Patents

Literature

146results about How to "Simple and cost-effective to manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycrystalline group iii metal nitride with getter and method of making

ActiveUS20100151194A1Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

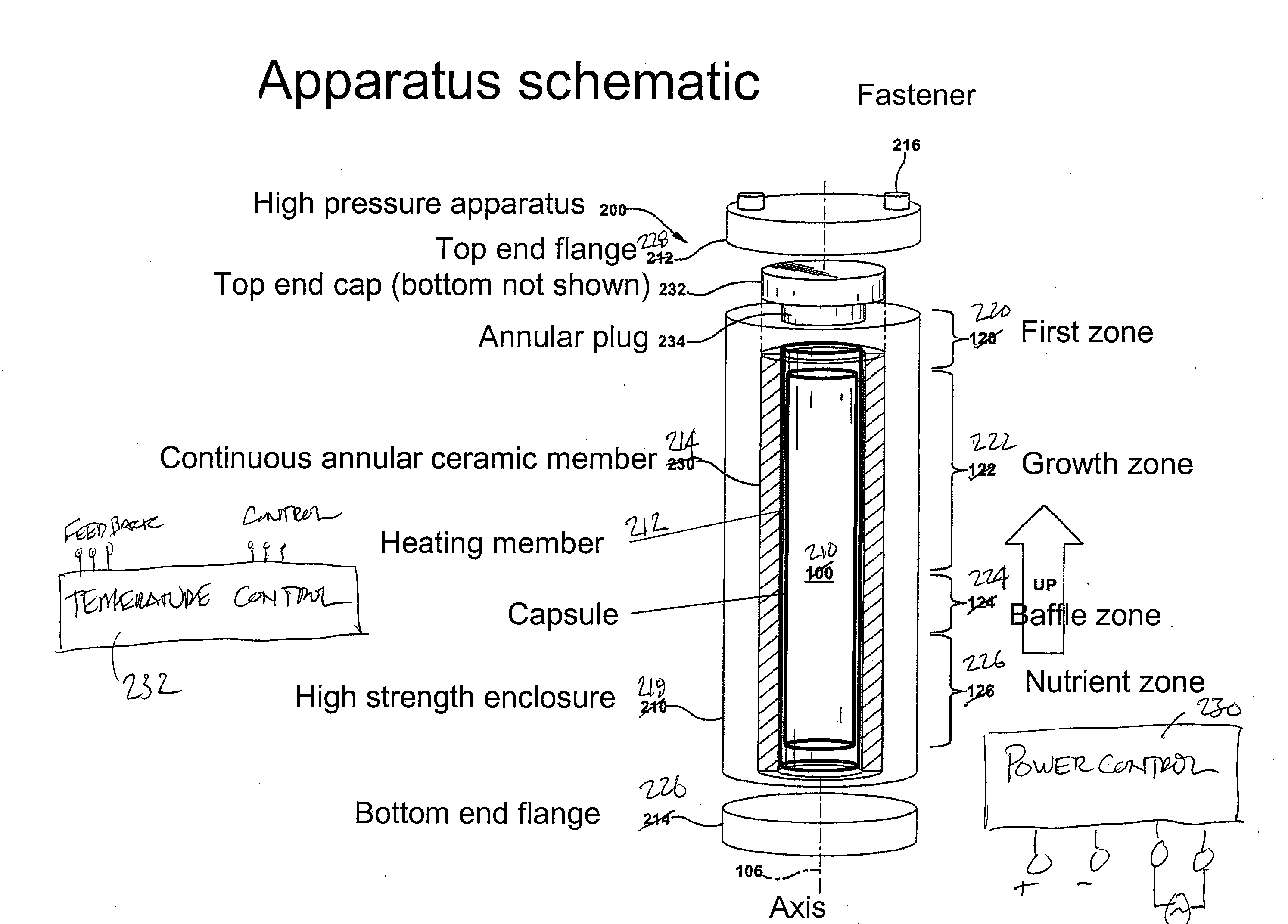

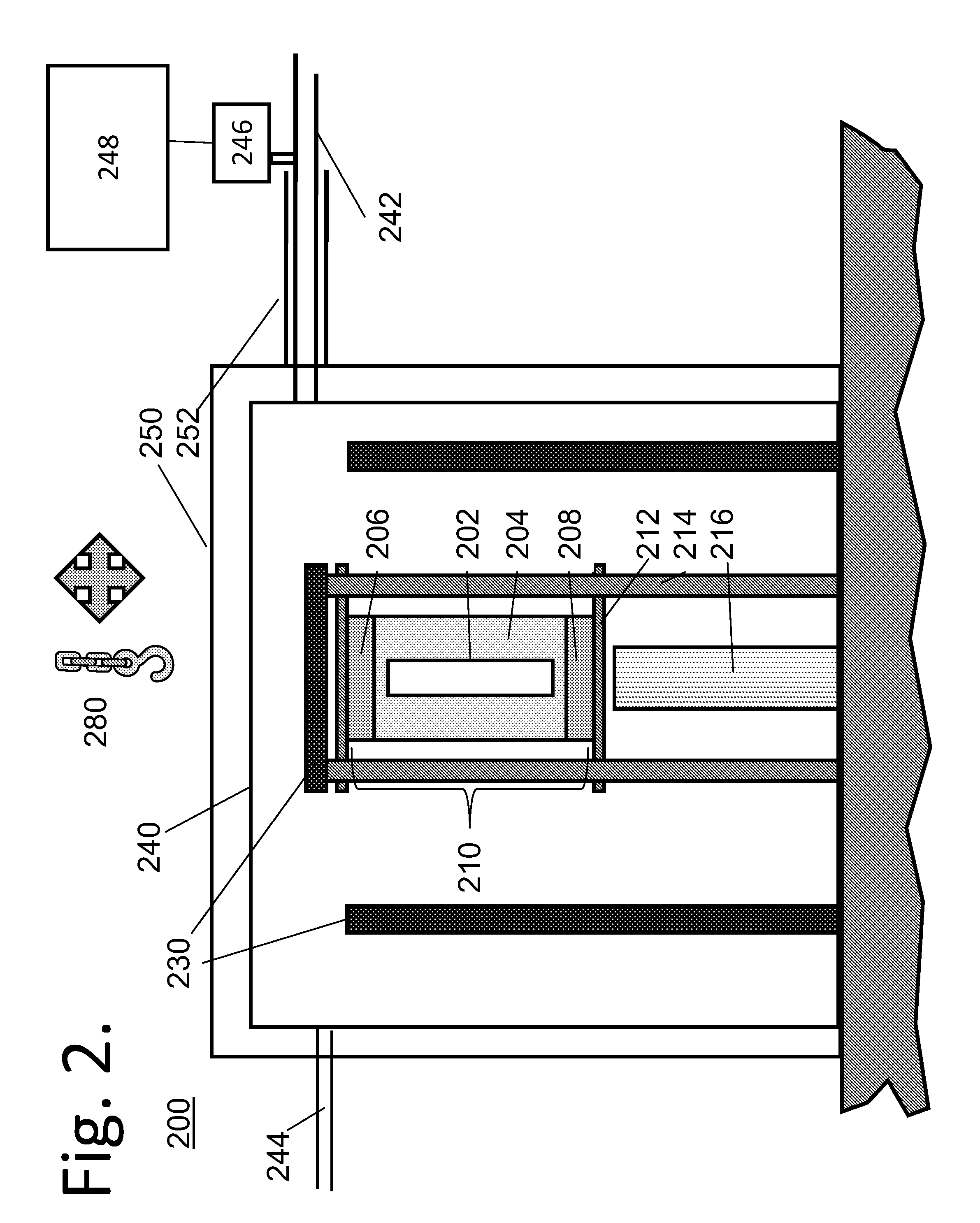

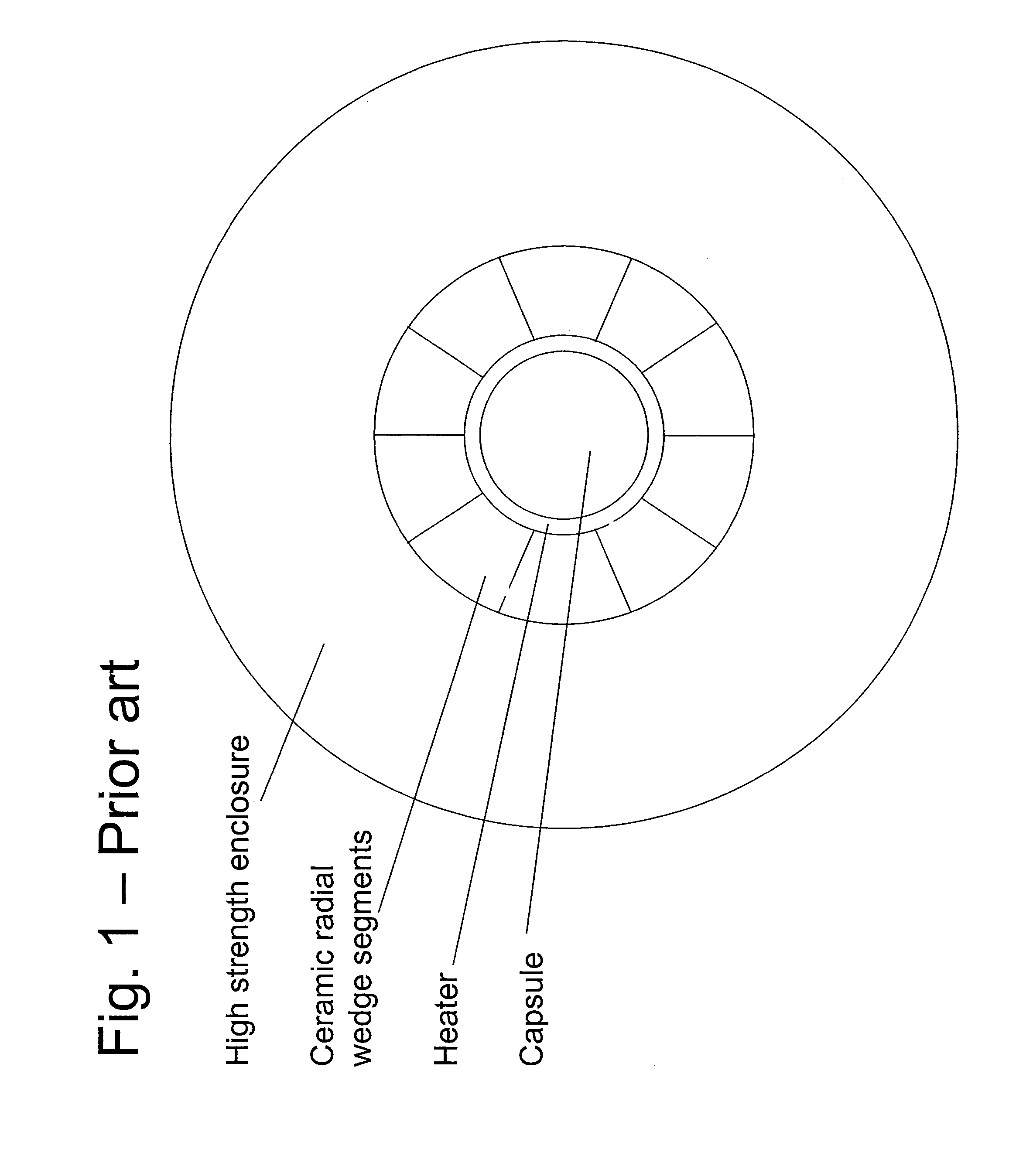

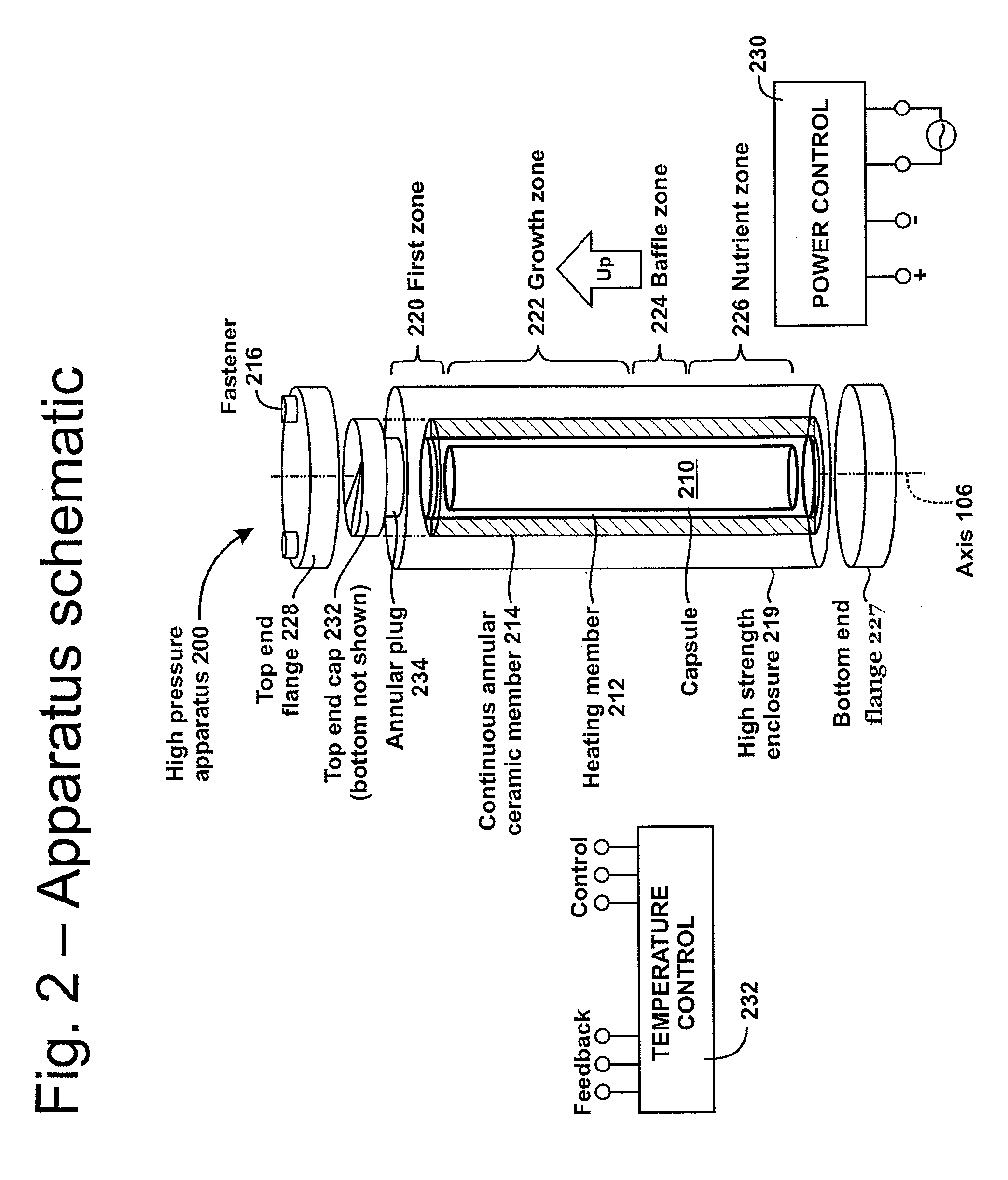

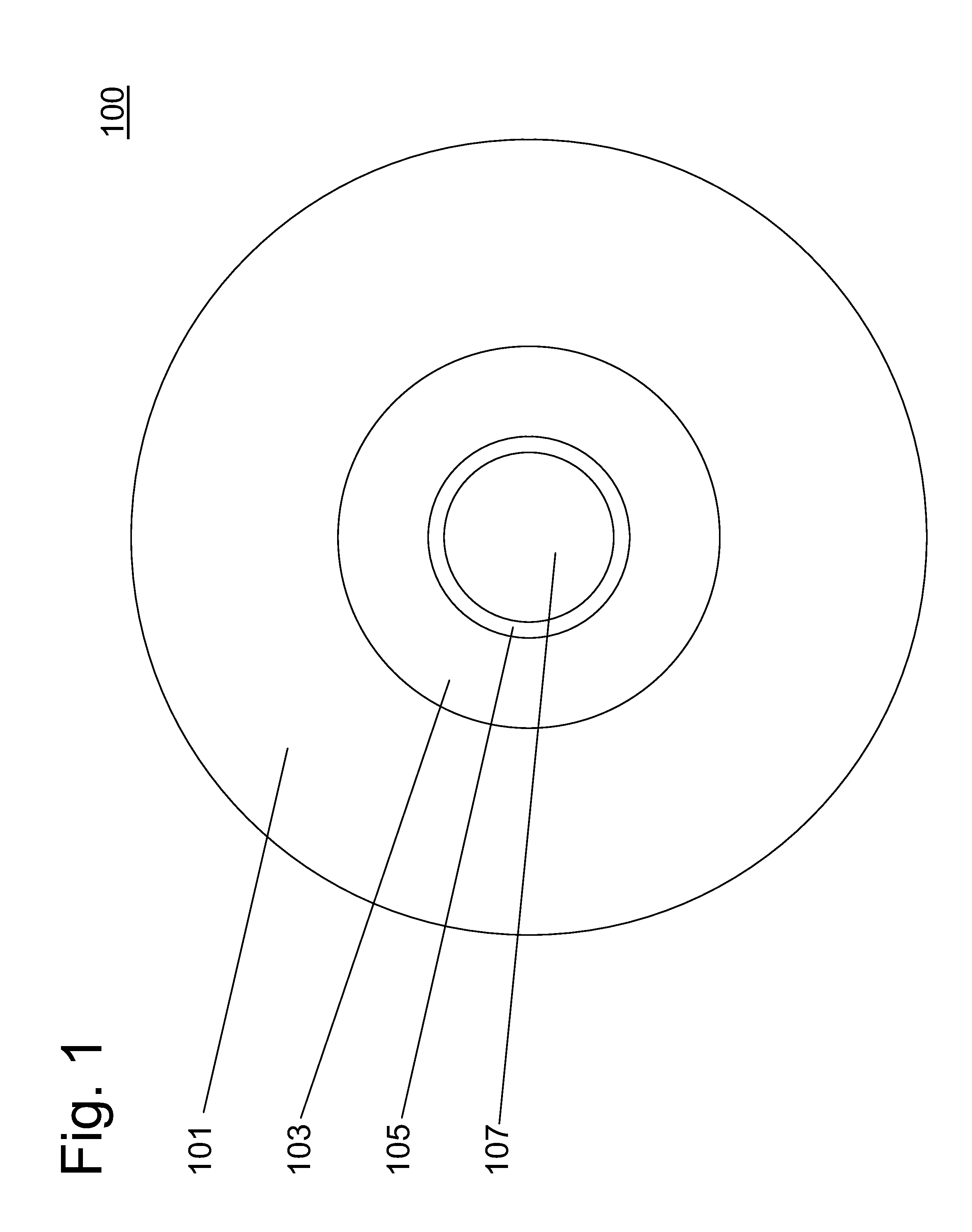

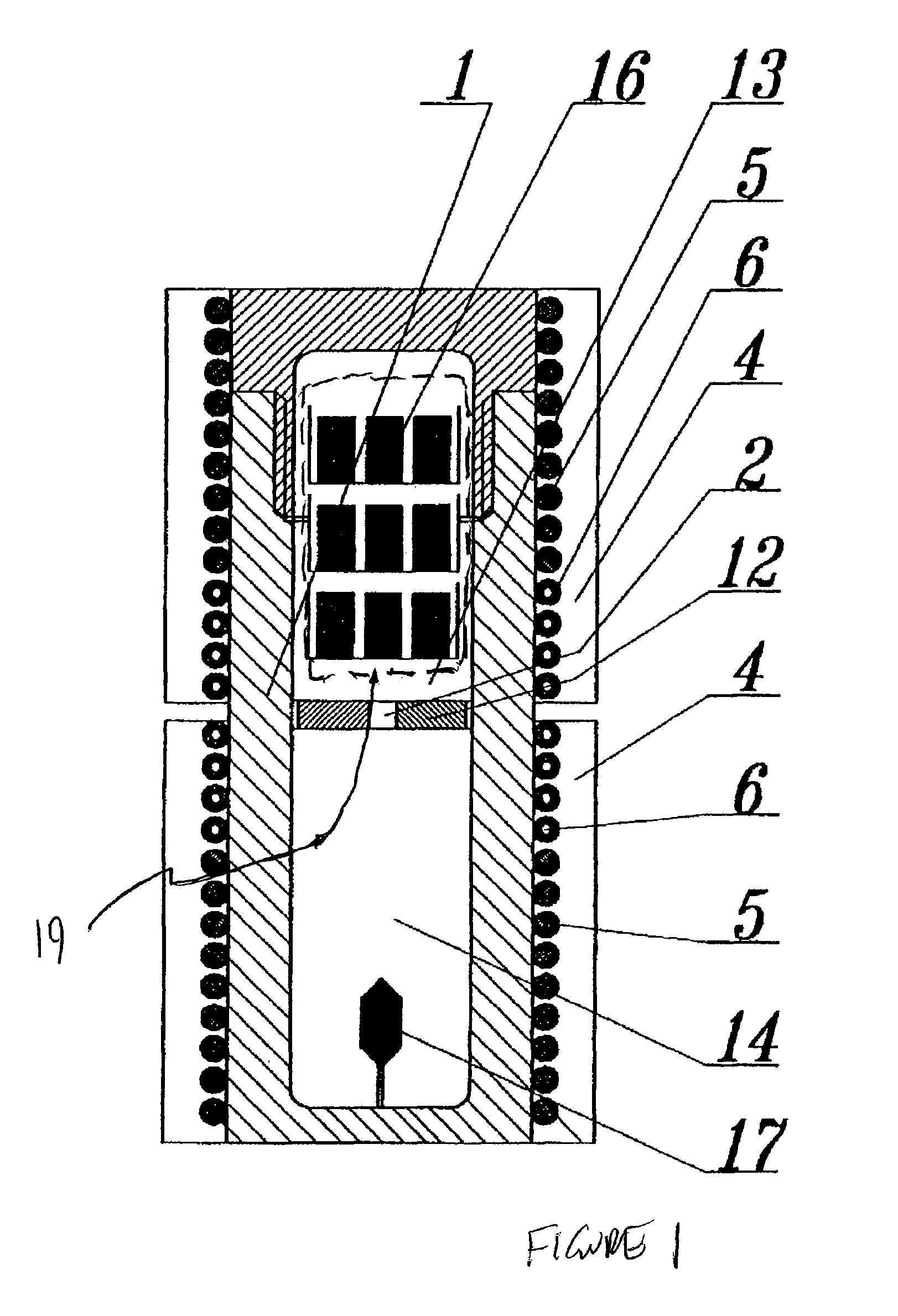

High pressure apparatus and method for nitride crystal growth

ActiveUS20090301387A1Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

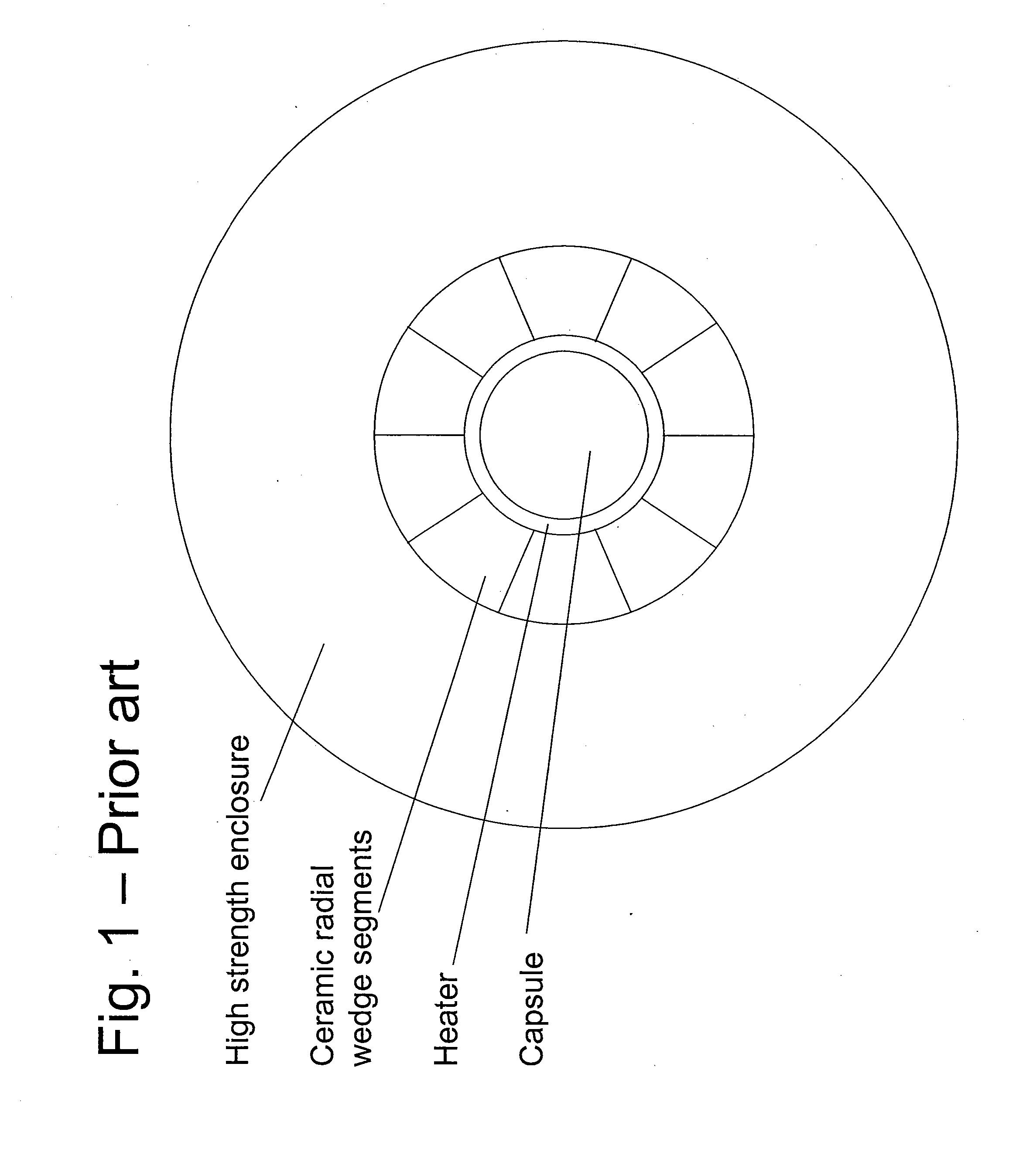

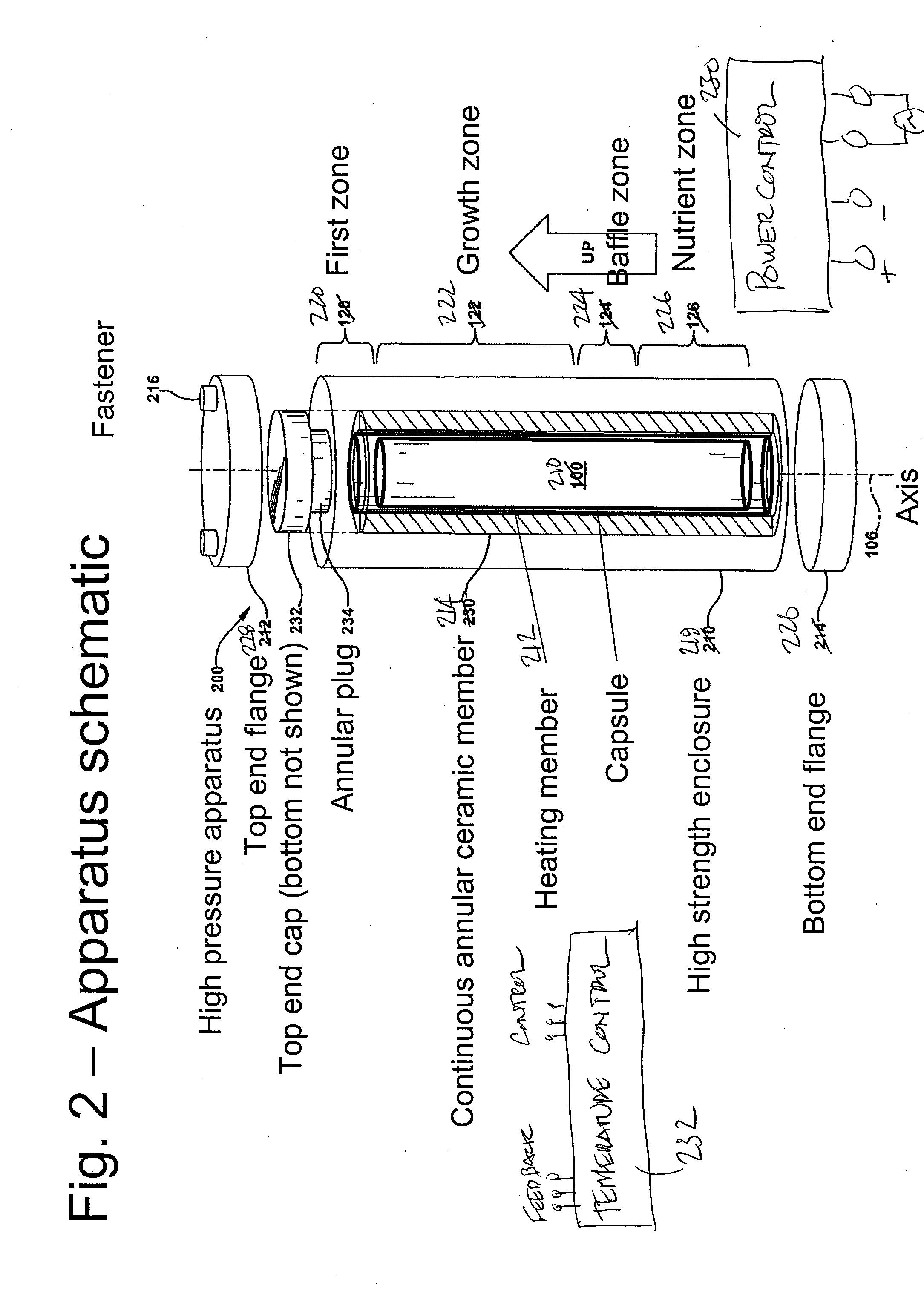

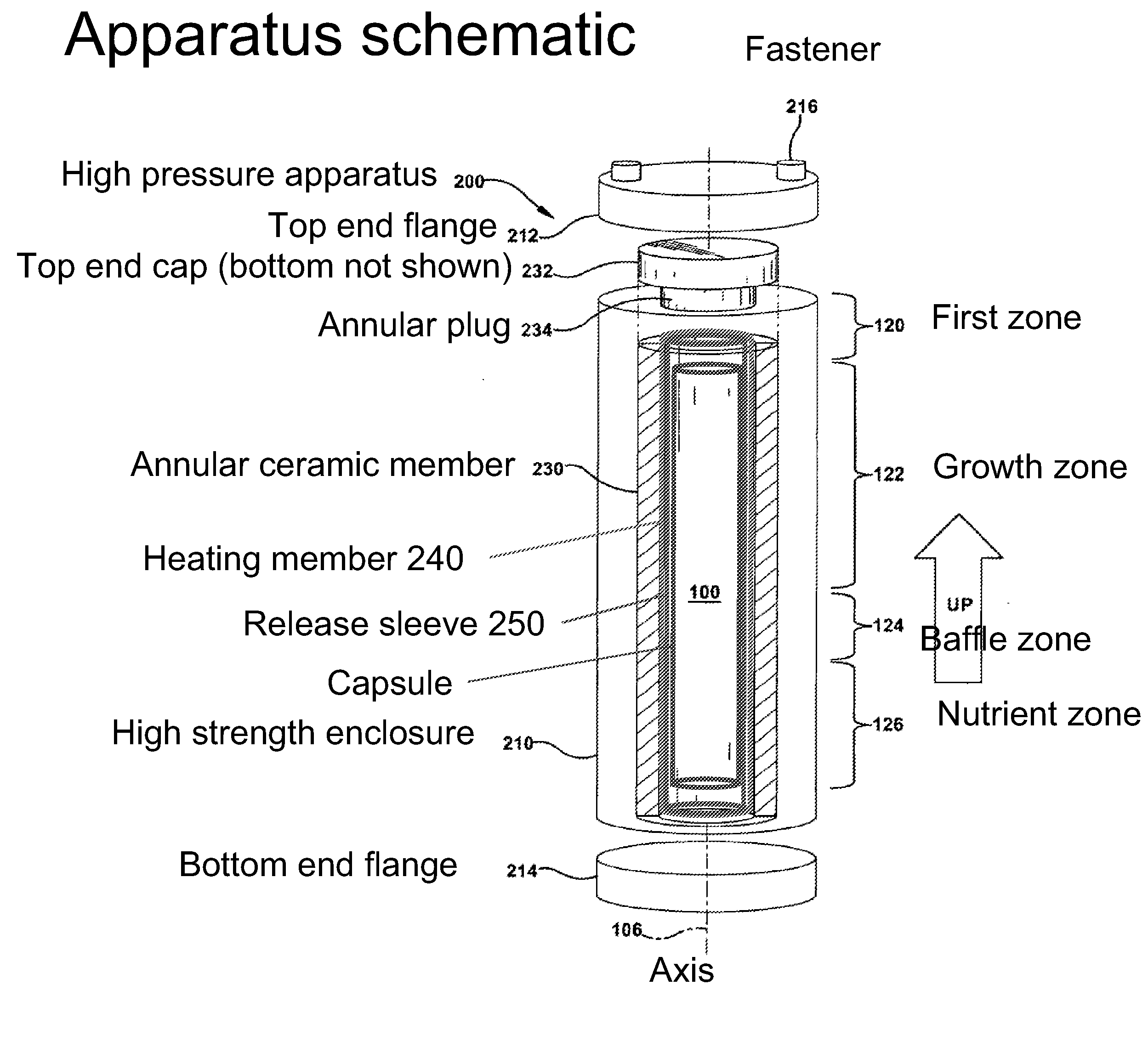

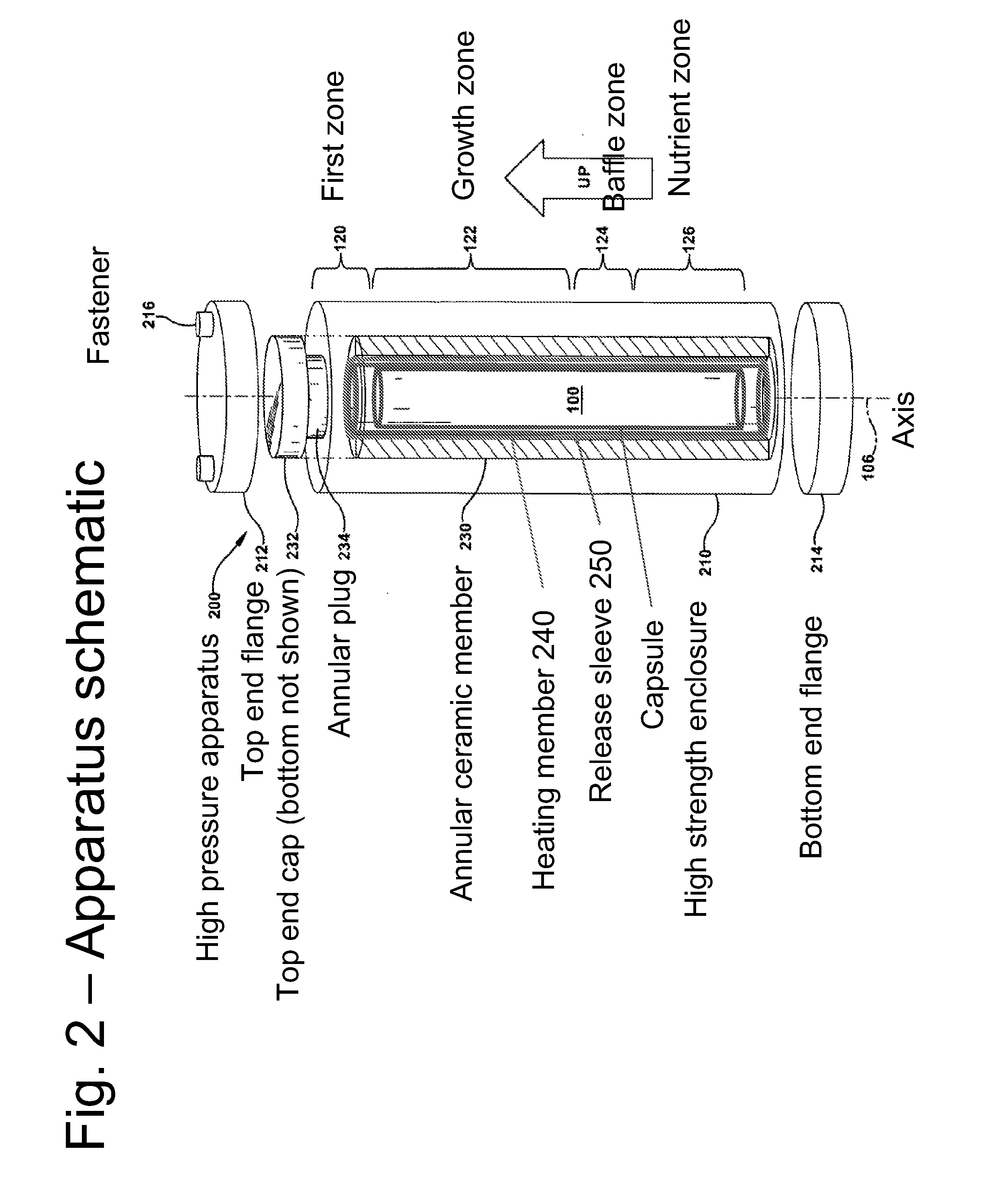

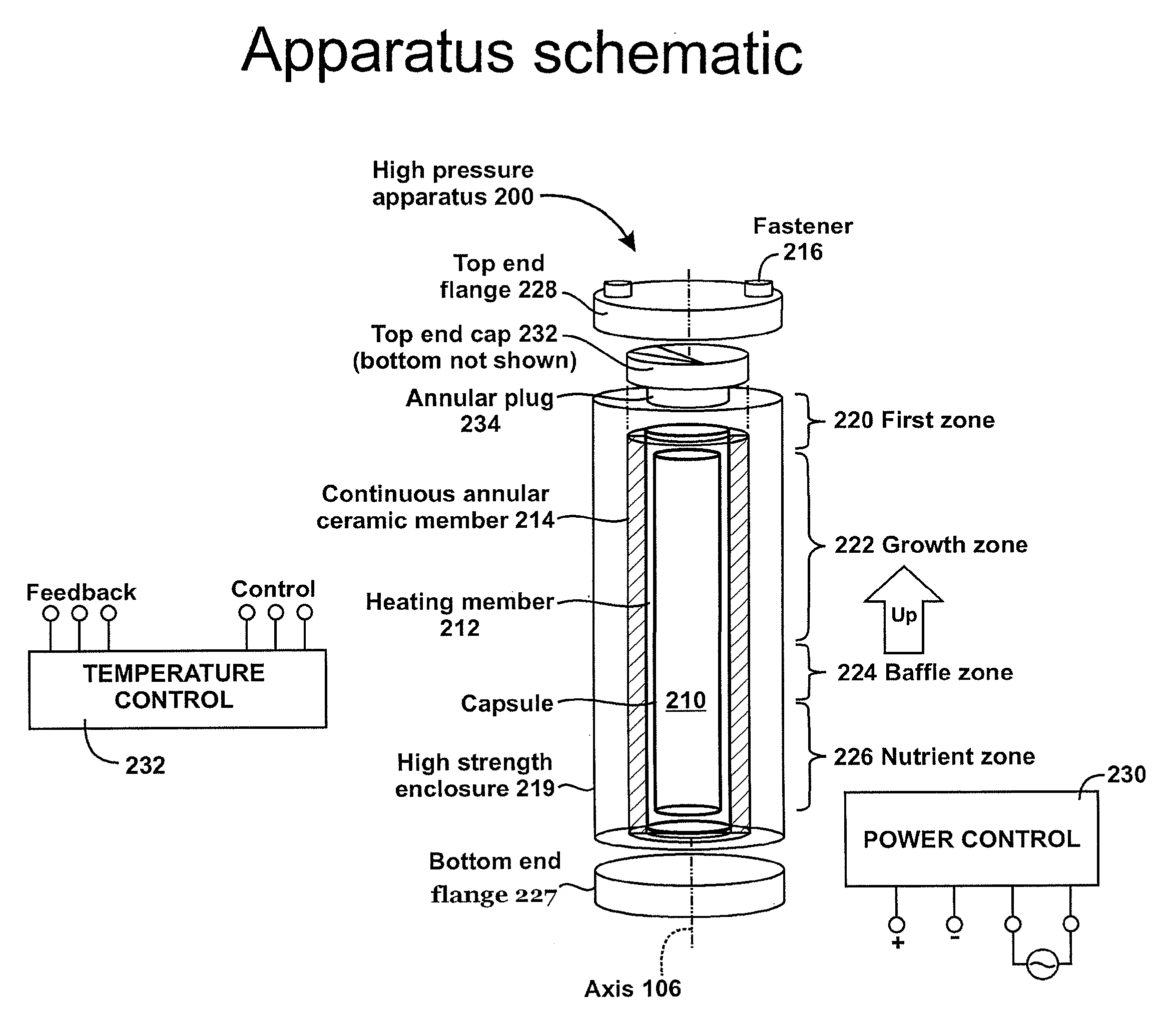

