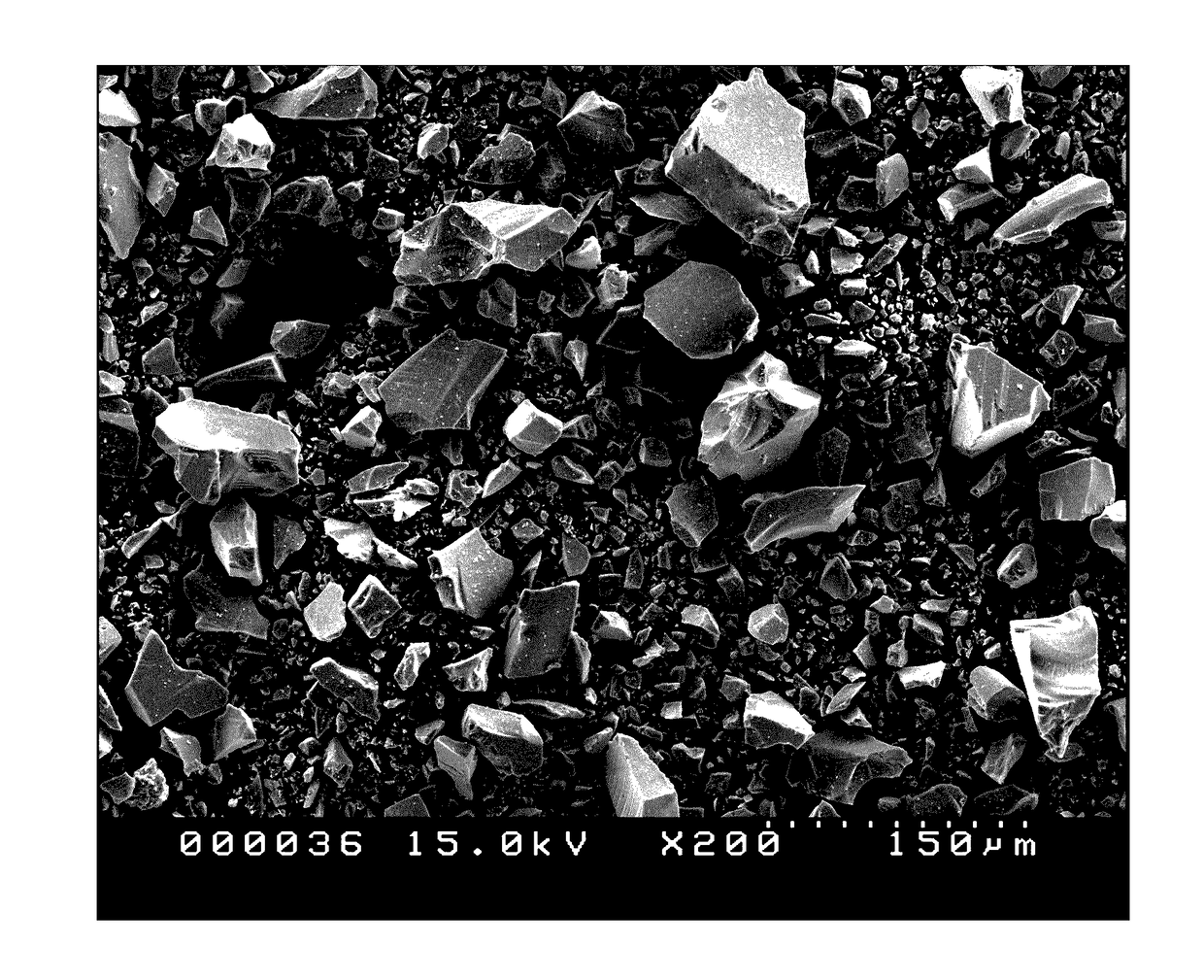

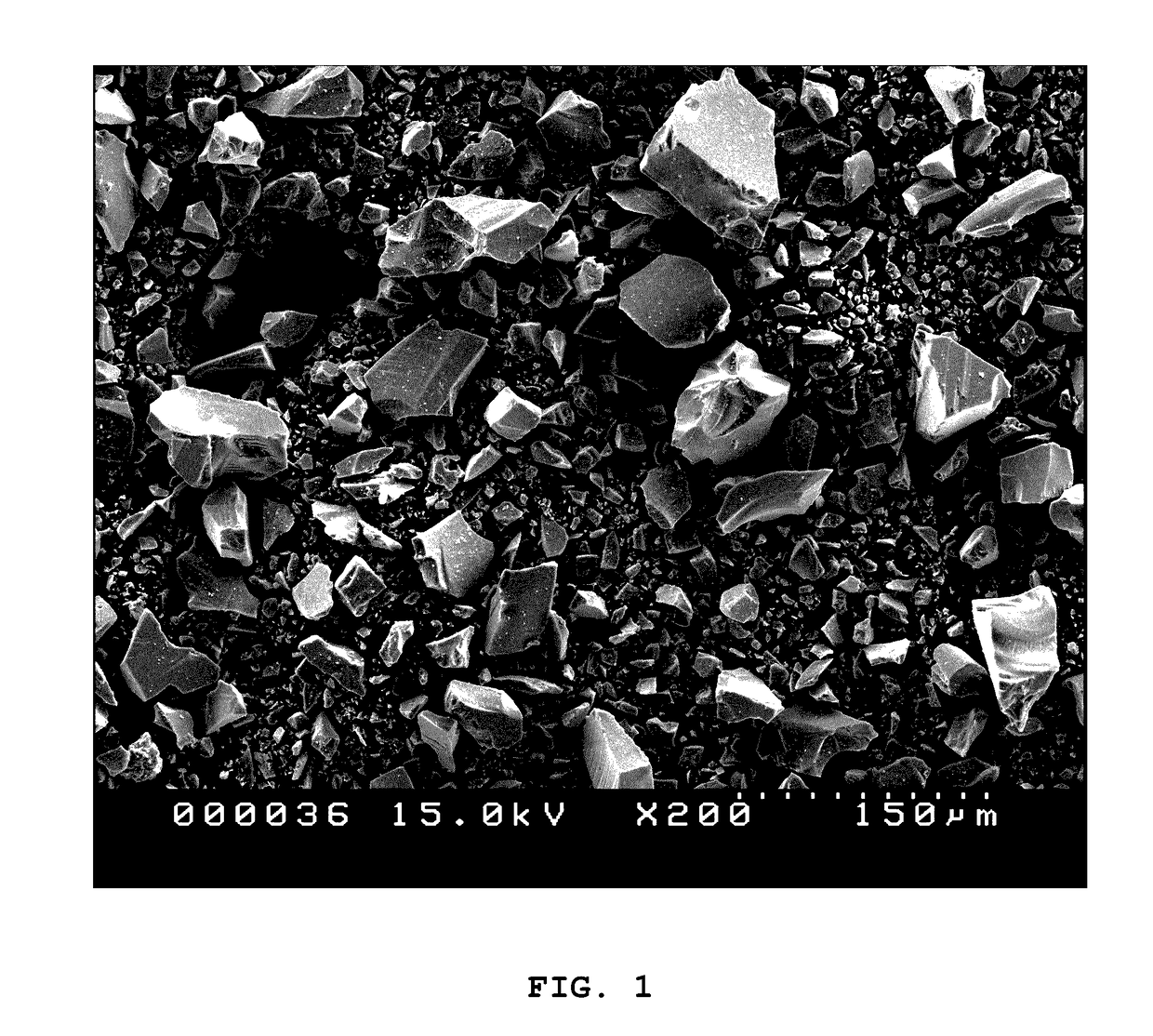

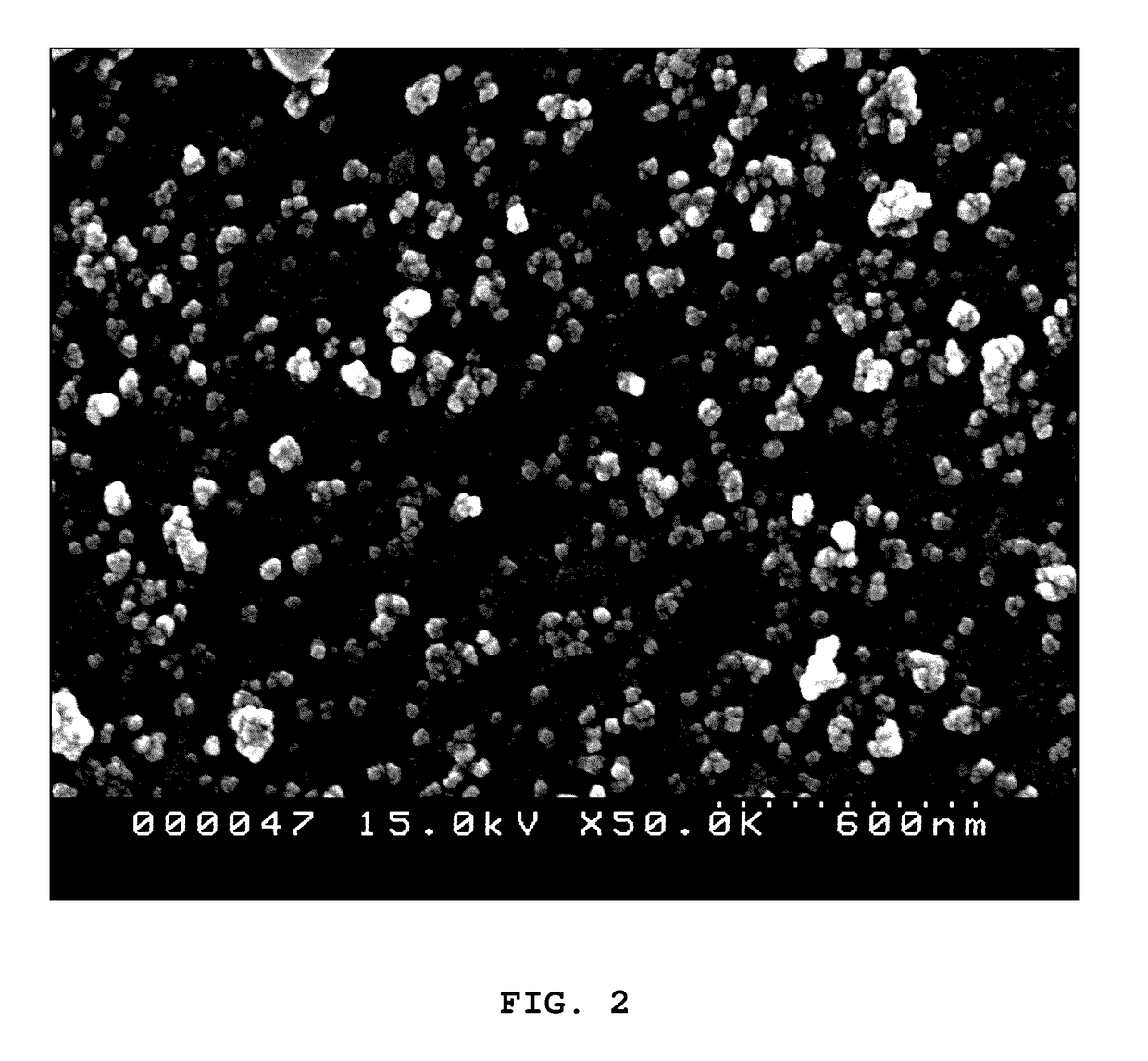

Molding material for 3D printing based on crushed amorphous glass having irregular shape, molding method for 3D printing, and molded body

