Patents

Literature

654results about How to "Maintenance free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

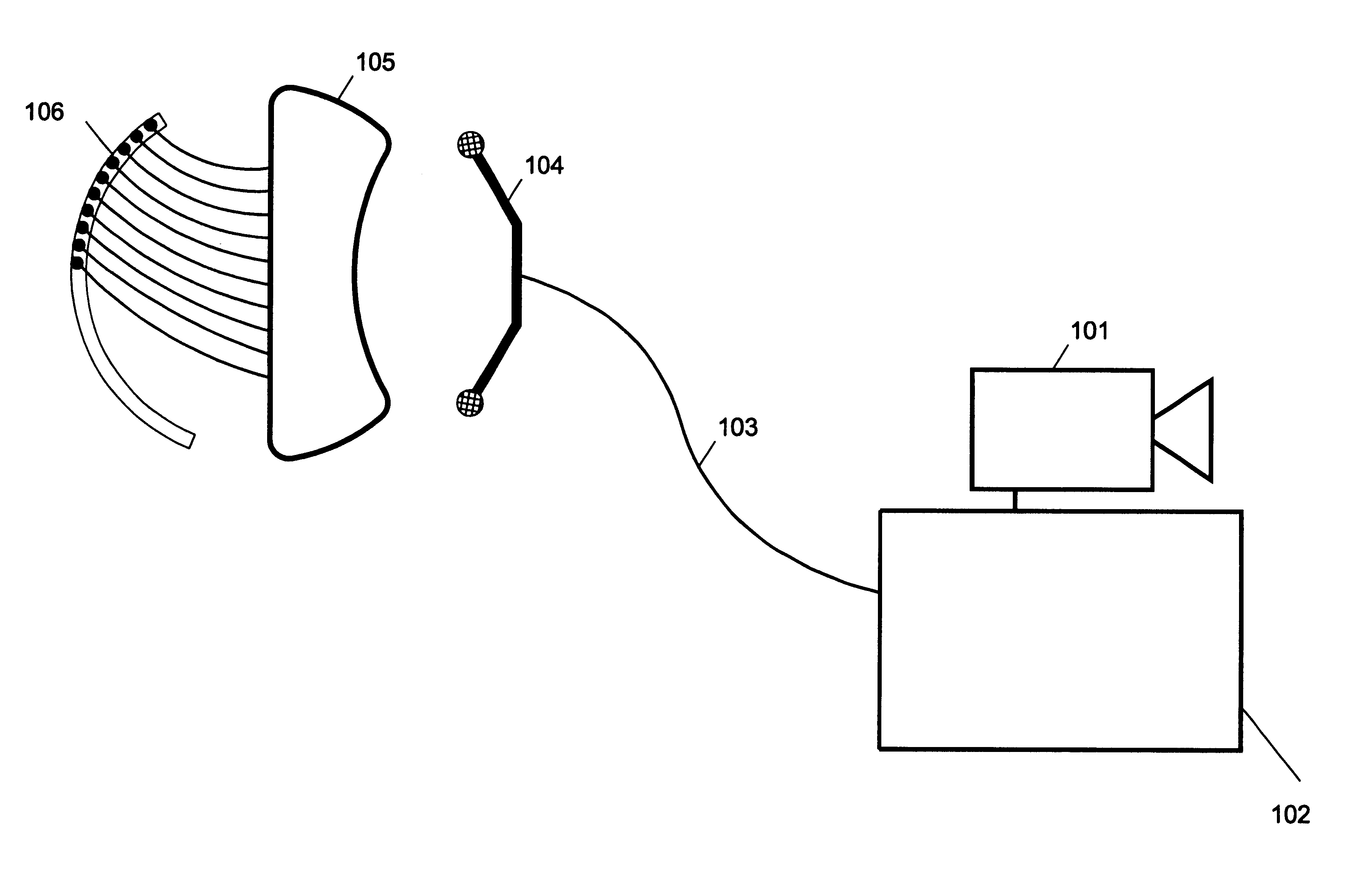

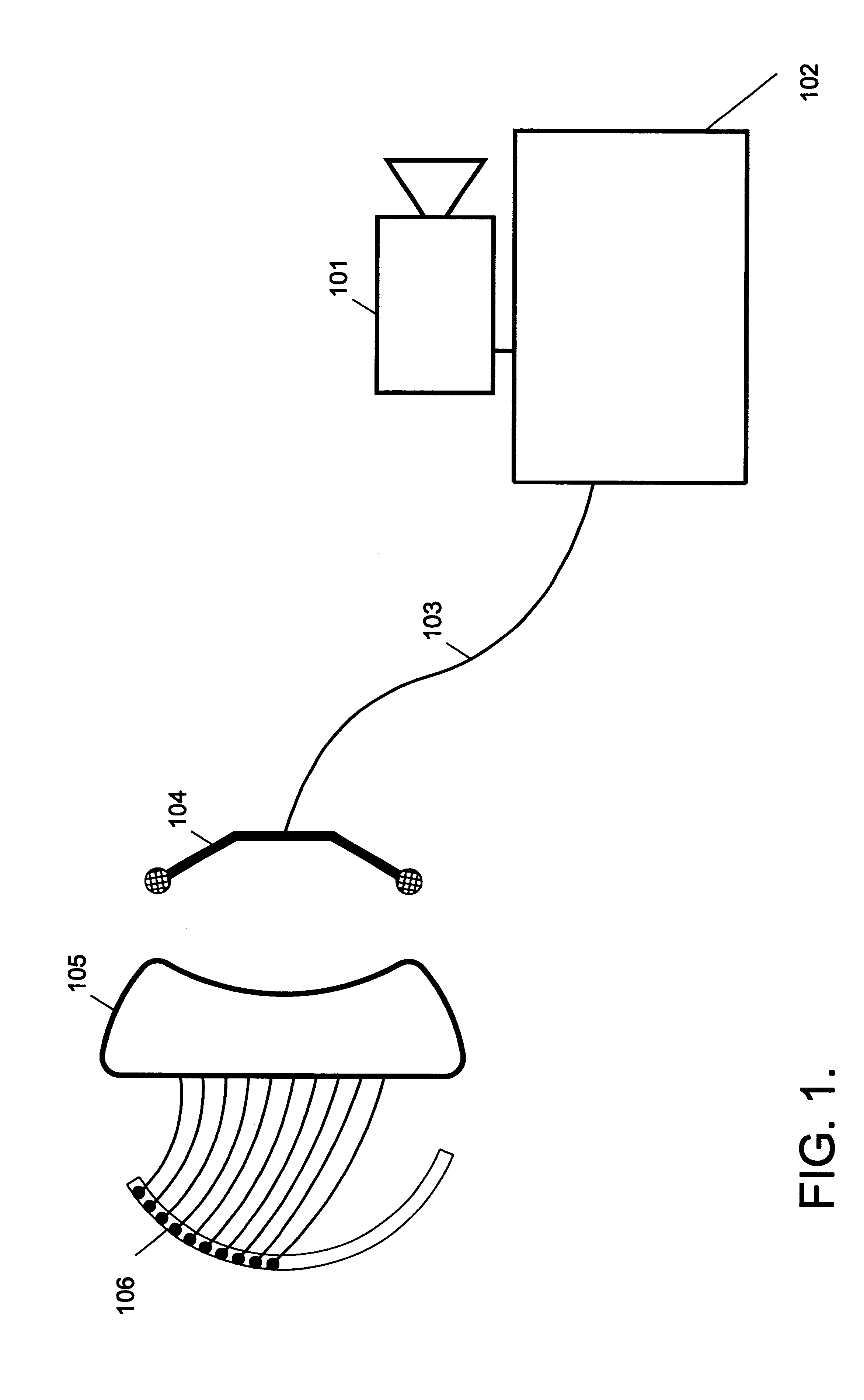

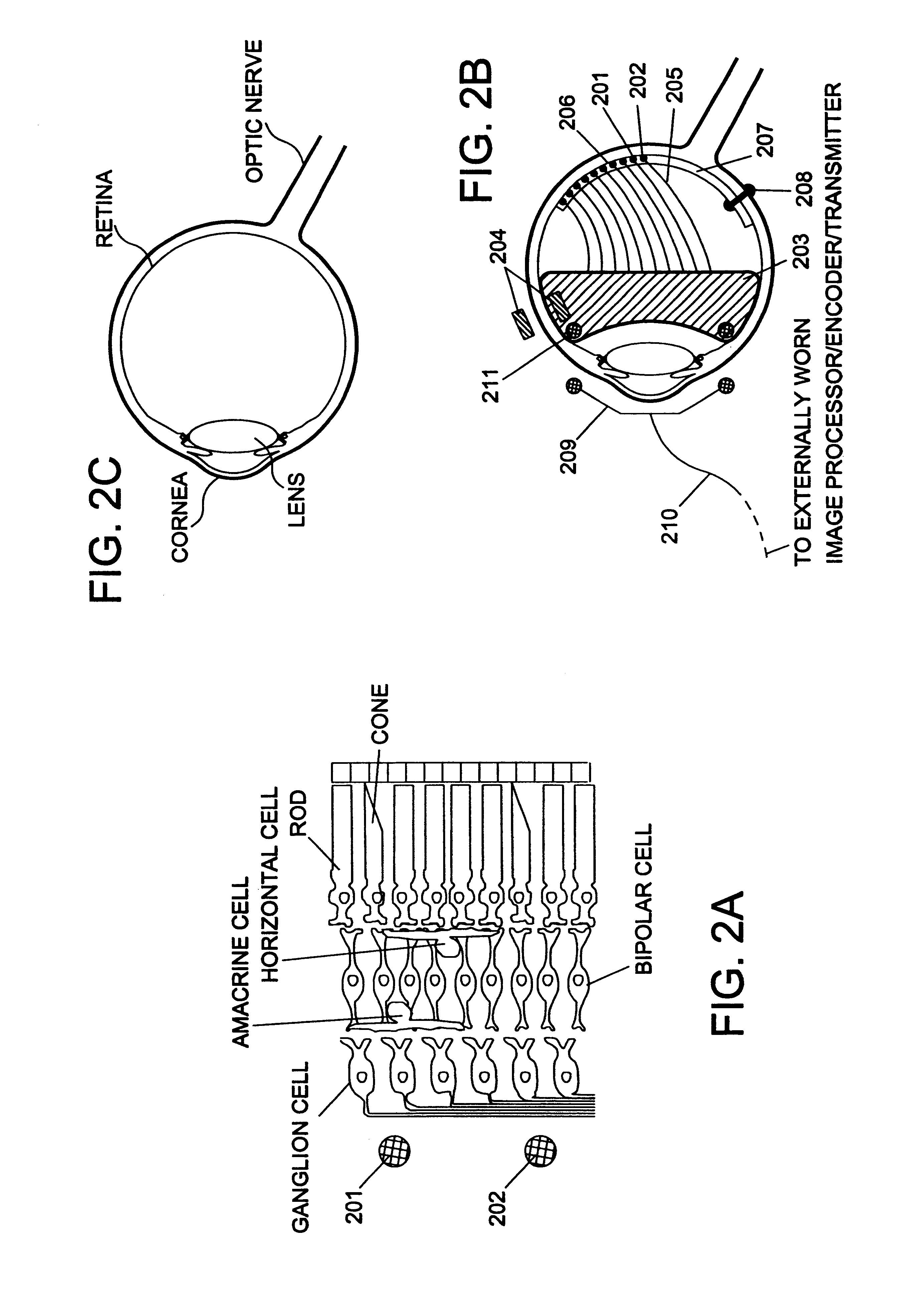

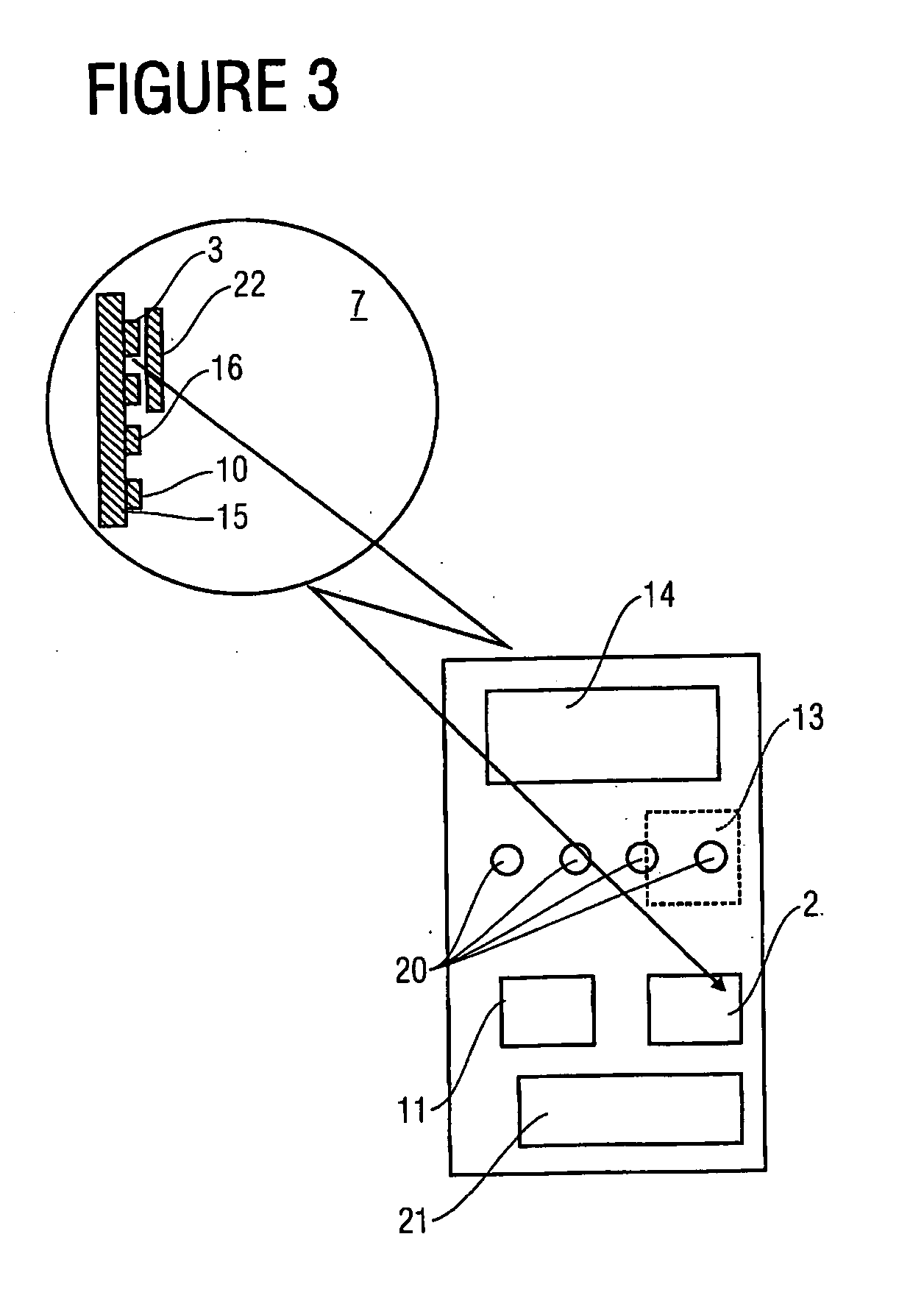

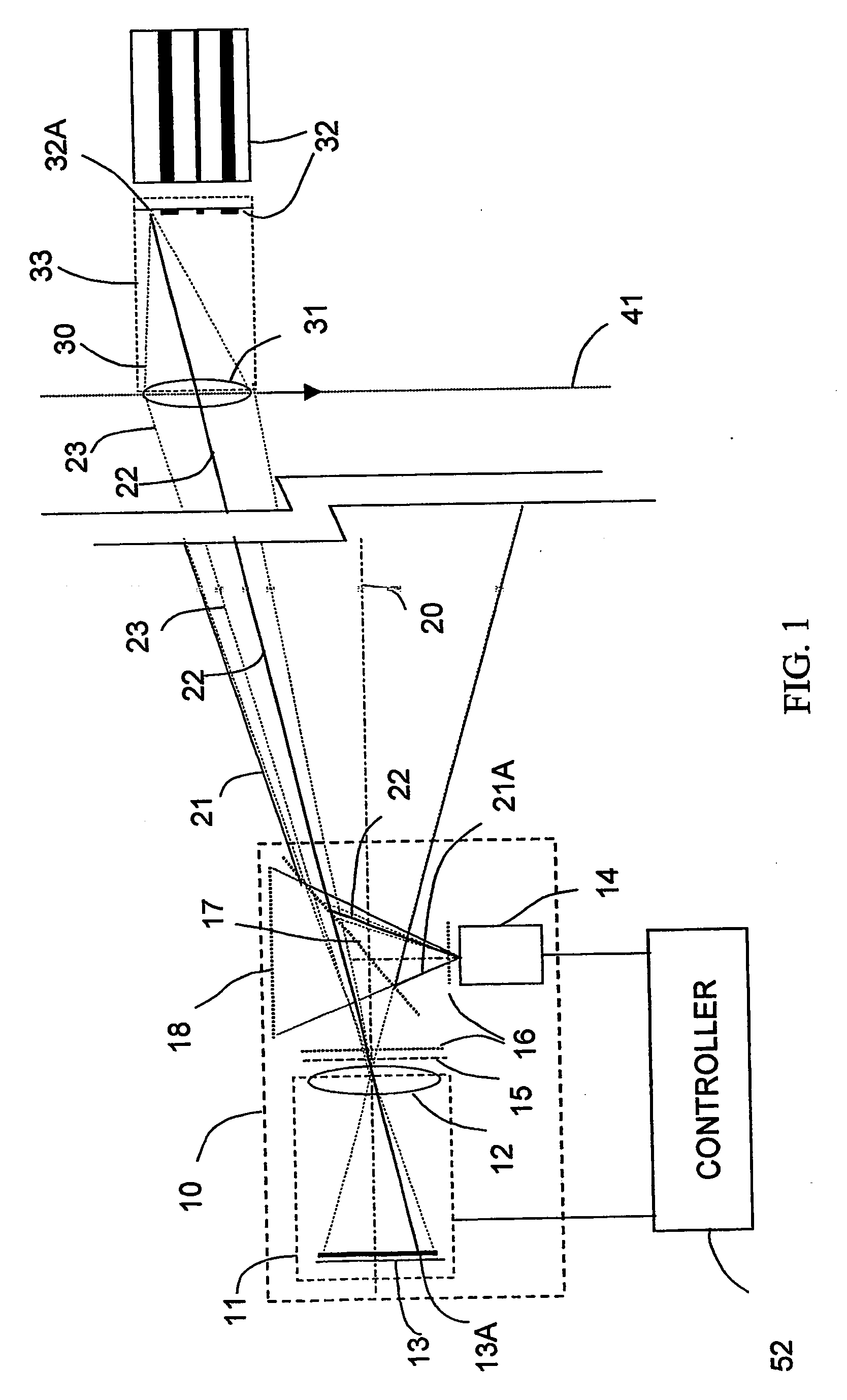

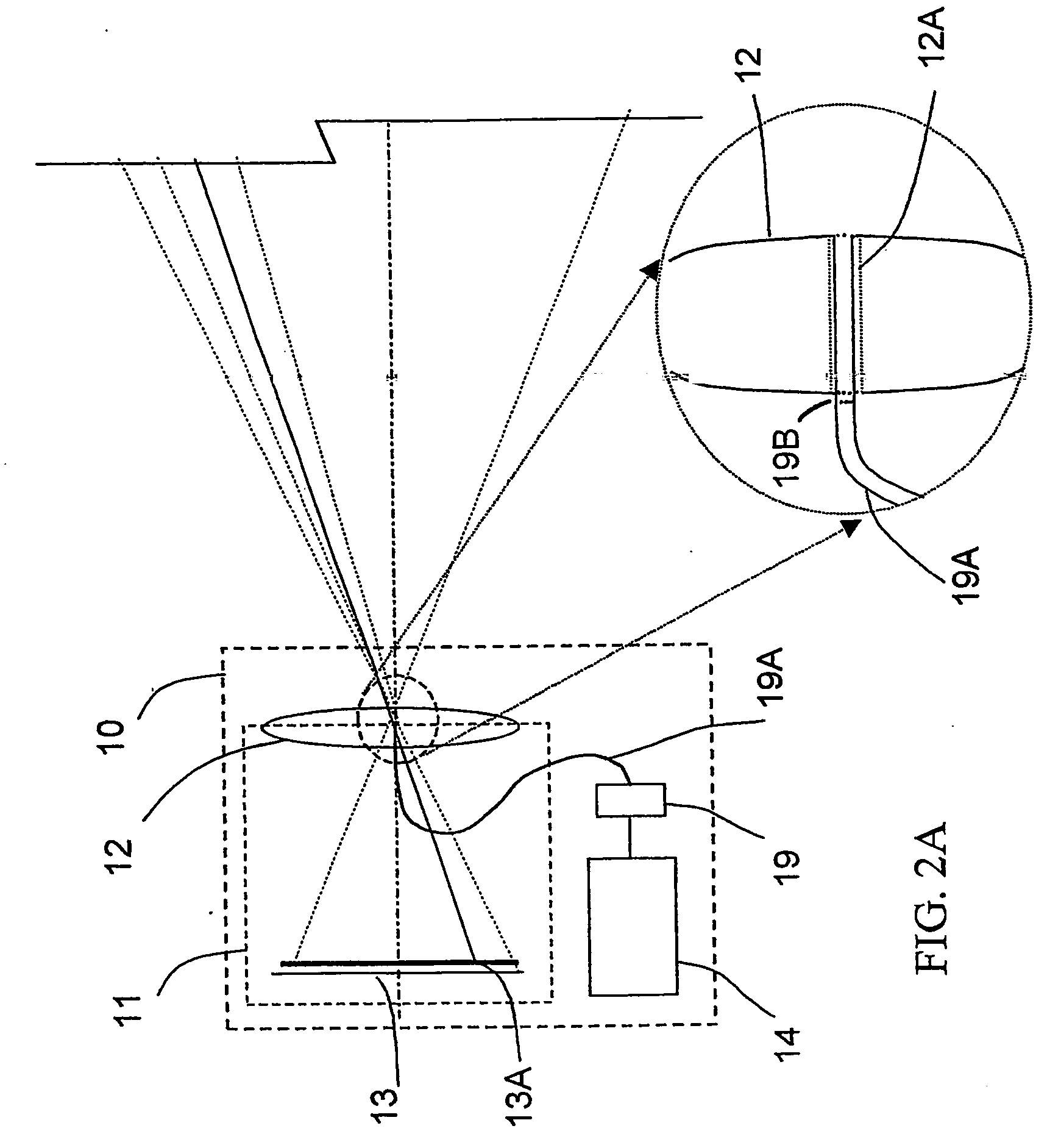

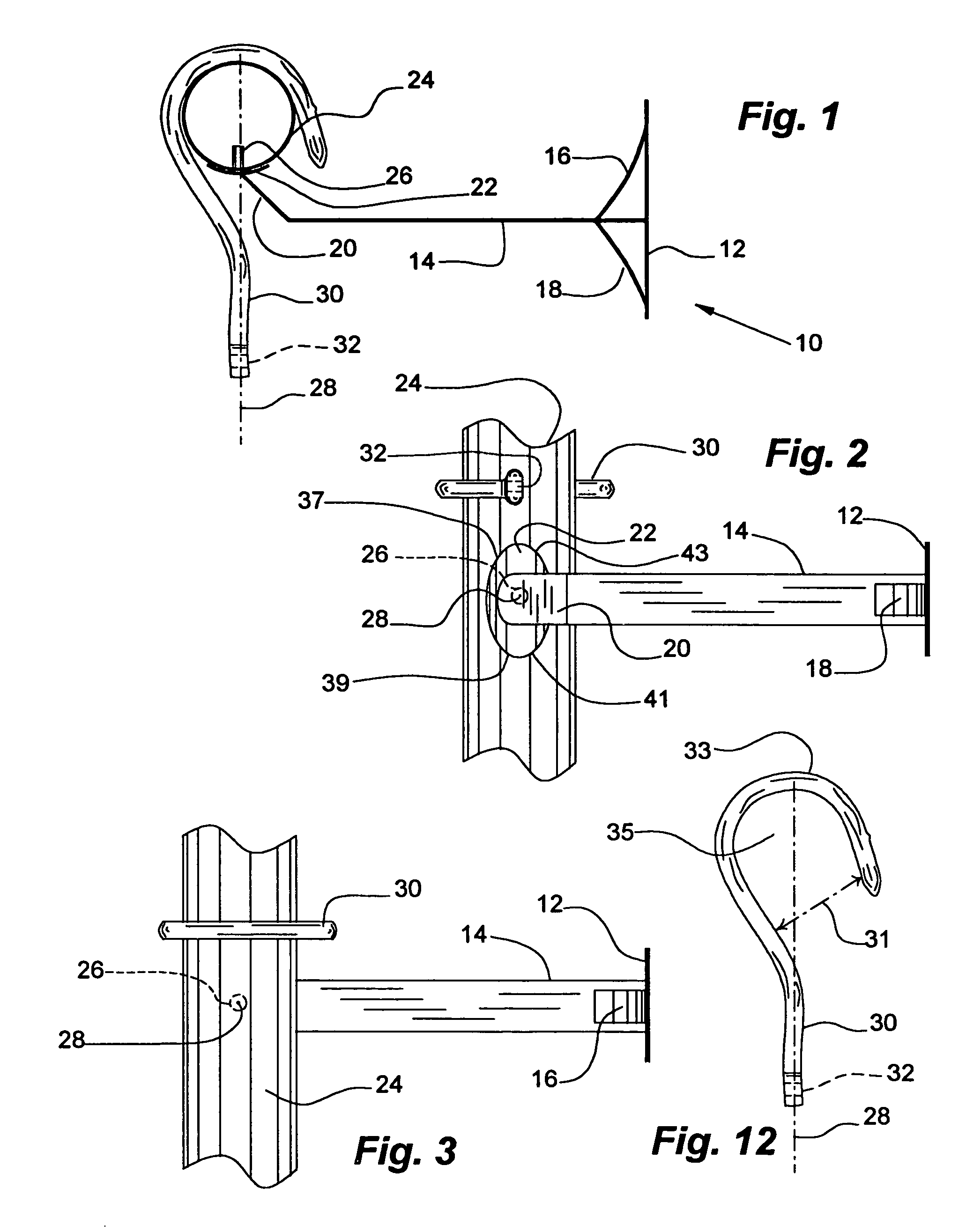

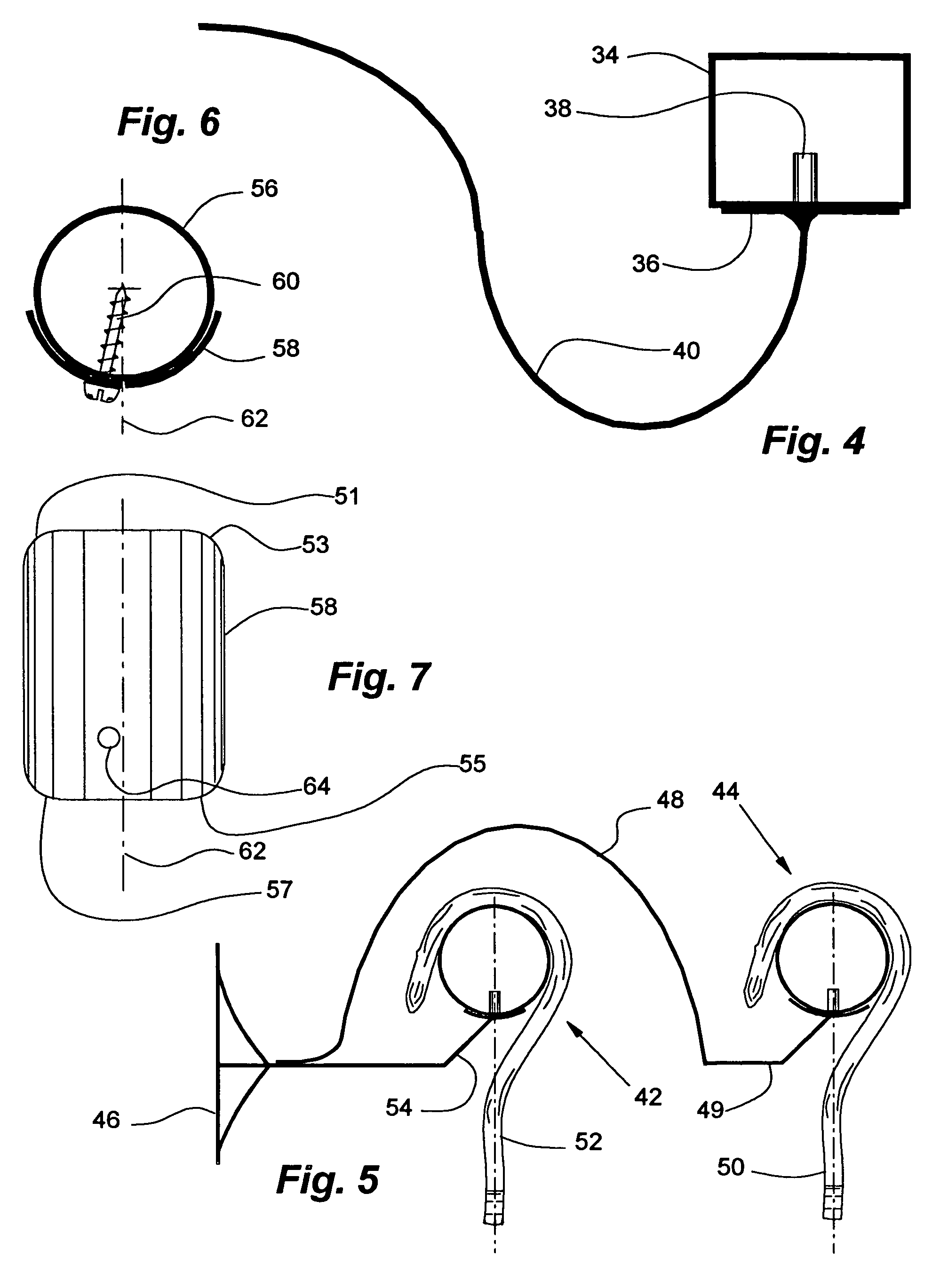

Retinal stimulator

InactiveUS6458157B1Maintenance freeReduce in quantityHead electrodesExternal electrodesTelecommunications linkIntegrated circuit

An apparatus facilitating the delivery of electrical stimulation to physiologically excitable retinal nerve cells includes: (a), a receiver / decoder / stimulator comprising a semiconductor integrated circuit and other components hermetically sealed within a capsule, implanted and fixed within the eye of the patient such that it may receive power, and decode information from (b), an externally worn image processor / encoder / transmitter comprising an image detector, an image processor capable of translating the image into an array of discreet pixels of varying intensity, encoding the pixel information into a series of discreet data bursts representing the chosen current amplitude, pulse duration, stimulating electrode or electrodes, and reference electrode or electrodes, and transmitting this data to the receiver / decoder / stimulator through a tuned, inductive communication link such that the system may deliver controlled, charge balanced, diphasic, constant current stimulus pulses to (c), discreet metallic electrodes on a flexible, multiple site electrode array implanted on, near or under the surface of the retina. The apparatus provides for flexibility in the external image processing system such that future advancements in processing techniques shall not require revision surgery or modification to the implanted receiver / decoder / stimulator. Safeguards to protect the patient from the delivery of inappropriate stimulus are incorporated into the apparatus, and a method of external collection of diagnostic data from the implanted receiver / decoder / stimulator is described.

