Preparation method of spherical yttrium oxide powder

A technology of yttrium oxide and powder, which is applied in the field of preparation of spherical granular yttrium oxide powder, can solve the problems of unfavorable industrial production application, high energy consumption of industrial production, and difficult industrial production, so as to facilitate popularization and use and reduce industrial production Low energy consumption and low difficulty in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

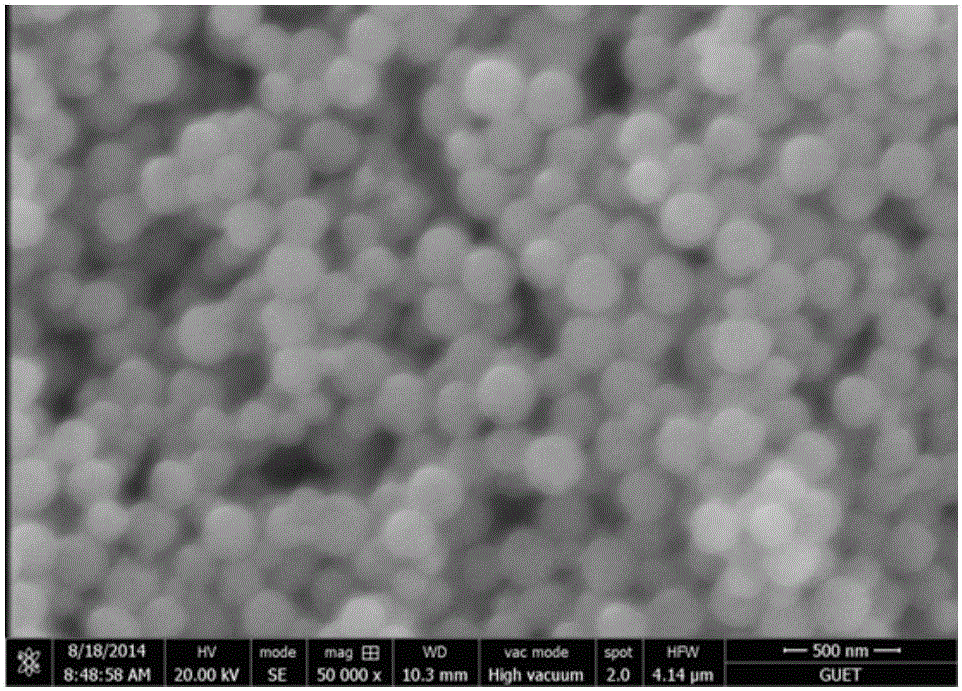

Embodiment 1

[0039] A preparation method of spherical yttrium oxide powder, comprising the following steps:

[0040] (1) Preparation of initial powder of yttrium oxide precursor:

[0041] Dissolve yttrium salt-yttrium nitrate in water to obtain a concentration of 0.05mol. L -1 The aqueous solution of yttrium nitrate is 30 times of the amount of yttrium ion substance according to the amount of the precipitating agent, and the concentration is 0.5mol. L -1The precipitating agent solution, the precipitating agent is urea, stirred and dissolved to obtain a mixed solution, the surfactant cetyltrimethylammonium bromide (CTAB) was added according to 0.1% of the mixed solution mass, stirred and dissolved, and kept at 95°C Stir the reaction for 1 hour, use the uniform precipitation method to obtain the precipitate of the yttrium oxide precursor, centrifuge or filter to separate the precipitate; wash the precipitate twice with distilled water, then soak it with absolute ethanol once, and dry it t...

