Patents

Literature

153results about How to "Reduce regularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

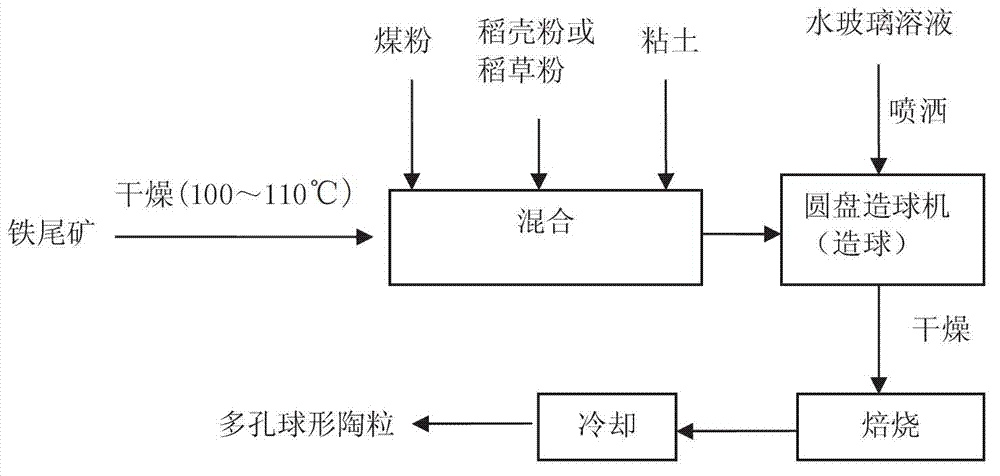

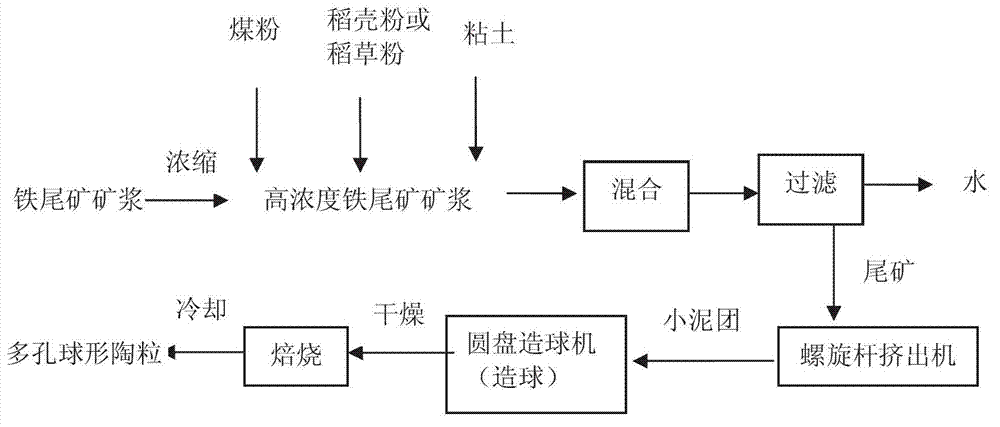

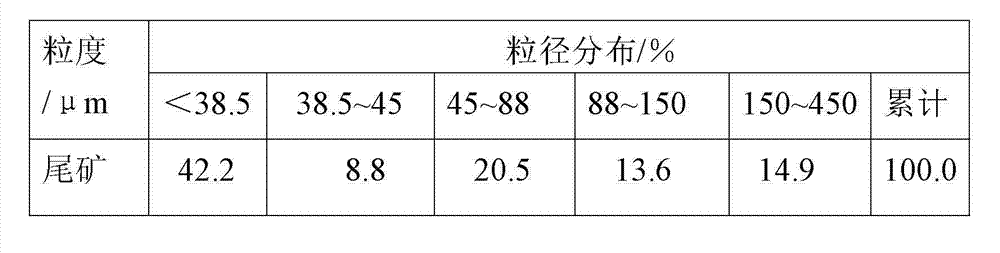

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

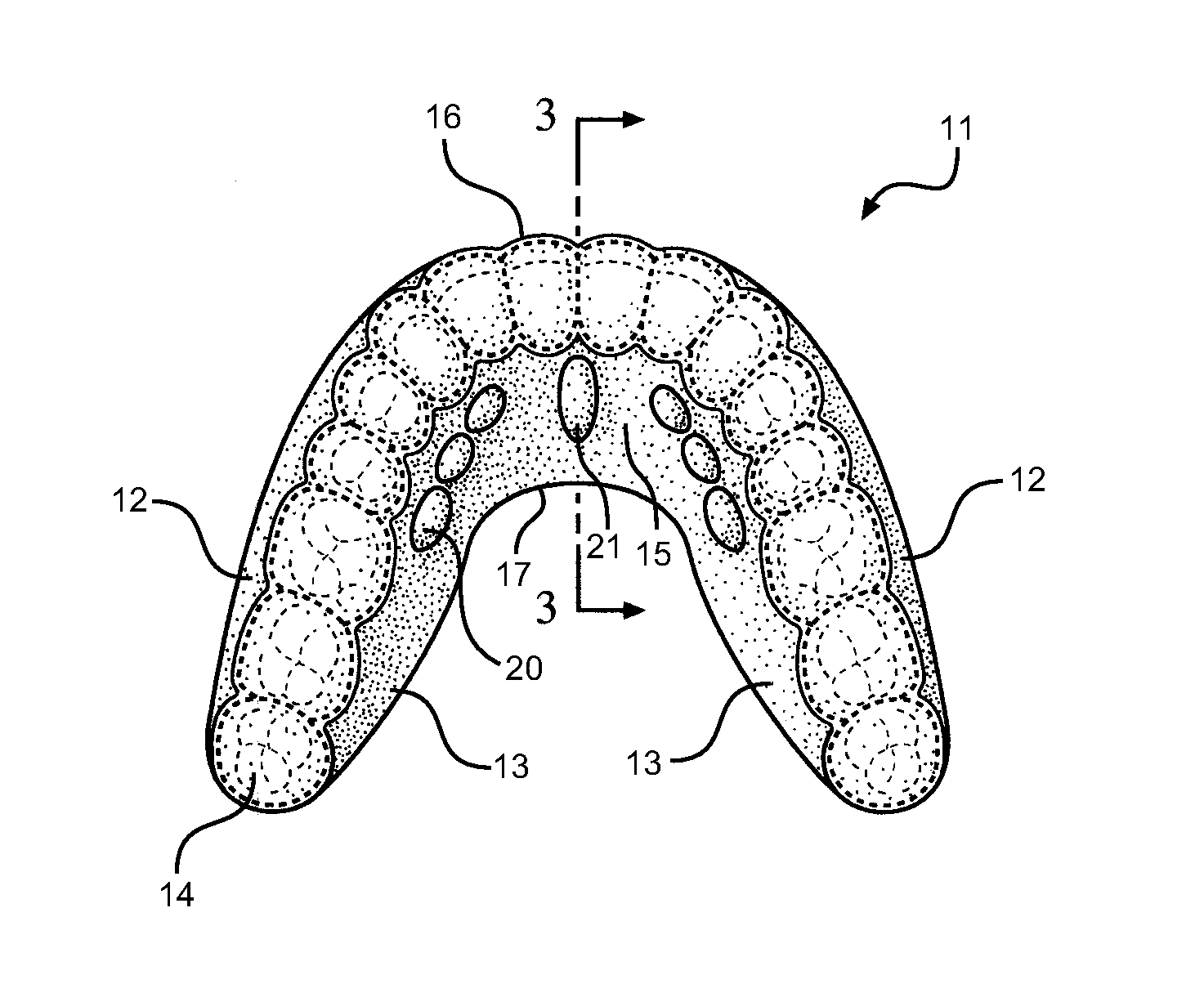

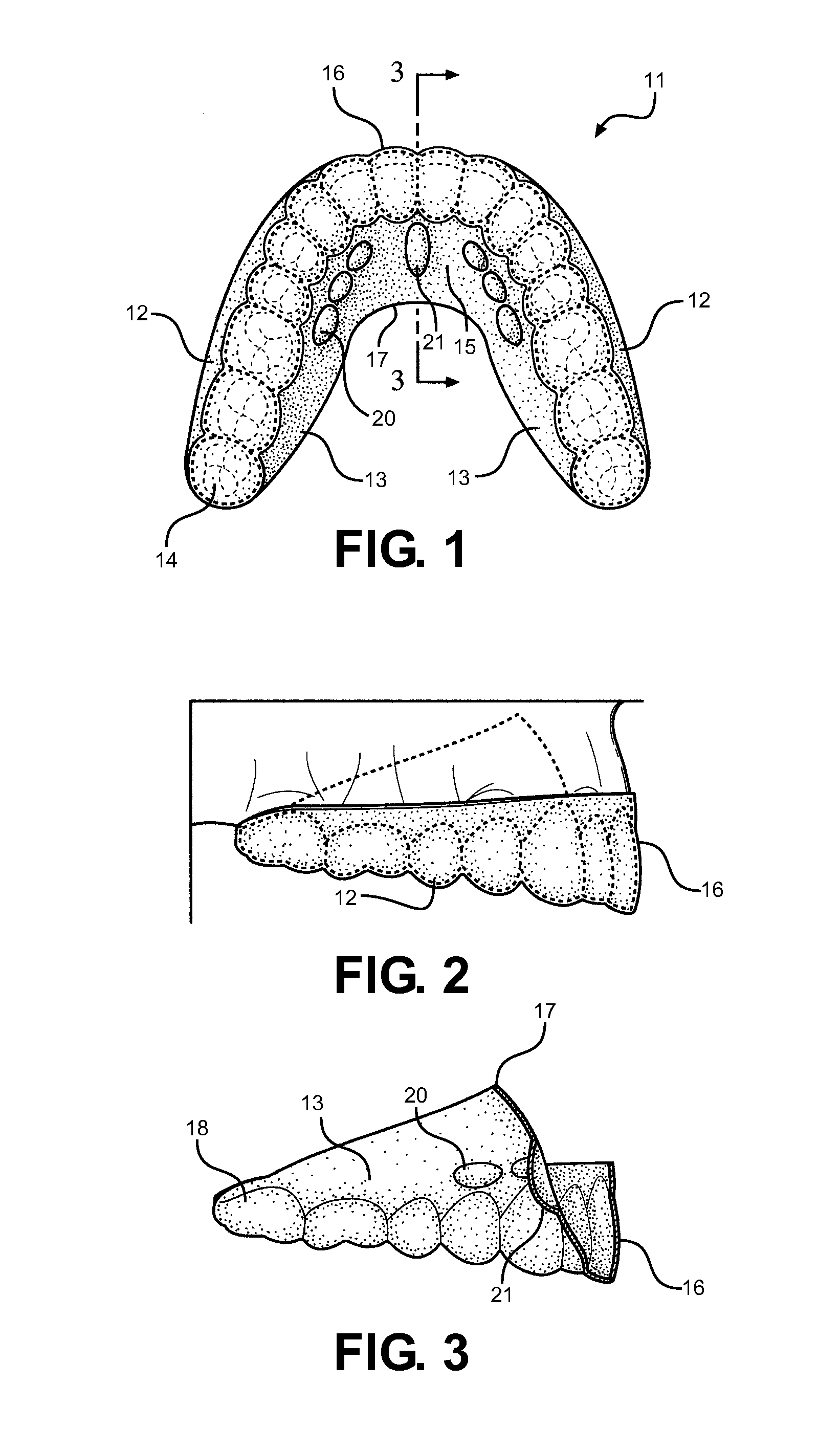

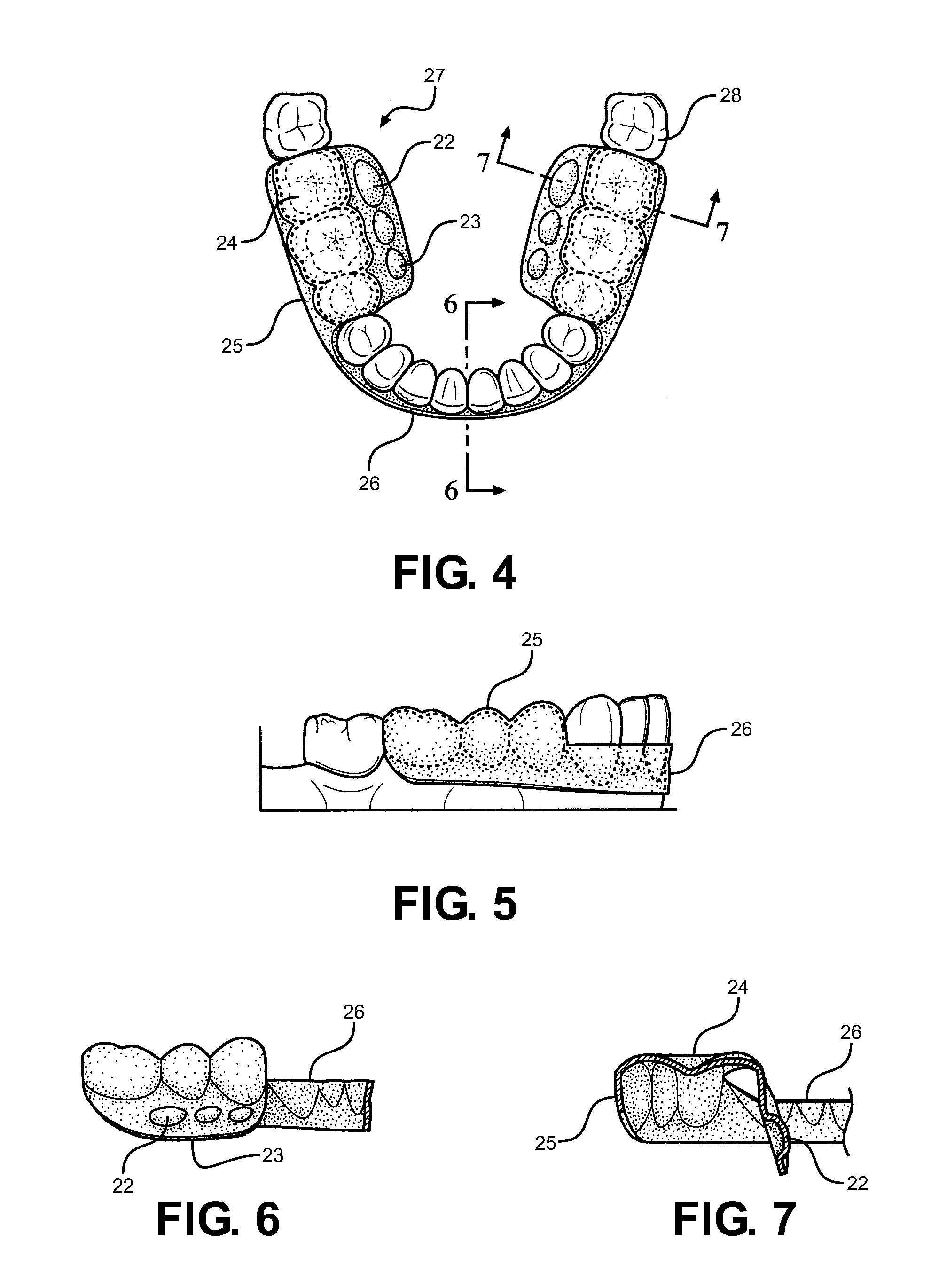

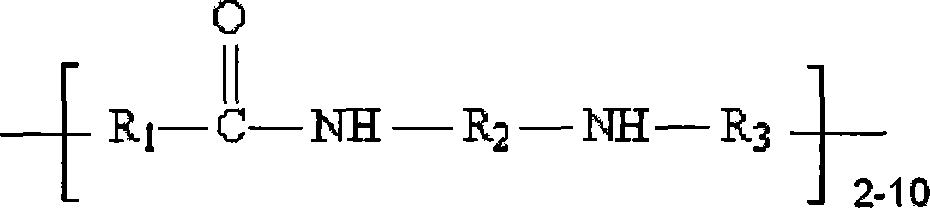

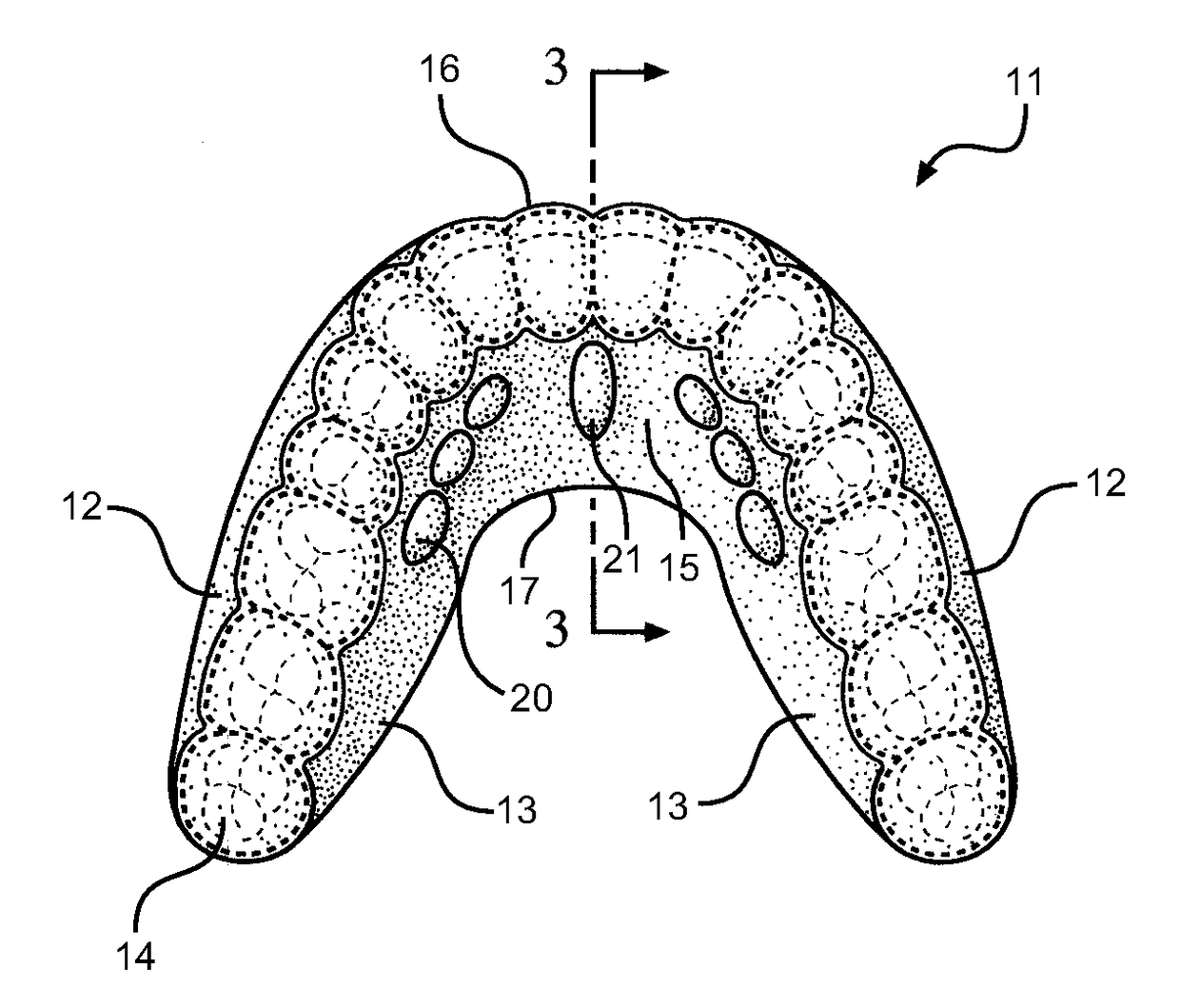

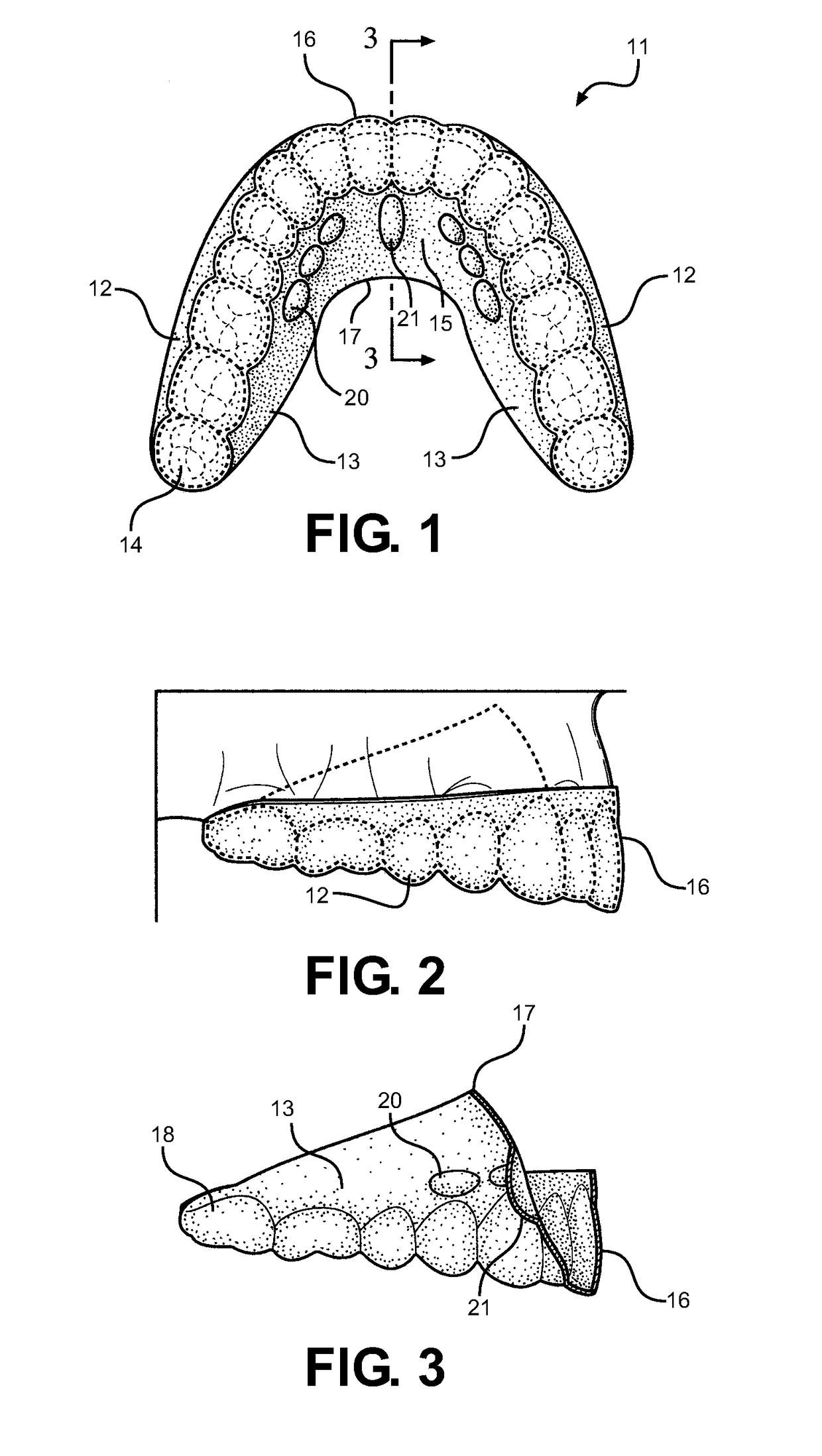

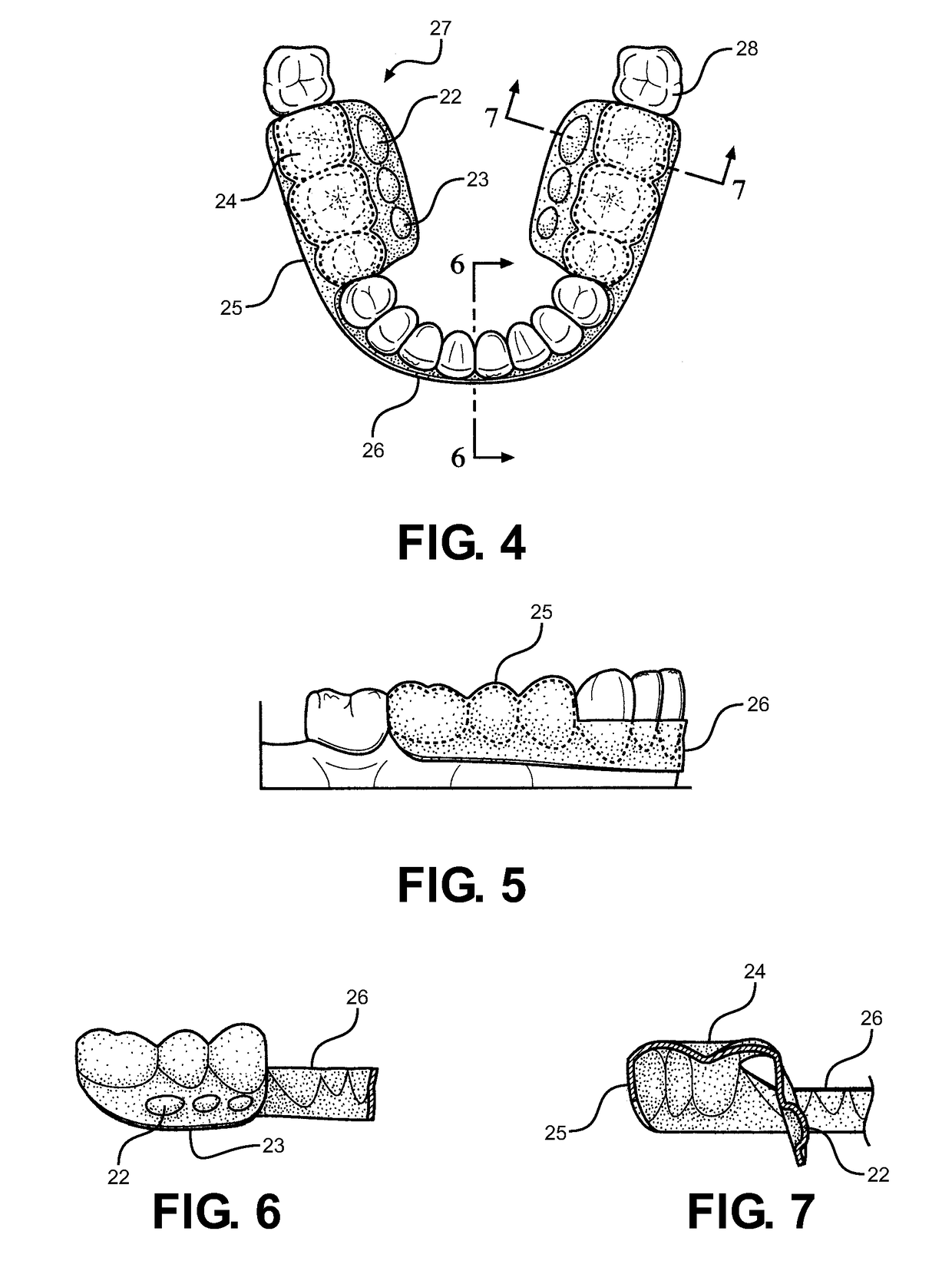

Method and Oral Appliance for Improving Air Intake and Reducing Bruxism

ActiveUS20130298916A1Alleviating numerous medical conditionImprove performanceSnoring preventionNon-surgical orthopedic devicesDiseaseThroat

Provided is a soft flexible oral appliance having protuberances that mimic naturally occurring dental Tori. An upper, palatial appliance and a lower, mandibular appliance may be used in conjunction or separately to alleviate a variety of disorders, improve facial tone, and increase physical performance. The appliances are lightweight, thin, and do not prohibit normal speech patterns when in use. Small protuberances are strategically molded along key surfaces of each appliance to stimulate nerves in the tongue and affect forward protrusion. Forward positioning of the tongue dilates the airways of the throat improving breathing while the use is sleeping, playing sports, or talking. It also reduces bruxing, or grinding of the teeth. A method is further provided, for adding protuberances to other types of oral appliances, thereby conferring some of the benefits listed above on appliances originally intended for other dental uses.

