Patents

Literature

208 results about "Silicon alkoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

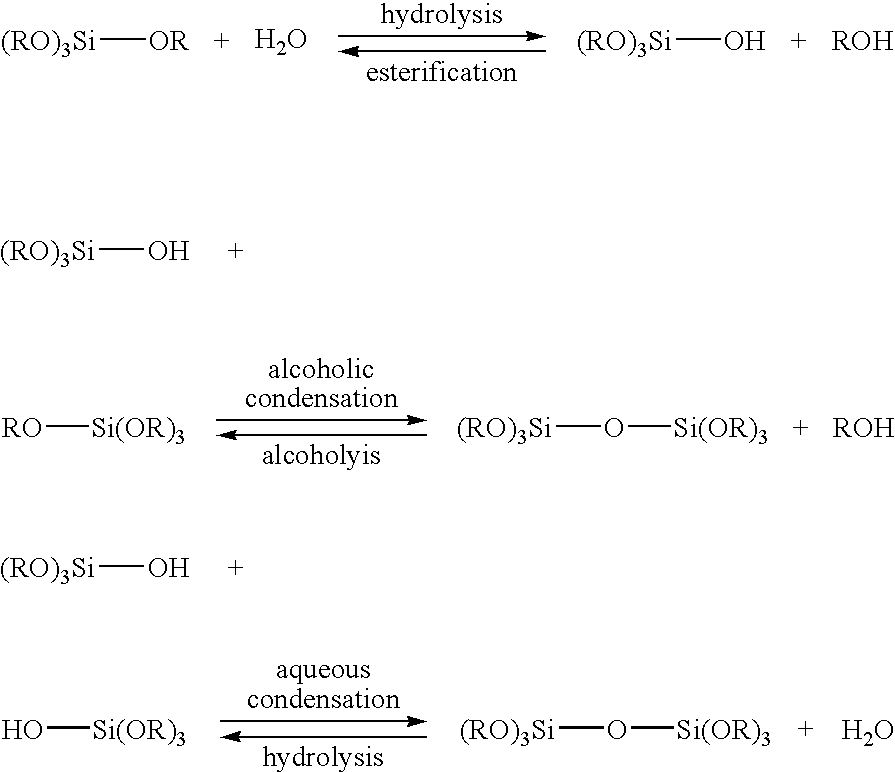

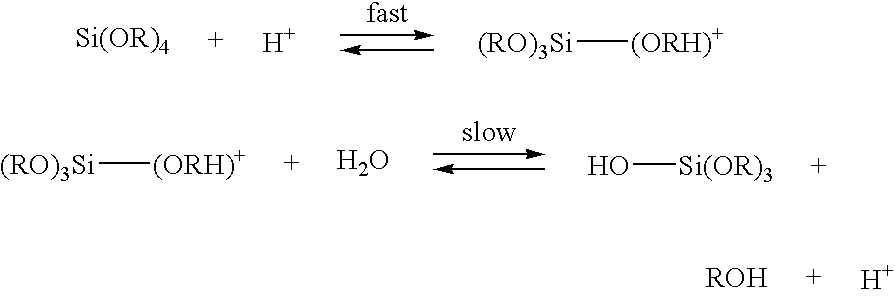

Silicon alkoxides are a group of alkoxides, chemical compounds of silicon and an alcohol, with the formula Si(OR)₄. Silicon alkoxides are an important precursor for manufacture of silica-based aerogels.

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

Process for the production of articles covered with silica-base coats

InactiveUS6465108B1Reduce the degree of polymerizationImprove responsePretreated surfacesLiquid/solution decomposition chemical coatingCooking & bakingAlcohol

Coating liquid prepared by dissolving an acid and a silicon alkoxide into alcohol, containing at least one of either a silicon alkoxide or a hydrolyzate thereof (including a partial hydrolyzate) in an amount of 0.010 to 3% by weight (in terms of silica), an acid in terms of 0.0010 to 1.0 normality, and water in terms of 0 to 10% by weight is coated on a substrate to produce an article coated with a silica-based film. By this method for producing a silica-based film coated article, an excellent silica-based film coated article can be obtained without requiring baking and pretreatment. Furthermore, a functional film coated article excellent in durability can be produced in a short period of time and safely by using the abovementioned silica-based film as a primer film and applying thereon an organosilane having a hydrolyzable group and a functional group having a specific function or a hydrolyzate thereof.

Owner:NIPPON SHEET GLASS CO LTD

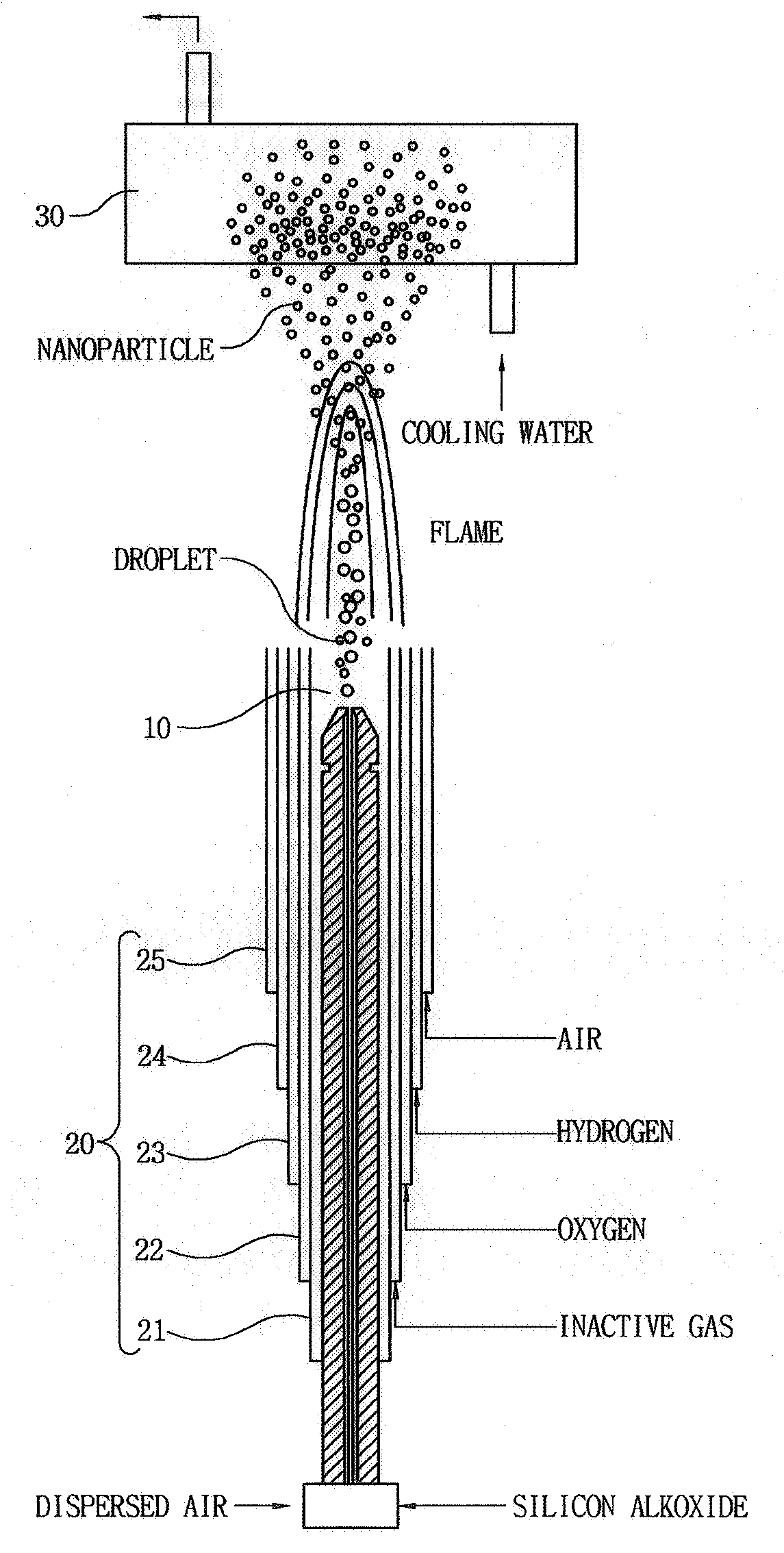

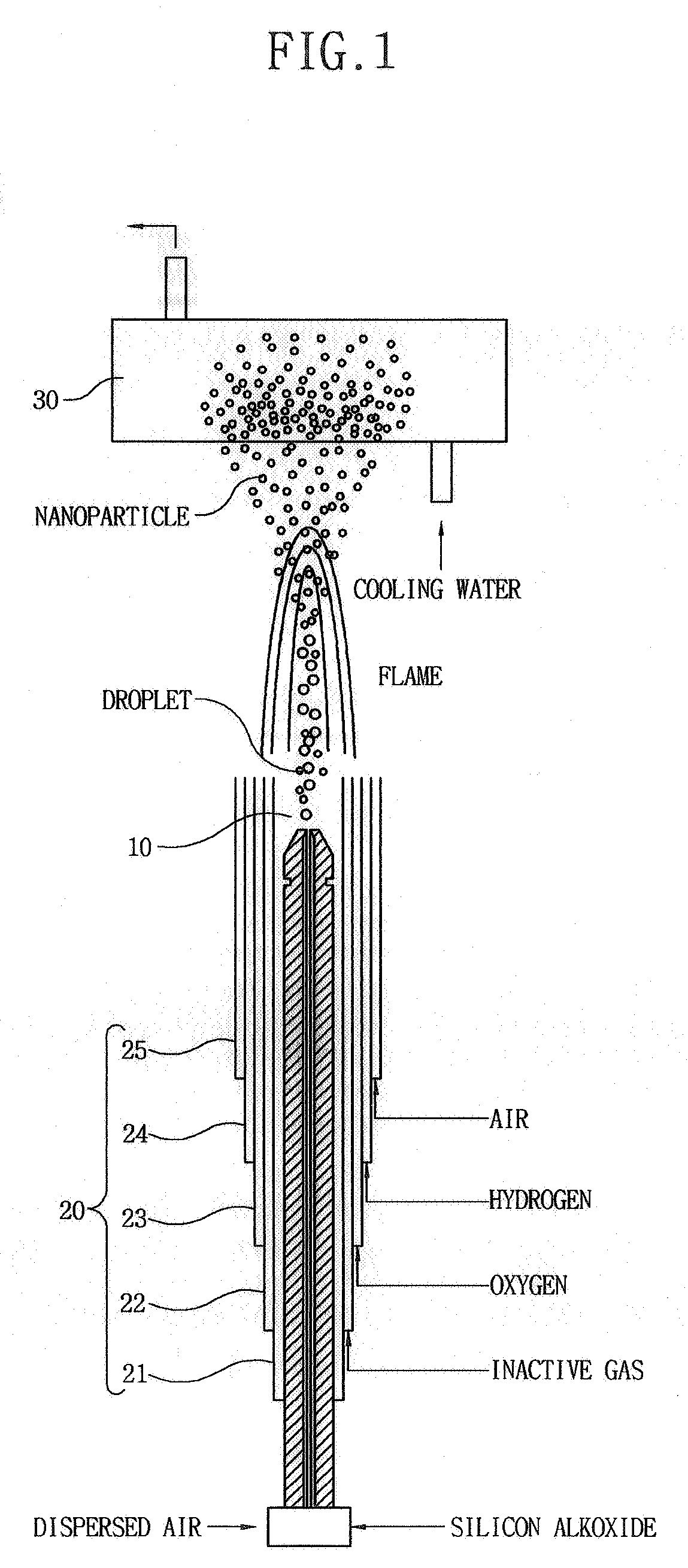

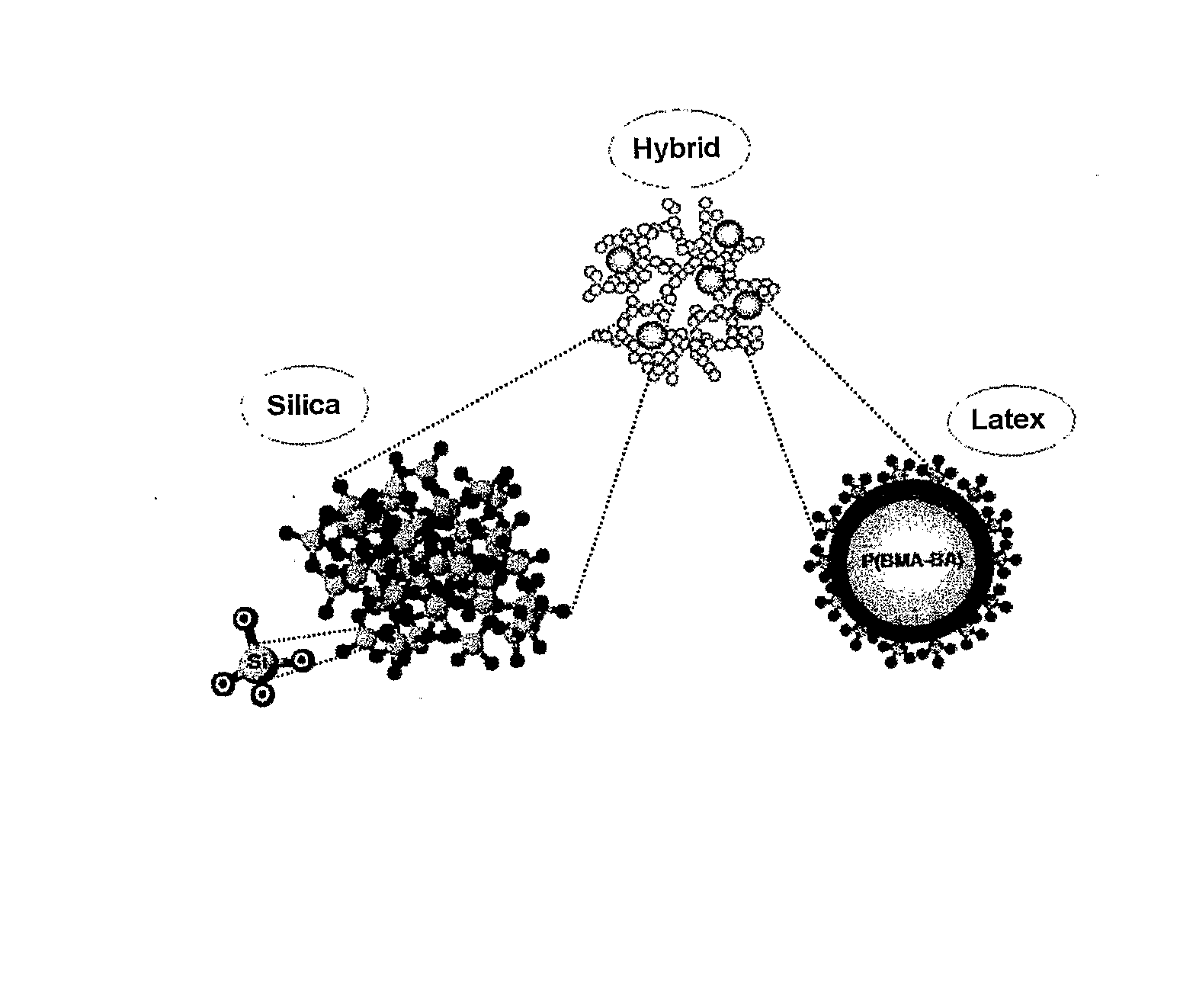

Method for making silica nanoparticles by flame spray pyrolysis adopting two-fluid nozzle

The invention relates to a method for making silica nanoparticles using a flame reactor, which includes a droplet spray having a two-fluid nozzle and a burner of a quintuple tube structure. In this method, droplets of silicon alkoxide as liquid Si compound are sprayed through the droplet spray of the flame reactor. A flame is generated by the flow of inert gas, oxygen, hydrogen and air simultaneously into the burner of the flame reactor. The liquid Si compound is delivered through the flame of the burner to produce silica nanoparticles having a mean particle size ranging from 9 nm to 68 nm. Resultant nanoparticles are collected and recovered in a particle collector. The droplets sprayed under high pressure from a silicon alkoxide solution are directly oxidized in the flame, thereby producing spherical silica nanoparticles.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

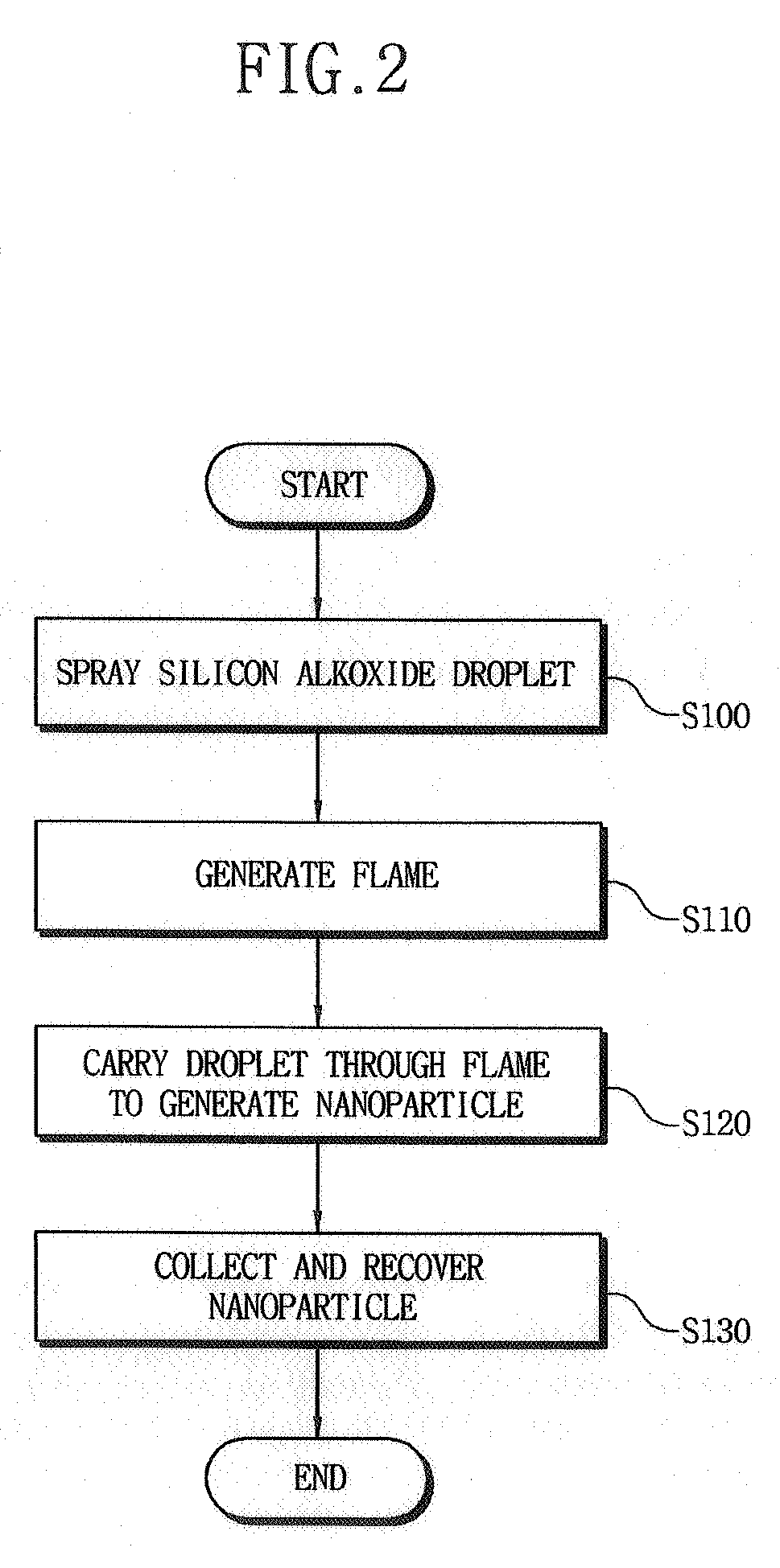

Process for the Preparation, Under Subcritical Conditions, of Monolithic Xerogels and Aerogels of Silica/Latex Hybrids, Modified with Alkoxysilane Groups

InactiveUS20080188575A1Improve insulation performanceHigh mechanical strengthSilicaOther chemical processesColloidal silicaMethacrylate

The invention relates to a process for the preparation of monolithic xerogels and aerogels of silica / latex hybrids under subcritical conditions. In the two-stage synthesis of these alcogels in the presence of an acid-base catalyst, the hydrolysis and polycondensation of a silicon alkoxide are carried out in an organic medium containing excess water. A latex consisting of polybutyl methacrylate and polybutyl acrylate, modified with alkoxysilane groups, is first synthesized and then incorporated in the mixture either in the first stage in order to effect its co-hydrolysis with the silicon alkoxide, or in the second stage to effect its co-condensation with the previously hydrolysed colloidal silica. The resulting alcogels are aged, washed, and dried under subcritical conditions. This process gives hybrid products containing 0.1-50 wt-% of latex and having a density of 300-1300 kg / m3, a porosity of 40-85%, a specific surface area of 400-900 m2 / g and a mean pore diameter of 2-12 nm. The products are resistant to atmospheric humidity and moisture, have better mechanical properties than the corresponding inorganic products, and can be used as thermal, acoustic and electrical insulators.

