Patents

Literature

921results about "Mould separation apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

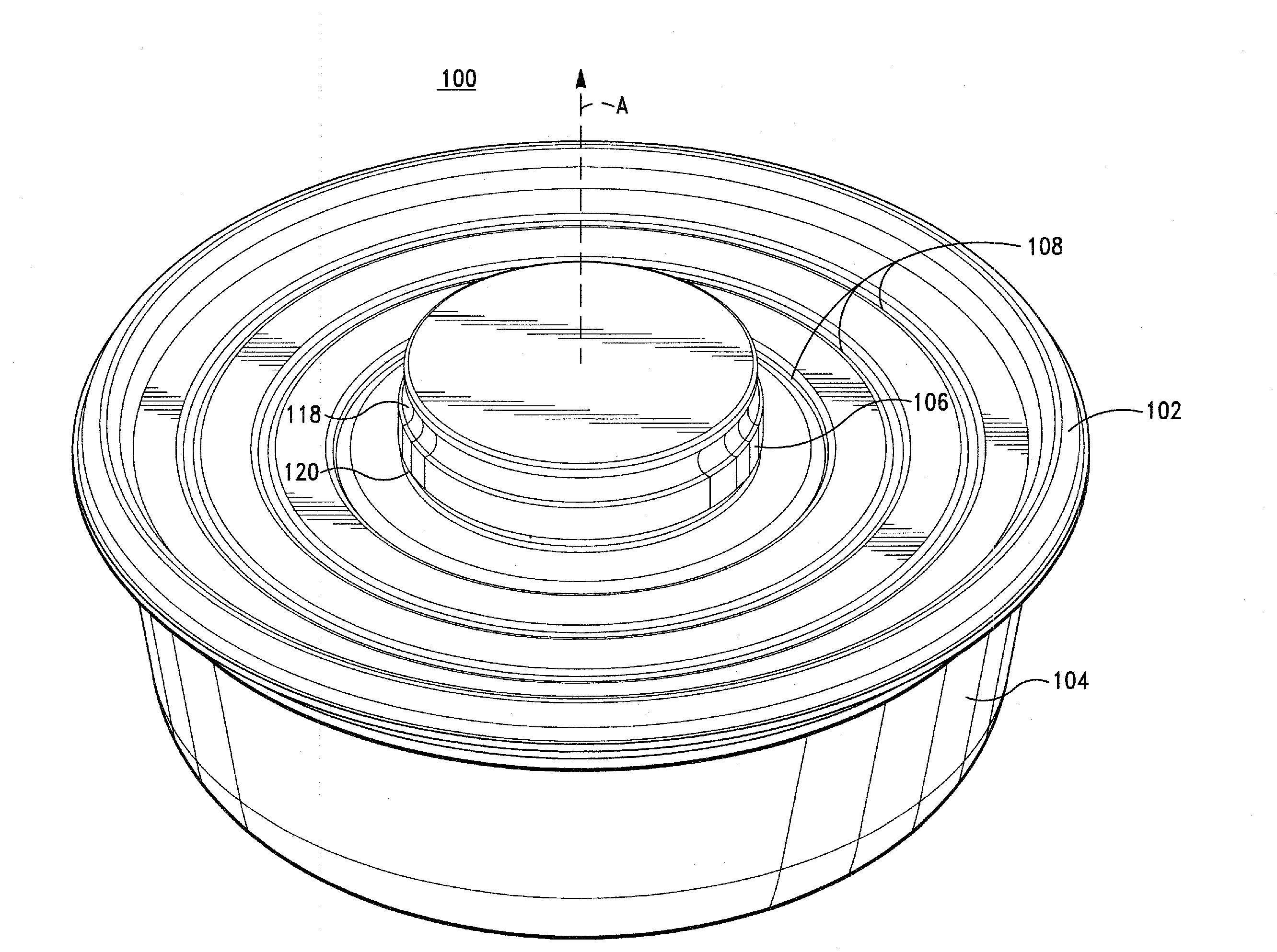

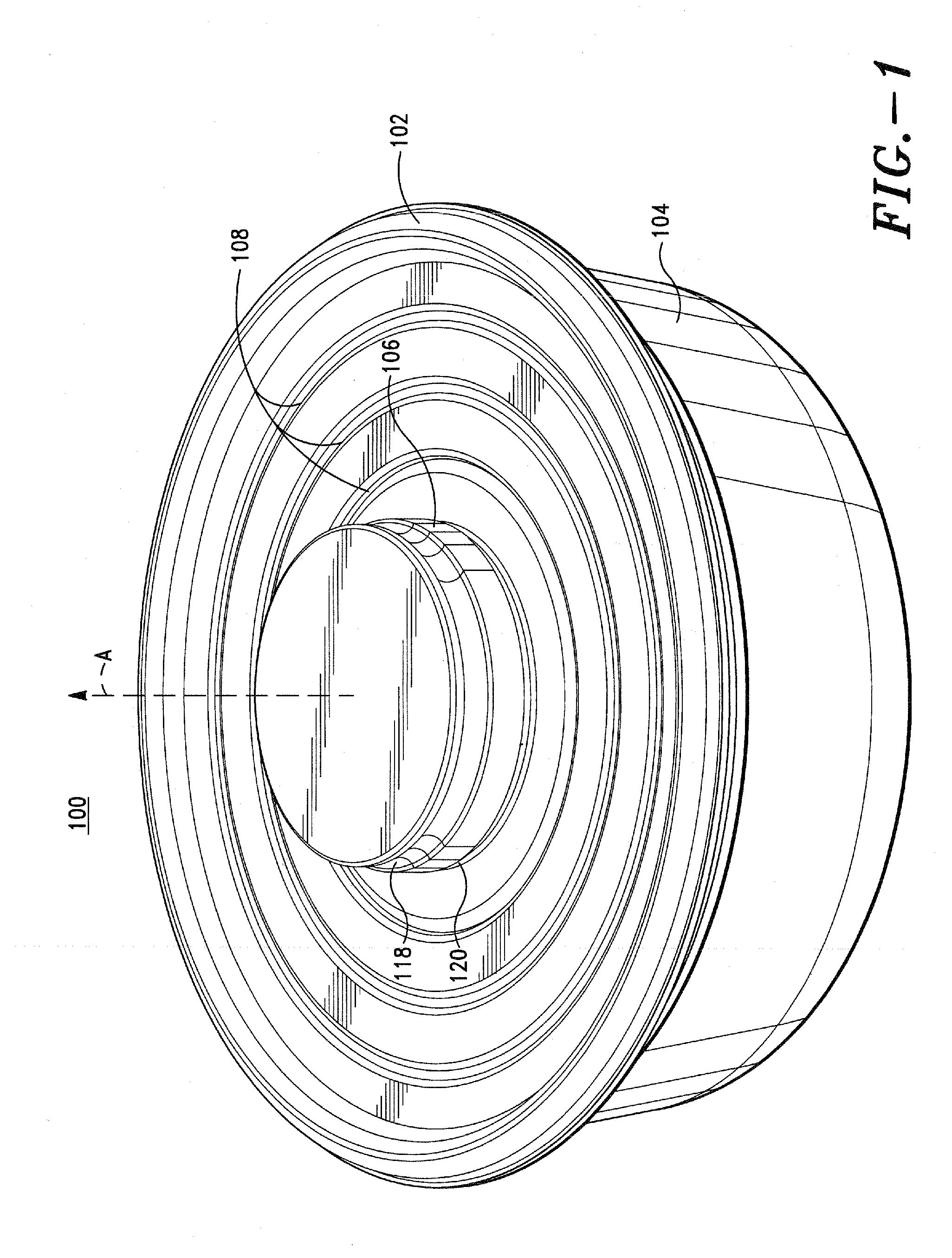

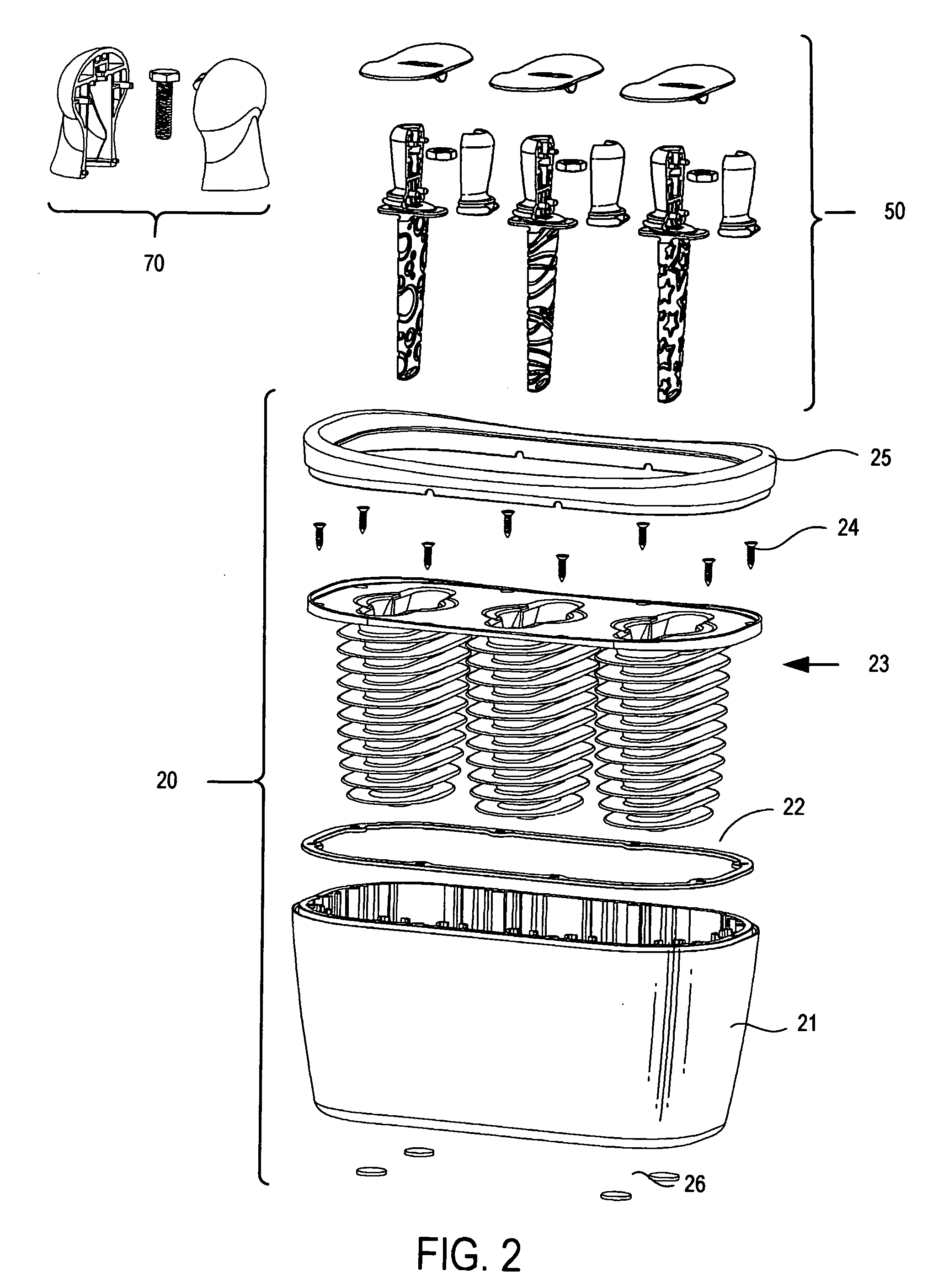

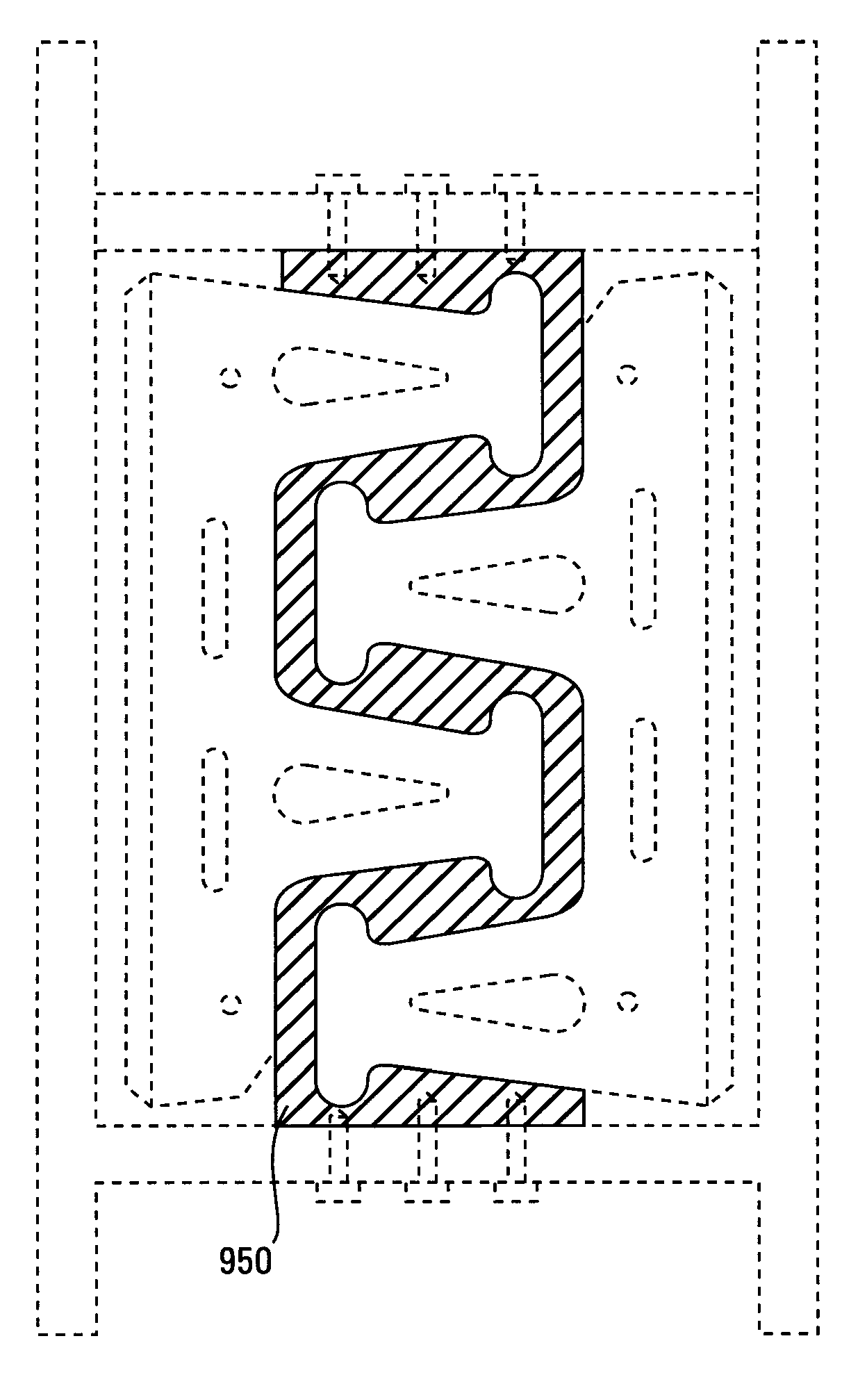

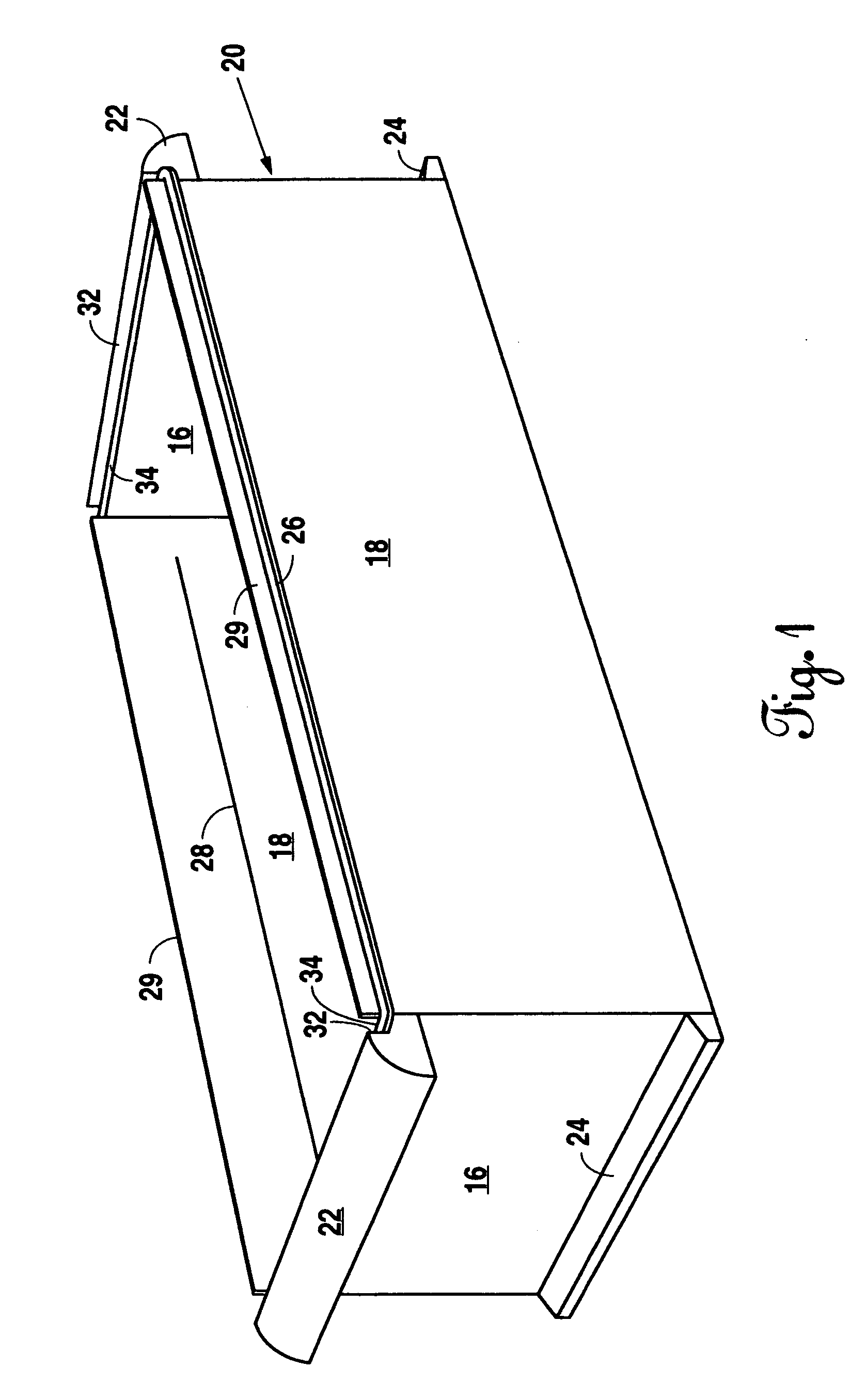

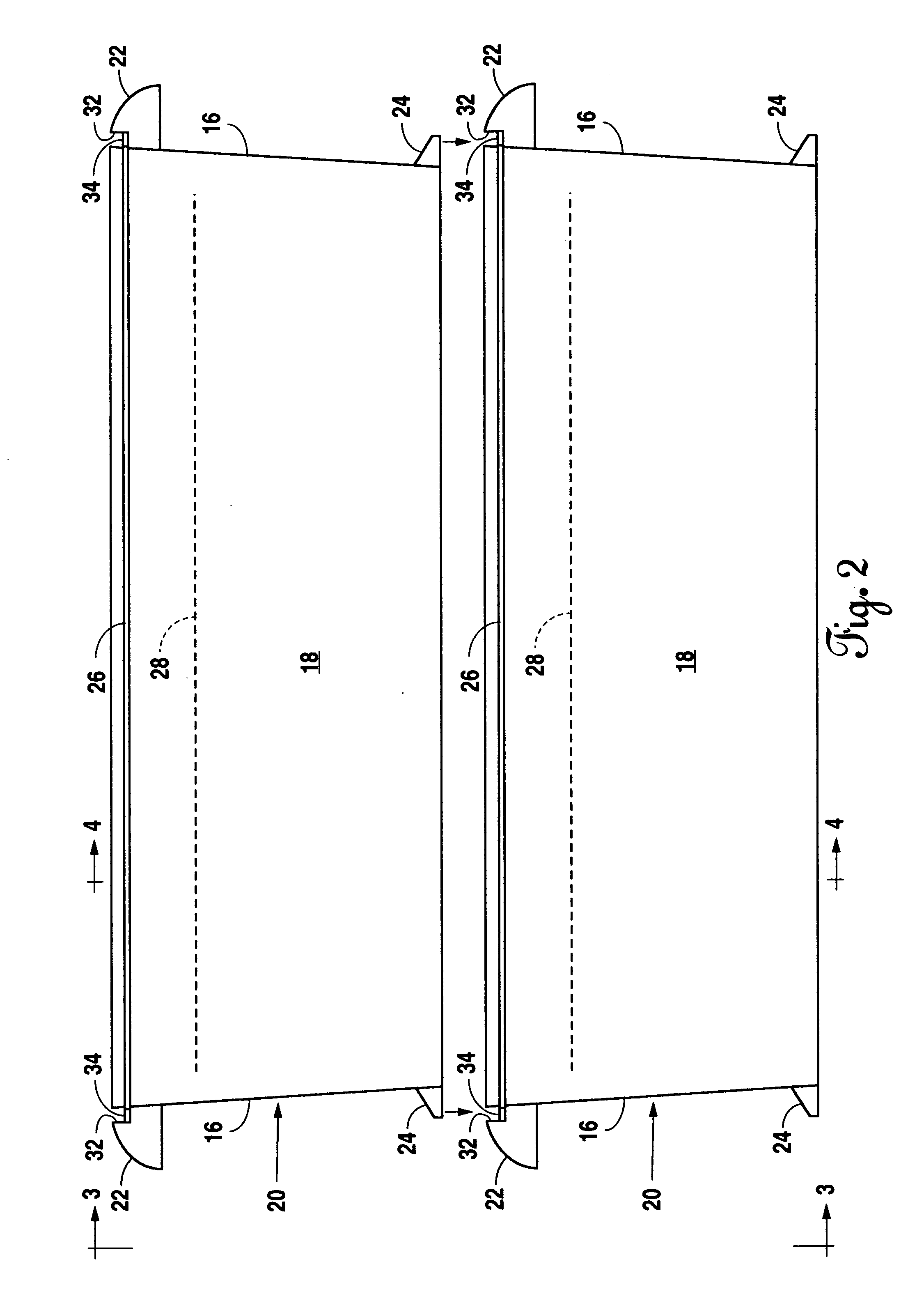

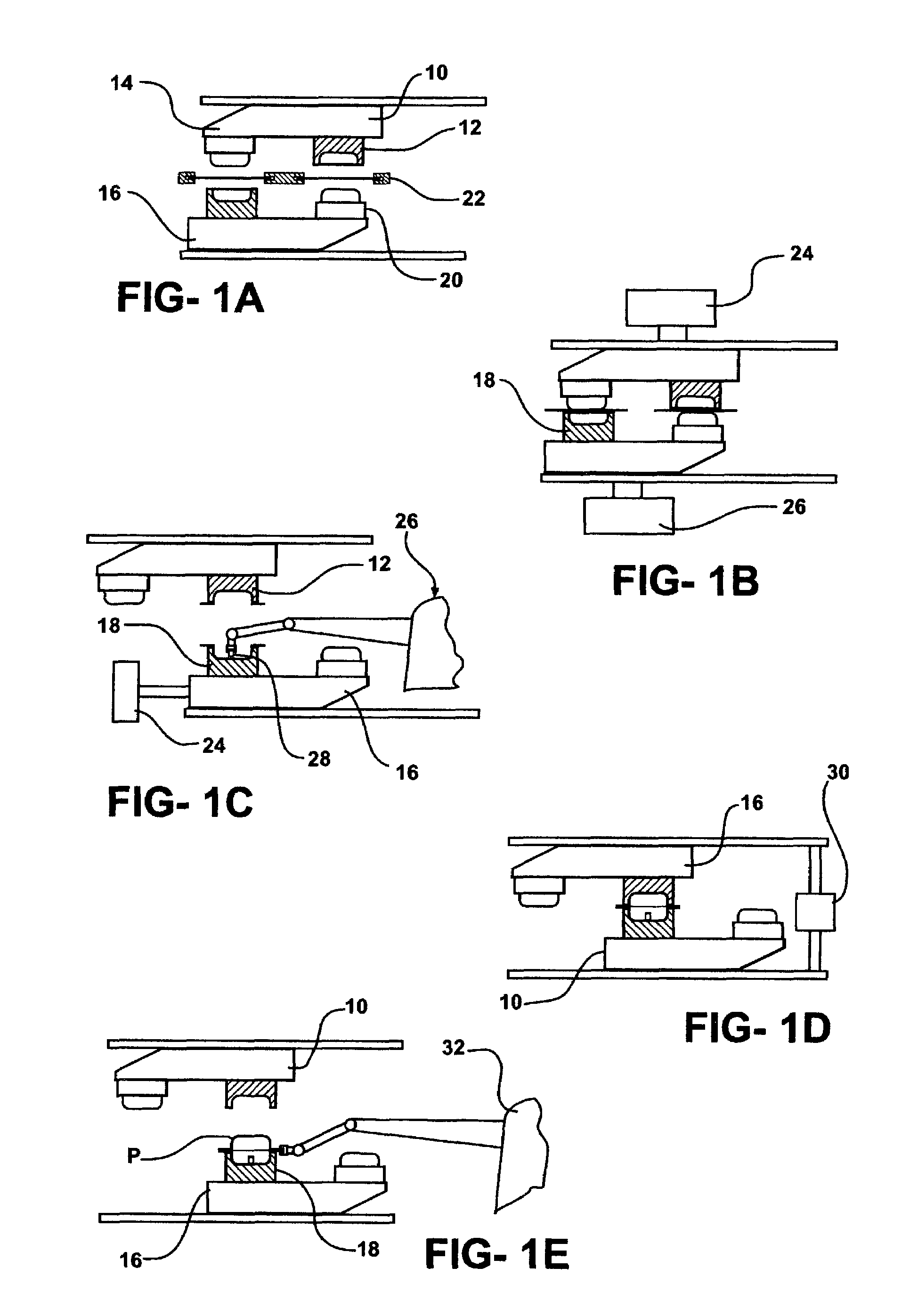

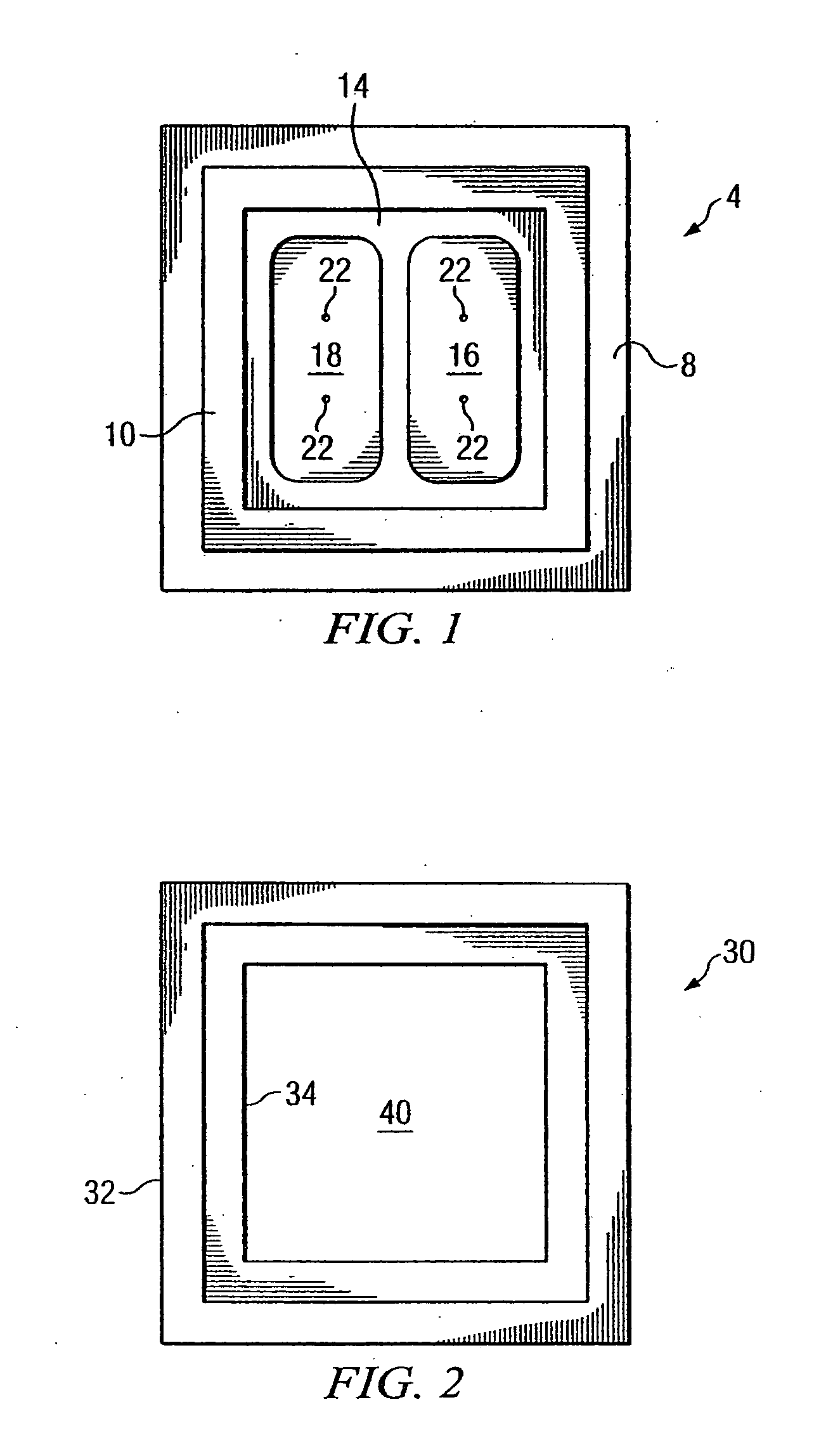

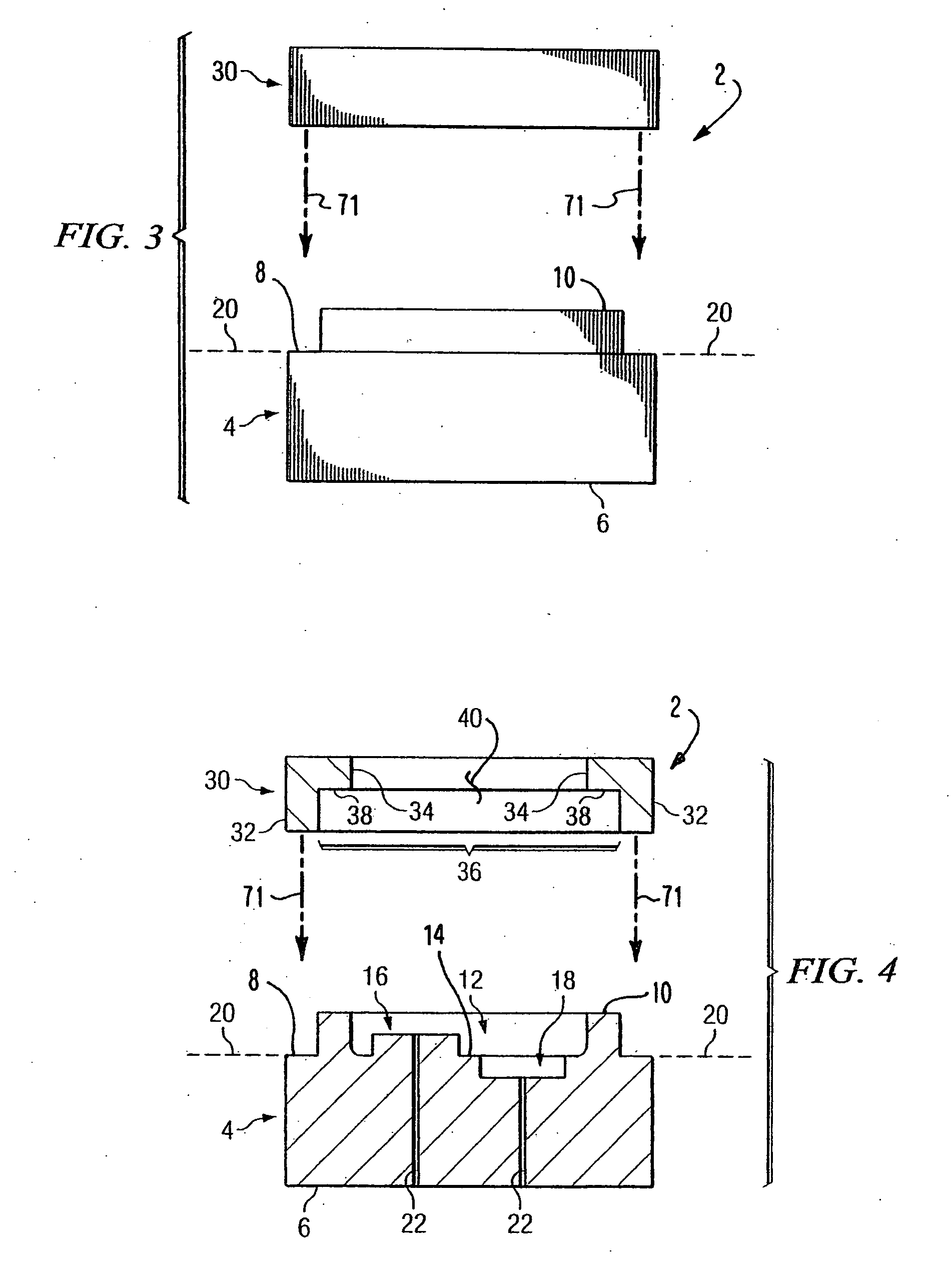

Systems and methods for removing lenses from lens molds

ActiveUS20070035049A1Efficient heatingFacilitate agitationMould separation apparatusConfectioneryEngineeringWedge shape

