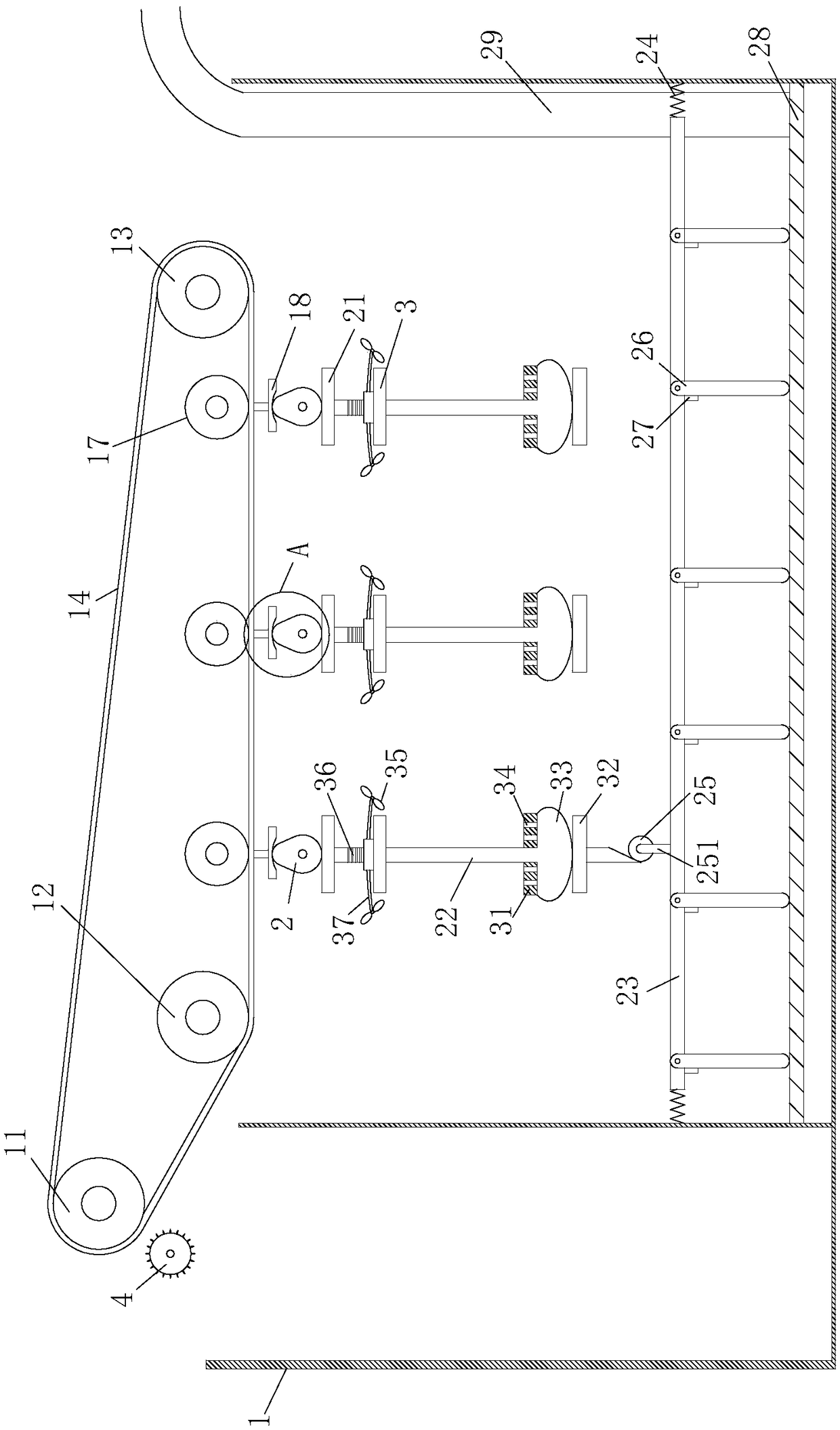

Patents

Literature

280results about How to "Keep clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

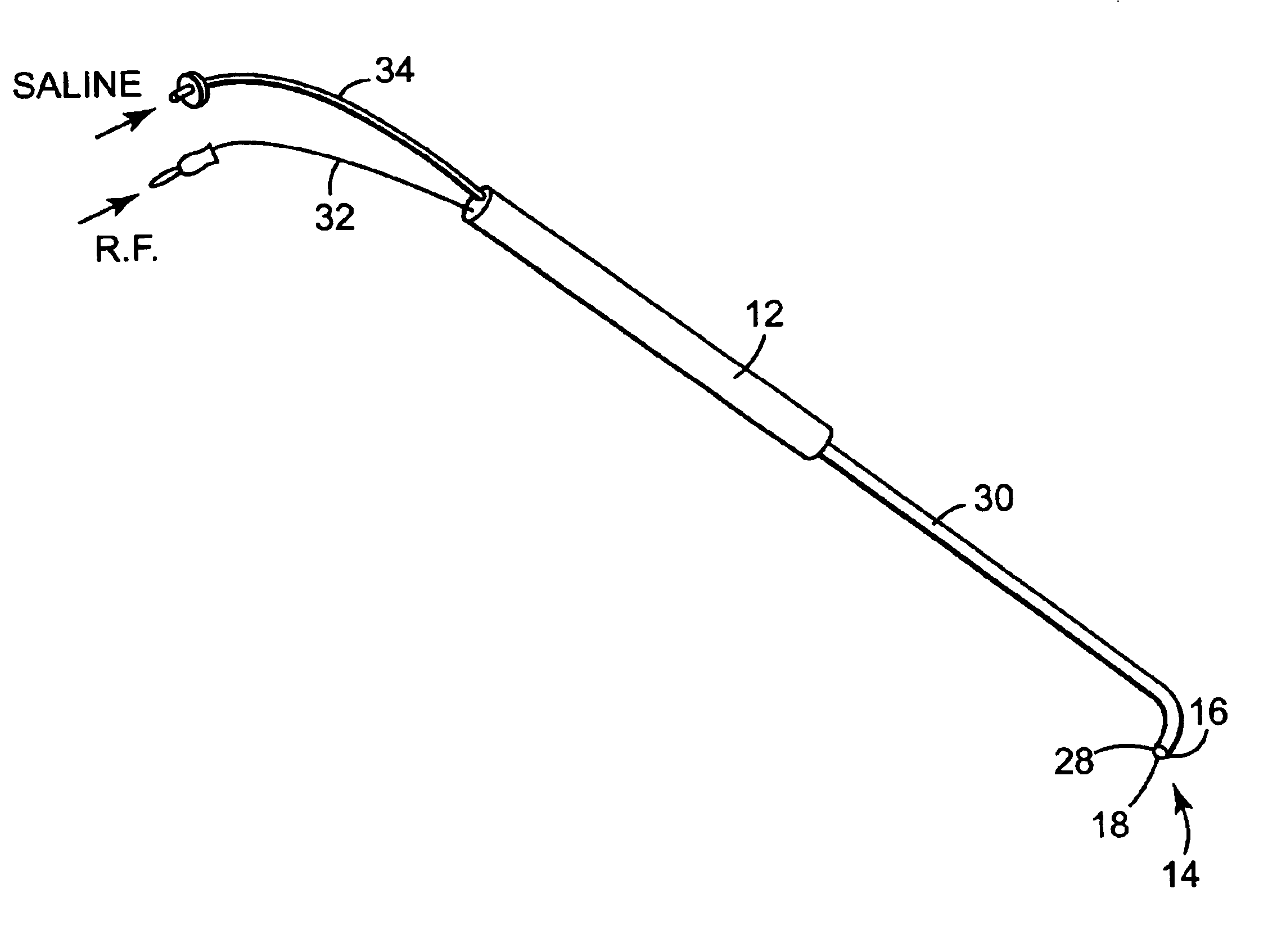

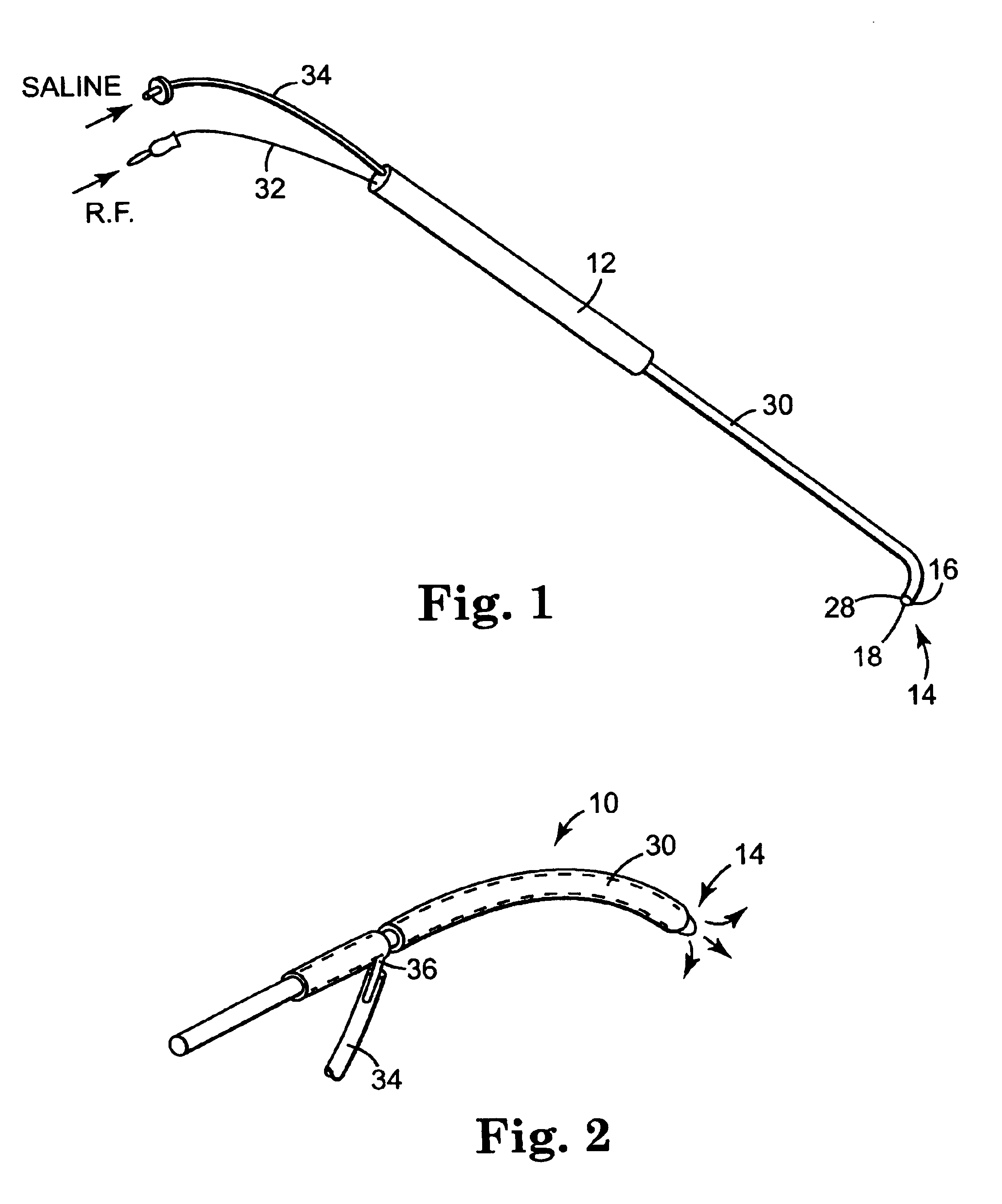

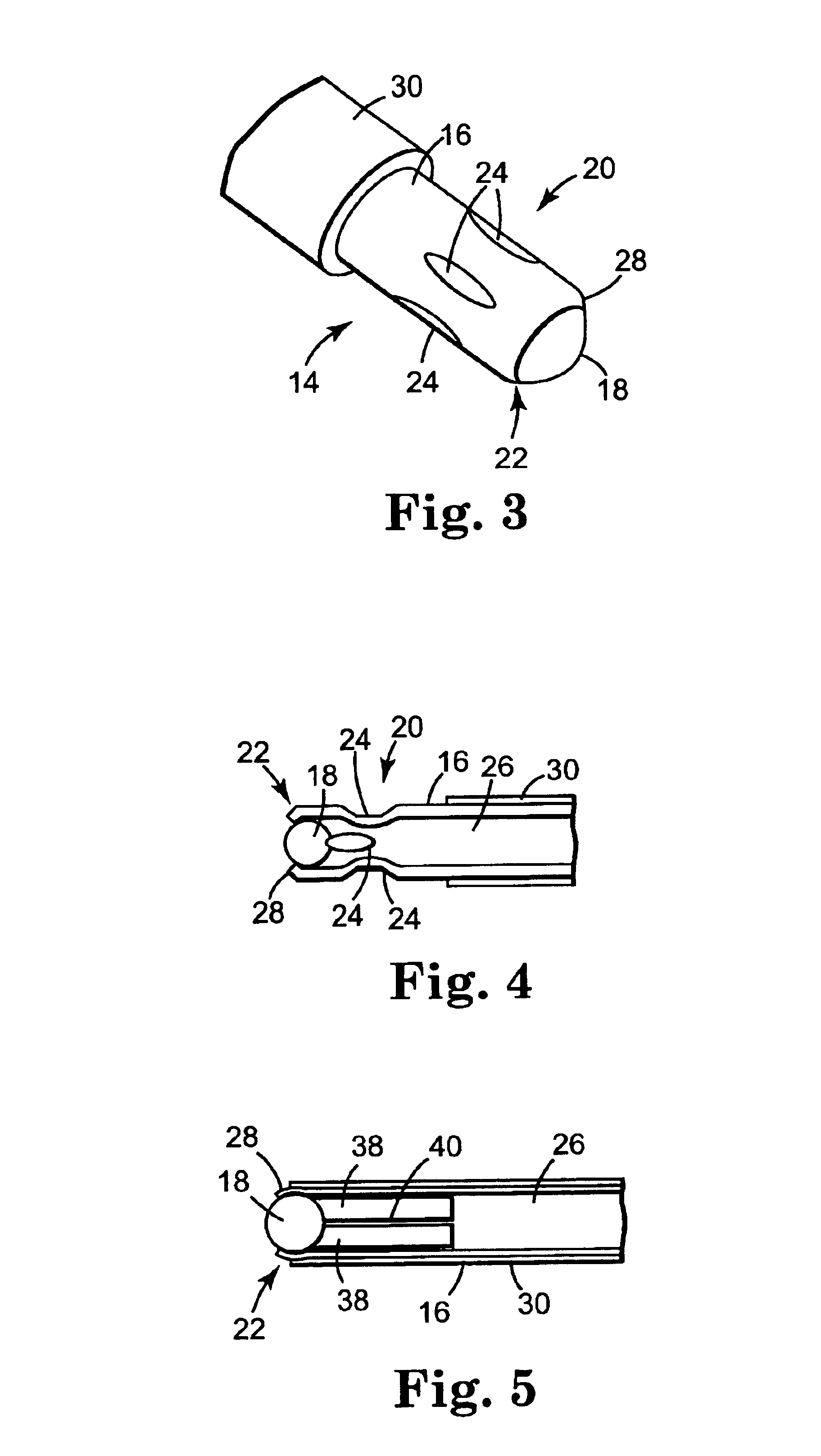

Pen-type electrosurgical instrument

An electrocautery device is disclosed. In accordance with one aspect of the invention, the electrocautery electrode / tip is provided with a hollow, conductive tube terminating at its distal end in a ball point type tip. Fluid, preferably conductive fluid, is applied to the proximal end of the hollow electrode / tip, and expelled from the distal end thereof during electrocautery. The ball point distal tip allows the distal tip to be directly applied to the tissue and “rolled” or slid along the tissue. This allows the distal tip to be moved across the tissue without dragging or snagging on the tissue. In addition, the conductive fluid expelled from the distal tip further lubricates the distal tip as it moves across the tissue. If conductive fluid is used, the conductive fluid emanating from the electrode / tip conducts the RF electrocautery energy away from the distal tip so that it is primarily the fluid, rather than the distal tip that actually accomplishes the cauterizing of tissue. That is, the fluid serves as a “virtual” electrocautery electrode. Since it is the fluid, rather than the distal tip that cauterizes, coagulates and ablates, no burns or perforations are made to the tissue, reducing the amount of debris at the site. Also, the flow of fluid through the electrode / tip tends to keep the distal tip clean and cool.

Owner:MEDTRONIC INC

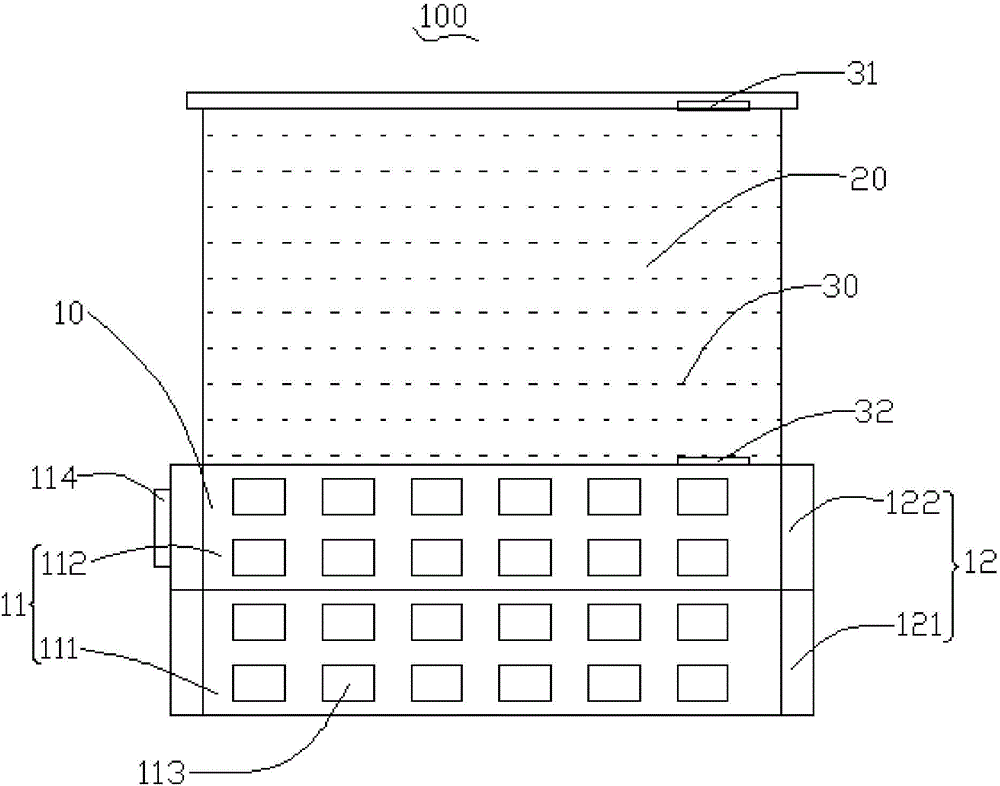

Electronic device and operation method thereof

InactiveCN104423433AKeep cleanProtect electronic equipmentDetails for portable computersEmbedded systemSolid-state

The invention discloses an electronic device and an operation method thereof. The electronic device comprises an electronic device body, a flexible display screen connected with the electronic device body, a current electrorheological fluid layer arranged on the flexible display screen; the electrorheological fluid layer can be switched between the liquid state and the solid state under the effect of an electric field, and the flexible display screen can be supported by the electrorheological fluid layer under the solid state.

Owner:LENOVO (BEIJING) CO LTD

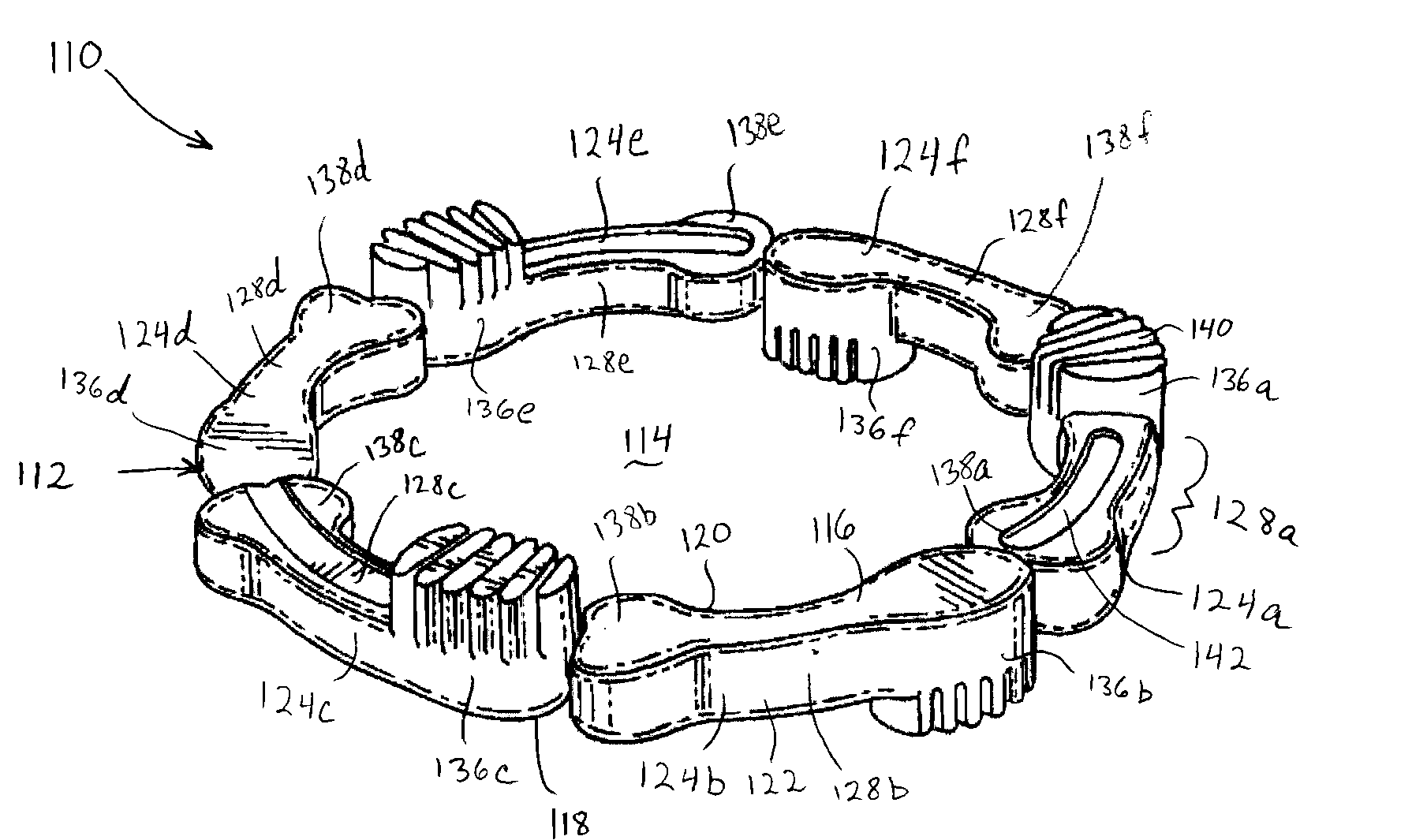

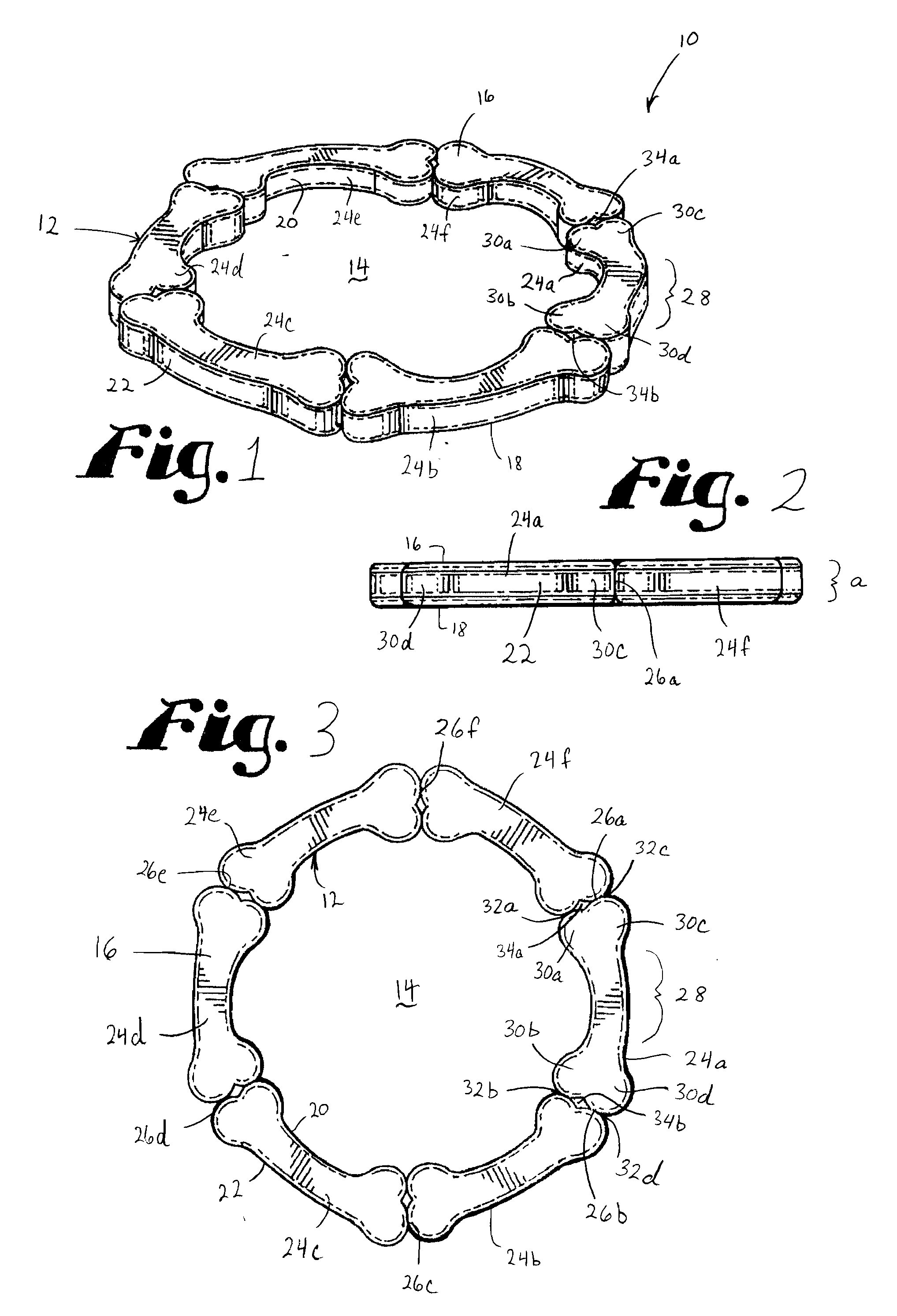

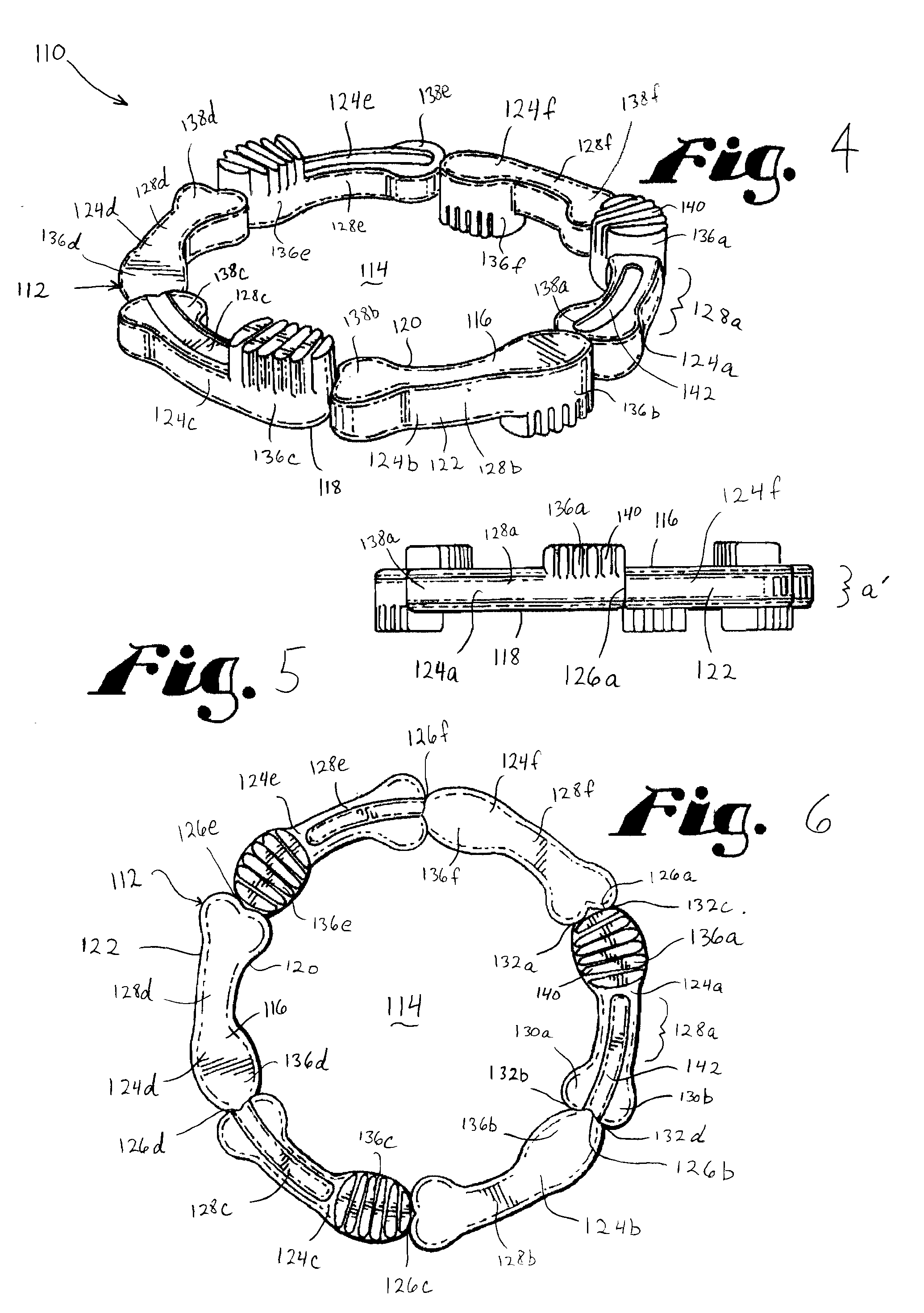

Edible Pet Chew

InactiveUS20090120372A1Improve maneuverabilityKeep cleanAnimal feeding stuffWorking-up animal fodderWeaknessFracture line

An edible pet chew having a non-branching body configured to at least partially enclose an open space between portions of the body, and is preferably in the form of a ring with a central opening. The width or thickness of the chew is sized to fit within the mouth of pet of pre-determined size for chewing action, but the overall dimension of the chew is such that the chew cannot be swallowed whole by the pet. One or more lines of weakness may also be formed in the body of the pet chew to serve as pre-determined fracture lines along which the pet chew will break into smaller pieces. The pet chew may be formed of segments that are sized to provide a recommended single portion for the pet.

