Novel single ion polymer electrolyte and preparation method and application thereof

A polymer and single-ion technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as reducing battery energy efficiency and service life, reducing battery charge and discharge current stability, and limiting the application of polymer electrolytes, etc., to achieve Improved heat resistance, strong electrochemical stability, easy to grasp and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

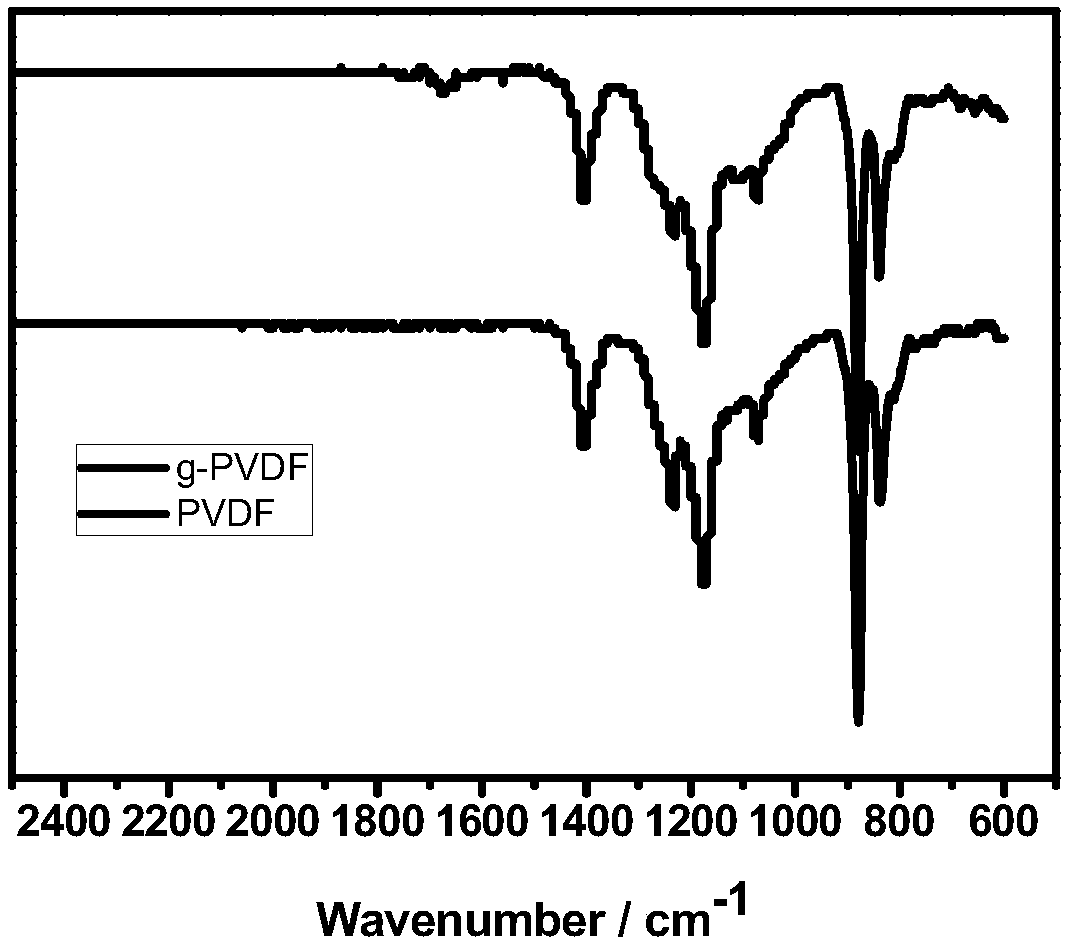

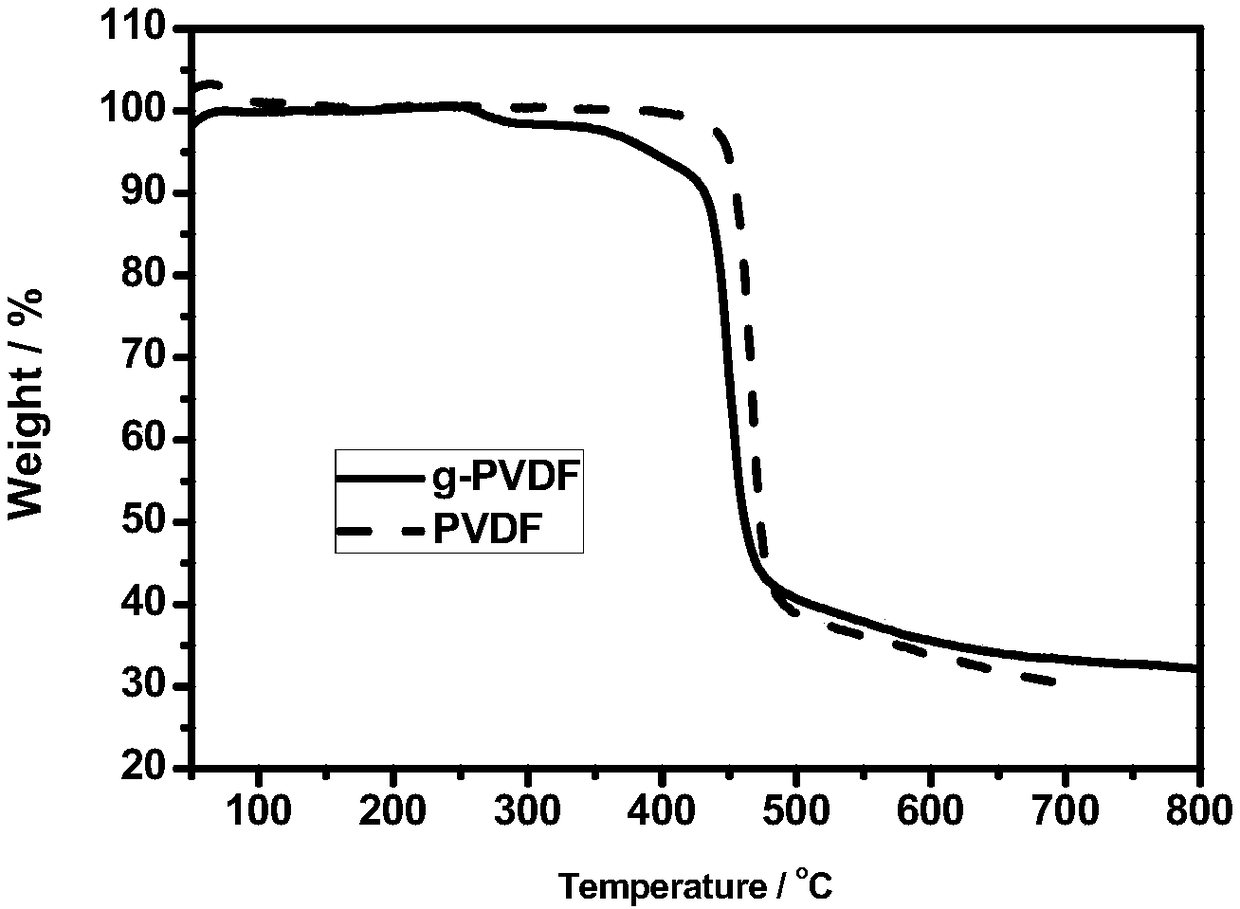

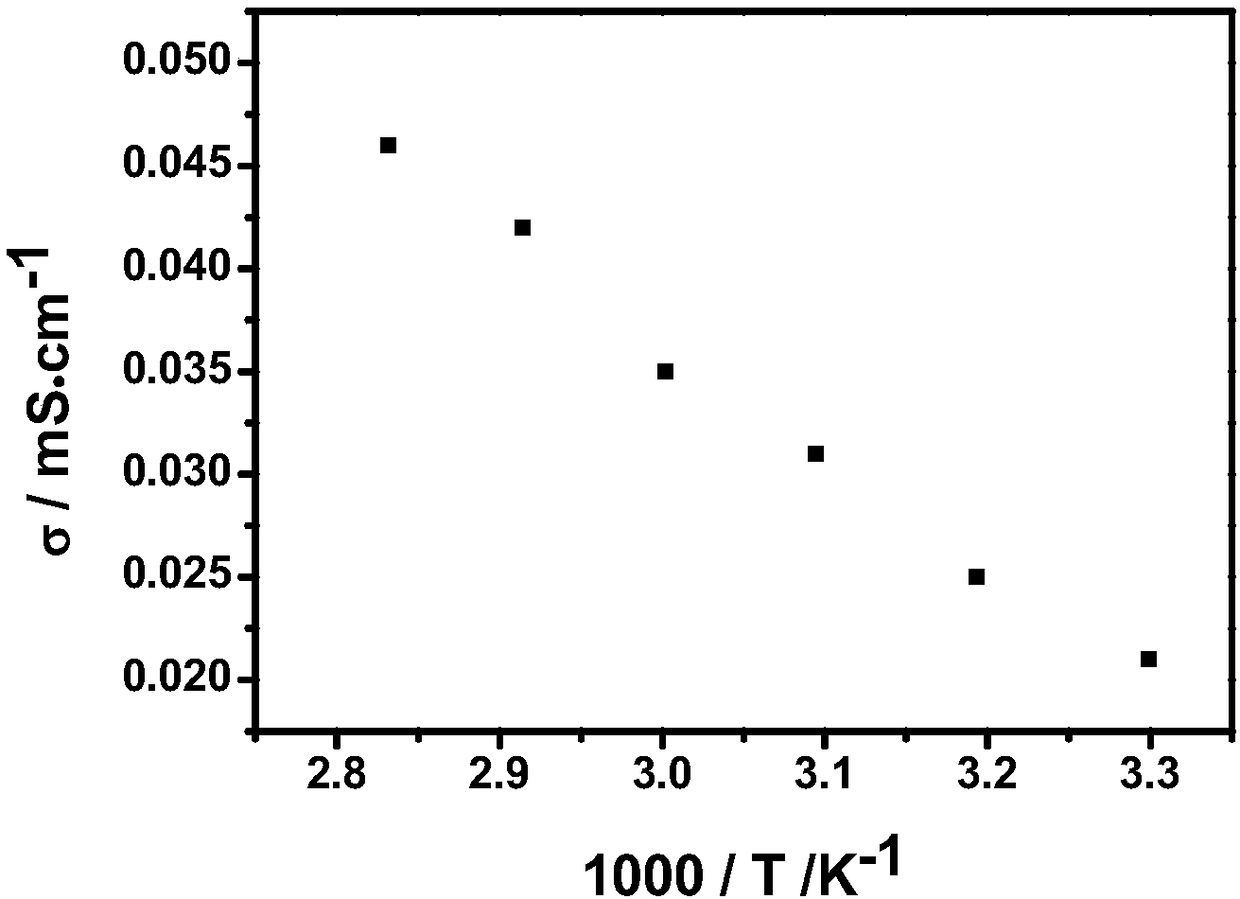

[0043] (1) 1 g of base powder polyvinylidene fluoride (PVDF) powder was vacuum-dried and hermetically sealed, then put into an irradiation bottle, and irradiated with a dose of 100 kGy in a cobalt source chamber.

[0044] (2) Dissolve the pre-irradiated powder in 30mL (N,N-dimethylformamide) DMF solvent, add 5mmol of hexafluorobutyl methacrylate and 2-acrylamide-2 to the uniformly dissolved base solution - 5 mmol of methylpropanesulfonic acid, after the oxygen in the solution was pumped out by a double