Patents

Literature

33 results about "Integral abutment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

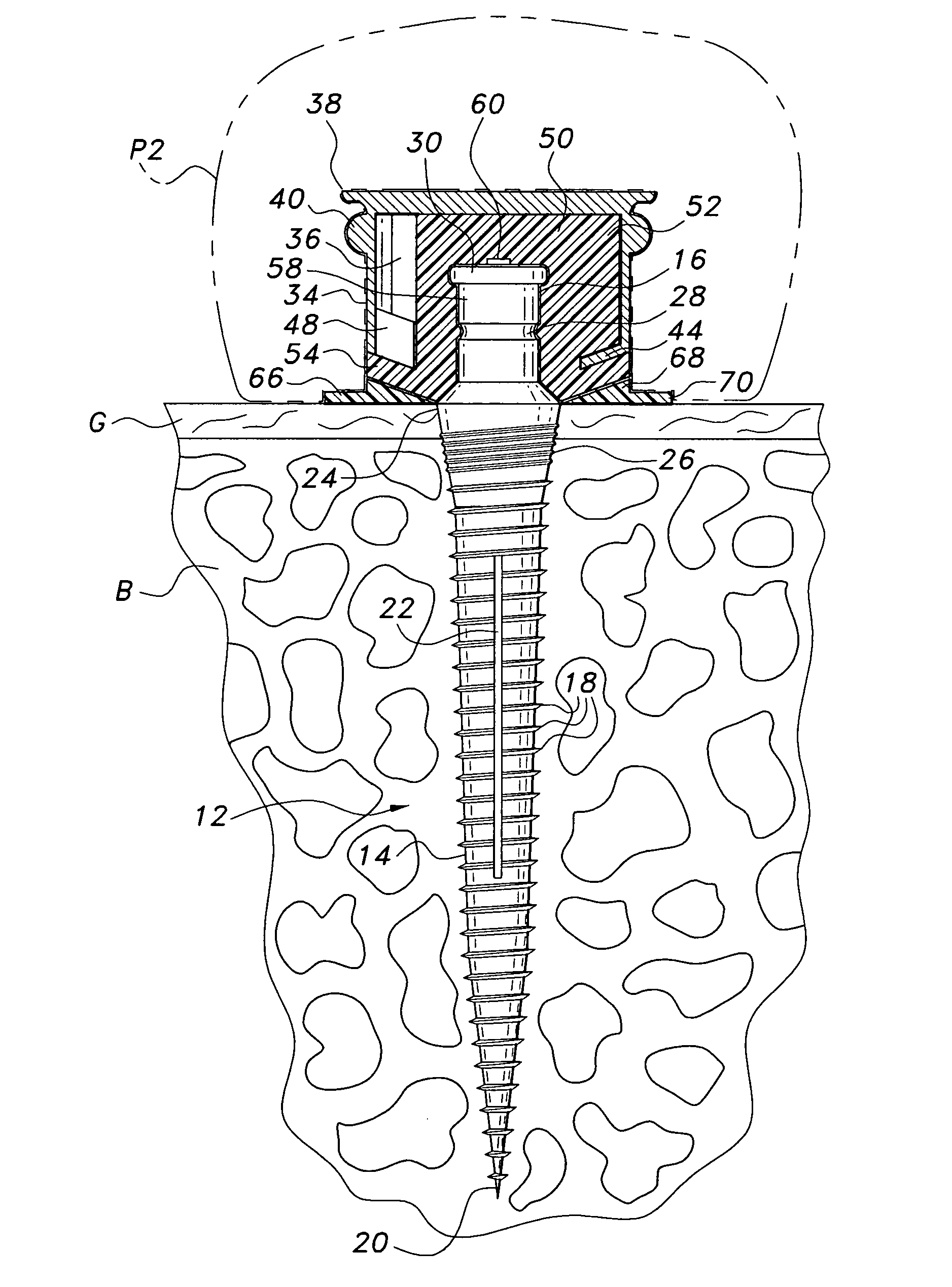

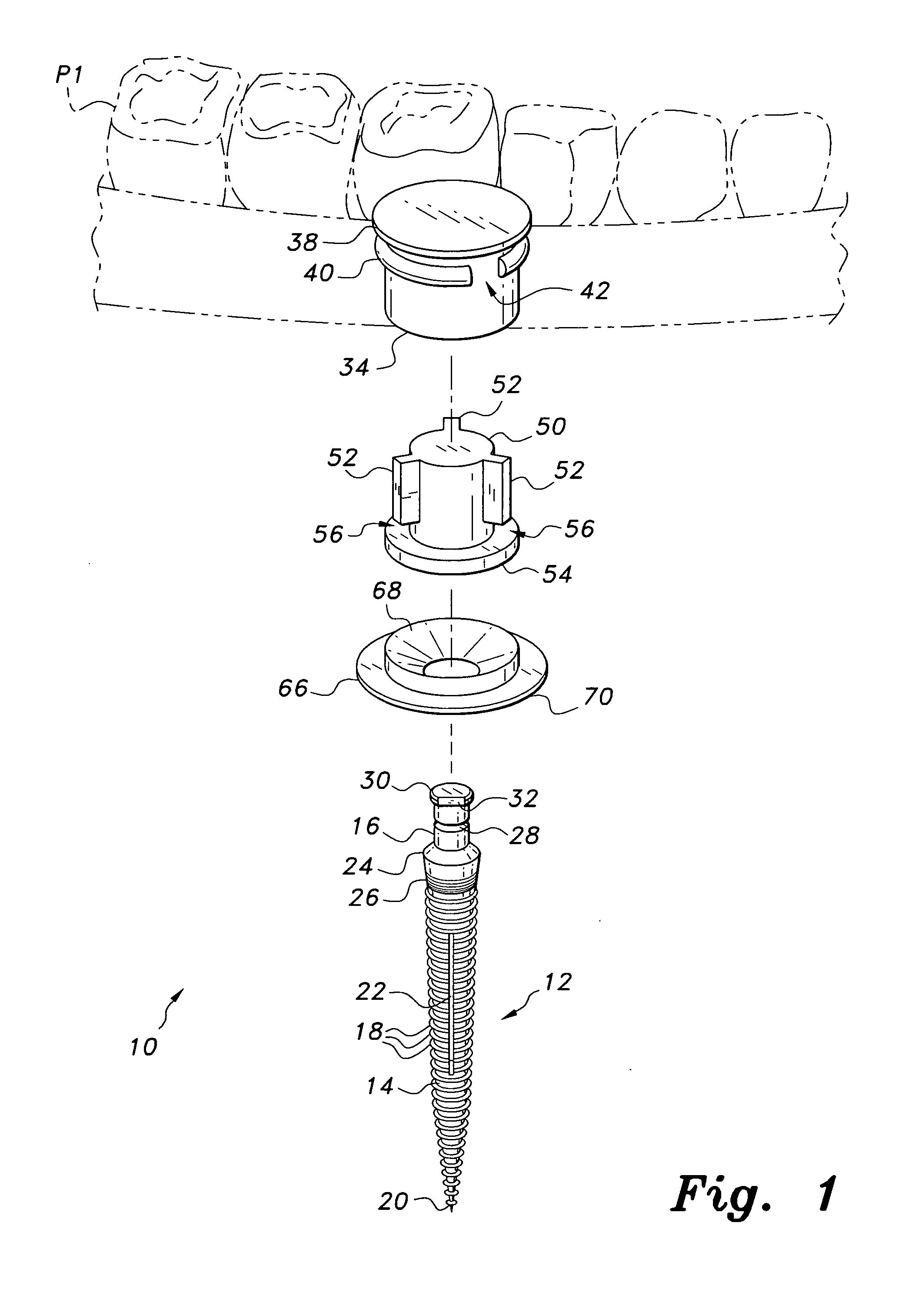

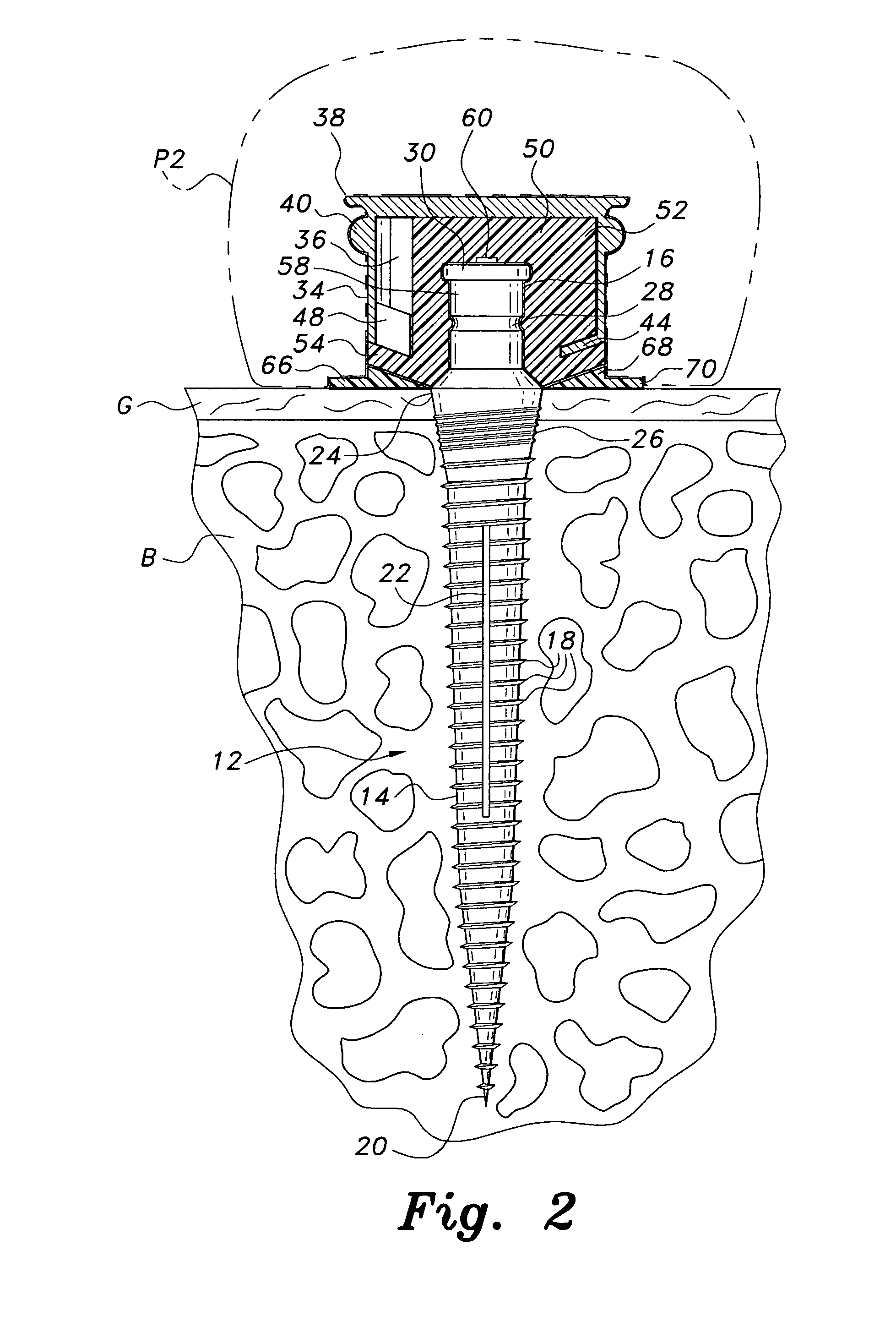

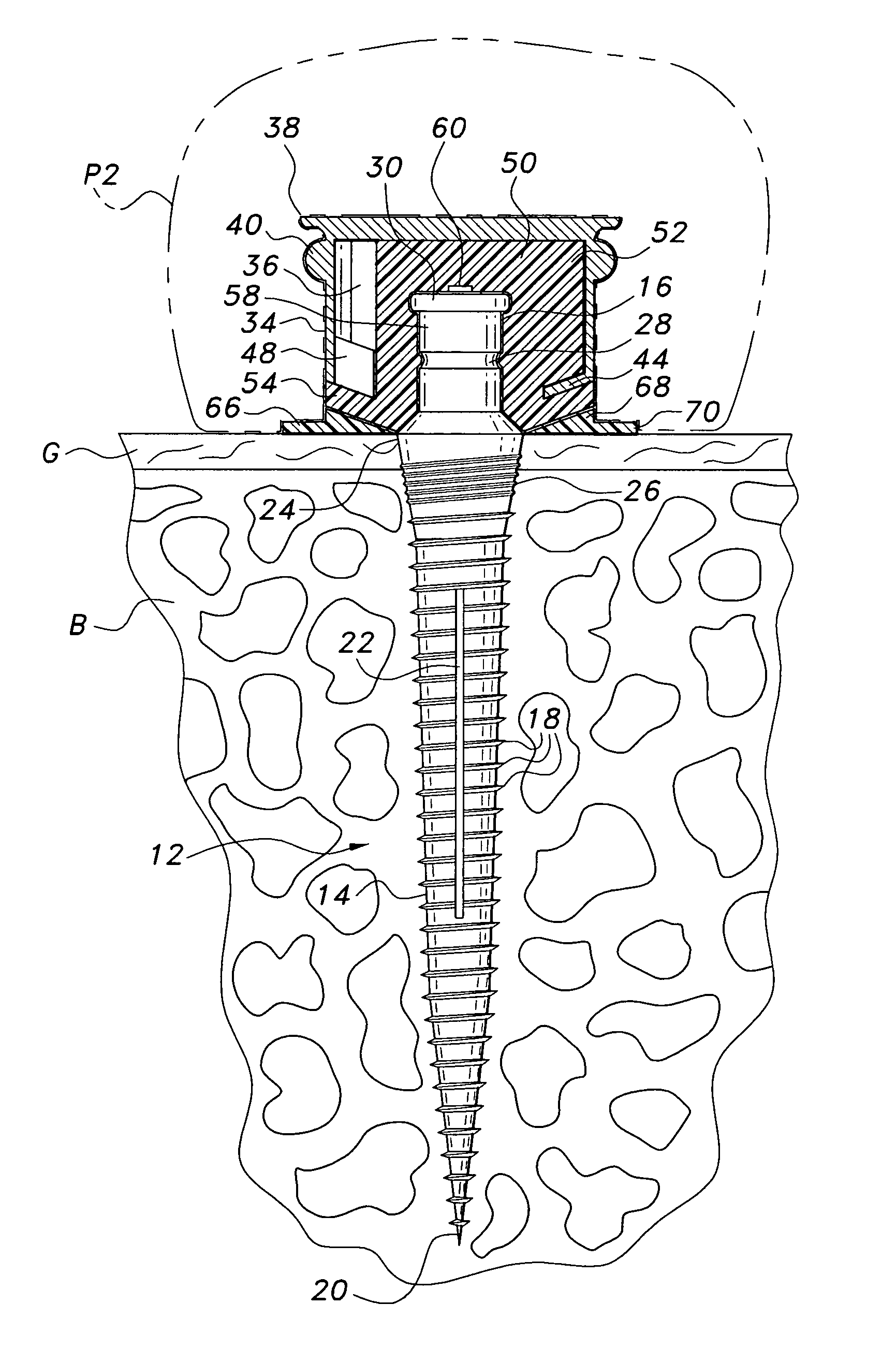

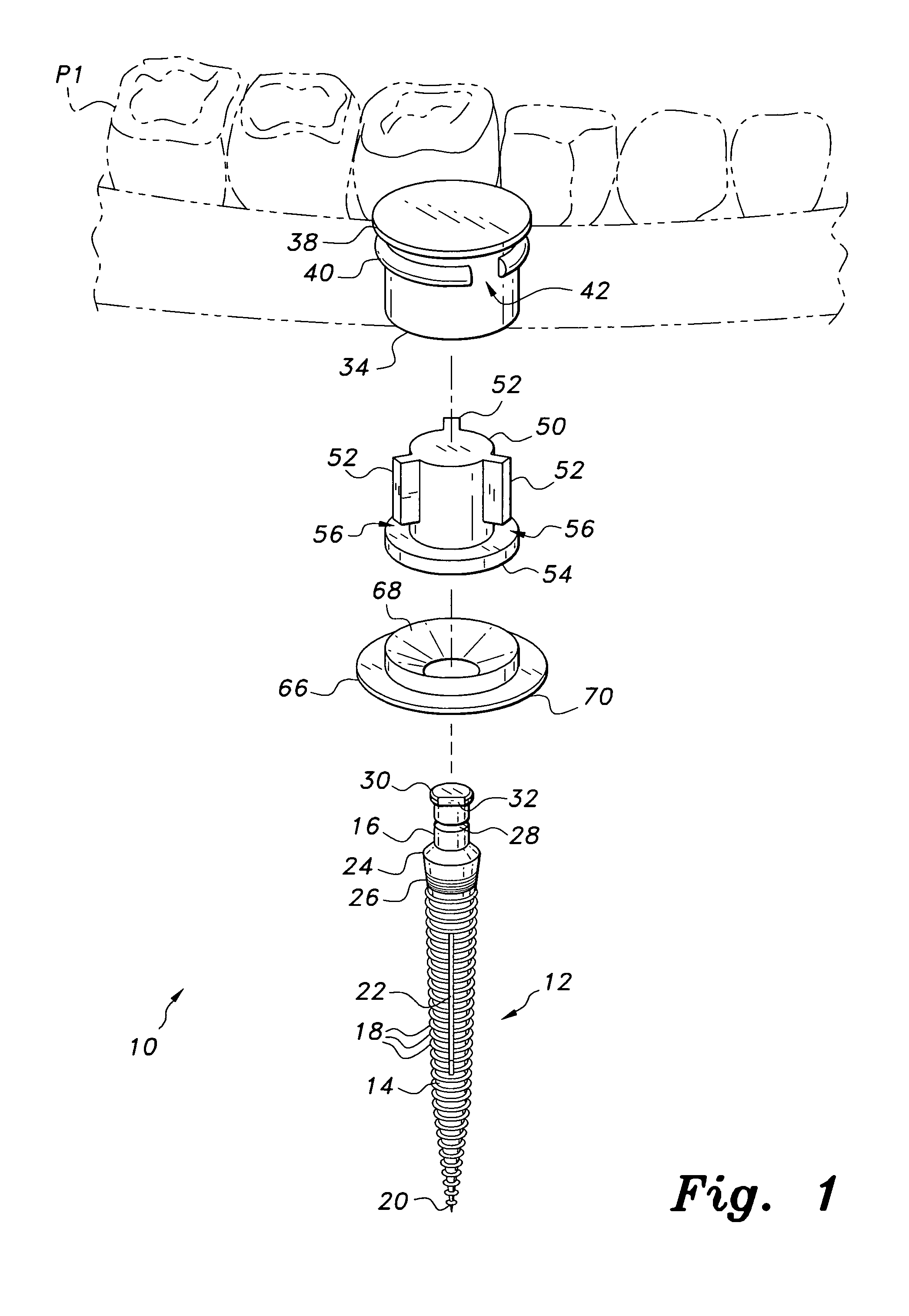

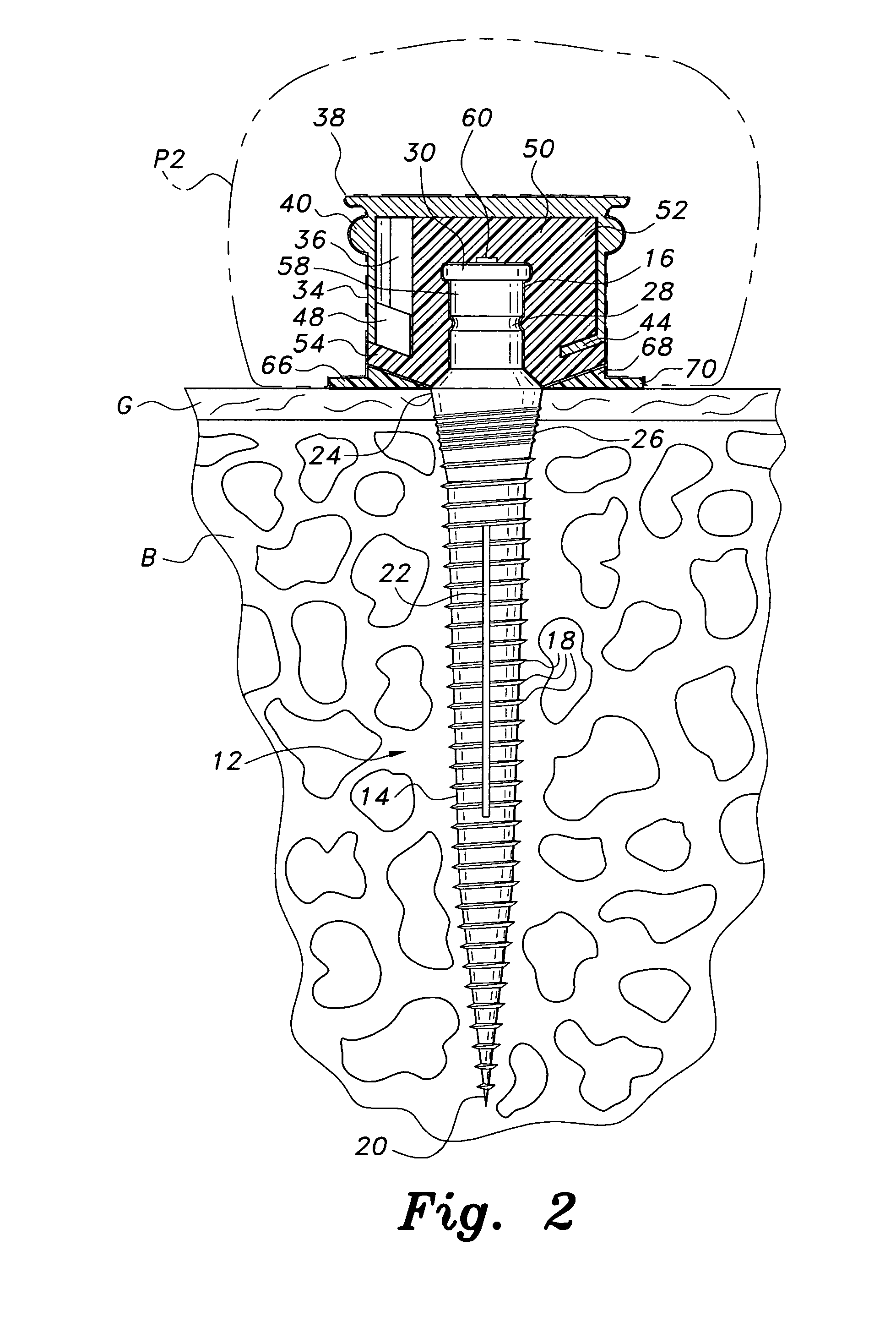

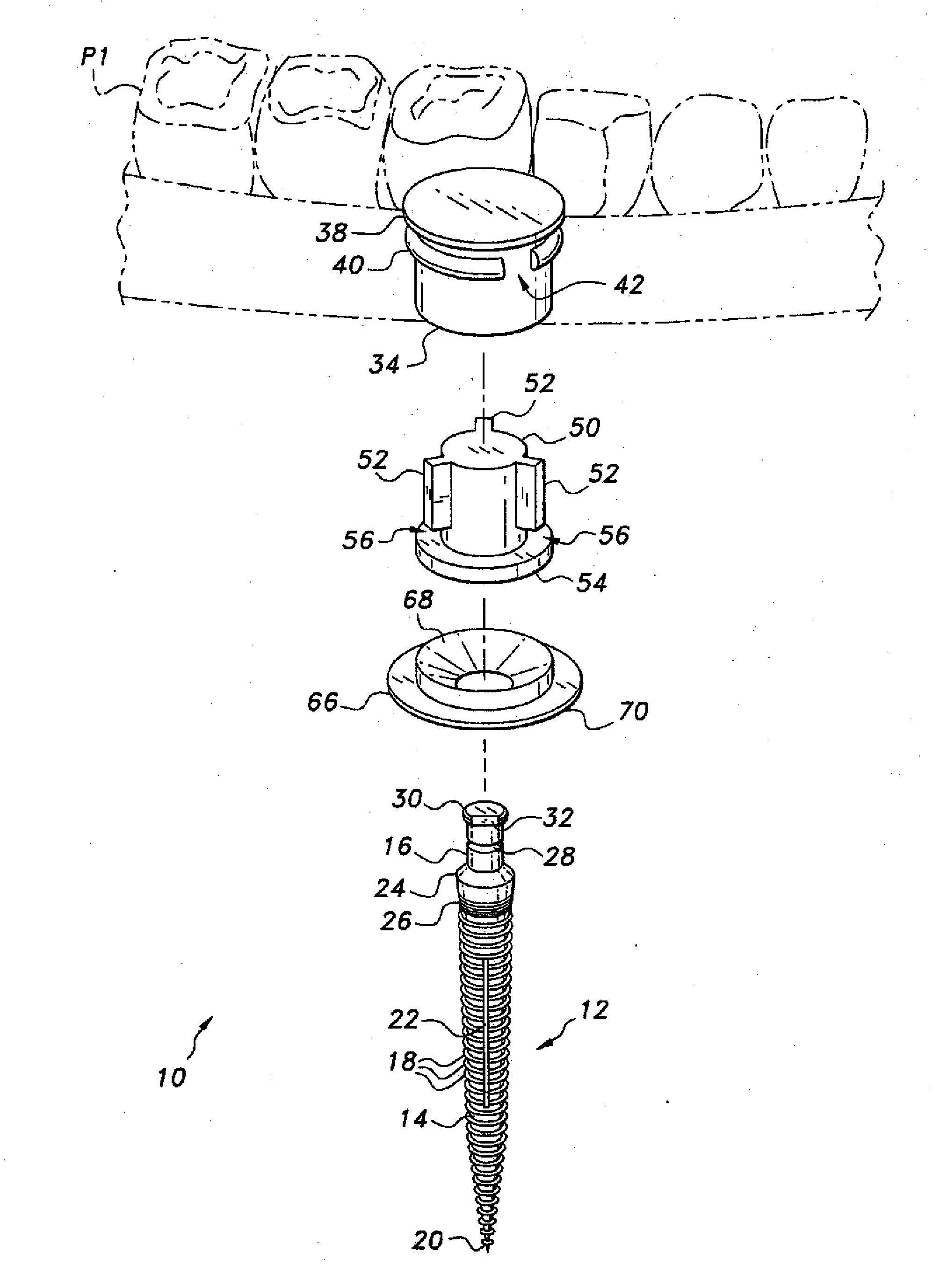

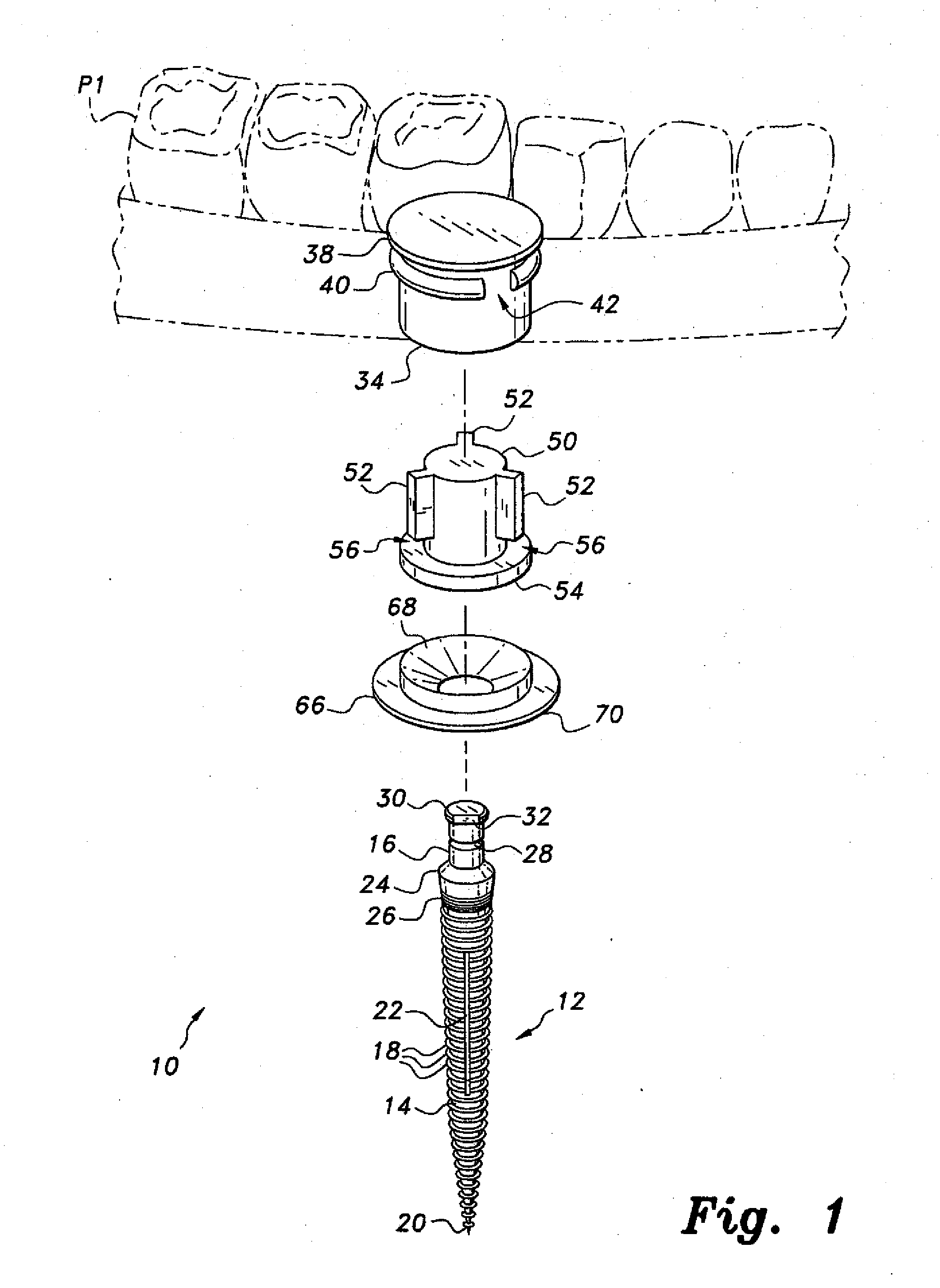

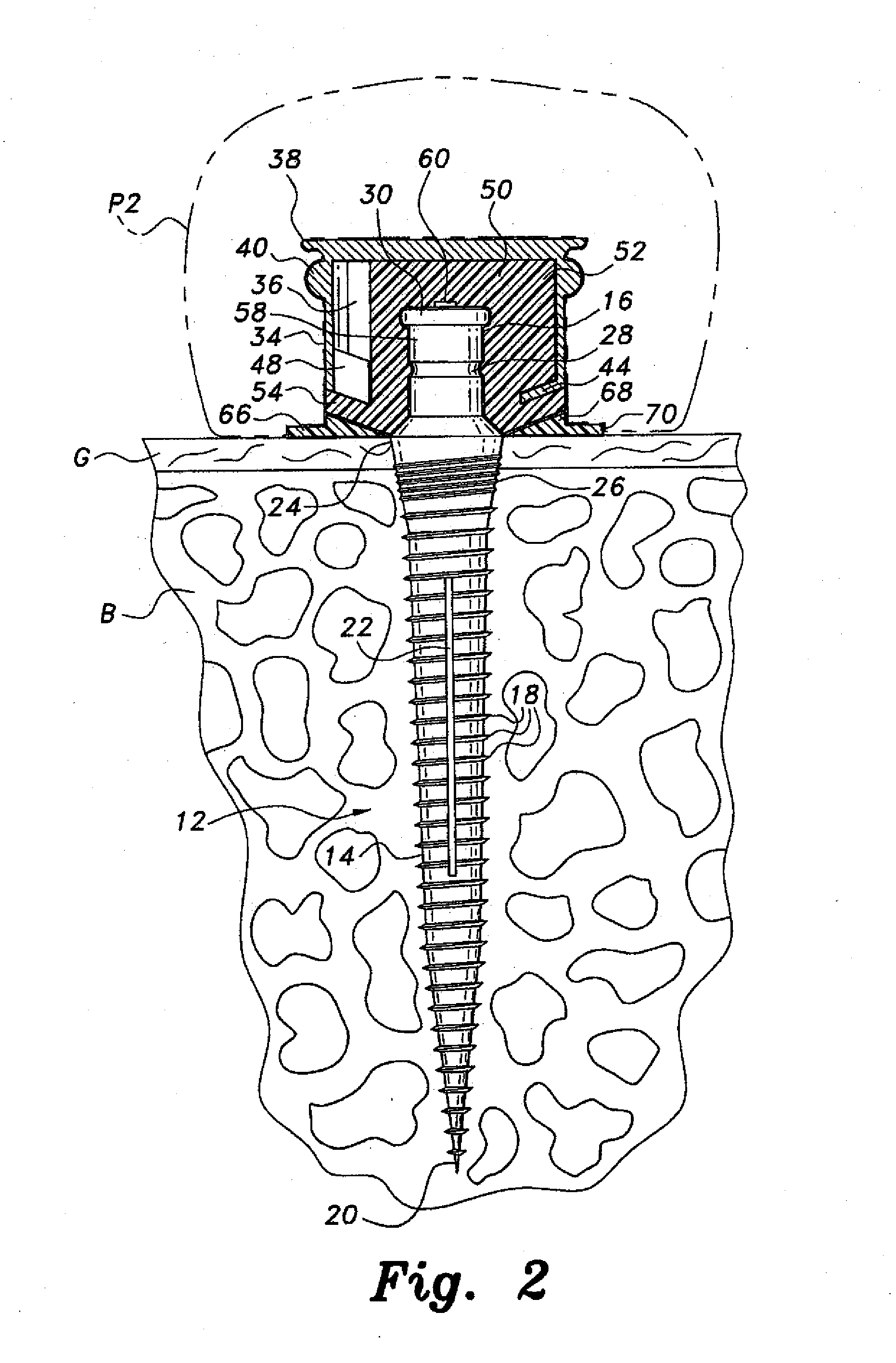

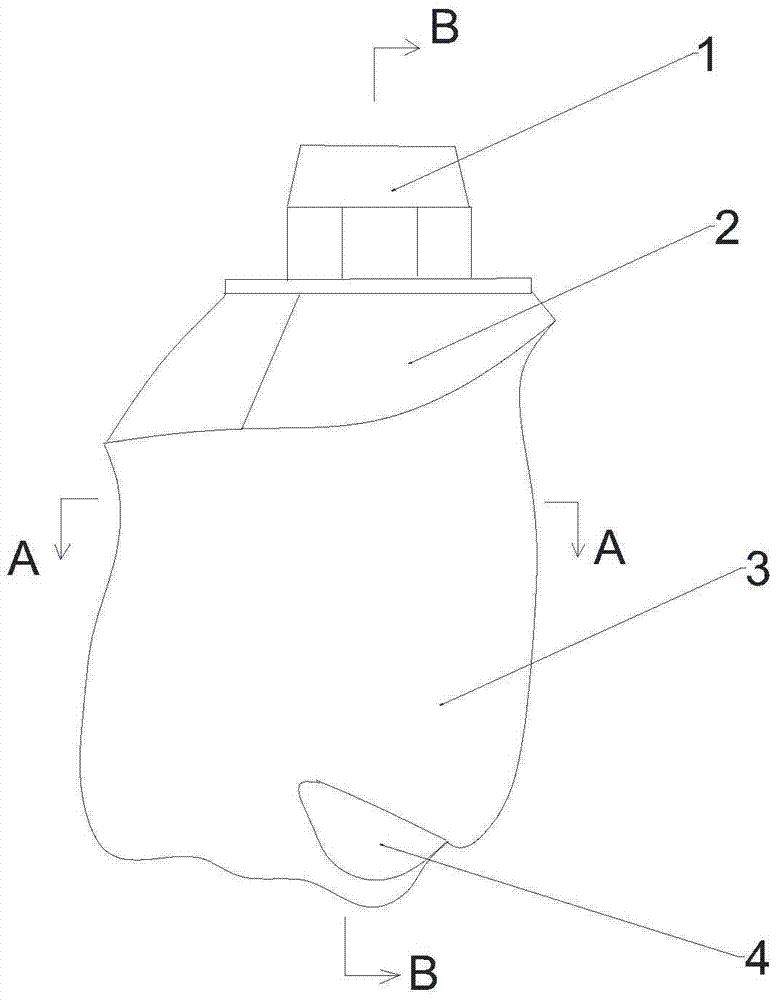

Dental implant system

The dental implant system includes implants having integral abutments therewith for the removable or fixed attachment of plural or single prosthetic teeth, as appropriate. The system for removable dental prostheses includes a metal housing permanently installed in the removable prosthesis, and a rubber retentive insert installed in the housing. The insert is removably installed over the abutment of the implant to secure the dental prosthesis thereto. The system includes transfer copings for transferring an impression to the lab for manufacture of the prosthesis, and lab processing copings and analogs for handling and forming the prosthesis during manufacture. The system may be assembled as a kit having some or all of the above components.

