Patents

Literature

328 results about "Faying surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A faying surface is one of the surfaces that are in contact at a joint. Faying surfaces may be connected to each other by bolts or rivets, adhesives, welding, or soldering. An example would be steel pipe flanges, in which the connected ends of the flanges would be faying surfaces.

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

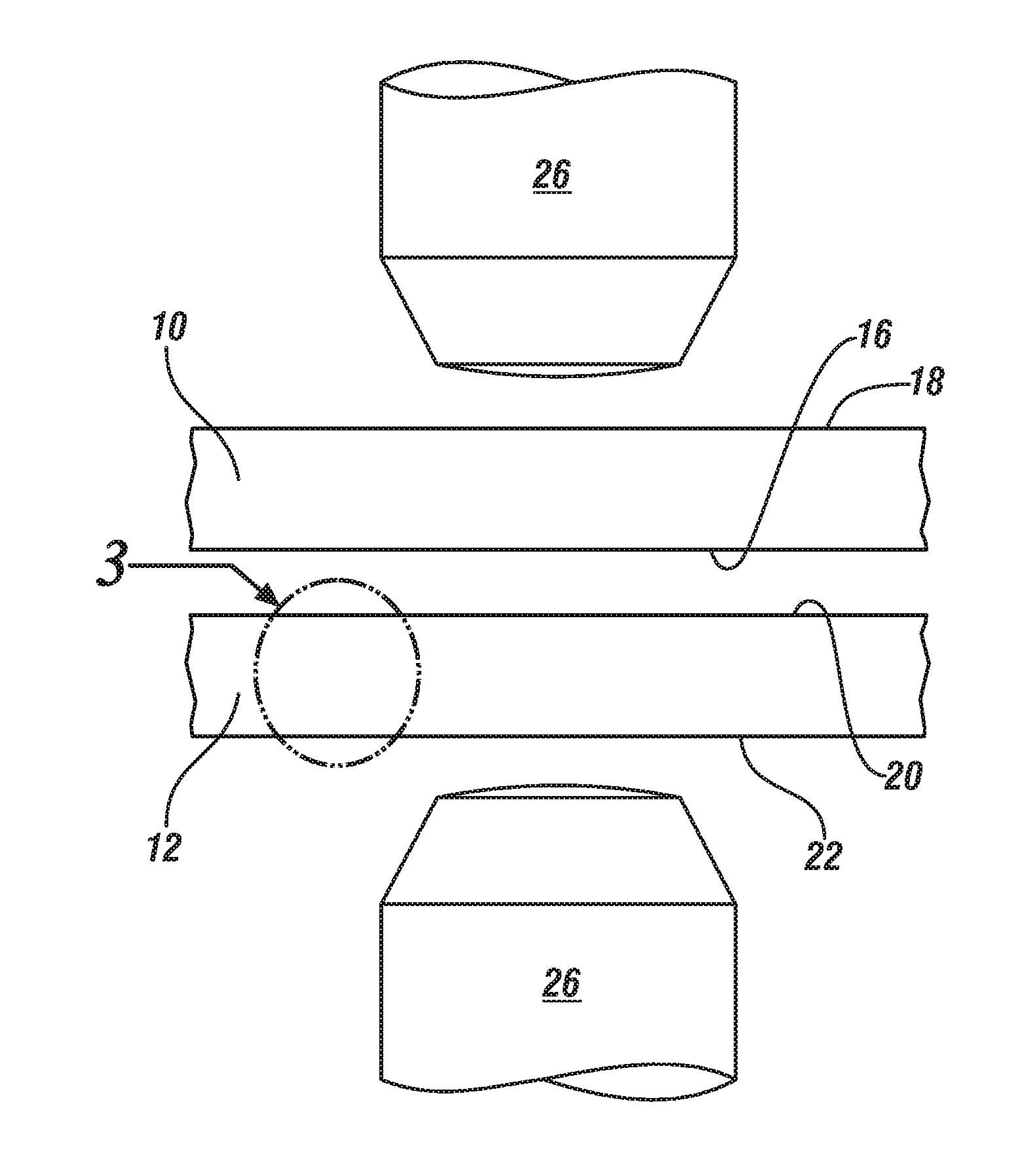

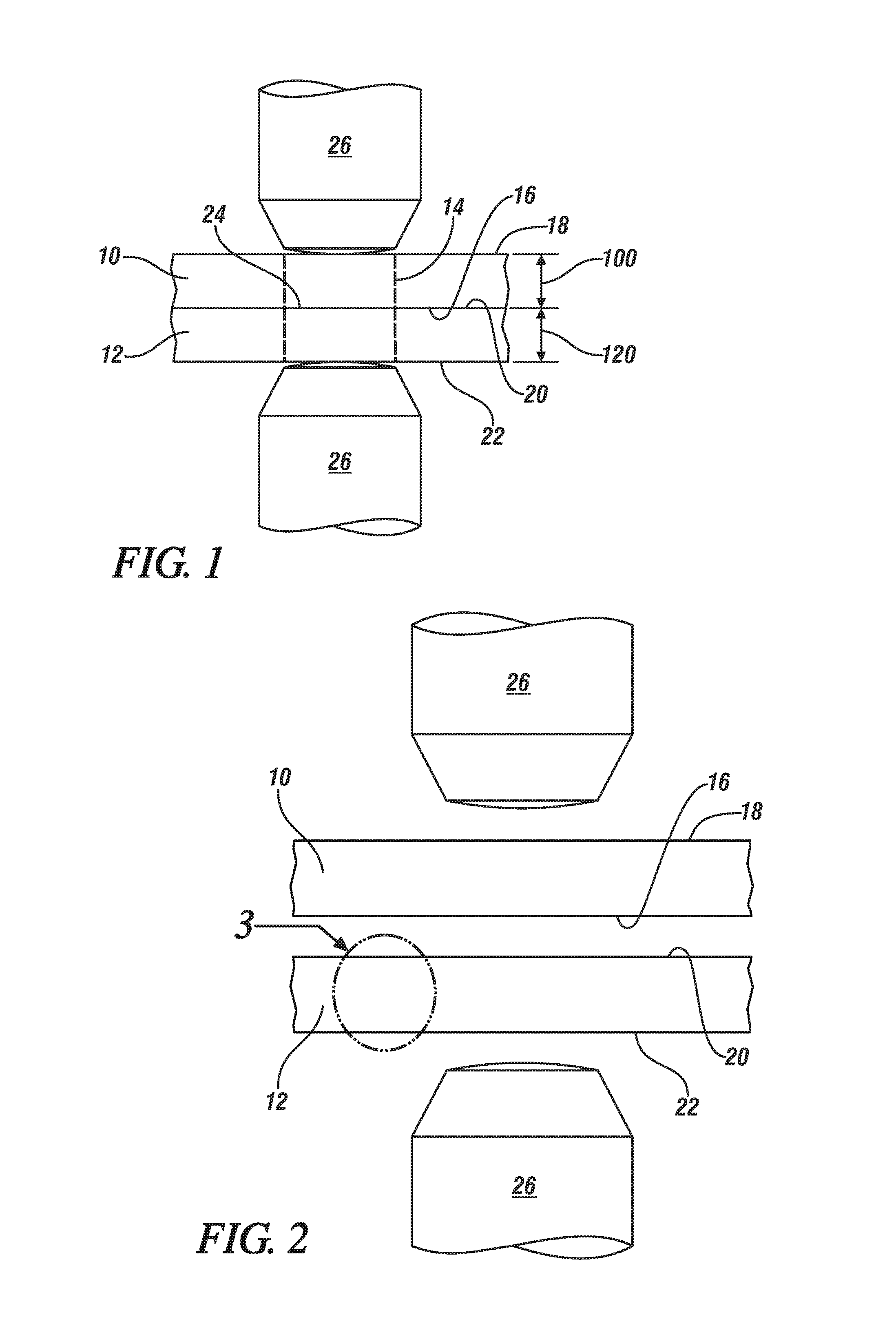

Multi-stage resistance spot welding method for workpiece stack-up having adjacent steel and aluminum workpieces

ActiveUS20170106466A1High peel strengthReduce proliferationWelding electric supplyWelding/soldering/cutting articlesSpot weldingMaterials science

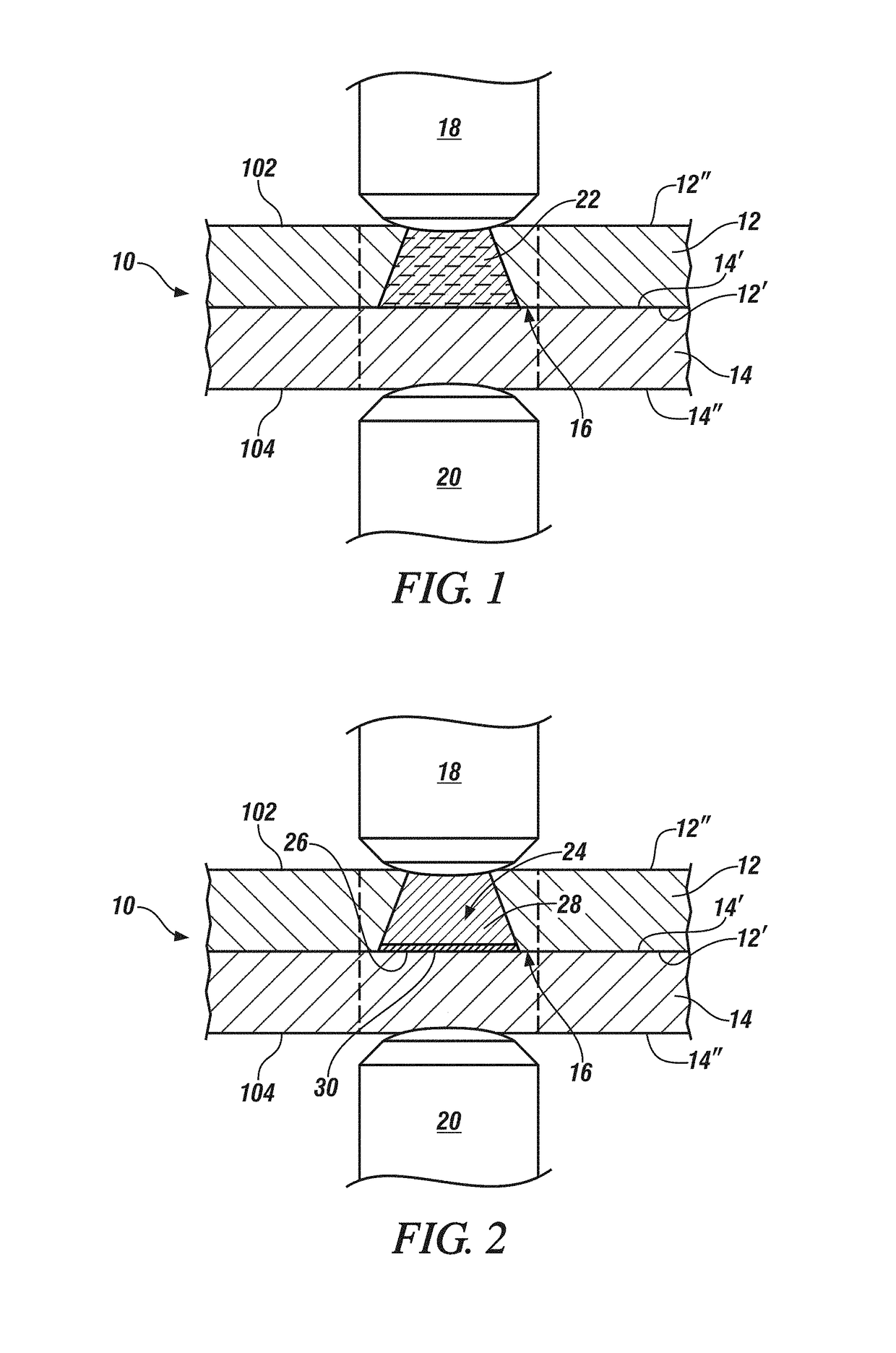

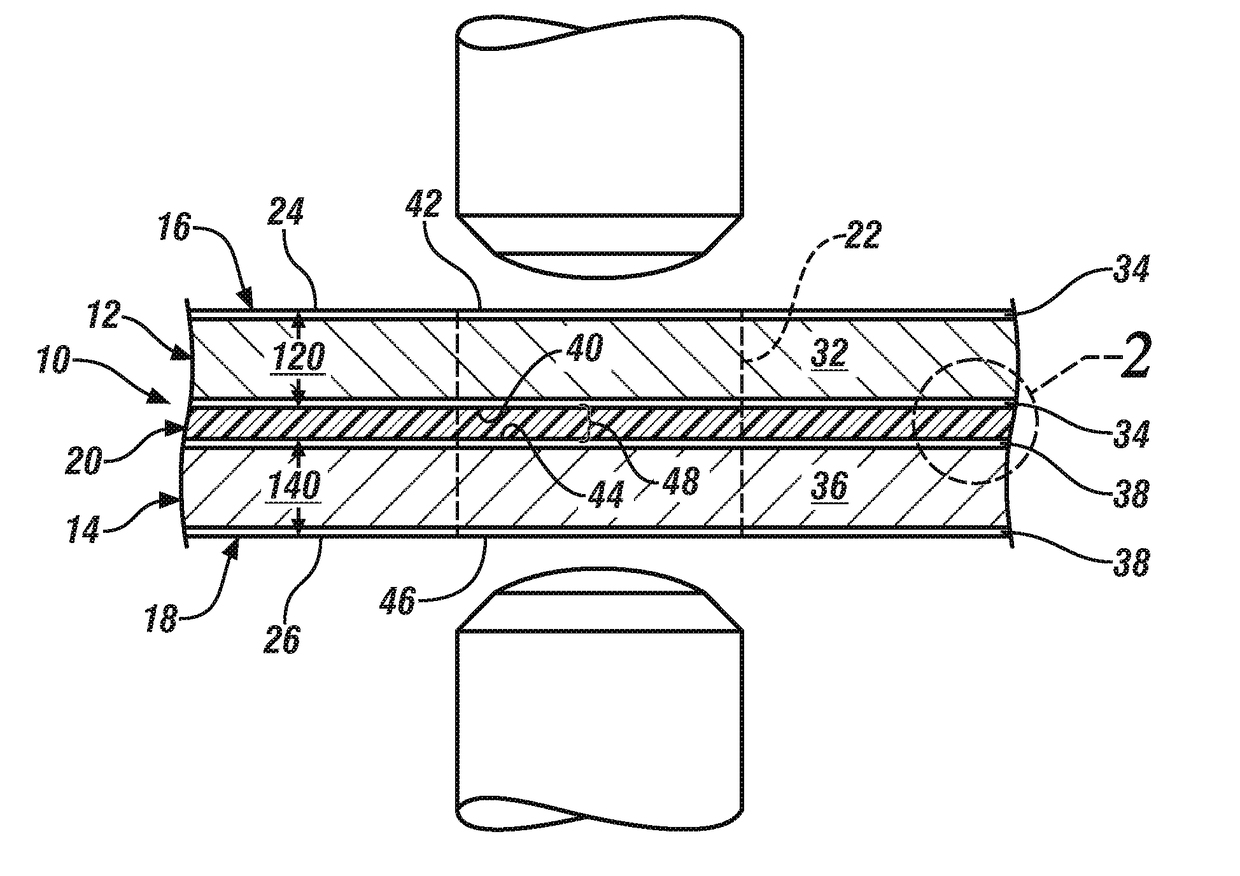

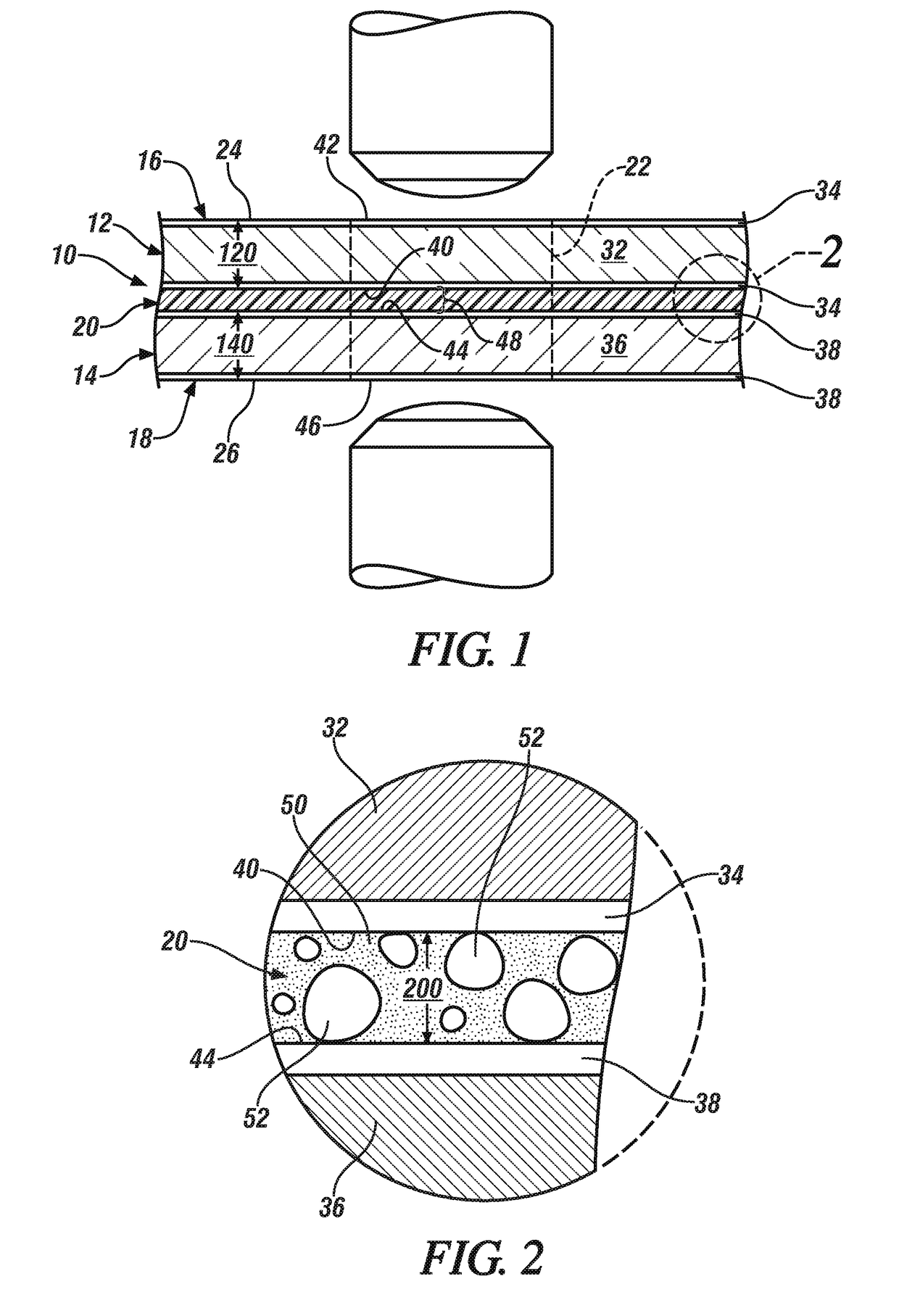

A workpiece stack-up that includes at least a steel workpiece and an adjacent and overlapping aluminum workpiece can be resistance spot welded by a multi-stage spot welding method. The multi-stage spot welding method involves initially forming a weld joint between the steel and aluminum workpieces. The weld joint extends into the aluminum workpiece from the faying interface of the two workpieces and includes an interfacial weld bond area adjacent to and joined with the faying surface of the steel workpiece. After the weld joint is initially formed, the multi-stage spot welding method calls for remelting and resolidifying at least a portion of the weld joint that includes some or all of the interfacial weld bond area. At least a portion of the resultant refined weld joint may then be subjected to the same remelting and resolidifying practice, if desired. Multiple additional practices of remelting and resolidifying may be carried out.

Owner:GM GLOBAL TECH OPERATIONS LLC

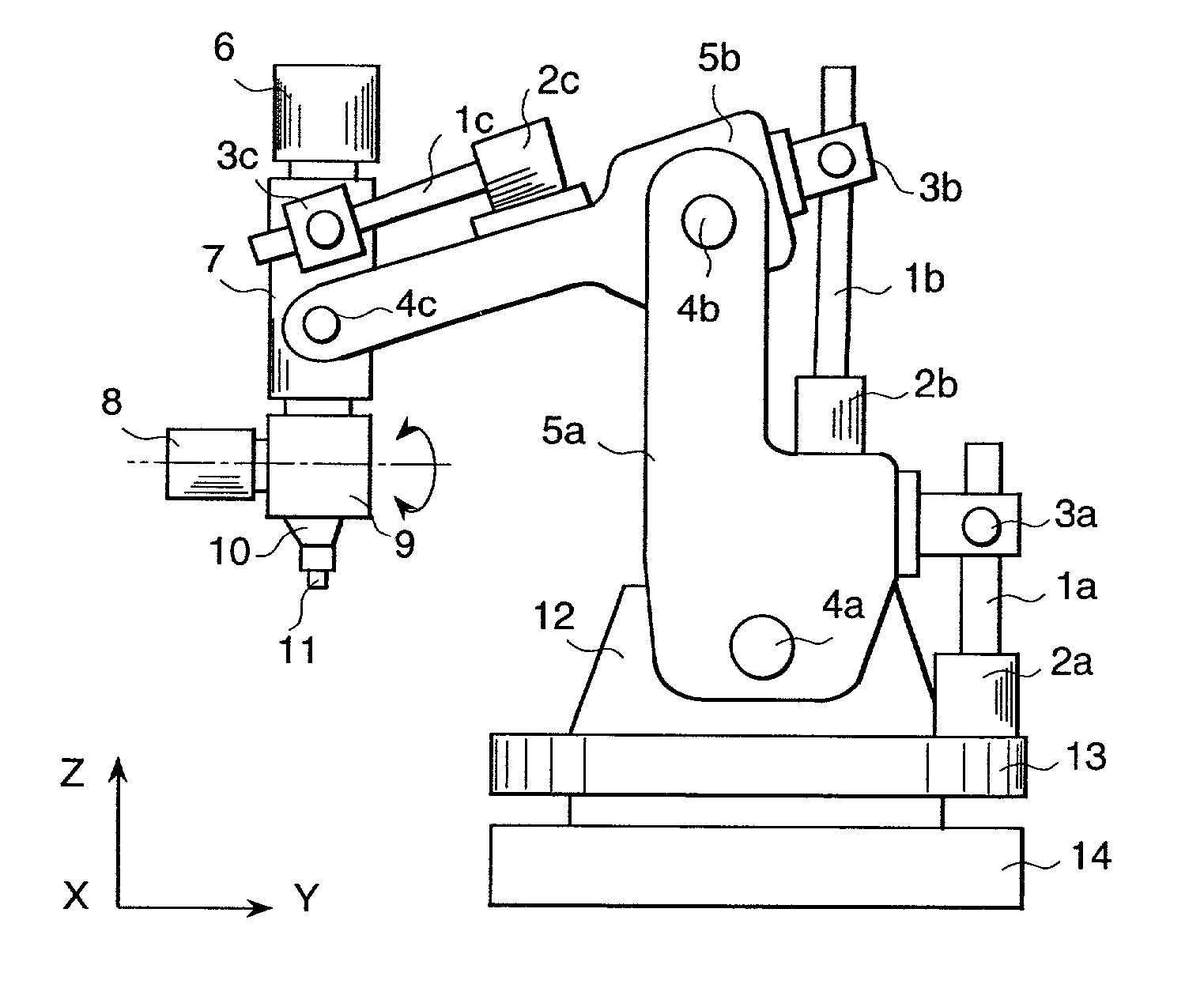

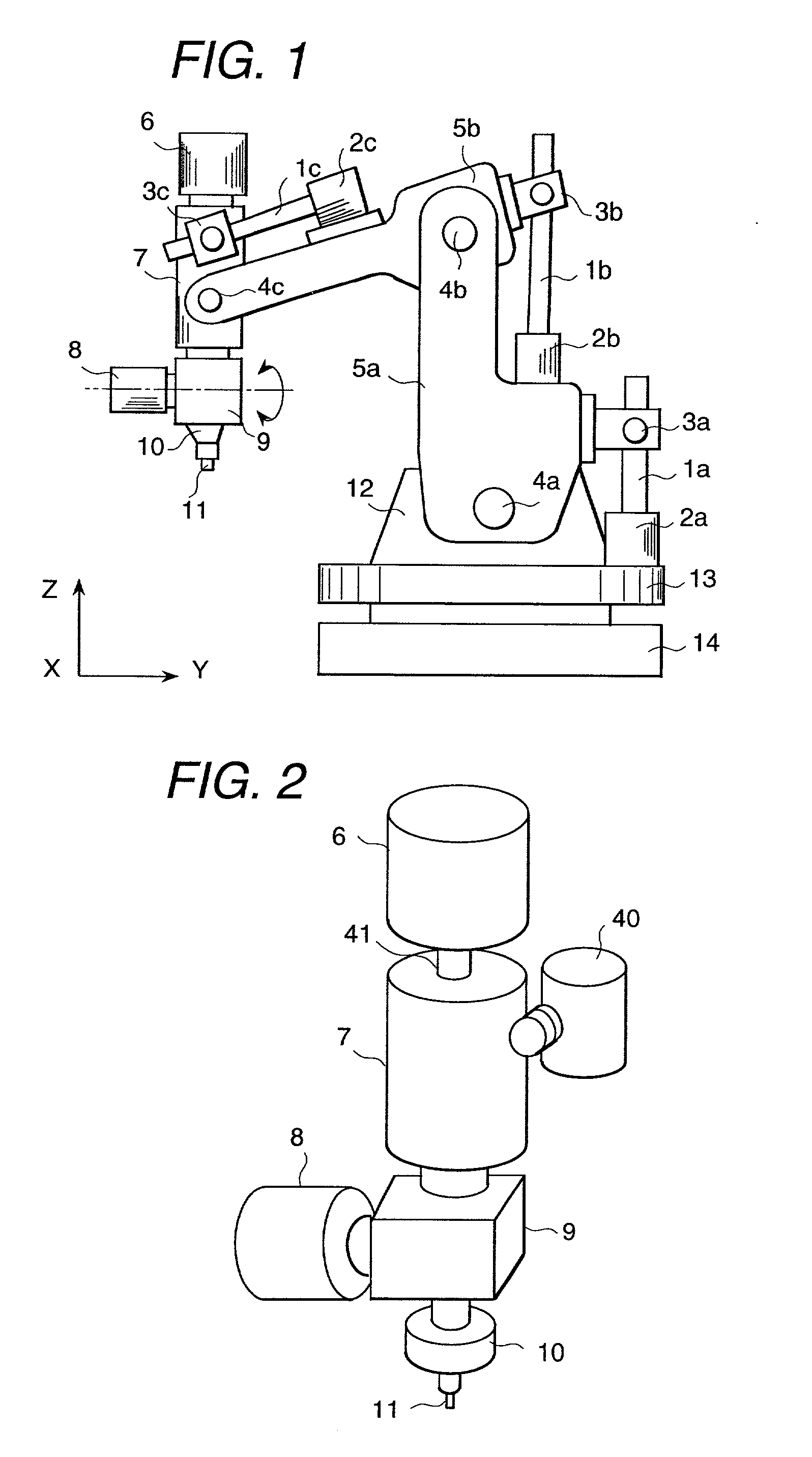

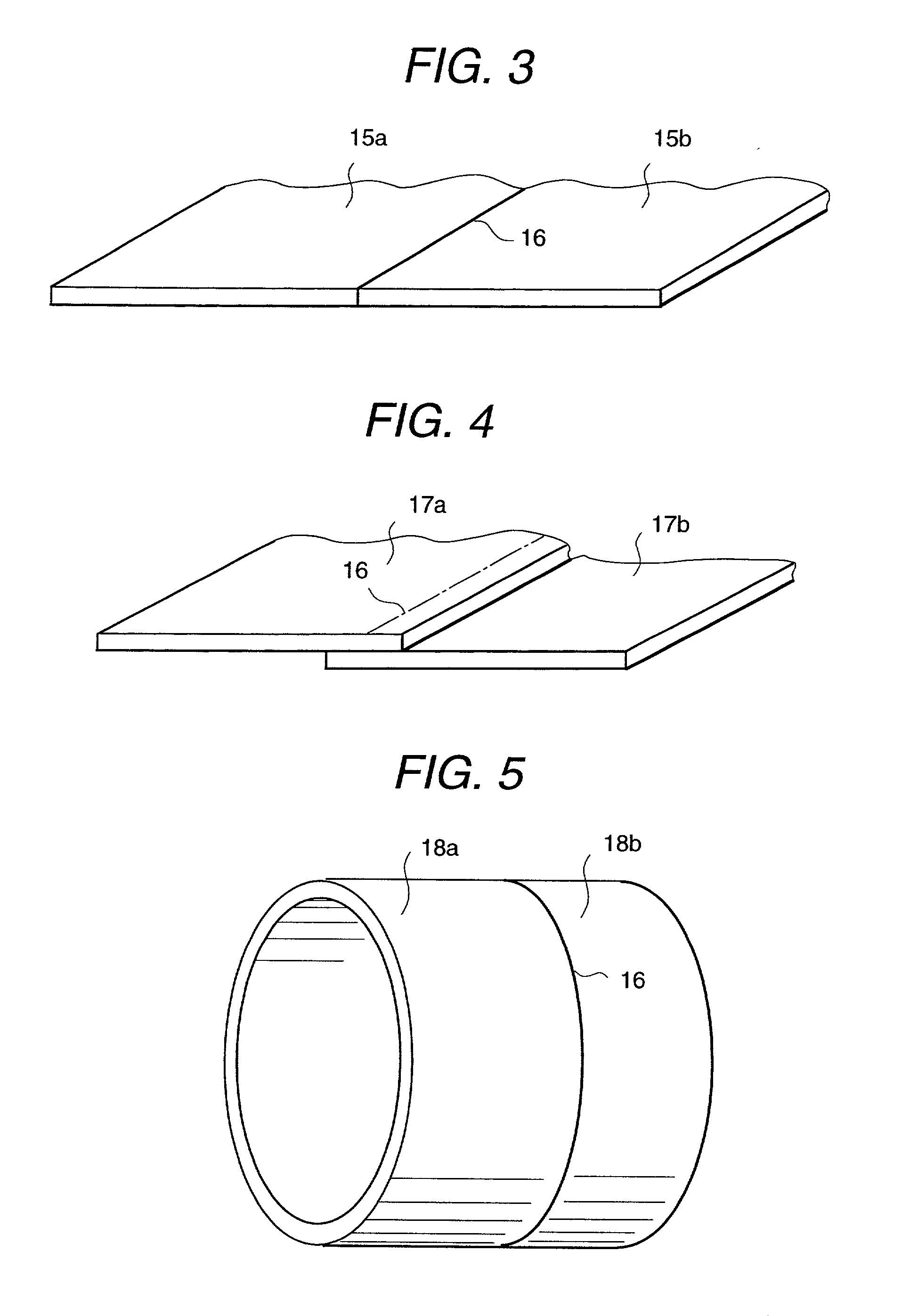

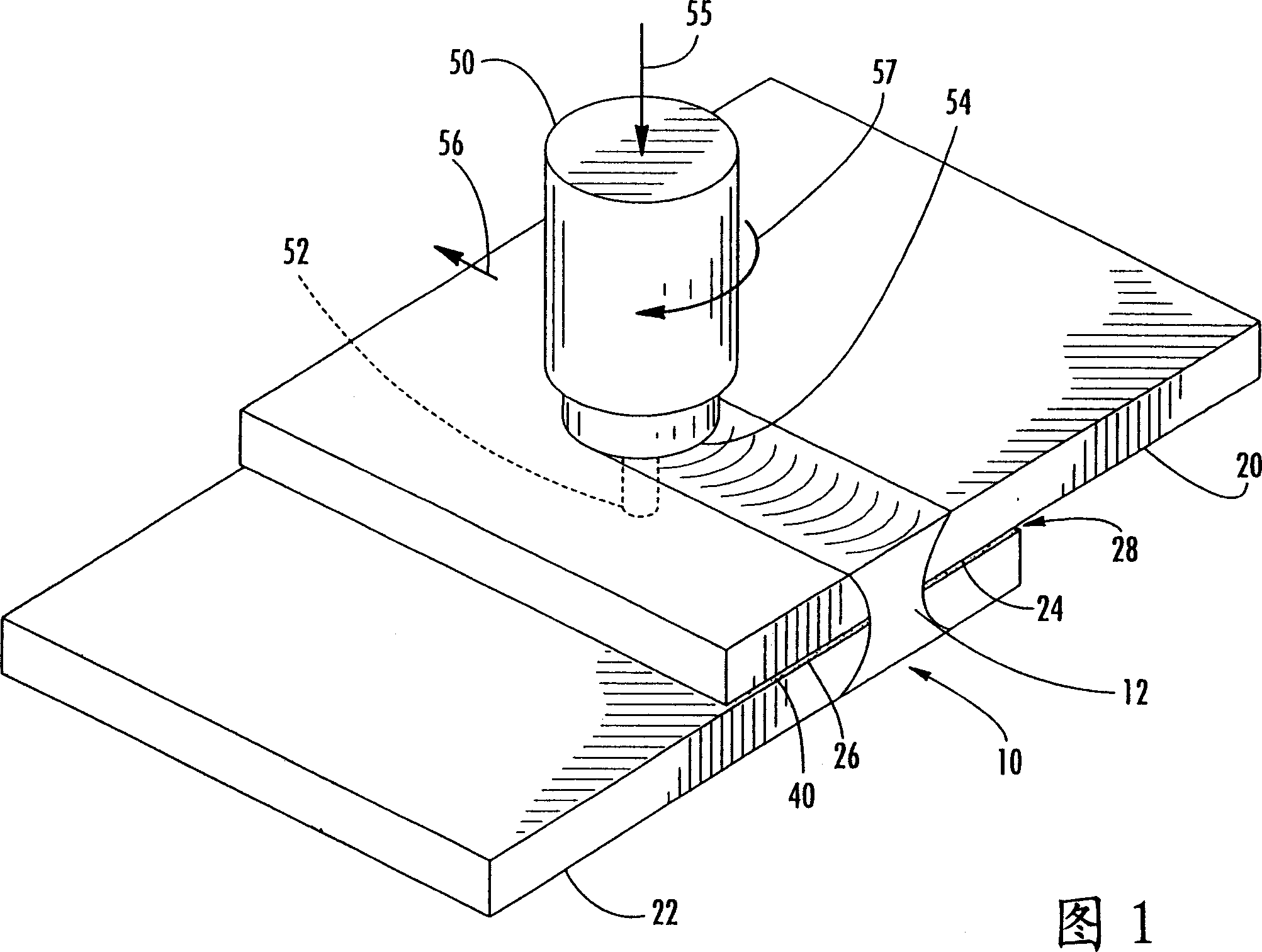

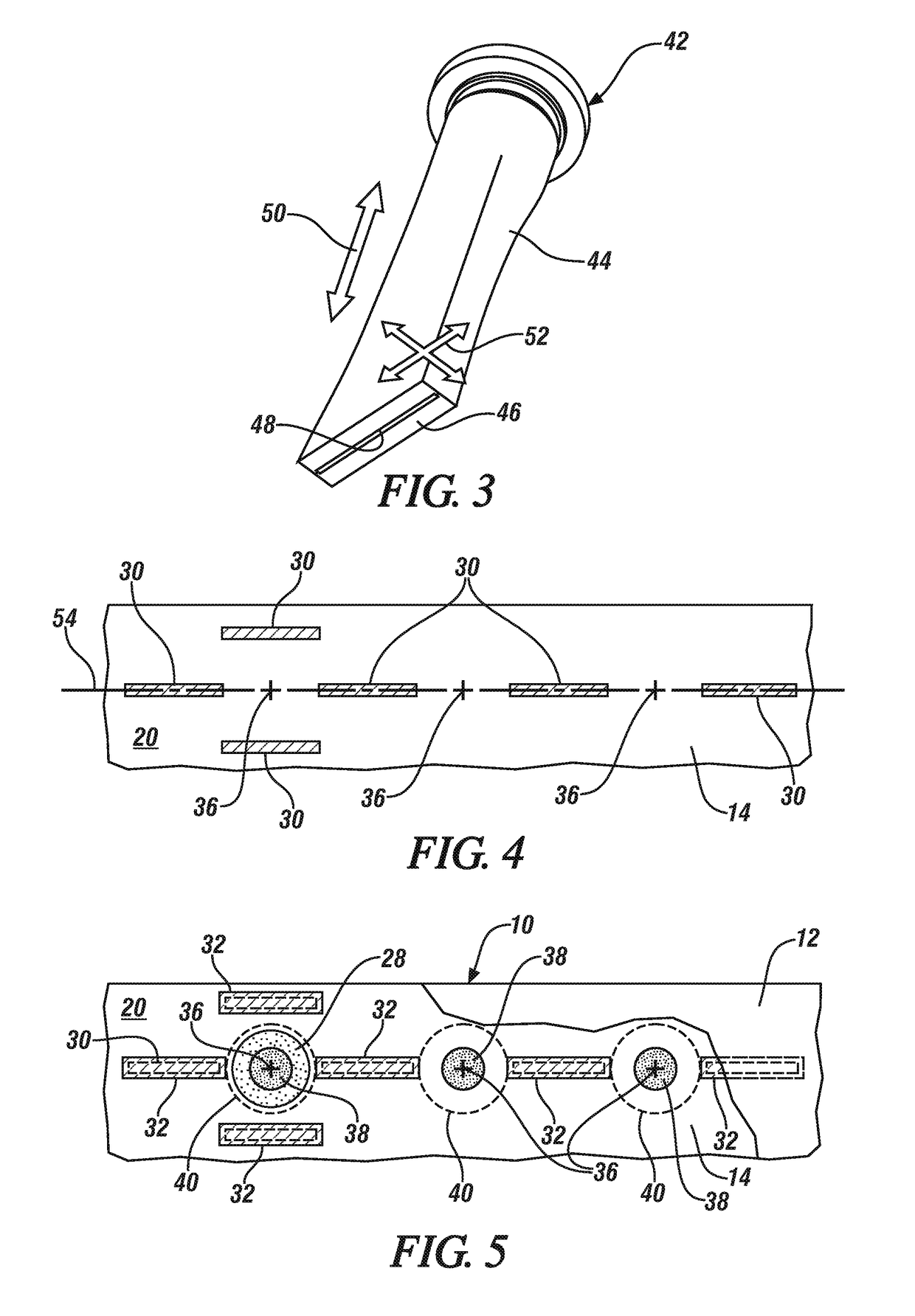

Friction stir welding method and apparatus, and welded structure

InactiveUS20020145031A1Welding/cutting auxillary devicesAuxillary welding devicesRotational axisGeometric relations

It is an object of the present invention to provide a friction stir welding method and apparatus capable of maintaining a rotating tool and workpieces at a substantially constant geometrical relation for arbitrary curved surfaces having a three-dimensional shape, as well as a welded structure obtained thereby. The present invention resides in a friction stir welding method comprising joining workpieces while setting rotational angles of two rotational axes of a rotating tool which the two rotational axes are rotatable in intersecting directions or perpendicularly intersecting directions independently of rotation of the rotating tool, detecting a normal line direction with respect to joint surfaces of the workpieces and a tangential direction of a joint line, and joining the workpieces in three-dimensional directions while setting, on the basis of the detected normal line direction and tangential direction, an angle relative to a normal line direction, as well as a tangential direction, at a tip end of the rotating tool, and also resides in a friction stir welding apparatus using the said method.