Owner:DENTAL CHOICE HLDG LLC

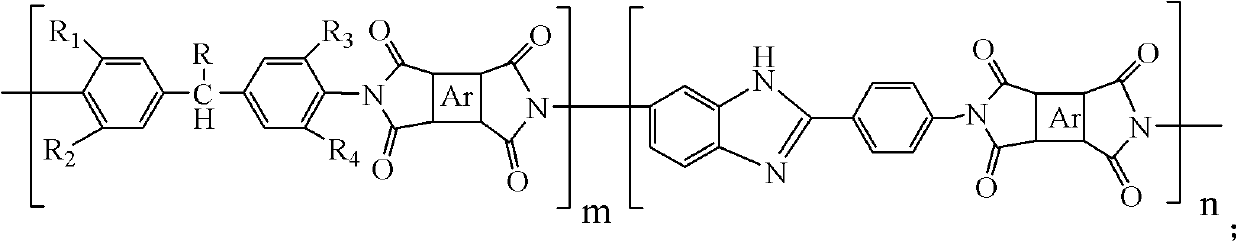

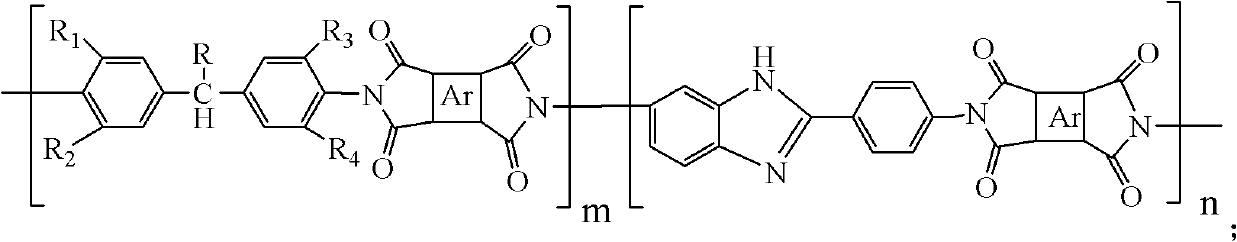

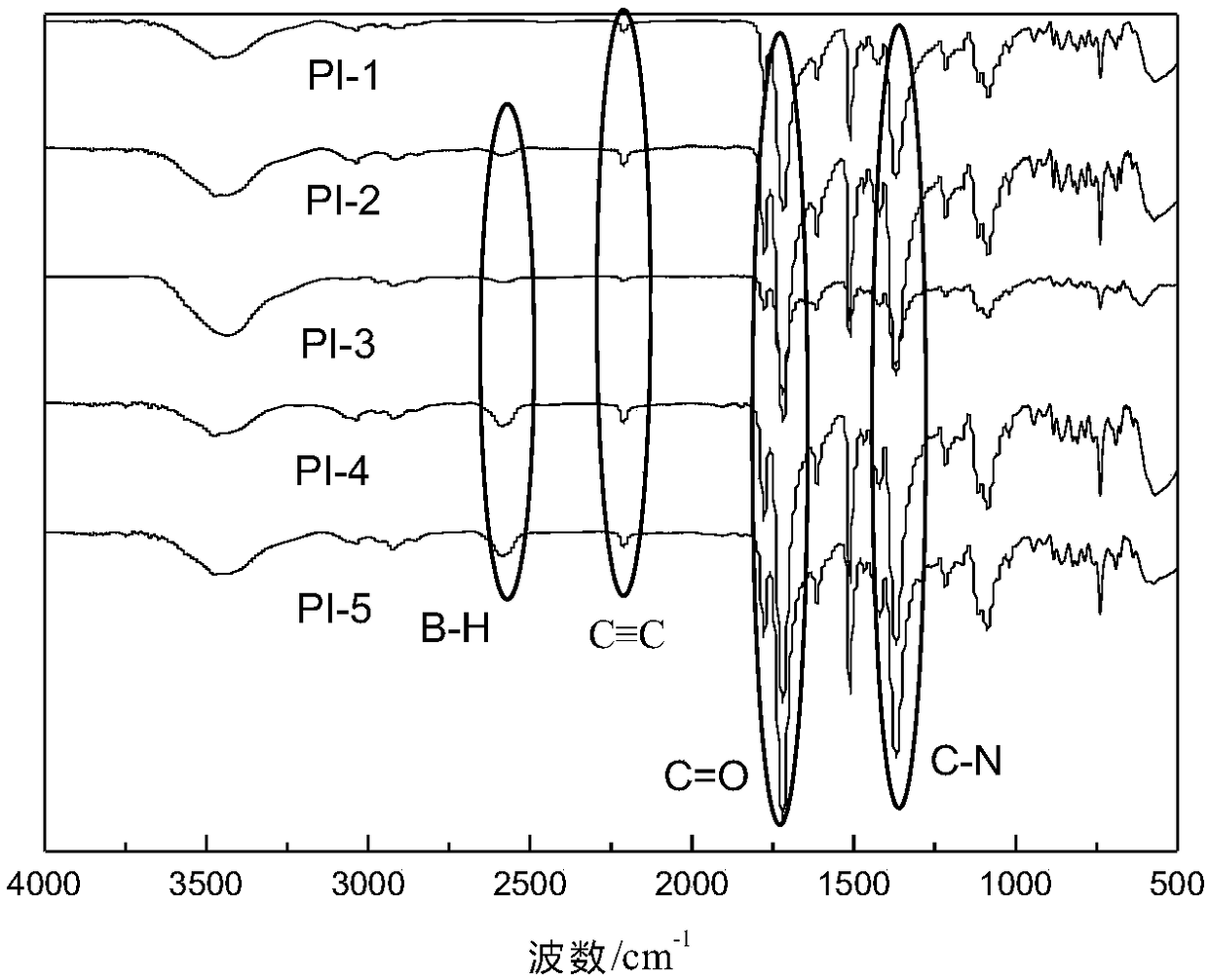

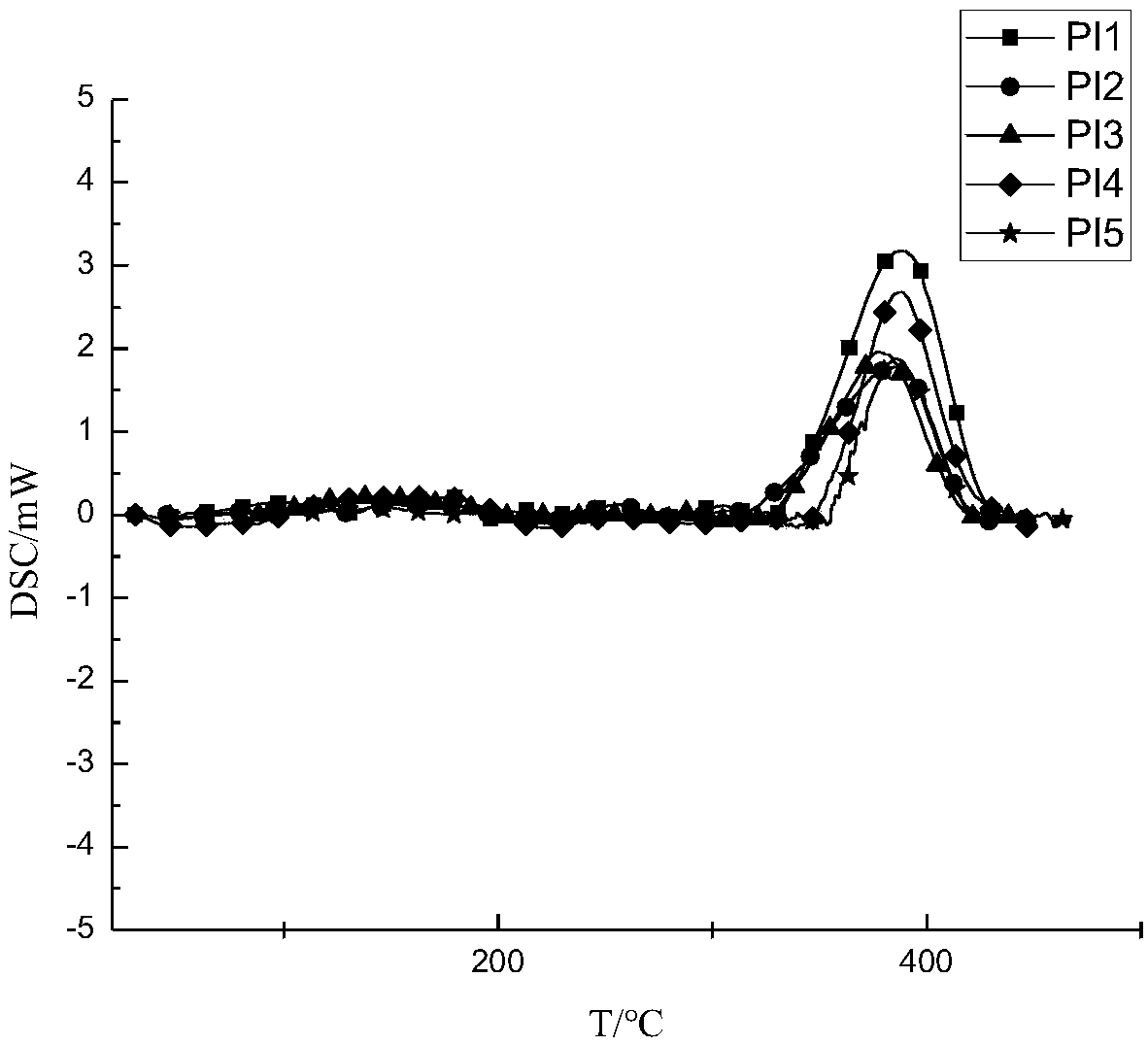

Polyimide containing benzimidazole unit and preparation method thereof

The invention relates to polyimide containing a benzimidazole unit and a preparation method thereof. The polyimide has the following structural formula. The preparation method comprises the following steps of: firstly, performing the reaction on 2,6-disubstituted aniline and aldehyde under the acidic condition to generate a diamine compound 3,3',5,5'-tetra-substituted aromatic diamine; and then, after mixing the synthesized aromatic diamine and a heterocyclic diamine monomer 6-aminophenyl-2-aminobenzimidazole according to a certain ratio, performing the reaction on the mixture and a dianhydride monomer in an organic solvent to obtain the polyimide. The polyimide provided by the invention has excellent solubility property, can be dissolved in conventional solvents such as NMP (N-methyl-2-pyrrolidone) and DMAc (dimethyl acetamide), has excellent heat resistance and mechanical property and has excellent thermal properties of glass-transition temperature of over 410 DEG C, decomposition temperature of over 500 DEG C and the like.

Owner:DONGHUA UNIV

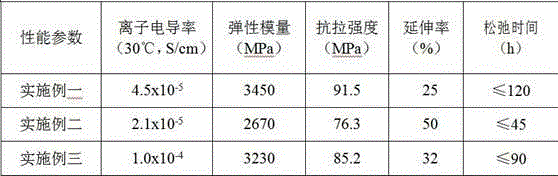

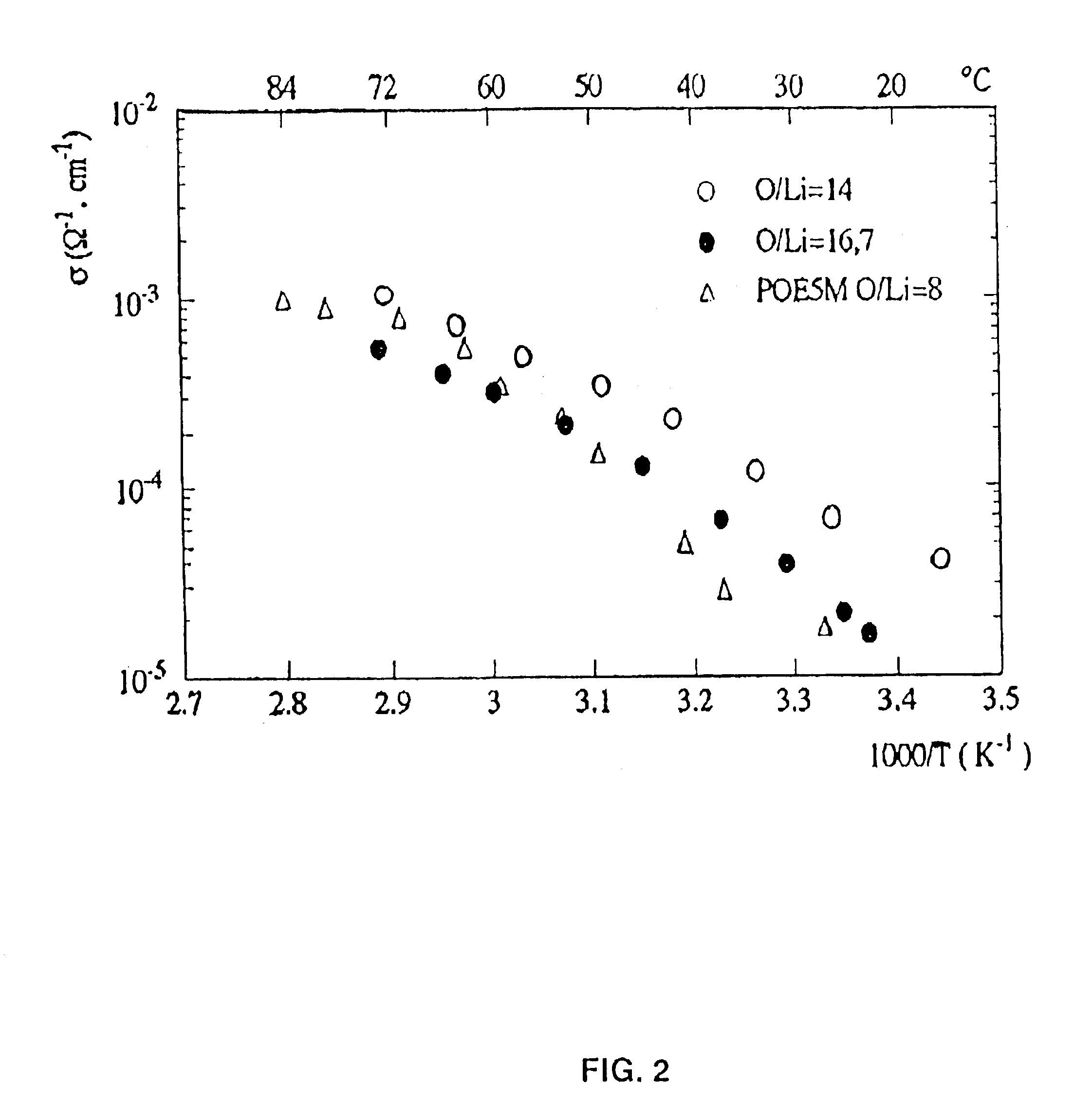

Polymer composite material solid electrolyte and preparation method thereof

InactiveCN104600357AImprove thermal performanceImprove athletic abilityFinal product manufactureLi-accumulatorsCross linkerLithium-ion battery

The invention discloses a polymer composite material solid electrolyte and a preparation method thereof. The method employs an inorganic nano-particle and a lithium salt to fill an aqueous polymer and enables the polymer to be crosslinked with polyisocyanate for preparing the solid electrolyte, and belongs to the technical field of lithium ion batteries. The technical scheme is characterized in that the method is based on a water solution pouring process, 60%-80% by mass of the aqueous polymer, 10%-40% by mass of a lithium salt, 2.0%-8.0% by mass of an inorganic nanometer filling material and 2.0%-8.0% by mass of a polyisocyanate cross-linking agent are employed for obtaining the electrolyte. The polymer composite material prepared by utilizing the method has the characteristics of high ion conductivity, excellent mechanical properties and short relaxation time, and the forming technology of the material is simple and accords with green environment-protection requirements.

