Patents

Literature

580results about How to "Improve Assemblability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

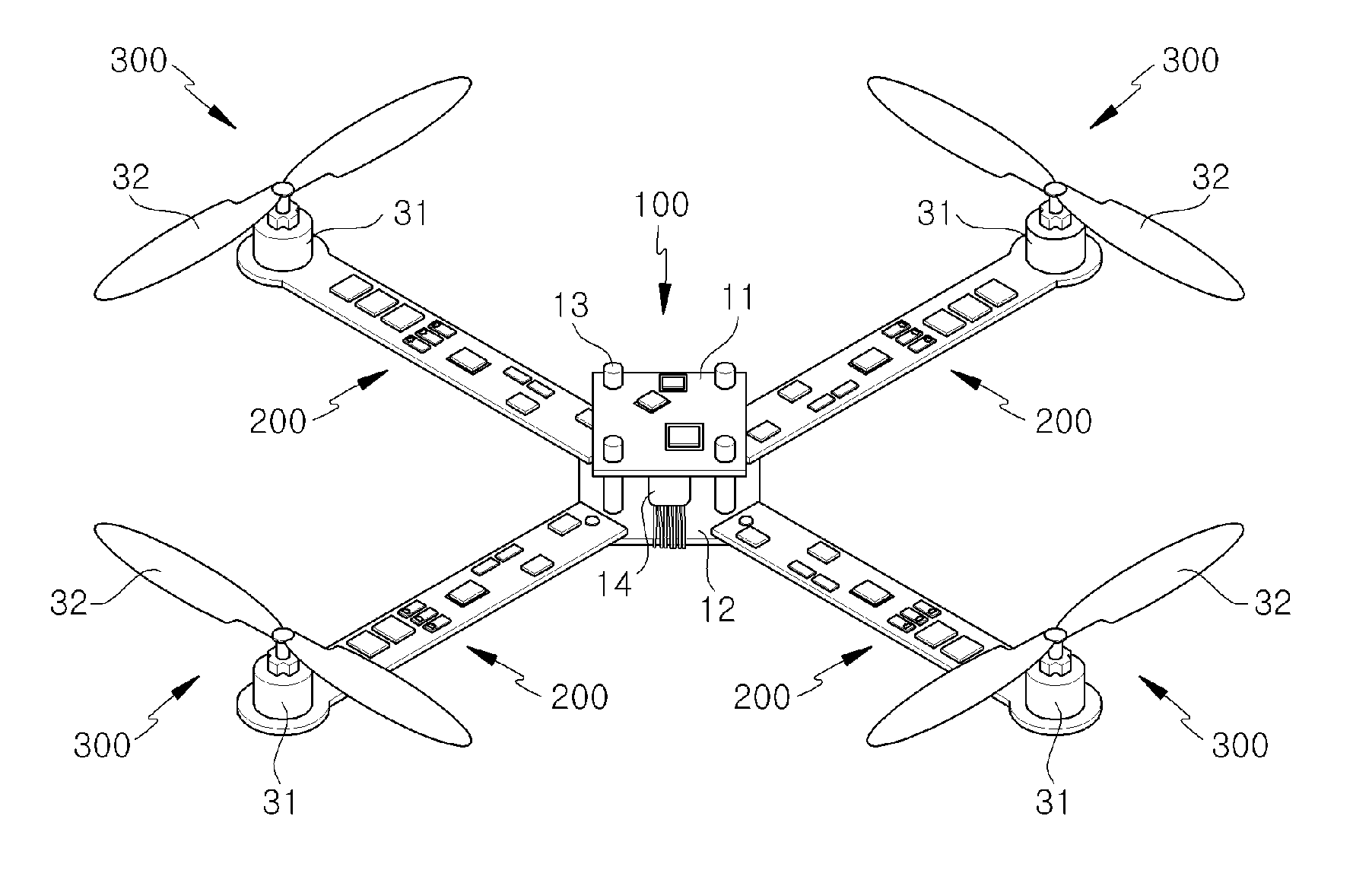

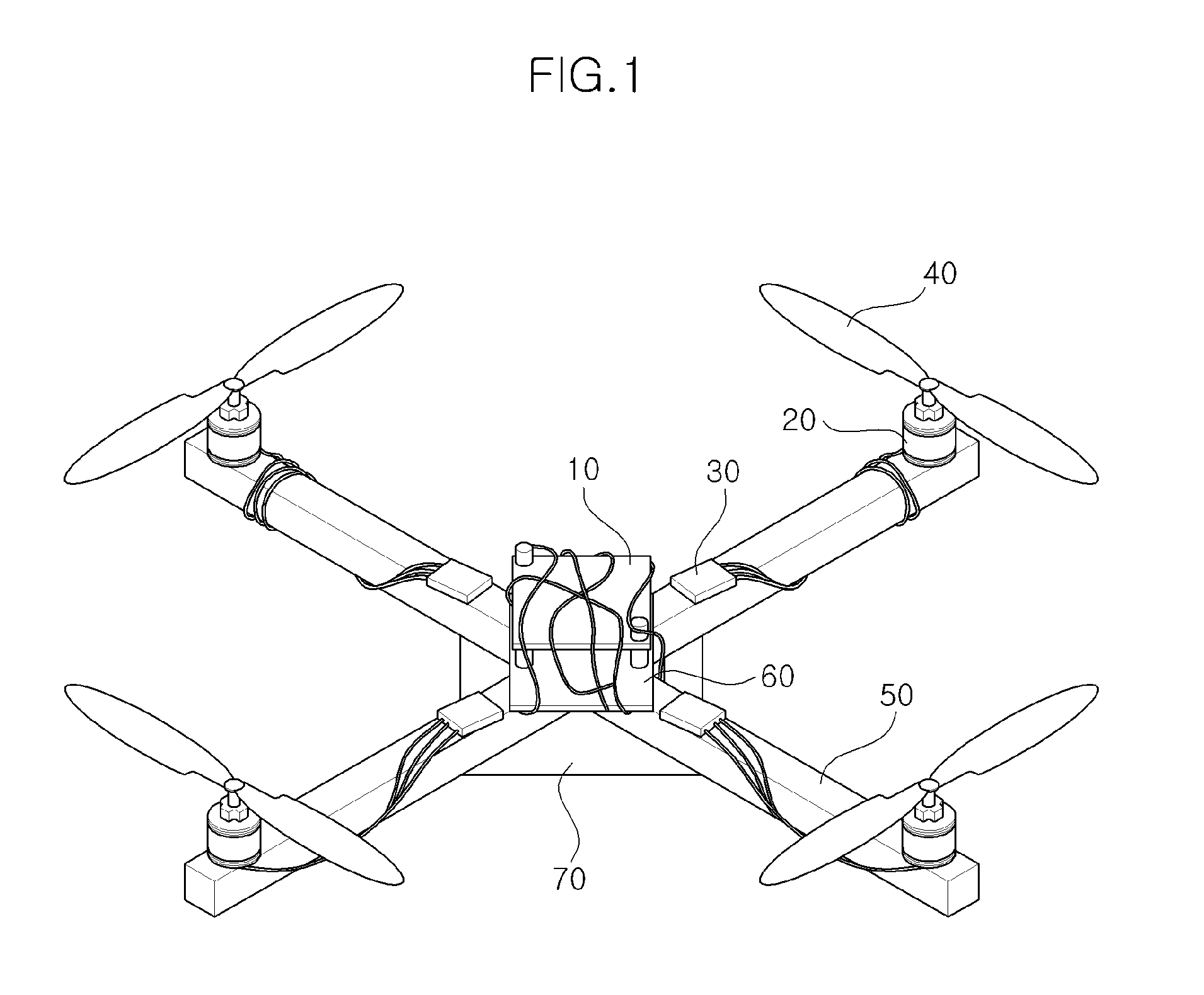

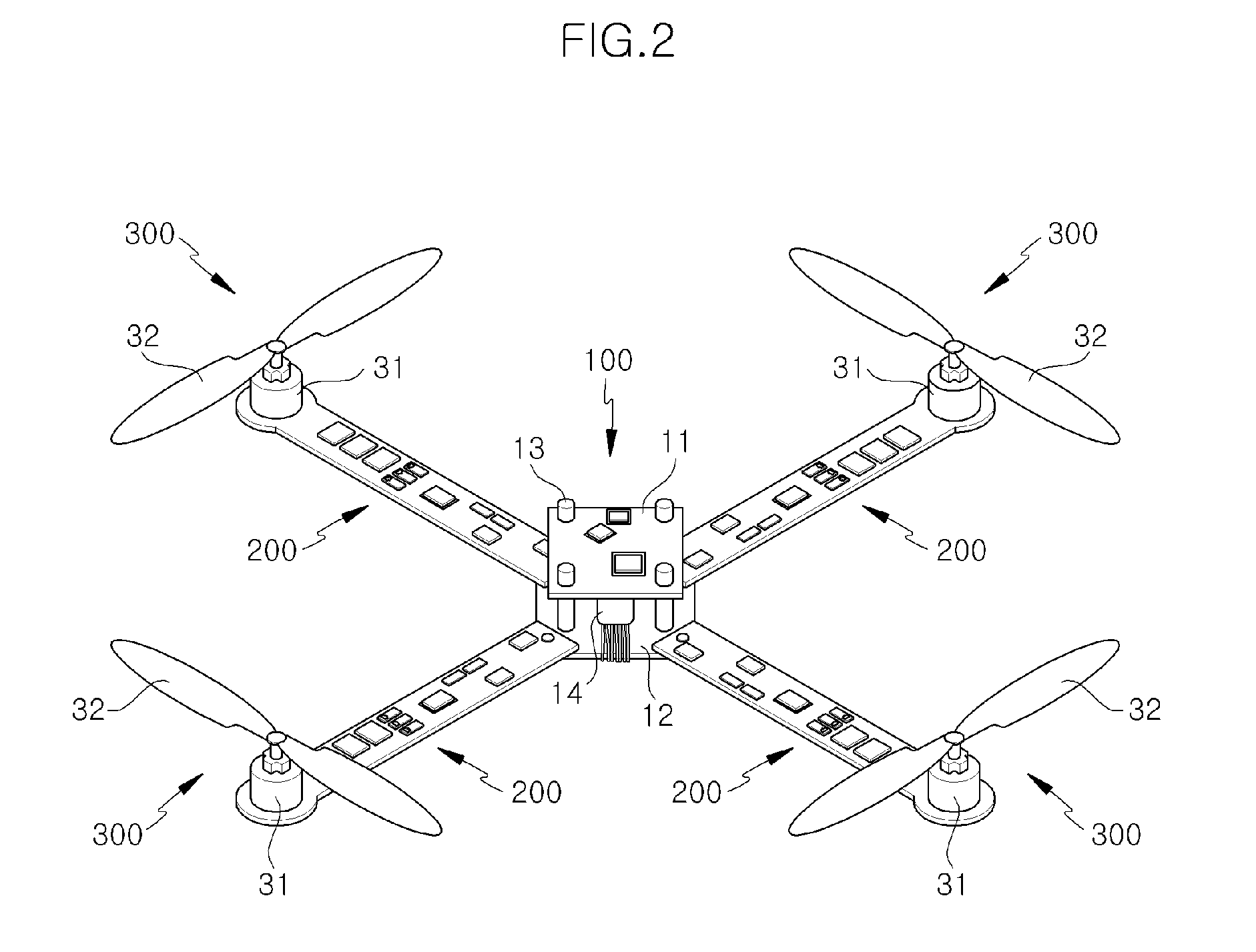

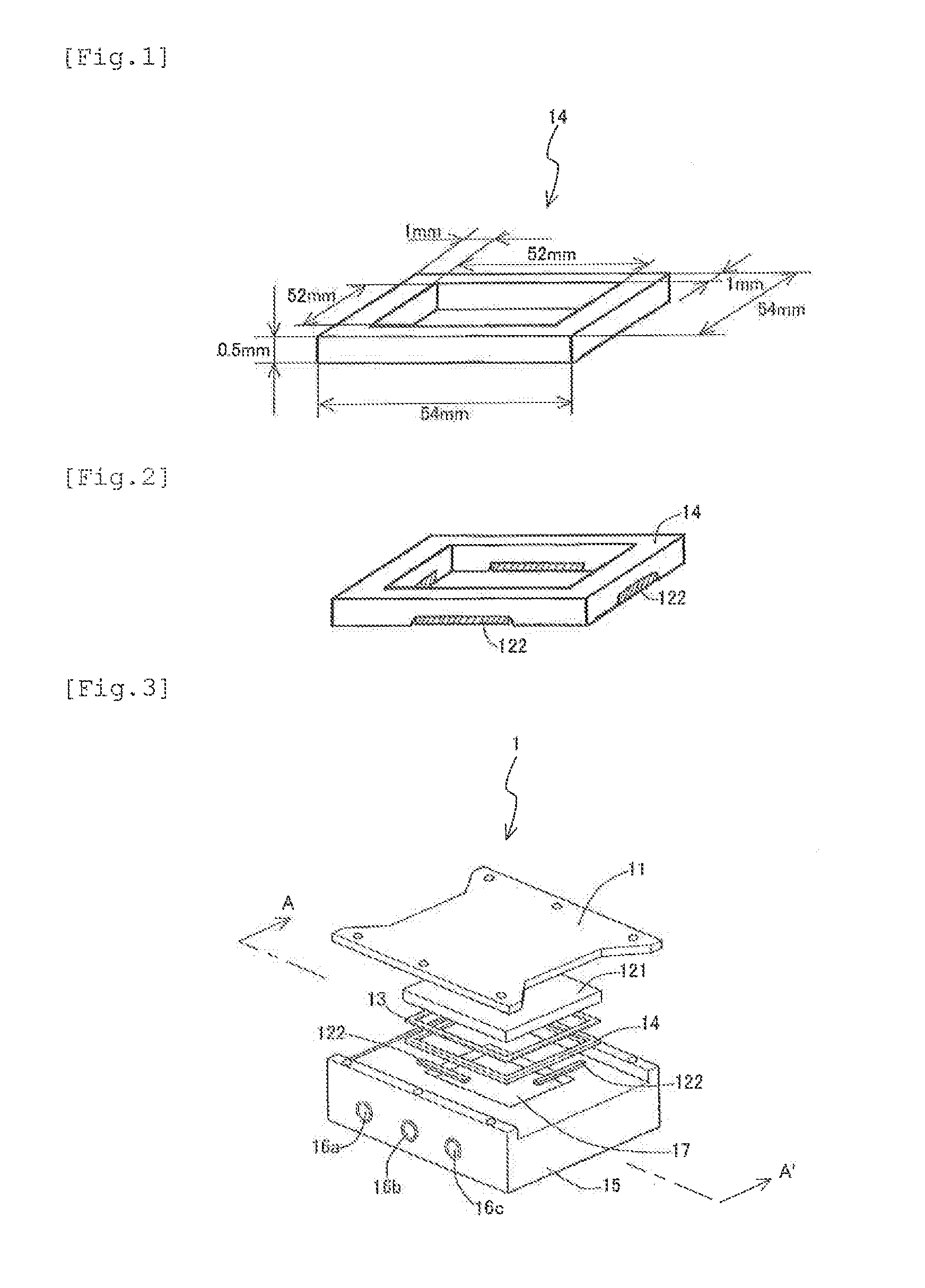

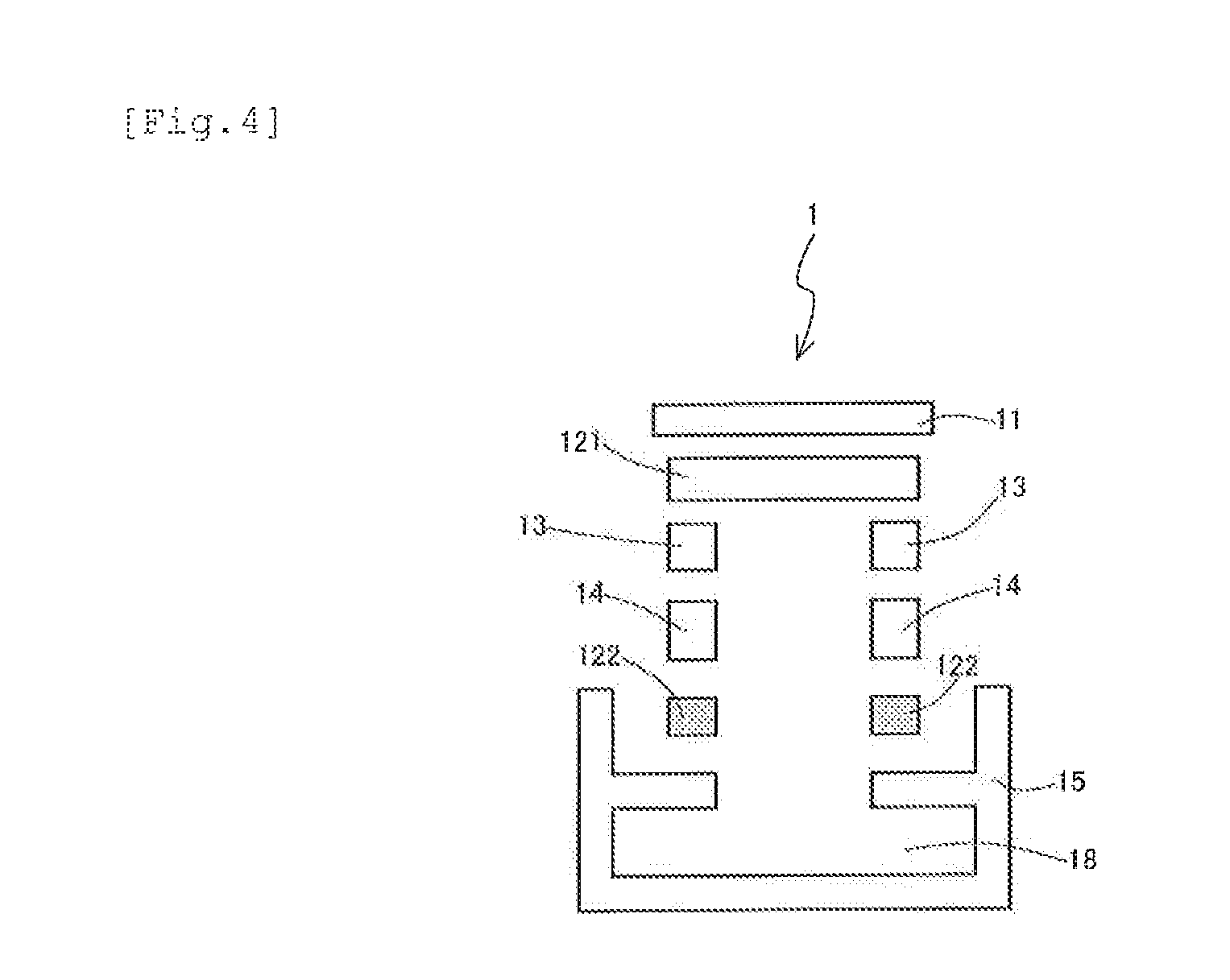

Unmanned Flying Vehicle Made With PCB

InactiveUS20120056041A1Simple structureMinimized in sizeUnmanned aerial vehiclesRemote controlled aircraftControl powerFlight vehicle

The present invention relates to an unmanned flying vehicle using a PCB including a main board controlling power supply and flying operation, a motor rotating a propeller by changing electric energy into mechanical energy, a PCB frame changing a signal from a remote controller and connecting the main board with the motor, a propeller generating an impellent force by from rotation by the motor, a receiver receiving a control signal of the remote controller, and a remote controller controlling a motor rotation speed of a quadrotor and direction change, and accordingly, the structure of the unmanned flying vehicle can be simplified so that the flying vehicle can be down-sized and light-weighted, and assemblability can be improved.

Owner:DREAM SPACE WORLD CORP

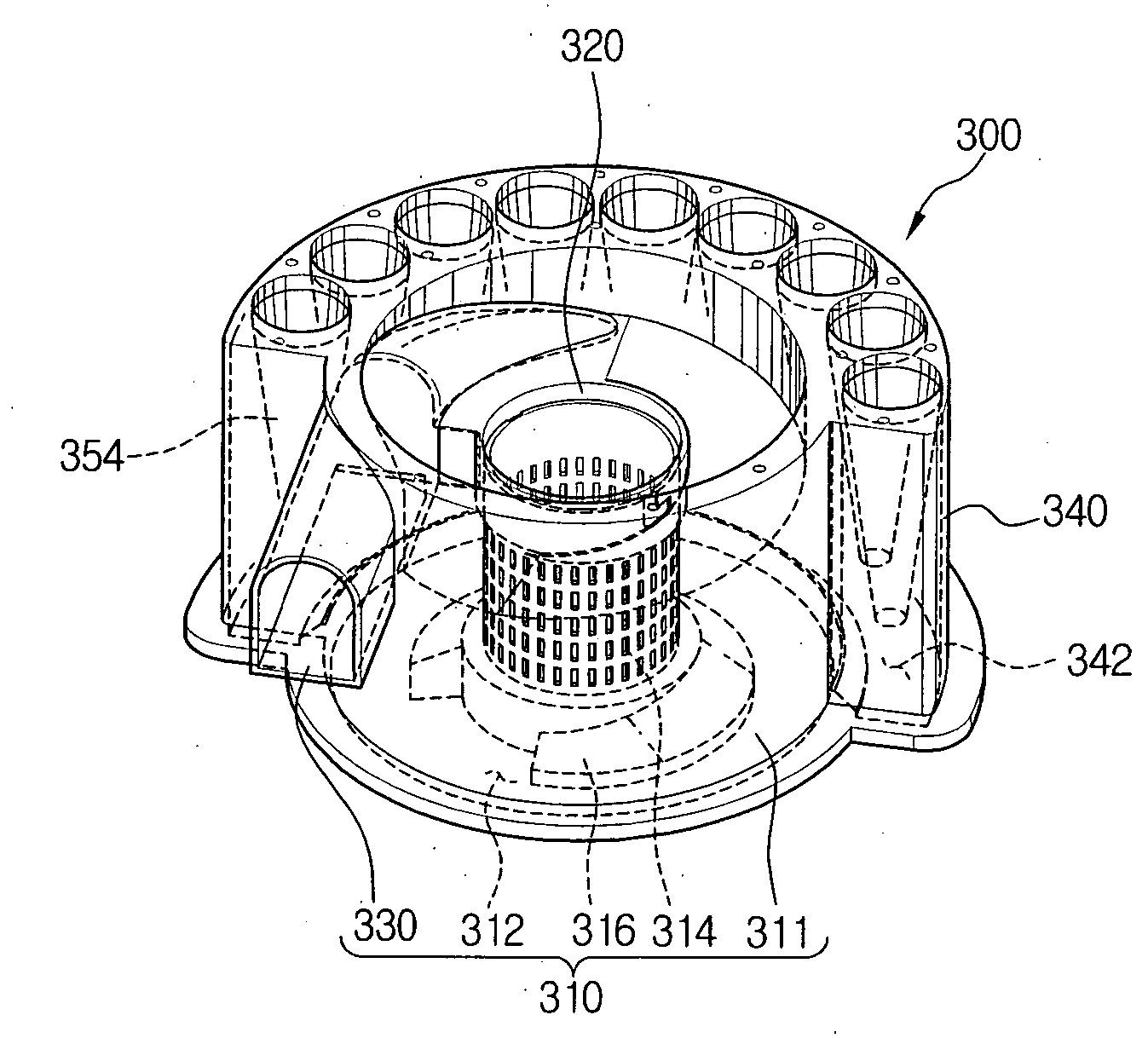

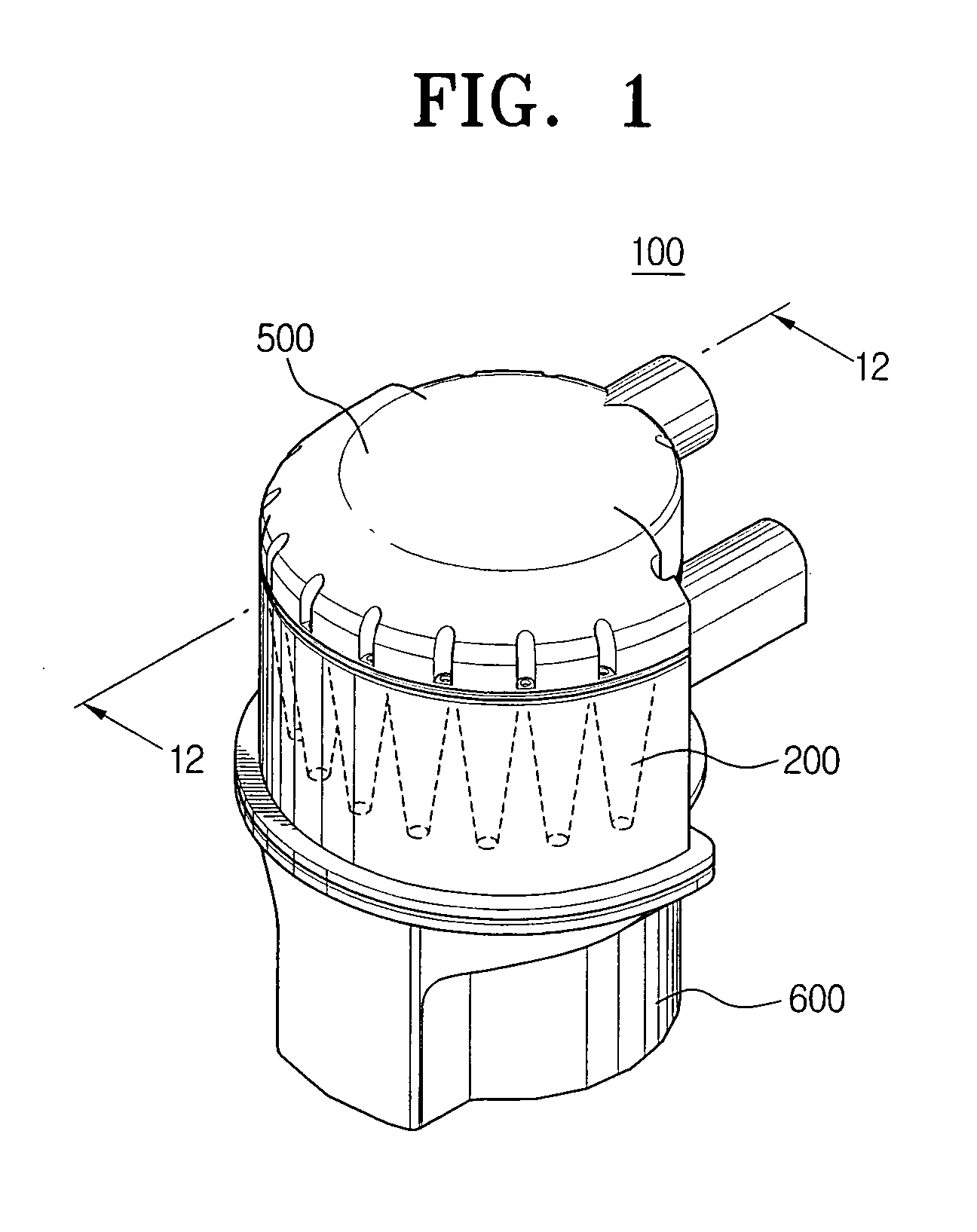

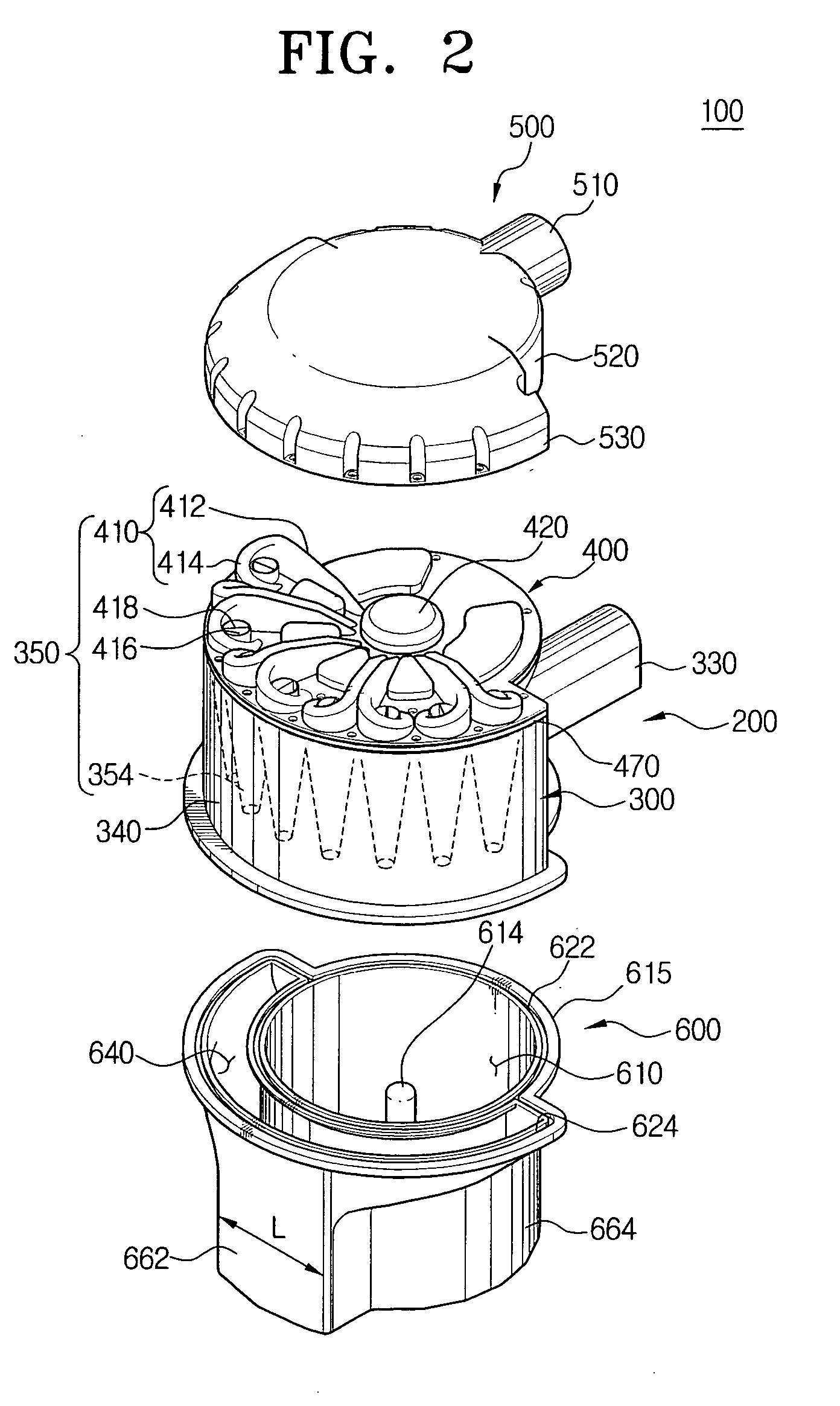

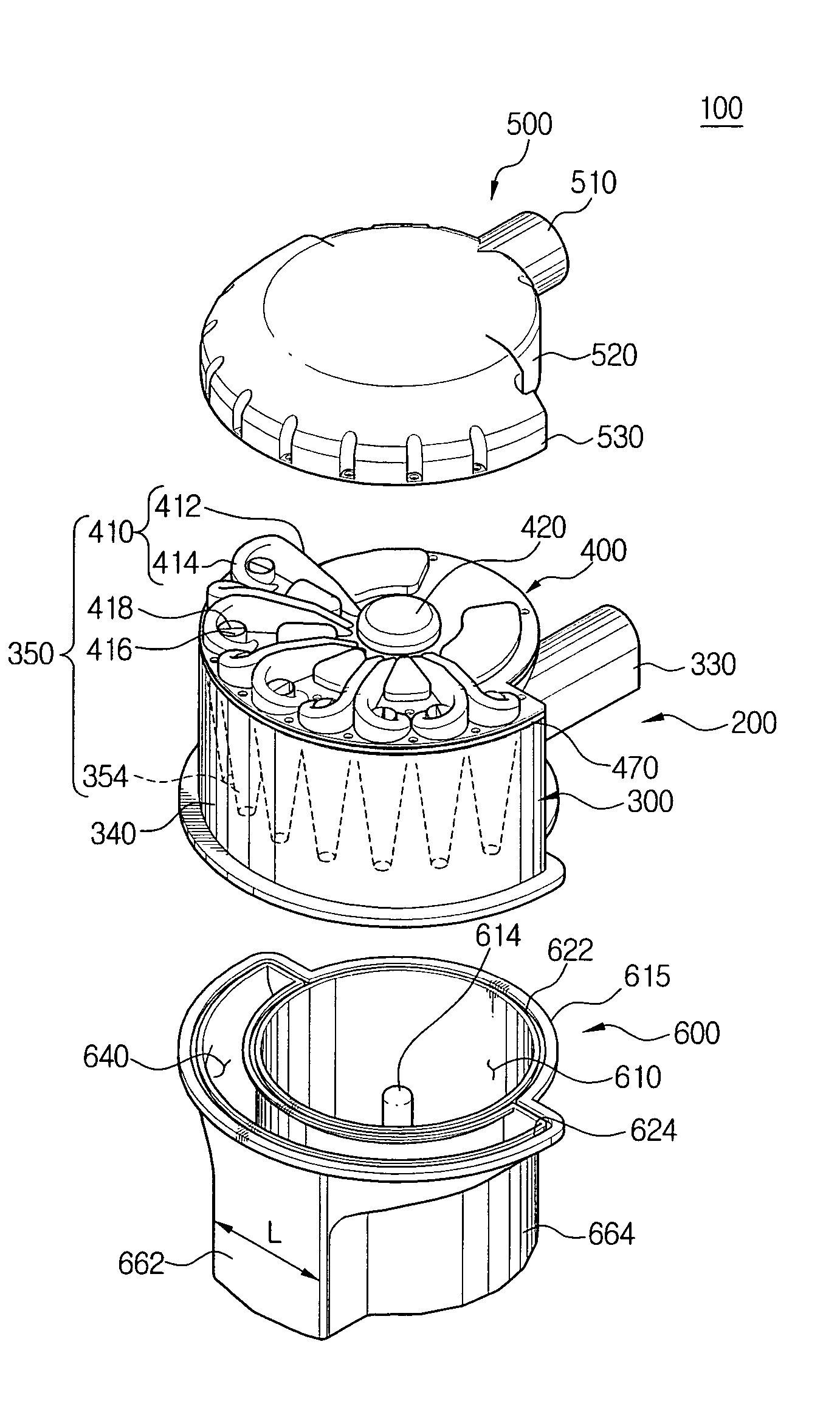

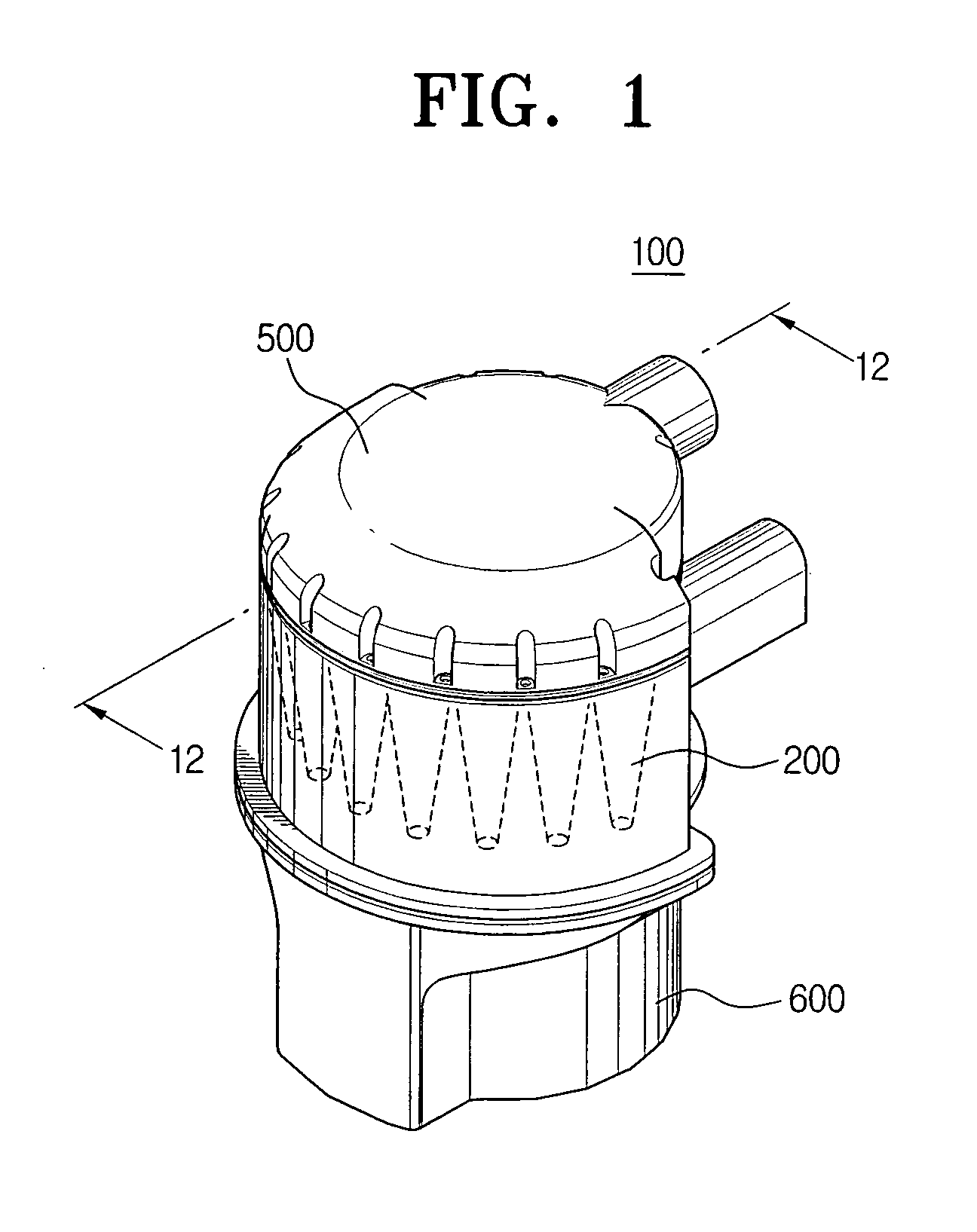

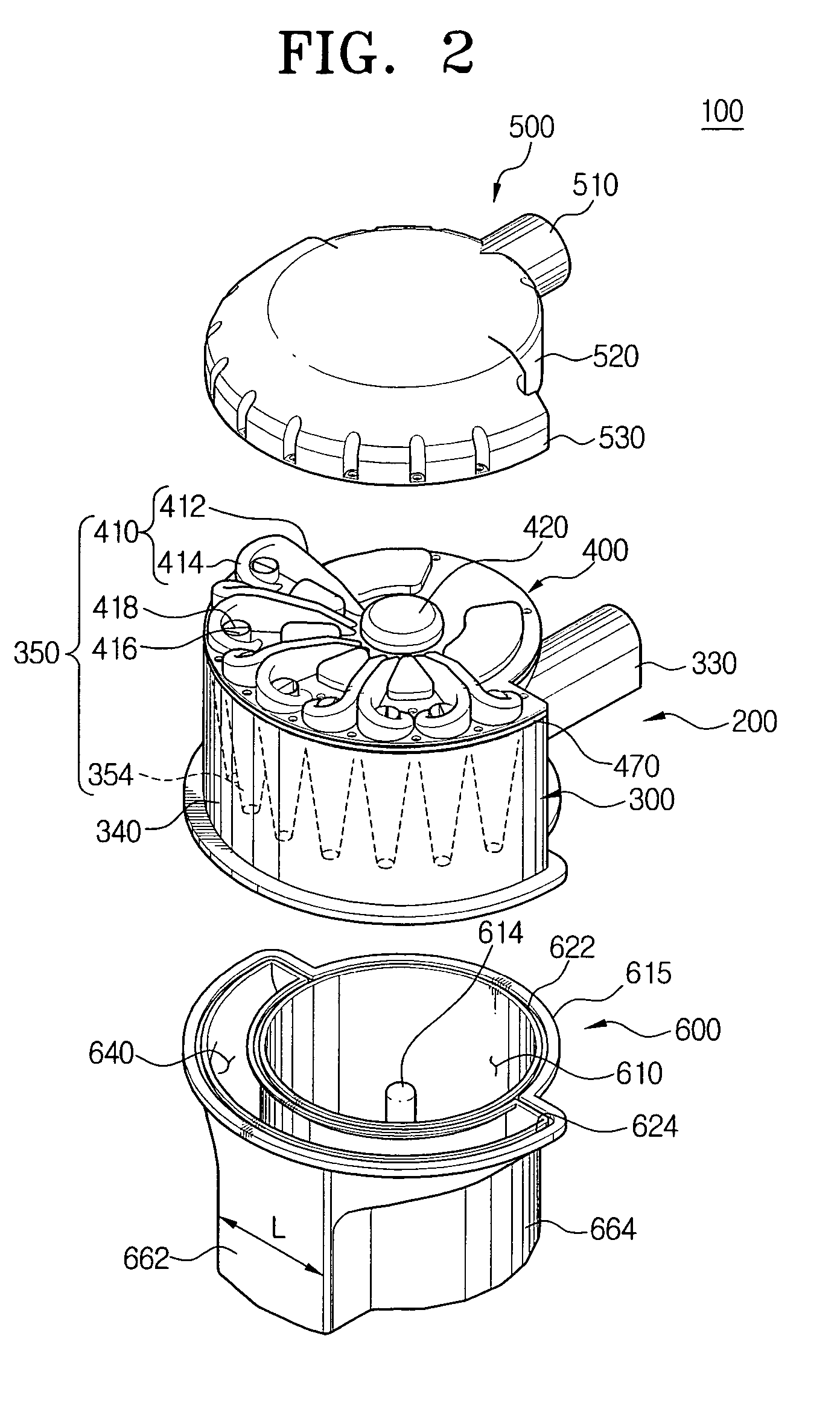

Cyclone vessel dust collector and vacuum cleaner having the same

InactiveUS20050252180A1Small sizeLarge amount of dust collectionCleaning filter meansSuction filtersCycloneMarine engineering