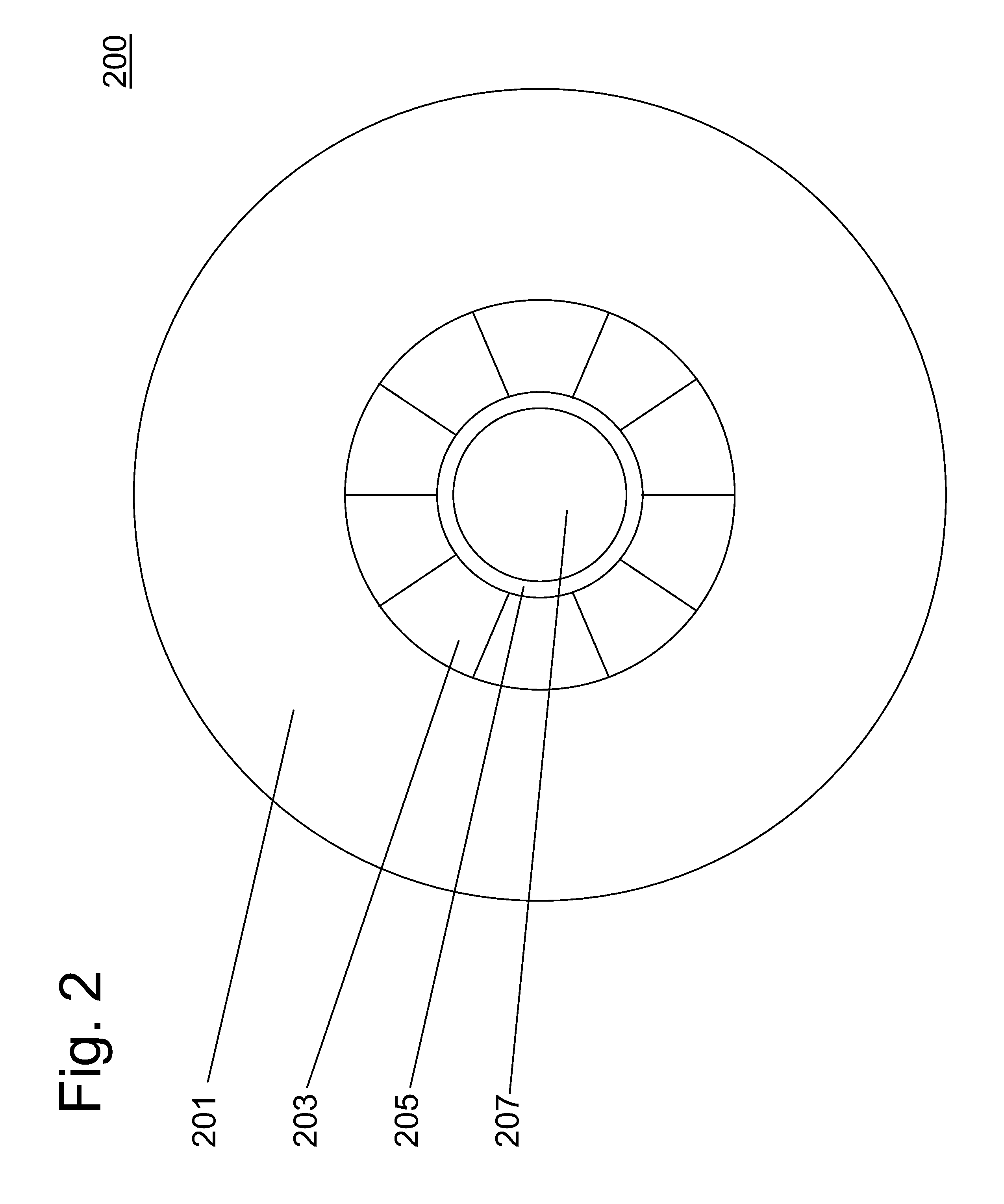

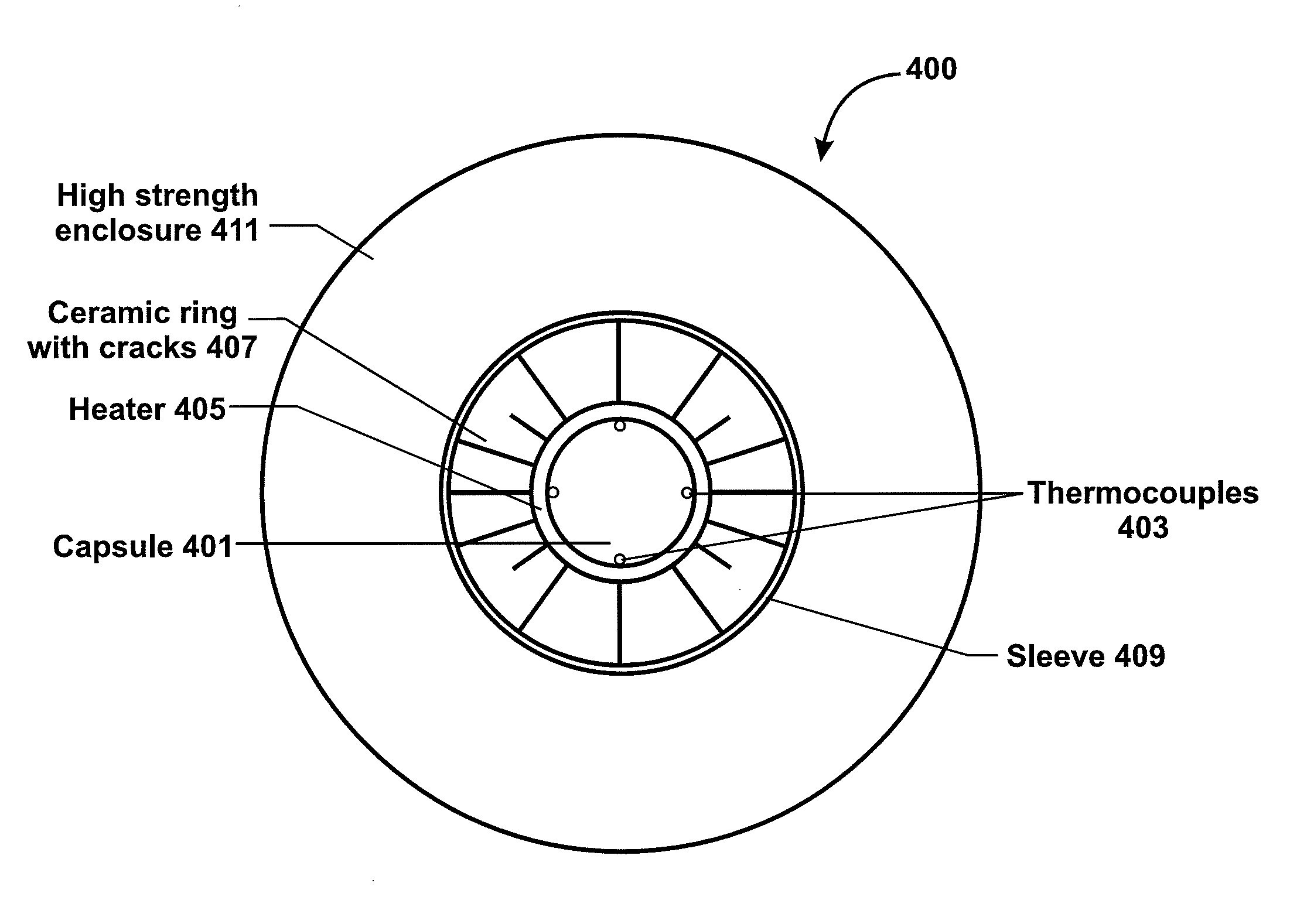

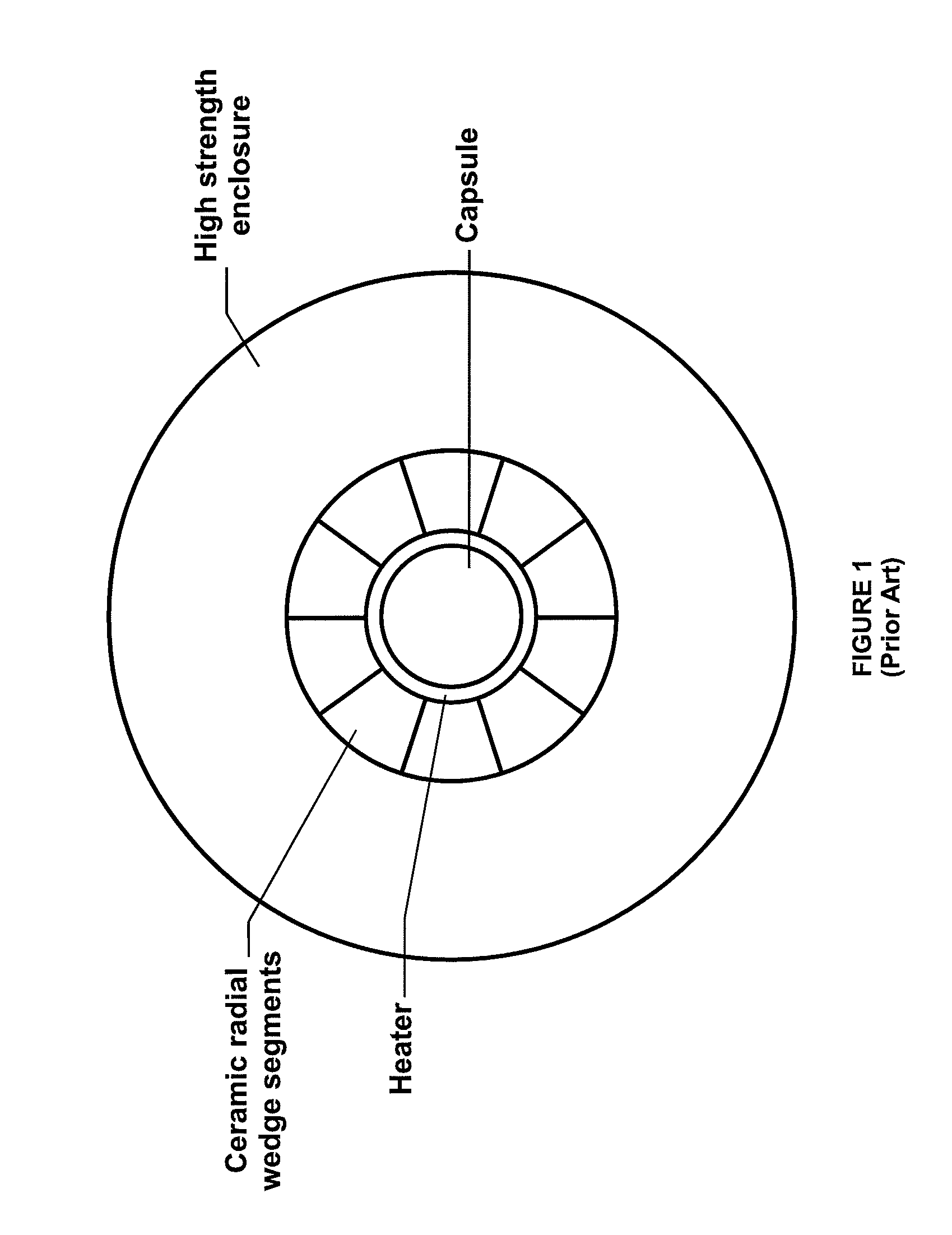

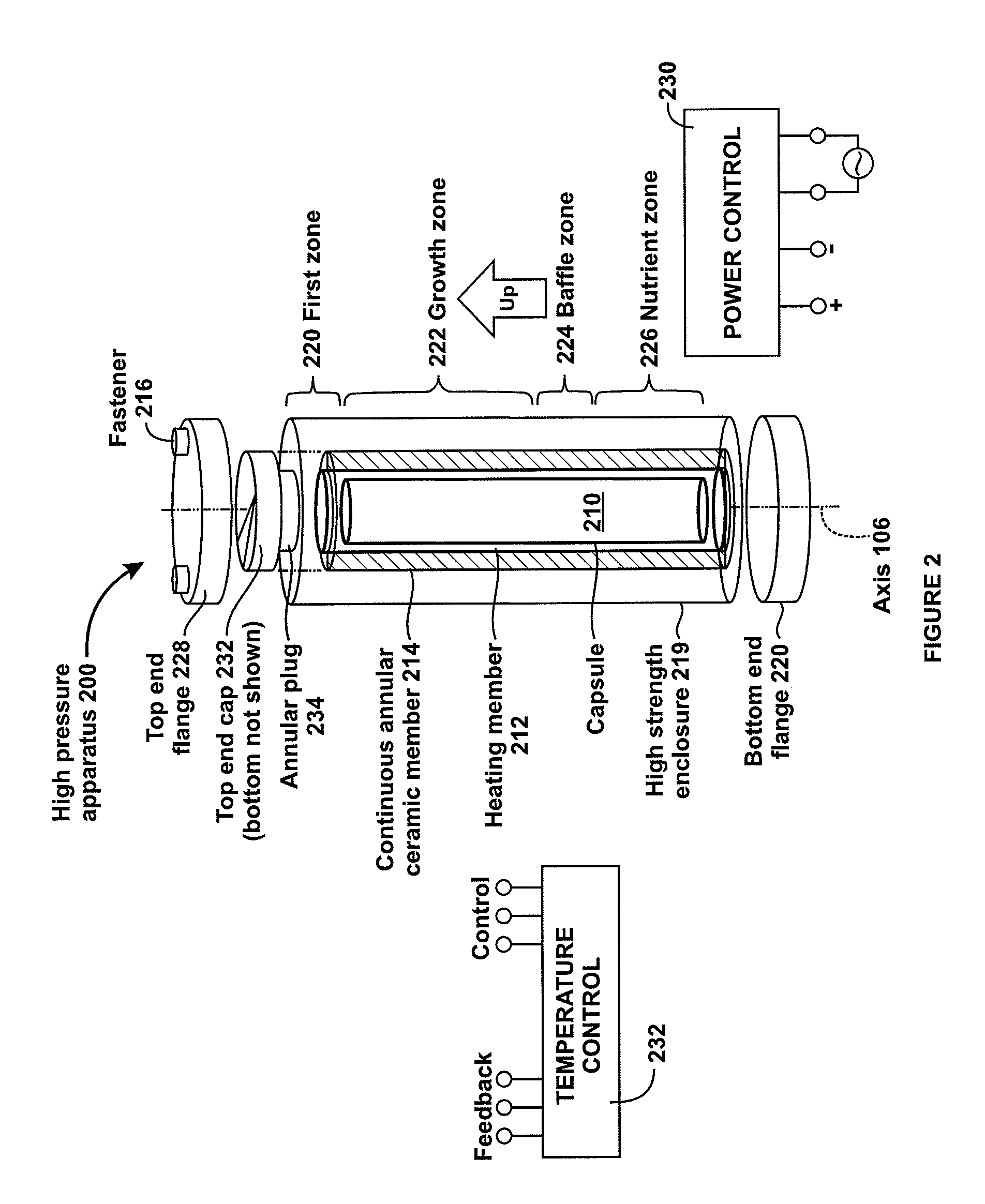

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. IN a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

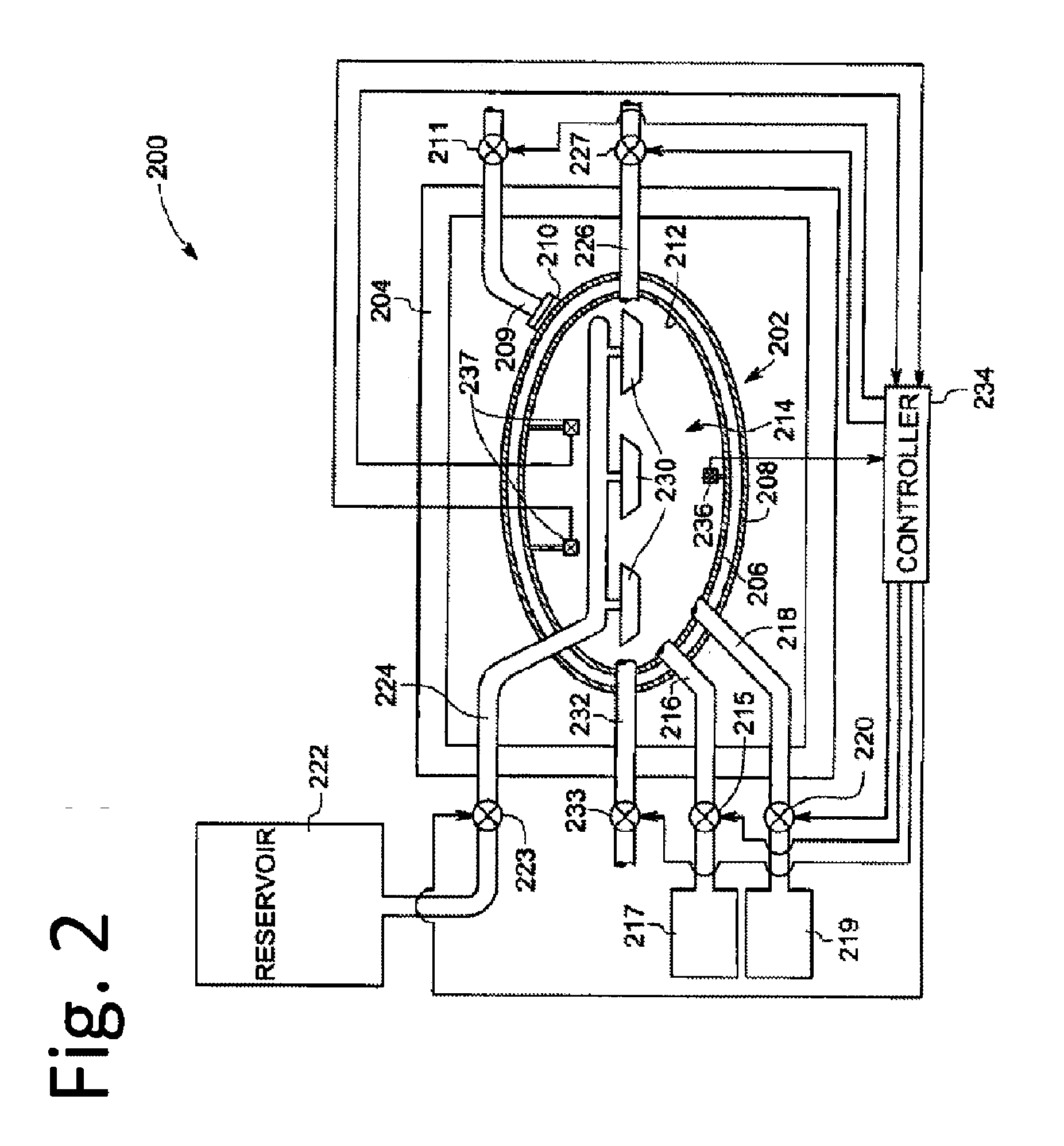

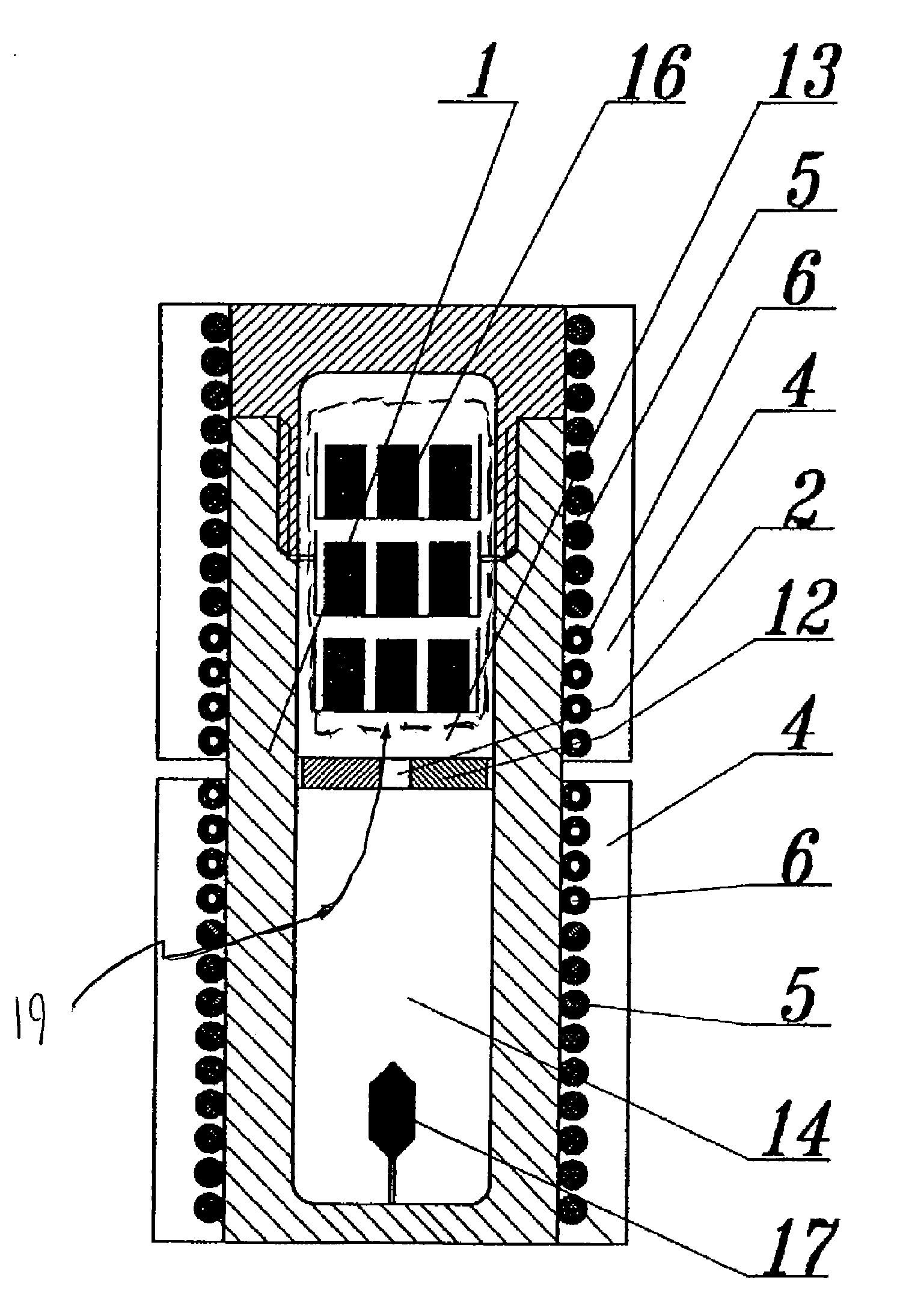

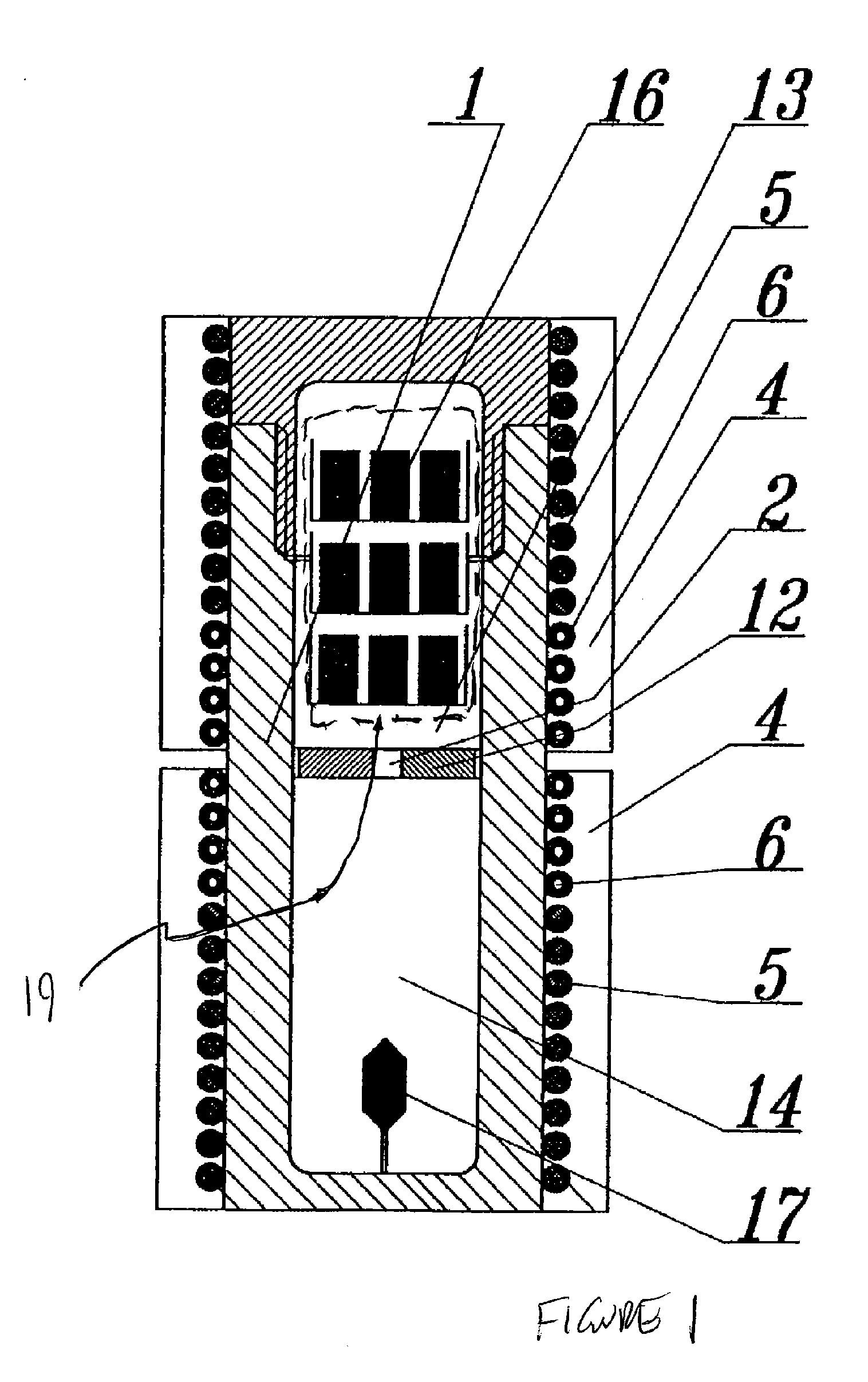

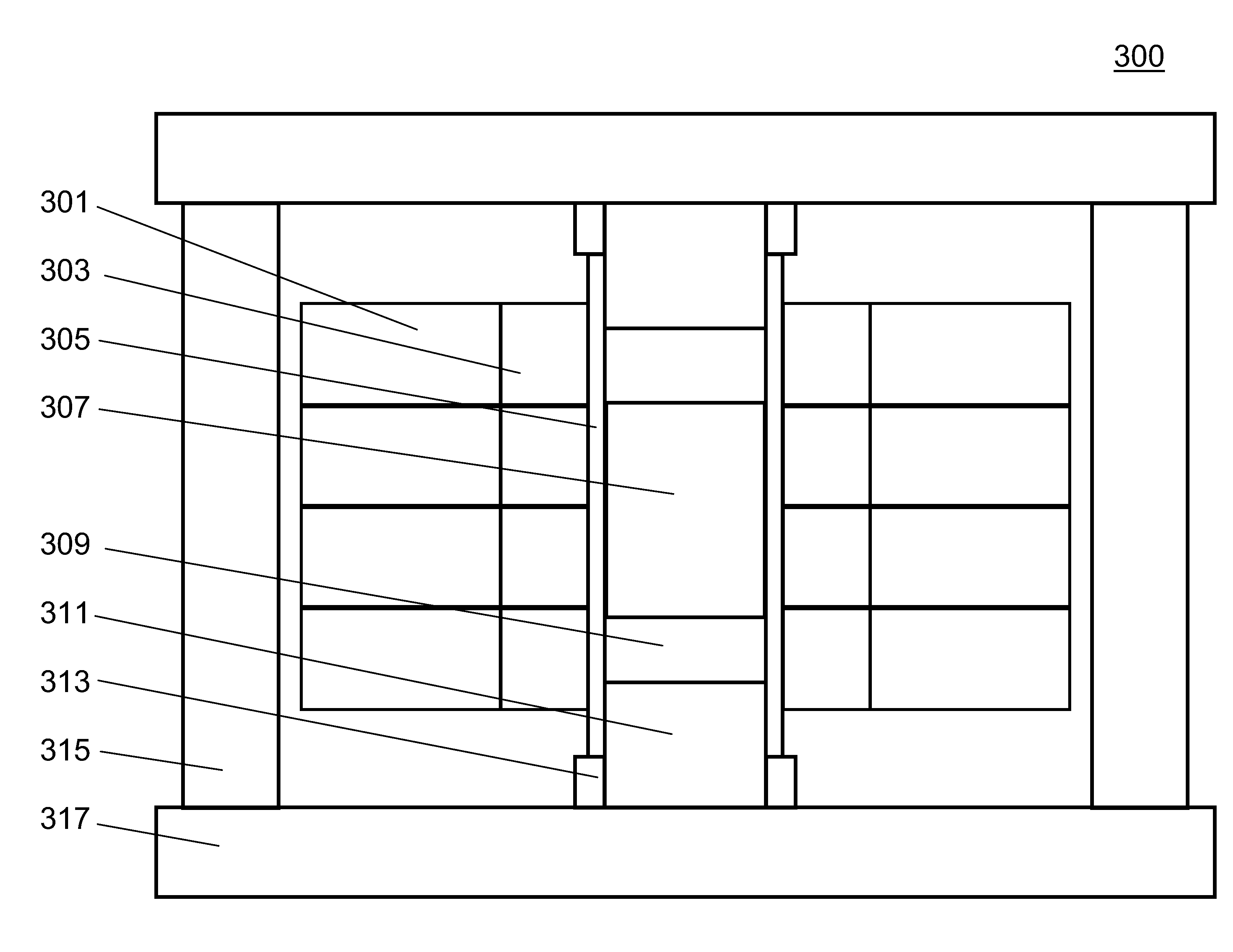

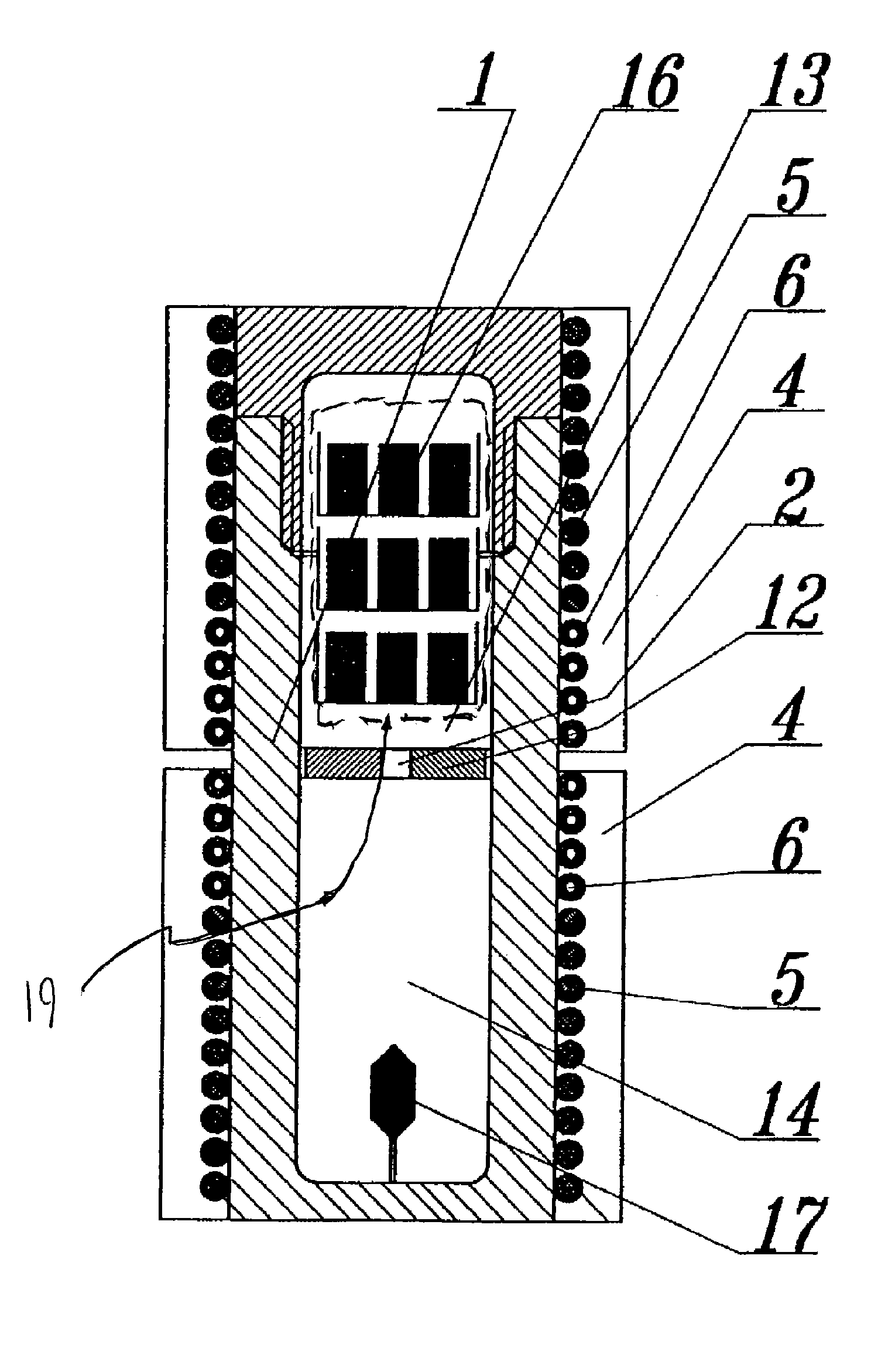

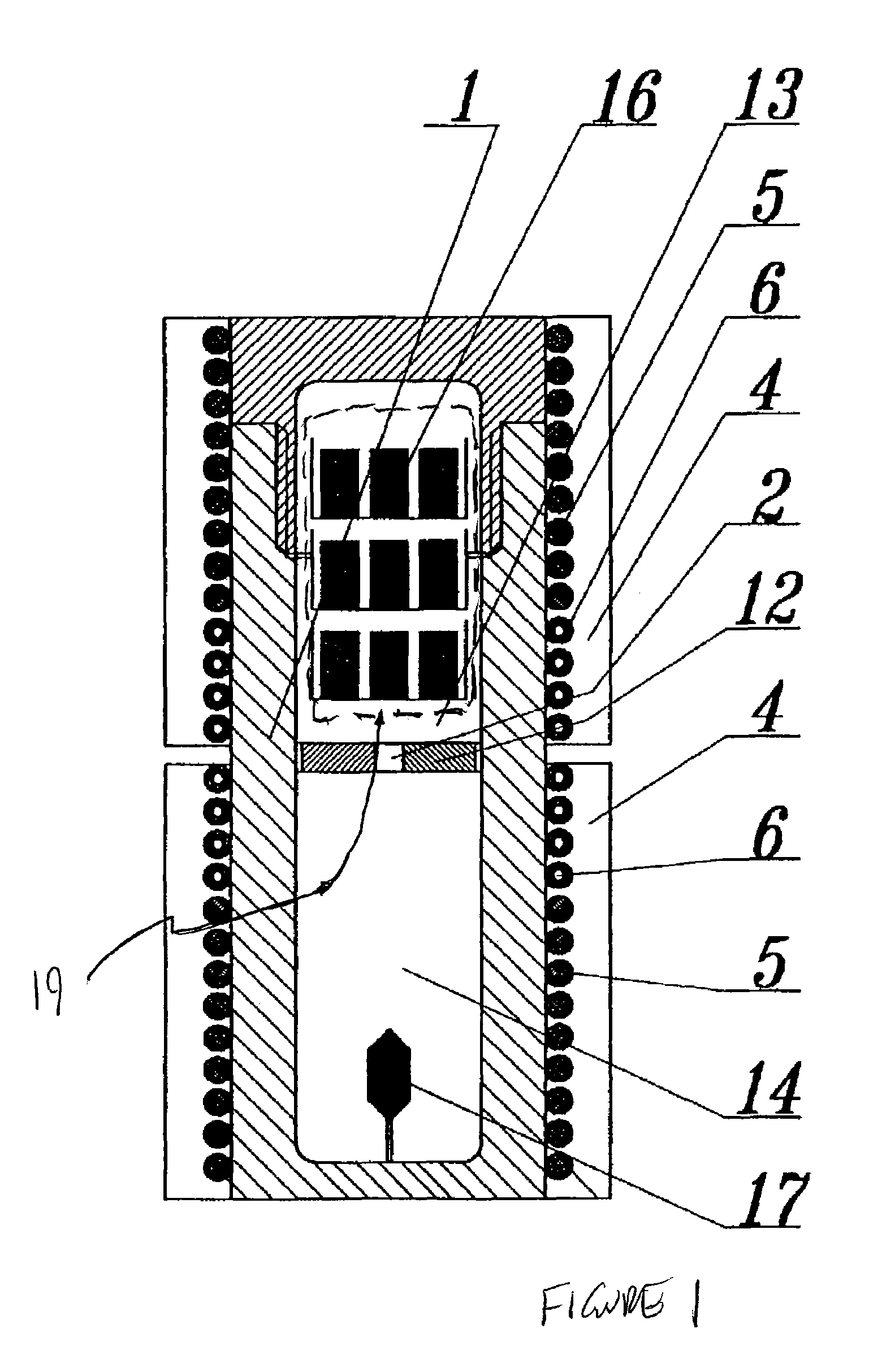

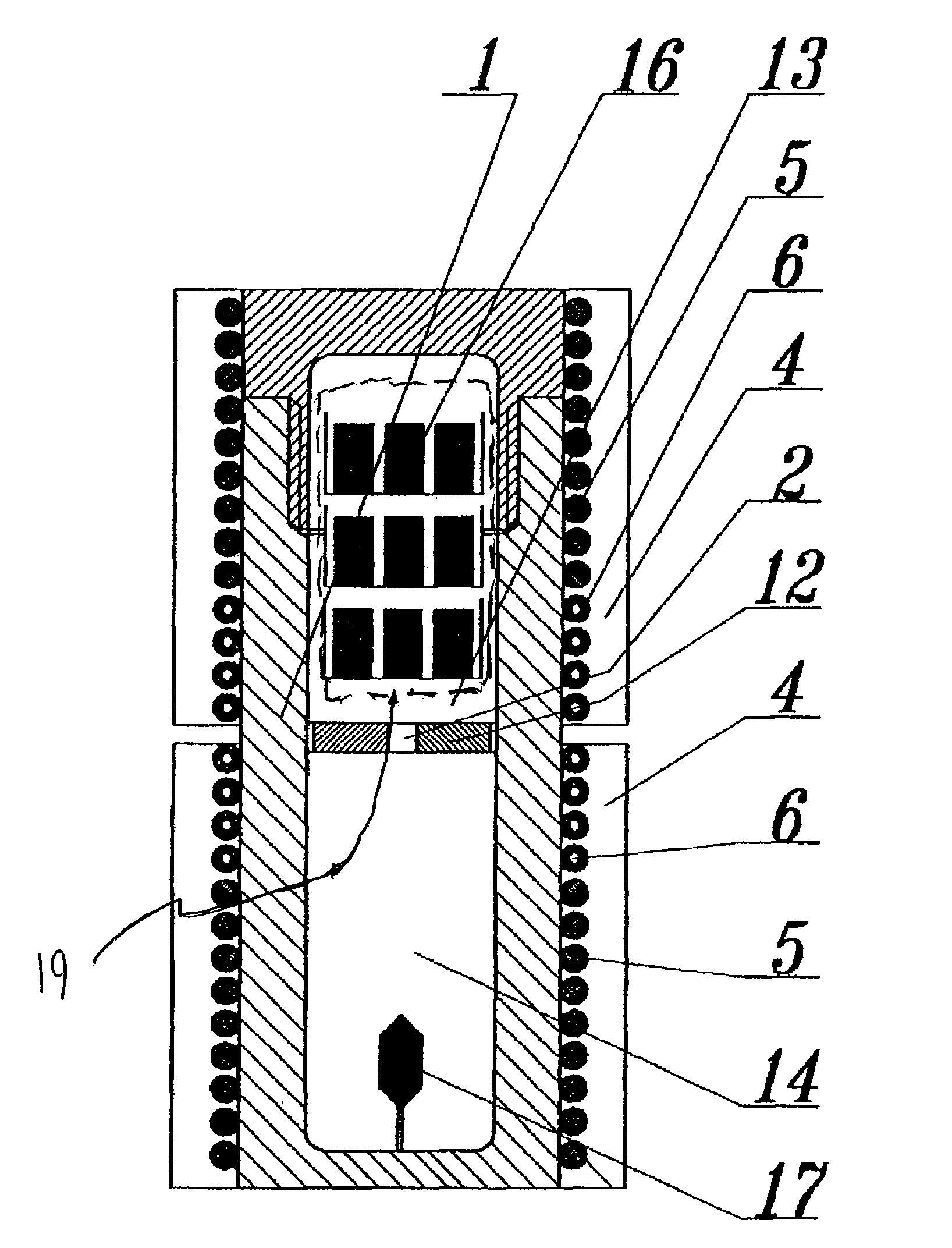

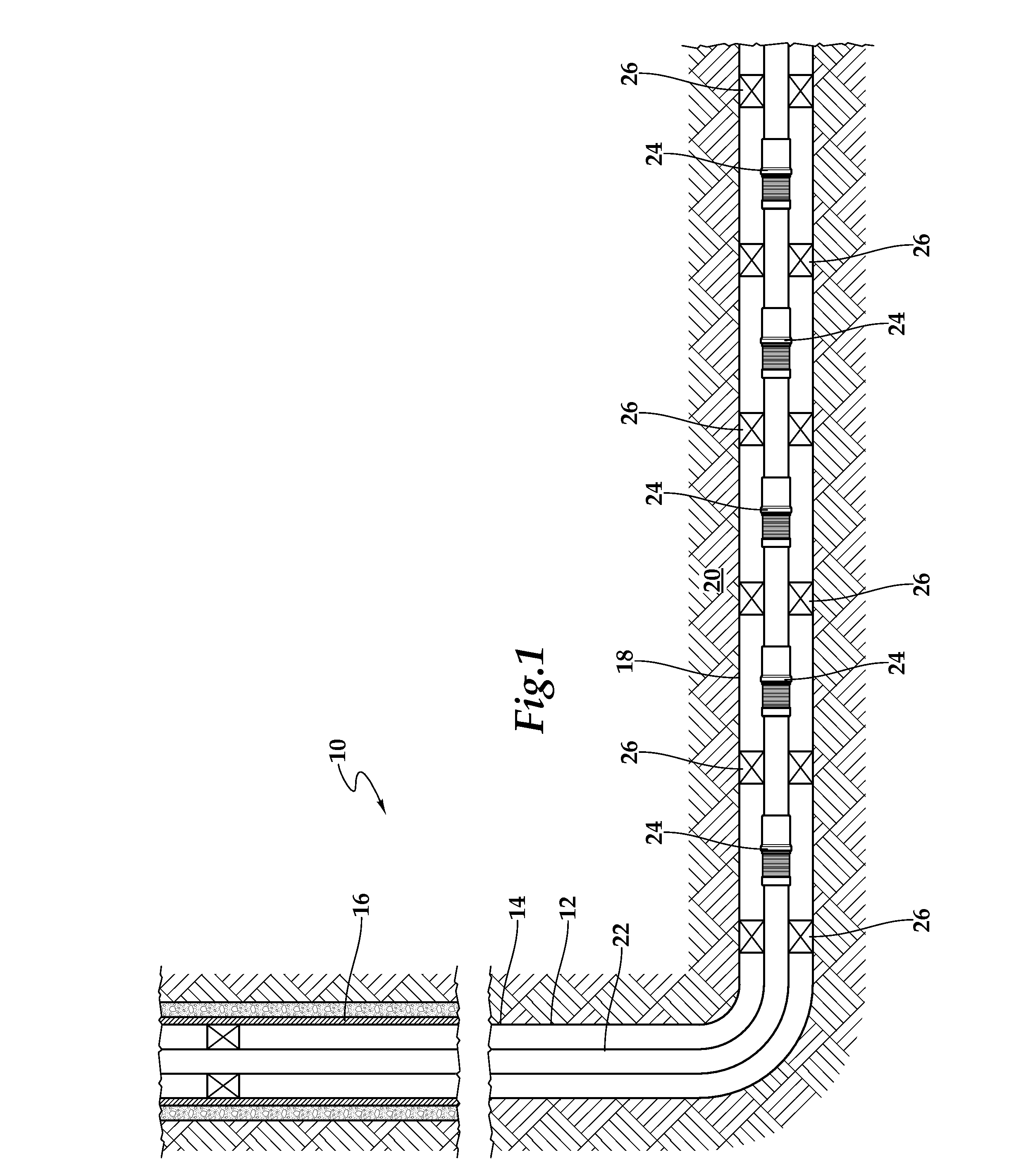

Plant and method for large-scale ammonothermal manufacturing of gallium nitride boules

InactiveUS20110100291A1Simple and cost-effective to manufactureSafe and cost-effectivePolycrystalline material growthFrom normal temperature solutionsNuclear engineeringGallium nitride