Owner:WORTHINGTON WILLIAM B

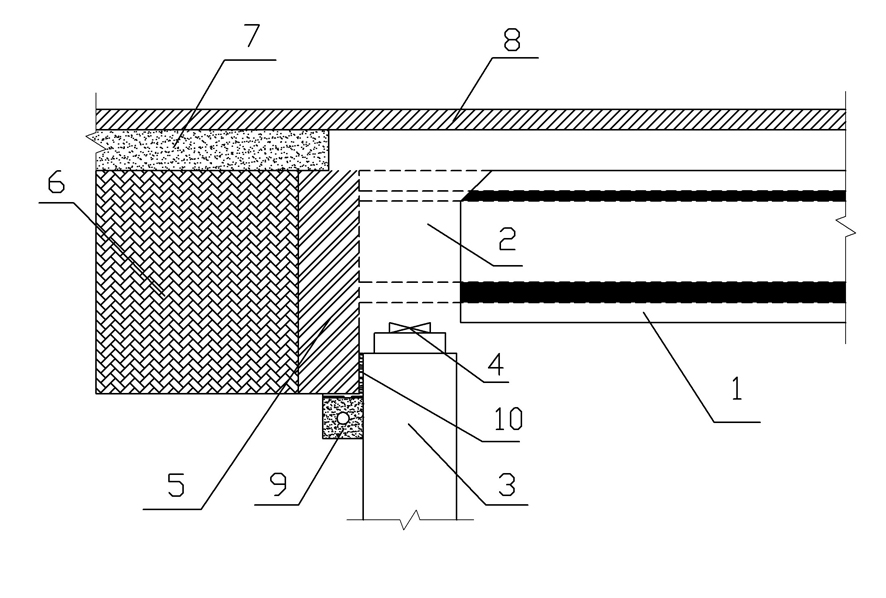

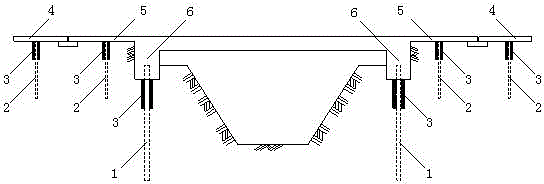

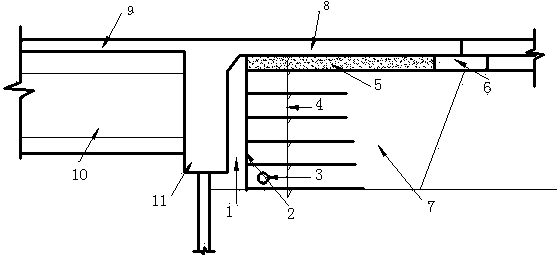

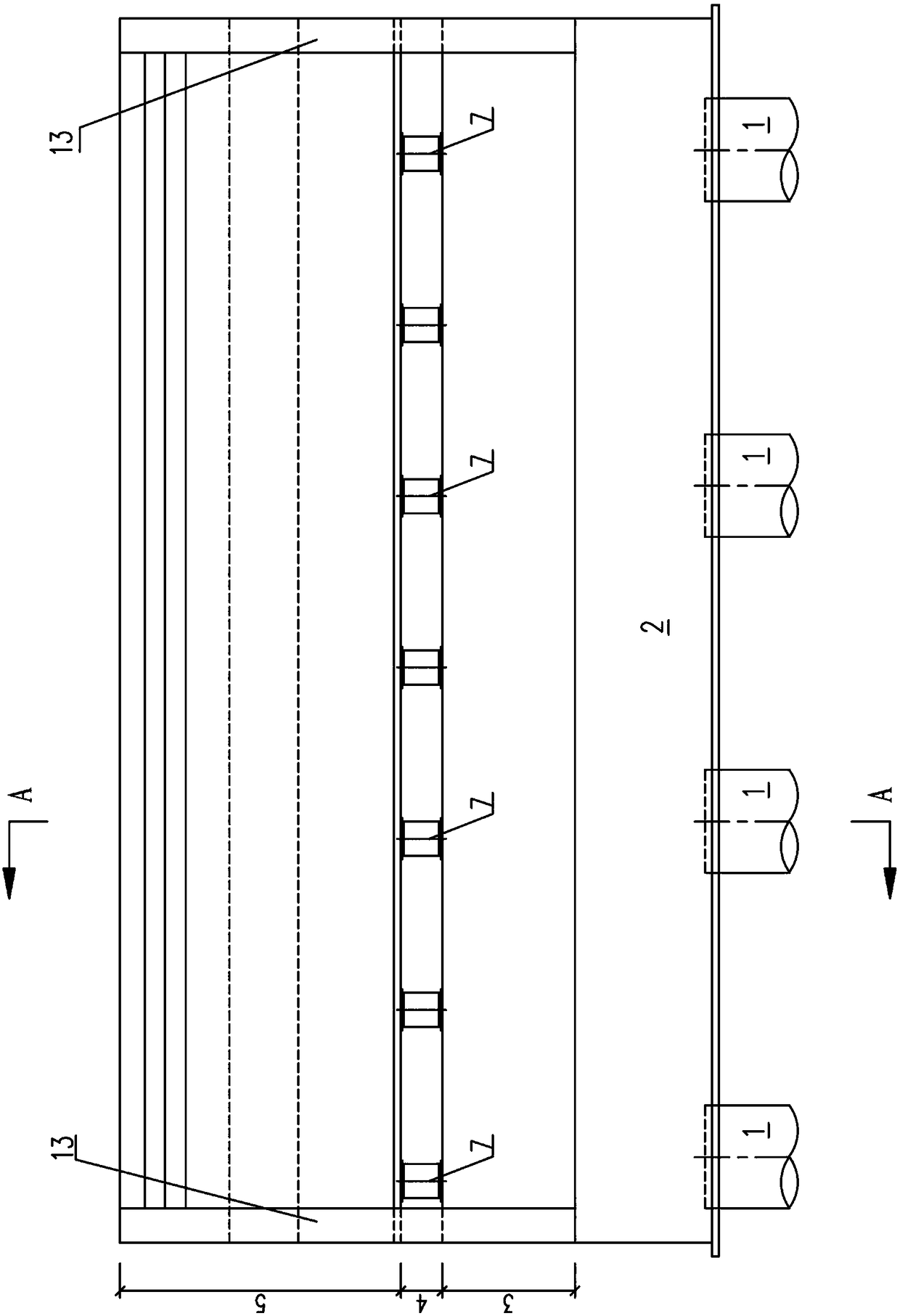

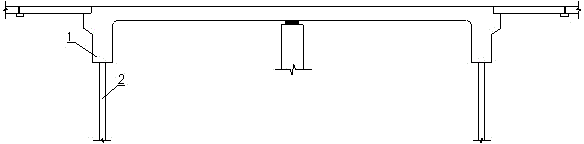

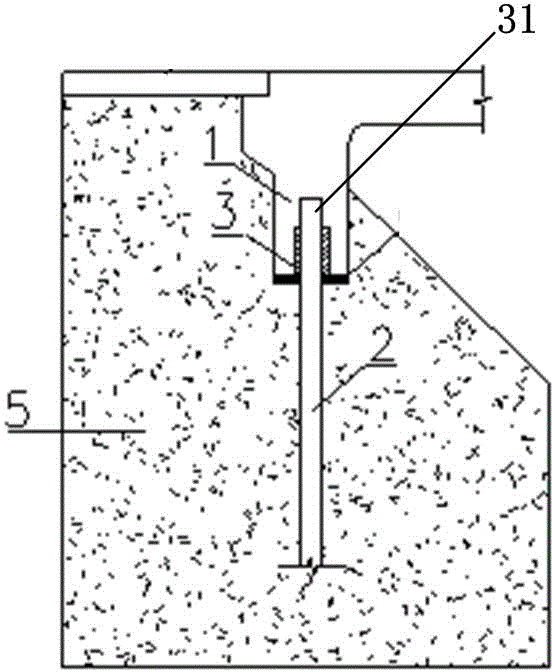

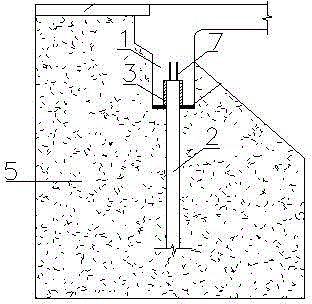

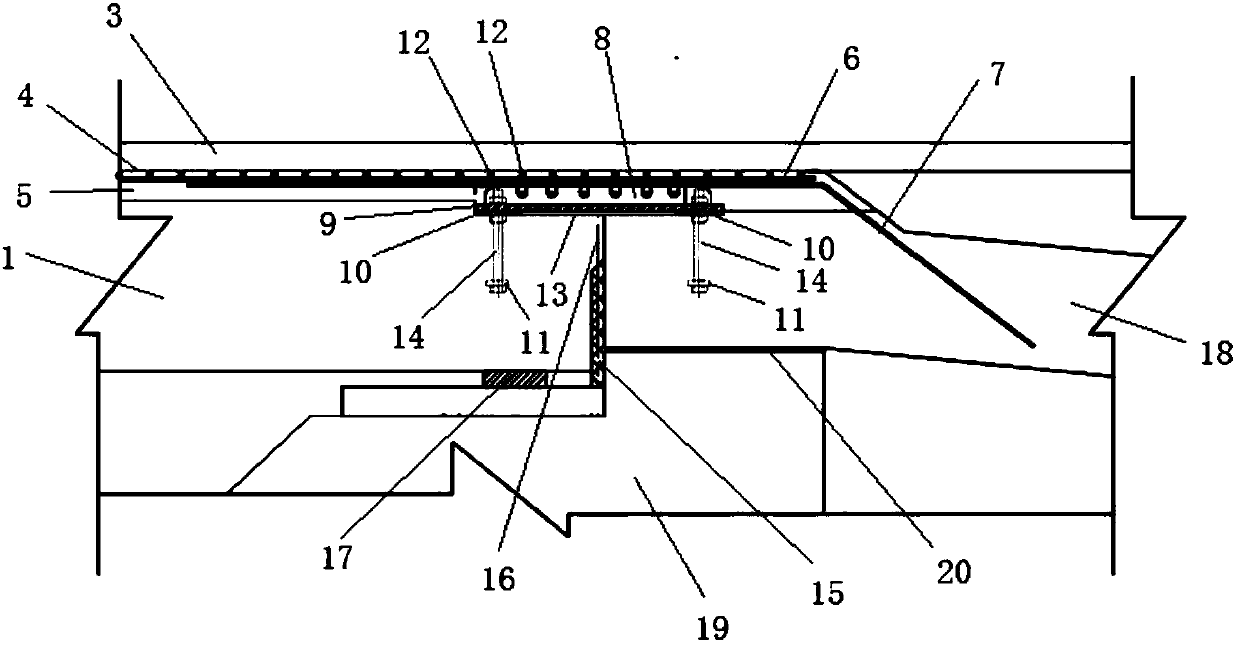

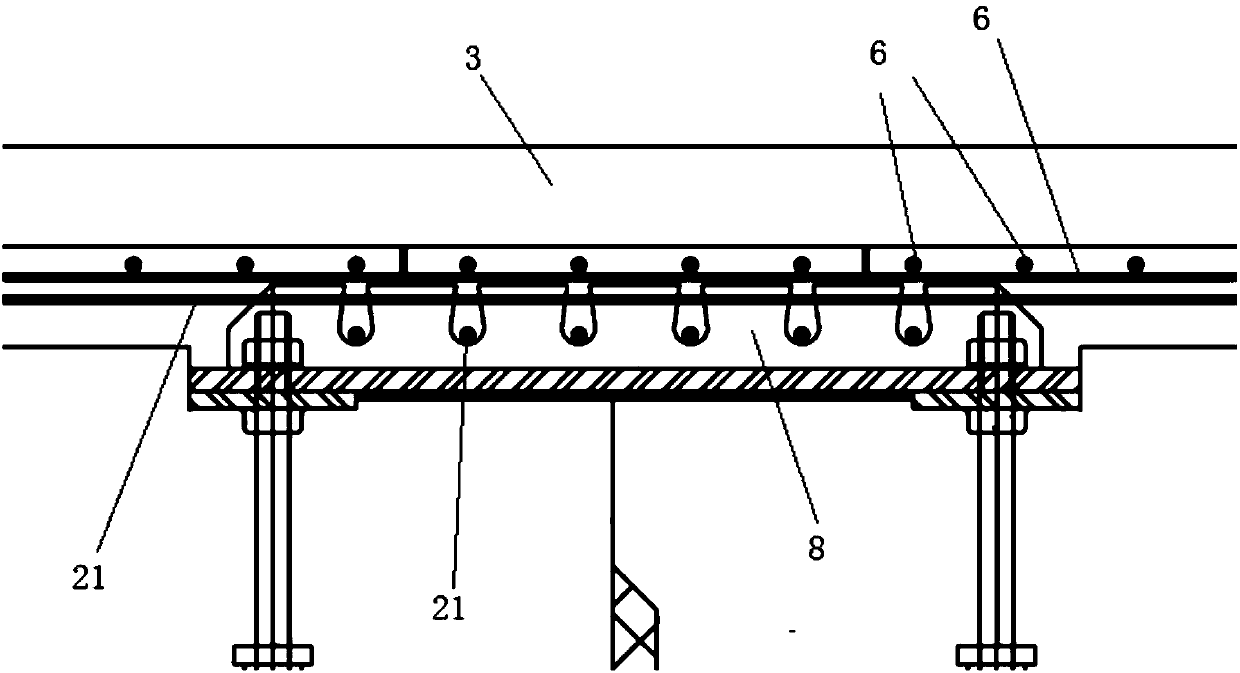

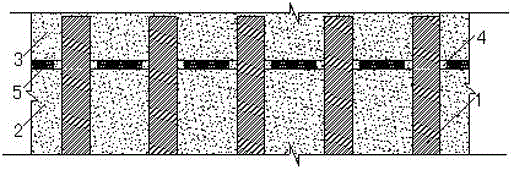

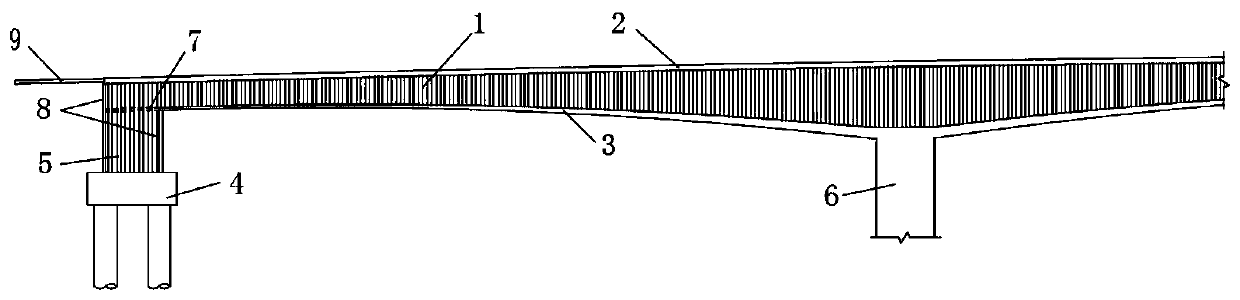

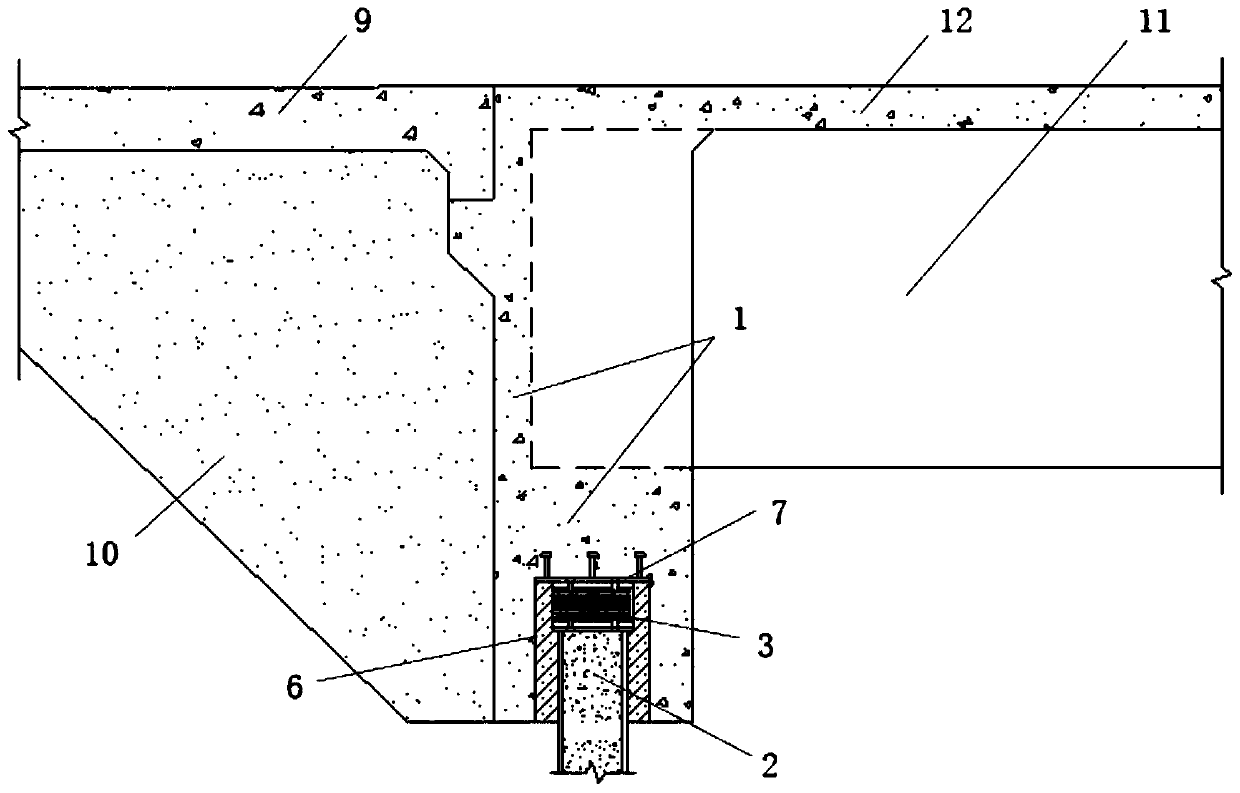

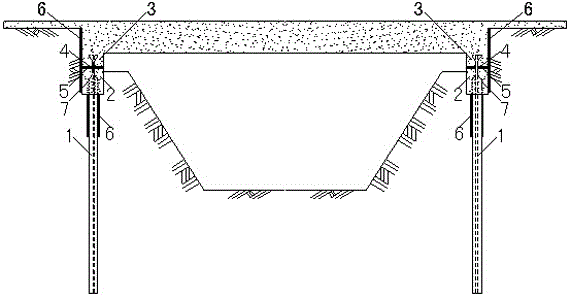

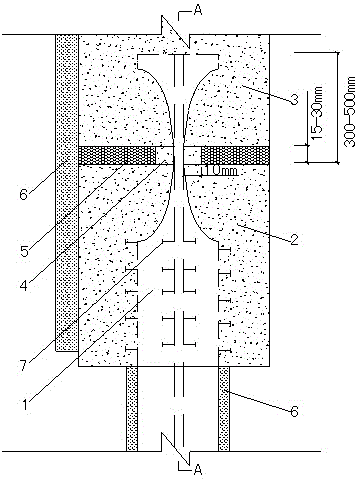

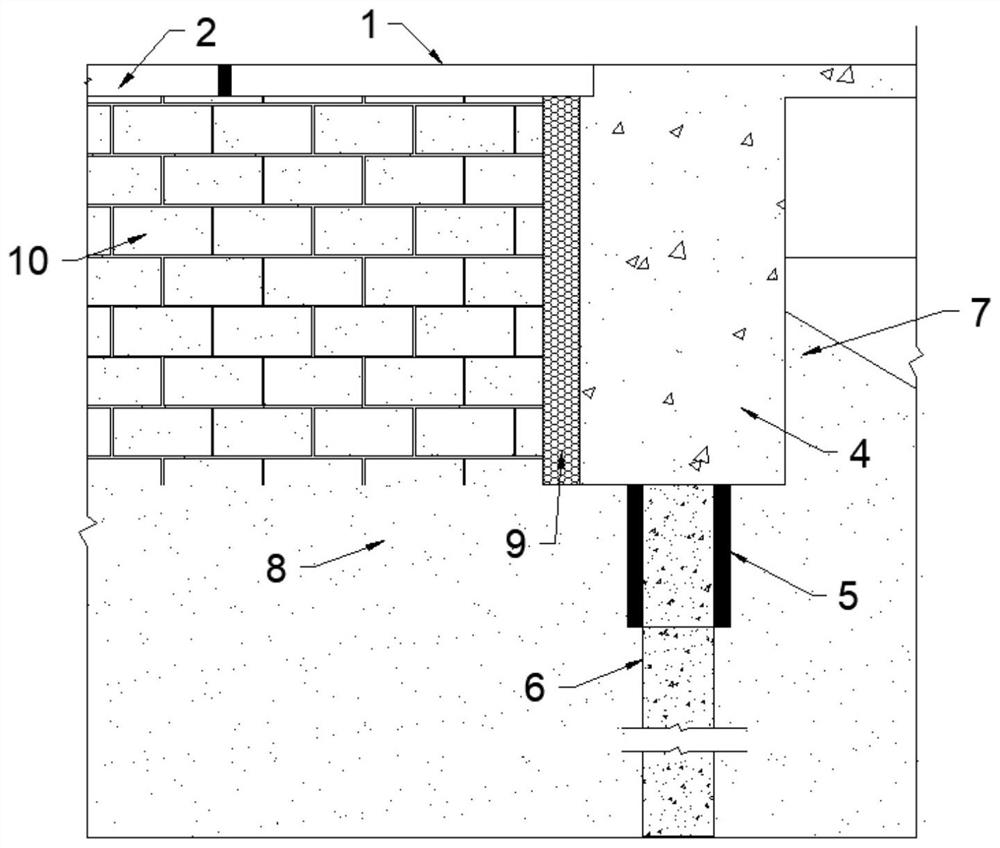

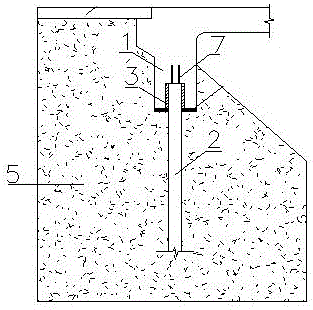

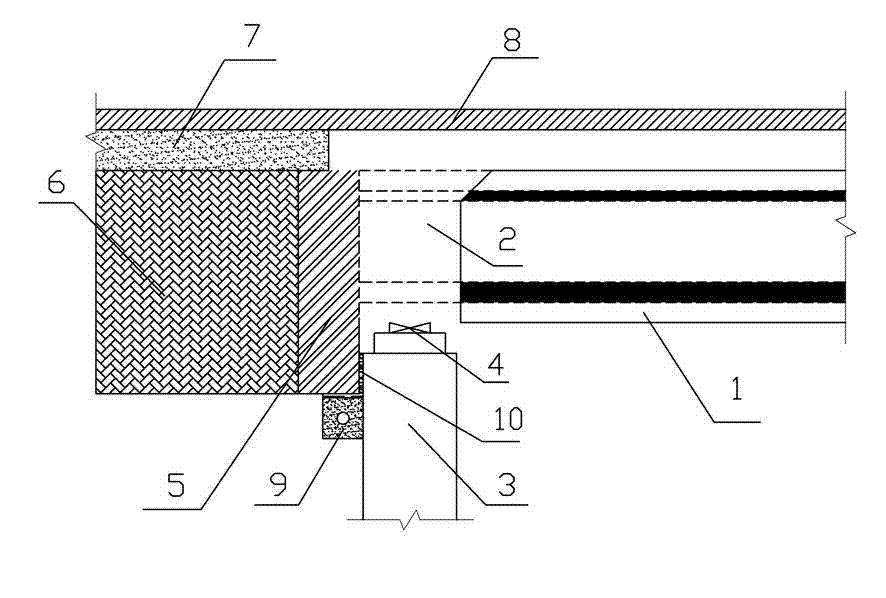

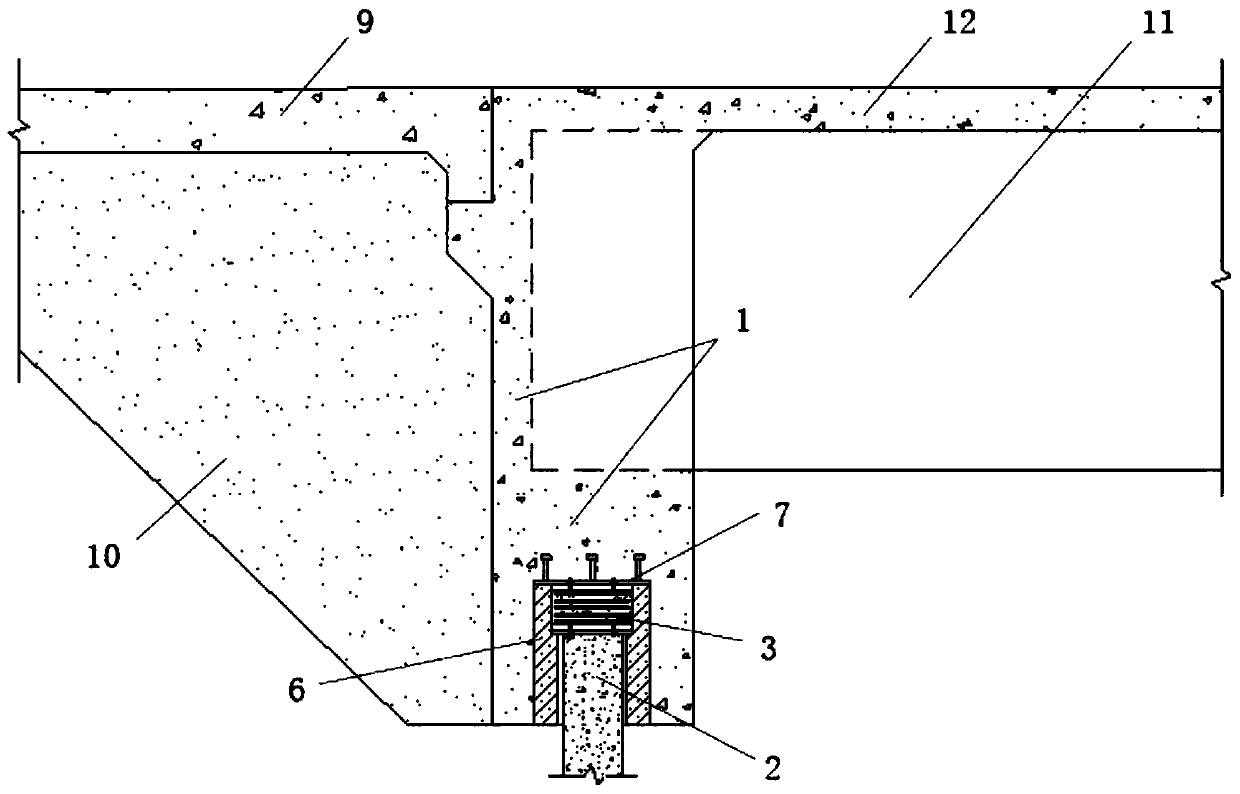

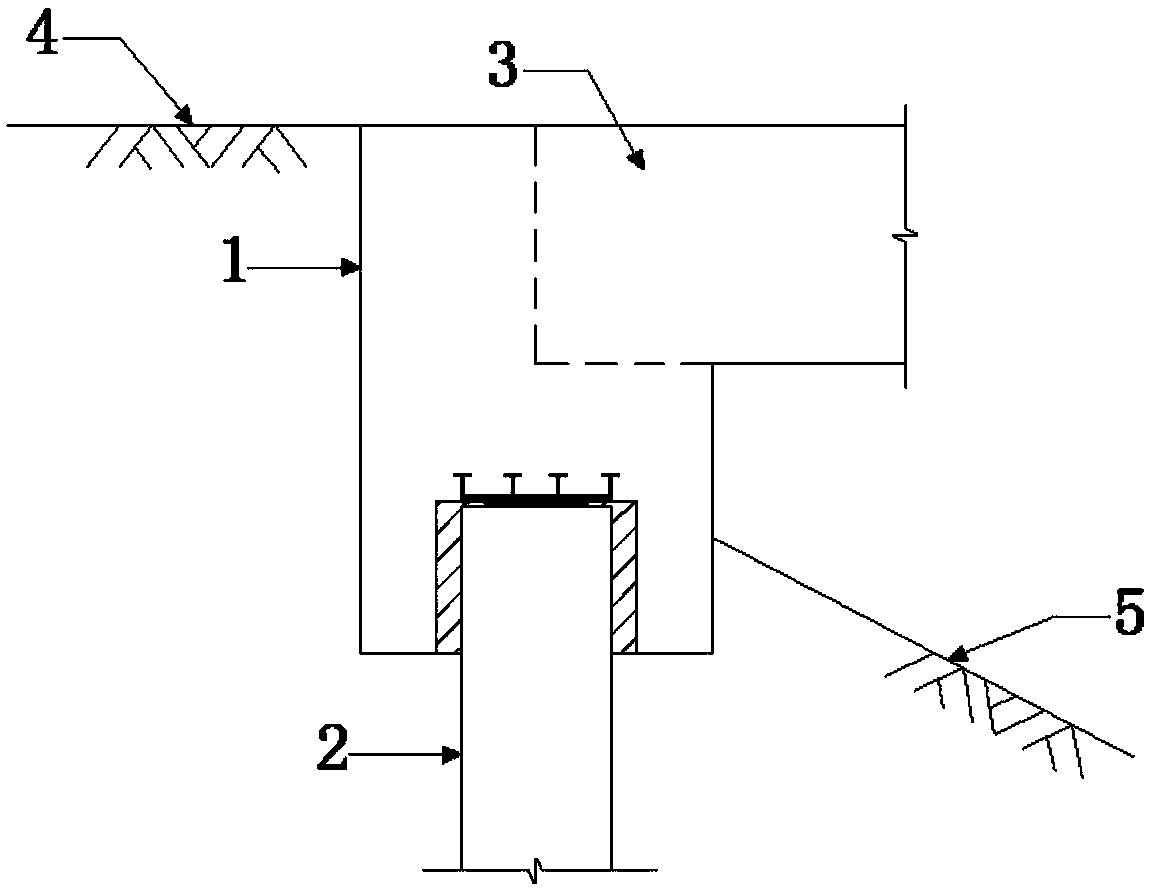

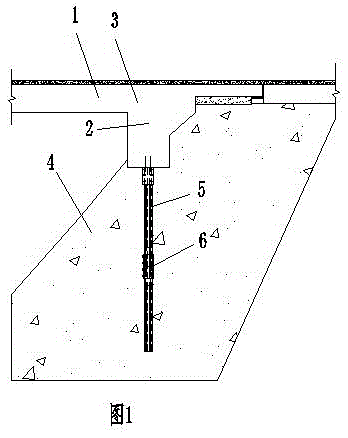

Method for arranging semi-integral hidden expansion joint for abutment and bridge girder

InactiveCN102061667AExtended service lifeImprove riding performanceBridge structural detailsBituminous waterproofingArchitectural engineering

The invention discloses a method for arranging a semi-integral hidden expansion joint for an abutment and a bridge girder, which comprises the steps of: first arranging a semi-integral abutment below the end of the bridge girder, arranging a sliding base on the abutment, and placing the end of a girder body on the sliding base, wherein the sliding base is independent from the abutment; arranging a crossbeam on the base in the girder body and pouring the crossbeam and the end of the girder body integrally and fastening the girder with the back wall; filling dam soil outside the back wall, arranging a butt strap on the dam soil and paving an asphalt waterproof layer on the butt strap and the bridge floor integrally; filling a foam material in the crack among the back wall, the dam soil and the semi-integral abutment; and finally arranging an effective drainage system in a position contacted with the dam soil, behind the semi-integral abutment. In the technical scheme, retraction devices at both ends of the bridge girder are omitted and a soil filled structure is adopted to solve the problem caused by extension of the bridge girder, thereby greatly improving the driving smoothness, reducing the impact of vehicles and prolonging the service life of the bridge girder effectively.

Owner:河南省新开元路桥工程咨询有限公司

Dental implant system

The dental implant system includes implants having integral abutments therewith for the removable or fixed attachment of plural or single prosthetic teeth, as appropriate. The system for removable dental prostheses includes a metal housing permanently installed in the removable prosthesis, and a rubber retentive insert installed in the housing. The insert is removably installed over the abutment of the implant to secure the dental prosthesis thereto. The system includes transfer copings for transferring an impression to the lab for manufacture of the prosthesis, and lab processing copings and analogs for handling and forming the prosthesis during manufacture. The system may be assembled as a kit having some or all of the above components.

Owner:WORTHINGTON WILLIAM B

Dental implant system

The dental implant system includes implants having integral abutments therewith for the removable or fixed attachment of plural or single prosthetic teeth, as appropriate. The system for removable dental prostheses includes a metal housing permanently installed in the removable prosthesis, and a rubber retentive insert installed in the housing. The insert is removably installed over the abutment of the implant to secure the dental prosthesis thereto. The system includes transfer copings for transferring an impression to the lab for manufacture of the prosthesis, and lab processing copings and analogs for handling and forming the prosthesis during manufacture. The system may be assembled as a kit having some or all of the above components.

