Patents

Literature

66results about How to "Full range of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

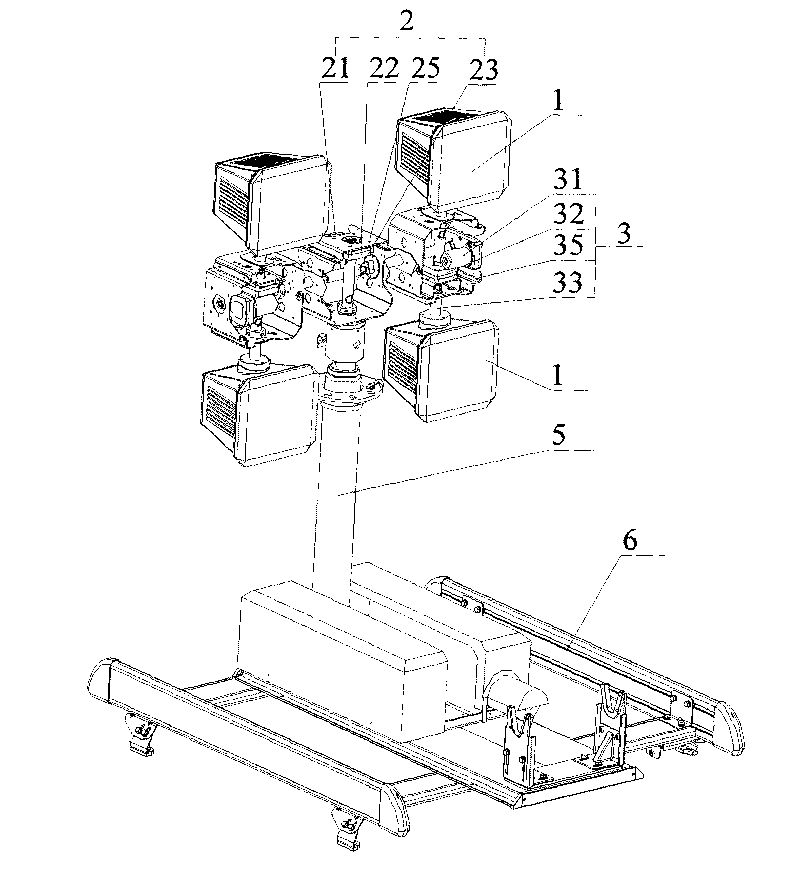

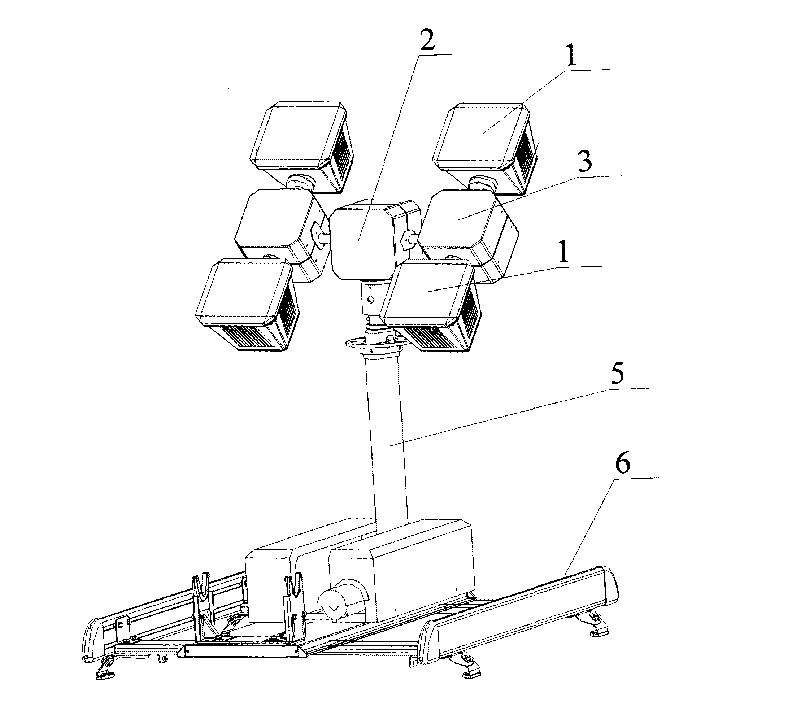

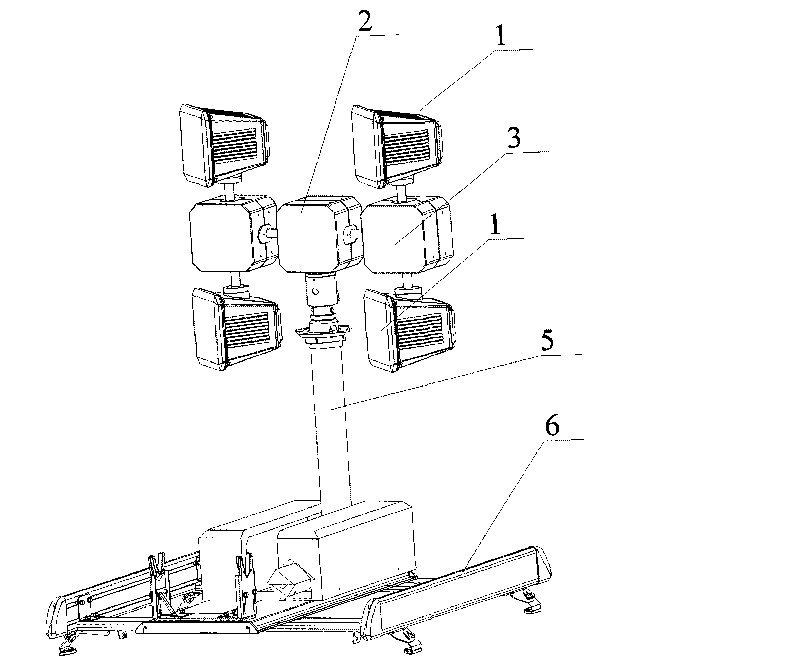

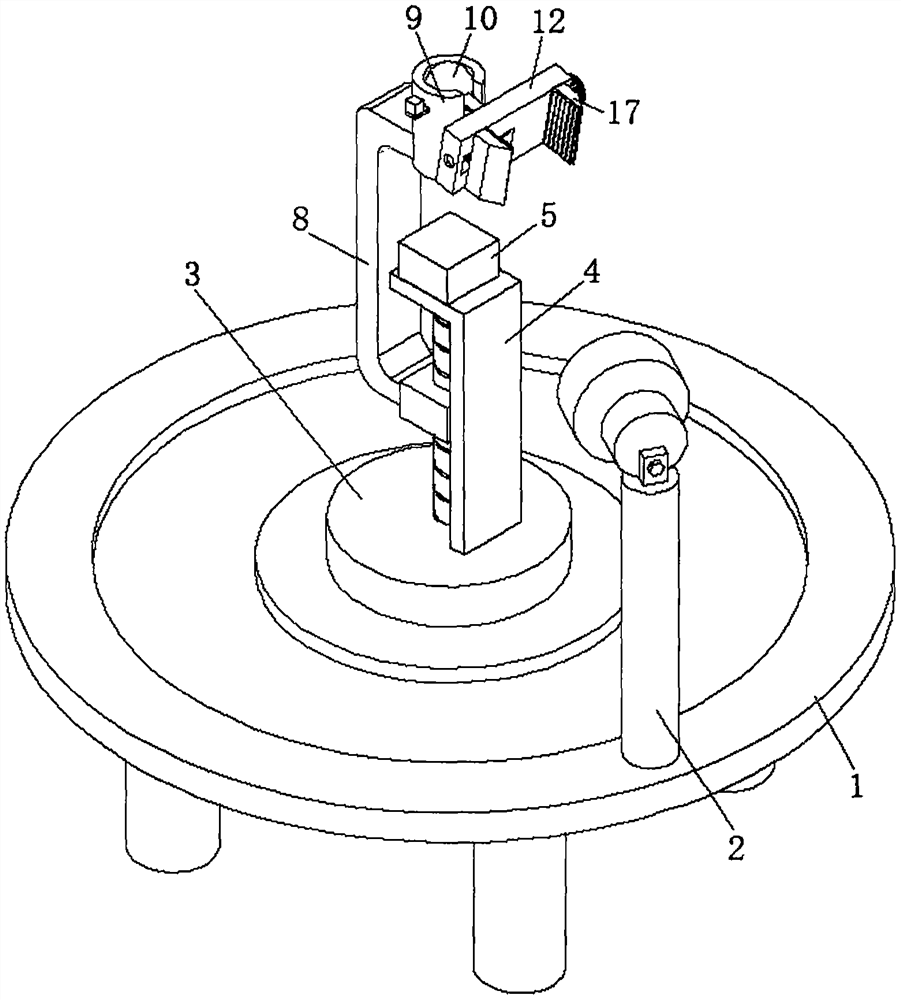

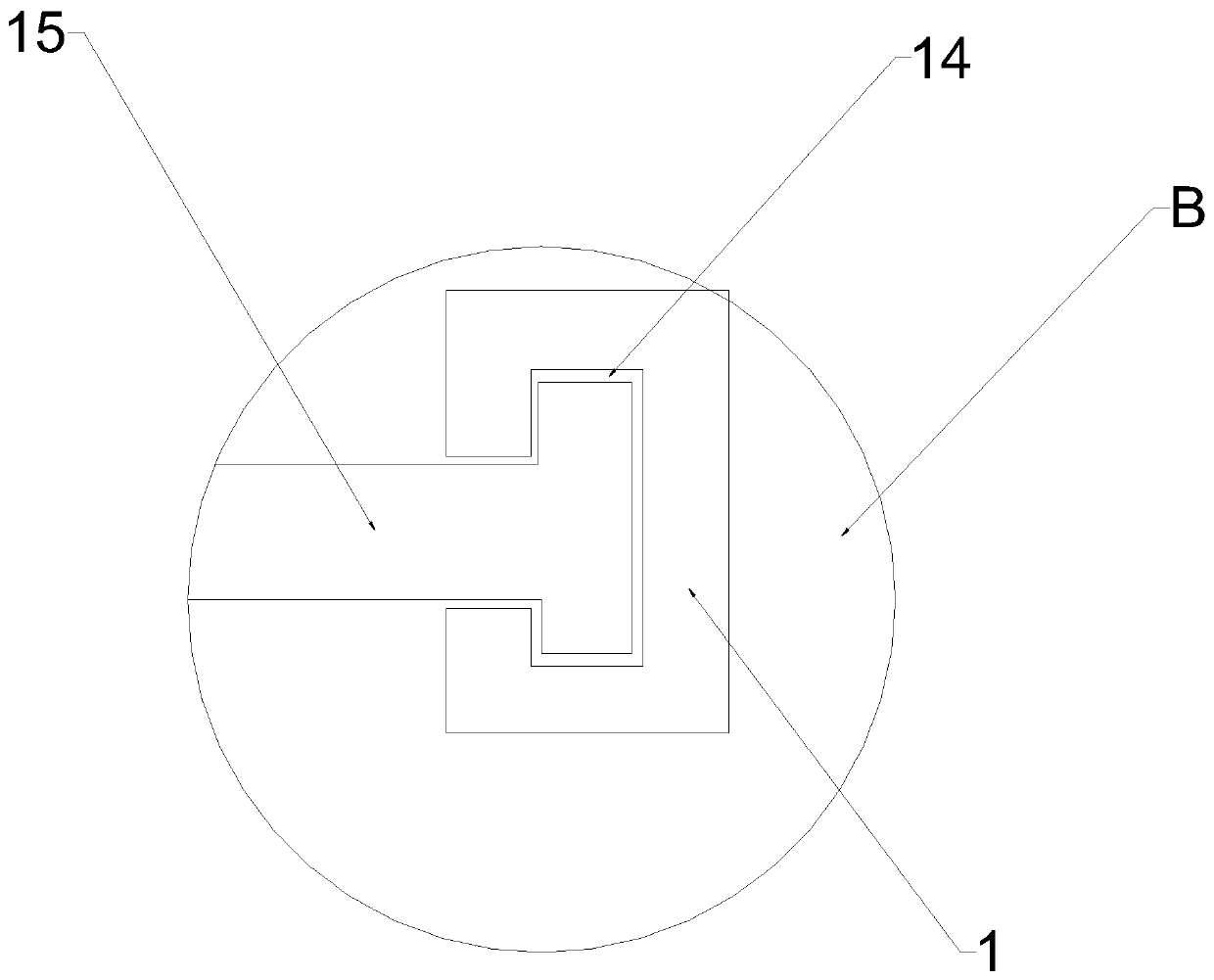

Omnidirectional rotating lamp

InactiveCN101761889AFull range of rotationFull rotationElectric circuit arrangementsElectric lightingIrradiationTripod head

The invention discloses an omindirectional rotating lamp which comprises a lamp main body connected with a holder mechanism. The holder mechanism which drives the lamp main body to realize omindirectional rotation comprises a control device and at least two holders, wherein the two holders are connected together in a rotating manner, one is a main holder, and the other is an auxiliary holder. The auxiliary holder is connected with the lamp main body in a rotating manner to drive the lamp main body to rotate at 360 DEG, and the main holder is connected with the auxiliary holder in a rotating manner to drive the auxiliary holder to rotate at 360 DEG. Both the main holder and the auxiliary holder are connected with the control device which respectively controls rotating angles of the lamp main body and the auxiliary holder in two vertical directions. The provided omindirectional rotating lamp has the advantages of simple structure, small volume, simple as well as convenient operation, no dead corners for irradiation and omindirectional adjustment.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