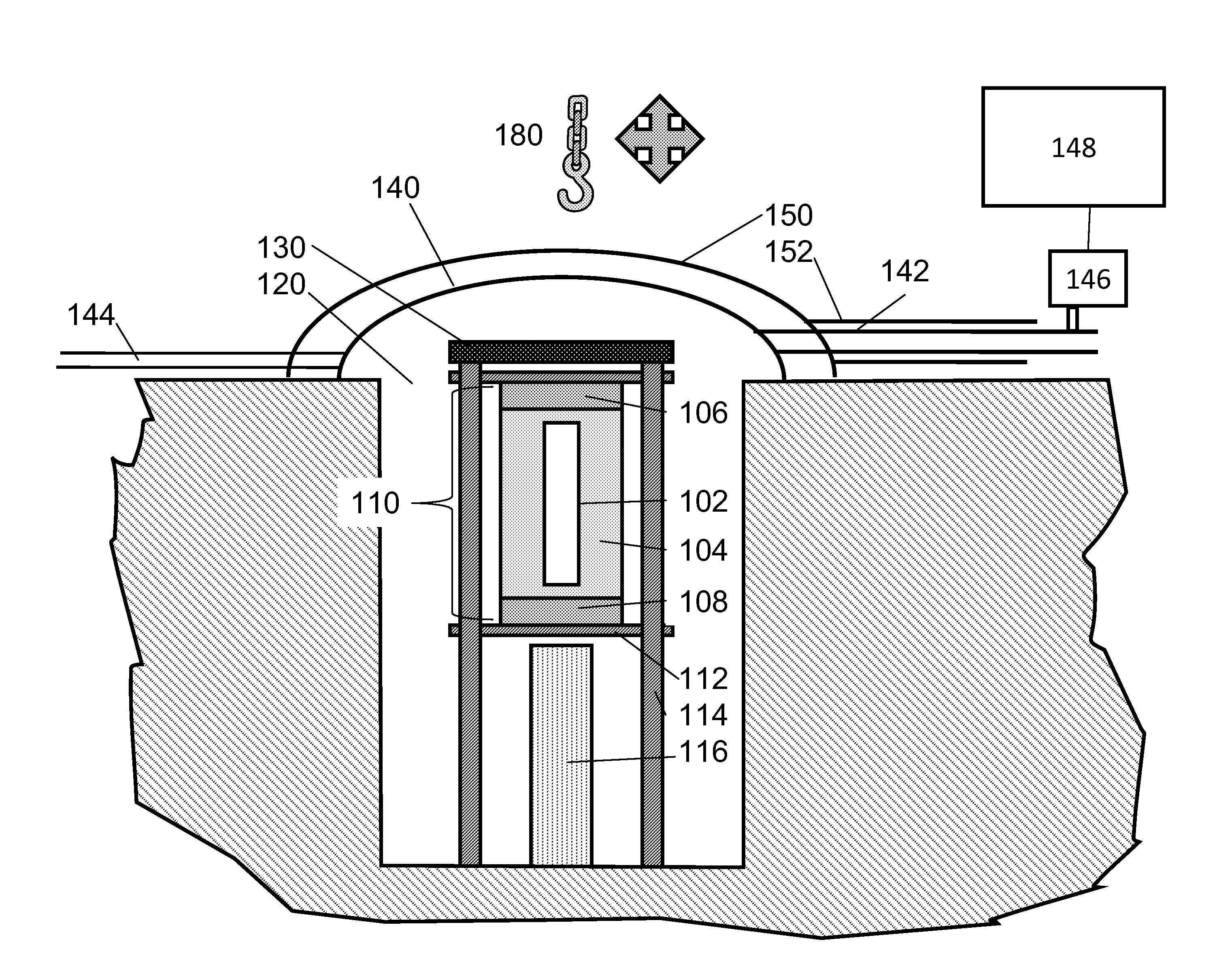

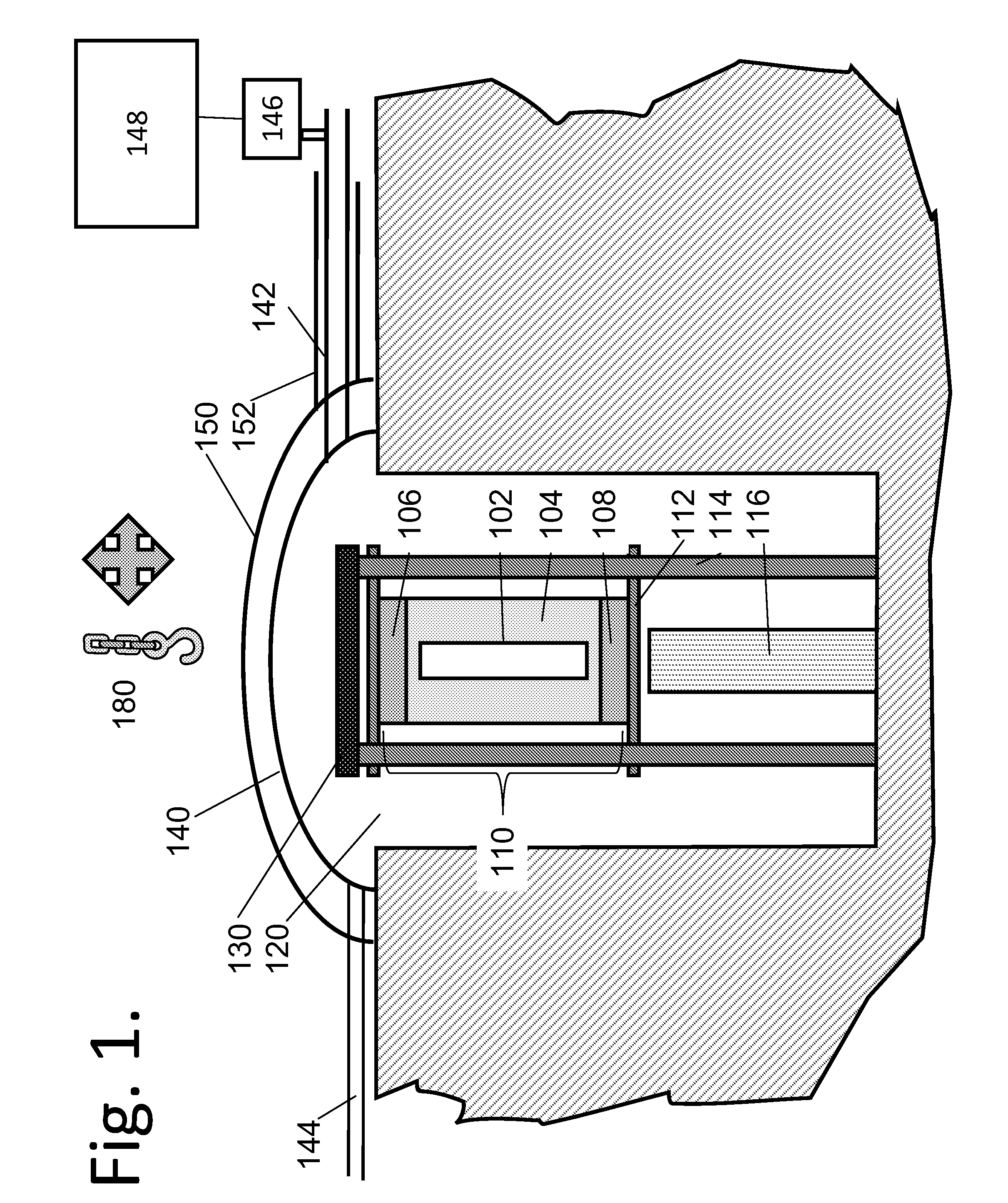

A method of operating a high pressure system for growth of gallium nitride containing materials. The method comprises providing a high pressure apparatus comprising a growth region and feedstock region. The high pressure reactor comprises a high pressure enclosure and is configured within a primary containment structure. The method includes operating an exhaust system coupled to the primary containment structure. The exhaust system is configured to remove ammonia gas derived from at least 0.3 liters of ammonia liquid.

Owner:SORAA

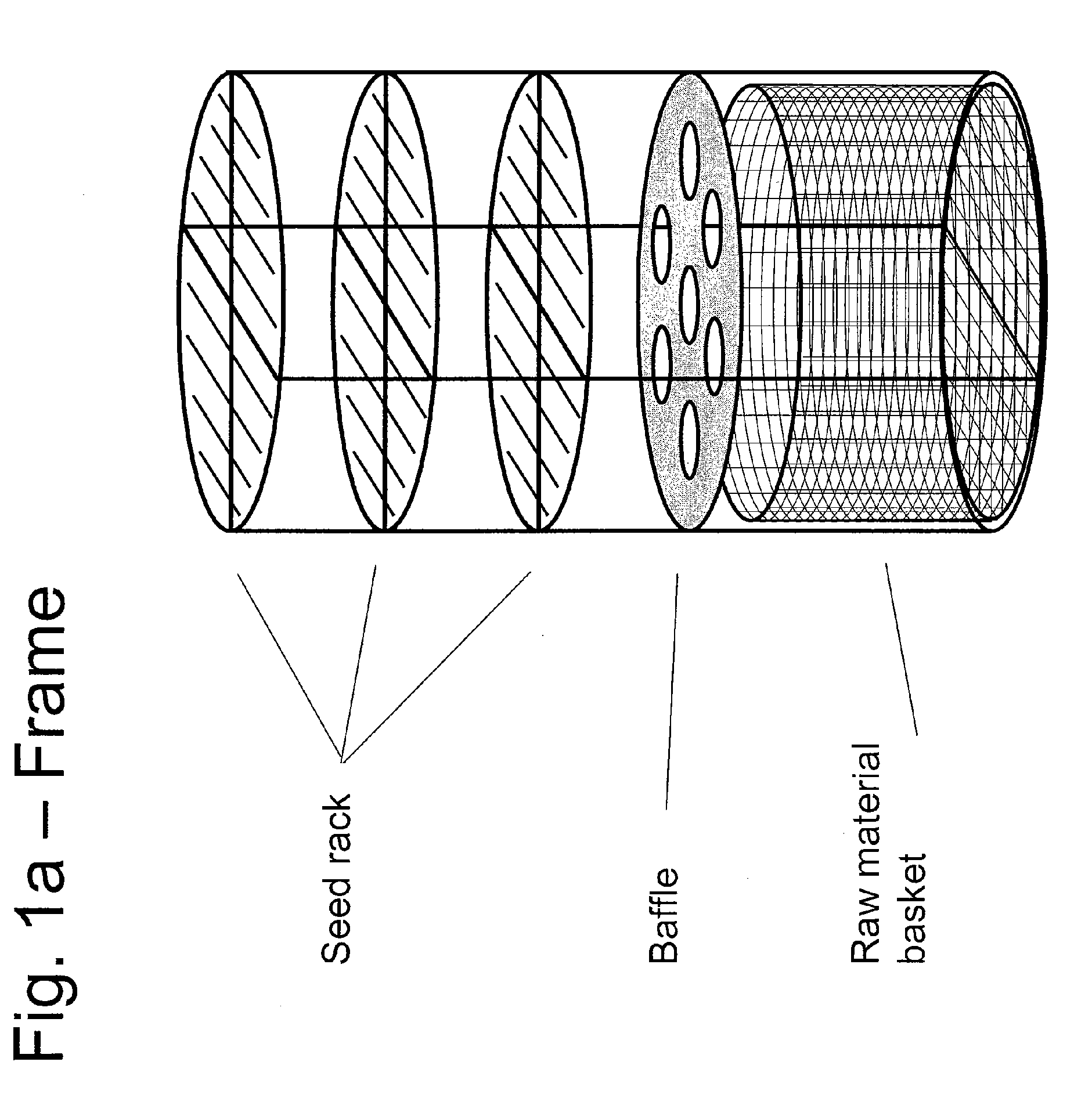

Process and apparatus for growing a crystalline gallium-containing nitride using an azide mineralizer

ActiveUS20100031874A1Increase in sizeCost effectivePolycrystalline material growthFrom normal temperature solutionsDopantCost effectiveness

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

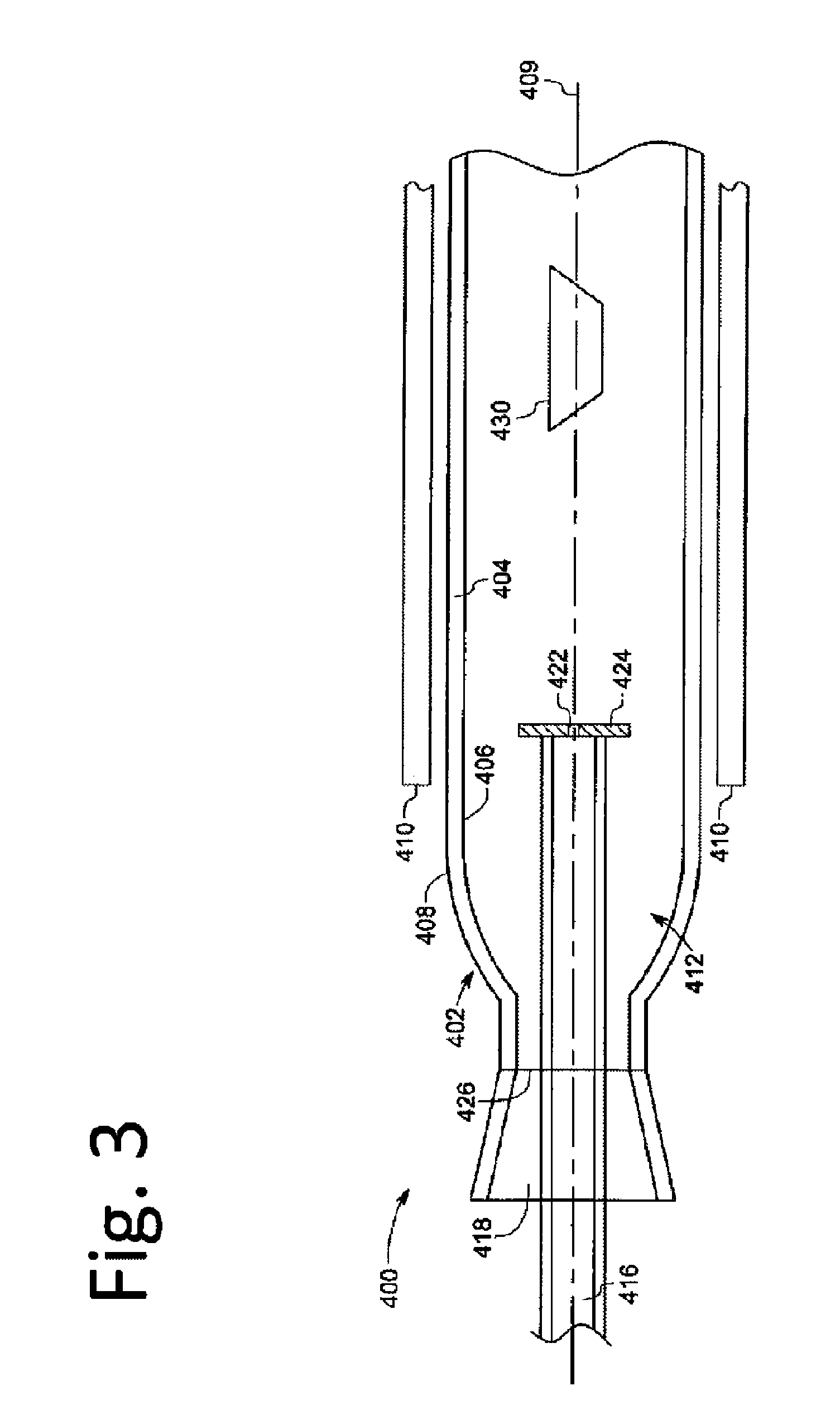

High pressure apparatus and method for nitride crystal growth

InactiveUS20100147210A1Simple and cost-effective to manufactureEasy to disassemblePolycrystalline material growthFrom normal temperature solutionsControl systemPower control system

An improved high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a release sleeve, a heater, at least one ceramic segment or ring but can be multiple segments or rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively. Following a run, the release sleeve may be at least partially dissolved or etched to facilitate removal of the capsule from the apparatus.

Owner:SORAA

High pressure apparatus and method for nitride crystal growth

ActiveUS8097081B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

Owner:SLT TECH

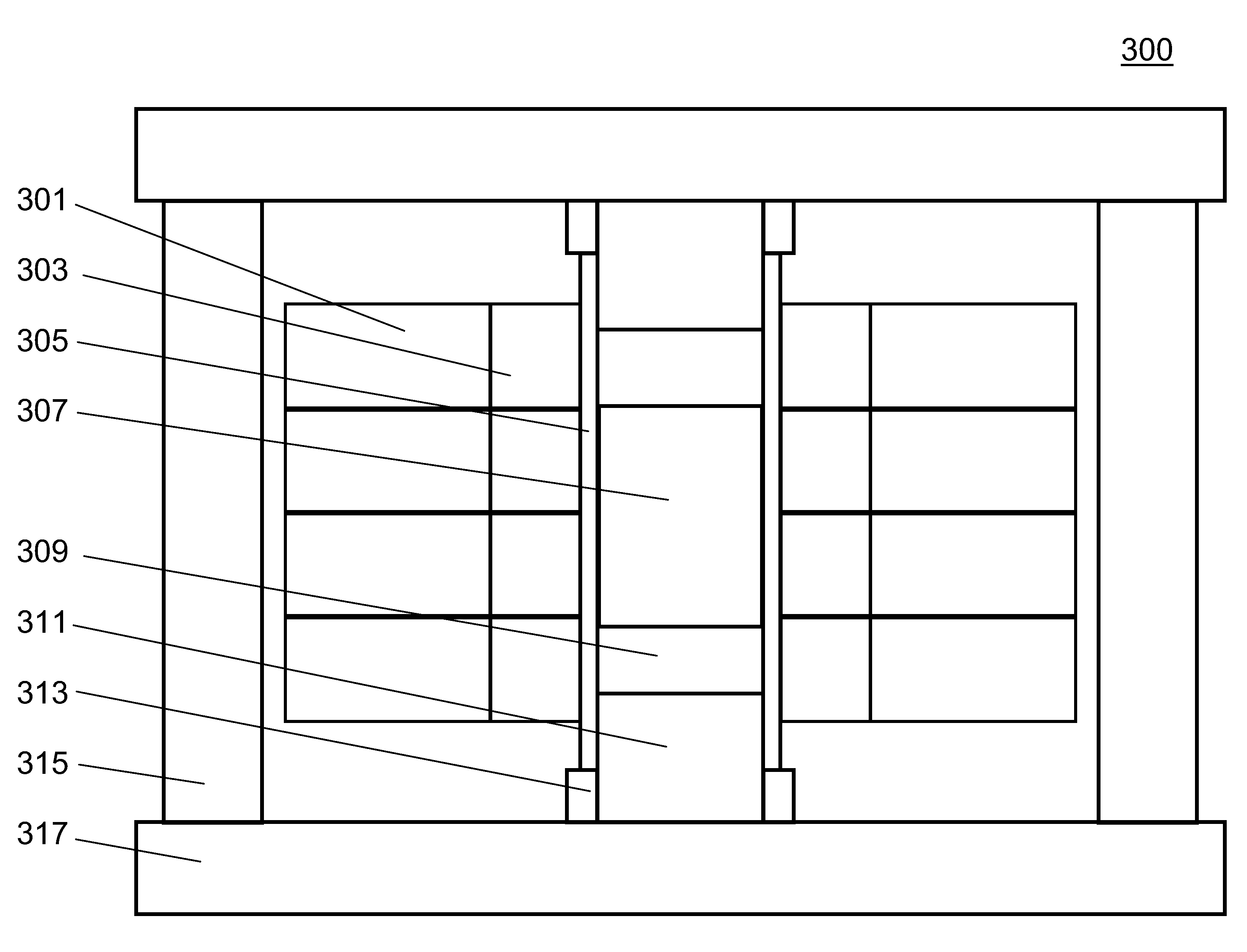

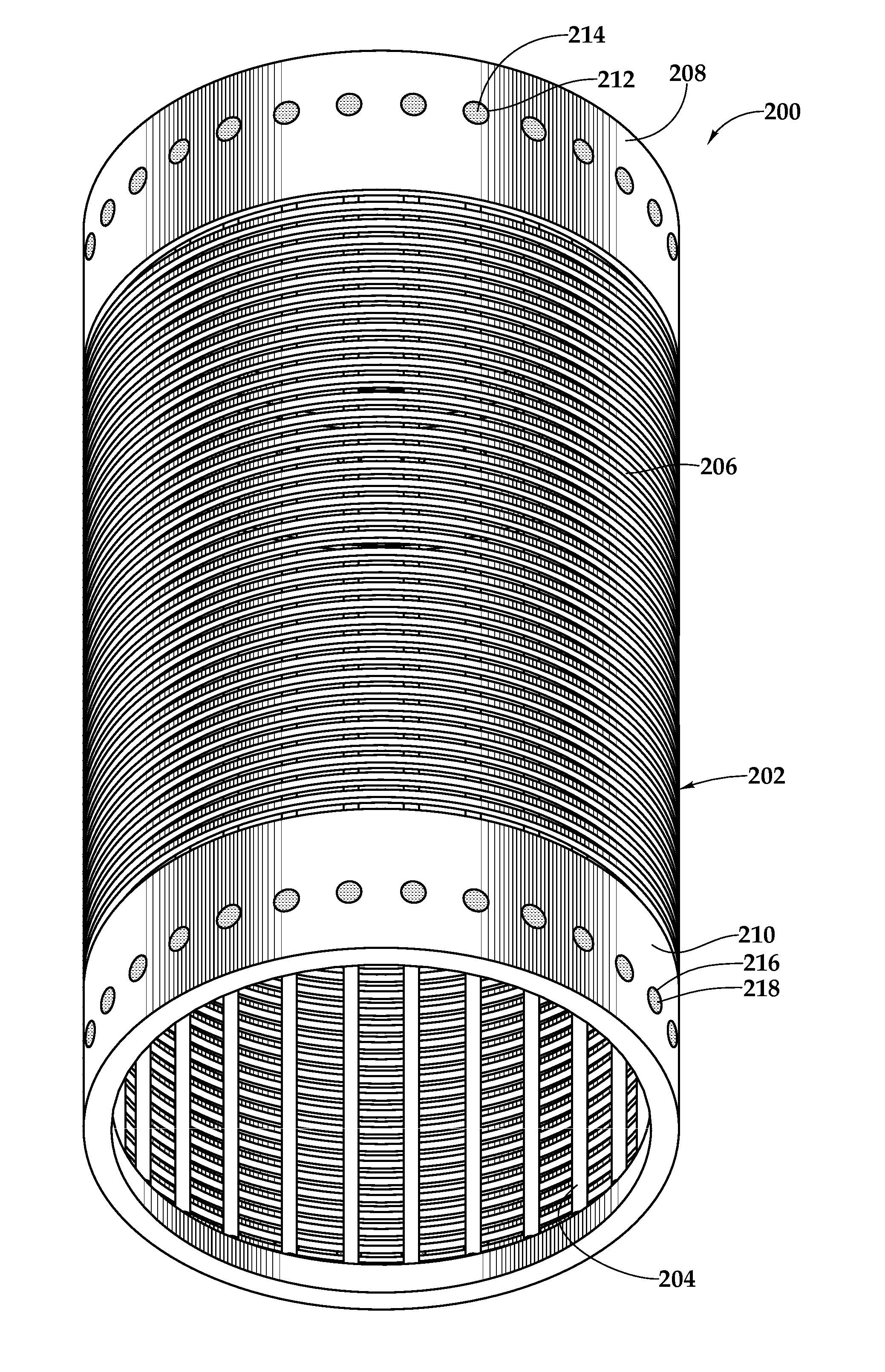

High Pressure Apparatus with Stackable Rings

InactiveUS20120137966A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

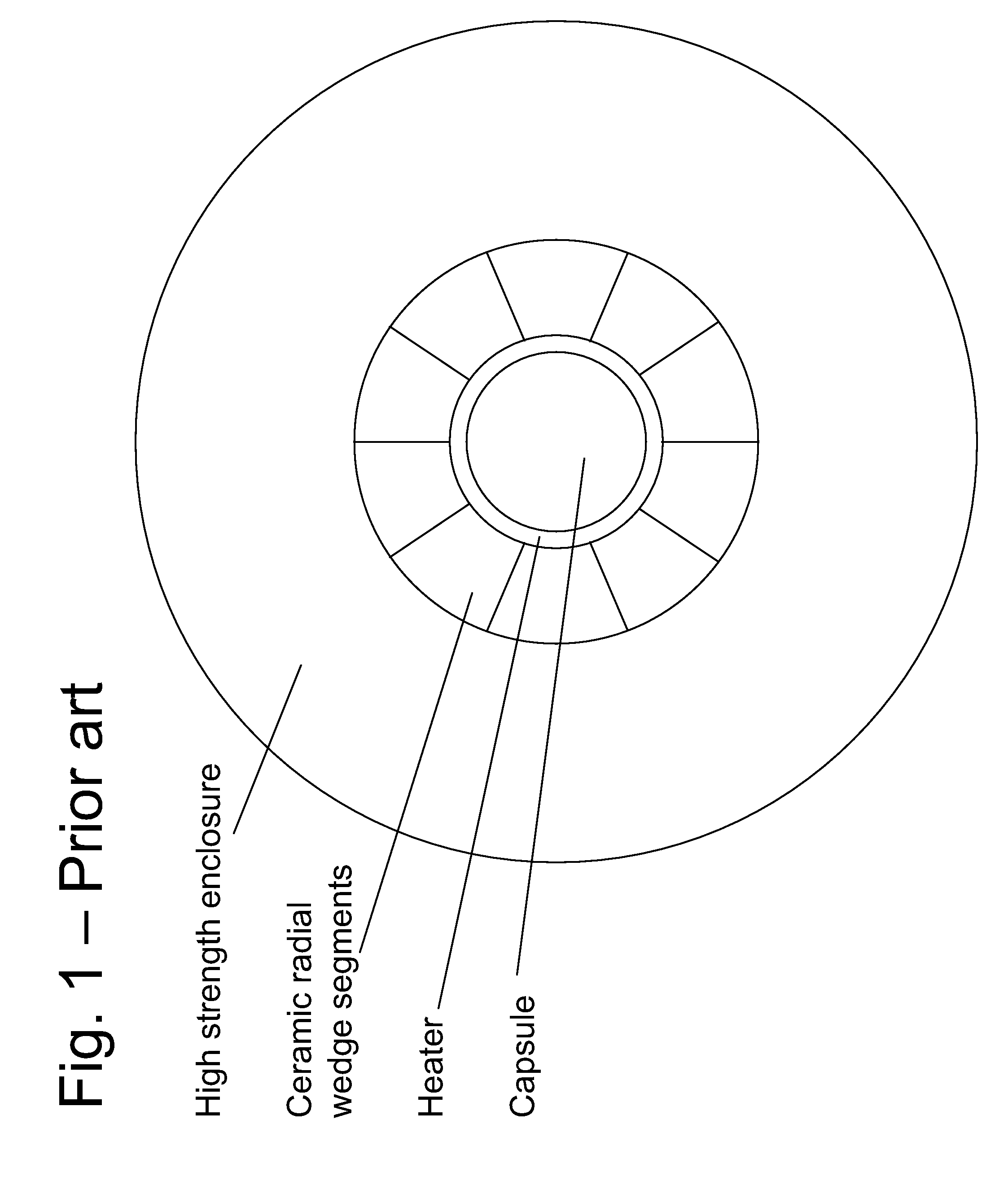

A high pressure apparatus and related methods for processing supercritical fluids is described. The apparatus includes a capsule, a heater, at least one ceramic ring with one or more scribe marks and / or cracks present. The apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. The apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:ELMHURST RES +1

High pressure apparatus and method for nitride crystal growth

ActiveUS8303710B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

Process and apparatus for growing a crystalline gallium-containing nitride using an azide mineralizer

ActiveUS8323405B2Increase in sizeCost effectivePolycrystalline material growthFrom normal temperature solutionsDopantGallium nitride

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

Process and apparatus for large-scale manufacturing of bulk monocrystalline gallium-containing nitride

ActiveUS8021481B2Simple and cost-effective to manufactureIncrease pressurePolycrystalline material growthFrom normal temperature solutionsGallium nitrideMaterials science

A method for large-scale manufacturing of gallium nitride includes a process for reducing and / or minimizing contamination in the crystals, for solvent addition to an autoclave, for improving or optimizing the solvent atmosphere composition, for removal of the solvent from the autoclave, and for recycling of the solvent. The method is scalable up to large volumes and is cost effective.

Owner:SLT TECH

Polycrystalline group III metal nitride with getter and method of making

ActiveUS8461071B2Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

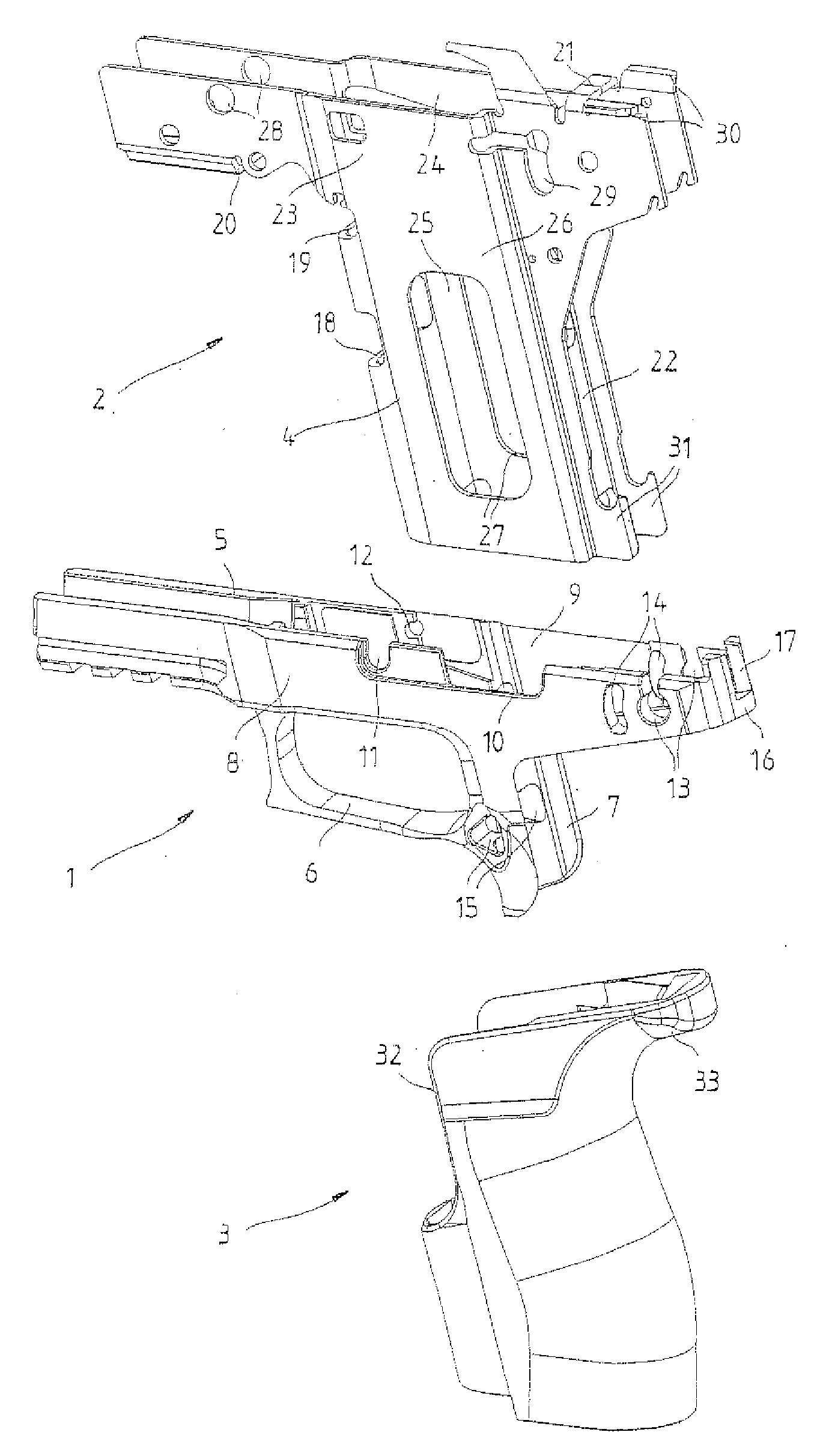

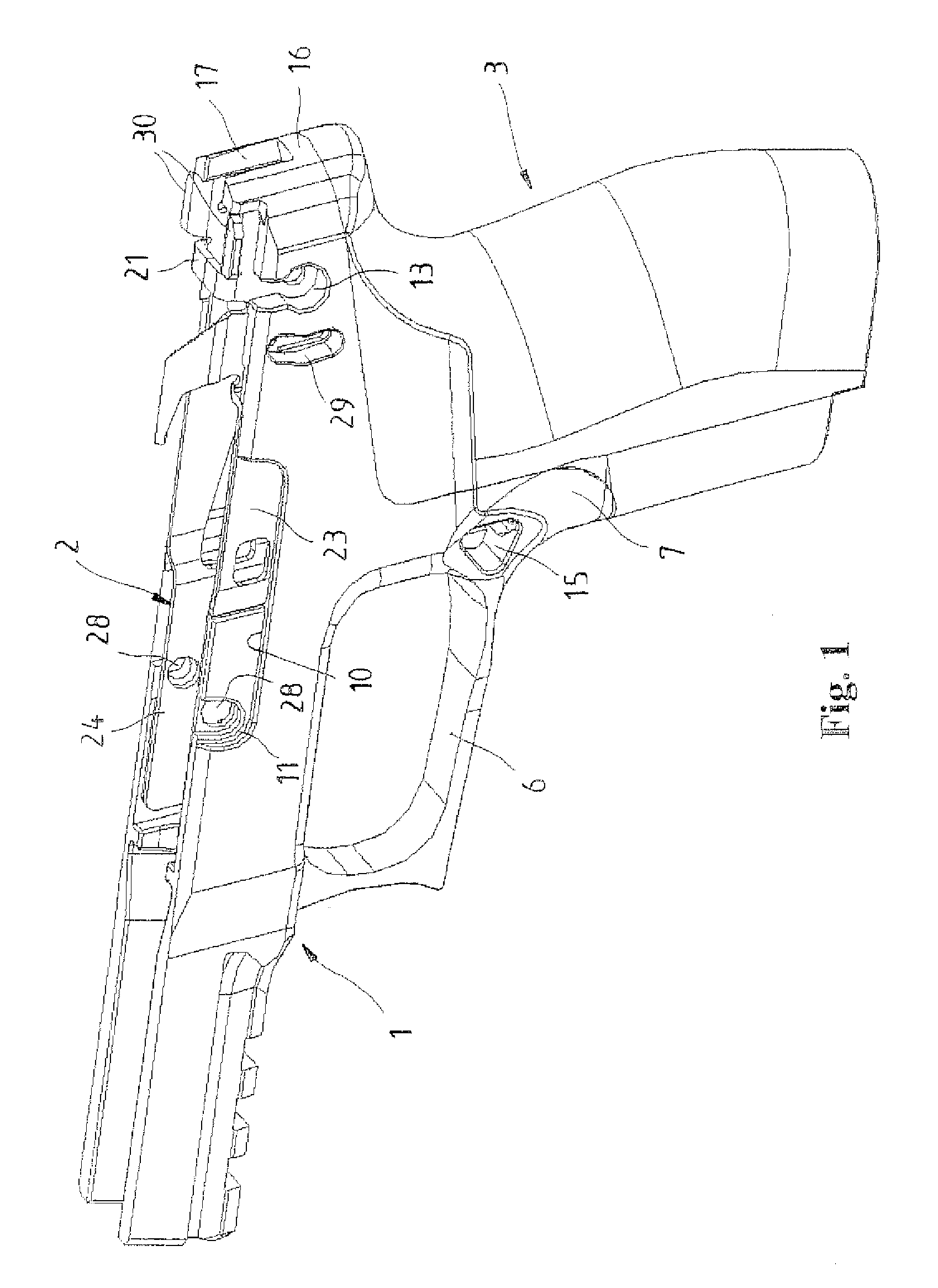

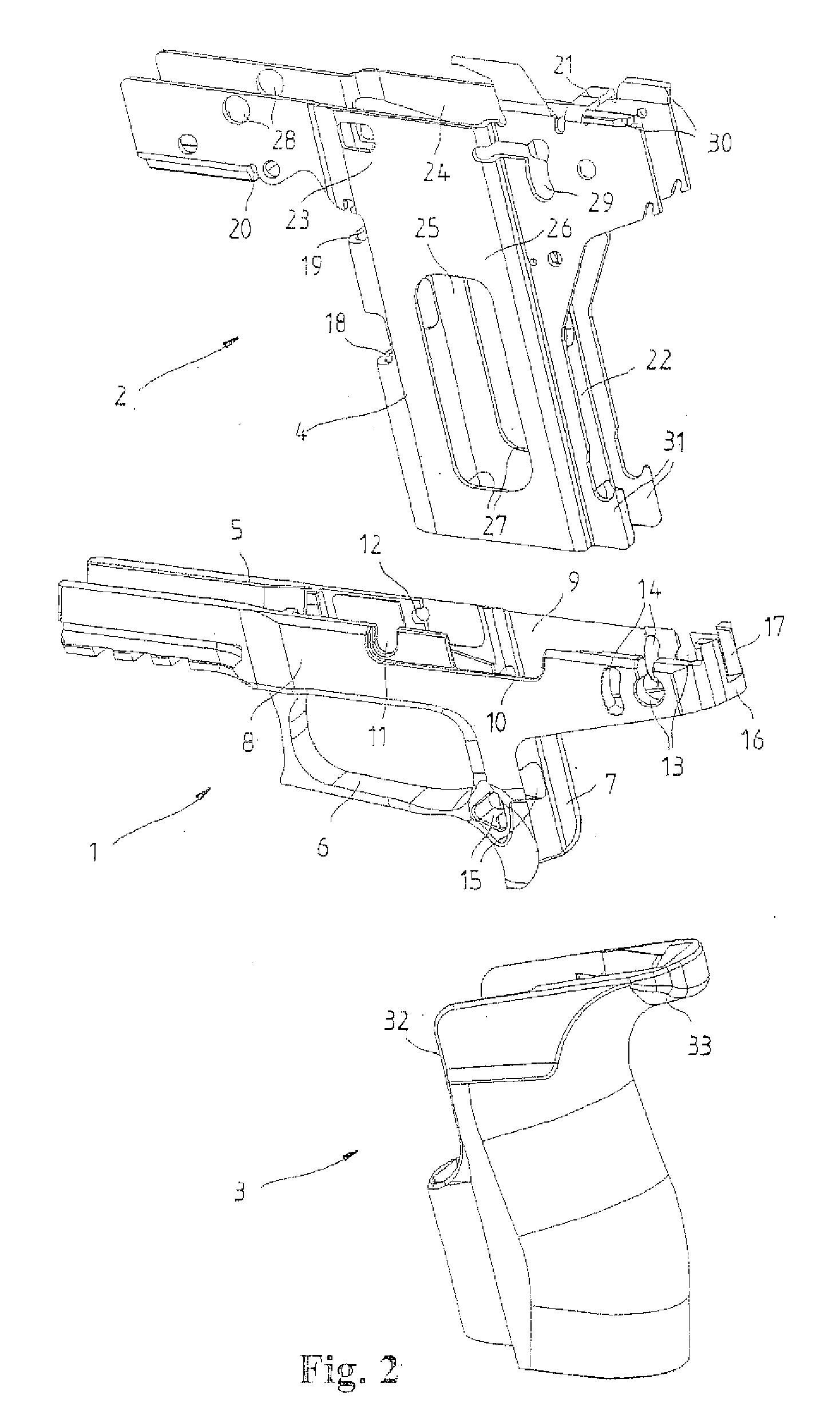

Grip for a handgun

InactiveUS20080060247A1Simple and cost-effective adaptationSimple and cost-effective to manufactureWeapon assembly/disassemblyBreech mechanismsEngineeringMechanical engineering

The invention relates to a grip for a handgun, in particular a pistol, having a grip module (1) made of plastic and a metal carrier element (2) that is insertable into said grip module (1). In order to enable a simple and cost-effective adaptation to the widest variety of demands of the marksman, a magazine shaft (4), projecting downward from the grip module (1) and onto which is slipped a grip shell module (3), is formed as a part of the carrier element (2).