Owner:MARS INC

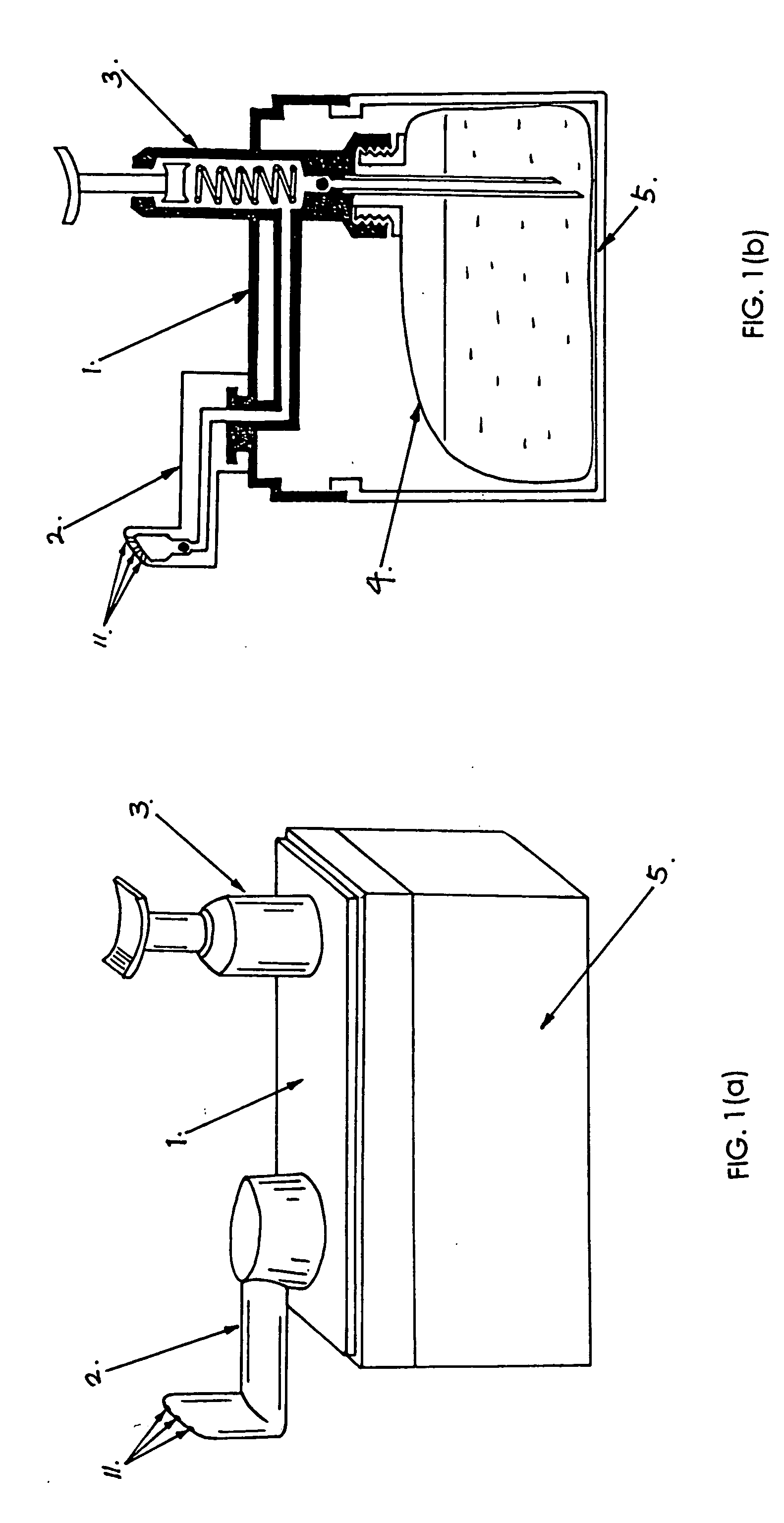

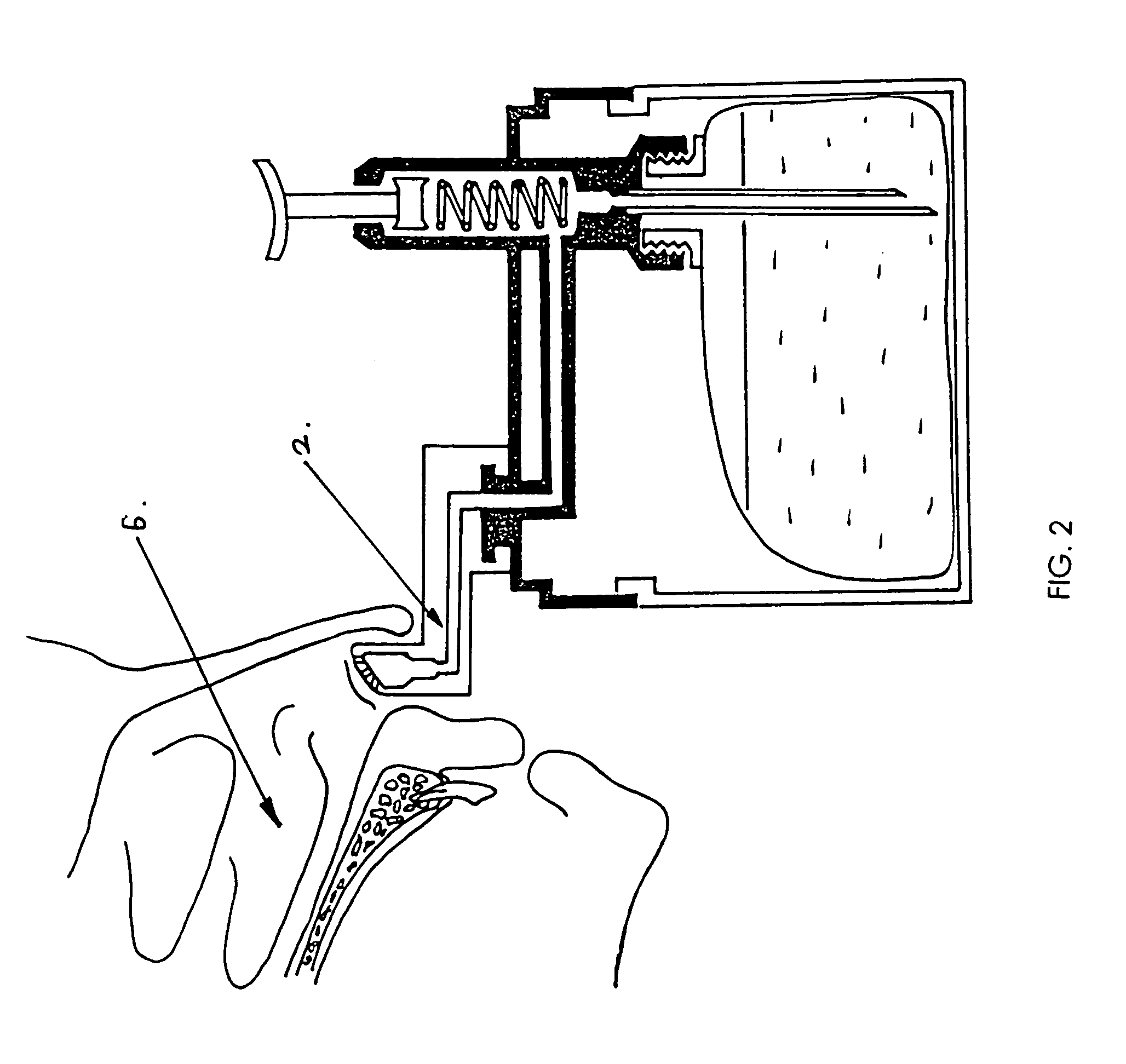

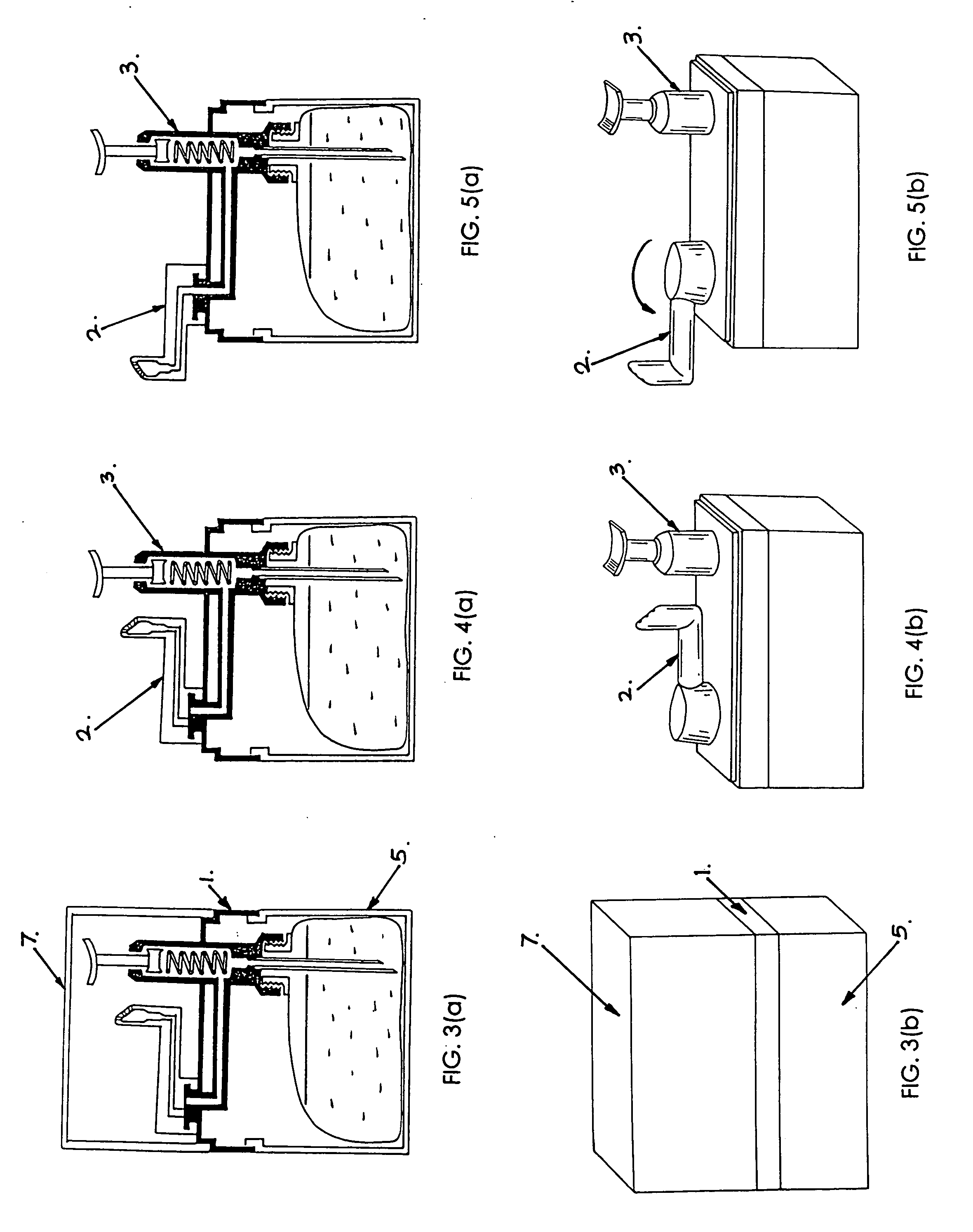

Portable saline nasal spray

A portable saline nasal spray is a device designed to remove allergens or other harmful substances from the human nasal cavity in effective and convenient way. The portable saline nasal spray includes a spray pump that is operated by a finger, a spray nozzle that is ergonomically designed to effectively spray into the nasal cavity, and a disposable saline pouch that can be purchased separately. Not like other existing method, instead of forcing the saline solution to flow though the nasal cavity, this invention sprays the saline solution effectively over the whole surface of the nasal cavity. Because saline solution is sprayed, it requires only small amount of solution for daily use. This invention utilizes factory prepared sterile saline solution contained in disposable pouch that makes the nasal cleaning procedure much more simple and convenient. Just one small pouch of saline solution can be used for a whole week of twice a day nasal cleaning. Furthermore, because it is designed to be a leak-free portable device, it would look nice to keep anywhere, and the user can even carry it in his / her most favorite bag and use it anytime at anywhere they want.

