All-directional moving and high-low lifting carrying AGV car with comb teeth

A technology of all-round movement and trolley, which is applied in the direction of lifting devices, etc., can solve the problems of unsuitability for car transportation, high cost, and limited application, and achieve the effects of improving stability and versatility of transportation, improving load capacity, and facilitating functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail, but the scope of protection of the present invention is not limited to the following examples, all technical schemes obtained by adopting equivalent replacement or equivalent transformation forms are all within the scope of protection of the present invention .

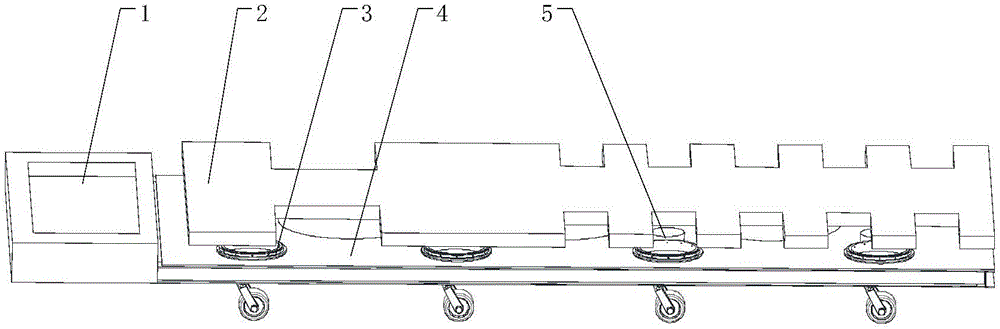

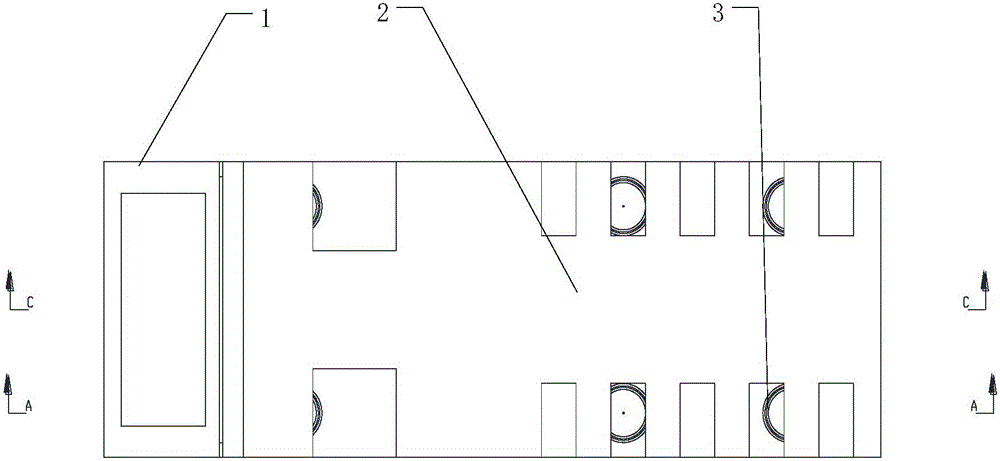

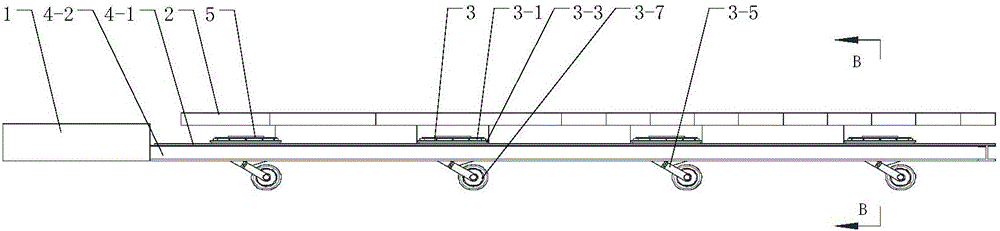

[0035] as attached Figure 1 to Figure 11 As shown, it is a transport AGV trolley with comb teeth for all-round movement and height lifting according to the embodiment of the present invention. Mechanism 5 is composed of 8 lifting disc mechanisms 3, which are symmetrically arranged in two rows and multiple rows in the lifting disc fixing hole 4-1-1 provided on the fixed bottom plate 4-1 of the body support frame 4. The lower plane of the comb bearing plate 2 is provided with several raised columnar bodies, which are installed in the comb tooth fixing holes 4-1-2 provided on the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com