Patents

Literature

87 results about "Aircraft industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

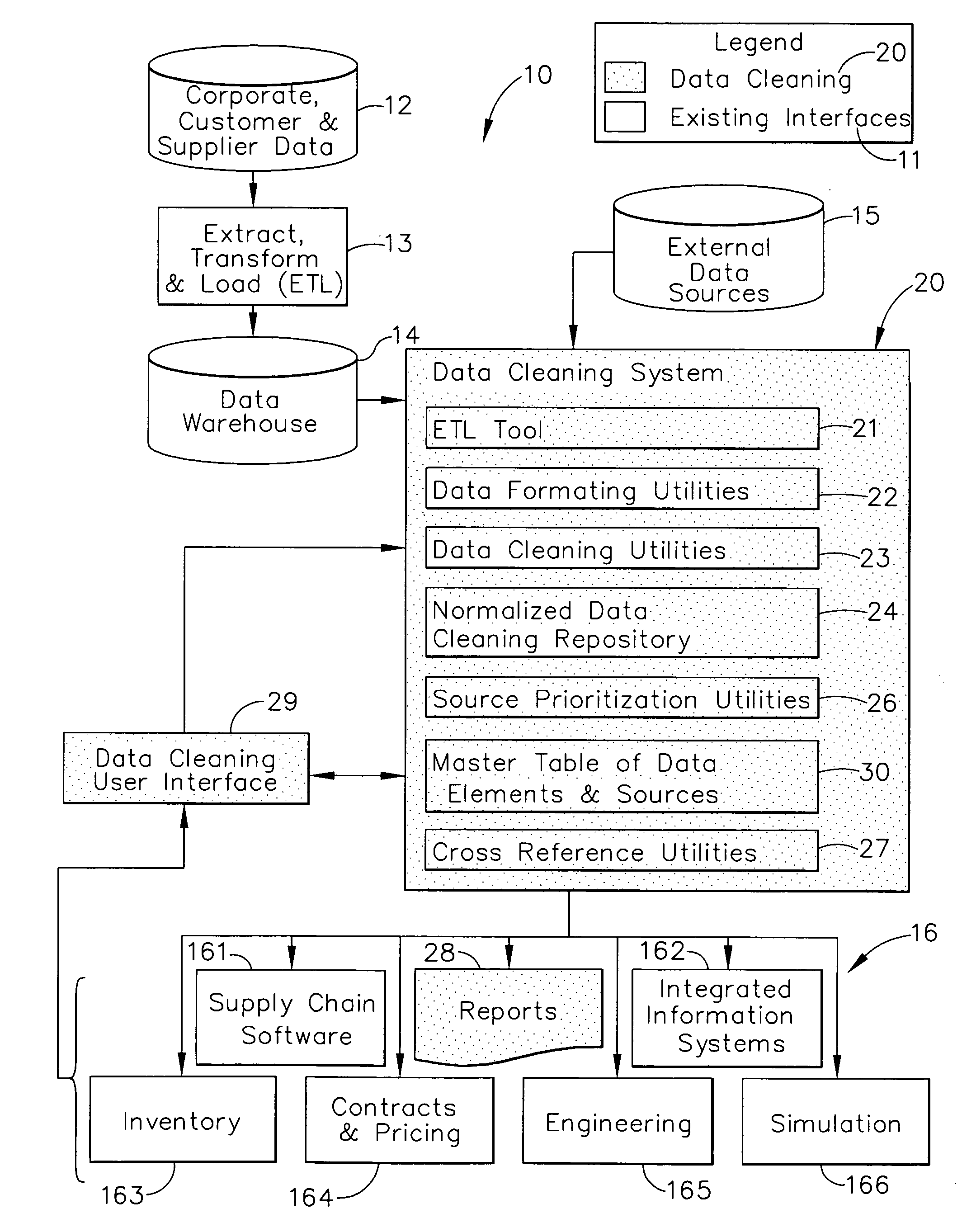

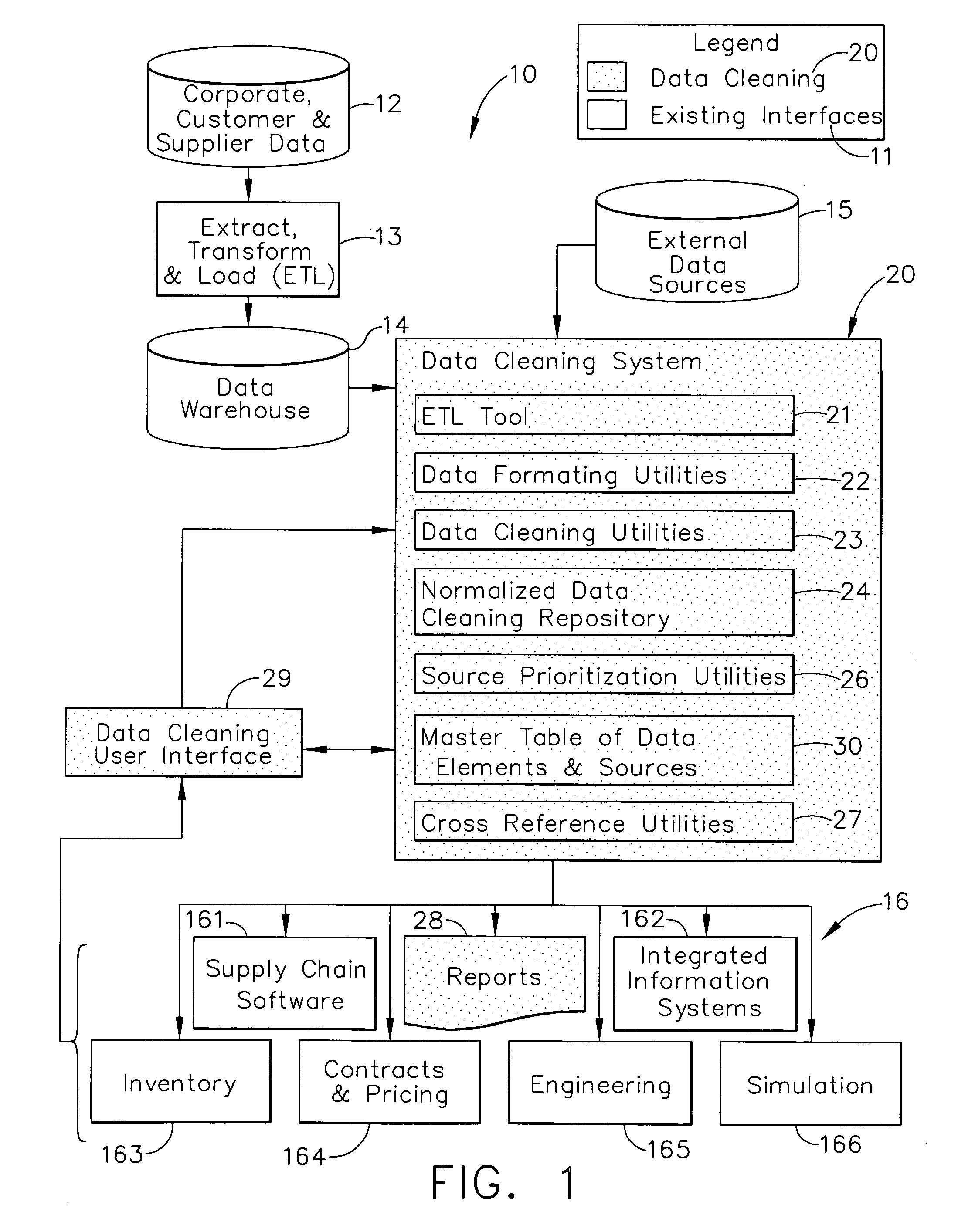

Adaptive data cleaning

InactiveUS20060238919A1Digital data information retrievalRecord information storageAnalysis dataData system

A data cleaning process includes the steps of: validating data loaded from at least two source systems; appending the validated data to a normalized data cleaning repository; selecting the priority of the source systems; creating a clean database; loading the consistent, normalized, and cleansed data from the clean database into a format required by data systems and software tools using the data; creating reports; and updating the clean database by a user without updating the source systems. The data cleaning process standardizes the process of collecting and analyzing data from disparate sources for optimization models enabling consistent analysis. The data cleaning process further provides complete auditablility to the inputs and outputs of data systems and software tools that use a dynamic data set. The data cleaning process is suitable for, but not limited to, applications in aircraft industry, both military and commercial, for example for supply chain management.

Owner:THE BOEING CO

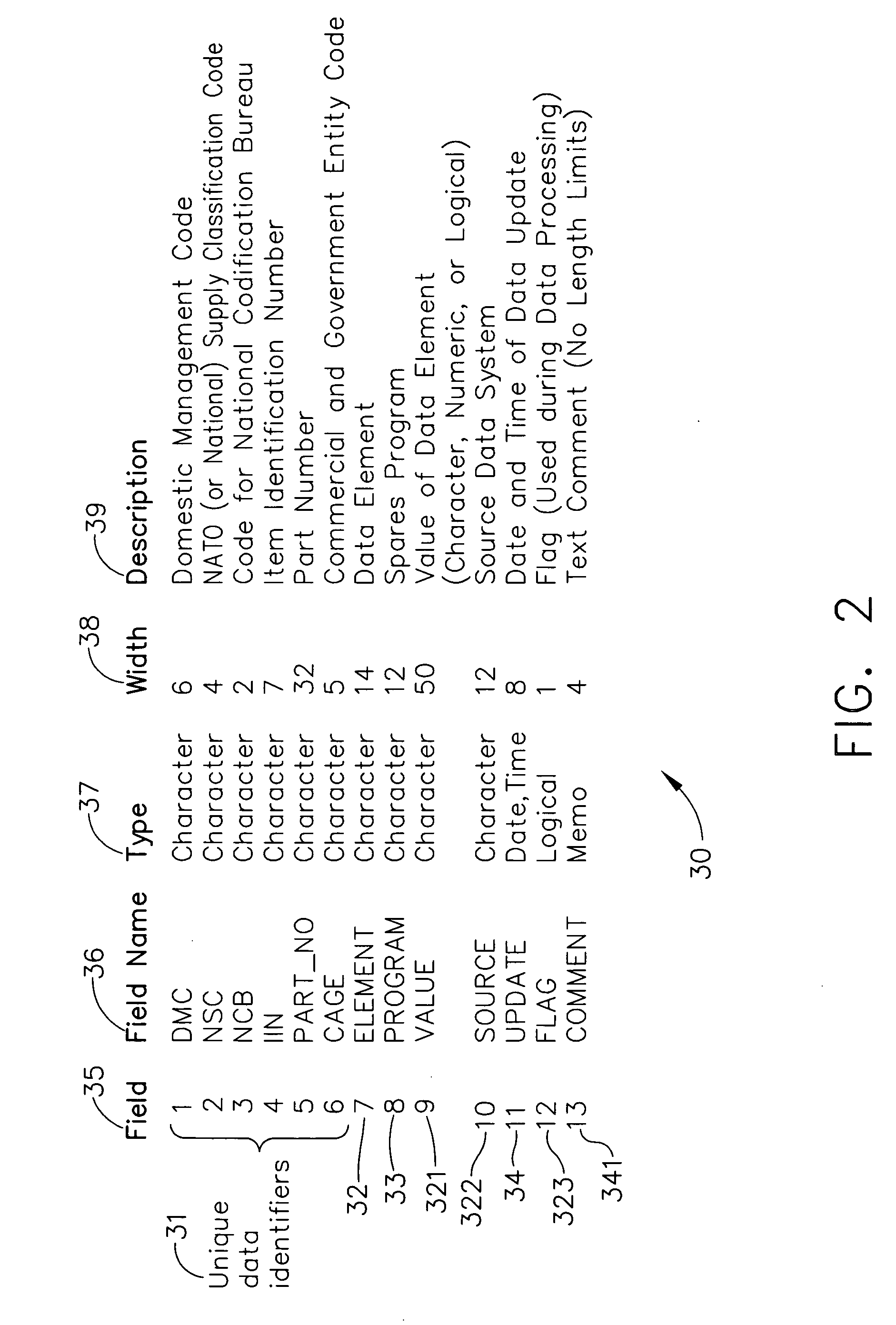

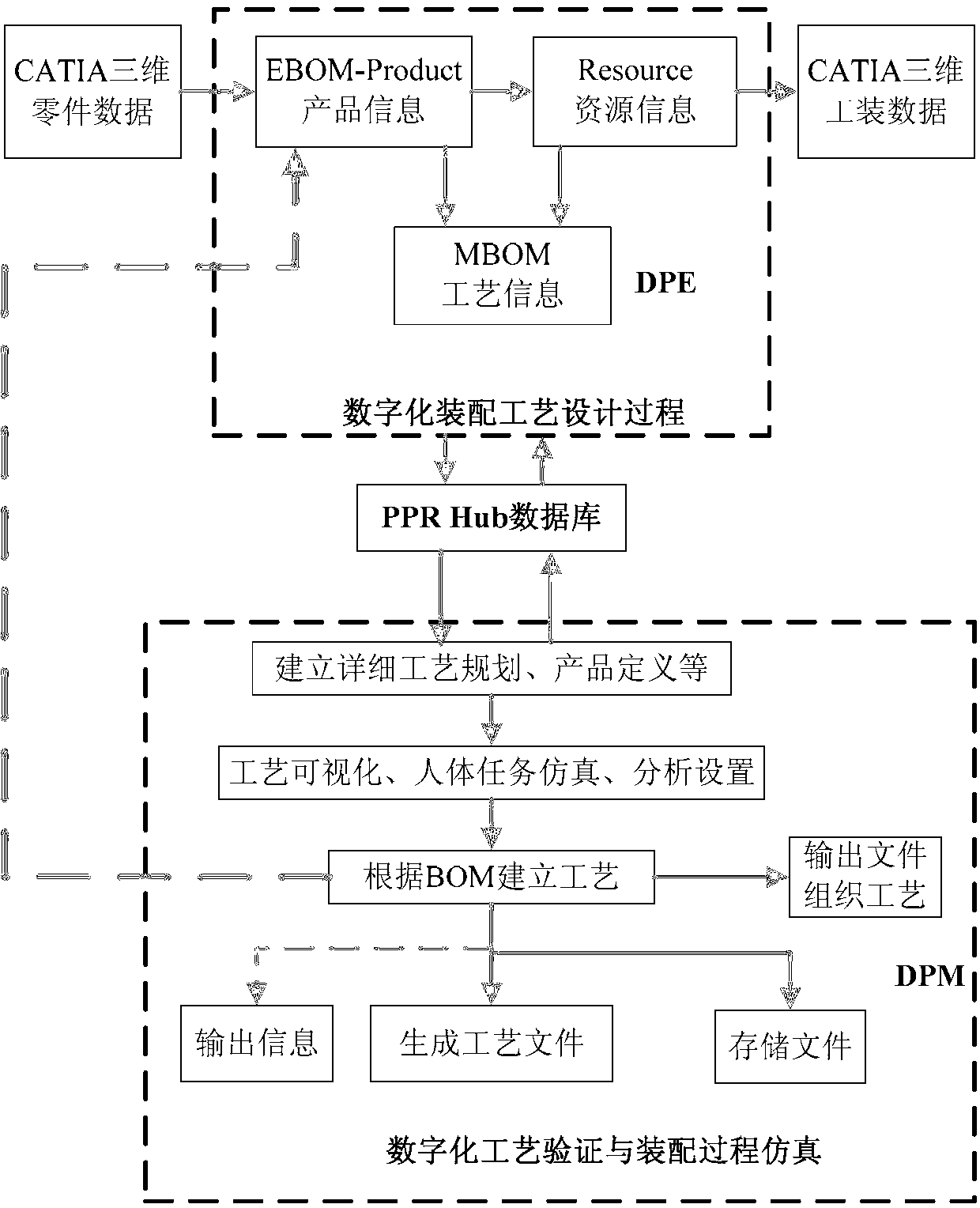

Aircraft assembly data visualization method based on Web

ActiveCN103020393ARealize online browsingReduce redundancySpecial data processing applicationsBill of materialsSimulation

The invention relates to an aircraft assembly data visualization method based on Web. The method comprises four steps as follows: step 1, setting up system architecture and development environment; step 2, visualization AO (Assembly Order) designing; step 3, assembling process simulation; and step 4, using in an assembly site. The method is used for realizing visual online browse of data such as BOM (Bill of Material), AO, product information and the like, and the assembly quality and the working efficiency of aircrafts are increased. The method has a better practical value and a wide application prospect in the aircraft industry.

