Material continuous conveying device for cement production line

A conveying device, technology of a production line, applied in the direction of transportation and packaging, packaging, loading/unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

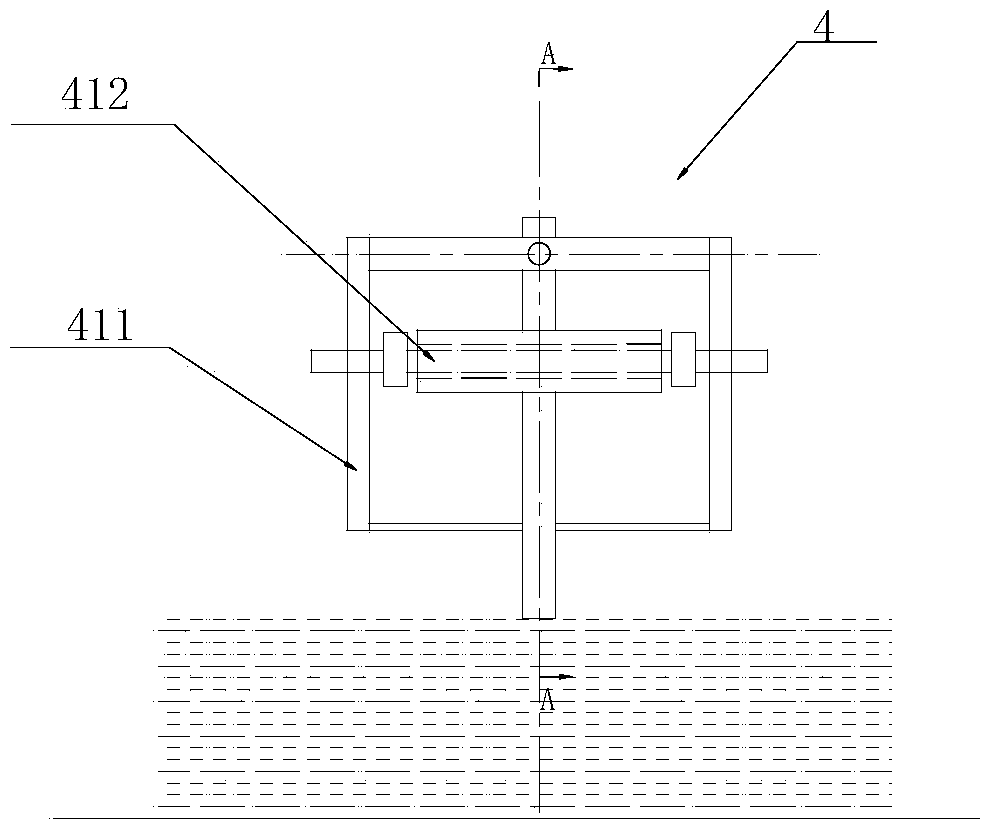

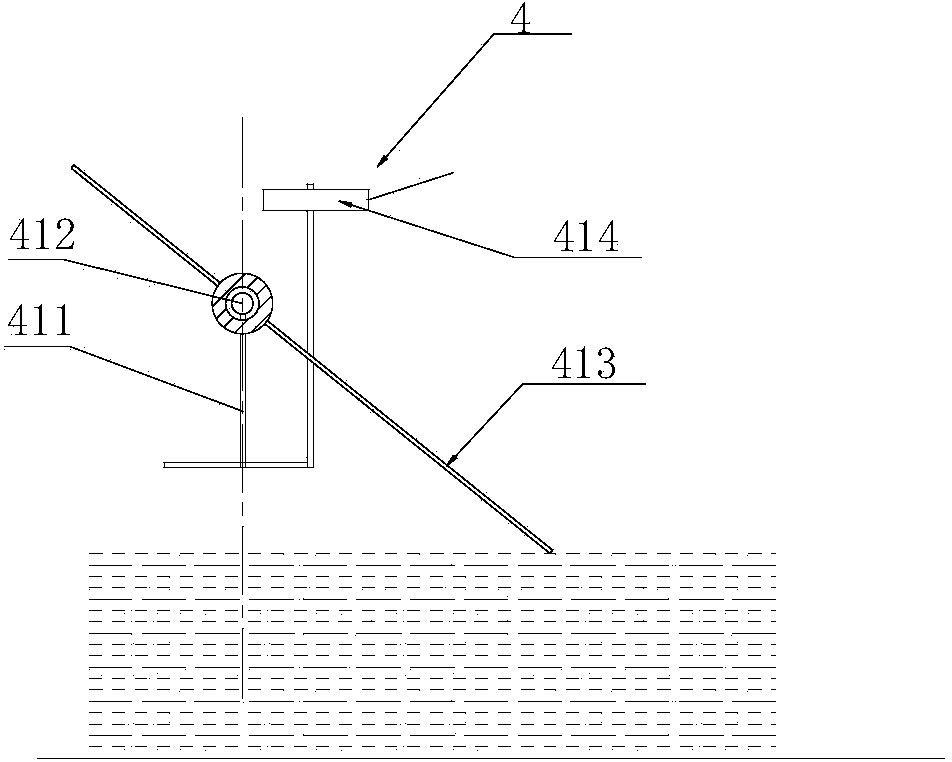

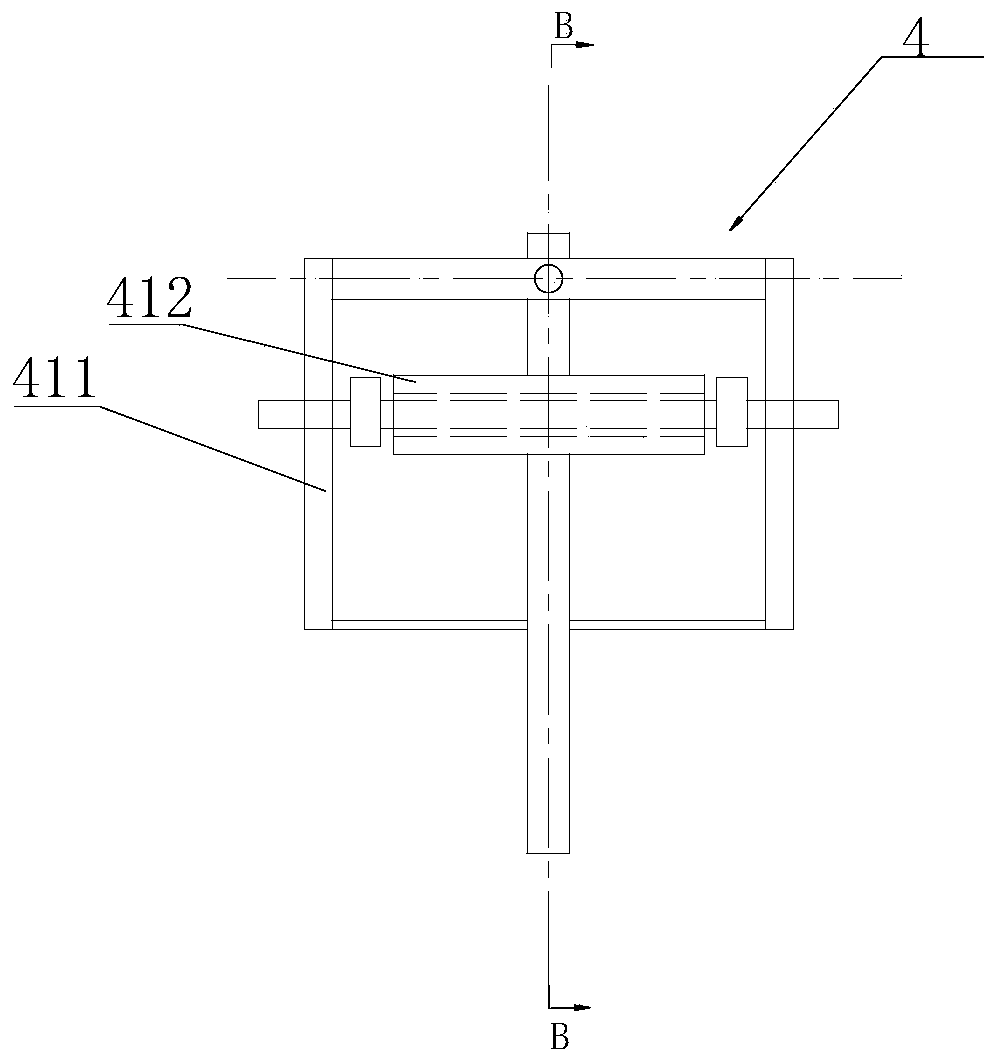

[0016] Example 1, please refer to Figure 1 to Figure 4 , A continuous material conveying device for a cement production line, comprising a silo 1, a rapping device 2 installed on the wall of the silo, the rapping device is a well-known technology, and the main thing is to shake the material stuck on the silo through vibration To ensure normal material transportation, the material conveyor belt 3 located below the silo also includes an opening and closing mechanism 4 that controls the opening and closing of the rapping device. The opening and closing mechanism is fixedly installed above the material conveyor belt 3.

[0017] In this embodiment, the opening and closing mechanism 4 adopts a trigger type opening and closing mechanism 410, the trigger type opening and closing device includes a fixing bracket 411, a rotating shaft 412 is installed on the fixing bracket, and a detection rod 413 is installed on the rotating shaft. The upper end of the detection rod is the detection end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com