Patents

Literature

51results about How to "Reduce crystallization tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paint for H grade polyurethane enamelled wire with good saline water needle performace capable of directing welding at low temp.

InactiveCN1597815AImprove heat resistanceQuality improvementPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to an H-grade wire coating enamel that has good salt water pinhole performance and can be directly welded at low temperature, containing hydroxyl component, sealed isocyanate component and solvent, where its hydroxyl component has an acid value less than 2, a hydroxyl value of 150-300, and number-average molecular weight of 1500-5000, and as synthesized, the raw materials has at least m-phthalic acid, p-phthalic acid, adilic acid, glycerin and a kind of dibasic alcohol in the weight ratio of 1 to (0.2-2) to (0.2-0.5) to (0.5-3) to (0.5-1.5); and its sealed isocyanate component is partially added of MDI by mixed polyalcohol that at least has a dibasic alcohol and a tribasic alcohol; in the paint base, the equivalent ratio of isocyanate base to OH is (0.9-1.2) : 1, and it reaches H-grade and has good salt water pinhole property of paint film, tin daubing temperature less than or equal to 375 deg.C.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

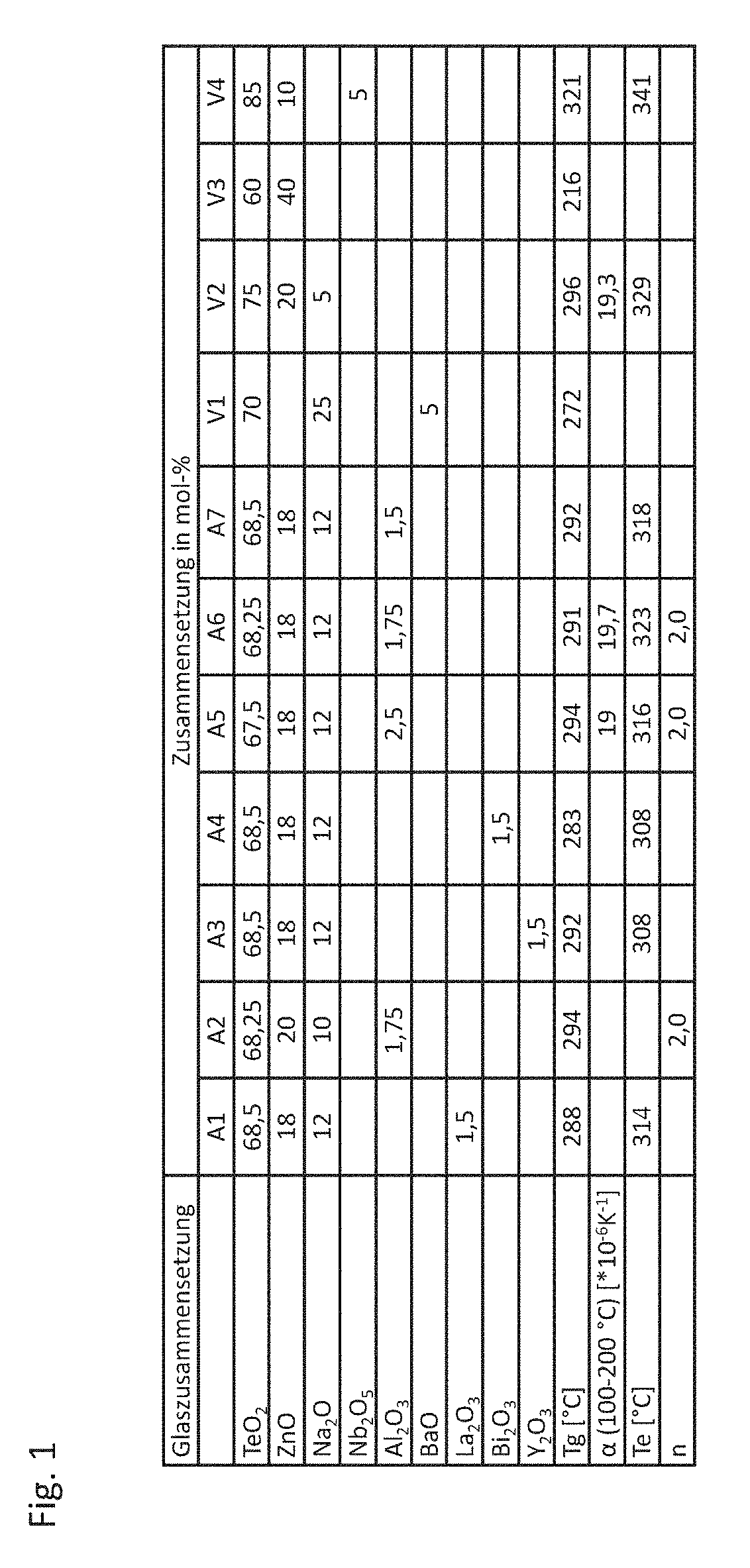

Aluminoborosilicate glass and method for the production of crystallite-free gradient index lenses

ActiveUS20050137075A1Reduce crystallization tendencyImprove optical qualityOptical elementsAlkali metal oxideIon exchange

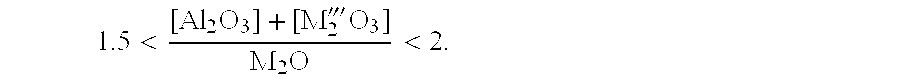

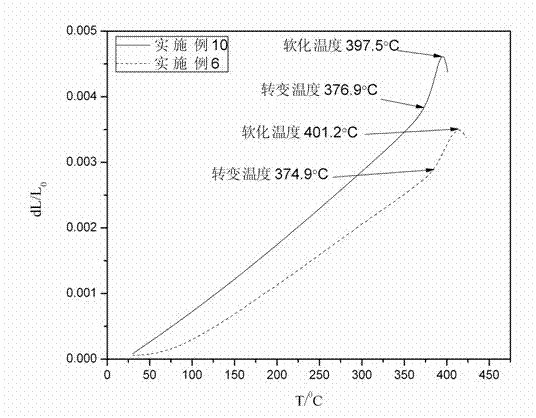

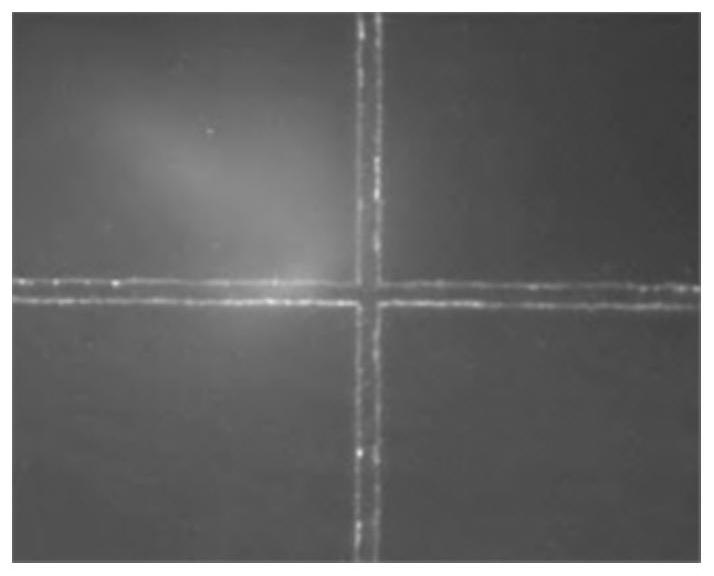

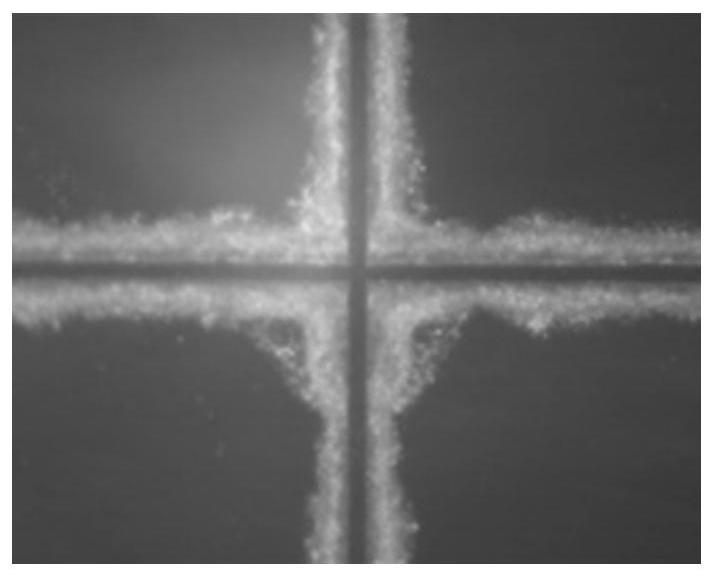

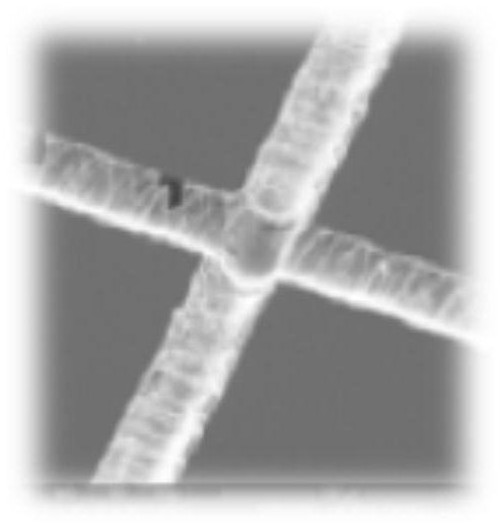

The invention is directed to an aluminoborosilicate glass containing alkali metals for the production of optical components with refractive index gradients which are generated by ion exchange of monovalent metal ions in a base glass comprising at least silicon oxide, boron oxide, aluminum oxide and an alkali metal oxide, particularly for the production of gradient index lenses (GRIN lenses). The object of the invention, to find a novel possibility for producing GRIN lenses based on aluminoborosilicate glasses in which the glass has an appreciably reduced tendency toward crystallization in subsequent thermal treatment processes, is met according to the invention in an alkali-containing aluminoborosilicate glass for the production of optical components with refractive index gradients generated by ion exchange of monovalent, refractive index-changing metal ions in a base glass of SiO2, A12O3, a metal-(III)-oxide (of B and / or Ga) and at least one metal-(I)-oxide (of Li, Na, K and / or Rb) in that defined molar ratios of metal-(III)-oxides to the metal-(I)-oxides of the base glass are adjusted within a given range in order to appreciably reduce the tendency toward crystallization of the glass for subsequent thermal treatment processes. Point defects caused by crystallites in the GRIN lenses produced in this manner are drastically reduced in this way.

Owner:GRINTECH

Flat panel liquid crystal display such as for a laptop computer,

InactiveUS6707526B2Improve heat resistanceFavorable processing rangeStatic indicating devicesNon-linear opticsHigh resistanceAlkali free

Flat panel liquid-crystal displays, such as for laptop computers. The displays include twisted nematic displays, supertwisted nematic displays, active matrix liquid-crystal displays, thin film transistor displays, and plasma addressed liquid-crystal displays. The displays are furnished with glass substrates. The glass substrates exhibit high resistance to thermal shock, a high transparency over a broad spectral range in the visible and ultra violet ranges and the glass being configured to be free of bubbles, knots, inclusions, streaks, and surface undulations, which glass substrates are made from alkali-free aluminoborosilicate glasses. There are also provided analogous thin-film photovoltaics.

Owner:SCHOTT AG

Aluminoborosilicate glass and method for the production of crystallite-free gradient index lenses

ActiveUS7482296B2Reduce crystallization tendencyImprove optical qualityOptical elementsAlkali metal oxideRefractive index

The invention is directed to an aluminoborosilicate glass containing alkali metals for the production of optical components with refractive index gradients which are generated by ion exchange of monovalent metal ions in a base glass comprising at least silicon oxide, boron oxide, aluminum oxide and an alkali metal oxide, particularly for the production of gradient index lenses (GRIN lenses). The object of the invention, to find a novel possibility for producing GRIN lenses based on aluminoborosilicate glasses in which the glass has an appreciably reduced tendency toward crystallization in subsequent thermal treatment processes, is met according to the invention in an alkali-containing aluminoborosilicate glass for the production of optical components with refractive index gradients generated by ion exchange of monovalent, refractive index-changing metal ions in a base glass of SiO2, Al2O3, a metal-(III)-oxide (of B and / or Ga) and at least one metal-(I)-oxide (of Li, Na, K and / or Rb) in that defined molar ratios of metal-(III)-oxides to the metal-(I)-oxides of the base glass are adjusted within a given range in order to appreciably reduce the tendency toward crystallization of the glass for subsequent thermal treatment processes. Point defects caused by crystallites in the GRIN lenses produced in this manner are drastically reduced in this way.

Owner:GRINTECH

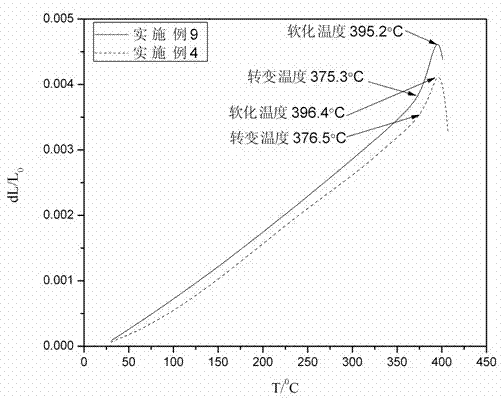

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

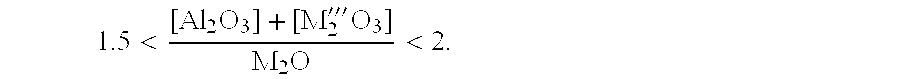

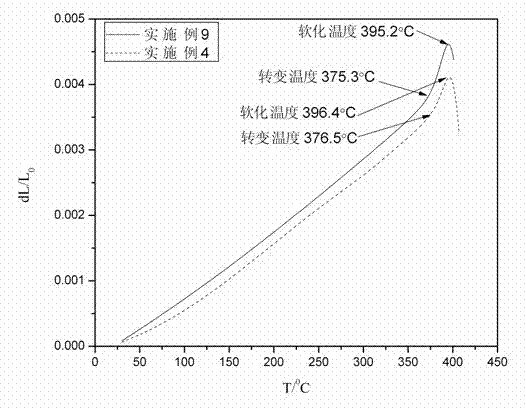

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Iodonium salt photoinitiators containing urethane groups for cationic curing

InactiveUS6380277B1Stable to hydrolysisCost-effective and simple mannerSilicon organic compoundsCarbamic acid derivatives preparationCarbamatePhotoinitiator

The present invention relates to iodonium salts containing urethane groups of reduced crystallization tendency, to a process for their preparation, and to their use for the radiation curing of cationically curing compositions.

Owner:GOLDSCHMIDT GMBH

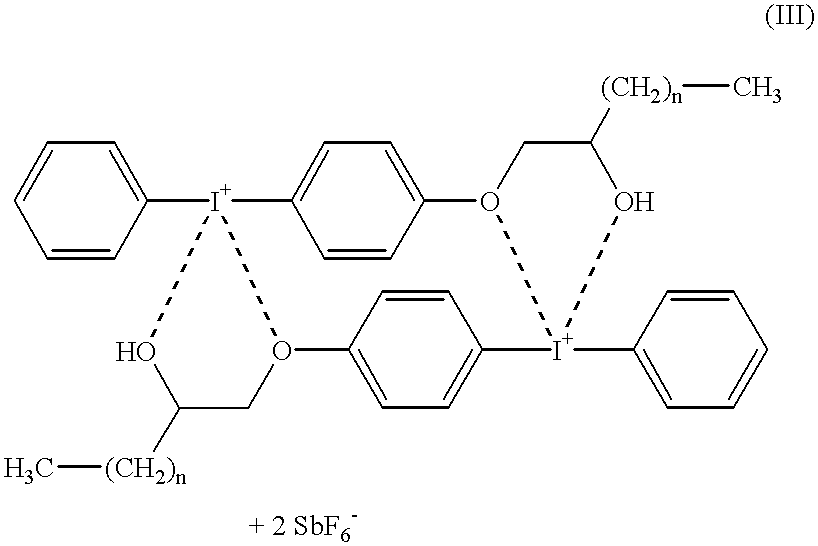

Photoinitiators for cationic curing

InactiveUS6365643B1Improve compatibilityCost-effective and simple mannerSilicon organic compoundsPhotomechanical apparatusPhotoinitiatorAromatic hydrocarbon

The invention relates to modified cationic photoinitiators which exhibit a reduced tendency to crystallize, to a process for reducing the crystallization tendency of cationic photoinitiators, and to the use of the photoinitiators of the invention for the radiation curing of cationically curing compositions. The inventive cationic photoinitiators have the formula (IV):whereR1 is a radicalR2 is a radicalin which Ar is a monovalent aromatic hydrocarbon radical and D being a radicaland the remaining variables are defined herein.

