Paint with low VOC (Volatile Organic Compound) for aircraft and preparation method thereof

A technology of aircraft and coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as environmental pollution, surface defects, and shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 prepares the hydroxyl polyester resin of caprolactone monomer modification

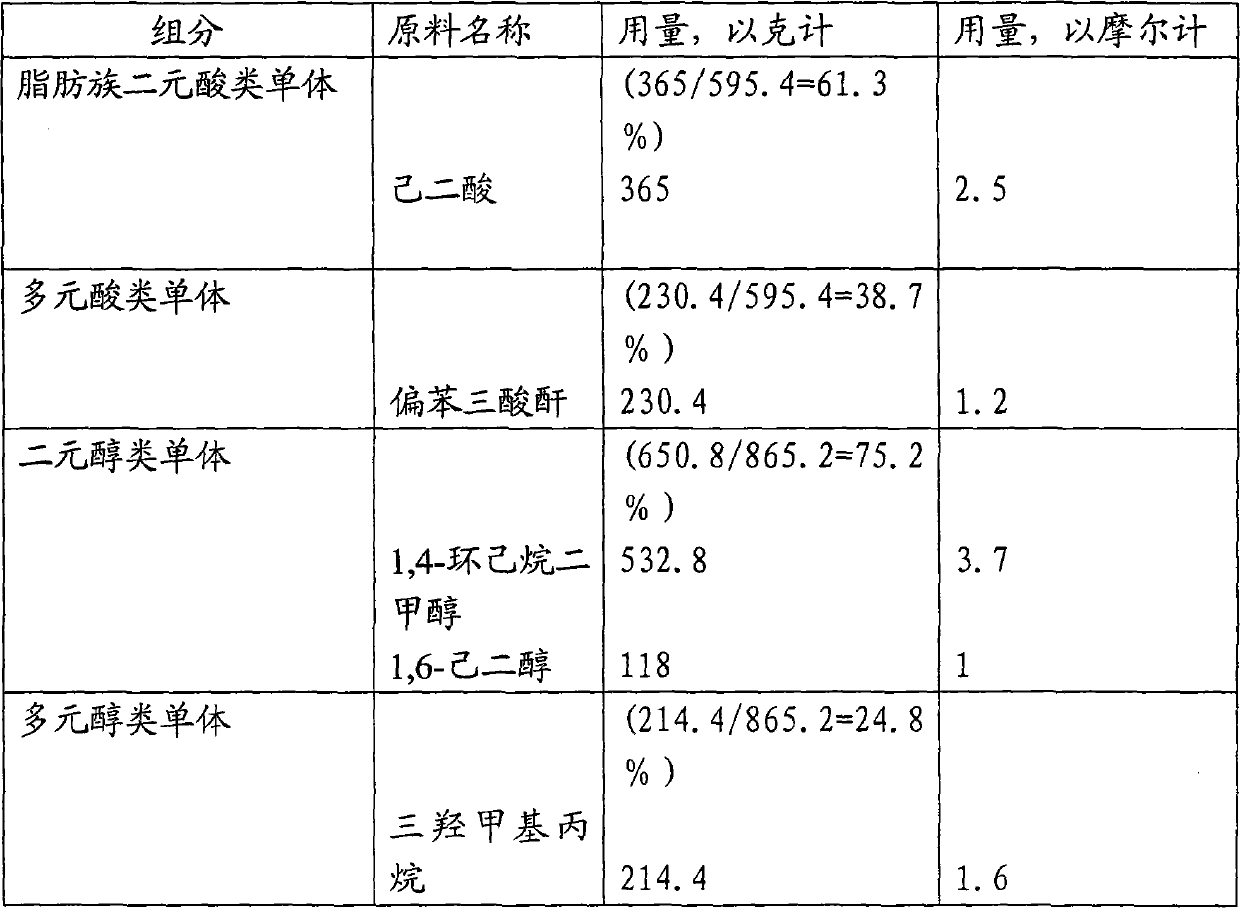

[0047] (1) Formula

[0048] Using acid monomers, alcohol monomers and caprolactone monomer ε-caprolactone as raw materials, the dosage of each monomer is as follows: in the total weight of acid monomers, aliphatic dibasic acid monomers account for 60-90% %, the balance is polybasic acid monomer trimellitic anhydride, in the total weight of alcohol monomers, polyol monomers account for 5-25%, and the balance is dibasic alcohol monomers, the total amount of acid monomers and alcohol The molar ratio of the total amount of quasi-monomers is 1:1.3-1.85; the caprolactone monomer ε-caprolactone accounts for 5-15% of the total weight of all monomers, and the specific formula is shown in Table 1.

