Vibration breaking-down shovel

A technology for leveling coal and leveling coal, which is applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of not meeting the shipping requirements of the railway transportation management department, high labor intensity of the post, affecting the loading efficiency, etc. The effect of helping to spread coal, improving shipping efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

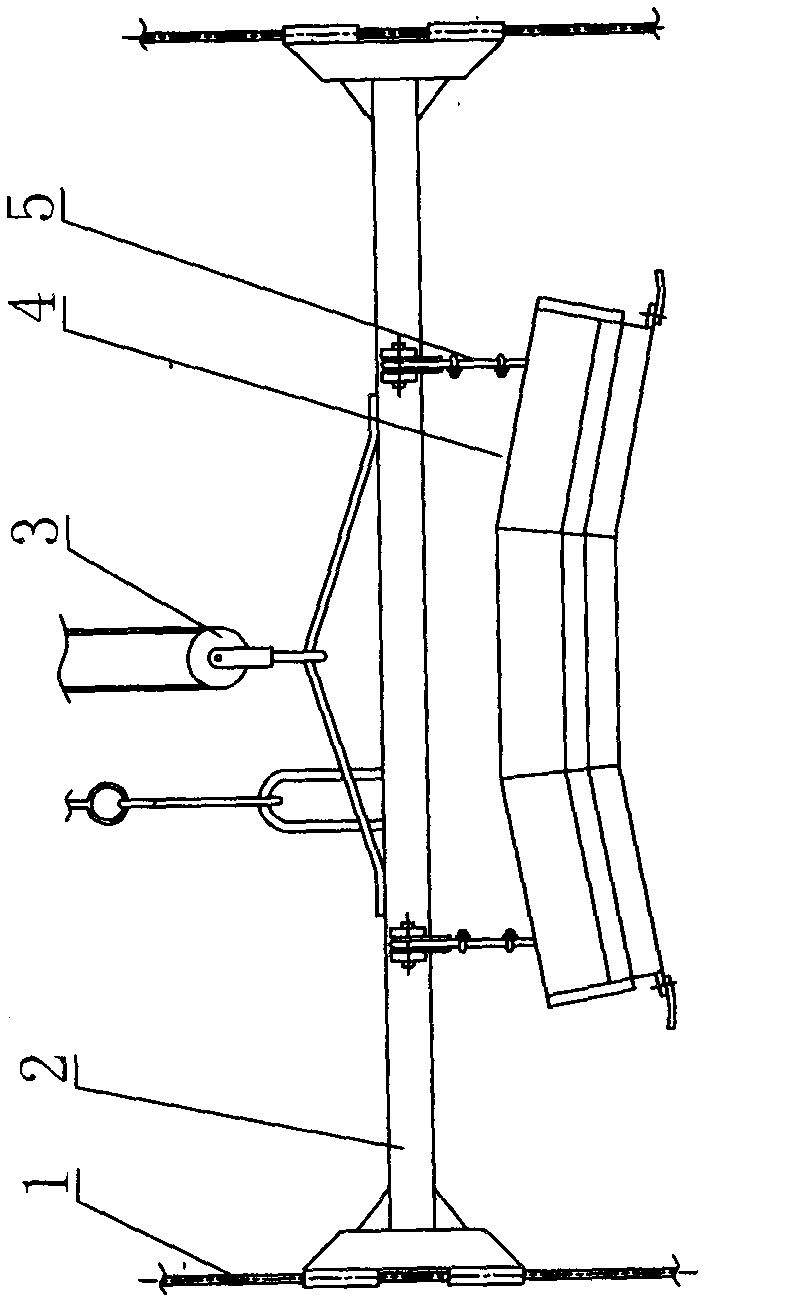

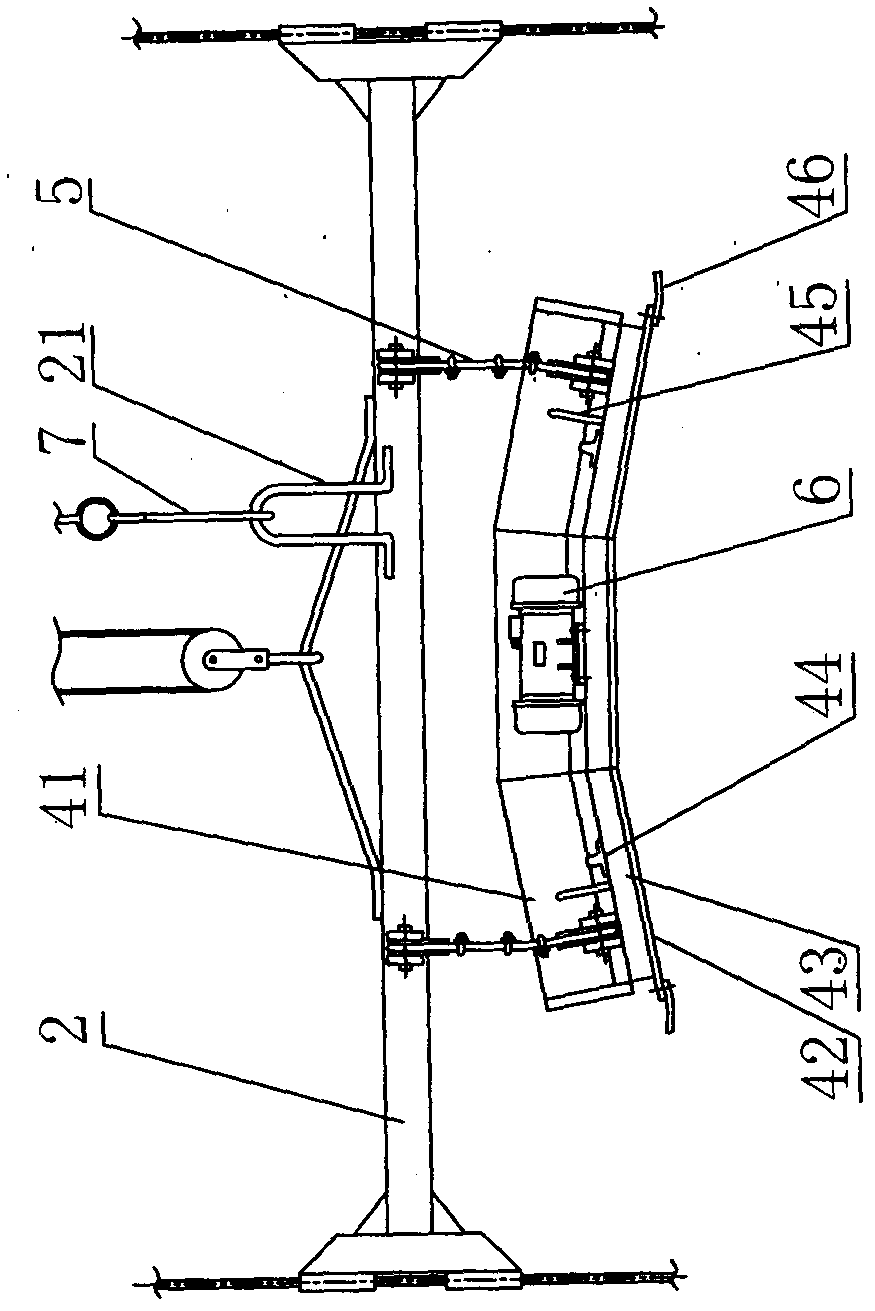

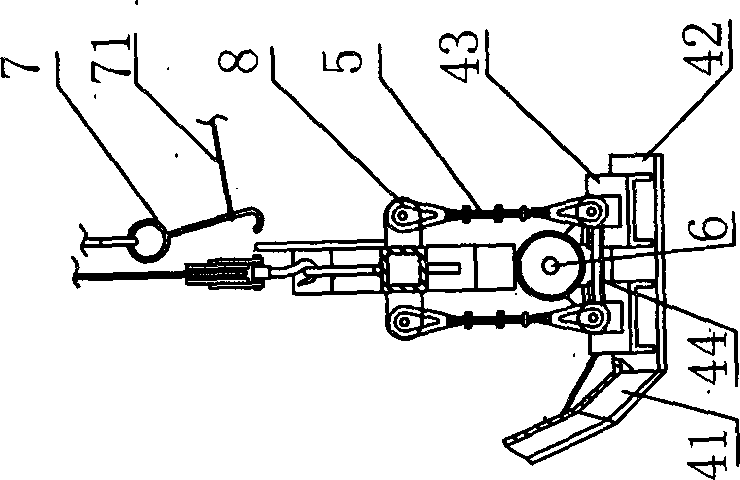

[0020] like figure 1 , figure 2 , image 3 As shown, a vibrating coal leveler includes a frame 2, and the two ends of the frame 2 are movably connected to the cable slideway 1 perpendicular to the ground through sliding sleeves, and the upper part of the frame 2 is connected with a lifting Device 3, the lower part of the frame 2 is connected with a flat coal device 4 through a plurality of flexible cables 5, the flat coal device 4 includes a flat coal plate 42 and a front baffle 41 fixed on the front of the flat coal plate, the flat coal The plate 42 is adapted to the width of the train carriage, and the vibration motor 6 is fixed on the flat coal plate 42 .

[0021] Described flat coal plate 42 is the arch shape with low middle and high in both sides.

[0022] The both sides of described flat coal plate 42 have coal retaining skin pad 46, prevent cinder from overflowing.

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com