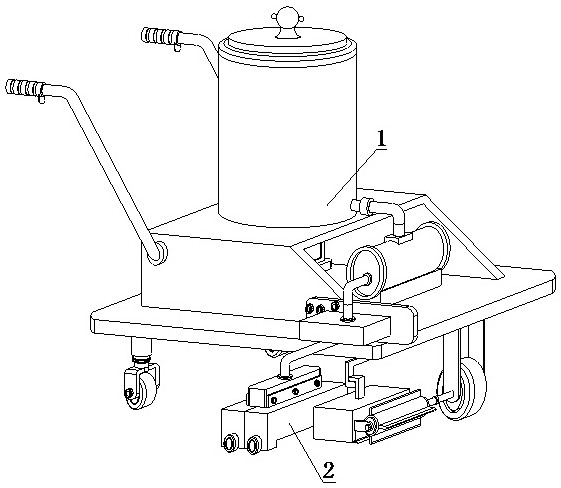

Road marking machine with splash-proof mechanism for highway engineering and implementation method thereof

A marking machine and road technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of messy road markings, hindering paint spraying operations, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

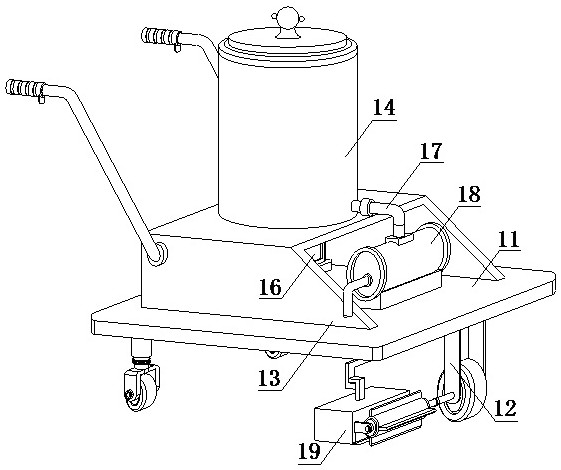

[0041] In order to better demonstrate the road marking machine with anti-splash mechanism for highway engineering, this embodiment now proposes an implementation method for road marking machine with anti-splash mechanism for highway engineering, including the following steps:

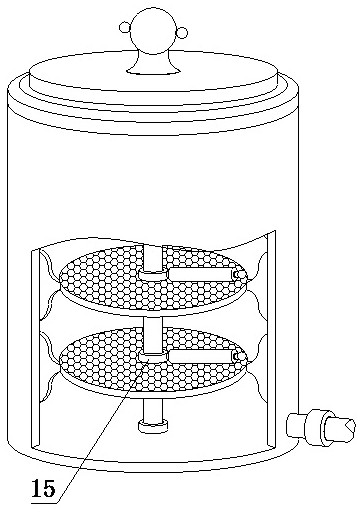

[0042] Step 1: Put the marking paint in the paint bucket 14, start the drive motor 16 to drive the rotating shaft 151 to rotate, cooperate with the drain plate 152 to drive the stirring blade 153 and the comb teeth 154 to stir the paint, stir properly when the temperature is high, and continue to stir when the temperature is low. Use the friction sleeve 157 to fit the leakage plate 152 to frictionally rotate to generate heat to keep the paint warm and prevent it from coagulating due to low temperature;

[0043] Step 2: Push the equipment to walk along the road operation point. When walking, the roller 12 on the same side of the pressure pump 18 rolls and cooperates with the transmission shaft 198 to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com