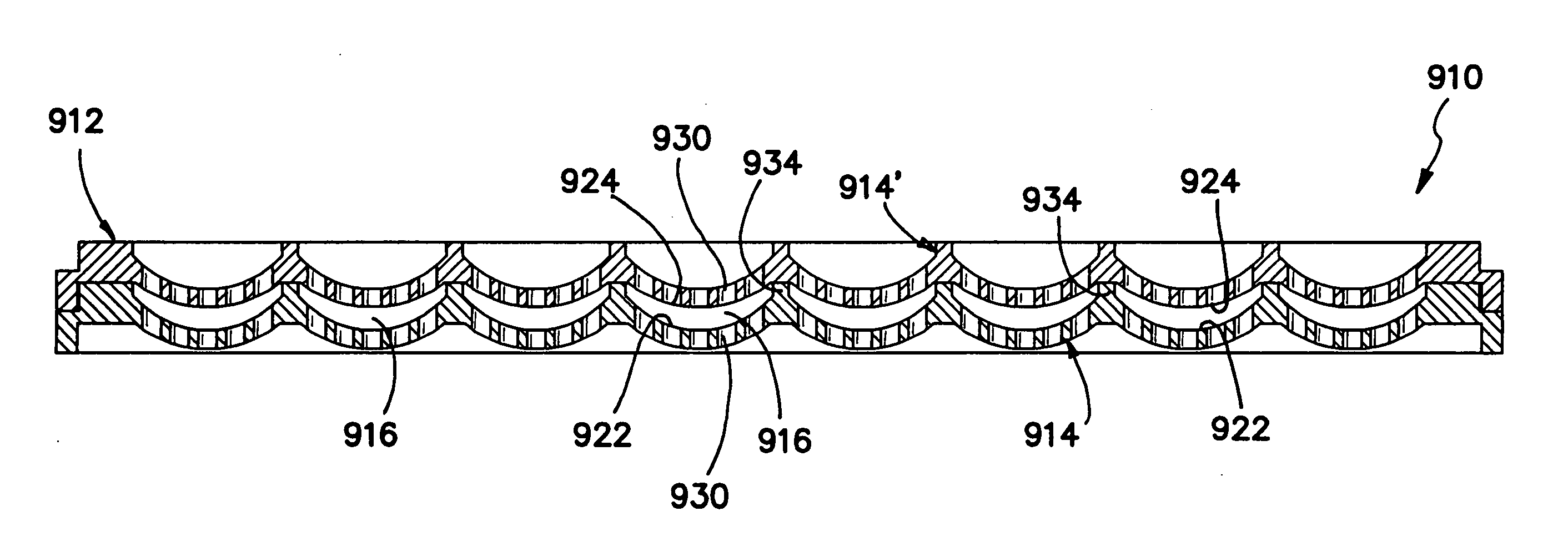

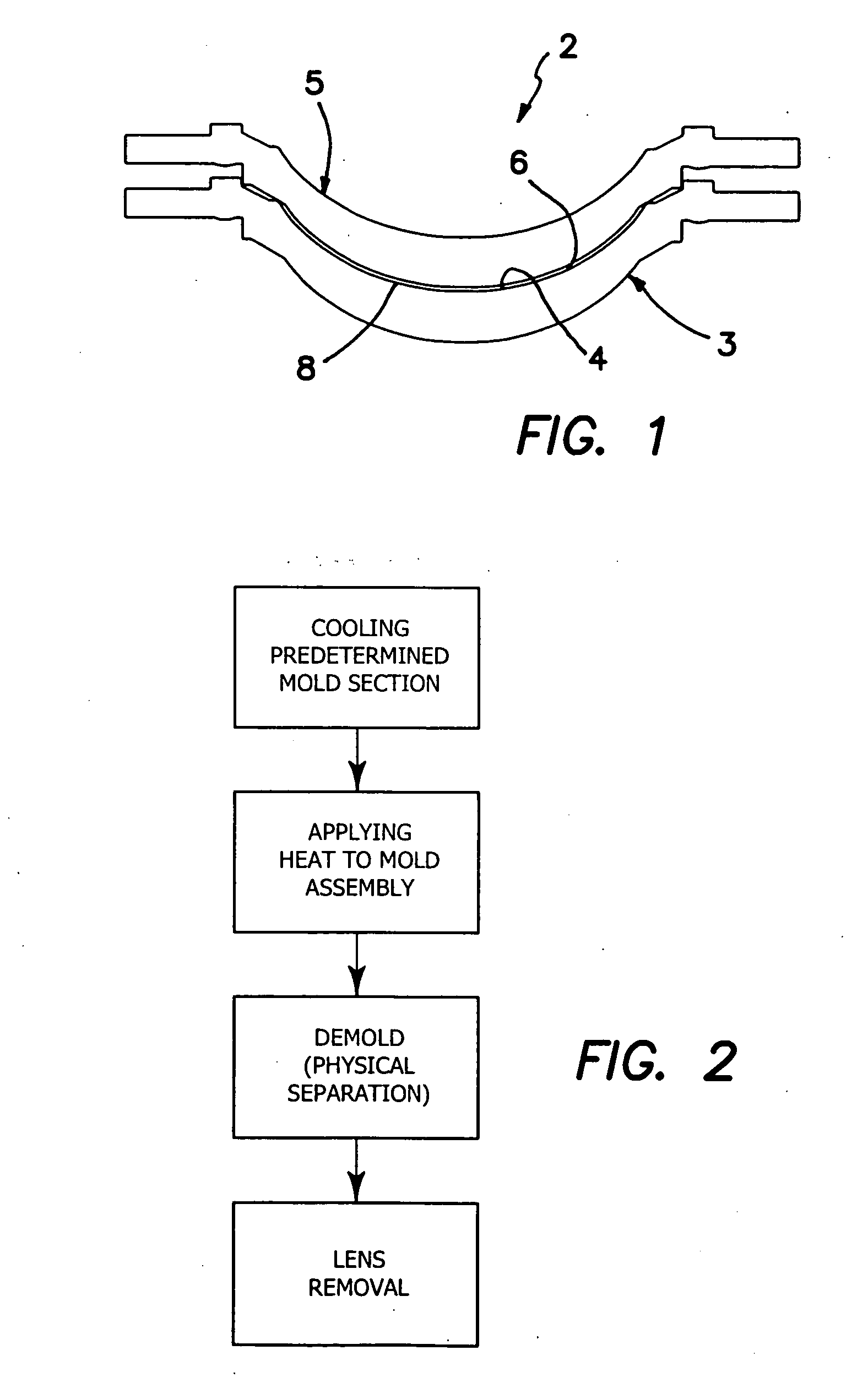

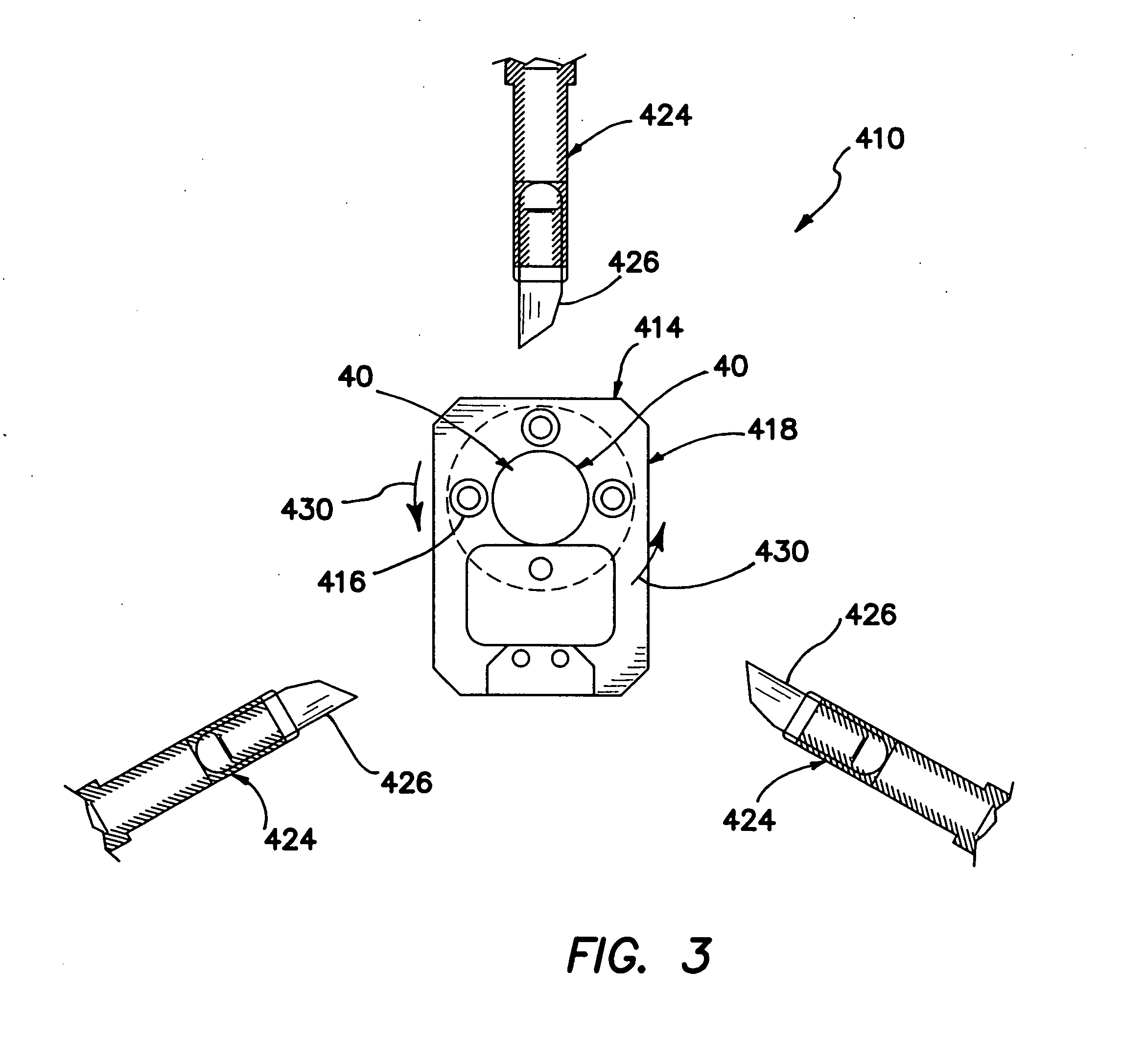

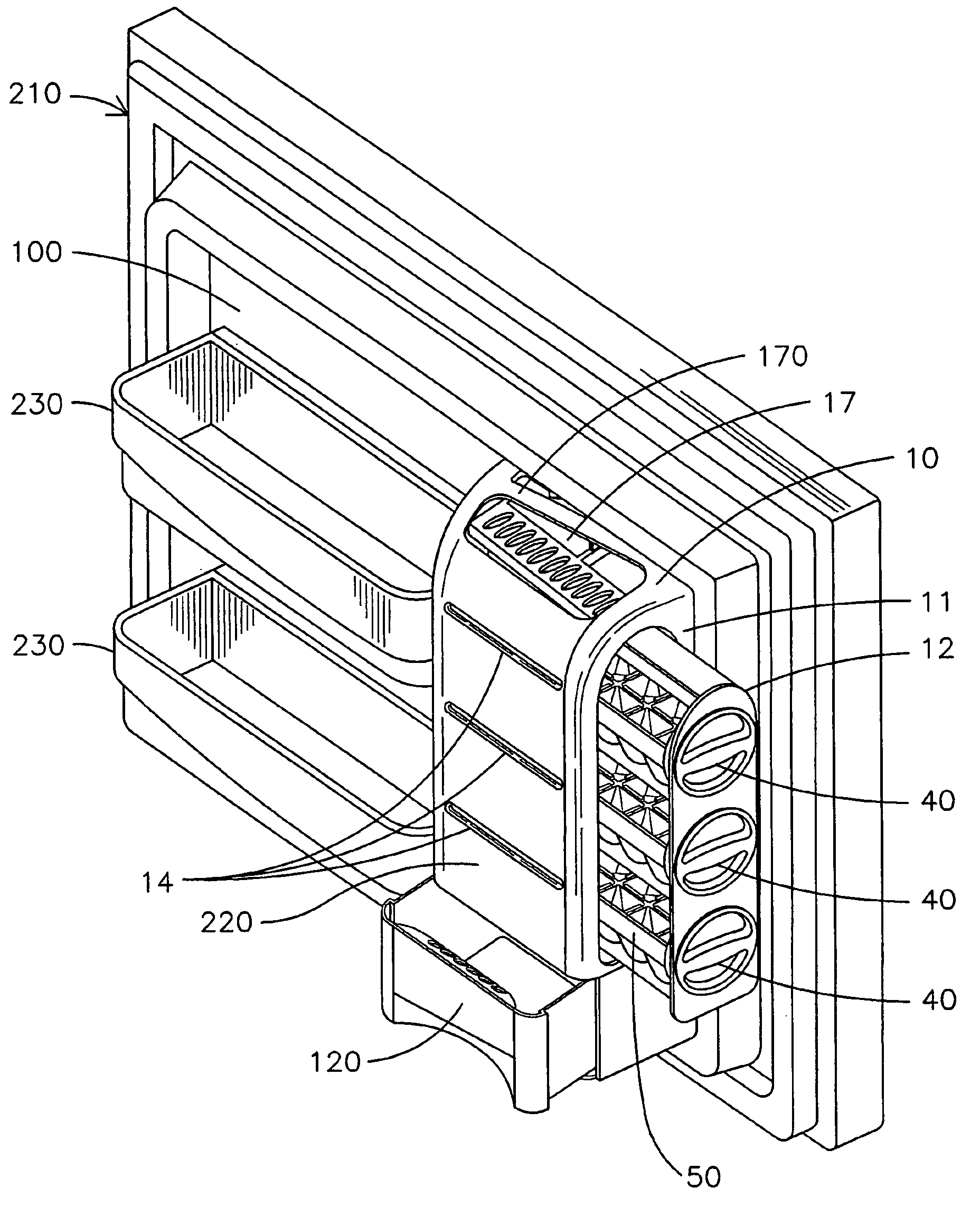

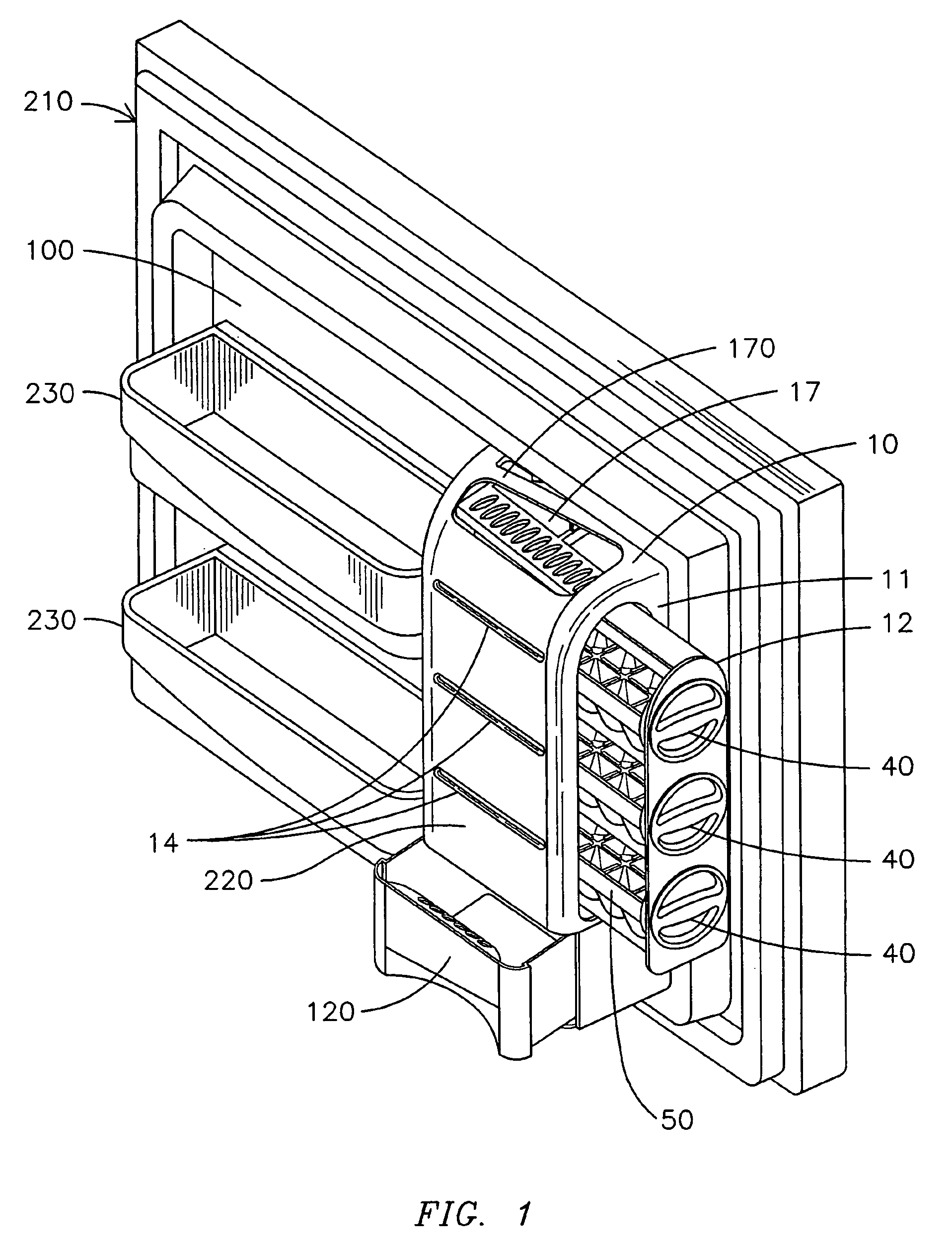

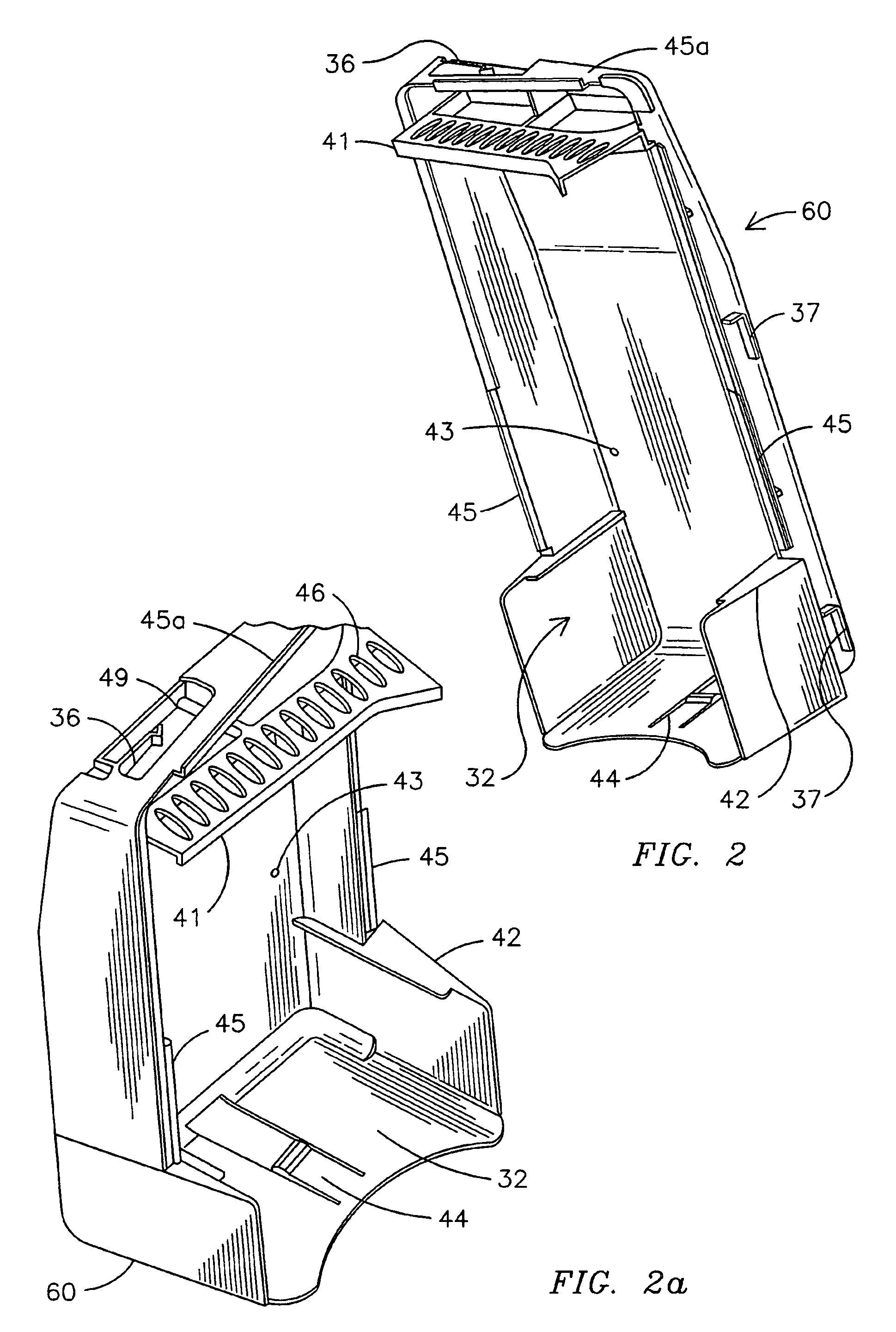

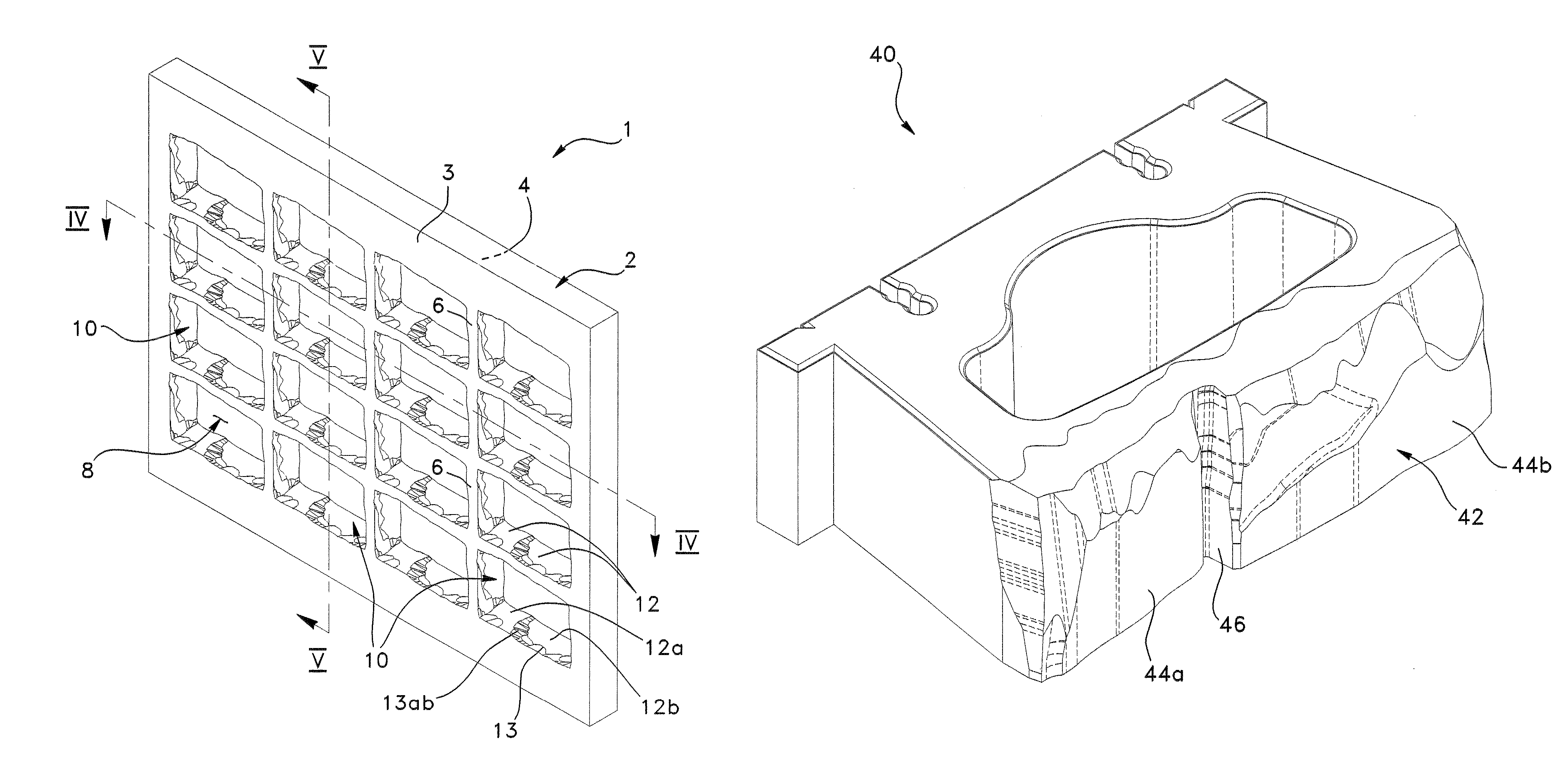

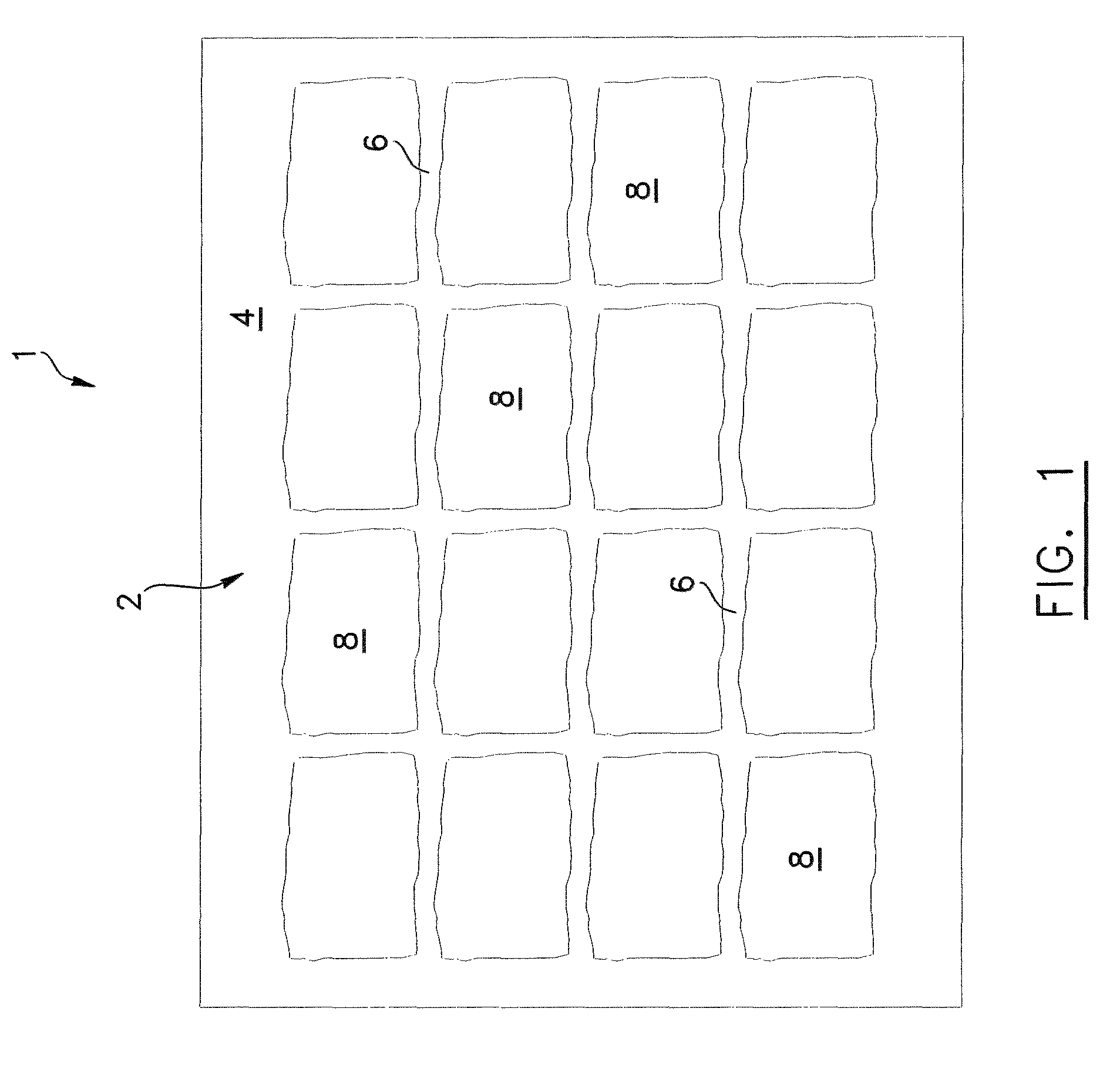

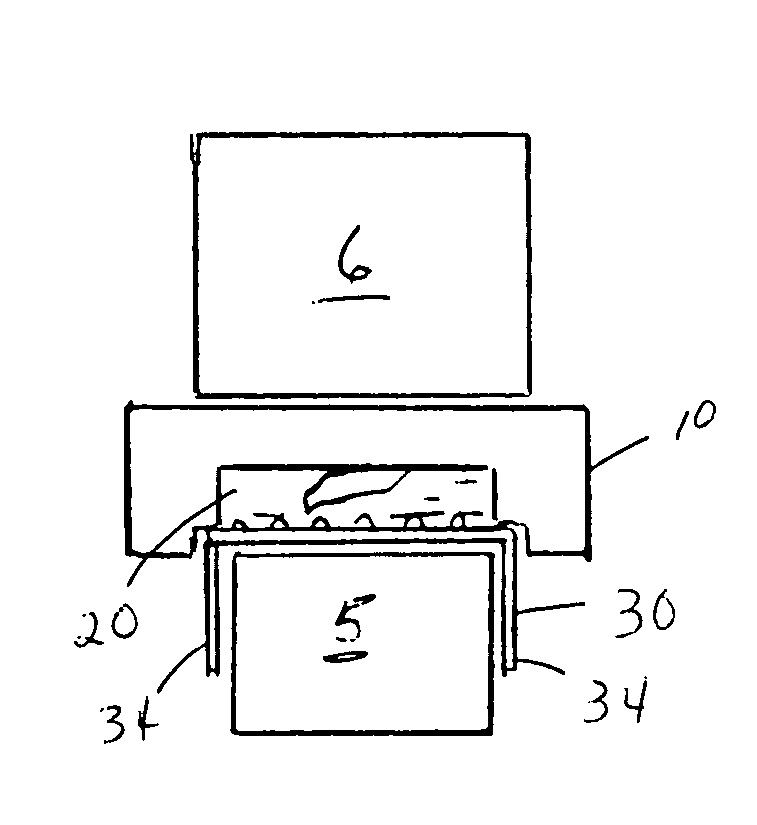

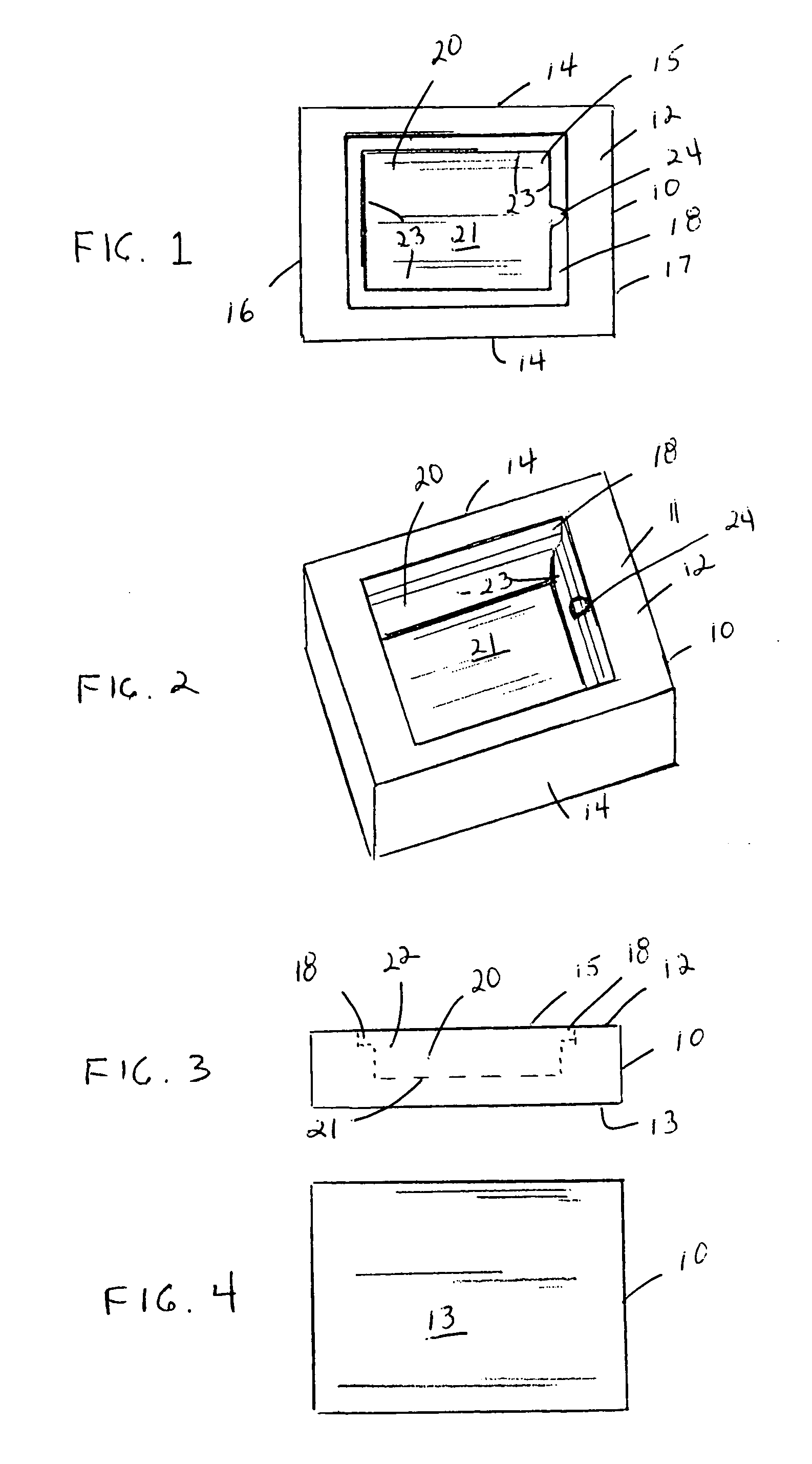

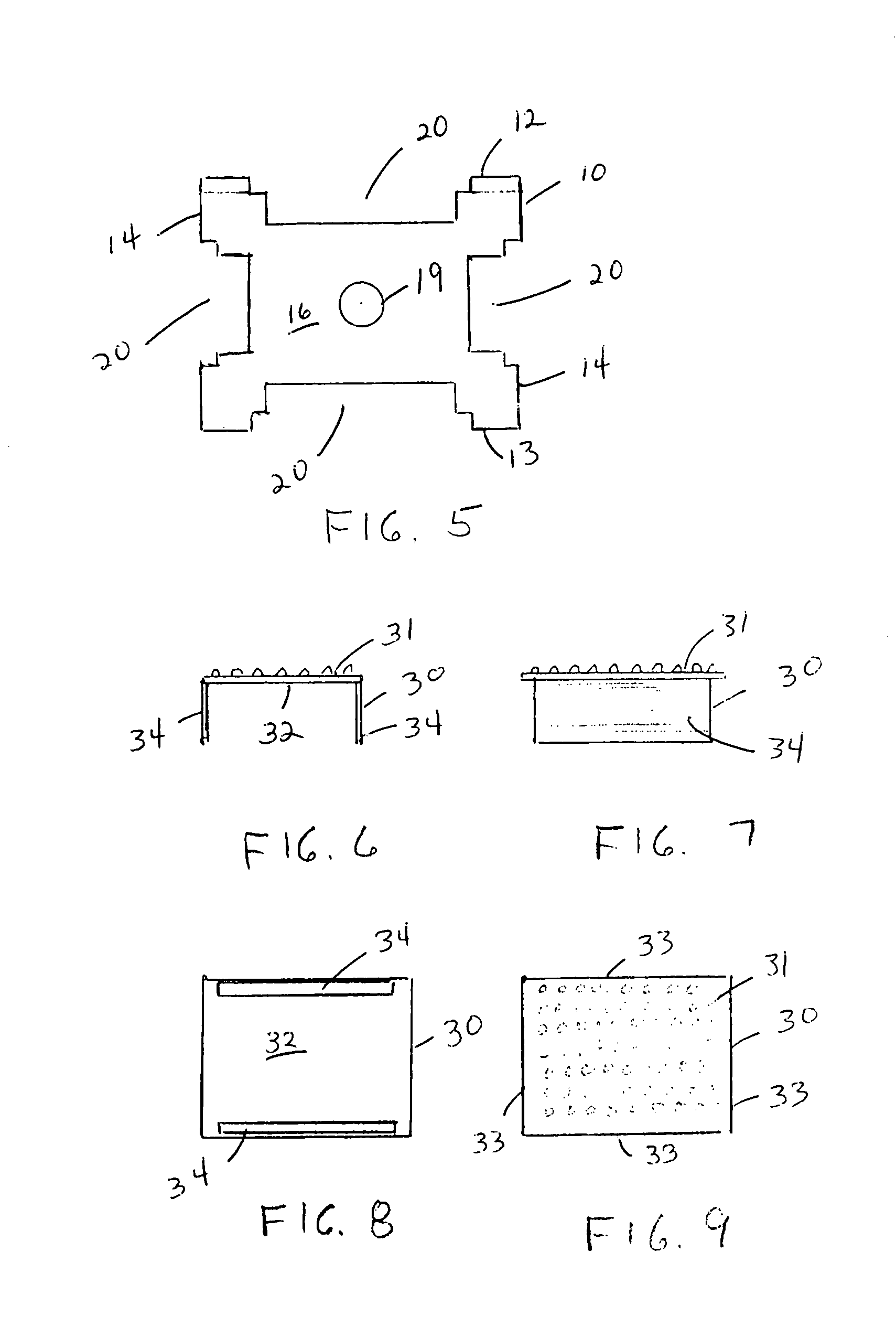

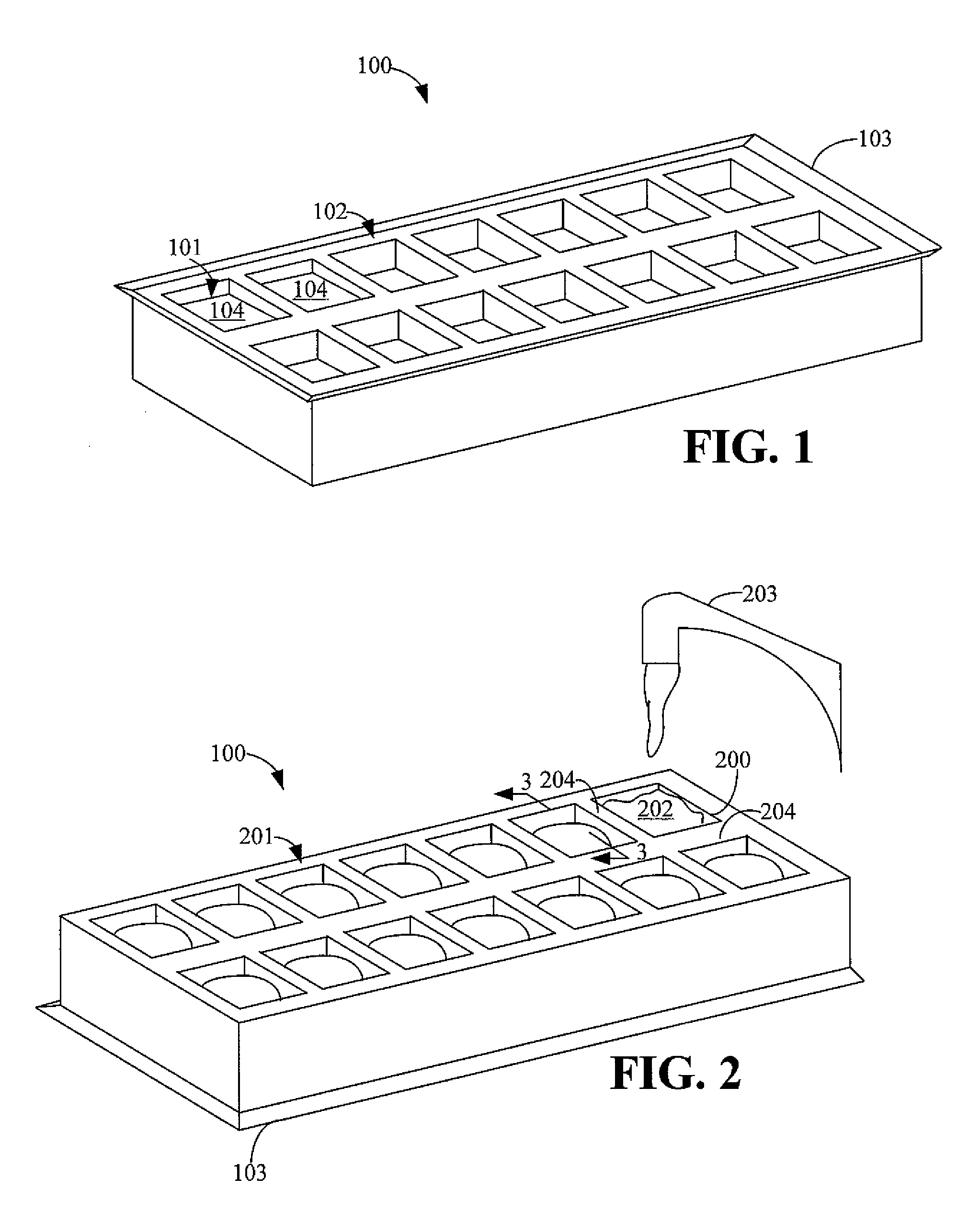

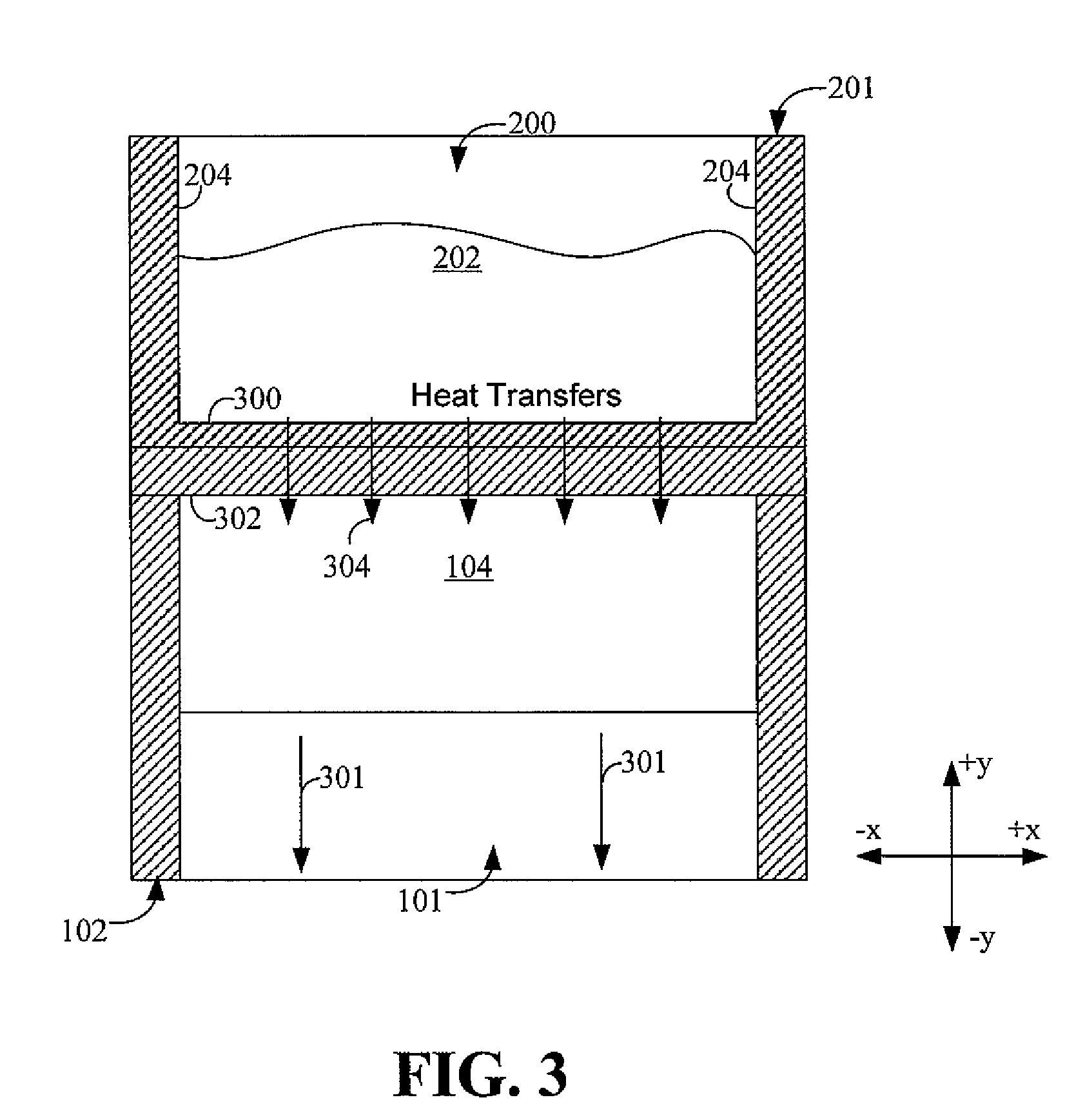

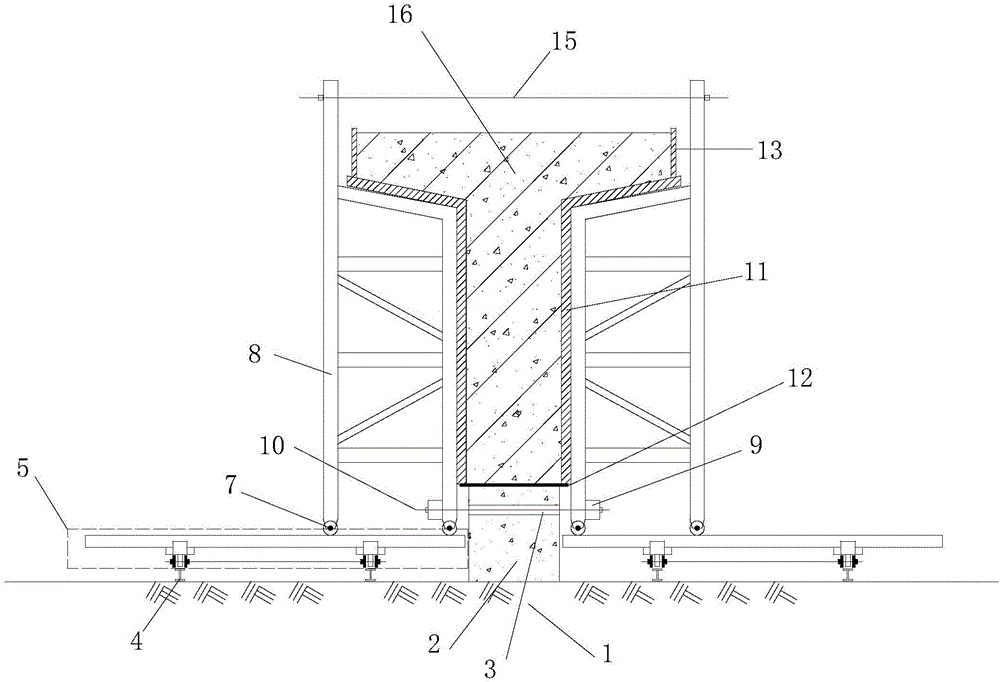

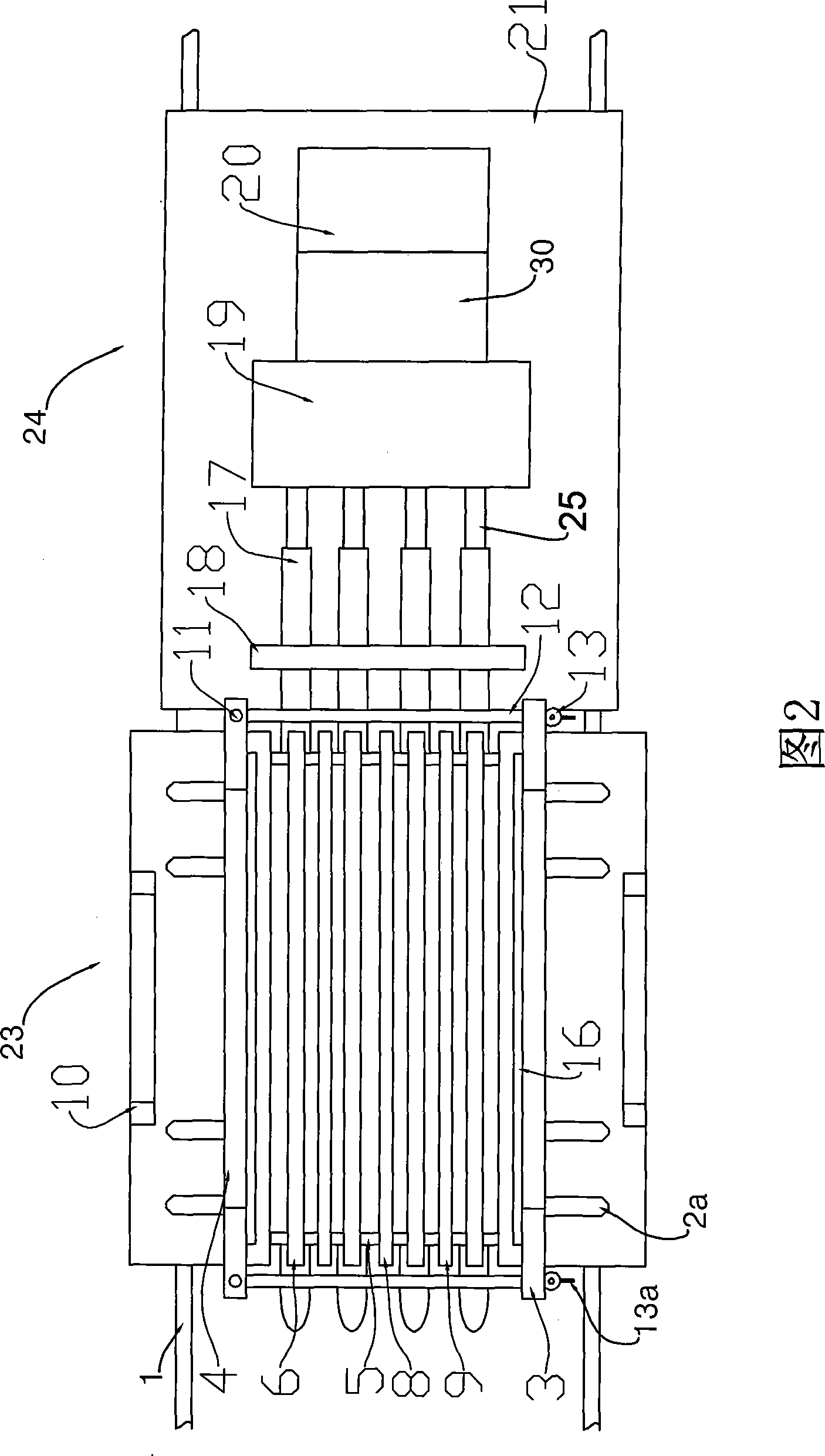

Methods and apparatus for separating mold sections, removing a lens product from the separated mold sections, and transferring the lens product to a processing tray are provided and include contacting assembled mold sections with a warm fluid to break fused portions between the mold sections, and using one or more wedge shaped elements to pry apart and separate the mold sections, one from the other. A vacuum head having multiple vacuum ports is employed for lifting the newly molded lens product from a mold section and for releasing the lens from the vacuum head into a processing tray. A cylinder of flowing air directed around the circumference of the lens is effective to maintain the lens in an unfolded position as the lens is being released into the processing tray. A tray set including multiple trays holding multiple lenses is provided and includes features for enabling visual and / or mechanical distinction of the trays and lenses held thereby.

Owner:COOPERVISION INT LTD

Ice cube making device for refrigerators

InactiveUS7204092B2Mould separation apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:MABE MEXICO S DE R L DE

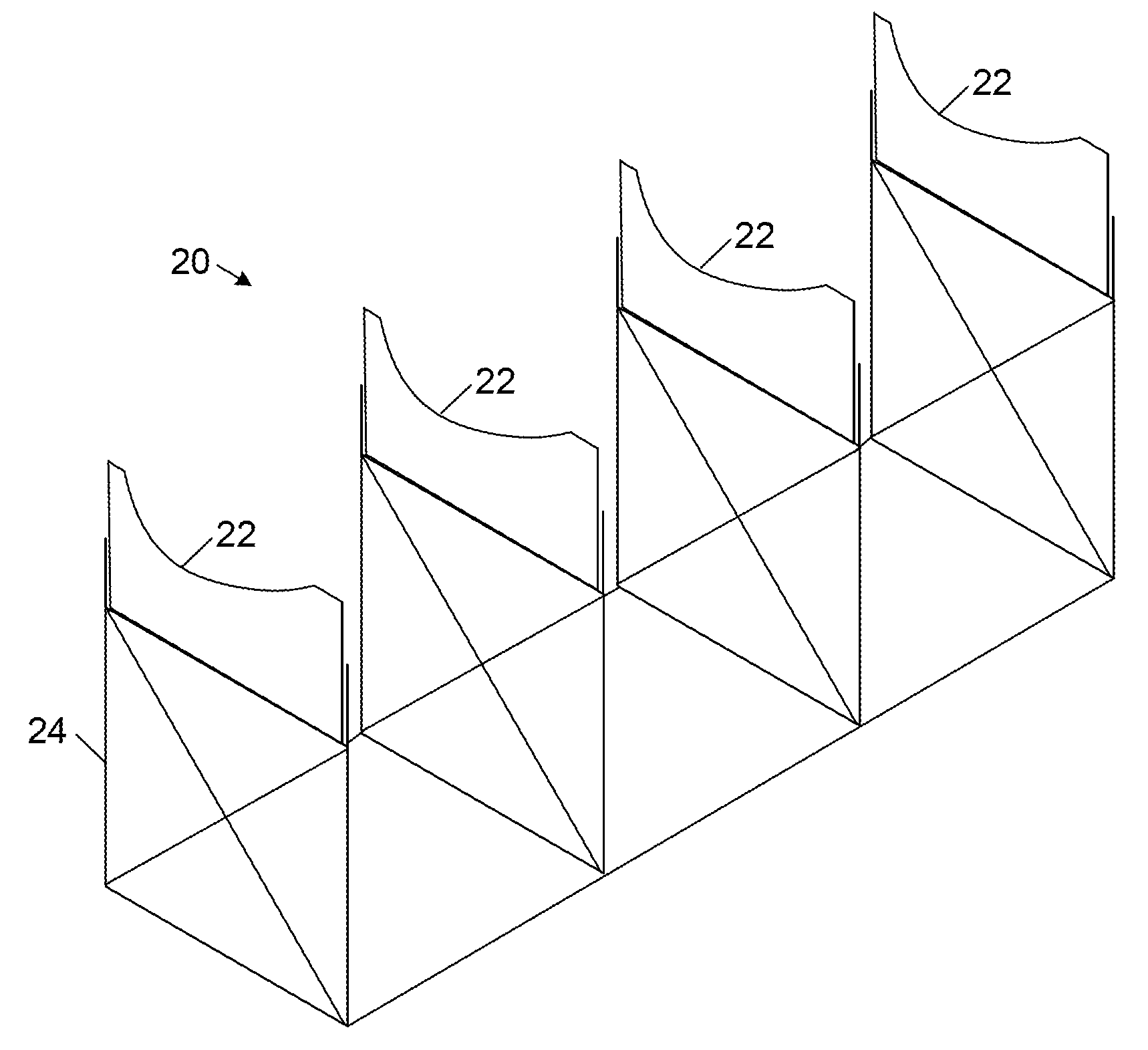

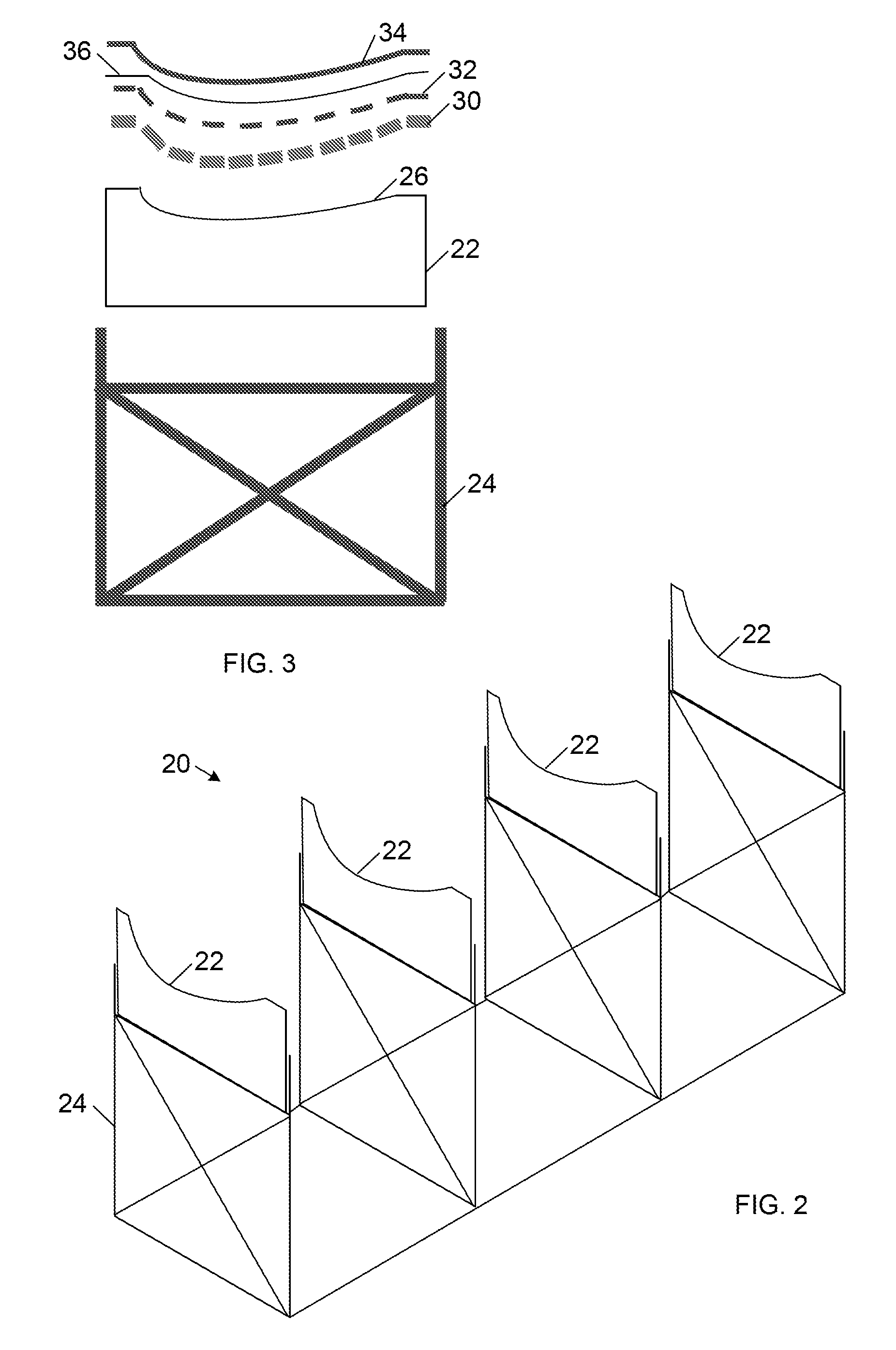

Molding apparatus for producing dry cast products having textured side surfaces

ActiveUS8101113B2Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

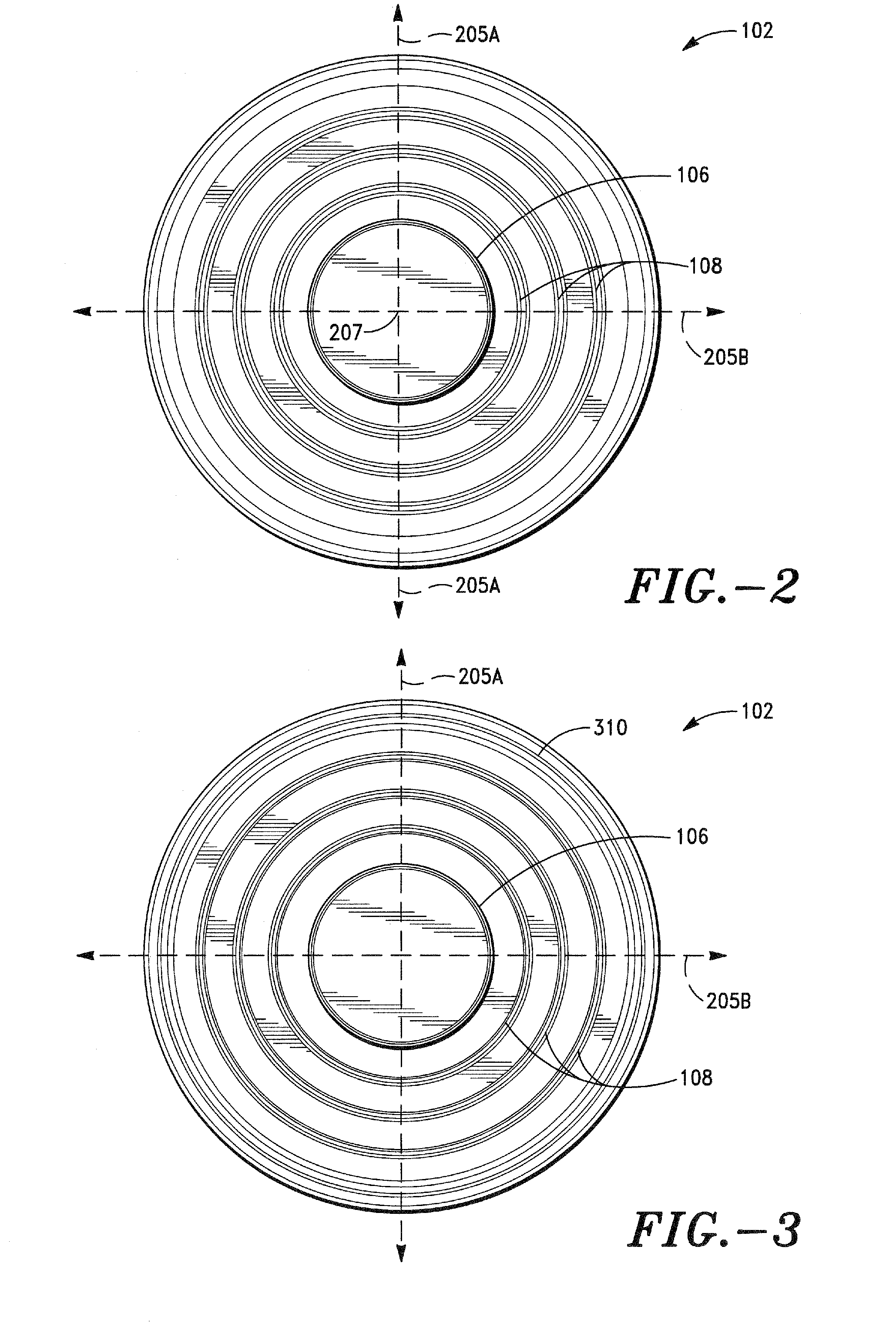

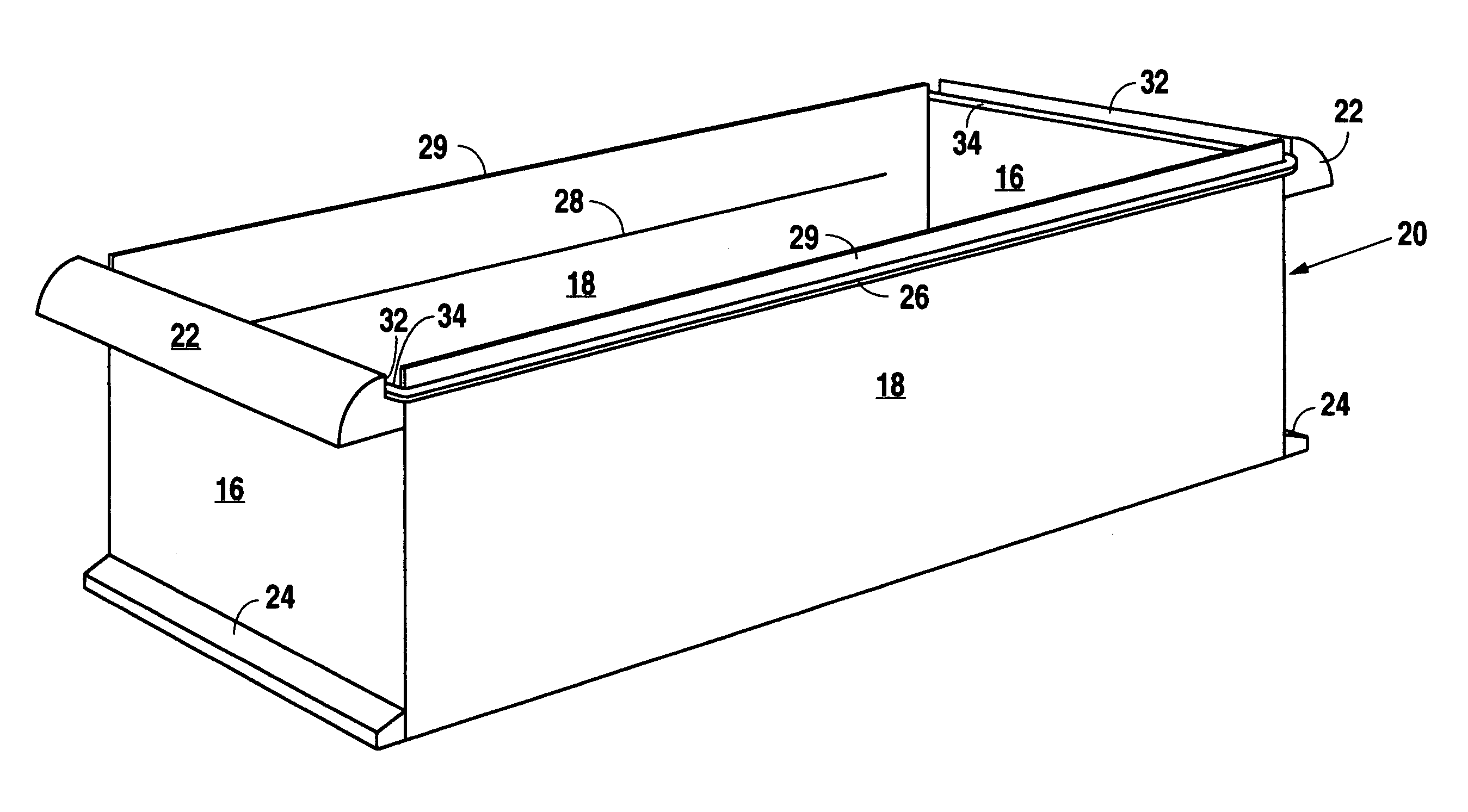

Container having an articulated cover

InactiveUS20090166369A1Sufficient structural rigiditySolve the lack of rigidityMould separation apparatusFoundry mouldsMechanical engineeringStructural rigidity

The covers stack together in two different ways. First, the covers can be stacked into an “aligned” stack. The aligned stack provides structural rigidity for bulk handling during manufacturing. Second, the covers can be stacked into a “locked” stack. The locked stack provides even more structural rigidity than does the aligned stack and is useful when storing unused covers. The cover includes a first closure portion, an engagement portion, and an alignment portion. The base includes a second closure portion. The first closure portion of the cover is sealingly engageable with the second closure portion of the base to define a sealed storage area. The alignment portion of the cover is engageable with the alignment portion of a second cover to form an aligned cover stack. The engagement portion of the cover is engageable with the engagement portion of a second cover to form a locked cover stack. The cover further includes at least one articulation element circumscribing the engagement portion of the cover and that provides flexibility to the cover allowing the engagement portion of the cover to easily articulate upwardly or downwardly.