Owner:HITACHI LTD

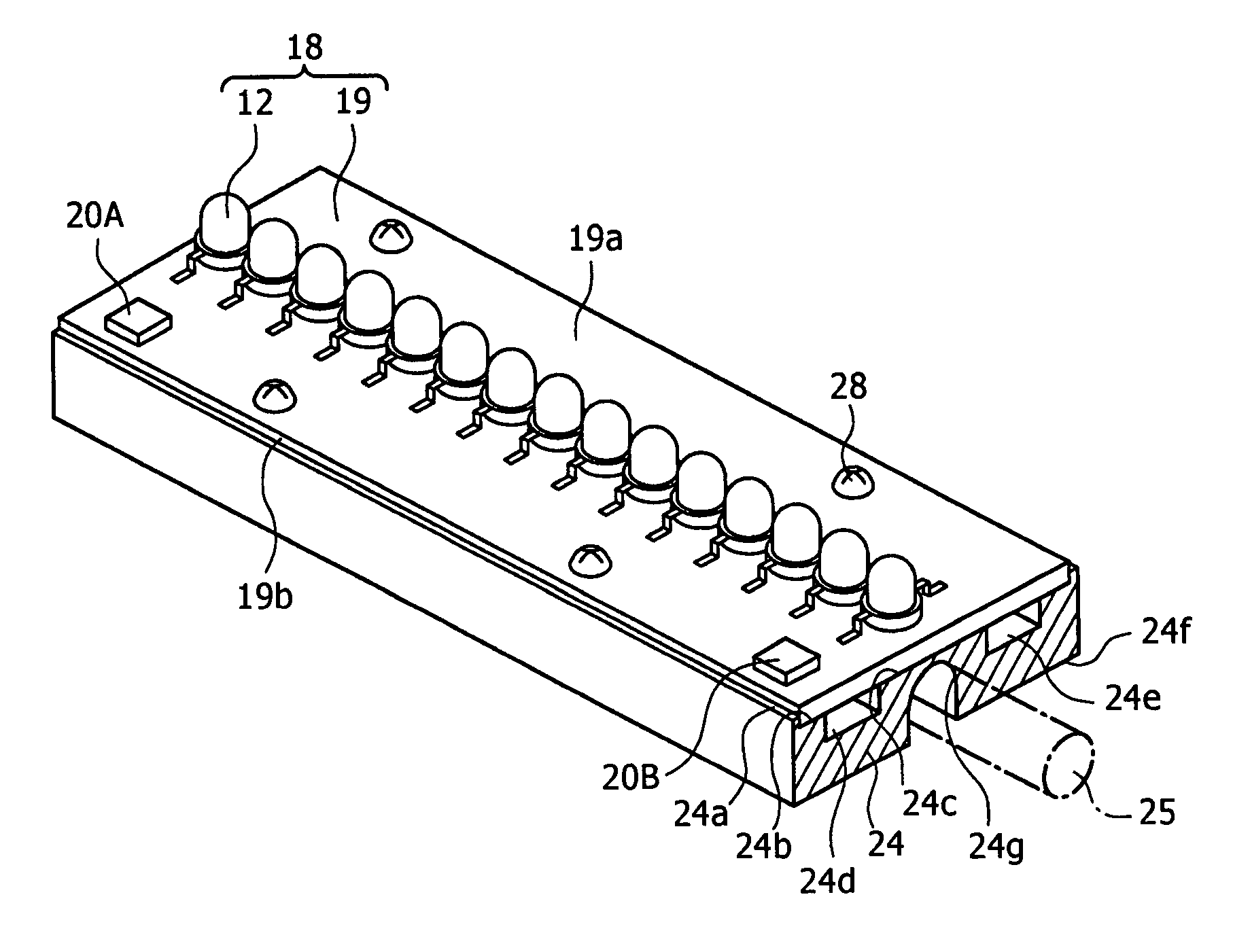

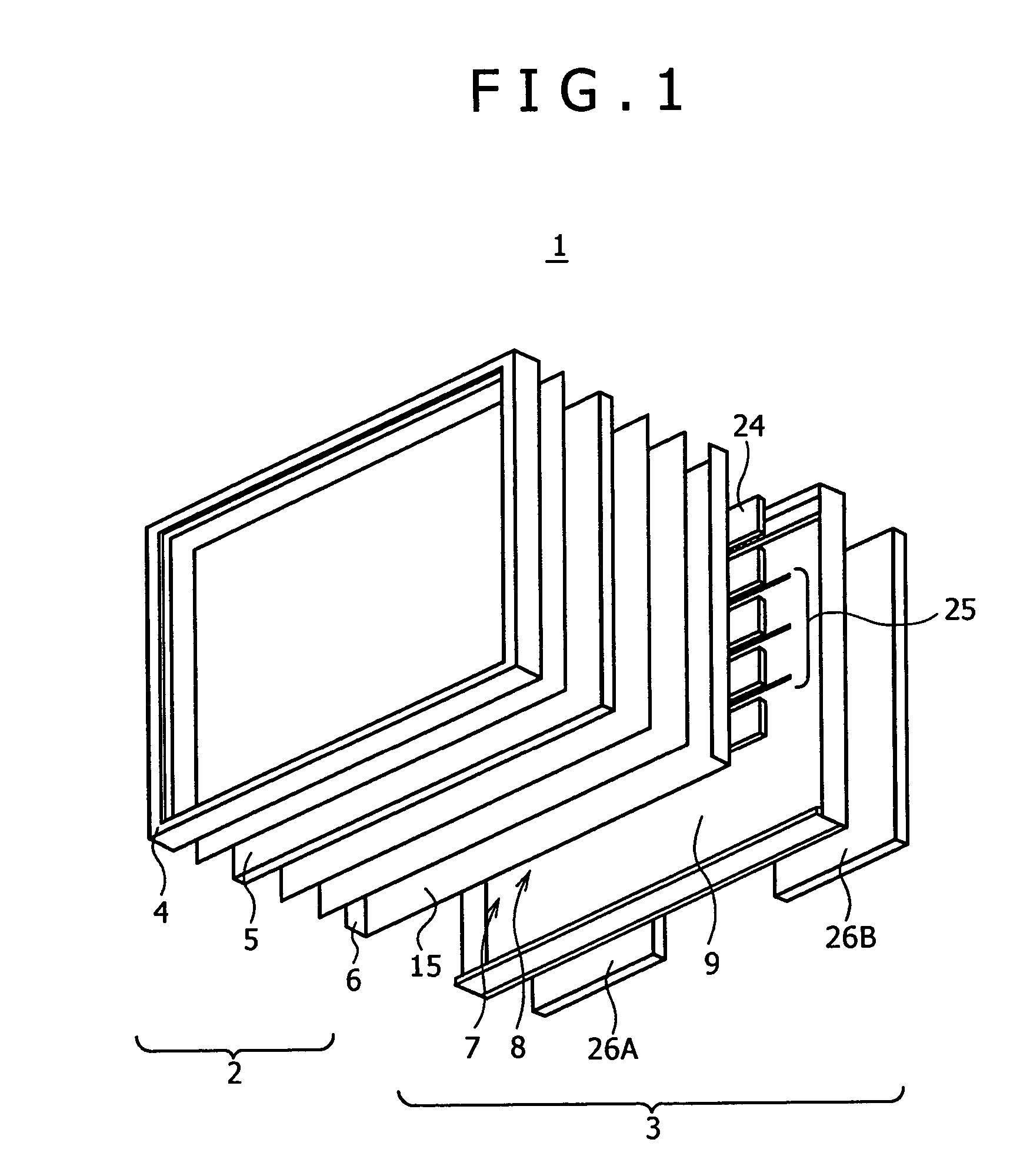

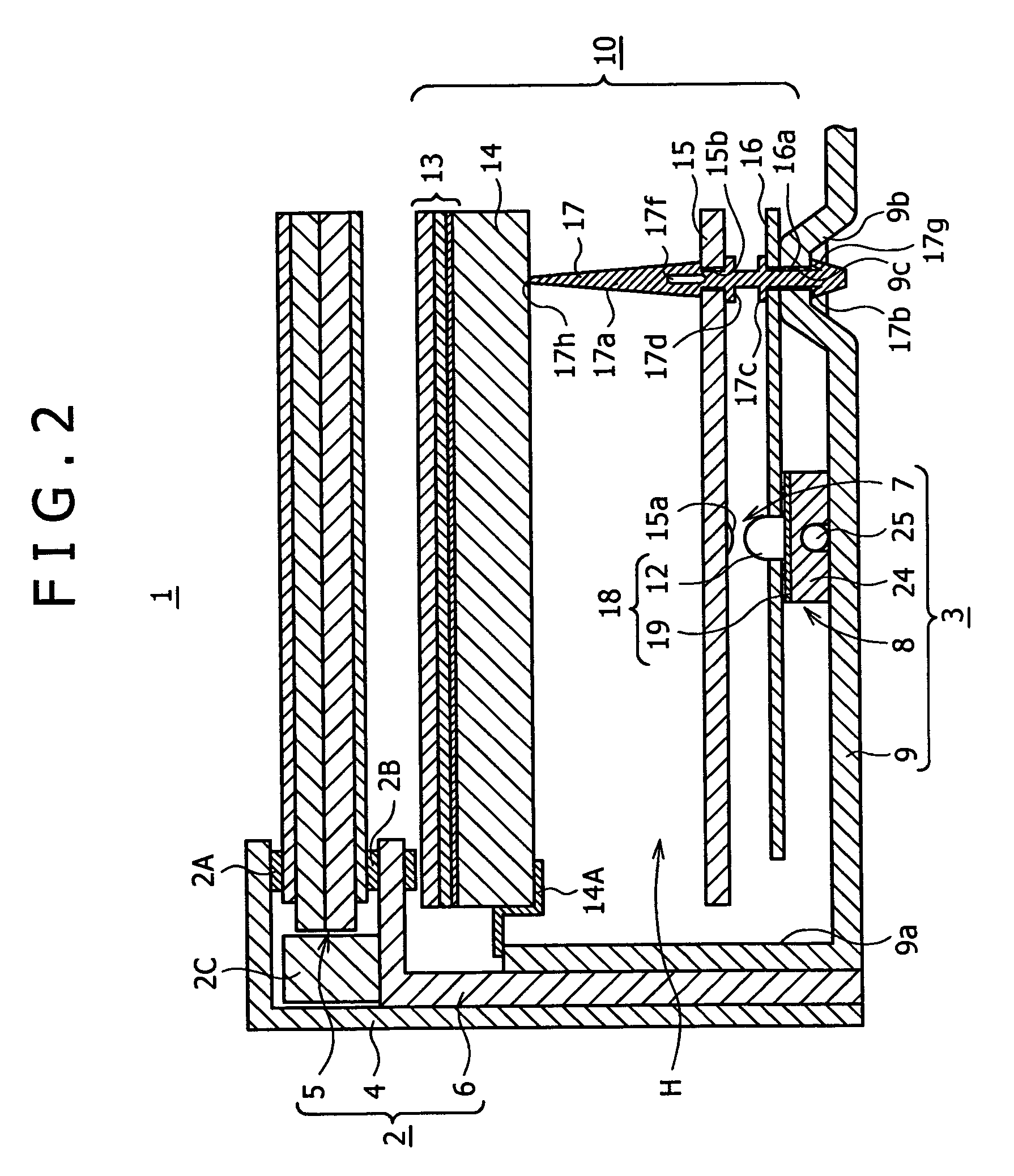

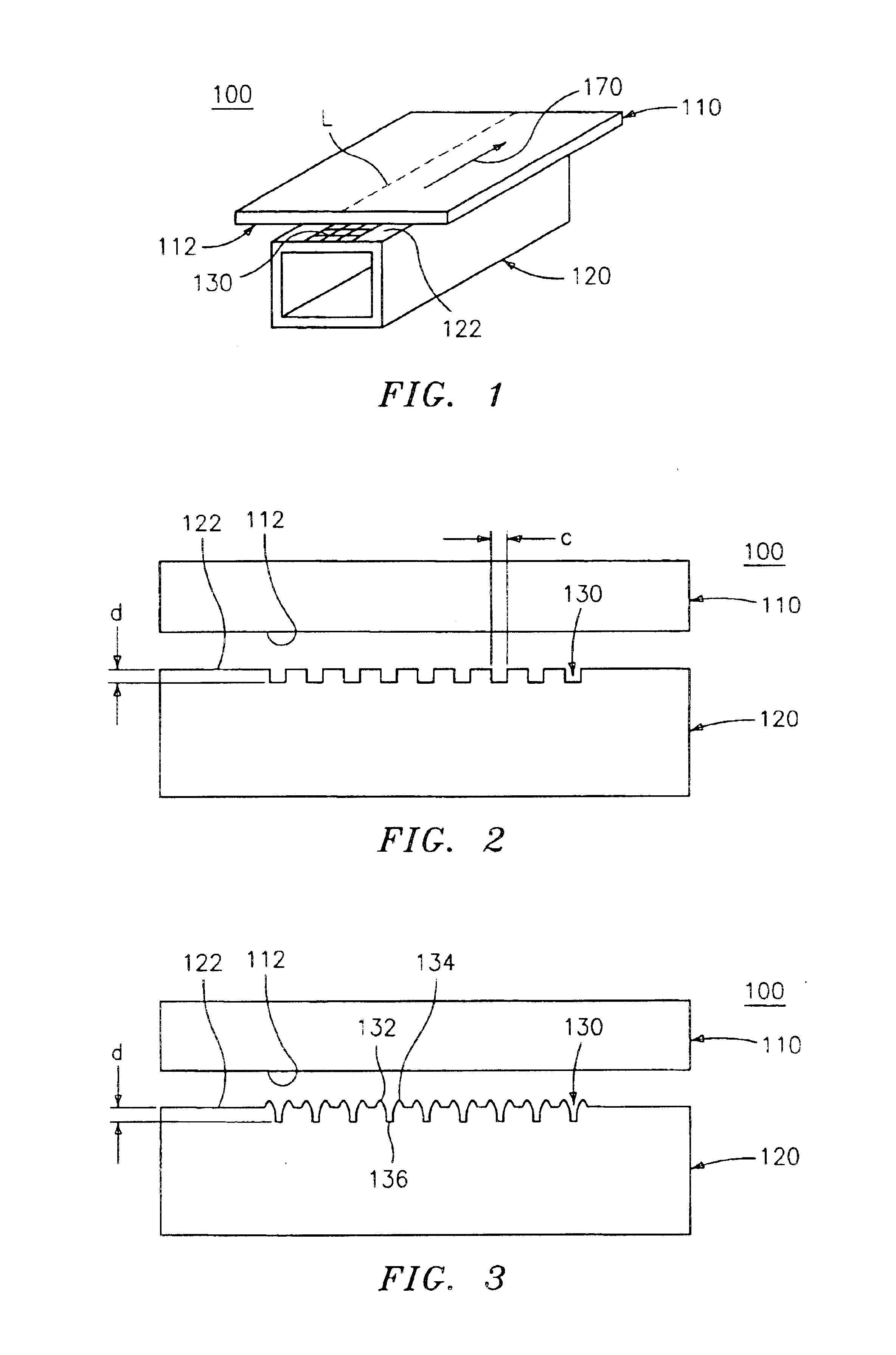

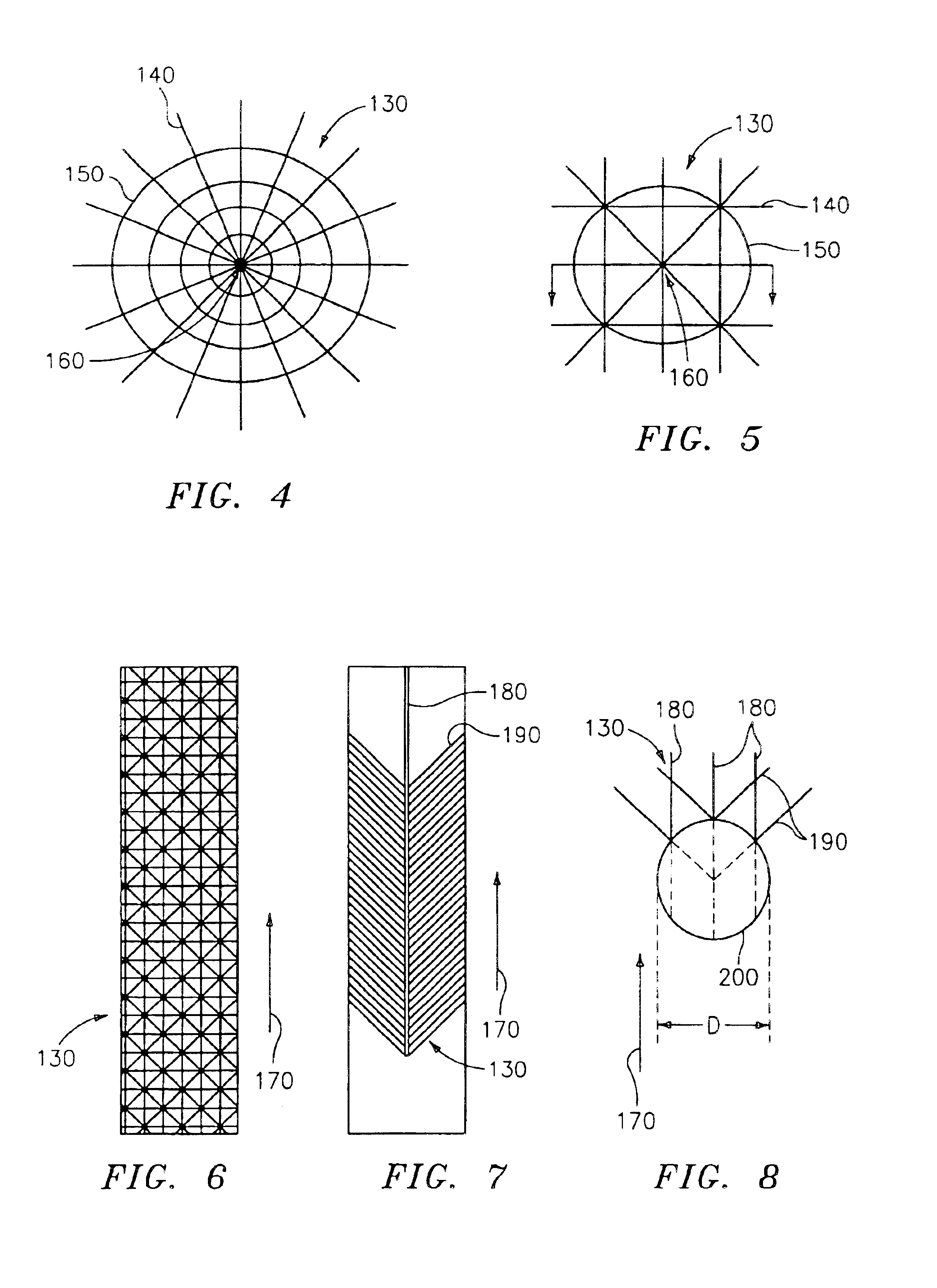

Radiator for light emitting unit, and backlight device

InactiveUS7431475B2Increasing the thicknessLow efficiencyMeasurement apparatus componentsLighting heating/cooling arrangementsLight-emitting diodeHeat pipe

The present invention provides a radiator for a light emitting unit, annexed to the light emitting unit including a multiplicity of light emitting diodes mounted on substantially the same axis line on a first principal surface of a wiring substrate. The radiator includes a radiating plate and a heat pipe. The radiating plate is combined with the wiring substrate, with a first principal surface faced as a faying surface to a second principal surface opposite to the first principal surface of the wiring substrate, and is provided with a heat pipe fitting portion. The heat pipe is mounted into the heat pipe fitting portion of the radiating plate while keeping close contact with the inner wall of the heat pipe fitting portion. The heat generated from the light emitting diode group is transferred to a radiating means through the radiating plate and the heat pipe.

Owner:SONY CORP

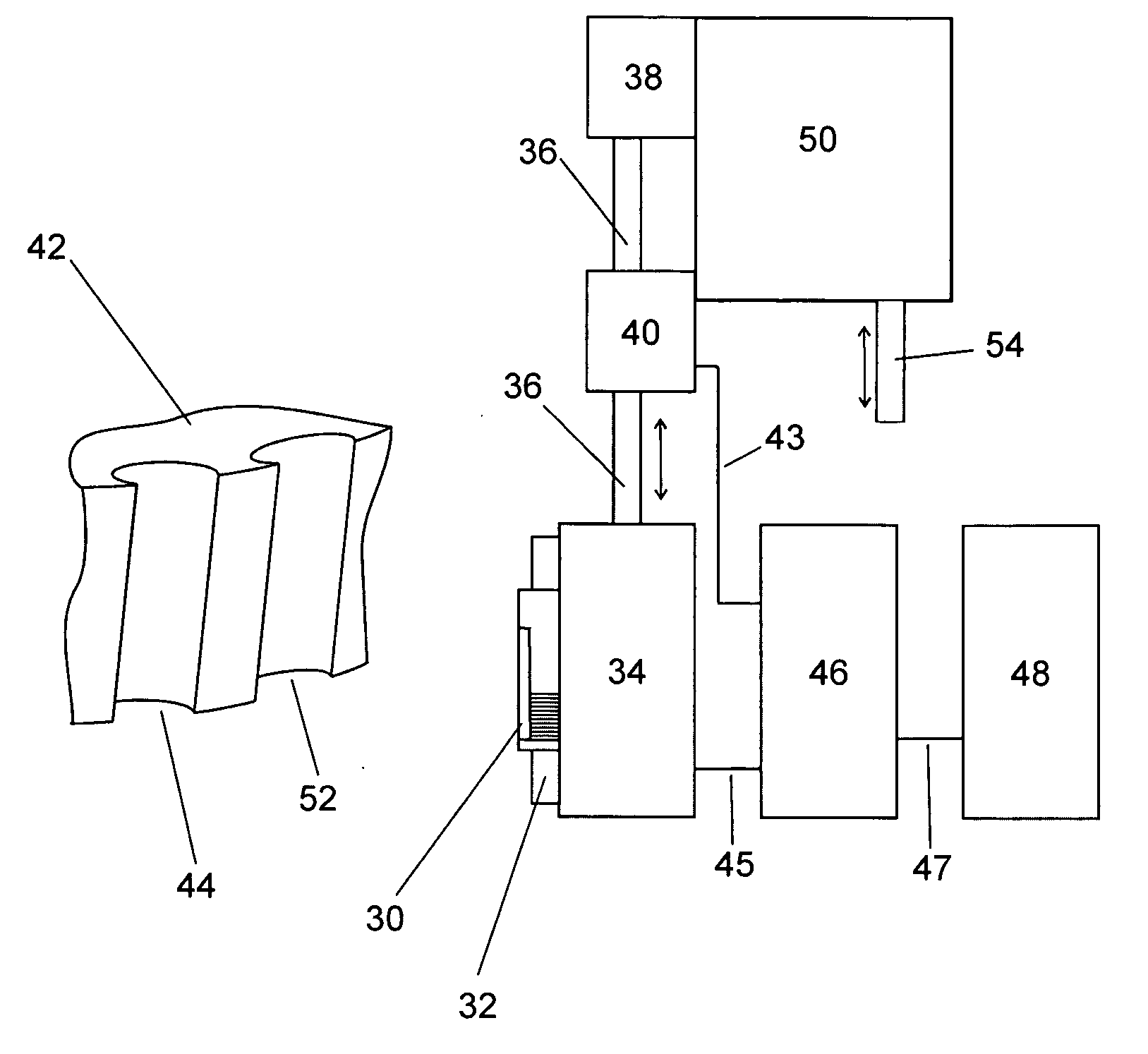

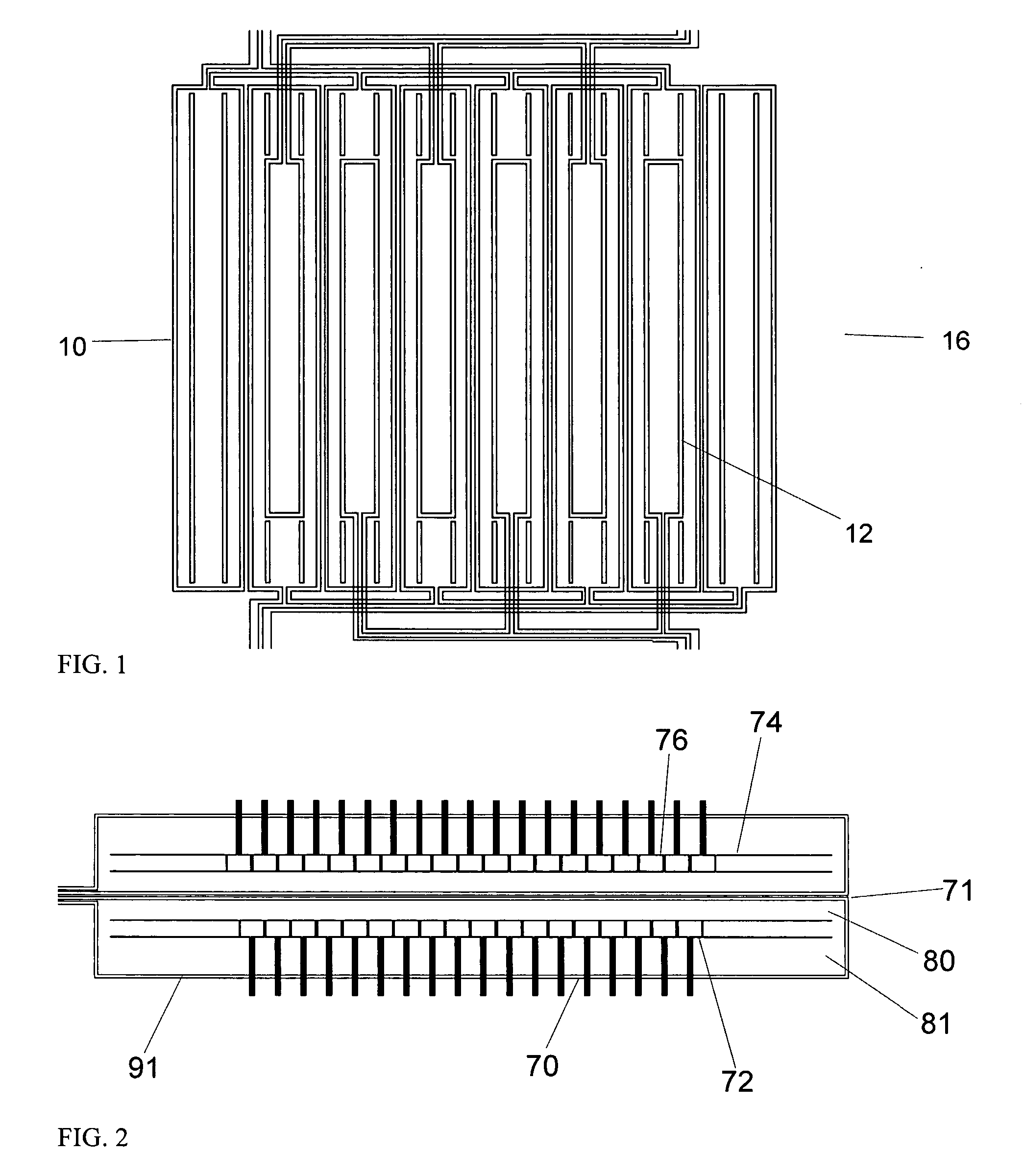

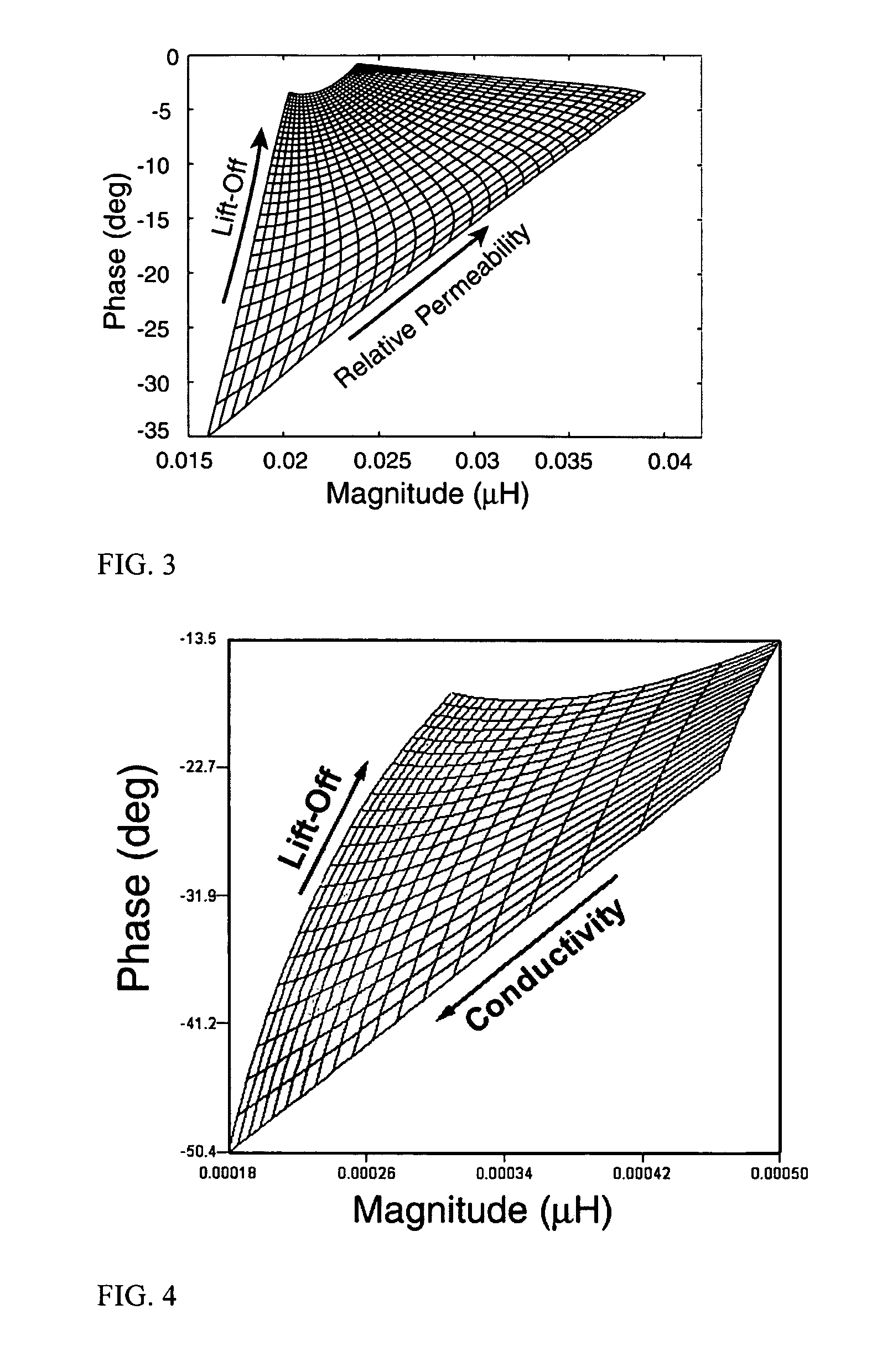

Material characterization with model based sensors

InactiveUS20070069720A1Improve crack detection reliabilityImprove reliabilityMaterial magnetic variablesSensor arrayElectric field sensor

Nondestructive material condition monitoring and assessment is accomplished by placing, mounting, or scanning magnetic and electric field sensors and sensor arrays over material surfaces. The material condition can be inferred directly from material property estimates, such as the magnetic permeability, dielectric permittivity, electrical property, or thickness, or from a correlation with these properties. Hidden cracks in multiple layer structures in the presence of fasteners are detected by combining multiple frequency magnetic field measurements and comparing the result to characteristic signature responses. The threshold value for indicating a crack is adjusted based on a high frequency measurement that accounts for fastener type. The condition of engine disk slot is determined without removal of the disk from the engine by placing near the disk a fixture that contains a sensor for scanning through the slot and means for recording position within the slot. Inflatable support structures can be placed behind the sensor to improve and a guide can be used to align sensor with the slot and for rotating the disk. The condition of an interface between a conducting substrate and a coating is assessed by placing a magnetic field sensor on the opposite side of the substrate from the coating and monitoring at least one model parameter for the material system, with the model parameter correlated to the interfacial condition. The model parameter is typically a magnetic permeability that reflects the residual stress at the interface. Sensors embedded between material layers are protected from damage by placing shims on the faying surface. After determining the areas to be monitored and the areas likely to cause sensor damage, a shim thickness is determined and is then placed in at least one area not being monitored by a sensor. The condition of a test fluid is assessed through a dielectric sensor containing a contaminant-sensitive material layer. The properties of the layer are monitored with the dielectric sensor and correlated to contaminant level.

