Friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft

A titanium-aluminum alloy and friction welding technology, applied in the field of friction welding, can solve the problems of low tensile strength of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

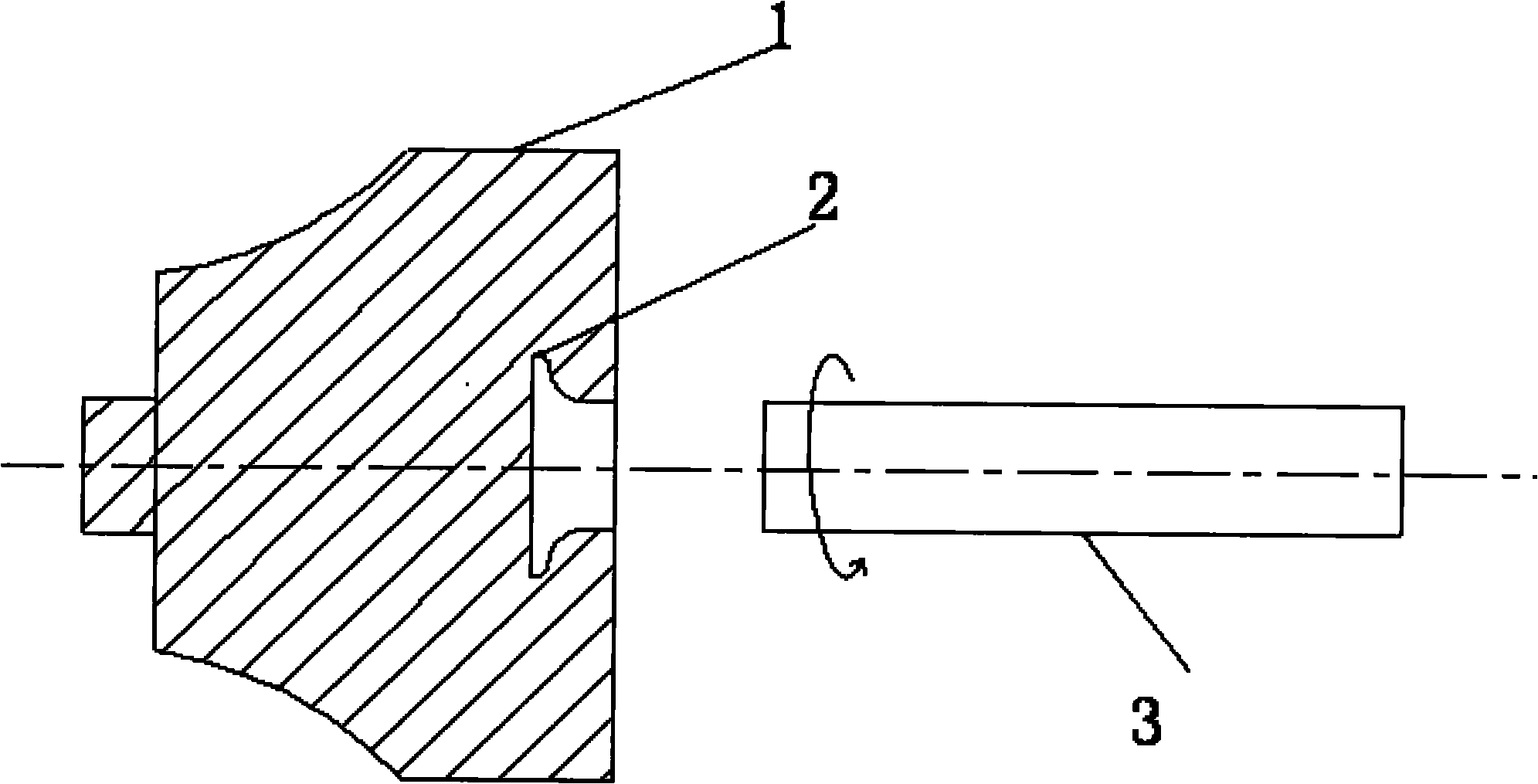

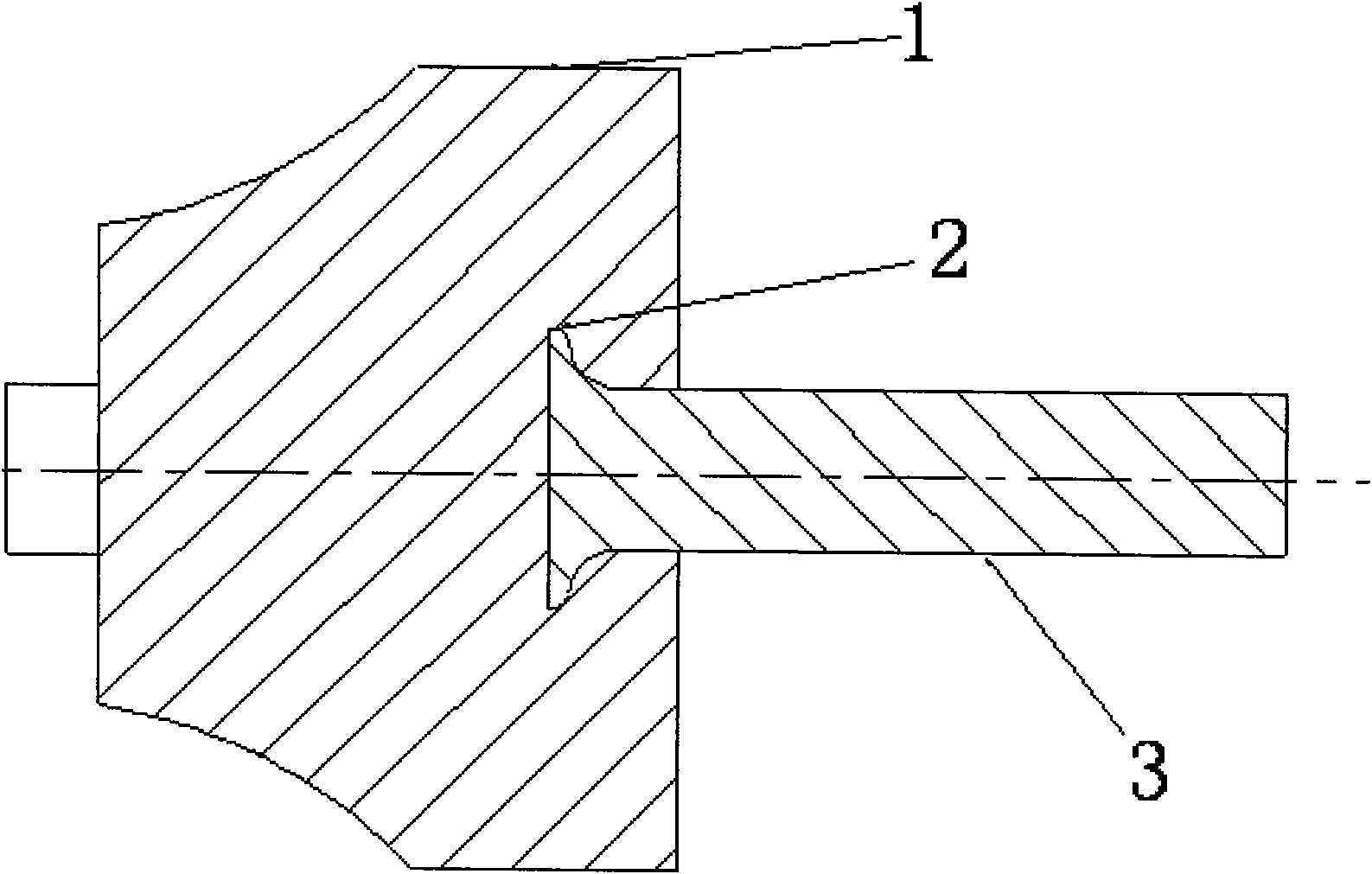

[0027] Embodiment 1: refer to figure 1 , figure 2 , the specific steps of the friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft are as follows:

[0028] a. The titanium-aluminum alloy turbine 1 to be welded is subjected to stress-relief heat treatment before welding, the heating temperature is 600°C, and the holding time is 1.5; b. An embedding groove 2 in the shape of a rotating body is processed on one side of the titanium-aluminum alloy turbine 1, and the groove depth is 10mm , the minimum inner diameter is the same as the outer diameter of the quenched and tempered steel shaft; c, grinding the surface of the titanium-aluminum alloy turbine 1 to be welded and the quenched and tempered steel shaft 3 to be welded, and cleaning with acetone; d, the titanium-aluminum alloy turbine 1 to be welded and the quenched and tempered steel shaft 3 are respectively clamped in the movable fixture and the rotary fixture of the rotary ...