Owner:EVONIK DEGUSSA GMBH

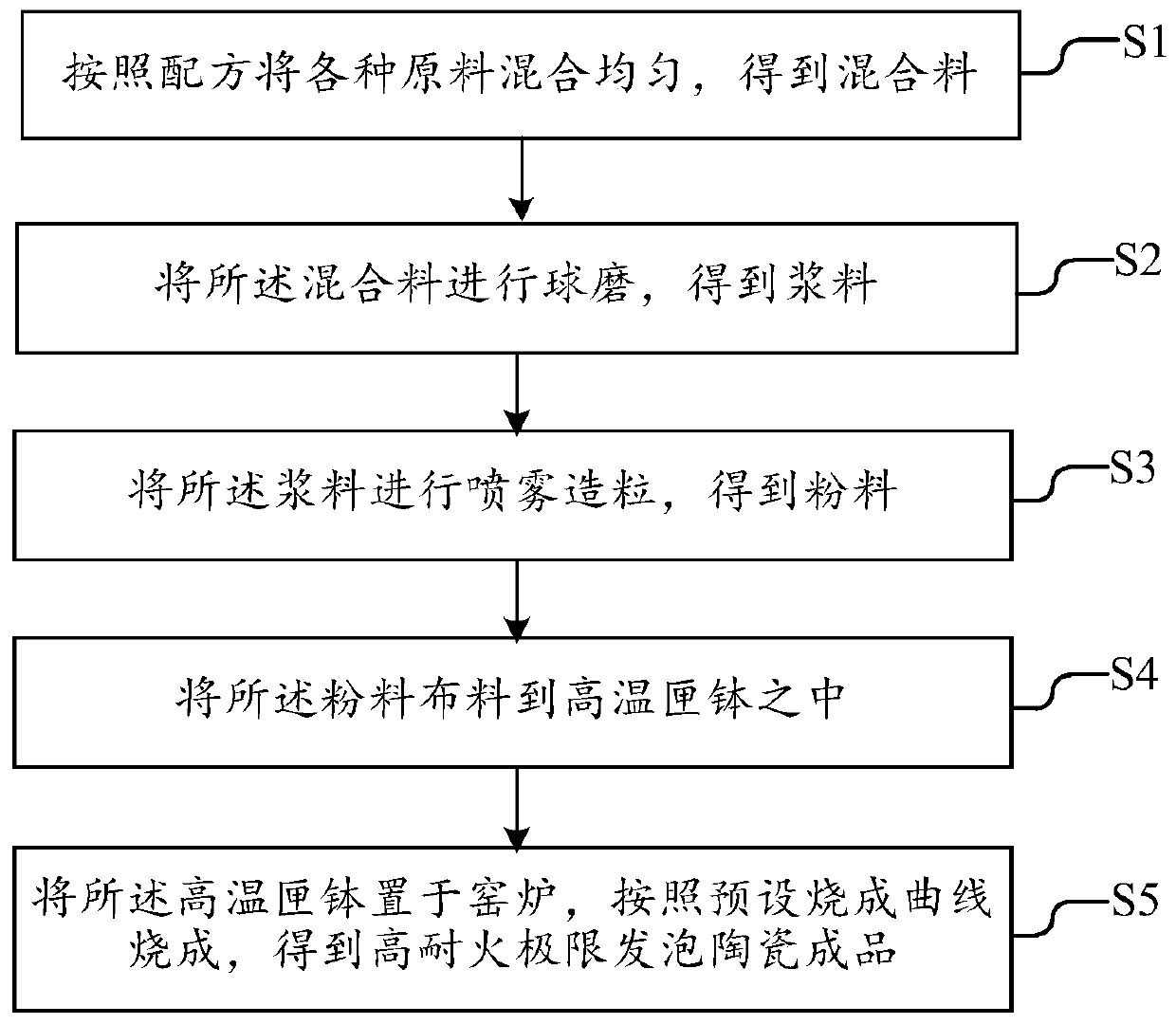

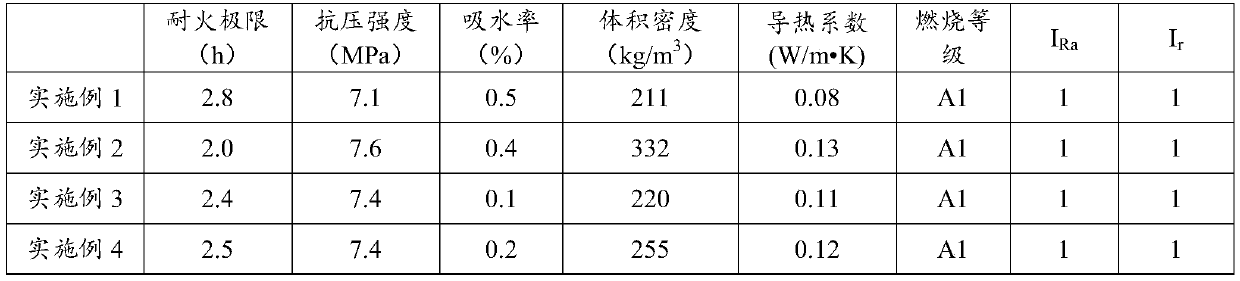

High fire resistance limit foamed ceramic and preparation method thereof

InactiveCN110526681AReduce crystallization tendencySmall coefficient of thermal expansionCeramic materials productionCeramicwareThermal expansionLithium compound

The invention discloses a high fire resistance limit foamed ceramic. The foamed ceramic is mainly prepared by the following raw materials in parts by weight: 90-95 parts of Luoyuan red tailings, 1-5 parts of a lithium compound, 1-3 parts of clay, 0.5-1 part of a foaming agent, and 0.2-1 part of a stabilizer, and the sum of parts by weight of each raw material component is 100 parts, wherein the lithium compound is one or more selected from spodumene, lithium porcelain stone, lithia mica, amblygonite, petalite, lithia mica, and zinnwaldite. The lithium-containing compound is added into the formula, the Li particle has a small radius and large electric field strength, so that the Li particle has the effect of strengthening a network, and thereby a thermal expansion coefficient of the foamedceramic can be reduced, crystallization tendency is reduced, fire resistance of the foamed ceramic can be improved, and application fields of the foamed ceramic is broadened.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Paint with low VOC (Volatile Organic Compound) for aircraft and preparation method thereof

ActiveCN102174286AGuaranteed performanceReduce construction VOCPolyurea/polyurethane coatingsWaxPolyolefin

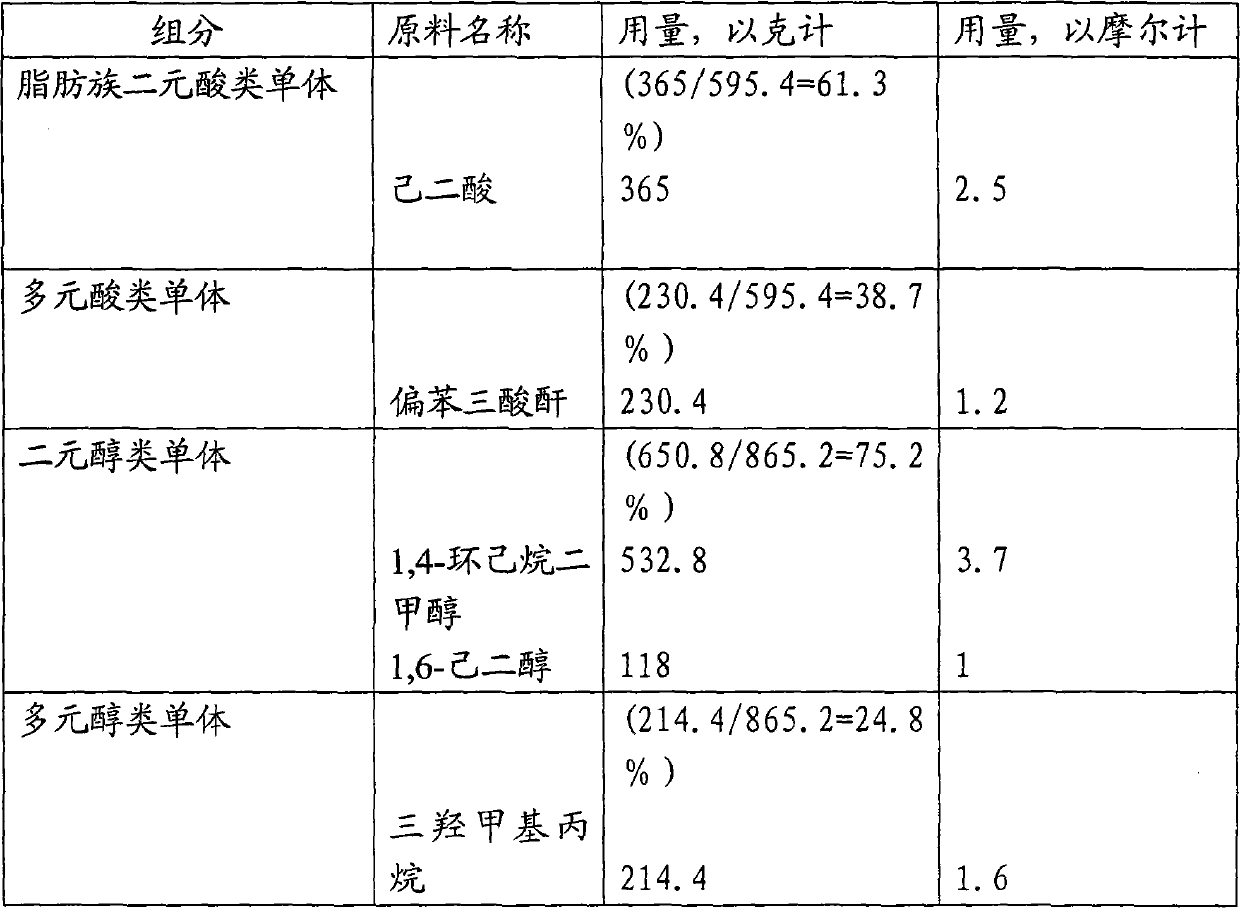

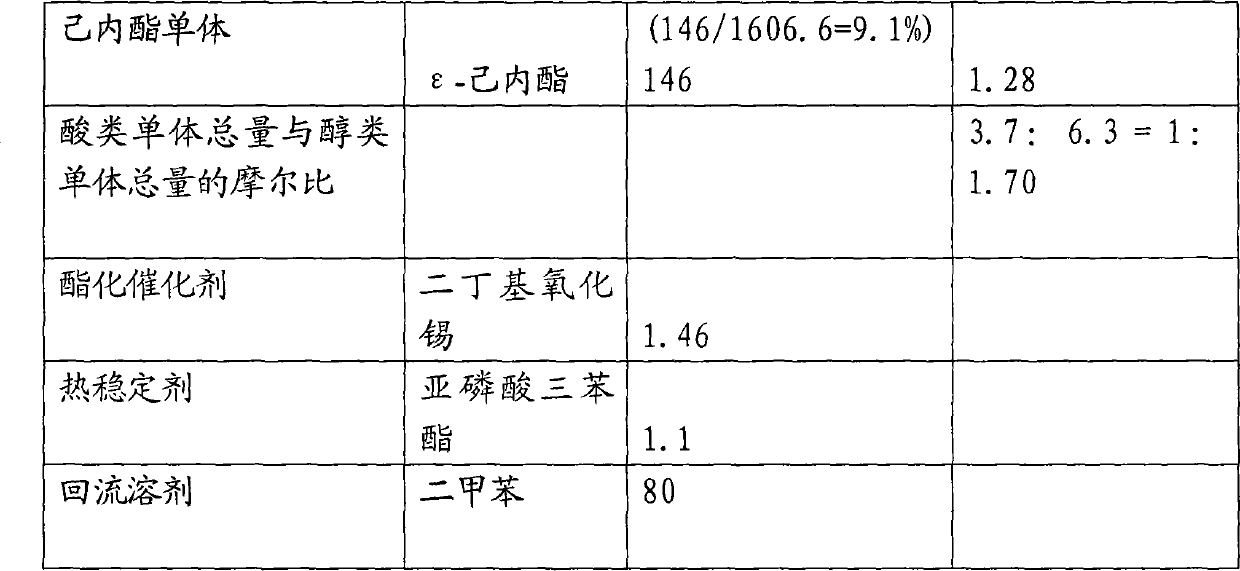

The invention relates to a paint with low VOC (Volatile Organic Compound) for an aircraft and a preparation method thereof. A component A of the paint is HDT-LV2 produced by the French Rhodia Company and has a nonvolatile matter content of 100 percent by weight; a component B of the paint consists of the following components in percentage by weight: 20-60 percent of caprolactone monomer modified hydroxyl polyester resin, 3-15 percent of polycaprolactone polyol resin, 5-50 percent of paint, 1-3 percent of dispersant, 0.1-1 percent of composite flatting agent, 0.05-0.15 percent of acetylacetonetype catalyst, 0.1-0.4 percent of hinderdeamine type light stabilizer, 0.2-0.6 percent of polyolefin wax type anti-settling auxiliary agent and the balance of mixed solvent; and the mixing ratio of the component A to the component B is (0.8-1.5):1 according to the molar ratio of NCO to OH. Comprehensive performance of the paint can meet requirements of aircraft industry and the paint has low construction VOC.

