Nano TiB2 particle reinforced metal-base composite material and preparation method thereof

A technology of particle reinforcement and composite materials, which is applied in the field of composite materials, can solve problems such as insufficient strength, and achieve the effects of increasing tensile strength at room temperature, improving material performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

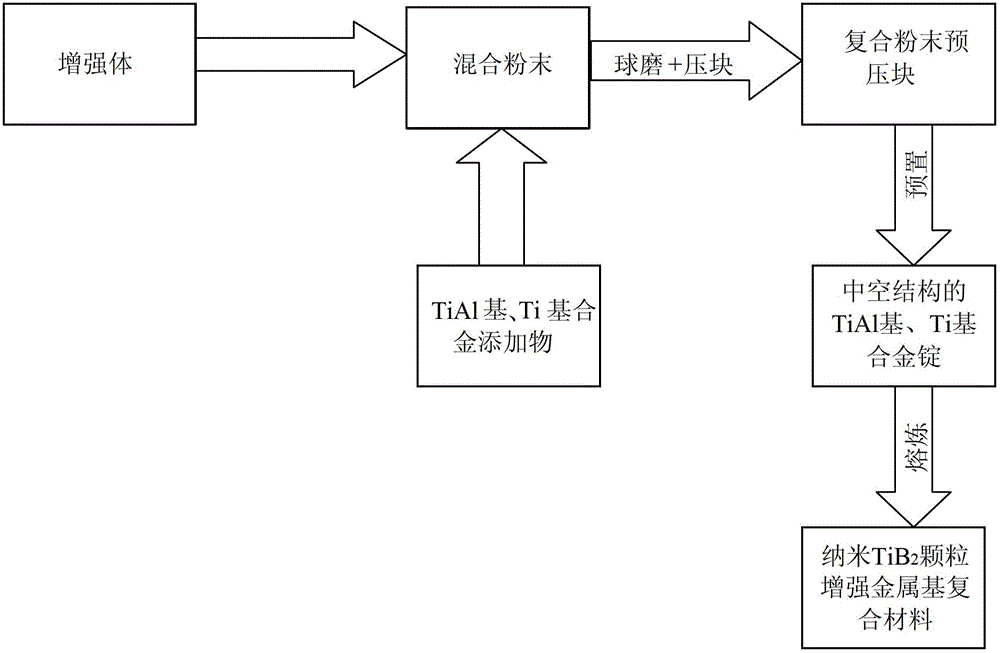

[0028] The present invention also provides a kind of above-mentioned nano-TiB 2 A method for preparing particle-reinforced metal matrix composites, the preparation method makes TiB 2 The fine and dispersed particles are distributed in the metal matrix material to ensure that the strength, toughness and high temperature strength of the composite material are improved at the same time, such as figure 1 Shown in the flowchart, the concrete steps of the preparation method are as follows:

[0029] The first step is augmentation body preprocessing.

[0030] Ultrafine Nano TiB 2 Particle pretreatment: After mixing the reinforcement particles and metal additives, they are compounded on a ball mill to form a composite powder; the metal additives use the same alloy scrap or alloy powder as the matrix alloy. The volume ratio of the reinforcement particles to the metal additive is 1:2 to 2:1.

[0031] The conditions of the composite ball milling are as follows: the ball milling time i...

Embodiment 1

[0036] Example 1: Preparation of 5vol%TiB 2 Reinforced TiAl-based composites, using TiB 2 The particle size is 20nm.