ActiveUS20180194662A1Improve liquidityImprove sinterabilityMaterial nanotechnologyAdditive manufacturing apparatusShell moldingGlobular shaped

The present invention relates to a forming material for three-dimensional (3D) printing, a forming method for 3D printing, and a formed object, wherein, while being based on an amorphous glass powder shaped irregularly, the forming material for 3D printing ensures excellent flowability and sinterability such that it enables the formation of high-quality products at high speed. The forming material for 3D printing consists of a parent glass powder in the form of an unmelted powder irregularly shaped by crushing amorphous glass; and a spherical nanopowder that has an average particle diameter equal to or less than 1 / 50th of the average particle diameter of the parent glass powder and is mixed in such a way that it can be disposed on a surface of the parent glass powder to enhance the flowability of the irregularly shaped parent glass powder during the formation of an object by 3D printing.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

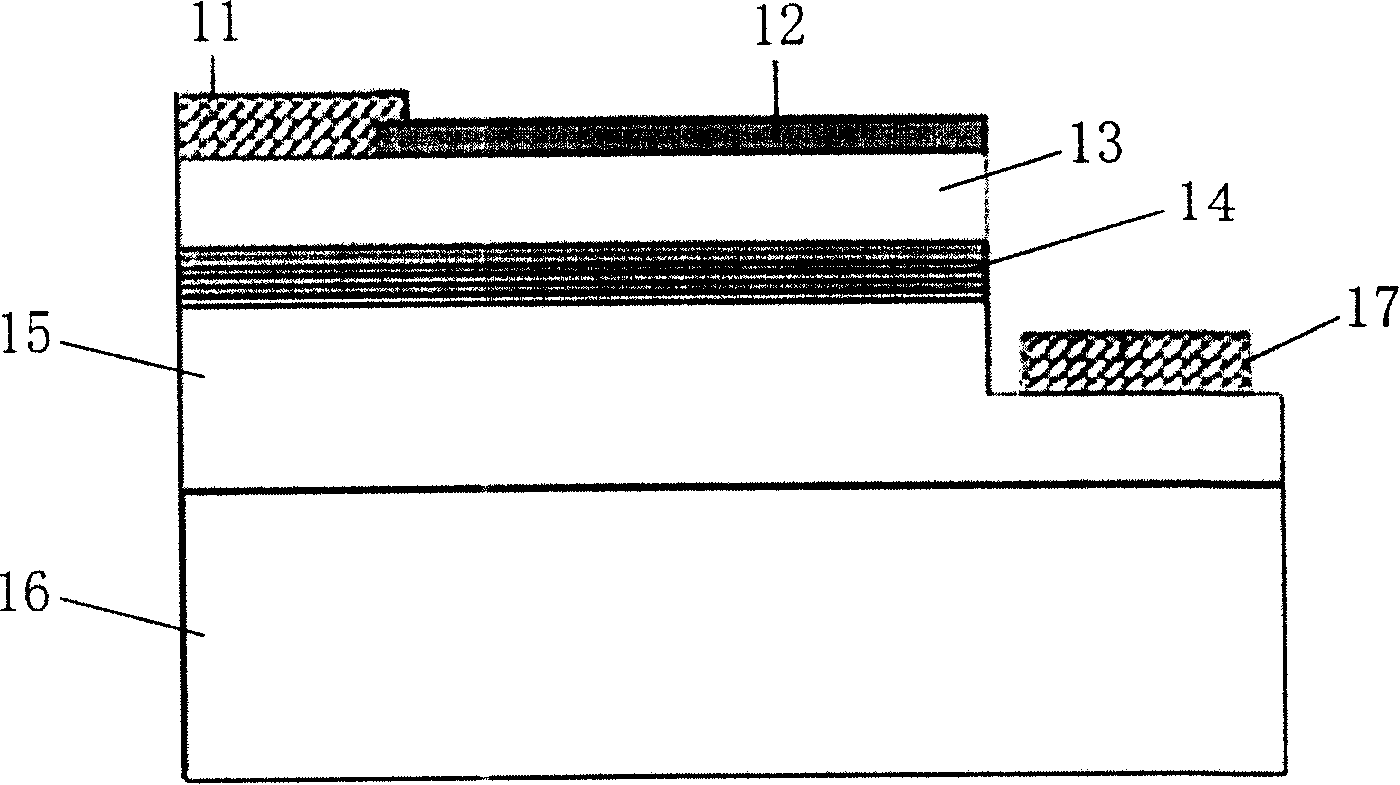

