Patents

Literature

55 results about "Road marking machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Road marking machine is a kind of mechanical device that makes road markings on the surface of highway, runway, parking lots to keep the traffic order and safety. Road marking machines usually can be divided into three categories: thermoplastic paint, cold paint and two-component paint type, depending on the coatings.

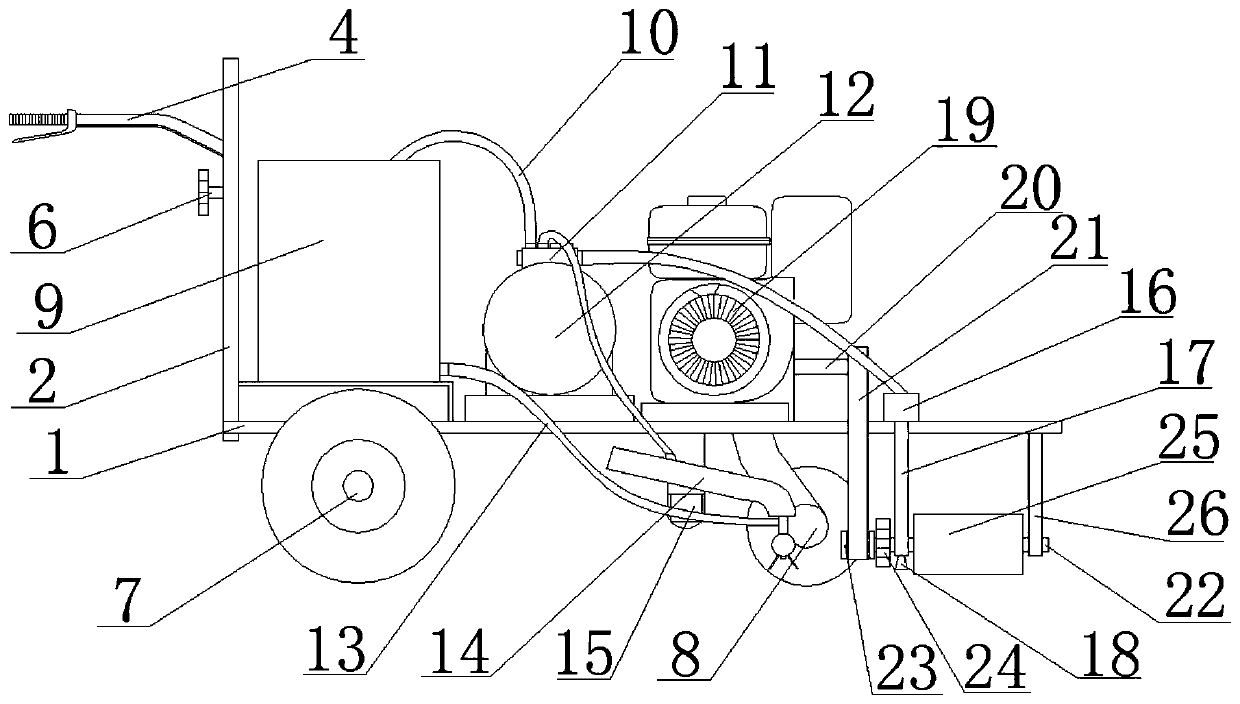

Road guideline scriber

ActiveCN101021056AImprove efficiencyGuarantee the construction qualityRoads maintainenceAir compressionGuideline