Owner:CHA BYUNG KWON

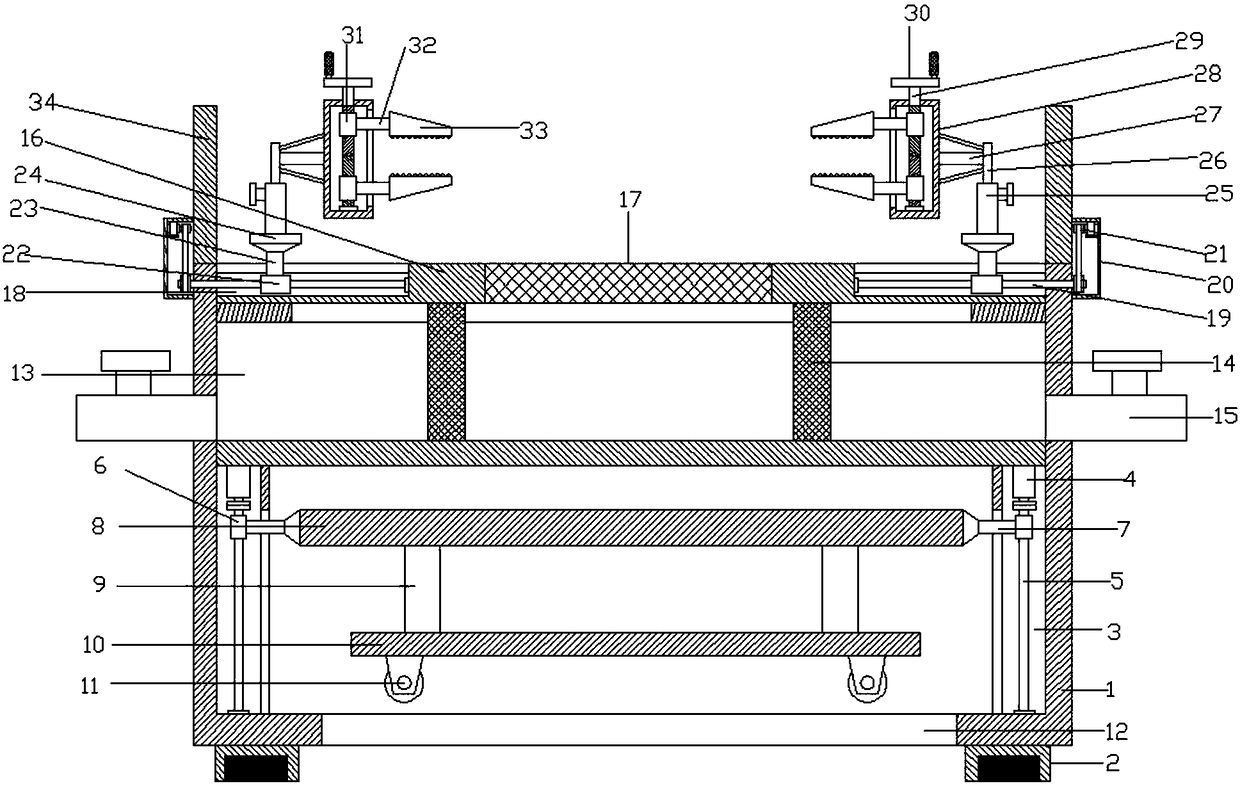

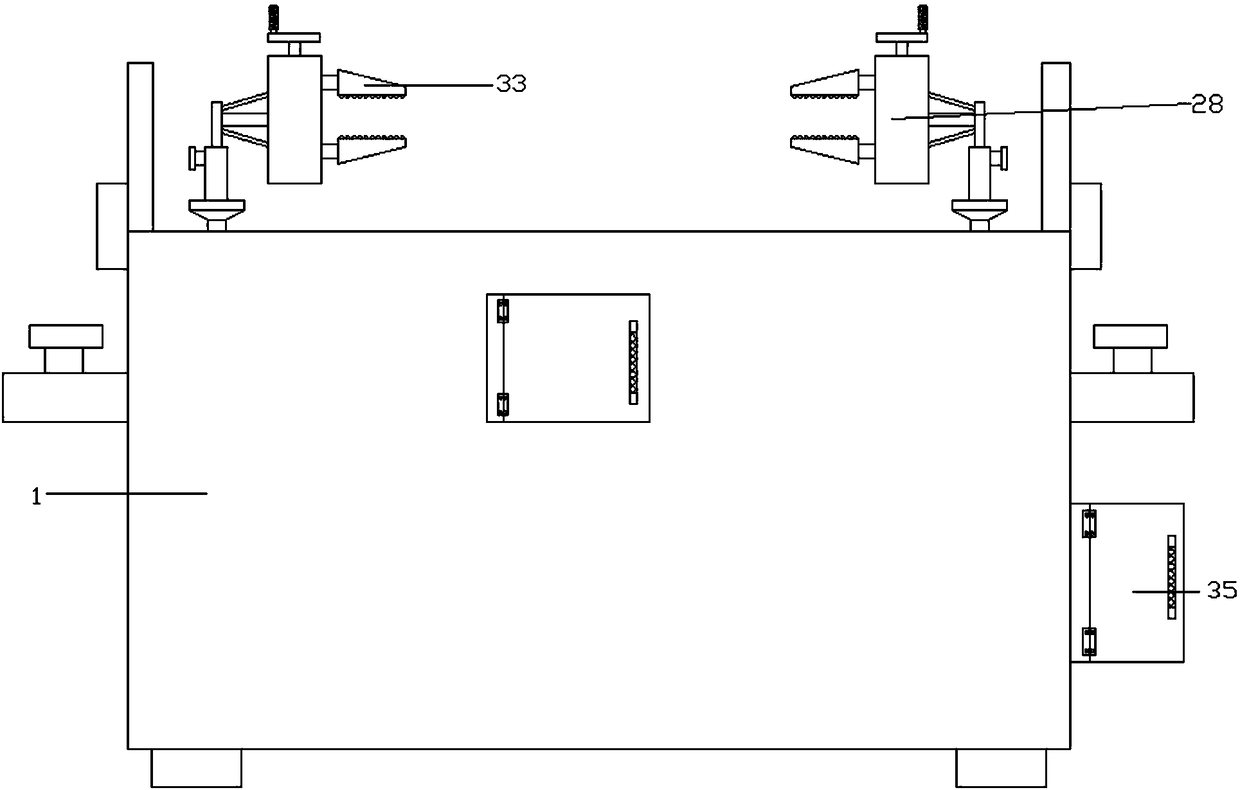

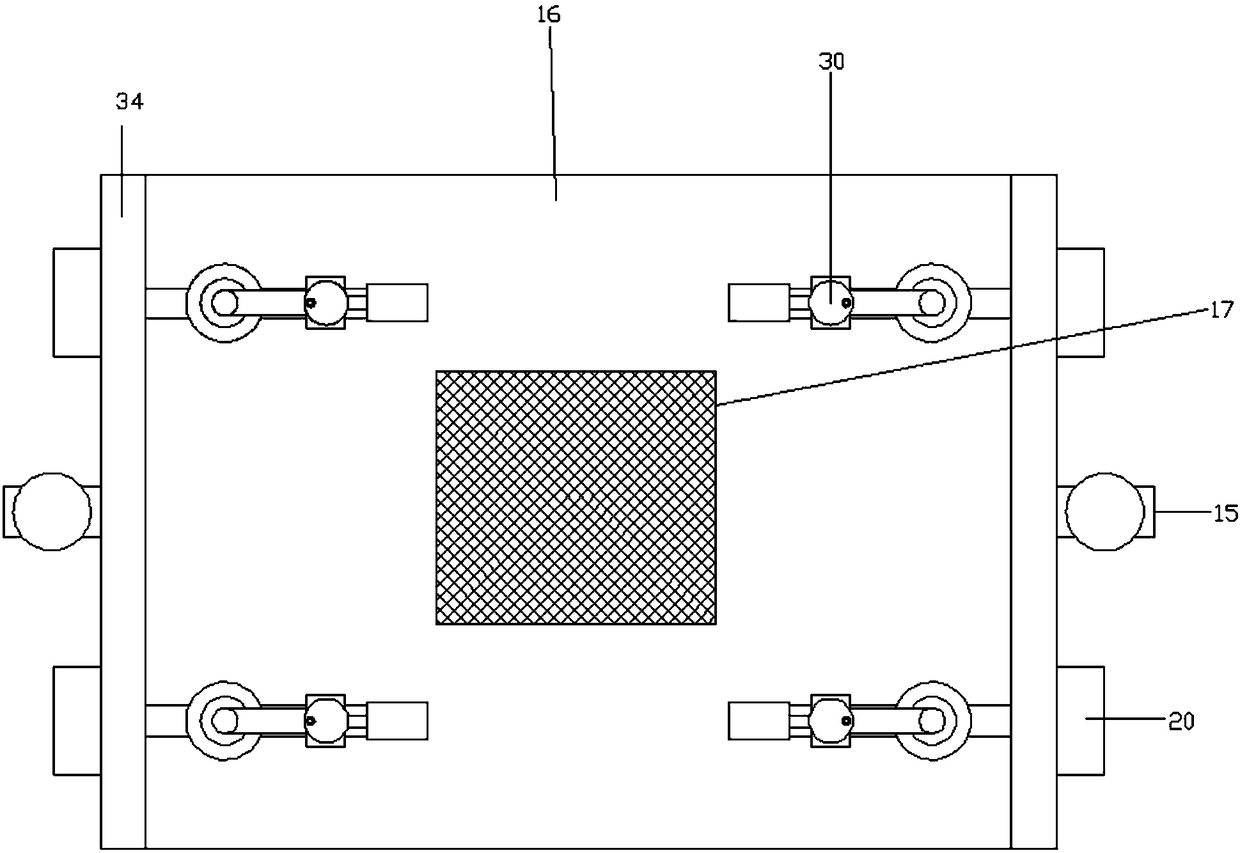

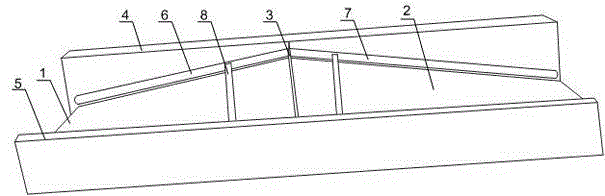

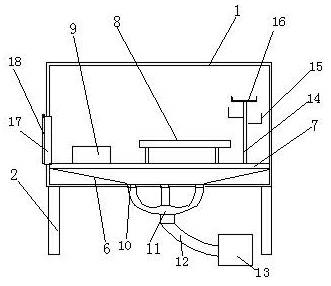

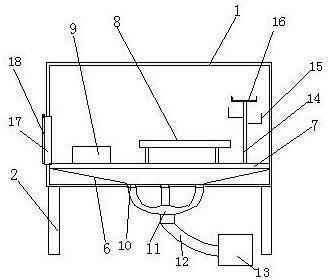

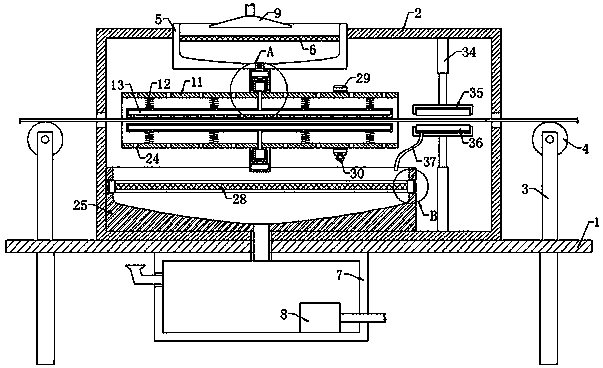

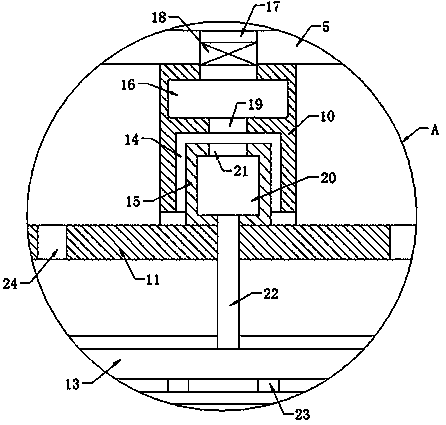

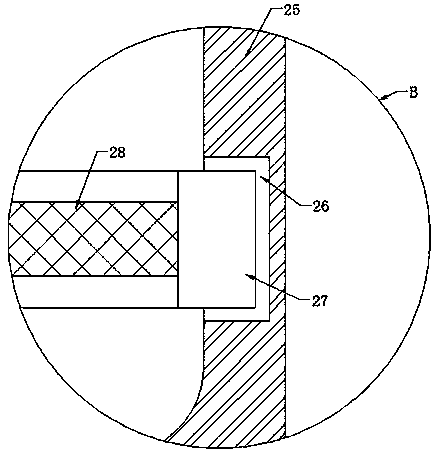

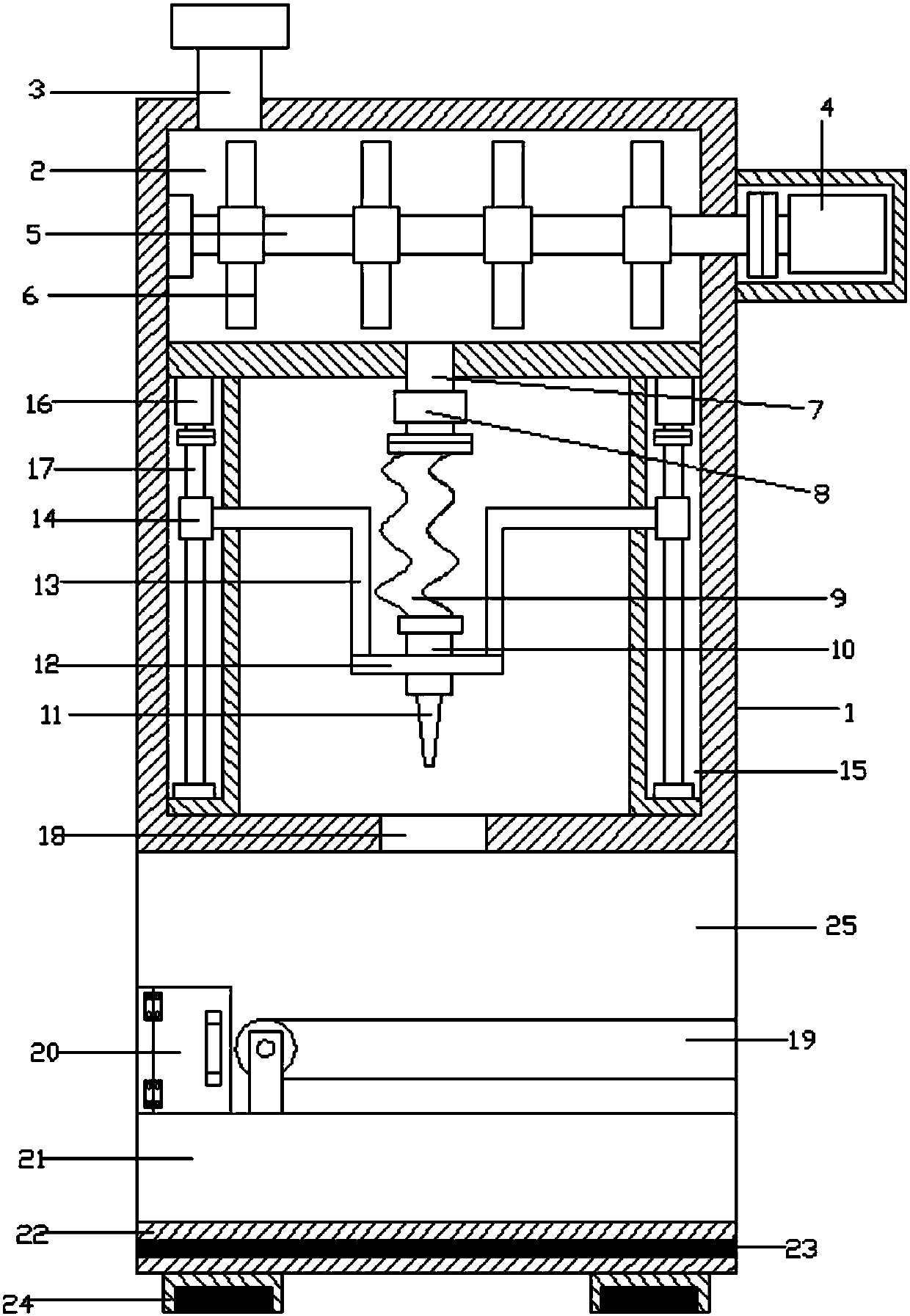

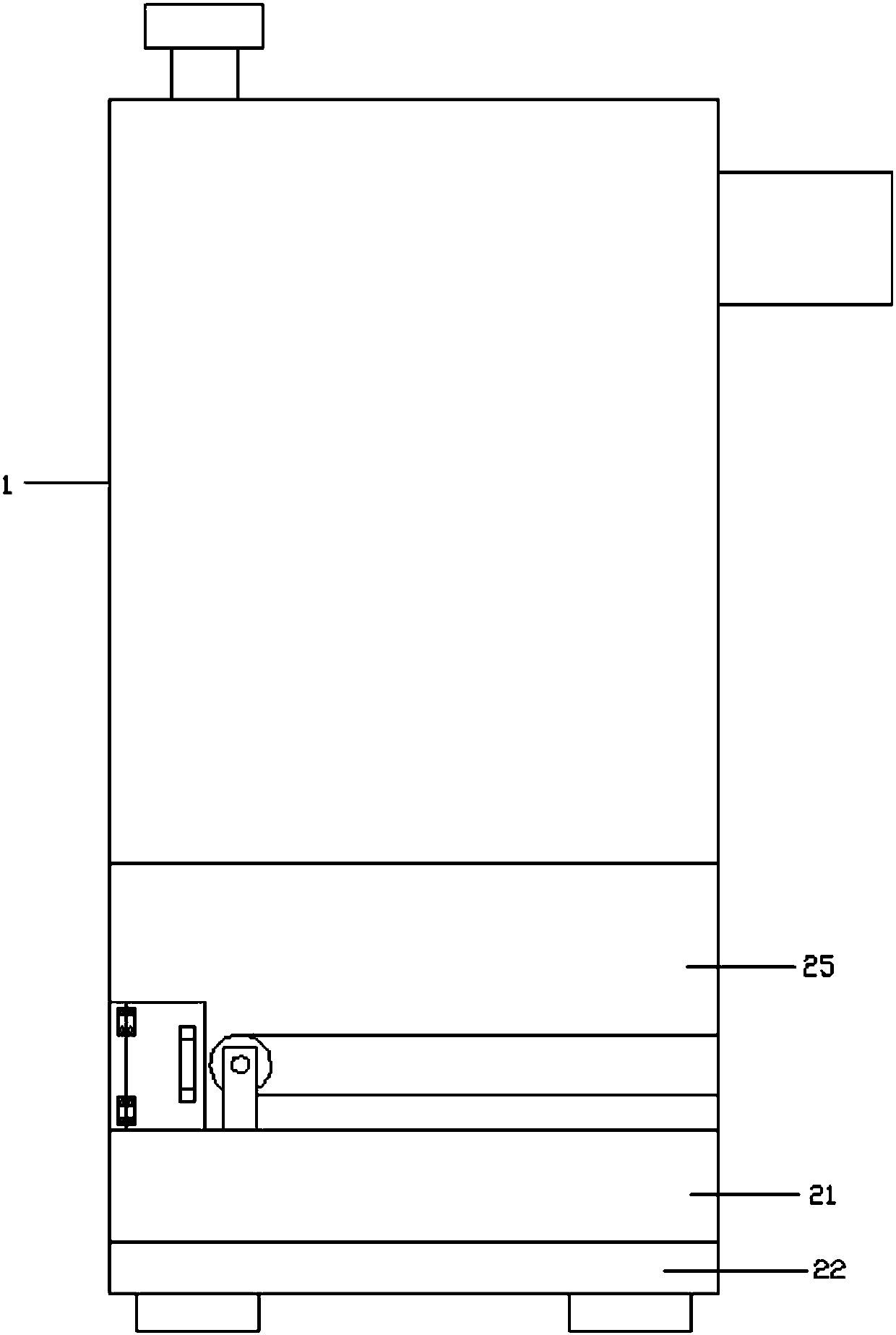

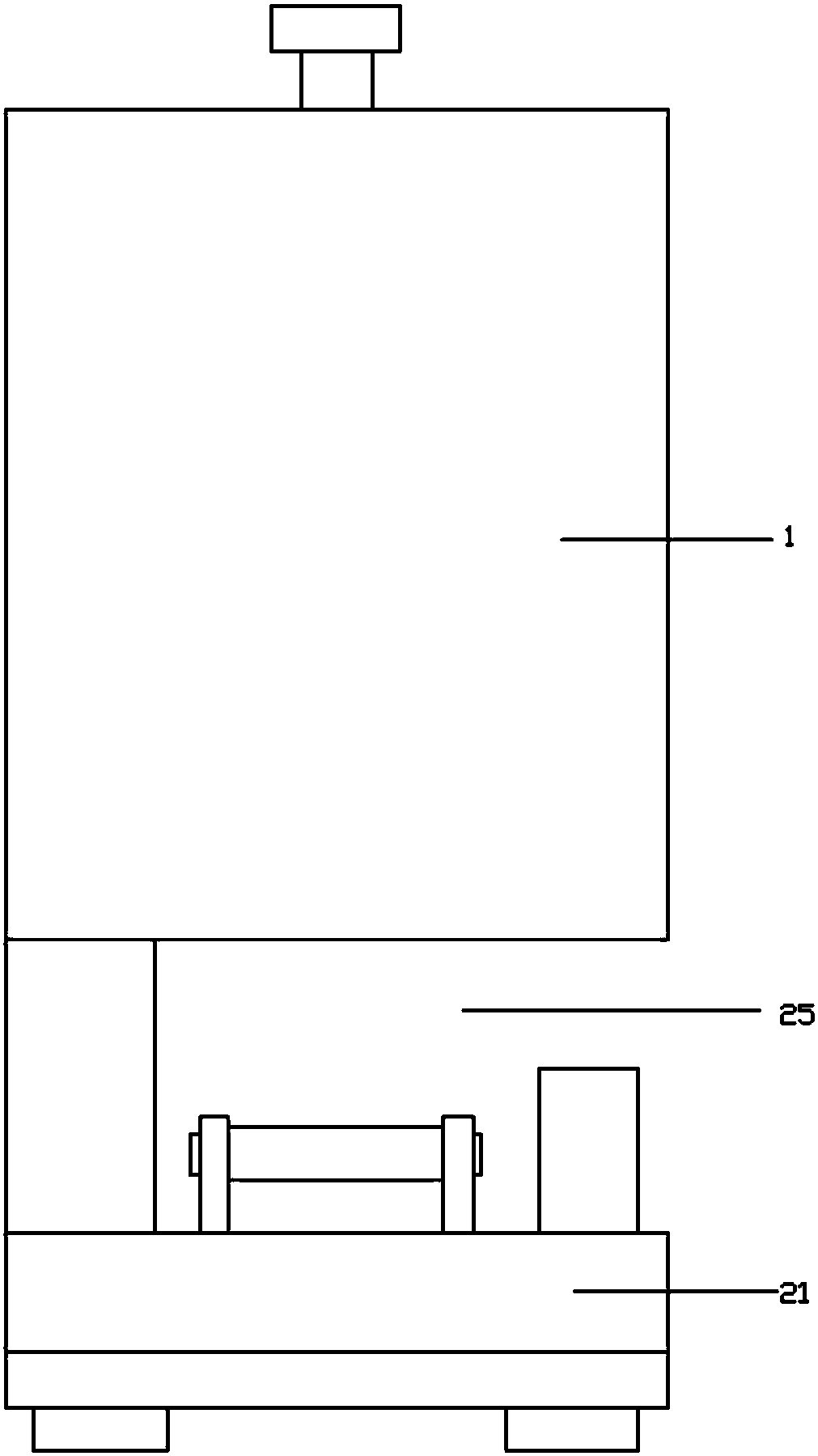

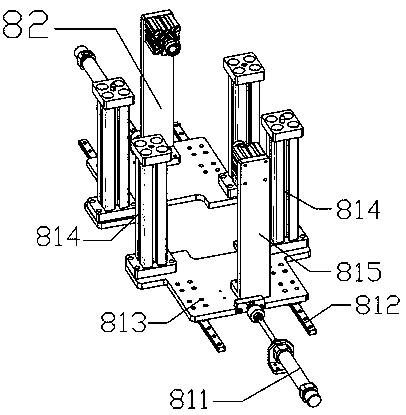

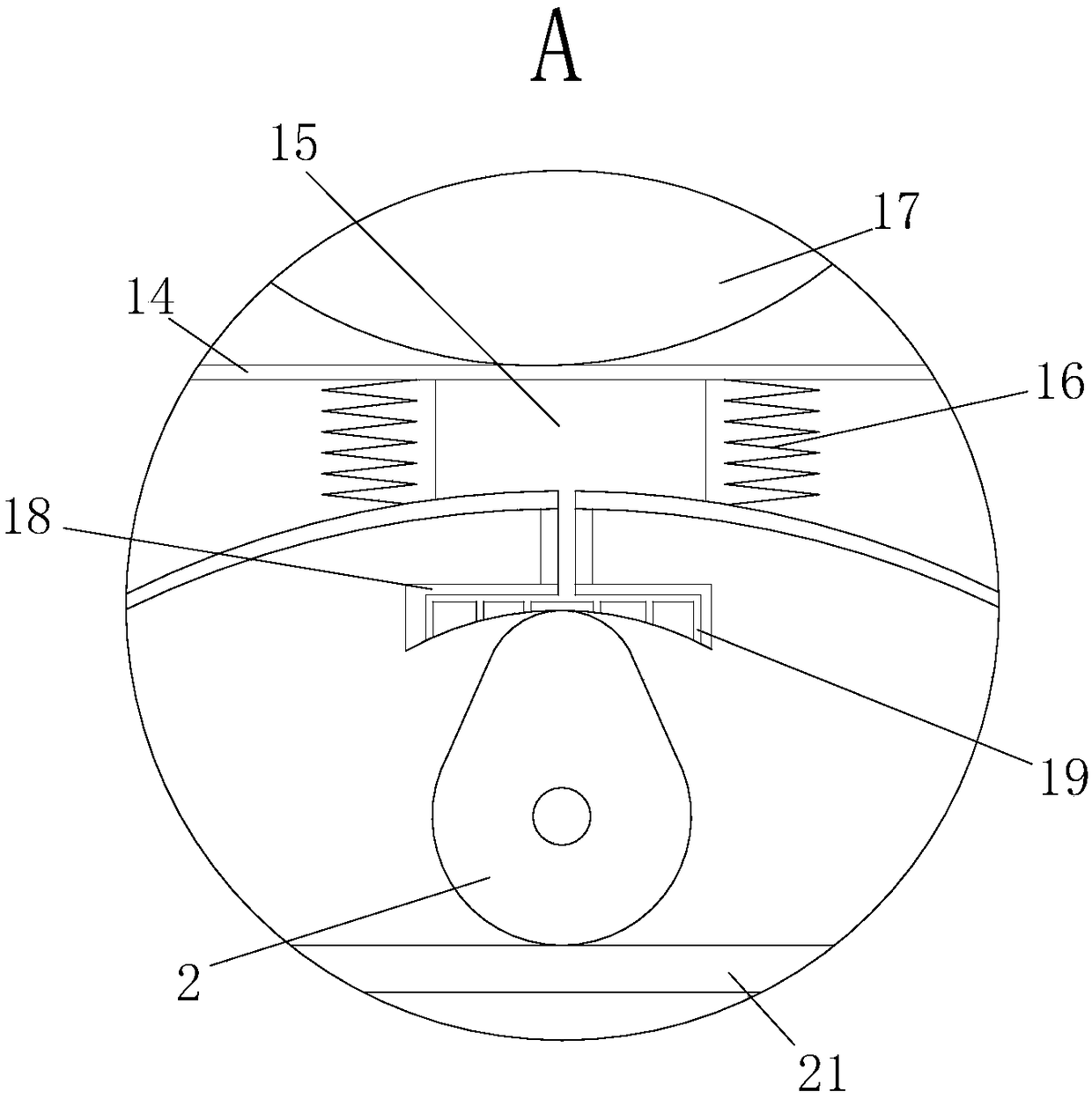

Mechanical equipment maintenance platform

InactiveCN108177132AEnsure stabilityKeep cleanWork holdersWork benchesMechanical equipmentWaste management

The invention discloses a mechanical equipment maintenance platform. The mechanical equipment maintenance platform comprises a base, wherein first sliding grooves are arranged in the left and right ends in the base, and first sliders are arranged in the first sliding grooves; a connecting block is arranged between the first sliders, the lower side of the connecting block is provided with a connecting plate, and the four corners of the lower side of the connecting plate are provided with rollers; a waste liquid storing cavity is arranged at the upper end in the base, and a support plate is arranged at the upper side of the waste liquid storing cavity; second sliding grooves are arranged in the four corners of the upper end of the support plate, and second sliders are arranged in the secondsliding grooves; third connecting rods are arranged at the upper sides of the second sliders, support blocks are arranged on the third connecting rods, support pipes are arranged at the upper sides ofthe support blocks, and support rods are arranged at the upper sides of the support pipes; fourth connecting rods are arranged in the support rods, third sliding grooves are arranged at the inner sides of the fourth connecting rods, and third sliders are arranged at the upper and lower ends in the third sliding grooves; and fifth connecting rods are arranged at the inner sides of the third sliders, and clamping plates are arranged in the fifth connecting rods. The mechanical equipment maintenance platform can effectively facilitate the movement and fixing of equipment and can conveniently maintain the mechanical equipment.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

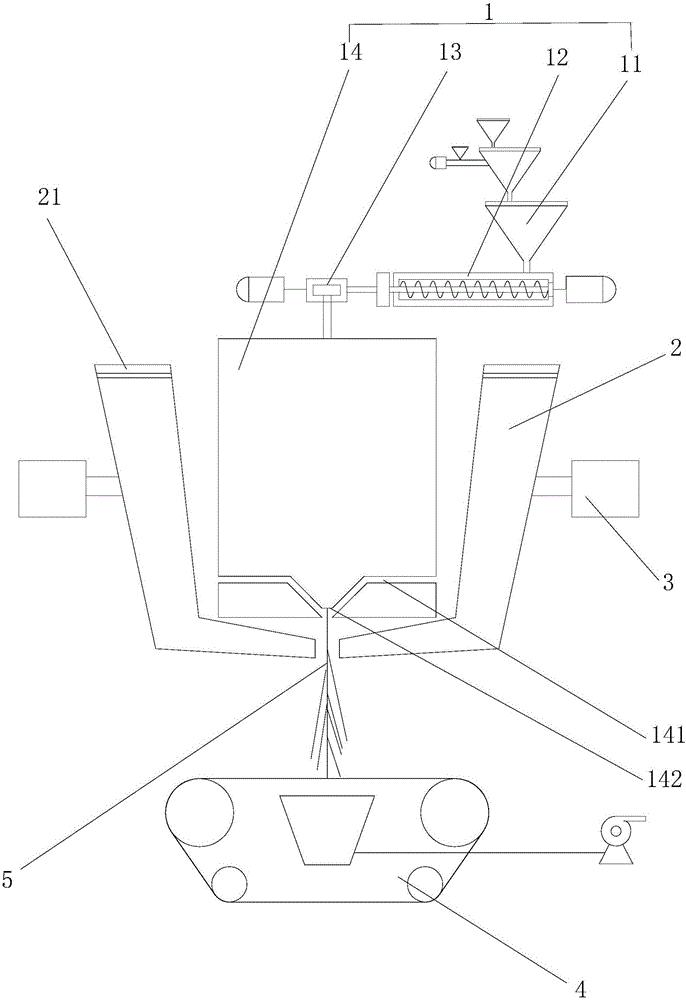

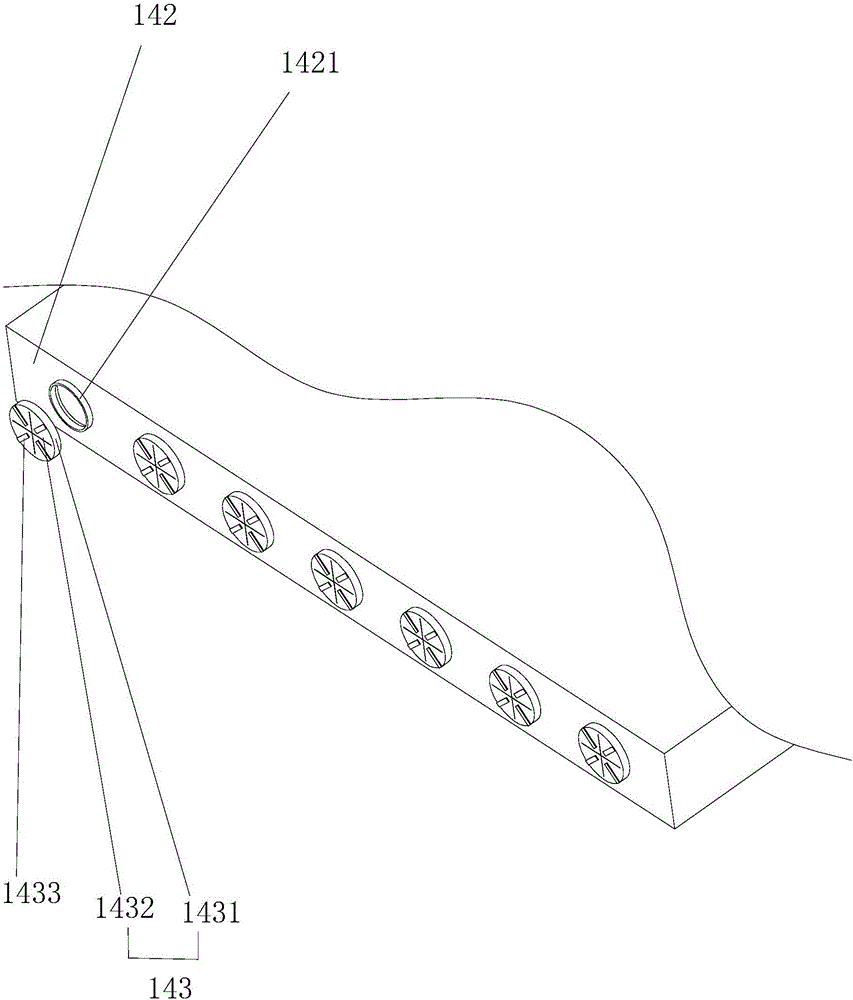

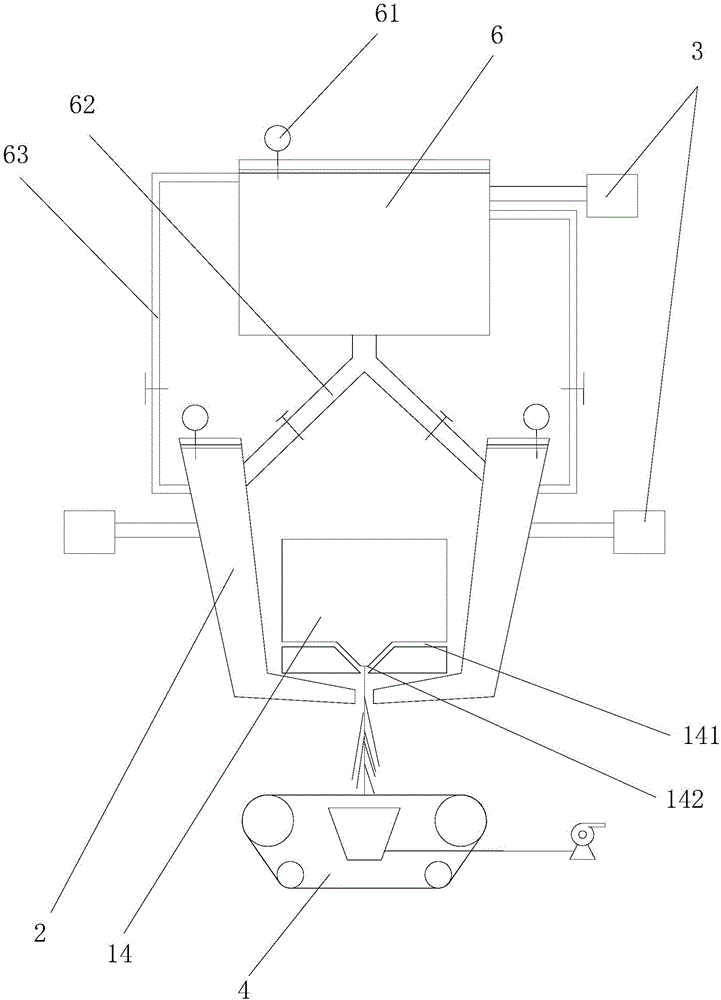

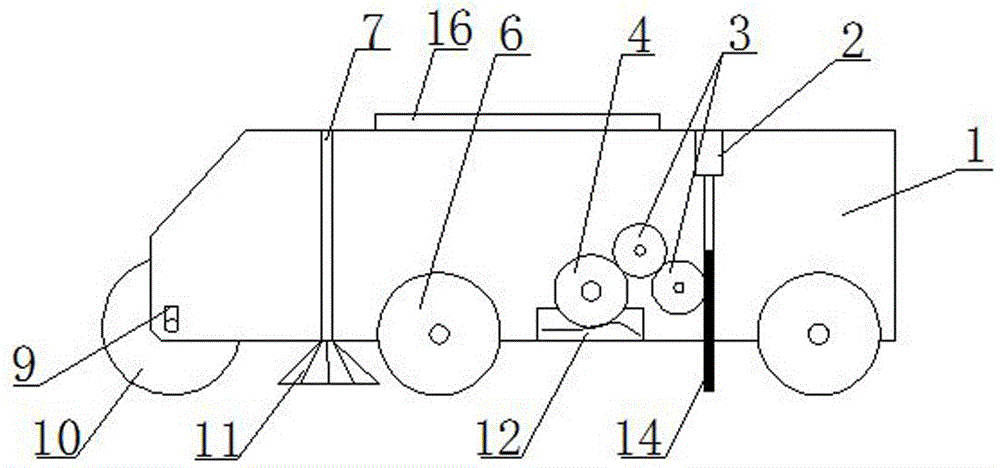

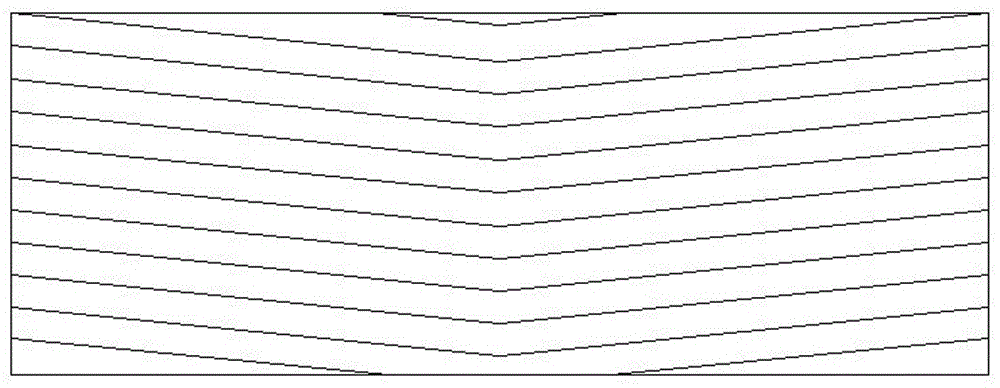

Device and method for manufacturing non-woven fabric by mixing melt-blown subject as carrier and short cut fibers

The invention discloses a device and method for manufacturing a non-woven fabric by mixing a melt-blown subject as a carrier and short cut fibers. According to key points of the technical scheme, the non-woven fabric comprises a melt-blown device and a feeding device. The melt-blown device comprises a traction air flue and a spinneret plate located at one end of the traction air flue. The traction air flue is located on one side close to the feeding device, the feeding device comprises a sealed storage tank, one end of the sealed storage tank close to the spinneret plate is provided with a feeding port, a damping device is arranged at the position of the feeding port, and the feeding device further comprises a pressurization device which pushes ultra short fibers to flow to the feeding port, so that the ultra short fibers overcome resistance of the damping device to be squeezed out of the sealed storage tank. The device achieves the effects that product process requirements are met, the working environment can be ensured, and the cost is low.

Owner:量子金舟(天津)非织造布有限公司

Road line marker with energy saving function

InactiveCN105862561AKeep cleanNot easy to peel offRoads maintainenceElectric machineryAutomotive engineering

The invention discloses a road marking machine with energy-saving function, which comprises a car body, wheels and a solar power supply device; a thread cleaning roller is installed in front of the car body, and the threads on the thread cleaning roller are left and right symmetrical; the car body There is a paint box in the body; the car body is provided with a feeding roller above the paint box, and the lower end of the feeding roller extends into the paint box; the feeding roller is equipped with a motor to drive its rotation; the car body There is a cylinder inside, and a brush is connected to the lower end of the cylinder, and the bottom end of the brush extends to the ground; an equalizing roller group is arranged between the feeding roller and the brush, and the feeding roller conveys the paint through the equalizing roller group Give the brush; the car body is provided with a dust suction device between the threaded cleaning roller and the hair brush, the dust suction device includes a dust suction cover positioned at the lower end of the car body, and a fan located in the dust suction cover; the dust suction cover Connected with pipes. The invention has simple structure, reasonable design, can save a lot of labor force, and has broad market prospect.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

