Patents

Literature

386 results about "Contraction joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contraction joints are planes, usually vertical separating concrete in a structure or a pavement placed at a designed location. Contraction joint is placed in such a way that it interferes least with the performance of the structure as well as prevents formation of objectionable shrinkage cracks elsewhere in concrete. Contraction Joint in Pavement.

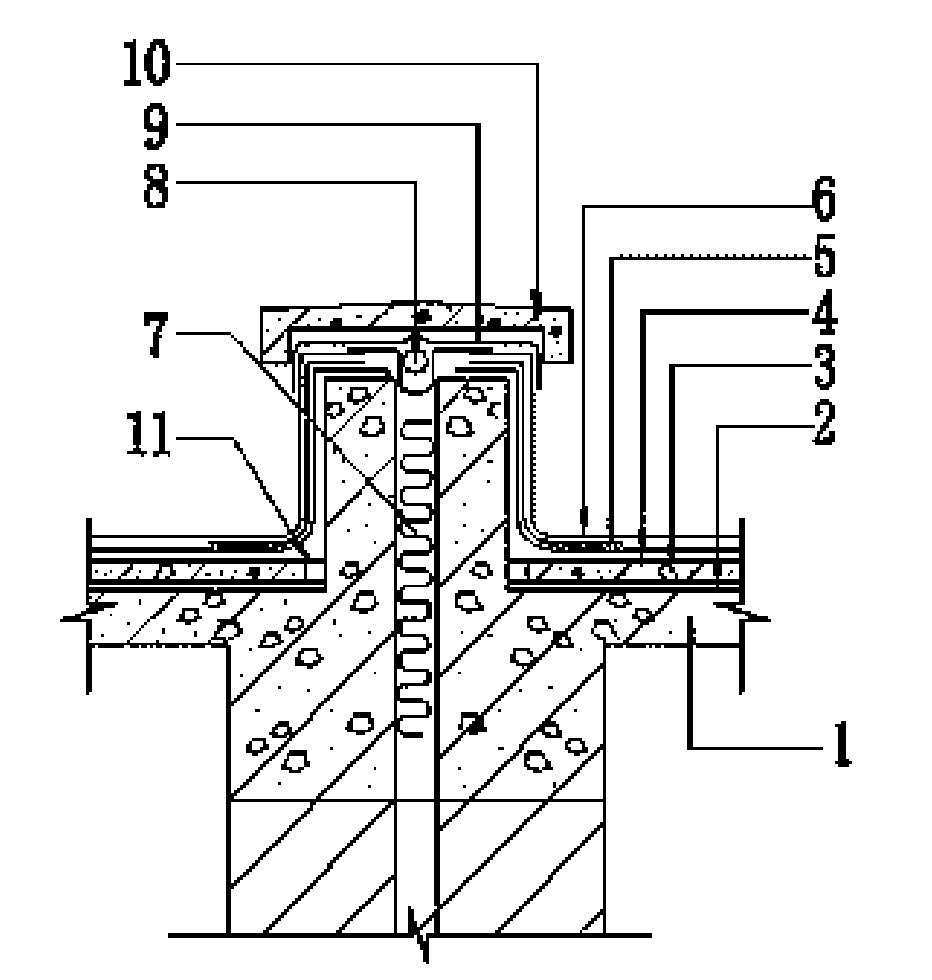

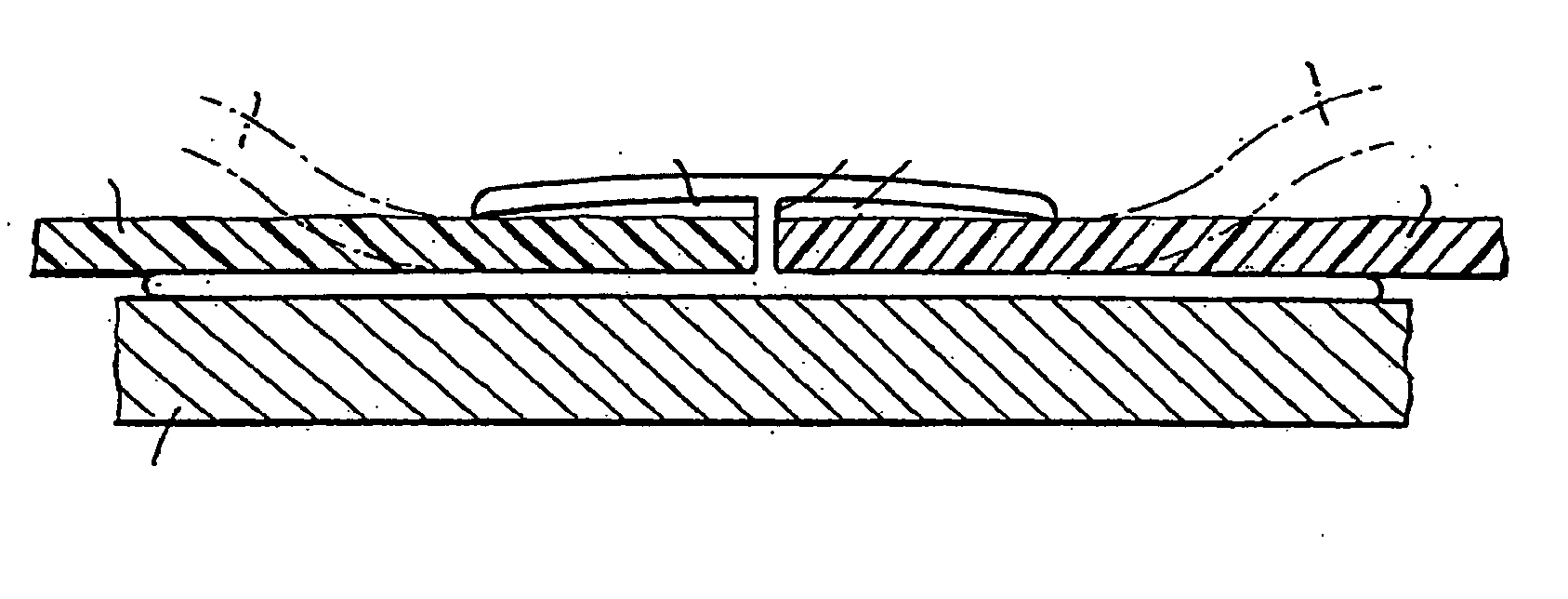

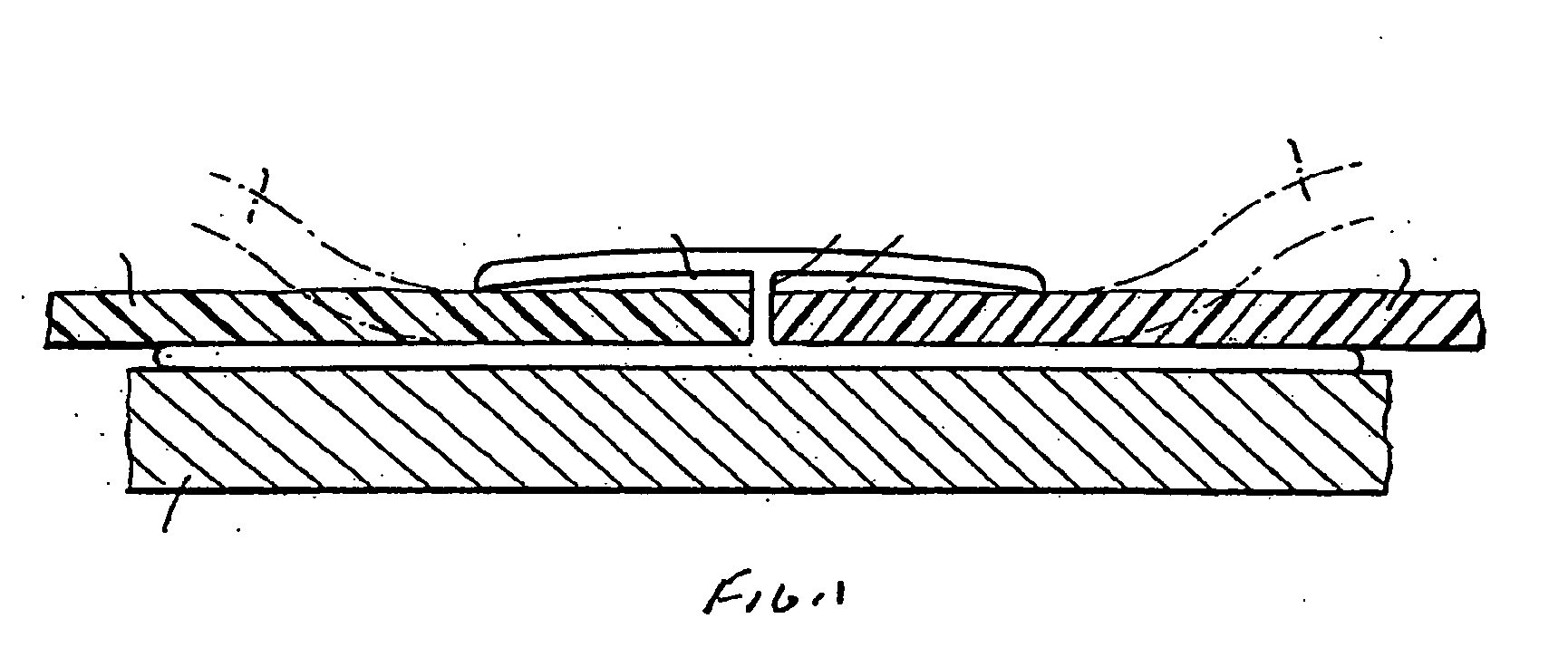

Vertical water-stop structure for concrete engineering expansion joint as well as manufacturing and construction methods for same

InactiveCN103774699ASolve the leakLow costArtificial islandsUnderground chambersUnderwaterEngineering

The invention relates to an underground (underwater) building waterproof device, and in particular to a vertical water-stop structure for a concrete engineering expansion joint as well as a manufacturing and construction methods for the same. The vertical water-stop structure comprises a deformation sheet and channel steel, and is characterized in that the deformation sheet is longitudinally arranged, one half is pre-buried in first-stage concrete, the other half is bulged out of a concrete section and externally arranged in a rectangular channel steel opening, and the channel steel is provided with a fixing element and filled with maltha; the surface of the channel steel opening and the section of the first-stage concrete are provided with asphalt felts at the both sides of the deformation sheet, the exposed fixing element is detached after asphalt is cooled, and then second-stage concrete is arranged. According to the vertical water-stop structure disclosed by the invention, the problem of water seepage of a water conservancy project due to the differential settlement or diastrophism of a stratum can be solved, and moreover, labour can be saved and construction period can be shortened.

Owner:福建九鼎建设集团有限公司

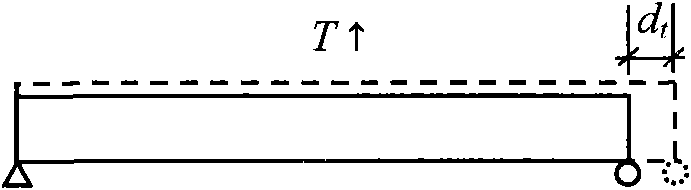

Intelligent diagnosis method for bridge telescopic seam injury based on girder end longitudinal displacement

InactiveCN101782372AReduce in quantitySimple methodOptically investigating flaws/contaminationUsing optical meansControl lineLong term monitoring

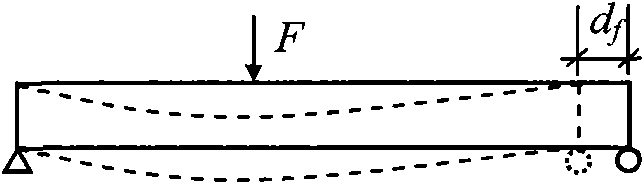

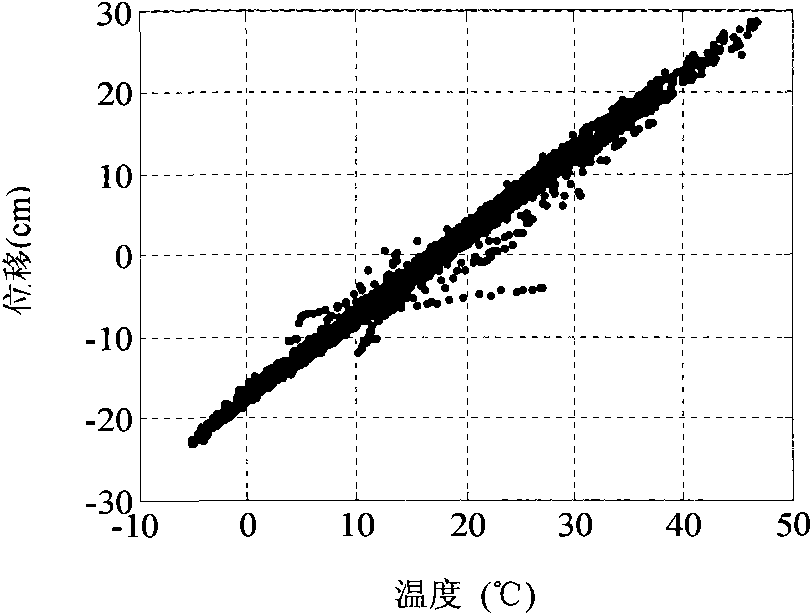

The invention relates to an intelligent diagnosis method for bridge telescopic seam injury based on girder end longitudinal displacement. The long-term monitoring data of main girder longitudinal displacement, temperature and vertical acceleration after a bridge is built are obtained by mounting a small number of sensors on the bridge; a relevance model of the main girder longitudinal displacement, the bridge temperature and the vertical acceleration in a healthy state is established step by step; the influence of the main girder temperature and the vertical acceleration on the longitudinal displacement can be eliminated on the basis of the relevance model, and the environment condition uniformization displacement which can reflect a working state of a telescopic seam is obtained. When the method is applied to the injury diagnosis of the telescopic seam, the monitoring data in an unknown state are processed just by adopting the established relevance model, and finally, the environment condition uniformization displacement of the healthy state and the unknown state is simultaneously input into a mean value control map; and if the telescopic seam generates injury, a sample point of the control map can exceed a control line, thereby realizing the intelligent recognition on the injury of the telescopic seam.

Owner:SOUTHEAST UNIV

Stress-controller multi-level-open anchor stock and anchor construction method

ActiveCN106759326AShorten the lengthIncrease anchoring forceExcavationsBulkheads/pilesEngineeringProcess requirements

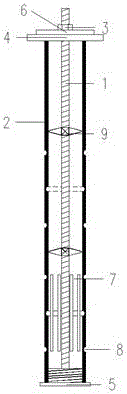

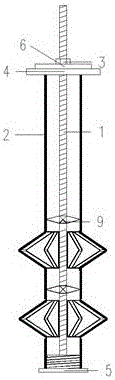

The invention discloses a stress-controller multi-level-open anchor arm and an anchor construction method. The stress-controller multi-level-open anchor arm comprises a screw rod. A base is fixed to an anchoring end. A free end passes a pallet. The space between the pallet and the end portion of the free end is the free section of the screw rod. The screw rod section between the pallet and the base forms the anchoring section. Adjusting screw nuts are screwed in the free section. A sleeve pipe is mounted on the anchoring section in a sleeving mode. M expansion seams which are in parallel with the axial direction of the screw rod are formed in the sleeve pipe to make M stripes be formed between the expansion seams. Z grooves are formed in each stripe. Two adjacent grooves on a same stripe are separately arranged in the inner wall and outer wall of the sleeve pipe in a crisscrossing mode. The stress-controller multi-level-open anchor stock has the advantages of being good in anchoring effect, small in use amount, low in process requirement, strong in anti-pulling capacity and the like. The method comprises the steps of assembling anchor arms, cleaning sites, drilling holes, cleaning holes, installing anchor arms, grouting and the like. The method has the advantages of being fast in construction speed, simple in process procedure and the like.

Owner:CHONGQING UNIV +1

Sectional cutting and overall craning method for supporting beam in deep foundation pit multilayered reinforced concrete

ActiveCN103510523AImprove turnover rateGuaranteed Quality ControlFoundation testingExcavationsSupporting systemReinforced concrete

The invention discloses a sectional cutting and overall craning method for a supporting beam in deep foundation pit multilayered reinforced concrete. The method comprises the steps of internal force measurement, cutting and dismantling, transferring in the foundation pit, entirely craning of the supporting beam, off-site crushing of the supporting beam and the like. The method is to construct on an underground horizontal thin slab structure without special requirement on the construction platform. A steel pipe supporting system of the underground thin slab structure is not required to be reinforced, but holes and expansion joint positions are reserved for the underground horizontal thin slab to be locally reinforced. When the supporting beam is cut off and dismantled, the steel pipe stand is not required for the lower part. The single input of the steel pipe stand material is greatly reduced on the site, and the steel pipe stand can be dismantled in advance to improve the turnover rate of the steel pipe stand.