Owner:SAVICKI ALAN F

Method for pouring and molding large scale disposal wallboard and mould carriage thereof

InactiveCN101439553AHigh strengthImprove product qualityDischarging arrangementMould separation apparatusWire cuttingSlurry

The invention discloses a method for one-time wallboard perfusion moulding on a large scale and a pan car thereof. A die of the bottom plate of a wallboard is fixed inward the internal part of the bottom plate of the pan car at equal distance; dies of the side wall of the wallboard are respectively fixed inward the front side plate and the back side plate of the pan car at equal distance; therefore, after the case of the pan car is fully filled with pasty slurries, a vibrator leads to the vibration of the whole case on the front side plate and the back side plate; after the vibration, a finished product is obtained after initial setting, wallboard cutting, steam curing, pan car removal of shuttering and other processes; therefore, 20-200 wallboards are processed in one time. The wallboard cutting is realized in the form of steel wire cutting or clapboard partition; a steel wire netting is embedded in the wallboard, so as to greatly enhance the strength of the wallboard; therefore, the invention has the advantages that the inner wallboard of the pan car is formed by large-scale one-time injection moulding by using the die, the precision of the die is high, the product quality is reliable, the injection amount is large, the production efficiency is greatly improved and the cost is saved.

Owner:朱春生

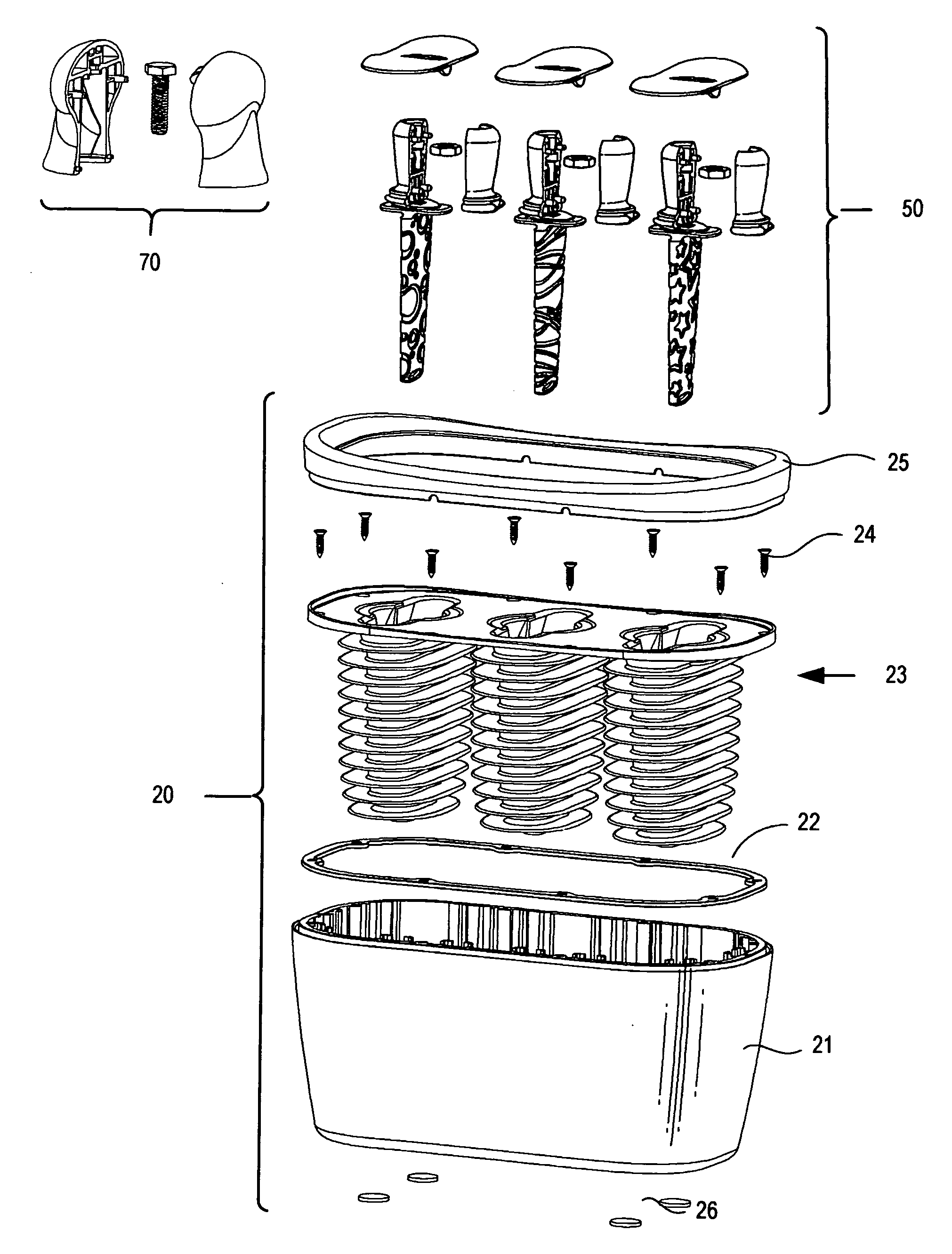

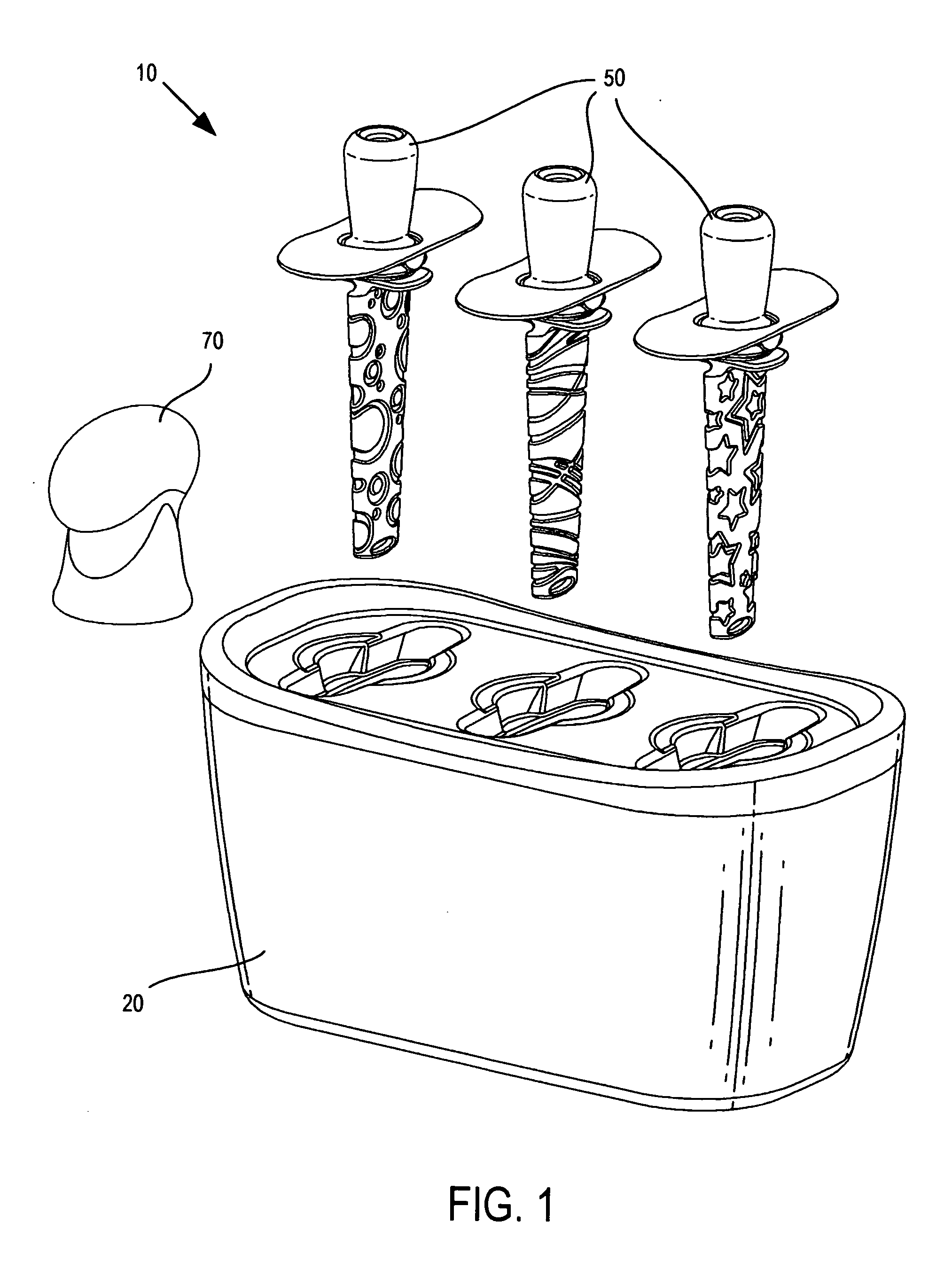

Method and apparatus for making frozen comestibles

ActiveUS20100183789A1Increase forceSufficient forceTurning machine accessoriesMould separation apparatusRefrigerantMechanical engineering

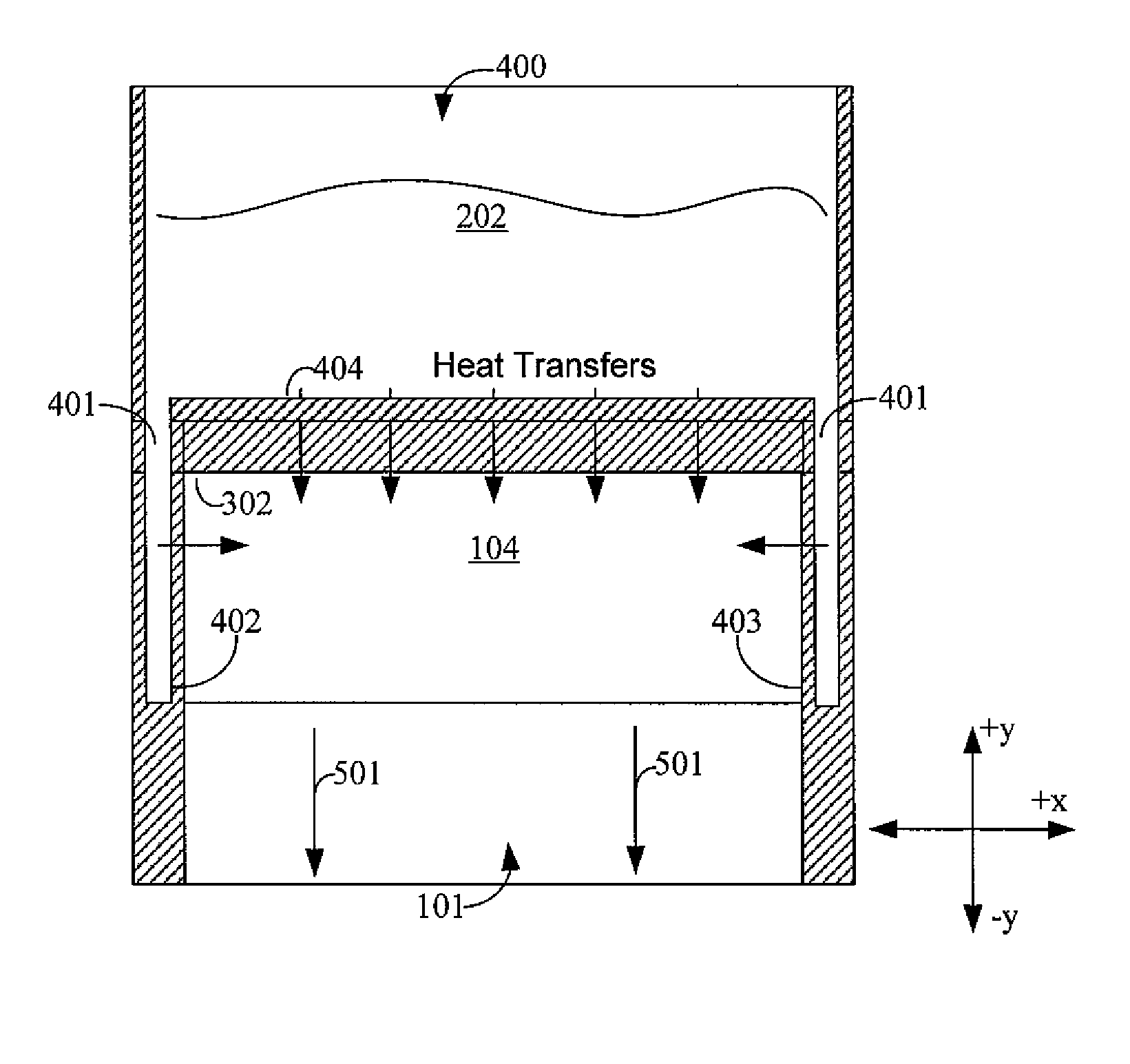

A frozen comestible maker suitable for home use includes single or multiple molding cavities for forming frozen comestibles, a heat exchanger for maximizing the heat transfer away from the fluid that is being frozen in the molding cavities, a refrigerant solution with a depressed freezing point in contact with the heat exchangers, a base container to seal the refrigerant solution from the fluid that is being frozen, and a bezel piece to retain spills and aid with handling. The refrigerant solution is captured between the molding cavities and the base container. One or more sticks, a drip cup, and an extraction tool may be provided with the frozen comestible maker for preparing and extracting shaped frozen comestibles, such as ice pops and popsicles, therefrom.