Disclosed are a cyclone vessel dust collection and a vacuum cleaner including the same. The cyclone vessel dust collector comprises a cyclone vessel main-body including a primary cyclone vessel unit for separating dusts from dust containing air, and one or more secondary cyclone vessel units for separating dusts from the air passing through the primary cyclone vessel unit, the secondary cyclone vessel units being arranged to surround at least a part of the primary cyclone vessel unit; and a dirt collection bin for receiving dusts or the like separated by the cyclone vessel main-body, wherein the cyclone vessel main-body has an outer circumference with a non-constant radius. Therefore, the cyclone vessel dust collector can have a dust collection capability of large capacity with a small size.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

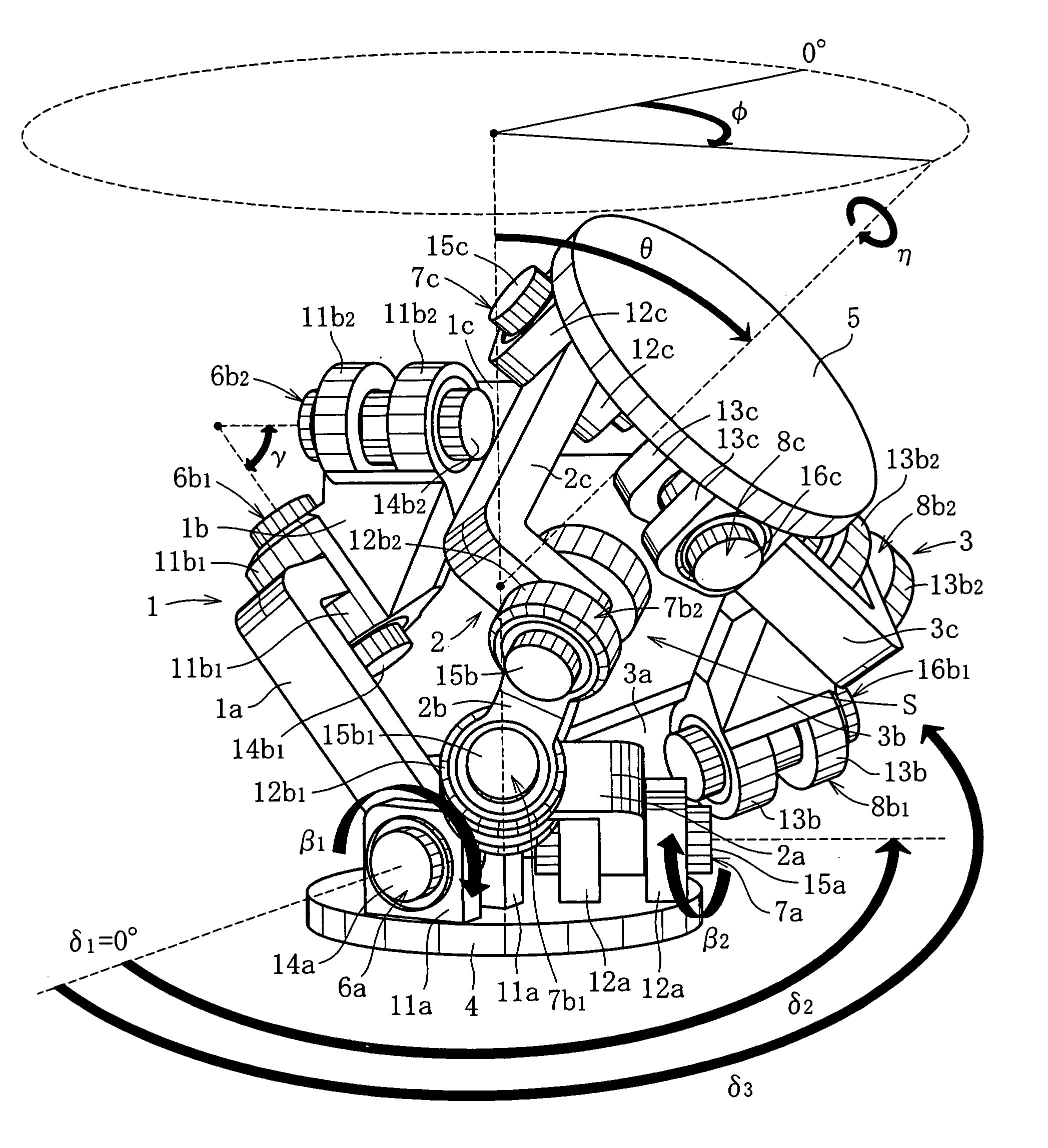

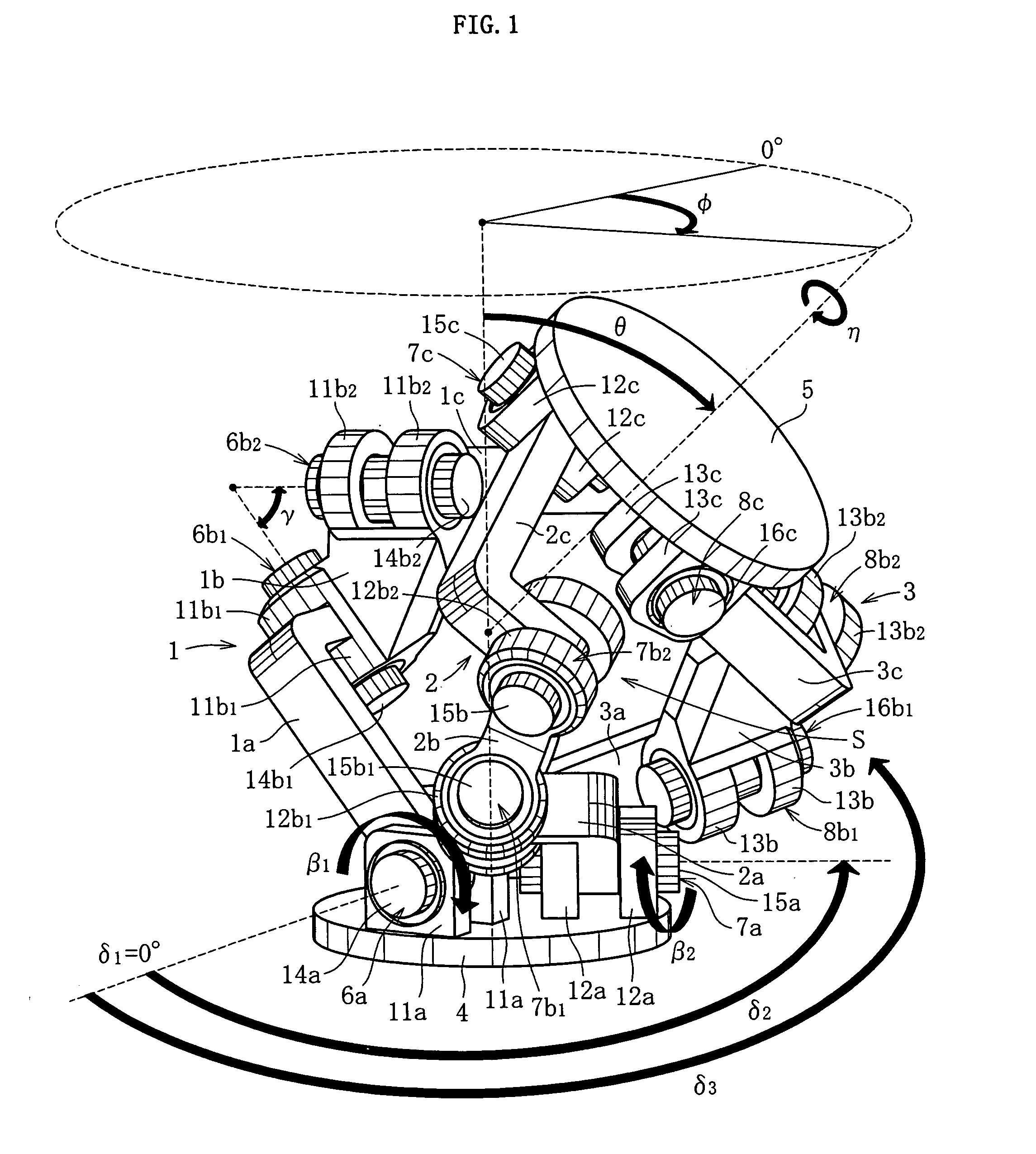

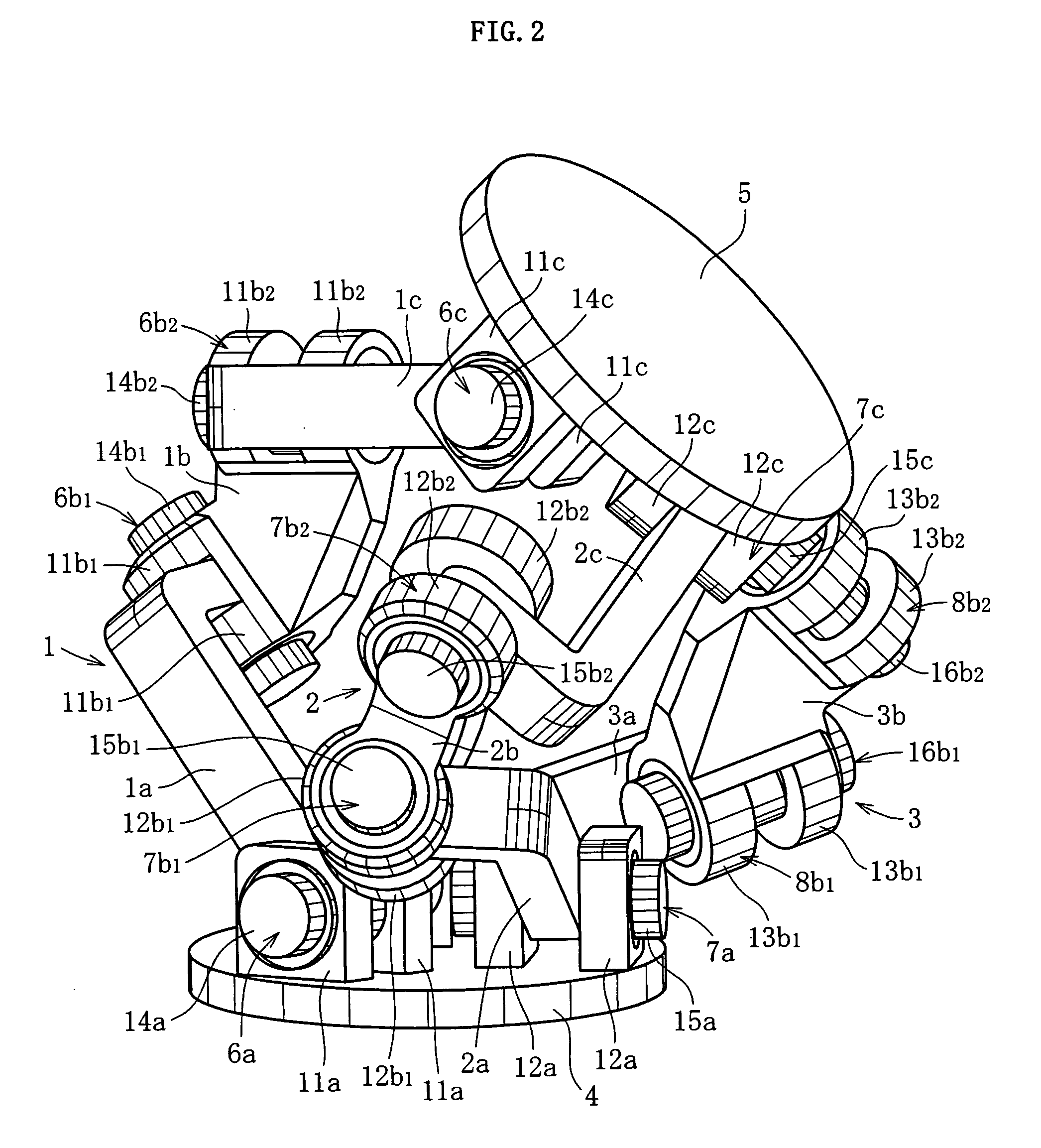

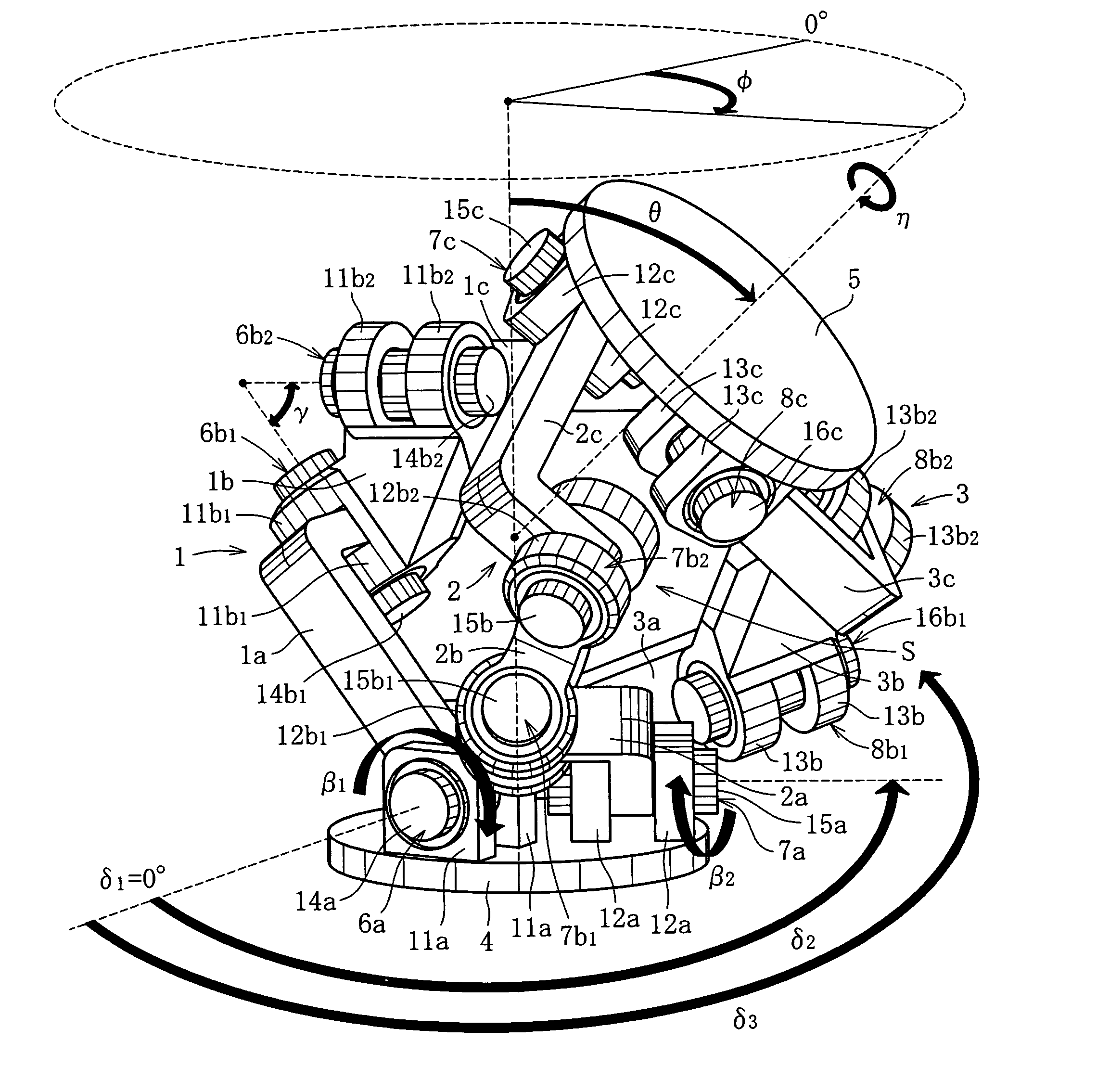

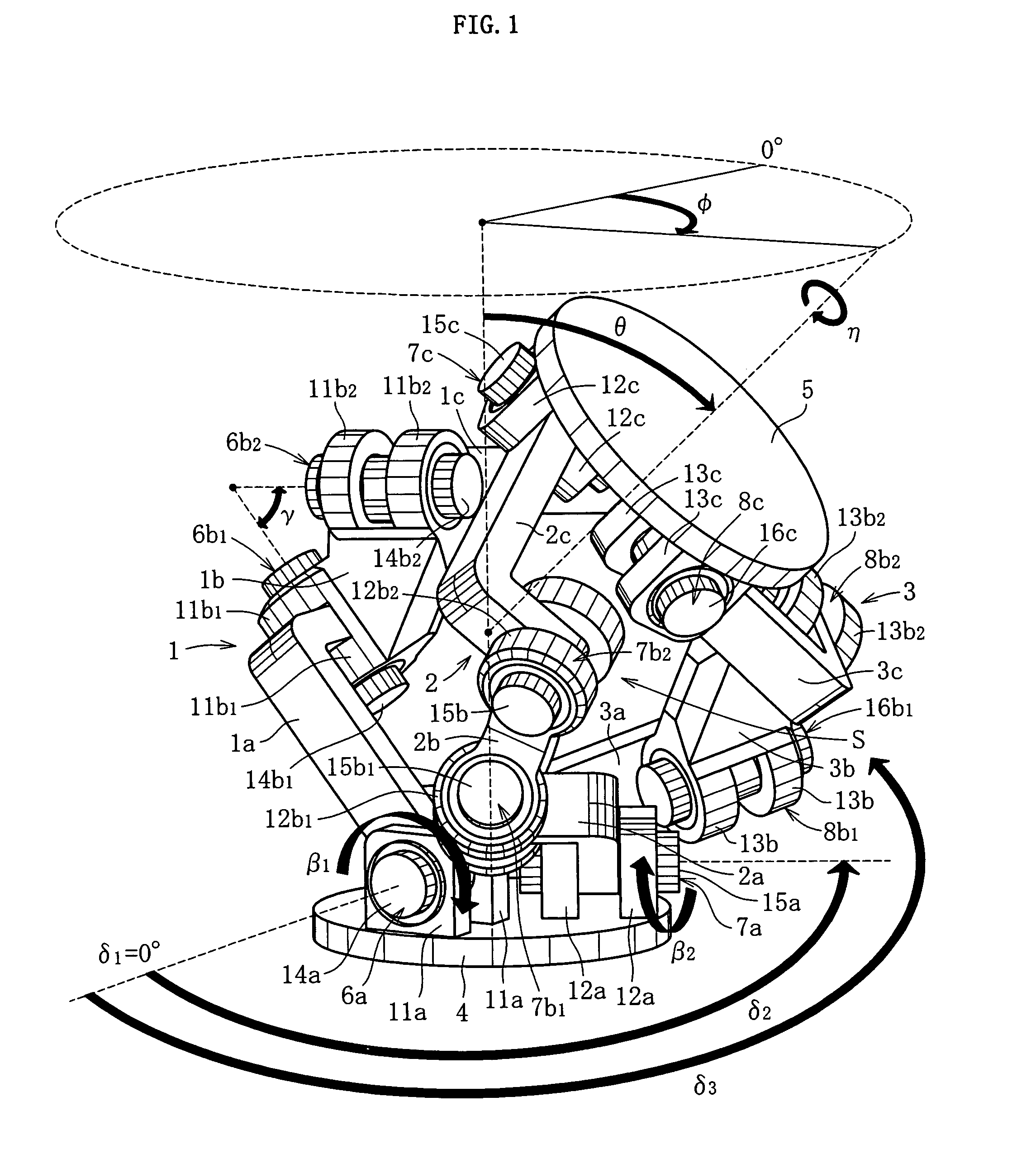

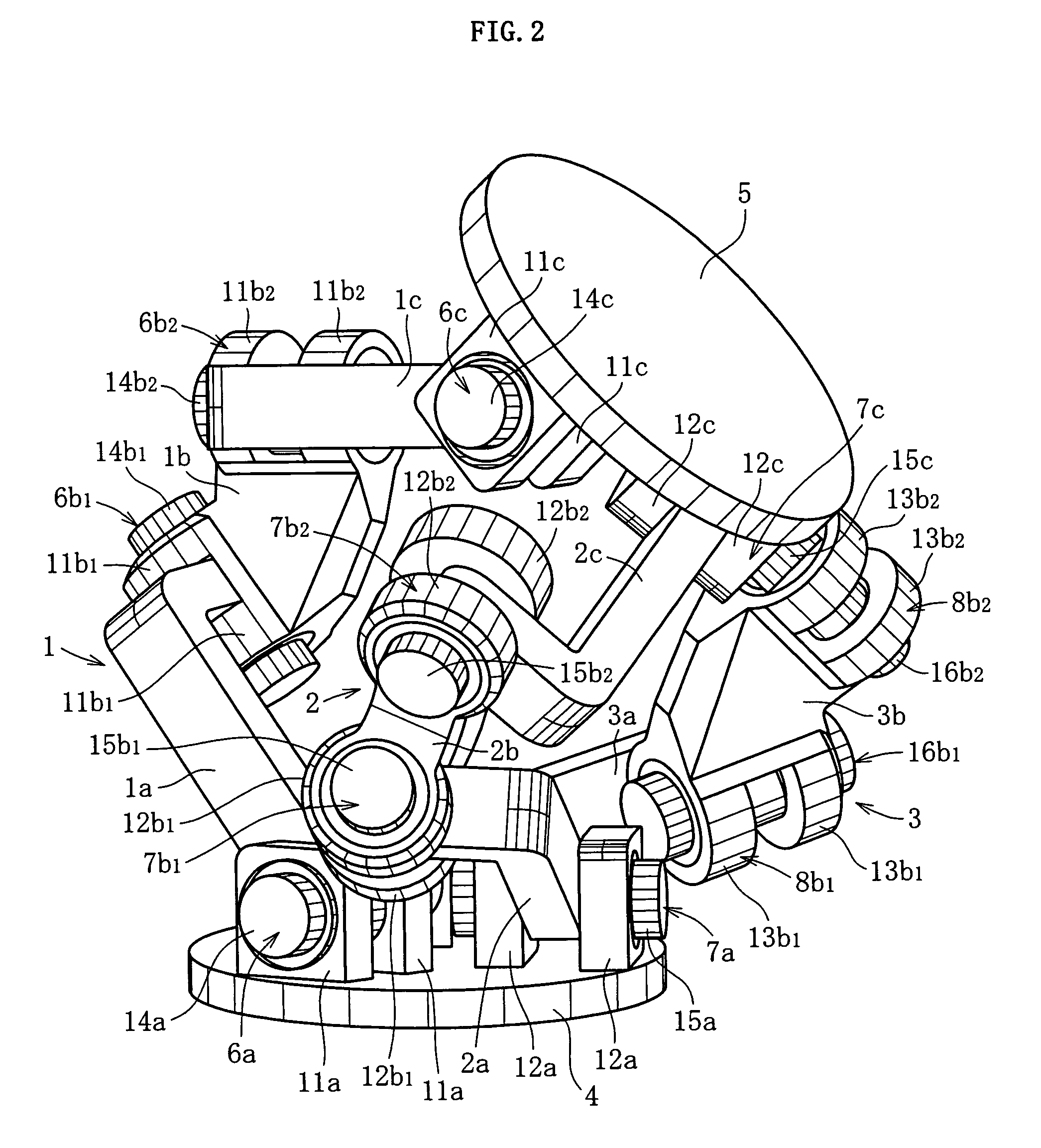

Linkage system

ActiveUS20050159075A1Improve rigidityImprove AssemblabilityProgramme-controlled manipulatorJointsEngineeringActuator

A linkage system which offers high rigidity and good assemblability and producibility, and enables parts such as rotary transmission components and actuators to be readily installed. A linkage system includes an input member disposed on an input side, an output member disposed on an output side, and three or more link mechanisms, each link mechanism consisting of end links rotatably coupled to the input member and the output member, respectively, a center link rotatably coupled to the end links on the input side and the output side, and four revolute joints by which the end links are rotatably coupled to the input and output members, and to the center link. The link mechanism being geometrically identical with respect to a center cross-sectional plane relative on the input and output sides. Each of the revolute joints of the link mechanism includes bearings that support at both ends of the revolute joint.

Owner:NTN CORP

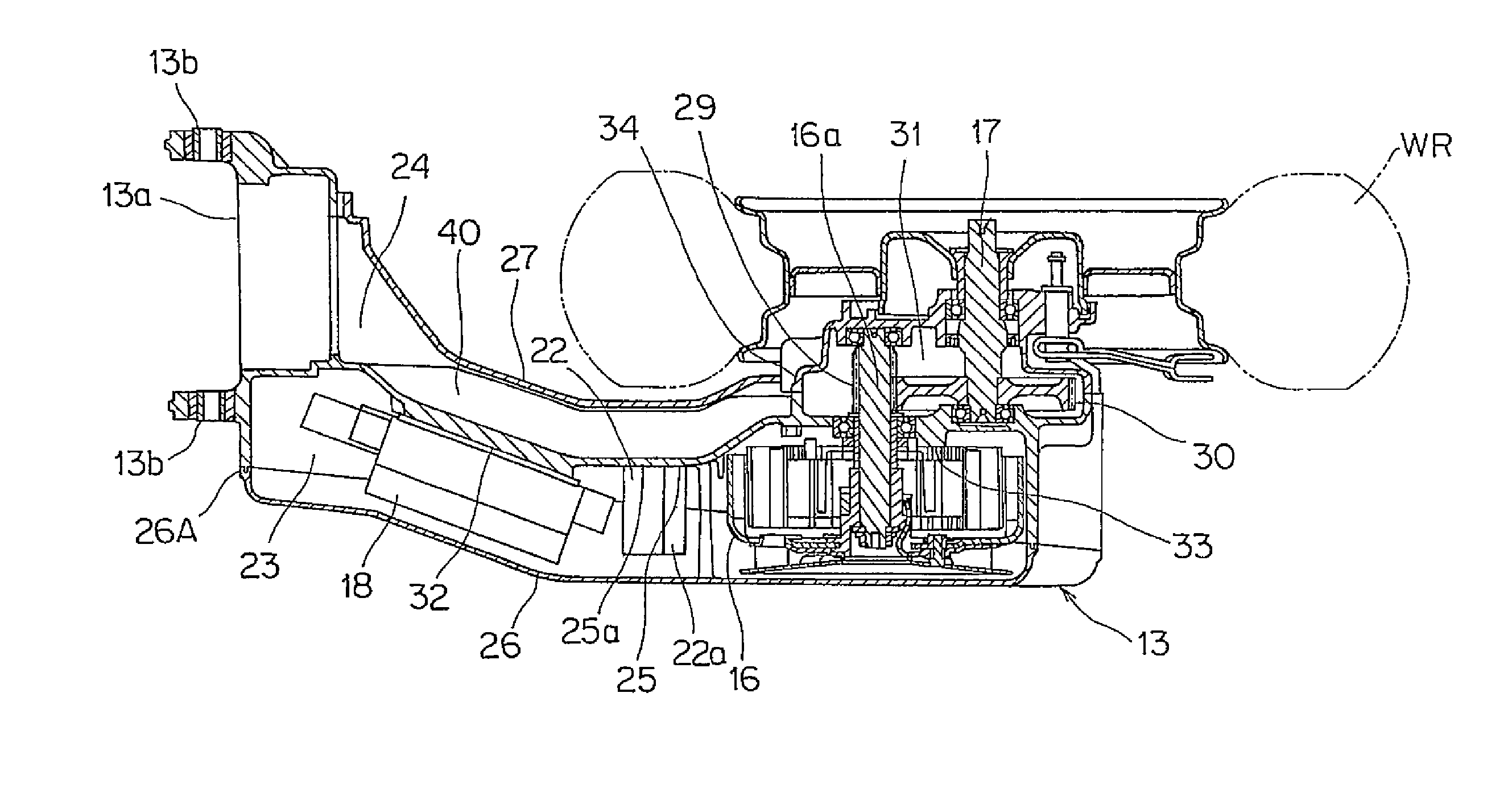

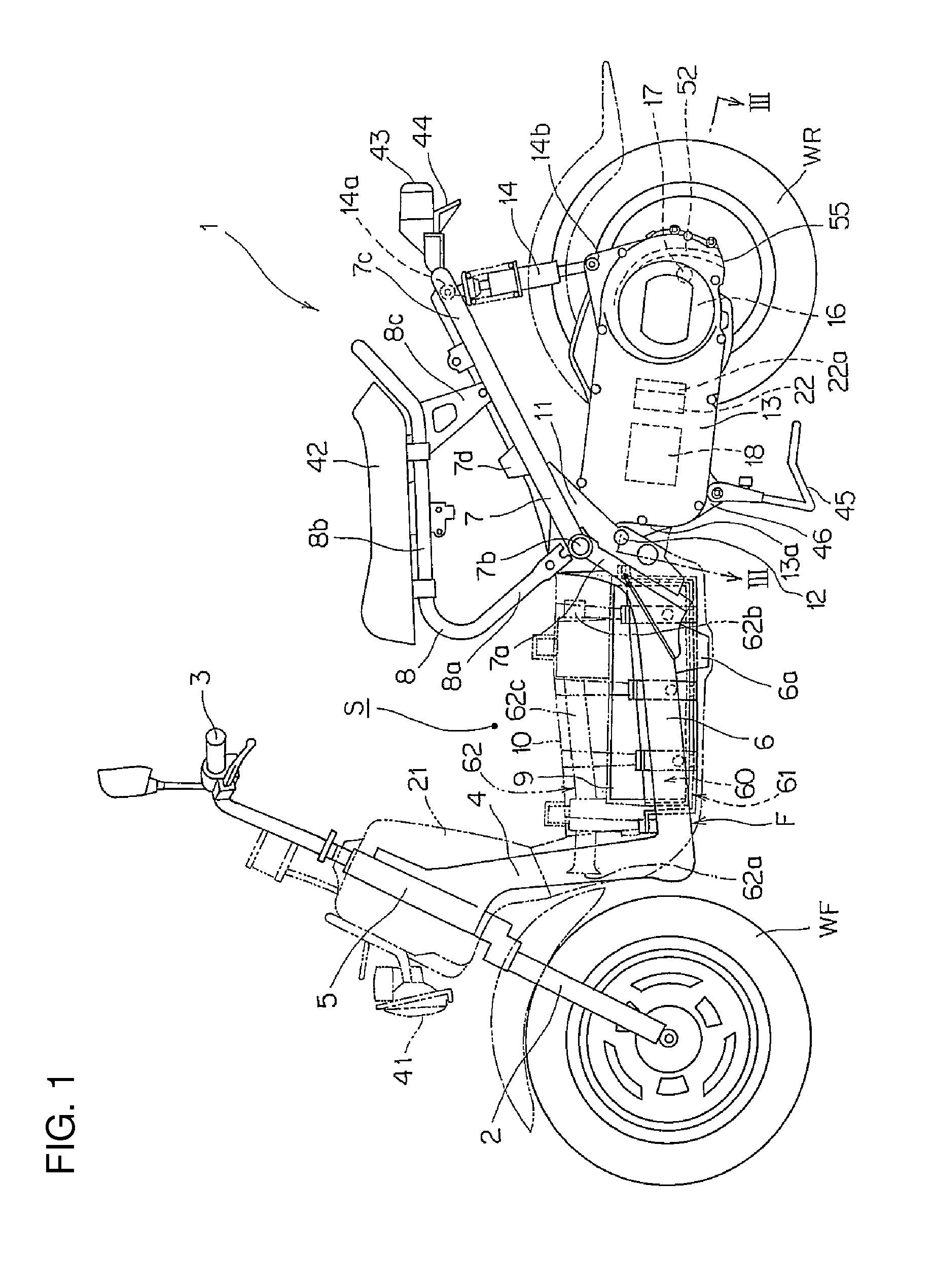

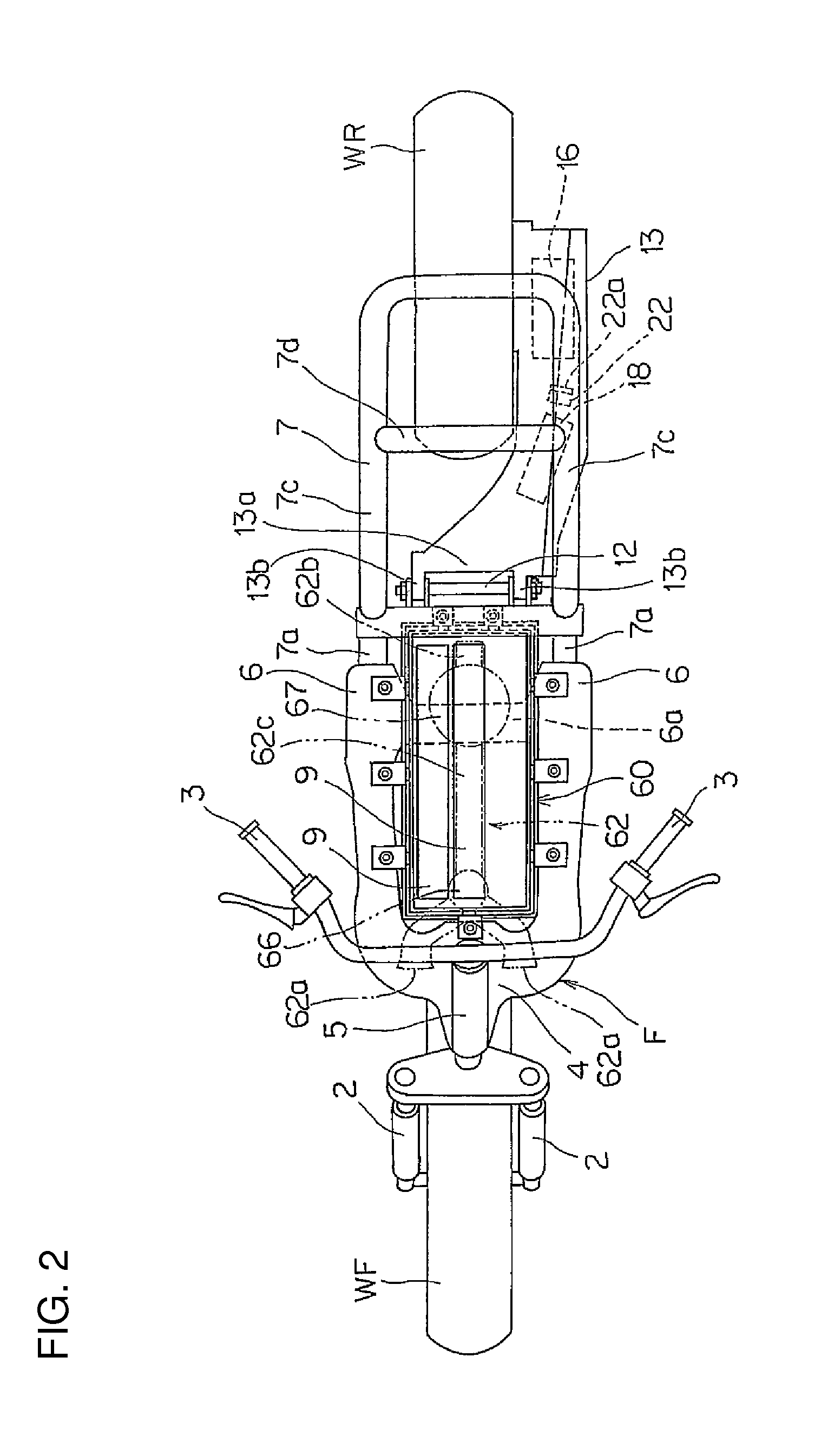

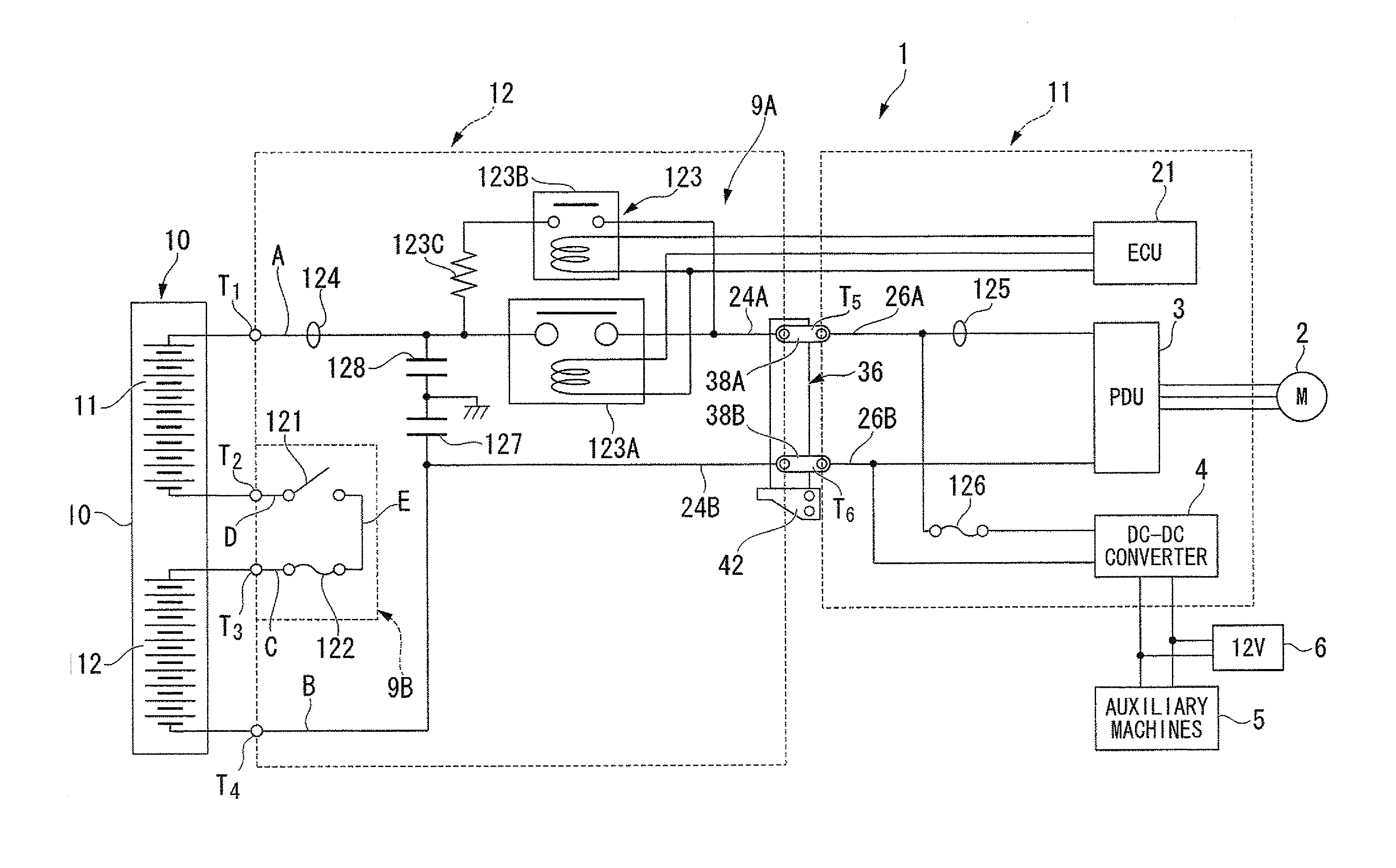

Battery Temperature Regulating System And Method For An Electric Vehicle, Battery Housing Box For An Electric Vehicle, And Vehicle Incorporating Same

InactiveUS20100163326A1Accurate temperatureImprove maintainabilityCell temperature controlCells structural combinationElectrical batteryElectric vehicle

A battery housing structure, in an electric vehicle, is operable to regulate a temperature of a battery disposed between front and rear wheels of the vehicle. The battery housing structure includes a main housing body for receiving the battery, inlet and outlet ports for respectively supplying air to and discharging air from the main housing body; and a fan for discharging air from the main housing body. A bypass passage is provided in the battery housing structure for selectively connecting a downstream side of the fan with the inlet ports. First and second air flow control valves are also provided in the battery housing structure for selectively controlling and routing the flow of air within the battery housing structure.