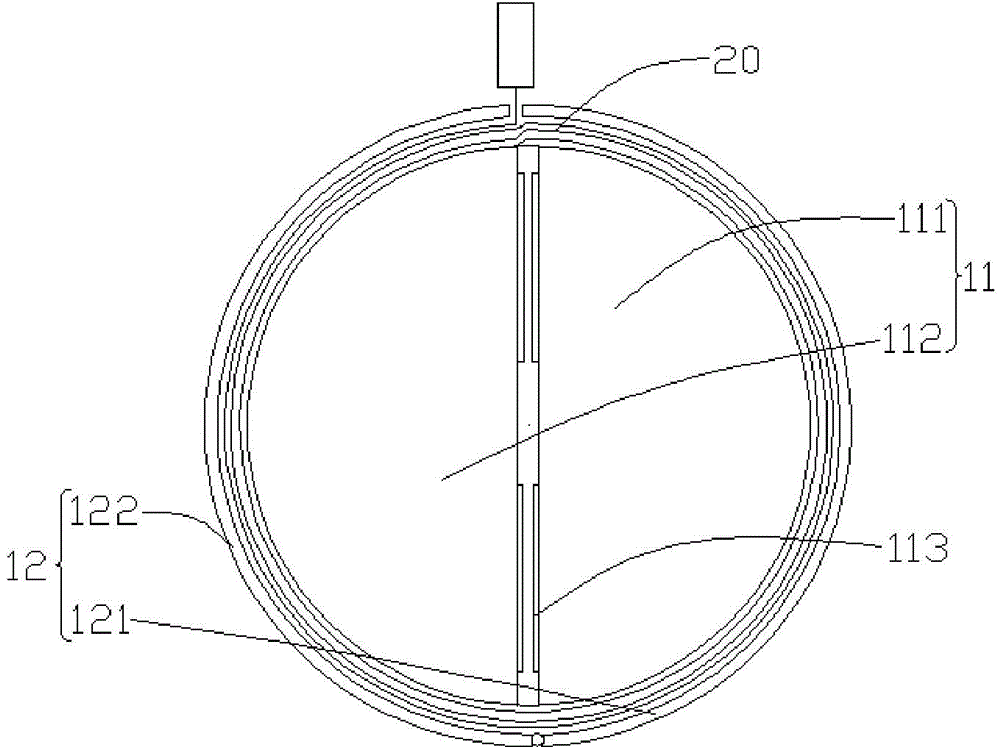

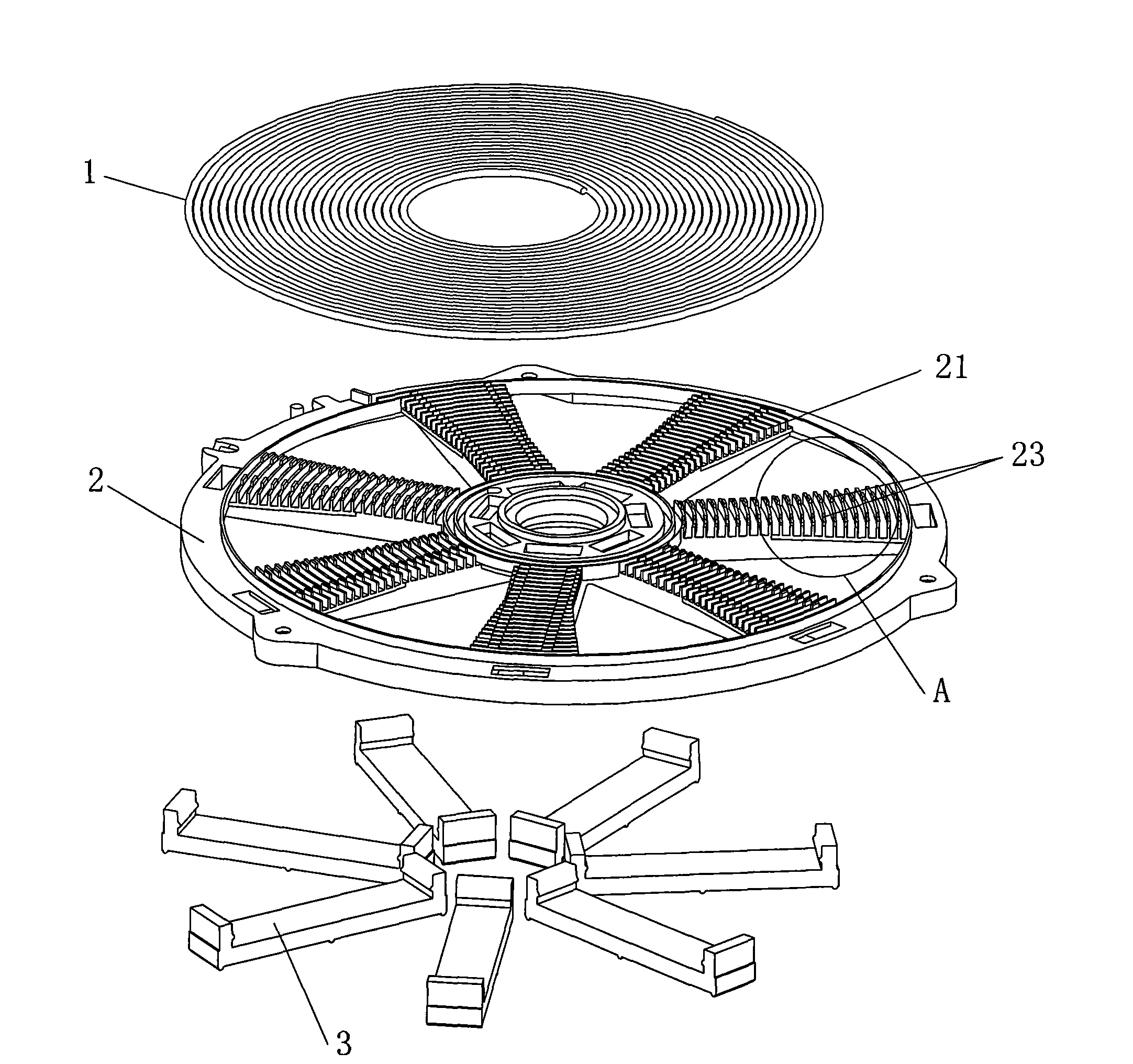

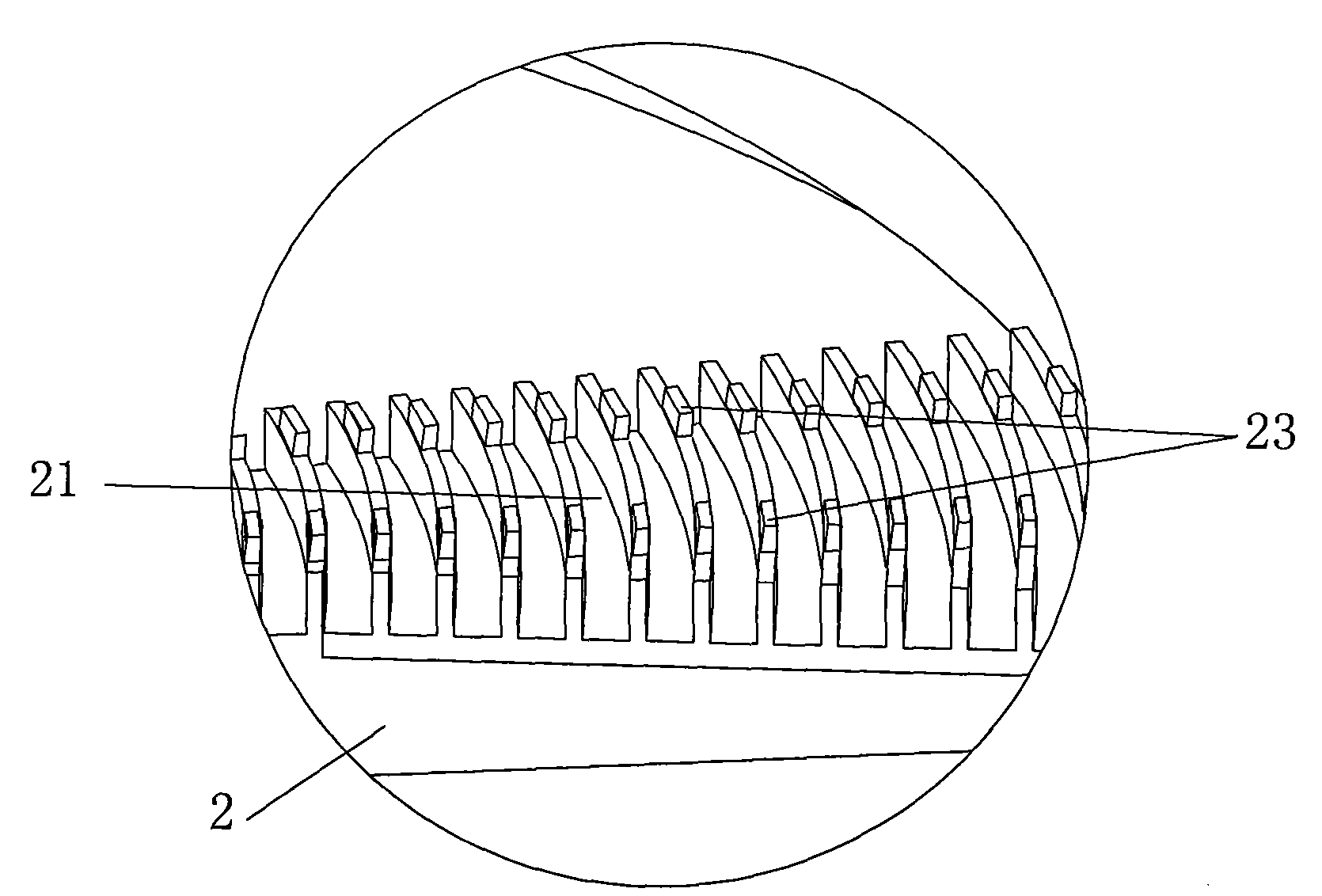

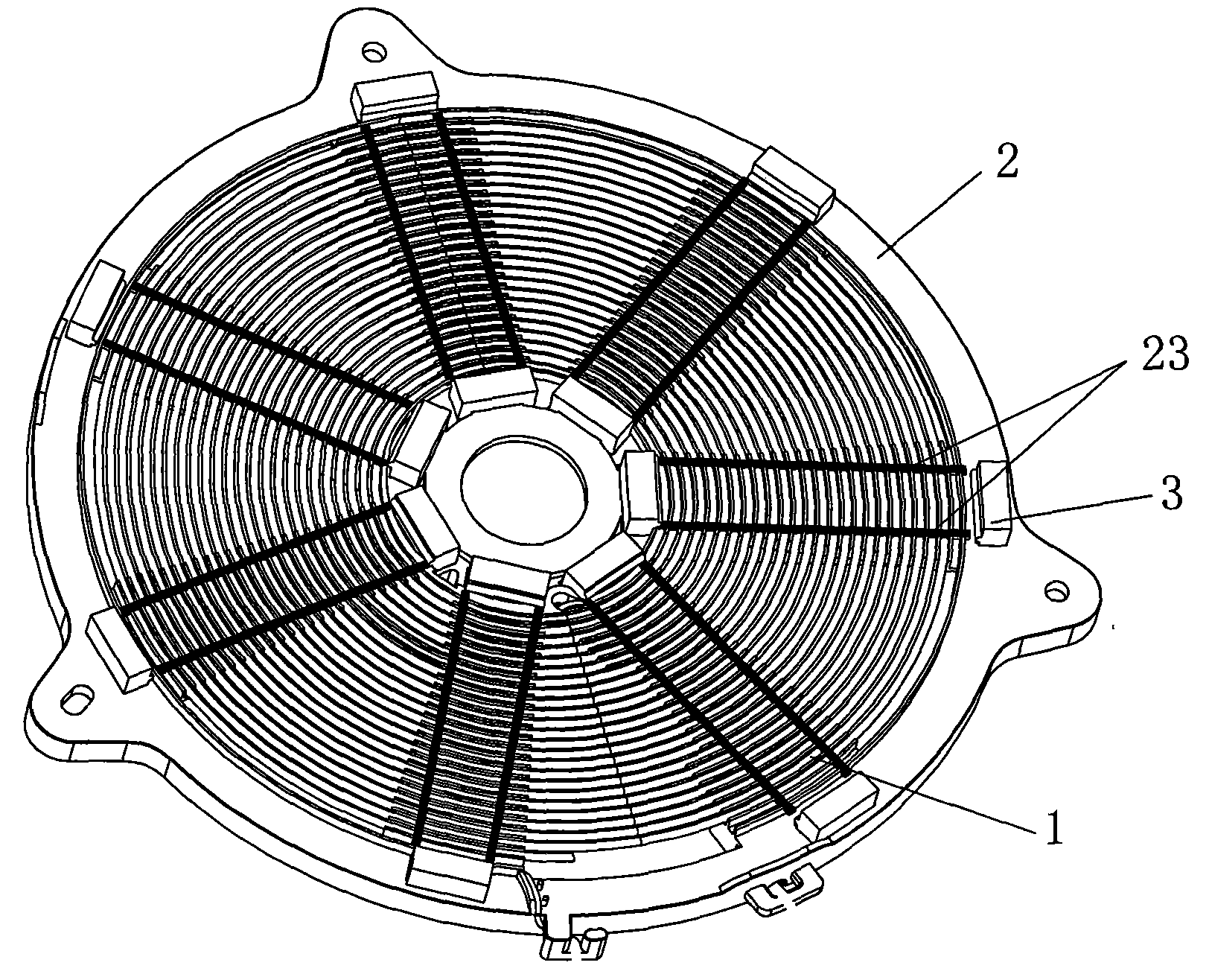

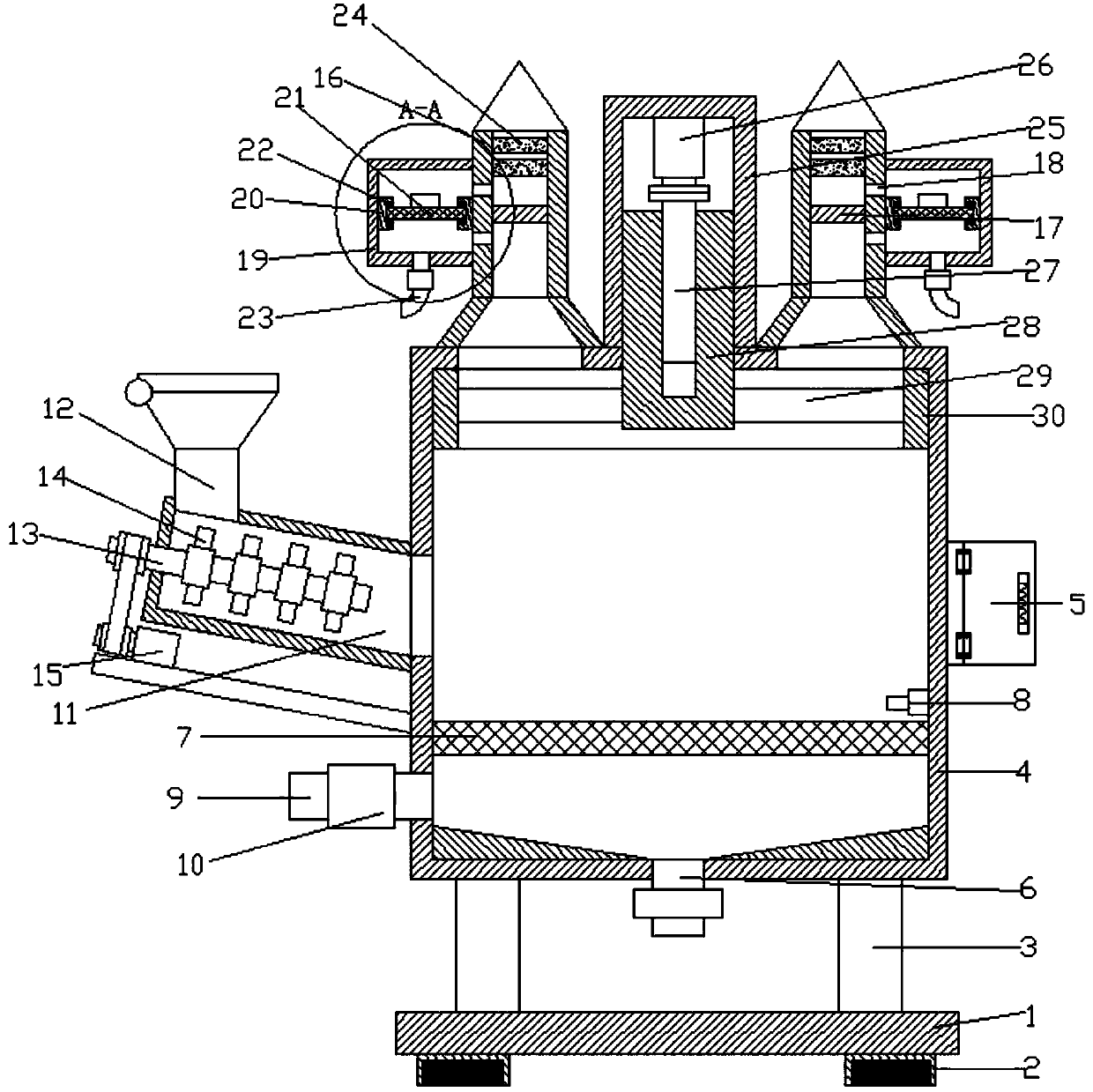

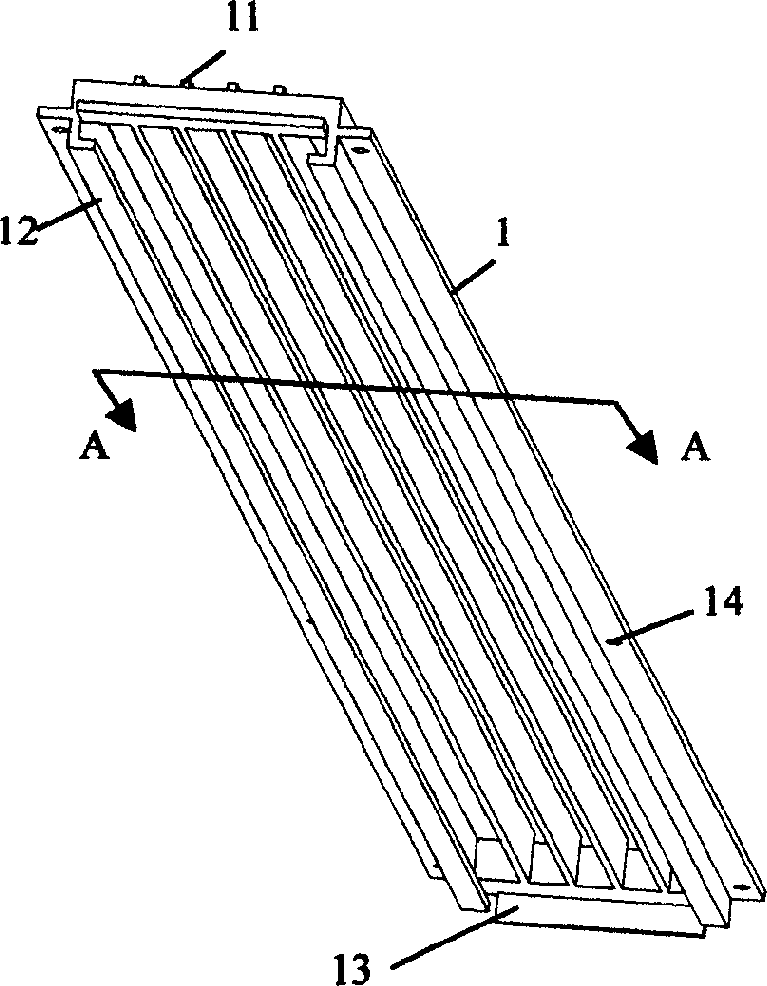

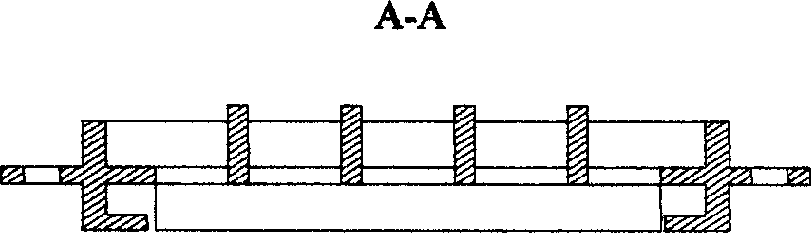

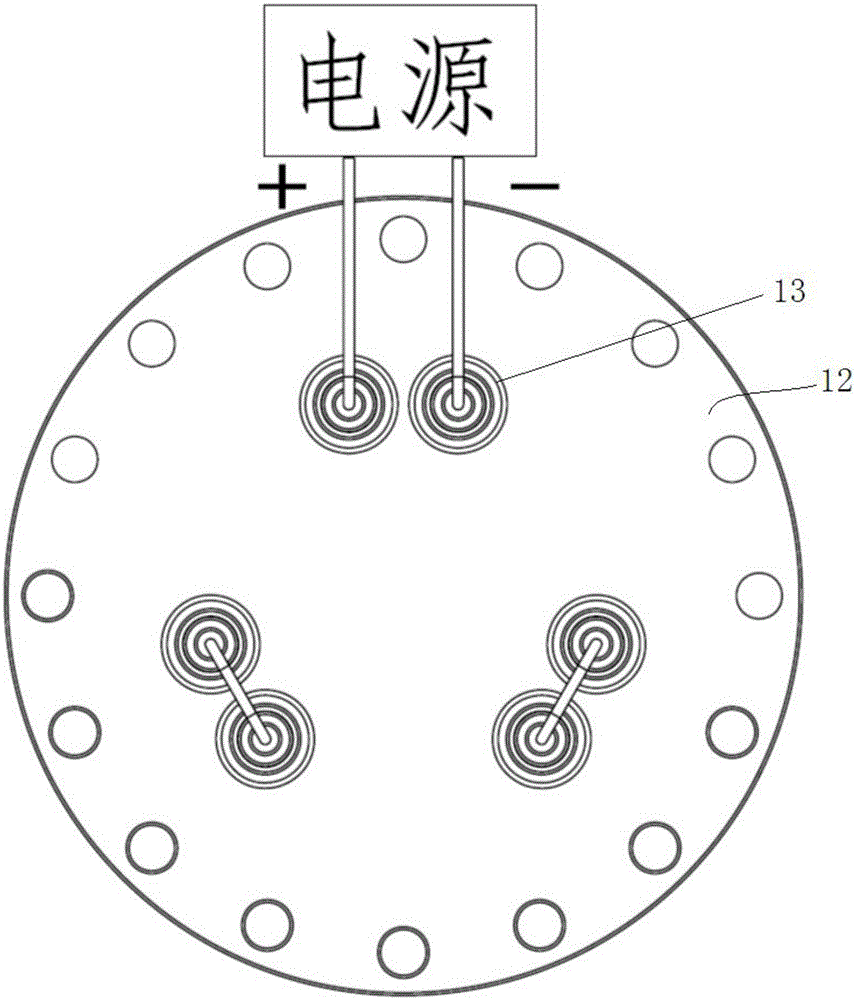

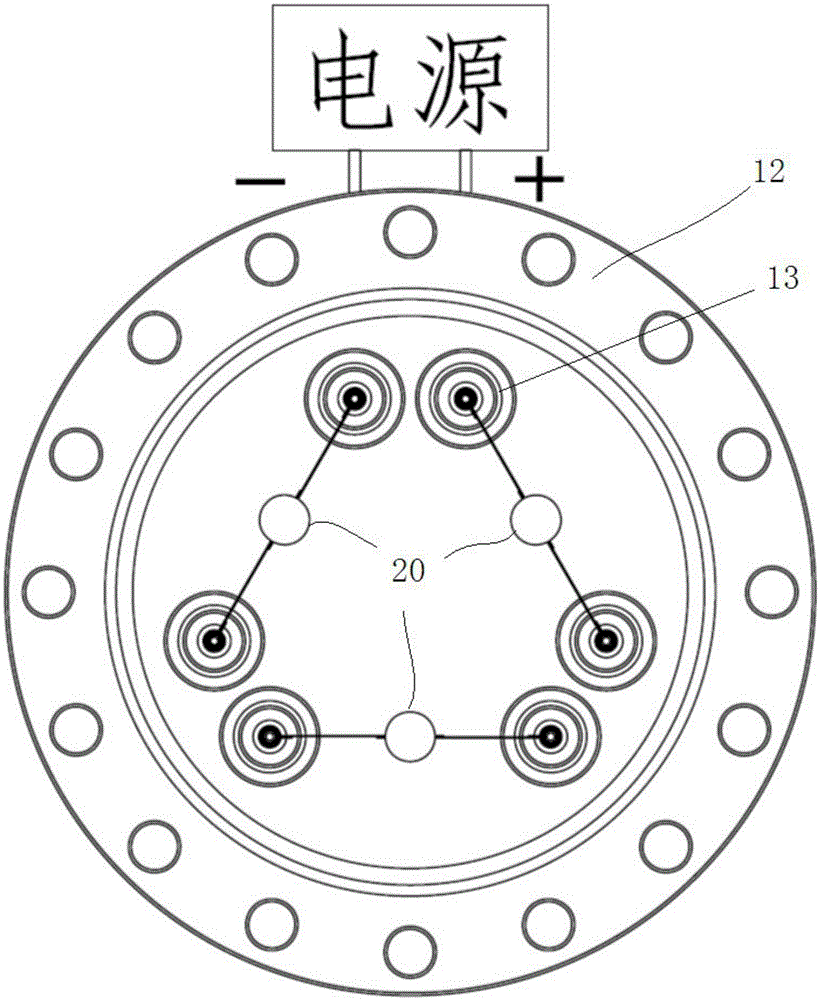

Electromagnetic induction coil panel and manufacturing process thereof

ActiveCN102098819ASimplify the production processKeep cleanDomestic stoves or rangesCoil arrangementsElectromagnetic inductionHot press

The invention discloses an electromagnetic induction coil panel, which comprises a coil winding, a plastic bracket and a plurality of magnetic stripes, wherein the coil winding is wound in a wire casing on the upper surface of the plastic bracket; the plurality of magnetic stripes are arranged in a plurality of accommodation grooves formed on the lower surface of the plastic bracket respectively; and one or more positioning lug bosses are arranged on the two sides of each of the wire casing and the accommodation grooves, and are hot-pressed to embed the coil winding into the wire casing and partially wrap the magnetic stripes. The manufacturing process comprises the following steps of: 1, winding the coil winding in the wire casing on the upper surface of the plastic bracket; 2, clamping the magnetic stripes in the accommodation grooves on the lower surface of the plastic bracket; and 3, simultaneously heating the two surfaces of the plastic bracket to heat, soften and deform the positioning lug bosses on the two sides of each of the wire casing and the accommodation grooves, and pressing the lug bosses to embed the coil winding into the wire casing and integrate the coil winding and the wire casing and partially wrap the magnetic stripes. According to the manufacturing process, a process flow is simplified and working environment is clean and sanitary; and the coil panel has a secure and stable structure.

Owner:MIDEA GRP CO LTD

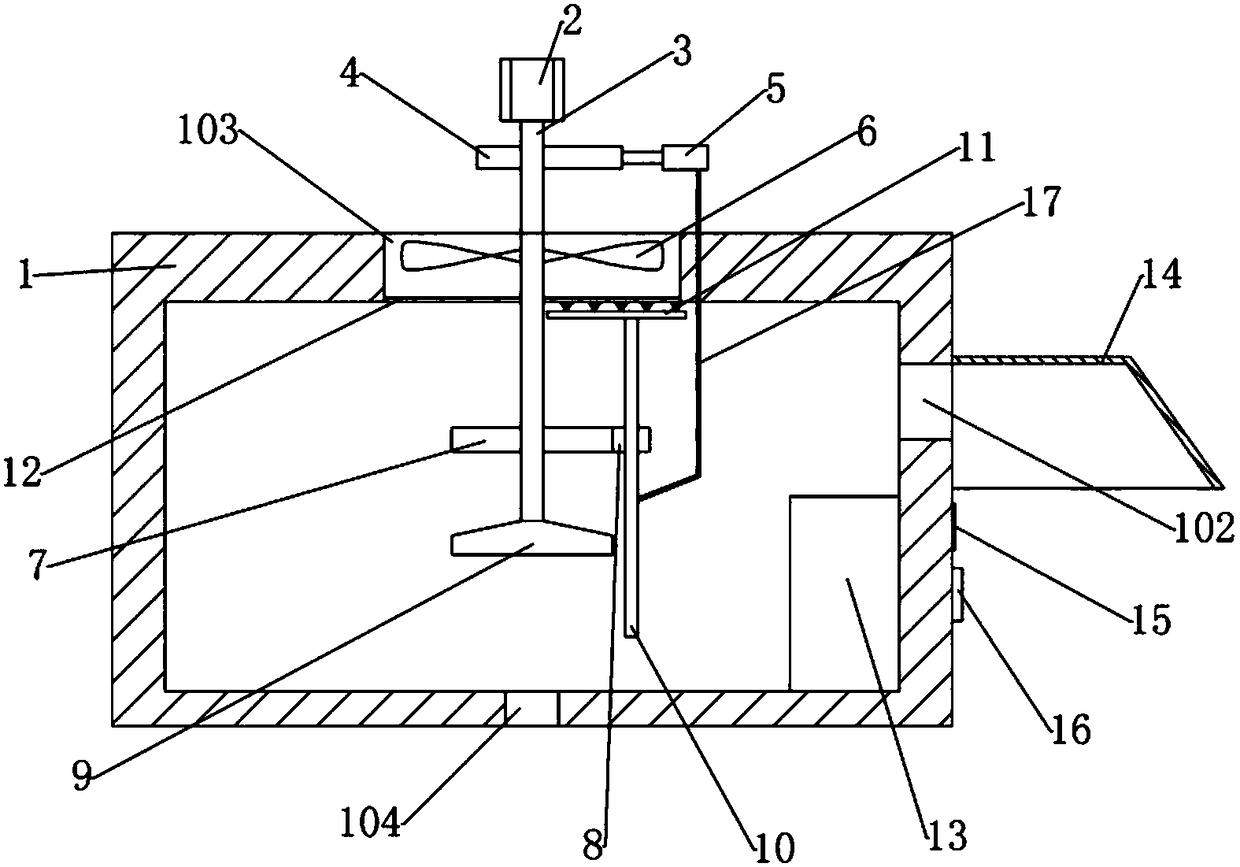

Environment-friendly garbage incineration equipment

The invention discloses environment-friendly garbage incineration equipment. The environment-friendly garbage incineration equipment comprises a bottom plate, supporting columns are arranged at the four corners of the upper side of the bottom plate, an incineration furnace is arranged on the upper sides of the supporting columns, an electric control cabinet is arranged on the right side of the incineration furnace, and a furnace rate is arranged at the lower end of the interior of the incineration furnace. An igniter is arranged at the right end of the upper side of the furnace grate, an air inlet pipe is arranged at the left end of the lower side of the furnace grate, a smashing cavity is formed in the left side of the incineration furnace, and smoke exhausting pipes are arranged at the left end and the right end of the upper side of the incineration furnace. A separation plate is arranged in each of the smoke exhausting pipe, air vents are formed in the outer ends of the upper side and the lower side of each separation plate, and a filtering cavity is formed in the outer side of each air vent. A mounting groove is formed in each filtering cavity, a filtering screen is arranged between the mounting grooves, an active carbon adsorption layer is arranged on the upper side of each separation plate, a supporting pipe is arranged between the smoke exhausting pipes, a second motor is arranged at the top end of the interior of the supporting pipe, and a screw rod is arranged on the lower side of the second motor. A telescopic rod is arranged on the outer side of the lower end ofthe screw rod, connection rods are arranged on the left side and the right side of the lower end of the telescopic rod correspondingly, and a scraping ring is arranged on the outer side of each connection rod. The environment-friendly garbage incineration equipment can effectively improve the incineration efficiency, and cleaning of the interior of the incineration furnace after incineration is facilitated.