Owner:何金城

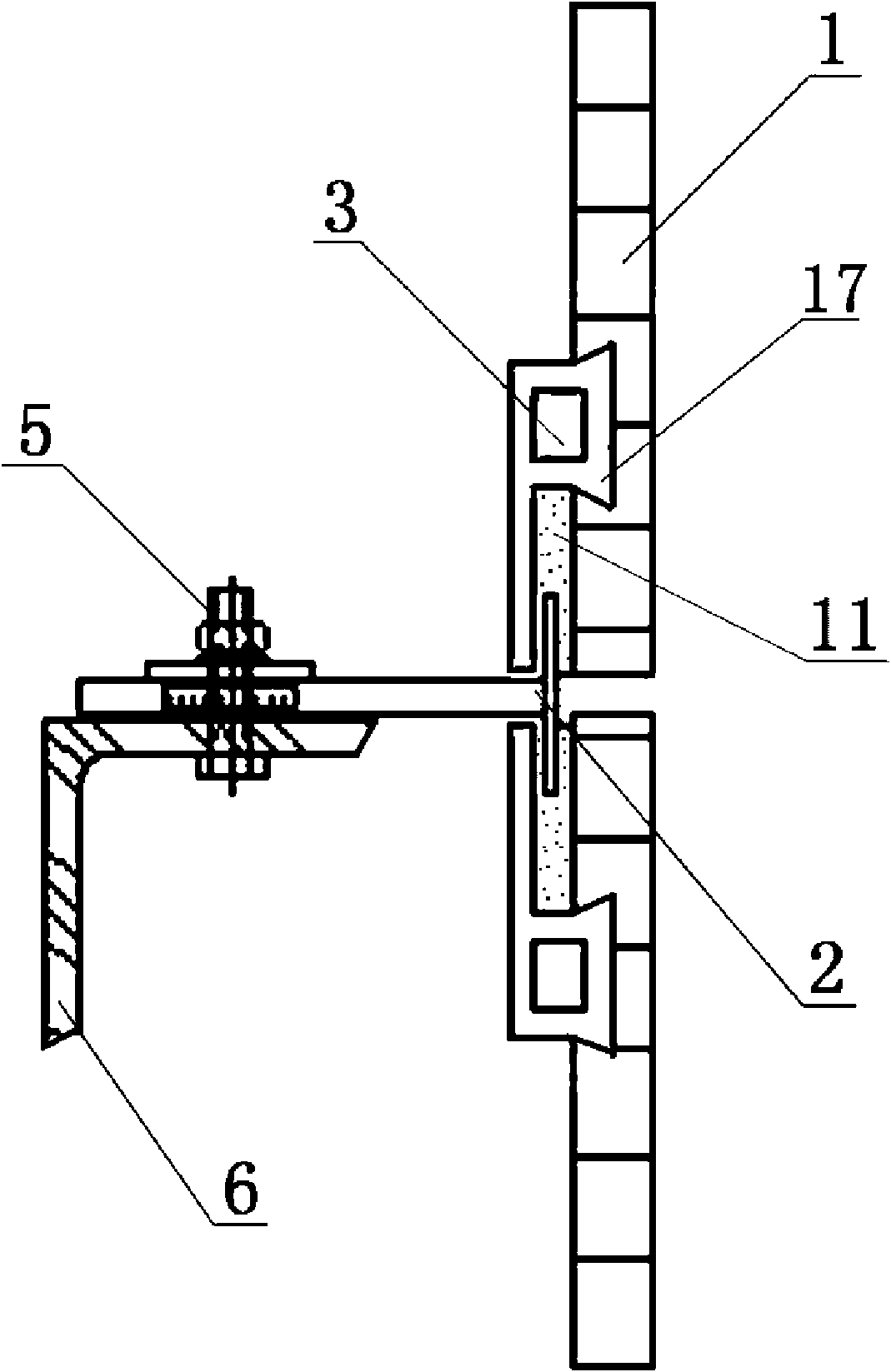

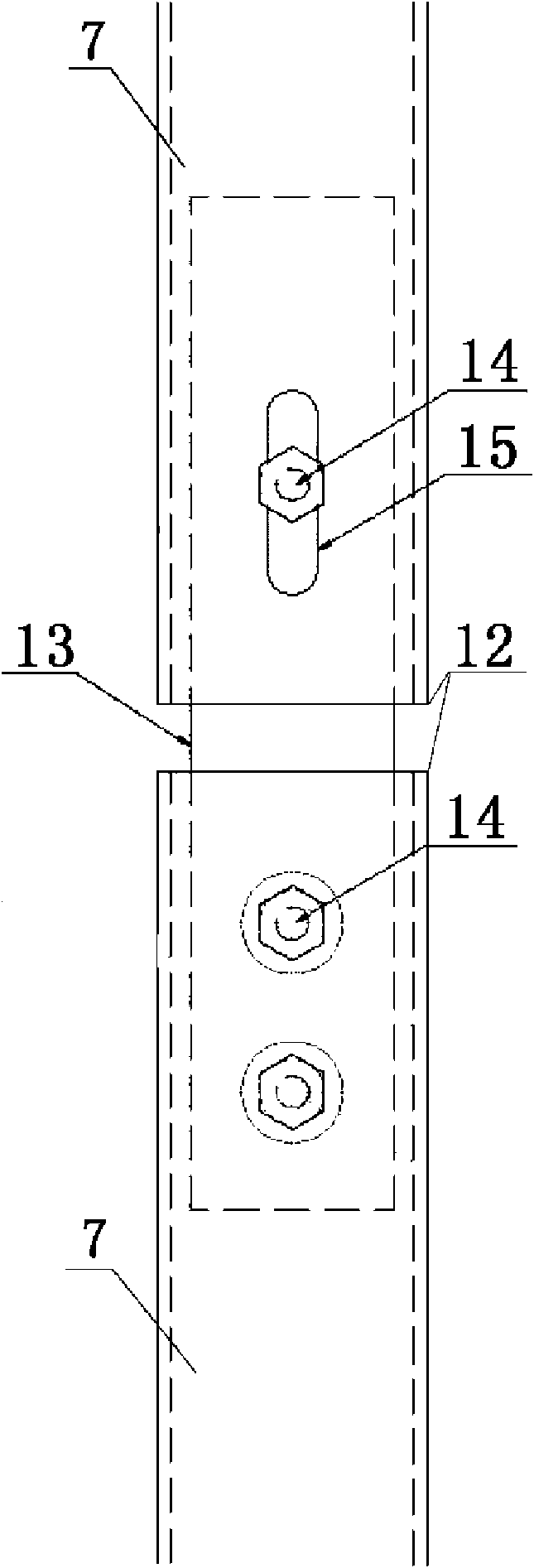

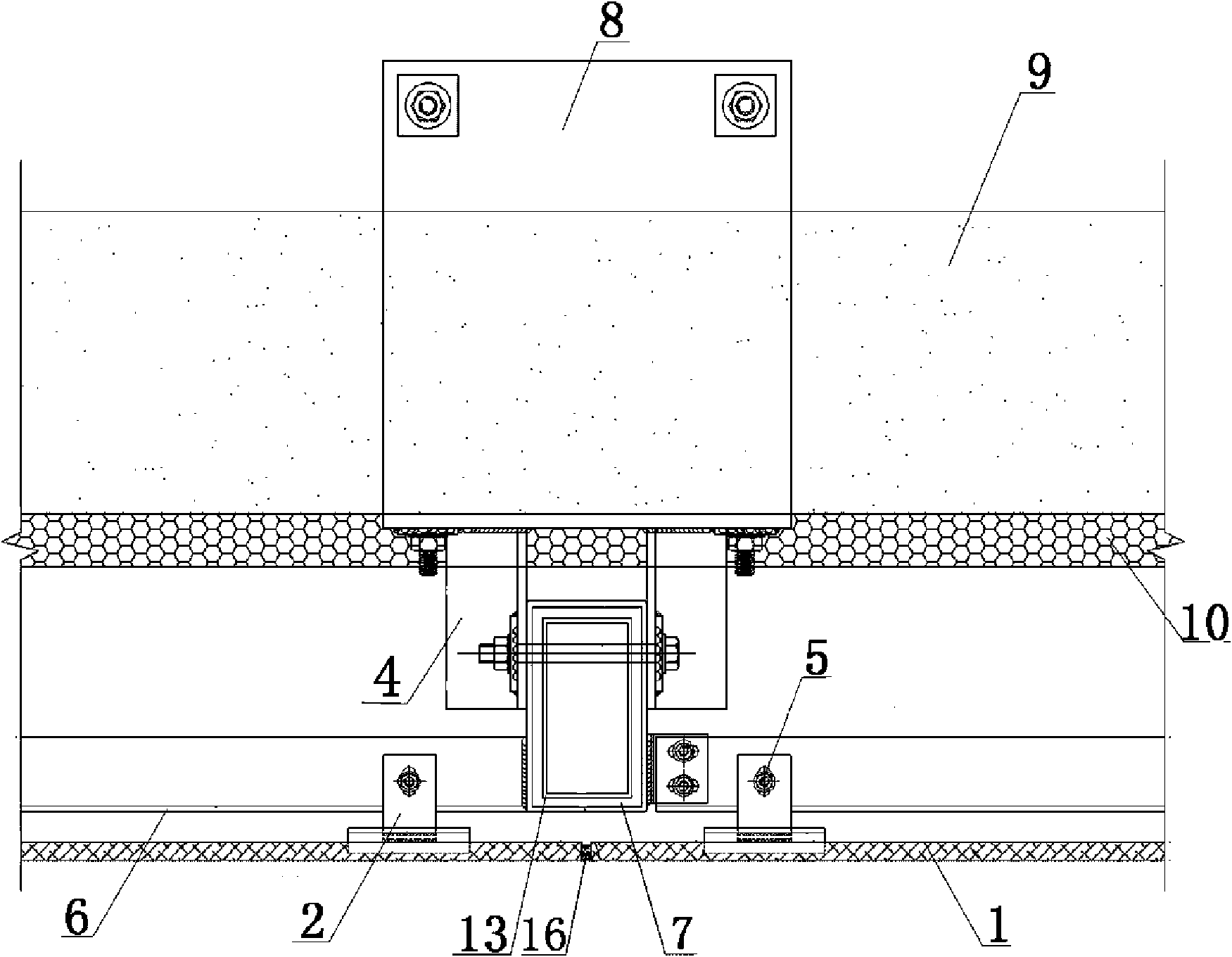

Drily hung vitrolite wall surface decoration system and construction method thereof

InactiveCN101824895ASatisfy self-expanding deformationFulfil requirementsCovering/liningsWallsKeelHigh rise

The invention relates to a drily hung vitrolite wall surface decoration system and a construction method thereof. A main building wall body is connected with a preembedded piece; the preembedded piece is connected with vertical keels through floor connecting pieces; the vertical keels are vertically connected with a transverse keel; the transverse keel is provided with a dilatation joint at each floor; a steel lock pin is inserted between the two vertical keels of the upper part and the lower part of the dilatation joint, one end of the steel lock pin is fixedly connected with a vertical keel through bolts, and the other end is in flexible connection with an oblong hole of the other vertical keel; the back of the vitrolite is provided with at least a pair of dovetail grooves; the dovetail grooves are connected with anchoring pieces in an embedded mode; the heads of the anchoring pieces are clamped into the dovetail grooves at the back of the vitrolite; a cavity for penetrating and anchoring the head of a T-shaped hanging piece is formed between an anchoring plate and the back of the vitrolite; the head of the T-shaped hanging piece extends to the cavity; the cavity is filled with epoxide resin anchoring glue; and a pectoral plate of the T-shaped hanging piece is fixedly connected with the transverse keel through a stainless steel bolt. The invention solves the problem of dry hanging vitrolite wall surface decoration systems on high rise buildings.

Owner:BEIJING CONSTR ENG GRP CO LTD

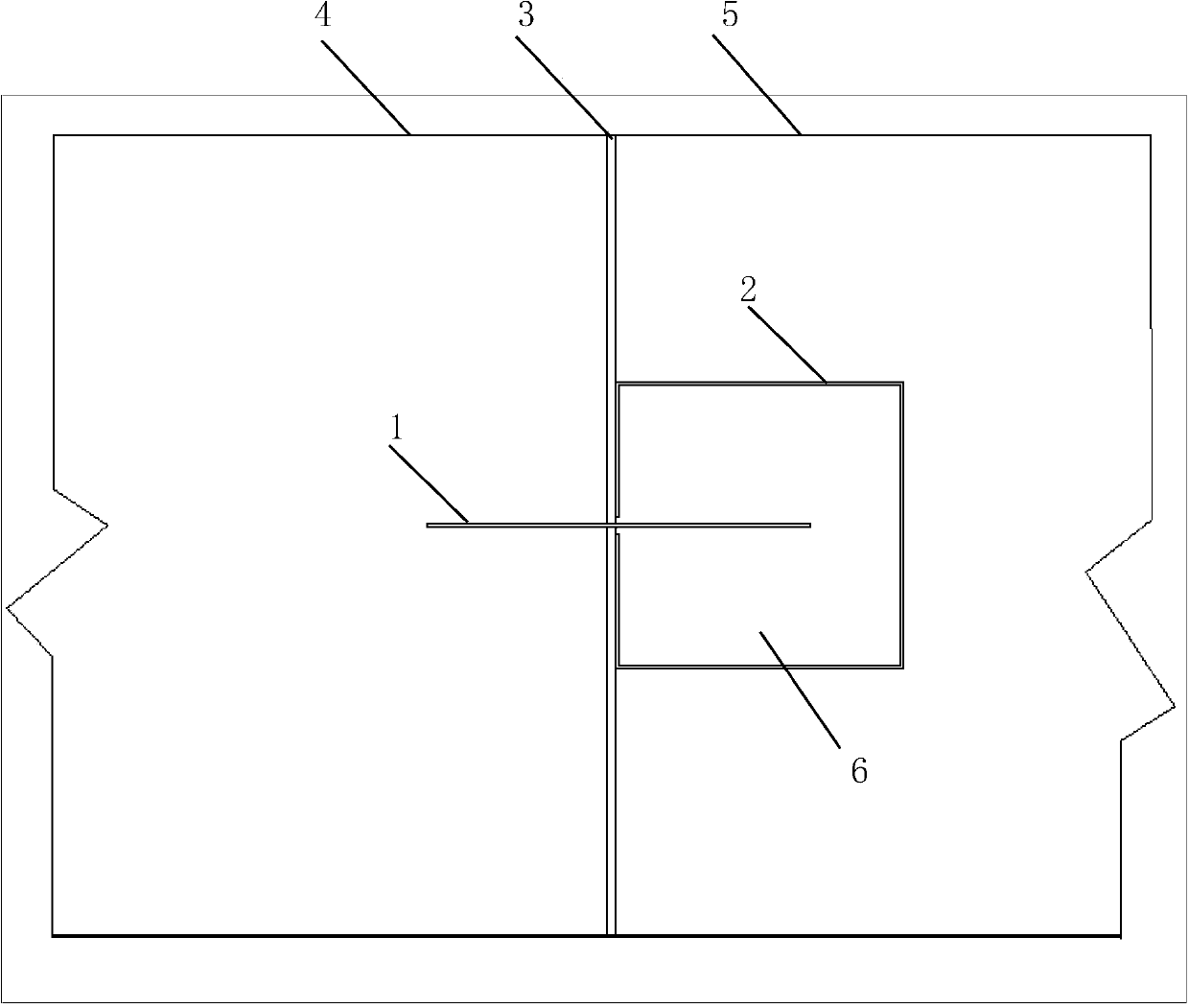

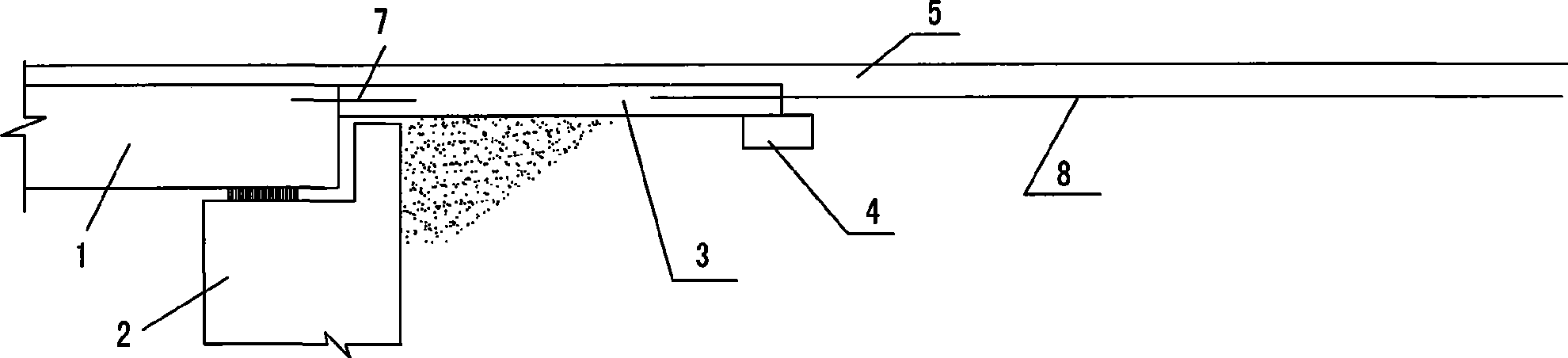

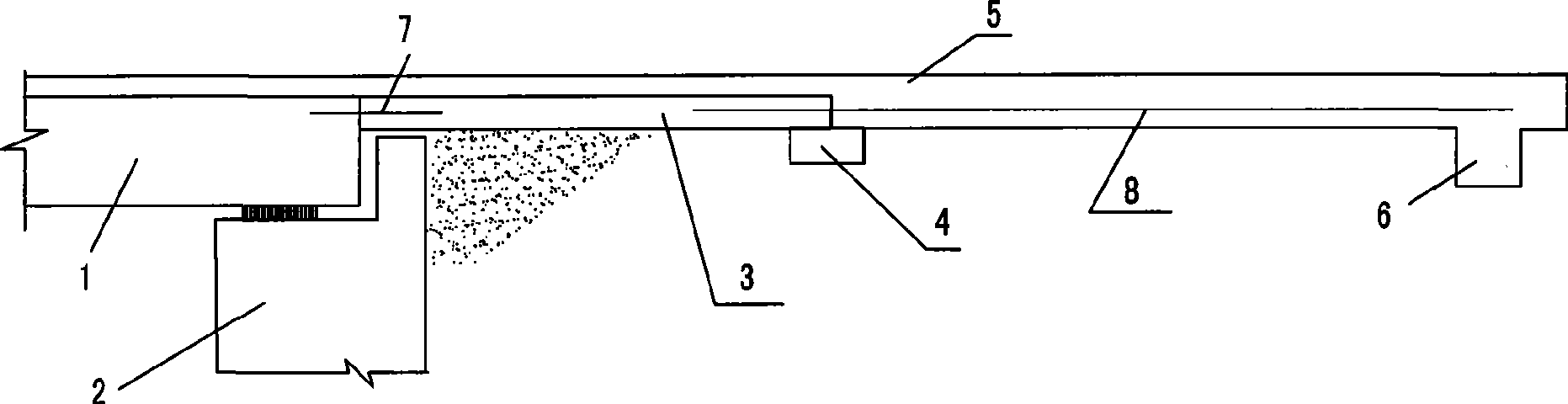

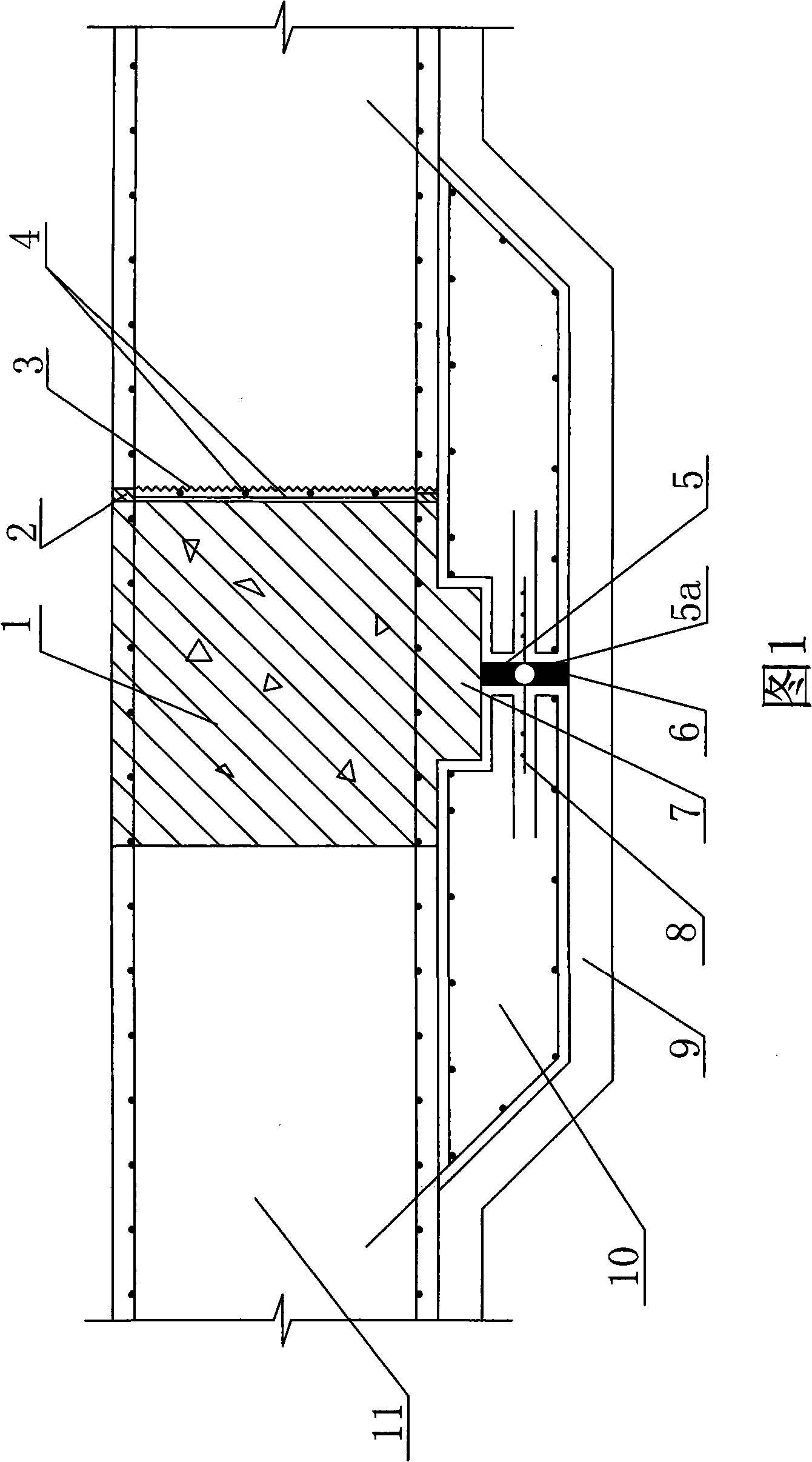

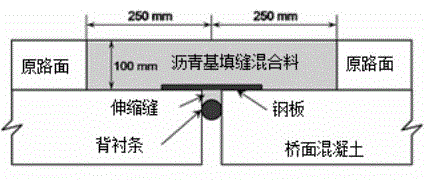

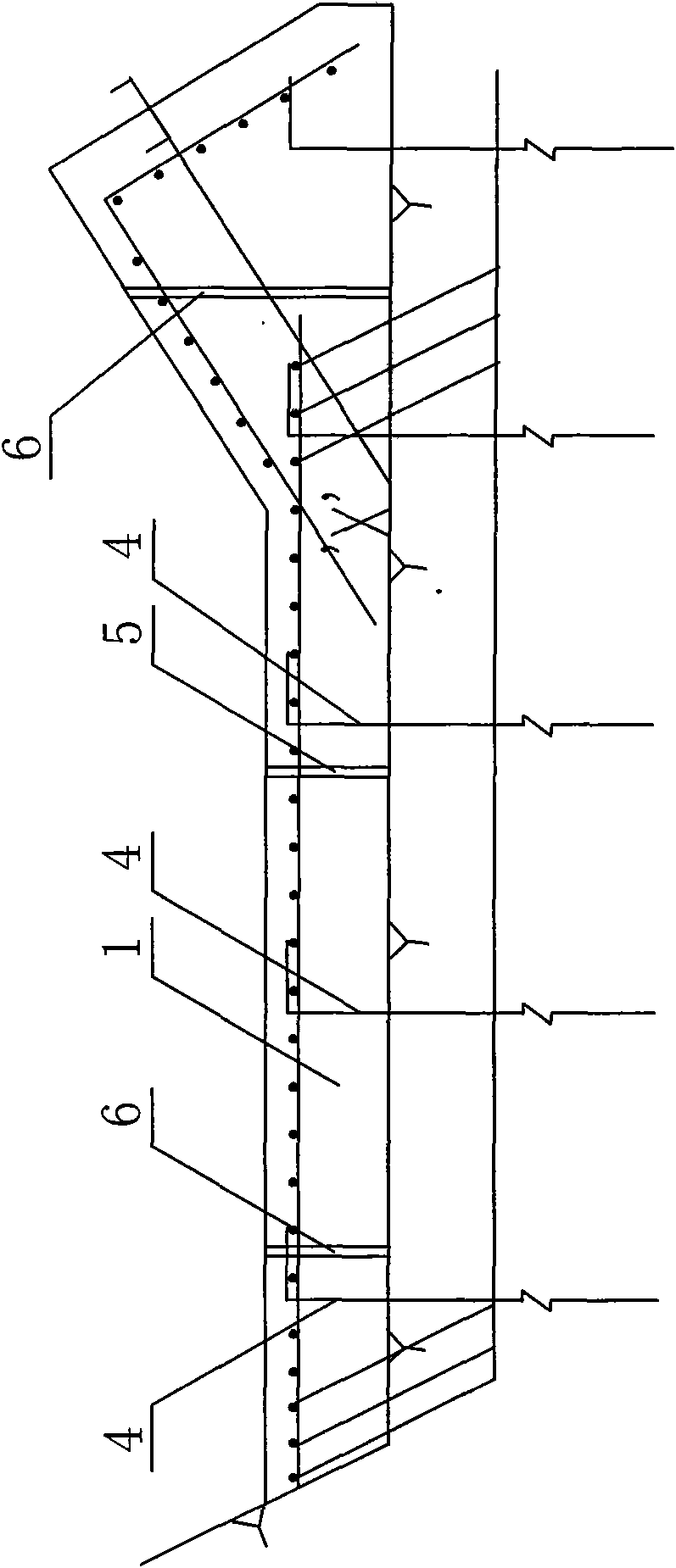

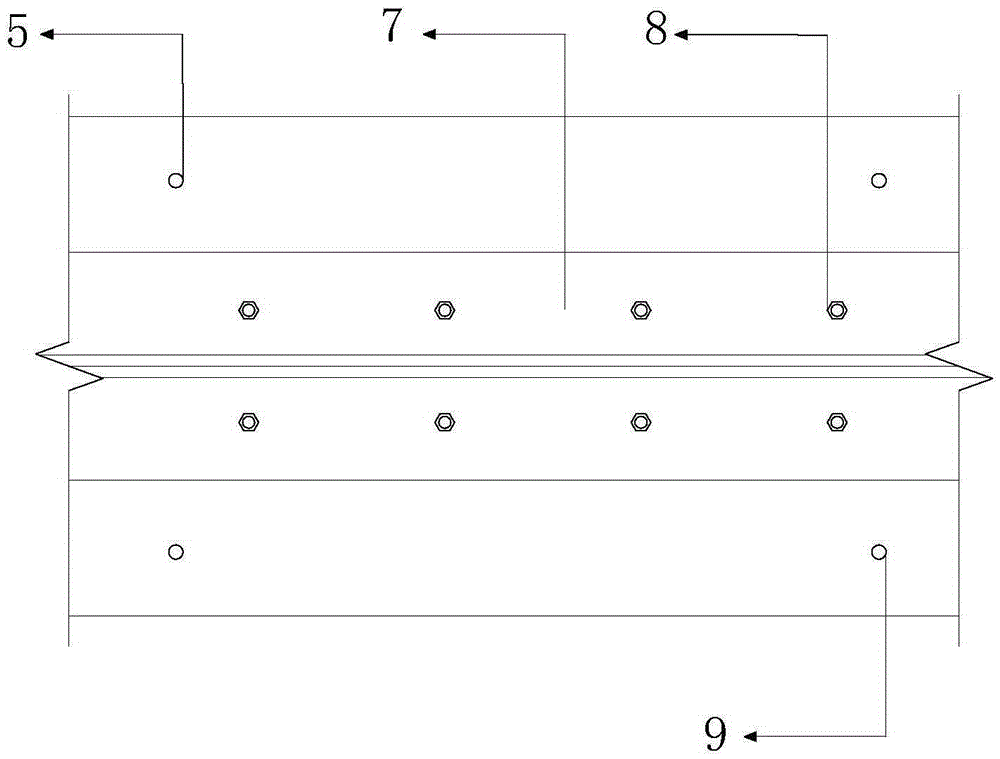

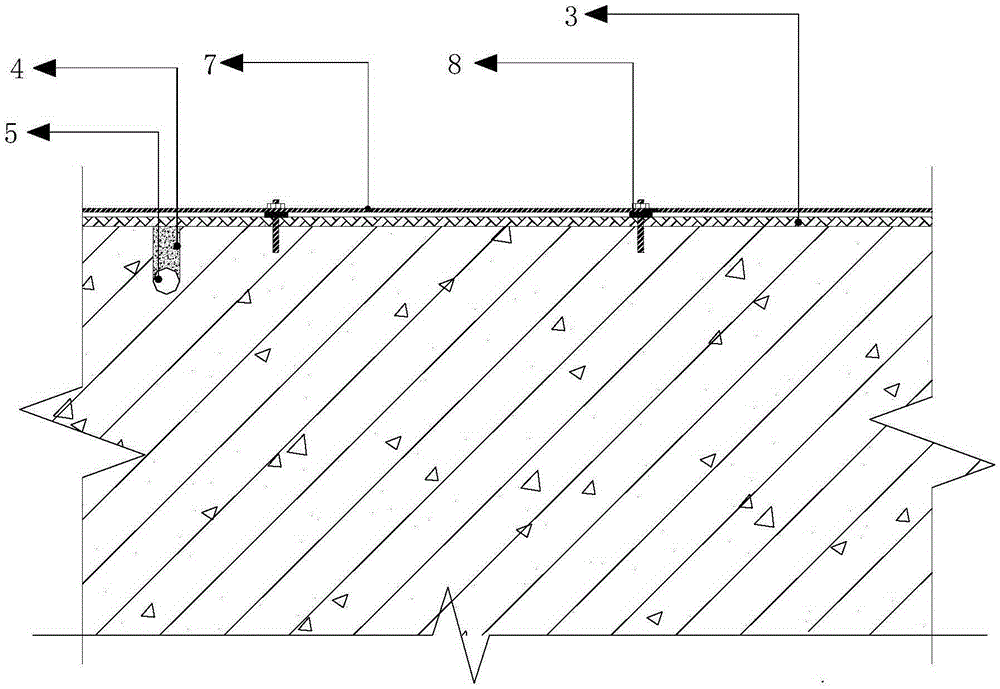

Structure of continuously reinforced link road pavement for seamless bridge

InactiveCN101440602AImprove driving comfort performanceIncreased durabilityBridge structural detailsAbutmentRoad surface