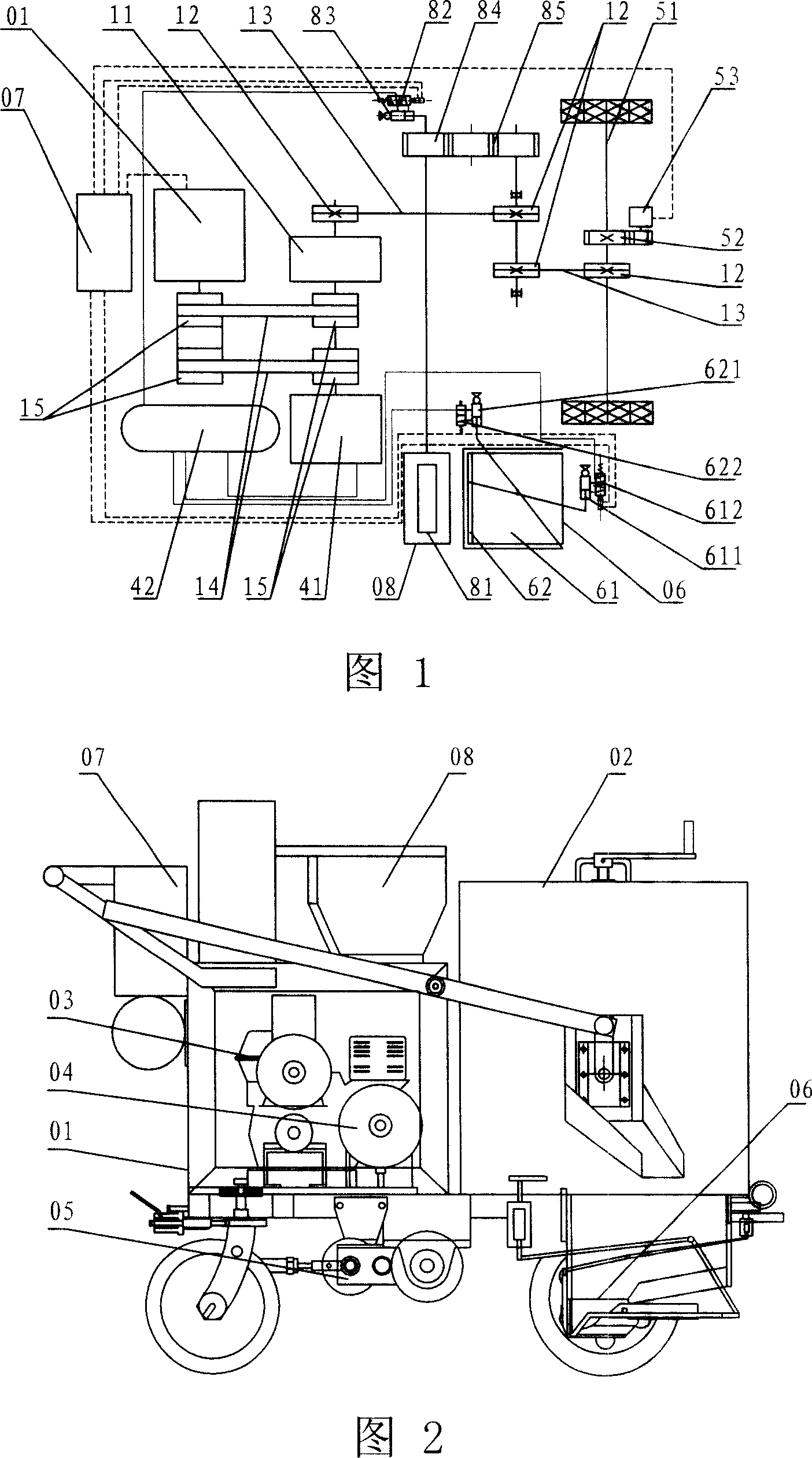

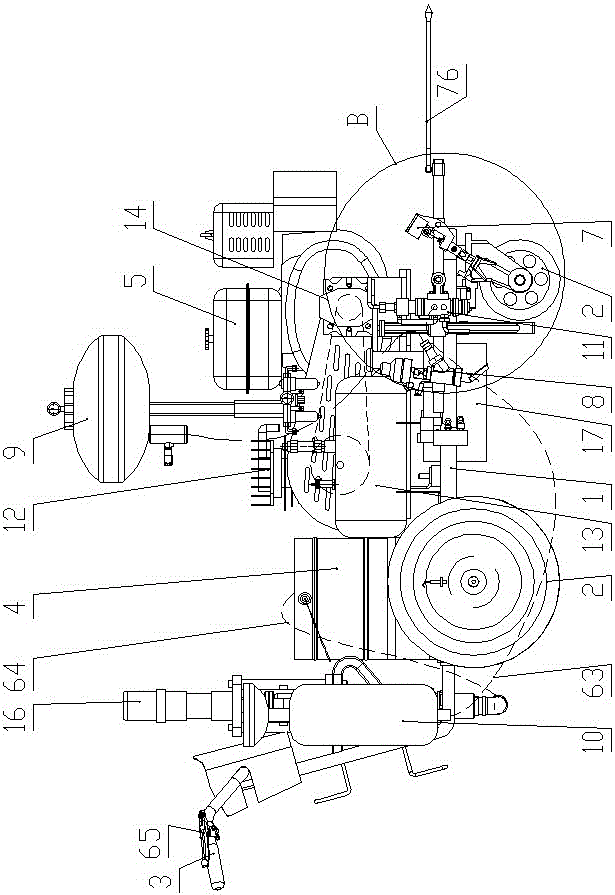

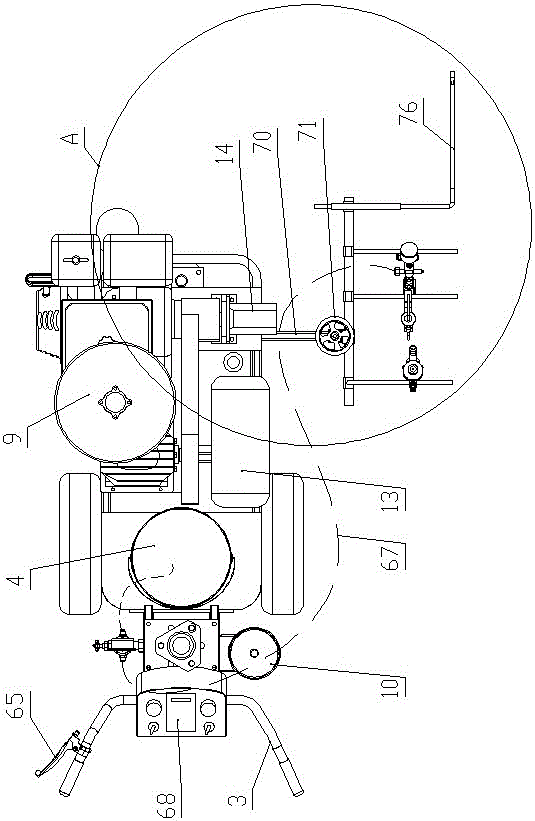

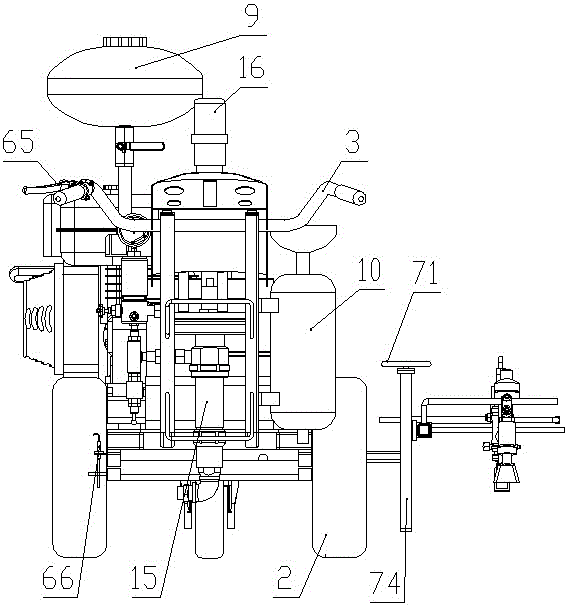

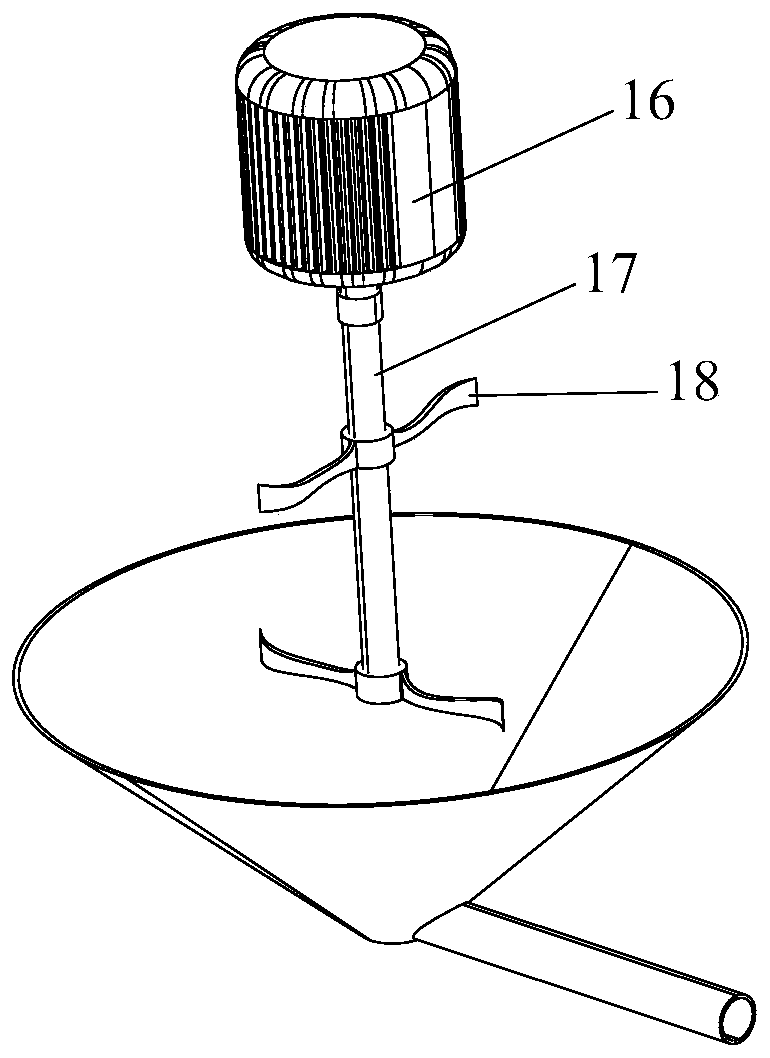

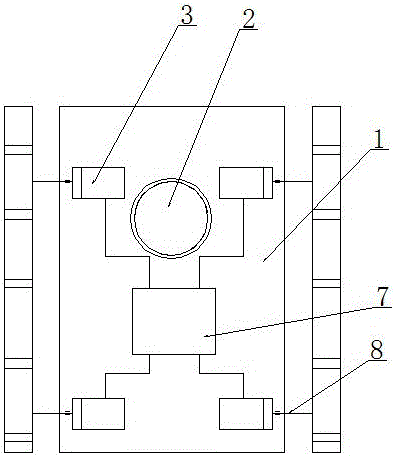

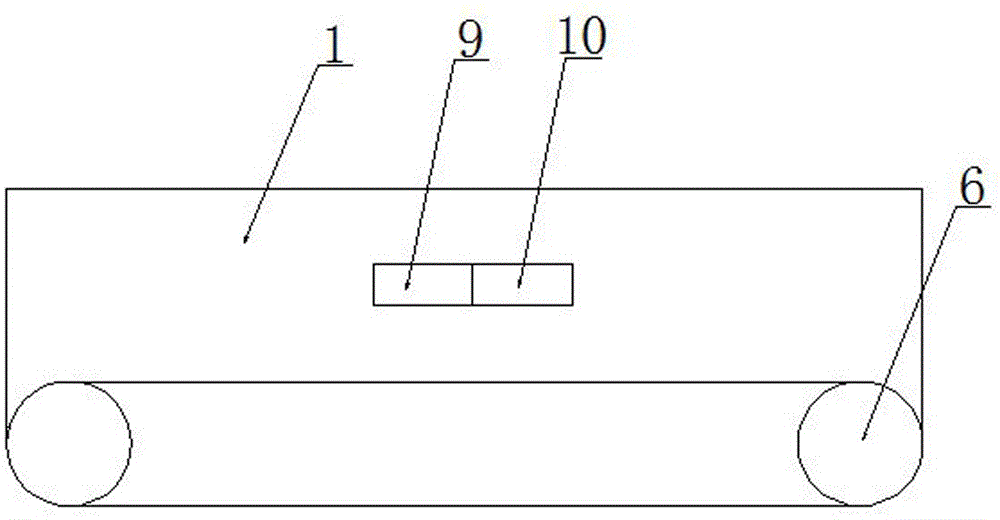

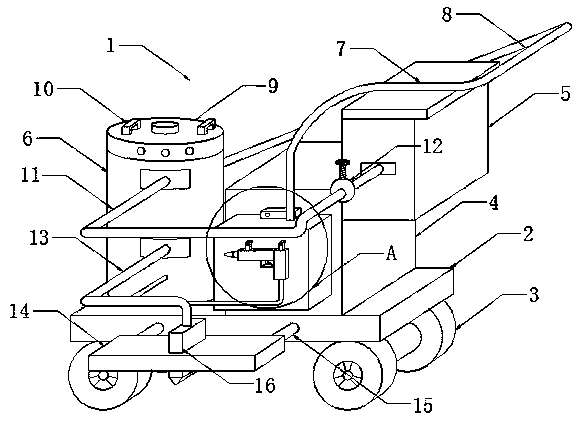

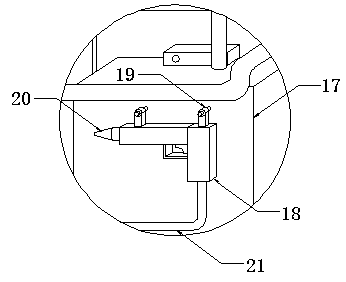

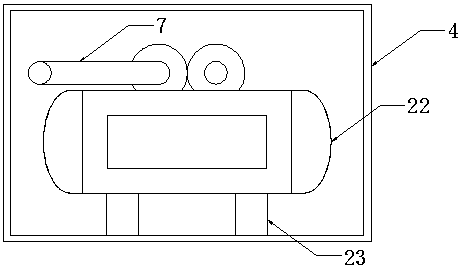

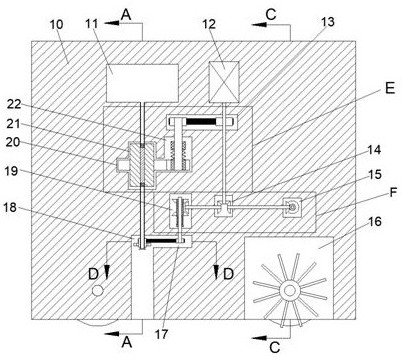

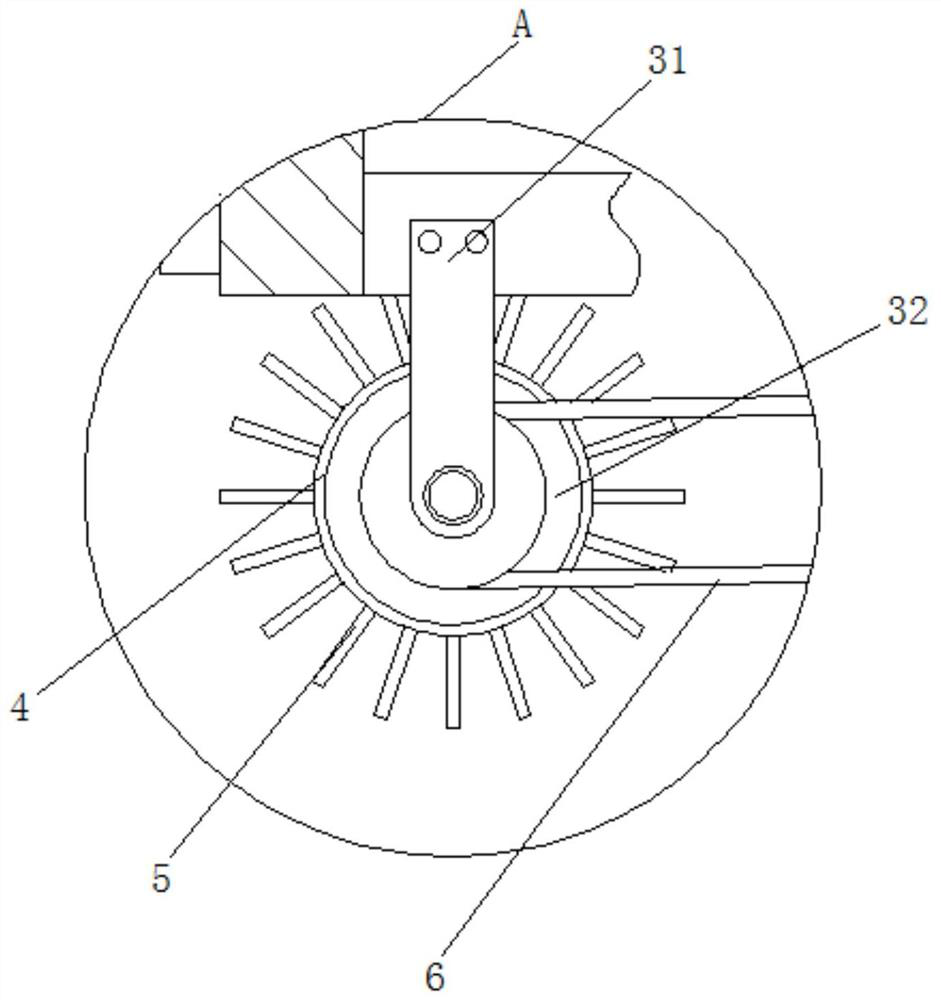

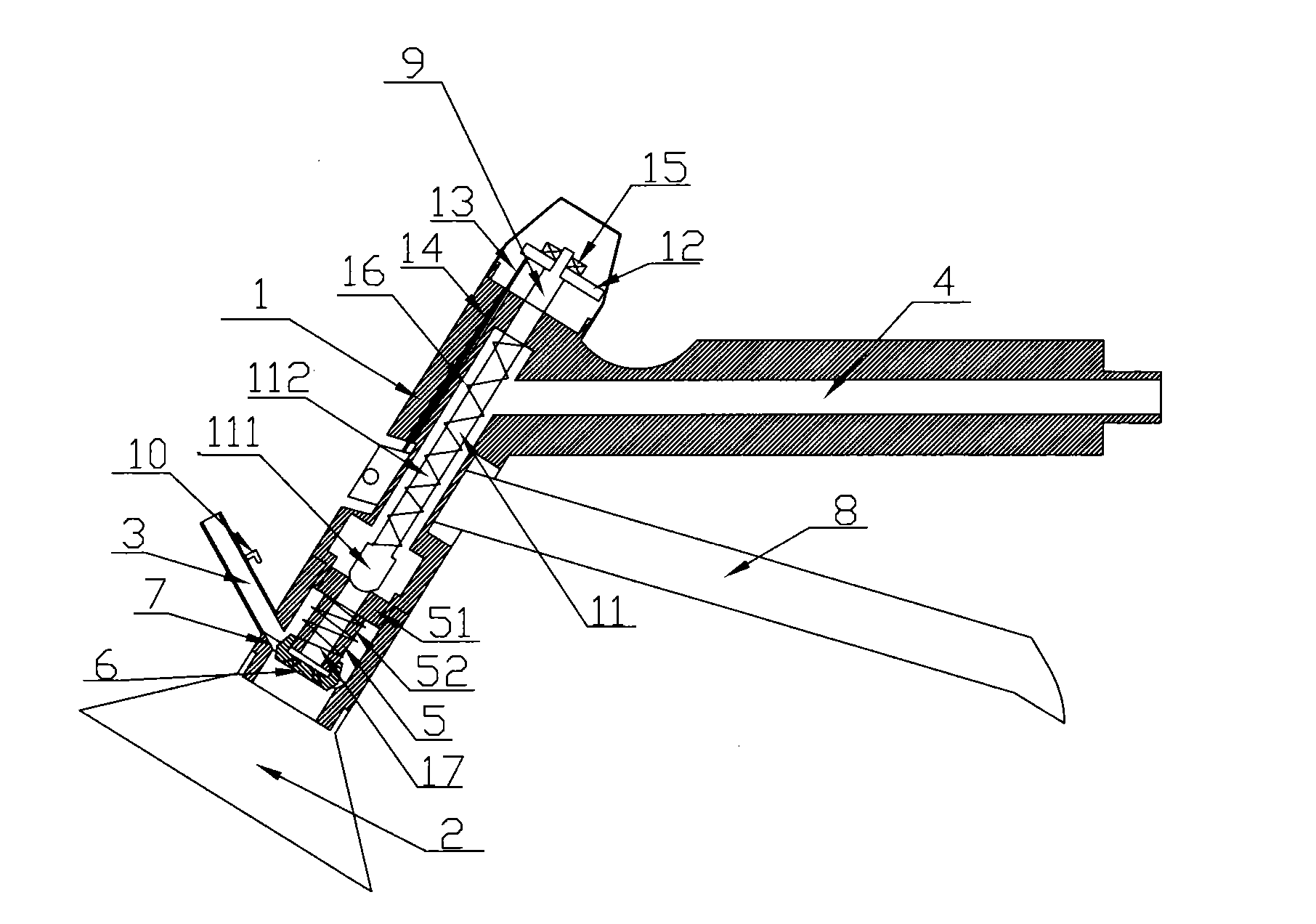

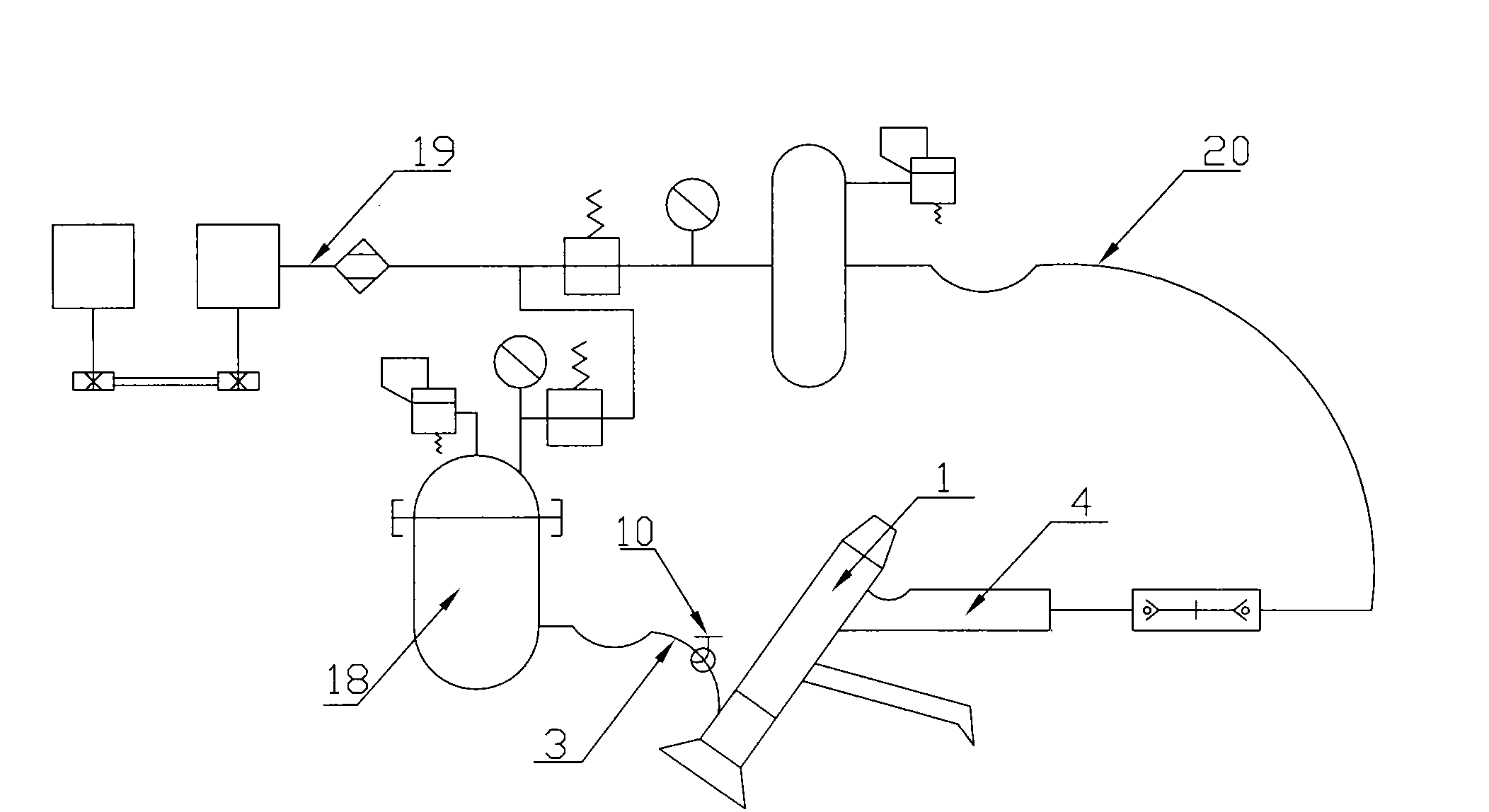

The road marking machine includes a vehicle frame, lacquer barrels, an engine, an air compression system, a walking system, a road marking system and a control system, as well as an increased bead spreading system. The bead spreading system is one bead spreading machine including a solenoid valve connected to the air compression system and the control system, a cylinder and a driving gear interlinked with the walking system. The bead spreading system spreads beads while the road marking machine marks, and this results in high construction efficiency and high construction quality.

Owner:朱建新

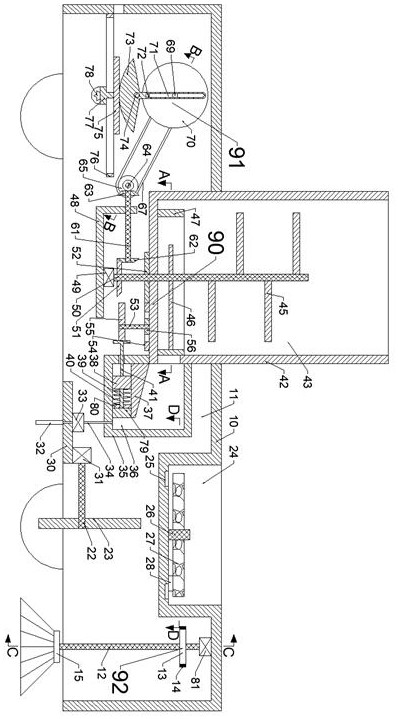

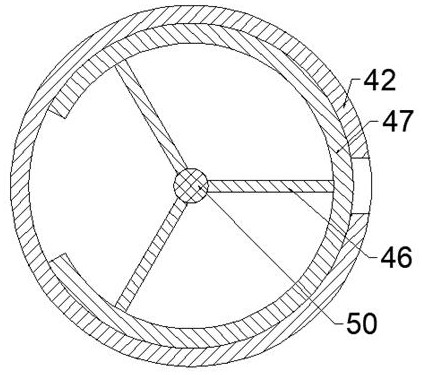

Hydraulic-control differential pressure system of plunger pump type cold-paint road marking machine

ActiveCN105757011AImprove construction efficiencyHigh failure rateServomotorsPiston pumpsDifferential pressureControl system

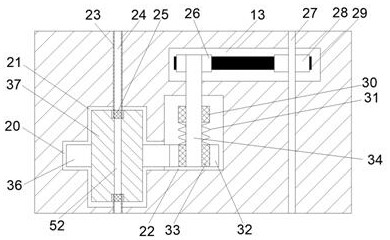

A hydraulic-control differential pressure system of a plunger pump type cold-paint road marking machine comprises a hydraulic pump, a high-pressure plunger pump, an automatic reciprocating cylinder, a hydraulic oil tank and an energy accumulator which are all arranged on a frame of the plunger pump type cold-paint road marking machine. An inlet of the hydraulic pump is connected with the hydraulic oil tank through an oil pipe; an outlet of the hydraulic pump is connected with the automatic reciprocating cylinder through an oil pipe; both the automatic reciprocating cylinder and the high-pressure plunger pump are arranged vertically and the automatic reciprocating cylinder is right above the high-pressure plunger pump; the lower end of a piston rod of the automatic reciprocating cylinder is hinged to the upper end of a plunger rod of the high-pressure plunger pump; a discharge outlet of the high-pressure plunger pump is connected with the energy accumulator through a discharging pipe. The hydraulic-control differential pressure system is simple in structure, long in service life and low in equipment failure rate, and further is high in construction efficiency and convenient to operate and steer due to the fact that the control system is less prone to being affected by equipment vibration and external signals.

Owner:天途路业集团有限公司

Semi-automatic control road marking machine

InactiveCN105887645AImprove cleanlinessNot easy to peel offRoads maintainenceAutomatic controlSpray nozzle

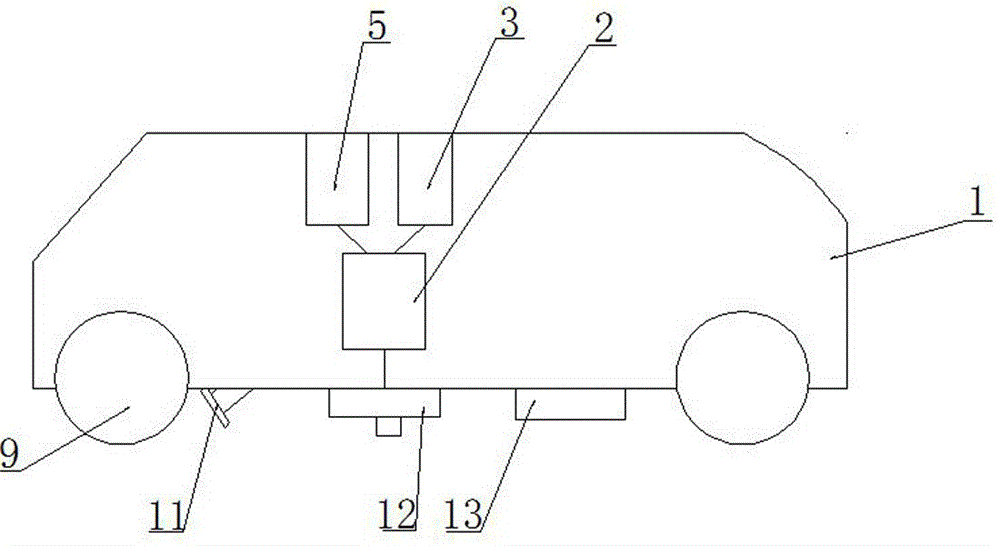

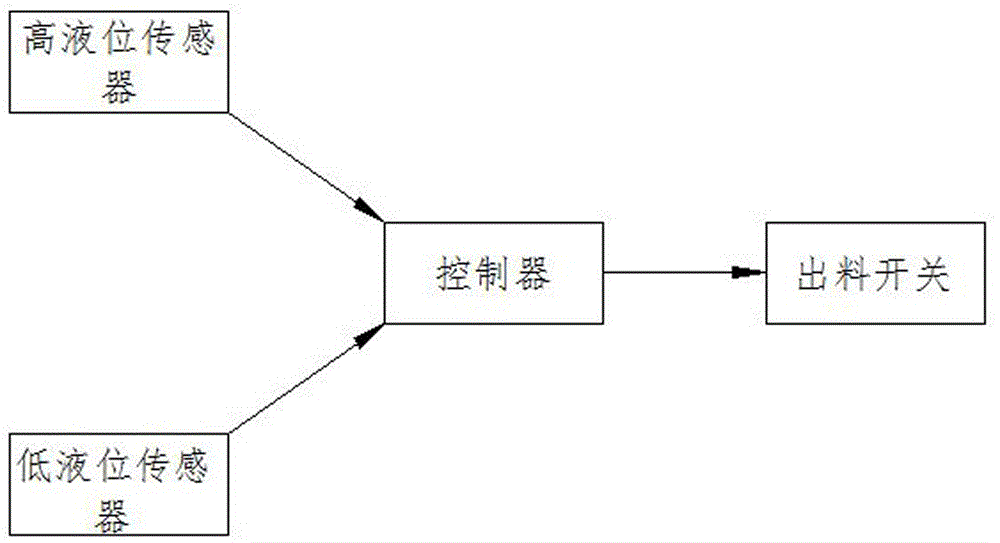

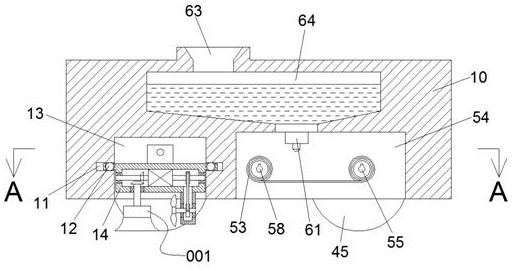

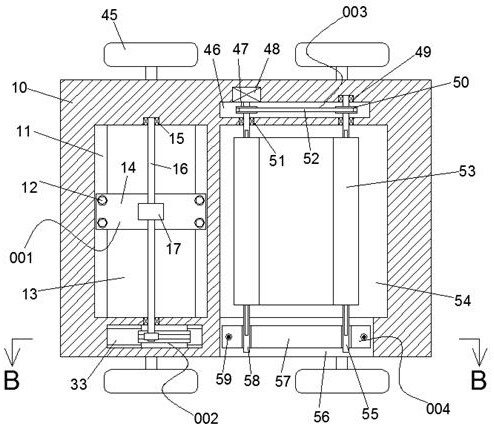

The invention discloses a semi-automatic control road marking machine. The semi-automatic control road marking machine comprises a vehicle body and wheels, wherein a distribution mechanism and a controller are arranged in the vehicle body; a heating mechanism, a storage bin and a blower are arranged at the bottom of the vehicle body in the movement direction of the vehicle body sequentially, and a heater is arranged in the heating mechanism; a plurality of spray nozzles are arranged at the lower end of the storage bin, and a high-liquid-level sensor and a low-liquid-level sensor for detecting high and low liquid levels are arranged in the storage bin respectively; the blower is arranged obliquely downwards along the front end of the vehicle body; the distribution mechanism comprises a curing agent bin, a liquefier bin and a blender, the curing agent bin and the liquefier bin are connected to a feeding port of the blender through pipelines, and a discharging port of the blender is connected with the storage bin. The semi-automatic control road marking machine is simple in structure and reasonable in design, can save large amount of labor and has broad market prospect.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

Construction method of road markings

Owner:北京顺捷通畅交通设施工程有限公司

Automatic spraying machine for road fonts and patterns

InactiveCN111608062ASave writingWriting level is not requiredRoad cleaningRoads maintainenceDrive wheelStructural engineering

The invention discloses an automatic spraying machine for road fonts and patterns. The automatic spraying machine for road fonts and patterns comprises a device body with driving wheels correspondingly mounted on the front and rear end surfaces left and right; a cleaning cavity is formed in the position, close to the left side, in the lower side end face of the device body; sliding grooves are correspondingly formed in the left wall and the right wall of the cleaning cavity; the left sliding groove and the right sliding groove which correspond to each other are slidably installed in the cleaning body through rolling balls; and a cleaning device capable of cleaning a road surface needing to be printed is arranged in the cleaning body. Fonts or patterns needing to be sprayed on the road surface are printed on a spraying scroll in a hollowed-out manner; fonts or patterns on the spraying reel are printed on the road surface through the dye spraying head, so that manual trial of the road marking machine for writing on the road surface is omitted, the working efficiency is improved, the trial threshold is reduced, and no requirement is required for the writing level of workers.

Owner:浦江鑫丹机械科技有限公司

Road milling machine

ActiveUS8939515B2Improved material transport of materialRoads maintainenceCutting machinesEngineeringRoad surface

The invention relates to a road milling machine, with a milling drum housing partially surrounding a milling drum, wherein the opening between the milling drum housing and the surface of the material to be milled can be closed off by a hold-down device. The distance between the axis of rotation and the hold-down device increases in the specified direction of rotation of the milling drum at least over a section of the gap between the milling drum and the hold-down device. The particular configuration of the hold-down device leads to an improvement in transport of the milled material to the transport arrangement. The gap width increasing in the direction of rotation of the milling drum improves material flow with a relatively small power requirement and relatively low wear of the milling drum.

Owner:WIRTGEN GMBH

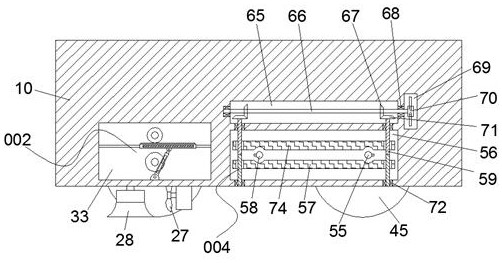

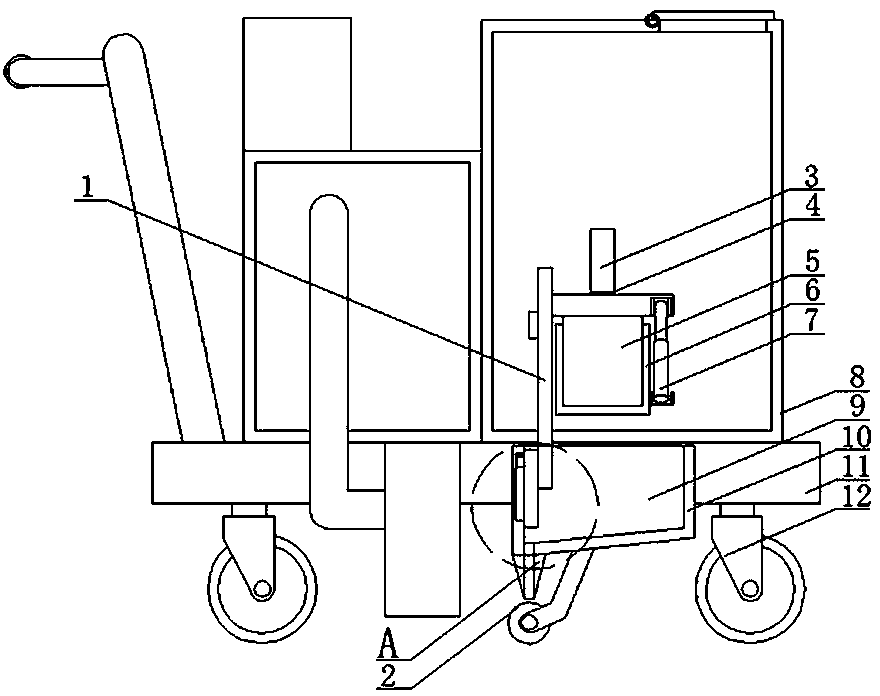

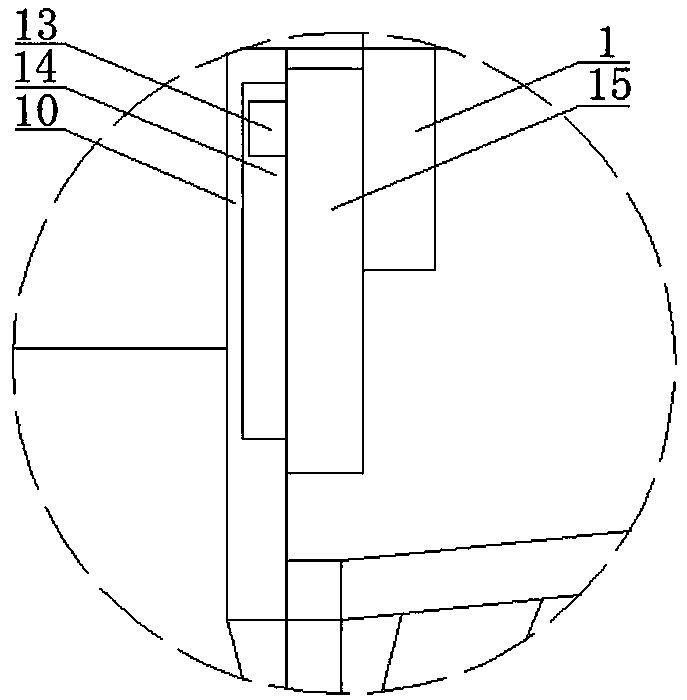

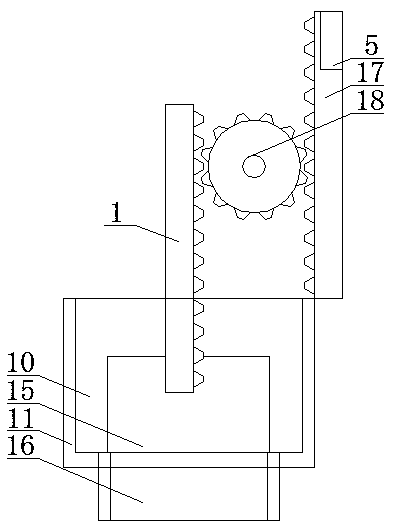

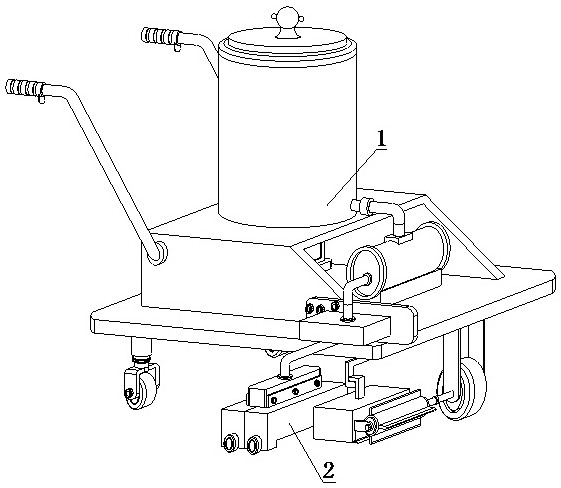

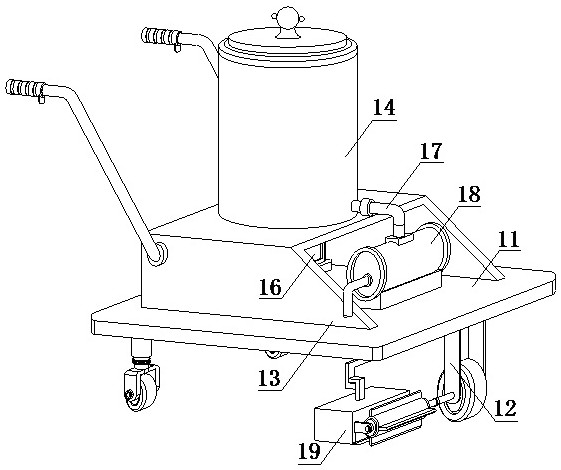

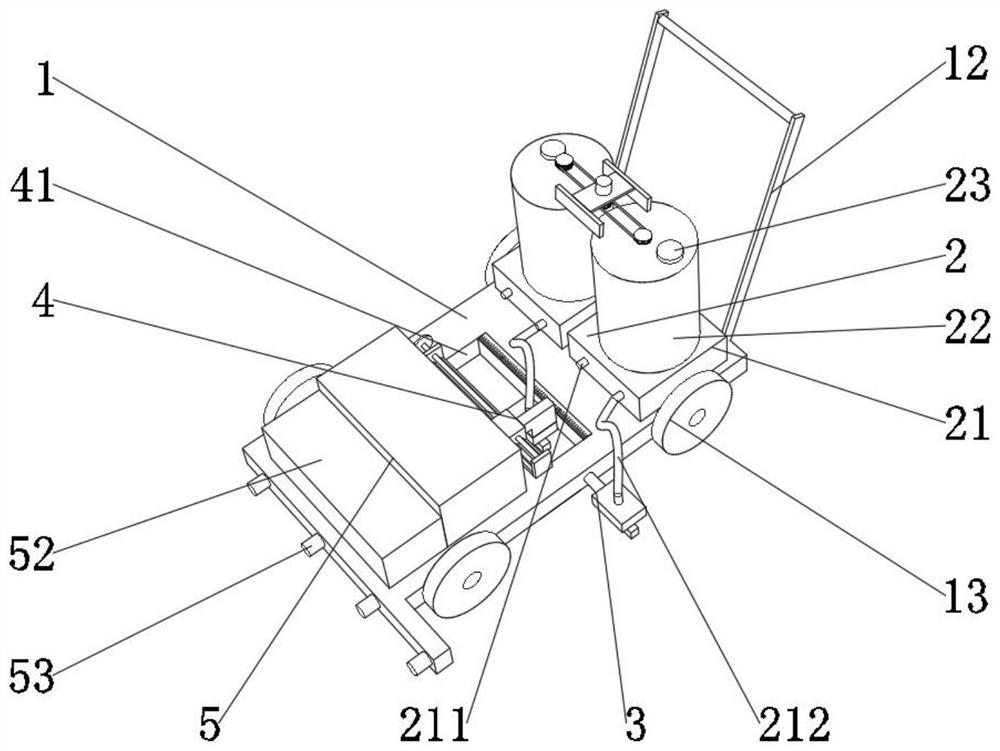

Rapid feeding equipment for road marking machine

InactiveCN108716181AEasy accessReduce labor intensityRoads maintainenceEngineeringUltimate tensile strength

The invention discloses rapid feeding equipment for a road marking machine. The rapid feeding equipment comprises a machine body, wherein a bearing block is fixed on one side of the machine body, a marking device is arranged at the lower end of the bearing block, a bearing slot is formed in the upper end of the bearing block, a sliding chute is formed in the side wall of one end in the bearing slot, a sliding block is mounted in the sliding slot, a baffle is fixed on one side of the sliding block, a first straight rack is fixed on one side of the baffle, and the upper end of the first straightrack penetrates through the bearing slot and extends to the upper end of the bearing block; and a coating bucket is fixed at the upper end of the machine body, a discharging device is arranged on thecoating bucket, and a second straight rack is fixed on one side of the discharging device. According to the rapid feeding equipment, the injection amount of a coating can be automatically controlled,so that the labor intensity of a worker is alleviated; the output amount can be effectively controlled, so that the overflowing of the coating is avoided, the wasting of the coating is avoided, the working efficiency is improved, and the marking quality is guaranteed; and the rapid feeding equipment is simple in structure and convenient to operate.