Owner:BEIHANG UNIV

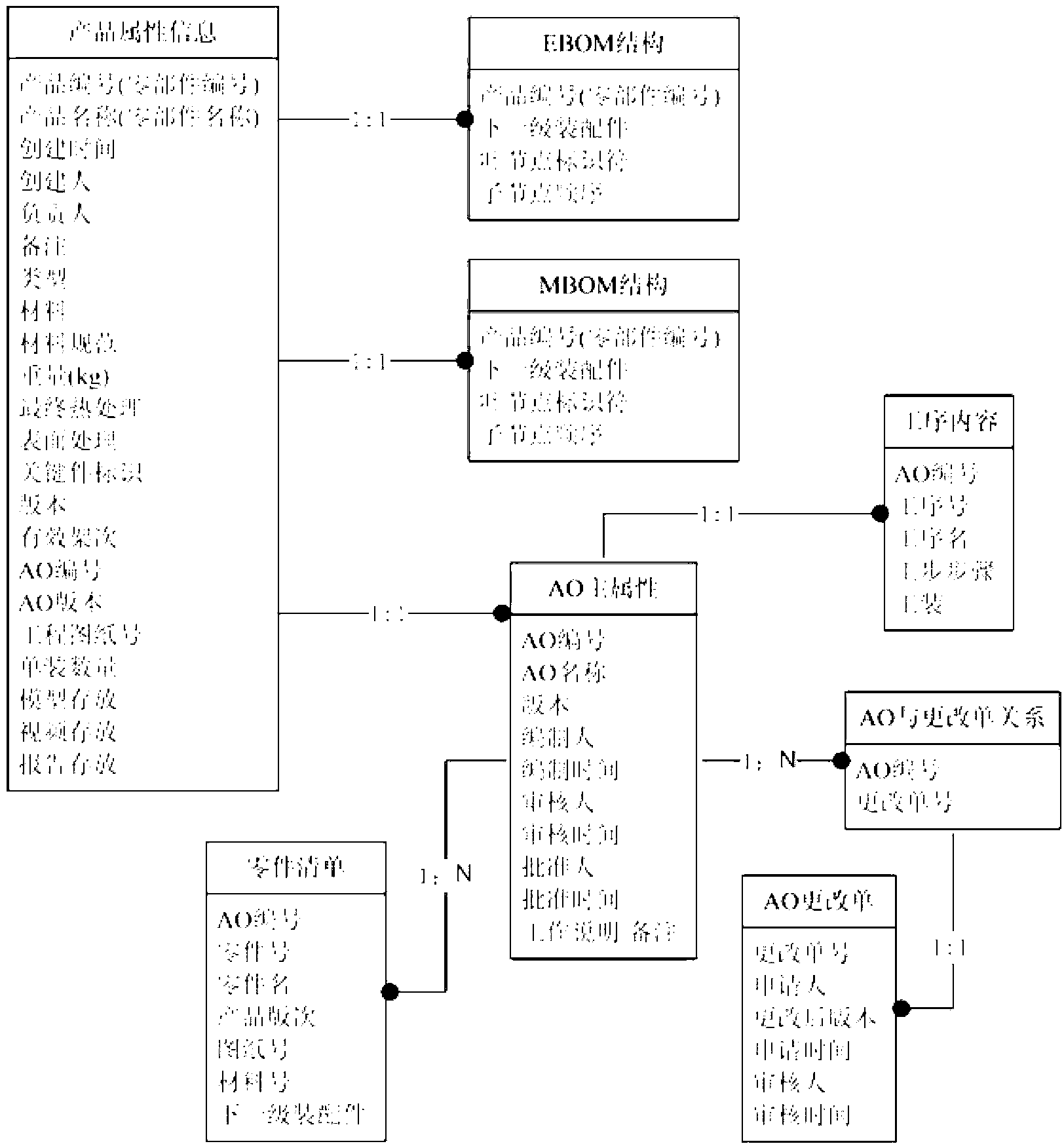

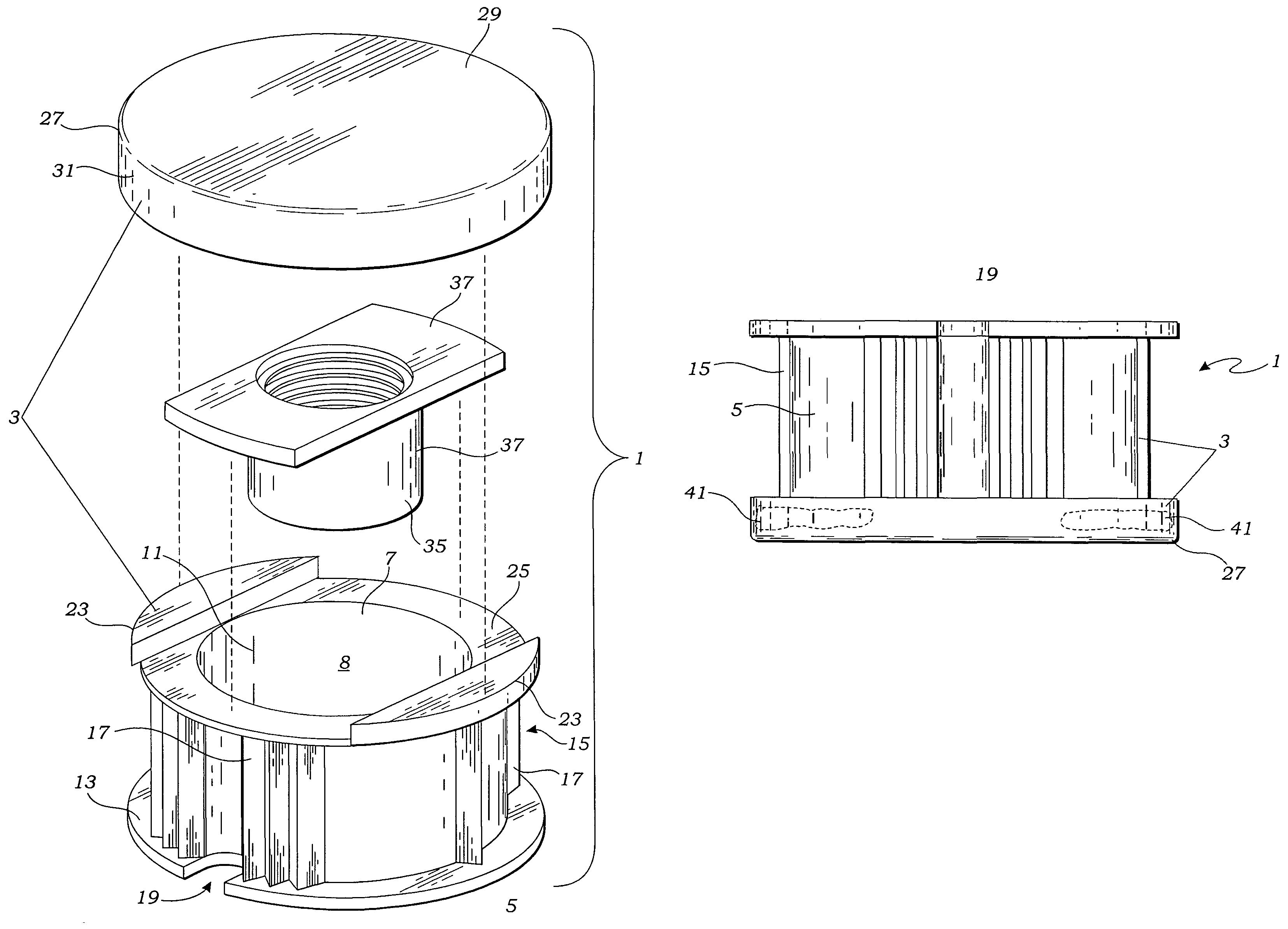

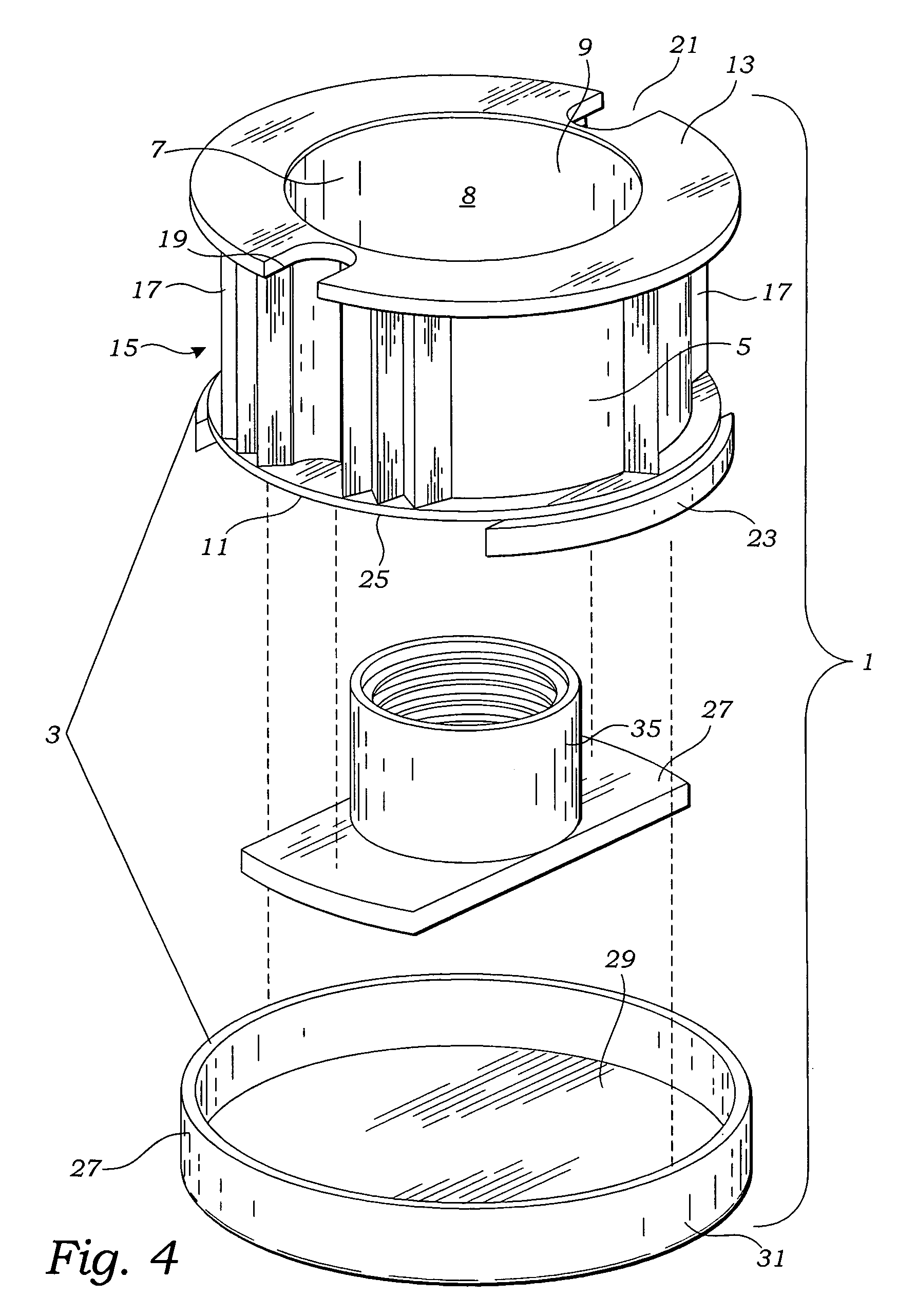

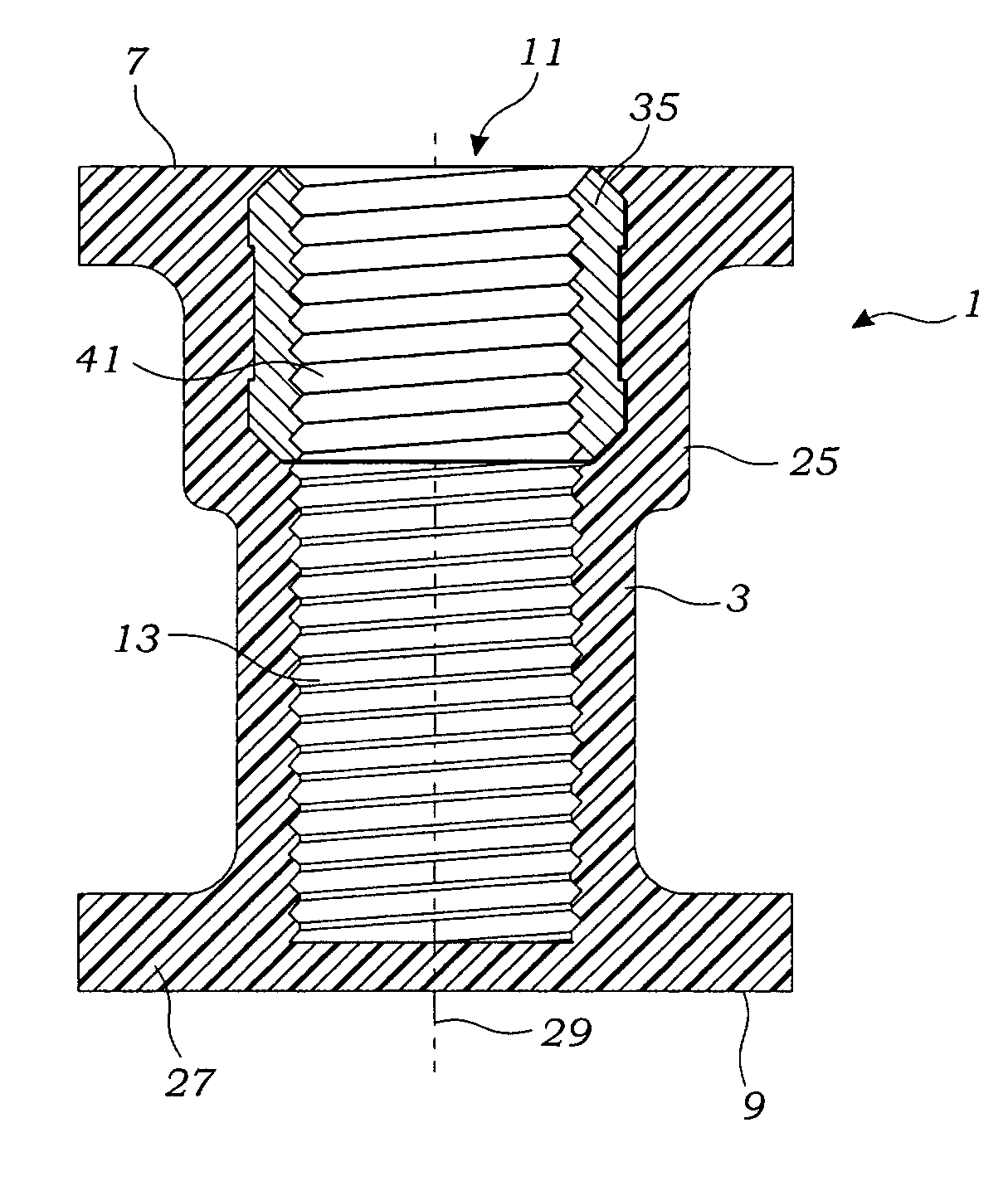

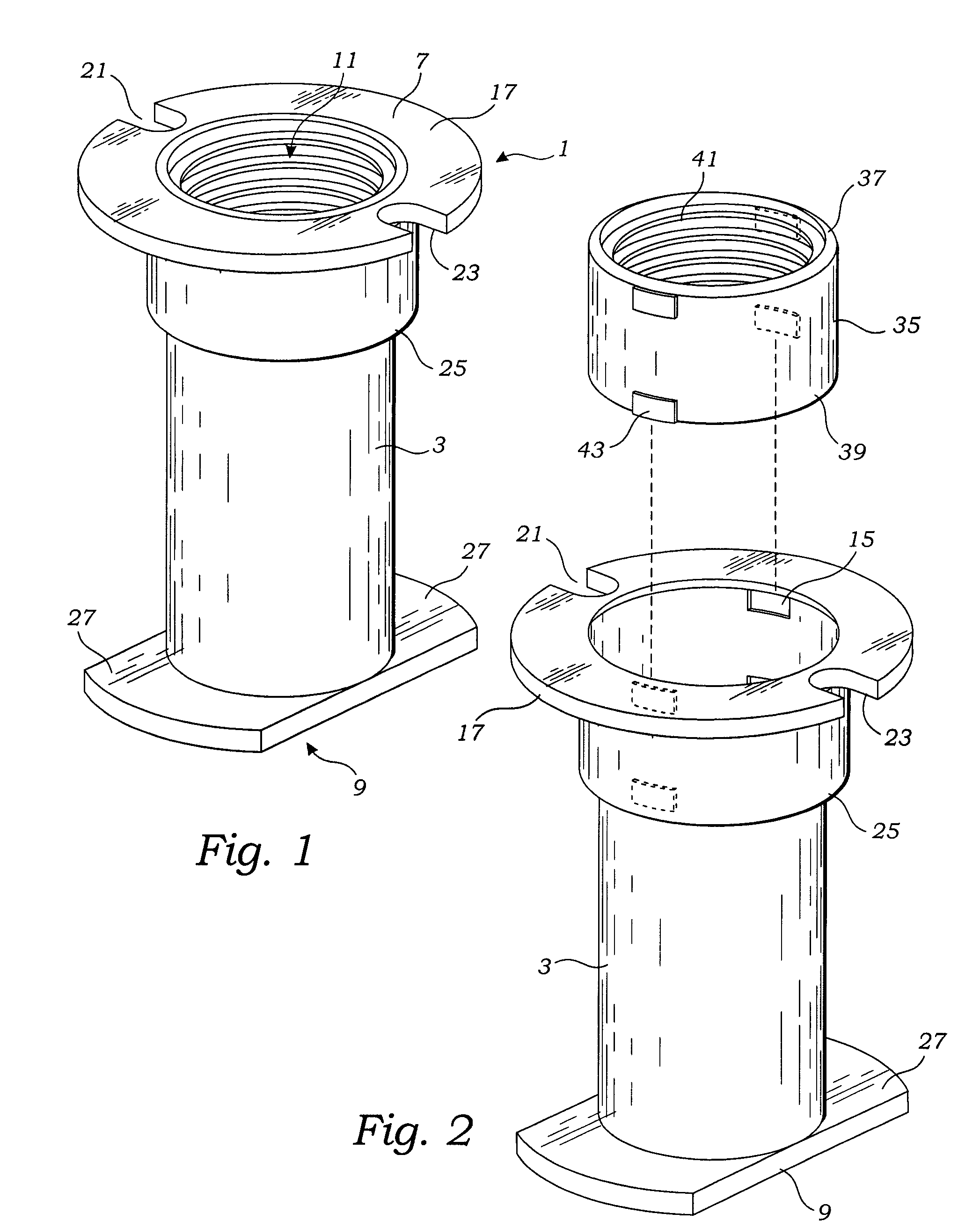

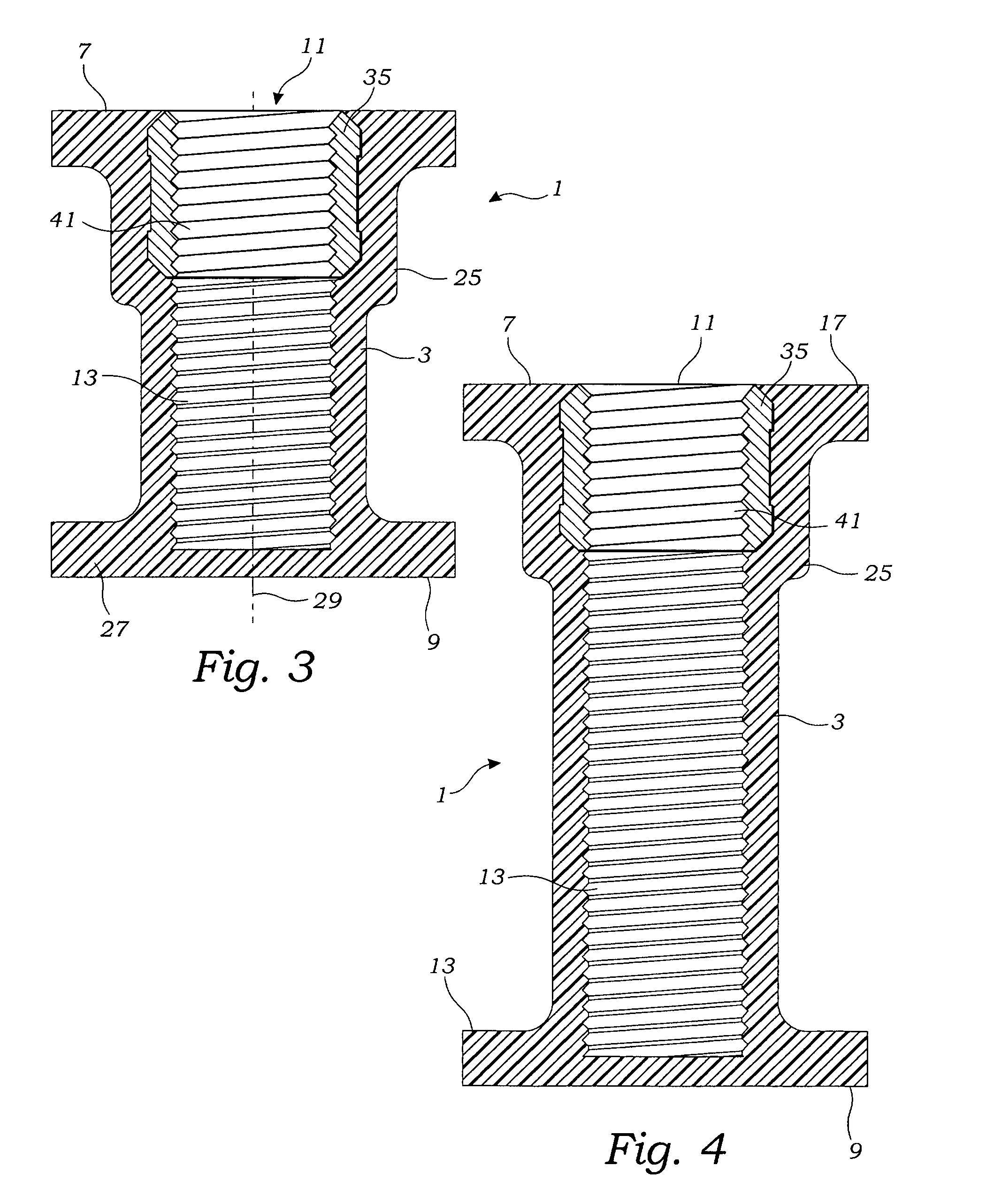

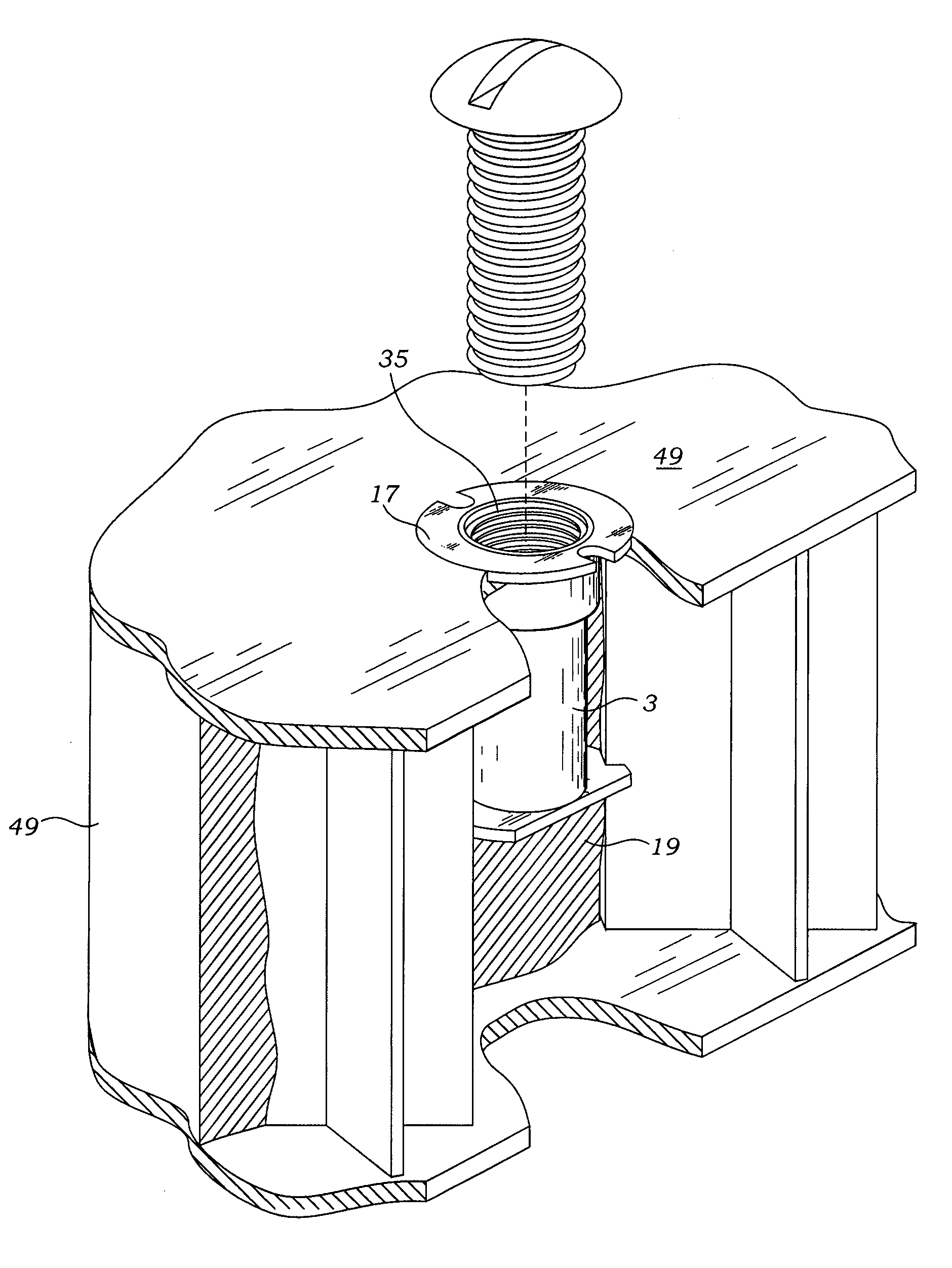

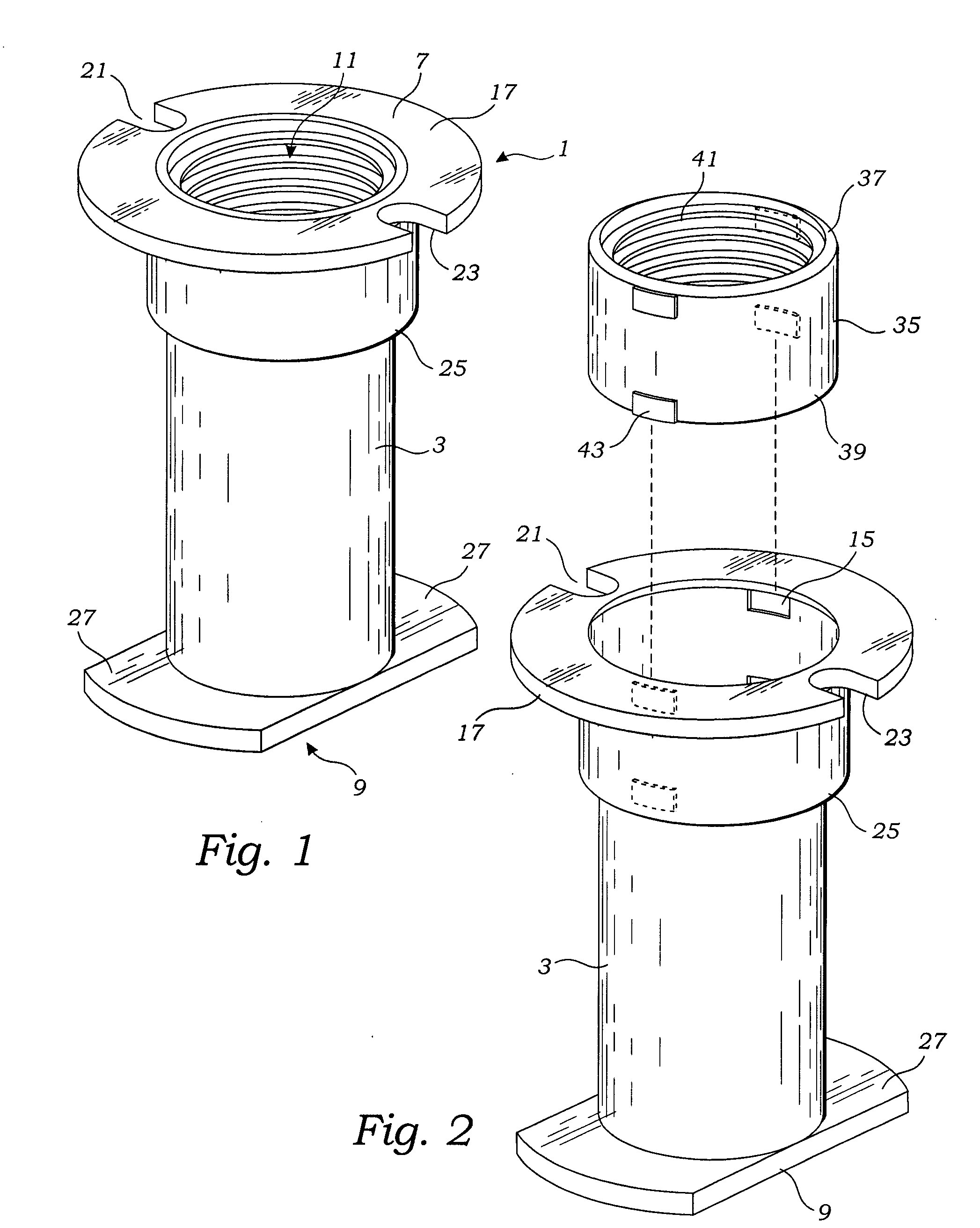

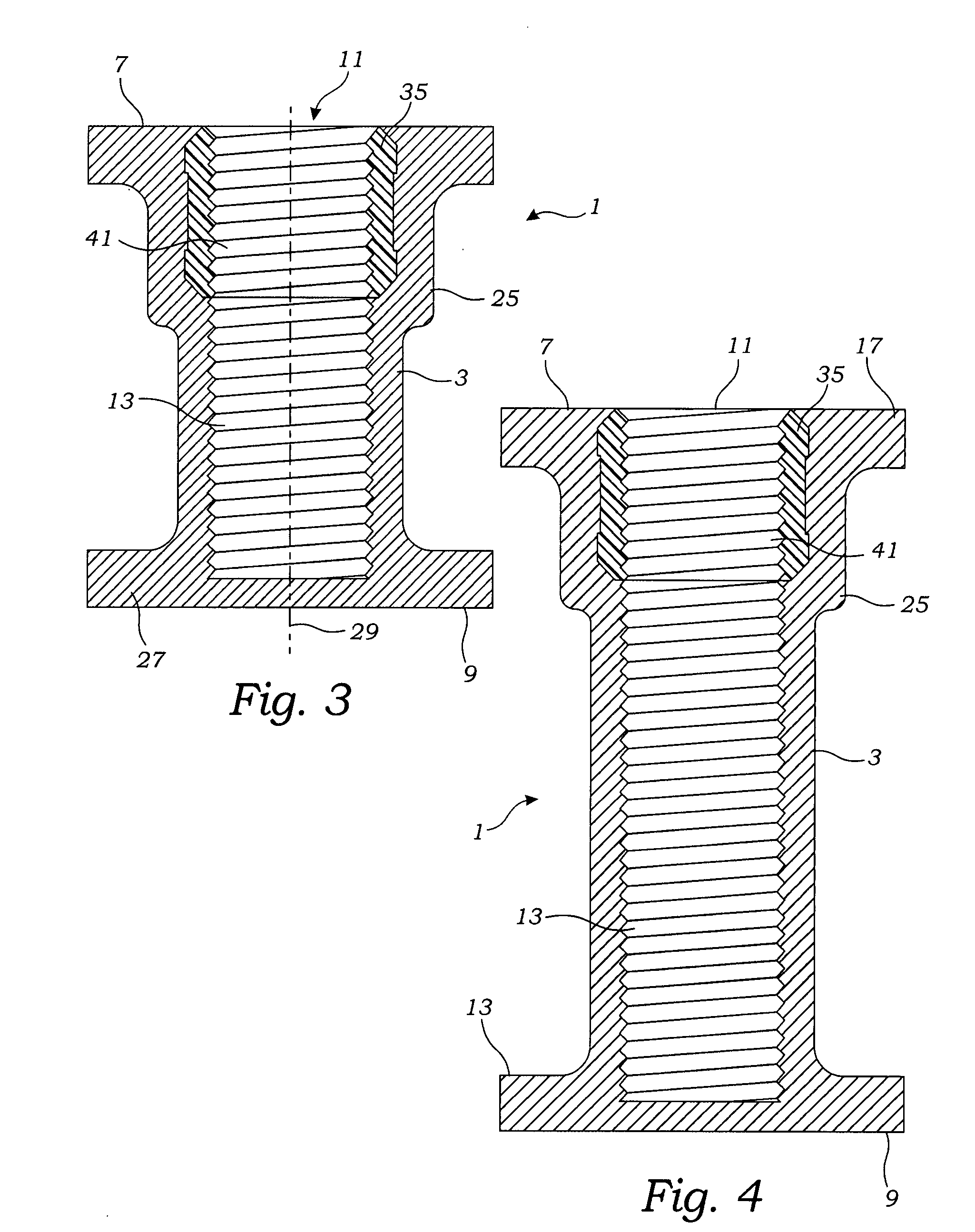

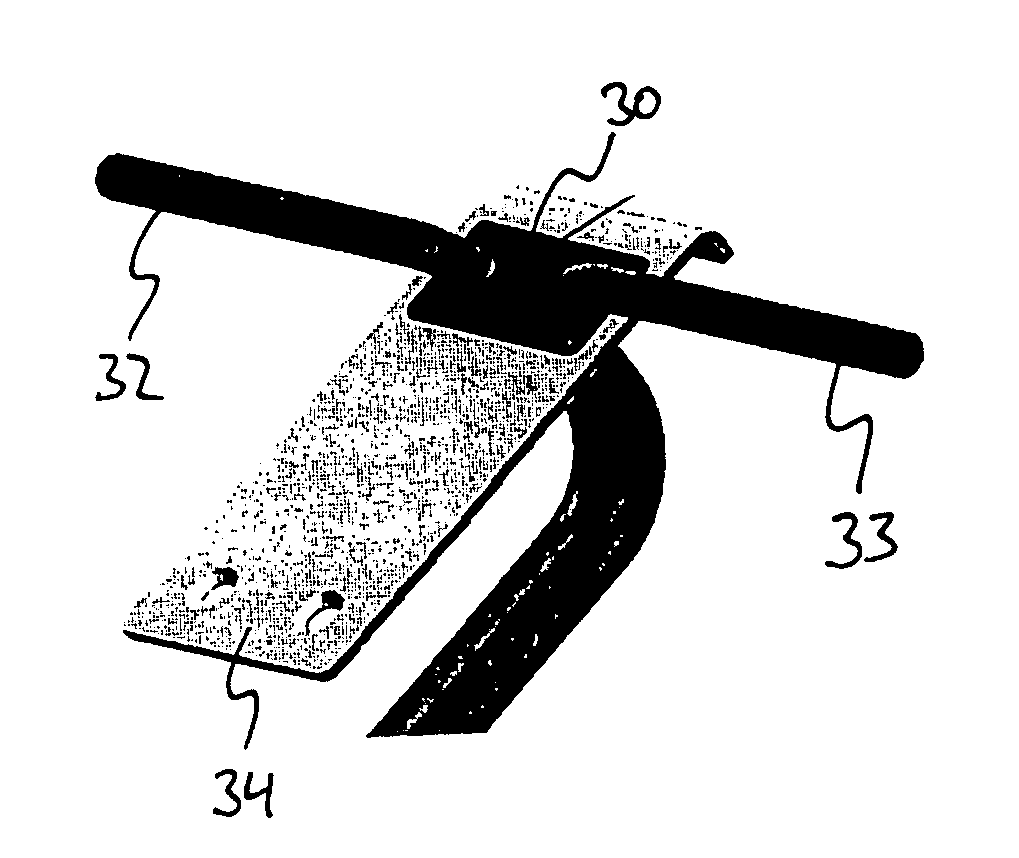

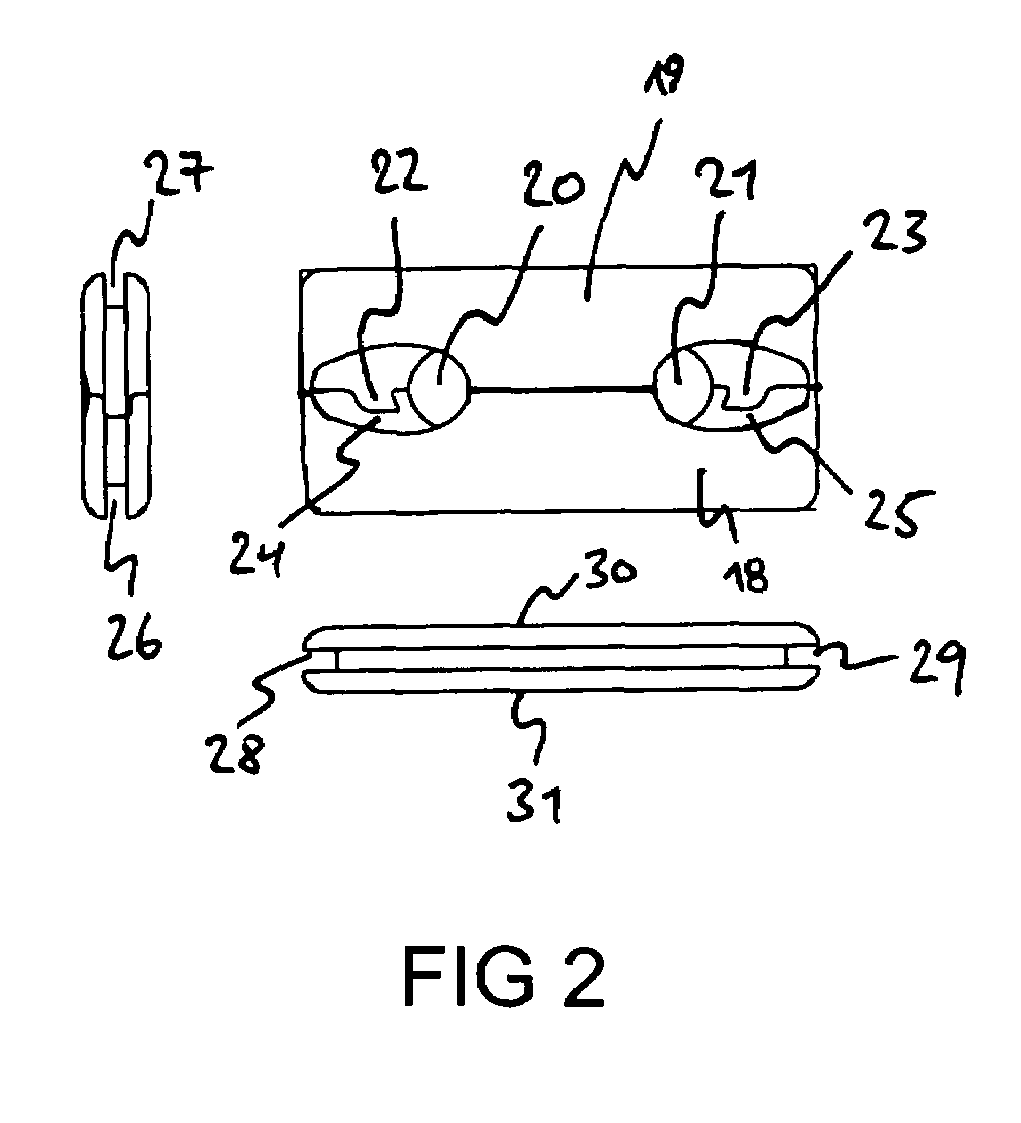

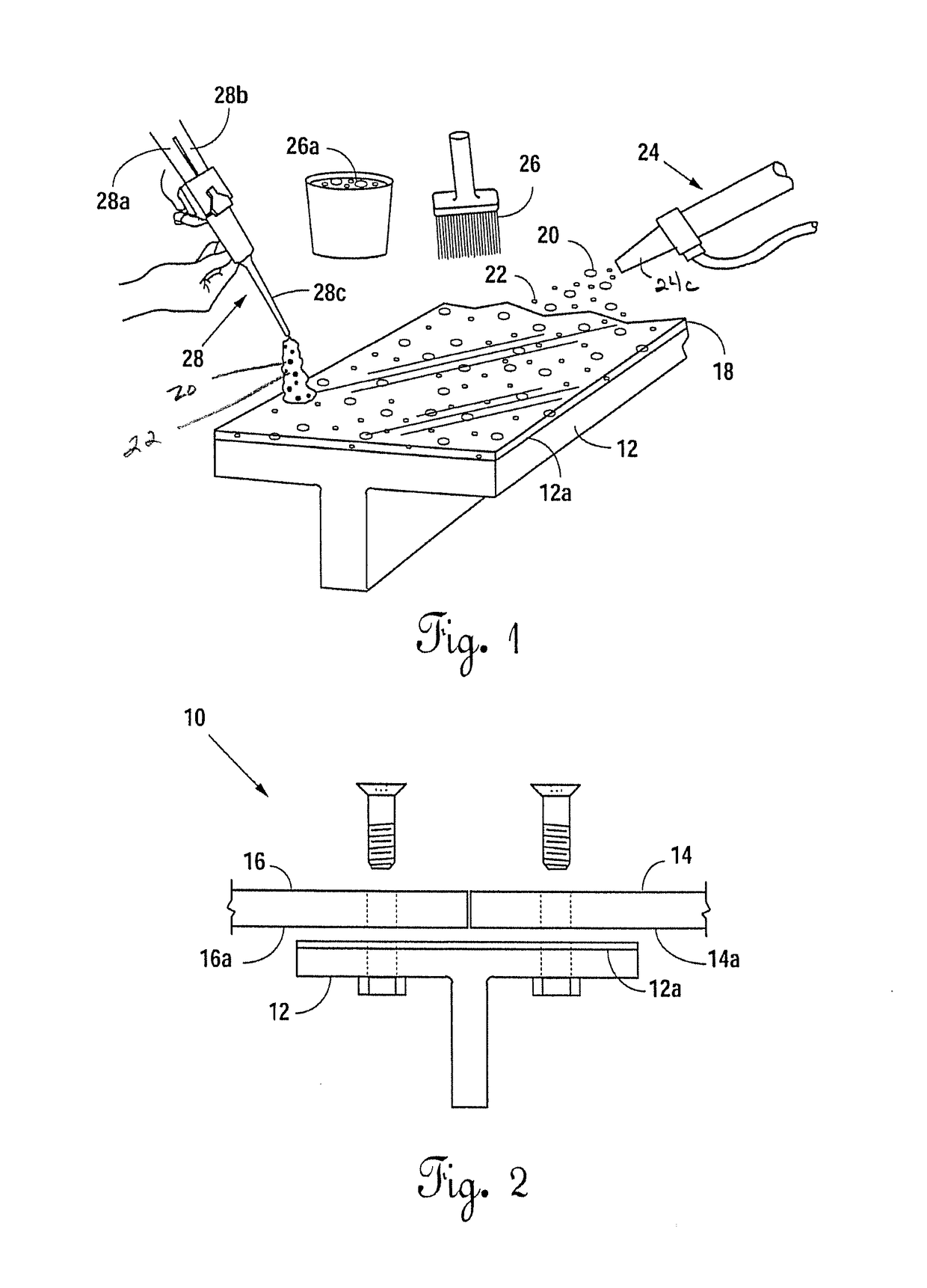

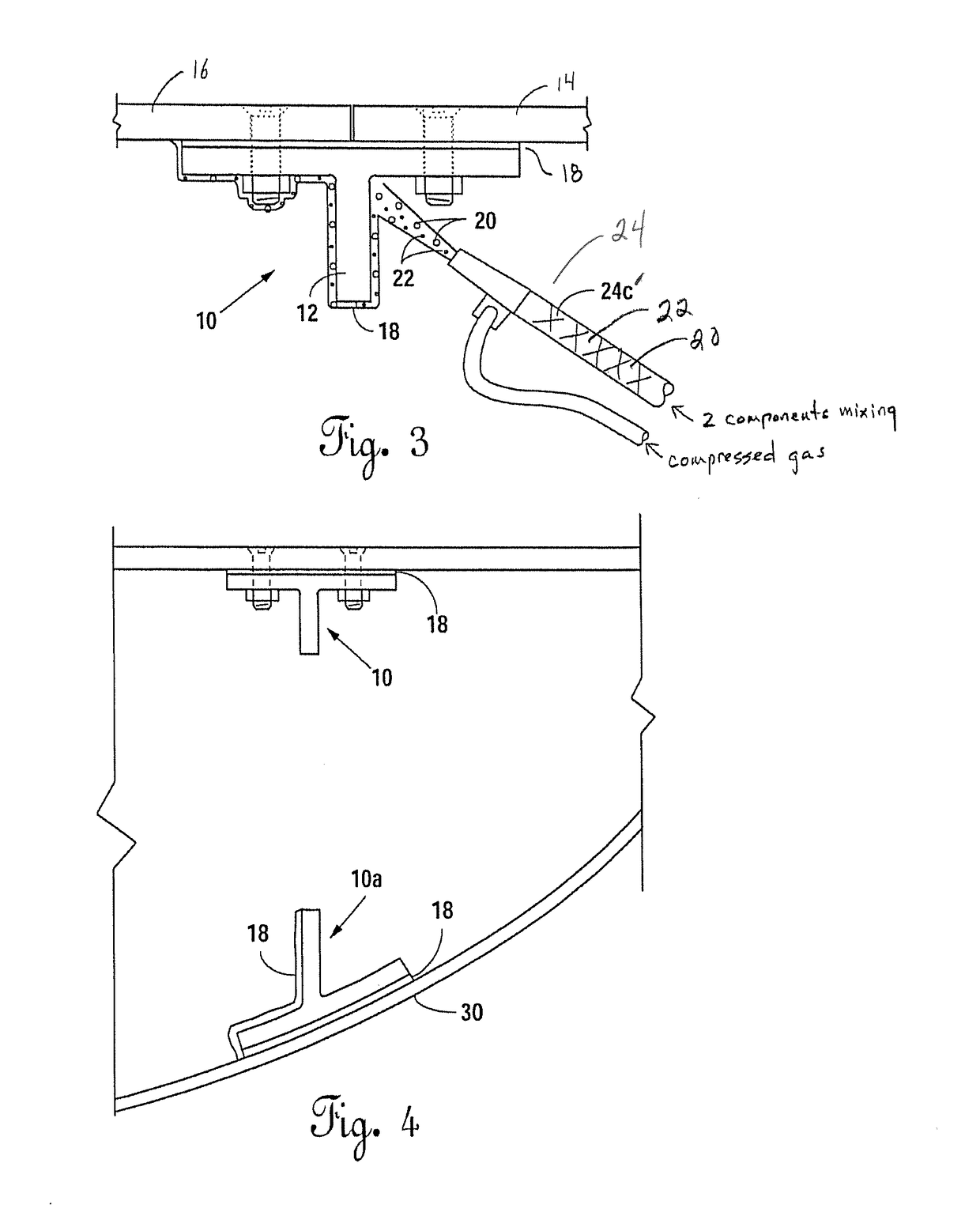

Inset panel fastener

ActiveUS7195436B1Simple engagementPoint of failureRemovable ornamentalMaterial gluingHoneycombAcoustic wave

An inset panel fastener anchors into honeycomb substrates employed in the aircraft industry. The inset panel fastener provides significantly increased load carrying capabilities with a simple inexpensive construction. The inset panel fastener includes a plastic casing and a central floating fastener element. The casing includes a body, disk and cap. The body is generally barrel shaped including a central chamber for holding the fastener element which is preferably a female fastener. The disk radially projects from the top of the body and includes a fill hole and vent hole. Meanwhile, the cap engages and covers the bottom of the barrel shaped body. The cap is affixed in place using a weld, such as a sonic weld.

Owner:NMC GROUP +1

Composition for fire-protection coating

InactiveUS6425947B1Improve fire performanceImprove adhesionFireproof paintsAntifouling/underwater paintsThermal insulationAircraft industry

The invention relates to compositions for the application of coatings primarily to wood and metal structures and installations, which have high fireproofing and thermal insulation properties, and can be used in construction, the aircraft industry, rail transport and shipbuilding. The composition includes a foaming system, which itself includes pentaerythritol or sorbitol, ammonium polyphosphate, boric acid, urea, filler and pigment, and also resin as a binder.

Owner:ISLE FIRESTOP LTD

Inset panel fastener

An inset panel fastener is provided primarily for honeycomb substrates, such as those employed in the aircraft industry. The inset panel fastener includes a plastic body portion and a metal female threaded nut positioned within the body. The body includes a cylindrical barrel shape having a top and a bottom. A bore extends through the body from the top to form an opening for receipt of a male fastener. The metal nut has locking threads and is positioned in body's bore at the body's top proximal extremity. The body further includes non-locking plastic female threads integrally formed into said body's bore. The plastic female threads have the same diameter as the metal threads and are immediately adjacent to the metal threads so as to form continuous threads for permitting receipt of a male threaded fastener. The metal female threads are locking threads to provide a locking action for locking a male fastener to the inset panel fastener. Meanwhile, the plastic female threads provide primary load bearing capabilities for the inset panel fastener.