Owner:SHANGHAI UNIV

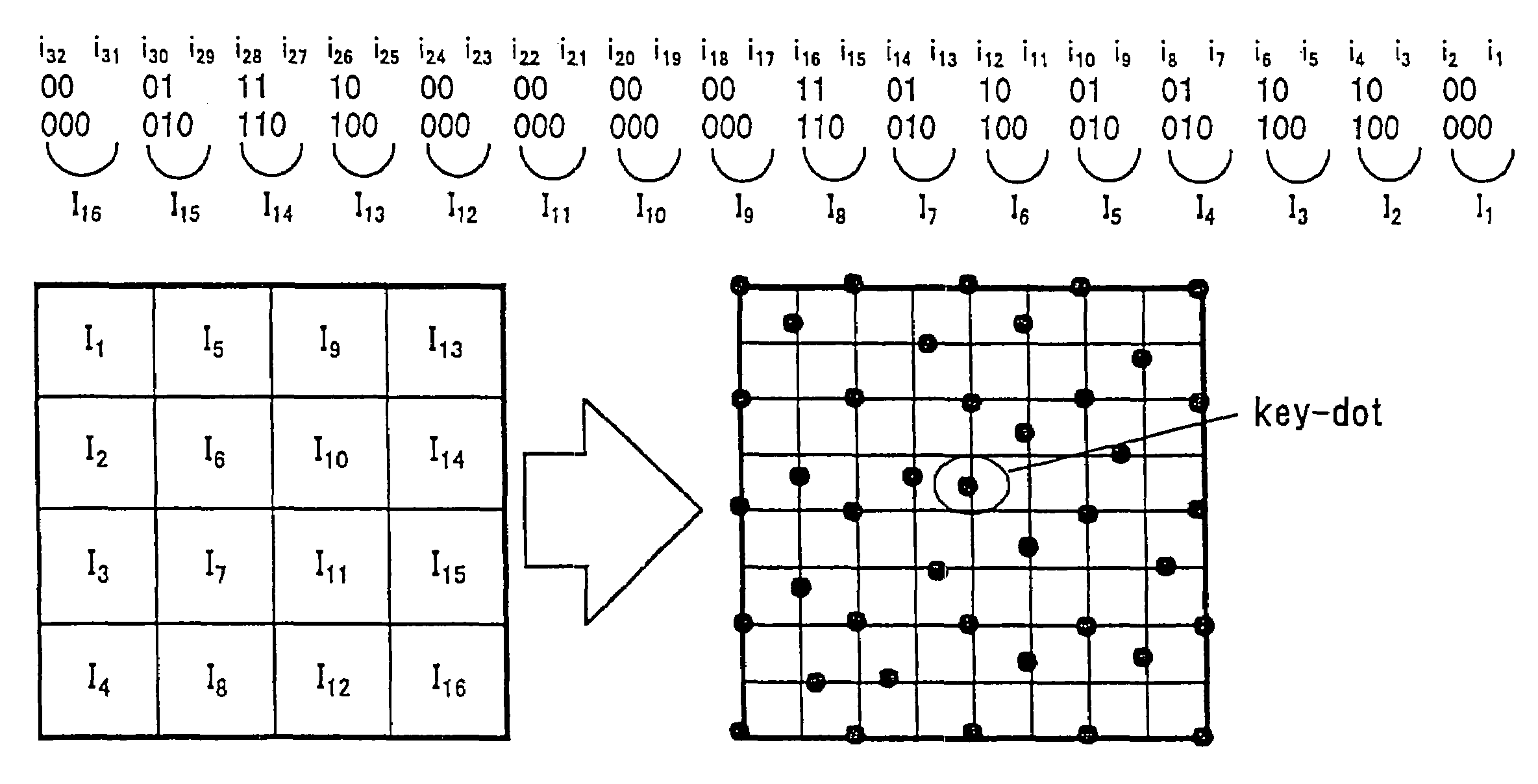

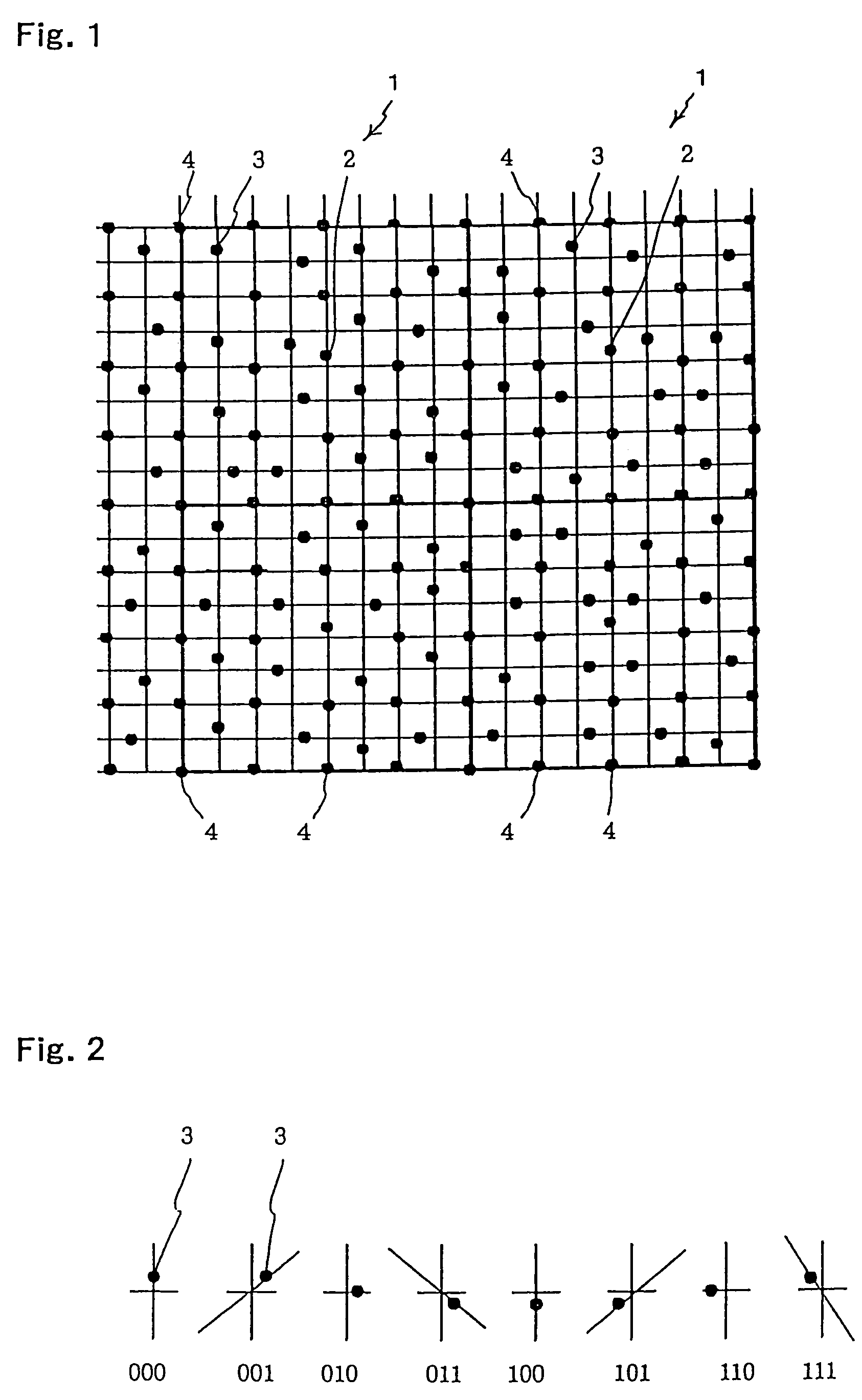

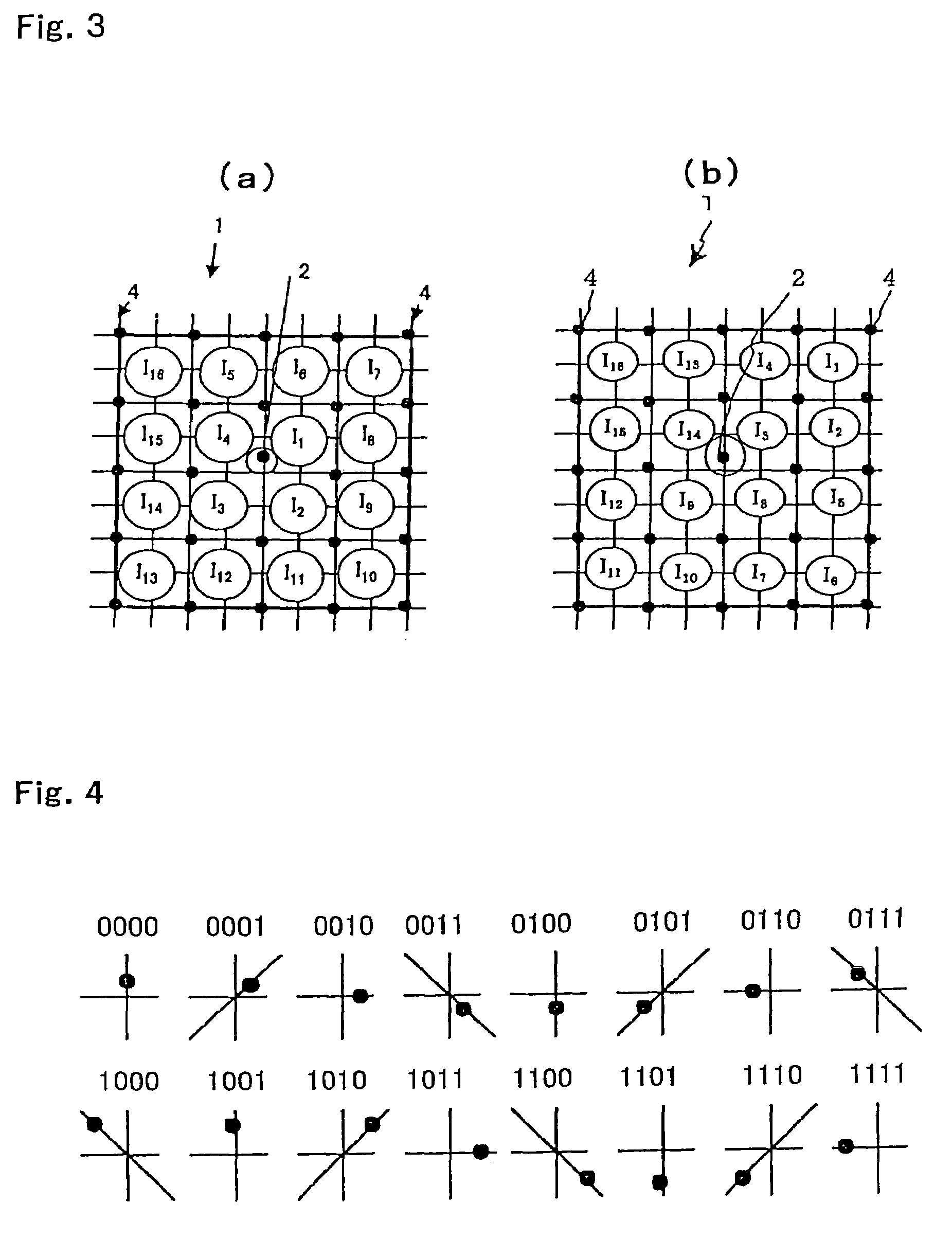

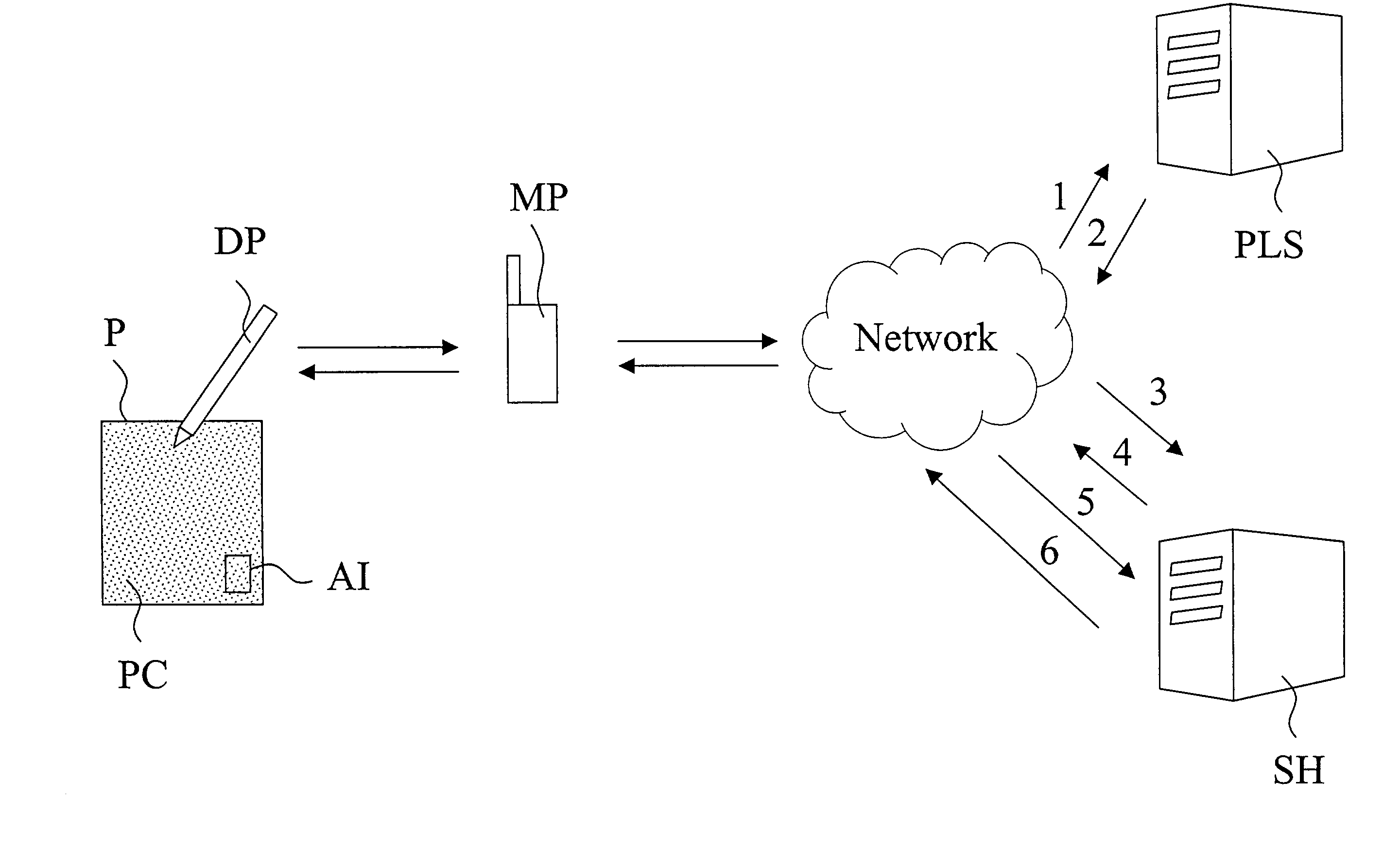

Information input/output method using dot pattern

InactiveUS7475824B2Reduce regularityInput/output for user-computer interactionRecord carriers used with machinesCrucial pointAlgorithm

A plurality of lattice dots are disposed in a rectangular shape and set as a block, and they are regularly and continuously disposed, and a dot that forms one of the lattice dots which exists in the block is disposed by being shifted unidirectionally and is set as a key dot, and by setting the key dot as a representative point, a plurality of information dots are disposed, and by setting a center which was surrounded by the lattice dots of four points as a hypothetical point, and by setting this as a start point of a vector, at an end point of which, a plurality of information dots which have various information are arranged in accordance with a predetermined rule by a dot code generation algorithm to thereby generate a dot pattern.

Owner:YOSHIDA

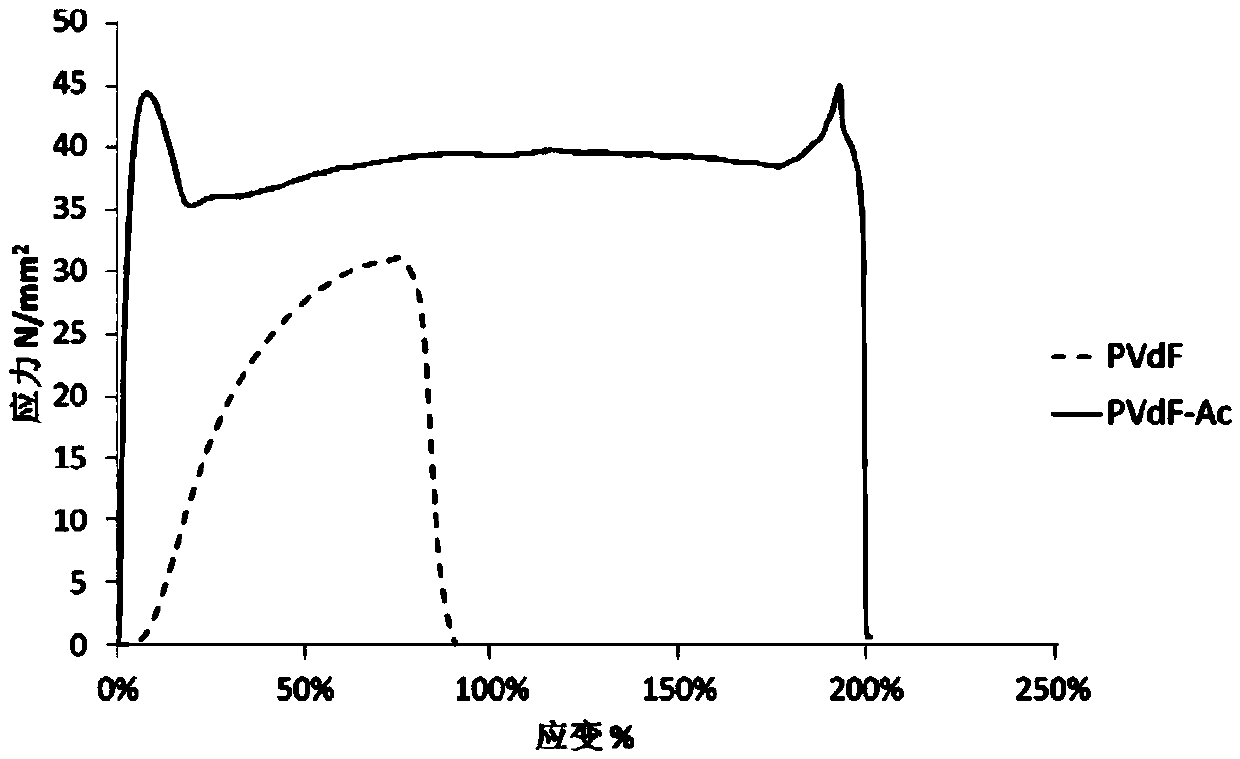

Adhesive and lithium ion battery with same

ActiveCN105514488AGood processing performanceImprove adhesionCell electrodesSecondary cellsElectrical batteryBattery energy

The invention relates to the field of lithium ion battery materials, and in particular relates to an adhesive and a lithium ion battery with the same. The adhesive is a polymer containing structure units shown as the formulas I, II, III and IV, and the number-average molecular mass of the adhesive is 0.5 million to 1.2 million. The invention also relates to the lithium ion battery, comprising a positive electrode piece, a negative electrode piece, a separator and electrolyte, wherein the positive electrode piece comprises the adhesive. With the adhesive, the flexibility of the positive electrode piece can be improved greatly, so that the problems of processing, battery performance and the like, caused by crisp electrode pieces, can be avoided, the compaction density can be enhanced, and the energy density of the battery can be further improved.

Owner:NINGDE AMPEREX TECH

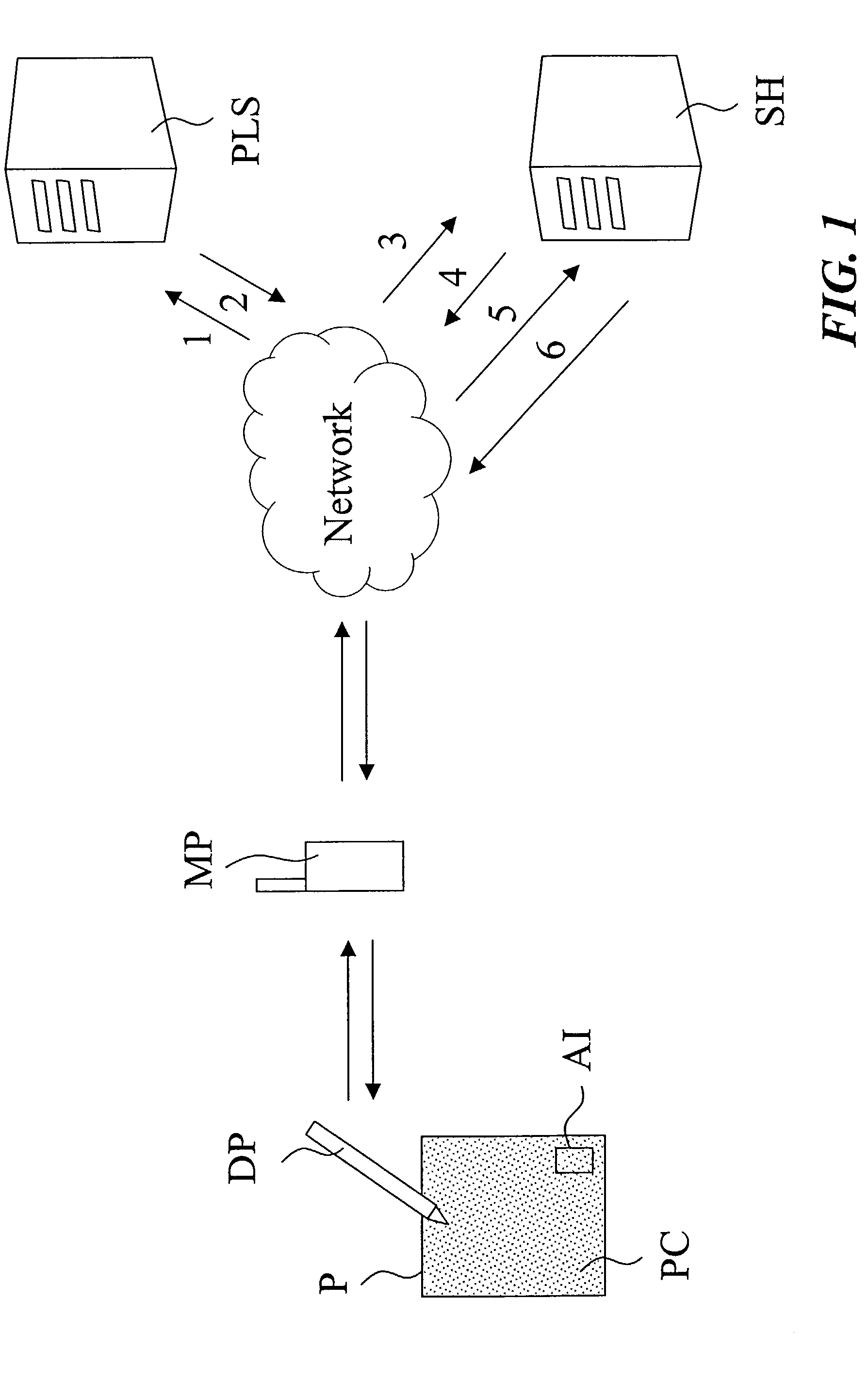

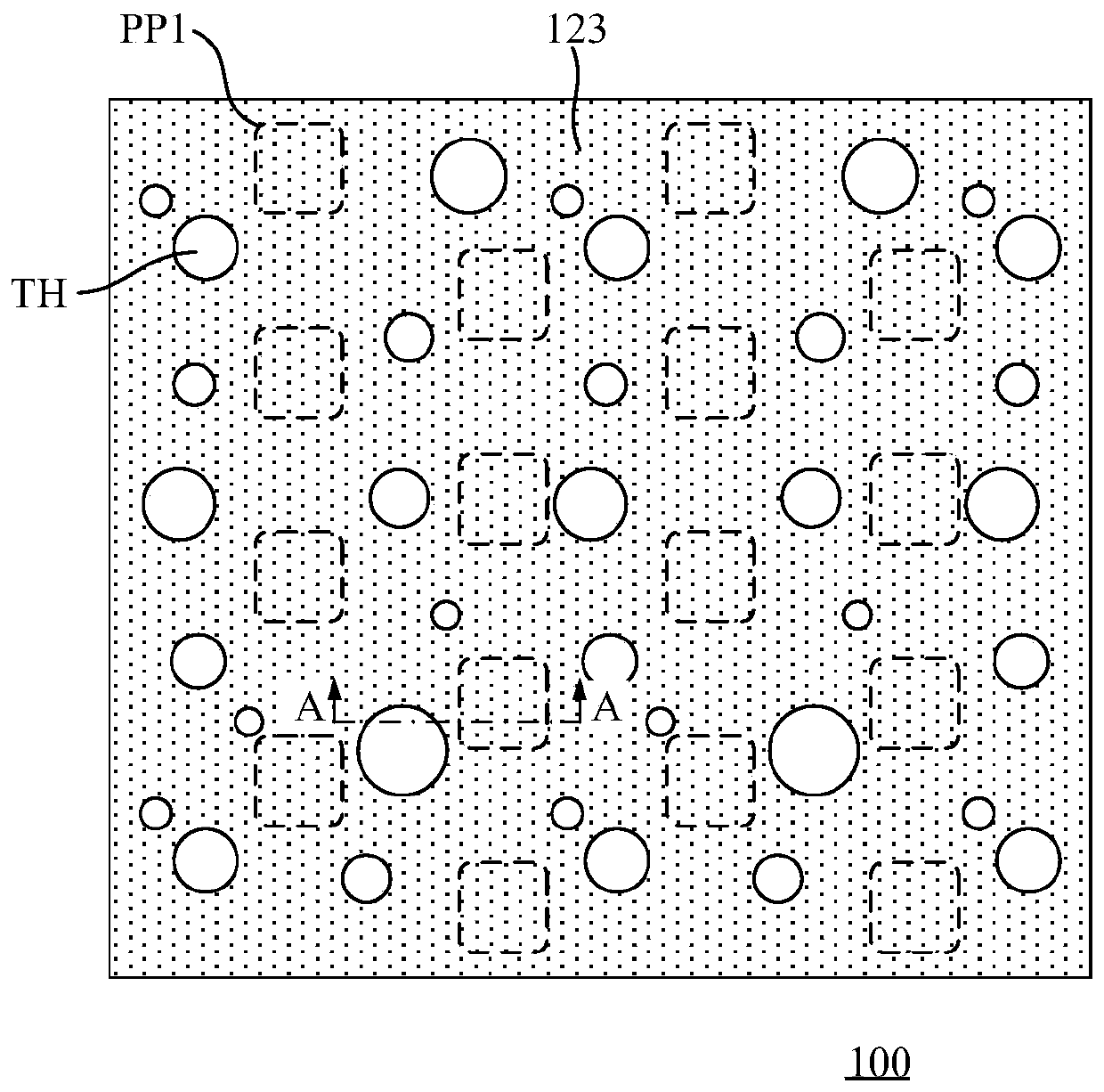

Encryption protocol

ActiveUS7249256B2Give problemEnough timeUser identity/authority verificationTelevision systemsDelayed timeComputer hardware

The present invention relates to a method, a system and a computer-readable medium storing computer-executable components in connection with transfer of information data to a recipient. The invention is based on the idea that generation of random number data and the calculation of digital signatures are performed before information data is accessible to a digital pen. Since asymmetric encryption of data is a demanding operation for said digital pen to perform in terms of processing power, a lot of time can be saved if the generation of random number data and asymmetric encryption of said random number data is performed in advance, when the pen is in an idle, non-communicating mode, for example during battery loading of the pen or when the pen is lifted from the position-coded paper. This alleviates delay times when the pen is in its communicating mode.

