Damping silicon rubber with relatively small temperature effect and preparation method thereof

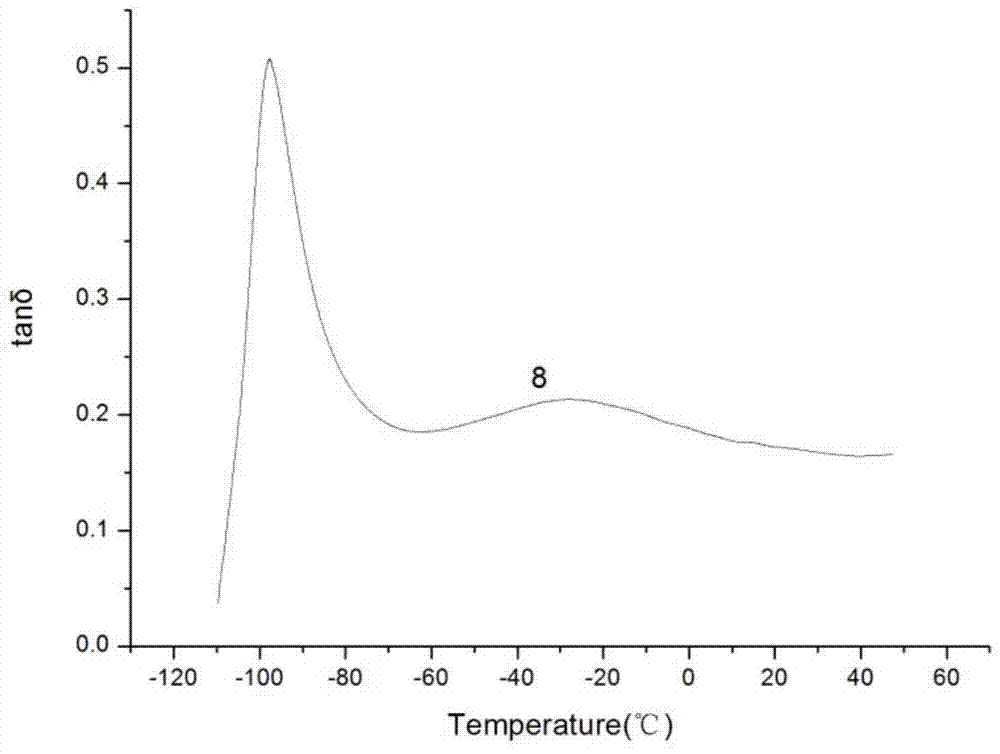

A temperature effect, silicone rubber technology, applied in the field of damping silicone rubber and its preparation, can solve the problems of material damping performance having a great influence, the damping effect of the damping material is not good, and cannot be used as an elastic body, etc., and achieves stable damping performance and damping. Good effect and heat resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