Owner:CHINA NAT OFFSHORE OIL CORP +2

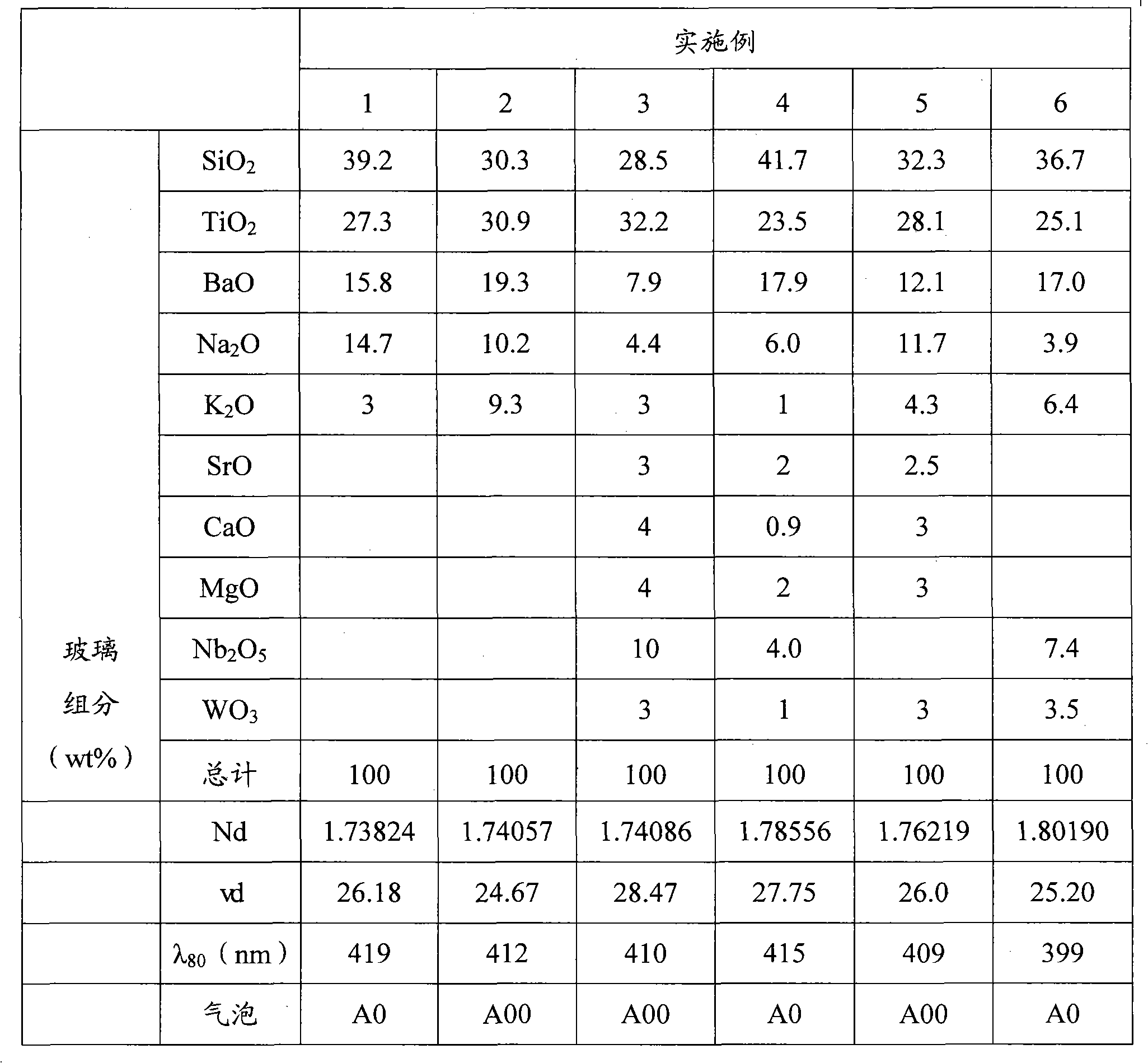

Optical glass and optical element

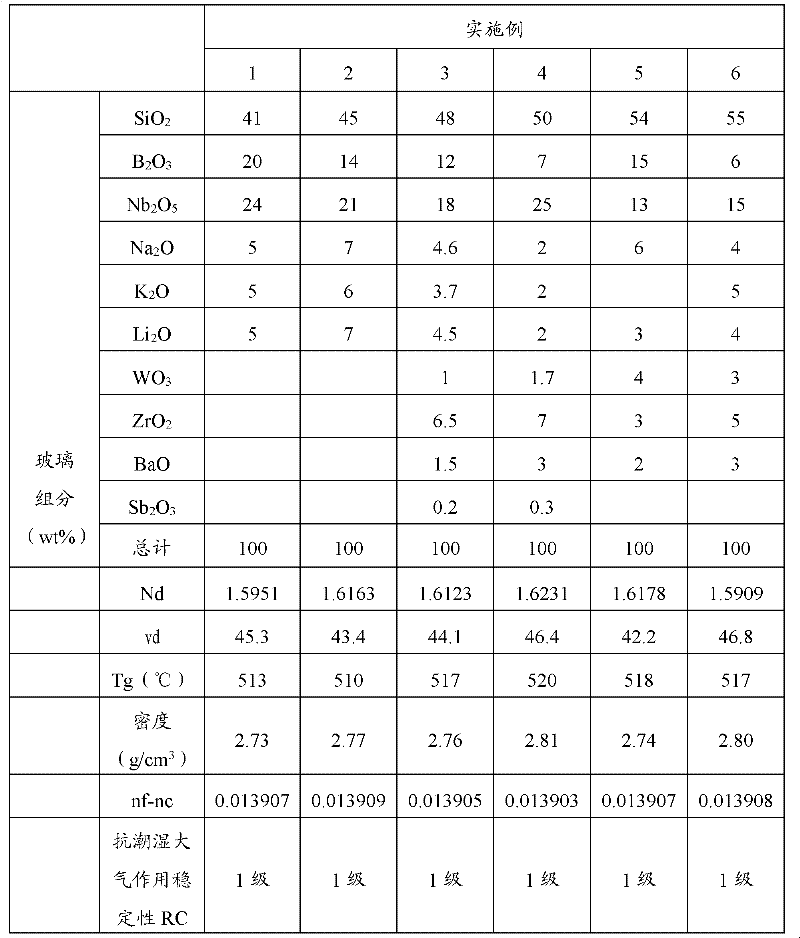

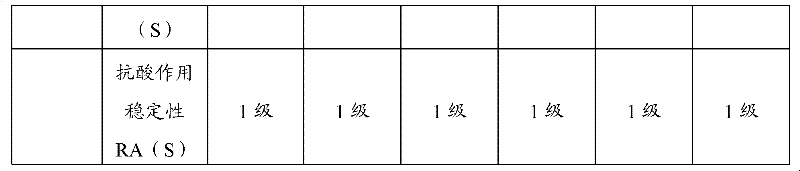

InactiveCN102199001AMaintain devitrification resistanceImprove thermal stabilityOptical elementsRefractive indexImaging equipment

The invention discloses an optical glass, comprising the following components: 40wt%-55wt% of SiO2, 5wt%-20wt% of B2O3, 13wt%-25wt% of Nb2O5, 3wt%-20wt% of R2O, 0-5wt% of WO3, 0-10wt% of ZrO2, 0-5wt% of BaO, and 0-0.5wt% of Sb2O3, wherein the R2O includes one or a plurality of components selected from a group of Na2O, K2O and Li2O. The optical glass provided by the invention does not need to be added with non-green elements. Experiment results show that the optical glass provided by the invention has a refractive index of 1.59-1.63, an abbe number of 42-47, which satisfies requirements of modern imaging equipment.

Owner:CDGM OPTICAL GLASS

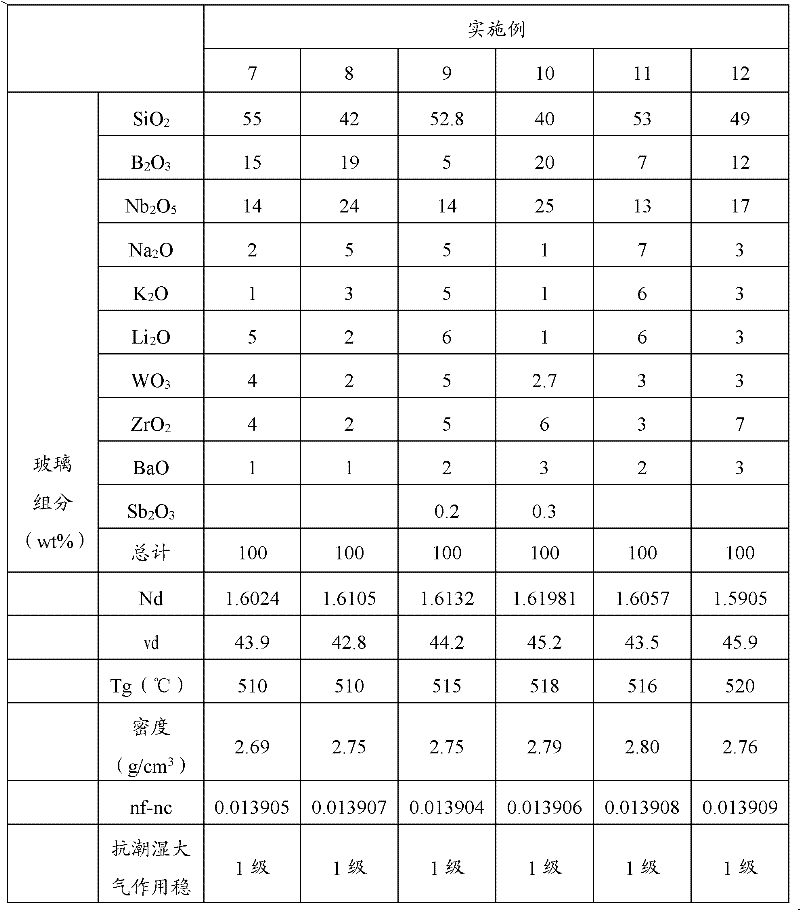

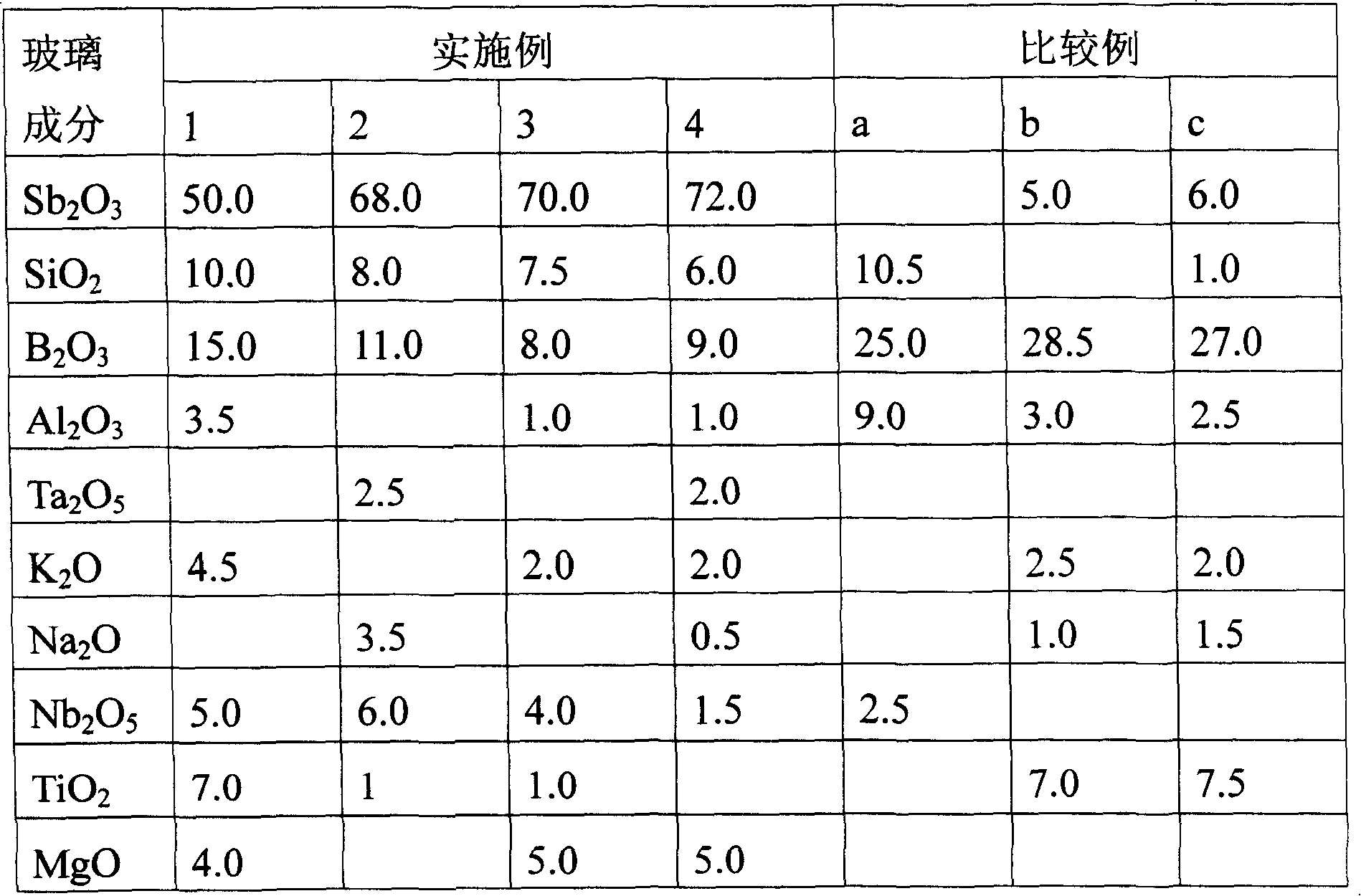

Optical glass with negative anomalous dispersion

InactiveCN101215081ALarge negative anomalous dispersionImprove stabilityRefractive indexOptical glass

The invention is an optical glass equipped with negatively anomalous dispersion, which belongs to the technical field of optical glass equipped with negatively anomalous dispersion and high refractive index, and resolves the problem of larger abbe coefficient and lower refractive index of the existing optical glass. The invention is composed of the following components, Sb2O3, SiO2, B2O3, Al2O3, Ta2O5, K2O, Na2O, Nb2O5, TiO2, MgO and ZrO2, wherein the contents of the above components are respectively 50-75%, 5-10%, 8-15%, 0-5%, 0-5%, 0-5%, 0-5%, 1-10%, 0-10%, 0-10%, 0-5%. The invention is equipped with bigger negatively anomalous dispersion value (PgF), high refractive index (nd) and smaller abbe coefficient (vd), wherein the refractive index value is with the range of 1.78-1.81, the abbe coefficient is with the range of 23-25, the negatively anomalous dispersion is an optical constant with the range of 0.598-0.612, and the invention is equipped with the effect of correcting the second order spectrum, perfect stability, and has no harmful compositions as plumbum, arsenium and the like, and no high price oxide .

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

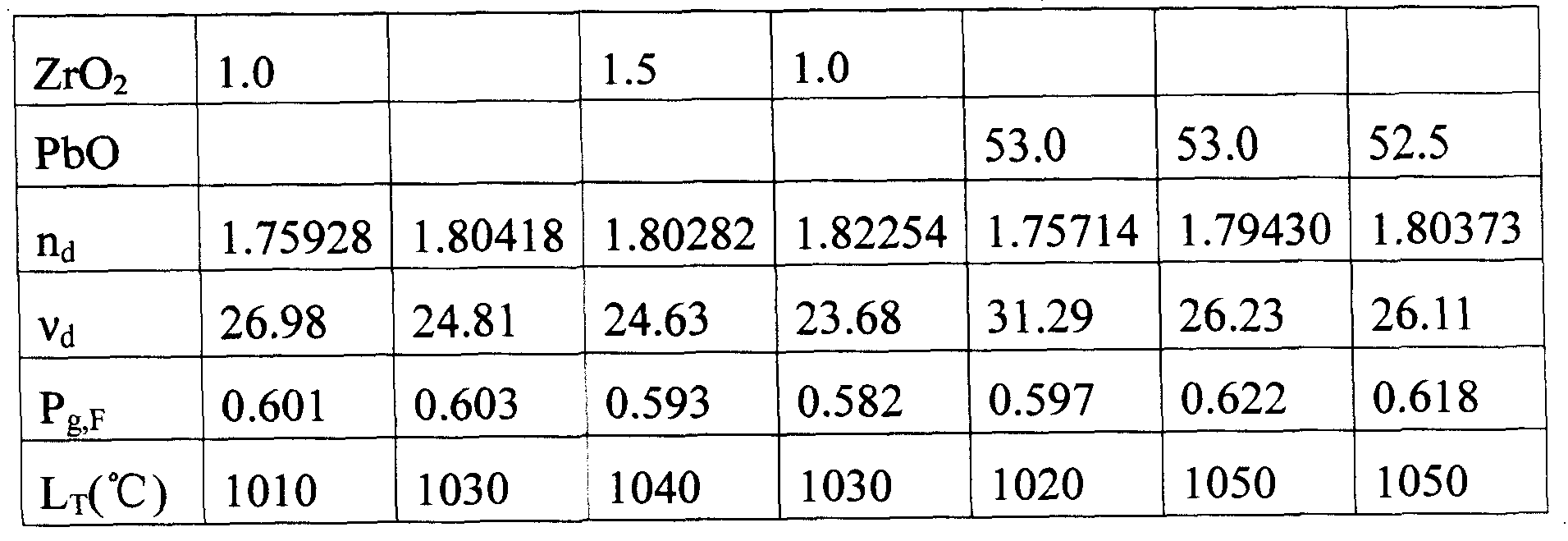

Optical glass and optical element

ActiveCN101857357AHigh refractive indexGood chemical stabilityOptical elementsRefractive indexLength wave

The invention discloses an optical glass and an optical element. The optical glass consists of the following components: 28 to 43 by weight percent of SiO2; 23 to 33 by weight percent of TiO2; 6 to 20 by weight percent of BaO; and 6 to 20 by weight percent of R2O; and R2O consists of K2O and / or Na2O. As shown by an experiment result, the optical glass is not added with clarificant, and does not need to be added with non-environment-friendly elements, the refractive index is 1.72 to 1.82, the Abbe number is 24 to 29, the corresponding wavelength is less than 420mm when the transmissivity is upto 80 percent, and thereby the need of modern imaging devices is satisfied.