Owner:NEWSOUTH INNOVATIONS PTY LTD

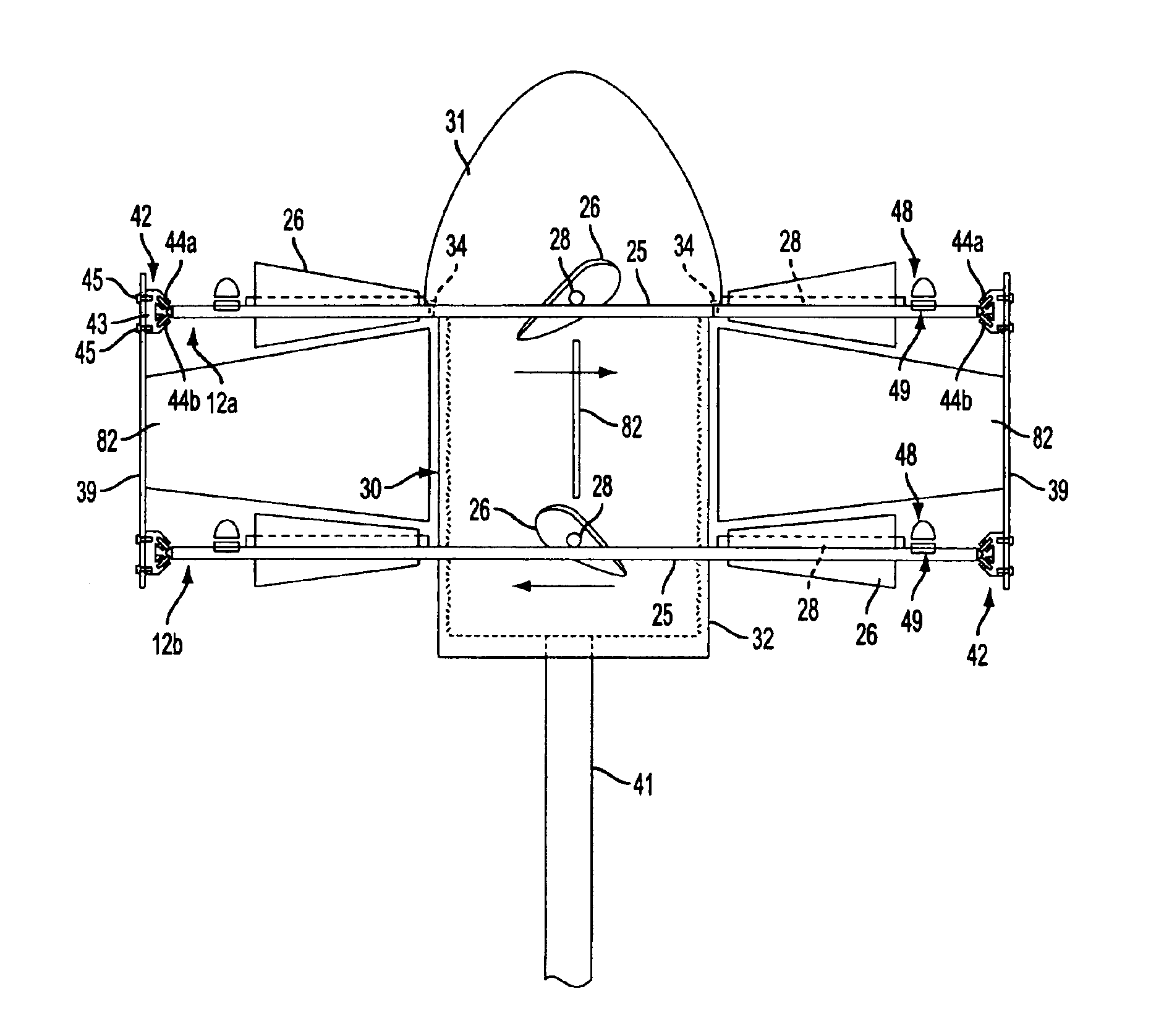

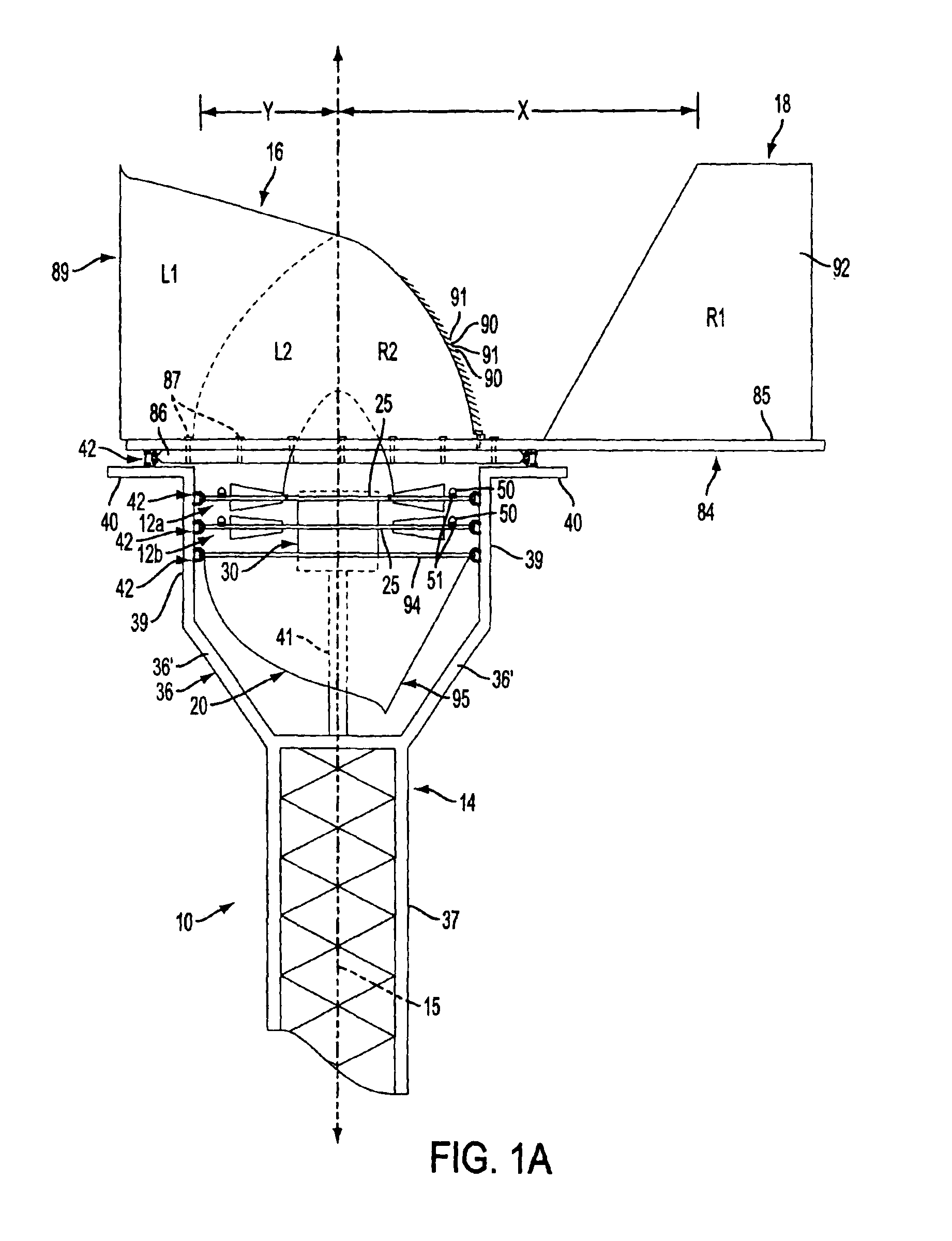

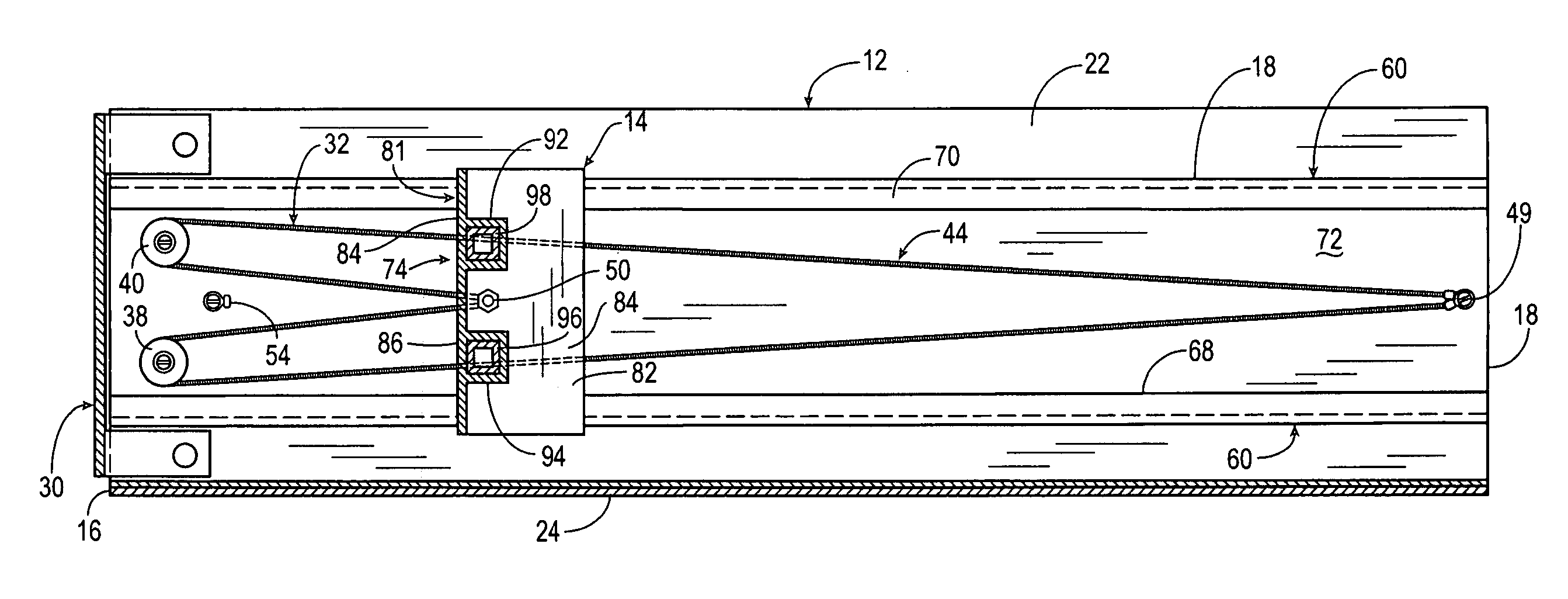

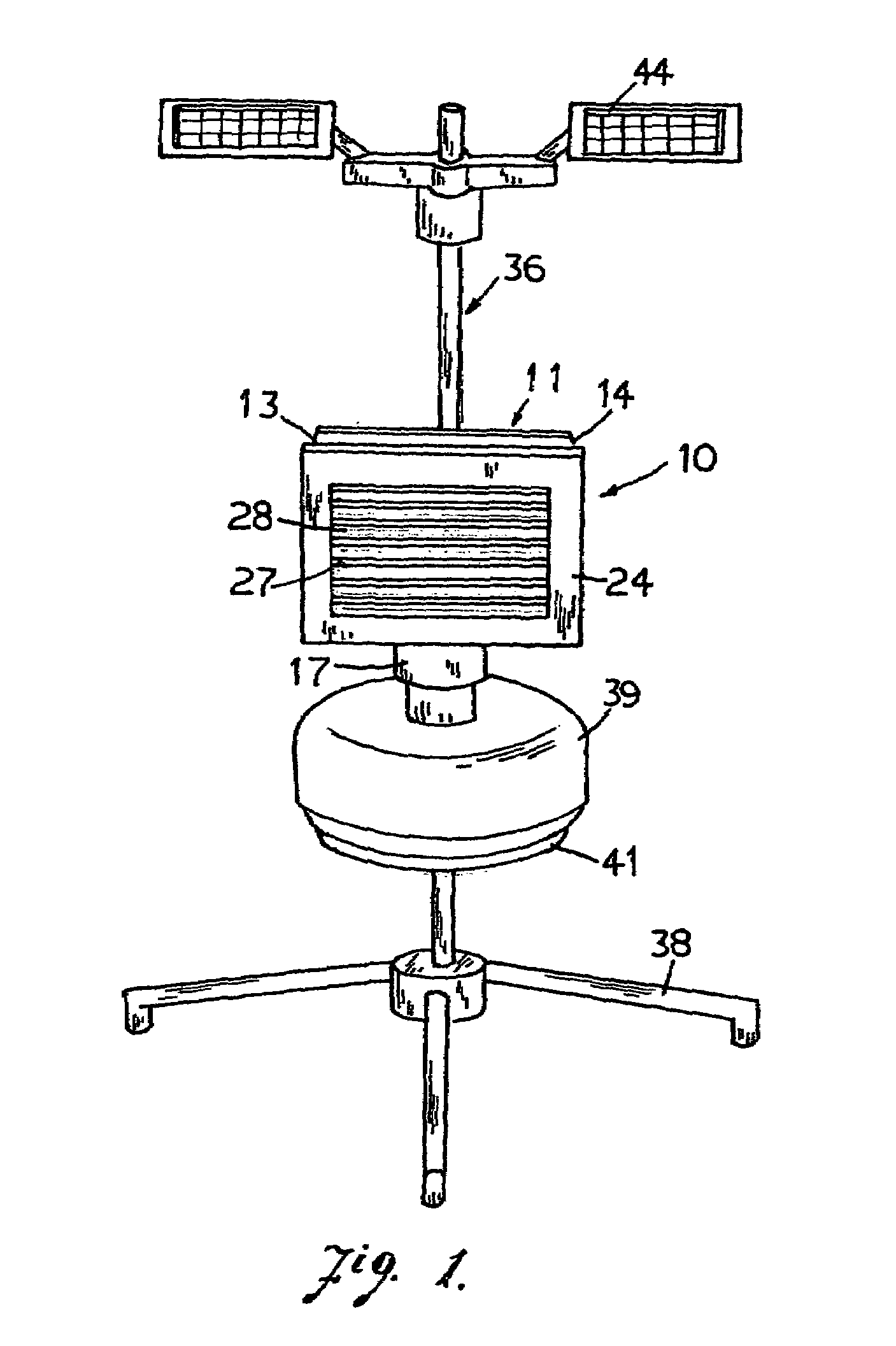

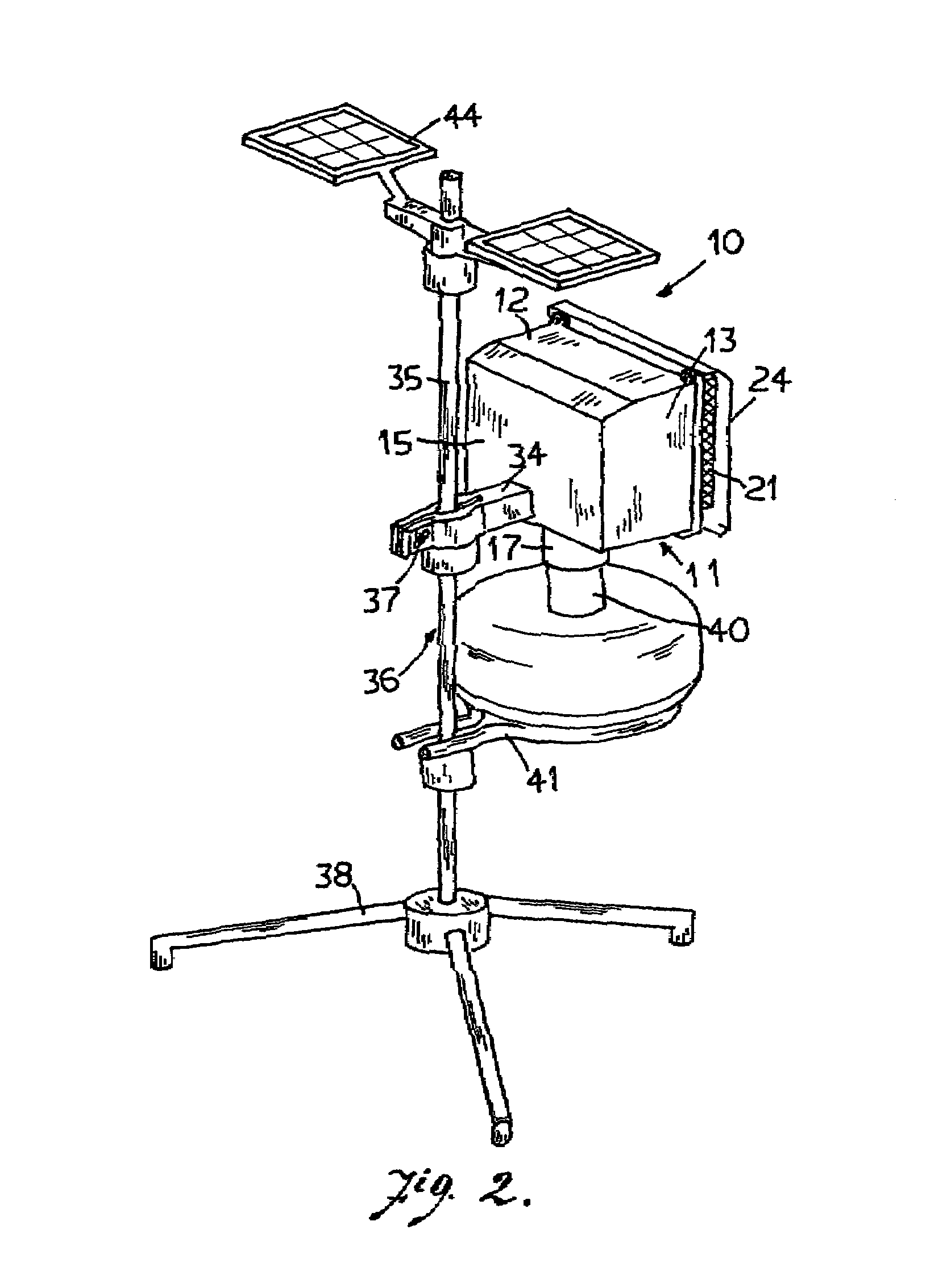

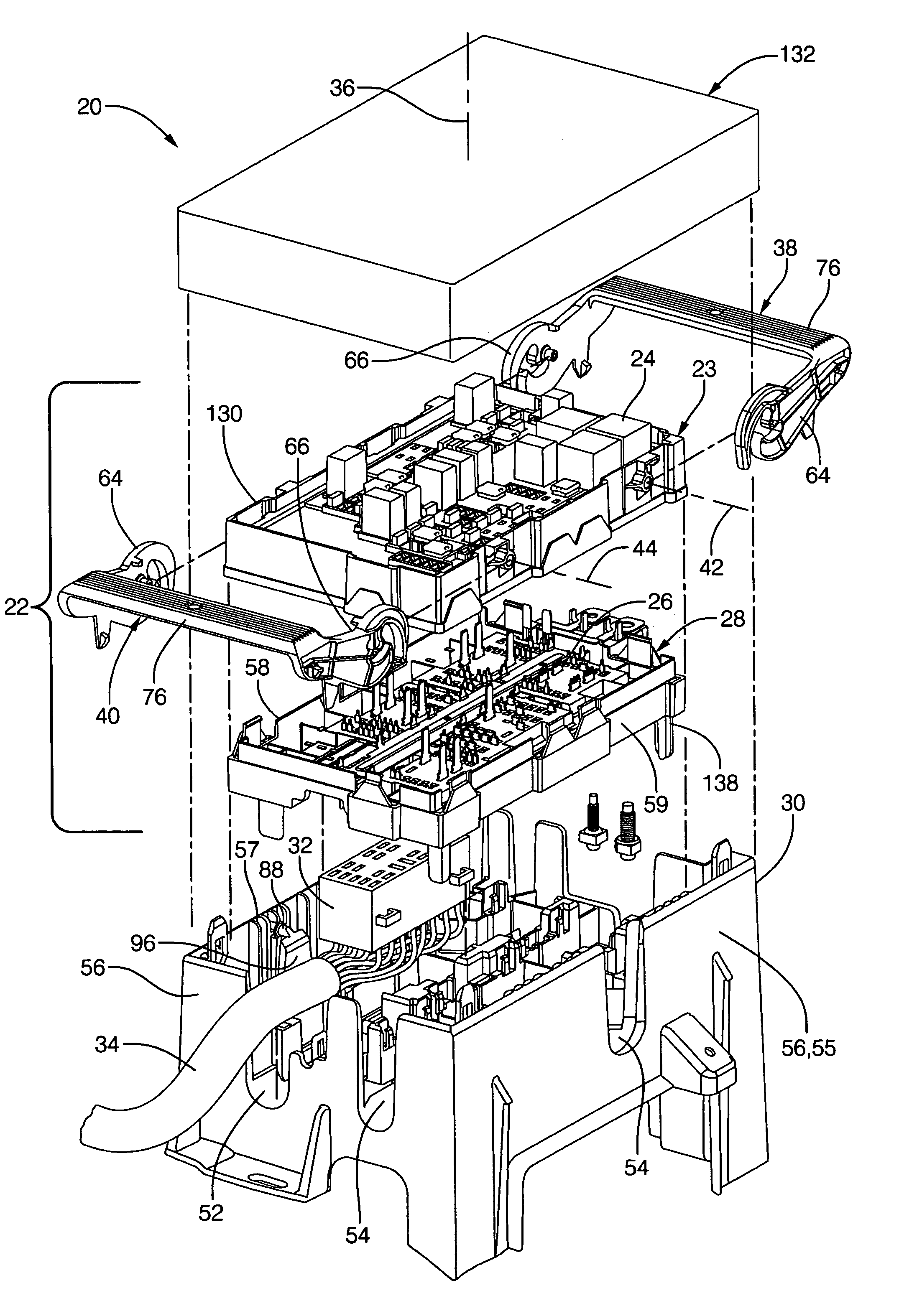

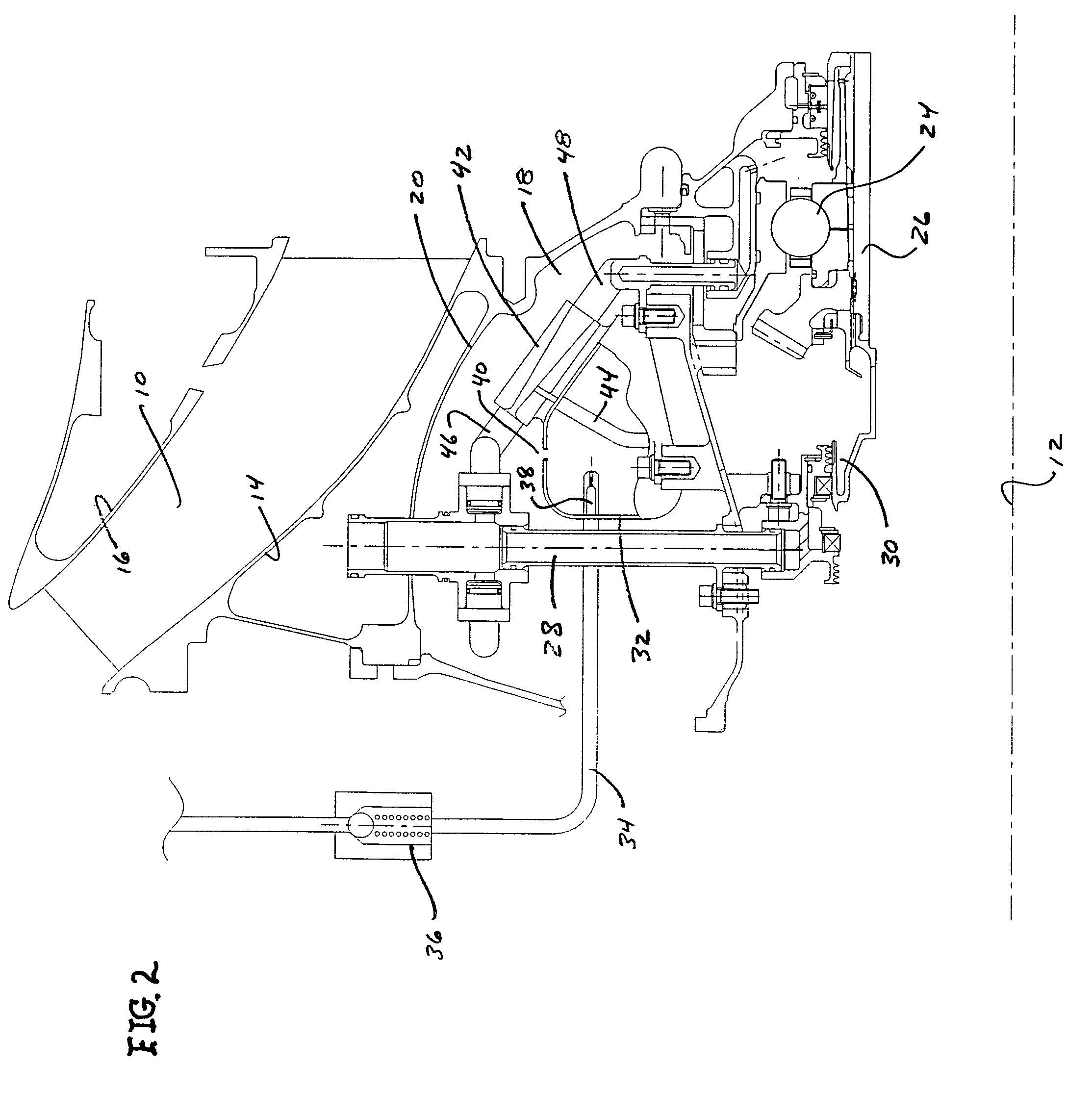

Wind energy conversion system

InactiveUS6952058B2Reduced weight and mass and costAdjustable sizePropellersWind motor supports/mountsWind energy conversionEngineering

A wind energy conversion system includes upper and lower wind turbines having counter-rotating blade assemblies supported for rotation about a vertical rotation axis, with each blade assembly carrying a rotor for rotation past a stator to produce an electrical output. The wind turbines are supported by a tower at an elevated position above the ground. Each wind turbine produces torque, and the wind energy conversion system provides for balancing the torques to avoid a net torque on the tower. Adjustment mechanisms are provided for adjusting blade pitch and for adjusting the size of an air gap between a stator and a rotor that comes into alignment with the stator as the rotor rotates therepast. The wind energy conversion system provides a hood for supplying intake air to a wind turbine and an exhaust plenum for exhausting air from the wind turbine, with the hood and the exhaust plenum being directionally positionable.

Owner:WECS

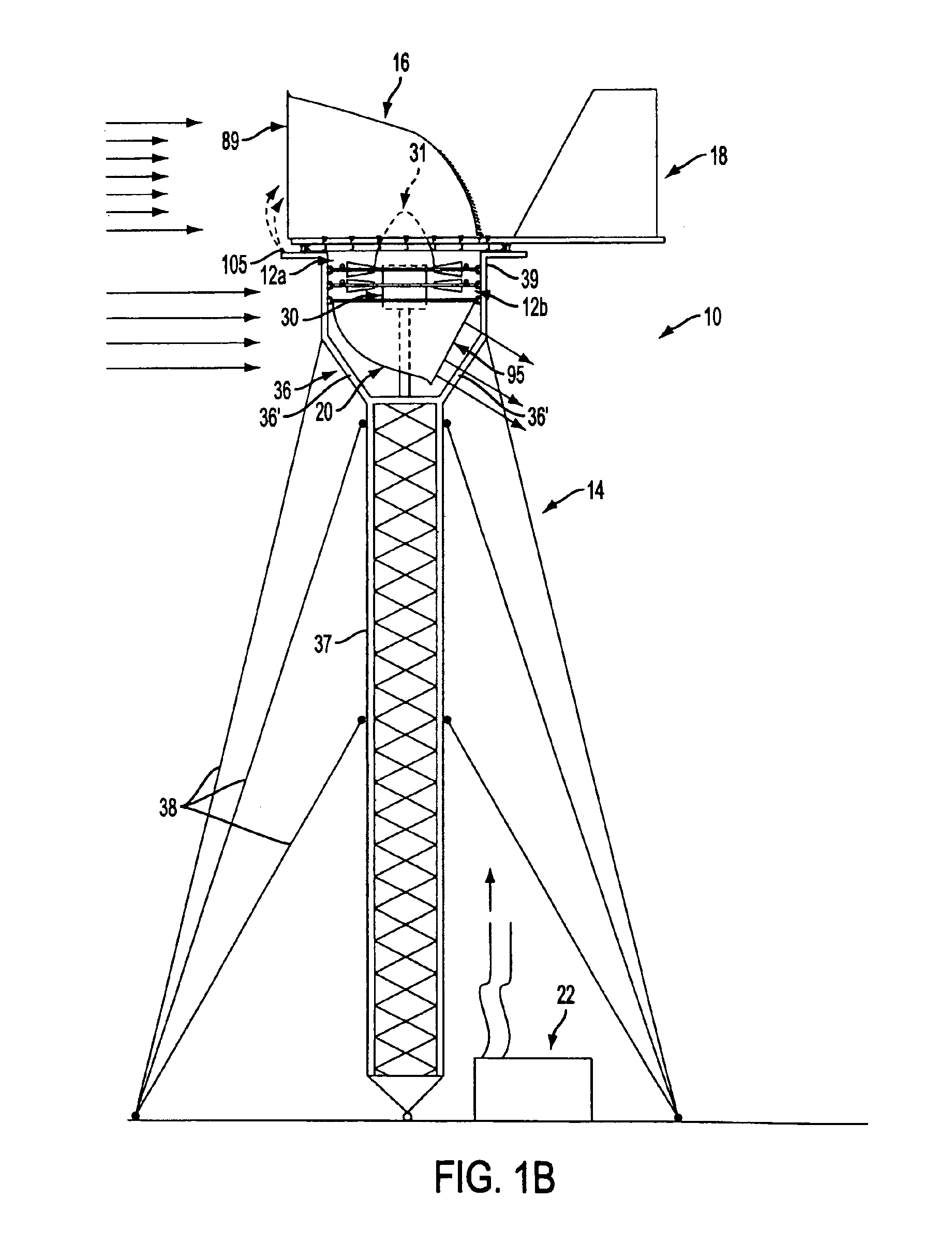

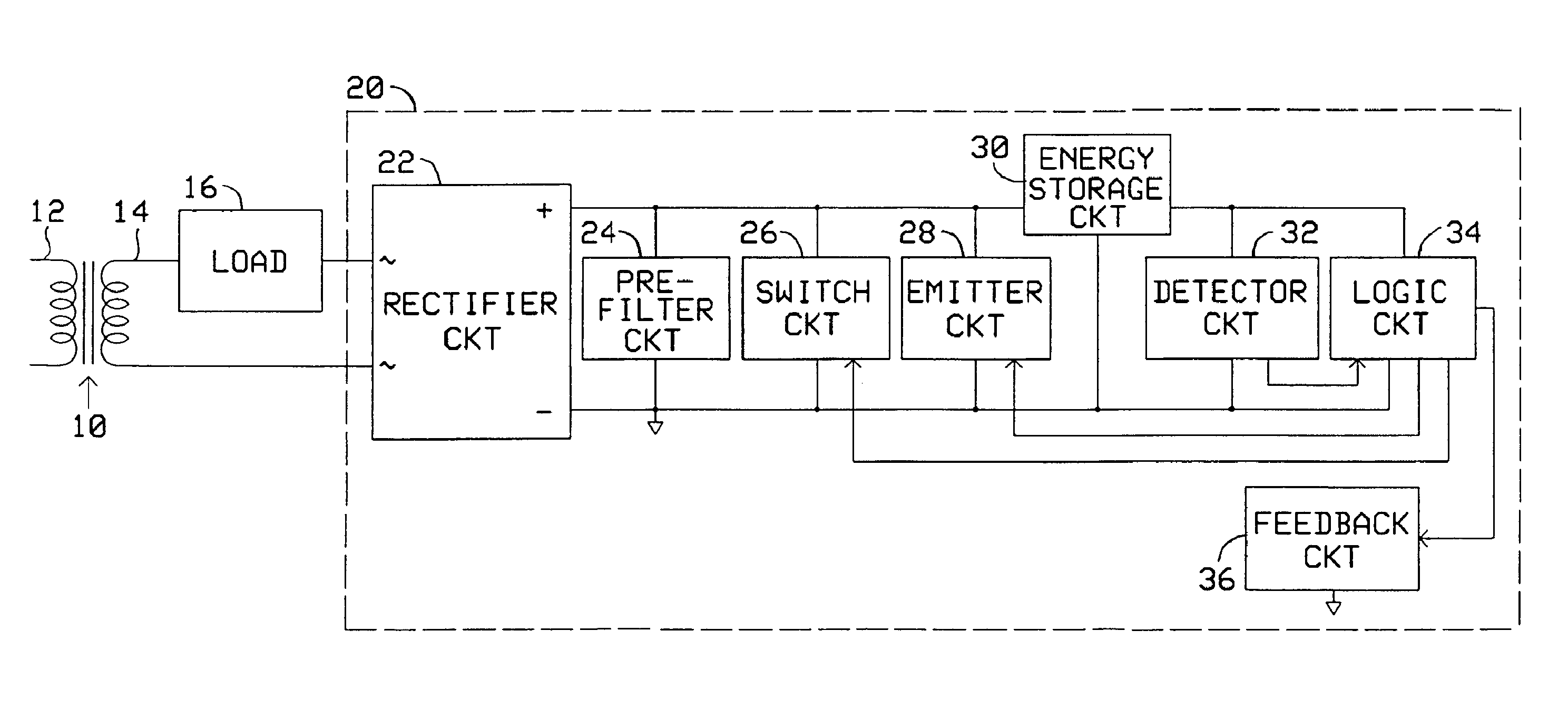

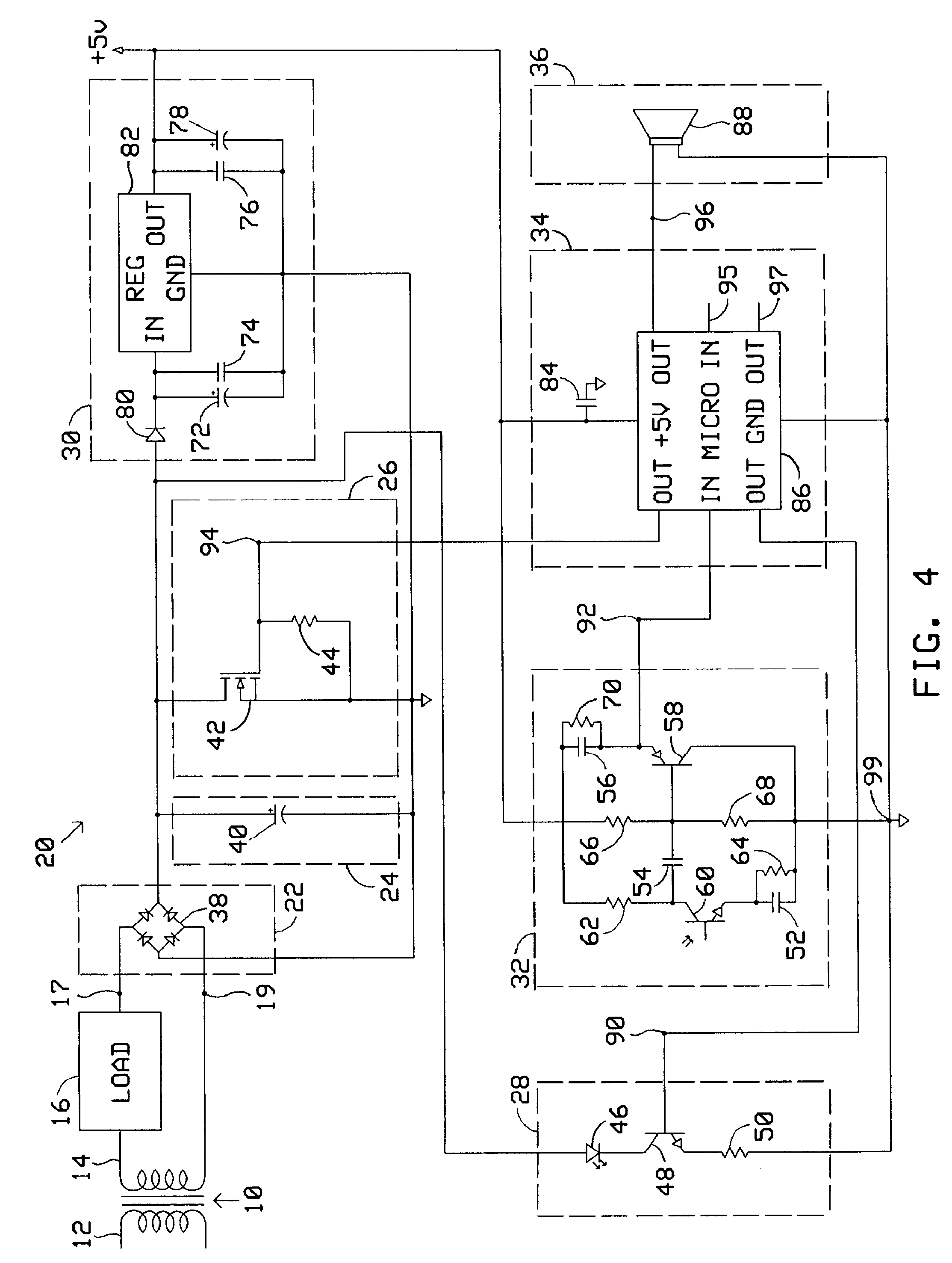

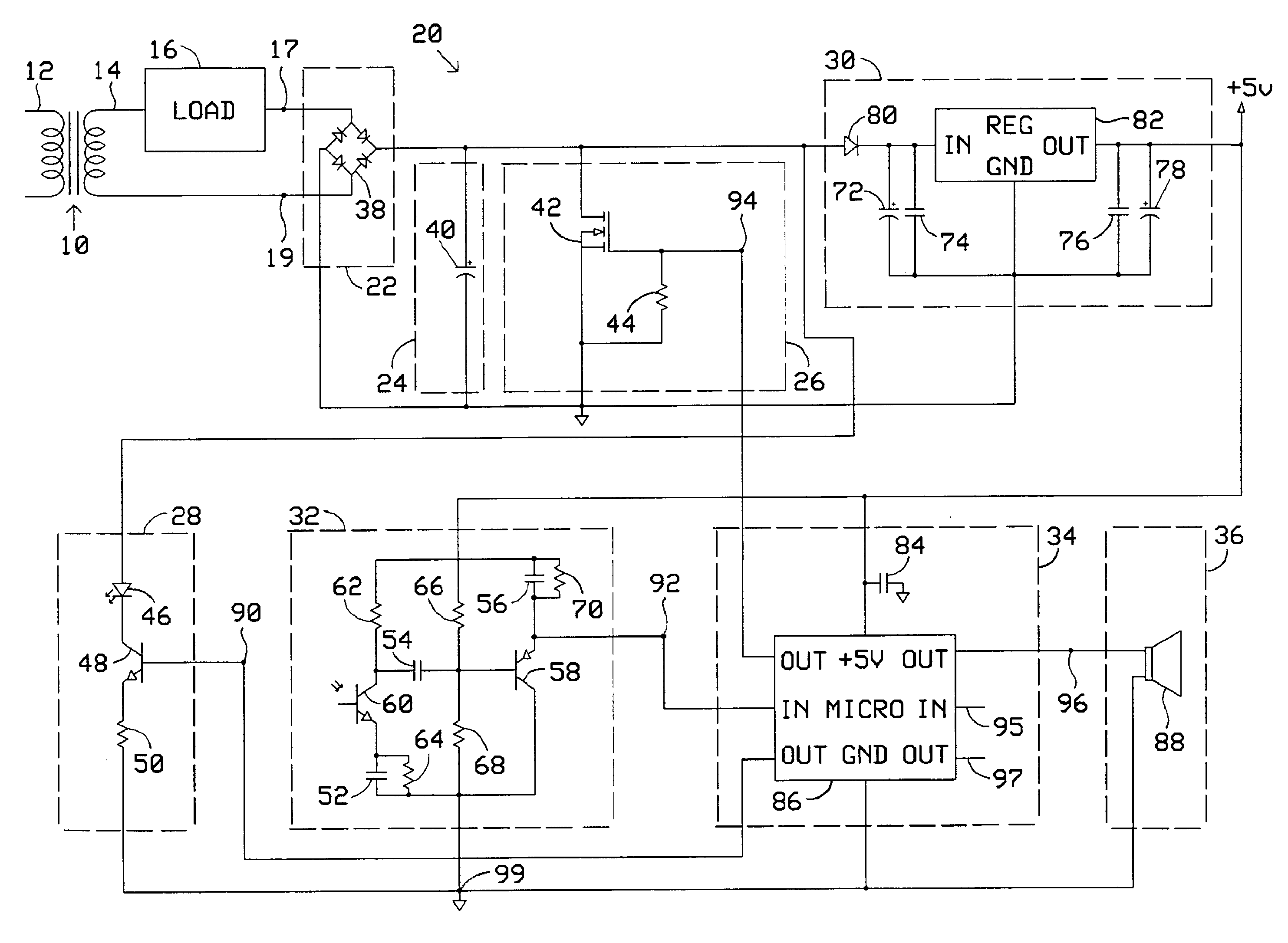

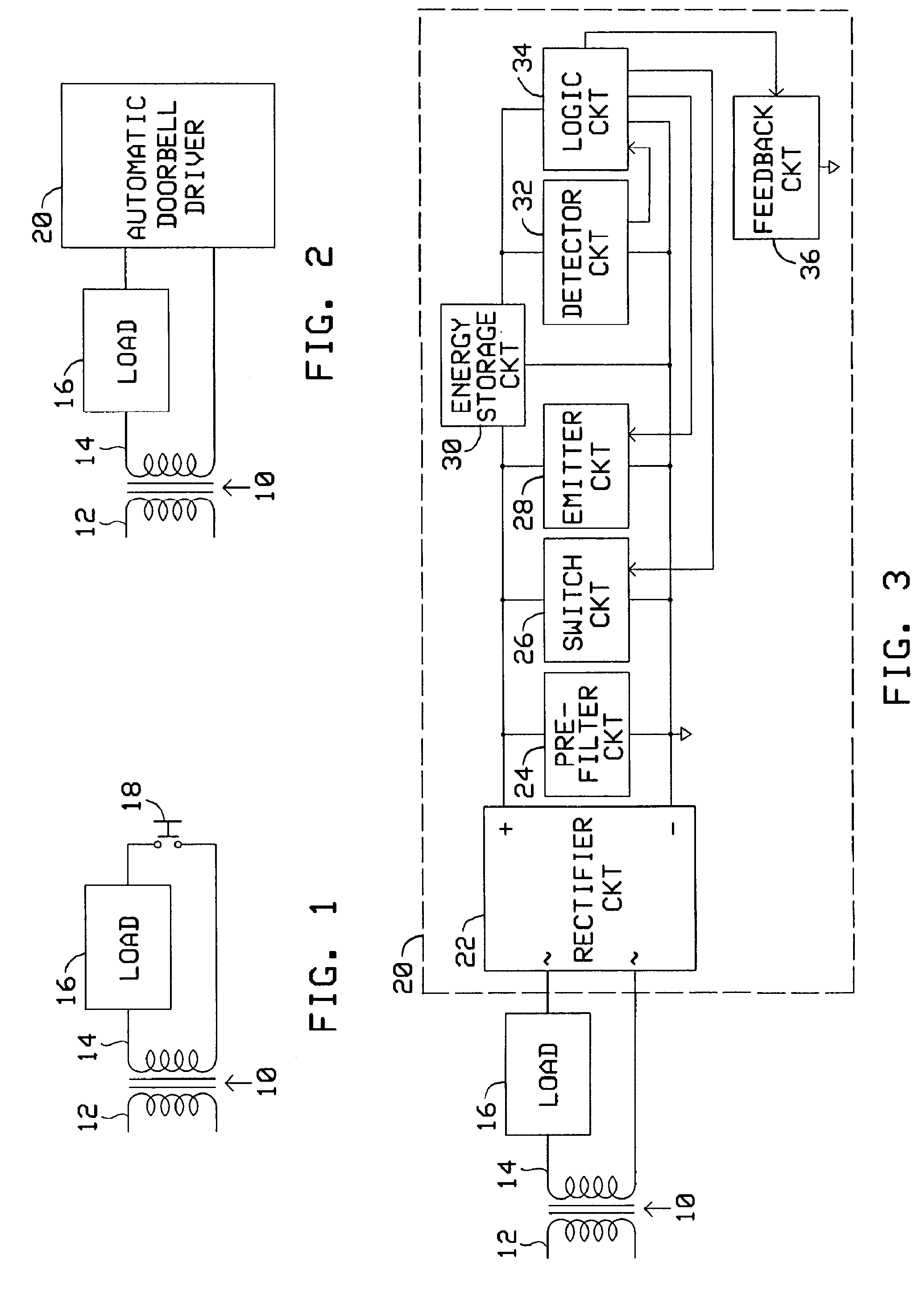

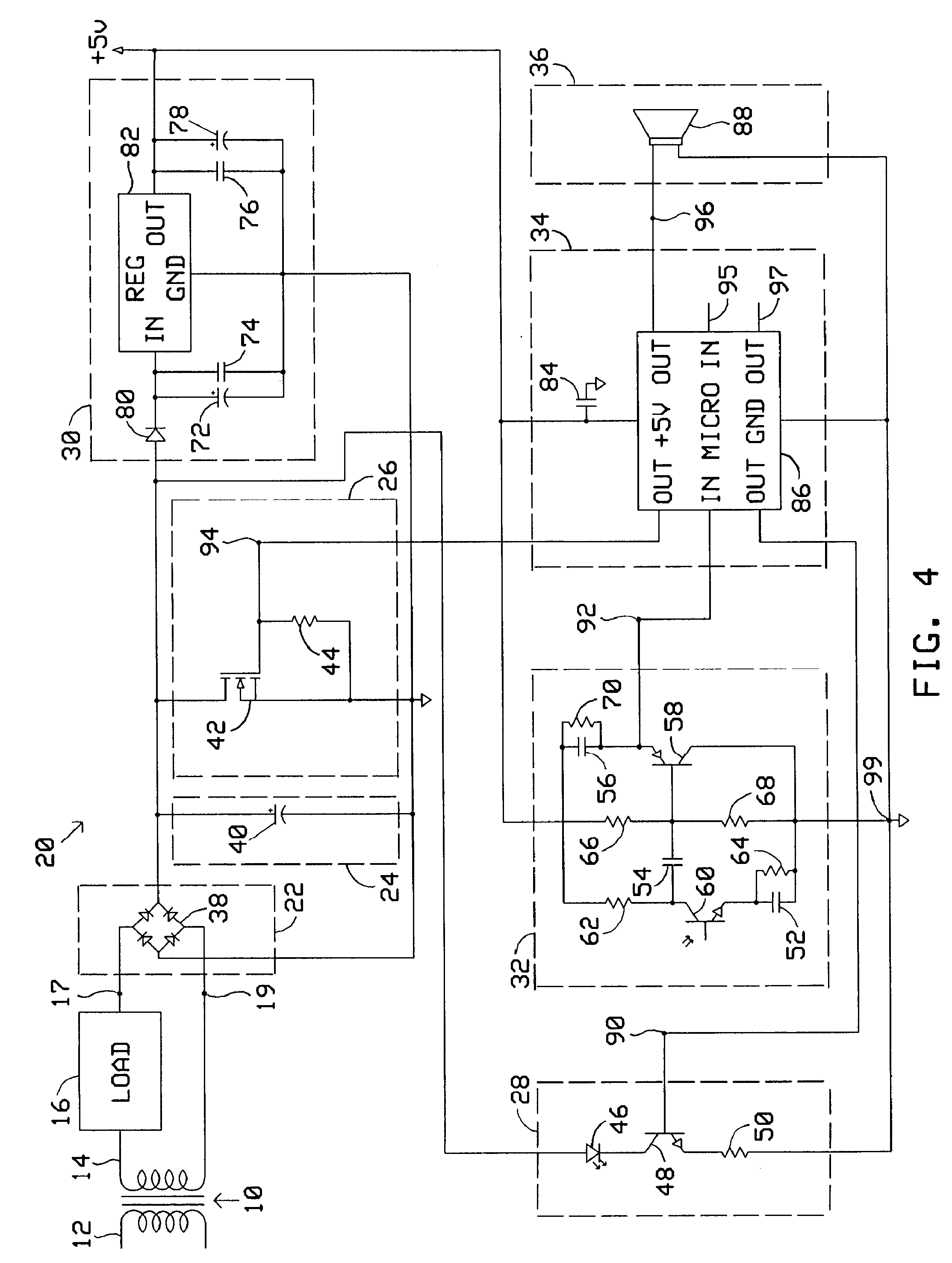

Automatic doorbell driver

ActiveUS7429924B2Easy to installMaintenance freeSignalling system detailsVisible signalling systemsDoorbellCoupling

Owner:LANGER PETER +1

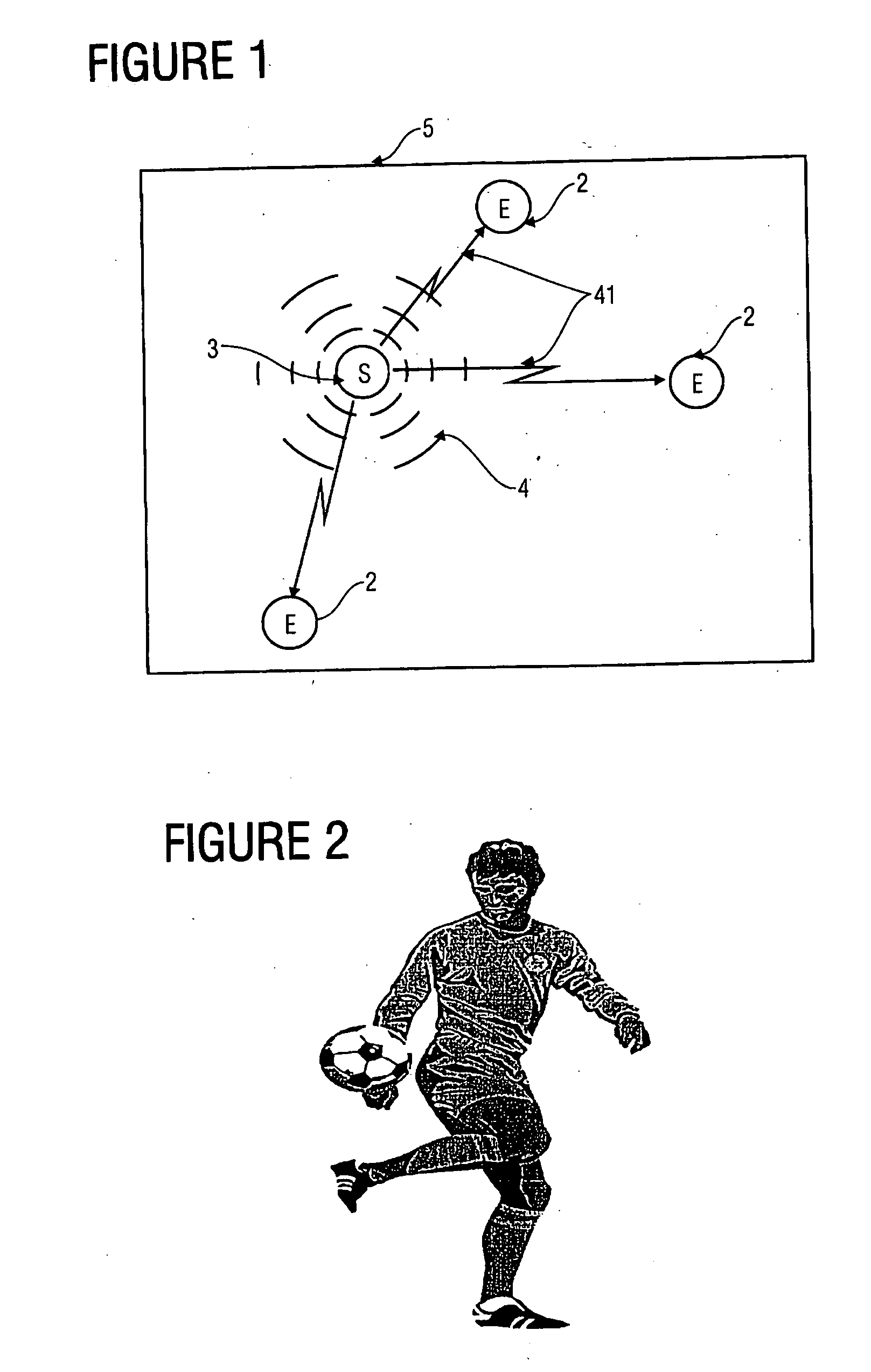

Movable device and receiver device for detecting contacts with the movable device

InactiveUS20070060425A1Simple and robust structureMaintenance freeHollow inflatable ballsHollow non-inflatable ballsEngineeringMobile device

The movable device includes a detector for detecting that an object is located in the vicinity of or at the movable device, as well as a transmitter module for transmitting two signals having different signals speeds. These two signals are received by a receiver, the receiver having a detector to ascertain whether the second signal arrives within a predetermined time period as of reception of the first signal, so as to provide, when this has been detected, a detector signal indicating that the movable device has been contacted by the object. Exemplary movable devices are game devices such as footballs. Exemplary objects are arms, legs, football shoes, rackets, bats, etc.