Owner:亚建科技有限公司

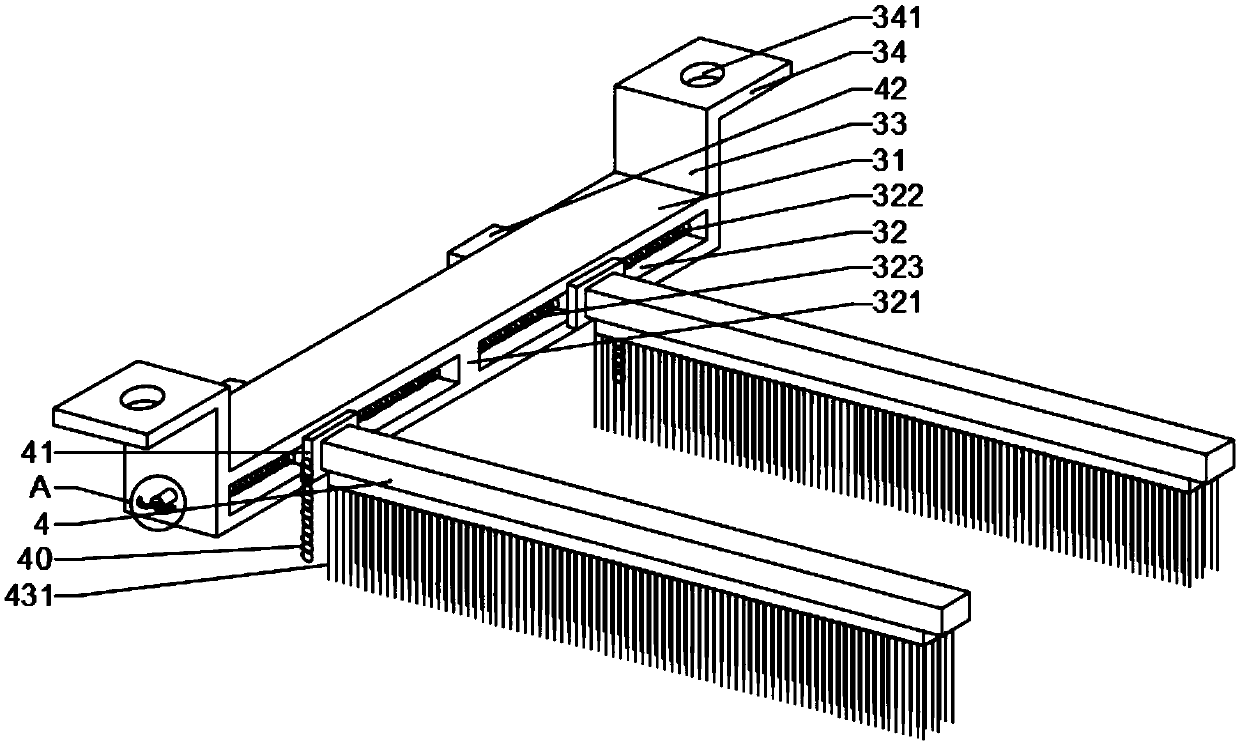

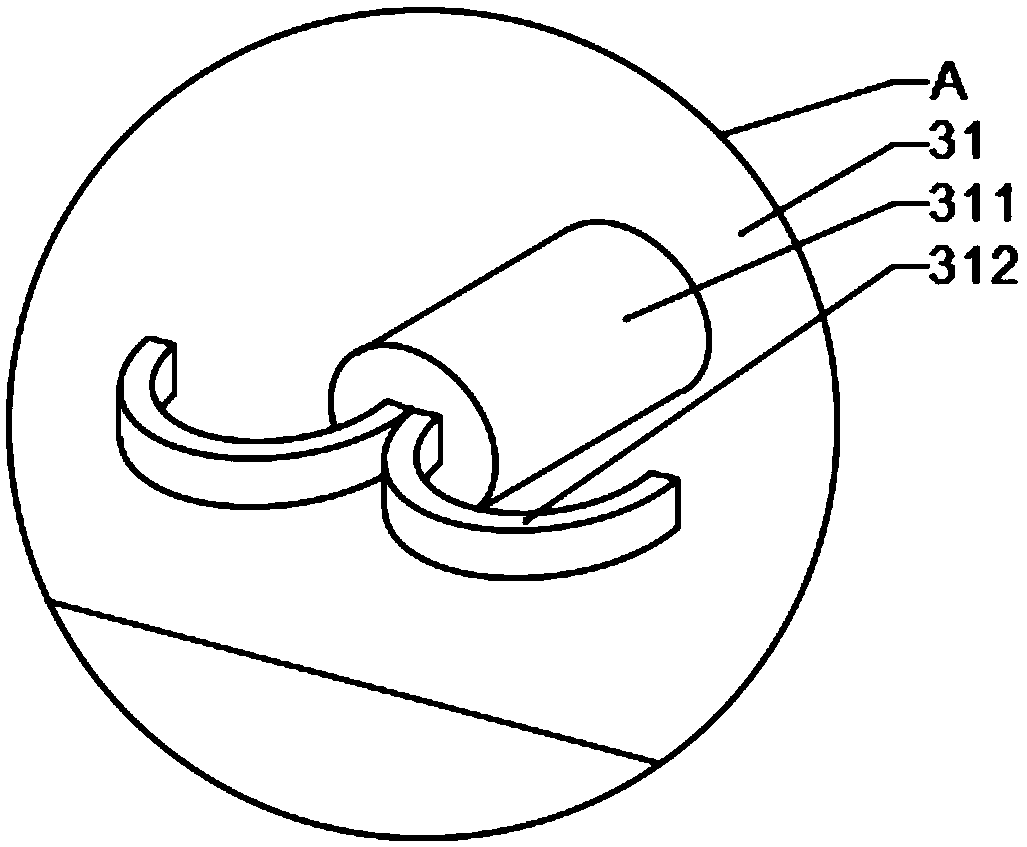

Road marking machine

PendingCN110306418AAvoid walking slowlyFull cleaningRoads maintainenceRoad constructionIndustrial engineering

The invention relates to the technical field of road construction equipment, and discloses a road marking machine. The road marking machine comprises a device bottom frame, wherein a mounting frame isfixedly arranged on the left side of the device bottom frame, a T-shaped groove is formed in the mounting frame, and a handrail is movably connected to the left side of the mounting frame. Accordingto the road marking machine, a sweeping tool is arranged at the forefront of the marking machine, so that the sweeping tool can clean rubbish to be sprayed in the advancing process of the marking machine, the slow advancing of the marking machine due to the fact that the manual cleaning speed is low is avoided, the working efficiency is improved, and the labor cost is reduced; a ventilating platearranged behind the sweeping tool is utilized, so that the dust which is not cleaned by the sweeping tool is fully cleaned, and the problem that the service life of the road is not long due to the fact that the road and the coating are not tightly attached is solved; and under the interaction of the ventilating plate and the sweeping tool, the construction quality is greatly improved, the workingefficiency is improved, the labor cost is reduced, and the reasonability and practicability of the device are improved.

Owner:江苏高强建设工程有限公司

Road marking machine with splash-proof mechanism for highway engineering and implementation method thereof

InactiveCN113047151AAvoid Obstructing Construction IssuesEnsure cleanliness and aestheticsRoads maintainenceAgricultural engineeringElectric machinery

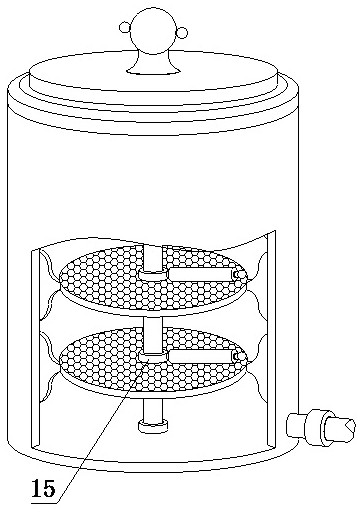

The invention discloses a road marking machine with a splash-proof mechanism for highway engineering and an implementation method of the road marking machine with the splash-proof mechanism for the highway engineering, the road marking machine comprises a feeding device and a marking device, and a rotating shaft is arranged in the middle of the upper end of a bottom plate of a coating barrel; the bottom end of the rotating shaft is fixedly connected with the output end of a driving motor at the lower end of the top plate of the rack, a leakage disc with stirring blades and comb teeth installed on the side wall is arranged on the outer wall of the rotating shaft, a fixing ring movably sleeves the outer wall of the rotating shaft at the upper end of the leakage disc, and a friction sleeve movably sleeves the outer wall of one side of the fixing ring through a connecting rod. The lower end of the friction sleeve abuts against the upper end surface of the leakage disc. A counterweight ball is arranged at one end, which is far from the fixing ring, of the connecting rod. The driving motor is started to drive the rotating shaft to rotate, the stirring blades and the comb teeth are driven to stir the coating in cooperation with the leakage disc, and during stirring, the friction sleeves are attached to the leakage disc to rub and rotate to generate heat to preserve heat of the coating; and the problem that low-temperature freezing paint obstructs construction is avoided.