The invention discloses a continuous reinforcement distribution wiring road structure for a seamless bridge, which comprises a structure continuing or deck continuing main girder (1), a semi-integral type or integral type abutment (2), a butt strap (3), a corbel (4) and a continuous reinforcement distribution wiring road (5); the near abutment end of the butt strap (3) is connected with the main girder (1) through a main steel reinforcement (7); the long abutment end of the butt strap (3) is positioned on the corbel (4); the continuous reinforcement distribution wiring road (5) is connected with the butt strap (3) through the adoption of a monolayer through steel reinforcement (8) set in full duration; and the bottom end of the continuous reinforcement distribution wiring road (5) can be provided with an anchoring block (6). The continuous reinforcement distribution wiring road structure removes telescopic seam between the girder end and the abutment and road-bridge telescopic seam between the bottom end of the butt strap and the wiring road, has convenient design and construction, is in particular suitable for middle and small-size bridges, and can effectively reduce the maintenance expense of the bridge.

Owner:HUNAN UNIV

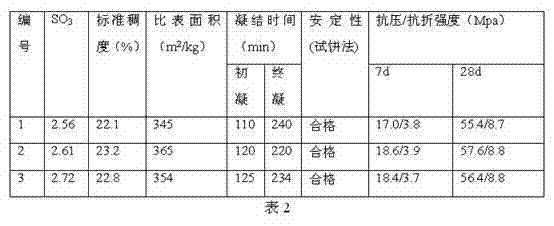

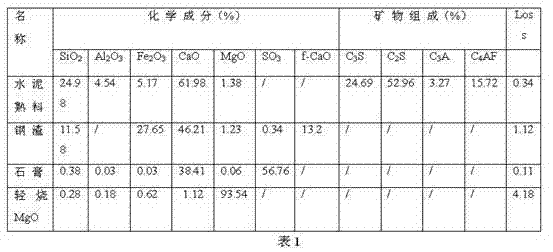

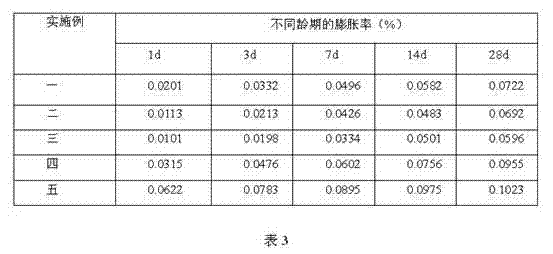

Minimum inflation low heat silicate cement

ActiveCN102173700AWith micro expansionReduce water demandSolid waste managementCement productionTemperature stressSlag

The invention discloses minimum inflation low heat silicate cement. The cement comprises the following components in percentage by weight: 75 to 95 percent of low heat silicate clinker, 1 to 10 percent of gypsum, 0.01 to 6 percent of lightly-burnt MgO, and 5 to 15 percent of steel slag. The minimum inflation low heat silicate cement can effectively reduce early concrete plastic cracking and temperature stress cracking generated by later hydrating adiabatic temperature rise, caused by adverse construction and maintenance conditions when the concrete is constructed. The prepared concrete has the advantages of high flowing performance, small dry shrinkage, little temperature contraction joint and the like, and can be applied in the fields of mass concrete, hydraulic concrete, high performance concrete engineering and the like which have high requirement on anti-cracking performance.

Owner:JIAHUA SPECIAL CEMENT

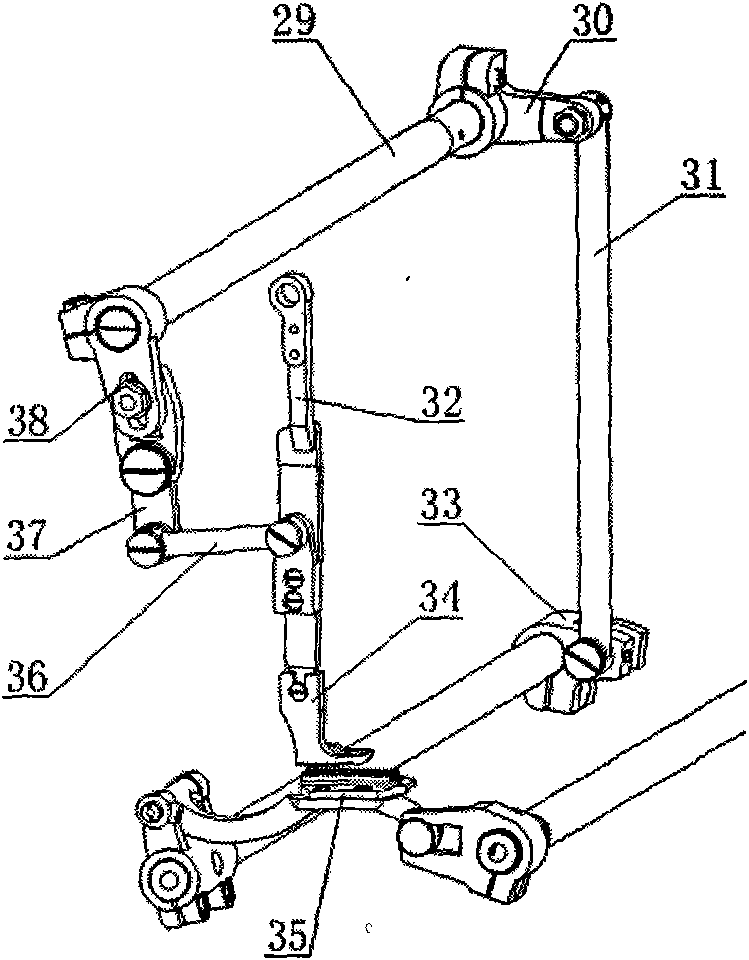

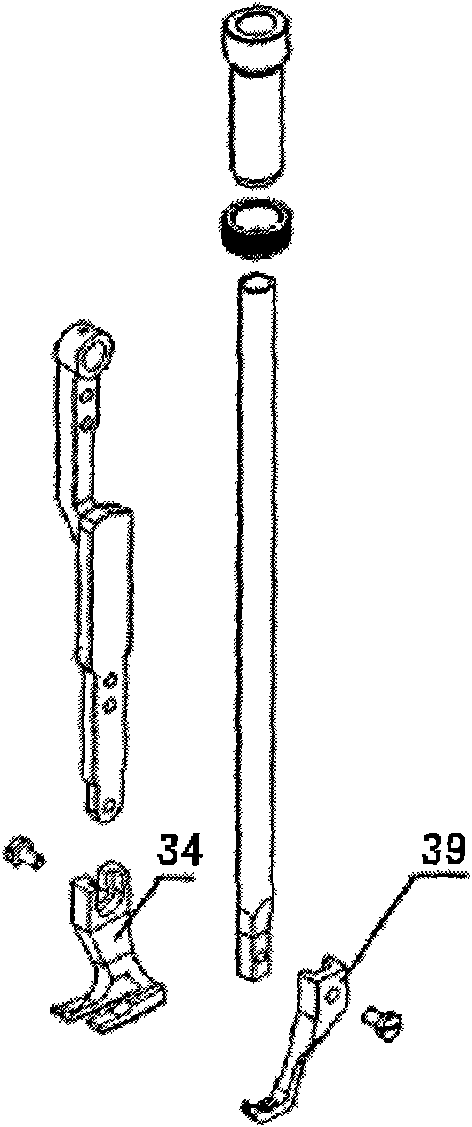

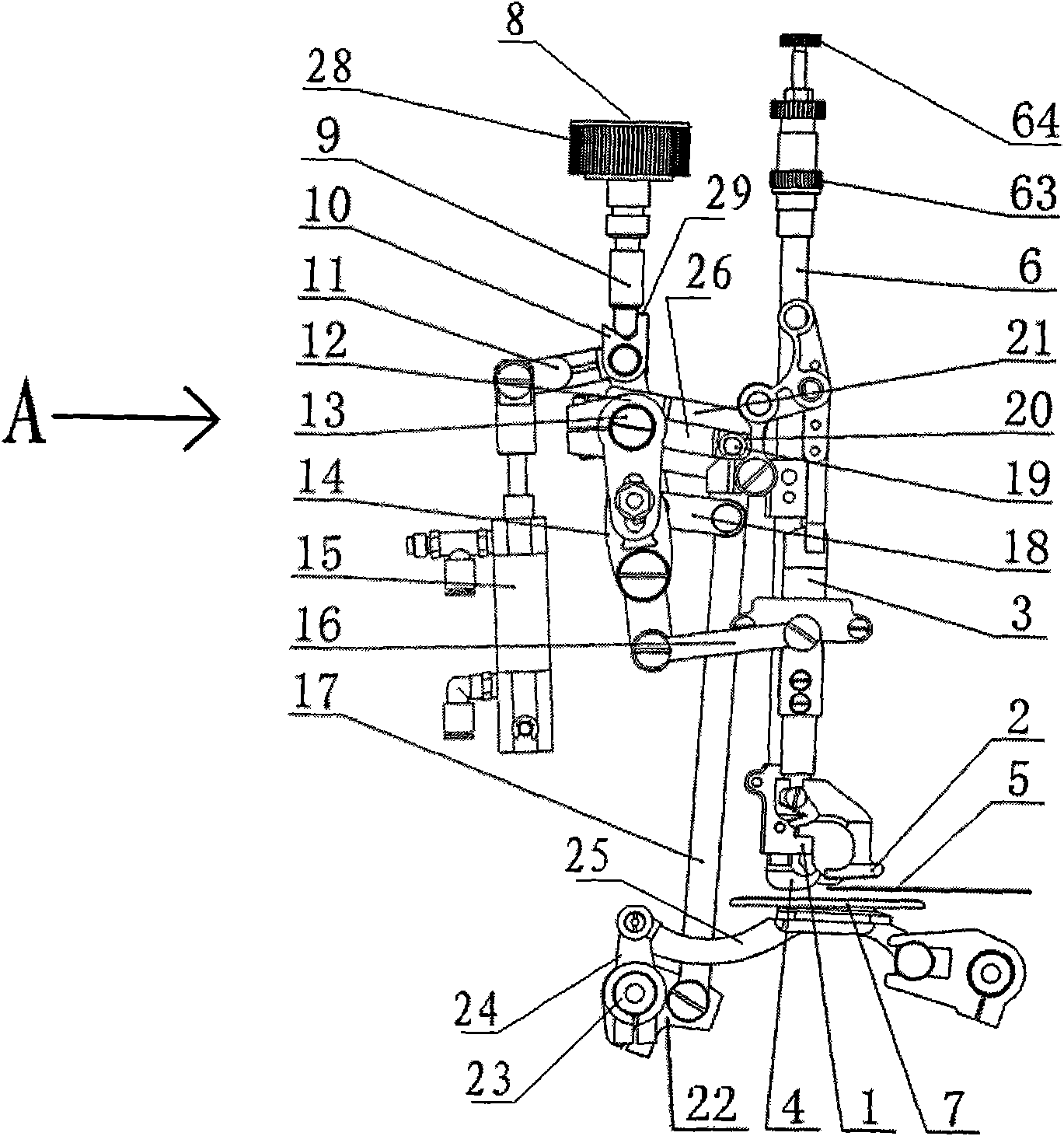

Upper differential feeding mechanism with contraction joint function of sewing machine and upper feeding wrinkling mechanism using same

ActiveCN101792956AIncrease or decrease the cloth feed amountAchieve the effect of upper differential shrinkage seamWork-feeding meansControl theoryContraction joint

The invention discloses an upper differential feeding mechanism with a contraction joint function of a medium-thickness material sewing machine, which comprises a presser foot oscillating shaft, a crank, a presser foot oscillating crank, a cloth feeding shaft, a cloth feeding crank, a crank connecting rod, a presser foot connecting rod I, a presser foot connecting rod II, an outer presser foot, an adjusting swing link shaft and an adjusting swing link, wherein the adjusting swing link is arranged on the adjusting swing link shaft and can adjust the swinging of the adjusting swing link shaft; the adjusting swing link shaft is connected with the crank through a connecting rod I; and the other end of the crank connecting rod is in slip connection with the crank. The upper differential feeding mechanism changes the cloth feeding amount of the outer presser foot to achieve an effect of an upper differential contraction joint. The invention also discloses an upper feeding wrinkling mechanism using the upper differential feeding mechanism, which uses the interaction of the outer presser foot and a rear presser foot to form wrinkles.

Owner:SHANGHAI HUIGONG NO 3 SEWING MACHINE FACTORY CHINA TYPICAL SEWING MACHINE

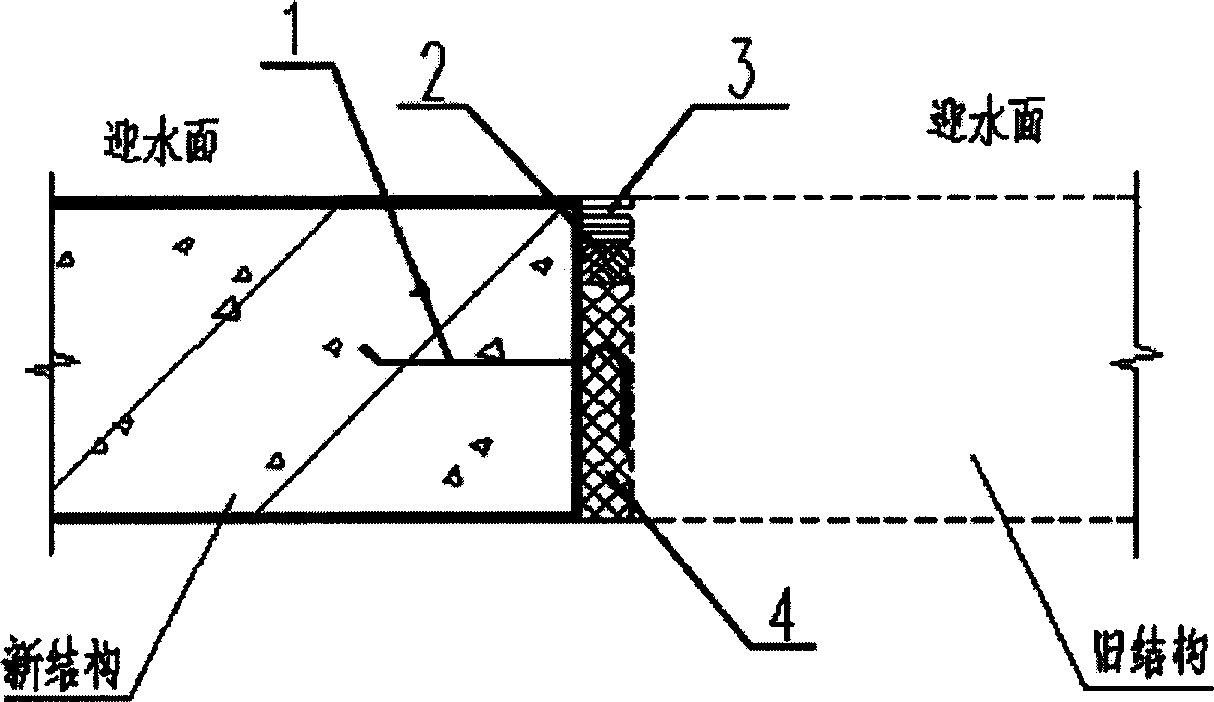

Method for constructing water-proof telescopic seam between new and old concrete building joints and structure thereof

InactiveCN1837528AOvercome positionOvercome immobilityBuilding insulationsArchitectural engineeringEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

Elastic concrete used for rapidly repairing expansion joint

The invention belongs to the field of building materials, and in particular relates to elastic concrete used for rapidly repairing an expansion joint. The elastic concrete is composed of three groups of materials, namely a material A, a material B and a material AC, wherein the weight ratio of the material A to the material B, to the material C is 1: (1-2.5): (8-18), the material A is composed of isocyanate or a prepolymer of the isocyanate, the material B is composed of the following components in parts by weight: 100-105 parts of polyhydric alcohols, 4-30 parts of a plasticizer, 5-20 parts of a chain extender, 0.01-1 part of a catalyst, 20-100 parts of a filler, 0-3 parts of an antioxidant, 0-3 parts of a defoamer, 0-30 parts of a coupling agent and 0-20 parts of a pigment, and the material C is aggregate. The elastic concrete has the advantages of high curing speed, adjustable curing time, good application property and self-leveling property. The elastic concrete is environment-friendly, good in toughness and small in contraction, has no generation of secondary cracking during operation process, good caking property with a base surface and excellent durability.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

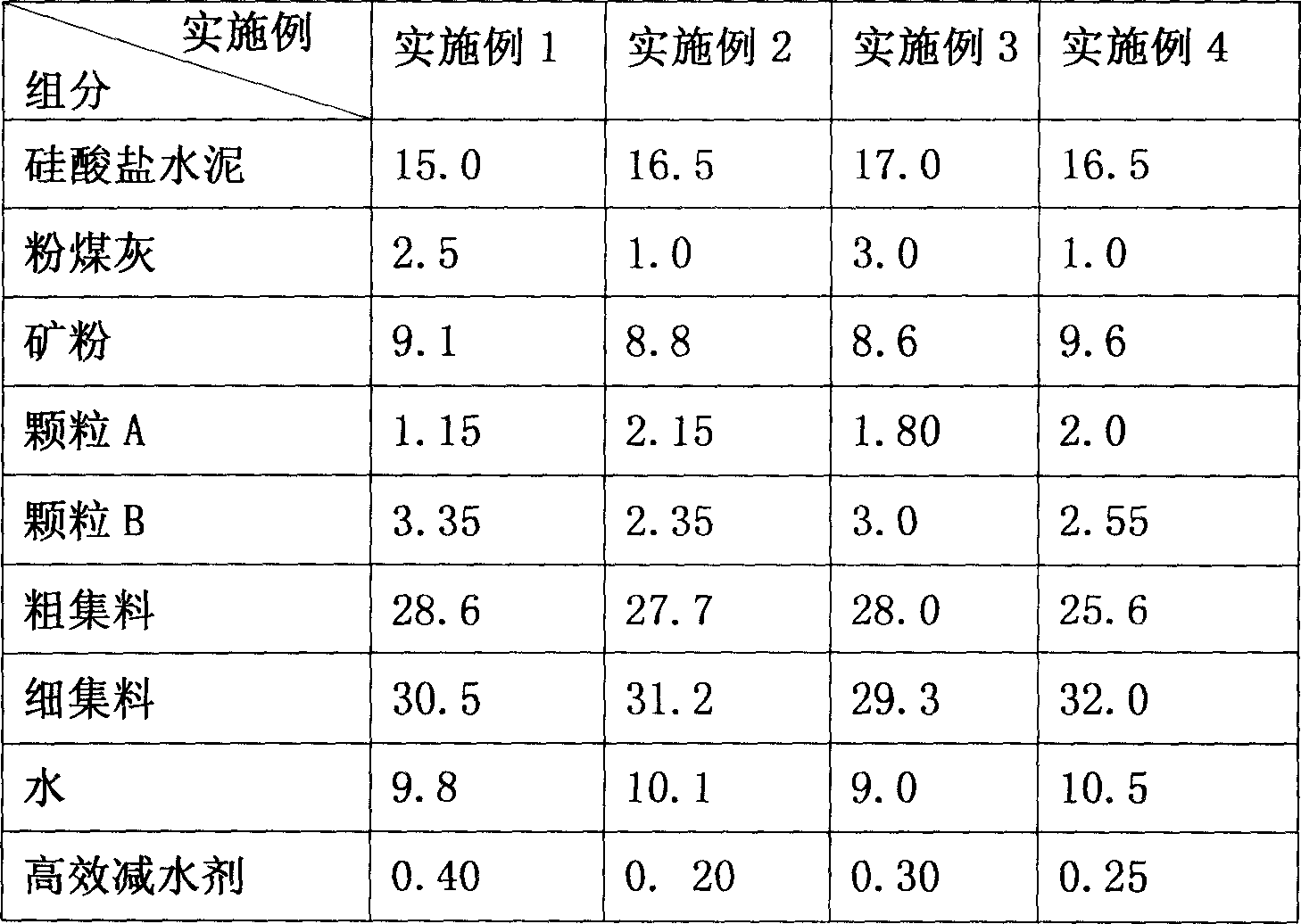

Sound sucking high elasticity concrete material for road

The sound absorbing high elasticity concrete material for road consists of Portland cement 15.0-17.0 wt%ú¼flyash 1.0-3.0 wt%ú¼ calcium carbonate mineral powder 8.6- 9.6 wt%ú¼crushed rubber tyre grain A 1.15-2.15 wt%ú¼ crushed rubber tyre grain B 2.35- 3.35 wt%ú¼ coarse aggregate 25.6-28.6 wt%ú¼ fine aggregate 29.3-32.0 wt%ú¼ water 9.0-10.5 wt% and efficient water reducing agent 0.20-0.40 wt%. The present invention has the advantages of full utilization of waste tyre, reducing environmental pollution, low cost, etc. and the deposited concrete road has high elasticity, high softness, reduces extension joint, less noise and environment friendship.