Owner:ANOTO AB

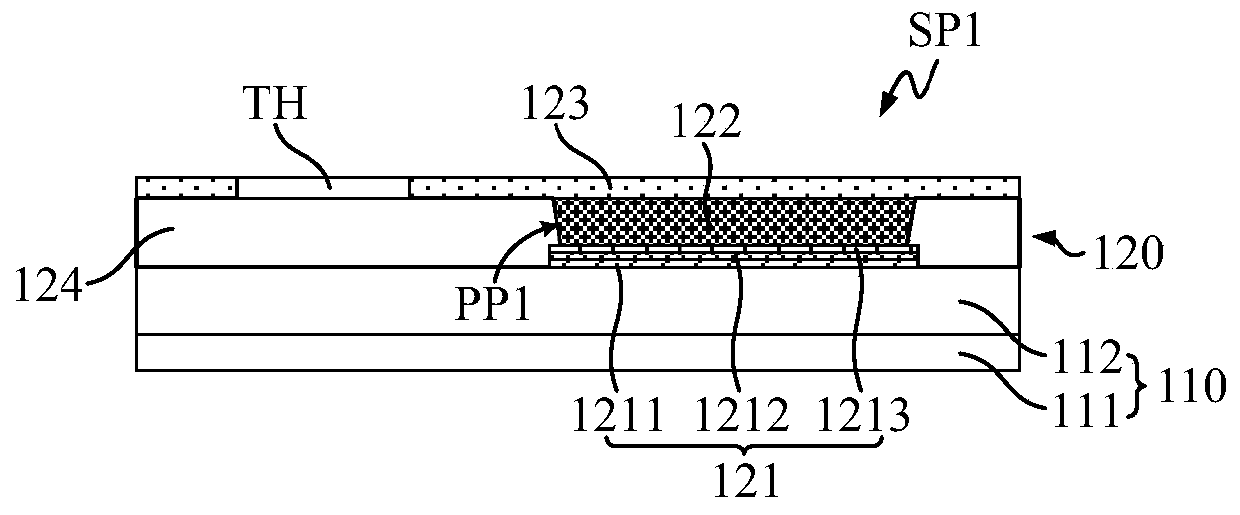

Light-transmitting display panel and manufacturing method thereof, and display panel

ActiveCN111009619AHigh light transmittanceImprove imaging effectSolid-state devicesSemiconductor/solid-state device manufacturingMaterials scienceLight transmission

The invention discloses a light-transmitting display panel and a manufacturing method thereof, and a display panel. The light-transmitting display panel comprises an array substrate and a light-emitting element layer, wherein the light-emitting element layer is located on the array substrate and includes a first electrode, a first light-emitting structure located on the first electrode and a second electrode layer located on the first light-emitting structure. A plurality of through holes with unequal sizes are distributed in the second electrode layer, and each through hole penetrates throughthe second electrode layer in a thickness direction of the light-transmitting display panel. According to the light-transmitting display panel provided by the embodiment of the invention, overall light transmittance of the second electrode layer is improved, and a diffraction phenomenon of the light-transmitting display panel on light rays is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

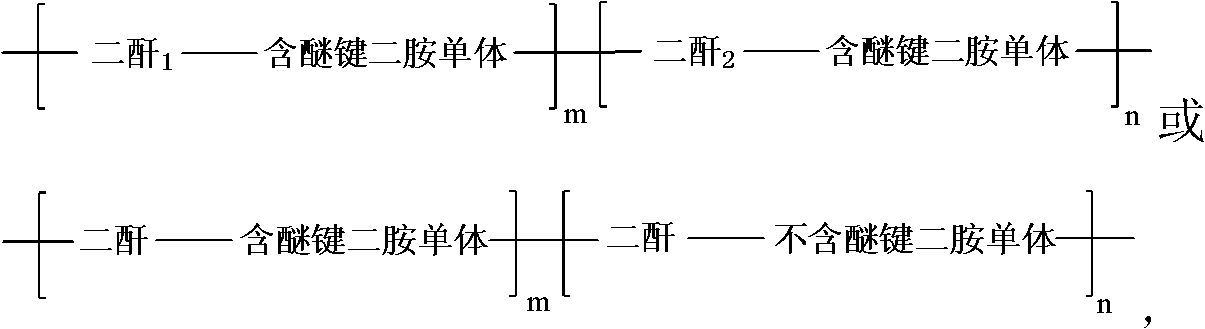

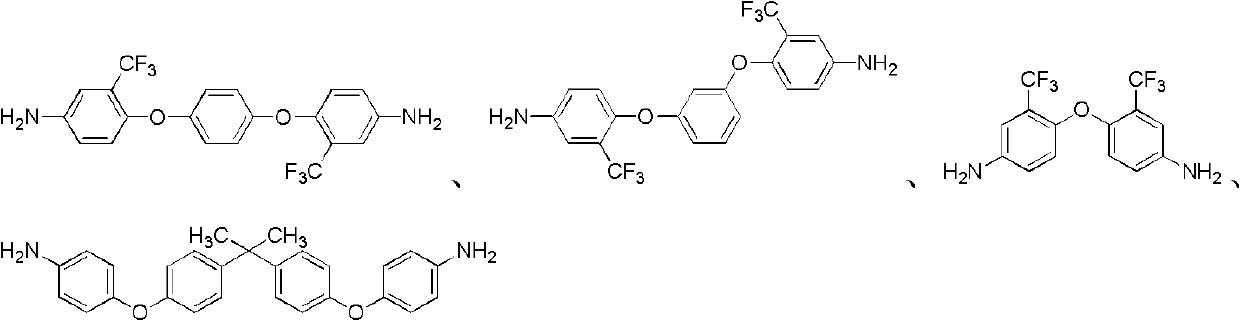

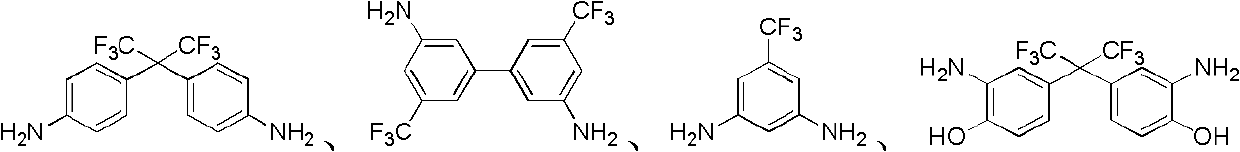

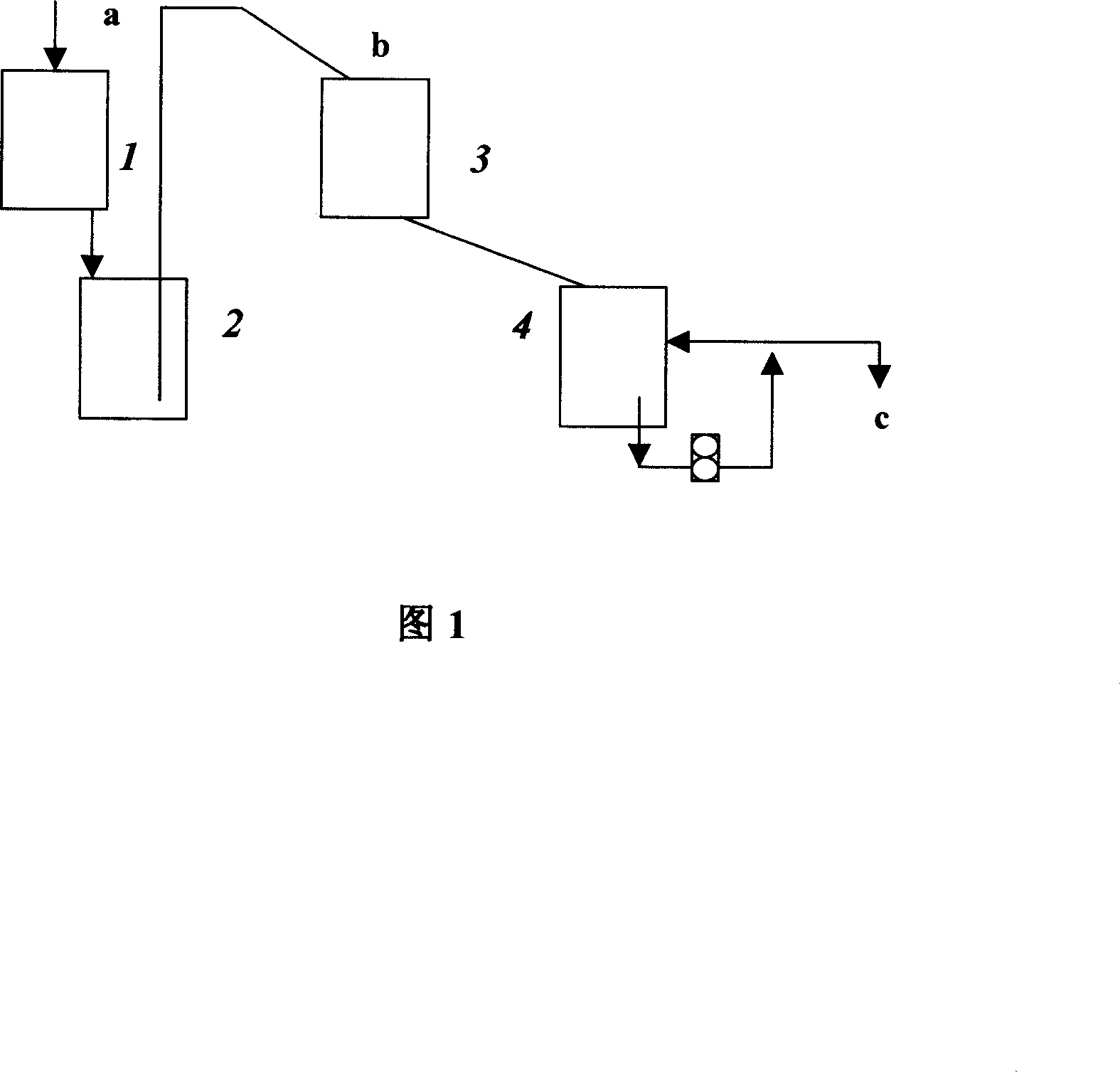

Soluble fluorinated polyimide material and preparation method thereof

The invention discloses a soluble fluorinated polyimide material. The material is prepared by copolymerization of three monomers. The preparation method comprises: condensing and copolymerizing two dianhydride monomers and a diamine monomer having an ether bond according to the molar ratio of the two dianhydride monomers to the diamine monomer of 1:1, wherein the molar ratio of the two dianhydride monomers is 1:1 to 1:10; or condensing and copolymerizing a diamine monomer without an ether bond, a diamine monomer without ether bond and a dianhydride monomer according to a molar ratio of the diamine monomers to the dianhydride monomer of 1:1, wherein the molar ratio of the diamine with the ether bond to the diamine without the ether bond is 1:1 to 1:10. The general structural formula of the material is shown in description. The material has high solubility, low moisture rate, high thermal stability and low absorption loss.

Owner:SOUTHEAST UNIV

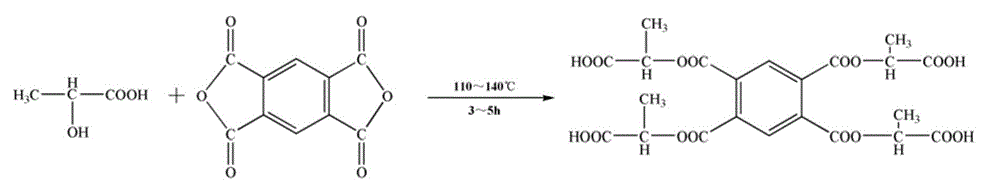

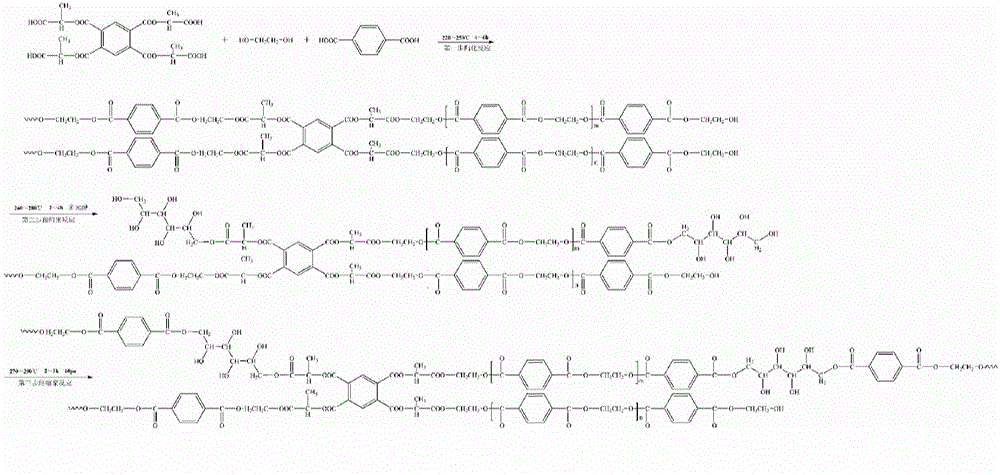

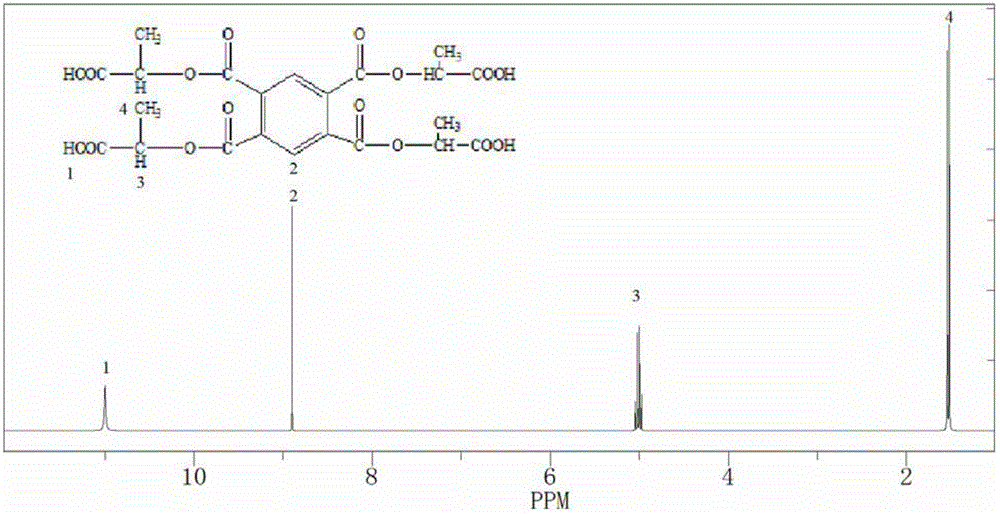

Low-melting point polyester synthesis method

The invention discloses a synthesizing method of low-fusing point polyester, which comprises the following steps: adopting terephthalic acid and ethandiol as raw material; possessing 15-40% m-phthalic acid, 5-25% azelaic acid and 2-10% neopentyl glycol with the molar rate of acid and alcohol at 1: 1.1-1.3; allocating even slurry; esterifying; condensing to synthesize low-fusing point polyester with fusing point at 100-160 Deg C.