Owner:INST SUPERIOR TECH

Nickel-based catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444737AHigh mechanical strengthHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNanowire

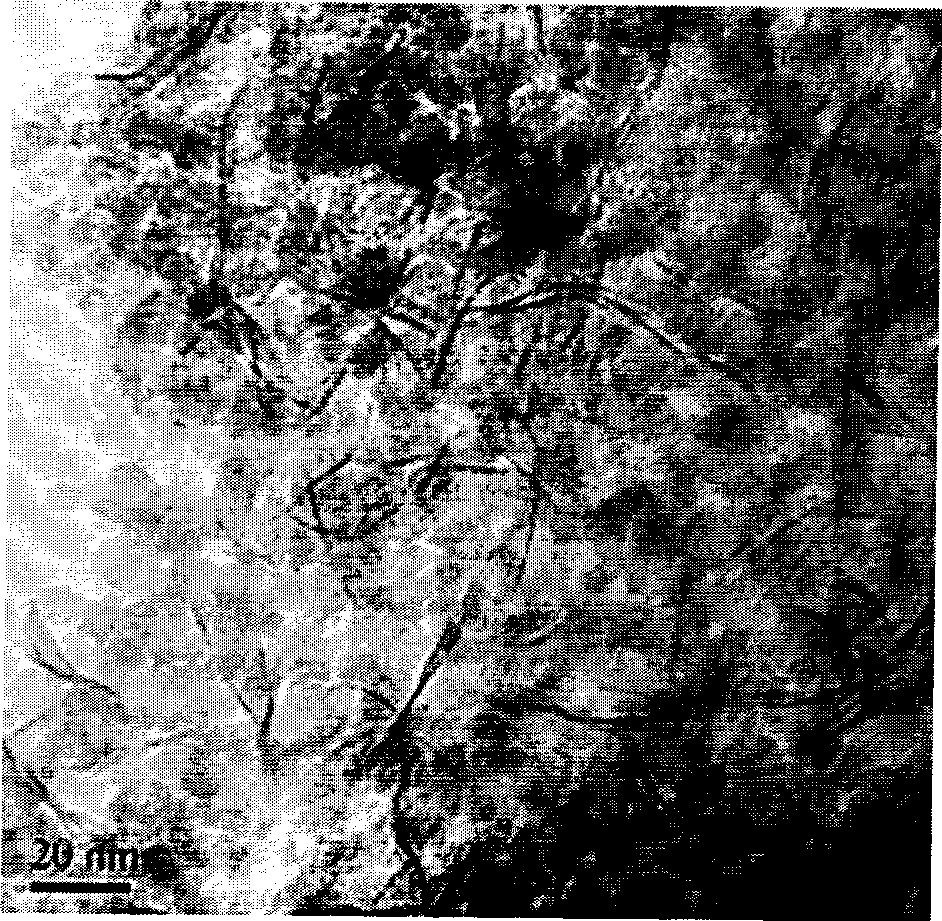

The invention discloses a nickel-based catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance nickel nanowire as an active component, and nano-particles of MgO or CaO or ZrO2 or TiO2 or CeO2 or compound nano-particles thereof as an adjuvant. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, nickel nitrate or magnesium nitrate or calcium nitrate or zirconium nitrate or cerous nitrate or complex nitrate thereof and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, and limits the selectivity of byproducts CH4 and CO at a lower level. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

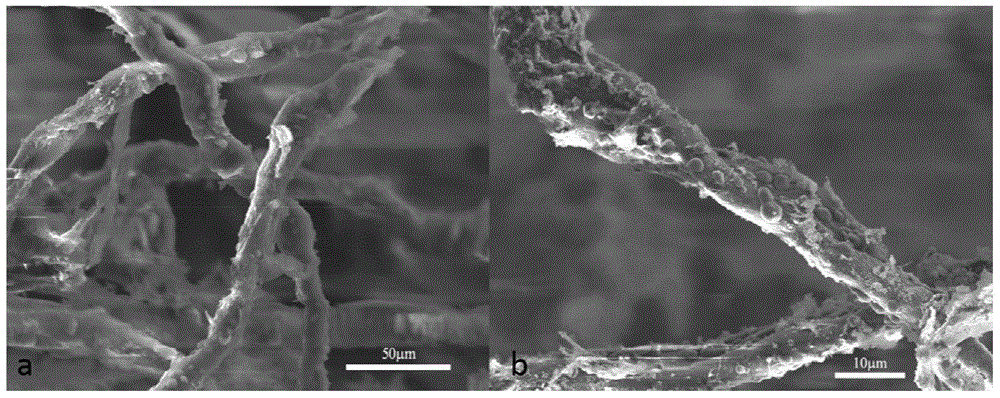

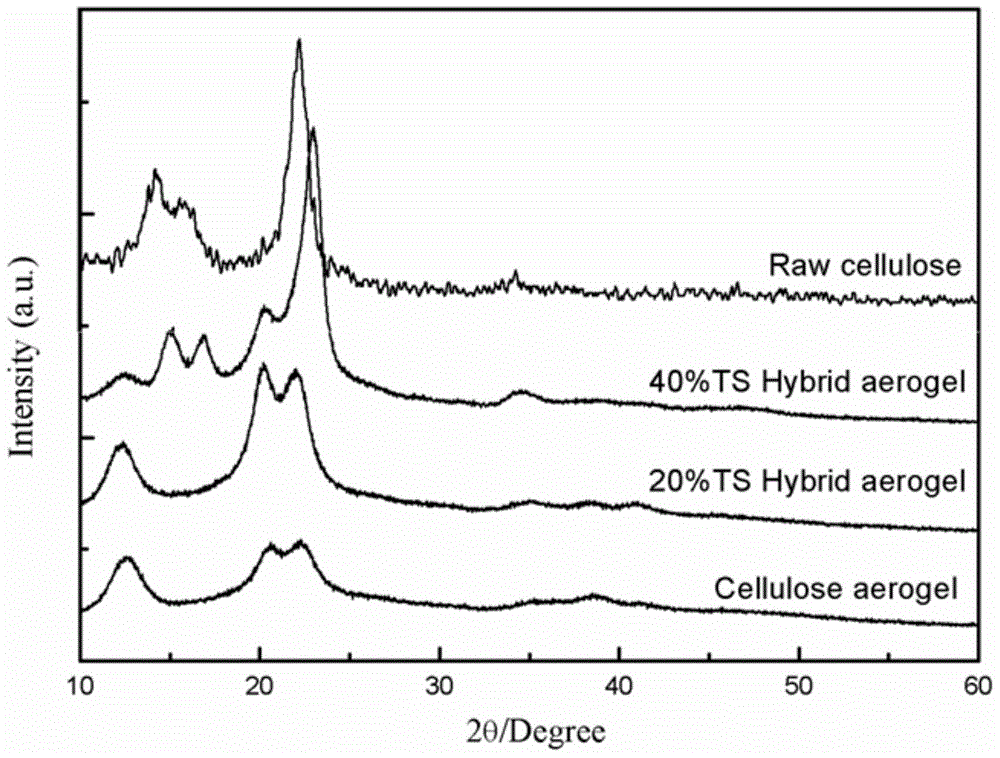

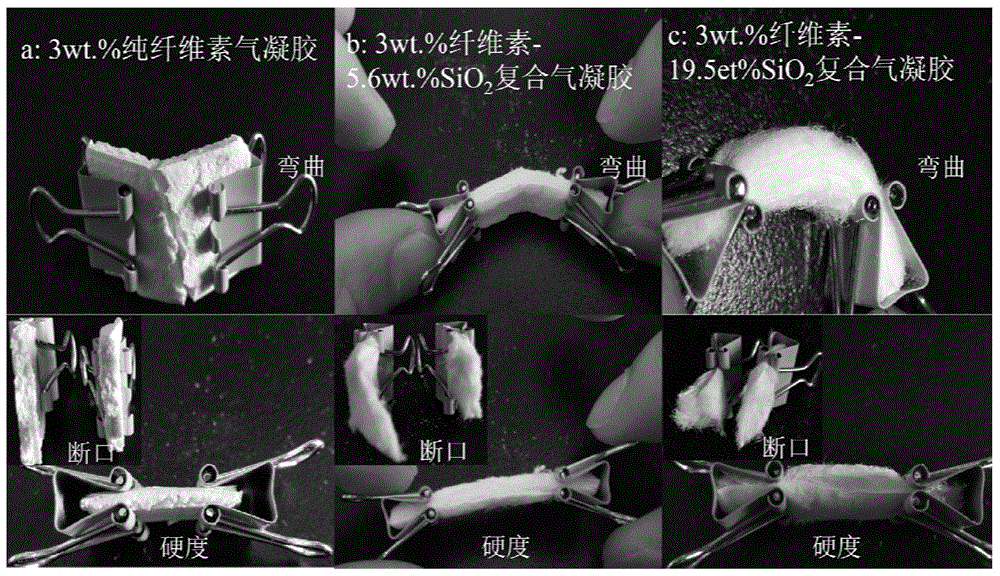

In-situ preparation method of cellulose-silicon dioxide composite aerogel

The invention discloses an in-situ preparation method of cellulose-silicon dioxide composite aerogel. The cellulose-SiO2 composite aerogel is prepared from cellulose and organic silicon alkoxide as raw materials and aqueous alkali as a solvent and a catalyst; the porosity of the composite aerogel can be up to 96.6%; and the density is 0.052g / cm<3>. The in-situ preparation method is simple, feasible, energy-saving and environment-friendly; the defects of poor dispersing uniformity, low controllability of composite content, poor stability of a composite phase and the like in the prior art are overcome; the prepared composite aerogel material has relatively low heat-conducting coefficient and good heat-insulating property, and has wide application prospects in the fields of civil industry and medium-low temperature heat protection with special requirements; and a basis is provided for application of the composite aerogel material in the field of heat insulation.

Owner:HAINAN UNIVERSITY

Coating composition of photocatalyst

InactiveUS20050233893A1Reduce the amount requiredSufficient photocatalytic activityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsColloidal silicaLiquid medium

A photocatalytic coating composition comprising a photocatalyst, a silicon alkoxide, a zirconium compound, colloidal silica, and a liquid medium, wherein a content of the zirconium compound in terms of zirconium atoms is 0.3 to 3 times by mole a content of the silicon alkoxide in terms of silicon atoms, which can form a coating film of a photocatalyst with a high adhesion strength to a substrate.