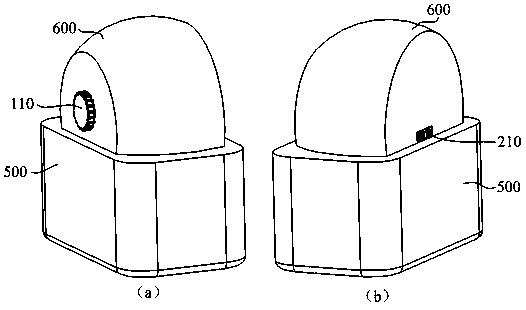

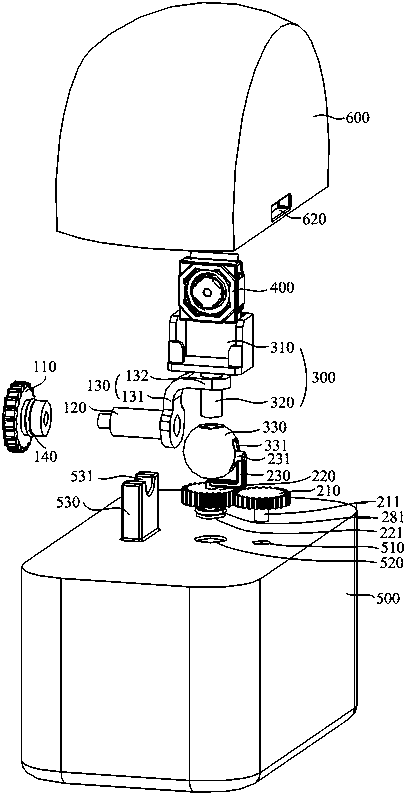

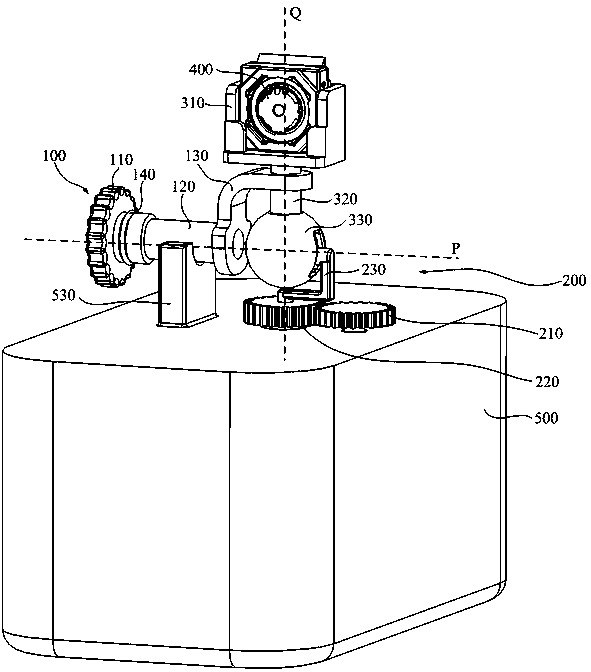

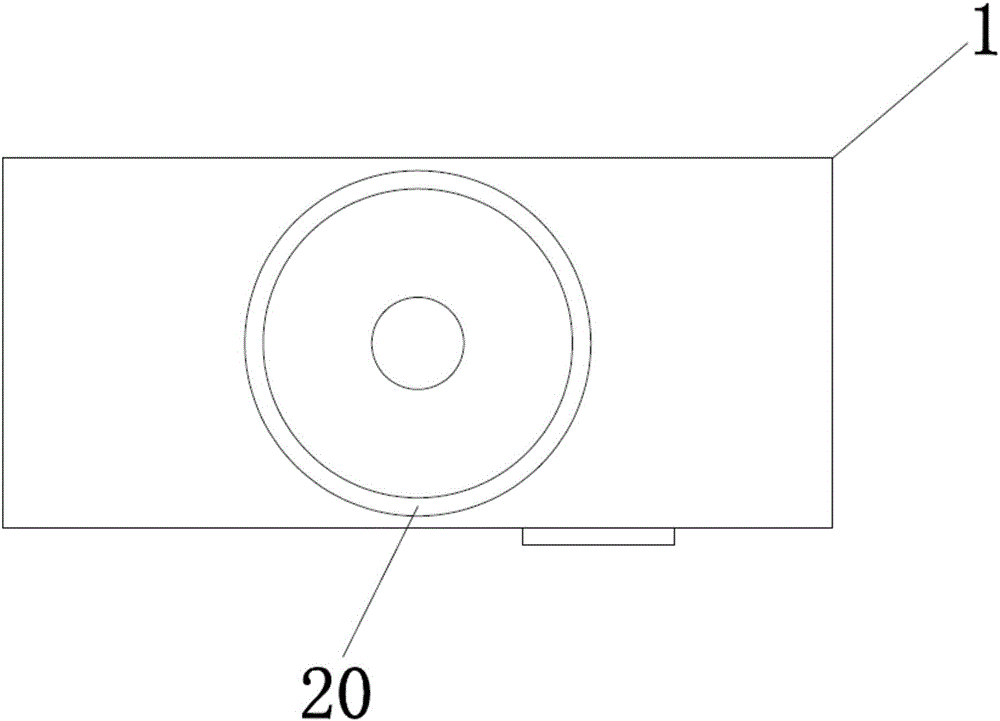

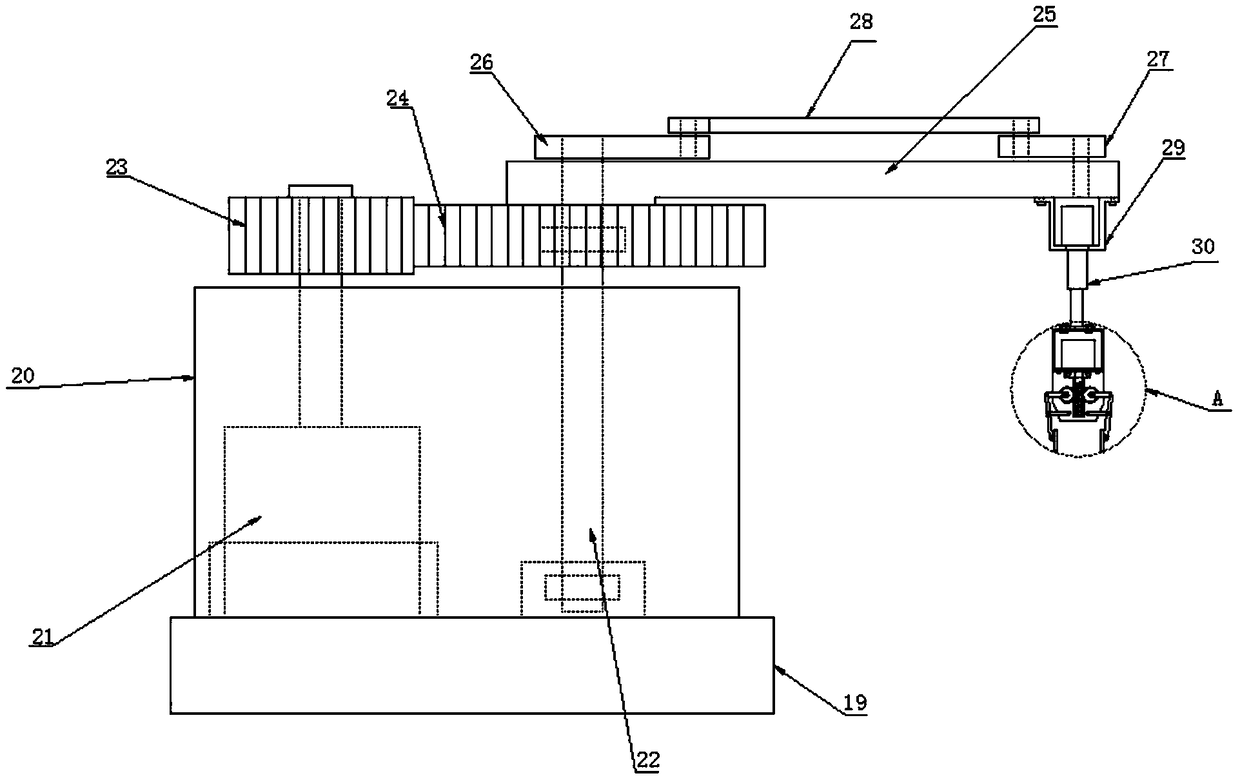

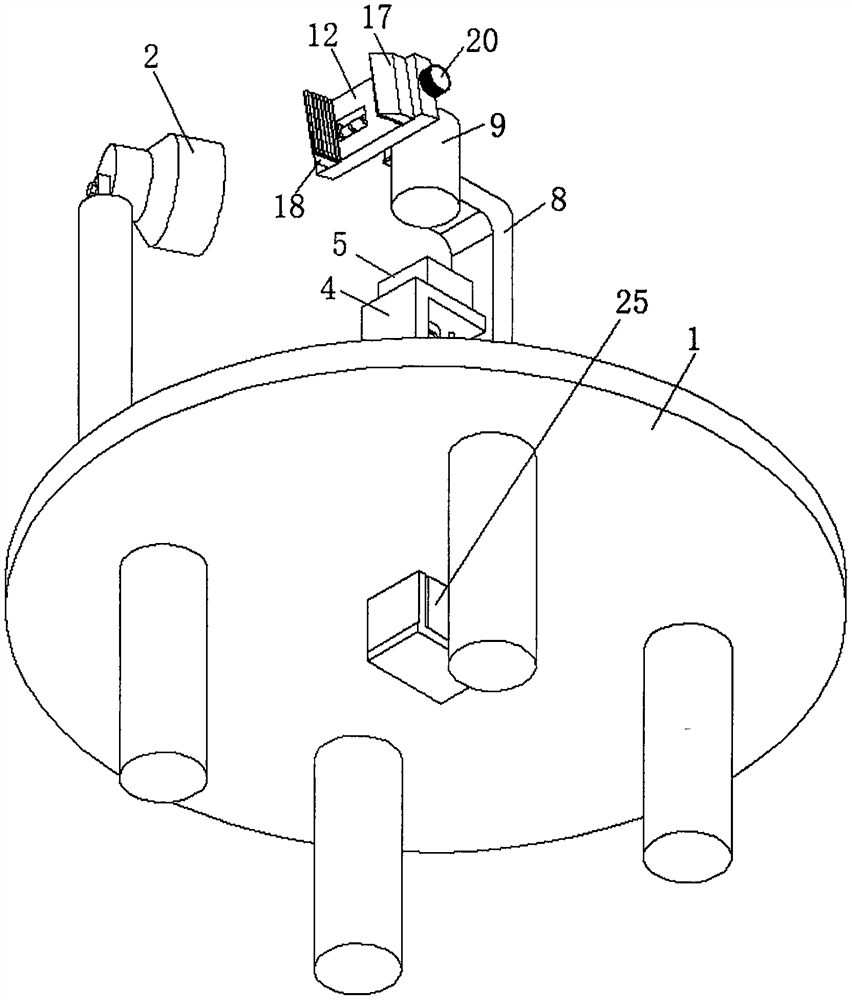

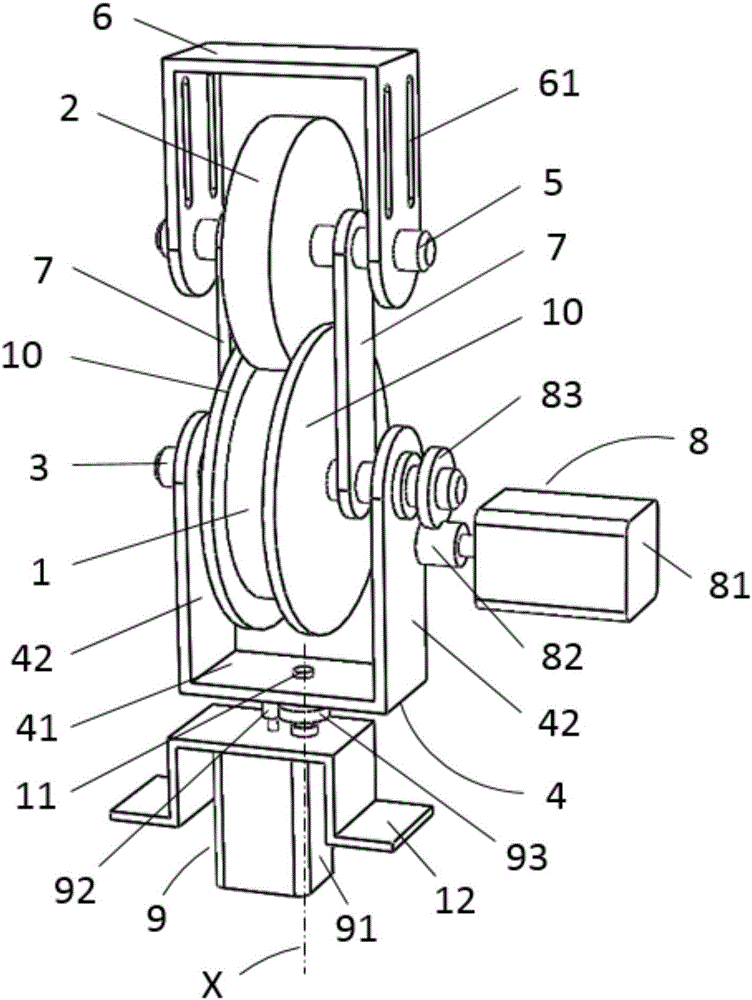

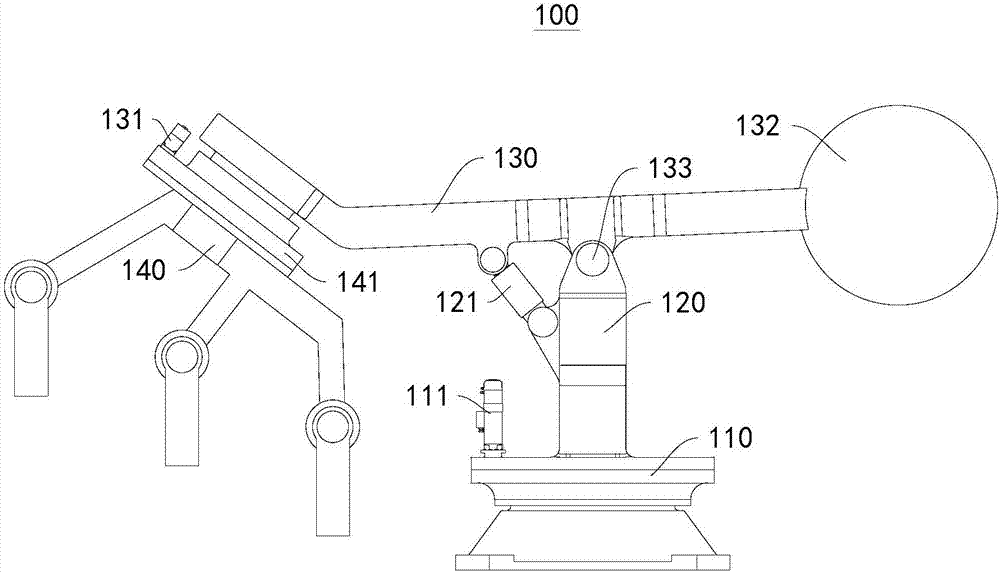

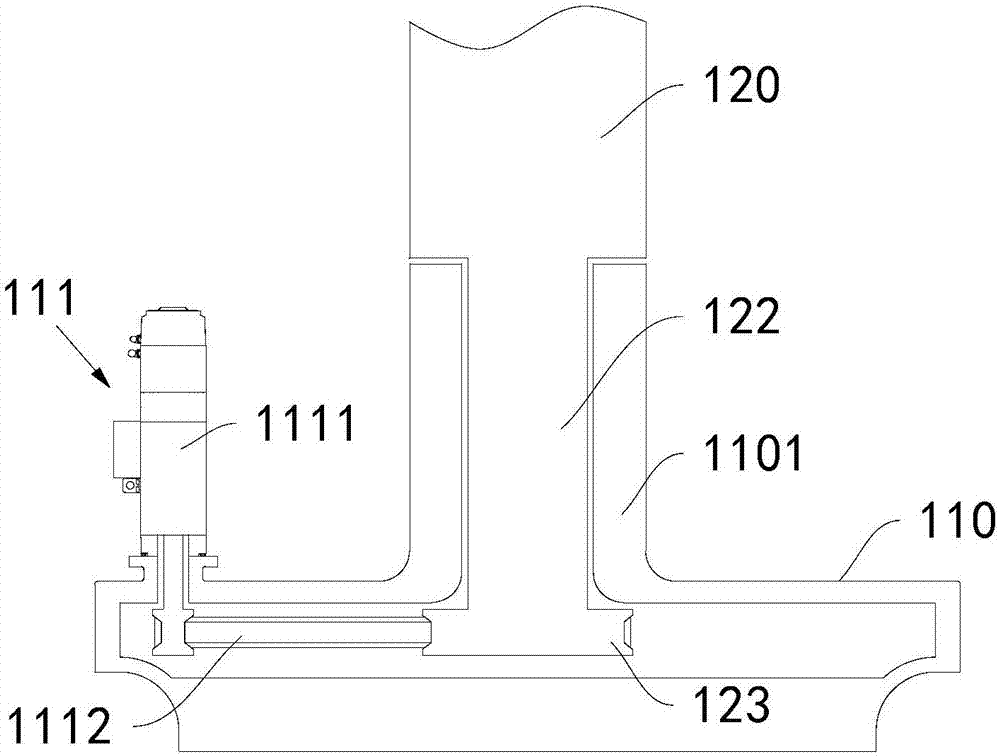

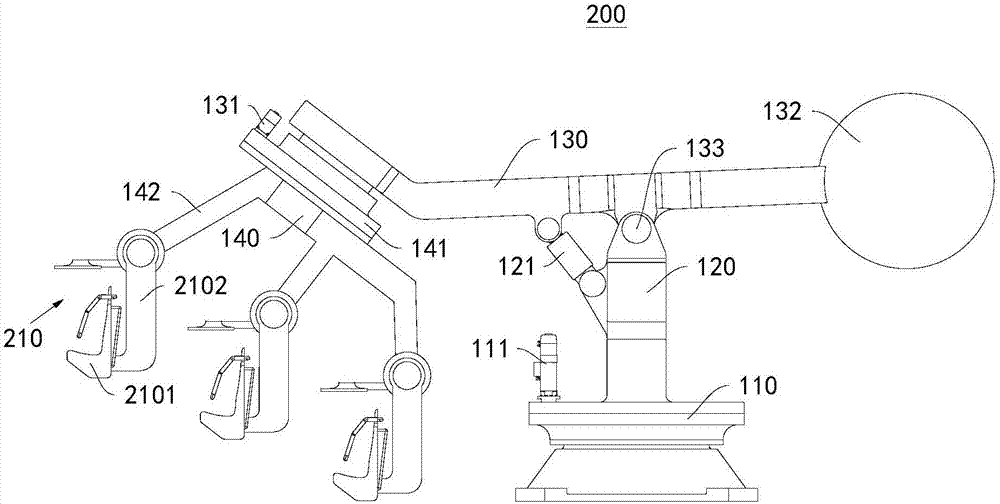

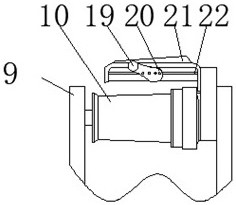

Rotary camera device

InactiveCN110195811AFull range of rotationEasy to useTelevision system detailsColor television detailsHorizontal axisEngineering

The invention discloses a rotary camera device. The device comprises a support, a camera, a horizontal driving assembly and a vertical driving assembly. The camera is arranged on the support, the horizontal driving assembly is connected with the support, and drives the support to rotate around a horizontal axis, so that the camera can rotate around the horizontal axis; and the vertical driving assembly is connected with the support, and drives the support to rotate around a vertical axis so as to realize the rotation of the camera around the vertical axis. The horizontal driving assembly and the vertical driving assembly are mutually independent and can be independently adjusted, so that omni-directional rotation of the camera is realized, and the camera is convenient to use.

Owner:GEER TECH CO LTD

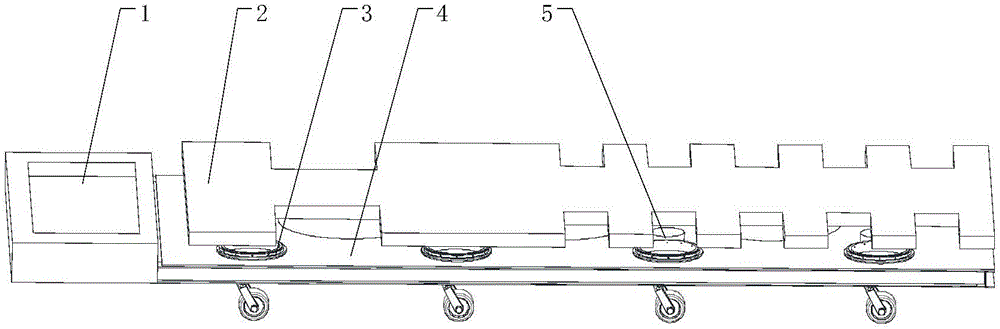

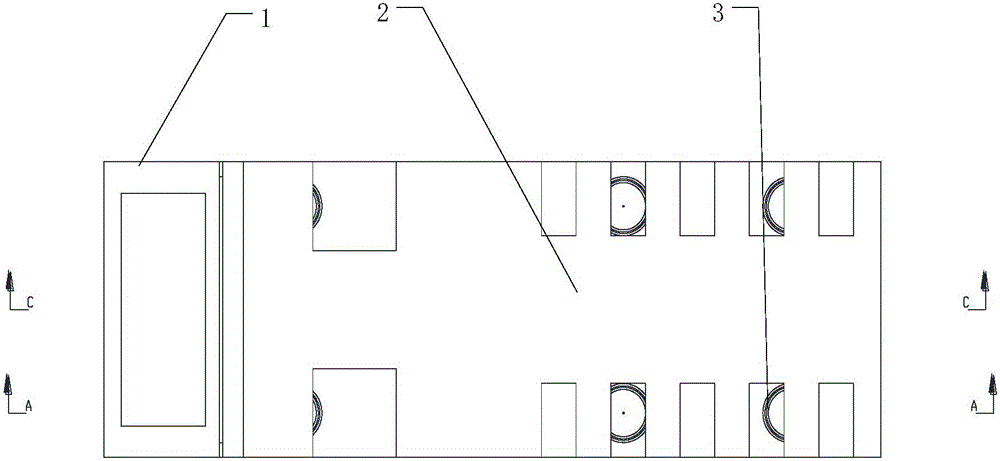

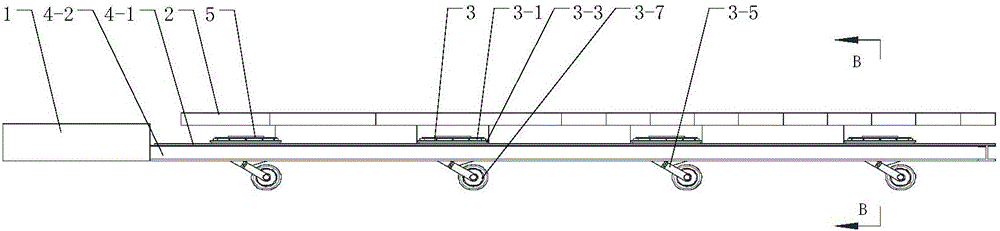

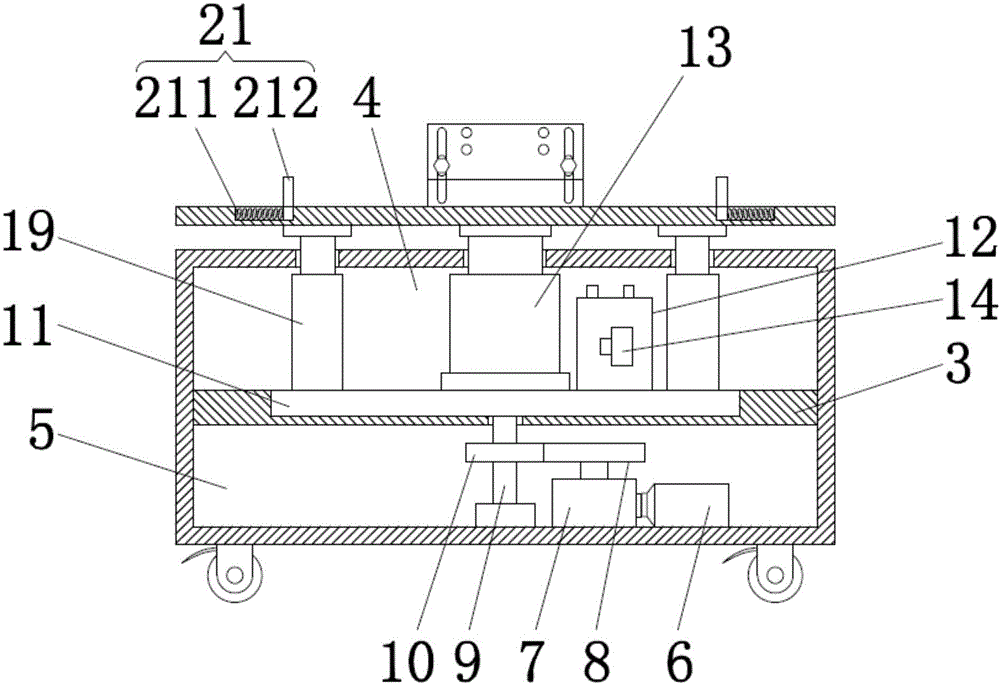

All-directional moving and high-low lifting carrying AGV car with comb teeth

The invention discloses an all-directional moving and high-low lifting carrying AGV car with comb teeth. The carrying AGV car consists of an electric control box, a comb tooth bearing plate, lifting disc mechanisms, a machine body support frame and steering mechanisms, wherein at least eight lifting disc mechanisms are provided, and are symmetrically positioned in lifting disc fixed holes formed in a fixed baseplate of the machine body support frame in two lines and multiple rows; multiple projected columnar bodies are arranged on the lower plane of the comb tooth bearing plate, and are mounted in comb tooth fixed holes formed in the upper plane of the fixed baseplate of the machine body support frame; the steering mechanisms are positioned in steering motor fixed holes formed in the fixed baseplate of the machine body support frame corresponding to the inner sides of the lifting disc mechanisms, and are engaged with the lifting disc mechanisms; and the electric control box is arranged at one end of the machine body support frame, is electrically connected with the lifting disc mechanisms and the steering mechanisms, and realizes control of the lifting disc mechanisms and the steering mechanisms. The carrying AGV car realizes all-directional movement and machine body lifting by using matching between the lifting disc mechanisms and the steering mechanisms, and has the advantages of scientific design, reasonable structure, flexible movement and high bearing capacity.

Owner:JIANGSU UNIV OF SCI & TECH

Rotary telescopic mechanical arm capable of rotating omni-directionally

ActiveCN106182080AReliable transmissionAchieve scaleProgramme-controlled manipulatorArmsRobotic armEngineering

Owner:南京宁信安躿医疗科技有限公司

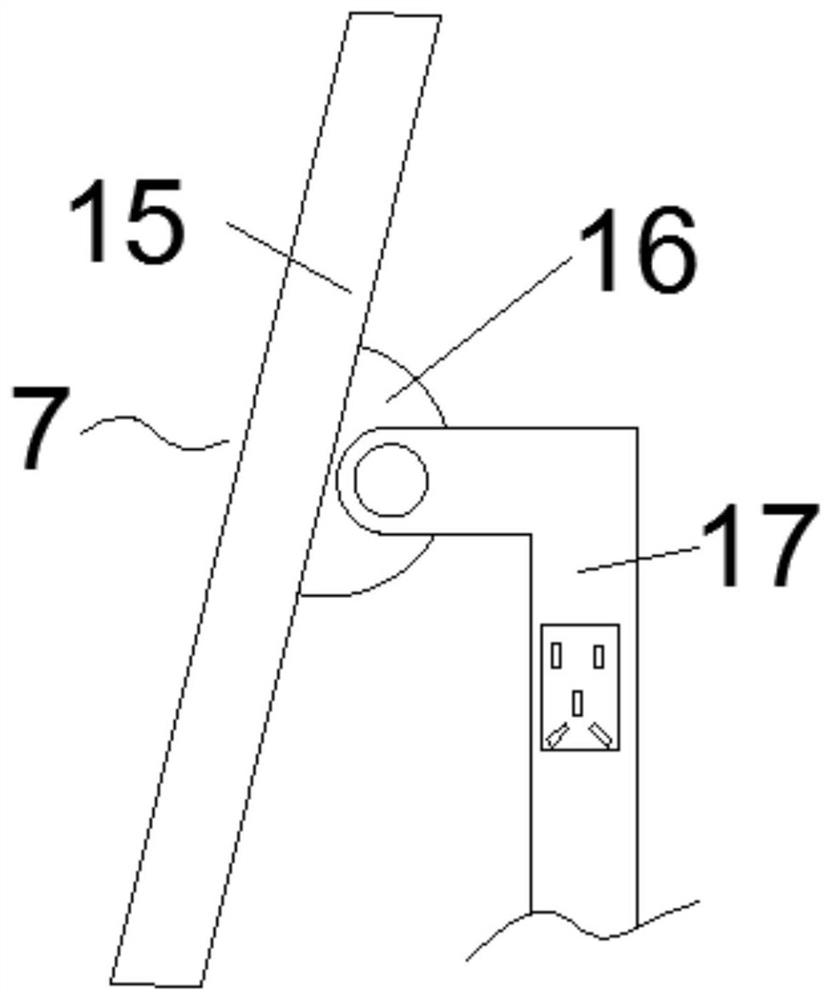

All-directional rotating type display screen bracket and display screen thereof

InactiveCN107524899AEasy to operateReasonable structural designStands/trestlesFluid-pressure actuator componentsHydraulic cylinderReducer

The invention discloses an all-directional rotating type display screen bracket. The all-directional rotating type display screen bracket comprises a base; a PLC is fixedly installed on the outer side wall of the base; an inner cavity of the base is divided into an upper bin chamber and a lower bin chamber by a partition plate; an output shaft of the motor is in transmission connection with an input shaft of a speed reducer; a driving gear is in engagement connection with a driven gear; a rotary rod penetrates through the partition plate and is fixedly connected with the middle of a rotary disc; a hydraulic driving device and a hydraulic cylinder are fixedly installed on the rotary disc, and a piston rod of the hydraulic cylinder penetrates through a top plate of the base and is fixedly connected with an installation plate; and a fixing mechanism is fixedly arranged on the installation plate. The invention further discloses a display screen. The display screen comprises the display screen bracket. According to the display screen, by arranging the display screen bracket used for the display screen, the structural design is reasonable, the display screen is firmly fixed, operation is convenient, the height of the display screen can be adjusted, all-directional rotating can be achieved, and the display screen bracket is worthy of popularization.