Owner:CDGM OPTICAL GLASS

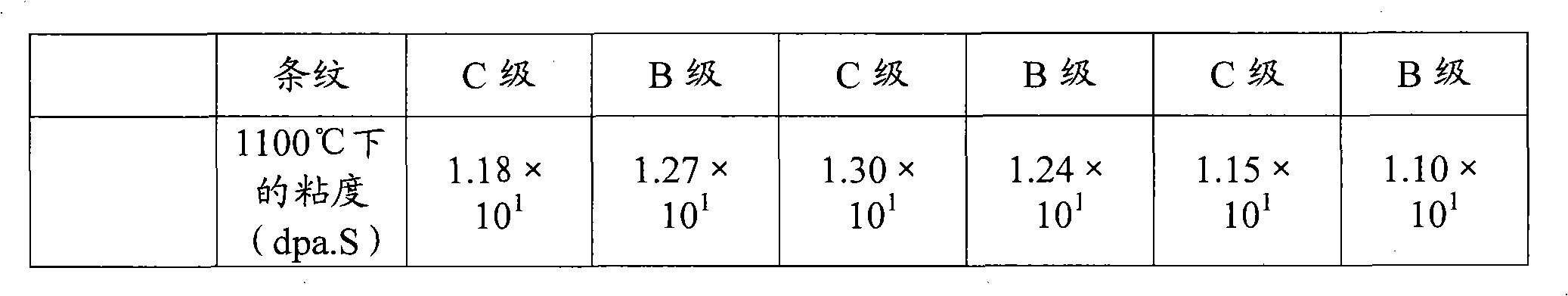

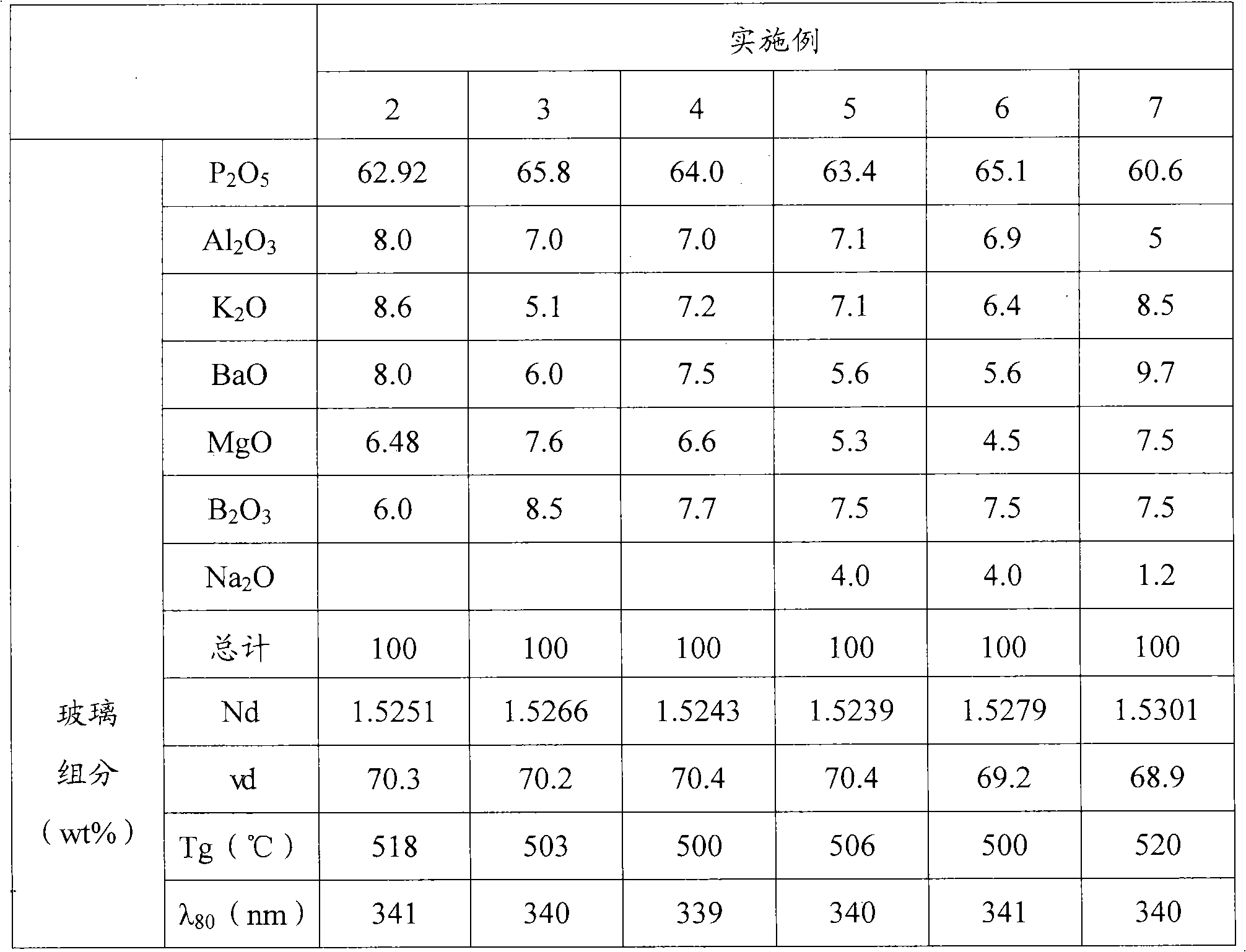

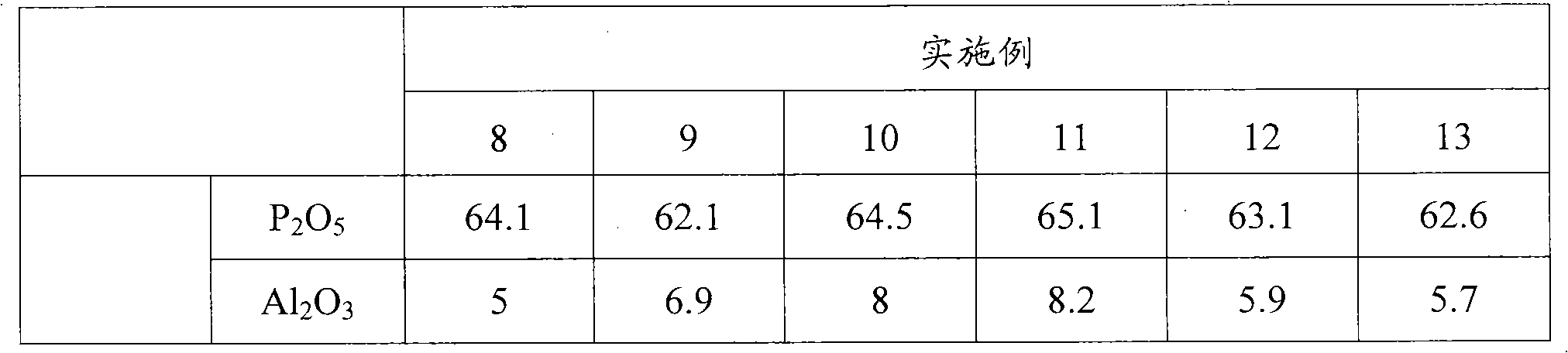

Optical glass and optical element

ActiveCN101805124AImprove mechanical propertiesImprove stabilityOptical elementsTransmittanceRefractive index

The invention discloses optical glass and an optical element. The optical glass comprises the following components: 55-66wt% of P2O5, 2-12wt% of Al2O3, 1-10wt% of K2O, 1-10wt% of BaO, 3-10wt% of MgO and 1-10wt% of B2O3. Experimental results show that the refractive index of the optical glass is 1.5-1.6, Abbe number is 67-72, and when the transmittance of the optical glass is 80%, the corresponding wavelength is less than 345nm and the transition temperature is lower than 520 DEG C, thereby lowering the cost in production.

Owner:CDGM OPTICAL GLASS

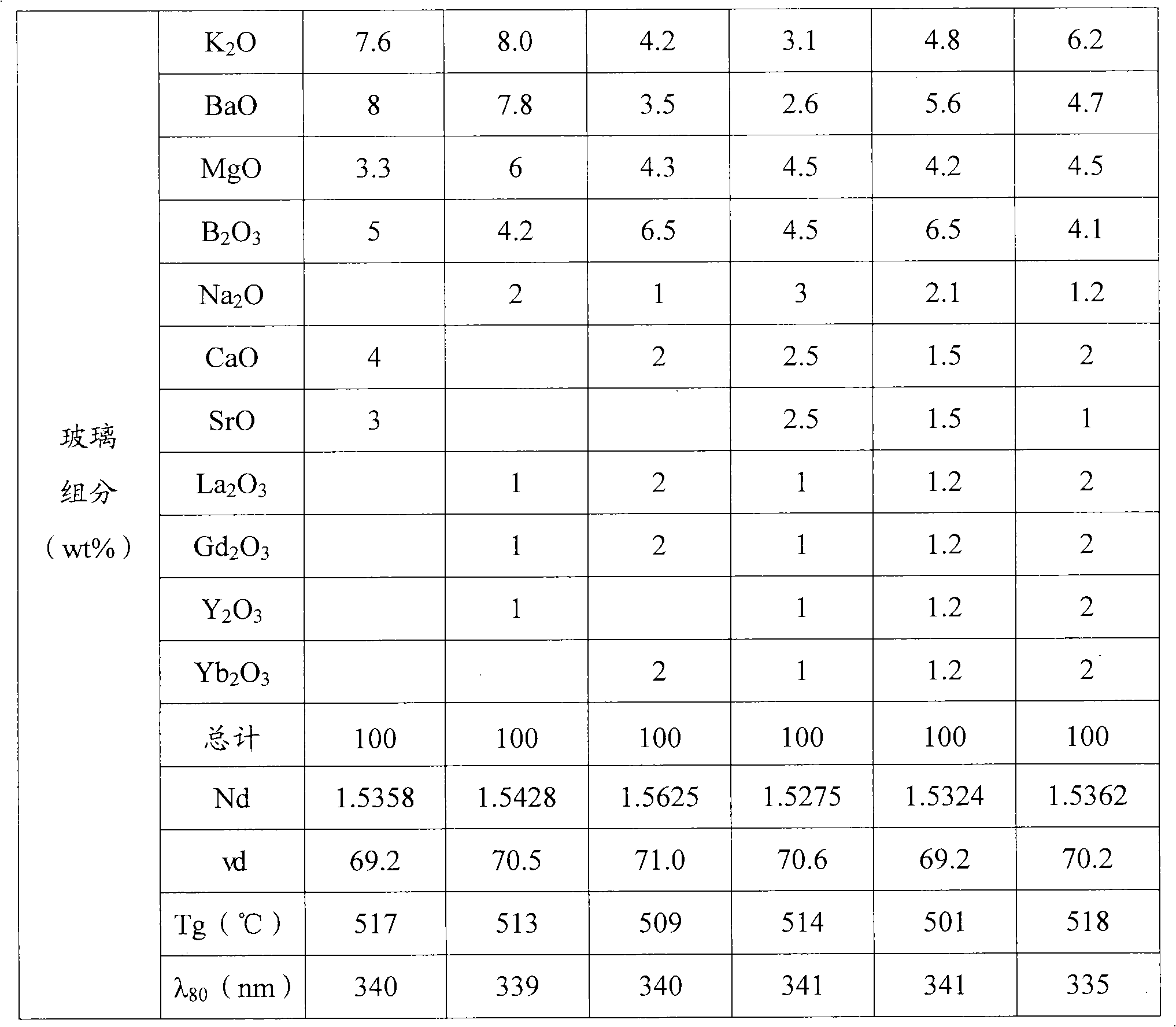

Hydrogenation process

ActiveCN103789022AIncrease flow rateReduce contentTreatment with hydrotreatment processesSaline waterThermodynamics

The invention relates to a hydrogenation process. The hydrogenation process includes: a step of feeding high-sulfur high-nitrogen heavy distillate oil adopted as a raw material through a hydrofining reaction zone and a hydrocracking reaction zone, wherein the raw material is mainly subjected to desulphurization, denitrification, deoxidation and aromatic saturation in the hydrofining reaction zone, a hydrocracking reaction is mainly performed in the hydrocracking reaction zone, and reaction products are fed into a hot high-pressure separator; a step of reducing pressure of hot high-pressure separation oil, mixing the hot high-pressure separation oil with hydrogen-containing gas, feeding the mixture into a hot low-pressure separator, feeding hot high-pressure separation gas into a cold high-pressure separator after the hot high-pressure separation gas is cooled by an air cooler to perform gas-oil-water three-phase separation, and injecting demineralized water before the hot high-pressure separation gas is fed into the air cooler; and a step of reducing the pressure of cold high-pressure oil, feeding the cold high-pressure oil into a cold low-pressure separation, feeding cold low-pressure separation oil to a distillation system after the cold low-pressure oil and the hot high-pressure gas are subjected to heat exchange, feeding hot low-pressure gas into the cold low-pressure separator after the hot low-pressure gas is cooled by the air cooler, and directly feeding hot low-pressure oil into the distillation system. The process can effectively solve a problem that operation stability is influenced by blocking of the air cooler of the hot low-pressure separation gas in a hydrocracking process for processing the high-sulfur high-nitrogen heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silver-aluminum paste for front fine grid of high-performance N-type solar cell and preparation method of silver-aluminum paste

InactiveCN113257457AInhibition formationImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAl powderSilicon alloy

The invention belongs to the field of N-type solar cells, and discloses silver-aluminum paste for a front fine grid of a high-performance N-type solar cell and a preparation method of the silver-aluminum paste. The silver-aluminum paste for the front fine grid of the high-performance N-type solar cell comprises the following raw materials: conductive silver powder, an organic carrier, glass powder and aluminum powder, and the oxygen content of the aluminum powder is 0.5-1%. The preparation method comprises the following steps of: uniformly mixing and stirring the conductive silver powder, the glass powder, the aluminum powder and the organic carrier; and grinding an obtained mixture to obtain the silver-aluminum paste. According to the silver-aluminum paste for the front fine grid of the high-performance N-type solar cell, the aluminum powder with high oxygen content and proper particle size is added, so that the formation of excessive aluminum-silicon alloy can be inhibited, the open voltage is improved, and the photoelectric conversion efficiency of the solar cell is improved after the solar cell is prepared from the silver-aluminum paste.

Owner:浙江奕成科技有限公司

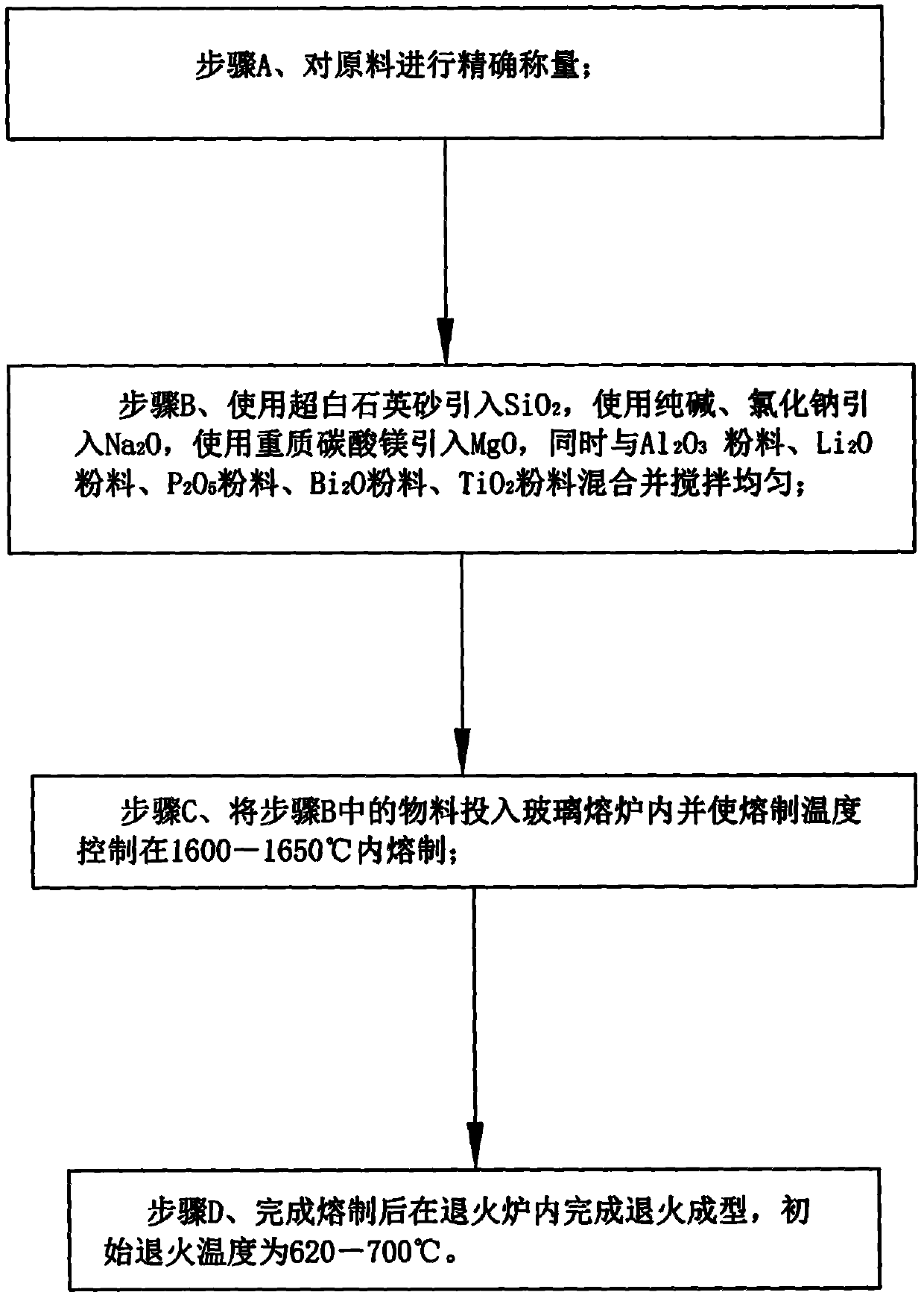

Aeronautic glass formula and preparation method of aeronautic glass

The invention discloses an aeronautic glass formula. The aeronautic glass formula comprises the raw material components: in percent by mass, 55-65% of SiO2, 15-25% of Al2O3, 10-15% of Na2O, 1-5% of Li2O, 1-5% of MgO, 1-3% of K2O, 1-3% of P2O5, 0.5-3% of Bi2O, 0.5-2% of TiO2 and 0.05-0.3% of Cl2, uniform mixing is performed, and melting is performed in a smelting furnace at a temperature of 1600-1650 DEG C. Meanwhile, the invention discloses a preparation method of the aeronautic glass. The preparation method comprises the following steps: (1) weighing the raw materials accurately, (2), introducing SiO2 by using ultra-white quartz sand, introducing Na2O by using soda ash and sodium chloride, introducing MgO by using heavy magnesium carbonate, and performing mixing with Al2O3 powder, Li2O powder, P2O5 powder, Bi2O powder and TiO2 powder, and performing uniform stirring; and (3), putting the mixture obtained in the step (2) into a glass melting furnace; and (4) completing annealing and molding in an annealing furnace. The formula is reasonable, the whole quality, mechanical strength and chemical stability of the glass can be ensured, and enlargement of the application range of the glass is facilitated; and meanwhile, the processing method is beneficial to improvement of the processing efficiency.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Wafer plasma cutting protection liquid, preparation method and application thereof