Owner:曹茂娟

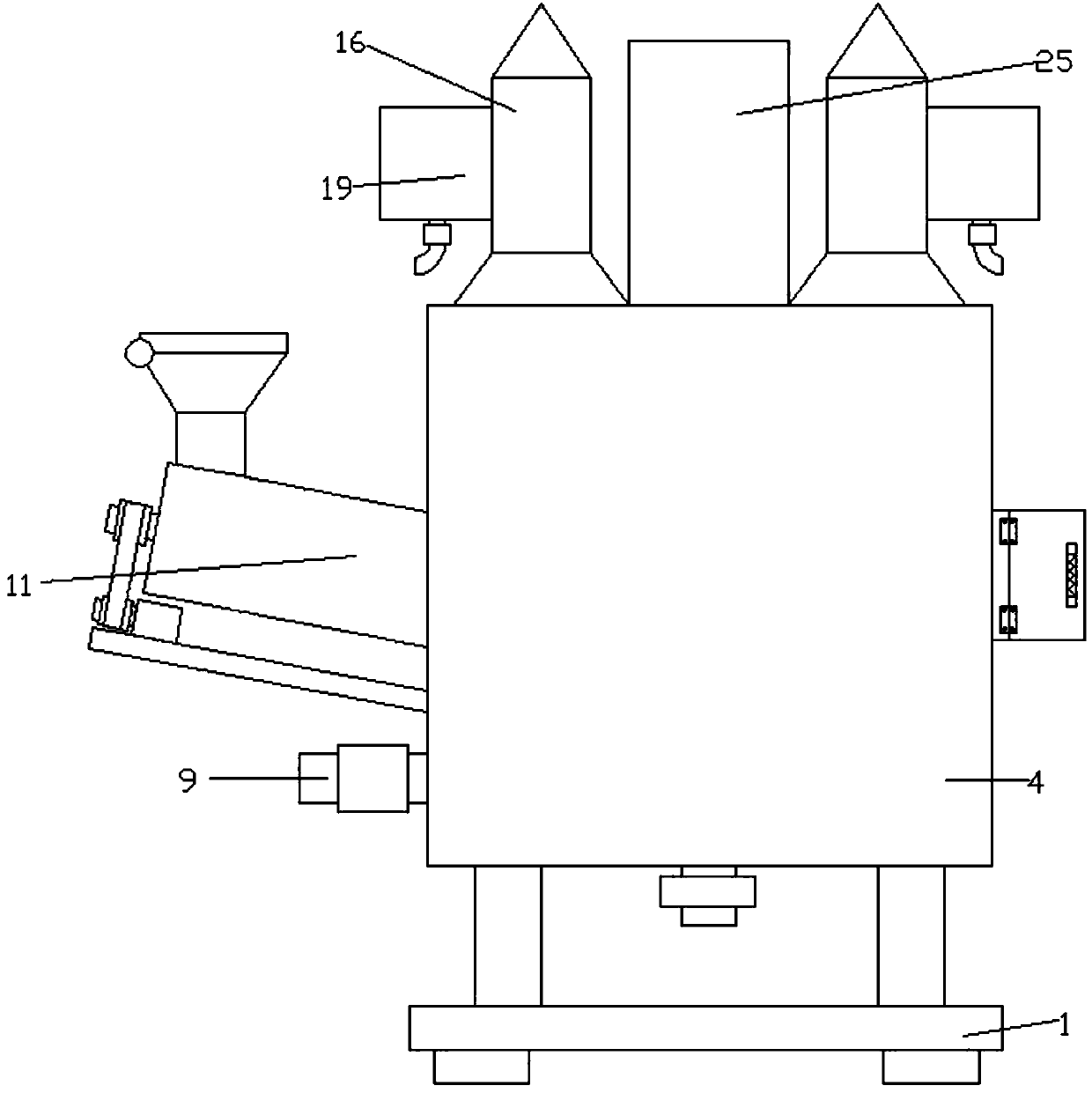

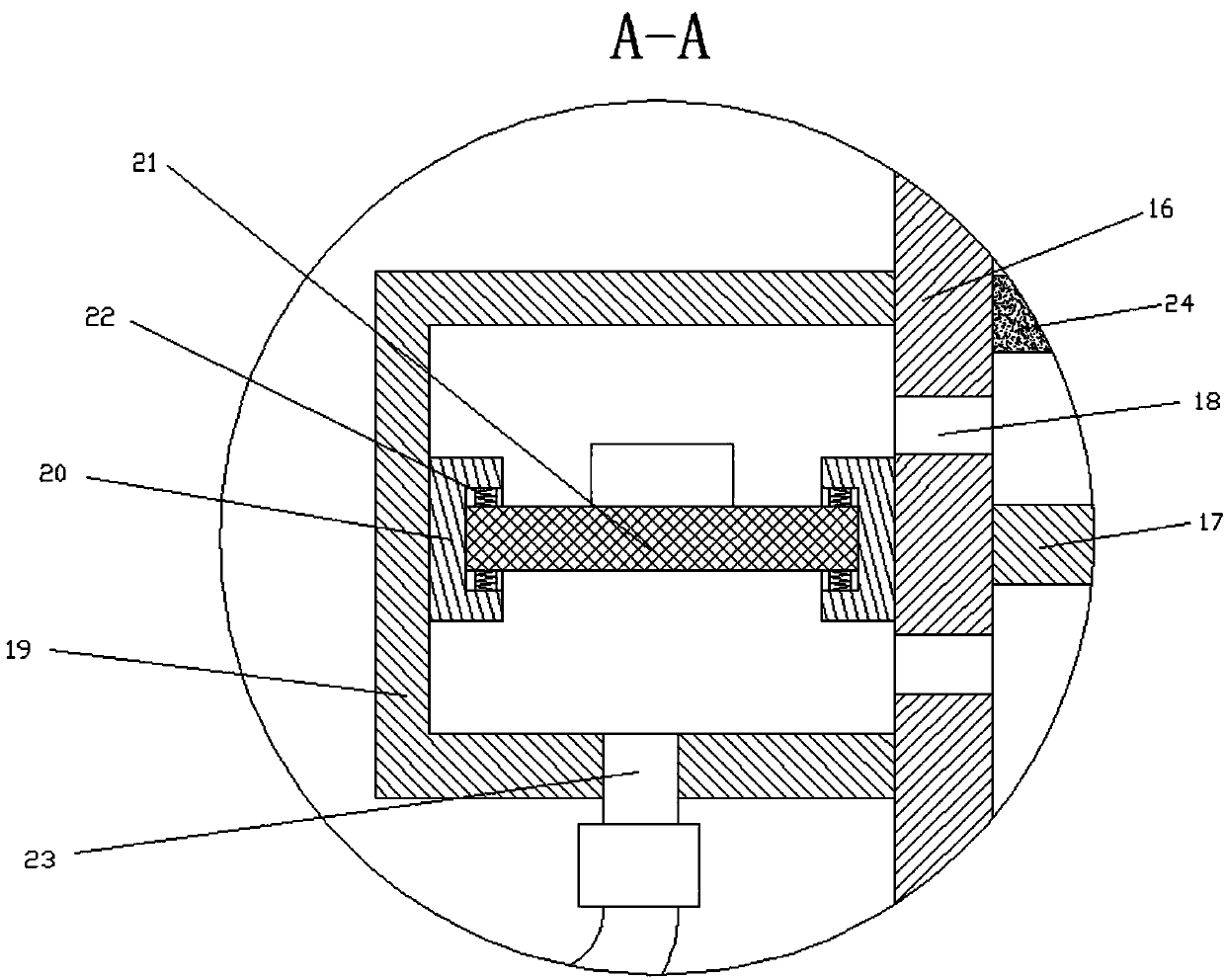

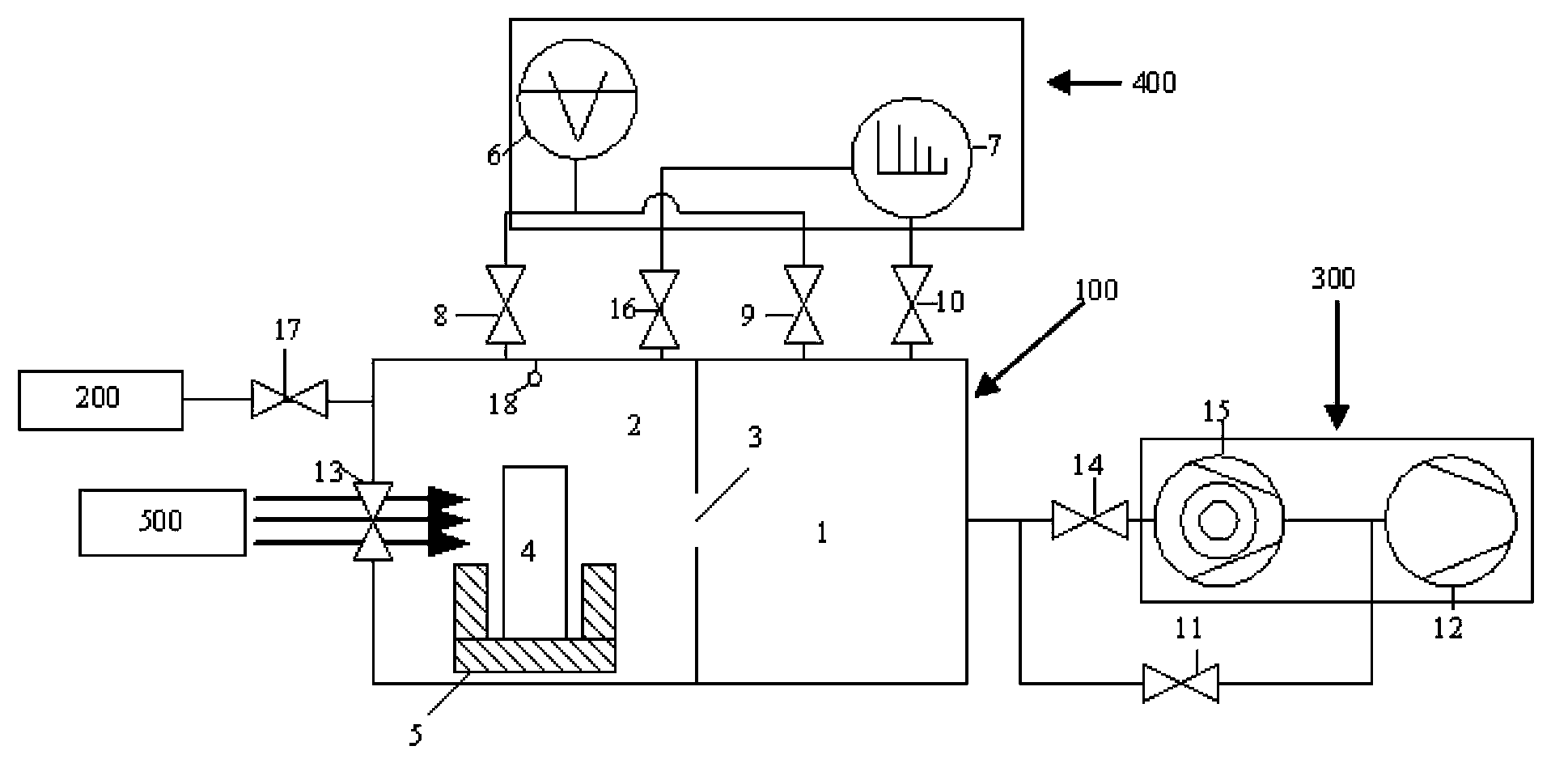

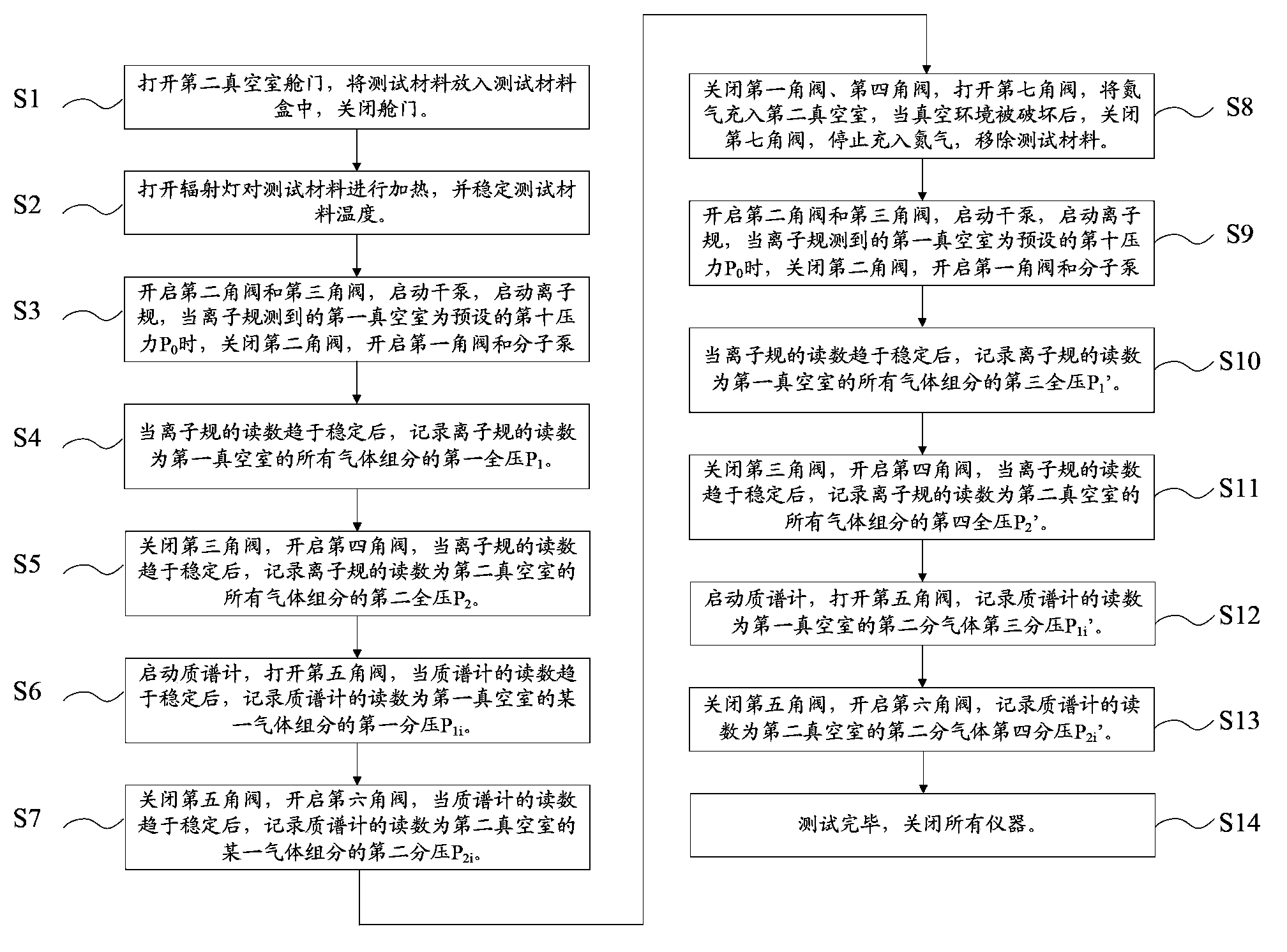

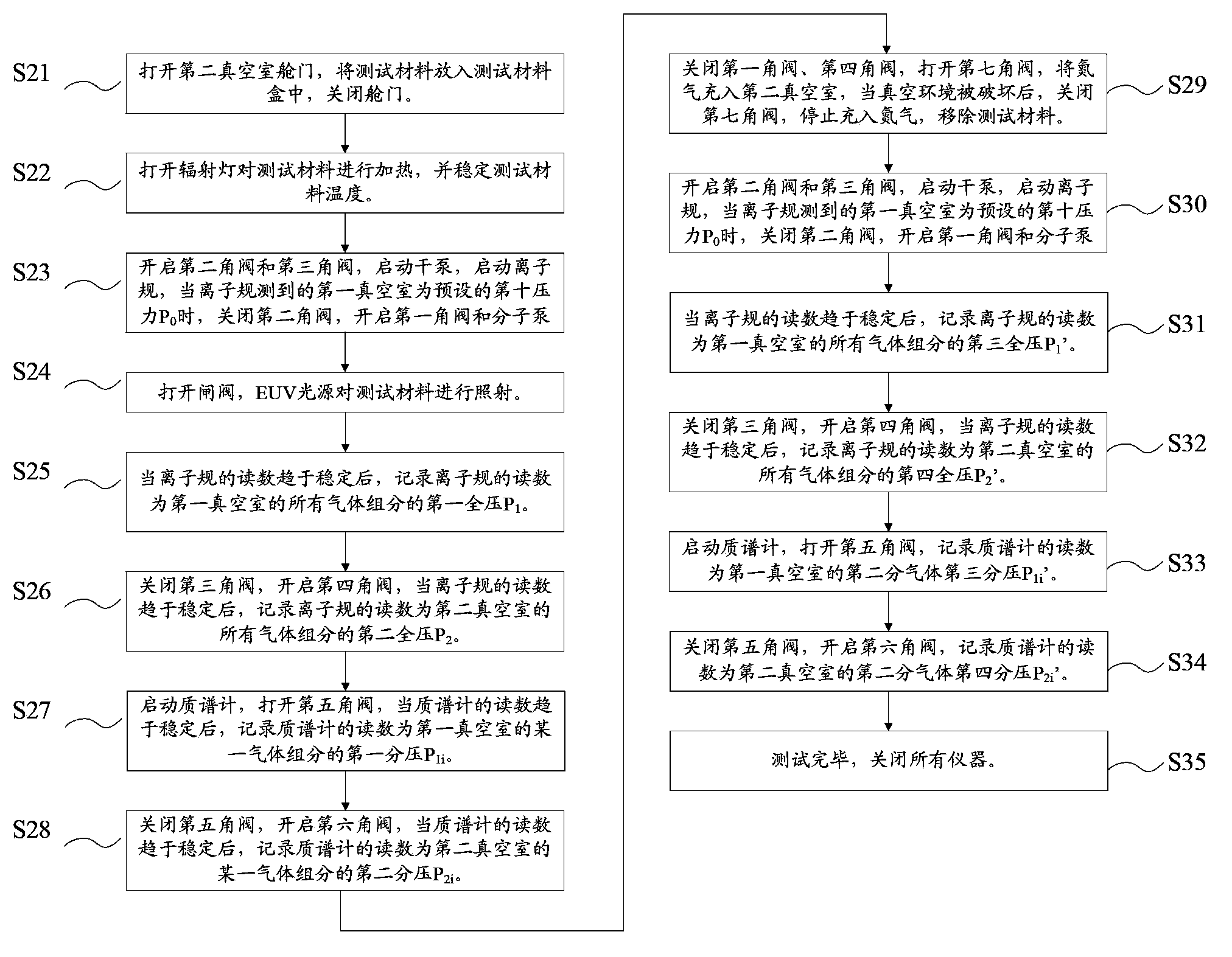

Device and method for testing outgassing rate of material

The invention provides a device for testing outgassing rate of a material, and the device comprises a vacuum chamber, a pump group, a testing system and a gas source. The vacuum chamber comprises a first vacuum chamber and a second vacuum chamber, the first vacuum chamber and the second vacuum chamber are separated by a spaced baffle provided with small holes, the second vacuum chamber is used for placing the test material, and the second vacuum chamber is provided with a radiation lamp; the pump group is connected with the vacuum chamber; the testing system is connected with the vacuum chamber; and the second vacuum chamber is charged with the gas source. The device tests gas pressure in the first vacuum chamber and the second vacuum chamber by the testing system, the total outgassing rate of all gases released by the test material can be tested, and the outgassing rate of one certain gas component released by the test material can be tested.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

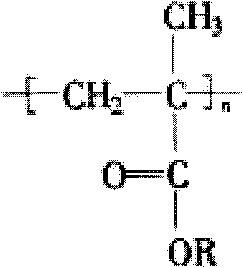

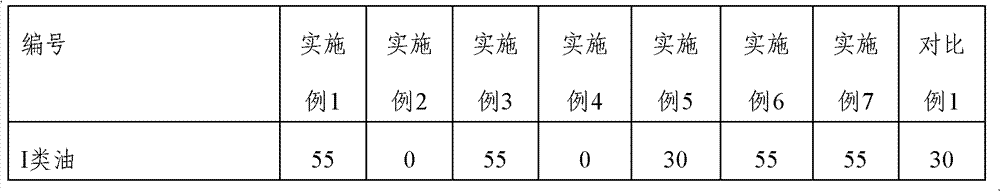

High-detergency hydraulic oil composition

The invention provides a high-detergency hydraulic oil composition. The composition comprises the following components by weight percent: base oil: 0-55 % of I-class oil and 45-100 % of II-class oil; and additives: 0.1-3 % of a PMA-type viscosity index improver, 1.0-1.6 % of an extreme pressure, clean, anti-wear complex agent, 0-0.01 % of a coagulation reducing agent, and 0-55 ppm of anti-bubble, wherein the amount of the additives is based on the amount of the base oil. The hydraulic oil composition has characteristics of wear resistance, anticorrosion, anti-oxidation and demulsification existing in traditional hydraulic oil, and further has detergency, and can reduce generation of paint film and greasy filth and maintain cleaning of the hydraulic system.

Owner:CHINA PETROLEUM & CHEM CORP

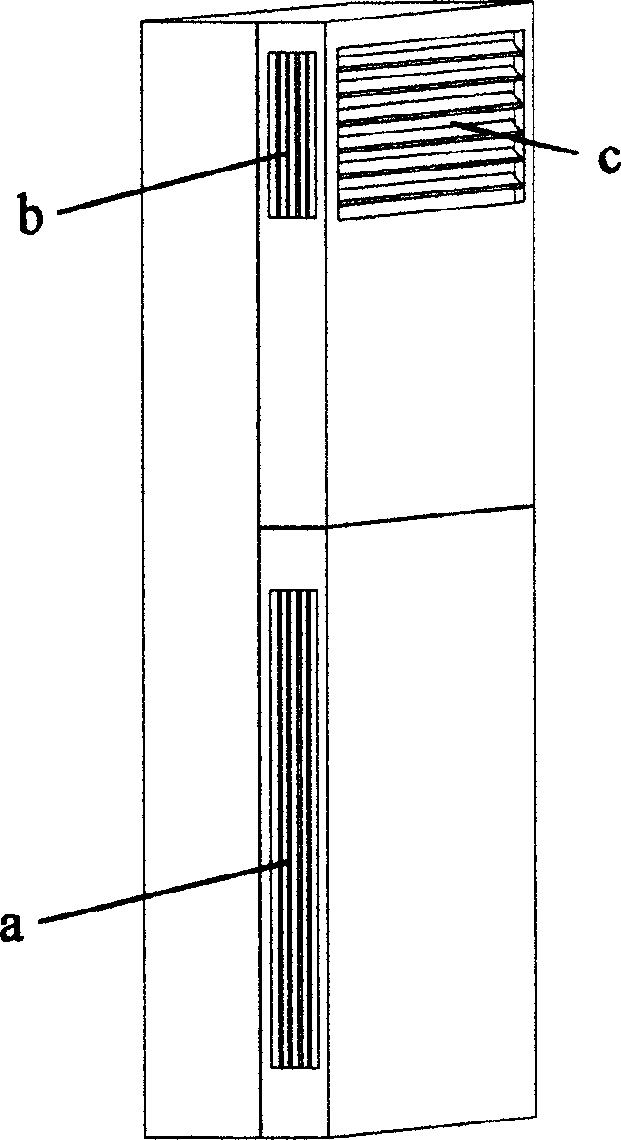

Ventilating apparatus and control method thereof

InactiveCN1740697AKeep cleanSimple and beautiful appearanceLighting and heating apparatusAir conditioning systemsElectrical and Electronics engineeringElectric machine

The invention is a kind of ventilating apparatus and its controlling method used on air conditioner. The ventilating apparatus includes ventilation door and air port assembly. The ventilating door is composed of baffle and grid. When starting the machine, ventilation door is rotated driven by motor and makes the grid rotate to the air port,then makes air enter into conditioner. When switching off the machine, ventilation door is reverse rotated driven by motor, rotate the baffle to the air port, blocking air inlet which make dust and sundries can not enter air conditioner. The rotating angle of ventilation door is controlled by journey switch.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

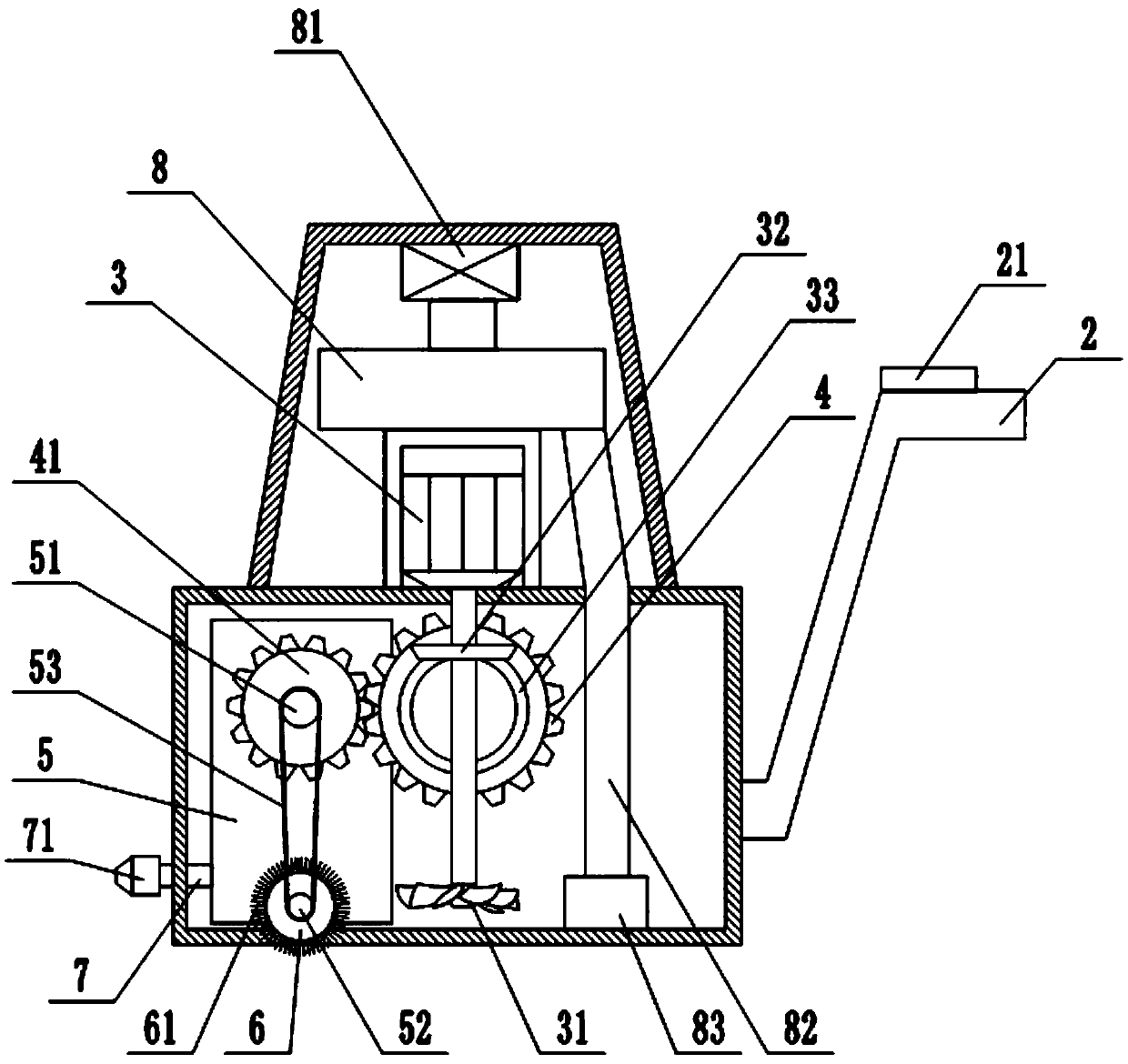

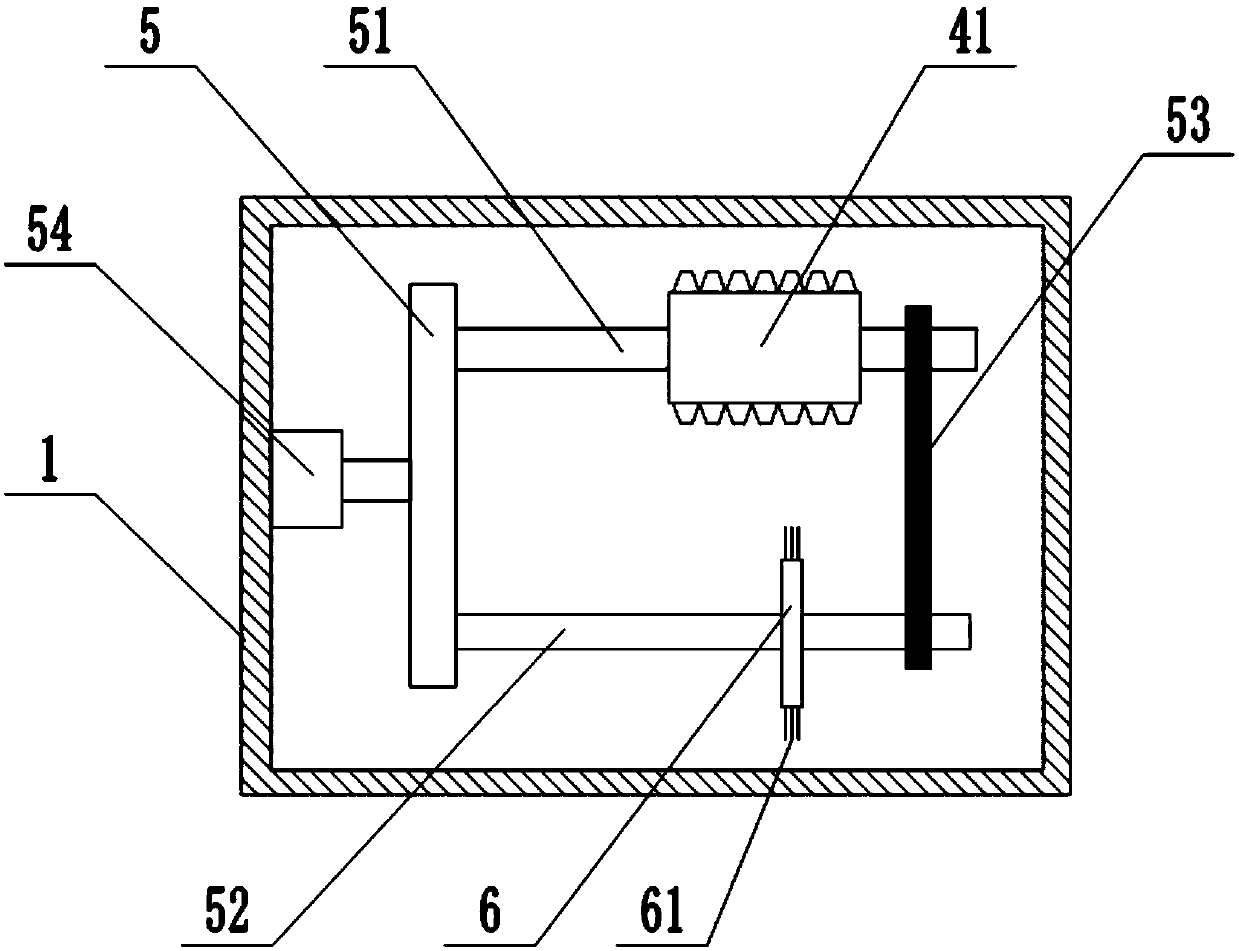

Milling machine waste collection device

InactiveCN104416411AImprove efficiencyKeep cleanMilling equipment detailsMaintainance and safety accessoriesScrapOperating environment

The invention discloses a milling machine waste collection device which comprises a plurality of collecting units which are connected in sequence. The collecting units are arranged at the bottom of an external milling machine. A great deal of metal scraps are produced from milling machining of large-sized workpieces, one or more milling machines can be subjected to centralized waste collection through the collecting units arranged at the bottom of the milling machine, efficiency of overall machining procedure of the milling machine is greatly improved, and cleanliness of the operating environment is guaranteed.

Owner:陈均

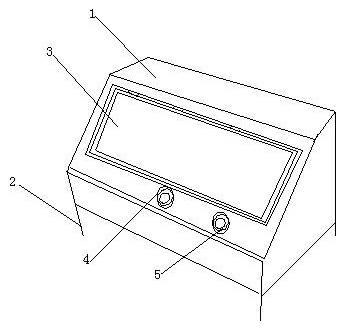

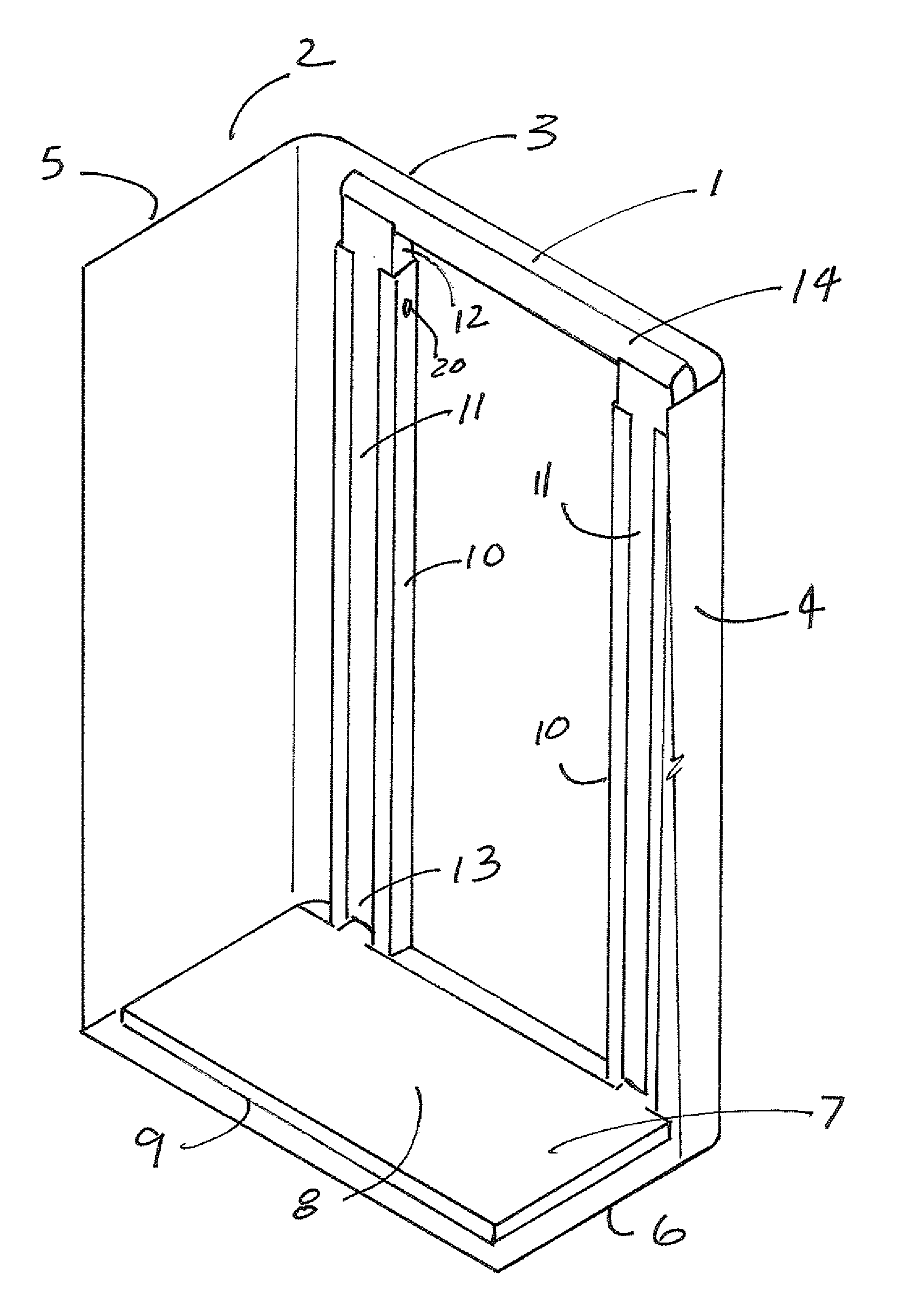

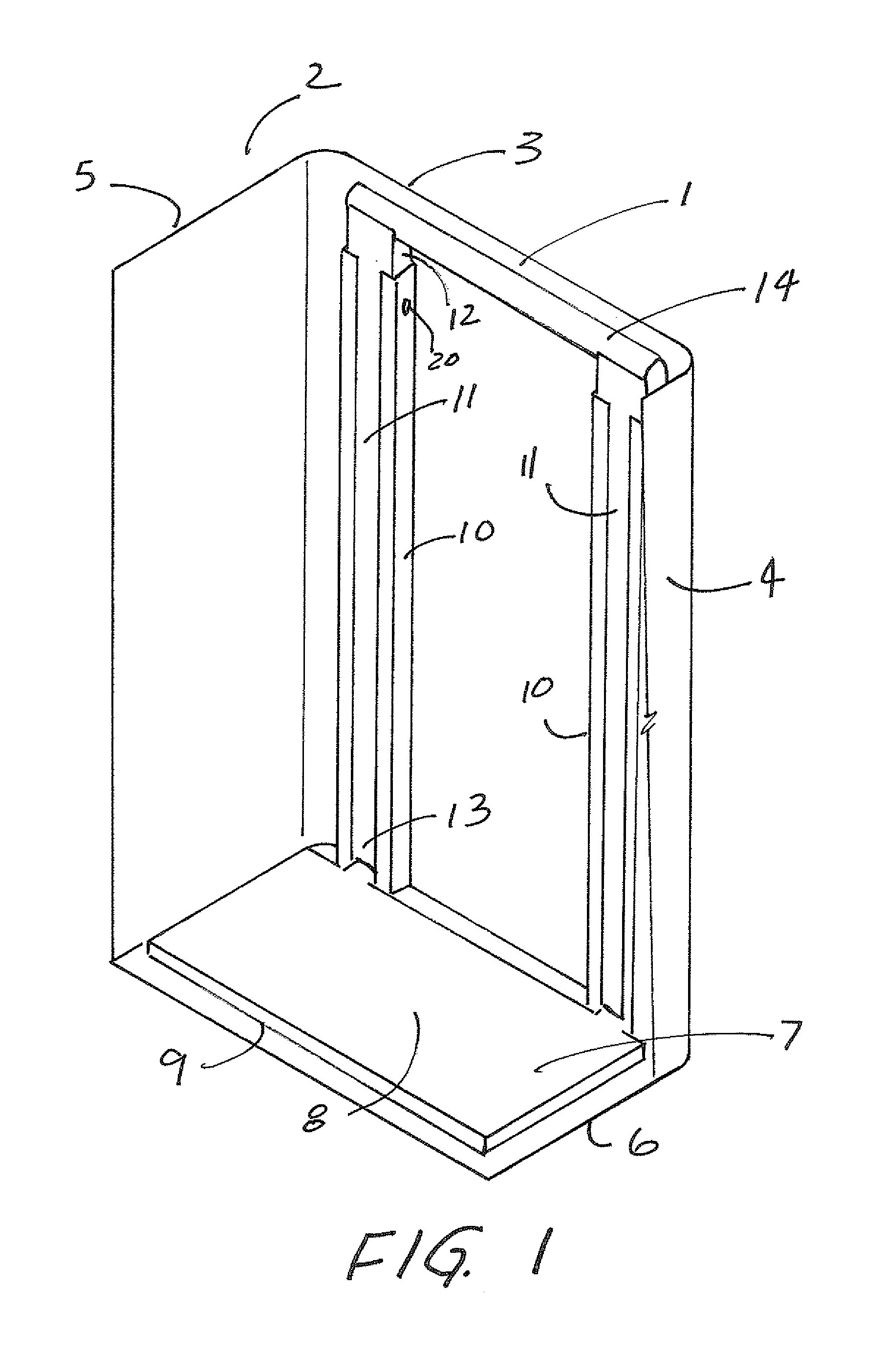

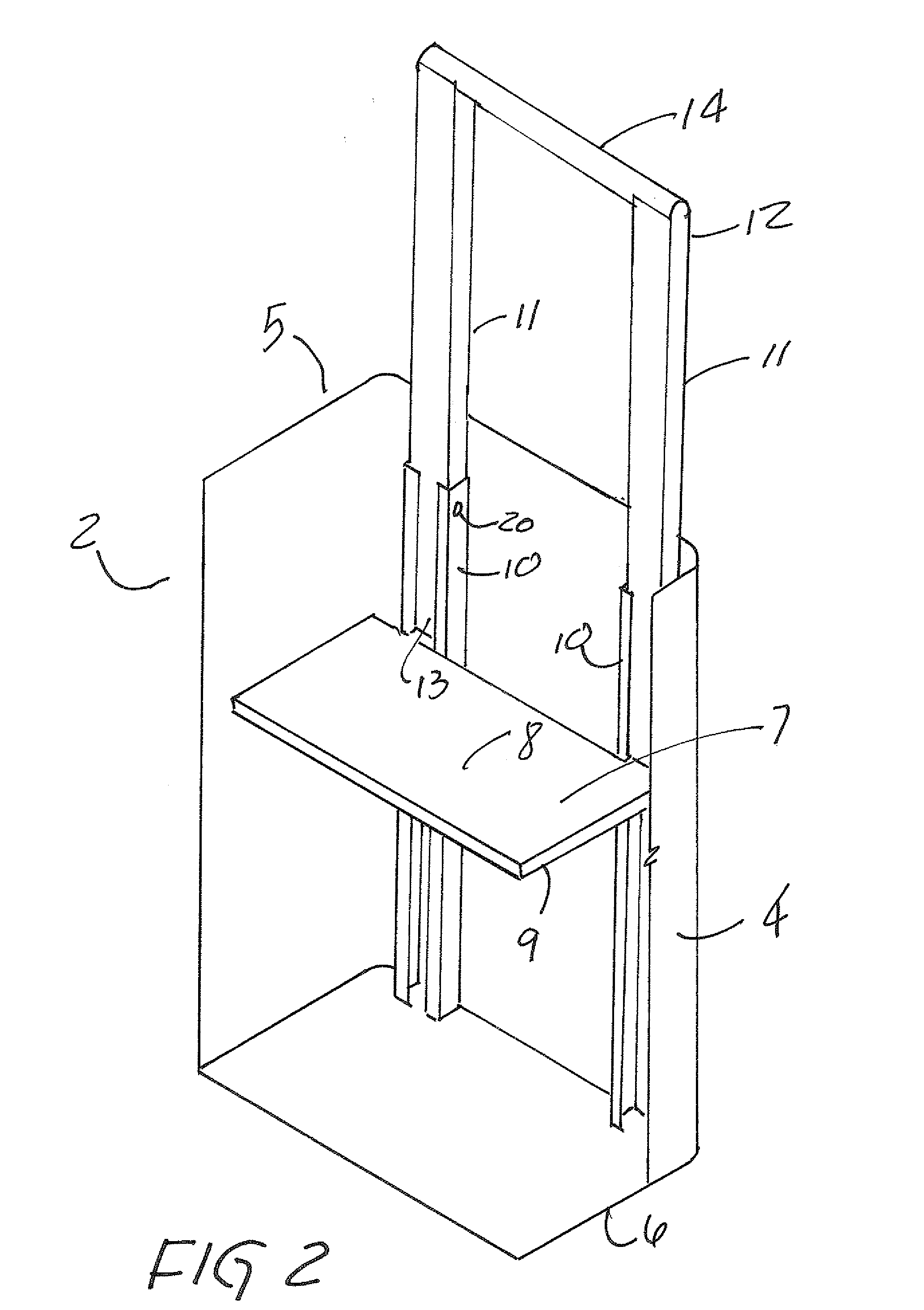

Operation box for filling ink powder into selenium drum

InactiveCN102692847AAvoid Toner SpillsKeep cleanElectrographic process apparatusEngineeringWorking environment

The invention discloses an operation box for filling ink powder into a selenium drum. The operation box comprises a box body provided with supporting legs, wherein the box body is connected with an observation region by virtue of a hinge, the box body at the lower part of the observation region is provided with a group of operating holes which are sheathed with dustproof sleeves, the bottom in the box body is hopper-shaped, the upper part of a collecting tank is provided with a separation net layer, the upper part of the separation net layer is provided with a tool placing frame, a working platform and a finished product platform, a plurality of dust collection holes are formed at the bottom of the box body, the lower part of each dust collection hole is connected with a multi-hole connector, and the lower part of the multi-hole connector is connected with dust collection equipment provided with a pipeline. The collecting tank, the tool placing frame, the working platform and the finished product platform are arranged in the box body, and the dust collection device is arranged at the bottom of the box body, so that ink powder is effectively prevented from overflowing when the powder is added in the selenium drum for a second time, thereby guaranteeing a working environment to be clean and operating personnel to be in good health...