Owner:WORTHINGTON WILLIAM B

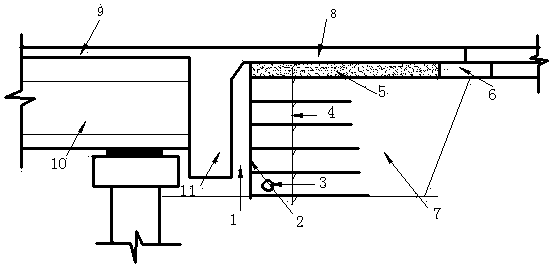

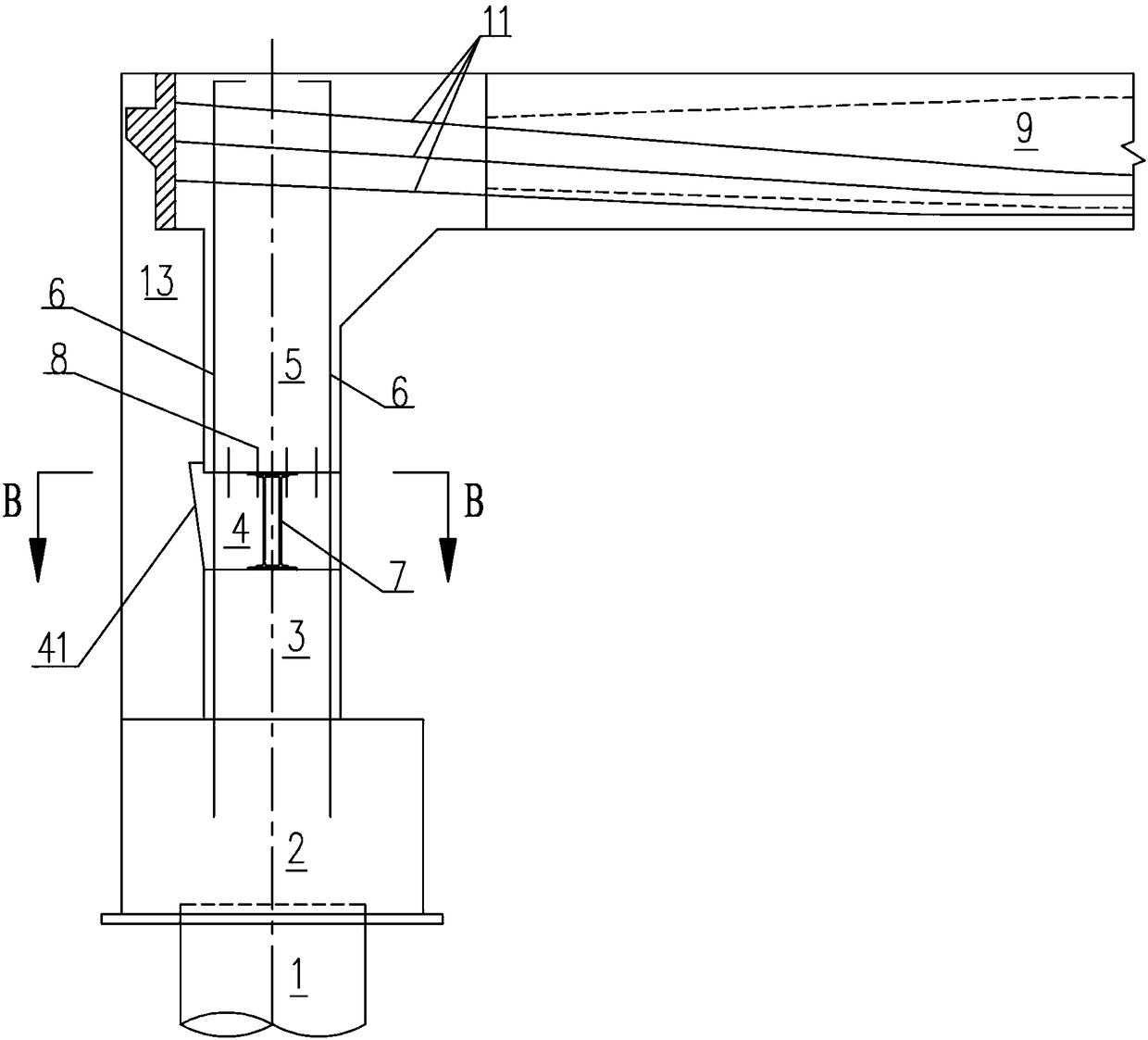

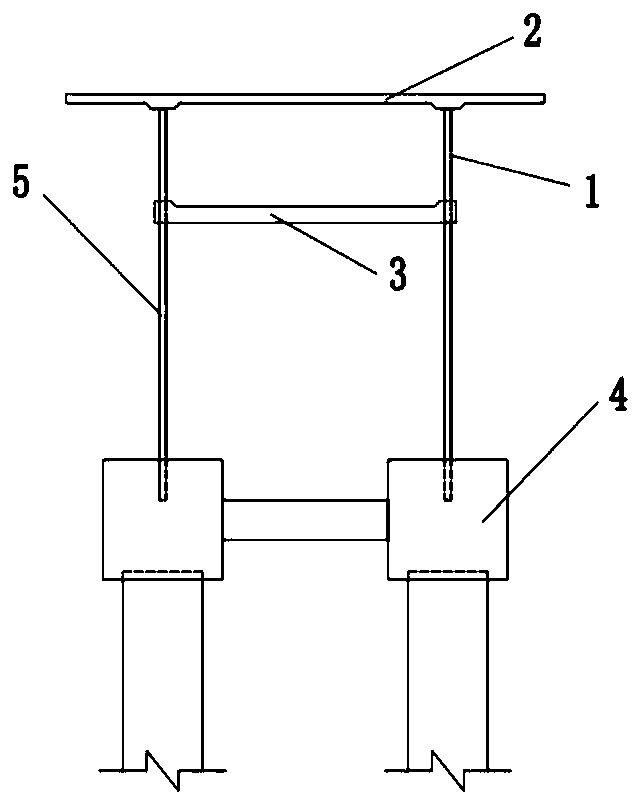

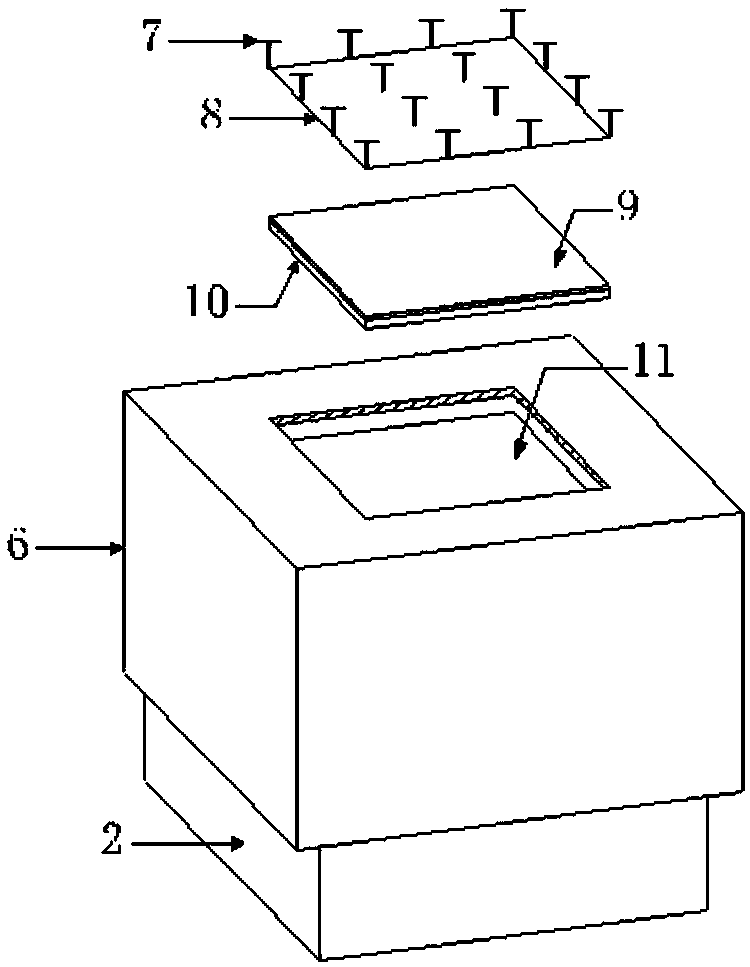

Seismic-resistant integral abutment bridge with energy absorption materials embedded in pier tops and construction method of seismic-resistant integral abutment bridge

InactiveCN104452578AReduce resistanceReduce internal forceProtective foundationBridge structural detailsEnergy absorptionAbutment

The invention relates to a seismic-resistant integral abutment bridge with energy absorption materials embedded in pier tops and a construction method of the seismic-resistant integral abutment bridge. The seismic-resistant integral abutment bridge comprises abutments, one sides of the abutments close to the earth are connected with connecting plates, the other ends of the connecting plates are connected with behind-abutment lapping plates, the connecting plates and the abutments are cast integrally, support piers are arranged below the abutments, miniature piers are arranged below the behind-abutment lapping plates and the connecting plates, the direction of the pier length or the long shaft of the support piers and the miniature piers is perpendicular to the longitudinal deformation direction of the bridge, and the energy absorption materials are filled between the tops of the support piers and the miniature piers and the surrounding earth, and the section of the energy absorption materials is identical with that of the piers. The seismic-resistant integral abutment bridge is simple in structure and reasonable in stress, the body damage of the support piers and the miniature piers is alleviated, and the seismic-resistant integral abutment bridge is high in longitudinal deformation and good in seismic resistance.

Owner:FUZHOU UNIV

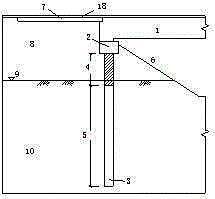

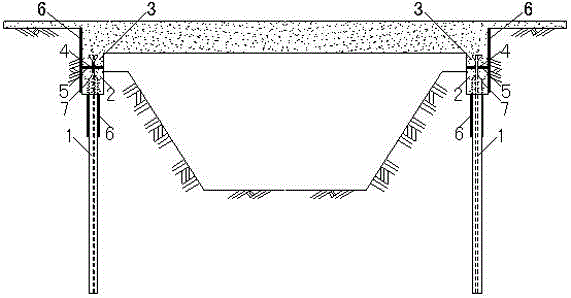

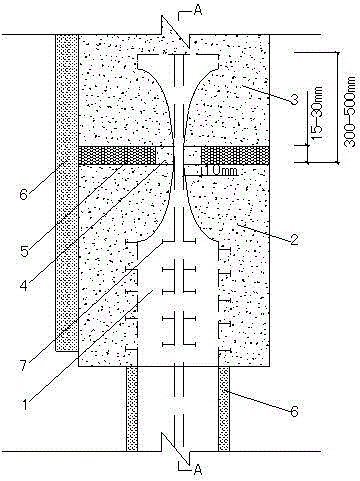

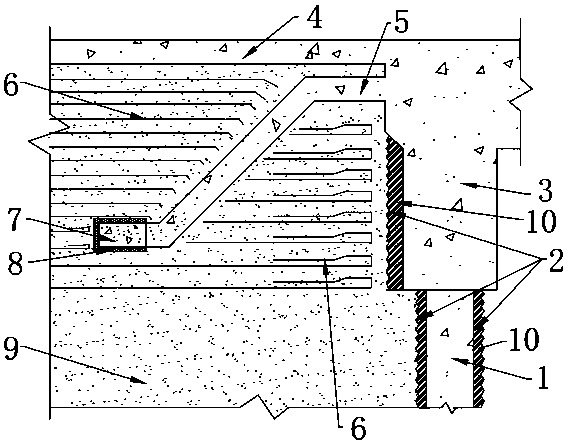

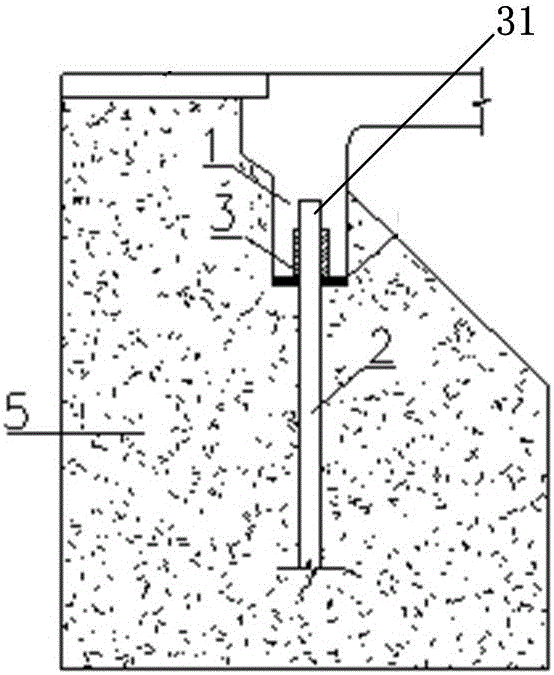

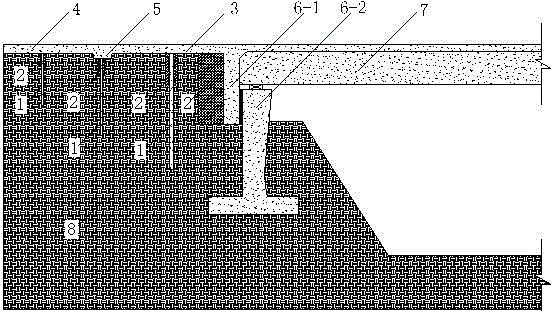

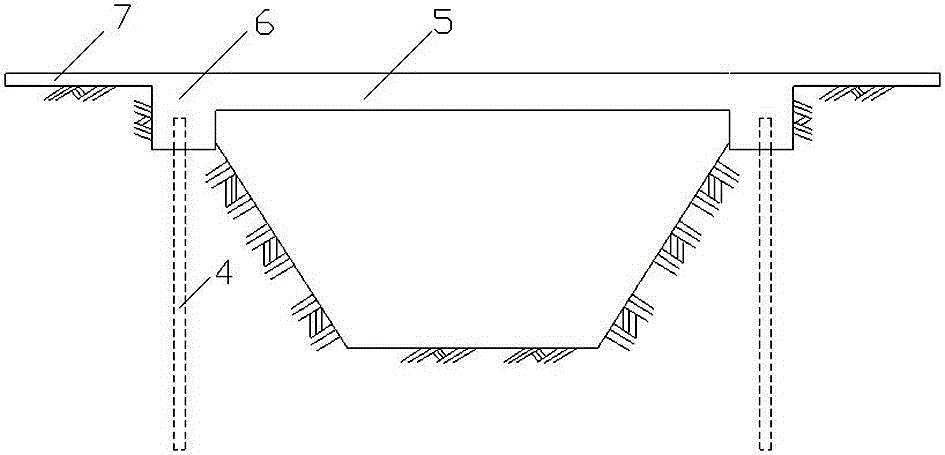

Abutment earth pressure elimination based abutment structure and construction method

InactiveCN104264581AEliminate lateral earth pressureAvoid bending damageRoadwaysBridge structural detailsAbutmentMechanical property

The invention relates to an abutment earth pressure elimination based abutment structure. The abutment earth pressure elimination based abutment structure comprises an abutment which is connected with a bridge slab and a butt strap; a main beam which is connected with the abutment is arranged below the bridge slab; one end of the butt strap is connected with the abutment and the other end of the butt strap is arranged on a corbel; an embankment with a local reinforcement structure is arranged below the corbel; a fine sand cushion layer is arranged between the embankment and the butt strap; a gap is formed between the embankment and the abutment. According to the abutment earth pressure elimination based abutment structure and construction method, the lateral earth pressure produced by the direct contact of the integral abutment and the embankment is eliminated through reserved gap; the embankment which is close to the abutment is reinforced and is not easy to settle and fall and accordingly the abutment is directly supported on the reinforced embankment and the bending failure of the butt strap is avoided; the limitation on the horizontal direction of the butt strap is small due to the fine sand cushion layer and accordingly the butt strap can freely move vertically and the integral mechanical property of a bridge and the driving comfort are improved.

