Linkage system

a linkage system and linkage technology, applied in the field of linkage systems, can solve the problems of insufficient rigidity of the link mechanism, the weight of the tool, or the load capacity of the traveling plate, and the entire mechanism and then the system itself becoming bulky, etc., to achieve good assemblability and production, high rigidity, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

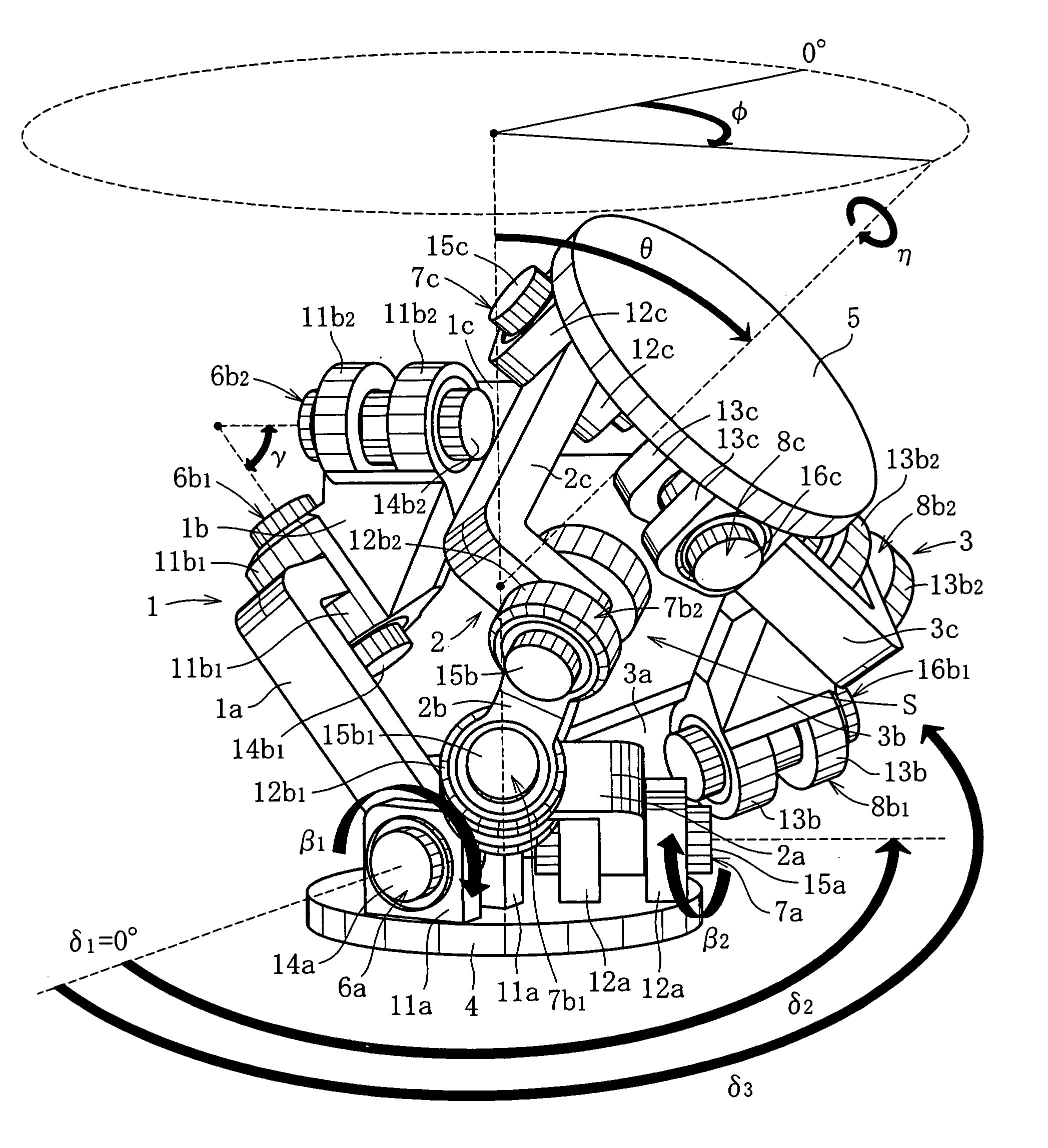

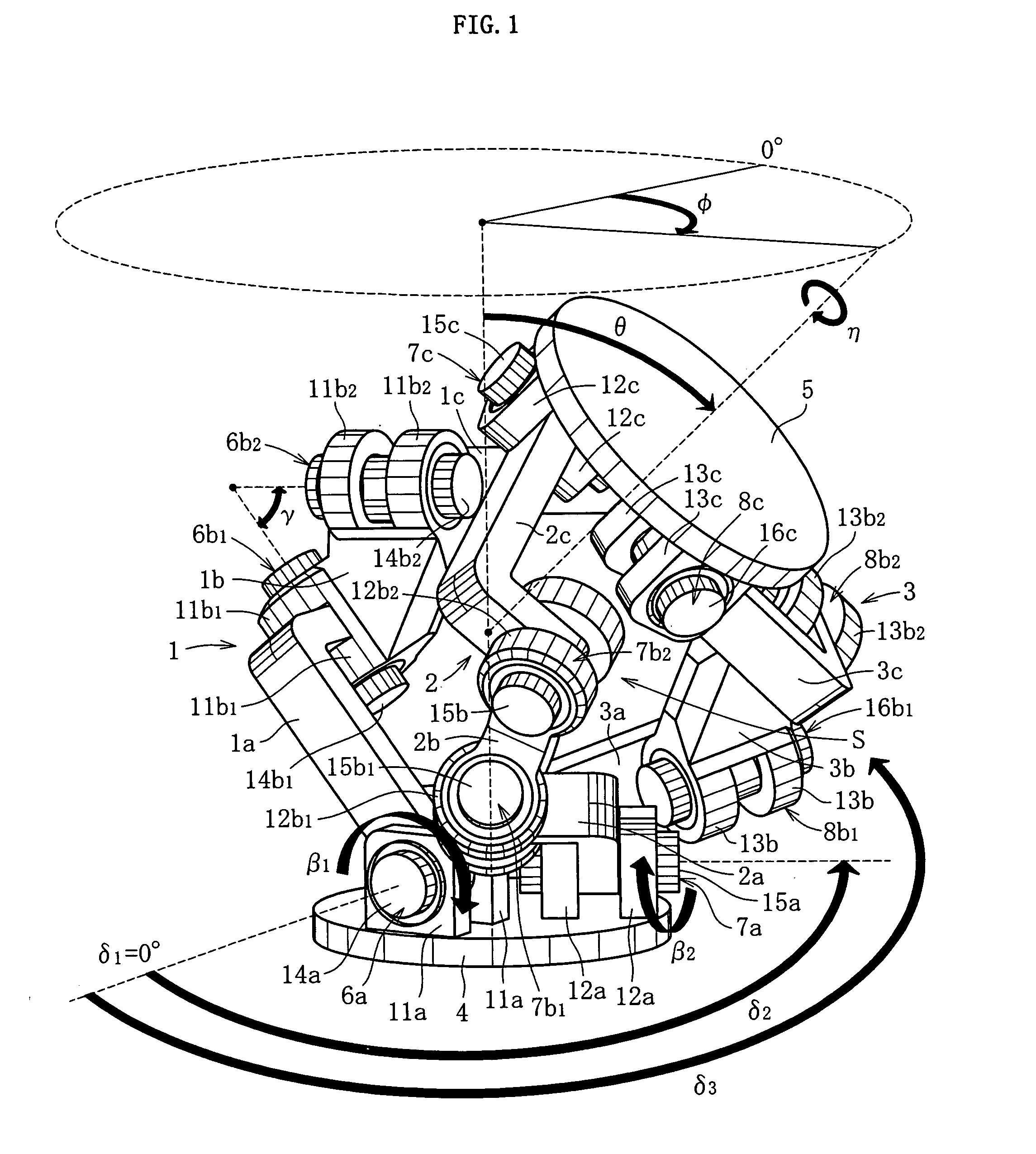

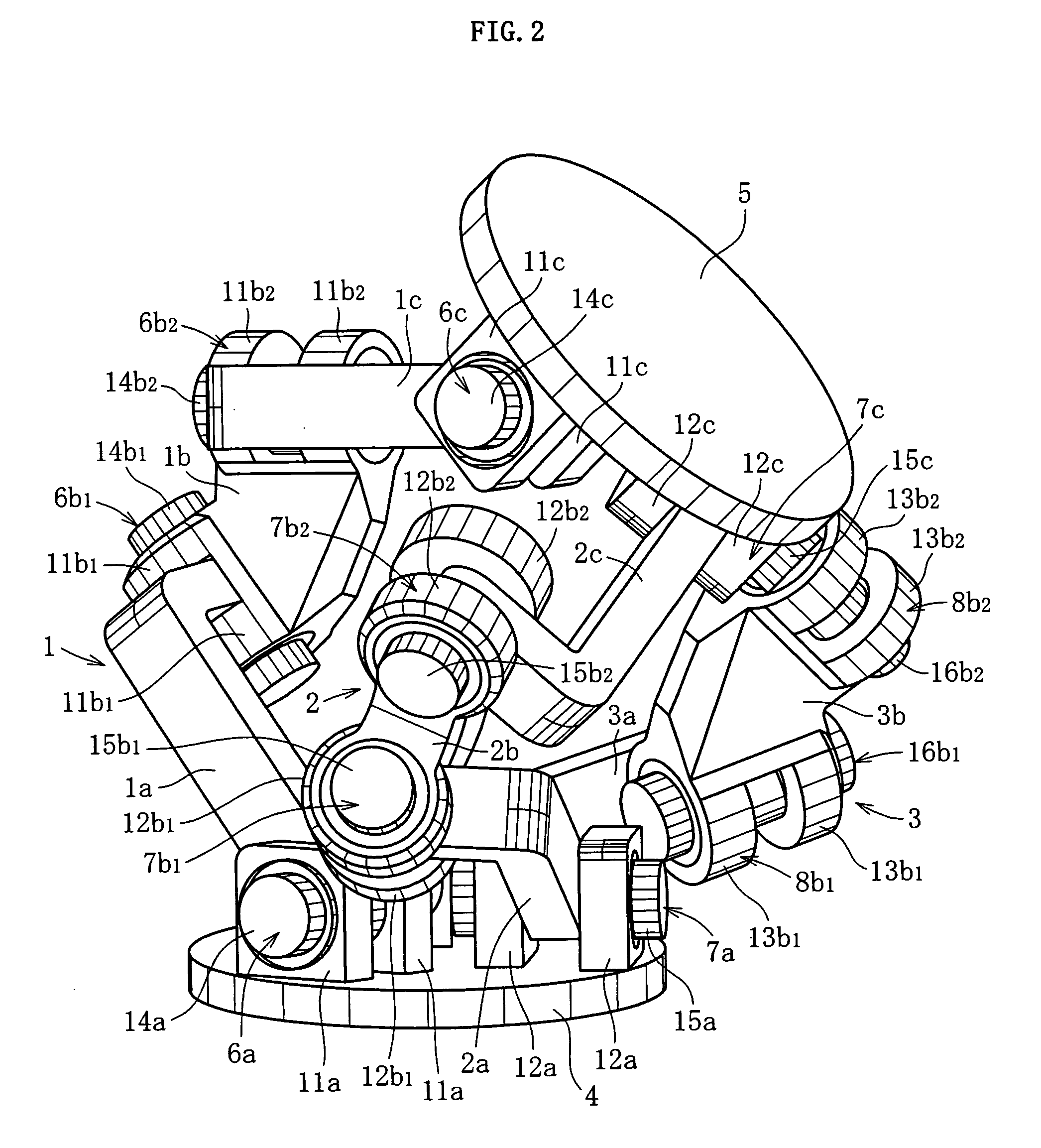

[0038]FIGS. 1 and 2 show linkage systems of the invention used, for example, for a joint of an articulated robot that performs complex processing or handling of goods in a three-dimensional space at high speed and with high precision. The system includes three sets of link mechanisms 1 to 3, which have a geometrically identical construction to one another. The basic structure of the link mechanisms 1 to 3 is as disclosed in the Japanese Patent Application No. 2003-40086 previously filed by the present applicant.

[0039] As shown in FIGS. 1 and 2, the link mechanism 1 (2, 3) forms a three-link chain, including an end link 1a (2a, 3a) provided on the input side and rotatably coupled to a disk-like input member 4, an end link 1c (2c, 3c) provided on the output side and rotatably coupled to a disk-like output member 5, a center link 1b (2b, 3b) rotatably coupled to both the end links 1a (2a, 3a) and 1c (2c, 3c) to connect both the end links, and four revolute joints 6a (7a, 8a), 6b1 (7b1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com