Embodiment 2

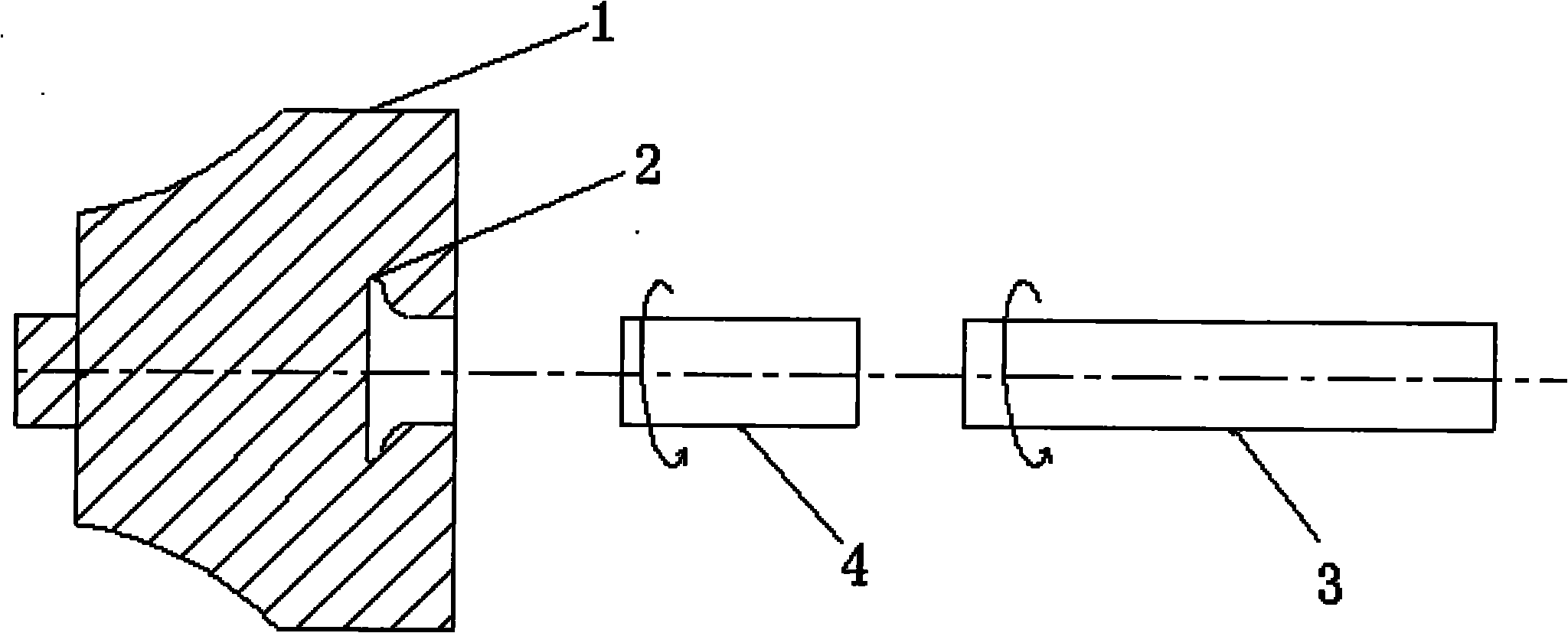

[0030] Embodiment 2: refer to image 3 , Figure 4 , the specific steps of the friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft are as follows:

[0031] a. The titanium-aluminum alloy turbine 1 to be welded is subjected to stress-relief heat treatment before welding, the heating temperature is 630°C, and the holding time is 2h; b. On the side of the titanium-aluminum alloy turbine 1, an embedding groove 2 in the shape of a rotating body is processed, and the groove depth is 10mm , the minimum inner diameter is equivalent to the outer diameter of the quenched and tempered steel shaft 3; c, select a suitable intermediate material 4, such as a superalloy, and first friction weld the intermediate material 4 and the quenched and tempered steel shaft 3, the friction pressure is 400Mpa, the top pressure is 600Mpa, the friction Shorten the pressure by 3mm, and hold the pressure for 5s; d. Process the excess intermediate material ...

Embodiment 3

[0033] Embodiment 3: refer to image 3 , Figure 4 , the specific steps of the friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft are as follows:

[0034] a. The titanium-aluminum alloy turbine 1 to be welded is subjected to stress-relief heat treatment before welding, the heating temperature is 670°C, and the holding time is 2.5h; b. An embedding groove 2 in the shape of a rotating body is processed on one side of the titanium-aluminum alloy turbine 1, and the depth of the groove is 10mm, the minimum inner diameter is equivalent to the outer diameter of the quenched and tempered steel shaft; c. Select a suitable intermediate material 4, such as titanium alloy, and first perform embedded friction welding between the intermediate material 4 and the titanium-aluminum alloy turbine 1, the friction pressure is 450Mpa, and the top pressure is 700Mpa , the pressure holding time is 5s, under the joint action of friction heat and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com