Owner:JENTEK SENSORS

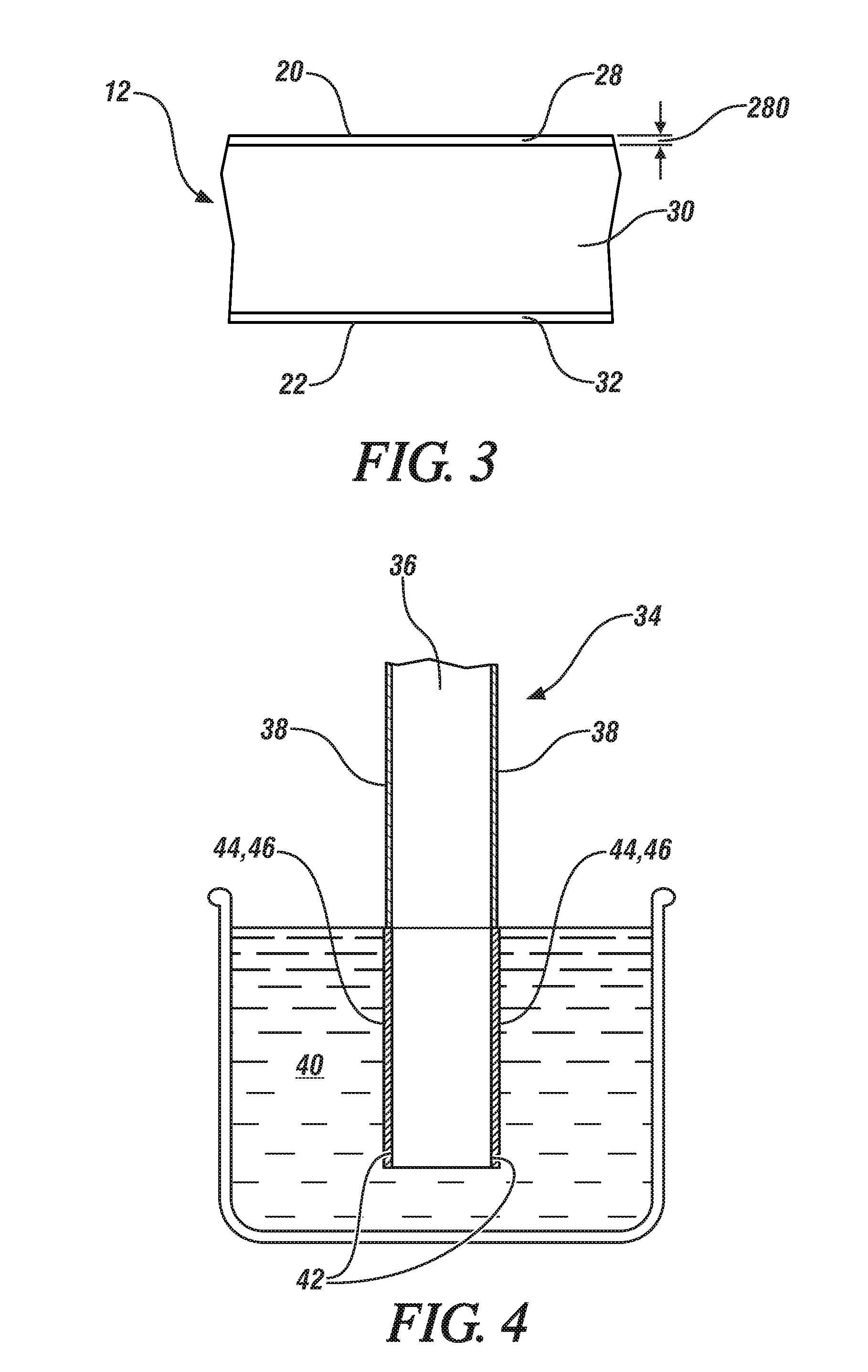

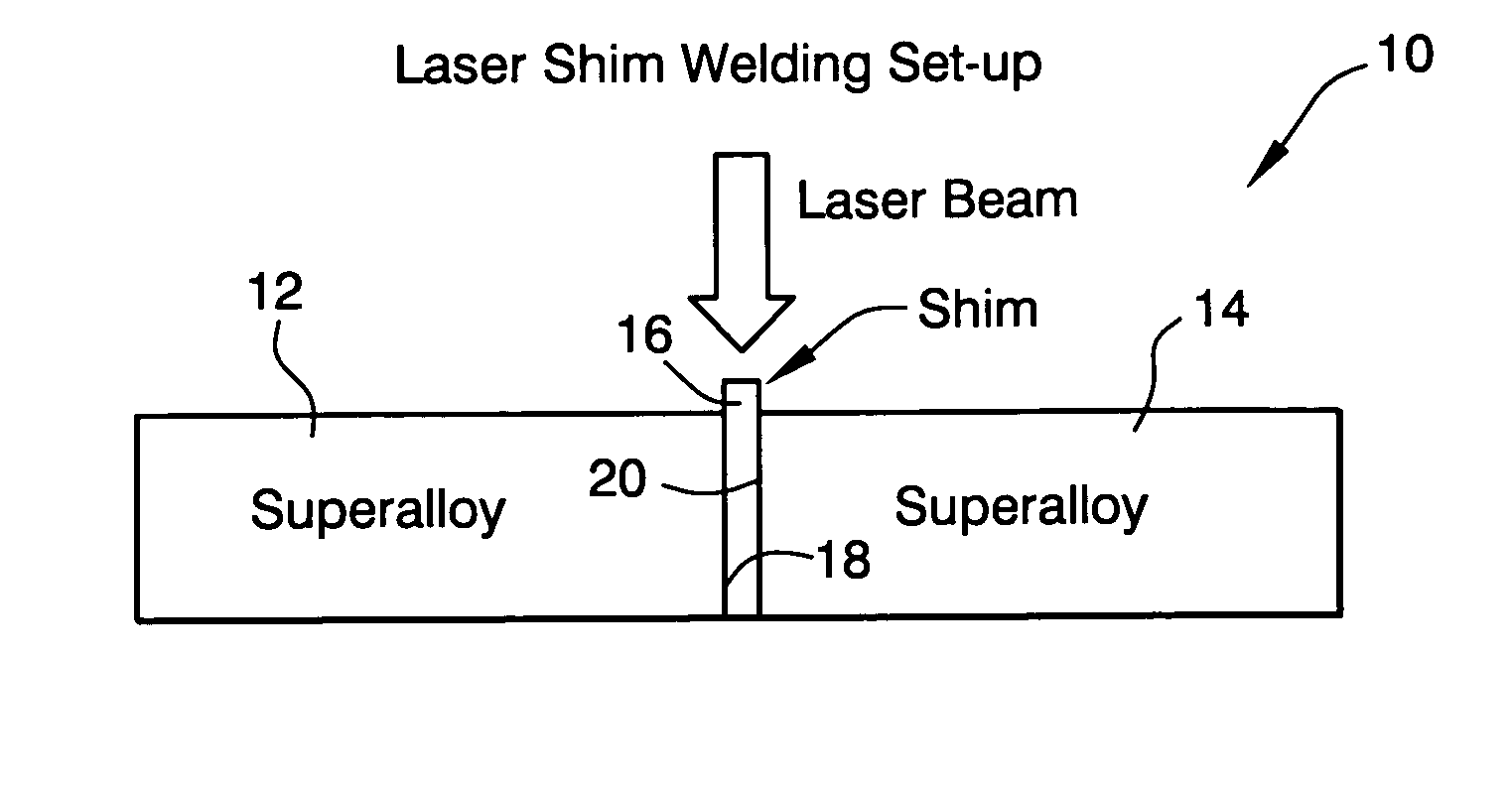

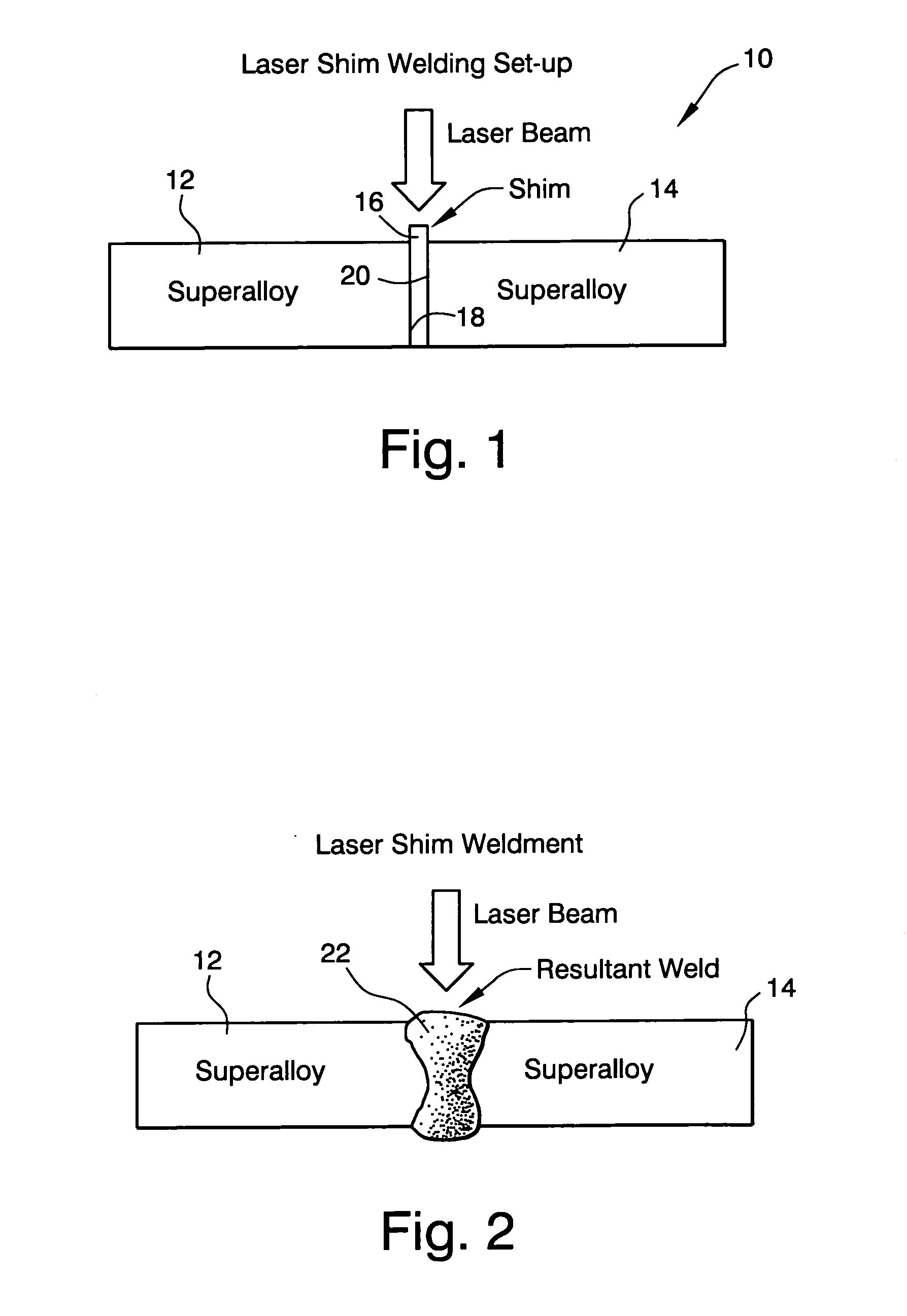

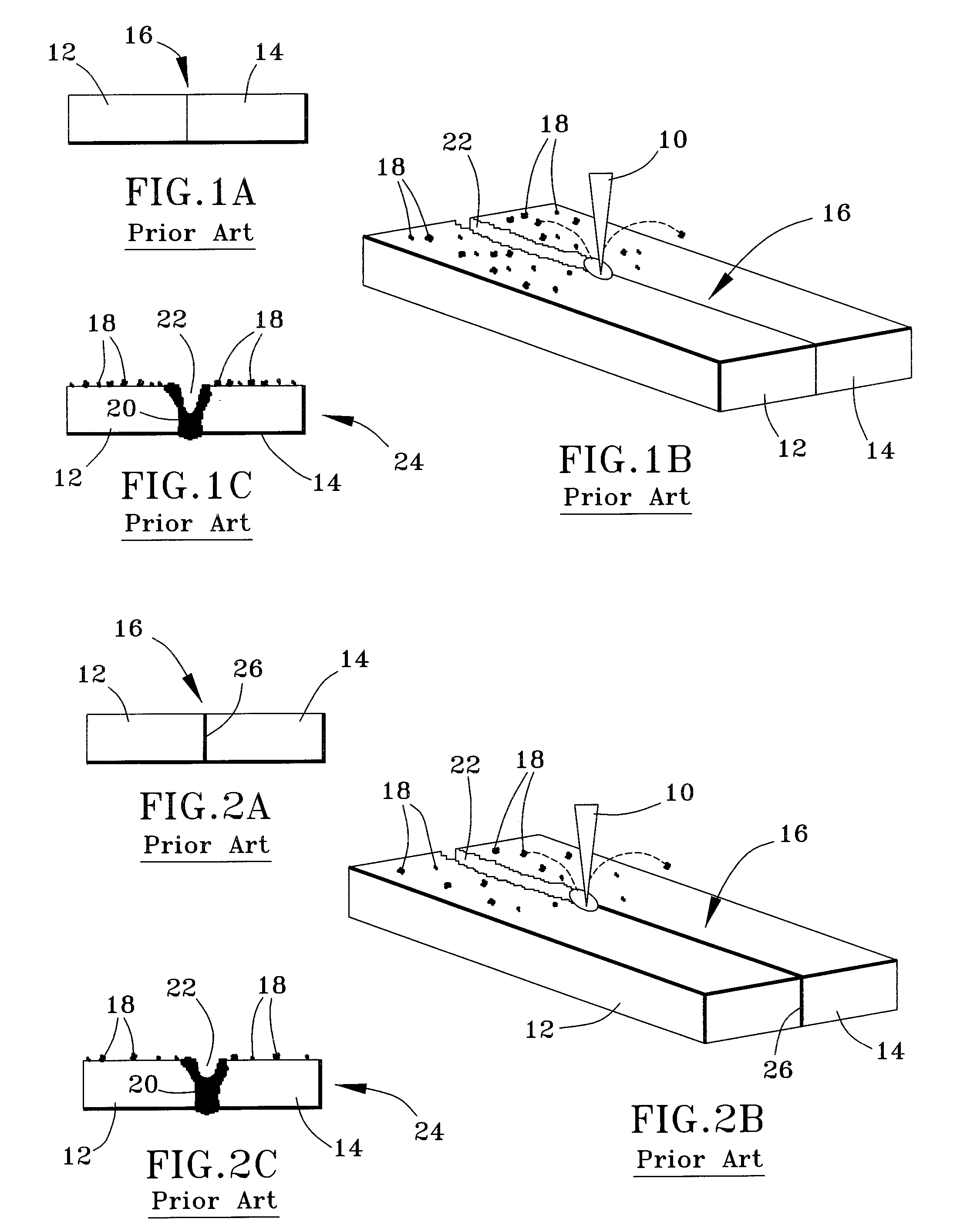

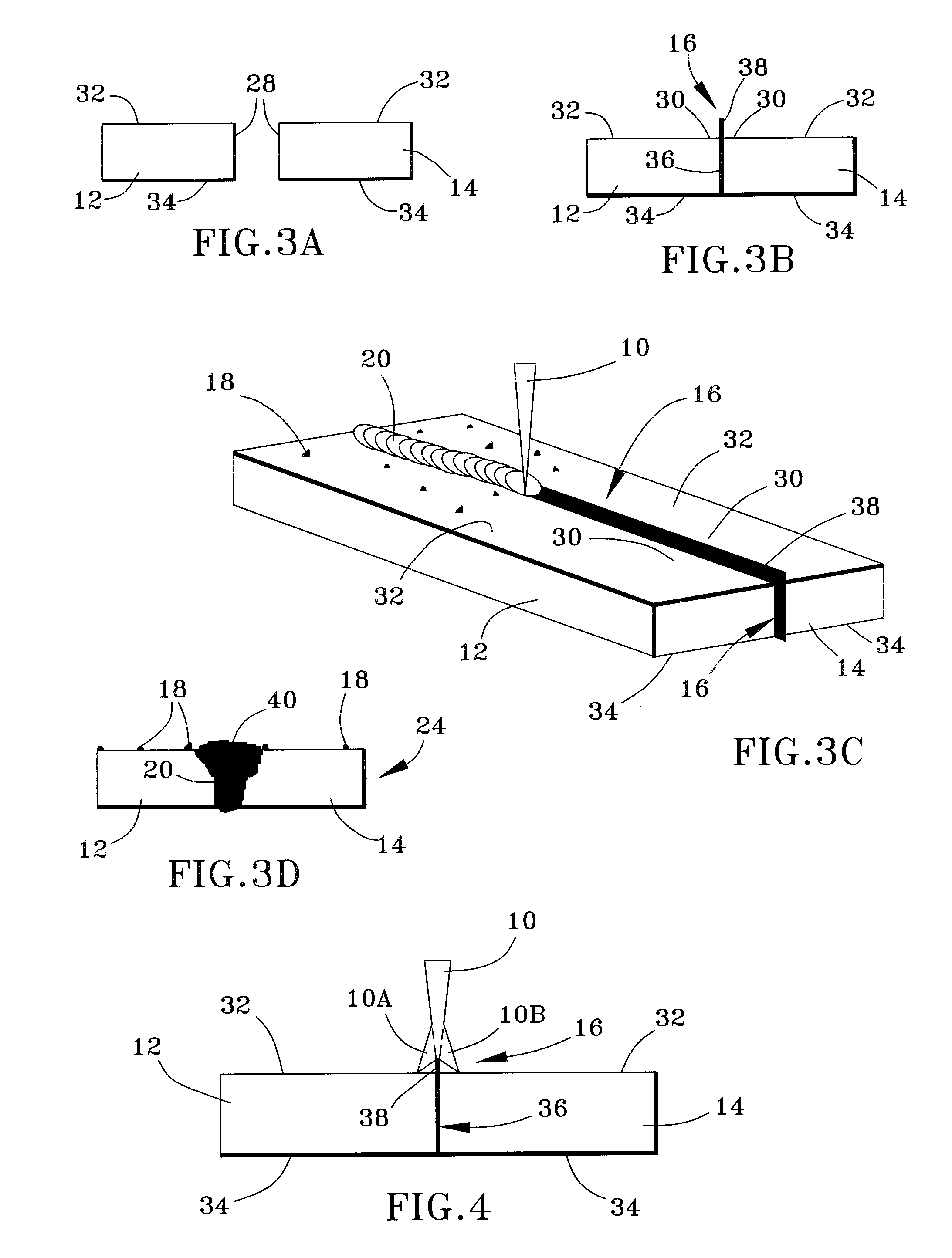

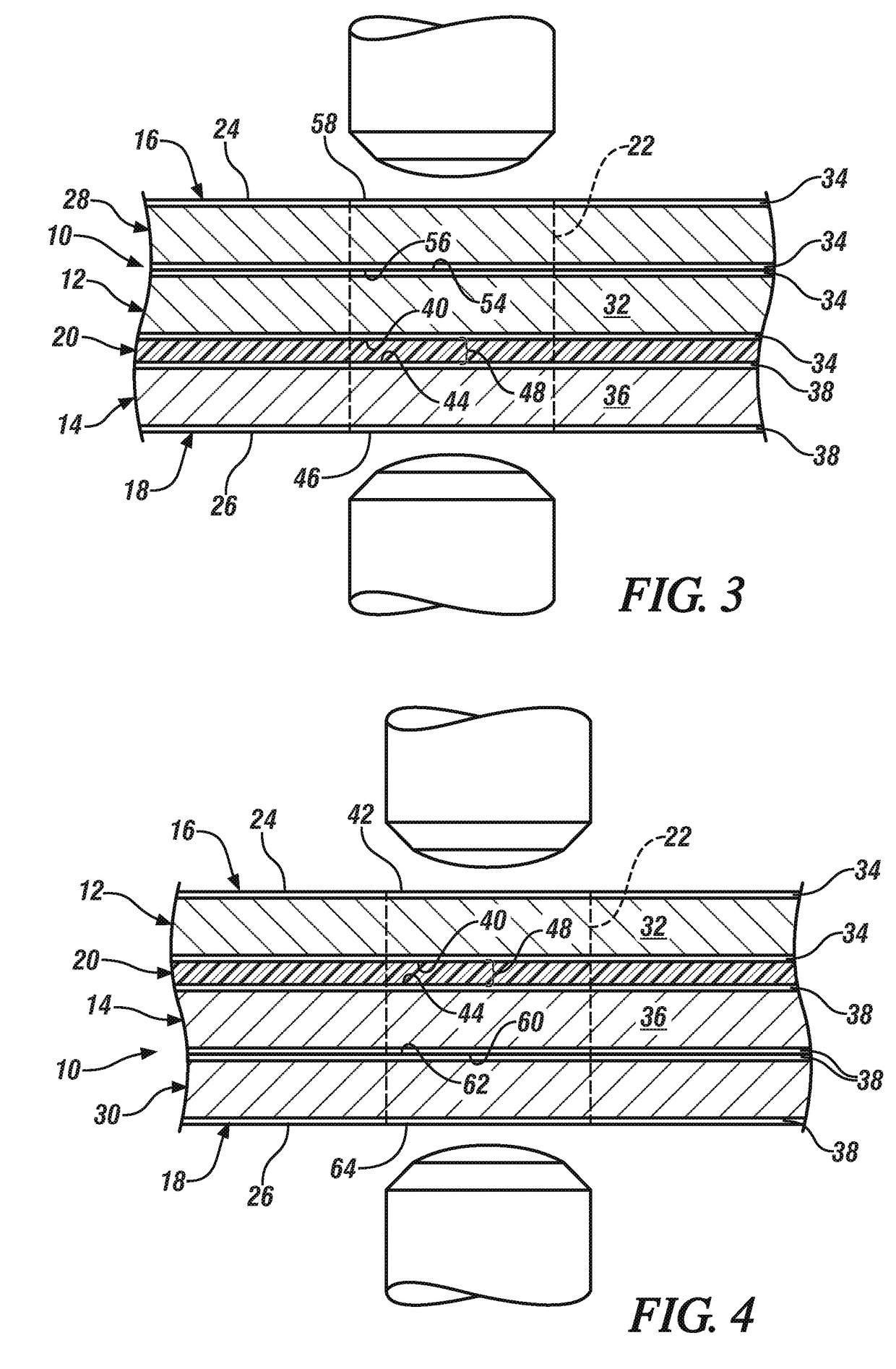

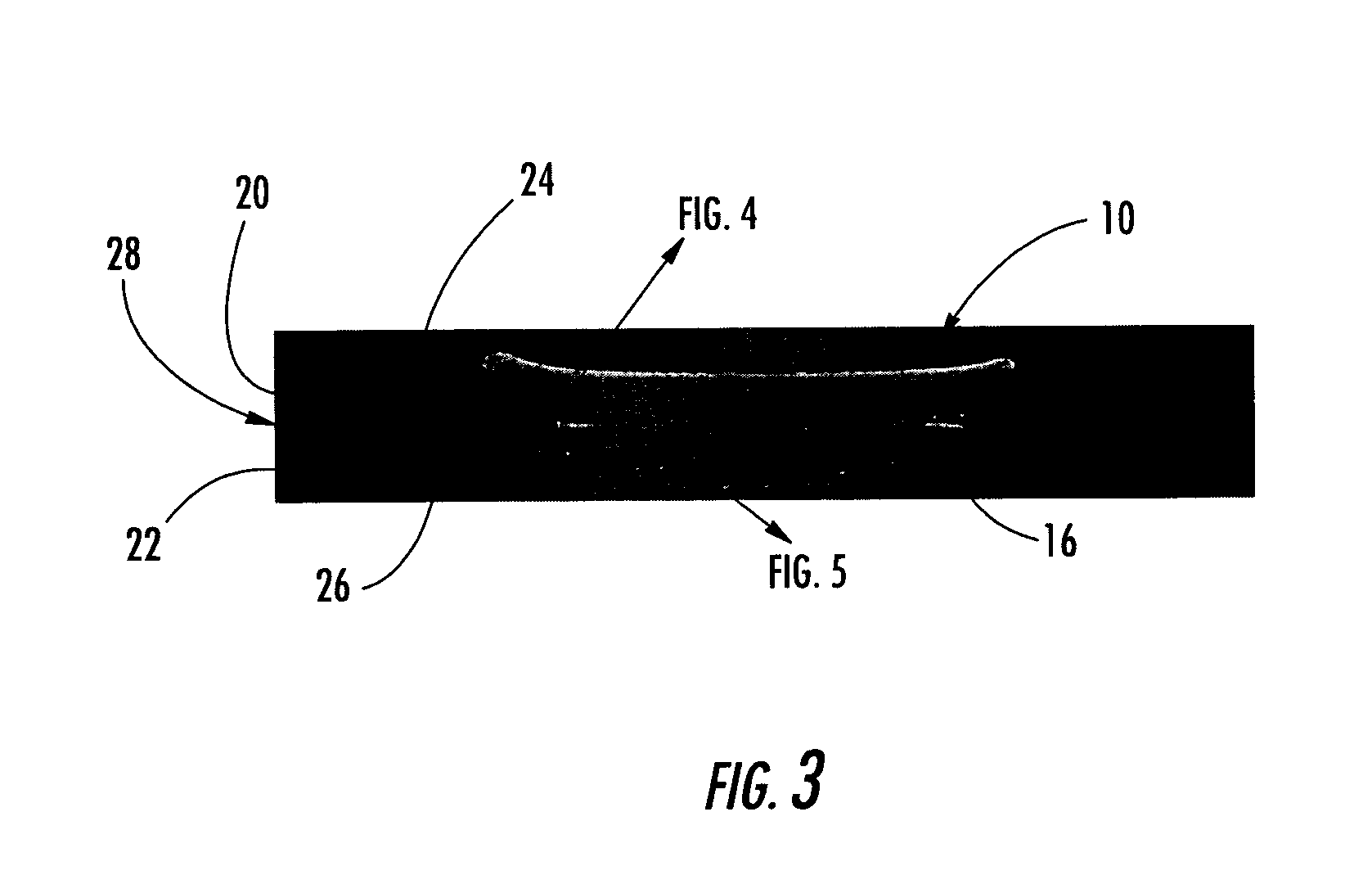

Shimmed laser beam welding process for joining superalloys for gas turbine applications

InactiveUS20070017906A1Improve developmentImproved low cycle fatigue lifeTurbinesEngine manufactureEngineeringSuperalloy

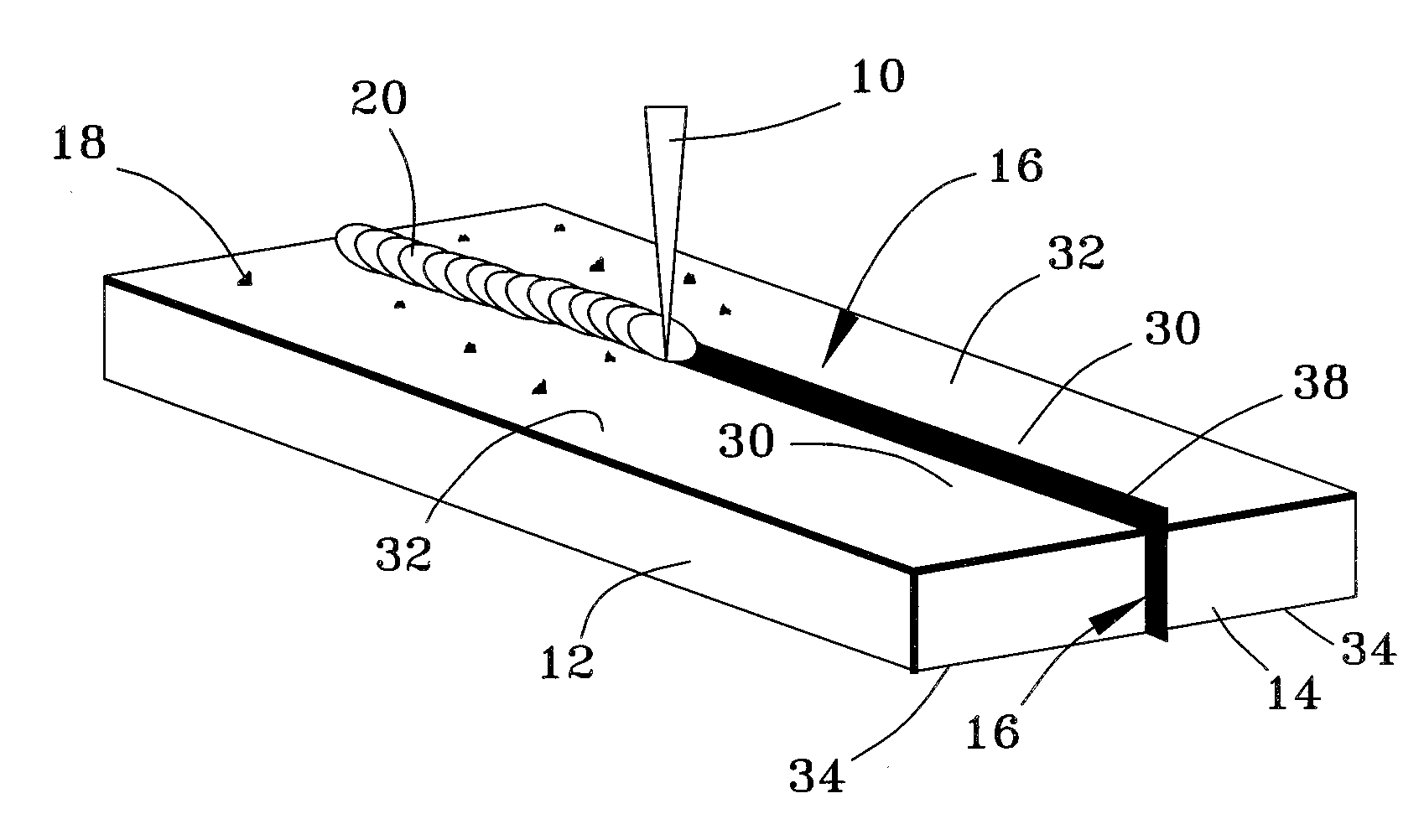

A method of laser beam welding at least two adjacent superalloy components includes (a) aligning the components along a pair of faying surfaces but without a backing plate; (b) placing a superalloy shim between the faying surfaces; (c) welding the components together using a laser beam causing portions of the superalloy components along the faying surfaces to mix with the superalloy shim; and cooling the components to yield a butt weld between the components.

Owner:GENERAL ELECTRIC CO

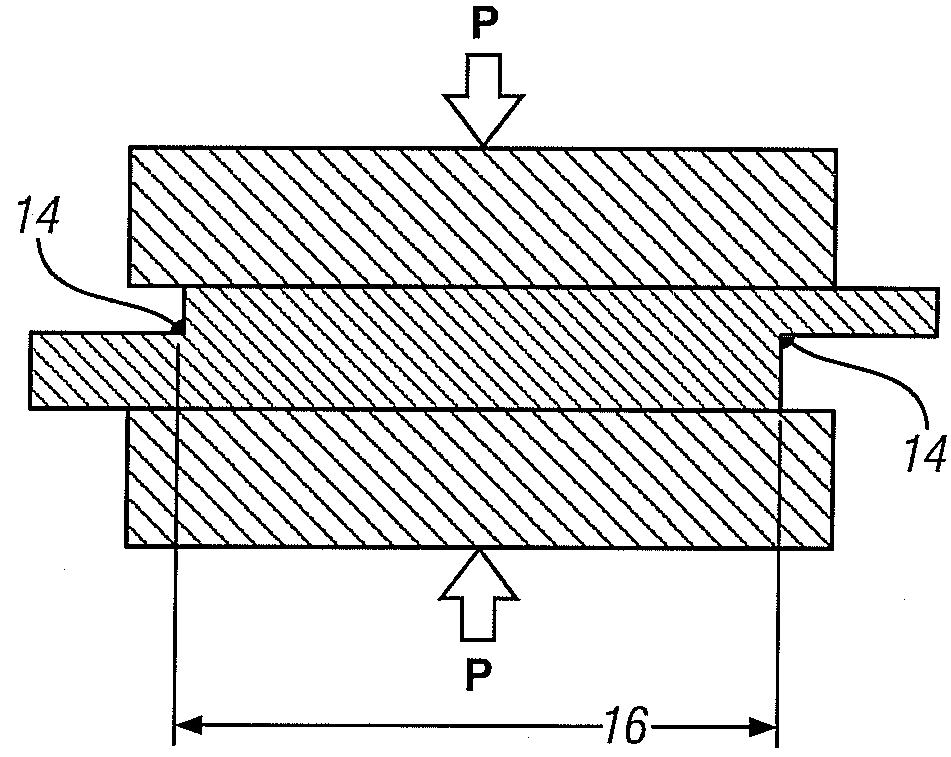

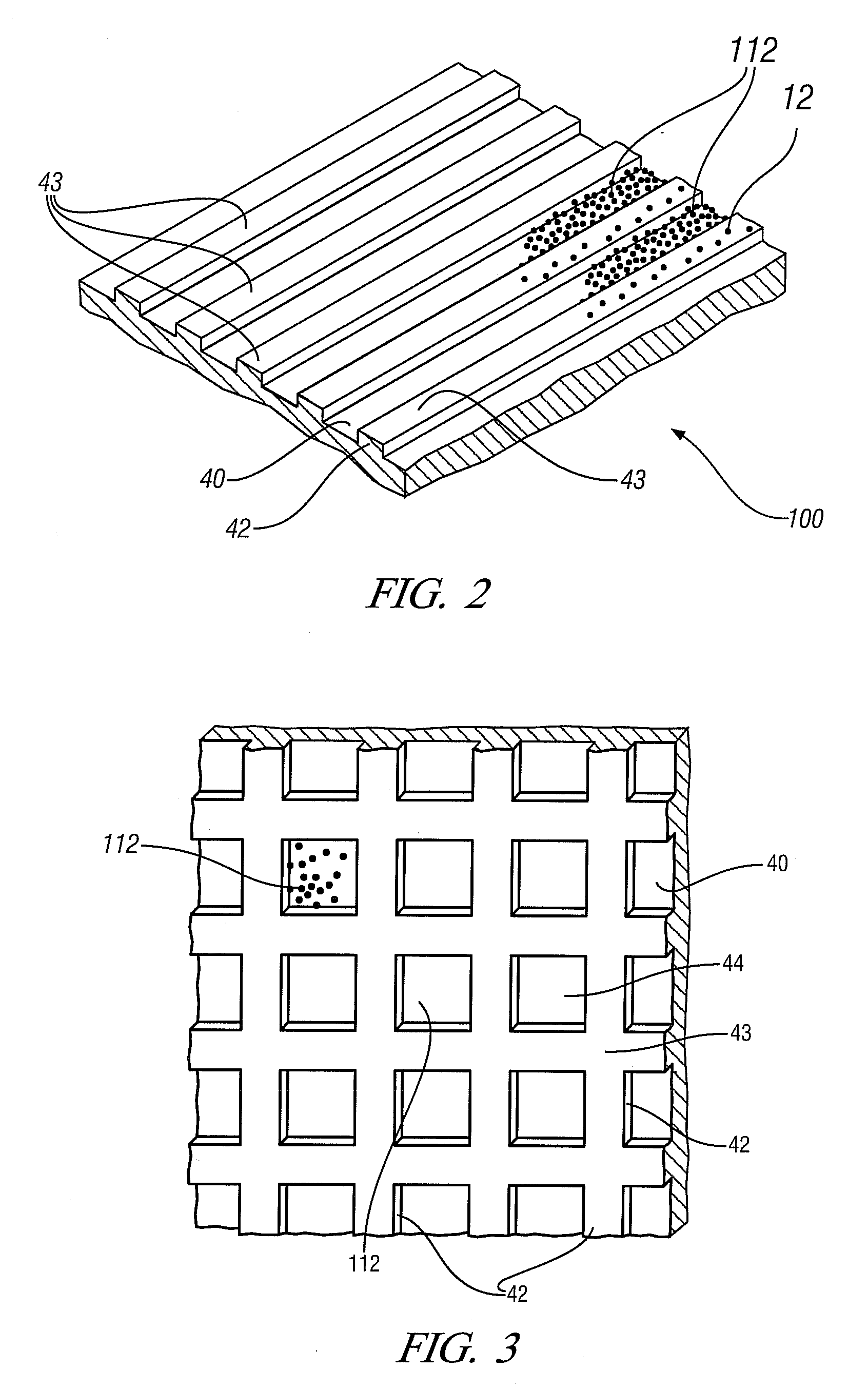

Welding light metal workpieces by reaction metallurgy

ActiveUS20100258537A1Minimize distortionDeformation MinimizationArc welding apparatusHigh frequency current welding apparatusReactive materialMaterials science

Aluminum alloy workpieces and / or magnesium alloy workpieces are joined in a solid state weld by use of a reactive material placed, in a suitable form, at the joining surfaces. Joining surfaces of the workpieces are pressed against the interposed reactive material and heated. The reactive material alloys or reacts with the workpiece surfaces consuming some of the surface material in forming a reaction product comprising a low melting liquid that removes oxide films and other surface impediments to a welded bond across the interface. Further pressure is applied to expel the reaction product and to join the workpiece surfaces in a solid state weld bond.

Owner:GM GLOBAL TECH OPERATIONS LLC

Control of intermetallic compound growth in aluminum to steel resistance welding

ActiveUS20170297136A1Thickness minimizationHigh strengthVehicle componentsWelding/cutting media/materialsManganeseElectric resistance welding

A method of resistance spot welding a workpiece stack-up that includes an aluminum workpiece and an overlapping adjacent steel workpiece so as to minimize the thickness of an intermetallic layer comprising Fe—Al intermetallic compounds involves providing reaction-slowing elements at the faying interface of the aluminum and steel workpieces. The reaction-slowing elements may include at least one of carbon, copper, silicon, nickel, manganese, cobalt, or chromium. Various ways are available for making the one or more reaction-slowing elements available at the faying interface of the aluminum and steel workpieces including being dissolved in a high strength steel or being present in an interlayer that may take on a variety of forms including a rigid shim, a flexible foil, a deposited layer adhered to and metallurgically bonded with a faying surface of the steel workpiece, or an interadjacent organic material layer that includes particles containing the reaction-slowing elements.