Owner:王卫华

Textile thread lubrication device

InactiveCN111304847AAccelerate oil wetting efficiencyKeep cleanTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringEnvironmental geology

The invention discloses a textile thread lubrication device. The textile thread lubrication device comprises a base; a box body is fixedly connected to the upper end of the base; a heating box is fixedly connected to the upper end of the box body; a first circular ring is fixedly connected to the lower end of the heating box; a cylinder is slidably connected to the inner wall of the first circularring; a plurality of springs are symmetrically and fixedly connected to the inner wall of the cylinder; one end, away from the inner wall of the cylinder, of the plurality of springs is fixedly connected with an arc-shaped plate in a hollow structure; and the first circular ring is provided with an oil guiding device for inputting oil in the arc-shaped plate. According to the textile thread lubrication device provided by the invention, the cylinder drives the arc-shaped plate to rotate, so that the oil in the heating box flows into the arc-shaped plate through the oil guiding device, and flows out from an oil guiding hole, thus comprehensive oil infiltration is carried out on textile threads, the oil infiltration efficiency on the textile threads with different thicknesses is accelerated,and the oil can be heated through a heating plate, so that the situation that the circulation of the oil is affected due to the solidification of the oil when the weather is cold, so that the oil infiltration efficiency of the textile threads is affected is avoided.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

Liquid filling machine for protecting filling head

The invention discloses a liquid filling machine for protecting a filling head. The liquid filling machine comprises a box, a stirring cavity is arranged at the upper end of the interior of the box, aliquid discharging pipe is arranged at the middle portion of the lower side of the stirring cavity, a liquid discharging soft pipe is arranged on the lower side of the liquid discharging pipe, a connecting pipe is arranged on the lower side of the liquid discharging soft pipe, the filling head is arranged on the lower side of the connecting pipe, an opening is formed in the lower side of the filling head, a fixing block is arranged on the outer side of the connecting pipe, the left and right ends of the upper side of the fixing block are provided with L-shaped connecting rods, the left and right ends of the lower side of the box are provided with sliding grooves, second motors are arranged at the upper ends of the interiors of the sliding grooves, lead screws are arranged on the lower sides of the second motors and are provided with sliding blocks, the interiors of the sliding blocks are connected with the L-shaped connecting rods, a groove is formed in the lower side of the box, a base is arranged on the lower side of the groove, a conveying belt is arranged on the upper side of the base, an electric control cabinet is arranged at the front end of the left side of the conveying belt, a base plate is arranged on the lower side of the base, a damping mat is arranged inside the base plate, and supporting bases are arranged at four corners of the lower side of the damping mat. Bymeans of the liquid filling machine, liquid filling of the equipment can be effectively facilitated, and cleanliness of the filling head can be effectively guaranteed.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

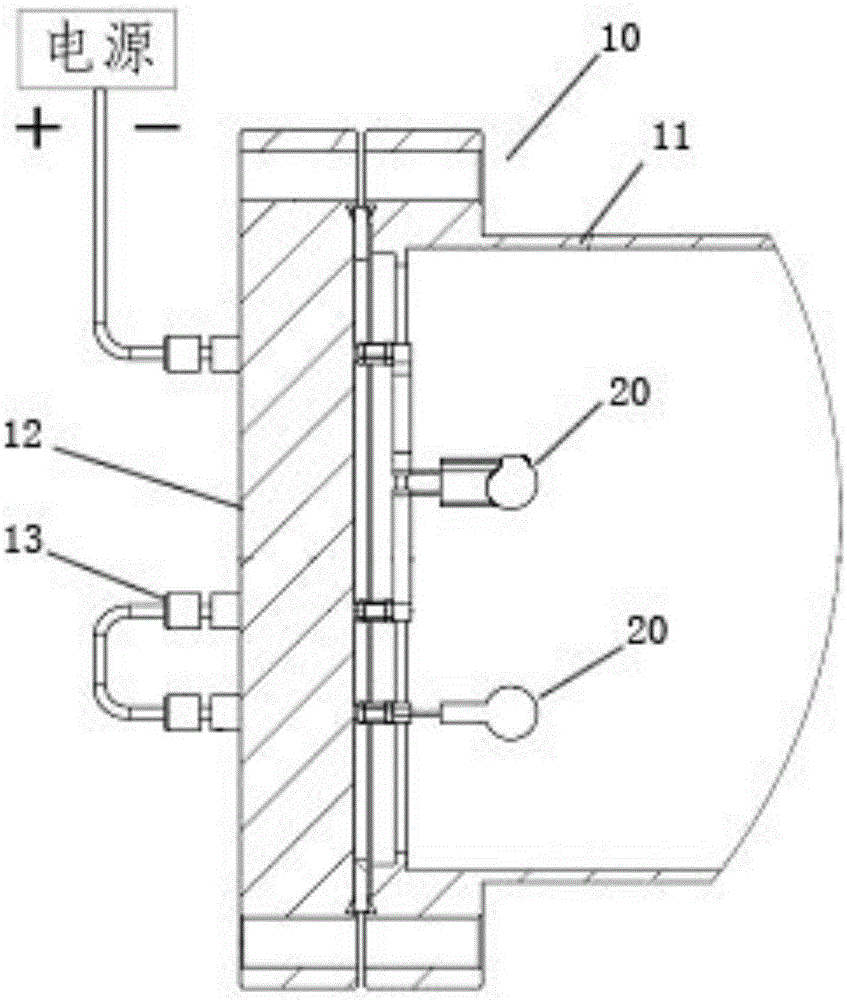

Field emission electron gun baking device and baking method of electron gun chamber

ActiveCN105140091AImprove thermal efficiencyKeep cleanElectric discharge tubesResistance wireThermal radiation

The invention discloses a field emission electron gun baking device and a baking method of an electron gun chamber. A heat source is arranged in the electron gun chamber, preferably is arranged close to related parts, and directly carries out thermal radiation on the parts, so that the heat-conducting efficiency is improved; gas molecules on the surfaces of the related parts fully escape; and when the electron gun chamber is in a working state, the vacuum degree in the electron gun chamber is not obviously reduced. In the existing technical solution, a gas is released by a resistance wire in the heating process; in order to avoid vacuum degree reduction in the electron gun chamber caused by the gas released by the resistance wire, the technical defects of low heating efficiency, insufficient temperature rise of partial parts and overheating of partial parts are generated due to the fact that the resistance wire can only be arranged outside the electron gun chamber. According to the field emission electron gun baking device disclosed by the invention, the technology bias is exactly overcome. The heat source is arranged in the electron gun chamber to bake the parts, so that the technical defect of poor thermal radiation effect due to the fact that a heating tape is adopted for heating in the prior art is overcome.

Owner:KYKY TECH

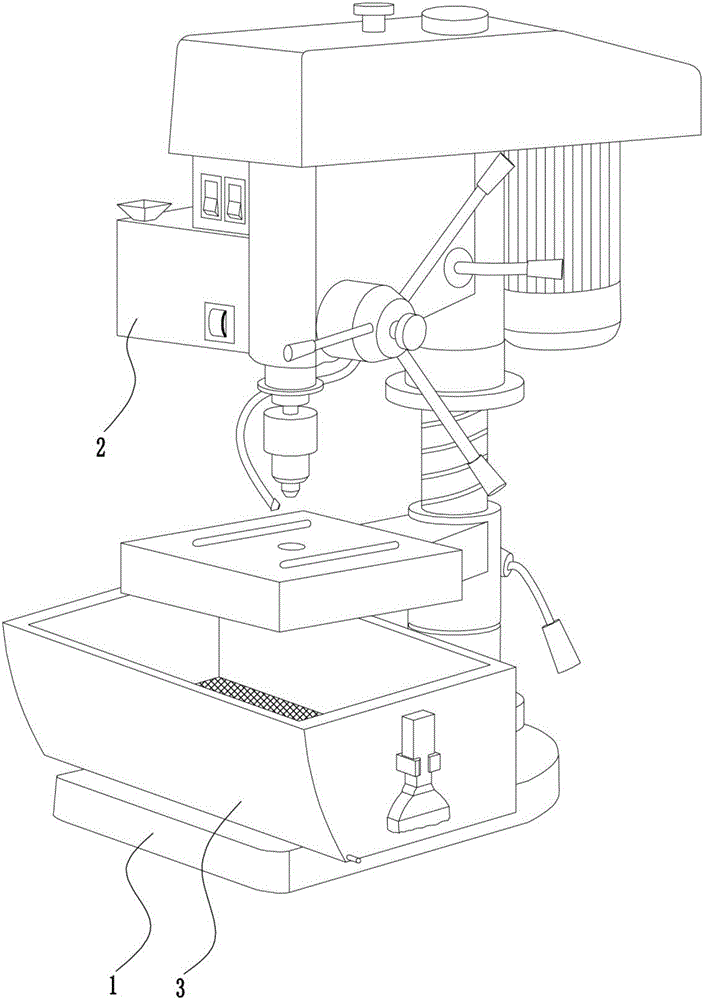

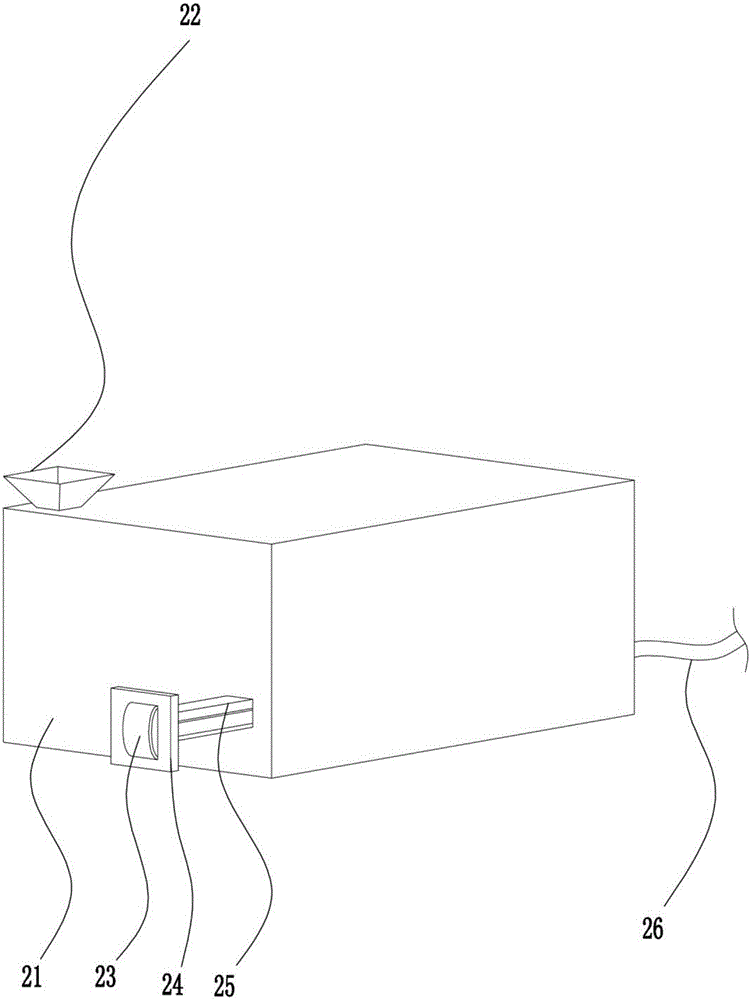

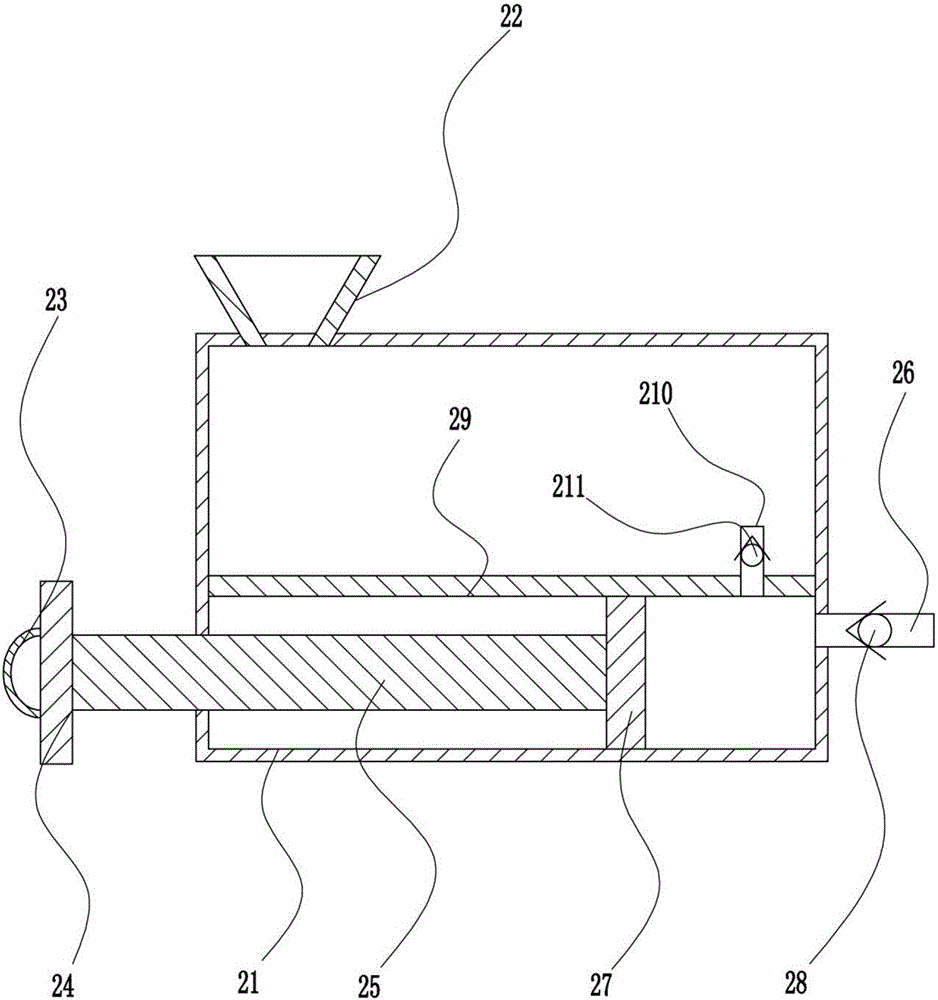

Novel multifunctional bench drill

InactiveCN106424843AGuaranteed smoothnessKeep cleanBoring/drilling componentsMaintainance and safety accessoriesScrapEngineering

The invention relates to a bench drill, in particular to a novel multifunctional bench drill. According to the technical purpose needing to be achieved, the novel multifunctional bench drill with a cooling function and a waste scrap collecting function is provided. To achieve the above technical purpose, the novel multifunctional bench drill is provided and comprises a drilling machine and the like. A cooling device is arranged on the left side of a feeding box of the drilling machine and comprises a box body, a feeding hopper, a handle, a fixing plate, a push rod, a bamboo joint pipe, a push plate, a first one-way valve, a partition plate, a communication pipe and a second one-way valve. The box body is connected to the left side of the feeding box in a screw connection manner. The feeding hopper is welded to the top of the box body. The partition plate is arranged on the right side in the box body and provided with the communication pipe. The second one-way valve is arranged in the communication pipe. According to the bench drill, a worker only needs to slightly push the push rod through the handle, the push rod pushes the push plate, the push plate extrudes cutting fluid, so that the cutting fluid flows to the workpiece machining position through the bamboo joint pipe, and the effect of cooling is achieved.

Owner:杨娇仔

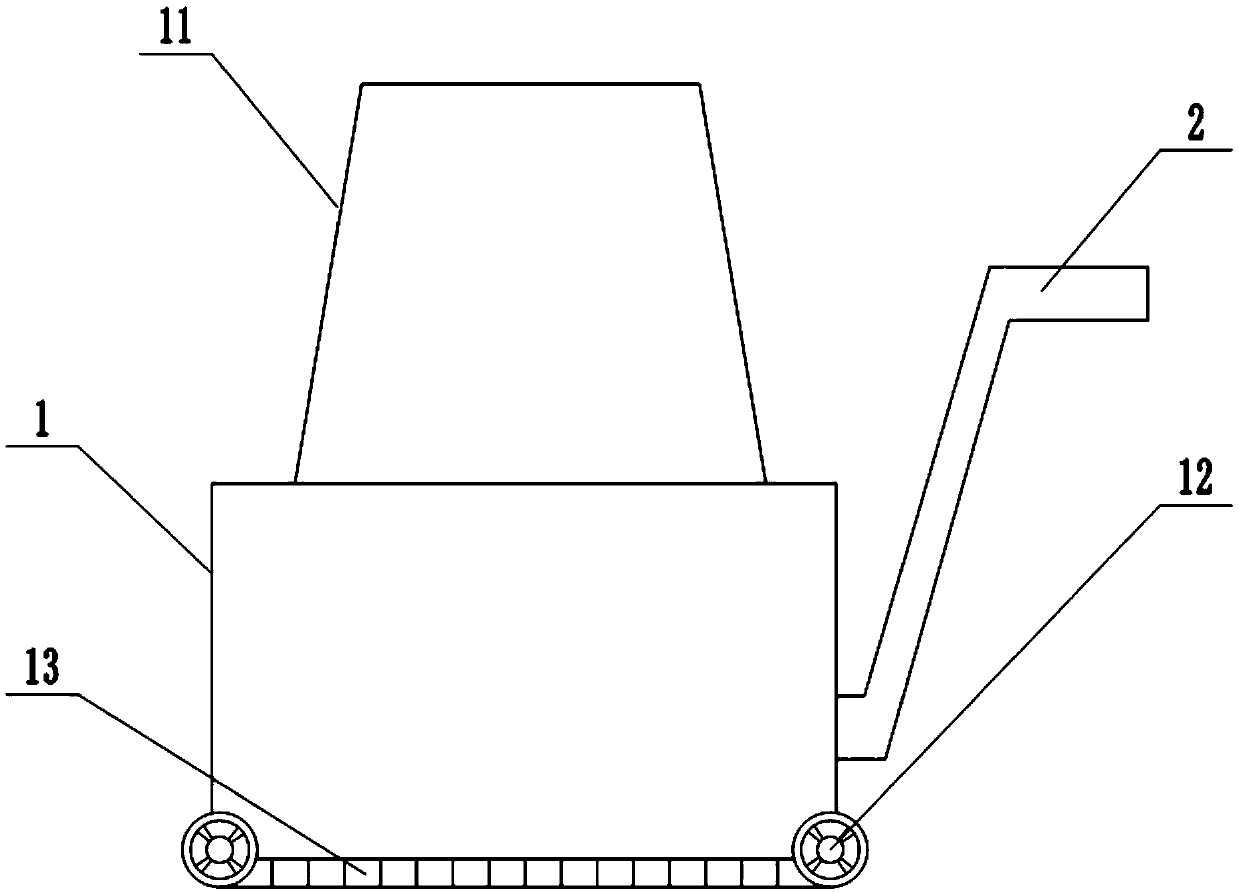

Floor tile gap cleaning device

InactiveCN109674401AKeep cleanSimple and efficient operationCarpet cleanersFloor cleanersEngineeringLeather belt

The invention relates to the technical field of household cleaning equipment, and discloses a floor tile gap cleaning device, comprising a case, a hood, a hand-push handle, a sweeping mechanism and adust absorbing mechanism; the sweeping mechanism comprises a motor, a fan, a first bevel gear, a second bevel gear and a first gear; a vertical plate is arranged in the case, a first rotating shaft and a second rotating shaft are rotatably connected to the vertical plate, a belt is connected between the first rotating shaft and the second rotating shaft, a second gear is fixedly connected to the first rotating shaft coaxially, a brush disc is coaxially conneced to the second rotating shaft, and hard bristle is densely distributed at the outer periphery of the brush disc. In the cleaning process, lime-sand mortar, wood bits and other small particles in the floor tile gaps are swept to the surfaces of the floor tiles by the sweeping mechanism, then dust along the road is completely adsorbedby the dust absorbing mechanism, and finally cleaning of the floor tile gaps is completed; the device overcomes the problems of complicated procedure, low efficiency and relatively high labor cost existing in cleaning of the floor tile gaps in the prior art.

Owner:象山谢海家具有限公司

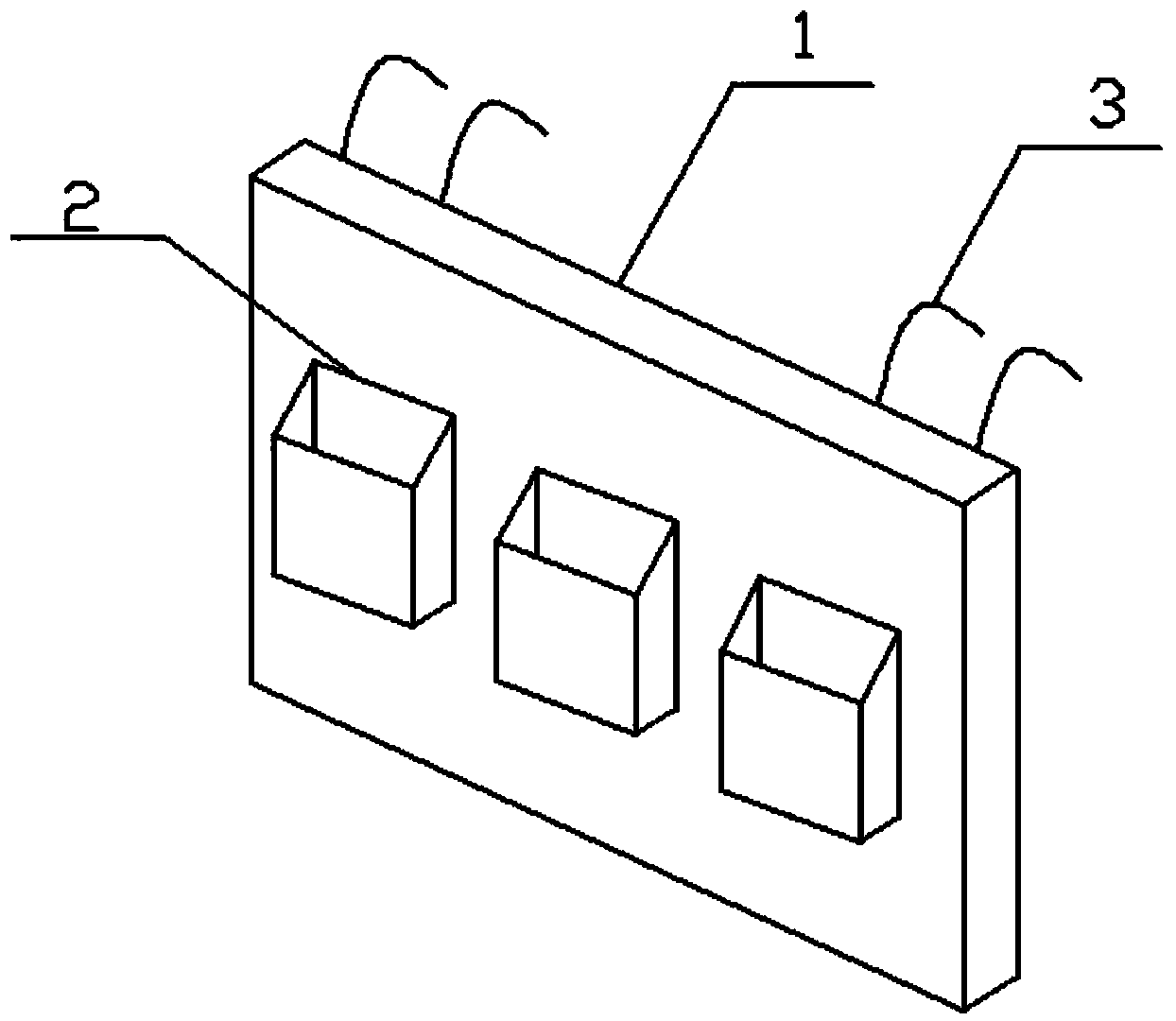

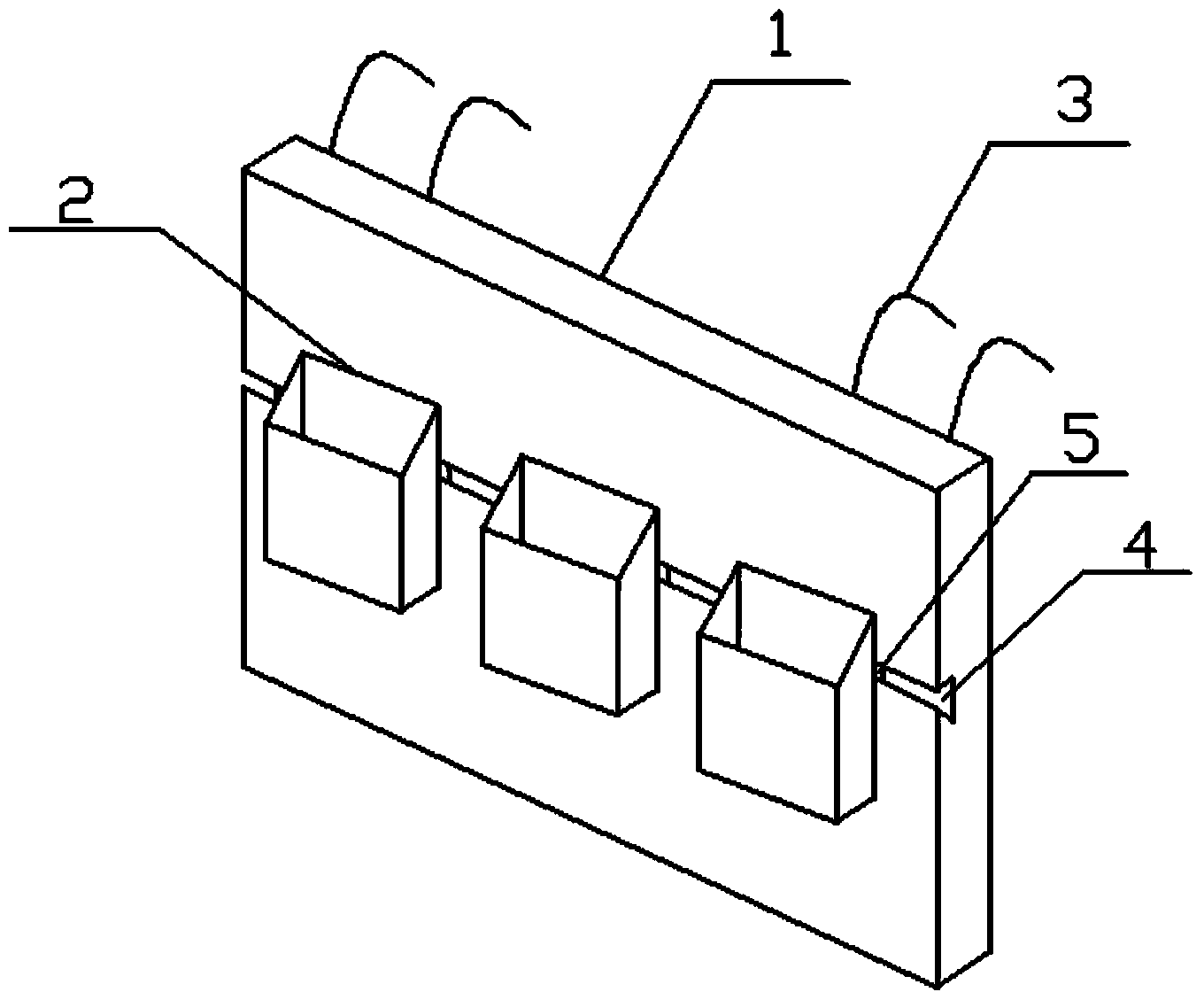

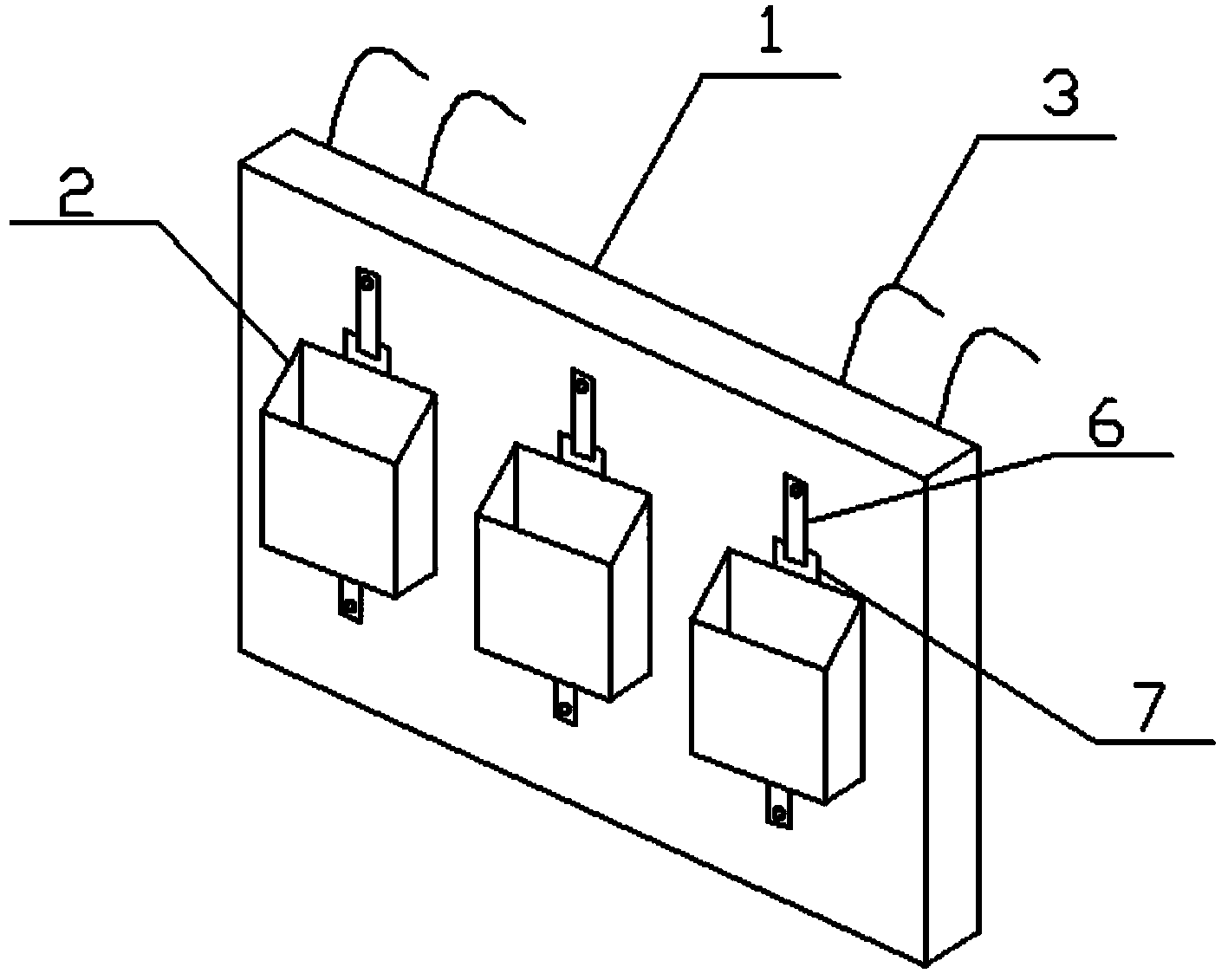

Suspension type waste accommodation device

InactiveCN103445927AAvoid Mixed ContaminationKeep cleanNursing bedsInfusion needlesDomestic wasteMedical treatment

The invention discloses a suspension type waste accommodation device, which comprises a baseplate and more than one accommodation box arranged on the baseplate, wherein connecting parts are fixed on the back side of the baseplate and used for hanging the accommodation device; the accommodation boxes comprise medical waste boxes. The connecting parts are arranged on the back side of the waste accommodation device, the waste accommodation device can be hung on a guardrail at the head of a patient's bed through the connecting parts, and the waste accommodation device comprises multiple accommodation boxes arranged in a classified manner, so that a nurse can place the waste generated during treatment into the corresponding accommodation boxes and the treatment tray can be kept clean. Meanwhile, the patient and the relatives can place domestic waste in corresponding accommodation boxes, so that domestic waste and medical waste can be placed separately, mixed pollution can be avoided, and cleanness and sanitation of a ward can be kept. Moreover, as the accommodation boxes are detachably arranged on the baseplate, the accommodation boxes can be taken down conveniently to facilitate waste collection and the accommodation boxes can be disinfected and cleaned conveniently.