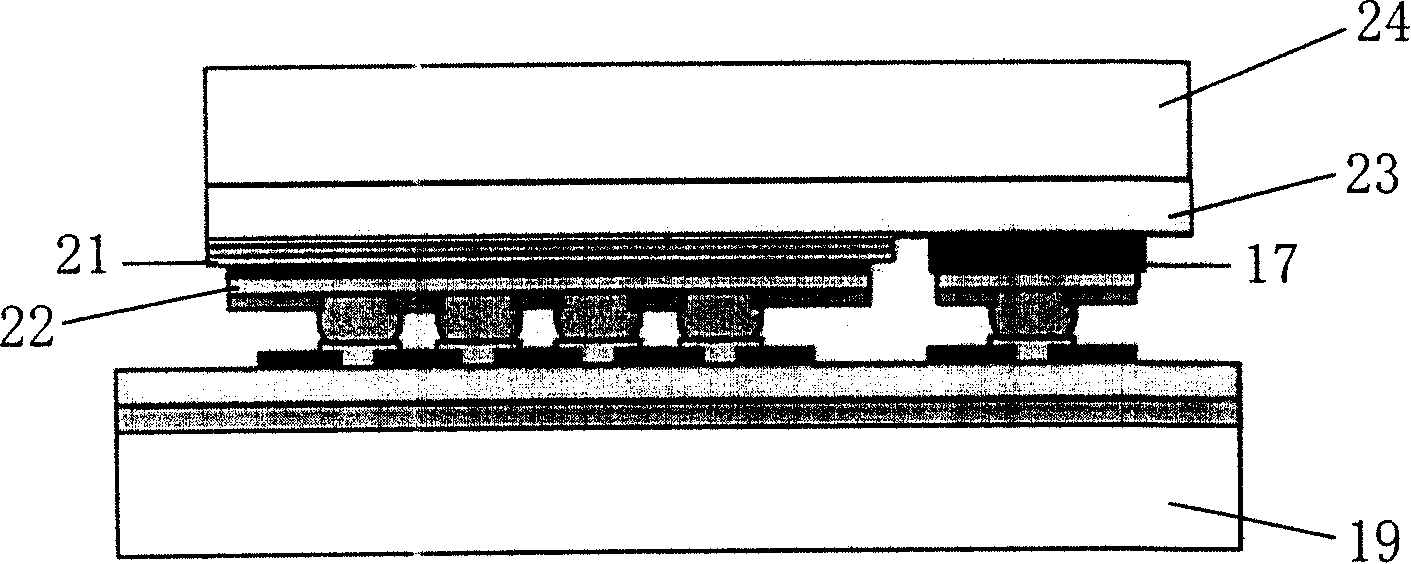

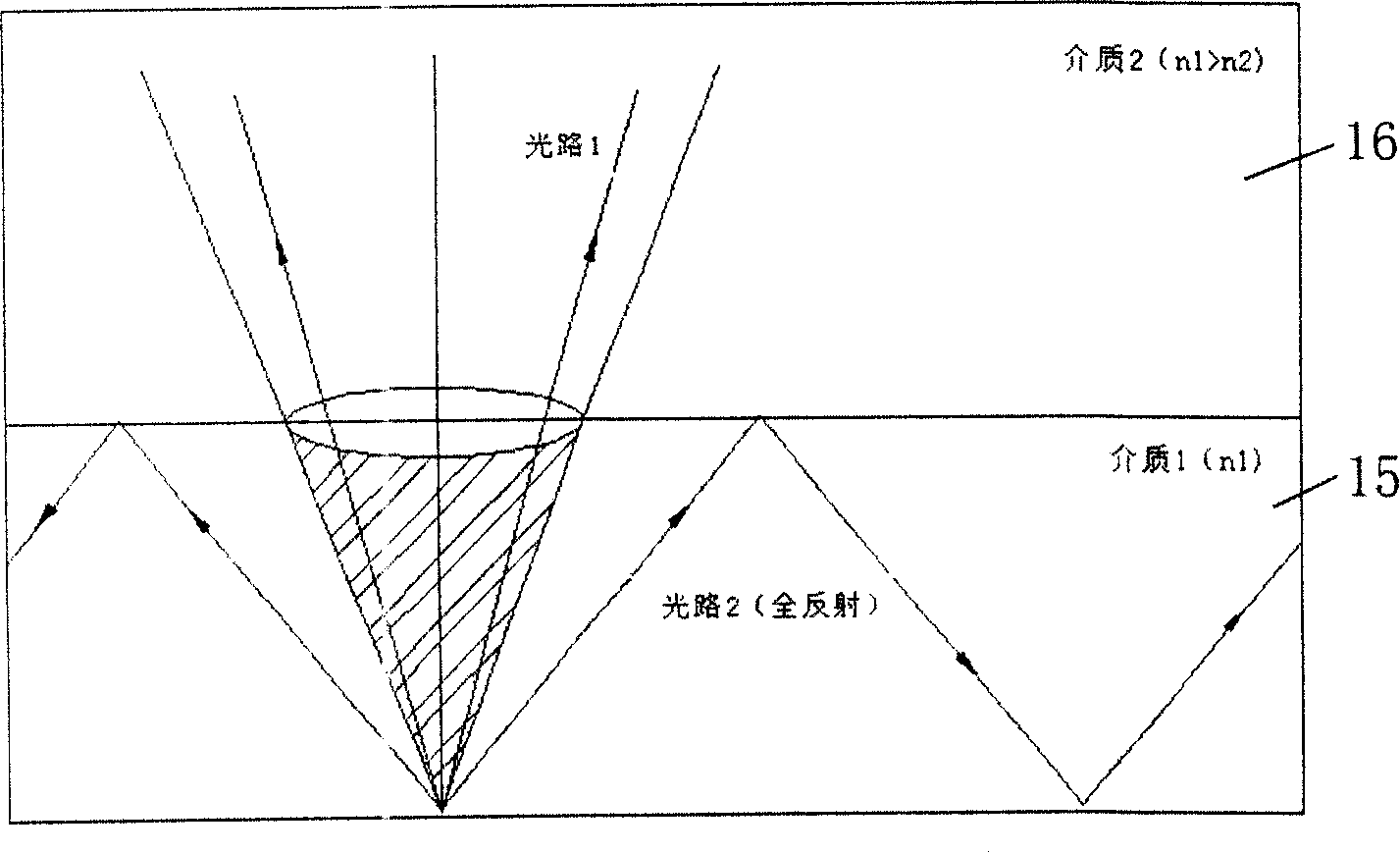

Method for improving luminance brightness of chip at the axial direction

The present invention discloses a method for improving axial brightness of chip, and is characterized in that the method further comprises the following procedures: step 1, a layer of nickel metal with the thickness between 1 nanometer and 50 nanometer is coated on the surface of a sapphire substrate by vapor deposition; step 2: the nickel metal is rapidly annealed for 30 seconds to 300 seconds with the temperature of 600 DEG C to 900 DEG C, then the nickel metal forms a globular shape with the diameter between 200 nanometers and 400 nanometers, and is used as a mask; step 3, the surface of the sapphire substrate is etched selectively and the depth is between 100 nanometers and 500 nanometers; step 4, the nickel metal on the sapphire substrate is cleaned; step 5, indium gallium nitride epitaxial layer grows from the sapphire substrate. The technical proposal of the invention can reduce the full reflection of emergent light and improve axial brightness.