Owner:SUMITOMO CHEM CO LTD +1

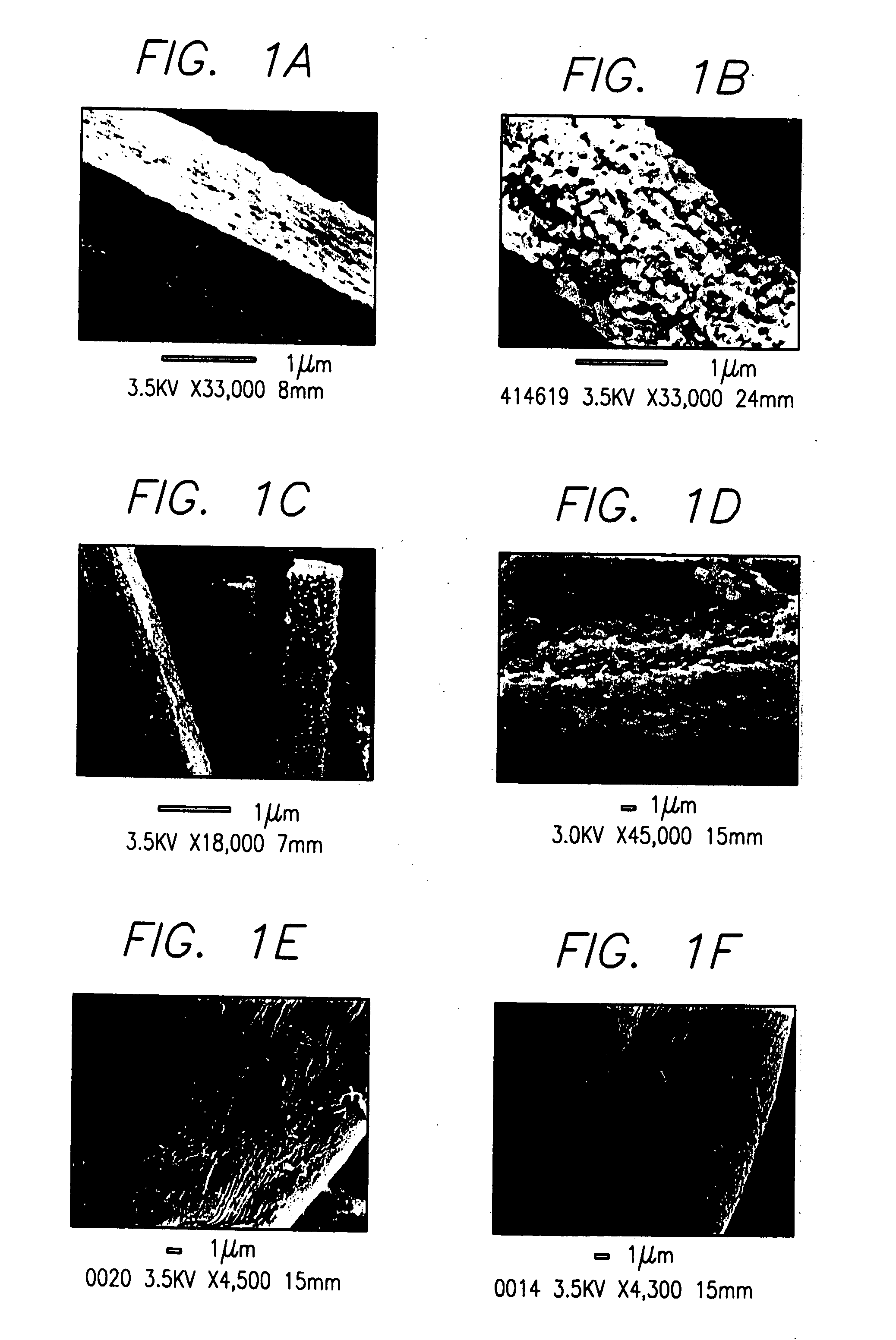

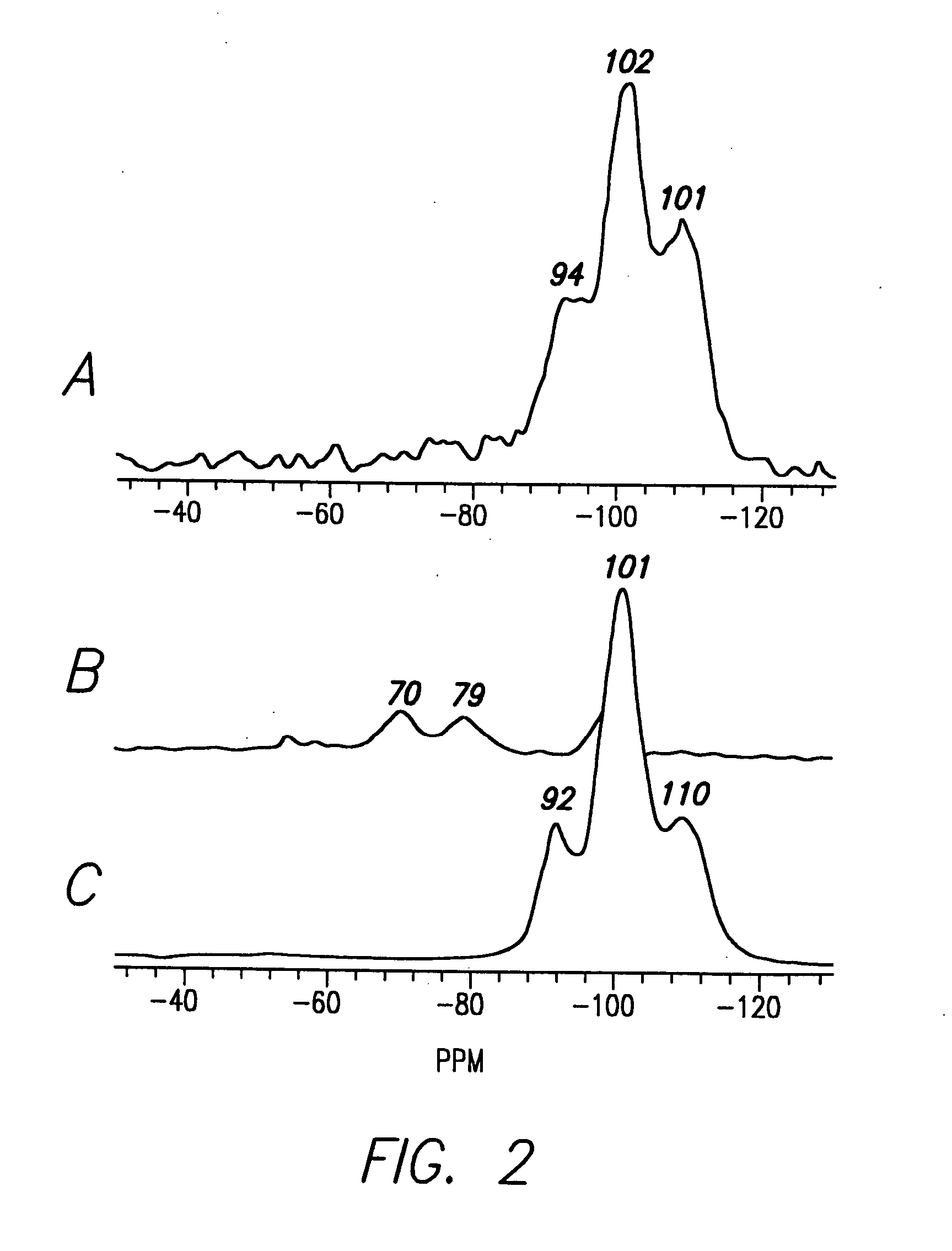

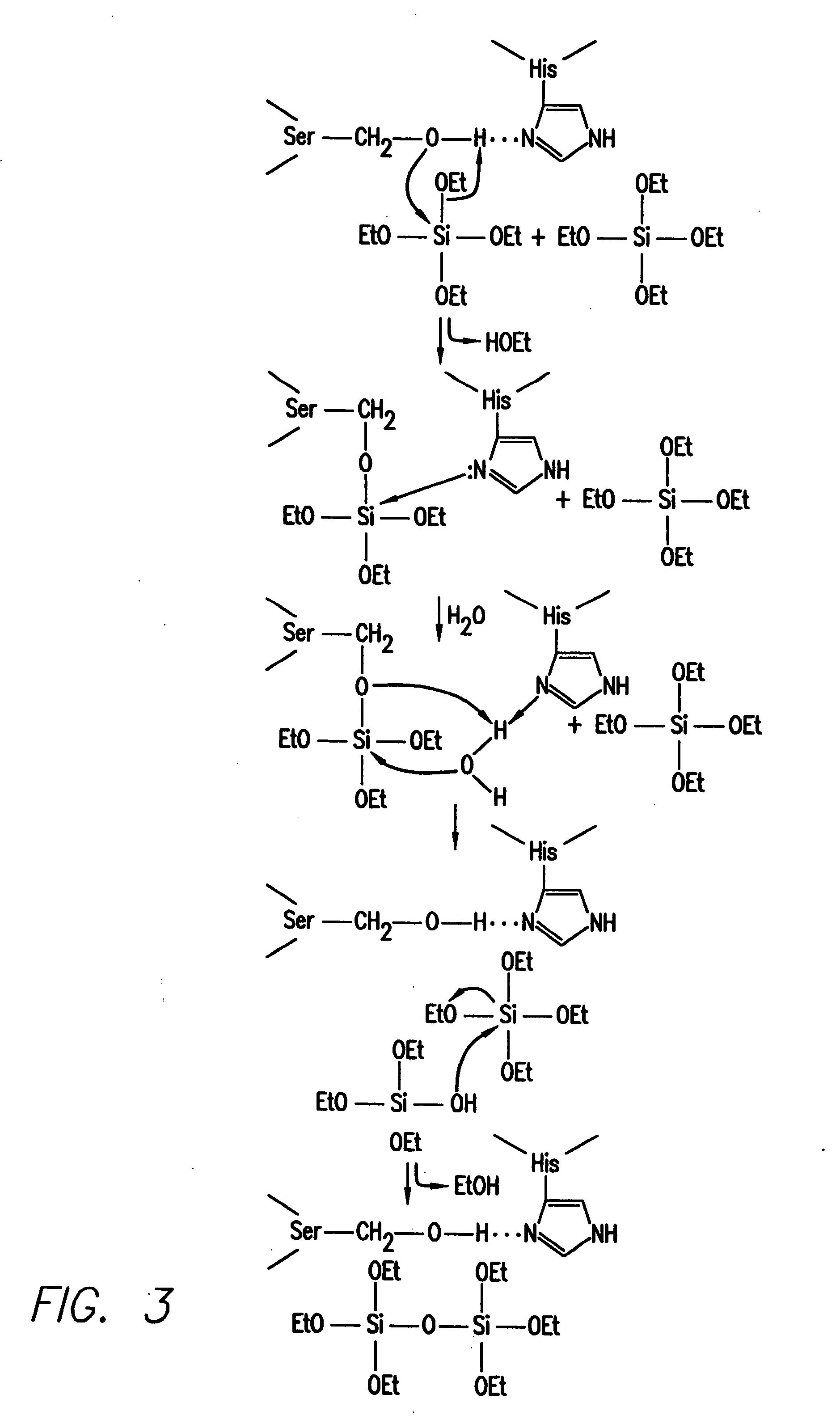

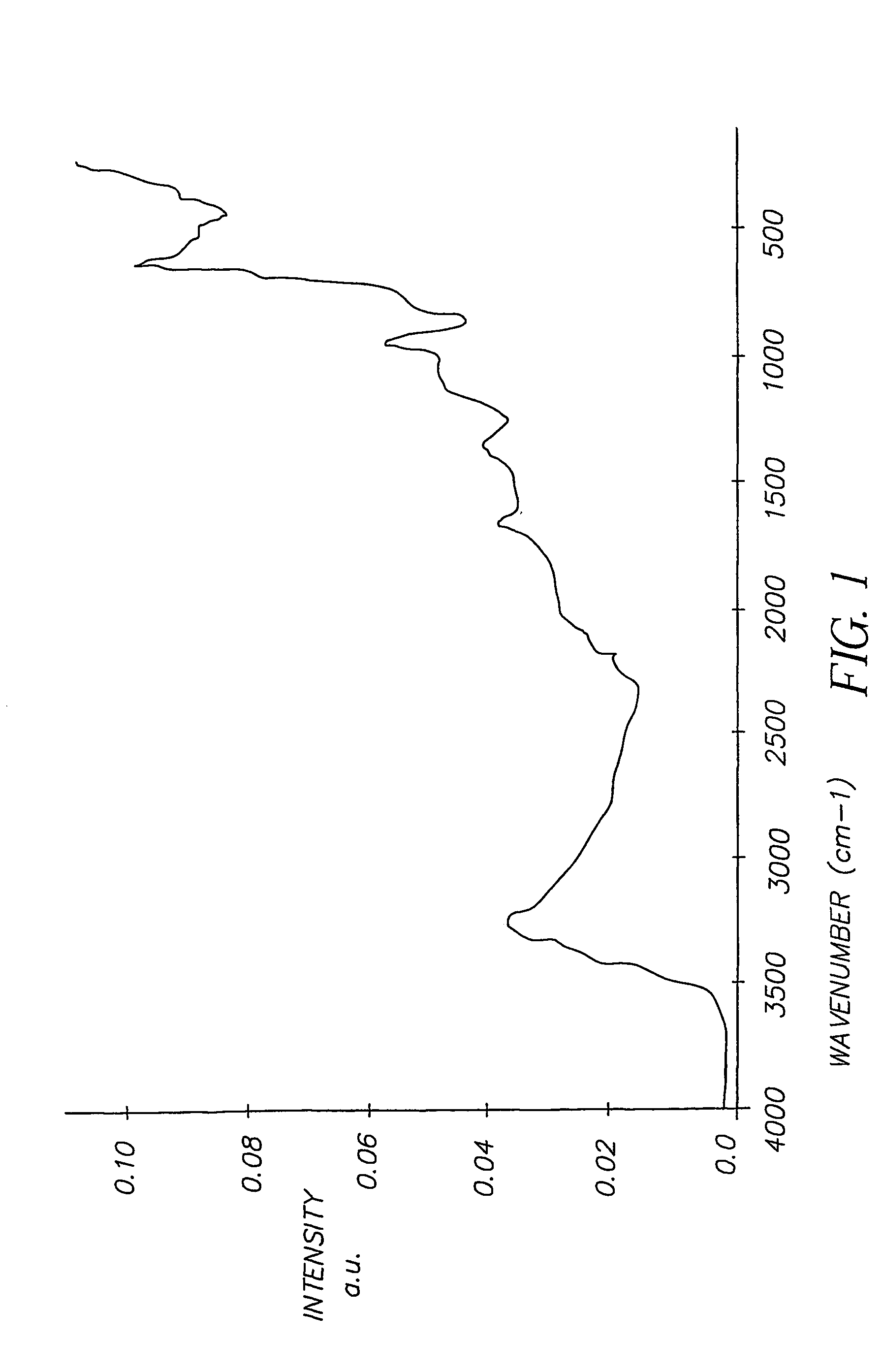

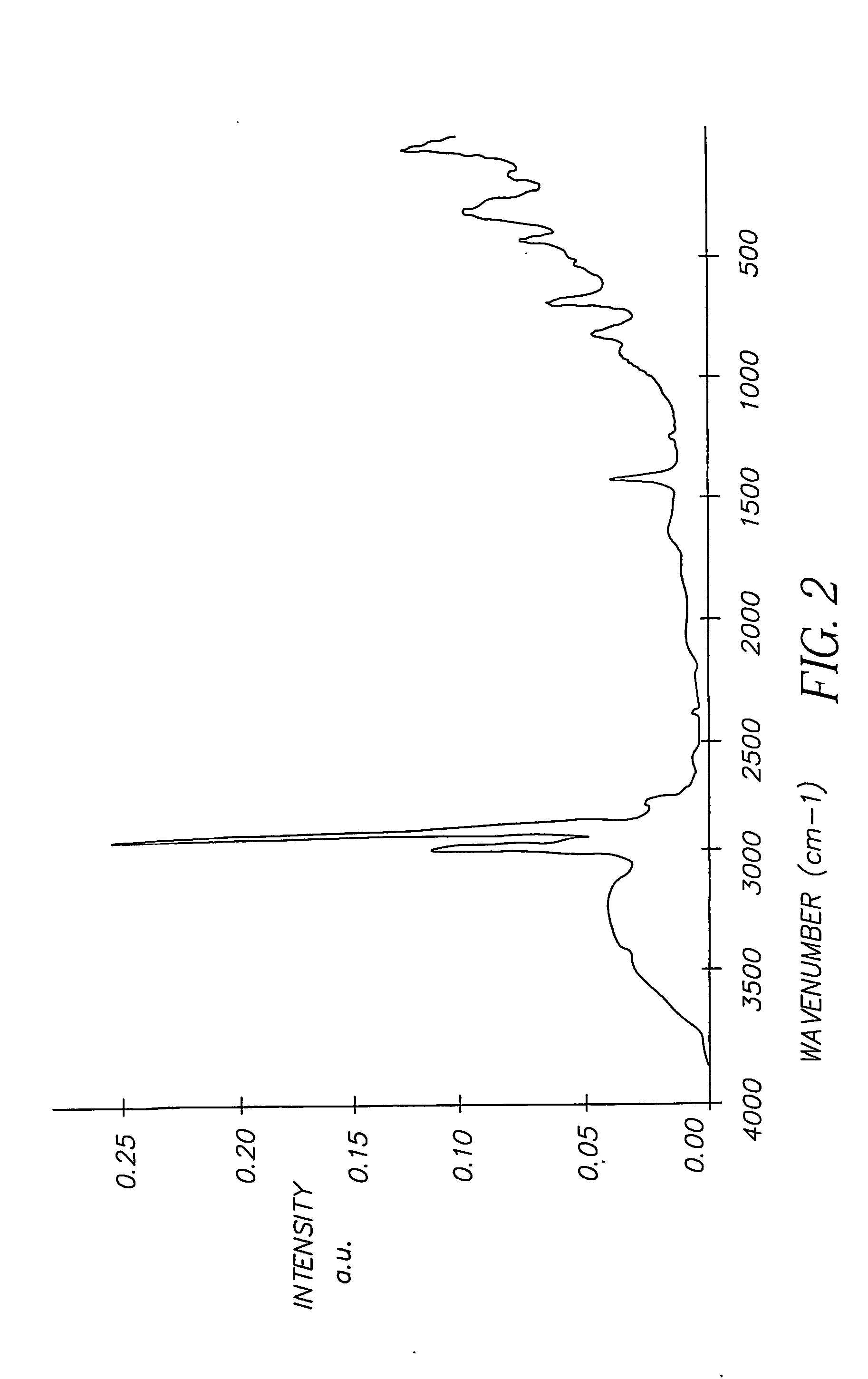

Methods, compositions, and biomimetic catalysts for the synthesis of silica, polysilsequioxanes, polysiloxanes, non-silicon metalloid-oxygen networks, polymetallo-oxanes, and their organic or hydrido conjugates and derivatives

InactiveUS20050090634A1SilicaOrganic-compounds/hydrides/coordination-complexes catalystsPolymer networkNanostructure

The in vitro polymerization of silica, silicone, non-silicon metalloid-oxane and metallo-oxane polymer networks, by combining a catalyst and a substrate to polymerize the substrate to form silica, polysiloxanes, polymetalloid-oxanes polymetallo-oxanes (metal oxides), polyorganometalloid oxanes, polyorganometallo oxanes, and the polyhydrido derivatives thereof, at about neutral pH. The nanostructure-directing catalysts have a nucleophilic functionality and a hydrogen-bonding acceptor group, and include: silicateins, enzymes that work by a mechanism functionally related to that of the silicateins; self-assembling peptides related to those synthesized and demonstrated capable of acting as biomimetic substitutes for the silicateins; non-peptide-based synthetic polymers containing a nucleophilic group and a hydrogen bonding amine such that the polymer functions by a mechanism of action related to that of the silicateins; materials having such chemical functionality as a nucleophilic group and or a hydrogen bonding amine which, acting in concert with nanoconfinement and or chemical functionality of the surface or matrix to which the functionality is attached, acts catalytically by a mechanism related to that of the silicateins; and small-molecule non-polymeric biomimetic catalysts that operate by the same mechanism as silicateins. The substrate is selected from groups consisting of silicon alkoxides, non-silicon metalloid alkoxides or metal alkoxides, and any organic, organometallic or hydrido derivatives of the foregoing; inorganic and organic oxygen-containing chelates of silicon, non-silicon metalloids or metals and any organic, organometallic or hydrido derivatives of the foregoing; and inorganic and organic esters of the hydoxides of silicon, non-silicon metalloids or metals and any organic, organometallic or hydrido derivatives of the foregoing; and inorganic and organic hydolyzable salts, complexes or conjugates of the hydroxides of silicon, non-silicon metalloids or metals and any organic, organometallic and hydrido derivates of the foregoing.

Owner:RGT UNIV OF CALIFORNIA

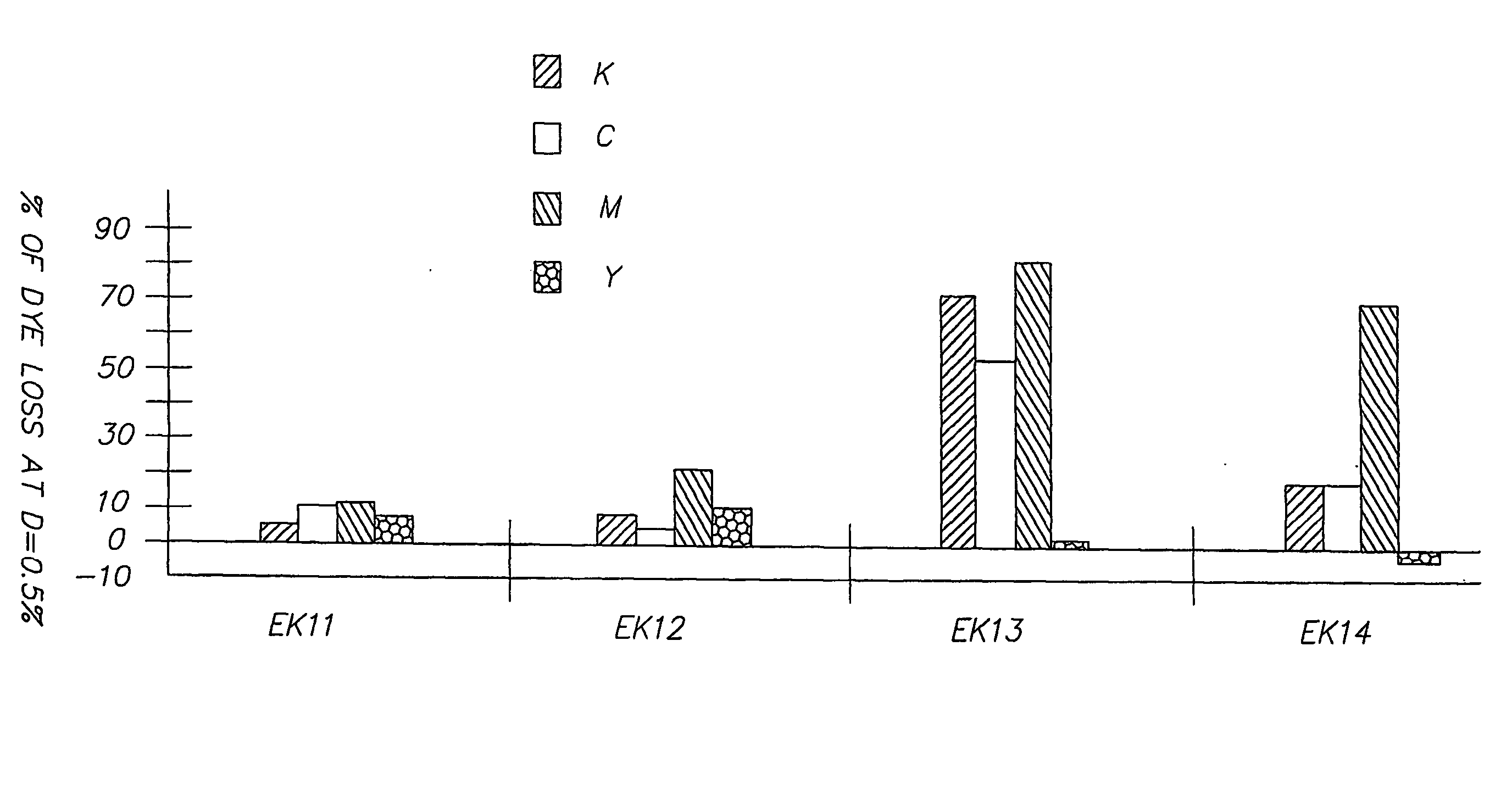

Inkjet recording element

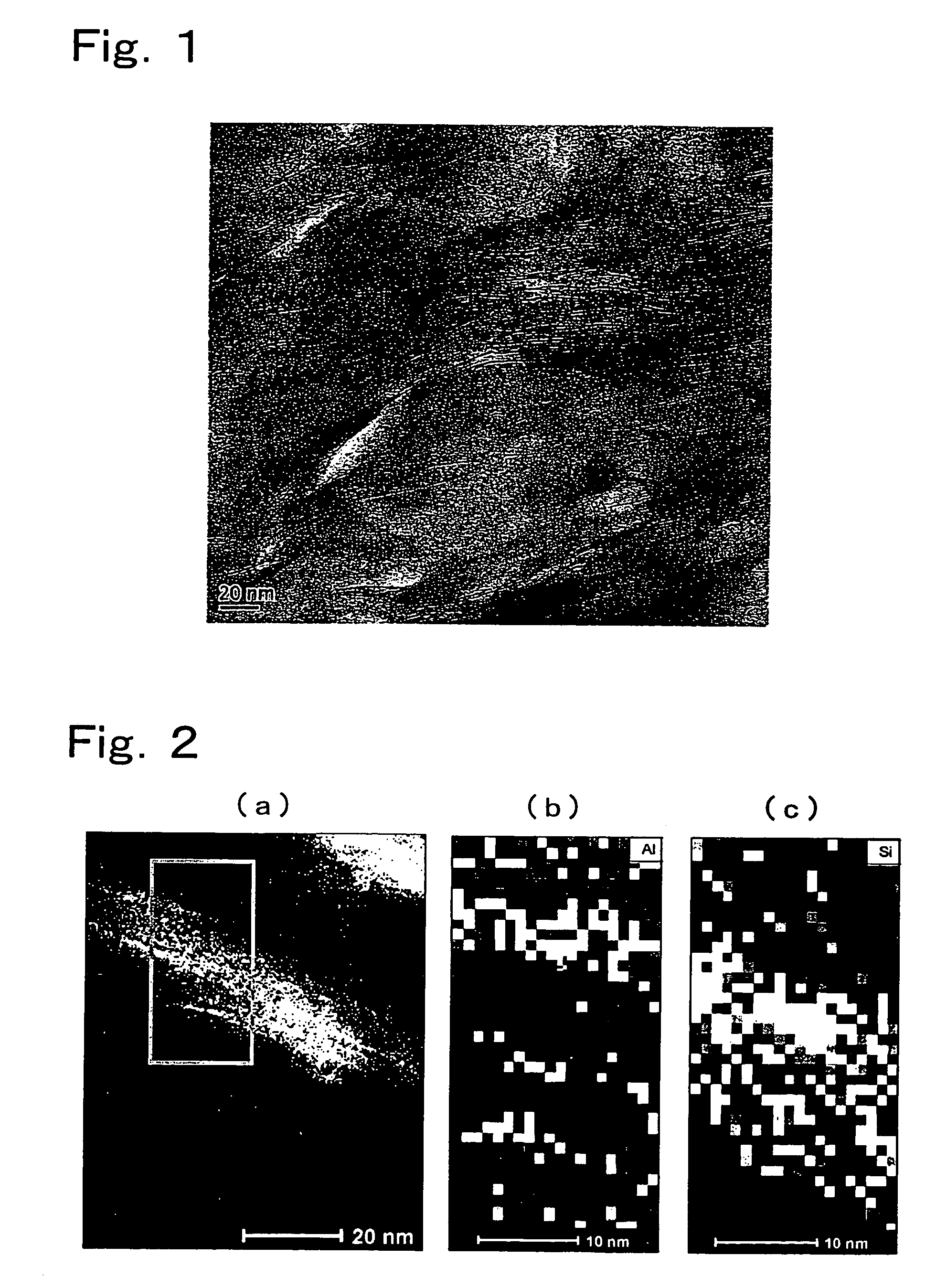

InactiveUS20050253916A1Improved dye keeping property in timeHigh glossPhysical/chemical process catalystsAluminium silicatesSilicon alkoxideRecord element

The present invention relates to an ink jet recording element having very good dye keeping properties in time. Said recording element comprises a support and at least one ink-receiving layer, said ink-receiving layer comprising at least one hydrosoluble binder and at least one aluminosilicate polymer obtainable by a preparation method consisting in treating an aluminum halide with a mixture of at least one silicon alkoxide only having hydrolyzable substituents and at least one silicon alkoxide having a non-hydrolyzable substituent, with an aqueous alkali in the presence of silanol groups, the aluminum concentration being maintained less than 0.3 mol / l, the Al / Si molar ratio being maintained between 1 and 3.6 and the alkali / Al molar ratio being maintained between 2.3 and 3; and then stirring the resulting mixture at ambient temperature in the presence of silanol groups for long enough to form the hybrid aluminosilicate polymer.

Owner:EASTMAN KODAK CO

Gas-barrier material, gas-barrier film and method for manufacturing the same

InactiveUS20020197480A1Good lookingSynthetic resin layered productsCoatingsPolyethylene oxideHigh humidity

A gas-barrier material comprising polyvinyl alcohol type resin, silicon alkoxide hydrolyzate and polyethylene oxide is provided. As a gas-barrier film prepared by laminating a gas-barrier layer comprising said gas-barrier material on a thermoplastic resin film and a gas-barrier film prepared by laminating a gas-barrier layer comprising said gas-barrier material on one surface of a thermoplastic resin film and by laminating a sealing layer on the surface of the gas-barrier layer at the opposite side to the surface on which the thermoplastic resin film is laminated are excellent in film appearance and show excellent gas-barrier properties even under high humidity, they can be used favorably as film for wrapping.

