Foamed cement composite slab and its production method

A foamed cement and composite board technology, applied in the field of construction, can solve the problems of complex construction, durability, sound insulation, poor waterproof and fire resistance, poor thermal insulation, etc., and achieve the effect of fast and convenient construction, efficient thermal insulation, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

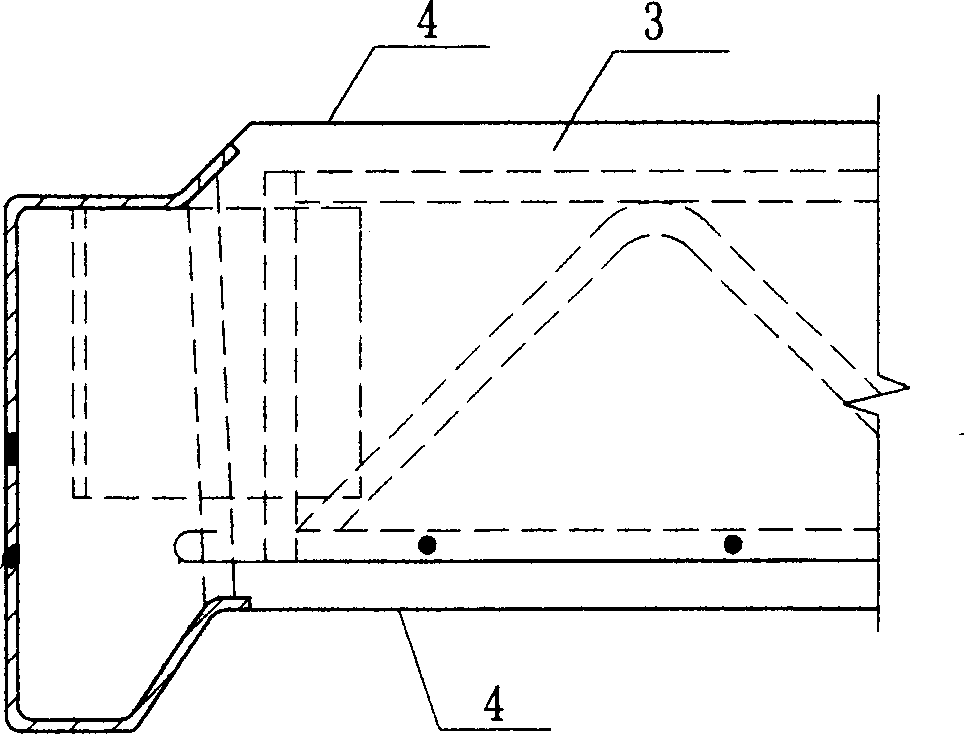

[0043] As shown in Figure 1, the square foamed cement composite panel structure of the present invention is generally applied to grid structure roof panels.

[0044] The present invention is mainly composed of main frame 1a, foamed cement 3, steel truss 2a and surface layer 4, and is characterized in that: the square foamed cement composite board uses foamed cement 3 as the core layer; Surface layer 4 reinforced by anti-cracking materials; steel truss 2a is arranged in the core layer of foamed cement 3, and is connected with main frame 1a; the square foamed cement composite board is composed of main frame 1a, foamed cement The core layer 3, the surface layer 4 and the steel truss 2a are compounded.

[0045] The standard size of the composite panel in this embodiment is: 3 meters wide and 3 meters long.

[0046] Its manufacturing method includes:

[0047] 1. First, put the main frame 1a on the production template;

[0048] 2. After the cement slurry is stirred evenly accordi...