Owner:HANGZHOU SILAN AZURE

Preparation method of titanium dioxide/nickel oxide double-shell hollow sphere

ActiveCN107803170AUniform particle sizeImprove mobilityMicroballoon preparationMetal/metal-oxides/metal-hydroxide catalystsFiltrationGlobular shaped

The invention discloses a preparation method of a titanium dioxide / nickel oxide double-shell hollow sphere. The preparation method includes the steps: (1) mixing tetrabutyl orthosilicate, ammonia water and absolute ethyl alcohol, heating mixture and separating, washing, drying and grinding products to obtain spherical silica; (2) mixing the spherical silica, the absolute ethyl alcohol, acetonitrile and the ammonia water, adding tetra-n-butyl titanate and separating, washing, drying, grinding and calcining the products to obtain spherical silica / titanium dioxide; (3) etching the spherical silica / titanium dioxide, centrifuging, washing, drying and grinding the products to obtain a titanium dioxide hollow sphere; (4) mixing the titanium dioxide hollow sphere and nickel nitrate hexahydrate solution, performing hydrothermal reaction and performing suction filtration, washing, drying, grinding and calcining on reacted products to obtain the titanium dioxide / nickel oxide double-shell hollow sphere. The prepared titanium dioxide / nickel oxide double-shell hollow sphere is provided with obvious shells.