Owner:TOKUYAMA CORP

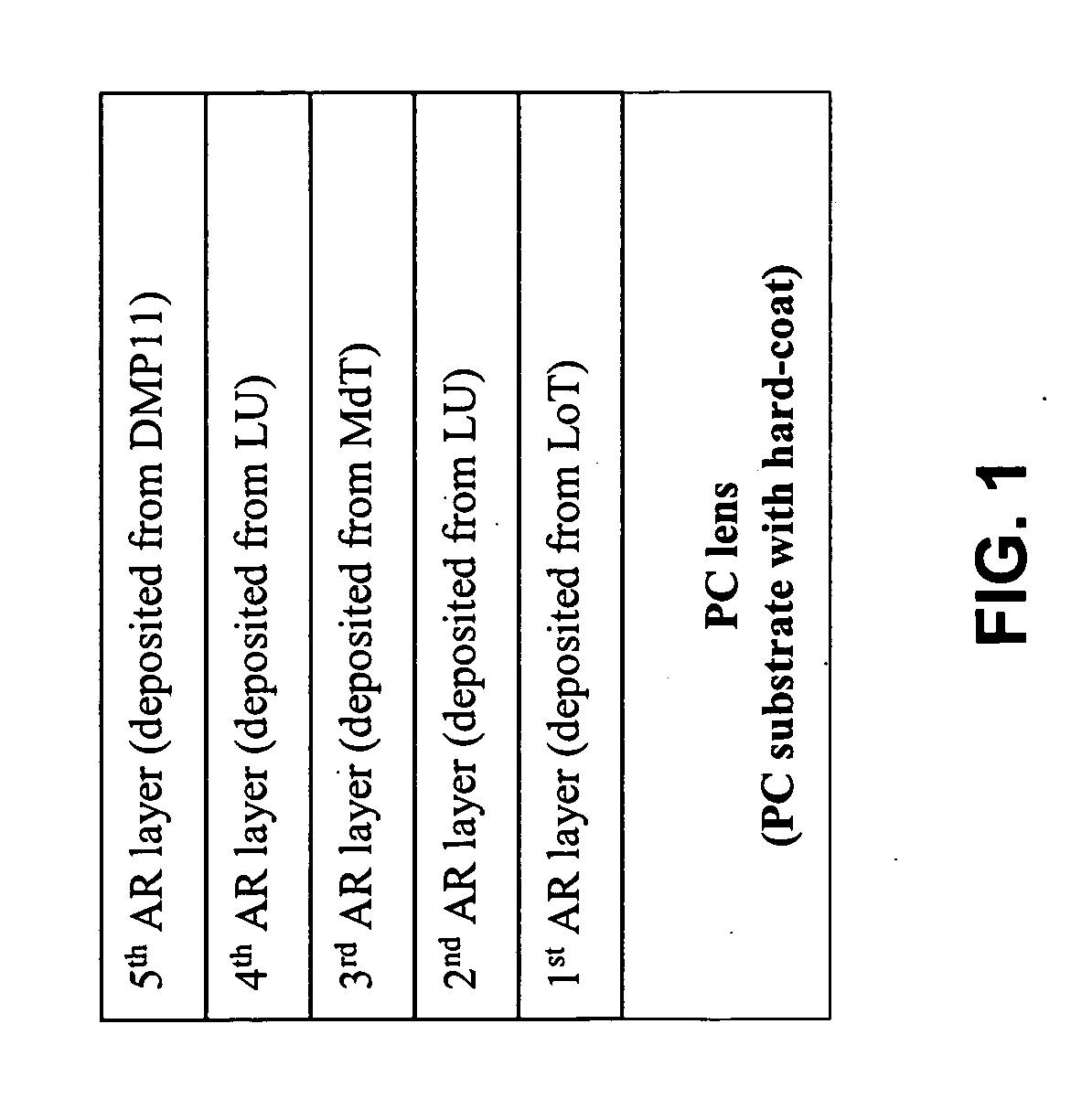

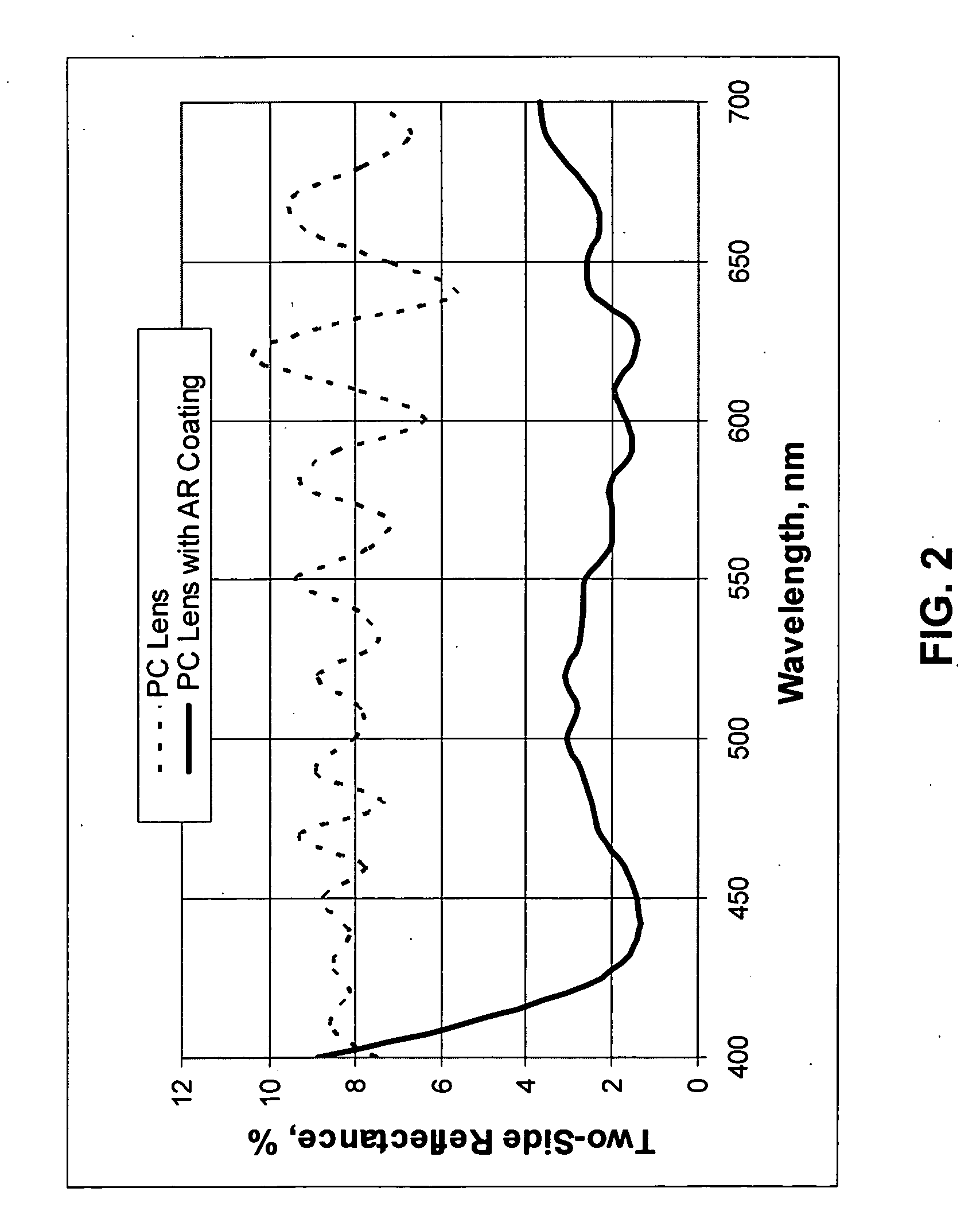

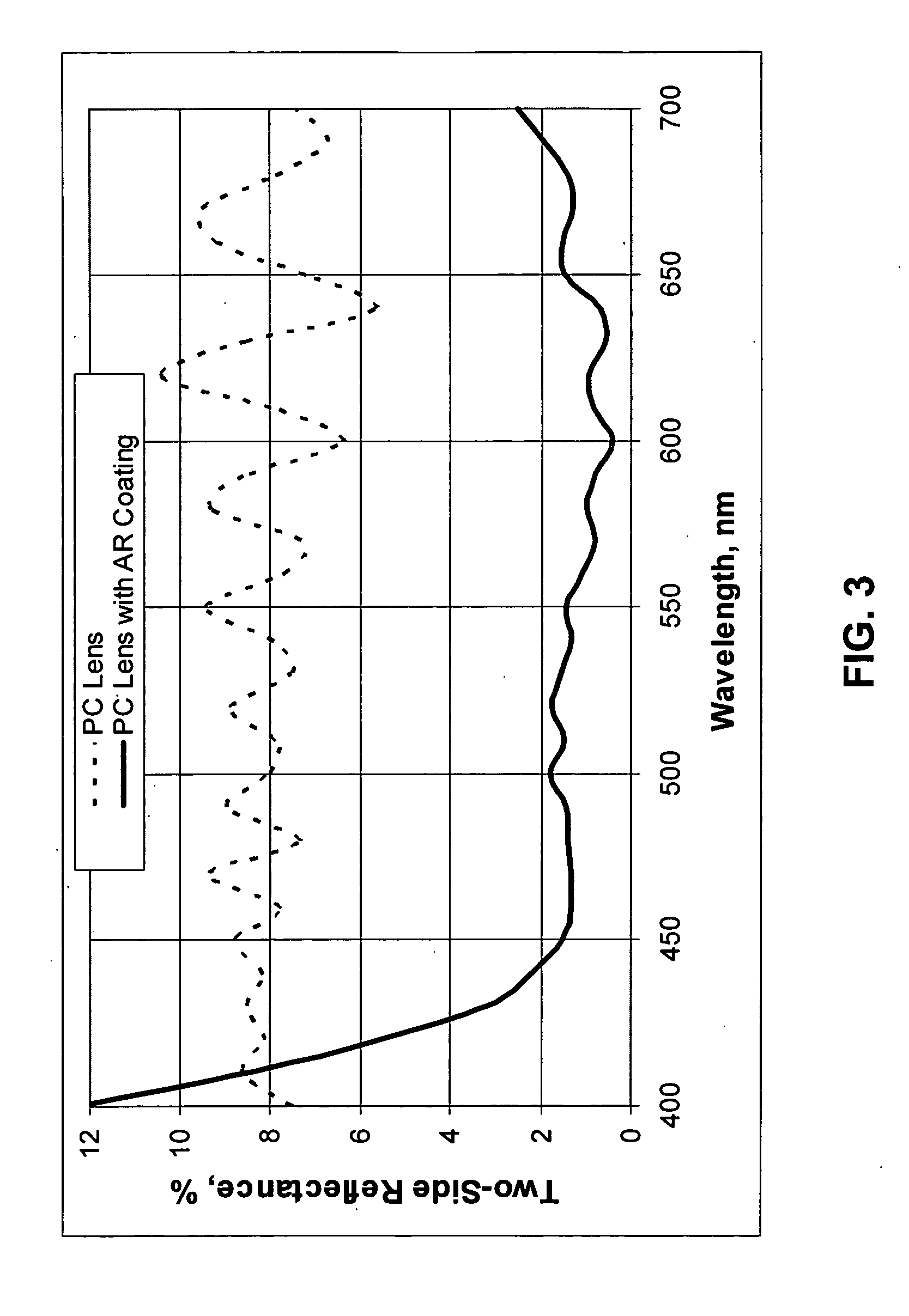

Antireflective coating compositions and methods for depositing such coatings

Coating compositions, and methods for depositing them on the surface of an article to produce an antireflection coating, are disclosed. In one embodiment, the coating composition includes a (meth)acrylate-functional silicon alkoxide, silica particles, a (meth)acrylate monomer, an epoxy(meth)acrylate oligomer, a photoinitiator, a solvent, an acid, and water. The relative amounts of these constituents are controlled such that, when the coating composition is deposited onto the surface of an article and cured, it has a refractive index less than about 1.60 at a wavelength of 510 nm. In another embodiment, the coating composition includes an organo-metallic compound other than an organo-metallic compound of silicon, an epoxy-functional silicon alkoxide, a non-epoxy-functional silicon alkoxide, a curing agent compatible with epoxy-functional molecules, a solvent, an inorganic acid, and water. The relative amounts of these constituents are controlled such that, when the coating composition is deposited onto the surface of an article and cured, it has a refractive index greater than about 1.70 at a wavelength of 510 nm. The coating compositions are deposited in a process that produces an antireflection coating in less than 90 minutes of processing time.

Owner:YAZAKI CORP

Gas-barrier film and gas-barrier coating agent, and method for production thereof

InactiveUS7157147B2Excellent gas barrier performanceBroad usSynthetic resin layered productsPaper coatingHigh humidityHydrolysate

Provided are a gas-barrier film which is a laminate comprising a substrate layer comprising a thermoplastic resin film and a gas-barrier layer comprising a hydrolysate of a silicon alkoxide, a stratified silicate and a polyvinyl alcohol base resin, wherein a radius (Rg) of gyration of a scattering matter which is measured by light scattering in the gas-barrier layer described above is 2.4 μm or less, and the silicon alkoxide and / or the hydrolysate thereof are present between the layers of the stratified silicate present in the above gas-barrier layer. The above film shows an excellent gas-barrier property even under such a high humidity as exceeding 90% RH.

Owner:TOKUYAMA CORP +1

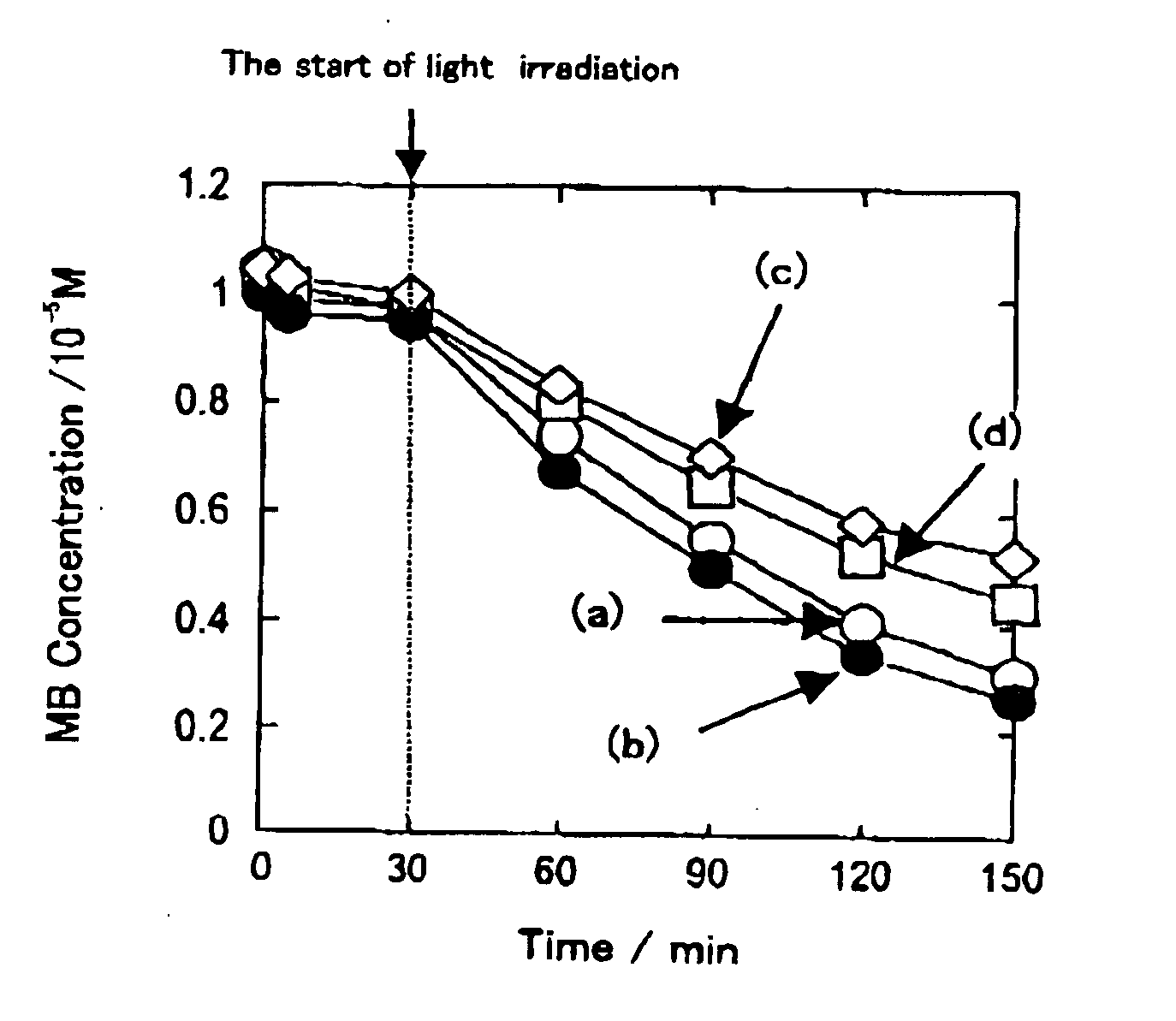

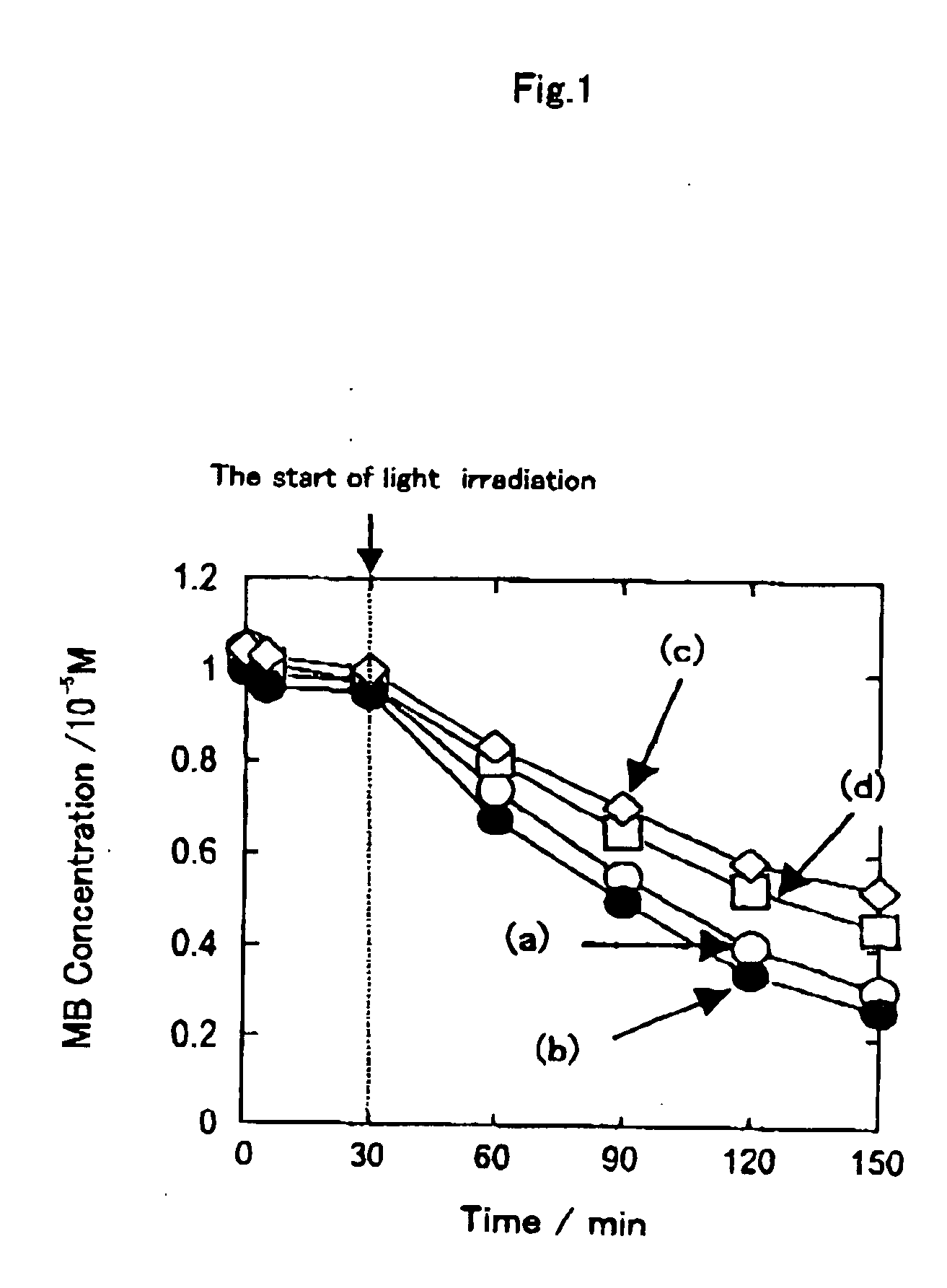

Photocatalyst self-cleaning finishing agent and preparation and application method thereof