Owner:CAIROS TECH

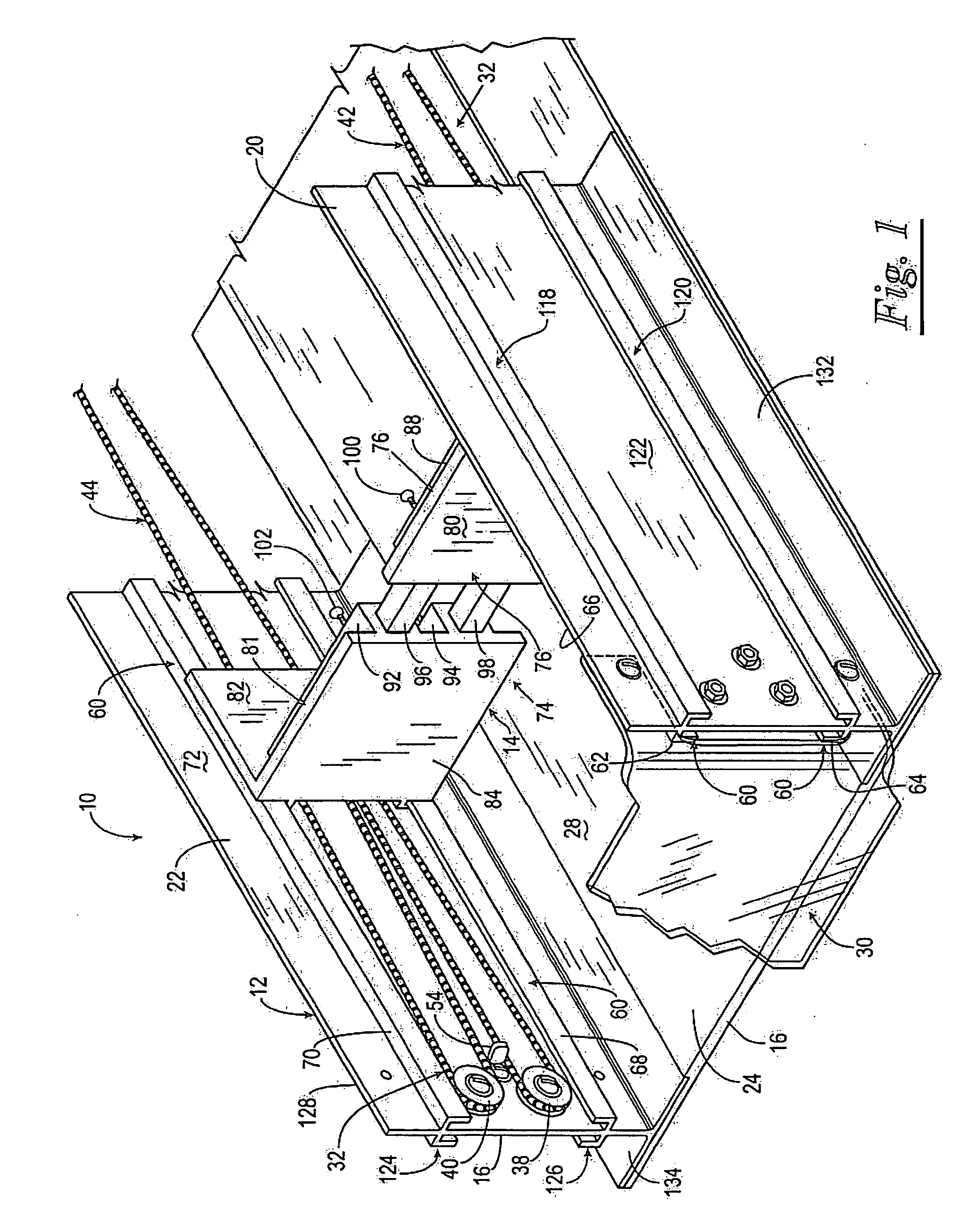

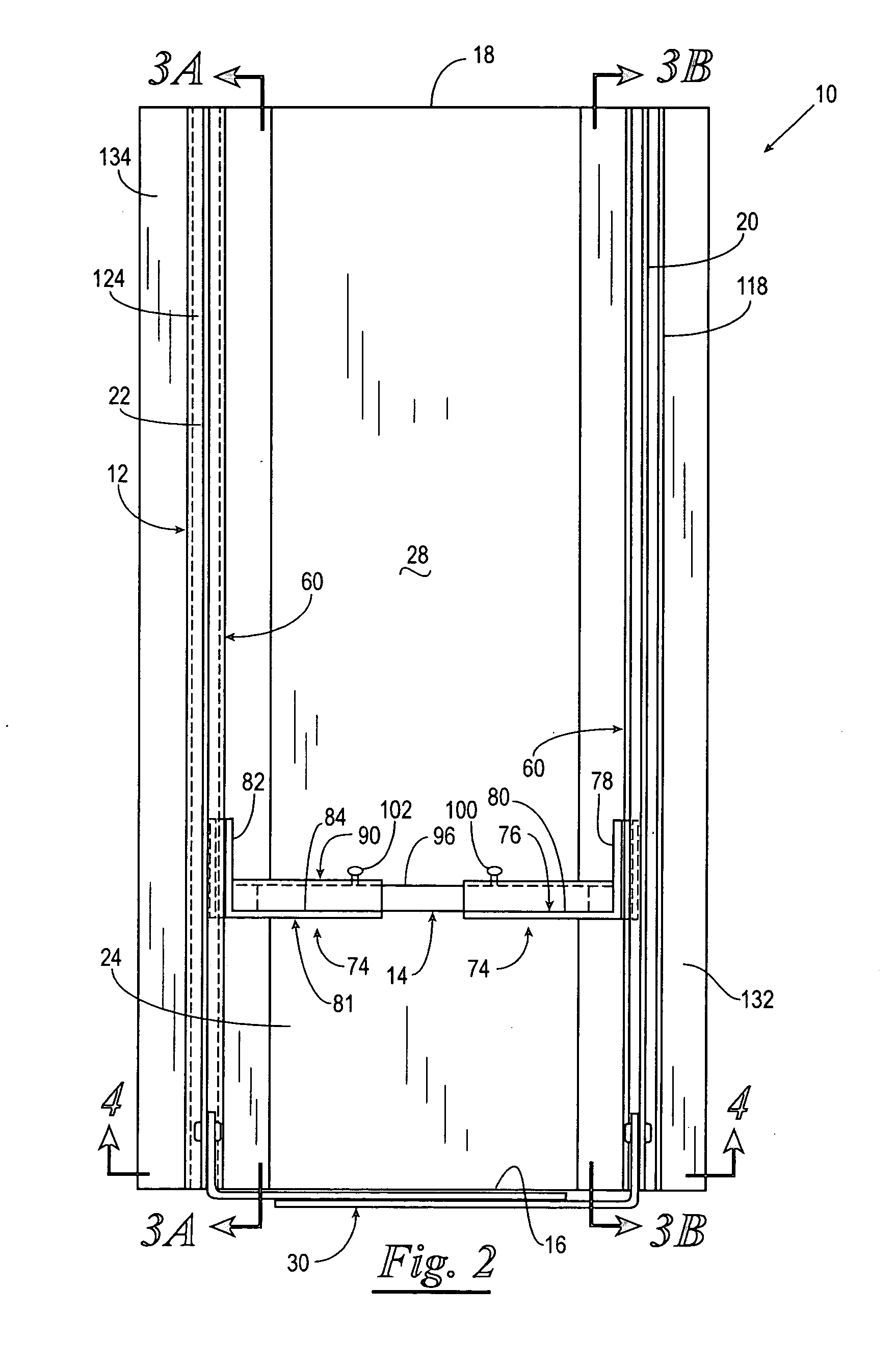

Merchandise display rack

InactiveUS20070108142A1Prevent forward movementReduce manufacturing costRacksShow shelvesEngineering

A merchandise display rack is provided for displaying a row of merchandise on a store shelf and feeding the row of merchandise forward on a store shelf as merchandise at the front of the row of merchandise is removed by a customer. The merchandise display rack includes a pusher frame, a pusher plate assembly and a pusher plate biasing assembly supported on opposing sidewalls of the display rack and connected to the pusher plate assembly.

Owner:EXCELL PRODUTS

Automatic Doorbell Driver

ActiveUS20070126574A1Easy to installMaintenance freeSignalling system detailsVisible signalling systemsDoorbellCoupling

An automatic doorbell driver that utilizes the power, wiring, and primary load of a conventional doorbell system. The automatic doorbell driver comprising coupling means for coupling the automatic doorbell driver to the conventional doorbell system; power supply means for supplying power to the automatic doorbell driver; sensing means for sensing an object in a proximity zone; and switching means responsive to the sensing means for coupling power to, and thereby controlling the energization and de-energization of, the primary load of the conventional doorbell system; whereby the automatic doorbell driver can easily convert the conventional doorbell system into an automatic doorbell system.

Owner:LANGER PETER +1

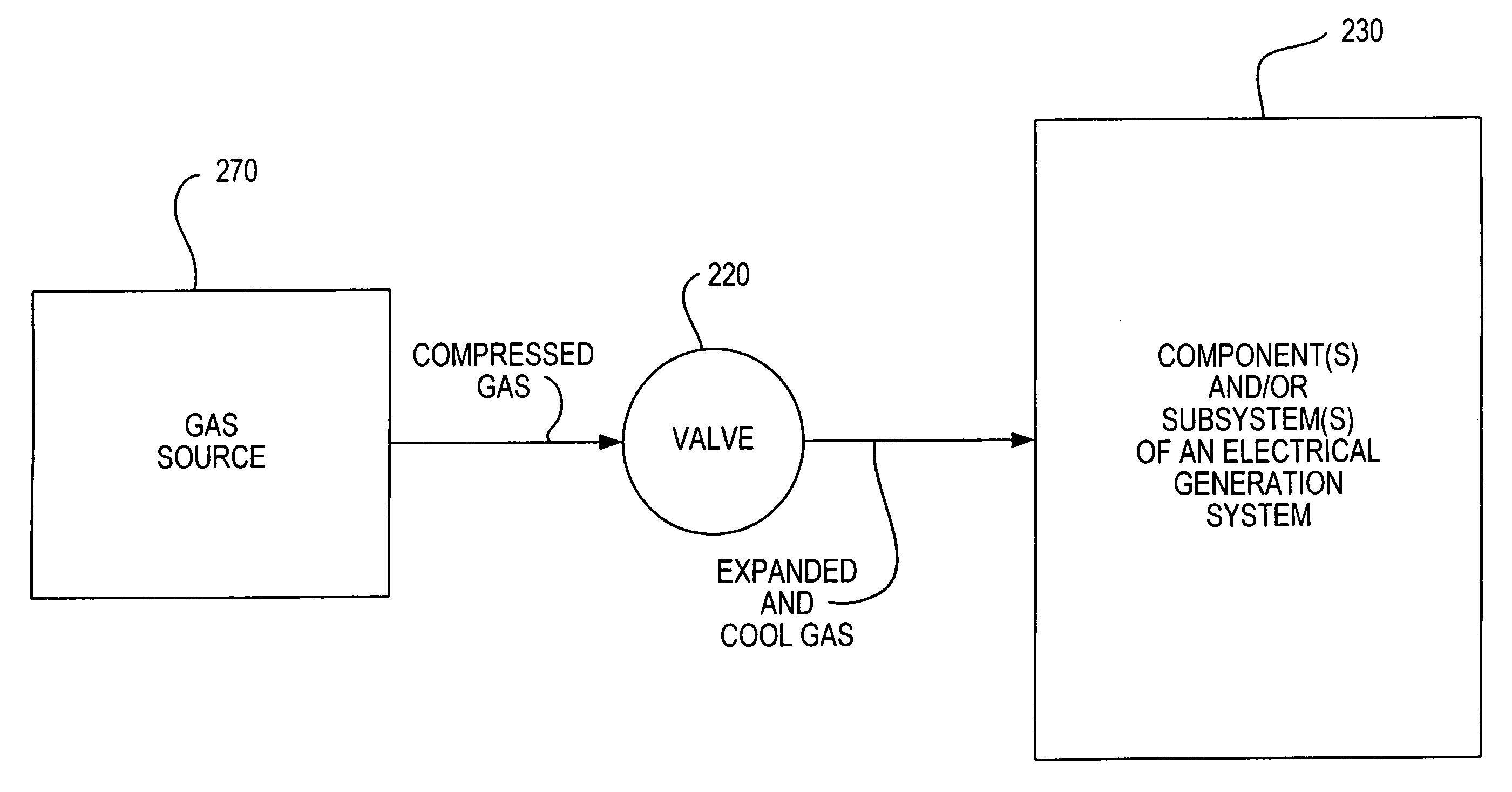

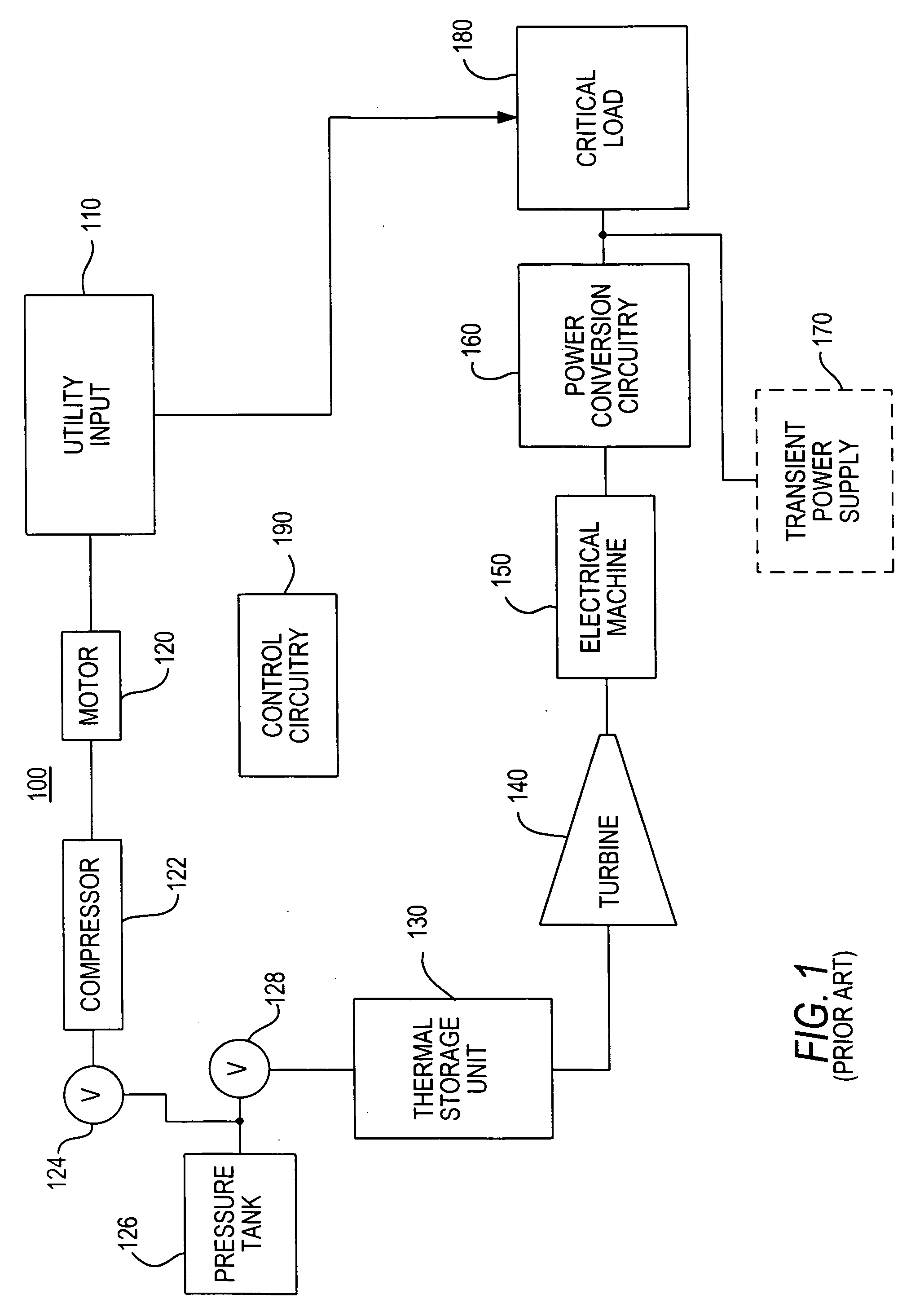

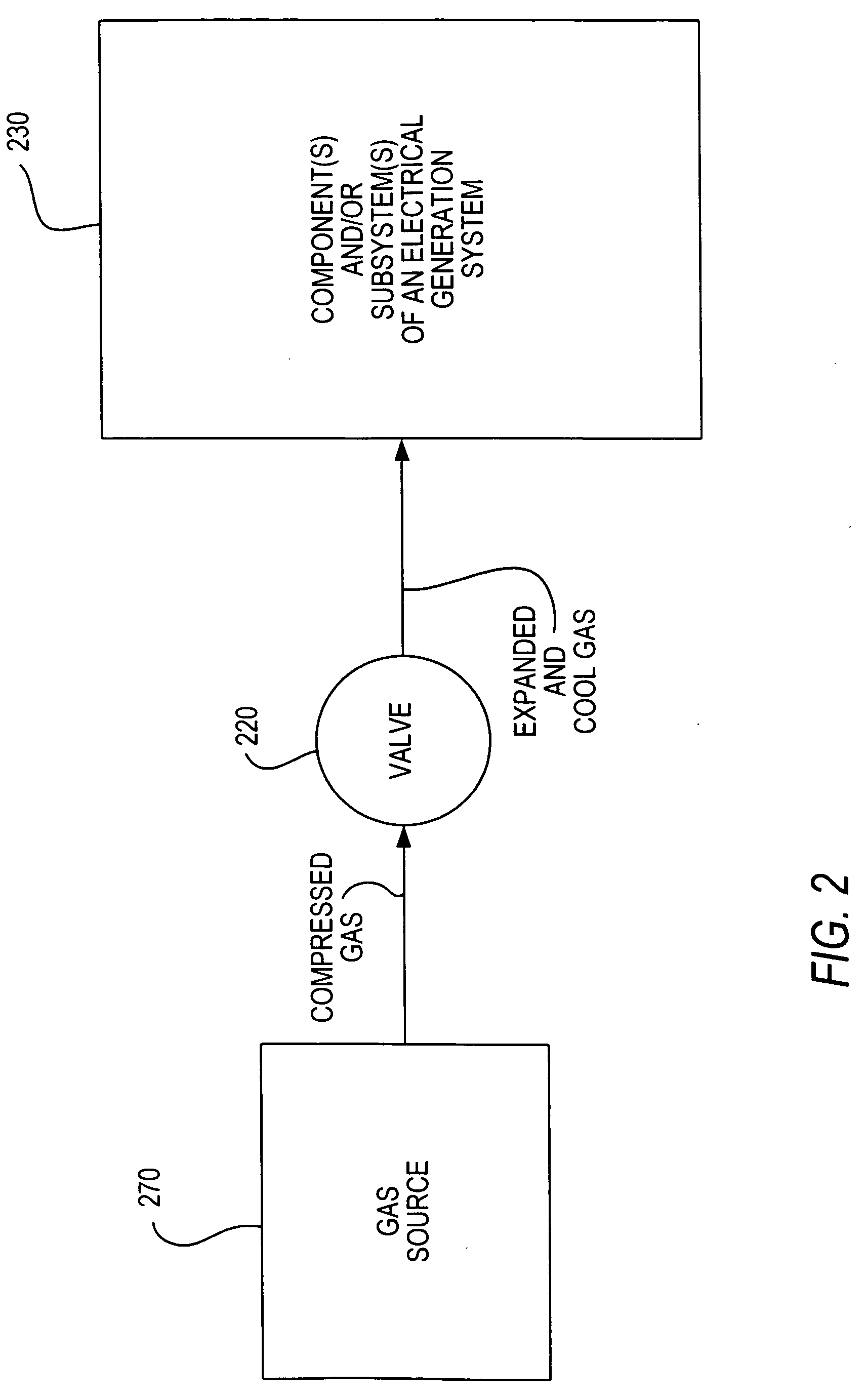

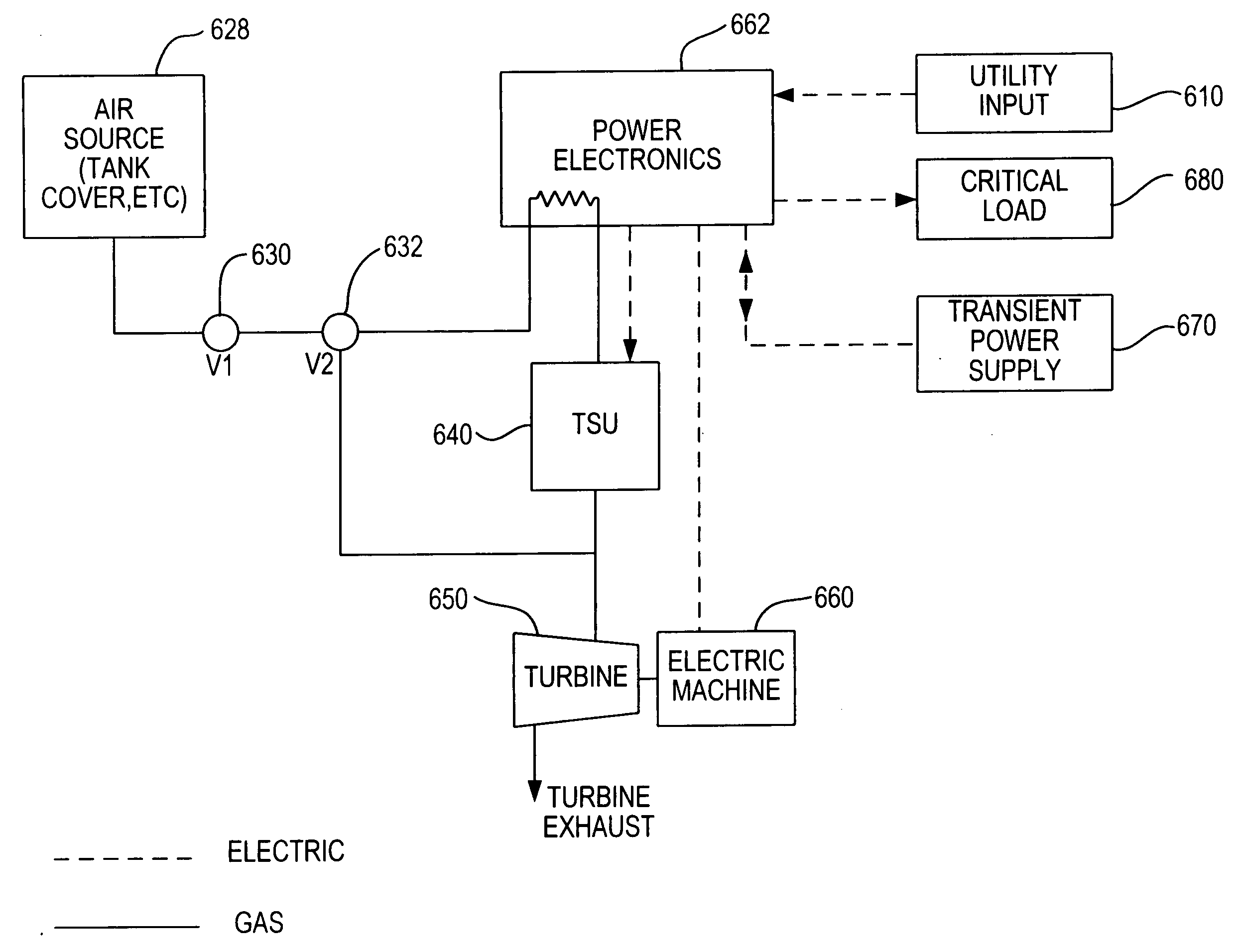

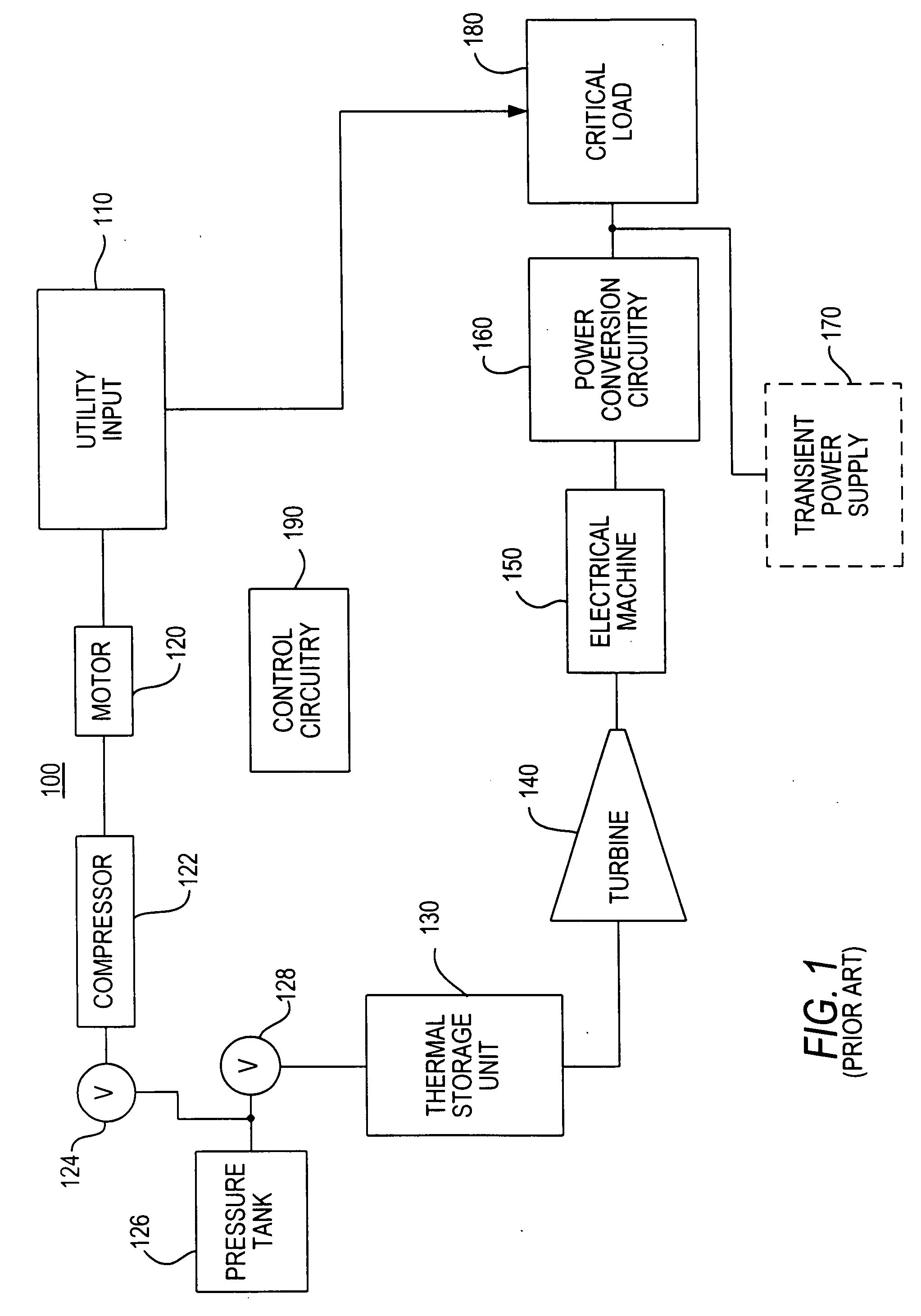

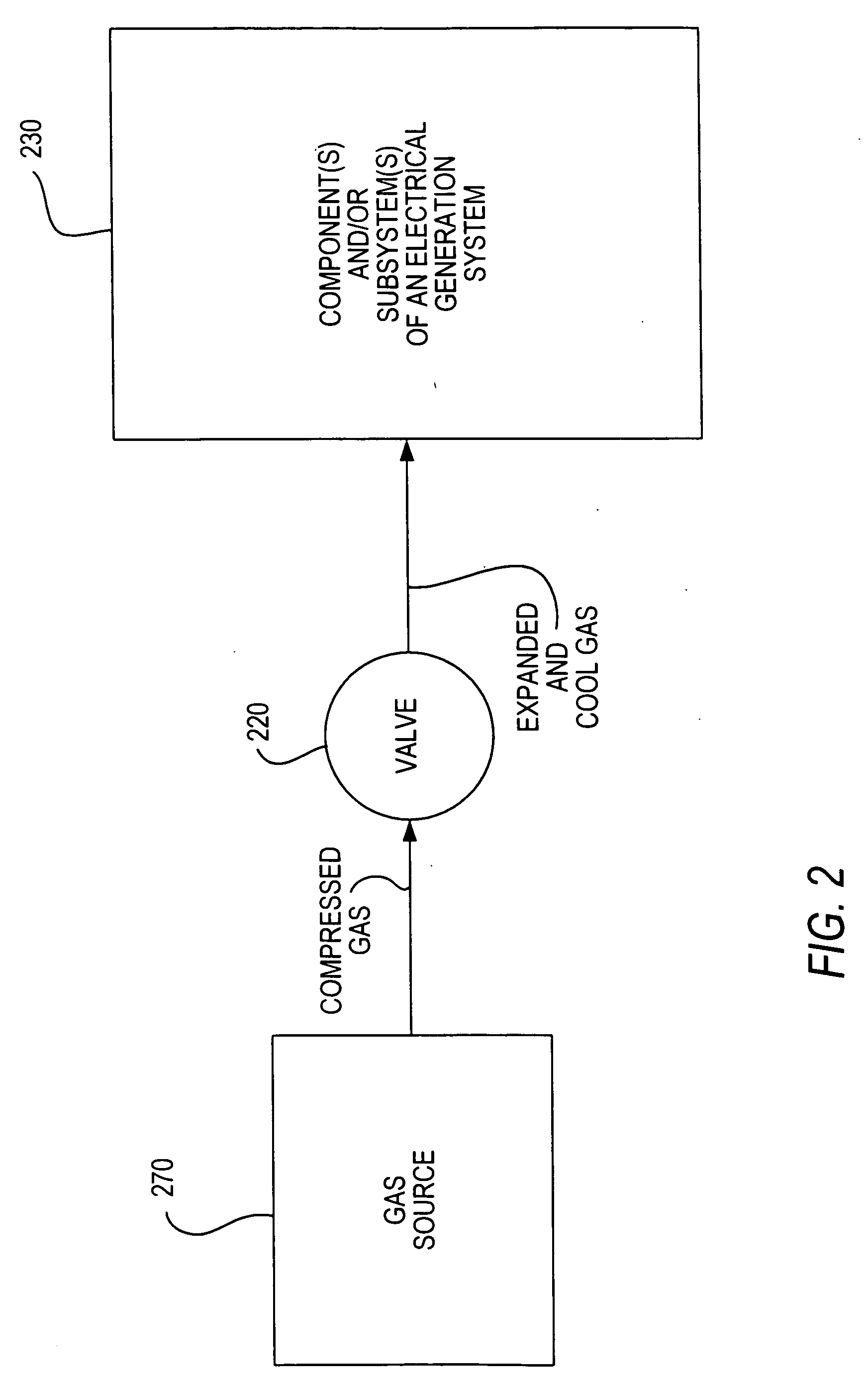

Systems and methods for providing cooling in compressed air storage power supply systems

InactiveUS20060059937A1Low operating temperatureLess costElectrical storage systemDomestic cooling apparatusElectric generatorEngineering

A system and method for cooling electrical machines (e.g., generators), sub-systems (e.g., power electronics), and components (e.g., bearings) in an electrical generation system such as a compressed air storage (CAS) energy system or a thermal and compressed air storage (TACAS) energy system is provided. Cooling is derived from the thermal expansion of a compressed gas, which may be the same gas used to drive a turbine-generator of CAS or TACAS energy system.

Owner:ACTIVE POWER INC

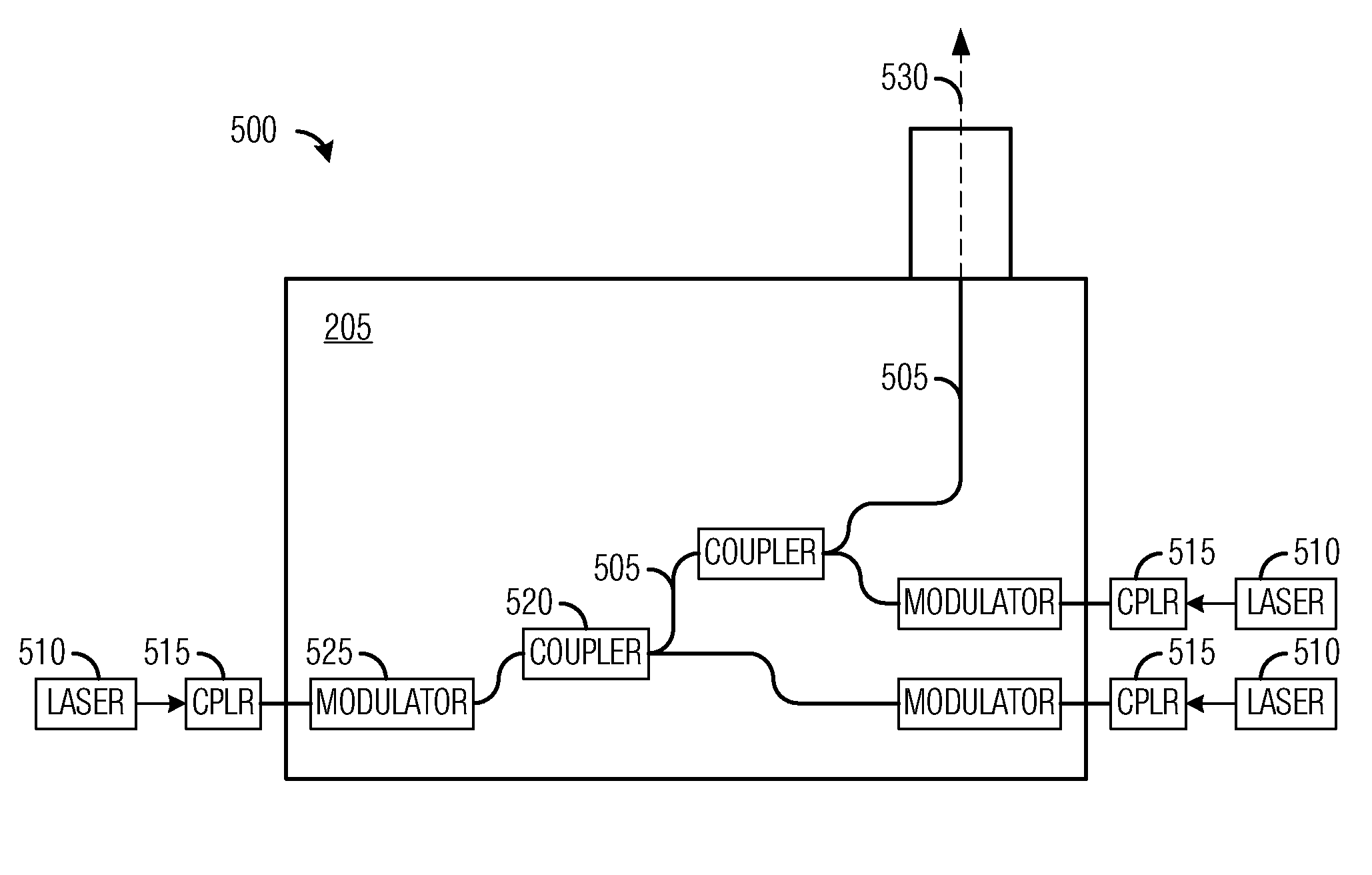

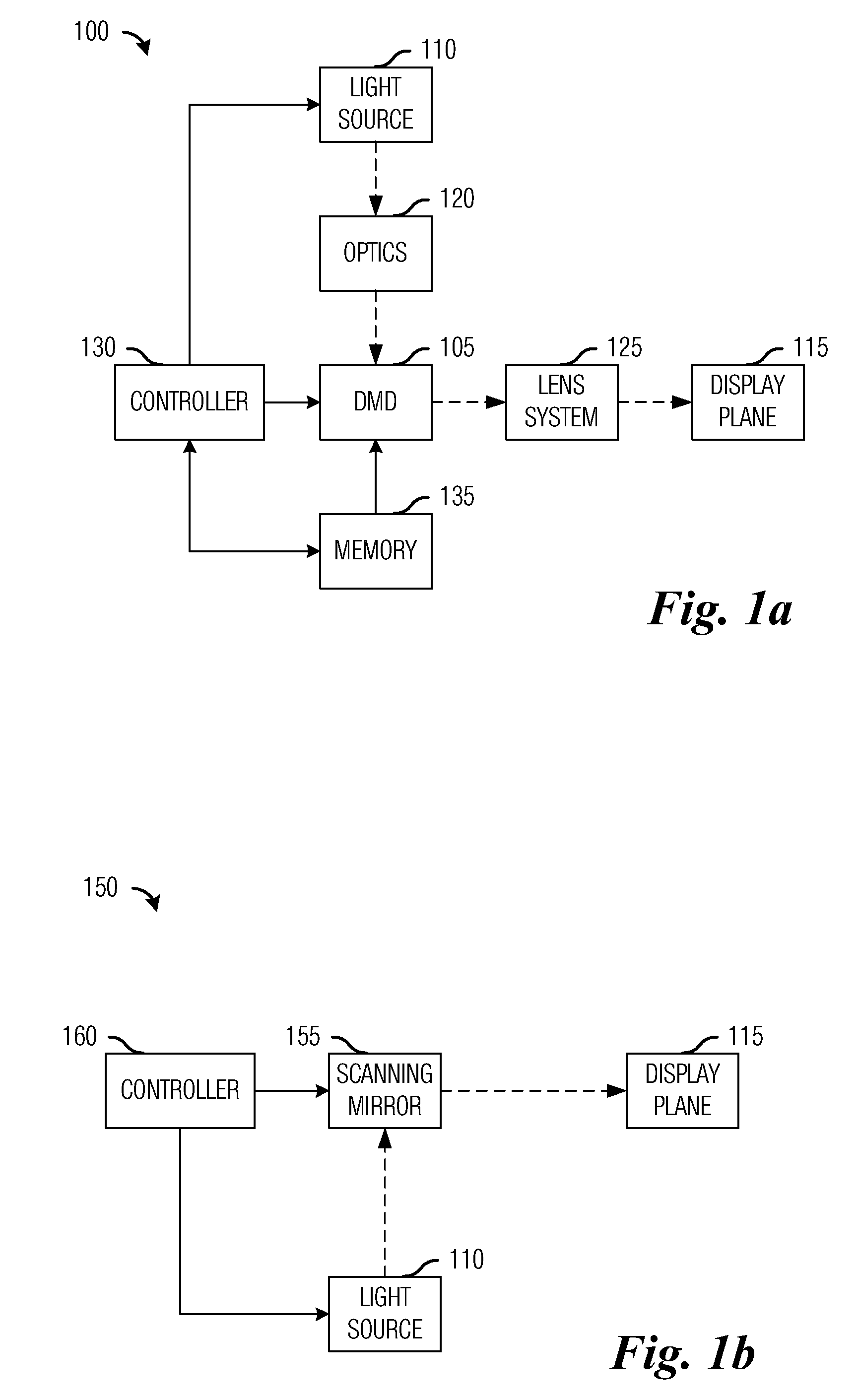

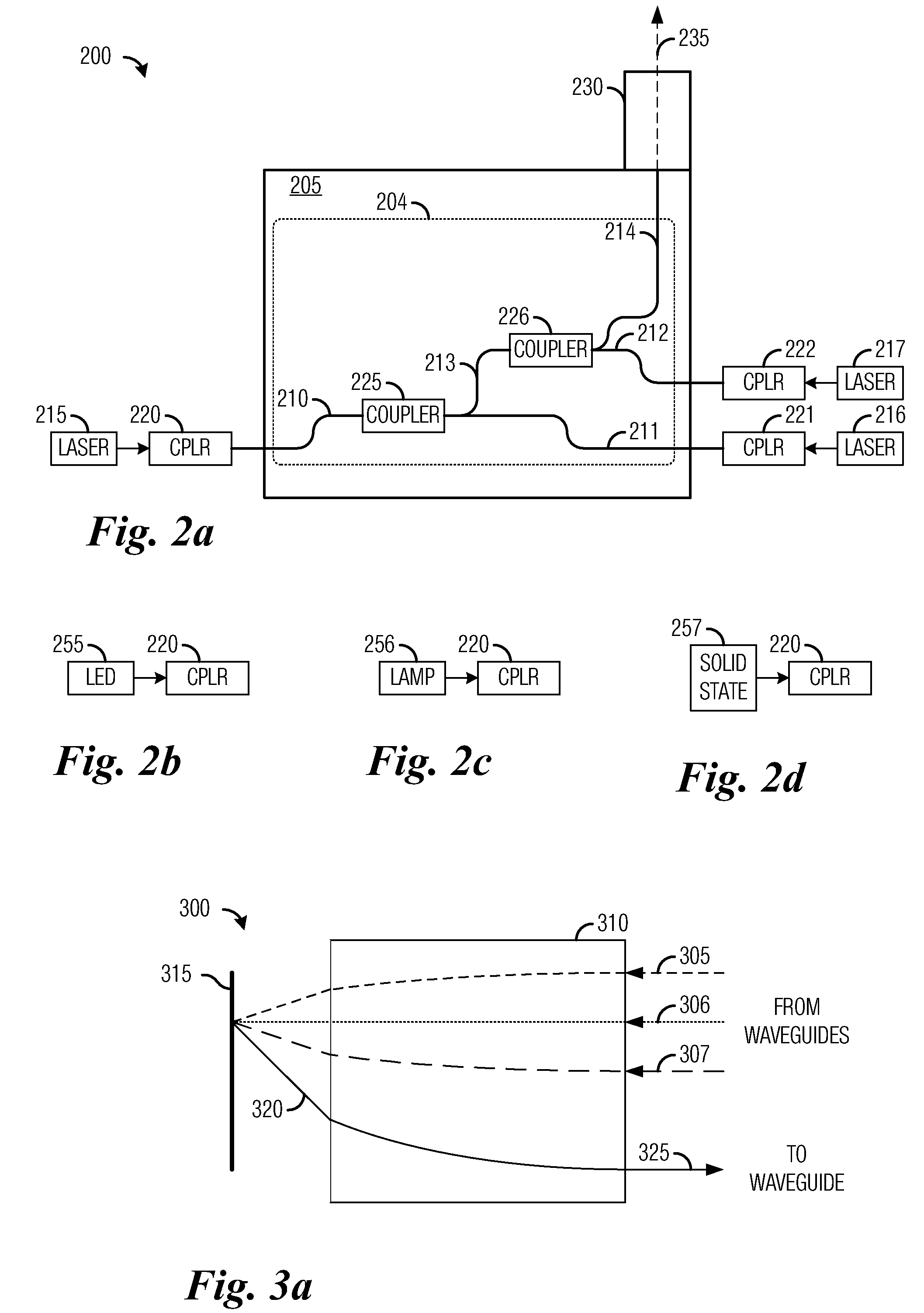

Illumination source and method therefor

ActiveUS7719766B2Made smallReduced mechanical tolerancesDisplay meansCoupling light guidesLight guideEffect light

An illumination source and a method therefor. A light source includes a light circuit configured to process light and direct light, and a lighting element optically coupled to the light circuit to provide multiple colors of light. The light circuit propagates light using light guides. The use of light guides eliminates the use of free space optical elements, enabling the creation of more compact light sources. Furthermore, the use of light guides may enable the creation of light sources with fewer mechanical restrictions, thereby making the light sources potentially more reliable and less expensive.