Owner:T SWISS ARMS TECH

High pressure apparatus with stackable rings

InactiveUS8435347B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids is described. The apparatus includes a capsule, a heater, at least one ceramic ring with one or more scribe marks and / or cracks present. The apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. The apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:ELMHURST RES +1

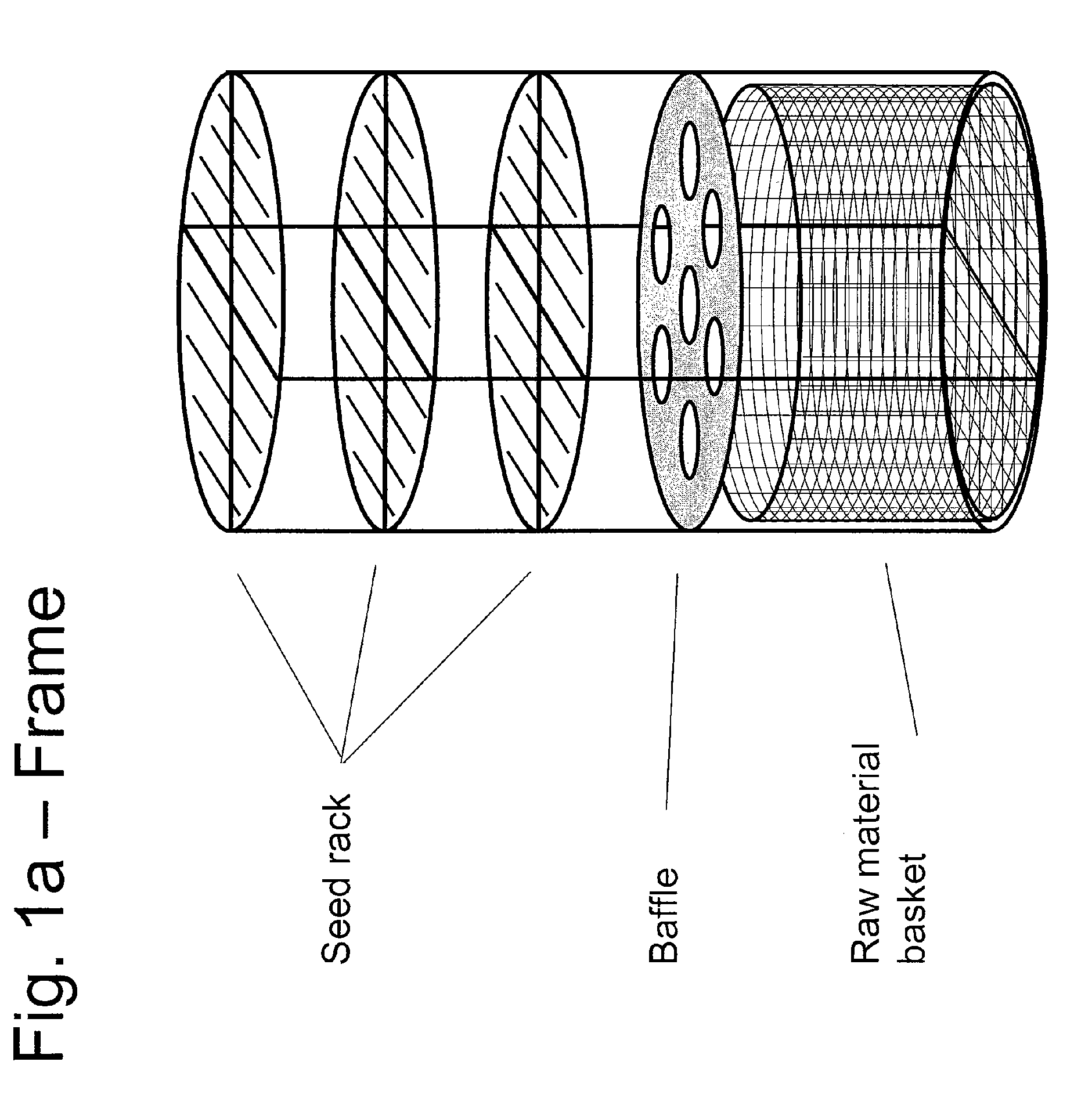

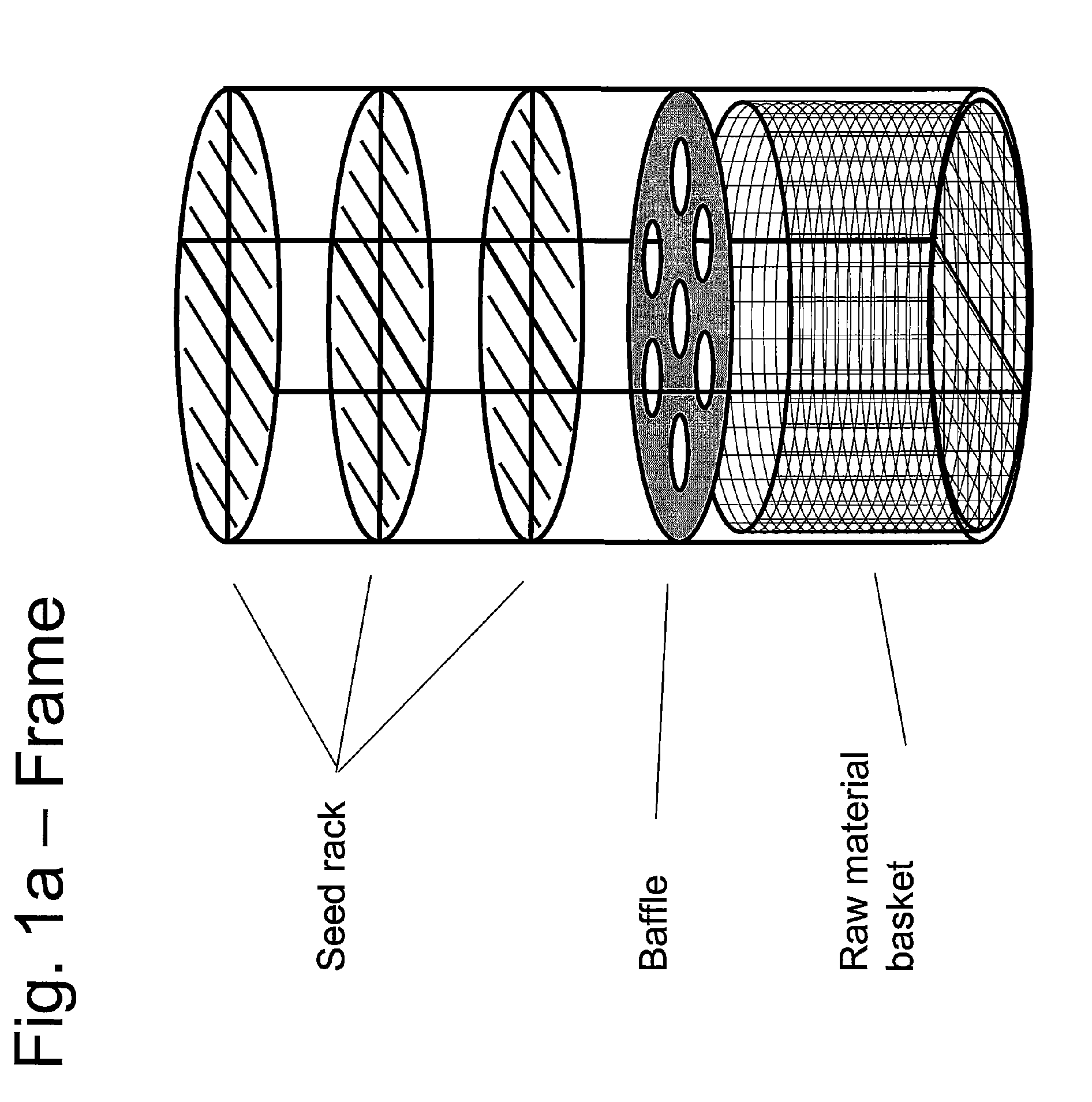

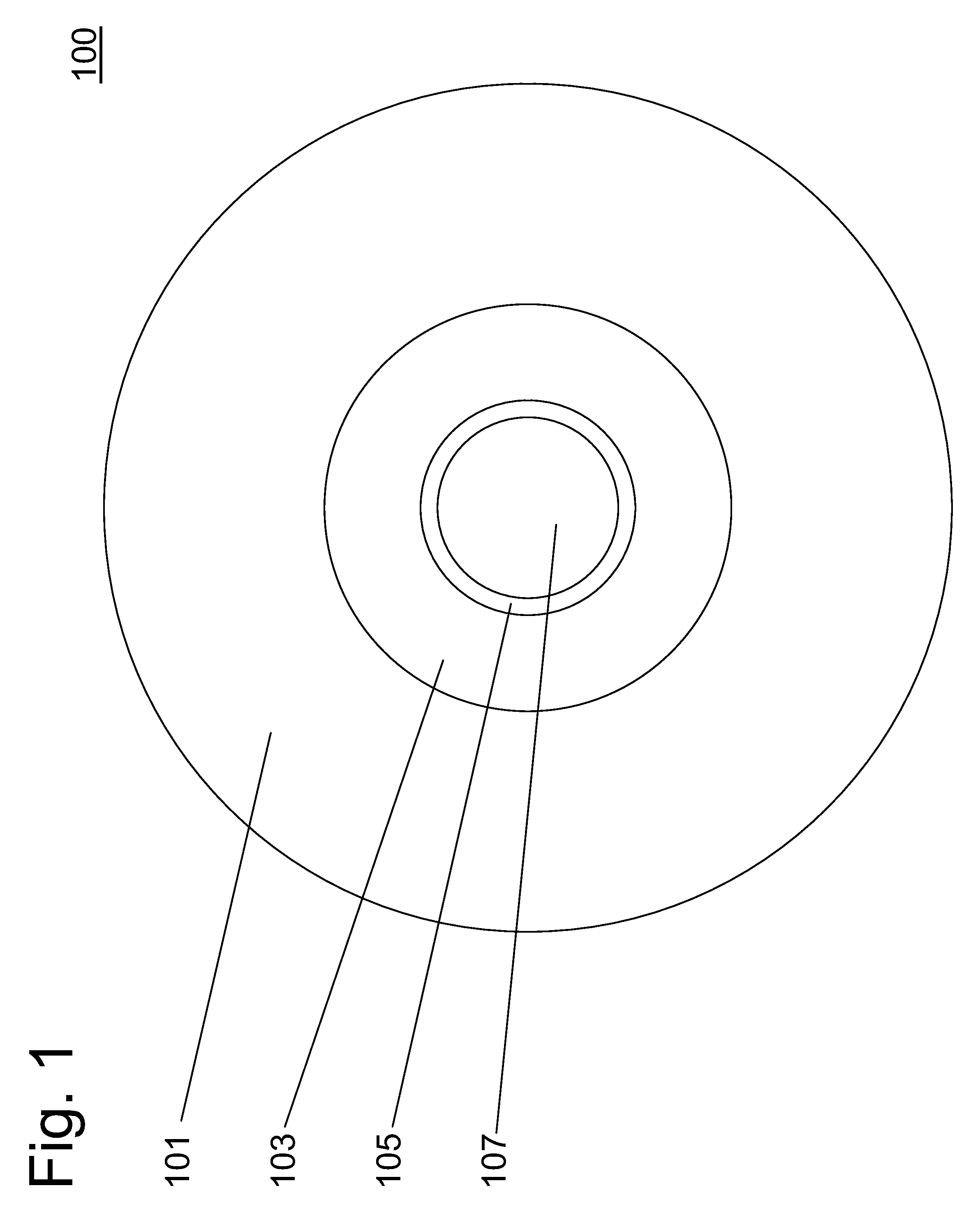

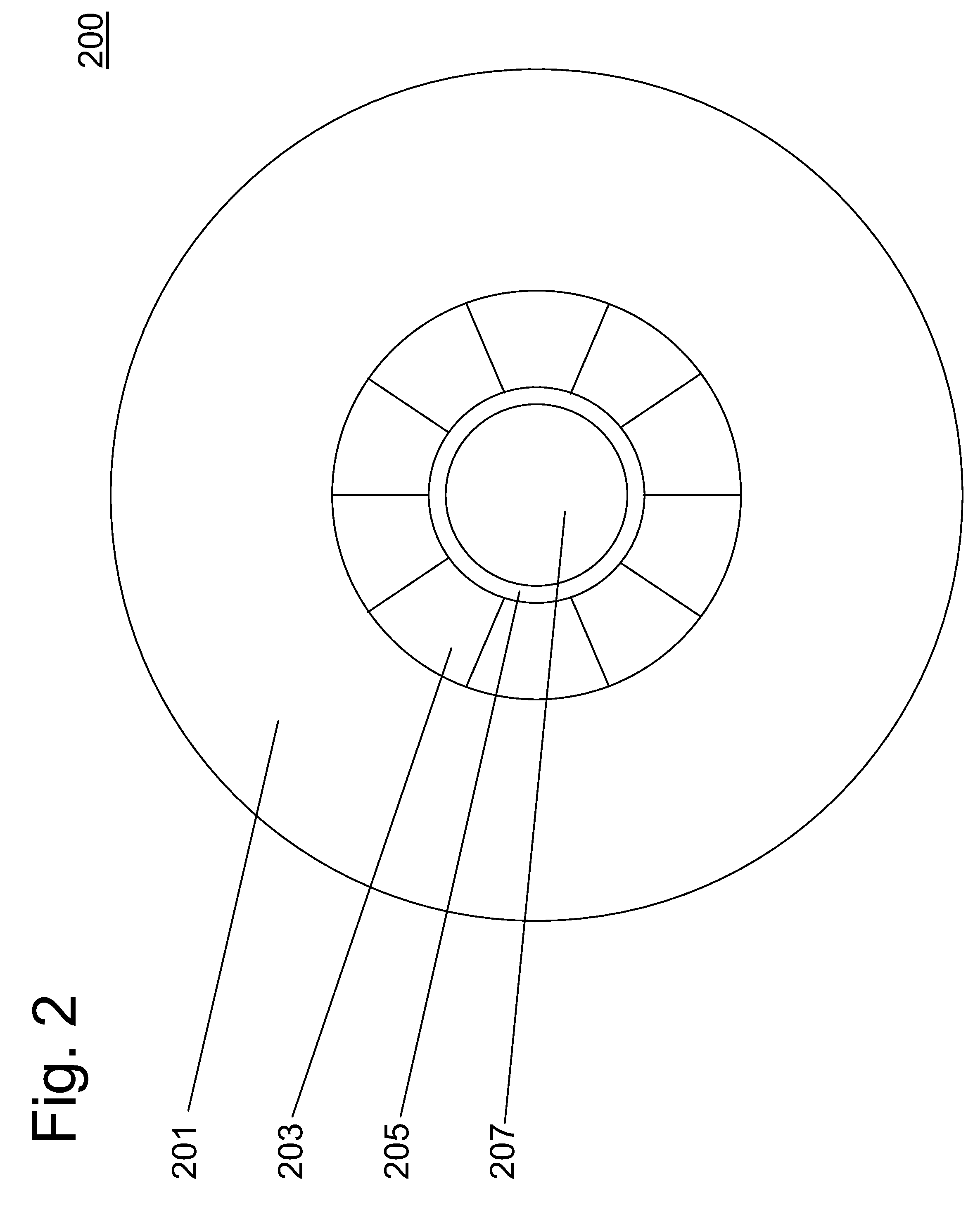

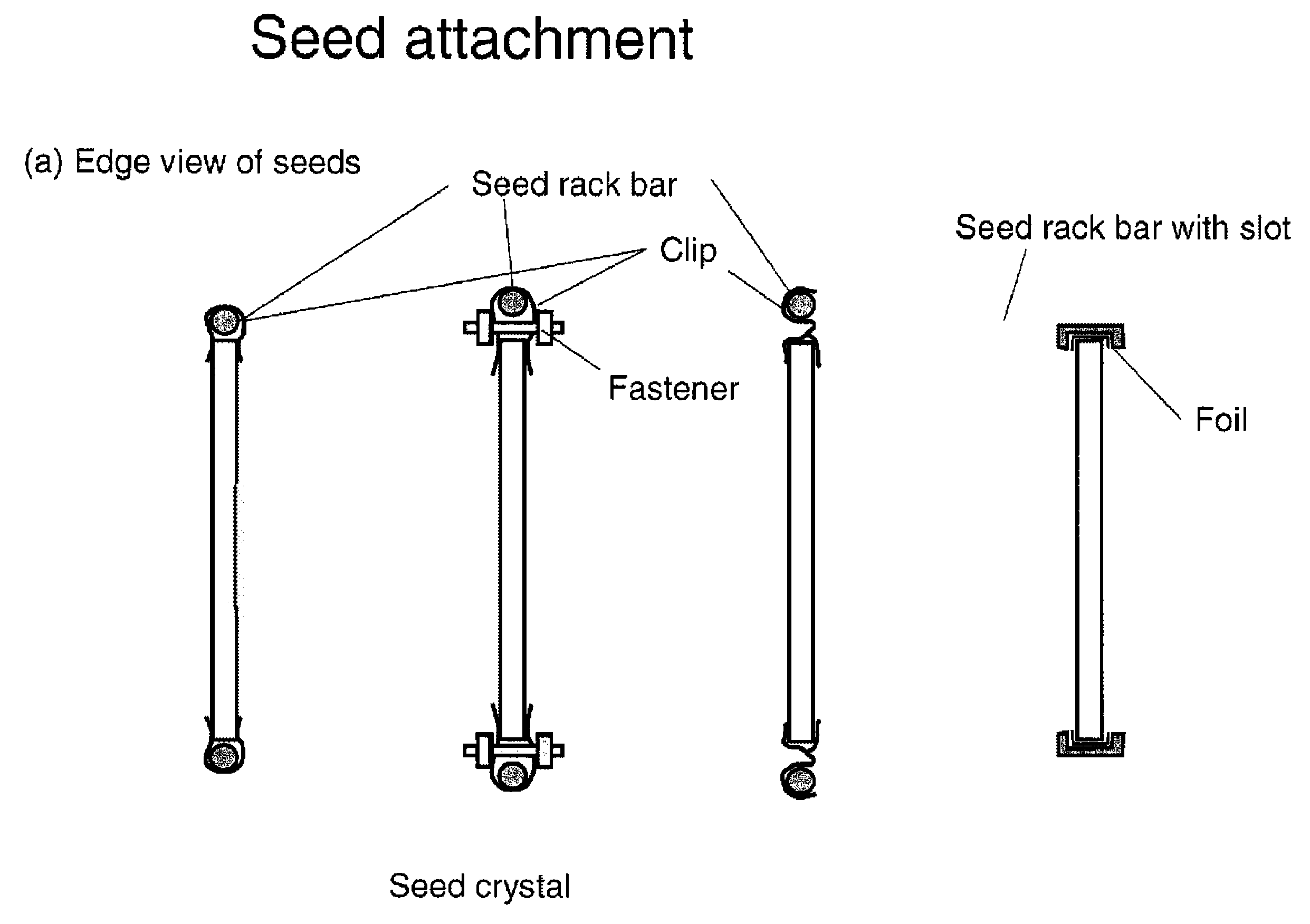

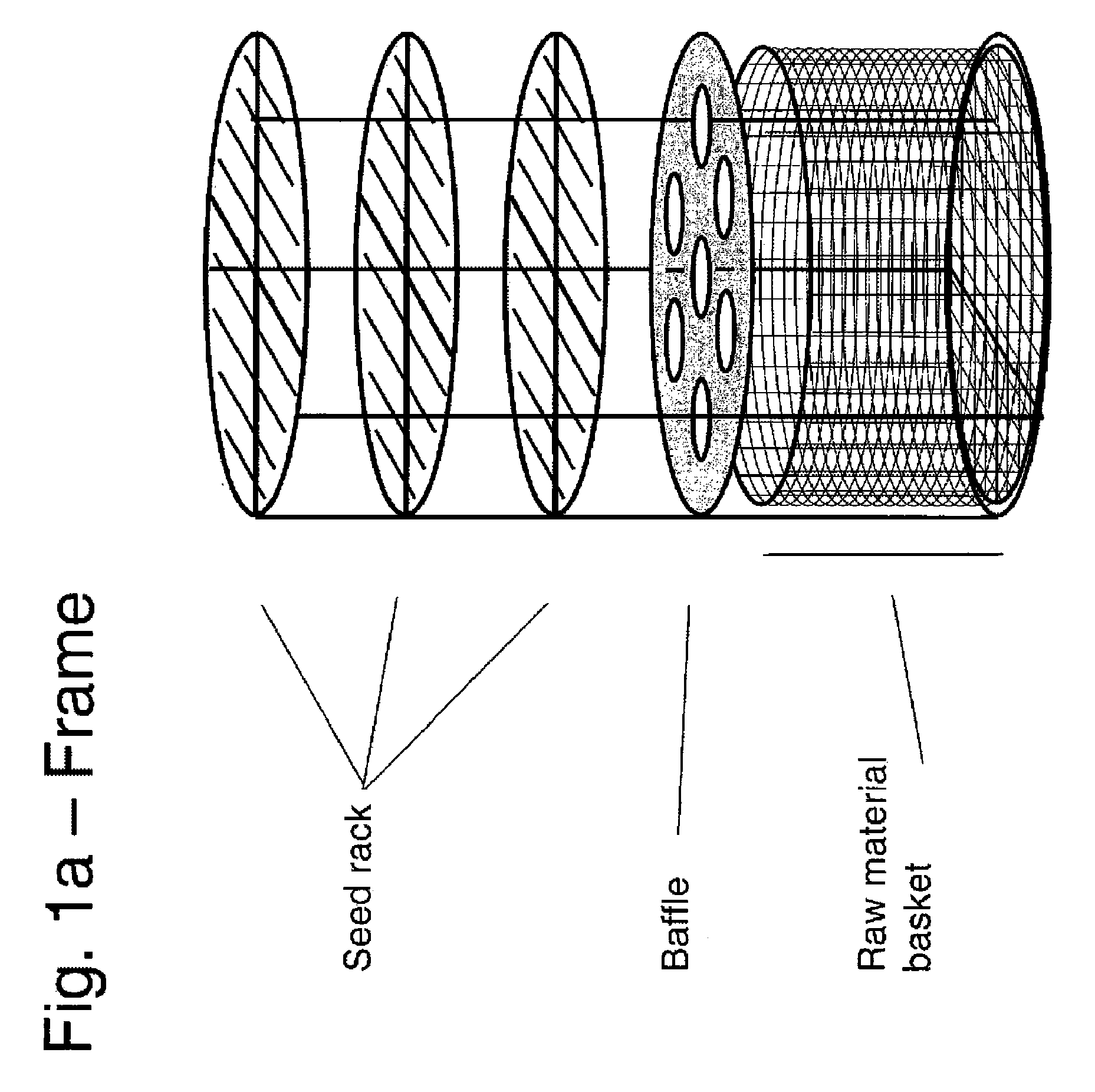

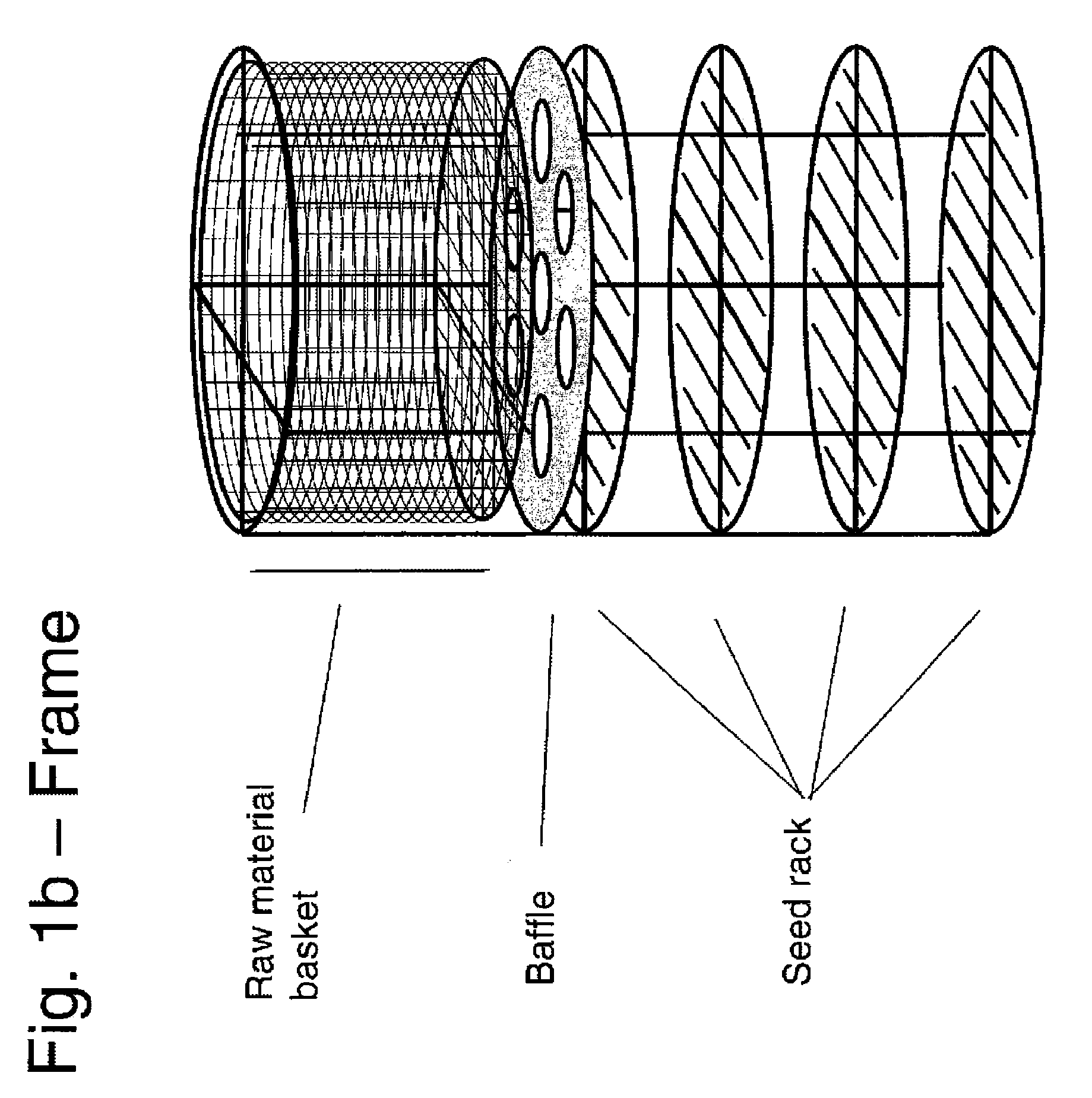

Apparatus and method for seed crystal utilization in large-scale manufacturing of gallium nitride

ActiveUS8430958B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthCost effectivenessGallium nitride

An apparatus and associated method for large-scale manufacturing of gallium nitride. The apparatus comprises a large diameter autoclave or internally-heated high pressure vessel, a seed rack, and a raw material basket. Methods include effective means for utilization of seed crystals. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

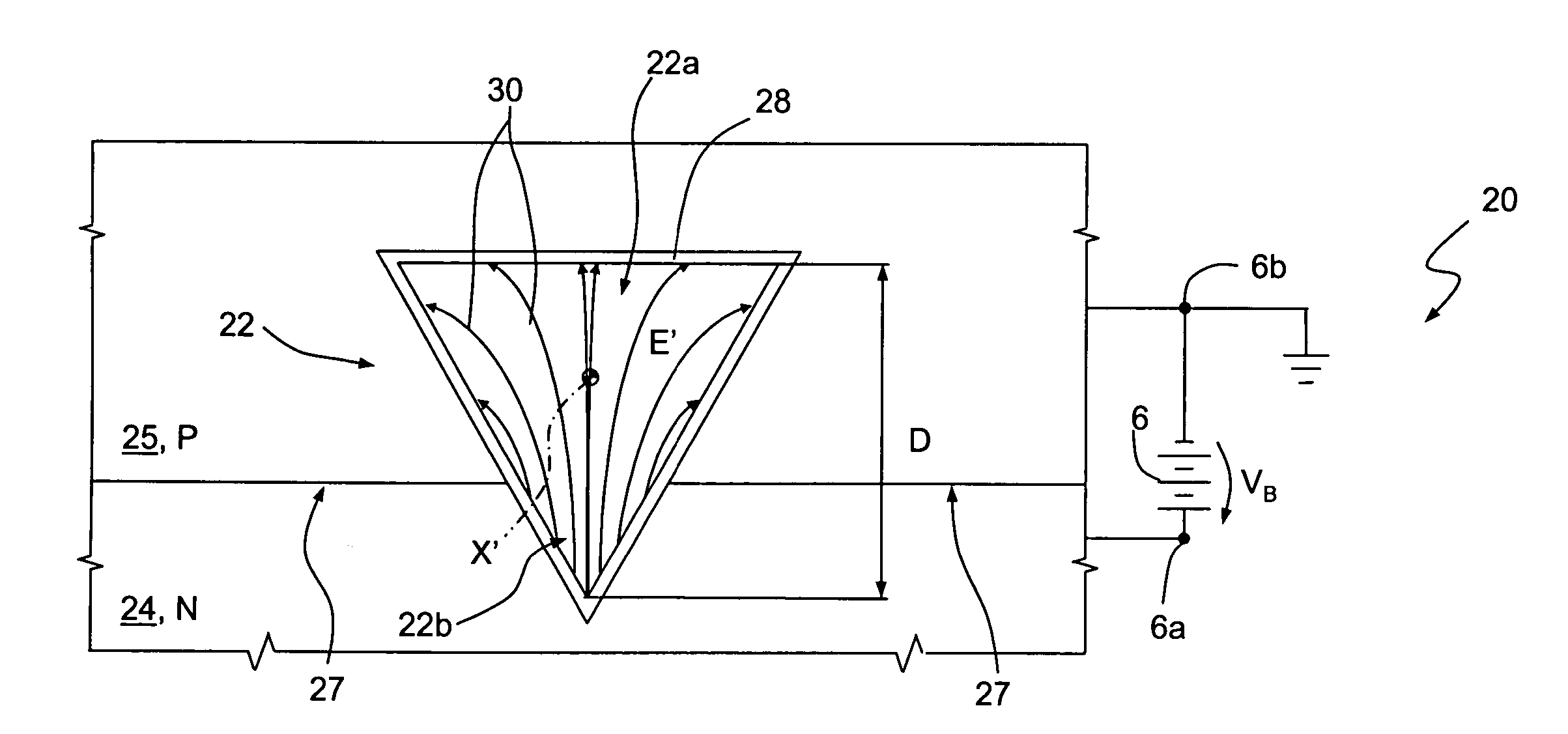

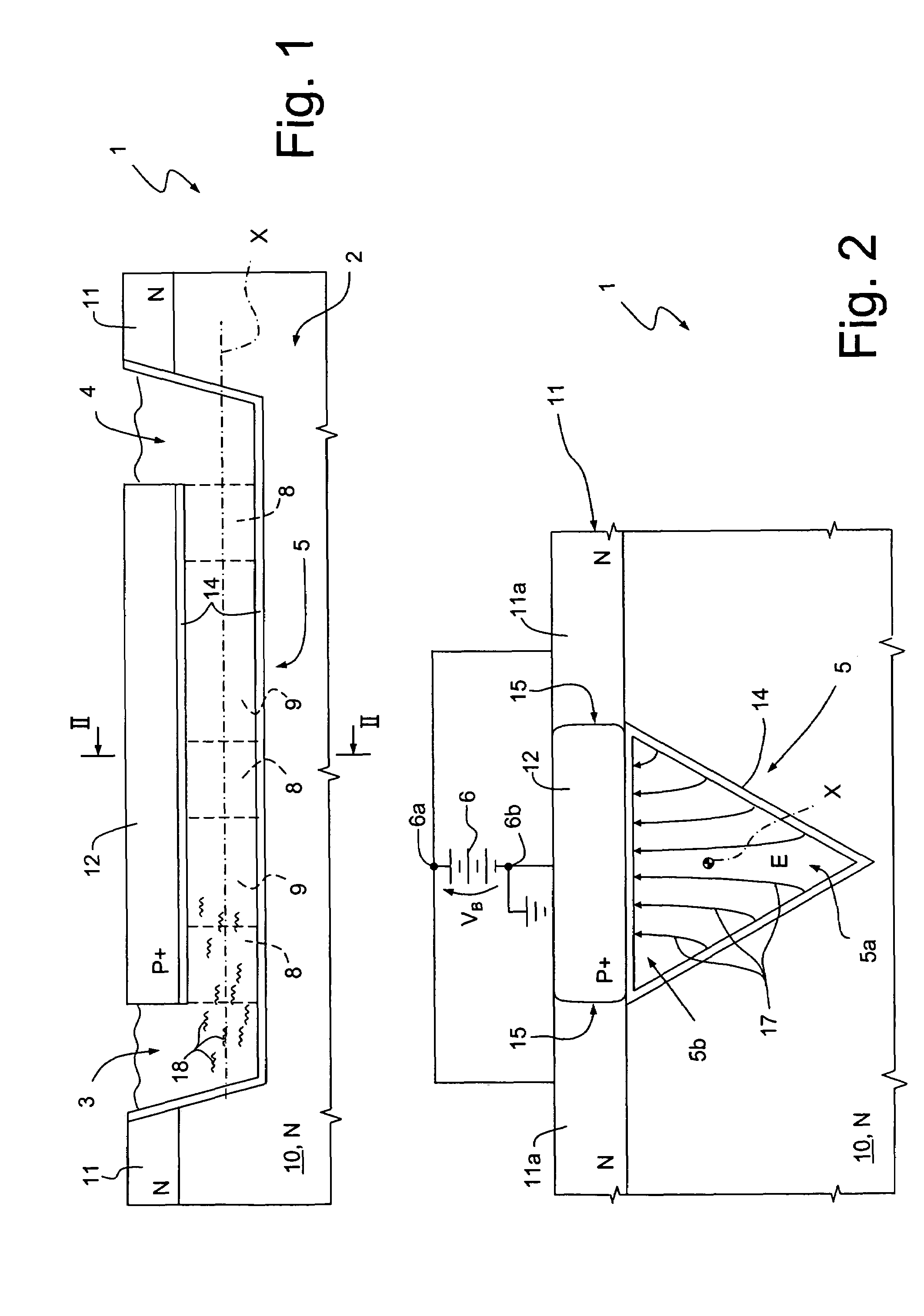

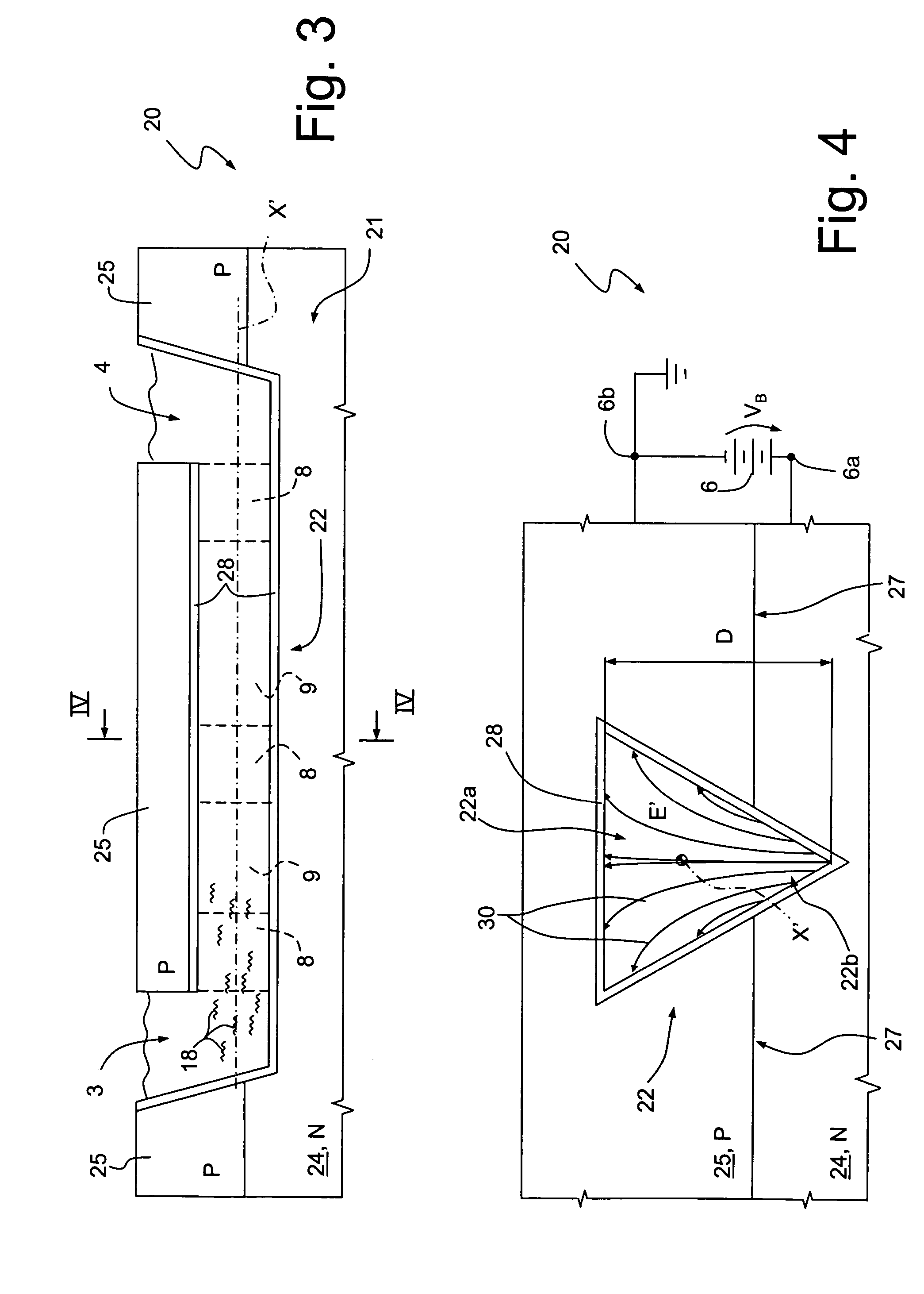

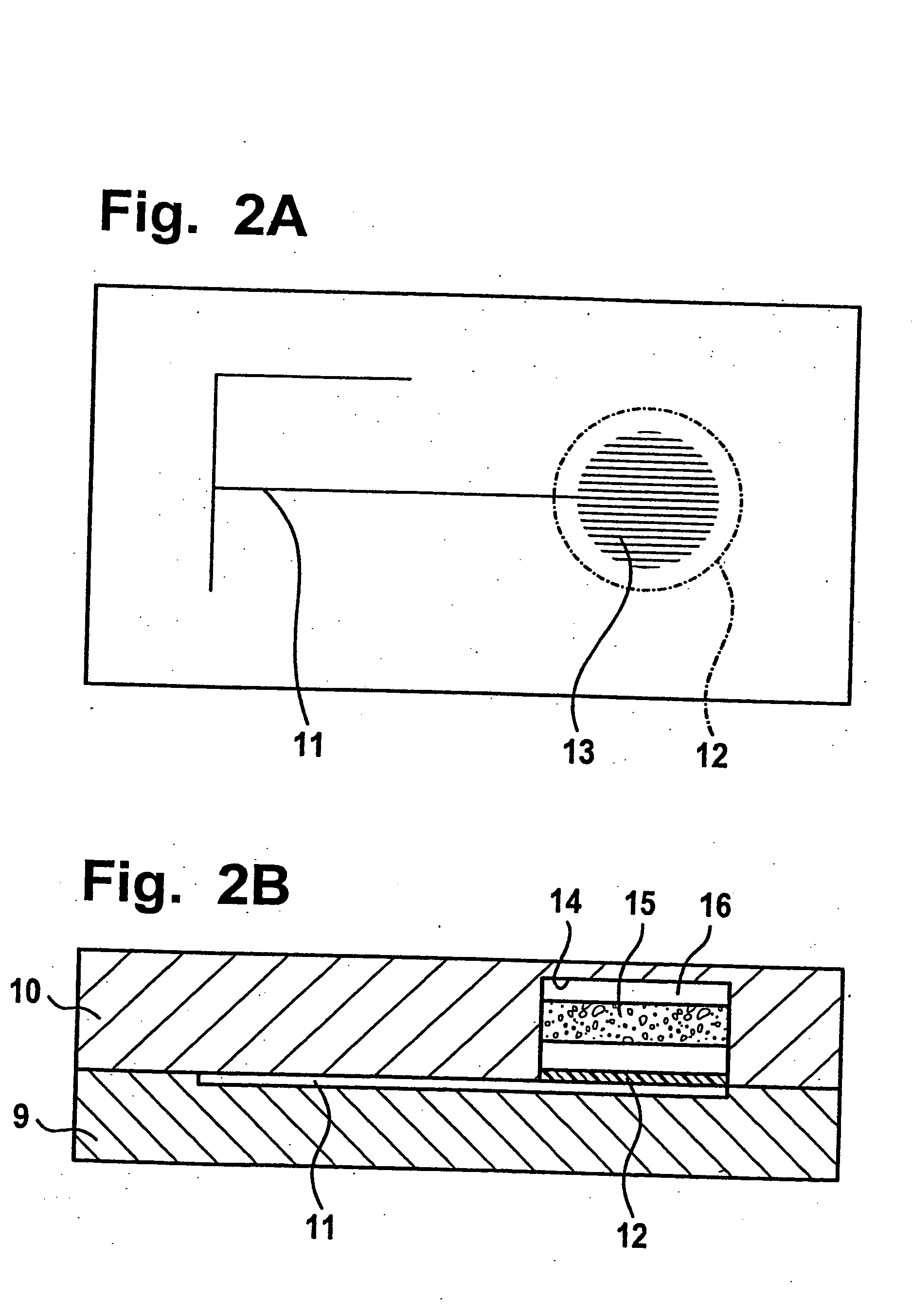

Microfluidic device and method of locally concentrating electrically charged substances in a microfluidic device

InactiveUS7485214B2Simple and cost-effective to manufactureImprove reaction speedElectrostatic separatorsSludge treatmentReaction rateRates reactions

A microfluidic device includes a microfluidic circuit, having an axis, and an electric field generator, arranged to establish an electric field (E) within at least a section of the microfluidic circuit, the electric field (E) being oriented transversally to the axis. The electric field is used to locally concentrate charged molecules, thus increasing the reaction rate.