ActiveCN113652128AImprove thermal stabilityReduce crystallization tendencySolid-state devicesSemiconductor/solid-state device manufacturingWaferOrganosolv

The invention provides a wafer plasma cutting protection liquid, a preparation method and application thereof. The wafer plasma cutting protection liquid comprises the following components in parts by weight: 5-40 parts of a water-soluble resin, 0.1-2 parts of a wetting agent, 0.1-2 parts of a defoaming agent, 0.1-2 parts of a free radical capturing agent, 5-20 parts of an organic solvent, and 34-89.7 parts of water. The wafer plasma cutting protection liquid can quickly form a film on the surface of a wafer, and has good heat resistance and removability. During wafer processing, by using the protection liquid, condensed silicon steam or other chippings generated in the processing process can be effectively prevented from being deposited on the surface of a chip. According to the invention, the wafer plasma cutting protection liquid has high thermal stability, the situation that the surface of a wafer is directly exposed to the external environment due to the fact that a protection film is decomposed when plasma cutting is carried out under the thermal effect of laser cutting or the high working temperature can be avoided, and the reliability and the yield of products are effectively improved.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

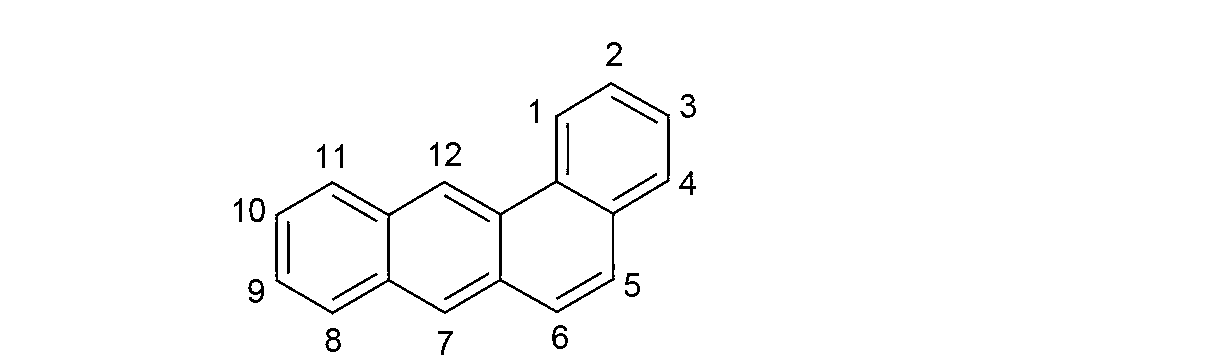

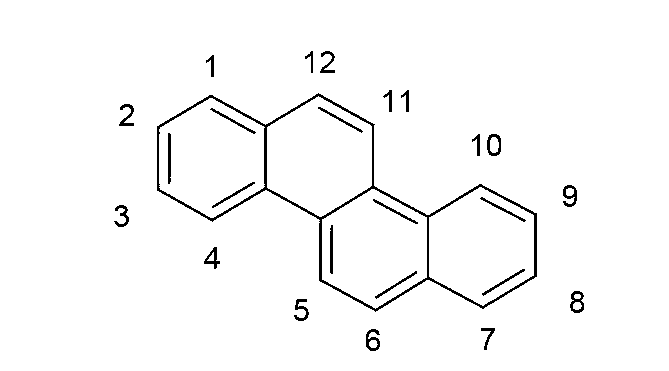

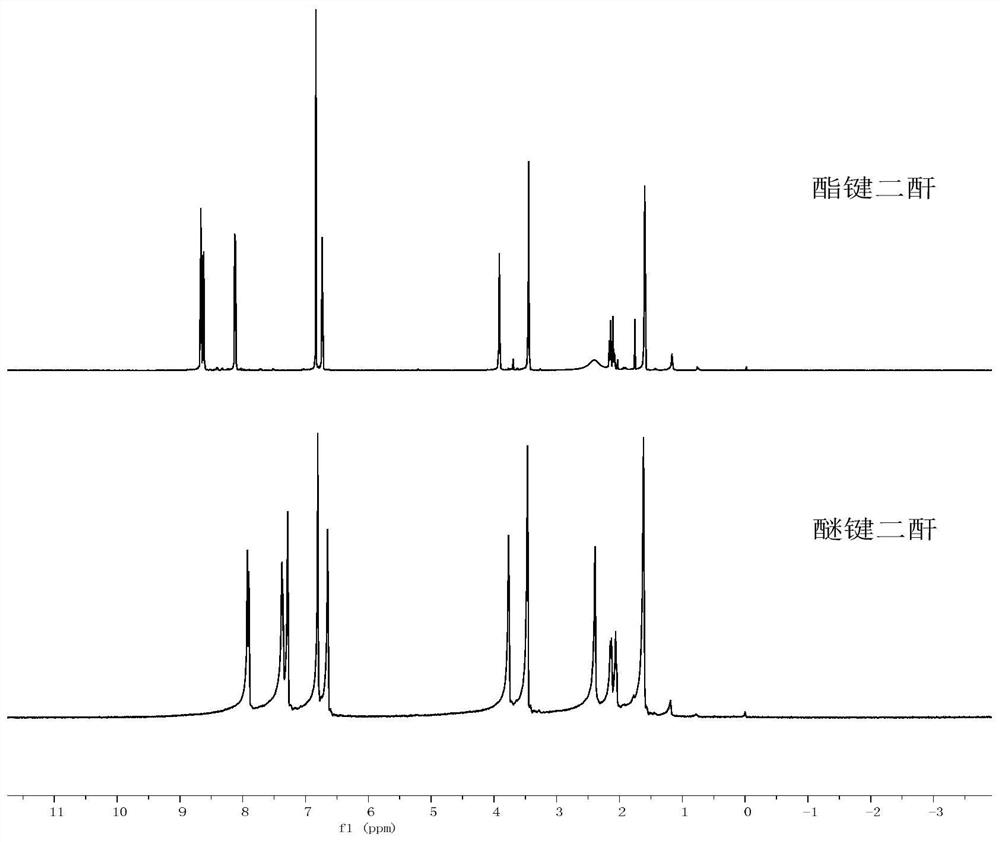

Materials for electronic devices

InactiveCN102791659AImprove efficiencyExtend your lifeOrganic compound preparationGroup 5/15 element organic compoundsDopantHost material

The present invention relates to compounds according to the general formula (I), the use thereof in electronic devices, preferably as a host material for fluorescent dopants or as a fluorescent dopant, to methods for producing the compounds according to formula (I), and to electronic devices containing compounds according to formula (I).