Owner:FUZHOU UNIV

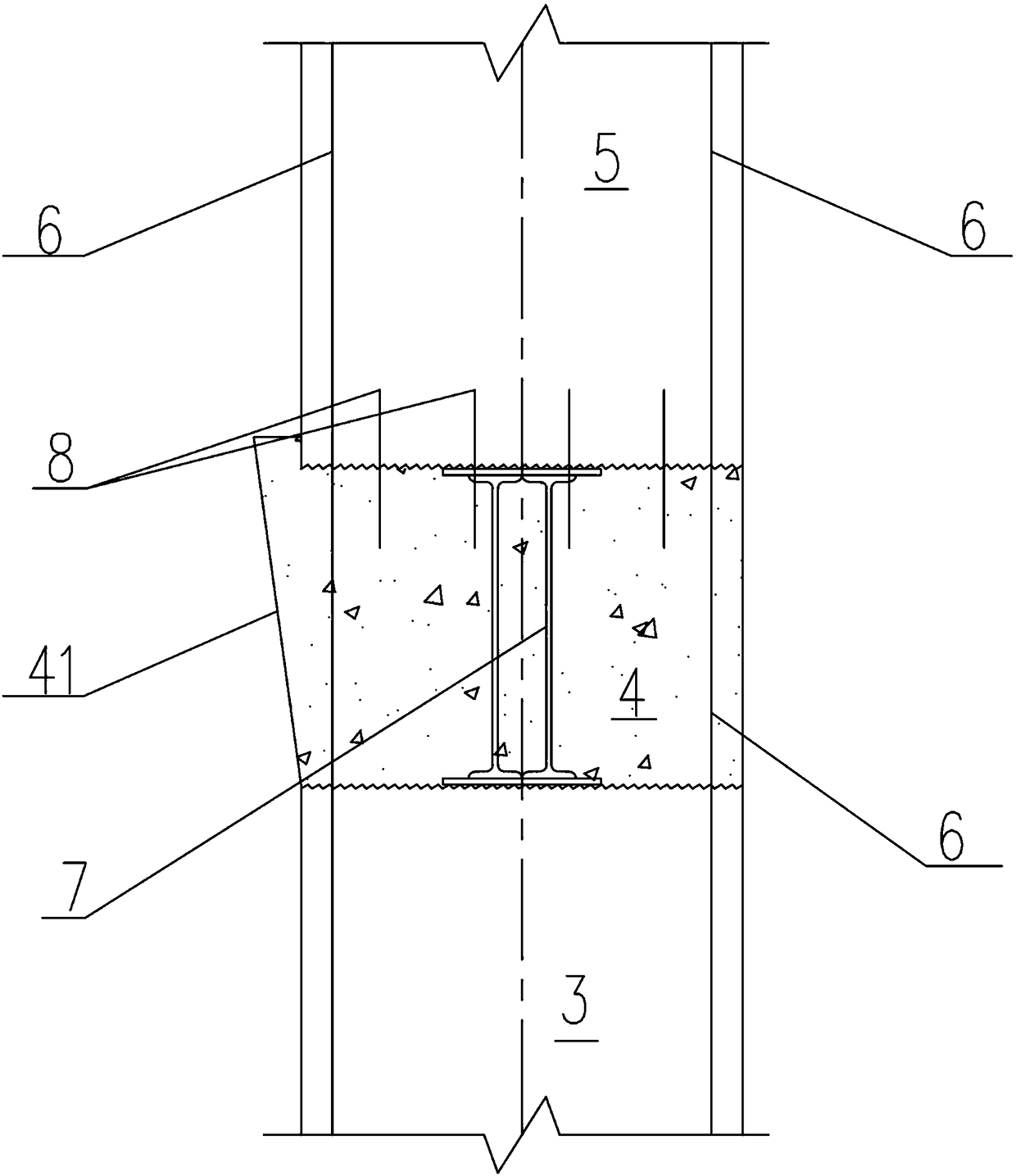

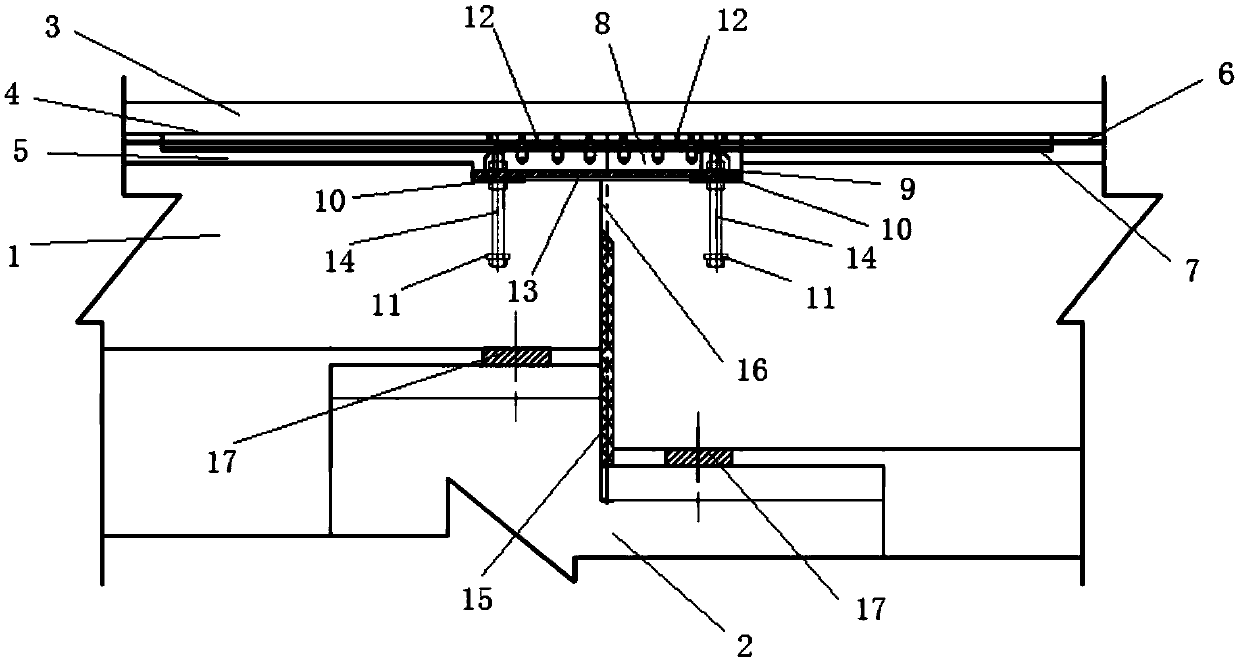

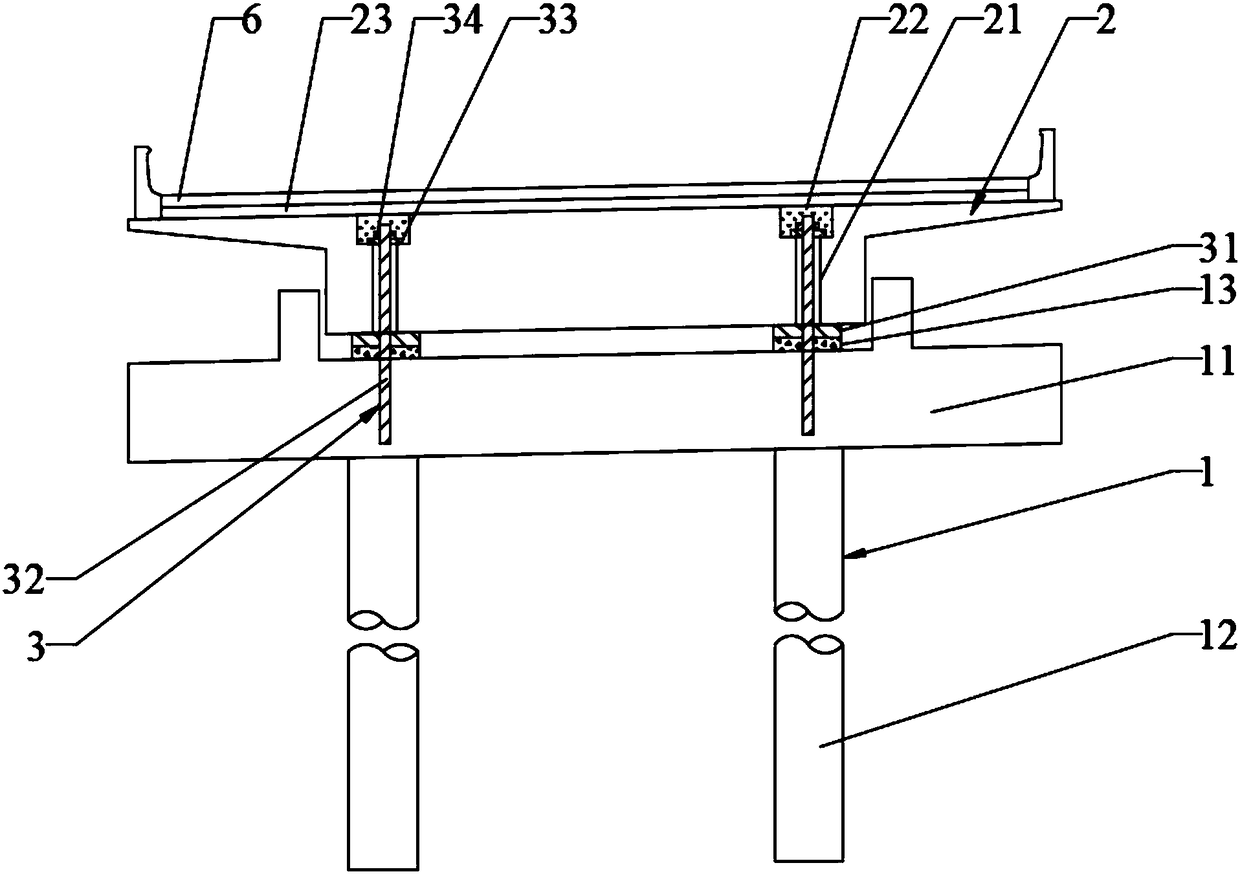

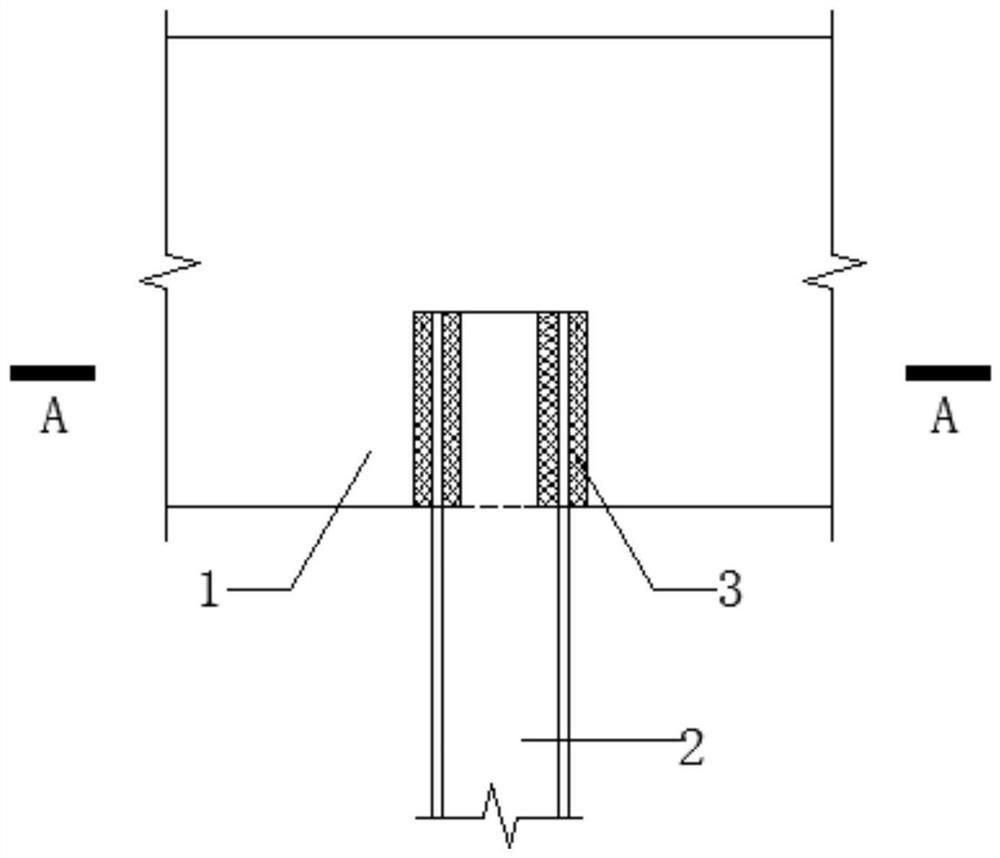

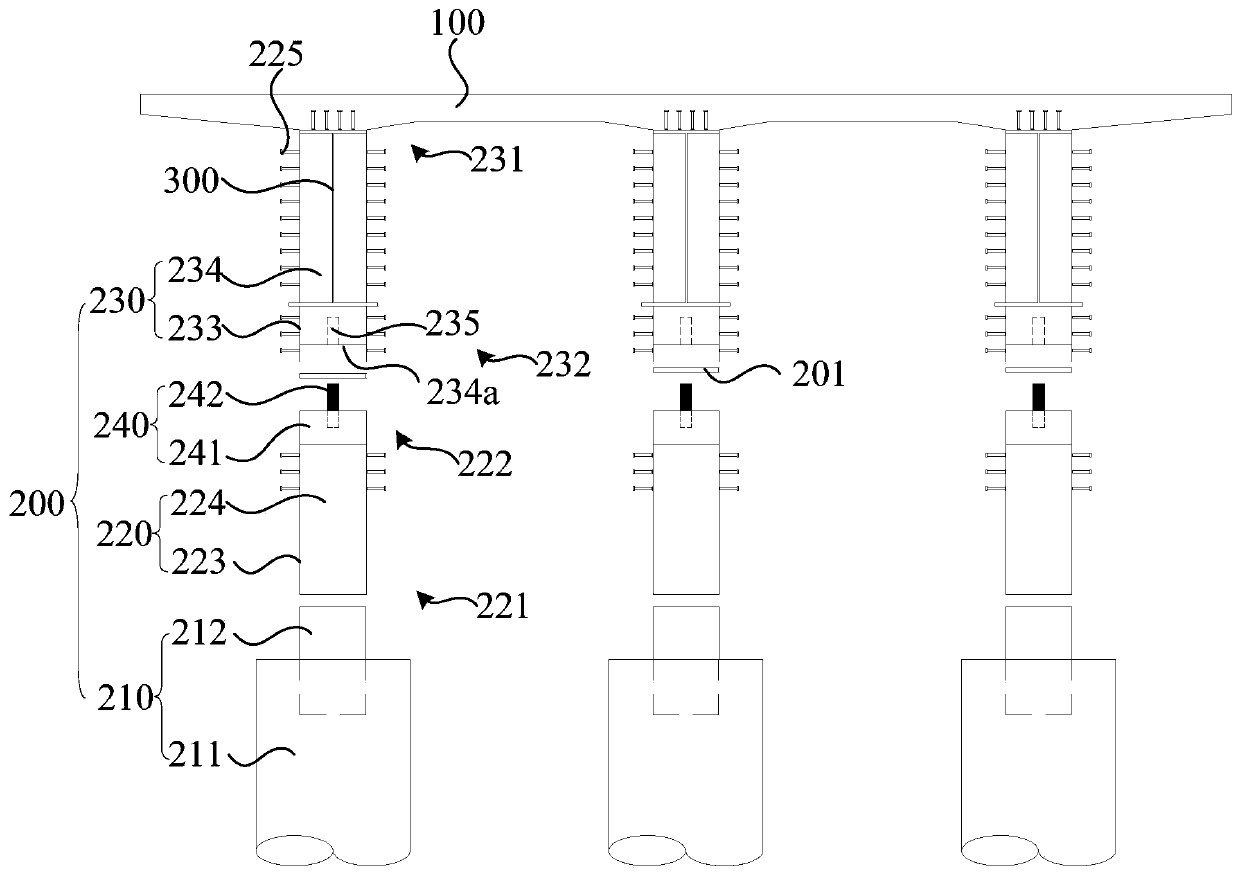

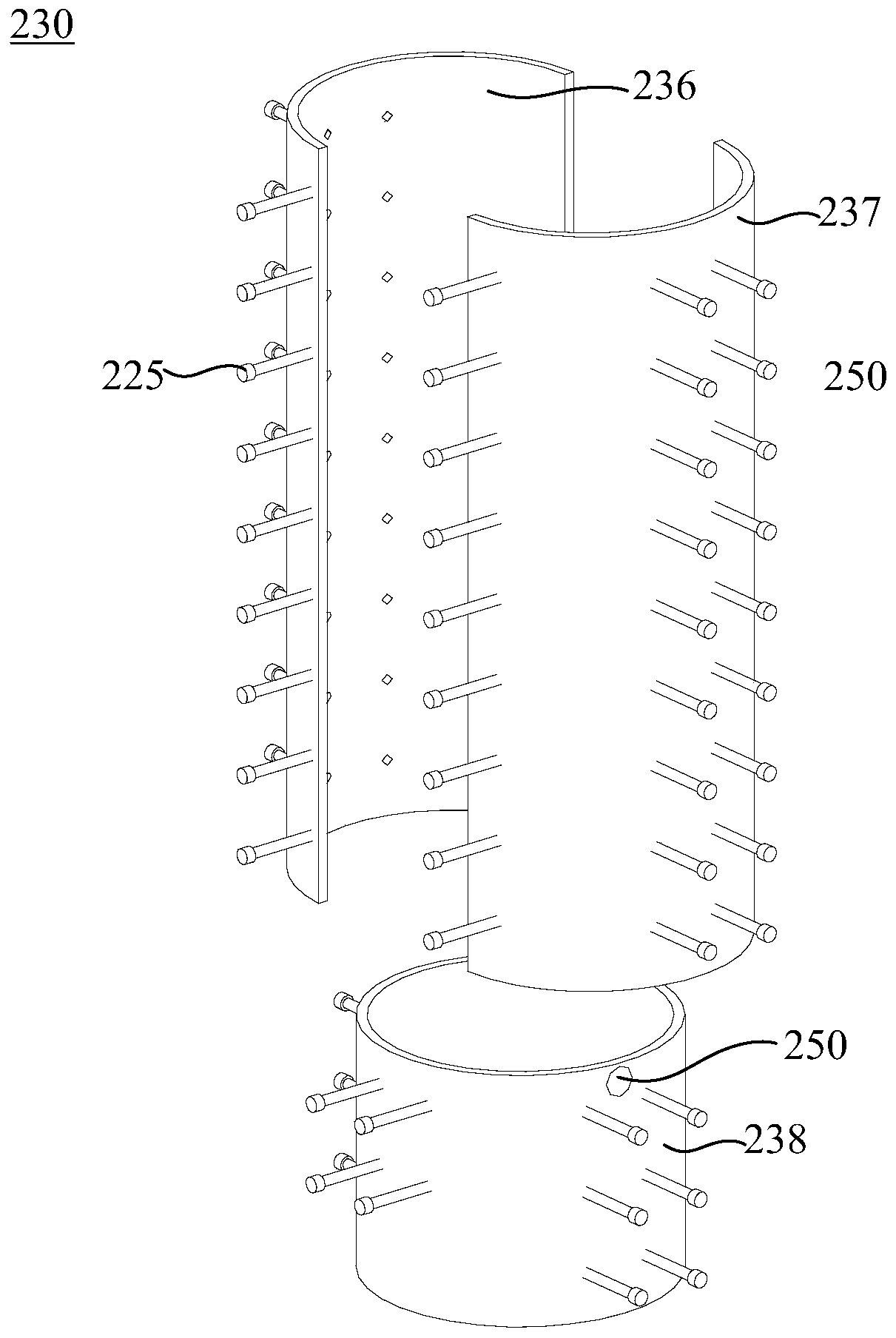

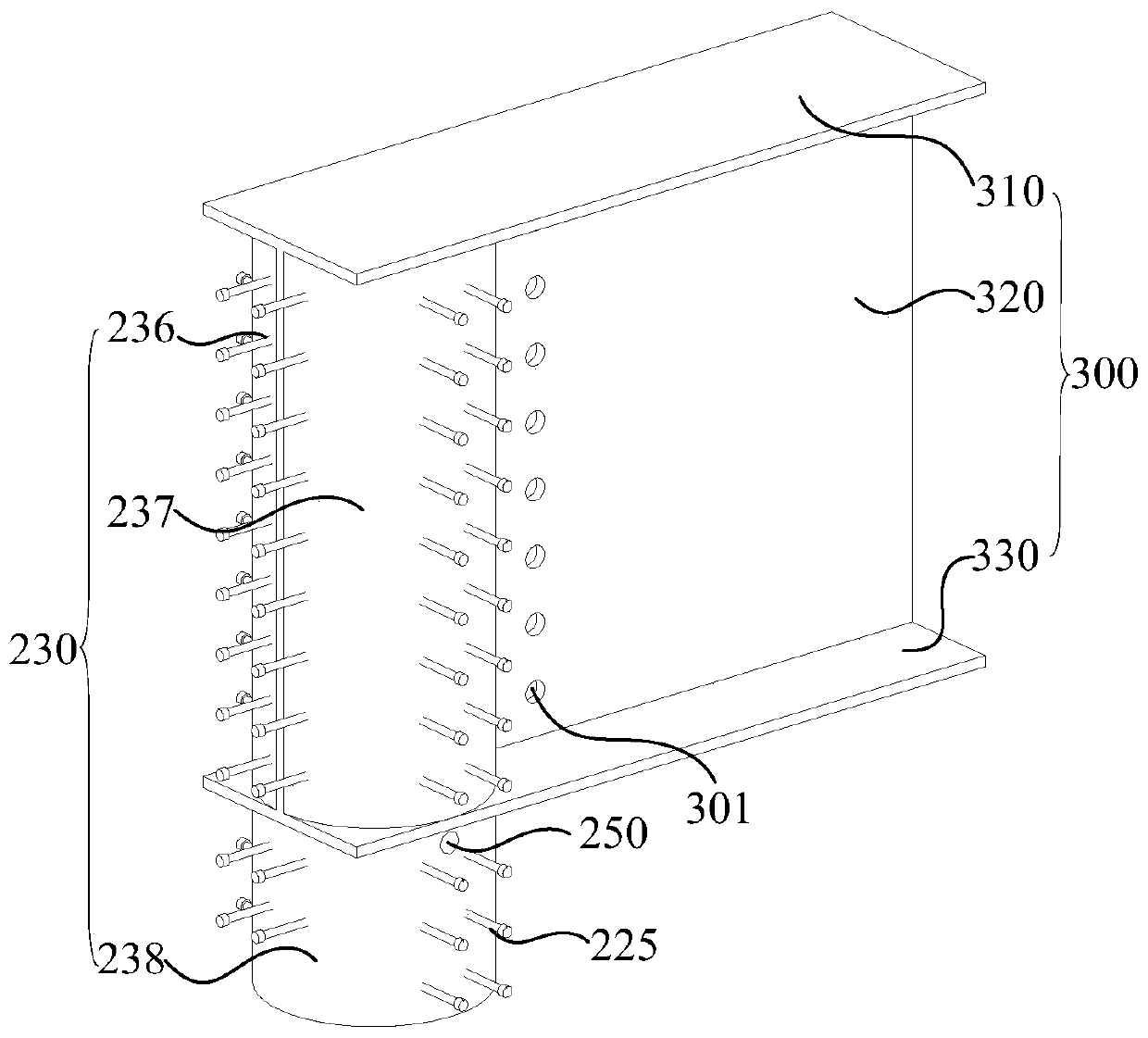

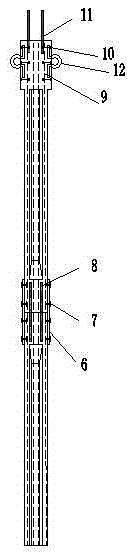

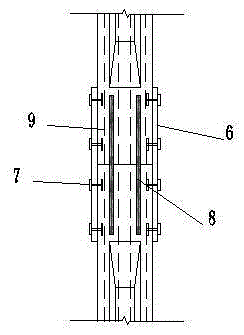

Construction method of integral abutment of jointless bridge and integral abutment

InactiveCN108265620ANo lossEasy to importBridge structural detailsBridge erection/assemblySupporting systemPre stress

The invention discloses a construction method of an integral abutment of a jointless bridge. The construction method comprises the steps of constructing an abutment bearing section at the upper end ofa bearing platform, fixedly connecting the bearing platform to the upper end of pile foundations, placing an abutment post-casting section formwork and a temporary supporting system on the abutment bearing section, placing the temporary supporting system in the abutment post-casting section formwork, filling sand in the abutment post-casting section formwork, constructing an abutment transition section on the filled sand in the abutment post-casting section formwork, integrally casting and consolidating the upper end of the abutment transition section and a main beam, washing away the filledsand in the abutment post-casting section formwork after longitudinal prestressed steel strands in the main beam are tensioned, pouring concrete into the abutment post-casting section formwork to formand maintain an abutment post-casting section, and sequentially connecting the abutment transition section, the abutment post-casting section and the abutment bearing section from top to bottom to form the integral abutment of the jointless bridge. The invention also discloses the integral abutment of the jointless bridge. The construction method of the integral abutment of the jointless bridge and the integral abutment increase the introduction degree of the prestress.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

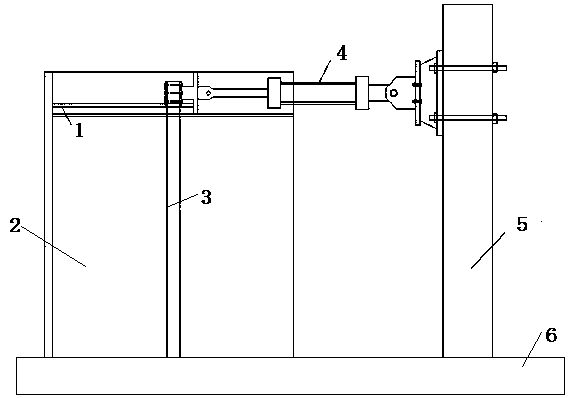

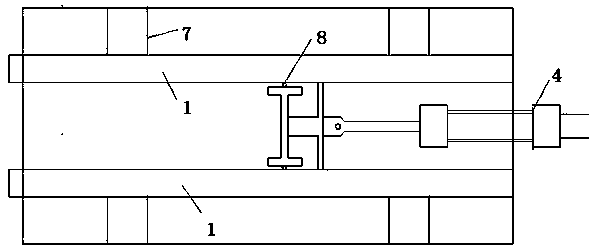

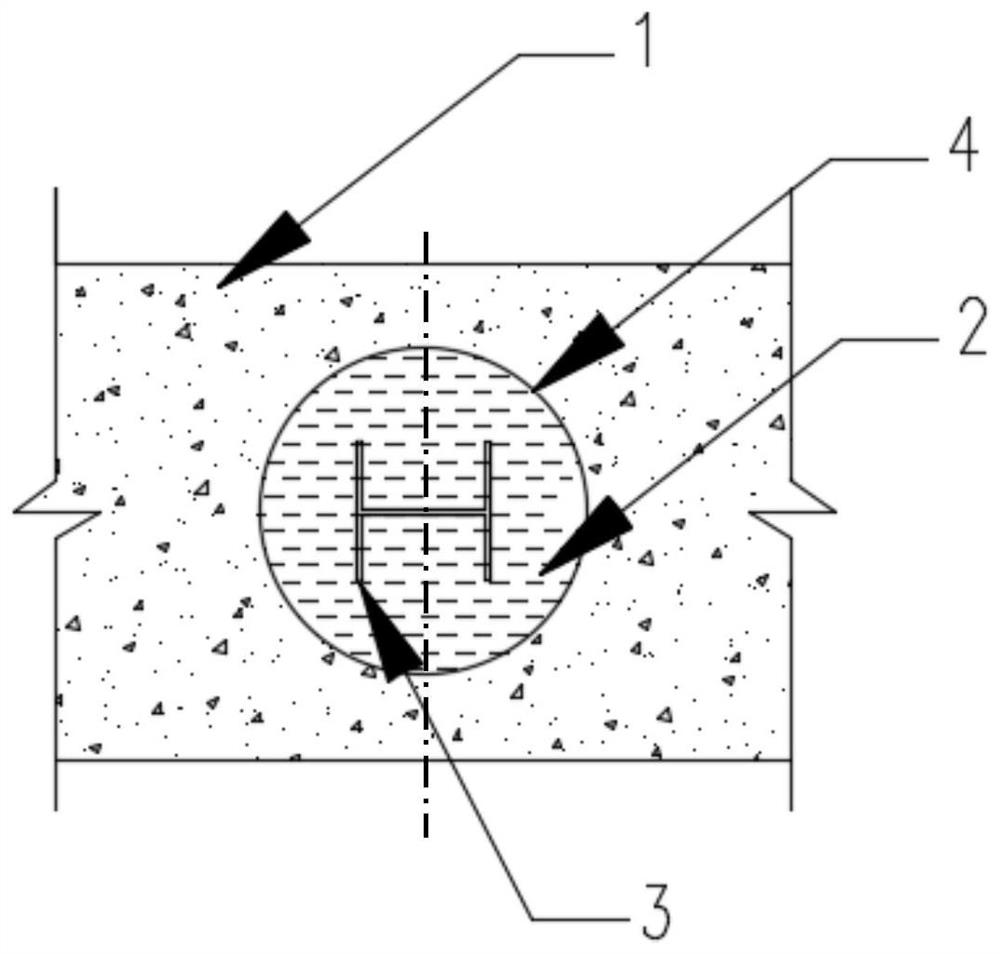

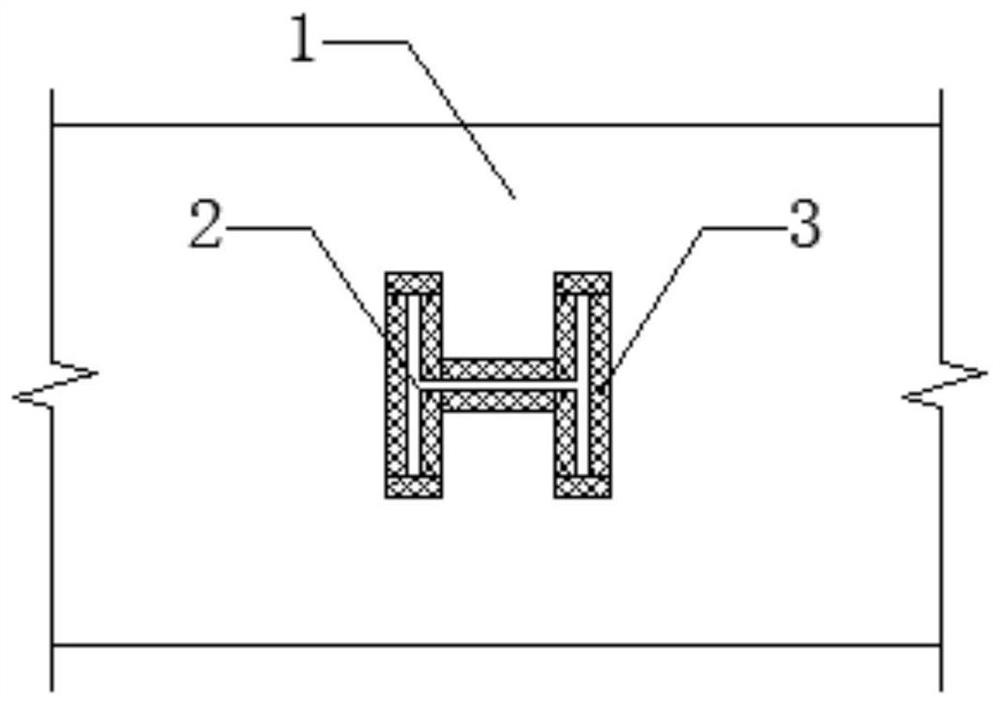

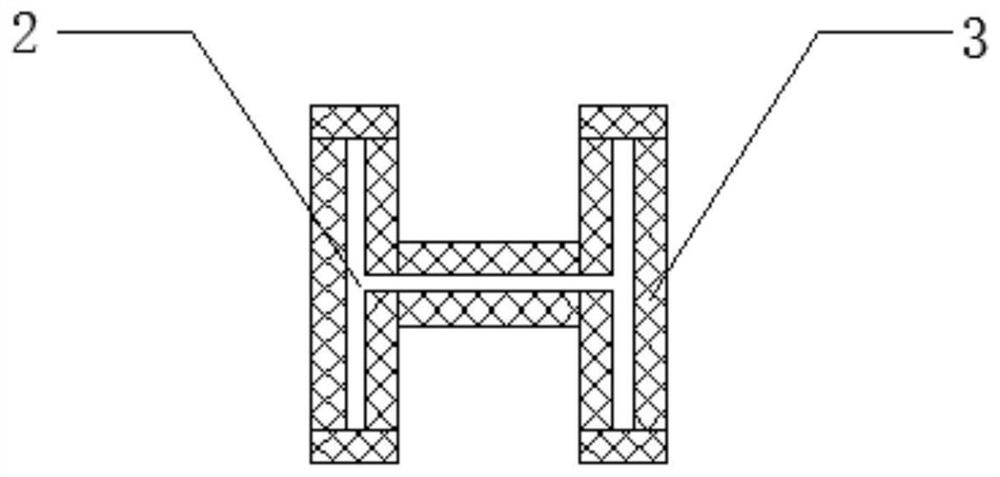

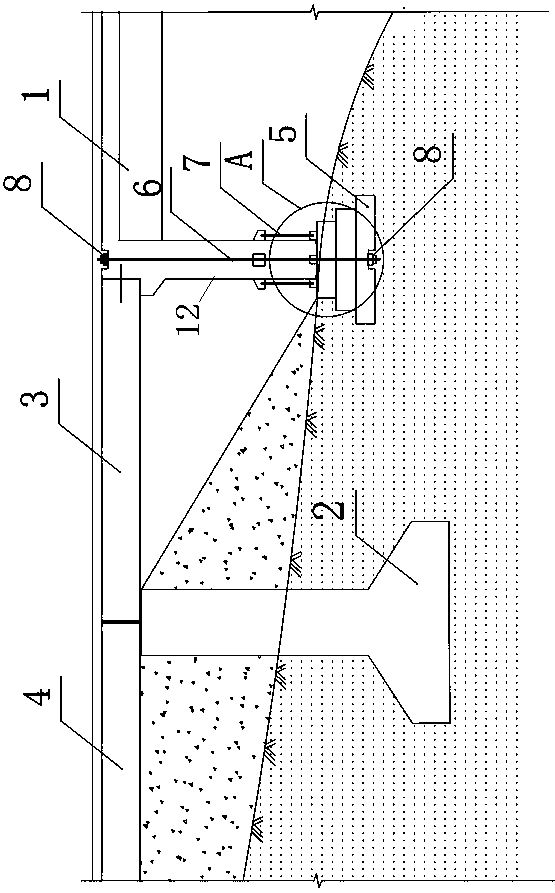

Structure which meets integral abutment pile-soil interaction boundary condition

The invention relates to a structure which meets the integral abutment pile-soil interaction boundary condition. The structure comprises a soil box and an MTS loader, and further comprises an H-shapedsteel pile and H-shaped steel beams; the soil box is fixed on a reaction floor; a reaction wall is arranged on the part, beside the soil box, on the reaction floor; the MTS loader is transversely arranged; the fixed end of the MTS loader is mounted on the reaction wall; the moving end of the MTS loader is connected with the H-shaped steel pile; the two H-shaped steel beams welded to the soil boxare symmetrically and transversely arranged on the parts, on the two sides of the H-shaped steel pile, of the upper portion of the soil box; the H-shaped steel pile is vertically arranged in the soilbox; flanges on the two sides of the upper end of the H-shaped steel pile are provided with pulleys; the inner sides of the flanges of the upper ends and the lower ends of the two H-shaped steel beamsare used as moving tracks of the pulleys on the same side of the flanges; the pulleys are in sliding fit with the flanges of the corresponding H-shaped steel beams; and the part, blow the pulleys, inthe soil box is filled with sand. The structure is convenient to construct, torsion of the H-shaped steel piles can be greatly reduced, and the accuracy of test results is significantly improved.