Owner:厦门翔鹭化纤股份有限公司 +1

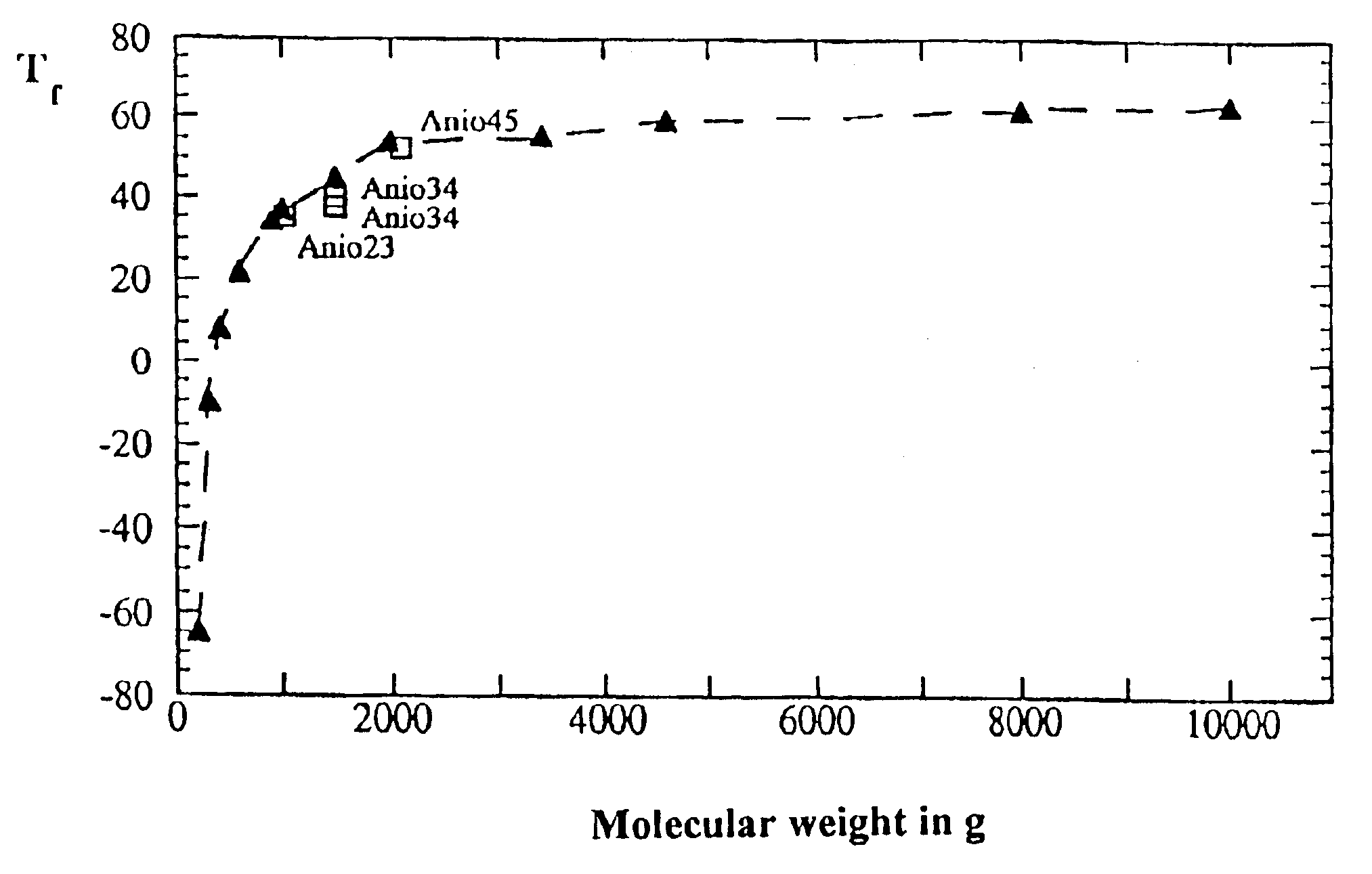

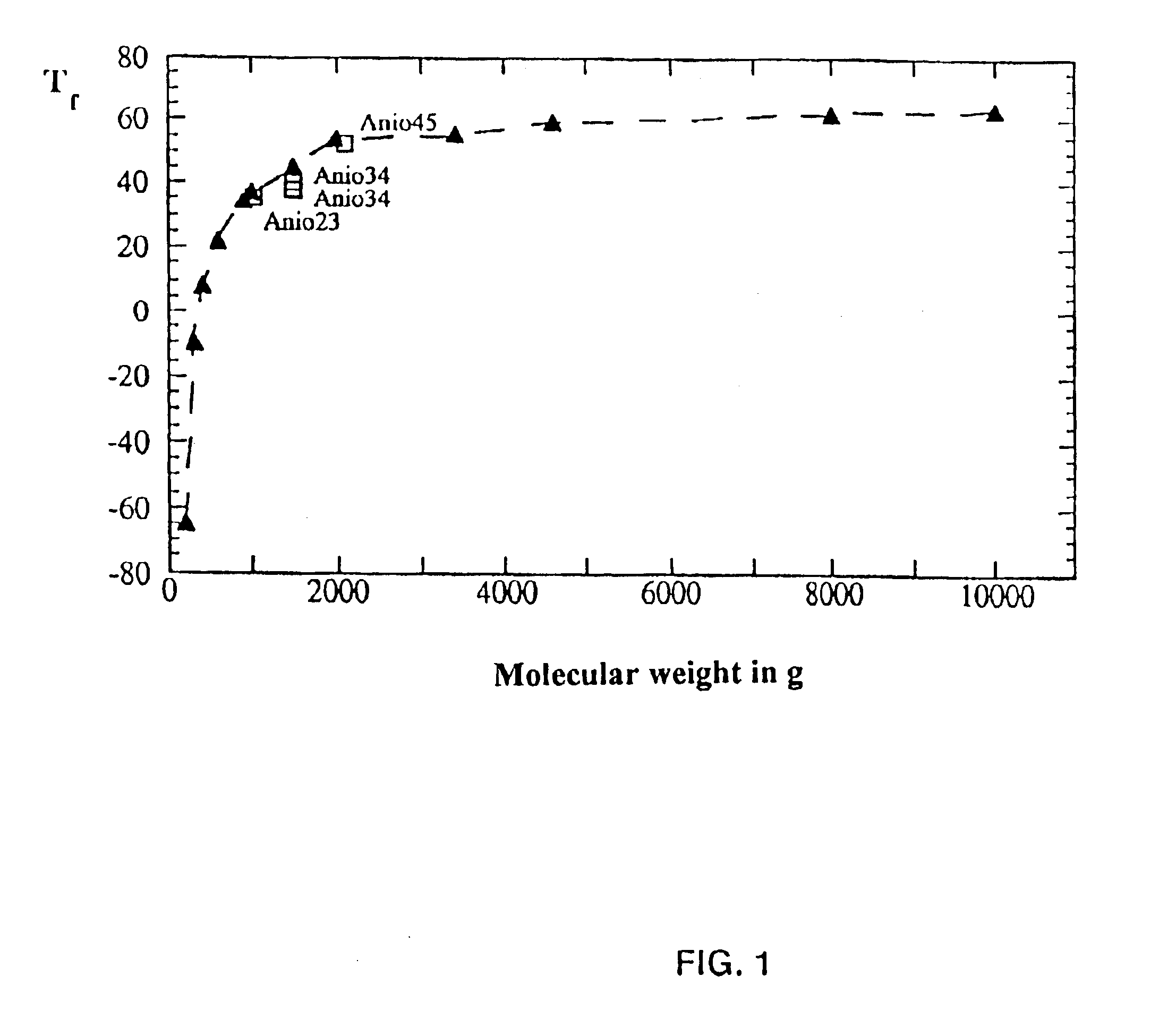

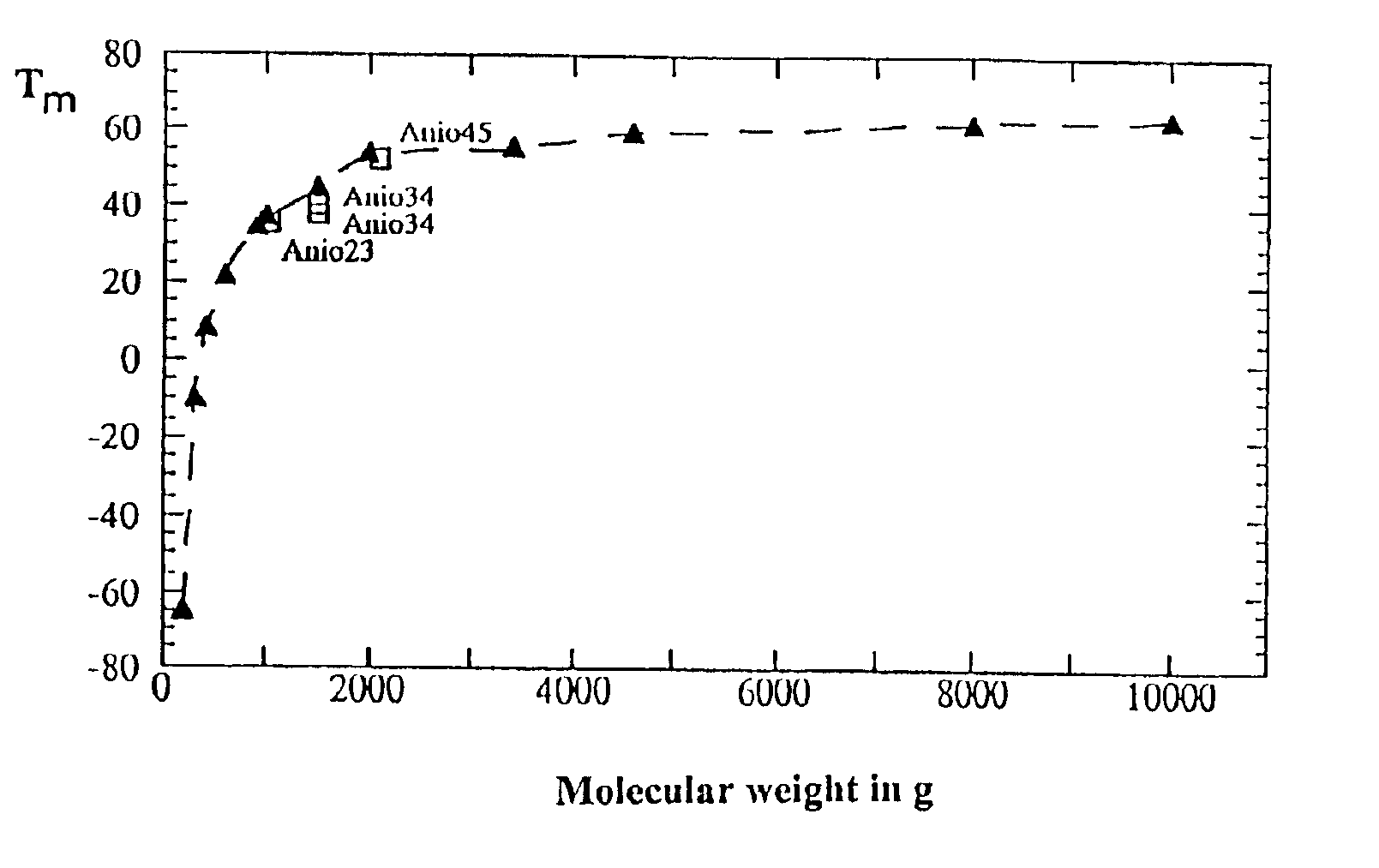

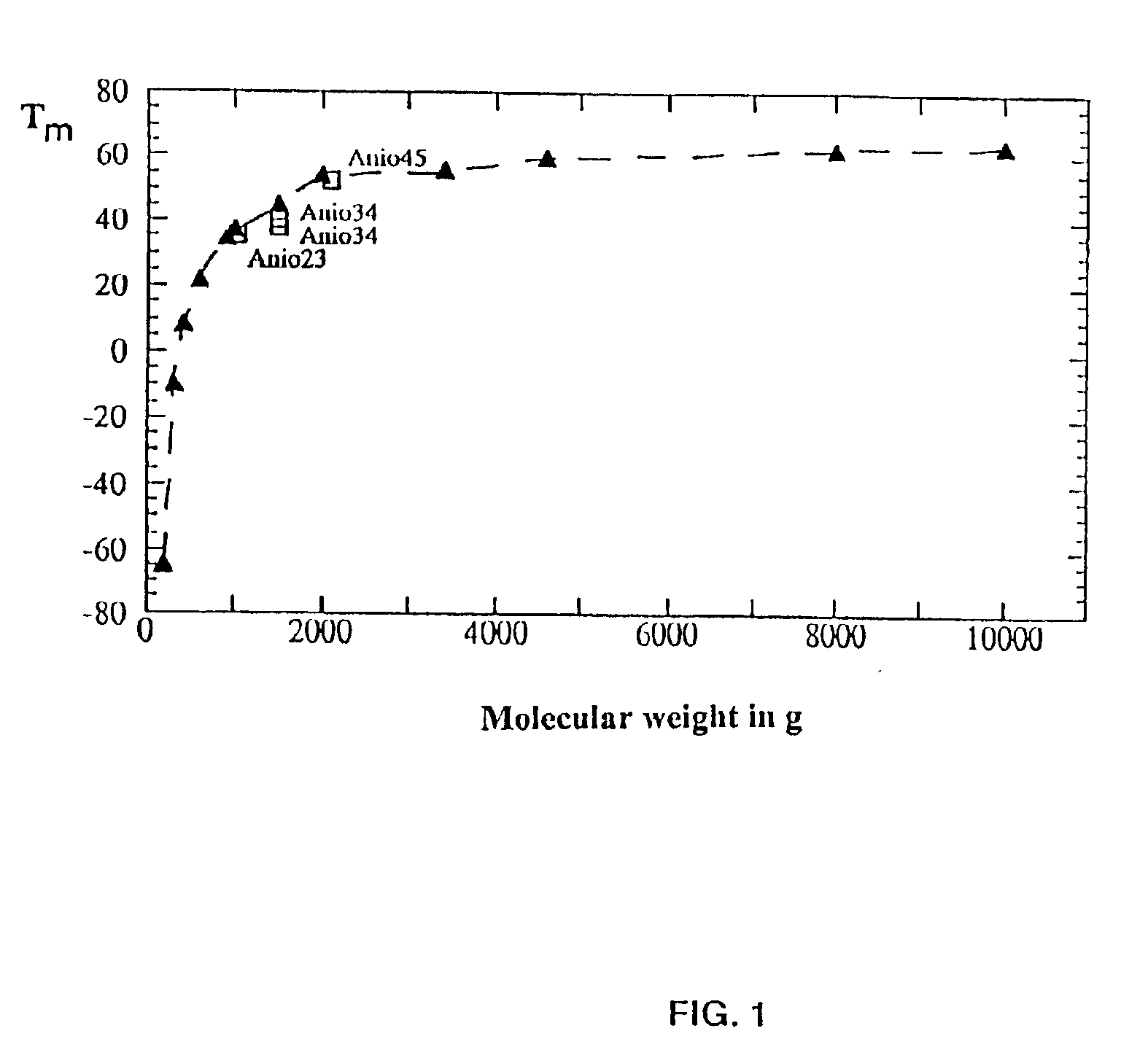

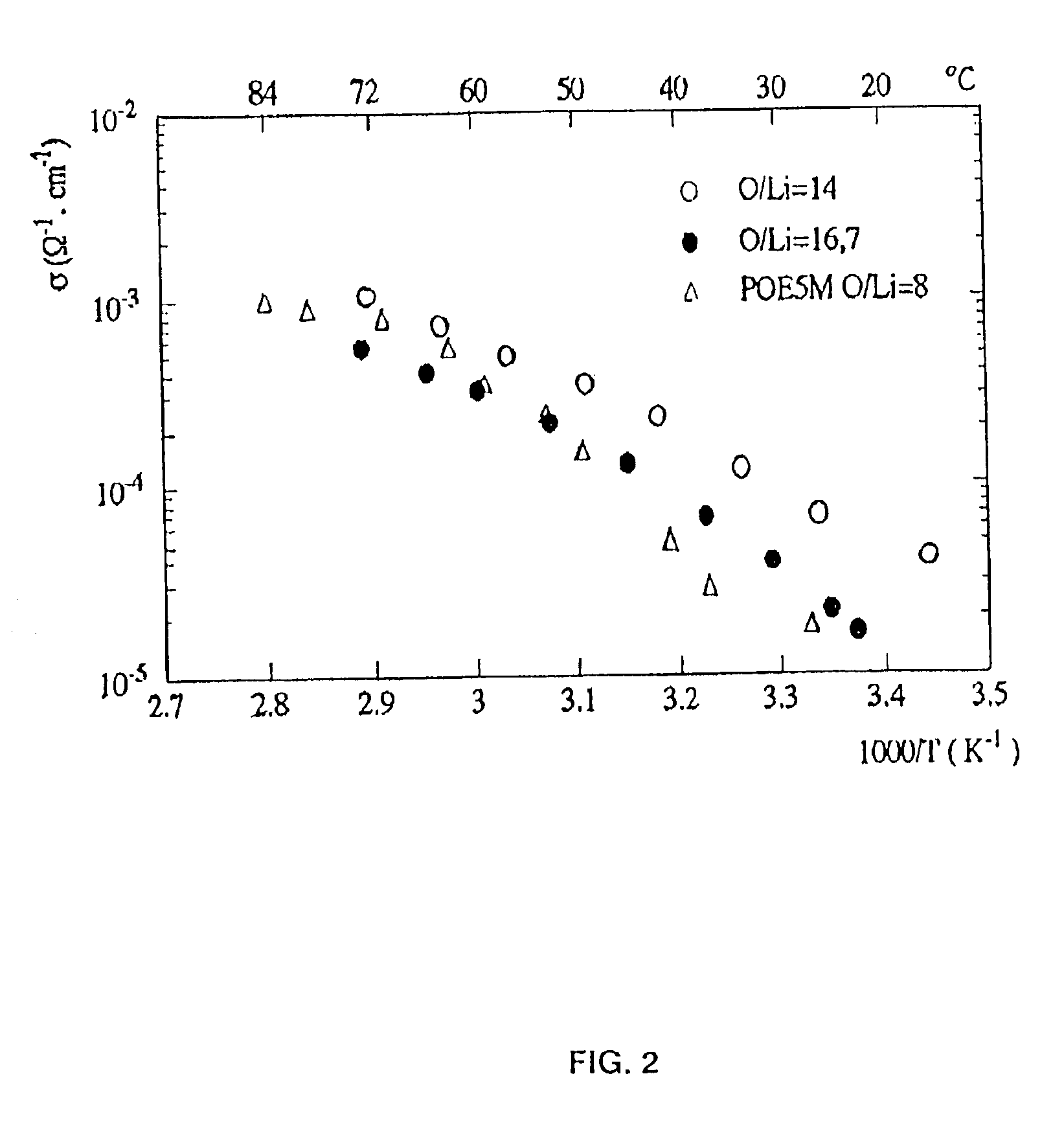

Copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function, process for preparation thereof and use thereof for producing materials with ionic conduction

InactiveUS6903174B2High reaction yieldLess impuritiesConductive materialSolid electrolyte cellsLithiumEthylene oxide

The invention concerns a copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function. The copolymer comprises ethylene oxide, —O—CH2—CHR— units in which R is a substituent containing a reactive function which is cross-linkable by free radical process, R may be different from one unit to the other, and possibly —O—CH2—CHR′— units in which R′ is a substituent containing no reactive function which is cross-linkable by means of a free radical process, R′ may be different from one unit to the other. It is characterized by an excellent polymolecularity index I=Mw / Mn and a statistical distribution of the different monomer units. The copolymer is prepared by an anionic copolymerization process. The copolymer is useful for preparing a solid electrolyte having good mechanical properties, a good cationic conductivity and a good chemical compatibility with the electrodes of a generator operating with alkali metals such as lithium and sodium.

Owner:BATHIUM CANADA

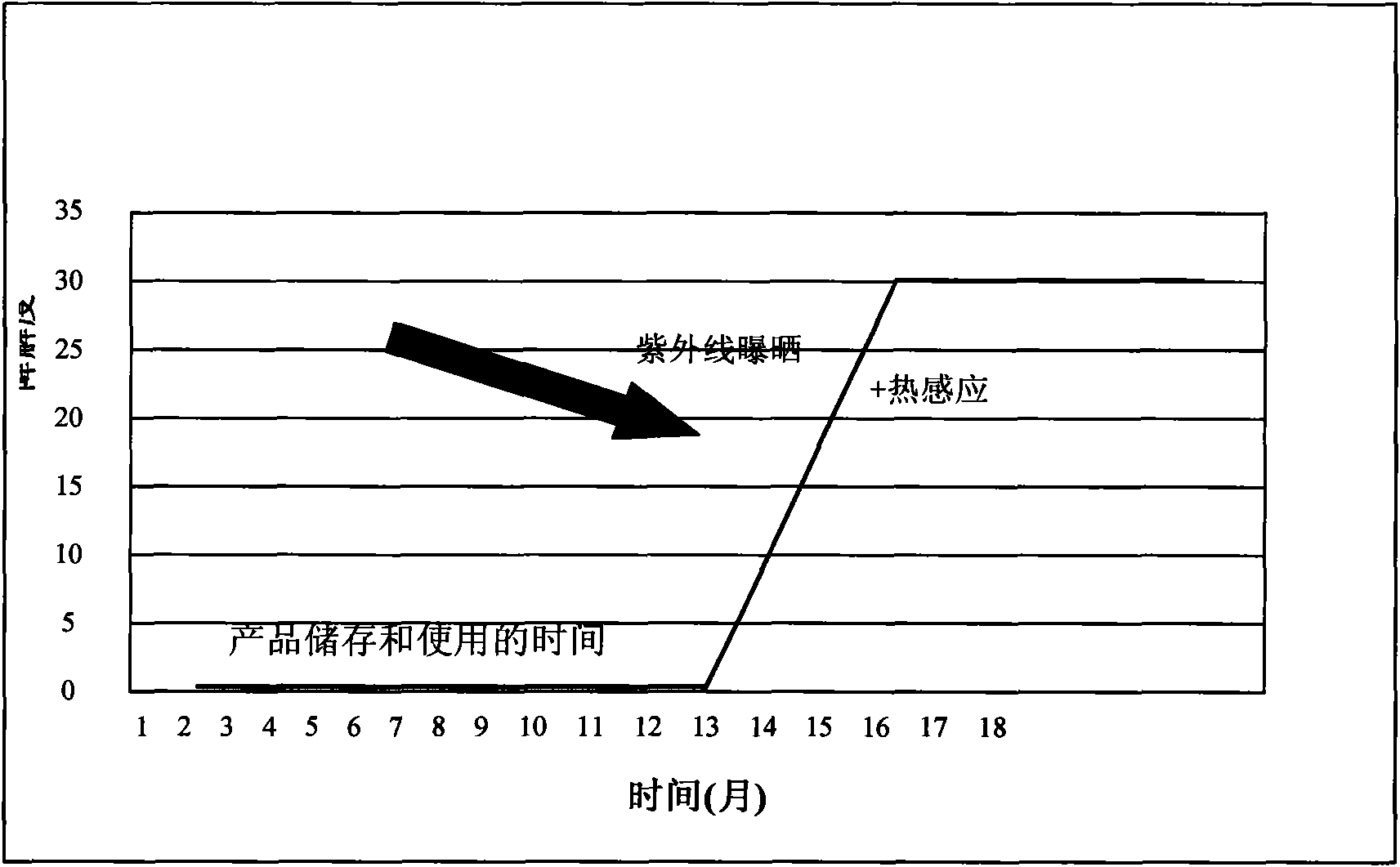

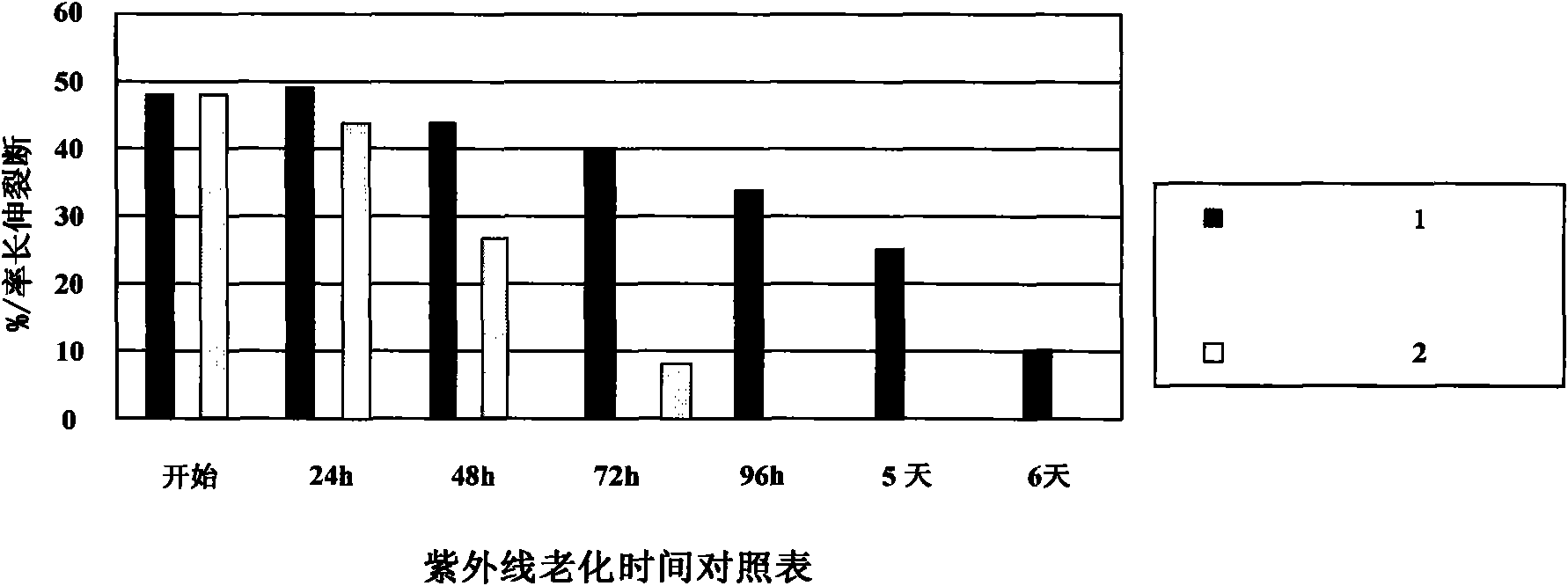

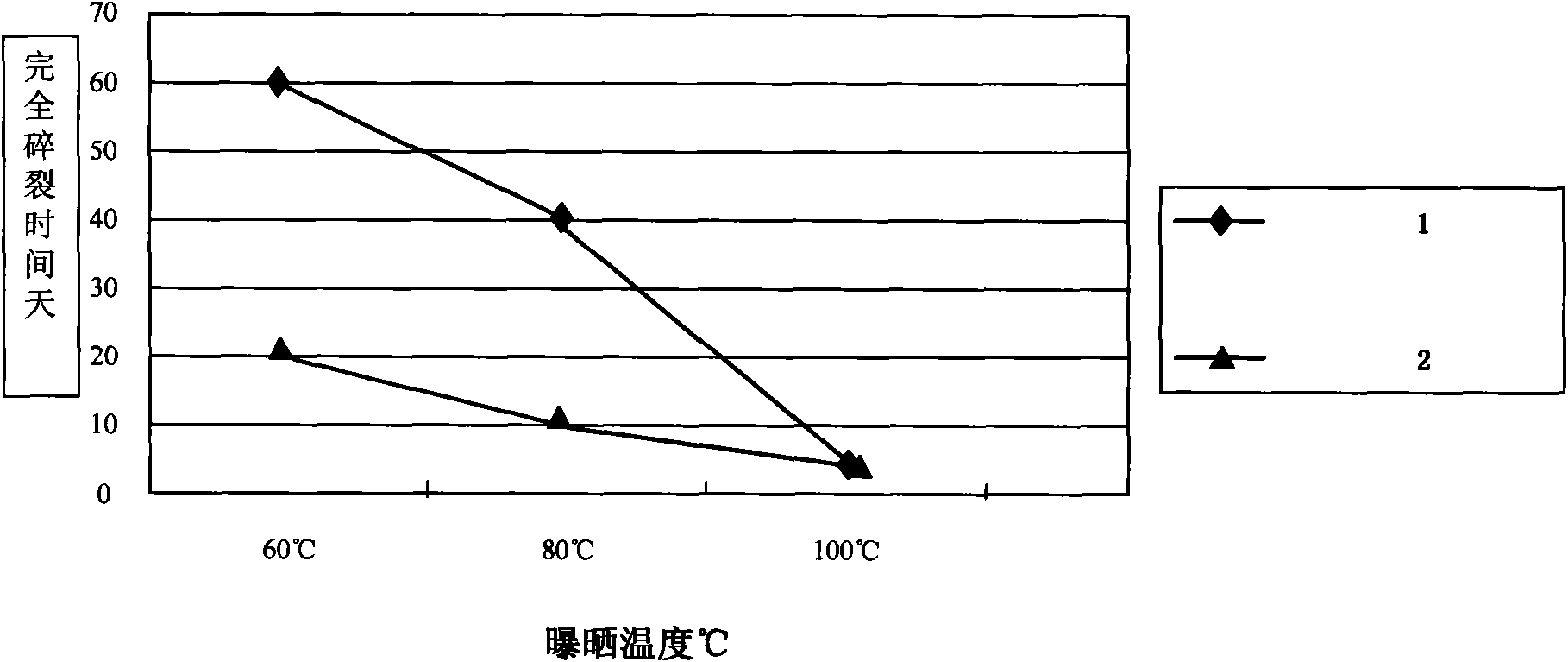

Degradable BOPP packing film and manufacturing method thereof

The invention discloses a degradable BOPP packing film and a manufacturing method thereof; the packing film is formed by co-extrusion of three layers of materials, namely surface-layer materials, core-layer materials and inner-layer materials, wherein the surface-layer materials and the inner-layer materials are formed by blending the following components by weight percent: 90-93 percent of random copolymer polypropylene modified raw materials, 4-7 percent of smoothing agents and 2-4 percent of antisticking agents; and the core layer is formed by copolymerization of the following components by weight percentage: 90-93 percent of homopolymer polypropylenes, 4-7 percent of binary polyketone polymers and 2-4 percent of anti-static agents. The manufacturing method thereof comprises the preparation of random copolymer polypropylene modified raw materials, the preparation of surface-layer materials and inner-layer materials, the preparation of core-layer materials, chilling and dual-axis two-way stretching, thus obtaining the degradable BOPP packing film. The packing film can meet the performance requirements of small commodity packages such as cigarettes, food, beverages, stationery and the like, and can simultaneously complete the degradation in a shorter time, thereby realizing the harmless automatic treatment of two-way stretching polypropylene films and the protection of environment.

Owner:QINGDAO ENER PACKAGING TECH +1

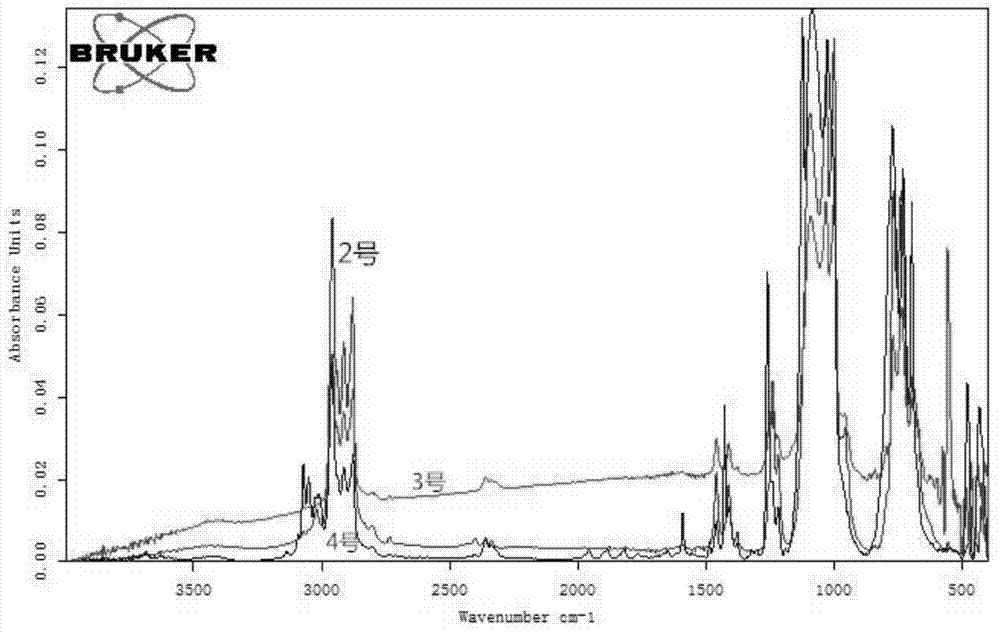

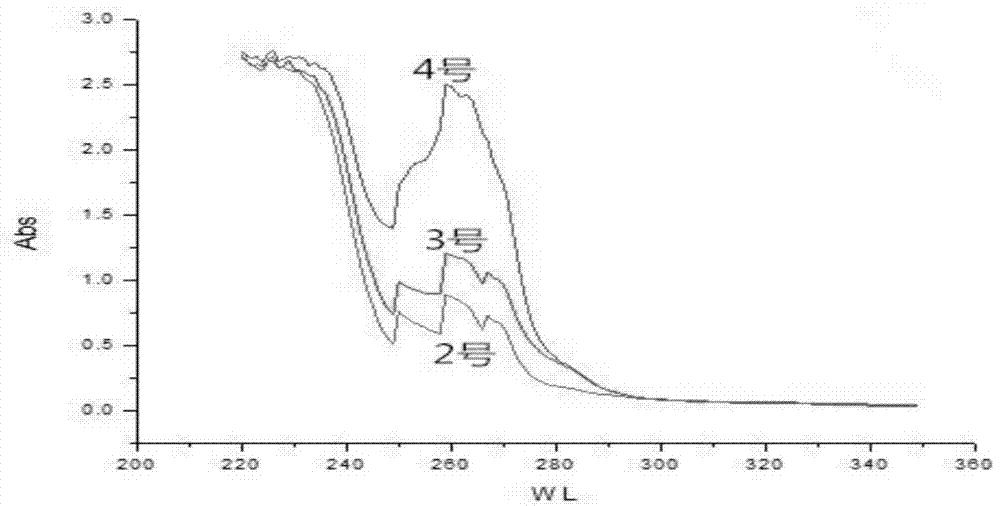

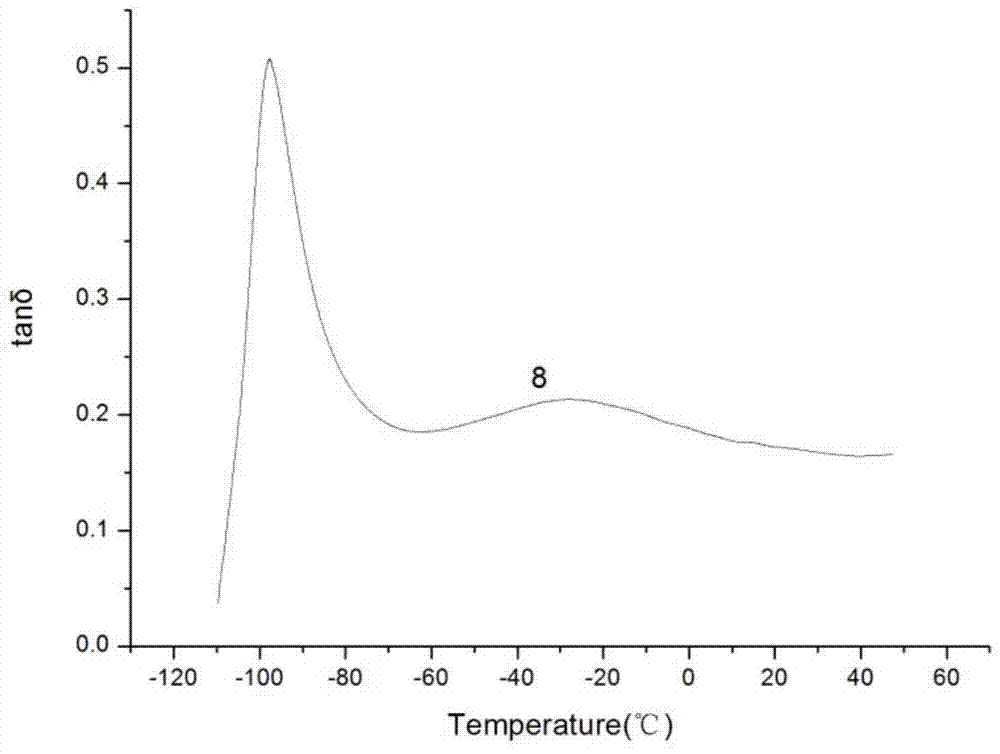

Damping silicon rubber with relatively small temperature effect and preparation method thereof

The invention relates to damping silicon rubber with a relatively small temperature effect and a preparation method thereof. The crude rubber of the damping silicon rubber is characterized in that a main chain of the crude rubber of the silicon rubber consists of methyl phenyl silicone chain elements, diethyl silicone chain elements, dimethyl silicone chain elements and methyl ethylene silicone chain elements with different content; the molecular weight of the crude rubber is more than 400 thousands; the crude rubber is prepared by copolymerizing methyl phenyl cyclosiloxane, diethyl cyclosiloxane, dimethyl cyclosiloxane and methyl ethylene cyclosiloxane in the presence of initiators of polypropylene oxide and the like. The crude rubber with the structure has good damping property in a relatively wide temperature range after being vulcanized, the dynamic loss factor and the modulus hardly change along with temperature changes, and the damping silicon rubber belongs to the field of organic silicon high polymer.

