Construction structure for horizontal spliced seams of vertical joints of sandwich thermal insulation wall

A technology of horizontal joints and thermal insulation walls, applied in thermal insulation, building structure, building thermal insulation materials, etc., can solve the problems of poor waterproof and thermal insulation performance at the joints, difficult construction at joints, and inconvenient concrete pouring, etc. The site is clean and tidy, the construction steps are simple and convenient, and the effect of simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

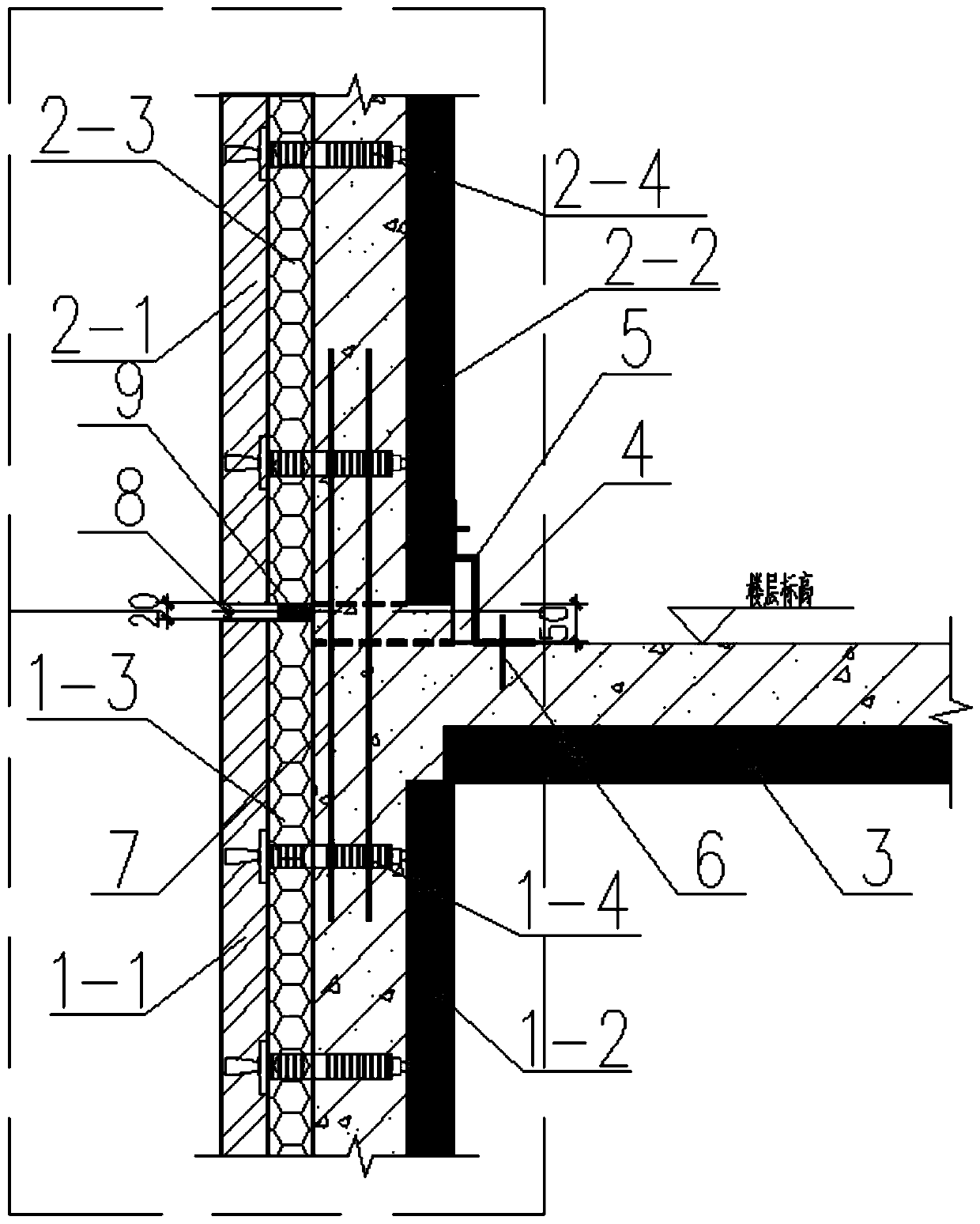

[0020] see figure 1 , a construction structure of vertical joints and horizontal joints of sandwich insulation walls, a gap is left between the lower inner leaf wall 1-2 and the upper inner leaf wall 2-2; one end of the laminated floor 3 is placed on the lower inner leaf wall 1-2 The height of the first concrete poured in the upper and lower insulation walls is up to the floor elevation, and it is integrated with the cast-in-place floor above the laminated floor 3. The floor elevation is lower than the upper inner leaf wall 2-2 and the upper The lower end of the outer leaf wall 2-1; between the floor elevation and the bottom of the upper inner leaf wall 2-2, 4 square wooden strips are used to support the mold, and the square wooden strips 4 are connected with the upper inner leaf wall 2-2 and the first concrete Fixed connection; the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com