Owner:PROPELLER

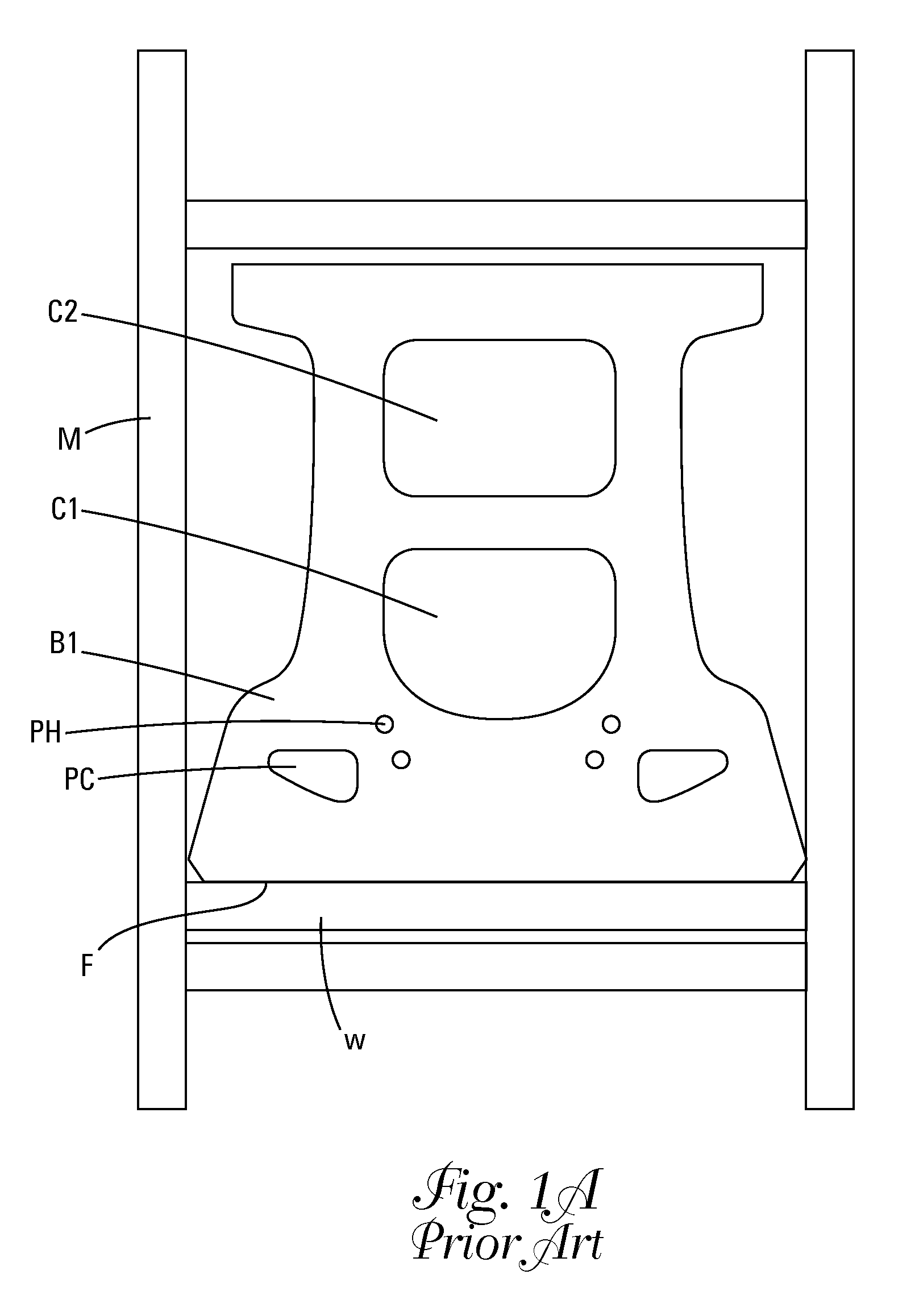

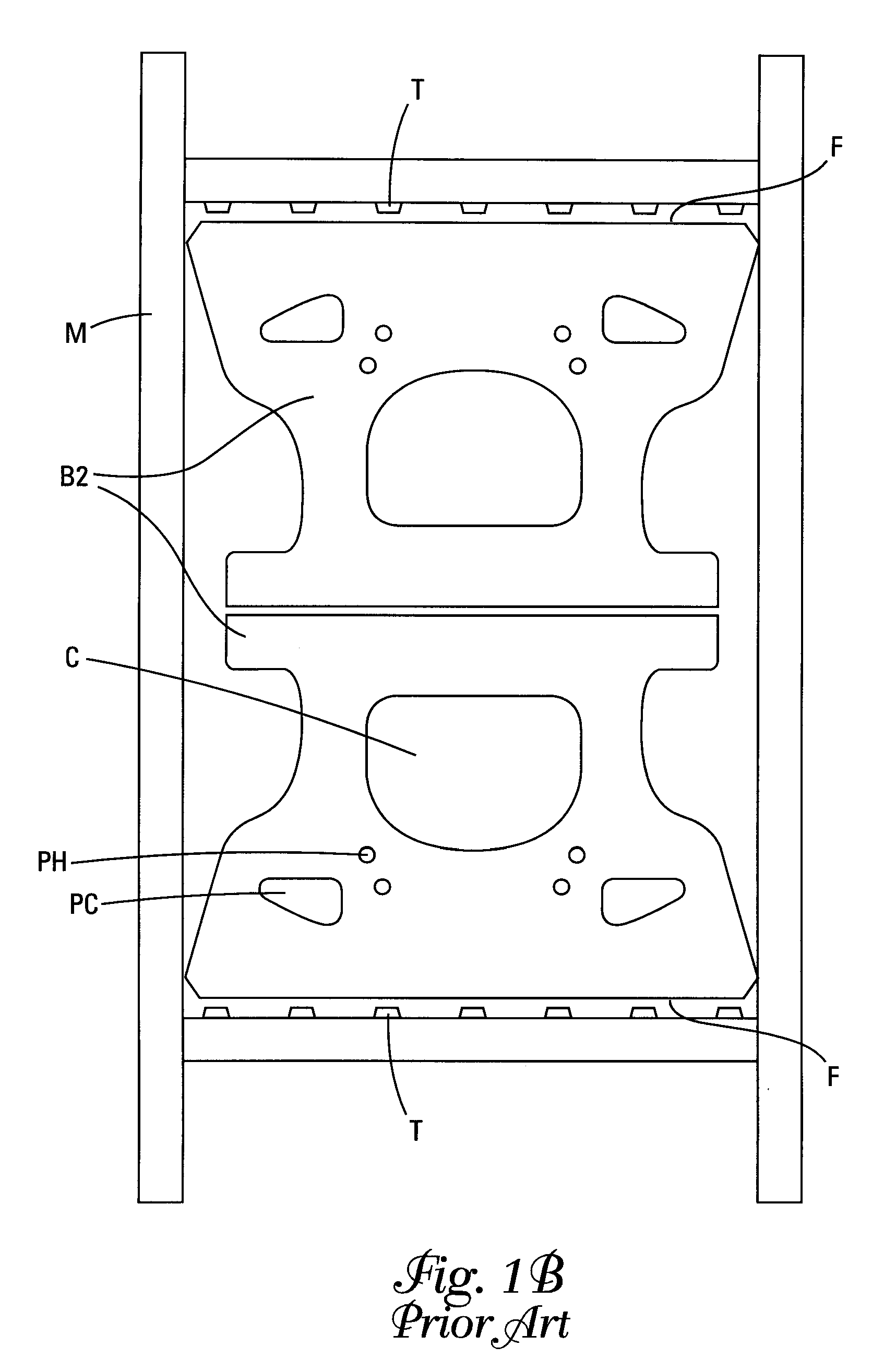

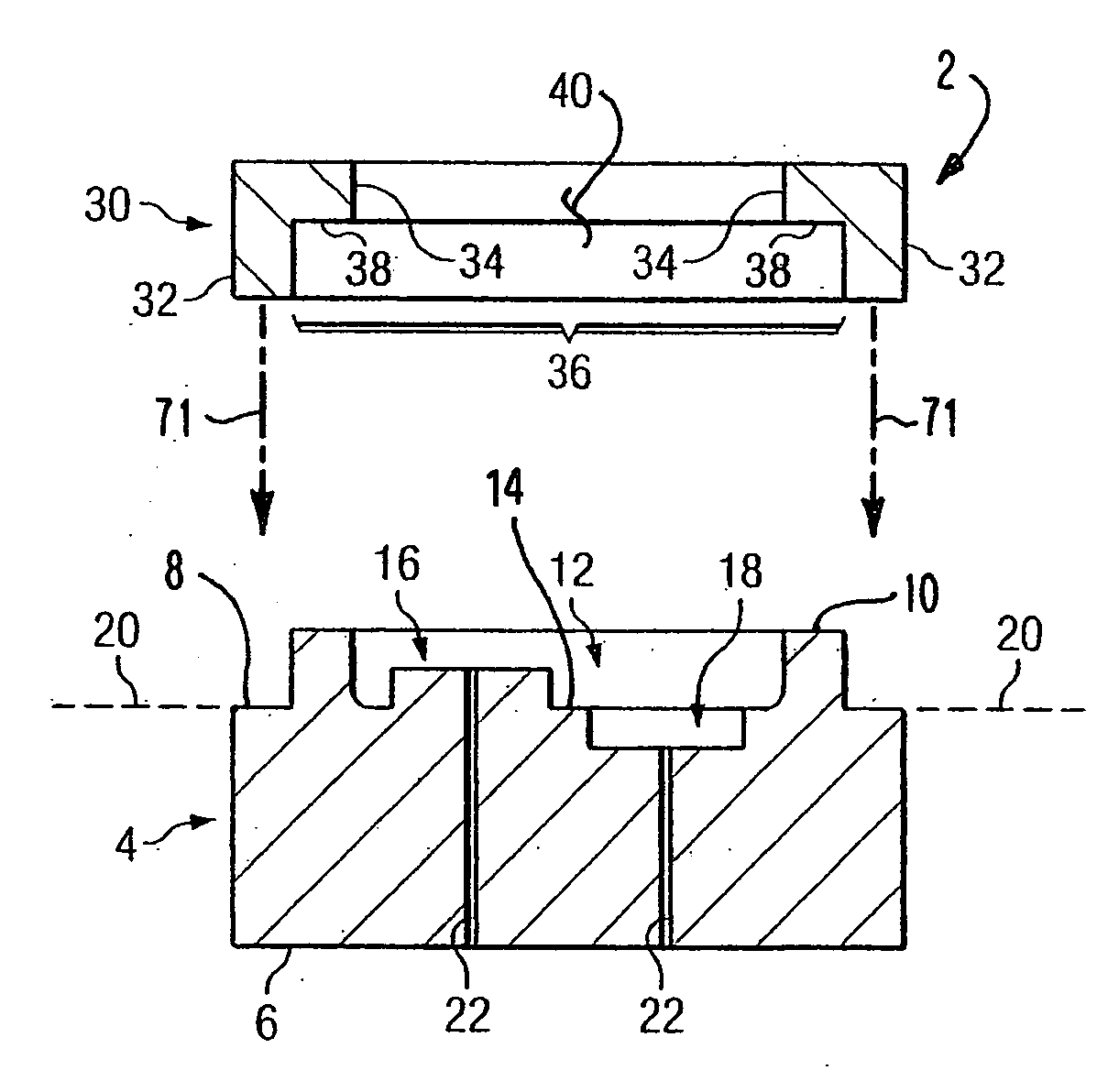

Mold box for making first and second wall blocks

InactiveUS7780141B2Maximize useFast constructionMould separation apparatusLighting and heating apparatusFace sizeEngineering

A method of making a wall block and a mold box therefore. The wall block design maximizes the use of the mold box. The method produces wall blocks having a large surface area front face compared to the front face size of prior art blocks. The blocks have about one third more front surface area. This results in faster construction of walls and a faster construction sequence. The method of making the blocks makes efficient use of mold space and material, resulting in higher production yields and / or higher total daily production square footage.

Owner:KEYSTONE RETAINING WALL SYST

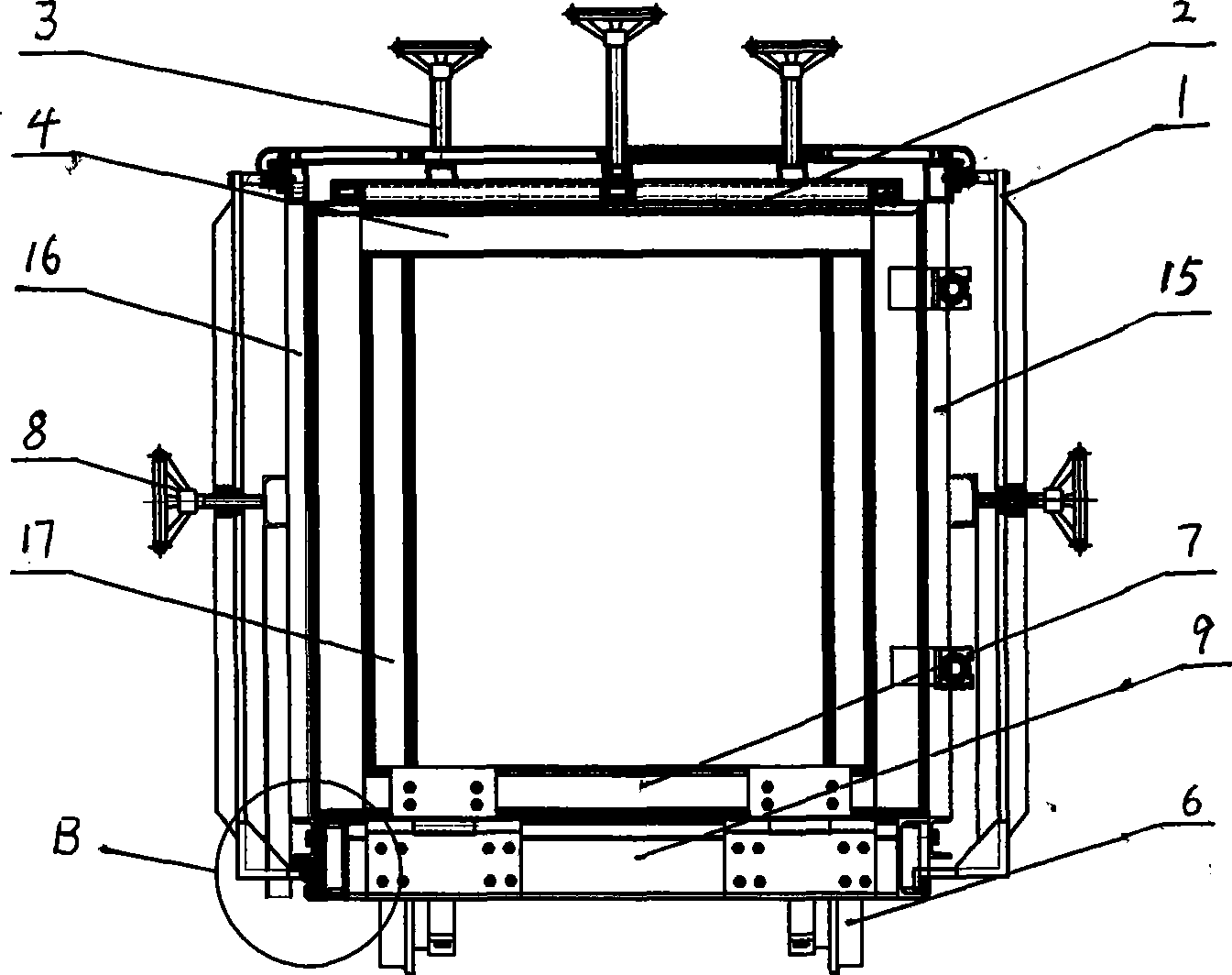

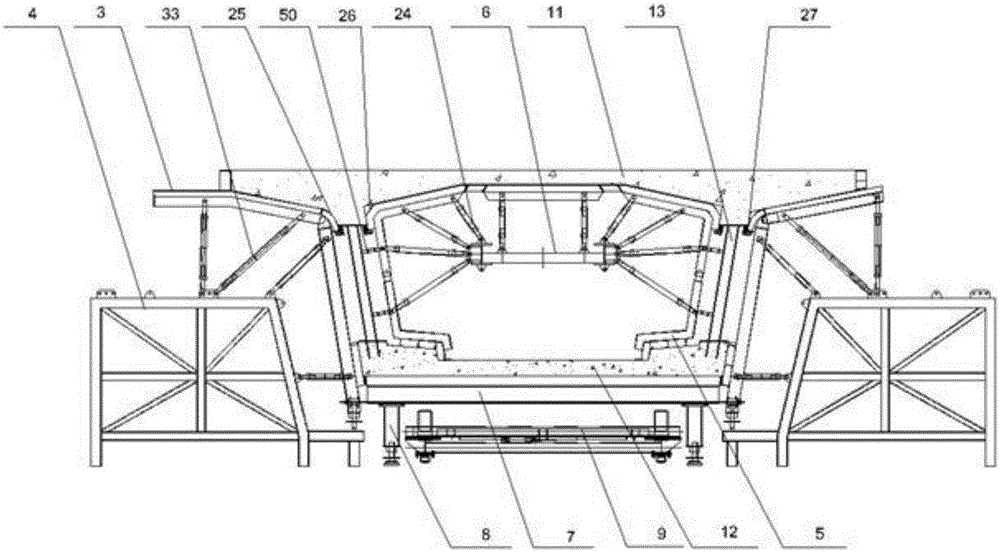

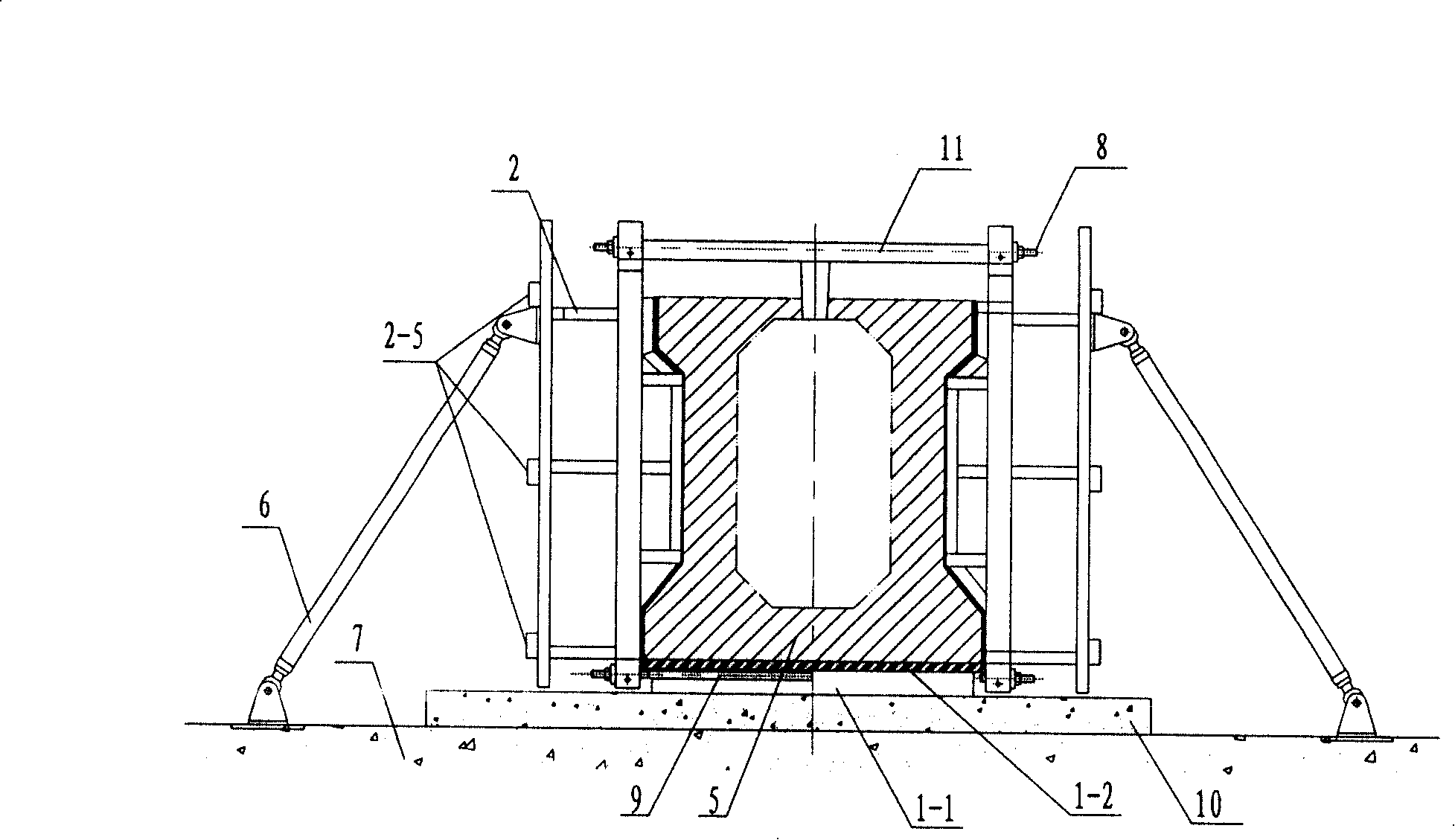

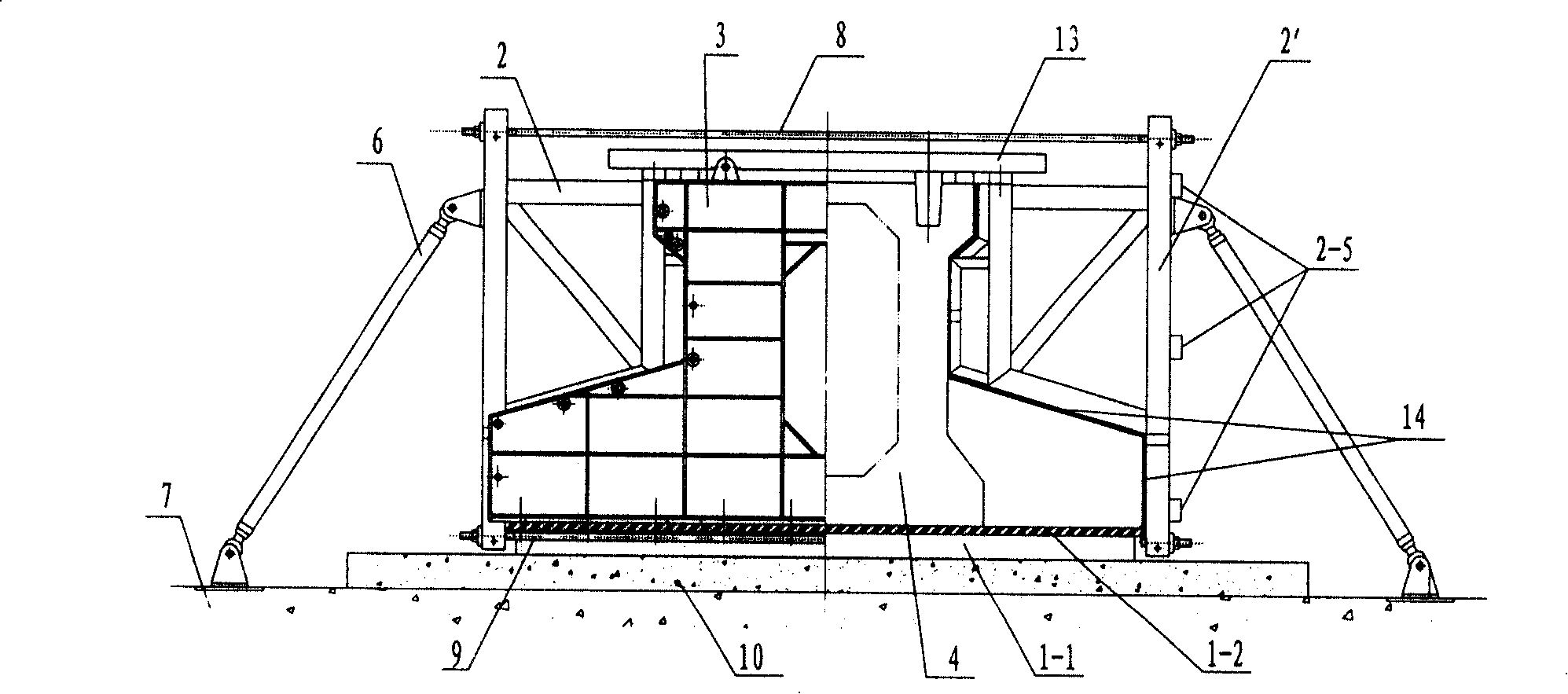

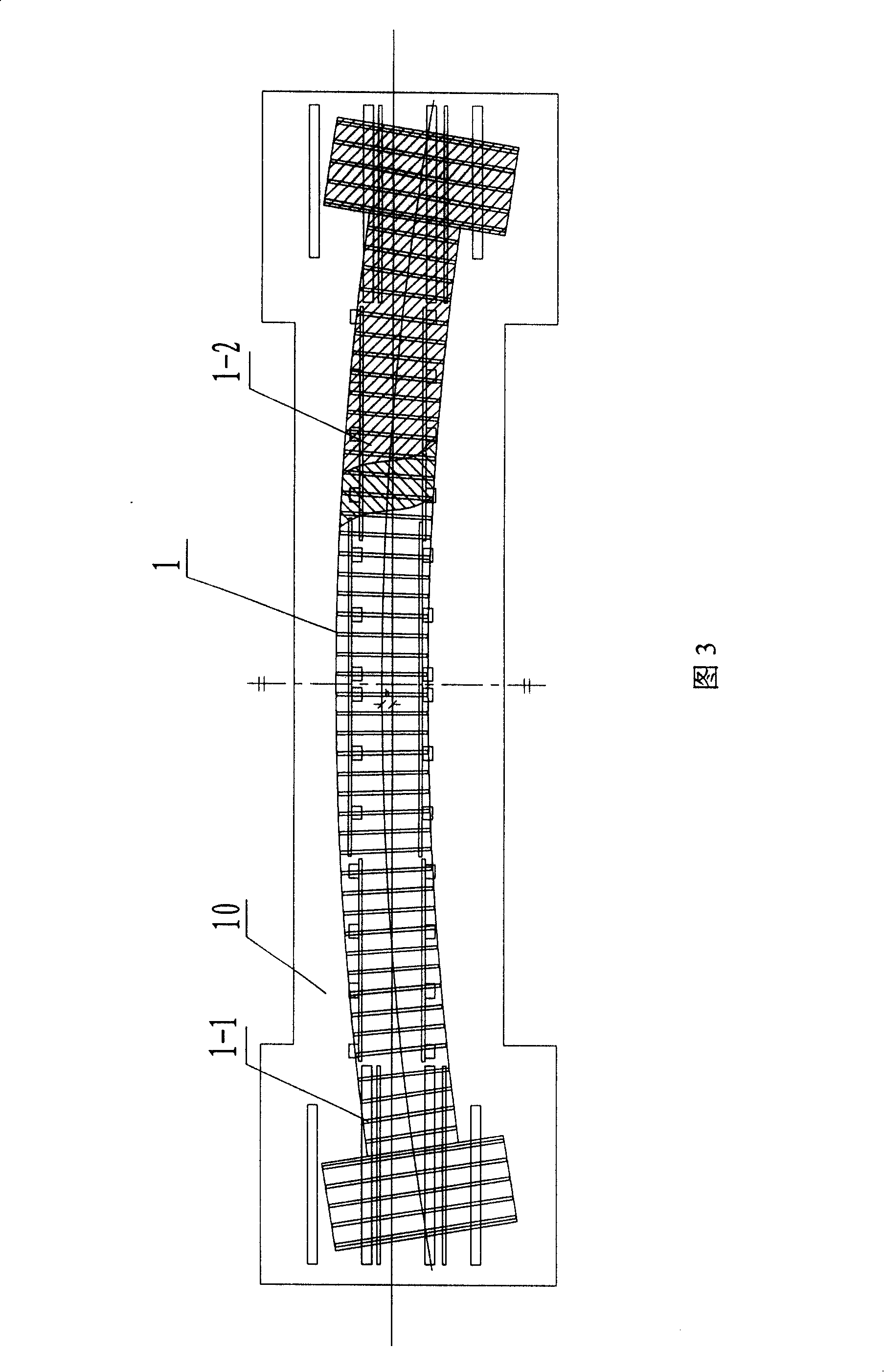

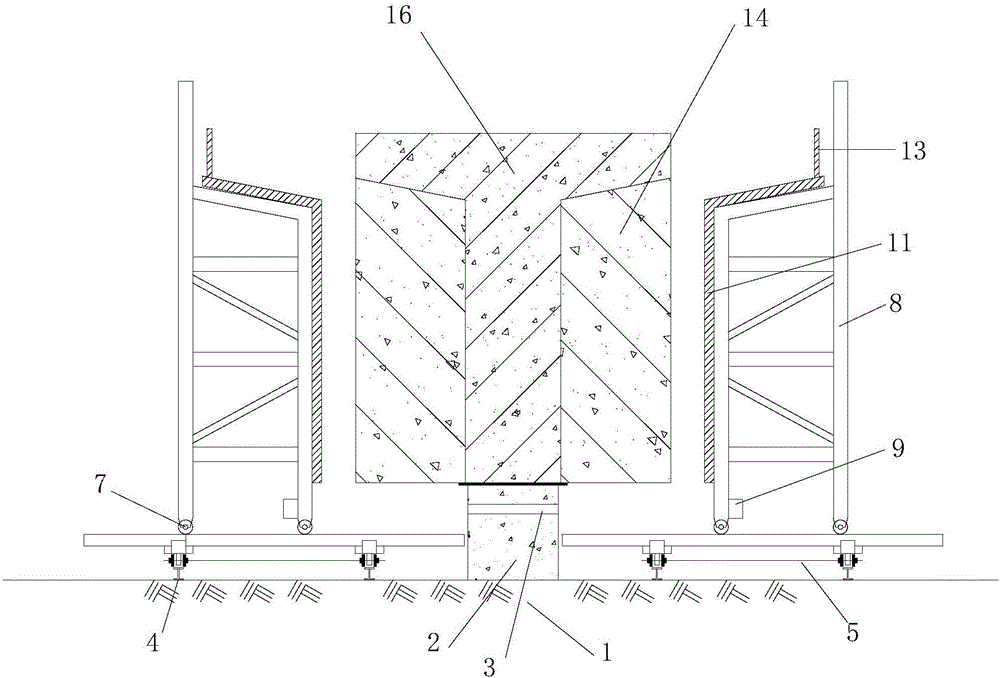

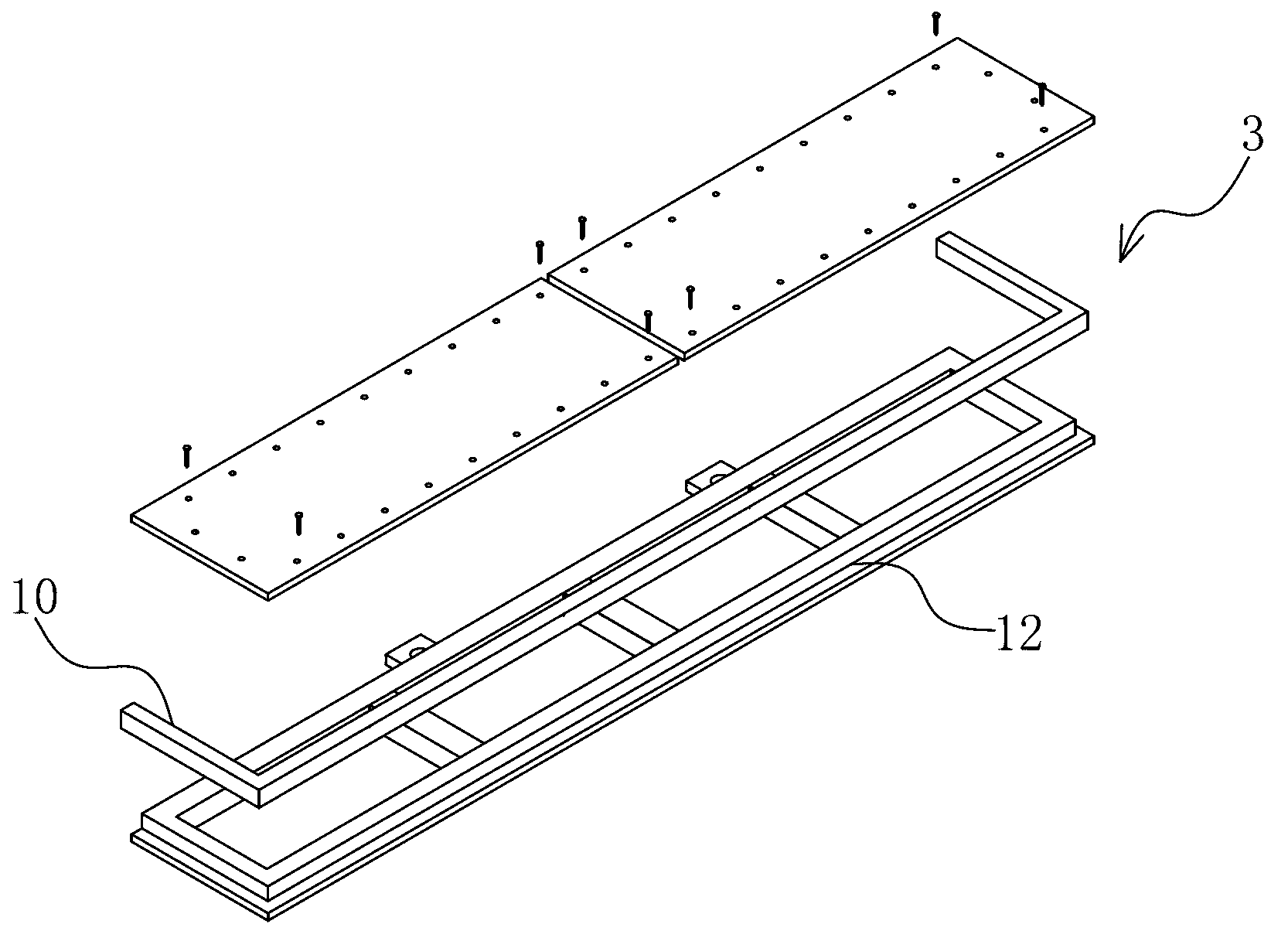

Stub matching prefabricated form system used for corrugated steel web composite structure girder bridge

ActiveCN105848839ASolving Die-in DifficultiesEasy to moldMould separation apparatusMouldsGirder bridgePush pull

The invention discloses a stub matching prefabricated form system used for corrugated steel web composite structure girder bridge. The system includes a fixed end mould, a fixed end mould holder, an outer mould, an outer mould holder, an inner mould, an inner mould holder, a bottom mould, a bottom mould holder, a bottom mould trolley, a hydraulic system and the like. The fixed end mould includes an upper part and an under part, and a push-pull moving block which is convenient to enter mould for the corrugated steel web is disposed on the upper part opposite of the corrugated steel web. A three-way position adjustment device is disposed on a girder of the outer mould which accurately positions the space attitude of the corrugated steel web. A sealing device on steel-concrete composite is disposed on the steel-concrete composite area, and the device has the locate function of the corrugated steel web. The parts of the mould are assembled and accurately positioned by the hydraulic system according to the structure size of the girder sections. The system overcomes the problems that the installation accuracy requirement of the corrugated steel web is high and the reinforcement cage integral installation is difficult, and the prefabrication construction of the composite girder sections has high-quality and high-efficient.

