Heat transfer cell for heat exchanger and assembly, and methods of fabricating the same

a heat exchanger and heat transfer cell technology, applied in indirect heat exchangers, lighting and heating apparatuses, laminated elements, etc., can solve the problems of increasing the burden of workers, reducing work efficiency, increasing fabrication costs, etc., to prevent downward sagging, improve heat exchange efficiency, and reduce the vortex and resistance of fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

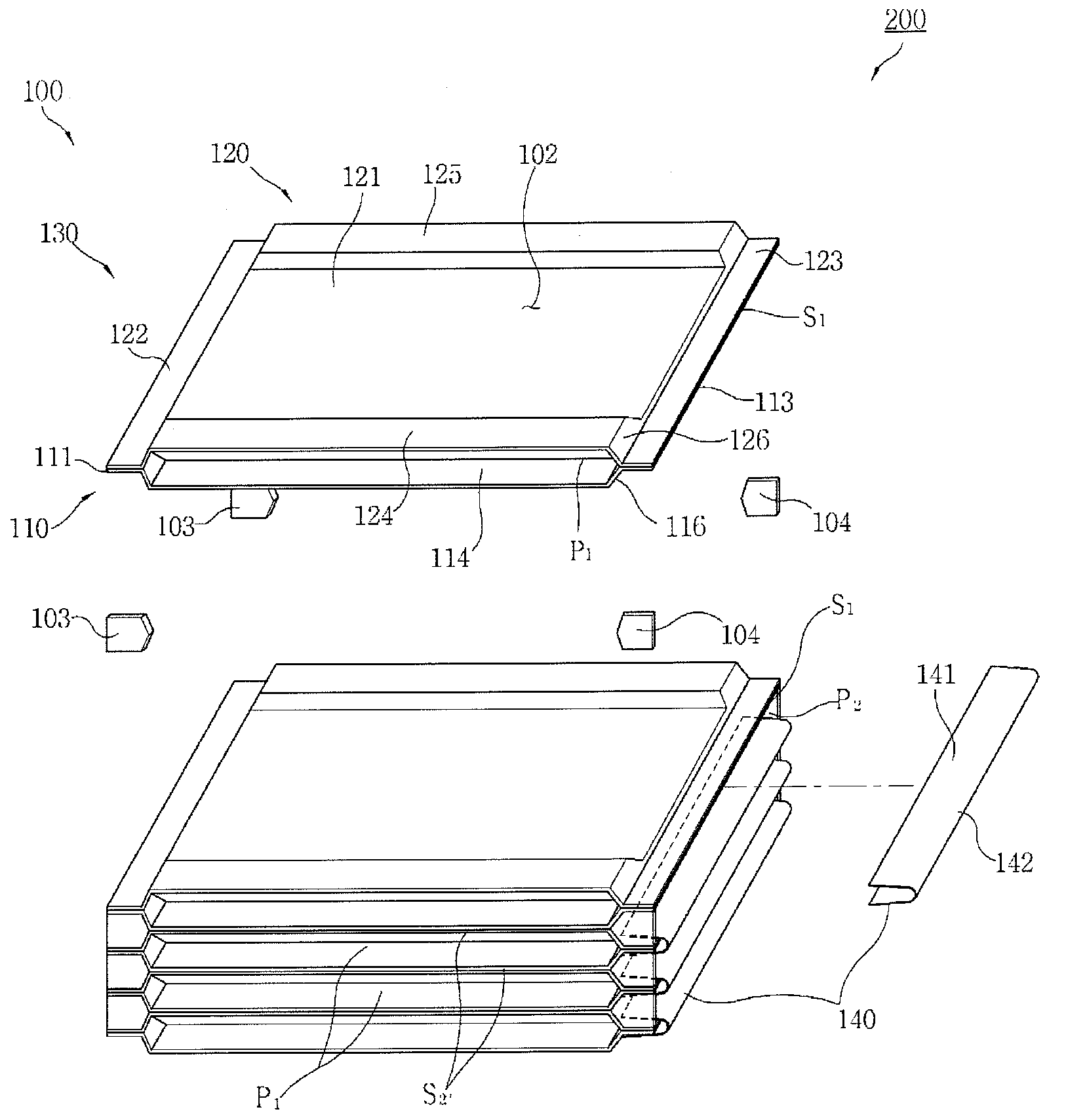

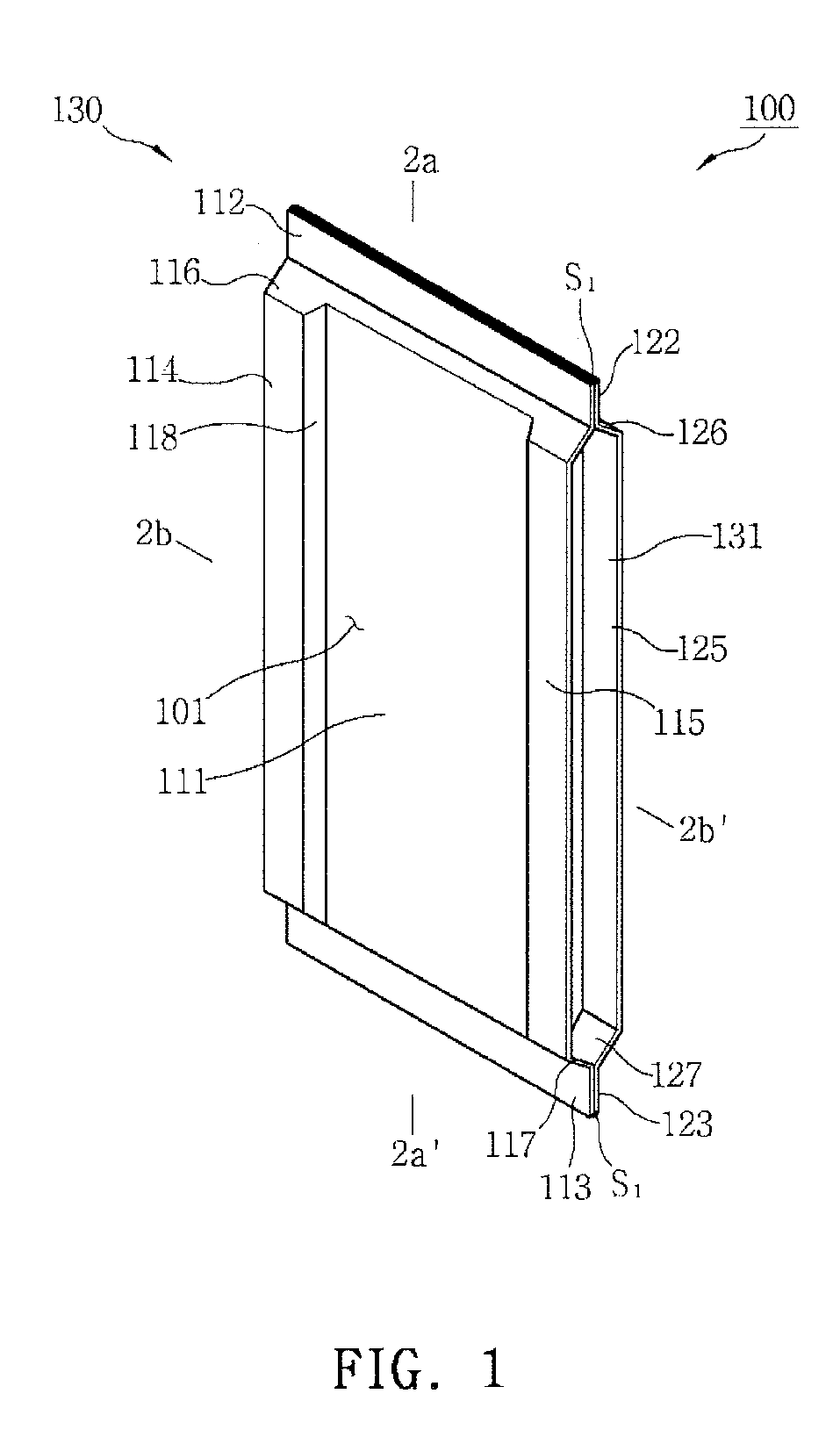

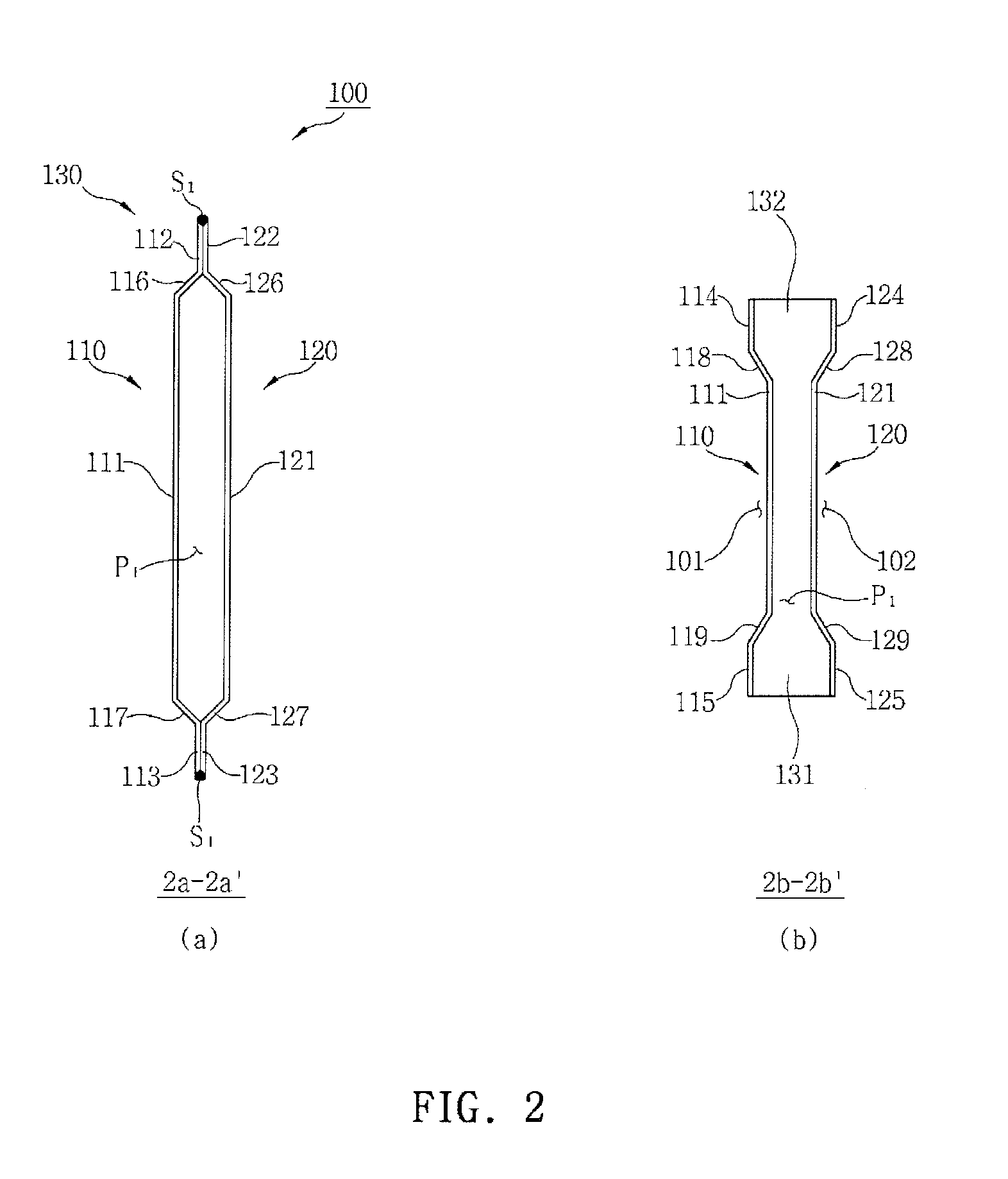

[0078]According to the present invention, as illustrated in FIGS. 1 and 2, the heat transfer cell 100 includes a cell body 130 having a first (or transverse) fluid passage P1, i.e. an internal fluid passage, through which a fluid flows in one direction. The cell body 130 is obtained by welding a pair of heat transfer plates 110 and 120, which are opposite to each other in a mirror image.