Owner:SHANGHAI JIAO TONG UNIV

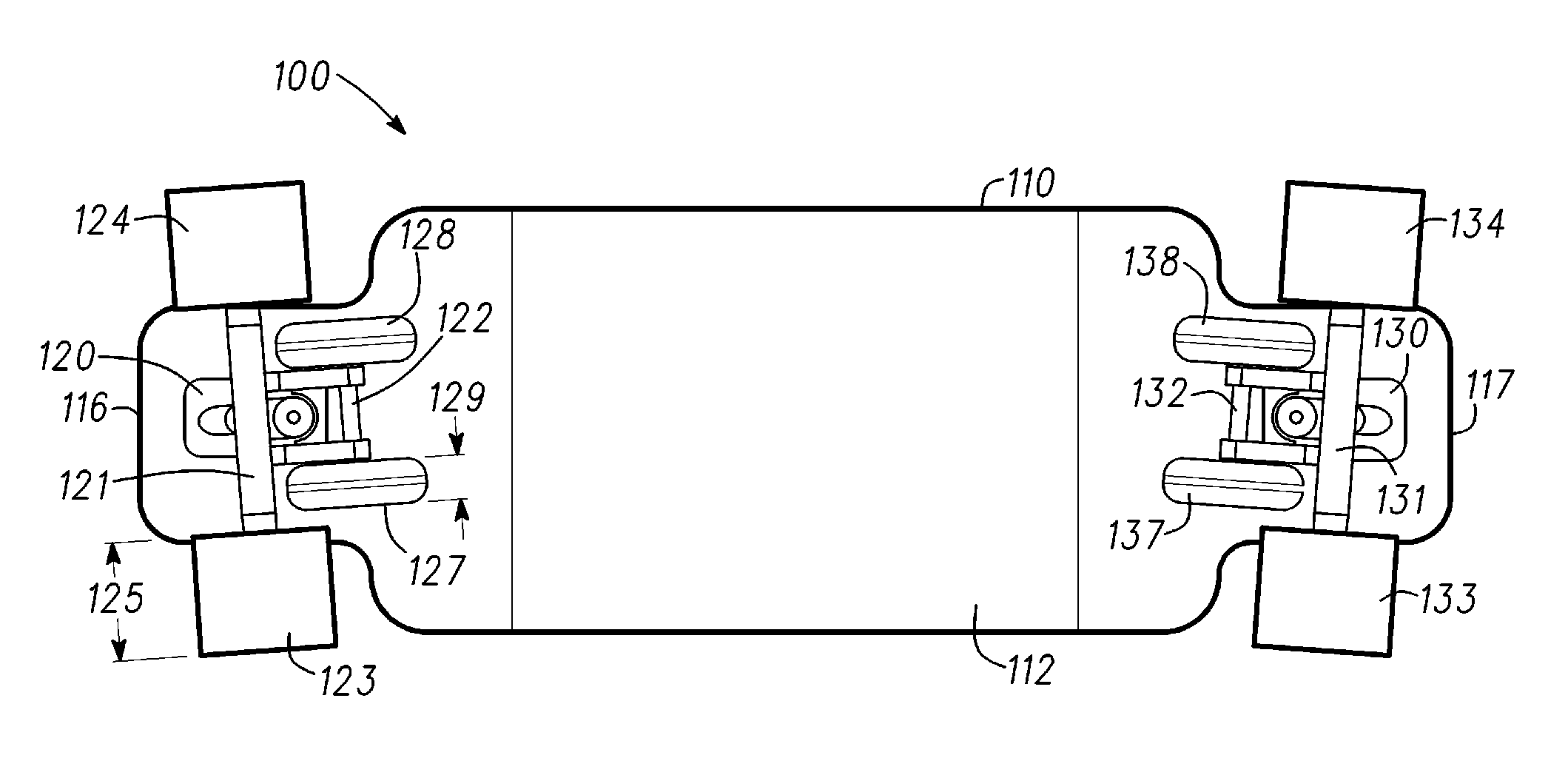

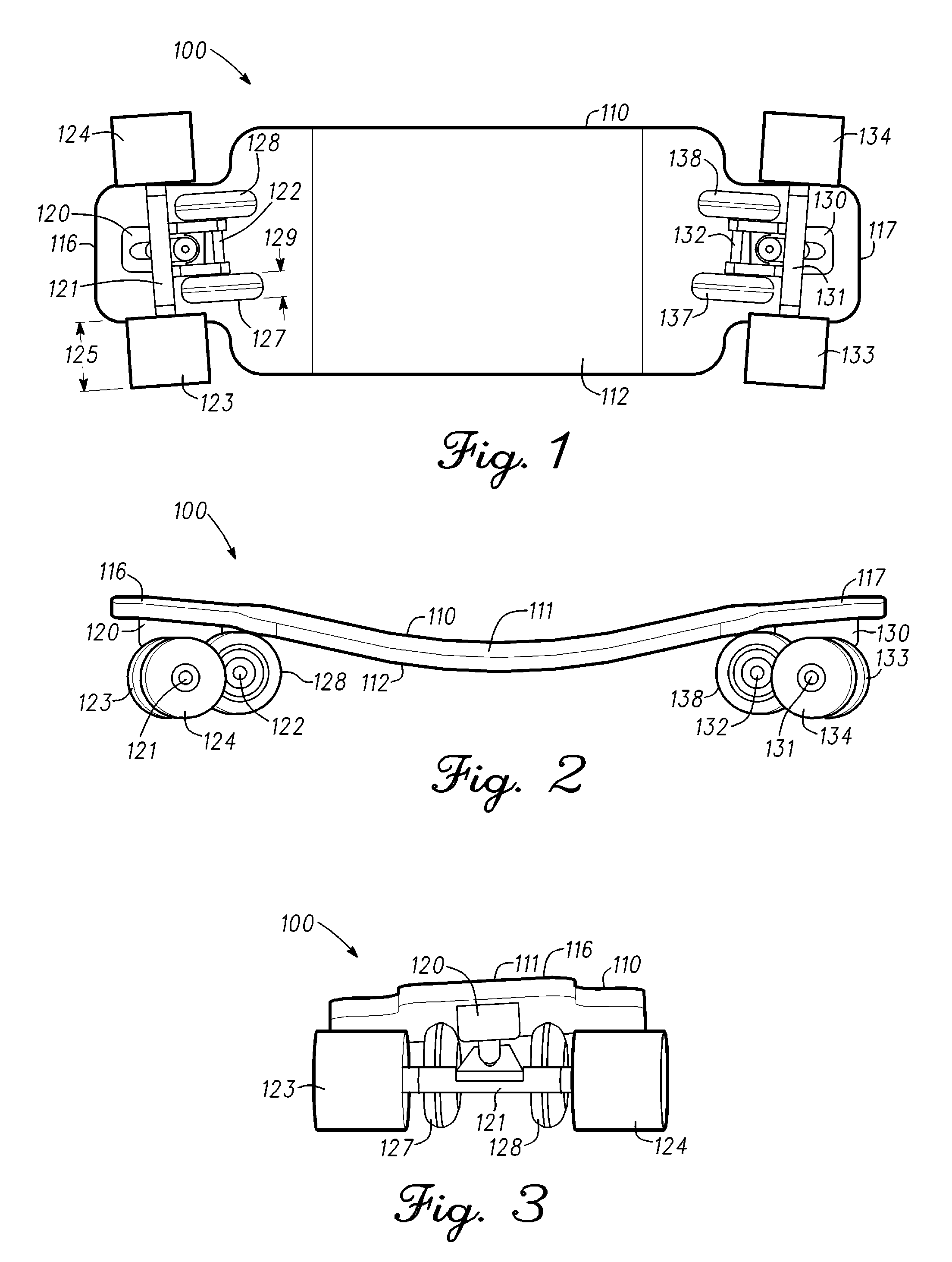

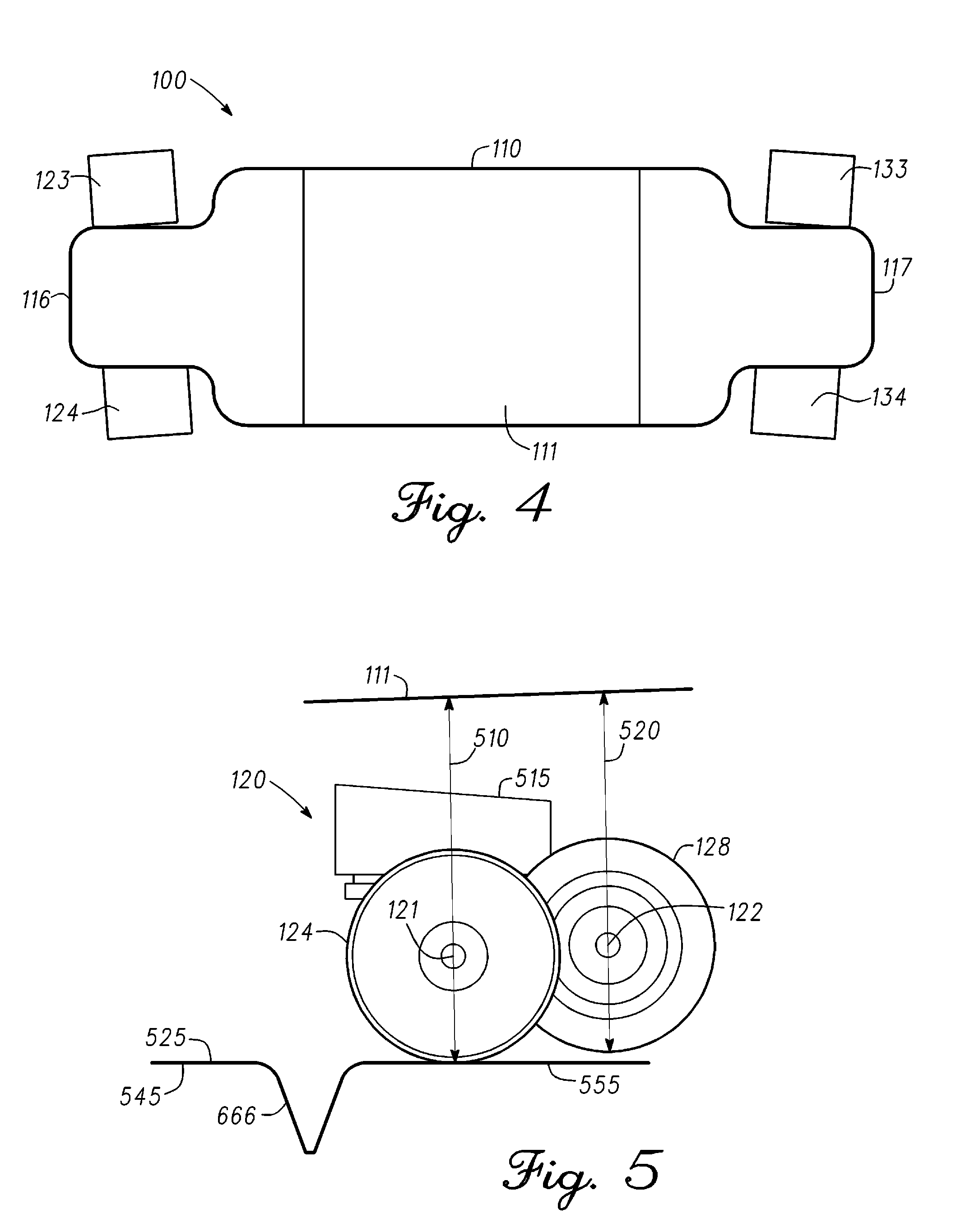

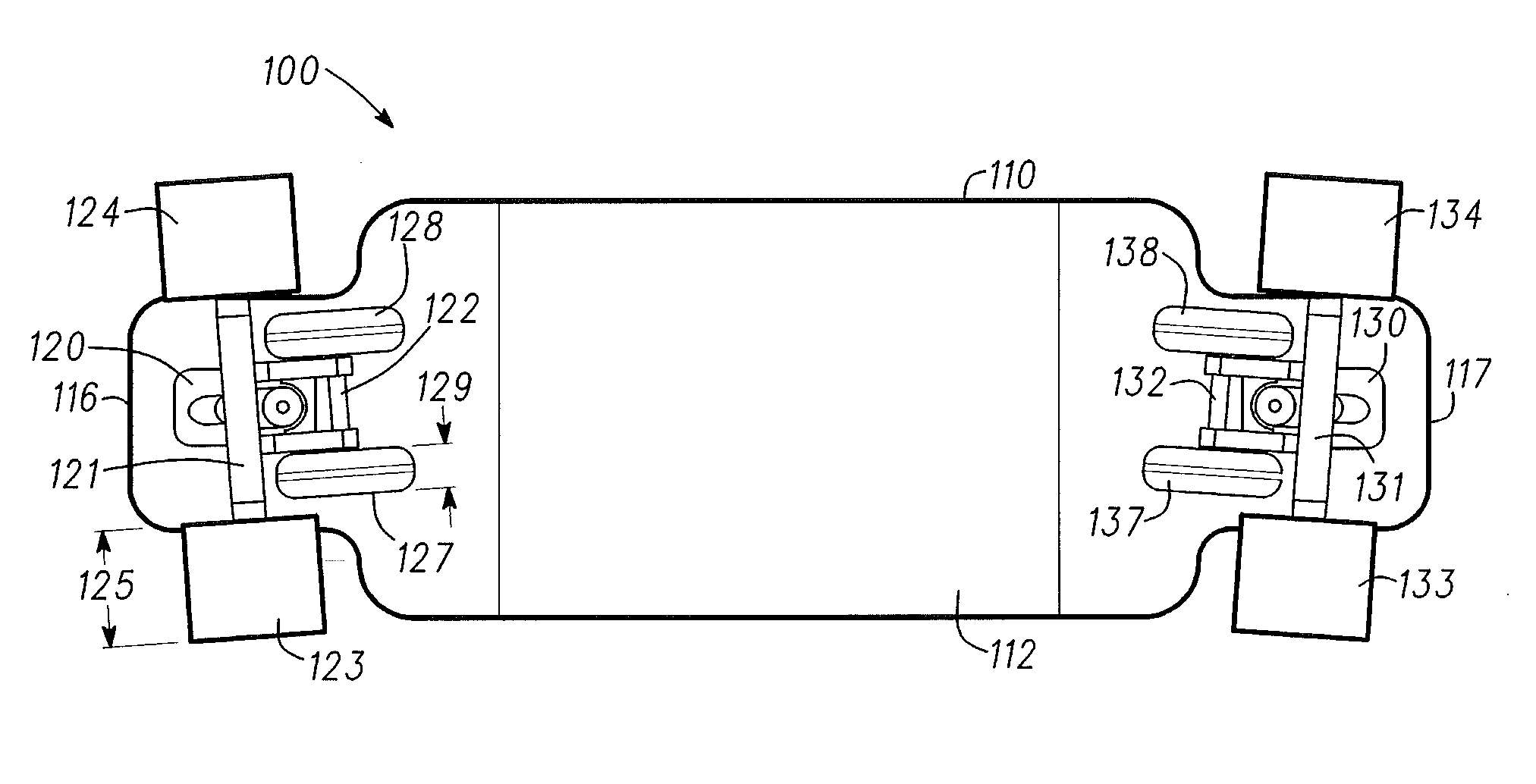

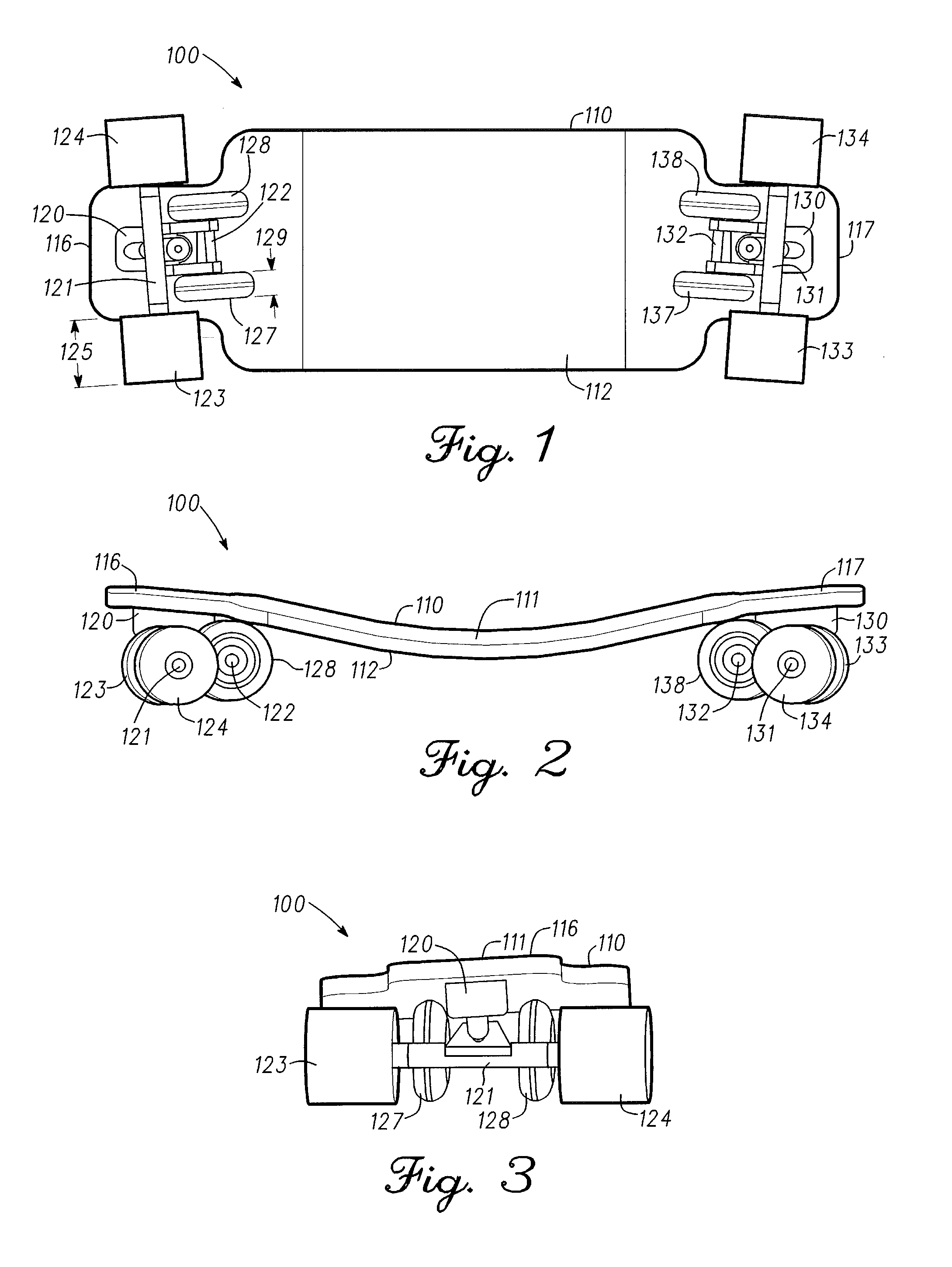

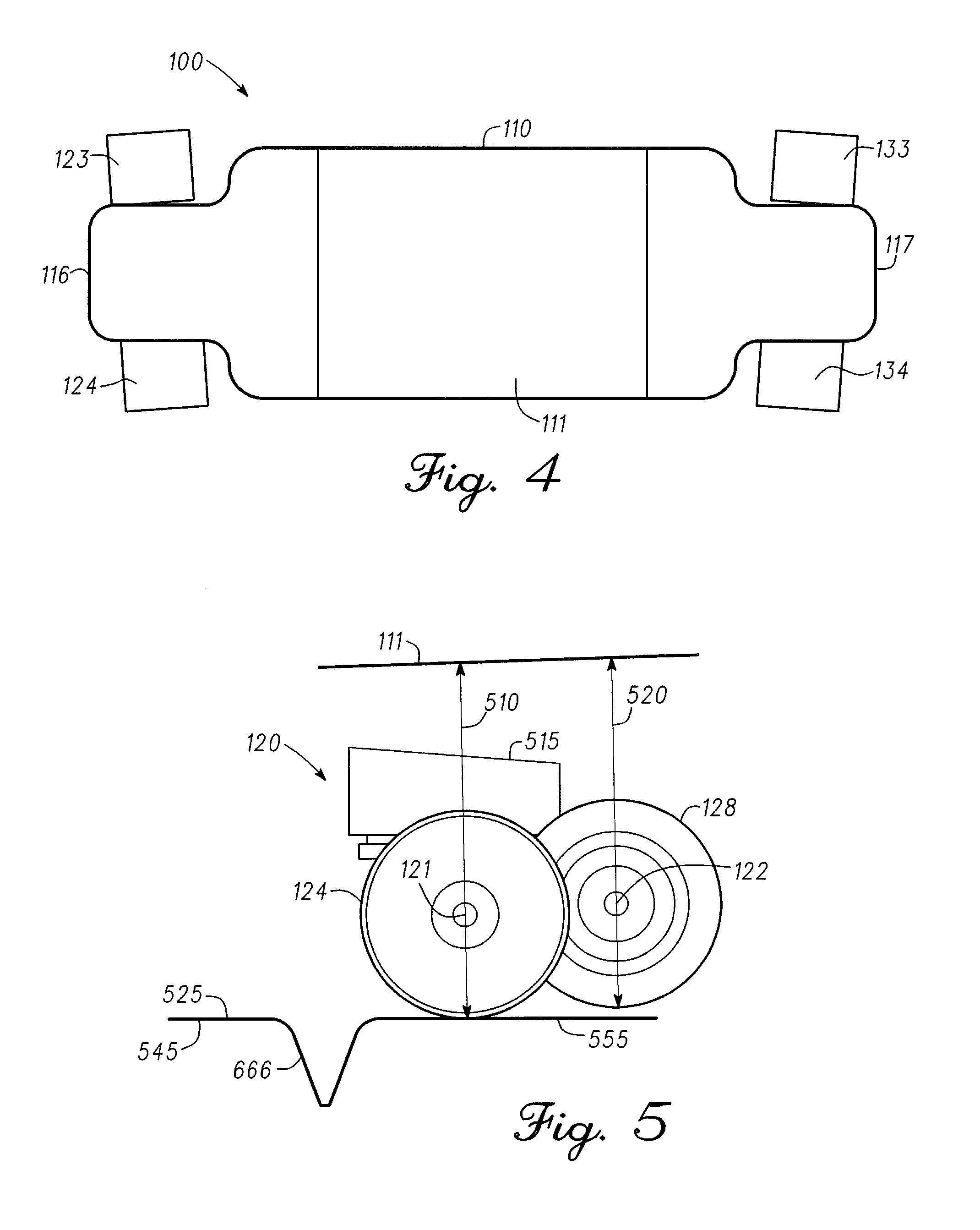

Dual axle skateboard and truck with outboard secondary wheels and method

Improved skateboards and methods of obtaining or providing skateboards with improved trucks. Trucks have two axles or axes, two primary wheels, and two secondary wheels, and skateboards have eight wheels, four in front and four at the rear portion of the skateboard. The four primary wheels support most or all of the weight of the skateboard when the skateboard is on a flat surface, and the two secondary wheels support the weight of one portion of the skateboard (e.g., front or rear) when the primary wheels cross a crack (e.g., a sidewalk contraction joint). In various embodiments, the secondary wheels are located outboard of the primary wheels. Further, in a number of embodiments, the axis of rotation or axle of the primary wheels remains parallel to that of the secondary wheels, whether the skateboard is going straight or turning.