Owner:STMICROELECTRONICS SRL

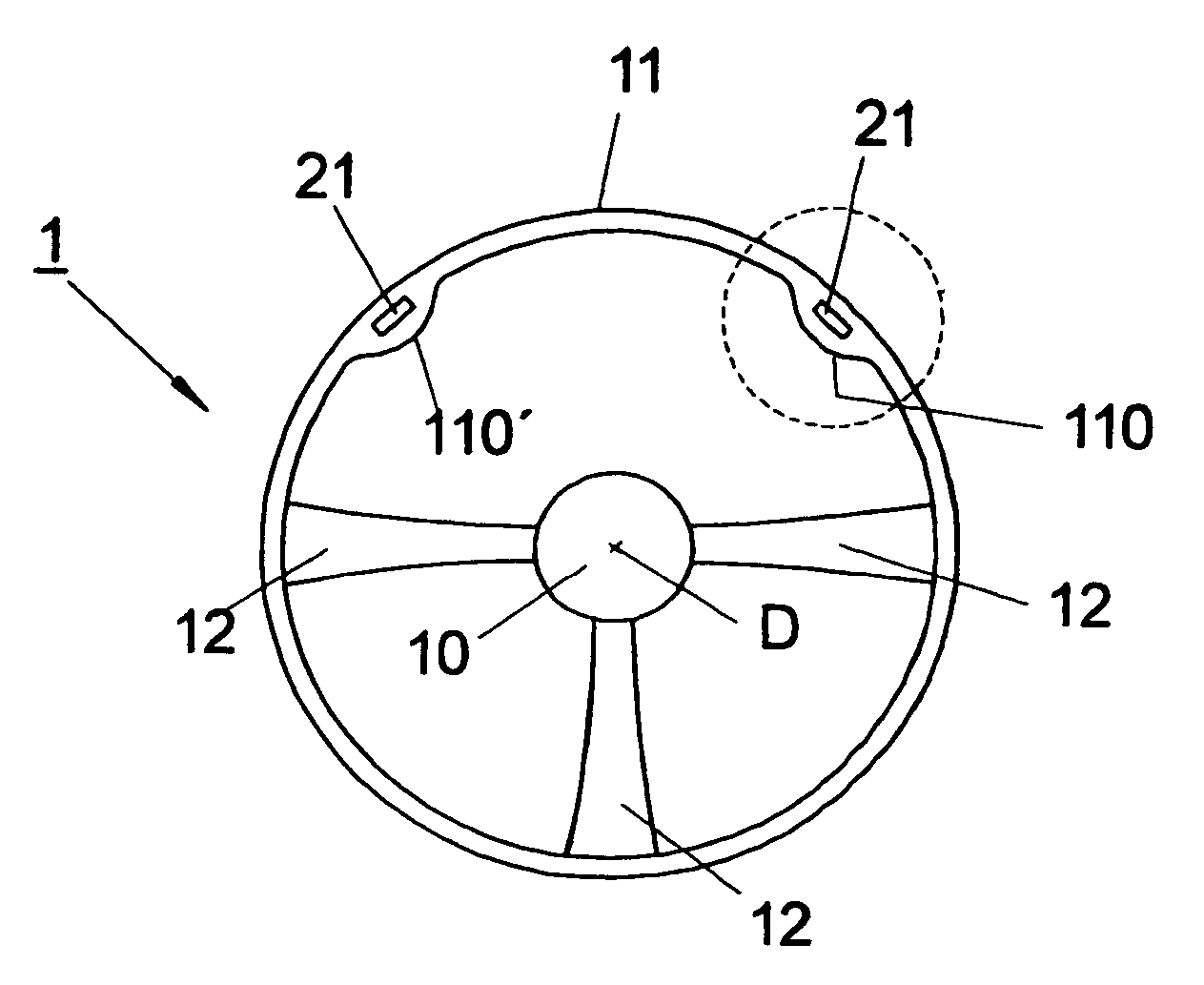

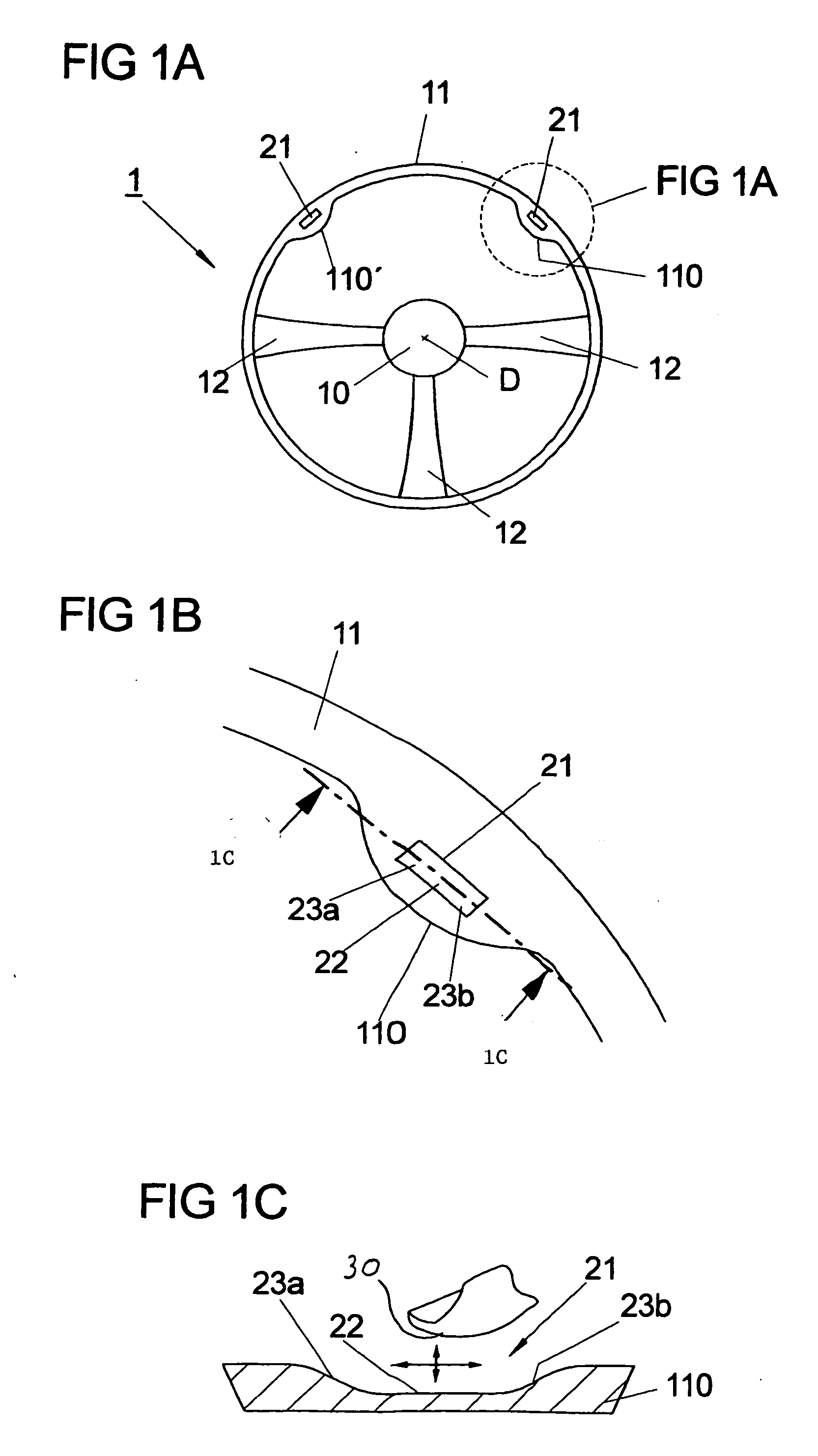

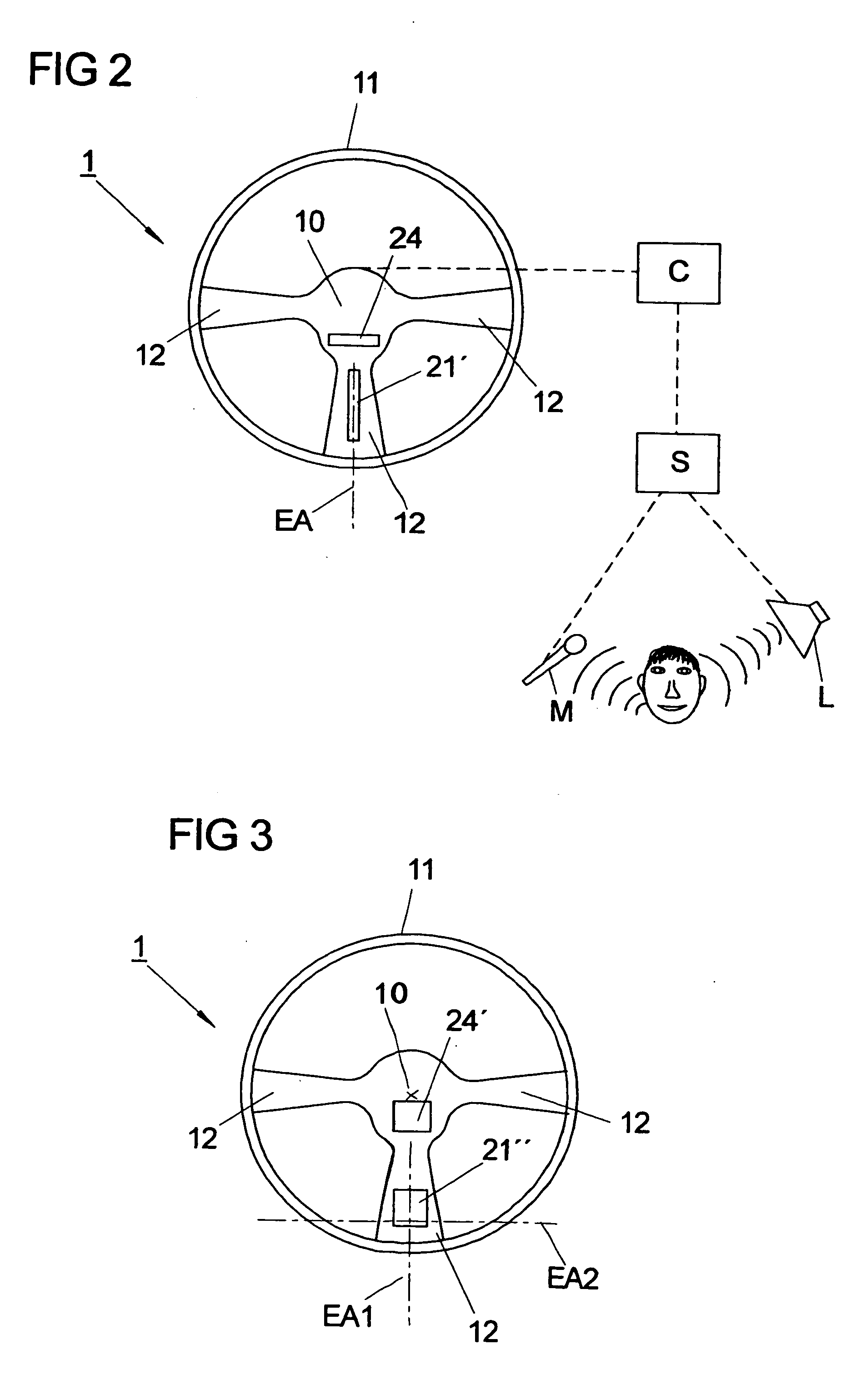

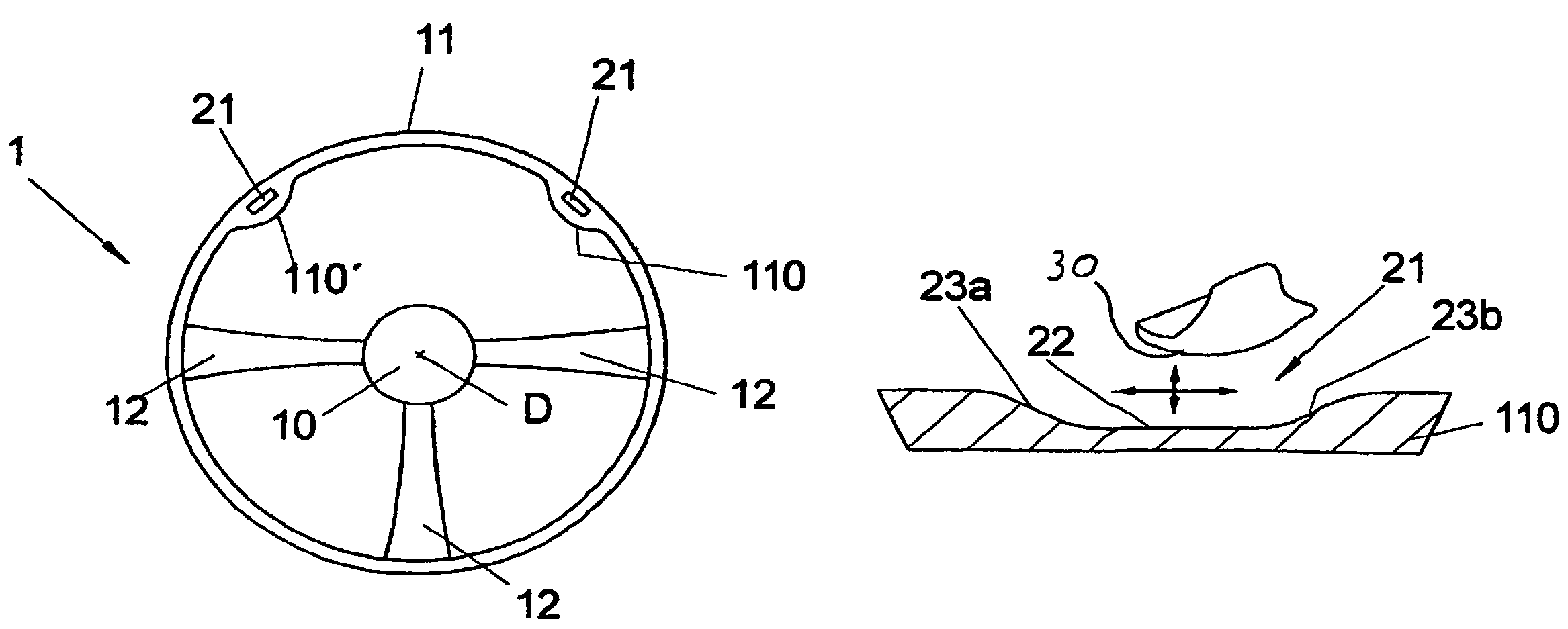

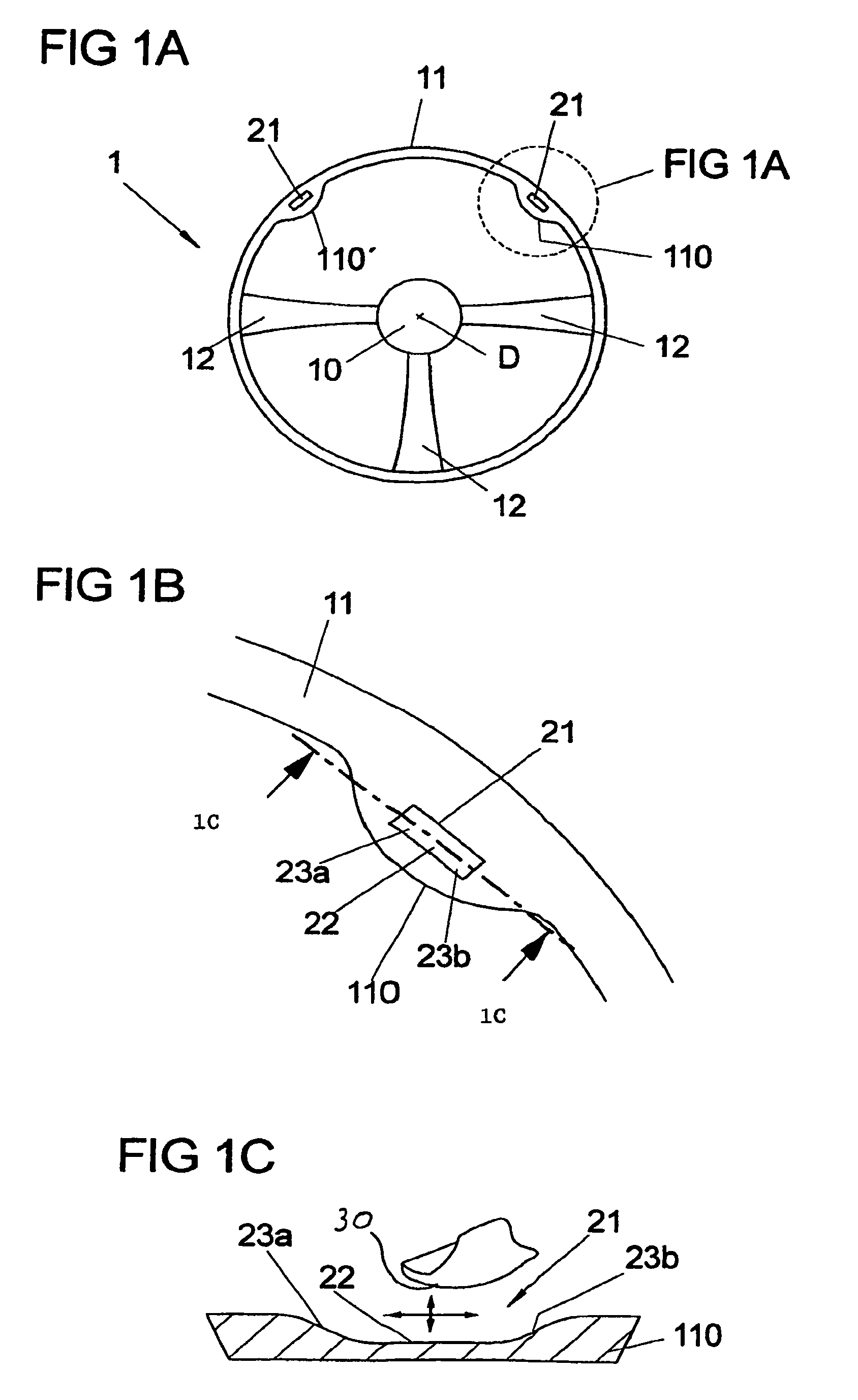

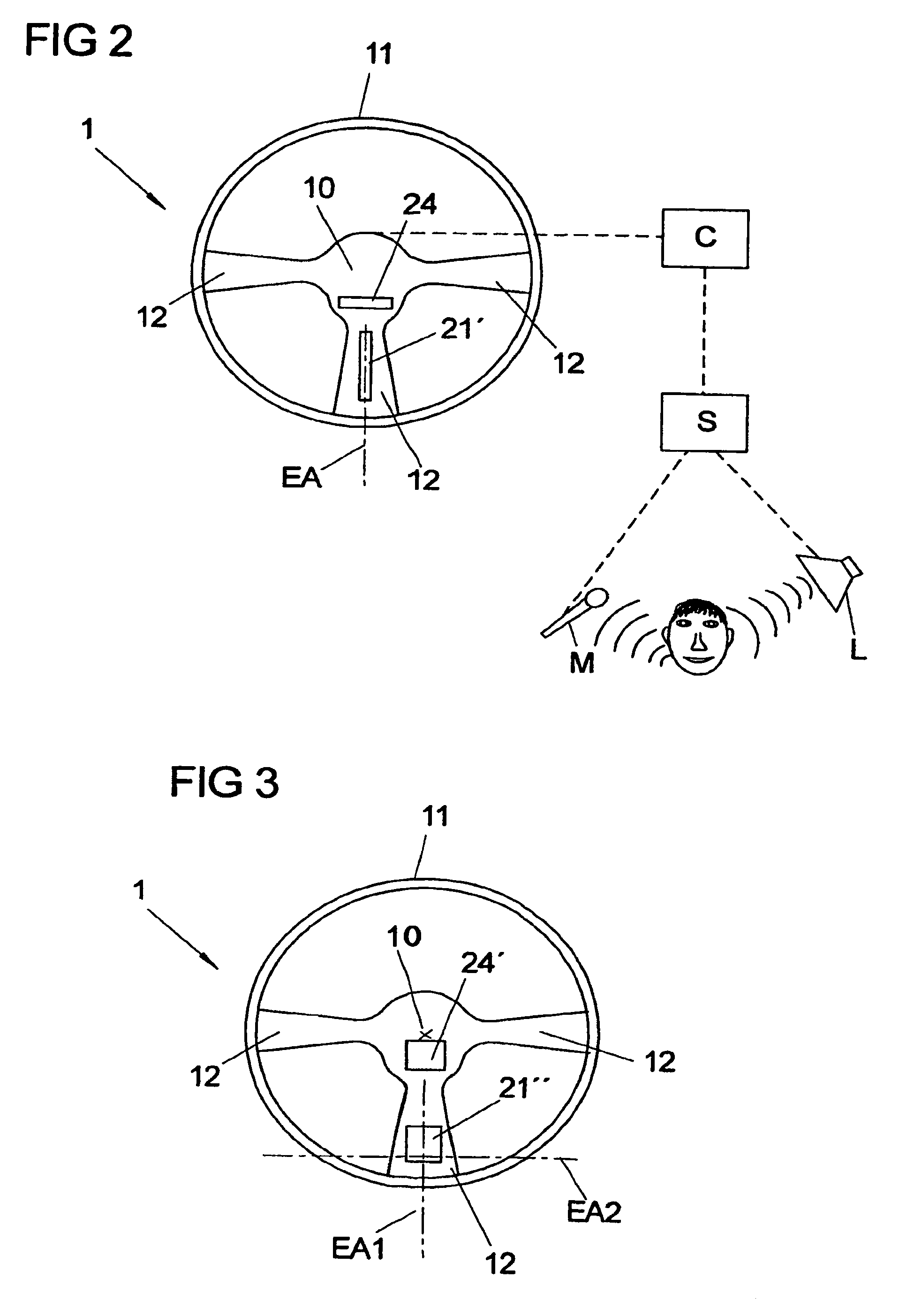

Steering wheel for a motor vehicle

InactiveUS20050189159A1Increasing impairmentSimpler and cost-effective manufactureControlling membersMechanical apparatusOptical reflectionSteering wheel

A steering wheel for a motor vehicle is provided having a hub element, a steering wheel rim, at least one steering wheel spoke for attaching the steering wheel rim to the hub element and at least one activation device which is arranged on the hub element, the steering wheel rim or the steering wheel spoke for controlling and / or regulating an assembly of a motor vehicle. The activation device is preferably embodied as an optical reflection sensor device with a functional face. Such a sensor device operates without mechanically moving parts and during the service life of the steering wheel it is independent of general scratching and soiling of its functional faces. In addition, the functionality of the measurement of distances and / or speeds of the objects located above the functional faces of the sensor device permits further functions to be integrated without requiring further separate devices in order to do so.

Owner:TAKATA PETRI AG

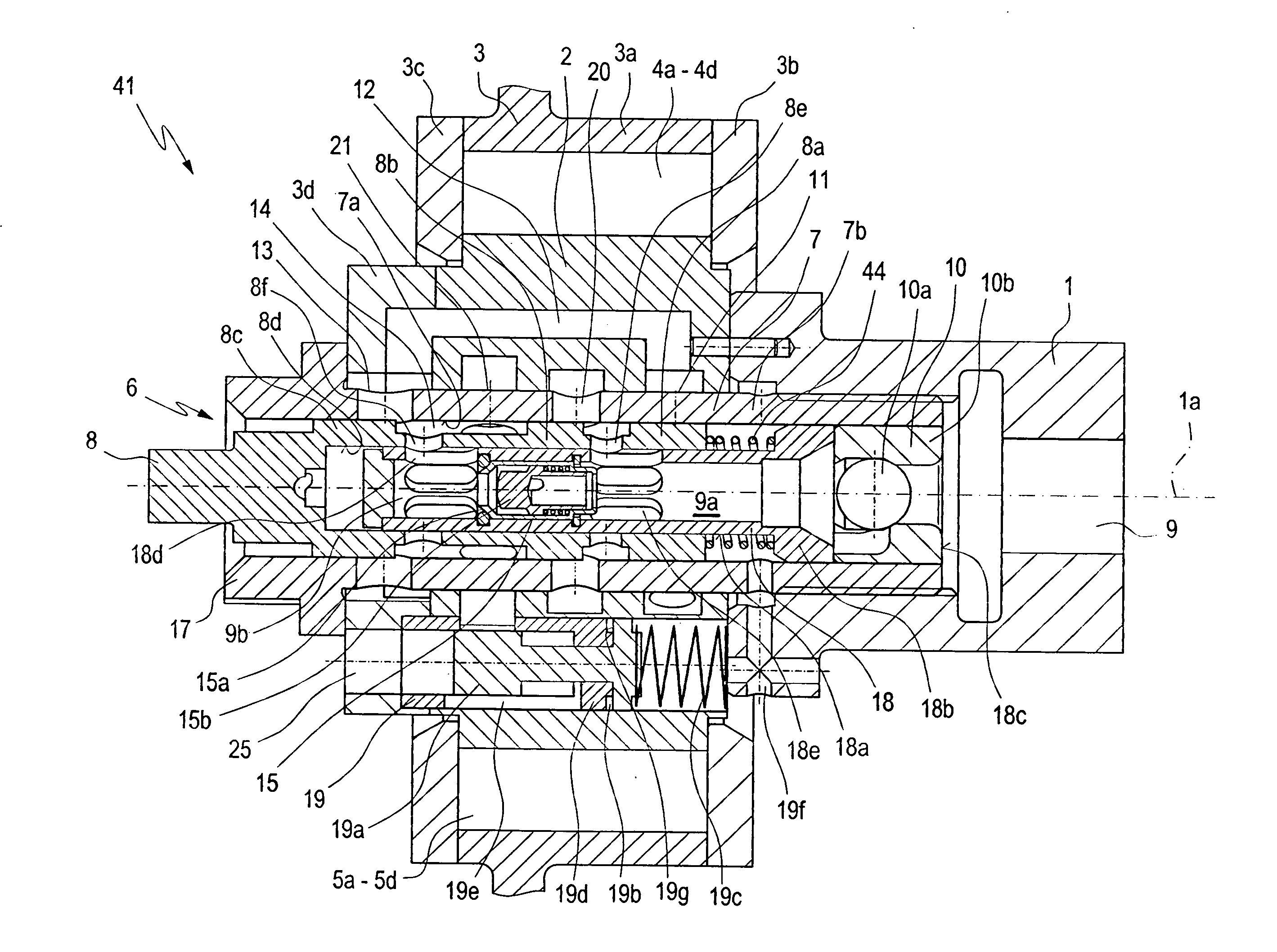

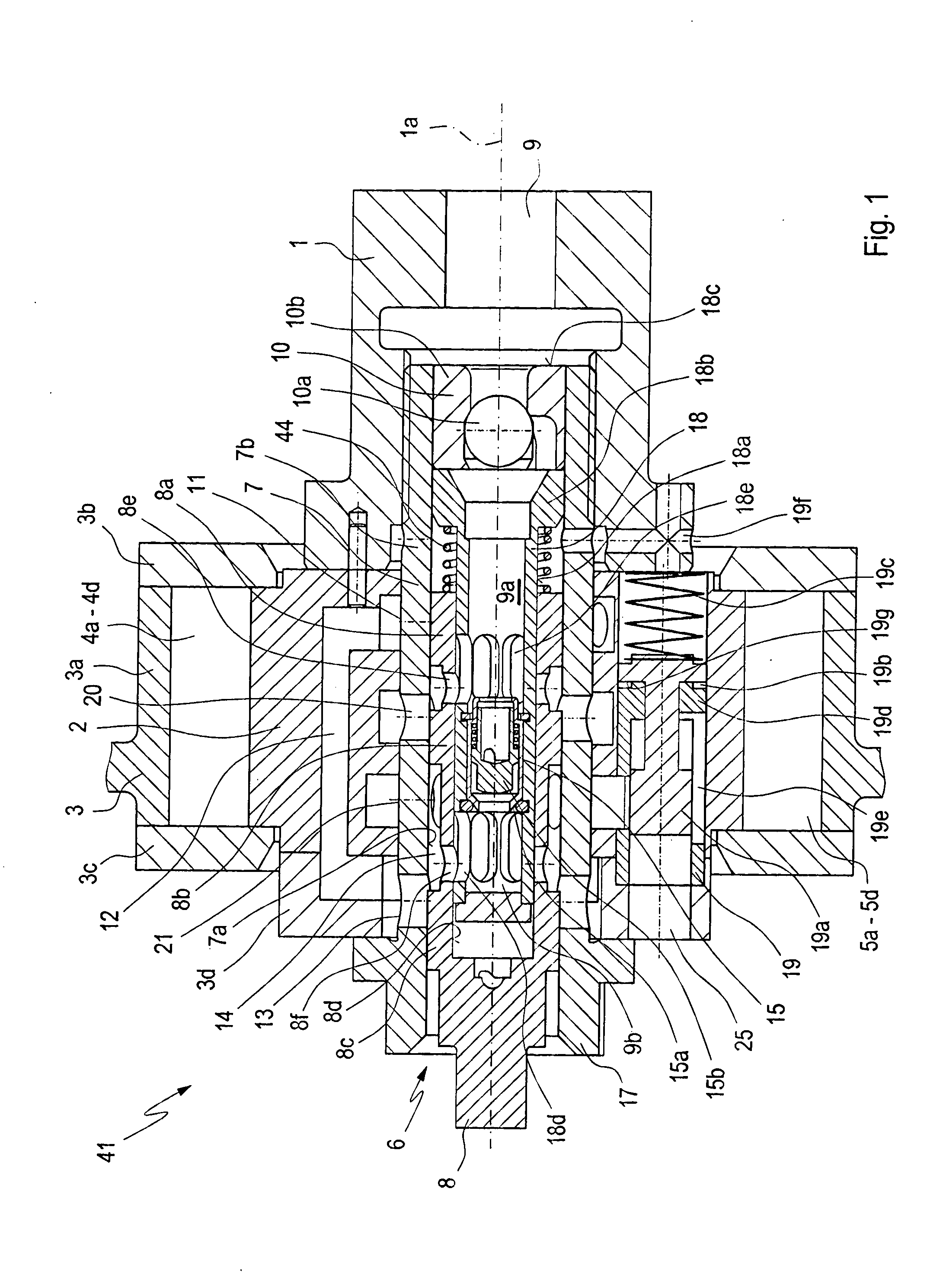

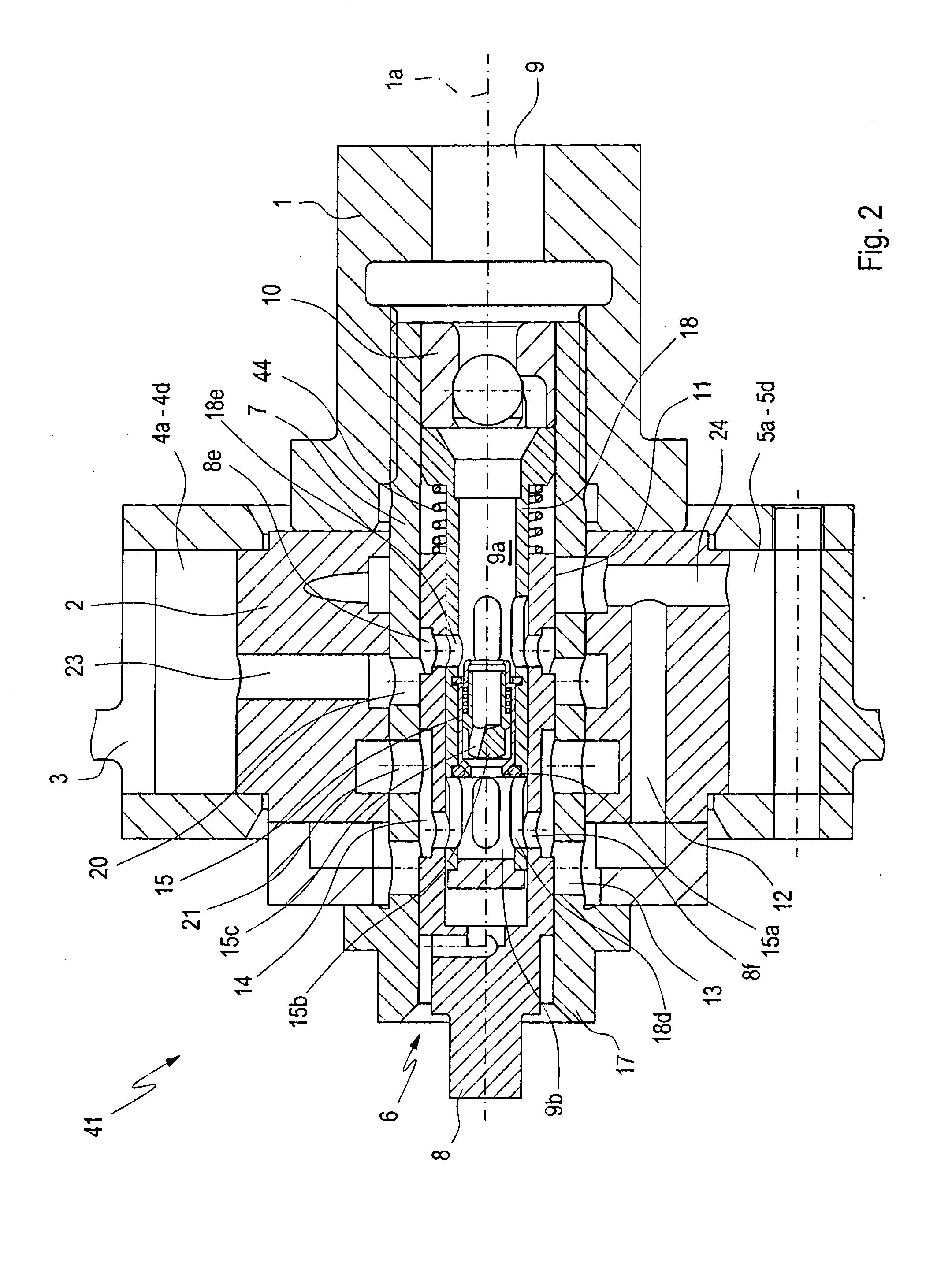

Camshaft adjustment device

ActiveUS20090159024A1Compact designSimple and cost-effective to manufactureYielding couplingValve drivesExternal combustion engineInternal combustion engine

In an adjustment device for adjusting the phase position of a camshaft relative to a crankshaft of an internal combustion engine which includes a hydraulic system for supplying hydraulic fluid under pressure to the adjustment device for the controlled admission to, and release thereof from, operating chambers of the adjustment device under the control of a control device including a control valve, the operating chambers are in communication with one another via control valves to permit flow of hydraulic fluid from one set of operating chambers to another by the varying torques effective on the camshaft or by controlling fluid supply to the operating chambers from the hydraulic fluid supply system.

