Polaroid grinding equipment for display screen

A technology of polarizer and display screen, which is used in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc. operation and other problems to achieve the effect of improving the overall quality and removing burrs and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

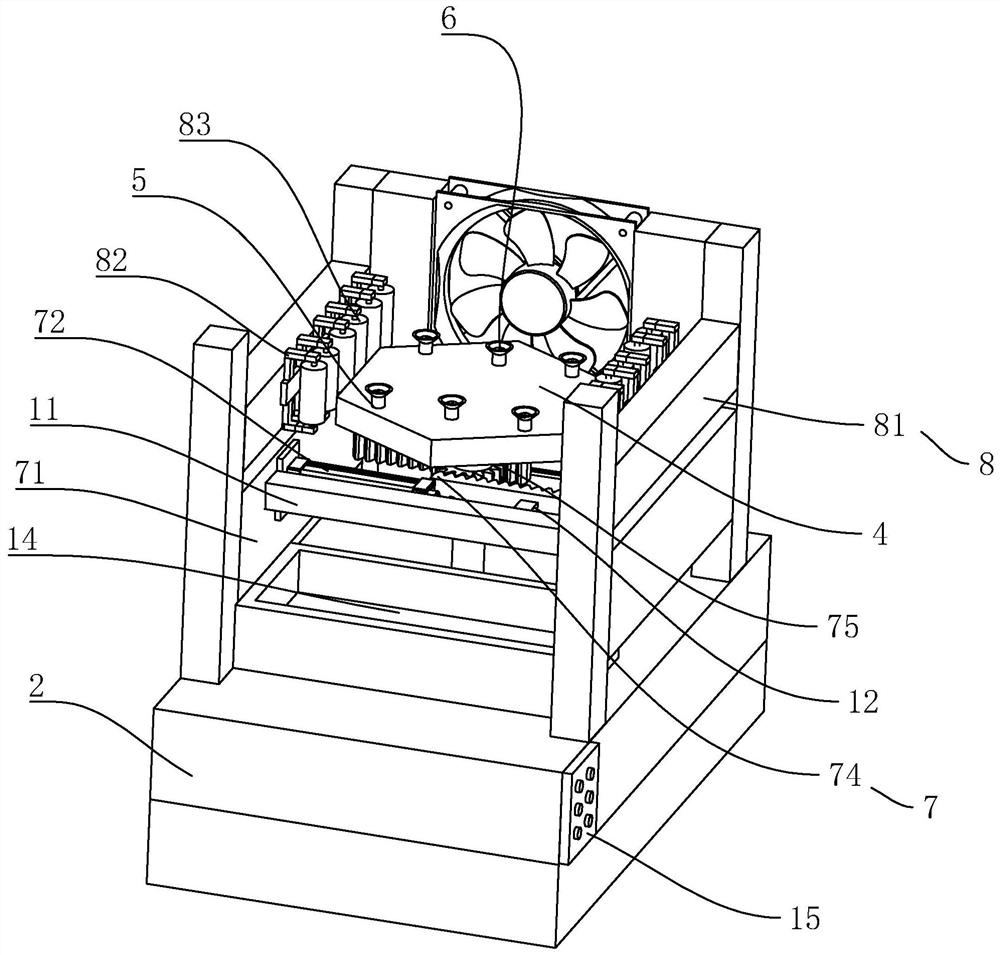

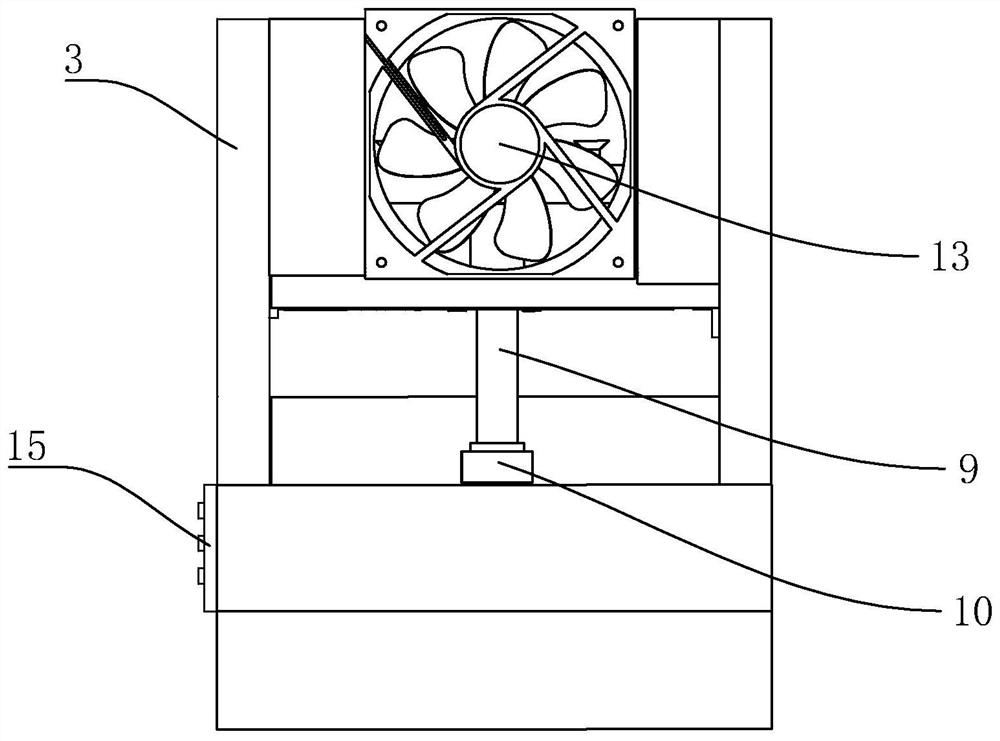

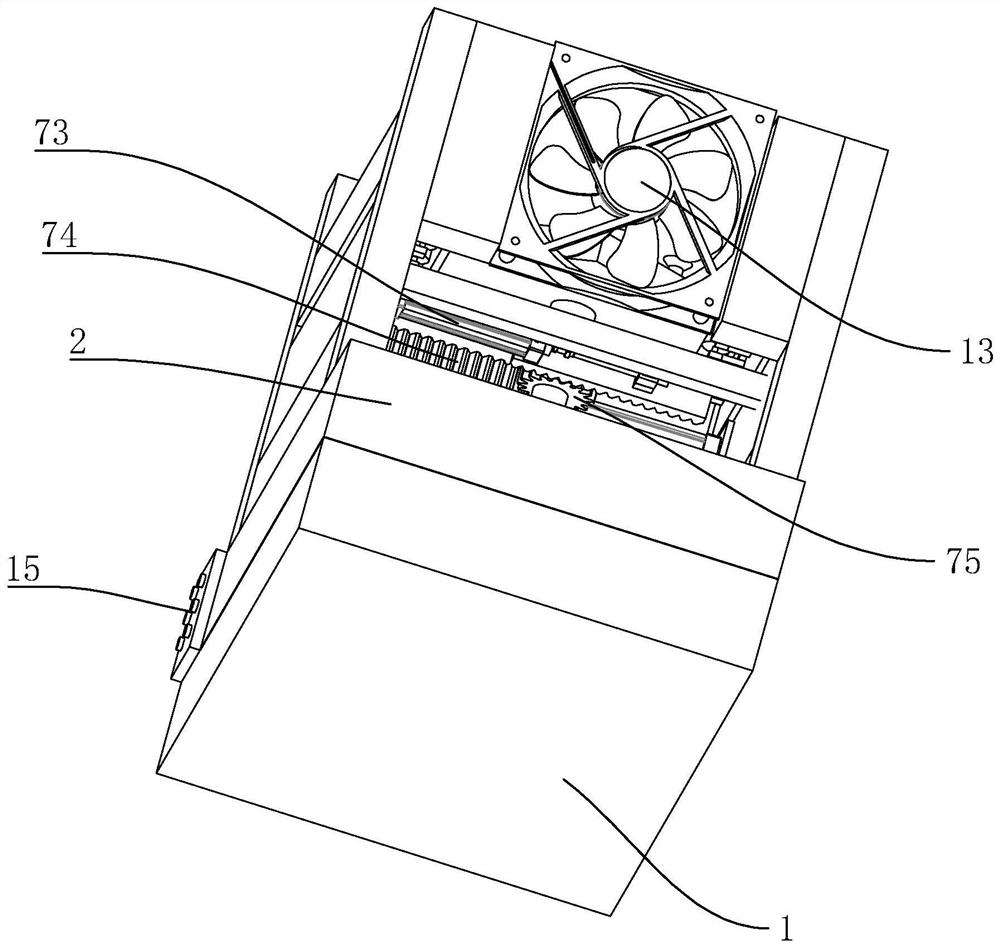

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] A kind of polarizer grinding equipment for display screen, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a workbench 2 arranged on the base 1 and a support frame 3 installed on both sides of the workbench 2. The workbench 2 is provided with a grinding boss 4, and the surface of the grinding boss 4 is also provided with There are several installation holes 5, and vacuum suction cups 6 are also arranged in the several installation holes 5. Both sides of the grinding boss 4 are provided with an adjustment assembly 7 installed on the support frame 3, and the top of the grinding boss 4 is also provided with a grinding assembly 8. The adjustment assembly 7 includes a fixedly connected mounting plate 71 positioned on the support frame 3 on both sides. , the first push cylinder 72 and the second push cylinder 73 respectively loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com