Owner:GM GLOBAL TECH OPERATIONS LLC

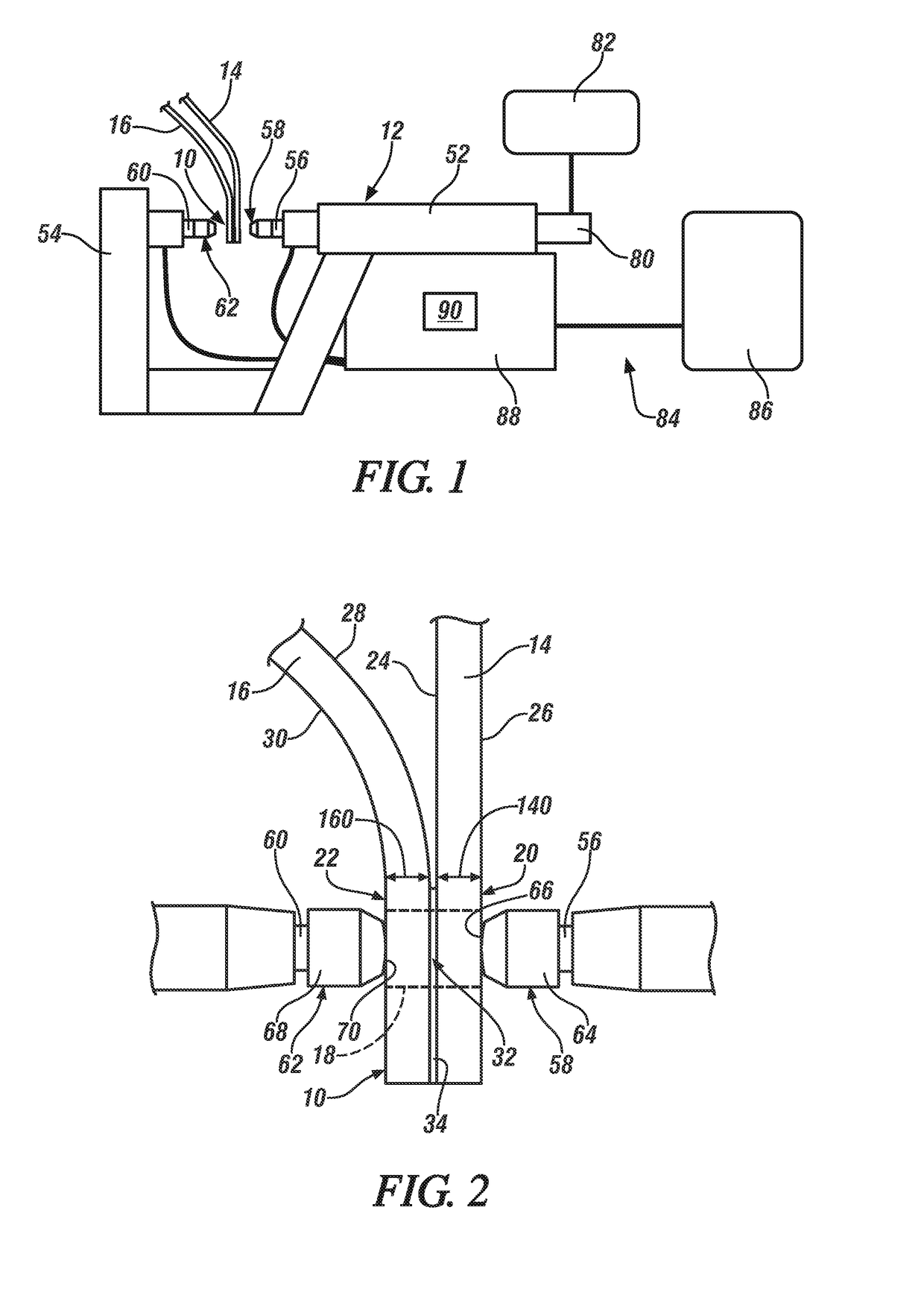

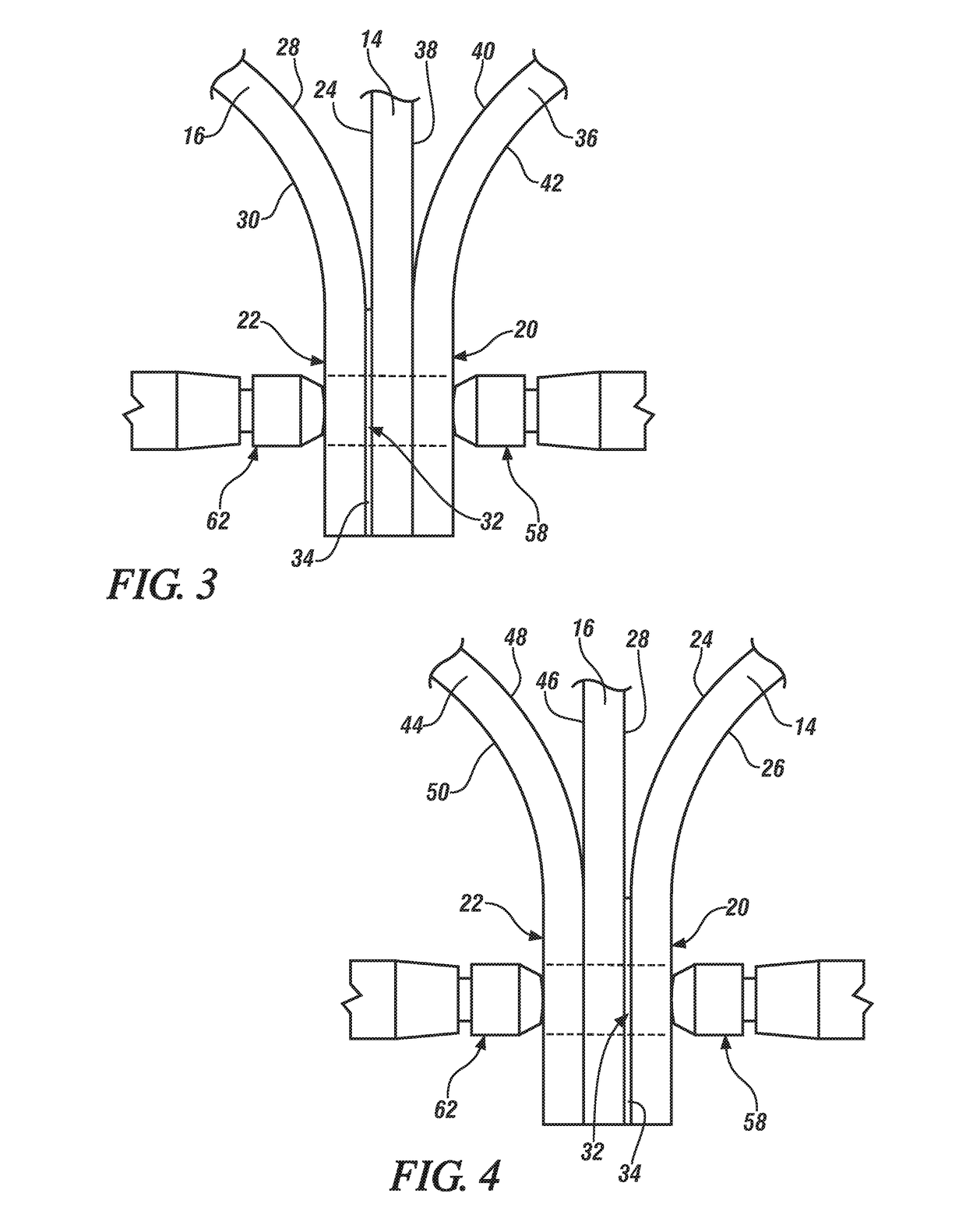

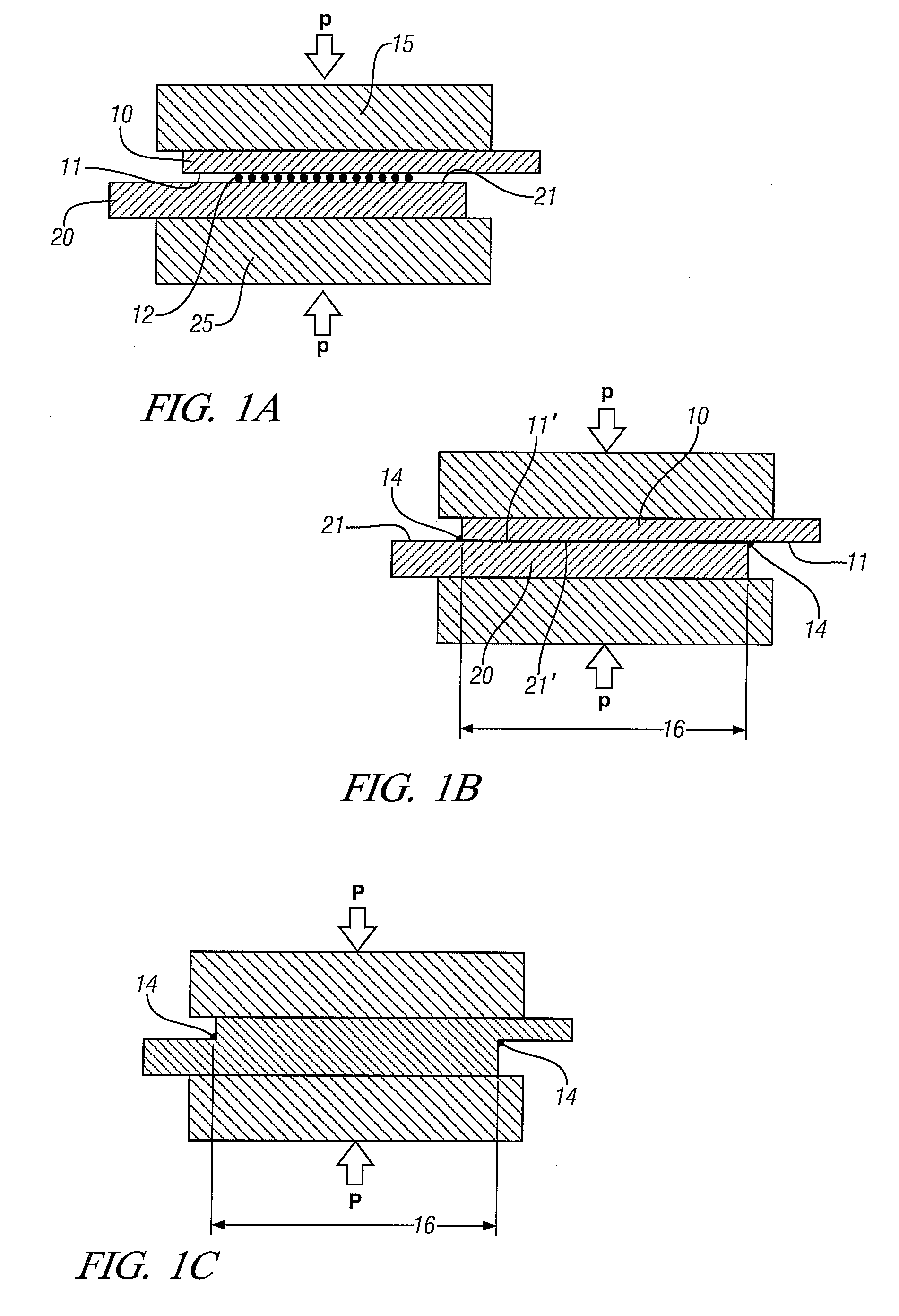

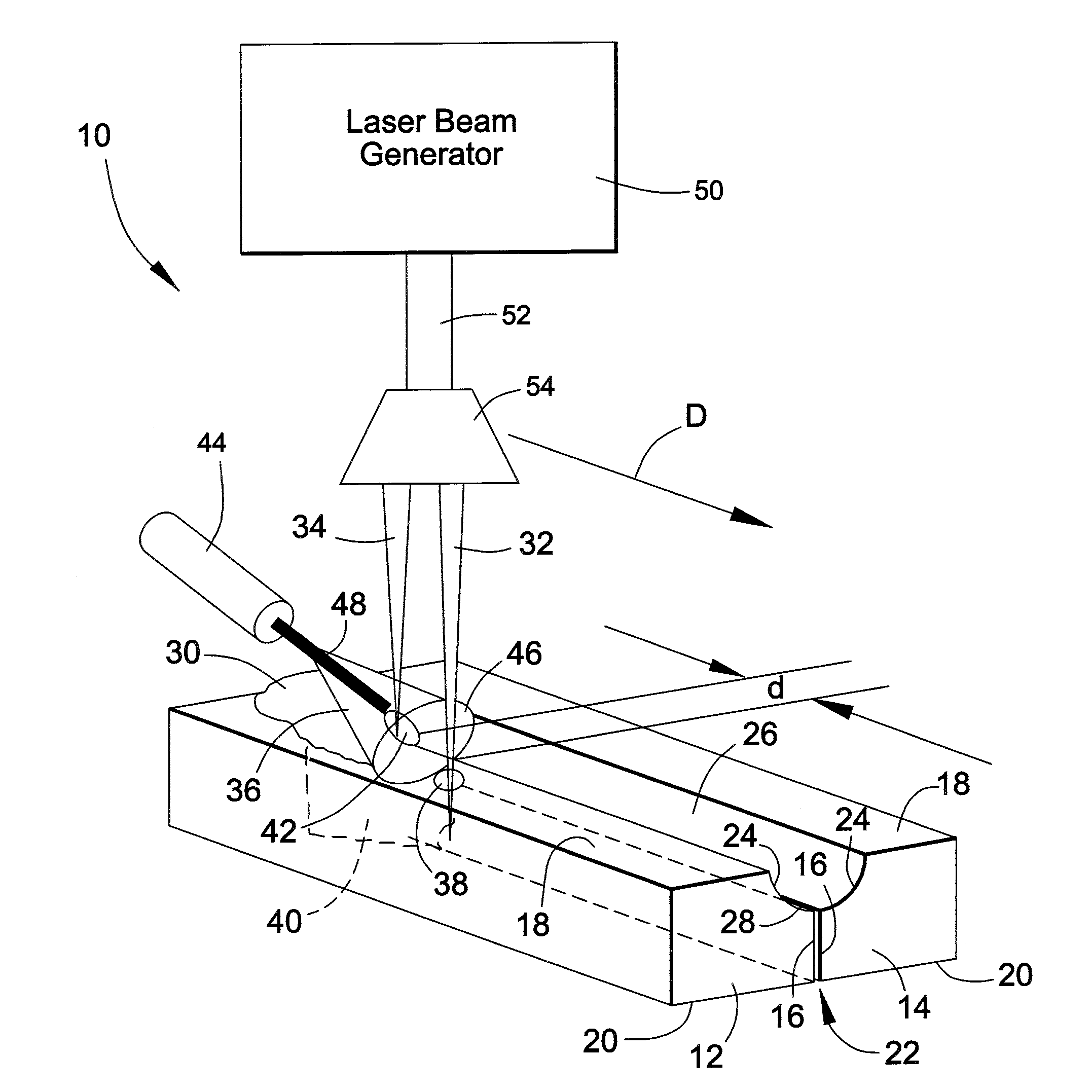

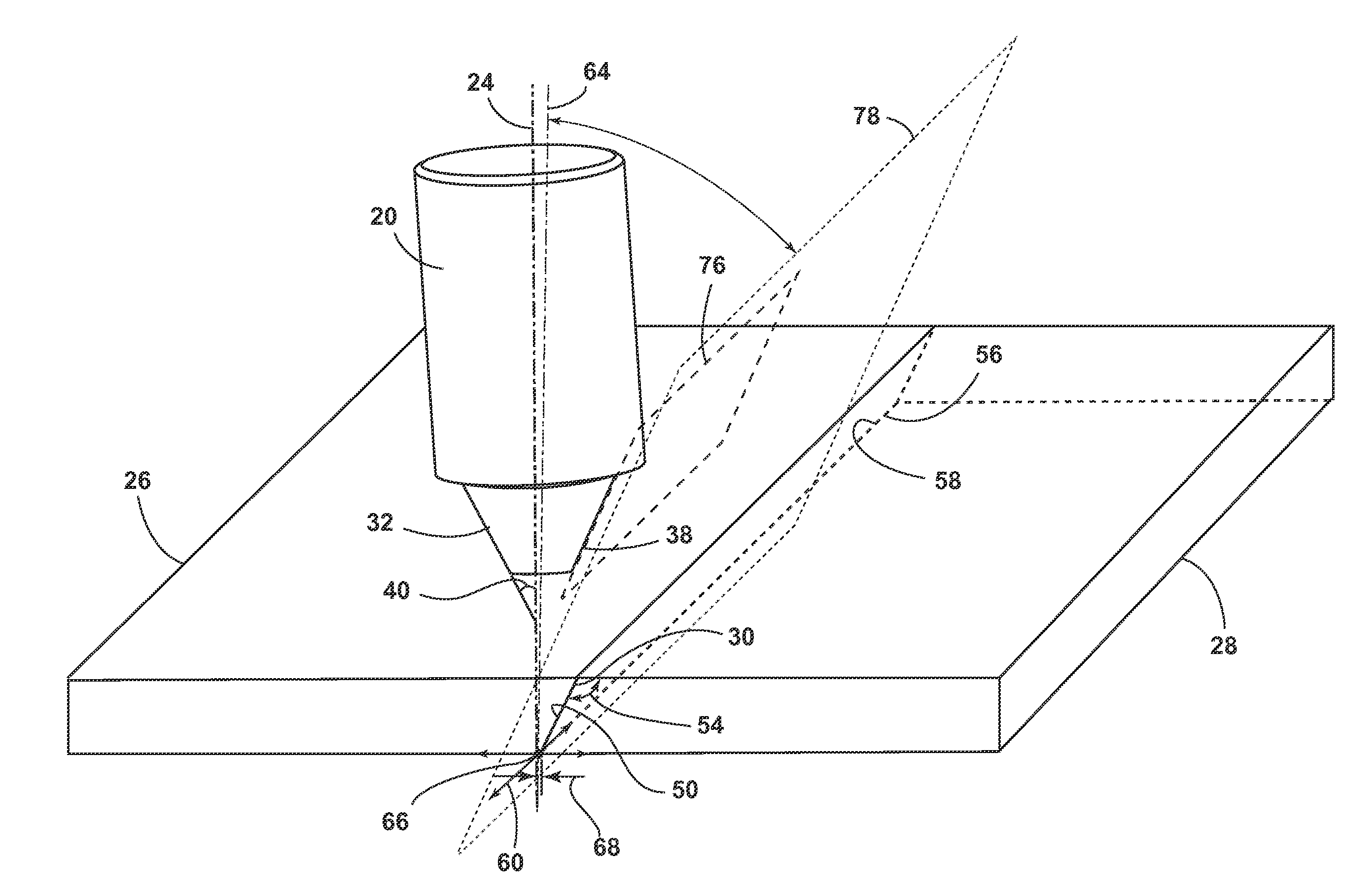

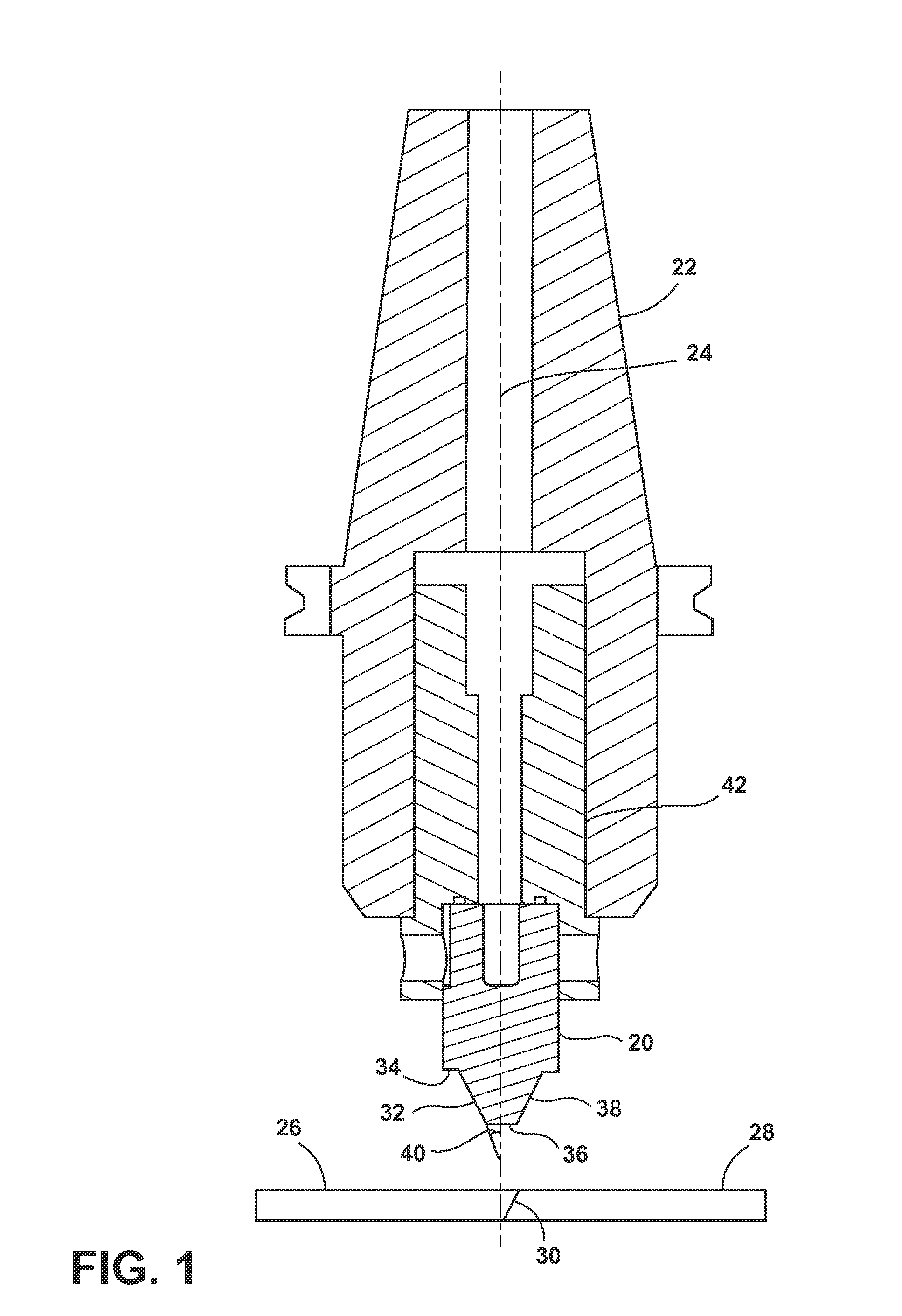

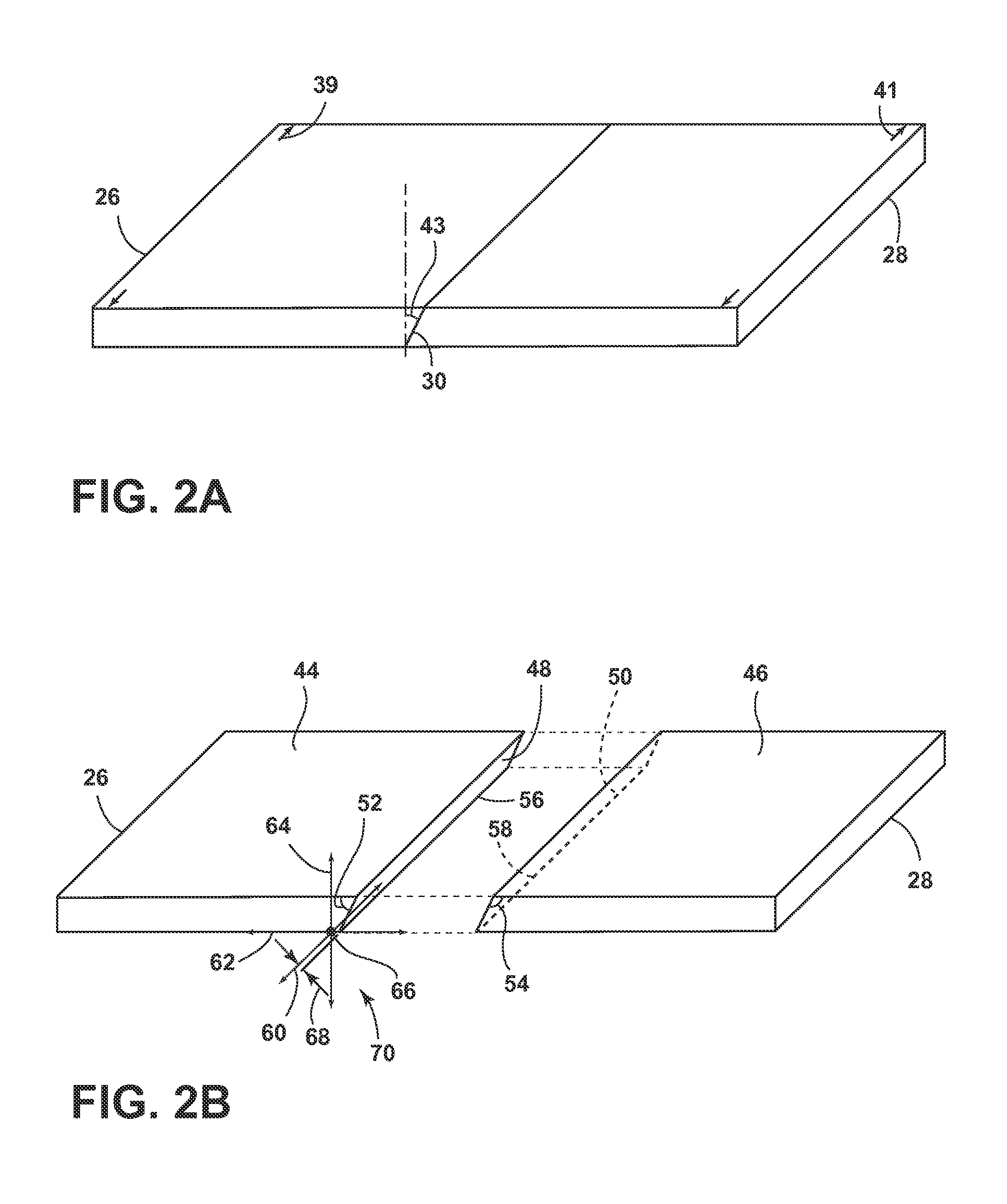

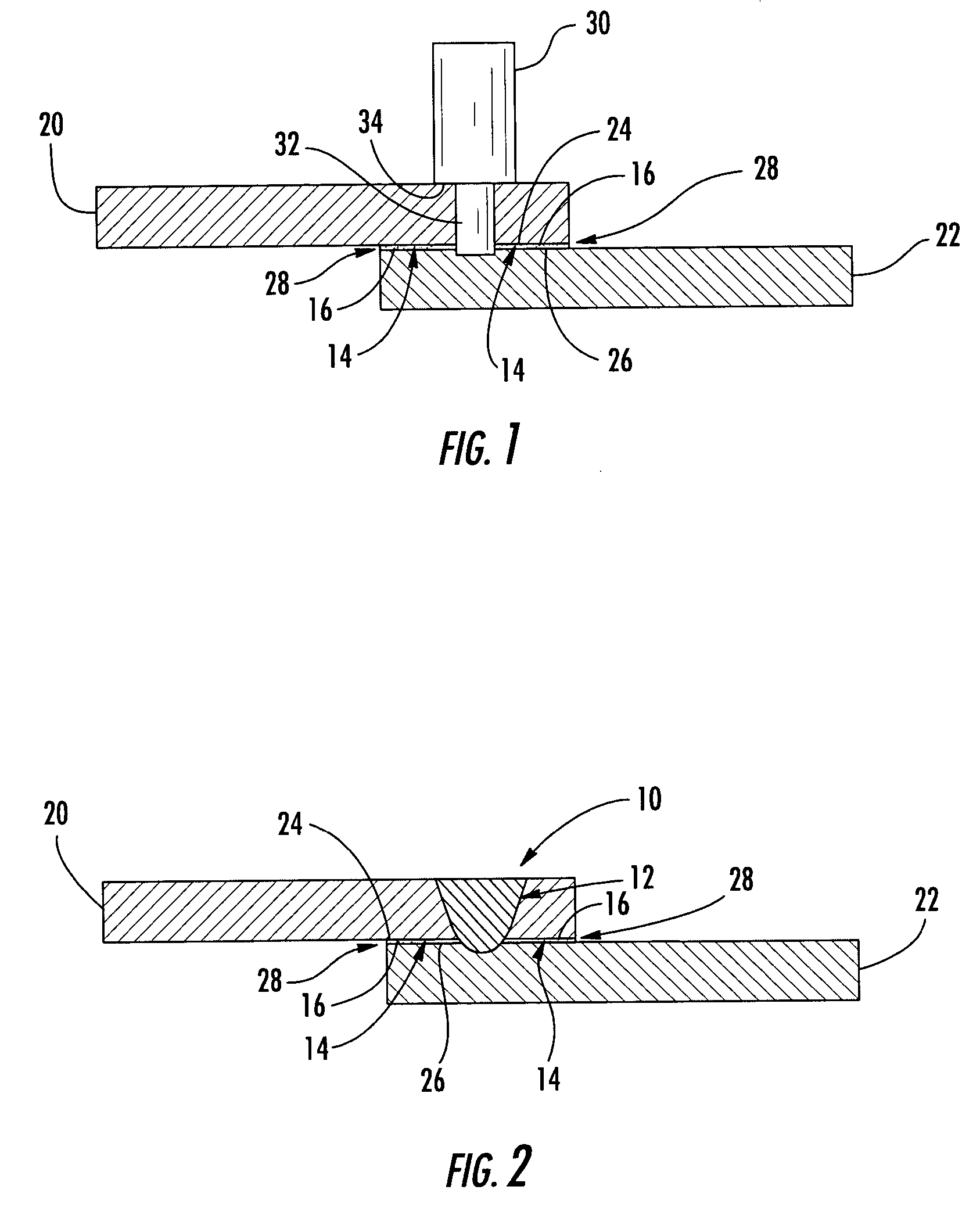

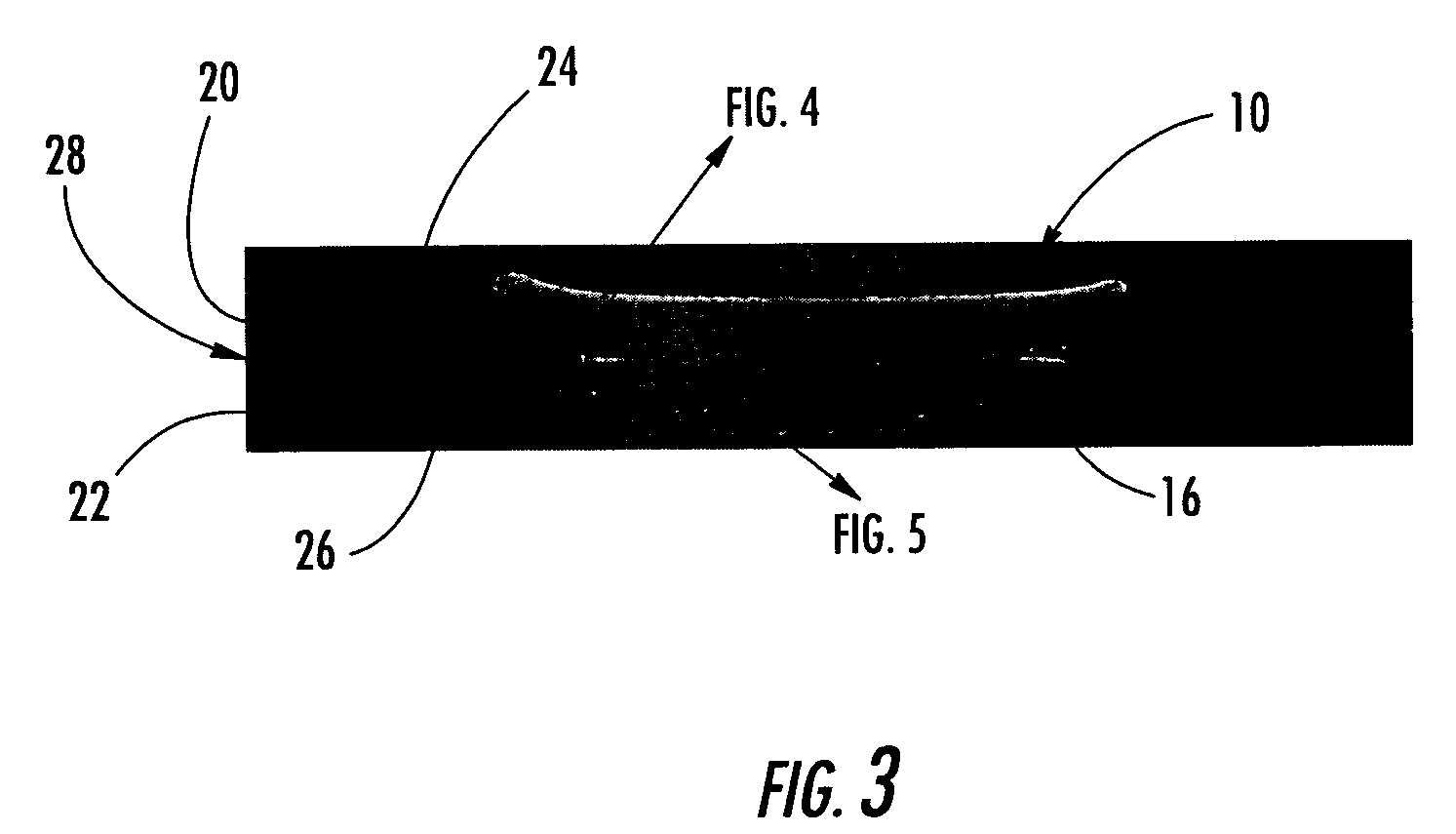

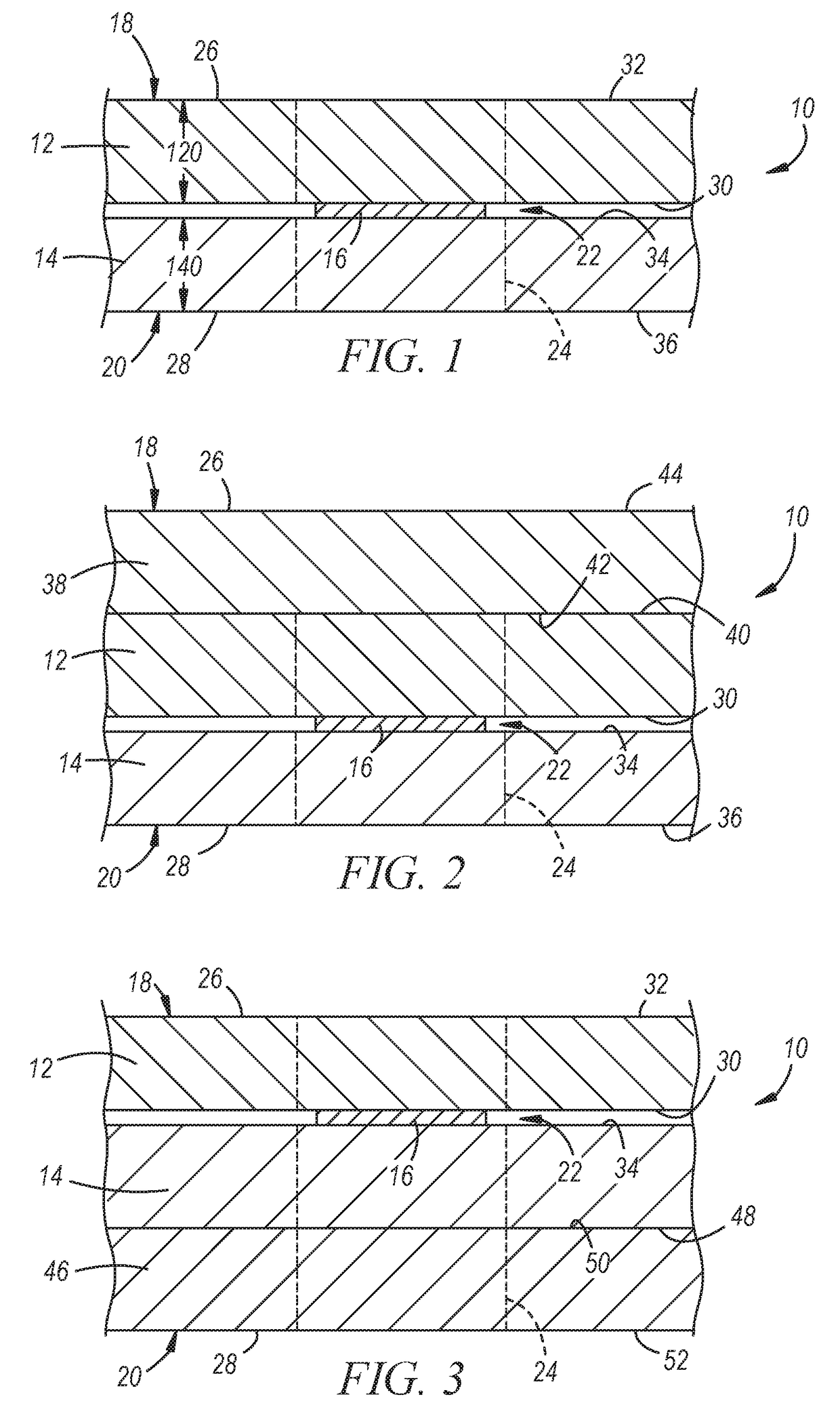

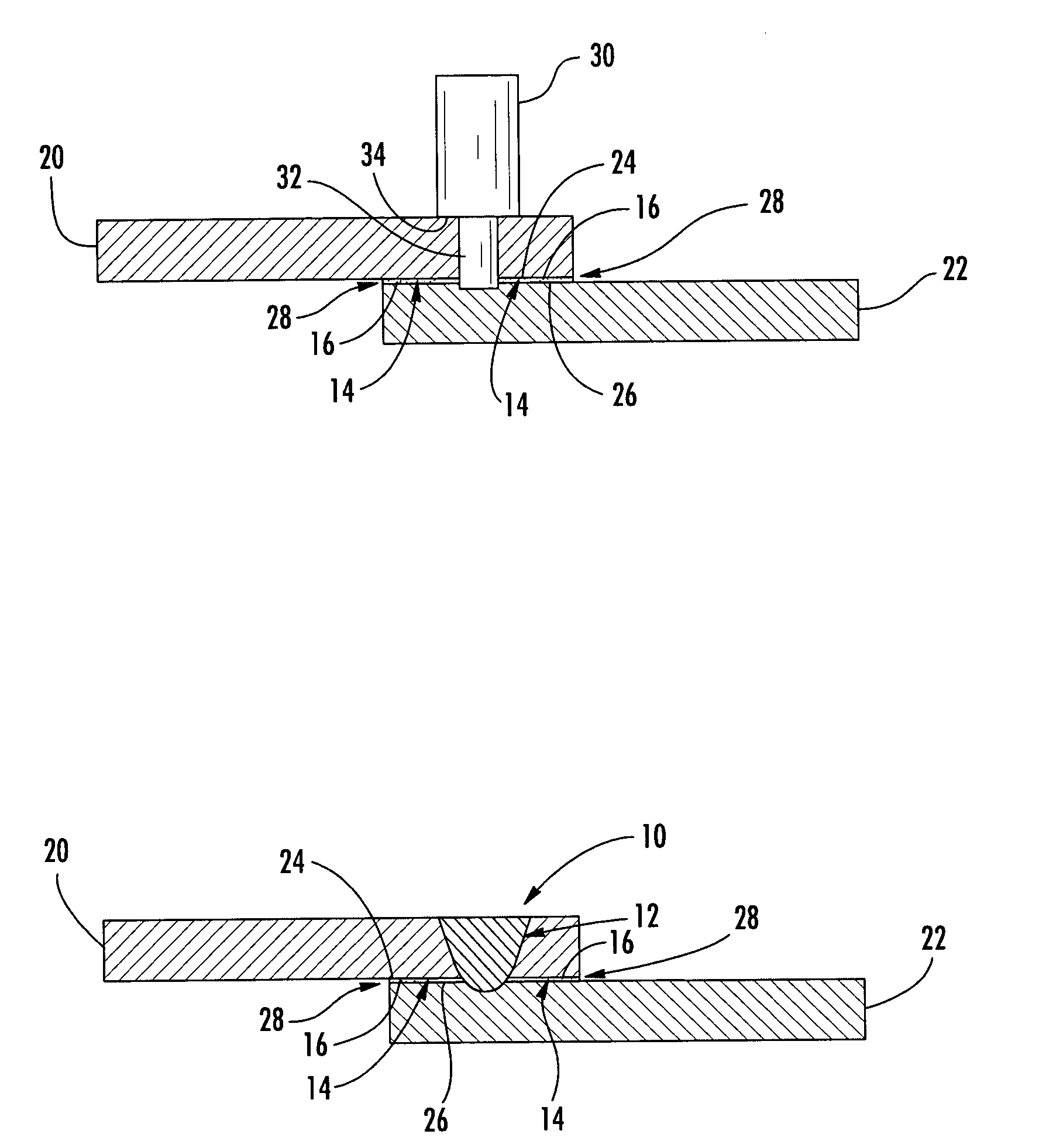

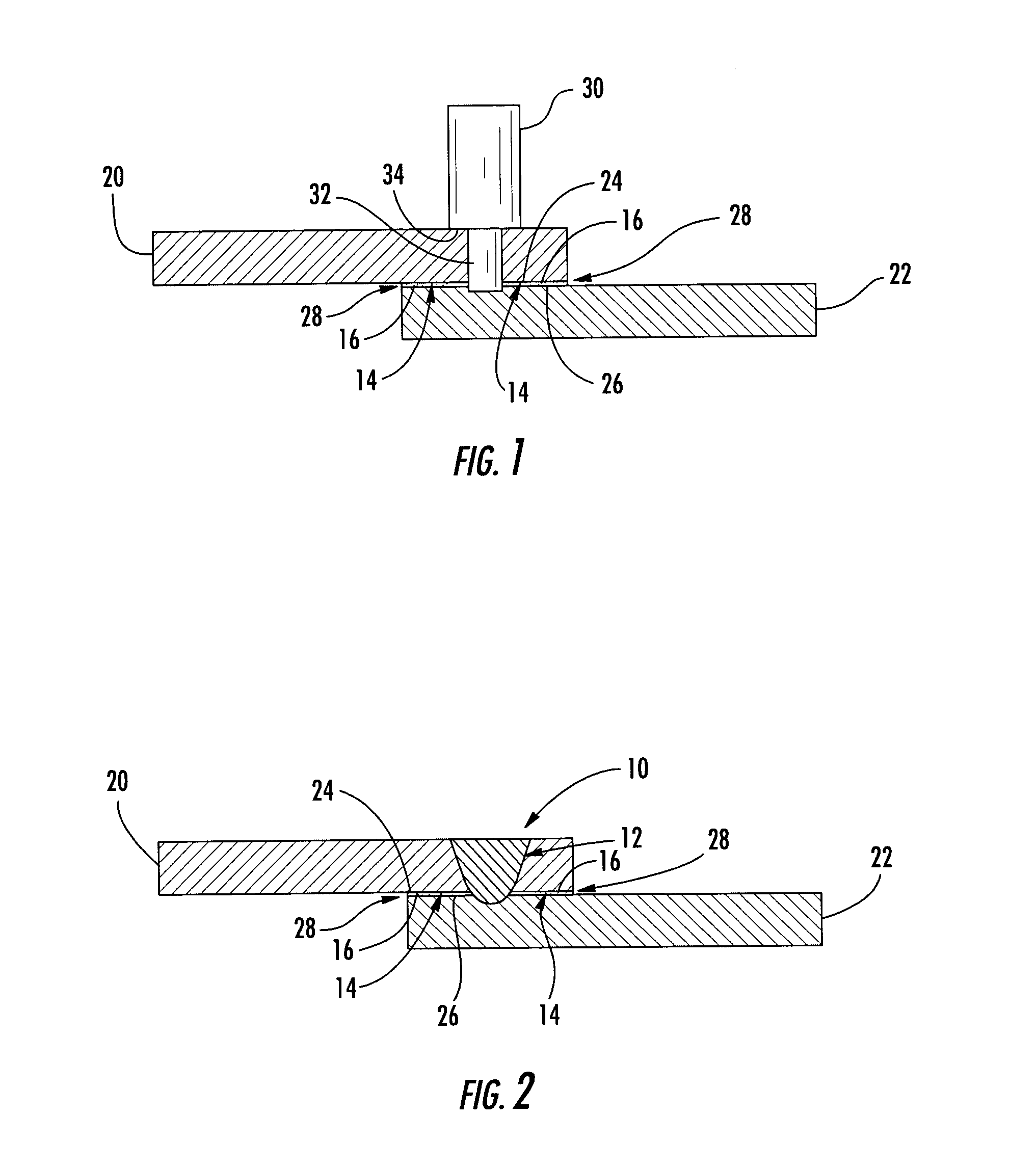

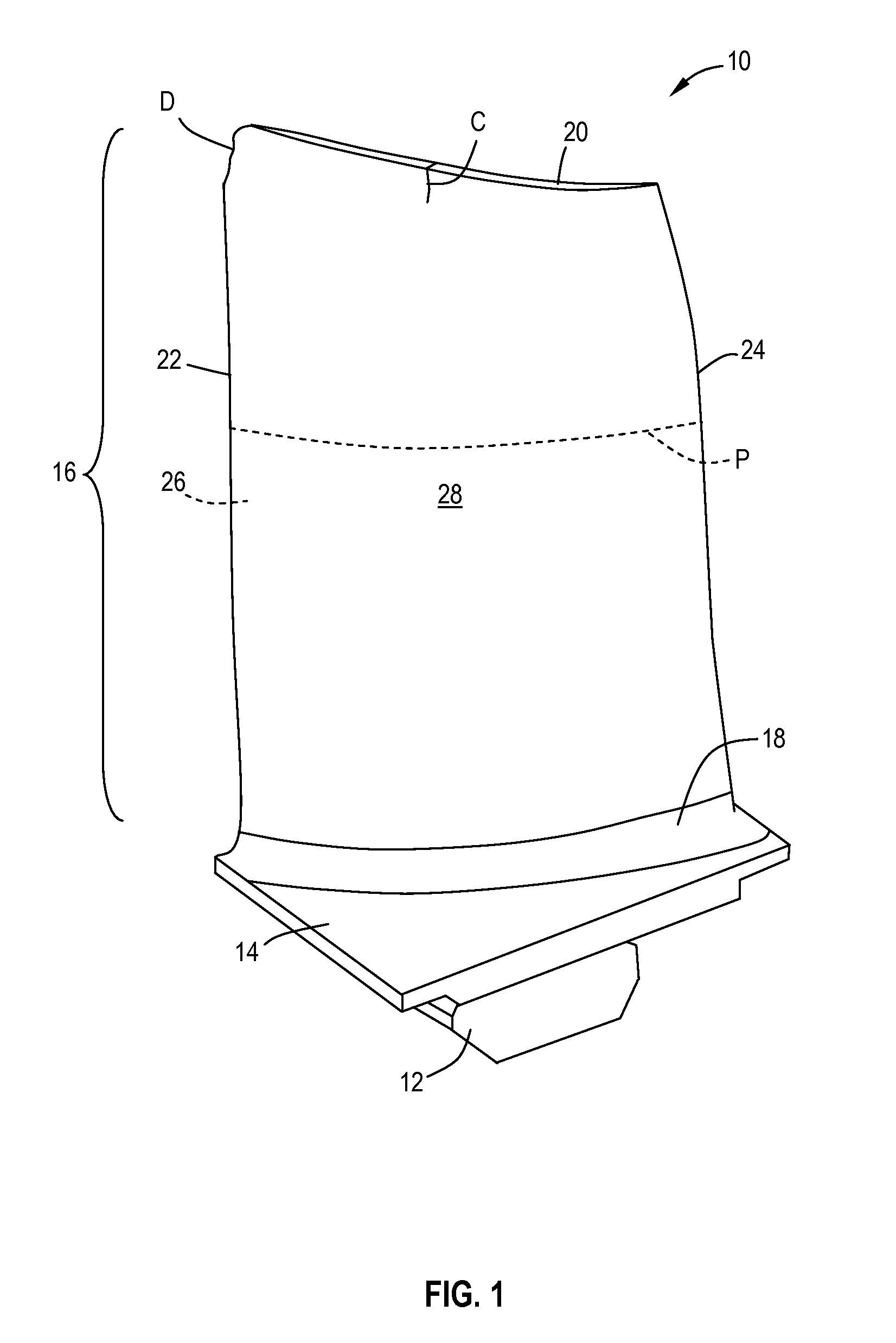

High-powered laser beam welding and assembly therefor

InactiveUS20100243621A1Reduce discontinuityReduce incidenceWelding/soldering/cutting articlesMetal working apparatusLight beamEngineering

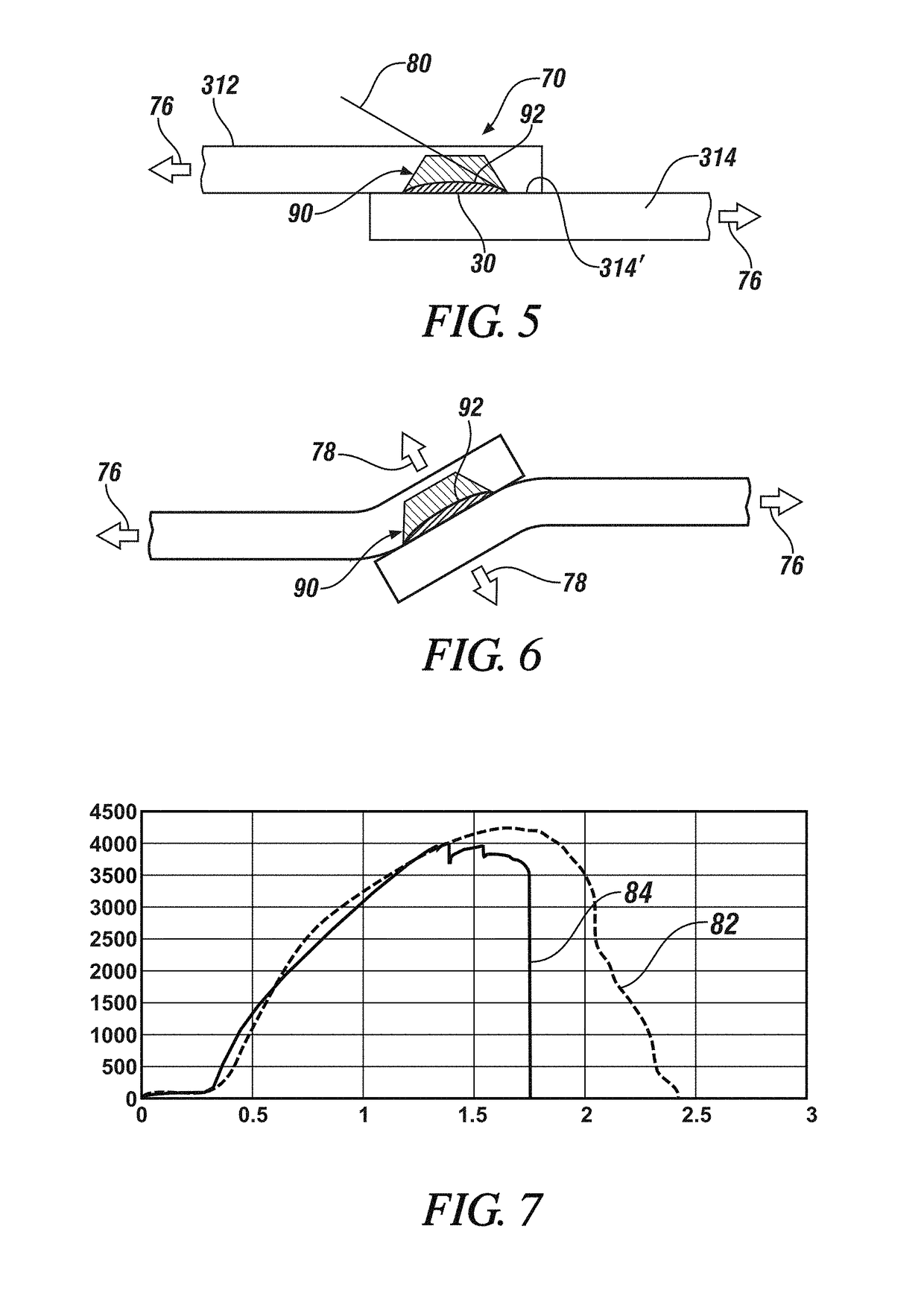

A welding method and an assembly for performing the method. Articles to be welded are placed together so that faying surfaces thereof face each other, a joint region is defined by the faying surfaces and juxtaposed surfaces of the articles, a shim is between and contacts the faying surfaces, and an edge portion of the shim protrudes from the juxtaposed surfaces. The articles are welded together by projecting onto the joint region a high-powered laser beam that is focused on the juxtaposed surfaces and intentionally unfocused on the edge portion of the shim so that portions of the laser beam are diffracted by the edge portion onto the juxtaposed surfaces. The laser beam and its diffracted portions melt the shim and the faying and juxtaposed surfaces of the articles. Cooling of the articles yields a welded assembly having a weld joint entirely through a through-thickness of the welded assembly.

Owner:GENERAL ELECTRIC CO

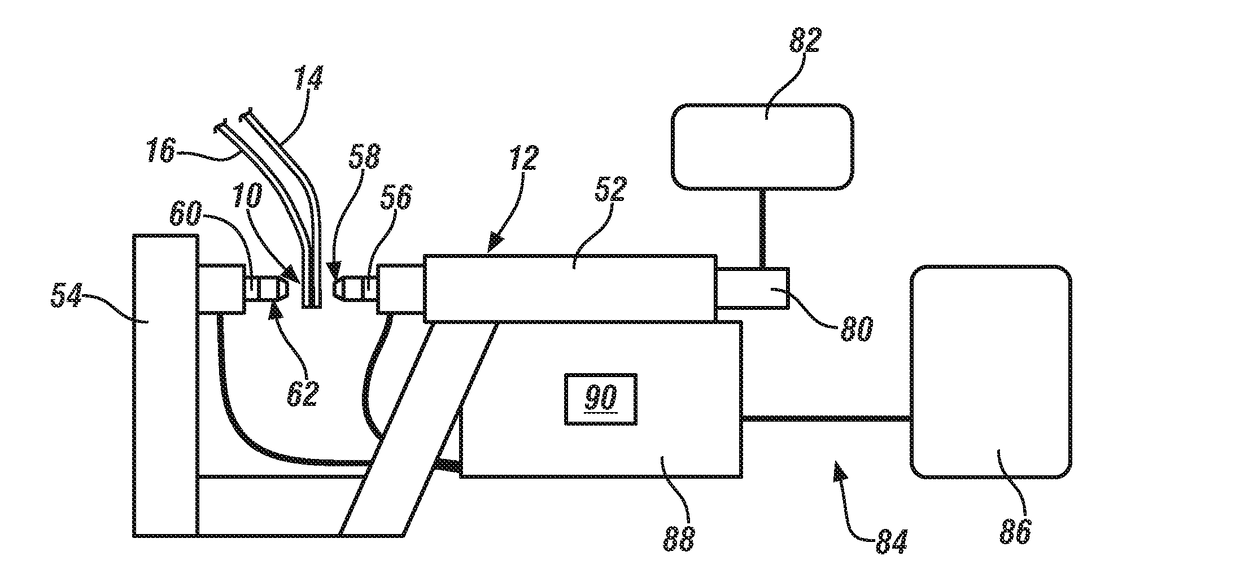

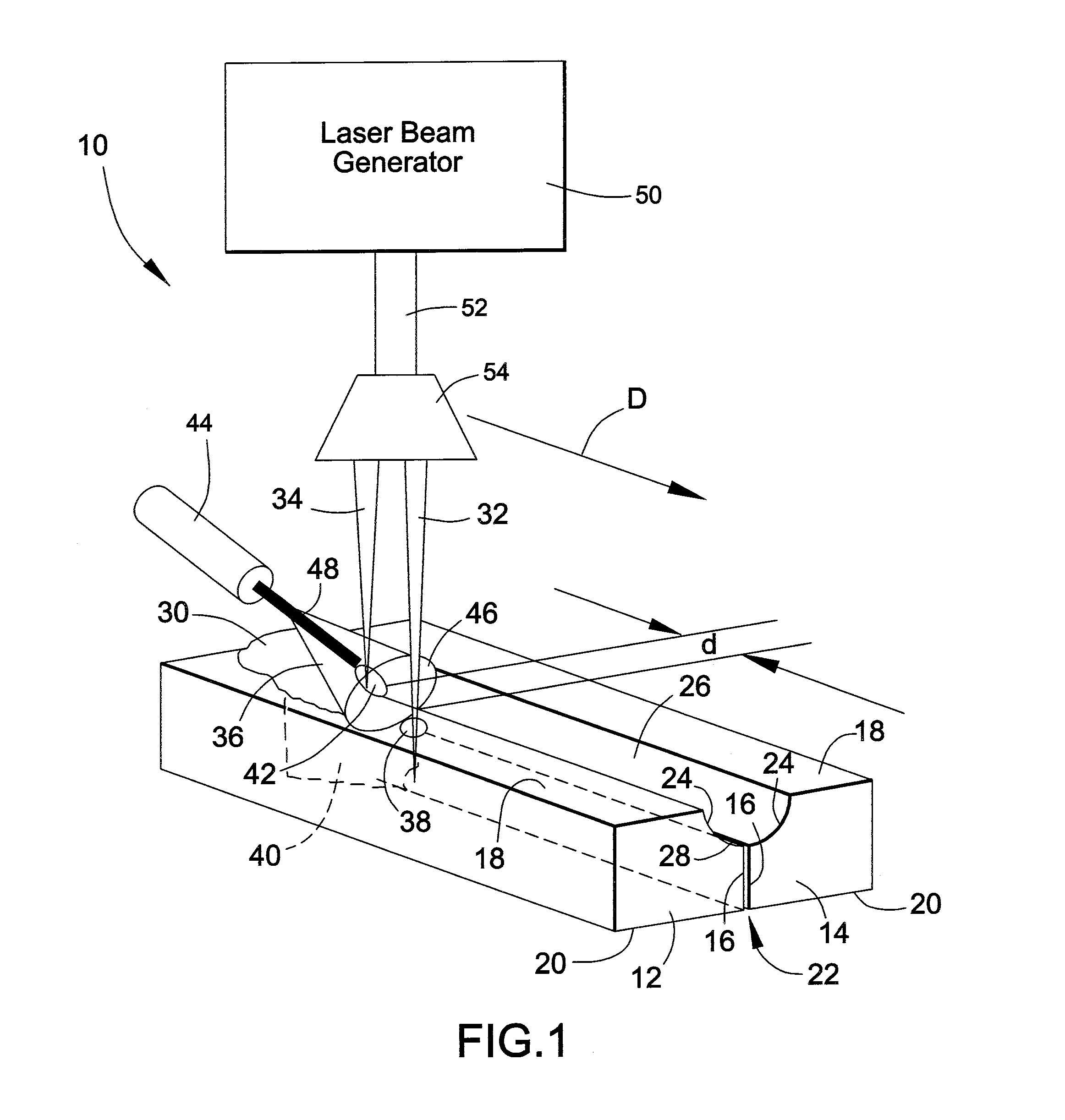

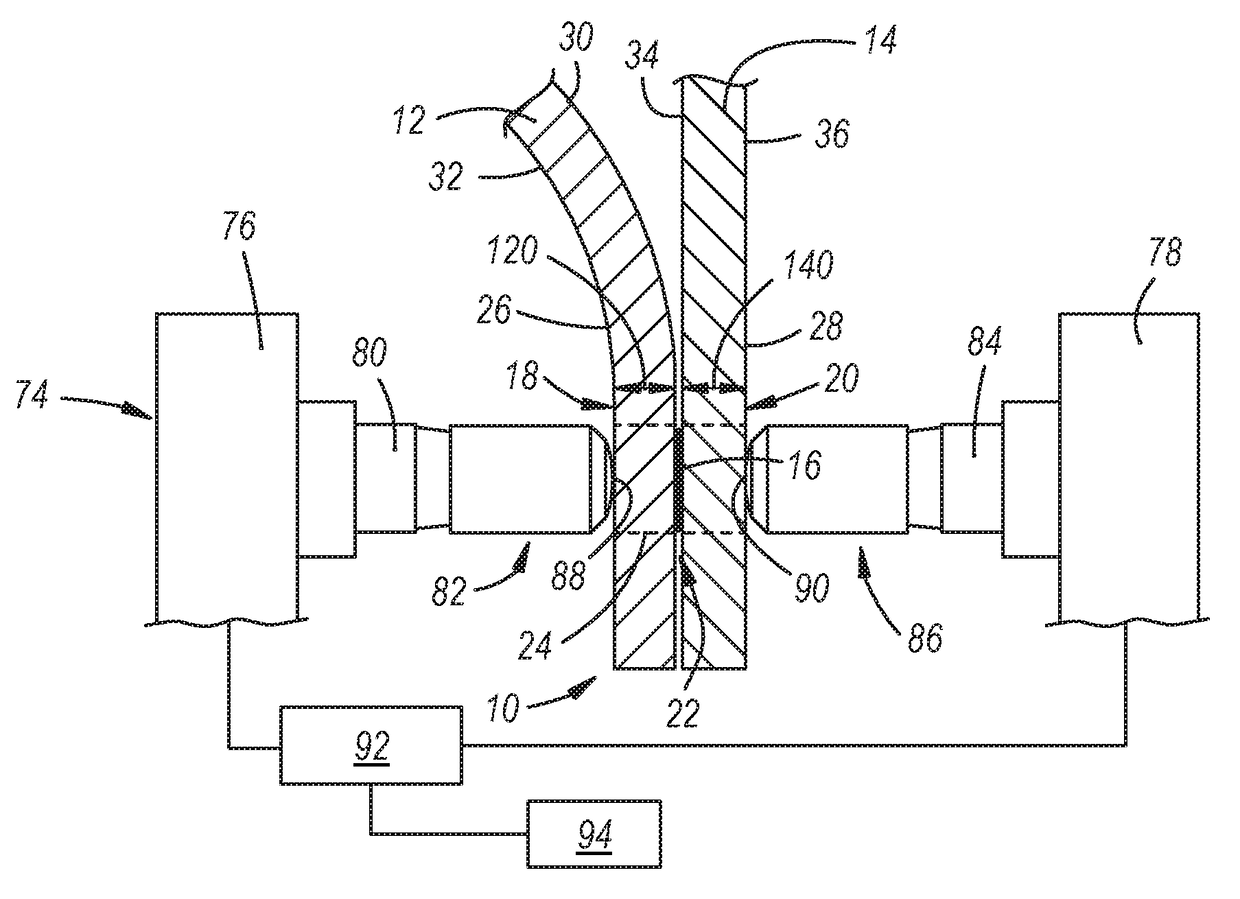

Hybrid laser arc welding process and apparatus

