Aeronautic glass formula and preparation method of aeronautic glass

A glass and aviation technology, applied in the field of aviation glass formulation and preparation, can solve the problems of high production cost of aviation plexiglass, insufficient optical performance, affecting optical properties, etc., to ensure quality, mechanical strength and chemical stability, and improve the application Range, gloss-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

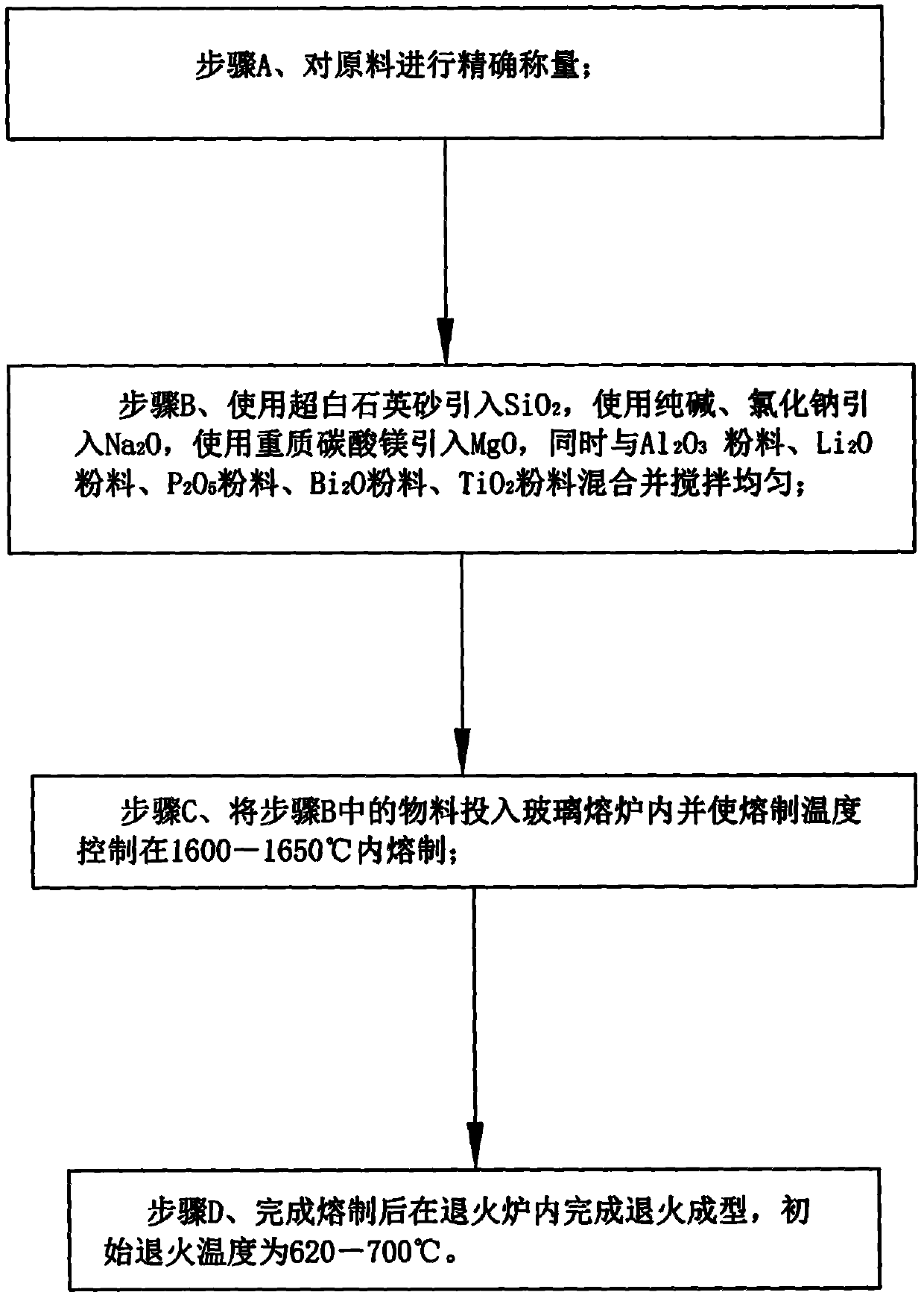

[0017] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a schematic flow chart of the processing method of the present invention.

[0018] See figure 1 , an aviation glass formula, including raw material components in terms of mass percentages are as follows: SiO 2 55-65%, Al 2 o 3 15-25%, Na 2 O 10-15%, Li 2 O 1-5%, MgO 1-5%, K 2 O 1-3%, P 2 o 5 1-3%, Bi 2 O 0.5-3%, TiO 2 0.5-2%, Cl 2 0.05-0.3% is mixed evenly and melted in a melting furnace at a temperature of 1600-1650 ° C, and annealed and formed in the annealing furnace at the same time.

[0019] The initial annealing temperature in the annealing furnace is 620-700°C.

[0020] The formula of the present invention is reasonable, contains SiO 2 It is beneficial to improve the overall mechanical strength, chemical stability and thermal stability of the glass, containing Al 2 o 3 It is beneficial to reduce the thermal expansion coefficient and chemical toughening. Containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com