[0049] Table 1

[0050]

[0051]

[0052] Note 1: The data in the brackets in Table 1 is the percentage of the amount of the monomer;

[0053] Note 2: The raw materials for preparing cap...

Embodiment 2

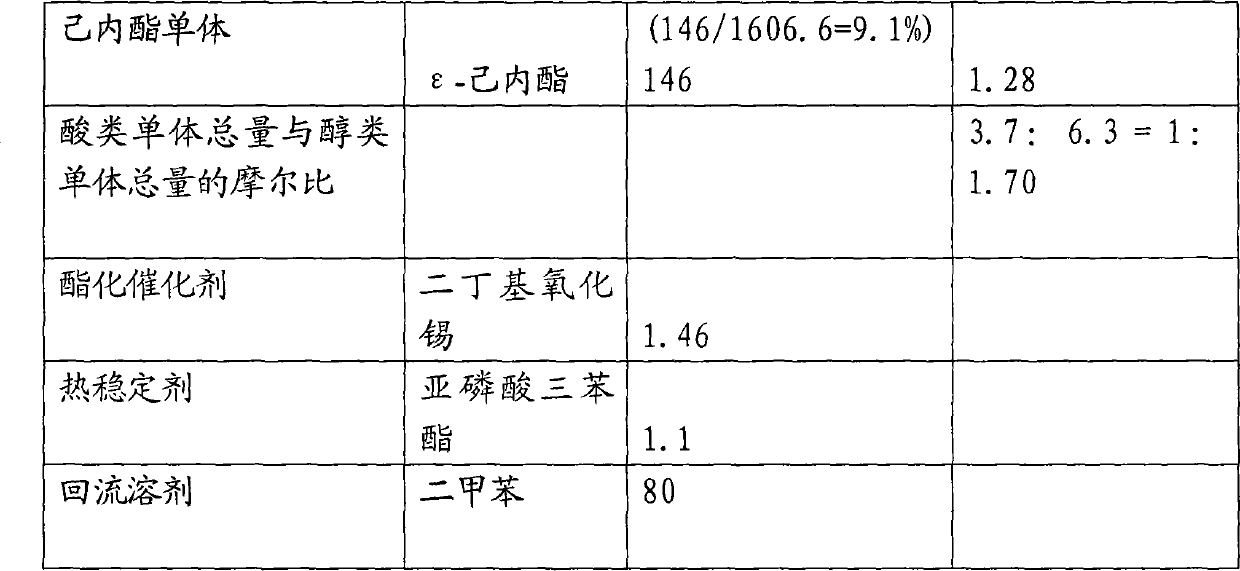

[0059] Embodiment 2 prepares polycaprolactone polyol resin (referred to as polyol resin)

[0060] (1) Formula

[0061] Using caprolactone monomer ε-caprolactone and alcohol monomers as raw materials, the amount of each monomer is as follows: In the total weight of the monomers, the caprolactone monomer ε-caprolactone accounts for 60-90%, and the balance It is an alcohol monomer, and its specific formula is shown in Table 3.

[0062] table 3

[0063]

[0064] Note 1: The data in brackets in Table 3 is the percentage of the amount of the monomer;

[0065] Note 2: The raw materials used for preparing polycaprolactone polyol resin are not limited to the raw materials used in Table 3, and can be selected from the raw materials listed below: the alcohol monomers used are 1,4-butanediol, 1,6-hexane Diol, nonanediol, decanediol, neopentyl glycol, 2-methyl-1,3 propanediol, diethylene glycol, 1,4-cyclohexanedimethanol or trimethylolpropane One or more; the ring-opening catalyst u...

