Inspection equipment

A technology for inspecting equipment and components, which is applied in the field of radiographic inspection equipment and inspection equipment, can solve the problems of oversize, inconvenient use, disassembly, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

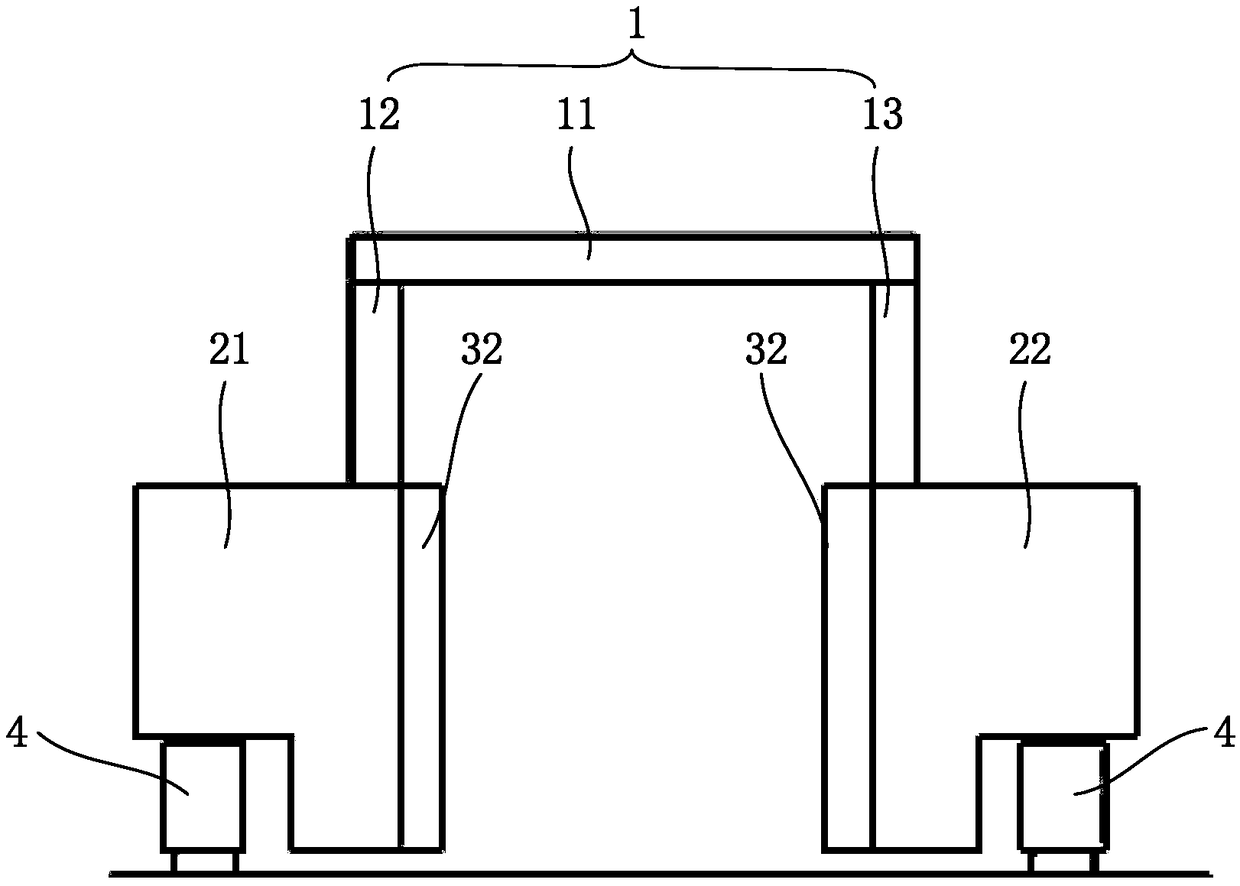

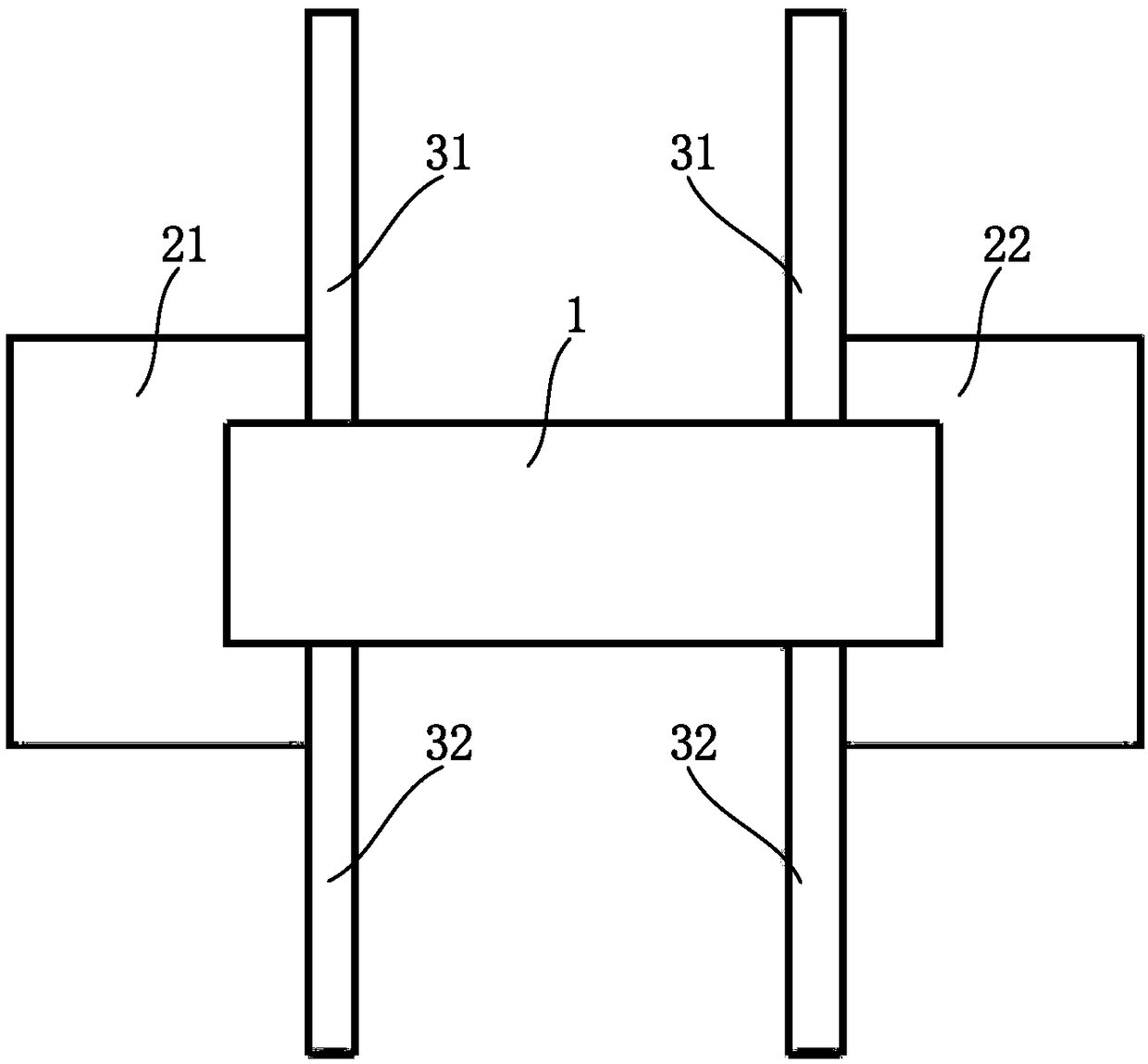

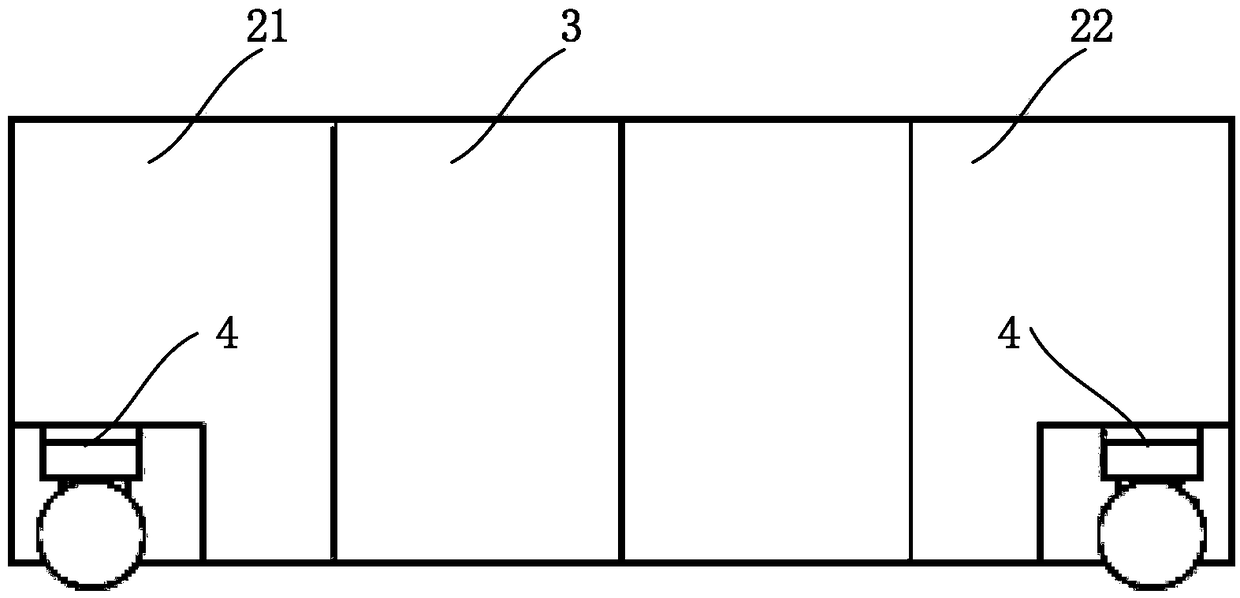

[0040] Combine below Figure 1 ~ Figure 4 The technical solution provided by the present invention is described in more detail.

[0041] see figure 1 , the embodiment of the present invention provides an inspection device, which includes a boom 1 , a cabin assembly 2 and a traveling device 4 . The arm frame 1 is arranged on the cabin assembly 2 in a liftable manner; the running device 4 is arranged on the bottom of the cabin assembly 2 and is at least partly located directly below the cabin assembly 2 .

[0042] The inspection device is formed with an inspection channel for scanning vehicles or containers and the like. The radiation detection device includes a radiation source and a detector. The cabin assembly 2 is used for installing components such as a radiation source. The boom 1 is used to install detectors and other components. The arm frame 1 is a liftable structure. When transporting, the arm frame 1 is retracted; when working, the arm frame 1 is opened to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com