Owner:DAIMLER AG

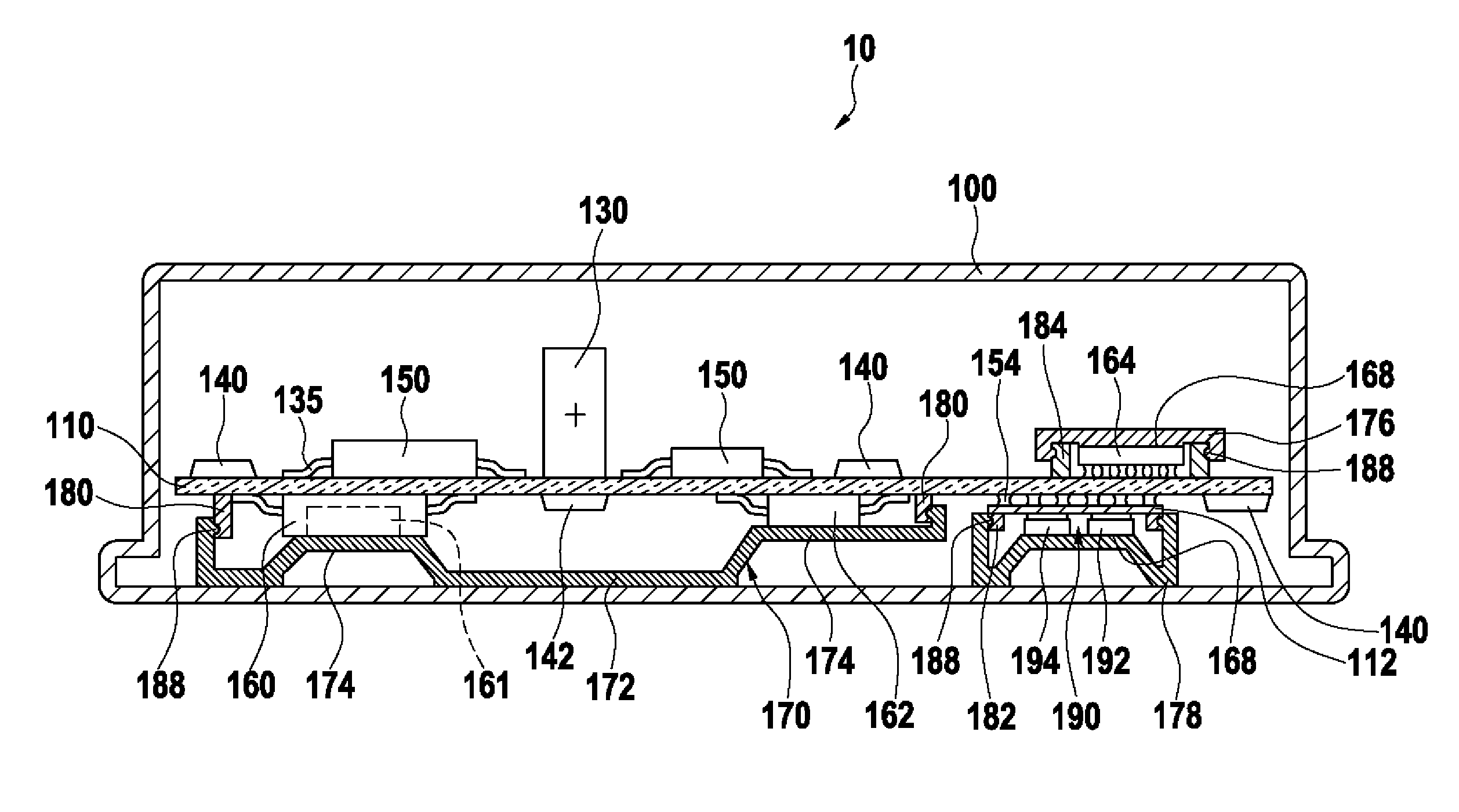

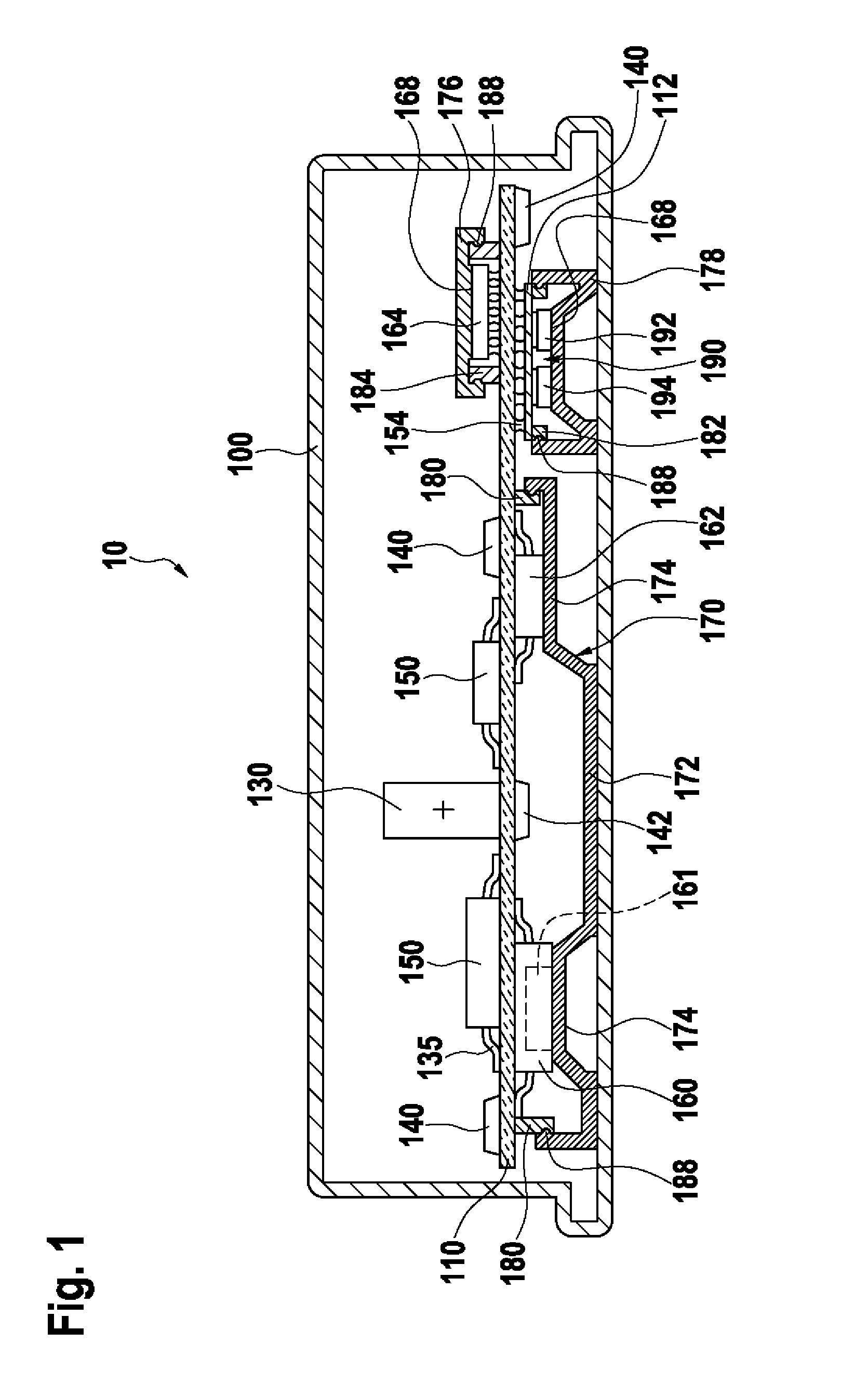

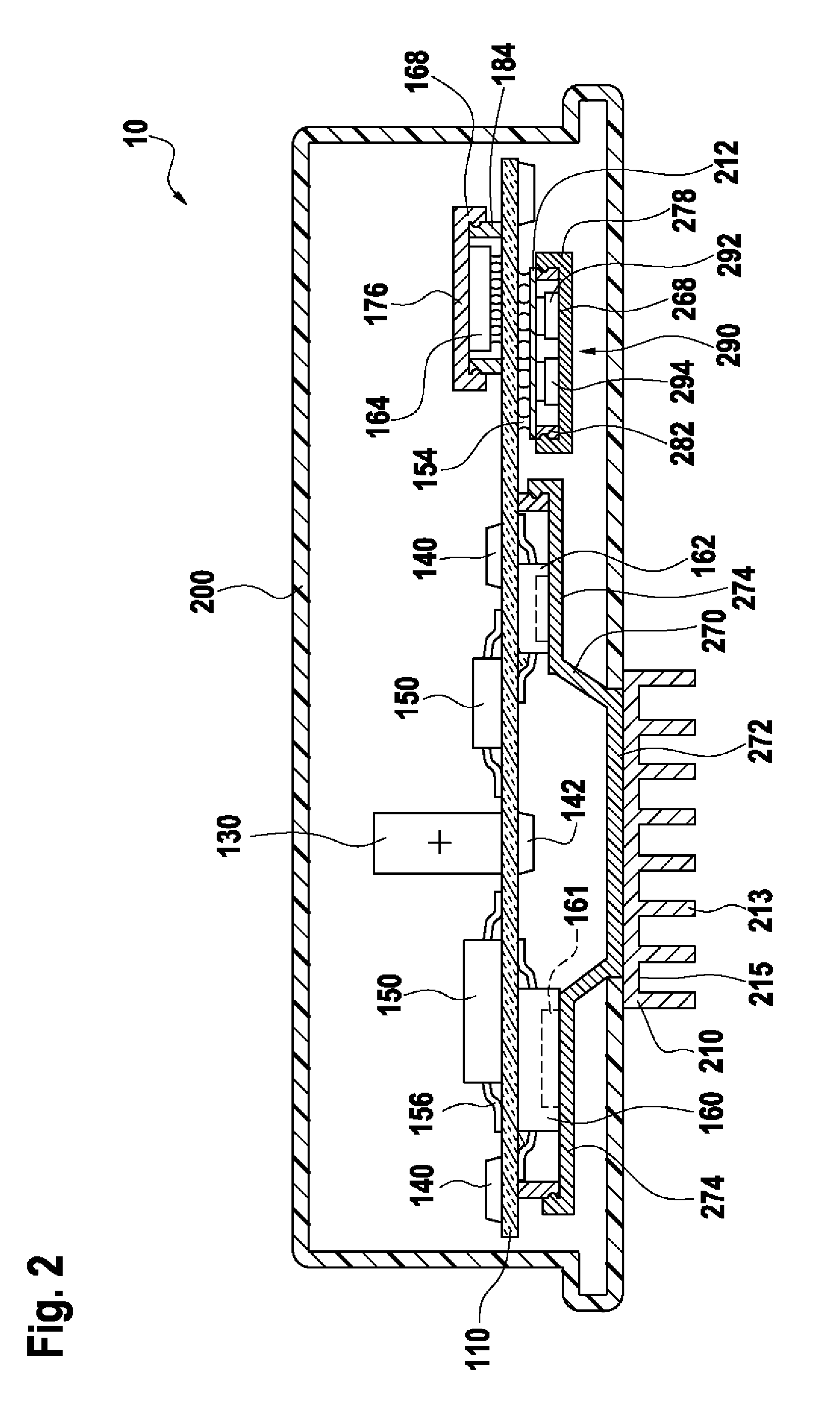

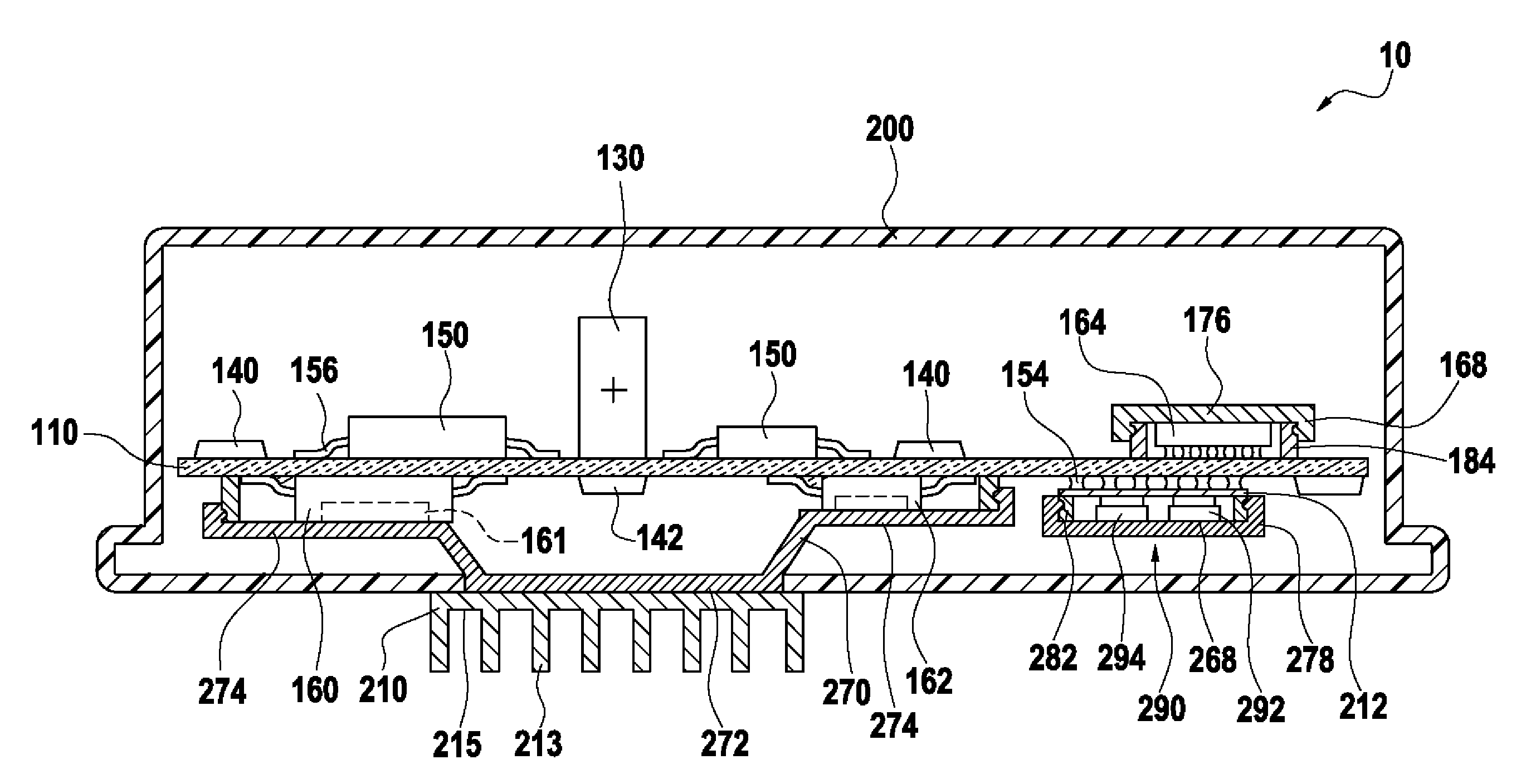

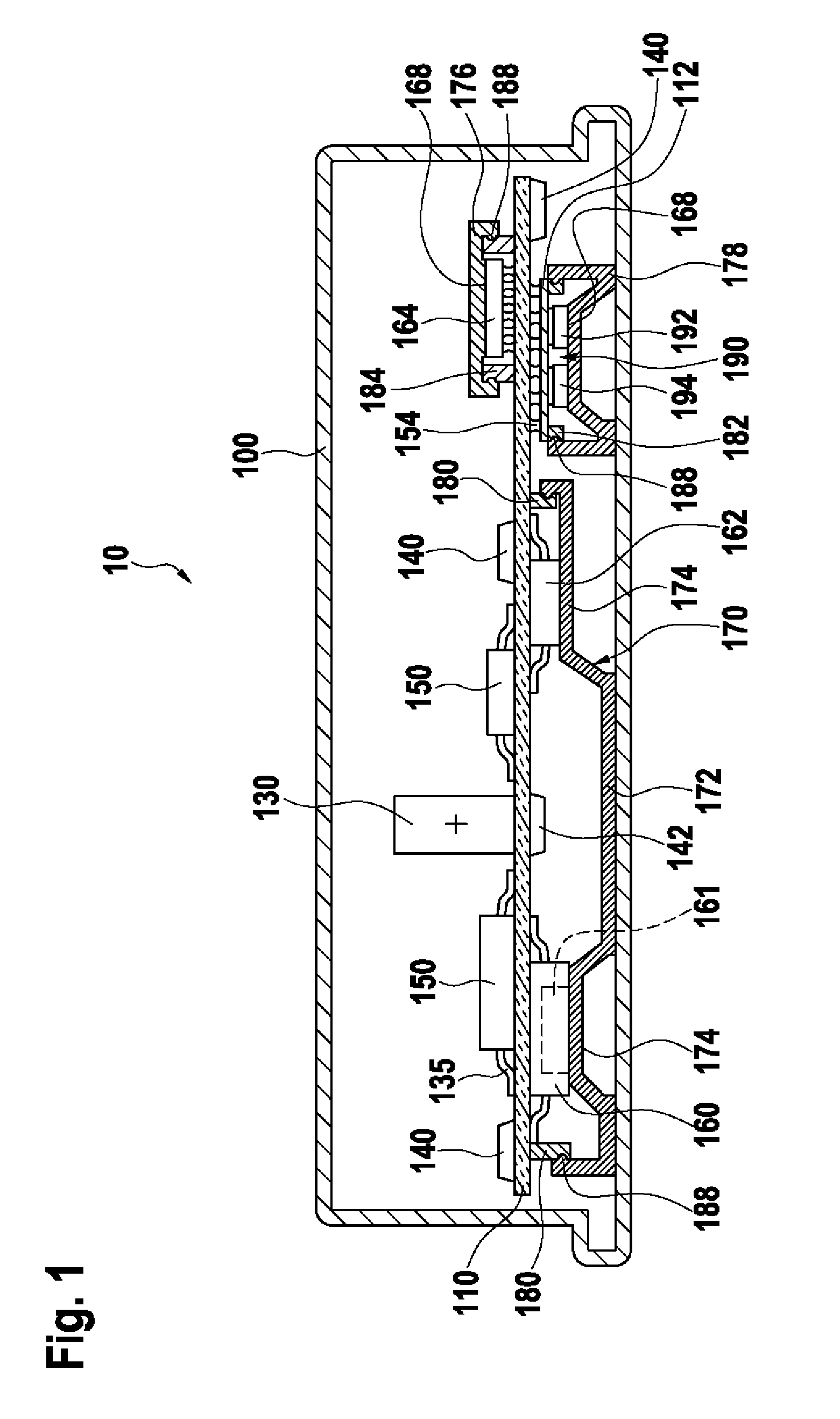

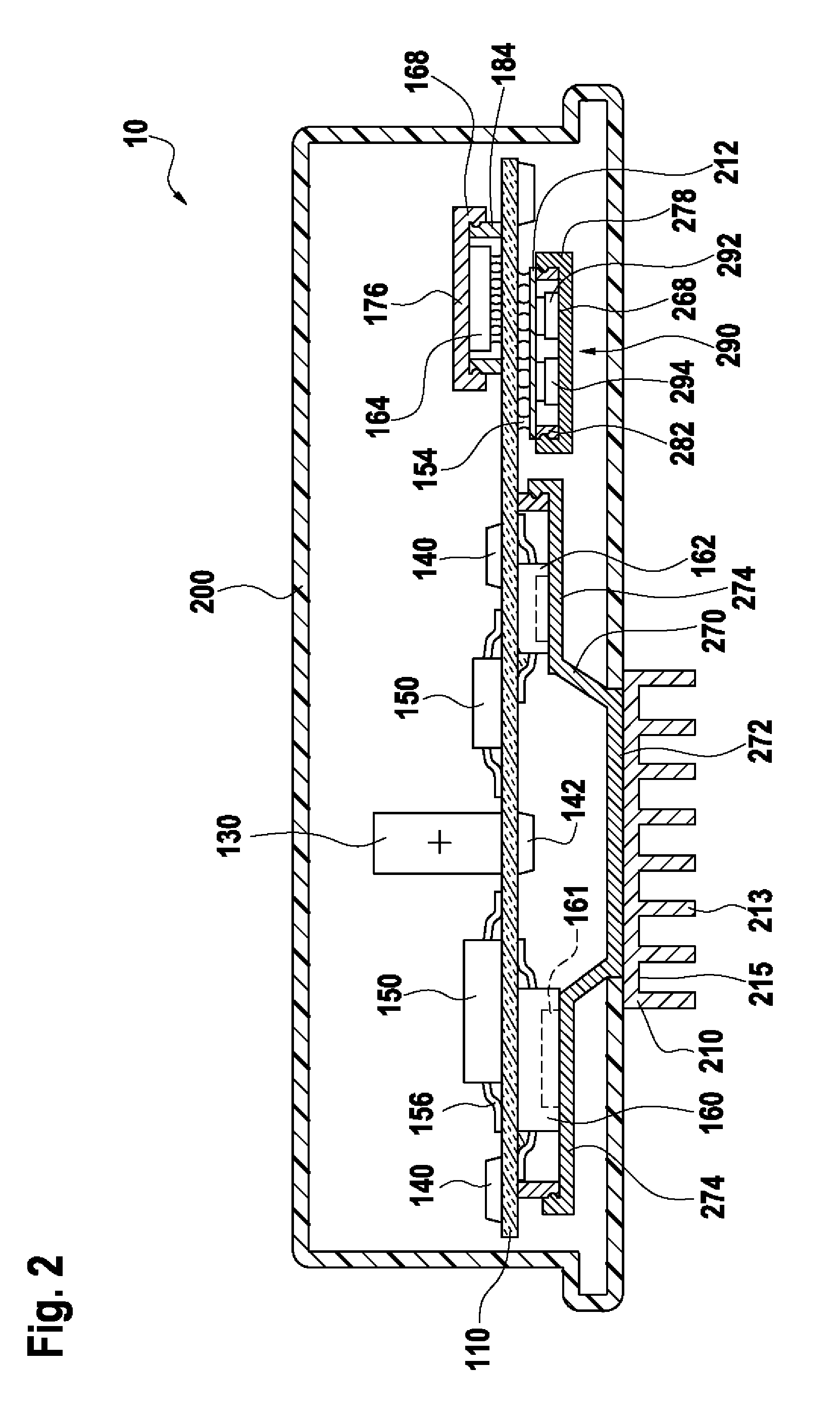

Electronic control device

InactiveUS20120300405A1Simple and cost-effective to and to installSimple and cost-effective to manufactureMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

The invention relates to an electronic control device (10) having electronic components (160, 162) on a circuit board (110) which are shielded from electrical and / or magnetic interference fields. According to the invention, an electrically conductive sheet metal part (170) is arranged on the circuit board (110) which forms a Faraday cage for the electronic components (160, 162) with the circuit board. The electrically conductive sheet metal part (170) is furthermore in thermal contact to the electronic components (160, 162) and in thermal contact to the housing (100) of the control device (10) and thereby deflects heat from the electronic components (160, 162) into the housing (100).

Owner:ROBERT BOSCH GMBH

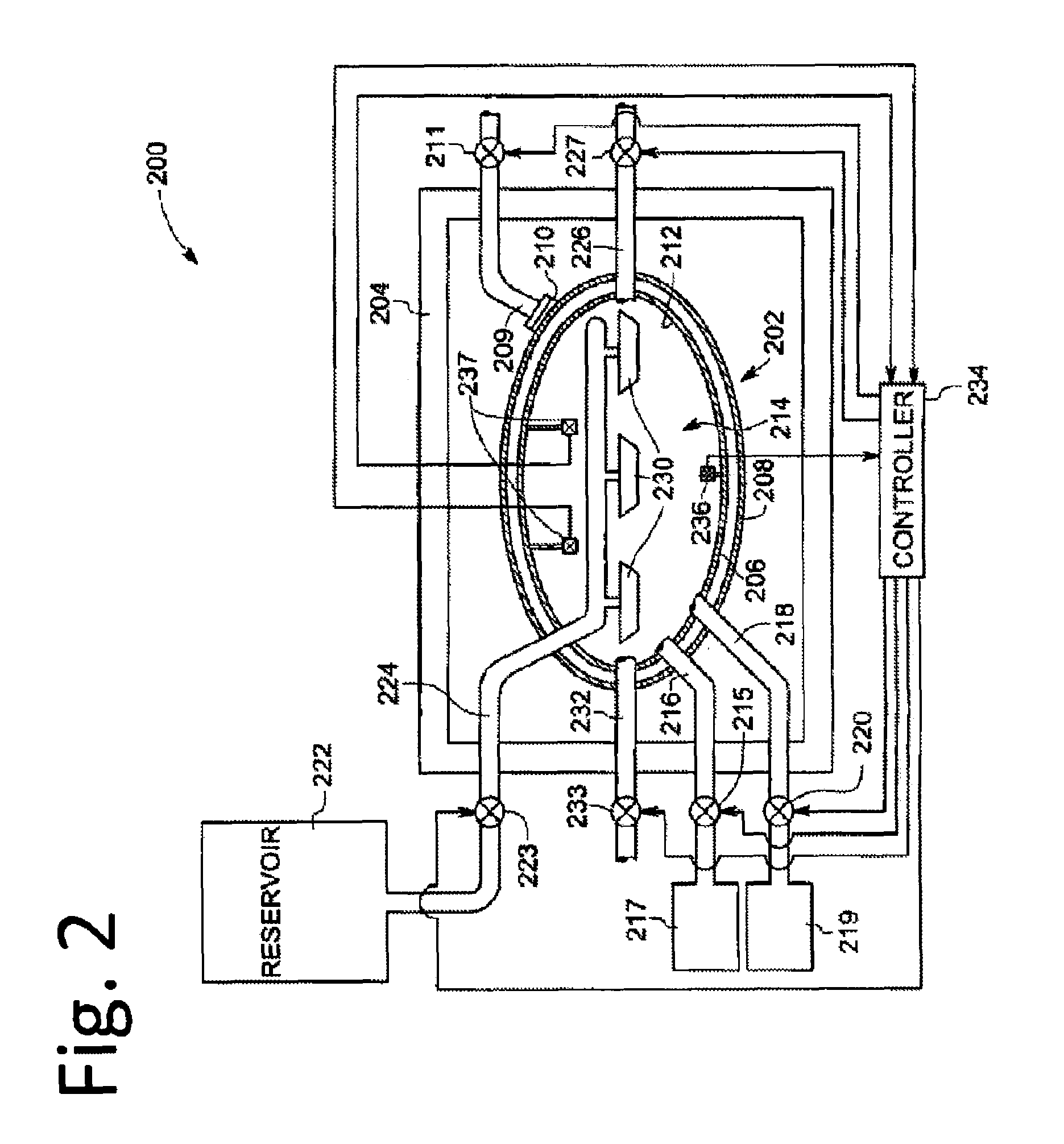

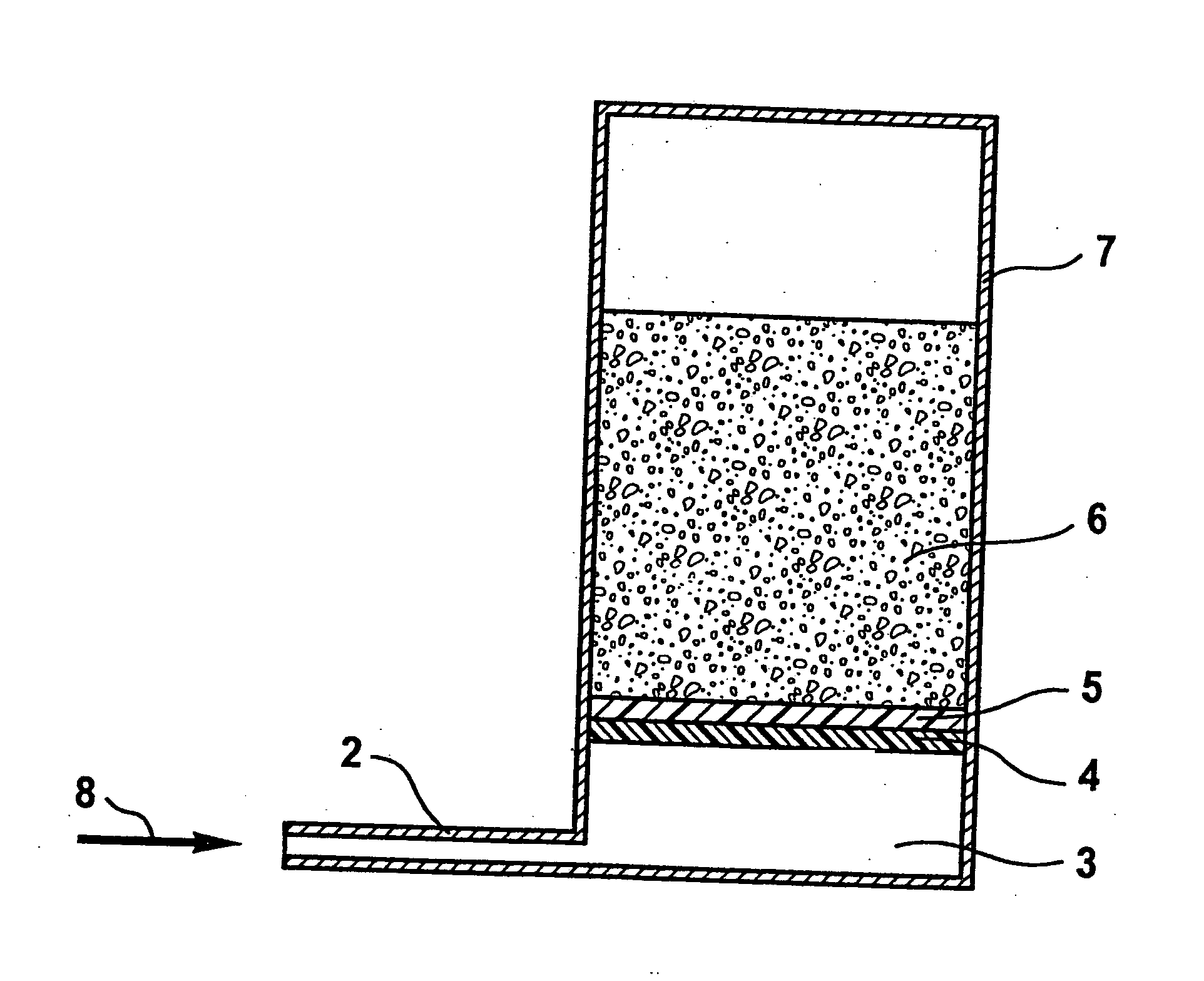

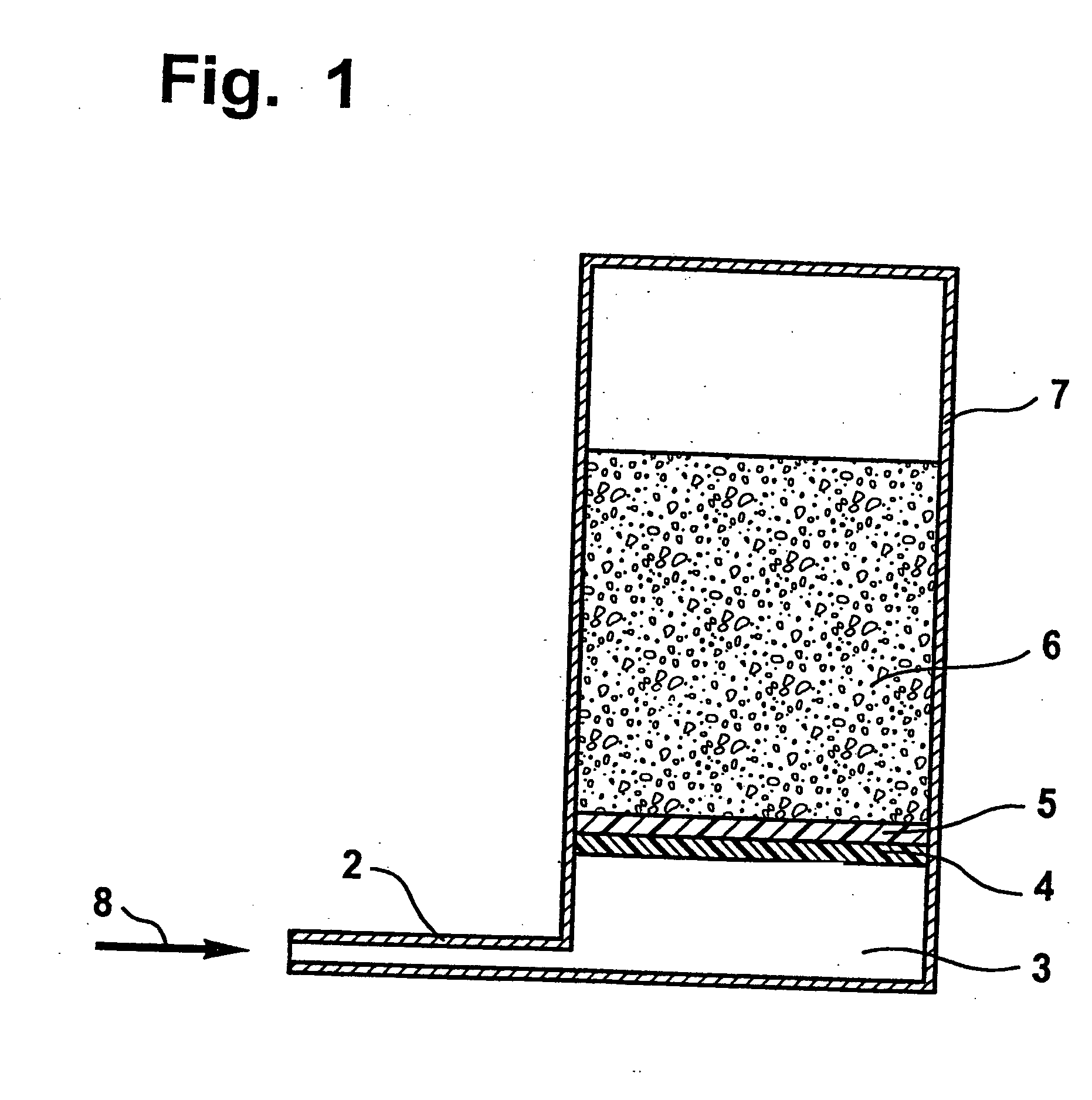

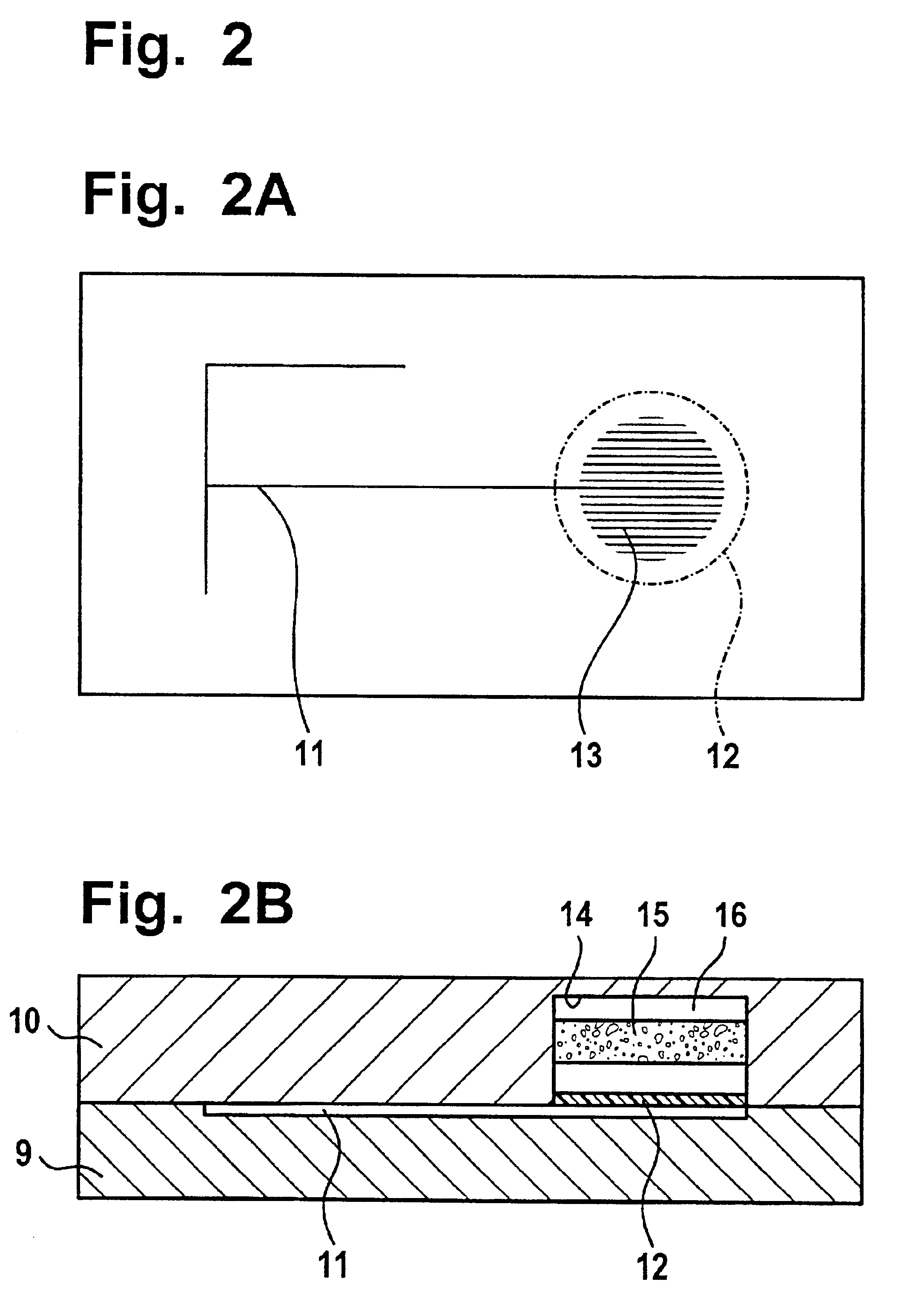

Pump for low flow rates

InactiveUS20050006309A1Reduce flow ratePrevent penetrationUltrafiltrationFlexible member pumpsEngineeringMembrane configuration

Owner:ROCHE DIABETES CARE INC

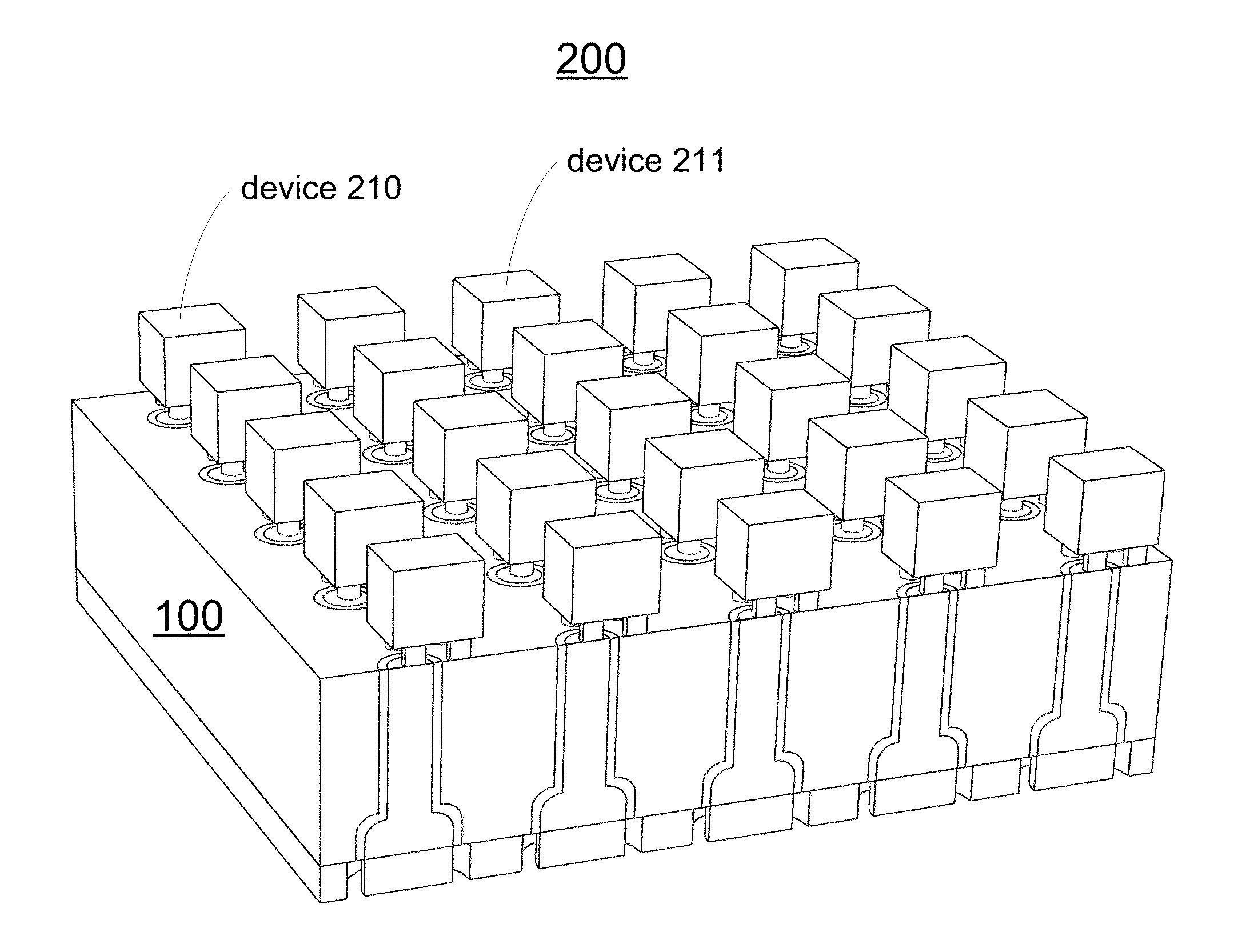

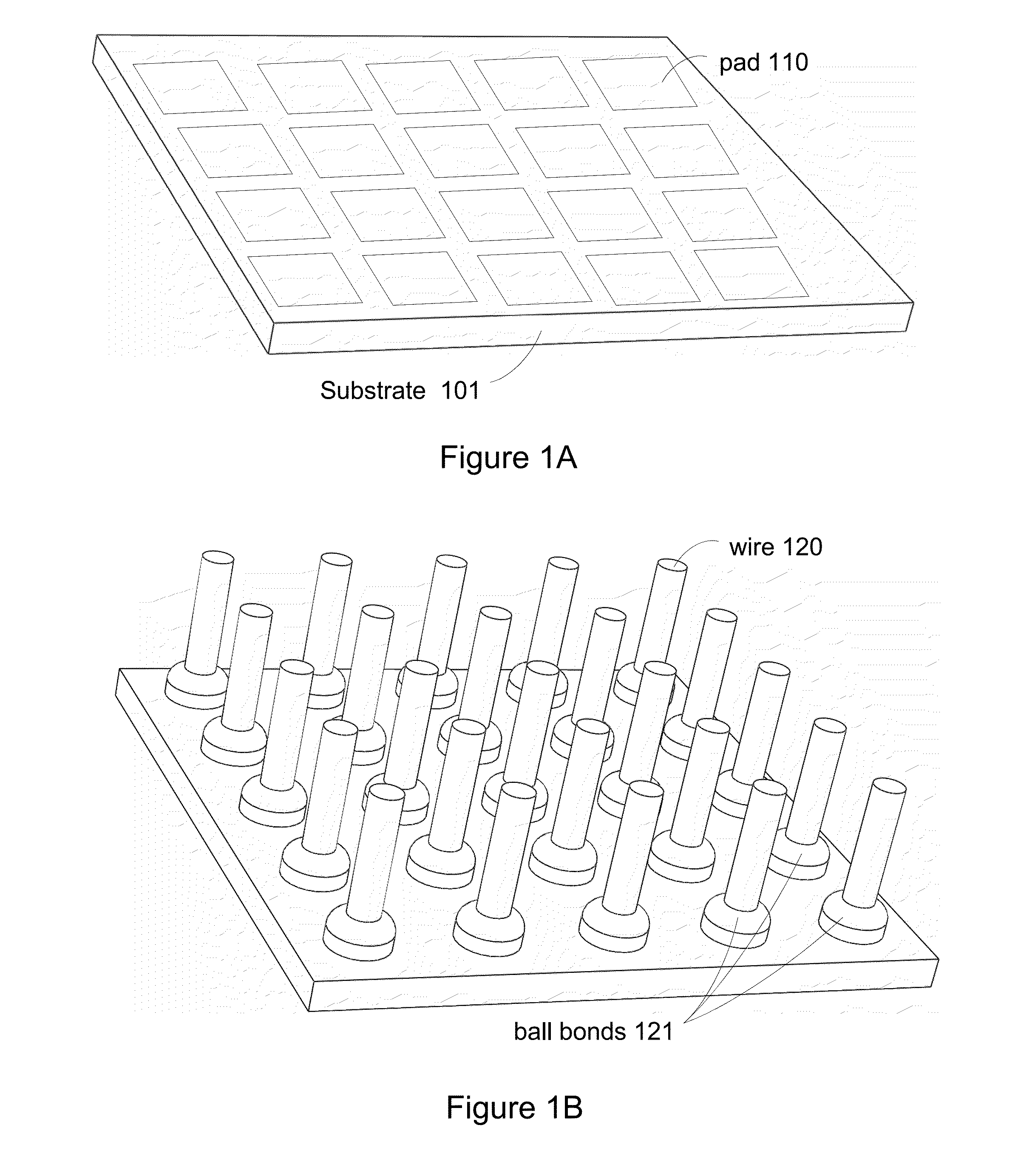

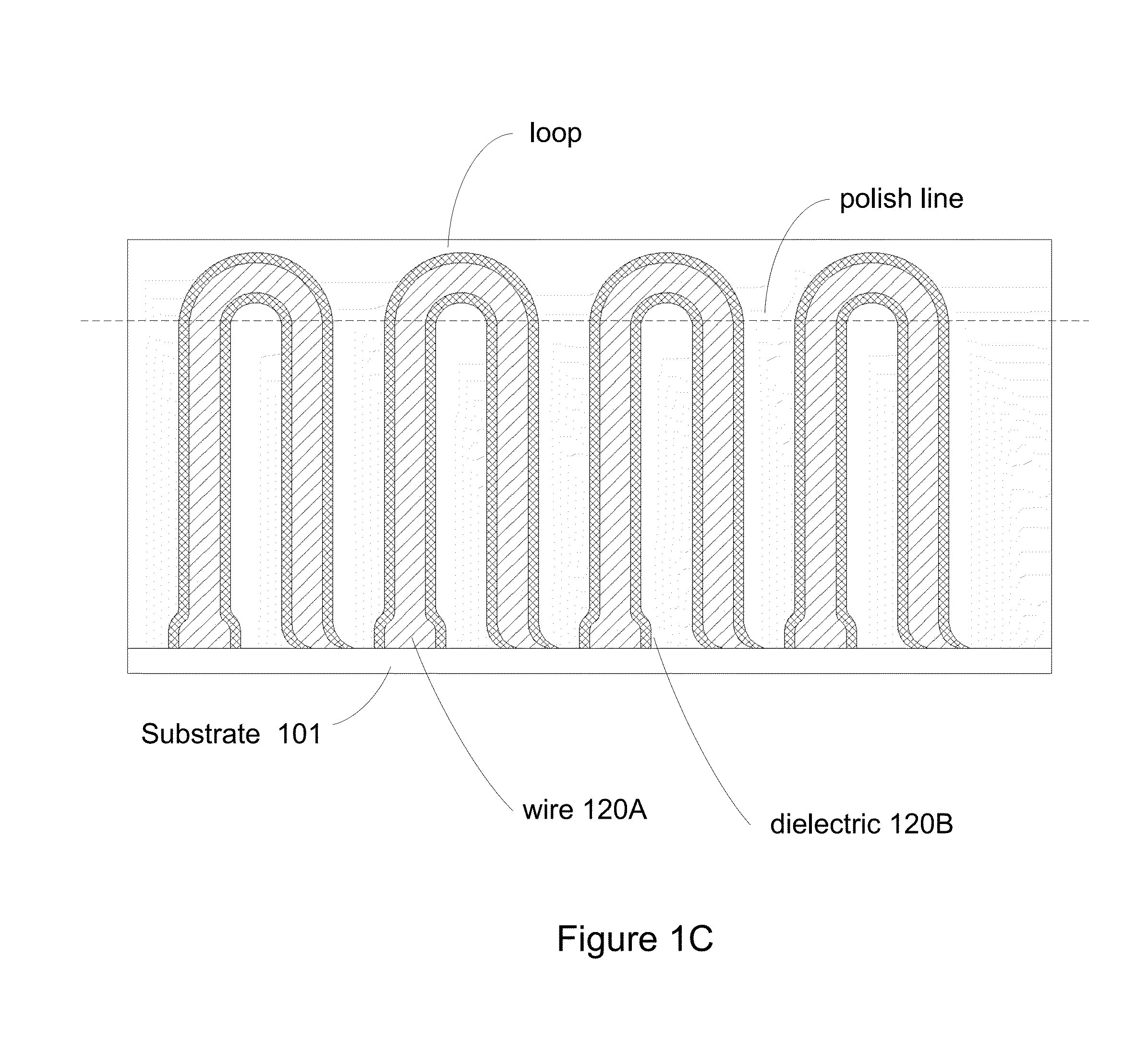

Heat spreading substrate with embedded interconnects

ActiveUS8946757B2Simple and cost-effective to manufactureSemiconductor/solid-state device detailsSolid-state devicesEngineeringGrain structure

Heat spreading substrate with embedded interconnects. In an embodiment in accordance with the present invention, an apparatus includes a metal parallelepiped comprising a plurality of wires inside the metal parallelepiped. The plurality of wires have a different grain structure than the metal parallelepiped. The plurality of wires are electrically isolated from the metal parallelepiped. The plurality of wires may be electrically isolated from one another.

Owner:INVENSAS CORP

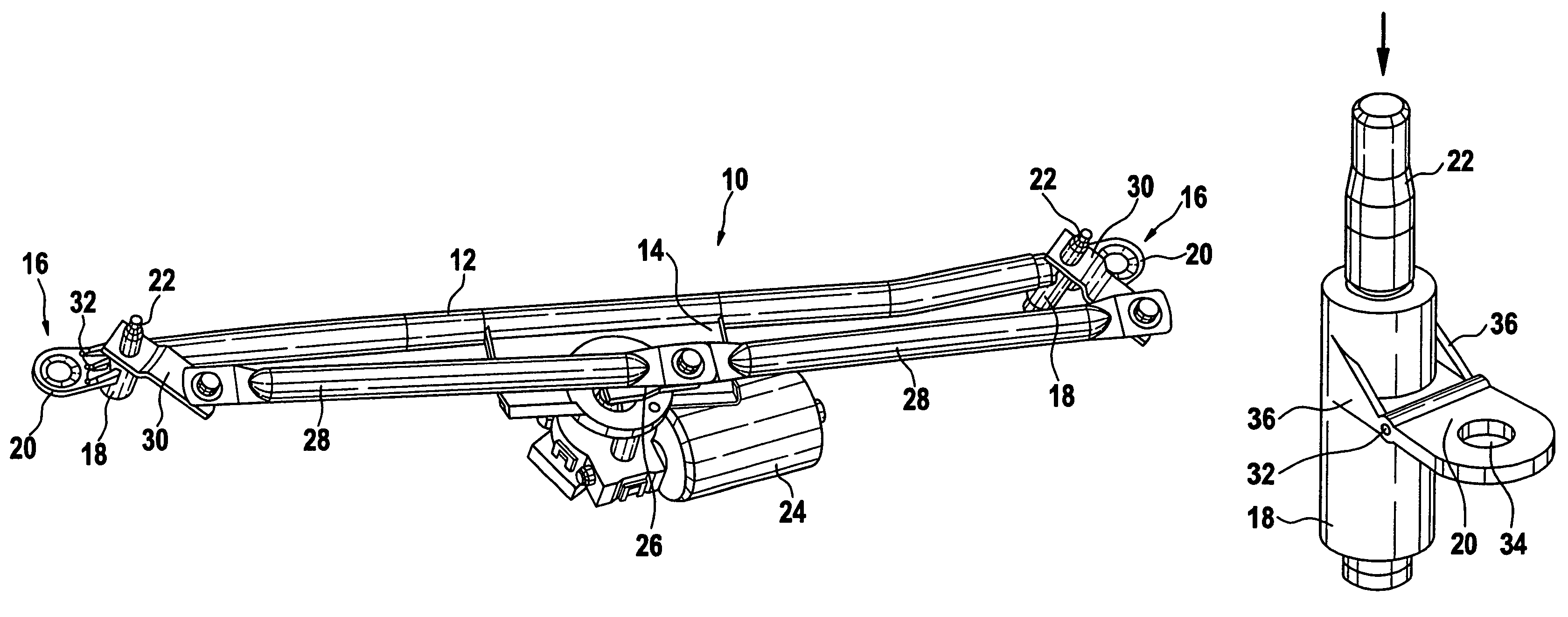

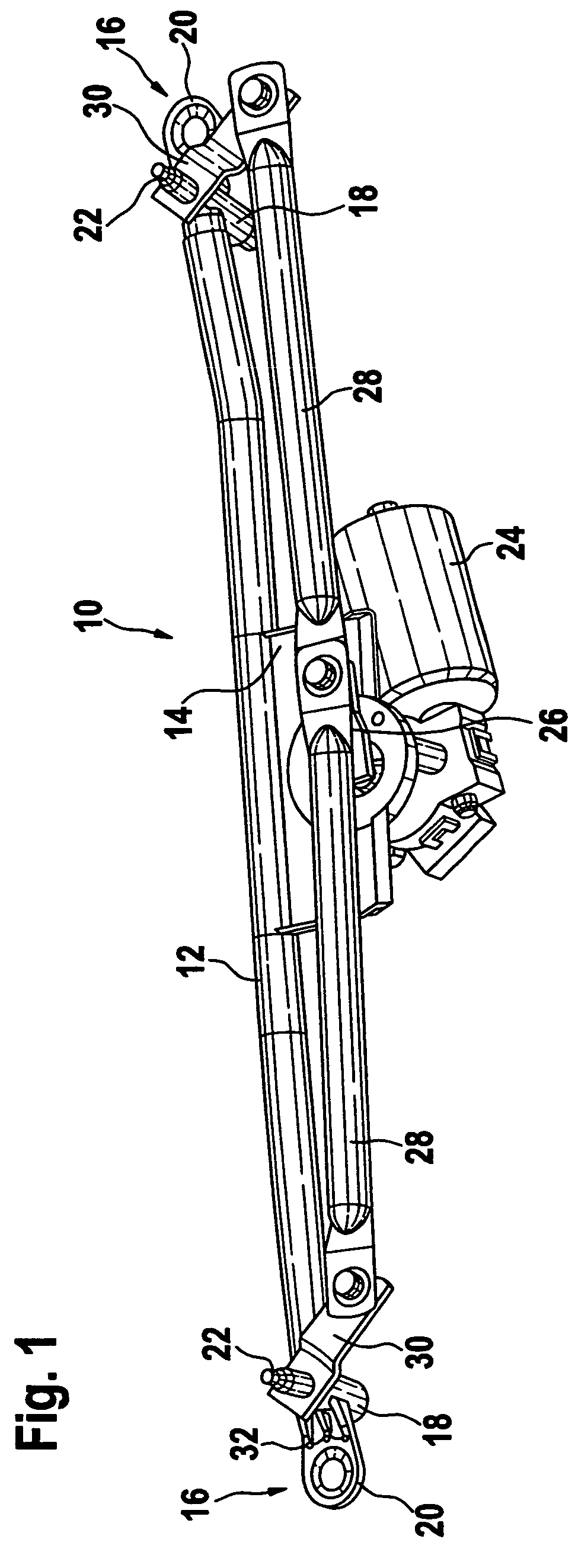

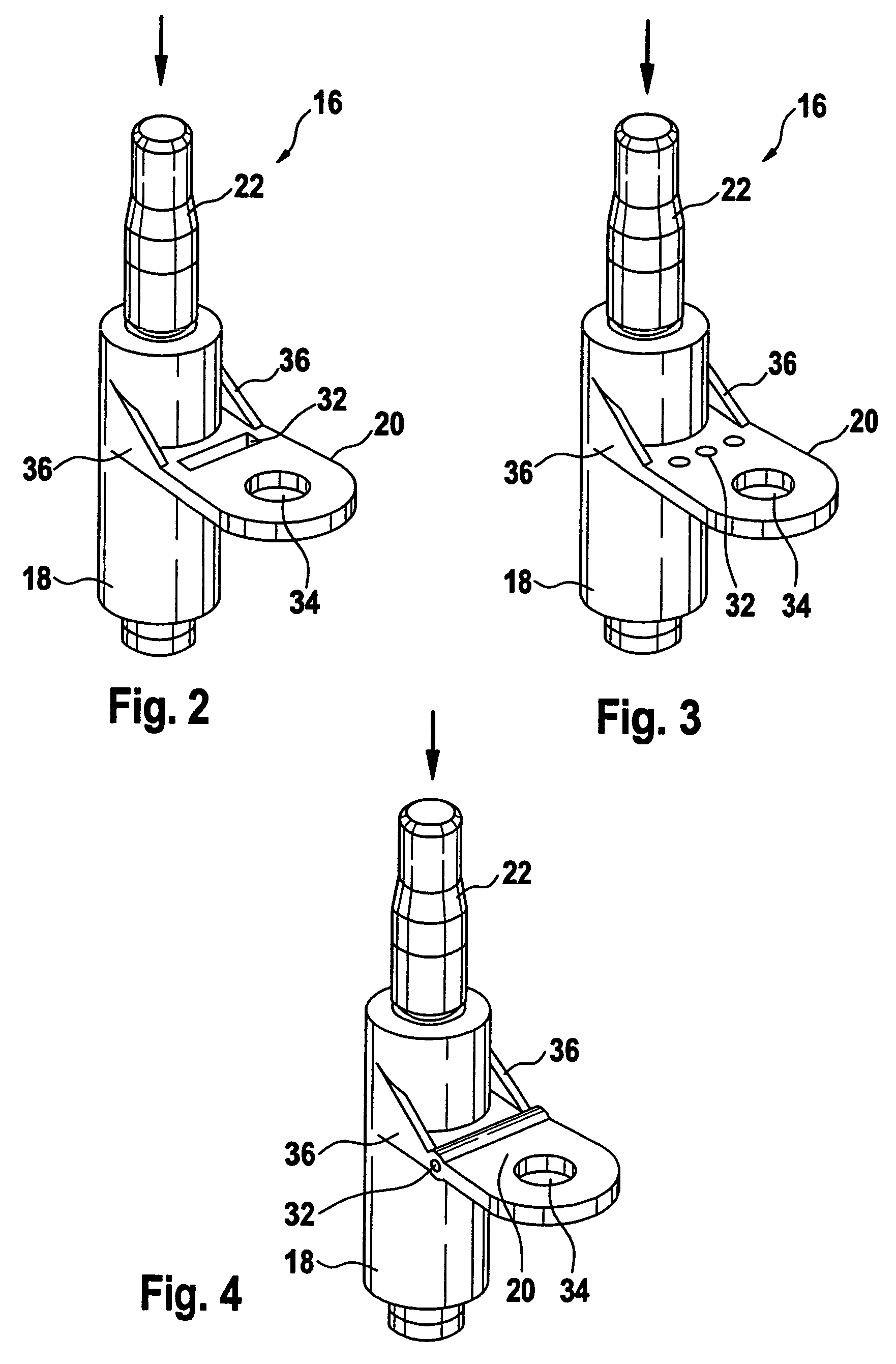

Winshield wiping device

InactiveUS7891043B2Cost-effectivePracticalFurniture joining partsEngineering emergency devicesBreaking pointWindshield

Disclosed is a windshield wiper device (10), comprising a wiper bearing (16) which is essentially composed of a molded tube (18) that can be fastened to a motor vehicle by means of a fastening element (20). A wiper shaft (22) to which a wiper lever can be fastened is positioned in the molded tube (18). A predetermined breaking point (32) is provided on the fastening element (20) in such a way that the wiper bearing (16) is able to dip into the interior of the motor vehicle in case a defined and essentially axial force acts on the wiper shaft (22). The predetermined breaking point (32) is embodied as a hole in this case.