[0079]The heat transfer plate 110 or 120 includes a heat transfer area 111 or 121 shaped of a substantially quadrilateral panel, a pair of first flanges 112 and 113, or 122 and 123 bent from opposite upper and lower edges of the heat transfer area 111 or 121 in one direction when viewed from FIG. 1 and having a height difference with respect to the heat transfer area 111 or 121, and a pair of second flanges 114 and 115, or 124 and 125 bent from opposite left-hand and right-hand edges of the heat transfer area 111 or 121 in the direction opposite the bending direction of the first flanges 112 and 113,...

second embodiment

[0097]According to the present invention, as illustrated in FIGS. 4 and 5, the heat transfer cell 100a includes a cell body 130a having a first fluid passage P1, i.e. an internal fluid passage, through which a fluid flows in one direction, by welding a pair of heat transfer plates 110a and 120a, which are opposite to each other in a mirror image.

[0098]As in the first embodiment, the heat transfer plates 110a and 120a includes a pair of first flanges 112a and 113a, or 122a and 123a and a pair of second flanges 114a and 115a, or 124a and 125a, each of which is bent and extends in a direction perpendicular to each other and has a height difference with respect to the heat transfer area 111a or 121a shaped of a substantially quadrilateral panel.

[0099]The cell body 130a includes the first fluid passage P1 therein which has open opposite ends by welding the heat transfer plates 110a and 120a that are opposite to each other in a mirror image, weld lines S2 that weld and seal faying surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com