Structure of continuously reinforced link road pavement for seamless bridge

A technology for connecting road surfaces and seamless bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as maintenance and replacement of expansion joints, achieve the effects of reducing maintenance costs, obvious social benefits, and improving driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

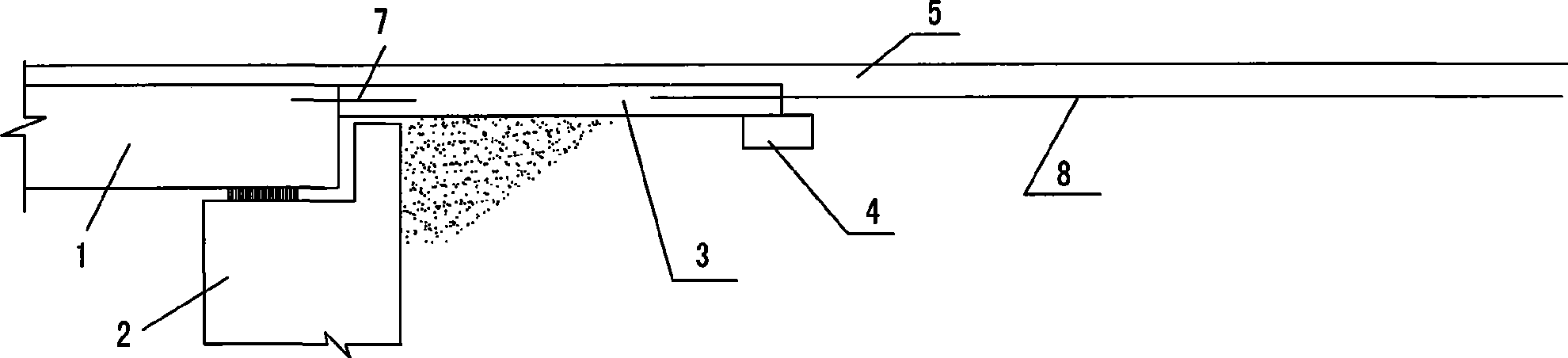

[0012] Such as figure 1 As shown, the main girder 1 with continuous structure or bridge deck is installed on the semi-integral or integral abutment 2, the near abutment end of the butt plate 3 is connected with the main girder 1 through the main rib 7, and the far abutment end of the butt plate 3 is placed on the corbel 4 On the one hand, the connection line surface 5 is connected to the butt plate 3 by using a single-layer full-length steel bar 8 set in a full width within a certain range, and the bridge joint of the seamless bridge is cancelled.

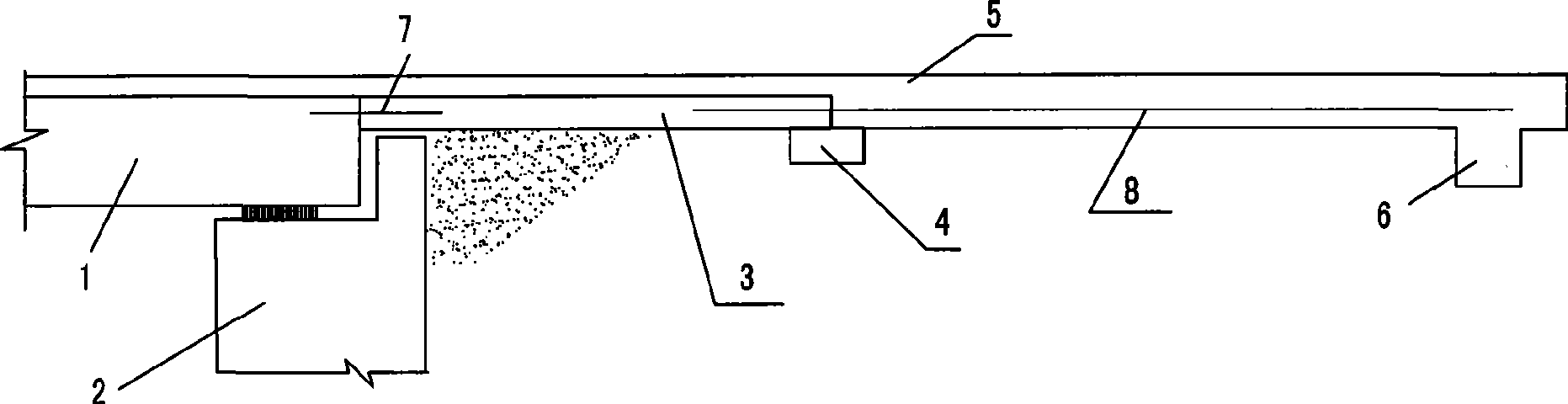

[0013] Such as figure 2 As shown, the main girder 1 with continuous structure or bridge deck is installed on the semi-integral or integral abutment 2, the near abutment end of the butt plate 3 is closely connected with the main girder 1 through the main reinforcement 7, and the far abutment end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com