Automatic deviation-rectifying concrete road spreading and road marking machine

A technology for concrete roads and automatic deviation correction, which is applied in the direction of roads, roads, road repairs, etc. It can solve problems that affect construction progress, long construction period, time-consuming and laborious, etc., and achieve the effects of ensuring construction quality, reducing construction costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

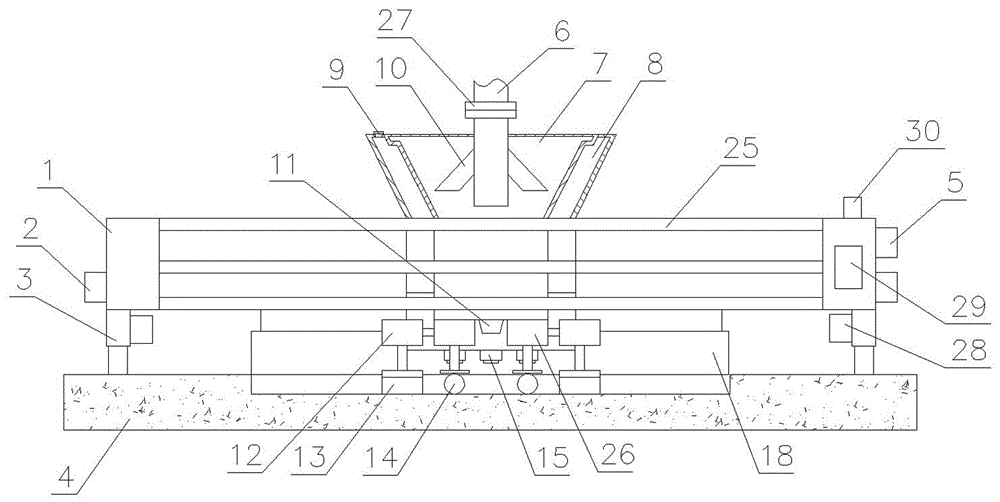

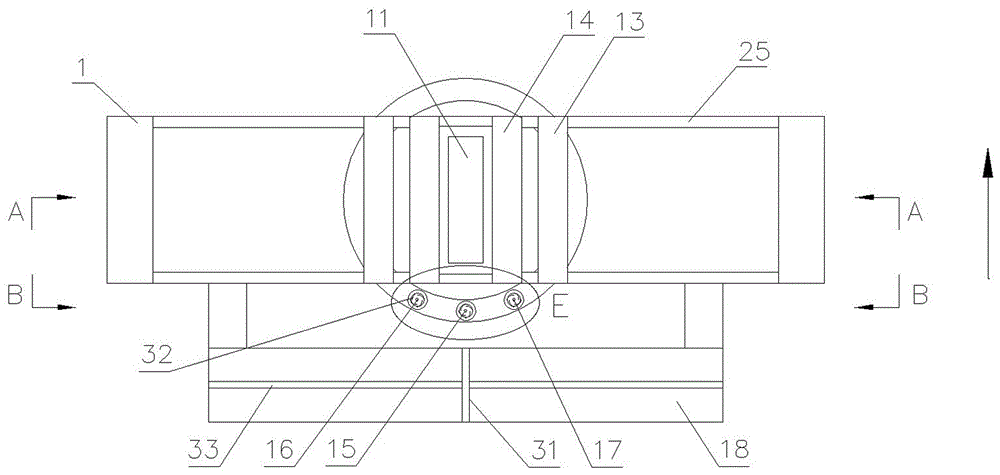

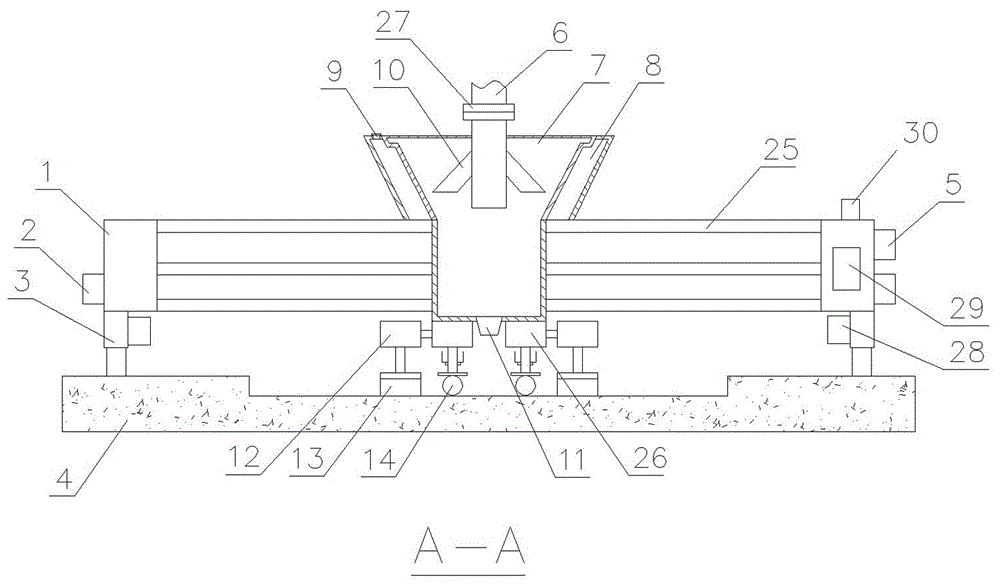

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] as attached Figure 1-10 As shown, an automatic deviation correcting concrete road paving and road marking machine includes a truss 1, a concrete hopper 7 arranged on the truss 1 through a traverse track 25, a feed pipe 6 connected to the concrete hopper 7, and a The discharge port 11 at the lower end of the concrete hopper 7, the cage lifting control device 26 which is arranged at the lower end of the concrete hopper 7 and is fixedly connected with the discharge port 11, is arranged at the lower end of the concrete hopper 7 and is fixedly connected with the discharge port 11 as a whole The vibrating lifting control device 12, the material feeding stirring cage 14 connected to the stirring cage lifting control device 26, the vibrating device 13 connected to the vibrating lifting control device 12, the walking wheel 3 arranged under the truss 1, the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com