Owner:CCCC SECOND HARBOR ENG +2

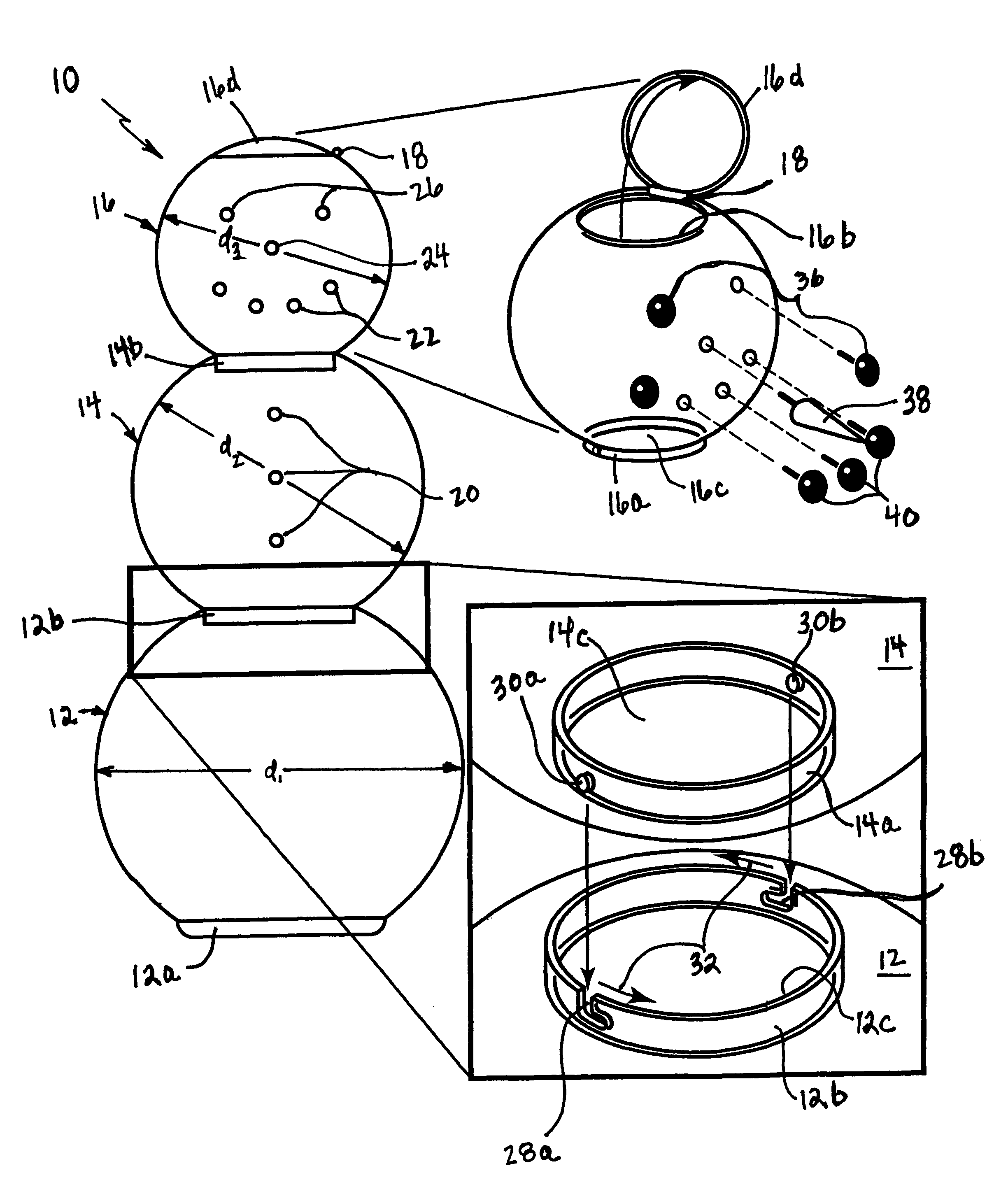

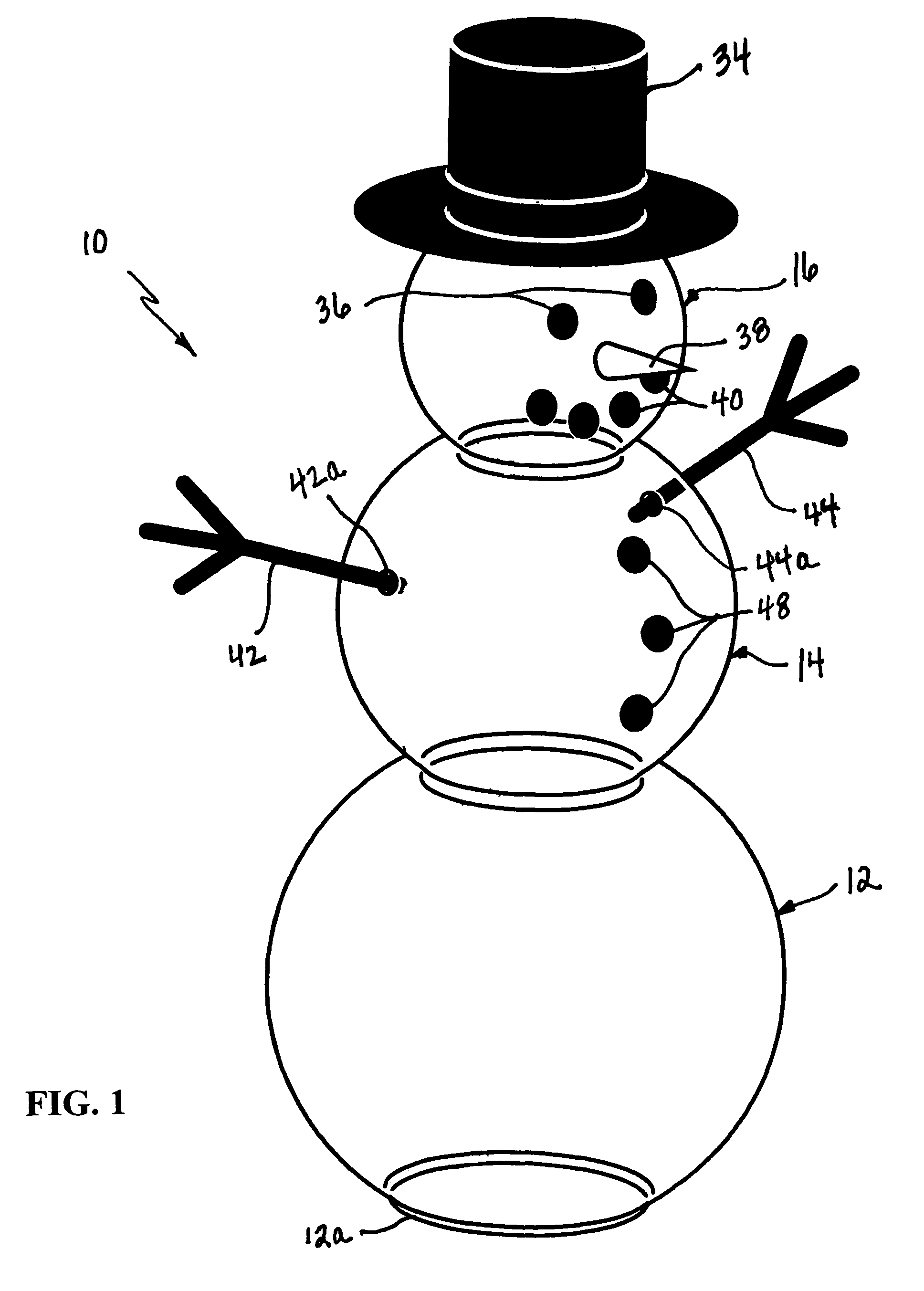

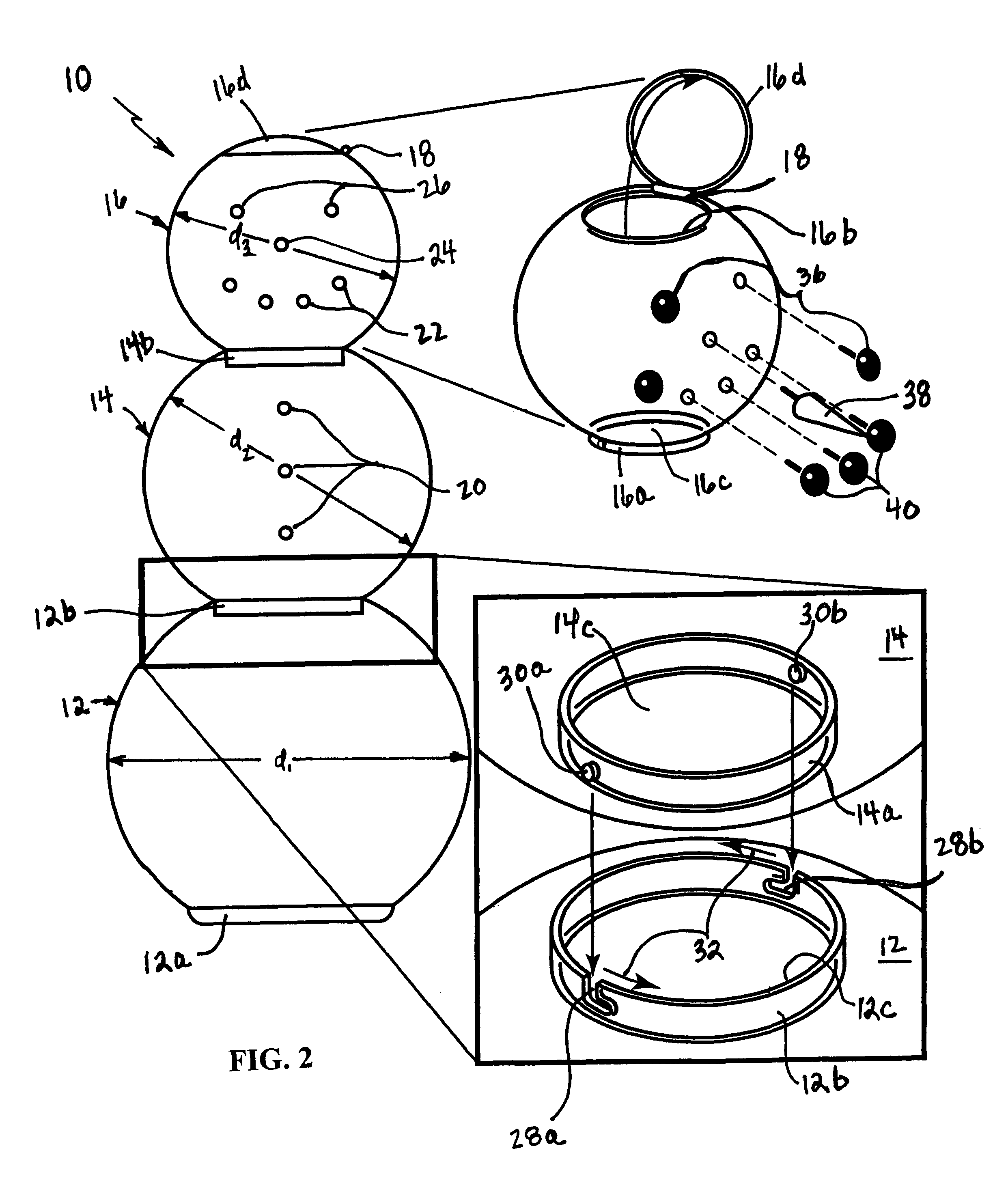

Snowman mold

ActiveUS7963500B1Easy to shapeReliable wayMould separation apparatusLighting and heating apparatusCouplingEngineering

A mold for forming a snowman includes lower, intermediate and upper generally spherical, hollow members comprised of clear plastic. Each plastic member includes an upper aperture for filling the member with snow. The lower member includes a generally flat base portion for positioning stability and an upper connection ring adapted for secure coupling to a lower connection ring on the intermediate member. The intermediate member also includes an upper connection ring adapted for secure coupling to a lower connection ring on the upper member. The three connected members form a hollow, vertical structure which when filled with snow provides a snowman of classic shape, symmetry and proportions. The individual spherical hollow members are easily connected and disconnected, with the intermediate and upper members having apertures for receiving eye, nose, mouth and arm indicia, with the upper member further including a hat mounting arrangement in one embodiment.

Owner:HOLIDAY ANGELA C

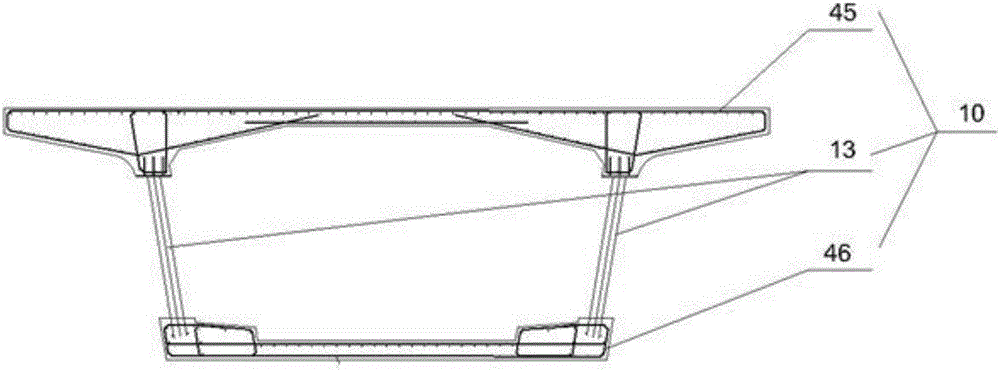

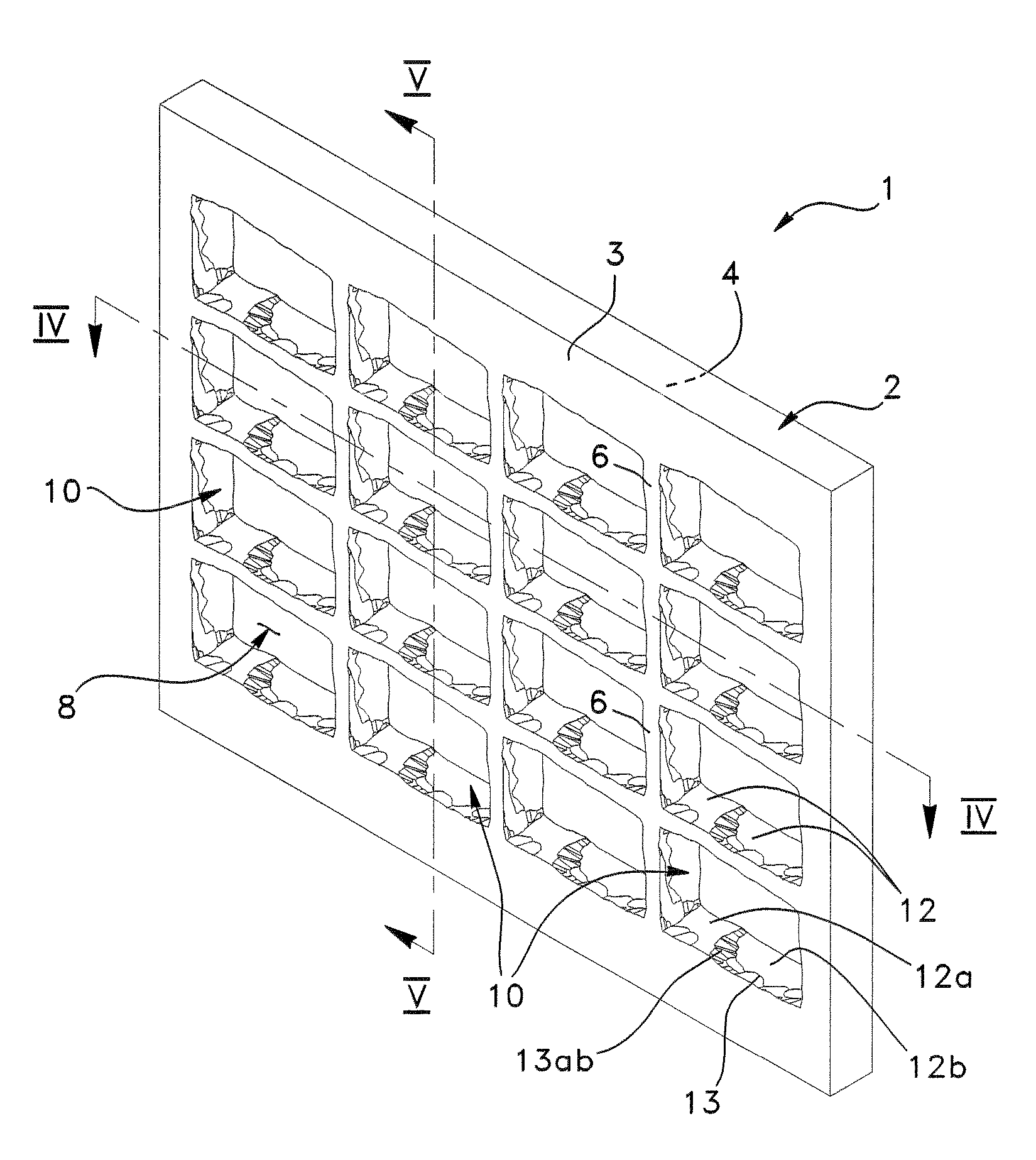

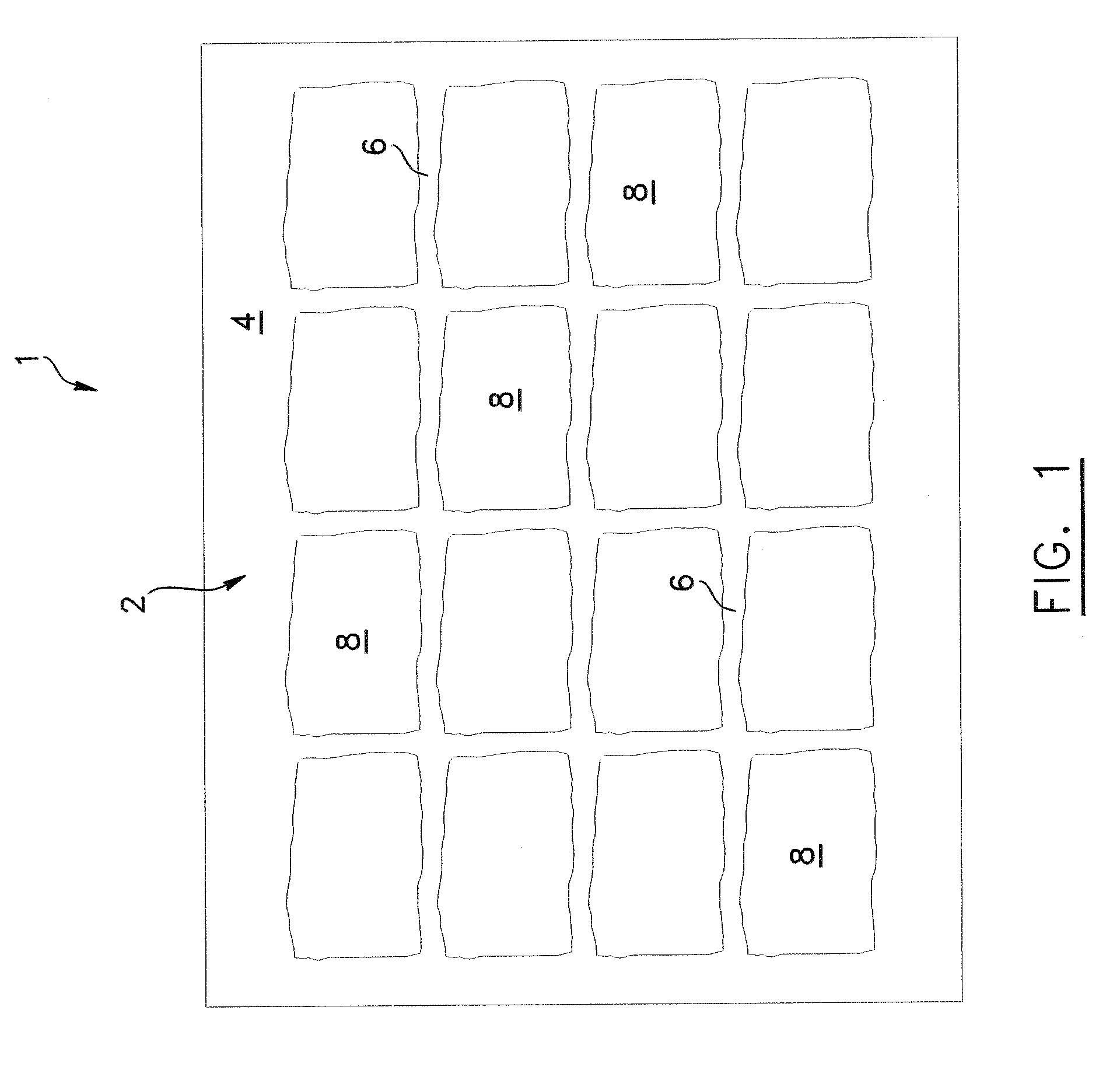

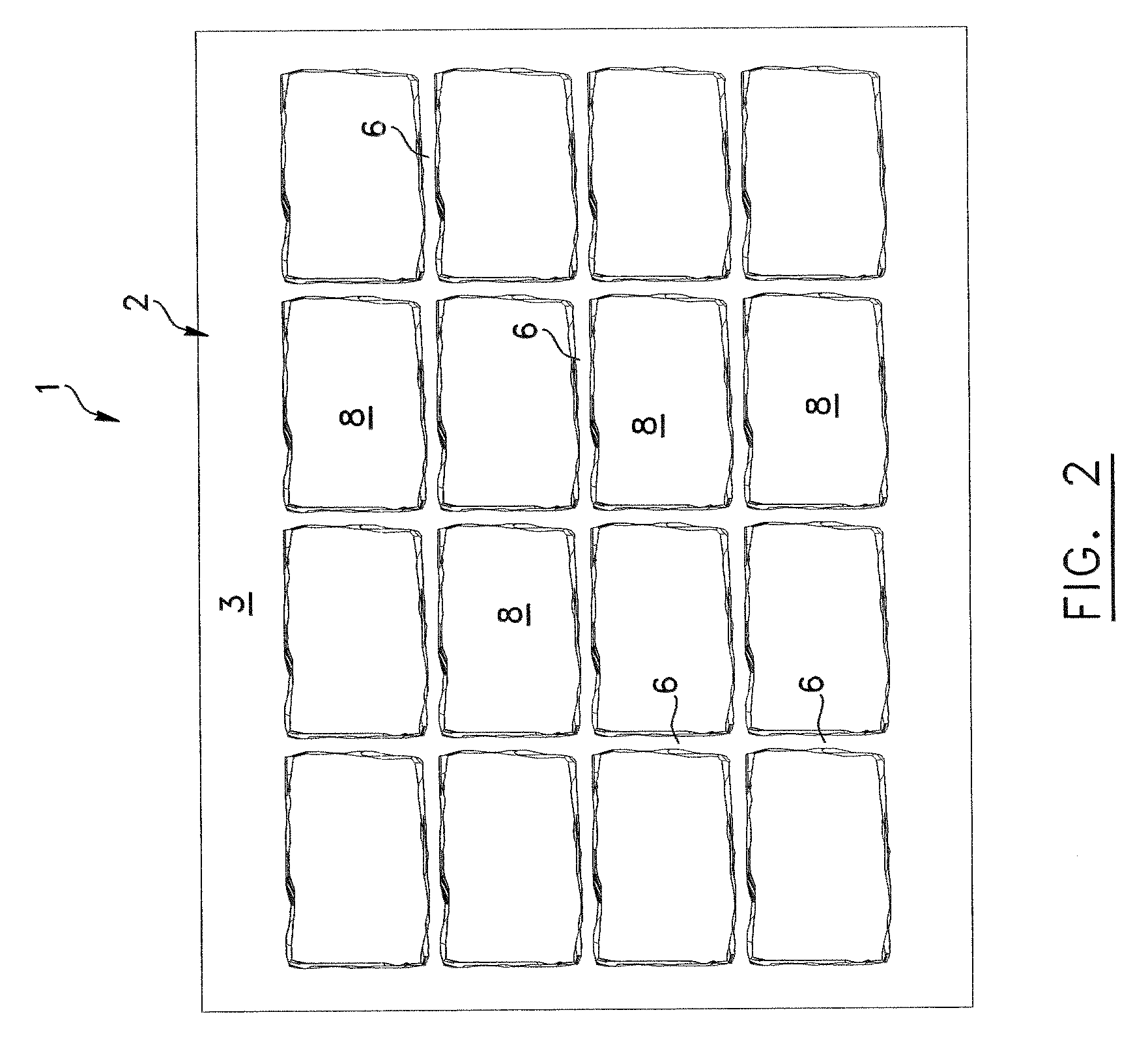

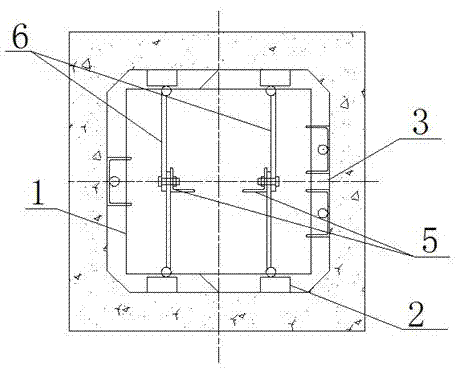

Curvature radius adjustable prefabricated box-beam mold and construction method thereof

ActiveCN101181796ASmooth and beautiful surfaceReduce manufacturing costMould separation apparatusMouldsEngineeringPeriod length

The invention discloses a prefabricated box girder mold with adjustable curvature radius and an installation and construction method of the mold. The invention adopts the concept of replacing the curved line with a folded line of a fixed length, and accurately sets out the bottom mold, so that the side mold is designed by It is composed of several fixed-length fixed sections. An elastic change section is set between the fixed-length fixed sections, and an adjustment link rod is set between the fixed-length fixed sections to realize the function of adjusting the curvature of the fixed-length broken line. At the same time, the adjustment insert section is embedded in the side mold The adjustment of inner and outer arc length changes can not only meet the needs of fixed section and variable curvature prefabricated building components, but also meet the production or construction needs of continuous variable section and variable curvature prefabricated building components. The prefabricated box girder mold with adjustable curvature radius of the present invention can not only meet the overall needs and accuracy requirements of the design curvature change, but also has a smooth and beautiful surface, with as few or no traces of template joints as possible.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Molding Apparatus for Producing Dry Cast Products Having Textured Side Surfaces

ActiveUS20060249881A1Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

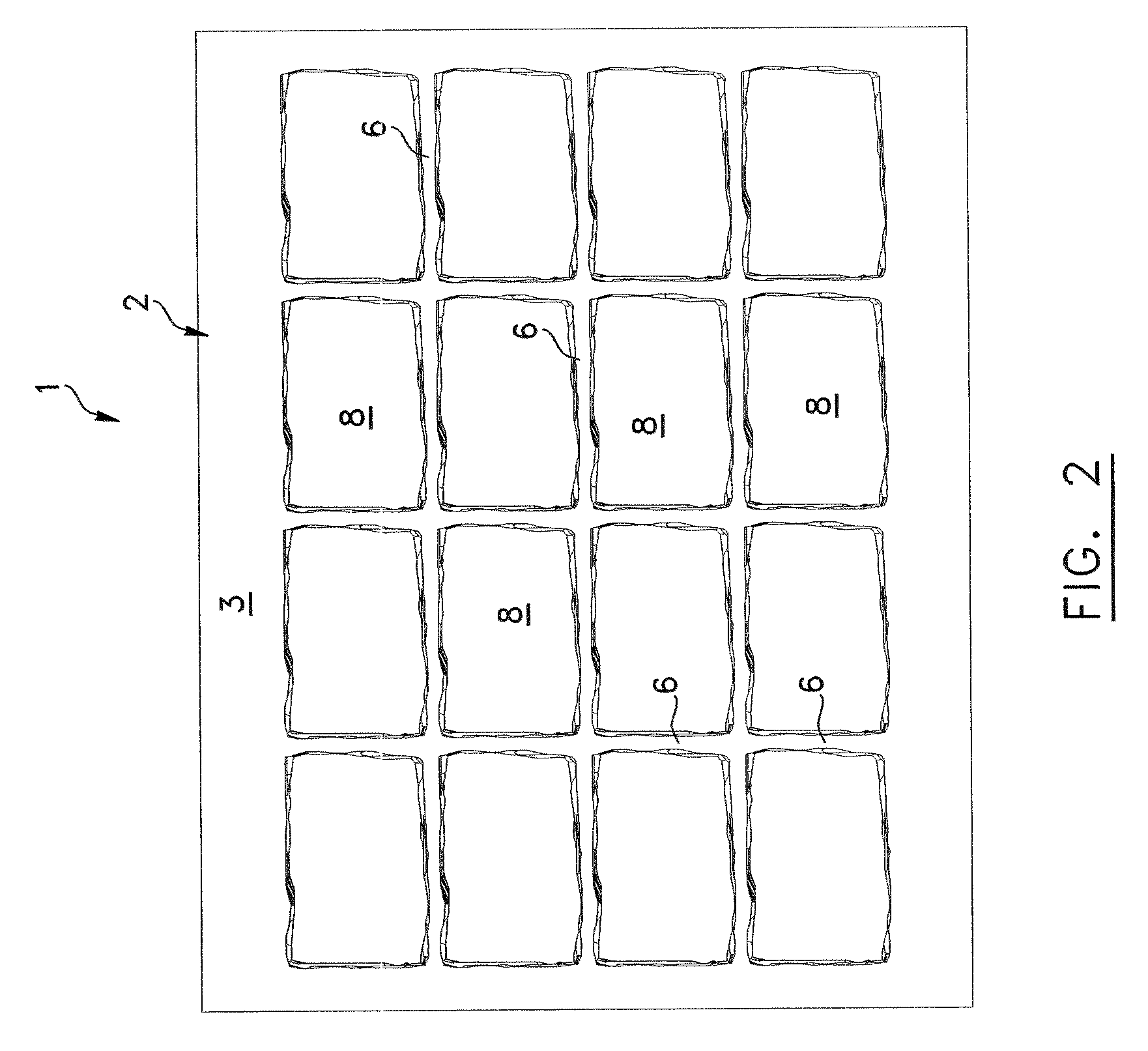

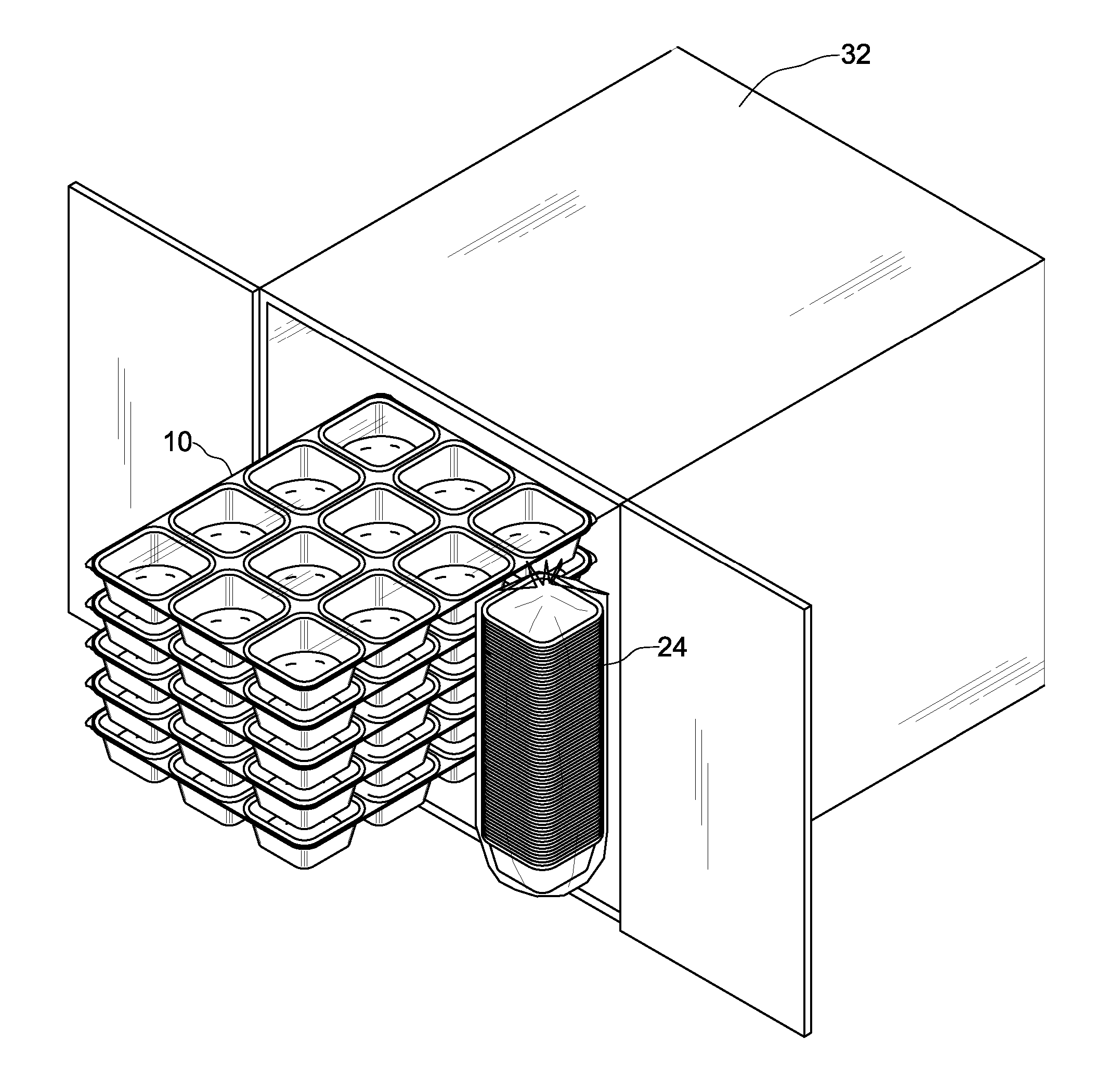

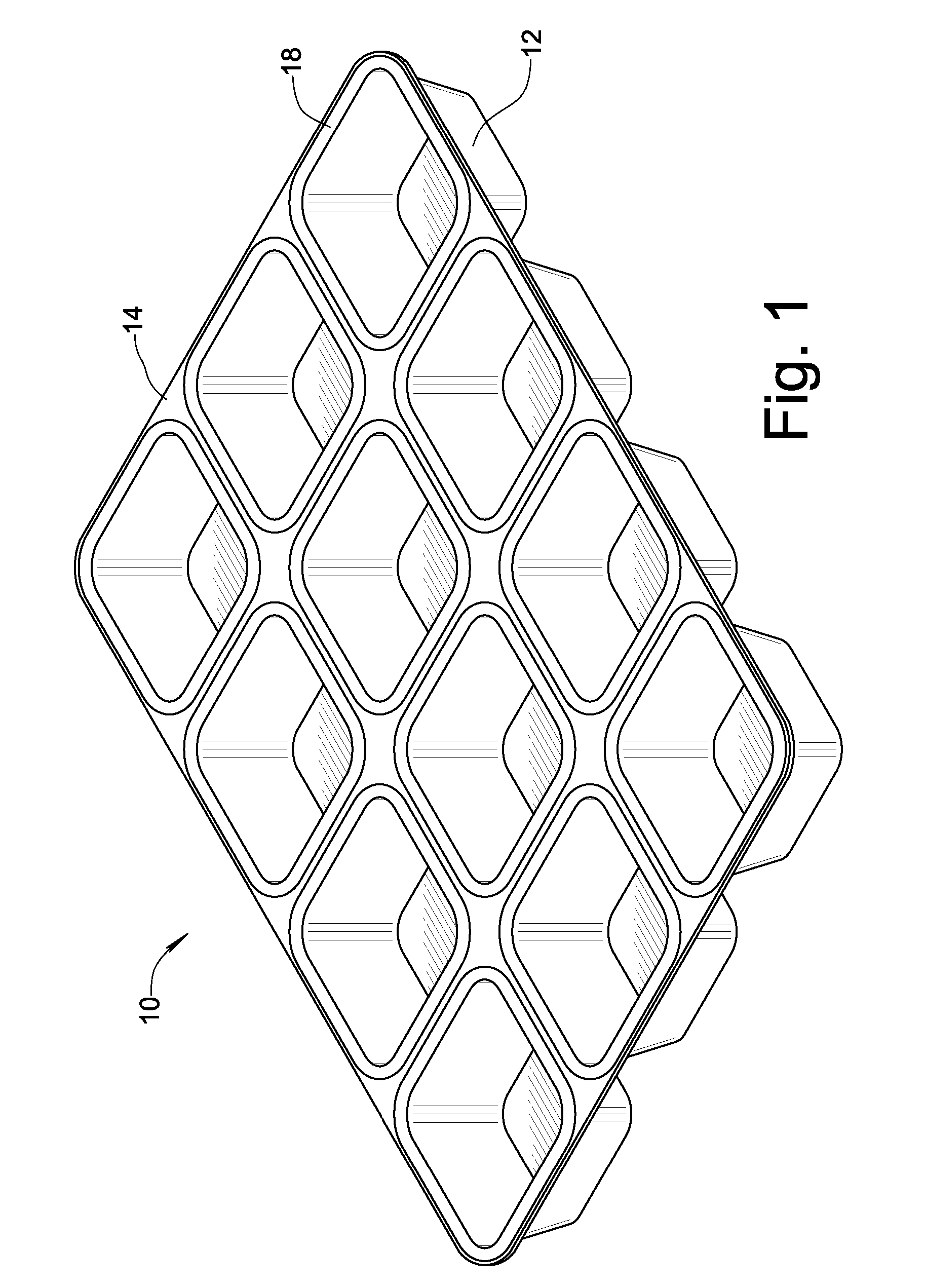

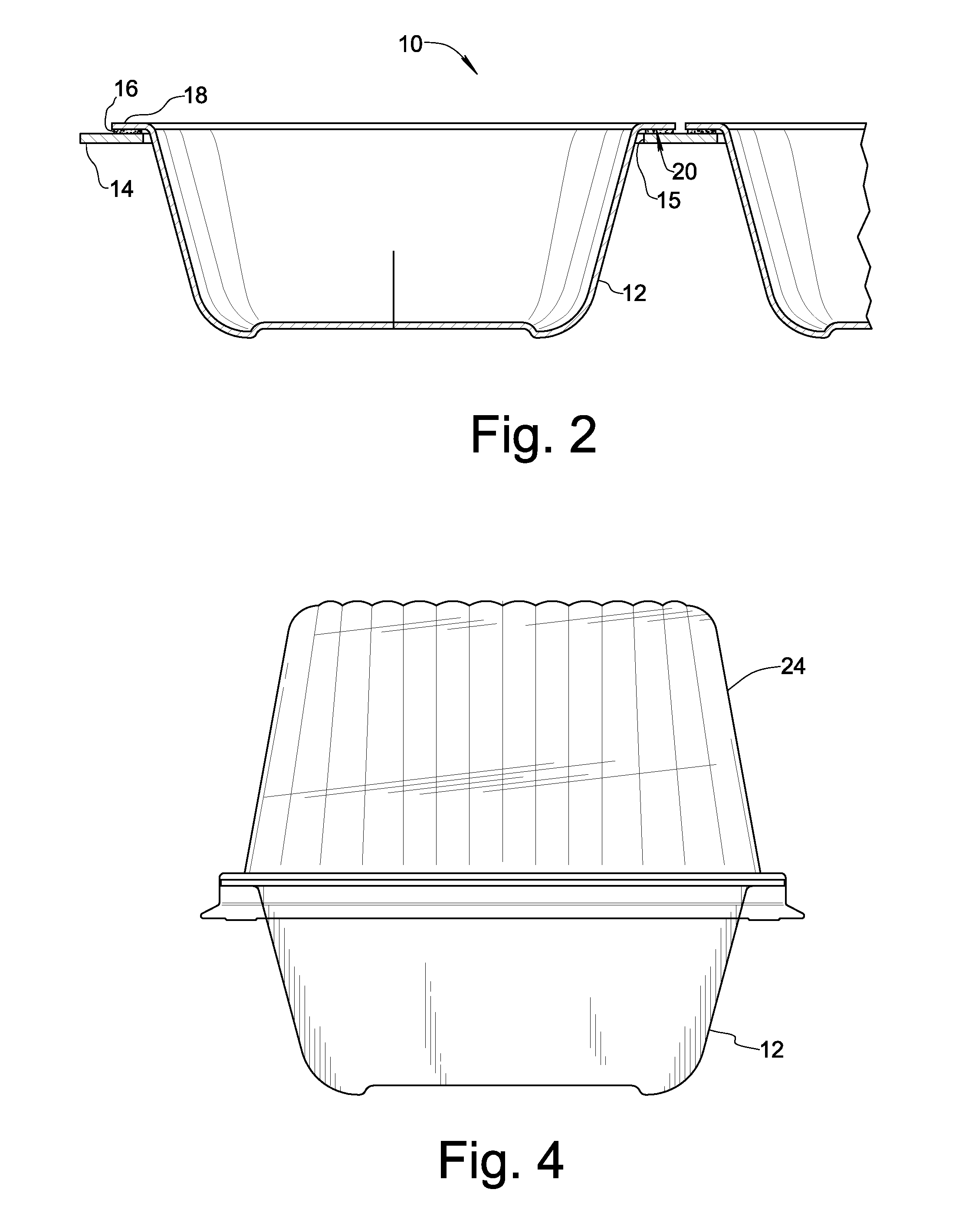

Method And Packaging For Baked, Thaw And Serve, Or Microwavable Goods

InactiveUS20070108089A1Envelopes/bags making machineryMould separation apparatusMicrowaveSupport matrix

Packaging for heatable food portions comprises an ovenable tray including a plurality of serving containers connected by a detachable support matrix. In one embodiment, the support matrix is attached to the serving containers by hot melt glue which melts during baking or heating to automatically release the support matrix from the serving containers. Pre-filled trays are shipped with display covers fitted to the serving containers, such that the covers may be placed on the individual serving containers after the food portions are baked and the serving containers are separated from the support matrix to provide individually packaged, freshly baked food portions for display.