Owner:FUZHOU UNIV

Integral abutment bridge structure based on composite flexible piles and construction method thereof

InactiveCN104612142AImprove mechanical performanceEasy to crackClimate change adaptationBridge structural detailsLap jointCut and fill

The invention relates to the field of bridges, in particular to an integral abutment bridge structure based on composite flexible piles and a construction method thereof. The structure comprises an abutment horizontally arranged along a revetment, wherein the abutment is supported by the multiple vertical flexible piles embedded in the revetment, the flexible piles are composed of an ordinary concrete area embedded in the ground under the earth surface line and an ultra-high-performance fiber reinforced concrete composite material area connected to the ordinary concrete area, filling soil is stacked in the spaces between the abutment and the shoreside ground and between the flexible piles and the shoreside ground, approach slabs are laid on the filling soil, and the bear-abutment end of each approach slab is in lap joint with the end of a main beam arranged on the abutment. The structure aims to solve the problem that due to the fact that ordinary concrete piles are high in rigidity and poor in longitudinal-bridge-direction deformability and the tensile strength design value of ordinary concrete is small, concrete cracking can be caused easily under the external influence, or even fracture failure of the section of a pile foundation structure can be caused finally.

Owner:FUZHOU UNIV

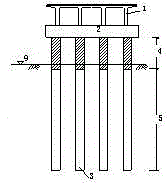

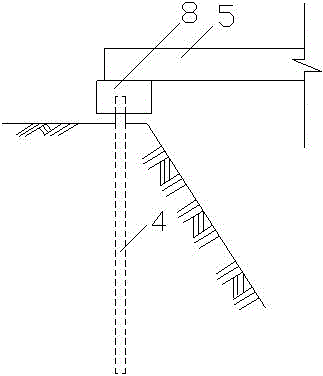

Abutment reaming hole construction for optimizing deformation capability of integral abutment bridge

InactiveCN104831618AGood deformabilityImprove deformation abilityBridge structural detailsEngineeringAbutment

The invention discloses an abutment reaming hole construction for optimizing deformation capability of an integral abutment bridge. The construction comprises an abutment reaming hole, a deformation layer and supporting piles. The abutment reaming hole is arranged at the supporting surface of the bottom part of an abutment. The lower ends of the supporting piles are buried in the ground, and the upper ends stretch into the abutment reaming hole. The tops of the piles support the abutment. The deformation layer is arranged between the abutment reaming hole and the supporting piles arranged in the hole. The mode of connection of the tops of the supporting piles and the abutment is rigid connection or flexible connection. The methods used in flexible connection include hinge connection and slide connection. The force bearing characteristic of the abutment reaming hole construction is optimized so that force bearing performance is guaranteed and deformation capability of the abutment bridge is enhanced.