Owner:MERCK PATENT GMBH

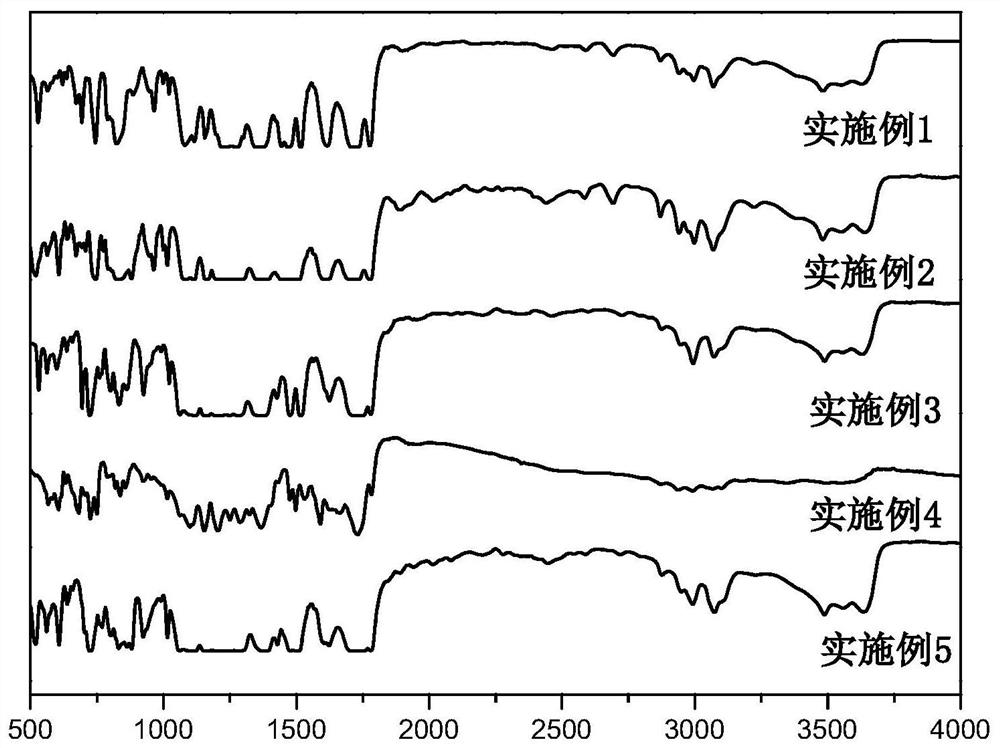

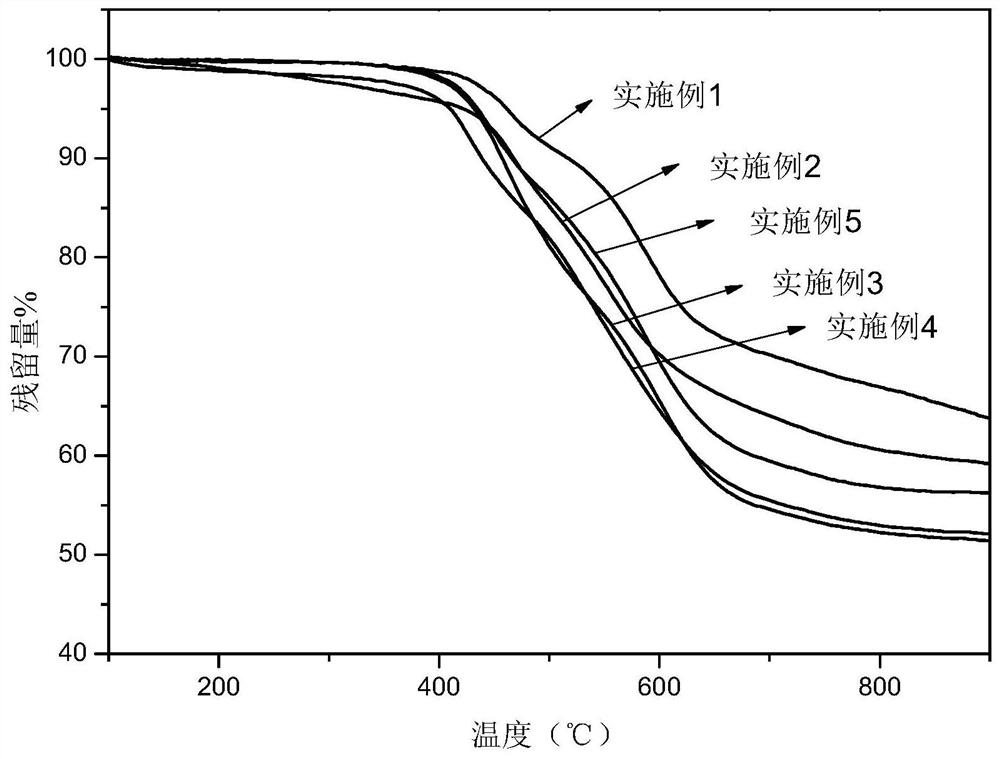

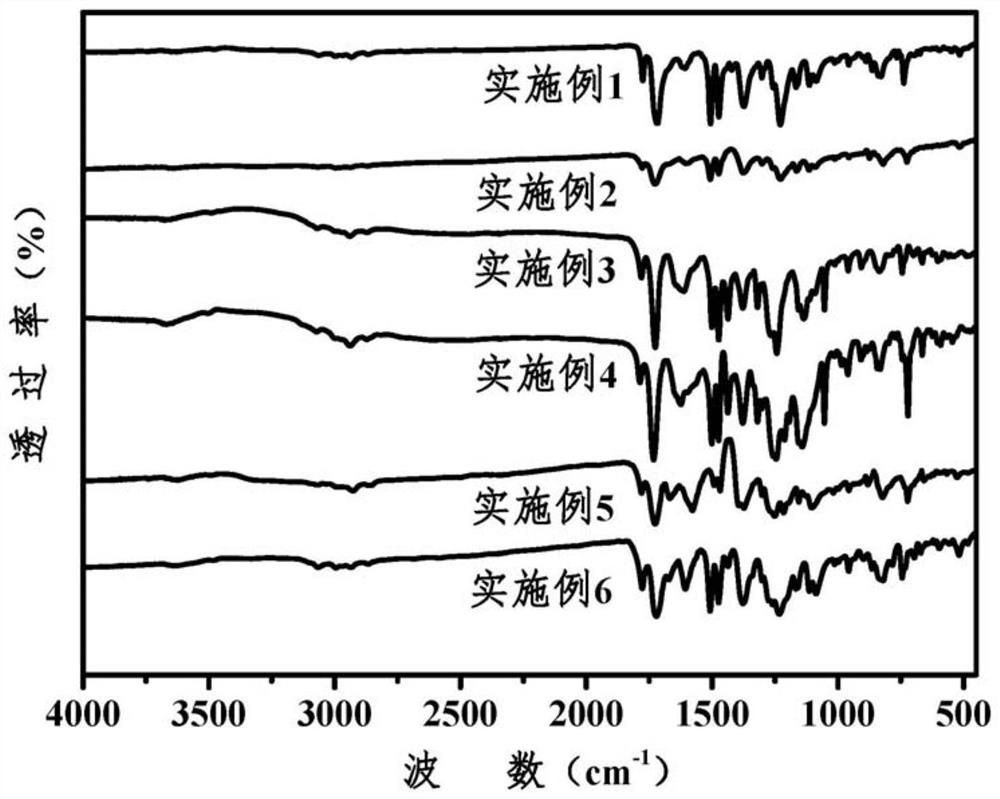

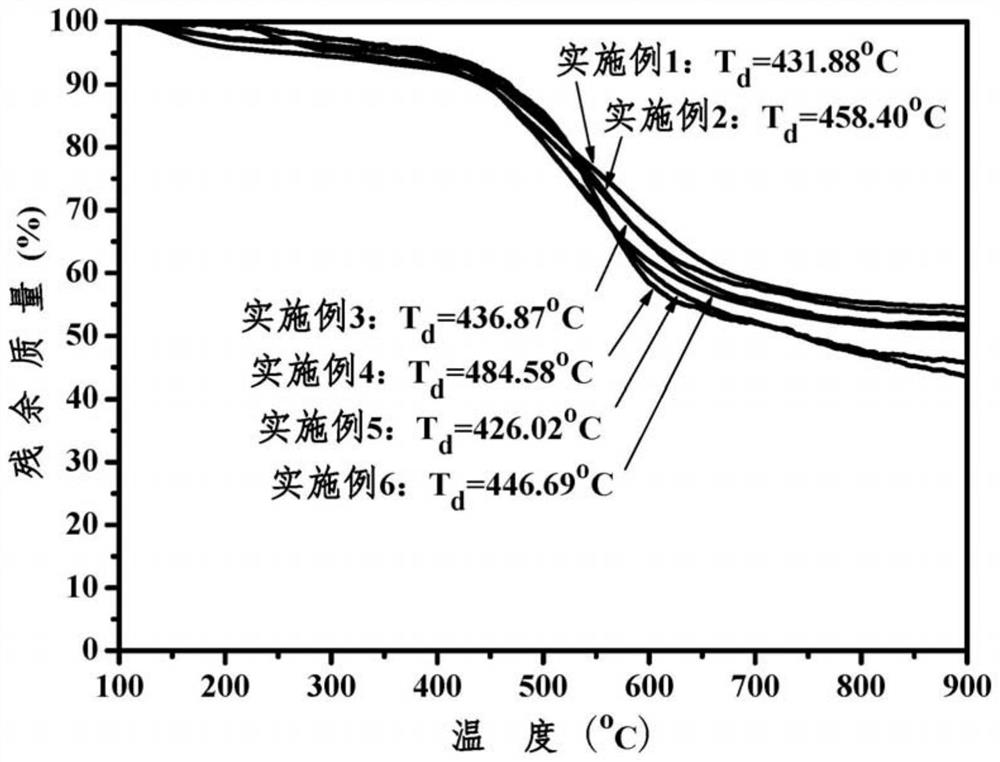

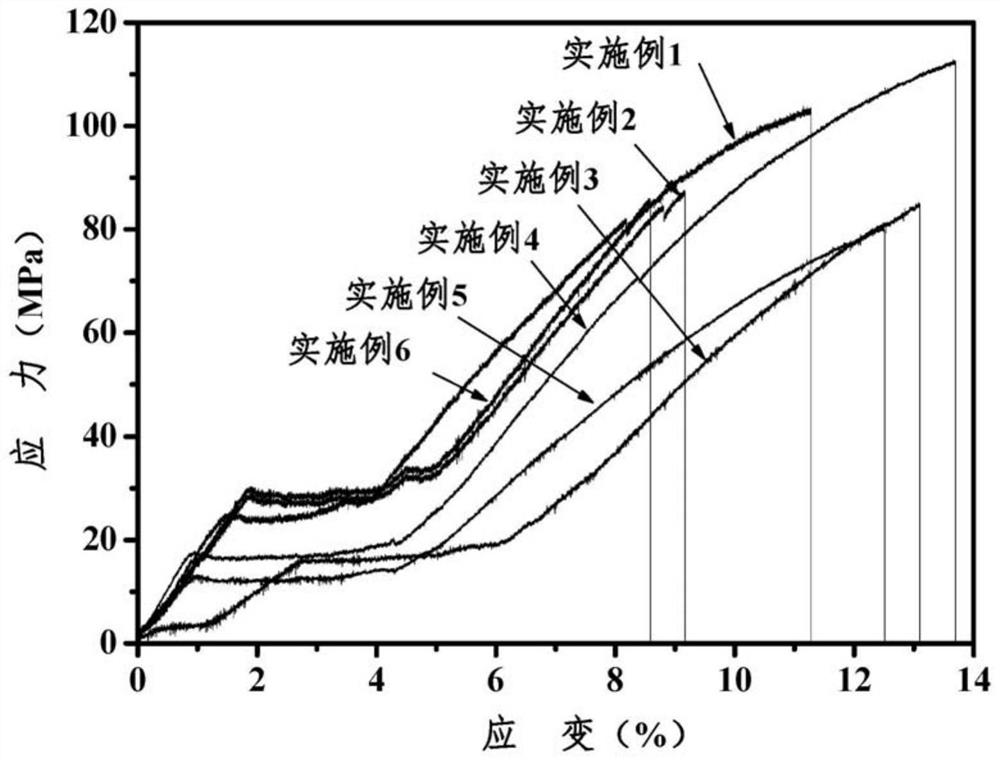

Polyimide with main chain containing benzo norbornene structure and preparation method thereof

ActiveCN113388109ALow dielectricLow dielectric constantPhotovoltaic energy generationPolymer scienceIsomerization

The invention discloses polyimide with a main chain containing a benzo norbornene structure and a preparation method thereof, and belongs to the technical field of high polymer materials. Starting from p-benzoquinone and cyclopentadiene, the dianhydride monomer containing the benzo norbornene structure and the polyimide with the main chain containing the benzo norbornene structure are efficiently synthesized through D-A reaction, isomerization, nucleophilic substitution, a two-step method and other reactions. Starting from p-benzoquinone and cyclopentadiene, the dianhydride monomer containing the benzo norbornene structure and the polyimide with the main chain containing the benzo norbornene structure are efficiently synthesized through D-A reaction, isomerization, nucleophilic substitution, a two-step method and other reactions. Norbornene bicyclic ring is used as a side group, so that regular stacking among polyimide molecular chains is destroyed, the free volume is increased, and the dielectric constant can be reduced. And double bonds of bornene are further crosslinked under high heat, so that the thermal properties, mechanical properties and solvent resistance of the material are improved. The prepared polyimide material has the advantages of excellent thermal properties and mechanical properties, simple synthesis process, low cost, good solubility, excellent solvent resistance and low dielectric constant.

Owner:NANCHANG UNIV

Raw material batch for preparing magma rock fibers and preparation method of magma rock fibers

ActiveCN111517659AAbundant resourcesEasy access to resourcesGlass making apparatusSolid waste managementFiberMetallurgy

The invention discloses a raw material batch for preparing magma rock fibers and a preparation method of the magma rock fibers. The raw material batch is characterized in that the raw material batch is a raw material batch which is used for producing magma rock fibers and is prepared by uniformly mixing 50-90% of magma rock, 10-50% of gasification furnace slag and 0-30% of auxiliary raw materialsin percentage by weight and grinding the mixture until the particle size is smaller than 80 meshes; the preparation method of the magma rock fiber comprises the following steps: heating the raw material batch to 1420-1500 DEG C, melting for 7-24 hours, and drawing to obtain the magma rock fiber. With application of the method, the raw materials are rich in resource and easy to obtain, industrial solid waste gasification slag is fully utilized, waste is turned into wealth, and the production cost is reduced; the auxiliary raw materials facilitate the design of chemical components and main mineral components of the prepared magma rock fiber material, improve the melting property of the glass, are beneficial to fiber forming and wiredrawing performance improvement, are more suitable for wiredrawing operation, are convenient for large-scale stable industrial production, and are high in practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Paint for H grade polyurethane enamelled wire with good saline water needle performace capable of directing welding at low temp.

InactiveCN100345924CImprove heat resistanceQuality improvementPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to an H-grade wire coating enamel that has good salt water pinhole performance and can be directly welded at low temperature, containing hydroxyl component, sealed isocyanate component and solvent, where its hydroxyl component has an acid value less than 2, a hydroxyl value of 150-300, and number-average molecular weight of 1500-5000, and as synthesized, the raw materials has at least m-phthalic acid, p-phthalic acid, adilic acid, glycerin and a kind of dibasic alcohol in the weight ratio of 1 to (0.2-2) to (0.2-0.5) to (0.5-3) to (0.5-1.5); and its sealed isocyanate component is partially added of MDI by mixed polyalcohol that at least has a dibasic alcohol and a tribasic alcohol; in the paint base, the equivalent ratio of isocyanate base to OH is (0.9-1.2) : 1, and it reaches H-grade and has good salt water pinhole property of paint film, tin daubing temperature less than or equal to 375 deg.C.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