ActiveUS20120000892A1Increase welding depthEliminate stomataEngine manufactureArc welding apparatusEngineeringWeld seam

A welding method and apparatus for welding workpieces together by conducting a laser beam welding process on a joint region that includes a weld seam defined by and between faying surfaces of the workpieces, and then conducting a hybrid laser arc welding process on the joint region. The laser beam welding process entails causing a first laser beam to travel along the joint region, penetrate the weld seam and form a weldment. The hybrid laser arc welding process remelts the weldment by simultaneously causing an electric arc and a second laser beam to overlap and travel along the joint region and form a weld pool in the weldment. On cooling, a weld joint is formed within the joint region and its weld seam.

Owner:GENERAL ELECTRIC CO

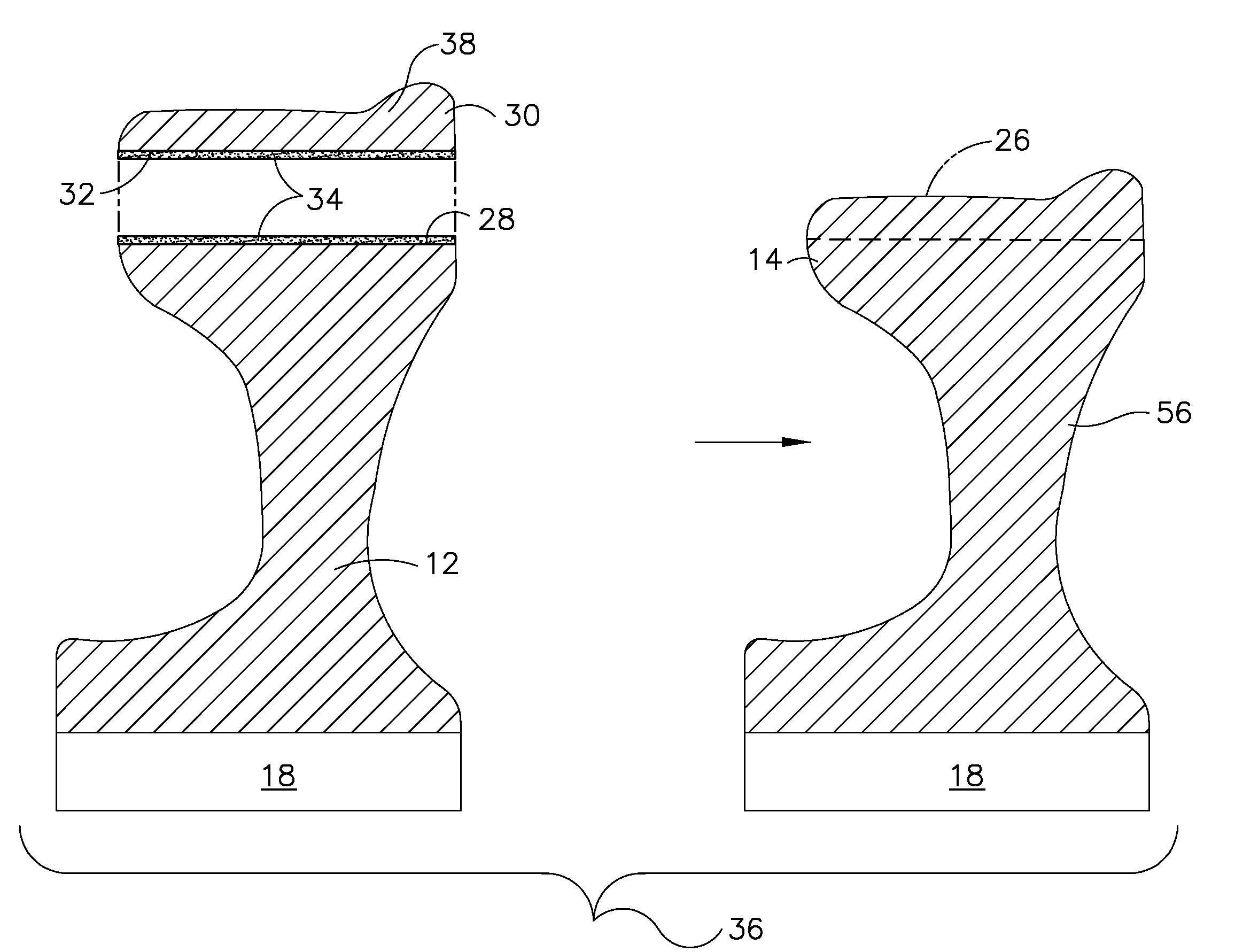

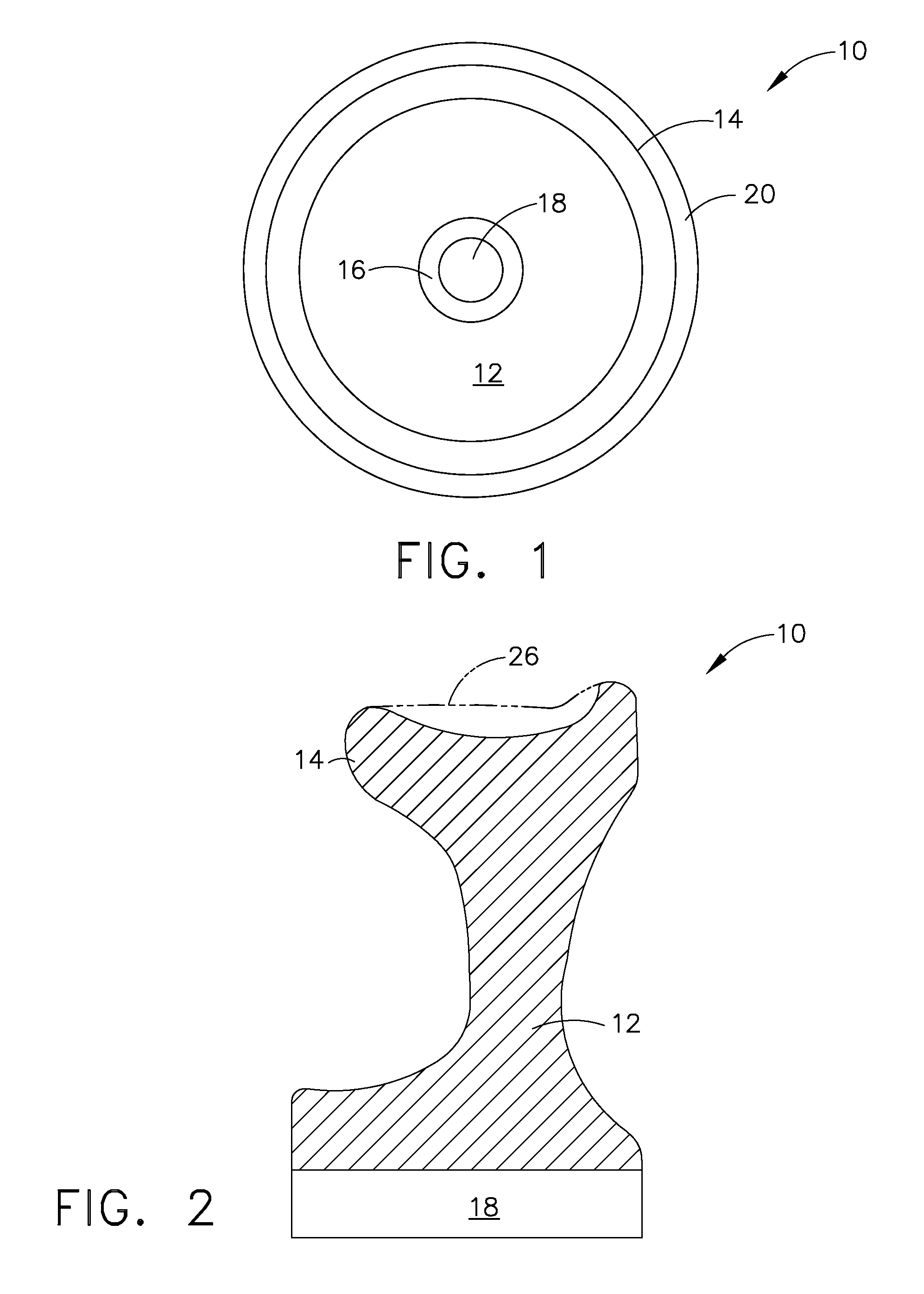

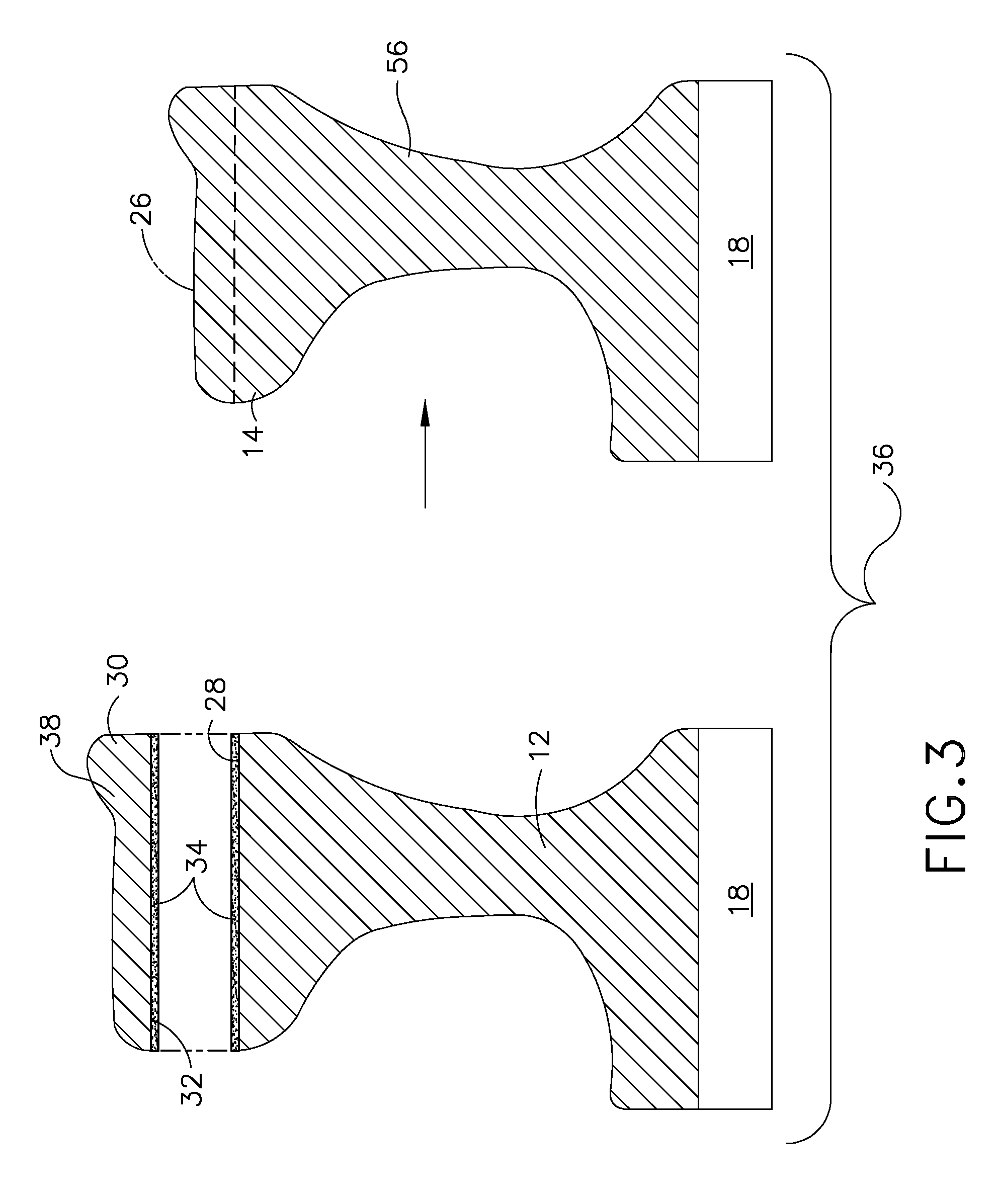

Method for repair of rail wheels and repaired article

A method includes shrink fitting a ring member about a railroad wheel body and metallurically bonding the ring member to the railroad wheel body. A wheel assembly includes an inner portion obtained from a worn railroad wheel, a ring member disposed about the inner portion, and suitable electroplating material disposed on at least one of the faying surfaces. The wheel assembly may be heated under suitable conditions to provide diffusion bonding across interfacing faying surfaces to produce an integral wheel structure. Appropriate quenching, tempering, and finishing processes may be utilized to obtain desired properties. An article formed thereby includes an inner body portion obtained from a worn railroad wheel and a metallurically bonded outer circumferential portion. The outer portion may comprise a composition selected for desired wear characteristics.