Owner:夏金龙

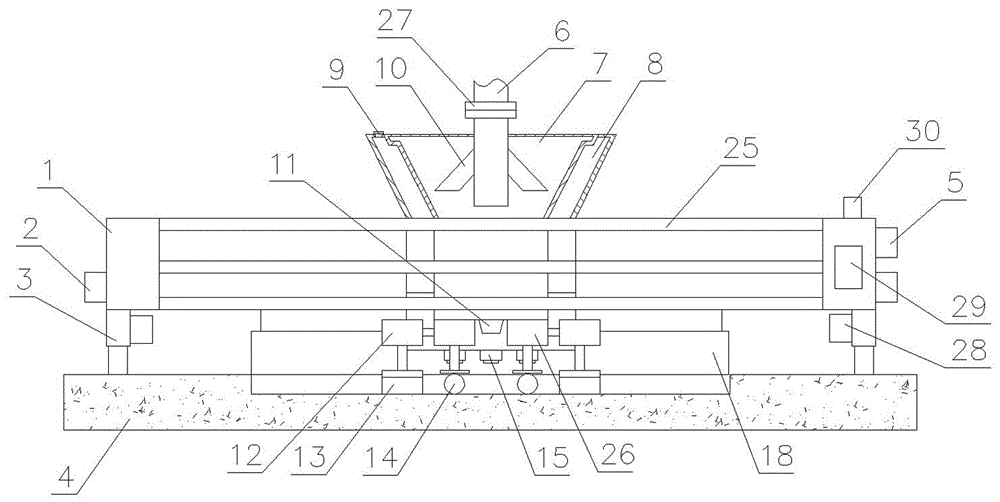

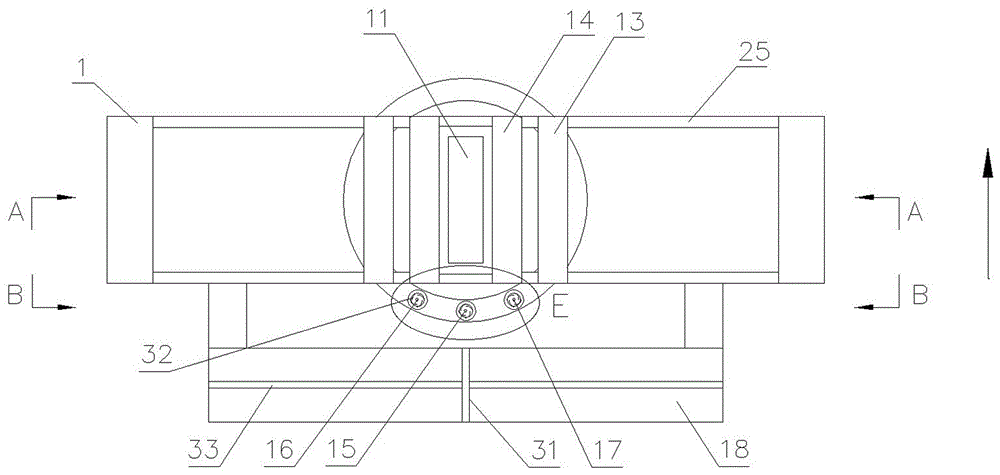

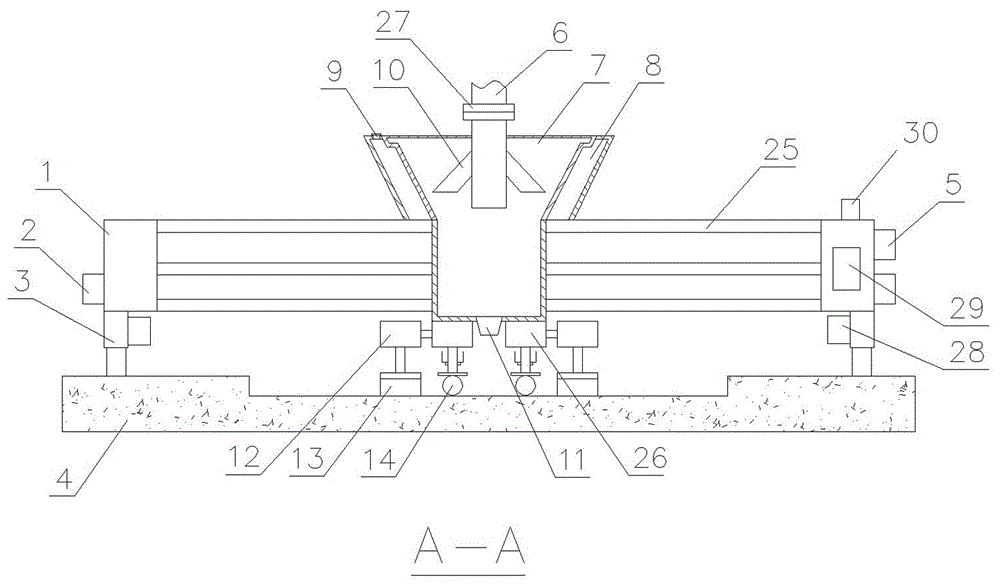

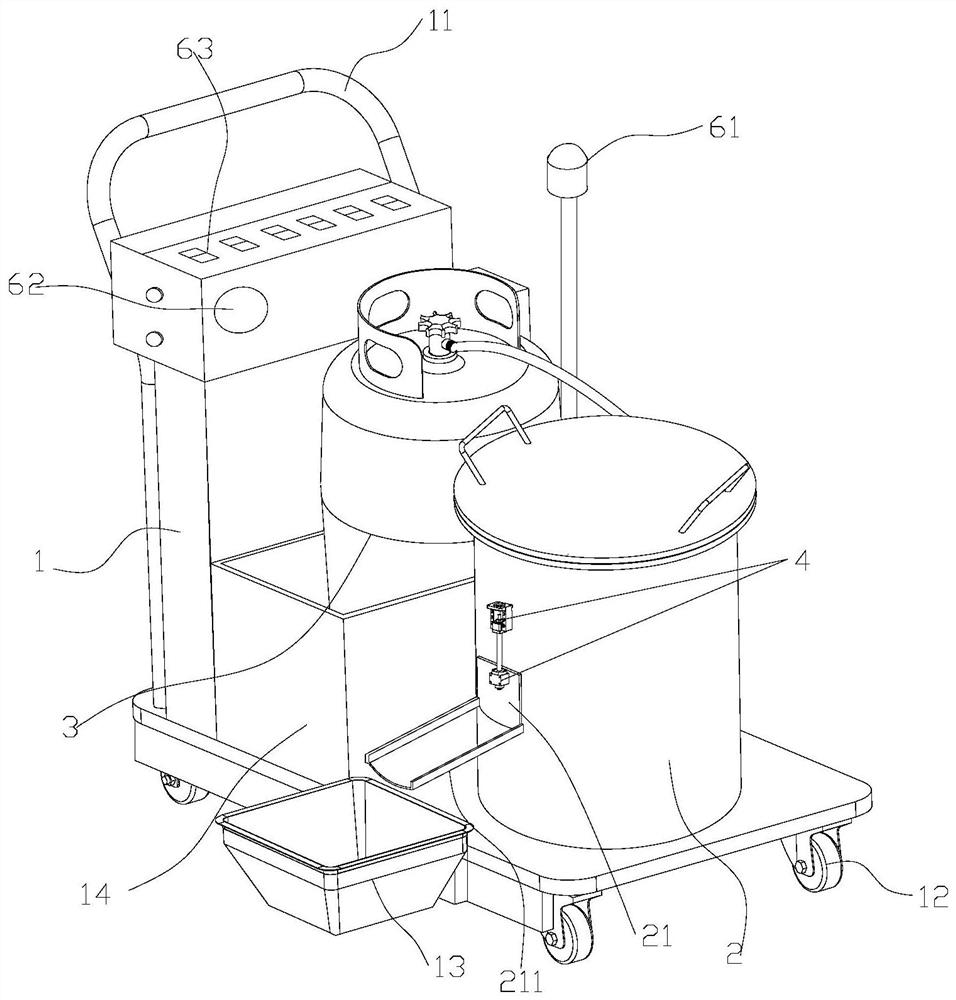

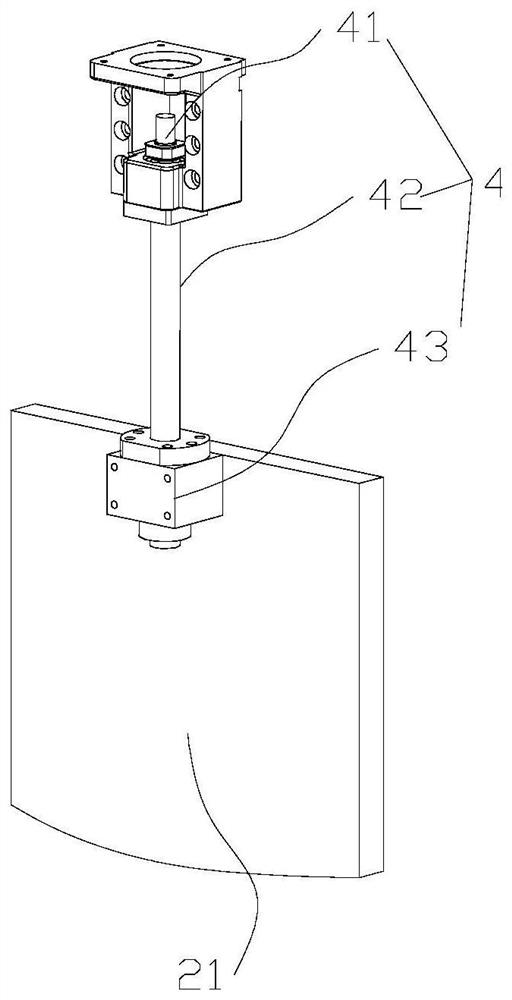

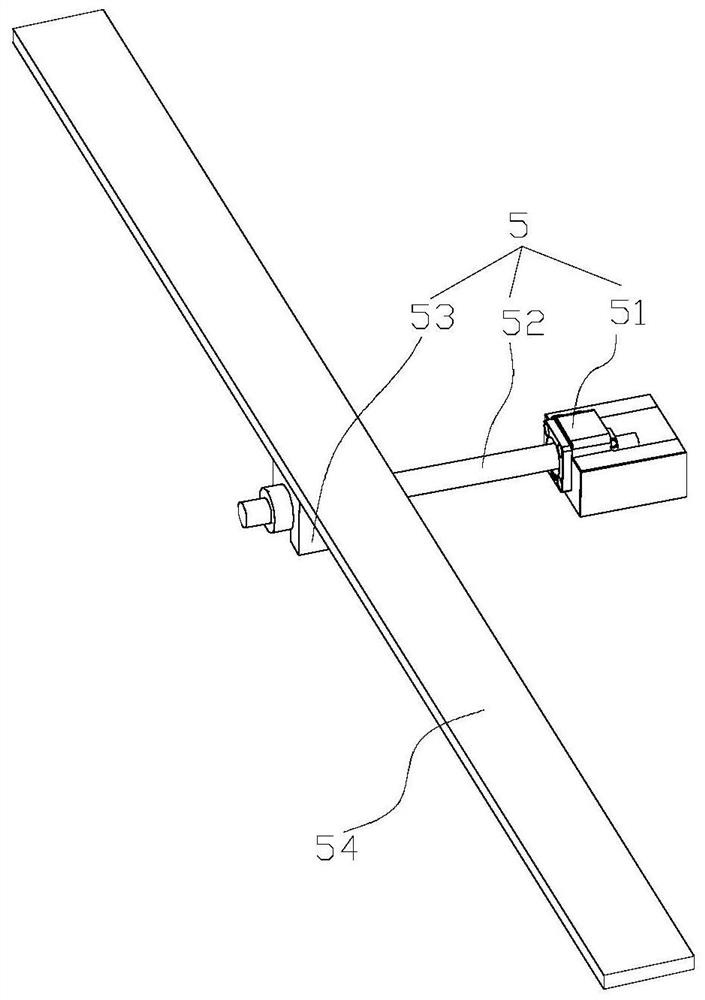

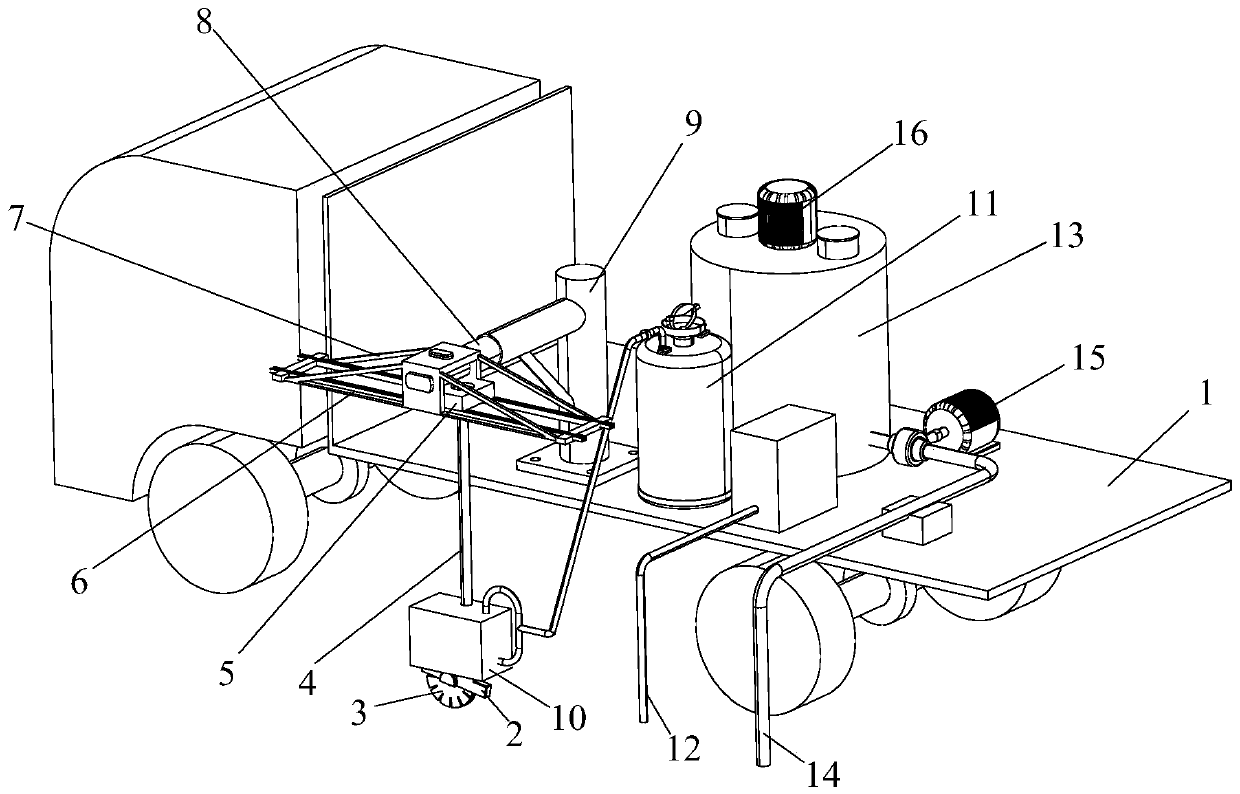

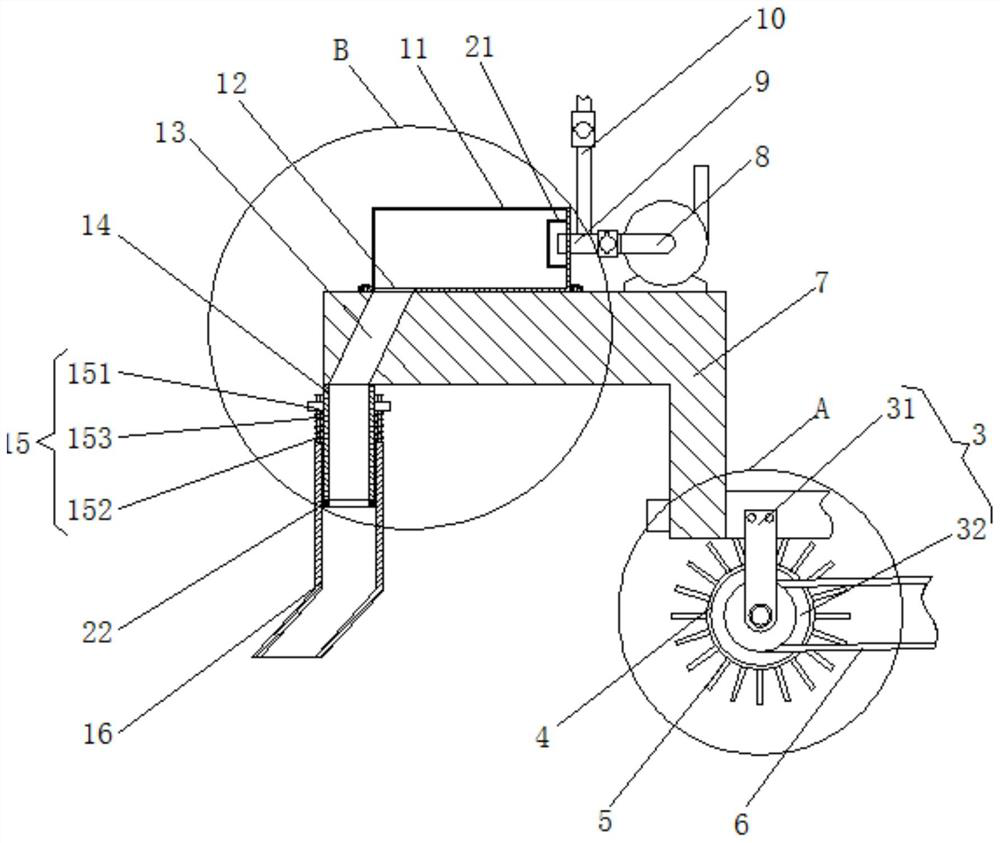

Self-propelled road marking machine

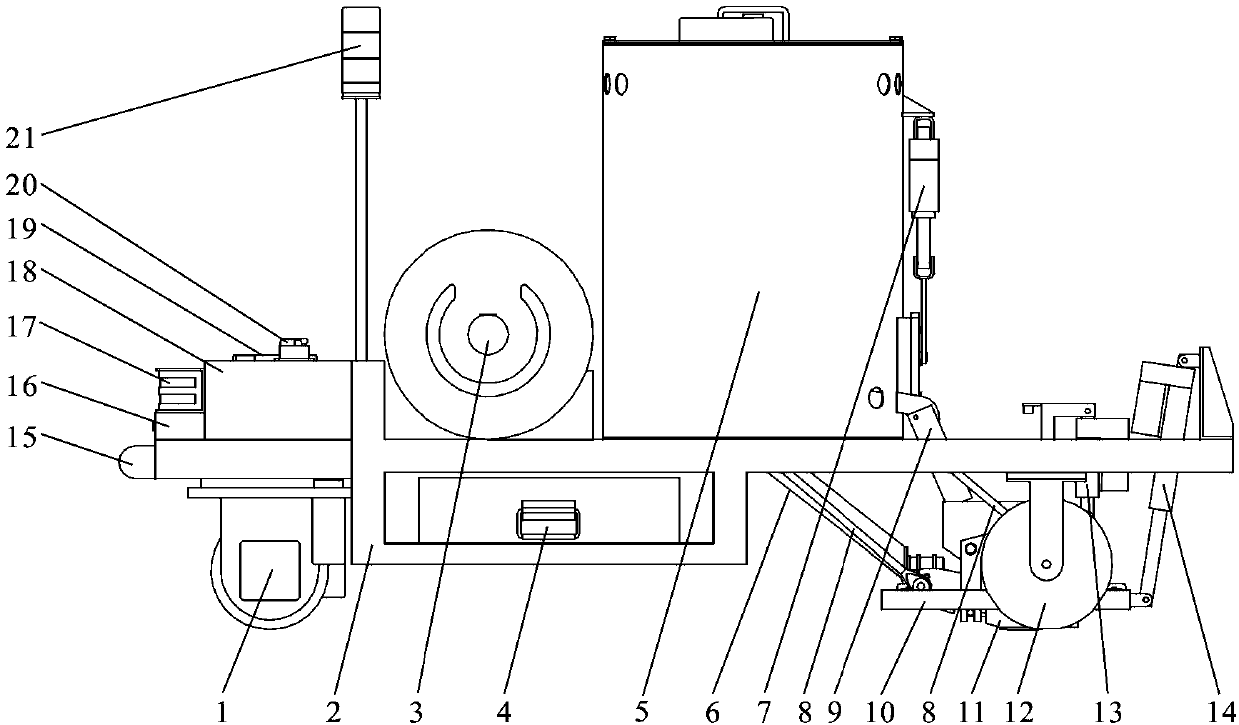

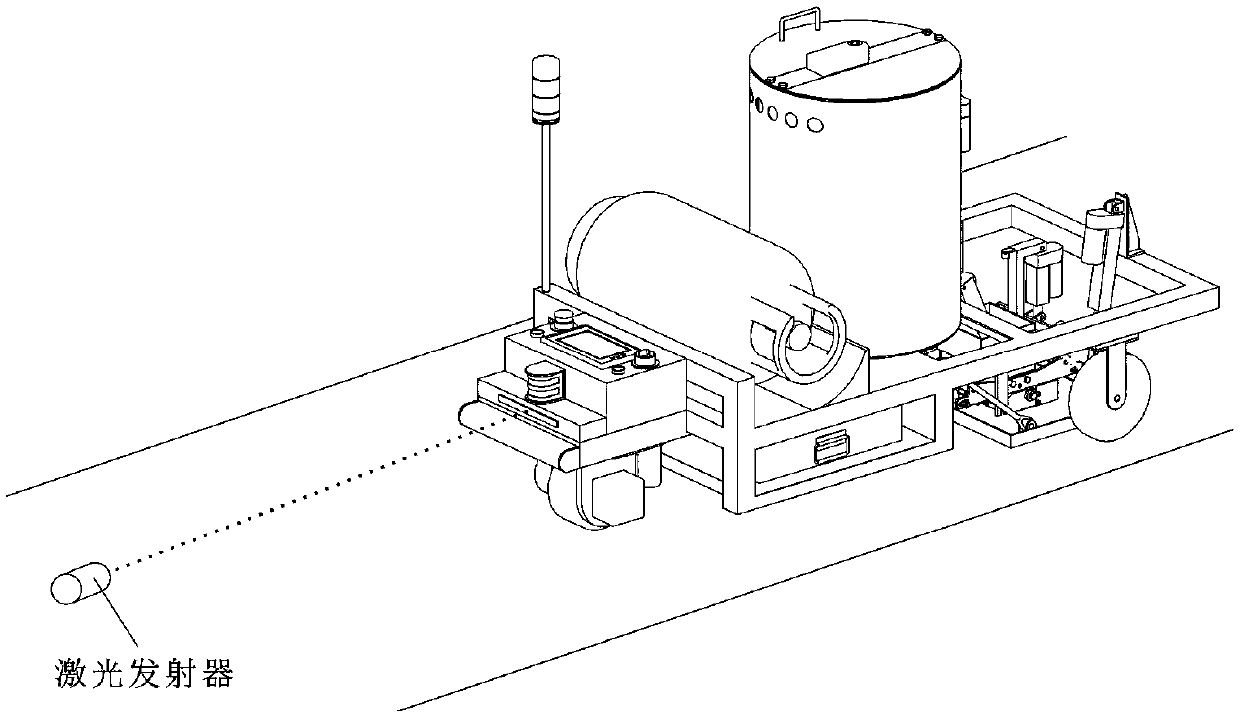

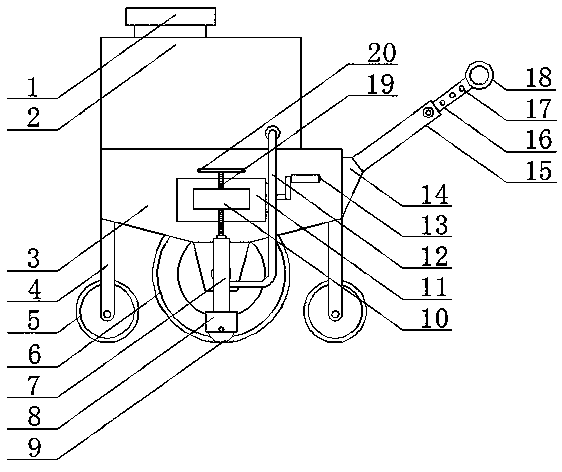

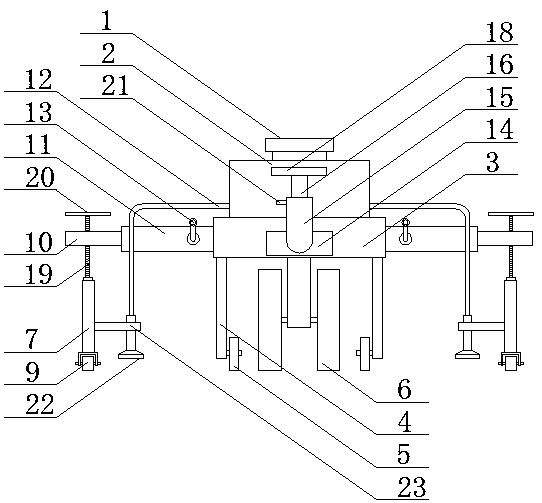

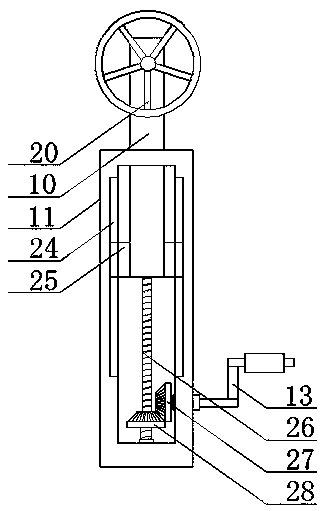

PendingCN107829360ASolve the real problem that the straightness of the marking line is not highHigh degree of automationRoads maintainenceVehicle frameSteering wheel

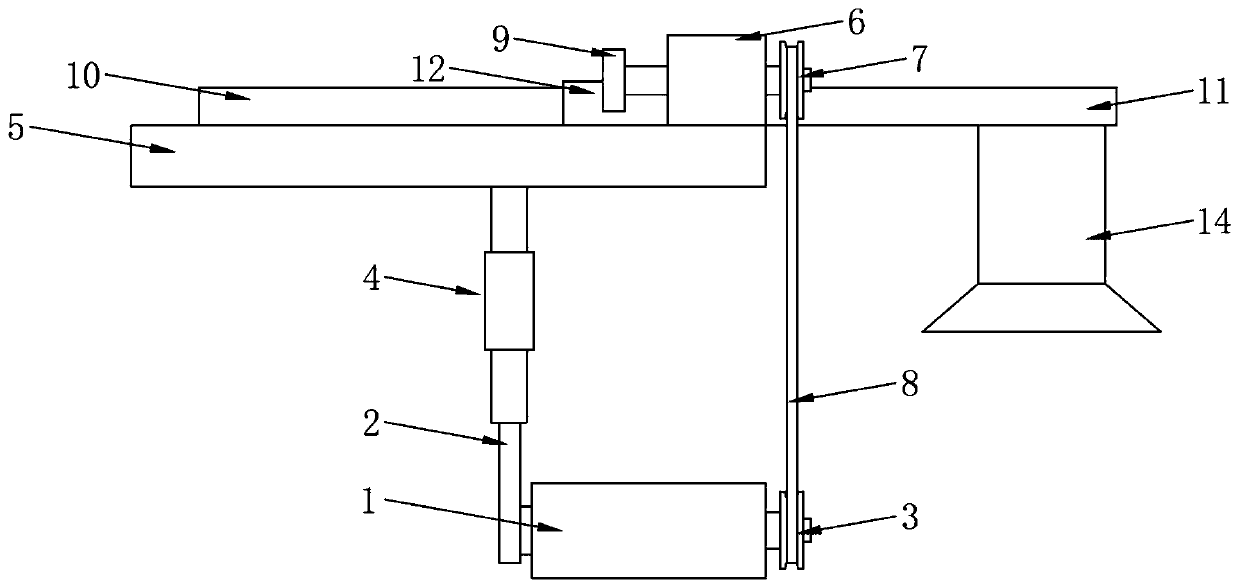

The invention relates to a self-propelled road marking machine structure. The self-propelled road marking machine structure comprises a vehicle frame, wherein a steering wheel and two fixed caster wheels are mounted at the lower part of the vehicle frame to form a self-propelled tricycle chassis structure which is supported by three wheels and is driven and realizes steering through the front wheel; a battery pack is mounted at the middle of the vehicle frame; a mechanical anti-collision device and a laser receiver are fixedly mounted in the forefront of the vehicle frame; an obstacle sensor is arranged directly above the laser receiver; an electrical control box is arranged on the side surface of the laser receiver; an audible and visual warning device is mounted at the top of the vehicleframe; a liquefied gas tank and a paint bucket are fixedly mounted at the middle position of the upper part of the vehicle frame; a marking hopper and a lifting device are mounted at the tail part ofthe vehicle frame; and flaming heads are mounted at the bottom of the paint bucket and the side surface of the hopper. The invention discloses a novel design scheme of a road marking machine and designs a self-propelled road marking machine high in automation degree, high in marking accuracy and high in work efficiency, so that the development needs of advanced road marking are further met.

Owner:山东大道智慧交通股份有限公司 +1

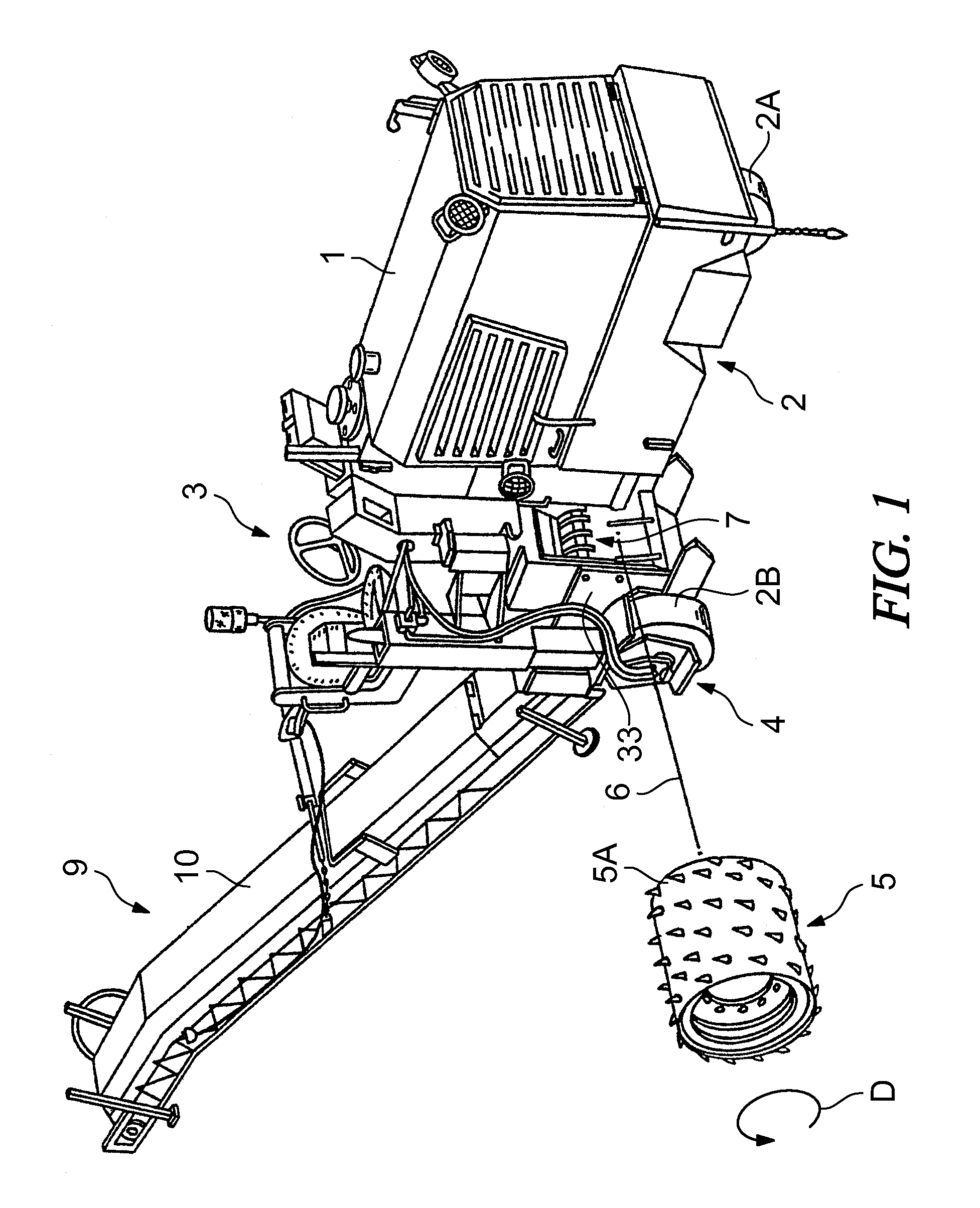

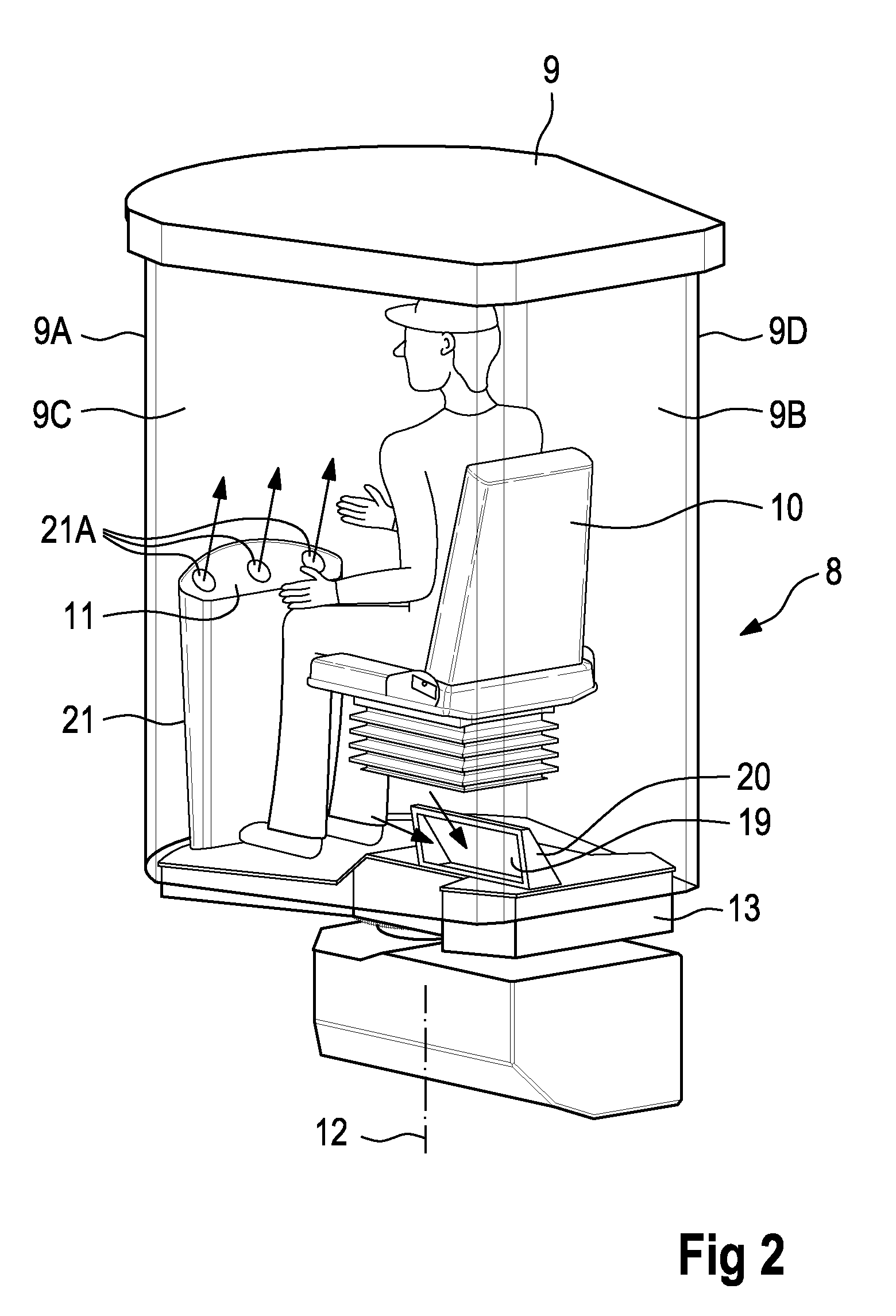

Construction machine, in particular road milling machine, miner, recycler or stabilizer

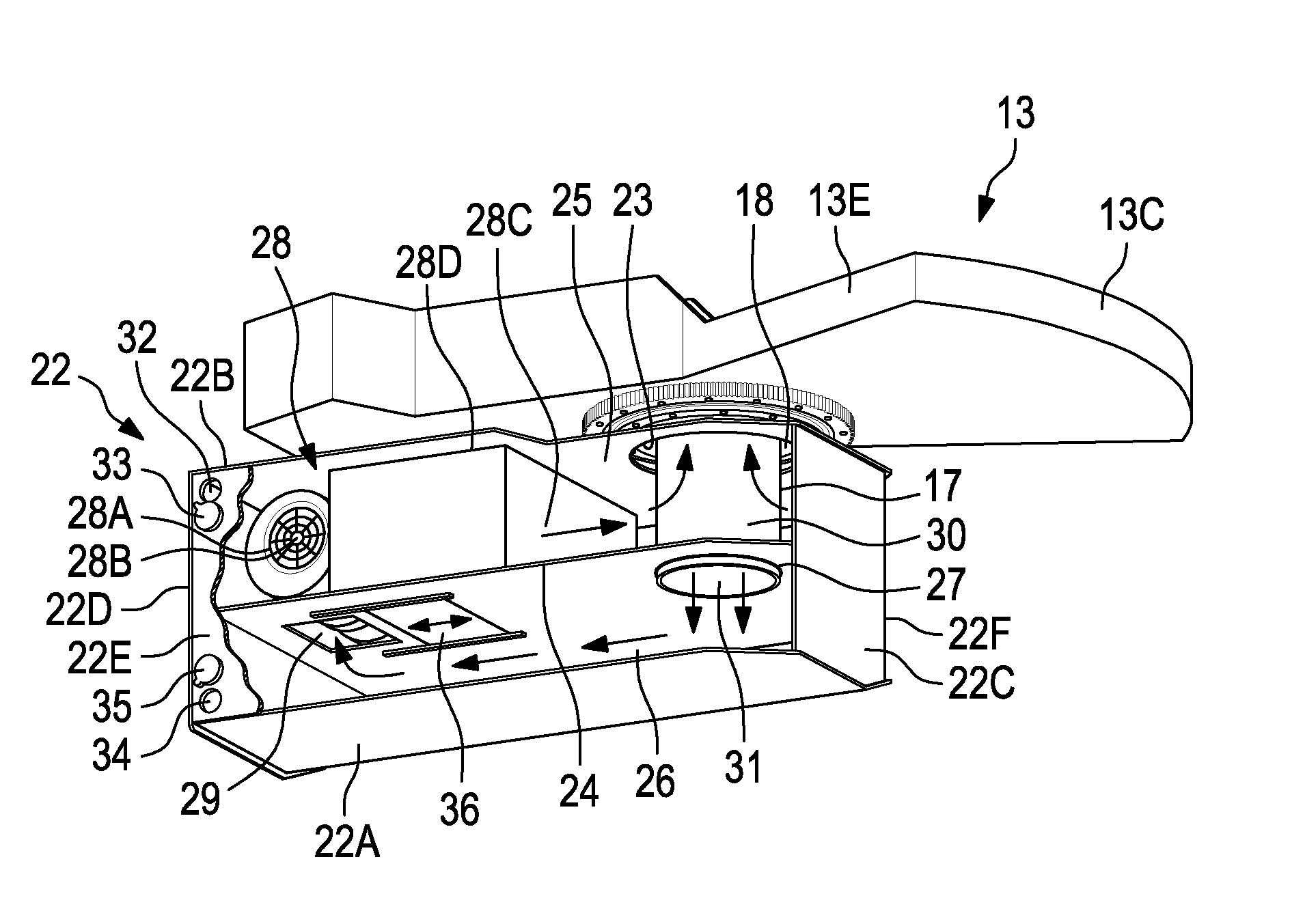

ActiveUS8096609B2Simple wayImprove distributionVehicle seatsVehicle heating/cooling devicesFresh airAir treatment

The construction machine according to the invention is distinguished by the fact that an air-processing apparatus (28) is arranged outside the cab (9) on the machine frame (2), wherein a device (13, 22) for feeding processed and / or fresh air into the cab and used air from the cab is provided, said device having a feed air duct for processed air for the cab and a discharge air duct for used air from the cab. The feed air duct of the air-processing apparatus (13, 22) is connected to the outlet (28C) of the air-processing apparatus (28) and the discharge air duct is connected to the inlet (28B) of the air-processing apparatus. In a construction machine whose control station is rotatably arranged on the machine frame, the arrangement with the air-processing apparatus outside the cab has the decisive advantage that it is not necessary to run hoses and / or lines between the rotatable cab and the machine frame. A preferred embodiment of the construction machine provides for the feed and discharge air duct of the air-processing apparatus (13, 22) to have an outer section (30) which is formed by a component connected to the machine frame in a rotationally fixed manner and an inner section (31) which is formed by a component connected to the cab in a rotationally fixed manner, wherein the outer section encloses the inner section. Thus concentric air conduction via the swivel joint of the control station is possible.

