T-beam factory-like prefabricated supporting formwork system and construction method

A factory-like and systematic technology, applied in the direction of manufacturing tools, mold separation devices, ceramic molding machines, etc., can solve the problems of low construction efficiency and difficulty in ensuring the accuracy of formwork repeated assembly, shorten the construction period, reduce formwork assembly time, and improve construction efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The steel structure welding process, the bolt connection construction process, the concrete pouring construction process, etc. of this embodiment will not be repeated in this embodiment, and the embodiment of the structure related to the present invention will be focused on.

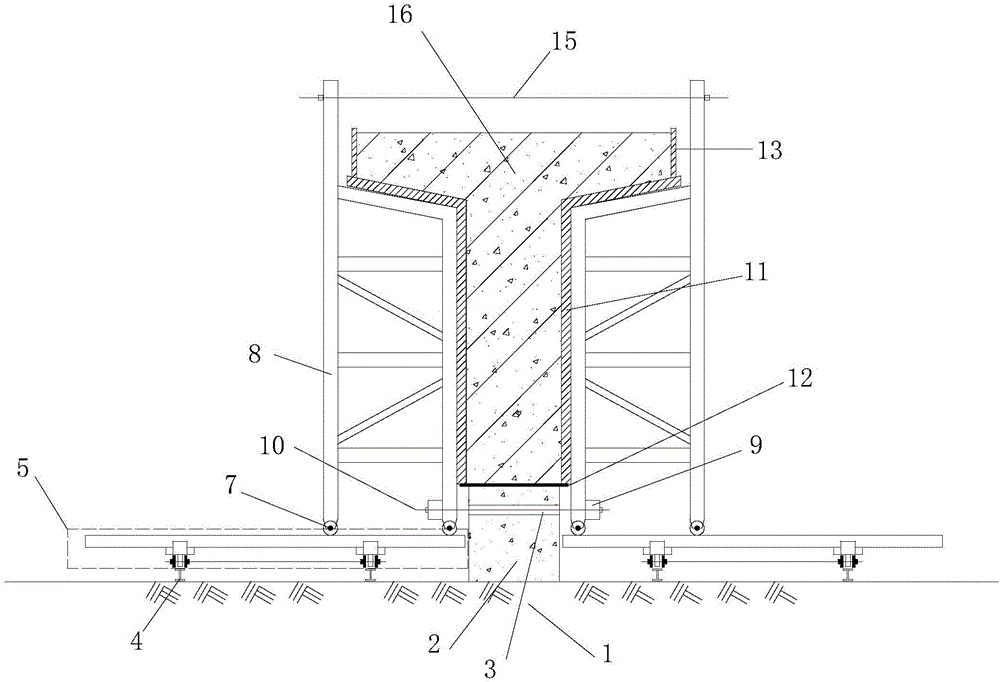

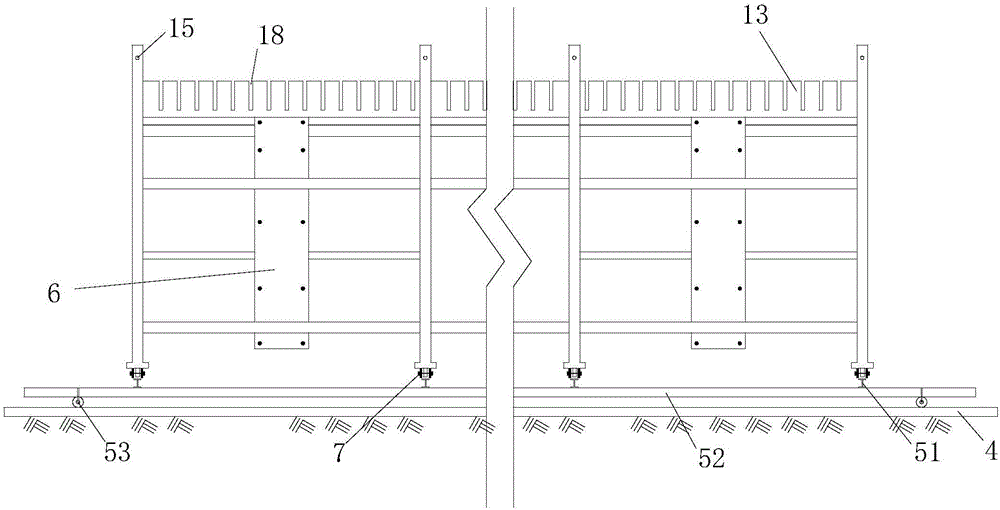

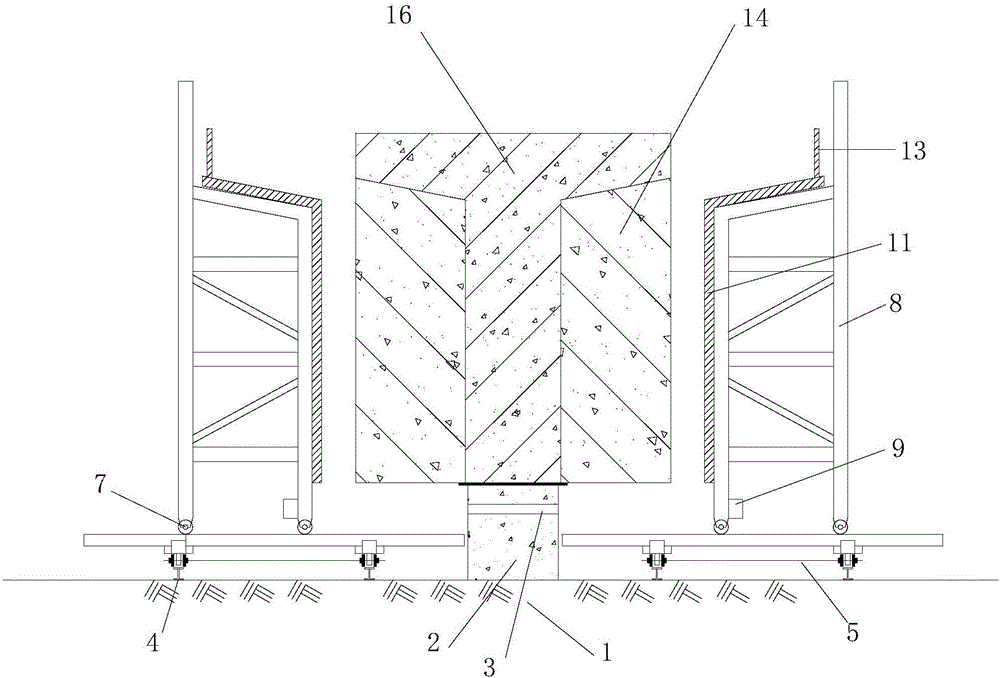

[0031] figure 1 It is a structural schematic diagram of the T-beam industrialized prefabricated formwork system of the present invention. refer to figure 1 As shown, the T-beam factory prefabricated formwork support system of the present invention mainly includes: pedestal (2), longitudinal movement platform (5), wing plate formwork (6), formwork back frame (8), longitudinal rail (4), transverse movement Track (51), bottom formwork (12), web side formwork (11), top plate formwork (13).

[0032] refer to figure 1 As shown, the pedestal (2) is pre-embedded PVC pipe (3) evenly along the longitudinal direction of the T-beam, and the bottom formwork (12) is arranged on the top of the pedestal (2); t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com