Owner:TEXAS INSTR INC

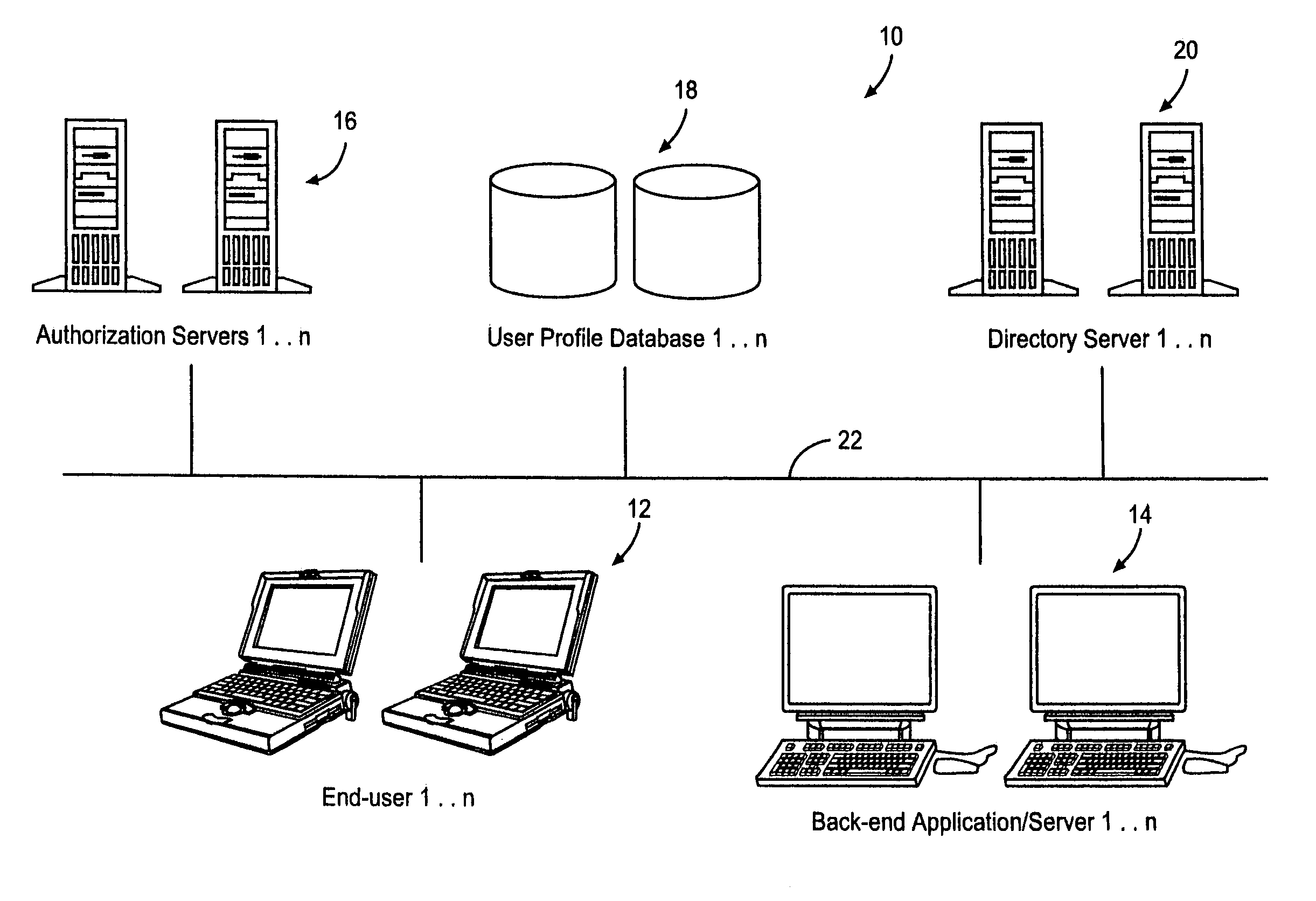

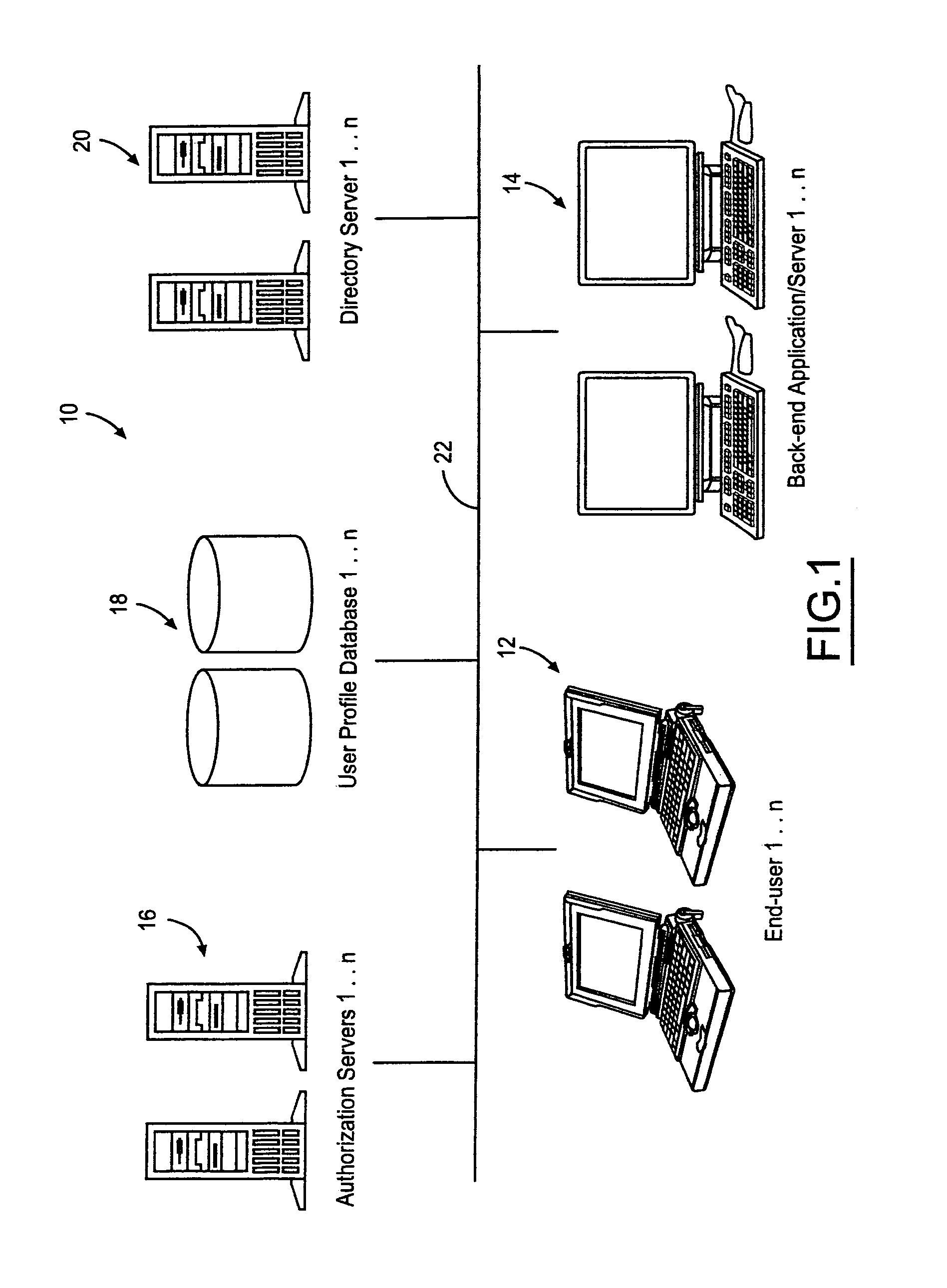

Authentication, application-authorization, and user profiling using dynamic directory services

InactiveUS7209970B1Maintenance freeMultiple digital computer combinationsTransmissionComputer usersApplication software

A system and method for authenticating and authorizing computer users with a single, standard, directory-based set of applications. The invention combines dynamic directory services (DDS) with a directory access protocol such as the light weight directory access protocol (LDAP) to provide authentication and application-authorization for secured networks, applications, and programs. Dynamic information such as session information or user ID numbers is stored in a directory each time a user logs into the systems and is maintained in the directory until the user logs out. While the information exists in the directory, it can be queried by other programs, applications, or networks that use a directory service to authenticate or authorize the user for the program, application, or network.

Owner:SPRINT SPECTRUM LLC

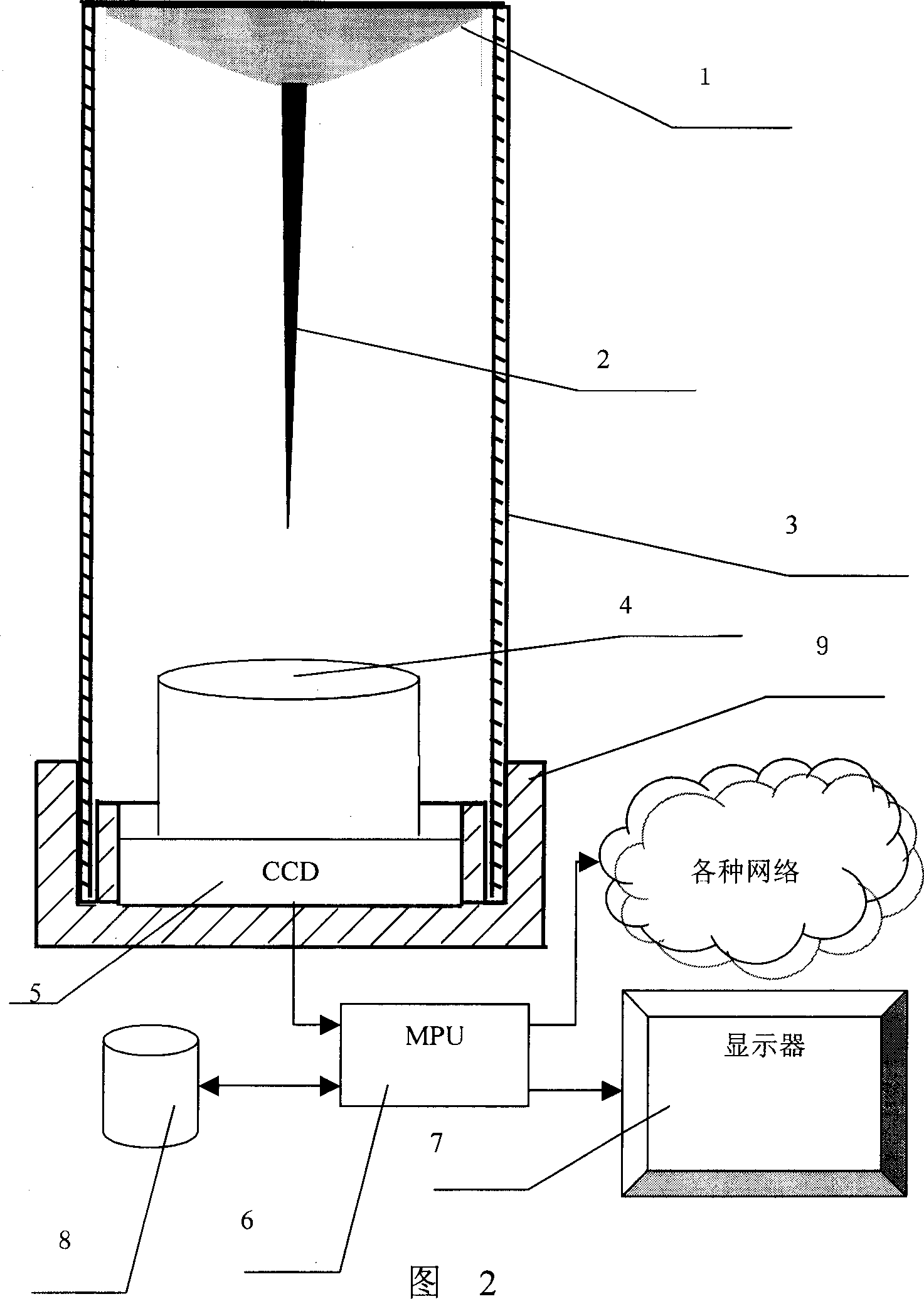

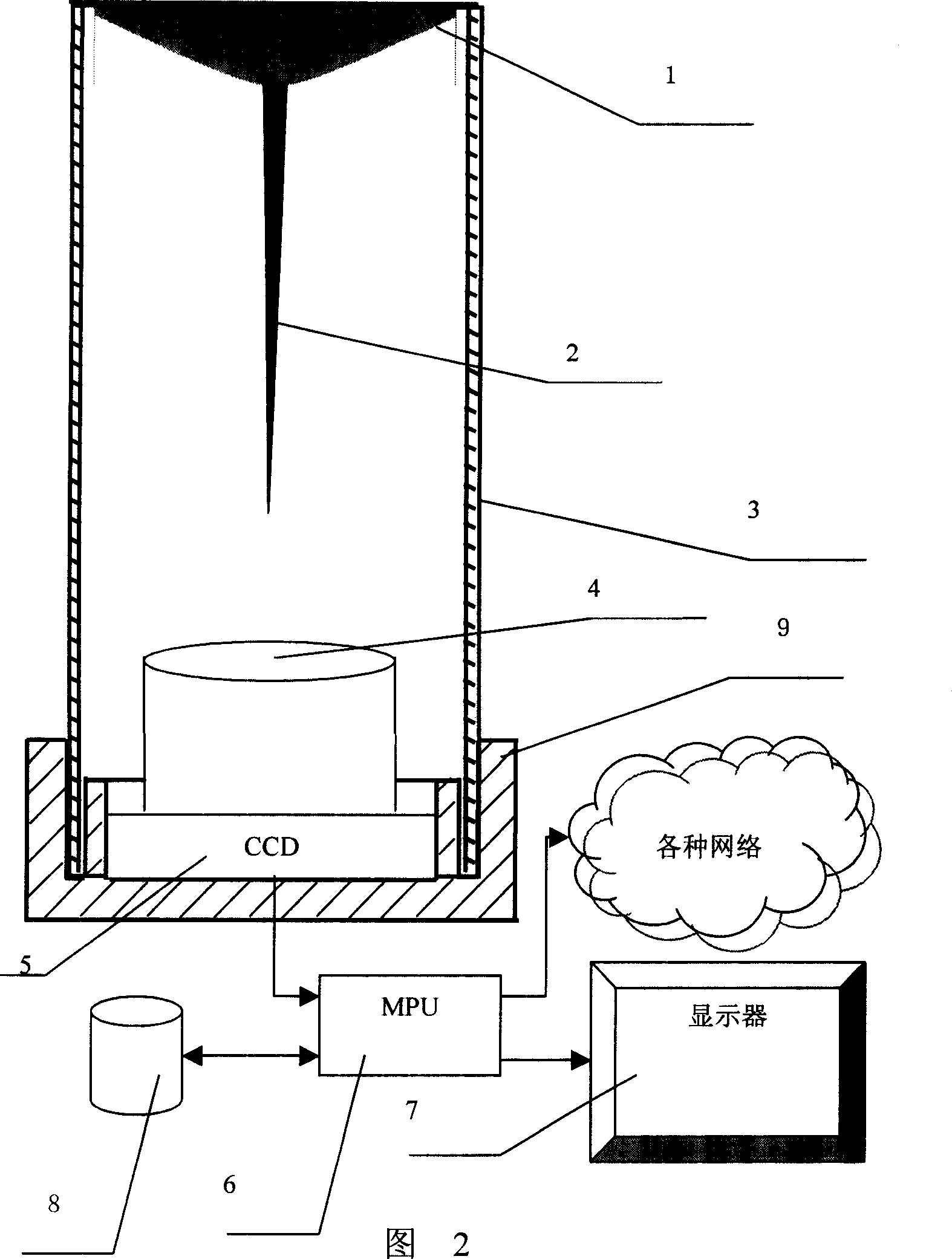

Intelligent tunnel safety monitoring apparatus based on omnibearing computer vision

InactiveCN1852428ACarry out the function of monitoringLow maintenanceImage analysisClosed circuit television systemsDisplay deviceVision sensor

The monitoring equipment includes microprocessor, video sensor in use for monitoring site of tunnel, and communication module for communication outside. Microproceesor includes following modules: reading module for image dada in use for reading information of video image transferred from video sensor; file storage module in use for storing data collected by video sensor to storage device; real time playing module on site connected to external display device is in use for playing monitored image on site in real time. Output of the video sensor is connected to microprocessor through communication. Using all directional computer vision sensor monitors tunnel site, processes and analyzes images. Using detected variation character for fire flame in early phase, the invention finds early fire in tunnel as well as obtains traffic data including vehicle flowrate, and occupancy ratio, speed, and traffic accident etc.

Owner:ZHEJIANG UNIV OF TECH

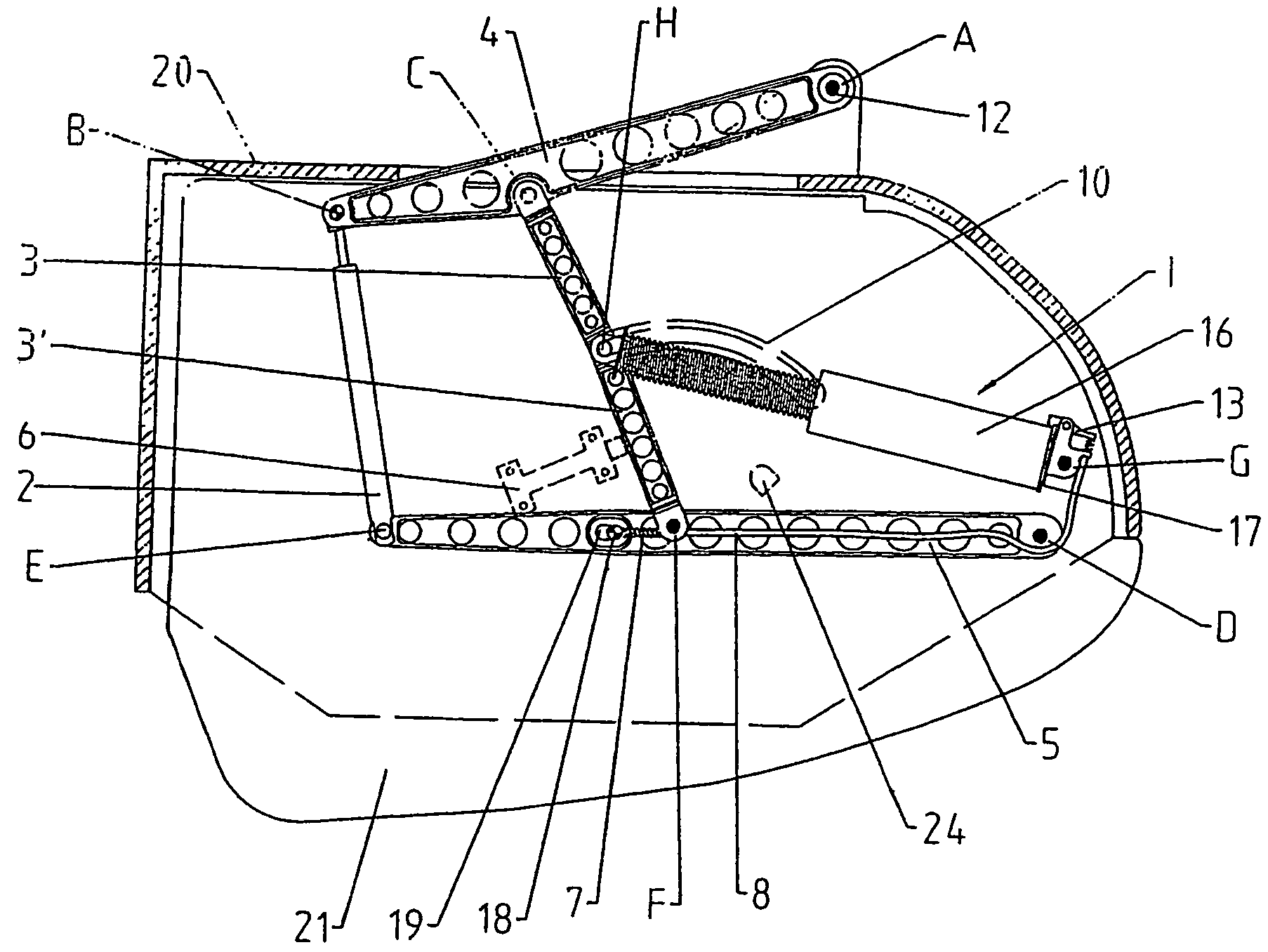

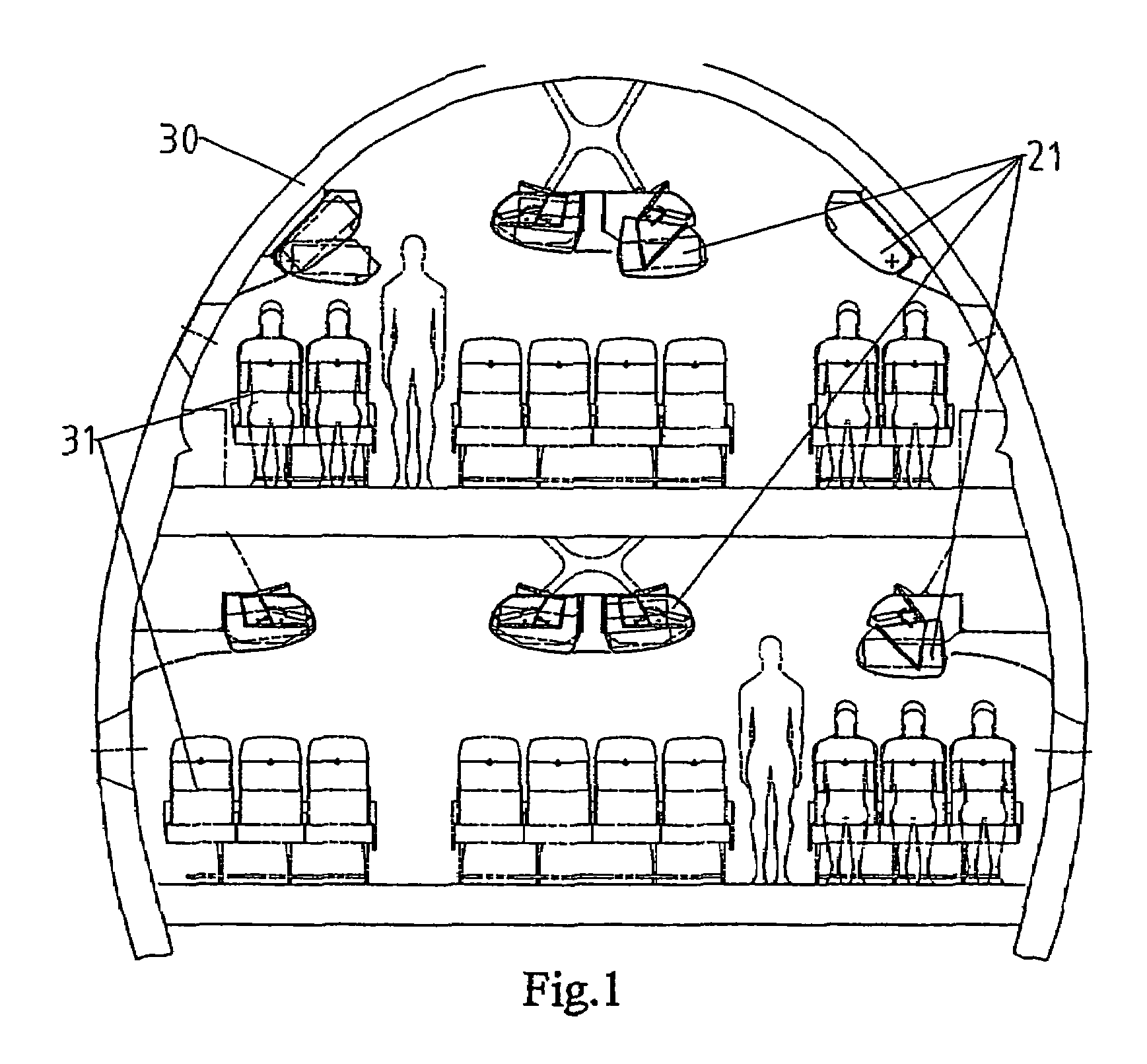

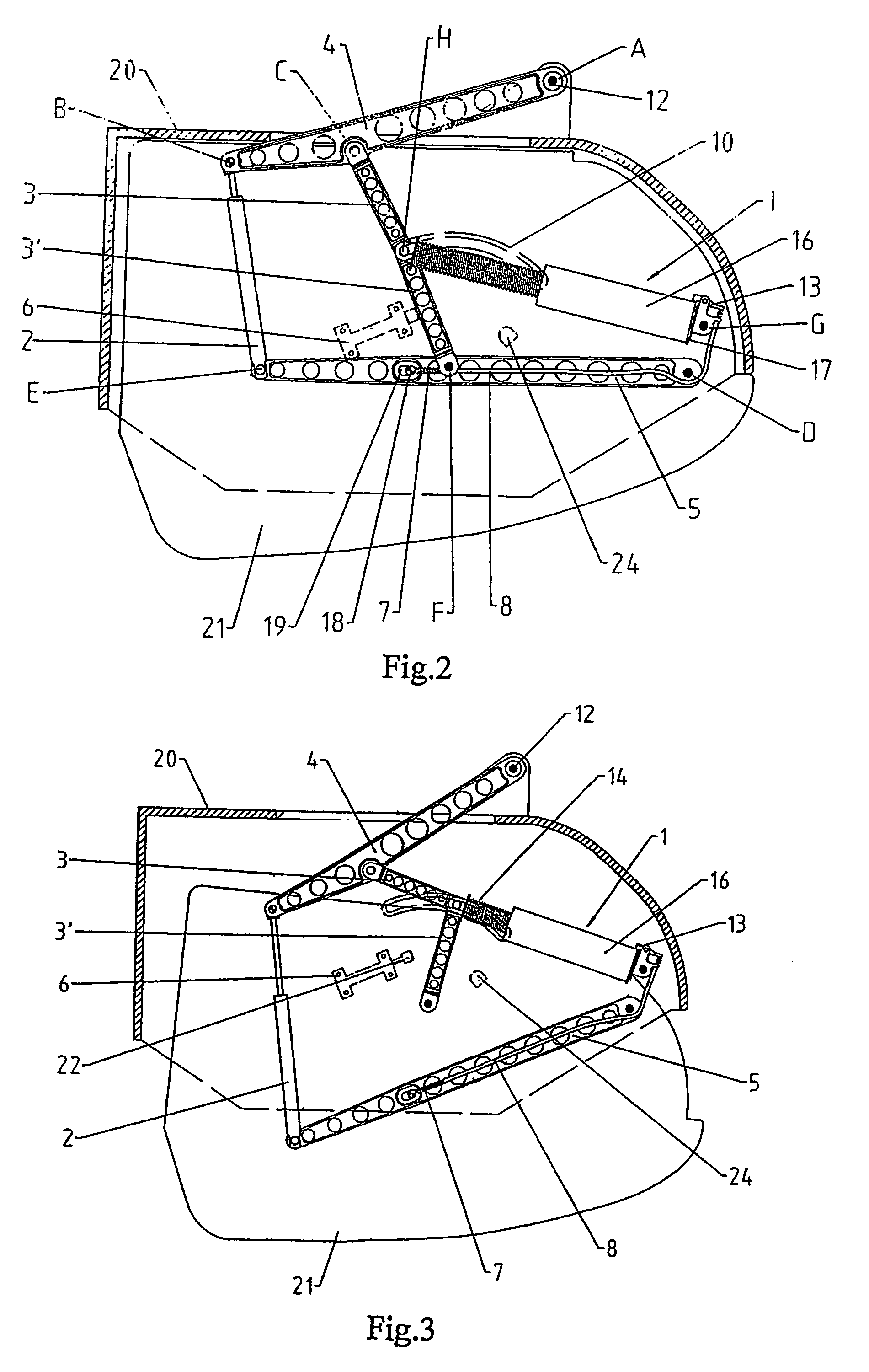

Suspension device for lowerable luggage compartments

A suspension device for a lowerable luggage stowage compartment has at least one spring element for assisting the movement of the compartment into a closed position against the force of gravity, and at least one damping element for damping the movement of the compartment into an opened position. A weight detector detects the weight of the compartment, and at least one additional spring element can be actuated based on the detected weight of the compartment. A retention device is provided for fixing the additional spring element. The suspension device provides a compartment that is easy to handle and easy to close even when fully loaded.

Owner:FACC

Systems and methods for providing cooling in compressed air storage power supply systems

InactiveUS20060059936A1Lower operating temperatureSmall sizeDomestic cooling apparatusAc-dc conversionThermal energyElectric machine

A system and method for cooling electrical machines (e.g., generators), sub-systems (e.g., power electronics), and components (e.g., bearings) in an electrical generation system such as a compressed air storage (CAS) energy system or a thermal and compressed air storage (TACAS) energy system is provided. Cooling is derived from the thermal expansion of a compressed gas, which may be the same gas used to drive a turbine-generator of CAS or TACAS energy system.