Owner:KARSTEN MFG CORP

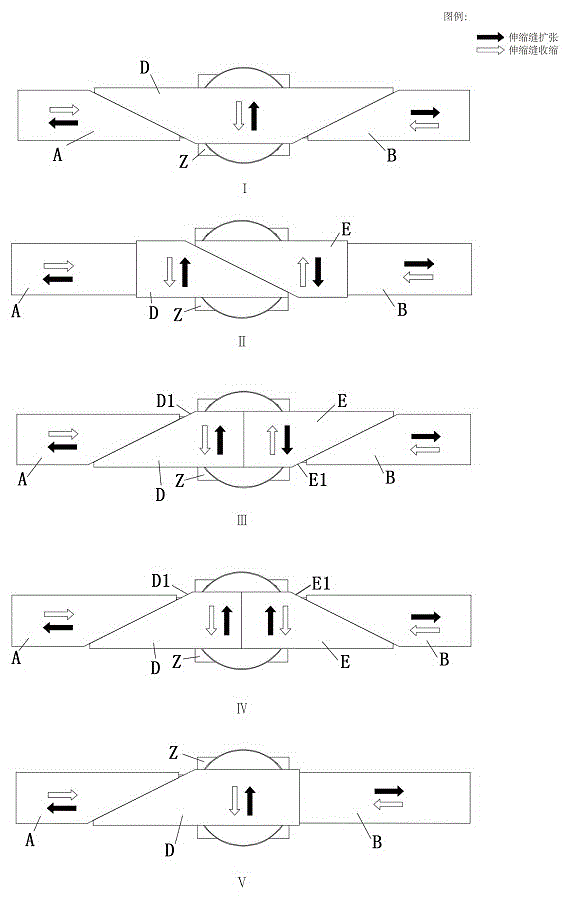

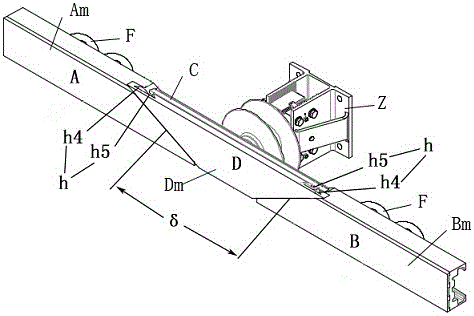

Jointless telescopic connector with contact rails

ActiveCN105742840ARun fastGuaranteed cooperationCoupling device connectionsNon-rotary current collectorElectrical conductorEngineering

The invention relates to a jointless telescopic connector with contact rails. The jointless telescopic connector with the contact rails comprises two contact rail segments, a limiting guide body, a contact surface slide block and an electrical conductor, wherein the two contact rail segments are in connecting fit with sliding clearances through the limiting guide body; at least one contact surface slide block is arranged on the limiting guide body or substrates of the contact rail segments; the external contact surface of the contact surface slide block and the external contact surfaces of the contact rail segments are located on the same working surface; the contact surface slide block partially or completely covers a telescopic gap between the two contact rail segments; at least one edge of the contact surface slide block is a bevel edge; the included angle of the sideline of the bevel edge and the telescopic direction of the contact rail segments is smaller than 90 degrees; when the two contact rail segments displace in the length direction to cause a change of the telescopic gap, the contact surface slide block correspondingly displaces along the direction vertical to the telescopic direction of the contact rail segments to adapt to the change of the telescopic gap on the contact working surface; and meanwhile, at least one electrical conductor is connected with the limiting guide body or / and the two contact rail segments to achieve electrical conduction.

Owner:HUNAN HUAPIN RAIL TRANSIT CO LTD

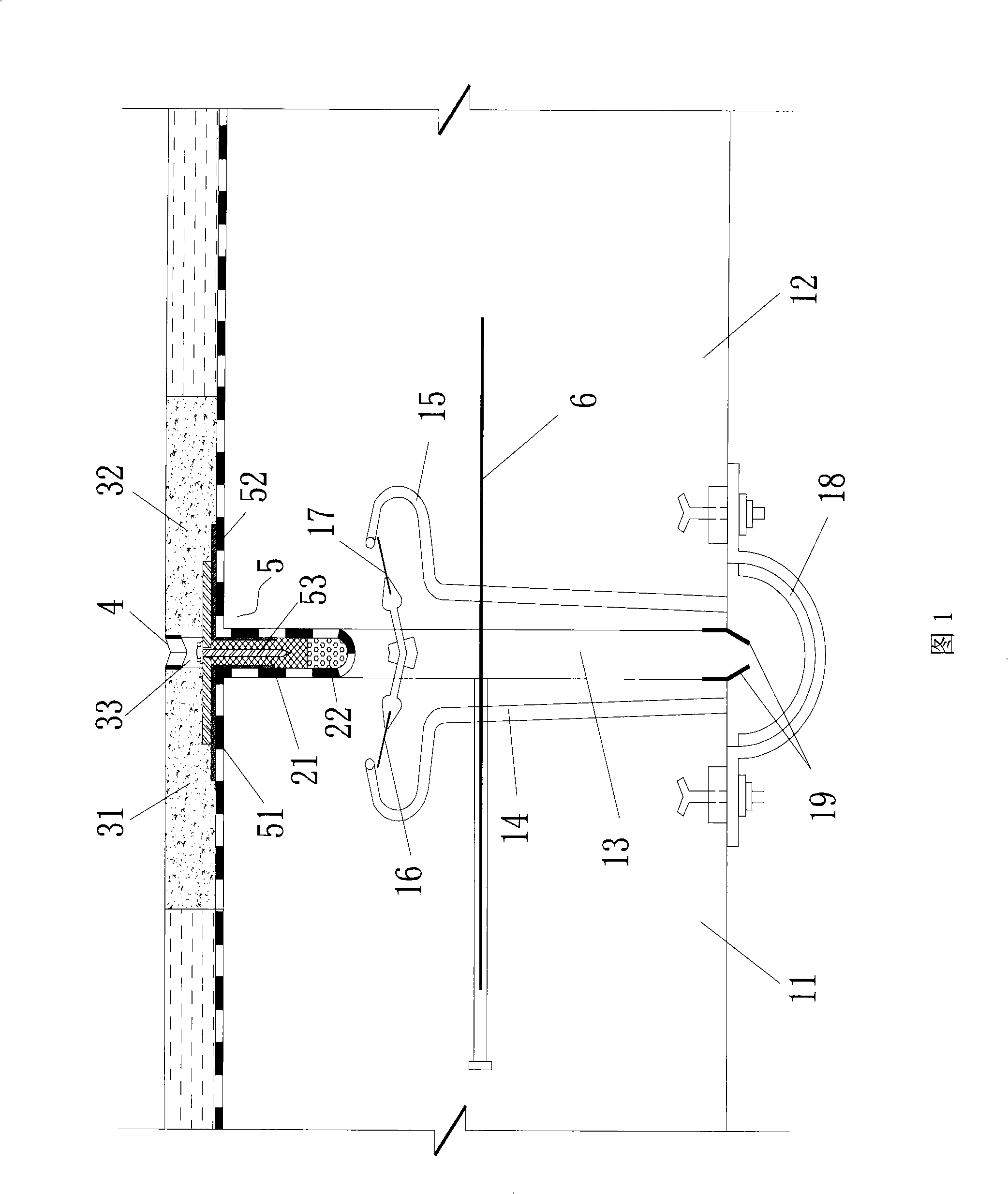

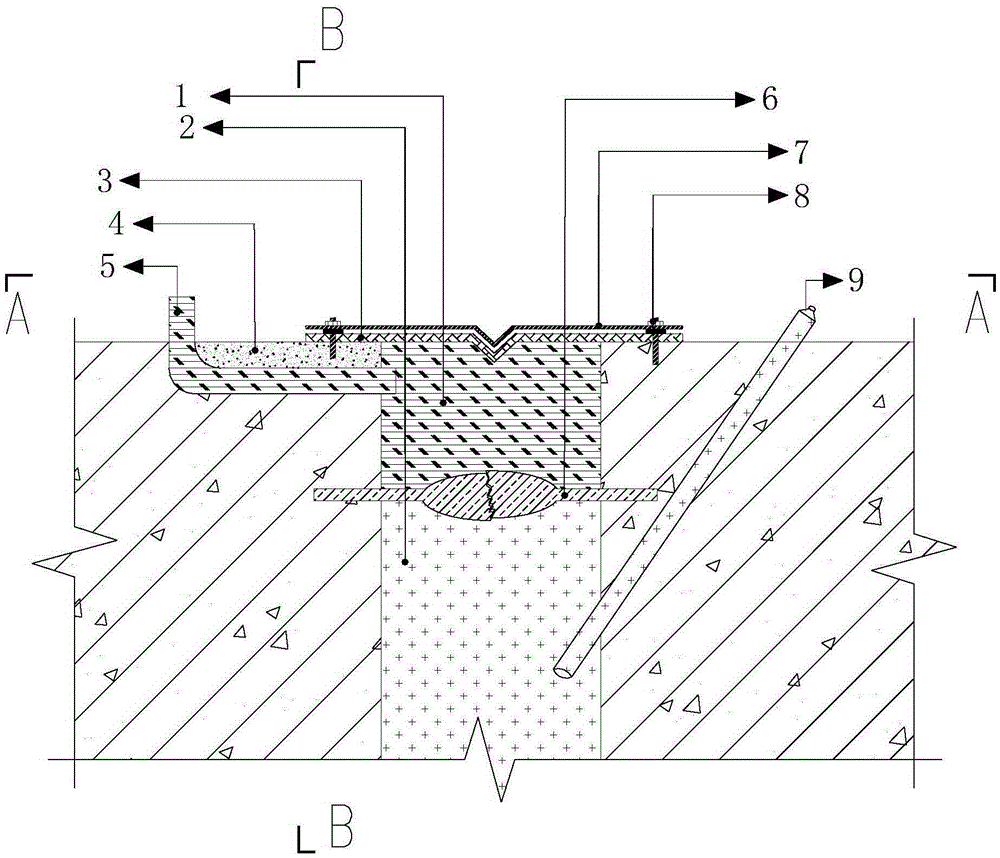

Water proof method for underground structure top board expansion joint also serving as urban roads base and the structure

ActiveCN101307622AImprove waterproof performanceGuaranteed waterproof performanceArtificial islandsUnderwater structuresEngineeringJoint spaces

The invention discloses a dilatation joint waterproof method for an underground structure roof which is used as an urban roadbase as well, wherein, a dilatation joint space is arranged between a first roof and a second roof of an underground structure. The method comprises the following steps that: firstly, a grouting pipe and a steel-edged rubber watertight strip are respectively arranged inside the first roof and the second roof; secondly, a drain tank is arranged under the rubber watertight strip; thirdly, a 'U'-shaped waterproof roll is arranged inside the dilatation joint space, and rubber strips and water absorption materials are filled into the 'U'-shaped waterproof roll; a stainless steel pressure plate is also arranged on the 'U'-shaped waterproof roll; fourthly, an elastic concrete layer is laid on the 'U'-shaped waterproof roll, and 'W'-shaped rubber watertight strips are glued in gaps of the elastic concrete layer. The invention also provides a dilatation joint waterproof structure. The dilatation joint waterproof method and the dilatation joint waterproof structure guarantee the waterproof effect in multi-angle and multi-layer form and greatly reduce the late maintenance cost.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Basement bottom plate rear pouring tape construction method

ActiveCN101298781AImprove construction qualityFirmly connectedProtective foundationBuilding insulationsBasementEngineering

A late poured band construction method of basement soleplate belongs to the technical field of building construction, and is characterized in that a plain concrete cushion is poured and extended below a late poured band, a reinforced cushion as well as corresponding drainage ditches and dilatation joints are poured and installed above the plain concrete cushion; after the reinforcing steel bars of basement soleplate are finished to be bundled, one side of the late poured band is supported and poured with concrete, and the other side of the same basement soleplate is poured with concrete; the late poured band is cleaned and is poured with concrete so as to finally be sealed. The late poured band construction method of basement soleplate greatly reduces the operation capacity of chiseling off loosened concrete at both sides of the late poured band, thereby favourably guaranteeing the reliable connection between the basement soleplate and the reinforcing bar cushion, avoiding gaps between the basement soleplate and the reinforcing bar cushion due to shrinkage, effectively preventing groundwater from entering before the late poured band is sealed, and keeping dryness inside the basement; otherwise, the reinforcing steel bars under the basement soleplate are avoided to be buried by cement paste or sundries, thereby reducing the labor cleaning strength, and greatly improving the construction quality of late poured band.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

Waterproof processing method and structure for roof stretching seam

InactiveCN101666142AImprove waterproof performanceOvercome the disadvantages of poor integrityBuild-up roofsFloor slabWater leakage

The invention provides waterproof processing method and structure for a roof stretching seam. The method comprises the following steps: integrally pouring a roof floor and a waterproof blocking platform in the roof stretching seam position into a whole; after the roof to be concreted is initially solidified, demoulded and cleaned, adopting a dry laying bituminous felt layer as an isolating layer;sequentially laying a fine stone concrete waterproof layer, a cement mortar leveling layer, a macromolecule coiled material additional layer and a macromolecule coiled material waterproof layer on theisolating layer and filling foamed plastics in the stretching seam; filling a gasket material on the foamed plastics, sealing by a coiled material and covering a concrete cover plate on the top. Theinvention adopts a cast-in-situ reinforced concrete blocking platform as a flashing to reinforce the waterproof ability of a weak joint in the roof stretching seam position and prevent water leakage in the roof deforming seam position; and the roof floor and the waterproof blocking platform in the roof stretching seam position are integrally poured into a whole to overcome the defect of bad integrity of the prior method for building the waterproof blocking platform by bricks in the roof deforming seam position.

Owner:GUIYANG AL-MG DESIGN & RES INST

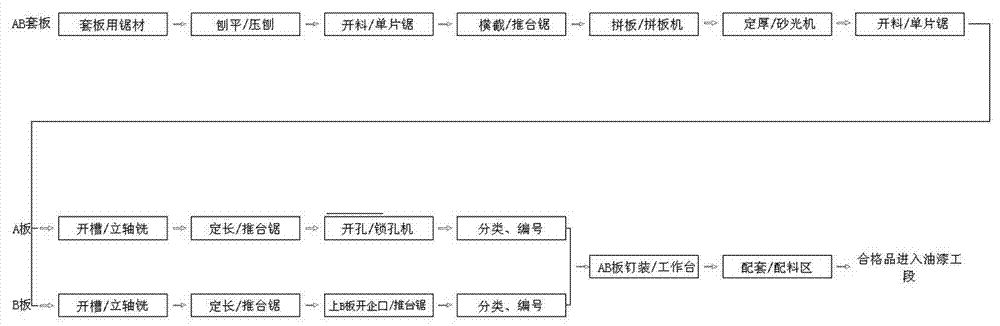

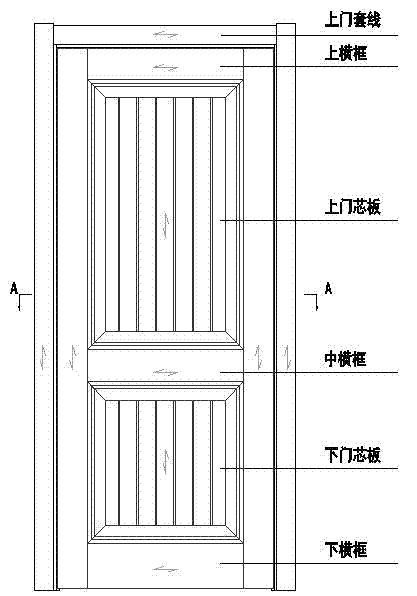

Manufacturing process of raw wood door

ActiveCN104760108AReduce the probability of shrinkage seamsAvoid late cracking defectsWood working apparatusParticulatesPollution

The invention provides a manufacturing process of a raw wood door. The manufacturing process comprises the steps of (1) synchronously preparing a door leaf, a plate A, a plate B and a door cover line; (3) painting through a paint room after preparing the parts above; maintaining; matching; warehousing a packing box. The raw wood door manufactured by the process has the advantages that the probability of contraction joints of the wood door in later use can be greatly reduced, and moreover, the defect of cracking of the raw wood door in later period can be avoided the pollution of air, in particular particles can be minimized according to the manufacturing process; 100% of high gloss paint can be achieved; 30% of energy charge can be saved; the environment is improved by 40%; operators can be protected well.

Owner:JIANGSU KENTIER SENGONG TECH

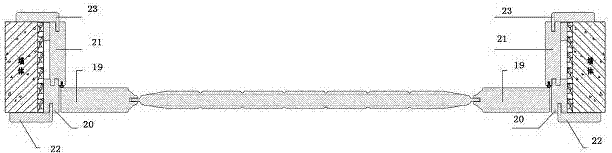

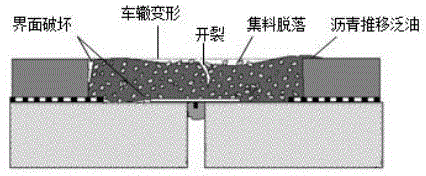

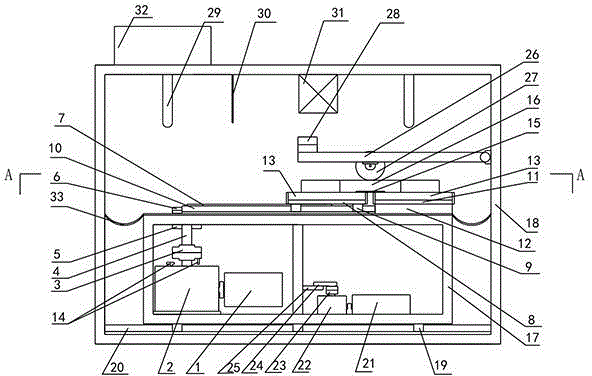

Fatigue cracking simulation testing method and apparatus for seamless expansion joint material of bridge

InactiveCN104034611AMaterial strength using repeated/pulsating forcesReciprocating motionEngineering

The invention relates to a fatigue cracking simulation testing method and apparatus for a seamless expansion joint material of a bridge. The testing method comprises the following steps: 1) placing two concrete members on a test platform and fixing the two concrete members to prepare an expansion joint structure with a groove; 2) paving a to-be-tested bridge seamless expansion joint material in the groove of the expansion joint structure so as to prepare a test piece; 3) setting testing temperature and maintaining the test piece at a constant temperature; 4) placing a tire on the surface of the test piece, adjusting wheel pressure and the relative travel distance and speed between the tire and the test piece and allowing the test piece and the tire to carry out relative reciprocating motion; 5) allowing the two concrete members to carry out relative reciprocating motion; and 6) measuring the tensile deformation of the bridge seamless expansion joint material and respectively recording the numbers of relative reciprocating motions of the concrete members and the tire during initial cracking and final cracking of the bridge seamless expansion joint. The testing method and apparatus can be used for determination of repeated loading frequencies needed by fatigue cracking of the bridge seamless expansion joint material under the action of both tire loading and bridge temperature contraction.

Owner:WUHAN UNIV OF TECH

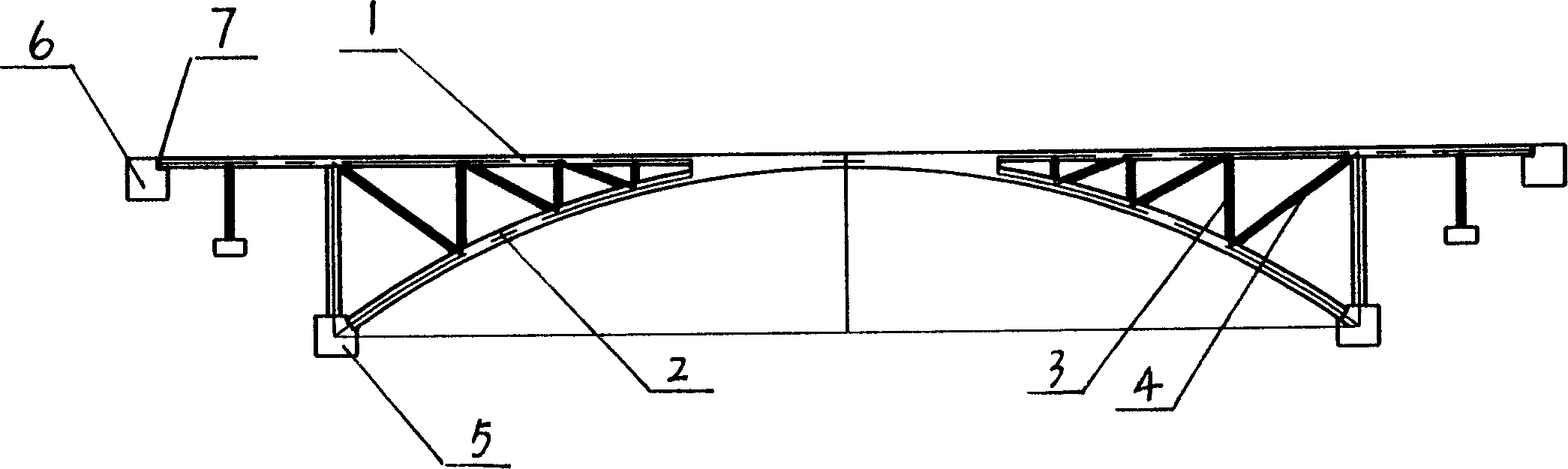

Prestressed concrete continuous truss frame arched bridge

The arch bridge is composed of upper chord, lower chord, upright posts, inclined bars, anchoring wall at bridge abutment. Supported by arch support, lower chord through upright posts, inclined bars supports upper chord. The upper chord as a continuous beam is articulated on anchoring wall at bridge abutment through hinges at two ends. There is contraction-joint between upper chord and anchoring wall at bridge abutment. The invention raises integrity of bridge, reduces deflection, vibration and jigging motion providing advantages of improving trafficked effect and durability of bridge. Comparing with box ribbed arch bridges, truss bridges etc, the invented arch bridge possesses general superiorities suitable to use in each classified highways.

