Foldable all-around drilling mechanism

An all-round and foldable technology, used in rotary drilling rigs, earth-moving drilling, impact drilling, etc., can solve problems such as narrowness and inconvenience in use, and achieve the effect of improving overall life, avoiding wear, and having good stress effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

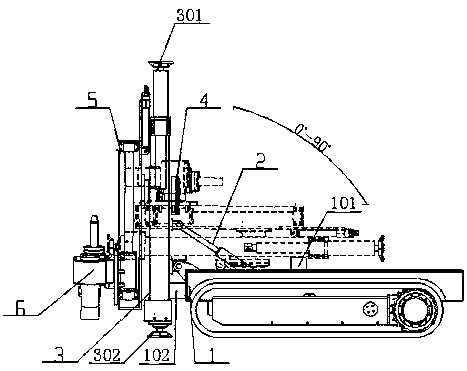

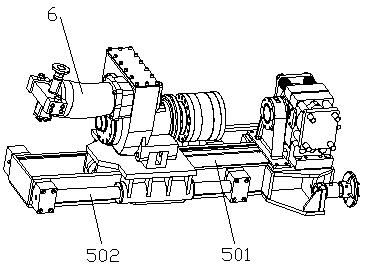

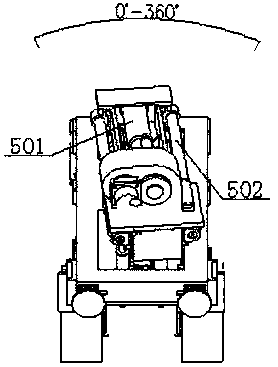

[0023] As shown in the figure, a foldable omnidirectional drilling mechanism includes a chassis 1, an overturning oil cylinder 2, an overturning frame 3, a slewing support 4, a guide rail 5 and a power head 6, and one end of the overturning frame 3 is hinged on the chassis 1 The front end, the other end of the reversing frame 3 is hinged in the middle of the chassis 1 through the reversing oil cylinder 2, and the folding of the reversing frame 3 is controlled by the expansion and contraction of the piston rod of the reversing oil cylinder 2; one end of the slewing support 4 is fixed on the reversing frame 3, and The other end of 4 is connected with the guide rail 5;

[0024] The above is the basic implementation of the present invention, and further improvements, perfections and limitations can be made on the basis of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flip angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com