Method and sealant for joints

A technology of sealants and seals, applied in welding equipment, transportation and packaging, manufacturing tools, etc., can solve the problems of lowering the quality of welded joints, loosening of sealants, and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be described in more detail with reference to the accompanying drawings, in which some, but not all, embodiments are shown. Indeed, the present invention may be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that this disclosure will satisfy appropriate legal requirements. In the drawings, the same reference numerals denote the same elements.

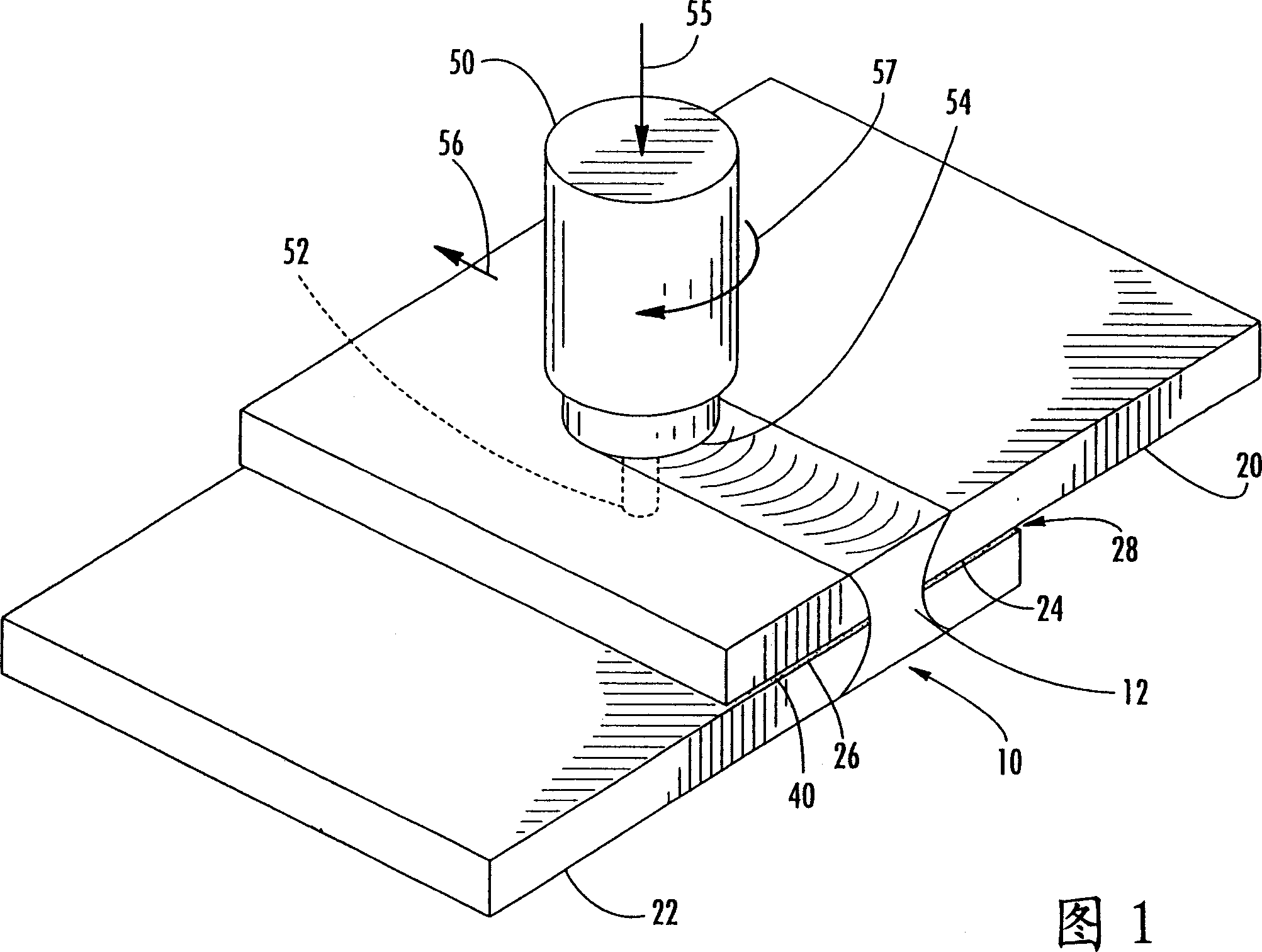

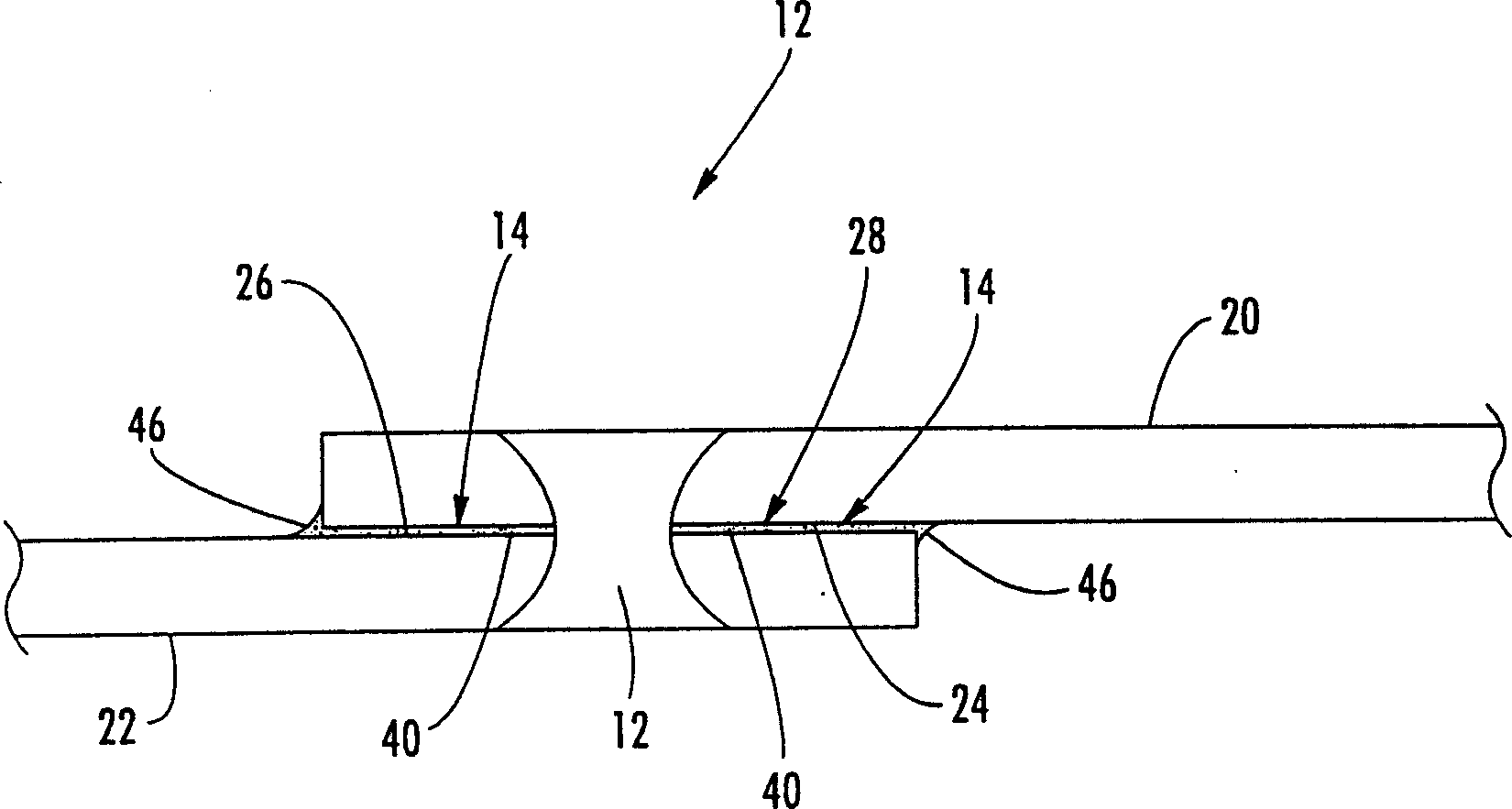

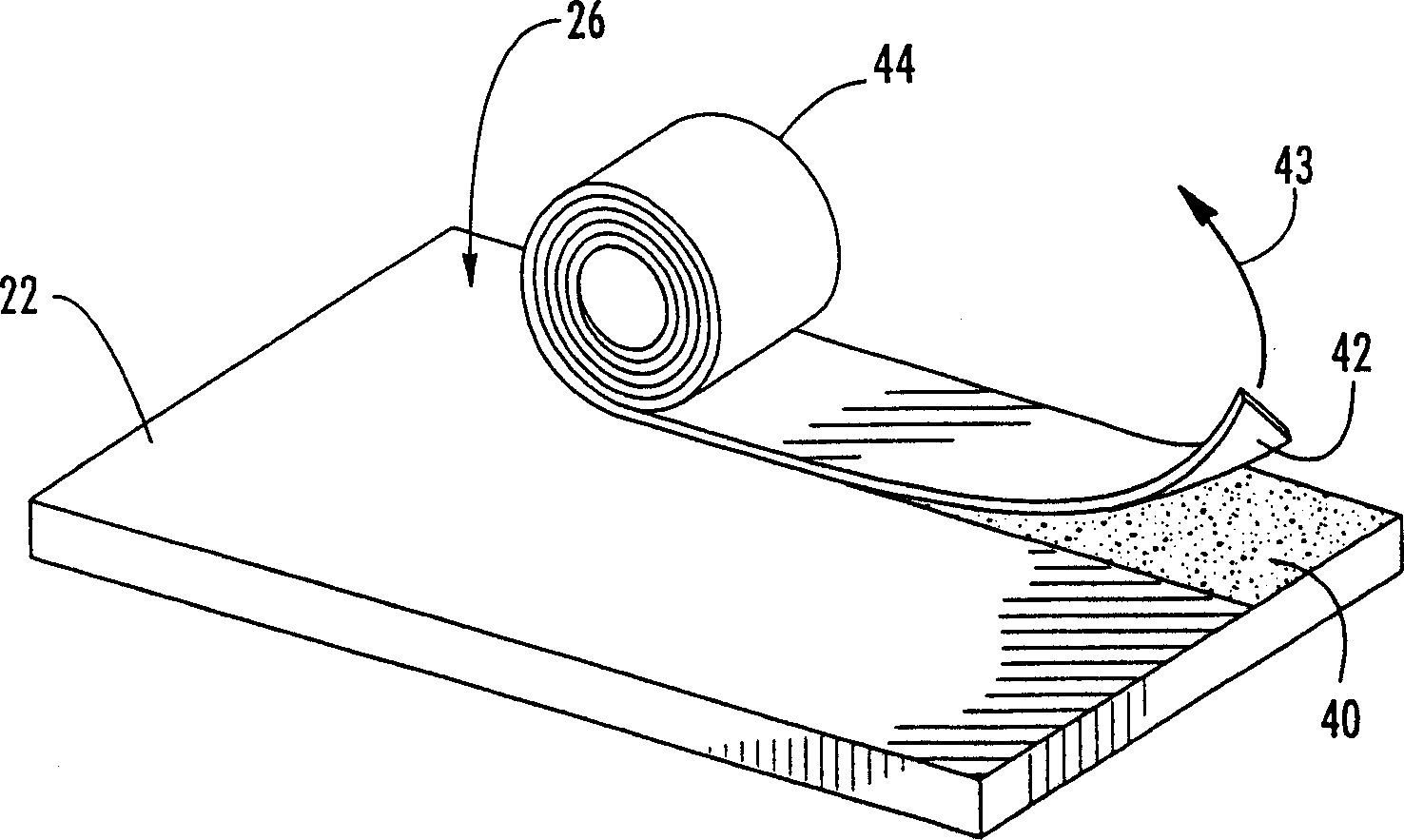

[0019] Referring now to the drawings, and in particular to FIG. 1, there is shown an apparatus for forming a joint 10 for connecting first and second structural members 20, 22. The method of the present invention typically joins two structural components, but it can also join a single structural component, such as a pipe component or other curved component with adjoining edges. Three or more structural members may also be optionally connected, and the structural members may be arranged in various configurations. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com