Owner:HONDA MOTOR CO LTD

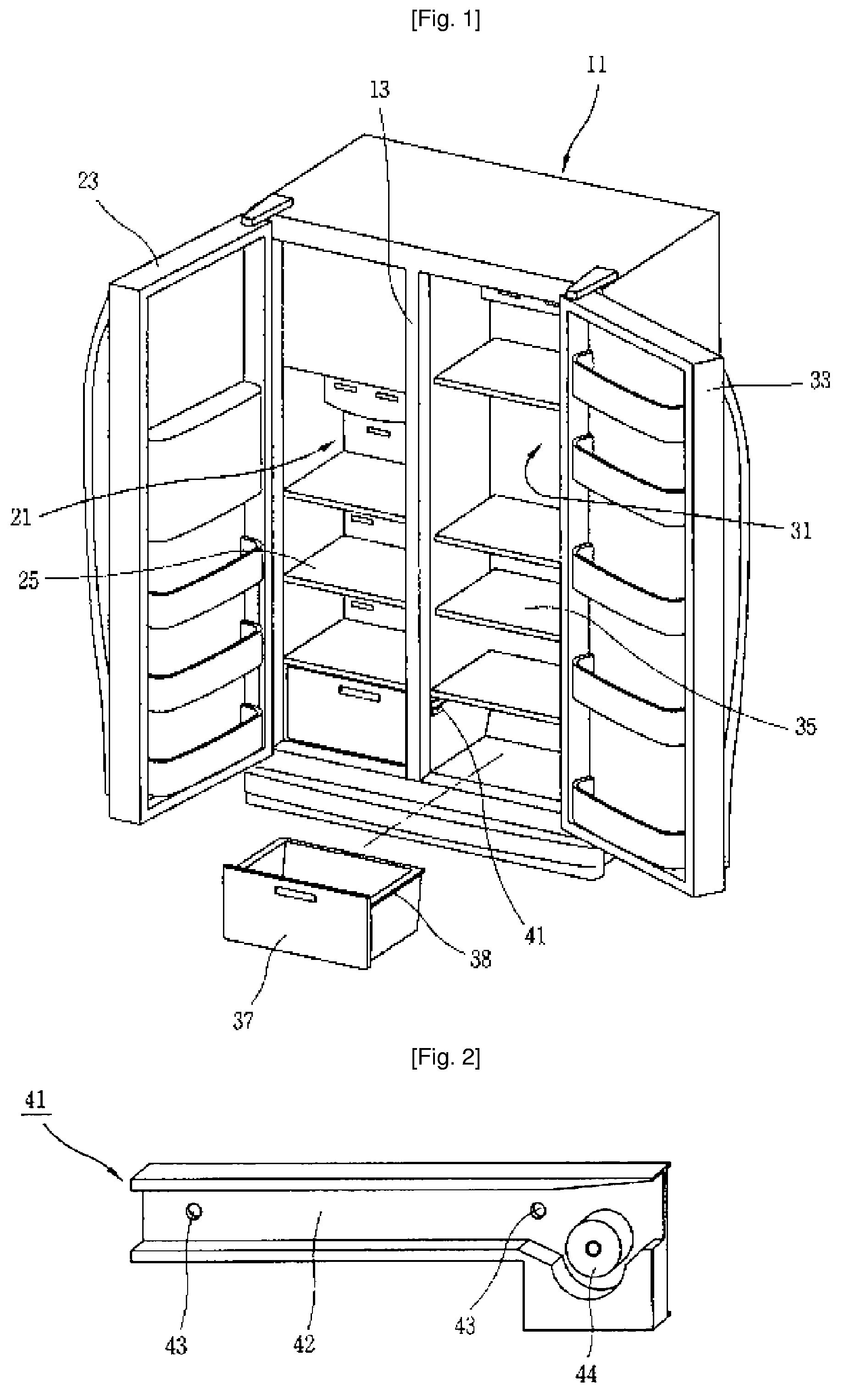

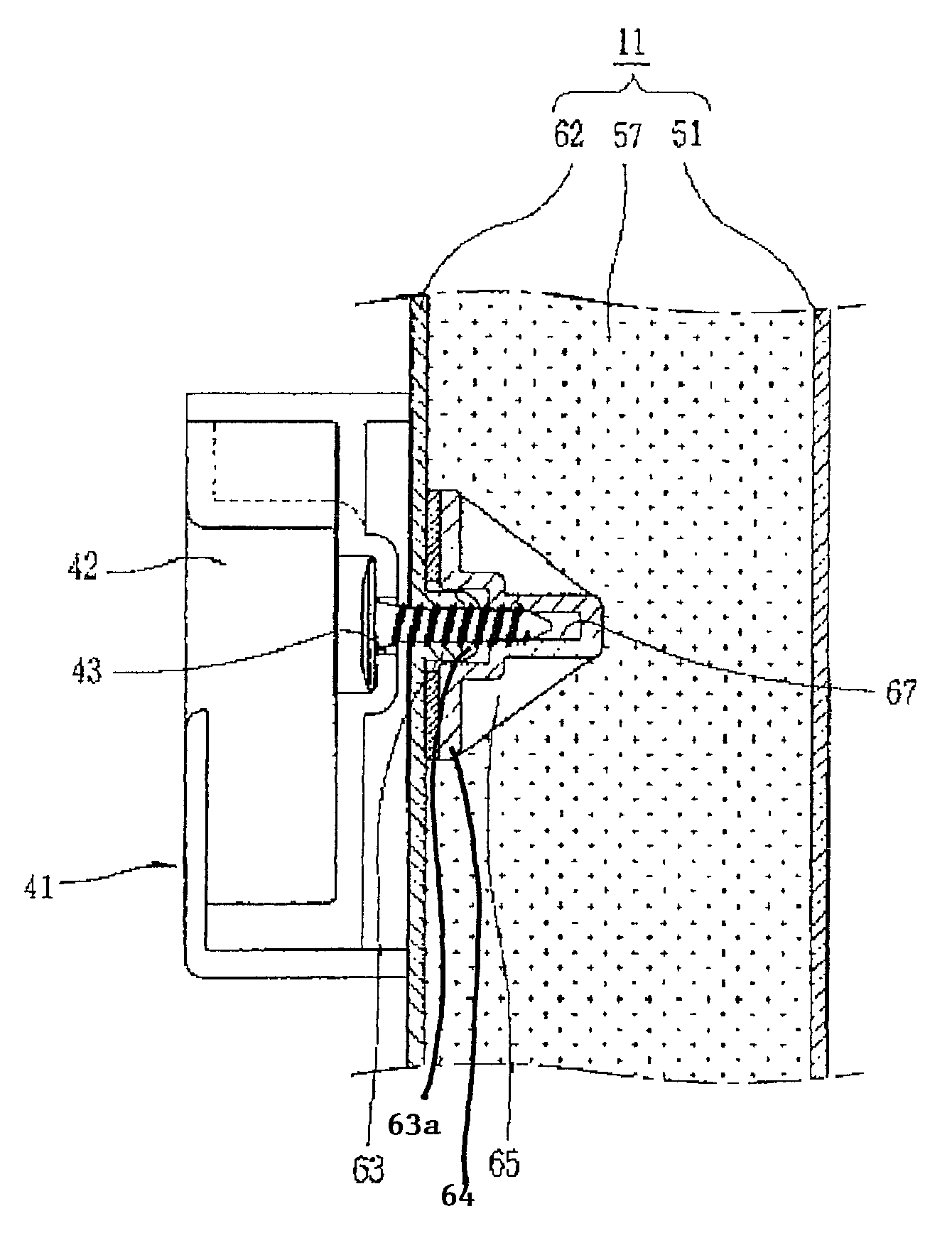

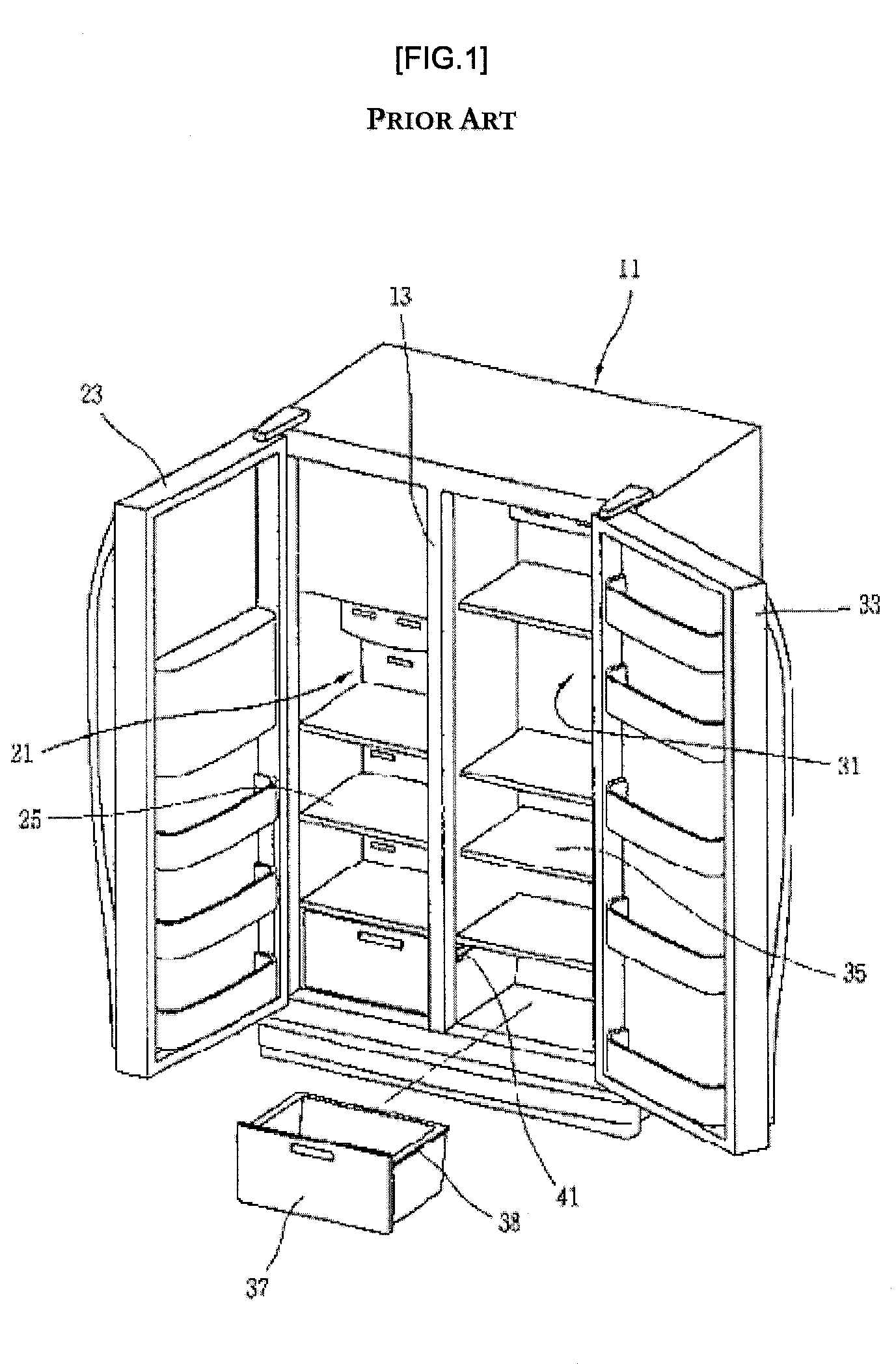

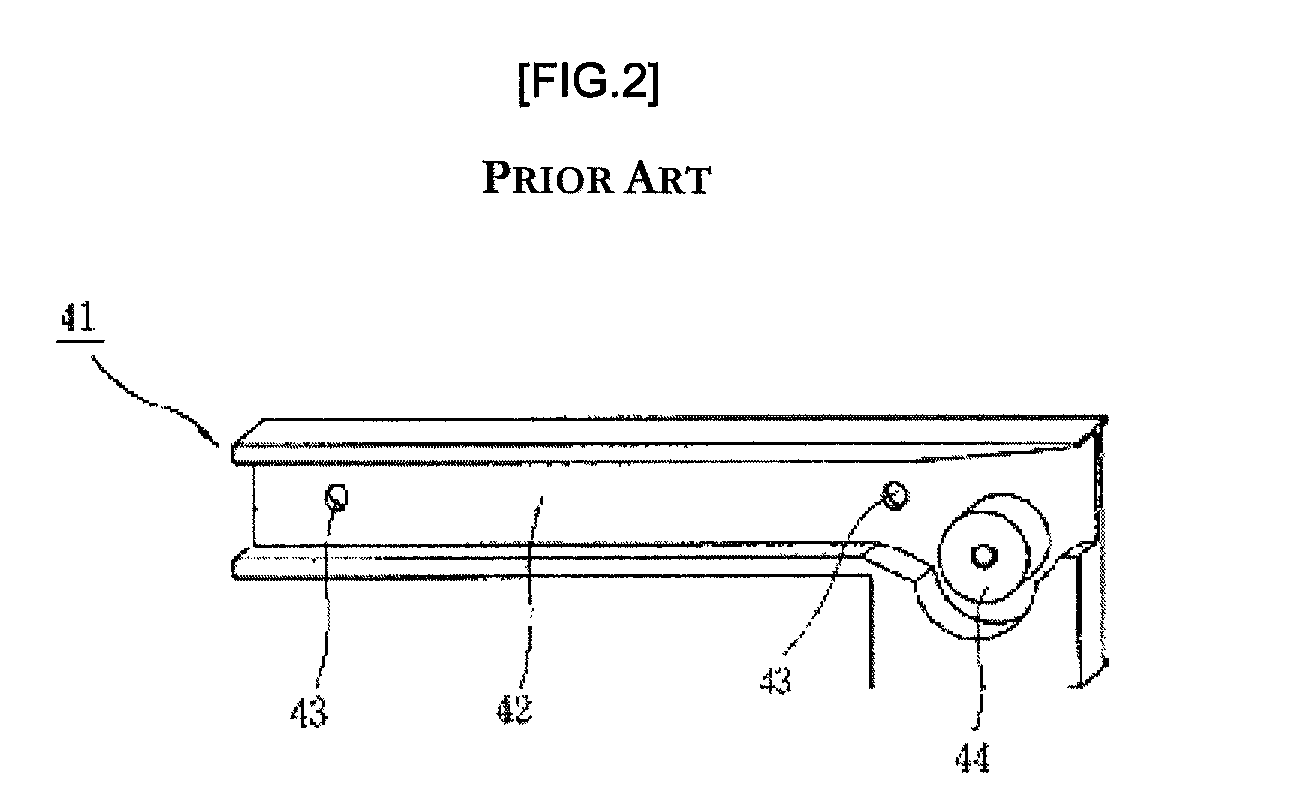

Refrigerator Body And Method Of Manufacturing The Same

ActiveUS20080048540A1Performed rapidly and easilyPrevent leakageLighting and heating apparatusMetal rolling stand detailsEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

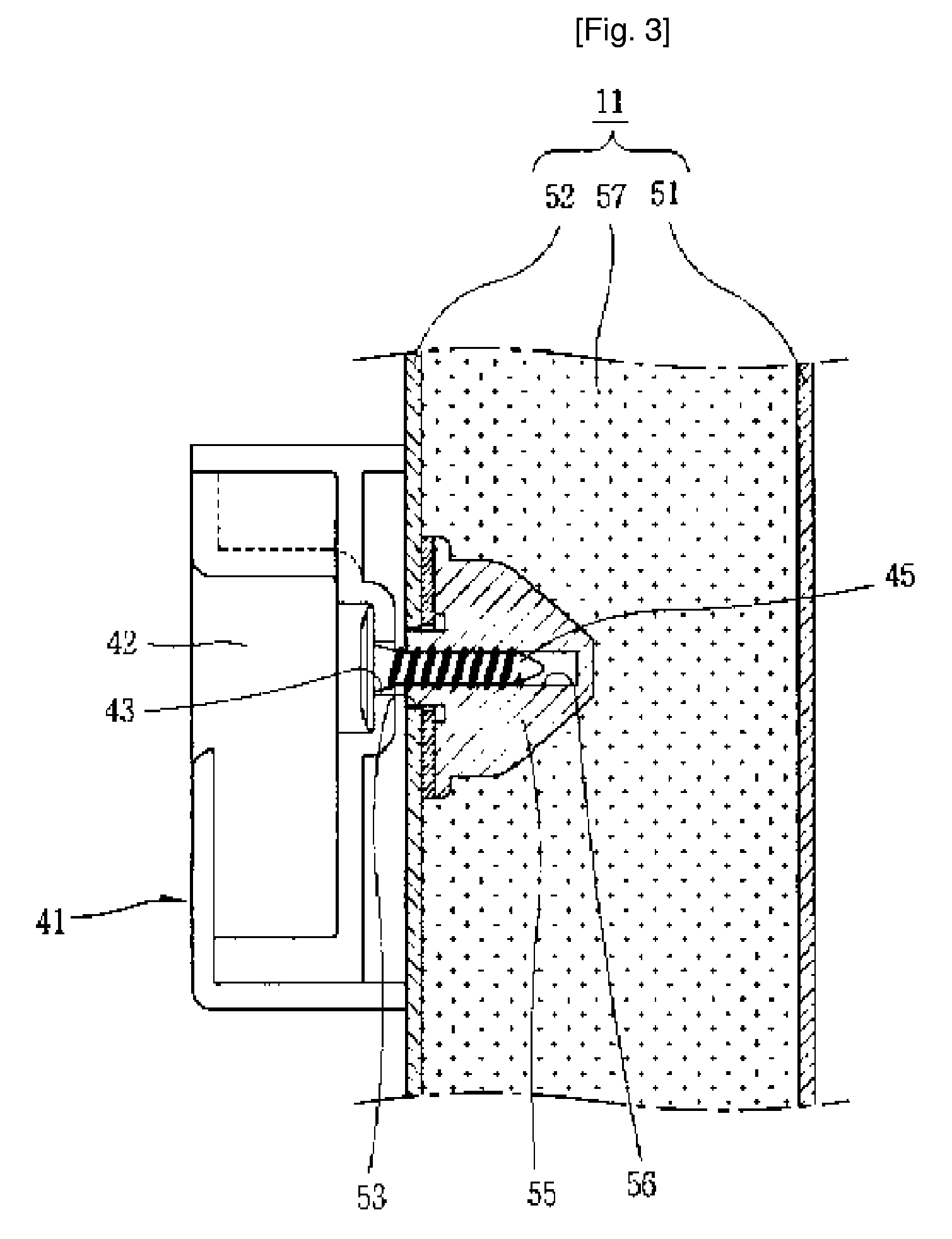

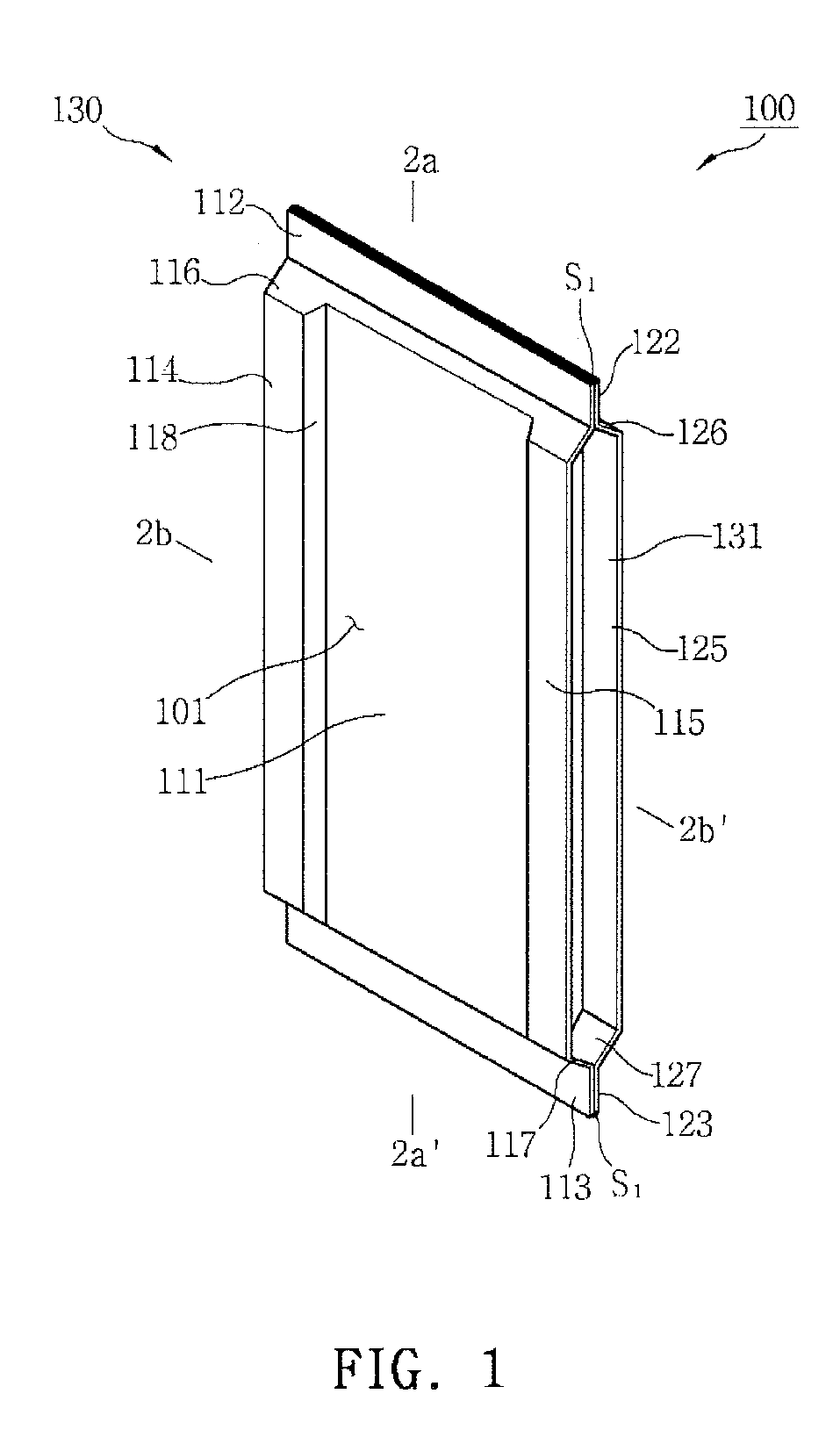

Battery module and manufacturing method thereof

PendingUS20190198952A1Improve workabilityLow costSecondary cellsCell lids/coversEngineeringBattery cell

The present invention provides a battery module, which includes: a battery group formed by stacking a plurality of battery cells, each of which includes electrode tabs; a cooling housing including a cooling plate located corresponding to one side of sides of the battery group, in which the electrode tabs are not extended, and side plates located on both sides of the battery group perpendicular to the one side of the sides, thus to house the battery group; a cover plate located on the other side of the battery group; and a front cover part and a rear cover part, which are located at outermost front and rear of the battery group on both sides in a direction in which the electrode tabs are extended.

Owner:SK ON CO LTD

Refrigerator body and method of manufacturing the same

ActiveUS8197019B2Performed rapidly and easilyPrevent leakageLighting and heating apparatusMetal rolling stand detailsMechanical engineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

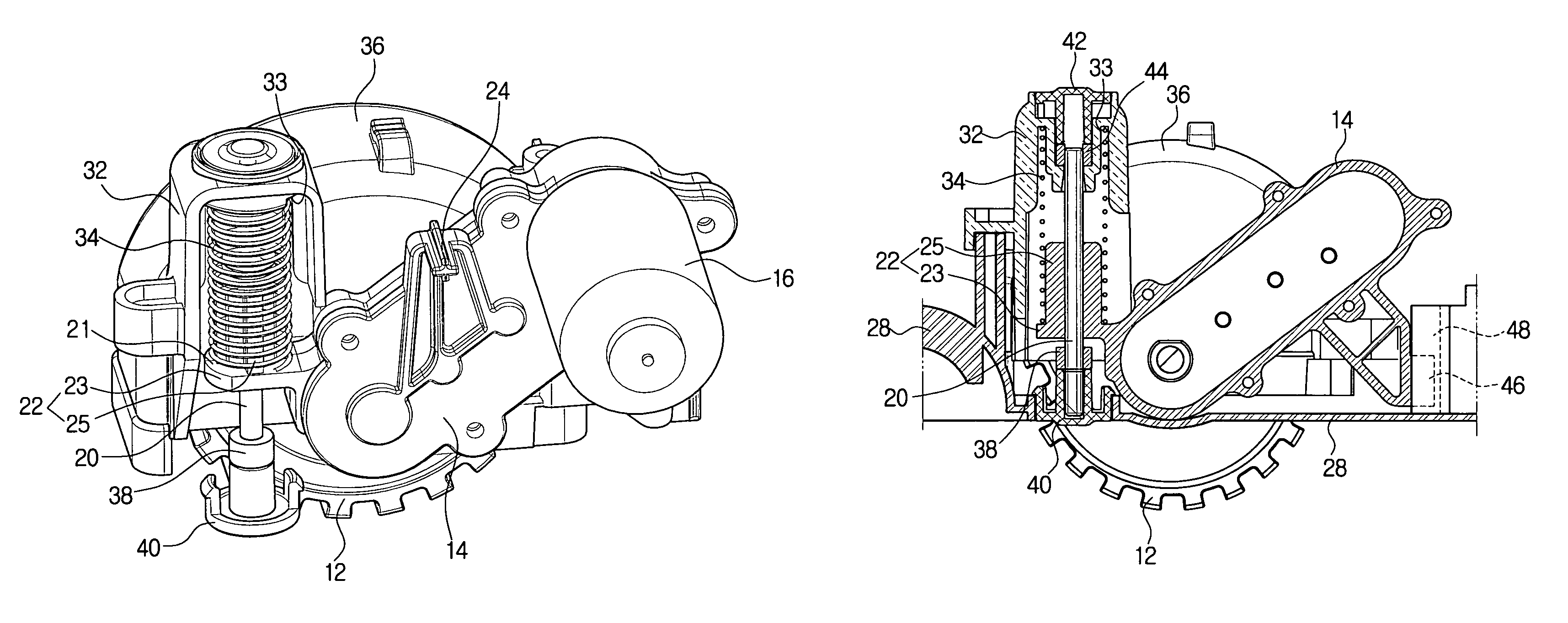

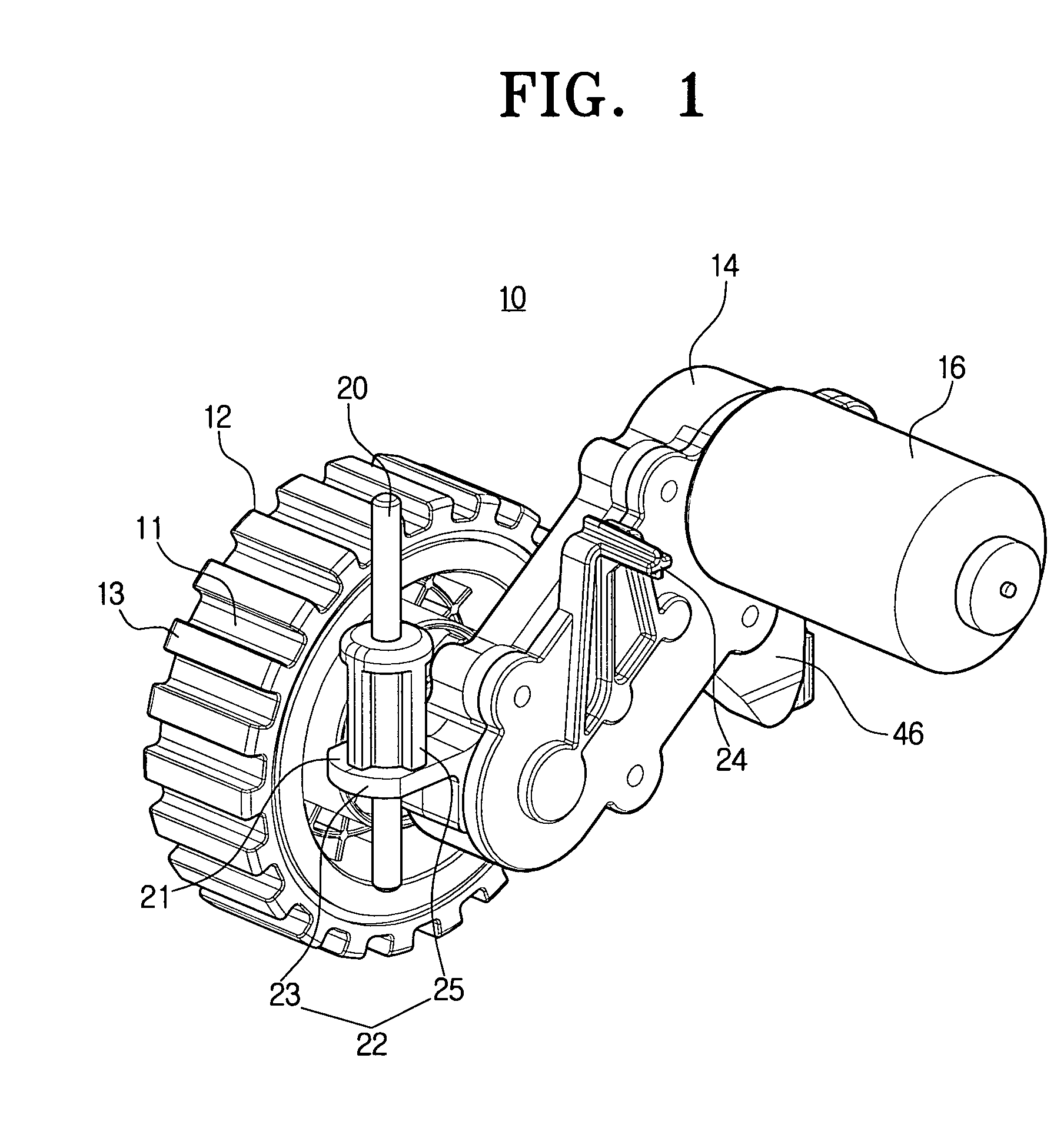

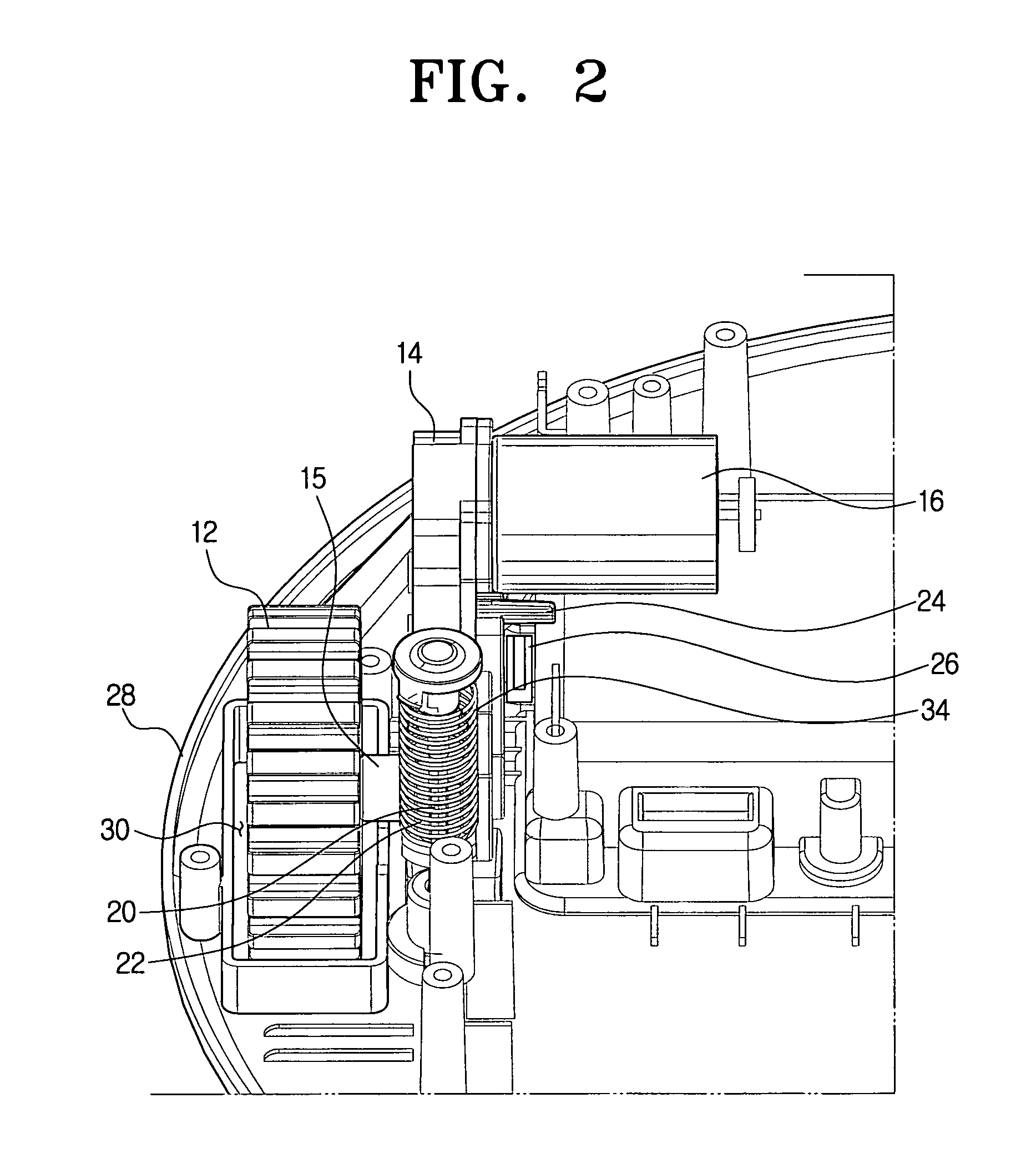

Wheel driving assembly of a moving apparatus

InactiveUS7975790B2Simple structureReduce widthElectric devicesElectric propulsion mountingDrive motorWheel drive

A wheel driving apparatus for a moving apparatus is provided. The wheel driving apparatus includes a wheel, a driving motor to generate a driving power to rotate the wheel, a gear box to transmit the rotational force of the driving motor to the wheel, and a guide shaft movable vertically with respect to the base member, wherein the wheel, the driving motor, the gear box, and the guide shaft are connected integrally with each other to move vertically with respect to the base member in unison.