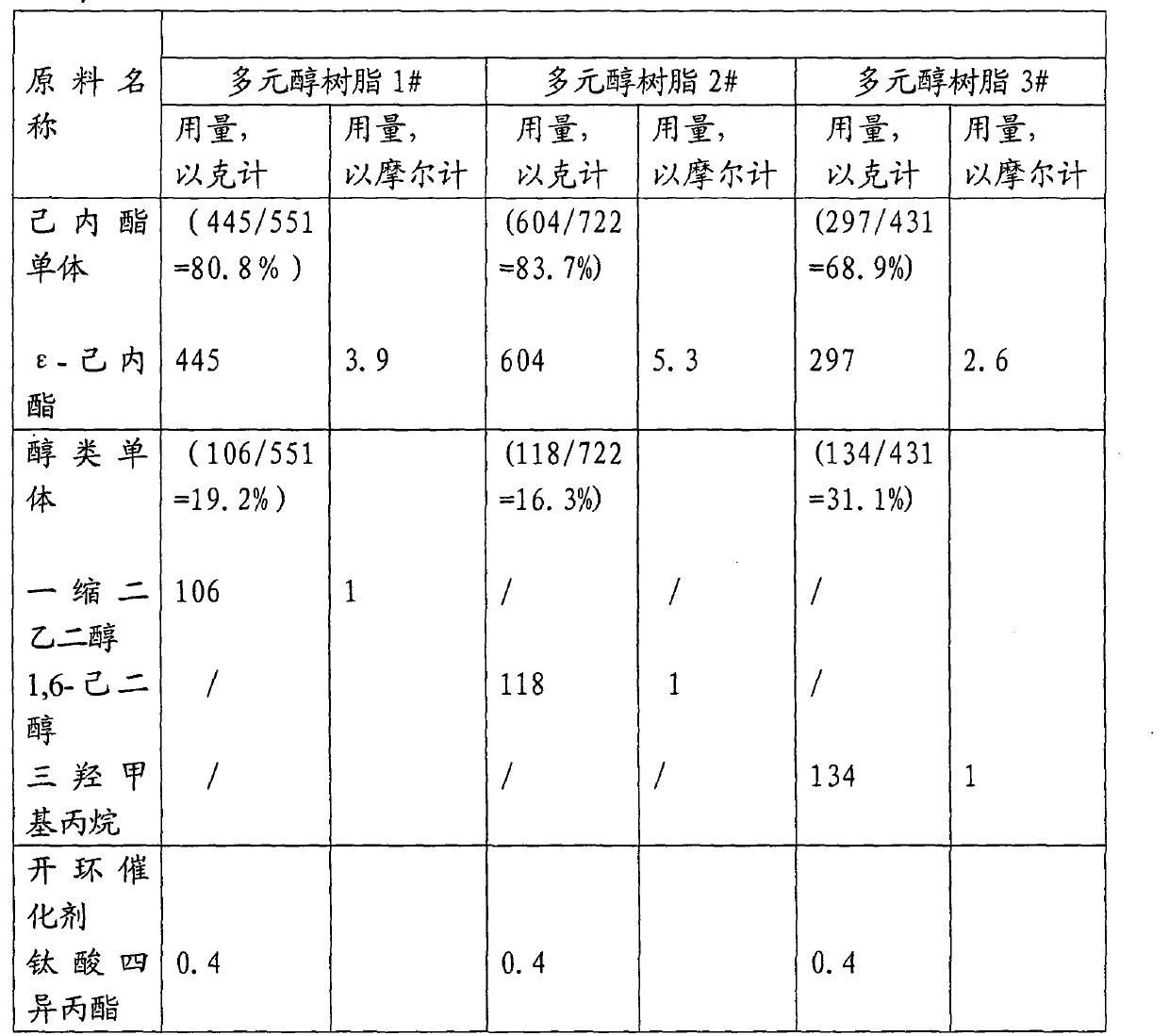

Embodiment 4

[0071] Embodiment 4 prepares component second 1#~2#

[0072] (1) Formula

[0073] Component B is made up of following components, and by weight percentage, each component consumption is as follows:

[0074] Caprolactone monomer-modified hydroxyl polyester resin 20-60%, polycaprolactone polyol resin 3-15%, pigment 5-50%, dispersant 1-3%, composite leveling agent 0.1-1% , 0.05-0.15% of acetylacetonate salt catalyst, 0.1-0.4% of hindered amine light stabilizer, 0.2-0.6% of polyolefin wax anti-sedimentation aid, and mixed solvent as the balance. The specific formula is shown in Table 5.

[0075] table 5

[0076]

[0077]

[0078] Note: EFKA-3034 in Table 5 is an organo-modified polysiloxane leveling aid produced by Efka in the Netherlands; EFKA-3777 is a modified polyacrylate leveling aid produced by Efka in the Netherlands;

[0079] (2) Specific operation

[0080] Add caprolactone monomer-modified hydroxyl polyester resin, polycaprolactone polyol resin, dispersant, polyol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com