Owner:ROBERT BOSCH GMBH

Steering wheel for a motor vehicle

InactiveUS7441800B2Increasing impairmentMaintenance-freeControlling membersMechanical apparatusMobile vehicleOptical reflection

A steering wheel for a motor vehicle is provided having a hub element, a steering wheel rim, at least one steering wheel spoke for attaching the steering wheel rim to the hub element and at least one activation device which is arranged on the hub element, the steering wheel rim or the steering wheel spoke for controlling and / or regulating an assembly of a motor vehicle. The activation device is preferably embodied as an optical reflection sensor device with a functional face. Such a sensor device operates without mechanically moving parts and during the service life of the steering wheel it is independent of general scratching and soiling of its functional faces. In addition, the functionality of the measurement of distances and / or speeds of the objects located above the functional faces of the sensor device permits further functions to be integrated without requiring further separate devices in order to do so.

Owner:TAKATA PETRI AG

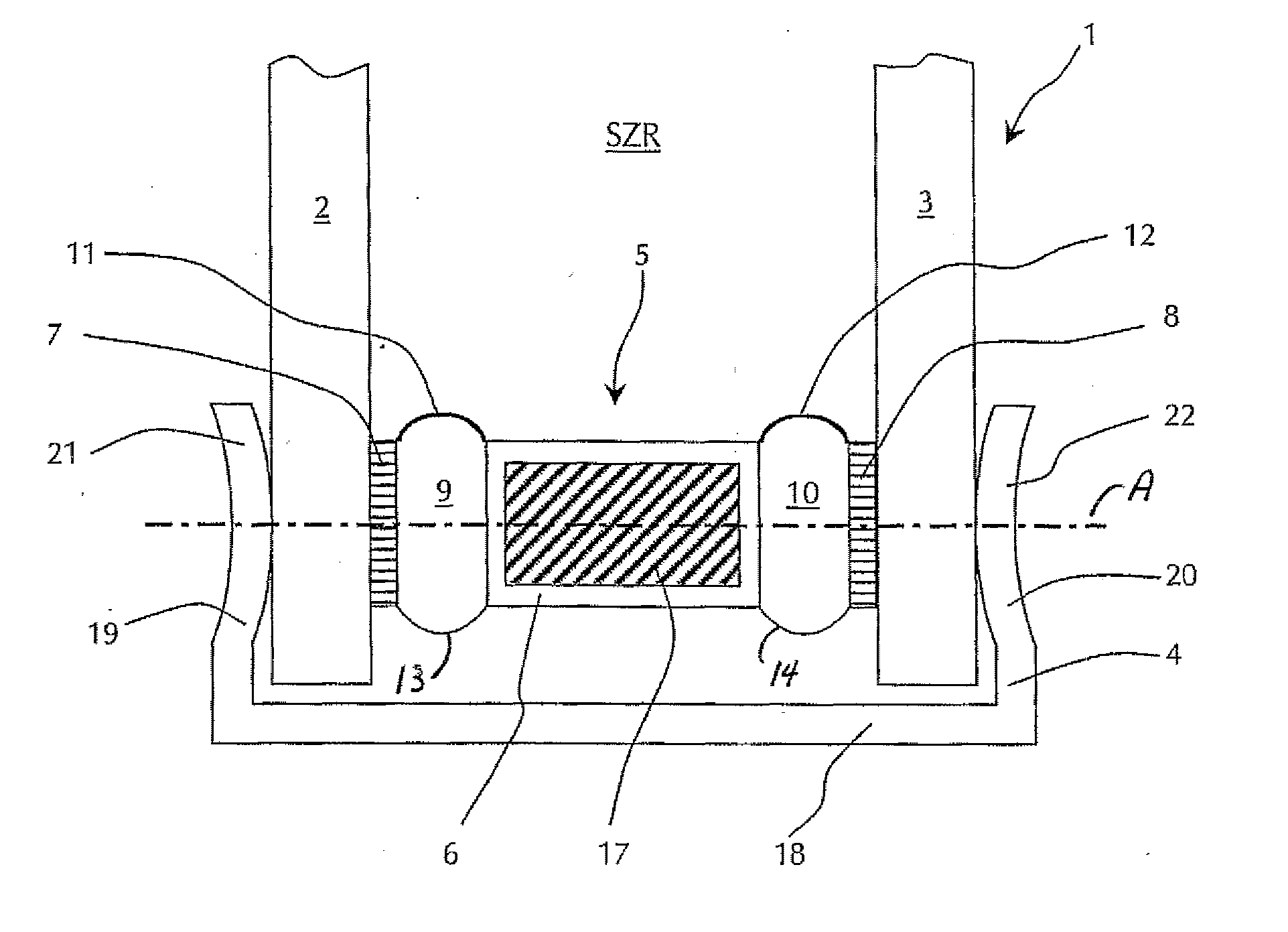

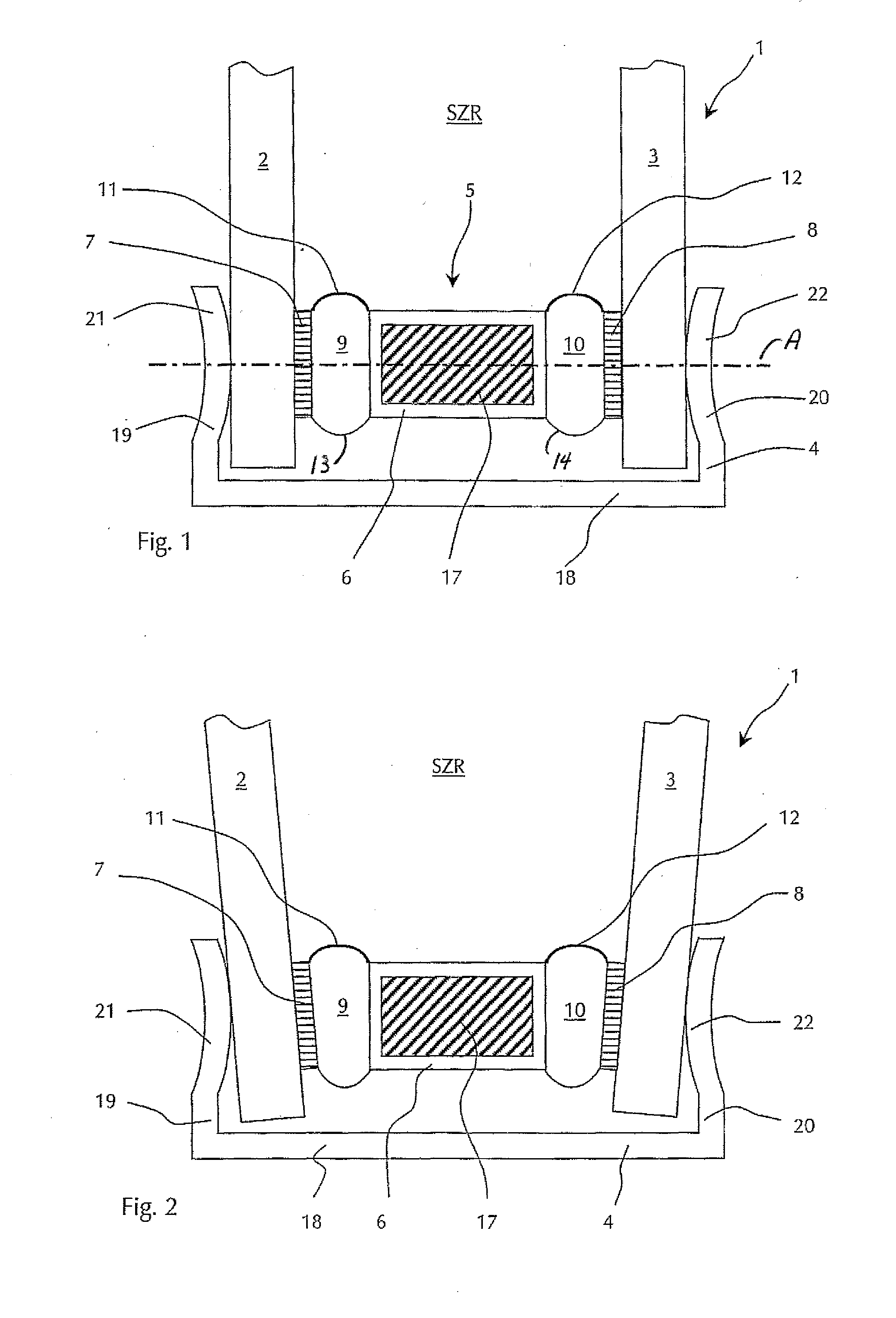

Insulating glass unit

InactiveUS20070087140A1Simple and cost-effective to manufactureMinimal adhesionDoors/windowsInsulated glazingAdhesive

An insulating glass unit having at least two glass panes, a fastener for fixing the position of the glass panes and a sealing element for setting a distance between two neighboring panes and for gas-tight, lateral insulation of the pane intermediate space enclosed by the panes, the sealing element containing at least one gas-tight middle part and two lateral gap seals, each of which is situated in the area between one of the glass panes and the middle part, at least one diffusion-tight cushion, which is essentially made of an elastic material, being situated in the area between the two gap seals of the sealing element. The inner surfaces of the cushion preferably have a metal layer vapor-deposited on them. In a preferred embodiment, the fastener is a metal clamp externally enclosing the panes which enables the insulating glass unit to be manufactured essentially without adhesive.

Owner:USD FORMTEILTECHN

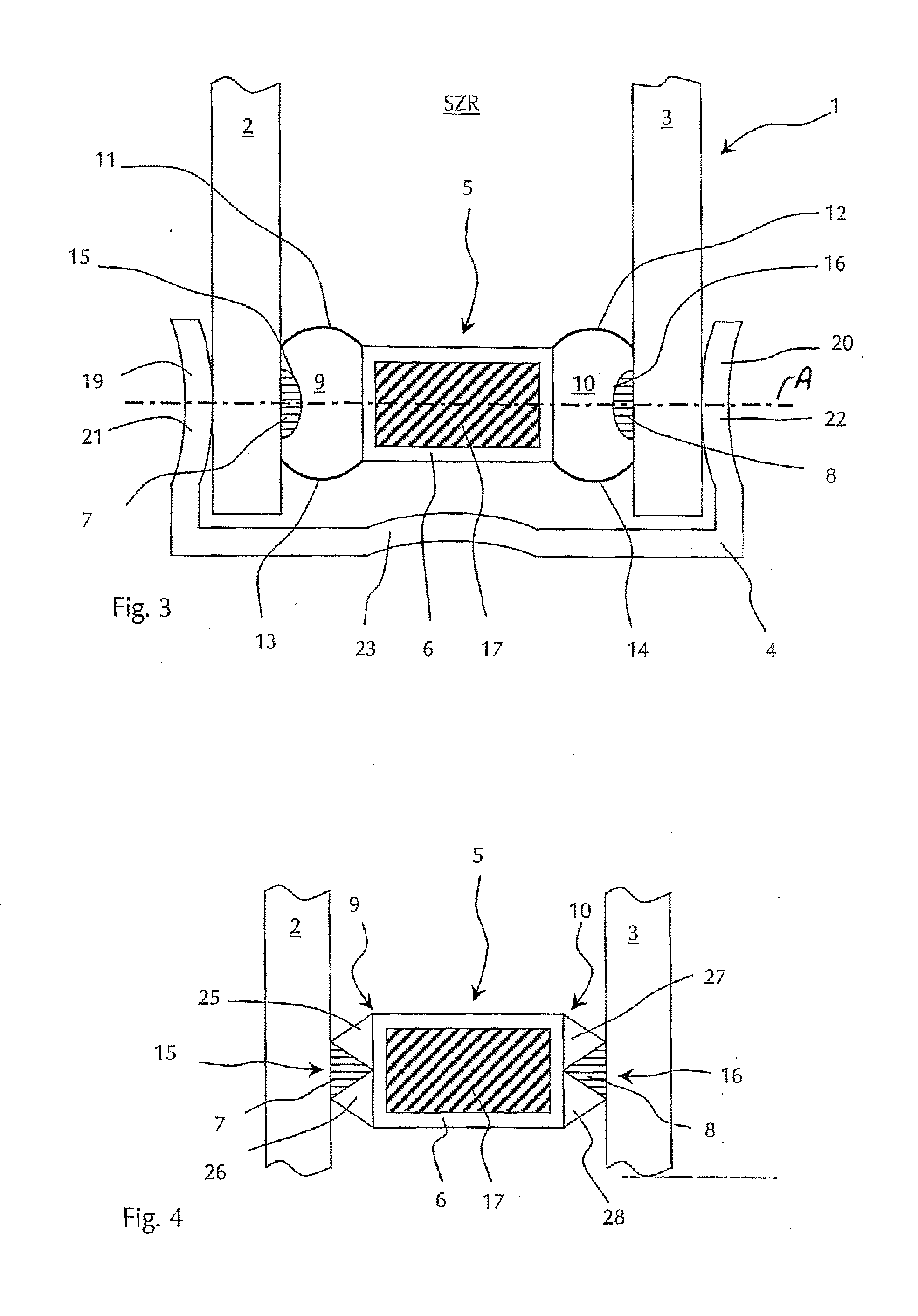

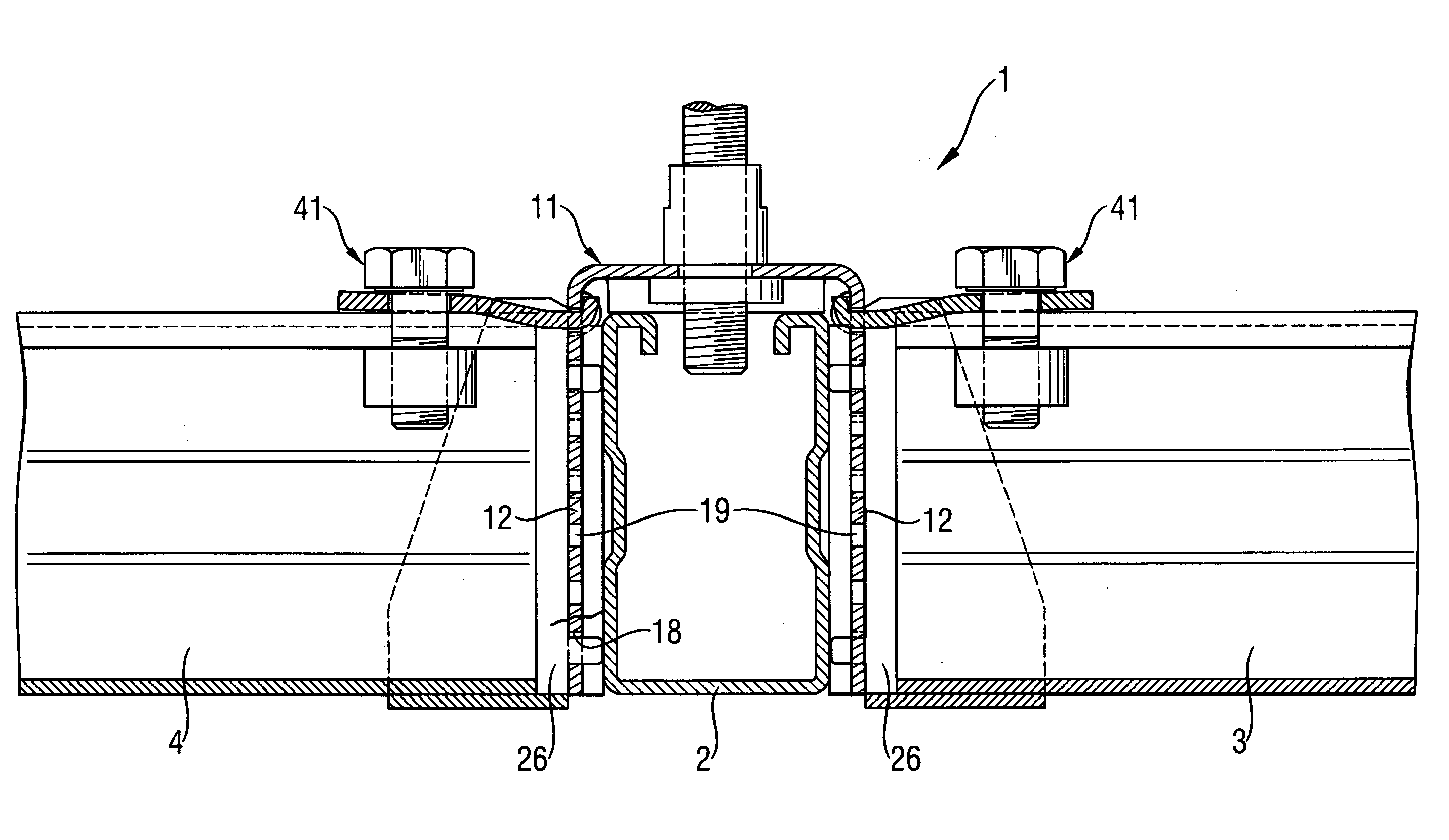

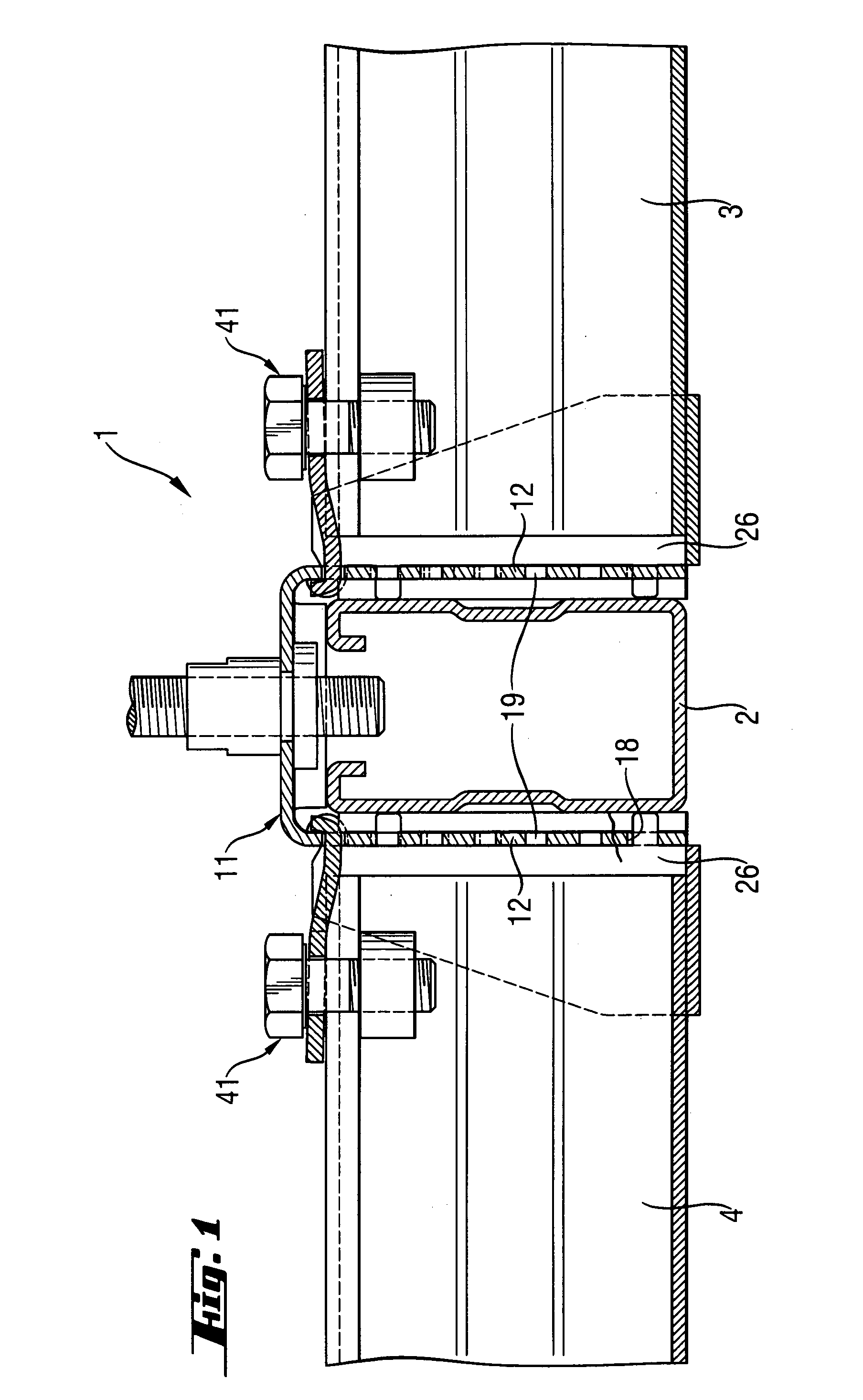

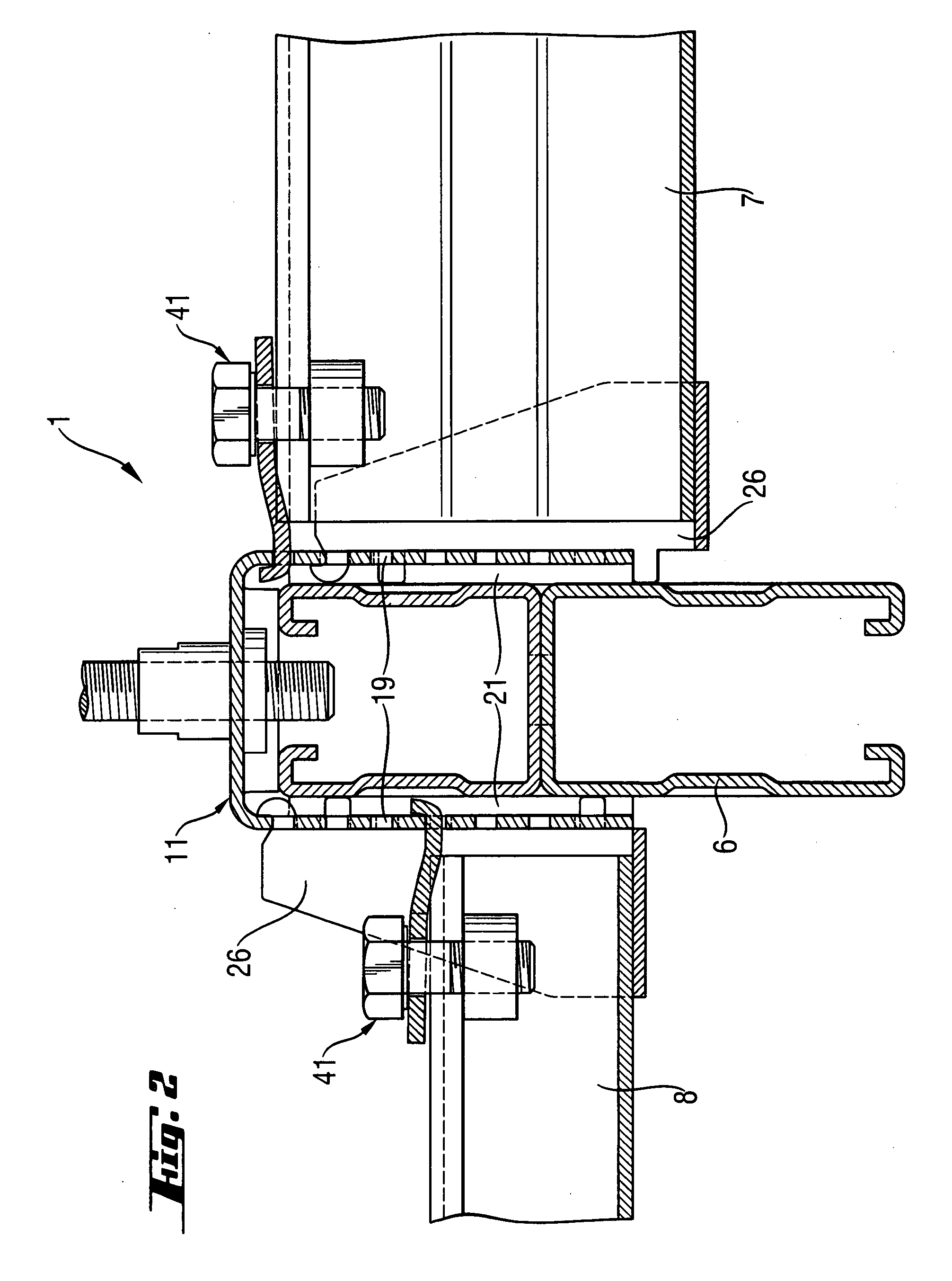

Connection device for connecting mounting rails

InactiveUS20050226683A1Increase flexibilitySimple and cost-effective to manufactureCeilingsRod connectionsMechanical engineering

Owner:HILTI AG

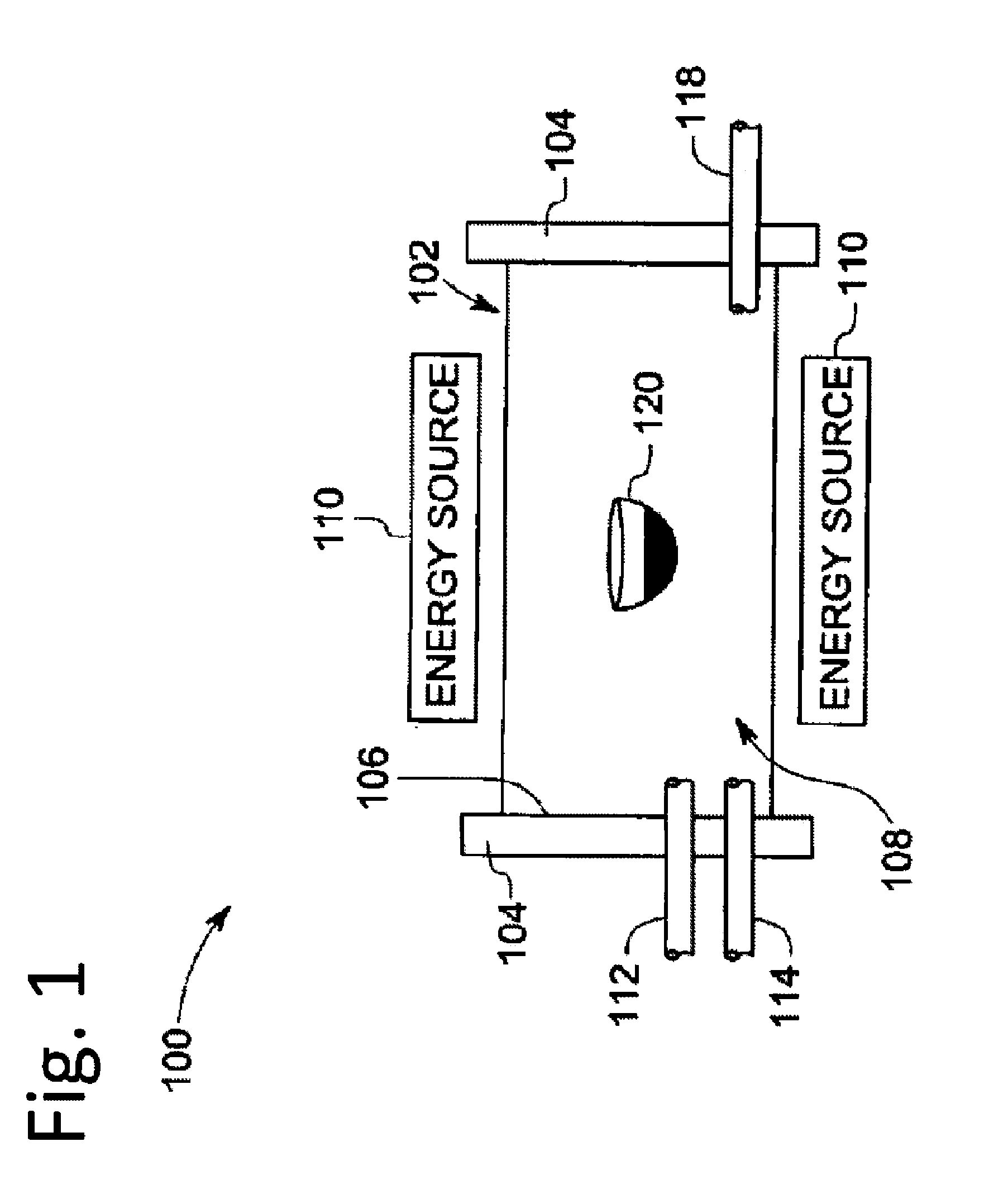

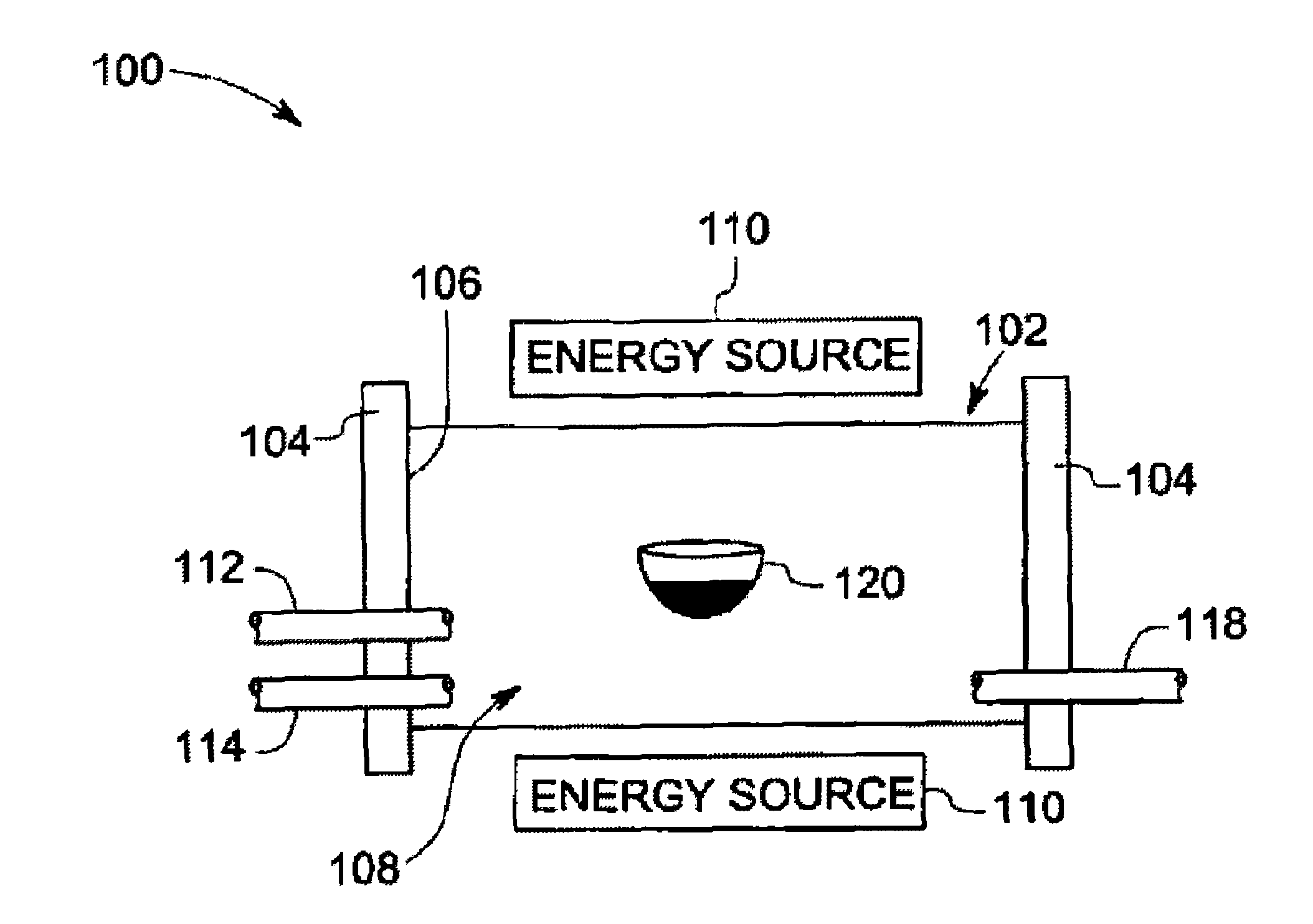

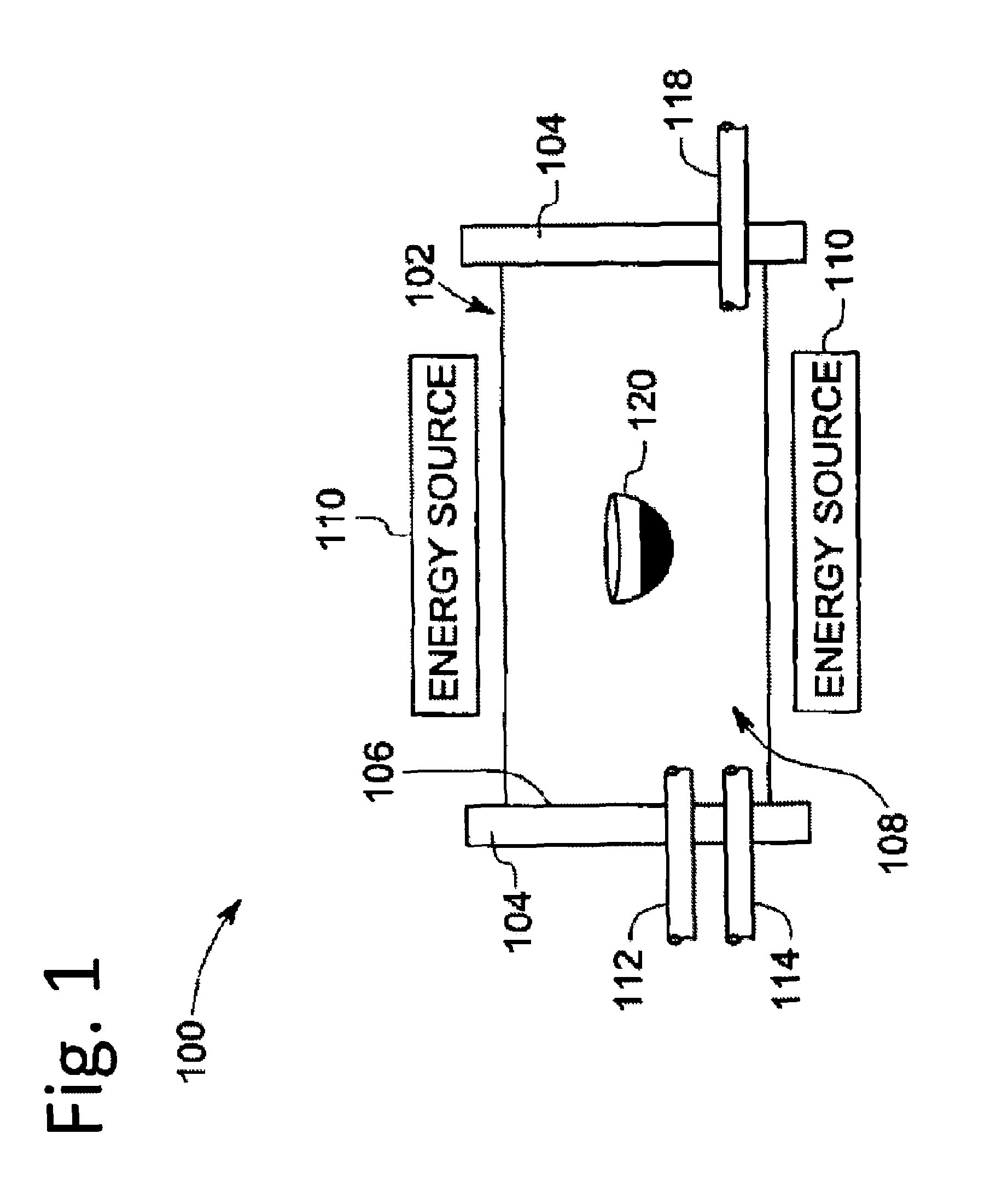

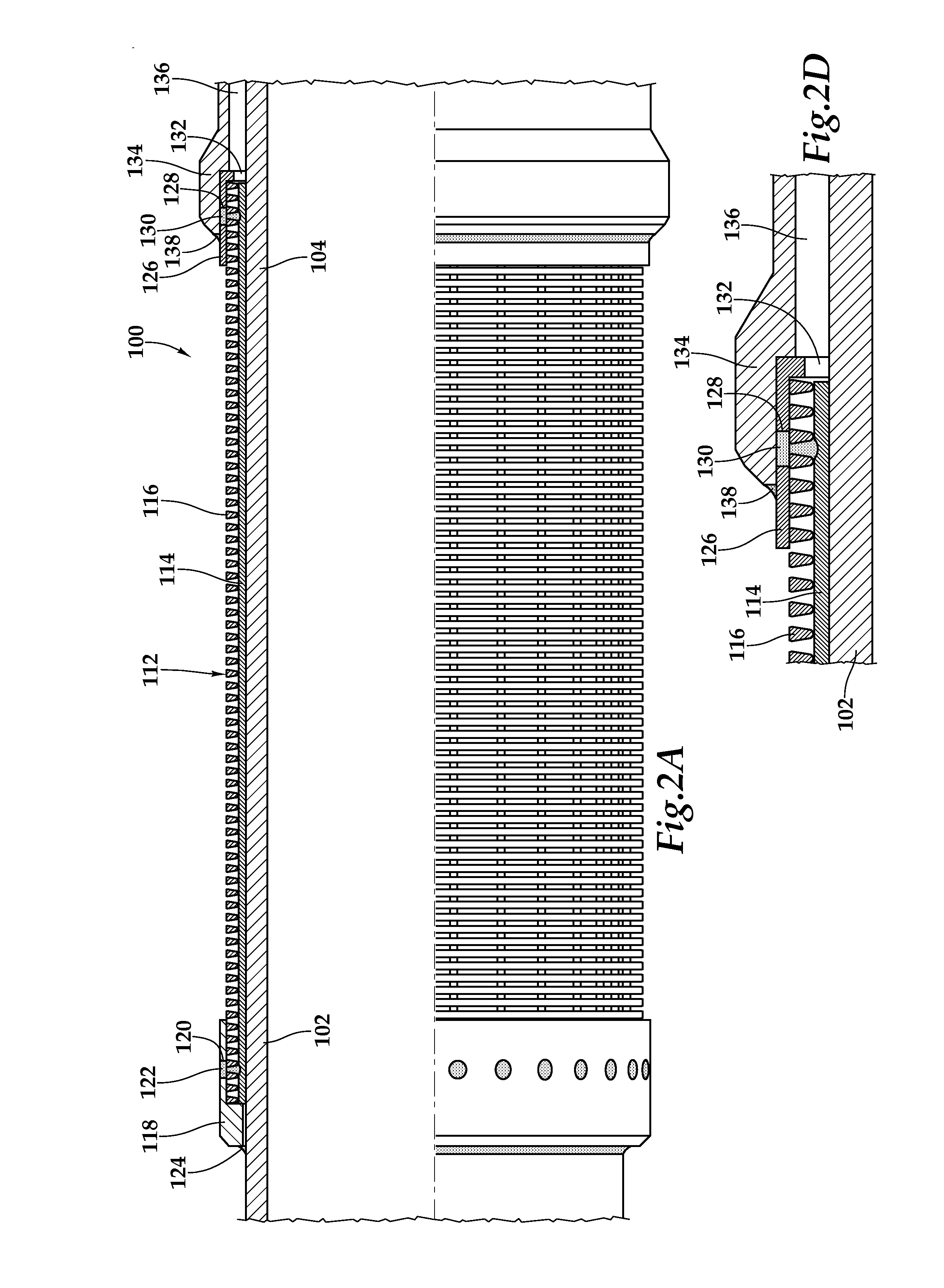

Control Screen Assembly Having Integral Connector Rings and Method for Making Same

InactiveUS20120048536A1Prevent inflowSimple and cost-effective to manufactureFluid removalMetal working apparatusMechanical engineeringEngineering

A screen jacket assembly for positioning around a base pipe (102) to form a sand control screen (100). The screen jacket assembly includes a screen jacket (112) formed from a plurality of circumferentially distributed axially extending ribs (114) and a screen wire (116) wrapped therearound. A pair of oppositely disposed connector rings (118, 126) is at least partially positionable around the first and second ends, respectively, of the screen jacket (112). The connector rings (118, 126) each have a plurality of openings (120, 128) in a sidewall portion thereof that are circumferentially alignable with at least a portion of the ribs (114) such that the connector rings (118, 126) are integrally connectable with the aligned ribs (114) via the openings (120, 128).