Owner:NMC GROUP +1

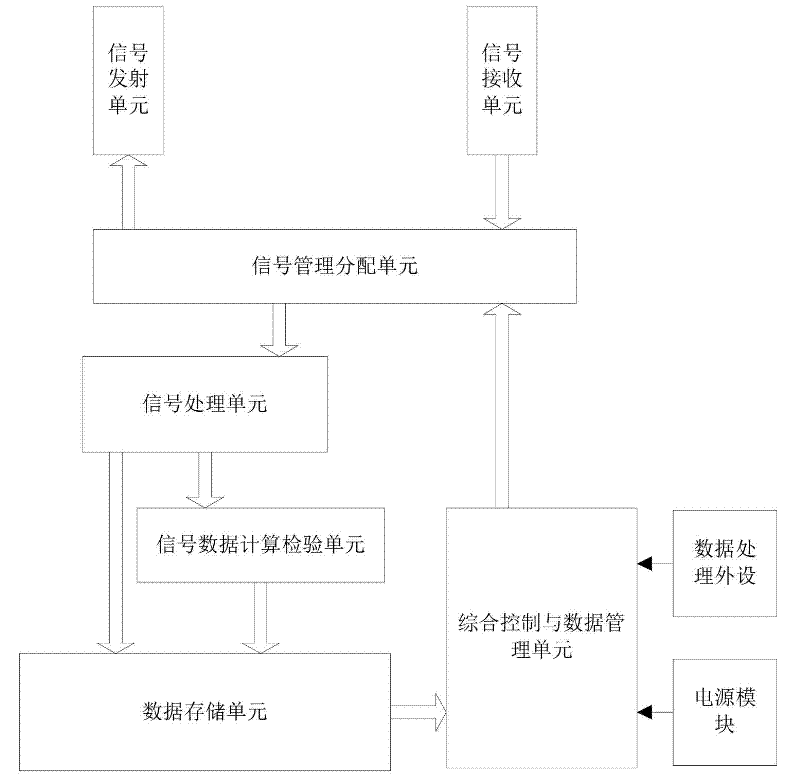

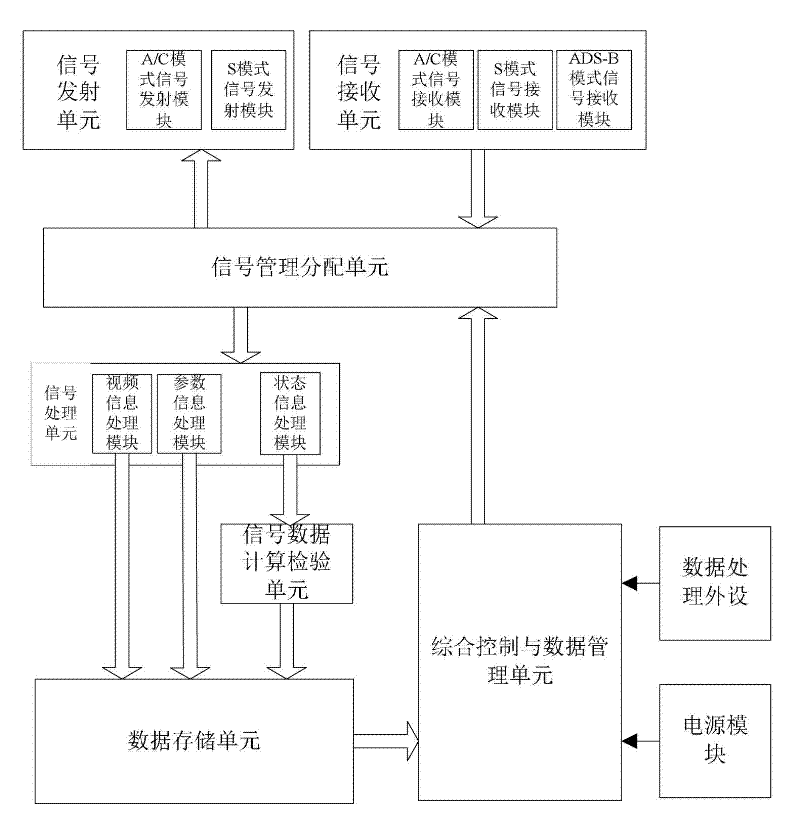

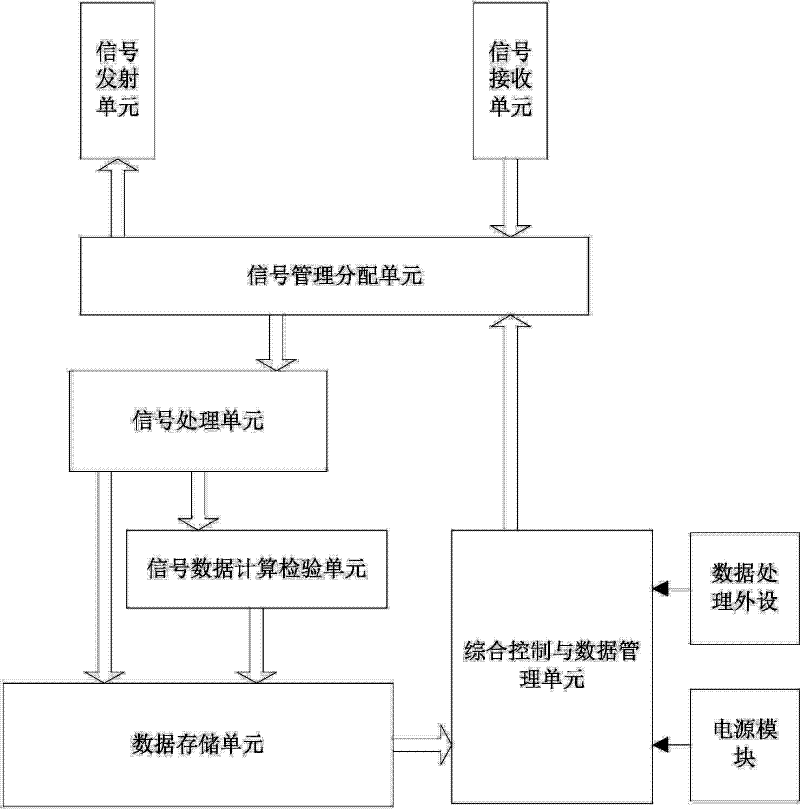

Regional airspace management monitoring system based on traffic alert and collision avoidance system (TCAS)

ActiveCN102364553ARealize monitoringRealize managementAircraft traffic controlAviationGeographic site

The invention discloses a regional airspace management monitoring system based on a traffic alert and collision avoidance system (TCAS). In the system, a signal inquiry unit is used to enquire an airplane installed with an A / C or S mode responder in a regional airspace. After a response signal returned by the airplane is received, the response signal is processed so as to obtain information, such as airplane heading, an airplane body state, a geographical position and the like. Simultaneously, an airborne ADS-B network can be integrated in the system so as to acquire the related state information through a mode of broadcast reception. In the invention, an air traffic warning anticollision concept which is widely approved in an aircraft industry is introduced into the ground. Usage is convenient and fast, and the system moves flexibly. The regional airspace management monitoring system of the invention can be widely used for military use or miniature airport grounding monitoring.

Owner:哈尔滨航卫航空科技有限公司

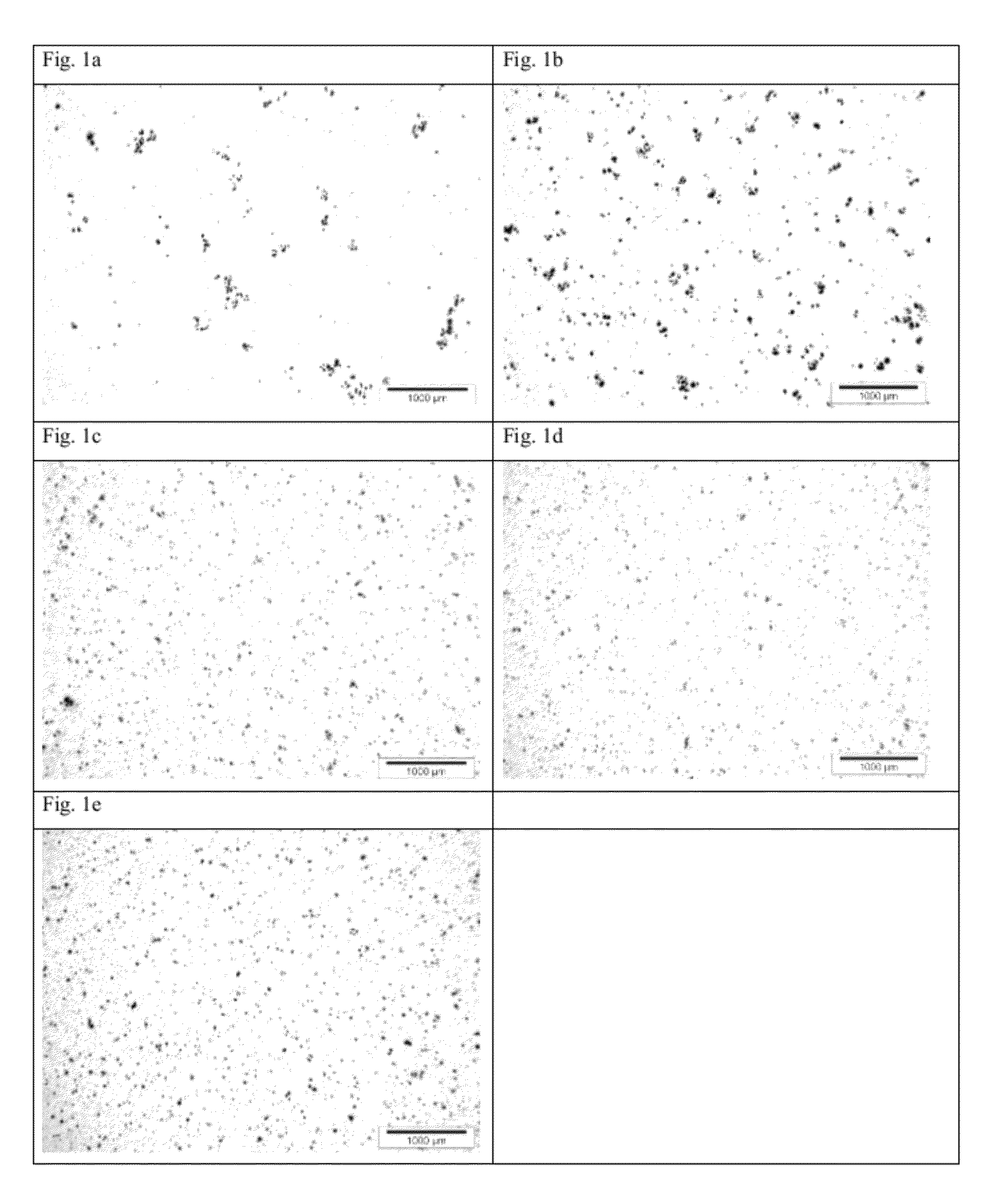

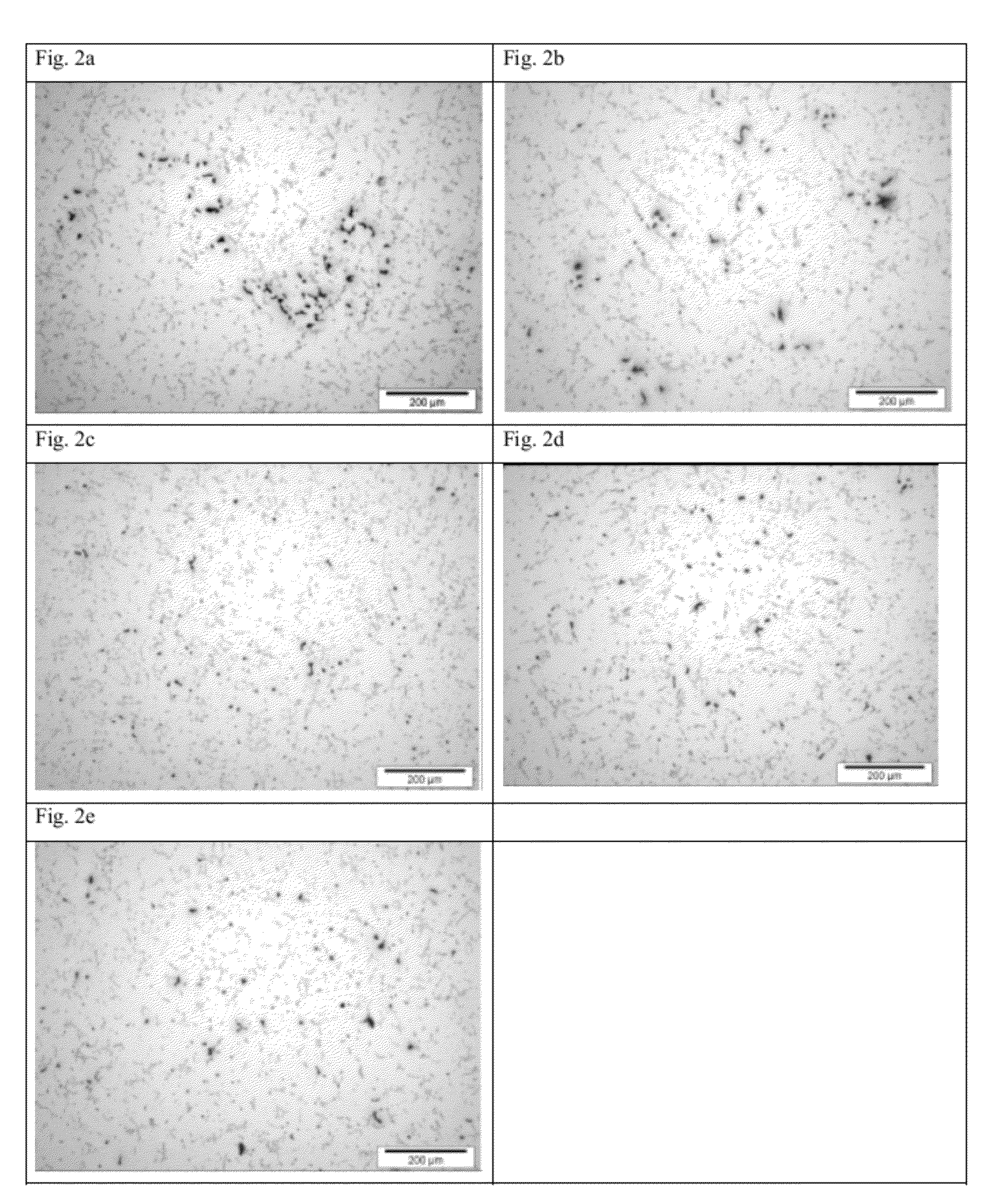

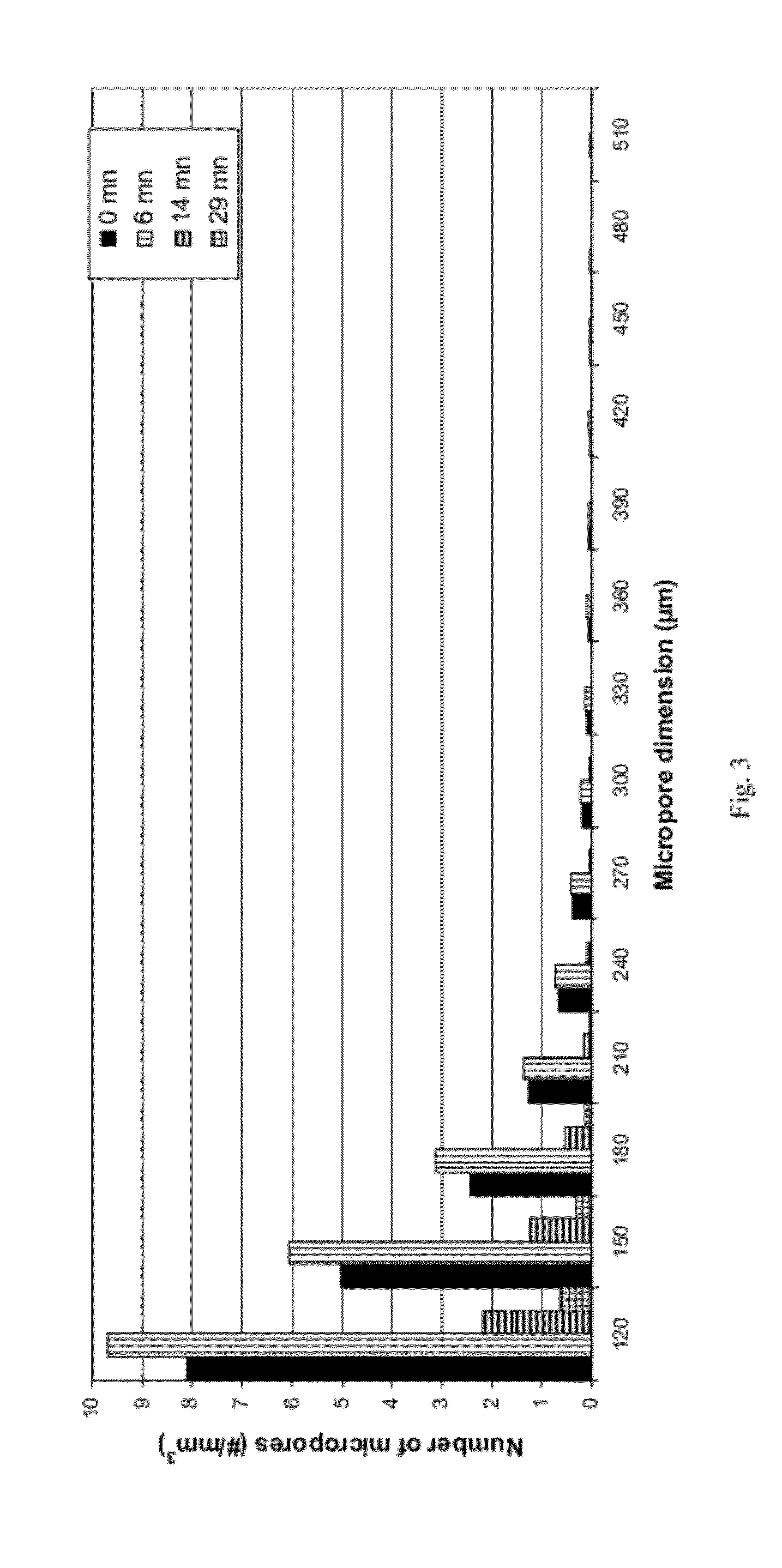

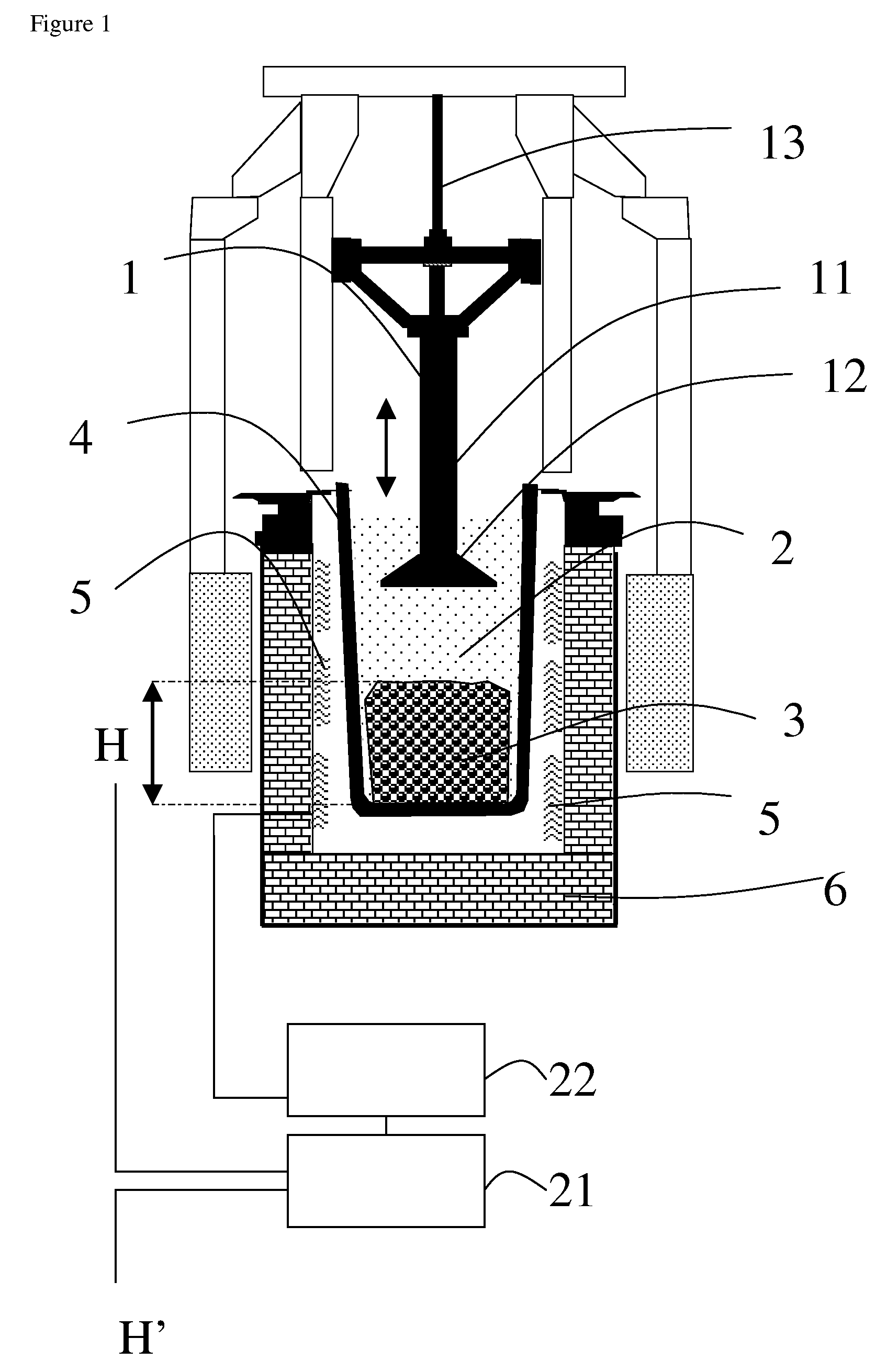

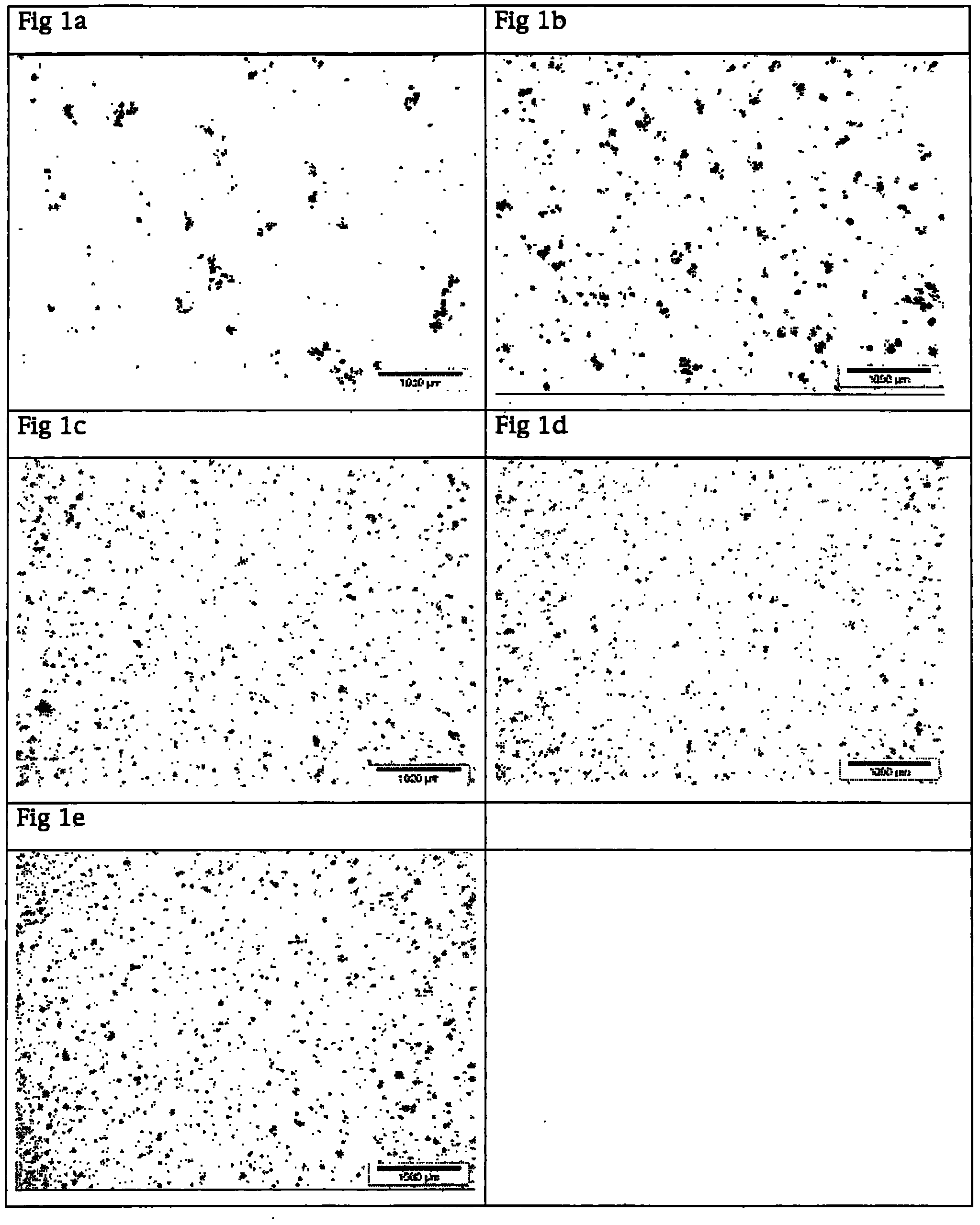

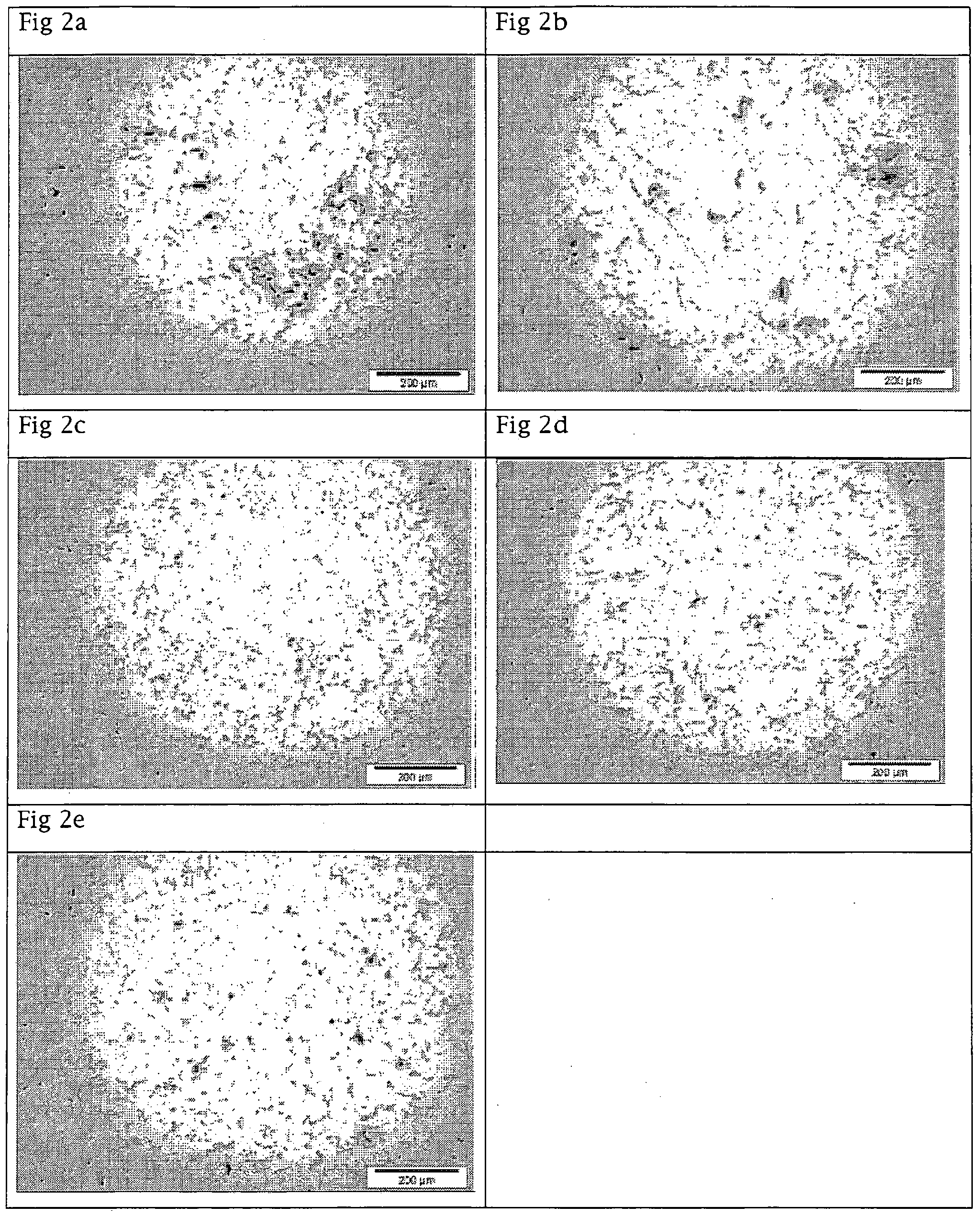

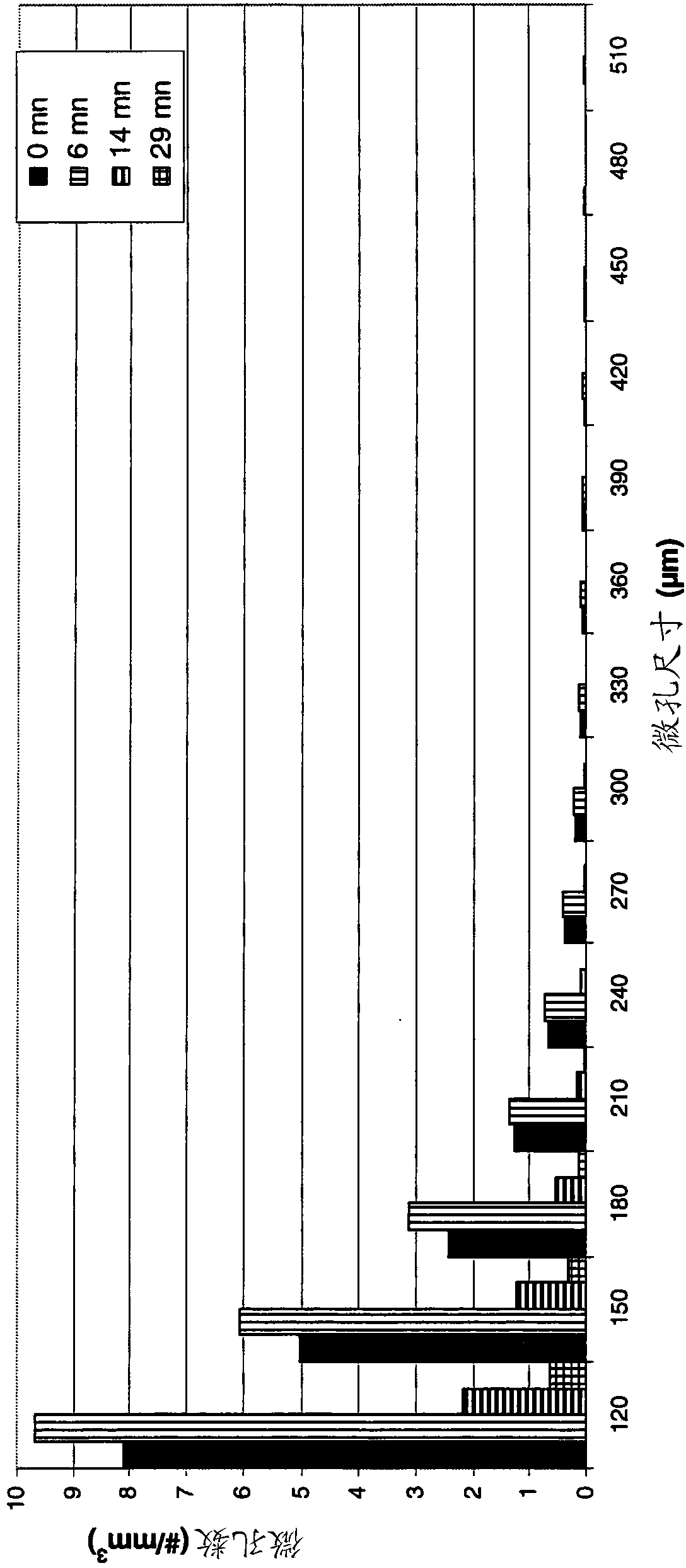

Manufacturing method of making aluminum alloy semi-finished product with improved microporosity

The invention relates to a manufacturing method for making an unwrought semi-finished product having at mid thickness a density of micropores of size greater than 90 μm less than 50% and preferably less than 20% of the density of micropores of size greater than 90 μm obtained by a method according to prior art. The method according to the invention comprises in particular an ultrasound treatment step for the molten metal bath in a furnace and / or a vessel using an immersed device comprising at least one ultrasound transmitter. The semi-finished products obtained according to the method of the invention are particularly advantageous for manufacturing by rolling sheets designed for the aircraft industry to produce spars, ribs, upper and lower wing skins and for manufacturing by extrusion sections designed for the aircraft industry to produce stiffeners.