Owner:SAMSUNG ELECTRONICS CO LTD

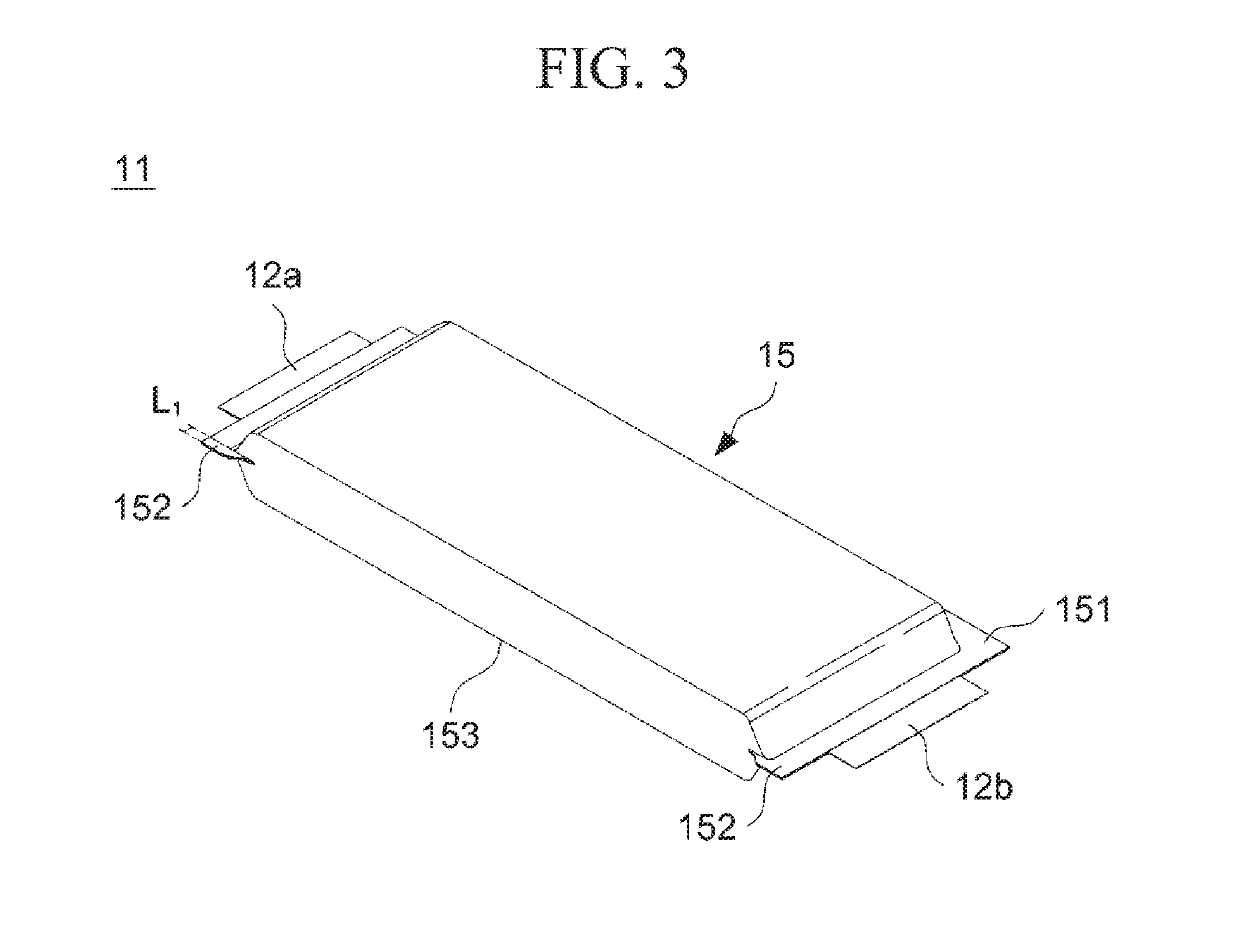

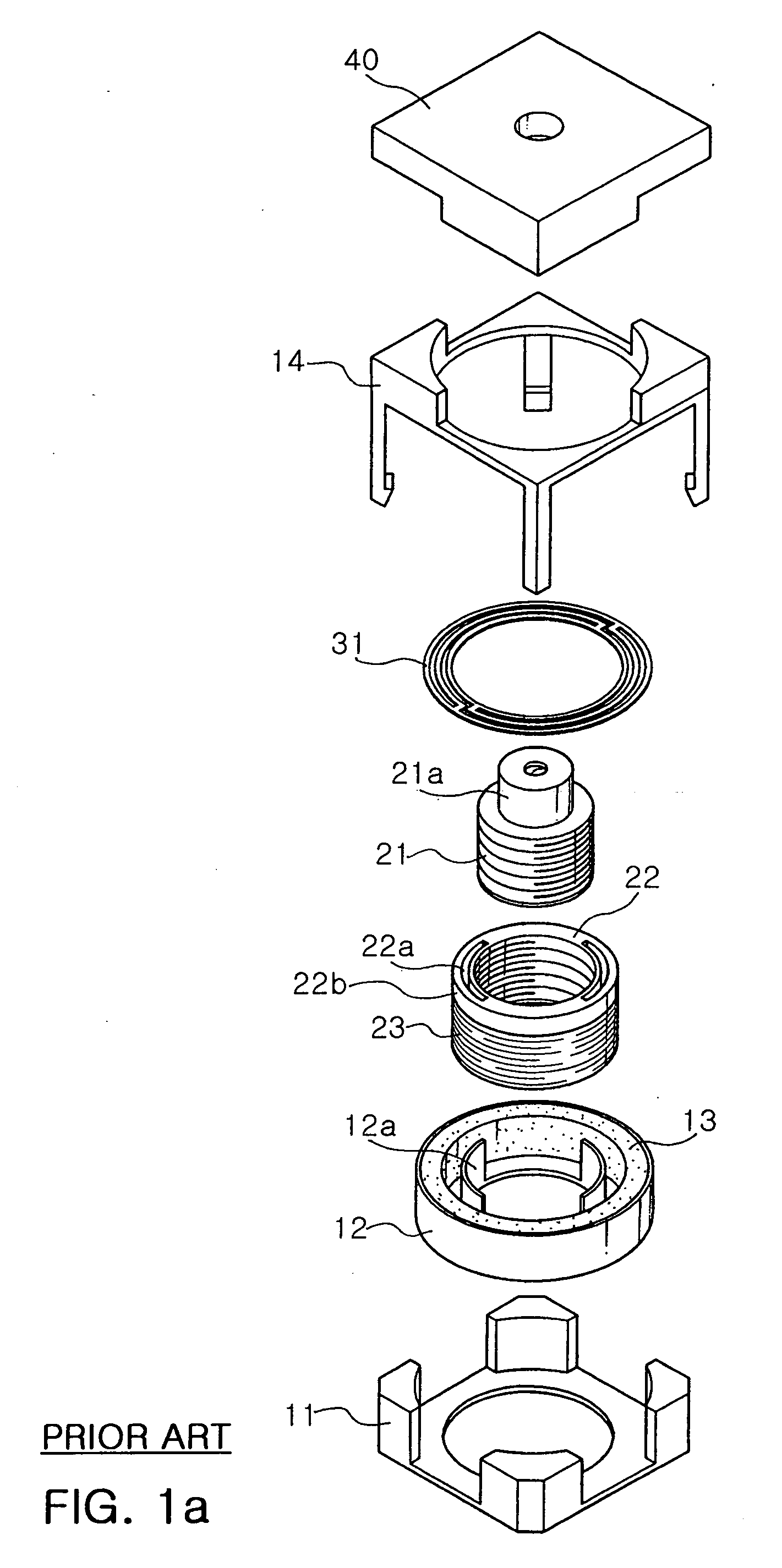

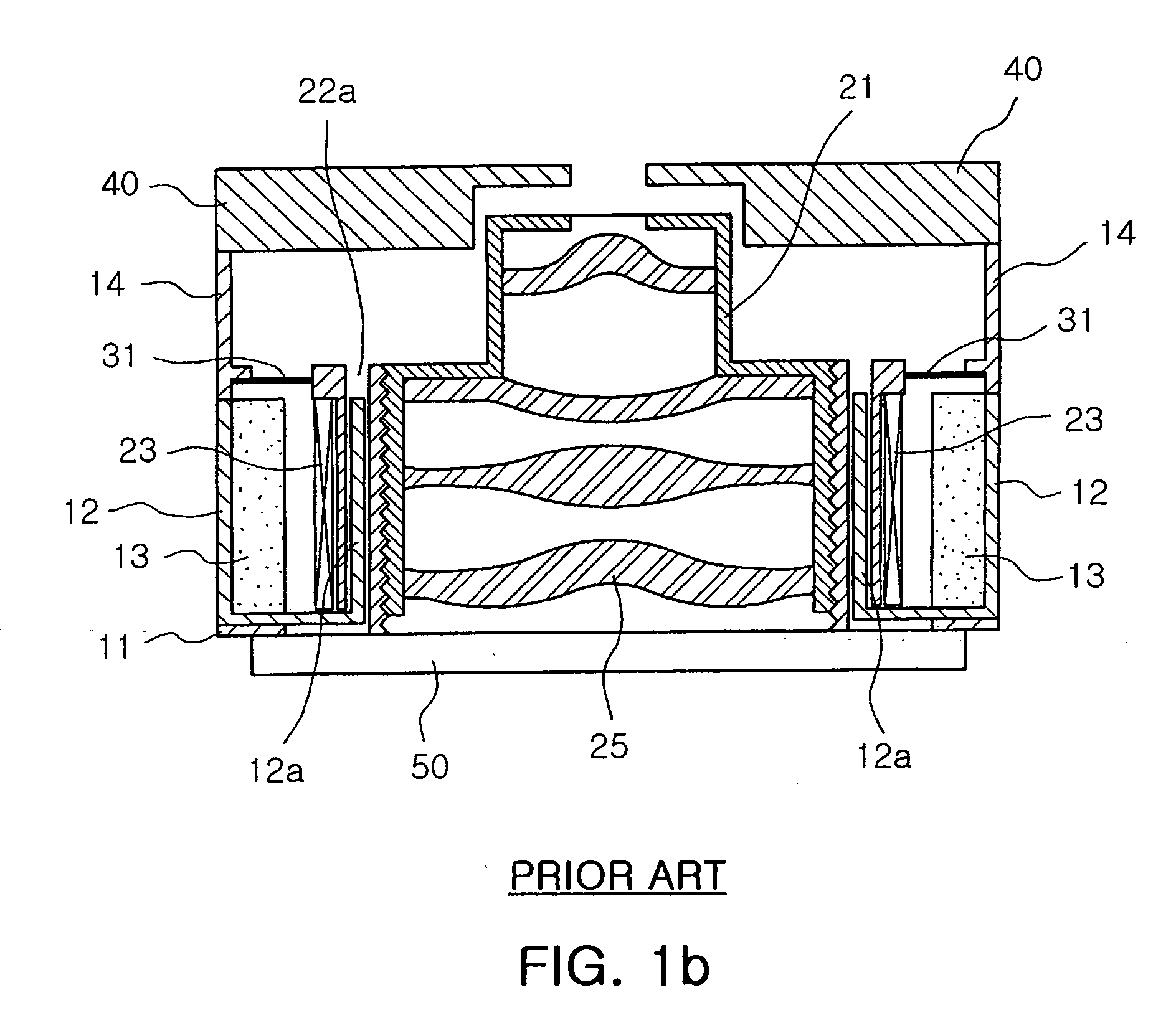

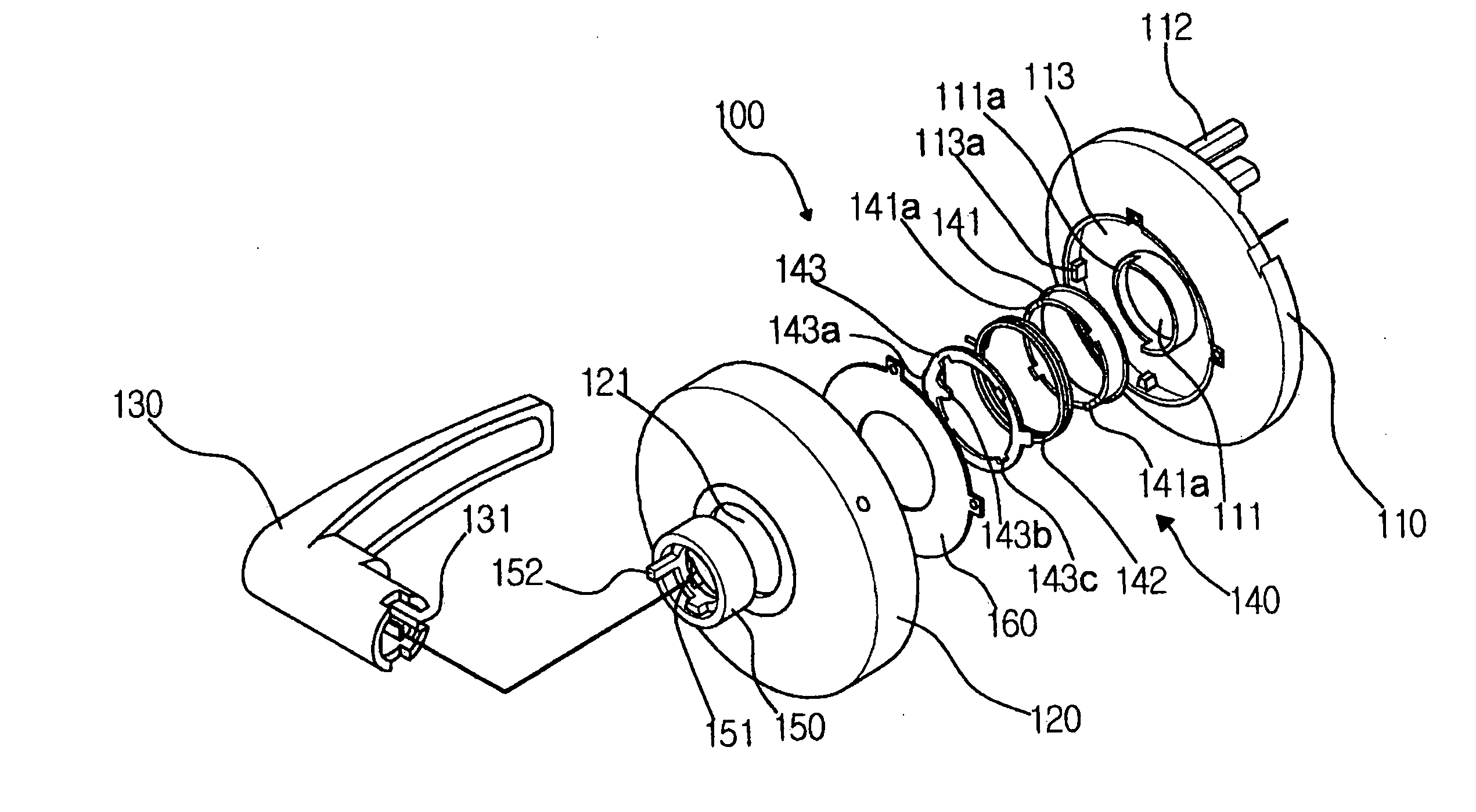

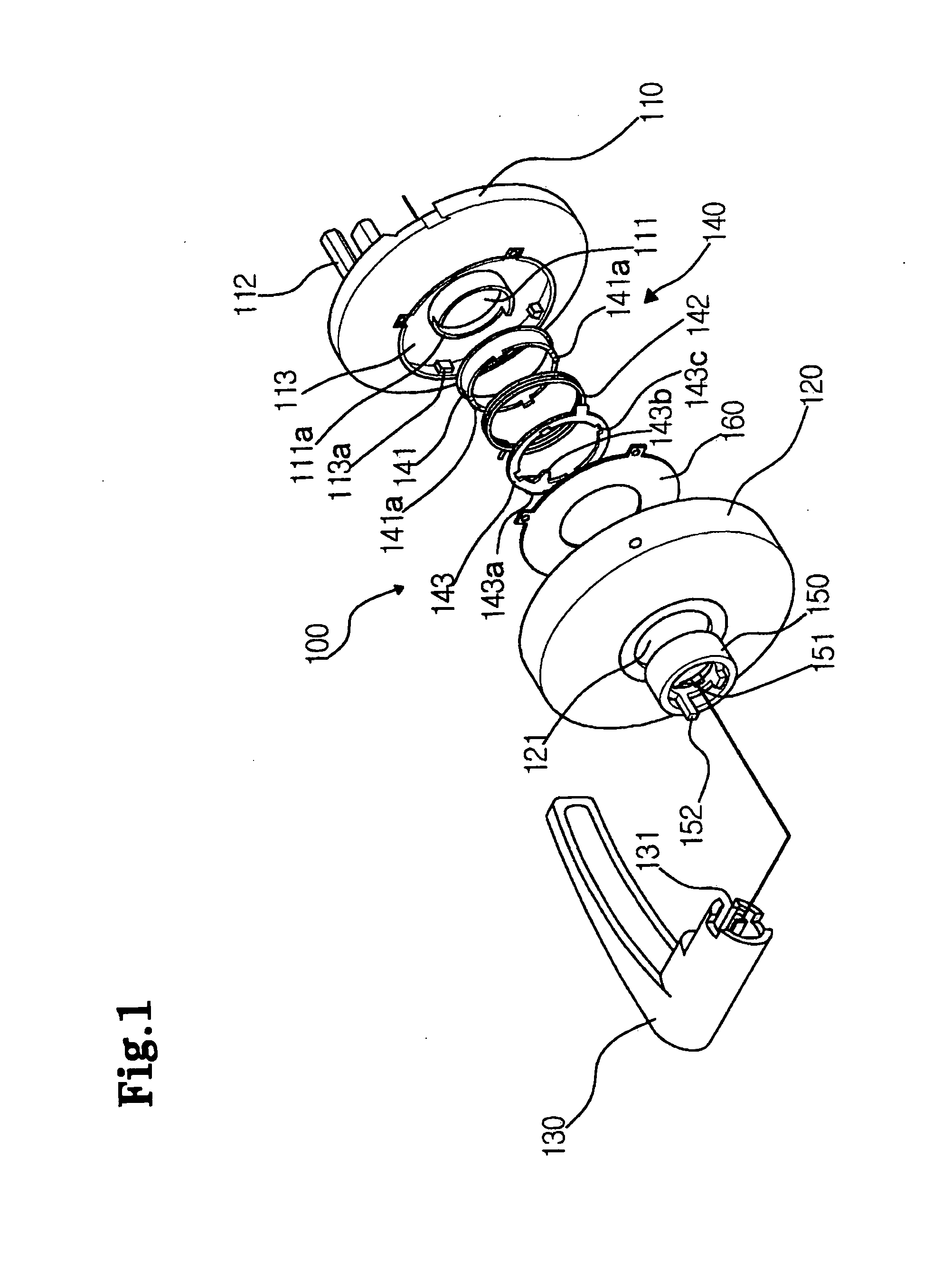

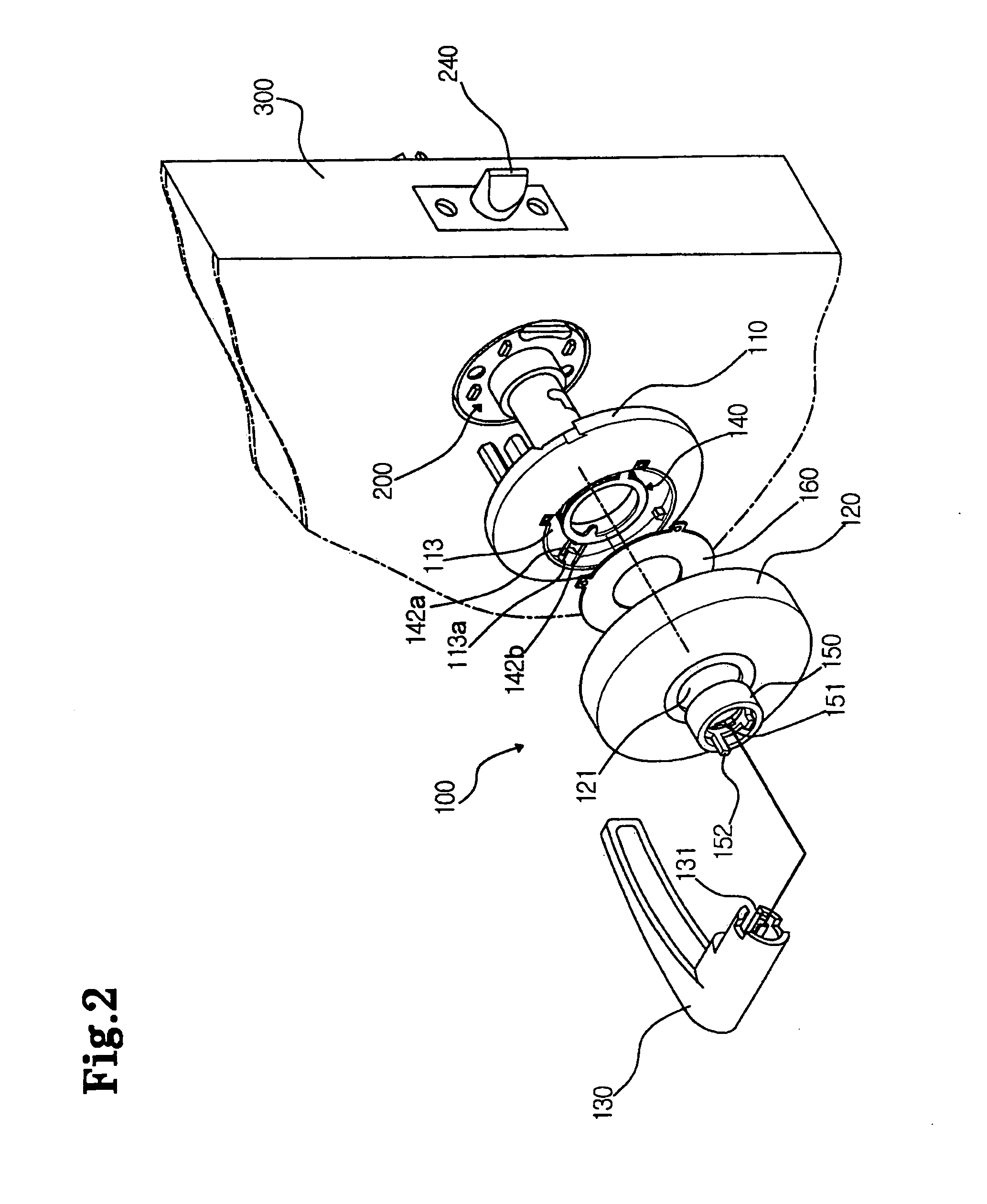

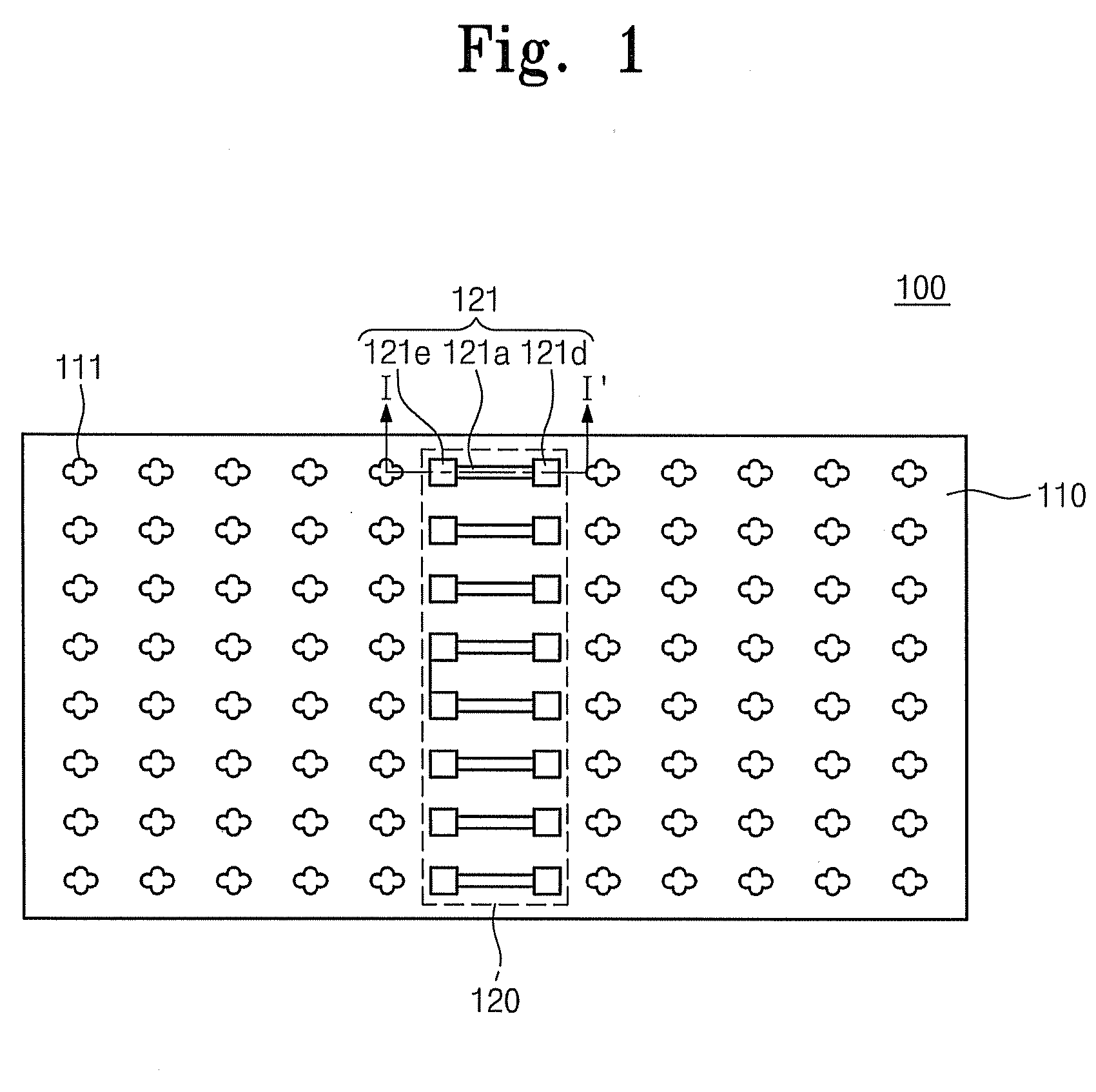

Lens transfer device improved in assemblability

A lens transfer device improved in assemblability. The lens transfer device includes a barrel holder. An upper case includes a first holder connector having a protrusion snap-fitted into a groove formed on an upper-outer circumference of the barrel holder, a first leaf spring connected to an outer circumferential portion of the first holder connector, and a first body connected to an outer circumferential portion of the first leaf spring. A lower includes a second holder connector having a protrusion snap-fitted into a groove formed on a lower-outer circumference of the barrel holder, a second leaf spring connected to an outer circumferential portion of the second holder connector, and a second body connected to the second leaf spring. A yoke is provided to mount a magnet assembly and mounted on the lower case. A coil is installed and spaced by a predetermined gap from the magnet assembly.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

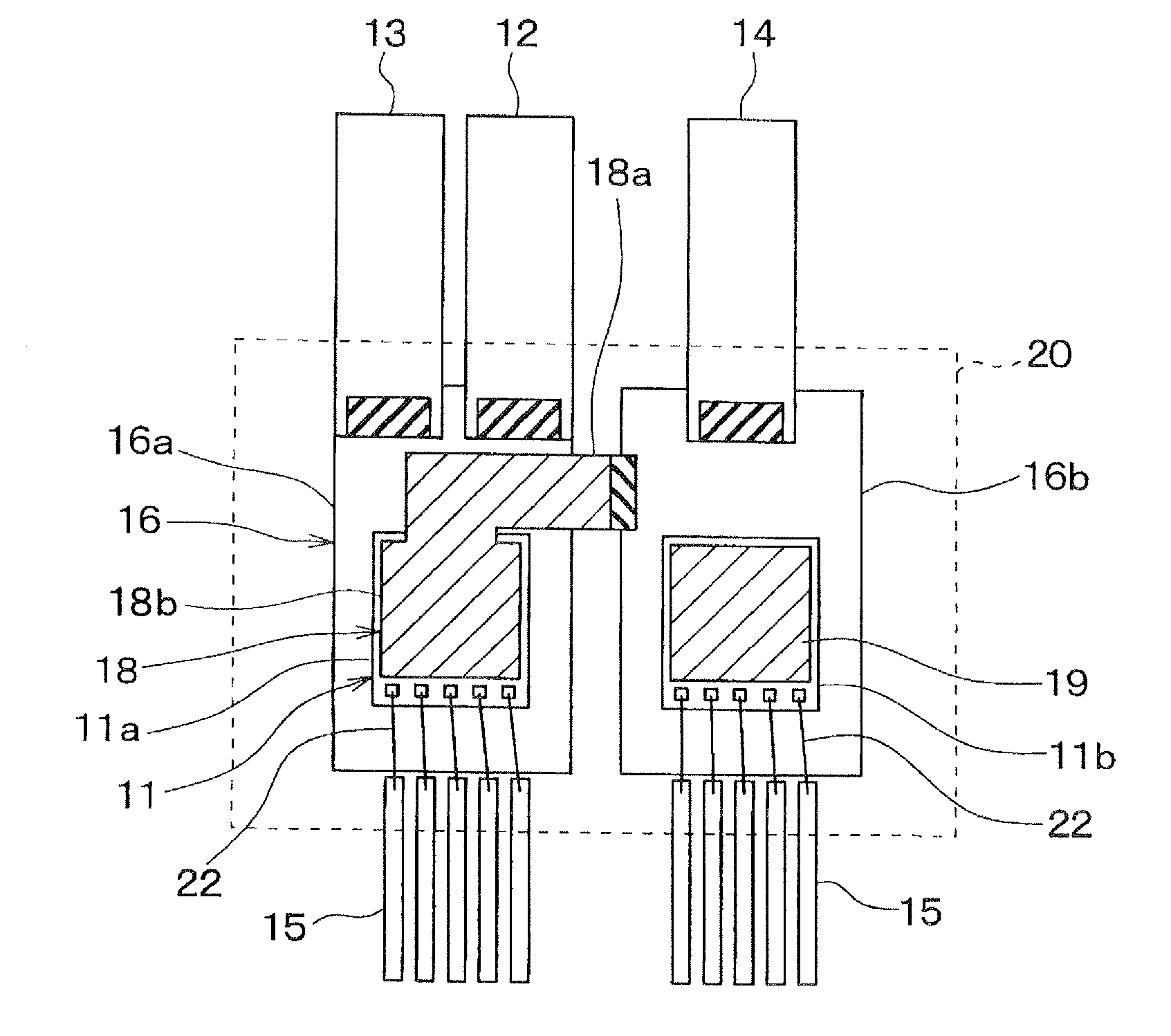

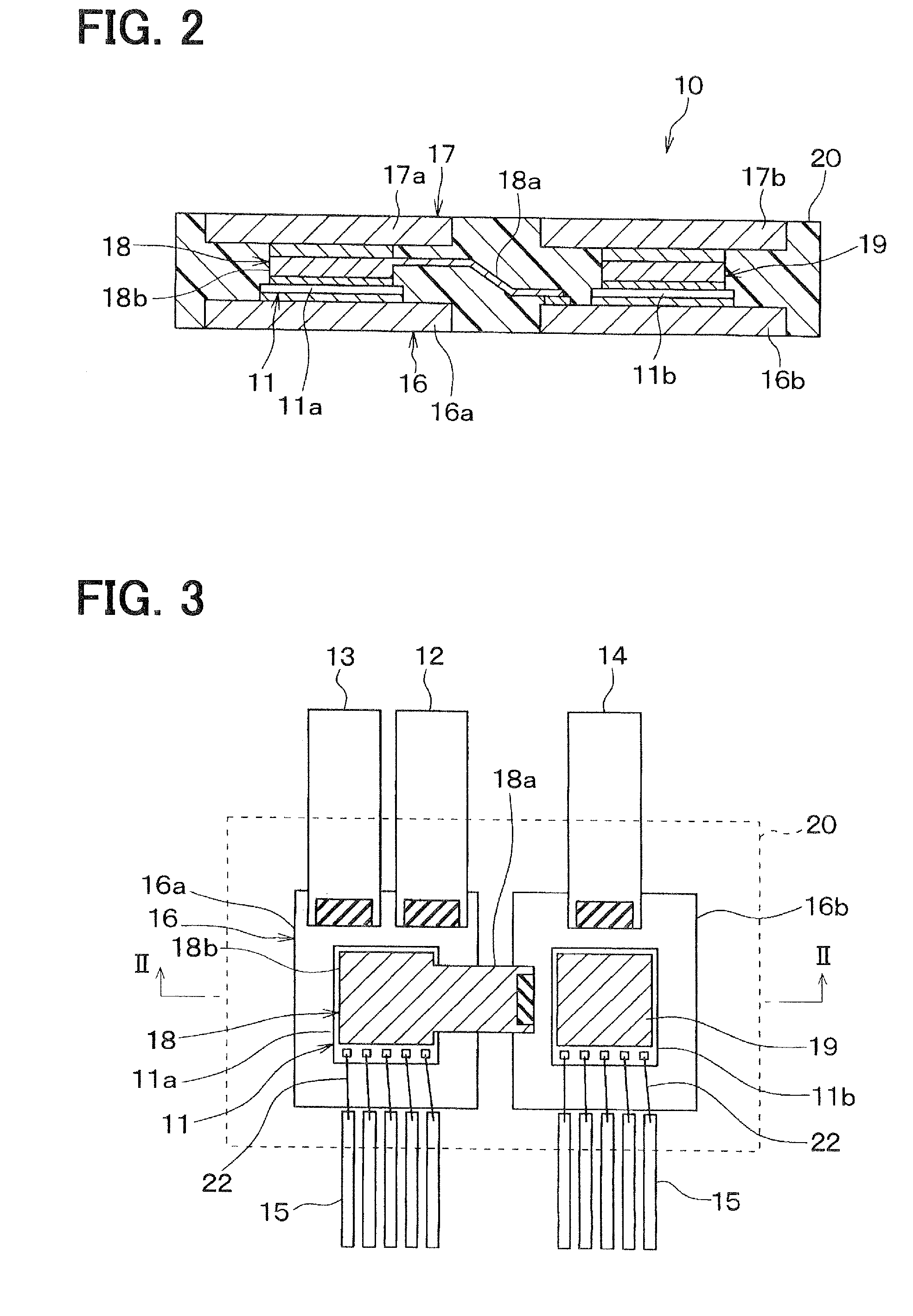

Semiconductor module and method of manufacturing the same

ActiveUS20120001308A1Reduce in quantityReduce areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

In a semiconductor module, a first heat sink is disposed on a rear surface of a first semiconductor chip constituting an upper arm, and a second heat sink is disposed on a front surface of the first semiconductor chip through a first terminal. A third heat sink is disposed on a rear surface of a second semiconductor chip constituting a lower arm, and a fourth heat sink is disposed on a front surface of the second semiconductor chip through a second terminal. A connecting part for connecting between the upper arm and the lower arm is integral with the first terminal, and is connected to the third heat sink while being inclined relative to the first terminal.

Owner:DENSO CORP

Cyclone vessel dust collector and vacuum cleaner having the same

InactiveUS7335241B2Small sizeLarge amount of dust collectionCleaning filter meansSuction filtersCycloneEngineering

Disclosed are a cyclone vessel dust collection and a vacuum cleaner including the same. The cyclone vessel dust collector comprises a cyclone vessel main-body including a primary cyclone vessel unit for separating dusts from dust containing air, and one or more secondary cyclone vessel units for separating dusts from the air passing through the primary cyclone vessel unit, the secondary cyclone vessel units being arranged to surround at least a part of the primary cyclone vessel unit; and a dirt collection bin for receiving dusts or the like separated by the cyclone vessel main-body, wherein the cyclone vessel main-body has an outer circumference with a non-constant radius. Therefore, the cyclone vessel dust collector can have a dust collection capability of large capacity with a small size.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Linkage system

ActiveUS7472622B2Improve rigidityImprove AssemblabilityProgramme-controlled manipulatorJointsEngineeringActuator

A linkage system which offers high rigidity and good assemblability and producibility, and enables parts such as rotary transmission components and actuators to be readily installed. A linkage system includes an input member disposed on an input side, an output member disposed on an output side, and three or more link mechanisms, each link mechanism consisting of end links rotatably coupled to the input member and the output member, respectively, a center link rotatably coupled to the end links on the input side and the output side, and four revolute joints by which the end links are rotatably coupled to the input and output members, and to the center link. The link mechanism being geometrically identical with respect to a center cross-sectional plane relative on the input and output sides. Each of the revolute joints of the link mechanism includes bearings that support at both ends of the revolute joint.

Owner:NTN CORP

Lithium sulfide-porpous carbon compound positive material for lithium ion battery and preparation method thereof

InactiveCN102163720AImprove conductivityStop the spreadCell electrodesPorous carbonSodium-ion battery

The invention provides a lithium sulfide-porpous carbon compound positive material for a lithium ion battery and a preparation method thereof. The positive material is formed by compounding lithium sulfide and ordered porous carbon, wherein the mass fraction of the lithium sulfide in the compound material is 20-80%; and the lithium sulfide exists in the pore spaces of the porous carbon. The preparation method comprises the following steps: firstly, carrying out ball milling on the ordered porous carbon and sulfur in the presence of inert gas; then carrying out thermal processing on the milled mixture at the temperature of 145-155 DEG C so that the sulfur fully is dispersed into the porous carbon; and finally, reacting lithium with the sulfur so as to generate the lithium sulfide by a chemical or electrochemical method, thereby obtaining the positive material provided by the invention. According to the invention, the preparation process is simple, and the raw material source is wide; the prepared positive material is used in a mode of pre-embedding lithium in a positive electrode, metal lithium is not required to serve as a negative electrode, and a carbon negative electrode, a silicon negative electrode and the like are used, thereby improving the safety performance and the assembling performance; the positive material has the advantages of good conductivity, high capacity and good circulation performance; and the positive material has a wide application prospect and the preparation method is suitable for industrial production.

Owner:CENT SOUTH UNIV

Resin foam and foam sealing material

InactiveUS20130017391A1Excellent in dustproofnessImprove AssemblabilityOther chemical processesFilm/foil adhesivesApparent densityCell diameter

There is provided a resin foam excellent in dustproofness and assemblability.The resin foam has a repulsive stress at 80% compression (repulsive stress when a resin foam is compressed by 80% of the initial thickness) of 1.0 to 9.0 N / cm2 and a tensile modulus of elasticity of 5.0 to 14.0 MPa. Preferably, the resin foam further has an average cell diameter of 10 to 180 μm and an apparent density of 0.01 to 0.10 g / cm3.

Owner:NITTO DENKO CORP

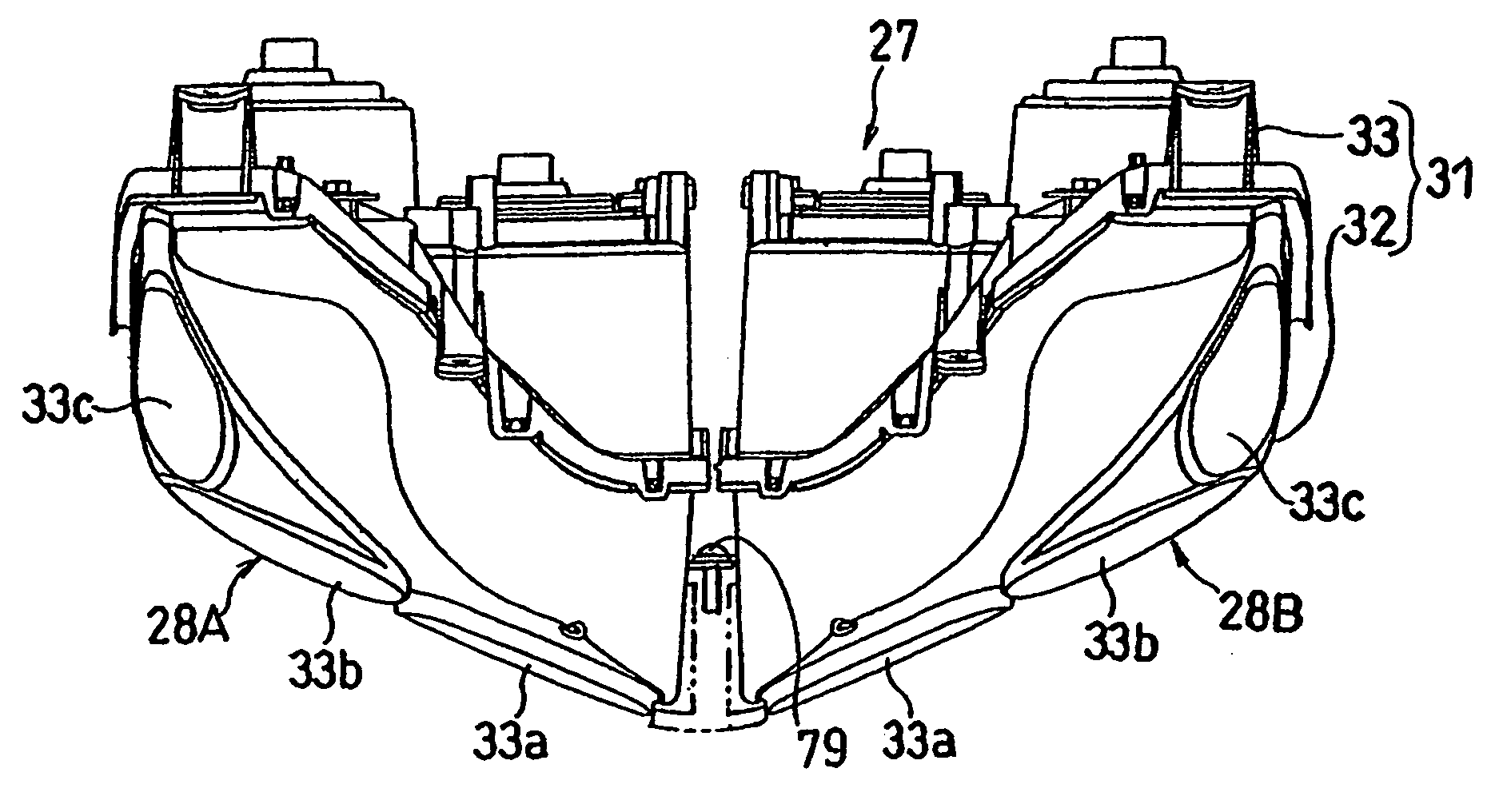

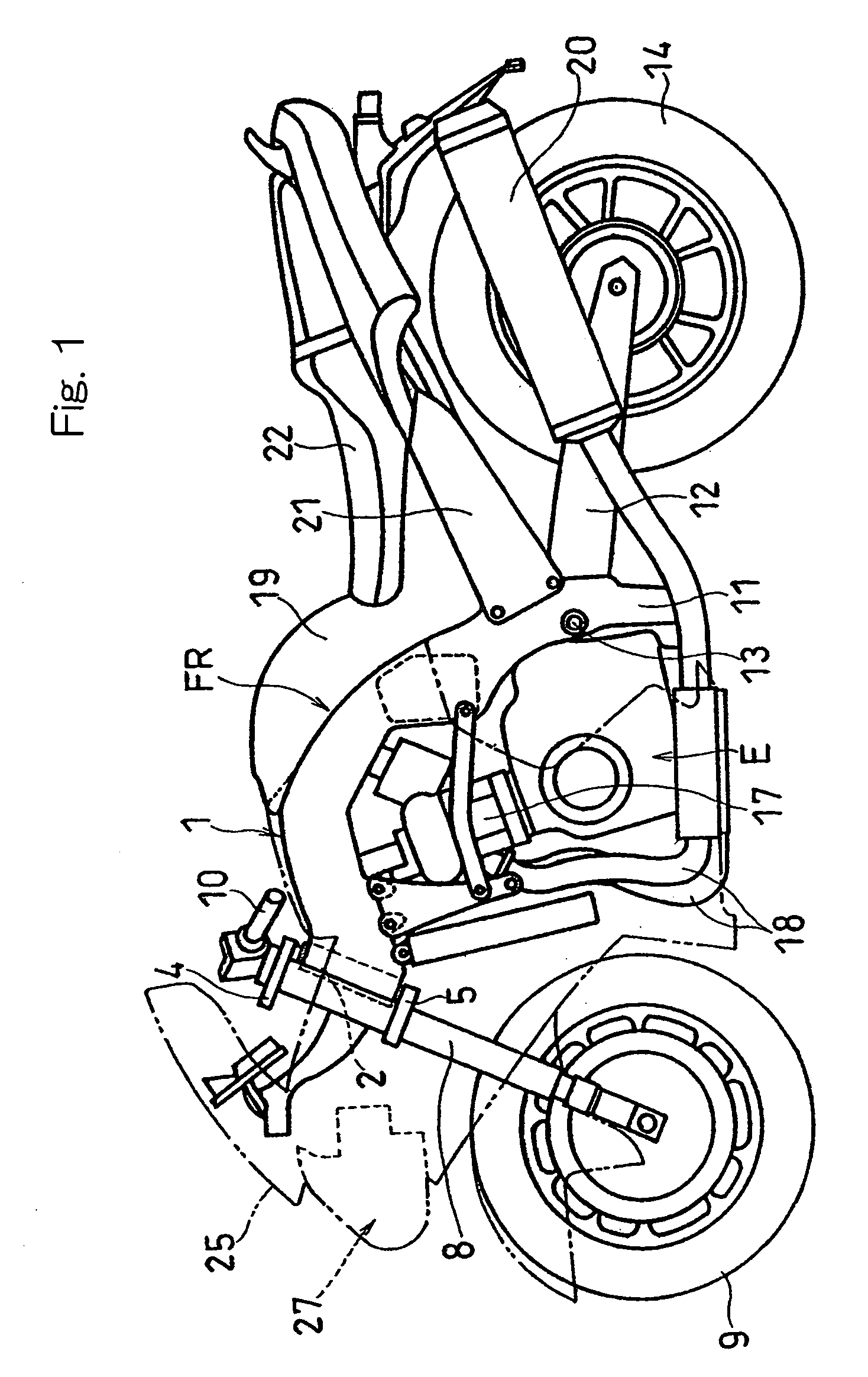

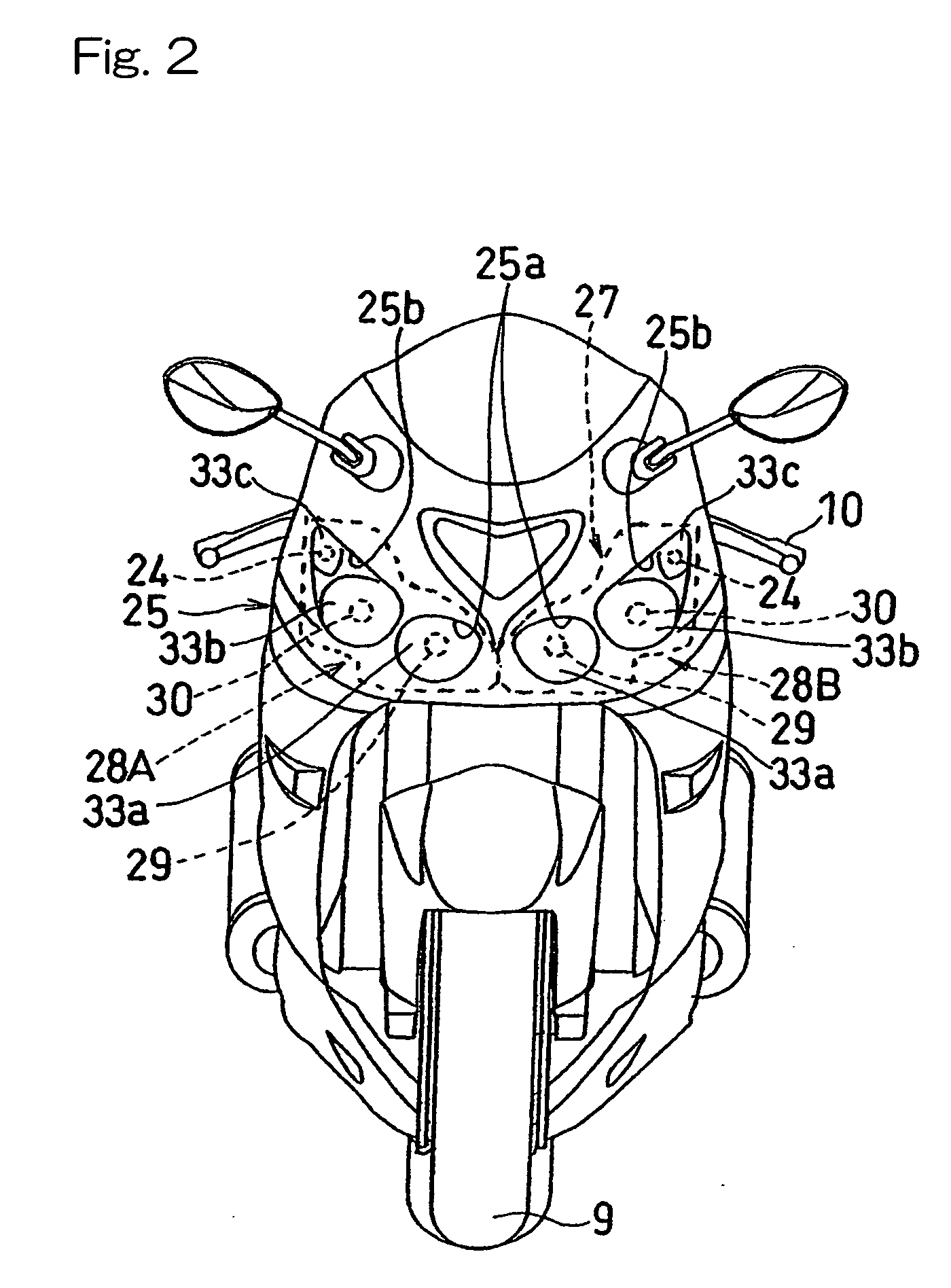

Vehicle headlight assembly and motorcycle utilizing the same

InactiveUS20070058381A1Improve productivityEliminate the problemVehicle headlampsLighting support devicesWaste managementAssembly design

To provide a vehicle headlight assembly designed to increase the productivity, the vehicle headlight assembly includes a light projecting group (34) accommodated within a casing (31) and including a plurality of light projecting units (29, 30). Each of the light projecting units (29, 30) in turn includes a light emitting element (37, 38), and a support member (40A, 40B) supported by and within the casing (31). The support members (40A, 40B) of each light projecting units (29, 30) cooperatively form a single holder (40A, 40B).

