Scraper type floor dung clearing system and construction method thereof

A scraper type and floor technology, which is applied in the field of livestock manure removal system and its construction, can solve the problems of hidden disease transmission, low efficiency, and difficulty, and achieve the effect of eliminating contact with disease infection, avoiding the crossing of feces, and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

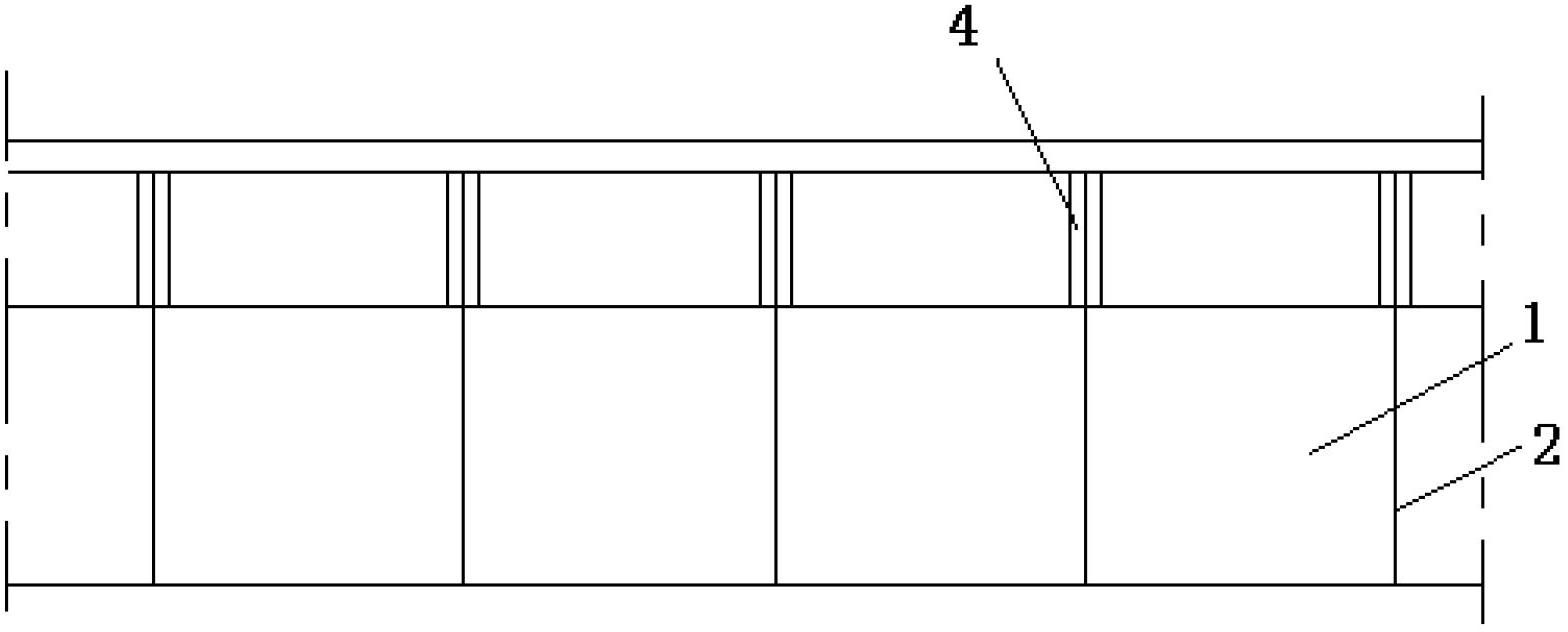

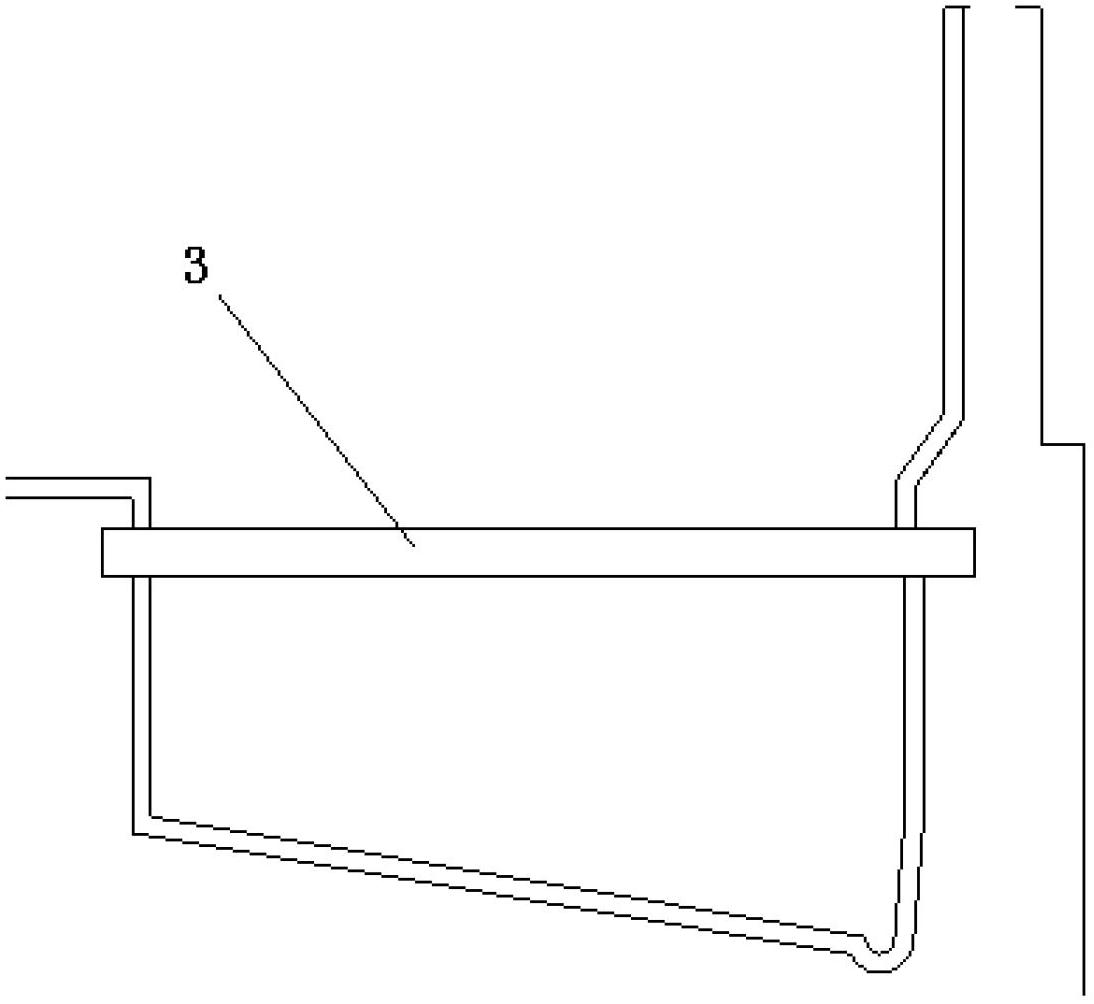

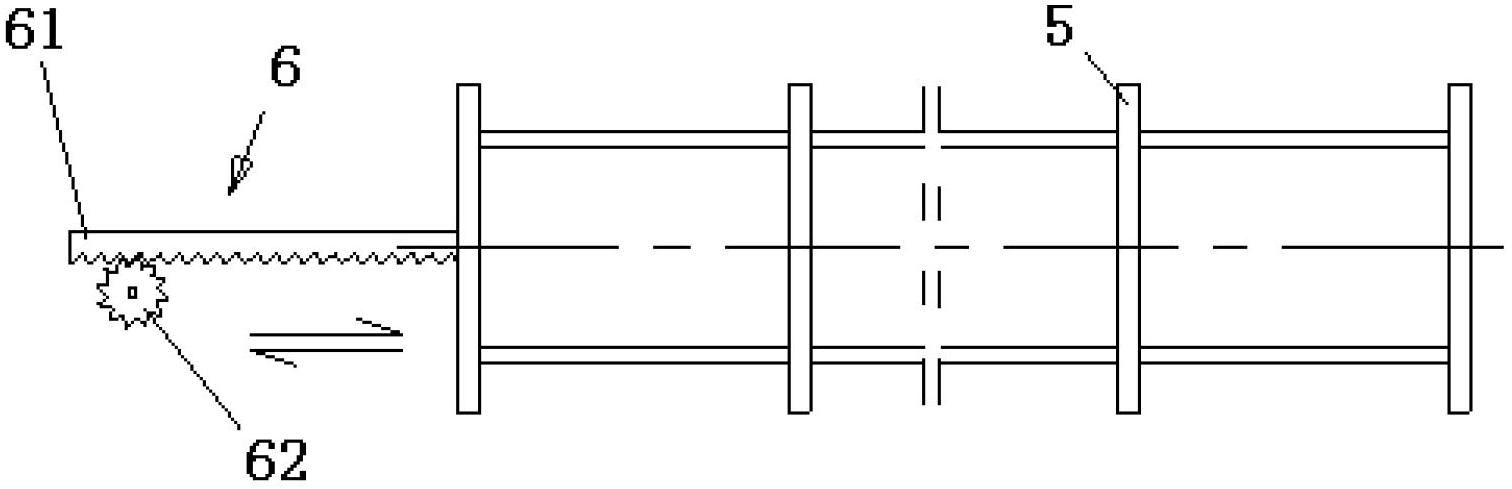

[0036] like figure 1 , figure 2 As shown, the structure of the pig house of the present invention is basically similar to that of the existing pig house. The pig house is divided into several pens 1 in parallel along the longitudinal direction (length direction), and every two pens 1 are separated by a partition 2 To make it an independent space for breeding, the center distance between two adjacent stalls 2 is defined as the width of the pen, and the defecation area of the pig house is located at one end of each pen 1 close to the side wall of the pig house. Below the defecation area, a longitudinal manure ditch is dug; the feature of the present invention is that: each pen 1 is provided with more than two beams 3 at intervals across the manure ditch, and a floor is set on the beams 3 along the longitudinal direction of the pig house. The floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com