ActiveCN102071568AGood dispersionImprove hydrophilicityAntifouling/underwater paintsFibre treatmentMicrosphereSilicon alkoxide

The invention relates to a photocatalyst self-cleaning finishing agent which comprises the following raw materials in part by mol: (1-10)*103 parts of sol, 1-10 parts of titanium alkoxide, (1-10)*10 parts of silicon alkoxide and 1-10 parts of metal salt. The photocatalyst self-cleaning finishing agent contains nano microspheres of metal, titanium and silicon. The invention also provides a preparation and application method of the photocatalyst self-cleaning finishing agent, a photocatalyst self-cleaning article formed by being processed by the photocatalyst self-cleaning finishing agent, and a processing method of the photocatalyst self-cleaning article. The photocatalyst self-cleaning finishing agent prepared in the invention has good dispersability, wherein a metal-doped silicon- and titanium-containing nano micro particle has better hydrophilcity and diameter of less than 30nm. The article processed by using the photocatalyst self-cleaning finishing agent can be used for effectively self-cleaning the dirt through the photocatalyst action of the metal-doped silicon- and titanium-containing nano micro particle under the environment conditions of visible light, air, moisture and the like.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

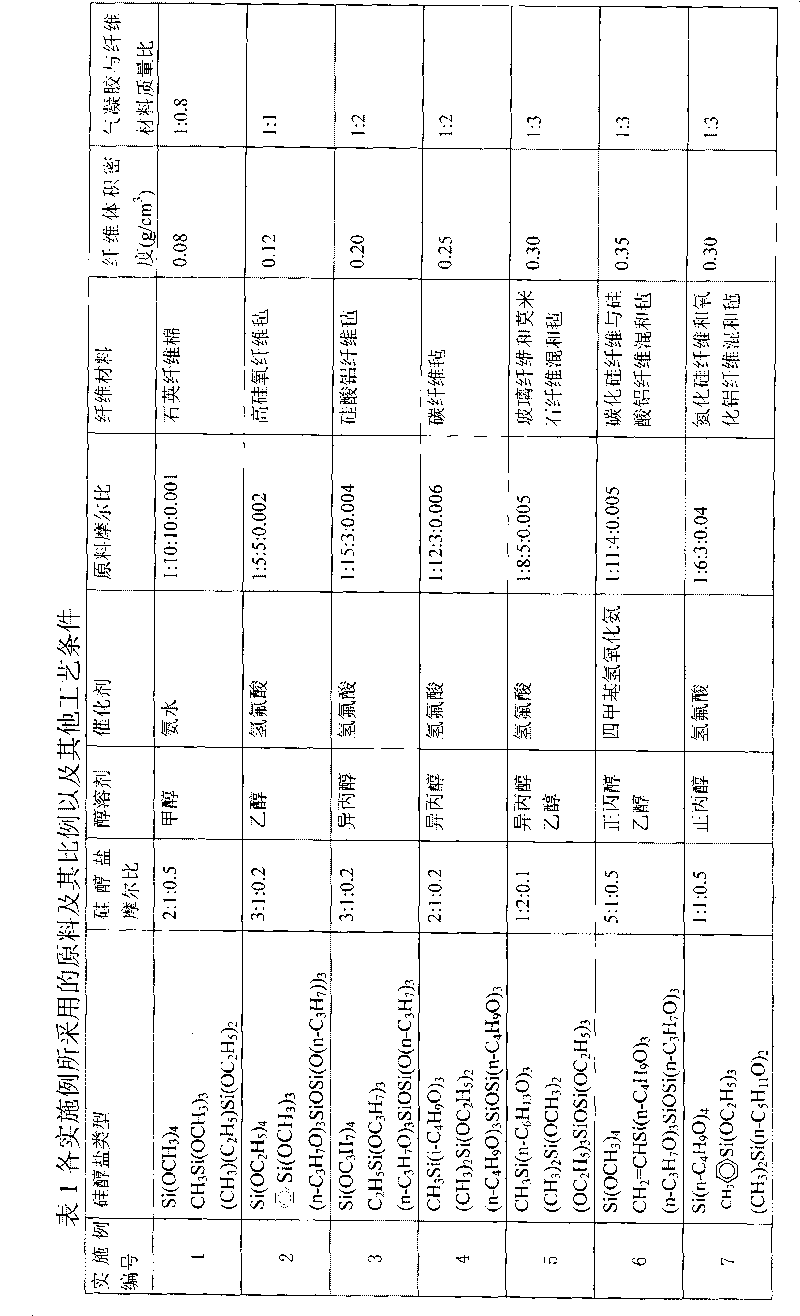

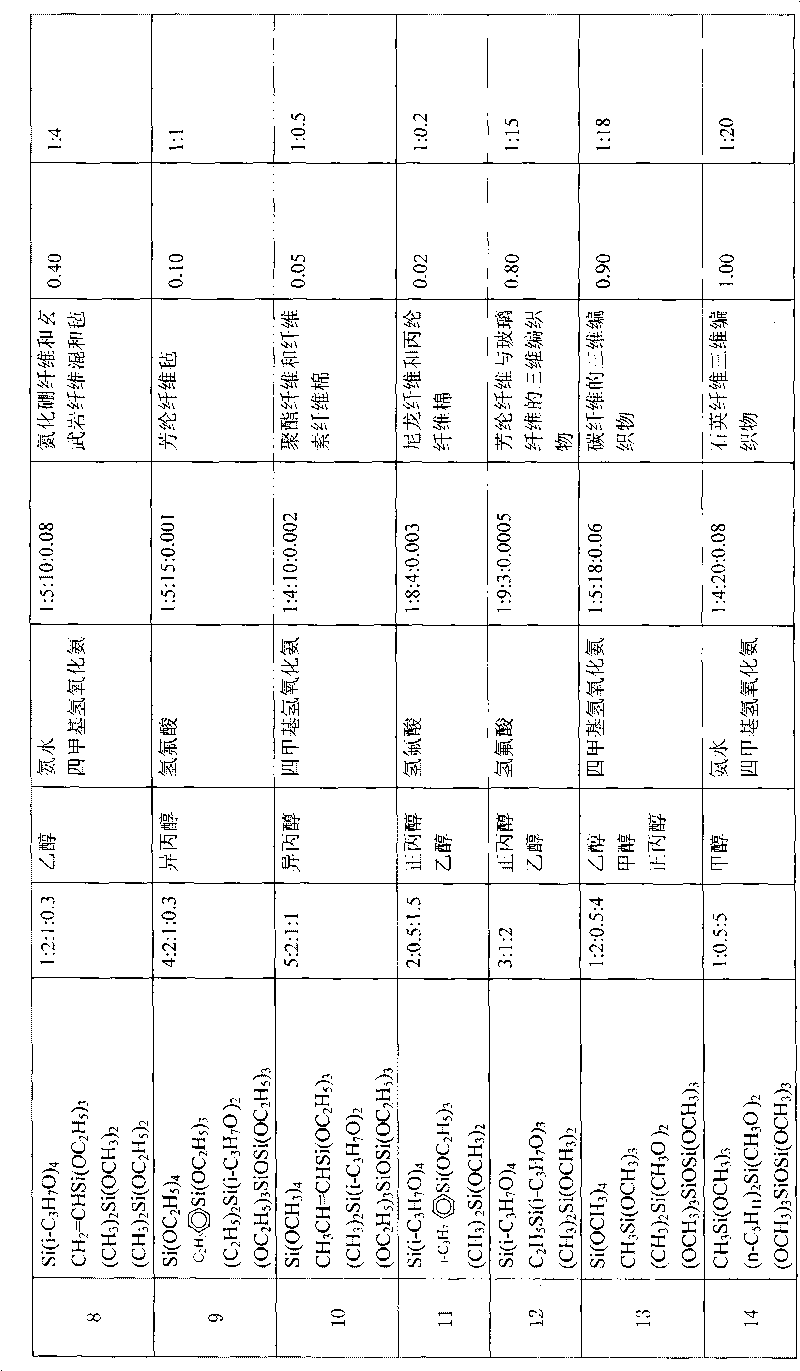

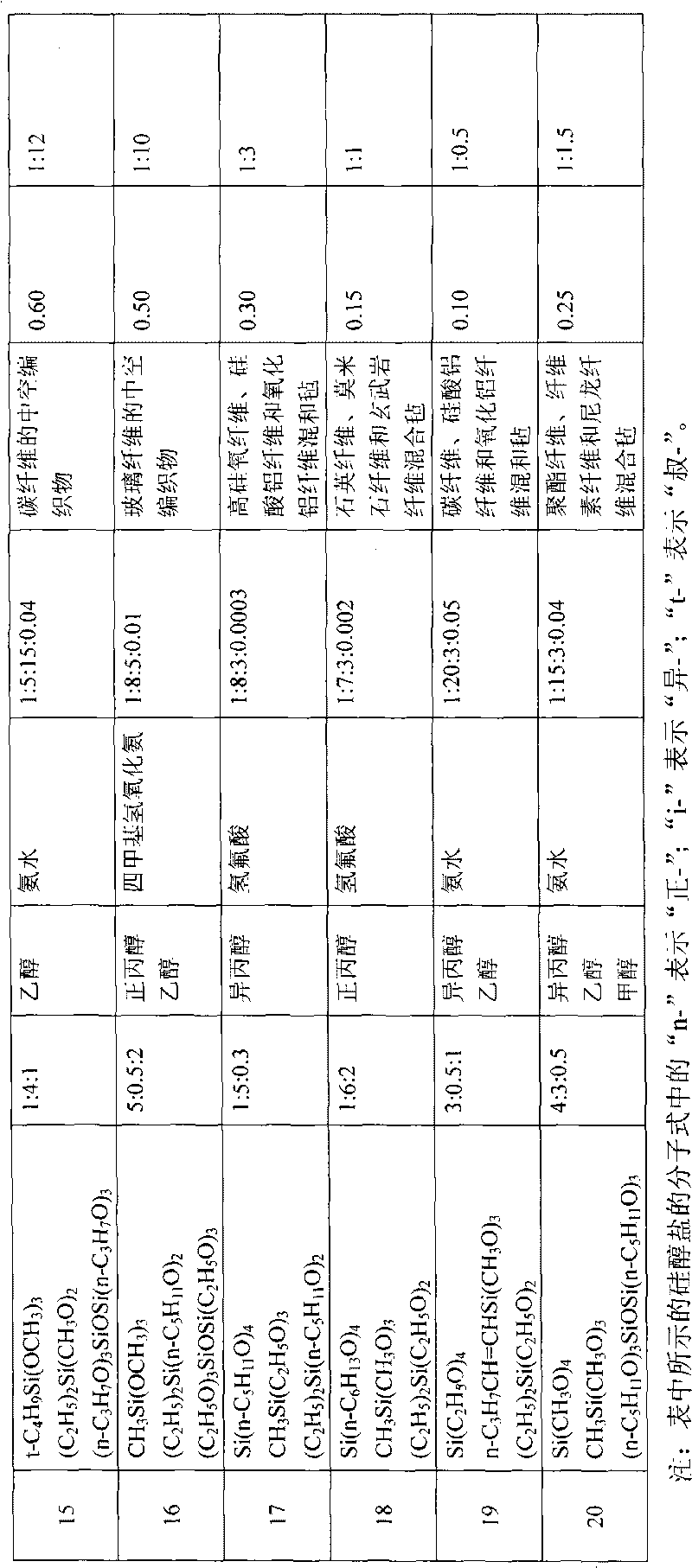

Multi-element aerogel composite material and preparation method thereof

The invention provides a multi-element aerogel composite material, comprising fiber materials and the multi-element aerogel, wherein the multi-element aerogel is prepared from multi-element silicon alkoxide. The invention also provides a method for preparing the multi-element aerogel composite material with simple process and easy operation, which comprises the steps of preparing silicon sol, gumming, gelatinizing, aging, supercritically drying and the like. The multi-element aerogel composite material has the advantages of good flexibility, high hydrophobicity, controllable structure and performance and the like, can be used in the field of civilian thermal insulation, and can meet special requirements of aviation, spaceflight or military and other fields.