Owner:海南同诺文化科技有限公司

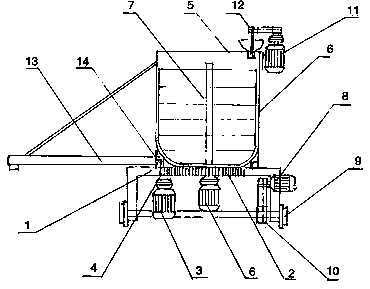

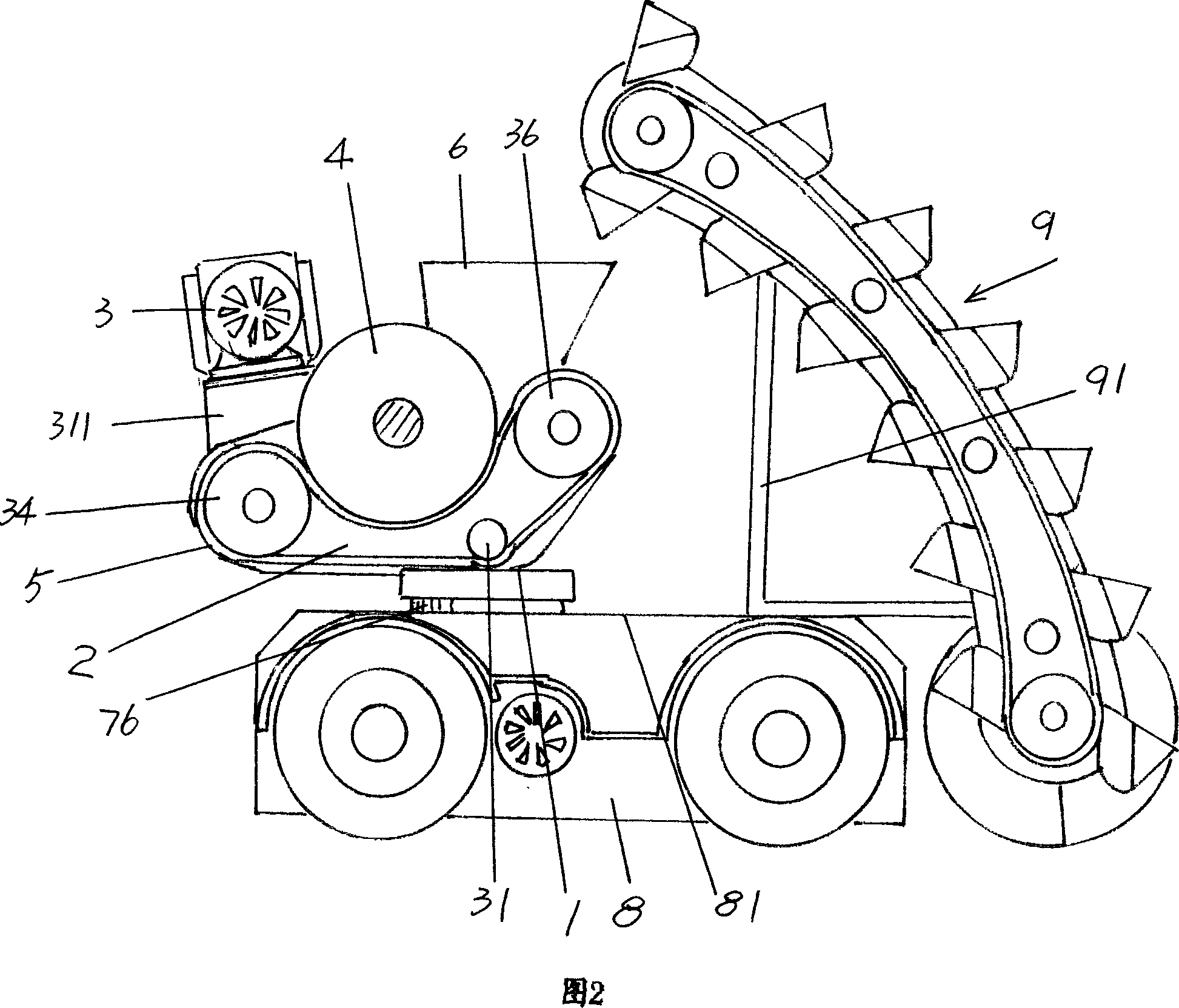

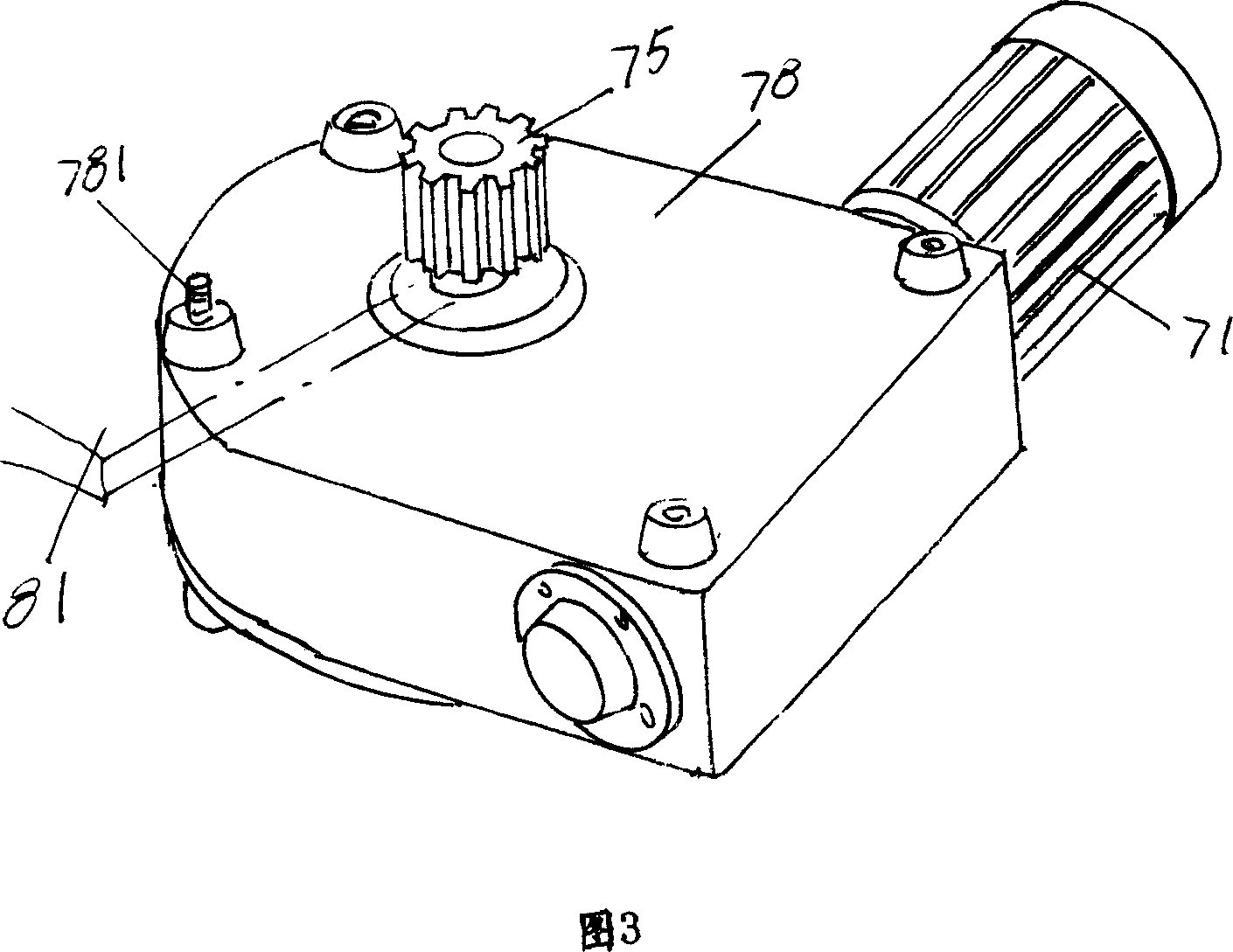

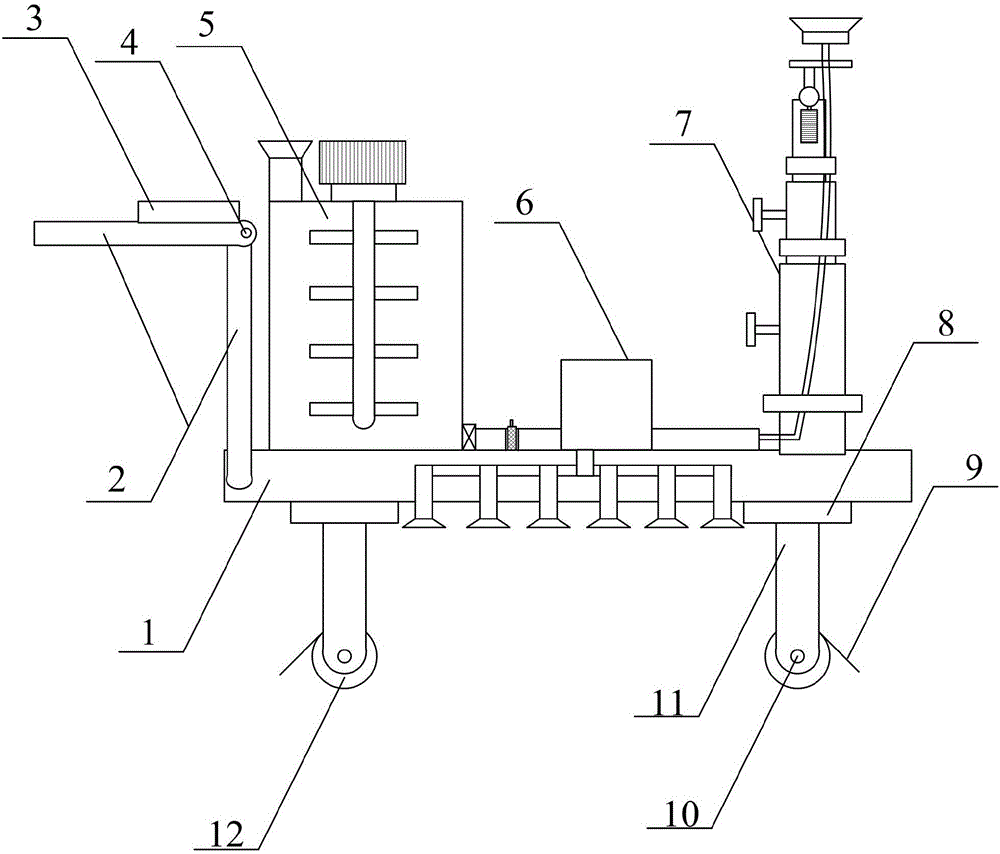

Rail-mounted omnidirectional rotation, agitation and pouring all-in-one machine

InactiveCN103817799AFull range of rotationTake advantage ofCement mixing apparatusOmnidirectional antennaGear wheel

A rail-mounted omnidirectional rotation, agitation and pouring all-in-one machine comprises a chassis with four travel wheels; a rotary toothed ring is arranged at the bottom of an agitation tank and meshed with a motor gear; an agitation shaft is arranged in the center of the agitation tank and connected with a main power motor; a material distributor is arranged at the upper part of the agitation tank and connected with a leather belt of a material distribution motor; a motor is arranged on the chassis with the four travel wheels and connected with a chain of a spindle chain wheel; a material distribution pipe is arranged on one side of the agitation tank and communicated and connected with the agitation tank. The rail-mounted omnidirectional rotation, agitation and pouring all-in-one machine combines agitation and pouring, can move back and forth along a rail, can rotate in all directions, can effectively utilize field space, saves manpower, improves production efficiency, is convenient and flexible to use, and is particularly suitable for being chosen and used by building block manufacturing enterprises.

Owner:闫瑞国

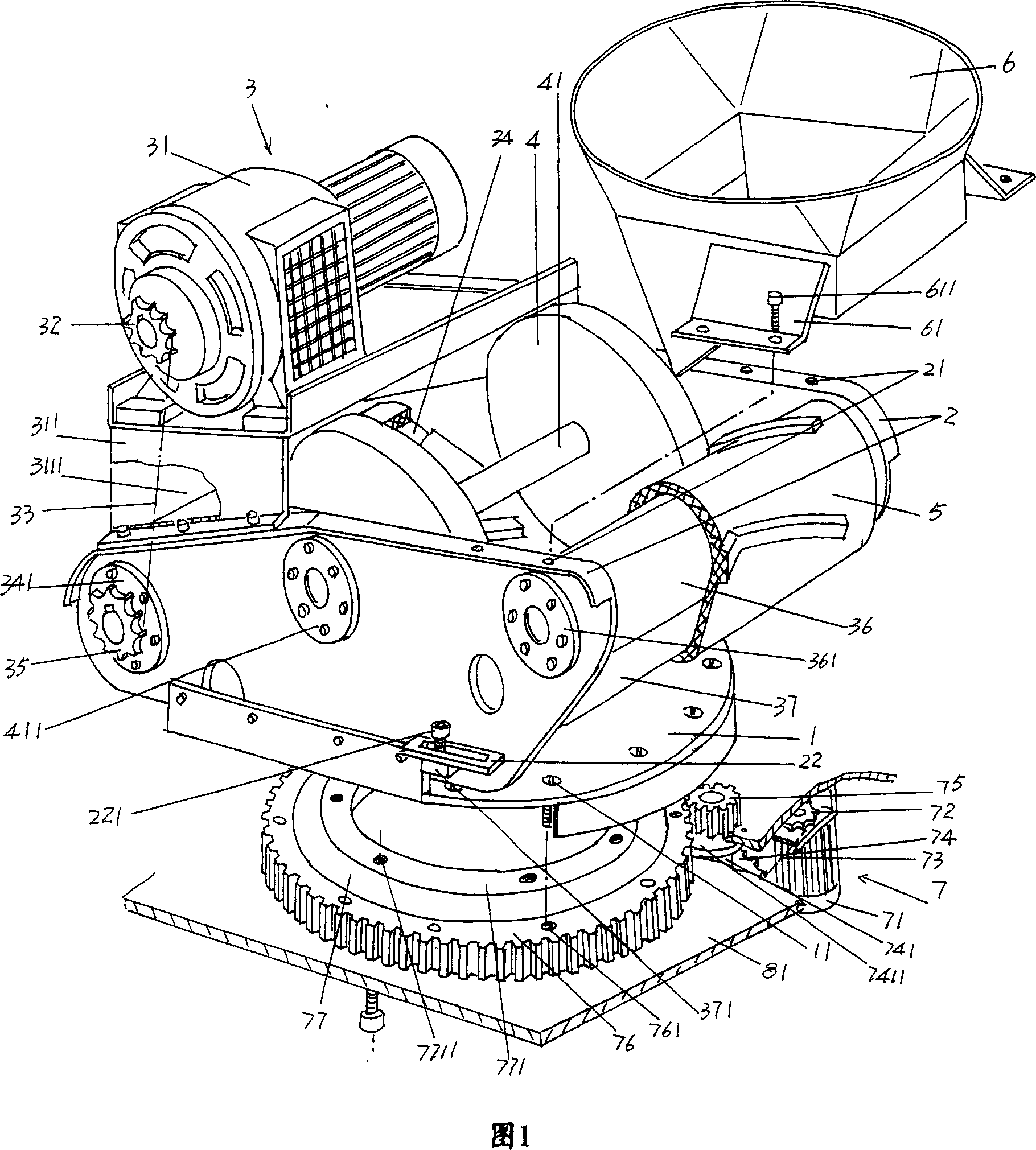

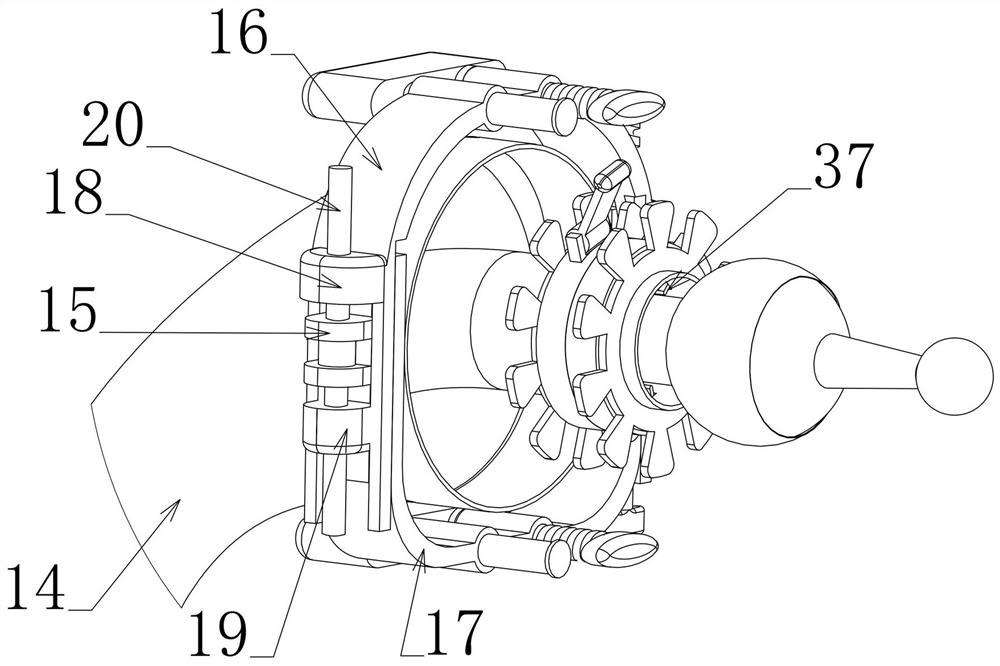

Throwing mechanism for cabin cleaning vehicle

InactiveCN101016118AEnsure safetyFull range of rotationThrowing machinesGearingTransmitterRolling chassis

The invention relates to a throwing device of chamber cleaner, used in dock or the like, comprising a base fixed on the chassis of cleaner, a support extended on the base, a power transmitter carried on a support couple, a throwing band combined on the power transmitter to form a transmission plane driven by the power transmitter, a press band wheel axially arranged on the support couple to press the throwing band, and a hopper fixed on the support hopper to feed the material of feeding device onto the throwing band. The invention can use hopper to throw material on the throwing band to one position to be stacked to be caught by claw, without man operation, while the rotator can realize 360 rotation of device.

Owner:常熟市诚达港务机械设备厂

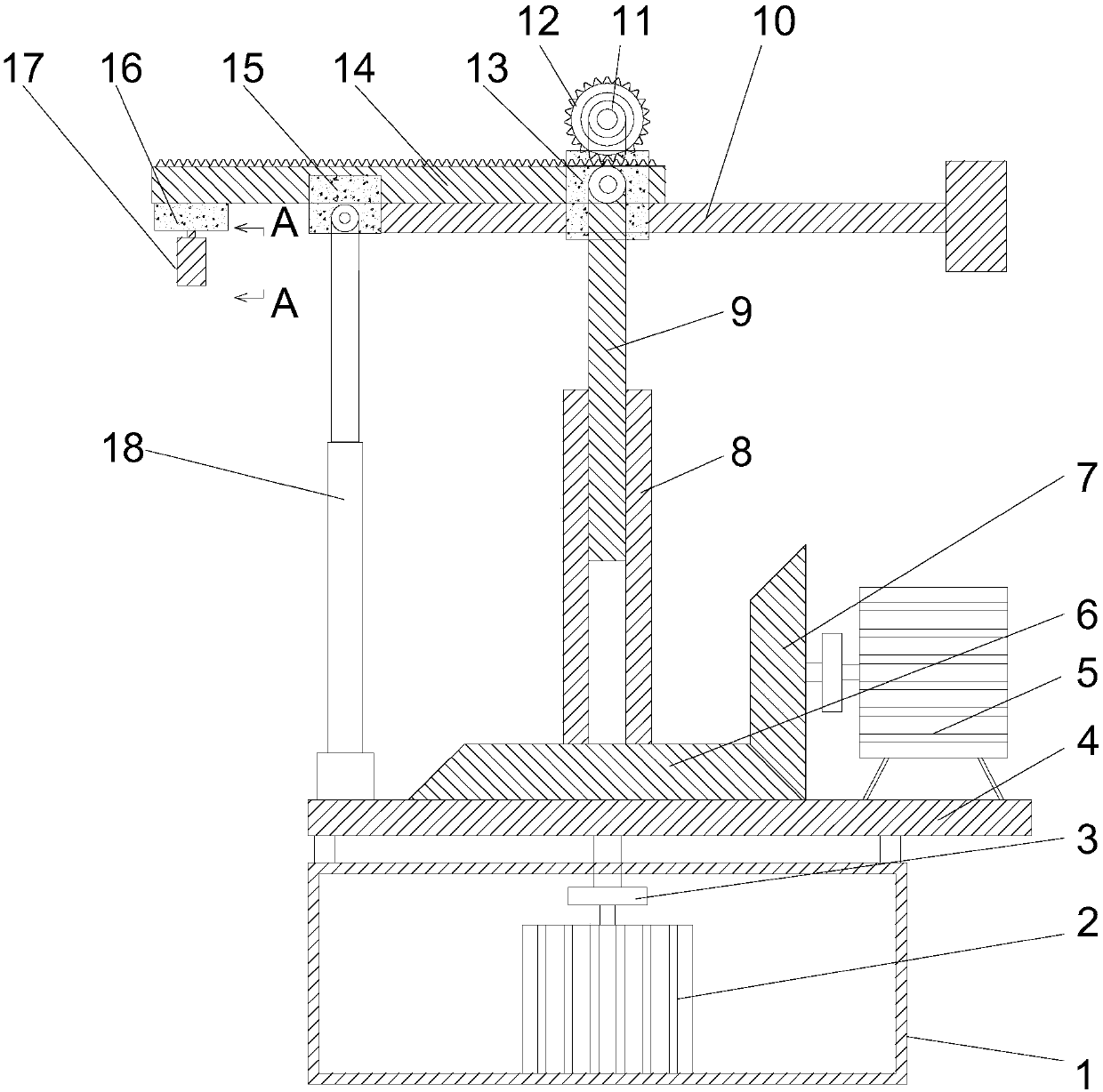

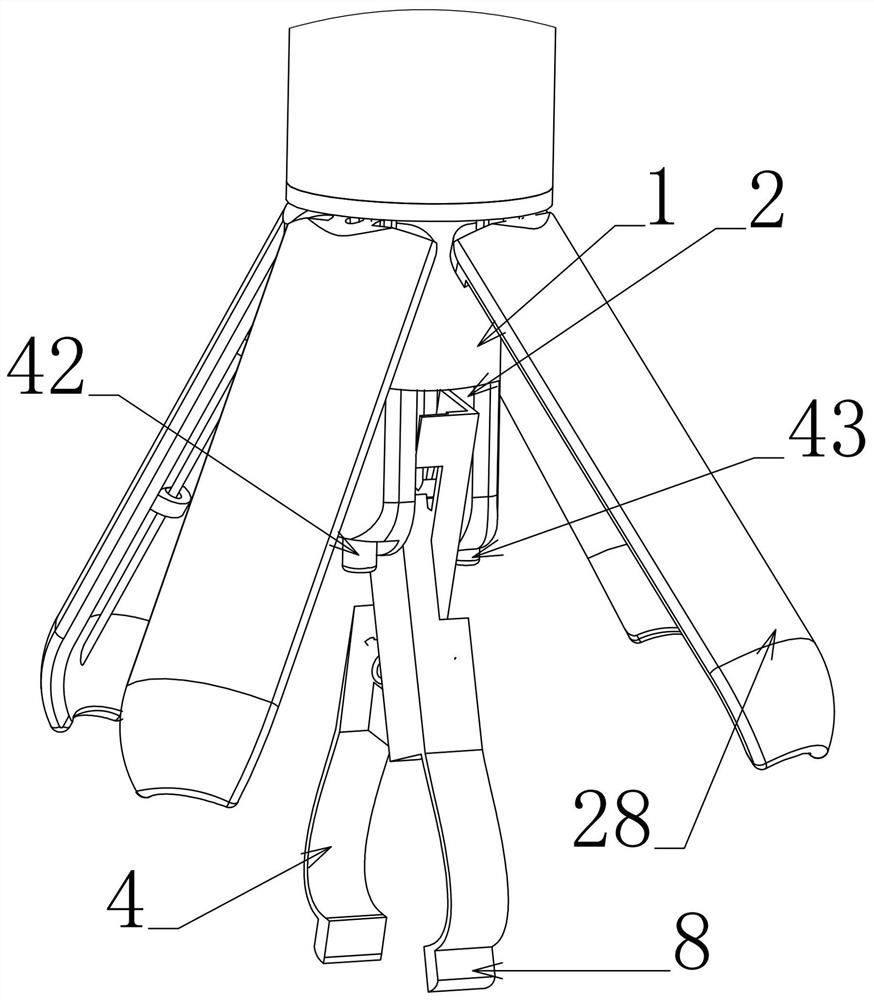

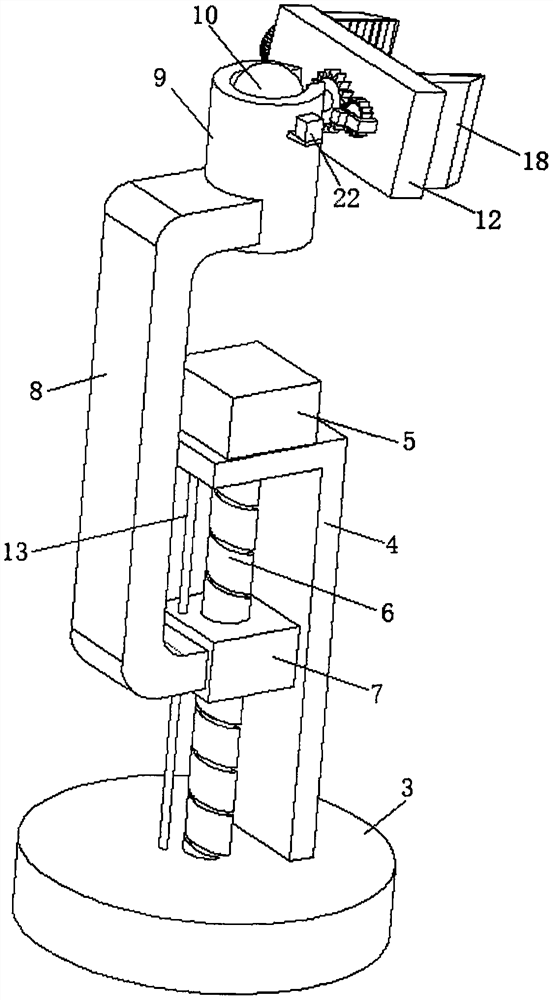

Three-axle manipulator

InactiveCN108044617AFull range of rotationEasy maintenanceProgramme-controlled manipulatorEngineeringManipulator

The invention discloses a three-axle manipulator. The three-axle manipulator consists of a mounting base, a rotating motor, a gearbox, a turntable, a lifting motor, a driven bevel gear, a driving bevel gear, a lead screw sleeve, a lead screw, a balance rod, a motor A, a driving gear, a transverse arm sleeve, a transverse arm, a support block, a hydraulic rod A, a jaw and a hydraulic rod B; the turntable can realize all-directional rotation on an XY plane under the effect of a rotating shop; through rotation of the lifting motor, the lead screw is driven to move up and down in the lead screw sleeve to realize upward movement of a Z axle; the transverse arm slides on the driving gear to realize movement in a Y-axle direction; a balance rod is mounted at the bottom of the transverse arm to conveniently control balance of the three-axle manipulator; and the three-axle manipulator uses the lead screw and the gear for transmission, and is convenient to maintain and less in cost and maintenance time.

