Vehicle-mounted lifting device

A lifting device and guiding device technology, applied in the direction of lifting device, etc., can solve the problems of motor current and voltage instability, circuit damage, motor drive consumes large electric energy, etc., and achieve the effect of improving loading and unloading efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

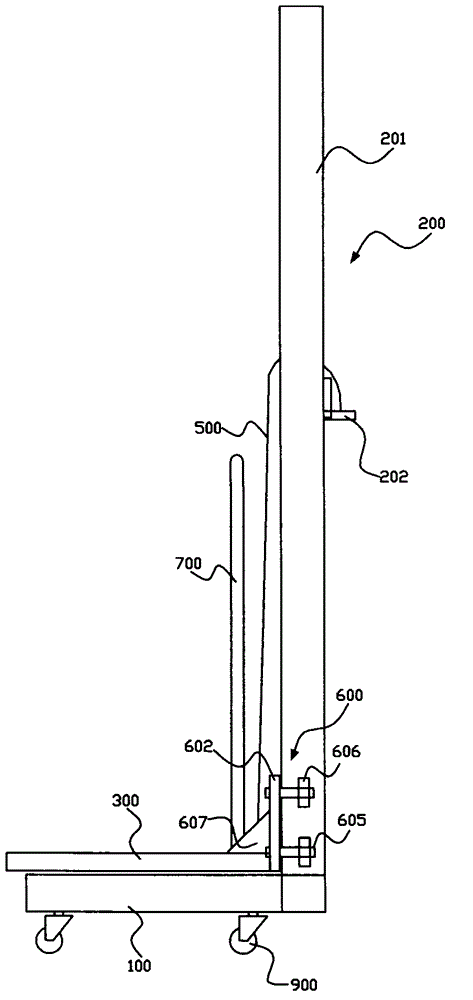

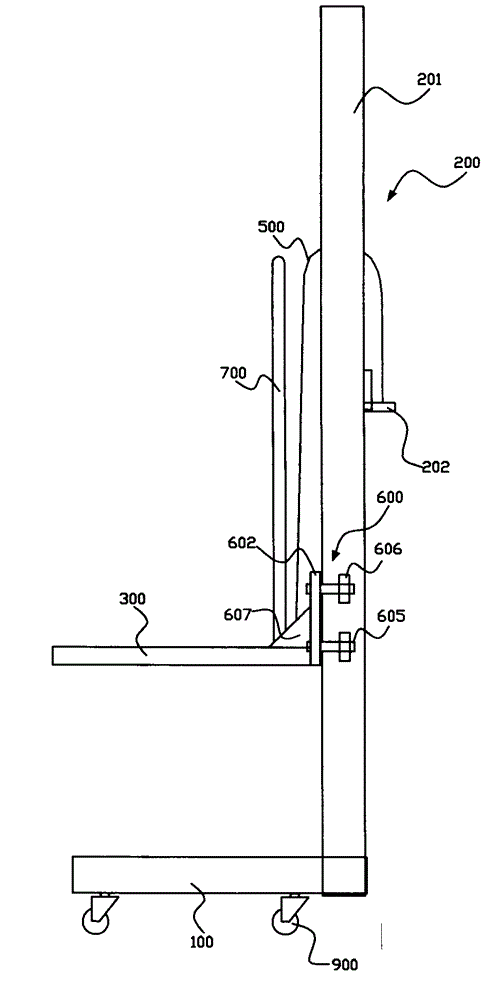

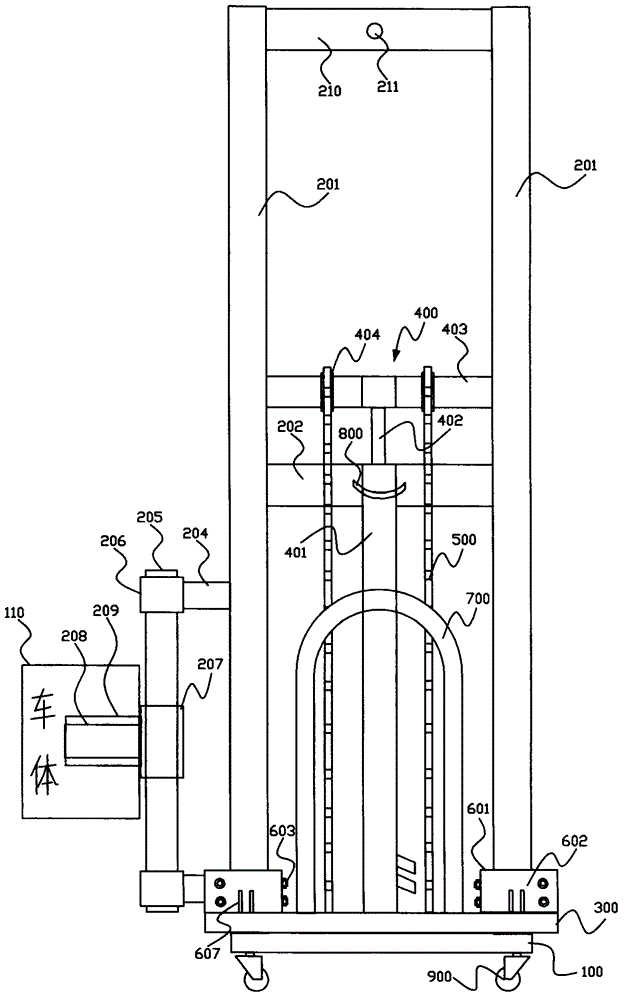

[0034] Such as Figure 1 to Figure 8 A vehicle-mounted lifting device according to an embodiment of the present invention is schematically shown, which includes a base 100 , a bracket 200 , a lifting plate 300 , a hydraulic device 400 and two chains 500 . The base 100 is located at the bottom of the vehicle-mounted lifting device, and the base 100 is a rectangular frame. The bracket 200 is fixed on one side of the base 100. The bracket 200 includes two side columns 201 and a horizontal beam 202. A groove 203 is arranged on the opposite inner side of the two side columns 201. The two ends of the beam 202 are respectively fixed on on the two jambs 201 . The lifting plate 300 is located above the base 100, and the lifting plate 300 is used to place the heavy object to be lifted. The side of the lifting plate 300 adjacent to the bracket 200 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com