Owner:RICH PRODUCTS

Stackable mold for making block ice

InactiveUS20070262230A1Efficient freezingHigh strengthMould separation apparatusLighting and heating apparatusEngineeringAirflow

A stackable mold for making block ice is disclosed. The bottom edges of the sidewall of the mold have stacking lips and the top edges of the sidewall have stacking ledges. The stacking ledges of a lower mold mate with the stacking lips of an upper mold, thereby allowing multiple molds to be stacked on top of one another. Guide lips along the sidewalls of the mold prevent slipping and shifting of the stacked molds. The tapered property of the molds creates space between the bottom of an upper mold and the top of a lower mold to allow airflow through the lower mold. A reinforcing lip extends along the top of the long sides for reinforcement.

Owner:MCDERMOTT CARLOS TOMAS JR

Construction method of hinged pull-type steel inner formwork and prefabricated hollow slab beam

ActiveCN102294741ASolve positioning difficultiesEasy to operateMould separation apparatusEconomic benefitsLinearity

The invention discloses a hinged draw type steel internal mould and a construction method for prefabricating hollow slab beams, which have the beneficial effects that: the defects that the adopted traditional air bag internal mould is difficult to position, is easy to upwards float, generates revealed reinforcement, is distorted indoors, does not have straight linearity and the like are avoided; and the invention has the characteristics of simplicity in operation, convenience in demoulding, greatly-shortened installation and dismantling times and convenience in backward use, has lowered cost, improved working efficiency, an obvious economic benefit, and is easy to popularize.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

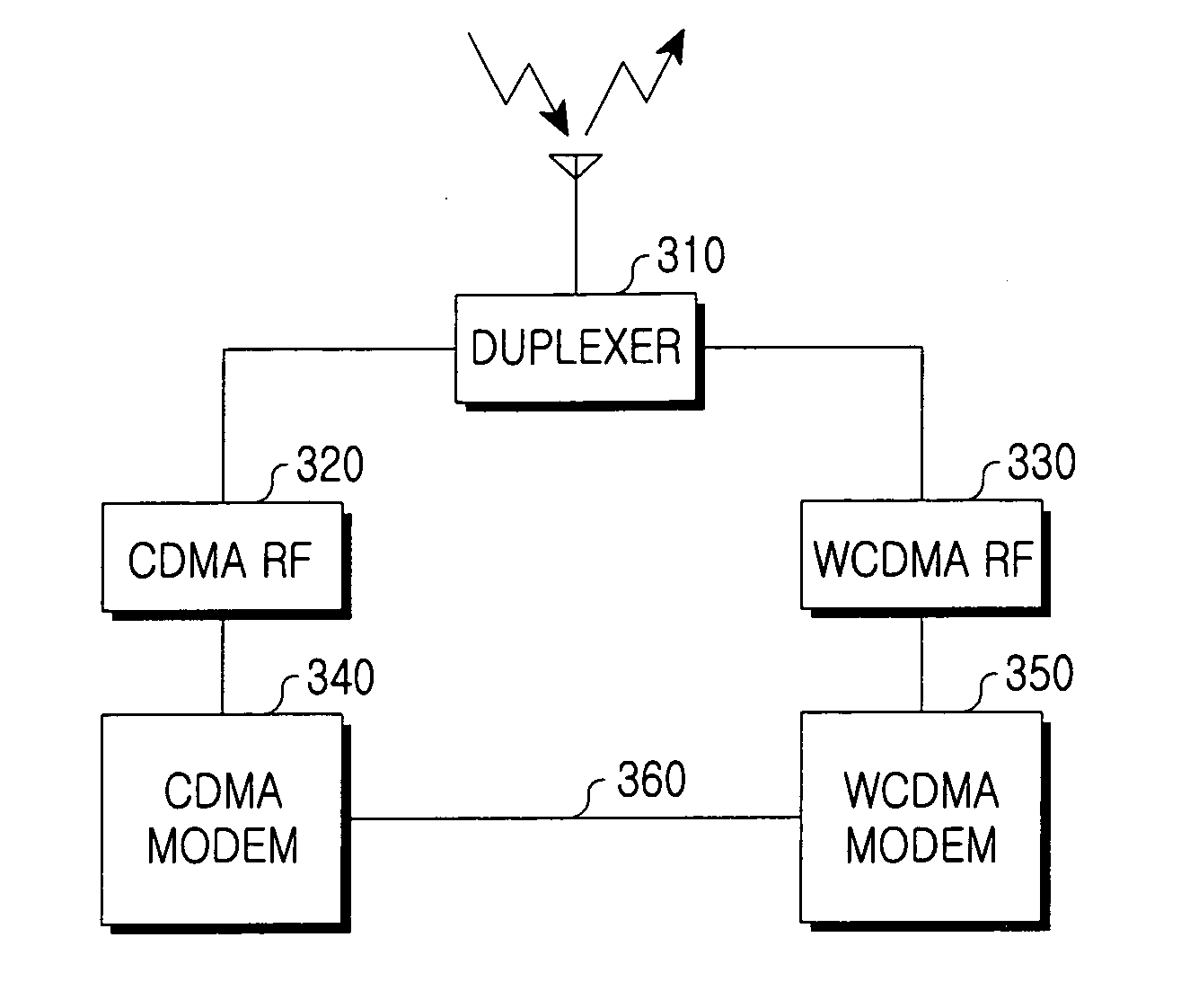

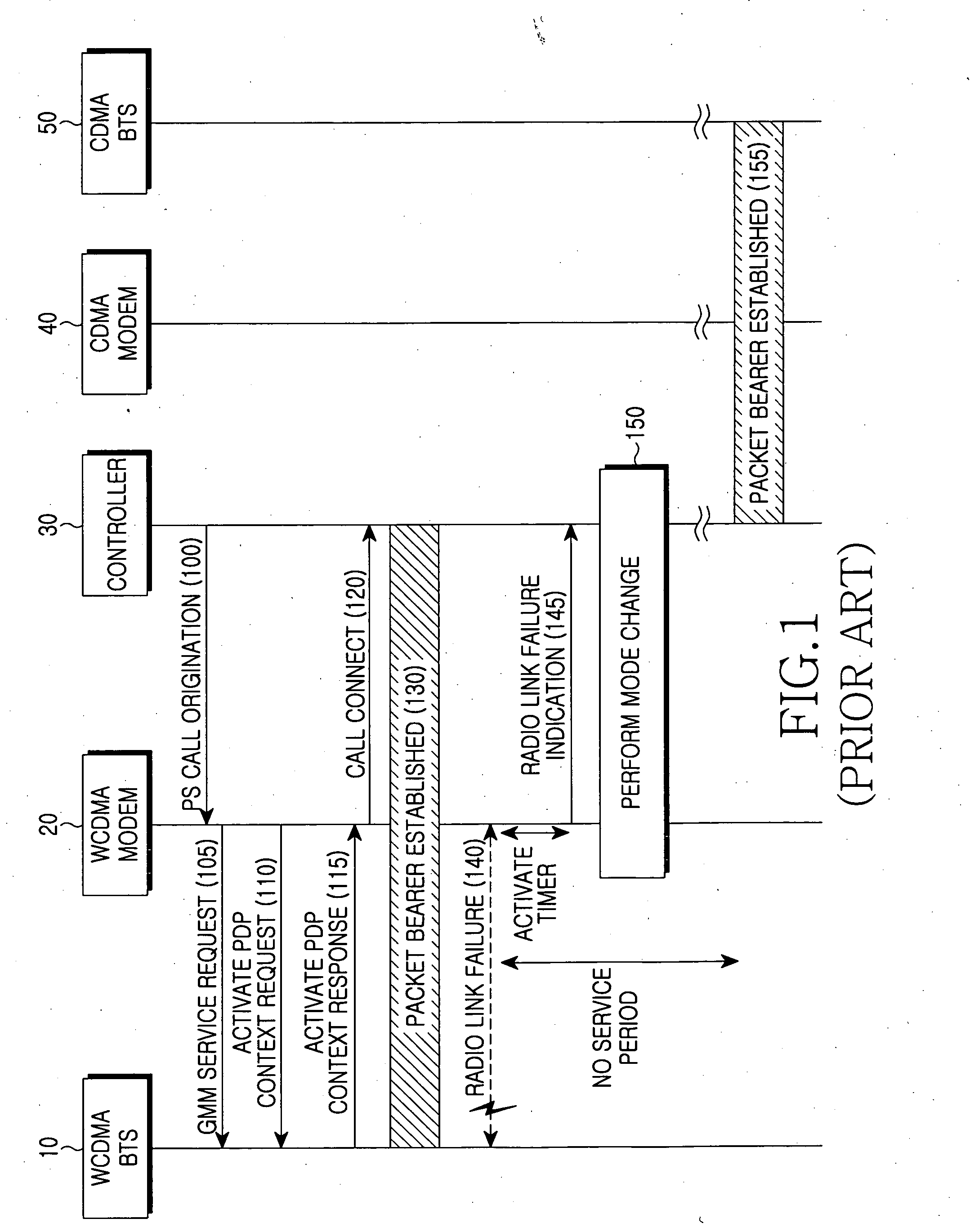

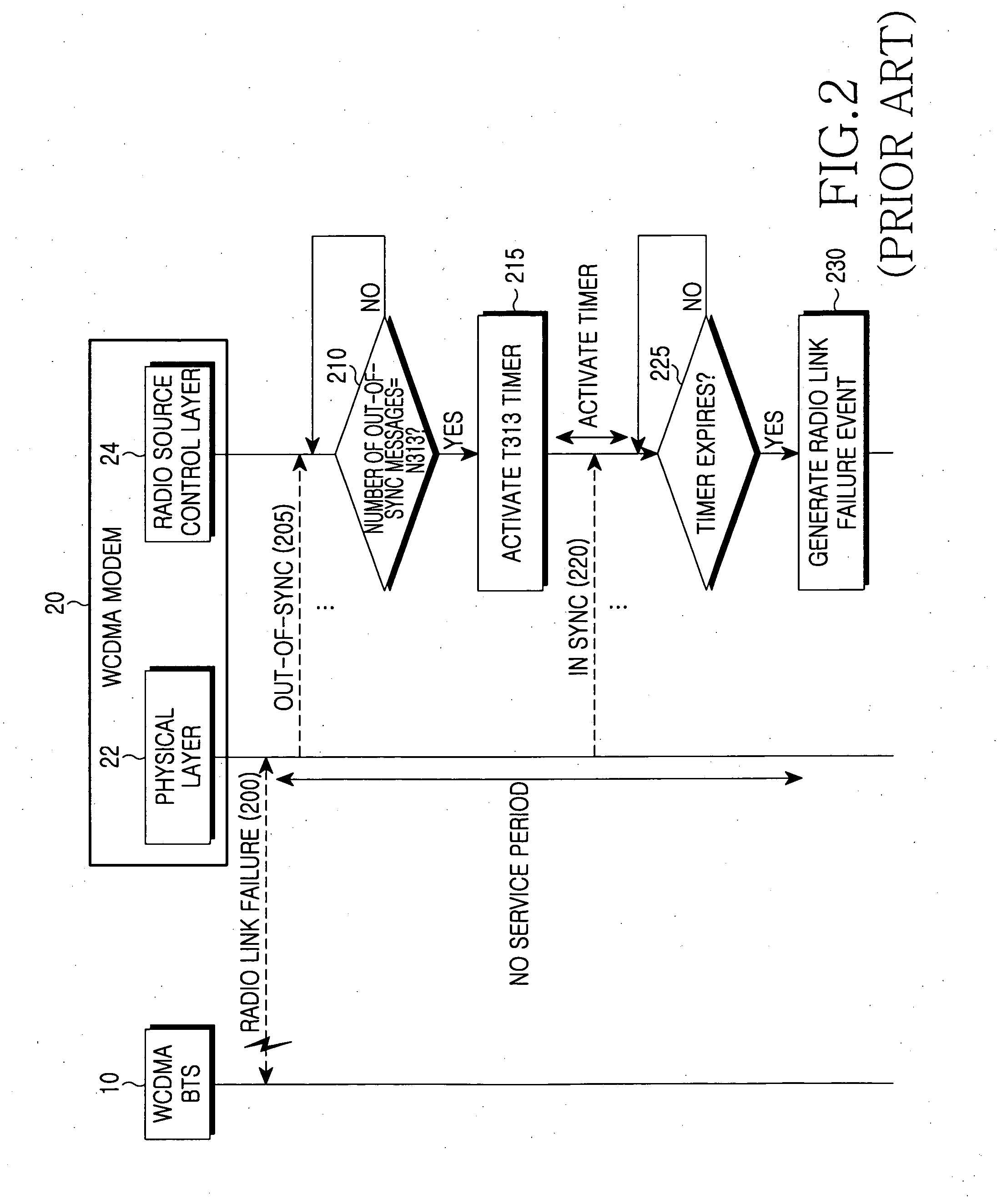

Handover method for minimizing packet call reconnection delay time between different mobile communication schemes and multi-mode terminal for the same

InactiveUS20070195733A1Minimize delay timeMinimize timeMould separation apparatusMouldsDelayed timeMode change

Provided is a function of minimizing a delay time of a packet call disconnect due to a handover between communication networks providing a communication service using different mobile communication technologies. To do this, even though a handover situation is generated during a packet service, the packet service is continuously provided by maintaining a current mode and performing a mode change after registration in a handover target network succeeds. Accordingly, since the packet service is not provided only while a packet call connecting process is performed, a delay time according to a packet call reconnection can be minimized.

Owner:SAMSUNG ELECTRONICS CO LTD

Cold mold

InactiveUS7234308B1Freeze fastIncrease production capacityMould separation apparatusLaboratory glasswaresTissue specimenThermal water

A metallic, reusable mold with one or more wells. The mold is kept within a cryostat at low temperature. The mold is removed from the cryostat and a tissue specimen is placed into a well within the mold. An embedding medium is added to the well around the tissue specimen. A pre-chilled chuck is then placed against the well opening. The mold with tissue specimen, embedding medium and chuck are returned to the cryostat and the specimen is frozen into a block. The mold and contents are removed and hot water poured against the mold releasing the block with attached chuck from the well. The chuck with attached block is then available for sectioning or other processing.

Owner:CRITZ CARL H

Ice cube tray and method for releasing a single cube from tray

InactiveUS8516835B2Mould separation apparatusLighting and heating apparatusMarine engineeringWarm water

Owner:HOLTER EDWARD CARL

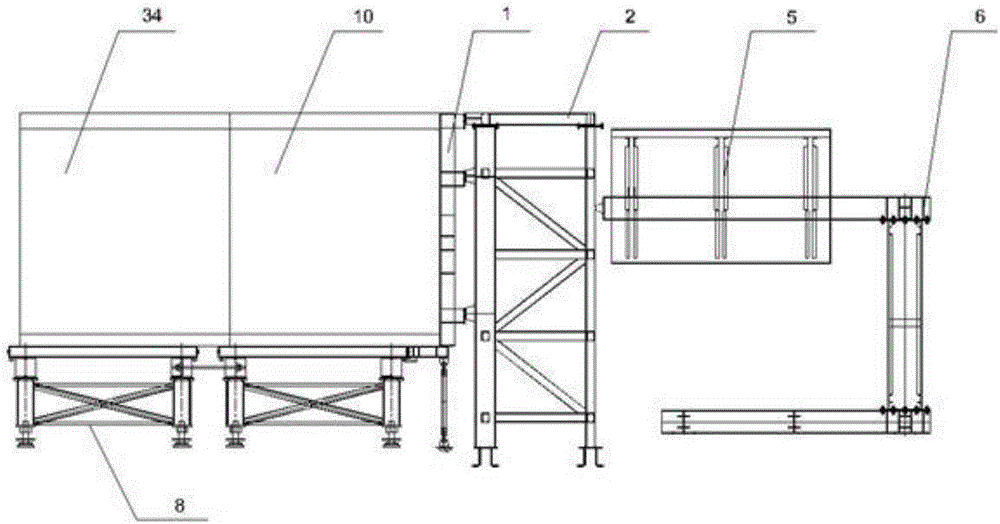

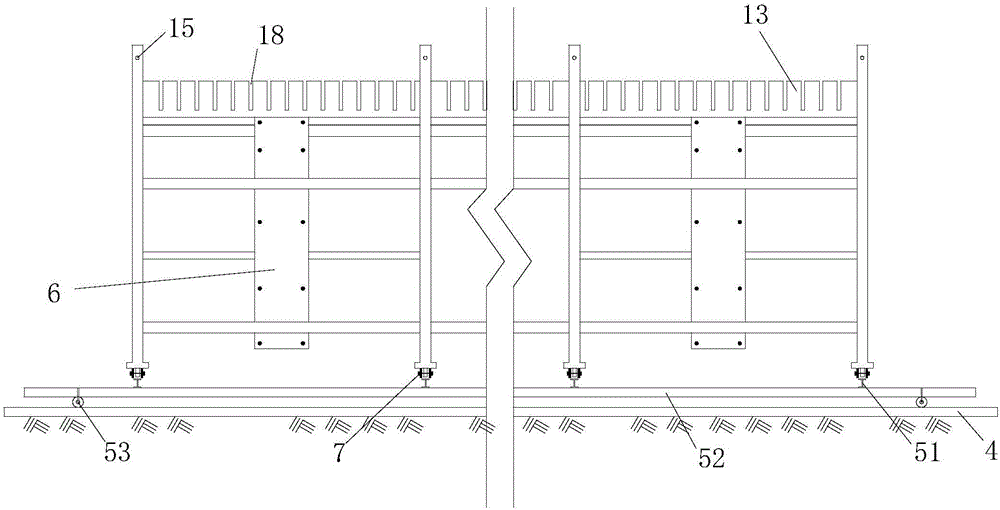

T-beam factory-like prefabricated supporting formwork system and construction method

ActiveCN105799056ADoes not affect vertical movementEasy constructionMould separation apparatusThreaded rodPulley

The invention relates to a T-beam factory-like prefabricated supporting formwork system and a construction method. The supporting formwork system comprises a pedestal, a longitudinally moving platform, a wing plate formwork, a formwork back frame, a longitudinal track, a transversely moving track, a bottom formwork, a web side formwork and a top plate formwork. The construction method comprises the main construction steps of (1) pedestal pouring, (2) track beam installing, (3) longitudinally moving platform installing, (4) formwork back frame assembling, (5) threaded rod installing and fixing, (6) concrete pouring and maintaining and (7) formwork removing. According to the T-beam factory-like prefabricated supporting formwork system and the construction method, the referred structure has the characteristics that disassembling and assembling are convenient, the construction efficiency is high, the formworks of a T-beam are fixed to the back frame, the top of the back frame is provided with pulleys and can horizontally and transversely move, and the whole supporting formwork system is placed on the longitudinally moving platform; the problems that mechanical removing, lifting and assembling of an existing T-beam prefabricated formwork are wasteful in construction time and effort, and the construction efficiency is low are solved; and good economic and technical benefits are achieved.

Owner:ZHEJIANG UNIV CITY COLLEGE

Wood-like concrete member die and manufacturing method thereof

InactiveCN101637939AEasy to processReduce manufacturing costMould separation apparatusMouldsLandscape designAdhesive materials

The invention relates to a wood-like concrete member die and a manufacturing method thereof. The invention aims at providing a die for producing a wood-like concrete member and a manufacturing methodof the die. The die for producing the wood-like concrete member comprises a die core and an external die frame. The die is characterized in that the die core is made of cementitious material, and backof the die core is bonded with the external die frame by adhesive materials. The wood-like concrete member manufactured by the die has the advantages of convenient machining and low preparation cost.From visual view, the die looks like a timber pile with barks. The die can be used for treatment of river channels, fences on the road sides and flower beds on passages in parks; and landscape designof gardens. The landscape design which is made from the wood-like concrete member has the advantages of perfect and verisimilar raw wood artistic effect, energy-saving and environmental-protection properties.

Owner:SHANGHAI SHANGTENG INDAL DEV

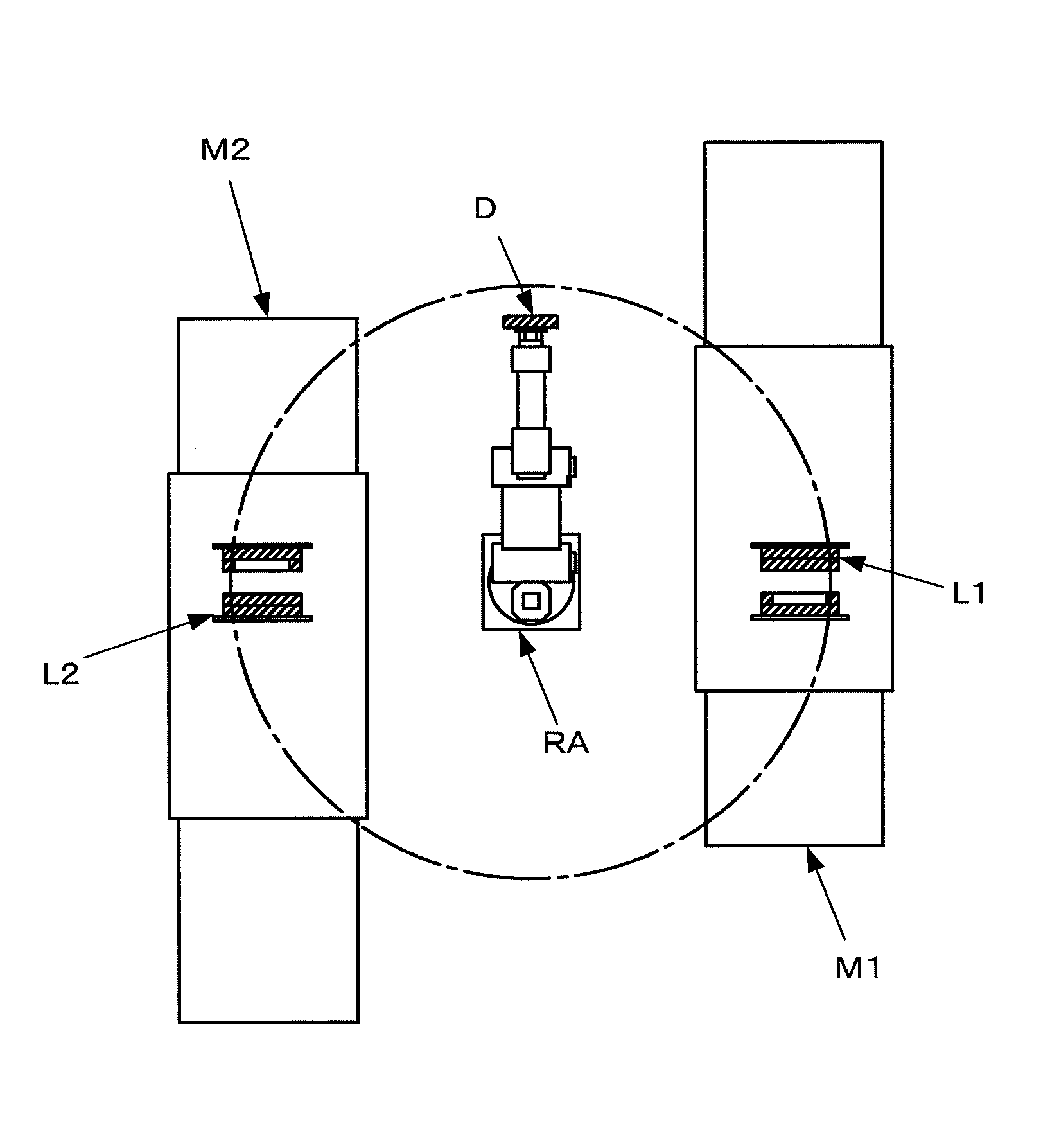

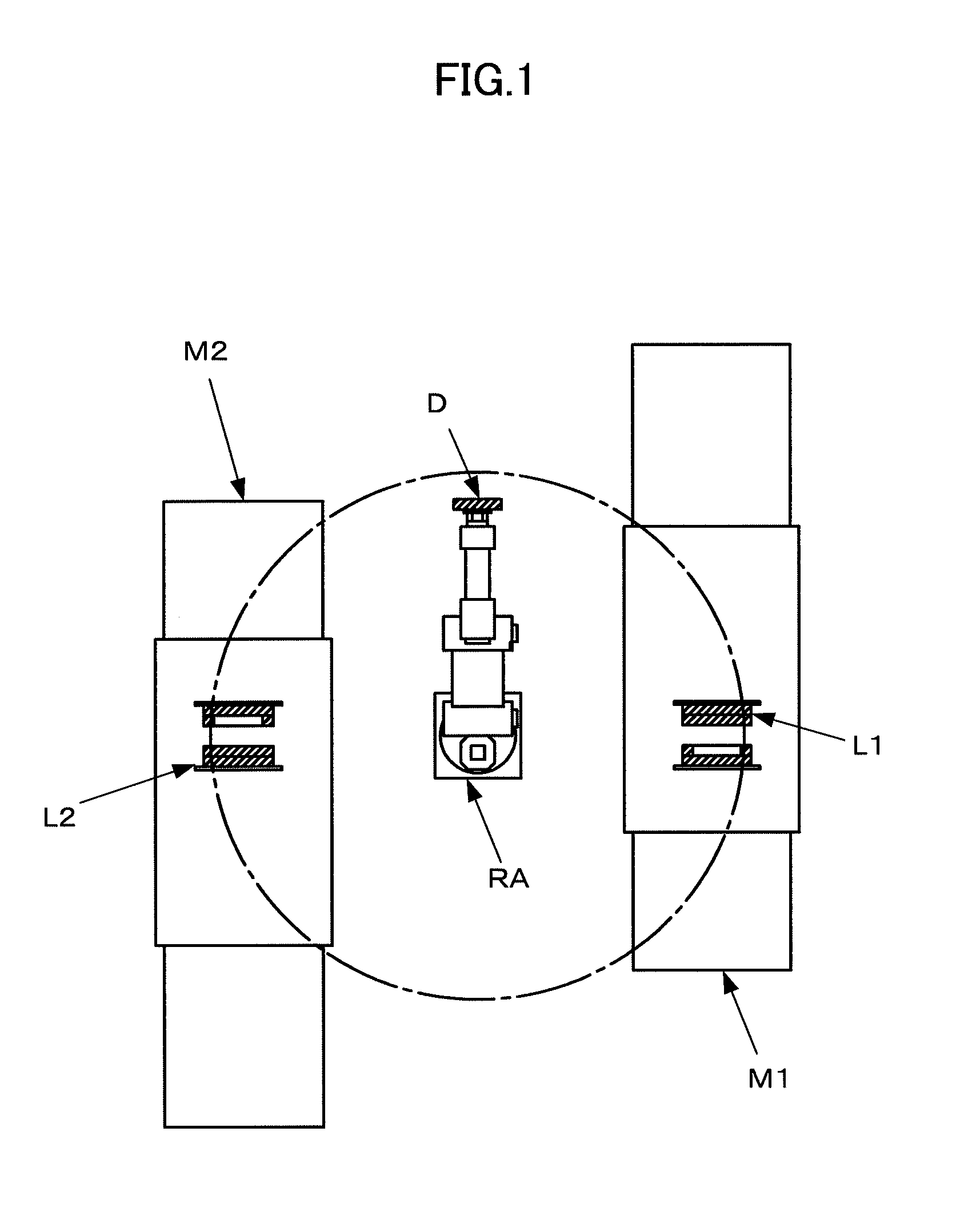

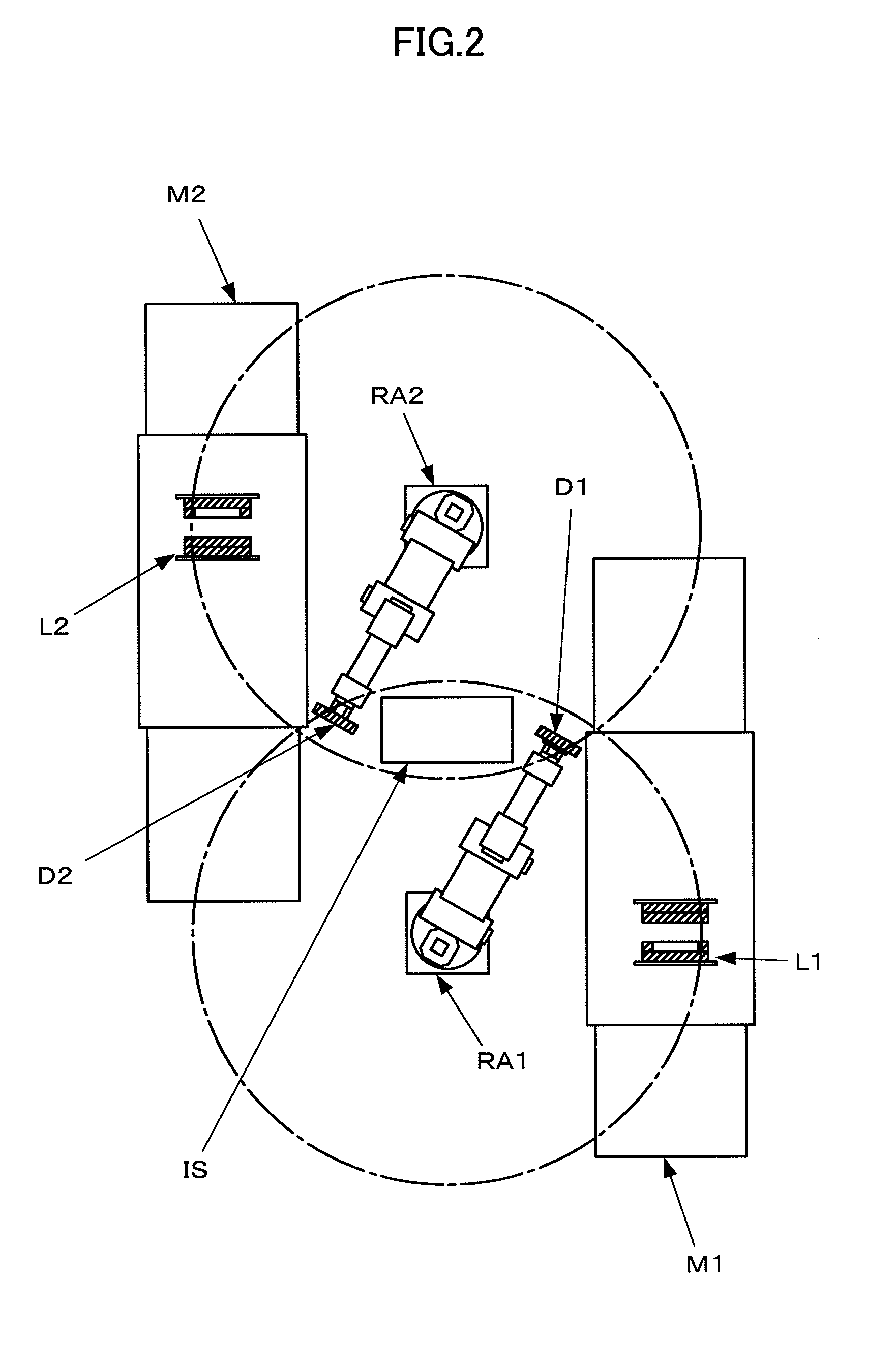

Manufacturing method and injection molding system for multi-color molded article

ActiveUS20140077410A1Preventing production of undesiredLack of versatilityButtonsRecord carriersInjection mouldingInjection molding machine

An injection molding system is configured to produce a multi-color molded article by simultaneously or sequentially injection-molding resins of a plurality of types by means of a plurality of injection molding machines. An insert mold is mounted in a mold of a first injection molding machine and a primary molded article is molded by this injection molding machine. Thereafter, a robot arm takes out the insert mold, along with the primary molded article, from the mold of the injection molding machine and attaches it to a mold of a second injection molding machine. A two-color molded article is injection-molded by the second injection molding machine and removed as a product.