Owner:SUZHOU UNIV

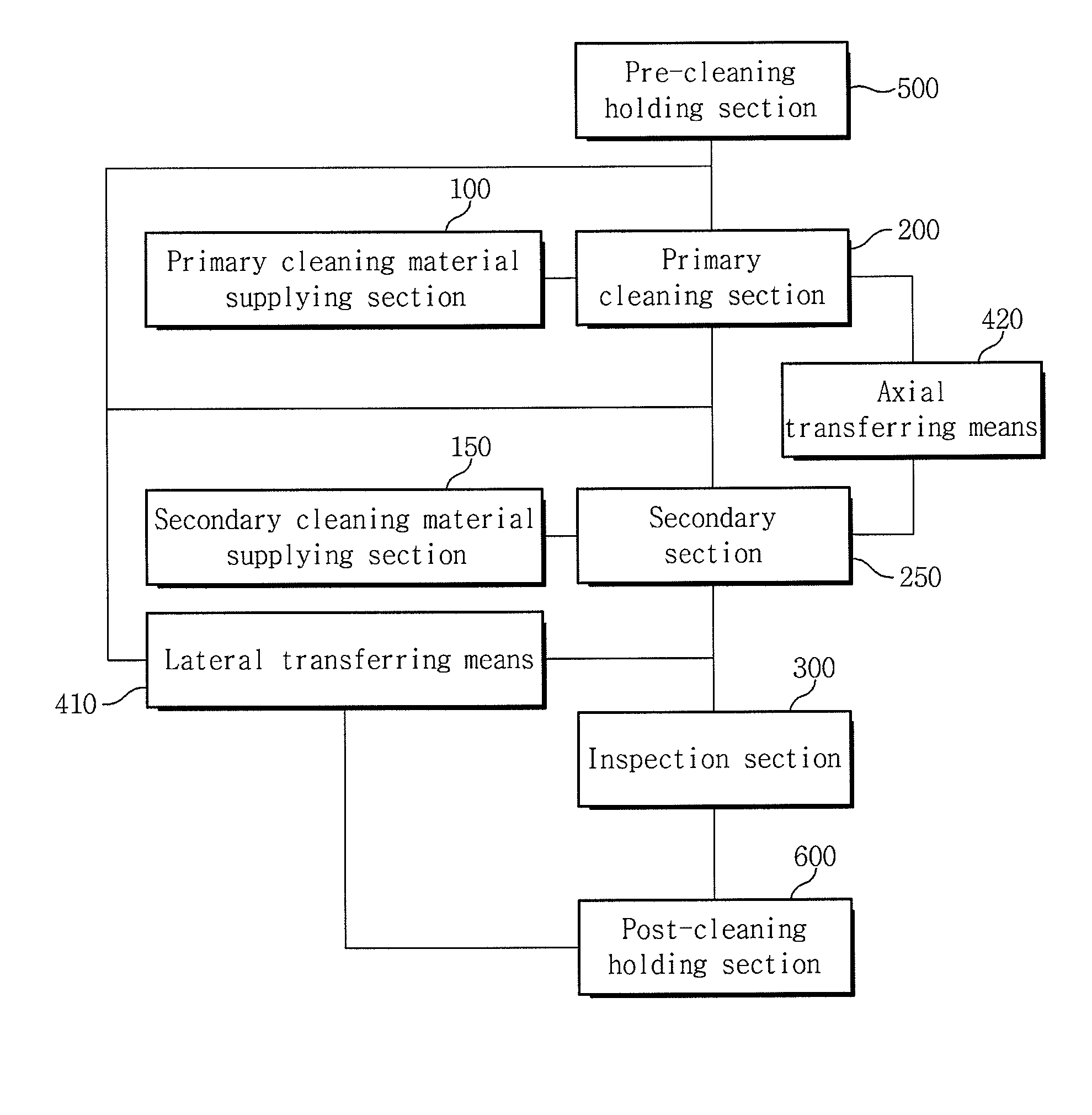

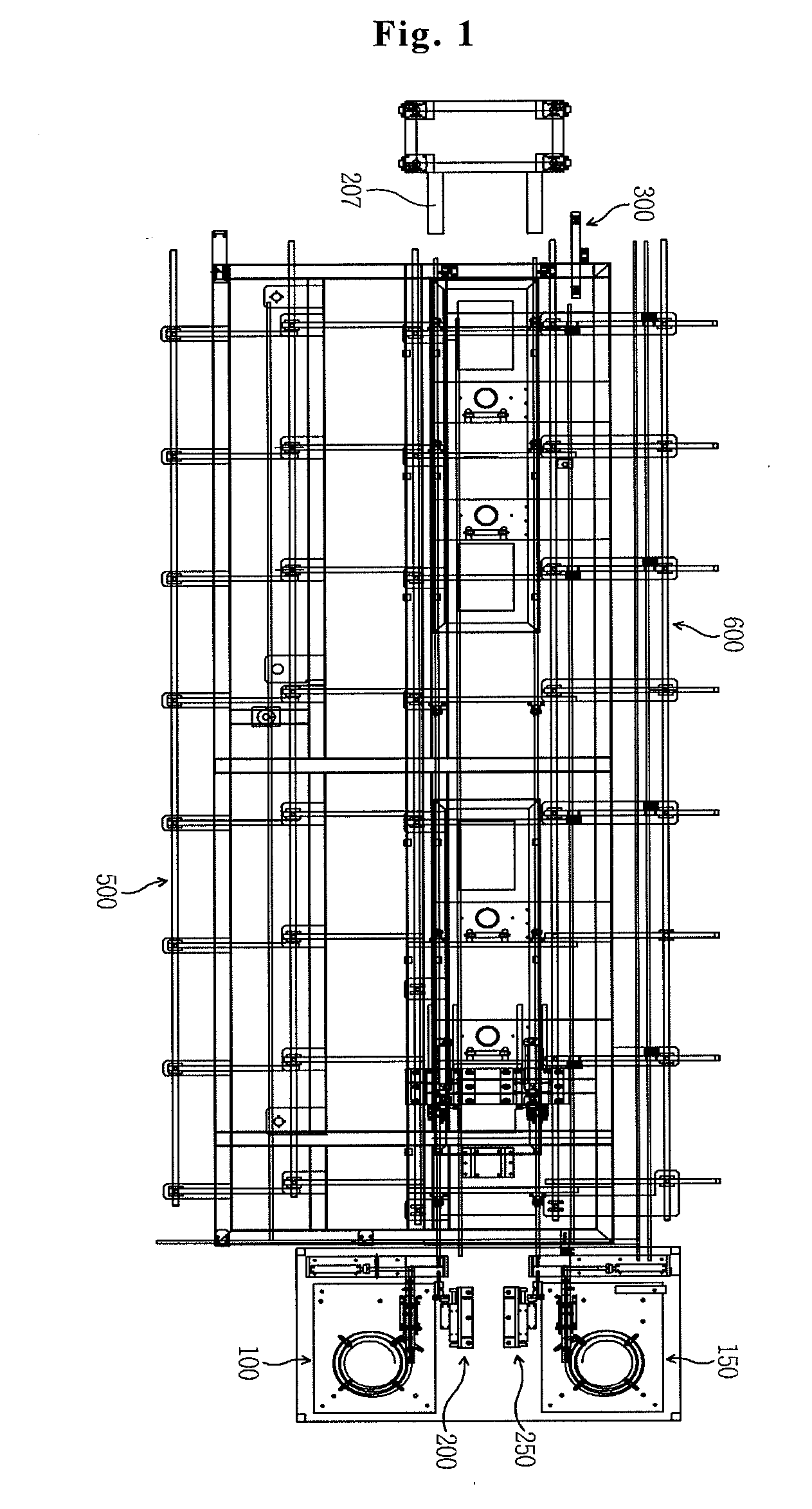

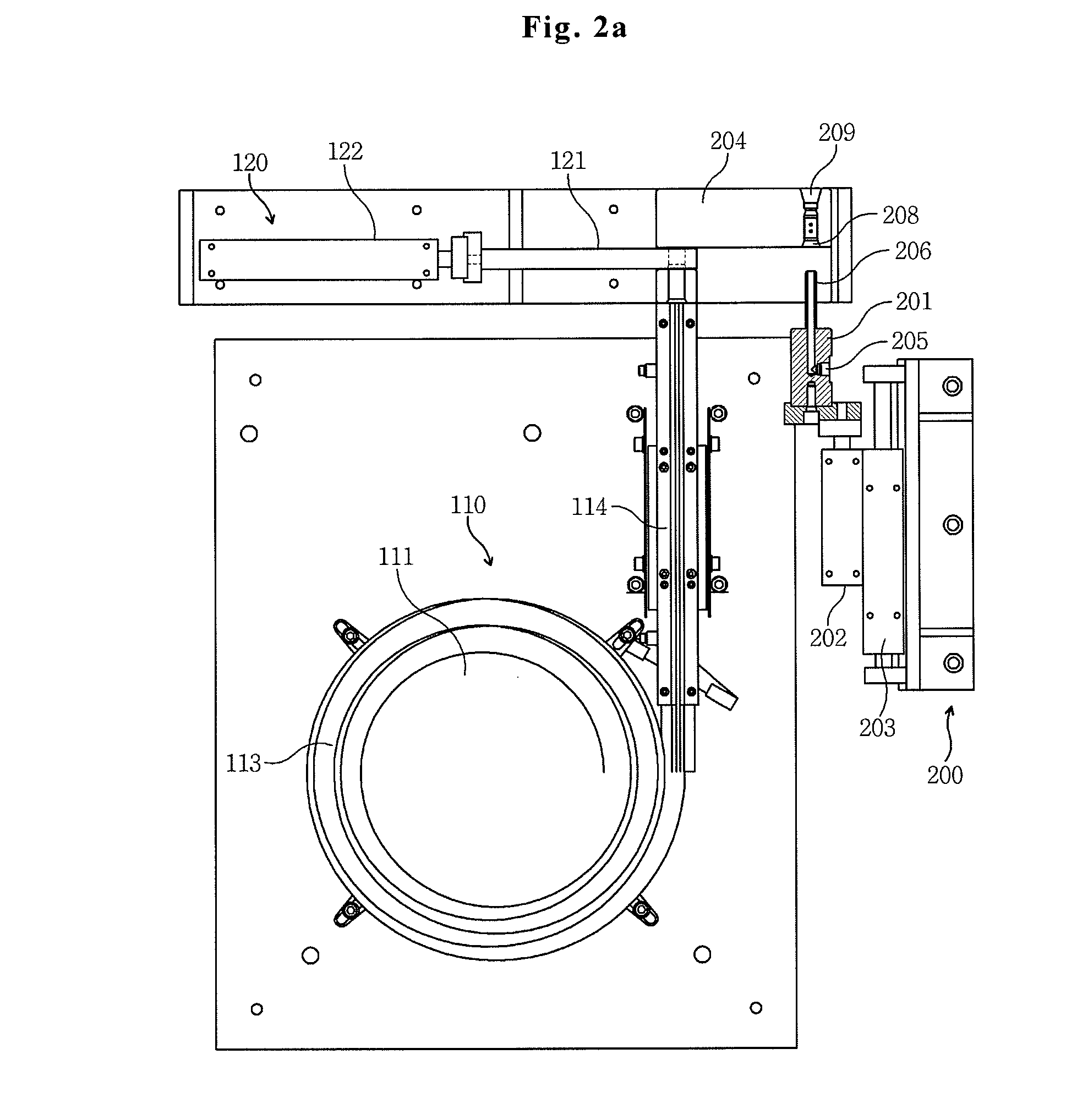

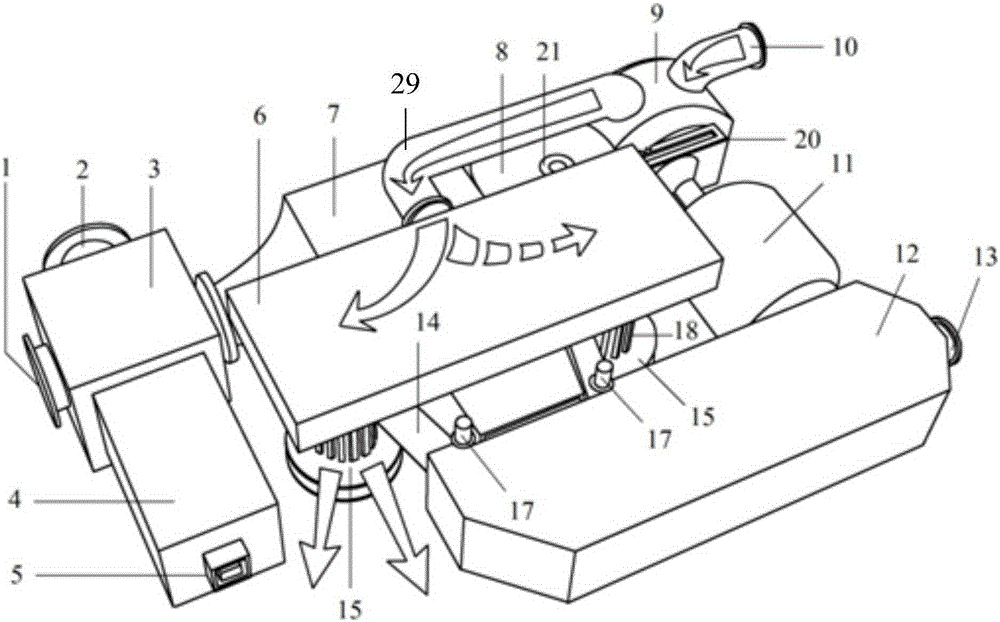

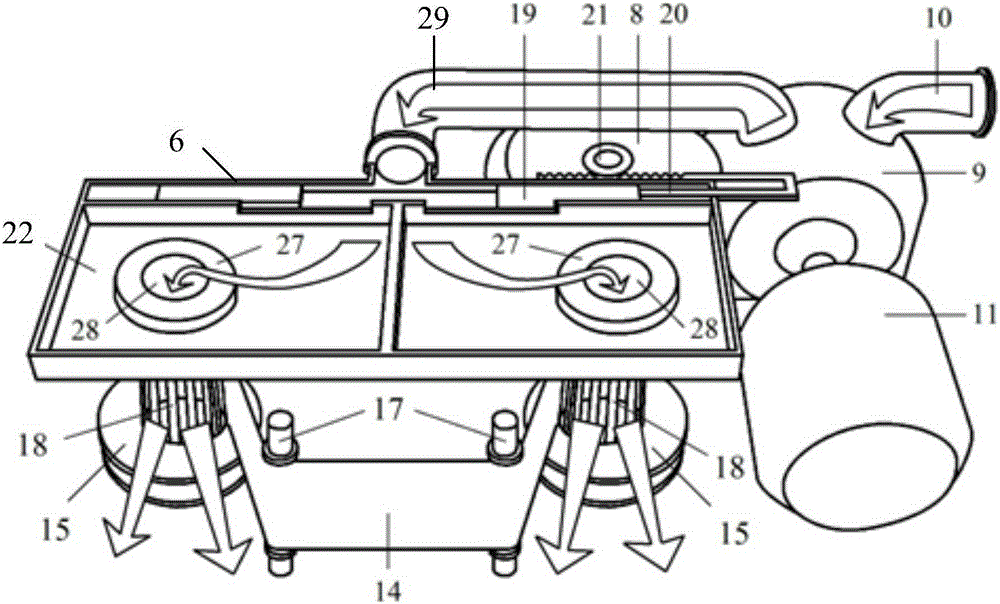

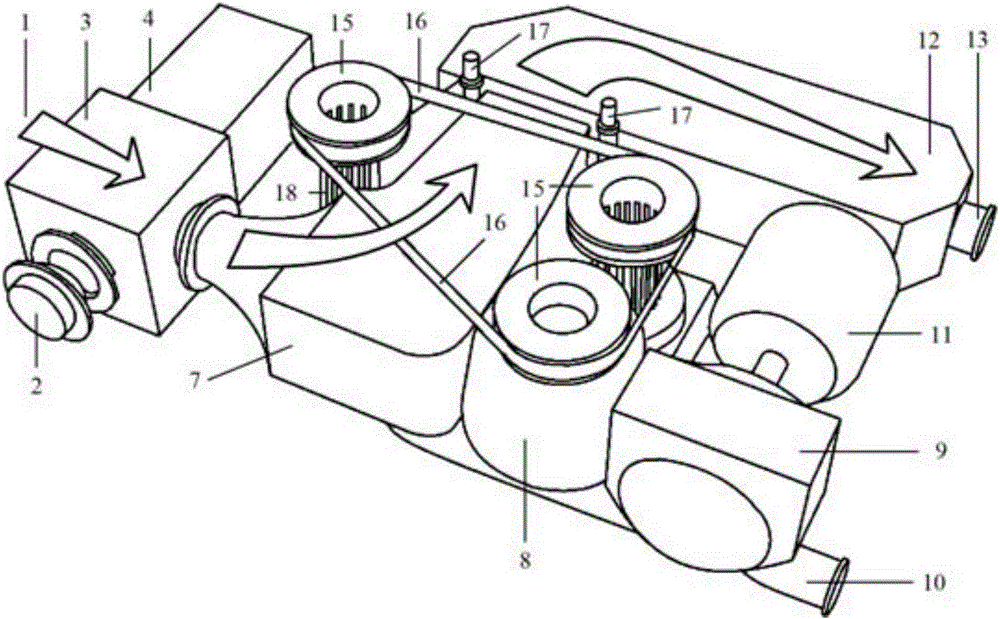

Automated Cleaning Equipment and Method for the Nuclear Fuel-Cladding Tube

ActiveUS20100195783A1Decrease productivityReduce diseaseNuclear energy generationHollow article cleaningMaterial supplyNuclear fuel

Disclosed is an apparatus for performing an automated cleaning of nuclear fuel cladding-tubes. The apparatus comprises a pre-cleaning holding section disposed at a first side of the apparatus, a primary cleaning-material supplying section and a primary cleaning section disposed at a second side of the apparatus, a secondary cleaning section and a secondary cleaning material supplying section disposed at the second side of the apparatus and beside the primary cleaning section, an inspection section disposed at a third side of the apparatus that is opposite to the second side, and a post-cleaning holding section disposed at the fourth side of the transferring section. The pre-cleaning holding section and the post-cleaning holding section includes a cladding-tube guide where the cladding-tube is loaded before and after cleaning. Primary and secondary cleaning material supply sections are disposed at a lateral side of the primary and secondary cleaning sections respectively.

Owner:KEPCO NUCLEAR FUEL CO LTD

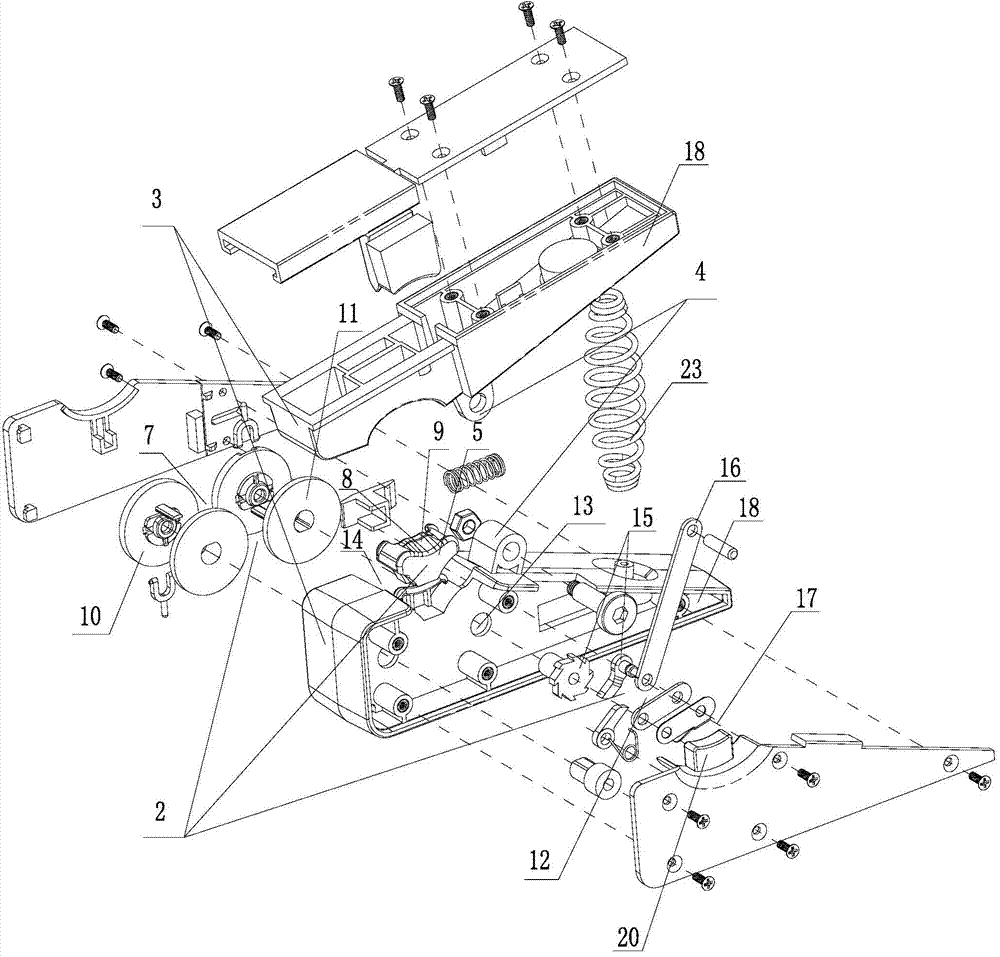

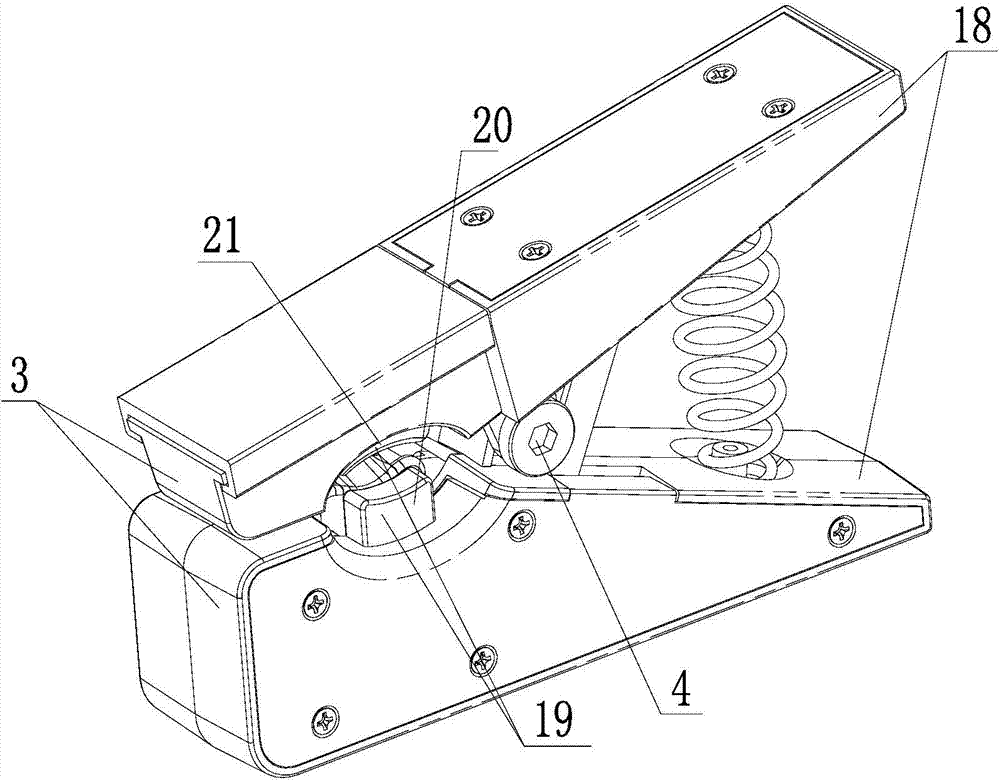

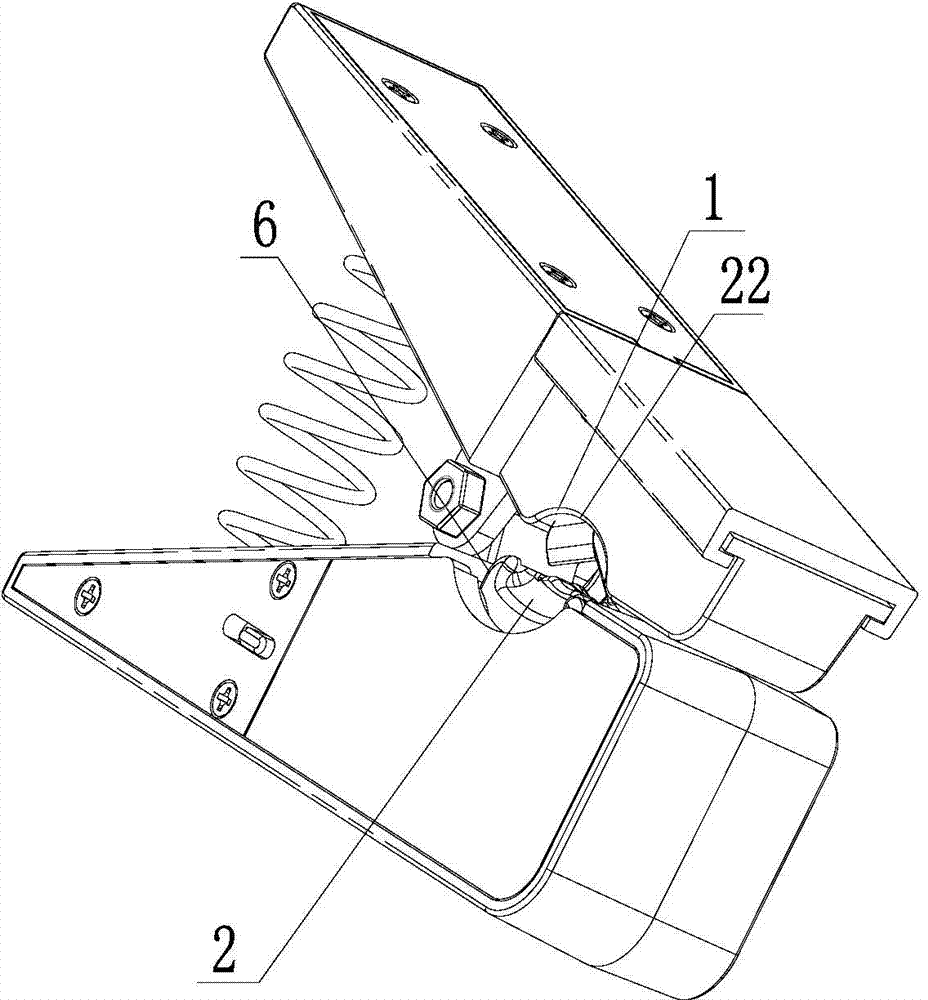

Clip type bottle opener for medical ampoule glass bottle

ActiveCN104773684AEasy to useKeep cleanOpening closed containersBottle/container closureBottle neckScrap

The invention discloses a clip type bottle opener for a medical ampoule glass bottle, belonging to the manufacturing technical field of medical auxiliary instruments. The clip type bottle opener for the medical ampoule glass bottle provided by the invention is convenient to use, and can sterilize the ampoule glass bottle, remove scraps of the ampoule glass bottle, cut the ampoule glass bottle and break off a bottle neck of the ampoule glass bottle which is needed to be opened in a using process, as well as can keep a scrap-removing device clean constantly. The clip type bottle opener comprises a cutting device and a sterilizing and scrap-removing device; the cutting device and the sterilizing and scrap-removing device are symmetrically mounted in different parts of a clamp head of a clamp frame structure; the sterilizing and scrap-removing device comprises a buffering pre-stressing mechanism, a sterilizing and scrap-removing belt and a supporting scrolling mechanism; the buffering pre-stressing mechanism and the cutting device are symmetrically mounted in different parts of the clamp head; the supporting scrolling mechanism is mounted on the clamp head below the buffering pre-stressing mechanism; the sterilizing and scrap-removing belt scrolled on the supporting scrolling mechanism steps across the buffering pre-stressing mechanism from the top and is tightened on the buffering pre-stressing mechanism through the supporting scrolling mechanism.