Owner:WIRTGEN GMBH

Directional road marking machine with variable paint spraying modes

The invention discloses a directional road marking machine with variable paint spraying modes. The directional road marking machine comprises a machine body, a storage cavity is formed in the machinebody, a paint spraying mechanism is arranged in the storage cavity, the paint spraying mechanism comprises a storage box fixedly arranged on the inner wall of the upper side of the storage cavity, andthe storage box penetrates through the inner wall of the upper side of the storage cavity; a material storage cavity is formed in the storage box, a supporting plate is fixedly arranged between the inner walls of the front side and the rear side of the storage cavity, a first motor is fixedly arranged at the upper end of the supporting plate, a first rotating shaft is rotatably arranged at the upper end of the first motor, and the first rotating shaft penetrates through the inner wall of the lower side of the material storage cavity. In using of the directional road marking machine, paint isintroduced into the built-in storage box, a spray head can be controlled to continuously spray paint or intermittently spray paint by controlling forward and reverse rotation of the motor, and if a mechanism deviating from the direction can be immediately corrected during walking, a drawn line is straight, and a built-in brush can clean a road surface to be sprayed with paint in advance.

Owner:SHENGZHOU MIXIANG ROAD FACILITIES CO LTD

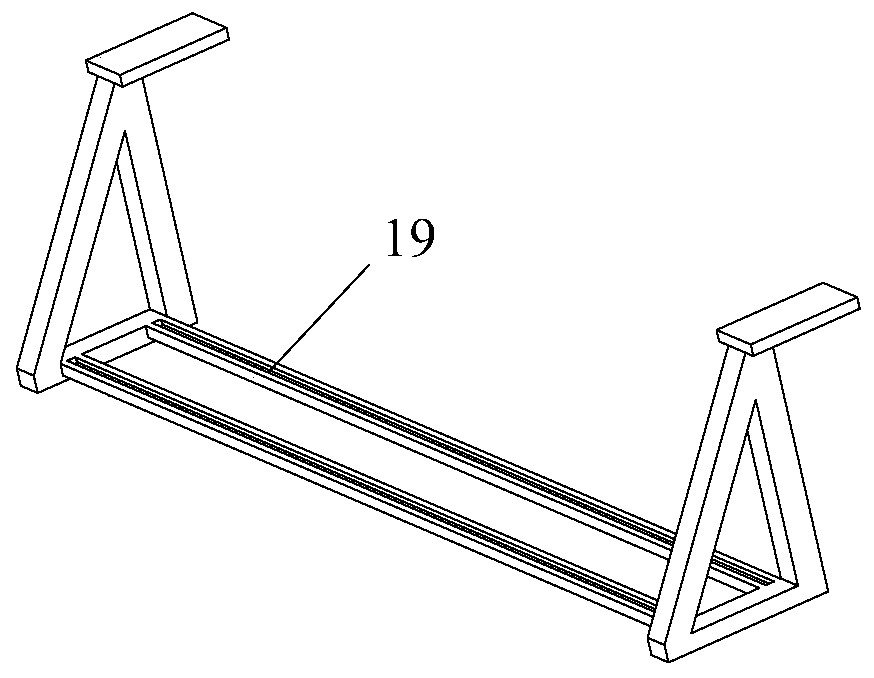

Automatic deviation-rectifying concrete road spreading and road marking machine

The invention discloses an automatic deviation-rectifying concrete road spreading and road marking machine. The automatic deviation-rectifying concrete road spreading and road marking machine comprises a truss, a concrete hopper, a feeding pipe, a material dropping opening, mixing cage lifting control devices, vibration lifting control devices, material conveying mixing cages, vibrating devices, walking wheels, walking motors, a control box, spraying material hoppers, spraying devices, a rolling roller, a longitudinal cutting blade and a transverse cutting blade, wherein the material conveying mixing cages are connected under the mixing cage lifting control devices; and the longitudinal cutting blade and the transverse cutting blade are arranged on the circumference of the rolling roller; a rotating bearing is arranged on the feeding pipe; and the spraying devices comprise paint chambers, partition plates, adjusting plates and spraying nozzles. As the nozzles of the spraying devices are arranged on the rear side of the material dropping opening, the spraying devices spray the construction ground to draw road markings while a paver is performing road surface laying construction, and the road markings are compacted and flattened by the rolling roller and contraction joints are cut; therefore, the just laid concrete and the sprayed markings form the same plane so that the duration is long.

Owner:HEBEI GUANGTONG ROAD & BRIDGE GRP

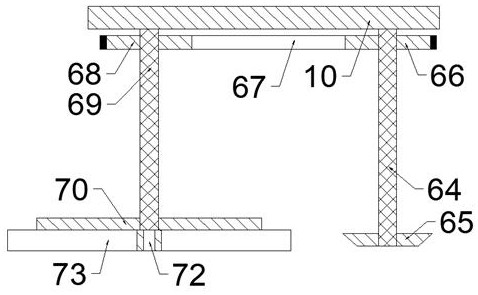

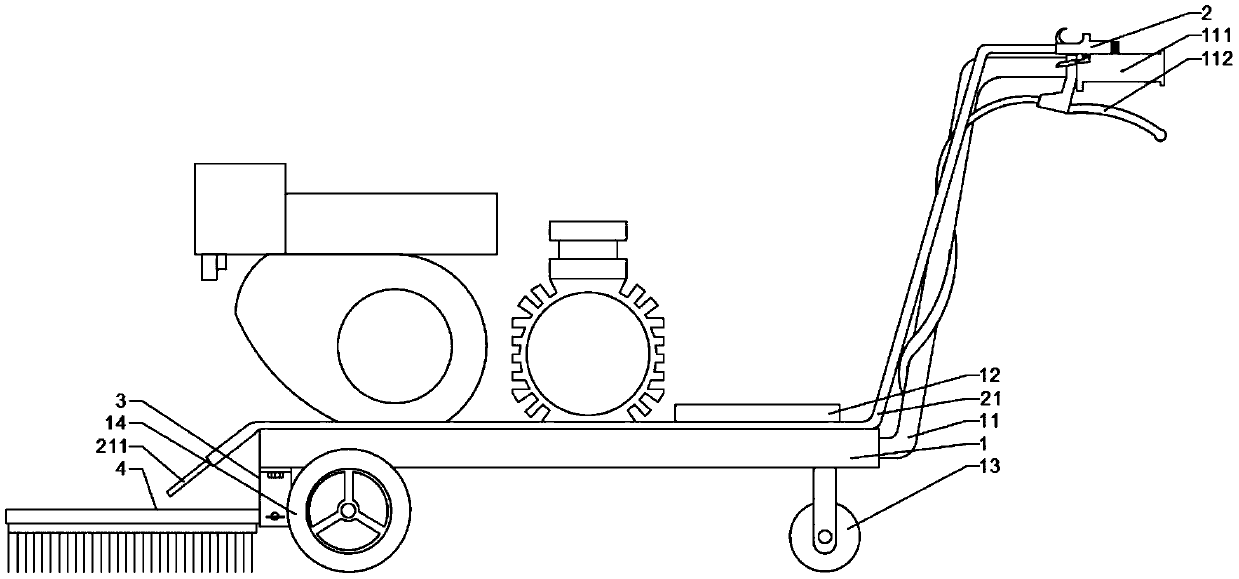

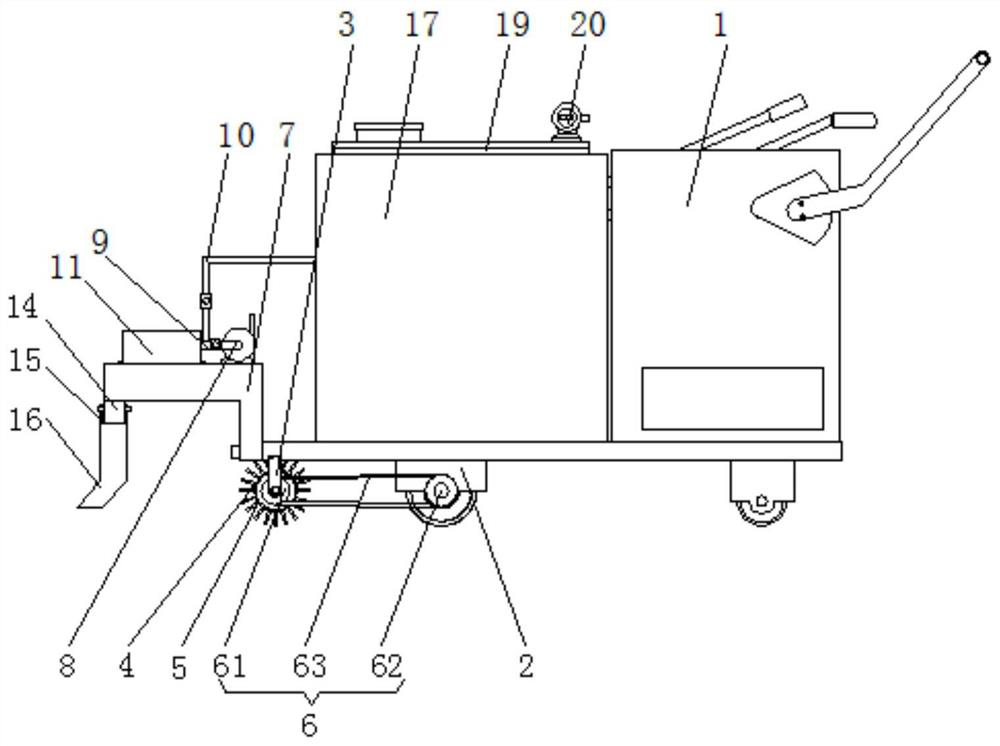

Hand-push type road marking machine

InactiveCN109653072AImprove cleanlinessJudgment accuracyRoad cleaningRoads maintainenceRoad surfaceGun barrel

The invention relates to the technical field of road equipment, in particular to a hand-push type road marking machine which comprises a marking machine body. A push rod is arranged at the left end ofthe marking machine body, a handle is arranged at the upper end of the push rod, a brake lever is arranged on a side of the handle, a gas gun is arranged on the handle, a gas gun barrel is arranged on the gas gun, the right upper end of the gas gun barrel extends into the gas gun in a communicated manner, and a gas nozzle is arranged at the left lower end of the gas gun barrel. The hand-push typeroad marking machine has the advantages that the hand-push type road marking machine is simple in structure and convenient to use, and the problems that dust can fall on pavements, which are clearedup in advance, again during marking by general road marking machines and whether marked lines are accurately or not cannot be accurately judged when hand-push marking machines advance can be effectively solved by the aid of the hand-push type road marking machine; the marking efficiency can be improved, the hand-push type road marking machine does not need to be frequently decelerated and even stopped for adjusting the directions and angles, accordingly, the marking speeds can be increased, and the marking quality can be improved.

Owner:南京壹久软件科技有限公司

Intelligent road marking machine

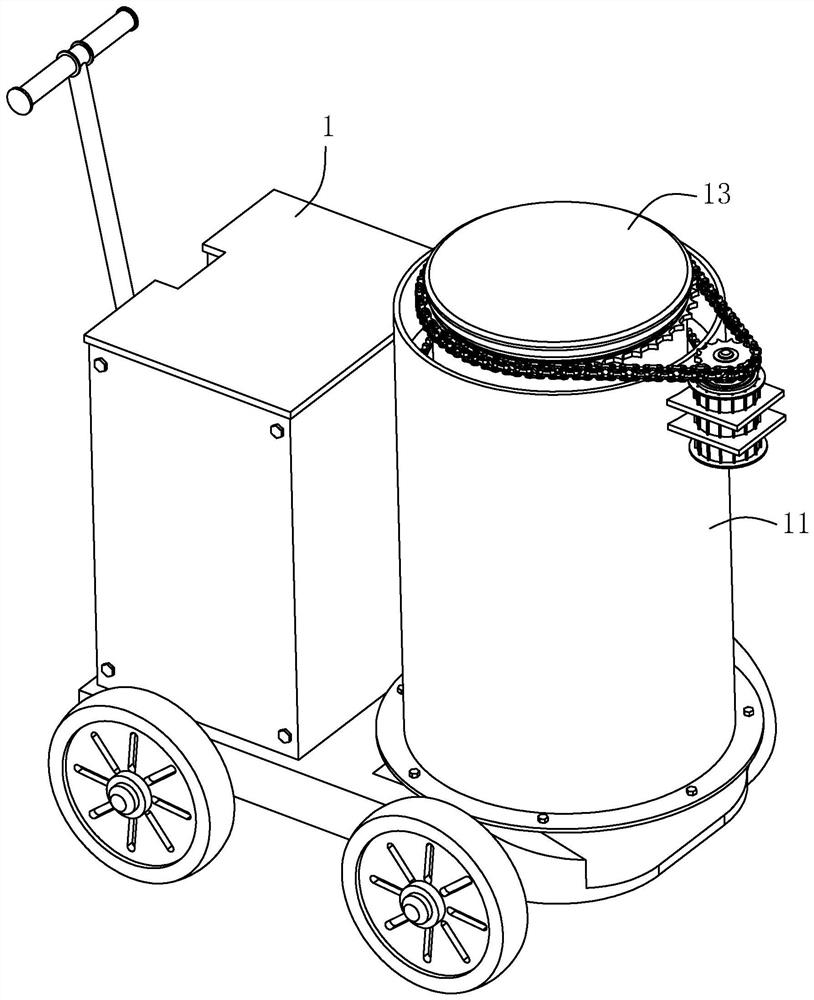

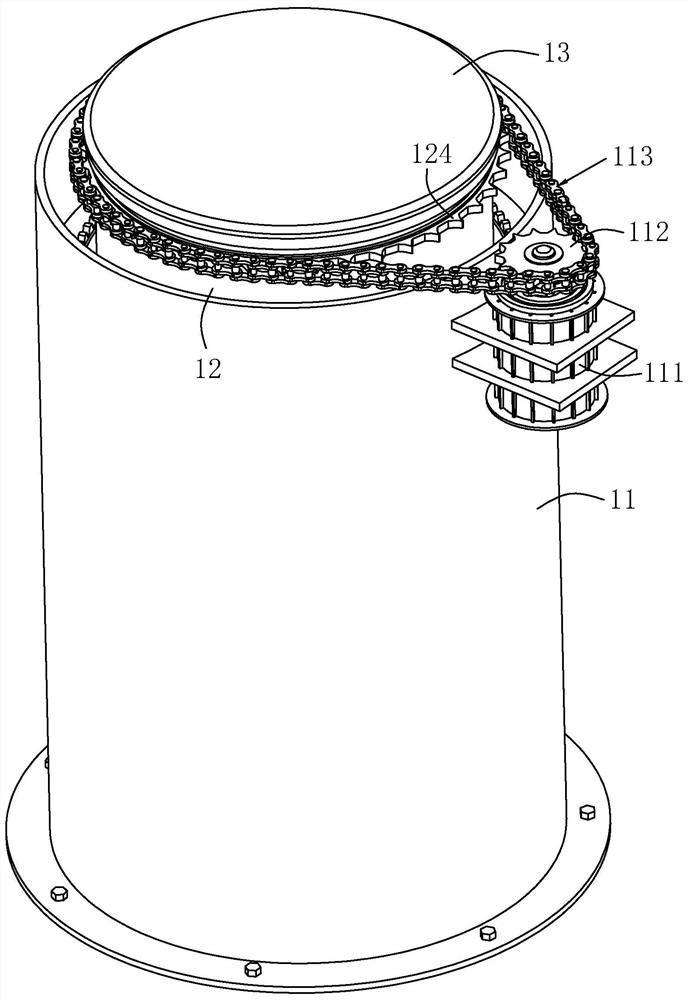

PendingCN113638302AImprove efficiencyRealize automatic feedingVisible signalling systemsAlarmsEngineeringPower apparatus

The invention discloses an intelligent road marking machine which comprises a base, a material barrel arranged on the base, a heating device and a first power device, the heating device heats marking materials in the material barrel, one side of the base is fixedly connected with a hopper, the material barrel is provided with a discharge port, and the discharge port is provided with a door body. The first power device is connected with the door body and used for opening or closing the discharging port. The door body can be opened through the first power device, after the door body is opened, a marking material in the material barrel can enter the hopper, therefore, the door body does not need to be opened manually, efficiency is higher; in addition, automatic feeding can be achieved through the control module and the position sensing module, and automatic marking can be achieved through the control module and the operation module.

Owner:广州大湾交通设施有限公司

Road marking machine

InactiveCN110983939AHigh degree of automationReduce lossRoads maintainenceRoad surfaceElectrical and Electronics engineering

The invention discloses a road marking machine. The road marking machine comprises a vehicle body, a grooving device used for forming a marking groove in the road surface, a first adjusting device used for controlling the grooving device to move in a first direction, a second adjusting device which is arranged on the vehicle body and used for controlling the first adjusting device to move in a second direction, and an asphalt pouring device which is arranged on the vehicle body and used for pouring white asphalt concrete into the marking groove, wherein the first direction and the second direction are both horizontal directions, and the first direction is perpendicular to the second direction. By means of the road marking machine, the road marking work efficiency can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Fully-automatic control road marking machine

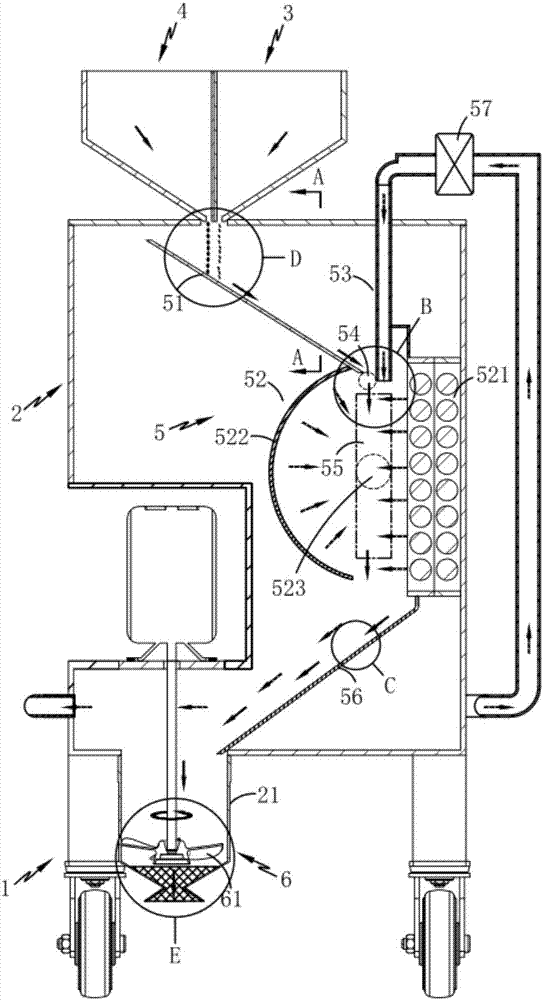

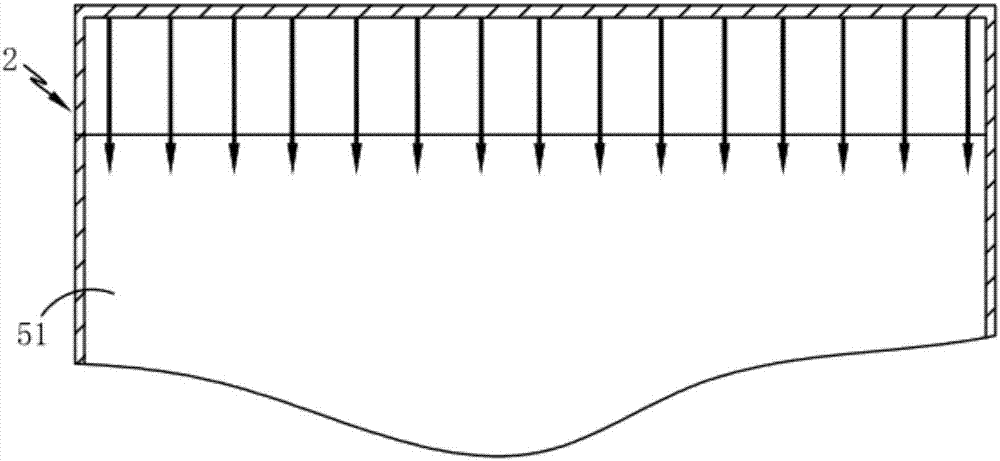

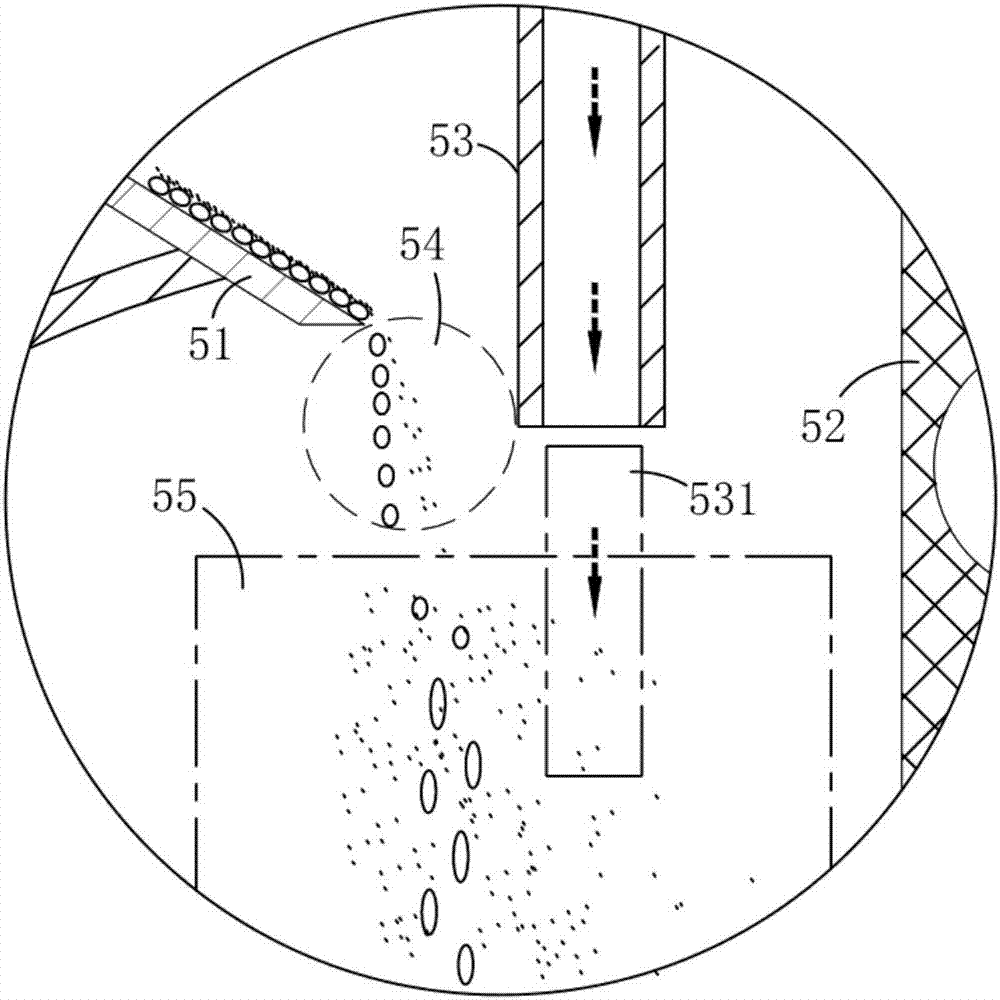

InactiveCN107503276AImprove mixing uniformityRefine Mixed PrecisionRoads maintainenceAutomatic controlMixed materials

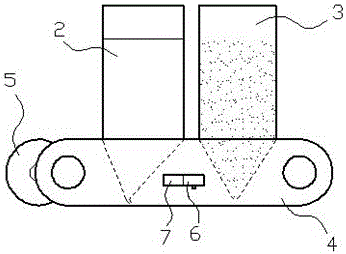

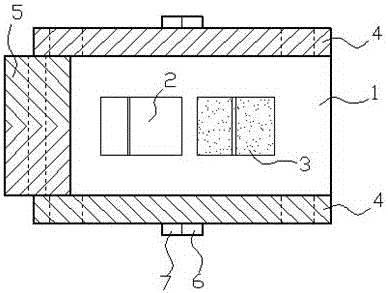

The invention relates to a high-efficiency melting road marking mechanism, which includes a bracket, a melting bin, a powder bin, a resin bin, a melting mixing component and a spraying component. The melting mixing component includes a first transmission component, a hot melt component and an airflow introduction component. The negative pressure zone is formed after the air flow is introduced into the component and flows out. The mixture of resin and powder transported by the first transmission component is in the process of falling, and the coating is formed while being liquefied in the melting zone by the hot melt component. The paint formed after melting by the melting and mixing component falls into the spraying chamber at the bottom of the melting chamber, and the paint is uniformly stirred and mixed by the internal stirring output part, and then the output spraying is carried out; the mixed material falling through the fixed ratio is carried out. At the same time of the liquefaction process, the contact area between the liquid resin and the powder is increased by the airflow, and the uniform mixing of the resin and the powder is realized, which solves the technical problem of poor mixing uniformity of the paint existing in the prior art.