Owner:GENERAL ELECTRIC CO +1

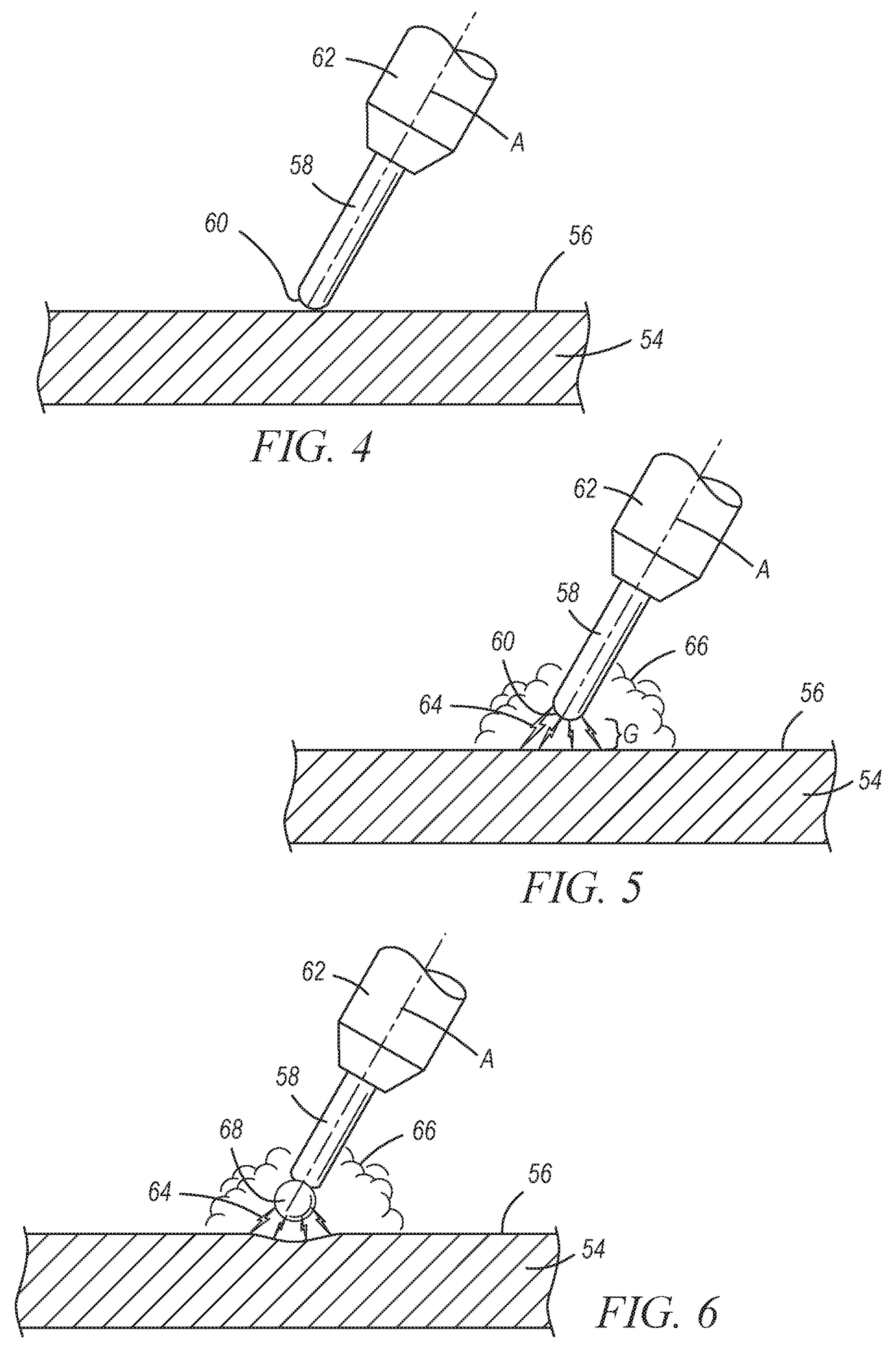

Method of friction stir welding

InactiveUS20140367452A1Avoid excessive wearStronger weld jointWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringMechanical engineering

A method of friction stir welding is provided. The method includes providing a stir tool configured to rotate about and move along a stir tool axis and includes a pin with a pin axial end surface and a pin tapered surface that extends radially outwardly from the pin axial end surface. The method further includes providing the first member with a first member faying surface and defining a normal line that is normal to the first member top surface, is perpendicular to a longitudinal axis, and extends through a reference point. The method further includes providing the second member with a second member faying surface and forming a joint interface between the first and second members. The method further comprises contacting the rotating pin with the second member faying surface, the stir tool axis being disposed at a side tilt angle upon contact.

Owner:FOCUS HOPE

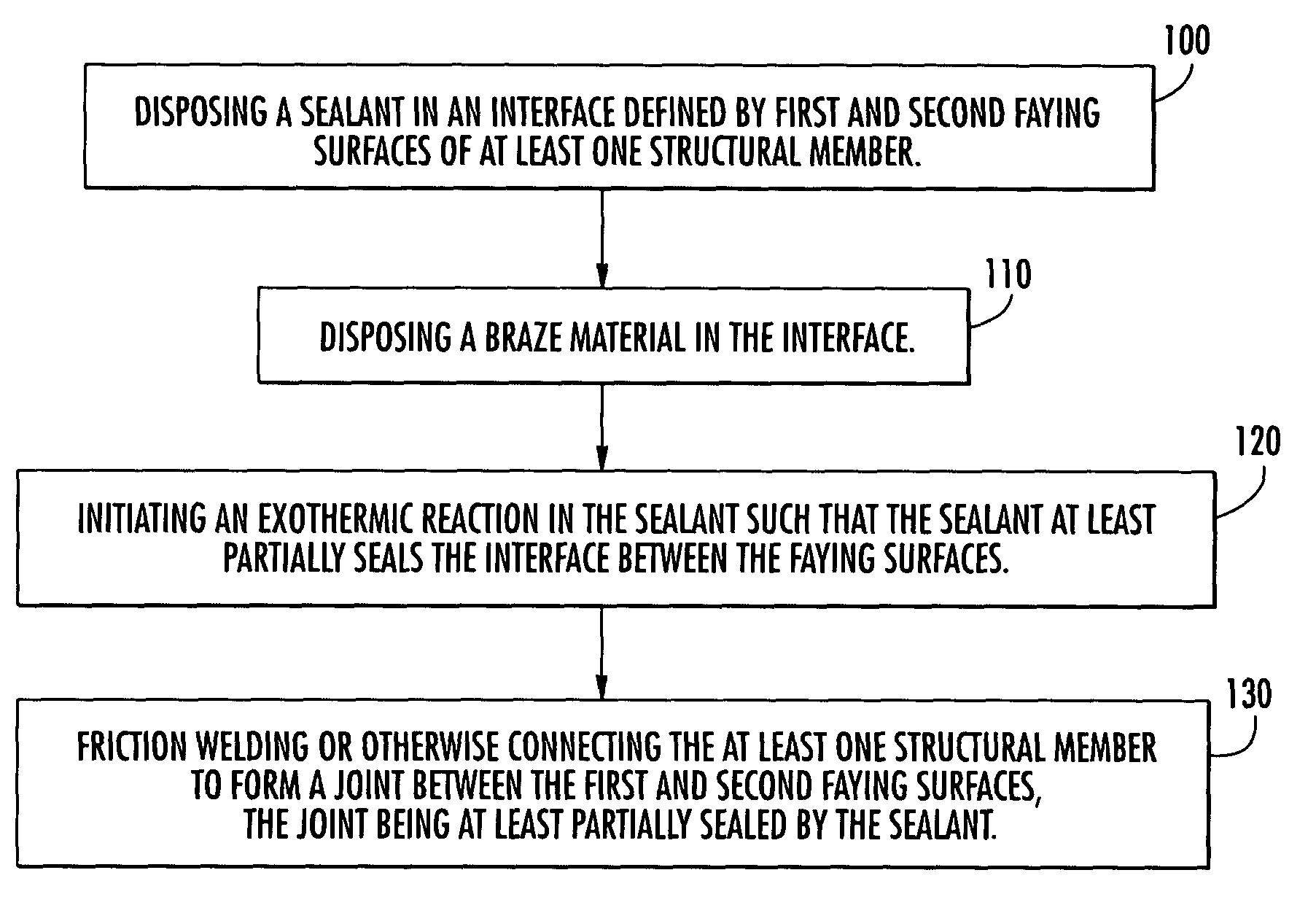

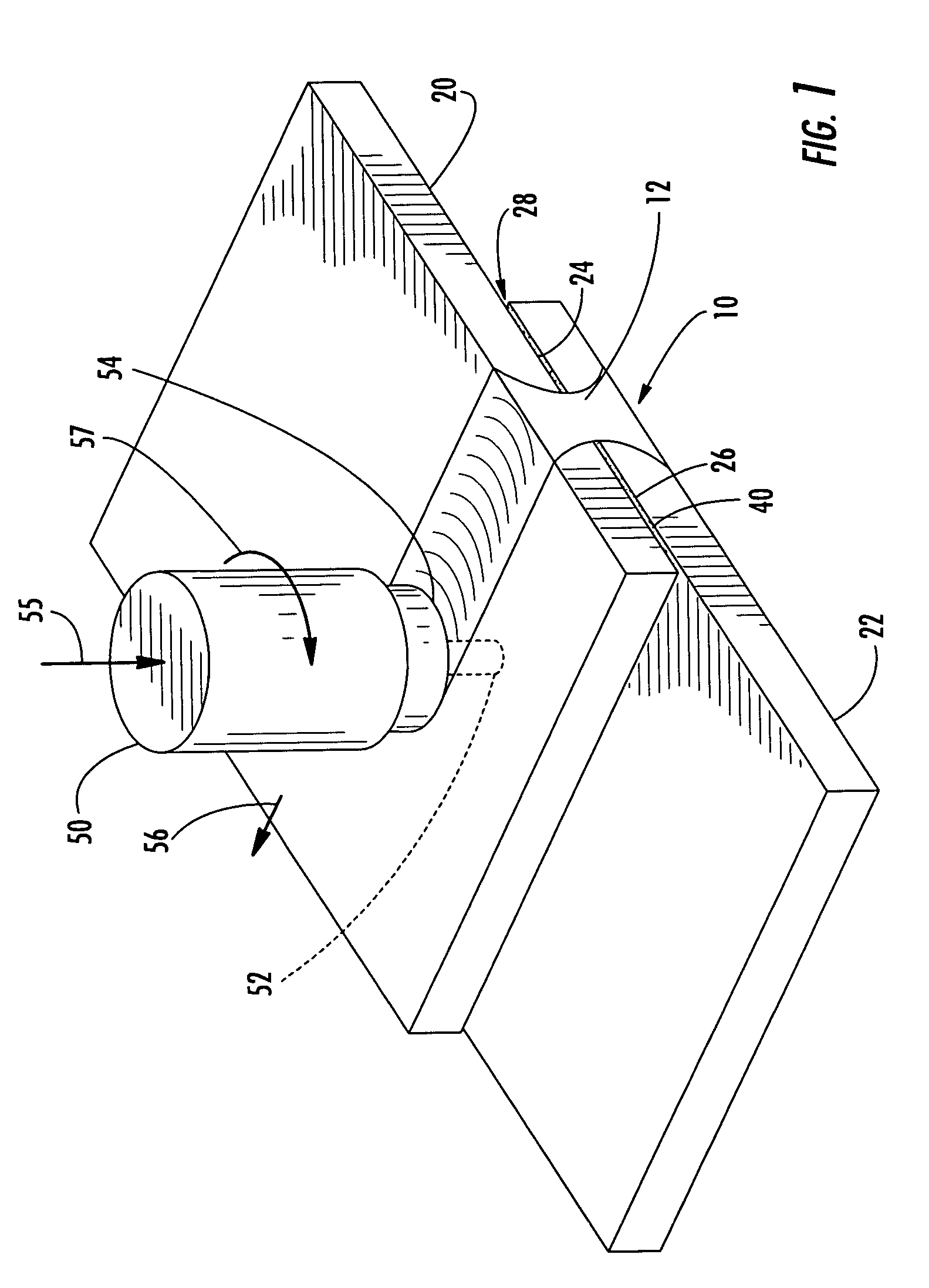

Method and sealant for joints

A joint between one or more structural members and an associated method are provided. The joint includes a friction stir welded joint or other connection between faying surfaces of the members, and an exothermically reacted sealant disposed in an interface defined by the faying surfaces. The exothermic reaction of the sealant in the interface can be initiated before, during, or after joining the structural members such that the sealant at least partially seals the interface. The sealant can fill the spaces between the structural members to prevent the entry of chemicals, moisture, debris, and other substances, thereby reducing the likelihood of corrosion of the joint or structural members at the interface. Further, the sealant can form a bond with the structural members, thereby increasing the strength of the connection between the members.

Owner:THE BOEING CO

Galvanized steel sheet lap-over laser welding method

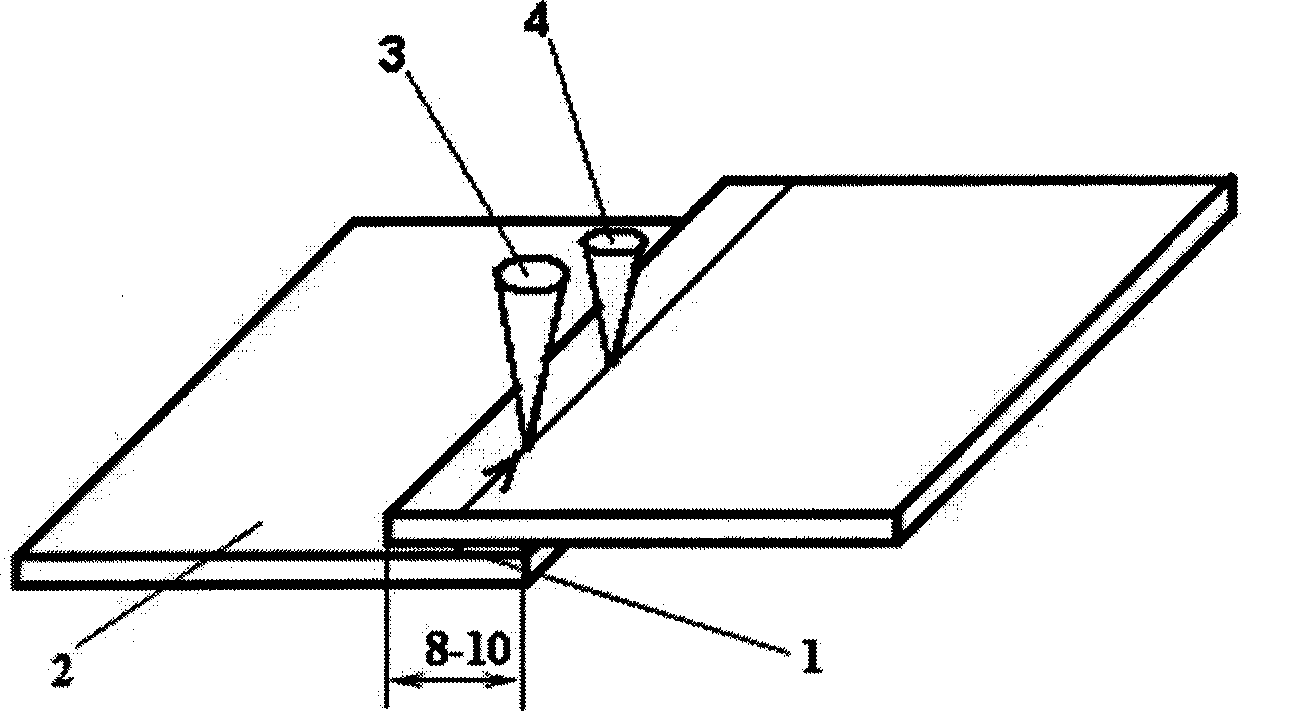

InactiveCN101508058AReduce manufacturing costImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusAlloyWeld seam

The invention discloses a laser welding method for lapping galvanized steel sheets, which comprises: placing a Al-Sn alloy foil containing 35 to 45 weight percent of Sn between faying surfaces of the steel sheets; and utilizing two laser beams of which the power is respectively from 2 to 3KW and from 3 to 4KW to weld welding seams, wherein the space of the laser beams is between 20 and 50mm and the welding speed is between 4 and 8m / min. The method has low production cost and stable welding quality; and the strength of the obtained welding seams is greater than that of base metal, no welding spatter exists on the surface, and the corrosion resistance of the welding seams is more than three times higher than that of by a sweeping-out method. The method can be used for laser welding of lapped welding seams of DP series, TRIP series and HSLA series hot galvanized steel sheets, and realizes high efficiency, low pollution and low waste material of welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of resistance spot welding aluminum to steel

ActiveUS20170291246A1Welding/soldering/cutting articlesResistance welding apparatusPower flowAdhesive

A method of resistance spot welding an aluminum workpiece and an adjacent overlapping steel workpiece is disclosed in which a source of a reactive metal in a diffusible state is located along a faying interface of an aluminum workpiece and an adjacent overlapping steel workpiece. The source of the reactive metal in a diffusible state may take on a variety of forms including (1) a composite adhesive layer that includes reactive particles dispersed throughout a structural thermosetting adhesive matrix or (1) a reactive alloy layer that confronts and is in proximate contact with a faying surface of the aluminum workpiece. Once the source of a reactive material in a diffusible state is in place and the workpiece stack-up is assembled, an electrical current is passed through the workpiece stack-up and between a set of opposed welding electrodes at a weld zone to ultimately produce a weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

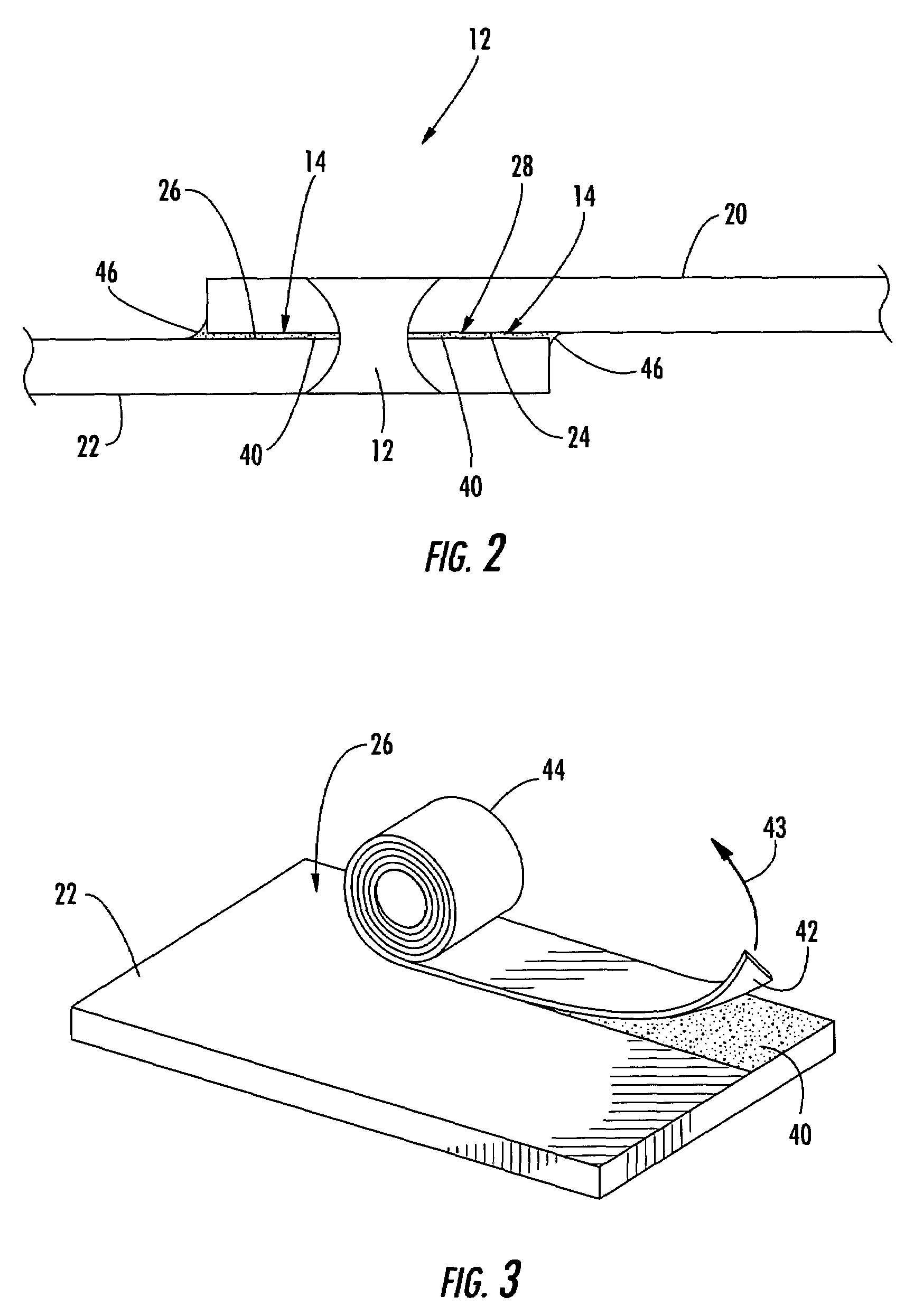

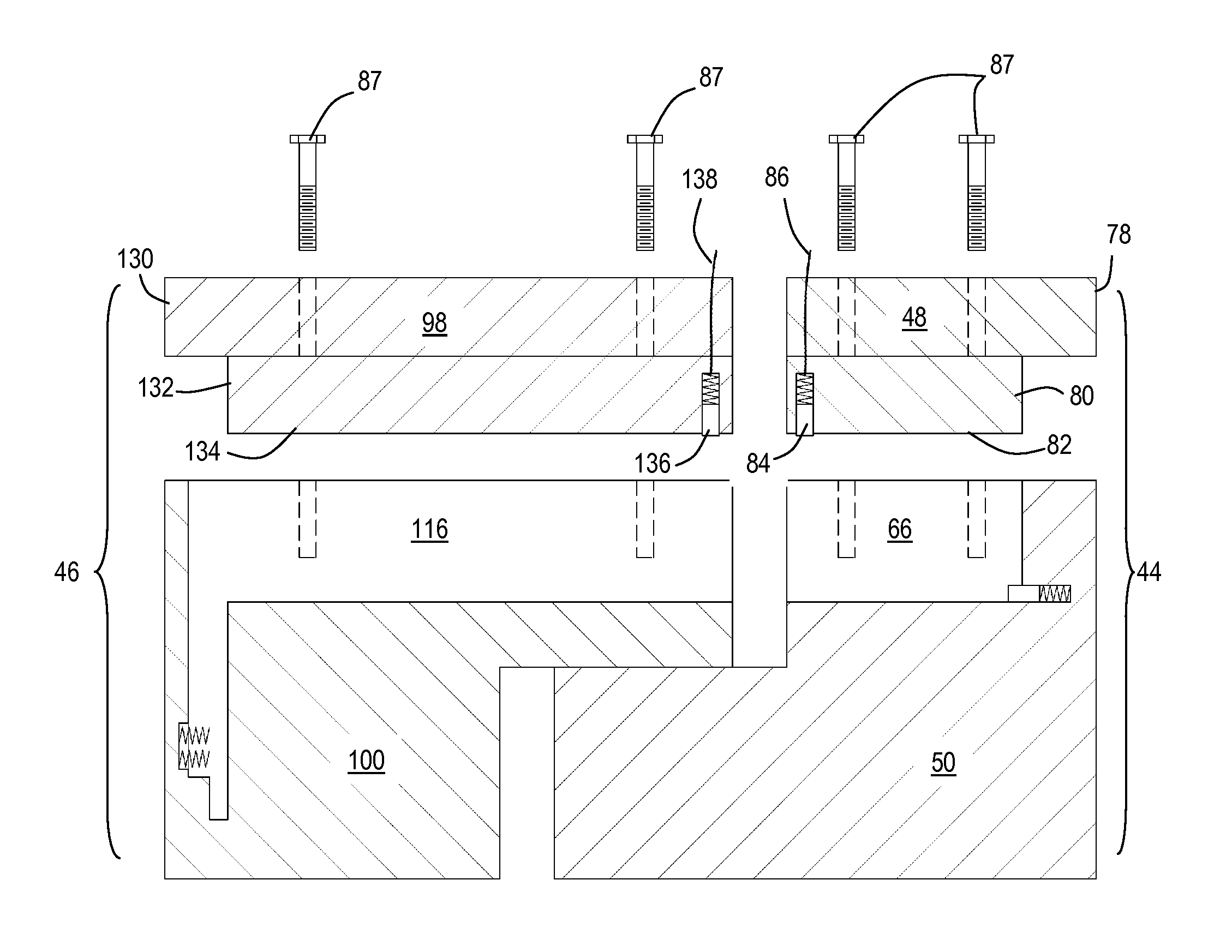

Method and sealant for weld joints

ActiveUS20050087582A1Reduce the possibility of corrosionEliminate riskWelding/cutting auxillary devicesAuxillary welding devicesSealantMoisture

A sealant for a weld joint and an associated weld joint and method are provided. The sealant includes aluminum and germanium and is characterized by a melting temperature that is lower than the melting temperature of the structural member that is joined. The sealant, which is disposed between faying surfaces of the structural members, can fill the spaces between the structural members to prevent the entry of chemicals, moisture, debris, and other substances, thereby reducing the likelihood of corrosion of the joint or structural members at the interface. Further, the sealant can be diffusion bonded to the faying surfaces, for example, by the heat generated during the joining process.

Owner:THE BOEING CO +1

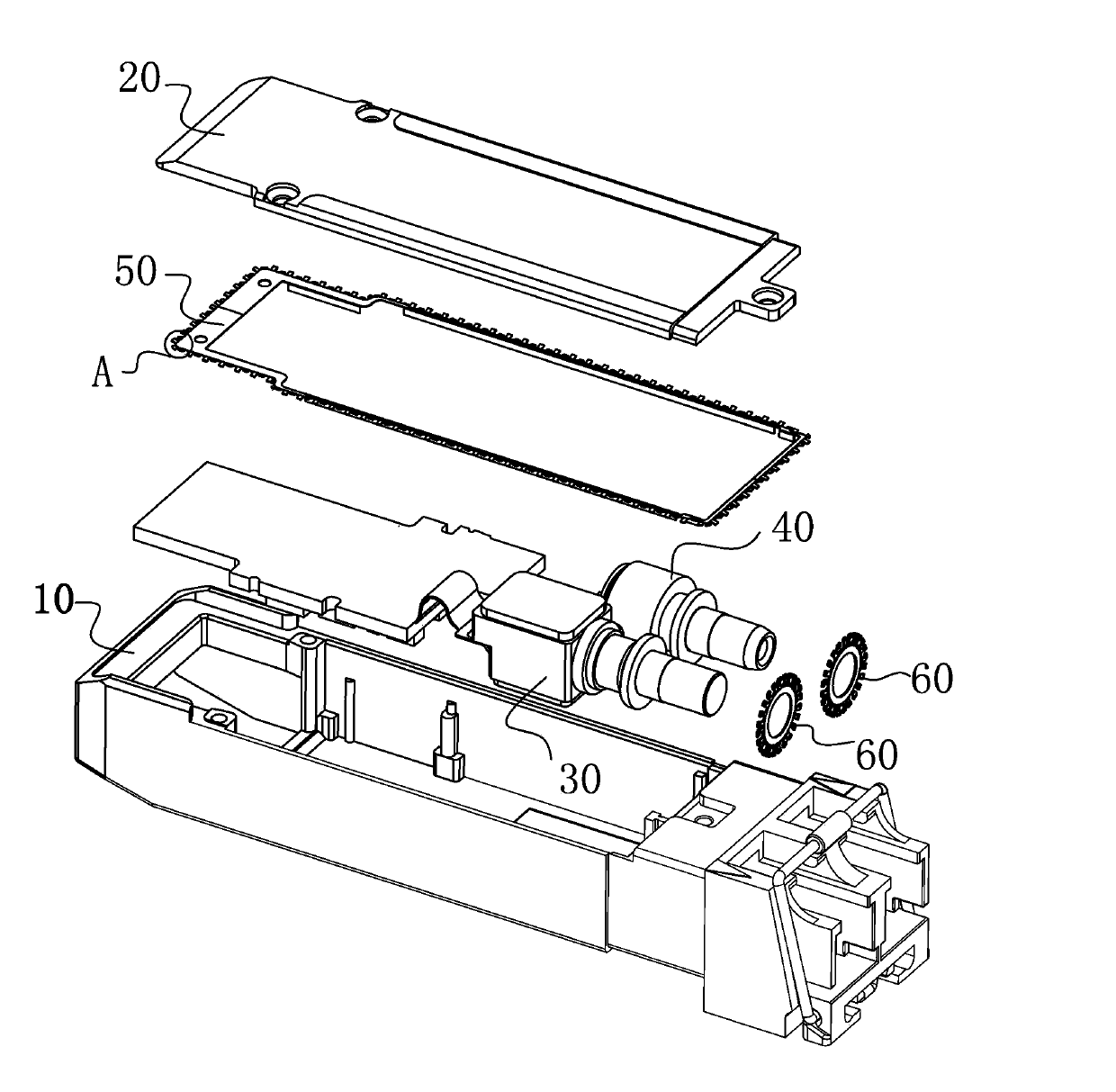

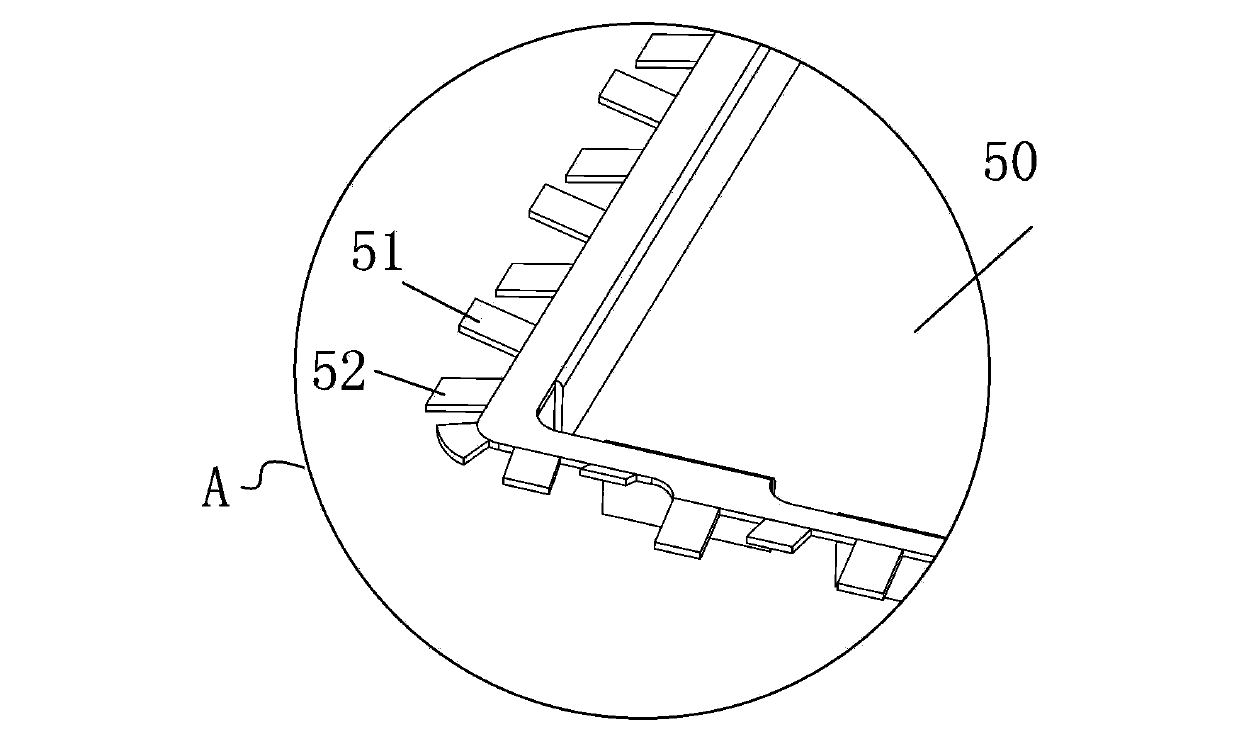

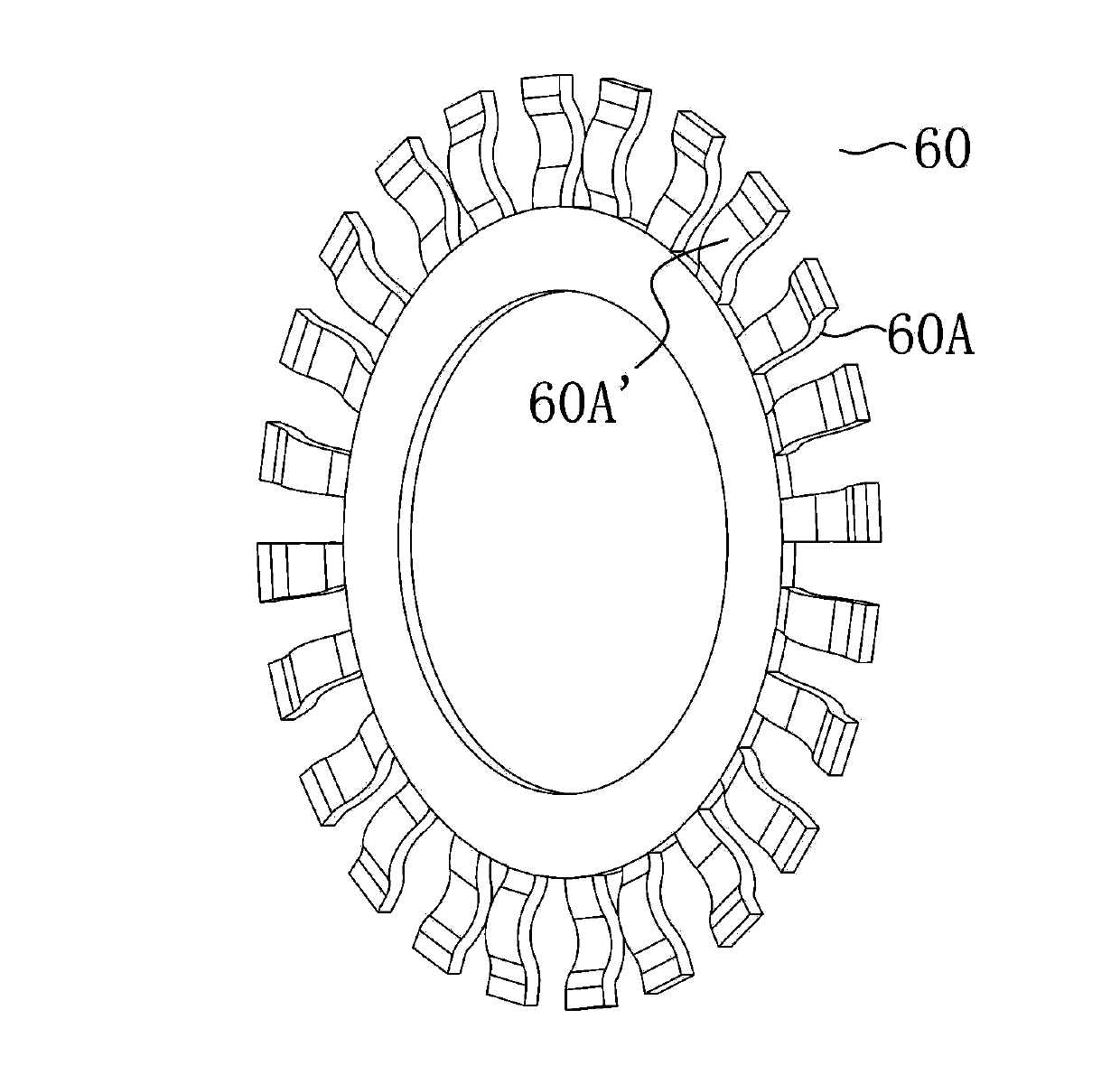

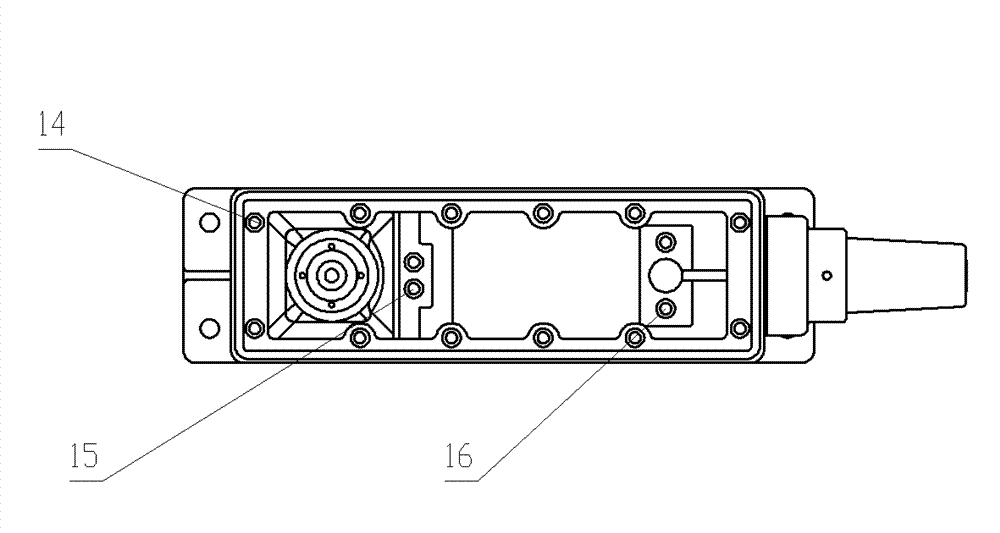

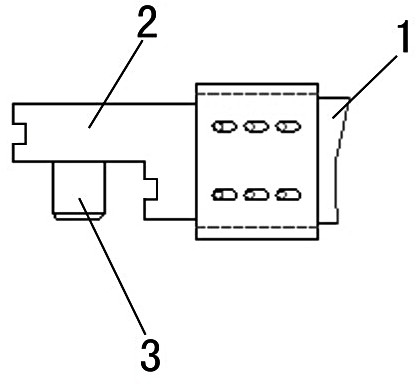

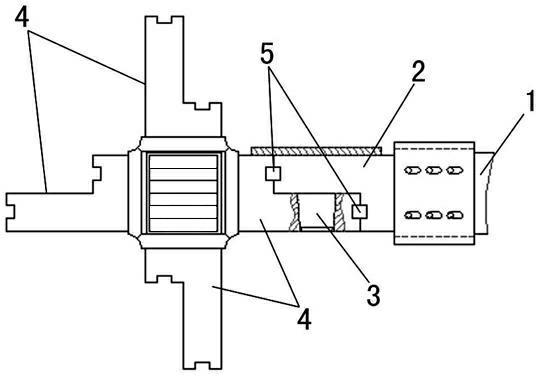

Pluggable optical transceiver module

InactiveCN103869426AImprove electromagnetic shielding performanceGuaranteed conductive connectionMagnetic/electric field screeningCoupling light guidesTransceiverElectromagnetic shielding

The invention provides a pluggable optical transceiver module, which comprises a base and an upper cover, wherein a light emitting assembly and a light receiving assembly are arranged in the base; an electromagnetic shielding gasket is also arranged on the periphery between the faying surfaces of the base and the upper cover; the surrounding edge of the gasket is provided with a plurality of elastic tooth sheets; one part of contacts of the elastic tooth sheets is formed into electric conduction connection after making contact with the surrounding edge of the upper cover; the other part of contacts is also formed into conduction connection after making contact with the surrounding edge of the base. Therefore, the contact points of the base and the upper cover are increased, a plurality of electric conduction connection points are formed, and therefore, the electromagnetic shielding effect is improved.