Owner:CONSTELLIUM ISSOIRE

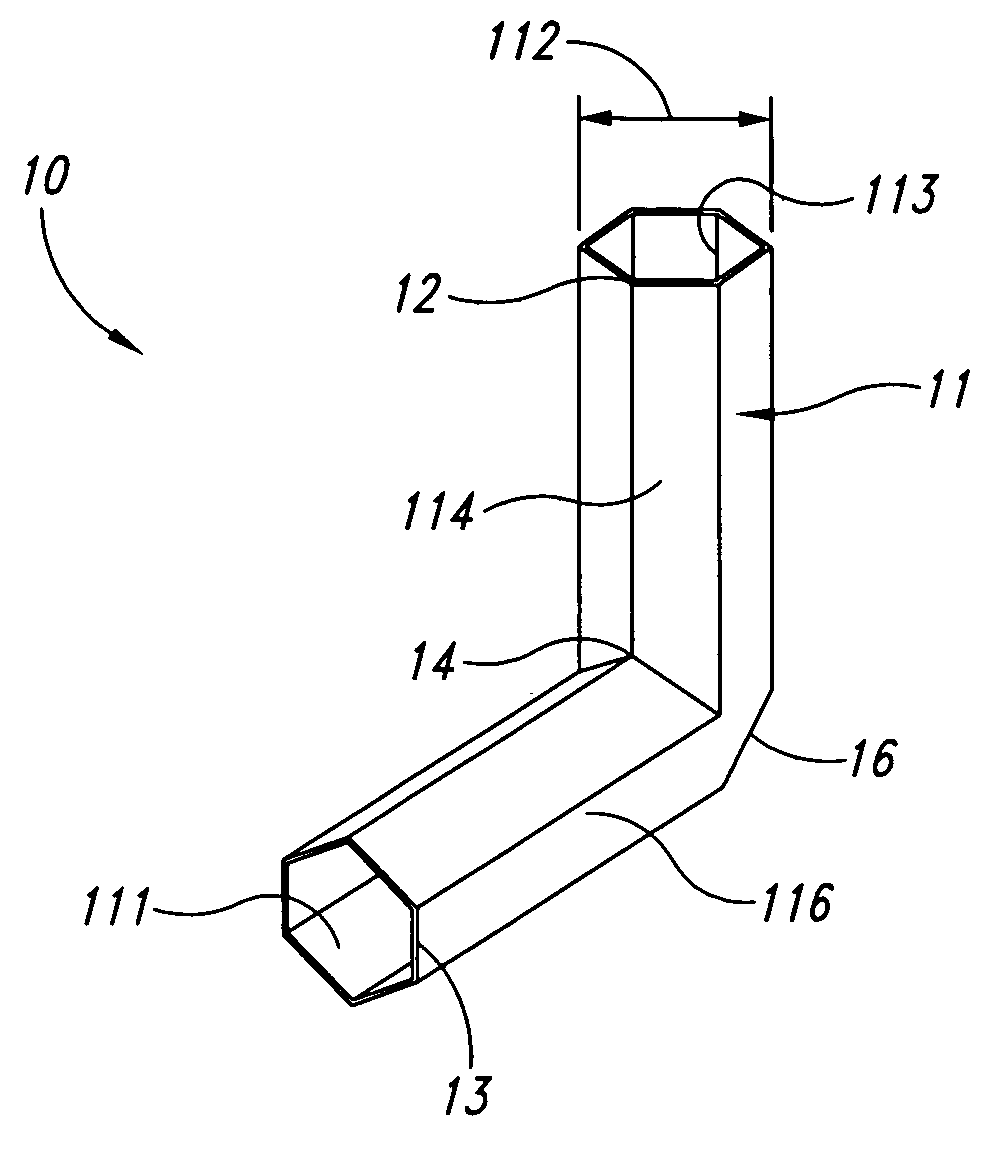

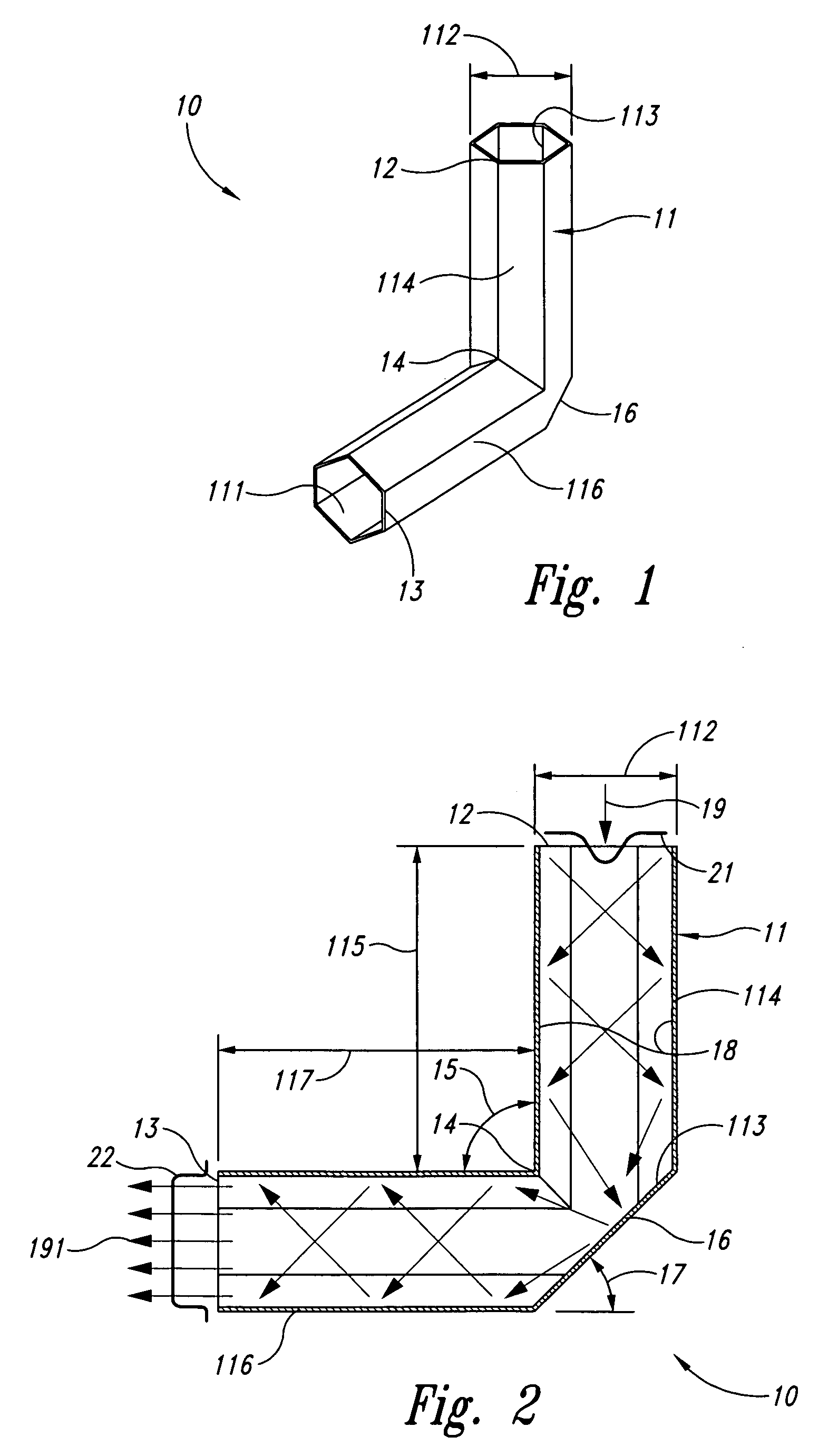

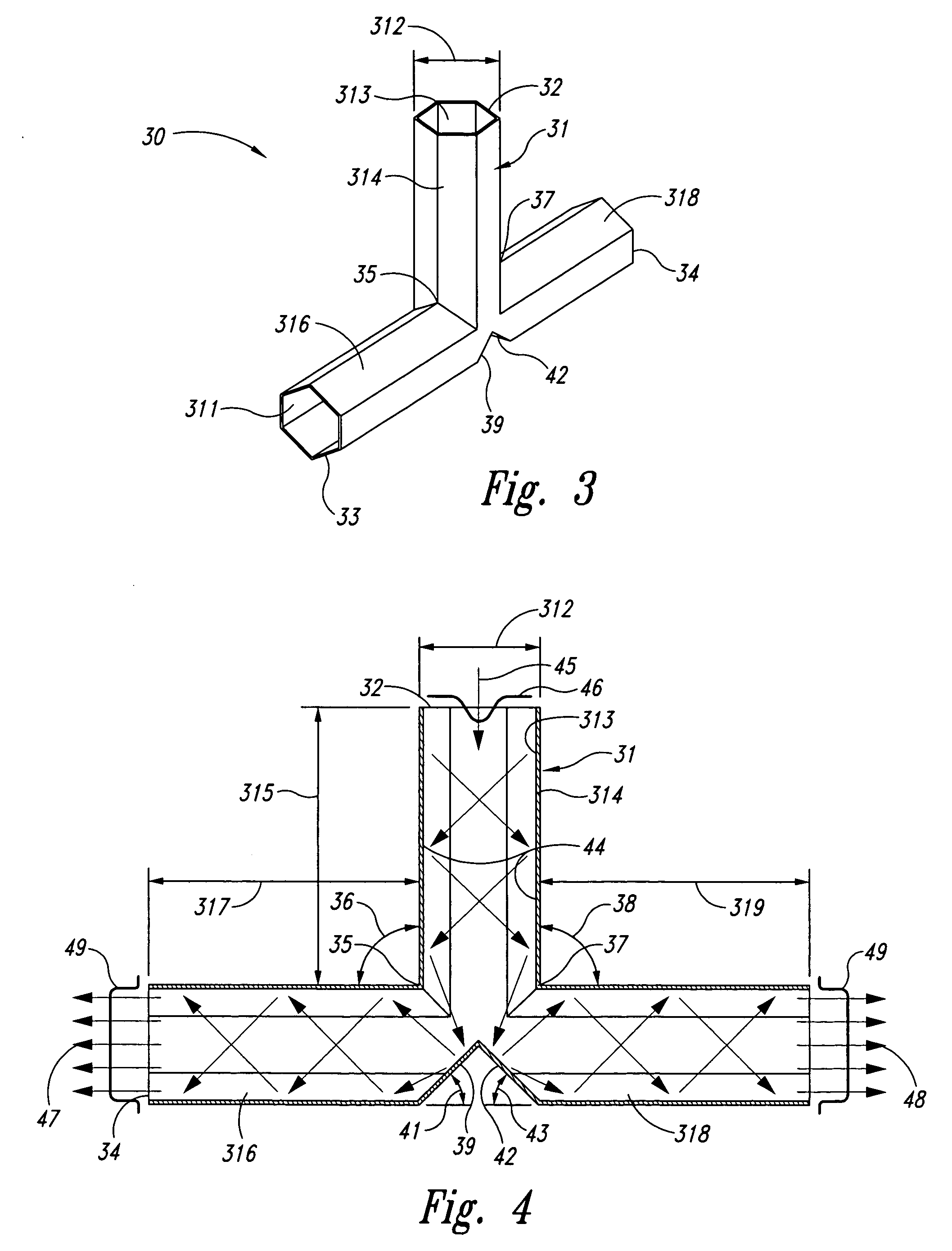

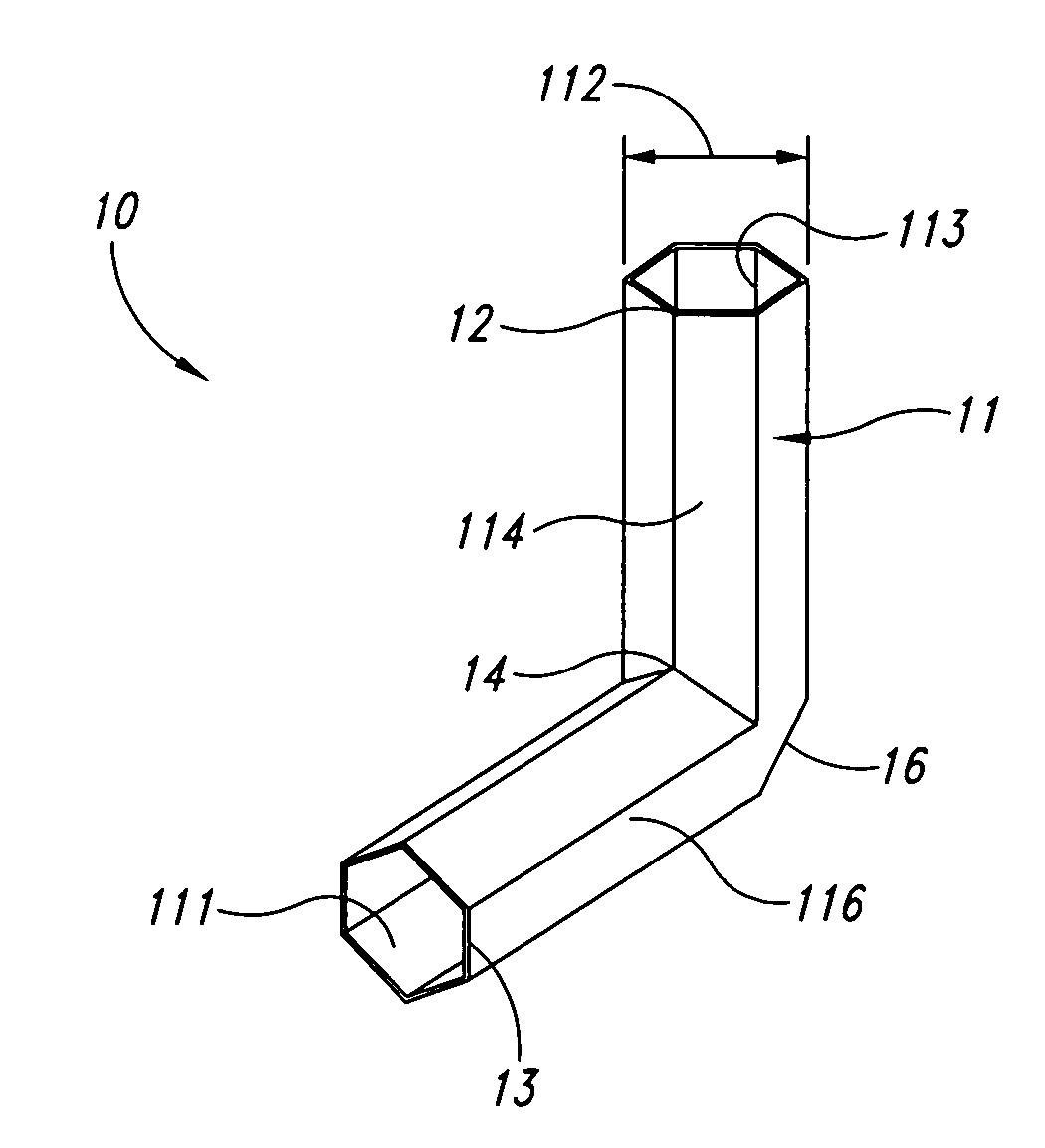

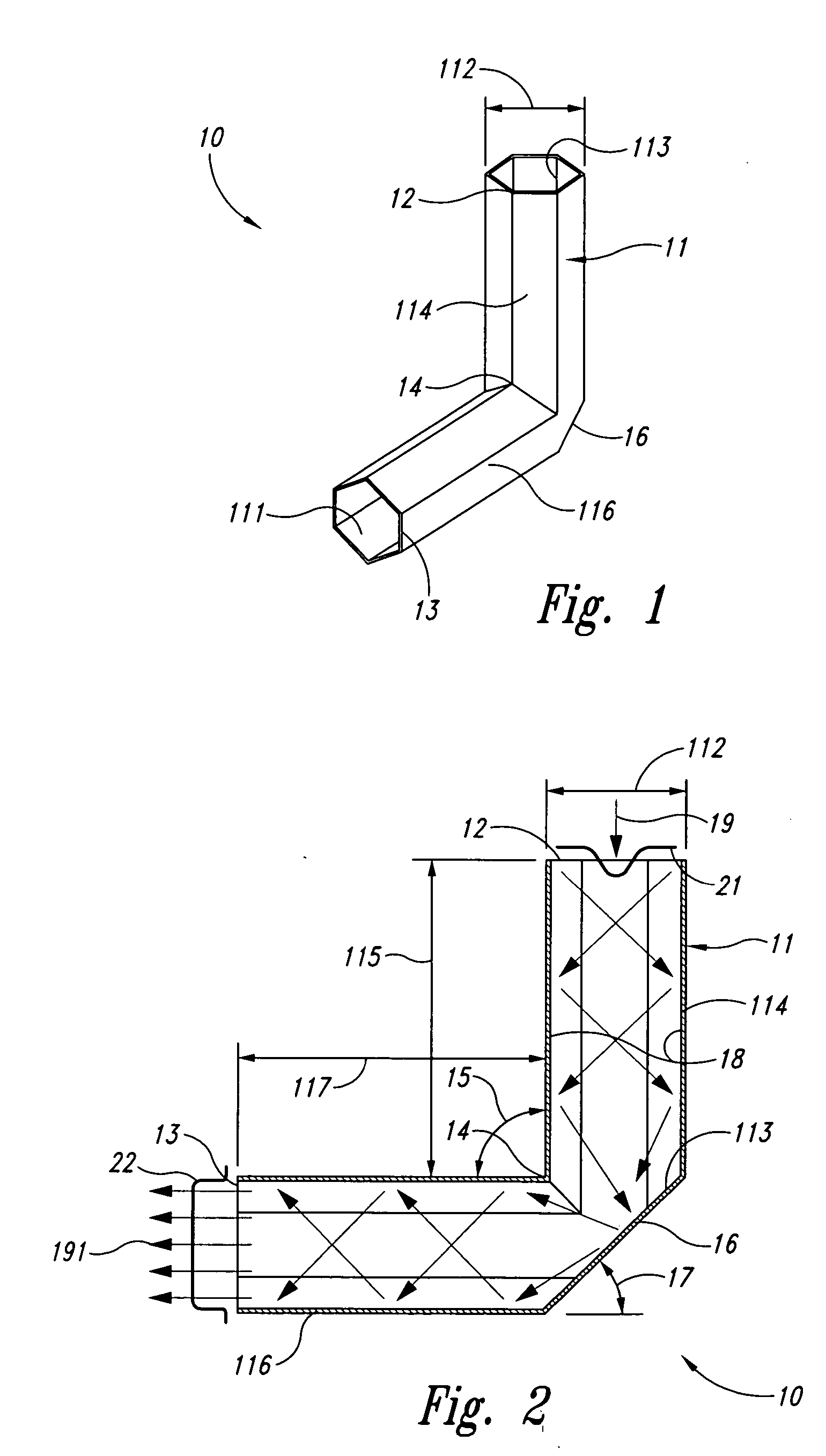

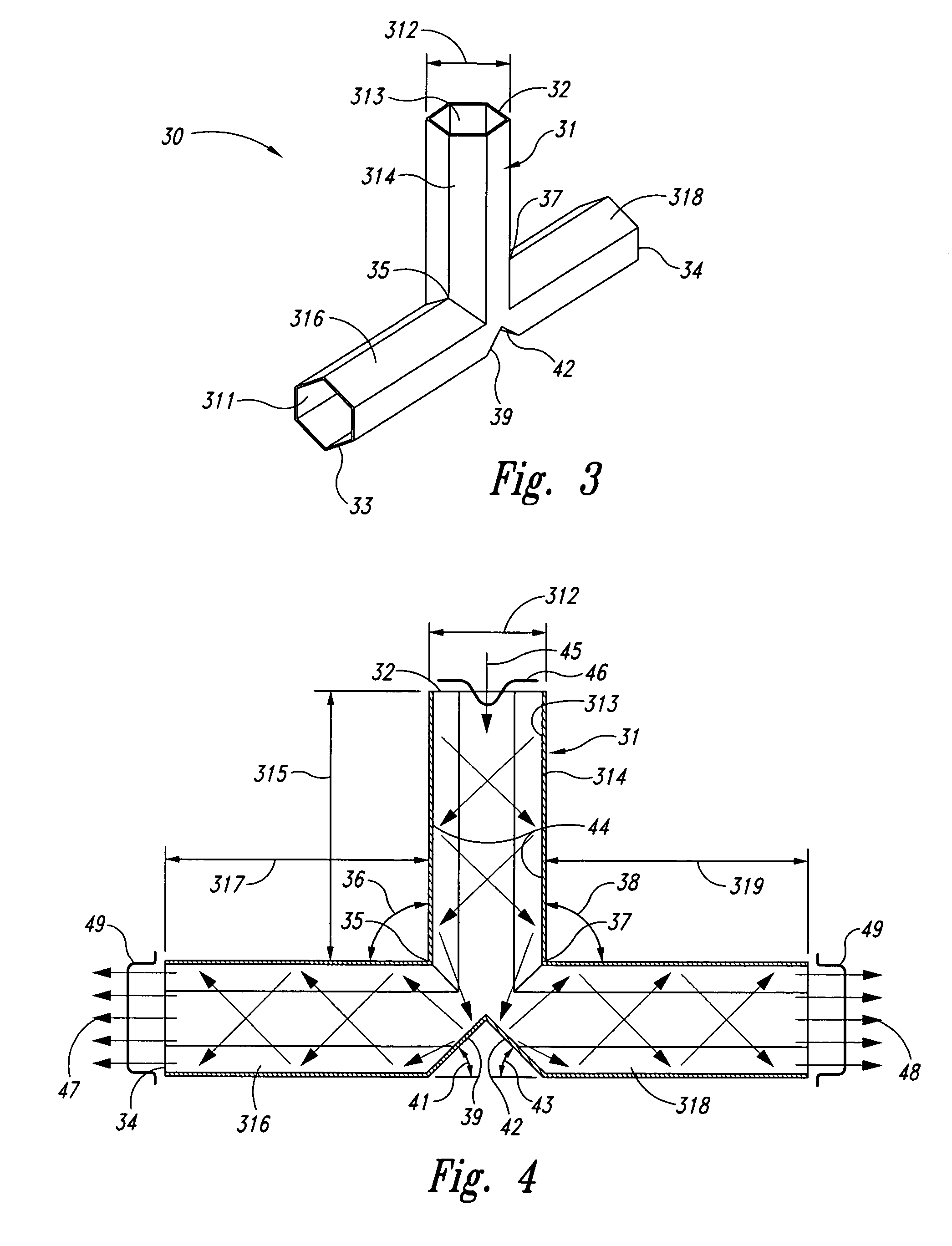

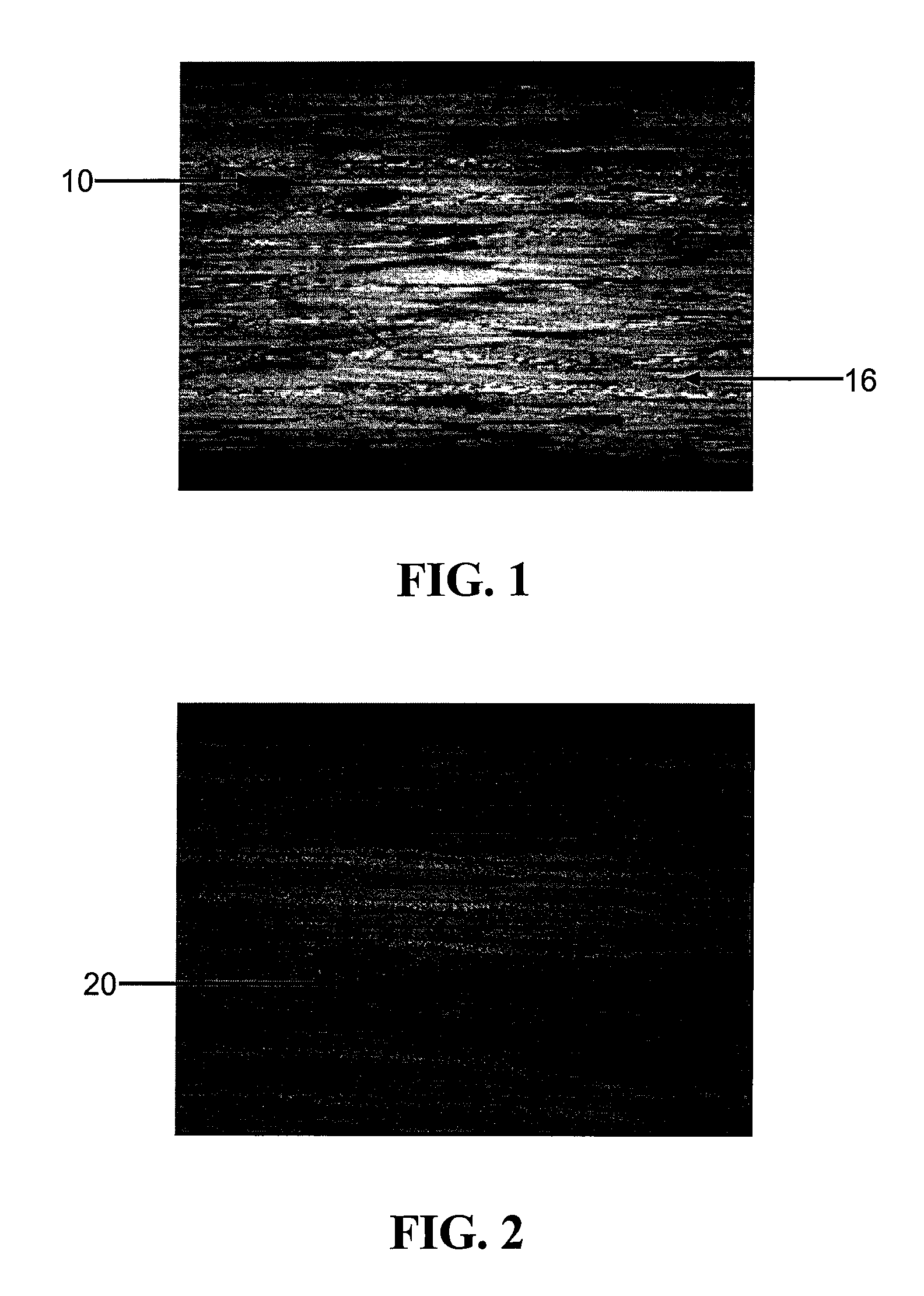

Hex tube light homogenizer splitter

A right angle light diverter includes a hexagonal tube that is bent at a right angle that is coated with a highly reflective coating on the inside surface. An incoming light beam may be homogenized upon entering an input port of the hexagonal tube and may be evenly diverted at a right angle at a reflection section while the homogenized profile may be maintained. A right angle optical splitter may include at least one additional output section. An incoming light beam may be homogenized and may be split into at least two outgoing beams that may be diverted at right angles at reflection sections. The right angle light diverter and the right angle optical splitter may be suitable for, but not limited to, applications in aircraft industry, both military and commercial. They may be used, for example, in connection with airborne laser programs, in commercial airplanes, and in military jets.