Owner:KAWASAKI HEAVY IND LTD +1

Door handle module and door lock using the same

InactiveUS20080307836A1Avoid deformationSimple structureWing handlesKeyhole guardsEngineeringTorsion spring

A door handle module and a door lock using the same are disclosed. The door handle module according to the present invention is provided with a hollow rotating piece, a torsion spring enclosing an outer circumference of the rotating piece and being engaged with the locking protrusion formed in the mounting recess by both ends thereof, and a hollow operating piece being fixed to the outside of the rotating piece and includes a shoulder edge formed on a circumference thereof to mount the both ends of the torsion spring and an operational edge formed on an inner circumference thereof to be connected to the handle. Accordingly, the handle that has been turned to open the door can be turned back by a recovery force of the torsion spring so as to be able to maintain its neutral position, and the structure of the door handle module and the door lock can be simplified.

Owner:HYUNDAI METAL

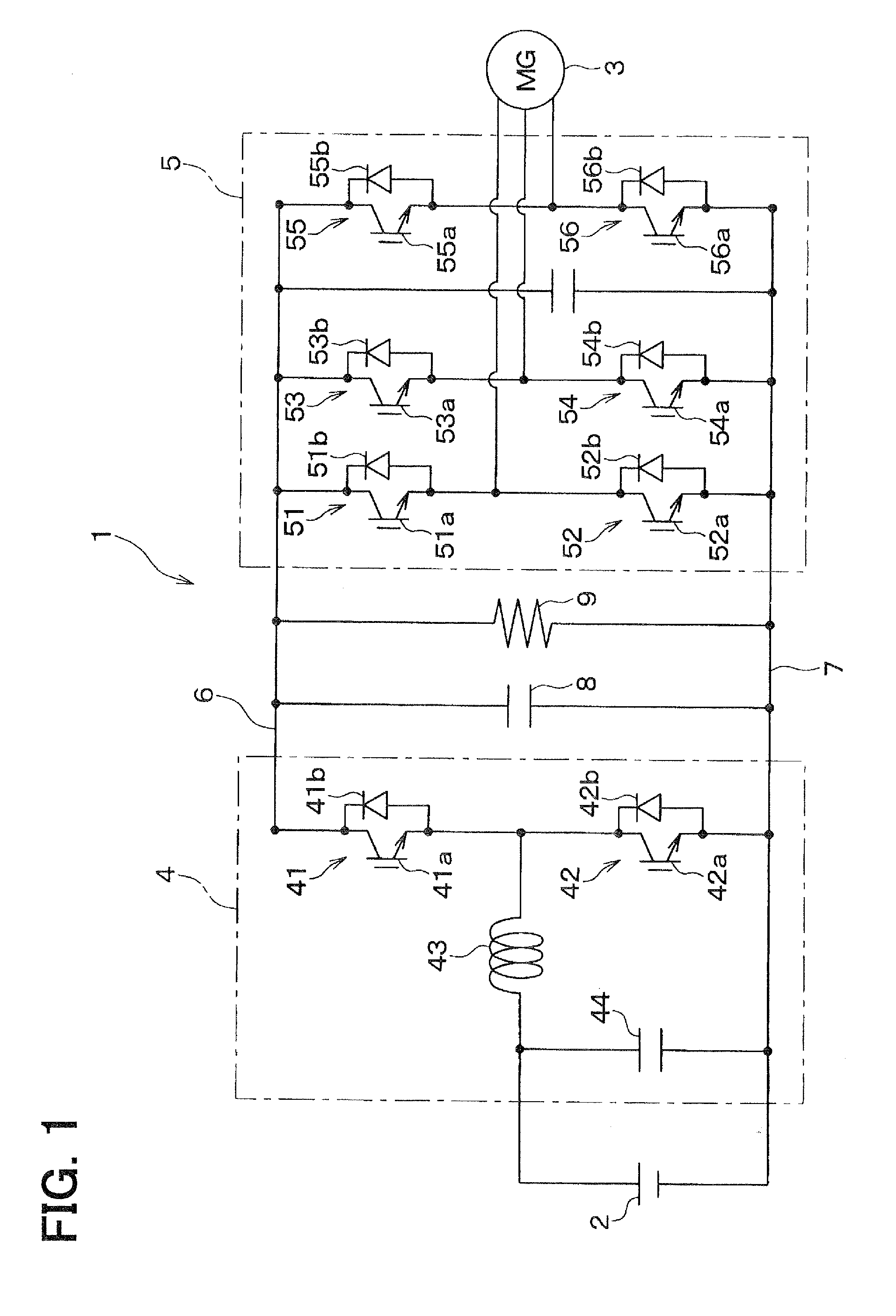

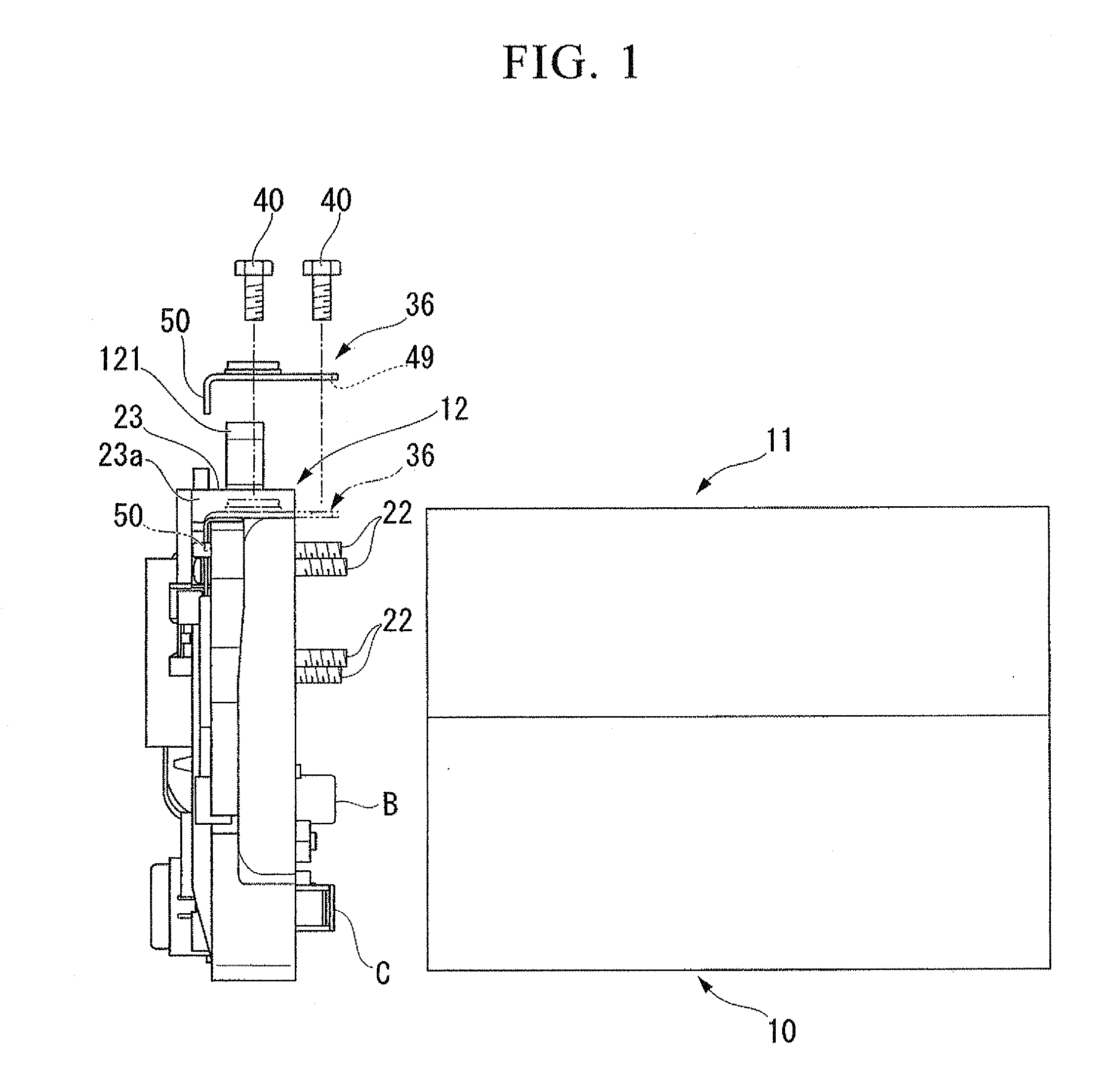

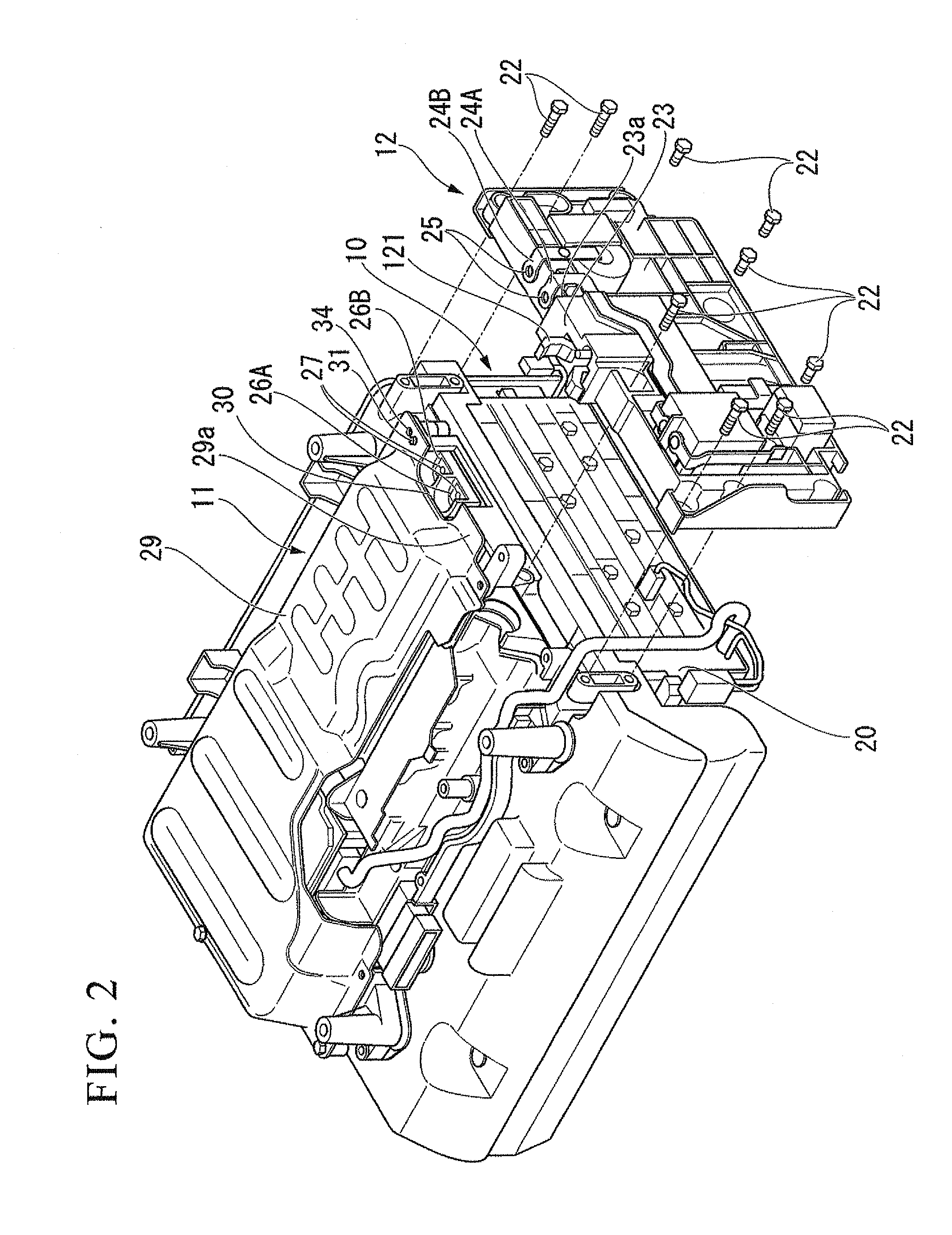

High-voltage electrical component unit for vehicles

ActiveUS20100127565A1Improve securityImprove AssemblabilityElectric devicesElectric propulsion mountingElectricityHigh pressure

Provided is a high-voltage electrical component unit for vehicles, including: an electrical storage device; a power control block disposed above the electrical storage device for controlling input-output power of the electrical storage device; and a power distribution block disposed across both side portions of the electrical storage device and the power control block for electrically connecting the electrical storage device and the power control block, the electrical storage device, the power control block and the power distribution block being fastened to one another, wherein a temporarily fastening section is provided at a separately-provided conductive functional component which electrically connects a connection terminal of the power distribution block and a connection terminal of the power control block, the temporarily fastening section engaging to both the power control block and the power distribution block to hold relative positions thereof.

Owner:HONDA MOTOR CO LTD

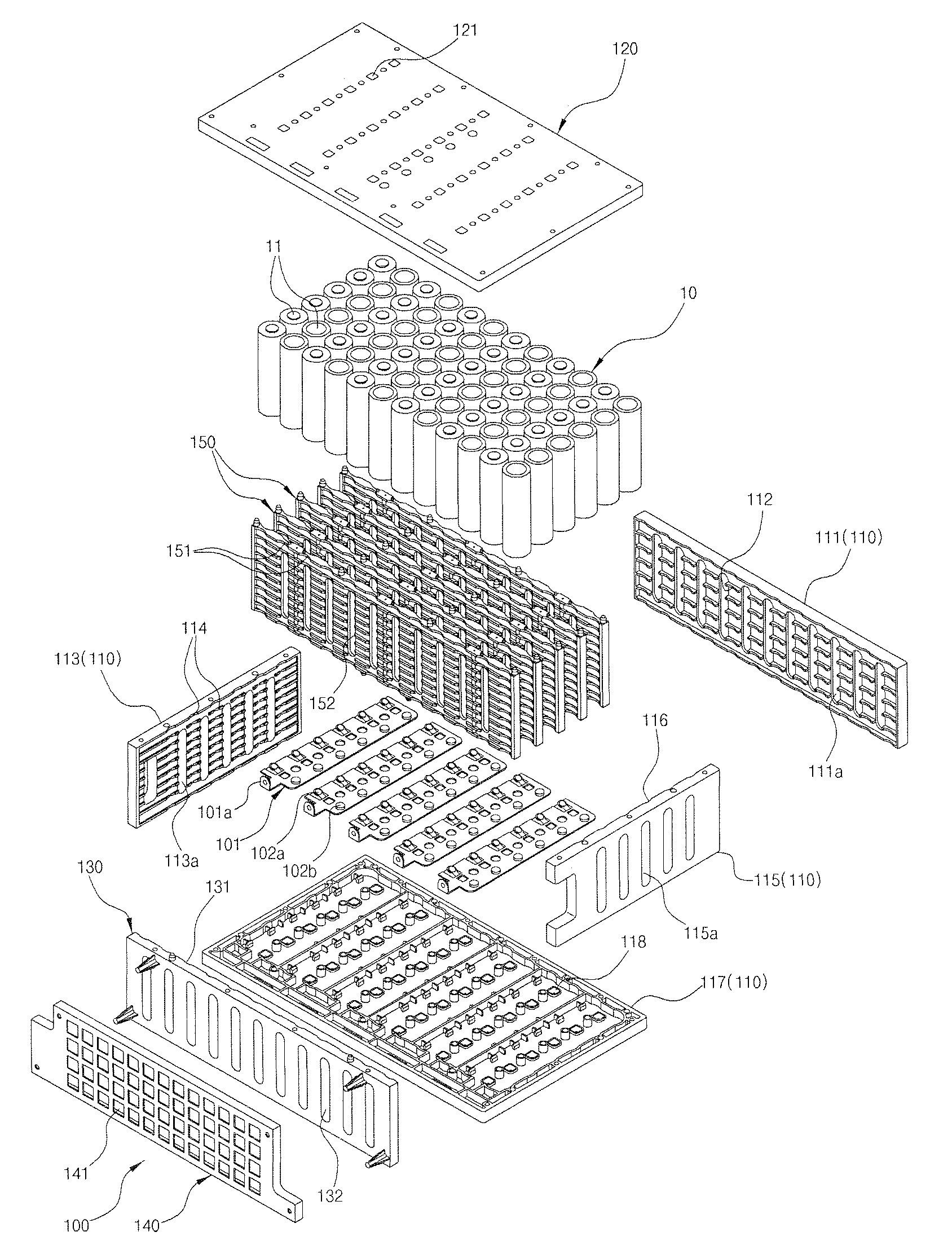

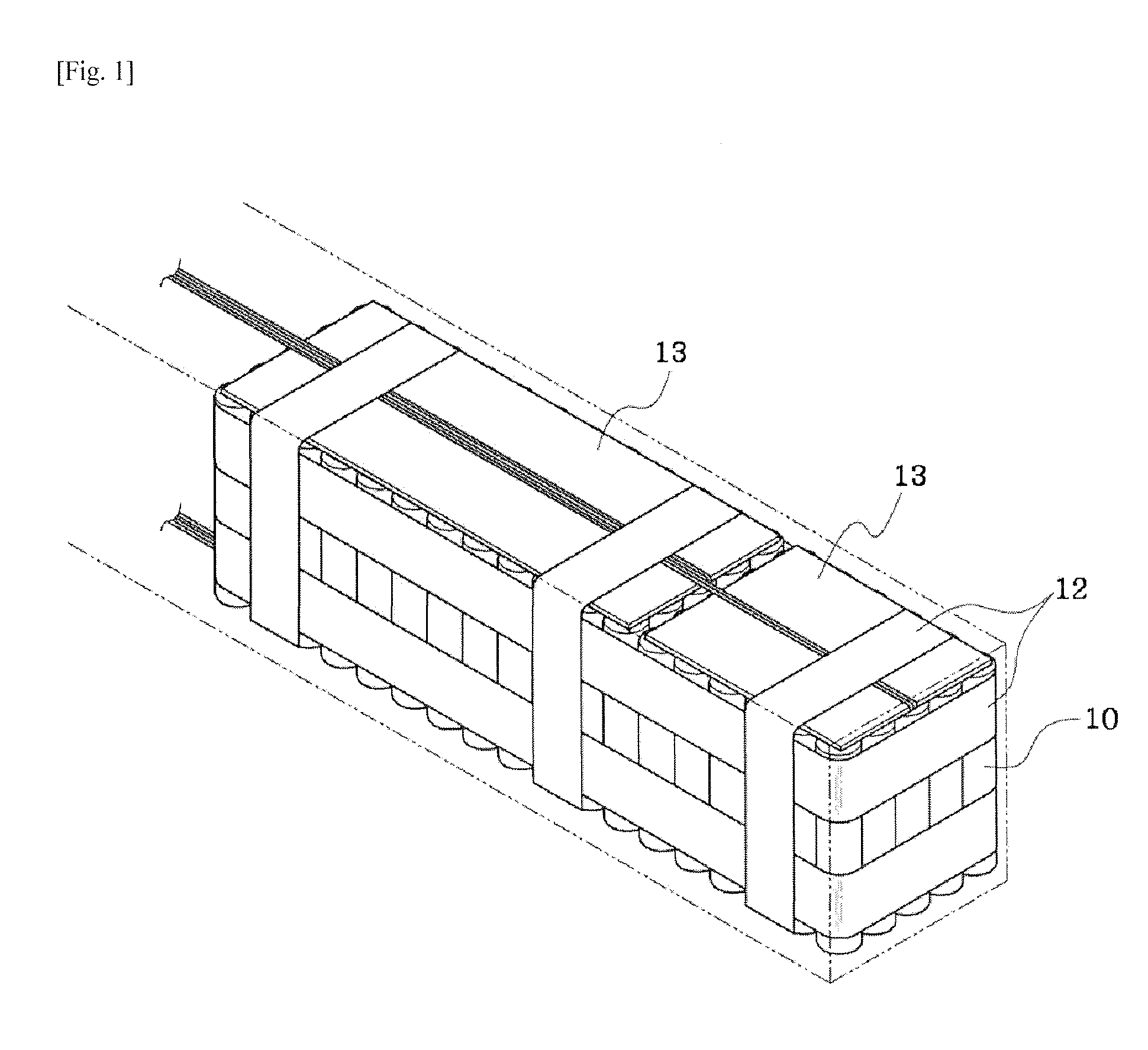

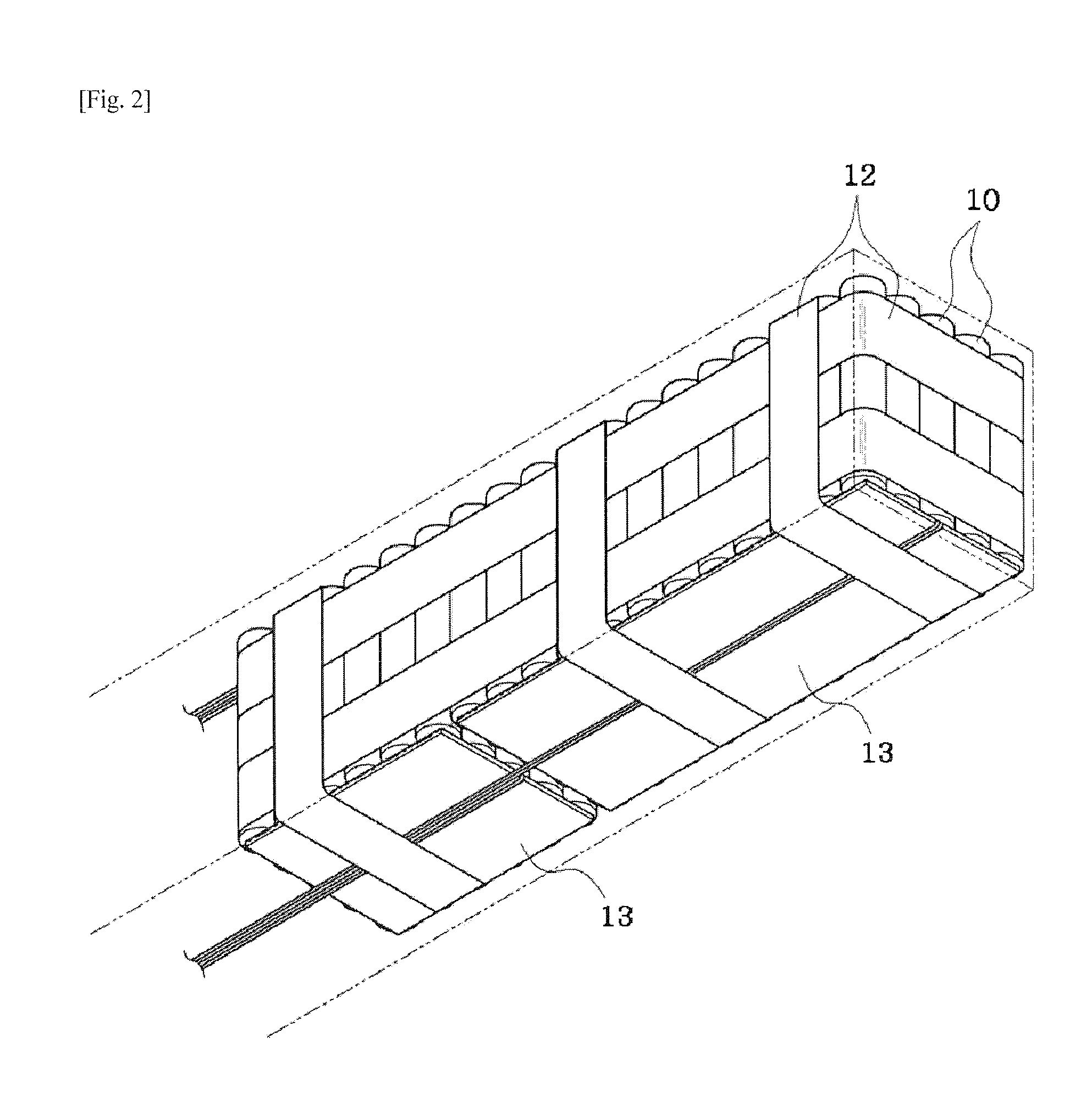

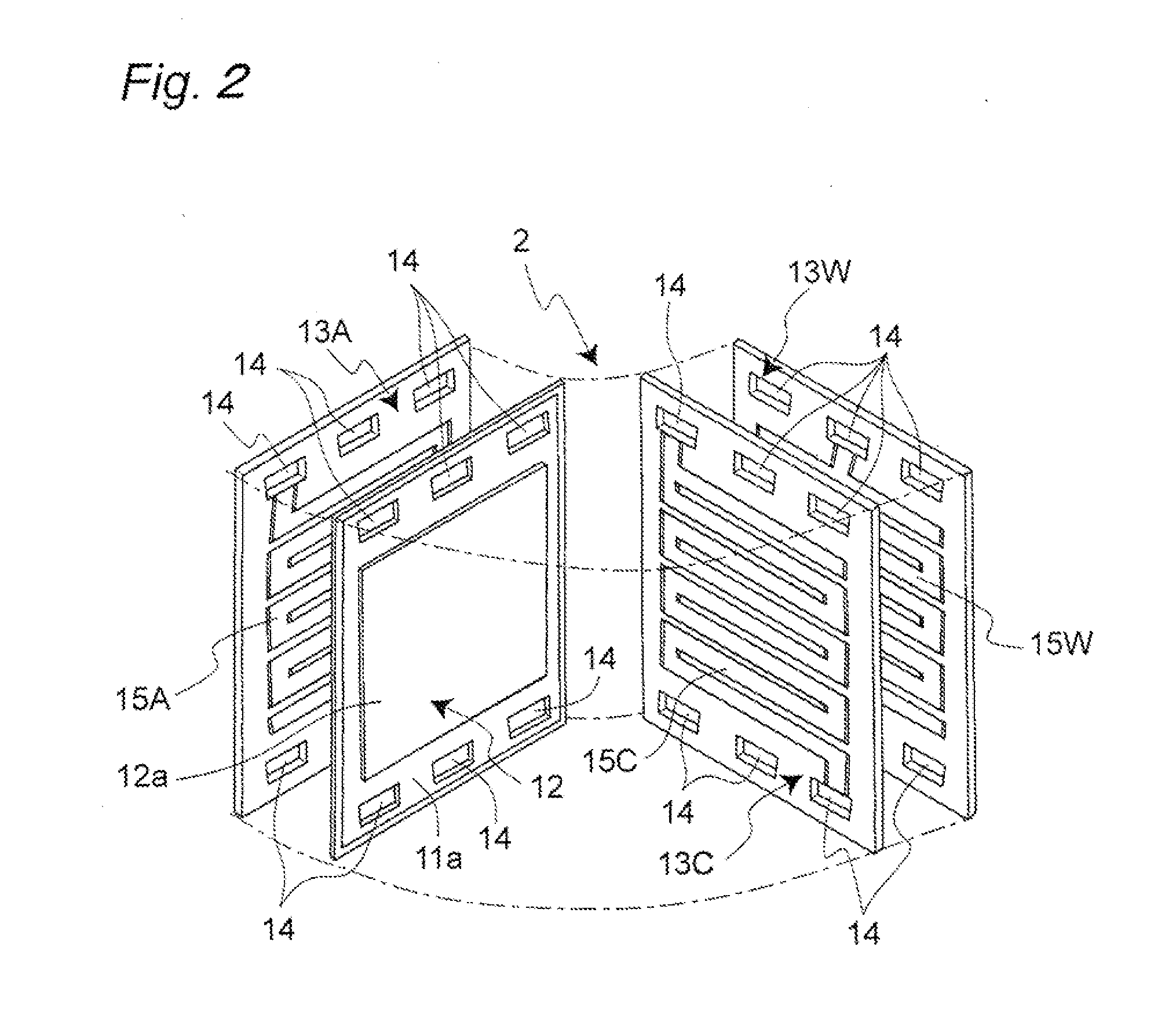

Cell Cartridge with a Composite Intercell Connecting Net Structure

InactiveUS20110287287A1Improve accuracyShorten the timePrimary cell to battery groupingSecondary cellsElectrical resistance and conductanceProduction rate

The present invention provides a cell cartridge with a composite cell interconnection network, in which plural unit cells are assembled and modularized in a case in a composite series-parallel connection manner. An object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells can be simply assembled, as opposed to conventional methods of binding the unit cells with glass tape, for example, to shorten the time required for assembly, improve assemblability and productivity, and increase the accuracy of manufacturing standards. Moreover, another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells are spaced at regular intervals to prevent problems caused by direct contact between the cells and by heat generated thereby, prevent problems such as cell performance degradation and reduced battery lifespan caused by the direct contact and the generated heat, and enable mass production of standardized and modularized battery packs. Furthermore, still another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which the structure of external terminals connected to cell terminals is modified to prevent a contact failure or excessive contact resistance between the cell terminals and the external terminals, and which can solve many other problems, caused by the welding of a nickel plate in conventional methods, such as welding defects, inconvenience of welding process, excessive assembly time due to the welding, degradation of assemblability and productivity, etc. To this end, a cell cartridge with a composite cell interconnection network is disclosed, the cell cartridge comprising: a plurality of unit cells; a case which accommodates the unit cells and is then assembled; a plurality of spacing members, each disposed between the unit cells accommodated in the case to space the unit cells a predetermined distance from each other; and a plurality of connection plates fixedly mounted on an inner side of the case and each including terminals connected to electrodes of the respective unit cells to connect the electrodes of adjacently arranged cells to each other, wherein the unit cells are connected to each other by the connection plates connected to the respective electrodes in a composite series-parallel connection manner.

Owner:ICEL SYST KOREA +1

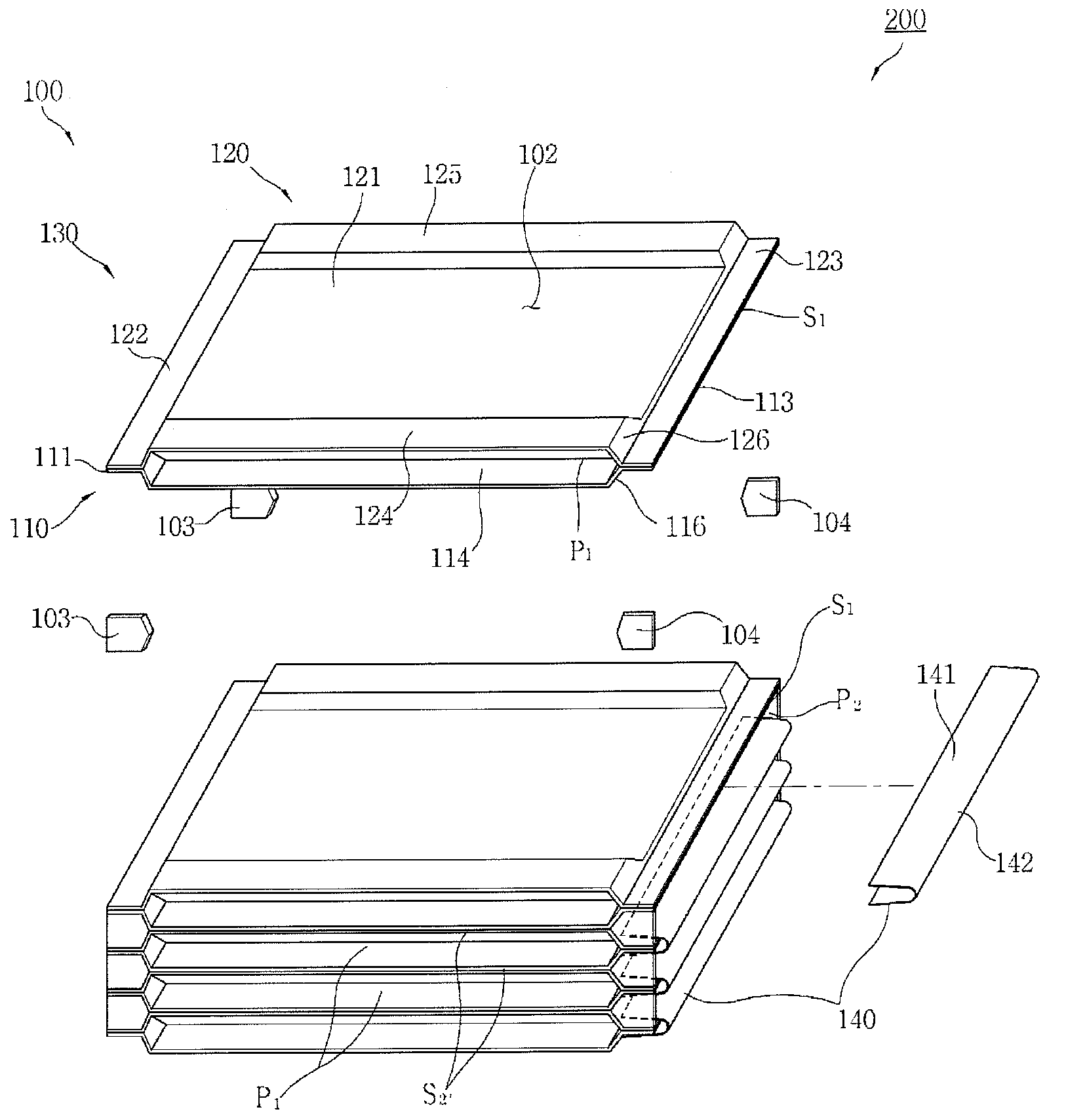

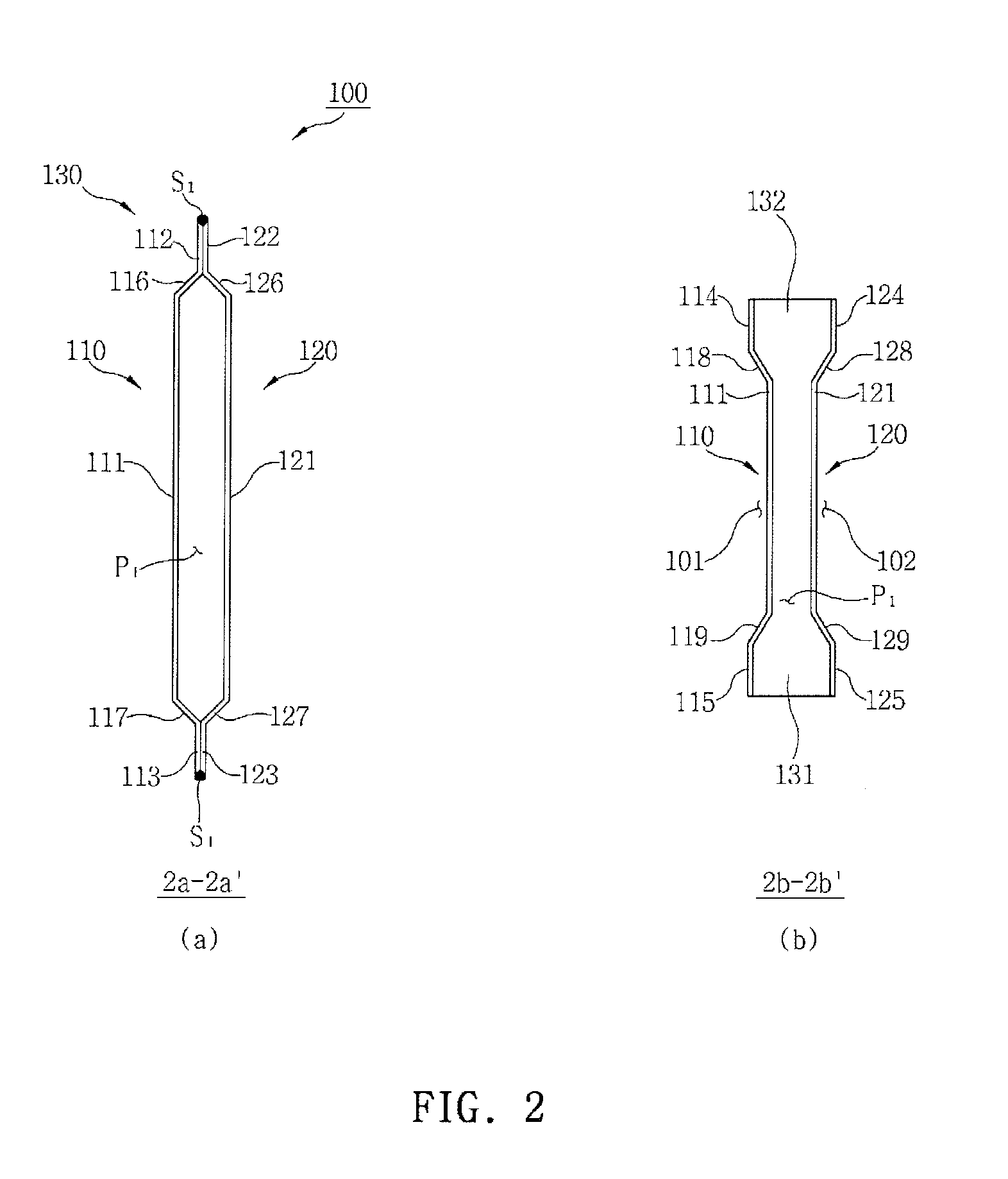

Heat transfer cell for heat exchanger and assembly, and methods of fabricating the same

InactiveUS20100006274A1Minimize vortexMinimize resistanceMetal-working apparatusCorrosion preventionHeight differenceEngineering

A heat transfer cell includes first and second heat transfer plates which have first and second heat transfer areas, and first and second flanges bent from the first and second heat transfer areas so as to have a height difference with respect to the first and second heat transfer areas. The first and second heat transfer plates are joined into a cell body so as to be opposite to each other in a mirror image, and the cell body having a first fluid passage therein, weld lines formed along the first contacting each other and along the second flanges contacting each other, and external recesses formed outside the heat transfer areas for second fluid passages intersecting with the first fluid passage at a right angle.