Owner:ACTIVE POWER INC

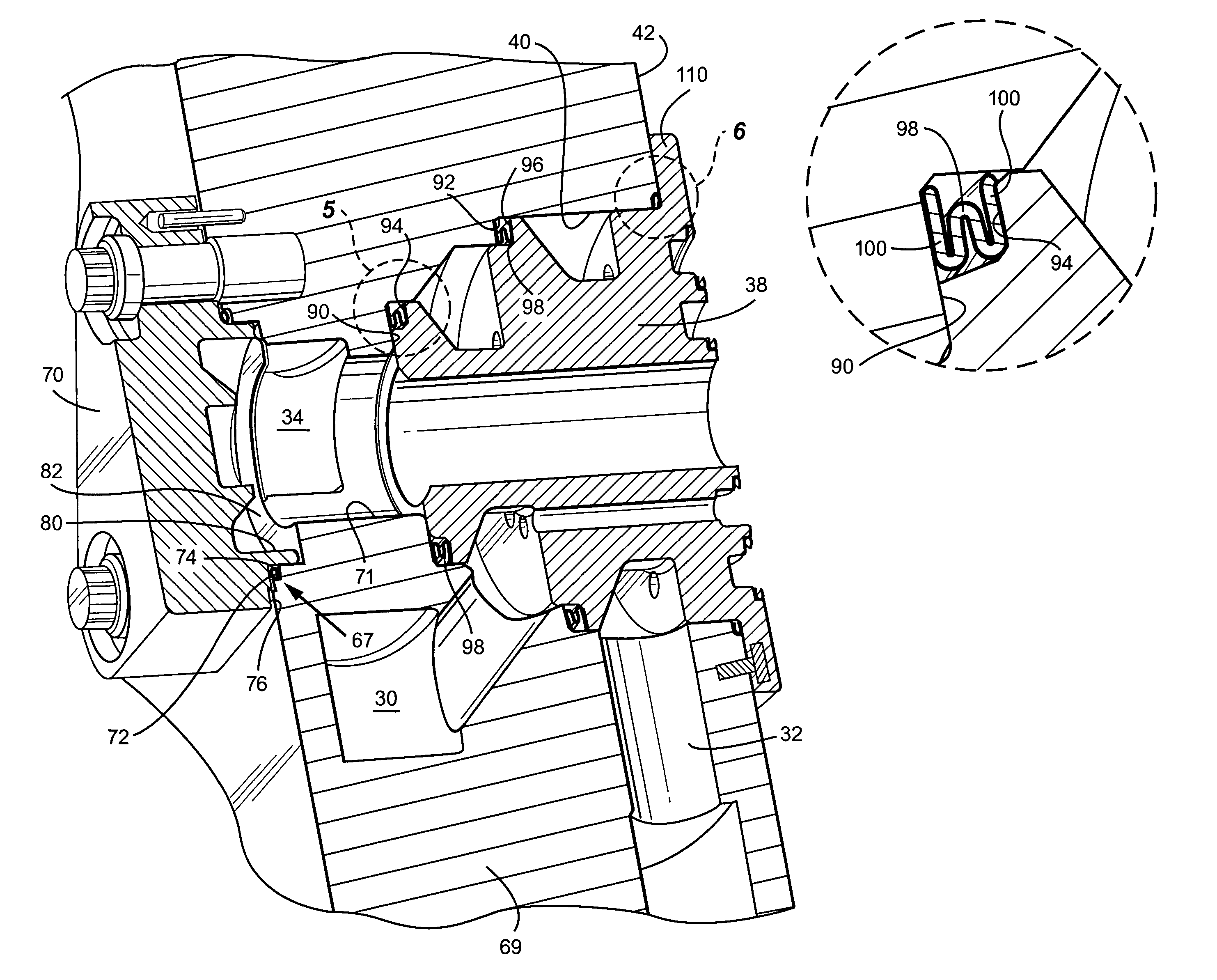

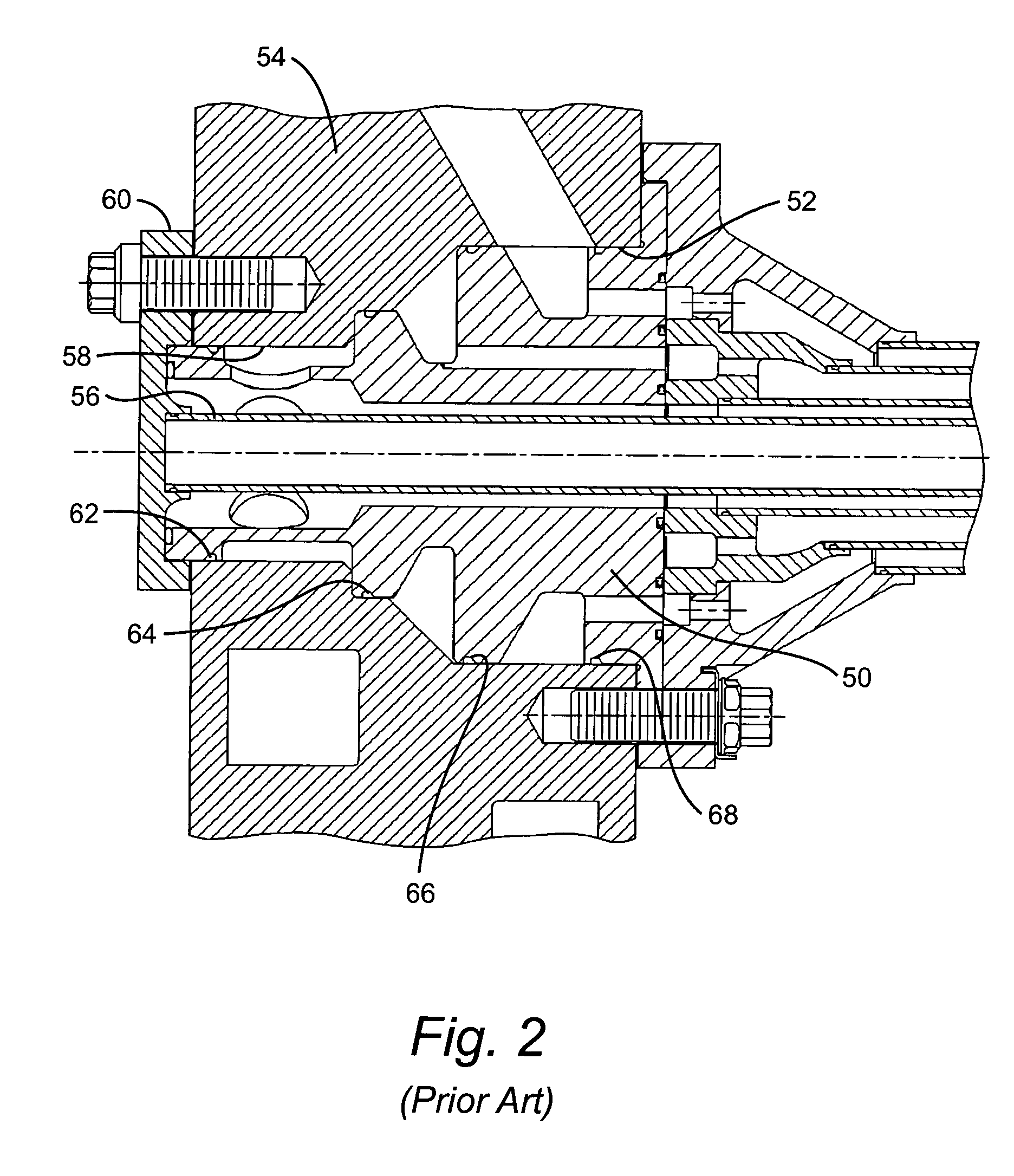

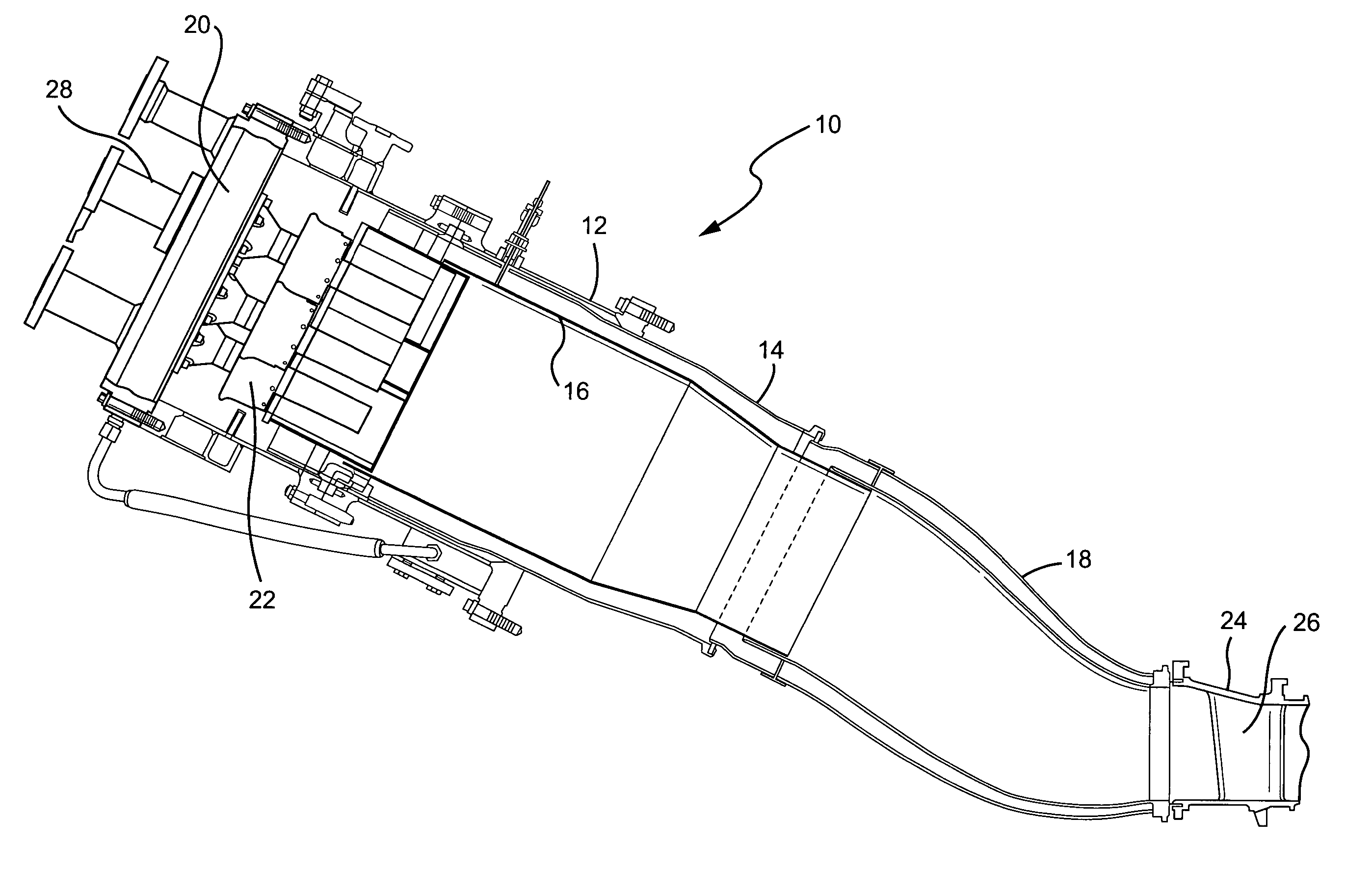

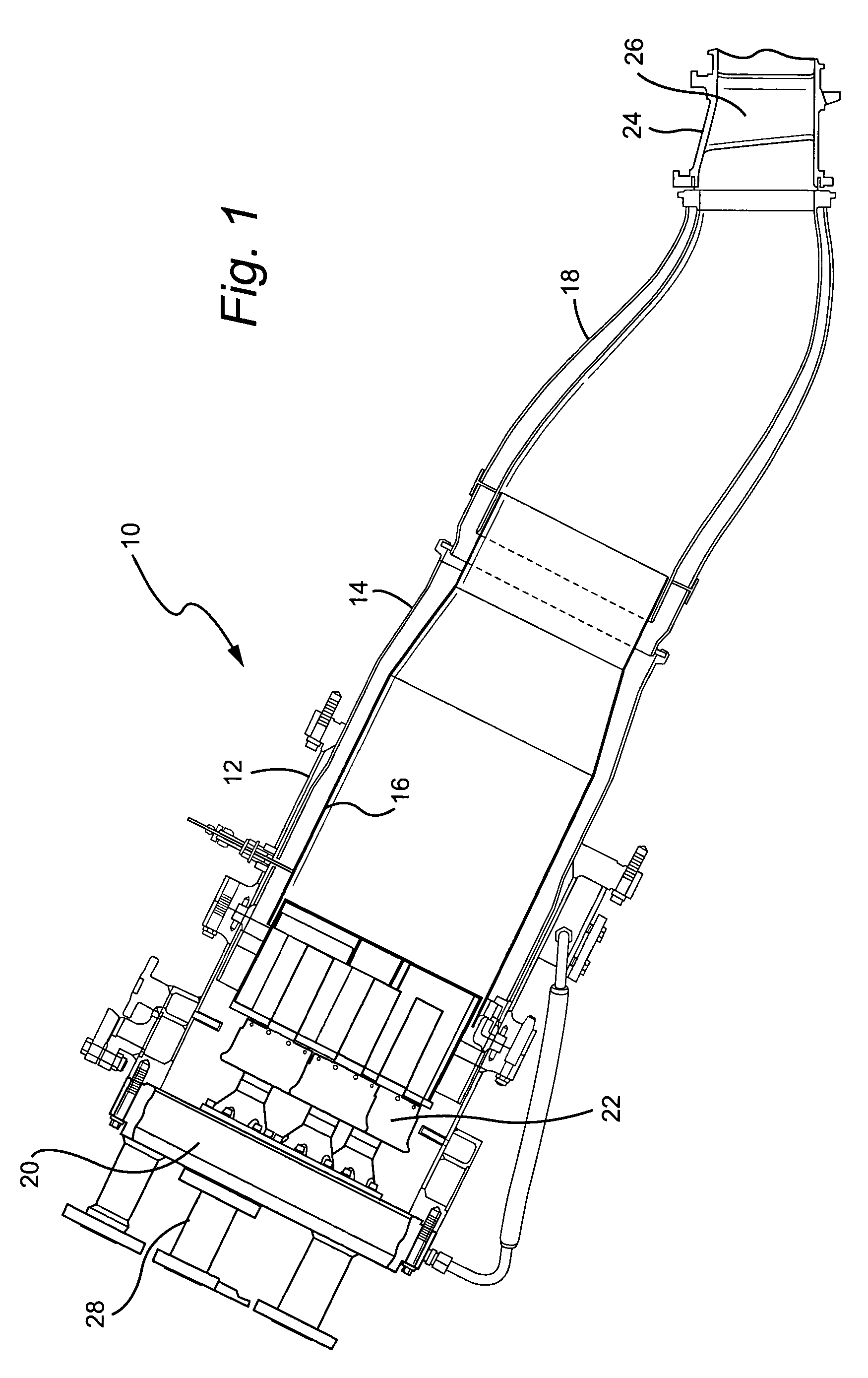

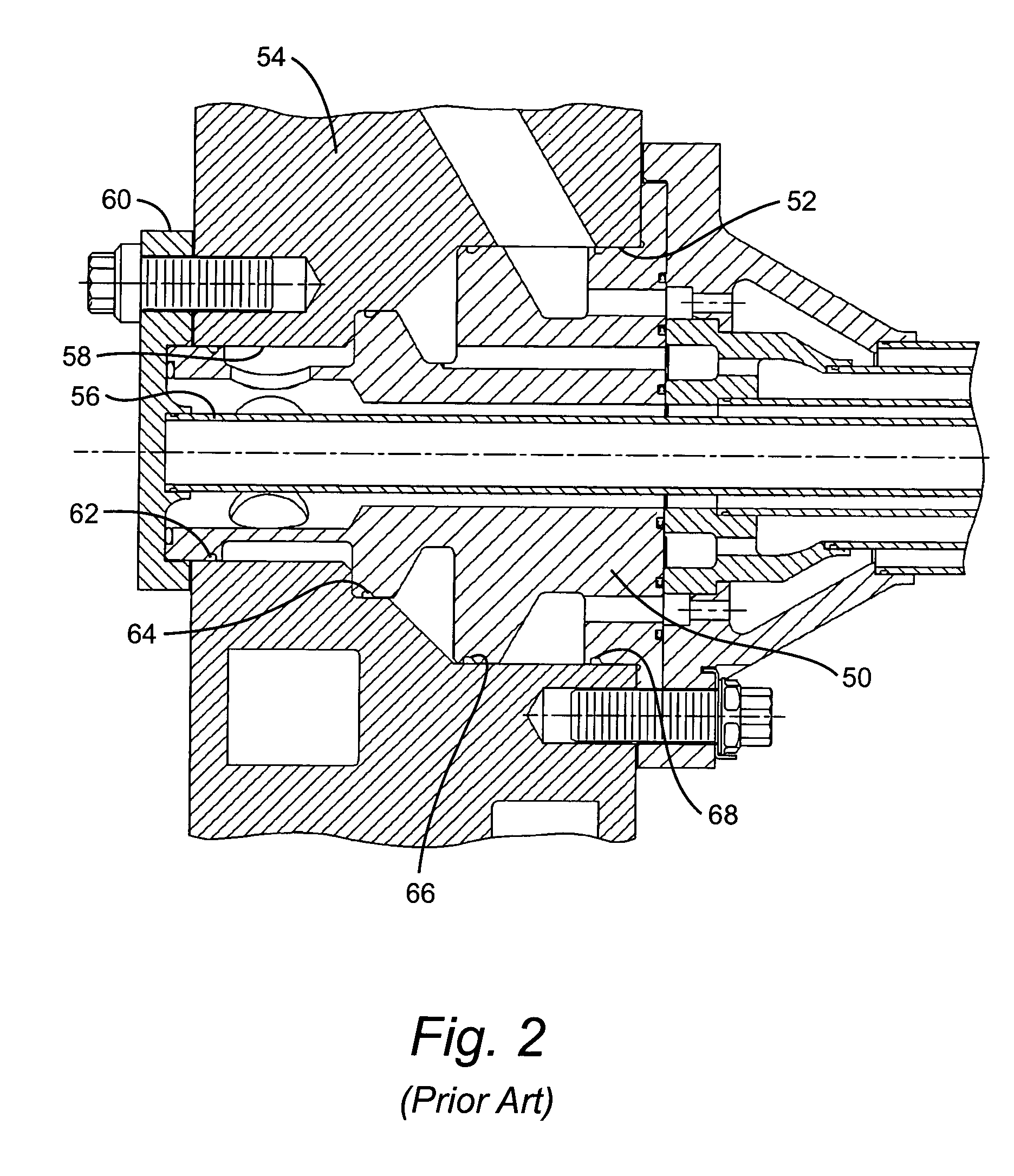

Turbine combustor endcover assembly

ActiveUS7134287B2Easy maintenanceMaintenance freeEngine sealsContinuous combustion chamberCombustorEngineering

The endcover assembly for a combustor includes an endcover having an aperture, an insert disposed in the stepped bore opening through an internal face of the endcover, a fuel cartridge extending through the insert and aperture and a seal cover on the external face of the endcover. Seal cover / endcover annular seals are disposed in registering axial cavities to seal against fluid leakage externally of the endcover assembly. Generally C-shaped and W-shaped seals are disposed in the cavities between the stepped shoulders of the insert and aperture to seal against leakage through the internal face of the endcover. The seals maintain sealing engagement during assembly and thermal distortion during turbine usage.

Owner:GENERAL ELECTRIC CO

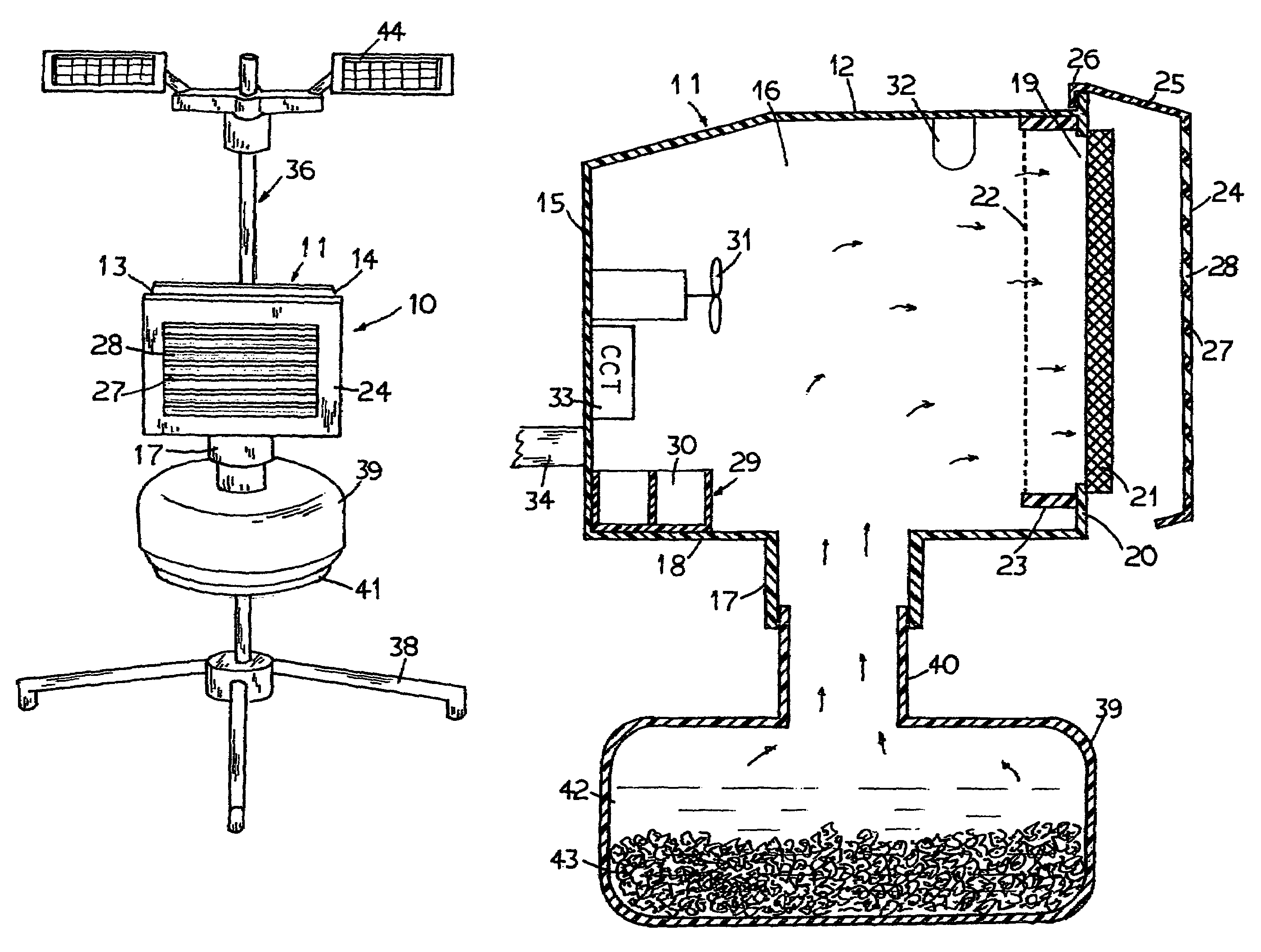

Mosquitoes eradicating system

InactiveUS7073287B2Maintenance-freeEasy to operateElectric shock equipmentsInsect catchers and killersElectricityDark color

A housing is provided for attracting and eradicating mosquitoes. The interior walls of the housing is painted with a dark color such as black and it is coupled to a water container with an air duct. An electrified conductive grid is mounted at a large front opening of the main housing. A mixture of water and charcoal is placed in the water container. A louver panel is mounted in front of the electrified conductive grid to provide a shield as well as a canopy against rain and sun light. An interior container having a plurality of open top compartment is located in the main housing with various selected organic materials placed in those compartments for creating an environment in the main housing attractive to various types of mosquitoes.

Owner:LAU LEUNG FAI

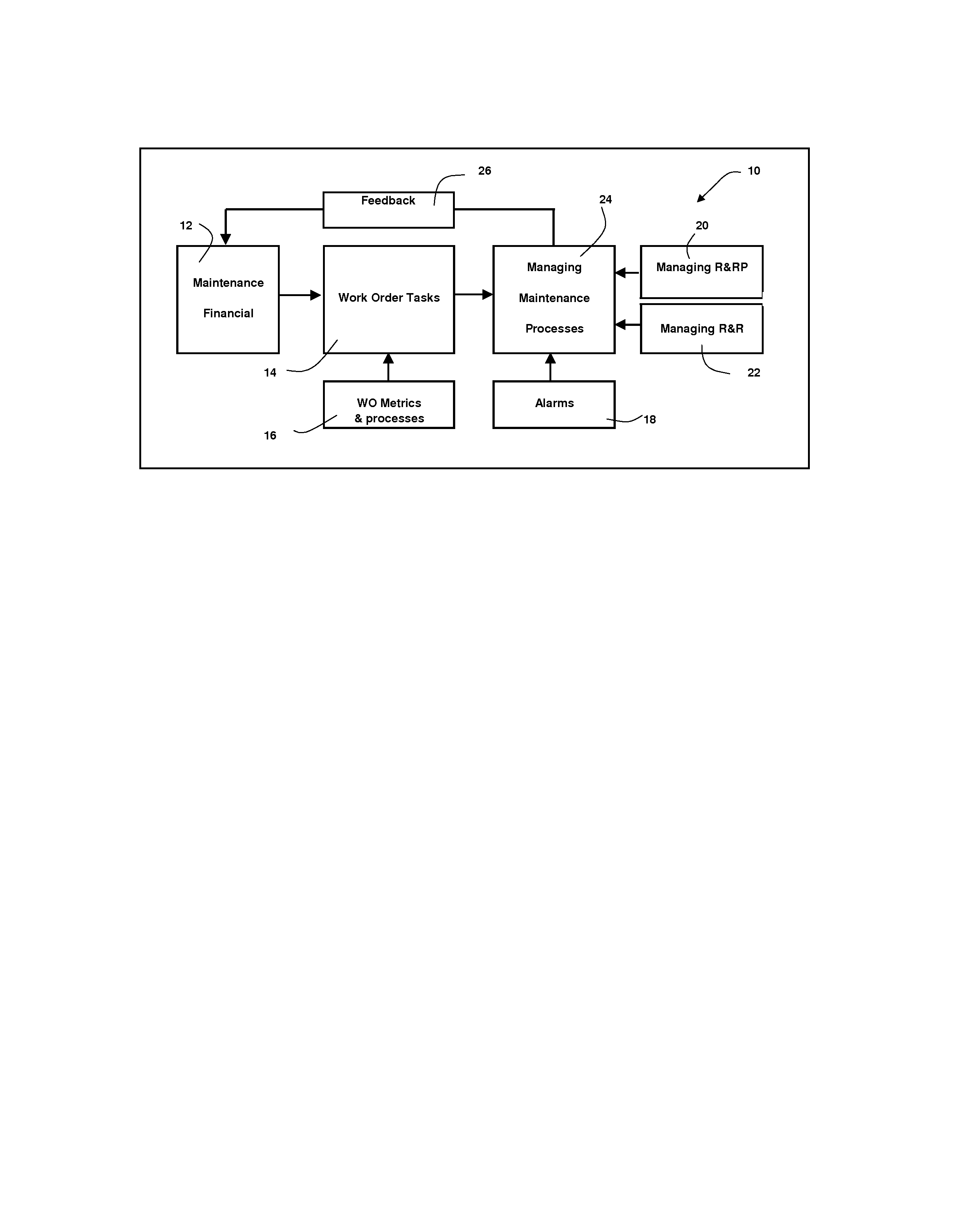

Eliminating sources of maintenance losses

Processes and software are provided for eliminating sources of maintenance losses in machine intensive environments such as manufacturing, processing and assembly plants.The processes and software include creating financial and work order metrics to trend maintenance variables, a process for creating work orders, a process for using alarms for integrating measurement technologies and spare parts, a process for managing repair and replacing activities and projects by improving documenting and communicating processes while involving users such as executives and senior managers.

Owner:ROSSI SERGIO J

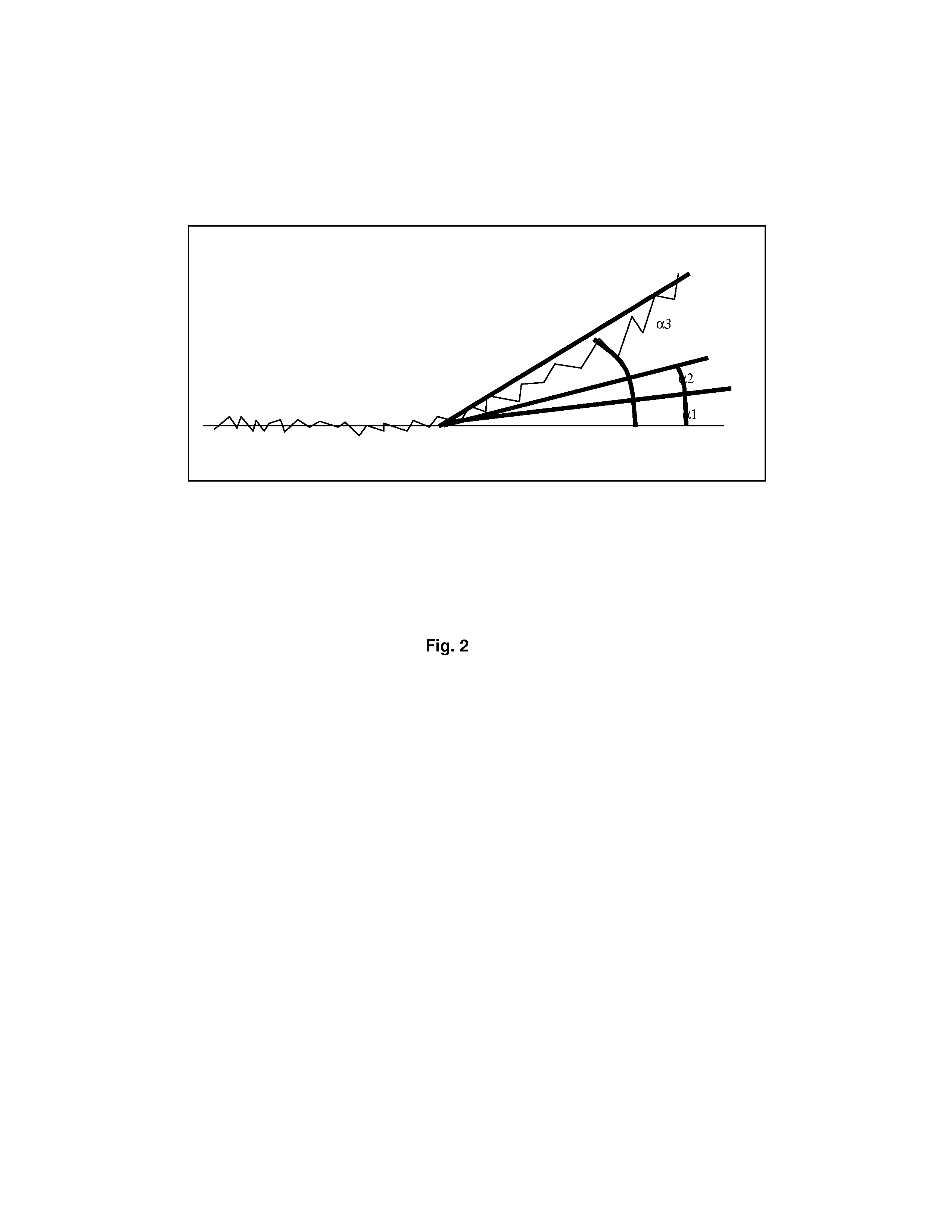

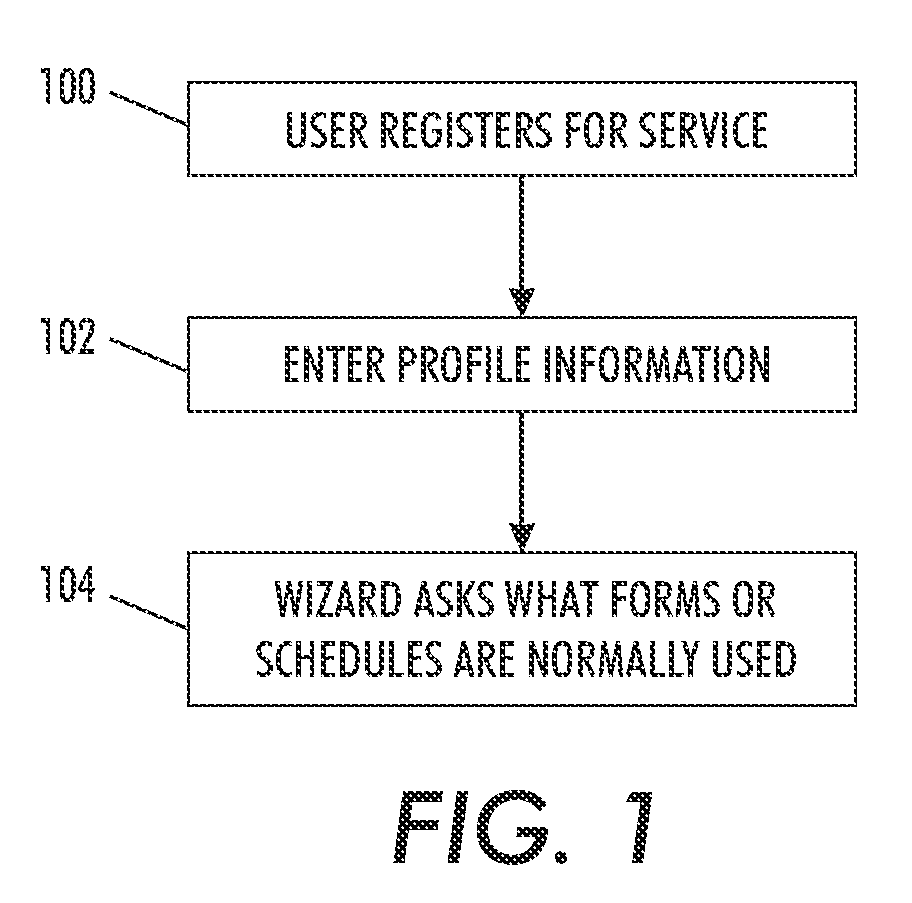

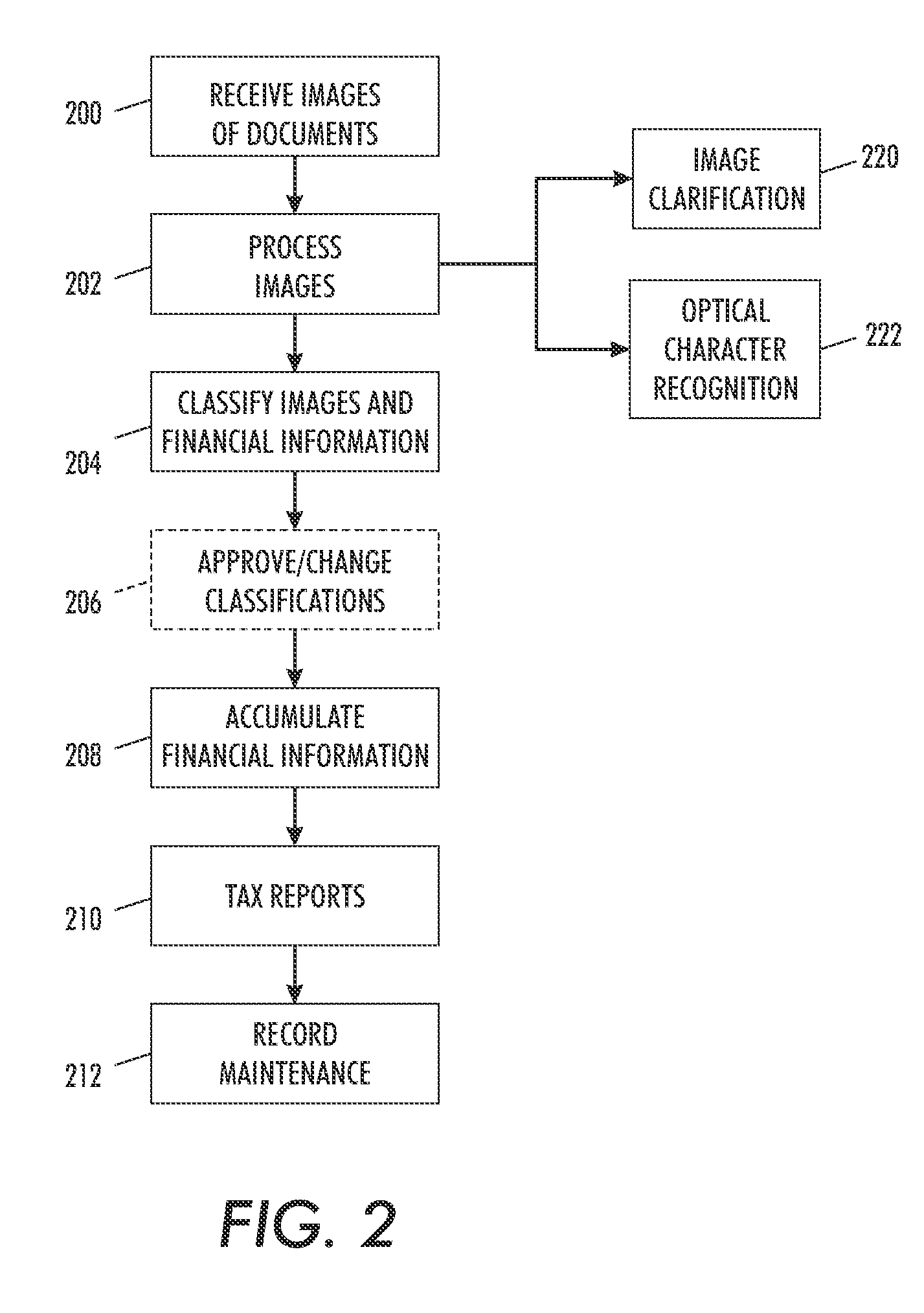

Centralized classification and retention of tax records

Owner:XEROX CORP

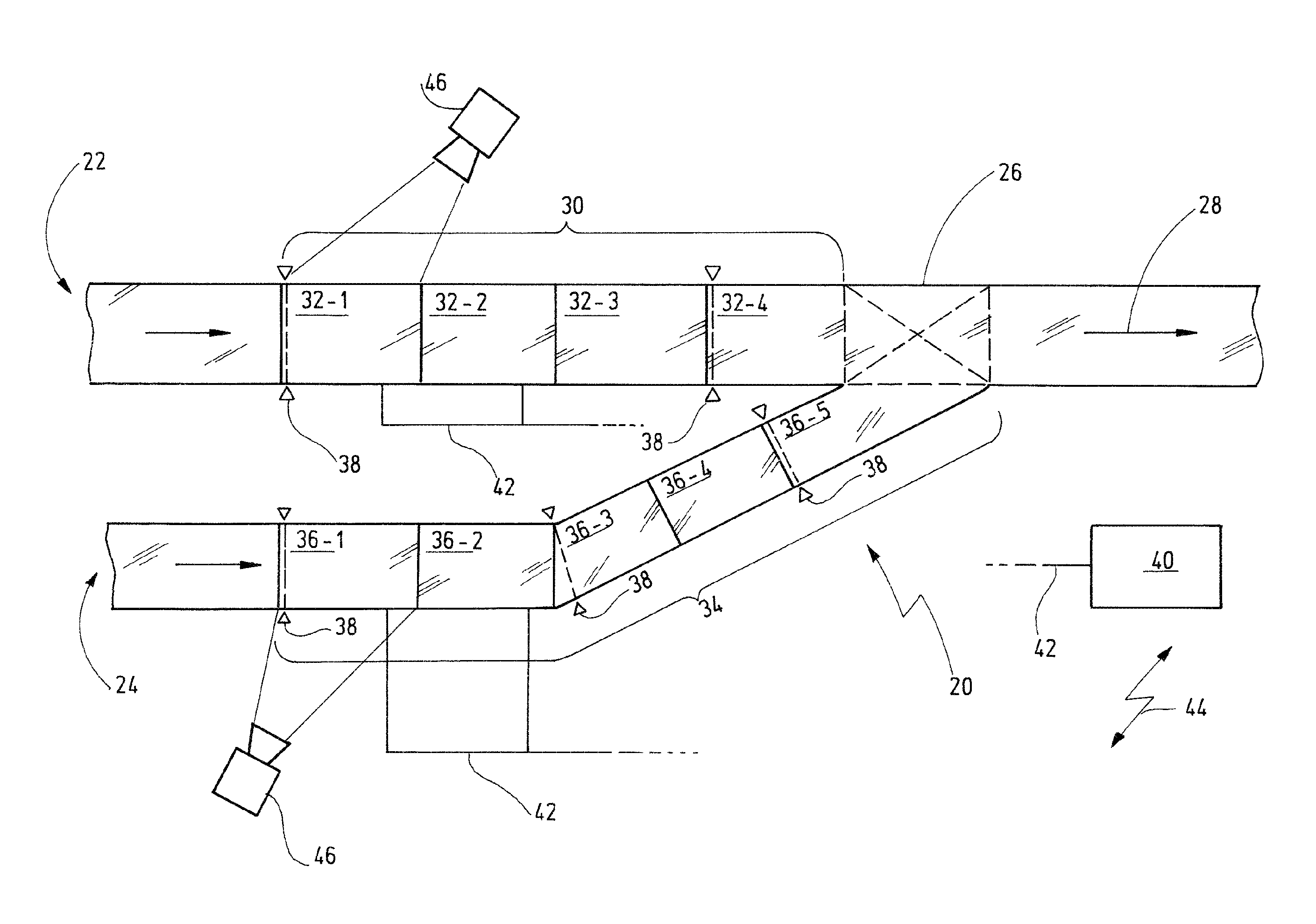

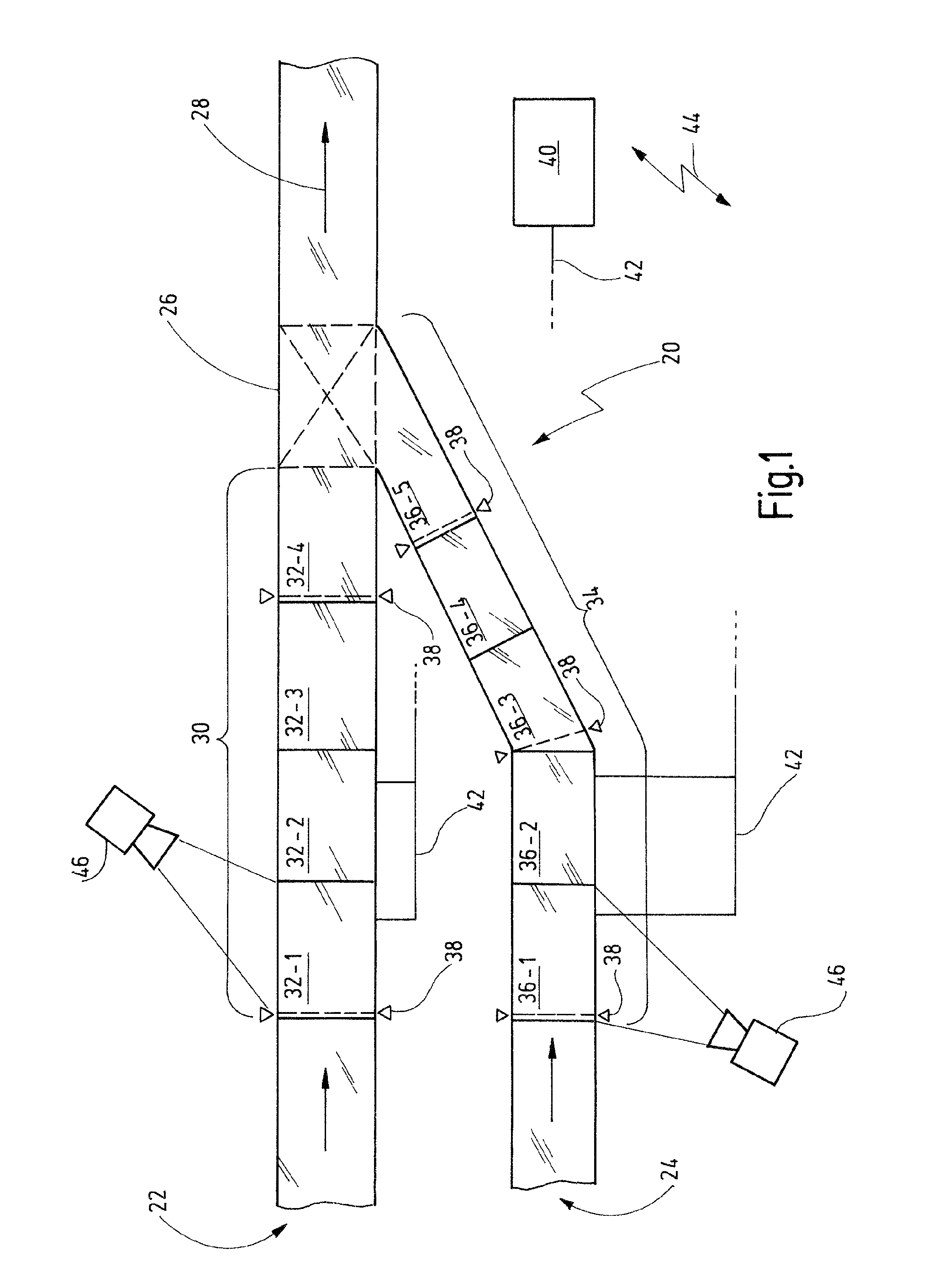

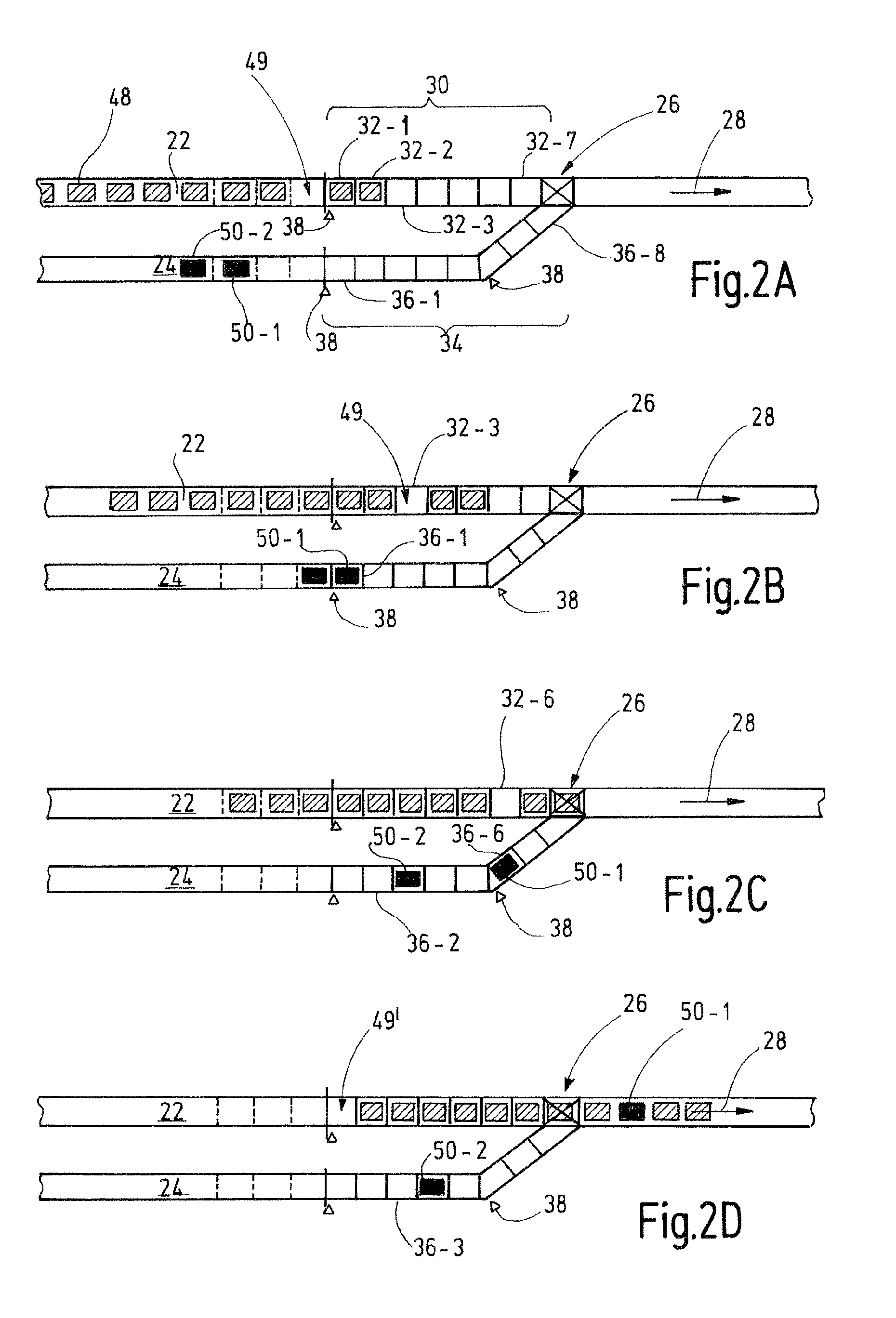

Material-flow control for collision avoidance in a conveyor system

ActiveUS8061506B2Efficient powerMaintenance freeControl devices for conveyorsMechanical conveyorsVolumetric Mass DensityEngineering

