Preparation method for superfine spherical stainless steel powder

A stainless steel and powder technology is applied in the field of preparation of fine spherical stainless steel powder, which can solve the problems of high technical difficulty, high cost, and limitation of the popularization and application of gas atomized stainless steel powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

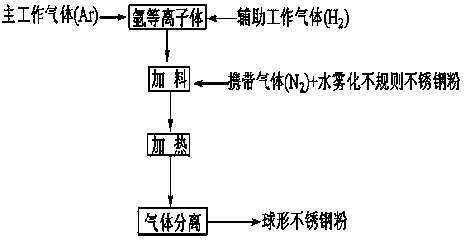

[0019] A kind of preparation method of fine spherical stainless steel powder, flow process is as follows figure 1 shown, follow the steps below:

[0020] 1. Establish a stable argon plasma torch: input 0.5MPa, 0.6MPa or 0.8MPa continuous main working gas argon flow into the plasma reactor, auxiliary working gas hydrogen input pressure is 0.5MPa, 0.6 MPa or 0.8MPa, induction coil Load to a certain power, the power can be 20 kW, 30 kW or 50 kW, at the same time the igniter discharges, the high voltage coil is inductively coupled and the igniter corona is triggered, and the argon gas is ionized to generate an argon plasma torch. At this time, maintaining a negative pressure in the entire plasma reactor can ensure the stable operation of the plasma torch.

[0021] 2. Use nitrogen gas to inject water atomized irregular stainless steel powder (raw powder) into the high temperature zone of the core of the argon plasma torch for heating. The heating time ends with the gas powder flo...

Embodiment 1

[0025] Example 1: The average particle size of raw material water atomized irregular stainless steel powder 316L is 9.8 μm, the oxygen content of the powder before spheroidization is 2300 ppm, and the powder tap density is 3.53 g / cm 3 , The input power of the argon plasma during the spheroidization process is 30kW, and the system negative pressure is maintained at 130mm Hg. The main plasma working gas argon and the auxiliary gas hydrogen pressure are both 0.5MPa. The pressure of the carrying gas nitrogen is 0.6MPa, the flow rate of the carrying gas is 600L / h, the feeding rate of water atomized irregular stainless steel powder is 40g / min, the average particle size of the powder after spheroidization is 10.3μm, and the oxygen content of the powder is 2230ppm , the powder tap density is 4.76 g / cm 3 .

Embodiment 2

[0026] Example 2: The average particle size of raw material water atomized irregular stainless steel powder 316L is 11 μm, the oxygen content of the powder before spheroidization is 2450 ppm, and the powder tap density is 3.68 g / cm 3 , The input power of argon plasma during the spheroidization process is 35kW, and the negative pressure of the system is maintained at 180mm Hg. The main plasma working gas argon and auxiliary gas hydrogen pressure are 0.6MPa. The pressure of the carrying gas nitrogen is 0.75MPa, the flow rate of the carrying gas is 700L / h, the feeding rate of water atomized irregular stainless steel powder is 35g / min, the average particle size of the powder after spheroidization is 11.6μm, and the oxygen content of the powder is 2430ppm , the powder tap density is 4.83 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com