LED lamp tube

A technology for LED lamps and lamps, which is applied to lampshades, lighting devices, light sources and other directions, can solve problems such as glare and uneven light, achieve low cost, simple production process, and overcome the problems of LED spot and glare.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

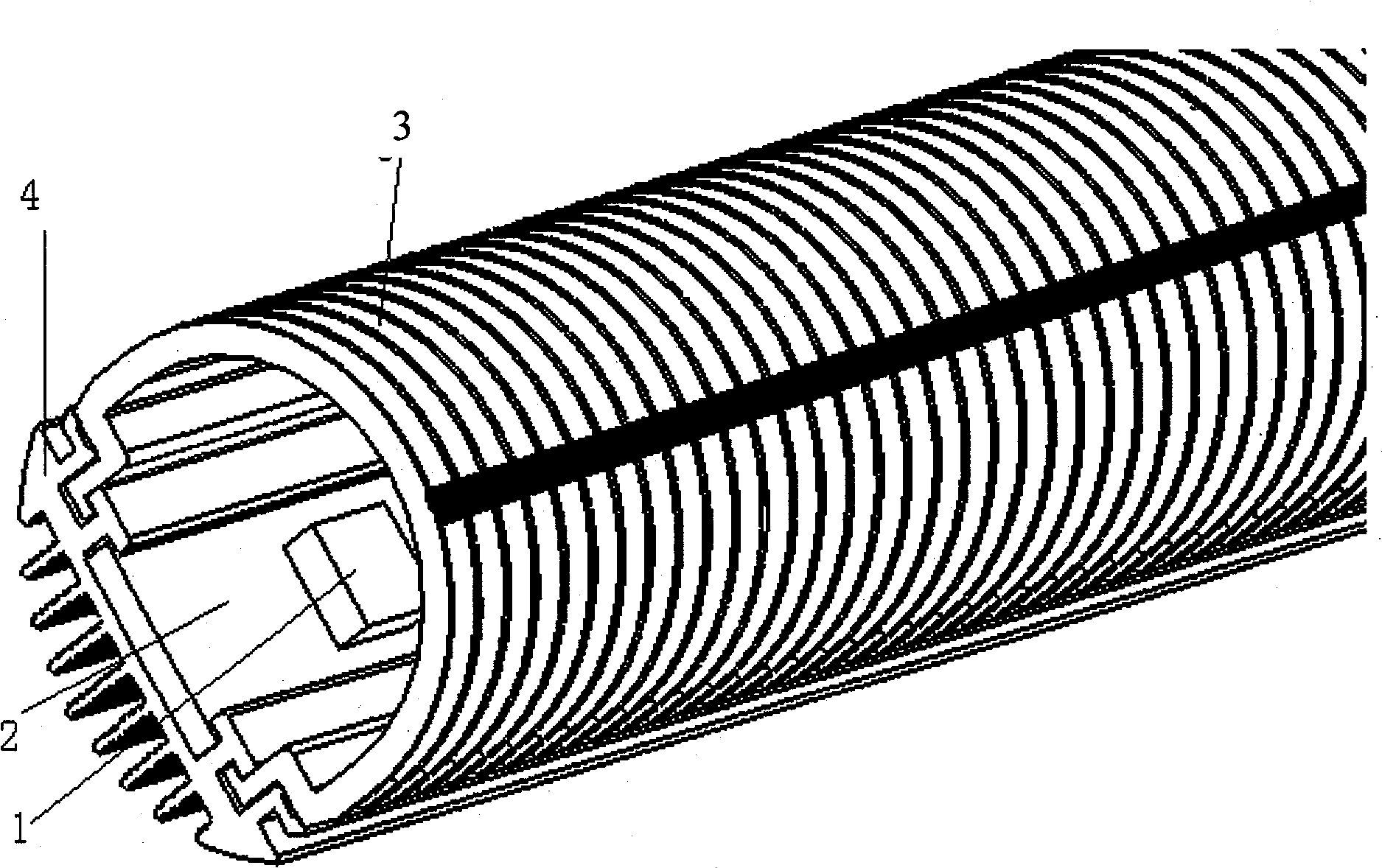

[0013] Such as figure 1 As shown, the lamp tube of this embodiment includes LED 1 , LED lamp board 2 , striped transparent cover 3 and tube base 4 . The LED lamp board 2 is equipped with LEDs, and the LED lamp board 2 and the striped light-transmitting cover 3 are fixed on the tube base 4 respectively. As a result, the point light emitted by a single LED 1 is converted into linear light.