Owner:SSI SCHAEFER PEEM

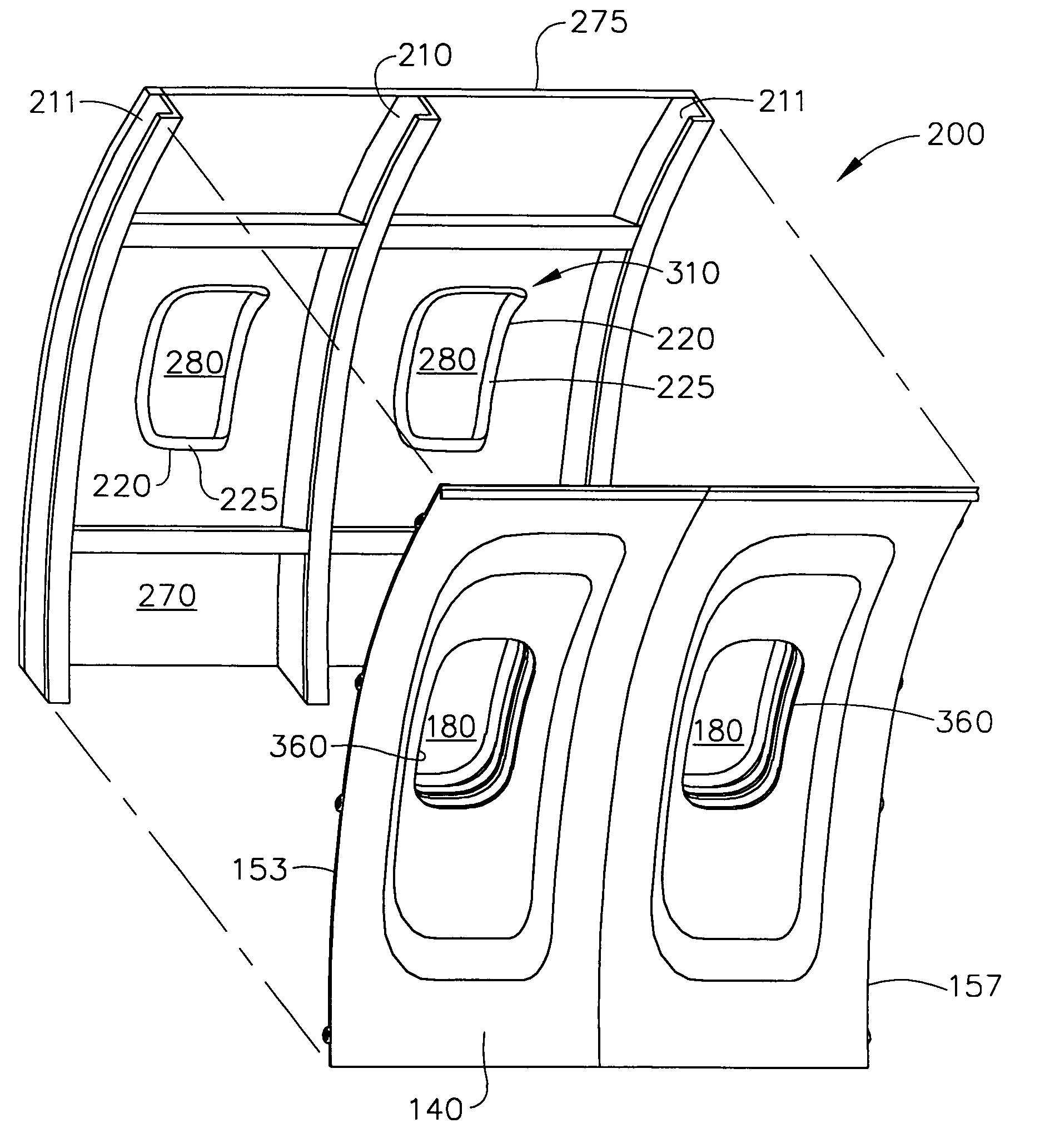

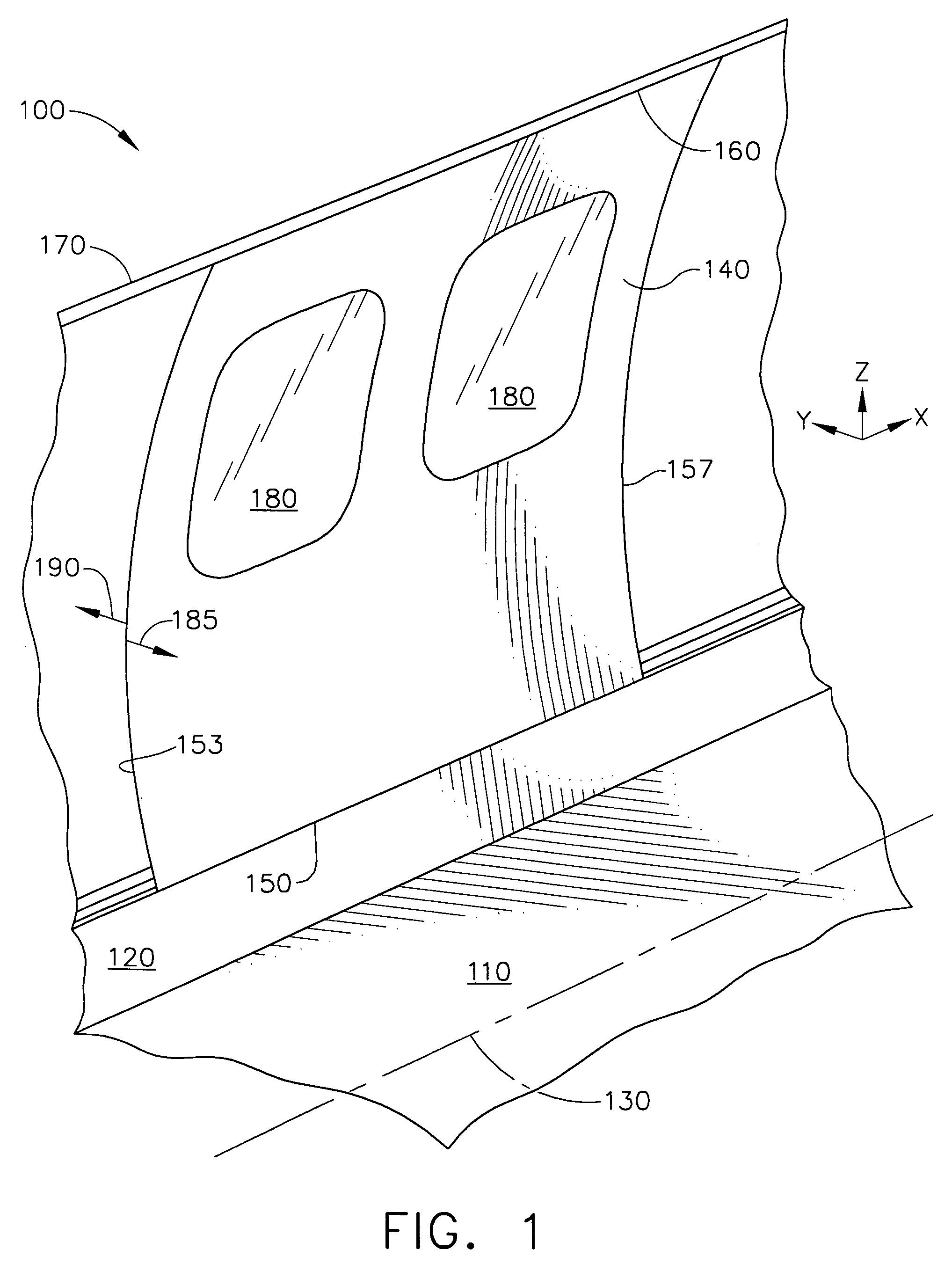

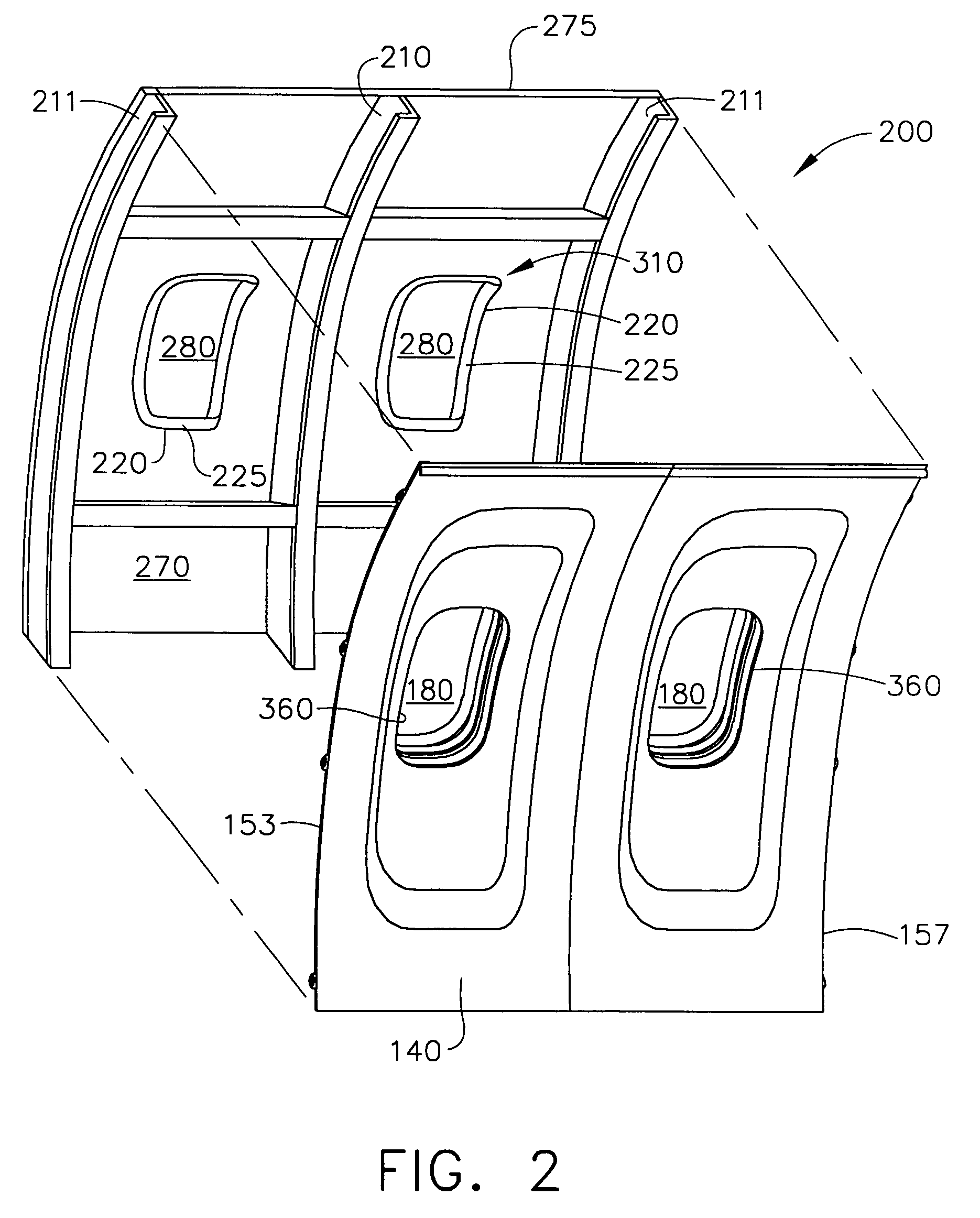

Integrated window belt system for aircraft cabins

Owner:THE BOEING CO

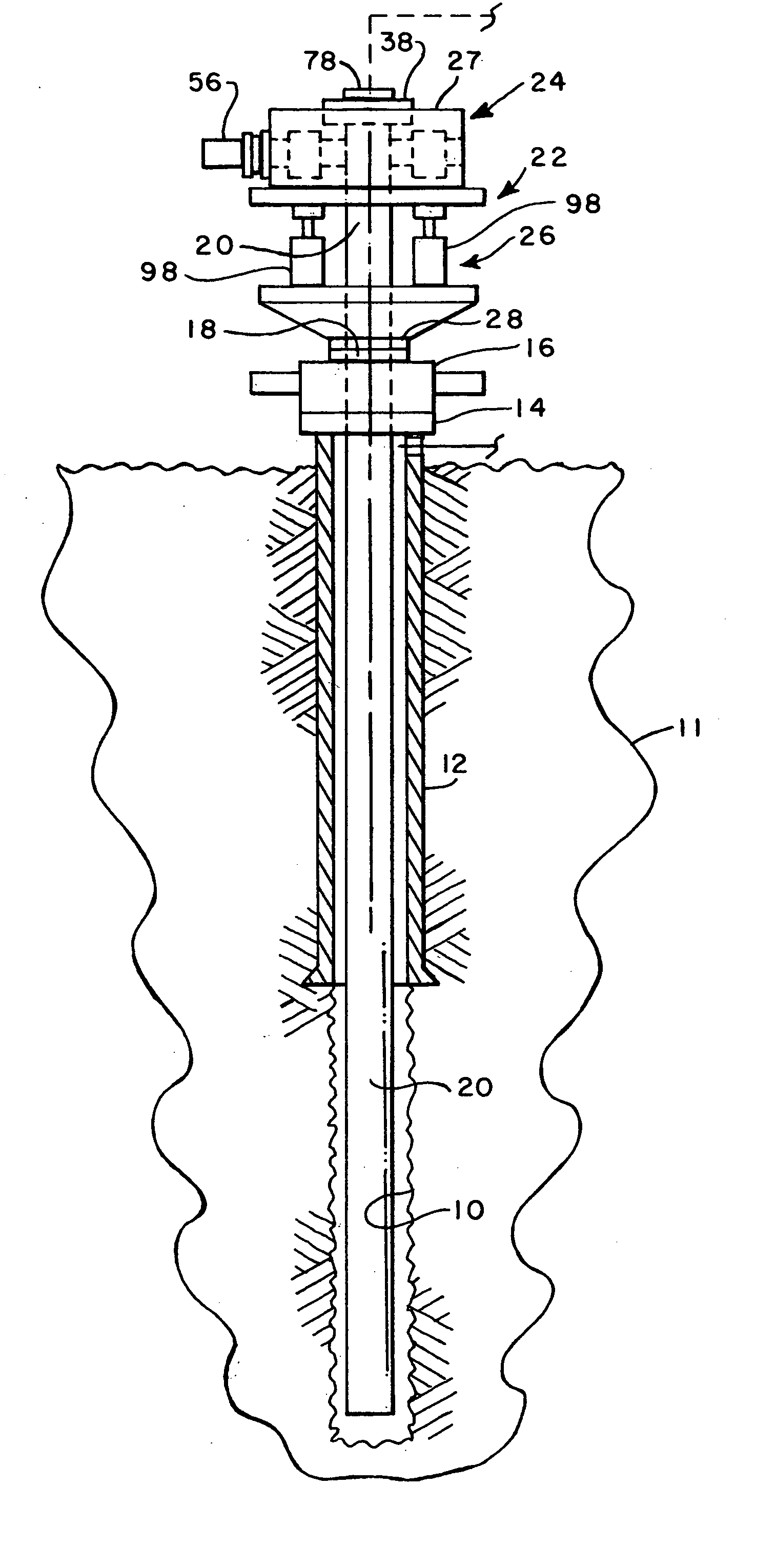

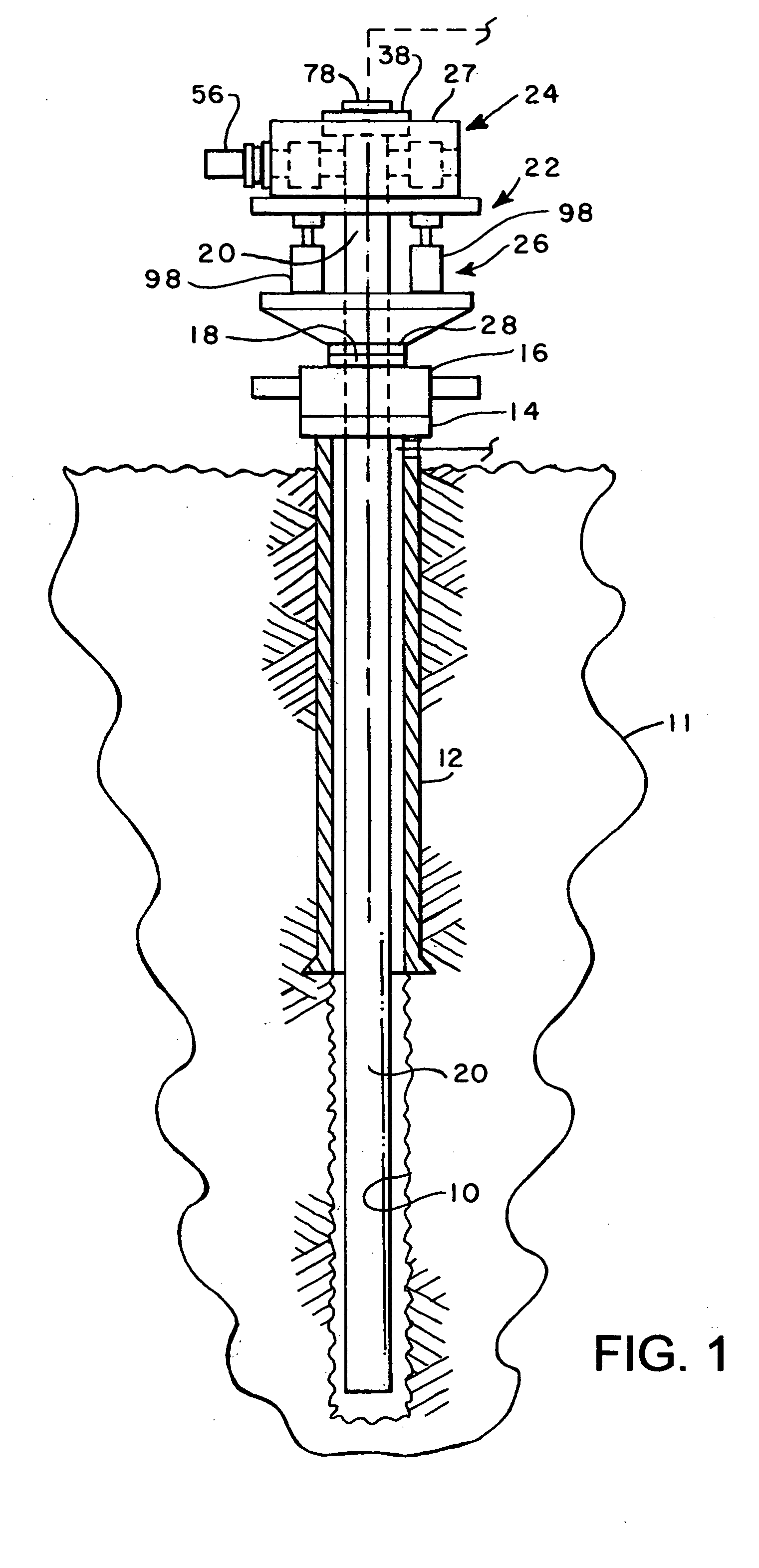

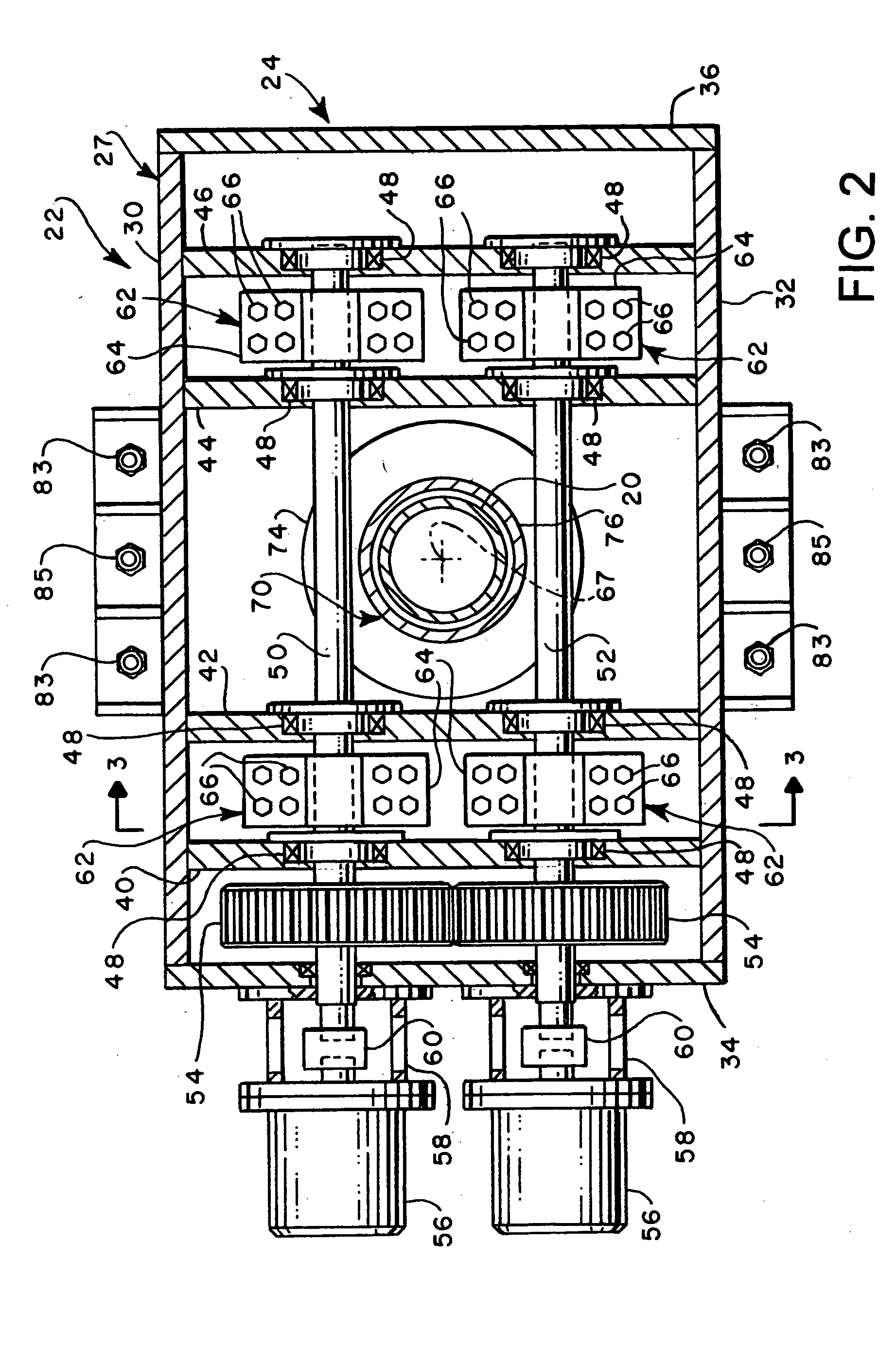

Well tubing/casing vibratior apparatus

InactiveUS20050155758A1Guaranteed uptimeEasy maintenanceFluid removalDirectional drillingElectric machineEngineering

A vibrator apparatus for inducing longitudinal vibrations in a well tubing or casing member for various operations, or for removing stuck tubing or casing. The apparatus includes a vibrator section with spaced apart rotatable shafts carrying eccentric weights and interconnected by timing gears. The shafts are driven by respective pressure fluid motors. The vibrator section is mounted on an isolator section including spaced apart pressure fluid cylinder assemblies for isolating vibrations generated by the apparatus from wellhead structure supporting the apparatus. A fluid flow circuit includes a pump, a manifold, flow control devices for generating fluid flow through the cylinder assemblies and accumulators for damping fluid pressure and flow fluctuations in the circuit.

Owner:DHR SOLUTIONS

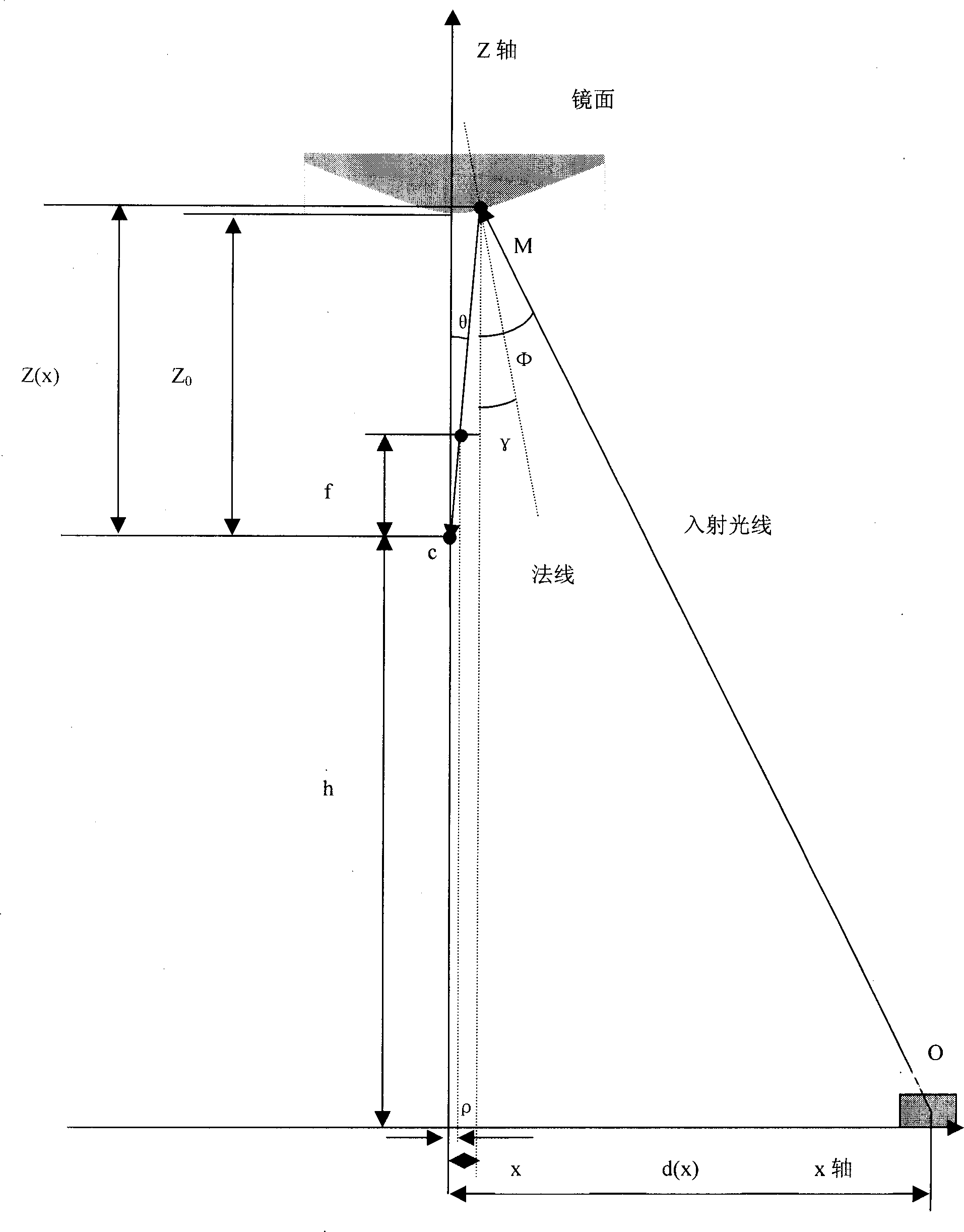

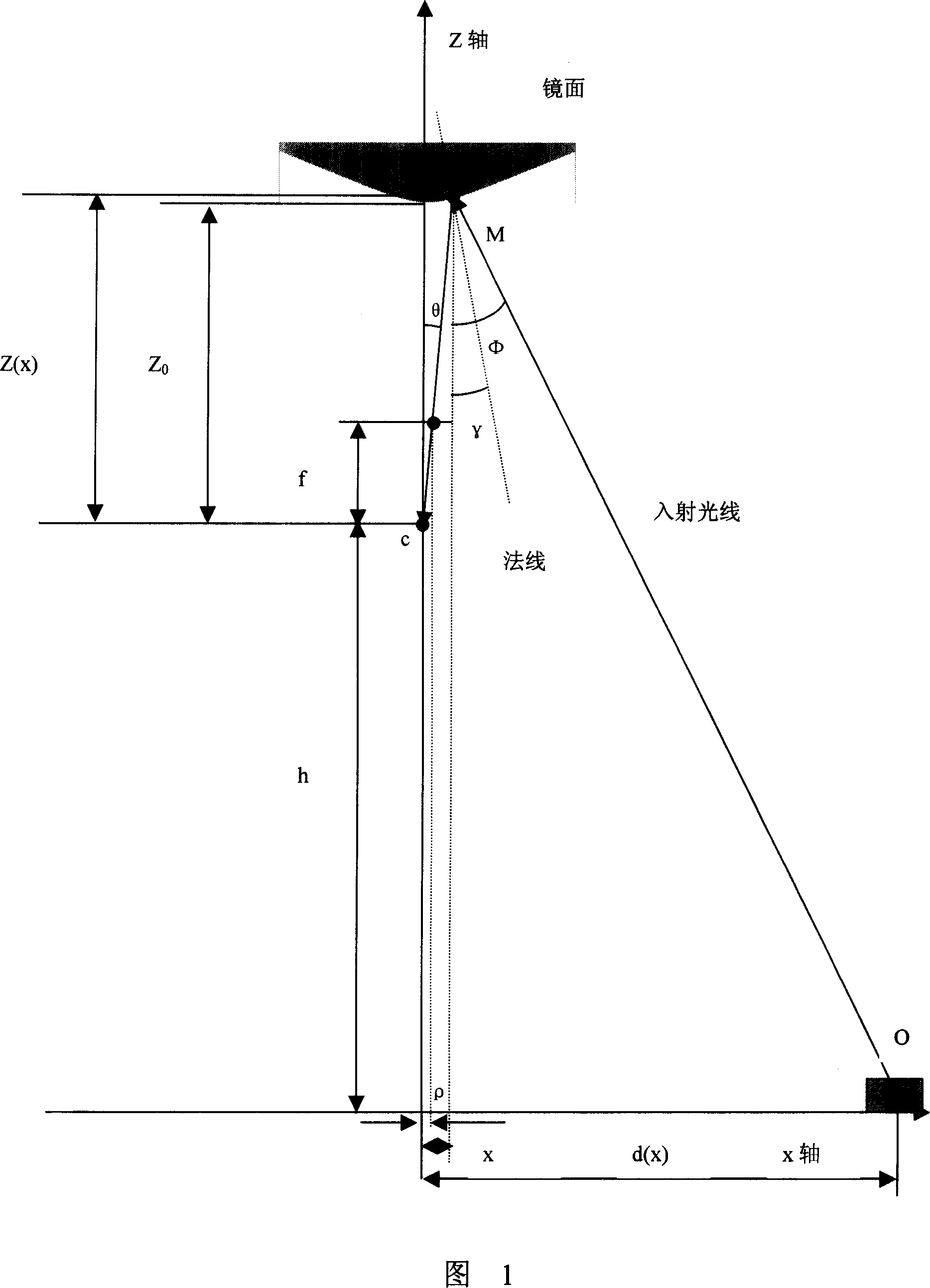

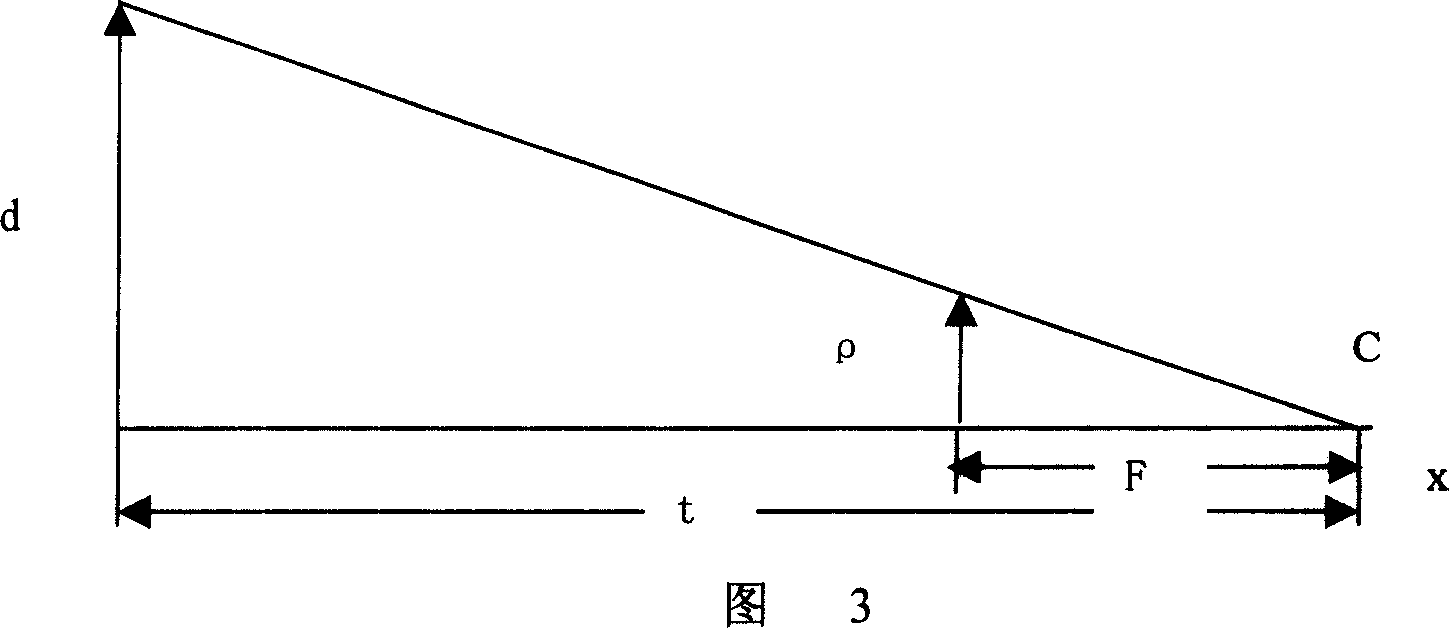

All-round computer vision-based electronic parking guidance system

InactiveCN101059909AWide detection rangeInstallation and maintenance without interferenceArrangements for variable traffic instructionsDetection of traffic movementGuidance systemVision based

An electric park induce system based on omnibearing computer vision comprises a microprocessor, an omnibearing vision sensor for detecting the park condition in a parker, and a communication module communicated with outer space, wherein the vision sensor is mounted above the park, the microprocessor detects the condition of each park part to provide dynamic internal induction and external induction to park. The inventive park check method has wide check range, non-interference installment, low energy consumption in maintenance, abundant check parameters, visual property, reliable check, high accuracy, easy statistic, simple operation, expandable property, or the like.

