Method for making silica nanoparticles by flame spray pyrolysis adopting two-fluid nozzle

a technology of flame spray pyrolysis and silica nanoparticles, which is applied in the field of making nanoparticles, can solve the problems of low yield of silica nanoparticles, large amount of energy consumed, and hardly applicable in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

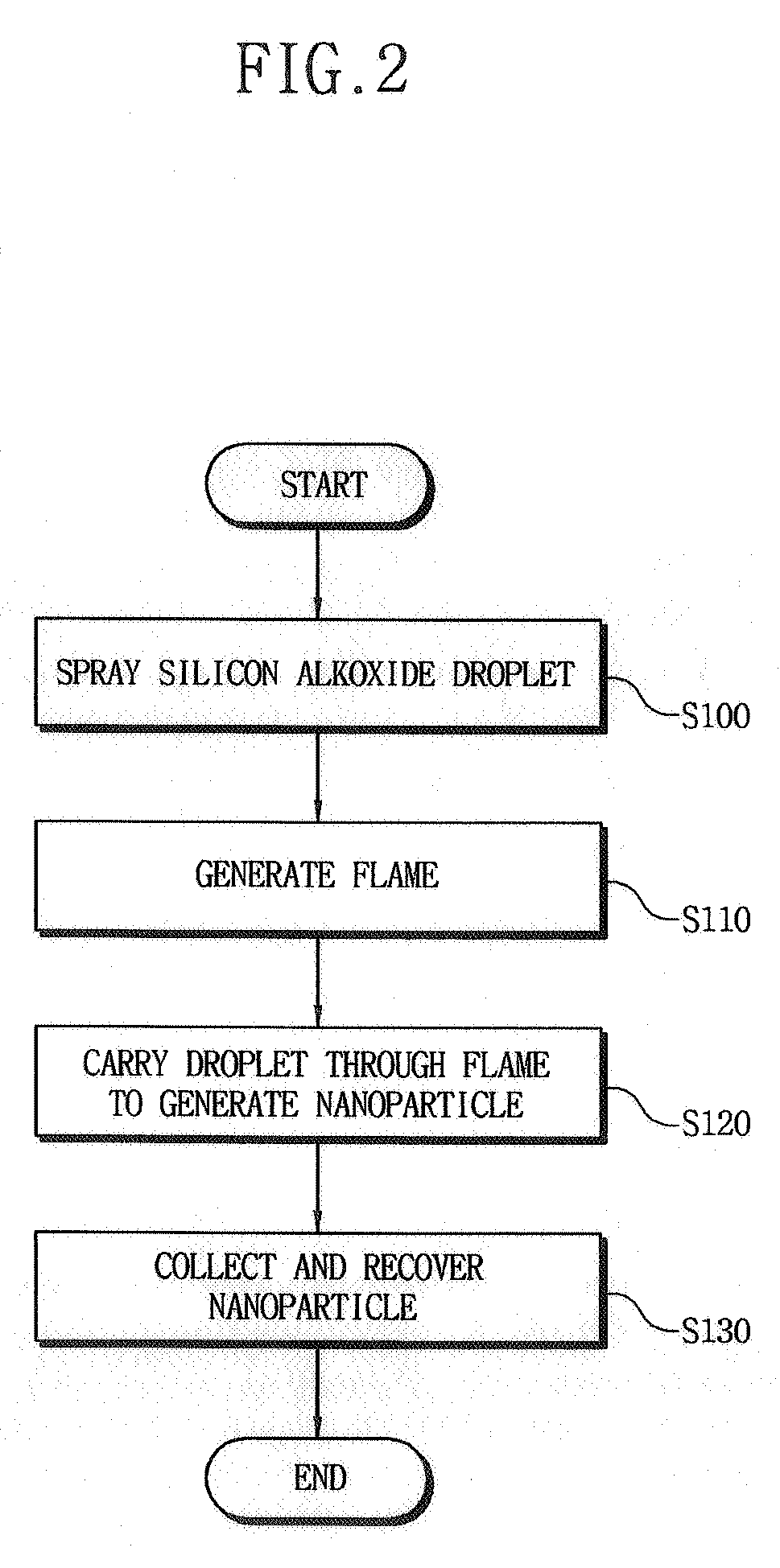

[0038]Example 1 was aimed to adjust the size of resultant particles by varying the pressure of dispersed air for micronizing liquid source material during the production of nanoparticles.

[0039]An experiment was carried out to make silica nanoparticles, in which silicon alkoxide (TEOS) mixed with ethanol were delivered through a flame under the following conditions.