Owner:SHANDONG UNIV

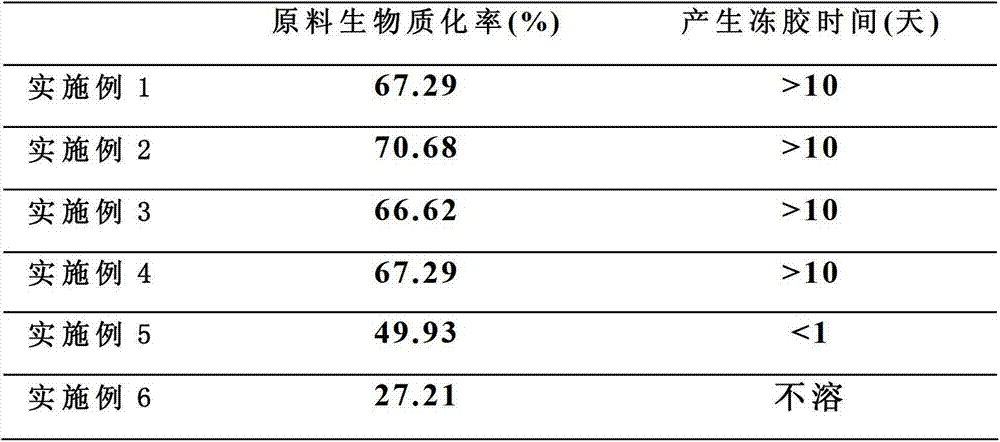

Alcohol-soluble copolyamide and preparation method thereof

The invention discloses alcohol-soluble copolyamide and a preparation method thereof. The alcohol-soluble copolyamide is characterized by being prepared by charging dicarboxylic acid, diamine, lactam and furan-2,5-dicarboxyic acid wchi are used as raw materials and carrying out fusion polycondensation to obtain the alcohol-soluble copolyamide, wherein the raw materials react in equivalent ratio of carboxyl to amino of 1:1. The novel alcohol-soluble copolyamide obtained by adopting the preparation method contains more than 60wt% of biomass-based raw material, has excellent alcohol solubility and can be applied to the fields of paints and binding agents.

Owner:苏州瀚海化学有限公司

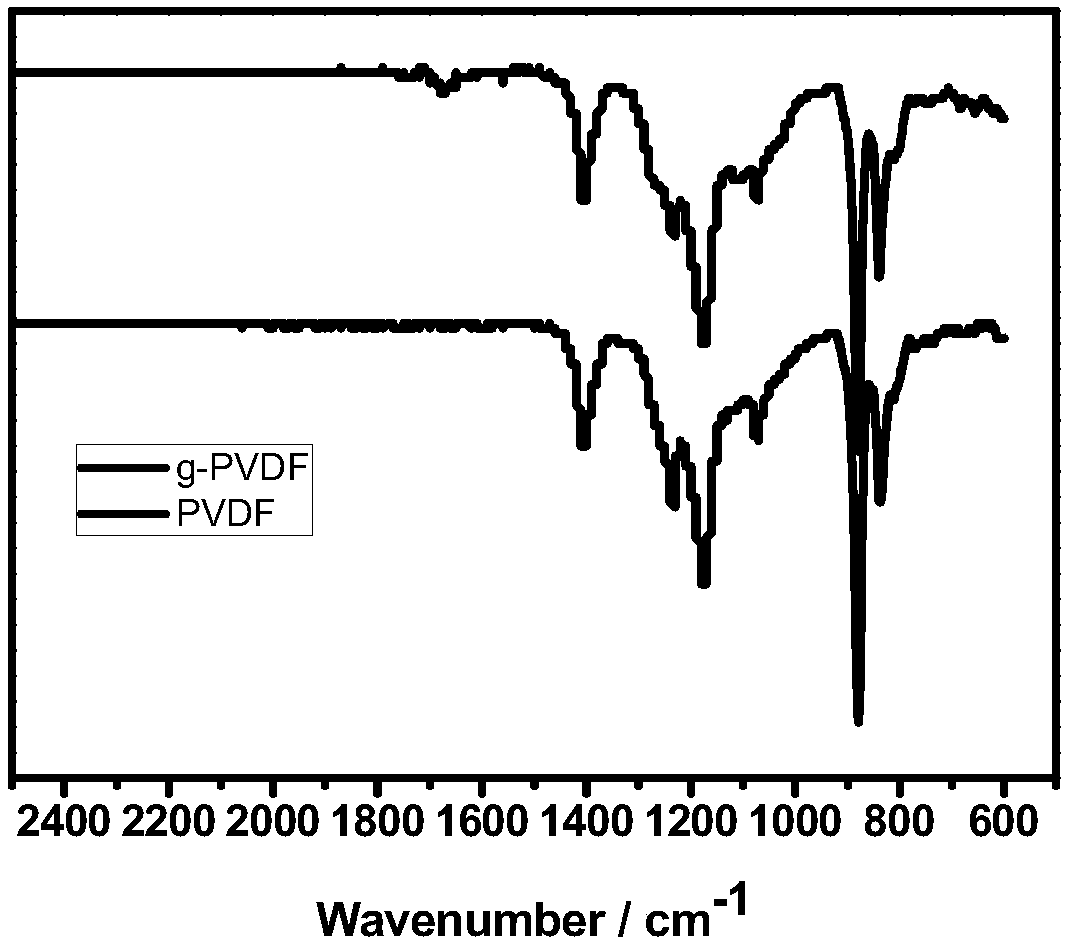

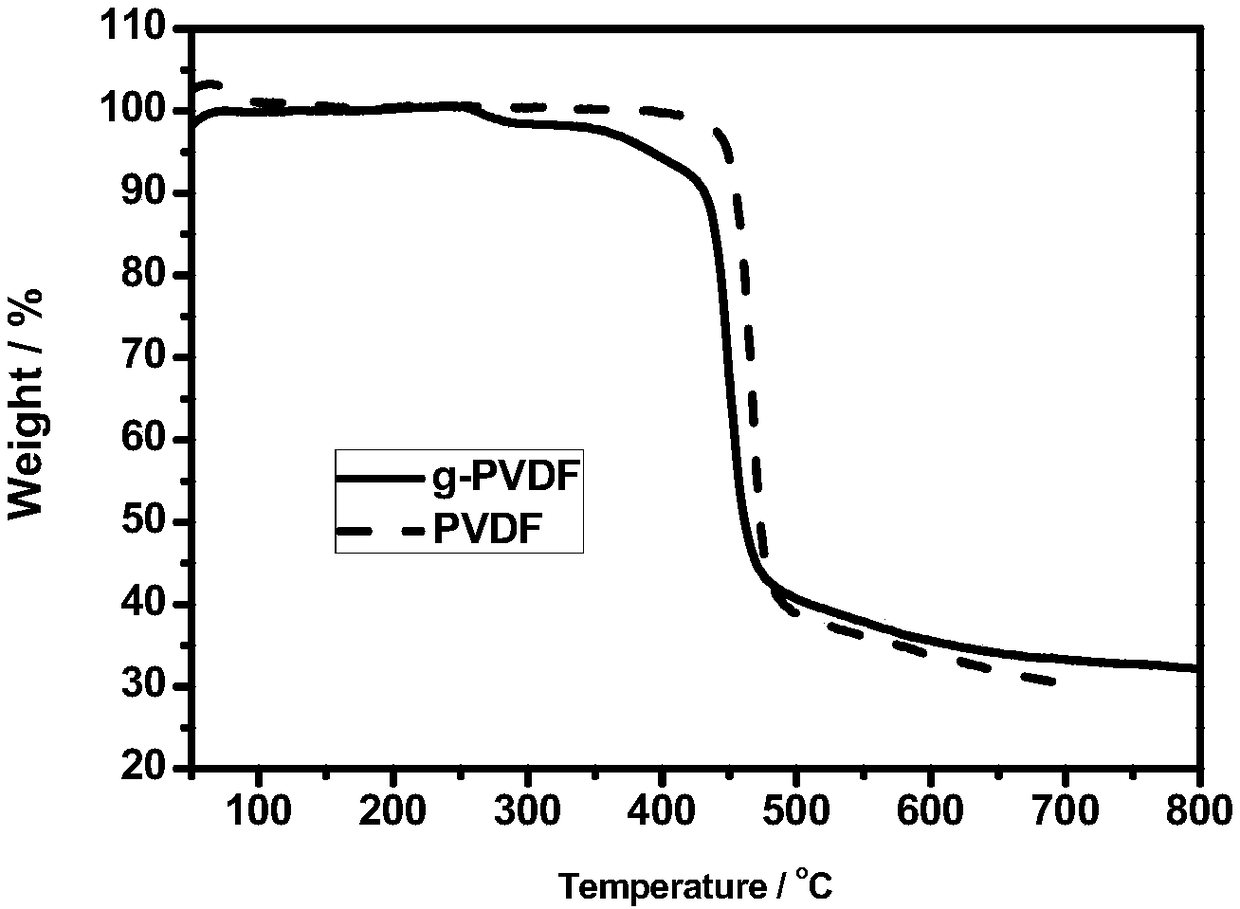

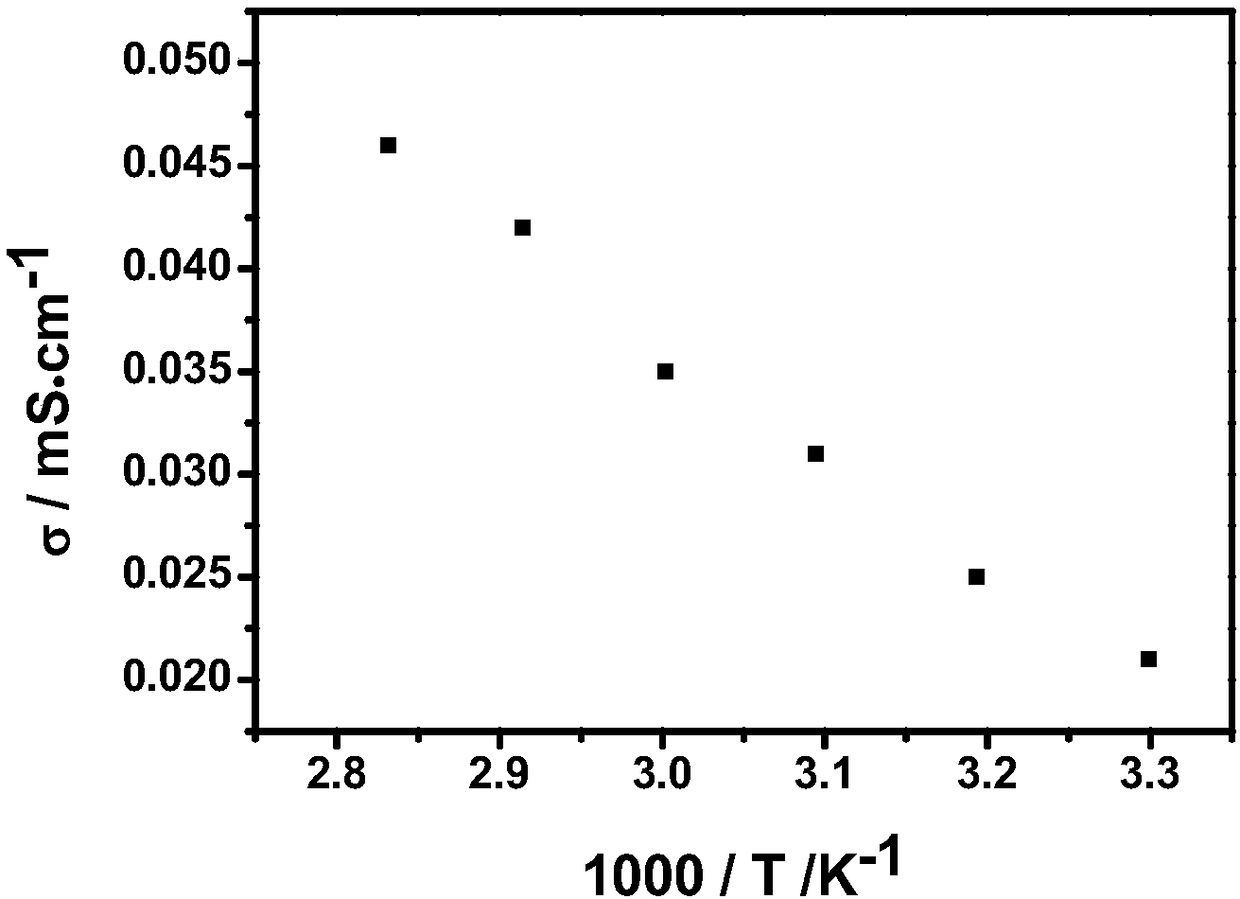

Novel single ion polymer electrolyte and preparation method and application thereof

The invention discloses a novel single ion polymer electrolyte and a preparation method and an application of the novel single ion polymer electrolyte. A radiation grafting method is used to synchronously graft two functional monomers on a powder substrate, wherein one monomer is a fluorine-containing monomer, and the other grafted monomer is a monomer comprising a lithium salt ion pair. The powder substrate is selected, the proportion of the monomers is regulated through the radiation grafting method without adding an initiator or a catalyst, and an evenly grafted pure double-monomer graftingmembrane is conveniently obtained. The grafting membrane is applied to a lithium ion battery, the lithium salt is not additionally added, only a small quantity of plasticizer is needed, and the grafting membrane has a prominent electrochemical performance. Meanwhile, the grafting membrane has the advantages of heat stability, size stability and mechanical property. The method is novel and effective, is simple, is low in cost and strong in operability, and is quite suitable for commercial production.

Owner:XIAMEN UNIV

Copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function, process for preparation thereof, and use thereof for producing ionically conductive materials

InactiveUS6855788B2High reaction yieldLess impuritiesCell electrodesConductive materialChemical compatibilityConductive materials

Owner:BATHIUM CANADA

Middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor

The invention discloses a middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor, and belongs to the field of high-performance carbon fiber preparation method. The middle-modulus carbon fiber preparation method comprises following steps: PAN precursor is delivered into a pre-oxidation furnace for pre-oxidation so as to obtain a pre-oxidized fiber body with a density ranging from 1.33 to 1.36g / cm<3>; the pre-oxidized fiber body is delivered into a low temperature carbonization furnace for low temperature carbonization so as to obtain a low temperature carbonized fiber body; the low temperature carbonized fiber body is delivered into a high temperature carbonization furnace for high temperature carbonization, and the carbon fiber with tensile strength ranging from 4500 to 5100MPa, tensile modulus ranging from 270 to 310GPa, and filament diameter ranging from 6 to 10<mu>m is obtained via carbonization. The middle-modulus carbon fiber preparation method is capable of realizing synchronous increasing of carbon fiber tensile modulus and strength, and solving key problems that the tensile strength of middle-modulus carbon fiber is reduced, and cost is high.

Owner:ZHONGFU SHENYING CARBON FIBER +1

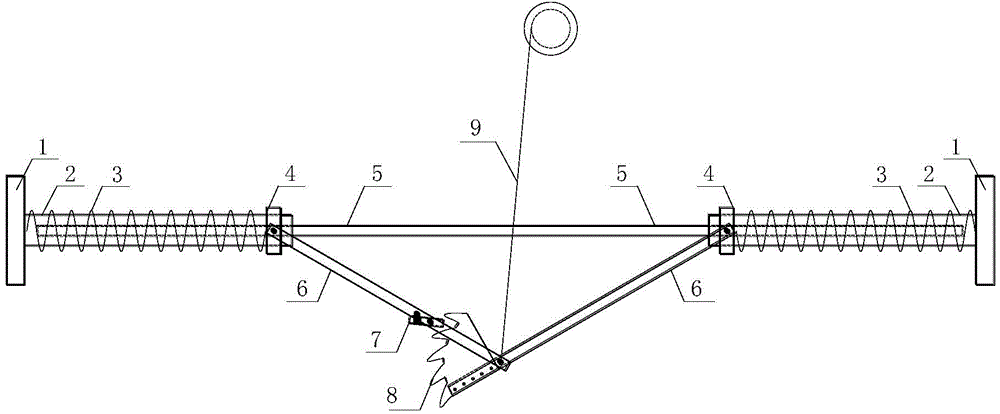

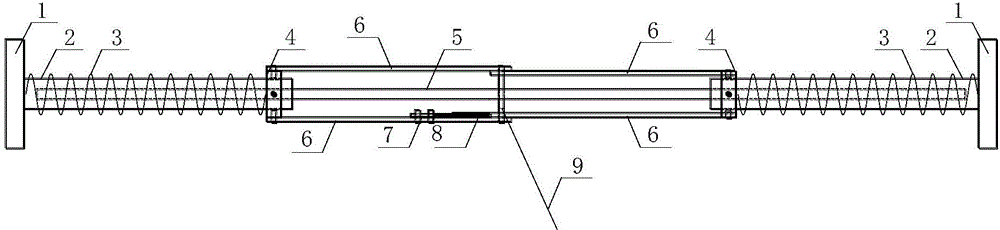

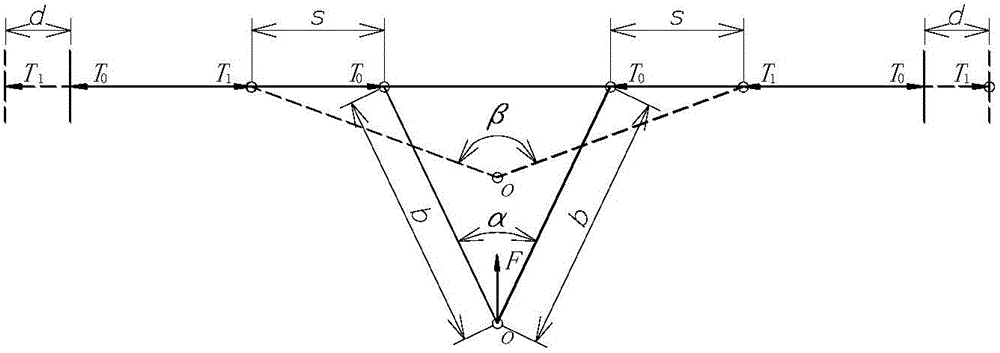

Concrete diaphragm wall lateral earth pressure cell embedding device

InactiveCN104863108AImprove survival rateUnlimited burial depthIn situ soil foundationSlurry wallPressure cell

The invention discloses a concrete diaphragm wall lateral earth pressure cell embedding device, and relates to an application technology for monitoring concrete diaphragm wall lateral earth pressure in a water control project risk assessment and control process. The concrete diaphragm wall lateral earth pressure cell embedding device comprises a steel guide rod, sleeves for being connected with earth pressure cell bases, and support rods; the sleeves (2) for being connected with the earth pressure cell bases can freely slide on the steel guide rod (5); when a guy wire (9) is tensioned, the support rods (6) push circular sliding blocks (4) sleeving the sleeves (2) to compress springs (3), the springs (3) push the earth pressure cell bases (1) and the sleeves (2) to be supported into concrete diaphragm wall lateral earth; a tooth-shaped block (8) and a locking block (7) at the tail ends of the support rods (6) form a graded locking device allowing the support rods (6) to be locked at different angles, so that requirements of different concrete diaphragm wall widths and hardness and softness of earth on two sides of the wall can be met. The concrete diaphragm wall lateral earth pressure cell embedding device can be widely used for embedding an earth pressure cell for monitoring lateral earth pressure of various cast-in-situ concrete diaphragm walls in a water control project.

Owner:HOHAI UNIV

Low-friction-coefficient and solvent-free type polyurethane adhesive and preparation method thereof

InactiveCN106520054AReduce crystallinityHigh transparencyPolyureas/polyurethane adhesivesPolyurethane adhesiveIsocyanate

The invention discloses low-friction-coefficient and solvent-free type polyurethane adhesive and a preparation method thereof and belongs to the field of polyurethane adhesive preparation. The adhesive is prepared from A component and B component, wherein the A component is prepared from modified polyester polyol and polyisocyanate which react with each other, and the B component is prepared from modified polyester polyol. By means of molecular design, the appropriate proportion of branched chain is introduced into the adhesive; thus, the regularity of the adhesive is reduced, a solidified adhesive layer of the adhesive has certain microcosmic unevenness, the microcosmic unevenness of a composite membrane is further obtained, the bonding force between surfaces is reduced, and the composite membrane has a low friction coefficient; as the branched chain is introduced into the adhesive, the crystalline of the molecular chain is reduced, the transparency of the adhesive is improved, the adhesive also can obtain lower viscosity and good coating performance, and the adhesive is wider in application range in the field of composite flexible package. The solvent-free adhesive has no solvent residue and is high in safety.