Owner:SHENZHEN NEOPHOTONICS TECH

Resistance spot welding aluminum to steel using preplaced metallurgical additives

InactiveUS20170297134A1Welding/cutting media/materialsWelding/soldering/cutting articlesMelting tankCopper

A method of resistance spot welding a workpiece stack-up that that includes an aluminum workpiece and an adjacent overlapping steel workpiece involves assembling the workpiece stack-up so that an intermediate metallurgical additive is positioned between the faying surfaces of the aluminum and steel workpieces. The intermediate metallurgical additive includes at least one of carbon, silicon, nickel, manganese, chromium, cobalt, or copper, and has the capability to counteract the growth and formation of Fe—Al intermetallic compounds within a molten metal weld pool created within the aluminum workpiece during resistance spot welding of the workpiece stack-up. In certain aspects of the disclosed method, the intermediate metallurgical additive may be one or more metallurgical additive deposits that are deposited onto the faying surface of the aluminum workpiece or the faying surface of the steel workpiece by an oscillating wire arc welding process.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and sealant for weld joints

InactiveUS6905060B2Reduce the possibility of corrosionRisk of timeWelding/cutting auxillary devicesAuxillary welding devicesSealantMoisture

A sealant for a weld joint and an associated weld joint and method are provided. The sealant includes aluminum and germanium and is characterized by a melting temperature that is lower than the melting temperature of the structural member that is joined. The sealant, which is disposed between faying surfaces of the structural members, can fill the spaces between the structural members to prevent the entry of chemicals, moisture, debris, and other substances, thereby reducing the likelihood of corrosion of the joint or structural members at the interface. Further, the sealant can be diffusion bonded to the faying surfaces, for example, by the heat generated during the joining process.

Owner:THE BOEING CO +1

Method of metallurgically bonding articles and article therefor

InactiveUS6844522B1Semiconductor/solid-state device detailsSoldering apparatusMaterials scienceLaser

Owner:GM GLOBAL TECH OPERATIONS LLC +1

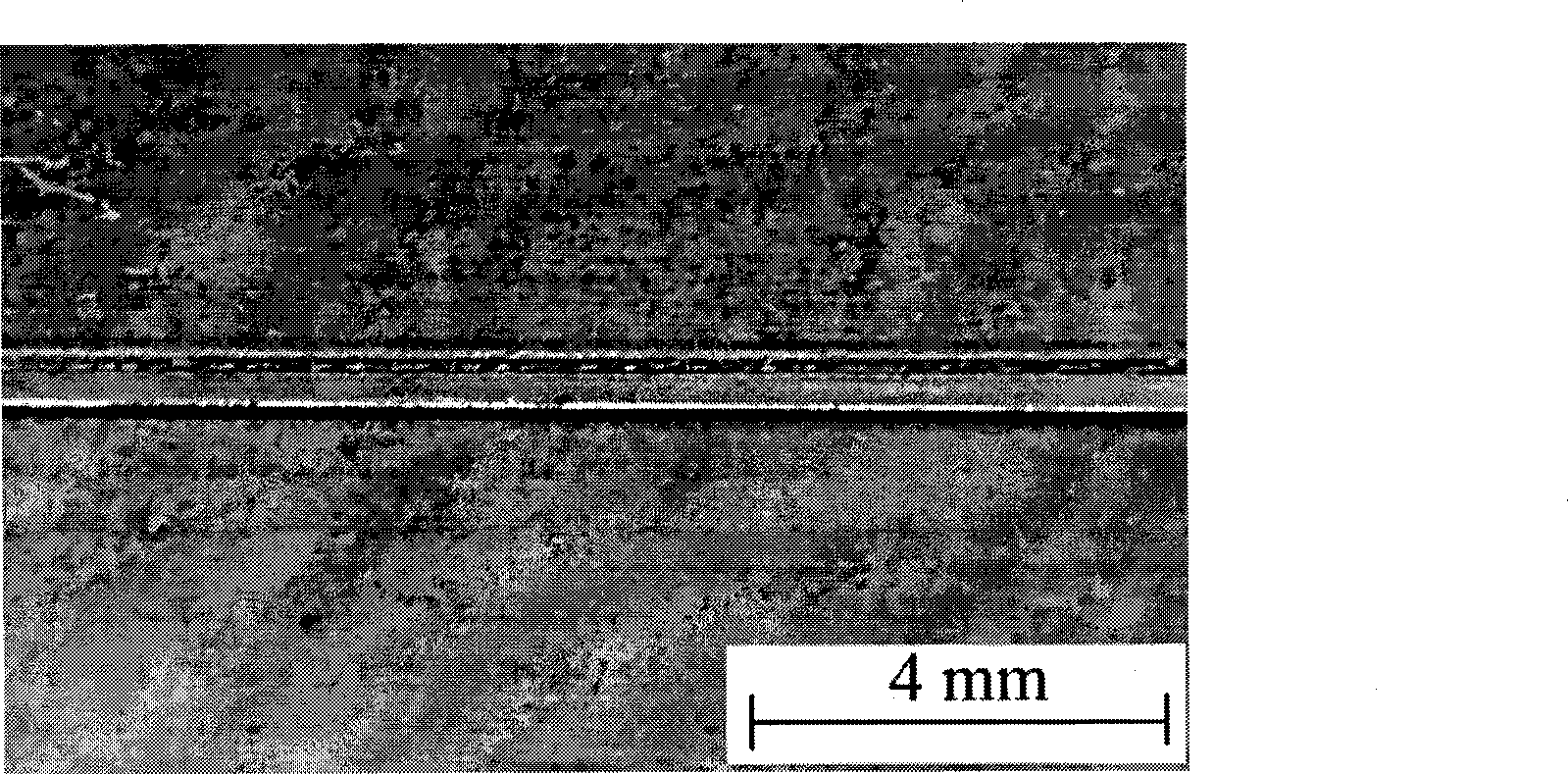

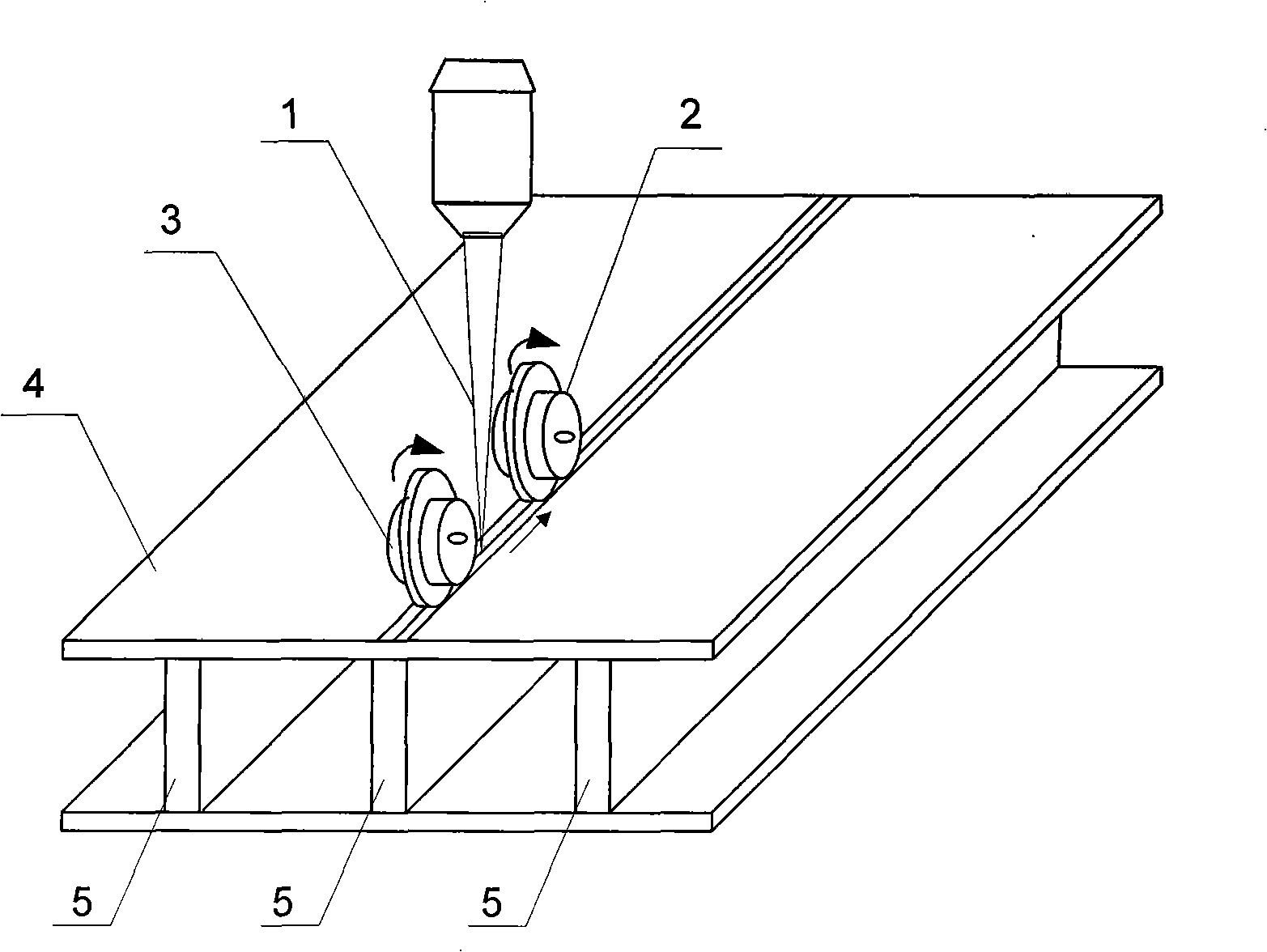

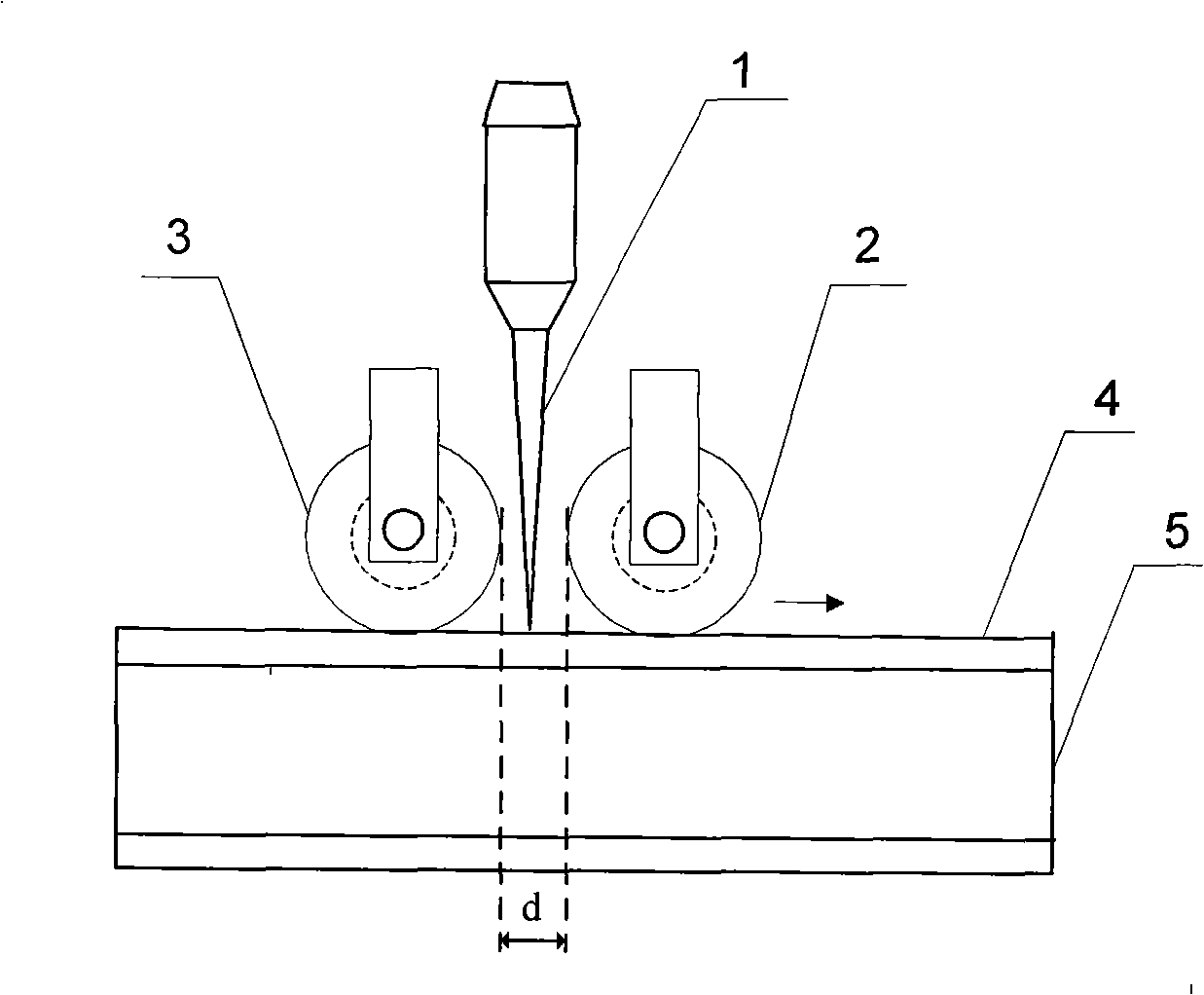

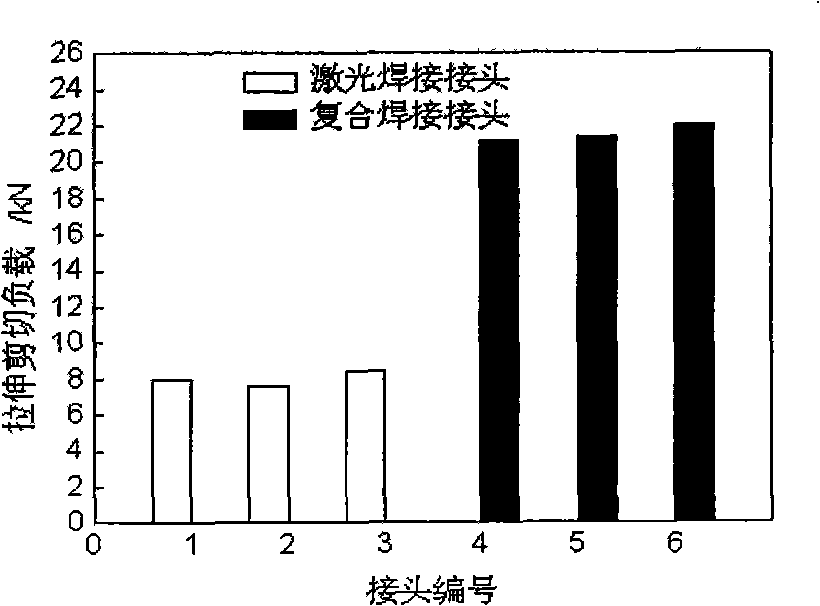

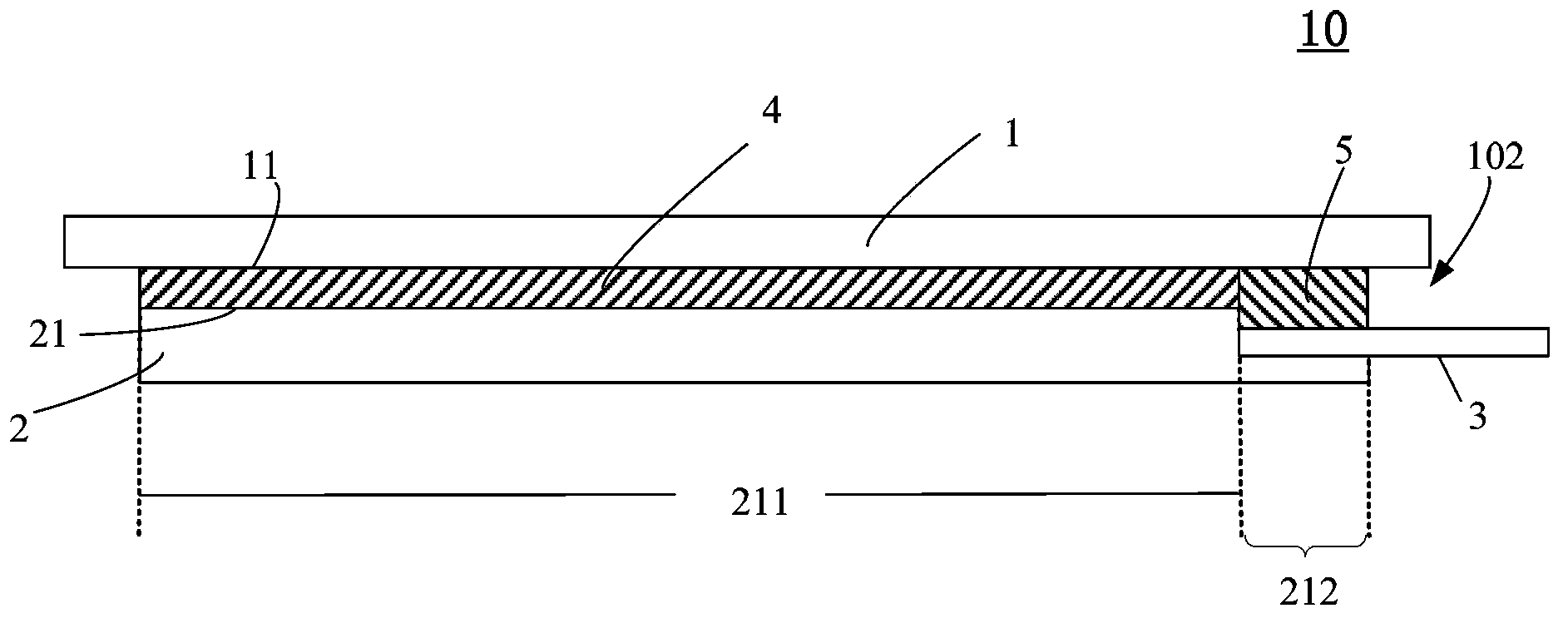

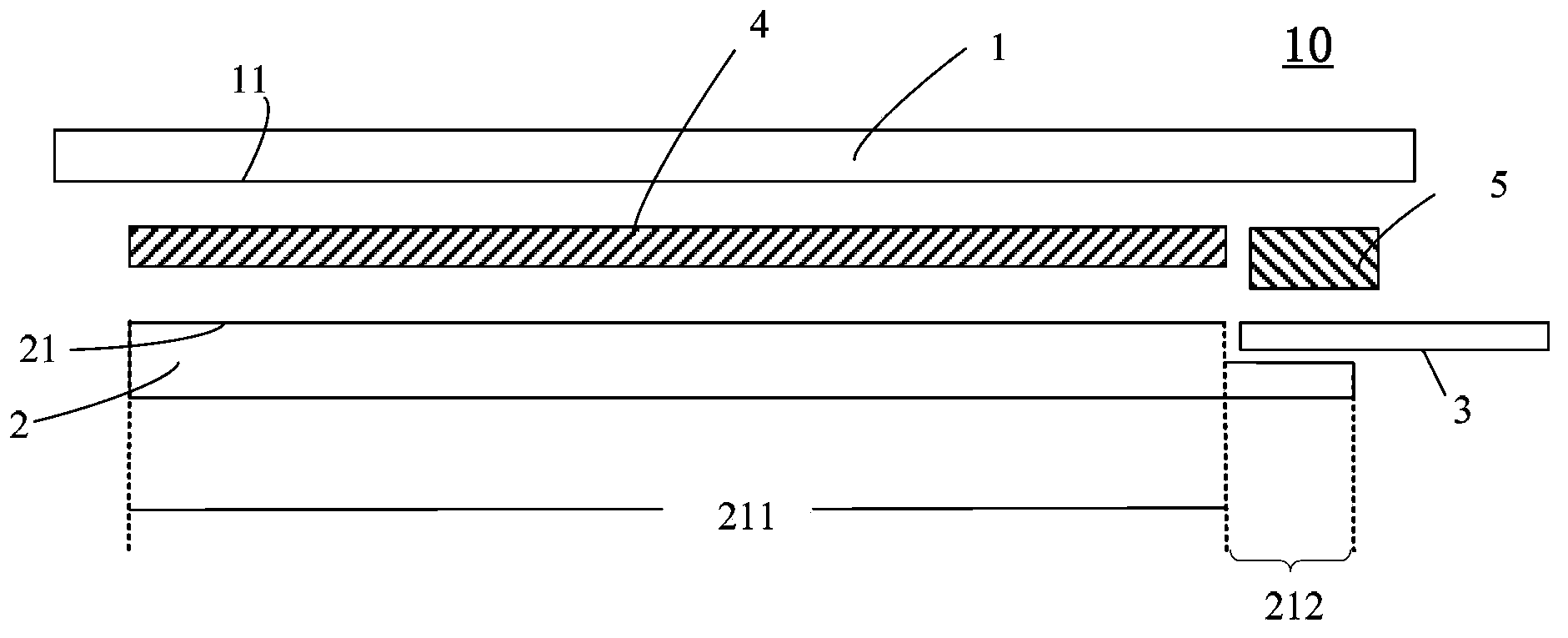

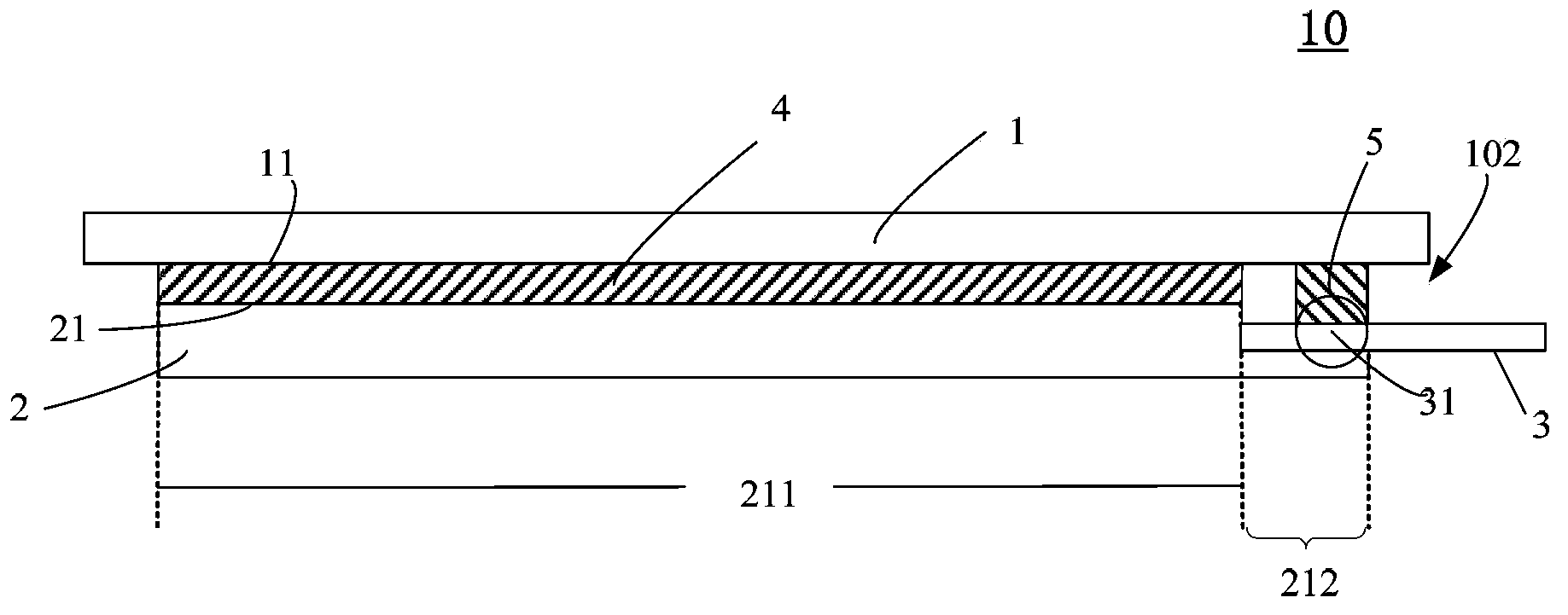

Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

InactiveCN101306491AFit tightlyImprove welding qualityWelding with roller electrodesLaser beam welding apparatusLight beamElectric resistance welding

A laser and electric-resistance seam-welding synchronous composite welding method for an envelope-framework structure relates to a novel laser and electric-resistance seam-welding synchronous composite welding method, belongs to the welding field, and aims to solve the problems in welding the envelope-framework structure by the single laser, such as narrow seam, low shear strength of the seam, a plurality of air vents on the faying surface of the envelope and the framework. The invention aims at the workpiece with the envelope-framework structure to be welded, and adopts the laser and the electric-resistance seam-welding synchronous composite welding; the electric-resistance seam-welding adopts double-roller single-side welding, two roller electrodes are disposed on the front and the back sides of the upper top surface of the envelope along the seam formed by the contact of the envelope and the framework, so that the envelope is pressed to the lower framework in the travel forward, and the laser beam is always positioned in the middle position of the two roller electrodes during the welding process. The seam formed by the welding method can improve the shear strength more than twice in comparison with the base material, and the air vent amount per area can be reduced from about 10% to about 2% of the laser welding.

Owner:HARBIN INST OF TECH

Touch display device and manufacturing method thereof

InactiveCN103729079AStress reliefAvoid uneven display brightnessInput/output processes for data processingDisplay devicePrinted circuit board

The invention provides a touch display device. The touch display device comprises a display module, a flexible printed circuit board, a touch module and a colloid layer, wherein the display module contains a display surface, the flexible printed circuit board is connected with the edge of the display surface, the touch module contains a faying surface arranged opposite to the display surface, the faying surface and the display surface are fit, an interval is formed between the touch module and the flexible printed circuit board, and the colloid layer fills the interval to fix the flexible printed circuit board to the faying surface of a touch panel. The flexible printed circuit board is fixed to the touch module through the colloid layer, so that the touch display device eliminates the stress generated when the flexible printed circuit board is bent, and solves the problems that the display module deforms due to the stress and further display brightness is uneven. The invention further provides a manufacturing method of the touch display device.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Method and sealant for joints

ActiveUS7090112B2Reduce the possibility of corrosionBuilding constructionsFuselagesFriction weldingEngineering

A joint between one or more structural members and an associated method are provided. The joint includes a friction weld joint or other connection between faying surfaces of the members, and an exothermically reacted sealant disposed in an interface defined by the faying surfaces. The exothermic reaction of the sealant in the interface can be initiated before, during, or after joining the structural members such that the sealant at least partially seals the interface. The sealant can fill the spaces between the structural members to prevent the entry of chemicals, moisture, debris, and other substances, thereby reducing the likelihood of corrosion of the joint or structural members at the interface. Further, the sealant can form a bond with the structural members, thereby increasing the strength of the connection between the members.

Owner:THE BOEING CO

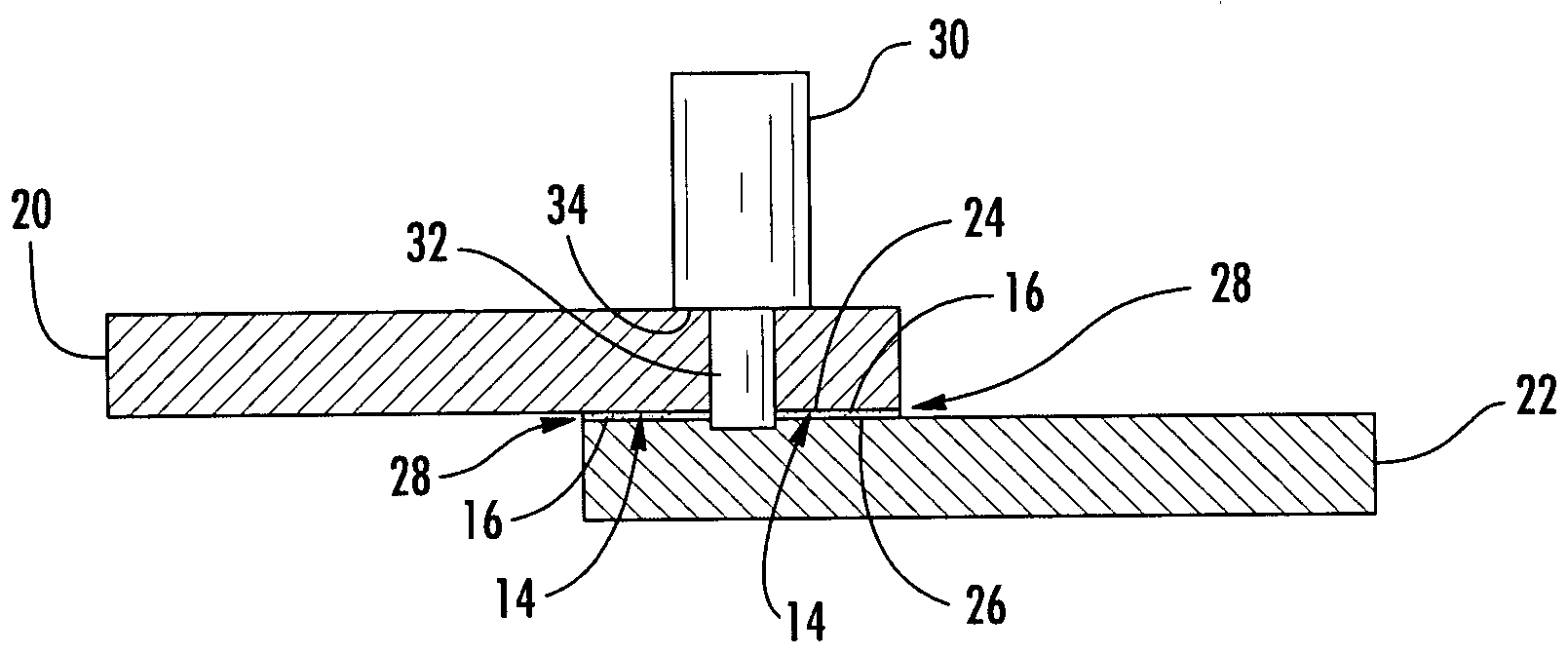

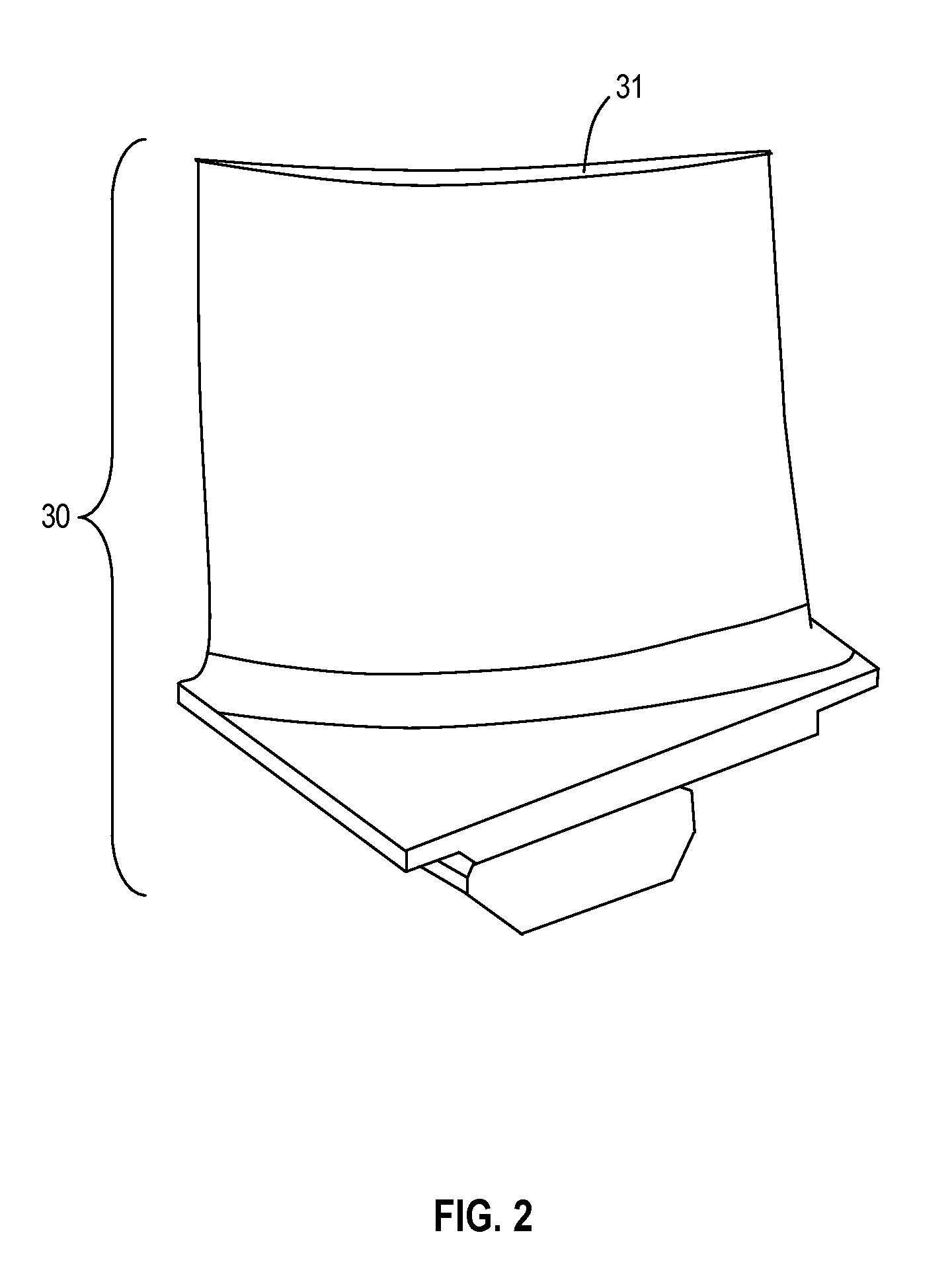

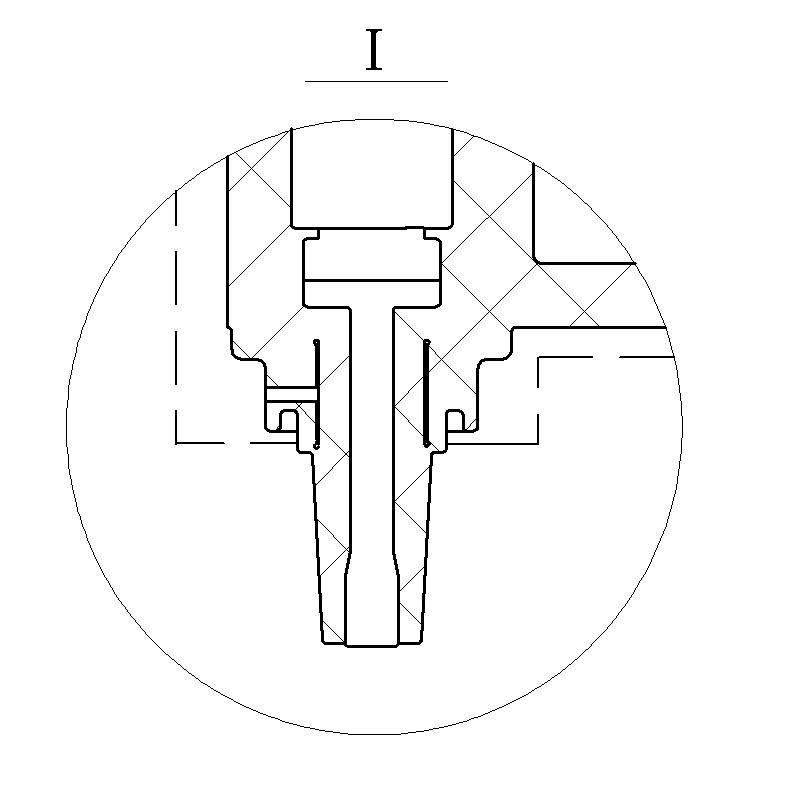

Repair alignment method and apparatus for turbine components

A turbine component repair apparatus includes: a first die having male and female halves for clamping a first section of a turbine blade with a platform and a root portion of an airfoil, the first die having a recess shaped to receive the root portion and retain a faying surface thereof in predetermined alignment; and a second die having male and female halves for clamping a repair section which defines a tip portion of the airfoil, the second die having a second recess shaped to receive the tip portion and retain a faying surface of the tip portion in predetermined alignment. The first and second dies have mating front faces configured to align their bottom surfaces in a common plane. A alignment device is removably attached to the second die to temporarily align the repair section in the absence of the male half of the second die.