Owner:QILU UNIV OF TECH

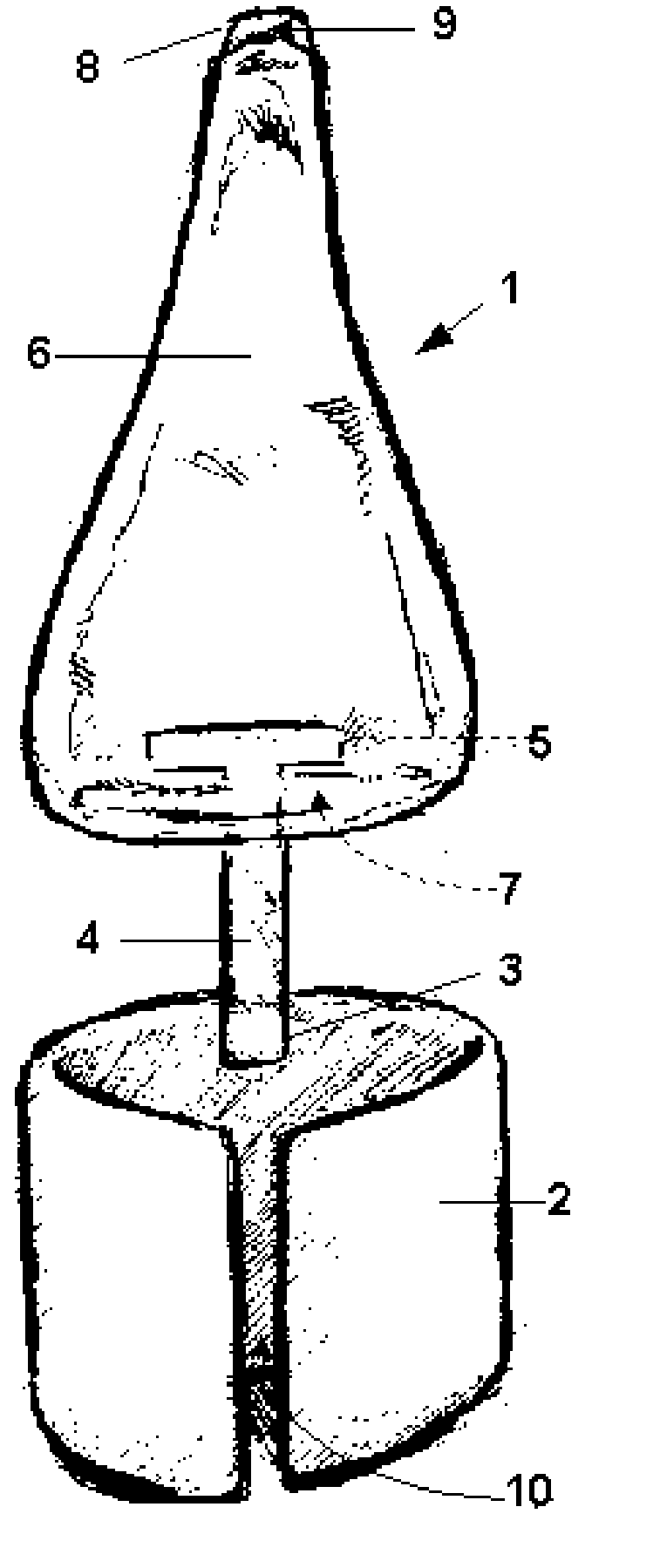

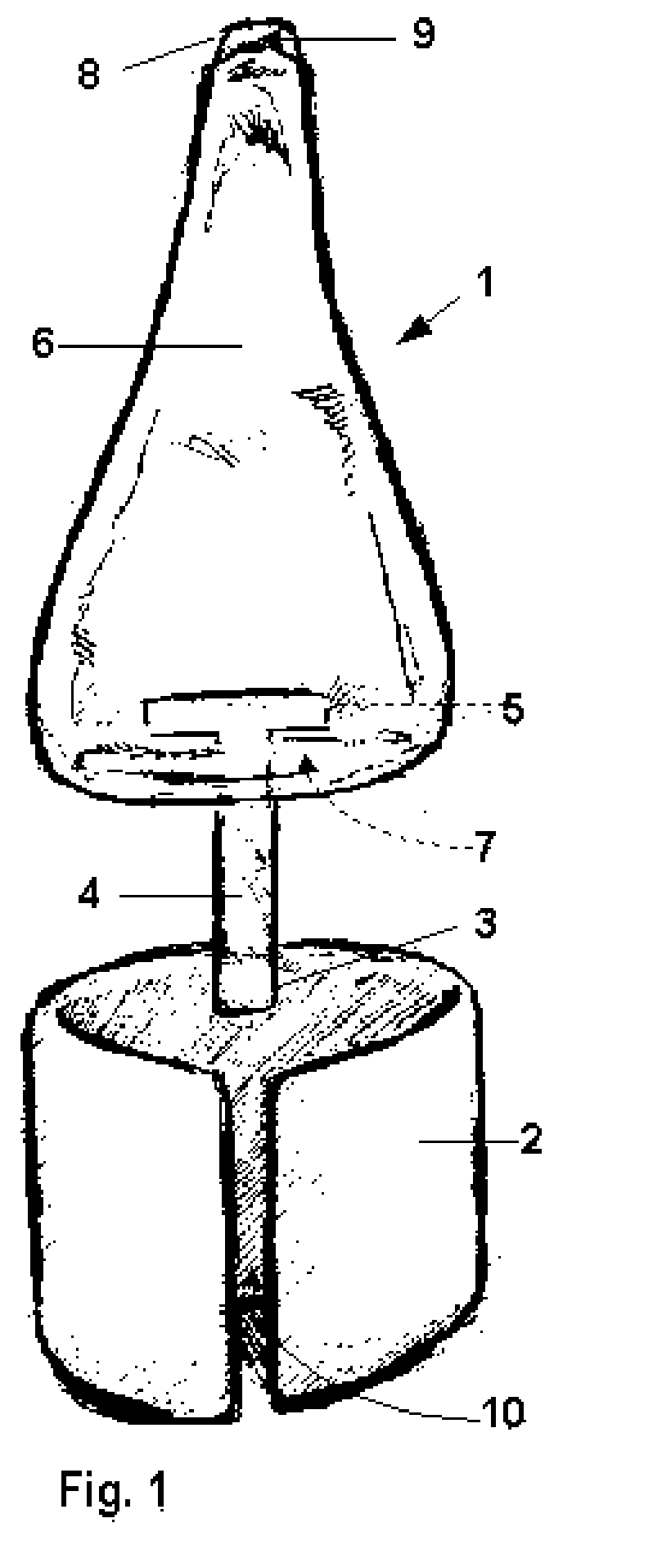

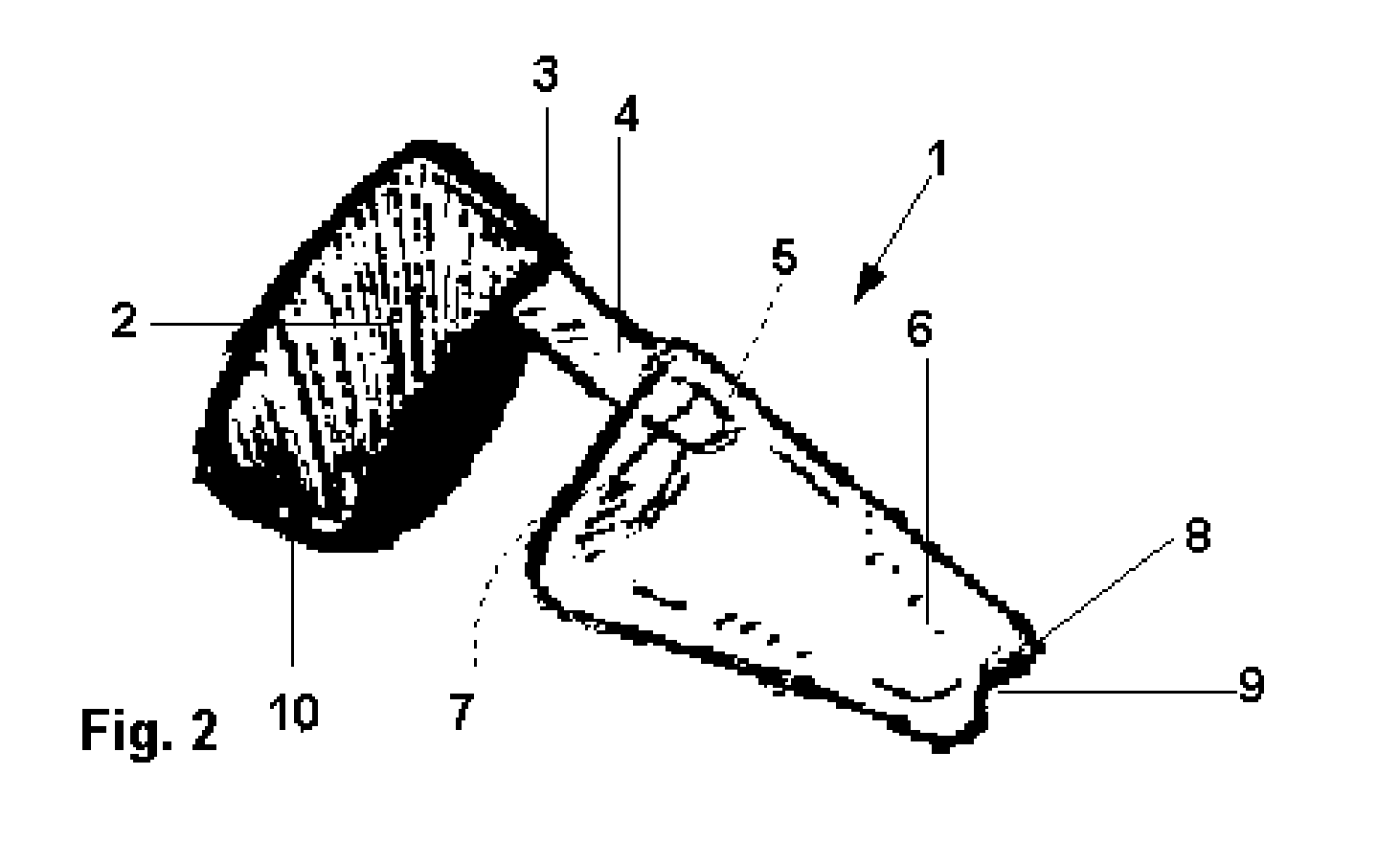

Guitar Slide

A Slide for musical stringed instruments which includes a globular shaped body made of a material, such as glass, brass, or metal, designed to illicit specific sounds when placed in contact with a string of a musical instrument, a finger ring, and a means to connect the finger ring to the globular shaped body, such means allowing the finger to bend normally. A second embodiment has a tapered cylindrical form for the body.