Owner:郑锦文

Dual-durometer divided bar

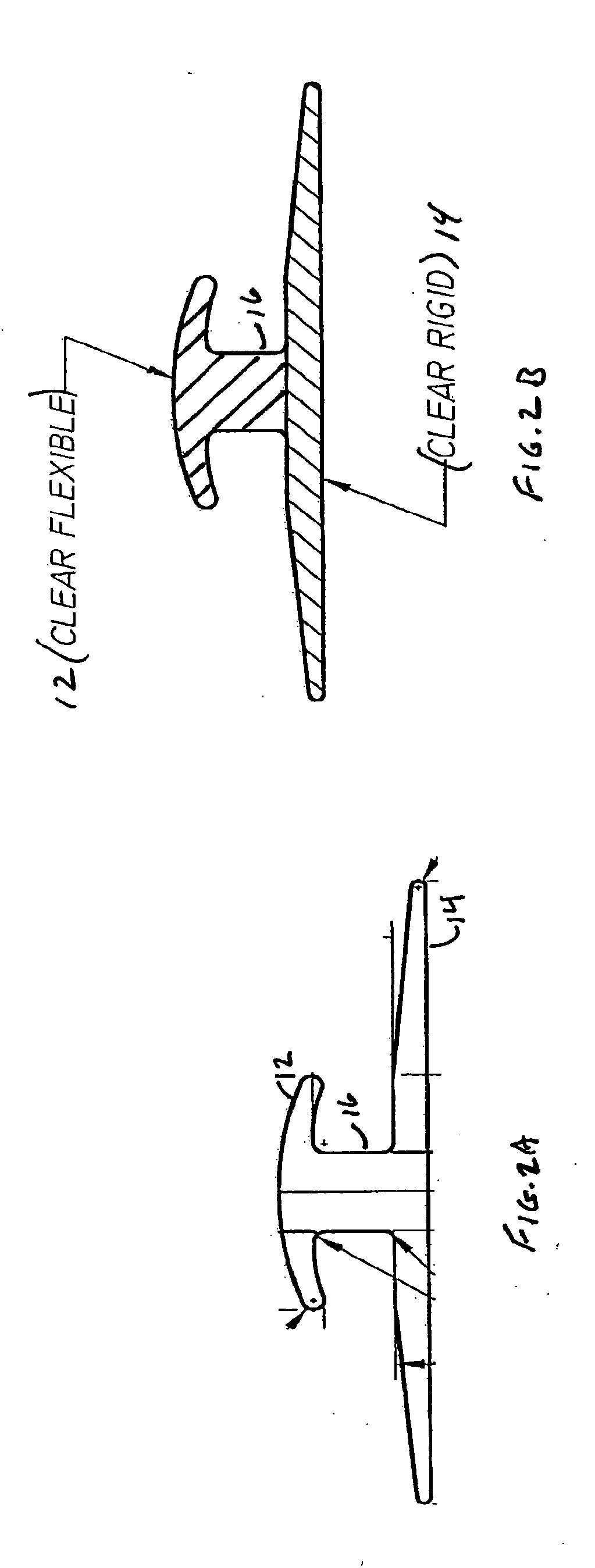

InactiveUS20060000176A1Improve sealingRoof covering using tiles/slatesLoad-supporting elementsEngineeringHardness

A divider bar for use with paneling, has a first and a second portion and a stem portion joining the first and second portions. The first and second portions are shaped and arranged to engage an edge region of at least one panel, and are made of a first and a second material, respectively. The first material is preferably more flexible than that of the second portion, and is such as to provide a good seal with a panel engaged by the divider bar. This characteristic of the divider bar can provide an expansion / contraction joint that maintains the seal even if the panel expands or contracts (e.g., due to temperature changes). Preferably, both materials are transparent and at least the first is colorless, the second in that case optionally having a coloring, or a decorative material being applied to the second portion of the divider bar to be visible through the transparent first portion. It is preferred that the product be made by extrusion, and especially by a co-extrusion process.

Owner:CRANE COMPOSITES

Dual axle skateboard, truck, and method

Improved trucks for skateboards, skateboards having improved trucks, and methods of obtaining or providing skateboards with improved trucks. Trucks have two axles or axes, two primary wheels, and two secondary wheels, and skateboards have eight wheels, four in front and four at the rear portion of the skateboard. The four primary wheels support most or all of the weight of the skateboard when the skateboard is on a flat surface, and the two secondary wheels support the weight of one portion of the skateboard (e.g., front or rear) when the primary wheels cross a crack (e.g., a sidewalk contraction joint). In various embodiments, the primary wheels are located outboard of the secondary wheels, are wider, or both. Further, in a number of embodiments, the axis of rotation or axle of the primary wheels remains parallel to that of the secondary wheels, whether the skateboard is going straight or turning.

Owner:KARSTEN MFG CORP

Joint grouting concrete for bridge expansion joint area and preparation method thereof

ActiveCN103570285AImprove impact resistance and energy dissipation capacityExtend your lifeArchitectural engineeringBasalt fiber

The invention discloses joint grouting concrete for a bridge expansion joint area. The joint grouting concrete comprises the following components in parts by weight: 1-3 parts of FERRO fibers, 2-4 parts of basalt fibers, 30-60 parts of steel fibers, 400-550 parts of cementing materials, 1000-1150 parts of basalt gravels, 650-800 parts of sand, 140-160 parts of water and 3-6 parts of additives. The invention also discloses a preparation method of the joint grouting concrete for the bridge expansion joint area. The joint grouting concrete for the bridge expansion joint area, which is disclosed by the invention, ensures that the impact energy consumption resistance of concrete is greatly enhanced under the condition that high bending resistance is provided, thereby prolonging the service life of the concrete and ensuring the driving safety.

Owner:JIANGXI GANYUE EXPRESSWAY +2

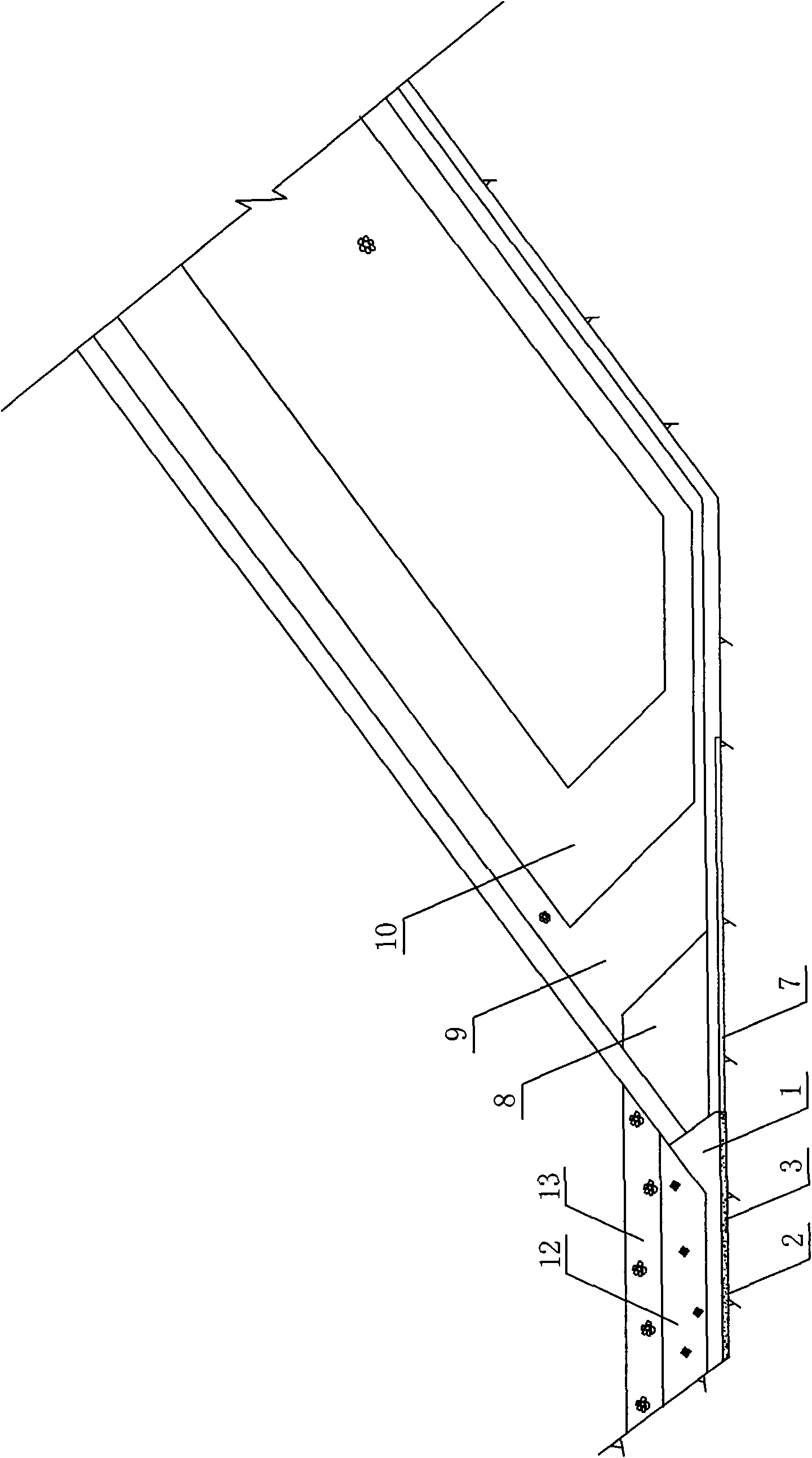

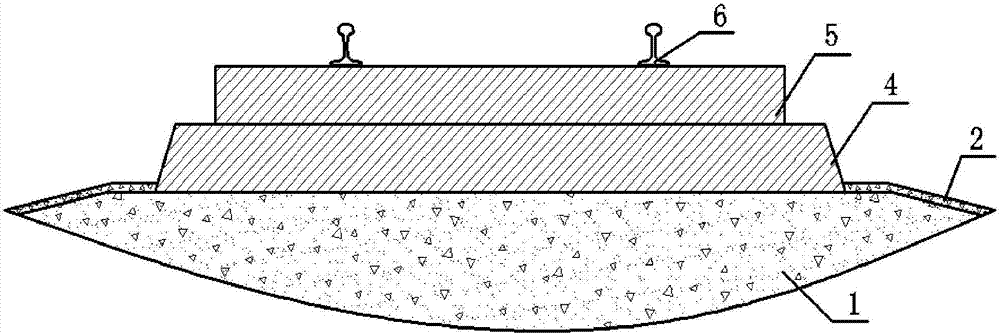

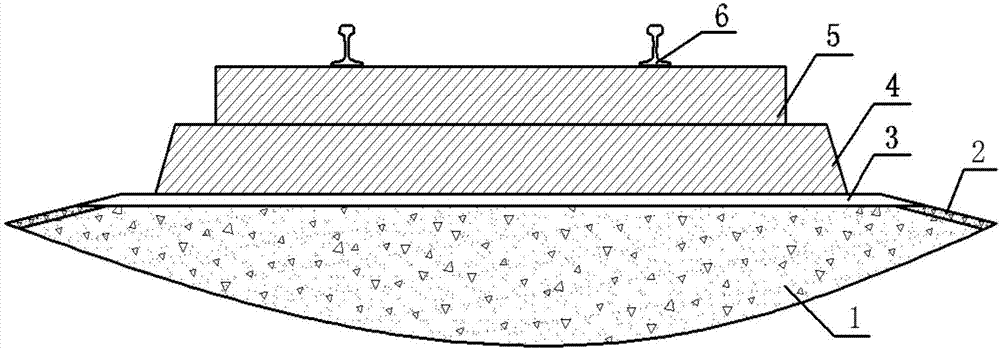

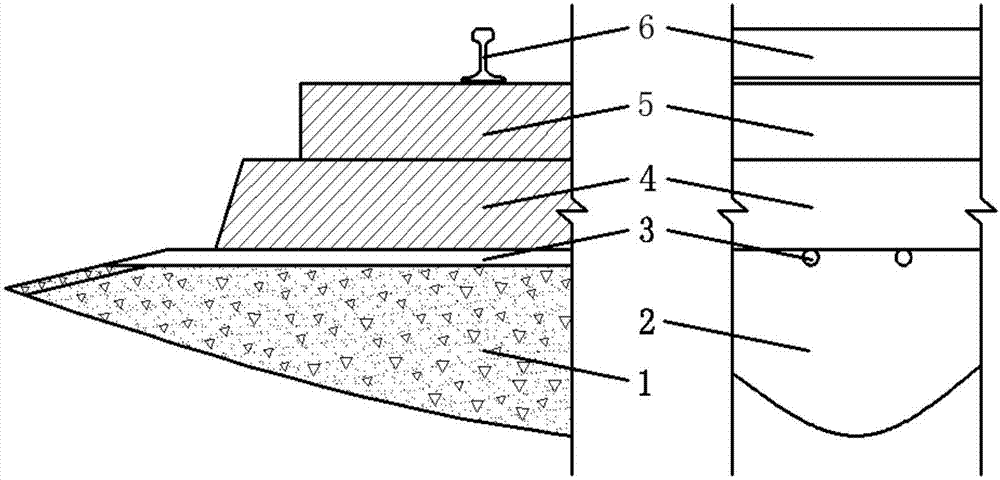

Face rockfill dam toe board structure constructed on completely weathered bed rock and construction method thereof

ActiveCN101644041AGuaranteed carrying capacitySolve the cracking problemEarth-fill damsRock-fill damsBedrockOn board

The invention relates to a face rockfill dam toe board structure constructed on a completely weathered bed rock and a construction method thereof. The invention aims at providing a face rockfill dam toe board structure constructed on a completely weathered bed rock and a construction method thereof. Due to the invention, a face rockfill dam toe board can be directly built on the completely weathered bed rock, thereby guaranteeing the safety of a dam body with the minimum project investment and the shortest construction period. The technical solution is as follows: the face rockfill dam toe board structure constructed on the completely weathered bed rock comprises a concrete toe board constructed on the completely weathered bed rock, wherein the toe board is downstream provided with an impervious connecting board; the top part of the impervious connecting board and a downstream pavement extend to filter material at the food of a downstream dam; an impervious blanket and waste residues are spread on the upper surface of the toe board; retraction gaps are arranged on the completely weathered bed rock and adjacent strongly-weathered or weakly-weathered bed rocks; and still water is arranged in the gaps. The face rockfill dam toe board structure is mainly used for face rockfill dam projects associated with deep and thick completely weathered bed rocks of two banks in conservancy andhydropower engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

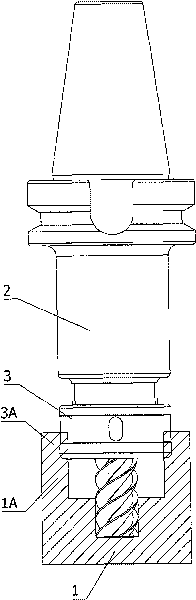

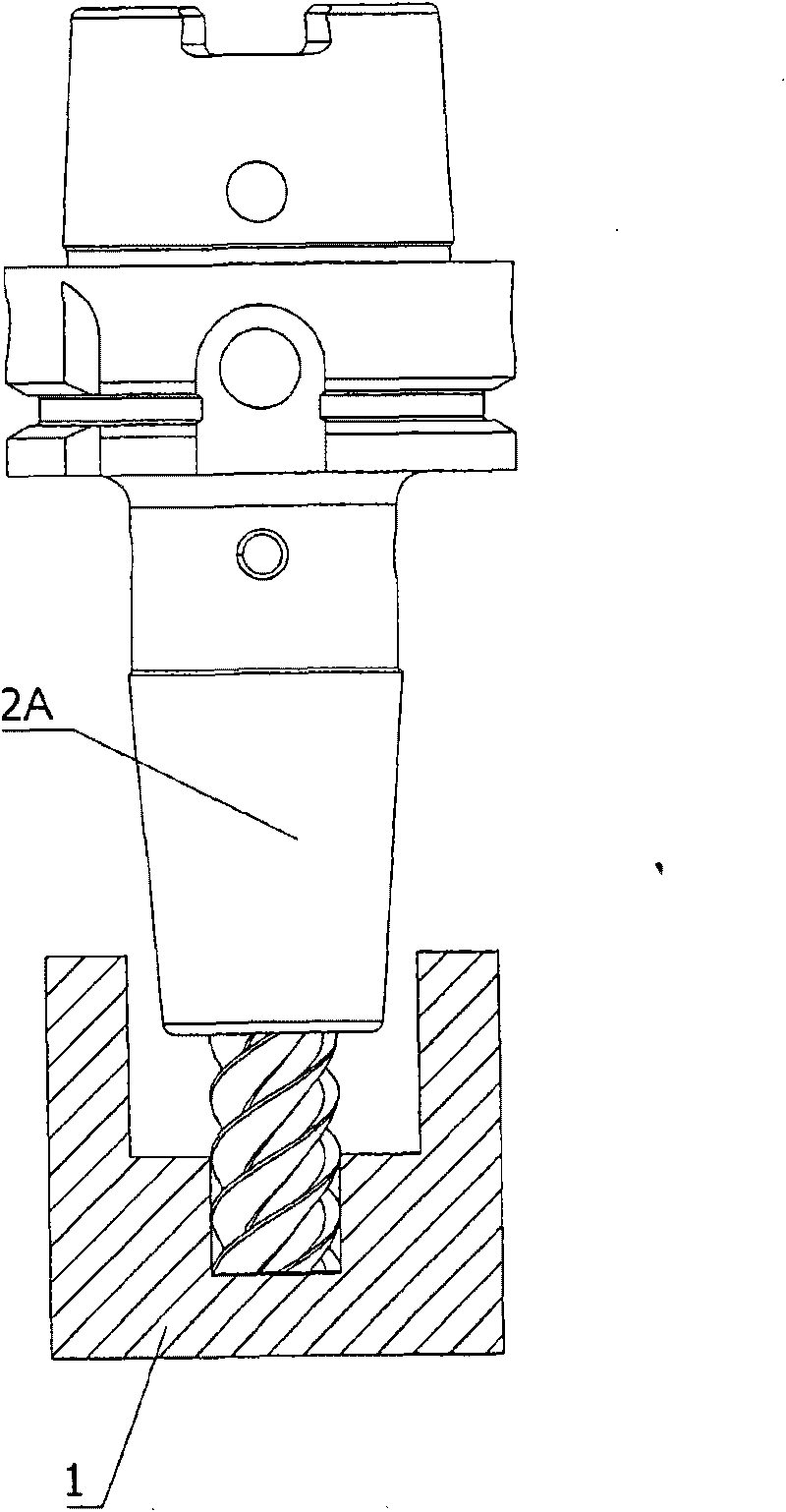

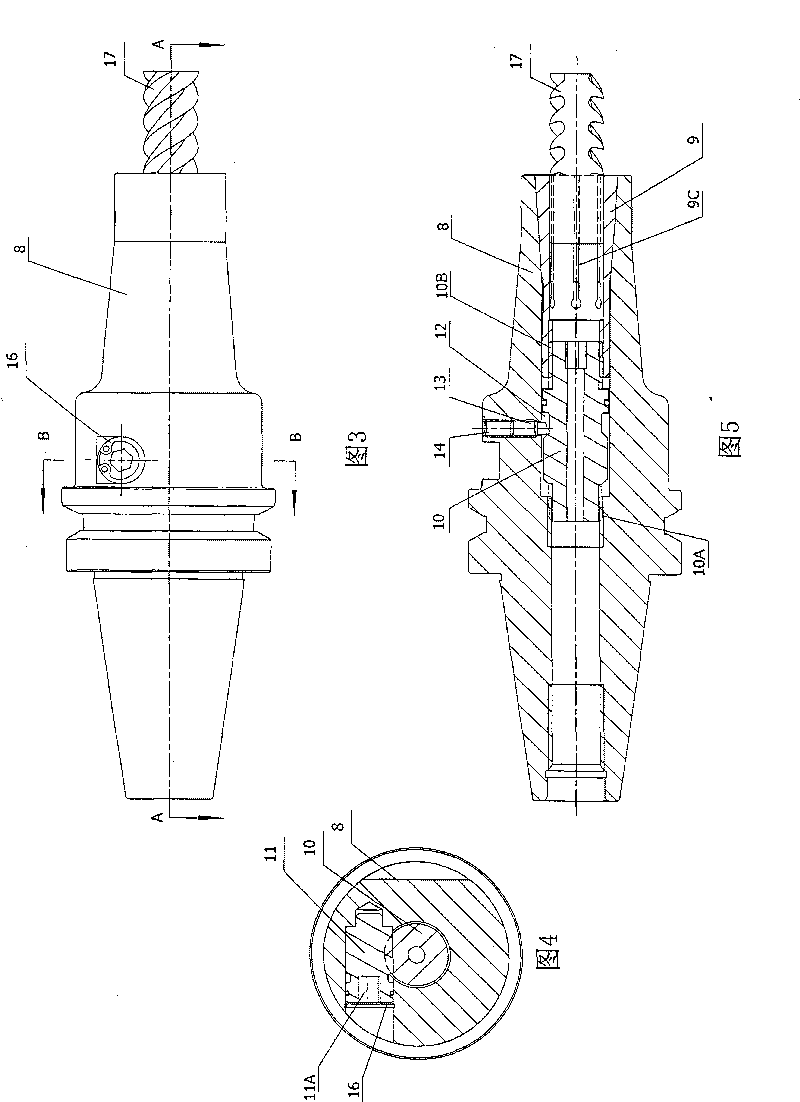

Worm-gear type collet chuck locking mechanism

InactiveCN101733671APrecise clamping and fixingReliable clamping and fixingPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention relates to a locking mechanism of machine tools and provides a lock device which is characterized by convenient replacement and regulation of tool, compact structure and high holding precision and can accurately, reliably and conveniently hold and fix the tool. The technical scheme of the invention is that a worm-gear type collet chuck locking mechanism comprises a main body having a cavity on a right half part; the right end of the cavity is of a cone shape; a cone-shaped collet chuck which is used for holding a knife handle and is matched with the cavity is arranged in the cavity; and the cone-shaped collet chuck is provided with a plurality of contraction joints along a cone-shaped bus direction. The inner side of the main body is provided with a pair of worm-gear mechanisms used for exerting an acting force on the cone-shaped collet chuck along the axial direction of the main body. A worm wheel in the worm-gear mechanism is coaxially arranged on the main body; the left end thereof is matched with the main body by the thread; the right end is matched with the left end of the cone-shaped collet chuck by the thread; and the thread directions of the left and right ends are reverse.