row pipe, under the protection of an inert gas, the reaction was carried out in a constant temperature oil bath at 60° C. for 48 hours to obtain a double graft polymer solution. The solution was purified by adding excess precipitant ethanol and water several times, and the precipitated powder obtained was dried in a vacuum oven for 24 hours. Then the dry powder was completely dissolved in N,N-dimethylformamide (DMF), cast into a film and then dried for 24 hours.

[0045] (3) Tr...

Embodiment 2

[0061] (1) 1 g of base powder polyvinylidene fluoride (PVDF) powder was vacuum-dried and hermetically sealed, then put into an irradiation bottle, and irradiated with a dose of 100 kGy in a cobalt source chamber.

[0062] (2) Dissolve 1 g of the pre-irradiated powder in 30 mL of DMF solvent, add 5 mmol of 2-acrylamide-2-methylpropanesulfonic acid to the uniformly dissolved base solution, and remove the oxygen in the solution with a double row tube, Under the protection of gas, the constant temperature oil bath is 60°C. After a certain period of reaction, the deionized water is purified several times, and the obtained precipitated powder is vacuum-dried for 24 hours and stored in a sealed tube. Put the powder stored in the sealed tube into the cobalt source chamber and irradiate again. Dissolve the irradiated powder again with a solution evenly, then put 5 mmol of hexafluorobutyl methacrylate into it, remove oxygen, and react in an inert gas-protected constant temperature oil b...

Embodiment 3

[0065] (1) Dissolve 1g of base powder vinylidene fluoride (PVDF) powder, 5mmol of hexafluorobutyl methacrylate and 5mmol of 2-acrylamide-2-methylpropanesulfonic acid in 30mL of DMSO solvent, and put it into Irradiation chamber.

[0066] (2) Precipitate the irradiated solution several times with precipitant methanol and deionized water, and dissolve the obtained precipitated powder in the organic solvent DMF again after drying. Cast into film.

[0067] (3) Soak the obtained film in 1mol / L LiOH solution for 48 hours.

[0068] The results show that, compared with Examples 1 and 2, different radiation and feeding sequences have a great influence on the grafting rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com