Owner:THE BOEING CO

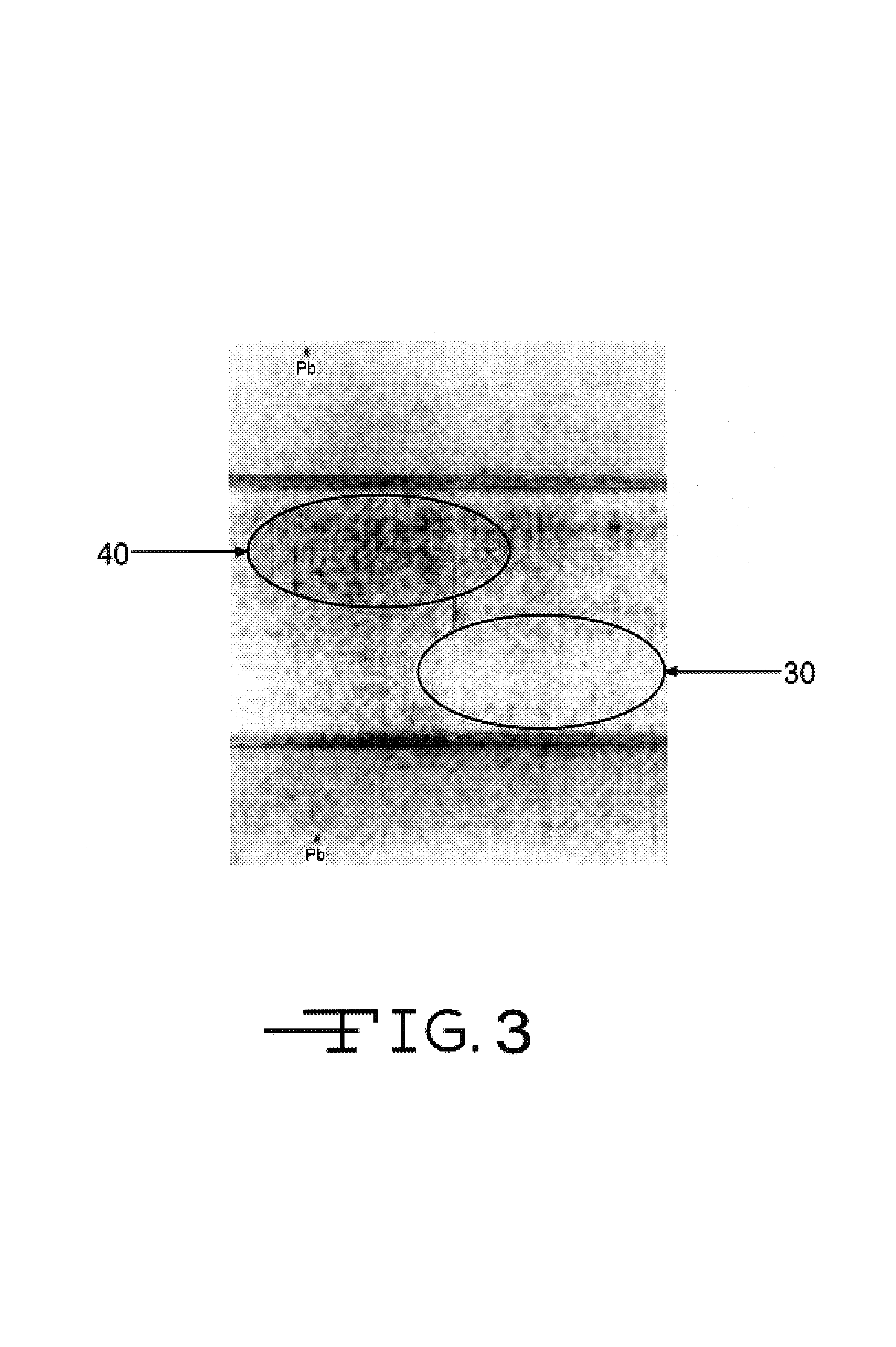

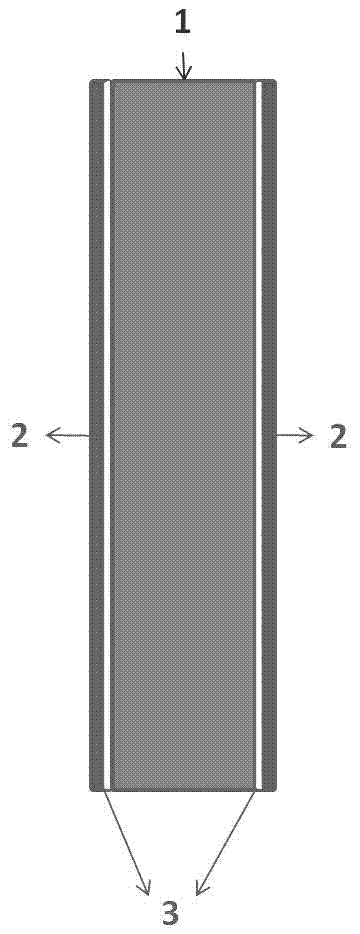

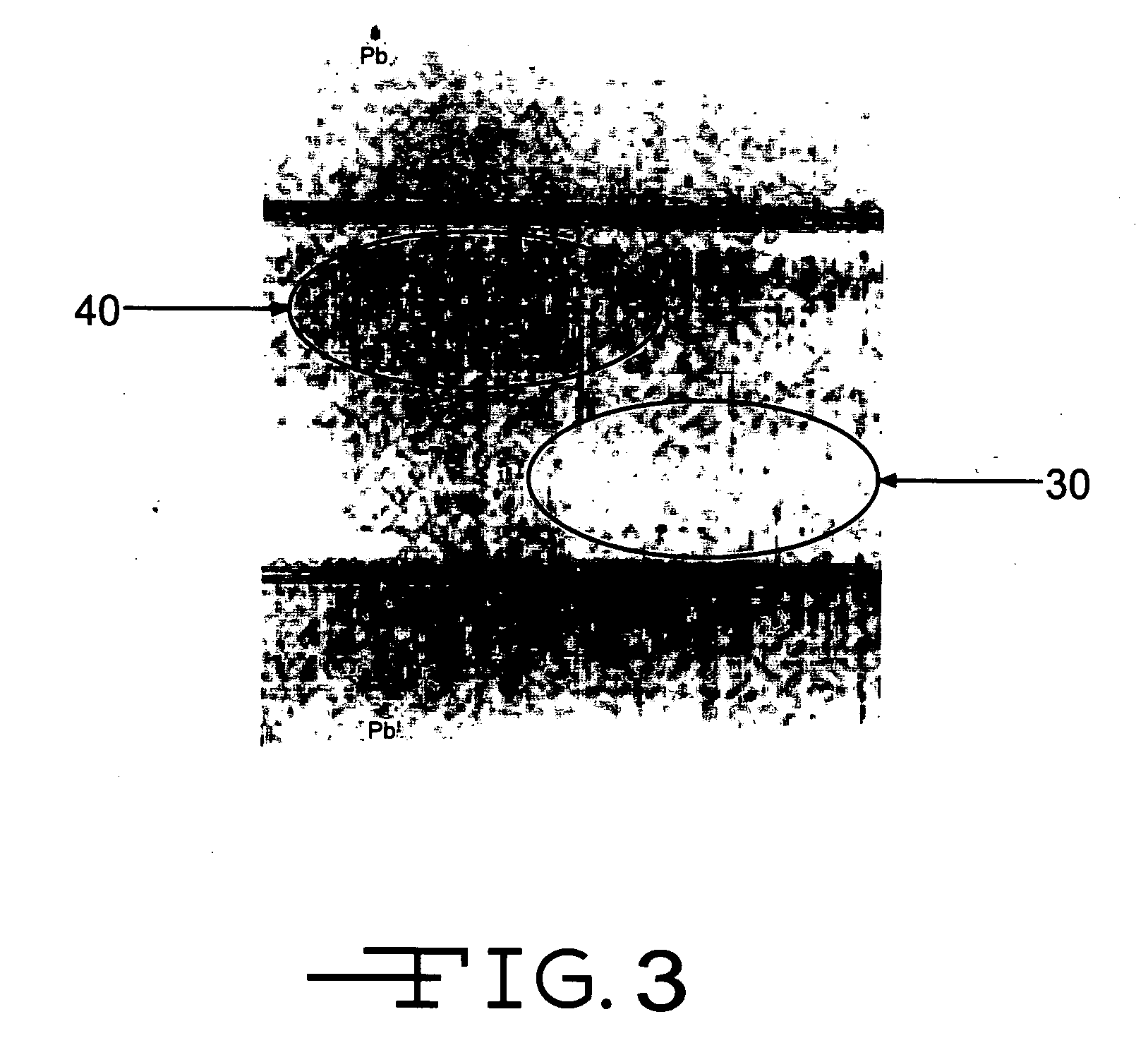

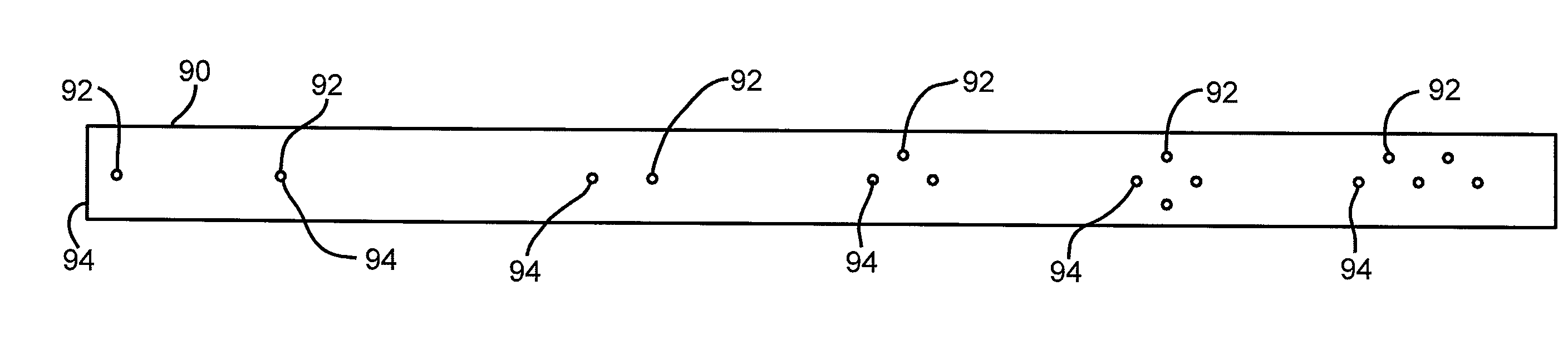

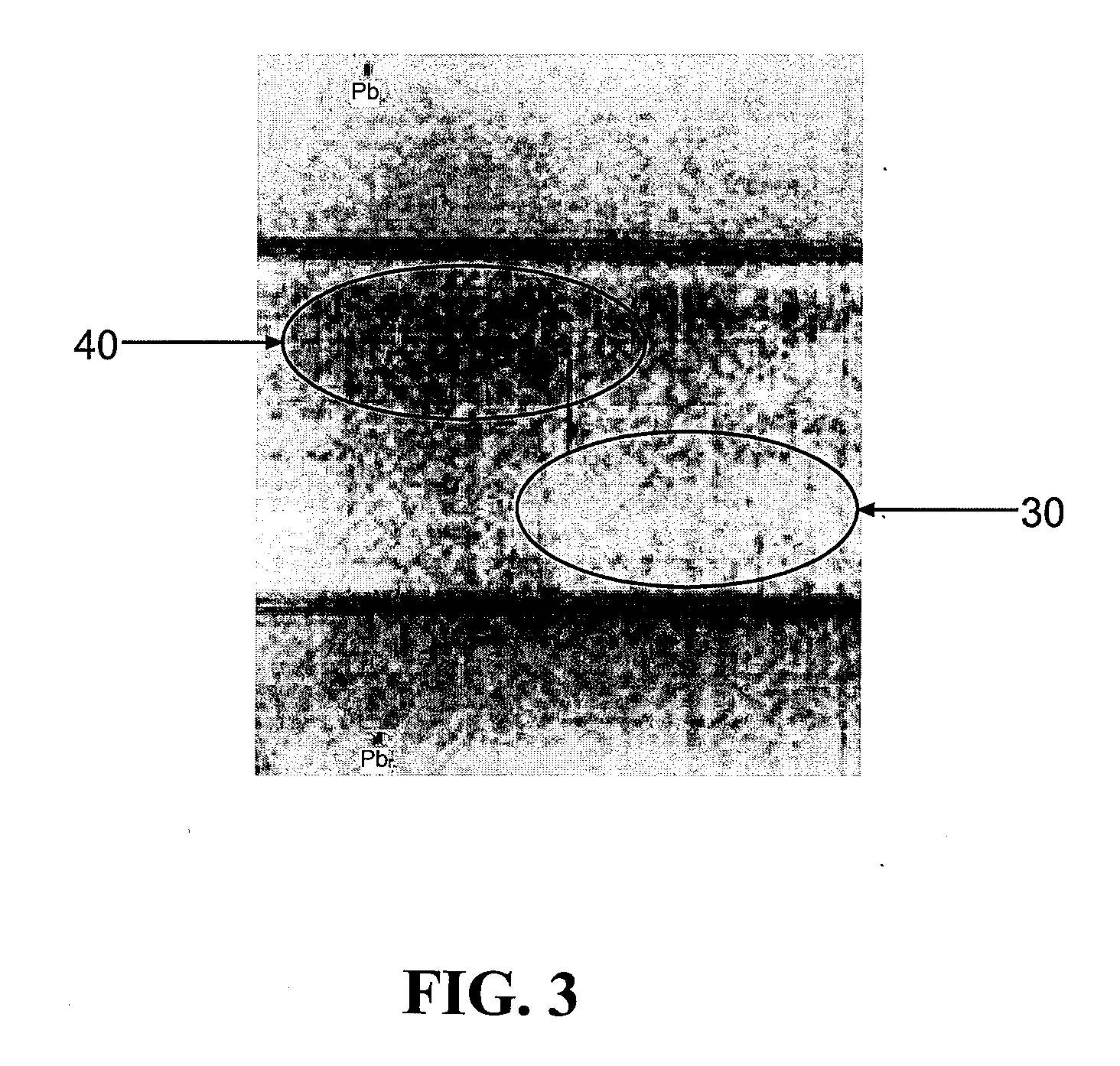

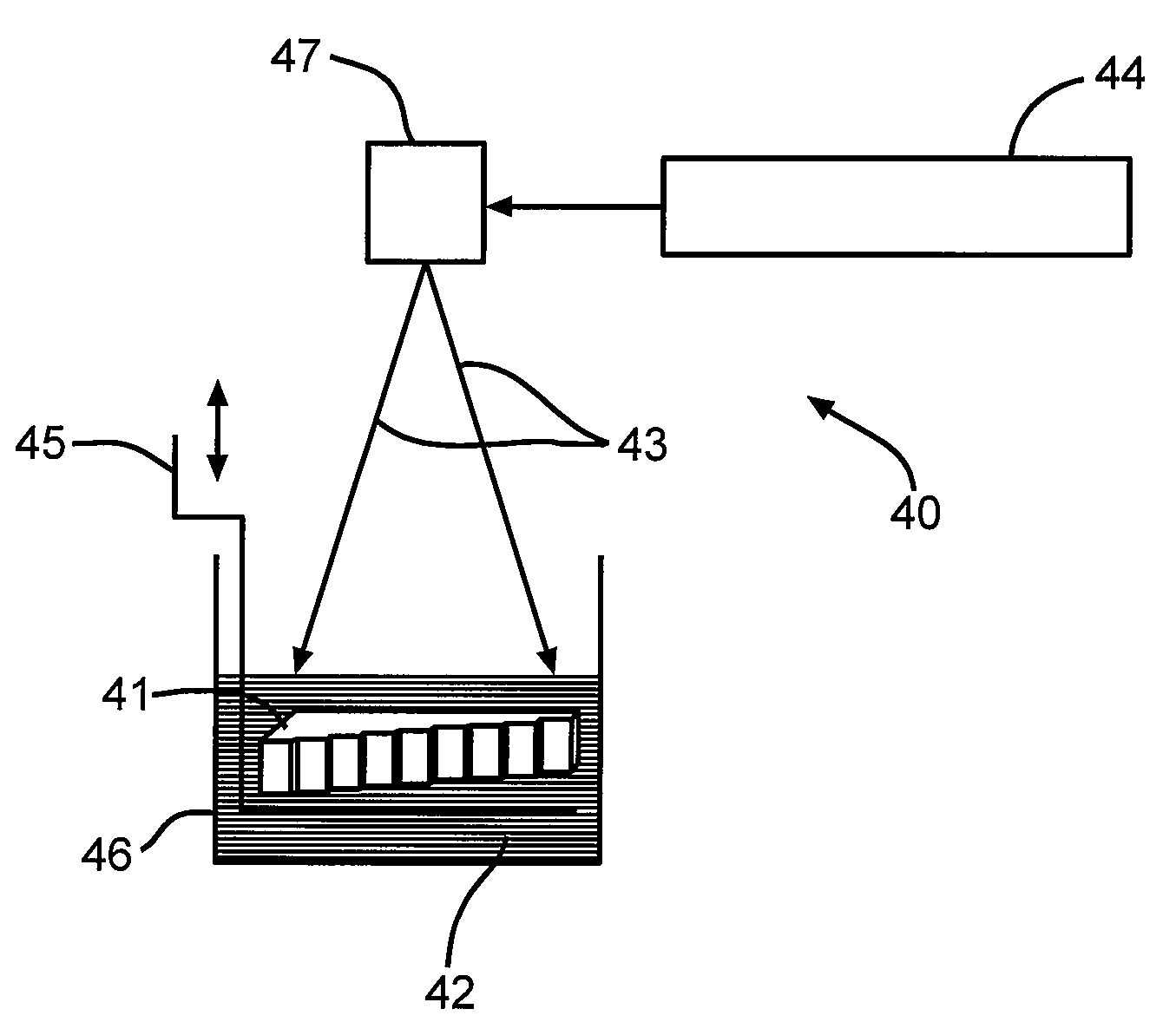

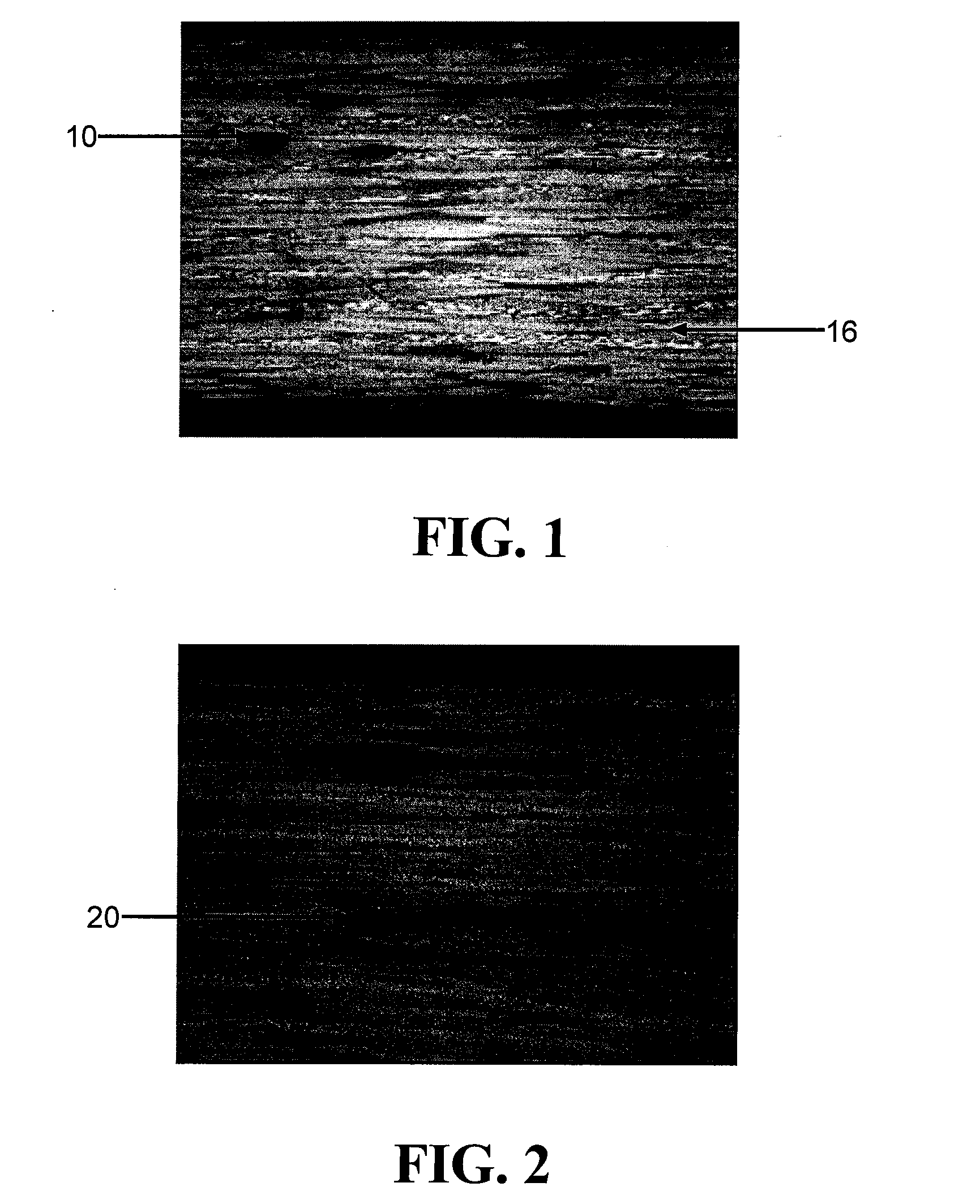

Porosity reference standard utilizing one or more discrete wires

InactiveUS7357014B2Material analysis using sonic/ultrasonic/infrasonic wavesAdditive manufacturing apparatusPorosityLithography process

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which may substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness and at least one discrete wire. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. The discrete wire may scatter and attenuate ultrasonic energy. The reference standard may replace more costly, porous, fiber-reinforced, composite reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

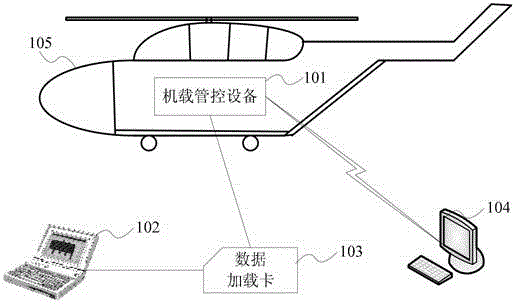

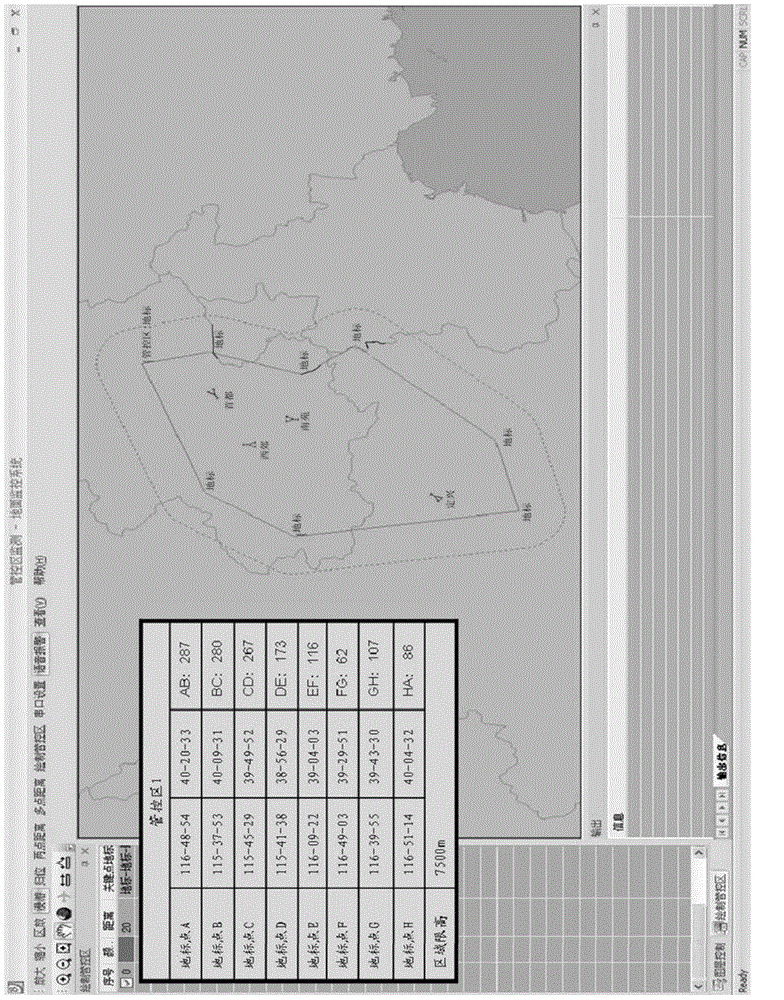

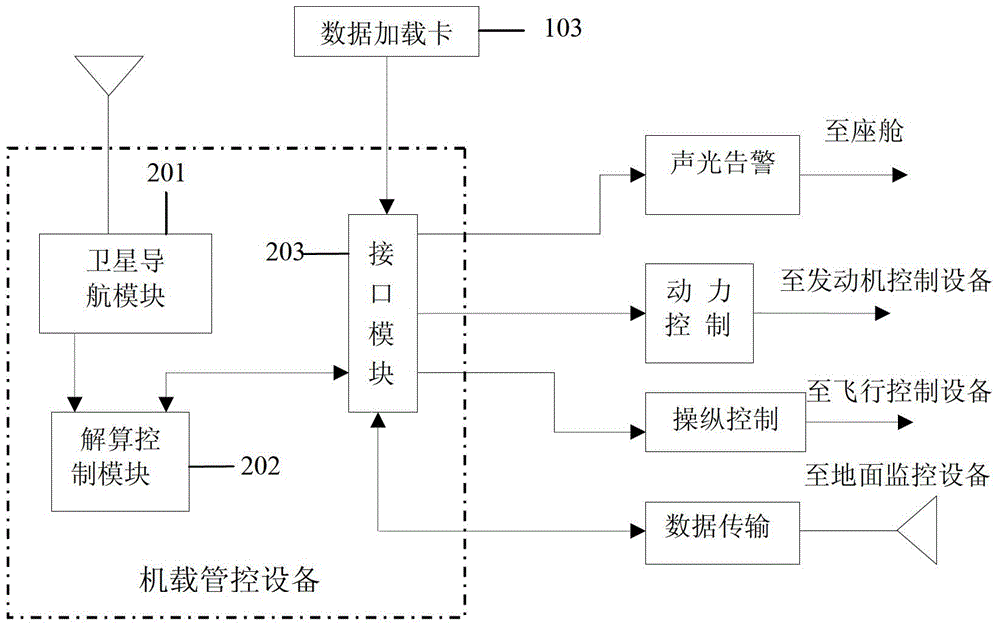

Aircraft border-crossing management and control method and system

The invention provides an aircraft border-crossing management and control method and a system. The aircraft border-crossing management and control method comprises: reading spatial geographical data of a management and control area; using a polygon approximation method to generate polygon management and control area information based on the spatial geographical data of the management and control area; acquiring flying parameters of an aircraft in real time through satellite positioning, the flying parameters including time, longitude and latitude, course, altitude, and velocity; and judging whether the aircraft crosses the border according to the polygon management and control area information and the flying parameters, and performing management and control processing on the aircraft that crosses the border. Through aircraft border-crossing management and control method, real-time management and control of the aircraft that crosses the border can be performed, truly realizing the capabilities of viewing, communicating, managing and checking, and facilitating the development of the low altitude aircraft industry.

Owner:CHONGQING XIANGYI AVIATION SCI & TECH

Inset panel fastener

An inset panel fastener is provided primarily for honeycomb substrates, such as those employed in the aircraft industry. The inset panel fastener includes a plastic body portion and a metal female threaded nut positioned within the body. The body includes a cylindrical barrel shape having a top and a bottom. A bore extends through the body from the top to form an opening for receipt of a male fastener. The metal nut has locking threads and is positioned in body's bore at the body's top proximal extremity. The body further includes non-locking plastic female threads integrally formed into said body's bore. The plastic female threads have the same diameter as the metal threads and are immediately adjacent to the metal threads so as to form continuous threads for permitting receipt of a male threaded fastener. The metal female threads are locking threads to provide a locking action for locking a male fastener to the inset panel fastener. Meanwhile, the plastic female threads provide primary load bearing capabilities for the inset panel fastener.

Owner:NMC GROUP

Production method of no-powder-falling interlayer structure super heat insulation gas gel composite material

ActiveCN103192582ASimple processExtended service lifeLaminationLamination apparatusAircraft industryAirplane

The invention belongs to the field of heat insulation and sound-proof material manufacturing, and in particular relates to a production method of a no-powder-falling interlayer structure super heat insulation gas gel composite material. According to the invention, inorganic fireproof cloth is pasted on the outer surface of a nano porous gas gel material; the performances of light quality, super heat insulation and the like of the gas gel material are kept, and meanwhile the problem of easiness in powder falling is solved, and nano dust is prevented from generating during the production and using process of the gas gel material, so that the gas gel material is more safe, healthy and environment-friendly, and compared with the non-composite gas gel material, the gas gel material is more even and uniform, and the appearance is more beautiful. The no-powder-falling interlayer structure super heat insulation gas gel composite material provided by the invention has the characteristics of chip and easily obtained raw materials, safe and simple production process, low cost and the like; the obtained material has the advantages of excellent nano porous material heat insulation performance and durable common material, and is widely applied to the heat insulation field of ship cabins, vehicle bodies, airplanes, industrial pipelines, building wall bodies and the like.

Owner:SHANGHAI GRAND SOUND BEYOND NOISE NEW MATERIAL

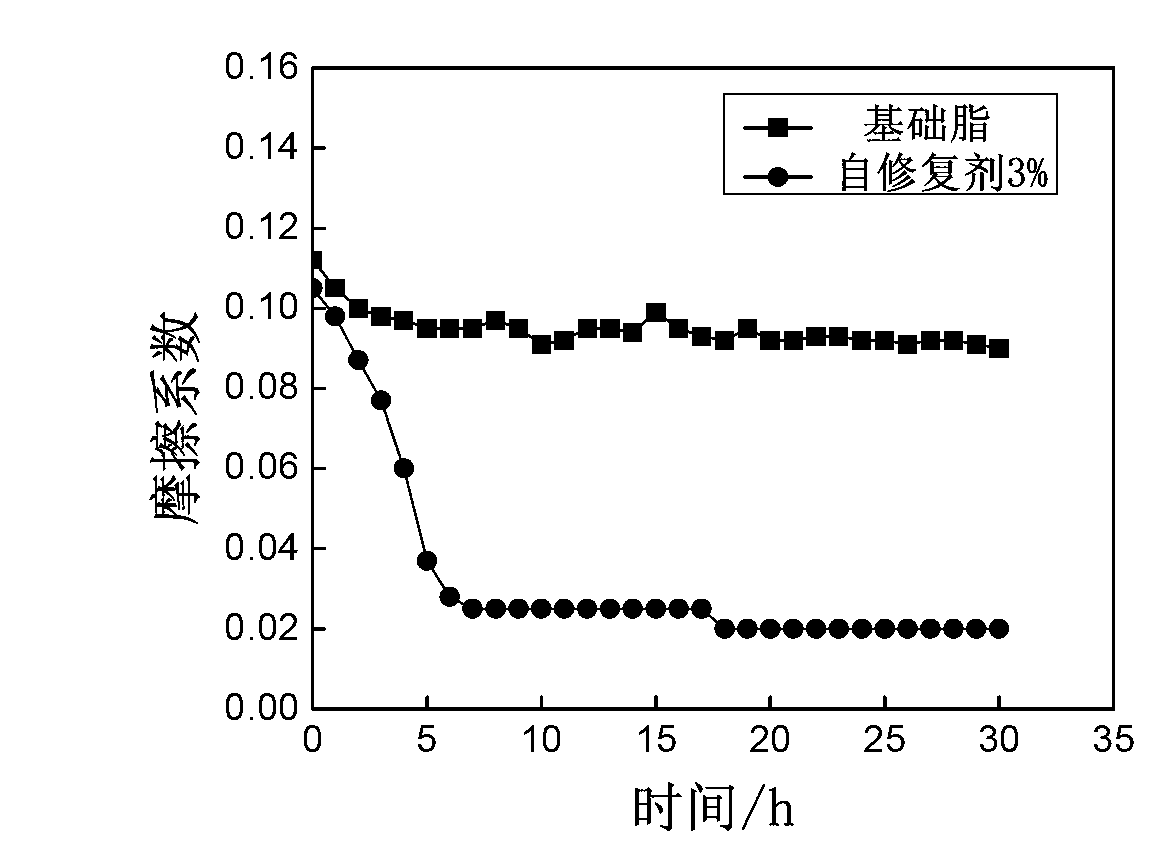

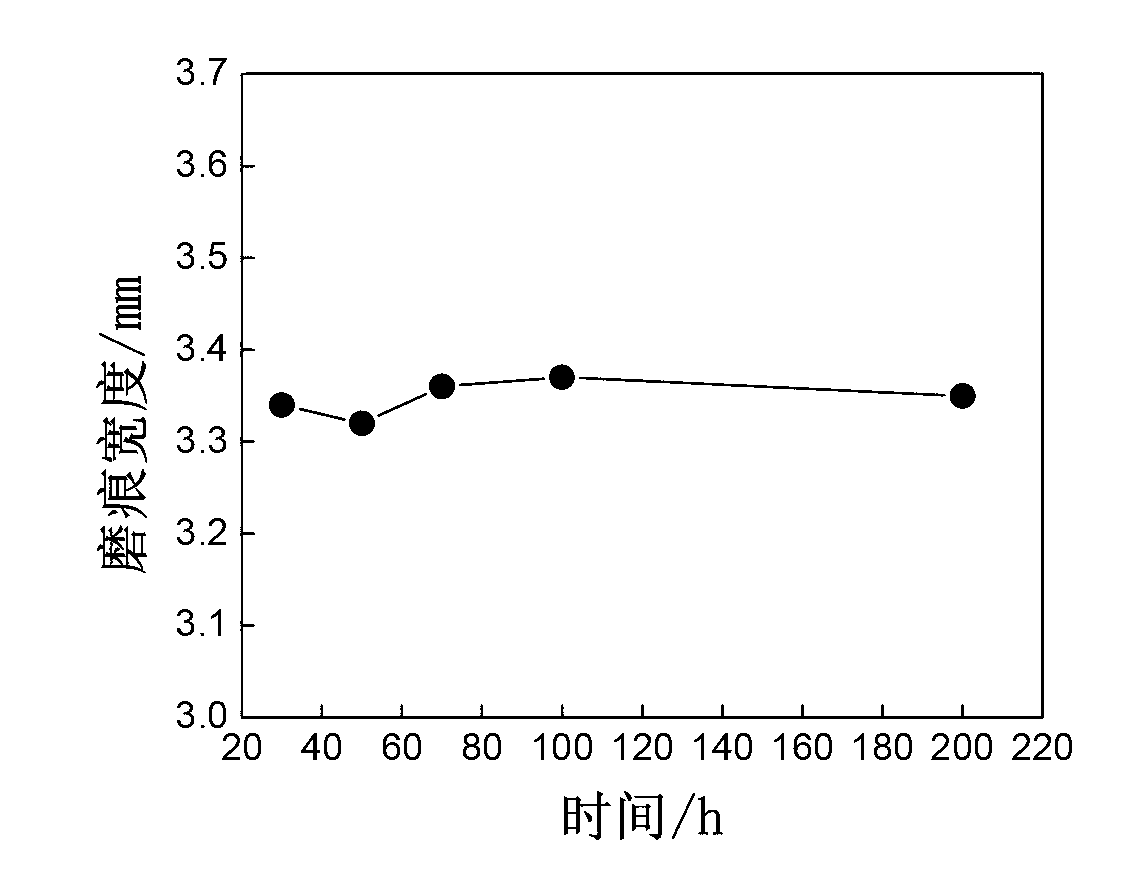

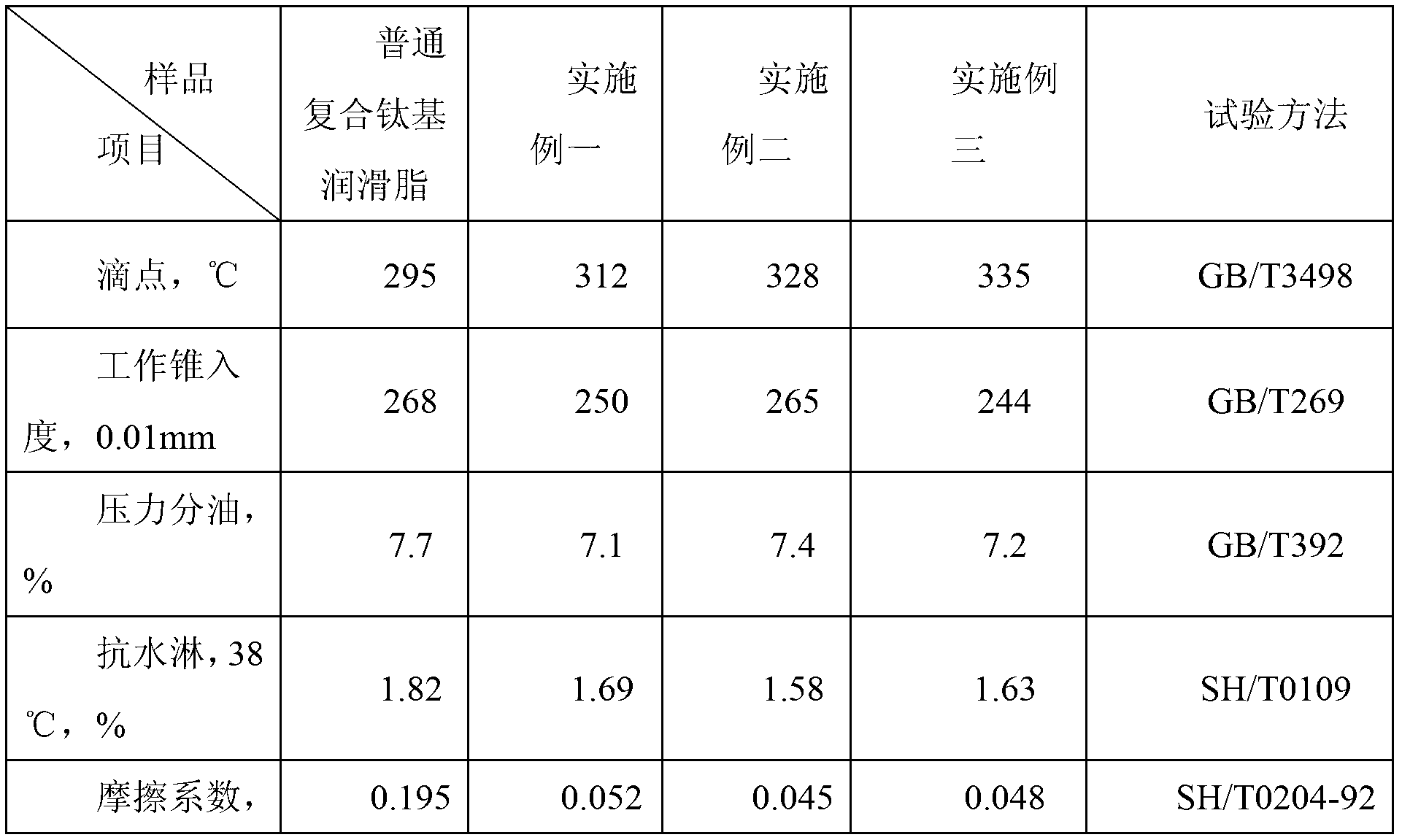

Self-repairing compound titanium-based grease and preparation method thereof

ActiveCN103160369AStable structureImprove heat resistanceLubricant compositionFood industryTetraisopropyl titanate

The invention provides a self-repairing compound titanium-based lubricating grease and a preparation method thereof, and relates to a lubricating grease and a preparation method of the lubricating grease. The lubricating grease has excellent antioxidant ability and bearing capacity, and is capable of repairing the surface of a wearing part and prolonging the service life of the friction part. The lubricating grease is prepared by mixing a base oil, a compound titanium soap thickening agent, an antioxidant additive, an anti-wear reagent at extreme pressure, an antifriction additive and a self-repairing lubricating material together; and the preparation method of the lubricating grease comprises the following steps of mixing the base oil with a high molecular acid and stirring, heating the temperature to the range of 80-90 DEG C, adding tetraisopropyl titanate and a low molecular acid, preserving heat and stirring, increasing the reaction temperature to the range of 120-150 DEG C, and then adding the left base oil and continuing increasing the temperature to the range from 200 to 220 DEG C and stirring; adding the self-repairing lubricating material after grease is formed, and stirring, and then adding other additives, and finally, grinding, homogenizing and degassing, thereby obtaining the self-repairing compound titanium-based lubricating grease. The self-repairing compound titanium-based lubricating grease is used for the automobile industry, the metallurgical industry, the food industry and the aircraft industry.