Embodiment 2

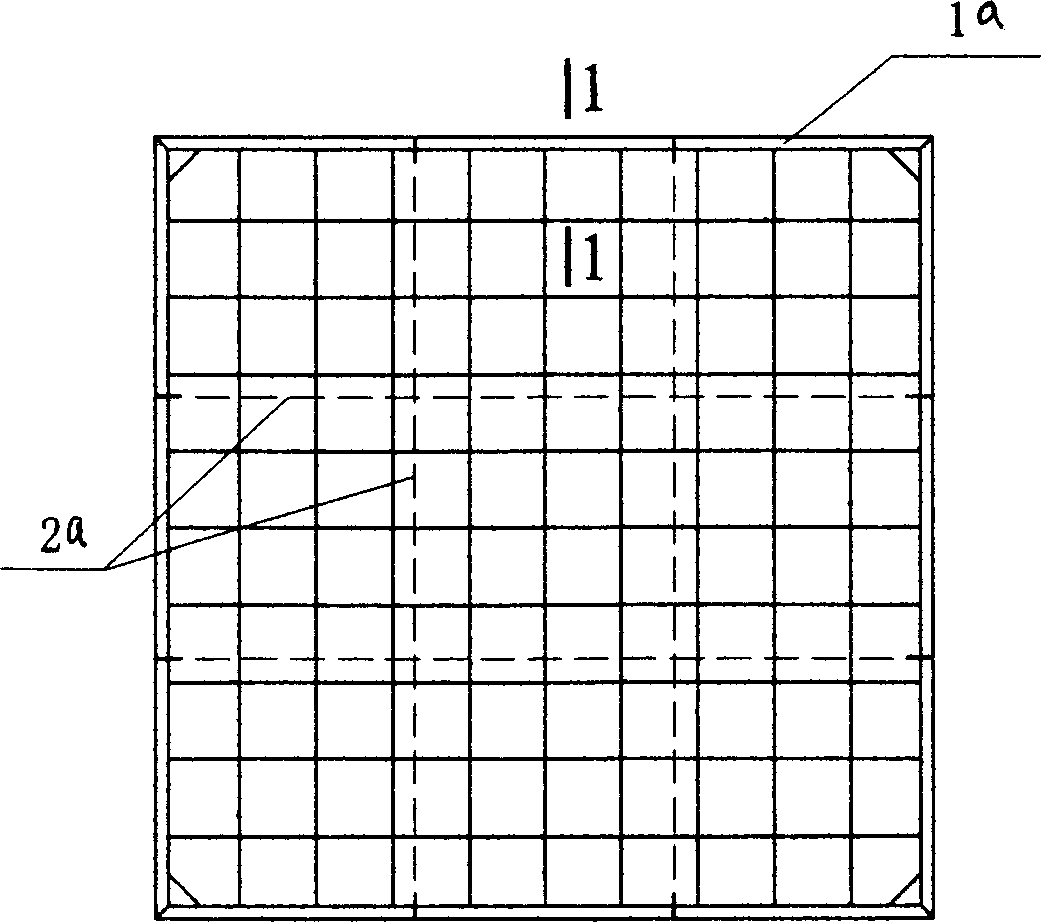

[0056] As shown in Figure 2, the rectangular foamed cement composite panel structure of the present invention is a roof panel used in conjunction with steel roof trusses and light steel structures. save space.

[0057] The present invention is mainly composed of main frame 1b, foamed cement 3, steel truss 2b and surface layer 4, and is characterized in that: the described rectangular foamed cement composite board uses foamed cement 3 as the core layer; There is a surface layer 4 reinforced by crack-resistant materials; a steel truss 4b is arranged in the foamed cement 3 core layer, and is connected with the main frame 1b; the square foamed cement composite board is composed of the main frame 1b, foamed The cement core layer 3, the surface layer 4 and the steel truss 2b are compounded.

[0058] The standard size of the composite panel in this embodiment is: 3 meters wide and 6 meters long.

[0059] Its manufacturing method includes:

[0060] 1. First, put the main frame 1b o...