Owner:海鹰空天材料研究院(苏州)有限责任公司

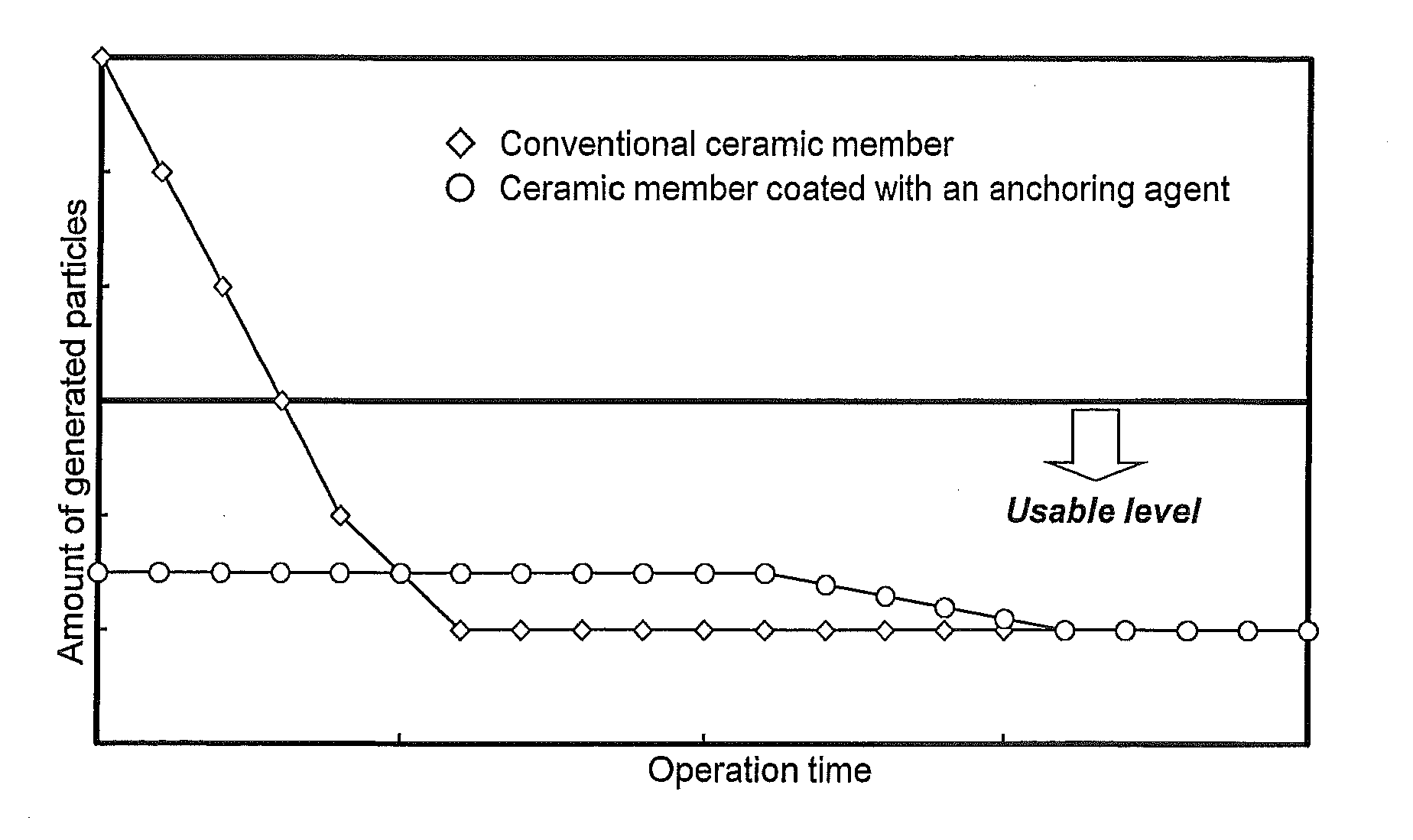

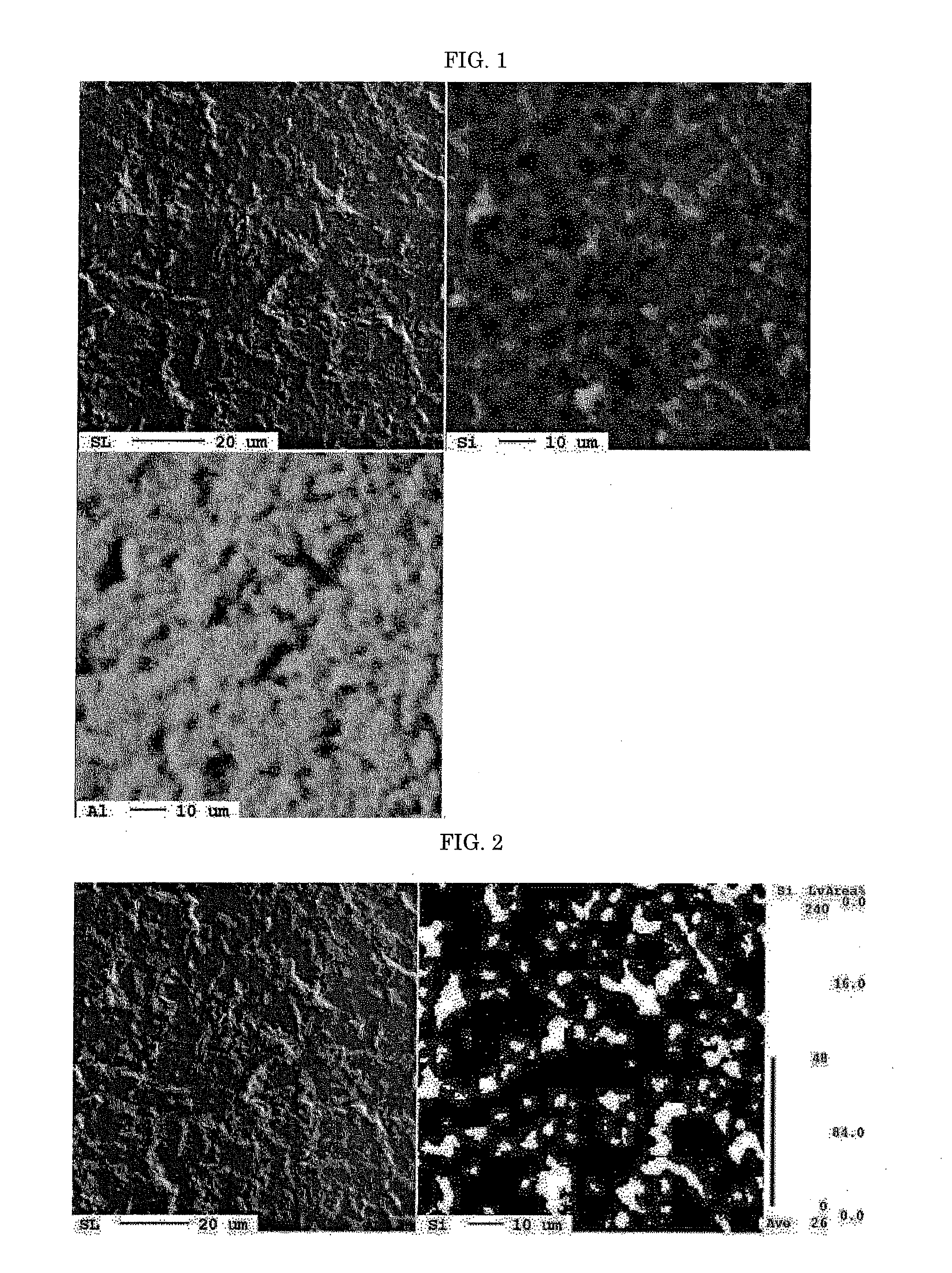

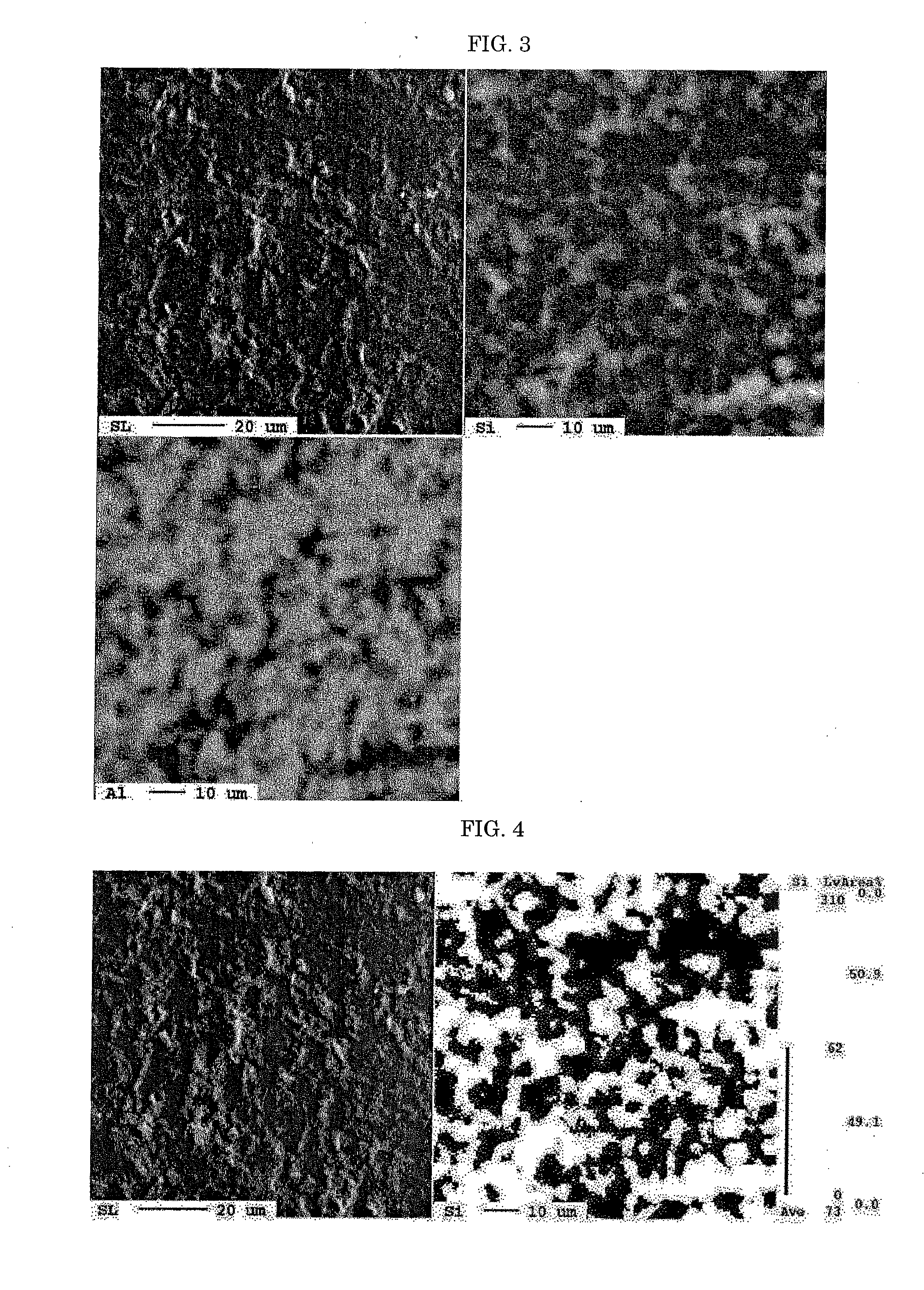

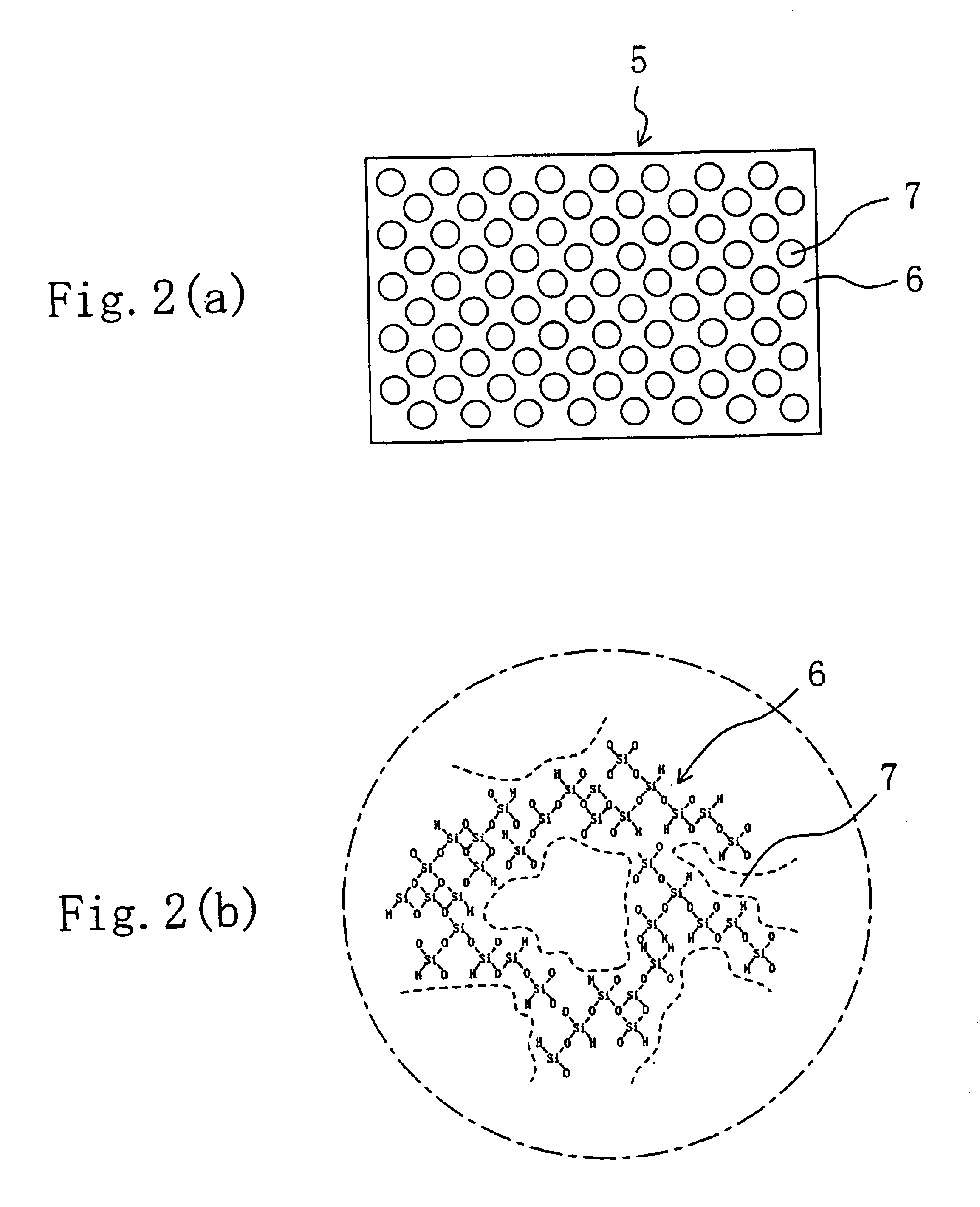

Surface-treated ceramic member, method for producing the same and vacuum processing apparatus

Disclosed is a surface-treated ceramic member which has a coating film-formed surface comprising a ceramic sintered body with a porosity of 1% or less and a sol-gel coating film of a silicon alkoxide compound polymer formed on at least a part of a ceramic sintered body, wherein the coating film and the surface of the body are coexistent in the coating film-formed surface. Specifically the area of the sol-gel coating film accounts for 5 to 80% of the total area of the coating film-formed surface. The surface-treated ceramic member has excellent corrosion resistance and is free from scattering of particles.

Owner:ULVAC INC +1

Catalyst for producing polybutylene succinate or copolyester thereof, and preparing mehtods of the catalyst

InactiveUS20110162205A1High activityQuality improvementTitanium compoundsHollow articlesAlcoholSilicon alkoxide

The present invention provides a catalyst used in the production of PBS or its copolyesters and the preparation method thereof. The method comprises the following steps: (1) adding titanium alkoxide, silicon alkoxide, dihydric alcohol and metal co-catalyst into the solvent and conducting the reaction at a temperature of about 80° C. to 180° C., then removing the unreacted materials and small molecular products in the reaction system; (2) adding complexing agent into the reaction system, then collecting catalyst from the products obtained in this step. Moreover, the method may comprises steps of: (1) adding titanium alkoxide, dihydric alcohol and metal co-catalyst into the solvent and conducting the reaction at a temperature of about 80° C. to 180° C., then removing the unreacted materials and small molecular products in the reaction system; (2) adding silicon alkoxide and complexing agent into the reaction system, then collecting catalyst from the products obtained in this step. The catalyst in the present invention has higher activity and thus the catalyst additional amount is reduced which will improve the quality of the products. Moreover, the catalyst in the present invention could be used alone in the production of PBS or its copolyester without the need for other materials and it won't react with water and thus could be stored for a long time. In sum, the catalyst in the present invention has a broad prospect in industrial application.

Owner:SHANGHAI HUAMING HI TECH GRP

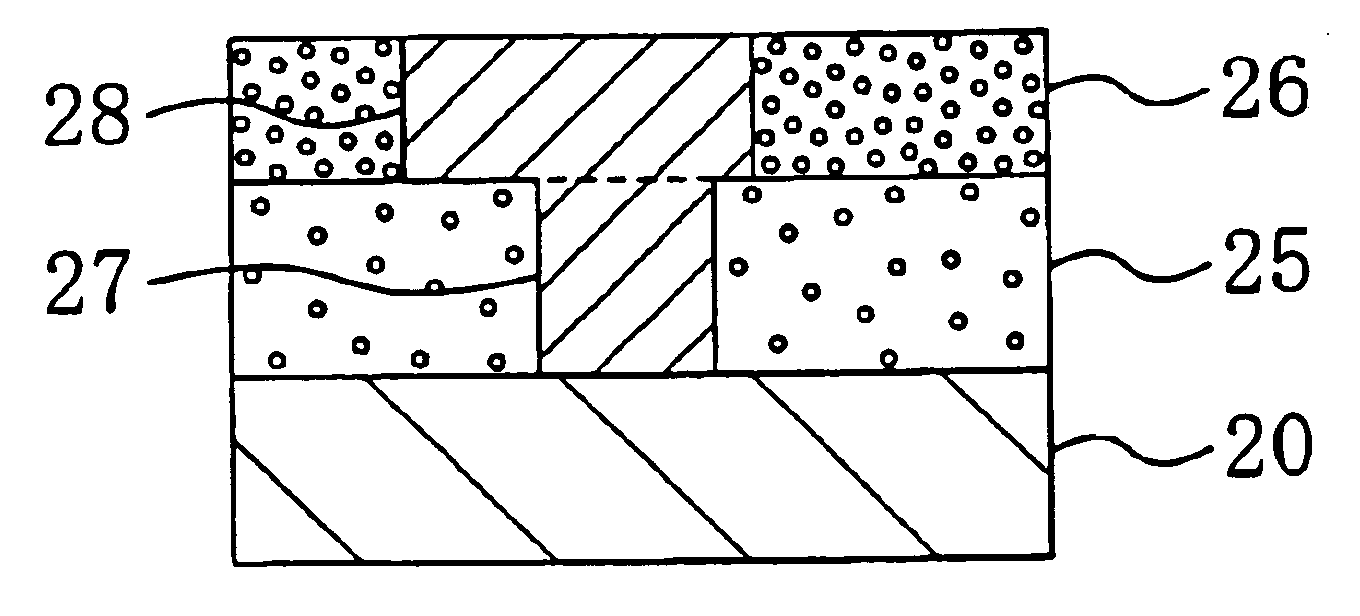

Porous, film, wiring structure, and method of forming the same

InactiveUS6873052B2Low dielectric constantRetain sufficient mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPlasma derivedOrganic compound

An organic-inorganic hybrid film is deposited on a substrate by introducing, into a vacuum chamber, a gas mixture of a silicon alkoxide and an organic compound and generating a plasma derived from the gas mixture. Then, a hydrogen plasma process is performed with respect to the organic-inorganic hybrid film by introducing, into the vacuum chamber, a gas containing a reducing gas and generating a plasma derived from the gas. As a result, an organic component in the organic-inorganic hybrid film eliminates therefrom and numerous fine holes are formed in hollow portions from which the organic component has eliminated, whereby a porous film composed of the organic-inorganic hybrid film is obtained.

Owner:GK BRIDGE 1

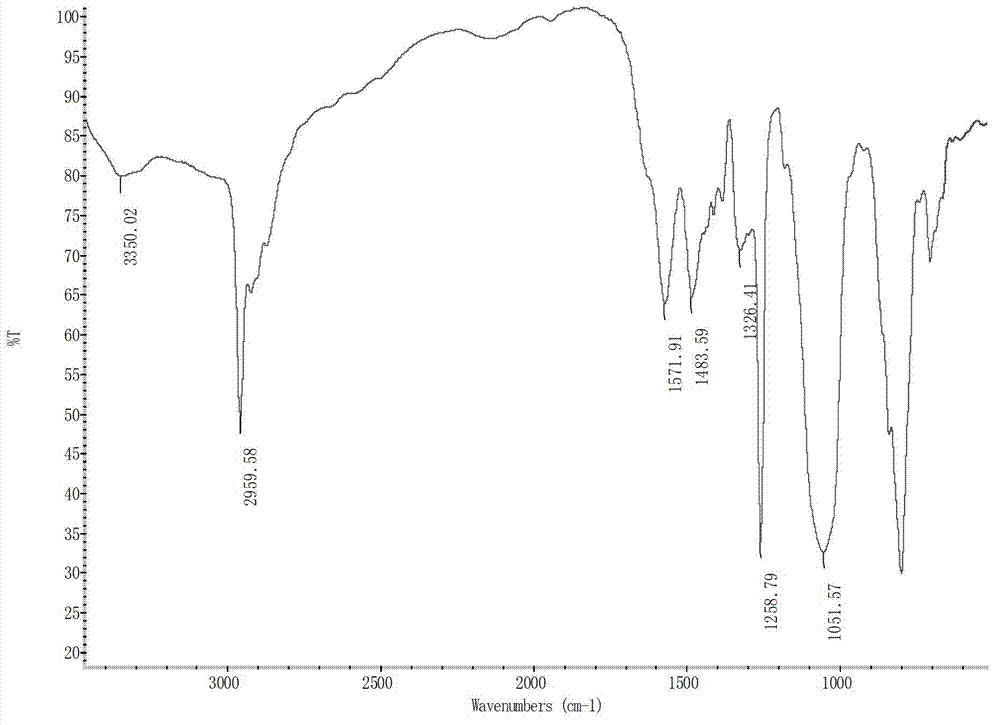

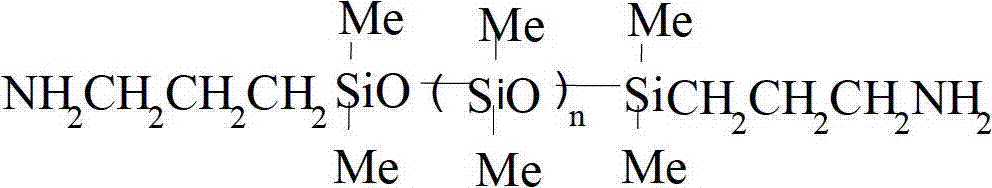

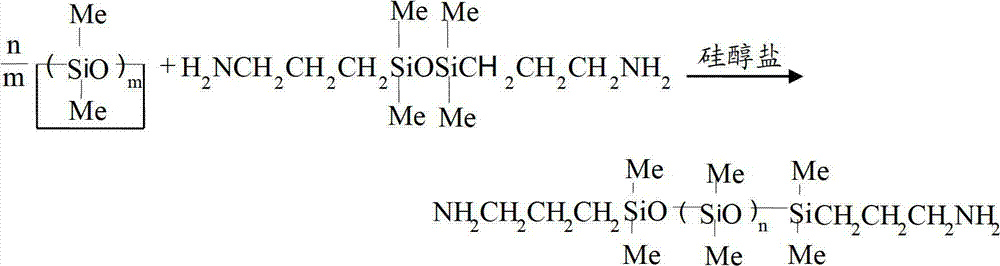

Method for preparing alpha, omega-bis(aminopropyl)polydimethylsiloxane

ActiveCN102775613AAdvantages of preparation processGood compatibilityGroup 4/14 element organic compoundsReaction rateDimethyl siloxane

The invention discloses a method for preparing alpha, omega-bis(aminopropyl)polydimethylsiloxane. A siliconate catalyst is prepared through alkali compound which is provided by the preparation method and then the catalyst has a good compatibility in the reaction solution, thus improving the catalytic reaction rate and obviously shortening the equilibrium reaction time. Raw materials are dehydrated before the reaction to eliminate the interference of end-capped hydroxy group and increase reaction efficiency. The final product synthesized has the characteristics of high amino termination yield, good stability and the like. The obtained product can be used as a basic raw material for siloxane-organic block copolymer and can also be used as an excellent conditioning agent in the hair care composition.

Owner:GUANGZHOU TINCI MATERIALS TECH

Aerogel material reinforced by fiber reinforcement and preparation method of aerogel material

InactiveCN106866093ADiffusion is easy to completeEasy to complete distributionSupercritical dryingPolymer science

The invention relates to an airgel material reinforced by fiber reinforcement and its preparation method. The width of the material is 0.5-1.5 meters, and the length is 5-30 meters. Its composition includes silicon dioxide airgel and reinforced continuous fiber, and its weight ratio is 1:0.5-2.5. The present invention also relates to (1), limiting and winding the continuous reinforcing fiber into a winding unit while keeping a certain gap between the continuous fibers; (2), disposing silicon alkoxide, alcohol solvent and basic catalyst according to a certain ratio (3) Immerse the silica sol into the continuous reinforcing fiber winding unit through the impregnation process; (4) After the silica gel is aged for a certain period of time, the surface is treated with a hydrophobizing agent; (5) The silica gel containing silica gel The continuous fiber winding unit of glue is supercritically dried. The material prepared by the invention has large specific surface area and low thermal conductivity, and can be applied in many fields such as fire retardation, sound insulation, gas adsorption and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

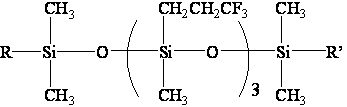

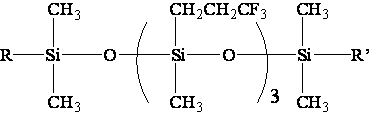

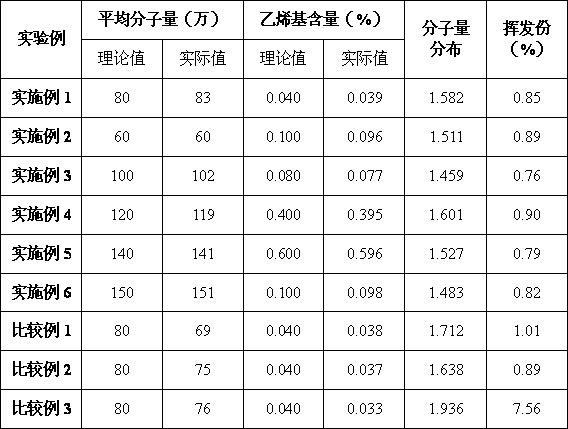

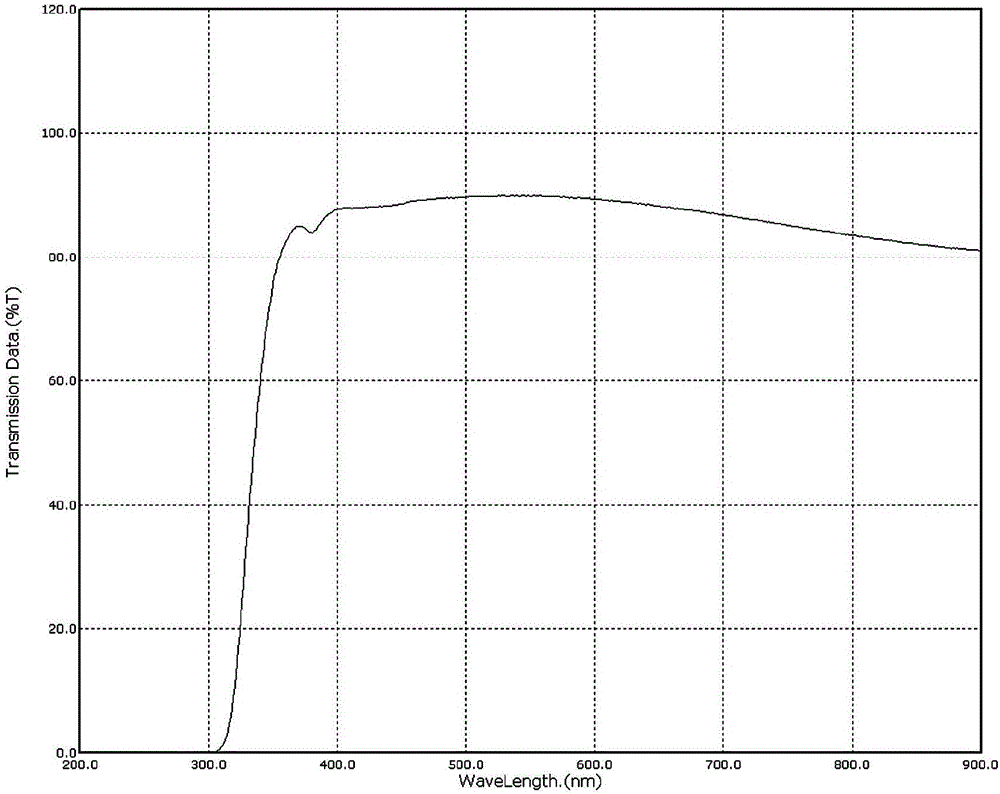

Preparation method of fluorosilicone rubber with controllable molecular weight

The invention relates to a preparation method of fluorosilicone rubber with the controllable molecular weight. According to the method, catalyst consumption is reduced, and the molecular weight is adjusted by a special end capping reagent, so that the molecular weight of the prepared fluorosilicone rubber is controllable, and the distribution is narrow. The method comprises the steps of (1) adding D3F and methyl-vinyl-cyclosiloxane to a reactor for dehydration, (2) adding a silanolate catalyst and the end capping reagent with the mass accounting for 0.0005-0.003% of the mass of D3F to the reactor, heating and starting reaction, (3) conducting temperature programming to about 130 DEG C after reaction starting, and polymerizing for 0.5h at a normal pressure, (4) dropping the pressure in the reactor to 26Pa-26000Pa, and reacting for 0.5h-3h, (5) adding fluorosilicone-base phosphate to neutralize, and (6) rising temperature to 180-200 DEG C, removing low-boiling-point substances at vacuum, cooling, and obtaining the rubber.