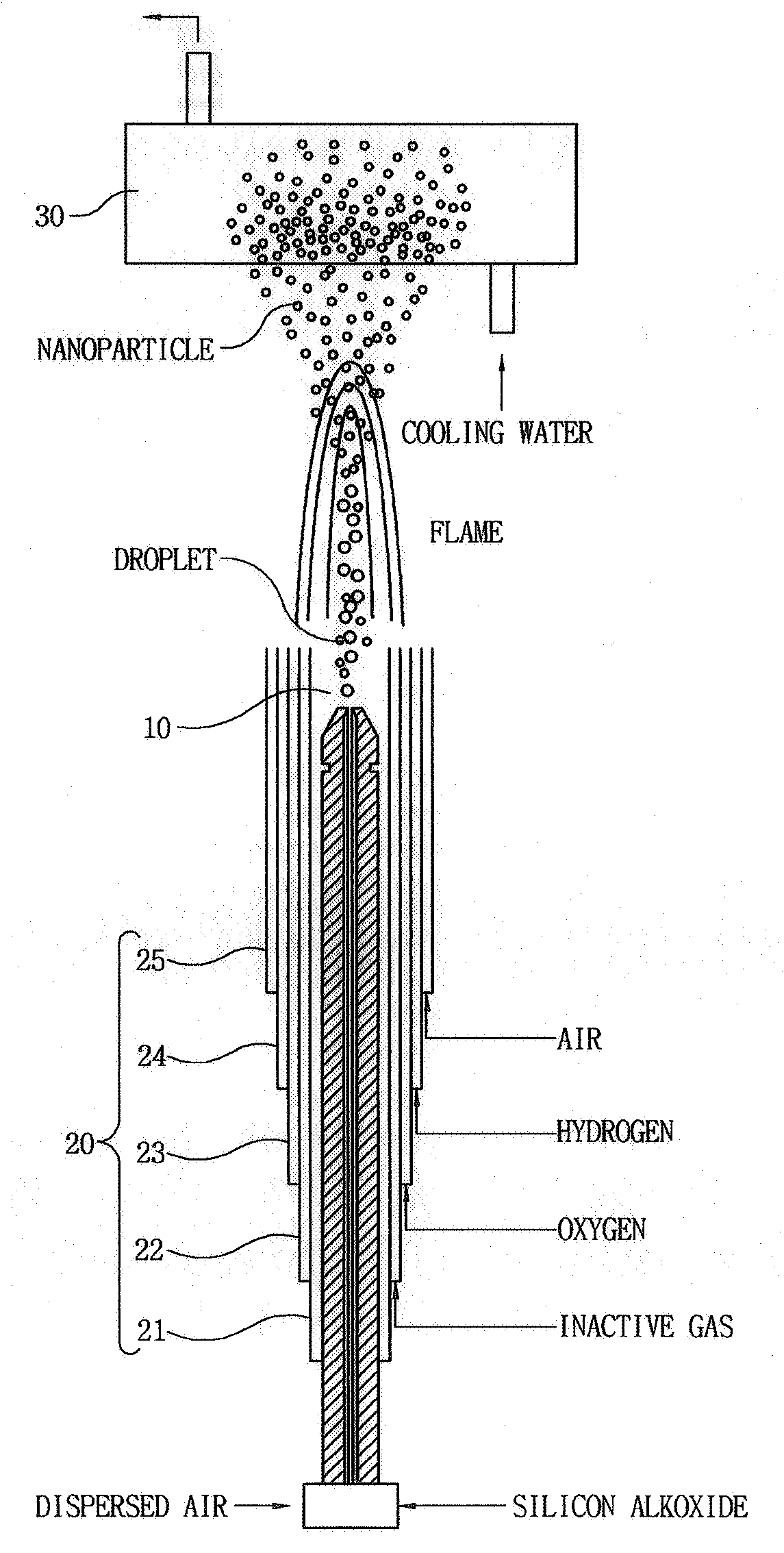

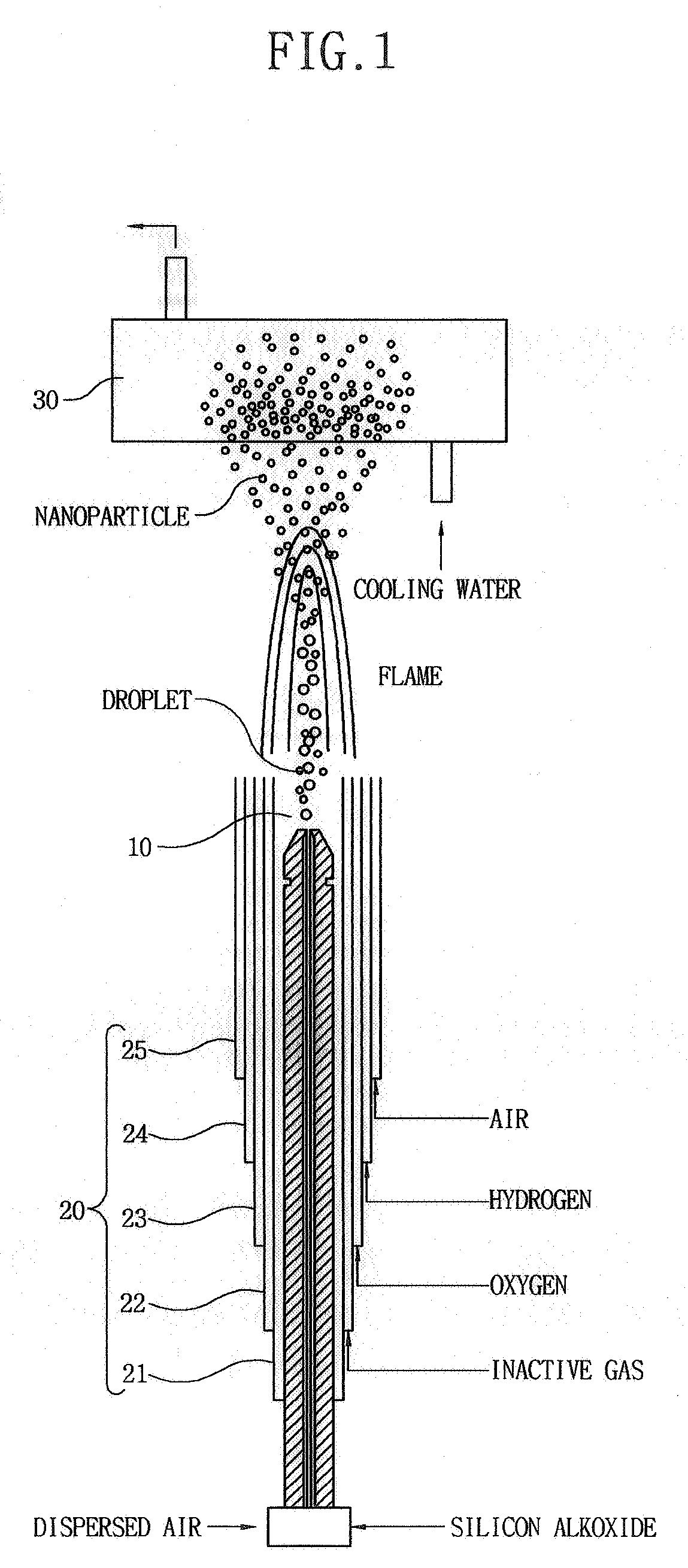

[0040]A liquid sample or TEOS was injected into the droplet spray 10 as shown in FIG. 1, where it was liquefied with dispersed air under high pressure. Then, the liquefied TEOS was flown into the first tube 21 in the center of the burner 20, and Ar, H, oxygen and air were blown respectively in their order into the second to fifth tubes 22 to 23 of the dispersion type burner 20, thereby producing flame.

[0041]Describing the flow rate of gas introduced into the flame reactor, dispersed air was blown into the first tube 21 of the burner 20 having the first to fifth tubes 21 to 25, at a volume fraction of 2% to 3% in the entire...

example 2

[0044]Example 2 was aimed to adjust the size of resultant particles by injecting a reactive material into a hot flame with different concentrations of 2.1×10−4 mol / l, 3.3×10−4 mol / l and 4.8×10−4 mol / l while maintaining constantly the pressure of dispersed air for micronizing liquid source material during the production of nanoparticles.

[0045]Describing the flow rate of gas blown into the flame reactor, the pressure of the dispersed air introduced into the first tube of the burner was maintained constantly at 3.0 kgf / cm2, which is 1% to 2% in volume of the entire flow rate of gas, in order to make a TEOS reactive material into fine droplets having molarities of 