Owner:EURO - APEX

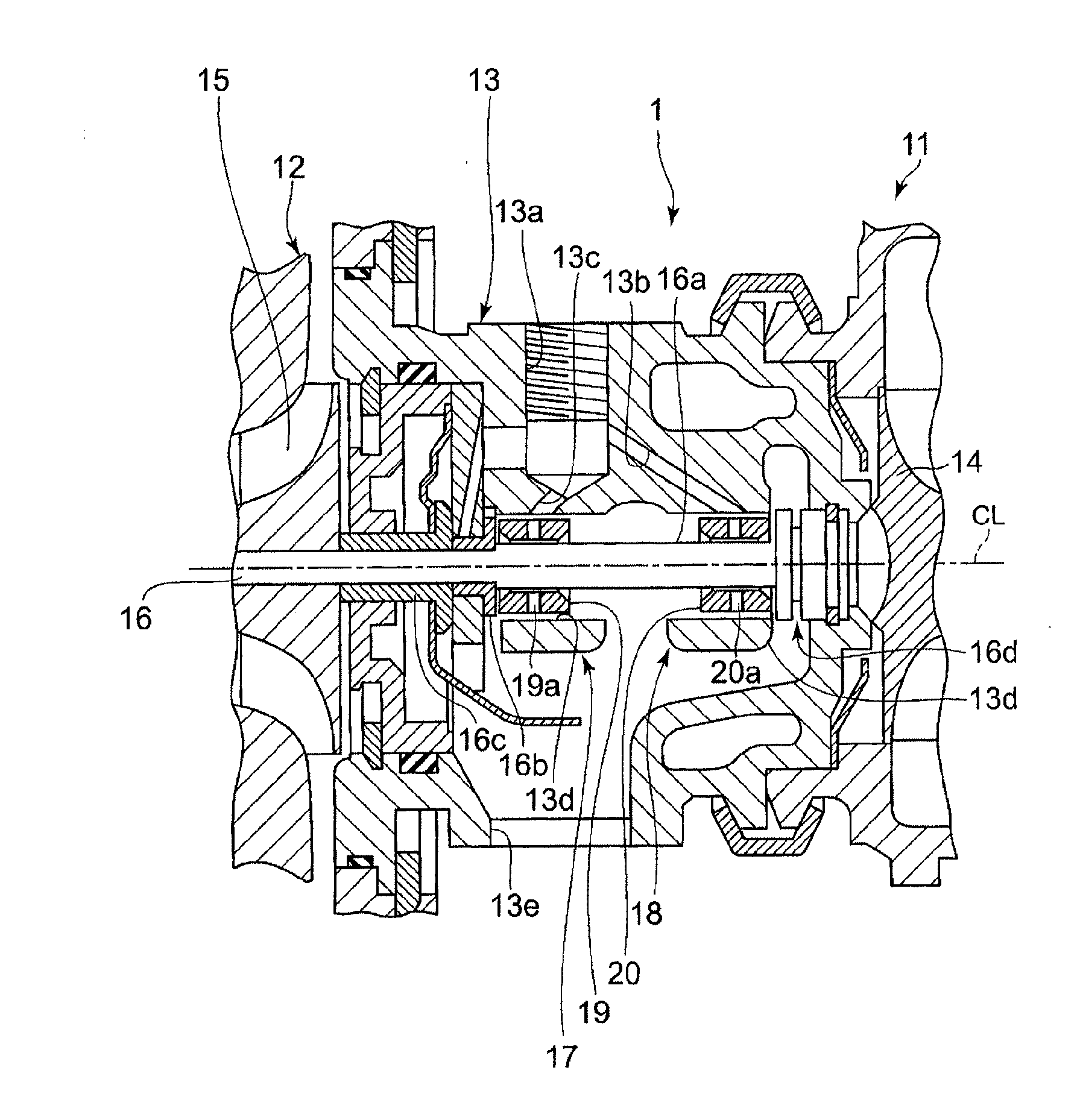

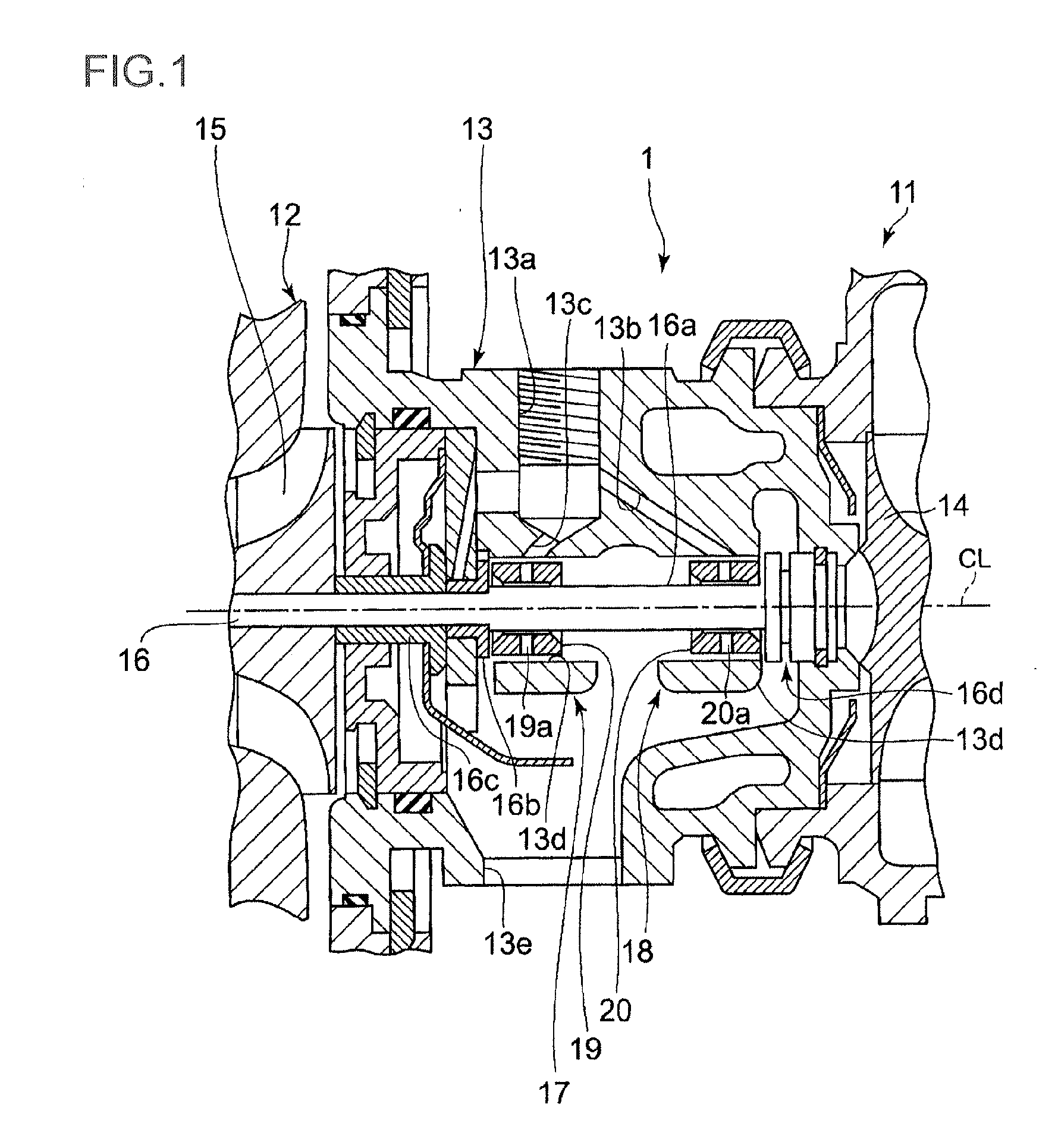

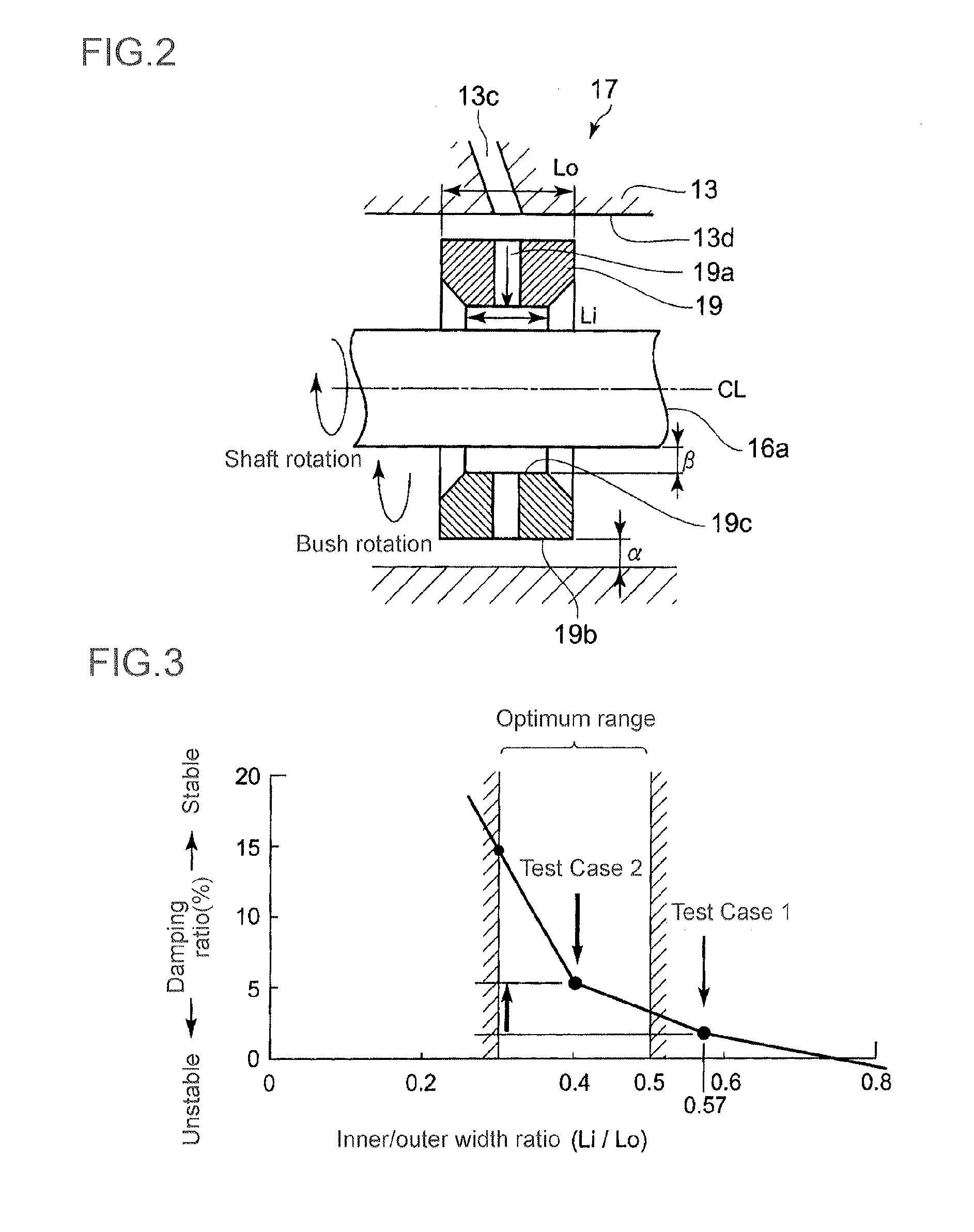

Bearing device for turbocharger

ActiveUS20140119898A1Improve stabilityReduce noiseEngine manufacturePump componentsTurbochargerEngineering

It is intended, with respect to a first floating bush bearing disposed on a compressor housing side and a second floating bush bearing disposed on a turbine housing side, to improve oscillation stability when a turbine rotor revolves at a high speed, reduce the number of parts, and facilitate processing and assemblability. Provided are a bearing housing (13) for a turbocharger (1), a rotor shaft (16) passing through the bearing housing (13), a first floating bush bearing (17) interposed between the bearing housing (13) and the rotor shaft (16) and disposed on a compressor housing (12) side and comprising a first floating bush, and a second floating bush bearing (18) that has the same shape as the first floating bush bearing (17) and is disposed on a turbine housing (11) side and comprises a second floating bush (20). The inner bearing width (Li) of the first and second floating bushes is formed to be smaller than the outer bearing width (Lo) by the same proportion in both bushes.

Owner:MITSUBISHI HEAVY IND LTD

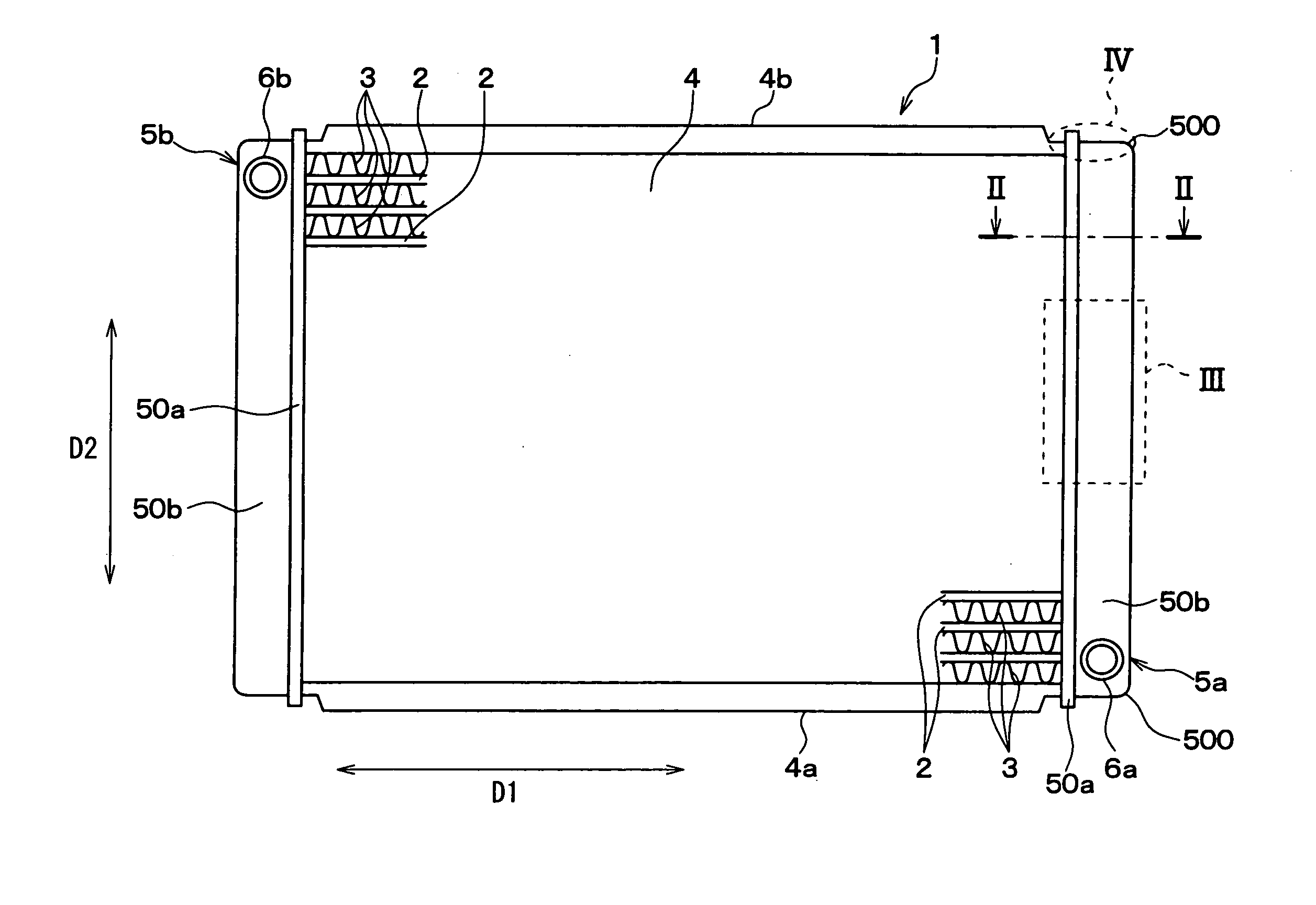

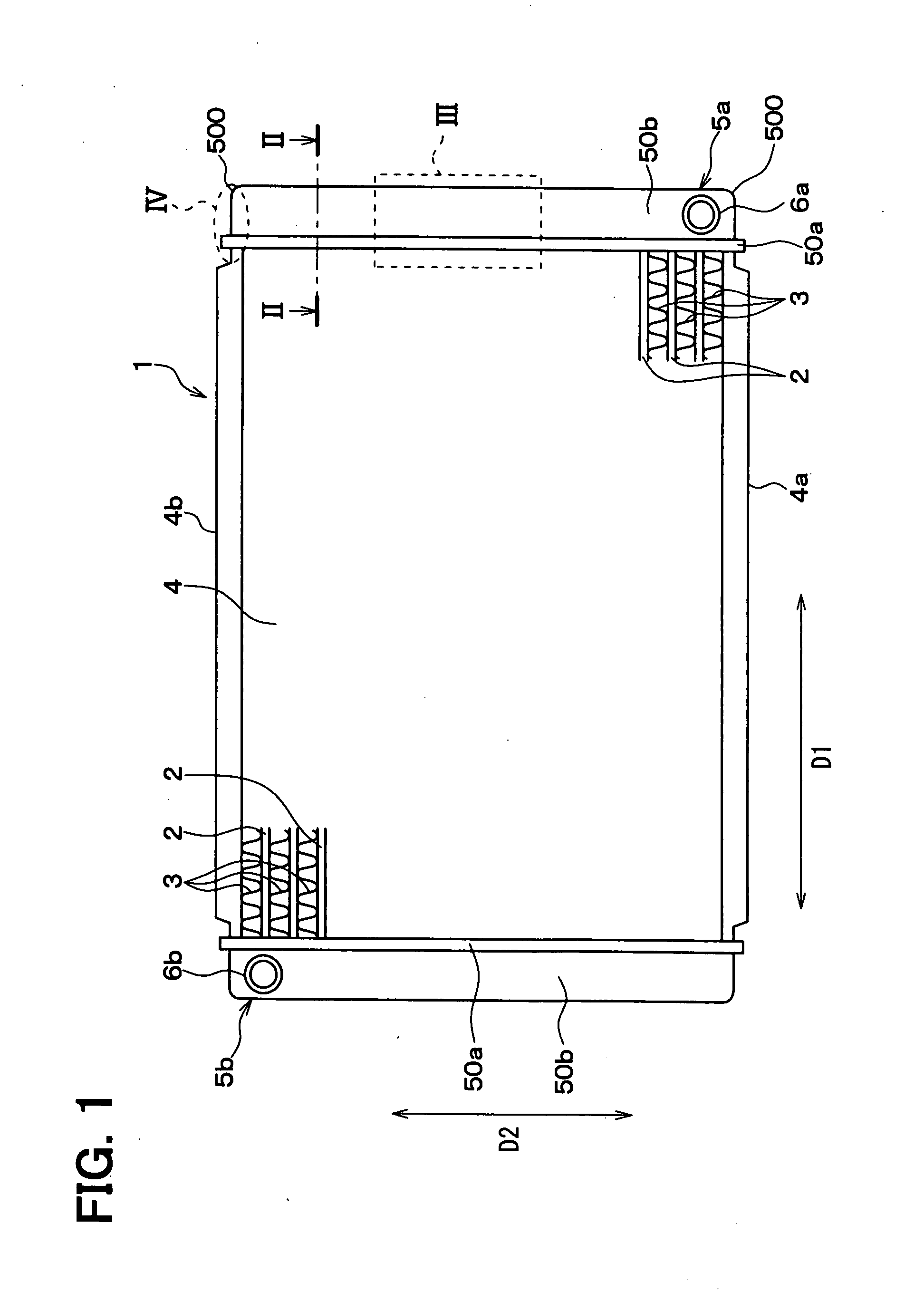

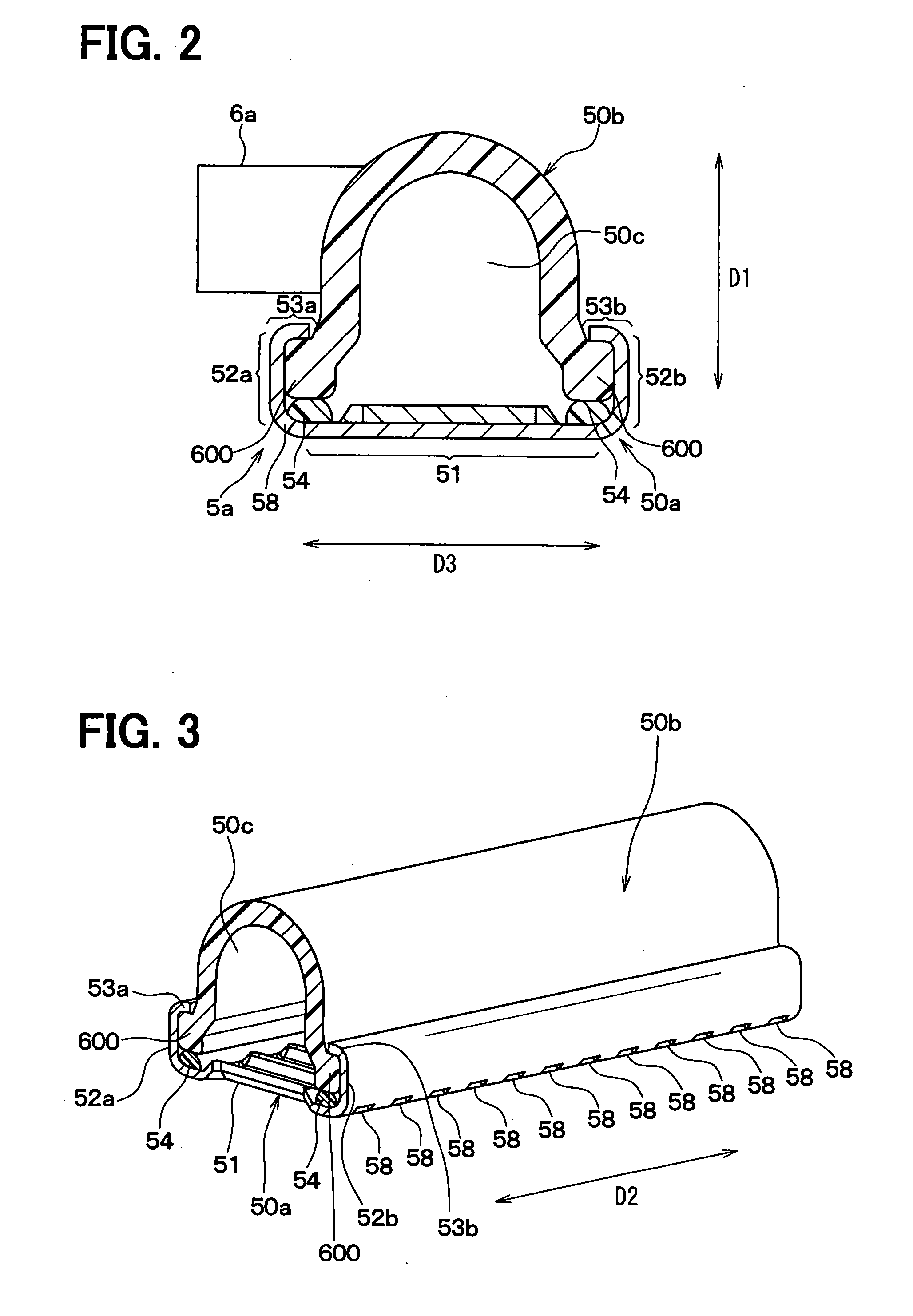

Method of manufacturing header tank for heat exchanger and heat exchanger having the header tank

InactiveUS20080121386A1Maintain durabilitySolve the lack of durabilityMetal-working apparatusHeat exchanger casingsEngineeringMechanical engineering

A method of manufacturing a header tank for a heat exchanger includes forming a first engagement portion in a core plate, placing a tank body relative to a base portion of the core plate, and moving a first wall portion toward the tank body such that the first engagement portion is engaged with the tank body. In the forming, a portion of the core plate is bent, the portion extending from the first wall portion. In the placing, the tank body is placed such that an opening of the tank body is covered by the base portion such that a tank inner space is defined. The first engagement portion is engaged with the tank body by moving the first wall portion toward the tank body.

Owner:DENSO CORP

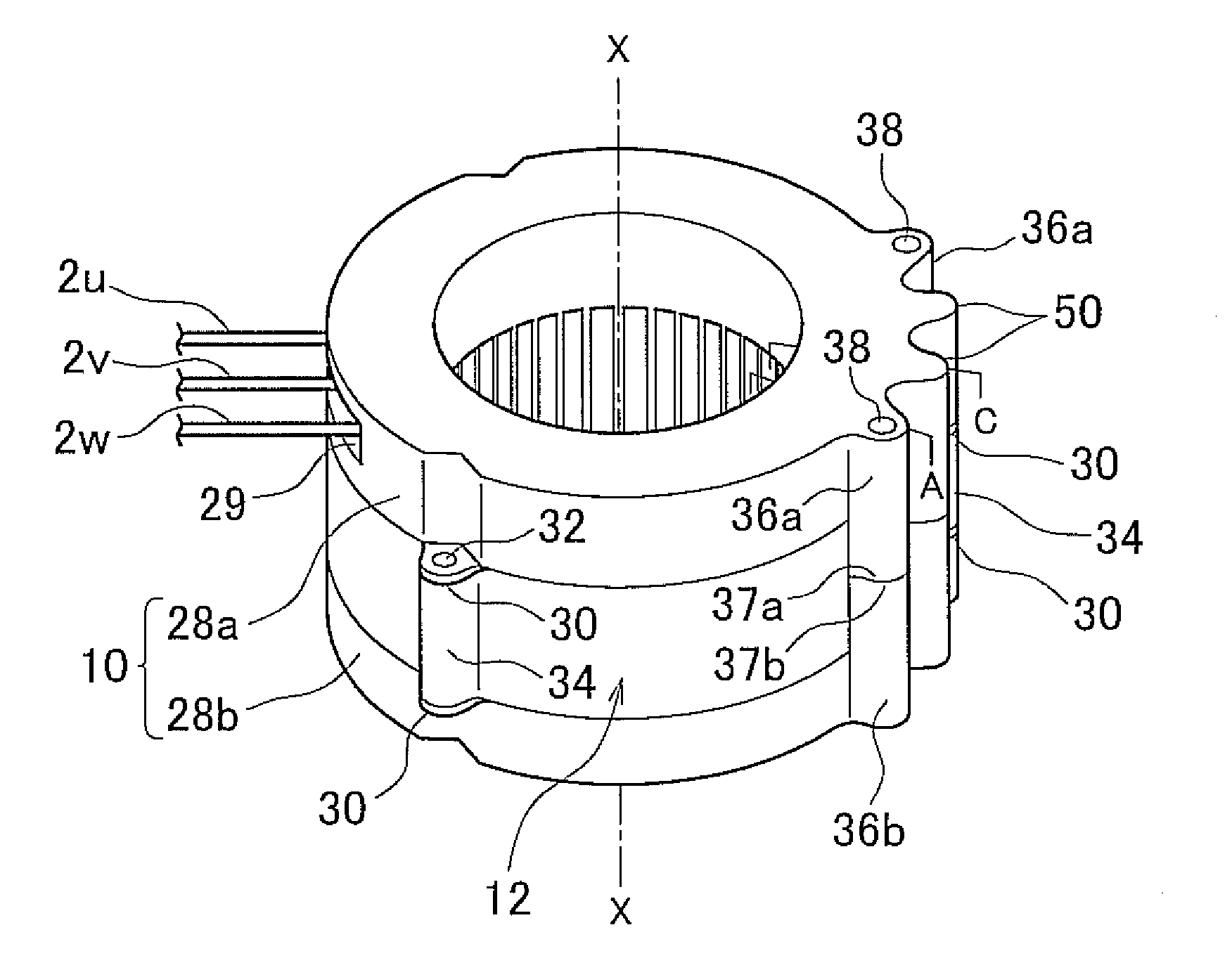

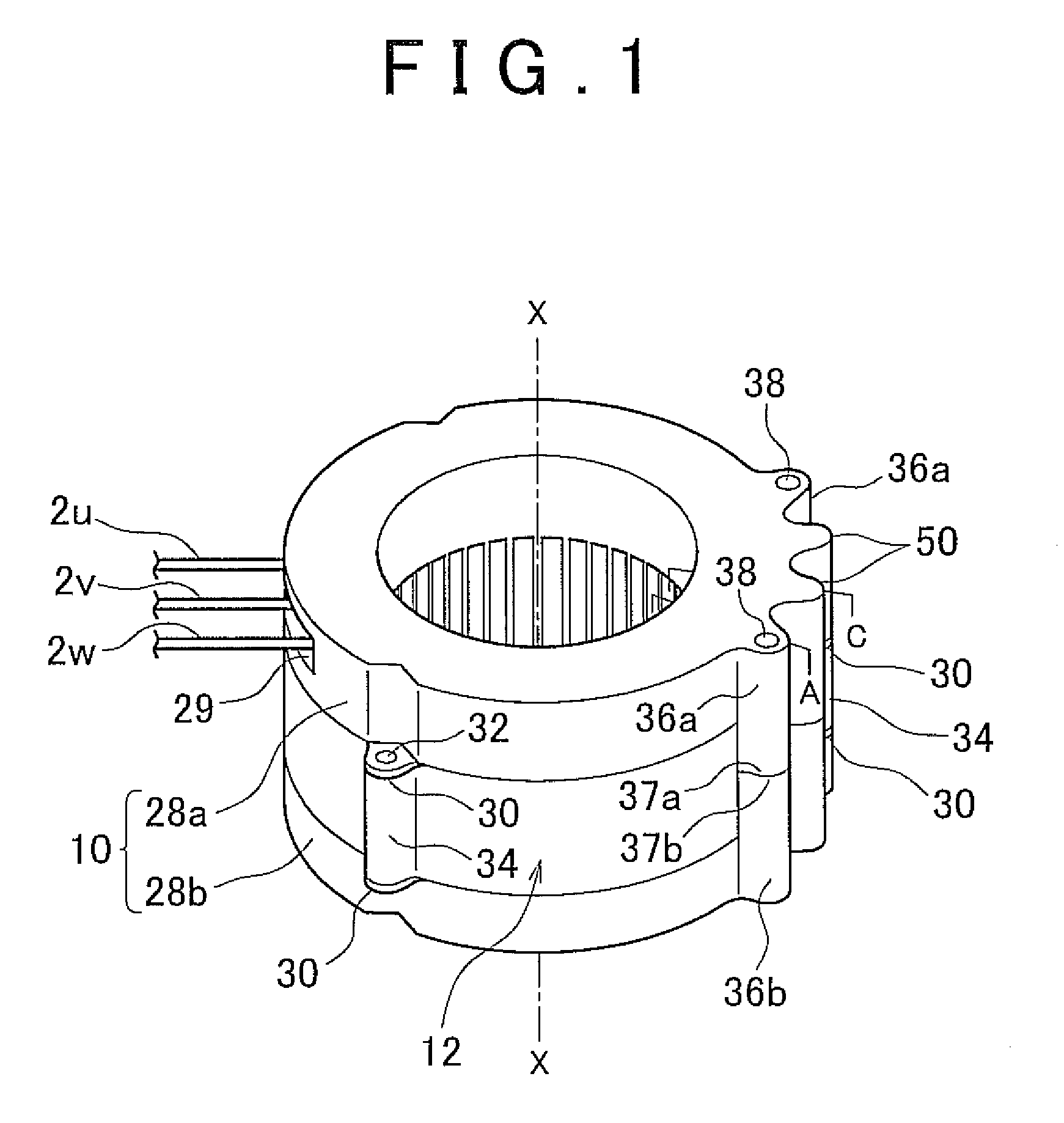

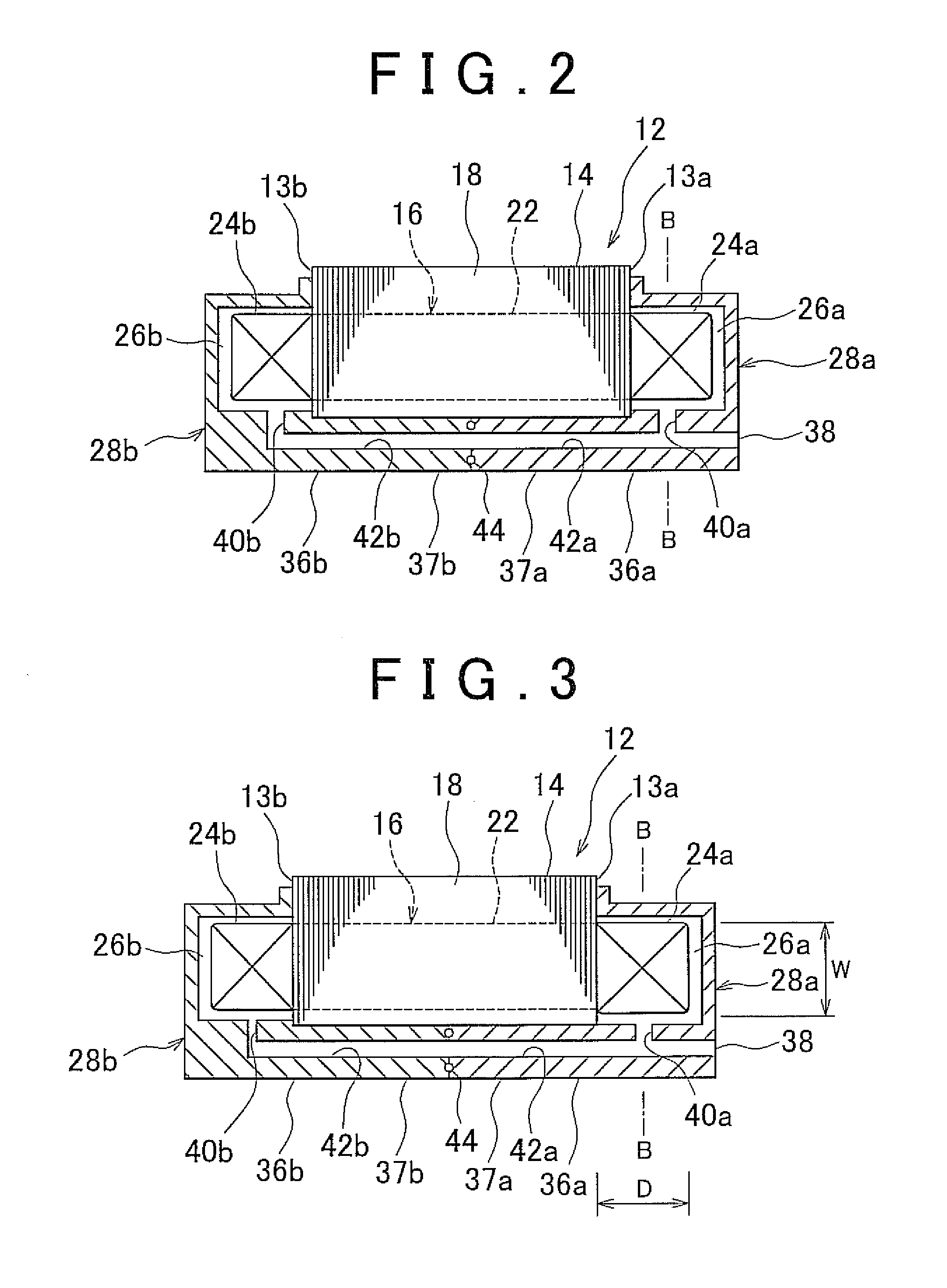

Cooling structure for rotary electric machine

ActiveUS20120091838A1Improve AssemblabilityImproves of mountabilityMagnetic circuit stationary partsCooling/ventillation arrangementElectricityElectric machine

A cooling structure for a rotary electric machine uses coolant to cool coil end portions that protrude outward, one from each end surface of a stator core, in a stator that includes a stator core and coils that are wound in a circumferential direction of the stator core. This cooling structure includes a lead side cover member that covers a lead side coil end portion to which a lead wire that supplies electricity to the coils is connected, and forms a first coolant chamber within which coolant is stored; and a non-lead side cover member that covers a non-lead side coil end portion positioned opposite the lead side coil end portion in the axial direction, and forms a second coolant chamber within which coolant is stored. A coolant communicating path is provided that communicates the first and second coolant chambers in a manner that enables coolant to flow therebetween.

Owner:TOYOTA JIDOSHA KK +1

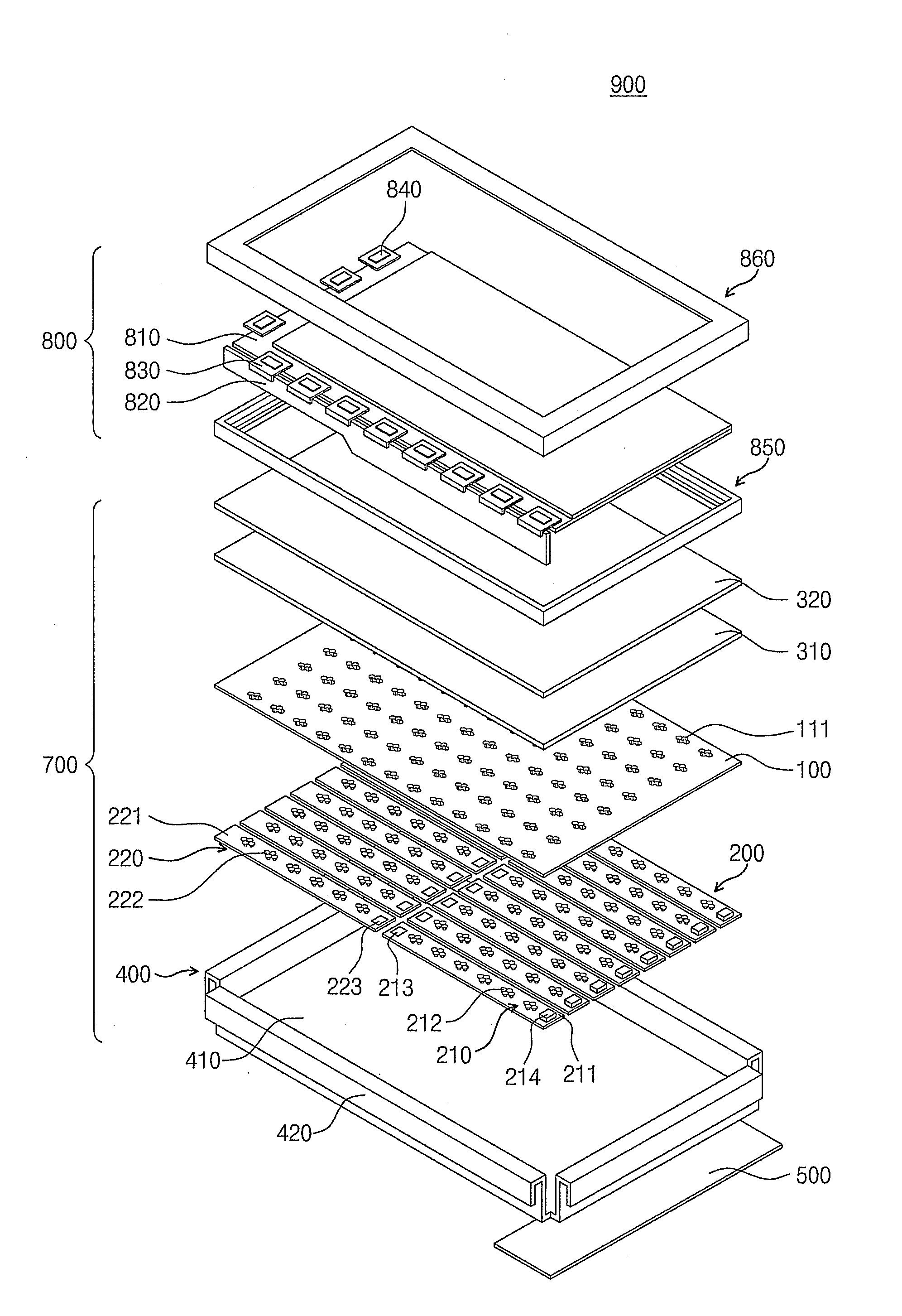

Reflector member, backlight assembly and display apparatus having the same

InactiveUS20080259240A1Improve assemblability and brightness uniformityImprove AssemblabilityNon-electric lightingPoint-like light sourceElectrical and Electronics engineering

In a backlight assembly, a reflector member includes a base sheet reflecting a light and a connecting line disposed on a face of the base sheet and, and transmitting signals. An input pad is disposed at a first end portion of the connecting line and receives the signals, and an output pad is disposed at a second end portion of the connecting line and outputs the signals transmitted through the connecting line.