Owner:WRIGHT SHAUN

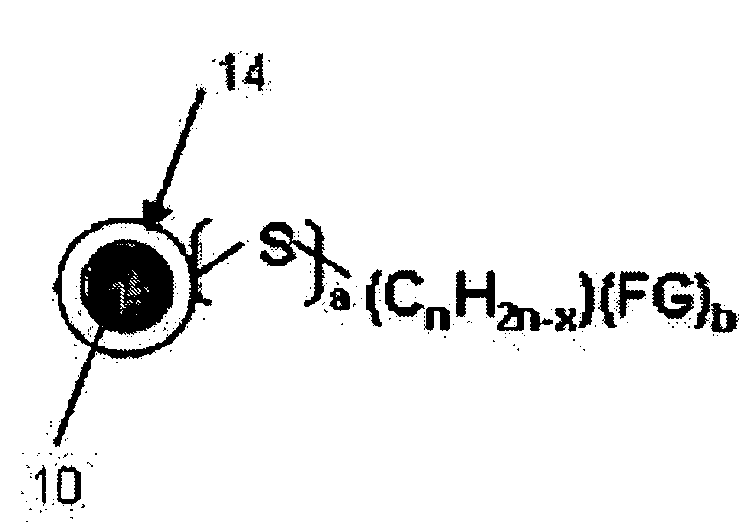

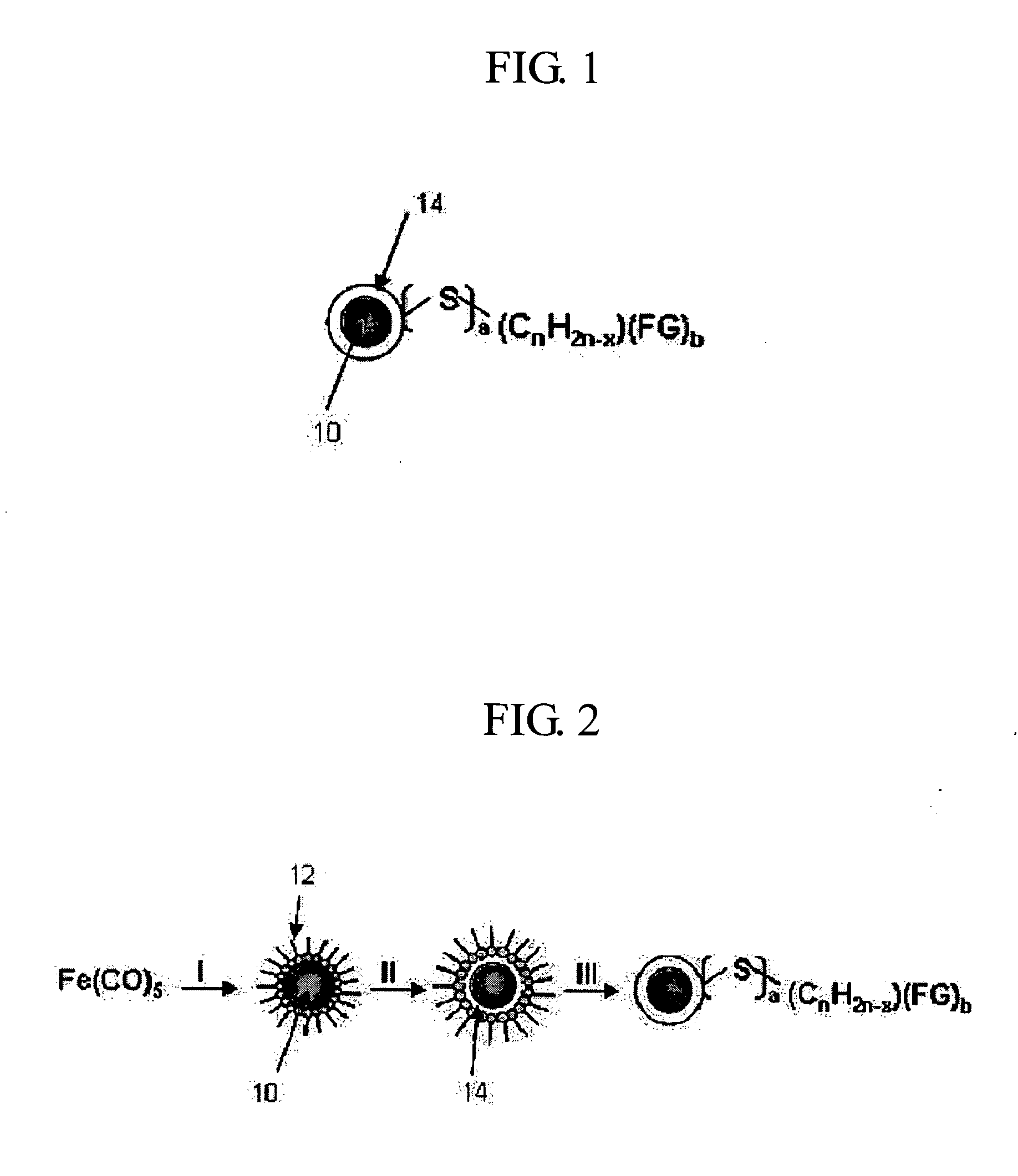

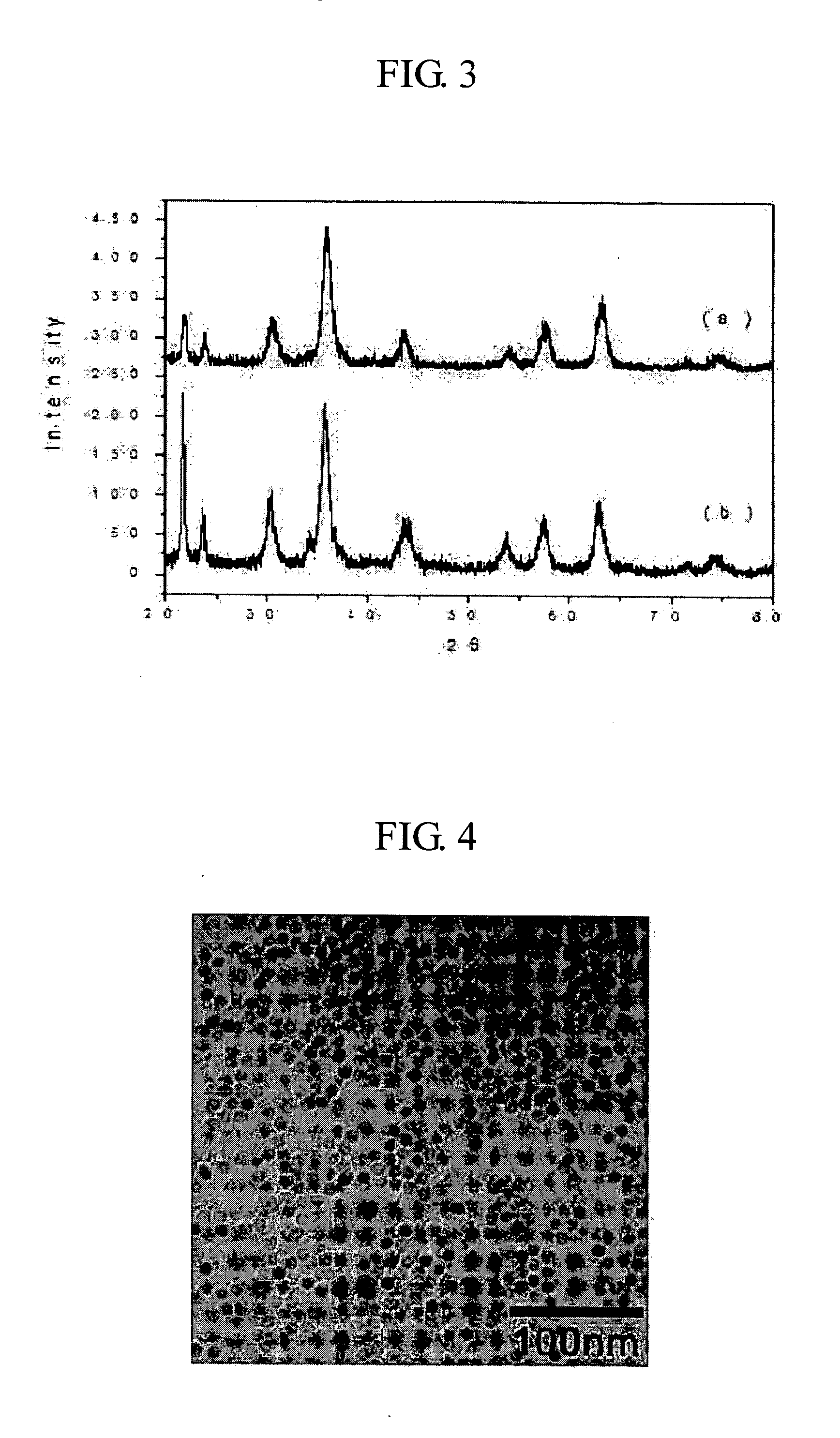

Uniform-sized hydrophilic metal oxide nanoparticles and preparation method thereof

InactiveUS20070248678A1Increased of dispersityGood size uniformityMaterial nanotechnologyPowder deliverySimple Organic CompoundsMetal oxide nanoparticles

The present invention provides for a metal oxide nanoparticle that contains a metal core, a shell formed on the surface of the core and consisted of the same metal as the core, and an organic compound containing an element capable of covalently bonding with the nanoparticle and a hydrophilic functional group. According to the examples, uniform-sized hydrophilic metallic oxide-based nanoparticles are obtained when superparamagnetic iron oxide particles, which have a globular shape and are less than 20 nanometers in size, are first synthesized in an organic solution, and then are converted to hydrophilic particles after undergoing surface modification.

Owner:KOREA INST OF SCI & TECH

LED lamp tube

InactiveCN101509628AOvercoming LED SpotsOvercome glarePoint-like light sourceElongate light sourcesGlobular shapedEngineering

The invention relates to an LED light tube which belongs to the technical field of lighting decoration. The LED light tube comprises an LED, a tube support, a light panel and a transparent cover. At least one surface of the inner surface and outer surface of the transparent cover is provided with a strip groove which has notching direction vertical to the direction of a light tube axle. The invention solves the problems of globular-shaped facula and glare of LED, and has the advantages of simple manufacturing technique and low cost.

Owner:天津市易伸技术有限公司

Aerogel and method for manufacture thereof

ActiveUS9216909B2Efficient productionGood heat insulationSilicaSynthetic resin layered productsEmulsionImaging analysis

Owner:TOKUYAMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com