Owner:FOSHAN XUNTUOAO TECH CO LTD

Automatic road marking machine

The invention discloses an automatic road marking machine. The automatic road marking machine comprises a car body, crawler wheels arranged at two sides of the car body, and a plurality of rotating shafts connecting the car body with the crawler wheels; the plurality of rotating shafts are provided with motors for driving the rotating shafts to rotate; a paint tank is arranged in the car body; the left side and the right side of the car body are symmetrically provided with laser emitters with vertically downward emission ends, and laser receivers are arranged closely to the laser emitters; and a controller is arranged in the car body, and the controller is respectively connected with the laser receivers and the motors through a control line group. The automatic road marking machine has the advantages of simple structure, reasonable design, saving of a lot of labor force, and wide market prospect.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

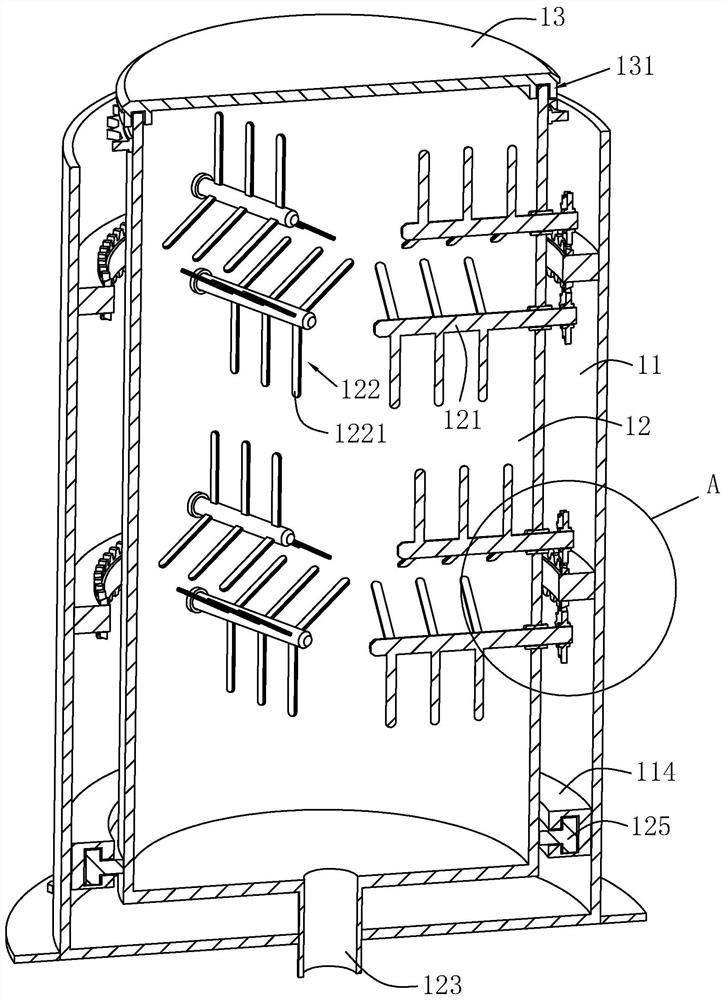

A road marking machine

ActiveCN109183594BPlay a stirring effectPrevent precipitationRoads maintainenceAgricultural engineeringStructural engineering

Owner:四川志德公路工程有限责任公司

Municipal road marking machine

InactiveCN112523058AEasy to convertEasy to replaceRoad cleaningRoads maintainenceElectric machineryPhotopigment

The invention discloses a municipal road marking machine which comprises a base, a mixing box is fixedly connected to the upper surface of the base, a first through hole is formed in the inner bottomwall of the mixing box, and a cover plate is rotatably connected to the interior of the first through hole. According to the municipal road marking machine, the mixing box and the conversion box are arranged in a matched mode, when the municipal road marking machine is used, a rotating rod is rotated through a handle, a cover plate is opened, fuel in the mixing box flows into the conversion box and finally flows into the marking box, and when pigment needs to be replaced, the rotating rod is rotated through the handle, the cover plate is closed, and then through rotation of a third motor, themotor drives the first screw rod and the second screw rod to rotate to drive the partition plate to slide, so that pigment in the other partition bin flows out through the first through hole, then theother rotating rod is rotated through the other handle, the other cover plate is opened, fuel in the mixing box flows into the conversion box and finally flows into the scribing box, and therefore the purpose of conveniently replacing the pigment is achieved.

Owner:于小辉

Automatic road marking machine

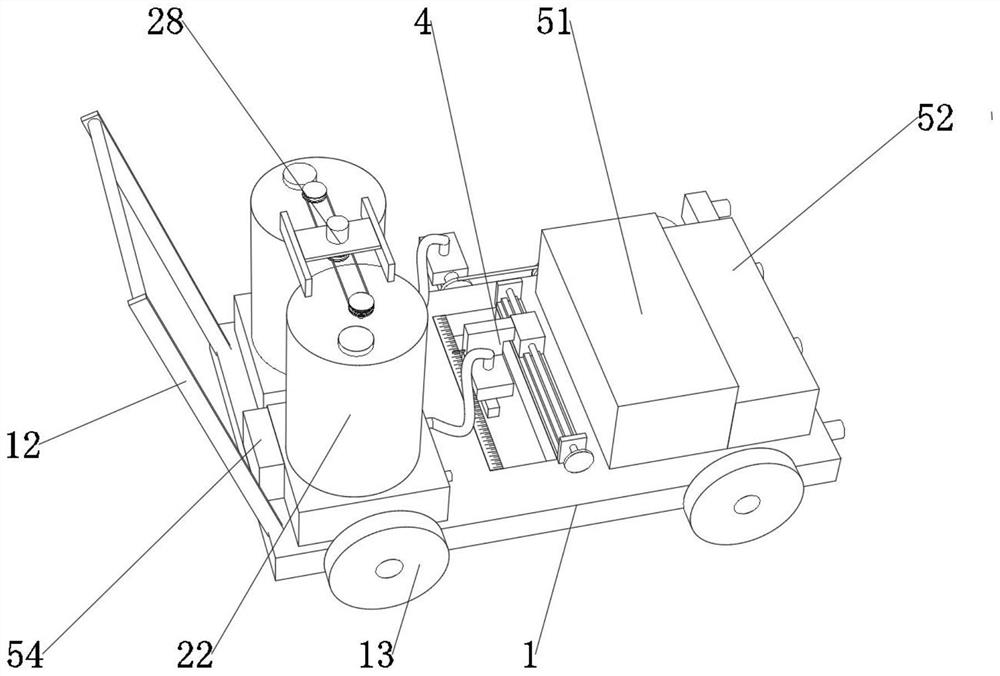

InactiveCN109183596AImprove applicabilityImprove work efficiencyRoads maintainenceWater storage tankPulp and paper industry

The invention discloses an automatic road marking machine, including a device body, wherein the device body includes a bottom plate; a pulley block is arranged at both ends of the bottom of the bottomplate; at one end of the top of the bottom plate, an air machine case body is fixedly installed; an air compressor is arranged inside the air machine casing; the other end of the top of the bottom plate is fixedly provided with a storage cylinder; a material storage box cover is arranged on the top of the material storage cylinder body, a cover handle is fixedly arranged at both ends of the top of the storage cover, in accordance with the prior art, the invention has the following beneficial effects: the device is provided with a water storage tank body, storage cylinder, the second connecting pipe and the pumping pump can convey the cleaning agent inside the water storage tank to the inner part of the material storage cylinder through the second connecting pipe by opening the pumping pump, thereby cleaning the inner part of the material storage cylinder, avoiding the tedious steps of removing the material storage cylinder, saving manpower and time, and improving the working efficiency of the device.

Owner:南京鑫亮交通设施有限公司

Road marking machine device capable of meeting various marking requirements

InactiveCN111851247AGuaranteed straightnessImplement simple conversionRoads maintainenceGear wheelElectric machinery

The invention discloses a road marking machine device capable of meeting various marking requirements. A main box body is included. A motor belt wheel cavity is formed in the main box body; a slidinggear cavity is formed in the lower side of the motor belt wheel cavity; a rotating block cavity is formed in the left side of the sliding gear cavity; a large straight gear cavity which penetrates through the rotating block cavity, extends rightwards to the sliding gear cavity and is connected with the sliding gear cavity is formed in the left side of the rotating block cavity; a line width adjusting cavity is formed in the lower side of the sliding gear cavity; a motor bevel gear cavity is formed in the right side of the line width adjusting cavity; and a forward bevel gear cavity is formed in the right side of the motor bevel gear cavity. According to a self-propelled marking machine, manual auxiliary pushing is not needed; and under the condition of rapid marking, straightness of a marking line can be ensured and a width of the marking line can be adjusted, the mechanism is suitable for the marking lines with different line width requirements, a spray head does not need to be manually replaced, marking efficiency is greatly improved, an intermittent paint spraying mechanism is adopted, simple conversion between a solid line and a dotted line is achieved, and dotted line markingcan be performed without manually controlling a spray head switch.