Owner:FUZHOU UNIV

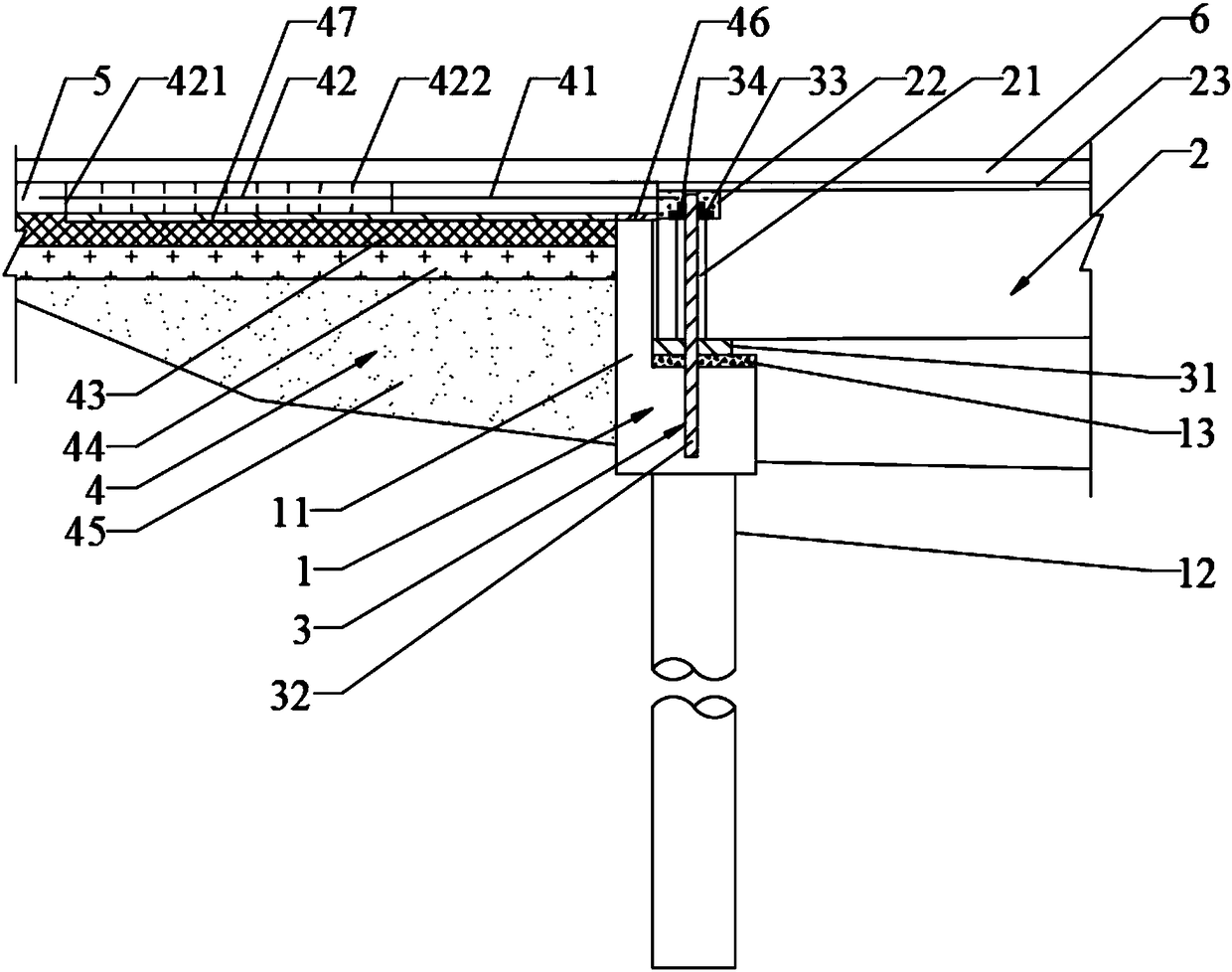

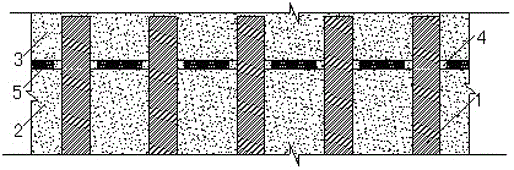

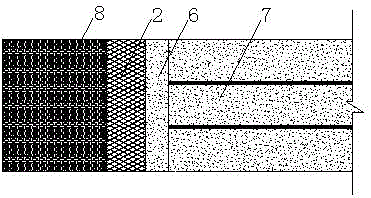

Semi-integral seamless bridge structure adapted to soft ground

ActiveCN106638256BReduce additional internal forceReduce dosageBridge structural detailsReinforced concreteBridge deck

The invention discloses a semi-integrated seamless bridge structure adaptive to a soft foundation. The semi-integrated seamless bridge structure comprises a main beam, piers, approach slabs and abutments, wherein the main beam and the approach slabs are connected into a whole, and the upper surface of the whole is sequentially paved with a bituminous concrete pavement layer, a waterproof layer and a leveling layer of a reinforced concrete pavement layer from top to bottom. Pavement steel bars are arranged in the reinforced concrete pavement layer. The main beam comprises a plurality of spans, a pull-press combined component is arranged between every two adjacent spans, and pull-press combined components are also arranged between the main beam and the approach slabs. Each pull-press combined component comprises a reinforcing steel bar, a PBL anti-shearing device perforated panel, a hole-penetrating steel bar, a pull-resisting top plate, a shallow embedded plate, deep embedded plates and a beam end trapezoidal lug pressing rod. The continuous main beam structure is simplified into the continuous pull-press combined components on a bridge deck, additional internal force brought by differential settlement to the structure is remarkably reduced, and material consumption is lowered; and meanwhile, side effects caused by adding of materials are avoided. The construction process and the structure form are simplified, the structure stress performance is improved, and the construction quality is easy to guarantee.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

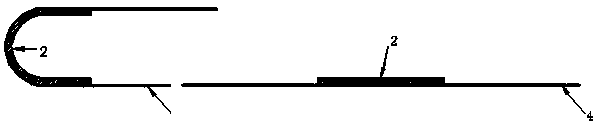

Novel integral abutment bridge with dog-bone shaped connecting structure and construction method

InactiveCN104562921AImprove longitudinal deformation abilityGuaranteed vertical bearing capacityBridge structural detailsBridge erection/assemblyFatigue damageRubber material

The invention discloses a novel integral abutment bridge with a dog-bone shaped connecting structure and construction method. The bridge comprises an end beam, a pile cap and an H-shaped supporting steel pile; a weak shaft of an H-shaped steel pile body is bent; the pile cap is connected with the end beam by the dog-bone shaped connecting structure, wherein the dog-bone shaped connecting structure is that a compressing rubber material fills in a connecting clearance between the pile cap and the end beam, and the pile cap and the end beam are connected through the H-shaped steel pile. According to the bridge, the H-shaped steel pile can bear the vertical load through the surface friction and even the end part, and moreover, the characteristics that the lateral rigidity of the weak shaft is low is utilized well; the rigidity of the connecting part is reduced by the dog-bone shaped connecting structure between the pile cap and the end beam, thus the rotating capacity of the connecting part is improved, the longitudinal deformation capacity of the bridge is increased, the allowable length of the bridge of the type is raised, a pile foundation is avoided excessive lateral displacement, the vertical bearing capacity of the pile is ensured, the internal force of the pile body is decreased, the fatigue damage of the temperature deformation of the bridge to the pile body is reduced, and as a result, the service life of the bridge is prolonged.

Owner:FUZHOU UNIV

Integral abutment based on corrugated steel plates and construction method thereof

PendingCN111155422AGuaranteed vertical bearing capacityProper connectionBridge structural detailsBridge erection/assemblyArchitectural engineeringAbutment

The invention discloses an integral abutment based on corrugated steel plates and a construction method of the integral abutment, the integral abutment comprises a box girder and a plurality of abutment foundations for supporting the box girder, the box girder comprises a concrete top plate, a concrete bottom plate and corrugated steel webs, and the corrugated steel webs are respectively connectedwith the concrete top plate and the concrete bottom plate; the corrugated steel webs are connected with the abutment foundation through the corrugated steel plate sets, and / or the bottom ends of thecorrugated steel webs directly extend downwards and are inserted into the bridge piers. Each corrugated steel plate set comprises a plurality of parallel corrugated steel plates. The construction method comprises the steps of manufacturing the corrugated steel webs in a factory, constructing pile foundations and abutment foundations, constructing corrugated steel plates, constructing box girder sections at the upper part of the abutment, constructing end cross beams, constructing corrugated steel web combined box girder sections, constructing box girder closure sections and the like. The integral abutment provided by the invention not only has large vertical bearing capacity, but also has proper horizontal displacement.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

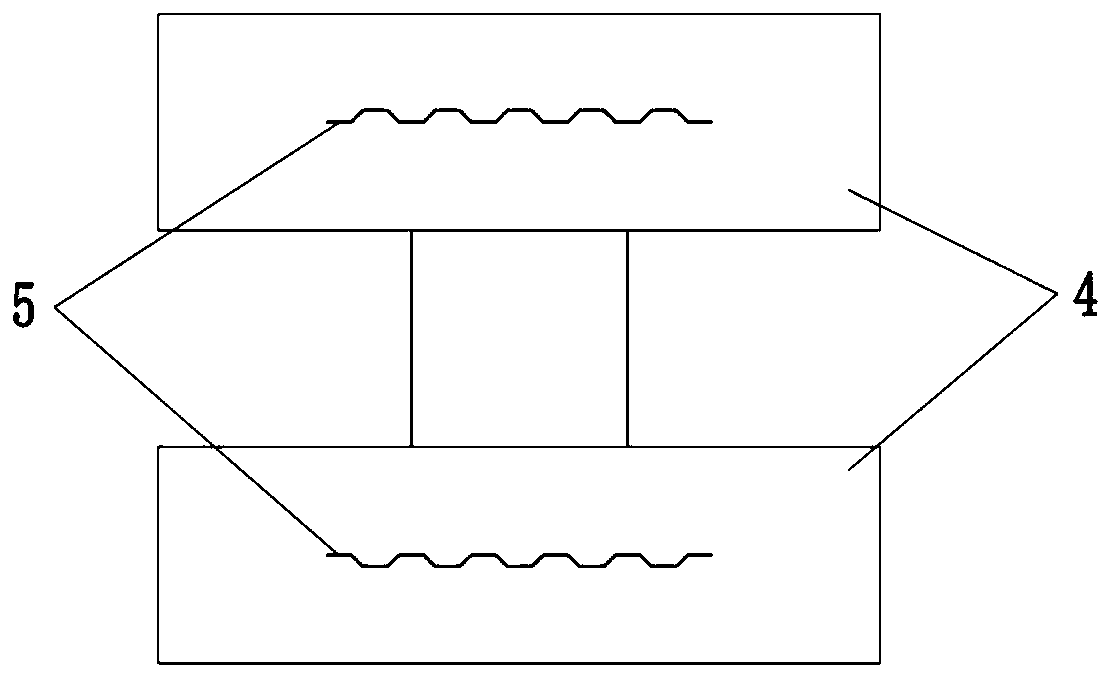

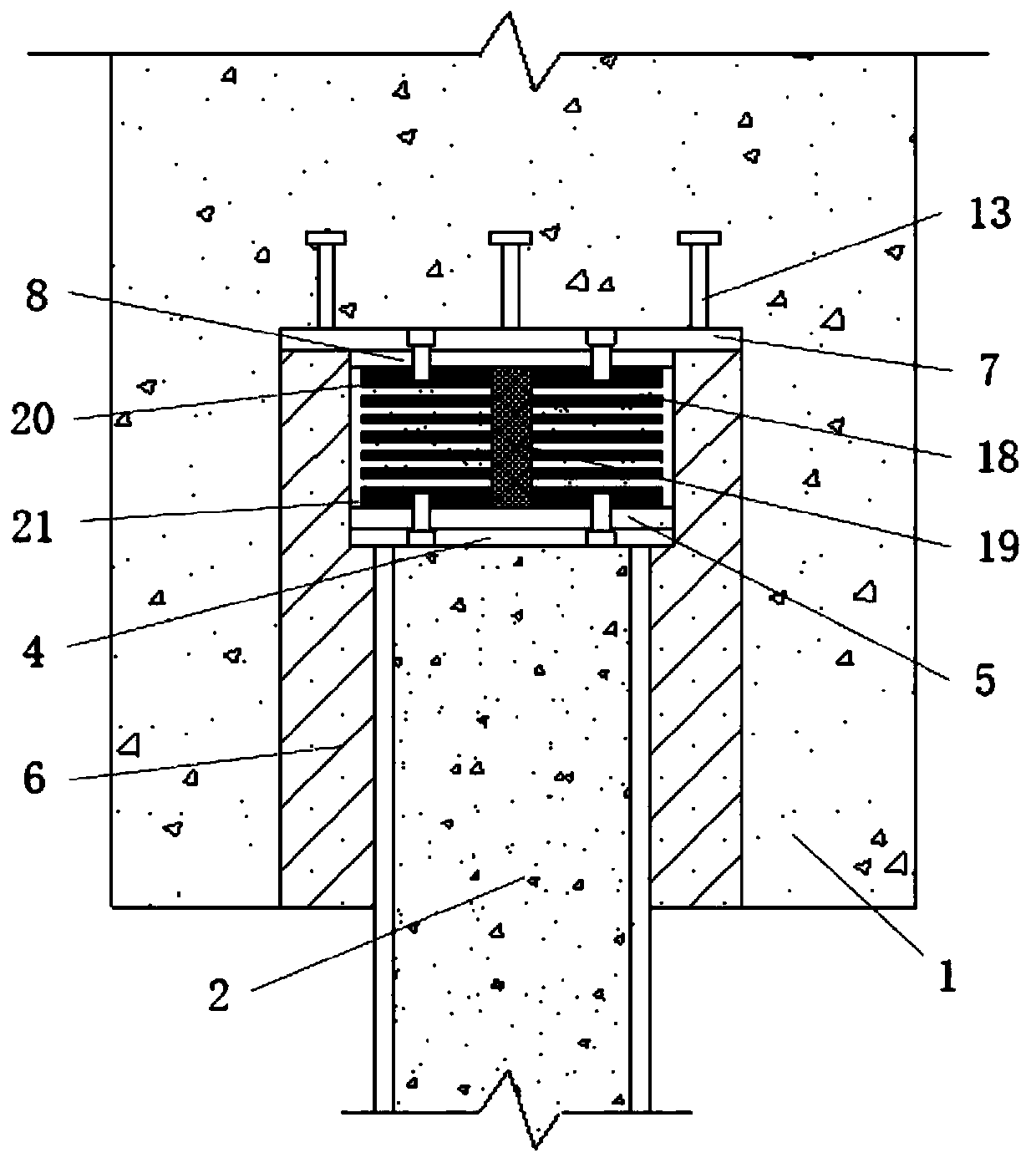

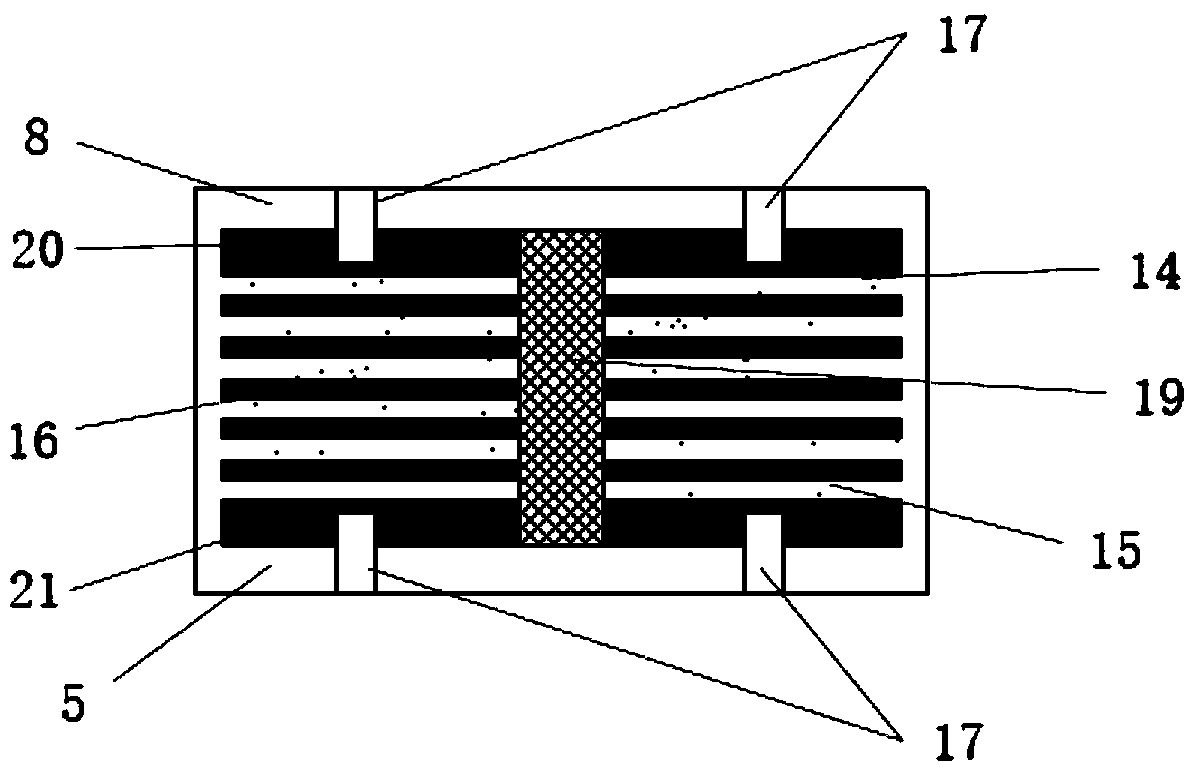

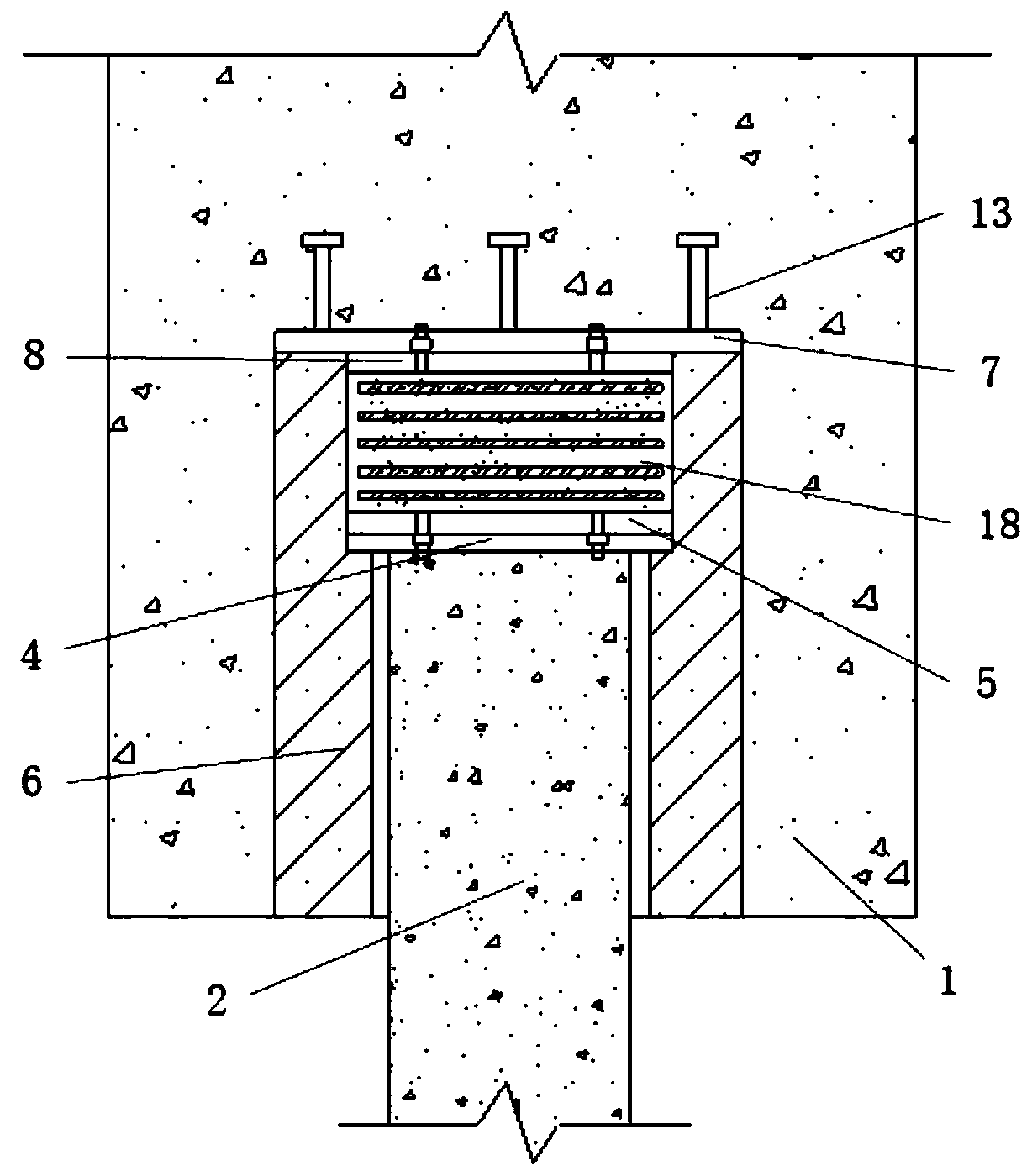

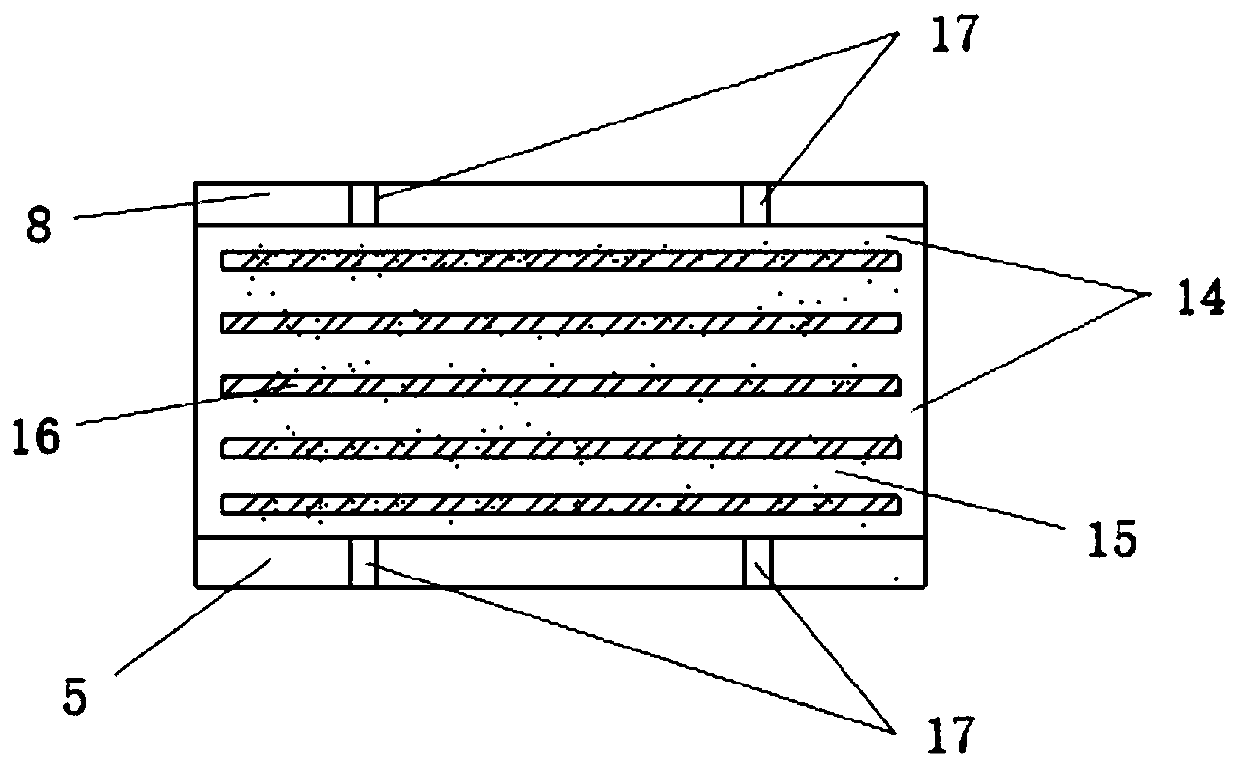

Integral abutment-steel pipe concrete pile joint of lead core laminated rubber device