Owner:JIAXING YONGJIA PRECISION MASCH MFG CO LTD

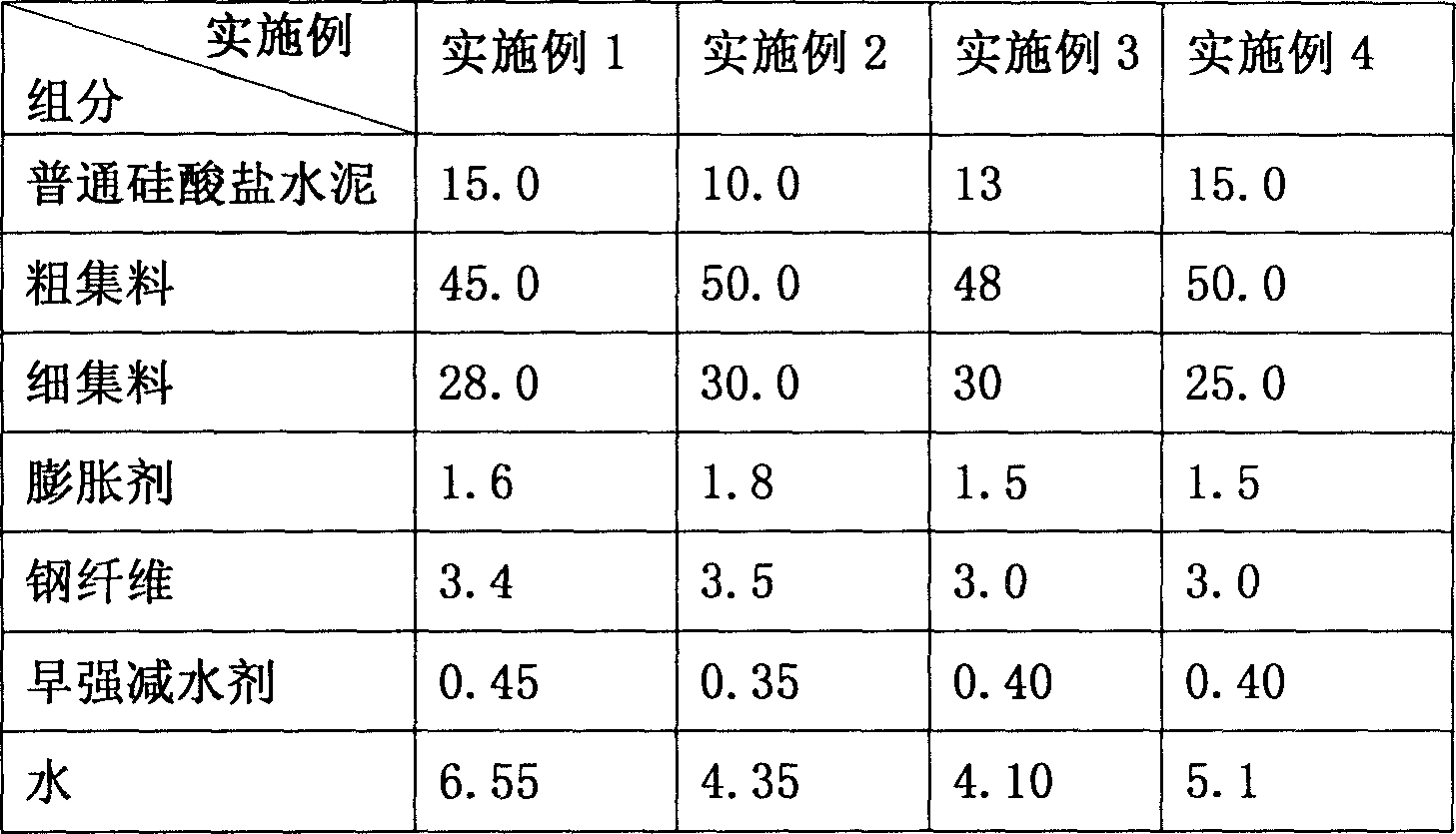

Early strength micro expansion steel fiber road concrete

The early strength microswelling steel fiber reinforced road concrete is used in building engineering. It consists of Portland cement 10-15 wt%, coarse aggregate 45-50 wt%, fine aggregate 25-30 wt%, water 4.1-6.55 wt%, expansion agent 1.5-1.8 wt%, steel fiber 3.0-3.5 wt%, early strength water reducing agent 0.35-0.45 wt%. By means of the steel fiber with high breaking strength, high impact strength and excellent wear resistance, the cement concrete road poured with the road concrete has shortened cure period, low maintenance cost, long service life, effectively reduced extension joint, less noise and environment friendship.

Owner:SHANGHAI JIAO TONG UNIV

Underground concrete structure expansion joint treatment structure and construction method thereof

InactiveCN105297782APrevent leakagePreserve the deformation functionArtificial islandsProtective foundationEngineeringHigh pressure

The invention discloses an expansion joint seepage treatment structure, constructed through a waterstop strip, of an underground concrete structure and a construction method of the expansion joint seepage treatment structure. Firstly, a slant grouting pipe is buried in one side of the seeping expansion joint to below the original buried waterstop strip, and foaming waterstop agents are injected for temporary water stopping; secondly, horizontal galvanized grouting pipes used subsequently are buried on the surface of the other side of the seeping expansion joint at intervals; thirdly, a galvanized steel plate and a sealing rubber plate which each correspond to an opening and are each provided with a V-shaped folding notch are customized, the waterstop sealing rubber plate, the galvanized steel plate and a gasket and a nut of a chemical bolt are sequentially installed, and the steel plate and the rubber plate are fixed in a screwed mode so that the expansion joint can be sealed; and finally, high-viscosity non-cured rubber liquid is injected into the expansion joint with high pressure, and a high-viscosity large-deformation waterproof layer is formed. According to the treatment method, three waterproof layers are formed, the structural design is scientific and ingenious, the construction process is simple, and the cost low. Therefore leakage can be completely prevented, the deformation function of the expansion joint is reserved, and the existing problem of seepage of the expansion joint is effectively solved.

Owner:SOUTHEAST UNIV

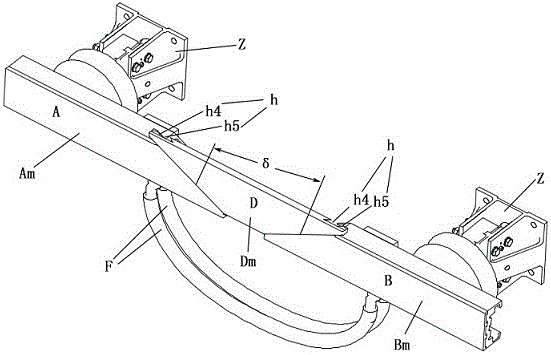

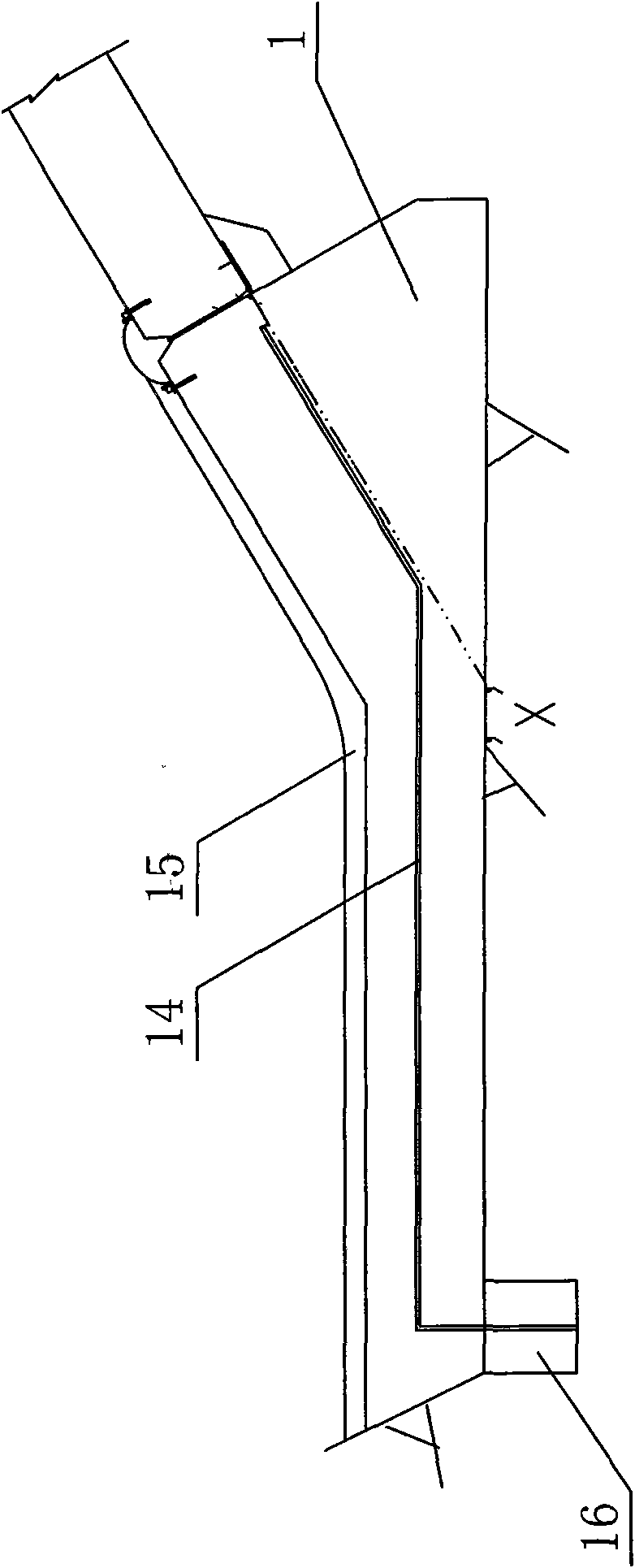

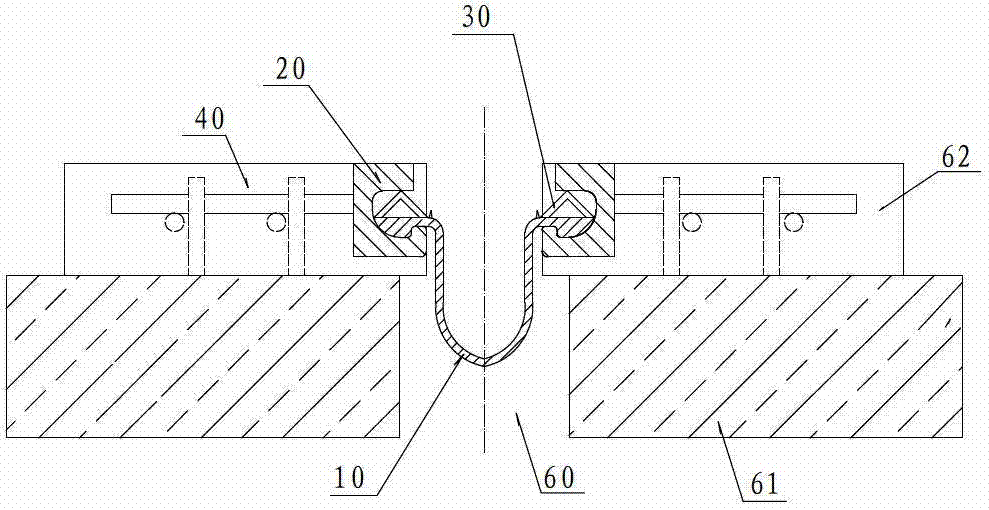

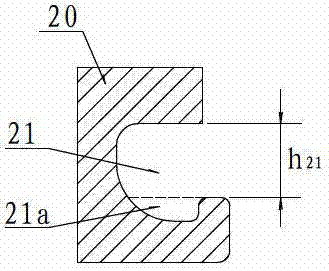

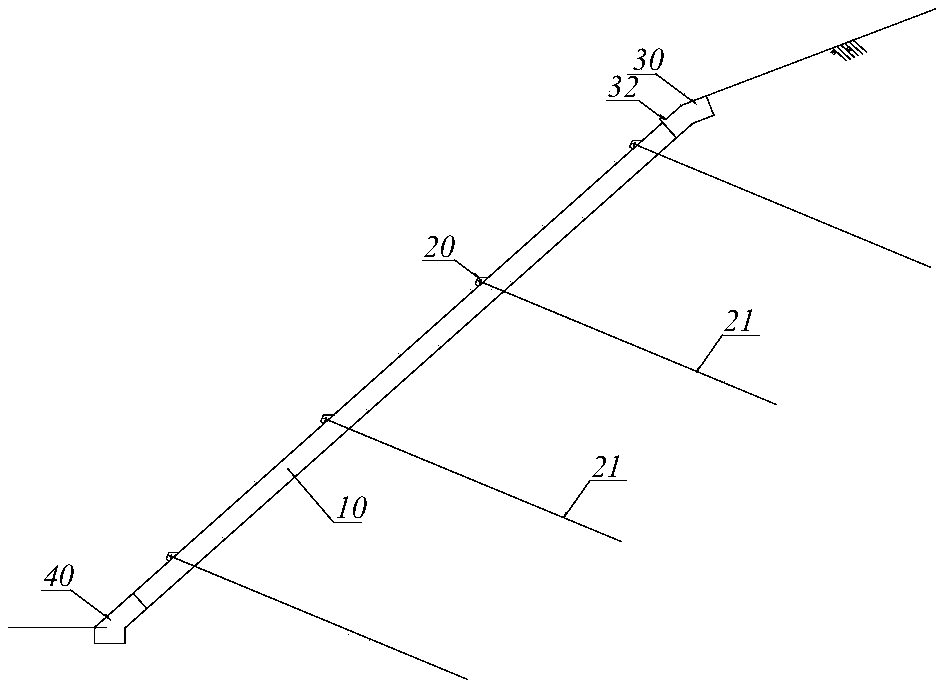

Changeable retractor device for railroad bridge

InactiveCN102787556ASolve the disadvantagesEasy to installBridge structural detailsEngineeringMechanical engineering

The invention discloses a changeable retractor device for a railroad bridge. A waterproof ribbon can be conveniently changed under a track base plate or a track bed under the condition of keeping normal use of a top track structure. The device comprises a pair of connection strips (20) fixed on two side walls of a contraction joint (60) via an anchorage member (40) and a waterproof ribbon (10) with two edges connected with the connection strips (20), wherein the connection strips (20) are provided with anchorage grooves (21) stretching towards a full length direction. Downward convex anchorage location bosses (11) are arranged at two edges of the waterproof ribbon (10), and the section shapes of the anchorage location bosses (11) are matched with the section shapes of lower grooves (21a) of the anchorage grooves (21); two edges of the waterproof ribbon (10) are pulled into the anchorage grooves (21) from the longitudinal ends of the connection strips (20); and a lock strip (30) is pressed in a gap between the upper surface of the waterproof ribbon (10) and the tops of the anchorage grooves (21) so that the waterproof ribbon (10) is in anchored connection with the connection strips (20).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