Owner:杭州楷围机械科技有限公司

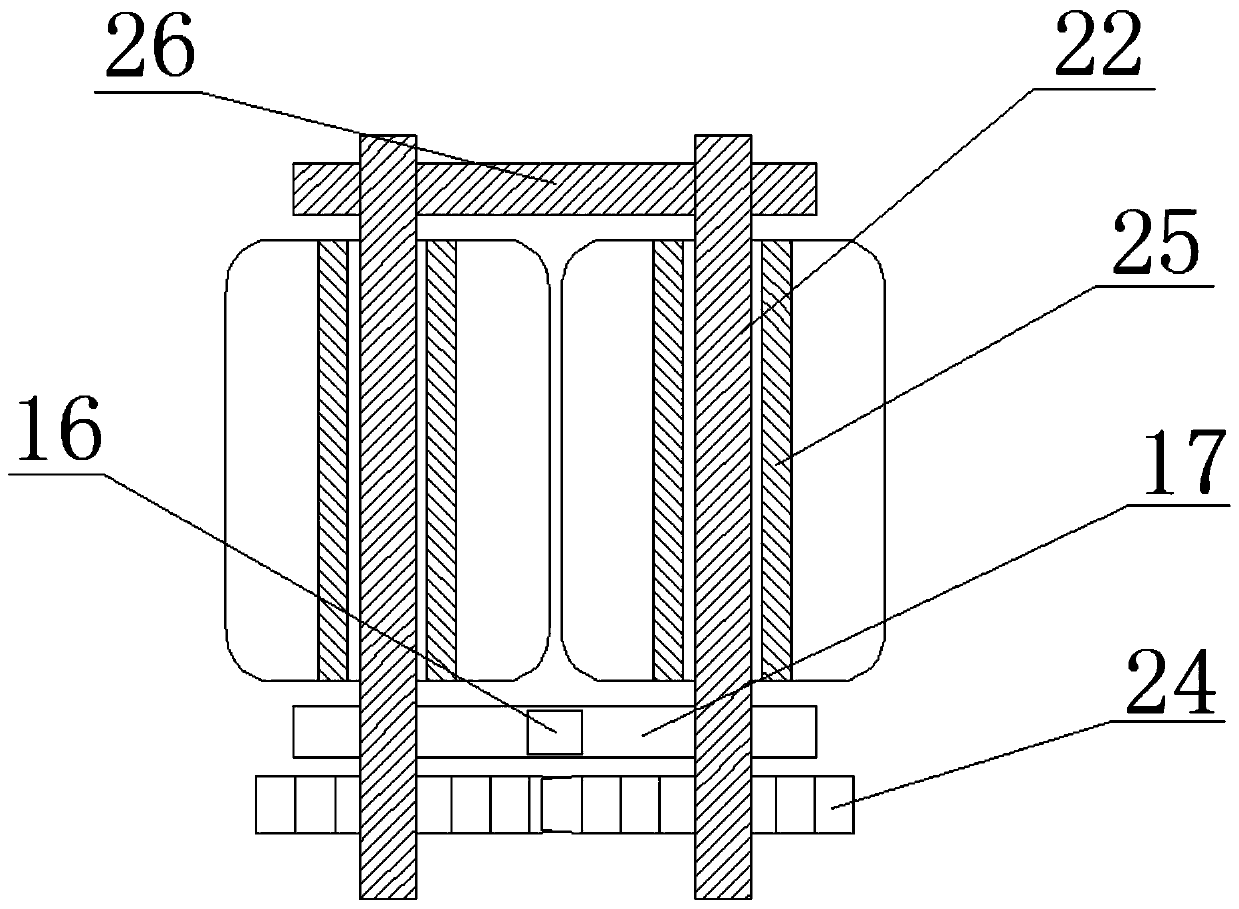

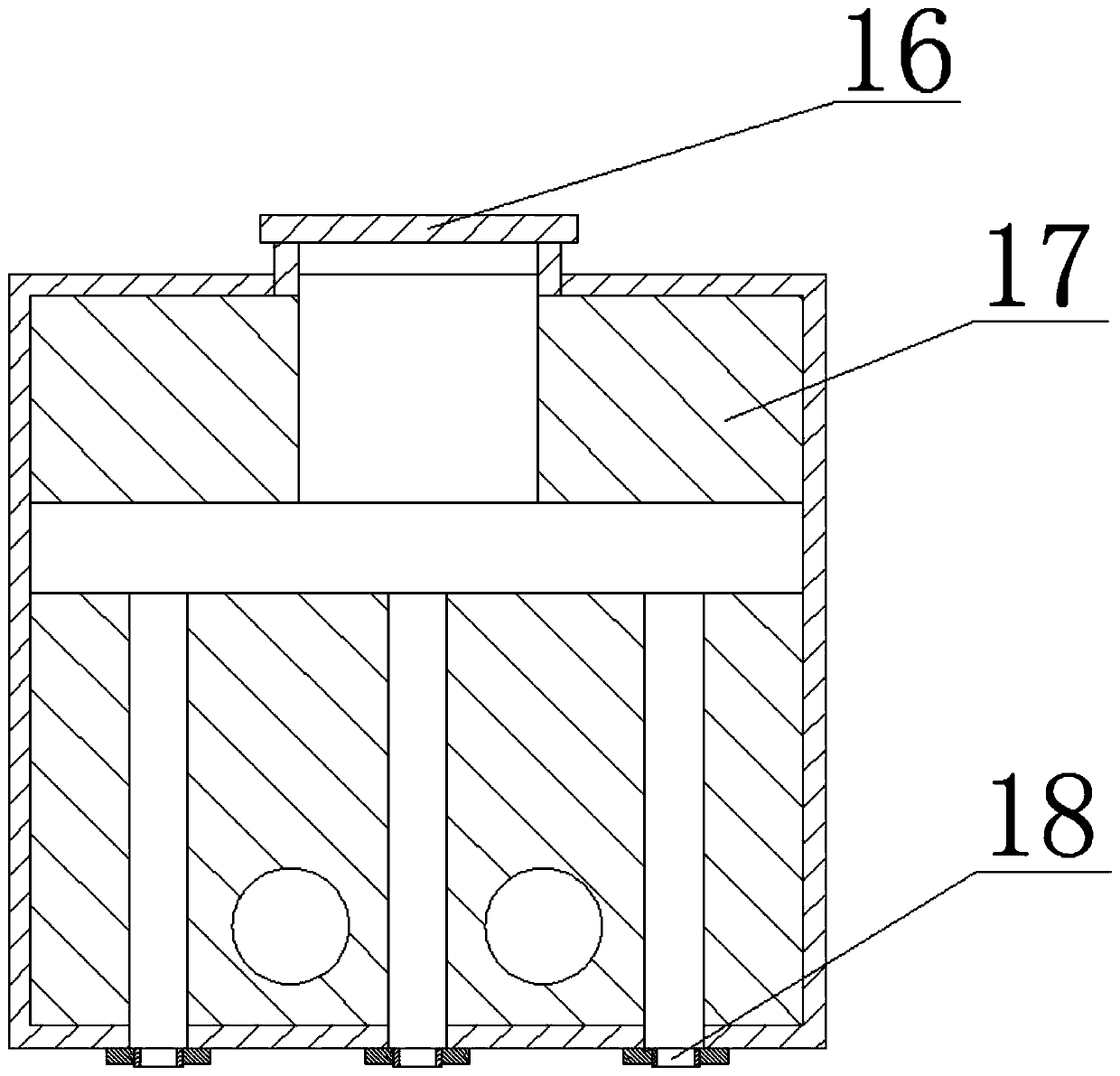

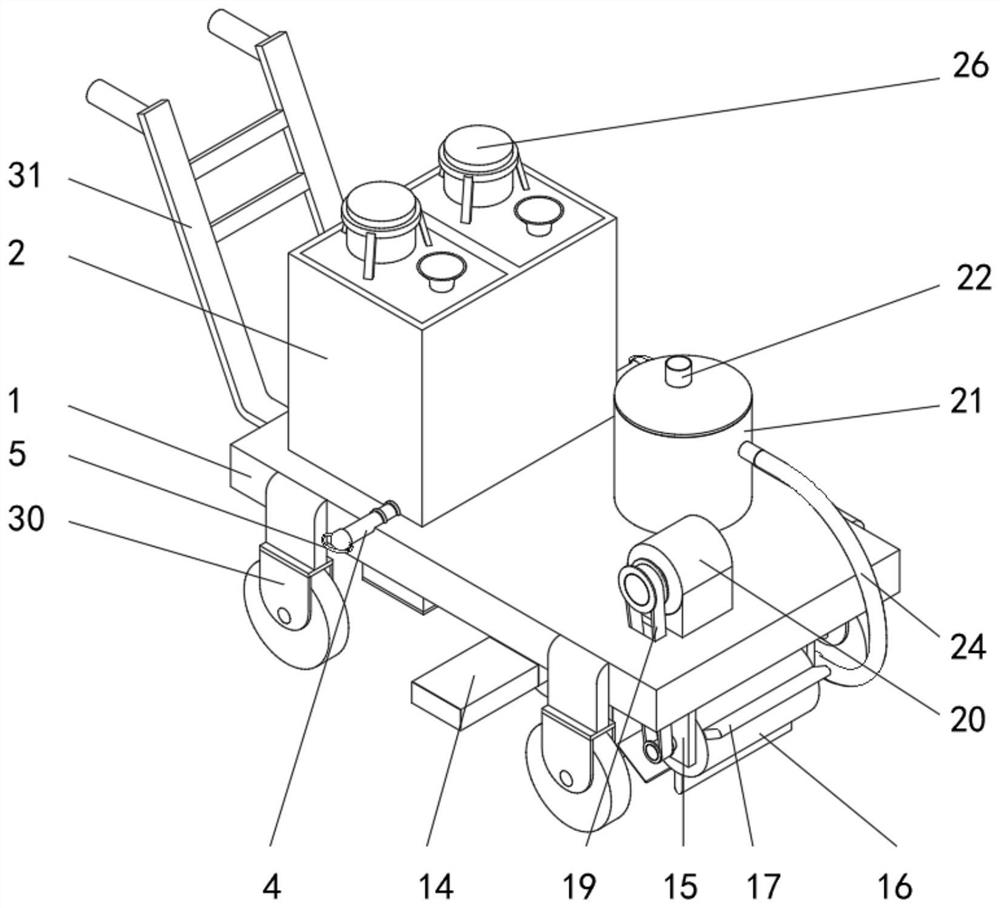

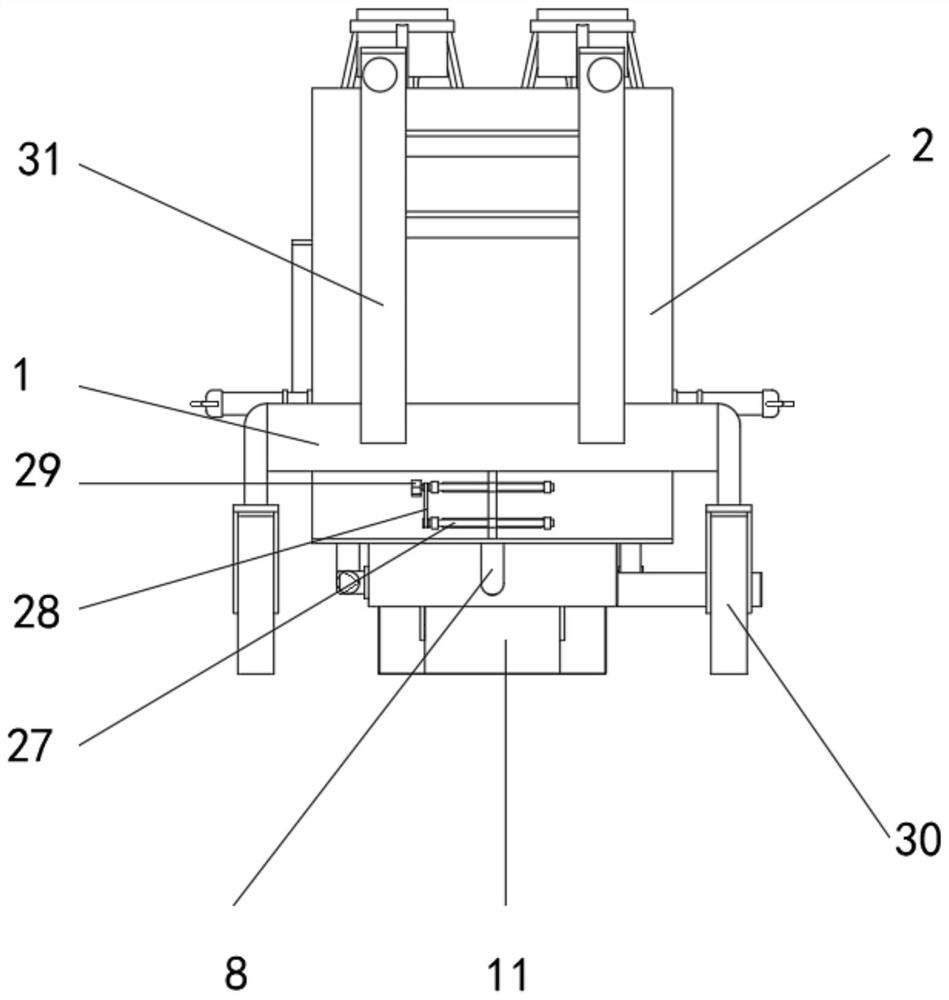

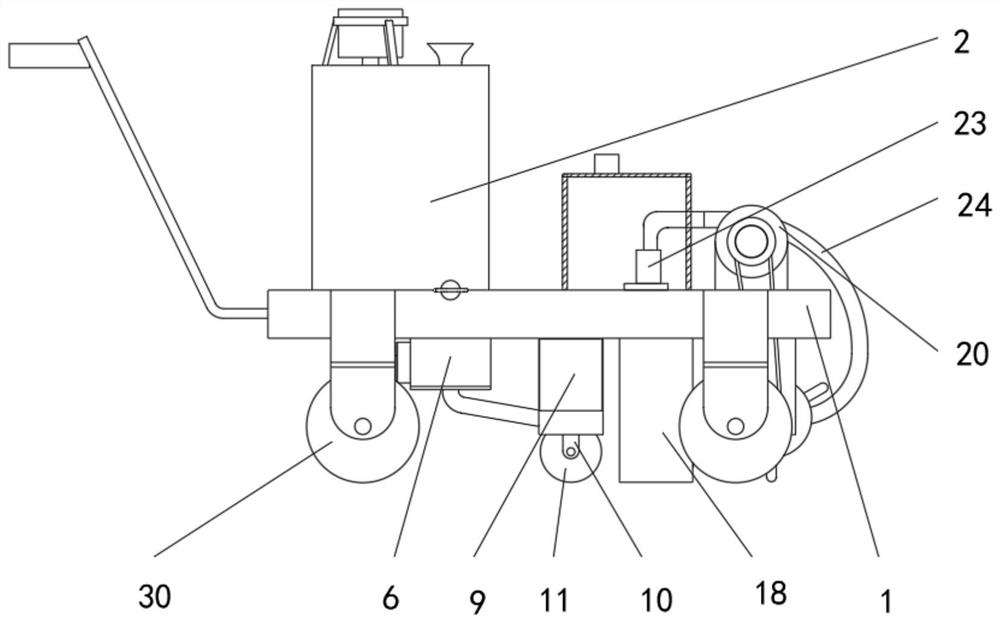

Gap spray coating device and road marking machine comprising same

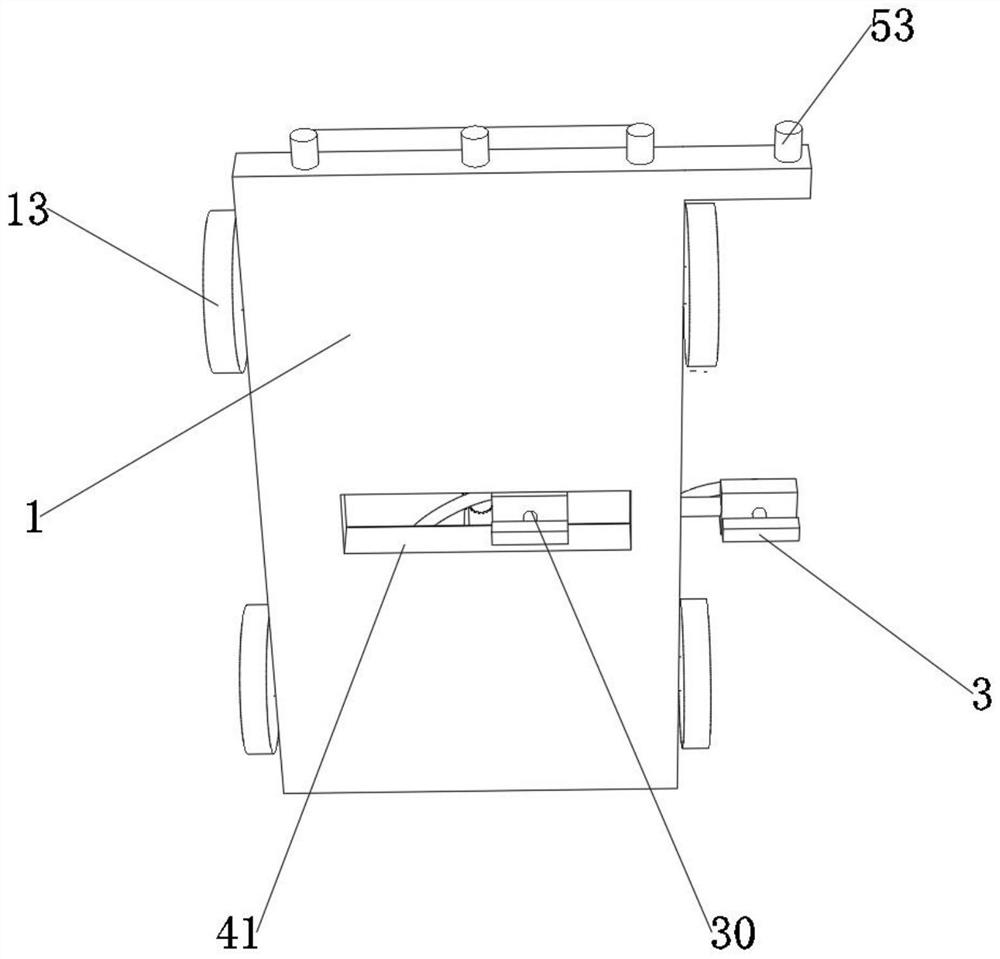

InactiveCN110258283AAchieve sprayingReduce labor intensityRoads maintainenceDrive wheelSpray coating

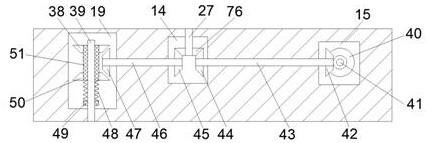

The invention discloses a gap spray coating device. The gap spray coating device comprises a driving wheel, a speed reducer, a left guide pipe and a rotary pipe, wherein one end of the driving wheel is connected with a bottom plate, and the other end of the driving wheel is provided with a first belt pulley; the speed reducer is arranged on the bottom plate, and the power input end of the speed reducer is provided with a second belt pulley; the second belt pulley and the first belt pulley are sleeved with a driving belt; the power output end of the speed reducer is connected with a speed reduction wheel; the left guide pipe communicates with a right guide pipe; the rotary pipe is arranged between the left guide pipe and the right guide pipe. Through arrangement of the driving wheel, the gap spray coating device records the moving distance of a road marking machine and transmits the moving distance to the speed reducer. The speed reducer drives the rotary pipe to rotate, so that the rotary pipe communicates with the left guide pipe and the right guide pipe at a full line to implement spray coating on the marking line and closes the left guide pipe and the right guide pipe at a dotted line to stop marking coating. There is no need to manually and repeatedly place markers and turn on and turn off a valve. The labor intensity is greatly reduced. The spray coating efficiency is improved.

Owner:安徽劲帆建设有限公司

A spraying device for a road marking machine

InactiveCN108978425AHeight adjustableSolve the problem that the height of the push handle cannot be adjustedRoads maintainenceSpray nozzleRoad surface