Owner:新元化学(山东)股份有限公司

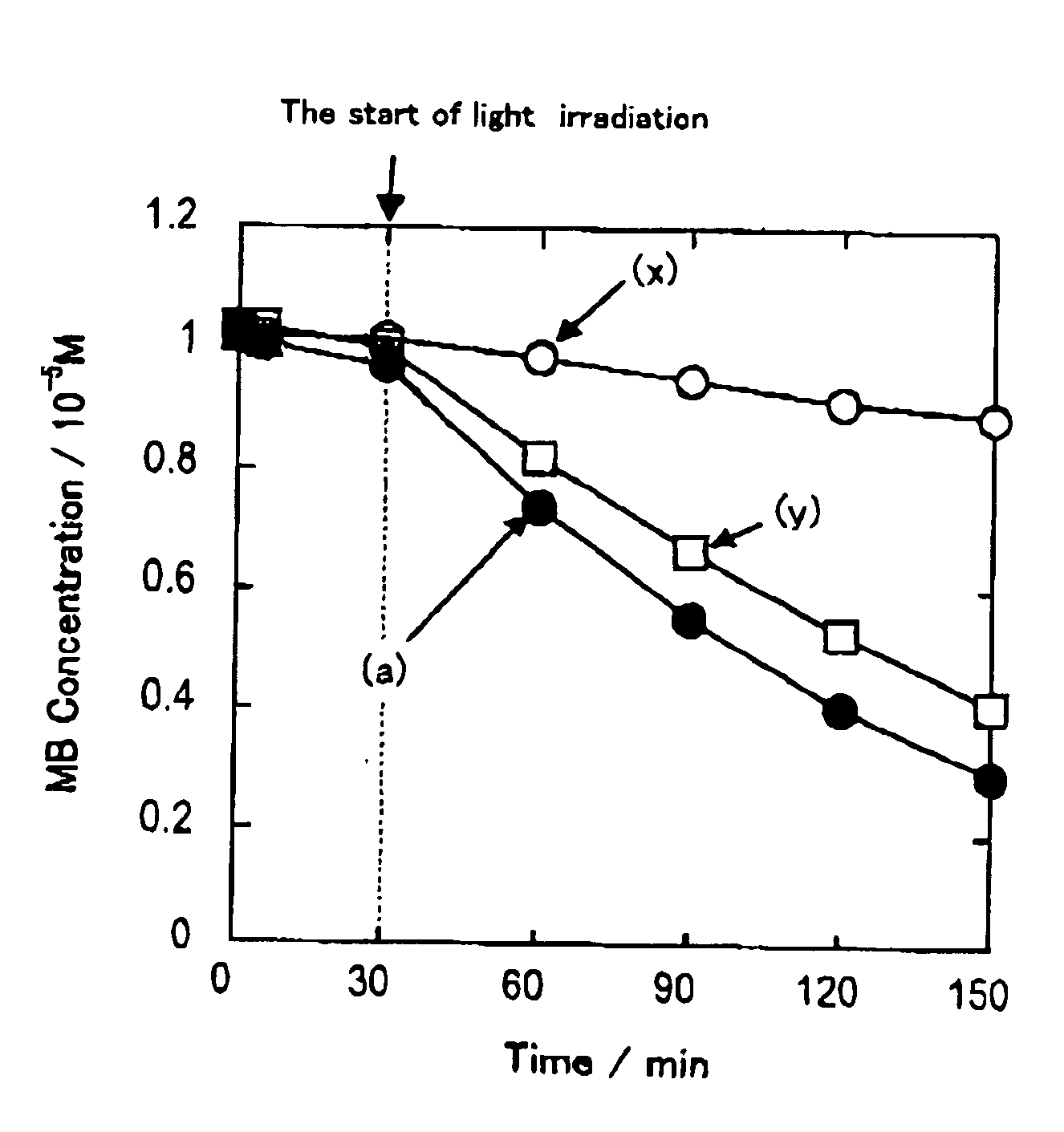

Preparation method of zinc-doped porous SiO2/TiO2 self-cleaning composite film

The invention relates to a preparation method of a zinc-doped porous SiO2 / TiO2 self-cleaning composite film, the zinc-doped porous SiO2 / TiO2 (porous Zn-SiO2TiO2) self-cleaning composite film is prepared by a titanium alkoxide composite sol precursor containing polyethylene glycol and a composite sol precursor of silicon alkoxide through a dip-coating method. The addition of SiO2 has inhibition effect to the growth of TiO2 crystal grain, and the addition of SiO2 is in favor of increasing the hydrophilcity of a TiO2 film; the gap of the film surface can effectively increase the surface area of the film, furthermore the self-cleaning efficiency of a film coating is increased; and the doping of the zinc ions can obviously increase the TiO2 photocatalysis efficiency. The zinc-doped porous SiO2 / TiO2 self-cleaning composite film can be used for increasing permeability and self-cleaning performance of the buildings, automobiles and solar energy glass plates, and has good application prospect.

Owner:JIANGNAN UNIV

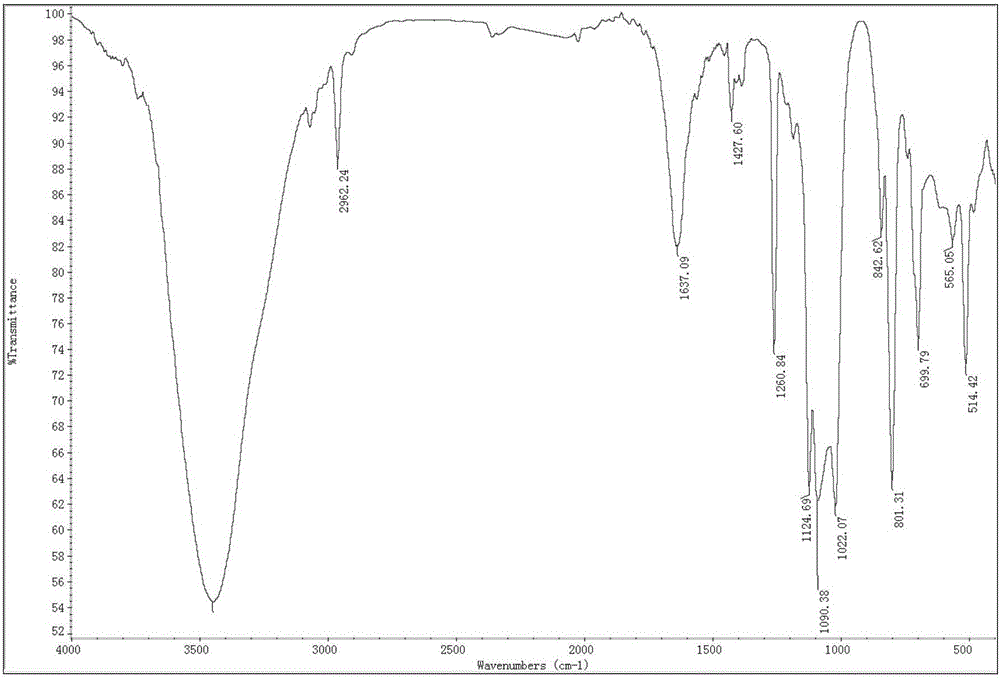

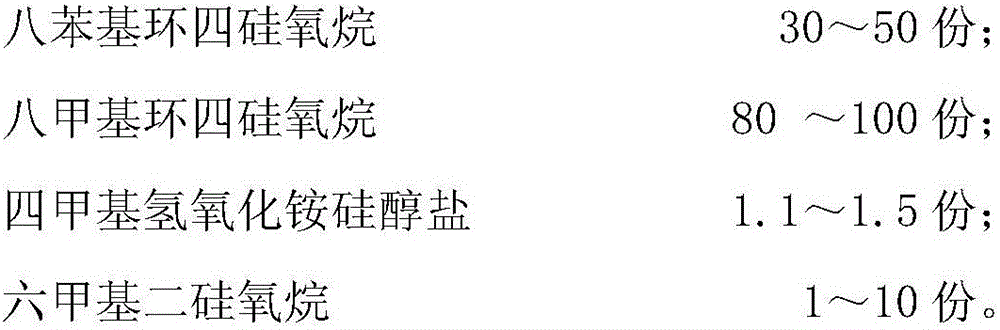

High-velocity phenylmethyl silicone oil and preparation method thereof

The invention provides a high-viscosity benzyl silicone oil, which comprises 30 to 50 parts of octaphenylcyclotetrasiloxane; 80 to 100 parts of octamethylcyclotetrasiloxane; 1.1 to 100 parts by weight. 1.5 parts of tetramethylammonium hydroxide silicon alkoxide; 1-10 parts of hexamethyldisiloxane. The present invention also provides a method for preparing the above-mentioned high-viscosity benzyl silicone oil. The high-viscosity benzyl silicone oil of the present invention has high quality, high refractive index, high and controllable viscosity, and can be applied to the preparation of silicone grease, low-temperature lubricating oil, shock absorption of precision instruments, special radiation protection high heat carrier for nuclear power plants, and sealing under continuous high temperature and many other fields.

Owner:SHANGHAI INST OF TECH

Article with Organic-Inorganic Composite Film and Process for Producing the Same

InactiveUS20070212571A1High mechanical strengthImprove wear resistanceCoatingsNatural mineral layered productsComposite filmProton

An article with an organic-inorganic composite film that contains silica as its main component and does not separate from the substrate after the Taber abrasion test prescribed in Japanese Industrial Standards (JIS) R 3212. This composite film is formed of a coating solution containing a hydrophilic organic polymer by a sol-gel process. In this solution, for example, the amount of silicon alkoxide exceeds 3 mass % in terms of a SiO2 concentration. When the coating solution contains a phosphorus source, the molality of protons is 0.0001 to 0.2 mol / kg while the number of moles of water is at least four times the total number of moles of silicon atoms contained in the silicon alkoxide. This sol-gel process allows a film with excellent mechanical strength to be obtained even when the substrate is not heated up to a temperature exceeding 400° C. and the film thickness exceeds 250 nm.

Owner:NIPPON SHEET GLASS CO LTD

Process for producing inorganic oxide organosol

ActiveUS20050154124A1Excellent in dispersion stability and long-term shelf stabilityImprove stabilityMaterial nanotechnologyLiquid surface applicatorsSolventPrimary alcohol

A process for producing an inorganic oxide organosol comprises the steps (A) and (B) of: (A) adding silicon alkoxide having two or more alkoxy groups bonded to a silicon atom or having one or more hydroxy groups bonded to a silicon atom and one or more alkoxy groups bonded to a silicon atom to a hydrophilic inorganic oxide sol containing a hydrophilic solvent having a boiling point (1 atm) of 100° C. or less in an amount of 25 to 100% by weight in a dispersion medium to treat surface of the inorganic oxide particles in the sol; and (B) replacing the dispersion medium of the surface treated inorganic oxide sol obtained in step (A) with a non-alcoholic organic solvent in the presence of a primary alcohol having 3 to 12 carbon atoms. The process gives an inorganic oxide organosol that has a good dispersibility and a low viscosity, is excellent in transparency, and shows a good compatibility with resin solutions.

Owner:NISSAN CHEM IND LTD

Preparation method of dimethicone with controllable viscosity

The invention relates to a preparation method of dimethicone with controllable viscosity, and belongs to the technical field of downstream products of organic silicon. The method is characterized in that hexamethylcy (D3) is adopted as a raw material, low-viscosity dimethicone (MDnM) with the viscosity of 5 to 50 mpa.s and hexamethyldisiloxane (MM) are adopted as end-capping reagents, tetramethyl ammonium hydroxide silicon alkoxide and potassium hydroxide (KOH) silica-alkoxide are catalyzed to generate the dimethicone with controllable viscosity in a polymerization-free manner, and the viscosity range of the dimethicone is 100-100000 mpa.s. Main raw materials used in the method are dissolved without a solvent, so that pollution is avoided; the end-capping reagents are good in end-capping effect, cheap and safer; the catalyst is easy to obtain and less in consumption; the dimethicone with high purity and controllable viscosity can be prepared in a polymerization-free manner only by changing the dispensing ratio of the hexamethylcy (D3) and the low-viscosity dimethicone (MDnM).

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Transparent thin film and method for production thereof

InactiveUS20050129927A1SilicaOrganic-compounds/hydrides/coordination-complexes catalystsWarm waterSilicon alkoxide

A method for producing a transparent thin film which comprises forming a gel film containing a composite metal oxide or hydroxide of a titanium compound and a silicon alkoxide from a solution containing a silicon alkoxide and a titanium compound having hydrolizability, and subjecting the gel film to a warm water treatment, to thereby precipitate titania crystallites of anatase-type and / or of a crystal phase having a lattice spacing of about 0.7 nm on the surface of the thin film. The method can be used for producing a novel transparent thin film exhibiting high photocatalyst activity and super hydrophilicity as well as high light transparency, without the need for a high temperature treatment.