Owner:GENERAL ELECTRIC CO

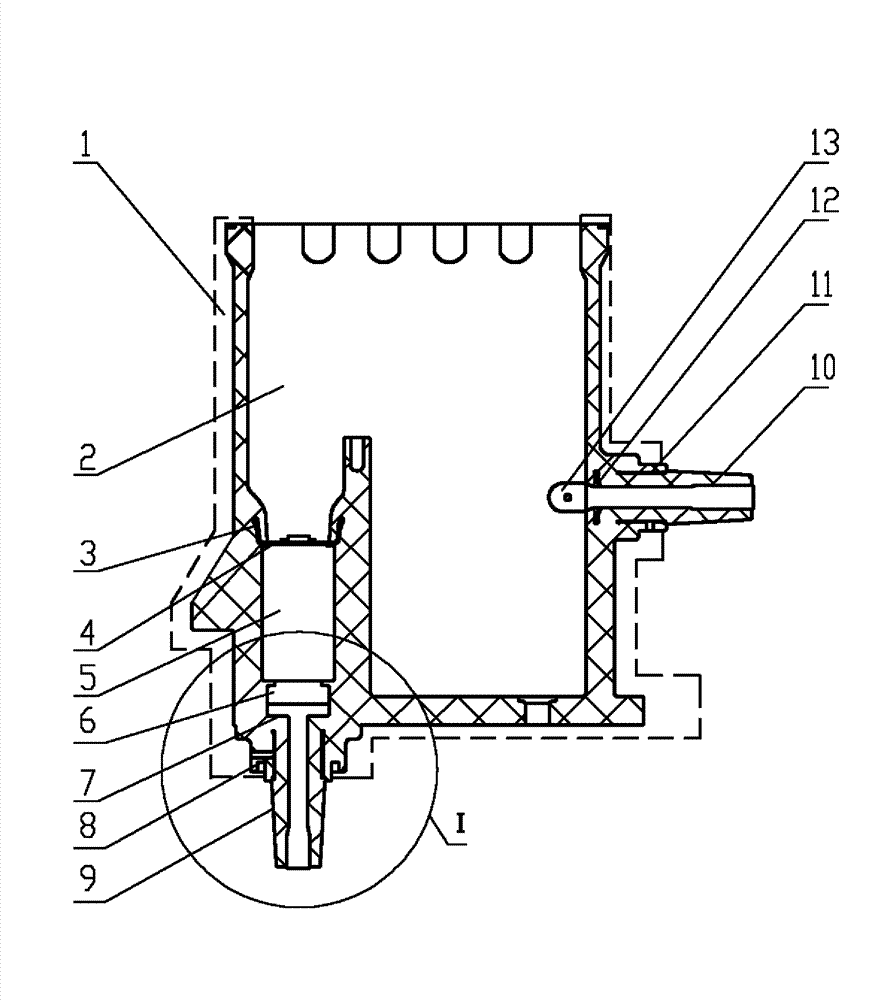

Solid insulating pole

ActiveCN102881508AIncrease the electric field strengthImprove insulation performanceHigh-tension/heavy-dress switchesAir-break switchesState of artCopper

The invention discloses a solid insulating pole, comprising a housing formed by an insulating layer and a ground layer externally coated the outer side of the insulating layer, a load switch chamber, an isolating switch chamber, a vacuum arc-extinguishing chamber, a copper part in a wire-incoming side casing, the wire-incoming side casing, an isolating switch static contact, an isolating switch moving cutter, a wire-outgoing side casing and the like. A faying surface of a moving end of the vacuum arc-extinguishing chamber is connected with a shielding cover, the shielding cover is in conducting connection with the moving end of the vacuum arc-extinguishing chamber by a conducting element, the shielding cover and a copper part in the wire-outgoing side casing are arranged in the insulating layer, and the copper part in the wire-outgoing side casing is electrically connected with a shielding ring; the connecting hole end face of the isolating switch static contact is provided with a flange, is in contact with a connecting hole end face of a static contact insert arranged on the housing by the flange and is fixed on the static contact insert by a bolt; and the outside of the wire-incoming side casing is provided with a waterproof indent skirt edge. Compared with the prior art, the solid insulating pole has the advantages that the structure is compact, the electric field in the pole is uniformly distributed, the local discharge valve is small, the discharge phenomena of an electrified body in the pole on the insulating layer can be obviously reduced, and the insulating performance of the pole can be increased.

Owner:GUANGXI YINHE DECOM ELECTRIC

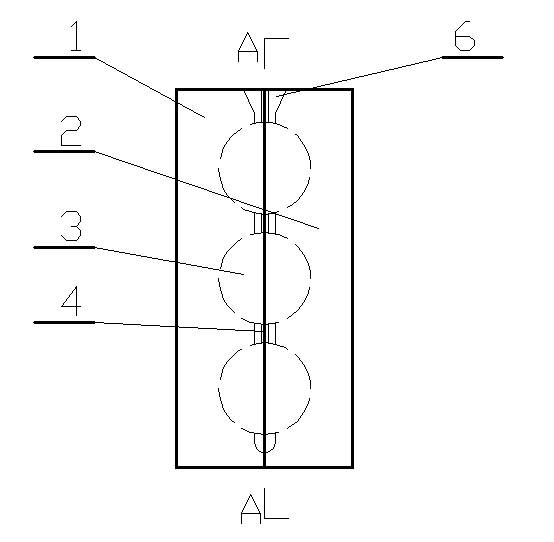

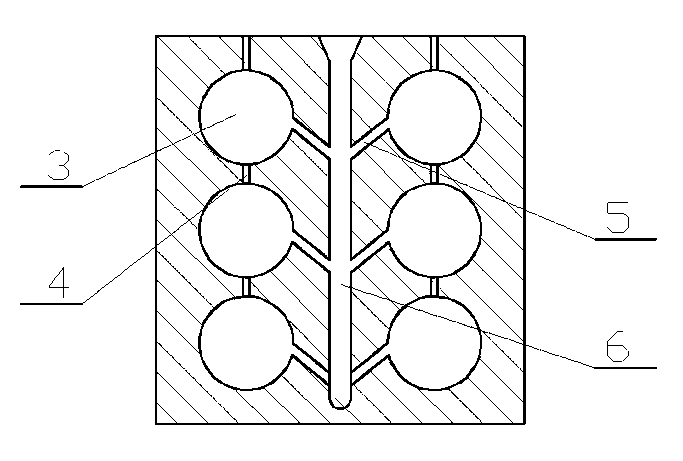

Steel ball casting die

The invention relates to a steel ball casting die. The steel ball casting die comprises two half dies, wherein the die adopts a left-right die assembly manner, and the faying surface of the two half dies is correspondingly provided with multiple half round ball grooves from top to bottom; when the two half dies are closed, the two half round ball grooves can form an integrated ball groove; the adjacent upper and lower ball grooves are communicated through an air groove; one sides of the ball grooves are provided with vertical pouring gates, and the pouring gates and the ball grooves are connected through a pouring branch channel; and air outlets of the air grooves and pouring ports of the pouring gates are formed in the top of the die. The steel ball casting die does not need to move through people in a using process, the labour intensity of workers is lightened, the molten steel use ratio is greatly improved and can achieve 93%, the product fineness is greatly improved, the finished steel ball has no sand falling and air ring, and the pouring time is short.

Owner:仇存红

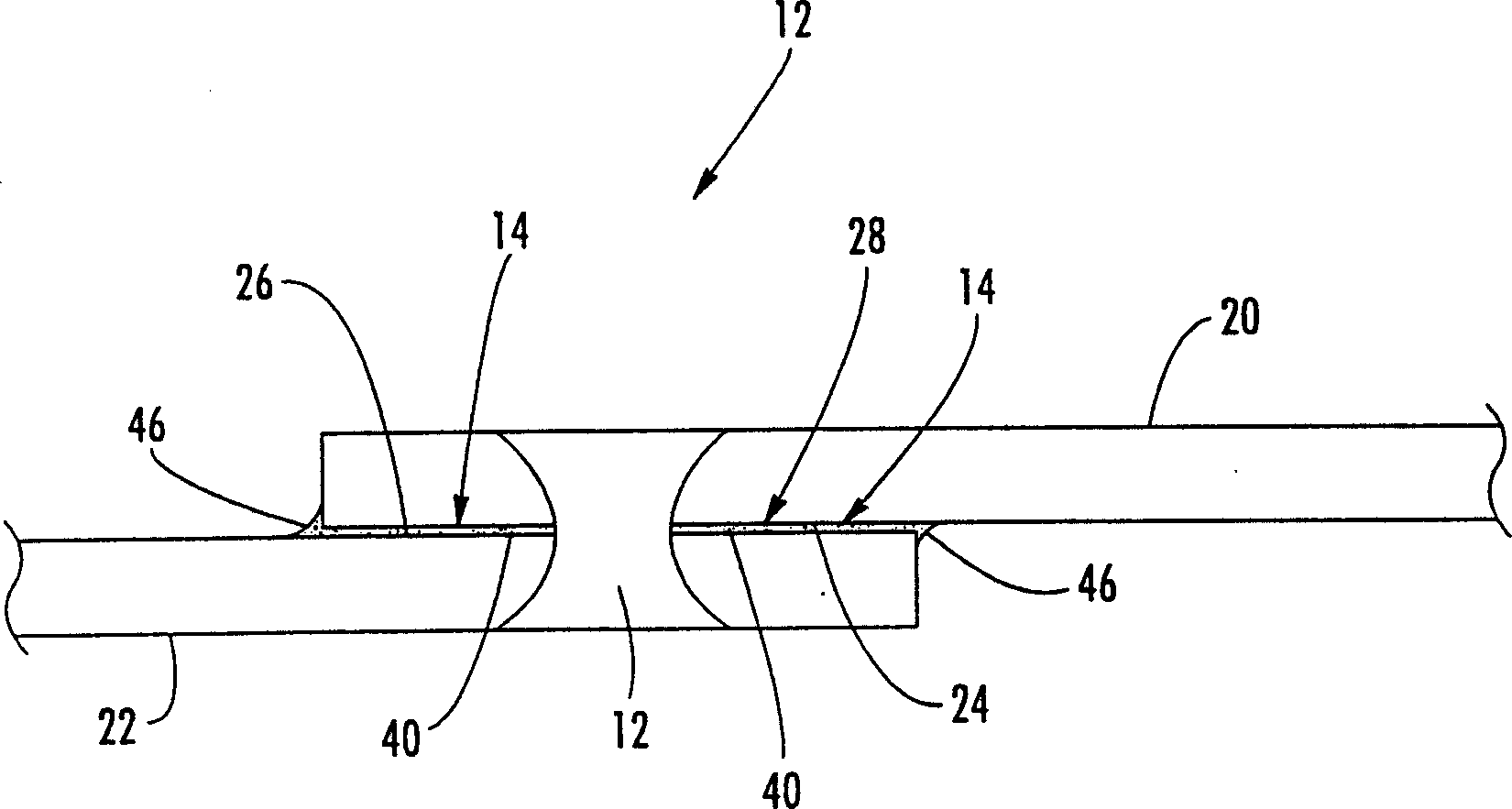

Method of electrical resistance spot welding

InactiveUS7432466B2Extended service lifeReduce morbidityOhmic-resistance electrodesElectrode featuresElectrical resistance and conductanceMetal sheet

A method of resistance welding comprising the steps of contacting a metal sheet with an electrode having an initial contact surface area at a force to provide a pressure to the metal sheet applying a current through the electrode to the metal sheet; measuring dimensional changes of the electrode; correlating dimensional changes in the electrode to changes in the initial contact surface area; and adjusting the force to compensate for the changes in the initial contact surface area of the electrode to maintain pressure to the metal sheet. The force may be adjusted by stepping the force to maintain pressure to the faying surface of the metal sheet to be welded. By maintaining the pressure at the faying surface the life cycle of the electrodes may be increased without forming discrepant welds. The current may also be stepped to further extend electrode life.

Owner:ARCONIC INC

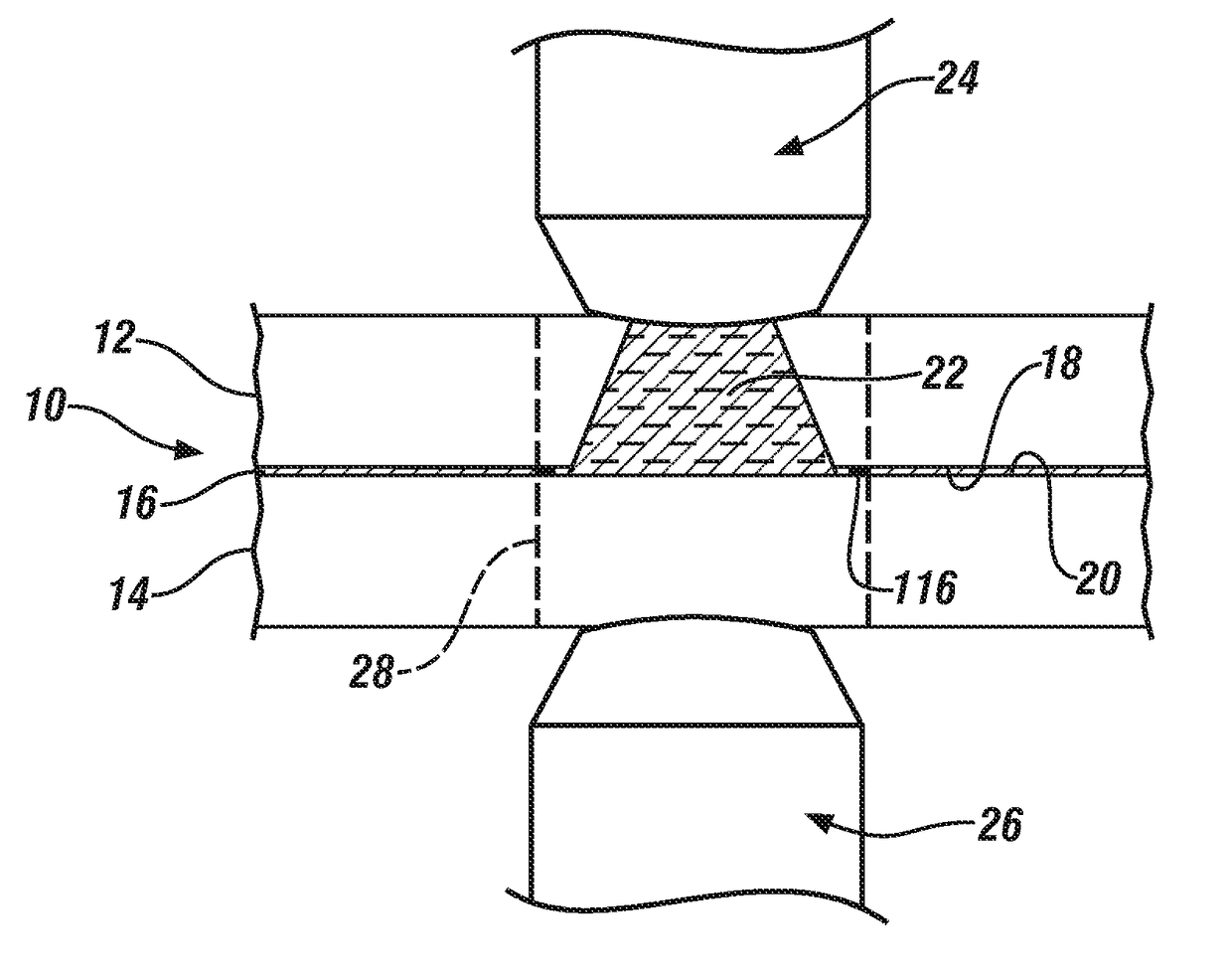

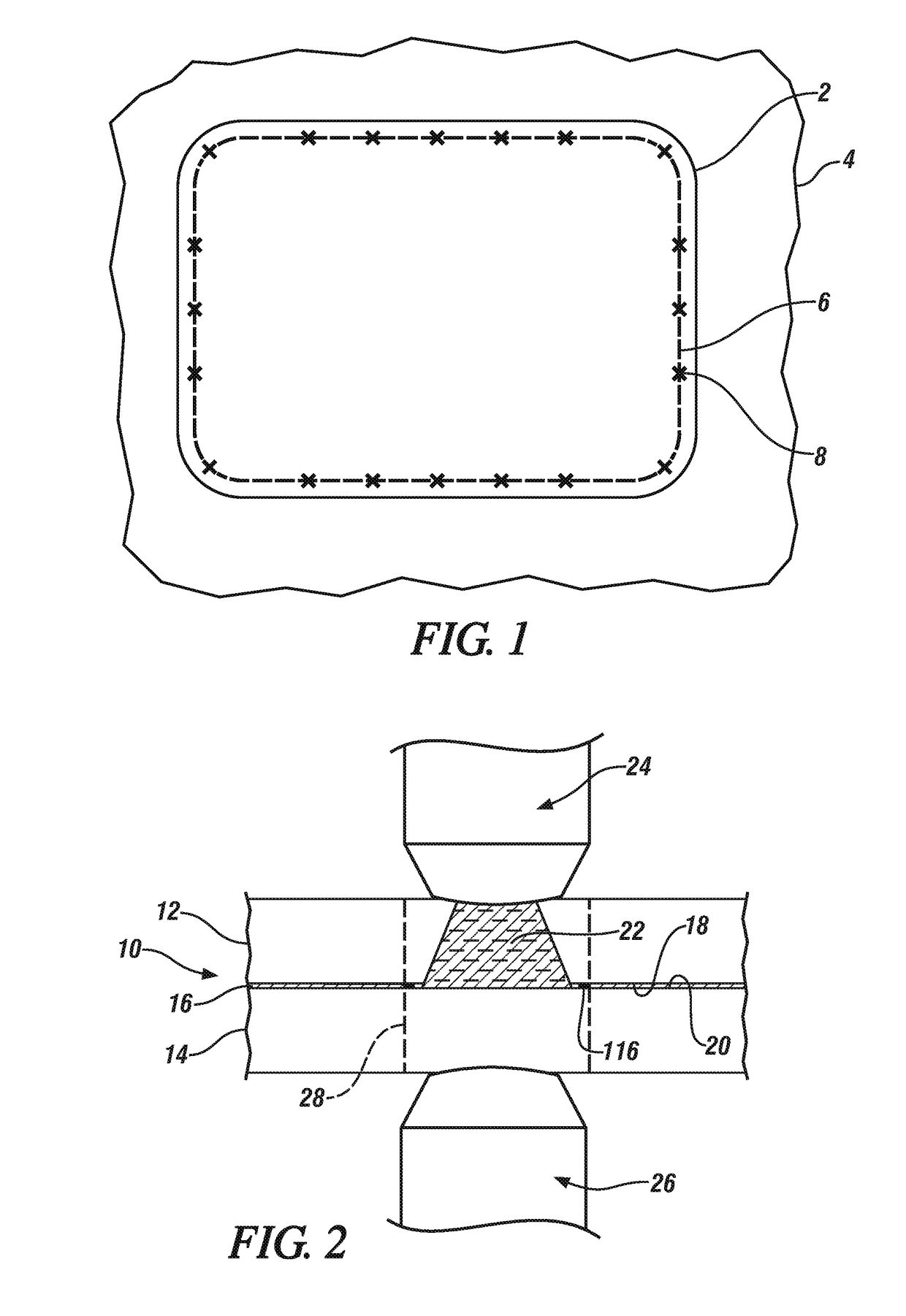

Joining of light metal alloy workpieces to steel workpieces using resistance spot welding and adhesive

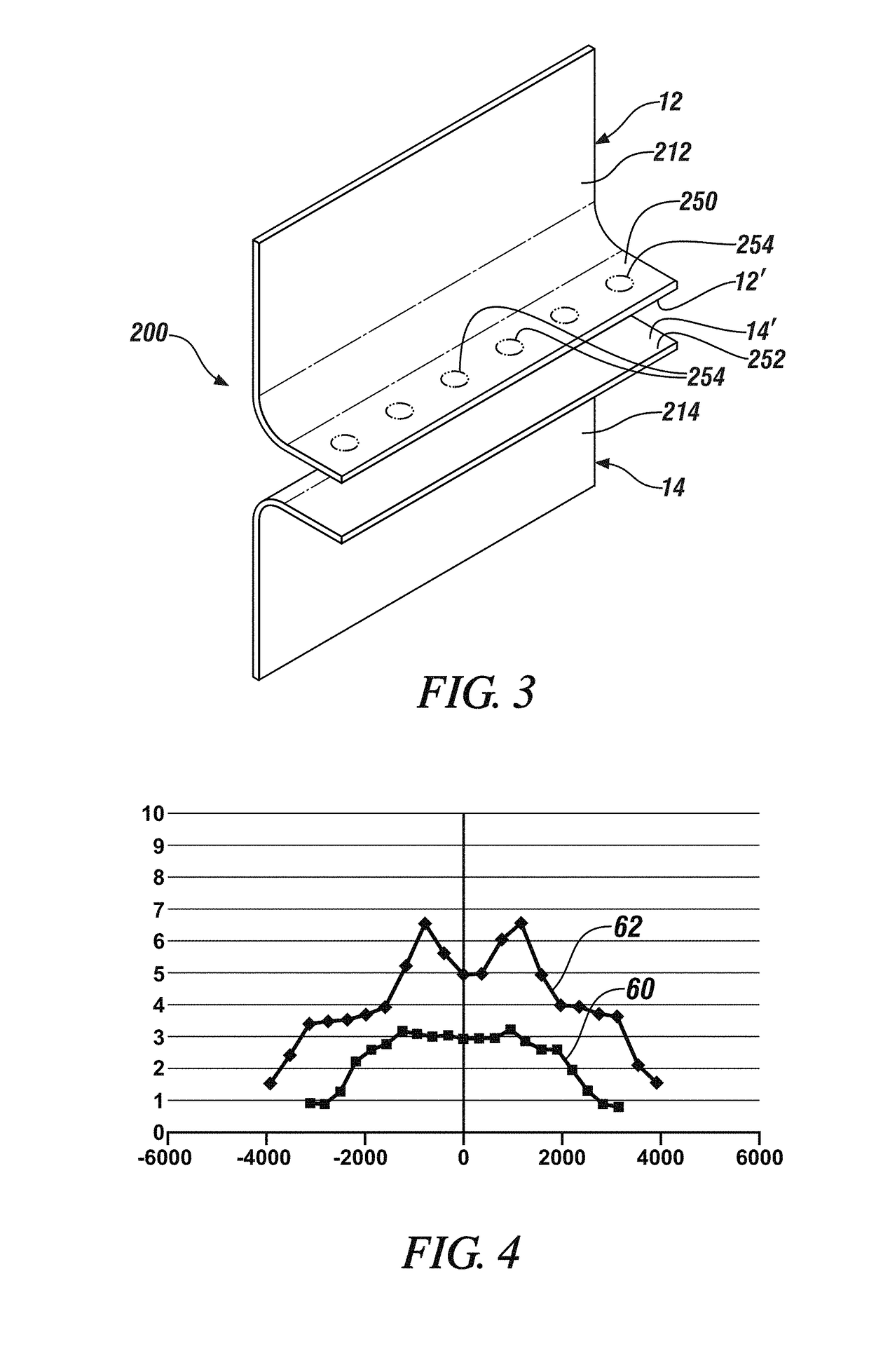

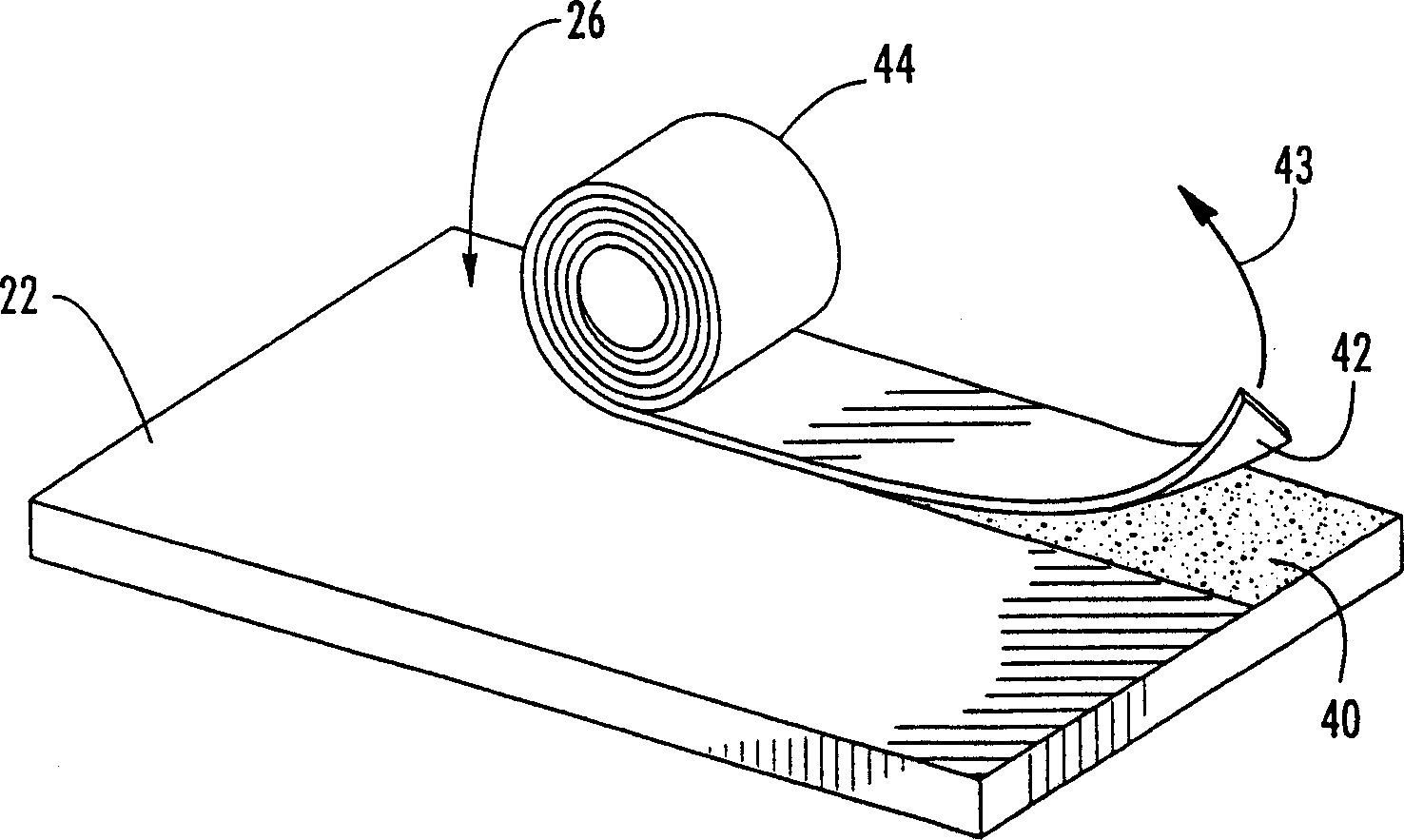

ActiveUS20170232548A1Adhesive processes with adhesive heatingAdhesive processes involving weldingSpot weldingFaying surface

A method of adhesive weld bonding a light metal workpiece and a steel workpiece is disclosed that includes applying a plurality of discrete adhesive ribbons to a faying surface of the light metal workpiece, the faying surface of the steel workpiece, or both faying surfaces, and then assembling the workpieces together to establish one or more adhesive zones between the faying surfaces of the light metal and steel workpieces and a plurality of adhesive free zones amongst the adhesive zone(s). The method further includes forming a resistance spot weld that bonds the the light metal workpiece and the steel workpiece together at a spot weld location within one of the adhesive free zones. The formed spot weld includes a weld joint contained within the light metal workpiece that bonds to the faying interface of the steel workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

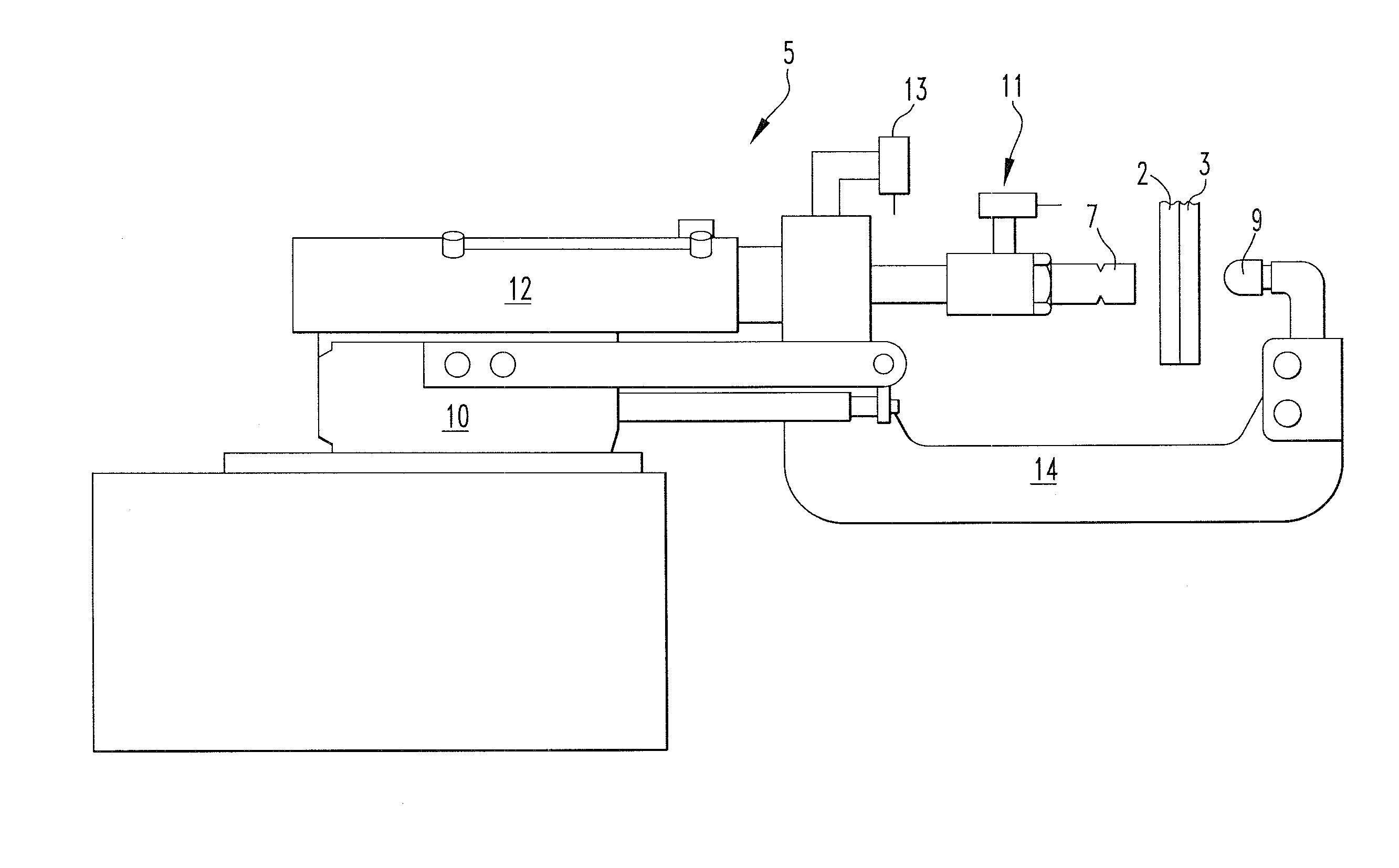

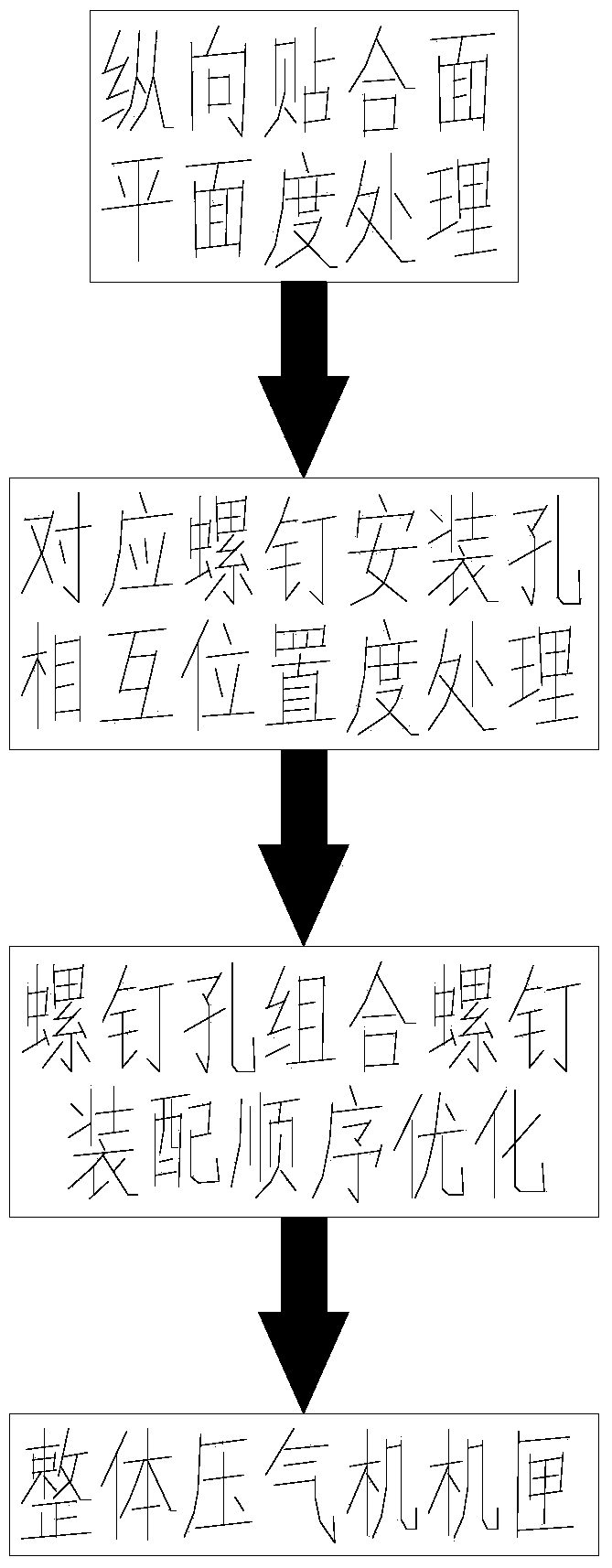

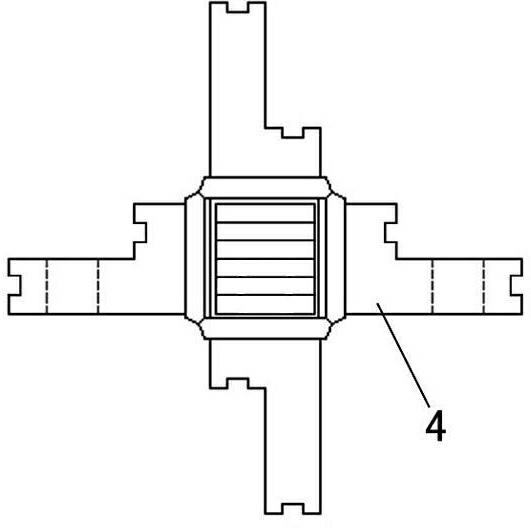

Method for machining half-and-half casings of gas compressor of aero-engine

The invention discloses a method for machining half-and-half casings of a gas compressor of an aero-engine. The method comprises the following steps that a, flatness processing is carried out on the longitudinal faying surfaces of the two half-and-half casings, wherein plane processing is carried out on the two half-and-half casings after rough machining in a mode that the base levels abut against each other so as to ensure the flatness of the longitudinal faying surfaces of the two half-and-half casings; b, the mutual location degree processing is carried out on corresponding screw installation holes in the longitudinal faying surfaces of the two half-and-half casings, wherein finish machining is carried out on at least part of screw installation holes which are correspondingly formed, and screws provided with locating cylindrical surfaces are arranged in the screw installation holes after the finish machining in a matched mode; c, the screws are assembled in the screw installation holes of the longitudinal faying surfaces of the two half-and-half casings according to the preset optimized assembly sequence; d, the two half-and-half casings form an integrated casing of the gas compressor. The method for machining the half-and-half casings of the gas compressor of the aero-engine adopts the half-and-half casing combined deformation control technology, combined deformation of the half-and-half casings is eliminated, the accuracy of consistency of repeated combination is good, and the application prospects are wide.

Owner:CHINA HANGFA SOUTH IND CO LTD

Steel structure building beam or pillar node interface

InactiveCN102561527AImprove bearing capacityHigh longitudinal tensile strengthBuilding constructionsBreaking strengthButt joint

The invention relates to a steel structure building beam or a steel structure pillar node interface, which is used for connecting convergent nodes of a steel structure building beam or a steel structure pillar and overcoming the shortages of toilsome assembly, bad accuracy, low connection strength, and the like in the existing connection mode. The steel structure building beam or pillar node interface is composed of joints of the end part of the beam or the pillar and joint seats converged on the node, wherein the joints lack a half at the end part in the horizontal direction to form a ladder shape. The shape and the size of the joint seats are the same with that of the joints. A connection insertion tenon is arranged on a mutual faying surface formed when the joint is butt jointed with the joint seat, the connection insertion tenon is vertical to the faying surface and a fastening structure for preventing the joint and the joint seat from horizontally separating is arranged at the faying position of the joint and the joint seat. According to invention, the steel structure building beam or pillar node interface has the beneficial effects that the faying mode bearing of the interface has large bearing capacity; the steel structure building beam-pillar node interface has high longitudinal tensile strength, is provided with the fastening member for preventing the joint and the joint seat from horizontally separating so that the connection of the node of the beam and the pillar has multi-directional higher anti-breaking strength, has a simple structure, and is convenient to manufacture and install; and with the adoption of the steel structure building beam or pillar node interface, the conditions are created for modularization, standardization and serialization of steel structure housing construction.

Owner:罗大威

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com