Owner:ZHEJIANG UNIV OF TECH

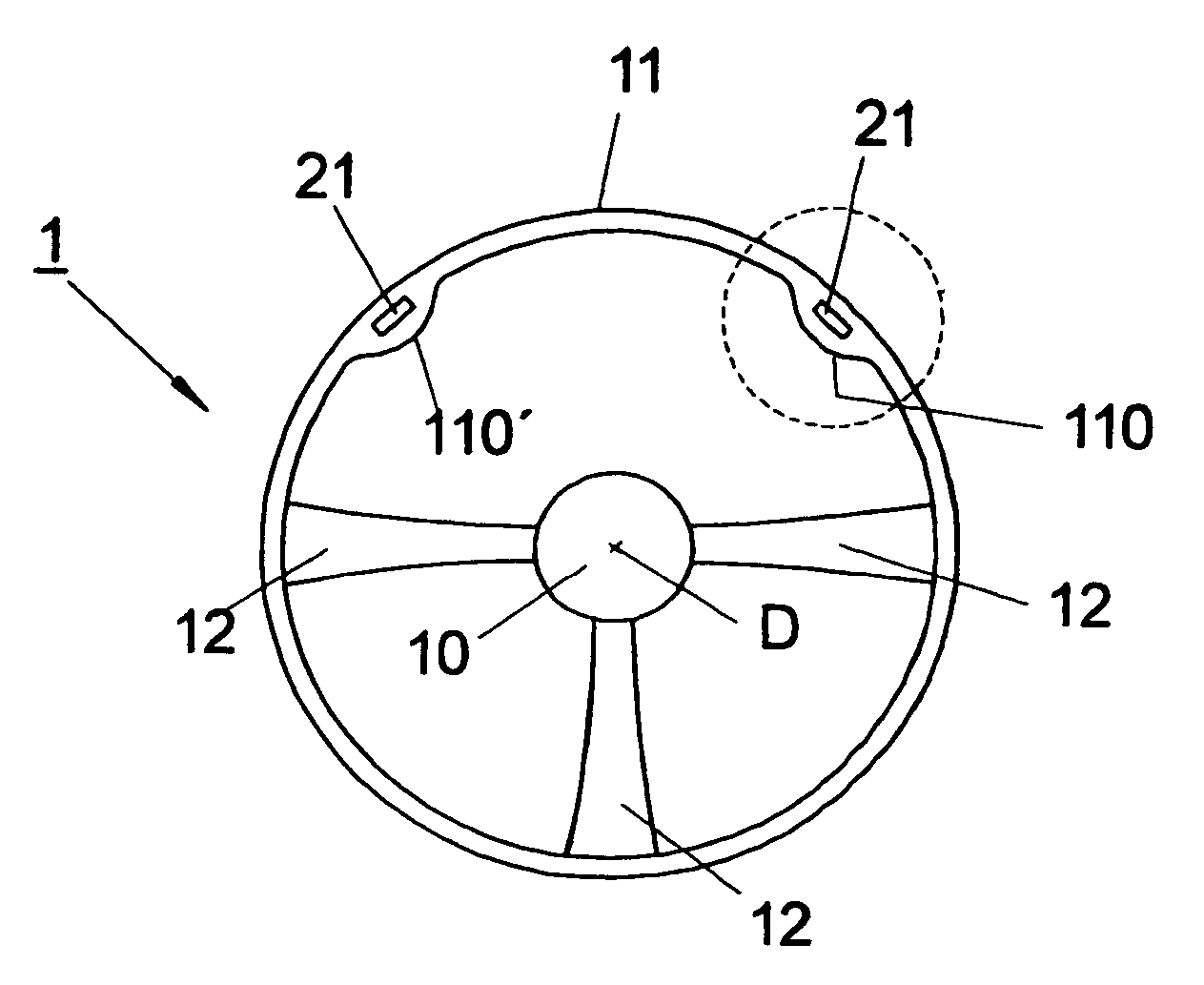

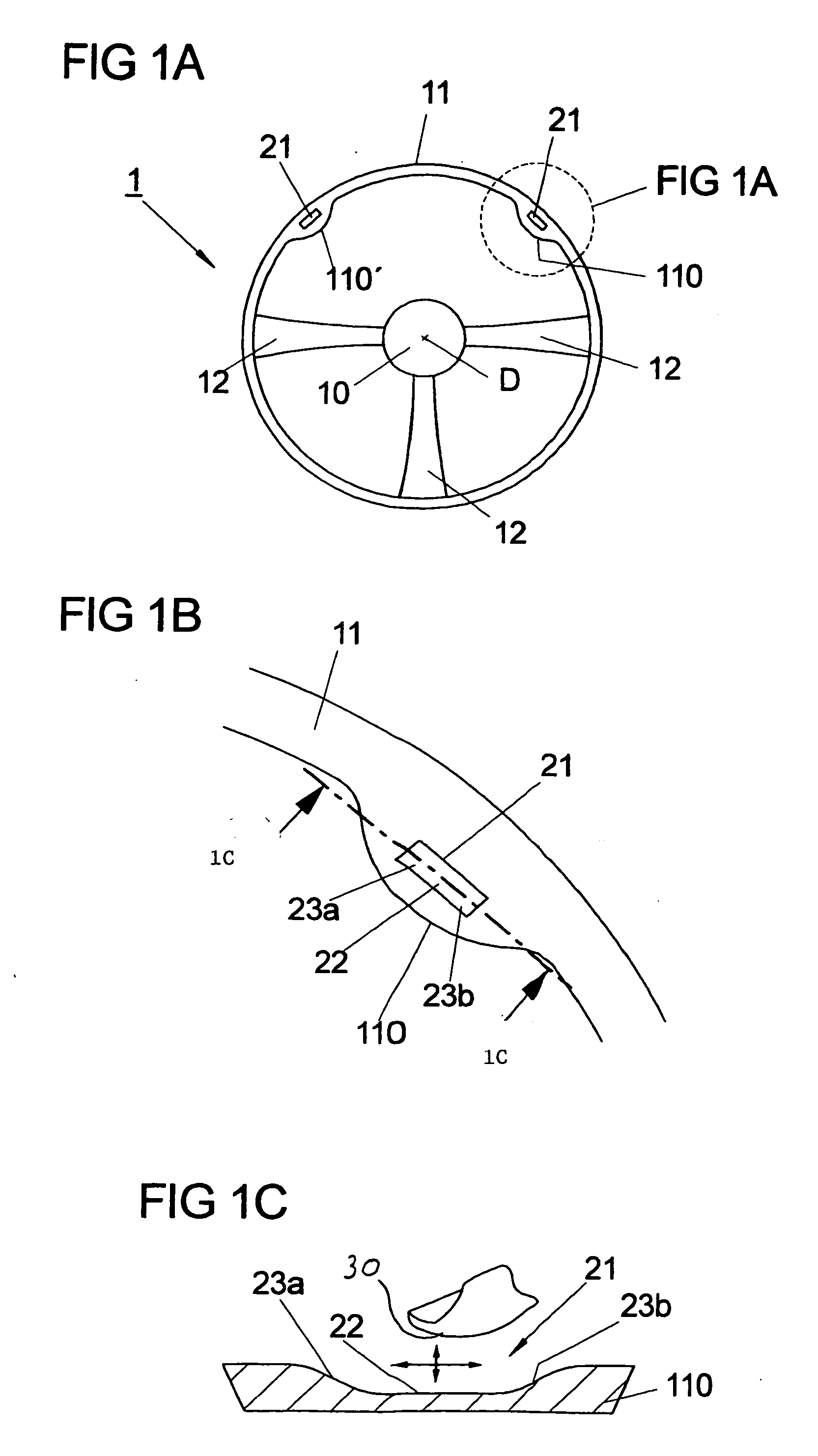

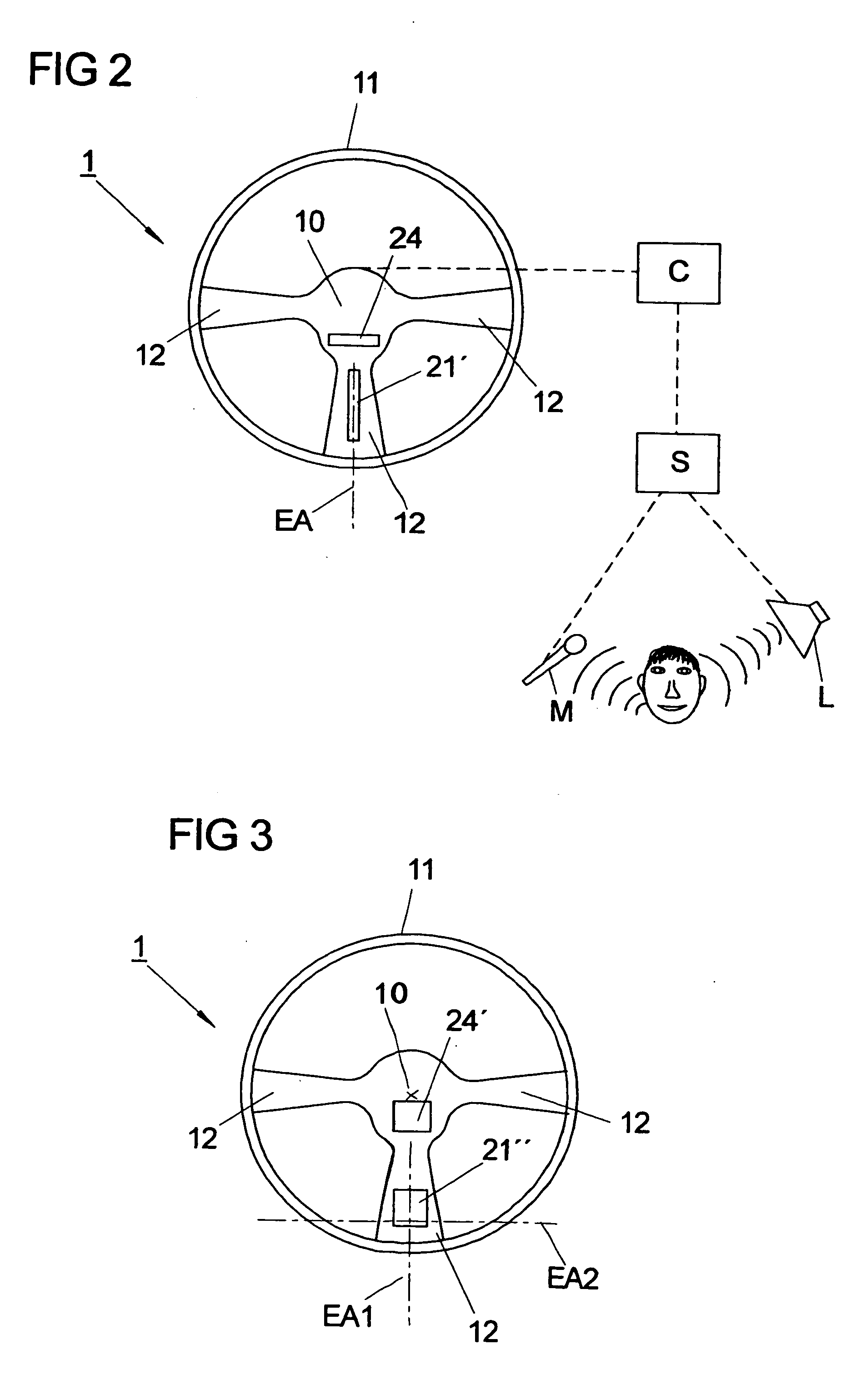

Steering wheel for a motor vehicle

InactiveUS20050189159A1Increasing impairmentSimpler and cost-effective manufactureControlling membersMechanical apparatusOptical reflectionSteering wheel

A steering wheel for a motor vehicle is provided having a hub element, a steering wheel rim, at least one steering wheel spoke for attaching the steering wheel rim to the hub element and at least one activation device which is arranged on the hub element, the steering wheel rim or the steering wheel spoke for controlling and / or regulating an assembly of a motor vehicle. The activation device is preferably embodied as an optical reflection sensor device with a functional face. Such a sensor device operates without mechanically moving parts and during the service life of the steering wheel it is independent of general scratching and soiling of its functional faces. In addition, the functionality of the measurement of distances and / or speeds of the objects located above the functional faces of the sensor device permits further functions to be integrated without requiring further separate devices in order to do so.

Owner:TAKATA PETRI AG

Turbine combustor endcover assembly

ActiveUS20050005610A1Easy maintenanceMaintenance freeEngine sealsContinuous combustion chamberCombustorEngineering

The endcover assembly for a combustor includes an endcover having an aperture, an insert disposed in the stepped bore opening through an internal face of the endcover, a fuel cartridge extending through the insert and aperture and a seal cover on the external face of the endcover. Seal cover / endcover annular seals are disposed in registering axial cavities to seal against fluid leakage externally of the endcover assembly. Generally C-shaped and W-shaped seals are disposed in the cavities between the stepped shoulders of the insert and aperture to seal against leakage through the internal face of the endcover. The seals maintain sealing engagement during assembly and thermal distortion during turbine usage.

Owner:GENERAL ELECTRIC CO

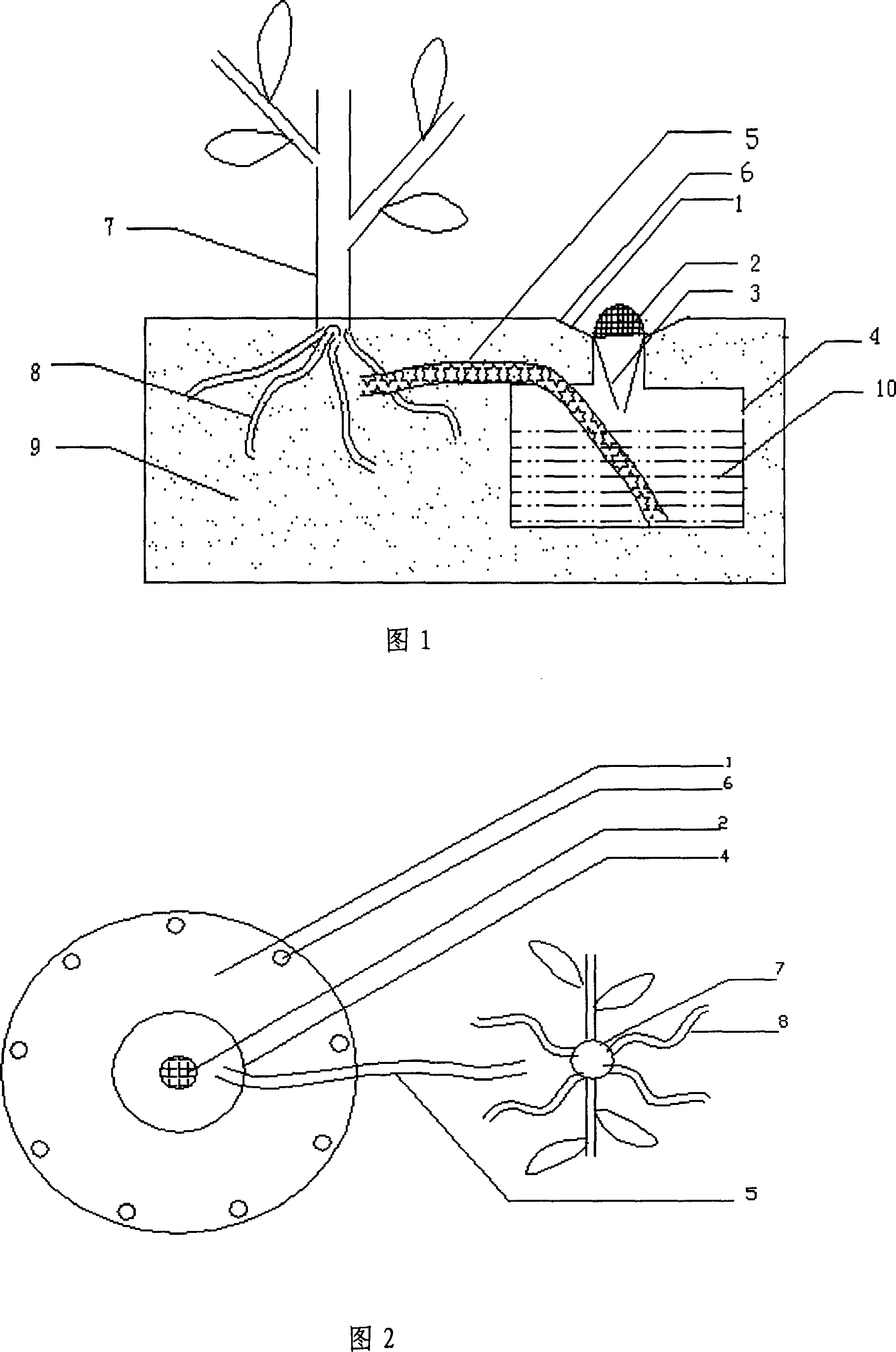

'Wick' type garden rain water collector

InactiveCN101019500ADrought resistanceConducive to growth and developmentGeneral water supply conservationSelf-acting watering devicesFilter funnelStormwater

The wick-type garden rain water collector consists of five parts including rain water collecting funnel to collecting surface water, filtering net to filter out impurity, movable inlet tongue to avoid evaporation loss of water, water collecting bottle to store water rain and wick type watering pipe to irrigate trees through permeation. The wick-type garden rain water collector may be used widely to irrigate trees durably and fight drought effectively.

Owner:张正梁

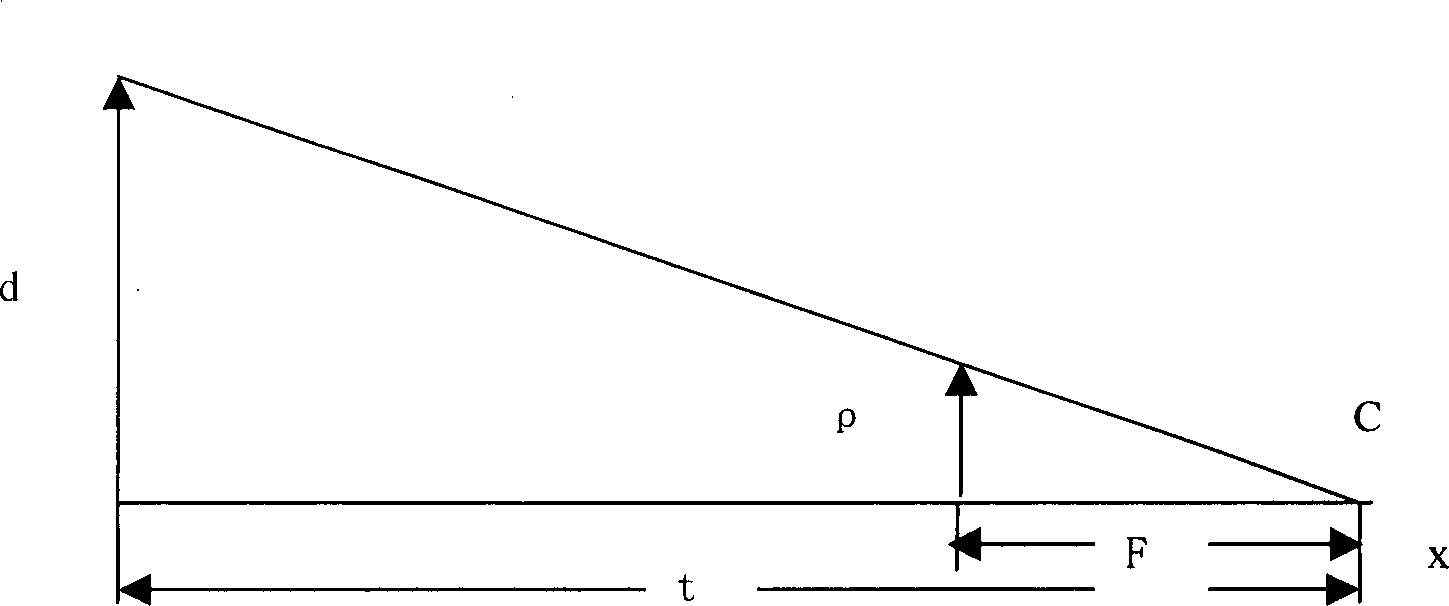

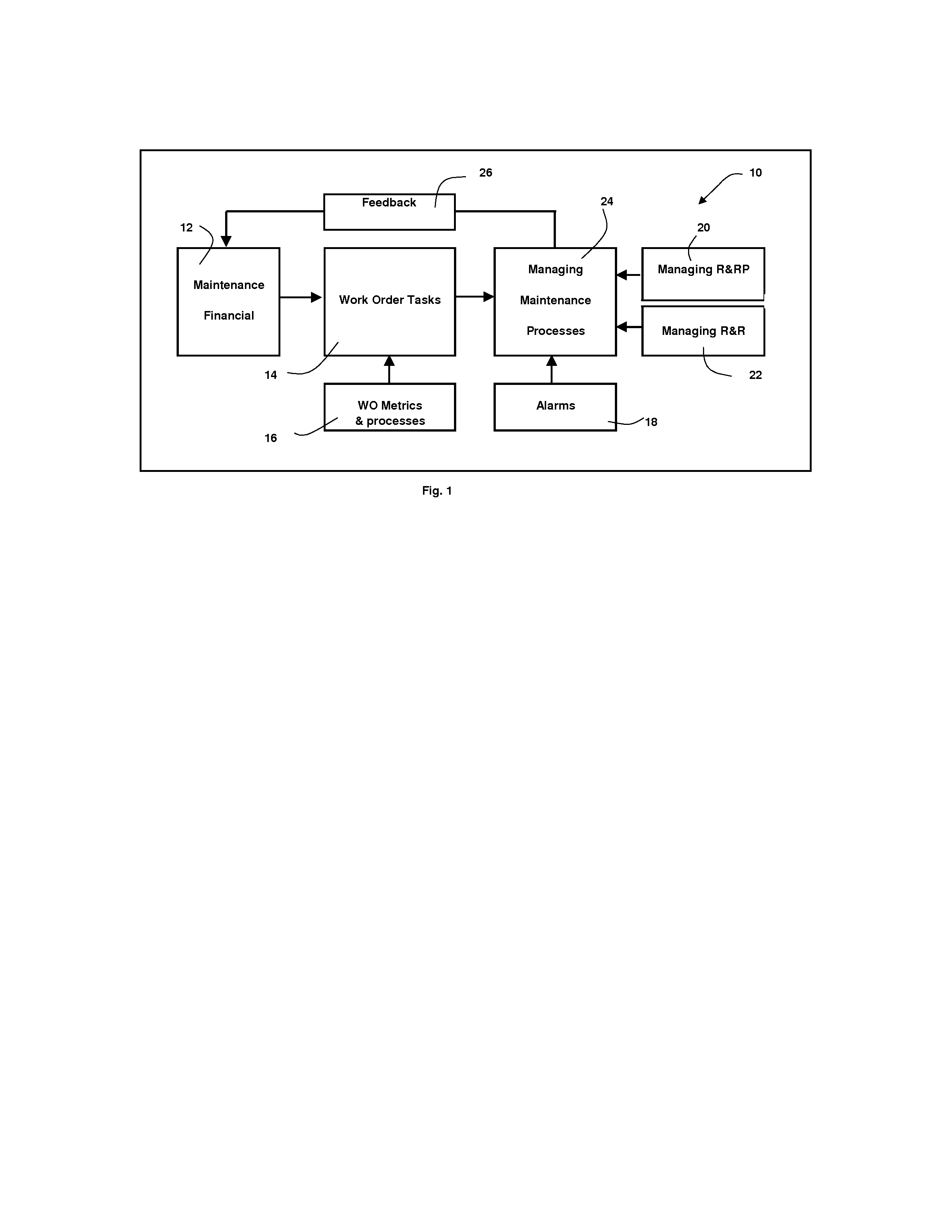

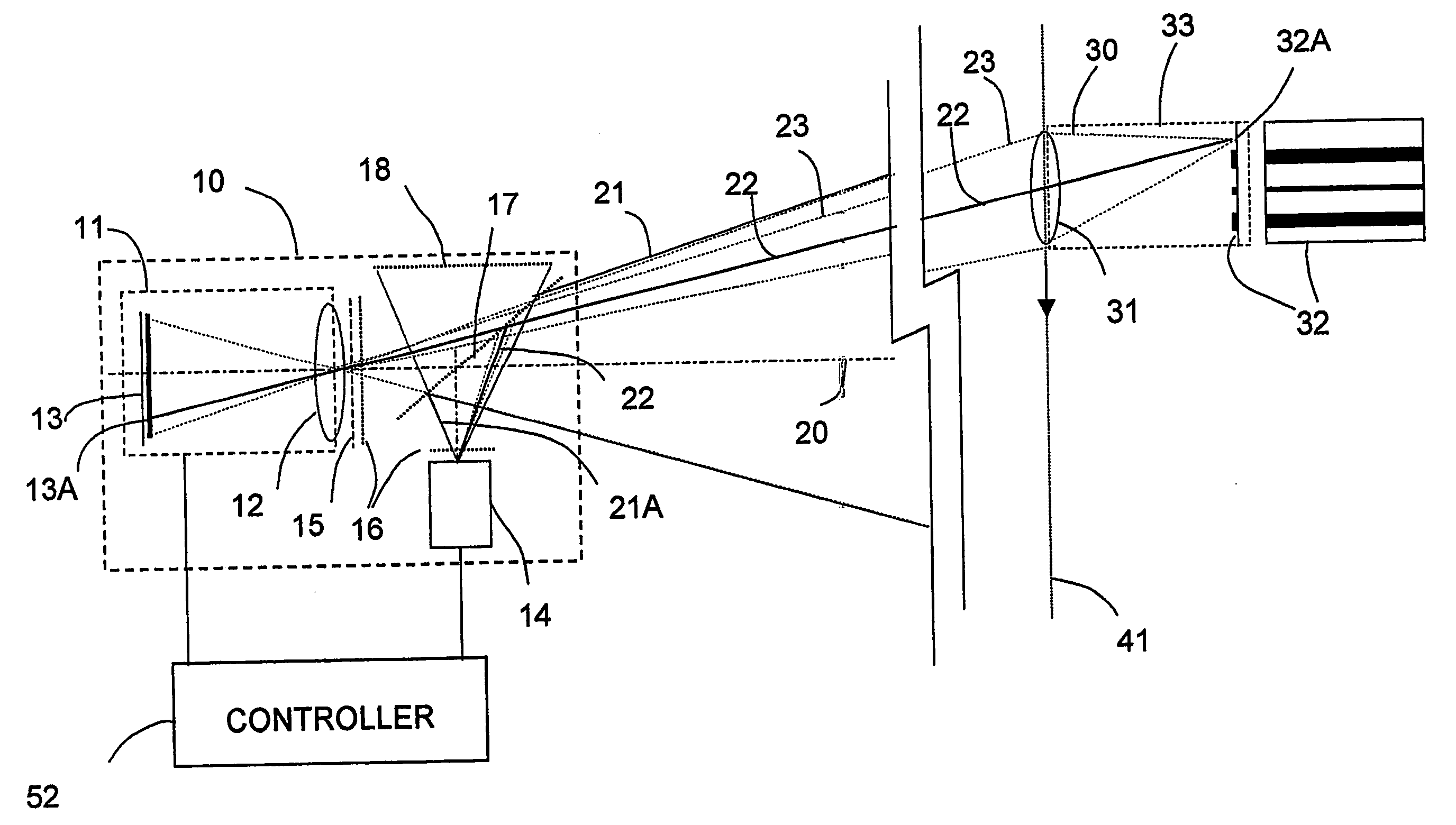

Automatic certification, identification and tracking of remote objects in relative motion

InactiveUS20060000911A1Prevent counterfeitingEasily affixedSensing by electromagnetic radiationOptical elementsImaging processingRelative motion

A method and apparatus for automatic certification, identification and tracking of remote objects in relative motion to a reading system, utilizing a novel tag affixed to an object and novel apparatus and techniques for automatically reading the tag information, its relative velocity, angle and position. The tag reader comprises an imaging system that undertakes real time image processing of the acquired images. Matching of the optical parameters of the imaging optics at the reader and the focusing optics at the tag ensure optical reliability and readability at large ranges. Novel types of tag designs are presented.

Owner:STEKEL AMIT

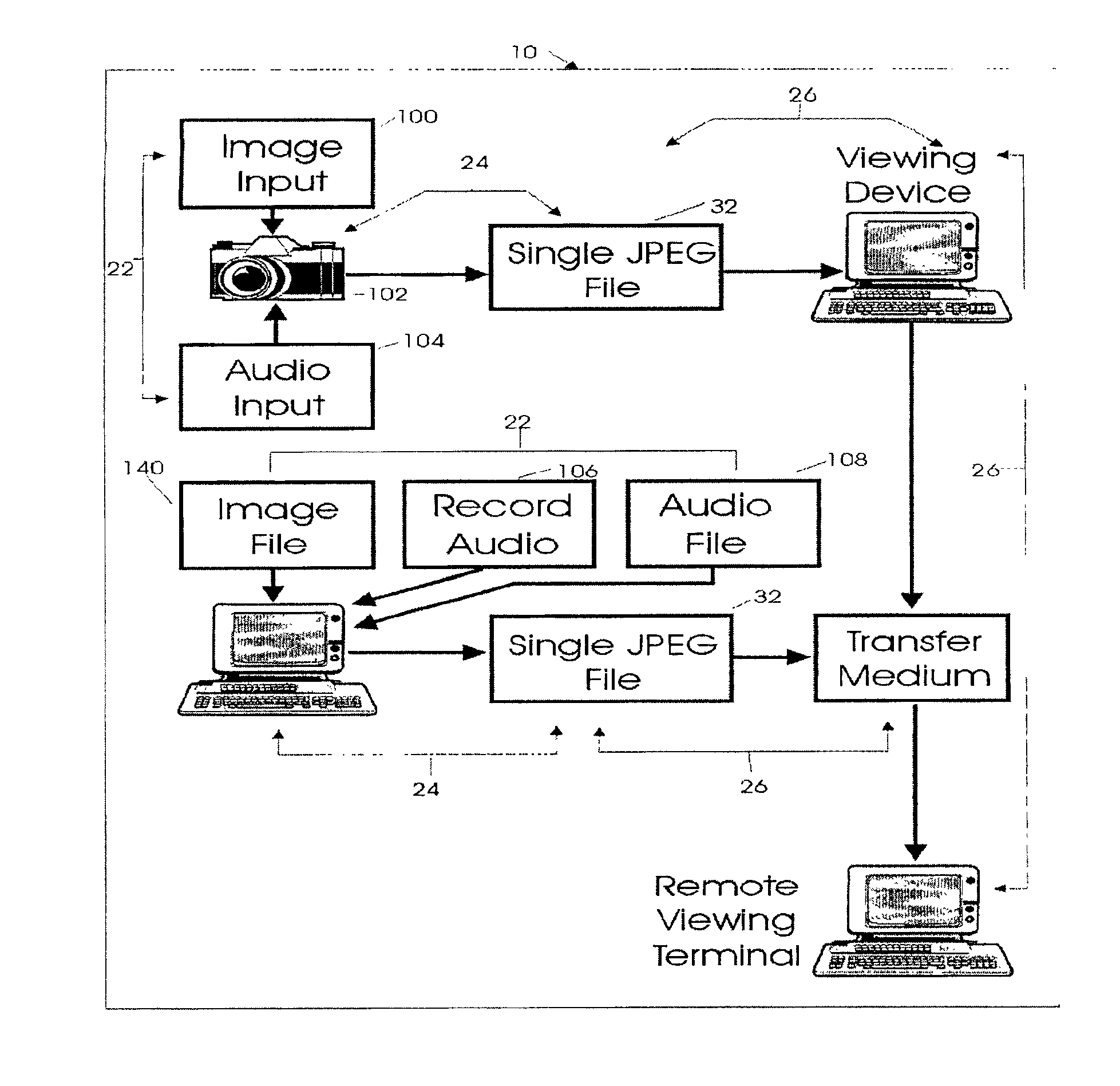

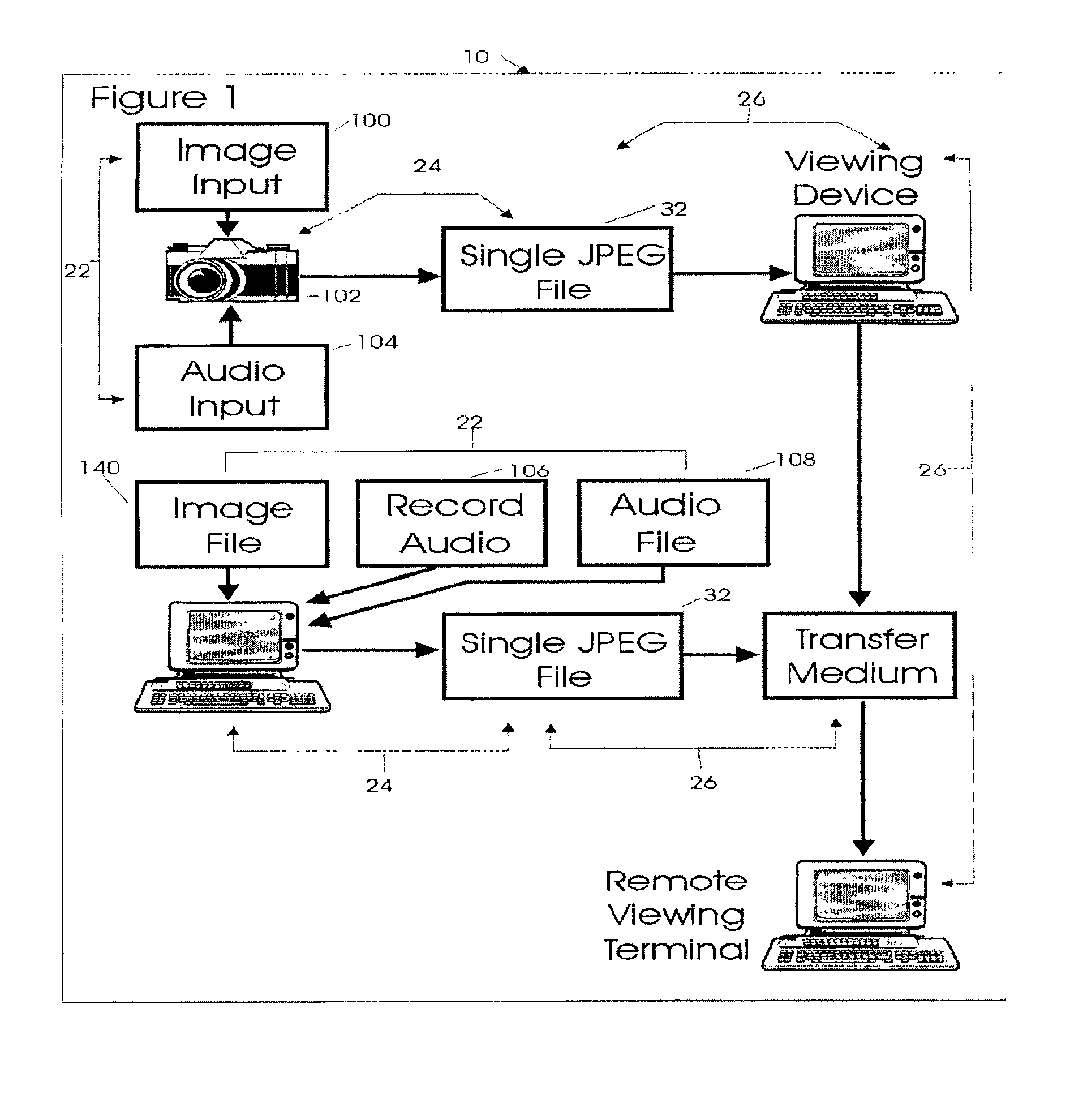

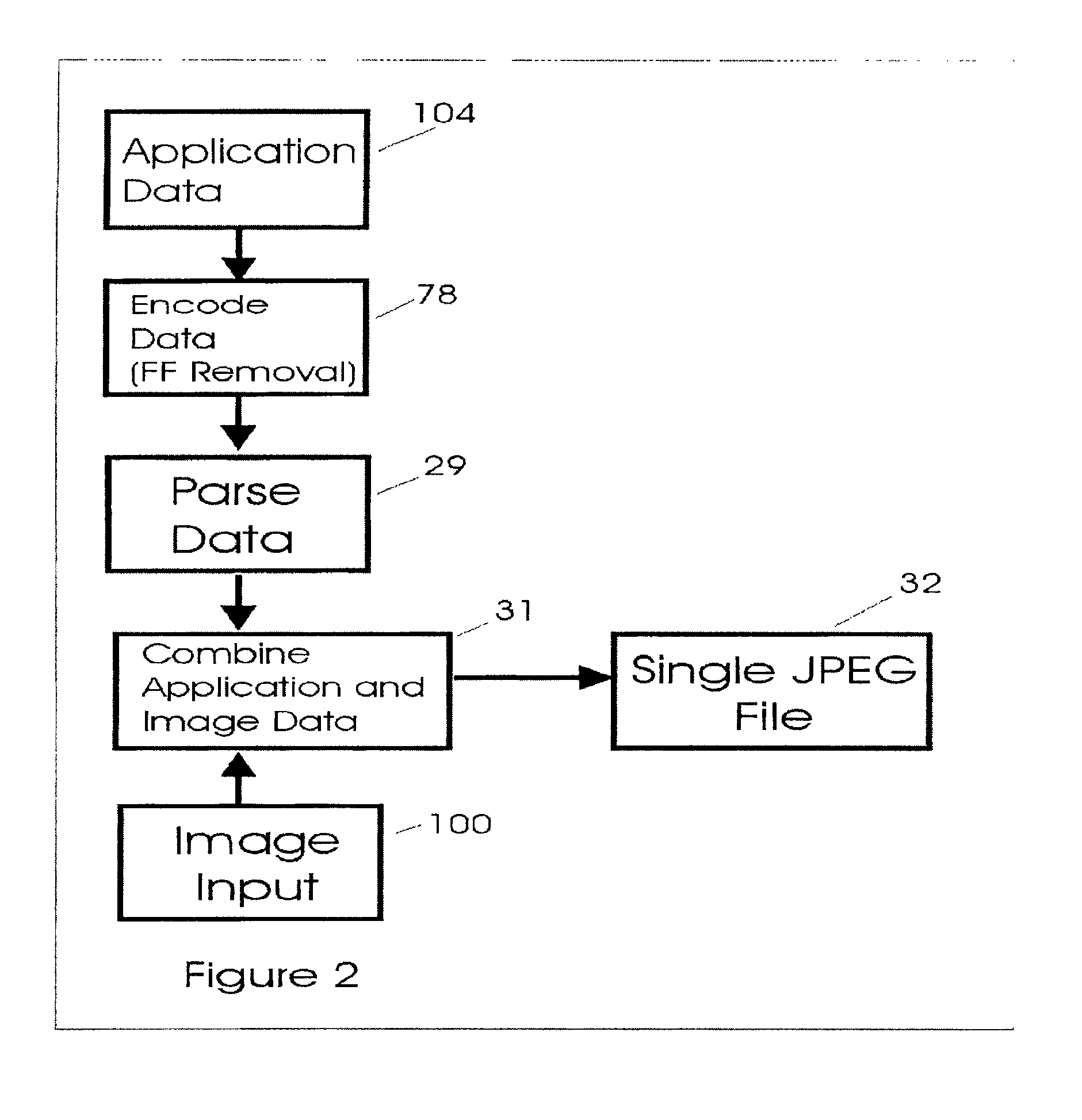

System and method of storing data in JPEG files

InactiveUS6915012B2Safe storageMaintenance freeTelevision system detailsStill image data indexingJPEGByte

The present invention comprises a system for communicating image data and other data. The system comprises a JPEG file having a JPEG data, at least one non-JPEG data, and a computer. The computer is programmed to read a predetermined number of sequential bytes of the non-JPEG data. The computer is also programmed to determine position of each byte in the sequential bytes that contain a JPEG marker and determine a locator byte, which is capable of indicating the position of any bytes in the sequential bytes that contain a JPEG marker. The computer is further programmed to write the locator byte in the JPEG file and write encoded bytes in the JPEG file. The computer writes the encoded bytes in the JPEG file in a manner wherein, for each byte in the sequential bytes, if the byte does not contain a JPEG marker, each byte is replaced with a bit, preferably written as 0, in the order of the byte's occurrence in the sequential bytes. If the byte does contain a JPEG marker, the byte containing a JPEG marker is replaced with a place holder bit, preferably written as 1 and in the order of the byte's occurrence in the sequential bytes.

Owner:SOUNDPIX

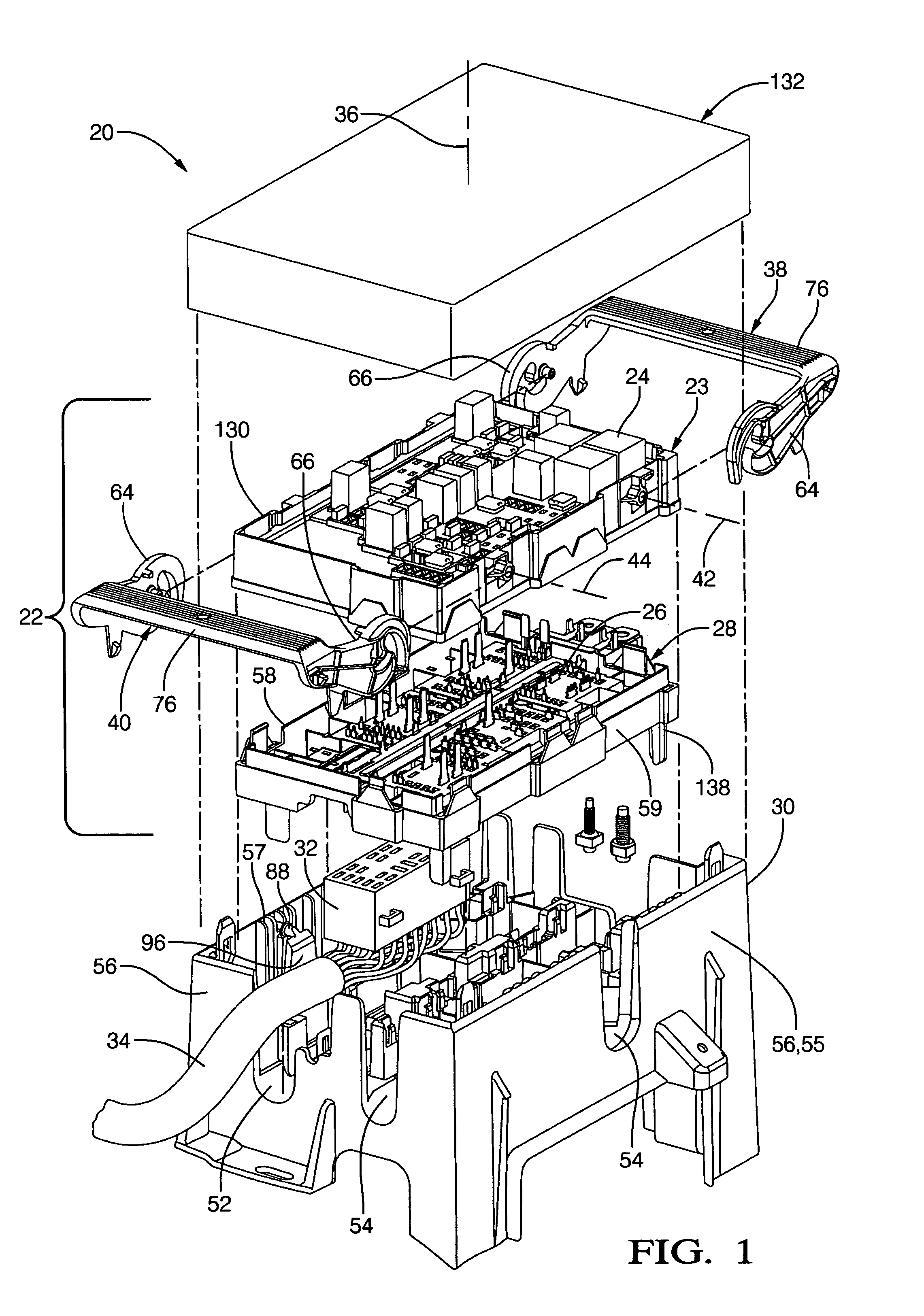

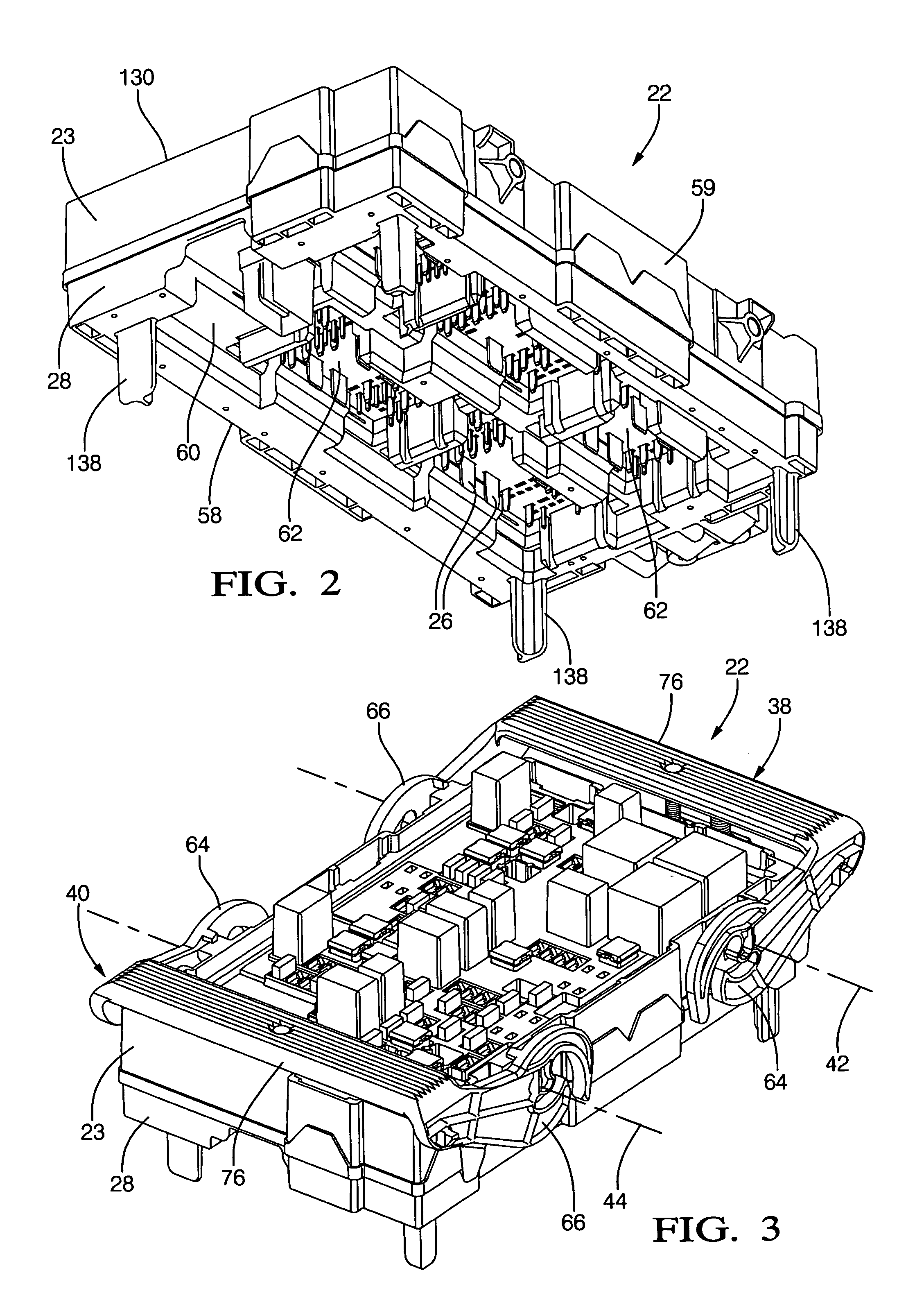

Electrical connector assembly

ActiveUS7094081B1Easy alignmentCapable of smooth andEngagement/disengagement of coupling partsVehicle connectorsLinear motionEngineering

The present invention provides an electrical connector assembly and a method of mating the same. The electrical connector assembly includes a panel sub-assembly which mates to at least one electrical connector body. Preferably two cam leveraging devices which rotate in opposing directions are mounted rotatably to the panel sub-assembly for sliding engagement of respective cam studs engaged rigidly to the electrical connector body. Opposing rotations of the cam leveraging devices along respective and parallel rotation axes causes the panel sub-assembly to move linearly along a mating axis disposed orthogonally to the rotation axes and toward the electrical connector body to a staged position. During linear panel sub-assembly movement from the disconnected position to the staged position, the cam studs slide against a first portion of a track carried by respective cam levers and which generally spirals radially inward toward the rotation axis. Reversing rotation of both cam leveraging devices causes the panel sub-assembly to continue linear movement toward the electrical connector body from the staged position and to a mated position. During linear panel sub-assembly movement from the staged position to the mated position, the cam stud lifts off of the first portion, and is caught by and slides along a second portion of the track to a mated end.

