Cast-in-place steel-concrete composite beam

An on-site pouring and concrete technology, which is applied in the field of composite beams, can solve problems such as complex operation, high structural cost, and difficult construction, and achieve the effects of overcoming the complexity of connection nodes, overcoming the large amount of steel used, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

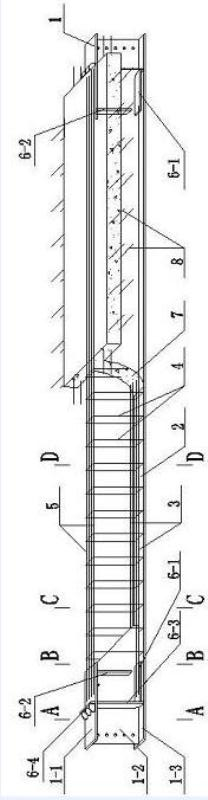

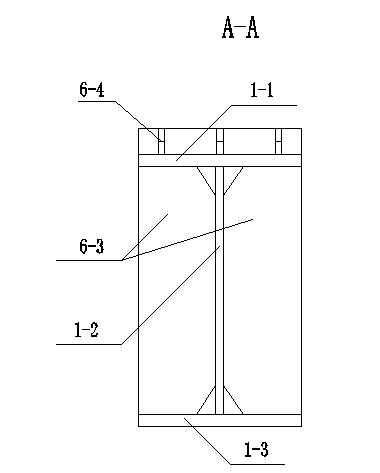

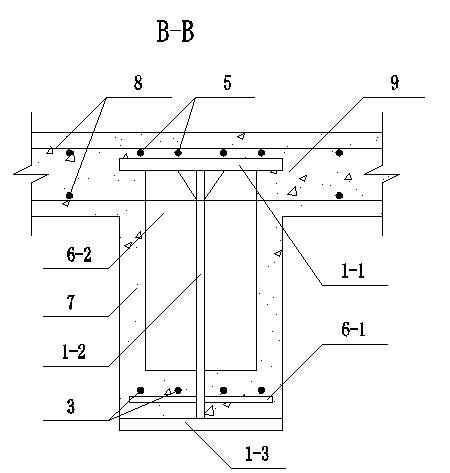

[0008] Specific implementation mode one: combine Figure 1-Figure 8 To illustrate this embodiment, a cast-in-place steel-concrete composite beam of this embodiment includes two I-shaped steel beam sections 1, steel plates 2 in the tension zone, multiple fire-resistant longitudinal reinforcements 3, multiple stirrups 4, multiple Longitudinal reinforcement 5 in compression zone, four longitudinal steel plate stiffeners 6-1, four transverse short steel plate stiffeners 6-2, four transverse long steel plate stiffeners 6-3 and concrete 7, each I-shaped steel beam section 1 The longitudinal length of the upper flange 1-1 is less than the longitudinal length of the lower flange 1-3, and the web 1-2 of each I-shaped steel beam section 1 has a right-angled trapezoidal structure, and the two I-shaped steel beams Section 1 is arranged along the longitudinal direction of any I-shaped steel beam section 1, and the oblique waists of the webs 1-2 of two I-shaped steel beam sections 1 are arr...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the I-shaped steel beam section 1 of this embodiment is made of Q235 steel, Q345 steel, Q390 steel or Q420 steel. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To describe this embodiment, the steel plate 2 in the tension region of this embodiment is made of Q235 steel, Q345 steel, Q390 steel or Q420 steel. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com