IGBT module structure reliability testing device having video monitoring function

A module structure and video monitoring technology, which is applied in the direction of measuring devices, single semiconductor device testing, semiconductor working life testing, etc., can solve problems such as key wire fusing, IGBT module failure, solder layer delamination, etc., to reduce false touches and misoperations The probability of increasing the load-bearing capacity and the effect of good fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

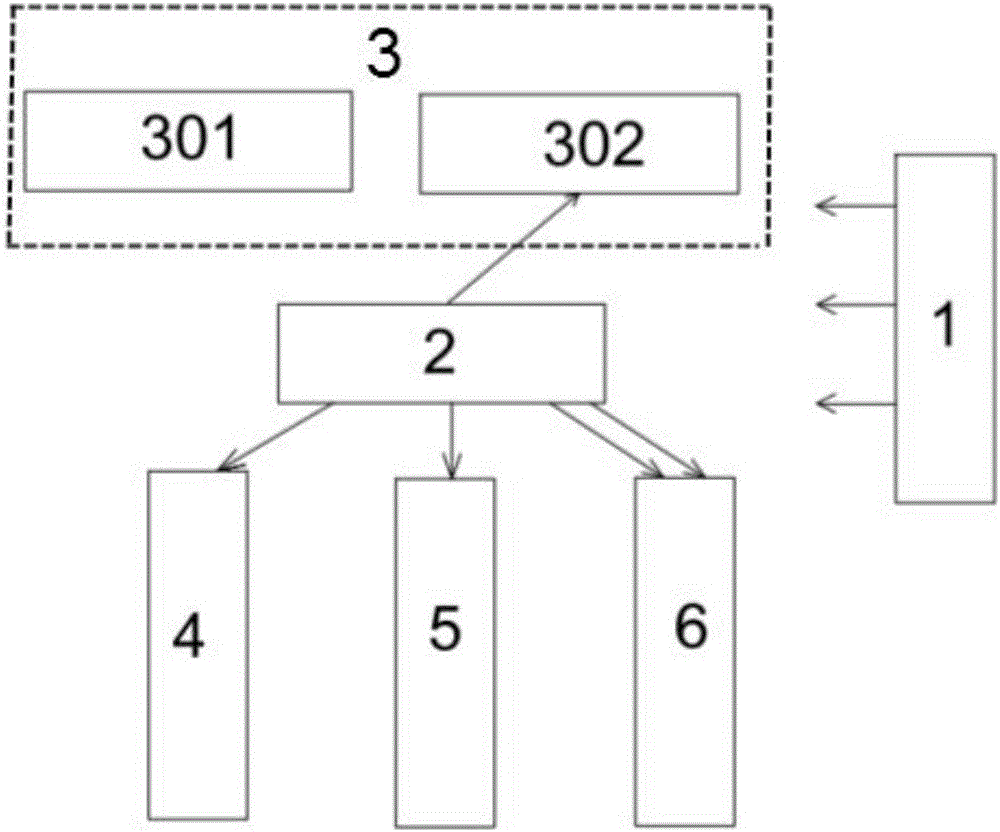

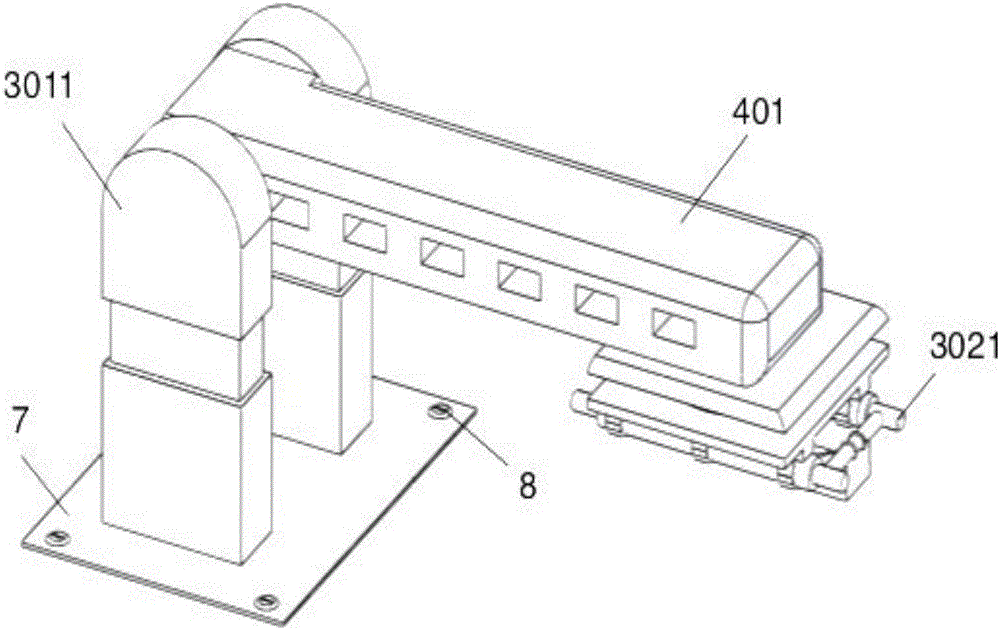

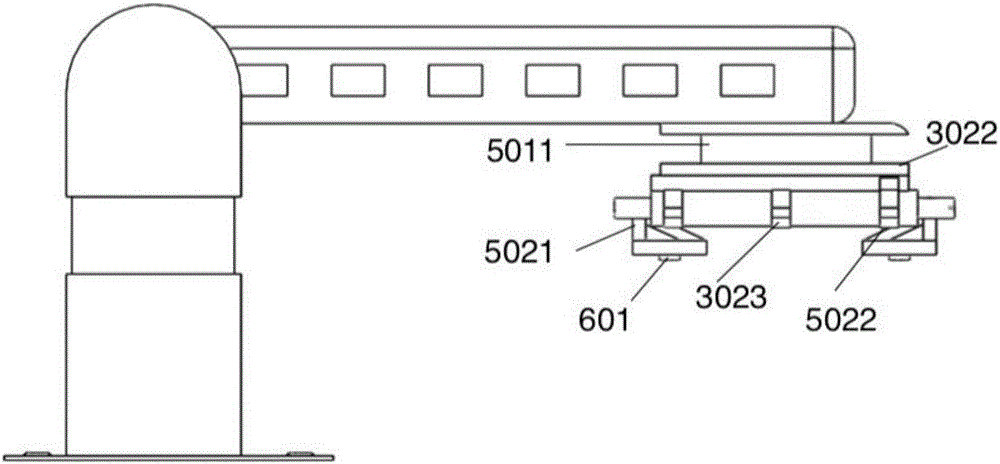

[0043] A kind of IGBT module structure reliability test device with video monitoring function, such as figure 1 As shown, it includes a power module 1 , an intelligent control module 2 , a sliding module 4 , a rotating module 5 , an acquisition module 6 and a telescopic module 3 . The power supply module 1 provides electric energy for other modules of the whole device. Described intelligent control module 2 comprises single-chip microcomputer module and computer, and the output end of single-chip microcomputer module in intelligent control module 2 connects the input end of sliding module 4, and sliding module 4 is output by the mode that slides on the sliding track by pulley; Described rotating module The input end of 5 is connected to the output end of the single-chip microcomputer module in the intelligent control module 2, and the output of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com