2.0×10−4 mol / l, 3.3×10−4 mol / l and 4.8×10−4 mol / l. In addition, Ar gas at 7% in volume fraction was blown into the second tube 22, hydrogen gas at 14% in volume fraction was blown into the third tube 23, oxygen gas at 21% in volume fraction was blown into the fourth tube 24, and air at 56% to 57% in volume fraction was blown i...

example 3

[0048]Example 3 was aimed to adjust the size of resultant particles by adjusting the flow rate of hydrogen gas used as fuel to 3% in volume fraction and then changing the flow rate of a TEOS reactive material.

[0049]Describing the flow rate of gas blown into the flame reactor, the pressure of the dispersed air introduced into the first tube of the burner was maintained constantly at 3.0 kgf / cm2, which is 2% in volume of the entire flow rate of gas, in order to make the TEOS reactive material into fine droplets having molarities of 2.1×10−4 mol / l, 3.3×10−4 mol / l and 4.8×10−4 mol / l. In addition, Ar gas at 8% in volume fraction was blown into the second tube 22, hydrogen gas at 3% in volume fraction was blown into the third tube 23, oxygen gas at 24% in volume fraction was blown into the fourth tube 24, and air at 63% in volume fraction was blown into the fifth tube 25. With these conditions, silica nanoparticles were produced.

[0050]FIG. 5 illustrates TEM photographs of nanoparticles pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com