Owner:JAPAN SCI & TECH CORP

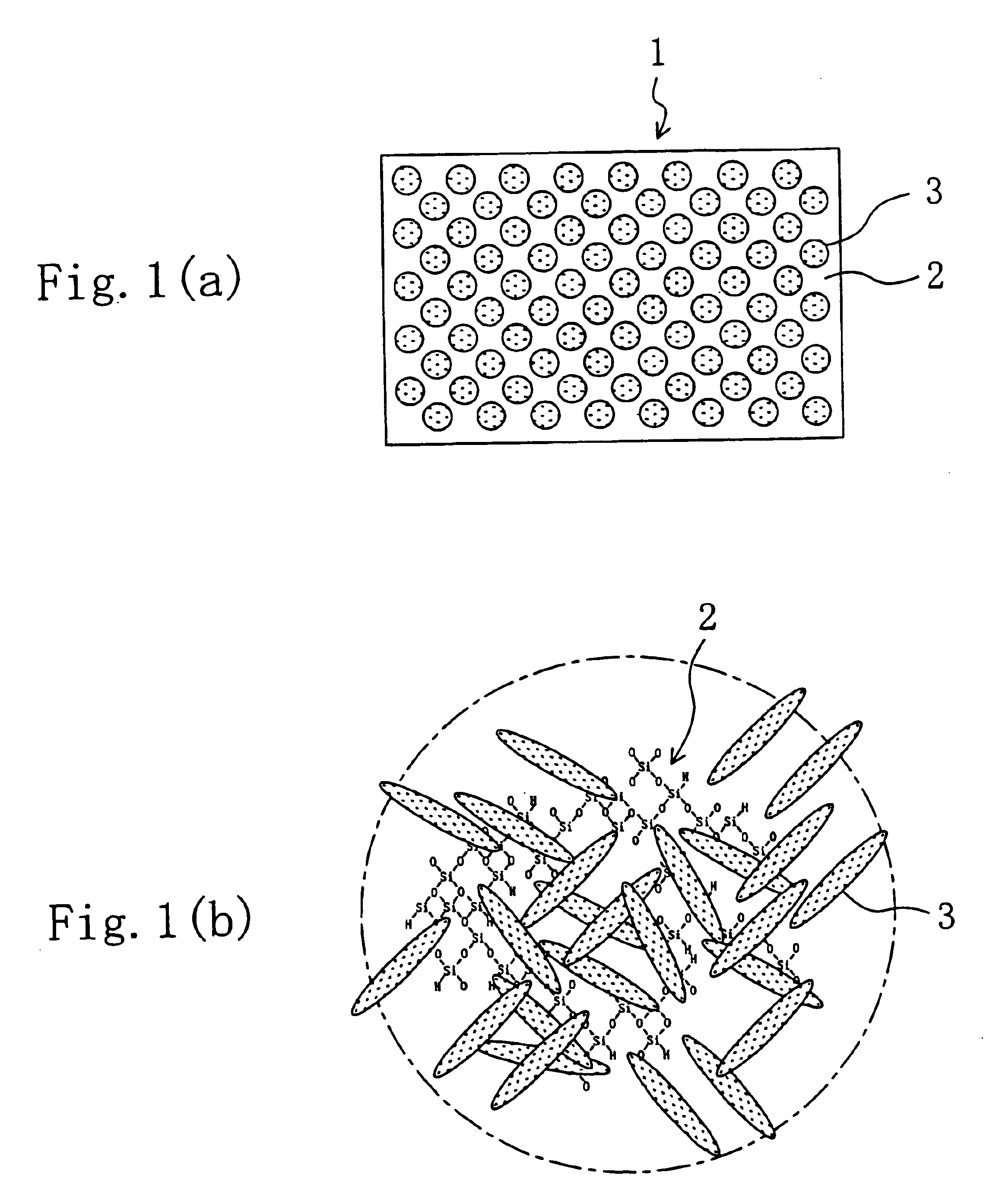

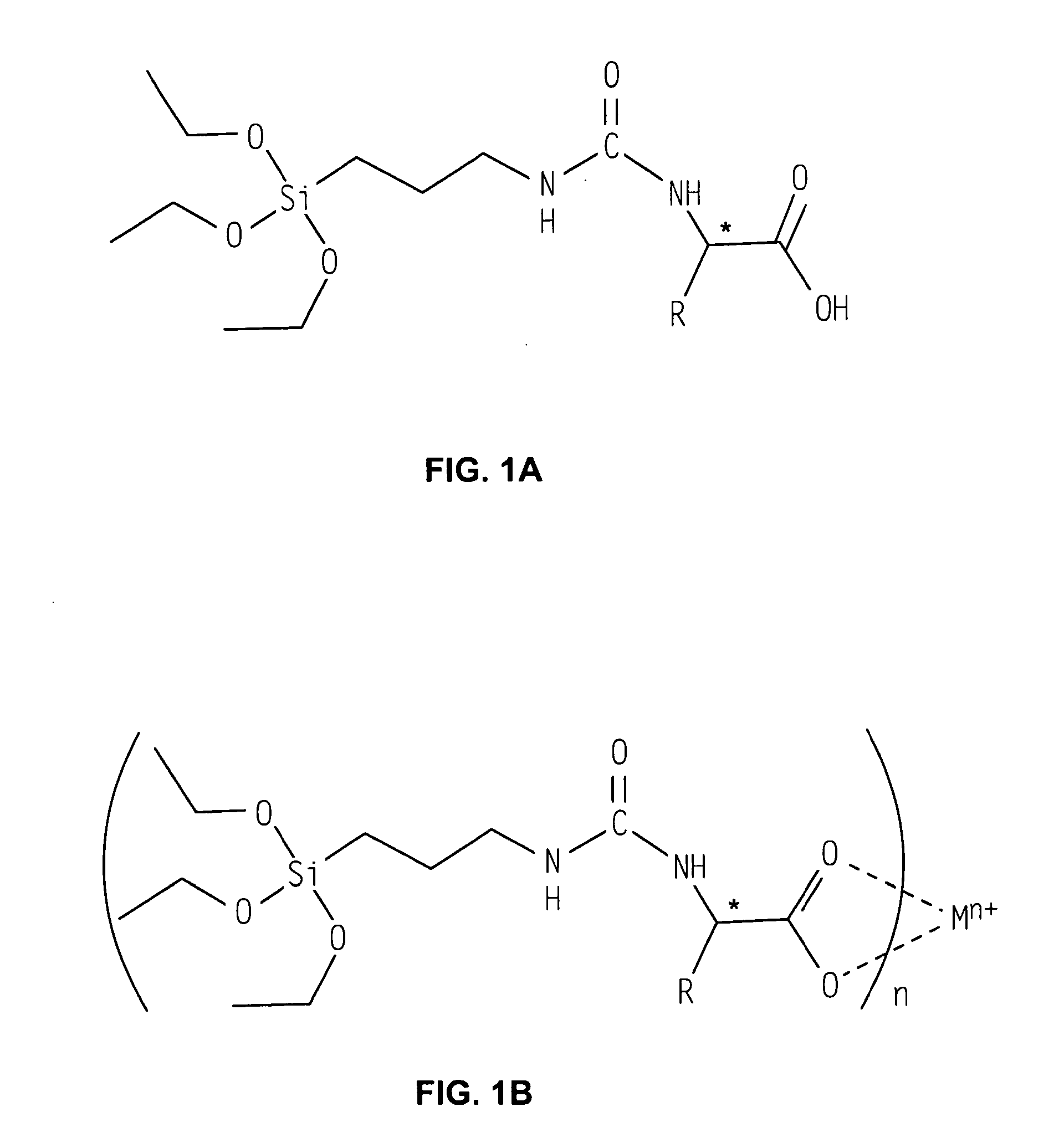

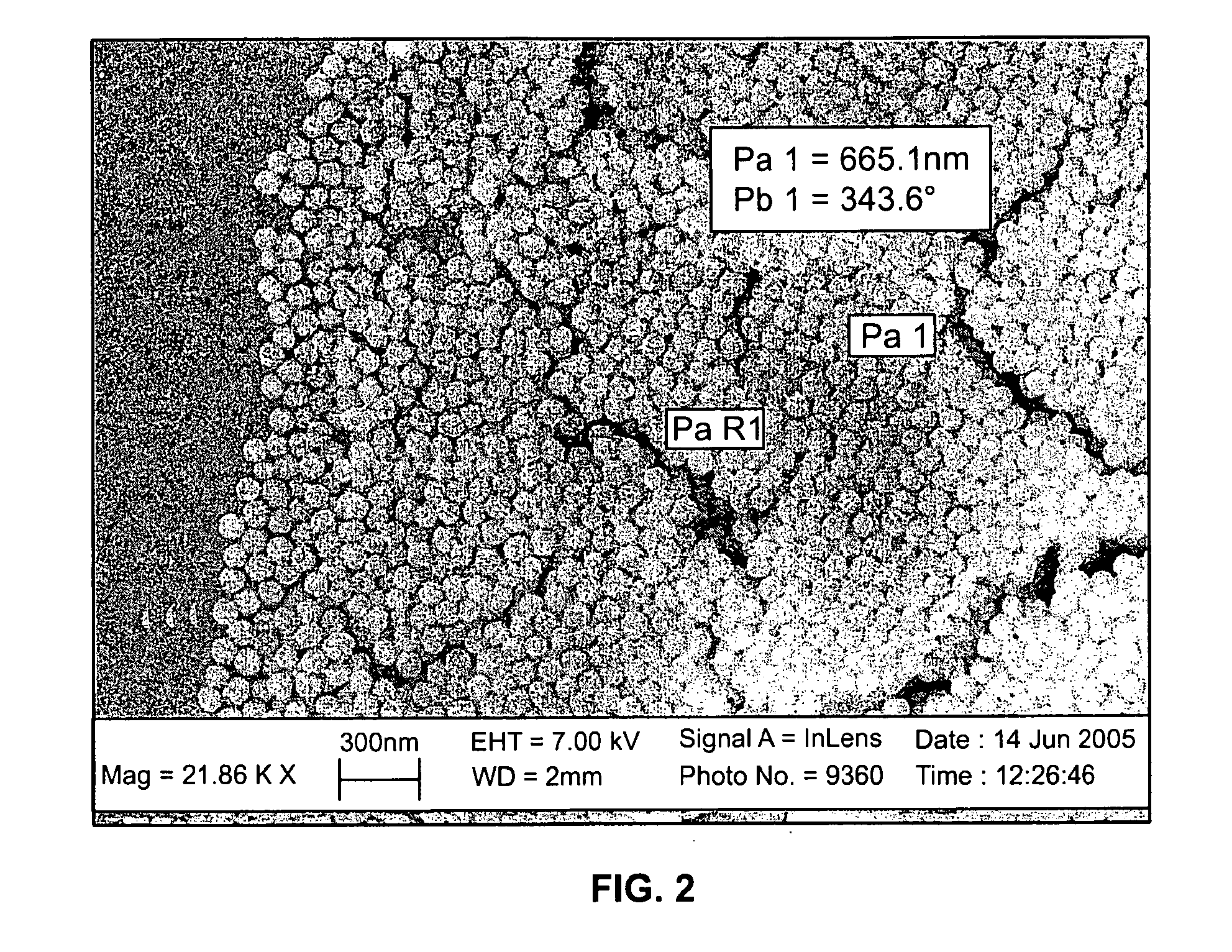

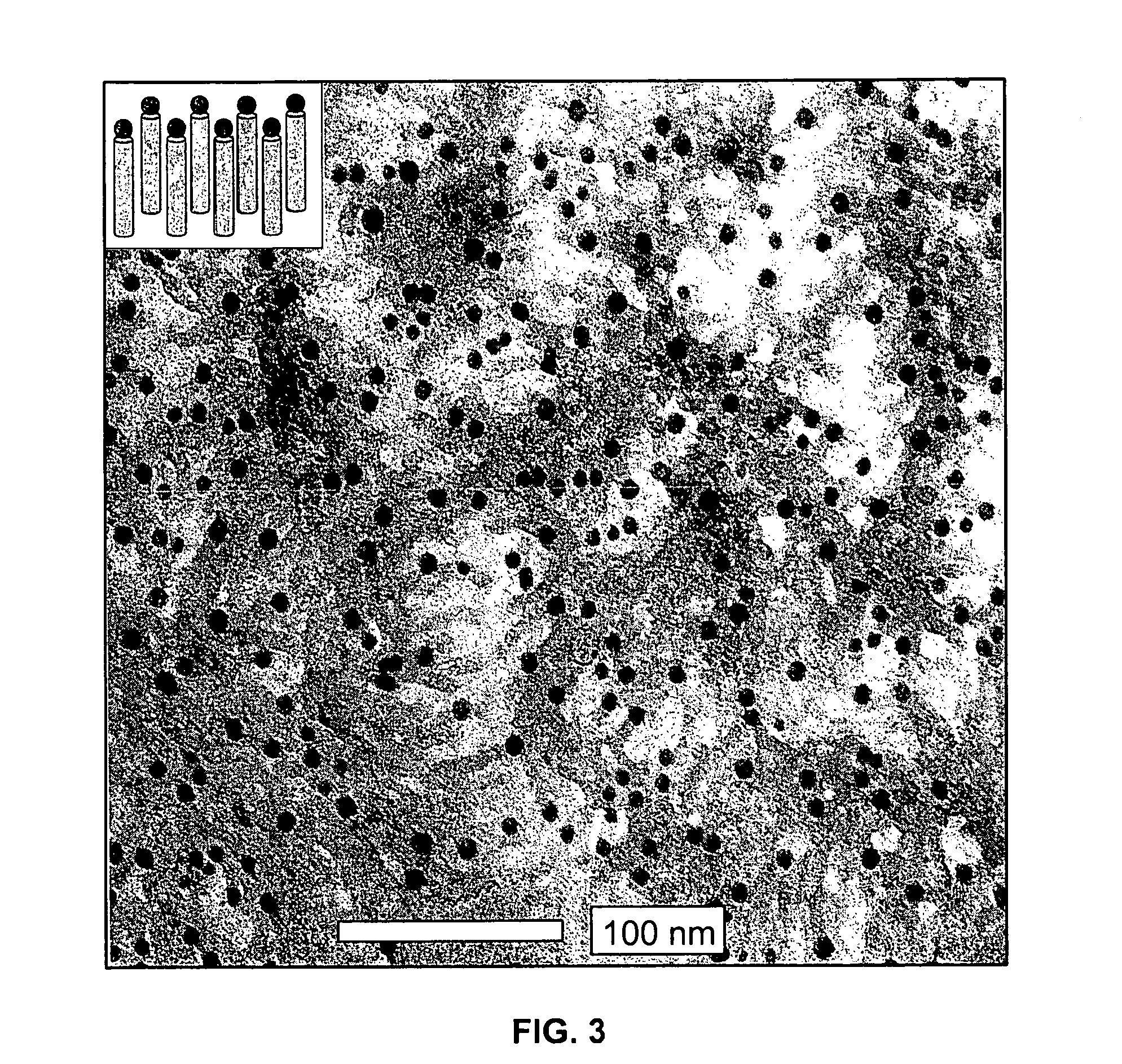

Sol-Gel Precursors and Products Thereof

The present invention provides a generalizable single-source sol-gel precursor capable of introducing a wide range of functionalities to metal oxides such as silica. The sol-gel precursor facilitates a one-molecule, one-step approach to the synthesis of metal-silica hybrids with combinations of biological, catalytic, magnetic, and optical functionalities. The single-source precursor also provides a flexible route for simultaneously incorporating functional species of many different types. The ligands employed for functionalizing the metal oxides are derived from a library of amino acids, hydroxy acids, or peptides and a silicon alkoxide, allowing many biological functionalities to be built into silica hybrids. The ligands can coordinate with a wide range of metals via a carboxylic acid, thereby allowing direct incorporation of inorganic functionalities from across the periodic table. Using the single-source precursor a wide range of functionalized nanostructures such as monolith structures, mesostructures, multiple metal gradient mesostructures and Stober-type nanoparticles can be synthesized.

Owner:CORNELL RES FOUNDATION INC

Preparation method for heat-conducting methylphenyl silicone oil

The invention relates to the technical field of organosilicon and discloses a preparation method for heat-conducting methylphenyl silicone oil to overcome the problem of heat resistance of silicone oil. The method comprises the following steps: adding rare earth oxide having undergone surface silane modification into phenylcyclosiloxane and dimethylcyclosiloxane monomers; carrying out in-situ ring-opening polymerization in the presence of a catalyst (CH3)4NOH silicon alkoxide and an end-capping reagent; decomposing the catalyst at 130 to 150 DEG C for 1 to 4 h; and then carrying out pressure reduction to remove low-boiling-point substances so as to obtain the heat-conducting methylphenyl silicone oil. The obtained methylphenyl silicone oil has silicone oil viscosity of 25 MPa.s to 12000 MPa.s and has excellent heat resistance.

Owner:浙江乾晟科技有限公司

Process of preparation of rare earth silicate phosphor

InactiveUS7138074B1Effective radiationEasy to prepareLuminescent compositionsRare-earth elementPhosphor

A rare earth element-activated rare earth silicate phosphor is prepared by the steps of (1) heating a rare earth carboxylate with an alkoxyalcohol to obtain a solution; (2) adding to the solution a silicon alkoxide and a compound of the element A, to prepare a mixture; and (3) subjecting the mixture to thermal decomposition.

Owner:FUJIFILM CORP +1

Supported metal catalysts

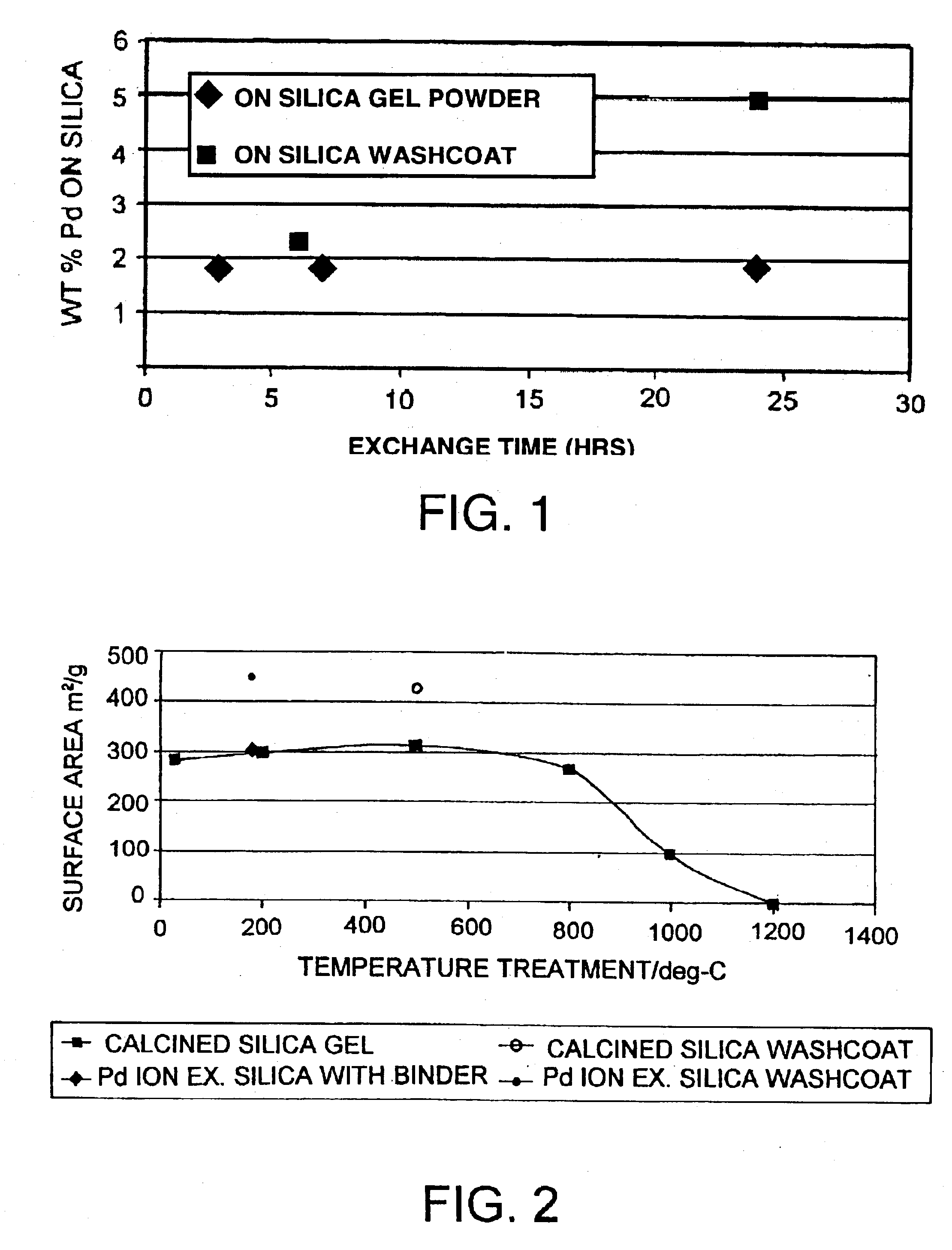

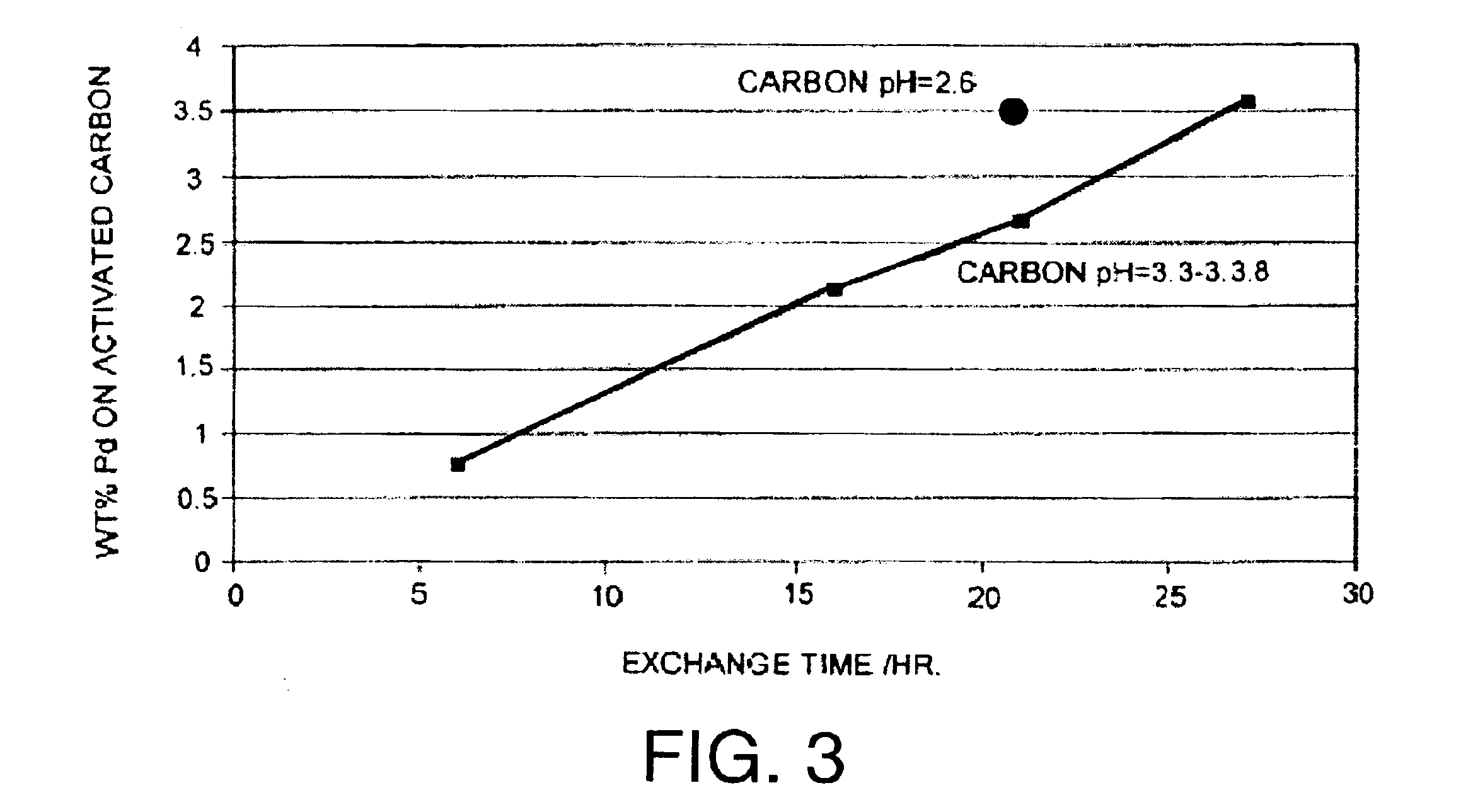

InactiveUS6916943B2Increased durabilityGood chemical compatibilityFatty acid hydrogenationCombination devicesMetal catalystFixed bed

A process of making a supported catalyst includes steps of preparing a washcoat containing a mixture of hydrolyzed silicon alkoxide and a filler, depositing the washcoat on a surface of a solid support, drying the washcoat deposited on the surface of the solid support to form a coating on the surface of the solid support, and distributing a metal catalyst on the coating. The resulting supported catalyst may be used in a reaction vessel, such as a fixed bed reactor, for effecting a catalytic reaction, such as catalytic hydrogenation of an edible oil. The washcoatings can be formulated to provide a viscous composition that can be applied to form a thick coating on a substrate. The dried washcoatings exhibit excellent stability, cohesive layering strength, and adhesive strength between the coating and a substrate.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com