Owner:XINGUANG NUMERICAL CONTROL TECH

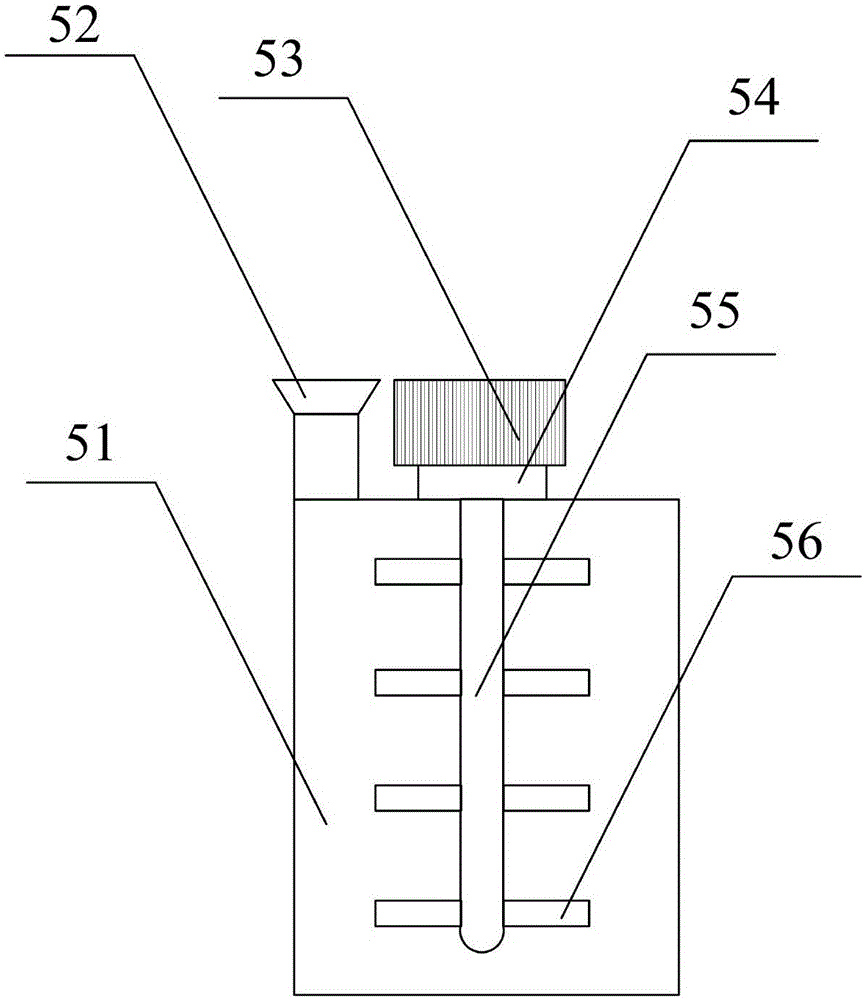

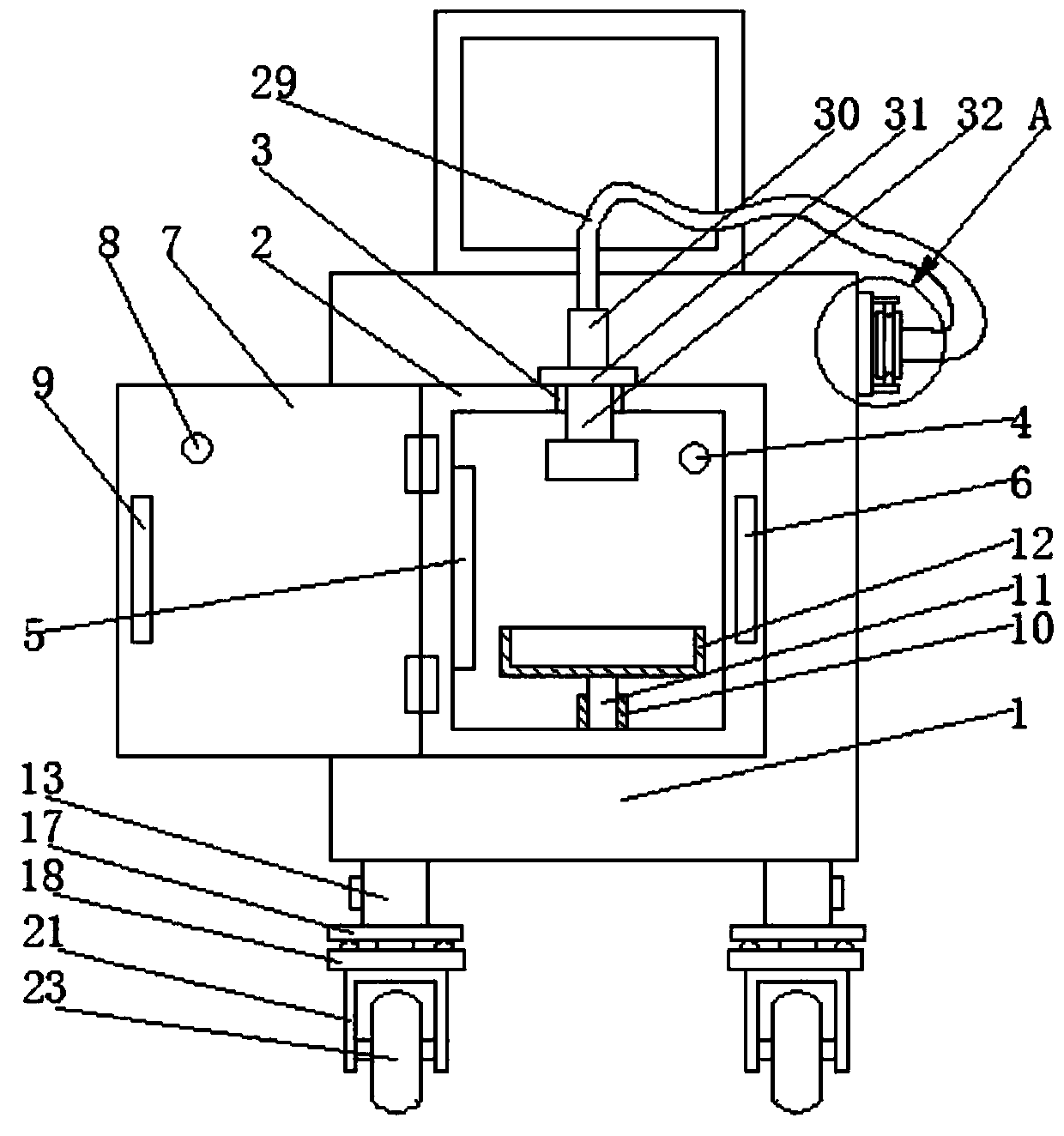

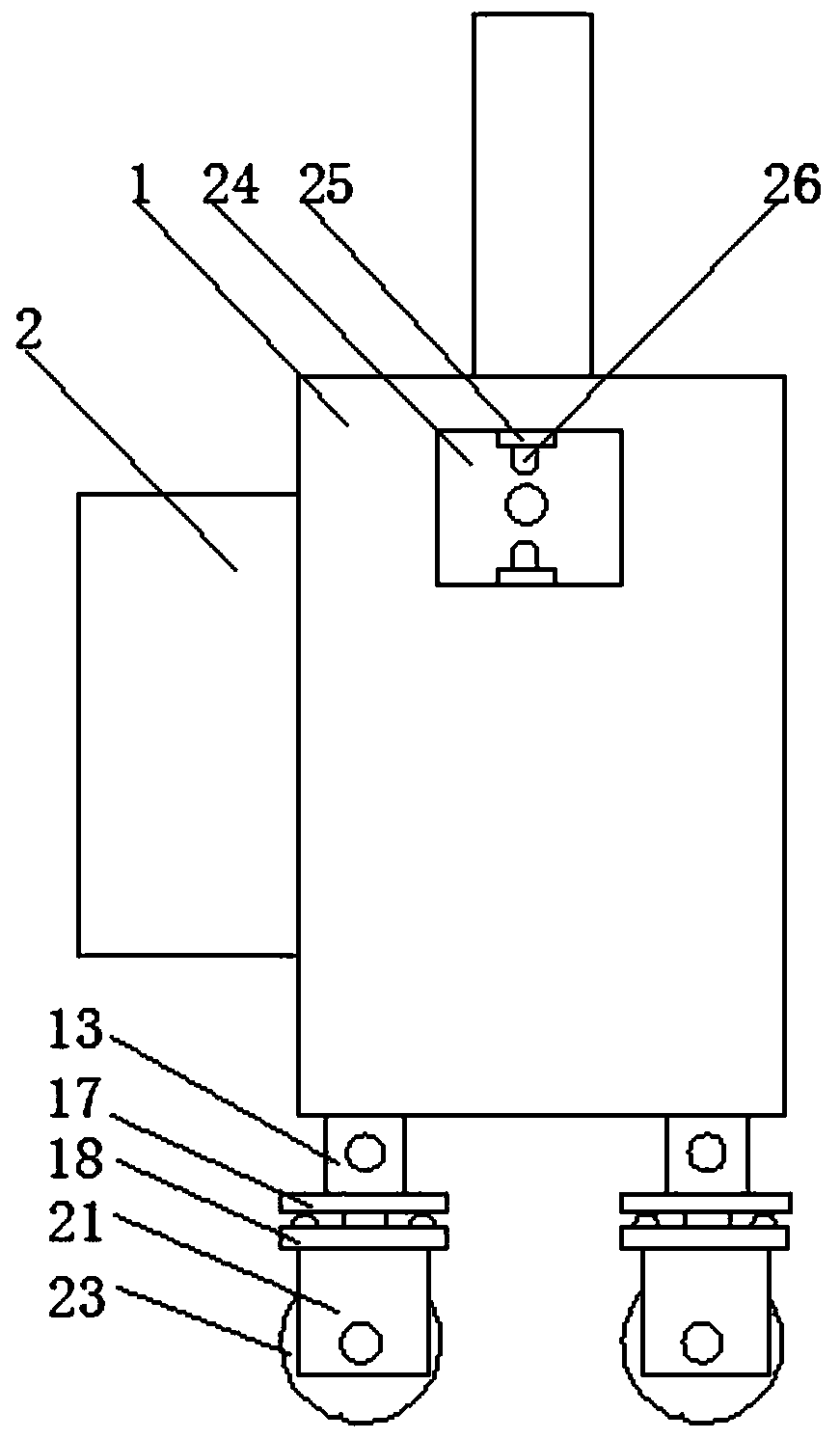

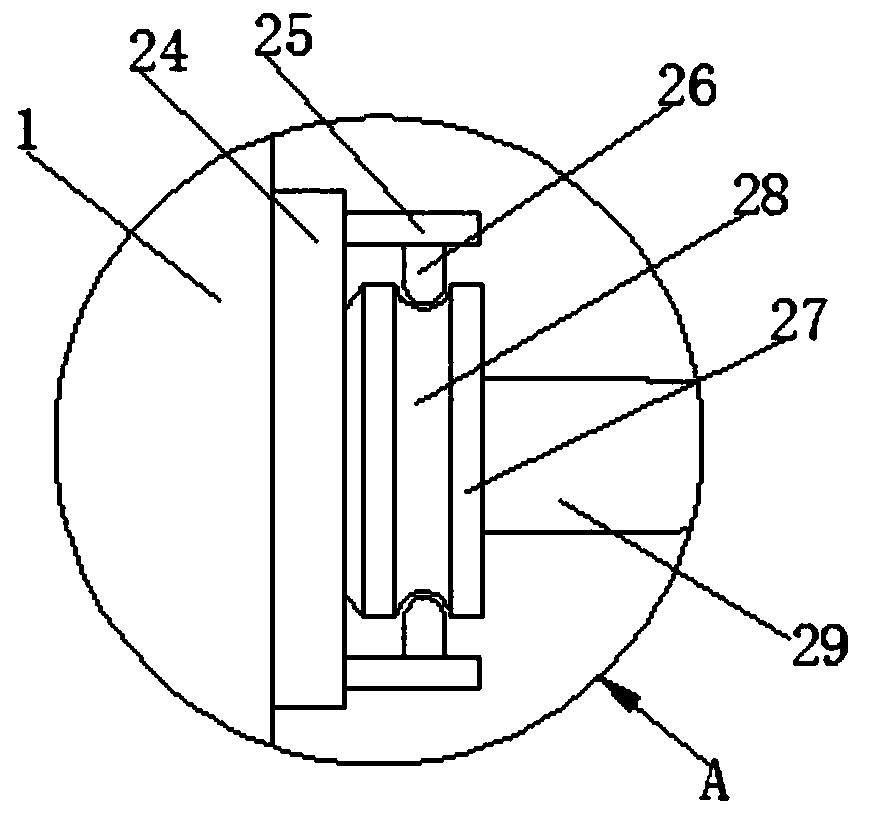

Agricultural chemical spraying trolley

PendingCN107432276AEasy to fixImprove uniformityInsect catchers and killersDrive shaftAgricultural engineering

The invention provides an agricultural chemical spraying trolley. The agricultural chemical spraying trolley comprises a base, a push rod, a controller, a fixing bolt, a stirring device, a conveying device, a spraying device, a fixing plate, brake discs, auxiliary fixing bolts, connecting plates and moving wheels, wherein the push rod is mounted at the left upper side of the base; and the controller is mounted at the upper side of the push rod. The brake discs are arranged, thereby being beneficial to conveniently fixing the equipment on an uneven bottom surface; the stirring device is arranged, thereby being beneficial to improving the fusion uniformity of different chemical reagents; a telescopic shaft is arranged, thereby being beneficial to performing chemical spray on plants of different heights through the equipment; an electromagnetic valve control button and an electromagnetic valve matches with each other, thereby being beneficial to regulating the discharge of the chemical reagents and preventing the chemical reagents from flowing out; a regulating switch, an auxiliary motor, a transmission shaft and a rotating shaft matches with each other, thereby being beneficial to realizing the all-directional rotation of an auxiliary nozzle; and a fixing ring is arranged, thereby being beneficial to conveniently fixing and clamping an auxiliary chemical delivery pipe.

Owner:朱晓

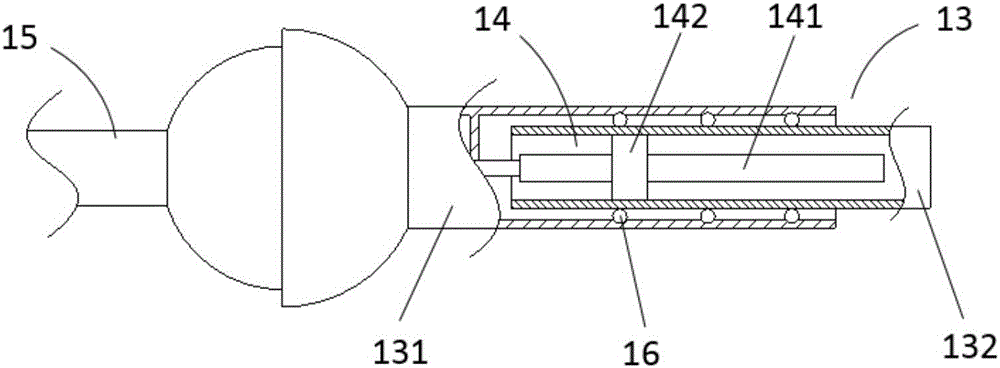

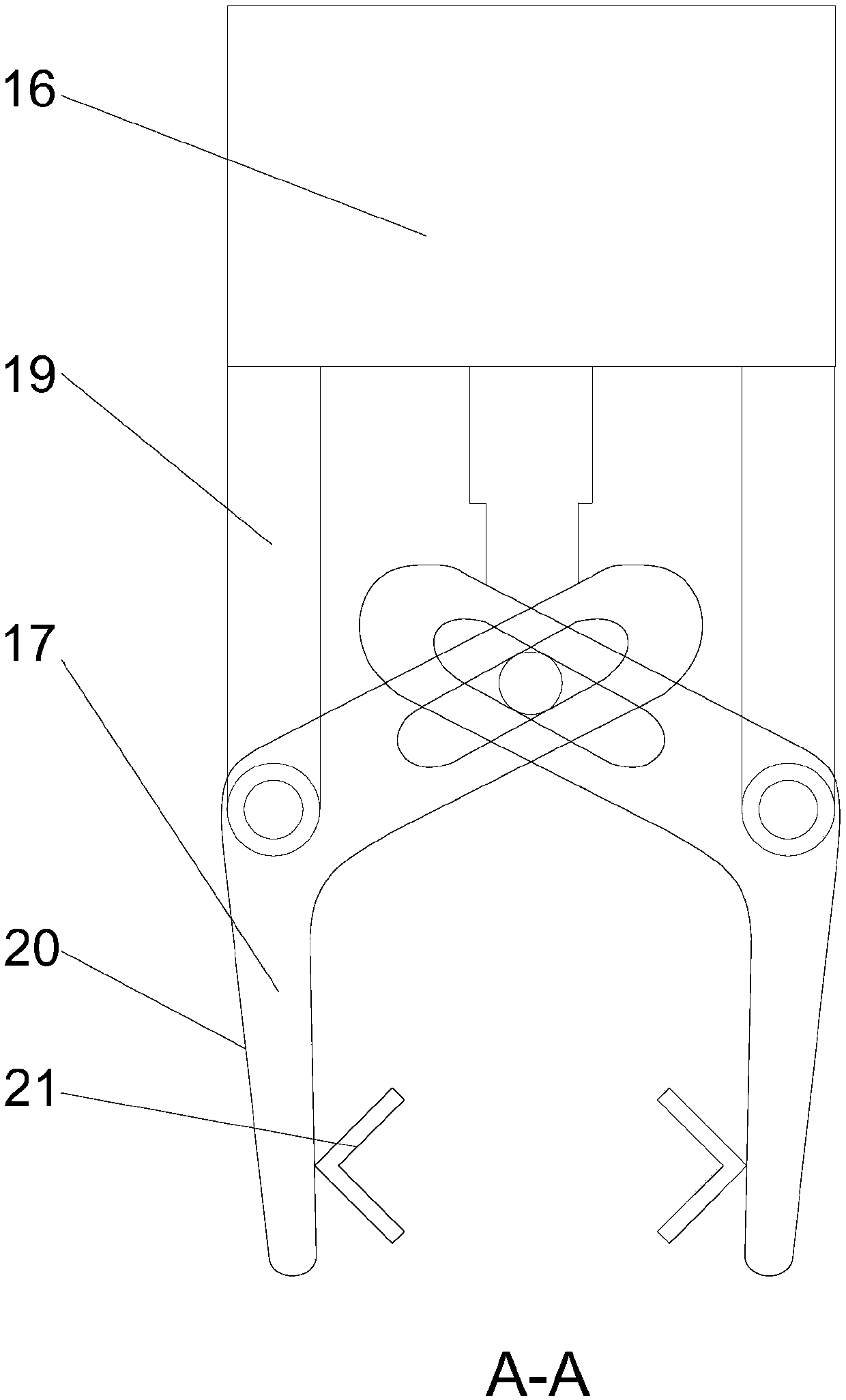

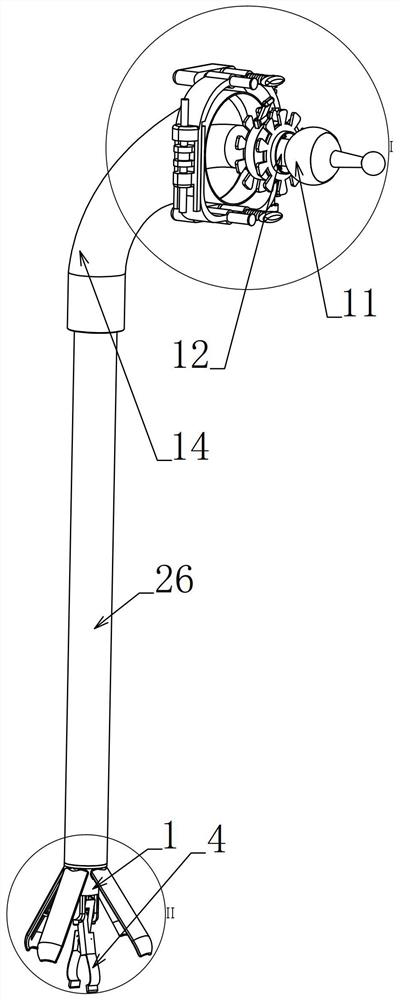

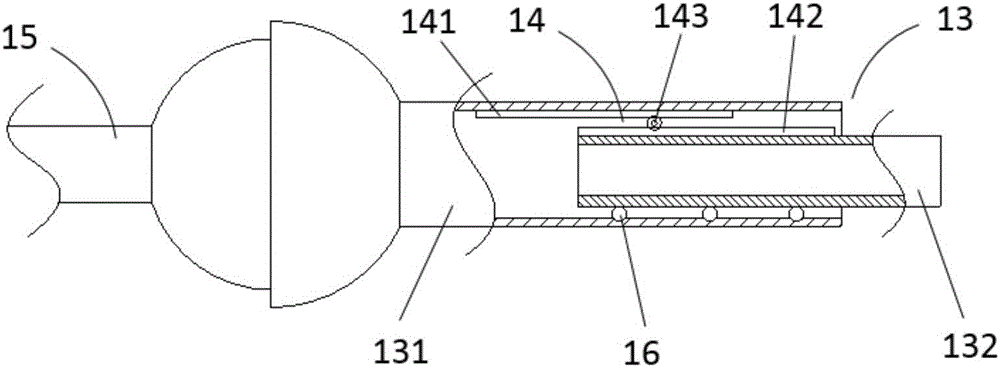

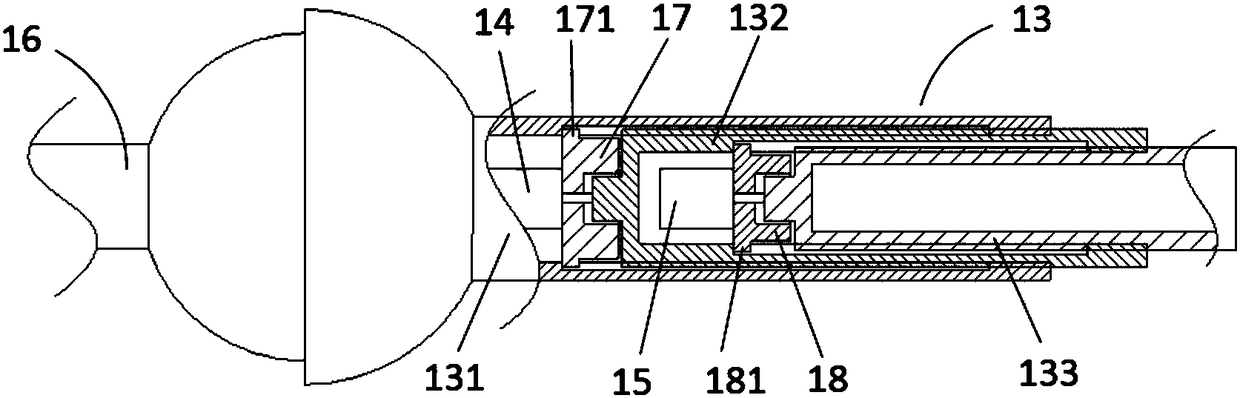

Foreign body removal apparatus for department of gastroenterology

The invention provides foreign body removal apparatus for the department of gastroenterology, effectively solves the problem that foreign bodies entering the esophagus mostly are fish bones, fruit pits, bone spurs, and the like, the foreign bodies all have sharp parts, and if the foreign bodies are not removed as soon as possible, the damage to the esophagus is easily caused, and at the same timesolves the problem that the foreign bodies can be pulled out in the opposite direction of the penetration direction by foreign body clamping apparatus when removing the foreign bodies that penetrate into the esophagus, and thereby the damage is minimized. The technical solution to solve the problem is as follows: the foreign body removal apparatus is characterized by comprising expansion apparatusused to expand the mouth, protection apparatus that passes through a space formed by the mouth expansion apparatus and extends into the esophagus, and the foreign body clamping apparatus that passesthrough the protection apparatus and clamps the foreign bodies. The esophagus can be protected while the problem of the damage to the esophagus is solved, and thereby the secondary damage is prevented.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Omnibearing multi-angle industrial robot

InactiveCN109278015AEasy to moveFull range of rotationProgramme-controlled manipulatorArmsEngineeringInverted u

The invention discloses an omnibearing multi-angle industrial robot. The omnibearing multi-angle industrial robot comprises a base, wherein the base is of an inverted U-shaped structure, a groove is formed in the middle position of a U-shaped groove of the base, and a first motor is arranged in the groove; a first conical gear is arranged at the bottom end of an output shaft of the first motor ina sleeving mode, and a connecting shaft penetrates through the base; a plurality of moving wheels located at the bottom end of the base are arranged on the connecting shaft in a sleeving mode, a second conical gear is arranged at the middle position of the connecting shaft in a sleeving mode, and the second conical gear is connected with the first conical gear in a meshing mode; and supporting plates are symmetrically arranged on the two sides of the top end of the base, and the top ends of the adjacent supporting plates are connected with each other through transverse plate. The omnibearing multi-angle industrial robot has the beneficial effects that omnibearing rotation of arms of the robot is effectively realized, and thus the robot grabs and transfers materials conveniently; and meanwhile, the omnibearing multi-angle motions of the robot are realized, manual input is effectively reduced, the working efficiency of the robot is improved, and the convenience is greatly brought for theindustrial production.