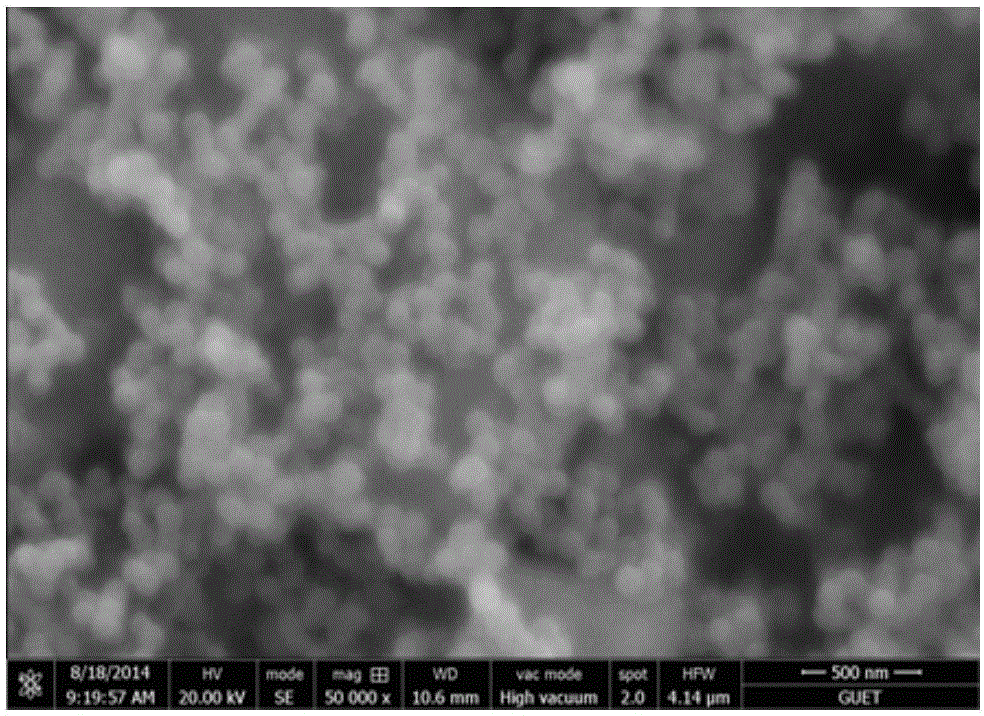

Embodiment 2

[0047] A preparation method of spherical yttrium oxide powder, comprising the following steps:

[0048] (1) Preparation of initial powder of yttrium oxide precursor:

[0049] Dissolve yttrium salt-yttrium nitrate in water to obtain a concentration of 0.1mol. L -1 The aqueous solution of yttrium nitrate is 10 times of the amount of yttrium ion substance according to the amount of precipitating agent, and the concentration is 1mol. L -1 The precipitating agent solution, the precipitating agent is urea, stirred and dissolved to obtain a mixed solution, the surfactant cetyltrimethylammonium bromide (CTAB) was added according to 0.5% of the mixed solution mass, stirred and dissolved, and kept at 90°C Stir the reaction for 3 hours, use the uniform precipitation method to obtain the precipitate of the yttrium oxide precursor, centrifuge or filter to separate the precipitate; wash the precipitate twice with distilled water, then soak it with absolute ethanol once, and dry it to obt...

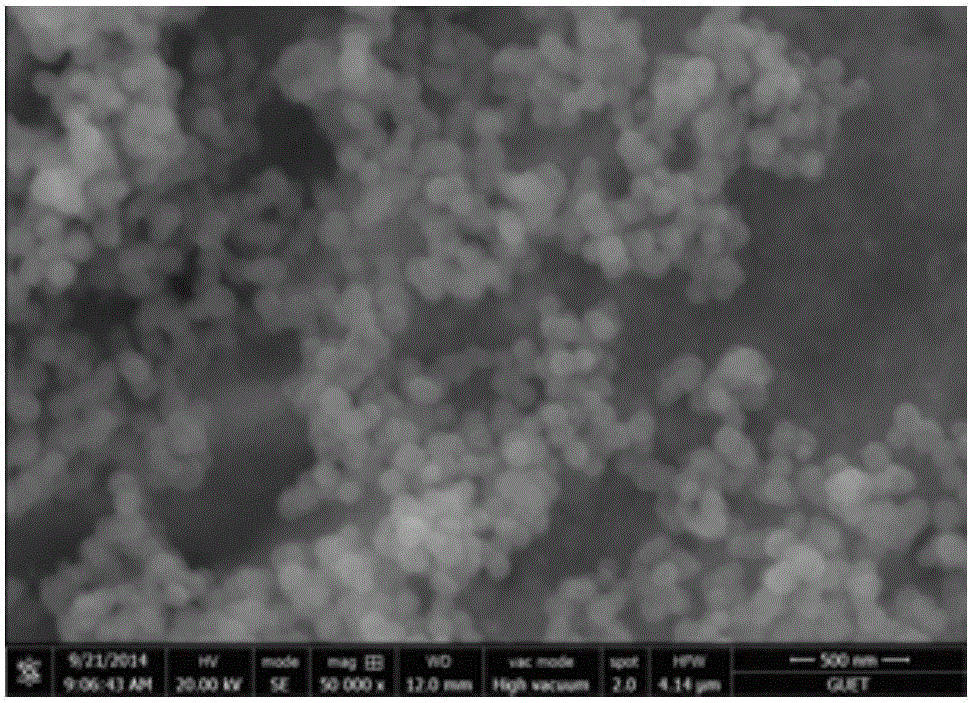

Embodiment 3

[0055] A preparation method of spherical yttrium oxide powder, comprising the following steps:

[0056] (1) Preparation of initial powder of yttrium oxide precursor:

[0057] Dissolve yttrium salt-yttrium nitrate in water to obtain a concentration of 0.075mol. L -1 The aqueous solution of yttrium nitrate is 0.5mol. L -1 Precipitating agent solution, the precipitating agent is urea, stirred and dissolved to obtain a mixed solution, the surfactant cetyltrimethylammonium bromide (CTAB) was added according to 0.3% of the mixed solution mass, stirred and dissolved, and kept at 92°C Stir the reaction for 2 hours, use the uniform precipitation method to obtain the precipitate of the yttrium oxide precursor, centrifuge or filter to separate the precipitate; wash the precipitate twice with distilled water, then soak it with absolute ethanol once, and dry it to obtain the yttrium oxide Precursor initial powder.

[0058] (2) Prepare the final powder of yttrium oxide precursor:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com