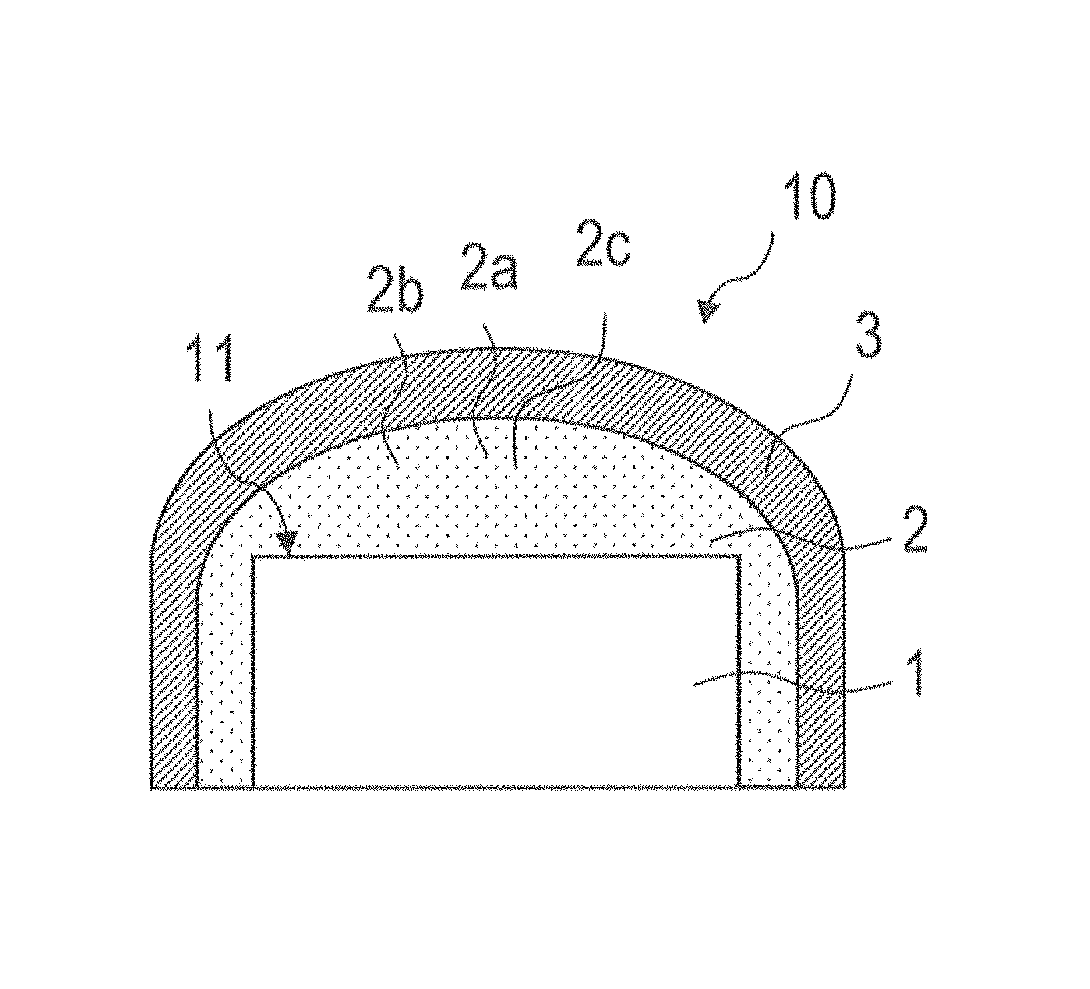

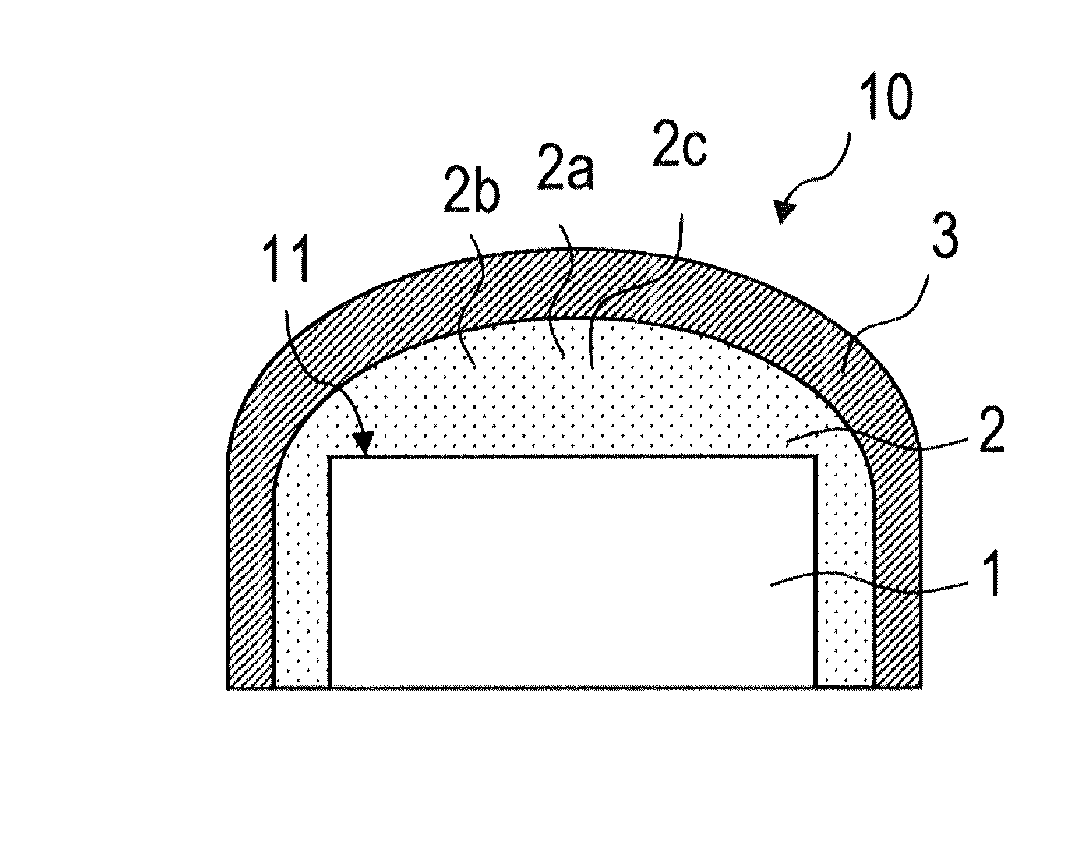

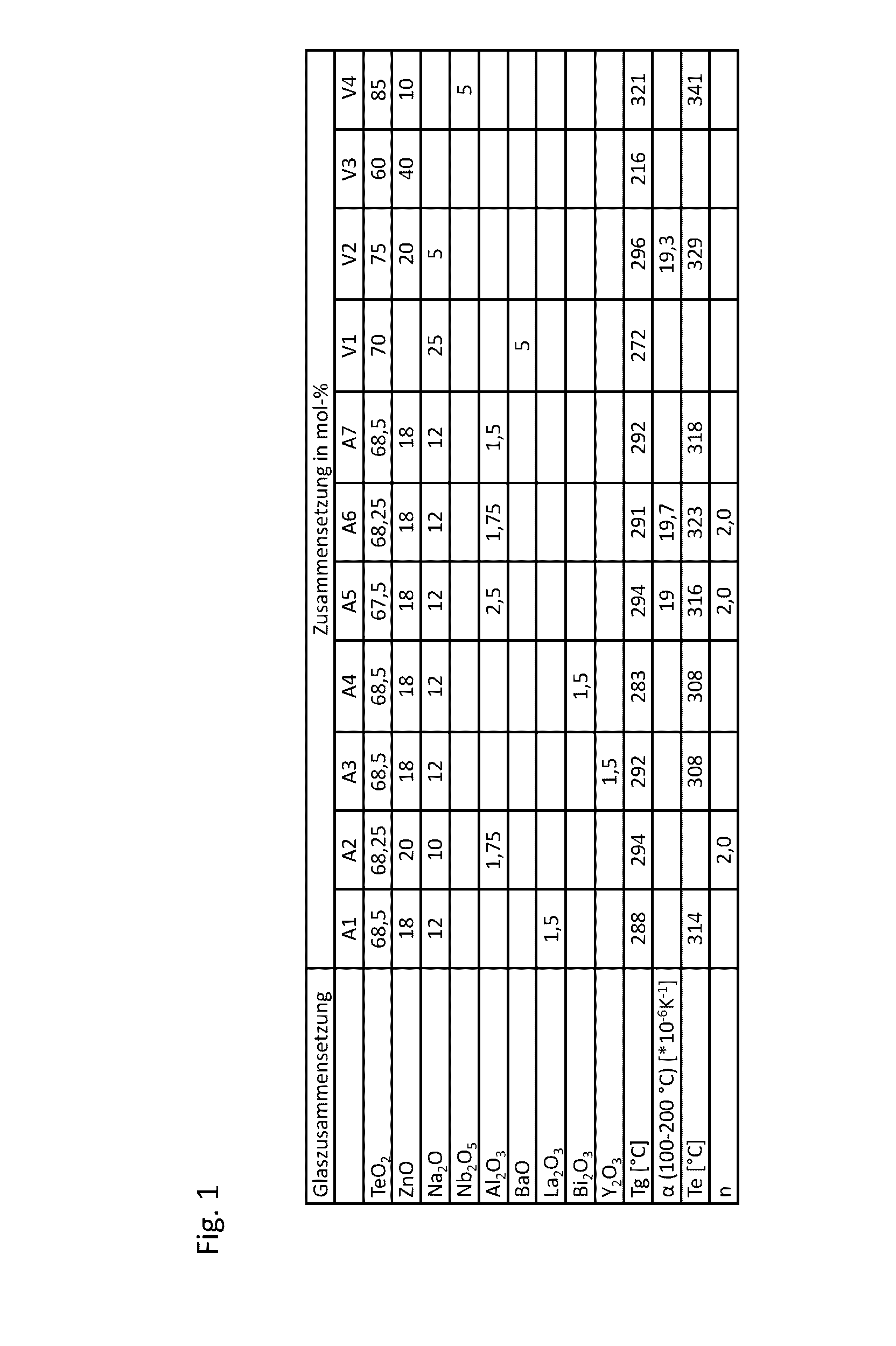

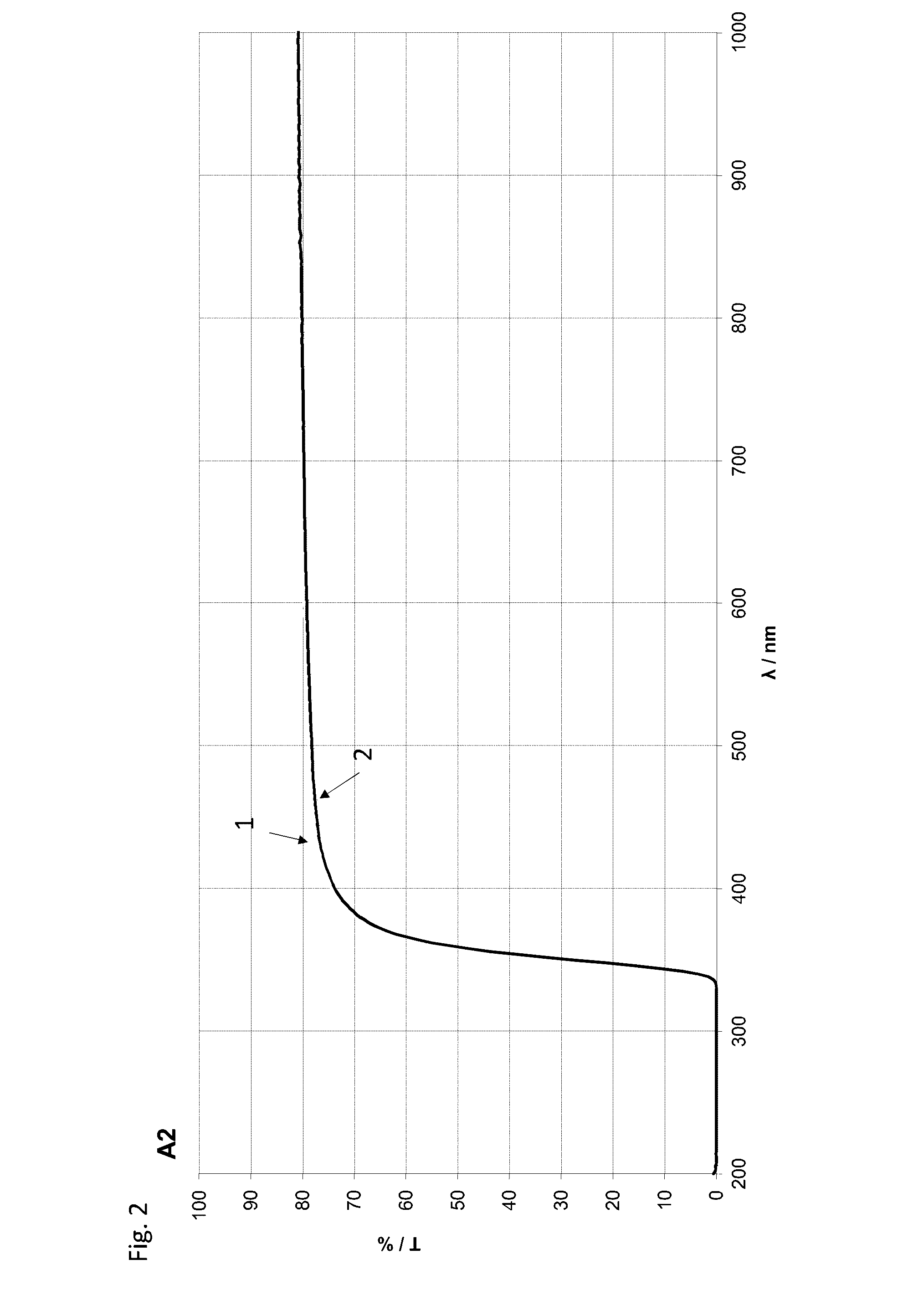

Conversion element, component and process for producing a component

ActiveUS9688910B2Low sintering pointLow softening temperatureLuminescent compositionsSemiconductor devicesChemical compositionSecondary radiation

A conversion element, a component and a method for producing the component are disclosed. In an embodiment the conversion element includes a phosphor configured to convert electromagnetic primary radiation into electromagnetic secondary radiation and a glass composition as matrix material in which the phosphor is embedded. The glass composition has the following chemical composition: at least one tellurium oxide with a proportion of 65 mole % as a minimum and 90 mole % as a maximum, R1O with a proportion of between 0 mole % and 20 mole %, at least one M12O with a proportion of between 5 mole % and 25 mole %, at least one R22O3 with a proportion of between 1 mole % and 3 mole %, M2O2 with a proportion of between 0 mole % and 2 mole %, and R32O5 with a proportion of between 0 mole % and 6 mole %.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

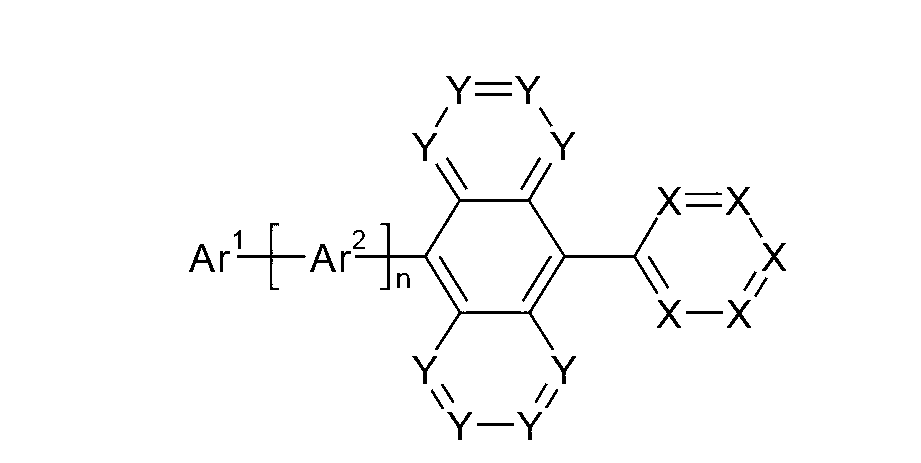

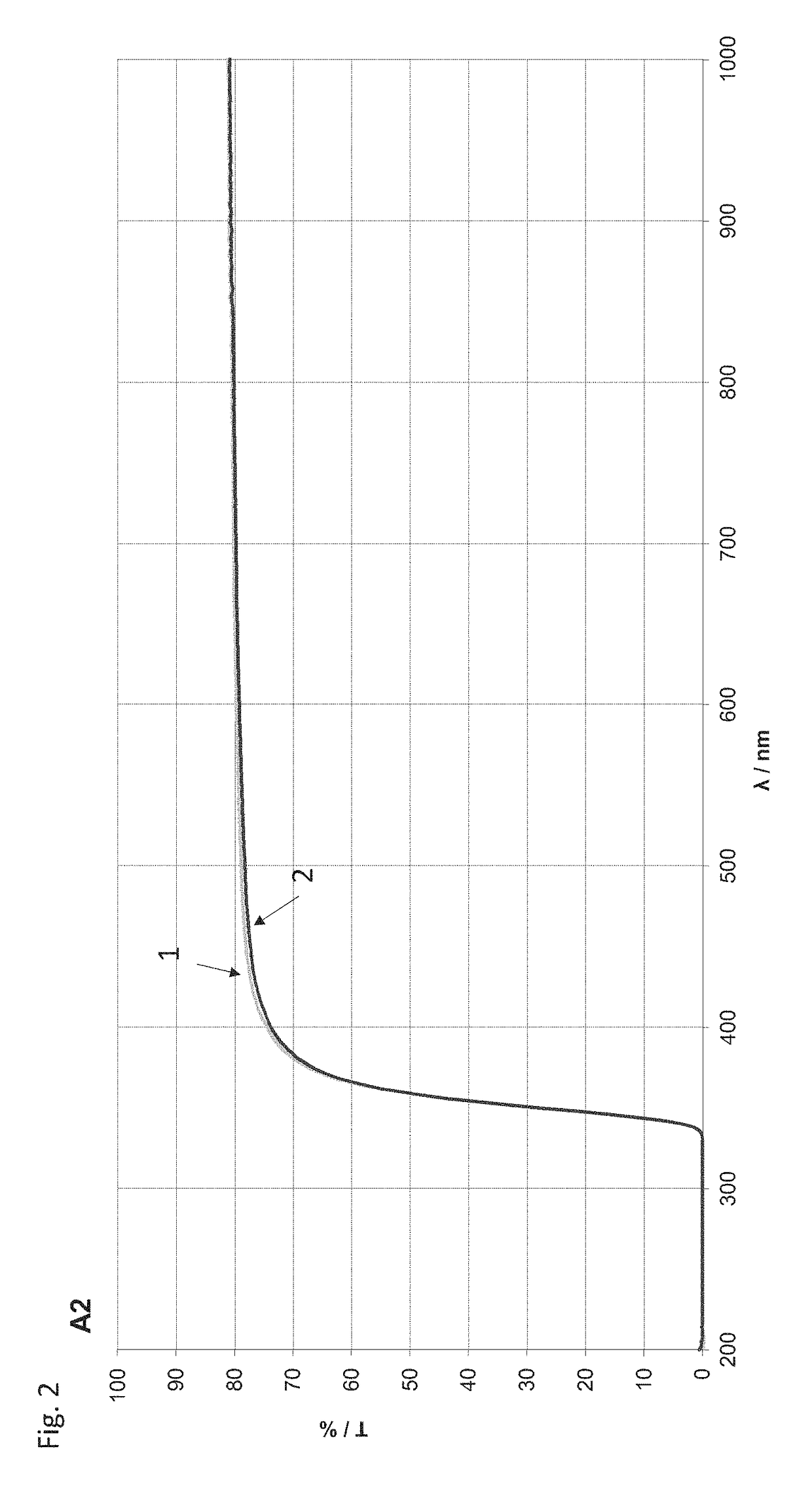

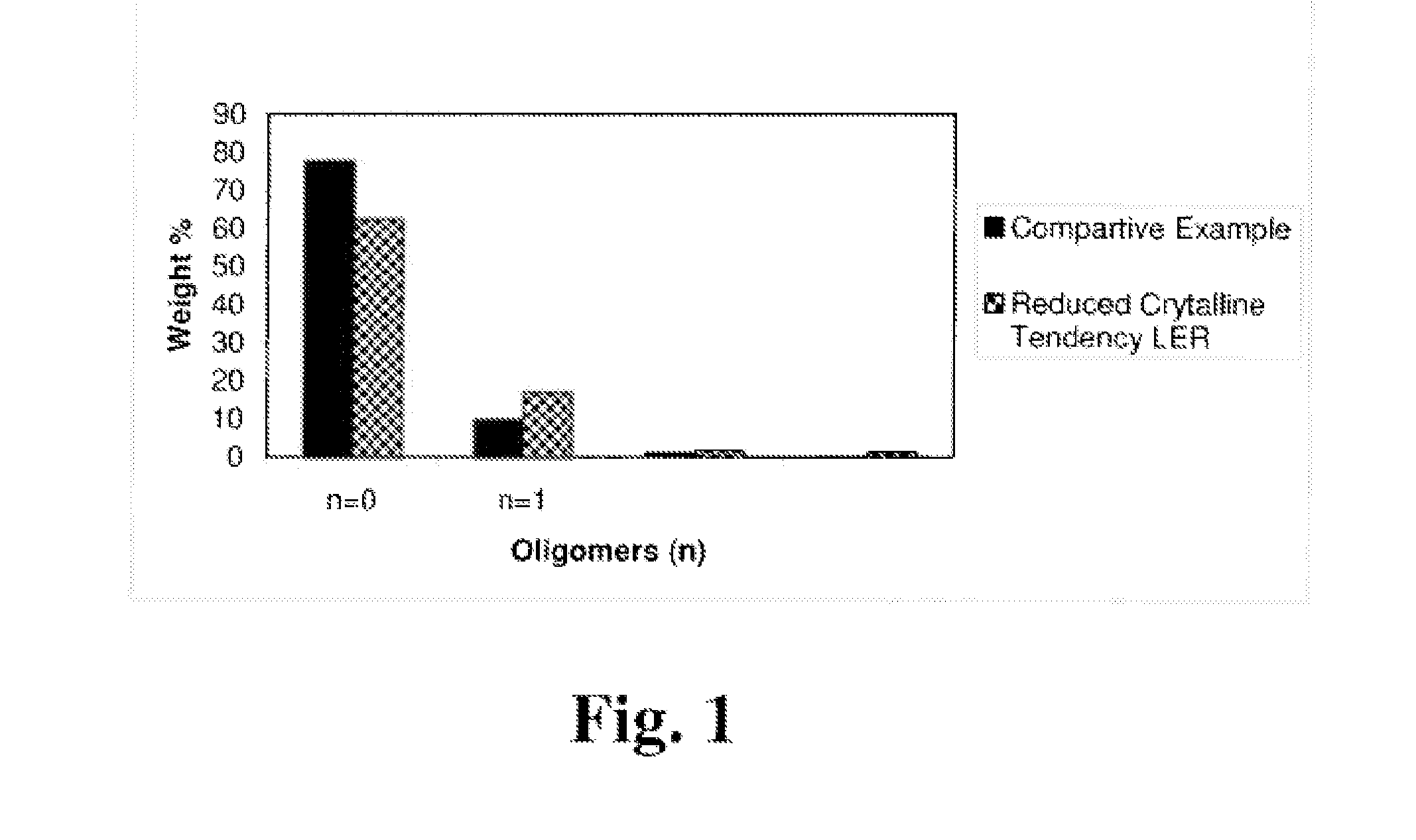

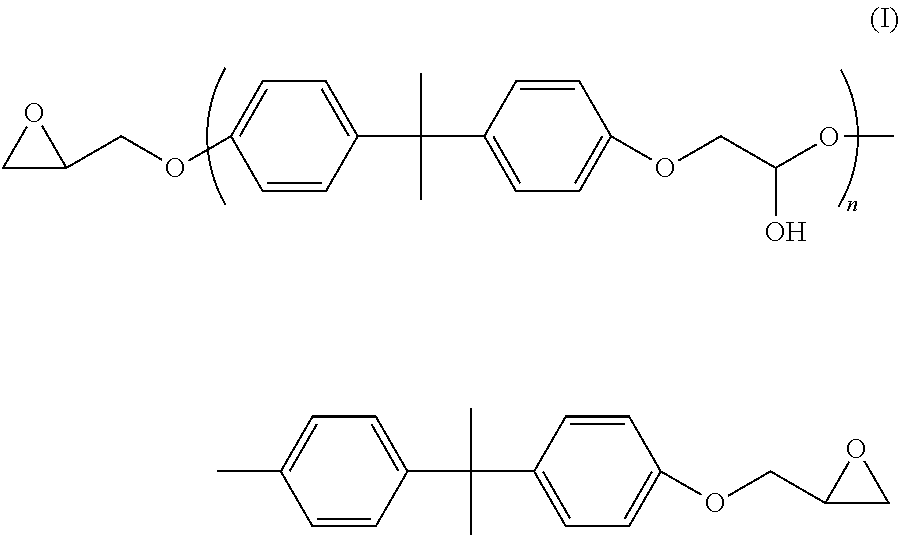

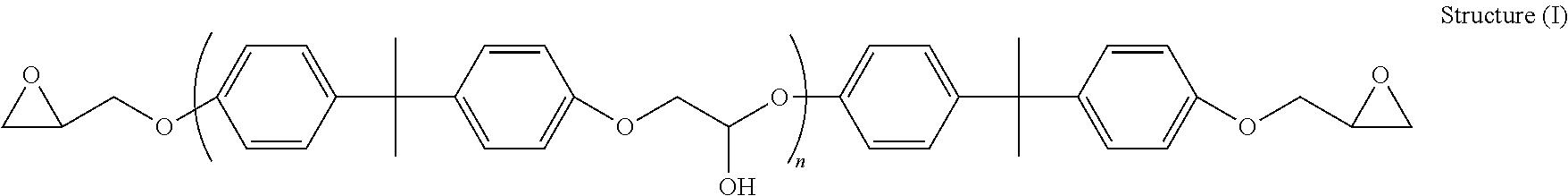

Liquid epoxy resin formulations

ActiveUS20140256856A1Reduce crystallization tendencyImprove the immunityOrganic chemistryEpoxyPolymer science

A liquid epoxy resin composition having a reduced tendency to crystallize including at least one liquid epoxy resin having the following generic chemical Structure (I): where n is 0 or an integer of 1 or more; and wherein n=0 is in the range of between about 1 wt % and about 90 wt %; wherein; n=1 is in the range of between about 7 wt % and about 20 wt %; n=2 is in the range of between about 0.8 wt % and about 3 wt %; and n=3 and above is in the range of about 0 wt % and about 2 wt %.