Owner:BEIJING COMENS NEW MATERIALS

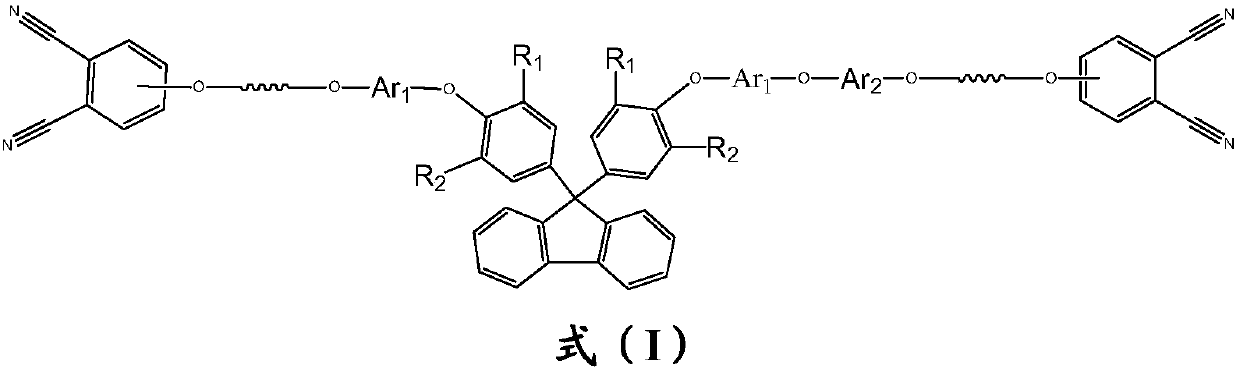

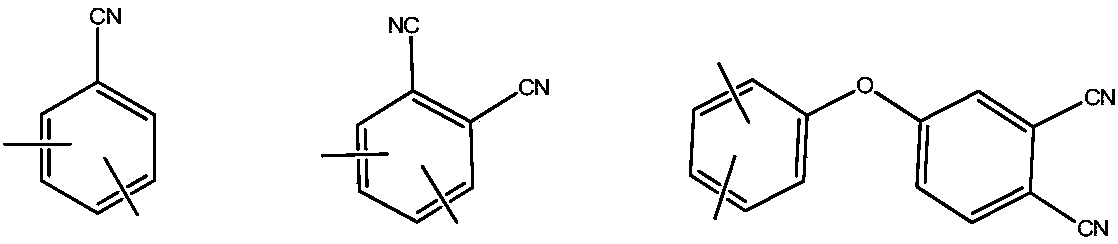

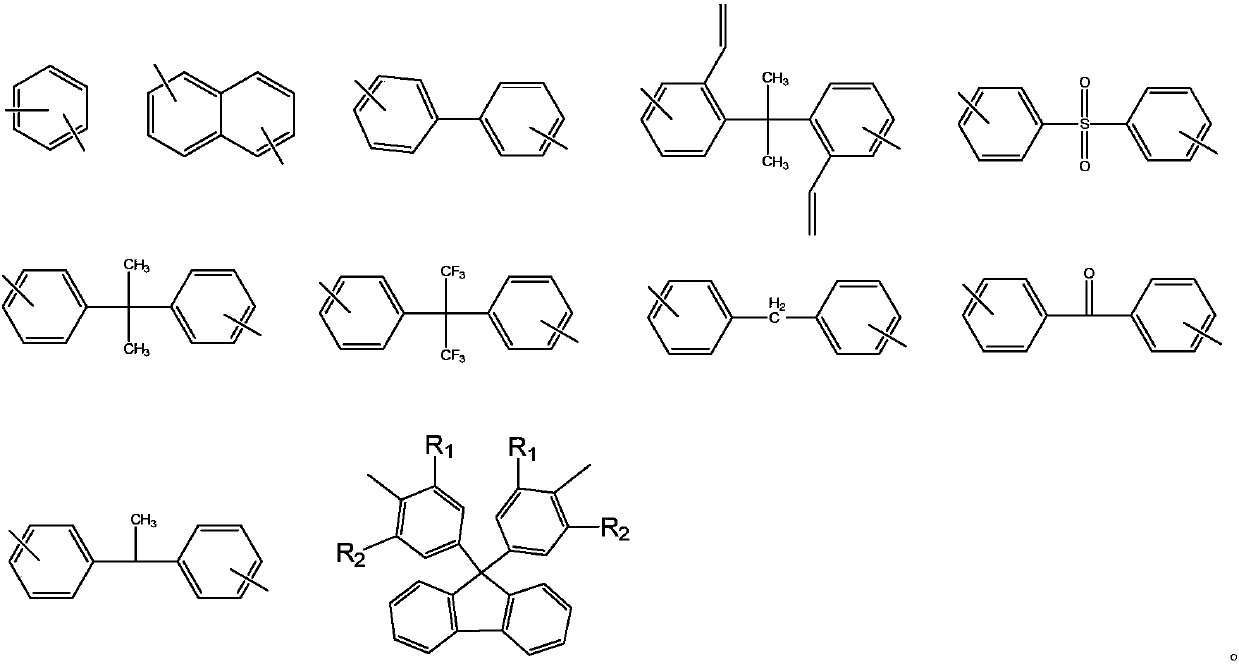

Phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer, phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile)condensate, and preparation method of oligomer

ActiveCN107903189ALow melting pointImprove solubilityCarboxylic acid nitrile preparationOrganic compound preparationSolubilityDecomposition

The invention discloses a phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer, a phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) condensate, and a preparation method of the oligomer. The phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer has chain segments with different lengths and a large-volume side group structure, so the oligomer has a low melting point and a good dissolvability, can be dissolved in DMF, NMP and other strong polar solvents, and also can be dissolved in THF, dichloromethane and a toluene and acetonitrile mixed solvent. The phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) condensate has excellent heat stability and mechanical performances, the 5% decomposition temperature in a nitrogen atmosphere is 499-528 DEG C, the residue mass rate at 1000 DEG C is 69-73.2%, and the bending strength is higher than 500 MPa. Thepreparation method of the phthalonitrile-terminated fluorine structure-containing poly(arylene ether nitrile) oligomer is simple and controllable, and can be applied to industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

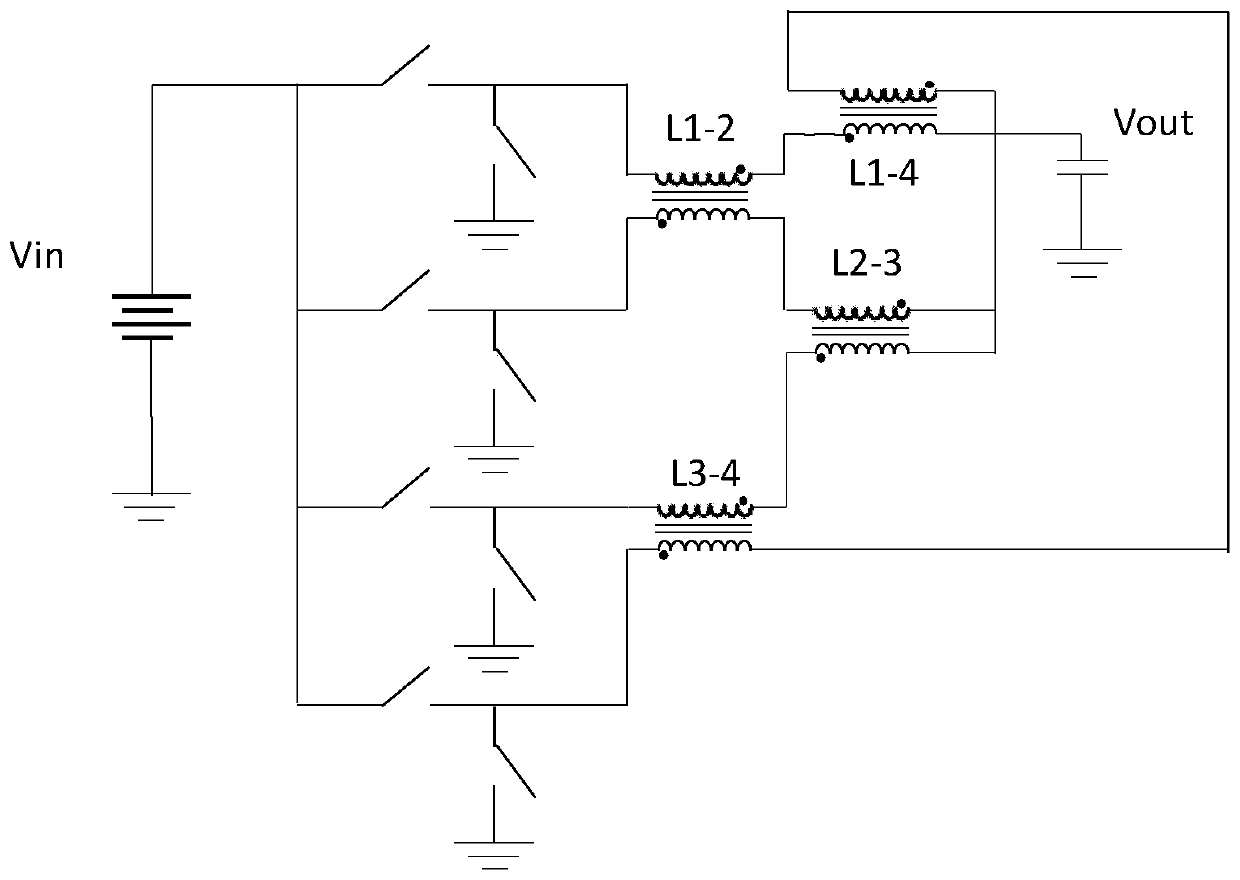

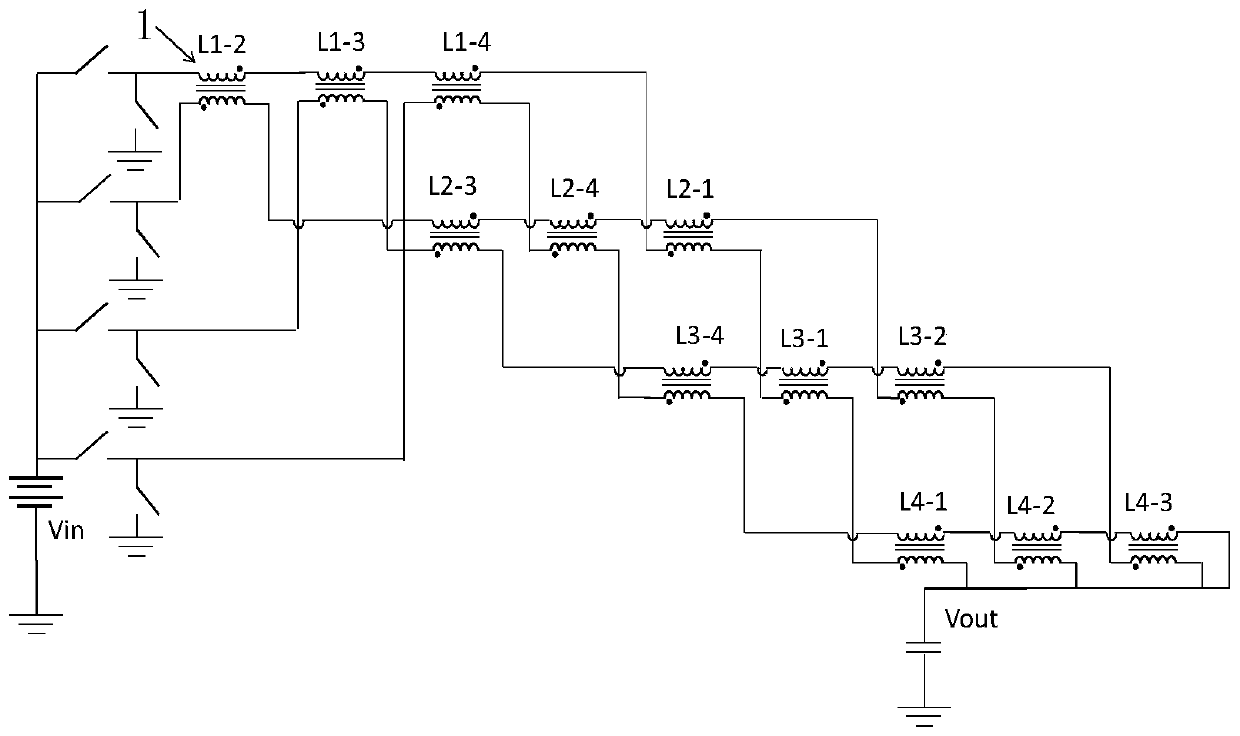

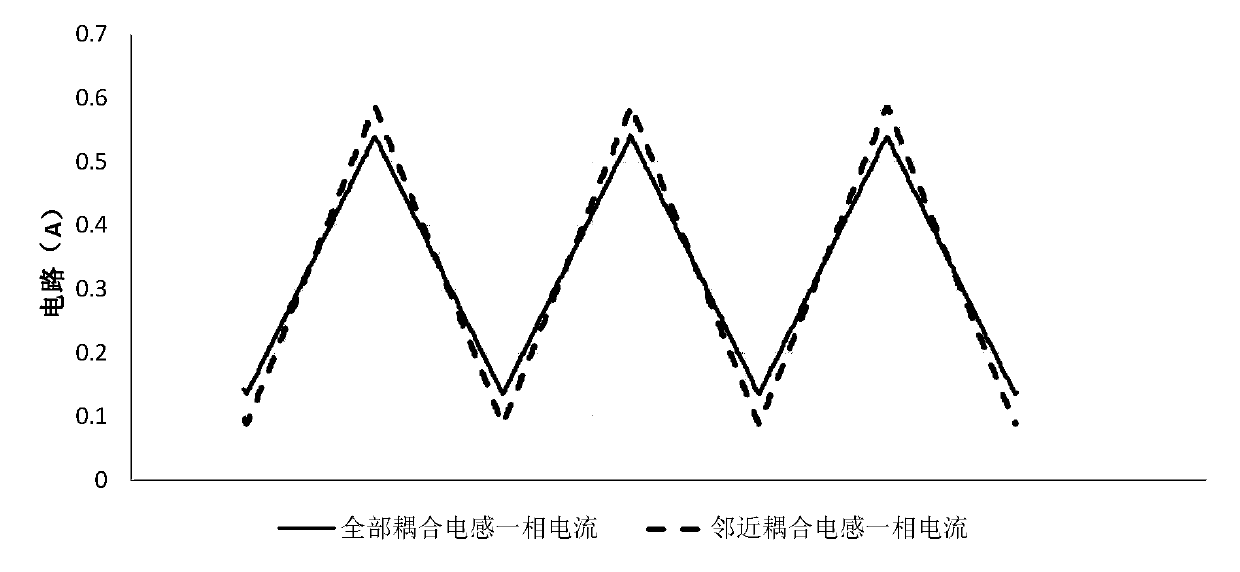

Full-coupling magnetic element

ActiveCN111341544AFirmly connectedReduce package thicknessTransformersTransformers/inductances coils/windings/connectionsSemiconductor chipHemt circuits

The invention relates to the technical field of coupling inductors, and particularly relates to and discloses a full-coupling magnetic element, which comprises at least two phases of circuits. Each phase of circuit is formed by connecting a plurality of coupling units, each two phases of circuits are directly coupled through at least one coupling unit, and the directions of magnetic fields generated by respective direct current components in the currents of the two phases of circuits are opposite. According to the full-coupling magnetic element, all phases are directly coupled to one another,and low output current ripples are achieved; the integrated full-coupling magnetic element has very high regularity and expandability, and has the advantages of small size, low cost, strong expansibility and high integration; and the full-coupling magnetic element can be integrated with a peripheral semiconductor chip into a single chip, or the full-coupling magnetic element can be directly manufactured on a wafer which is provided with a semiconductor chip in advance, so that a micro power supply management chip which is highly integrated and does not need an external magnetic passive deviceis formed, and the micro power supply management chip can replace traditional circuits and schemes such as power supply management based on discrete components, and is applied to multiple purposes.

Owner:杭州矽磁微电子有限公司

Preparation method of under-glaze red pottery tableware

InactiveCN101548843AReduce weightLower firing temperatureTable equipmentsClaywaresThermal insulationThermal stability

The present invention provides a preparation method of under-glaze red pottery tableware, including following steps: (1) select materials; (2) producing red ceramic clay; (3) biscuit firing, baking in oxidizing atmosphere with temperature of 950-1000 DEG, time 7.5-8 hours, heat insulation 7-8 hours; (5) cladding glaze, surface decoration processing; (6) baking color and drying in kiln, with a temperature of 740-760 DEG, time 3-4 hours, heat insulation 9-10 hours; (7) cladding transparent glaze, glaze firing with a temperature of 1050-1100 DEG, time 9-10 hours, heat insulation 11-12 hours; (8) checkout, packaging, warehousing. Applying the present invention, the red pottery tableware is provided with advantages of light weight, low baking temperature, low energy consumption, products easily weathering when breakage, reducing pollution to ecologic environment; and thermal stability of products is preferable, better preservation, high manufacturing yield; employing under-glaze decoration art, bright in color, fastness, elegant quality, conforming to life requirement of modern people.

Owner:翁汉荣 +1

Method for preparing poly(2-methyl butylene succinate) with high molecular weight (HMW)

The invention provides a method for preparing poly(2-methyl butylene succinate) with high molecular weight (HMW). The method comprises the following steps: heating 2-methyl succinic acid, butanediol and a catalyst to 110-170 DEG C in the presence of nitrogen to carry out esterification under normal pressure so as to obtain a polyester prepolymer; reducing the pressure of the polyester prepolymer and raising the temperature to 180-230 DEG C to carry out polycondensation so as to obtain poly(2-methyl butylene succinate); and finally adding a chain extender to carry out chain extension to obtainthe poly(2-methyl butylene succinate) with HMW. The method has the following advantages and positive effects: in the presence of methyl, the regularity of the main polymer chain is reduced and the symmetry of the chain is destroyed, thus changing the crystallization property of the polymer and then adjusting the biodegradability of the polymer; and the obtained 2-methyl polyester succinate is expected to have good biodegradability, thus really realizing biological recycling of limited resources.

Owner:QINGDAO UNIV OF SCI & TECH

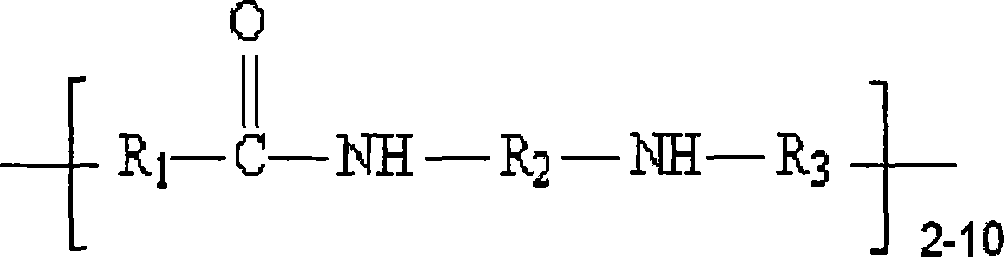

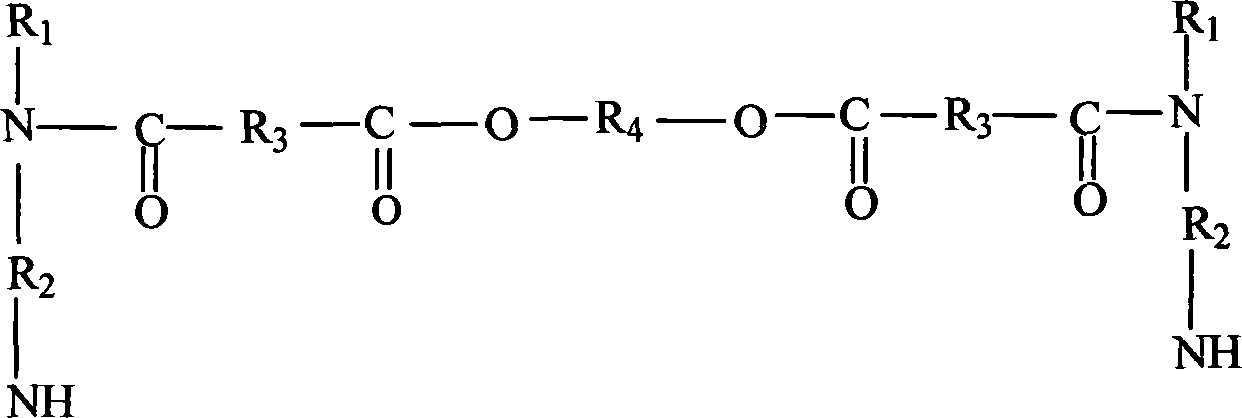

Hot-melt adhesive of thermal shrinkage polyester amide in use for material of thermal shrinkage, and preparation method

This invention relates to a polyesteramide hot-melt adhesive for pyrocondensation material, and its preparation method from polyamide and water PET. The polyesteramide hot-melt adhesive has a repeating structure shown in this invention, wherein, R1 is residue derived from dimmer acid; R2 is -(CH2)2-12- and its possible branched isomer; R3 is terephthalate polyester segment (derived from polyester residue), terephthalate oligomer, terephthalate dimmer or benzene ring. The preparation method comprises ester-amide exchange, alcoholysis and polycondensation. By utilizing waste polyester as part of the the raw material, the product cost is reduced without sacrificing product quality, and meanwhile white pollution is reduced. The preparation method does not need solvent recovery or product purification, and has such advantages as no pollution, and simple and stable process.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Method and Oral Appliance for Improving Air Intake and Reducing Bruxism

ActiveUS20180207022A1Numerous medical conditionImprove performanceChiropractic devicesSnoring preventionDiseaseThroat

Provided is a soft flexible oral appliance having protuberances that mimic naturally occurring dental Tori. An upper, palatial appliance and a lower, mandibular appliance may be used in conjunction or separately to alleviate a variety of disorders, improve facial tone, and increase physical performance. The appliances are lightweight, thin, and do not prohibit normal speech patterns when in use Small protuberances are strategically molded along key surfaces of each appliance to stimulate nerves in the tongue and affect forward protrusion. Forward positioning of the tongue dilates the airways of the throat improving breathing while the use is sleeping, playing sports, or talking. It also reduces bruxing or grinding of the teeth. A method is further provided, for adding protuberances to other types of oral appliances, thereby conferring some of the benefits listed above on appliances originally intended for other dental uses.