Owner:FANUC CORP

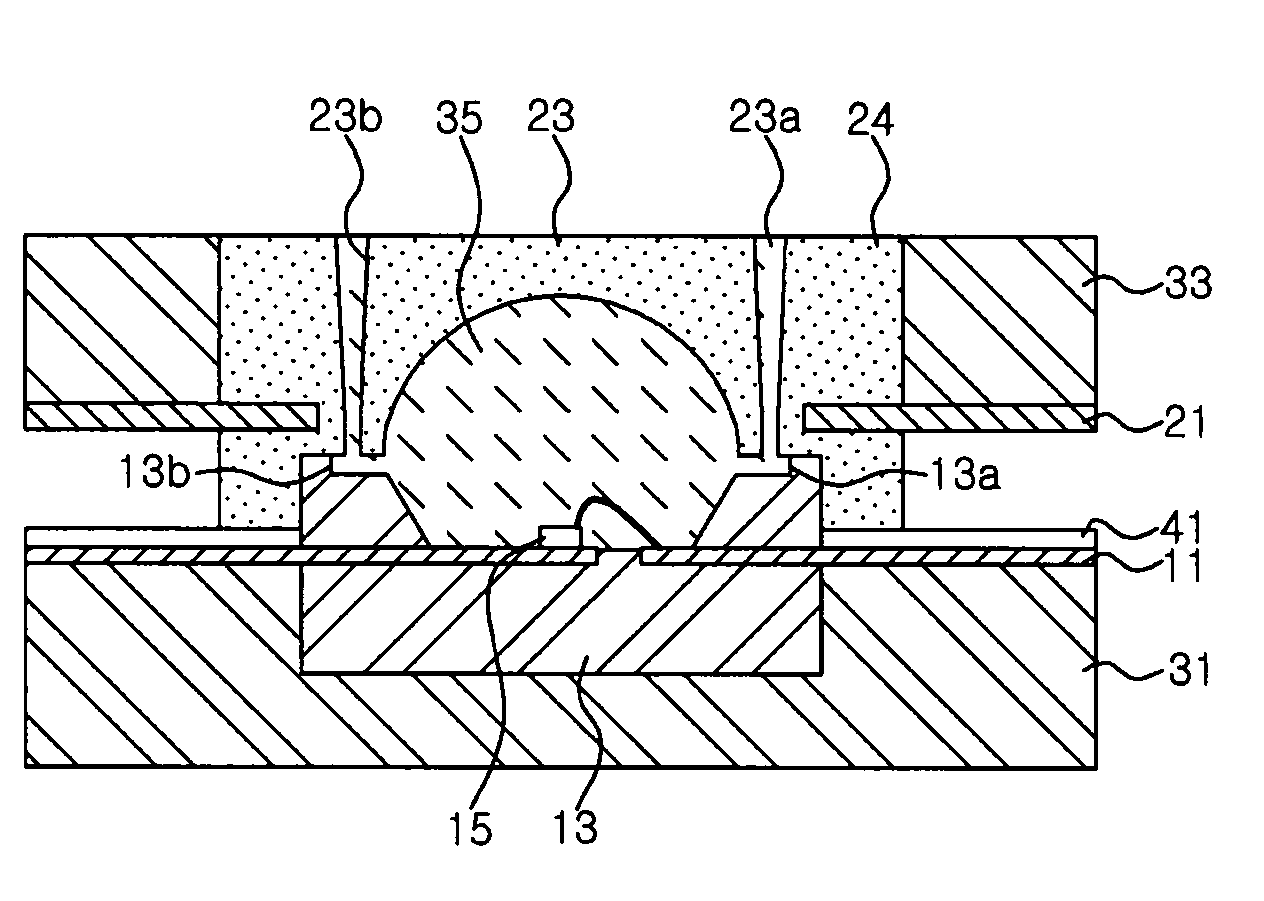

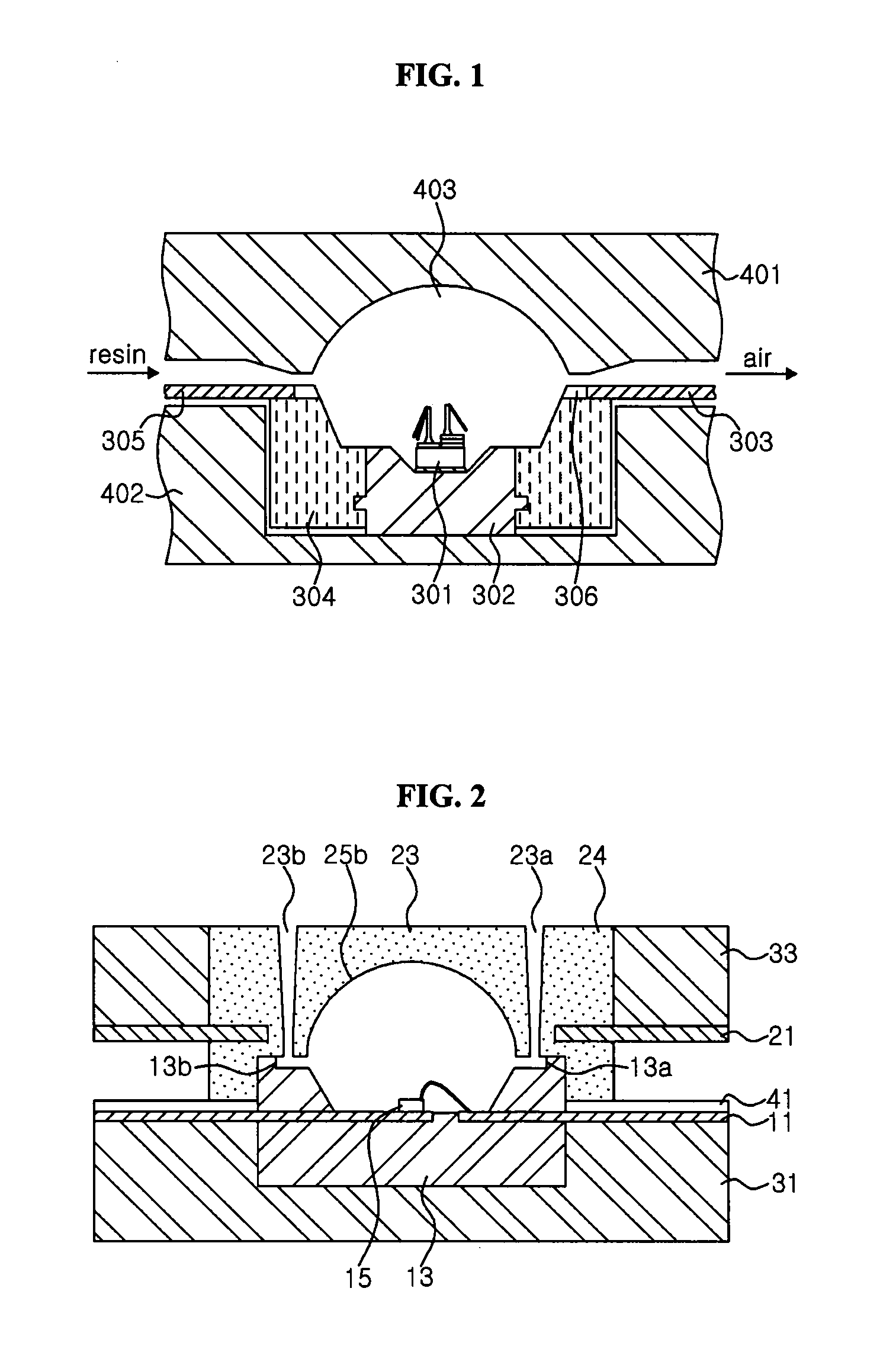

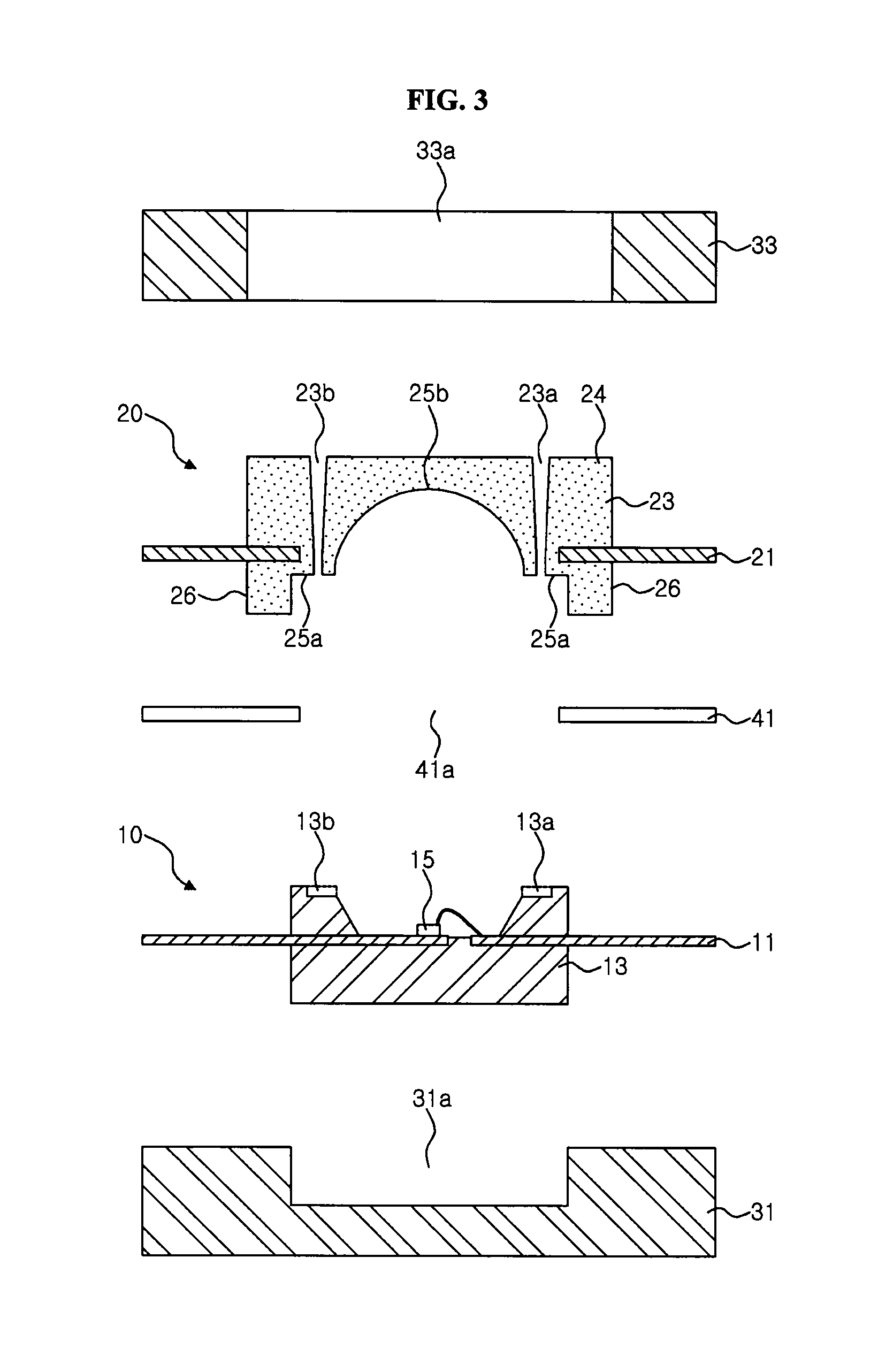

Mold for Forming a Molding Member and Method of Fabricating a Molding Member Using the Same

InactiveUS20080268559A1Avoid glitchesMold growthMould separation apparatusSemiconductor/solid-state device detailsMaterials scienceAir bubble

There are provided a mold for forming a molding member and a method for forming a molding member using the same. The mold includes an upper surface, and a lower surface having an outer peripheral surface and a concave surface surrounded by the outer circumference. Injection and discharge holes extend from the upper surface to the lower surface. Accordingly, after the mold and the package are coupled so that the discharge hole is directed upward, a molding member can be formed on the package by injecting the molding material through the injection hole, whereby it is possible to prevent air bubbles from being captured in the molding member.

Owner:SEOUL SEMICONDUCTOR

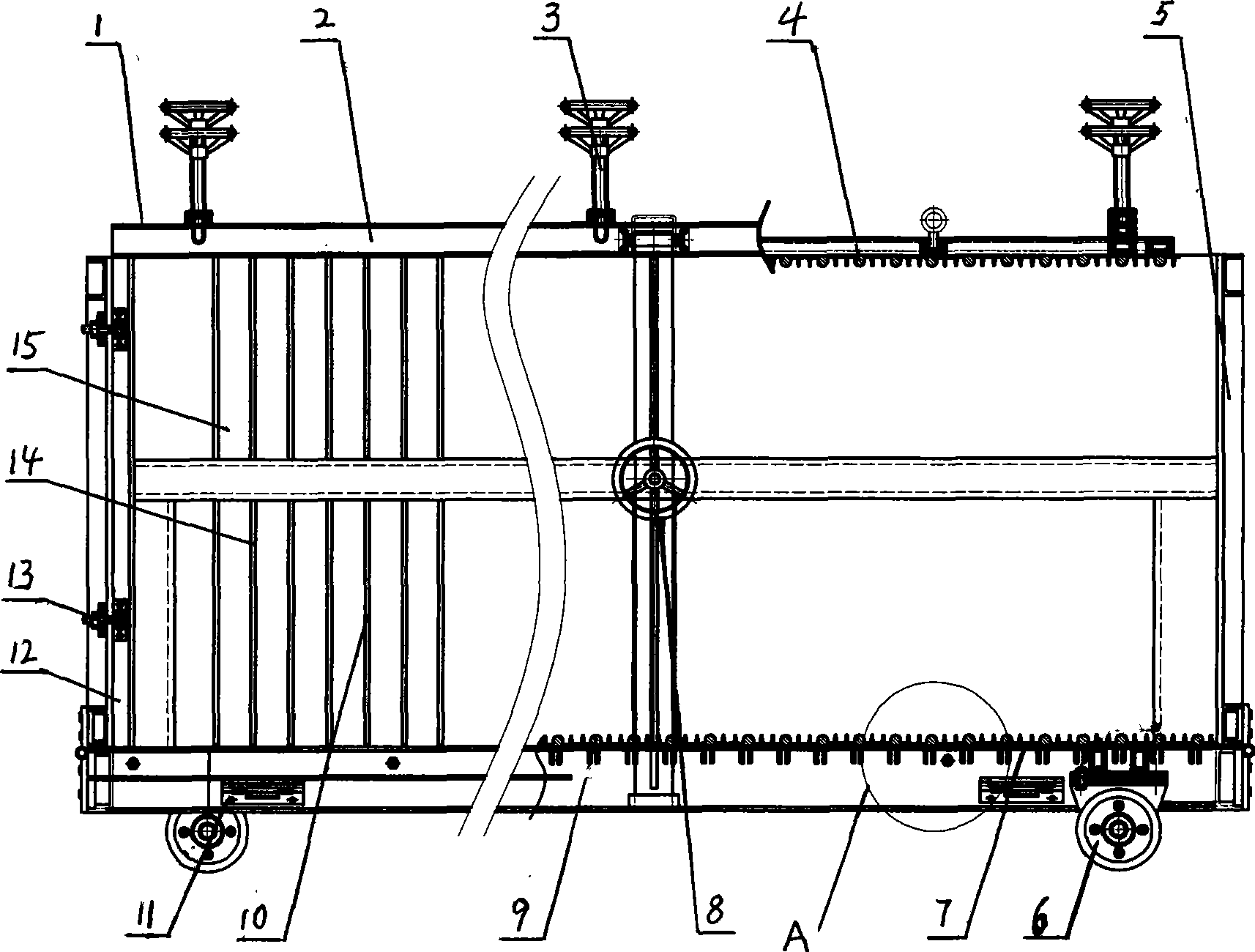

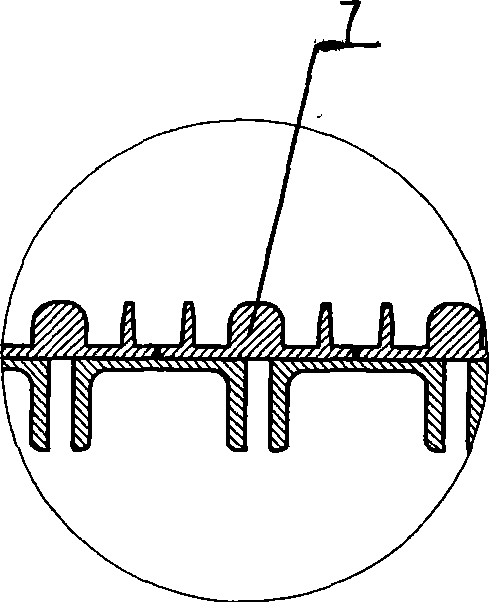

Multifunctional gypsum block die

InactiveCN101249668ALow priceReduce manufacturing costMould separation apparatusMouldsEngineeringGypsum block

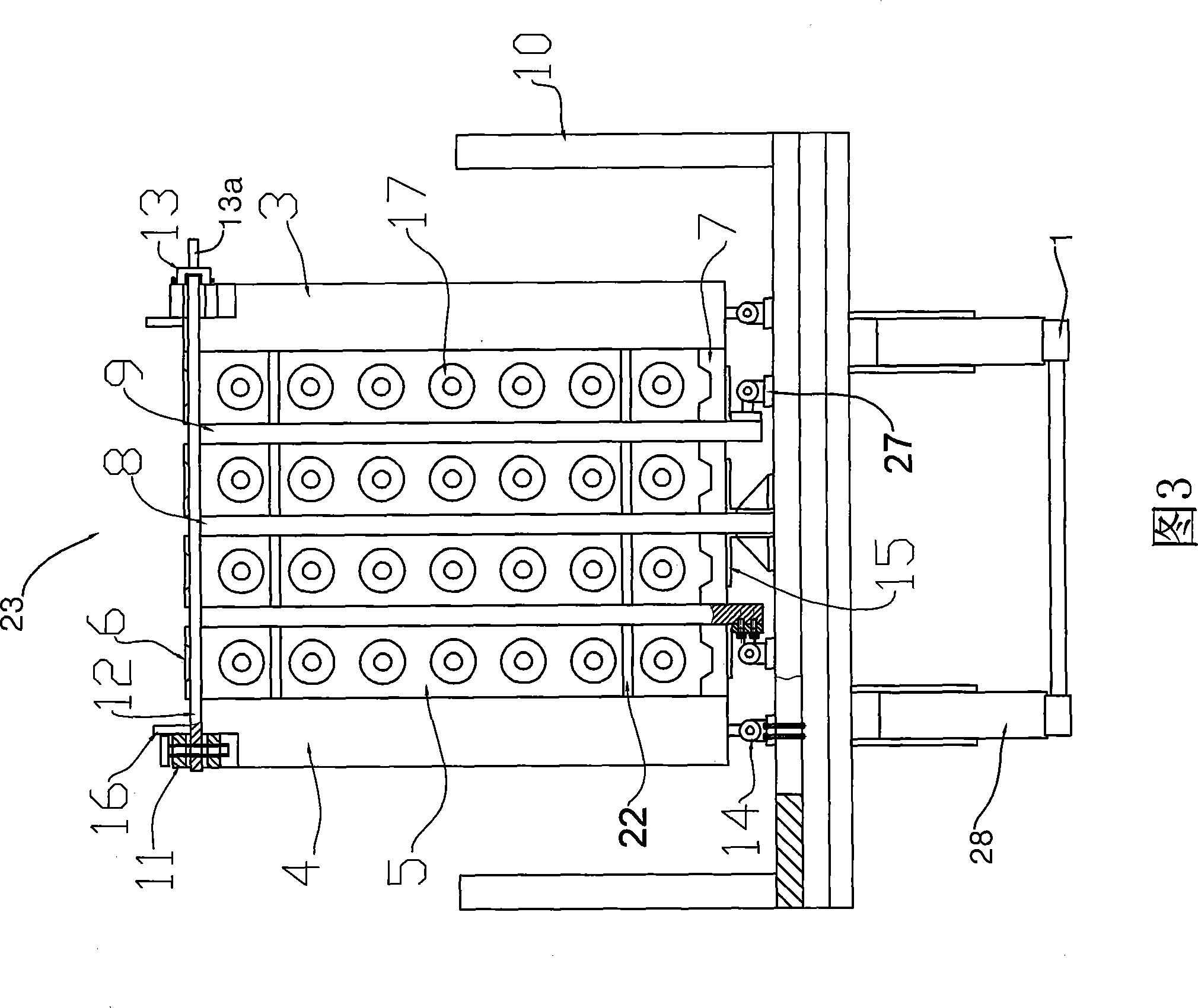

The invention relates to a multi-functional gypsum block mold. A rail is provided with a mold box carriage, the base of which is connected via a first hinge with a front side mold plate and a back side mold plate parallel to each other. A cavity formed by the front side mold plate and back side mold plate is divided into small cavities by diaphragms arranged in parallel. The left and the right heads of the small cavities are sealed by an end mold plate, which is connected with an upper mold and a bottom mold through the concave and convex surfaces of the end mold plate. The upper end of the front side mold plate and the back side mold plate are connected by a locking device. The base is equipped symmetrically with a strip hole along the vertical center line of the base. The lower end of the hinge is fixed on the base through the bolt of the strip hole. The end mold plate is fixed with a positioning pin, which is inserted into the pin slot of the diaphragm or the front side mold plate or back side mold plate. The mold can produce the gypsum block with different types and specifications through replacing the end mold plate, the bottom mold and the upper mold, achieves multiple functions for one machine, and saves production cost.

Owner:胡云模

Self-insulation concrete composite building block mold and using method thereof

InactiveCN103171036AEasy to makeSimple structureMould separation apparatusMachiningMaterials science

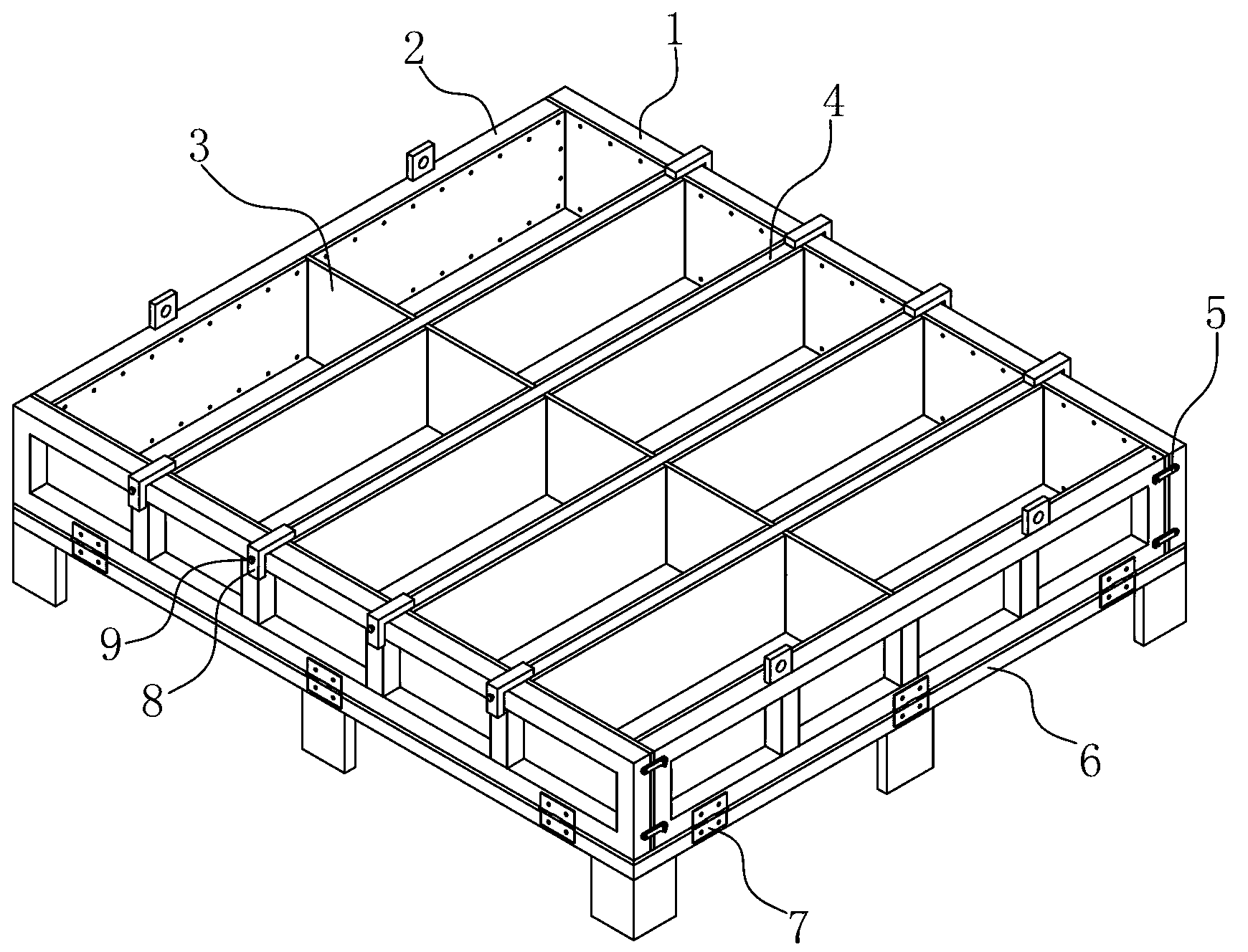

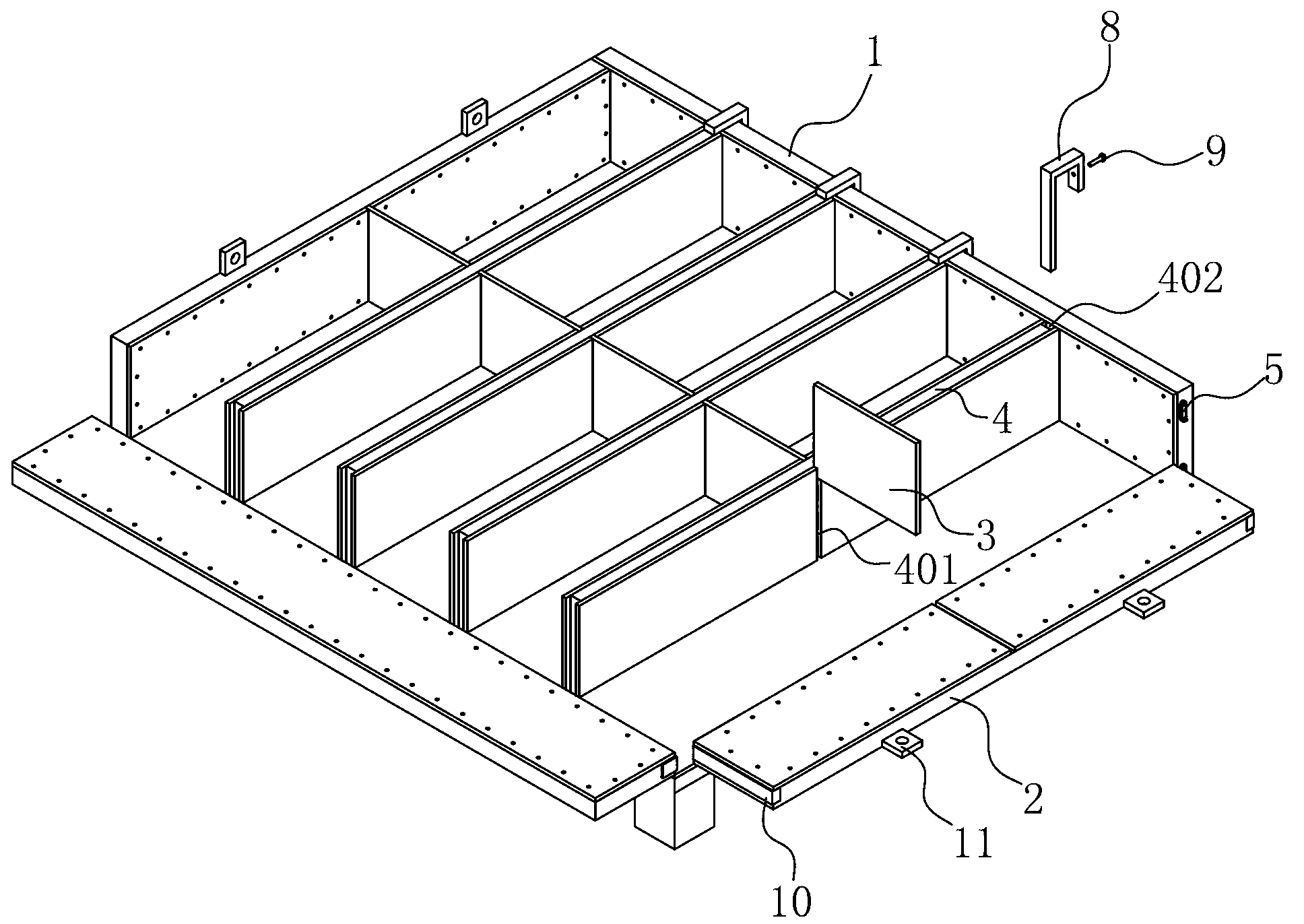

The invention relates to a self-insulation concrete composite building block mold. The self-insulation concrete composite building block mold comprises a cuboid mold frame and a separation plate assembly which is placed in the mold frame and is used for lattice division. The mold frame comprises a long lateral plate, a short lateral plate and a base plate. The lateral plates are connected with the base plate through hinges in an over-turning mode, and every two adjacent lateral plates are fixedly connected through hasps. The separation plate assembly includes a long separation plate and a short separation plate. Both ends of the long separation plate are provided with sockets. The long lateral plate is provided with plug-in members matched with the sockets. The design key points comprise that the plug-in members are reverse-hook type flat bars sleeving the upper end of the long lateral plate, namely the flat bars of the reverse-hook type plate bars at the inner side of the lateral plate are matched with the sockets of the long separation plate, the flat bars of the reverse-hook type flat bars at the outside of the long lateral plate are connected to bolts, and the reverse-hook type flat bars and the long lateral plate are fixed through the bolts. The self-insulation concrete composite building block mold has simple structure. It is convenient to operate and use. Building blocks with various sizes according to practical machining requirements can be manufactured. The self-insulation concrete composite building block mold is suitable for being used as a mold of various concrete building blocks or as a structural improvement of similar products.

Owner:仇心金

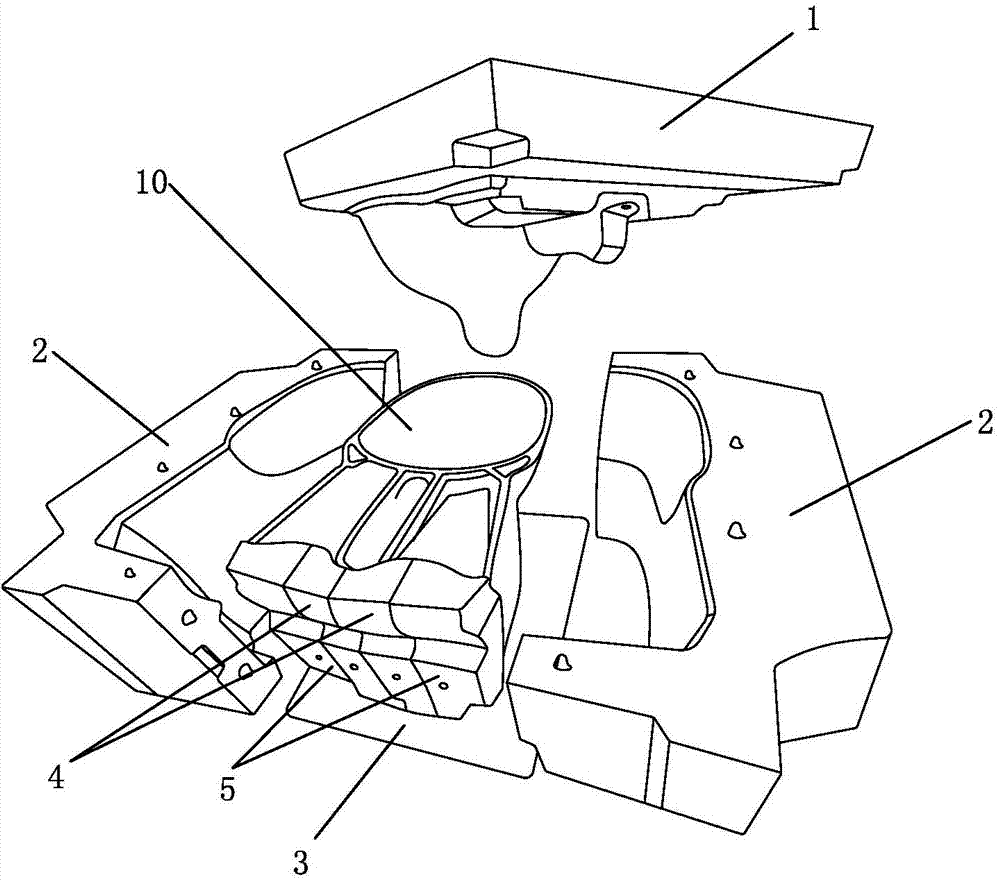

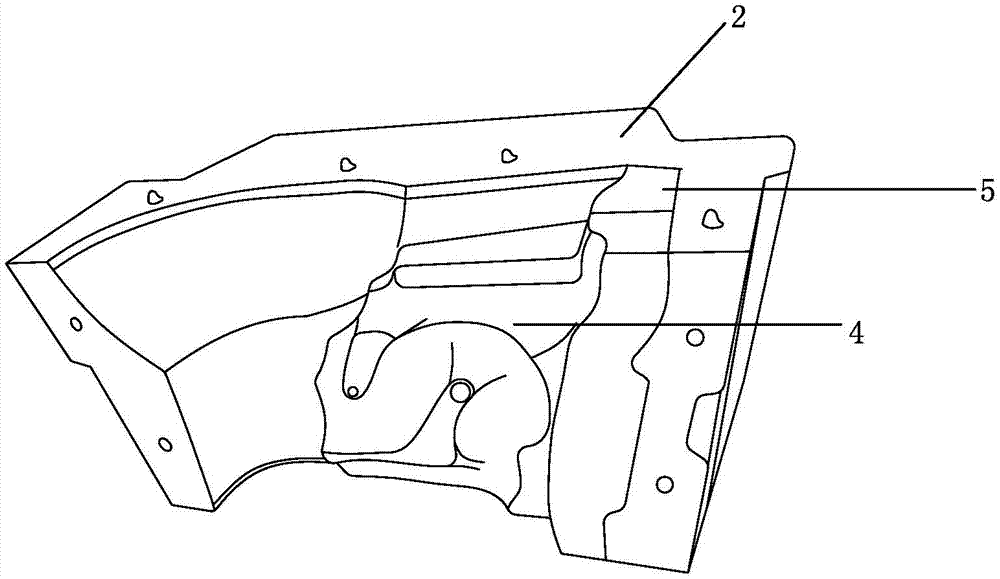

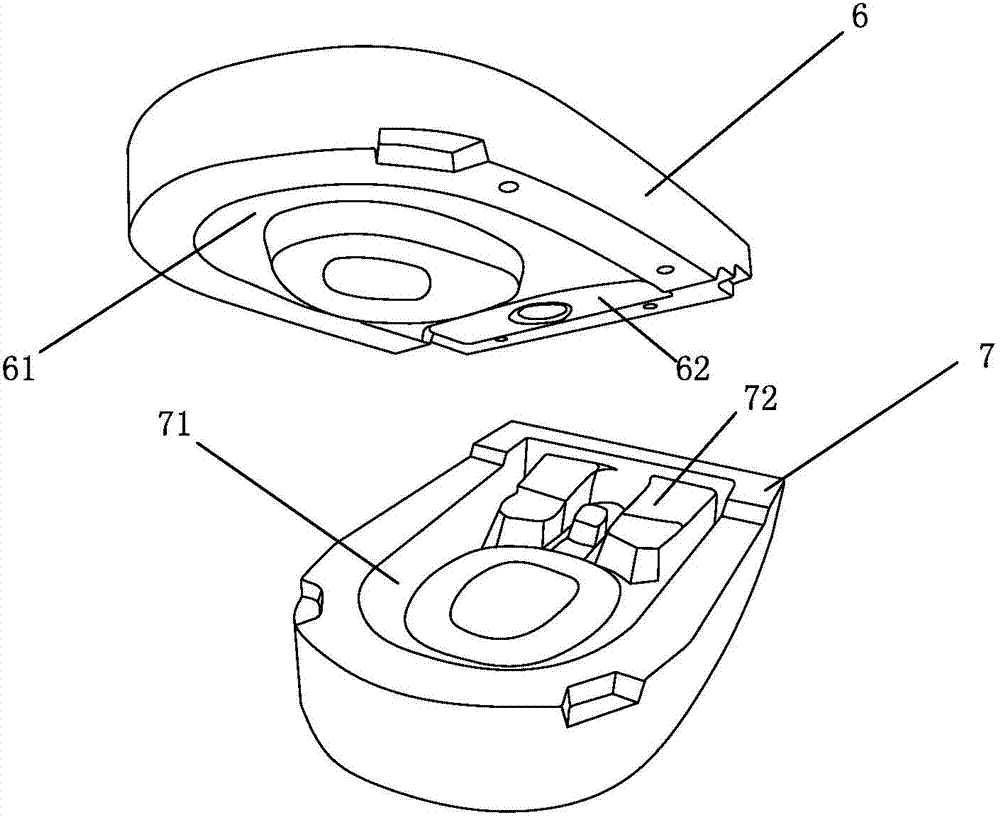

Pedestal pan mold, and mold splitting technology and pedestal pan thereof

InactiveCN103770202AEasy to moldConvenient mold opening operationWater closetsMould separation apparatusSewage treatmentMaterials science

The invention discloses a pedestal pan mold, and a mold splitting technology and a pedestal pan of the pedestal pan mold. The mold comprises a mold body and a seat ring mold, wherein the seat ring mold comprises an upper seat ring mold and a lower seat ring mold, an upper concave ditch is formed in the upper seat ring mold, a lower concave ditch is formed in the lower seat ring mold, and the seat ring mold is used for producing a seat ring with the complete water guide ring. The mold splitting technology comprises the steps that the pedestal pan is split into a pedestal pan body, the mold body and the seat ring mold, and the mold body and the seat ring mold are independently developed from the seat ring; the seat ring mold is divided into the upper seat ring mold and the lower seat ring mold, and is used for producing the seat ring with the complete water guide ring. The pedestal pan comprises a pedestal pan body at least provided with a bed pan, a sewage disposal pipeline and a jetting water way and a seat ring, the pedestal pan body and the seat ring are independently formed, the seat ring is provided with the water guide ring, and the seat ring is stuck to the top end of the pedestal pan body. According to the pedestal pan mold, and the mold splitting technology and the pedestal pan of the pedestal pan mold, the production efficiency can be greatly improved, the labor intensity of workers is reduced, and the production cost is reduced.

Owner:JOMOO KITCHEN & BATHROOM

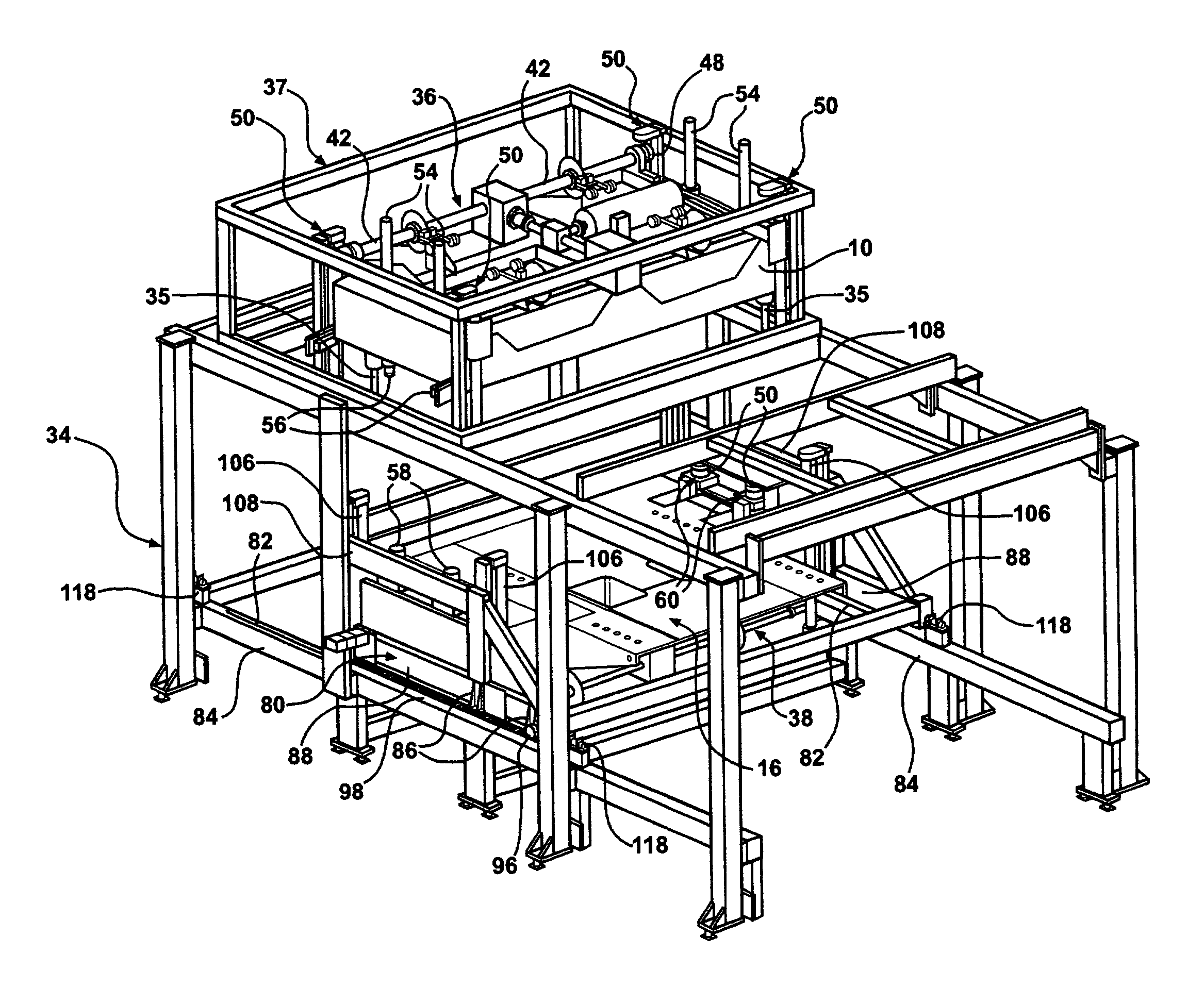

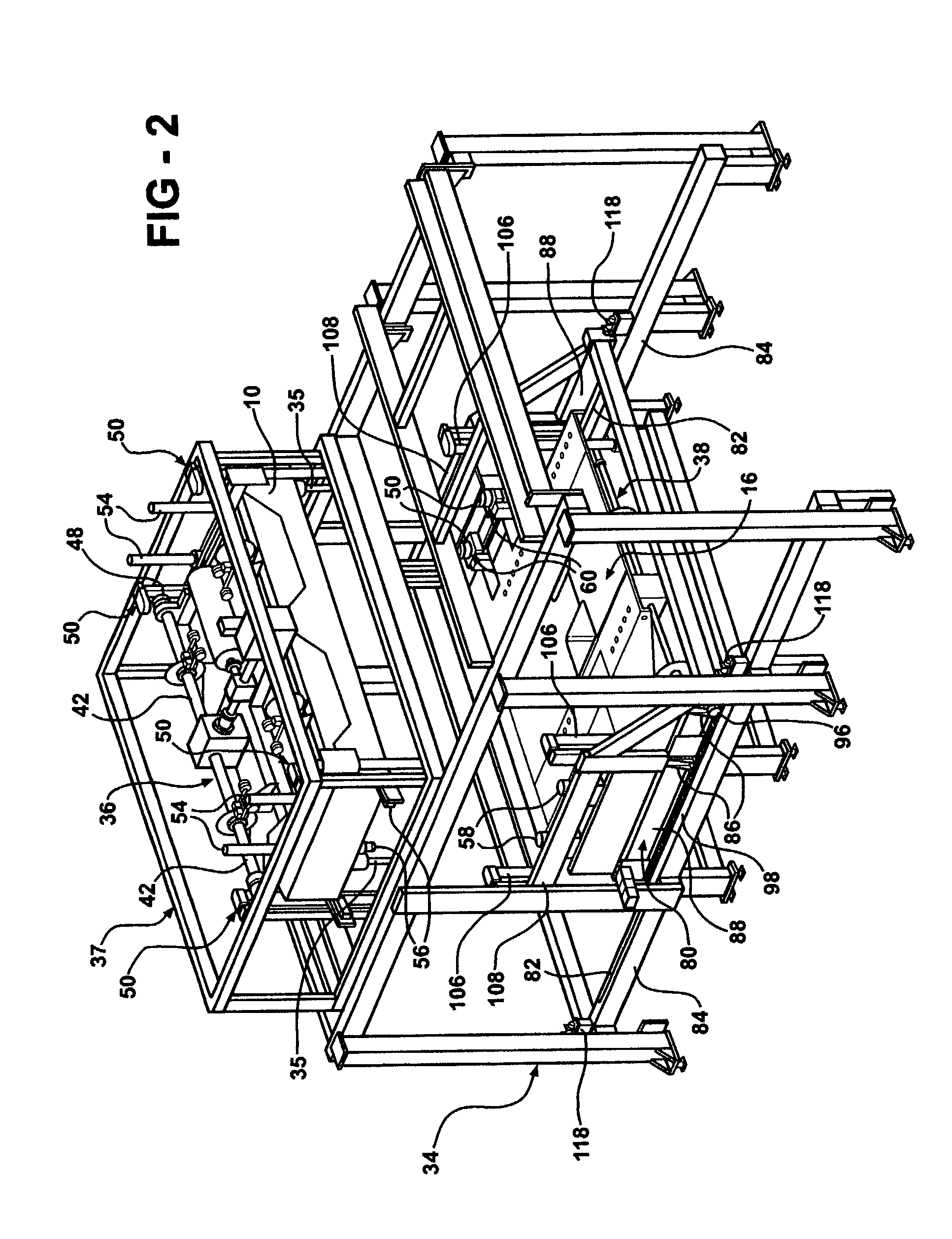

Forming station and process for twin sheet thermoforming

InactiveUS6969246B1Minimize the numberReduce complexityMould separation apparatusMouldsHydraulic cylinderFlange

A forming station for a thermoformer in which the lower platen is lowered and moved laterally on linear bearings on the machine frame after two sheets are formed in side by side mold-plug assist tool sets so as to align the respective molds and formed sheets. The formed sheets are squeezed together with flanges on the formed sheets thereby fused together by a draw mechanism including a series of hydraulic cylinders which are connected to coupled elements carried by the upper and lower platens so as create the squeezing movement when the cylinders are pressurized. A precision control is exercised over the operation of each of the cylinders using a position sensing device associated with each cylinder to insure equal movement of the output member of each cylinder. The lower platen vertical drive is activated in correspondence with the travel produced by the hydraulic cylinders to reduce the load on a brake holding the upper platen stationary.