Owner:SAMSUNG DISPLAY CO LTD

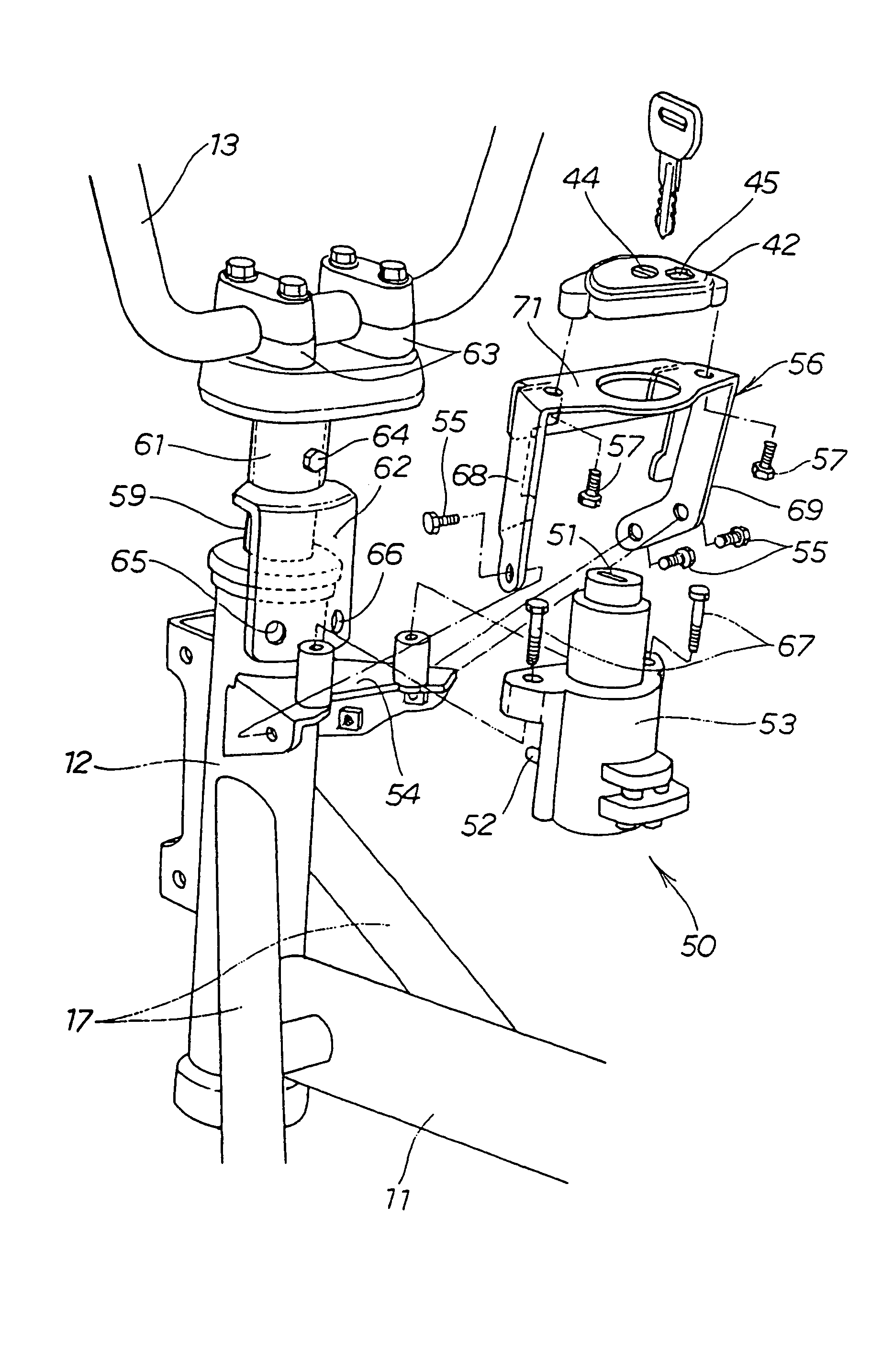

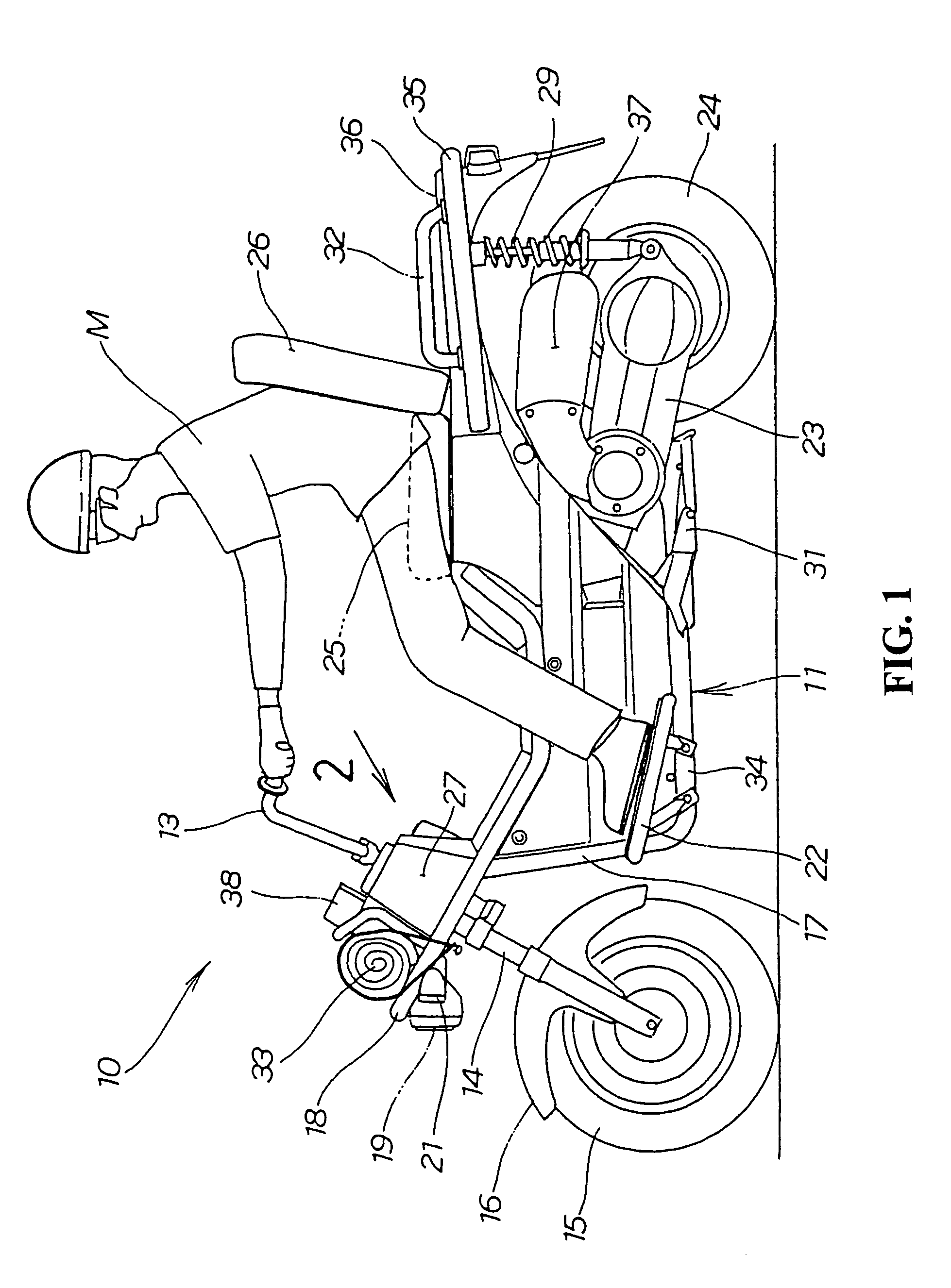

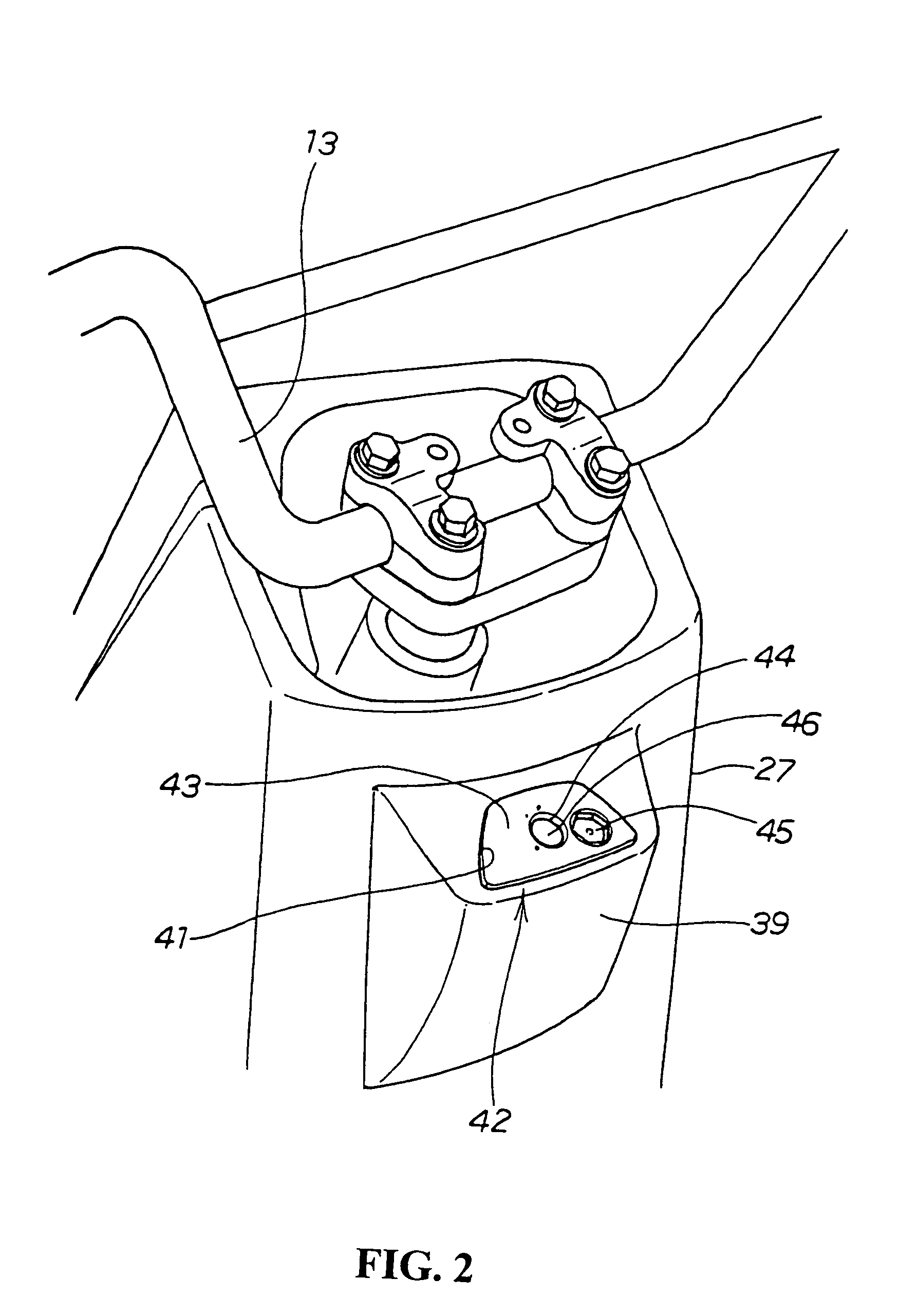

Vehicle provided with key cylinder device equipped with handle lock mechanism

InactiveUS7347071B2Improve AssemblabilityAvoid possibilityBicycle locksVehicle locksLocking mechanismEngineering

To provide a key cylinder device equipped with a handle lock mechanism which can maintain a handle lock mechanism of a key cylinder unit with a shutter to provide an improved assembleability of the key cylinder device. The bolts for fixing a shutter housing are attached from the back surface of the top plate of an inverted angular U-shaped bracket. Thus, even when a gap is generated between the shutter housing and a vehicle body cover, the bolts are not exposed and hence cannot be easily loosened. In addition, by mounting the key cylinder device in the vehicle body cover and then mounting the vehicle body cover thereon, assembleability can be improved.

Owner:HONDA MOTOR CO LTD

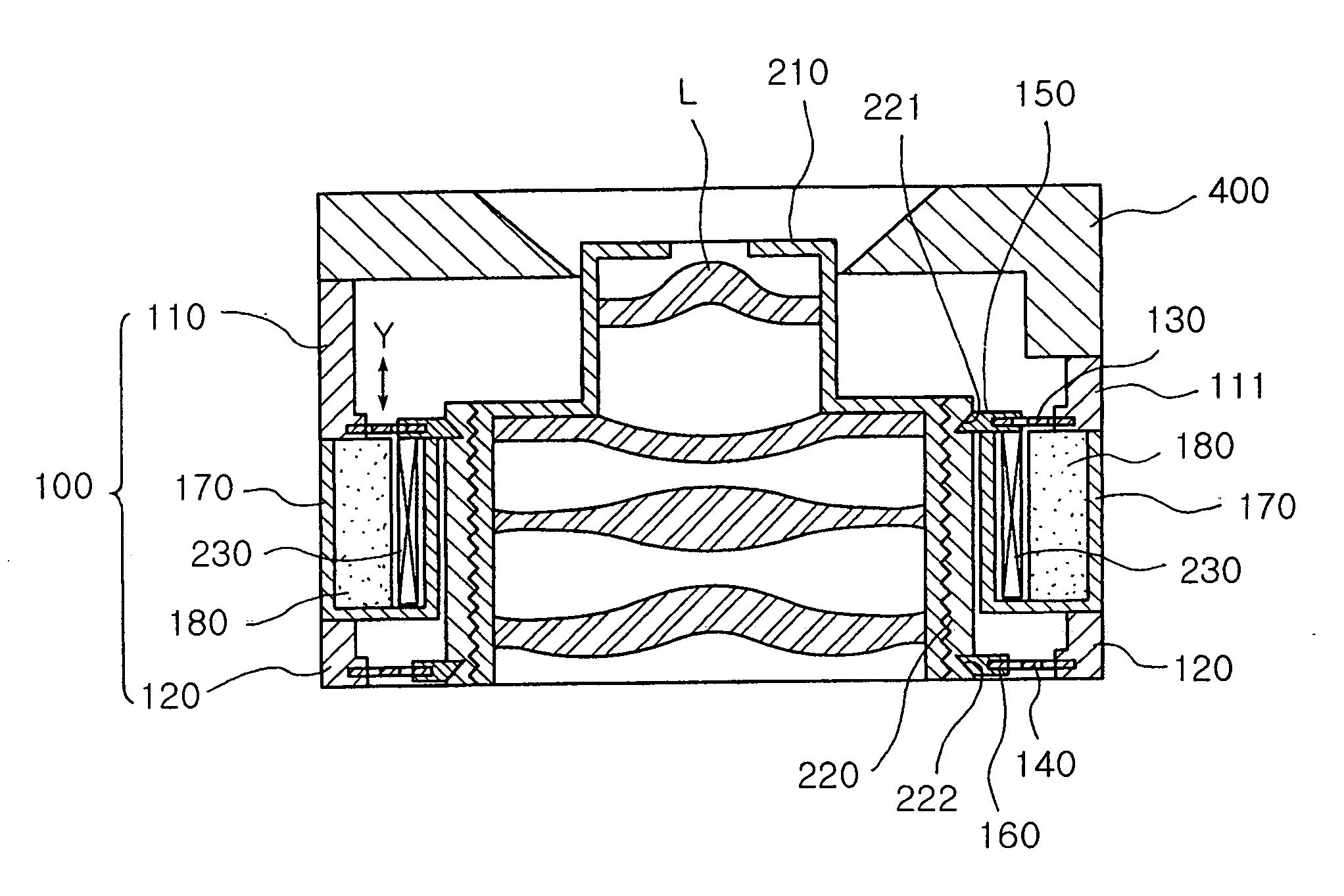

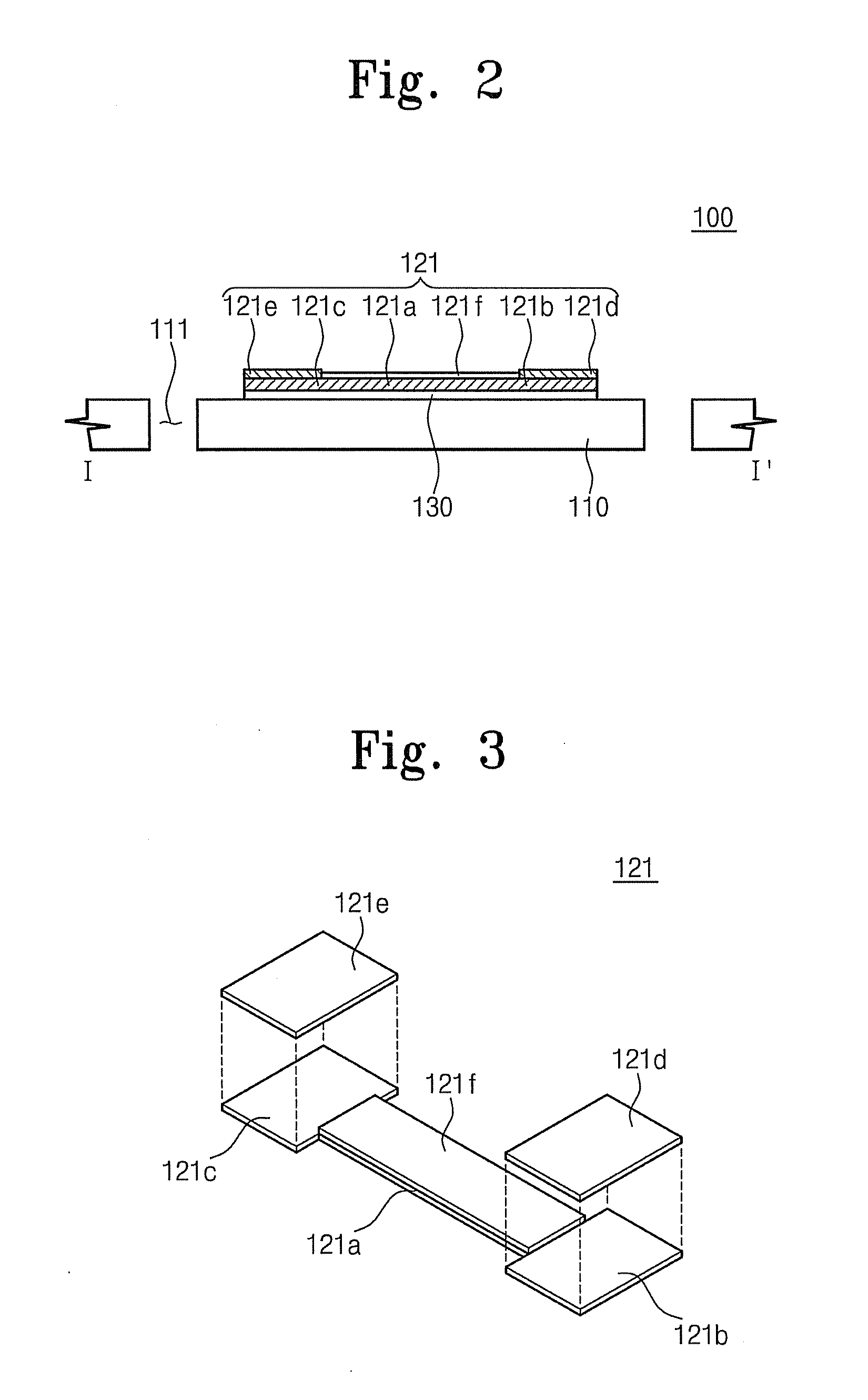

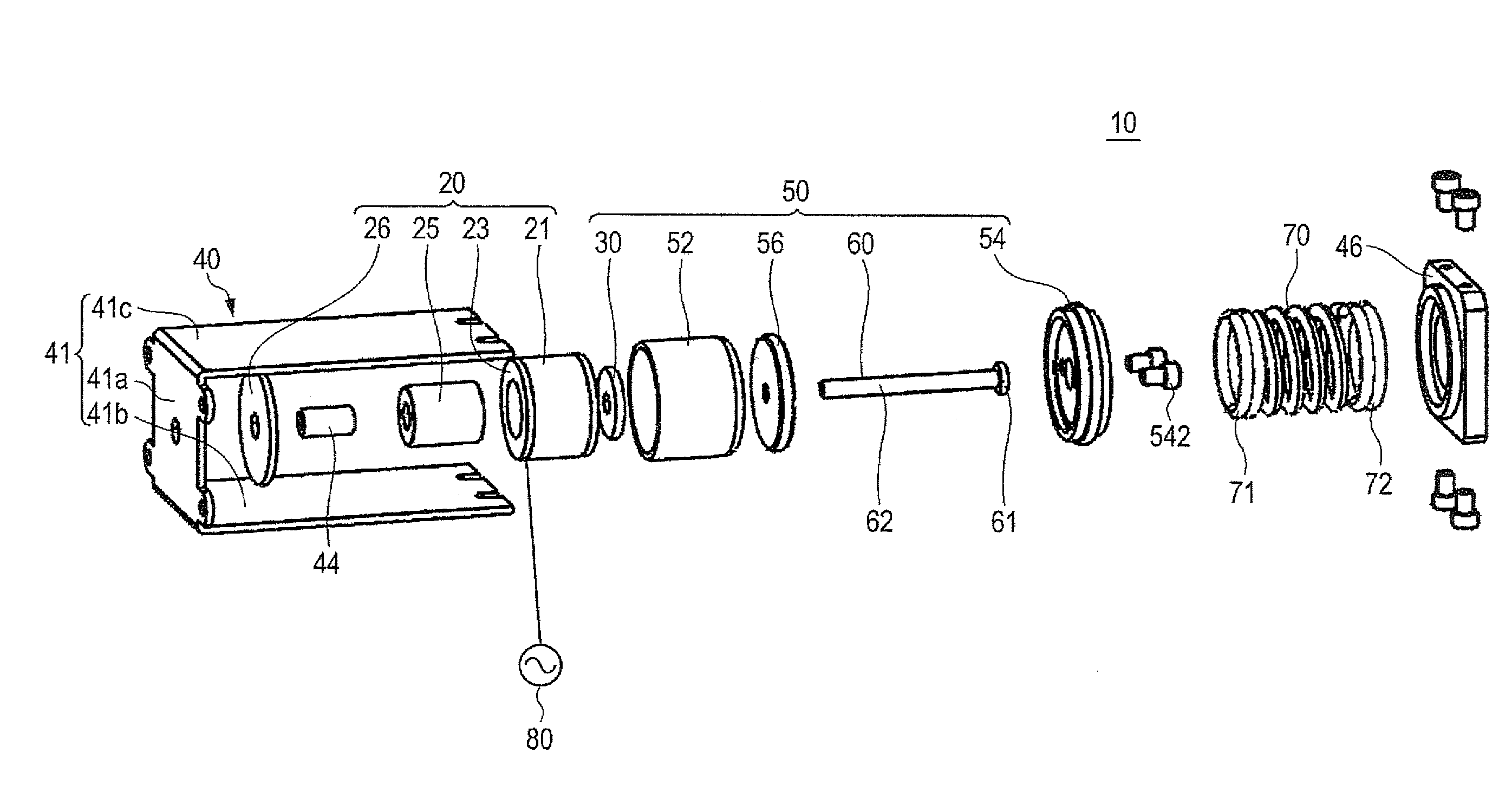

Linear actuator, electric brush, electric cutting machine and electric air pump

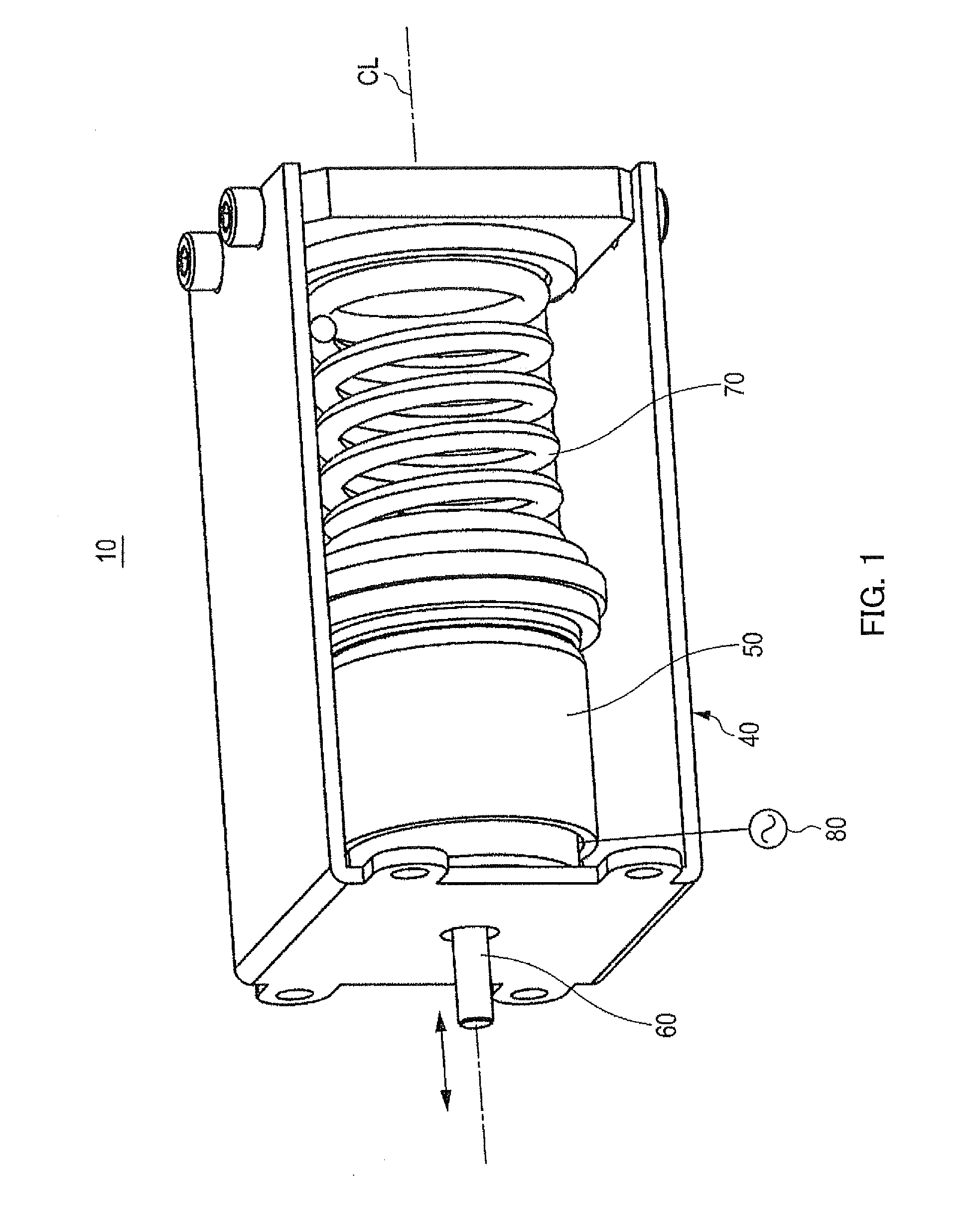

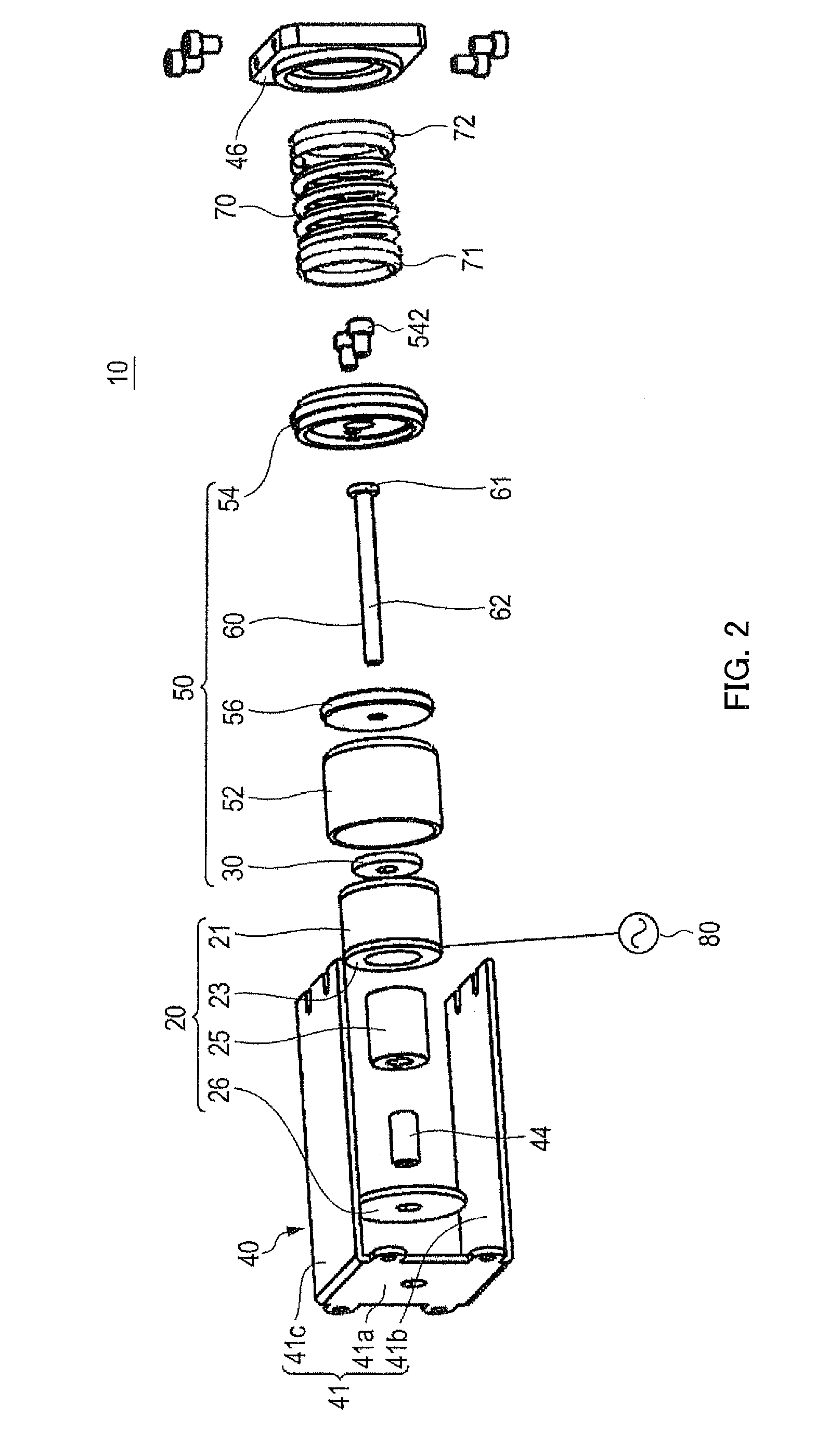

ActiveUS20160094115A1Stable linear reciprocationImprove AssemblabilityDynamo-electric machinesTooth cleaningReciprocating motionAir pump

A linear actuator that can achieve downsizing with a simple configuration, and can provide stable linear reciprocation while achieving improvement in assemblability and cost reduction. In the actuator, movable member 50 faces coil 21 in the winding axis CL direction of coil 21, and in addition, includes magnet 30 magnetized in the coil-winding axis CL direction in a unipolar fashion and output shaft 60 extending in the CL direction. Elastic body 70 is disposed along the coil-winding axis CL direction and configured to deform in that direction to supports movable member 50 such that movable member 50 can reciprocate along the coil-winding axis CL direction. Elastic body 70 is fixed to fixing body 40 and movable member 50 at both ends 71 and 72 in the coil-winding axis CL direction such that central air gap CG is formed between electromagnet 20 and magnet 30.

Owner:MITSUMI ELECTRIC CO LTD

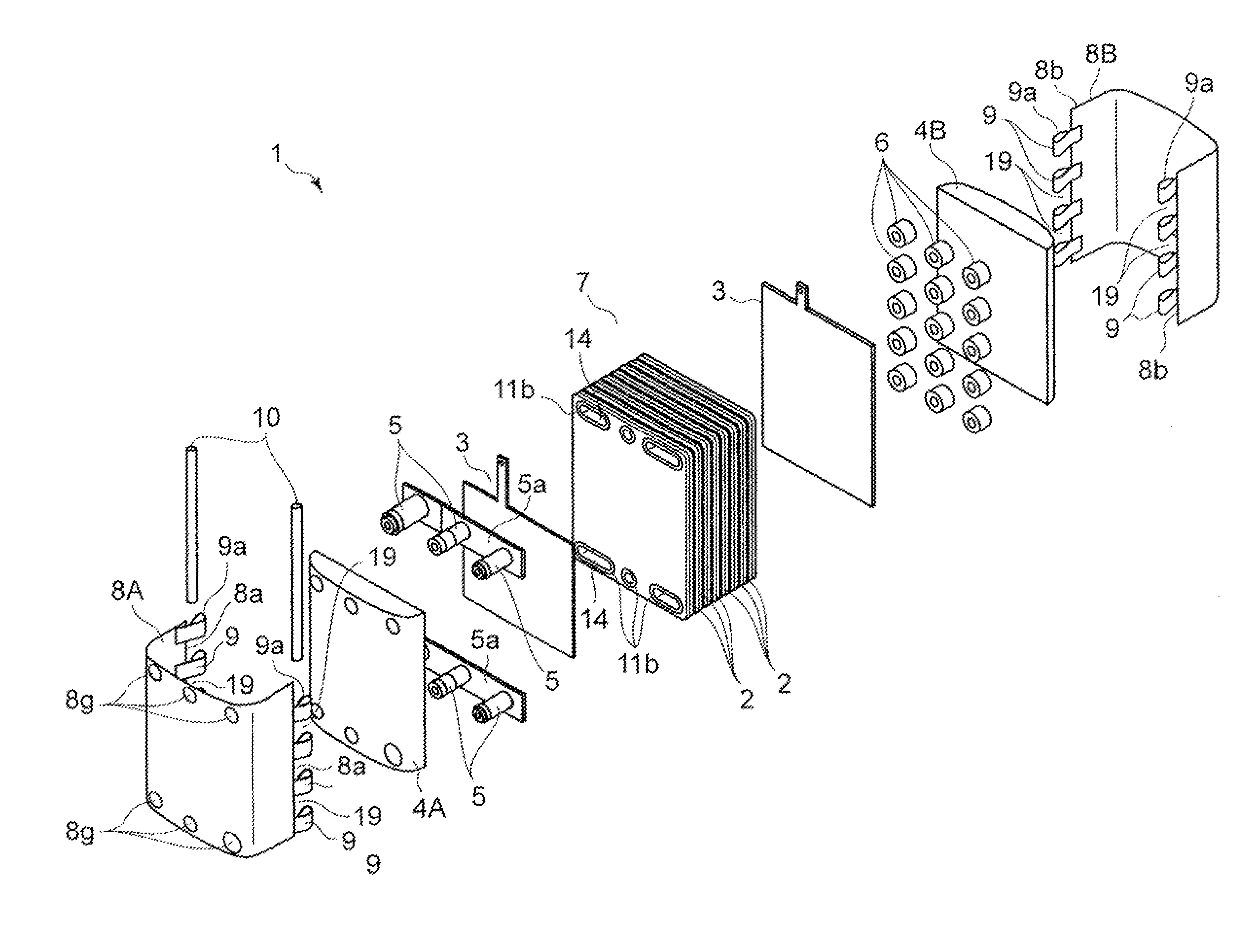

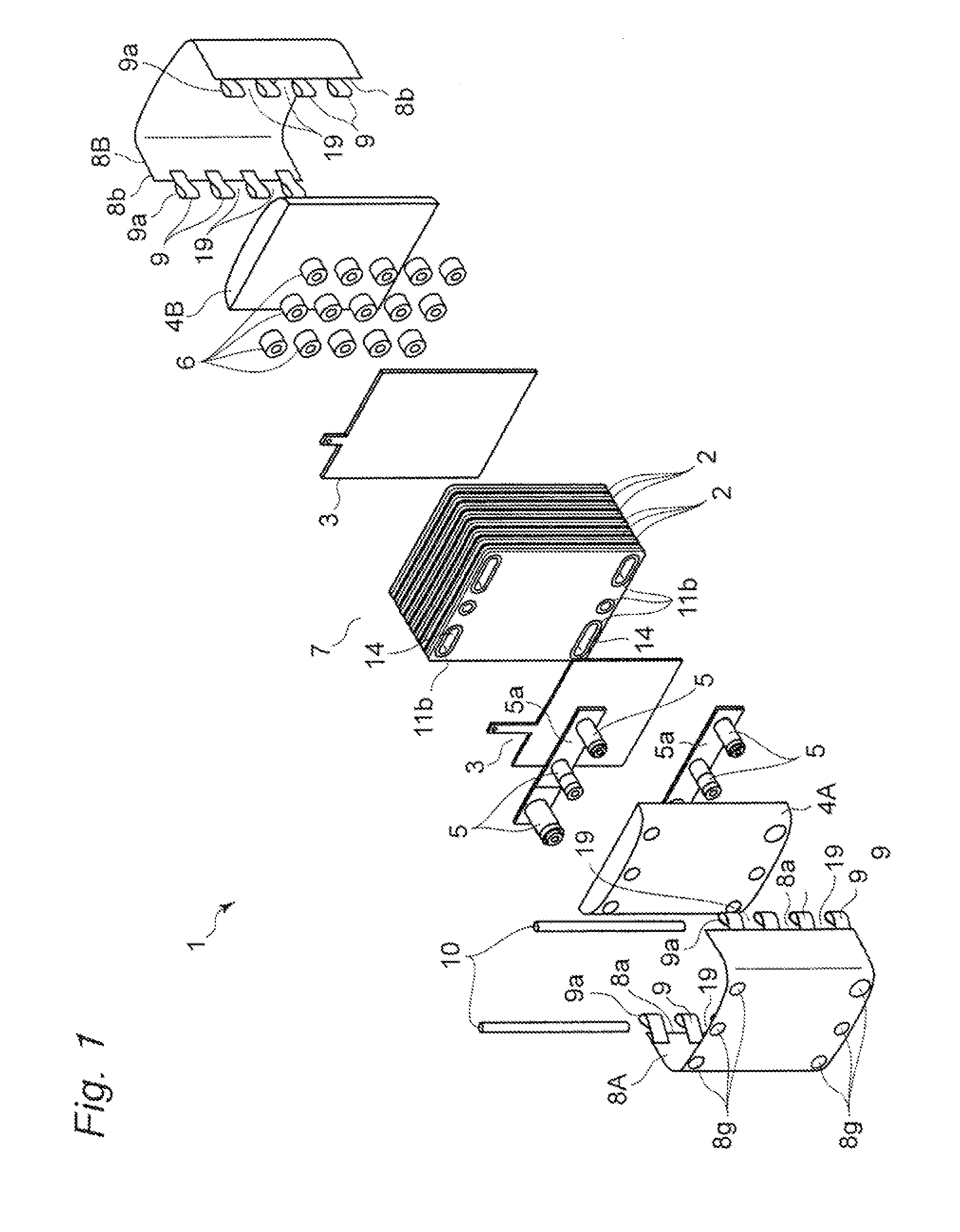

Polymer electrolyte fuel cell stack

ActiveUS20110294030A1Easy to adjustIncreased durabilityFuel cells groupingSolid electrolyte fuel cellsFuel cellsCoupling

When assembly is carried out by clamping a stacked product made up of a plurality of unit cell modules, paired end plates respectively disposed on both the sides thereof and the like by a plurality of fastening members, first coupling portions of one end portion of each of such plurality of fastening members and second coupling portions of the other end portions are combined to each other, and coupled with one pin member. Thus, a plurality of such fastening members are coupled.

Owner:PANASONIC CORP

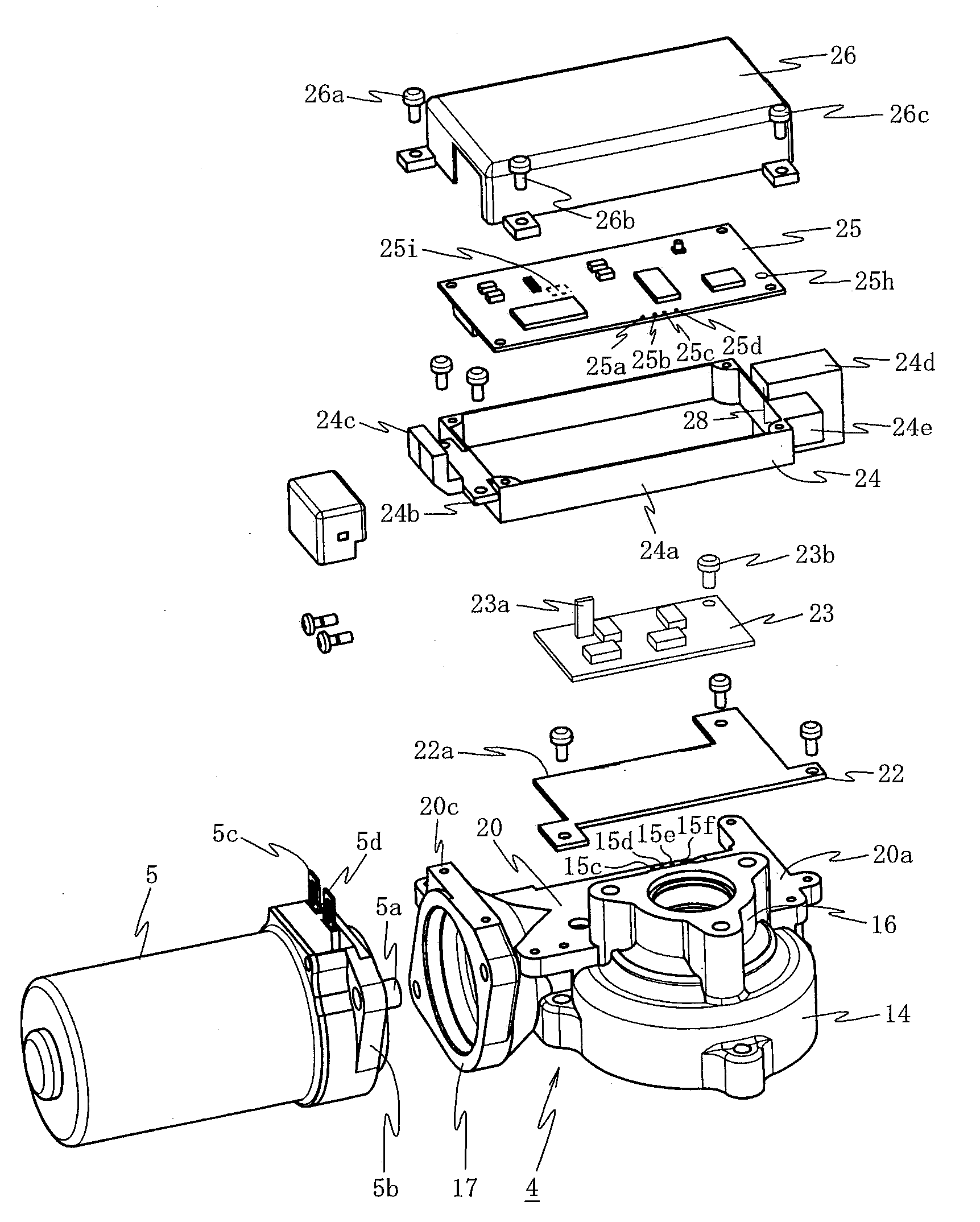

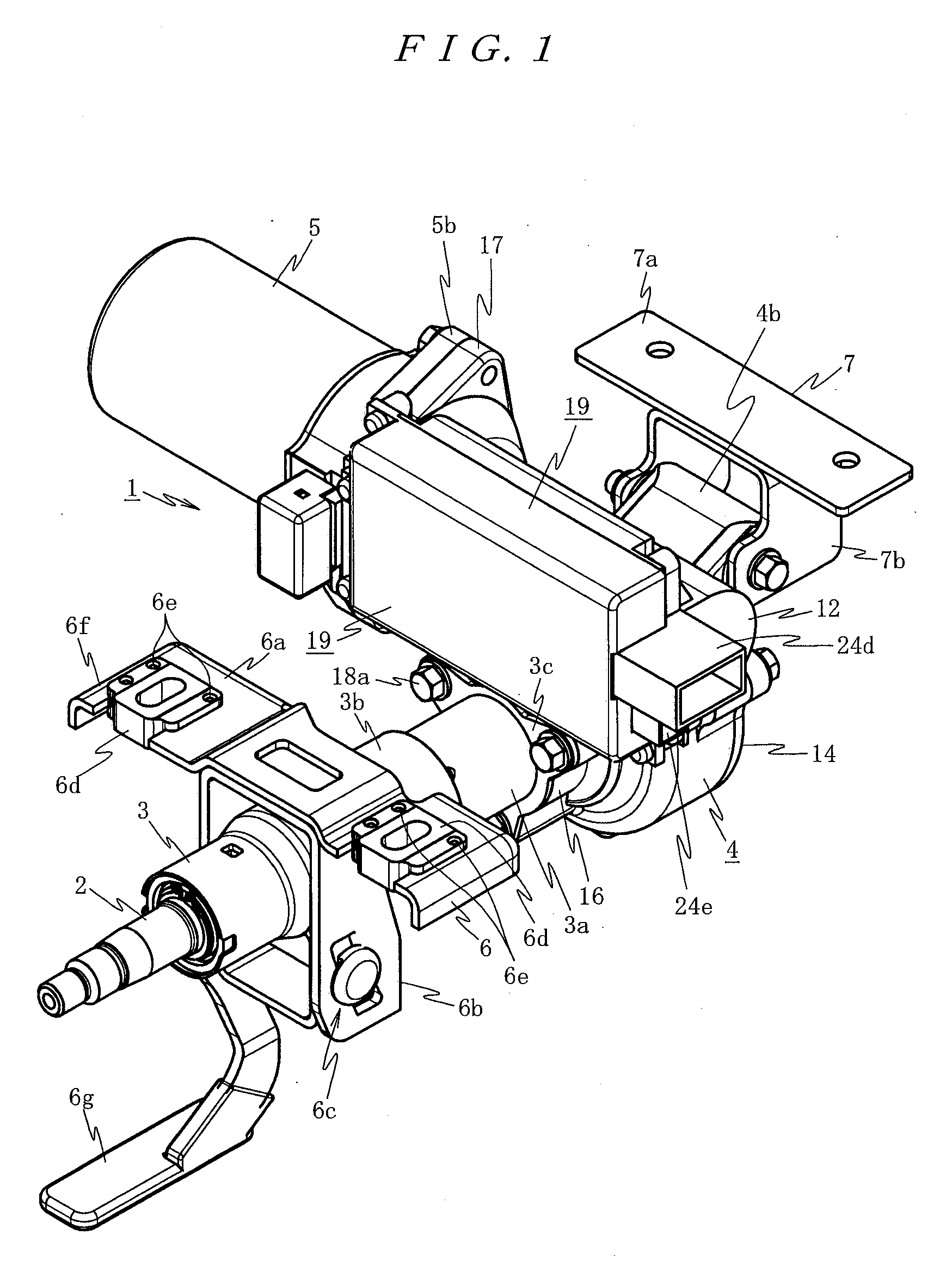

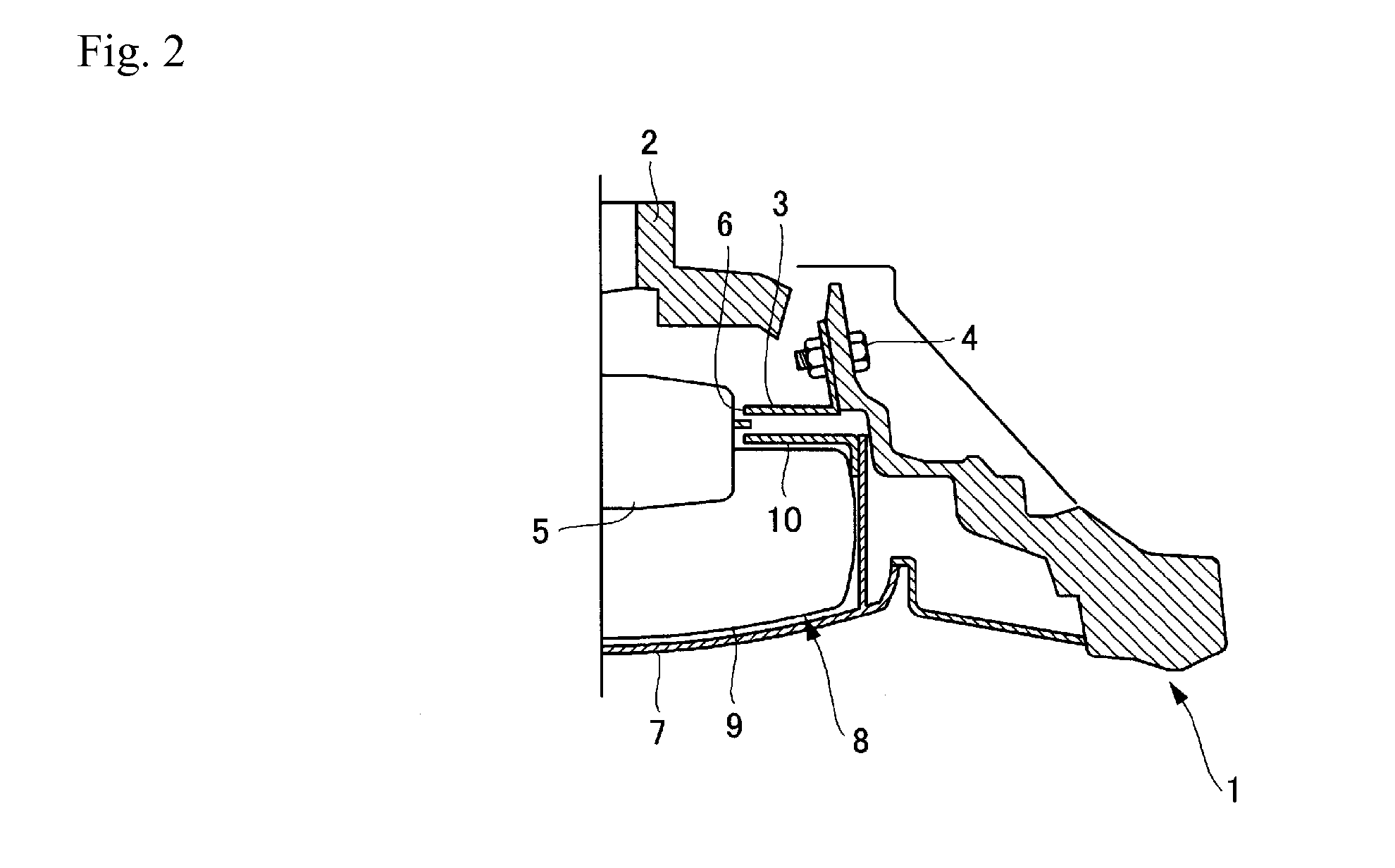

Electric Power Steering Apparatus

InactiveUS20090183940A1Improve electromagnetic compatibilityReduce in quantitySynchronous generatorsAssociation with control/drive circuitsElectricityElectric power steering

To provide an electric power steering apparatus in which ground processing for respective sections requiring a ground can be reduced to necessary minimum to improve assemblability. An electric power steering apparatus includes a steering column 3 having inserted therein a steering shaft 2 to which steering torque is transmitted and an electric motor 5 that transmits a steering assisting force to the steering shaft 2 via a reduction mechanism in a conductive reduction gear box 4. A control unit 19 including boards 23 and 25 mounted with control circuits that control to drive the electric motor is mounted on the reduction gear box 4, a connecting section of the electric motor 5 is electrically connected to the control unit 19 directly, and connection of the reduction gear box 4 and the control unit 19 to a ground is performed via a grounding line 29 disposed between the control unit 19 and a power feeding unit 30.