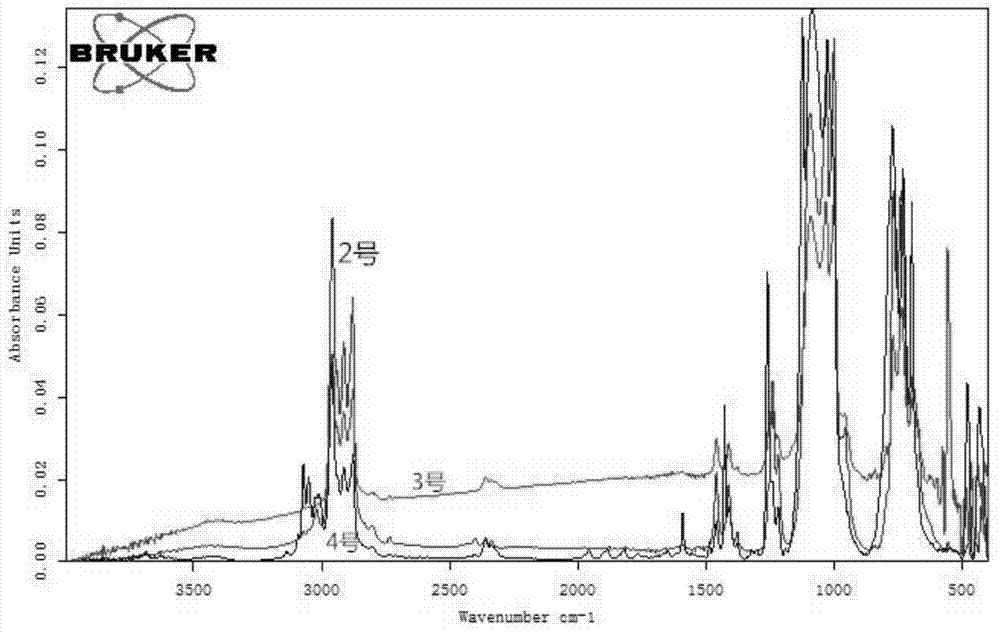

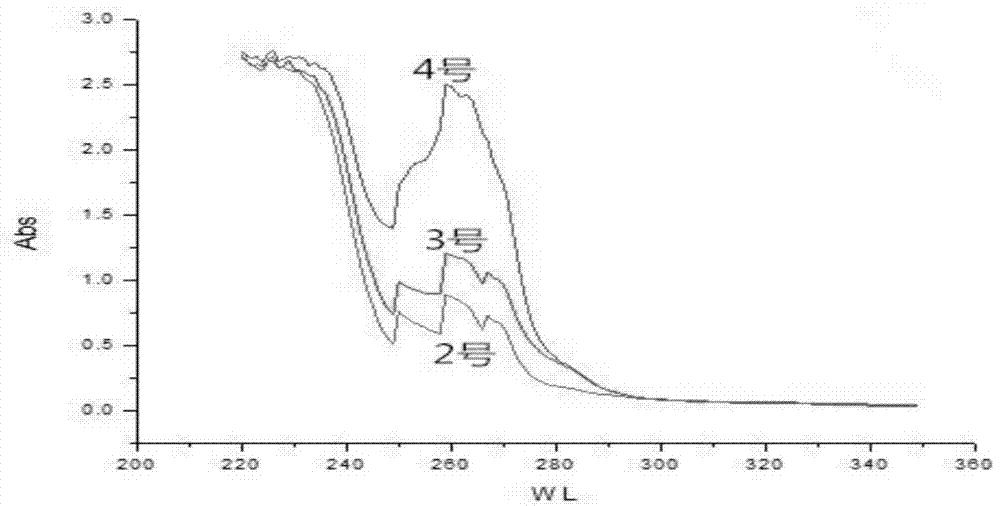

Embodiment 1

[0037] Example 1: Add 18.6g of tetramethyldivinyldisiloxane and 2g of sodium hydroxide powder into a pressure-resistant reactor, add 15ml of anhydrous toluene and 2g of polypropylene oxide with a molecular weight of 1000, seal the reactor, and raise the temperature React at 100°C for 1 hour, cool down to -5°C, press in 1.15g of sodium wire, gradually raise the temperature to 80°C, continue to react for 1hr, then add 40.8g of methylphenylcyclosiloxane and 45.9g of hexaethylcyclotri The mixture of siloxanes was reacted at 100°C for 2 hours, continued to heat up to 120°C to evaporate the toluene and reacted for 1 hour, and cooled to room temperature to obtain a sodium hydroxide silicon alkoxide initiator.

Embodiment 2

[0038] Embodiment 2: 9.3g of tetramethyldivinyldisiloxane and 1.425g of calcium hydroxide powder are added to a pressure-resistant reactor, 15ml of anhydrous toluene and 2g of polypropylene oxide with a molecular weight of 1000 are added, and the reactor is closed. Raise the temperature to 150°C for 1 hour, cool to -5°C, press in 1g of calcium wire, gradually raise the temperature to 80°C, continue the reaction for 1hr, then add 20.4g of methylphenylcyclosiloxane and 23g of hexaethylcyclotrisilane The mixture of oxanes was reacted at 100°C for 2hrs, continued to heat up to 120°C to evaporate toluene and reacted for 1hr, and then cooled down to room temperature to obtain calcium hydroxide silicon alkoxide initiator.

Embodiment 3

[0039] Example 3: As a comparison, a conventional method was used to prepare sodium hydroxide silicon alkoxide, 4g of sodium hydroxide powder was added to the reactor, 10.2g of methylphenylcyclosiloxane and 11.95g of hexaethylcyclotrisiloxane were added The mixture was heated up to 100°C for 1 hr, then added a mixture of 30.6 g of methylphenylcyclosiloxane and 35.85 g of hexaethylcyclotrisiloxane, reacted at 100°C for 2 hr, and continued to heat up to 120°C for 1 hr. Cool down to room temperature to obtain sodium hydroxide silicon alkoxide initiator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com