Owner:DENTAL CHOICE HLDG LLC

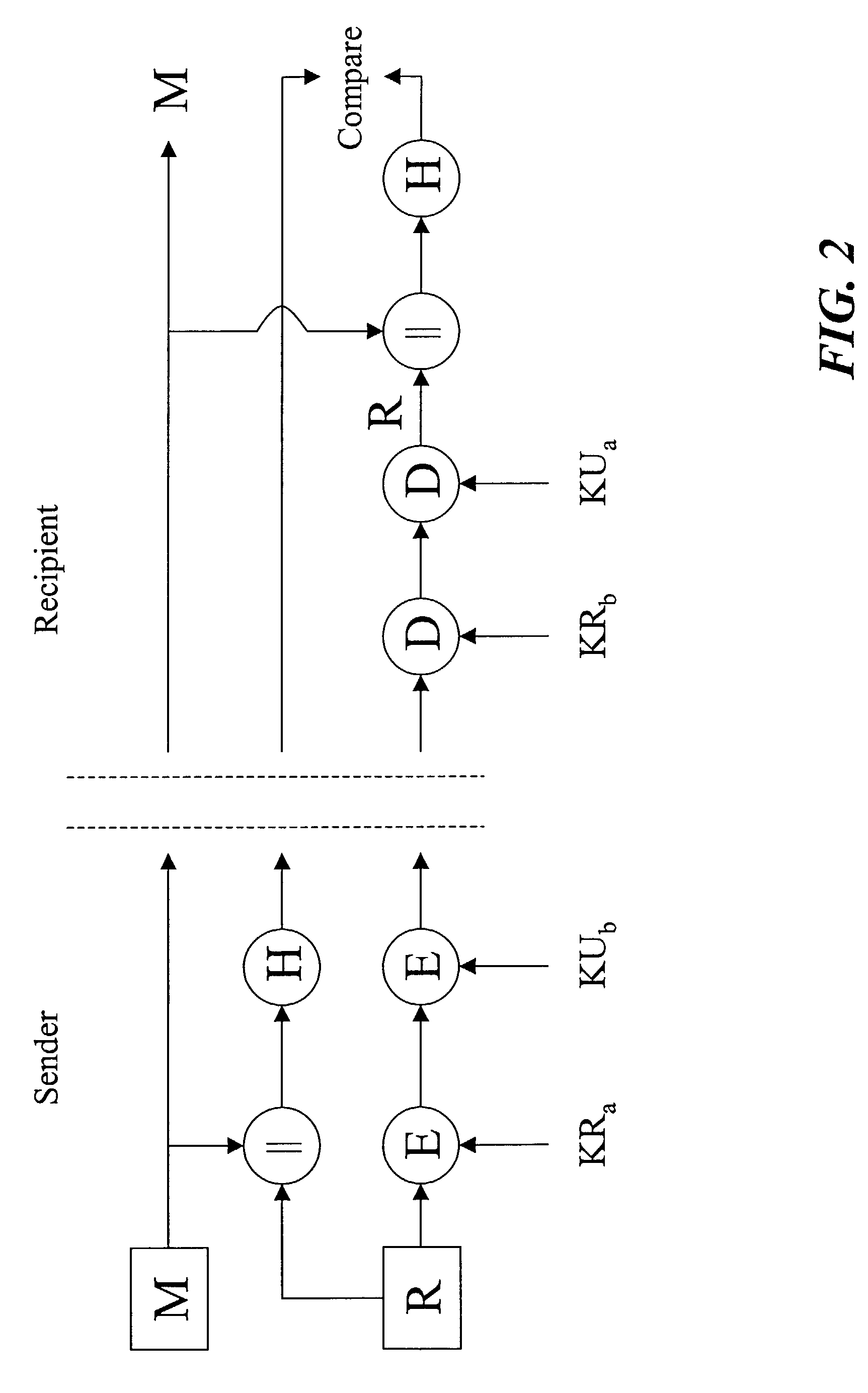

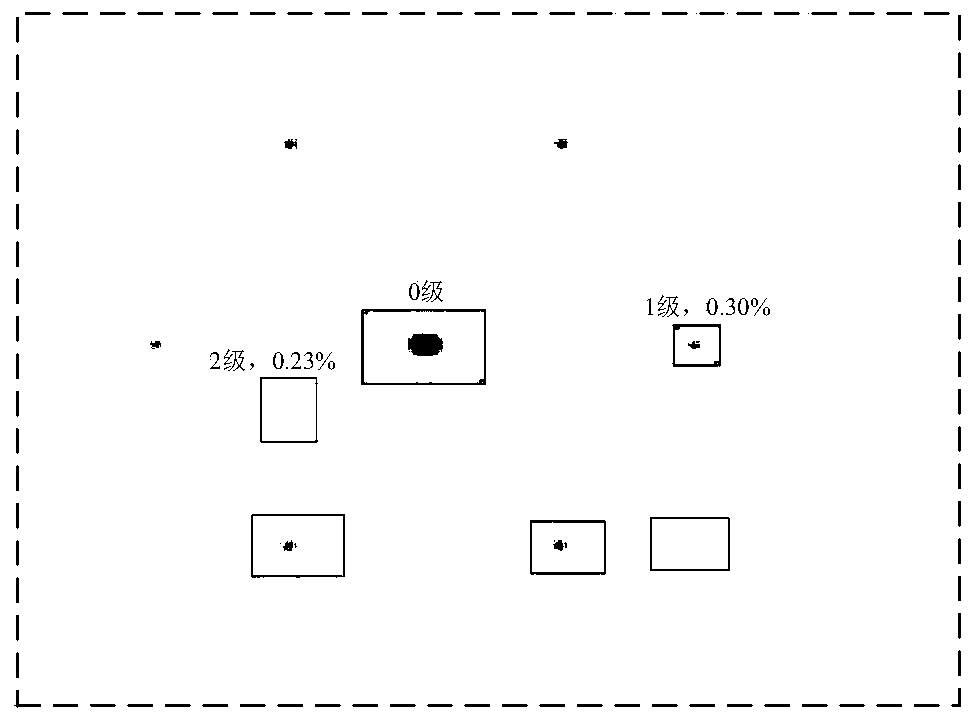

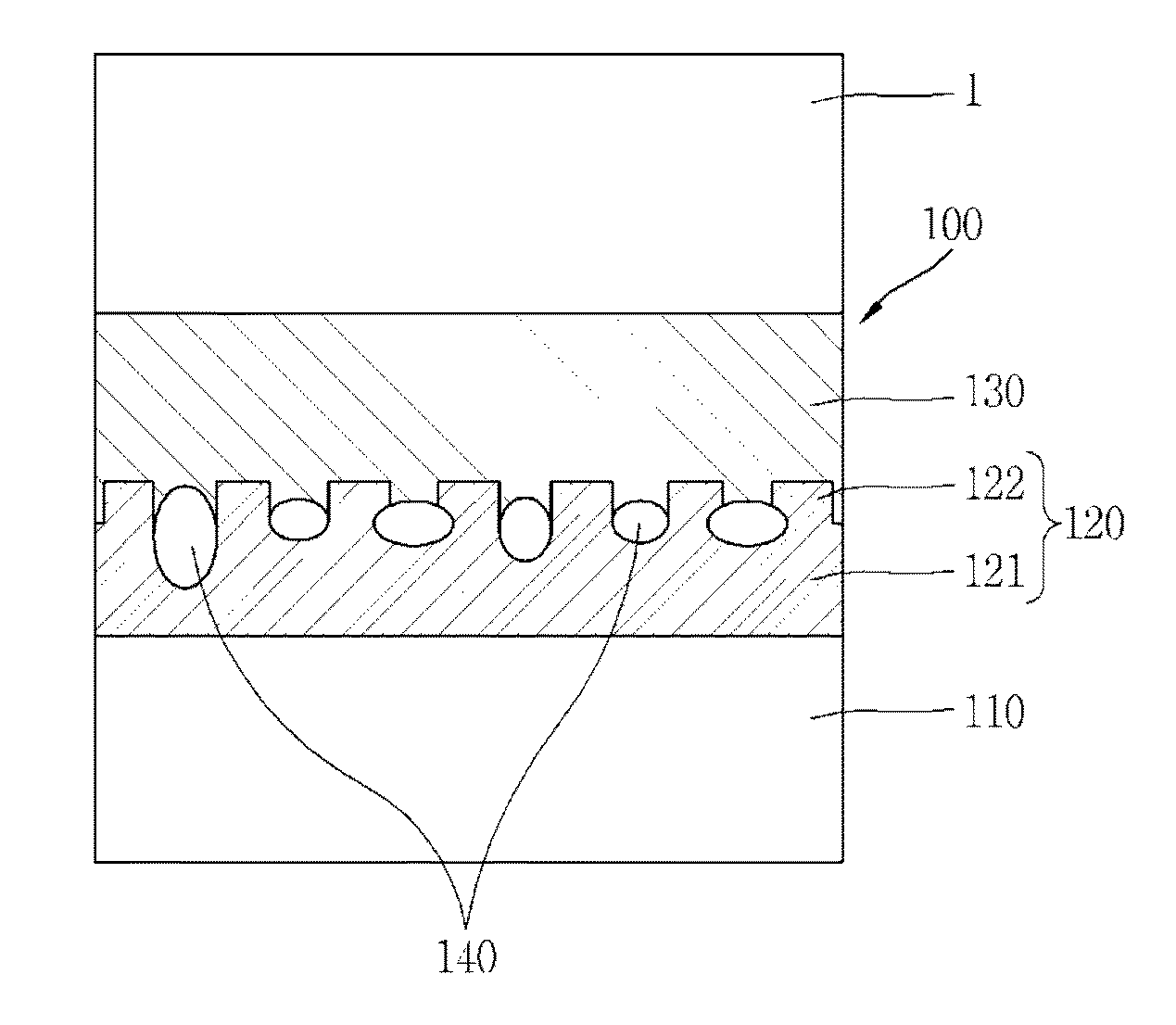

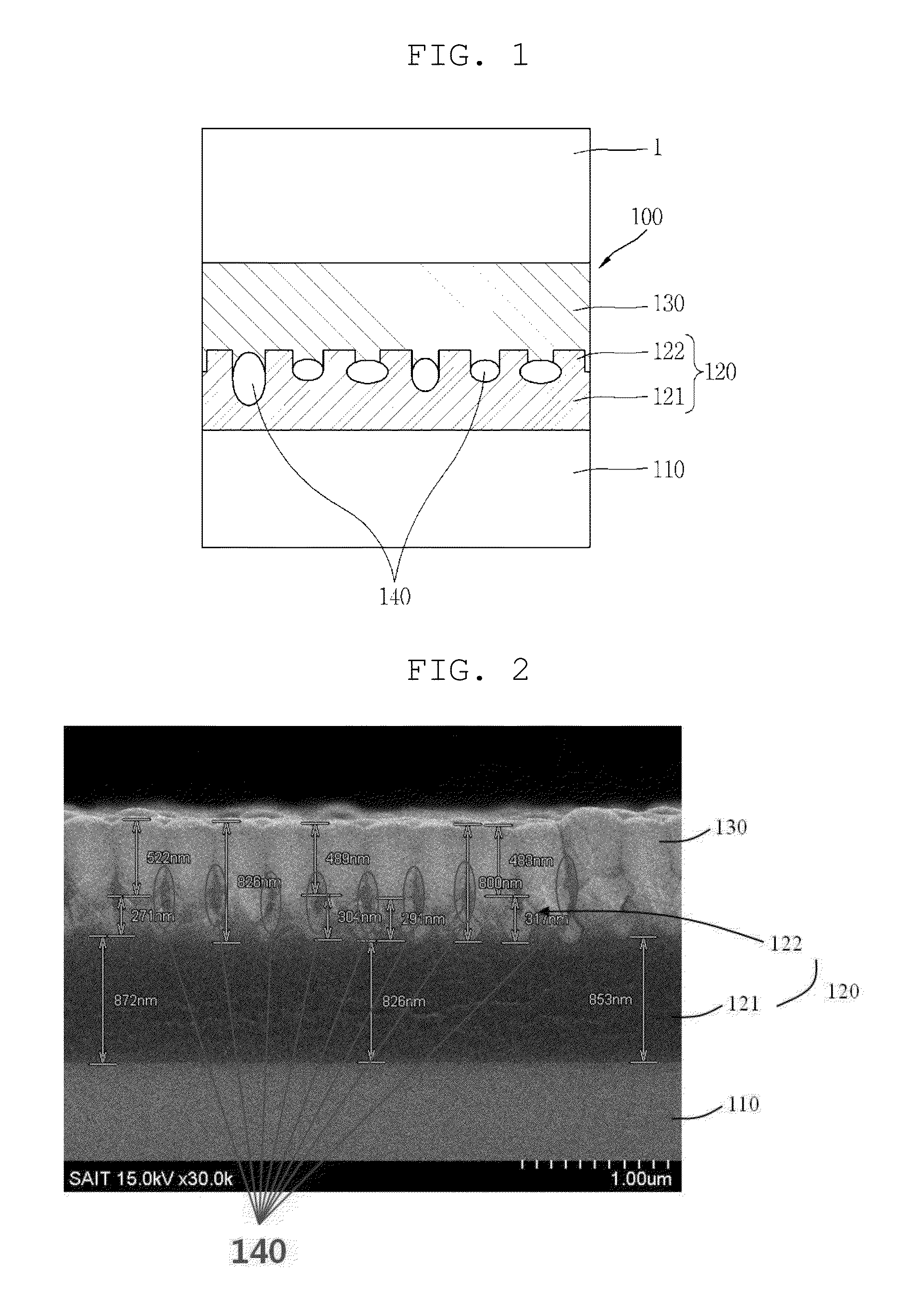

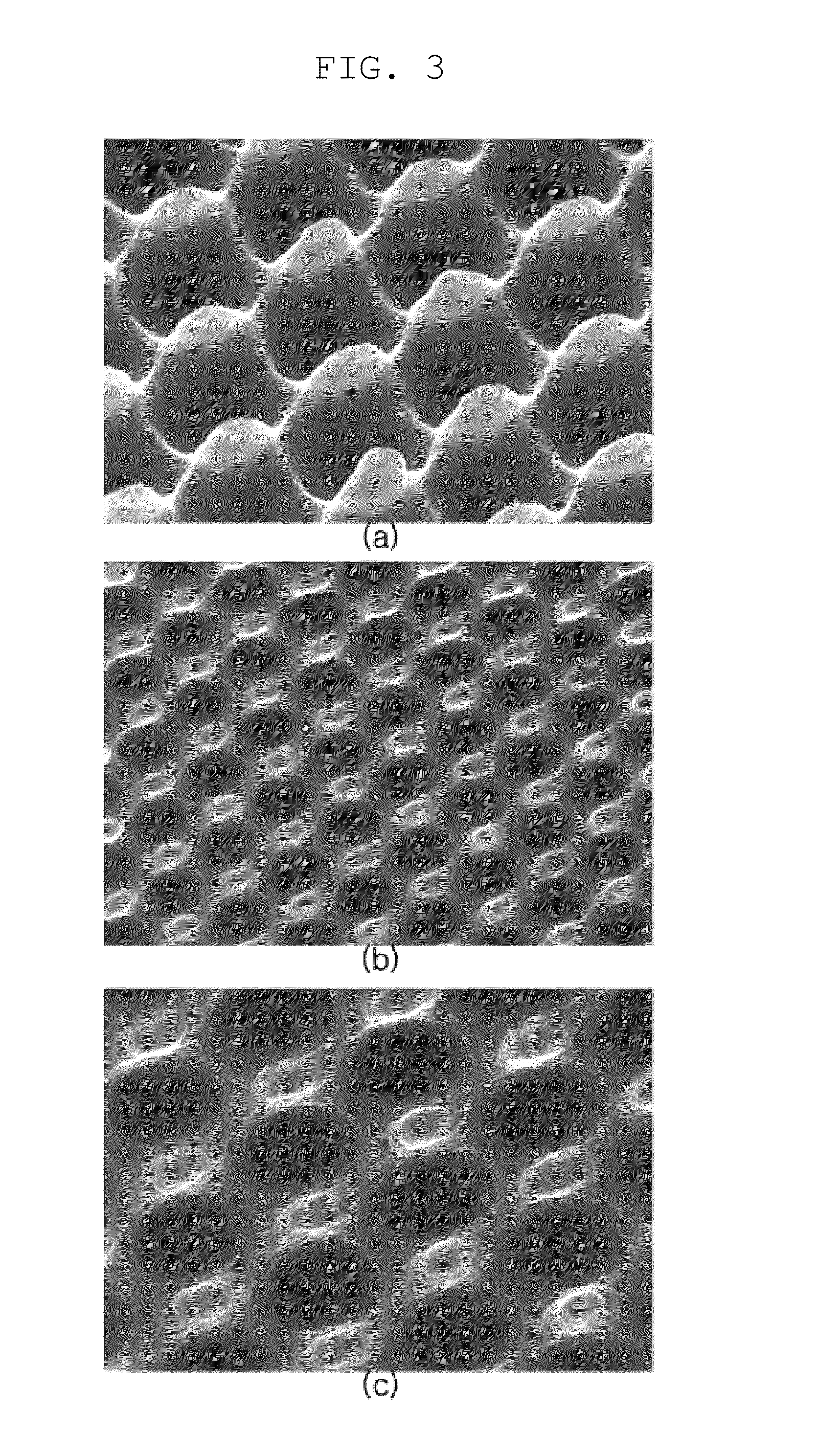

Light extraction substrate for organic light-emitting element, method for manufacturing same and organic light-emitting element including same

ActiveUS20160172632A1Wide wavelength rangeLight extraction efficiency can be improvedFinal product manufactureSolid-state devicesWavelength rangeAir voids

The present invention relates to a light extraction substrate for an organic light-emitting element, a method for manufacturing the same and an organic light-emitting element including the same, which can shed its dependence on light extraction in a specific wavelength range appearing in a light determining pattern of a cyclical form and induce light extraction in a broader wavelength range. To this end, the present invention relates to a light extraction substrate for an organic light-emitting element, a method for manufacturing the same and an organic light-emitting element including the same. The light extraction substrate is disposed on one surface through which light emitted from the organic light-emitting element is outwardly released and comprises: a base substrate; a light determining pattern formed on the base substrate; and a leveling layer formed on the light determining pattern and having a surface contacting the organic light-emitting element, wherein a plurality of air voids having a random shape and size are irregularly distributed on an interface between the light determining pattern and the leveling layer.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Branched chain type degradable hydrophilic polyester master batch and preparation method thereof

The invention provides a branched chain type degradable hydrophilic polyester master batch and a preparation method thereof. A degradable lactic acid group with a multi-branched chain structure and polyalcohol with a polyhydroxyl structure are introduced into a chain segment, excellent biodegradability and hygroscopicity are given to polyester, the degradability of polyester is further improved, a static contact angle of the surface of a copolyester chip is less than 60 degrees, and intrinsic viscosity is 0.45-0.52dL / g. The invention also provides a preparation method of branched chain type degradable hydrophilic polyester. The preparation method comprises the steps that reaction is carried out on benzenetetracarboxylic anhydride and lactic acid for preparing a branched chain monomer, then primary esterification reaction is carried out on the branched chain monomer, terephthalic acid and ethylene glycol, and then polyalcohol is added in a secondary prepolycondensation process for carrying out copolycondensation, and final polycondensation is carried out for preparing the branched chain type degradable hydrophilic polyester. The prepared polyester has the advantages of good hydrophility, fast biodegradation and the like and can be widely applied to the fields of home textiles, clothing, plastics and the like.

Owner:POLY PLASTIC MASTERBATCH SUZHOU +1

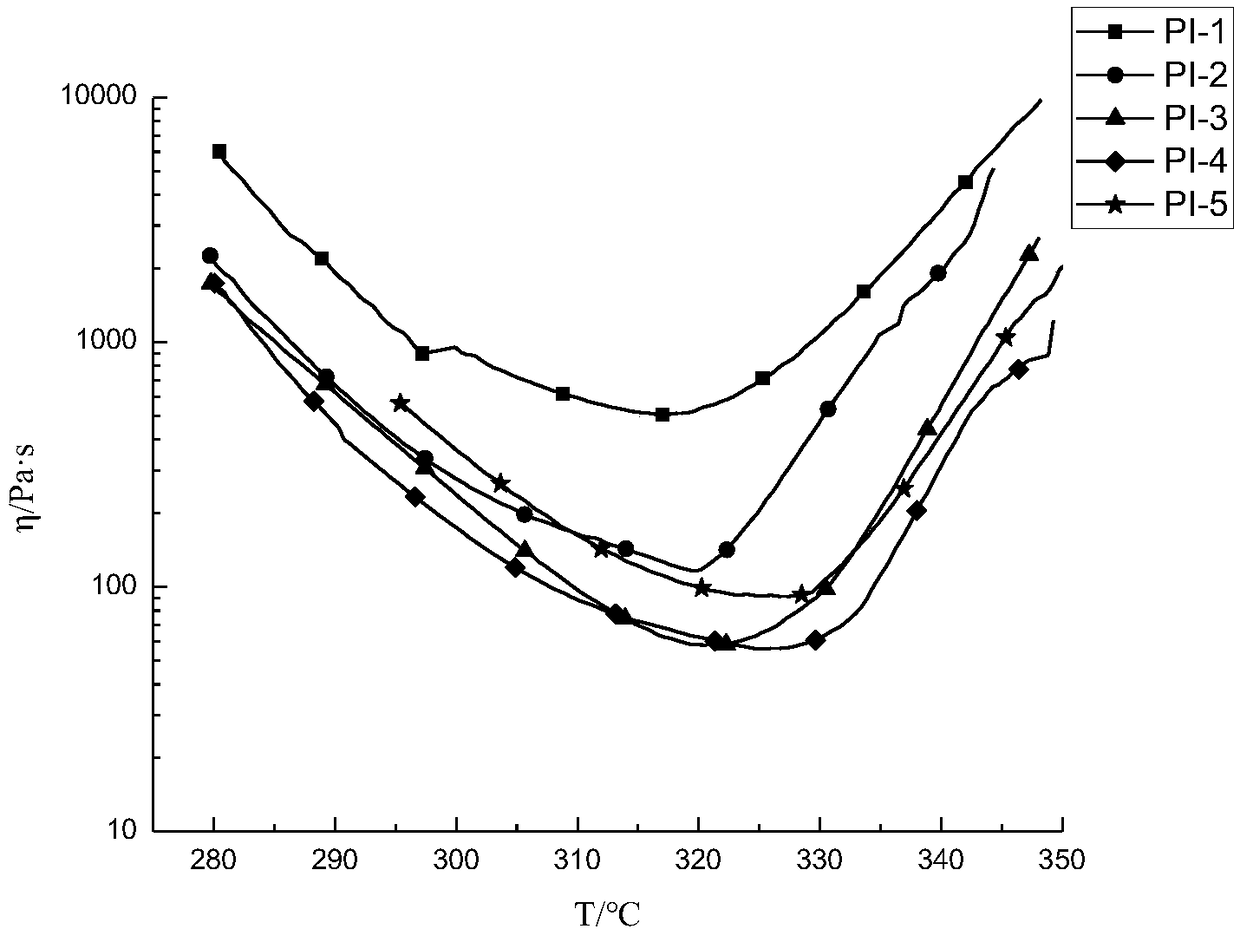

Low viscosity polyimide copolymerized thermosetting resin and preparation method and application thereof

The invention relates to the technical field of high molecular materials, and particularly relates to copolymerized polyimide thermosetting resin comprising a carborane structure and a preparation method and an application thereof. The copolymerized polyimide resin is prepared by thermally cross-linking and solidifying polyimide oligomers represented by a formula I as a raw material. The oligomersintroduce the carborane of a certain composition into a conventional thermosetting polyimide resin system by means of a copolymerization method, so that the conventional thermosetting polyimide resinhas relatively low hot melt viscosity and a higher glass-transition temperature (higher than 500 DEG C) and also has more excellent thermal oxidation resistance and heat stability resistance. Therefore, the thermosetting resin has the extremely low hot melt viscosity. The resin is more easily prepared into a composite material part of a complex structure through a conventional processing technology, can improve the thermal oxidation resistance of the material to a great extent, and has very high application value and innovation to prepare a light high strength high-temperature-resistant easily processed polyimide composite material for a structural material in the aerospace field.

Owner:BEIHANG UNIV

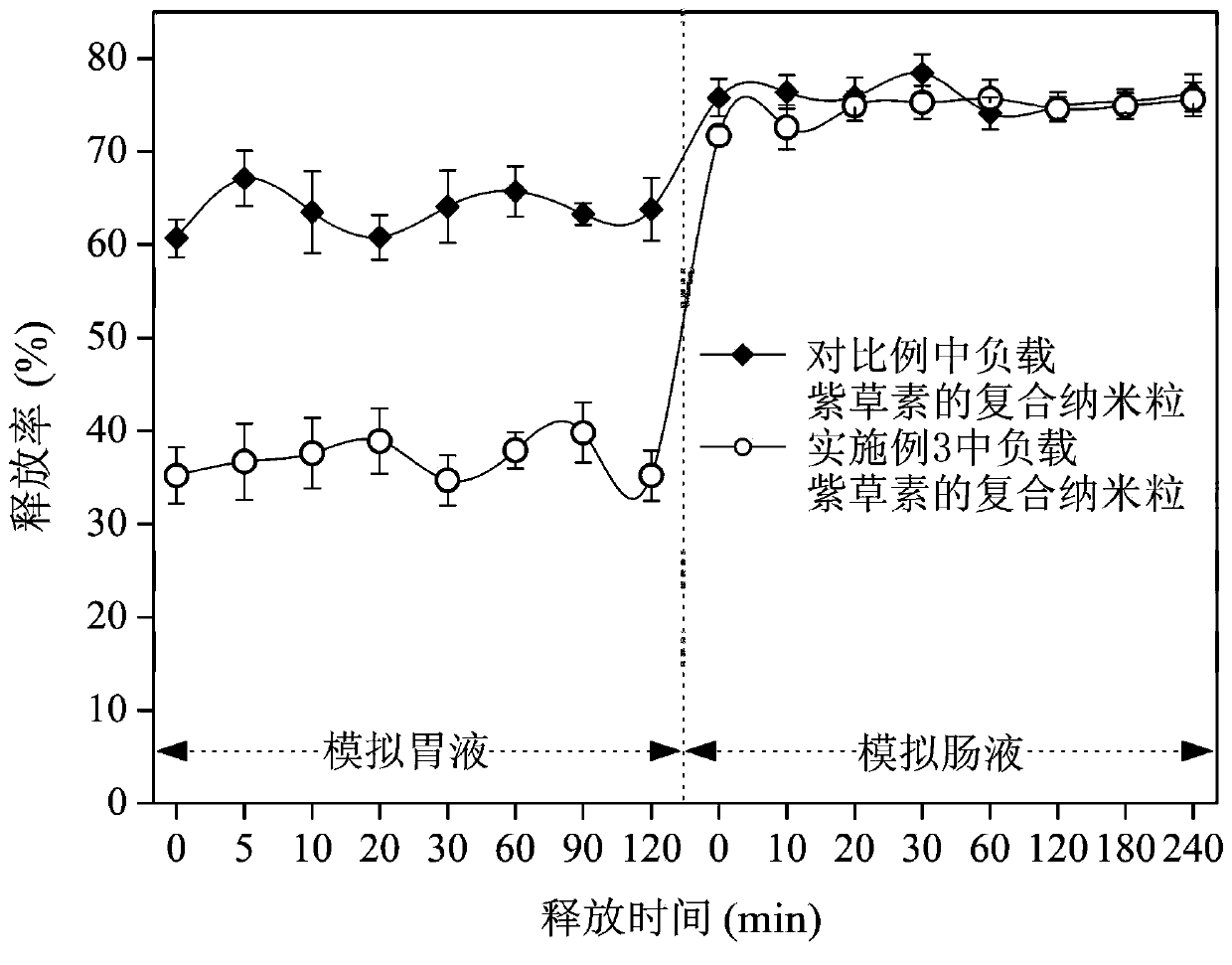

Mono-carboxyl chitosan/alkannin composite nanometer particles and preparation method thereof

ActiveCN110384684AImprove stabilityImprove accessibilityOrganic active ingredientsPharmaceutical non-active ingredientsEnvironmental resistanceCross-link

The invention discloses mono-carboxyl chitosan / alkannin composite nanometer particles and a preparation method thereof. Alkannin coated nanometer particles are prepared through ion gel coagulation effects of water-soluble mono-carboxyl chitosan and sodium tripolyphosphate, and then mutual cross-linking and assembling of hydrophilic macromolecule addition agents and the mono-carboxyl chitosan, composite nanometer particle being small in particle diameter, homogeneous in size, high in stability and good in biological activity are prepared. The method disclosed by the invention is simple and easyto operate, low in cost, mild in reaction condition, environmentally-friendly, safe and non-toxic, the obtained composite nanometer particles are resistant to gastric acid and high in stability, andthe orally-taken absorption and utilization rate of a Chinese herbal medicine namely alkannin and the target medicine release properties are effectively improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Activation technology of carbon fiber

InactiveCN108978178AIncrease polarityGood compatibilityCarbon fibresUltrasonic/sonic fibre treatmentActivated carbonFiber

The invention discloses an activation technology of carbon fiber, and relates to the field of fiber treatment. The activating technology comprises the following steps of (1) surface cleaning of the carbon fiber; (2) ultrasonic treatment of surface; (3) activating pretreatment; (4) preparation of a polymer solution; (5) impregnating treatment; (6) surface activation of the carbon fiber. The activation technology has the advantages that after the surface of the carbon fiber is treated by the purifying and ultrasonic treatment, the organic matters are introduced to the surface of the carbon fiber, the bonding property of the organic matters at the surface of the carbon fiber is strong, the activated carbon fiber has good polarity, and the compatibility is excellent; the application prospect is broad.

Owner:合肥岑遥新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com