Owner:HARBIN INST OF TECH

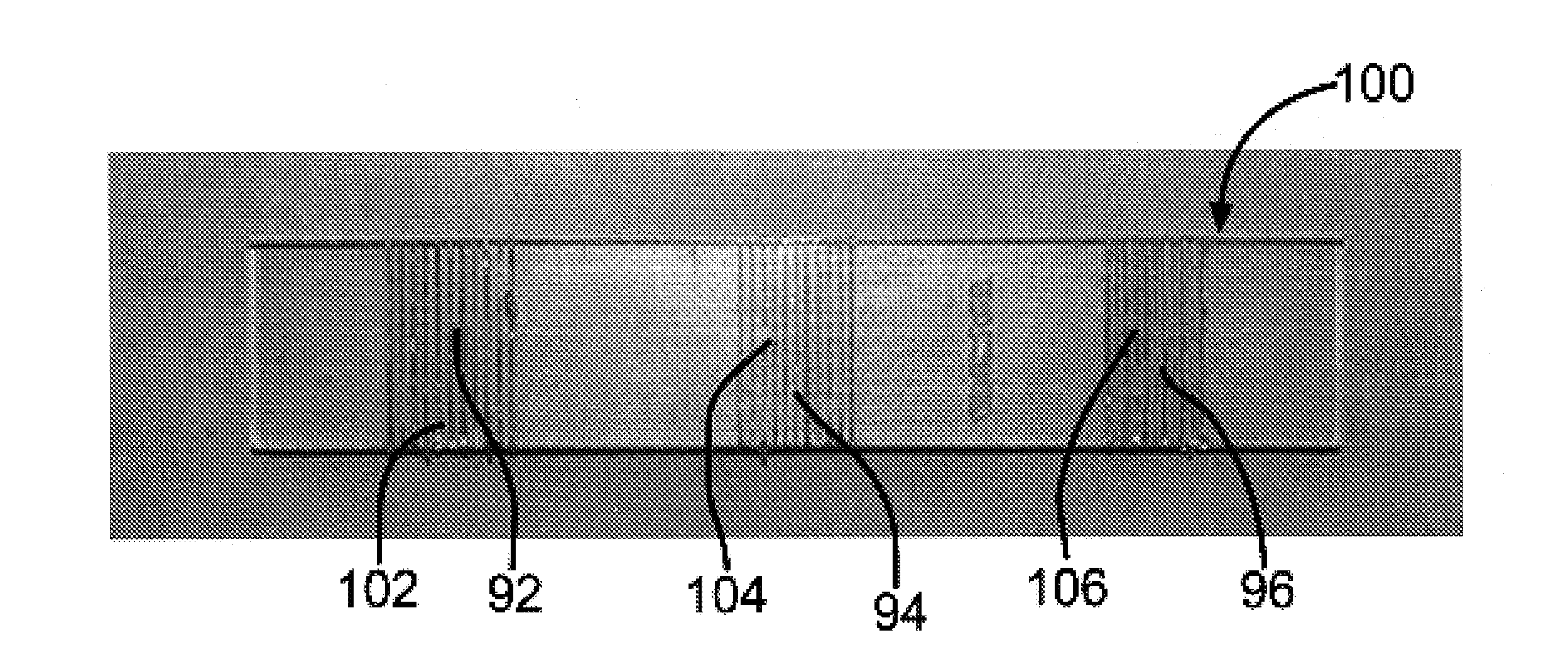

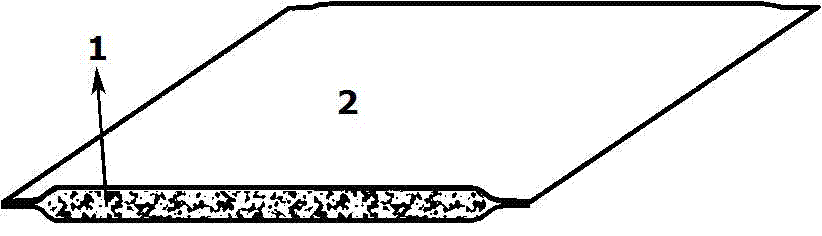

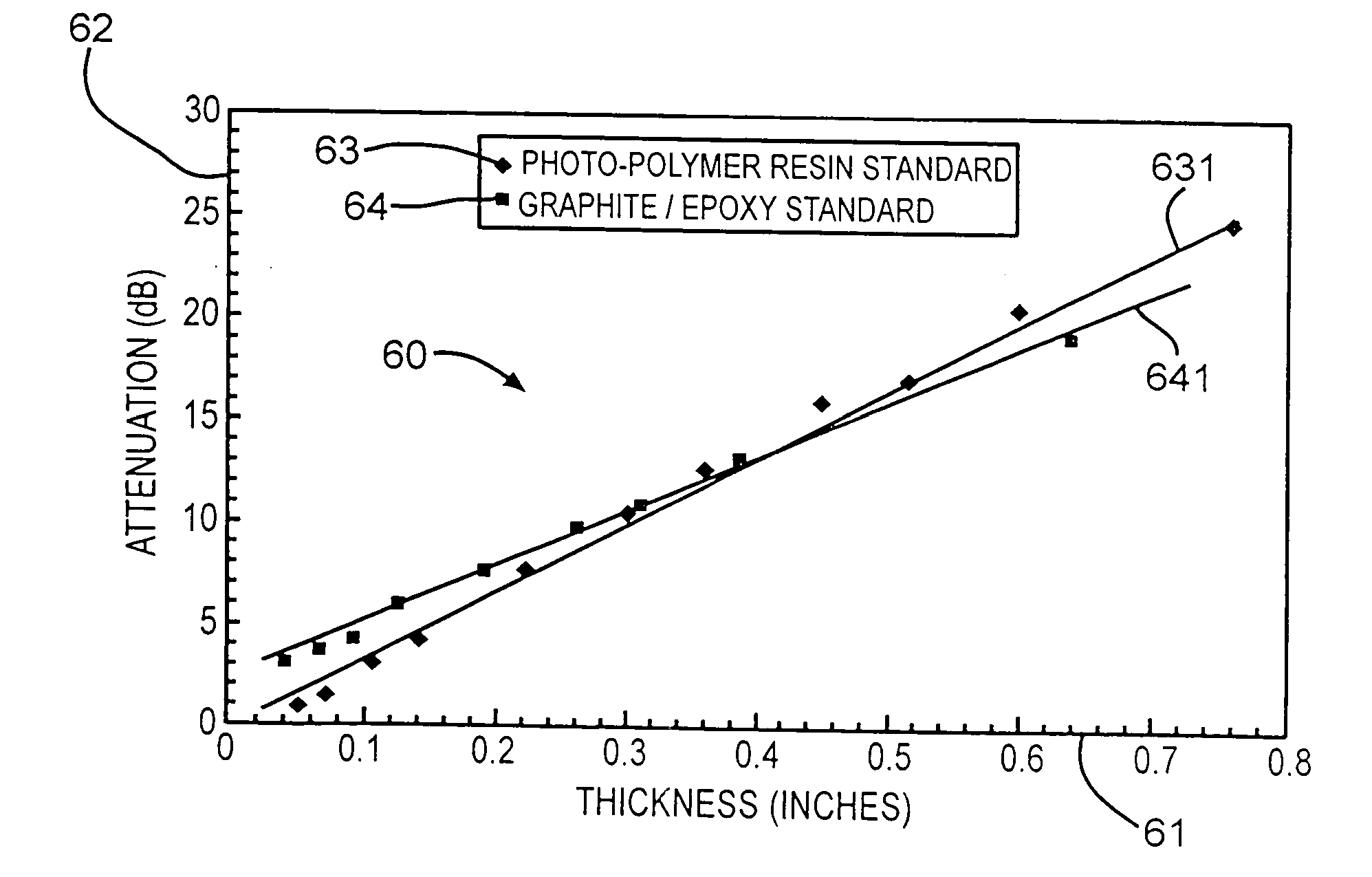

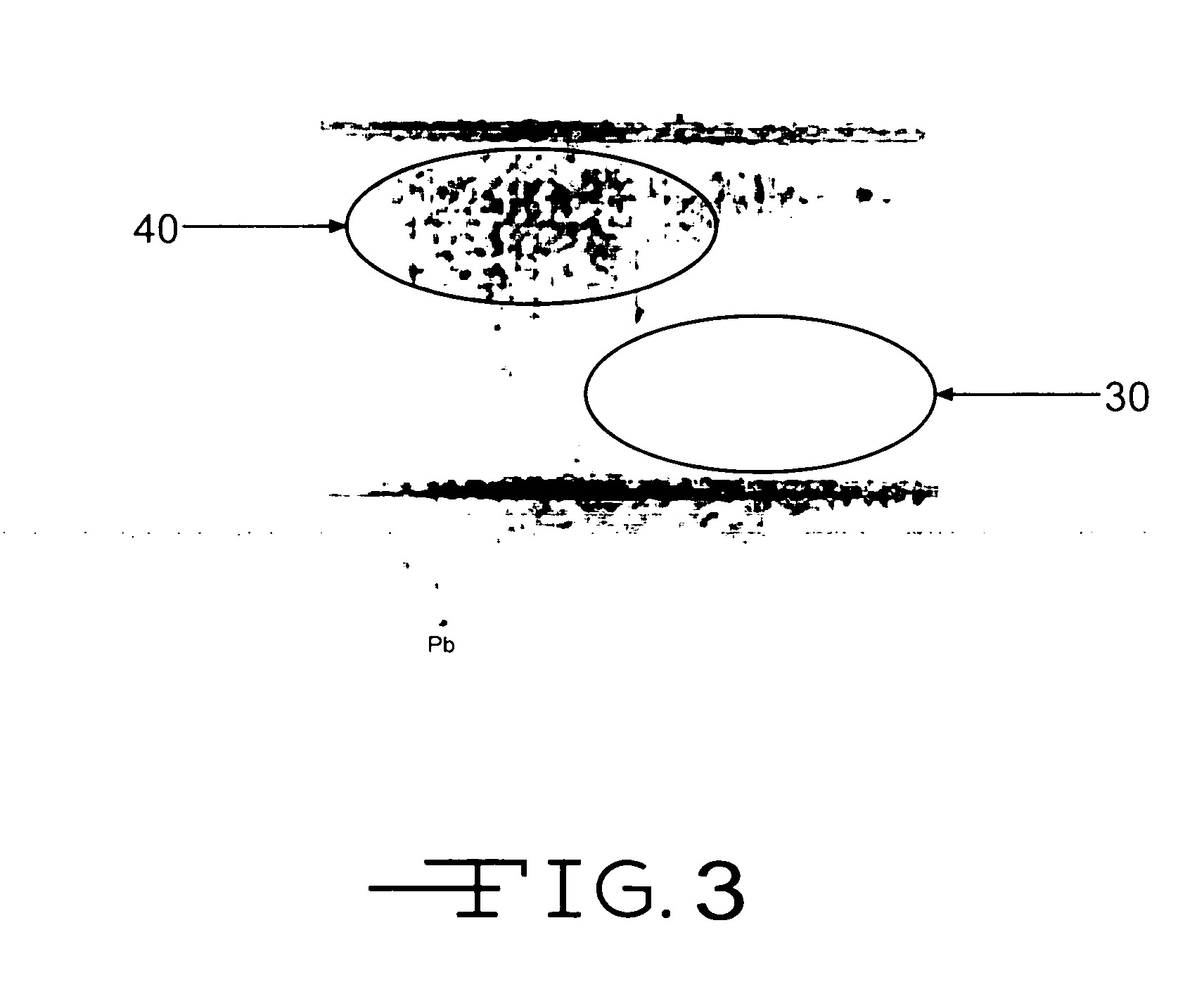

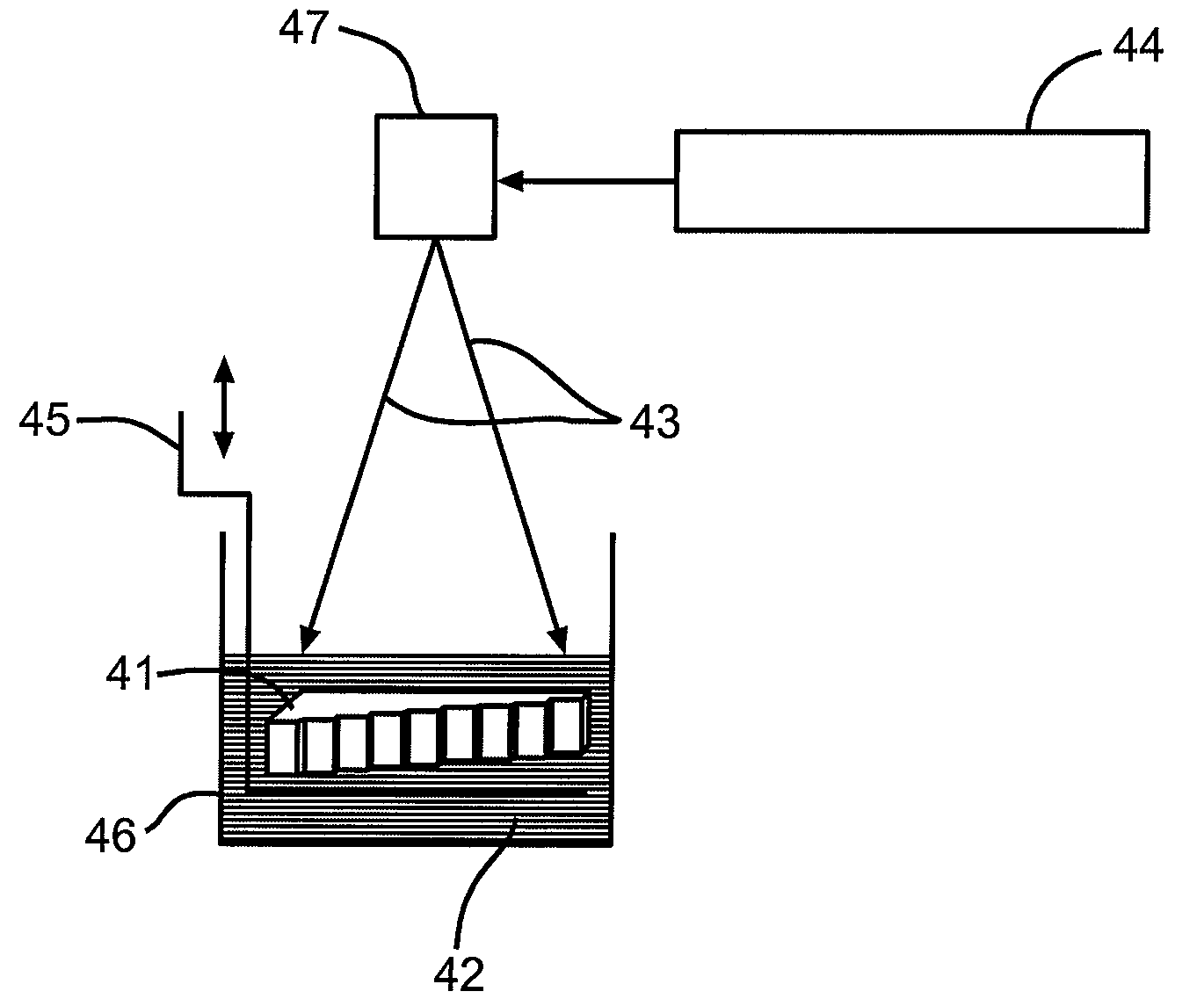

Porosity reference standard utilizing a mesh

ActiveUS20070107520A1Additive manufacturing apparatusMaterial analysis using sonic/ultrasonic/infrasonic wavesPorosityFiber

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness and at least one mesh. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. Use of the mesh produces a standard which transmits ultrasonic energy, with the mesh scattering and attenuating the energy. The manufactured reference standard may replace more costly porous, fiber-reinforced, composite reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

Porosity reference standard utilizing one or more hollow, non-cylindrical shafts

InactiveUS20080196475A1Multiple-port networksAdditive manufacturing apparatusPorosityLithography process

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which may substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness. The member may be defined by at least one hollow, non-spherical shaft. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. The non-spherical shaft may scatter and attenuate ultrasonic energy. The reference standard may replace more costly, porous, fiber-reinforced, composite reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

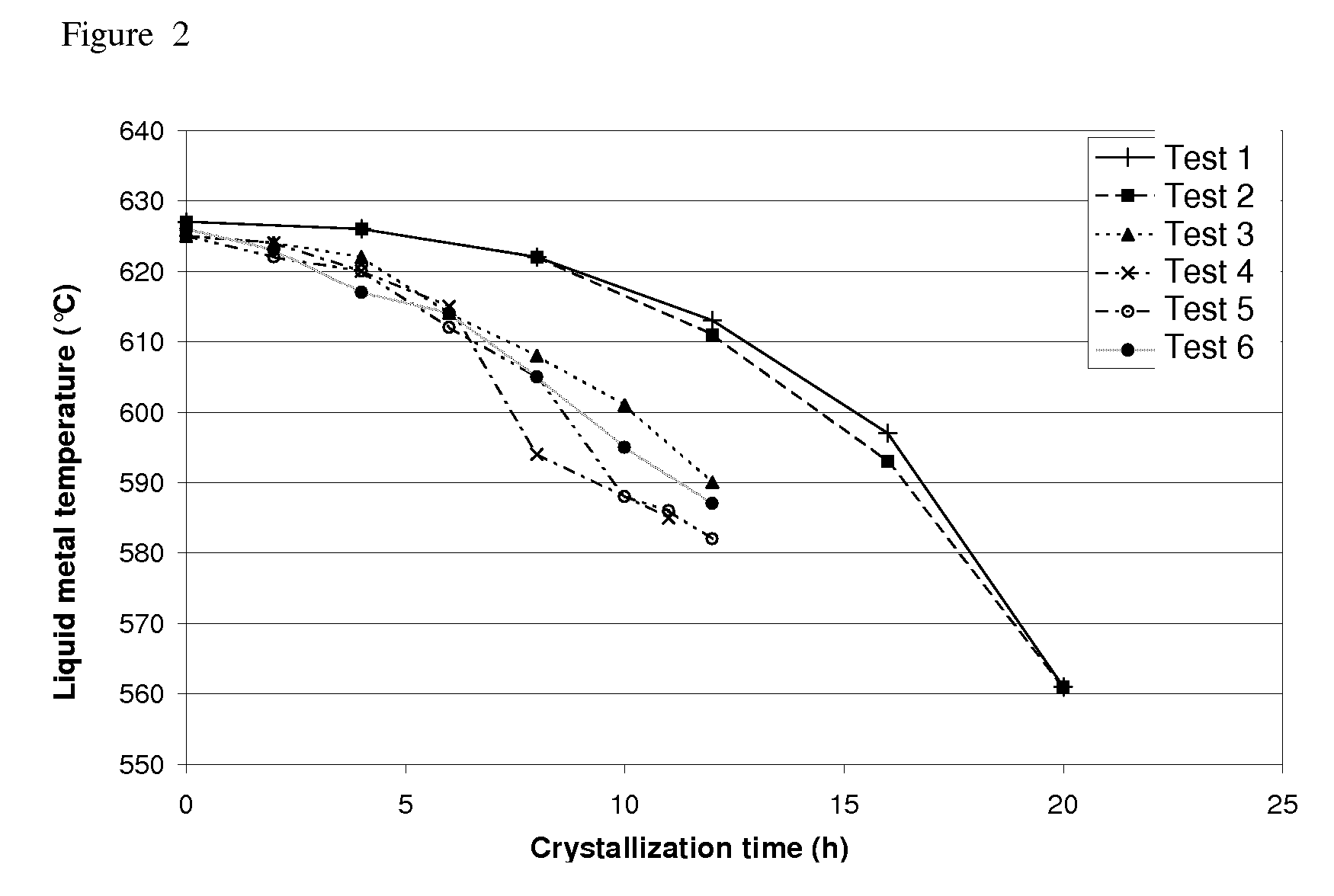

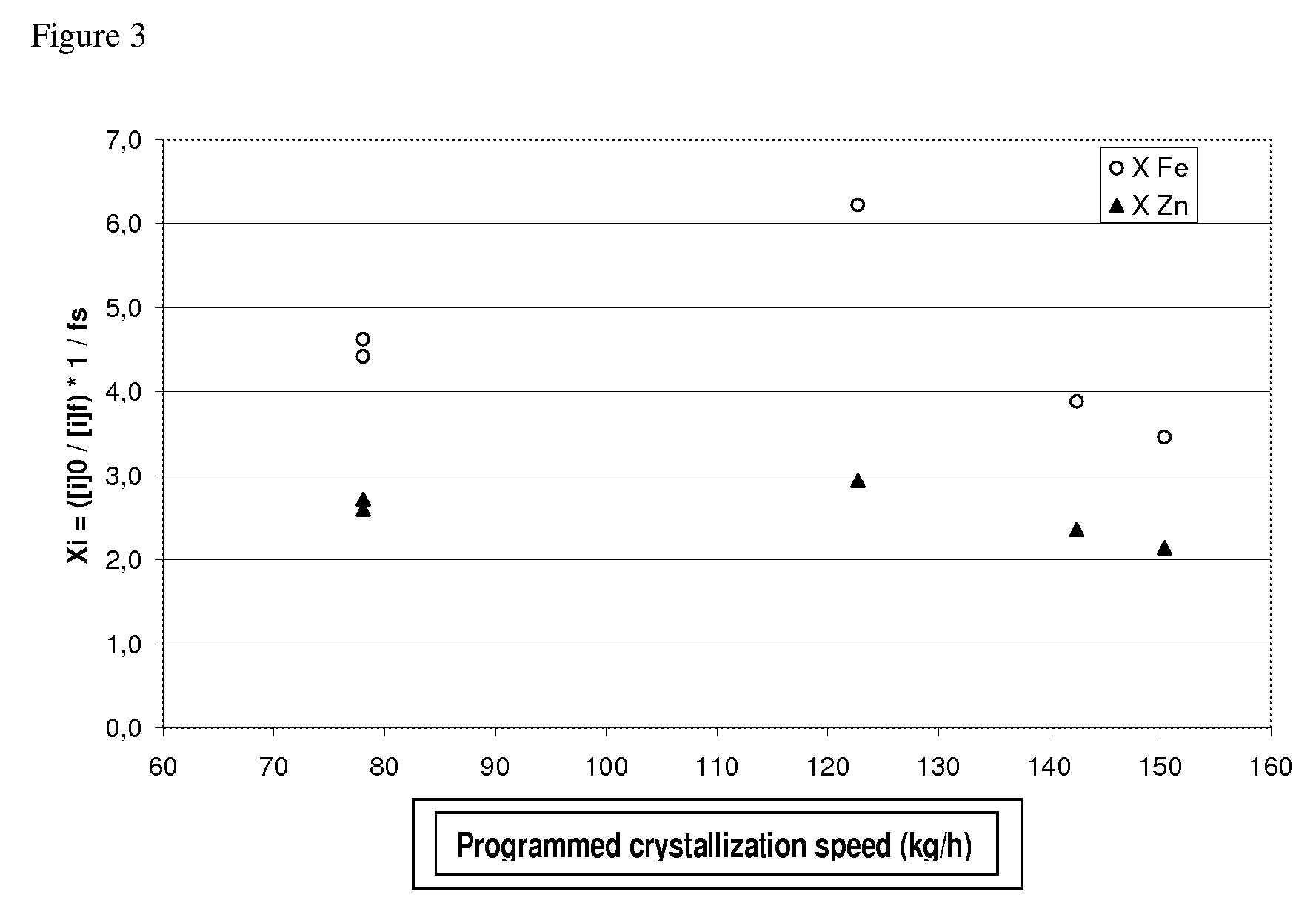

Process for recycling aluminium alloy scrap coming from the aeronautical industry

ActiveUS20090285716A1Easy to recycleManufacturing convertersElectric furnaceRecovery stageAircraft industry

A manufacturing process for a remelt block containing aluminum designed for making aluminum alloy for the aircraft industry in which scrap containing mainly aluminum alloys used in the aircraft industry is supplied during a supply stage, the scrap is melted in a smelting furnace in order to obtain an initial molten metal bath during a smelting stage, the initial molten metal bath is subjected to purification by fractional crystallization in order to obtain a solidified mass and a bath of residual liquid during a segregation stage, and the solidified mass is recovered in order to obtain a remelt block during a recovery stage. The invention is particularly useful for the recycling of aluminum alloys used in the aircraft industry as it makes it possible to purify scrap of series 2XXX or series 7XXX alloys for iron and silicon, without eliminating additive elements such as zinc, copper and magnesium.

Owner:CONSTELLIUM ISSOIRE

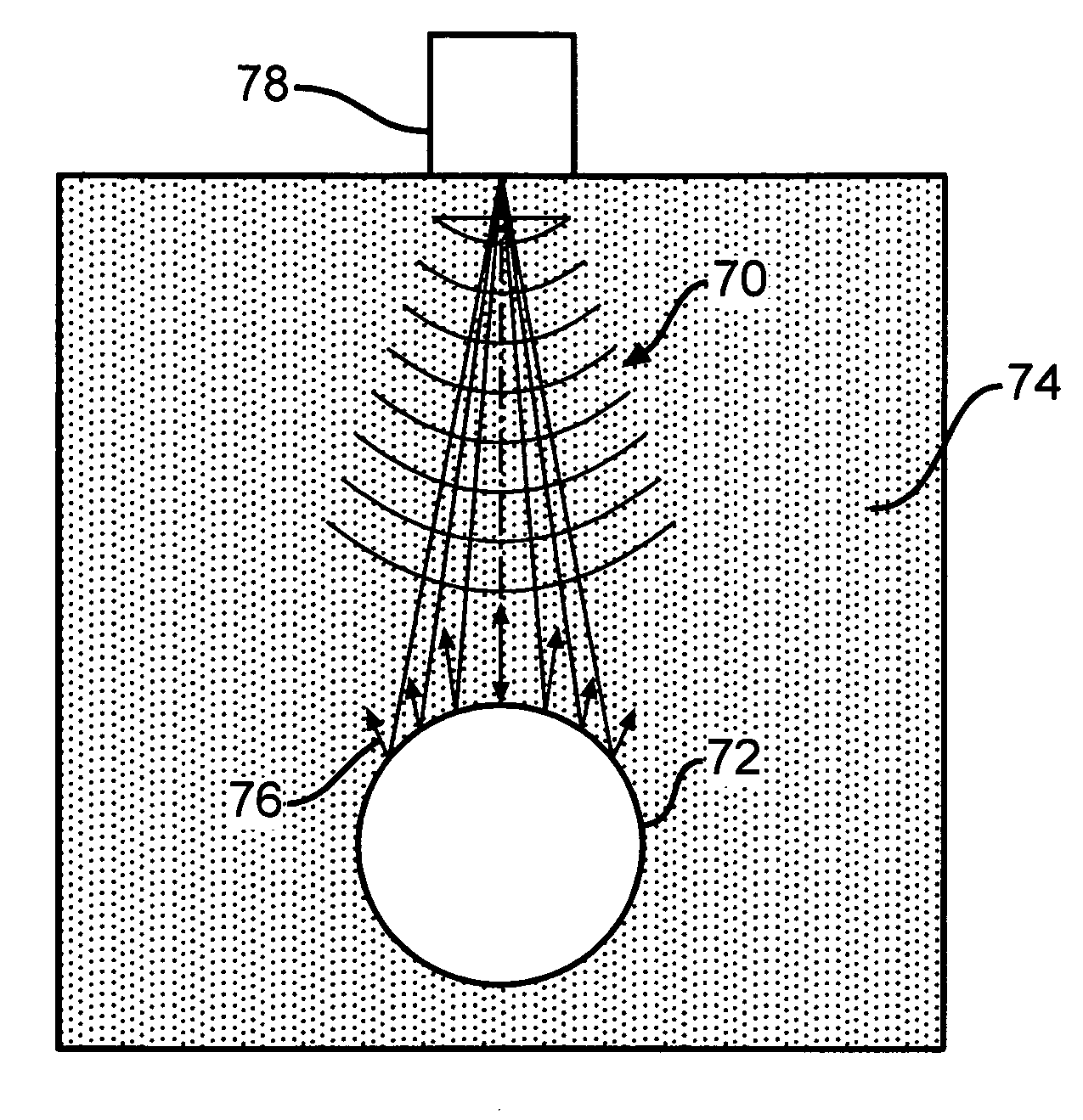

Semi-finished product made of aluminium alloy having improved microporosity and manufacturing process

The invention relates to a manufacturing method for making an unwrought semi-finished product having at mid thickness a density of micropores of size greater than 90 μm less than 50% and preferably less than 20% of the density of micropores of size greater than 90 μm obtained by a method according to prior art. The method according to the invention comprises in particular an ultrasound treatment step for the molten metal bath in a furnace and / or a vessel using an immersed device comprising at least one ultrasound transmitter. The semi-finished products obtained according to the method of the invention are particularly advantageous for manufacturing by rolling sheets designed for the aircraft industry to produce spars, ribs, upper and lower wing skins and for manufacturing by extrusion sections designed for the aircraft industry to produce stiffeners.

Owner:CONSTELLIUM ISSOIRE

Porosity reference standard utilizing one or more discrete wires

InactiveUS20070119256A1Additive manufacturing apparatusMaterial analysis using sonic/ultrasonic/infrasonic wavesPorosityFiber

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which may substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness and at least one discrete wire. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. The discrete wire may scatter and attenuate ultrasonic energy. The reference standard may replace more costly, porous, fiber-reinforced, composite reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