Owner:亚建科技有限公司

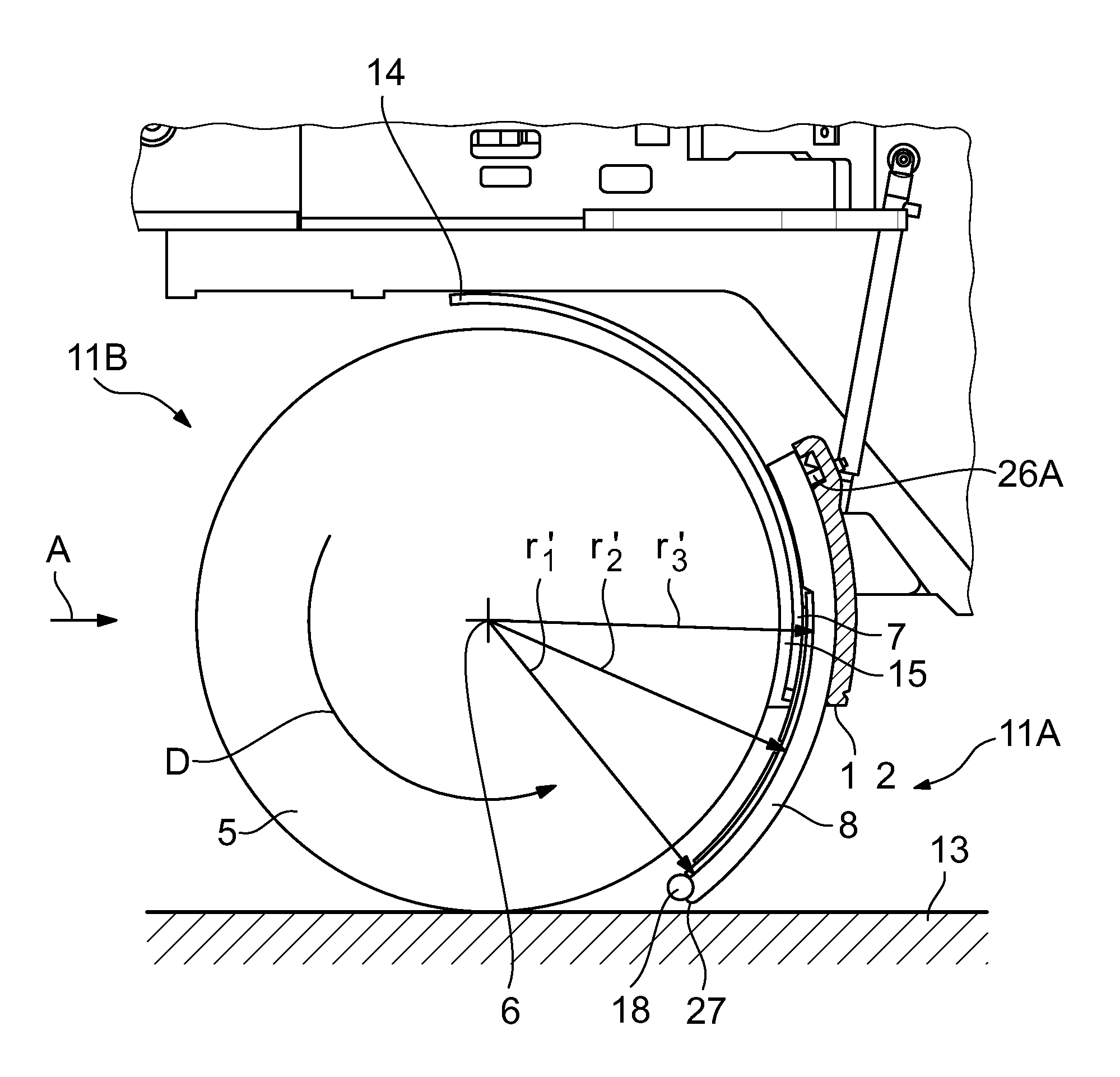

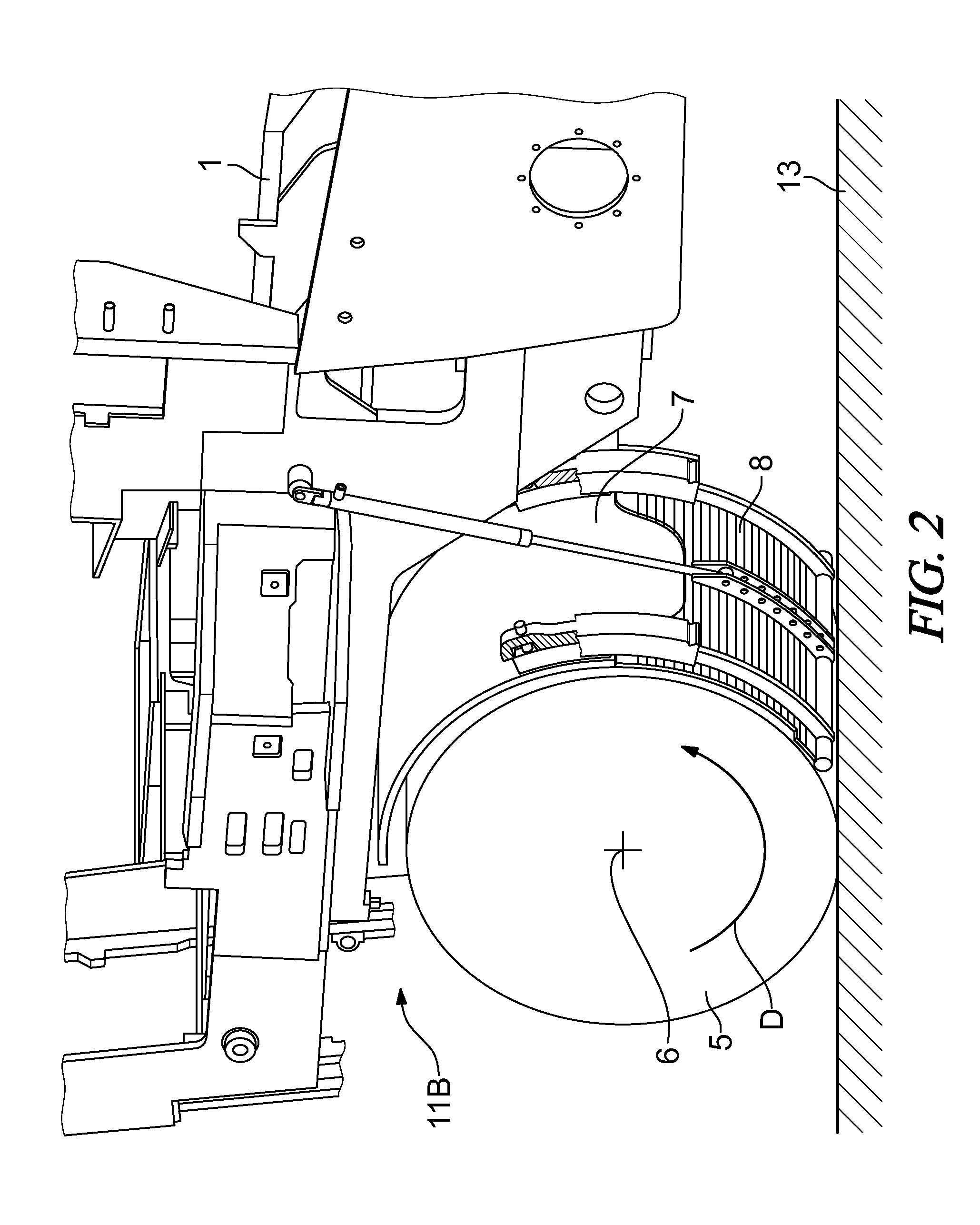

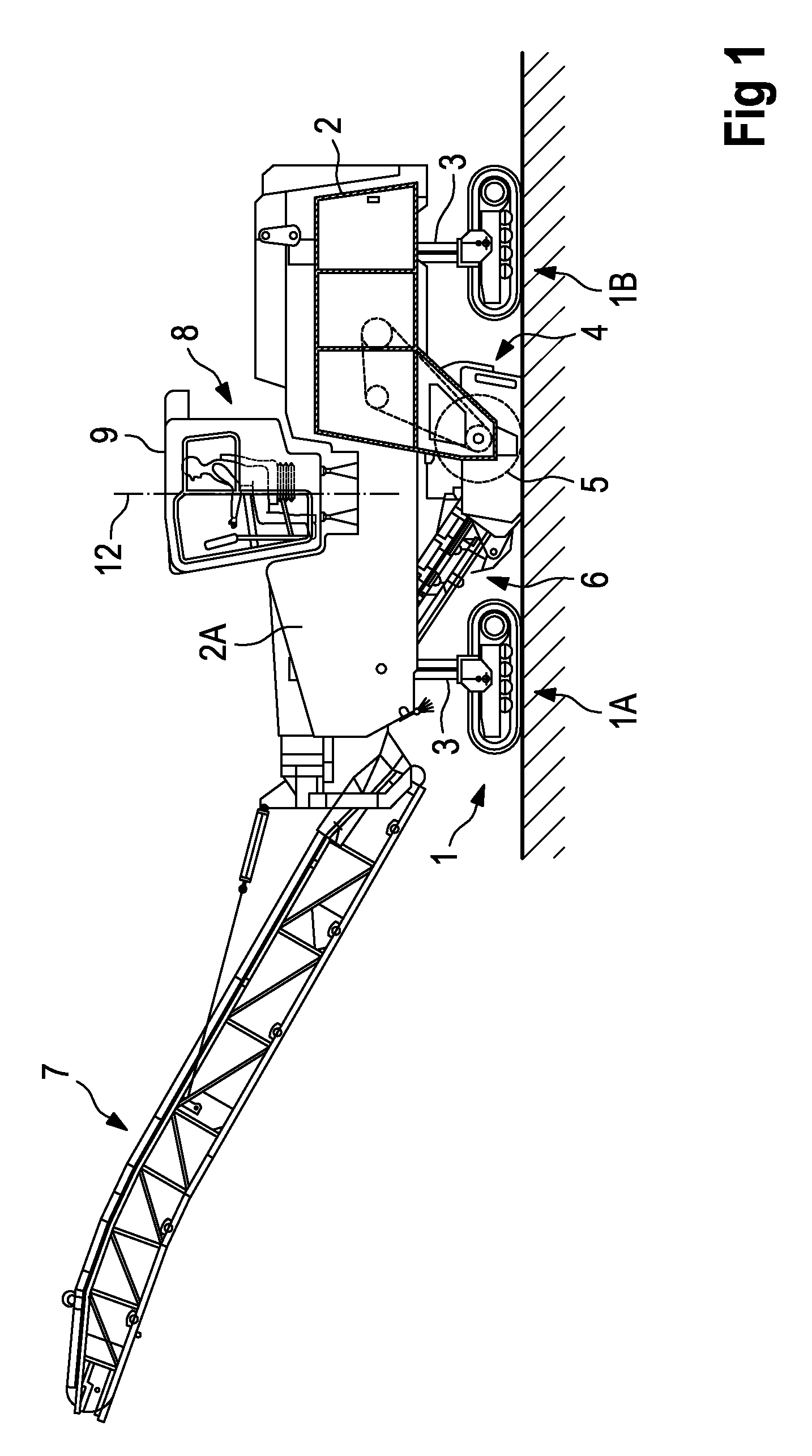

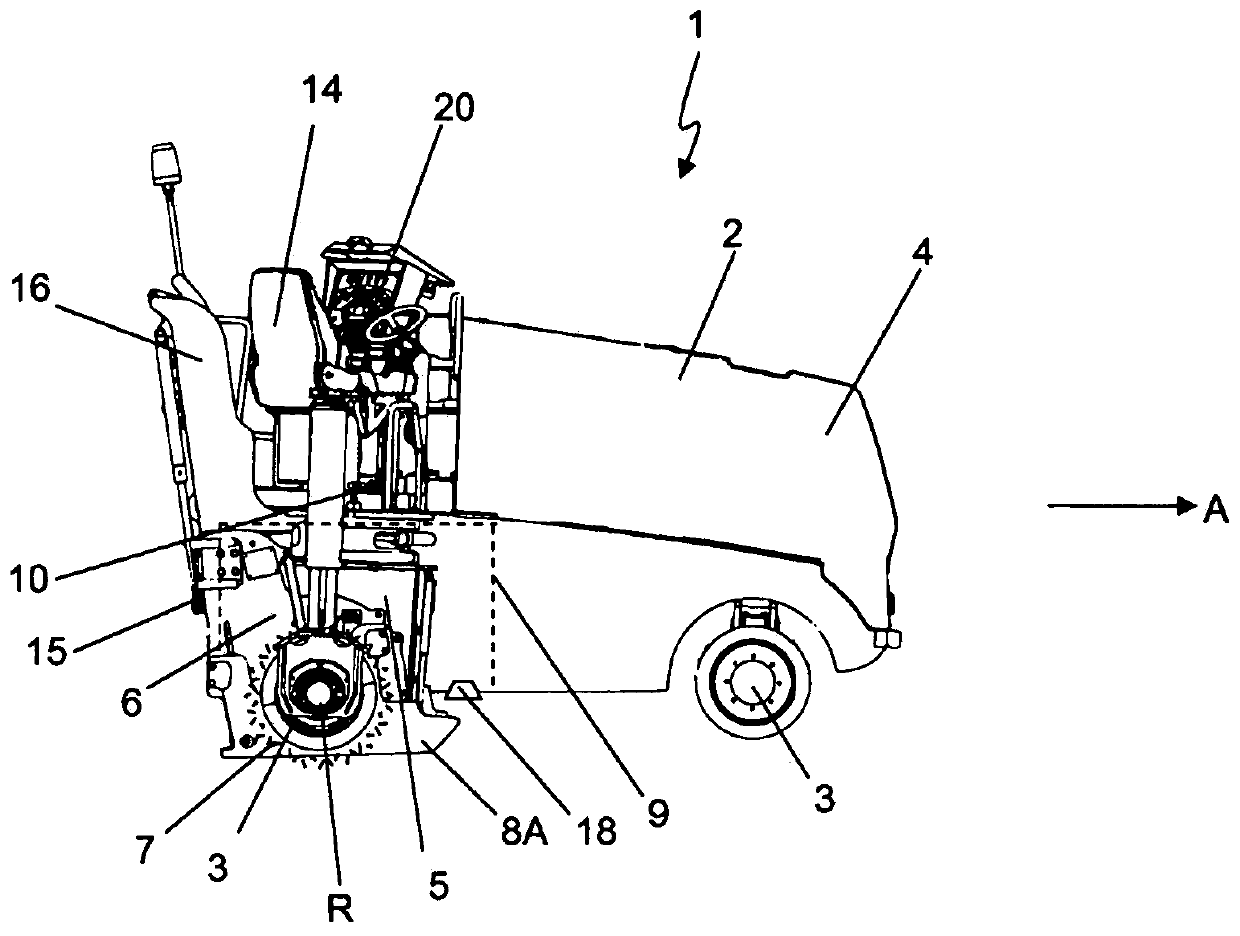

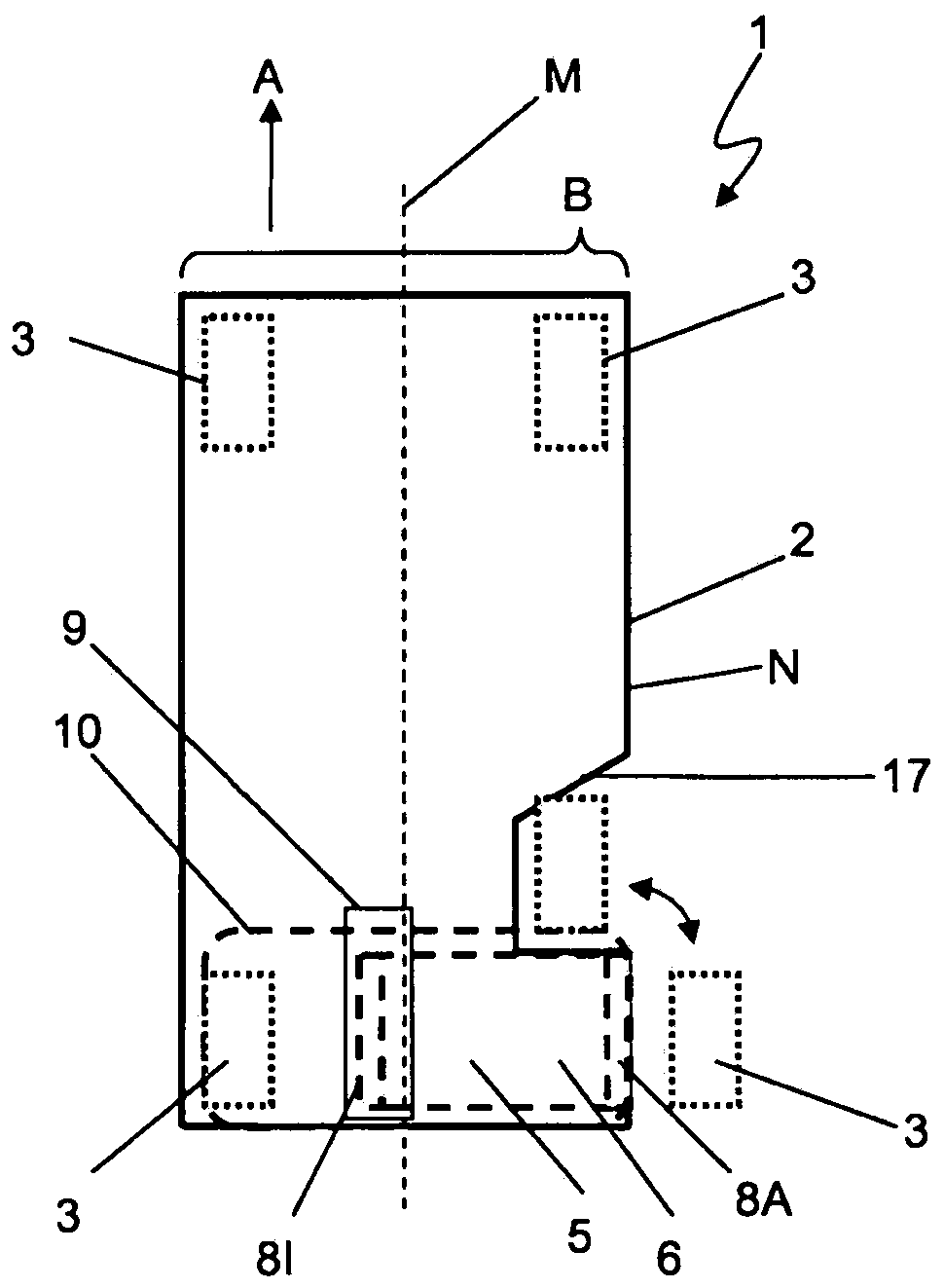

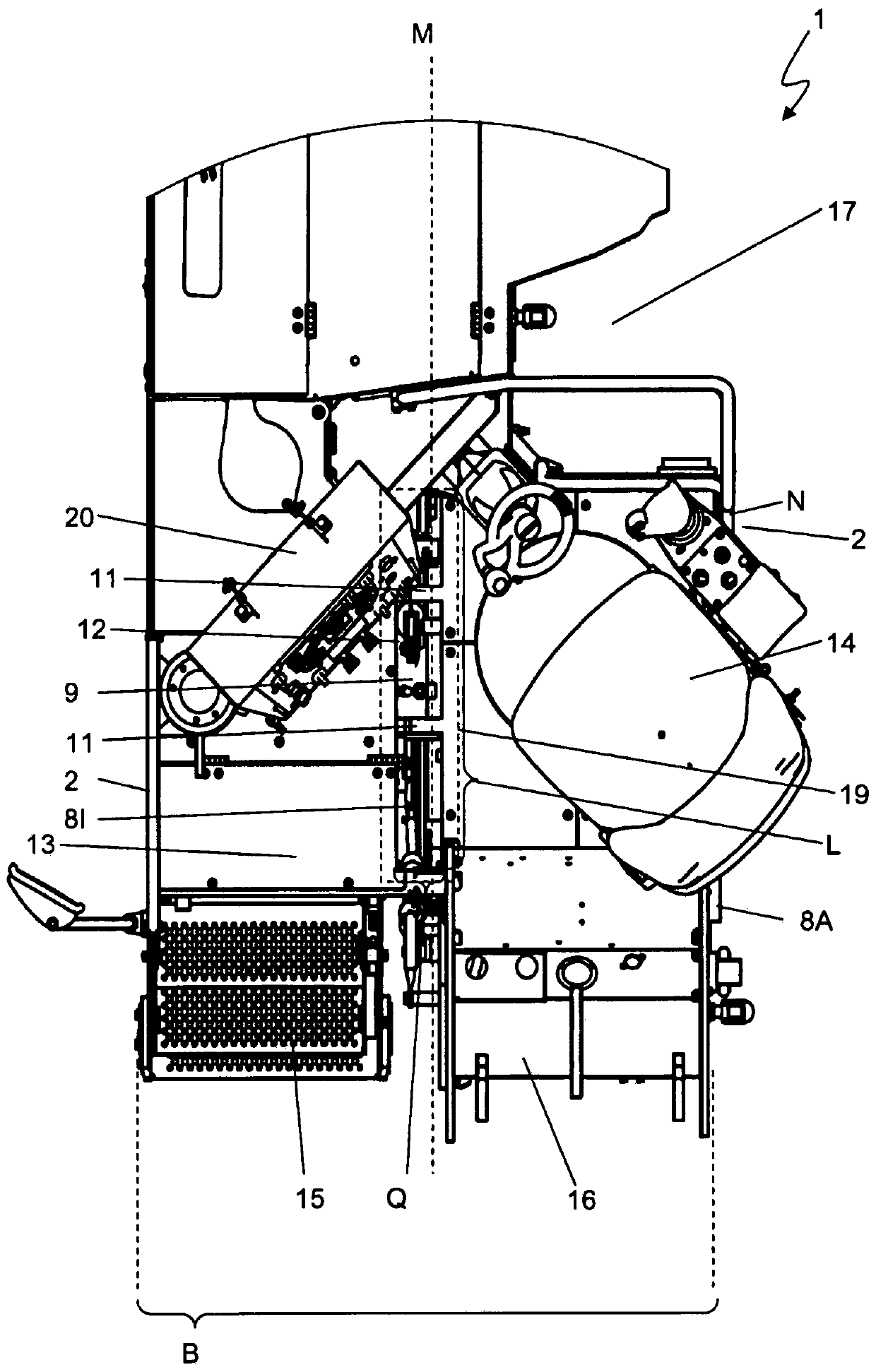

Road milling machine

The application relates to a road milling machine (1) having a machine frame (2), driving devices (3) connected to the machine frame, a drive motor (4), a driver's station (10), and a road milling apparatus (5) comprising a road milling drum (7) and a milling drum box (6) surrounding the latter and having height-adjustable side shields (8A, 8I) which are arranged transversely to the rotation axis(R) of the road milling drum. An outer side shield (8A) terminates substantially flush with an outer side of the machine frame, and an inner side shield (8I) is offset towards the longitudinal center(M) of the machine from an opposite outer side. An essential concept of the application consists in that a viewing shaft (9) is present so that the inner side shield and / or a road area in front of theinner side shield in the working direction (A) is at least partially visible from the driver's station.

Owner:BOMAG

Road marking machine

PendingCN113774777AIncrease storage spaceImprove efficiencySpraying apparatusRoad cleaningStructural engineeringIndustrial engineering

The invention belongs to the technical field of road marking devices, and particularly relates to a road marking machine. The road marking machine comprises a bottom plate, a push frame is installed on the rear side of the bottom plate, moving wheels are installed on the two sides of the bottom plate, a stirring mechanism, an adjusting mechanism and a cleaning mechanism are sequentially installed on the top of the bottom plate, a first spraying assembly is installed on one side of the bottom plate, and a second spraying assembly is mounted at the bottom of the adjusting mechanism; through cooperation of the stirring mechanism and the first spraying assembly, dyes of different colors can be rapidly switched for spraying, and through cooperation of the stirring mechanism, the adjusting mechanism and the second spraying assembly, two marked lines can be sprayed at the same time. According to the device, by arranging the stirring mechanism, dyestuff of different colors can be added into the two storage boxes correspondingly, when lines of different colors need to be sprayed, a worker only needs to detach a hose from a connector of one discharging box and connect the hose with a connector of the other discharging box, and the lines of different colors can be sprayed through a spray gun.

Owner:河北水利电力学院 +1

Fusion scribing machine for highway engineering

PendingCN112211082AQuality improvementRoad cleaningRoads maintainenceAgricultural engineeringAir blower

The invention relates to the technical field of road marking machines, and discloses a highway engineering fusion marking machine which comprises a fusion marking machine body, walking wheels are fixedly installed on the bottom faces of the two sides of the fusion marking machine body, a transmission roller assembly is arranged on one sides of the walking wheels, and the surface of the transmission roller assembly is fixedly sleeved with a flexible sleeve. A brush strip is fixedly connected to the surface of the flexible sleeve, a belt transmission mechanism is movably installed between the transmission roller assembly and the walking wheel, and a supporting frame is fixedly installed on the side face of one side of the fusion scribing machine body. Airflow is forcibly generated through asmall air blower, a tubular channel composed of a first ventilation valve pipe, a transition box, a first receding groove, a main air conveying pipe and an air expanding pipe is used in cooperation, the airflow is conveyed to a to-be-marked area on a road, and preliminary non-contact pre-cleaning operation is conducted on residual dust on the to-be-marked area on the road, and the quality of subsequent scribing operation of the device is improved.

Owner:侯义柱

Improved self-service road marking machine

InactiveCN104762870BControl arcIntelligently change the speedRoads maintainenceLaser transmitterDrive wheel

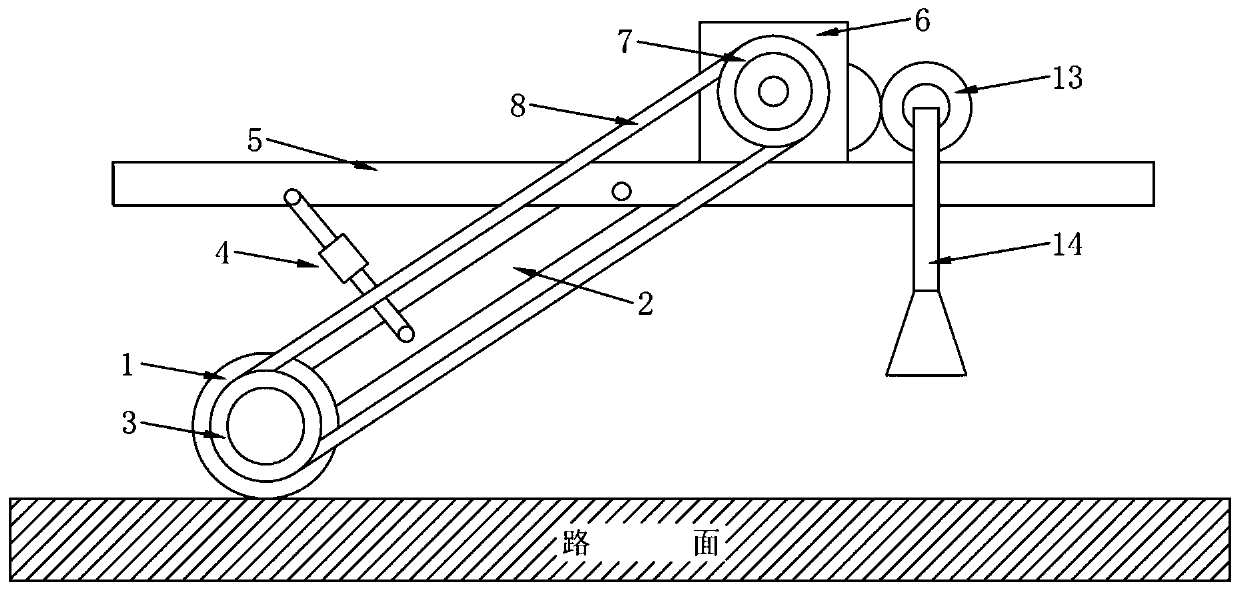

The invention relates to an improved automatic road line marker. The improved automatic road line marker comprises a road line marker body, a paint barrel, a glass bead barrel, and a left driving wheel and a right driving wheel connected to a driving motor electrically. Laser transmitters having vertically downward transmitting terminals are installed on the left and right sides of the body symmetrically. Laser receivers are also mounted next to the laser transmitters. The two laser receivers are coupled with a control chip. The control chip is coupled with an operating panel and the driving wheels. By adopting the improved automatic road line marker, standard straight lines and arcs can be efficiently drawn, firmness and flatness of paint adhered on the ground can be improved. The improved automatic road line marker is especially suitable for being used in areas such as mountain areas with poor road conditions and for drawing boundary traffic lines.

Owner:张黎 +24

Micro bead spray gun for pavement marker

The invention provides a micro bead spray gun for a pavement marker, which comprises a gun body, a dispersing nozzle arranged at a port at the front end of the gun body, a bead inlet pipe arranged atthe front end of the gun body, an air inlet pipe arranged at the rear end of the gun body, a gun mount arranged on the inner wall of the front end of the gun body and communicated with the air inlet pipe, and a nozzle movably connected with the front end of the gun mount; an annular spray tank communicated with the bead inlet pipe is arranged between the nozzle and the inner wall of the gun body;the gun body is provided with a spanner in screw connection; and an air control valve controlled by the spanner is arranged between the gun mount and the air inlet pipe. The micro bead spray gun can effectively adjust the consumption of micro beads, has high fineness and saves raw materials.

Owner:朱建新

Automatic road marking machine and implementation method

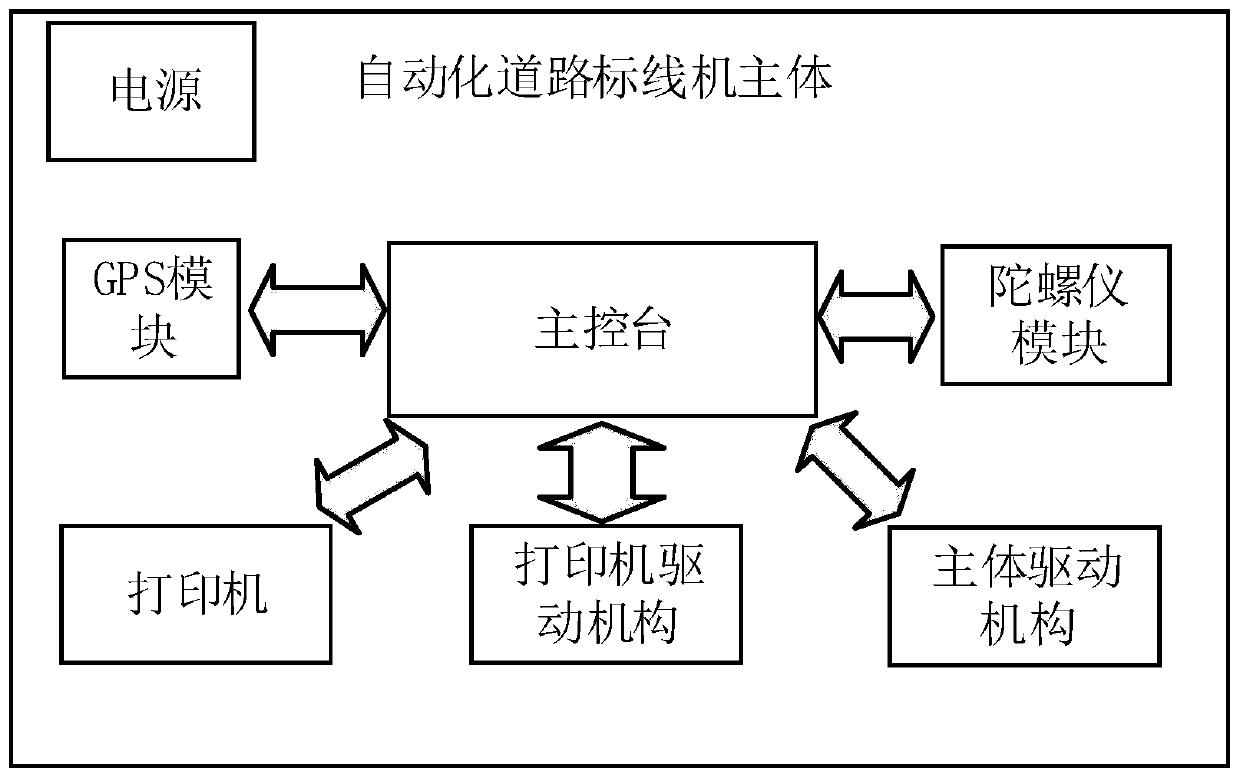

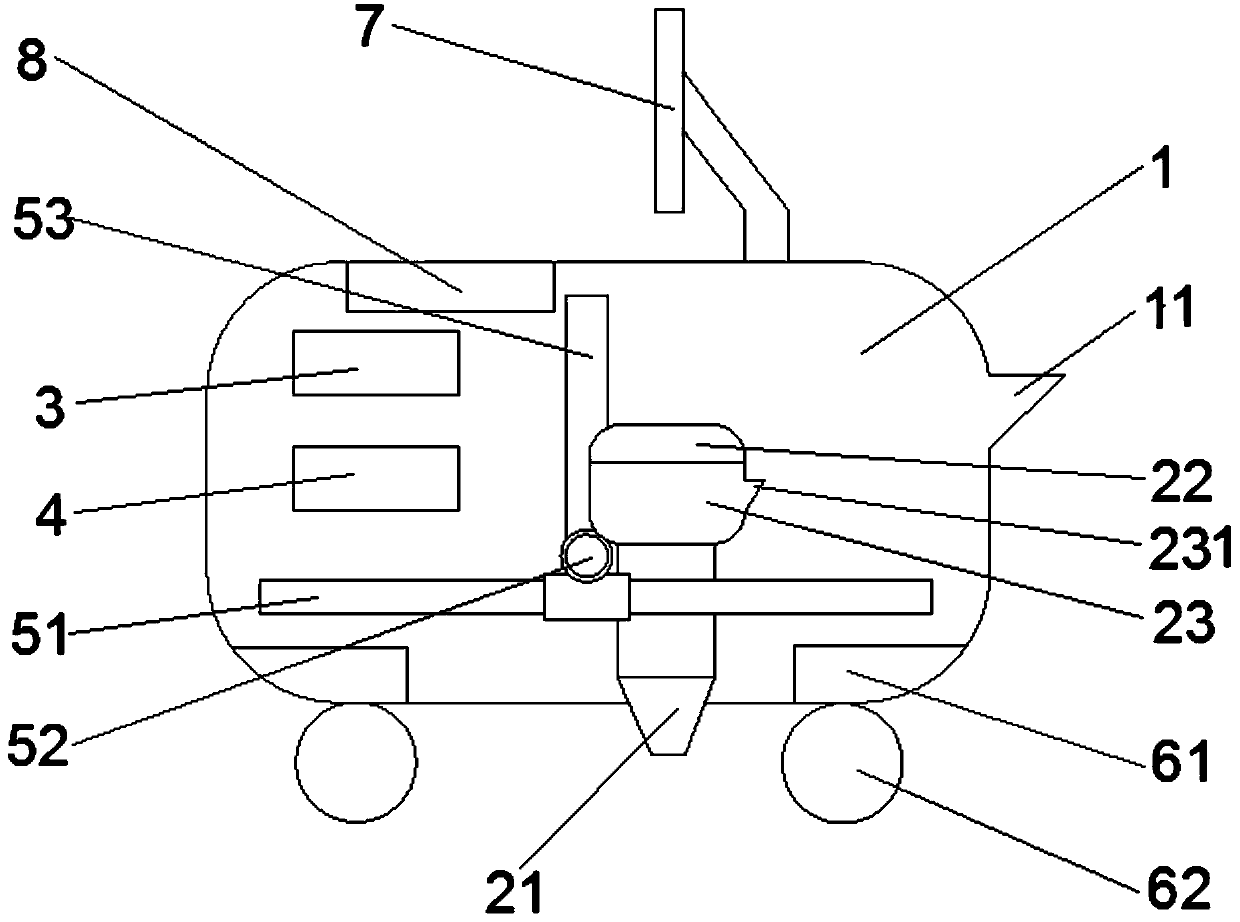

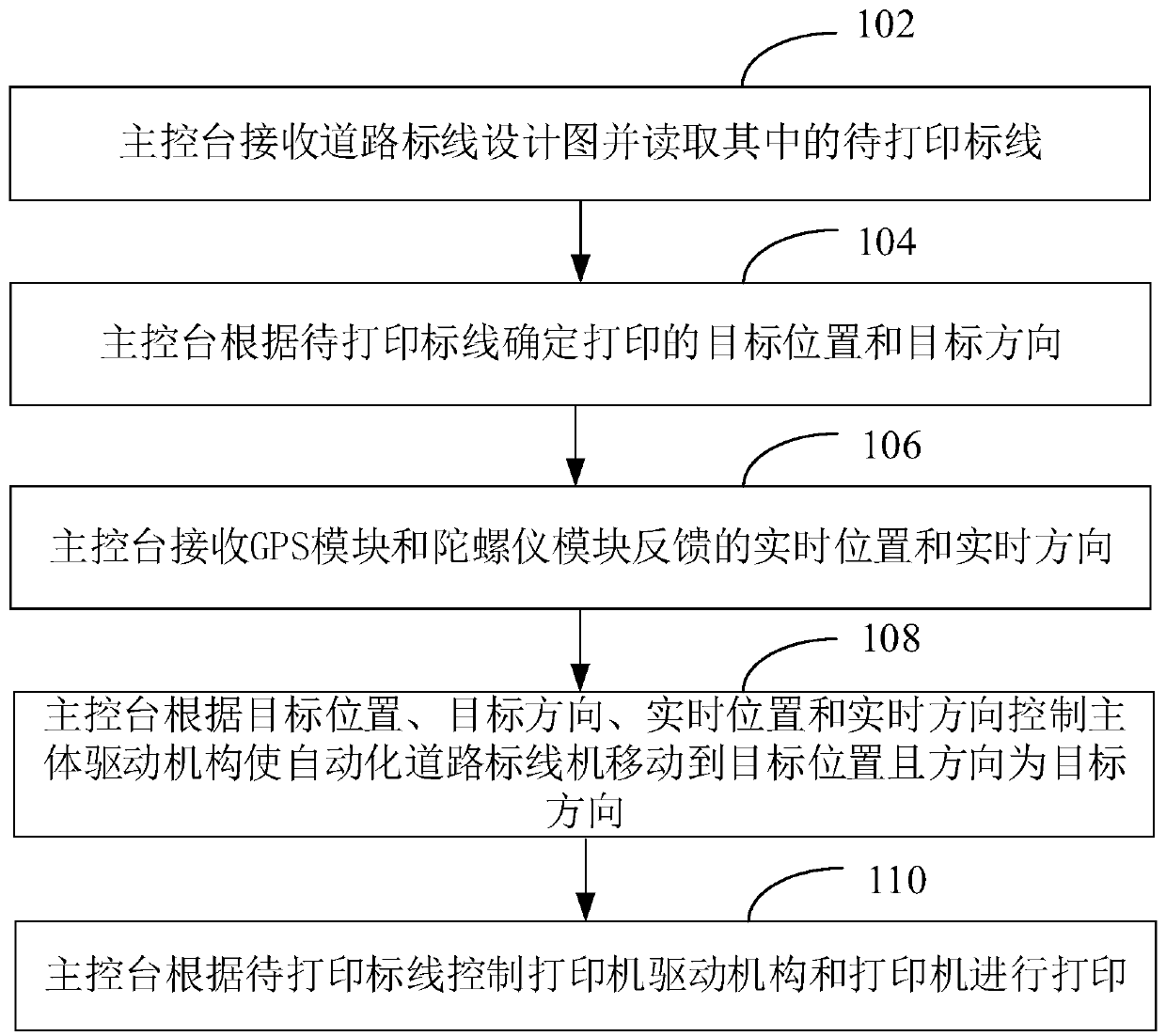

PendingCN111549640AFully automatedImprove efficiencySatellite radio beaconingRoads maintainenceComputer hardwareAutomatic control

The invention provides an automatic road marking machine. The automatic road marking machine comprises a main body, and a printer, a GPS module, a gyroscope module, a printer driving mechanism, a mainbody driving mechanism, a main console and a power supply which are mounted on the main body, the main console is connected with the GPS module, the gyroscope module, the printer, the printer drivingmechanism and the main body driving mechanism. And the main console is used for receiving the road marking design drawing and controlling the GPS module, the gyroscope module, the printer, the printer driving mechanism and the main body driving mechanism to operate to finish printing of a to-be-printed marking in the road marking design drawing. The GPS module and the gyroscope module are adopted, so that the marking machine can be accurately positioned, and the full automation of road marking is realized under the automatic control of the main console in cooperation with the printer, the printer driving mechanism and the main body driving mechanism. The road marking efficiency and precision are improved, and a large amount of labor cost is saved. In addition, the invention further provides an implementation method of the automatic road marking machine.

Owner:重庆新创科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com