Argon-arc welding-braze welding composite welding method for connecting the titanium alloy and steel

A hybrid welding and argon arc welding technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve problems affecting joint performance, etc., and achieve the effect of improving tensile strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

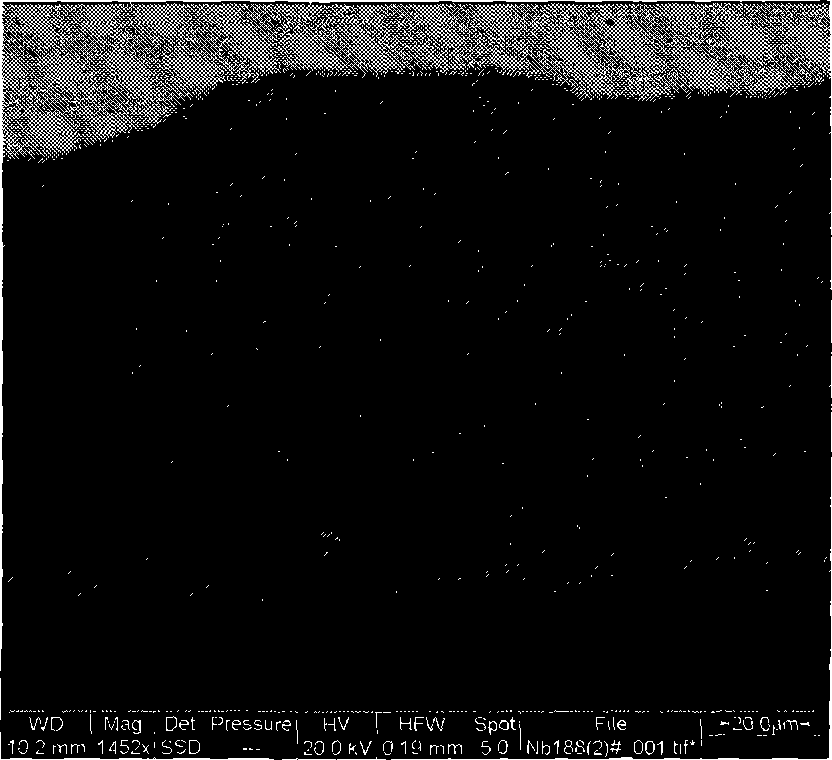

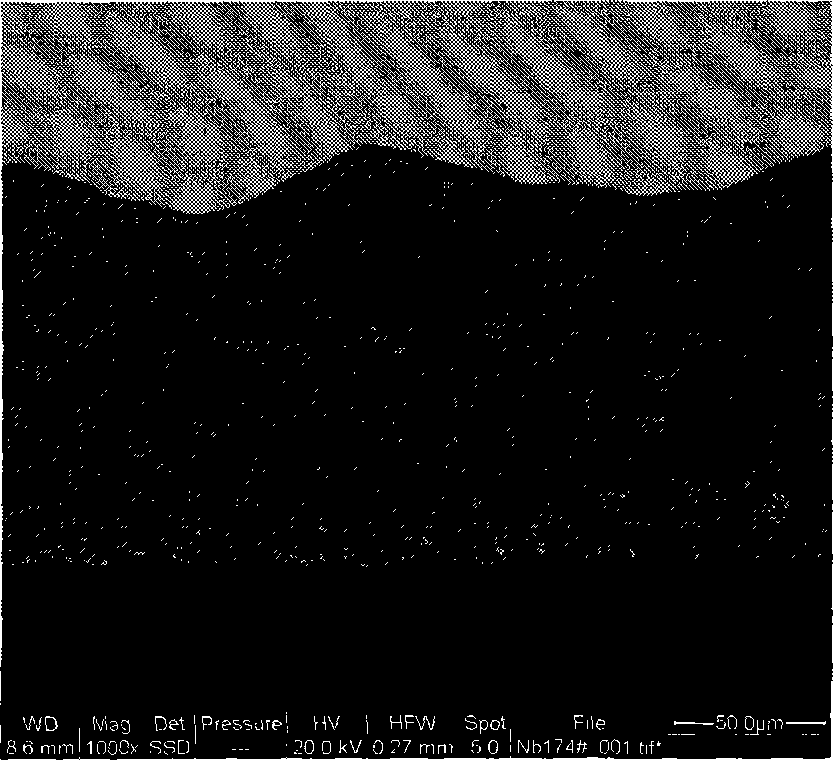

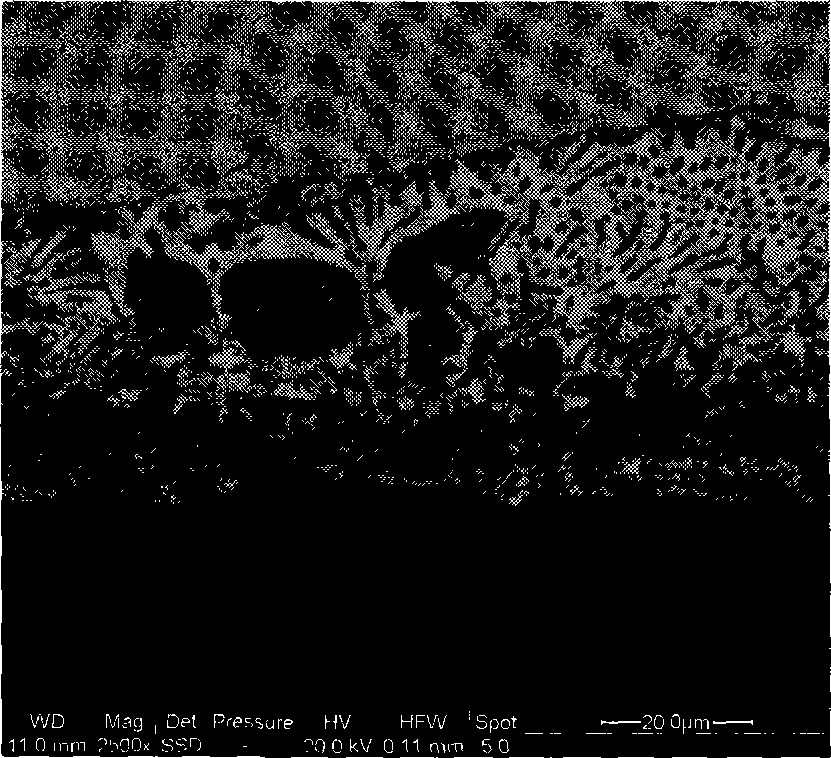

[0016] When welding titanium alloy and steel, Nb is used as the intermediate layer. First, the titanium alloy and Nb intermediate layer are welded by argon arc welding with titanium welding wire in the argon filled box, and then the titanium alloy + Nb intermediate layer and steel are brazed.

[0017] When welding titanium alloy and steel, Nb is used as the intermediate layer. First, the titanium alloy and Nb intermediate layer are welded by argon arc welding with titanium welding wire in an argon-filled box, and then the titanium alloy + Nb intermediate layer and steel are vacuum brazed.

[0018] The brazing filler metal is copper-manganese based filler metal or silver-copper-titanium filler metal. The composition of the silver-copper-titanium filler metal is as follows: the weight percentage of copper content is 25%-40%, and the weight percentage of titanium content is not more than 7 %, the balance is silver; copper-manganese-based brazing filler metals are two types: copper-mang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com