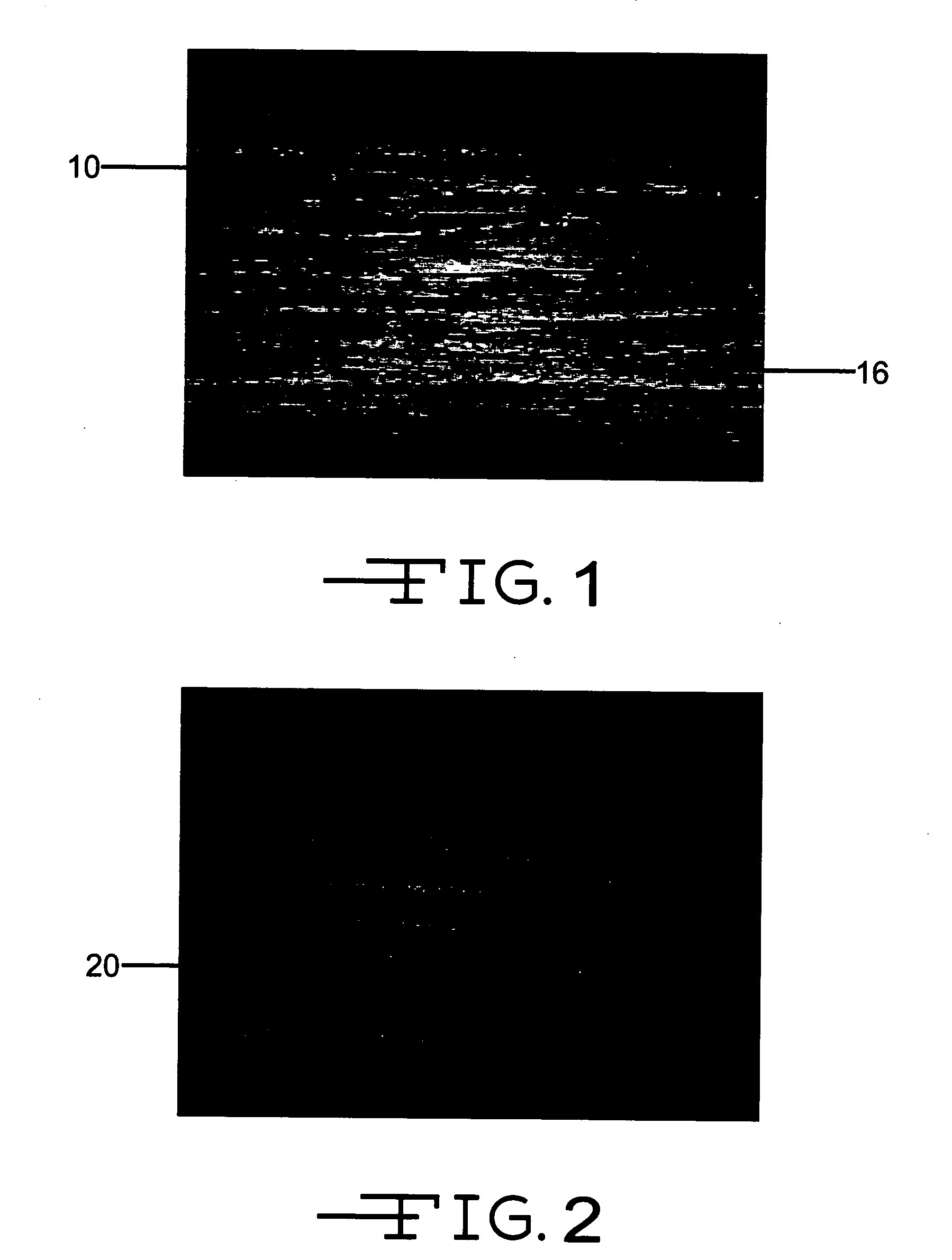

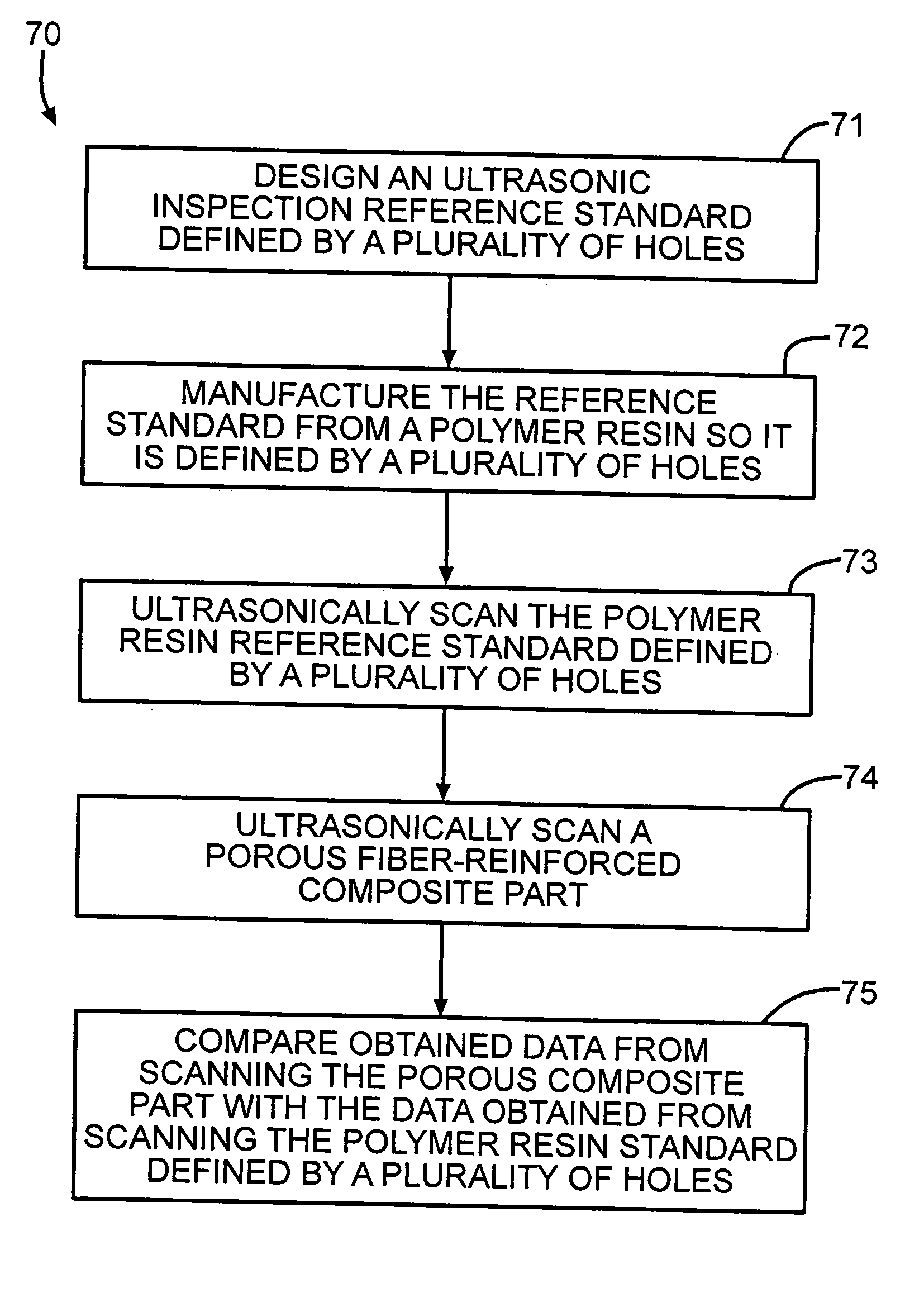

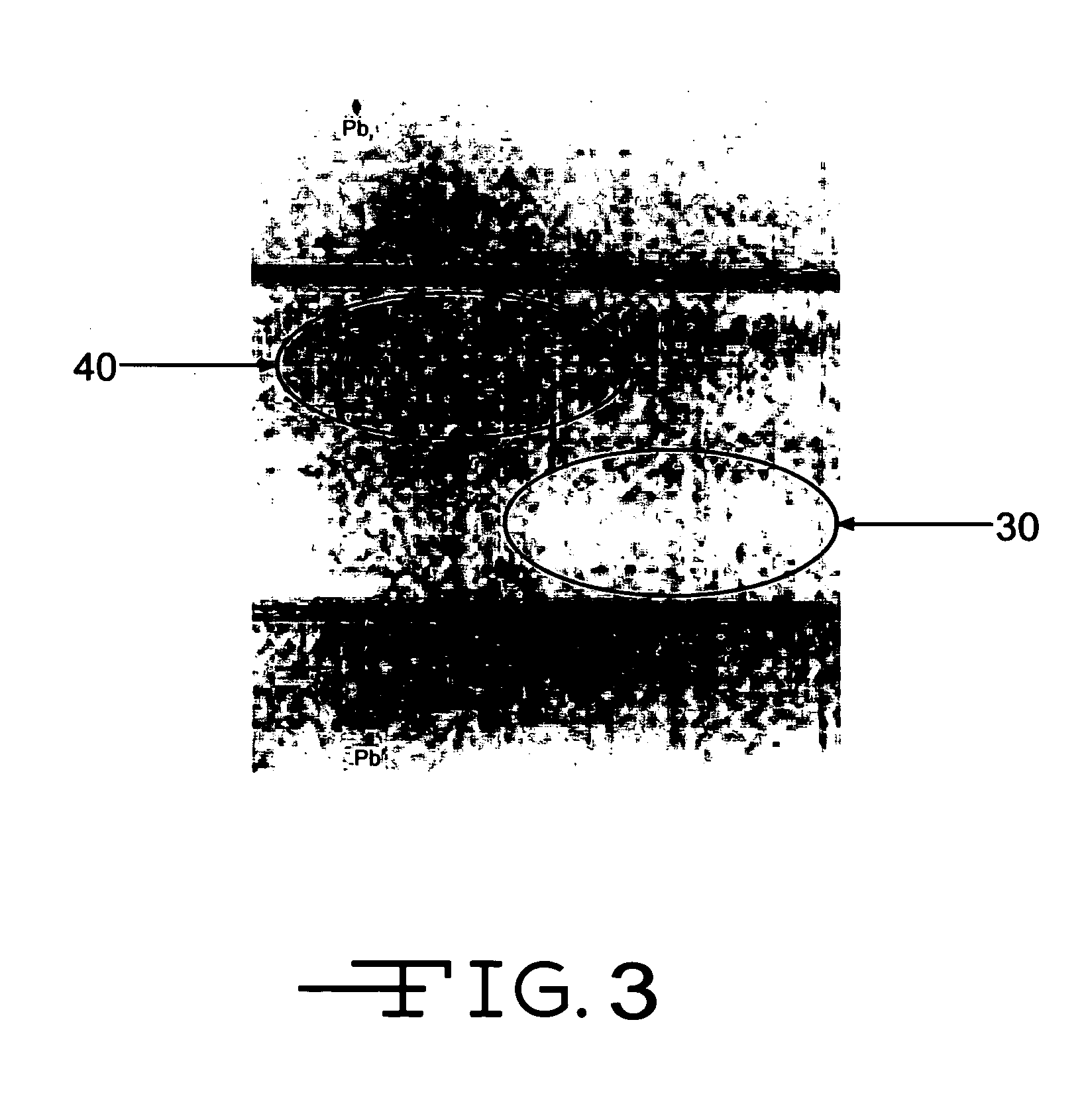

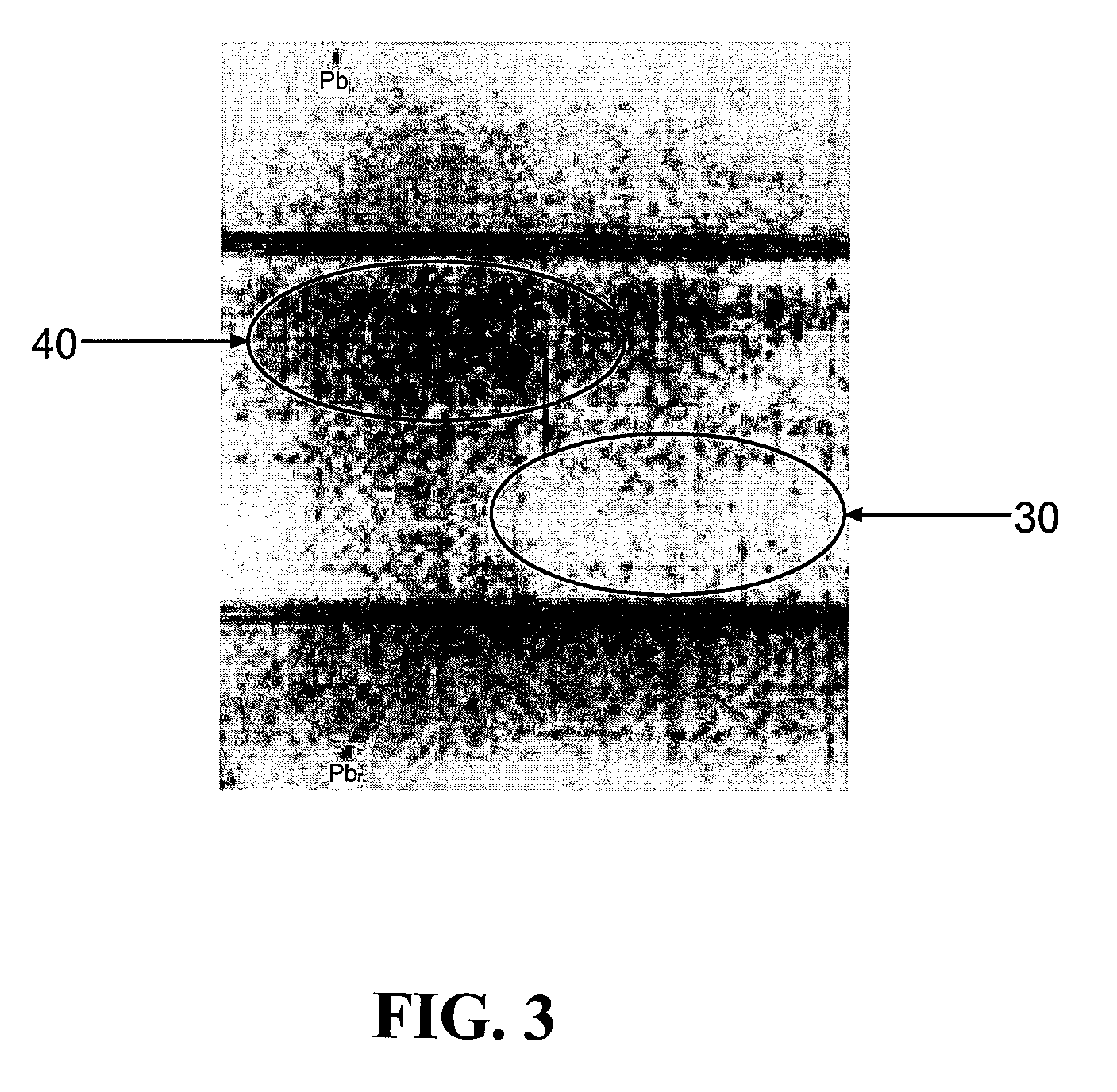

Ultrasonic inspection reference standard for porous composite materials

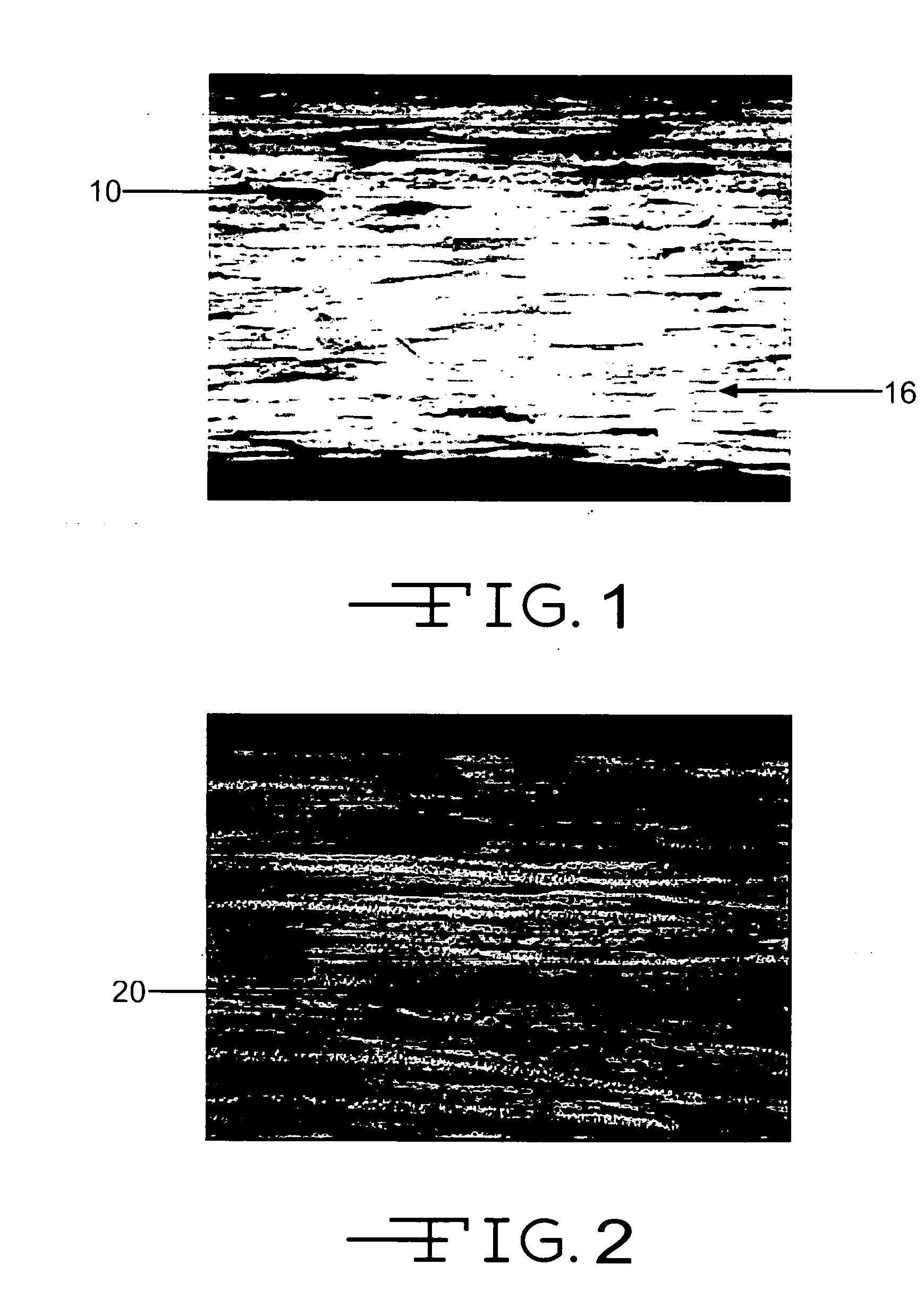

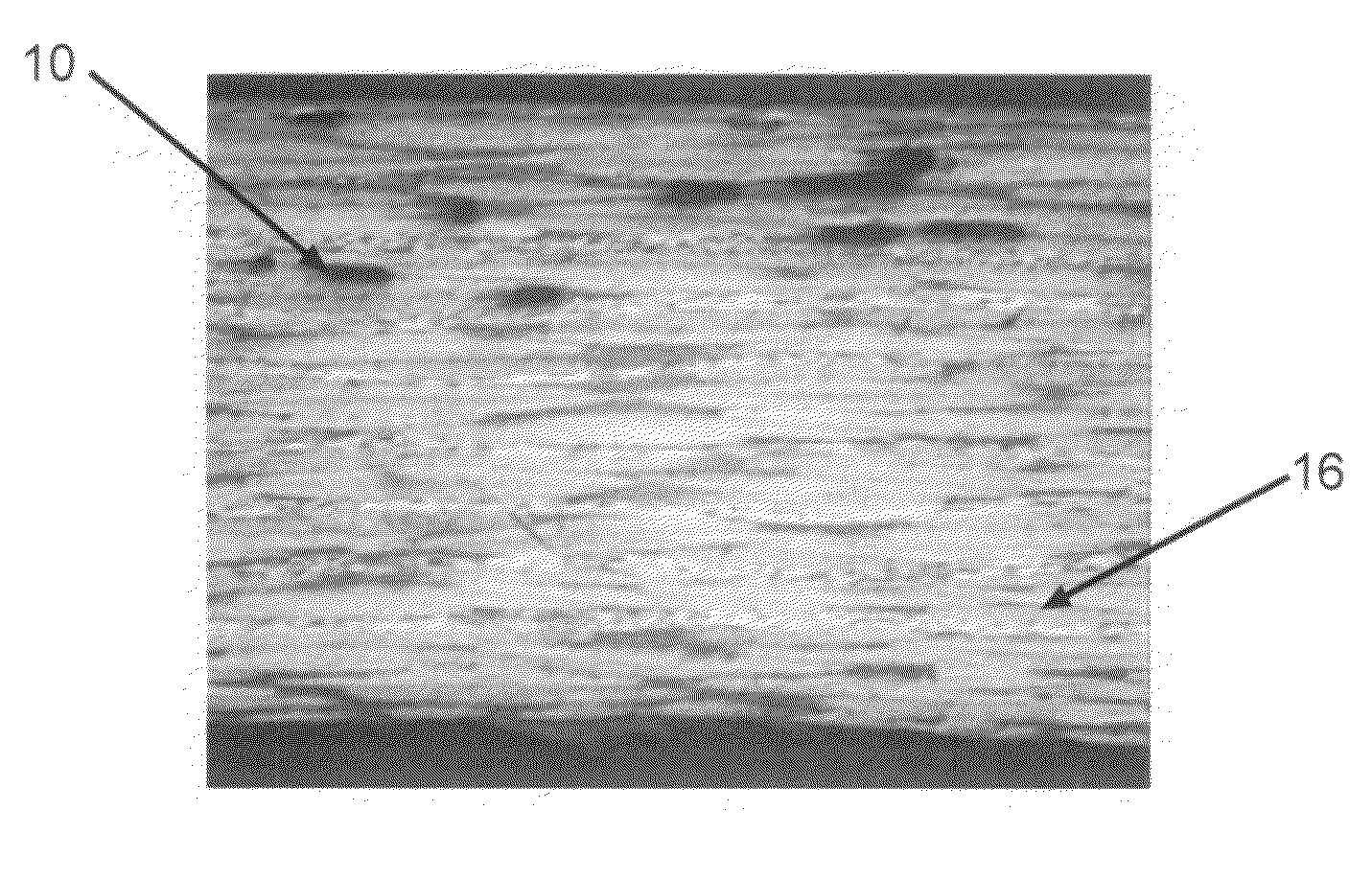

ActiveUS7424818B2Additive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesPolymer resinLithography process

An ultrasonic inspection reference standard for composite materials having porosity may include a member, having at least one thickness and defined by a plurality of holes, that is manufactured from a fiber-free polymer resin. The ultrasonic inspection reference standard may have similar acoustic properties to prior art, porous, fiber-reinforced, composite reference standards, at lower manufacturing cost. A photo-polymer resin reference standard, having at least one thickness and defined by a plurality of holes, may be created using a stereo lithography process. The polymer resin reference standard may replace more costly porous, fiber-reinforced, composite reference standards. The ultrasonic inspection reference standard, manufactured from a polymer resin, may be used for ultrasonic inspection of porous, fiber-reinforced composite parts in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

Pseudo porosity reference standard for cored composite laminates

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which substantially mimic the effect porosity has on ultrasonic sound as it passes through a cored composite laminate having porosity. An ultrasonic inspection reference standard for cored composite laminates having porosity may include a member having at least one thickness, at least one core, and at least one mesh. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. Use of the mesh may produce a standard which transmits ultrasonic energy, with the mesh scattering and attenuating the energy. Use of the core may aide in modeling a cored composite laminate. The manufactured reference standard may replace more costly porous, cored, composite laminate reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

Ultrasonic inspection reference standard for porous composite materials

ActiveUS20070089479A1Additive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesFiber-reinforced compositeAircraft industry

An ultrasonic inspection reference standard for composite materials having porosity may include a member, having at least one thickness and defined by a plurality of holes, that is manufactured from a fiber-free polymer resin. The ultrasonic inspection reference standard may have similar acoustic properties to prior art, porous, fiber-reinforced, composite reference standards, at lower manufacturing cost. A photo-polymer resin reference standard, having at least one thickness and defined by a plurality of holes, may be created using a stereo lithography process. The polymer resin reference standard may replace more costly porous, fiber-reinforced, composite reference standards. The ultrasonic inspection reference standard, manufactured from a polymer resin, may be used for ultrasonic inspection of porous, fiber-reinforced composite parts in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

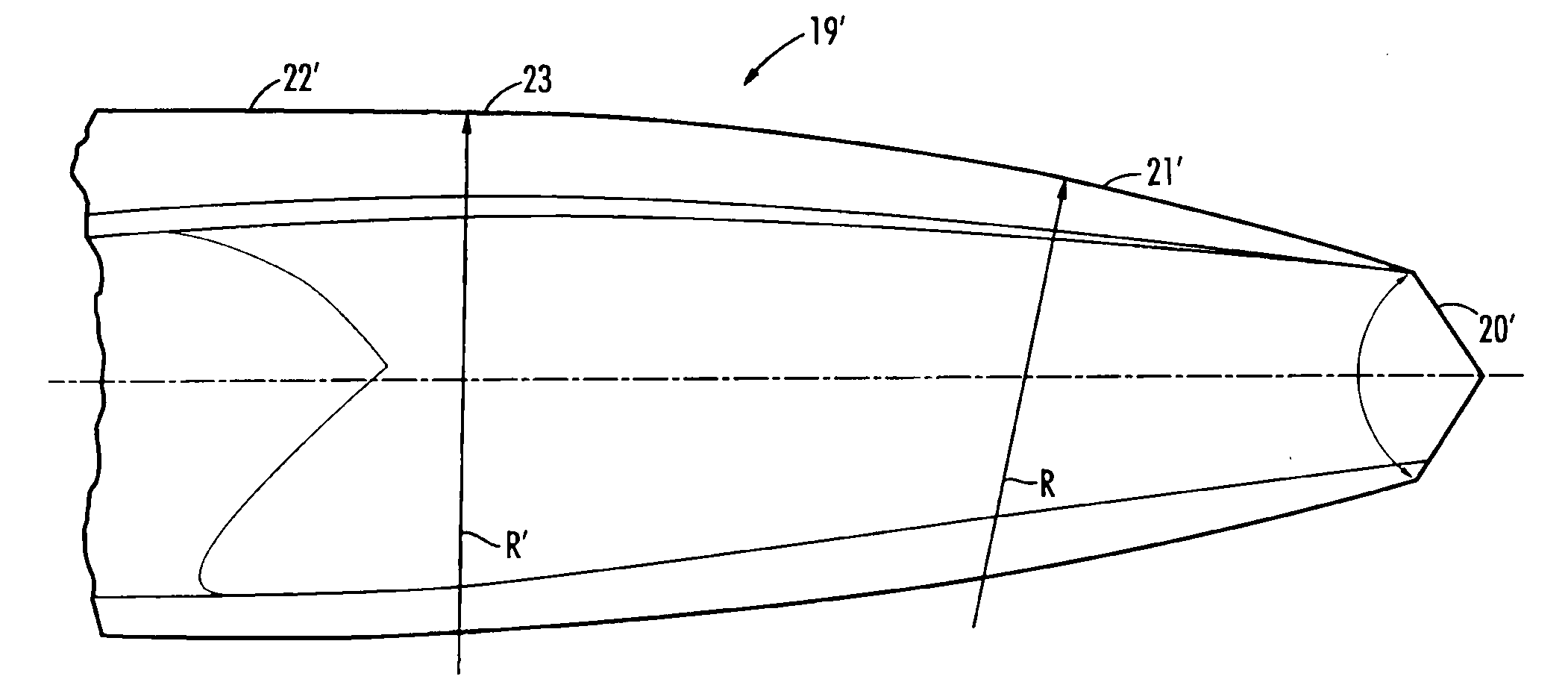

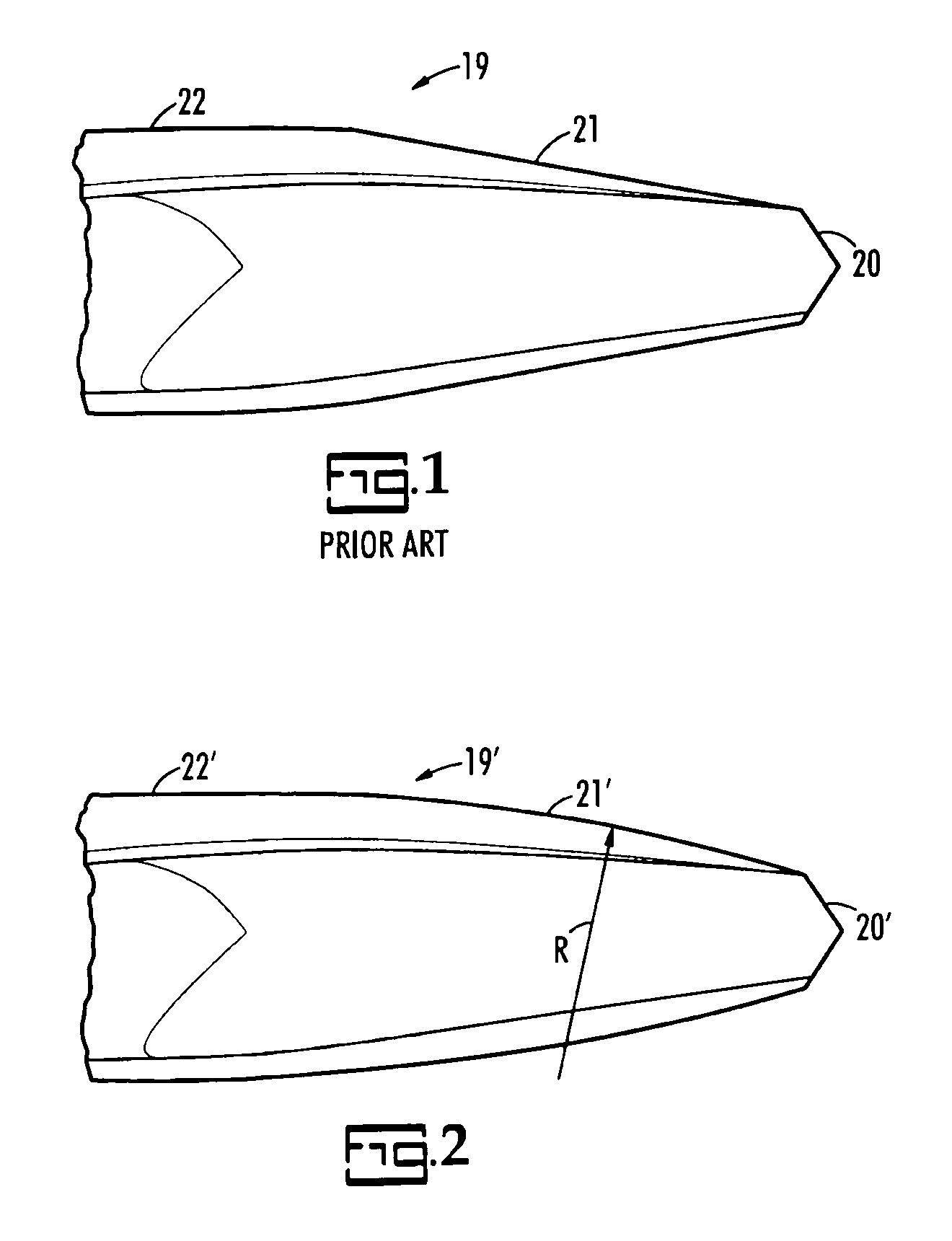

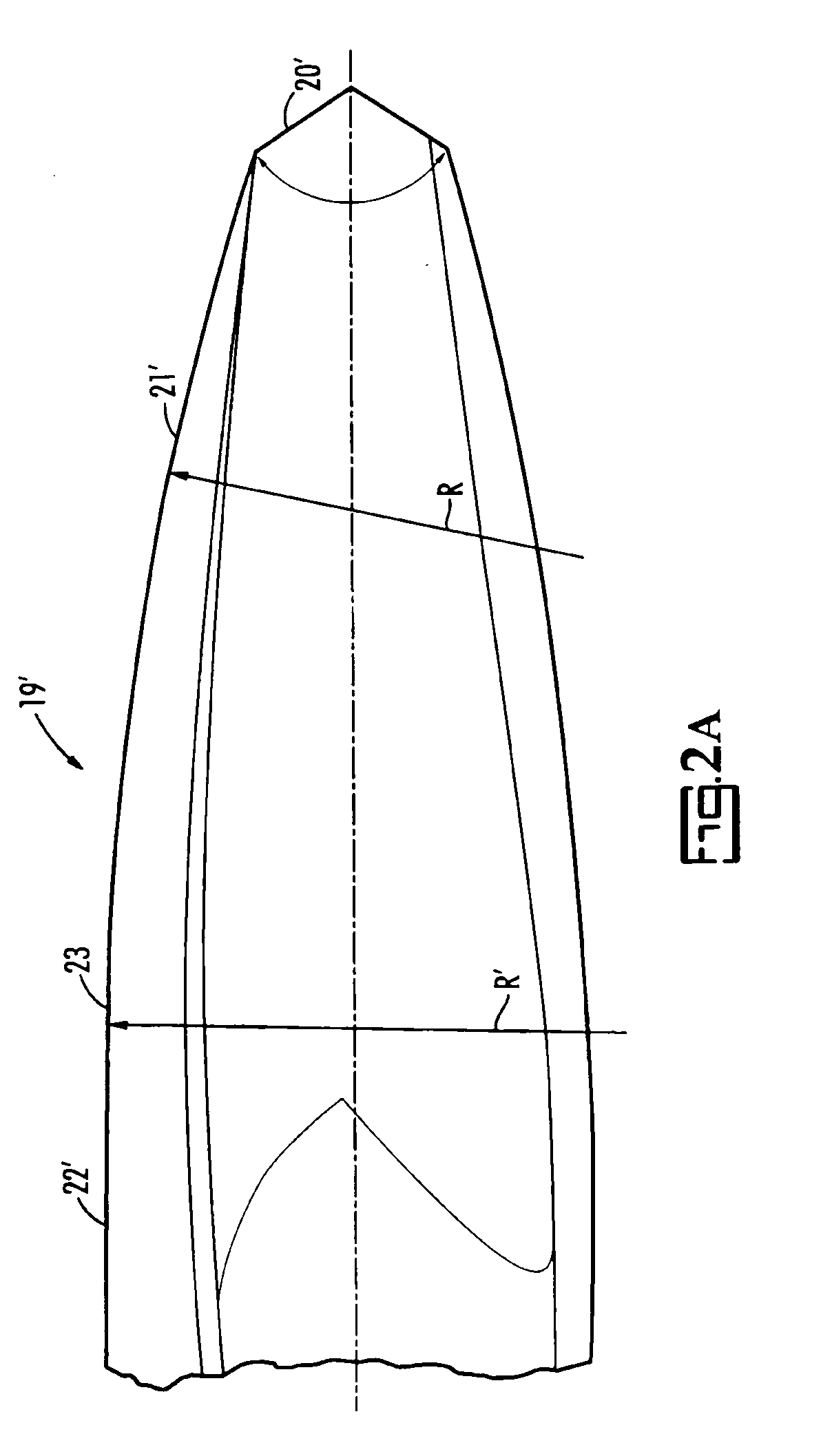

Drill bit for drilling holes in carboresin laminates

ActiveUS20100158627A1Minimal wear of drillShorten the timeAircraft componentsWood turning toolsFluteEngineering

A drill bit having features rendering it particularly effective in cutting holes in carboresin laminates of the type used in the aircraft industry. A pair of diametrically opposite lands slope radially inward at the working end of the bit to a pair of cutting edges disposed at an obtuse angle to one another and forming an efficient cutting tip. Notches with sloping ramps adjacent the cutting edges efficiently convey cut material to adjacent flutes. The lands curve radially inward between their full diameter portion and their cutting tips and the junction of the curved portion and the constant diameter portion of the lands is machined to provide a more gradual transition.