Owner:BROWN LLC

Methods and molds for producing customized hot pour products

Owner:COSMETIC GRP USA

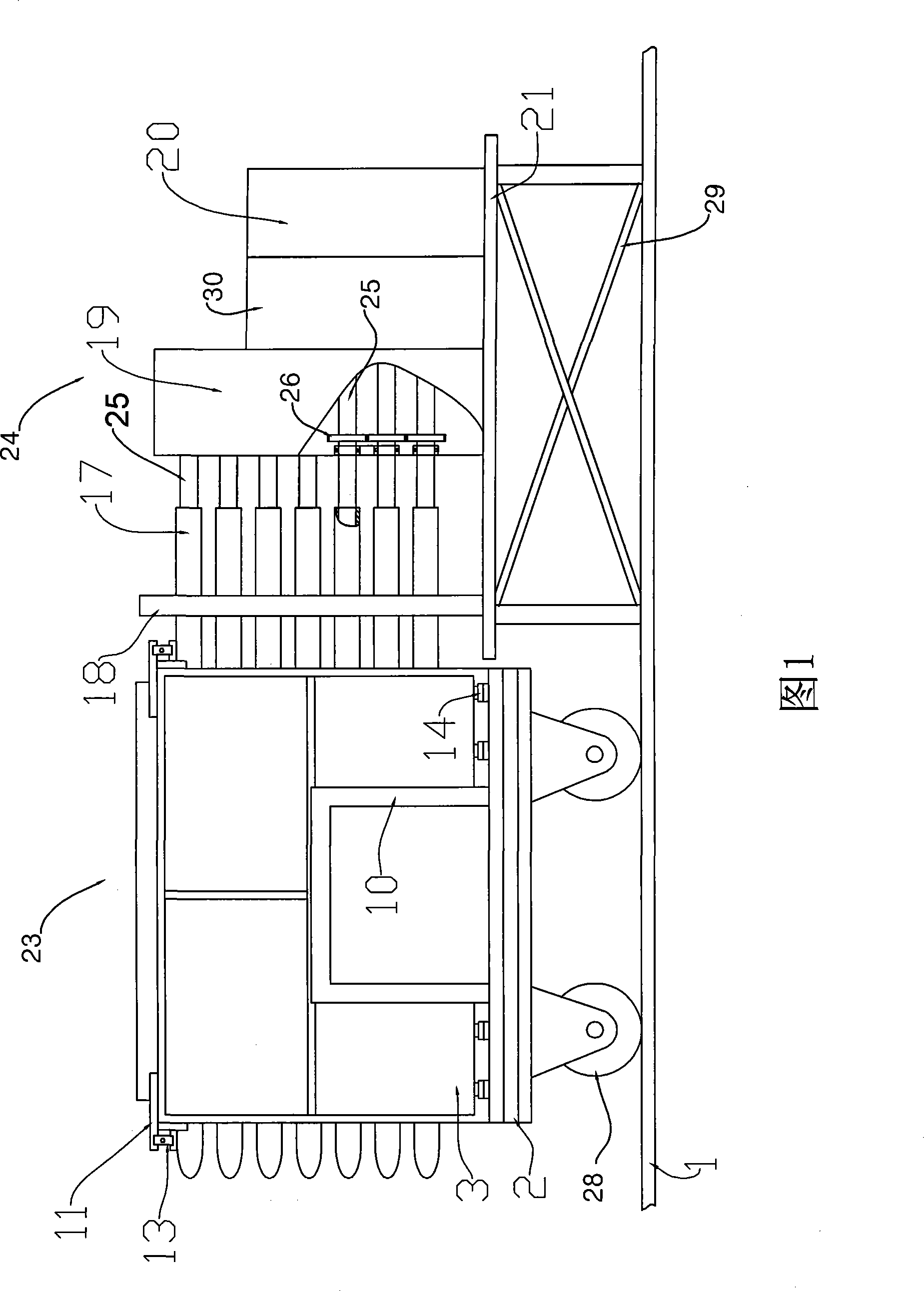

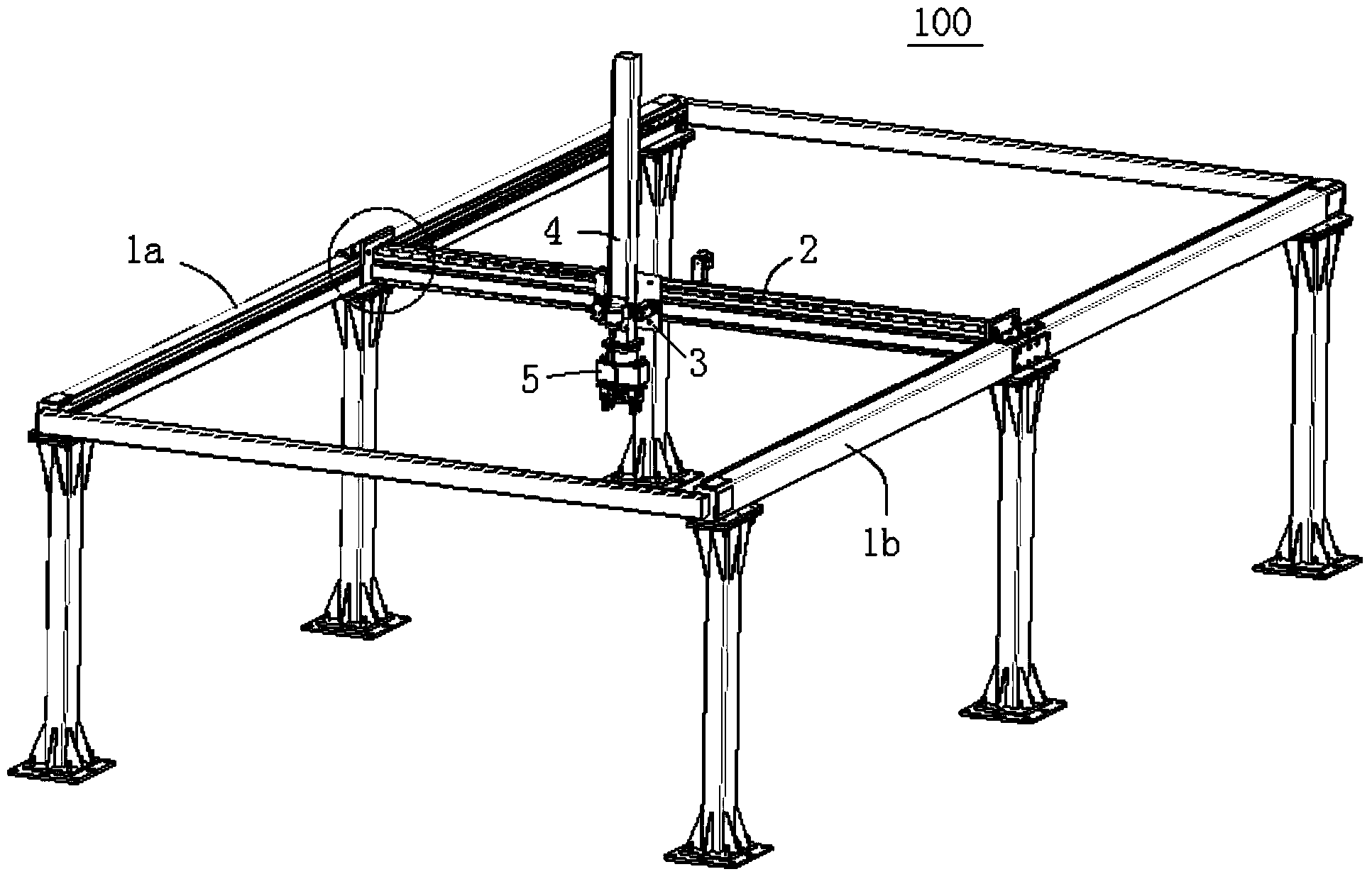

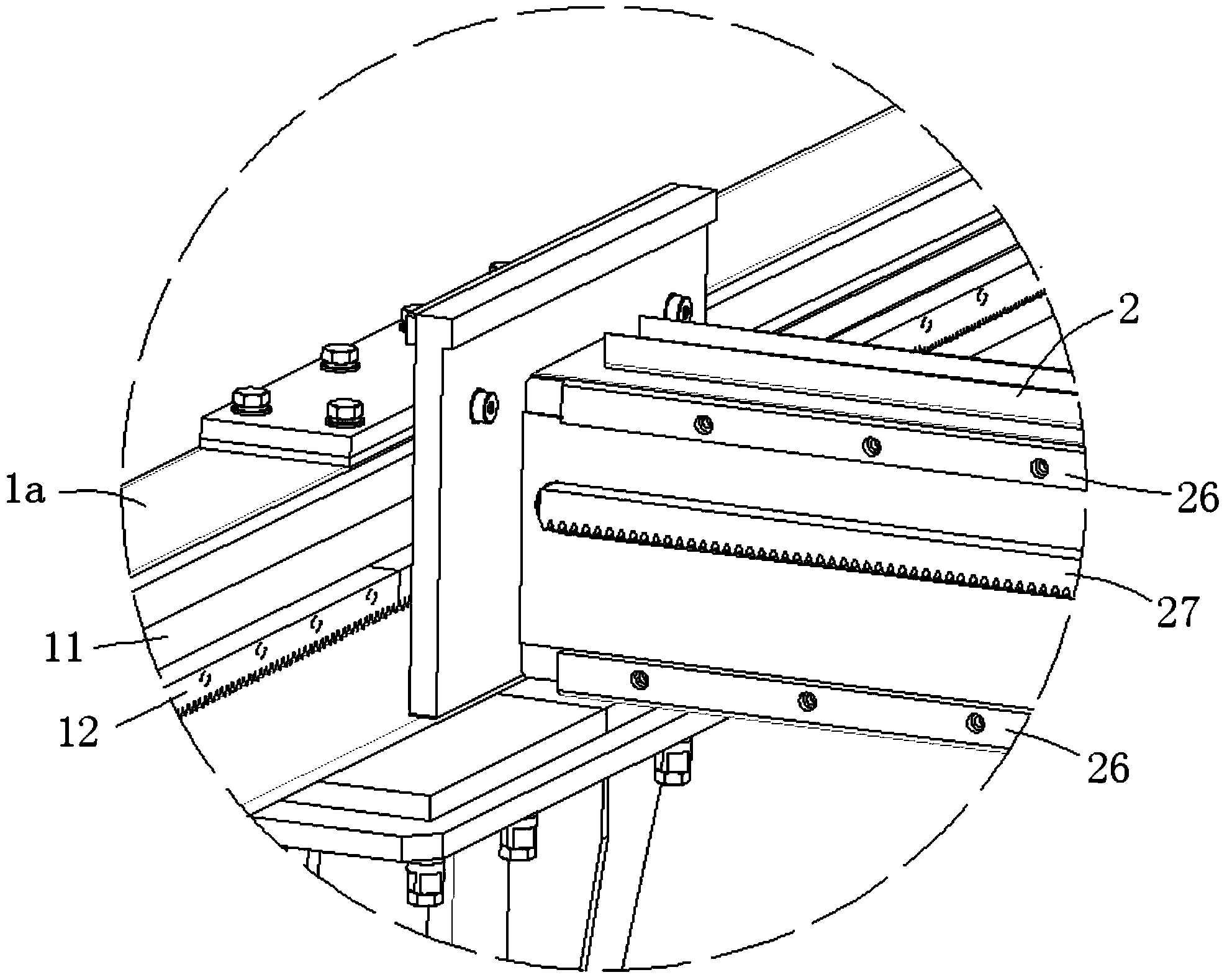

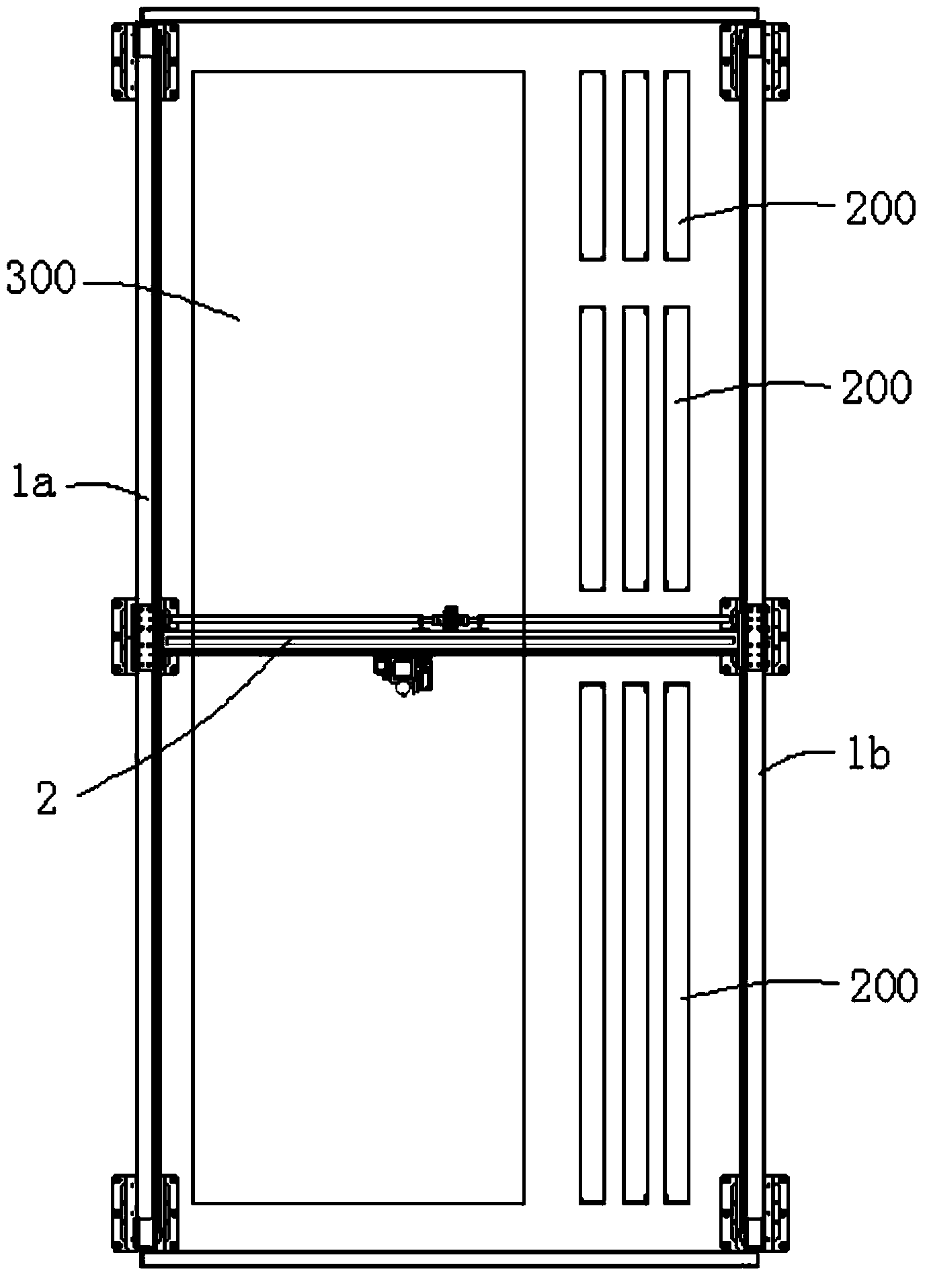

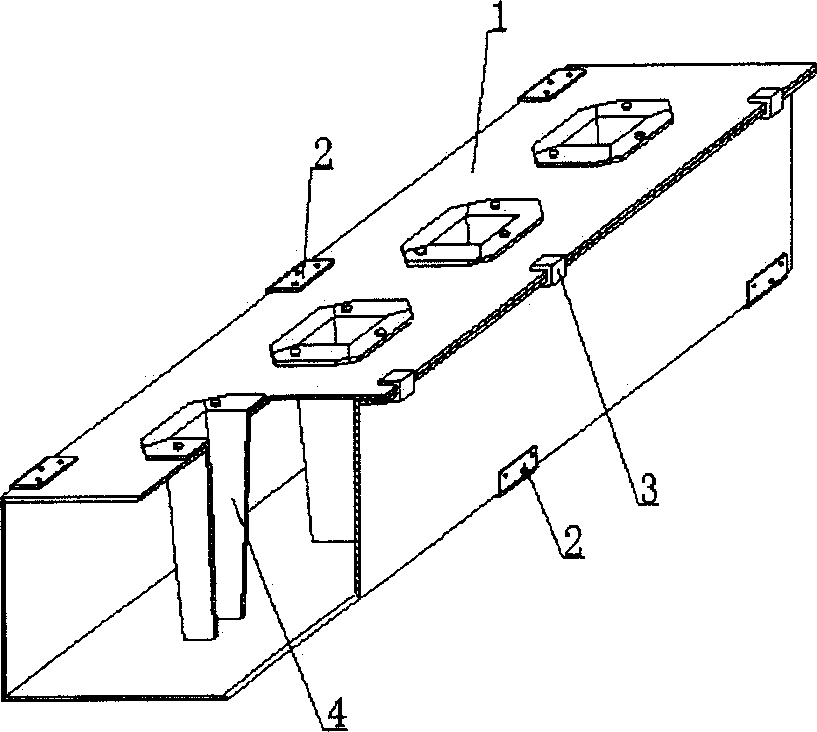

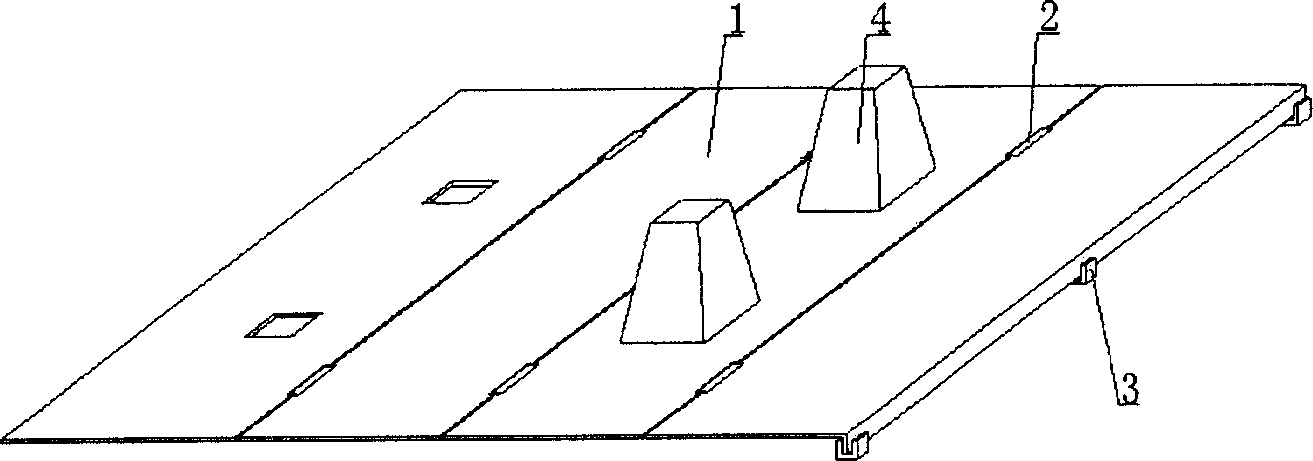

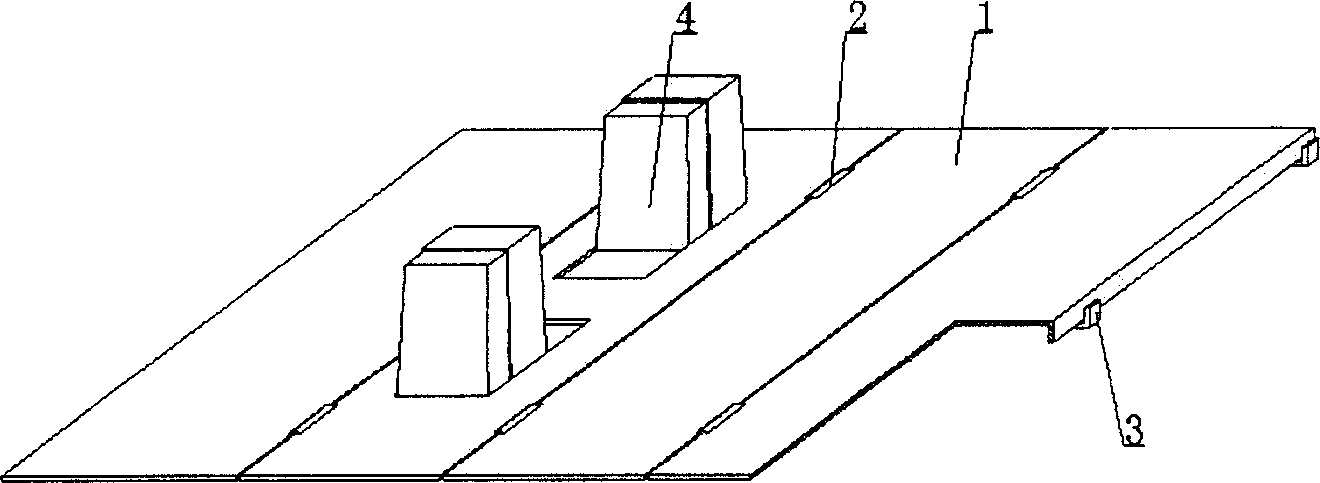

Automatic die assembling device

The invention provides an automatic die assembling device which comprises a left portal frame, a right portal frame, a cross beam, an installing plate, a vertical beam, a mechanical arm, a plotting device and a control system, wherein the mechanical arm and the plotting device are installed at the lower end of the vertical beam. A drawing of a precast concrete panel is manually input into the control system, then the control system controls the plotting device on the vertical beam to move to automatically plot the outline of the precast concrete panel on a steel die platform; finally according to a plotted outline line, the control system controls the vertical beam to move to work together with the mechanical arm so as to grab, transfer, place and fix a side die to automatically assemble the side die. The plotting of the outline of the whole precast concrete panel and the installing process of the side die are automatically carried out after an operator is input the drawing to the control system. The precision is high, the efficiency is high, the labor intensity of the operator is small, and the harm of a release agent to the operator does not exist.

Owner:CHANGSHA CTR ROBOTICS

Die in use for molding component of concrete filled double thin wall

InactiveCN1727152AReduce manufacturing costMould separation apparatusMouldsUltimate tensile strengthThin walled

Owner:邱则有

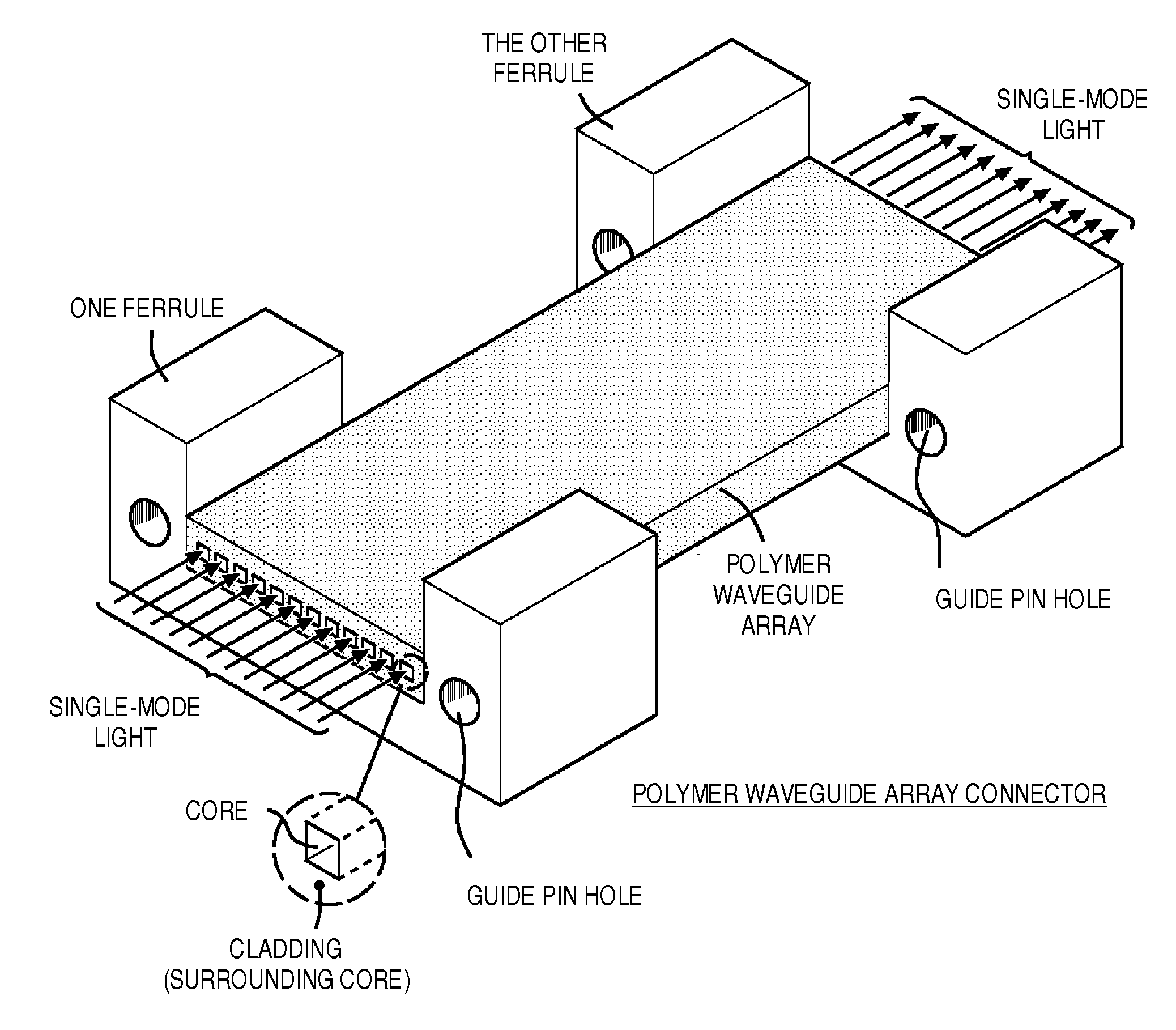

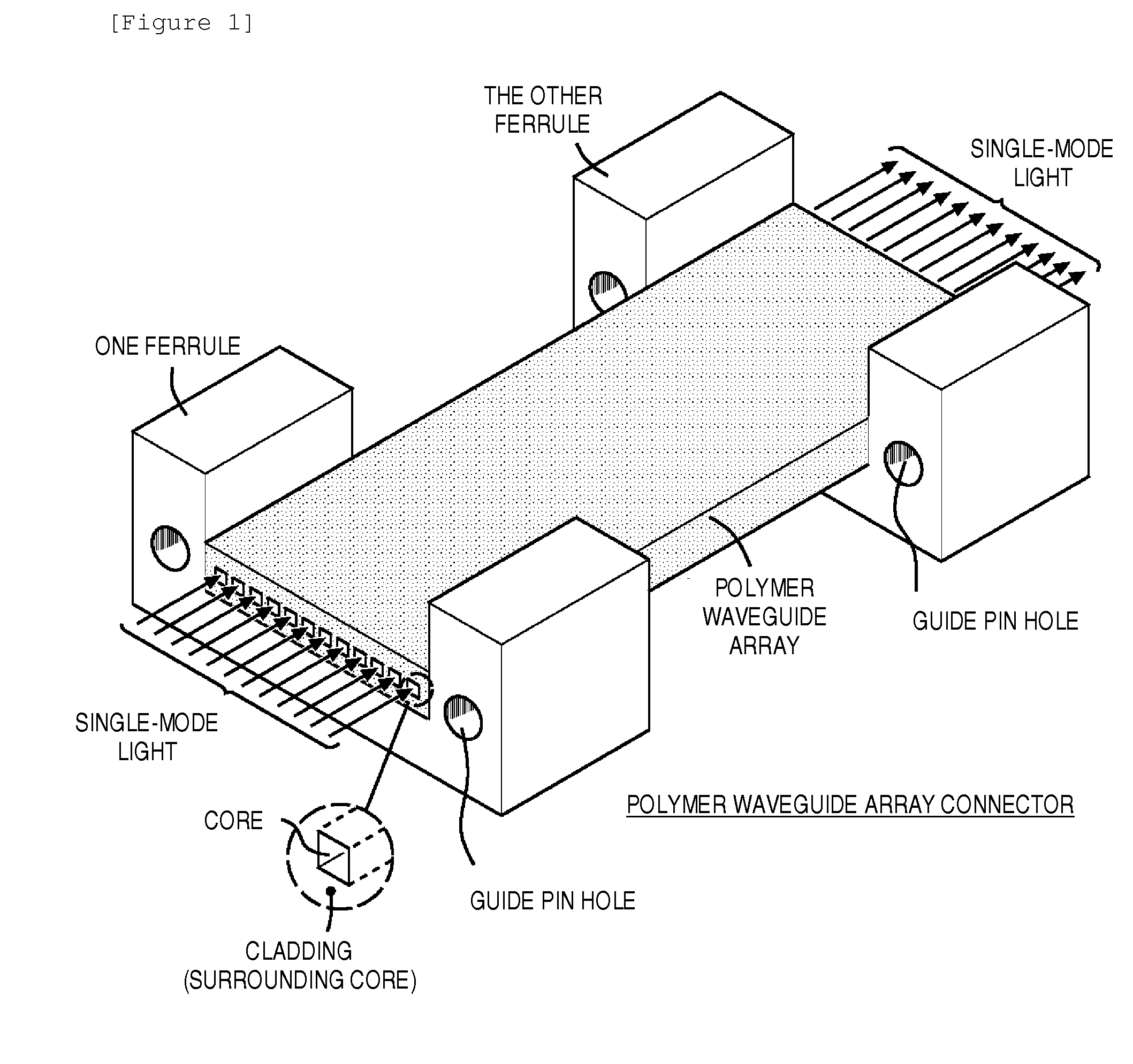

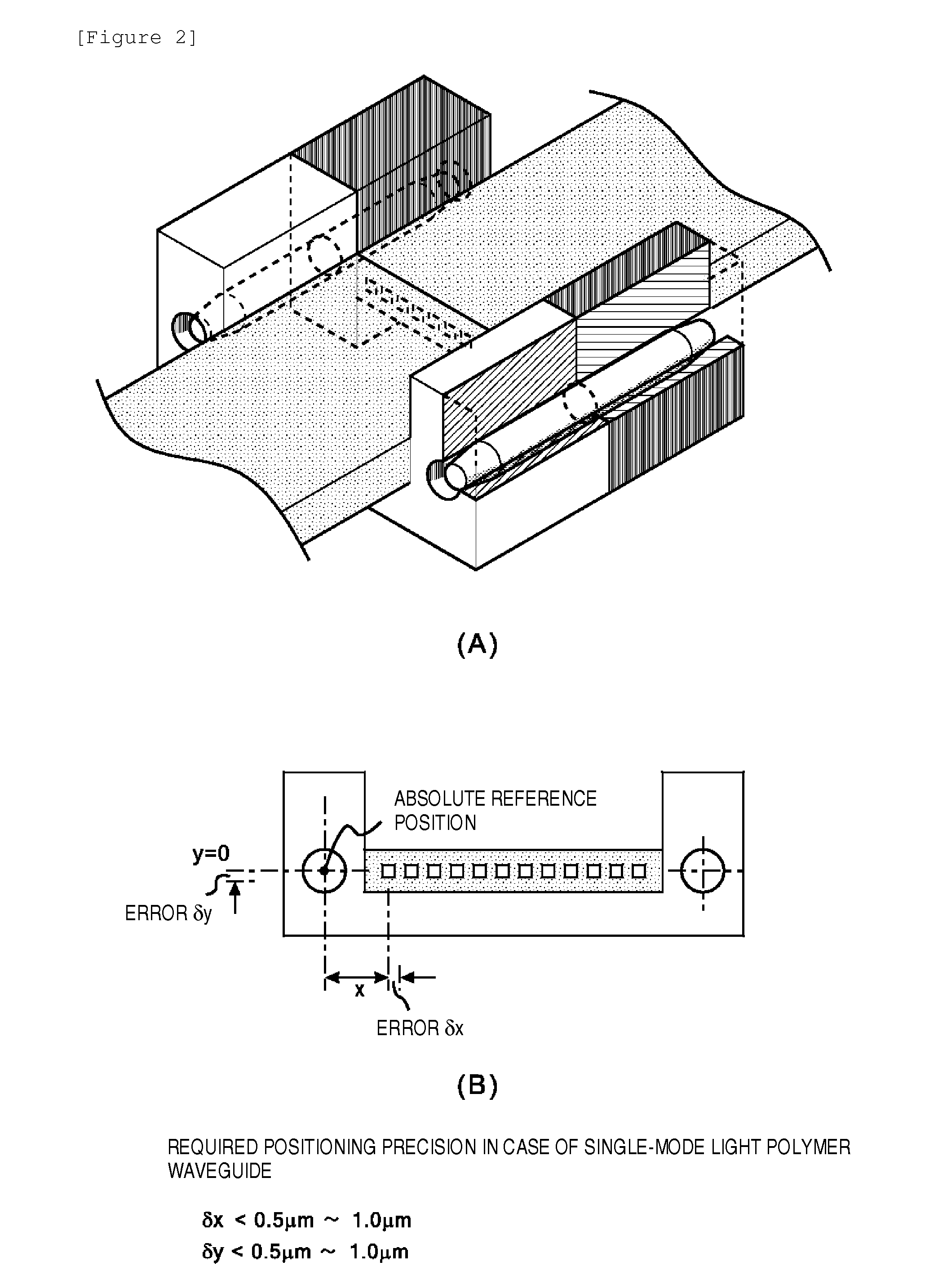

Method of forming single-mode polymer waveguide array connector

A method of forming a single-mode polymer waveguide array connector that provides precise alignment of a plurality of cores of polymer waveguide arrays with respect to an absolute reference position, such as a guide pin hole in a ferrule, when the polymer waveguide array connector is connected to another polymer waveguide array connector or provides precise alignment of a plurality of cores of a polymer waveguide array and a fiber array with respect to the absolute reference position when the polymer waveguide array connector is connected to a single-mode fiber array connector. A plurality of cores of single-mode polymer waveguide arrays or single-mode fiber arrays is precisely aligned with each other. In addition, there is provided a combination of a plurality of molds, e.g., a first mold (A) and a second mold (B), used in a plurality of processes in a specific method.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com