Owner:HALLIBURTON ENERGY SERVICES INC

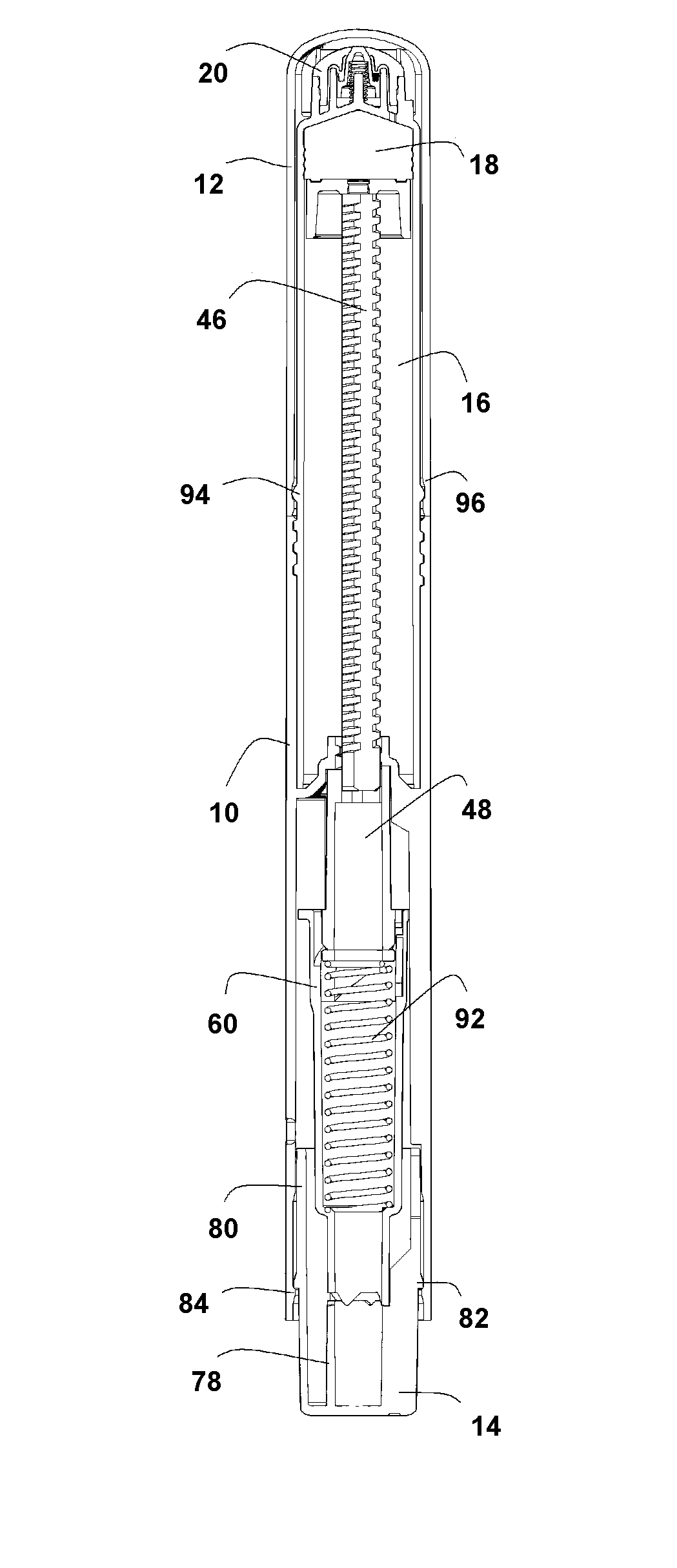

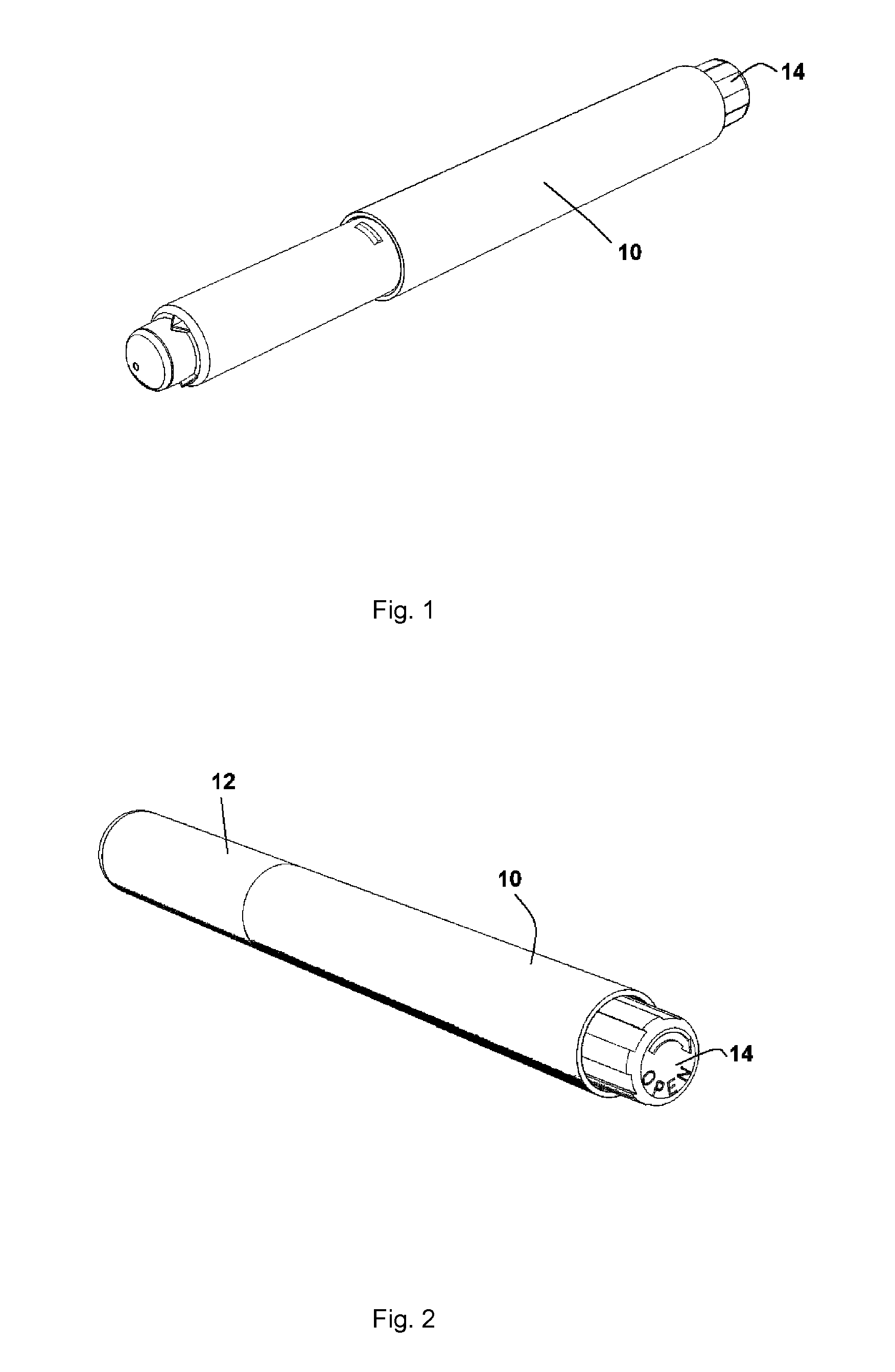

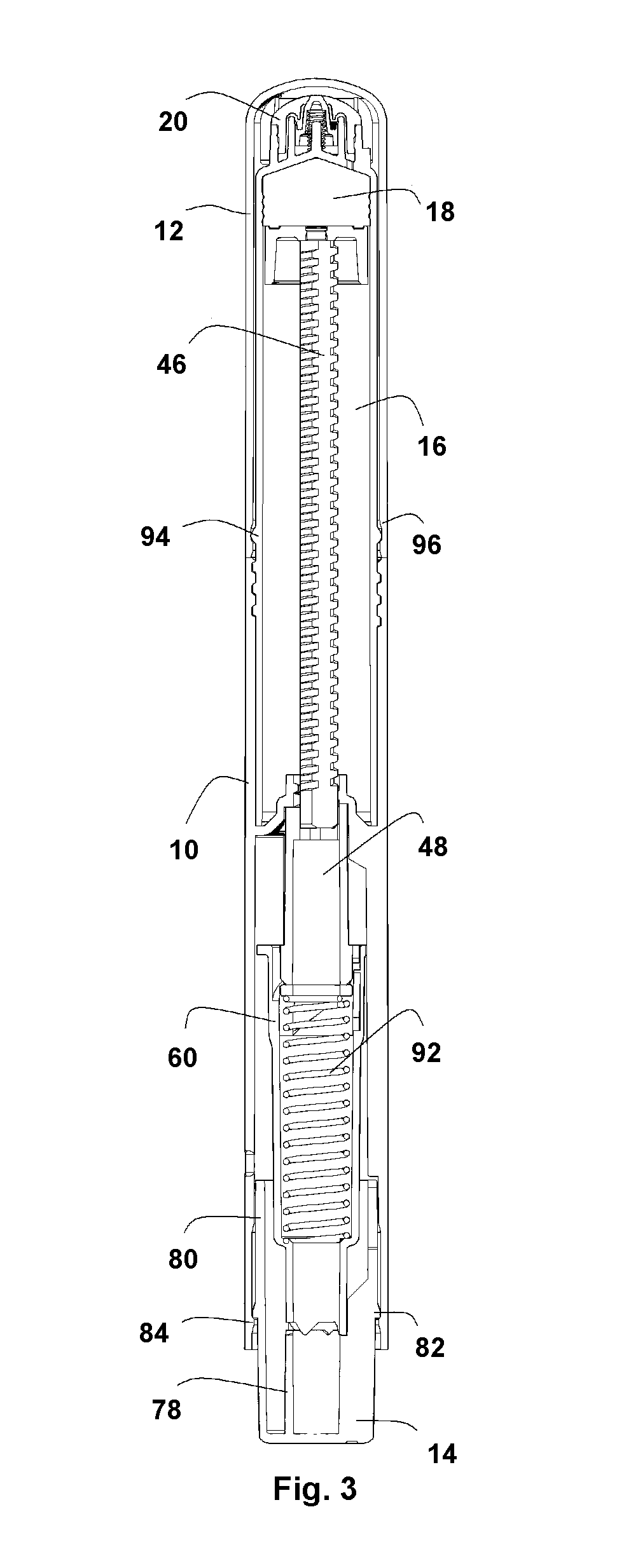

Delivery Device

ActiveUS20100305512A1Easy to operateImprove the forceInfusion syringesIntravenous devicesLinear motionEngineering

The present invention relates to a delivery device for delivering predetermined amounts of fluid, comprising a body (10), a container (16) filled with fluid to be delivered arranged inside said body, said container comprising an opening for expelling said fluid and a wall (18) movable inside said container (16), a threaded plunger rod (46) arranged movable inside said body (10) in the longitudinal direction and in contact with said movable wall (18), a manually operated push means (14, 60) movable in the longitudinal direction capable of, upon operation, move said plunger rod (46) towards said movable wall (18), thereby expelling fluid, and means for transforming a generally linear movement of said push means (14, 60) to a rotational movement of said plunger rod (46).

Owner:SHL MEDICAL AG

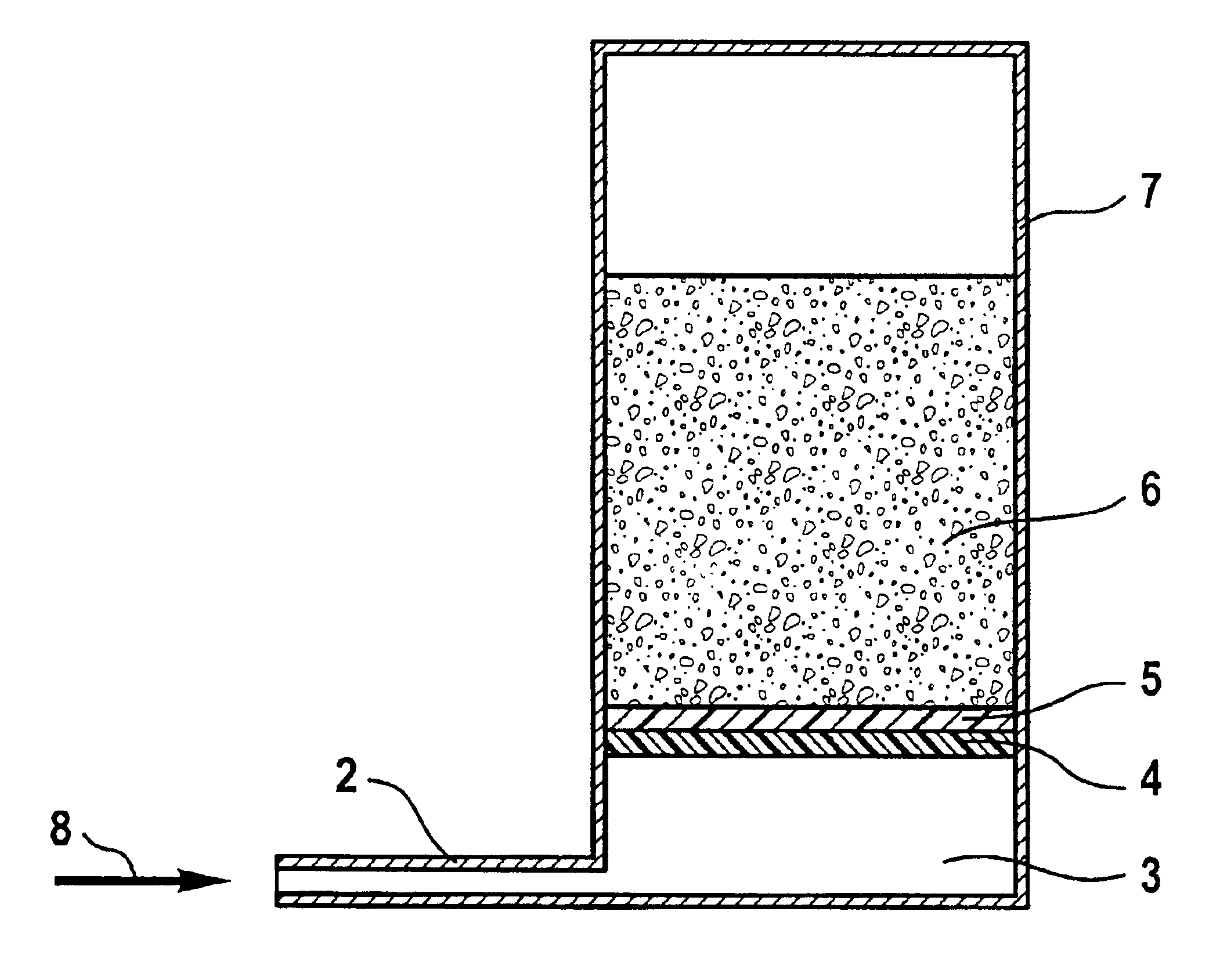

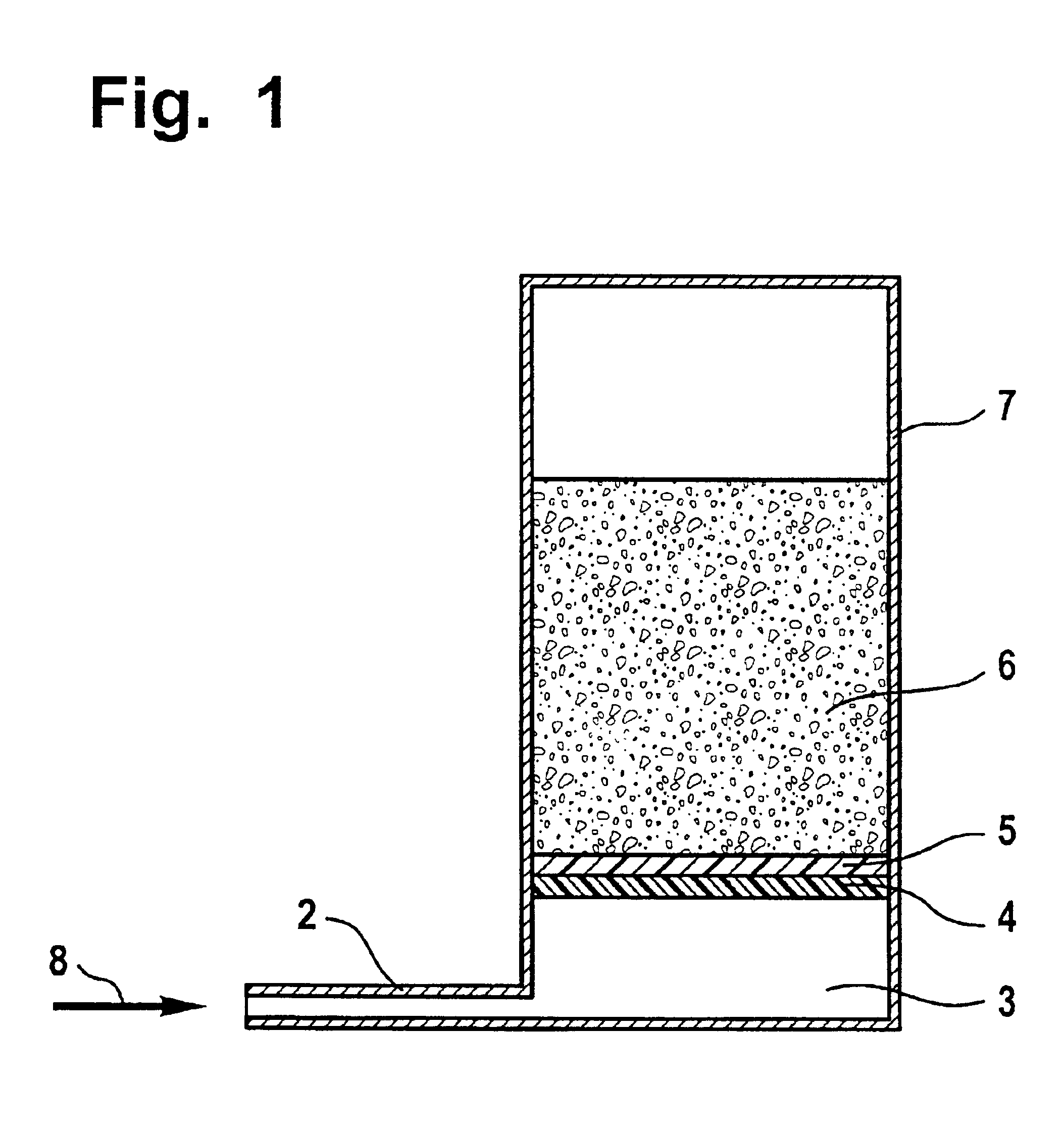

Pump for low flow rates

InactiveUS6860993B2Simple and cost-effective to manufactureEasy to manufactureFlexible member pumpsUltrafiltrationUltrafiltrationEvaporation

The present invention concerns a pump for flow rates from about 1 to 1000 nl / min in which liquid transport takes place by evaporation of a transport liquid through a wettable membrane. The pumps according to the invention are particularly suitable for applications in the field of medical diagnostics such as microdialysis or ultrafiltration.

Owner:ROCHE DIABETES CARE INC

Electronic control device

InactiveUS8929078B2Simple and cost-effective to and to installSimple and cost-effective to manufactureMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

The invention relates to an electronic control device (10) having electronic components (160, 162) on a circuit board (110) which are shielded from electrical and / or magnetic interference fields. According to the invention, an electrically conductive sheet metal part (170) is arranged on the circuit board (110) which forms a Faraday cage for the electronic components (160, 162) with the circuit board. The electrically conductive sheet metal part (170) is furthermore in thermal contact to the electronic components (160, 162) and in thermal contact to the housing (100) of the control device (10) and thereby deflects heat from the electronic components (160, 162) into the housing (100).

Owner:ROBERT BOSCH GMBH

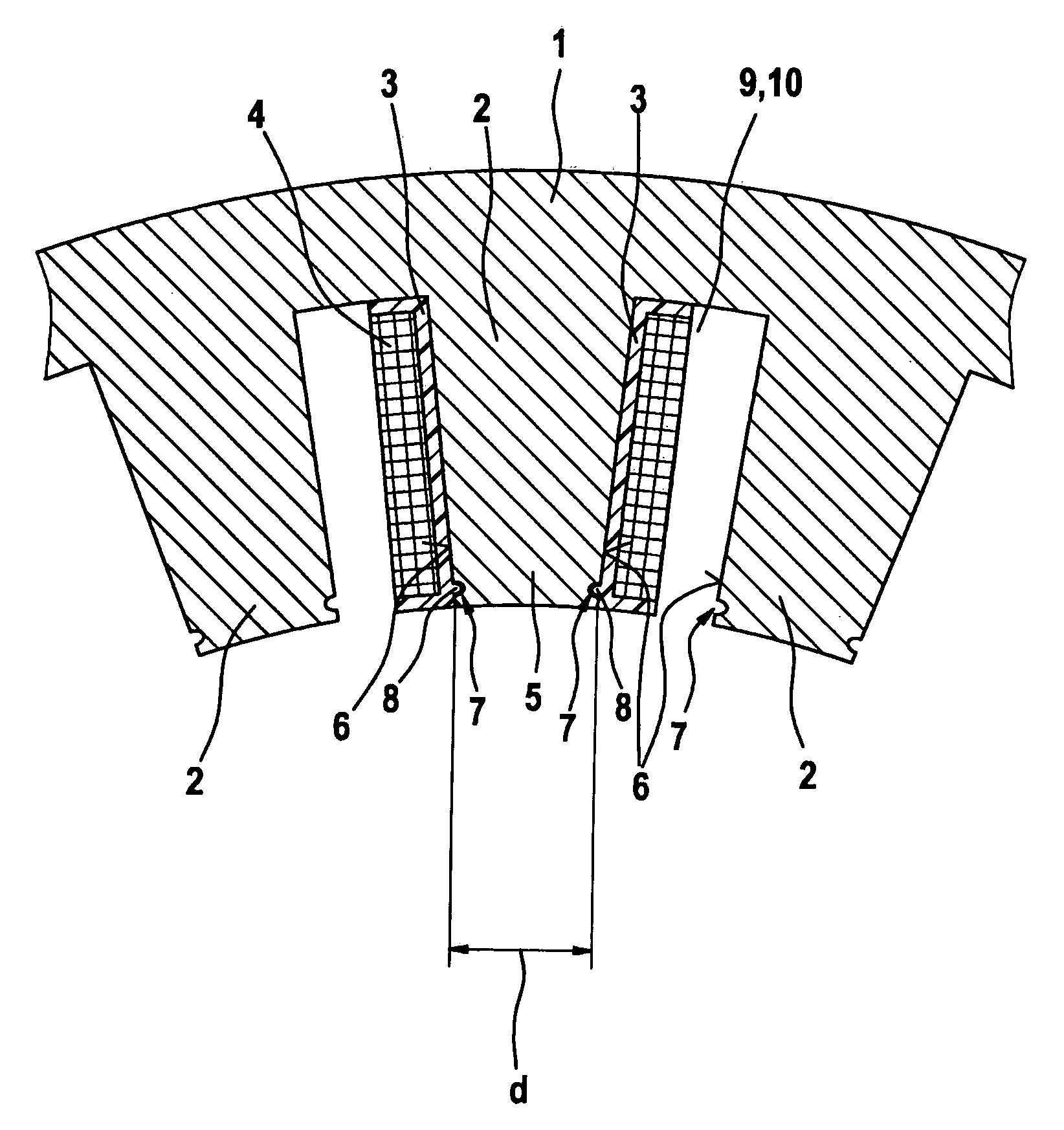

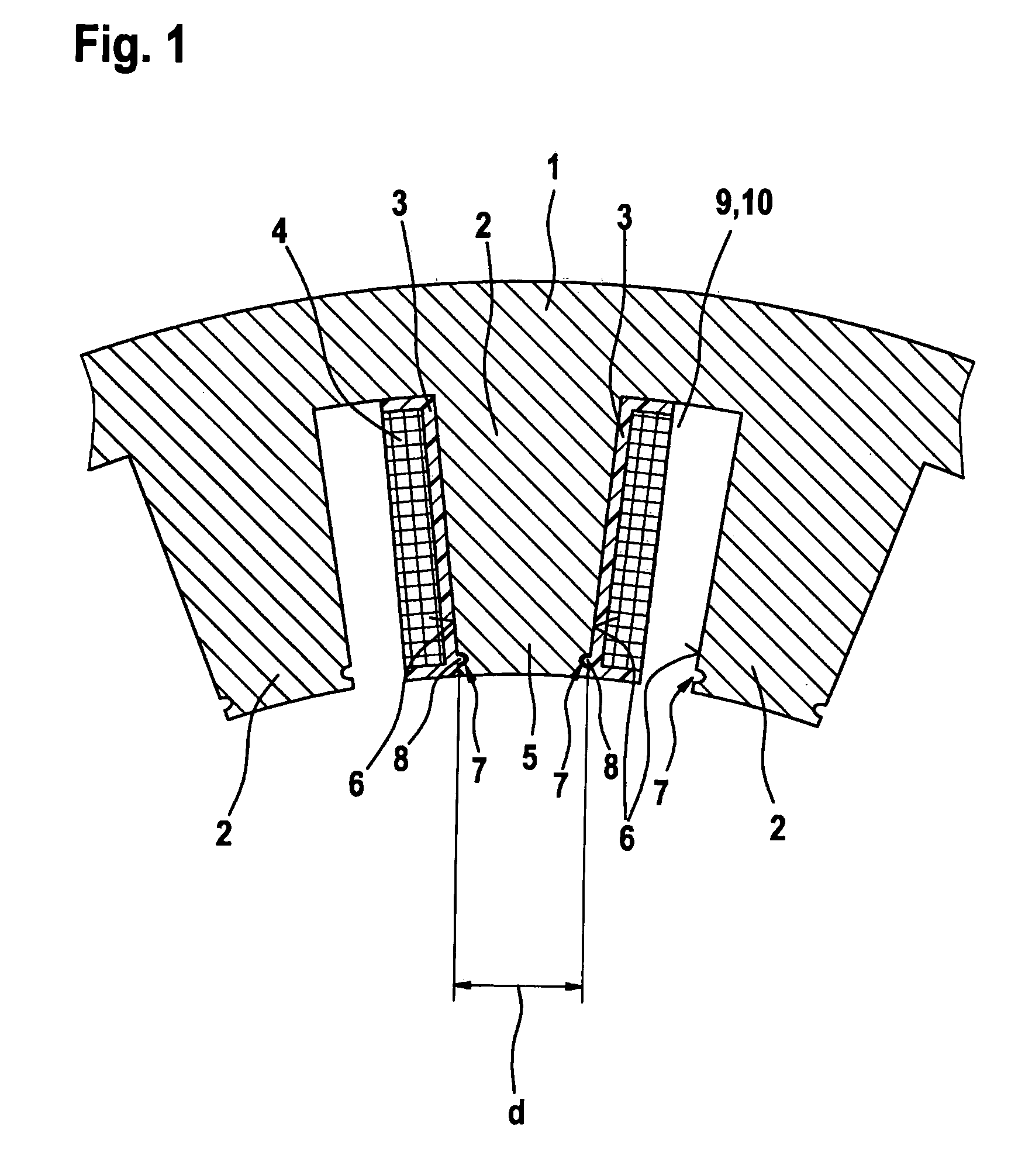

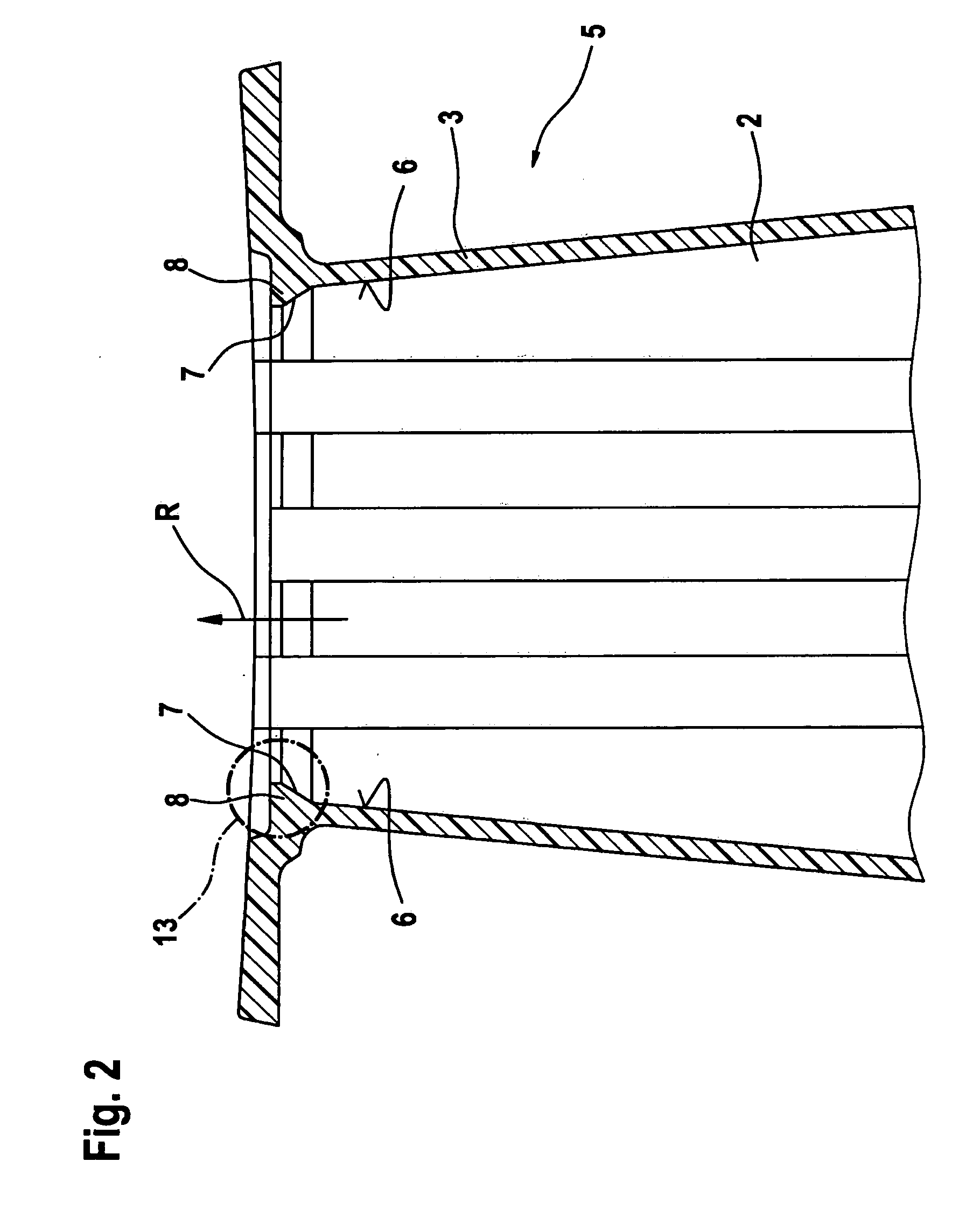

Stator of an electric machine

InactiveUS20110210640A1Simple and cost-effective manufactureOperating reliability can be highWindings insulation materialSynchronous generatorsElectric machineElectrical and Electronics engineering

The invention relates to a stator of an electrical machine, with at least one stator tooth and a coil wound outside of the stator, which coil has been pushed onto the stator tooth substantially radially. It is provided that the coil (4) is held radially on the stator tooth (2) by means of at least one form-fitting connection (13). Furthermore, the invention relates to an electrical machine with such a stator (1).

Owner:ROBERT BOSCH GMBH

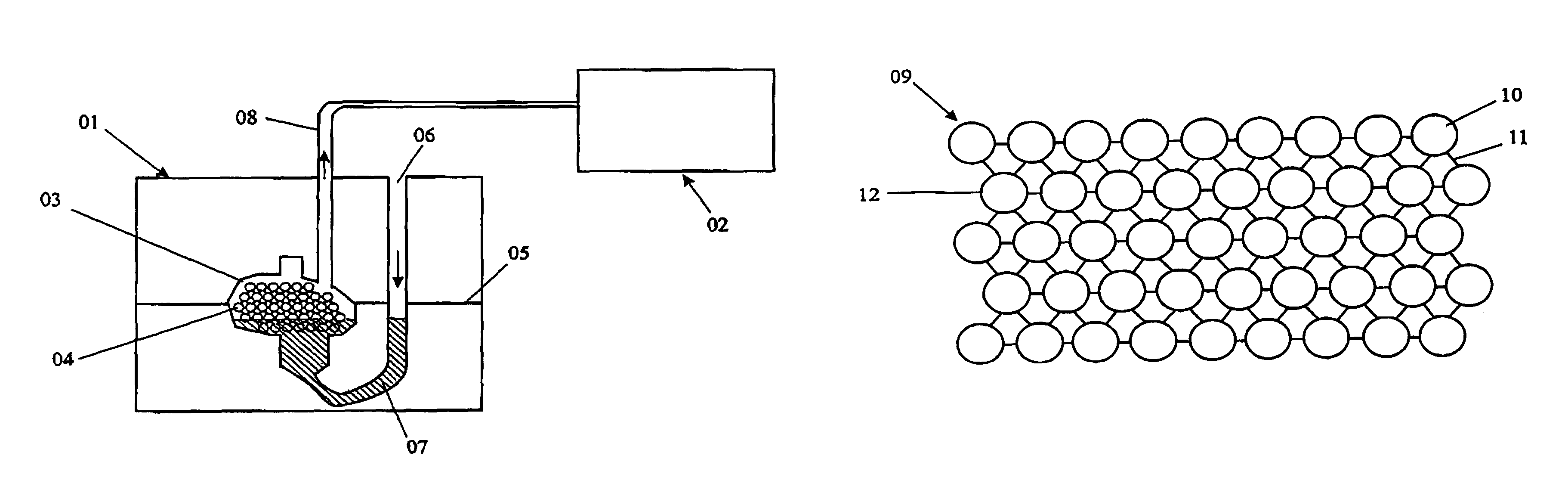

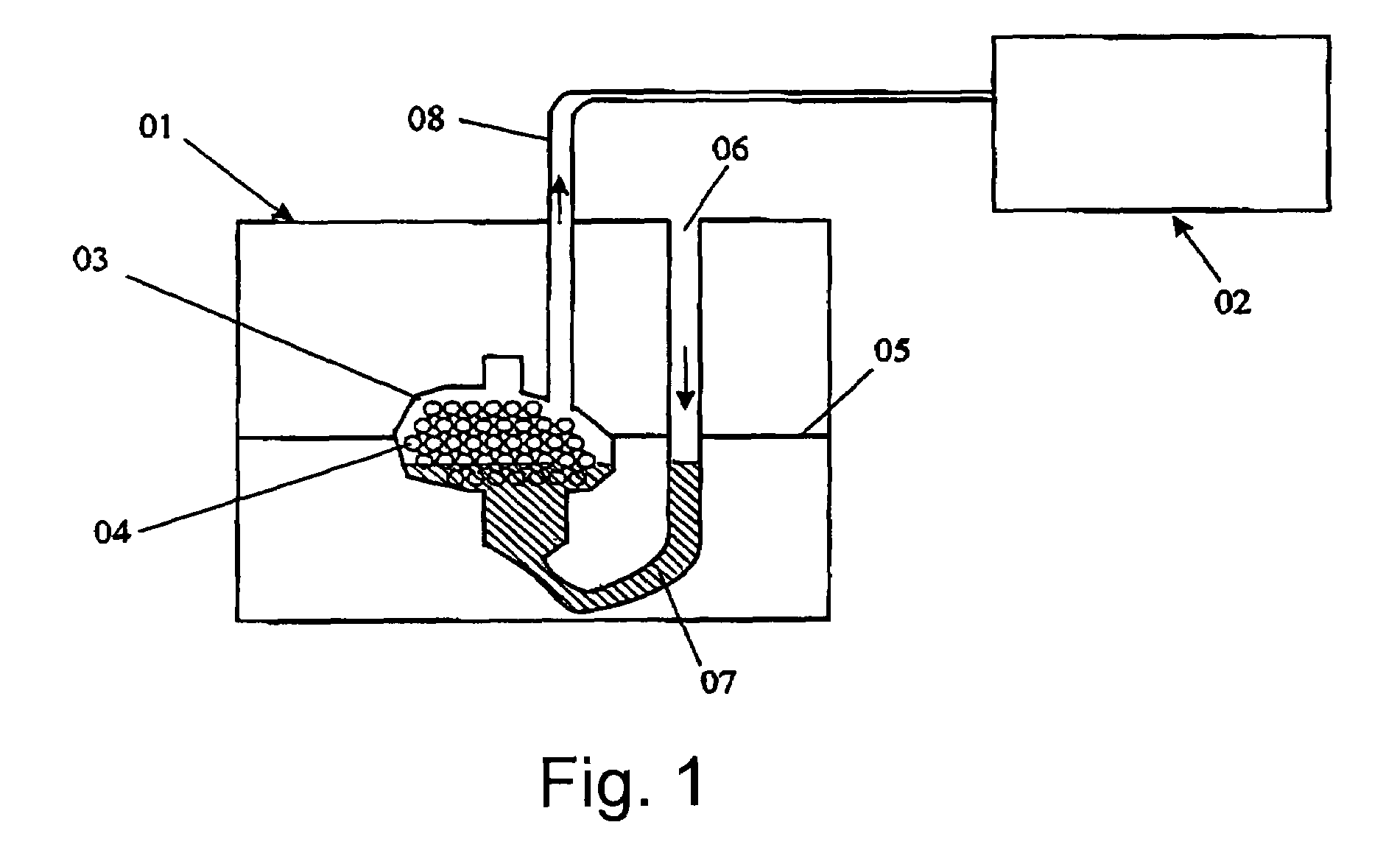

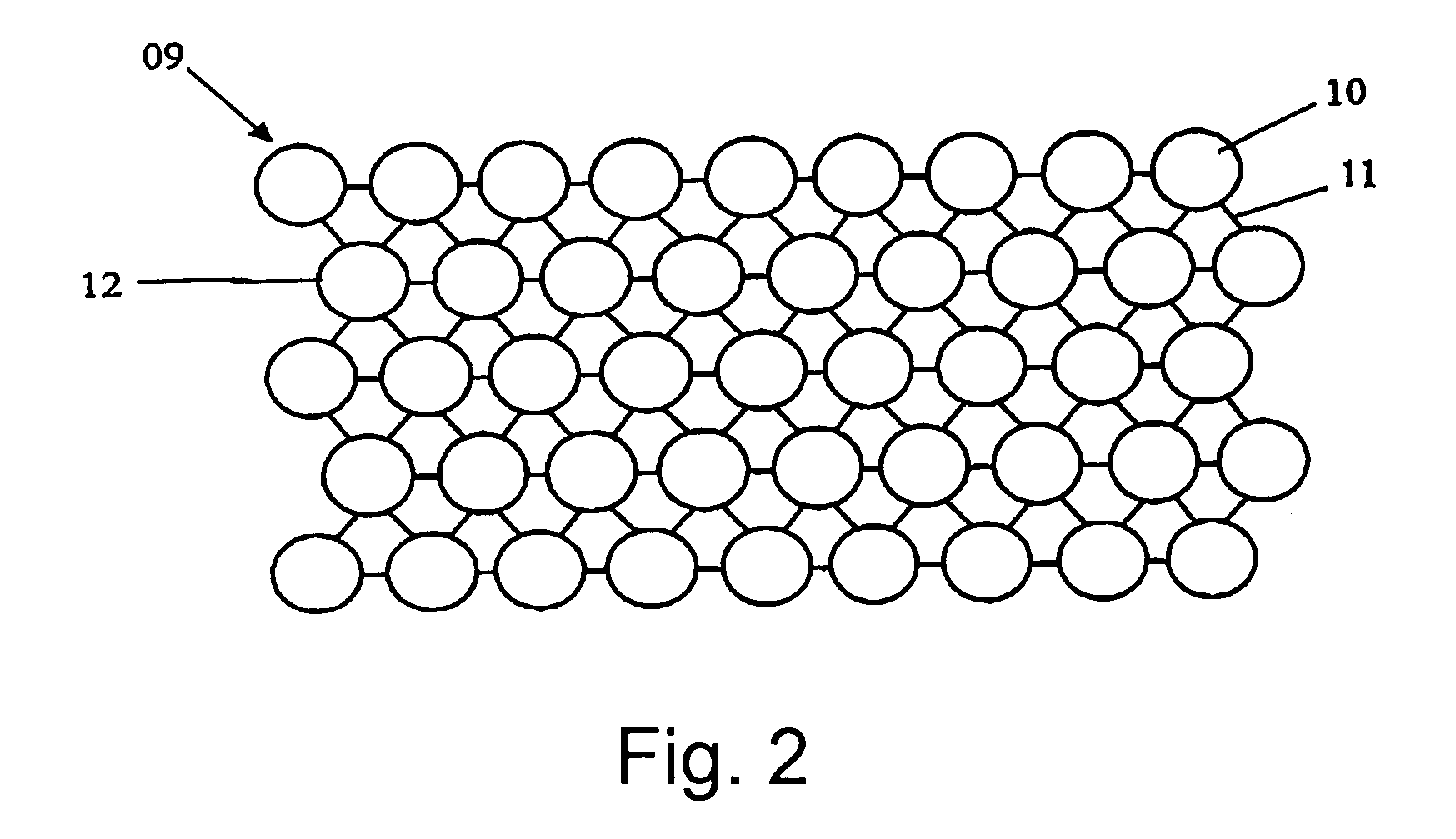

Method for manufacturing open porous components of metal, plastic or ceramic with orderly foam lattice structure

InactiveUS7588069B2Favorable and rational and quick manufactureEasy and cost-effective to manufactureFoundry mouldsFoundry coresMetal alloyLattice plane

The invention relates to a method for the manufacture of light open porous components of metal, metal alloys, plastic or ceramic of any geometry. Here, the component is produced through casting liquid material into a casting device (01), wherein a core stack (04) is mounted, cast and removed in a casting mold (03). The core stack (04) here is designed as a regular multi-dimensional core lattice (09) with defined core lattice planes (12), where each core lattice plane (12) is constructed of individual regular core bodies (10).

Owner:KURTZ +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com