Owner:MIR AFZAAL

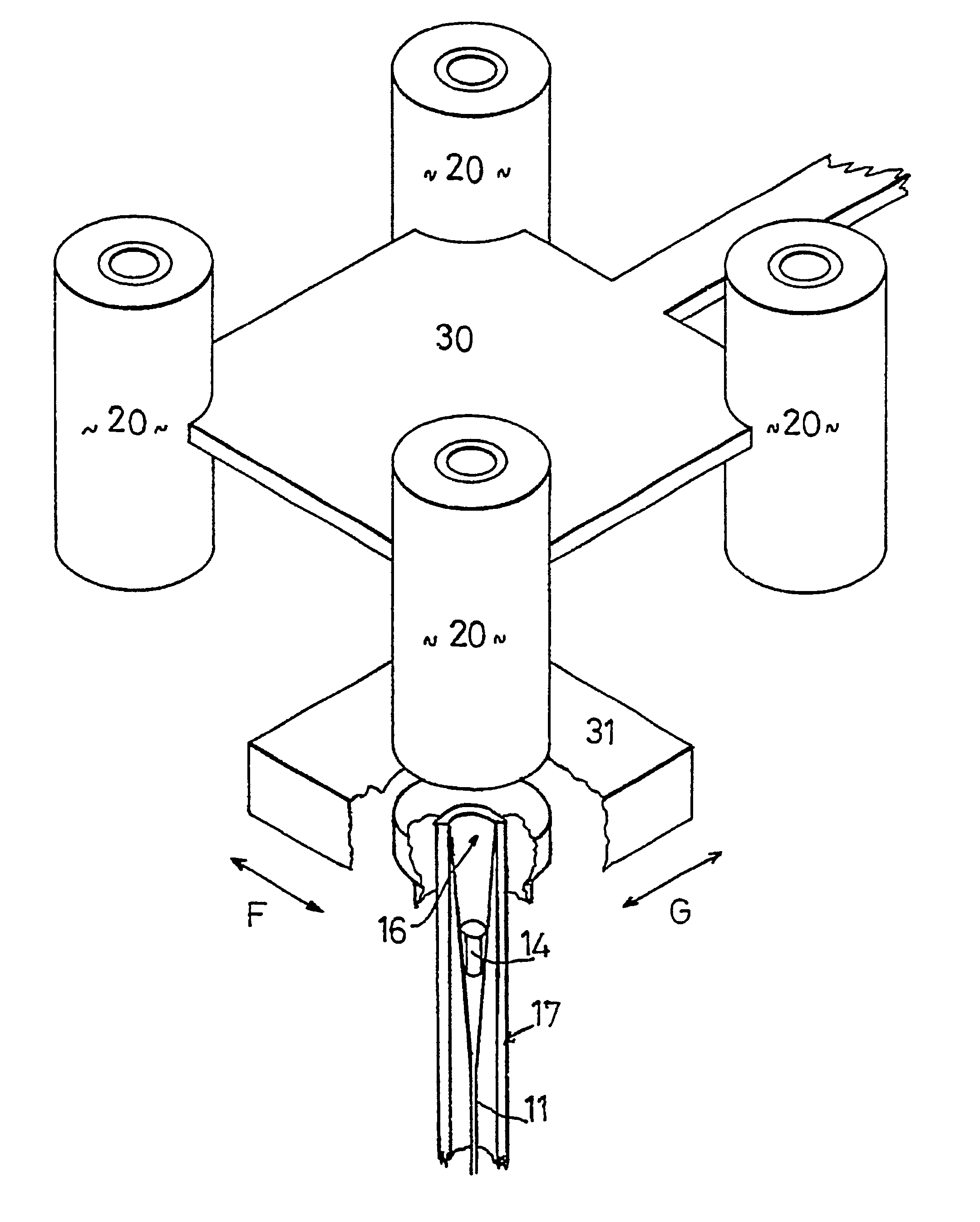

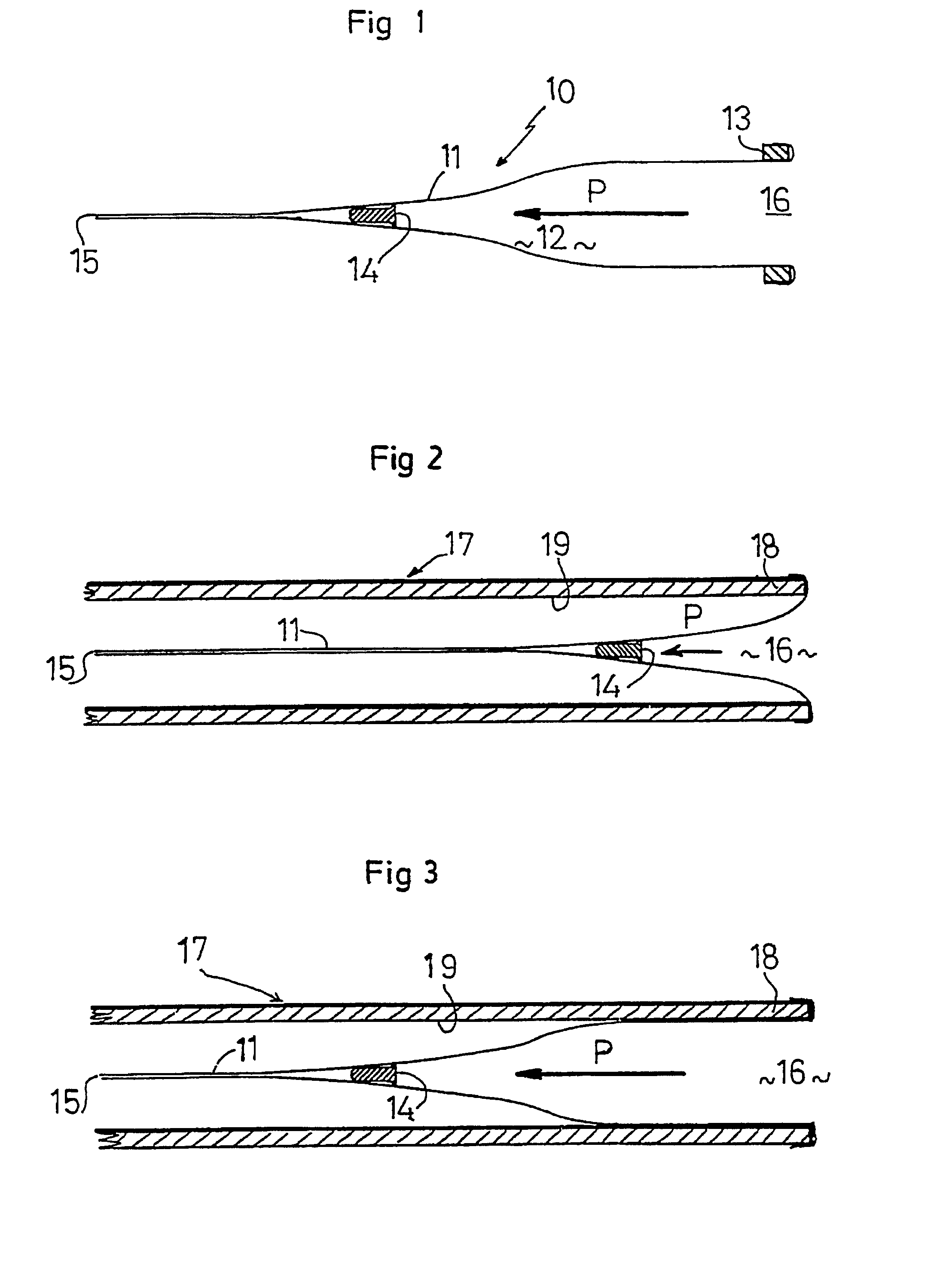

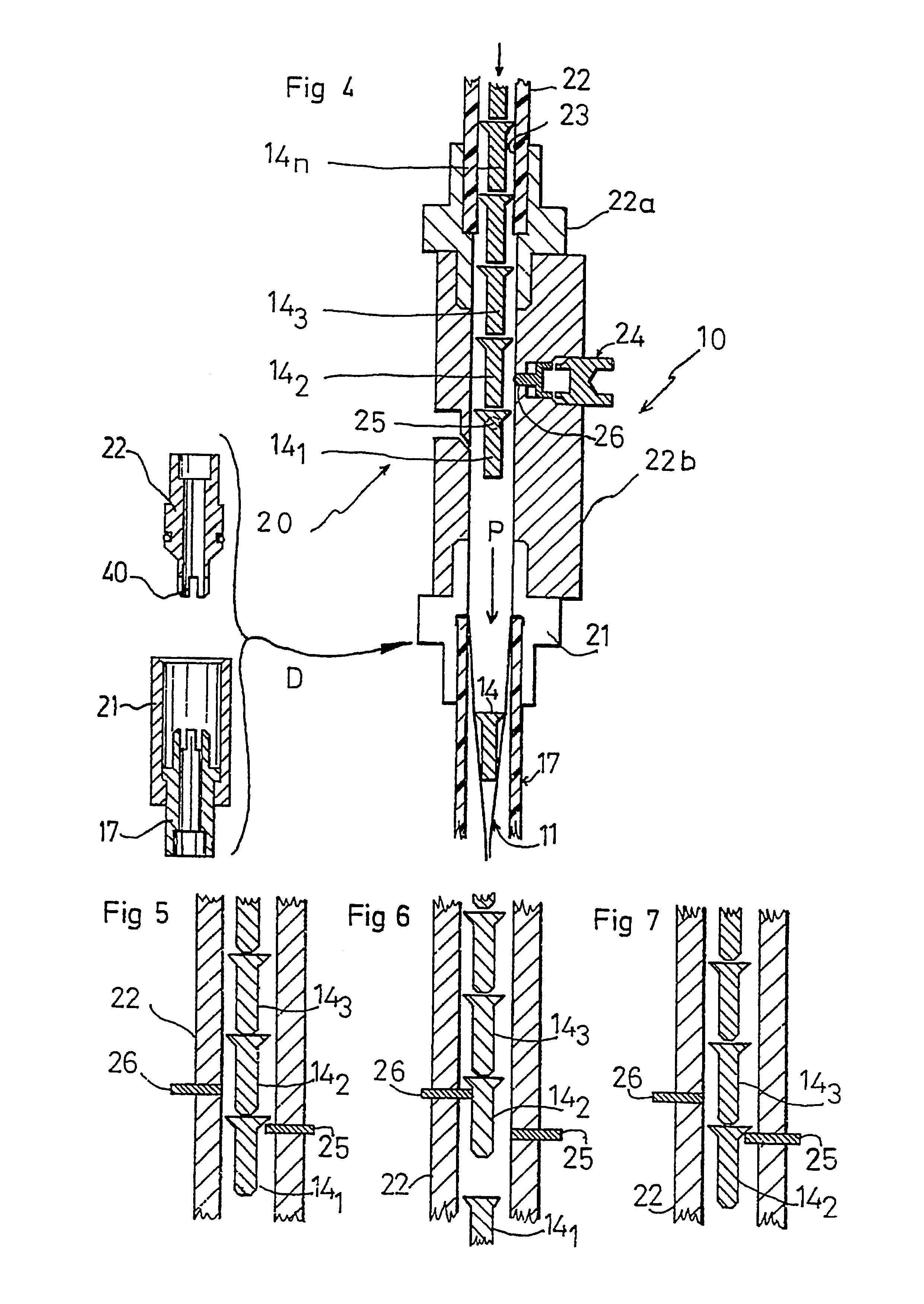

Device for distributing parts singly and a device for storing these parts

InactiveUS6260734B1Easy to useEasy to manufactureCoin-freed apparatus detailsBulk conveyorsEngineeringAircraft industry

A device for dispensing single components, in particular rivets of different shapes and sizes, wherein the rivets are conveyed to a riveting station one by one in a given direction along a path; the rivets are moved along and within an elastic sheath (11) by a pressure source (P); the device also includes a device for storing the components and includes a holder (24) for feeding the components one by one to the elastic sheath (11); the device provides for the uniform and steady feeding of rivets to riveting machines such as are used in the aircraft industry.

Owner:ATELIERS DE LA HAUTE GARONNE ETS AURIOL & CIE +1

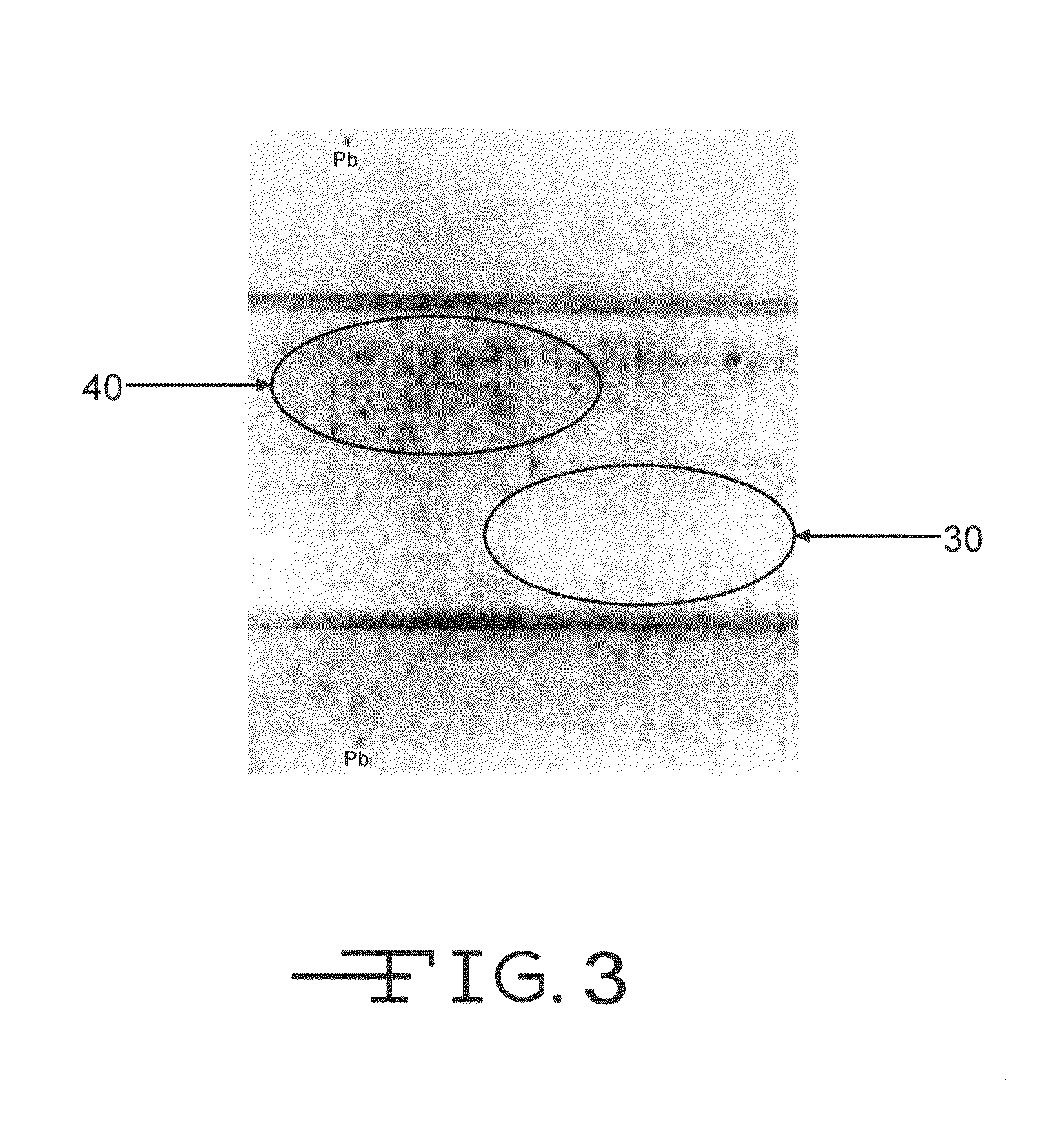

Pseudo Porosity Reference Standard for Metallic Interleaved Composite Laminates

InactiveUS20080087093A1Additive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesPorosityPolymer resin

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate, such as a metallic interleaved composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness, at least one metallic shim, and at least one mesh. A plurality of metallic shims and meshes may be disposed in alternating layers within the member. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. Use of the mesh may produce a standard which transmits ultrasonic energy, with the mesh scattering and attenuating the energy. Use of the metallic shim may aide in modeling a metallic laminate. The manufactured reference standard may replace more costly porous, fiber-reinforced, composite reference standards, such as porous metallic interleaved composite laminate reference standards, in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

High-tensile, malleable molded bodies of titanium alloys

The object of the invention is to create high-tensile molded bodies that are made of titanium alloys and are malleable at room temperature and that, compared with the metallic glasses, have macroscopic plasticity and work hardening, without other properties, such as breaking resistance, elastic elongation or corrosion behavior being thus greatly impaired. The molded bodies according to the invention are characterized in that they are made of a material that in its composition conforms to the formula Tia E1b E2c E3d E4e, where E1 comprises one or more elements of the group containing the elements Ta, Nb, Mo, Cr, W, Zr, V, Hf and Y, E2 comprises one or more elements of the group containing the elements Cu, Au, Ag, Pd and Pt, E3 comprises one or more elements of the group containing the elements Ni, Co, Fe, Zn, Mn and E4 comprises one or more elements of the group containing the elements Sn, Al, Ga, Si, P, C, B, Pb and Sb, where a=100−(b+c+d+e), b=0 to 20, c=5 to 30, d=5 to 30, e=1 to 15 (a, b, c, d, e in atomic %). The molded bodies have a homogenous microstructure, mainly comprising a glassy or nanocrystalline matrix with ductile dendritic body-centered cubic phase embedded therein. A third phase with low volumetric proportion can be present. Such molded bodies can be used as high-stress components, e.g., in the aircraft industry, space aviation and the automobile industry, but also for medical technical equipment and implants in the medical field.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

Hex tube light homogenizer splitter

A right angle light diverter includes a hexagonal tube that is bent at a right angle that is coated with a highly reflective coating on the inside surface. An incoming light beam may be homogenized upon entering an input port of the hexagonal tube and may be evenly diverted at a right angle at a reflection section while the homogenized profile may be maintained. A right angle optical splitter may include at least one additional output section. An incoming light beam may be homogenized and may be split into at least two outgoing beams that may be diverted at right angles at reflection sections. The right angle light diverter and the right angle optical splitter may be suitable for, but not limited to, applications in aircraft industry, both military and commercial. They may be used, for example, in connection with airborne laser programs, in commercial airplanes, and in military jets.

Owner:THE BOEING CO

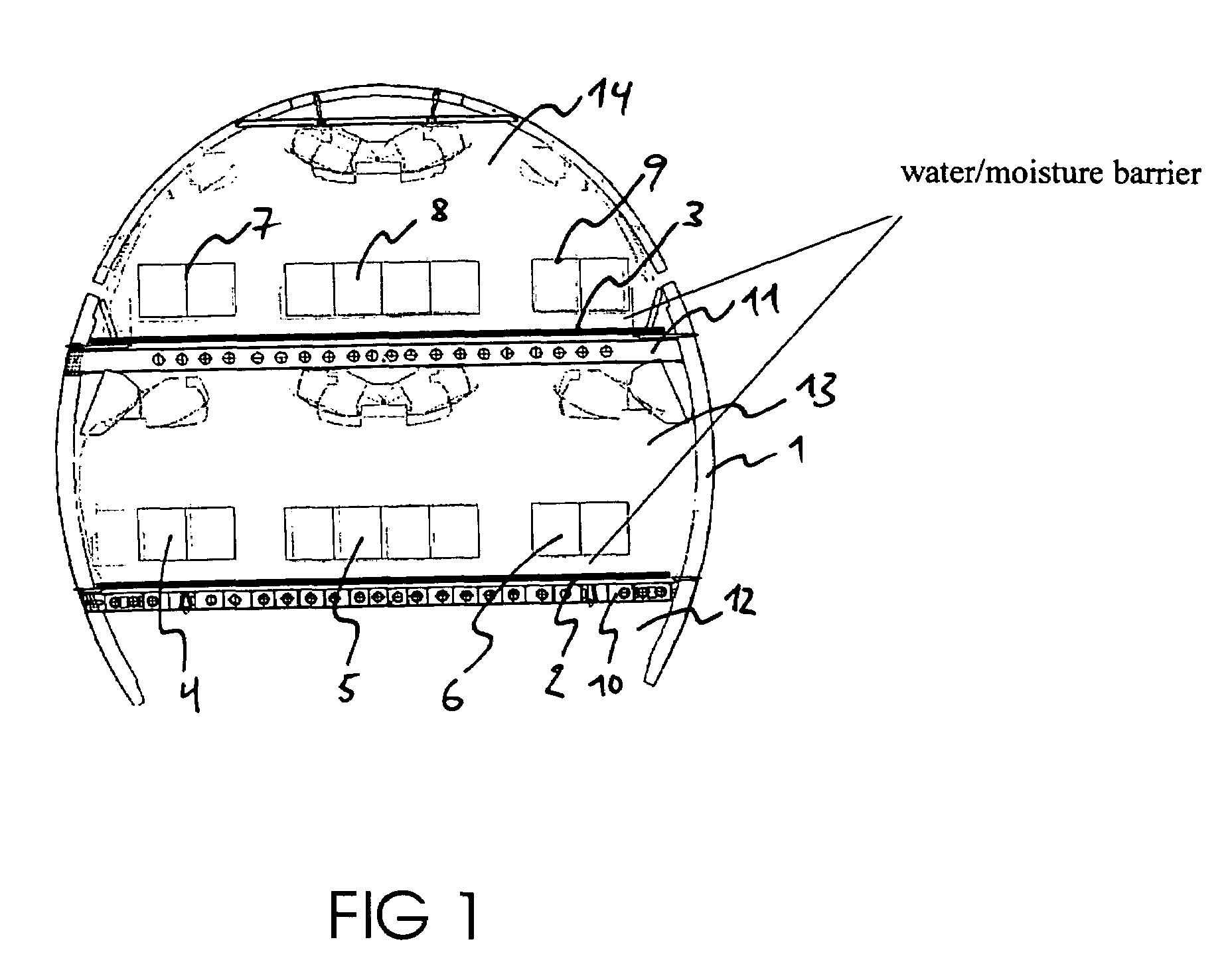

Leadthrough element

InactiveUS7262372B2Increase loadEnsure sealing performancePipesMulti-purpose toolsEngineeringAircraft industry

Leadthrough elements for waterproof or airtight leading through of one or several lines are often associated with a disadvantage in that the led-through lines are routed largely without protection, and in that the tight seal between the leadthrough element and the line deteriorates in the course of mechanical loads being exerted on the lines. According to one embodiment of the present invention, a leadthrough element is provided in which each line exits in such a way from the top of the leadthrough element that the line after exiting runs flat along the top of the leadthrough element. By integrating this leadthrough element in a floor panel of an aircraft, in particular an Airbus A380, an advantageous seal of the line leadthrough is ensured, wherein the leadthrough element protects the line against increased mechanical loads, and thus ensures a permanent seal of the line leadthrough, with said seal meeting the quality requirements of the aircraft industry even in the case of increased mechanical loads.

Owner:AIRBUS OPERATIONS GMBH

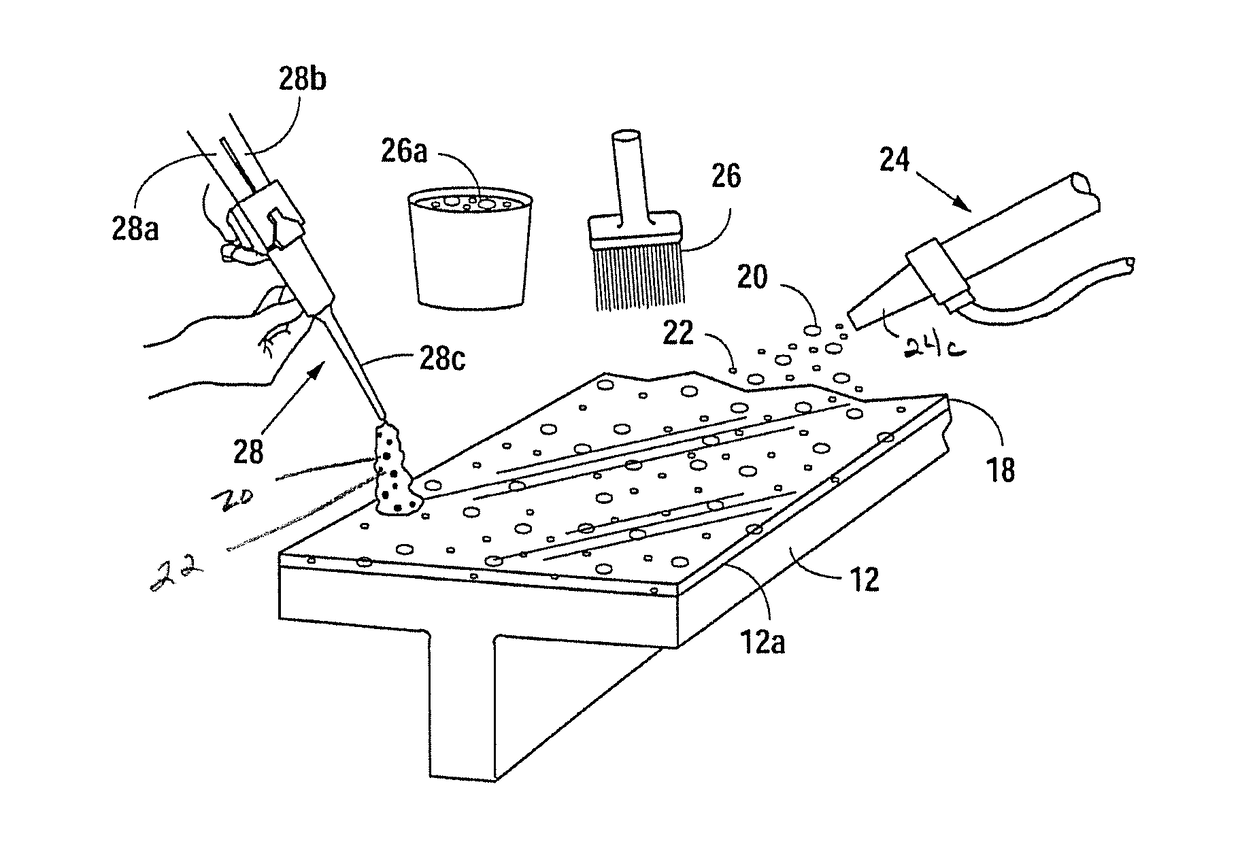

Clear sprayable sealant for aircraft parts and assemblies

ActiveUS20170282196A1Improve adhesionSolve the lack of adhesionPretreated surfacesSheet joiningAssembly lineEngineering

Applicant discloses a two part polymer mix for use in the aircraft industry that is applied with pneumatic mix and spray gun. The two part cartridge is used in the mix and spray gun so the mix is applied immediately upon mixing, but the two components are kept separated unless the gun is applying the mix. The mix cures to form a clear sealant that allows for inspection of cracks and corrosion beneath the sealant. It cures quickly so that the coated part may be further processed, for example in the assembly line during aircraft build.

Owner:THE PATENT WELL LLC

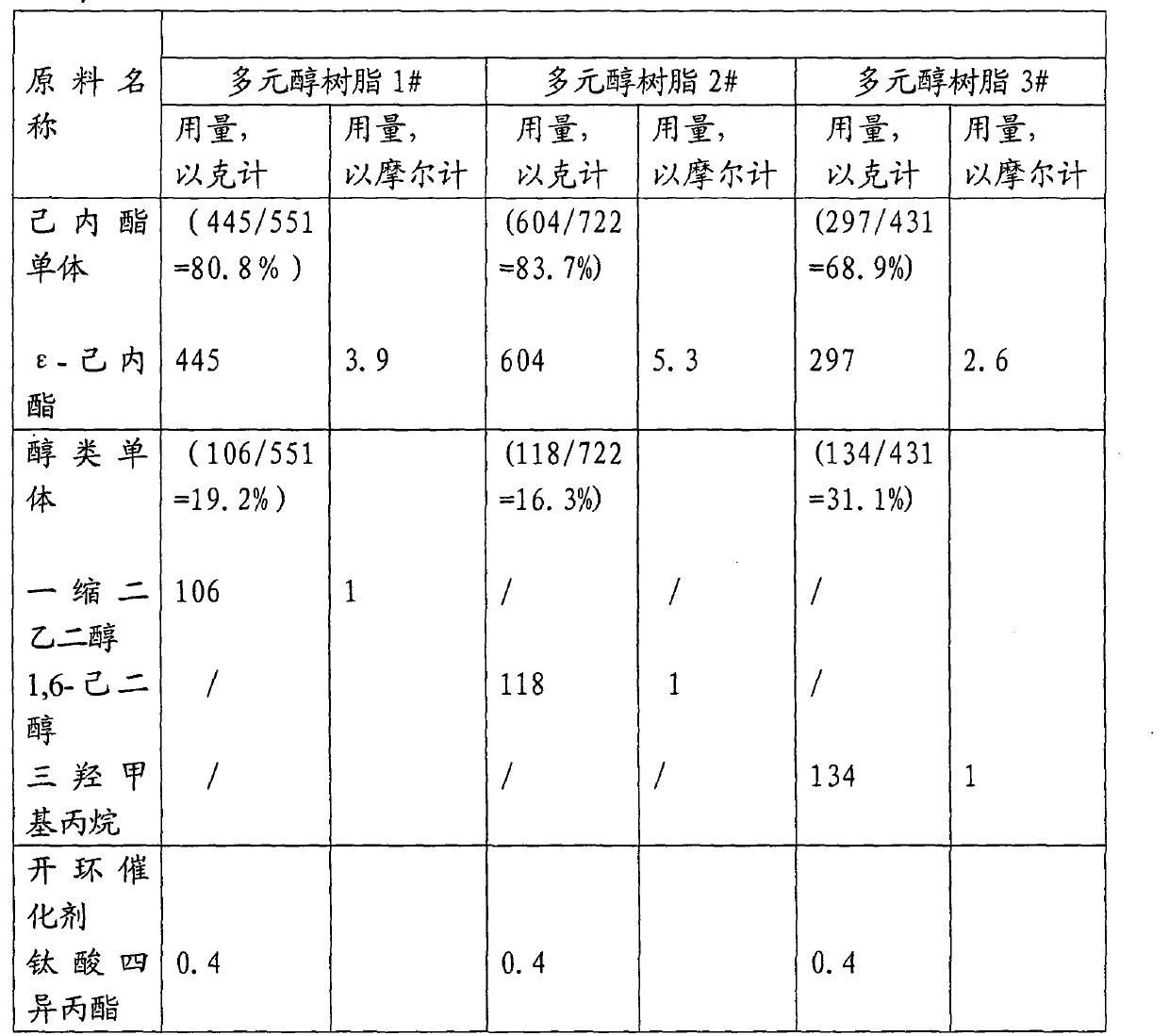

Paint with low VOC (Volatile Organic Compound) for aircraft and preparation method thereof

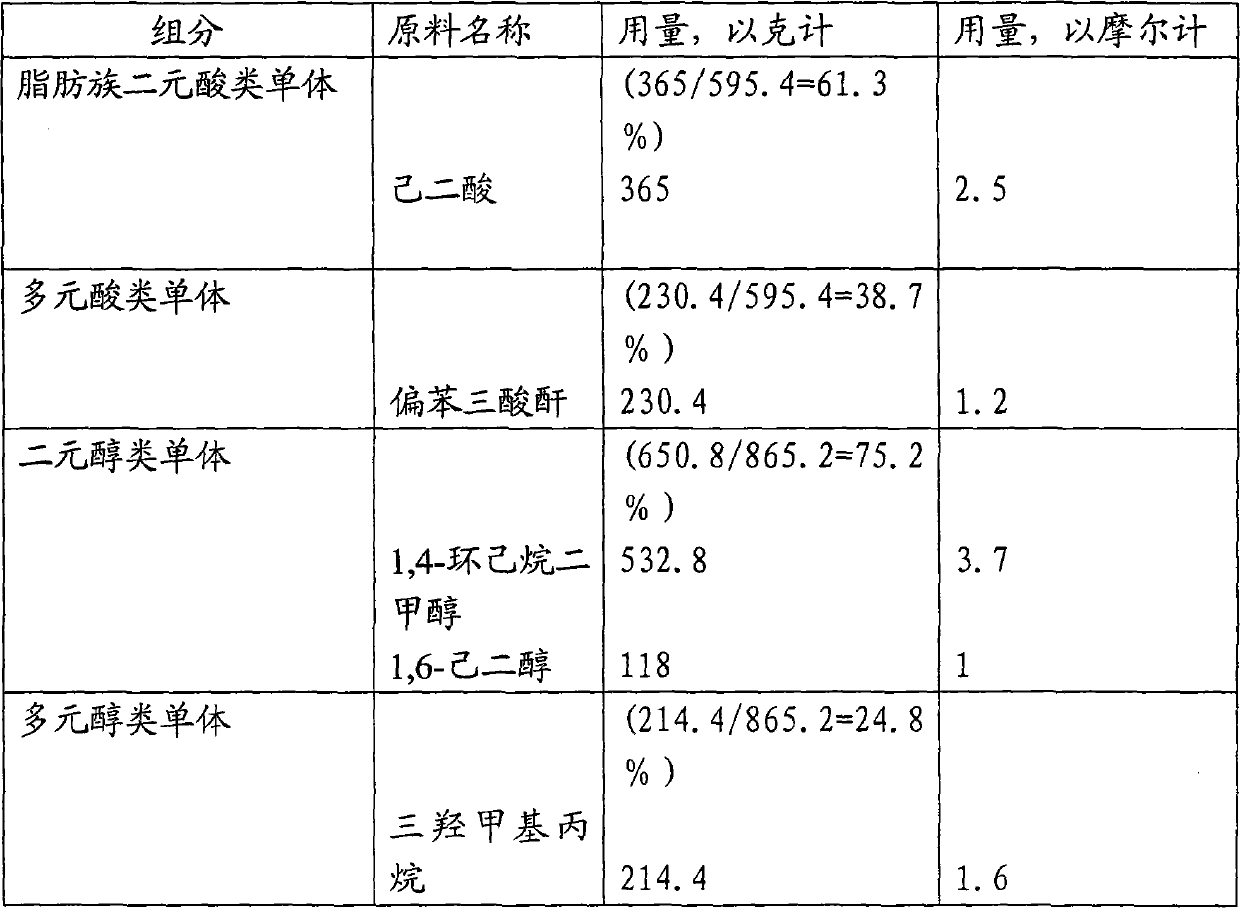

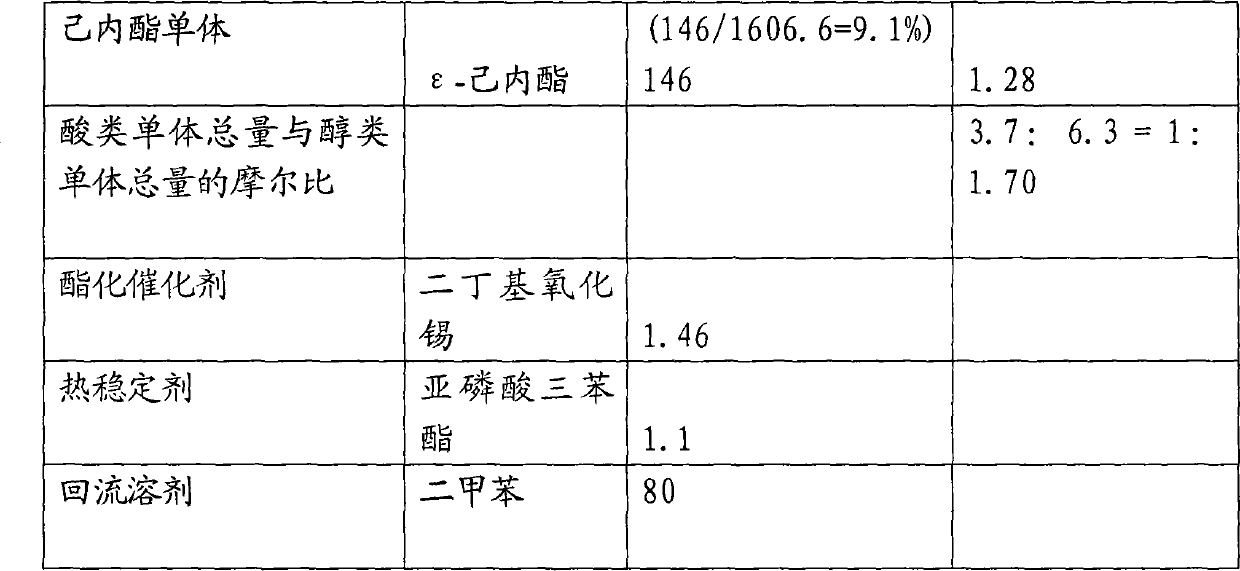

ActiveCN102174286AGuaranteed performanceReduce construction VOCPolyurea/polyurethane coatingsWaxPolyolefin

The invention relates to a paint with low VOC (Volatile Organic Compound) for an aircraft and a preparation method thereof. A component A of the paint is HDT-LV2 produced by the French Rhodia Company and has a nonvolatile matter content of 100 percent by weight; a component B of the paint consists of the following components in percentage by weight: 20-60 percent of caprolactone monomer modified hydroxyl polyester resin, 3-15 percent of polycaprolactone polyol resin, 5-50 percent of paint, 1-3 percent of dispersant, 0.1-1 percent of composite flatting agent, 0.05-0.15 percent of acetylacetonetype catalyst, 0.1-0.4 percent of hinderdeamine type light stabilizer, 0.2-0.6 percent of polyolefin wax type anti-settling auxiliary agent and the balance of mixed solvent; and the mixing ratio of the component A to the component B is (0.8-1.5):1 according to the molar ratio of NCO to OH. Comprehensive performance of the paint can meet requirements of aircraft industry and the paint has low construction VOC.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Porosity reference standard utilizing one or more hollow, non-cylindrical shafts

InactiveUS7694546B2Multiple-port networksAdditive manufacturing apparatusLithography processPolymer resin

The invention relates to pseudo porosity standards, and methods for their manufacture and use, which may substantially mimic the effect porosity has on ultrasonic sound as it passes through a composite laminate. An ultrasonic inspection reference standard for composite materials having porosity may include a member having at least one thickness. The member may be defined by at least one hollow, non-spherical shaft. The member may be manufactured from a fiber-free polymer resin using a stereo lithography process. The non-spherical shaft may scatter and attenuate ultrasonic energy. The reference standard may replace more costly, porous, fiber-reinforced, composite reference standards in the aircraft industry and in other non-aircraft applications.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com