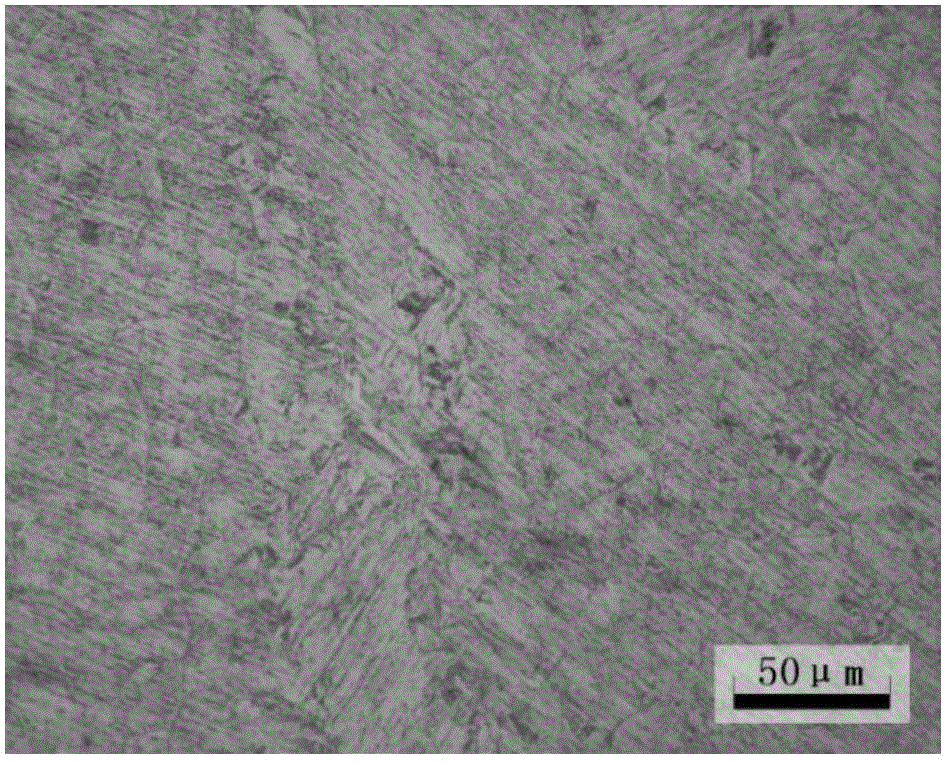

[0037] TiB 2 The particles are evenly mixed with TiAl powder, and the reinforcement TiB is guaranteed in the mixed powder 2 The volume ratio of particles to TiAl powder is 1:2, TiB 2 The particle size is 20nm. A ball mill is used for ball milling, the ball milling time is 1h, the ball milling speed is 200r / min, and the ball-to-material ratio is 2:1. After the ball milling, the temperature of the ball milling tank will be higher, and the tank can be opened after it is completely cooled. Open the ball mill tank in the vacuum operation box, and put the composite powder obtained after ball milling into the sample bag. The composite powder after ball milling was pre-compacted under atmospheric conditions of 25°C, the pressure was 1 MPa, and the holding time was 10 minutes, and it was used as a composite powder pre-compaction block. The compacted composite ...

Embodiment 2

[0039] Example 2: Preparation of 5vol%TiB 2 Reinforced TiAl-based composites, using TiB 2 The particle size is 80nm.

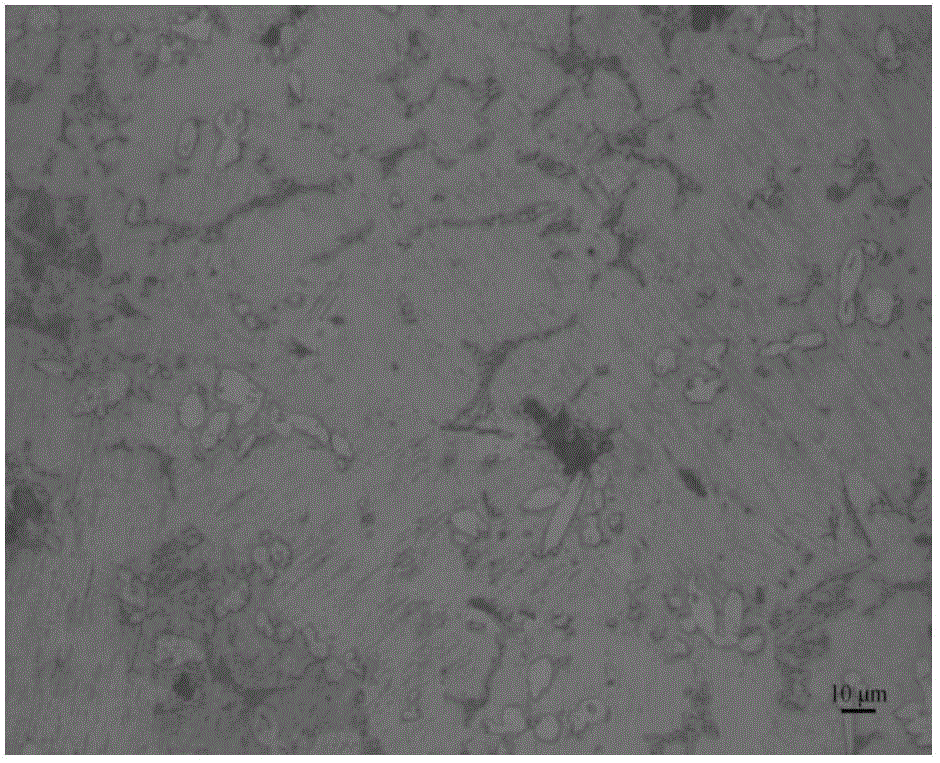

[0040] TiB 2 The particles and TC4 alloy chips are evenly mixed, and the volume ratio of reinforcement particles to TiAl alloy chips in the mixed powder is guaranteed to be 2:3, and TiB 2 The particle size is 80nm. A ball mill is used for ball milling, the ball milling time is 4 hours, the ball milling speed is 400r / min, and the ball-to-material ratio is 4:1. The composite powder after ball milling was pre-compacted under atmospheric conditions of 25°C with a pressure of 5 MPa and a holding time of 10 minutes, and it was used as a composite powder pre-compaction block. The pre-pressed block is pre-placed in the hollow TiAl alloy. Particle-reinforced titanium-aluminum matrix composites were smelted using an induction furnace. The melting conditions of the induction furnace are as follows: medium frequency induction furnace + graphite crucible melting, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com