Owner:雷钧皓

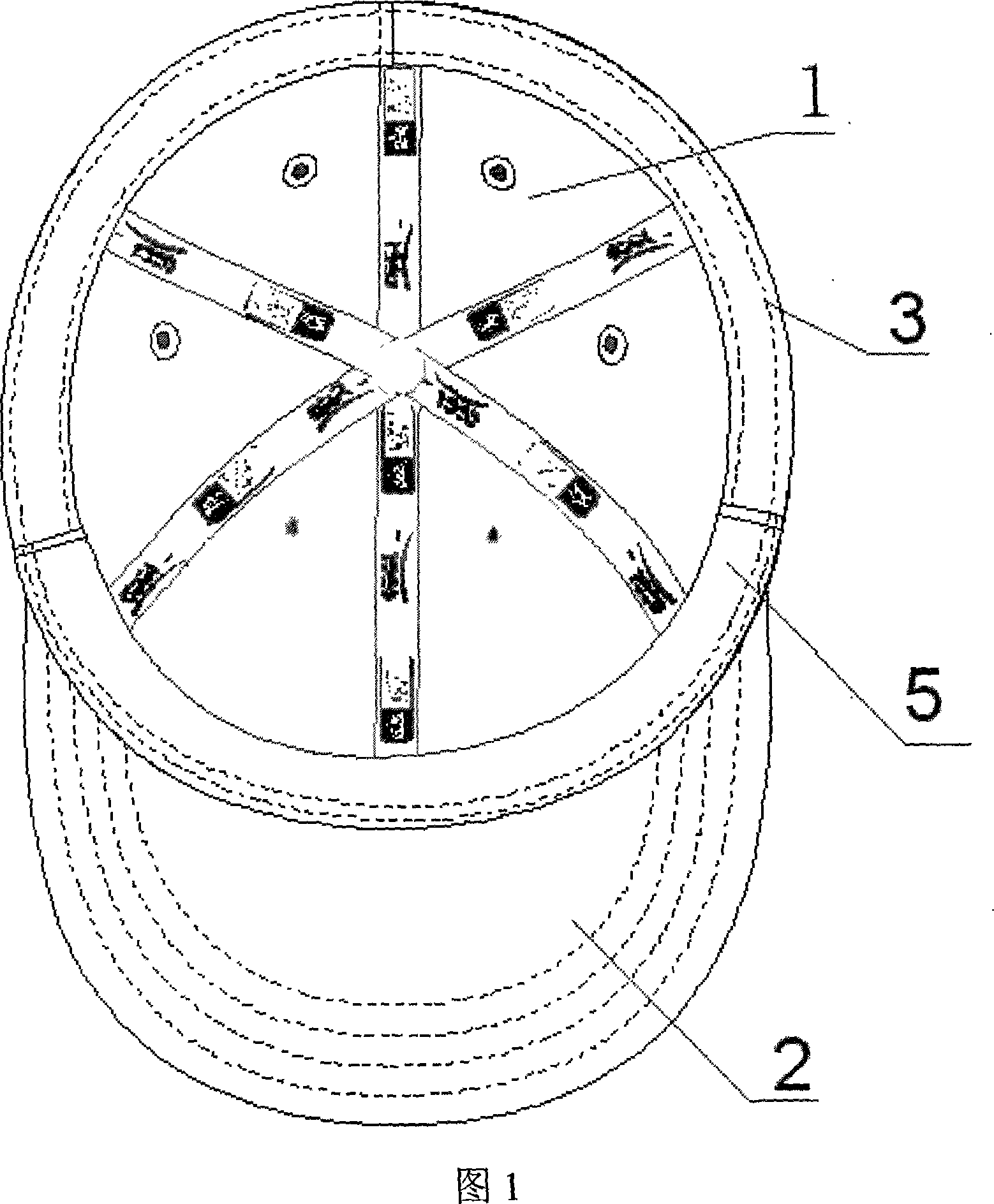

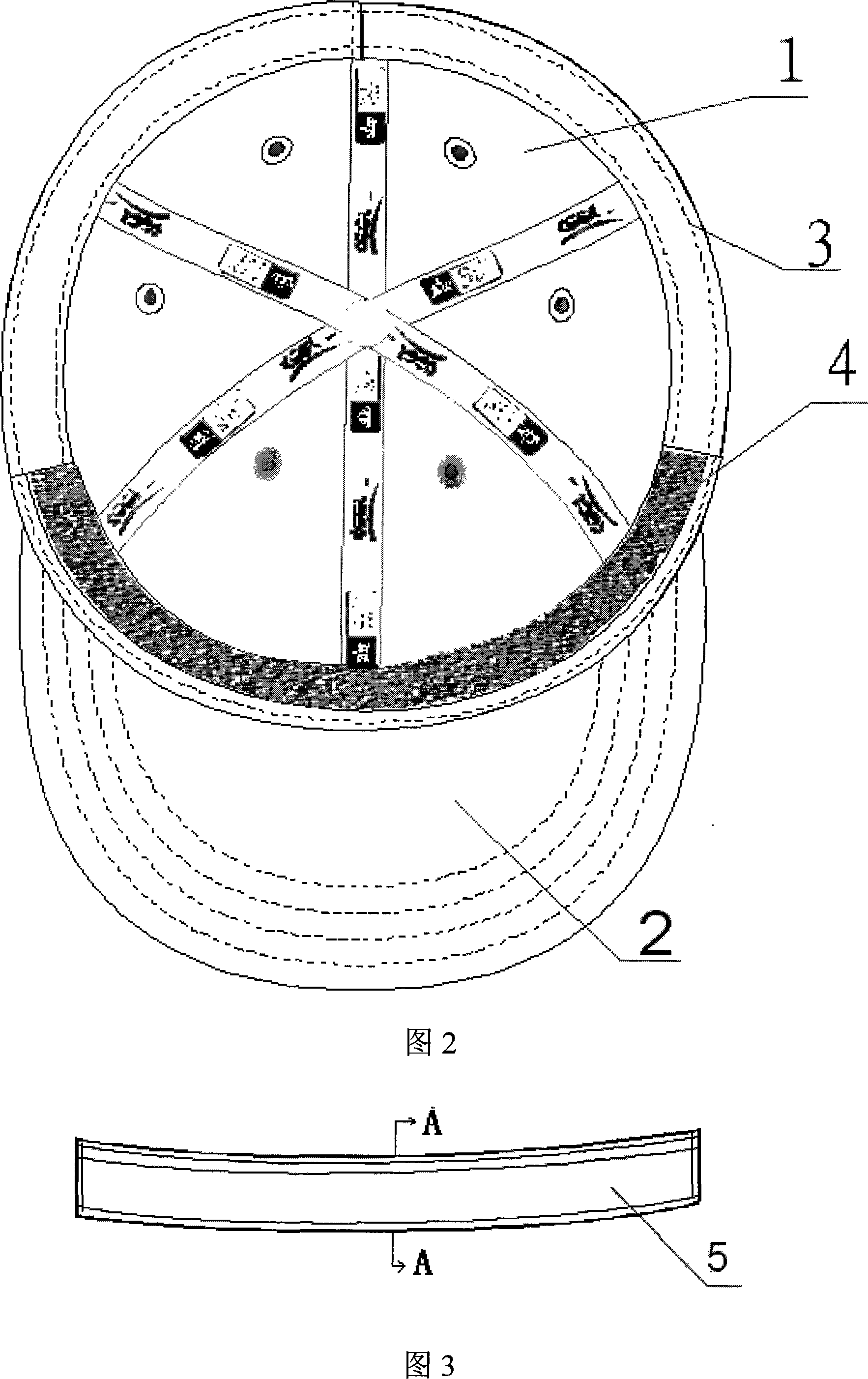

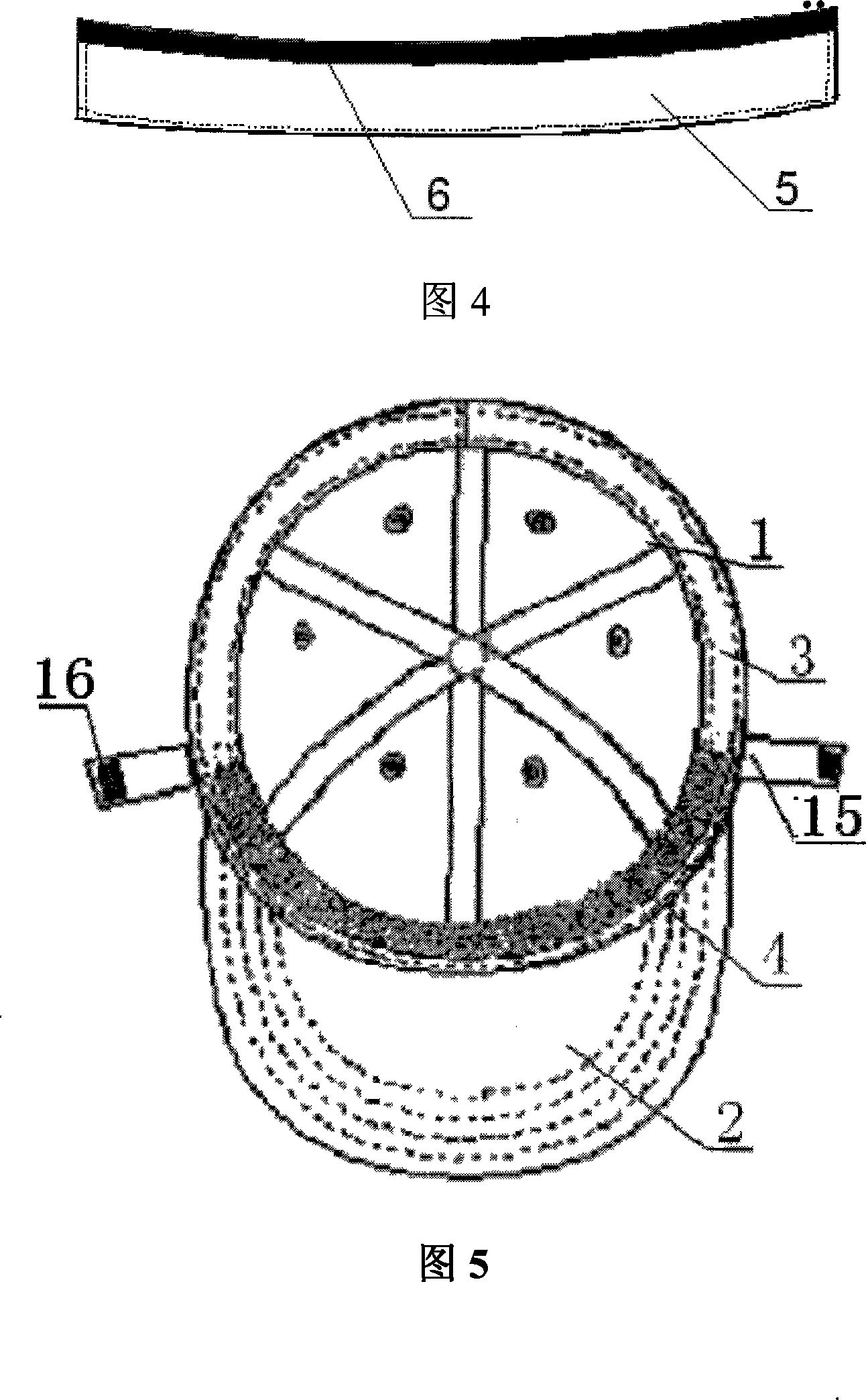

Changeable sweat belt type hygroscopic sweat-removing cap

The present invention relates to a replaceable sweatband type moisture-absorbing sweat-discharging anti-bacterial hat. It includes hat body and new-type functional sweatband. The new-type functional sweatband is movably connected with inner side of brim of hat body, and said new-type functional sweatband includes the following five-layer materials: first layer is moisture-absorbing sweat-discharging fabric material, second layer is high-strength water-absorbing non-woven fabric, third layer is antiseptic dust-less water-holding paper, fourth layer is air permeable water-proof PVC film and fifth layer also is moisture-absorbing sweat-discharging fabric material.

Owner:GUANGZHOU KING SHENG SEWING MANUFACTORY

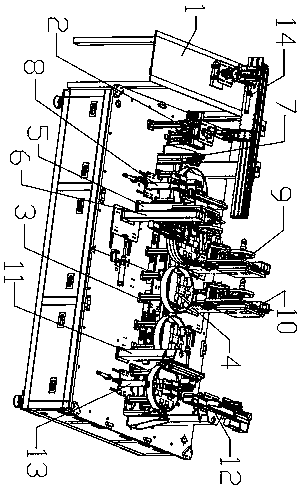

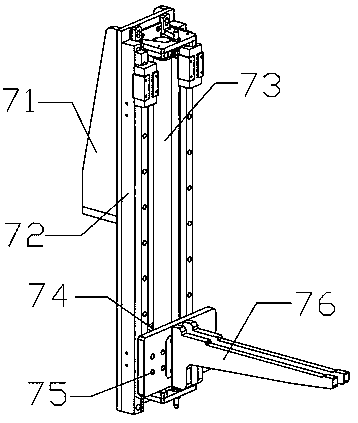

Automatic packaging equipment for lithium battery cell

ActiveCN109638307AKeep cleanImprove glue quality and efficiencyNon-aqueous electrolyte cellsFinal product manufactureManipulatorEngineering

The invention relates to automatic packaging equipment for a lithium battery cell. The device comprises an operation table, a feeding conveying device is arranged on the left side of the operation table, a positioning assembly is arranged on the right side of the feeding conveying device, a battery conveying device is arranged on the right side of the positioning assembly, a plurality of containing positions are arranged on the upper portion of the battery conveying device at equal intervals, and a protective clamp disc is arranged on each containing position. A first sealing cover taking andplacing mechanical arm, a first side face rubberizing device, a second side face rubberizing device, a first tail rubberizing device, a second tail rubberizing device, a fifth sealing cover taking andplacing mechanical arm and a battery discharging mechanical arm are sequentially arranged on the portion, located on one side of the battery conveying device, of the operation table in the battery conveying direction. The lithium battery is fully protected through the silica gel foam and the battery cell shell in the sealing cover, vibration in the conveying process is avoided, and the stabilityof the lithium battery in the conveying process is guaranteed. The full-mechanical operation is realized, the structure is compact, the packaging quality and efficiency of the lithium battery are improved, and the market application value is high.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

Range hood

ActiveCN108087931APrevent filter cloggingKeep cleanCombination devicesDomestic stoves or rangesPistonImpeller

The invention relates to the field of household electrical appliances and particularly relates to a range hood. The range hood comprises a rack and a tank body, wherein an exhaust inlet is formed in the side wall of the tank body; an exhaust outlet is formed in the top of the tank body; a draining outlet is formed in the center of the bottom surface of the tank body; a water collecting tank is also arranged in the tank body; a motor is arranged at the upper part of the tank body; a rotating shaft is connected to the lower part of the motor; a cam, impellers, a gear set and a rotating disk arealso connected to the rotating shaft from top to bottom; a piston cylinder is connected to the cam and is communicated with the water collecting tank; the impeller is arranged in the exhaust outlet; afilter screen is also arranged below the impeller, is fixed on the tank body and covers the exhaust outlet; the gear set and the rotating disk are arranged inside the tank body; the gear set is a planetary gear set; the rotating shaft is connected with a sun gear of the gear set; a stirring rod is also connected to a planet gear of the gear set; a brush plate is arranged at the upper end of the stirring rod; the lower end of the stirring rod and the bottom of the tank body are suspended; the rotating disk is arranged at the lower end of the rotating shaft. According to the scheme, the filterscreen is cleaned while lampblack is purified and blockage of the filter screen is prevented.

Owner:宁波隆锐机械制造有限公司

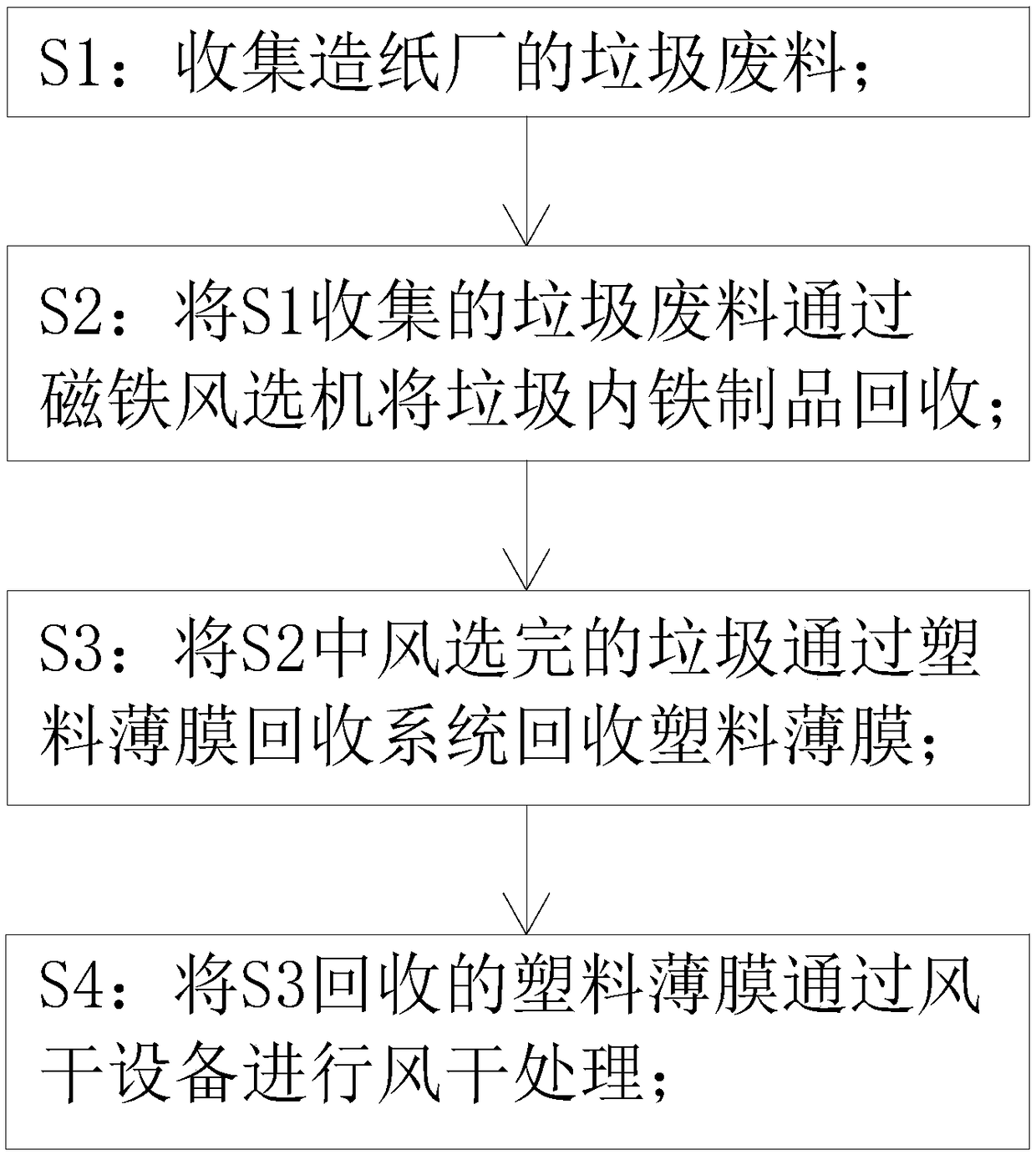

Waste plastic recycling process

The invention relates to the technical field of resource recycling and particularly relates to a waste plastic recycling process. The waste plastic recycling process comprises a frame body, wherein aplurality of first airbags are arranged in a rubber belt and are sequenced in an equal internal manner; first springs fixedly connected to the upper and lower inner walls of the rubber belt are arranged on two sides of each first airbag; at least three extrusion wheels are arranged between a first driving wheel and a second driving wheel; each extrusion wheel rotates along the upper surface of therubber belt; the arrangement distance of the extrusion wheels is equal to that of the first airbags; suction discs which are in the equal number of the first airbags and in positional correspondencewith the first airbags are fixedly connected to the surface of the rubber belt; at least three cams are arranged in the framework; and the cams rotate to be cooperated with the extrusion wheels to extrude the suction discs so as to extrude the first airbags through the rubber belt, the cams do not extrude the first airbags because the first airbags are in a compression state when the first airbagspass the next cam, and the different suction discs are extruded by extruded parts during the rotation of the cams for one cycle.

Owner:湖北卓安塑业有限公司

Garbage bag extractor

InactiveUS20120055933A1Ease in removal of wasteKeep cleanLarge containersRefuse receptaclesMechanical engineeringRack and pinion

A garbage bag extractor for removal of a garbage bag from a trash can where the extractor has a flat lifting platform fitted to the cross sectional shape of a trash can, vertical lifting arms, slide rails with a pull handle for manually raising the lifting platform in the trash can, supplemented with a rack and pinion drive with a mechanically driven pinion gear turning on a vertical gear rack riding in a rack guide.

Owner:JONES SCOTT M

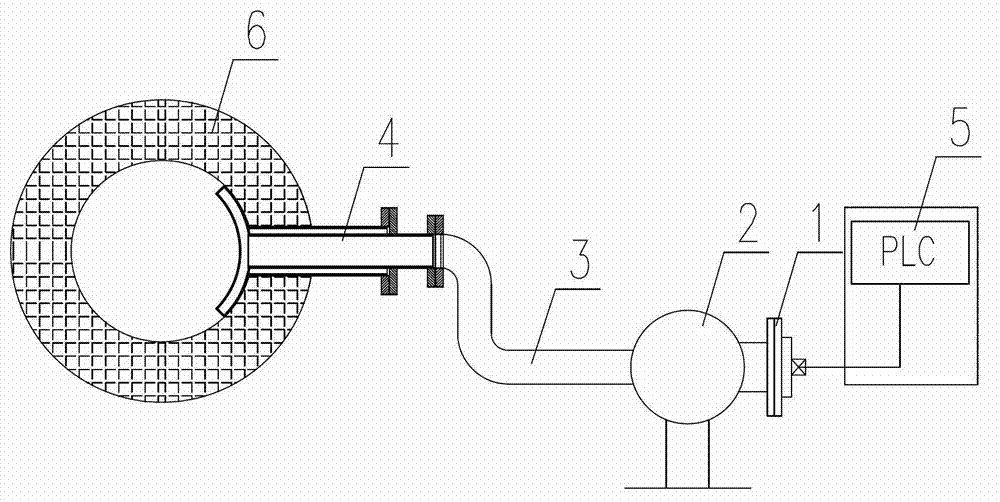

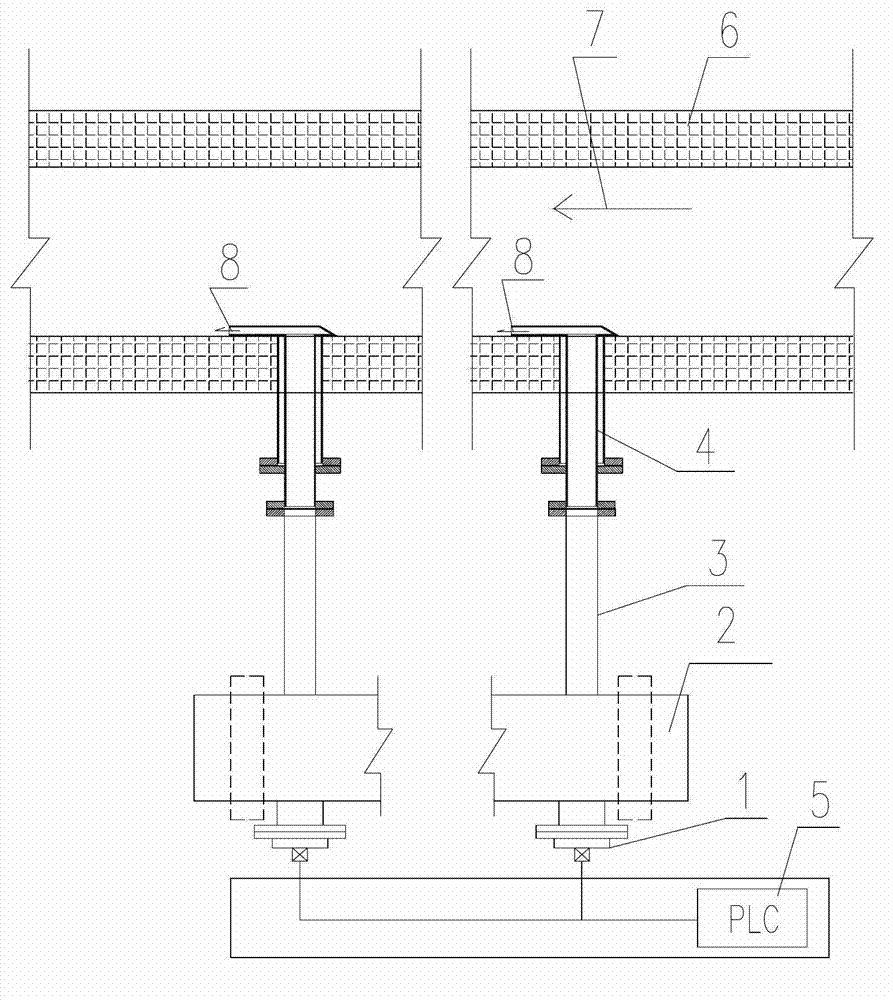

High-temperature coke oven raw coke oven gas pipeline cleaning device adopting compressed nitrogen injection

The invention relates to a high-temperature coke oven raw coke oven gas pipeline cleaning device adopting compressed nitrogen injection, which comprises a pulse valve, a gas bag, a pulse injection connecting pipeline, a pipeline nozzle and a pulse injection PLC control system, wherein one end of the pulse valve is connected with the pulse injection PLC control system; the other end of the pulse valve is connected with the gas bag; and the gas bag is connected with the pipeline nozzle through the pulse injection connecting pipeline. The device has the benefits that injection medium adopts compressed nitrogen, the compressed nitrogen in the gas bag is instantaneously injected into a cleaned high-temperature raw coke oven gas pipeline, injection gas stream filling a whole pipeline section is formed in the high-temperature raw coke oven gas pipeline, the pulse injection PLC control system can set the injection sequence and the injection time according to production practice, the cleaning of the pipeline is effectively maintained, and the pipeline is prevented from being blocked.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

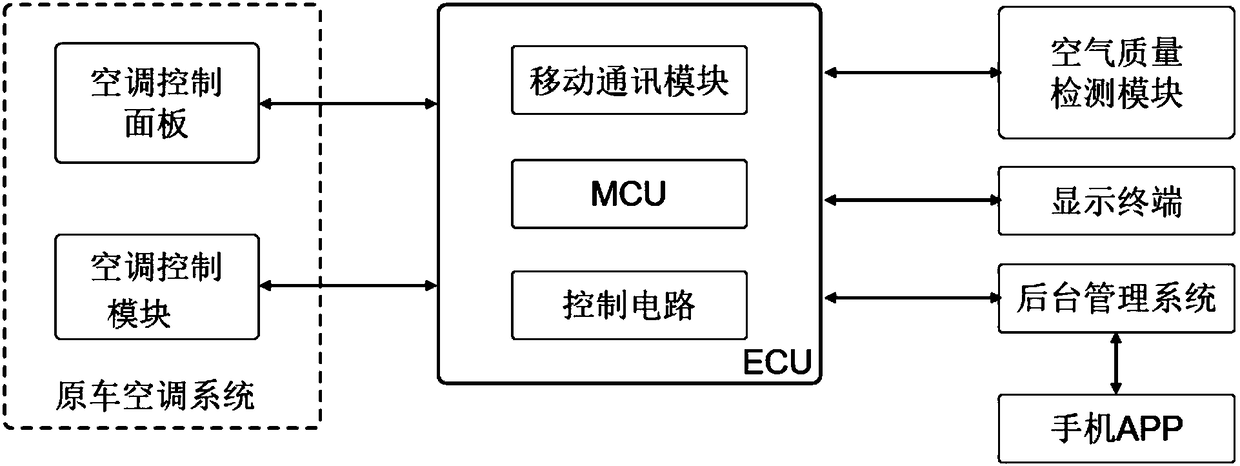

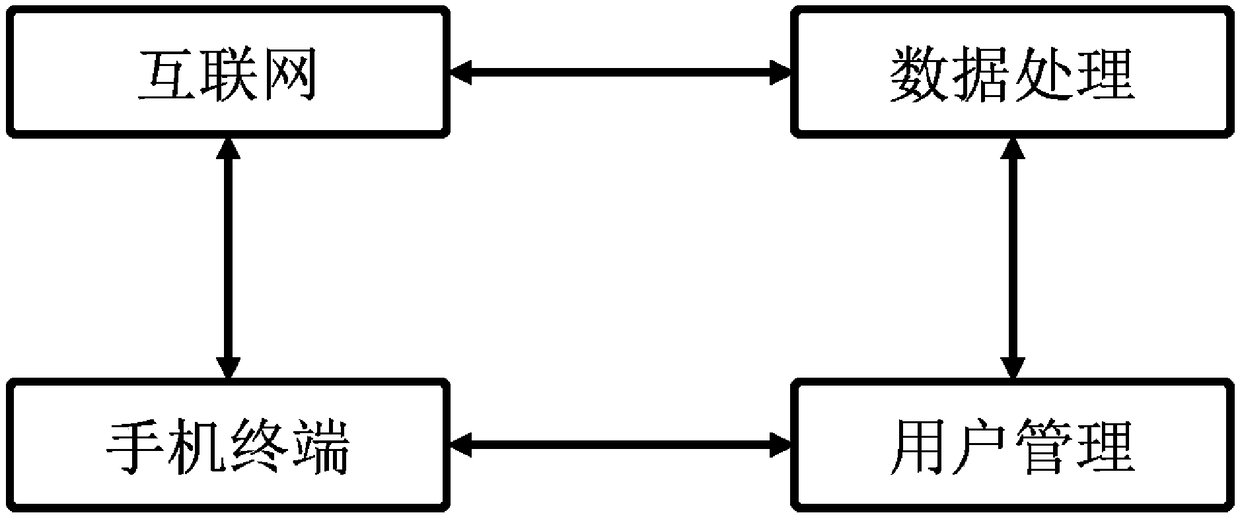

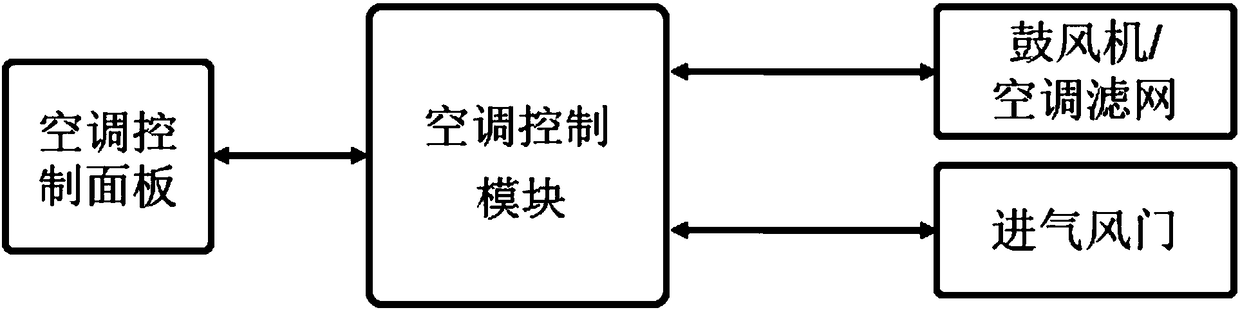

Vehicle air quality management system capable of achieving remote monitoring

PendingCN108162721AKeep cleanImprovement of manual switching air conditioning systemAir-treating devicesVehicle heating/cooling devicesEngineeringManagement system

The invention discloses a vehicle air quality management system capable of achieving remote monitoring. The vehicle air quality management system comprises an air quality detecting module, an ECU, a background management system, a mobile terminal APP, a display terminal and an air conditioning system; the ECU is connected with the air quality detecting module, the original vehicle air conditioningsystem, the background management system, the mobile terminal APP and the display terminal separately; the background management system includes an internet access module, a data processing module and a user management module; the display terminal is connected to the ECU, and the air conditioning system includes air conditioning control module, an air conditioning control panel, a blower, a filter screen and an air inlet damper. The vehicle air quality management system capable of achieving remote monitoring can detect air inside / outside a vehicle and upload quality information of the air inside / outside the vehicle to the background management system, a background can monitor and manage the quality of the air inside / outside the vehicle in real time, a vehicle owner can be reminded in timewhen the quality of the air inside the vehicle is poor, and the vehicle air quality management system is conducive to keeping the air inside the vehicle in a clean state.

Owner:美行车联网(广州)科技有限公司

Air filtering device with self-cleaning function

InactiveCN105344174AGood air filtrationKeep cleanGas treatmentDispersed particle filtrationEngineeringFilter strip

The invention discloses an air filtering device with a self-cleaning function. The provided air filtering device comprises an air cleaning device and a filtering strip cleaning device. The air cleaning device comprises a dirty air inlet, an air compressor, an air input pipe, an air mixer and left and right filters. The filtering strip cleaning device comprises a clean air inlet, an air sterilizer, a fan and a dust box. The air compressor blows dirty air from the dirty air inlet into the air input pipe. The air mixer shunts the dirty air to the left and right filters for filtering and purifying. When the air compressor detects that the air pressure in the air compressor is larger than the preset air pressure, the fan blows clean air from the clean air inlet to the air sterilizer for sterilization, the clean air after sterilization blows the air filtering strip in the dust box through strong force and self-cleaning of the filters is carried out. The air filtering device can carry out self cleaning of filters, and achieves an effect of keeping the filters clean without replacing of the filters.

Owner:ANYCHECK INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com