Owner:仇国璘

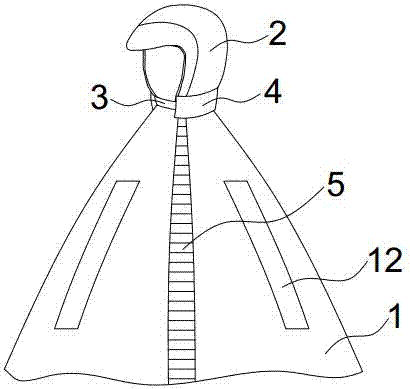

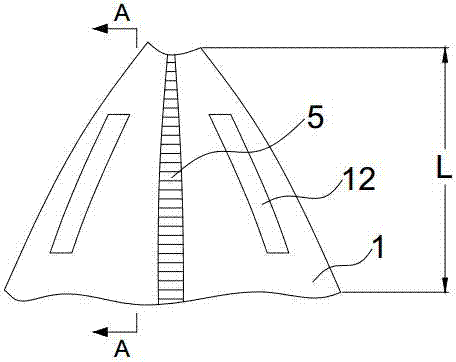

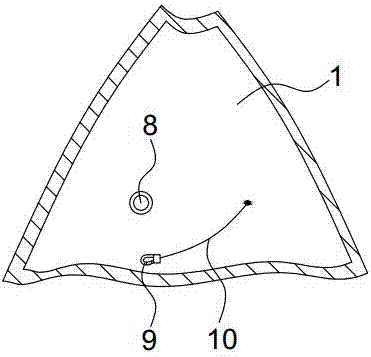

Safe raincoat

InactiveCN107951094AGood weather resistanceIncreased flexibility of useOvergarmentsVisibilityManufacturing technology

The invention discloses a safe raincoat, and belongs to the technical field of raincoat production. The safe raincoat comprises a hem and a safety helmet connected with the hem, a neck mobile ring isconnected between the hem and the safety helmet, a rain shield hem covering the neck mobile ring is connected to the lower end of the safety helmet, expansion areas are arranged at the centers of thefront surface and the back surface of the hem, and reflective strips are connected to both sides of each expansion area. The hem is the basic part structure of the raincoat, has an important effect onrain shield for the body and is applicable on a rainy day, and the comfort is good. The reflective strips have a warning effect, and the safety factor of a traveler can be greatly improved when the traveler goes out at night or on a day with low visibility. According to the safe raincoat, the rainproof performance is good, the use flexibility is high, rain resistance is high, and high safety is provided for the traveler.

Owner:ZHEJIANG OCEAN UNIV

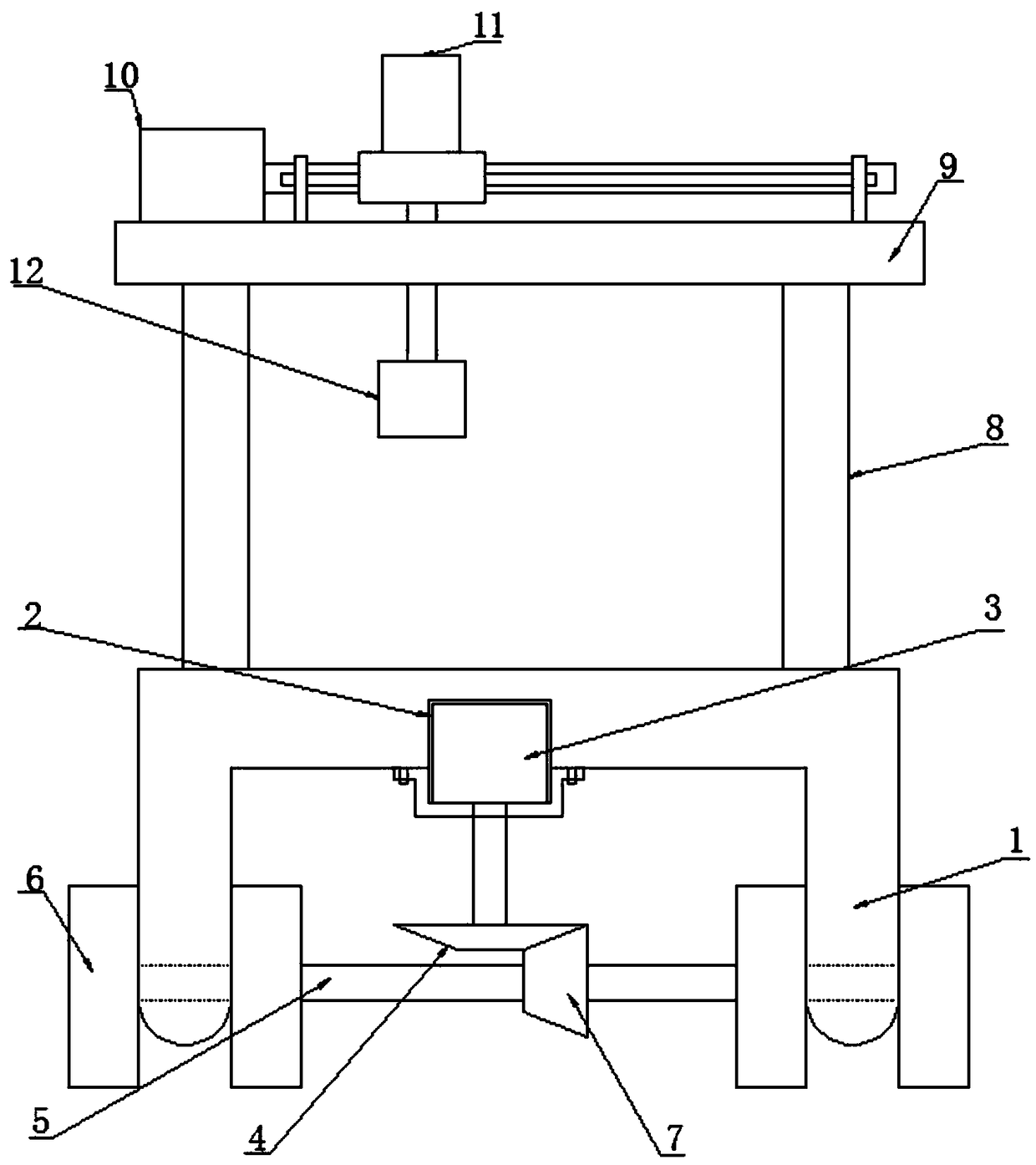

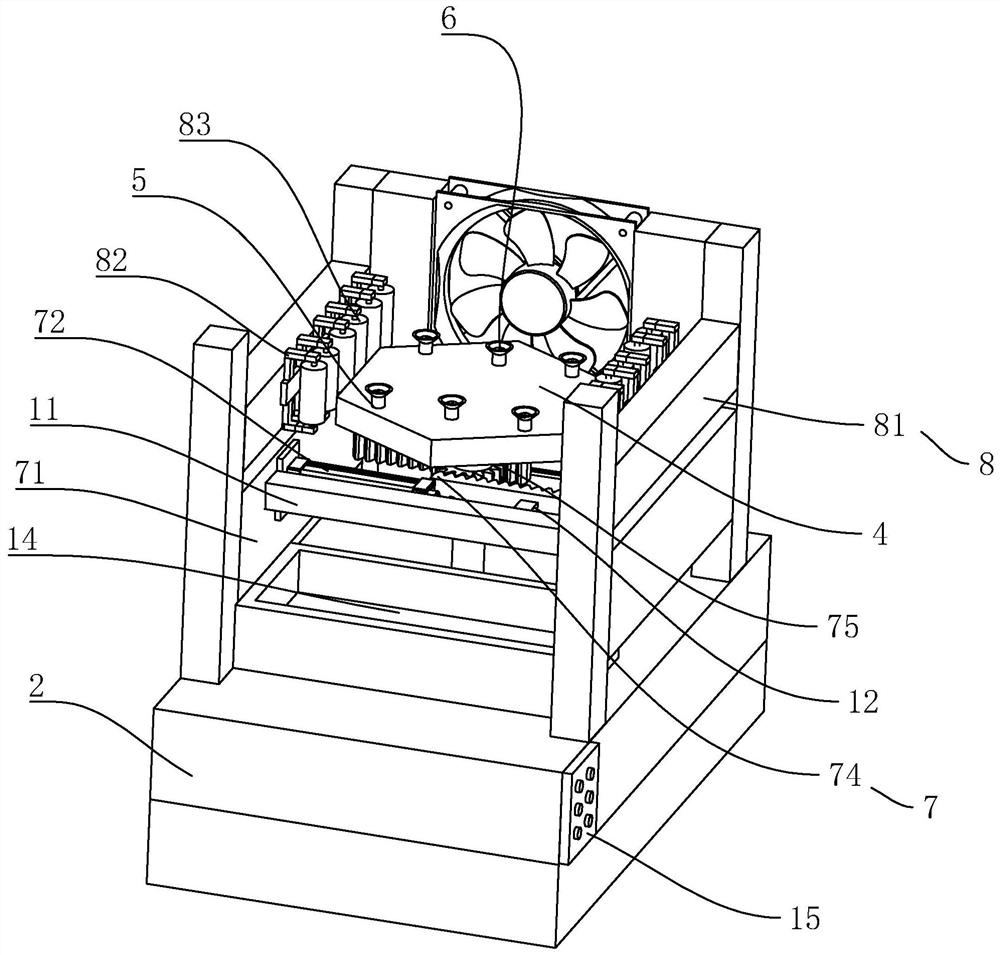

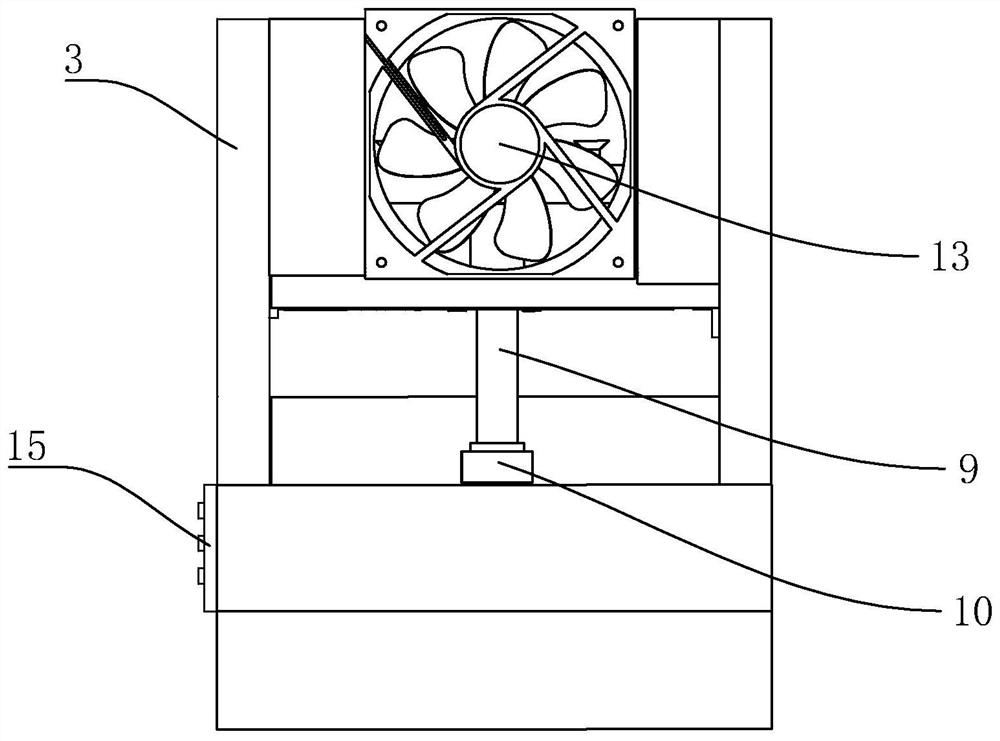

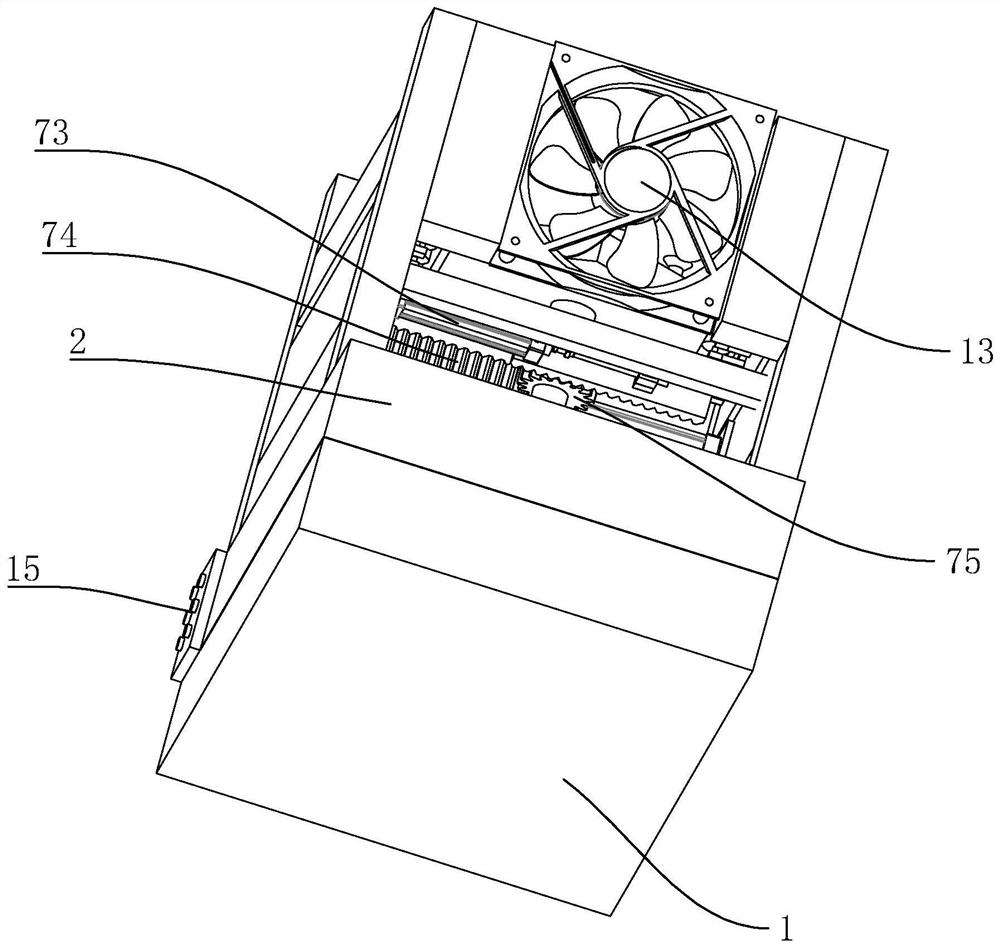

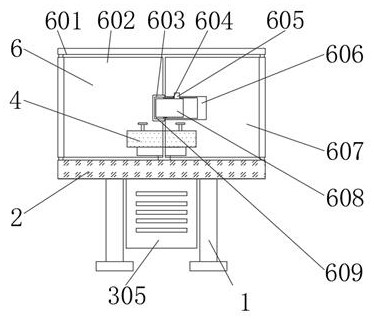

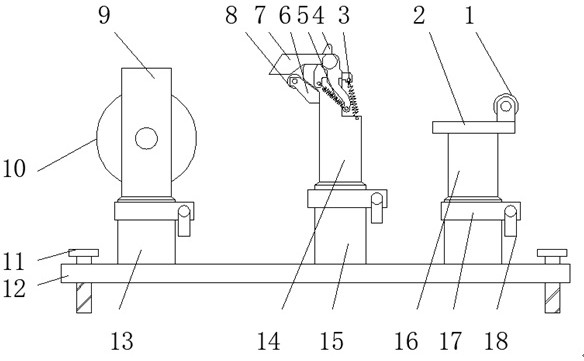

IGBT module structure reliability testing device having video monitoring function

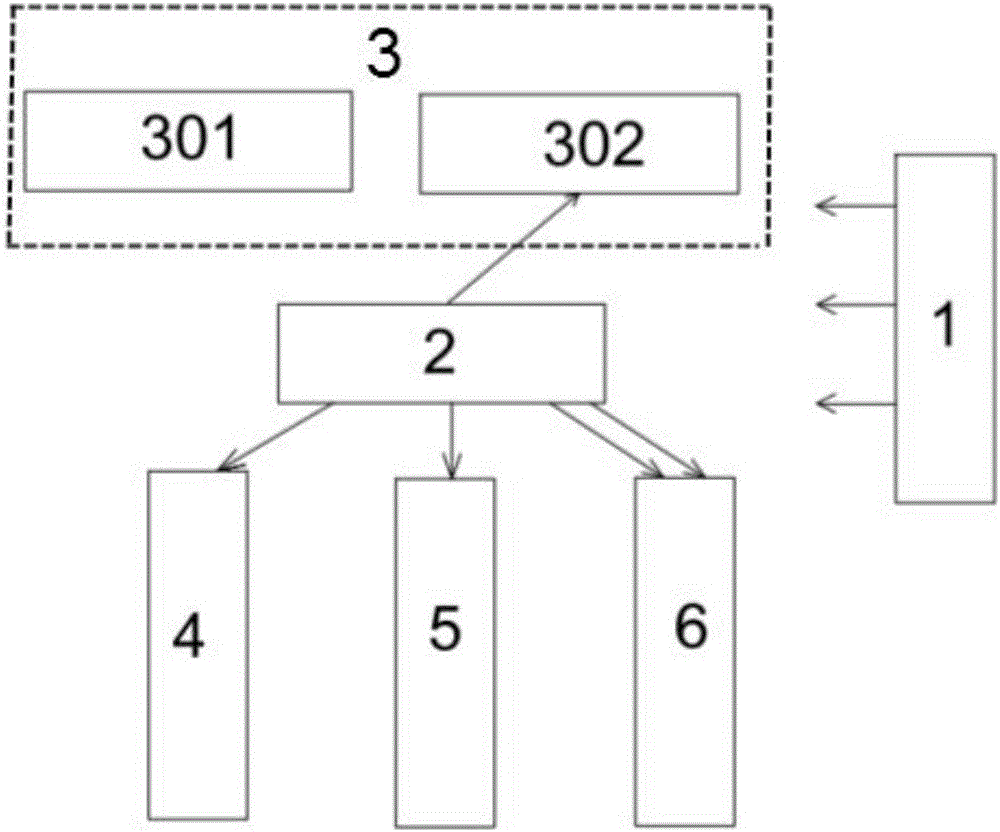

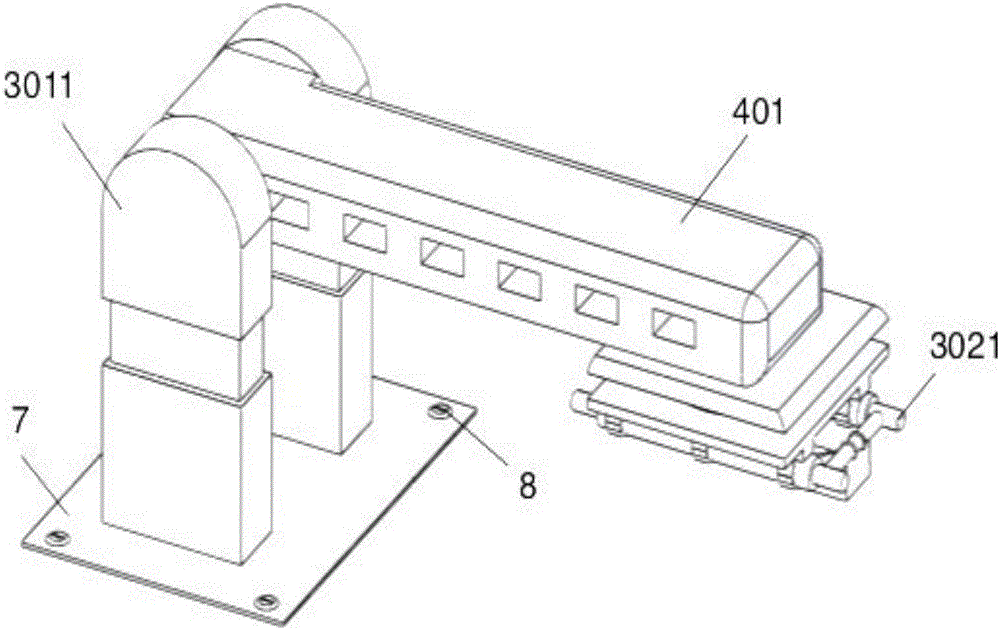

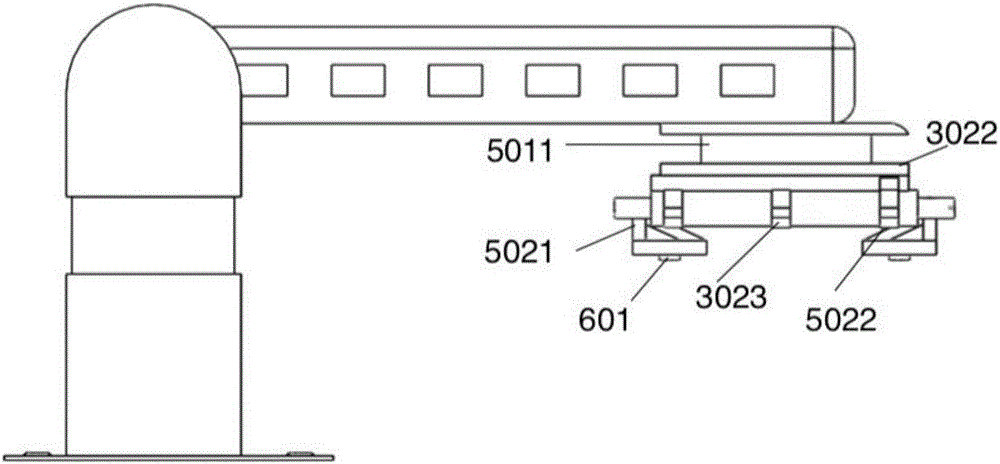

ActiveCN106324468AAvoid long runsReduce lossesSemiconductor operation lifetime testingSemiconductor characterisationVideo monitoringComputer module

The invention relates to an IGBT module structure reliability testing device having a video monitoring function. The IGBT module structure reliability testing device comprises a power supply module, a telescopic module, an intelligent control module, a sliding module, a rotating module, and an acquisition module. The power supply module is connected with other modules to provide electric energy. The intelligent control module is connected with the telescopic module, the sliding module, the rotating module, and the acquisition module to realize a test control function. The IGBT module structure reliability testing device is advantageous in that the design is reasonable; the constant changing of the internal chip, the solder layer, and the copper layer of the IGBT module during a testing process is acquired by adopting a visual sensor; the corresponding changing of the corresponding parts is determined, and the gradual changing of the internal structure of the IGBT is discovered, and after the IGBT loses efficacy, the part causing the failure of the IGBT is determined.

