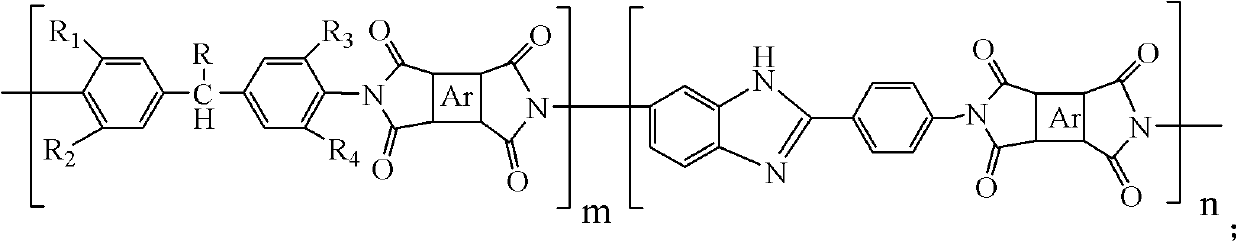

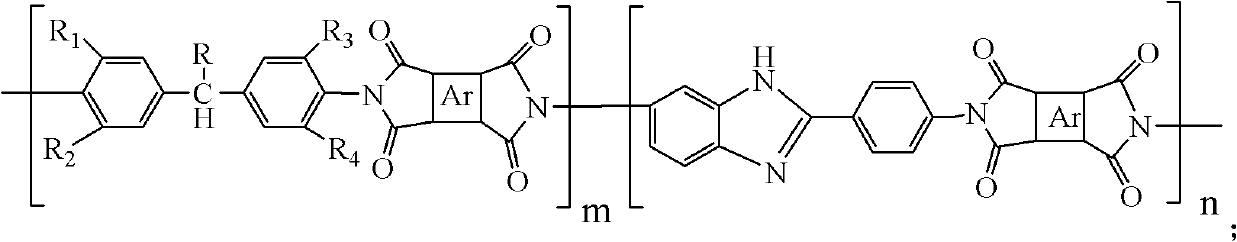

Polyimide containing benzimidazole unit and preparation method thereof

A technology of polyimide and benzimidazole, applied in the field of polyimide containing benzimidazole unit and its preparation, can solve problems such as thermal performance decline, achieve low cost, expand application scope, reduce regularity and interaction effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

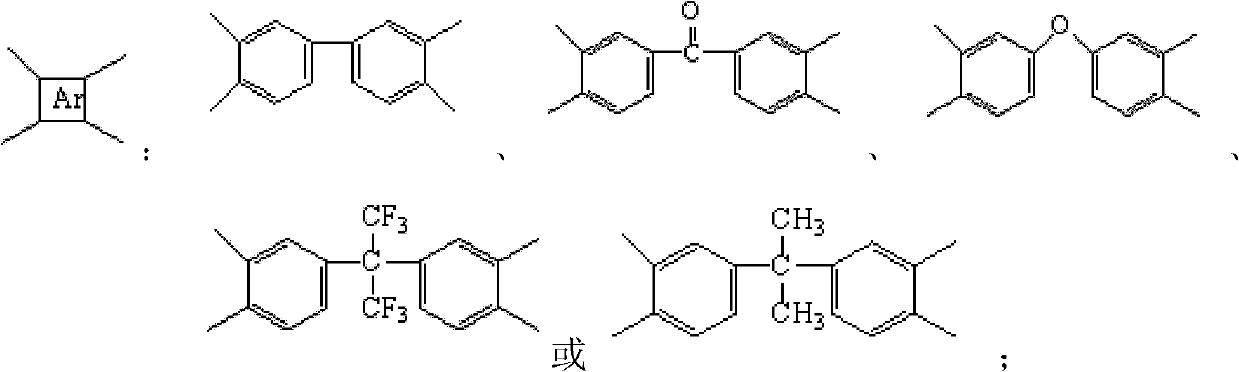

Method used

Image

Examples

Embodiment 1

[0023] (1) Synthesis of diamine monomer 3,3',5,5'-four substituent structure aromatic diamine

[0024] Add 30.4g (0.25mol) 2,6-dimethylaniline (or 2,6-dichloroaniline or 2,6-difluoroaniline), after being heated to 120 DEG C, dropwise add 17.8ml (0.12mol) benzaldehyde (or formaldehyde) and 5ml mass fraction 36~38% concentrated hydrochloric acid through the constant pressure dropping funnel in half an hour again, in After continuing to stir at this temperature for half an hour, the temperature of the reaction system was raised to reflux, and the temperature was lowered to 80° C. after the reaction was continued for 10 hours, and the reaction system was poured into 200 ml of 10% potassium hydroxide aqueous solution to terminate the reaction. After the obtained crude product was dried, it was further separated and purified by silica gel column chromatography to obtain a white crystal powdery diamine compound with a yield of about 80%. The diamine monomer is 3,3',5,5'-tetrasubstit...

Embodiment 2

[0029] The synthesis of 3,3',5,5'-tetrachloro-4,4'-diaminophenylmethane is the same as in Example 1.

[0030] In a 250ml three-necked round-bottomed flask equipped with a mechanical stirrer, water separator, condenser and nitrogen protection, the diamine monomer 3,3',5,5'-tetrachloro- 4,4'-diaminophenylmethane and BIA are mixed and added, and then the dianhydride monomer BPDA and 500ml NMP solvent in an equimolar amount to the total molar amount of the two diamine monomers, the solid content in the solution is 12% . After reacting and stirring at 120°C for 1 hour, continue to heat up to 200°C, keep the reaction temperature for 10 hours to obtain a viscous polymer solution, cool down to about 150°C, then pour the reaction solution into 500ml of ethanol to settle to end the reaction, and obtain a fibrous polymer solution. or strip-shaped polymer samples, the polymer was further rinsed twice with 1:1 ethanol and acetone, then suction-filtered, and vacuum-dried at 80°C for 10 h t...

Embodiment 3

[0033] The synthesis of 3,3',5,5'-tetrafluoro-4,4'-diaminophenyltoluene is the same as in Example 1.

[0034] In a 250ml three-necked round-bottomed flask equipped with a mechanical stirrer, water separator, condenser and nitrogen protection, the diamine monomer 3,3',5,5'-tetrafluoro- 4,4'-diaminophenyltoluene and BIA are mixed and added, and then the dianhydride monomer BTDA and 500ml DMAC solvent in an equimolar amount to the total molar amount of the two diamine monomers, the solid content in the solution is 10% . After reacting at 120° C. and stirring for 1 hour, the temperature was continued to rise to 190° C., and the reaction temperature was kept at 190° C. for 9 hours to obtain a viscous polymer solution. Cool down to about 150°C, then pour the reaction solution into 500ml of ethanol to settle to end the reaction, to obtain a fibrous or strip-shaped polymer sample, further wash the polymer twice with 1:1 ethanol and acetone, and then suction filter , vacuum drying at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com