Owner:BLUE CUBE IP

Conversion Element, Component and Process for Producing a Component

ActiveUS20160304776A1Reduce processing timeImprove light outcoupling efficiencyLuminescent compositionsSemiconductor devicesChemical compositionPhosphor

A conversion element, a component and a method for producing the component are disclosed. In an embodiment the conversion element includes a phosphor configured to convert electromagnetic primary radiation into electromagnetic secondary radiation and a glass composition as matrix material in which the phosphor is embedded. The glass composition has the following chemical composition: at least one tellurium oxide with a proportion of 65 mole % as a minimum and 90 mole % as a maximum, R1O with a proportion of between 0 mole % and 20 mole %, at least one M12O with a proportion of between 5 mole % and 25 mole %, at least one R22O3 with a proportion of between 1 mole % and 3 mole %, M2O2 with a proportion of between 0 mole % and 2 mole %, and R32O5 with a proportion of between 0 mole % and 6 mole %.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

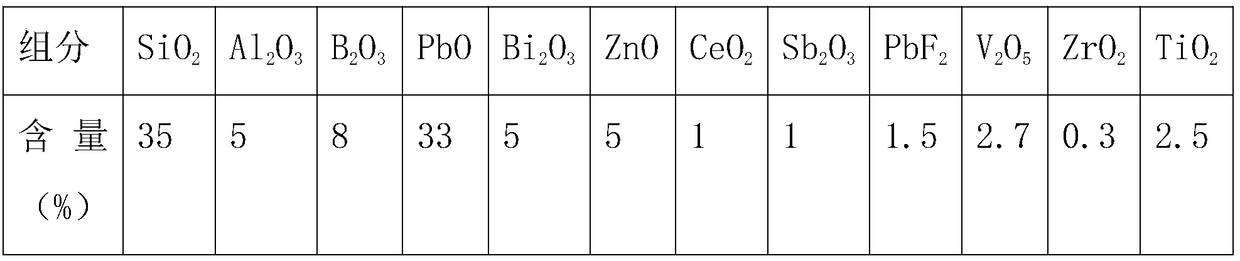

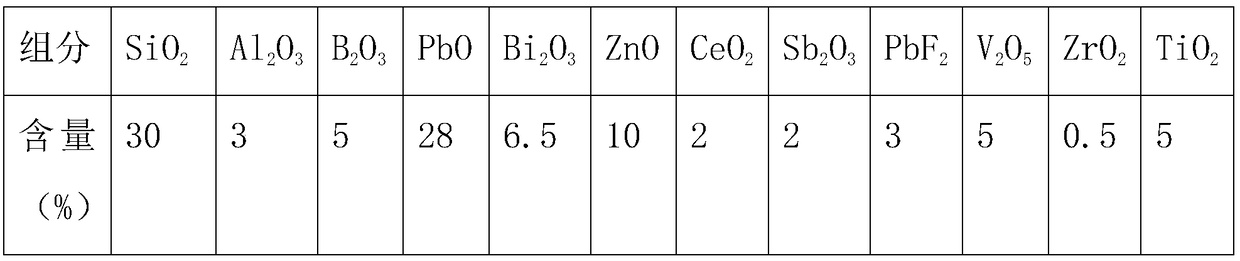

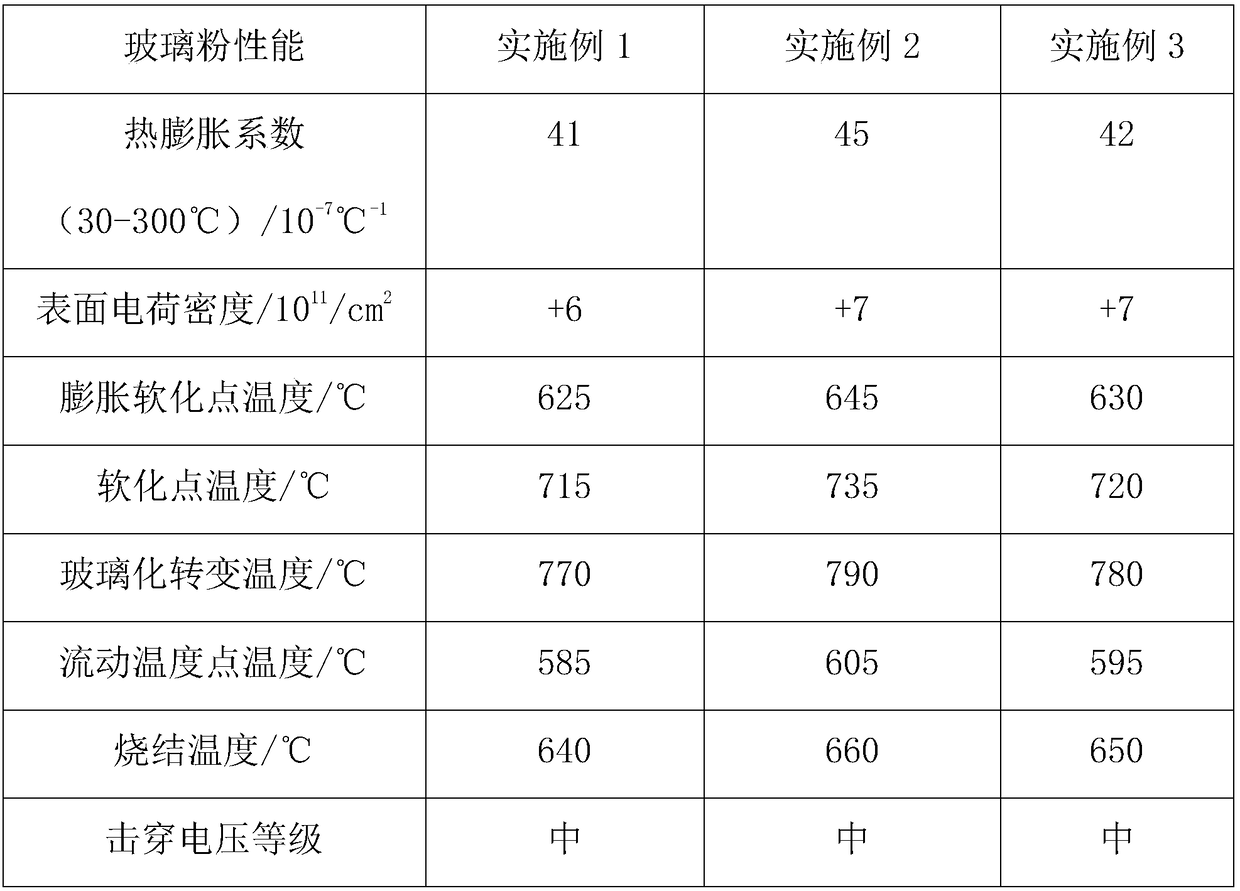

Glass powder for semiconductor passivation packaging and preparation method of glass powder

InactiveCN108863089AMeet the requirements of passivated packagesStrong enoughSemiconductorMaterials science

The invention provides glass powder for semiconductor passivation packaging and a preparation method of the glass powder. The glass powder is prepared from the following ingredients in percentage by mass: 30-60% of SiO2, 3-10% of Al2O3, 5-15% of B2O3, 28-55% of PbO, 0-10% of Bi2O3, 0-20% of ZnO, 0-2% of CeO2, 0-2% of Sb2O3, 0-3% of PbF2, 0-5% of V2O5, 0-0.5% of ZrO2 and 0-5% of TiO2. According tothe preparation method of the glass powder for the semiconductor passivation packaging, the operation is simple, the cost can be effectively saved, the prepared glass powder can meet requirement on the semiconductor passivation packaging, meanwhile, the glass powder has enough strength and breaking tenacity and can effectively resist comprehensive damage caused by illumination, cold, heat, wind, rain, bacteria and the like to the surface of a semiconductor device.

Owner:张其峰

Preparation method of heat-preservation foam glass

InactiveCN107892483AReduce viscosity change rateUniform and stable bubble diameterGlass shaping apparatusPotassiumFoam glass

The invention discloses a preparation method of heat-preservation foam glass, and relates to the technical field of glass processing. The heat-preservation foam glass is prepared from quartz glass, nanometer zeolite powder coated with bismuth oxide, potassium chloride, sodium carbonate, calcium oxide, aluminium oxide, zinc oxide, acidized bentonite and a foaming agent. By adopting the nanometer zeolite powder coated with bismuth oxide, the foaming temperature and crystallization tendency within the foaming temperature range can be reduced effectively, the synergistic effect of the nanometer zeolite powder and the acidized bentonite can be achieved, the viscosity change rate of the glass within the foaming temperature range can be substantially decreased, and therefore the firing temperature range is widened; the prepared foam glass has an even and stable foam diameter, and the heat preservation performance of the foam glass can be effectively improved.

Owner:蚌埠承永玻璃制品有限公司

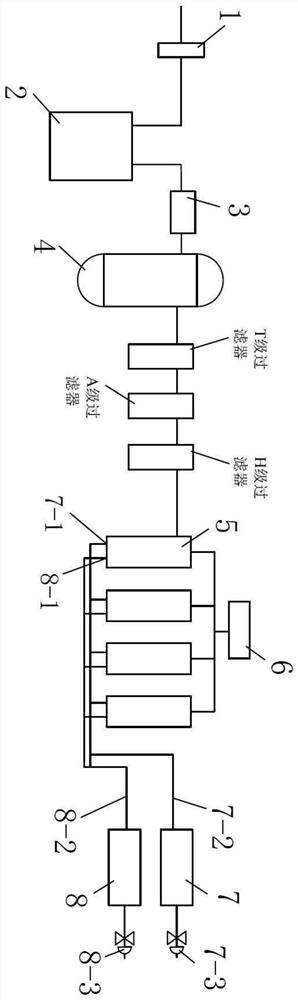

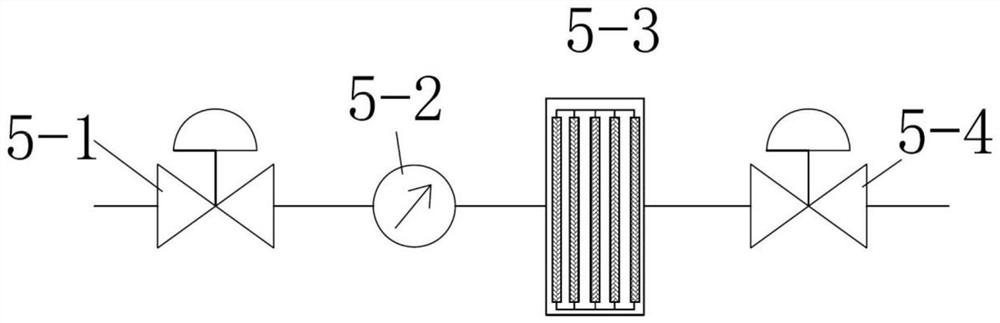

Oxygen production device of medical-grade high-temperature molecular sieve membrane adsorption tower and use method of oxygen production device

ActiveCN113023679AImprove the sterility rateHigh oxygen ion conductivityOxygen preparationMolecular sieveCeramic

The invention provides an oxygen production device of a medical-grade high-temperature molecular sieve membrane adsorption tower and a use method of the oxygen production device. The oxygen production device comprises a gas source access port, an air compressor, a C-grade filter, an air storage tank, a T-grade filter, an A-grade filter, an H-grade filter, 2-4 high-temperature carbonized ceramic-based molecular sieve adsorption units, a vacuum pump, an oxygen storage tank and a nitrogen storage tank which are communicated in sequence, the vacuum pump is arranged in the high-temperature carbonized ceramic-based molecular sieve adsorption unit, the high-temperature carbonized ceramic-based molecular sieve adsorption unit is communicated with the oxygen storage tank through an oxygen diversion pipeline, and the high-temperature carbonized ceramic-based molecular sieve adsorption unit is communicated with the nitrogen storage tank through a nitrogen diversion pipeline. The oxygen production device provided by the invention is provided with the molecular sieve of the adsorption tower of the oxygen ion conductive carbonized ceramic-based molecular sieve membrane with good cyclic utilization rate, and oxygen ions are adsorbed and desorbed under high-temperature vacuum, so that oxygen and nitrogen are efficiently separated, and the oxygen production purity is improved.

Owner:HUNAN VENTMED MEDICAL TECH CO LTD

Composite binder for lithium-sulfur battery and preparation method thereof

ActiveCN109980227AReduce regularityImprove reversible discharge capacityCell electrodesPolyesterLithium–sulfur battery

The invention relates to a composite binder for a lithium-sulfur battery and a preparation method thereof, and belongs to the field of chemical energy storage batteries. The binder is composed of PVDF(polyvinylidene fluoride) and PU (polyurethane), wherein PU is polyester polyurethane with a branched structure. If the total mass of the binder is 100%, the mass friction of PU is 10-30%, and the rest is PVDF. According to the method, a PVDF solution and a PU solution are mixed according to the proportion that PU occupies 10-30% of the total mass of PVDF and PU, and the mixture is stirred for more than two days to obtain the binder. The addition of PU enables PVDF with strong crystallinity to lose part of the crystalline state, thereby enabling the part where pores should appear to become compact, and maintaining the stability of the electrode structure. In addition, a polar functional group in PU inhibits the dissolution and diffusion of a polysulfide, thereby enabling the target binderto be excellent in electrode performance. The method is simple to operate, and the process and technology are easy to implement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-light-transmittance and high-refraction-index crystalline glass and production process thereof

InactiveCN109942184AHigh mechanical strengthGood chemical stabilityGlass shaping apparatusLithium oxideRefractive index

The invention discloses high-light-transmittance and high-refraction-index crystalline glass and a production process thereof. The high-transmittance and high-refraction crystalline glass is preparedfrom, by weight, 30-60% of silicon dioxide, 1-3% of aluminum oxide, 5-25% of titanium dioxide, 1-10% of calcium oxide, 3-10% of magnesium oxide, 3-10% of zinc oxide, 10-20% of barium oxide, 1-3% of lithium oxide, 0.01-0.05% of a decolorizing agent and 0.1-1% of a clarifying agent. The production process comprises the following steps that step 1, the raw materials are classified according to different types; step 2, the classified component raw materials are crushed by a crusher; step 3, the crushed component materials are put into a grinder for grinding. The high-light-transmittance and high-refraction-index crystalline glass and the production process thereof have the advantages that the high-light-transmittance and high-refraction-index crystalline glass can be provided, the lead elementin the crystalline glass is removed, the volatilization of the lead is reduced, the damage to the human body is reduced, the light transmittance and refraction index of the glass are also improved, and the product has stronger market competitiveness and brings higher earnings for enterprises.

Owner:安徽晶晶玻璃制品有限公司

Aromatic polyimide with main chain containing benzo norbornene structure and preparation method

ActiveCN113511980ASimple preparation processReduce manufacturing costOrganic compound preparationPhotovoltaic energy generationDiaminePara-Benzoquinone

The invention relates to aromatic polyimide with a main chain containing a benzo norbornene structure and a preparation method. The aromatic polyimide is characterized in that p-benzoquinone and cyclopentadiene are used as starting materials, and a diamine monomer containing a benzo norbornene structure and aromatic polyimide with a main chain containing a benzo norbornene structure are efficiently synthesized through a D-A reaction, nucleophilic substitution, reduction and a two-step method, so that the flexibility of a molecular chain is ensured, and the thermal performance is not obviously reduced. According to the invention, a norbornene bicyclic ring is used as a side group, so that the free volume between chain segments is increased, the solubility of the polymer is retained, and the dielectric constant of the material is reduced; the double ring has the sp2-configuration cis-double bond with the large polarity, such that the accumulation between macromolecules is ensured, the glass-transition temperature of the polymer is improved, and the double bond of the bornene can be subjected to cross-linking under the high heat so as to improve the thermal property and the mechanical property of the material; through copolymerization modification, the performance of the material is further widened, and the cost is reduced; and the aromatic polyimide has the advantages of low cost, simple synthesis process, low dielectric constant and excellent thermal and mechanical properties.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com