Owner:HEBEI UNIV OF TECH

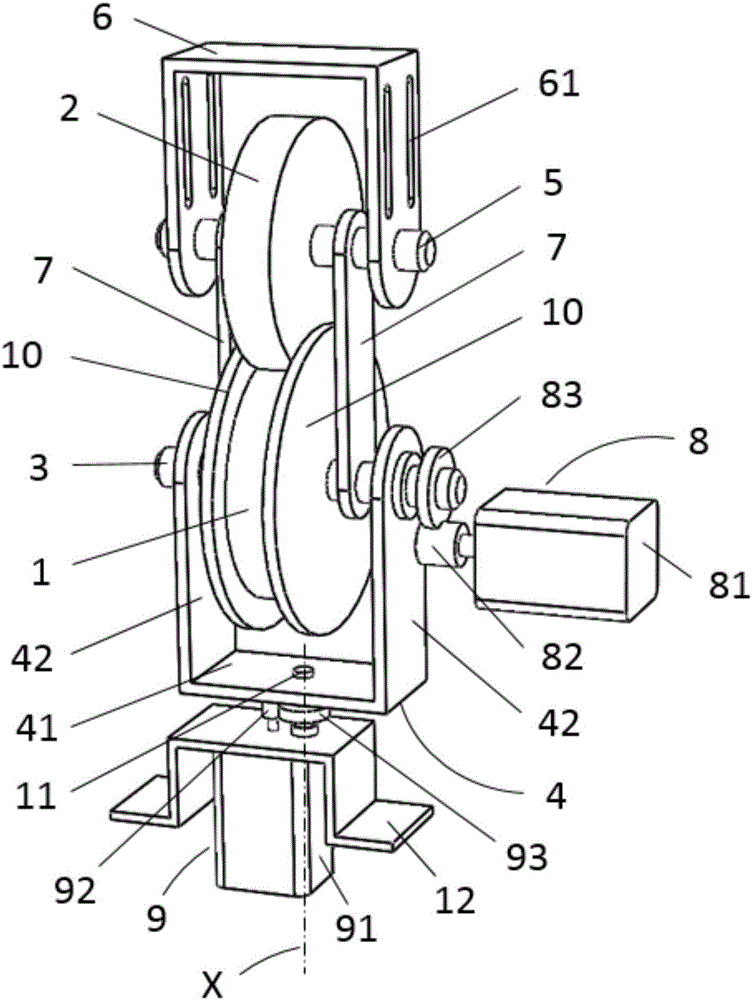

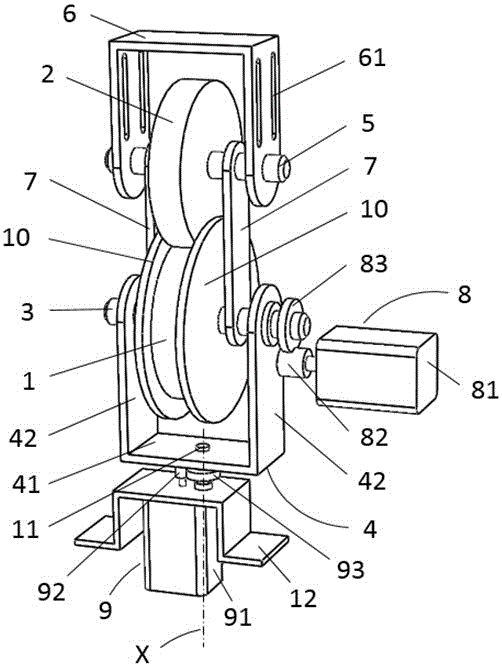

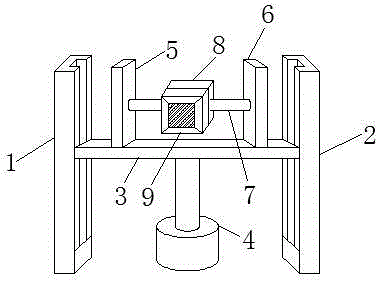

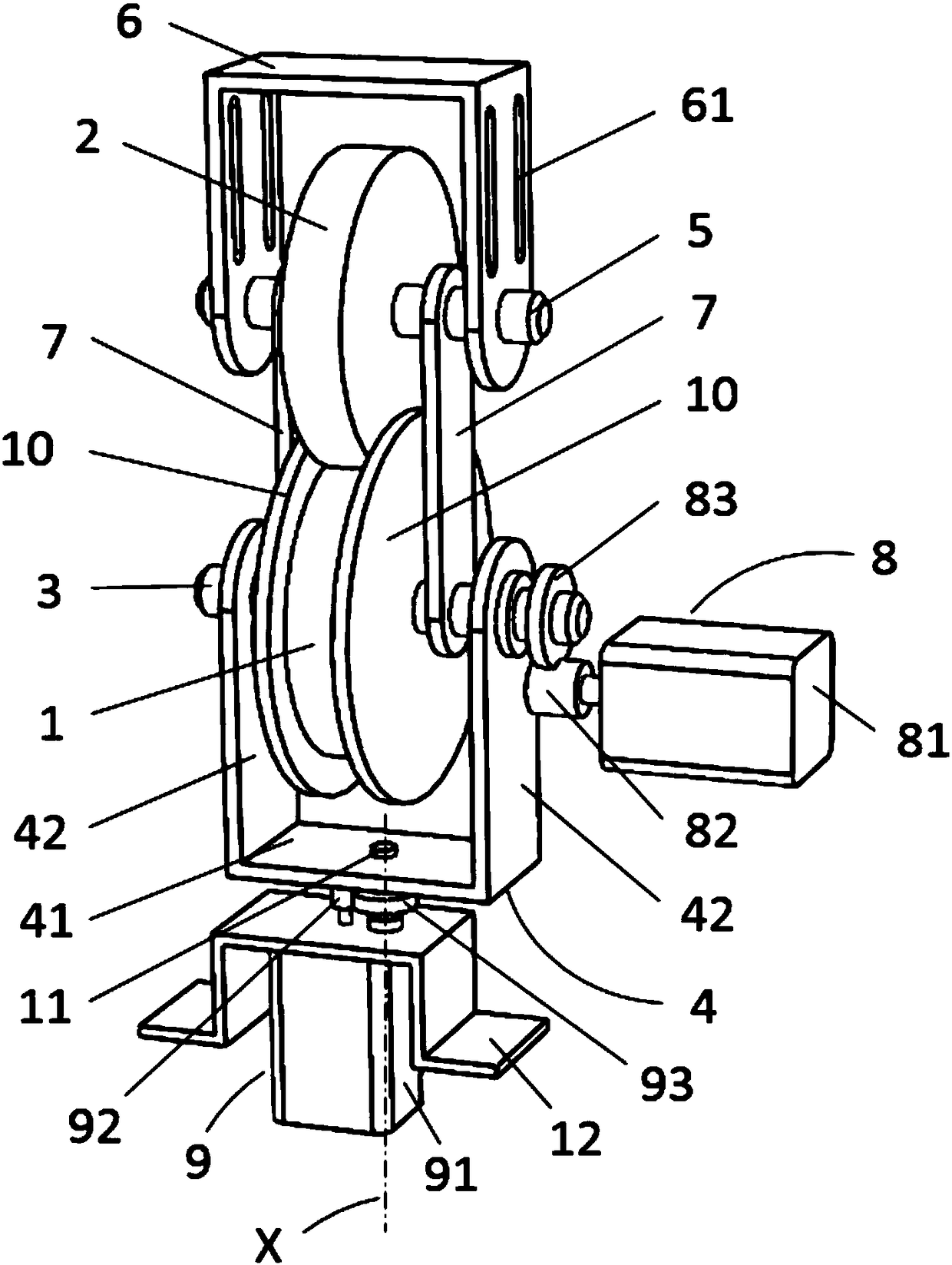

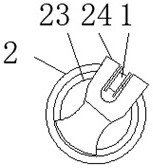

Mechanical joint capable of rotating omni-directionally

The invention discloses a mechanical joint capable of rotating omni-directionally. The mechanical joint comprises a first gear and a second gear which are engaged with each other. The first gear is arranged on a first rotary shaft in a penetrating manner and connected with a first support through the first rotary shaft. The second gear is arranged on a second rotary shaft in a penetrating manner and connected with a second support through the second rotary shaft. Connecting arms are arranged between the first rotary shaft and the second rotary shaft. The first rotary shaft is connected with a first drive device, and the first support is connected with a second drive device. By means of the design, the mechanical joint is driven by the second drive device to rotate around the axis X, the second gear and the second support are driven by the first drive device and the first gear to rotate around the first gear, and therefore the mechanical joint can rotate omni-directionally; and the mechanical joint has the beneficial effects of being simple in structure, low in cost, stable in structure and reliable in transmission.

Owner:南京宁信安躿医疗科技有限公司

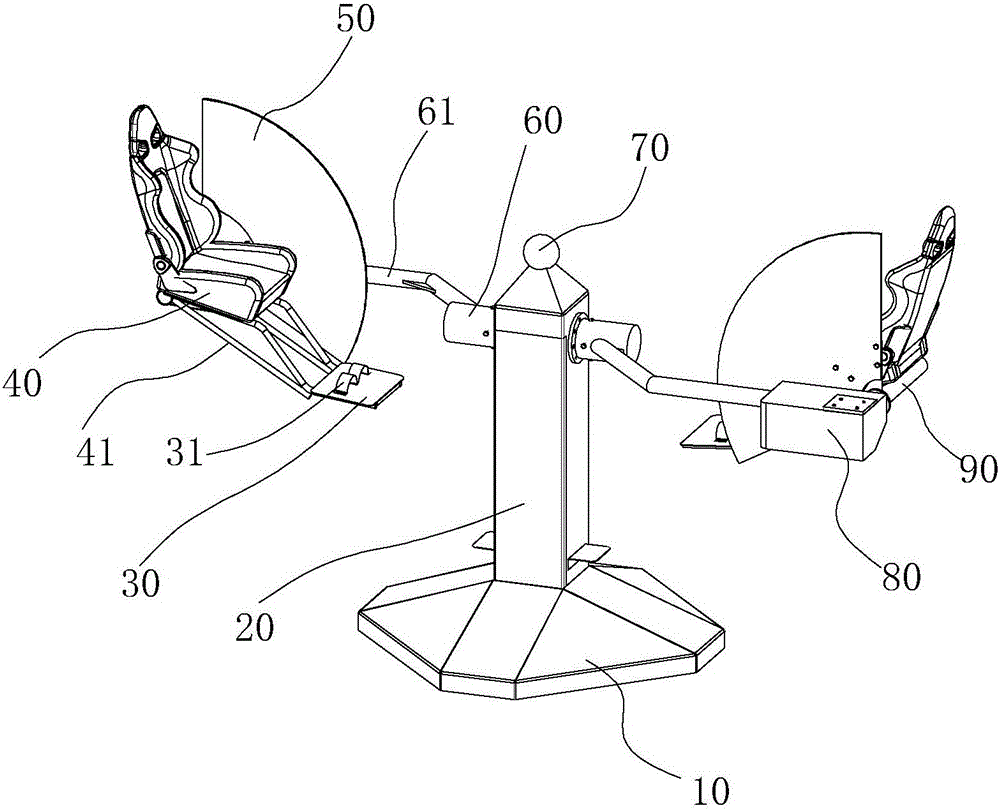

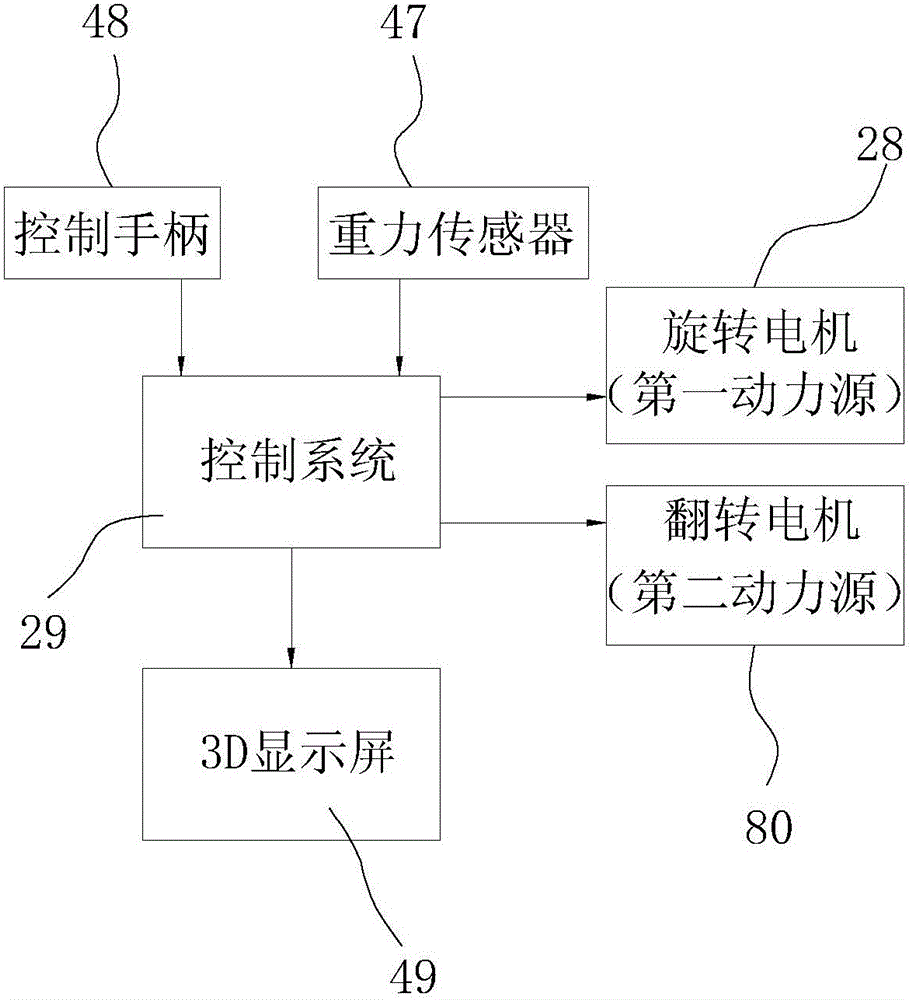

Bispin type turnover equipment and bispin type space cinema

InactiveCN105688425AFull range of rotationImprove experienceCinema apparatusControl systemMechanical engineering

The invention relates to bispin type turnover equipment and a bispin type space cinema. The bispin type turnover equipment comprises a supporting structure, a main rotary shaft driven by a first power source to rotate, auxiliary rotary shafts driven by second power sources to rotate, and two seats. A control system is arranged in the supporting structure. The first power source and the second power source are electrically connected with the control system. The main rotary shaft is connected to the upper end of the supporting structure, and the two ends of the main rotary shaft are provided with the second power sources and the auxiliary rotary shafts respectively. The seats and the auxiliary rotary shaft are fixedly connected or connected in a front-and-back sliding mode. The main rotary shaft is arranged on the supporting structure, the auxiliary rotary shafts are arranged at the two ends of the main rotary shaft respectively, the main rotary shaft is perpendicular to the auxiliary rotary shafts, the auxiliary rotary shafts are connected with the seats, and therefore the two seats, the main rotary shaft and the auxiliary rotary shafts rotate at the same time, the seats can rotate in an omni-bearing mode, users can interact along with scenes in movies or games, and user experience is improved.

Owner:深圳易万创新科技有限公司

Adjustable emergency lamp support

Owner:CHONGQING CHENGJI FIRE SAFETY TECH CO LTD

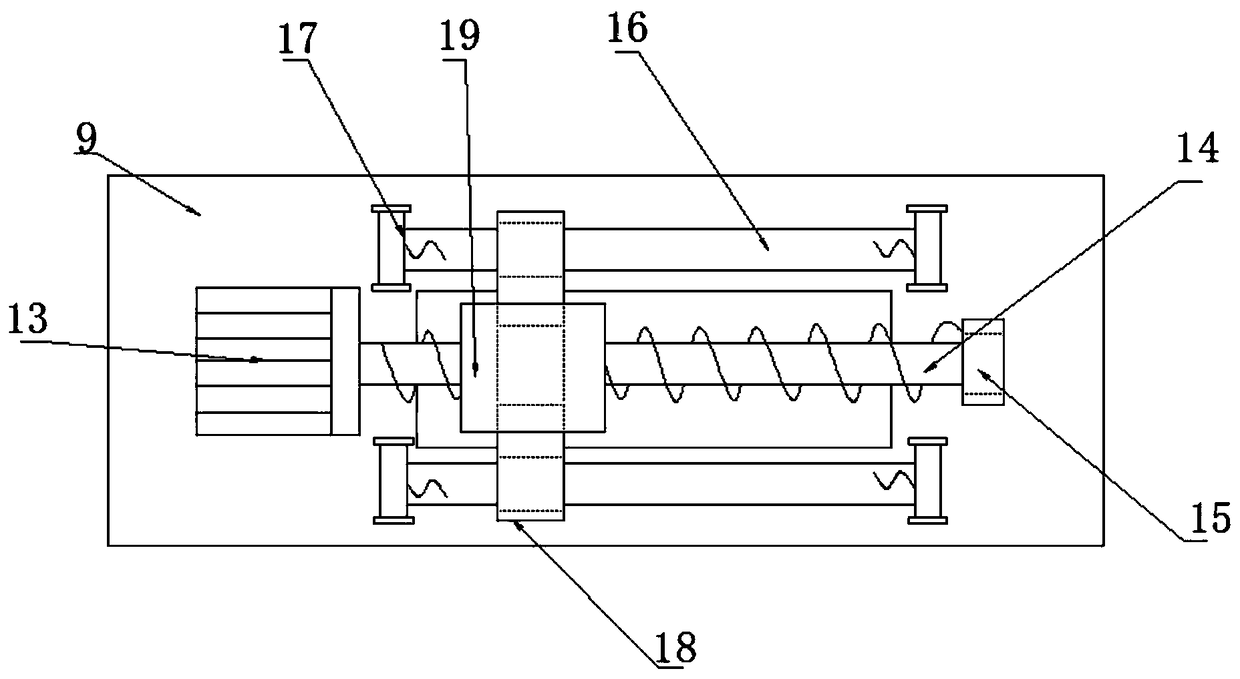

Multi-station laser welding automatic complete facility

InactiveCN111992883AImprove mobile stabilityAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses a multi-station laser welding automatic complete facility, and belongs to the technical field of automatic welding. The multi-station laser welding automatic complete facilitycomprises a workbench. The top of the workbench is connected with a laser welding piece, and the top of the workbench is rotationally connected with a base. The top of the base is connected with a supporting frame. The top of the supporting frame is connected with a first motor, the output end of the first motor is connected with a first lead screw, and the first lead screw is rotationally connected between the base and the supporting frame. The outer wall of the first lead screw is connected with a first sleeve in a threaded mode, the outer wall of the first sleeve is fixedly connected with aconnecting frame, and the end, far away from the first sleeve, of the connecting frame is connected with a cylinder. A ball is movably connected with the interior of the cylinder, the outer wall of the ball is rotationally connected with a rotating shaft, the end, far away from the ball, of the rotating shaft is fixedly connected with a working plate, and the outer wall of the working plate is connected with a clamping mechanism. By means of the control over the all-directional rotation of a workpiece, a welding mechanism can conveniently conduct multi-station welding operation on the workpiece, and the welding quality can be improved advantageously.

