Automatic die assembling device

A mold loading and automatic technology, applied in the field of construction machinery, can solve the problems of high labor intensity, heavy weight of magnetic side molds, and high pressure of magnetic pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0070] In order to solve the deficiencies of the prior art, the present invention provides an automatic mold loading device, which can automatically complete the contour plotting on the steel mold platform and the installation of side molds according to the CAD drawings of the concrete prefabricated parts, with high precision and high efficiency.

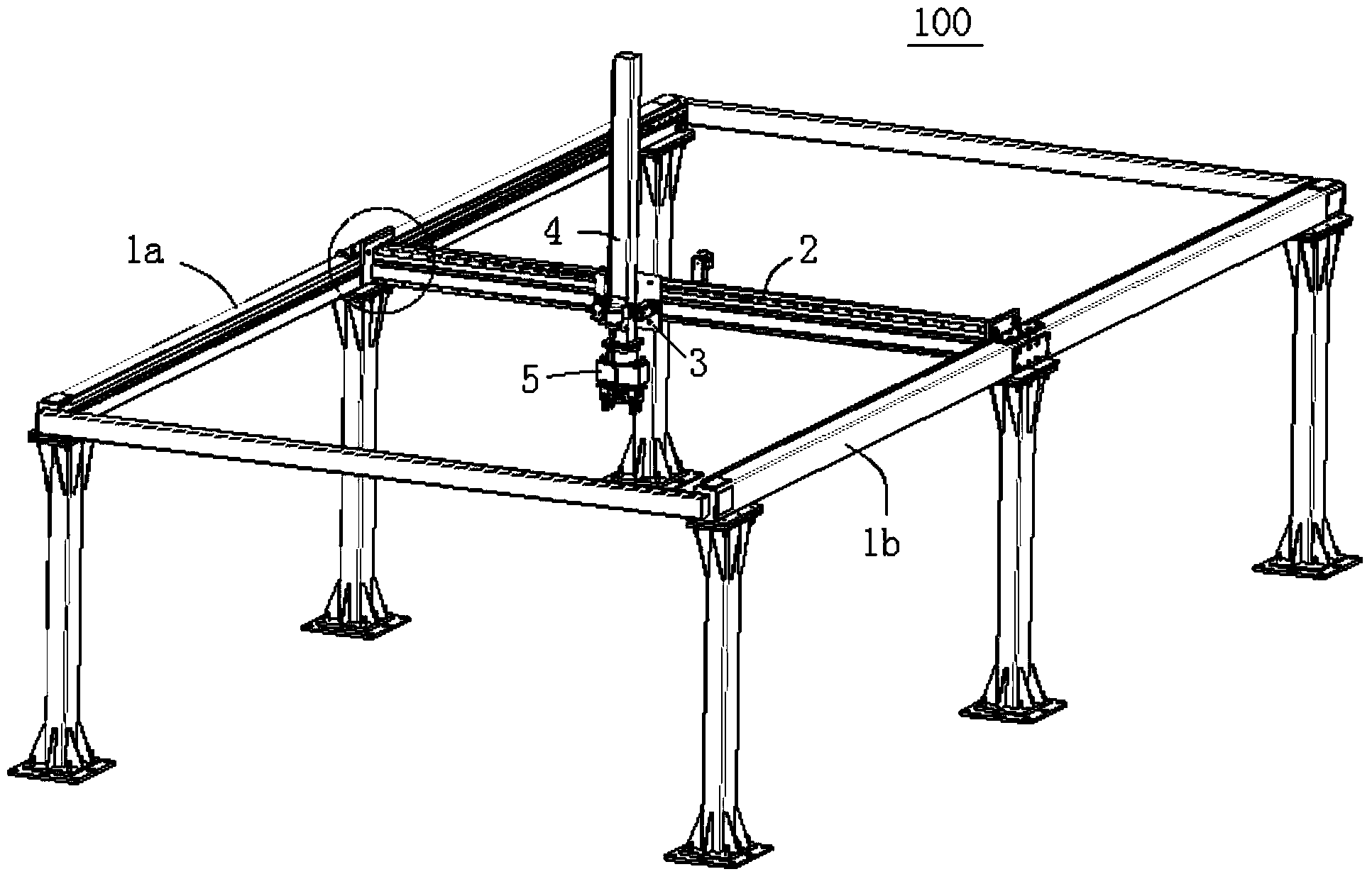

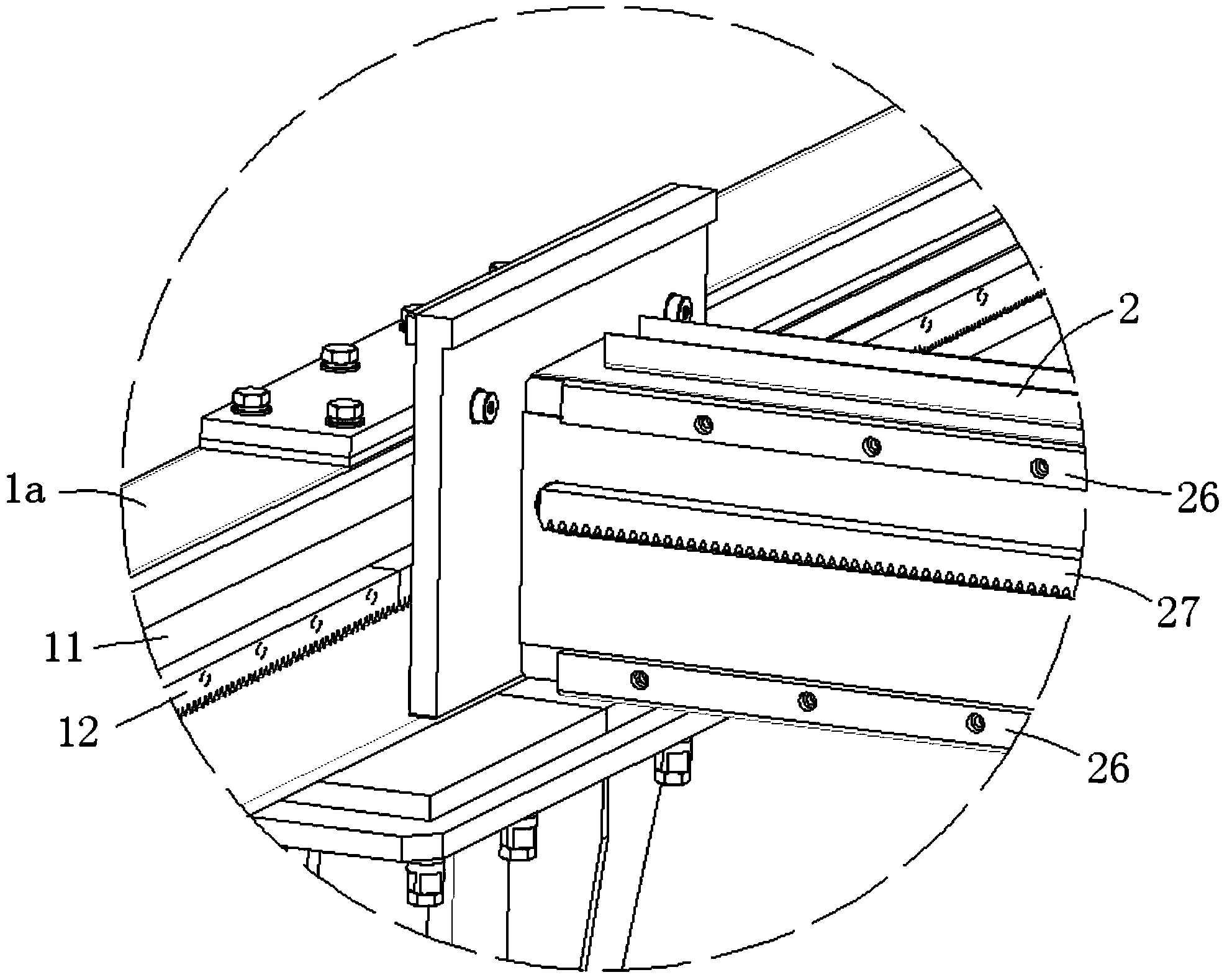

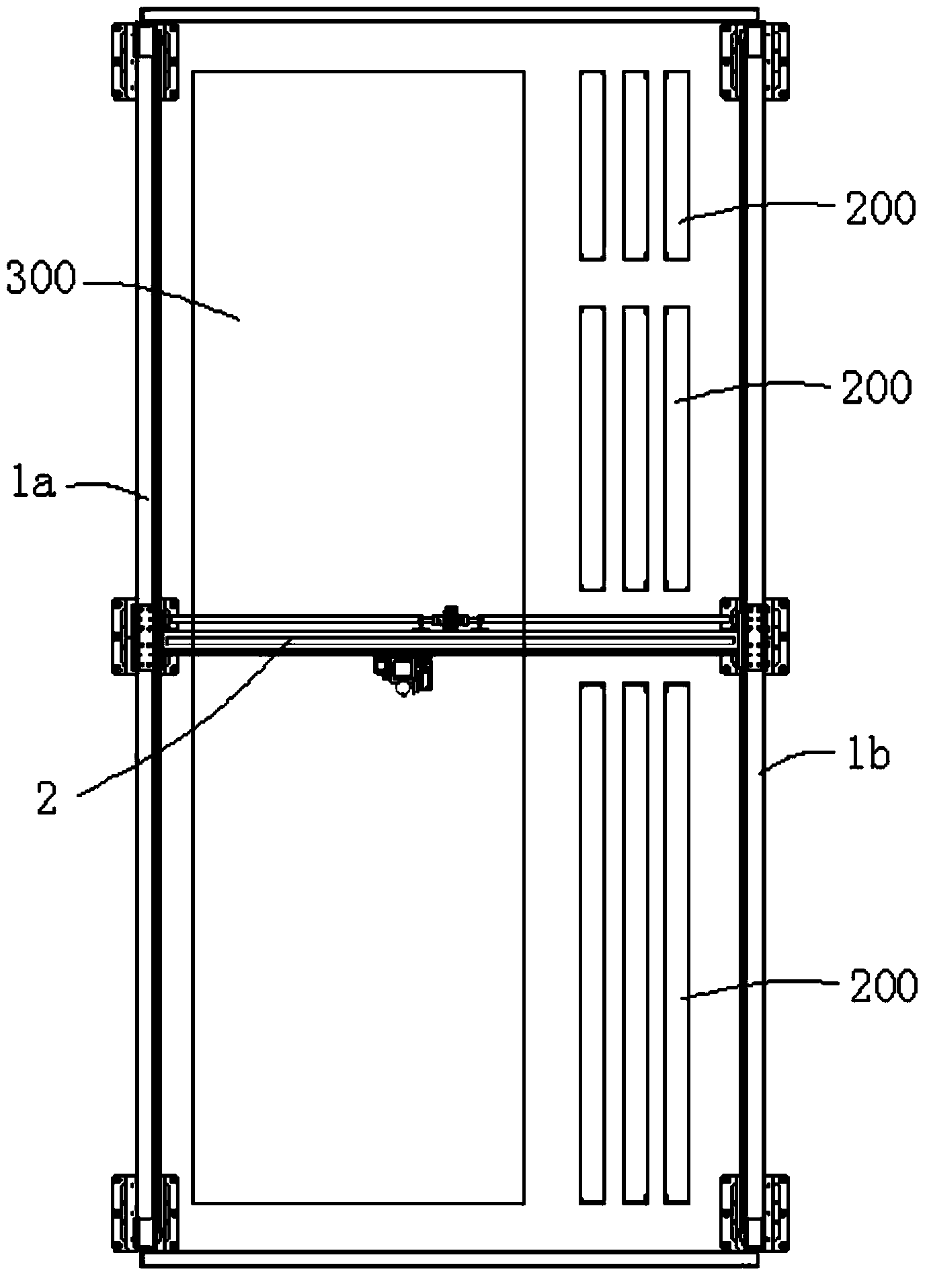

[0071] see figure 1 , image 3 , Figure 4 and Figure 9 , the present invention provides an automatic mold loading device 100, which includes a left gantry 1a and a right gantry 1b arranged longitudinally, a crossbeam 2 horizontally erected on the left gantry 1a and the right gantry 1b, an installation The mounting plate 3 on the crossbeam 2, the vertical beam 4 installed on the mounting plate 3 and vertically arranged, the manipulator 5 and the plotting device 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com