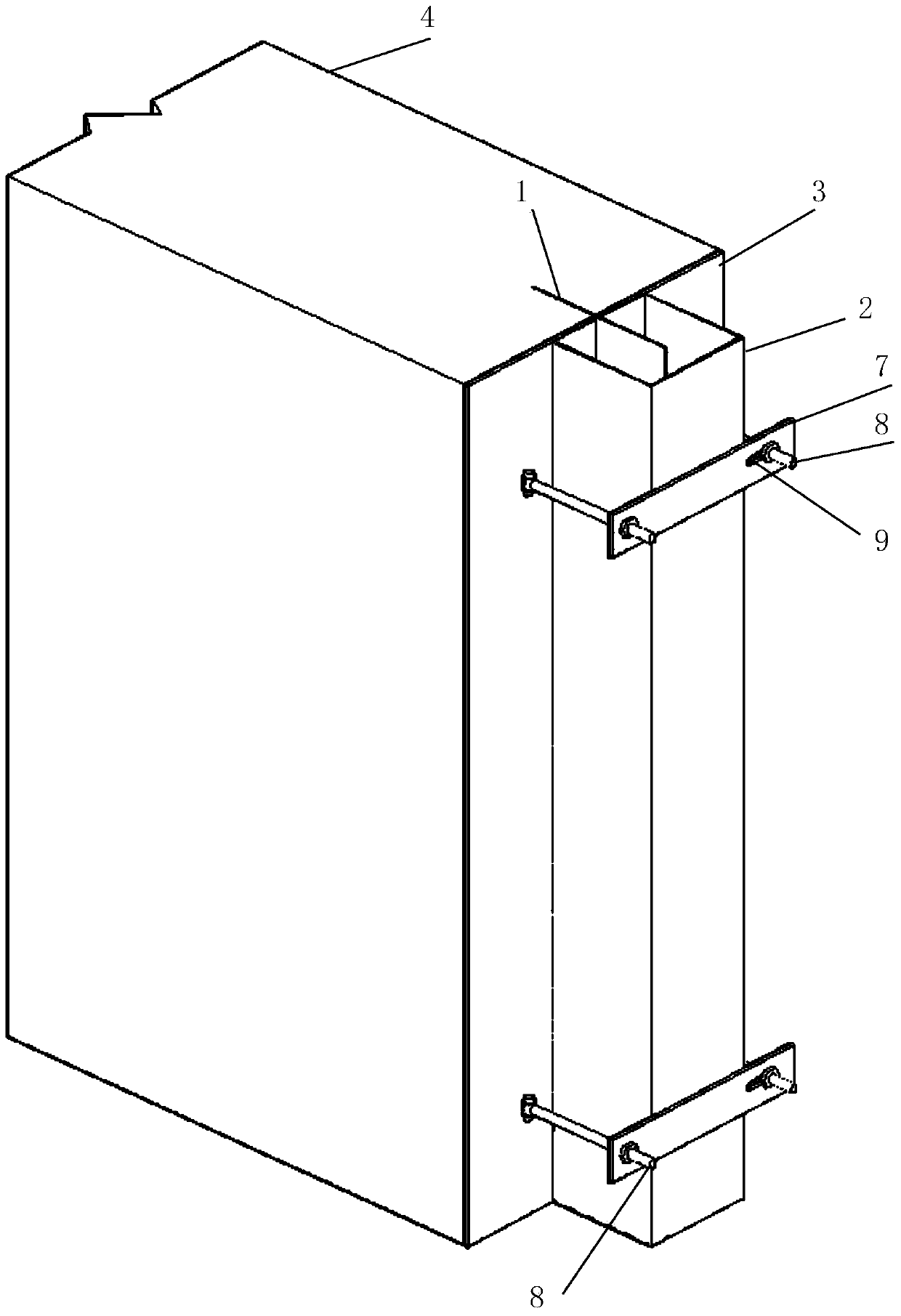

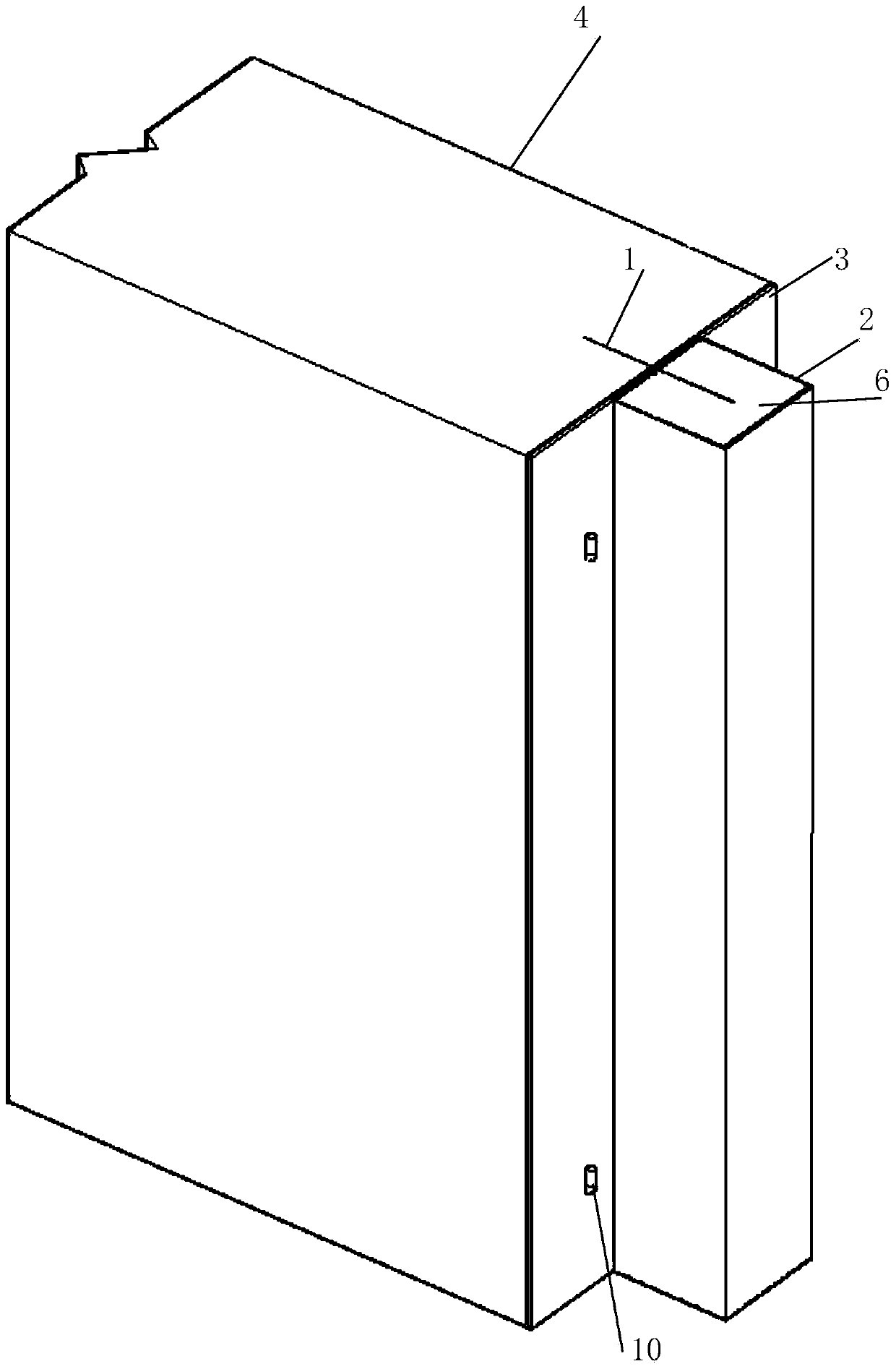

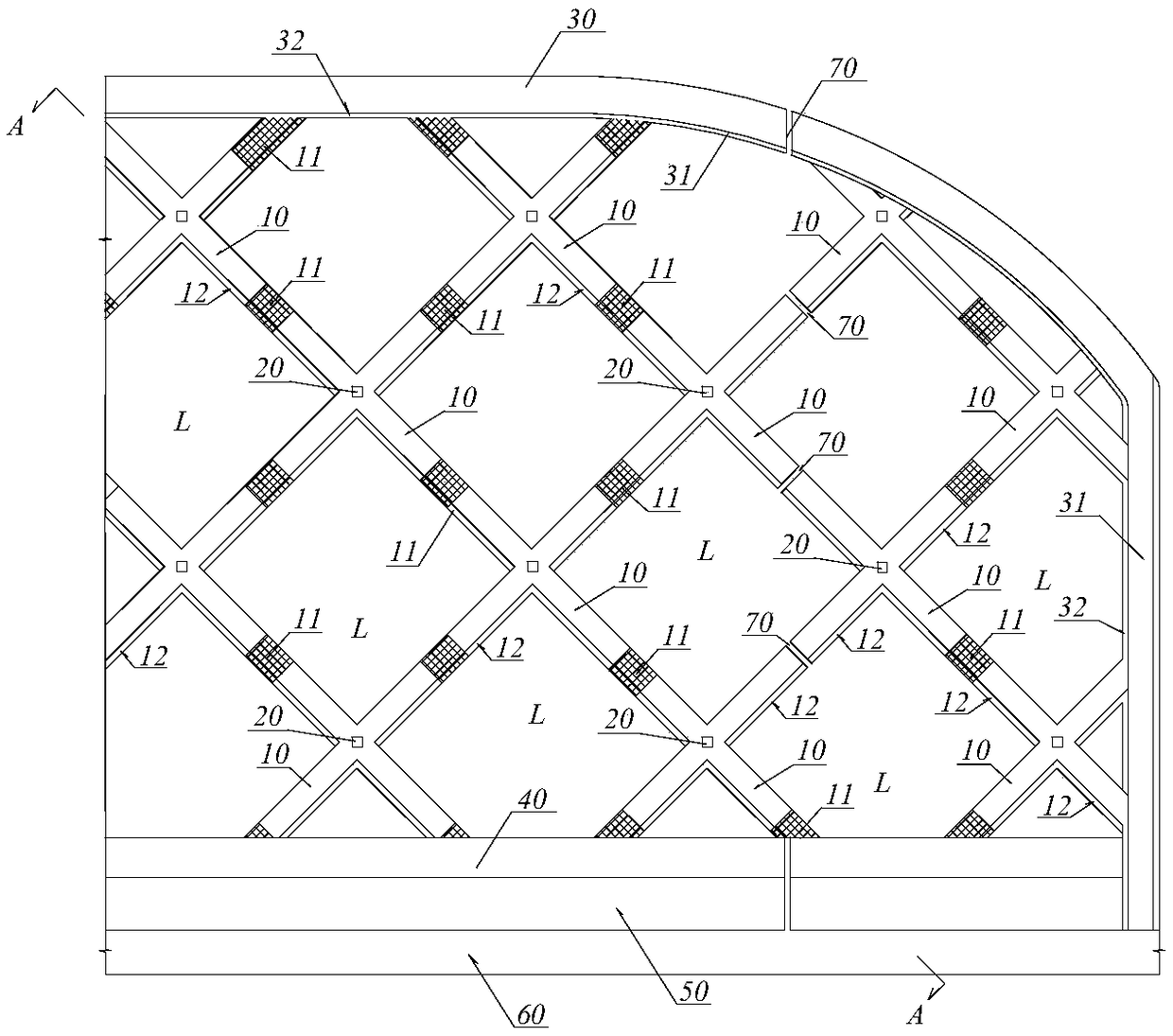

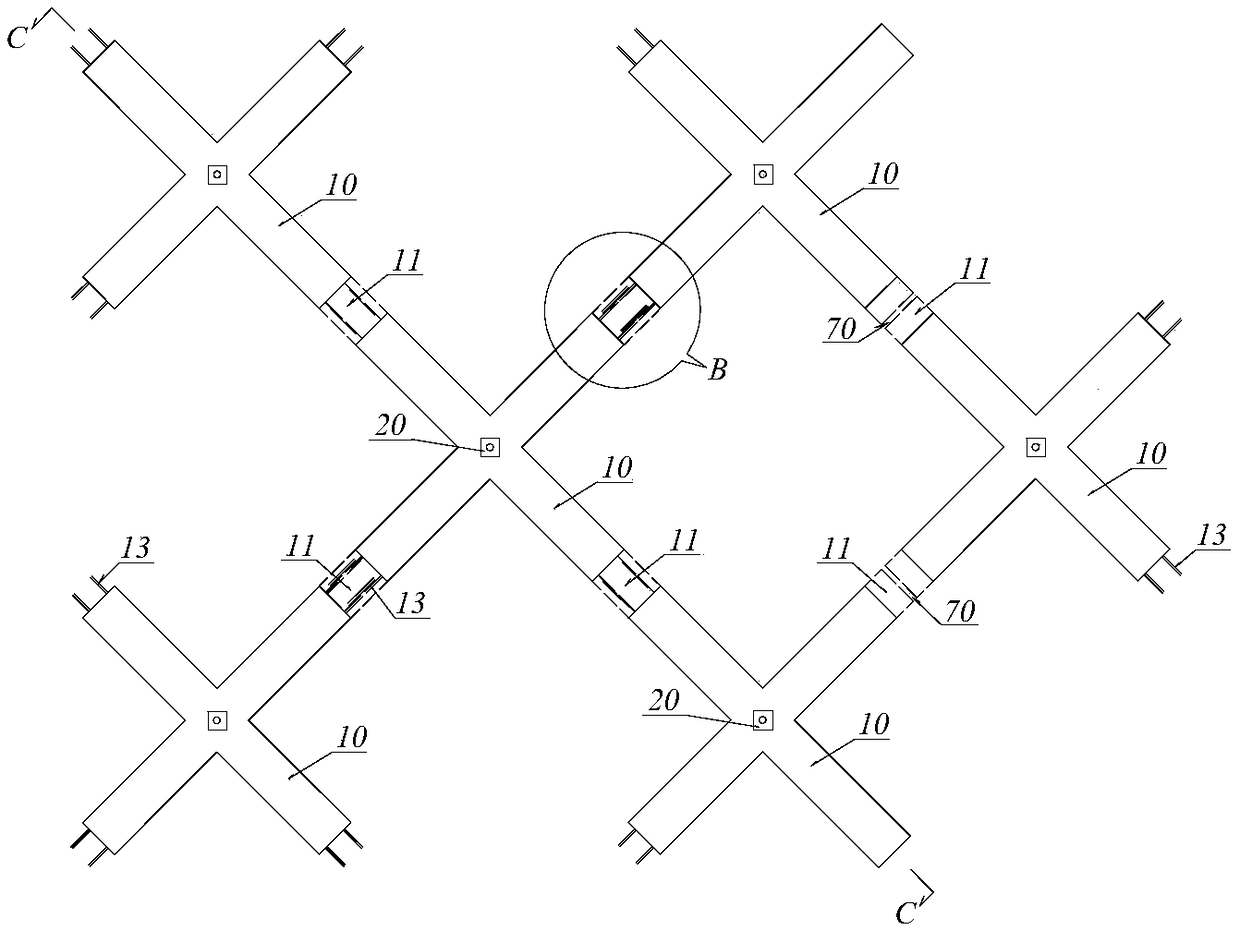

Split mounting type anchor frame beam structure and construction method thereof

PendingCN109356173AQuality improvementIncreased durabilityExcavationsBulkheads/pilesReinforced concreteButt joint

The invention relates to a split mounting type anchor frame beam structure and a construction method thereof. By means of the split mounting type anchor frame beam structure and the construction method, the construction efficiency and the construction quality of an anchor frame beam are effectively improved, and the overall supporting effect of the anchor frame beam structure is improved. The split mounting type anchor frame beam structure comprises reinforced concrete frame beams embedded under the slope surface of a side slope and anchor rods arranged at joints of the reinforced concrete frame beams, the inner ends and the outer ends of rod bodies of the anchor rods are correspondingly connected with a rock layer in a slope body and the reinforced concrete frame beams in an anchored manner. Each reinforced concrete frame beam is formed by split mounting of a frame beam prefabricated unit provided with two cross-shaped limbs and cast-in-place concrete sections, the corresponding limbsare in butt joint through the cast-in-place concrete sections between the end faces, or an expansion joint is formed through two disconnected cast-in-place concrete sections; and each anchor rod is composed of a steel anchor rod, a nut, a washer and a steel backing plate, wherein the nut, the washer and the steel backing plate are arranged at the exposed end of the steel anchor rod, and low prestress is applied to the steel anchor rod by screwing the nut.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Renovation method for treating mud pumping of plate-type ballastless track railway roadbed

The invention discloses a renovation method for treating mud pumping of a plate-type ballastless track railway roadbed. Drilling is conducted on the surface layer of a foundation bed through a special horizontal drilling machine, and then the method that hot air is injected into grouting hole passageways is adopted; accumulated water in a mud pumping disease area is subjected to treatment, and grouting is conducted in grouting holes after accumulated water treatment is completed; before grouting, telescopic seams of a base plate, cracks of the side edges and orifices of the opposite sides of the grouting holes are subjected to sealing treatment, and then grouting is successively conducted in the hole passageways according to a certain sequence; a uniform and compact water insulation layer with the certain strength is formed between the base plate and the surface layer of the foundation bed after grouting is completed; and the water insulation layer can obstruct water of cracks on the upper portion from invading into the surface layer of the foundation bed and can also block fine particle soil in the surface layer of the foundation bed on the lower portion to move upwards. According to the novel renovation method for treating mud pumping of the plate-type ballastless track railway roadbed, the mud pumping disease of the plate-type ballastless track railway roadbed can be well governed.

Owner:ZHEJIANG UNIV

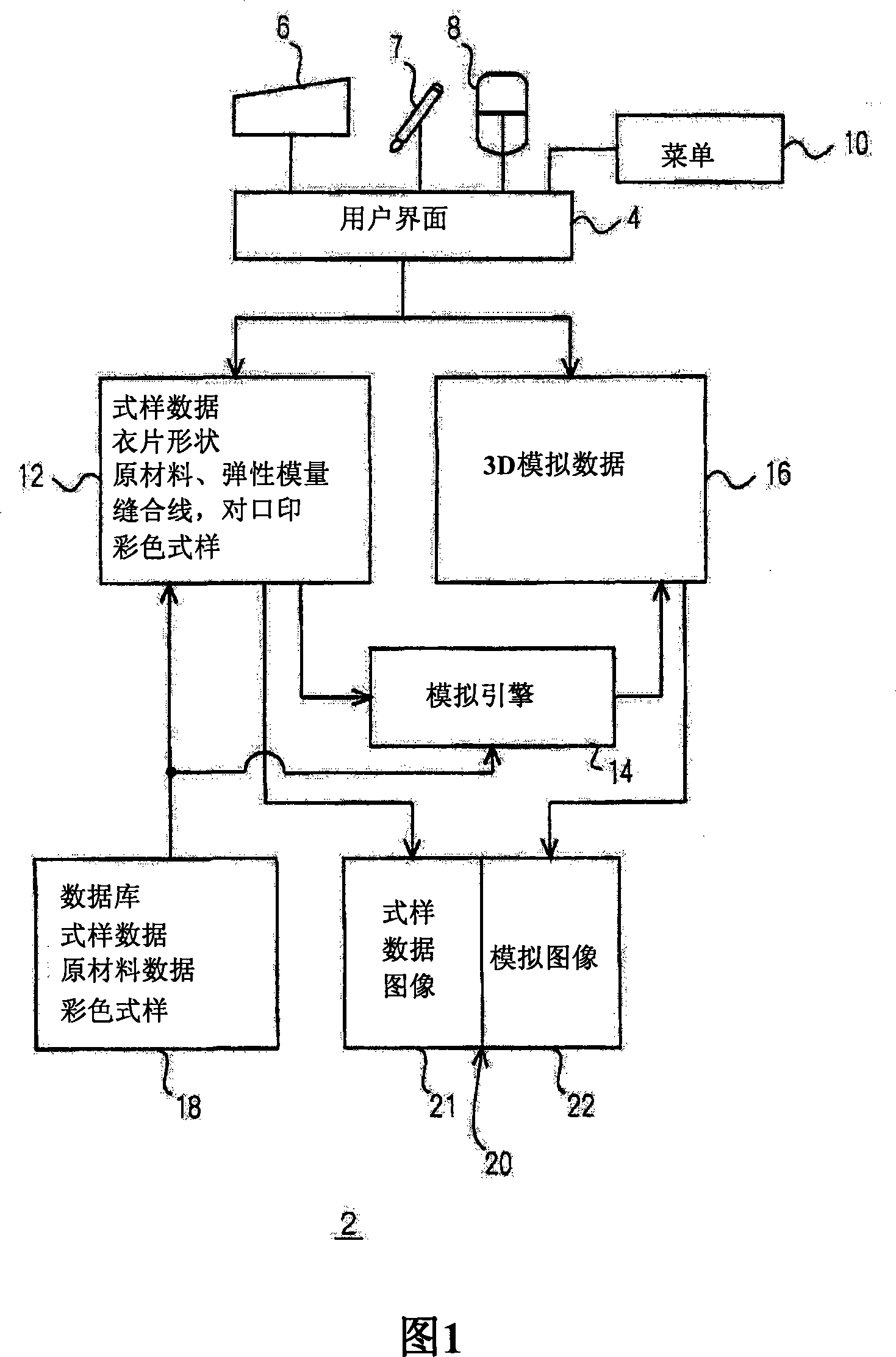

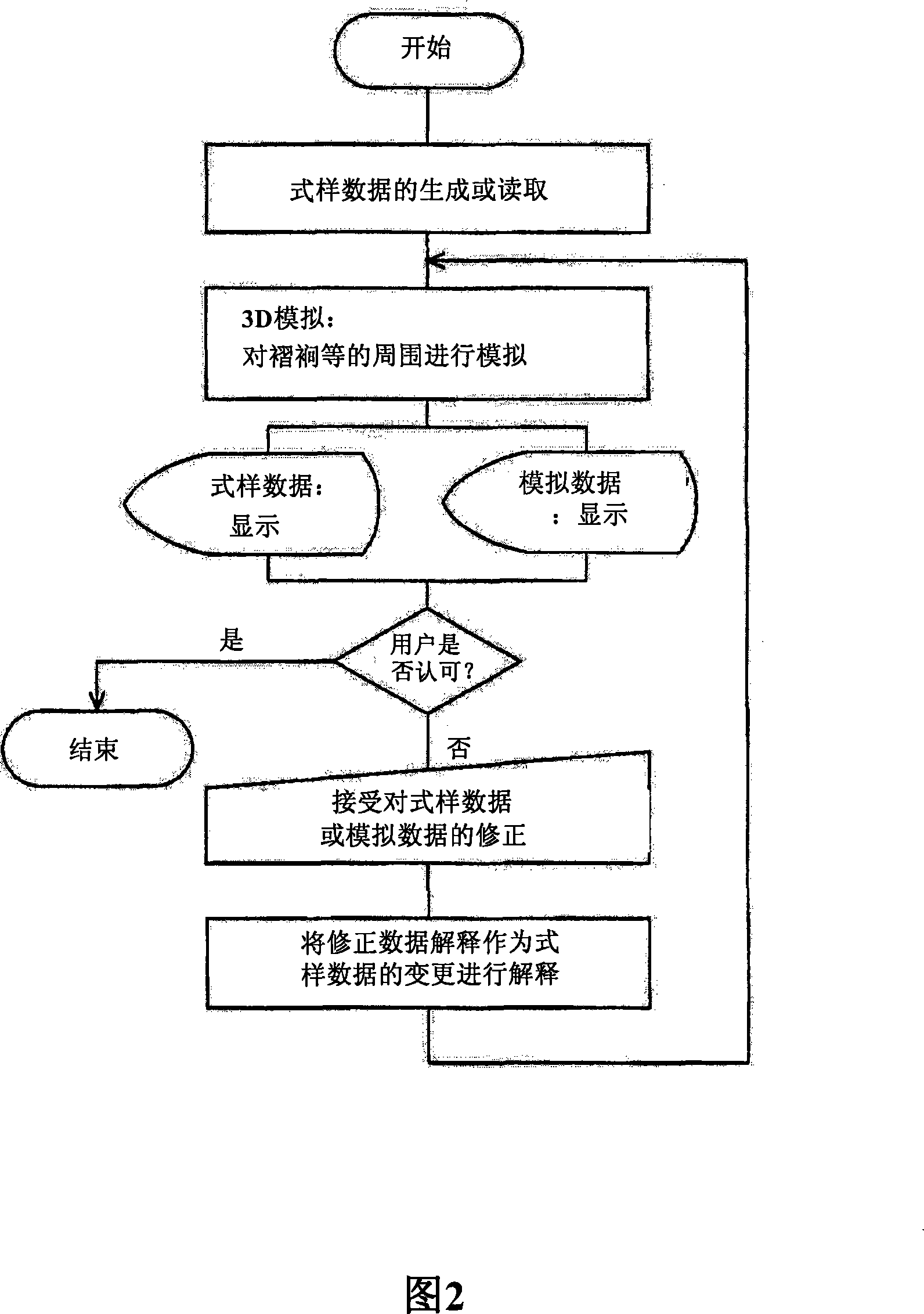

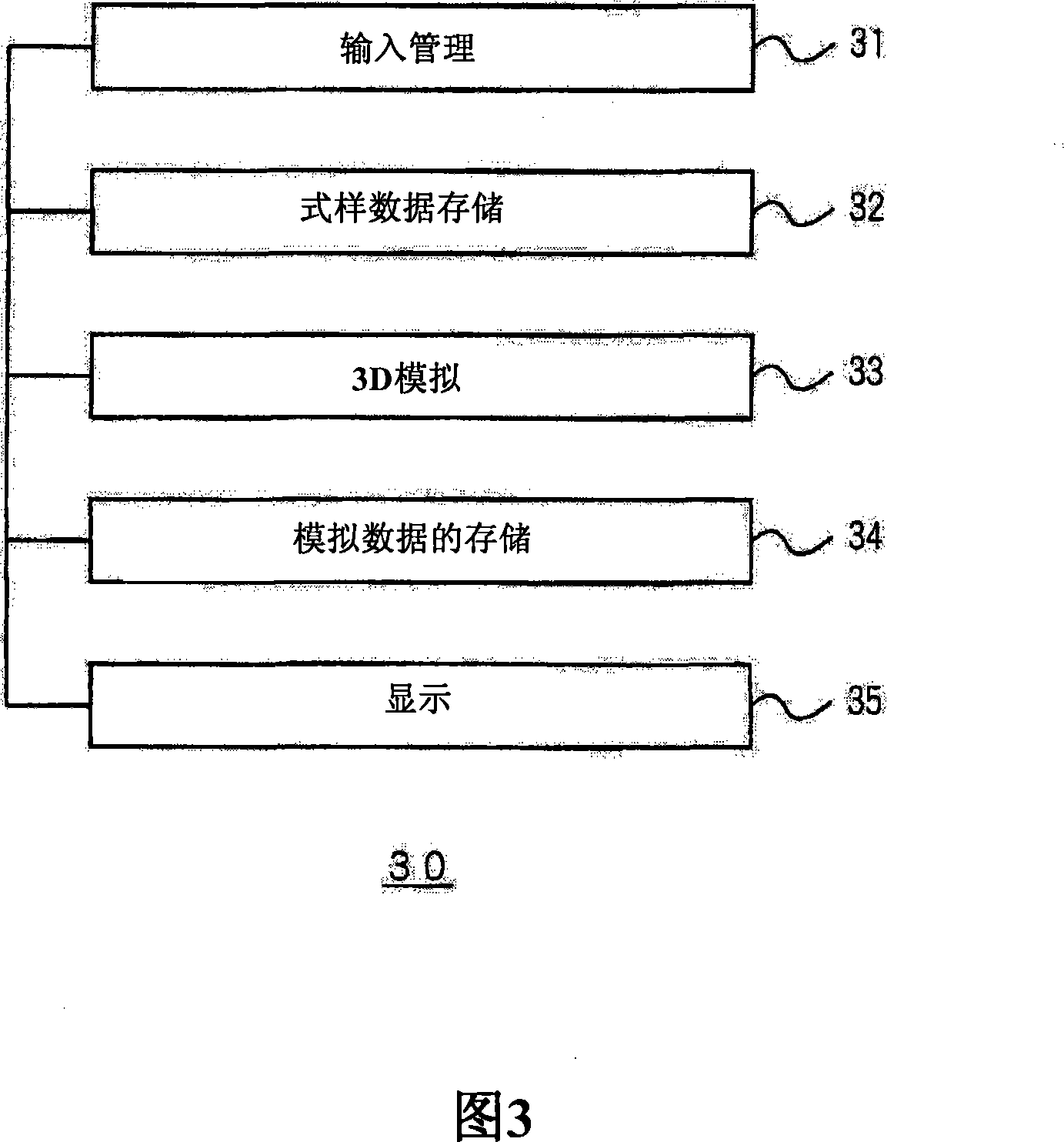

Device, method and program for generating pattern of cloth and silk

ActiveCN101209134AEasy Stereo DesignOptimize layoutDesign optimisation/simulationSpecial data processing applicationsDisplay deviceChange patterns

Storing pattern data on a memory portion (12), and implementing triaxiality simulation of the peripheral of contraction joint and pleat etc., then displaying on a display (20). In relative to the pattern data or analog image on the display, when user inputs alteration, to change pattern data and simulate again. For the vertical sewing parts of contraction joint and pleat etc., it is able to simulate with the pattern at one time, so as to design and use the pattern of contraction joint and pleat etc. in conversational mode.

Owner:SHIMA SEIKI MFG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com