Owner:JINAN G WEIKE SCI & TECH

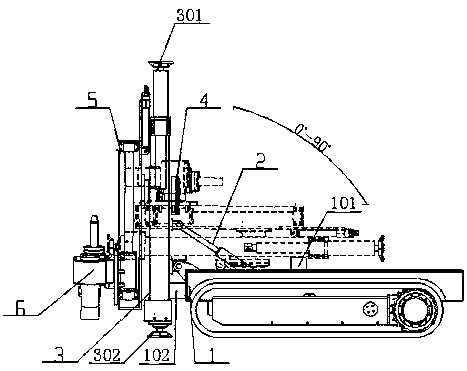

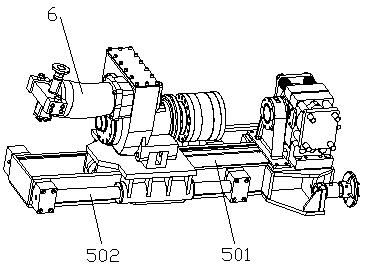

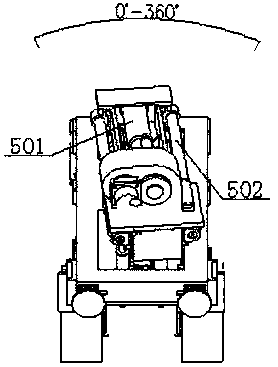

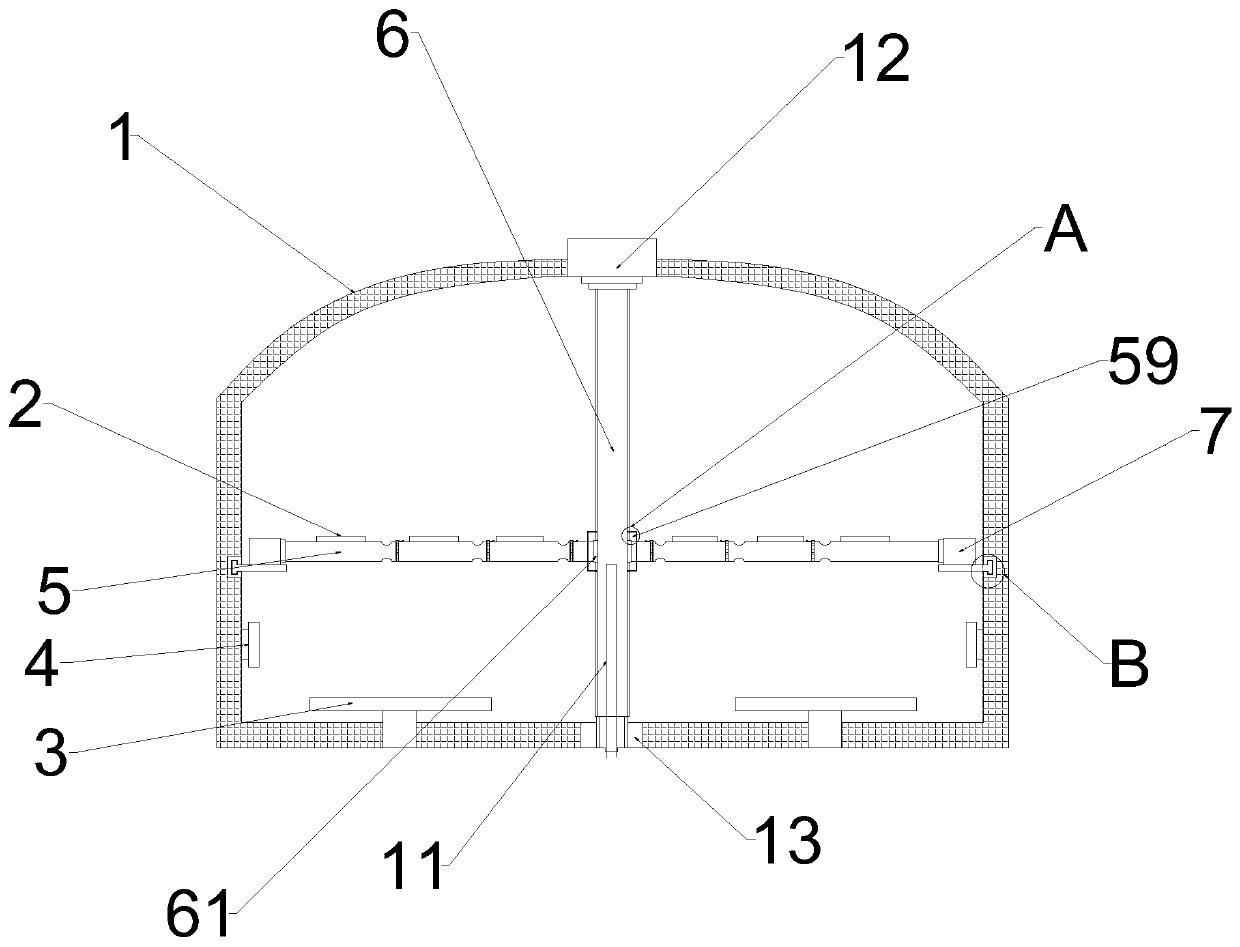

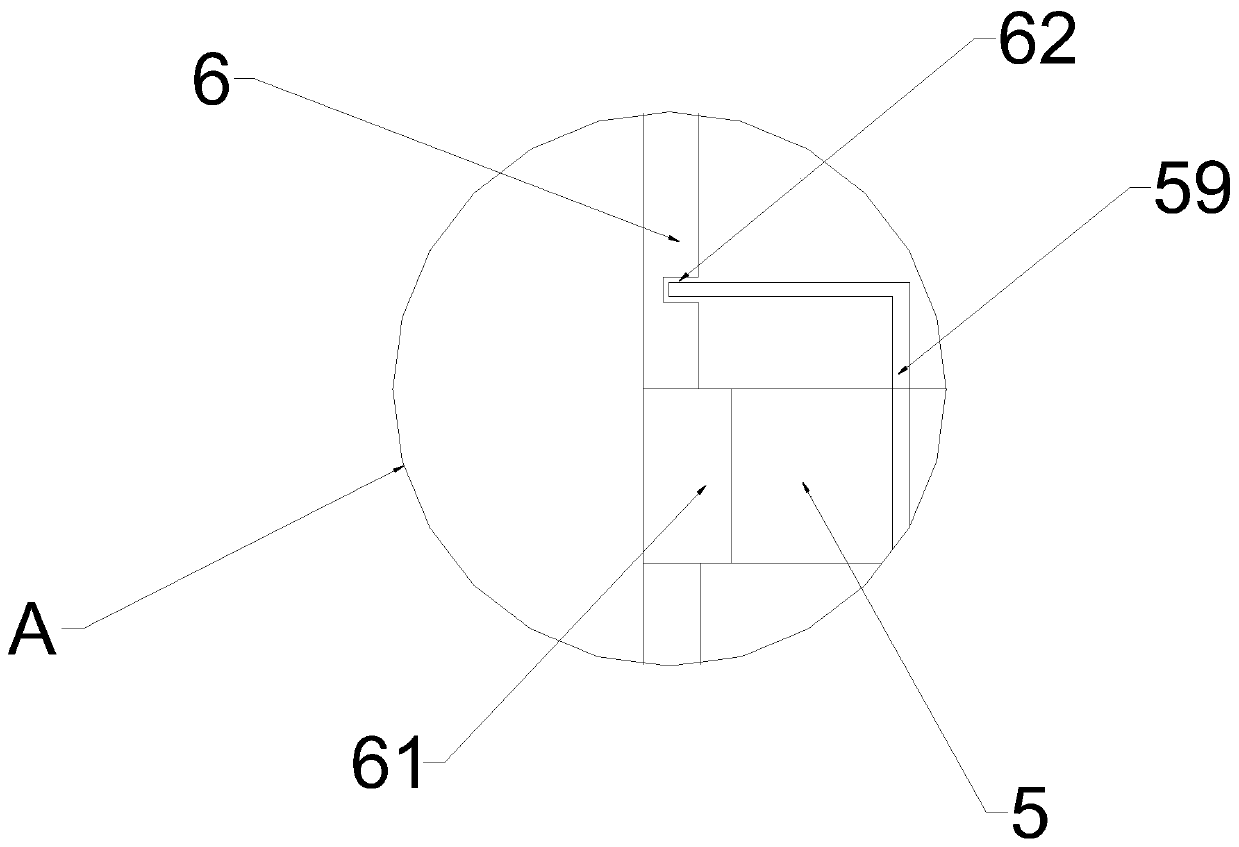

Foldable all-around drilling mechanism

InactiveCN110630175AMeet shipping requirementsAvoid dismantling and transportingConstructionsDerricks/mastsEngineeringSlewing bearing

The invention relates to a foldable all-around drilling mechanism which comprises a base plate, a turning oil cylinder, a turning frame, a slewing bearing, a guide rail and a power head, wherein the folding of the turning frame is controlled through the telescopic effect of a piston rod of the turning oil cylinder; one end of the slewing bearing is fixedly arranged on the turning frame; the otherend of the slewing bearing is connected with the guide rail; and the power head is arranged at the side, opposite to the side connected with the slewing bearing, of the guide rail. The foldable all-around drilling mechanism has the advantages that the structure is reasonable; the foldable all-around drilling mechanism has two states including a transportation state and a work state; the transportation requirements of a coal mine underground narrow roadway can be met; the machine dismounting transportation is avoided; the equipment fault probability caused by the assembly by unprofessional minepersonnel is effectively reduced; the installation and the use are convenient; convenience, high speed and reliability are realized; the construction range is effectively expanded, so that the efficiency is improved; the use effect is good; the stress effect of the power head is better; the abrasion generated by swinging is avoided; and the integral service life of the drilling mechanism is effectively prolonged. Compared with the prior art, the foldable all-around drilling mechanism has good market prospects and development space.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

Production apparatus for coated glass

The invention discloses a production apparatus for coated glass, belonging to the technical field of glass manufacturing. The production apparatus for coated glass comprises a device body of a cavitystructure, a plurality of substrate tables, and sputtering tables, wherein the device body is provided with orthogonal electric and magnetic fields; targets are placed on the sputtering tables; a gassupply pipe is arranged at the lower end of the side wall of the device body; the substrate tables are located directly above the sputtering tables; the lower end surface of each of the substrate tables is fixedly connected with a first connecting shaft which is of a hollow structure, and the open end of the first connecting shaft is connected with a vacuum pump through a vacuum pump pipeline; thefirst connecting shaft is internally provided with blocking block and an elevating mechanism used for driving the blocking block to move up and down so as to block an air exhausting hole; a filteringmechanism is arranged in the part, located between the air exhausting hole and the vacuum pump pipeline, of the first connecting shaft; and the elevating mechanism and the filtering mechanism are both electrically connected with a controller. The production apparatus of the invention can effectively recover a target material through filtering of the target material with a filter screen.

Owner:安徽富顺镀膜科技有限公司

Telescopic mechanical arm capable of rotating in omnibearing manner

ActiveCN106041997ASimple structureStable structureProgramme-controlled manipulatorArmsRobotic armEngineering

Owner:南京宁信安躿医疗科技有限公司

A multi-stage rotating telescopic mechanical arm

A multistage rotary and telescopic mechanical arm comprises a first gear and a second gear which are engaged with each other. The first gear is connected with a first support through a first rotating shaft. The second gear is connected with a second support through a second rotating shaft. Connecting arms are arranged between the first rotating shaft and the second rotating shaft. The first rotating shaft is connected with a first drive device. The first support is connected with a second drive device. The second support is connected with a telescopic external mechanical arm. The external mechanical arm comprises a first mechanical arm body, a second mechanical arm body and a third mechanical arm body. One end of the second mechanical arm body is arranged in a hollow cavity of the first mechanical arm body. One end of the third mechanical arm body is arranged in a hollow cavity of the second mechanical arm body. The first mechanical arm body and the second mechanical arm body are in threaded connection, and the second mechanical arm body and the third mechanical arm body are in threaded connection. The second mechanical arm body and the third mechanical arm body are each driven by an independent drive system. Multistage extension and retraction and omnibearing rotation of the mechanical arm can be achieved, and the multistage rotary and telescopic mechanical arm has the beneficial effects of being simple in structure and low in cost.

Owner:南京宁信安躿医疗科技有限公司

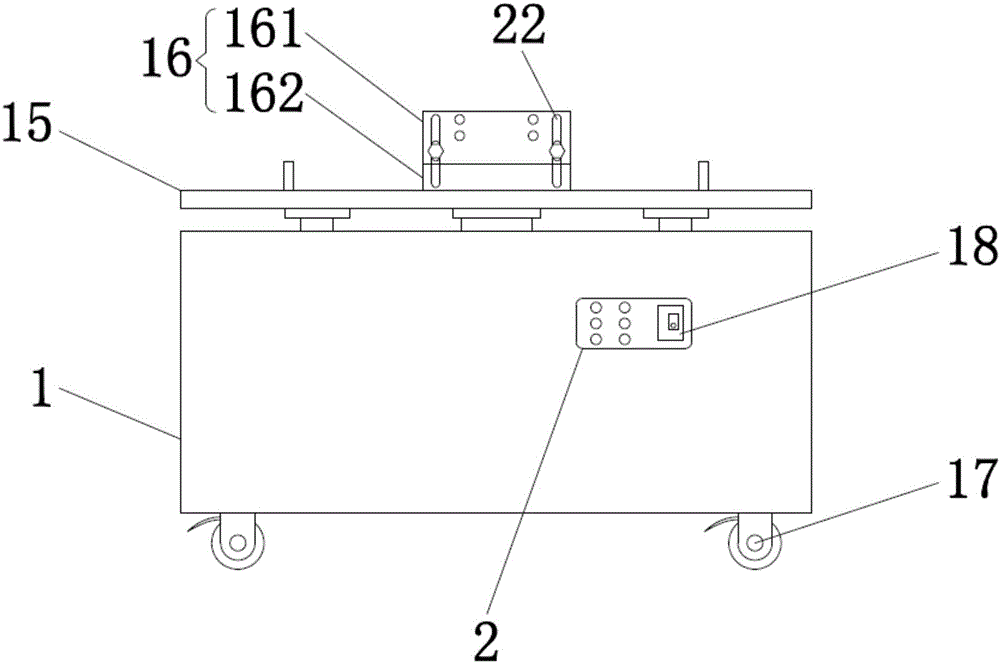

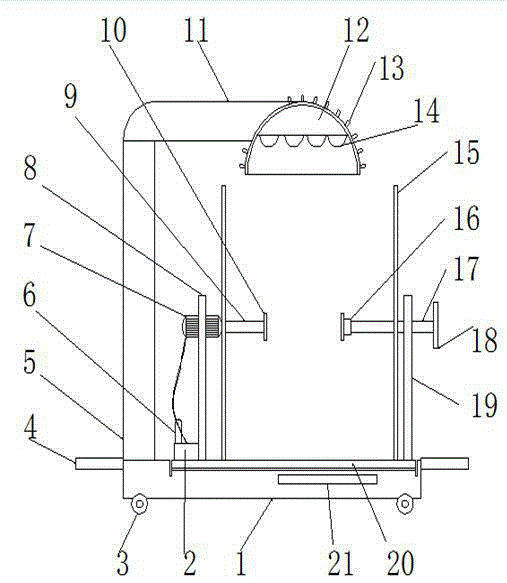

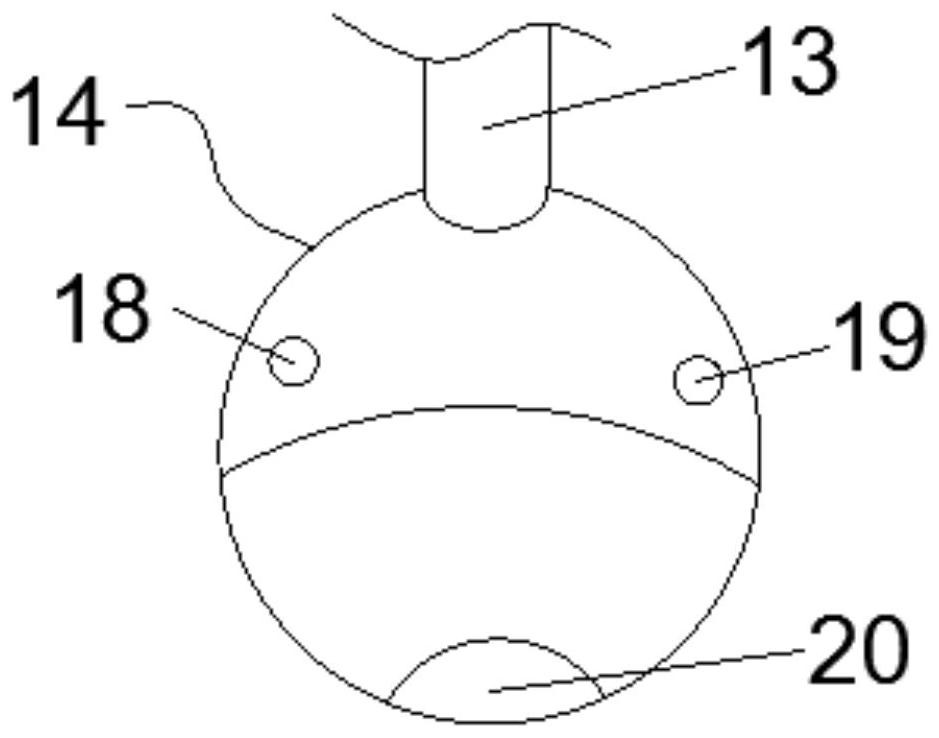

Multifunctional intelligent ultraviolet lamp

PendingCN106540289AAvoid harmImprove disinfection effectLavatory sanitoryRadiationBiochemical engineeringIdler-wheel

The invention discloses a multifunctional intelligent ultraviolet lamp. The multifunctional intelligent ultraviolet lamp comprises a pedestal and a support pillar; the bottom of the pedestal is provided with idler wheels; the upper left end of the pedestal is provided with the support pillar; the upper end of the support pillar is provided with a cross bar; the end part of the cross bar is provided with a lampshade; an ultraviolet lamp tube is arranged in the lampshade; a rotating carrying platform is arranged on the pedestal on the right of the support pillar; a left supporting plate and a right supporting plate are arranged on the rotating carrying platform; two reflective mirrors are arranged between the right supporting plate and the left supporting plate in parallel; a controller is arranged on the left lower side of the left supporting plate; a signal receiver is arranged on the controller; a rotating motor is arranged on the left supporting plate; a rotating shaft is arranged on the right end of the rotating motor; the right end of the rotating shaft is provided with a pressing block; a pressing screw rod is arranged on the right supporting plate; the right end of the pressing screw rod is provided with a handle; the left end of the pressing screw rod is also provided with a pressing block; and an infrared sensor is arranged on the front surface of the pedestal. The multifunctional intelligent ultraviolet lamp is simple and reasonable in structure, is excellent in heat dispersion performance, sterilization effect, and safety, and is convenient to carry.

Owner:TIANJIN GUANGZE NOBLELIGHT CO LTD

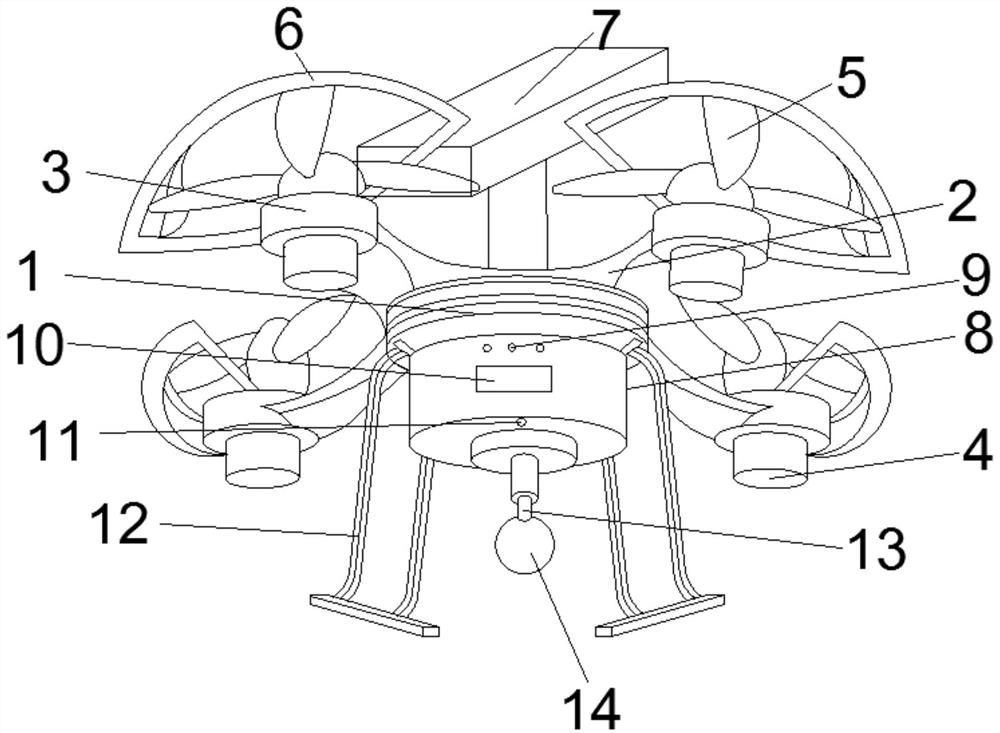

Unmanned aerial vehicle for photovoltaic power generation inspection

PendingCN112783212AEffective protectionAvoid damagePosition/course control in three dimensionsTransceiverUncrewed vehicle

The invention discloses an unmanned aerial vehicle for photovoltaic power generation inspection. The unmanned aerial vehicle comprises an unmanned aerial vehicle body, wherein motor fixing bases are fixedly installed on the periphery of the unmanned aerial vehicle body through supporting frames, driving motors are fixedly installed on the motor fixing bases, rotor wings are fixedly installed on power output shafts of the driving motors, the top part of the unmanned aerial vehicle body is provided with a power supply device, the power supply device comprises a photovoltaic panel, an adjusting part and a supporting rod, the bottom part of the unmanned aerial vehicle body is provided with a control device, the outer surface of the control device is provided with a wireless signal transceiver, the bottom part of the control device is provided with an information acquisition device through a rotating part, the information acquisition device comprises an infrared distance measurement detection probe, a sound wave detection probe and a camera, a heat dissipation device is arranged on one side of the unmanned aerial vehicle body, and a control chip is arranged in the control device. According to the unmanned aerial vehicle, remote wireless detection is realized, the operation is convenient, the working efficiency of photovoltaic power generation inspection is improved, and the labor intensity is reduced.

Owner:拓航科技有限公司

Ultrasonic detector and operating method thereof

PendingCN111012375ATimely disinfectionPrevent looseningUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsEngineeringUltrasonic testing

The invention discloses an ultrasonic detector and a working method thereof. With the ultrasonic detector, the problem of inconvenient disinfection of the detection head of an ultrasonic detector is solved, the detection head can be disinfected without disassembly, the disinfection is timely, the plug on the detection head and the socket on the detector are connected stably and are not easy to loosen, and the whole detector is convenient and rapid to move. The ultrasonic detector comprises a detector body, wherein the front end of the detector body is fixedly connected with a box body, a proximity switch is fixedly connected into the box body, a disinfection lamp is fixedly connected to the inner wall of the left side of the box body, the disinfection lamp and a proximity switch are connected with the power supply of the detector through conducting wires, a groove is formed in the front end of the right side of the box body, a box door is hinged to the left end of the box body, a proximity block is fixedly connected to the surface of the box door, a magnetic strip is fixedly connected to the surface of the box door, the lower end of the detector body is fixedly connected with a connecting sleeve, and the interior of the connecting sleeve is rotatably connected with a cylinder.

Owner:夏青青

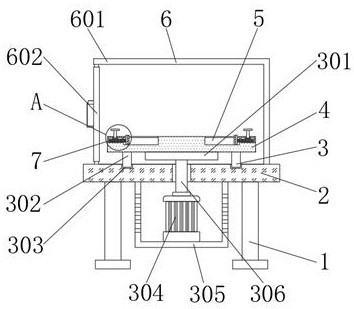

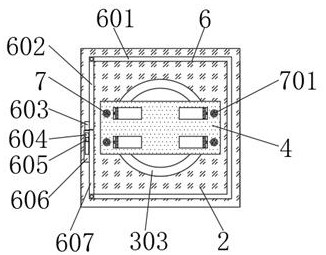

Polaroid grinding equipment for display screen

PendingCN113334185ADurable and stable adsorption and fixationRealize multi-angle and all-round rotationEdge grinding machinesGrinding drivesEngineeringPiston rod

The invention discloses a polaroid grinding device for a display screen, and aims to provide the polaroid grinding device for the display screen. The polaroid grinding device for the display screen is characterized by comprising a base, a working table arranged on the base and supporting frames installed on the two sides of the working table, a grinding boss is arranged on the working table, adjusting assemblies mounted on the supporting frames are arranged on the two sides of the grinding boss, a grinding assembly is further arranged above the grinding boss, each adjusting assembly comprises fixedly-connected mounting plates located on the supporting frames on the two sides, and a first pushing cylinder and a second pushing cylinder which are located on the mounting plates on the two sides correspondingly, and piston rod heads of the first pushing cylinder and the second pushing cylinder are provided with mounting bases.

