Novel OSB structure building template and preparation method thereof

A building formwork, a new type of technology, applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of large product thickness deviation, high production cost, low turnover times, etc., to achieve waterproof performance improvement, waterproof performance good, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

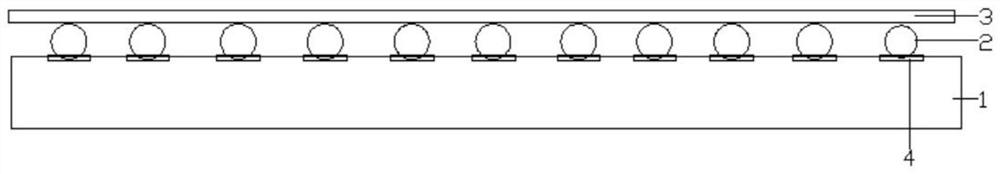

[0058] The novel OSB structure building formwork of the present application, structure such as figure 1 shown.

[0059] A preparation method of a novel OSB structure building formwork, comprising the following steps:

[0060] (1) According to the calculation in parts by mass, take 100 parts of pine rough flakes and fine flakes base material, the ratio of coarse flakes and fine flakes base material is 1:1, and the fine flakes are mainly used as filling (length 50-100mm , 25-50mm wide 50 parts of fine shavings, 100-150mm long, 50 parts of wide 50-75mm coarse shavings), 2 parts of emulsified paraffin, 15 parts of organic glue, 2 parts of tackifier, 4 parts of reinforcing fiber, 5 parts water;

[0061] (2) Put the two base materials of coarse shavings and fine shavings into a high-speed mixer for stirring. During the stirring process, use different spray guns to mix the above-mentioned additives such as organic glue, adhesive, emulsified paraffin, reinforcing fiber, and water in...

Embodiment 2

[0078] A new type of OSB structure building formwork, similar to Example 1, the difference is that it includes the following raw materials in parts by weight: 85 parts of planed base material, 2 parts of waterproofing agent, 10 parts of organic glue, 1 part of adhesive, 3 parts of water, 2 parts of reinforcing fiber, 1 part of hot-melt plastic particles.

Embodiment 3

[0080] A new type of OSB structure building formwork, similar to Example 1, the difference is that it includes the following raw materials in parts by weight: 90 parts of planed base material, 2.5 parts of waterproofing agent, 12 parts of organic glue, 1.5 parts of adhesive, 4 parts of water, 3 parts of reinforcing fiber, 1.5 parts of hot-melt plastic particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com