Owner:NSK LTD

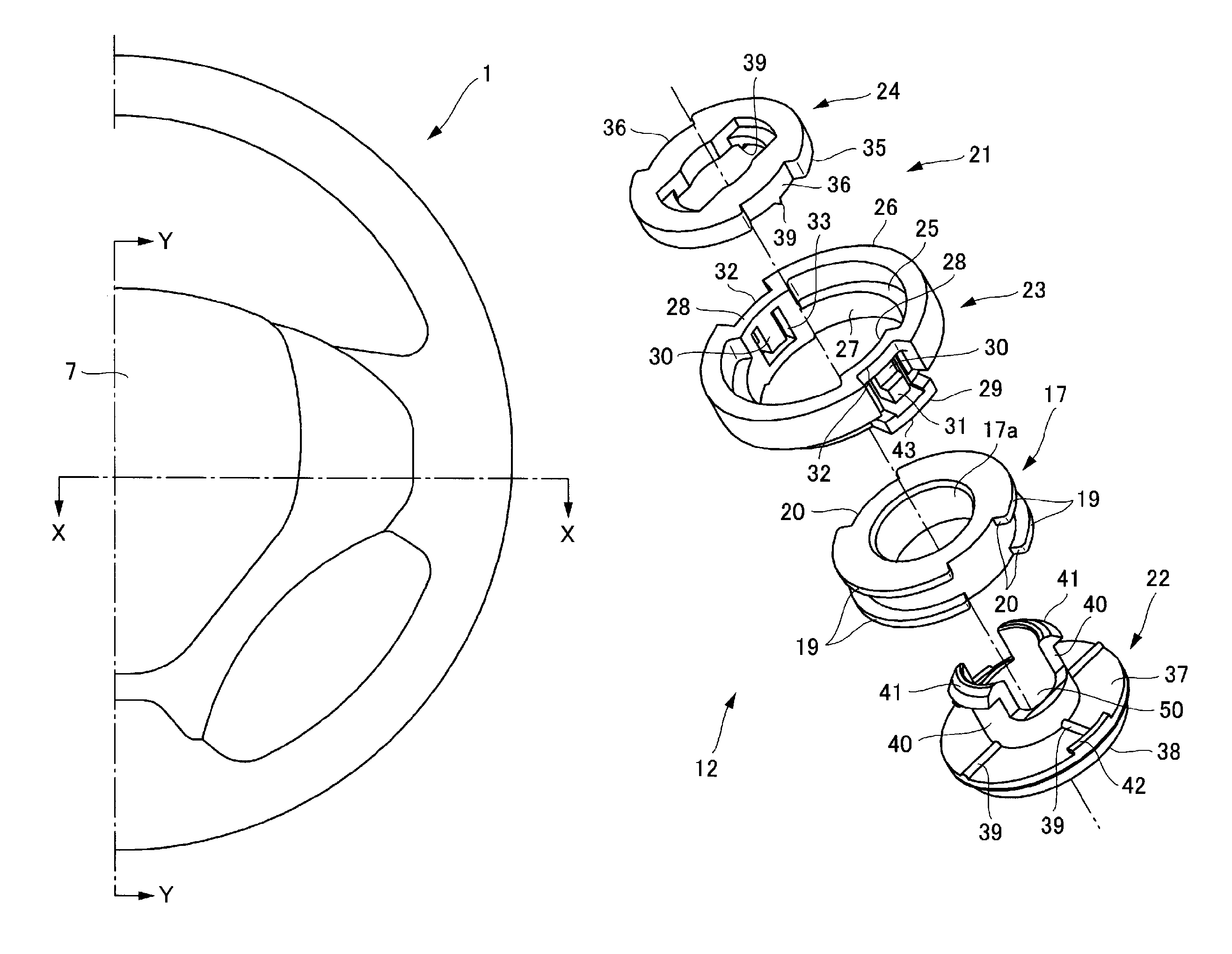

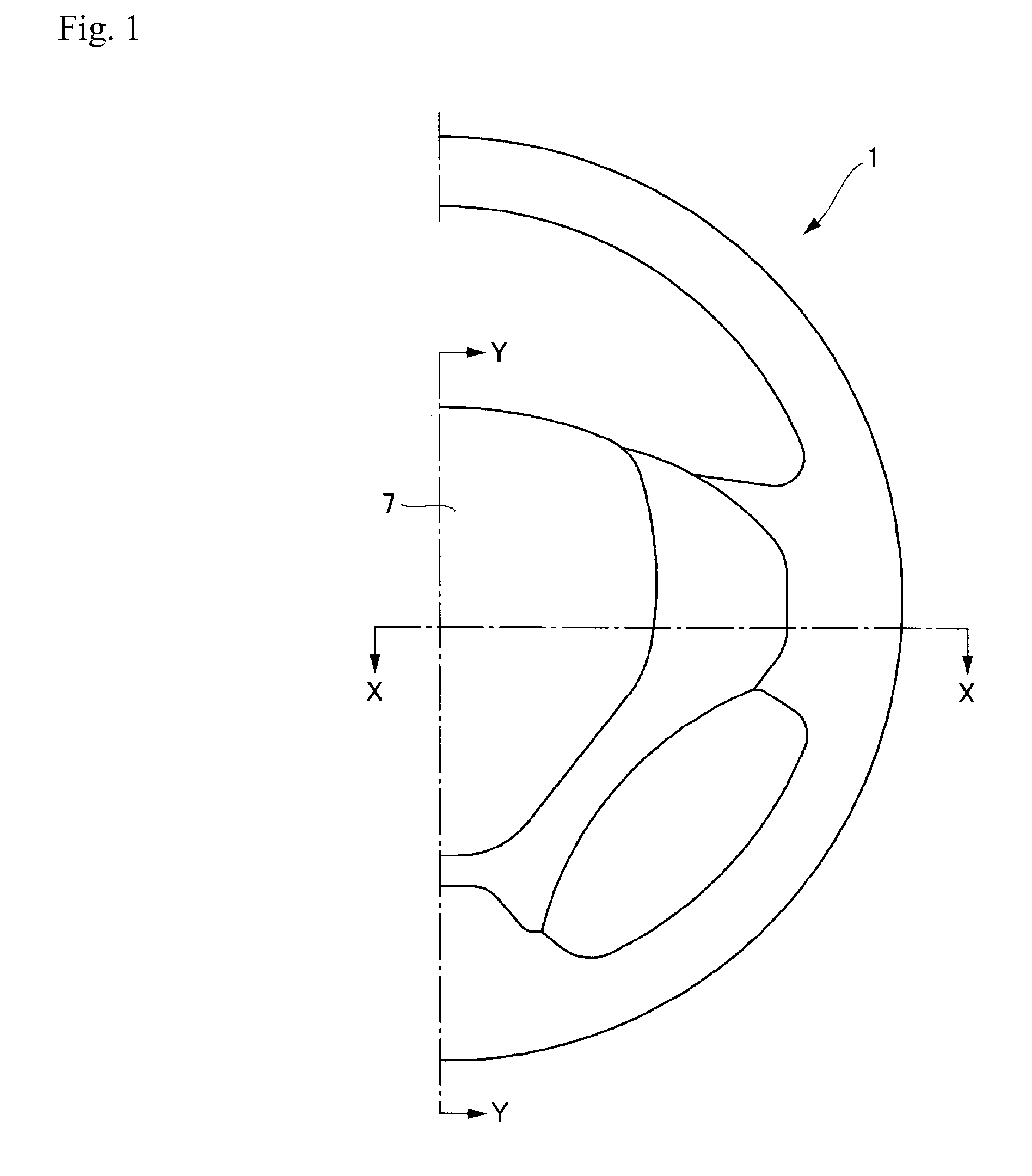

Steering wheel structure with airbag module

ActiveUS8985623B2Improve productivityImprove AssemblabilityPedestrian/occupant safety arrangementSteering linkagesSteering wheelAirbag

A steering wheel structure with an airbag module having a horn bracket fixed to a steering wheel, an airbag module having an inflator and serving as a weight, a spring unit installed between the airbag module and the horn bracket and transmitting vibrations of the steering wheel to the airbag module for configuring a dynamic damper. The spring unit including an elastic body that transmits the vibrations and a protector attached to the horn bracket and housing the elastic body therein in an elastically deformable manner.

Owner:AUTOLIV DEV AB +1

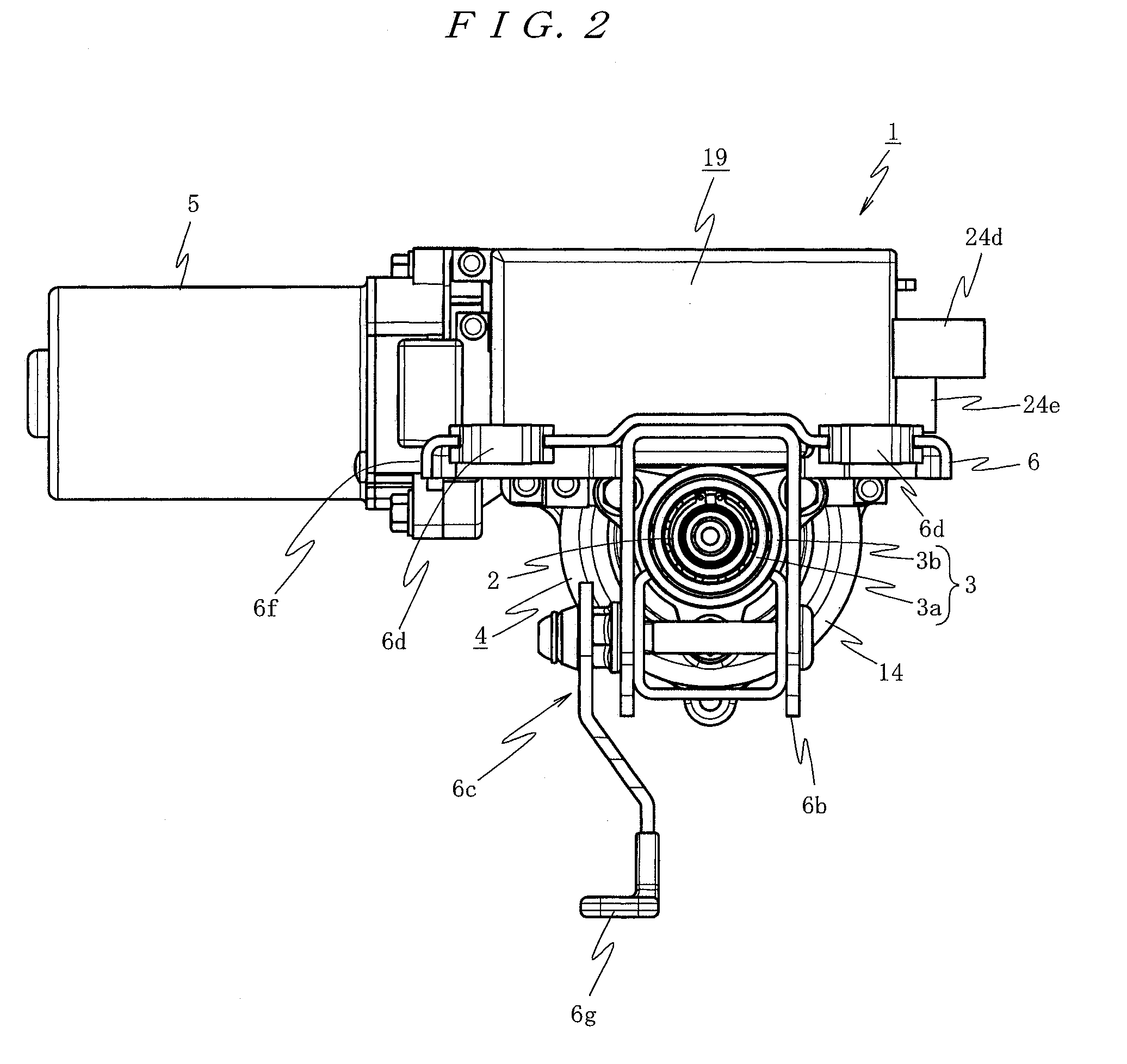

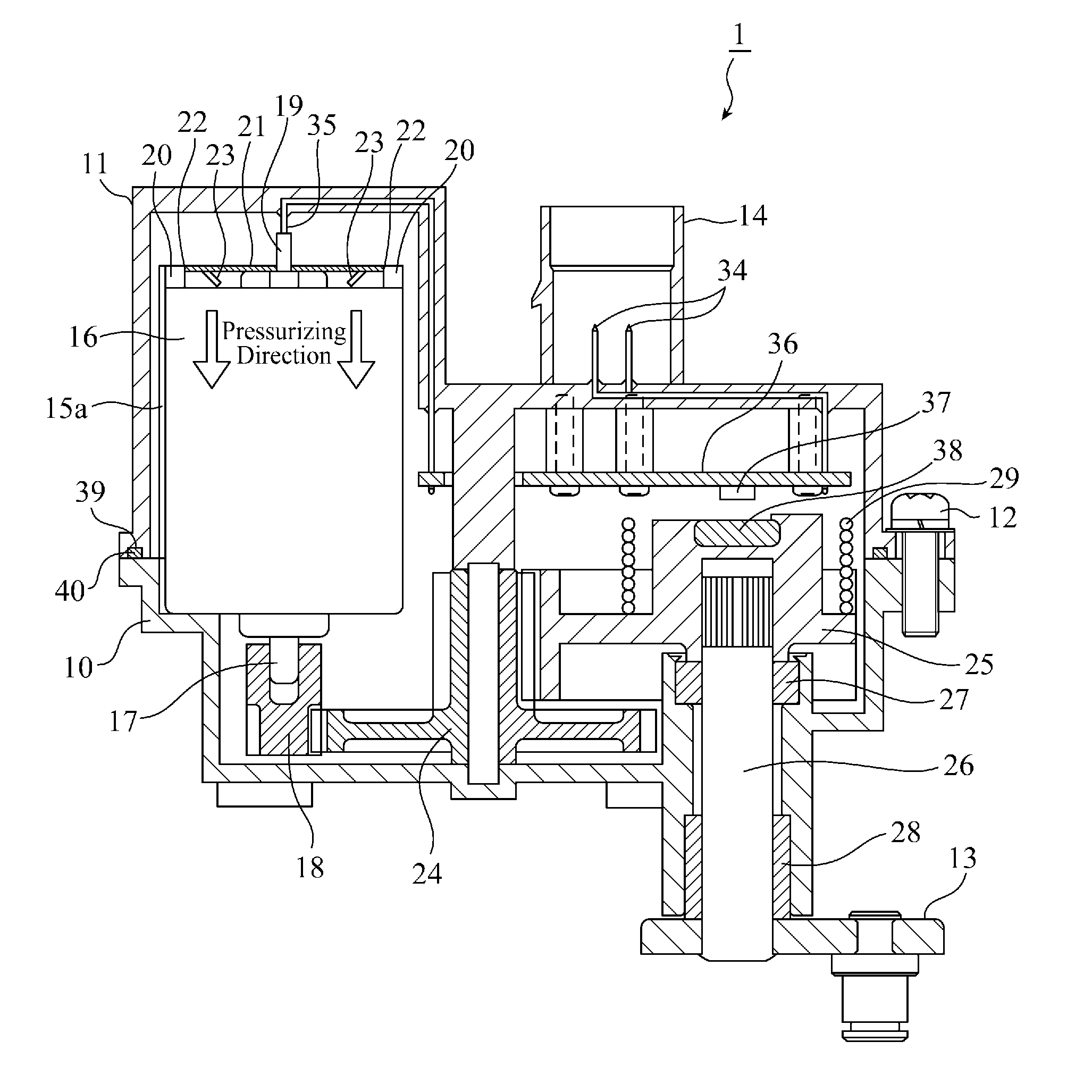

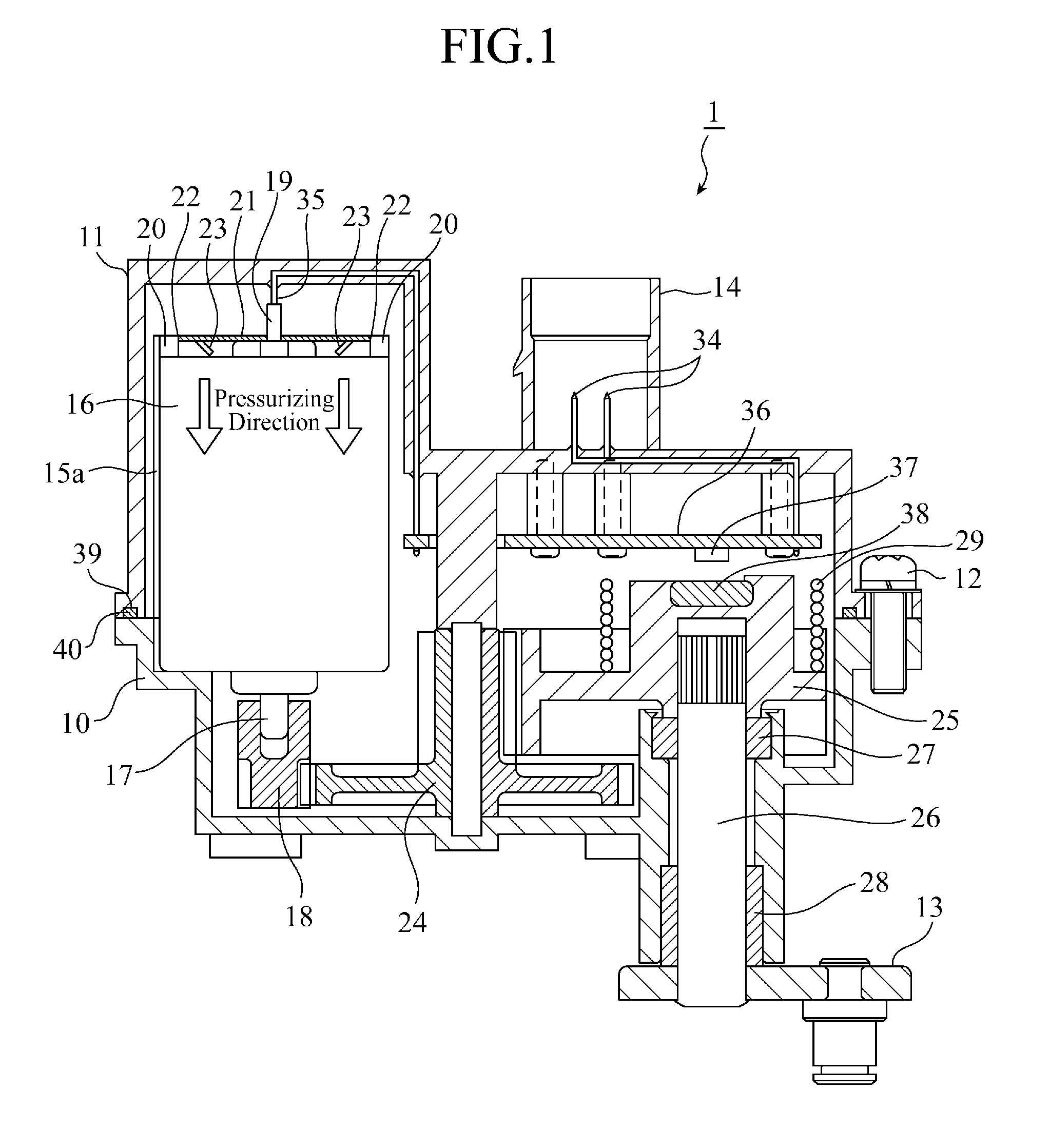

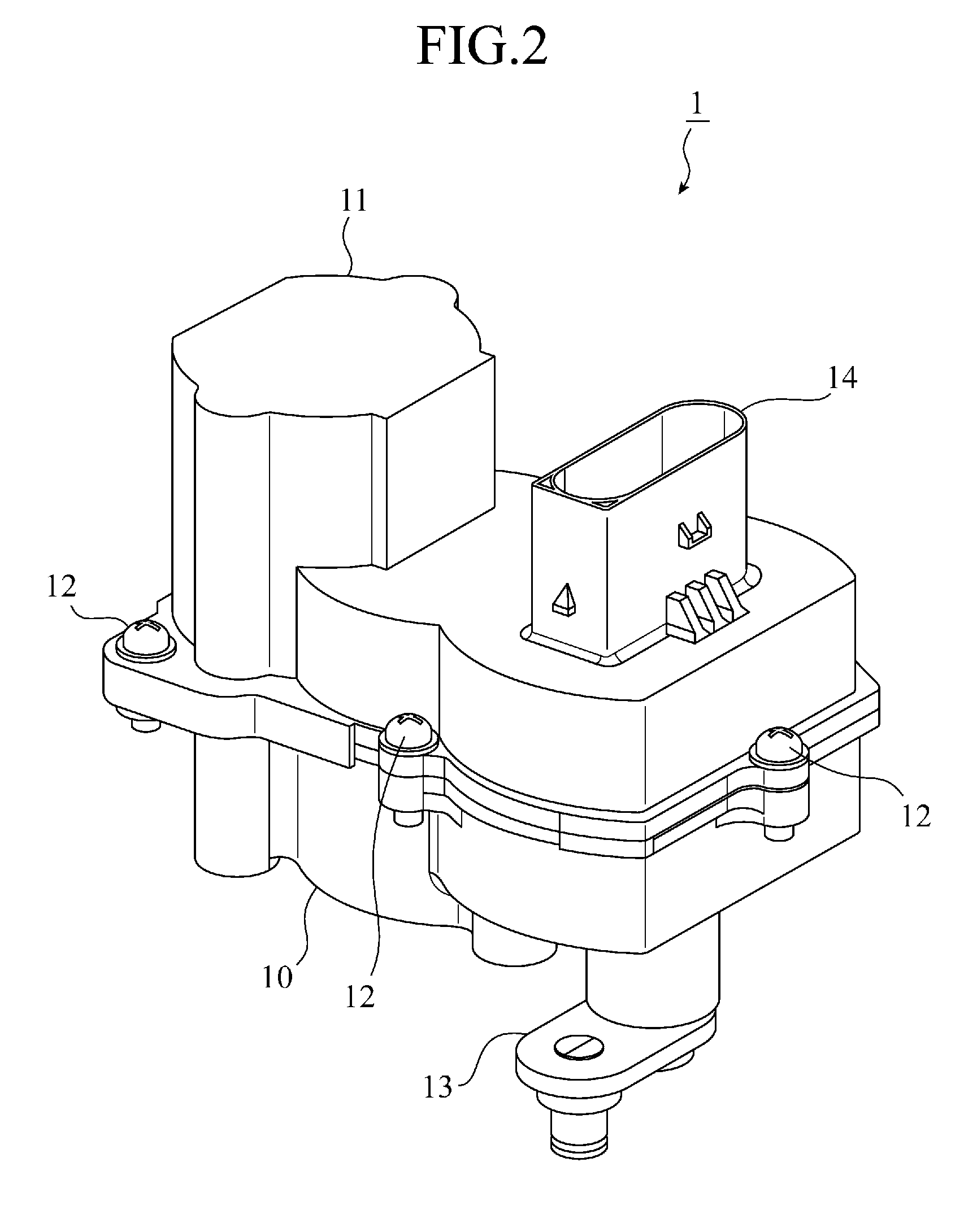

Electronically controlled actuator

ActiveUS20130049502A1Reduced life-timeReduce radiant heatInternal combustion piston enginesMechanical energy handlingActuatorTurbine

Owner:MITSUBISHI ELECTRIC CORP

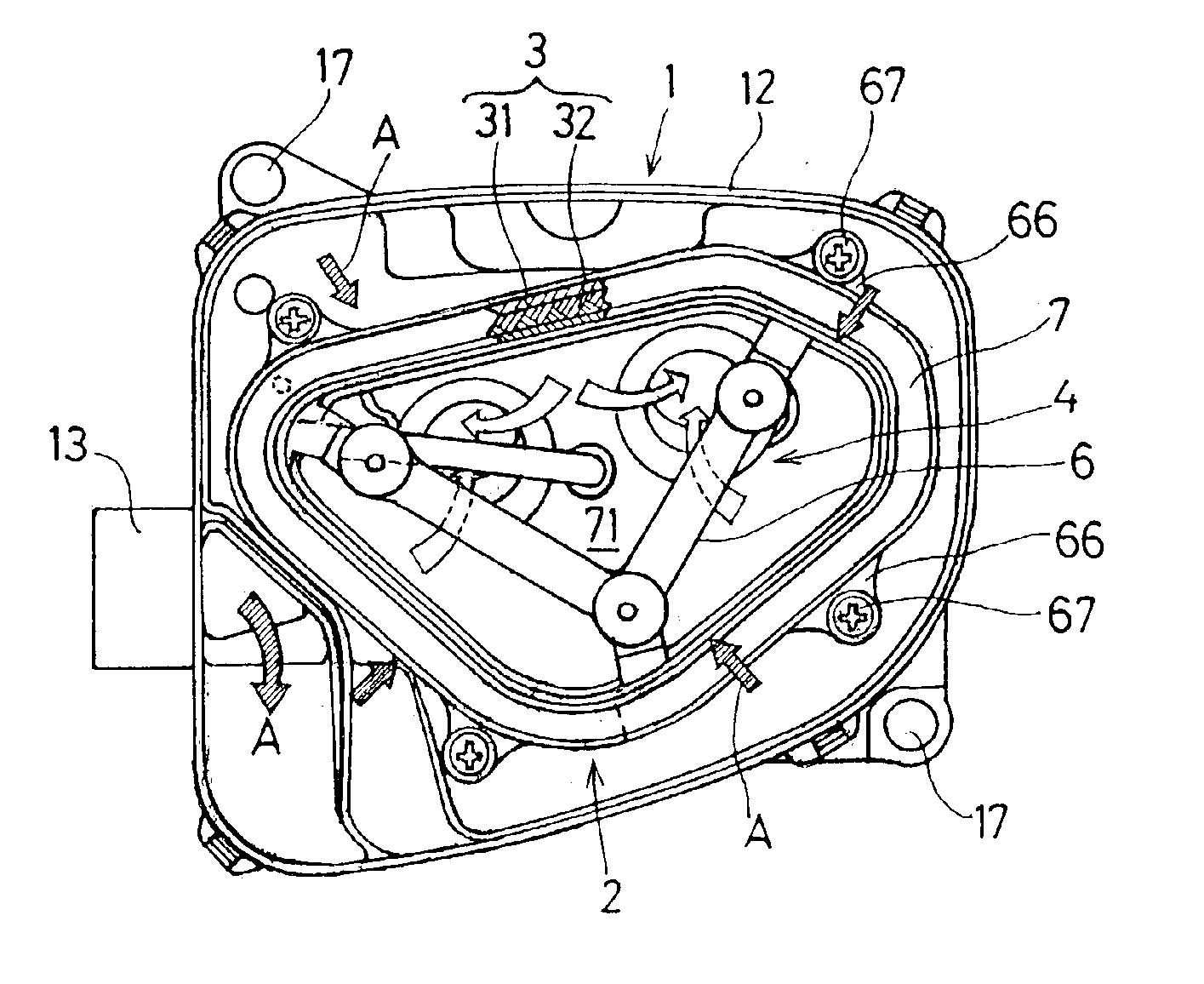

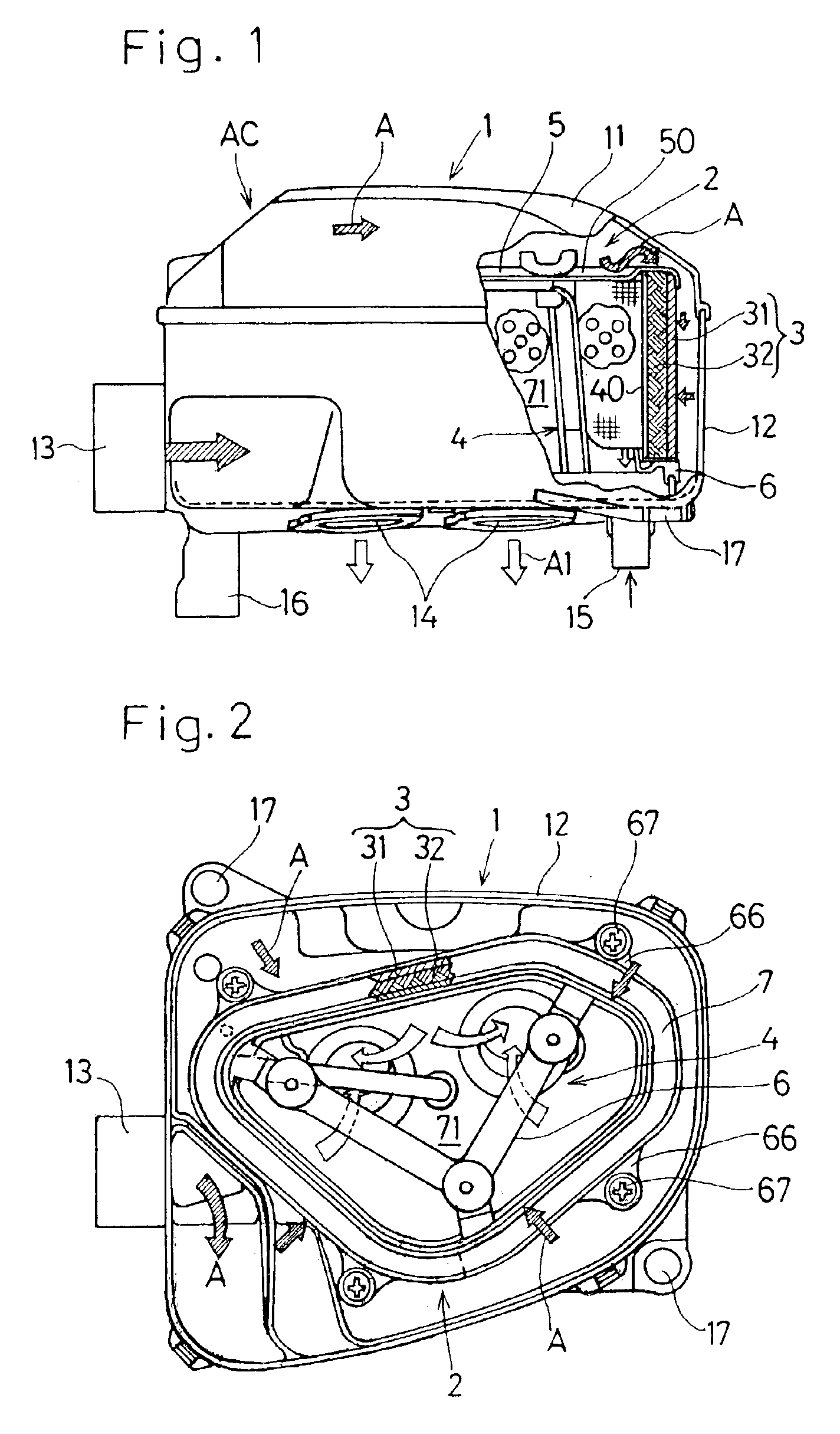

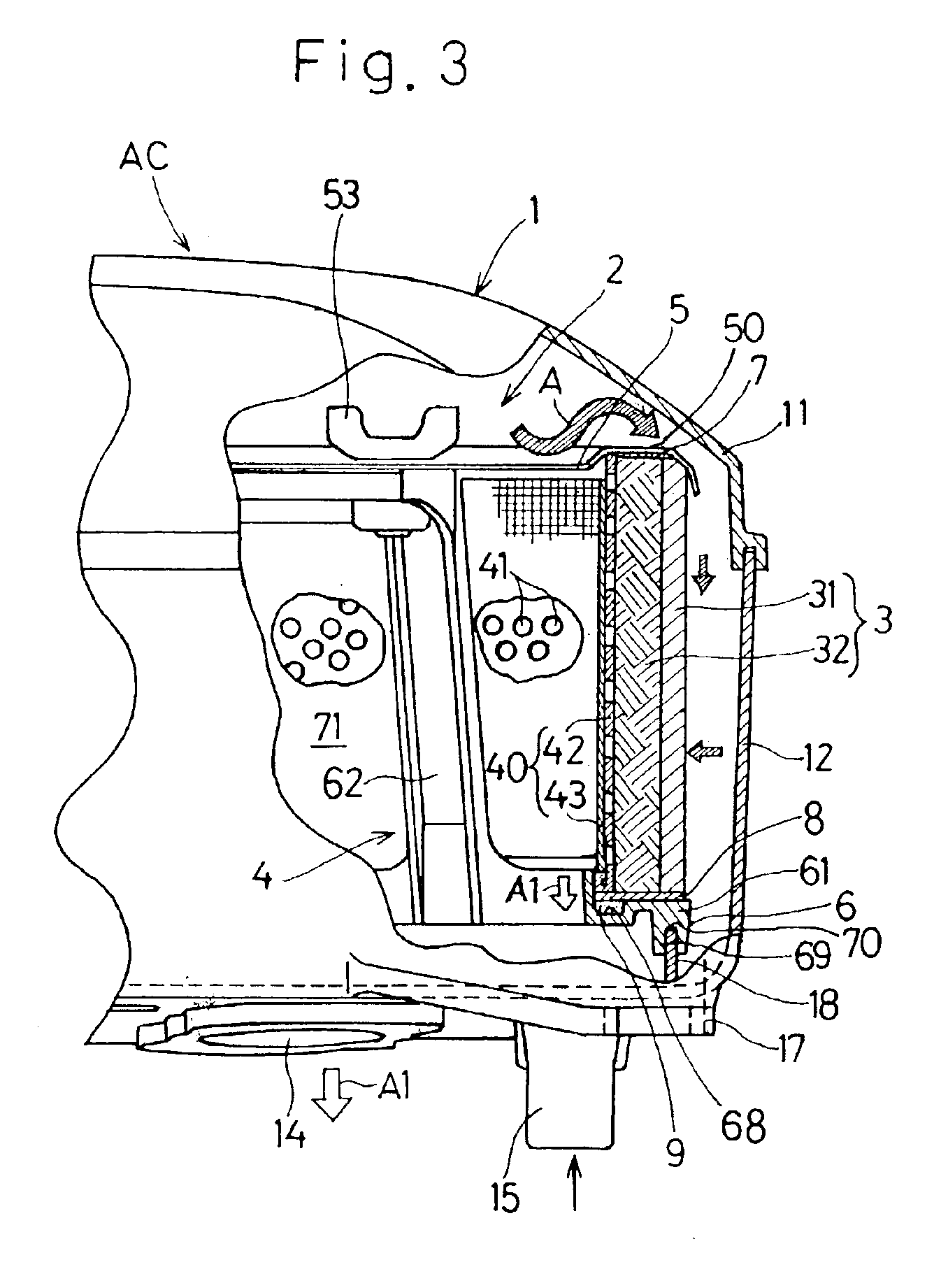

Air cleaner for combustion engine

An air cleaner is provided which is effective to retain a cleaner element 3 in a heteromorphic shape and which has an increased cleaning capability and an assemblability. The air cleaner includes a cleaner element 3 made of a urethane foam and formed in a tubular form having an endless wall and operable to pass an air therethrough in a direction across the thickness of the cleaner element to purify the air. The cleaner element 3 when viewed from top represents a heteromorphic shape, and first and second retainer plates 7 and 8 made of an elastic material effective to retain the heteromorphic shape of the wall, which plates 7 and 8 are bonded to upper and lower end faces of the cleaner element 3. The cleaner element 3 together with the first and second retainer plates 7 and 8 is carried by a holder assembly 4 and is accommodated within a cleaner housing 1 together with the holder assembly 4. The holder assembly 4 includes a first holder having a seat element for holding the upper end face of the cleaner element 3 through the first retainer plate 7 and a second holder 6 having a seat element 61 for holding the lower end face of the cleaner element 3 through the second retainer plate 8.

Owner:KAWASAKI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com