Owner:锡腾(无锡)精密工业有限公司

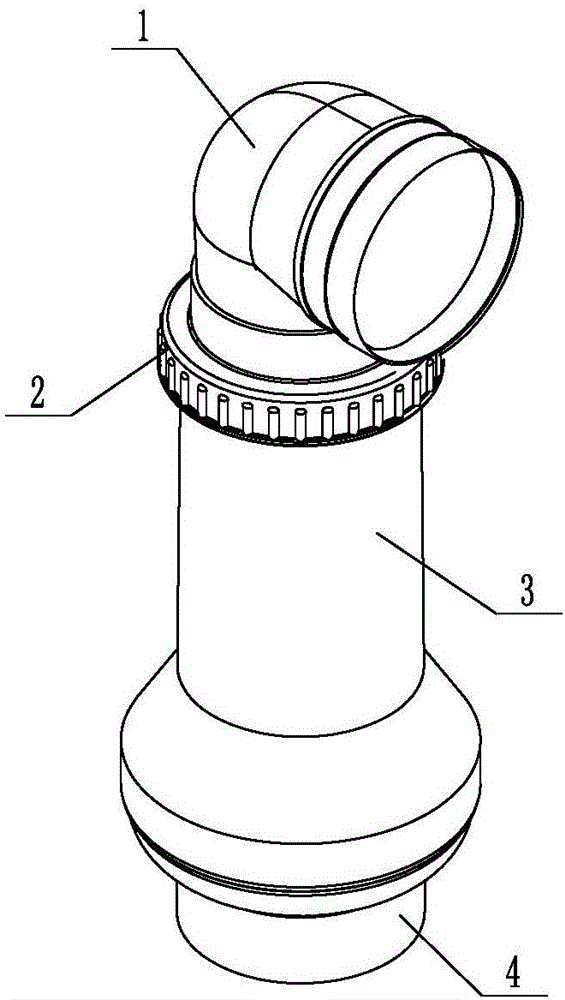

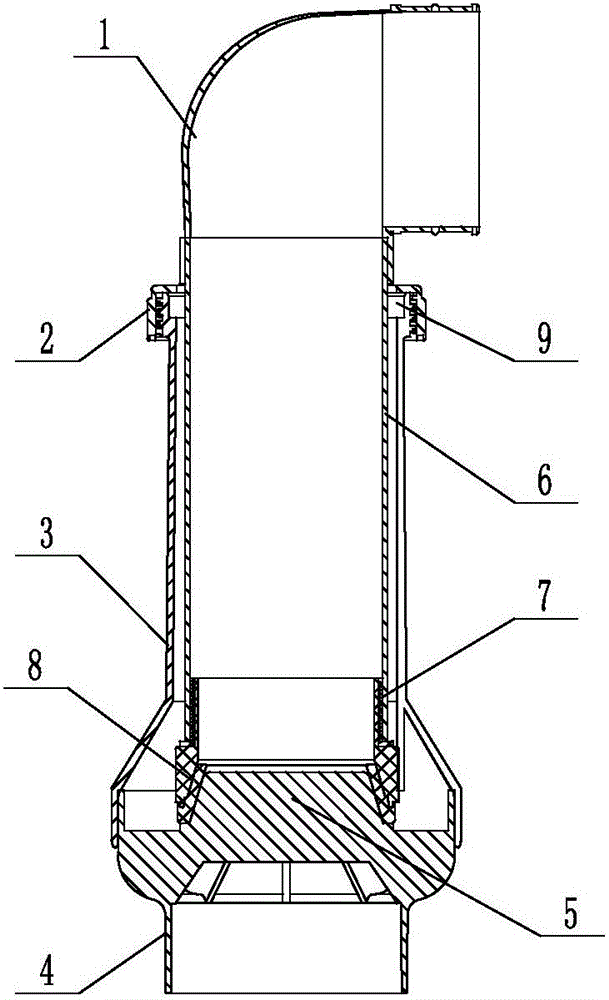

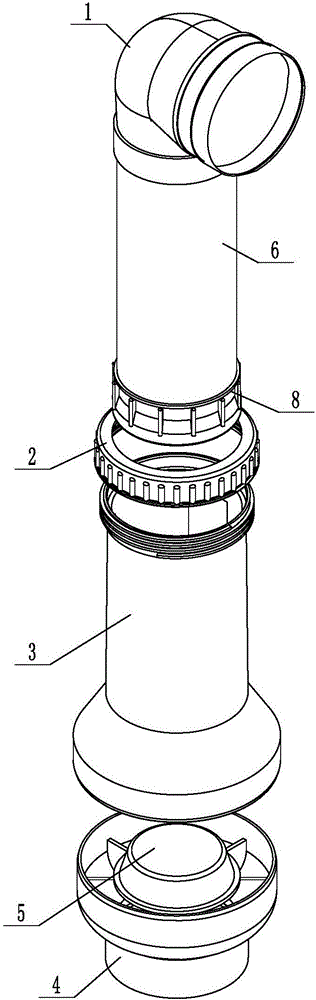

Lifting and switching-on and switching-off type hydrant

ActiveCN106321862ASimple structureEasy to switchLift valveValve housingsInvisibilityOmni directional

The invention provides a lifting and switching-on and switching-off type hydrant and relates to the technical field of water conservancy equipment. The lifting and switching-on and switching-off type hydrant comprises a bend, an inner pipe, an outer pipe, a pressing cover and a cork base. The bend is connected with the inner pipe, the inner pipe moves in the outer pipe, the upper end of the outer pipe is provided with the pressing cover, the outer pipe is connected with the cork base, the cork base is provided with a valve boss, the lower end of the inner pipe is provided with a valve composite part, and a valve is switched on or off through separation and reunion of the valve boss and the valve composite part. The hydrant is simple in structure, convenient to switch on or off, scientific in manufacturing process, economical and practical and can be widely applied to farm irrigation, urban green land and water supply and discharge and the like. By using the hydrant, lifting, switching-on, switching-off and omni-directional rotation can be performed, functions of invisibility and anti-collision and the like can be achieved by matching with a protective device for use, and the hydrant is practical, economic and advanced.

Owner:邱学东

Car model display stand convenient to clean

InactiveCN114305021AImprove practicalityPlace stableShow shelvesShow hangersEngineeringStructural engineering

The invention discloses a car model display stand convenient to clean, which comprises supporting legs, a support and a stand body, the supporting legs are arranged at the four corners of the bottom end of the support, the stand body is arranged at the top end of the support, a rotating mechanism is arranged between the support and the stand body, wheel grooves are formed in the four corners of the top end of the stand body, and the rotating mechanism is arranged in the wheel grooves. And a fixing structure is arranged on one side of each wheel groove, a protection structure is arranged at the top end of the support, and the protection structures are arranged on the outer side wall of the table body. The rotating mechanism is arranged at the bottom end of the car model display stand, so that a car model placed on the car model display stand can rotate by 360 degrees, a visitor does not need to walk around the car model to watch at other angles, and the visitor can stand in situ to watch and know the car model in all directions; the arrangement of the mechanism provides convenience for visitors, so that the overall practicability is improved.

Owner:江苏歌鹰航空科技有限公司

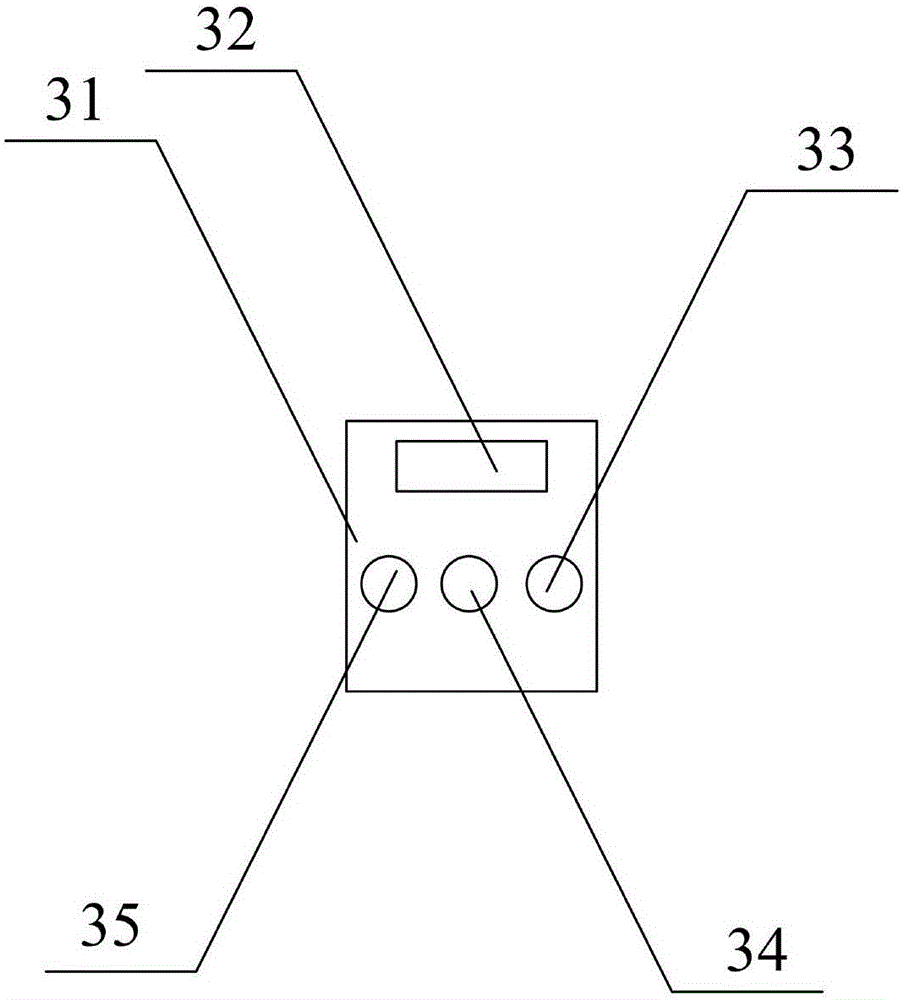

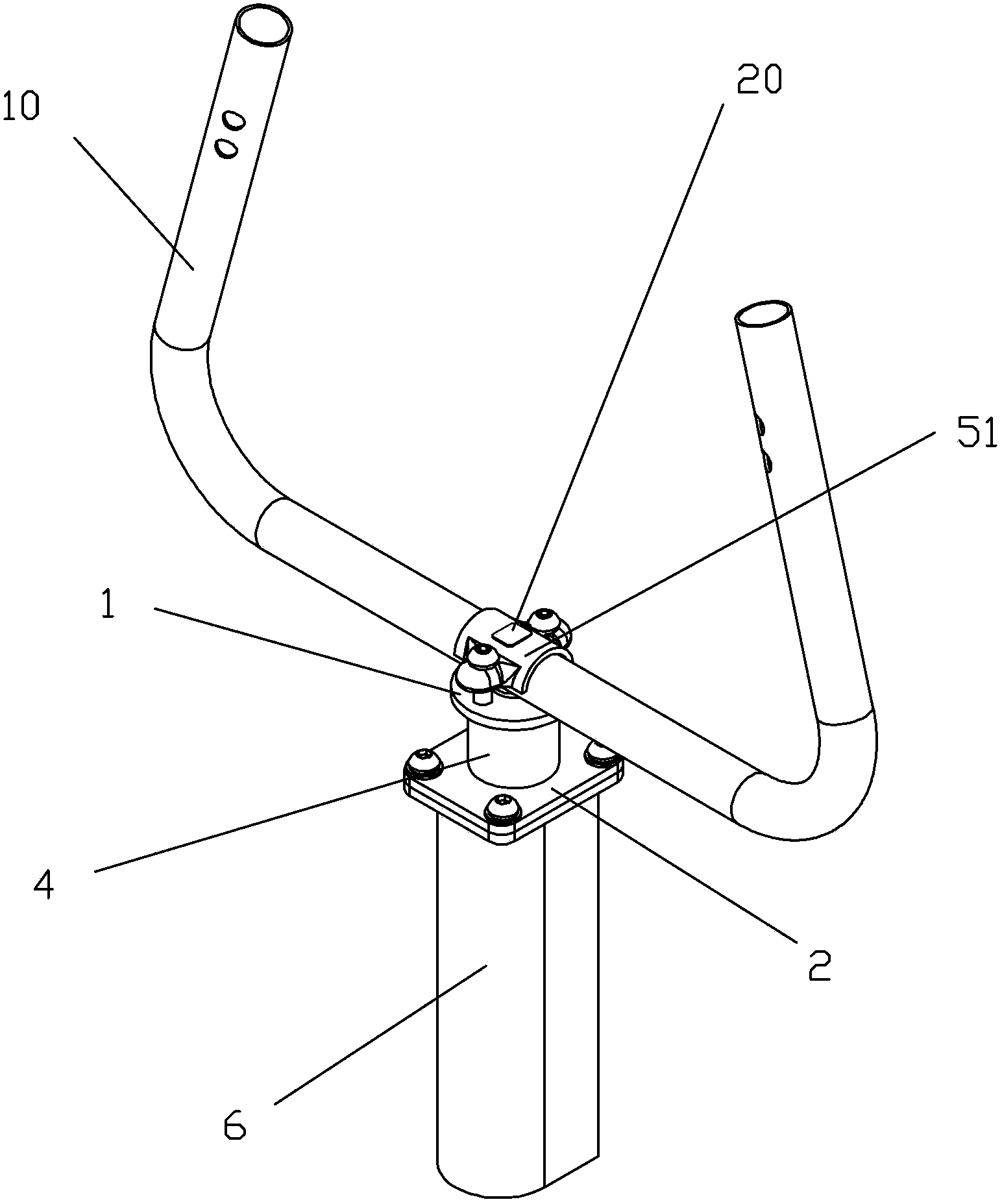

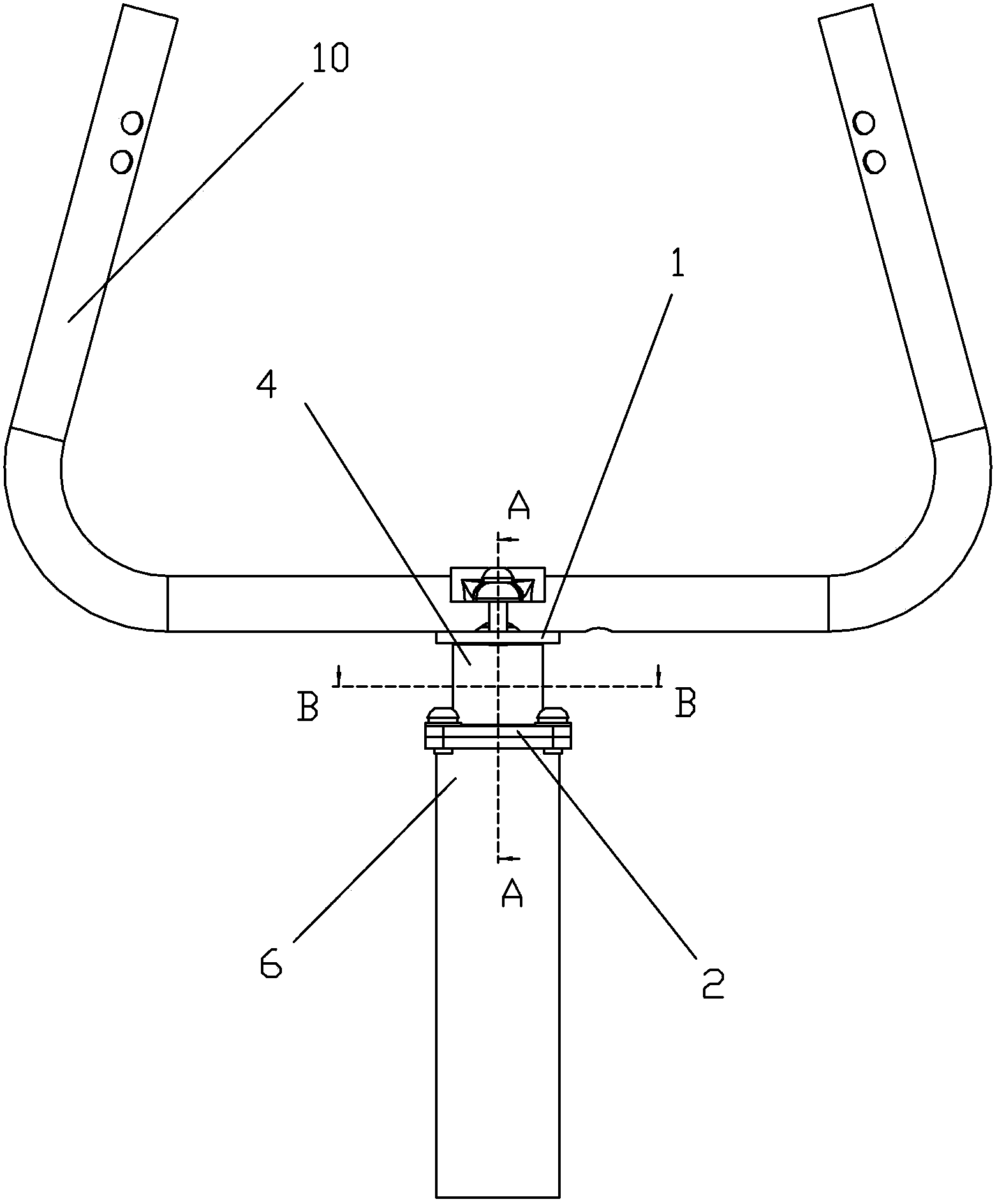

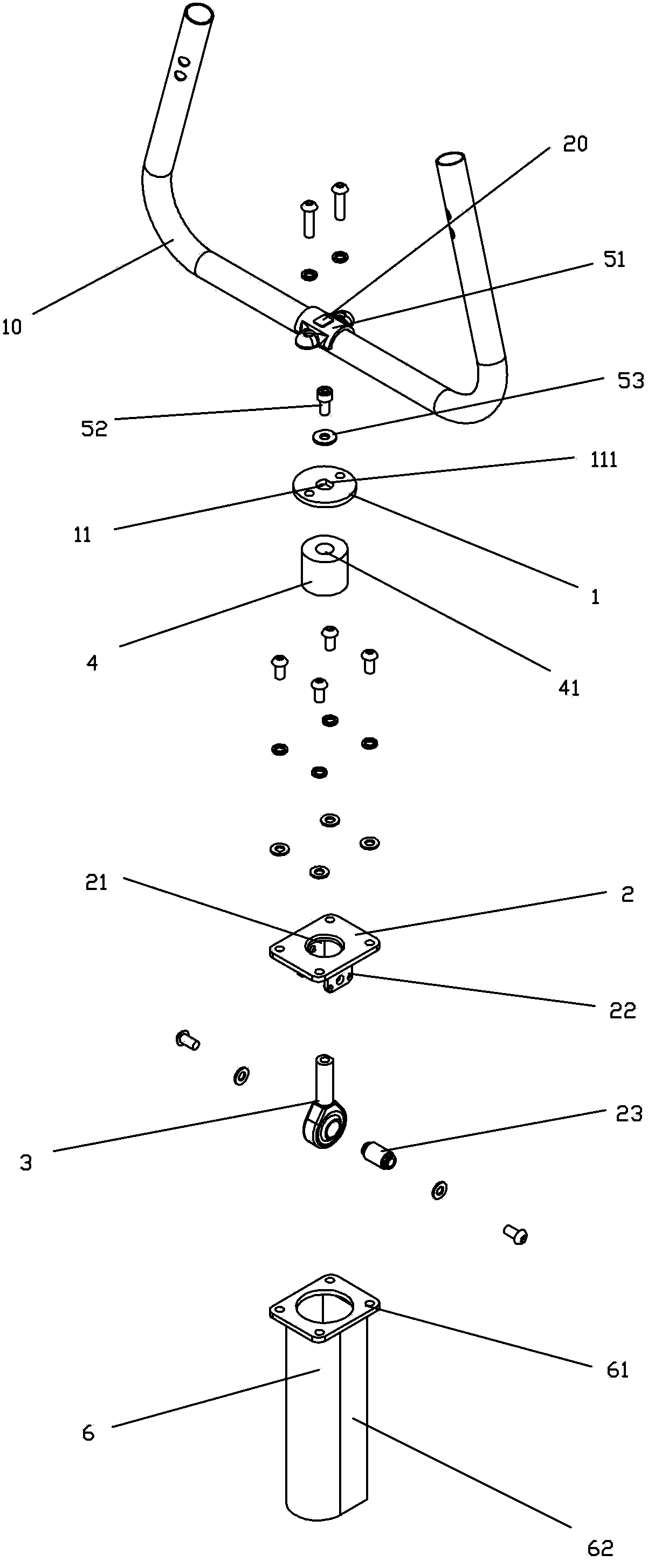

Direction operating mechanism for intelligent body building vehicle

ActiveCN102743836BFull range of rotationEasy to makeMovement coordination devicesCardiovascular exercising devicesVehicle frameEngineering

Owner:舒周文

Universal-movement device and flying experience device

InactiveCN107008013AFull range of rotationImprove user experienceAmusementsEngineeringUsage experience

The invention provides a universal-movement device and a flying experience device, and belongs to the field of sports apparatuses. The universal-movement device comprises a base, a first rotating arm, a second rotating arm and a third rotating arm. A first rotating shaft is connected between the base and the first rotating arm, a second rotating shaft is connected between the first rotating arm and the second rotating arm, and a third rotating shaft is connected between the second rotating arm and the third rotating arm; the axis of the first rotating shaft and the axis of the second rotating shaft are intersected or are in different planes, and the axis of the second rotating shaft and the axis of the first rotating shaft are intersected or are in different planes. The flying experience device comprises a riding device and the universal-movement device, and the riding device is connected with the third rotating arm in a rotating mode. The universal-movement device can achieve that one end, away from the second rotating arm, on the third rotating arm can reach more orientations. Persons can have more viewing angles and more experience modes through the flying experience device, and usage experiences of the persons are improved.

Owner:CHANGZHOU JINGANG NETWORK TECH

Anti-jamming thread guiding device for textile machinery

InactiveCN112850357AFull range of rotationAvoid stickingFilament handlingStructural engineeringMechanical engineering

The invention discloses an anti-jamming thread guiding device for textile machinery. The anti-jamming thread guiding device comprises a turning wheel, a fixing ring, a thread wheel and a base, wherein the base is provided with fixing nuts, the fixing nuts are provided with first telescopic rods, and the first telescopic rods are provided with clamping rings; the clamping rings are provided with adjusting nuts, and the adjusting nuts are connected with adjusting handles; and one first telescopic rod is connected with a first supporting column, and the first supporting column is connected with the thread wheel. According to the anti-jamming thread guiding device for the textile machinery, by arranging the clamping rings, the adjusting nuts and the adjusting handles, height adjustment of the device can be achieved, when the thread guiding device is used, different textile machines need to be adjusted; when the device is used, the adjusting handles are rotated, the adjusting handles drive the adjusting nuts to rotate, the adjusting nuts loosen the clamping rings, then the first supporting column, a second supporting column and a third supporting column can be pulled out for adjustment, and the height of the device can be adjusted.

Owner:江苏沁怡纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com