Owner:APTIV TECH LTD

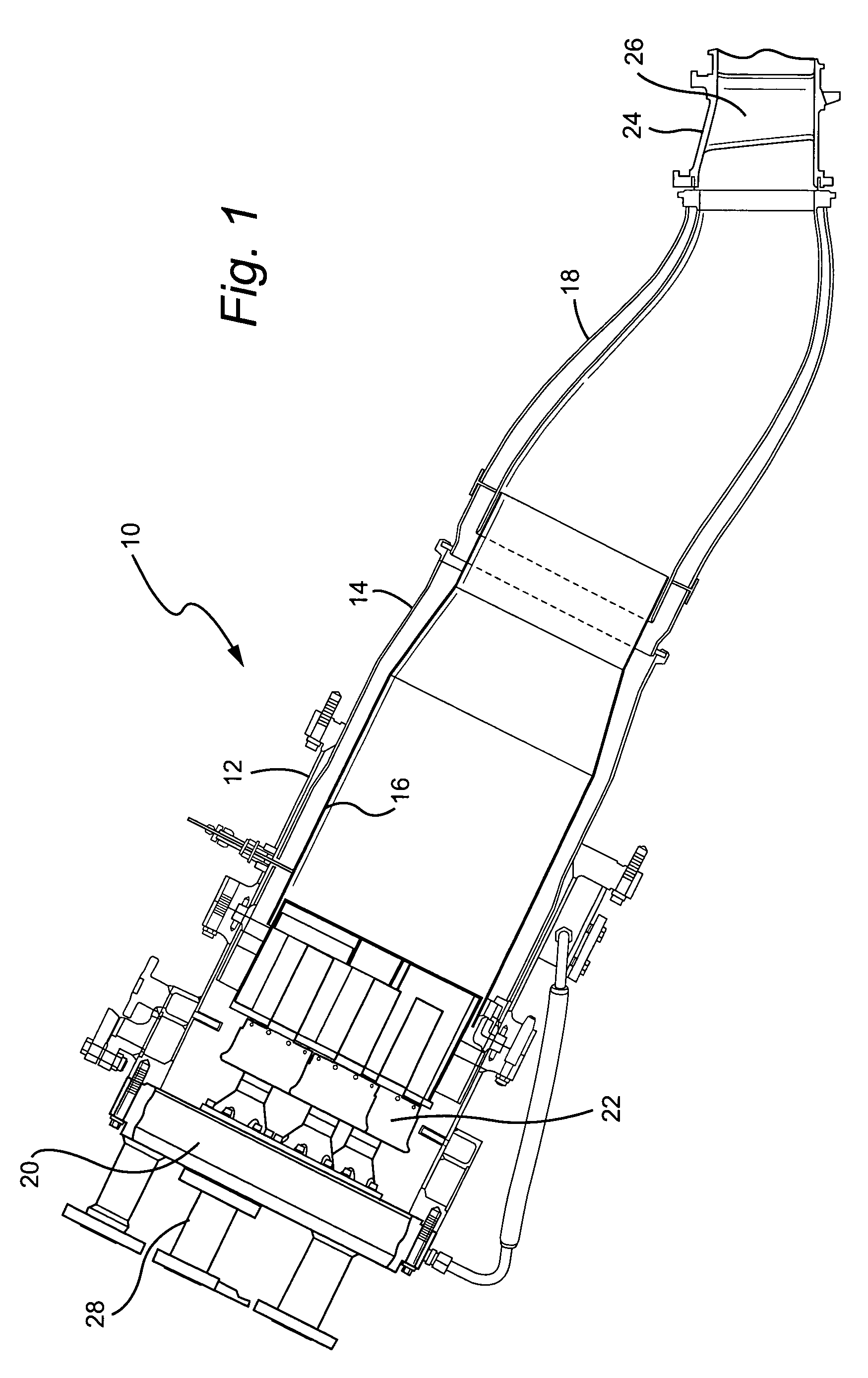

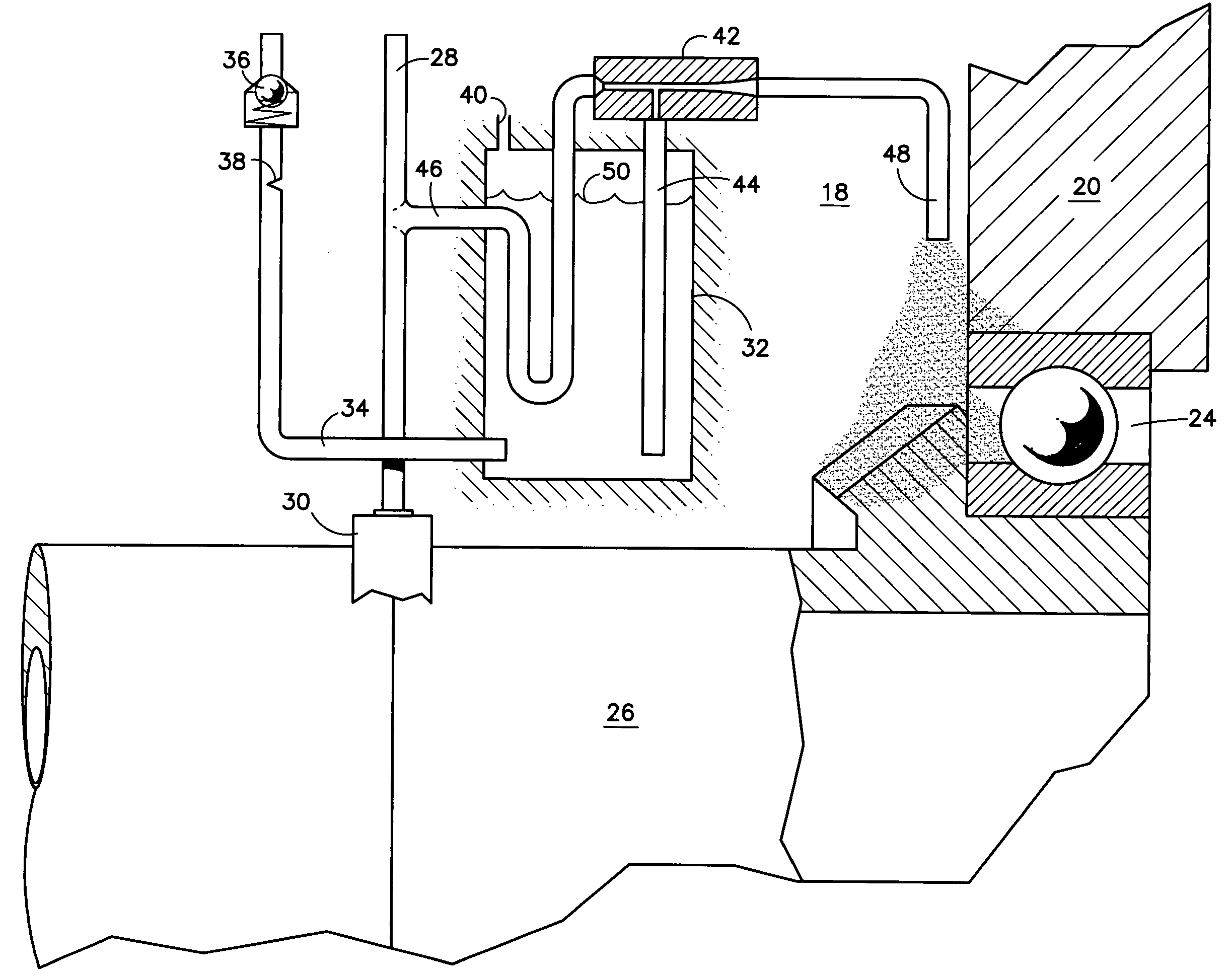

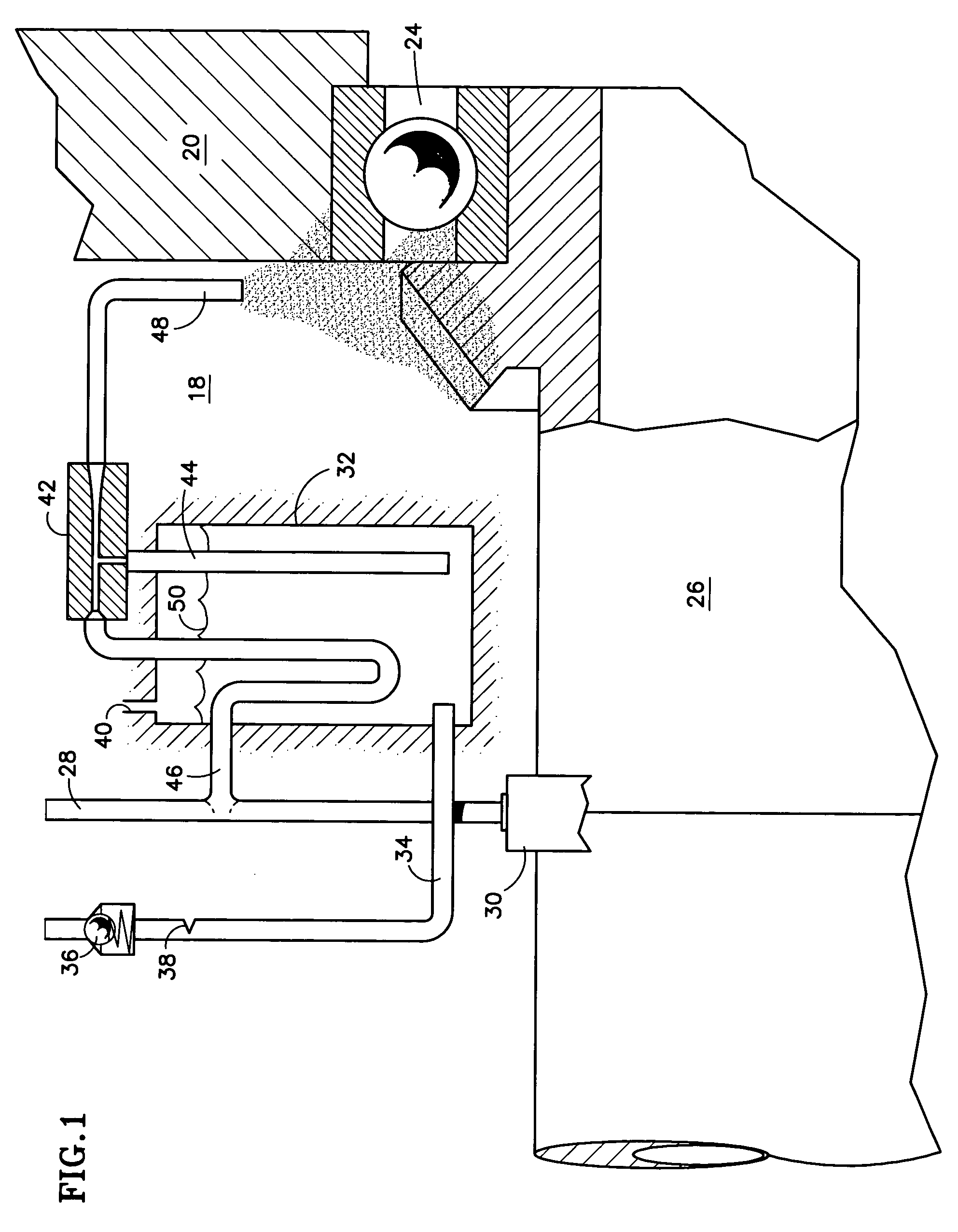

Failure tolerant passive lubrication system

ActiveUS7174997B2Light weightInexpensive and reliableTurbinesRolling contact bearingsHigh pressureNormal conditions

An auxiliary lubrication system for an aircraft turbine engine includes a reservoir 32 of lubricant 50 and a venturi 42 to suction lubricant out of the reservoir and direct an lubricant mist at a bearing 24 or other component requiring lubrication. The venturi is directly connected to a source of motive fluid, such as pressurized air extracted from an engine flowpath 10, and is continuously driven by the motive fluid. The auxiliary system accommodates a failure or malfunction of the primary, high pressure lubrication system. The auxiliary system operates during normal conditions, when the primary system is fully functional. If the primary system fails, the auxiliary system continues to operate for a limited time, until the lubricant in the reservoir is depleted, to provide an lubricant mist to the component being lubricated. The limited-duration lubricant supply allows the aircraft crew time to carry out actions required to safeguard the aircraft and its occupants.

Owner:RTX CORP

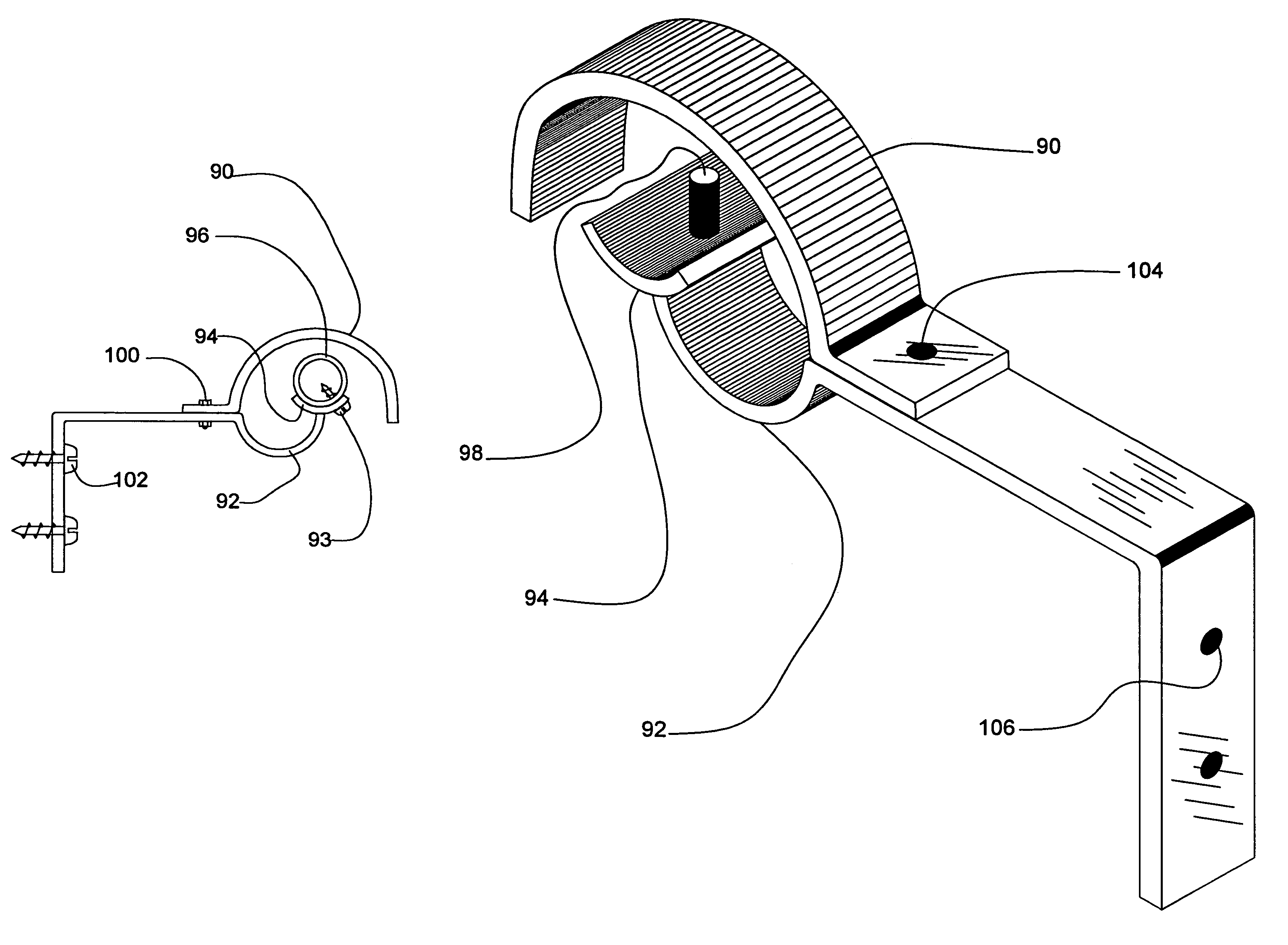

Pass through sliding drapery suspension system

InactiveUS7370839B2Easy to install directlySimple, ruggedDoor/window protective devicesCurtain suspension devicesRetention functionEngineering

A drapery mounting system comprised of a drapery rod member, a drapery hanger element, and a support member for the rod. The support member is positioned below and intermediate the respective opposed ends of the drapery rod. The support member includes a saddle, a support arm, and a retainer. The saddle is shaped to support a lower external portion of said drapery rod. The saddle extends laterally of the drapery rod for less than about the cross-sectional width of the rod to permit a drapery hanger to pass unimpeded over the saddle. The saddle element preferably has longitudinally opposed edges disposed along the drapery rod. The longitudinally opposed edges are generally convexly arcuate relative to a longitudinal axis of the drapery rod. The support and retention functions are separated. The saddle supports the rod and the retainer releasably retains the drapery rod in engagement with the saddle. A support arm supports from below the saddle. The drapery hanger is slidably supported on the drapery rod member for substantially unimpeded movement past the support member. The drapery hanger typically has a generally question mark shaped form including a hook portion with an open mouth and a depending leg portion, with the open mouth preferably being of sufficient width to pass the drapery rod member laterally therethrough.

Owner:PUTMAN MICHAEL

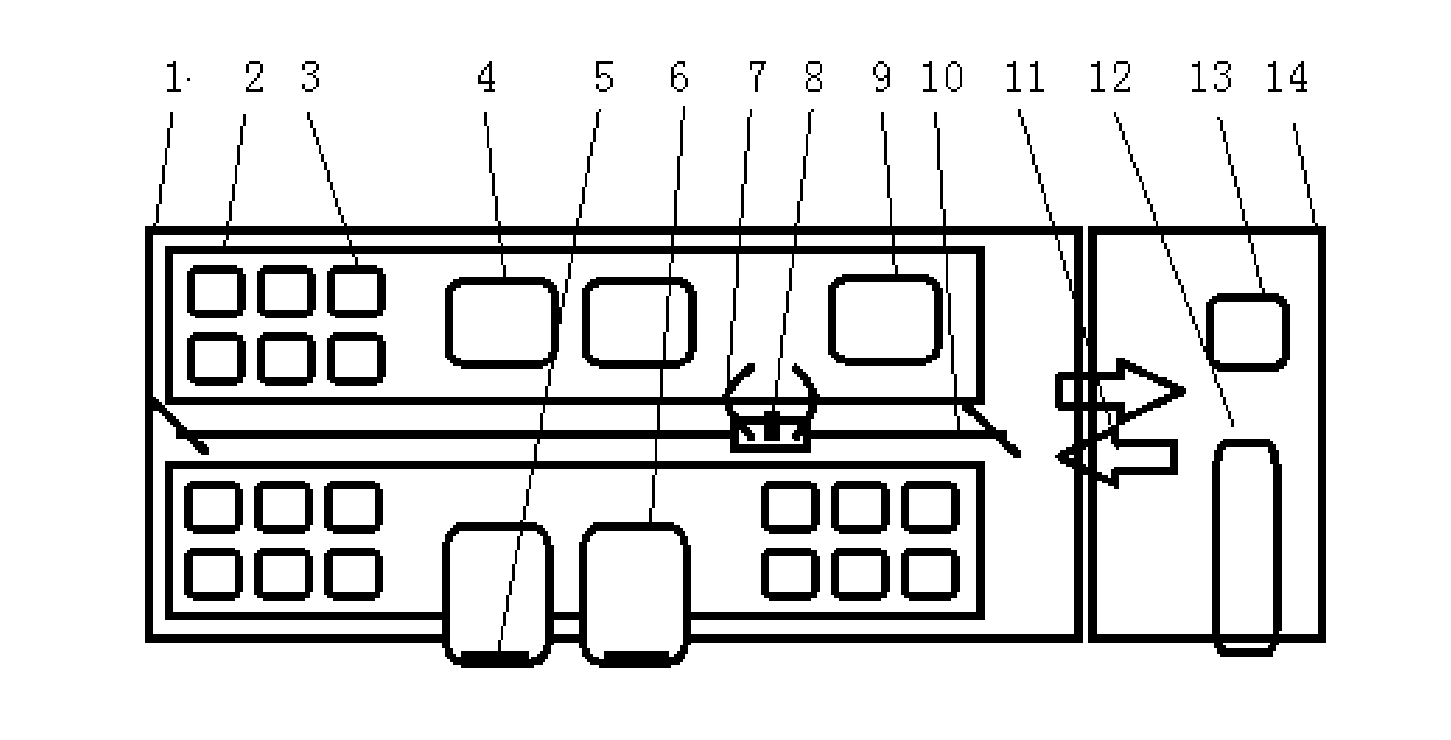

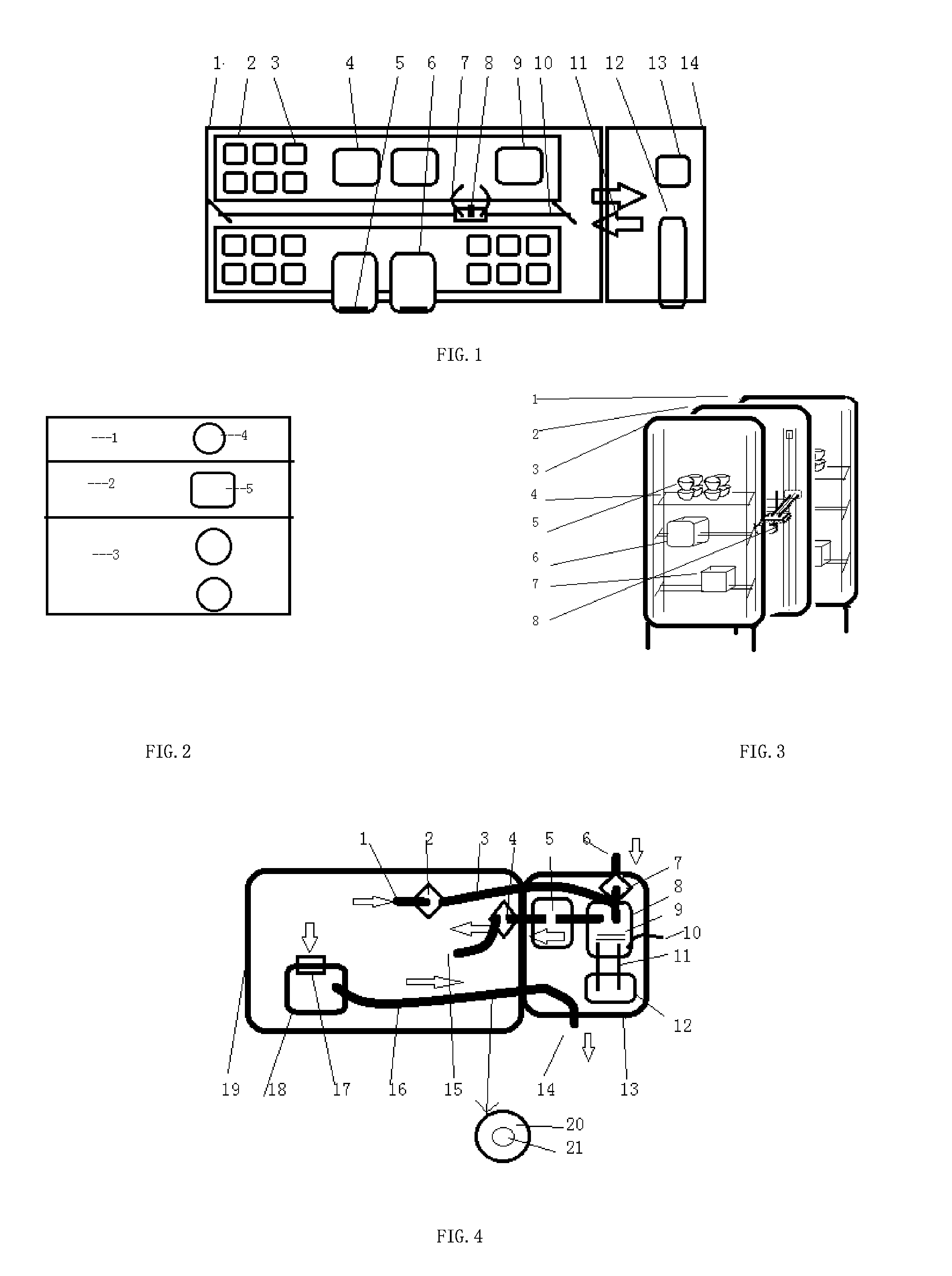

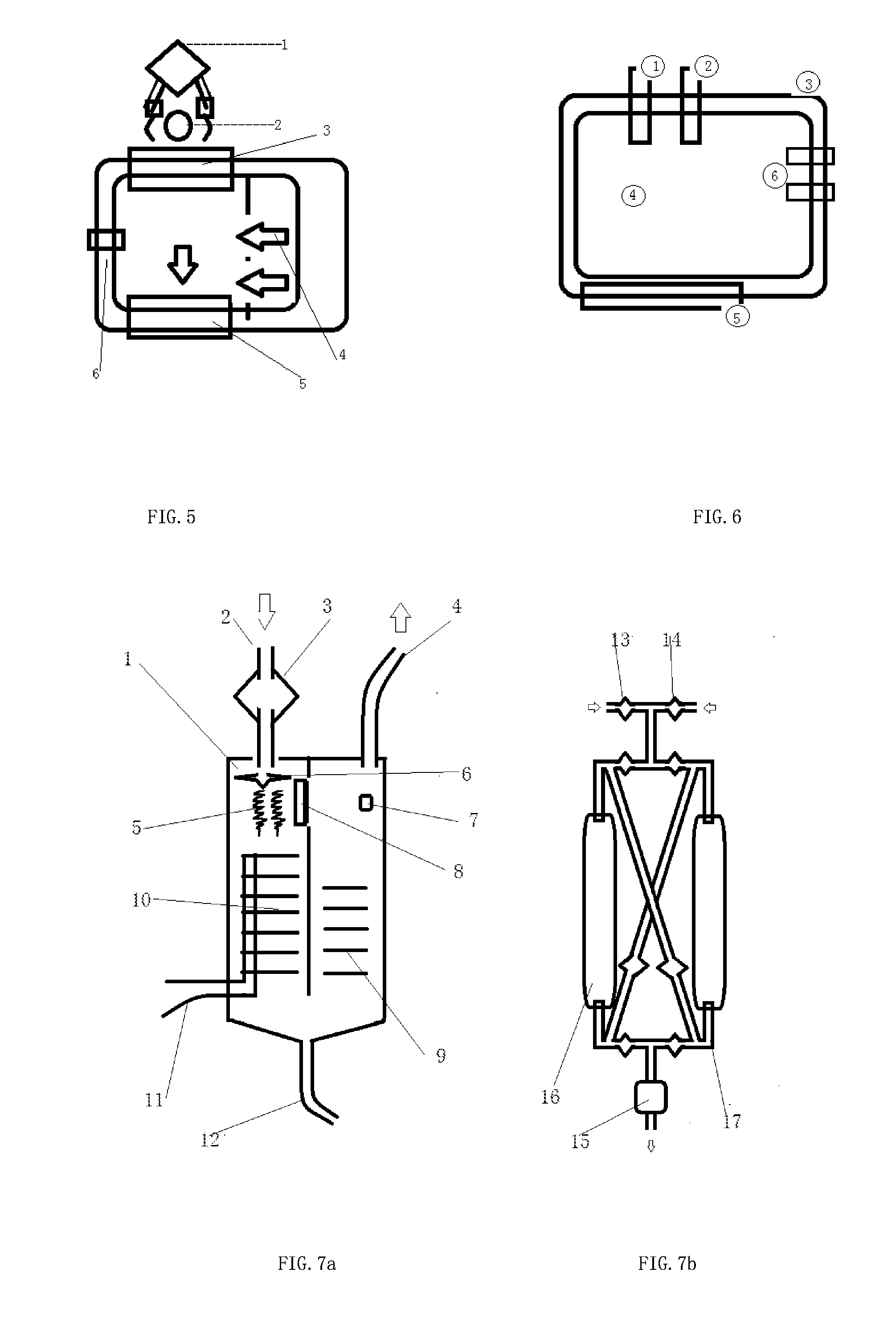

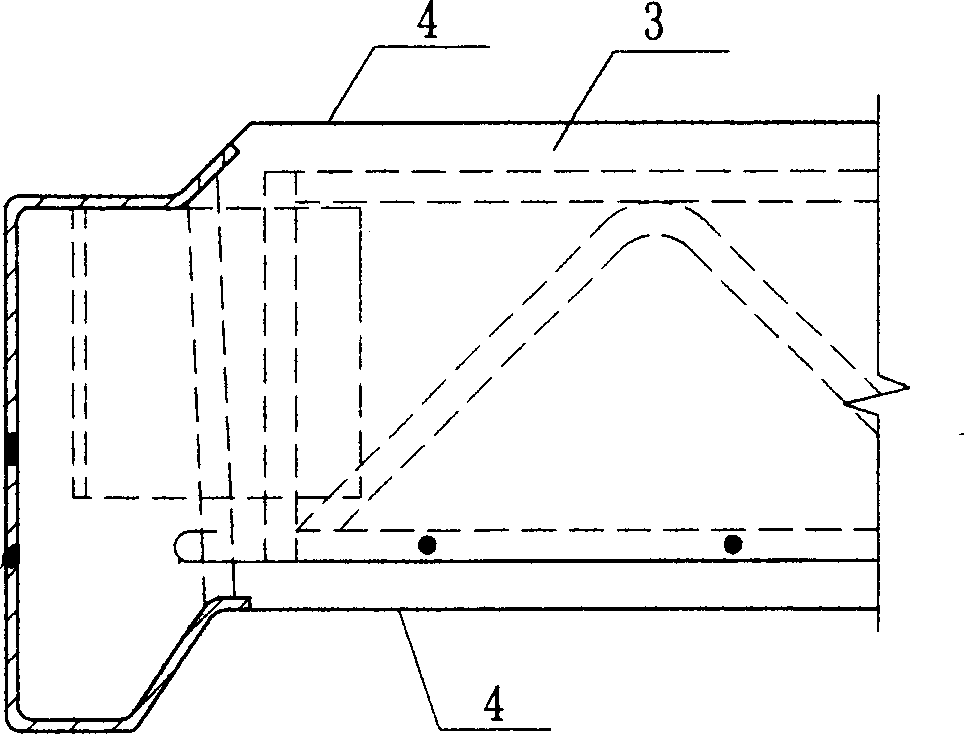

System for Automatically Cooking and Selling Frozen Food

ActiveUS20160379434A1PowerfulCost advantageLighting and heating apparatusCoin-freed apparatus detailsWork patternGreenhouse

Disclosed is an automatic-cooking-and-processing vending system for frozen-food, comprising the low-temperature chamber, the object-moving system, the product shelves, the low-temperature chamber equipment, the food container; the said low-temperature chamber equipment is inside the low-temperature chamber, or connected to the casing of the low-temperature chamber; the low-temperature chamber equipment contains hot-air source and the humid-air source; the product shelves is inside the low-temperature chamber with disposable food containers placed on; the object-moving system is inside the low-temperature chamber. This system has the air-circulating system, which can force the outer hot-and-humid air to come inside in one-way from a cold chamber, so as to isolate the hot-and-humid air. Further disclosed is a food-automatic-cook-and-processing system, which may be used in the automatic-cooking-and-processing vending system, comprising a series of auto piercing food-processing devices for disposable food containers and different foods, and with the working patterns of these devices.

Owner:HUANG ZISHENG

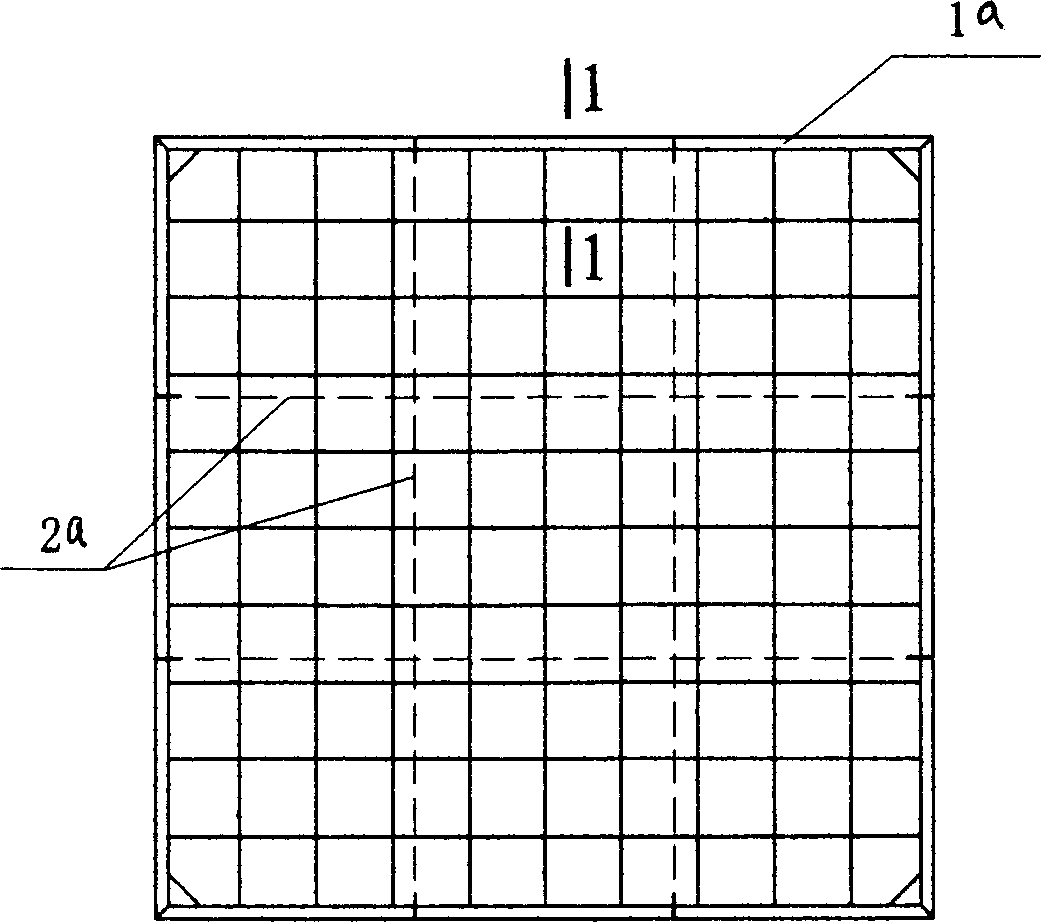

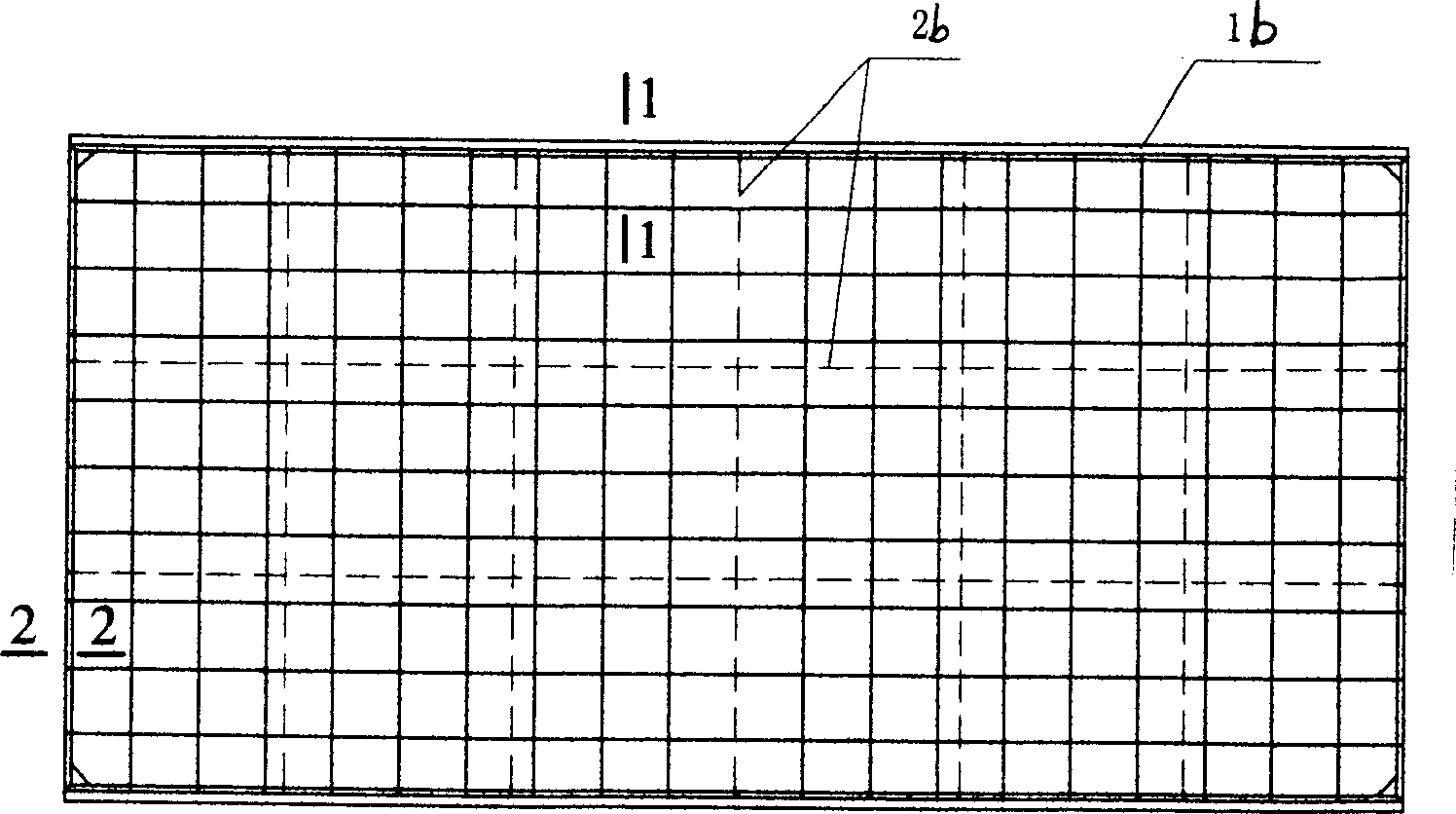

Foamed cement composite slab and its production method

InactiveCN1429698AEfficient thermal insulationGood weather resistanceCeramic shaping apparatusHeat proofingHigh resistancePolymer science

A composite foamed cement slab is composed of a main frame made of steel or concrete, a foamed cement core, a steel truss in the foamed cement core and connected to the main frame, and the surface layer reinforced by anticracking material. Its advantages are high heat-insulation and sound-proofness, high resistance to cracking, impact, water, acid and alkali, high durability and weatherability, light weight and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com