Embodiment 3

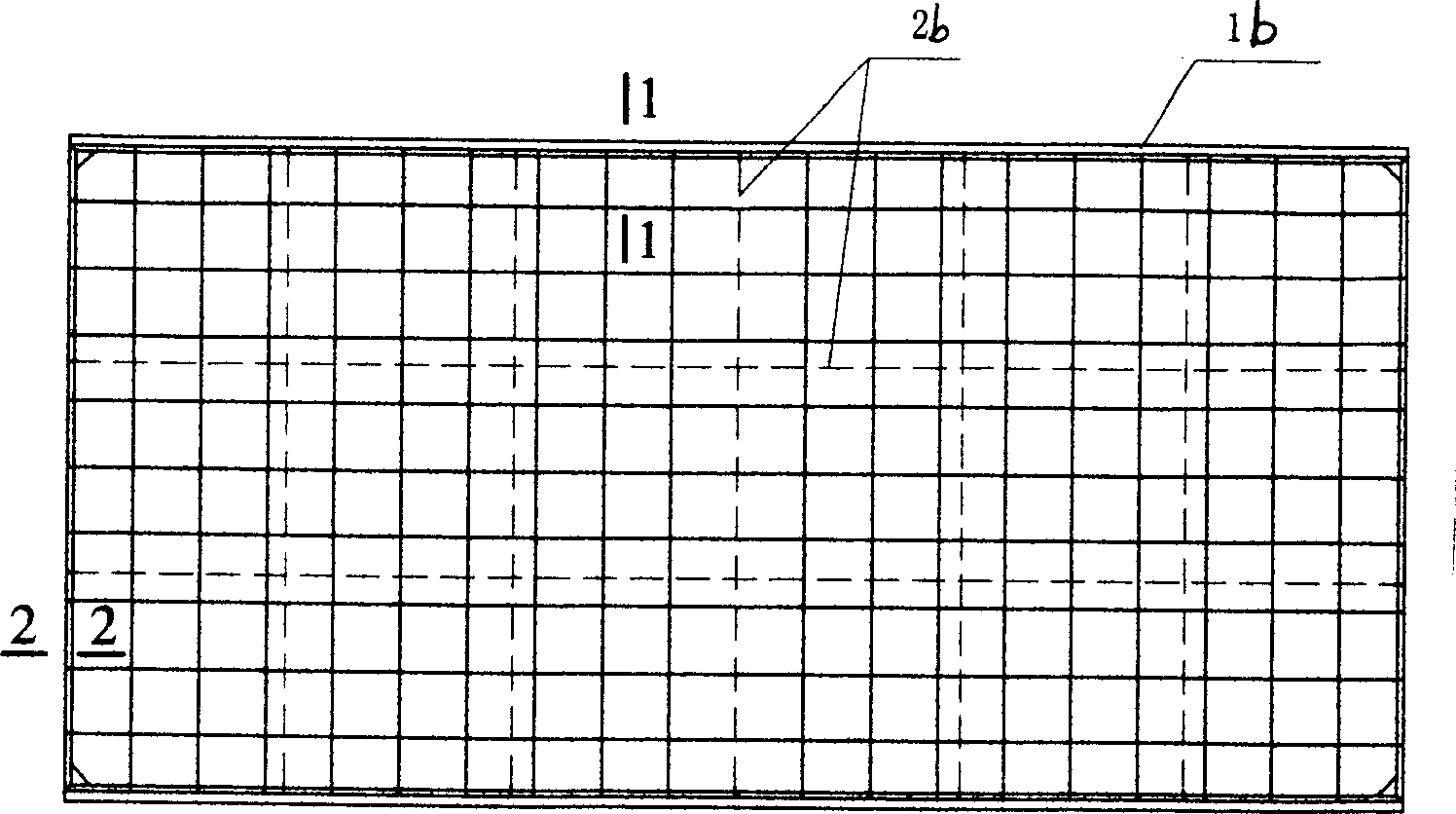

[0069] As shown in Figure 3, the elongated foamed cement composite panel structure of the present invention is a roof panel used in conjunction with steel roof trusses, light steel structures and 36-meter panels. Its long frame is designed as a ladder shape, and its purpose is to Save space when stacking and transporting.

[0070] The present invention is mainly composed of main frame 1c, foamed cement 3, steel truss 2c and surface layer 4, and is characterized in that: the strip type foamed cement composite board uses foamed cement 3 as the core layer; There is a surface layer 4 reinforced by crack-resistant materials; a steel truss 4 is arranged in the core layer of foamed cement 3, and is connected with the main frame 1c; the square foamed cement composite board is composed of the main frame 1c, foamed The cement core layer 3, the surface layer 4 and the steel truss 2c are compounded.

[0071] The standard size of the composite panel in this embodiment is: 1.5 meters wide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com