Embodiment 2

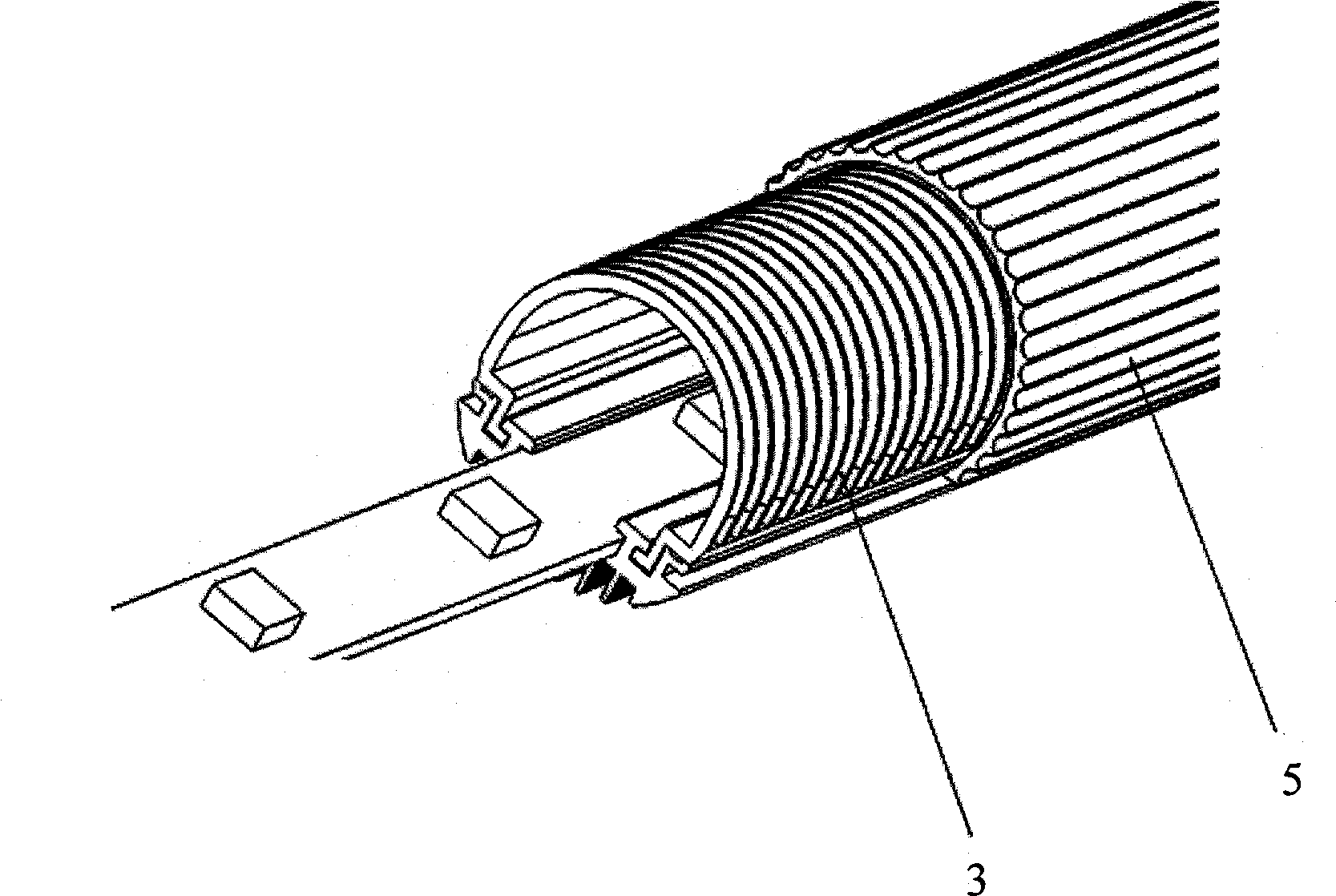

[0015] Such as figure 2 As shown, the lamp tube of this embodiment, in addition to including all the components of Embodiment 1, is also covered with a light-transmitting outer cover 5 outside the striped light-transmitting cover 3, and the light-transmitting outer cover 5 is fixed on the tube base. The stripe direction of the light-transmitting outer cover is parallel to the axial direction of the lamp tube. The lamp tube of this embodiment can convert point light emitted by a single LED 1 into planar light.

[0016] In the above two embodiments, on the inner and outer surfaces of the striped light-transmitting cover and the light-transmitting outer cover, the directions of the strip-shaped grooves are parallel to each other. In other embodiments, it can also be designed as a structure in which the slotting directions on their inner and outer surfaces are perpendicular to each other. lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com