Method for preparing alpha, omega-bis(aminopropyl)polydimethylsiloxane

A dimethylsiloxane and aminopropyl technology, applied in the alpha field, can solve the problems of low product yield and slow reaction rate, and achieve the effects of high amino end capping rate, eliminating interference and shortening the equilibrium reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

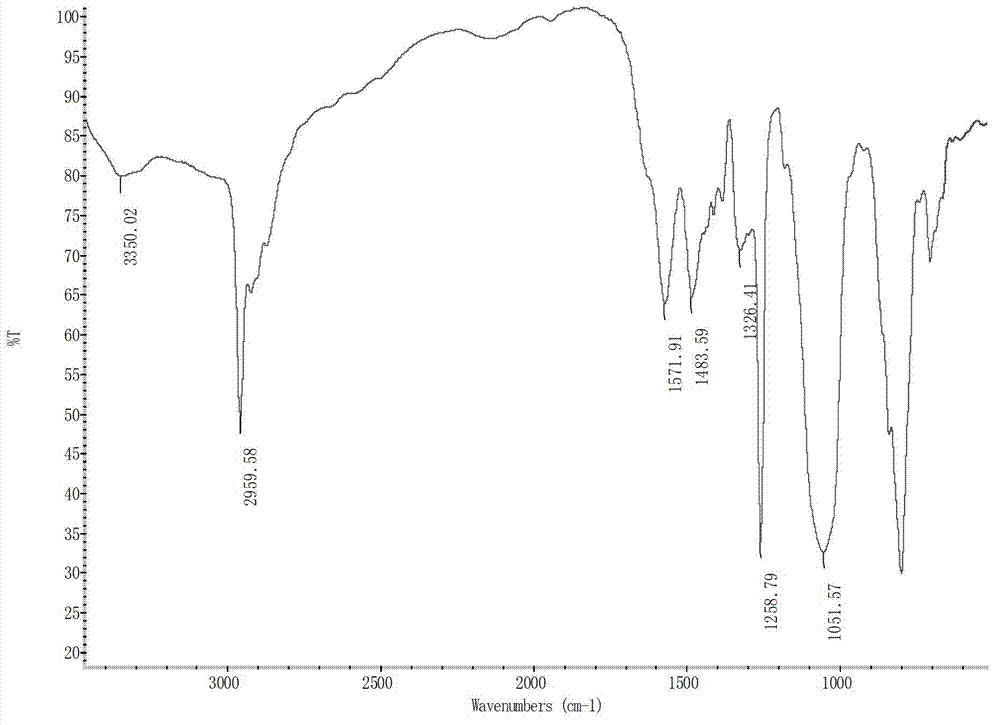

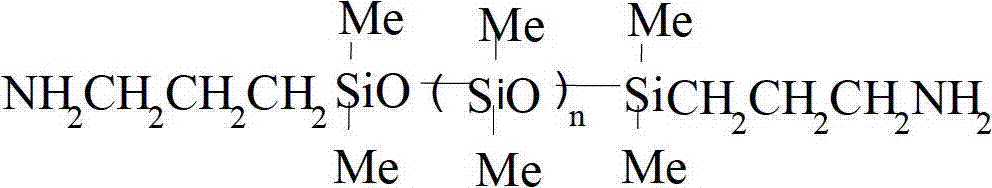

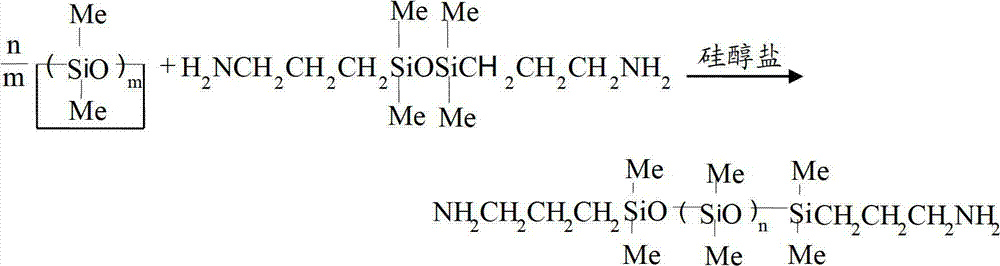

Image

Examples

Embodiment 1

[0032] In this embodiment, the preparation method of α, ω-bis(aminopropyl)polydimethylsiloxane comprises the following steps:

[0033] (1) Preparation of silicon alkoxide catalyst: Add 80g NaOH and 800g dimethylsiloxane mixed ring (DMC) into a stirred reactor, raise the temperature to 90°C at 7KPa, dehydrate for 4 hours, and obtain a uniform and transparent Oily NaOH siliconate (siliconate catalyst);

[0034] (2) Add 960g of hexamethylcyclotrisiloxane (D 3 ), remove moisture at 70°C and 2KPa; then add 1.2g of the silicon alkoxide catalyst obtained in step (1) to start the catalytic reaction, the temperature of the catalytic reaction is 110°C, and add 87.0g of 1,3-bis( 3-aminopropyl)-1,1,3,3-tetramethyldisiloxane for equilibrium reaction for 5 hours;

[0035] (3) Add H to the mixture obtained after the reaction in step (2) 3 PO 4 Neutralize the catalyst, and then remove the low boilers at 150°C and 0.5kPa to obtain the α,ω-bis(aminopropyl)polymer with a colorless and transp...

Embodiment 2

[0044] In this embodiment, the preparation method of α, ω-bis(aminopropyl)polydimethylsiloxane comprises the following steps:

[0045] (1) Preparation of silicon alkoxide catalyst: Add 80g NaOH and 800g dimethylsiloxane mixed ring (DMC) into a stirred reactor, raise the temperature to 90°C at 7KPa, dehydrate for 4 hours, and obtain a uniform and transparent Oily NaOH silicon alkoxide (siliconate catalyst);

[0046] (2) Add 1100g of dimethylsiloxane mixed rings into a reactor equipped with a stirrer and a nitrogen pipe, and remove moisture at 90°C and 5KPa; then add the silicon alkoxide catalyst obtained in step (1) 1.5g, start the catalytic reaction, the temperature of the catalytic reaction is 150°C, add 2.5g of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane after the catalytic reaction for 30min Equilibrium reaction, reaction 6h;

[0047](3) Add H to the mixture obtained after the reaction in step (2) 3 PO 4 Neutralize the catalyst, and then remove the low boilers ...

Embodiment 3

[0053] In this embodiment, the preparation method of α, ω-bis(aminopropyl)polydimethylsiloxane comprises the following steps:

[0054] (1) Preparation of silicon alkoxide catalyst: Add 80g NaOH and 800g dimethylsiloxane mixed ring (DMC) into a stirred reactor, raise the temperature to 90°C at 7KPa, dehydrate for 4 hours, and obtain a uniform and transparent Oily NaOH siliconate (siliconate catalyst);

[0055] (2) Add 1200g decamethylcyclopentasiloxane (D 5 ), remove moisture at 90°C and 4KPa; then add 2.5g of the silicon alkoxide catalyst obtained in step (1) to start the catalytic reaction, the temperature of the catalytic reaction is 150°C, and add 3.0g of 1,3-bis( 3-aminopropyl)-1,1,3,3-tetramethyldisiloxane for equilibrium reaction, reacted for 7 hours;

[0056] (3) Add H to the mixture obtained after the reaction in step (2) 3 PO 4 Neutralize the catalyst, and then remove the low boilers at 170°C and 1.0kPa to obtain the α,ω-bis(aminopropyl)polymer with a colorless an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com