PendingCN111005305AIncrease elasticityPromote absorptionBridge structural detailsBulkheads/pilesRubber sheetIntegral abutment

The invention relates to an integral abutment-steel pipe concrete pile joint of a lead core laminated rubber device. The integral abutment-steel pipe concrete pile joint comprises a concrete abutmentand a steel pipe concrete pile, the integral abutment-steel pipe concrete pile joint is characterized in that a lead core laminated rubber device is arranged at the top of the steel pipe concrete pile, the lead core laminated rubber device comprises laminated rubber and at least one lead core, the laminated rubber is formed by alternately laminating rubber sheets and stiffening steel plates in alayered mode, and a hole used for containing the lead core is formed in the laminated rubber. The invention further provides a construction method of the joint. The joint deformation capacity and theenergy absorption capacity can be improved, the joint deformation recovery time is shortened, and post-earthquake residual displacement is reduced.

Owner:TIANJIN UNIV

Seamless curved bridge adopting semi-rigid integral abutments

The invention relates to the field of bridge construction, in particular to a seamless curved bridge adopting semi-rigid integral abutments. The seamless curved bridge comprises the abutments, a girder and semi-rigid structures connecting the abutments with the girder, each abutment comprises an abutment cap and a pile foundation arranged below the abutment cap, a groove with an upward opening isformed in each abutment cap, a support cushion stone is arranged in each groove, protrusions matched with the grooves are arranged at the lower end of the girder, and the girder is arranged on the support cushion stones of the grooves through the protrusions; and each semi-rigid structure comprises a rubber spacer, a steel rod, a steel plate and bolts, and each rubber spacer is arranged between the corresponding support cushion stone and the girder. The seamless curved bridge has the beneficial effects that the structural design is simple, transverse bridge direction shearing force and deformation generated in the jointing position of the girder and a lap-joint plate can be effectively avoided, and the anti-seismic performance of the seamless curved bridge can be improved as well.

Owner:FUJIAN UNIV OF TECH

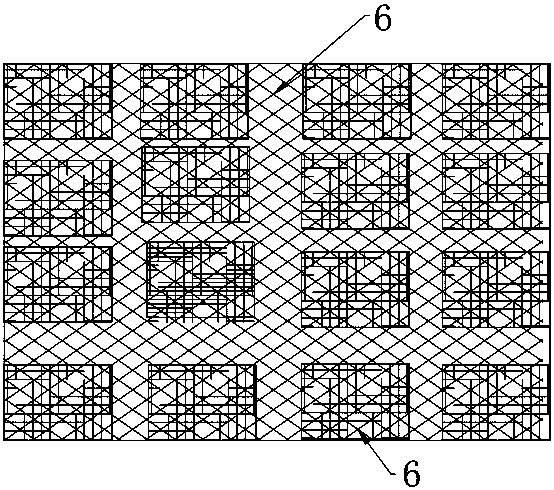

Integral abutment structure and construction method of earth pressure and filling settlement behind console

InactiveCN106638280BIncrease stiffnessPrevent collapseRoadwaysBridge structural detailsArchitectural engineeringAbutment

The invention relates to an integrated bridge abutment structure for controlling earth pressure behind an abutment and filled earth settlement and a construction method. The integrated bridge abutment structure comprises an abutment body and a lapping plate, wherein an upper filled earth layer and a lower filled earth layer which are reinforced and firmed by a plurality of layers of geogrids are laid above and below the lapping plate respectively in the vertical direction, the upper filled earth layer upward extends to be laid on the road surface, and the lower filled earth layer downward extends to be laid on the abutment. A first gap is reserved between the upper filled earth layer and the lower filled earth layer and the surface of the lapping plate and the surface of the abutment body respectively. An end opening formed in the upper horizontal end of the lapping plate is in rigid connection with the abutment body. The end portion of the lower horizontal end of the lapping plate is sealed by a rectangular steel sleeve, a second gap is reserved between the inner side of the rectangular steel sleeve and the outer side of the lower horizontal end of the lapping plate and is filled with a rubber layer immersed with grease, and the outer surface of the rectangular steel sleeve is coated with an anticorrosive coating. The integrated bridge abutment structure utilizes good deformation of the lapping plate and reinforcement and firming of the geogrids, is good in integrity, improves pavement strength and effectively controls settlement behind the integrated bridge abutment.

Owner:FUZHOU UNIV

Construction method of integral abutment bridge with dog-bone connection structure

InactiveCN104562921BImprove longitudinal deformation abilityGuaranteed vertical bearing capacityBridge structural detailsBridge erection/assemblyFatigue damageRubber material

The invention discloses a novel integral abutment bridge with a dog-bone shaped connecting structure and construction method. The bridge comprises an end beam, a pile cap and an H-shaped supporting steel pile; a weak shaft of an H-shaped steel pile body is bent; the pile cap is connected with the end beam by the dog-bone shaped connecting structure, wherein the dog-bone shaped connecting structure is that a compressing rubber material fills in a connecting clearance between the pile cap and the end beam, and the pile cap and the end beam are connected through the H-shaped steel pile. According to the bridge, the H-shaped steel pile can bear the vertical load through the surface friction and even the end part, and moreover, the characteristics that the lateral rigidity of the weak shaft is low is utilized well; the rigidity of the connecting part is reduced by the dog-bone shaped connecting structure between the pile cap and the end beam, thus the rotating capacity of the connecting part is improved, the longitudinal deformation capacity of the bridge is increased, the allowable length of the bridge of the type is raised, a pile foundation is avoided excessive lateral displacement, the vertical bearing capacity of the pile is ensured, the internal force of the pile body is decreased, the fatigue damage of the temperature deformation of the bridge to the pile body is reduced, and as a result, the service life of the bridge is prolonged.

Owner:FUZHOU UNIV

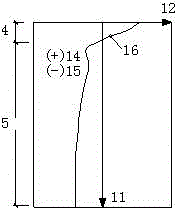

Integral abutment-H-shaped steel pile node anti-seismic structure locally using rubber concrete

PendingCN112176851AOverall small sizeStrong penetrating powerBridge structural detailsFoundation engineeringEarthquake resistanceCrack resistance

The invention discloses an integral abutment H-shaped steel pile node anti-seismic structure locally using rubber concrete, which comprises an abutment and an H-shaped steel pile embedded into the abutment along the length of the abutment, and the rubber concrete embedded into the concrete abutment is poured on the periphery of the top of the H-shaped steel pile. And the strength of the rubber concrete is basically consistent with that of concrete forming the abutment. Ordinary concrete can be alternately arranged with the rubber concrete in the length direction of the abutment, or corrugatedsleeves are arranged between the rubber concrete and the side face of the abutment. According to the integral abutment H-shaped steel pile node anti-seismic structure, the rotating capacity of the integral abutment H-shaped steel pile node is improved, the lateral rigidity is reduced, the allowable horizontal displacement of a top structure in the longitudinal direction of a bridge is increased, the ductility and crack resistance of concrete at the integral abutment H-shaped steel pile node are improved, and the anti-seismic property of the node is improved. The use of the rubber concrete is beneficial to solving the problems of environmental protection and resource shortage caused by waste rubber, and the social effect is remarkable.

Owner:TIANJIN UNIV

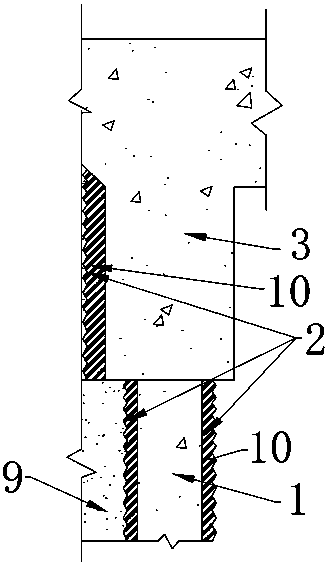

Integral bridge abutment structure for controlling subsidence of abutment backfill and construction method of integral bridge abutment structure

PendingCN112900243AReduce lateral earth pressureIncreased allowable value for horizontal lateral deformationBridge structural detailsBridge erection/assemblyBridge engineeringAbutment

The invention relates to improvement of an integral bridge abutment structure in bridge engineering, in particular to an integral bridge abutment structure for controlling subsidence of abutment backfill and a construction method of the integral abutment structure. The integral bridge abutment structure comprises a concrete pile foundation, a bridge abutment and an approach slab connected with the bridge abutment, wherein a corrugated metal plate is fixed to the rear surface layer of the bridge abutment, a plurality of layers of foam plates are laid upwards in the vertical direction between the approach slab and compacted abutment backfill and tightly attached to the corrugated metal plate, and a filling soil layer with the thickness of 20-30 cm is laid on each layer of foam plate. And the filling height of the foam plates and the filling layer is consistent with the height of the bridge abutment. According to the novel structure, the horizontal deformation capacity of the bridge under the action of temperature and earthquake load is greatly improved while settlement of the abutment backfill is effectively controlled.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

Improved integral abutment-H-shaped steel pile node anti-seismic structure adhered with rubber plates

PendingCN112176852AImprove the rotation effectIncrease horizontal displacementBridge structural detailsFoundation engineeringEarthquake resistanceAbutment

The invention discloses an improved integral abutment H-shaped steel pile joint anti-seismic structure adhered with rubber plates. The structure comprises an abutment and an H-shaped steel pile, the upper portion of the H-shaped steel pile is embedded into the abutment along the length of the abutment, and the rubber plates are arranged between the H-shaped steel pile embedded into the abutment and the abutment. The abutment is a concrete bridge abutment formed by concrete poured on the peripheries of the rubber plates. And the rubber plates are adhered to the peripheries of webs and flange plates of the H-shaped steel piles embedded into the abutment. The depth of the H-shaped steel pile embedded into the concrete bridge abutment is determined according to sufficient anchoring provided for the H-shaped steel pile. The node anti-seismic structure allows the steel piles and the abutment to relatively rotate to a certain degree, and the allowable longitudinal horizontal displacement of the top structure is increased. According to the node anti-seismic structure, the vertical bearing capacity can be guaranteed, meanwhile, the lateral rigidity is reduced, the structural ductility is improved, the longitudinal-bridge-direction horizontal displacement of the bridge body can be well absorbed, and the anti-seismic property and the energy consumption property of the node are improved.

Owner:TIANJIN UNIV

An abutment reaming structure for optimizing the deformation capacity of integral abutment bridges

InactiveCN104831618BGood deformabilityImprove deformation abilityBridge structural detailsAbutmentSupport surface

The invention discloses an abutment reaming hole construction for optimizing deformation capability of an integral abutment bridge. The construction comprises an abutment reaming hole, a deformation layer and supporting piles. The abutment reaming hole is arranged at the supporting surface of the bottom part of an abutment. The lower ends of the supporting piles are buried in the ground, and the upper ends stretch into the abutment reaming hole. The tops of the piles support the abutment. The deformation layer is arranged between the abutment reaming hole and the supporting piles arranged in the hole. The mode of connection of the tops of the supporting piles and the abutment is rigid connection or flexible connection. The methods used in flexible connection include hinge connection and slide connection. The force bearing characteristic of the abutment reaming hole construction is optimized so that force bearing performance is guaranteed and deformation capability of the abutment bridge is enhanced.

Owner:FUZHOU UNIV

Integral bridge multistage abutment flexible main abutment with replaceable dampers and application thereof

PendingCN110904825AAvoid damageIncrease power consumptionBridge structural detailsEarthquake resistanceArchitectural engineering

The invention relates to an integral bridge multistage abutment flexible main abutment with replaceable dampers. The integral bridge multistage abutment flexible main abutment comprises a main beam, aguide plate and a wiring road surface which are sequentially arranged. a main abutment and a rigid expanded foundation are sequentially arranged between the main beam and the guide plate from top tobottom, a secondary abutment is arranged between the guide plate and the wiring road surface, the main abutment and the rigid expanded foundation are pulled into a whole through prestressed tendons, and a plurality of dampers are arranged between the periphery of the main abutment and the rigid expanded foundation. The self-resetting capability and the anti-overturning capability of the integral abutment under the action of an earthquake are provided through the prestressed tendons. And meanwhile, the dampers are arranged between the main abutment and the rigid enlarged foundation, the lateralforce resistance is improved through the dampers, earthquake energy is consumed, and the dampers damaged after an earthquake can be replaced. The combination of the prestressed tendons and the dampers not only has good self-resetting capacity, but also has high consumption capacity, and damage to the abutment can be reduced to a certain extent. The method is suitable for the integral bridge withhigh requirements on deformation and anti-seismic property.

Owner:FUZHOU UNIV

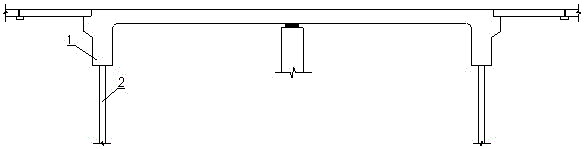

Method for arranging semi-integral hidden expansion joint for abutment and bridge girder

InactiveCN102061667BExtended service lifeImprove riding performanceBridge structural detailsBituminous waterproofingArchitectural engineering

The invention discloses a method for arranging a semi-integral hidden expansion joint for an abutment and a bridge girder, which comprises the steps of: first arranging a semi-integral abutment below the end of the bridge girder, arranging a sliding base on the abutment, and placing the end of a girder body on the sliding base, wherein the sliding base is independent from the abutment; arranging a crossbeam on the base in the girder body and pouring the crossbeam and the end of the girder body integrally and fastening the girder with the back wall; filling dam soil outside the back wall, arranging a butt strap on the dam soil and paving an asphalt waterproof layer on the butt strap and the bridge floor integrally; filling a foam material in the crack among the back wall, the dam soil and the semi-integral abutment; and finally arranging an effective drainage system in a position contacted with the dam soil, behind the semi-integral abutment. In the technical scheme, retraction devicesat both ends of the bridge girder are omitted and a soil filled structure is adopted to solve the problem caused by extension of the bridge girder, thereby greatly improving the driving smoothness, reducing the impact of vehicles and prolonging the service life of the bridge girder effectively.

Owner:河南省新开元路桥工程咨询有限公司

Semi-integral abutment bridge with energy-absorbing materials buried in multiple positions and its construction method

InactiveCN104594185BReduce resistanceReduce internal forceBridge structural detailsBridge erection/assemblyMulti siteEnergy absorption

The invention relates to a semi-integrated type bridge abutment bridge with multiple portions embedded with energy absorption materials and a construction method of the semi-integrated type bridge abutment bridge. The semi-integrated type bridge abutment bridge comprises a main girder. The main girder is connected with a bridge abutment. The bridge abutment comprises a lower bridge abutment body arranged on the lower portion of the main girder and used for supporting the main girder and an upper bridge abutment body connected with the end of the main girder. The upper bridge abutment body is connected with one end of a connection plate, and the other end of the connection plate is connected with a bridging slab. The joint of the connection plate and the bridging slab is provided with a corbel. The lower portions of the bridging slab, the connection plate and the corbel are provided with miniature piles respectively. The direction of the long edges or long shafts of the miniature piles should be perpendicular to the longitudinal deformation direction of the bridge. The pile length and section areas of the miniature piles at different positions are different from one another. The energy absorption materials are arranged among the bridge abutment, the miniature pile tops and the surrounding soil. The cross section of the energy absorption materials surrounding the miniature pile tops is square. The energy absorption materials between the bridge abutment and the soil behind the abutment are rectangular. By means of the bridge, the stress of the connection plate, the bridging slab and the bridge abutment is improved, the stability of the soil behind the bridge abutment is guaranteed, damage to miniature pile bodies is lowered, the longitudinal deformation ability of the bridge is not affected, and most importantly, the anti-seismic ability of the bridge is improved.

Owner:FUZHOU UNIV

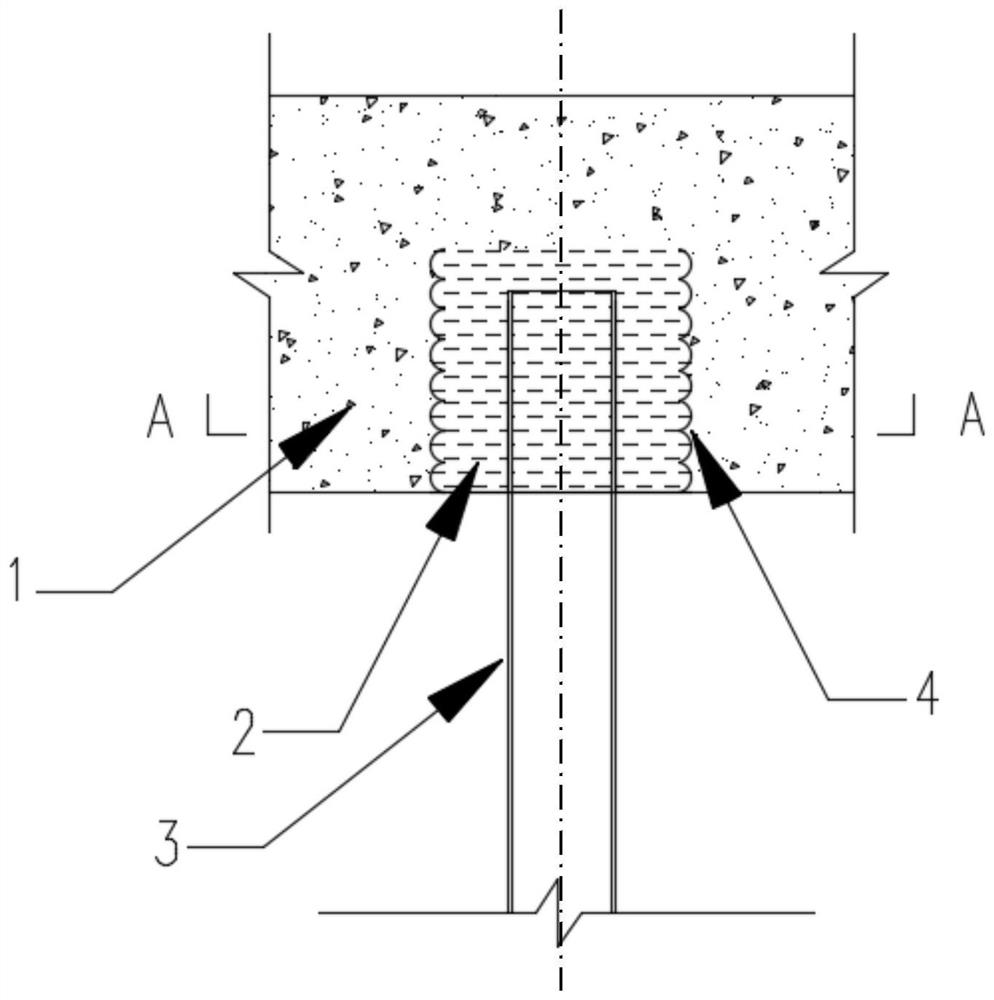

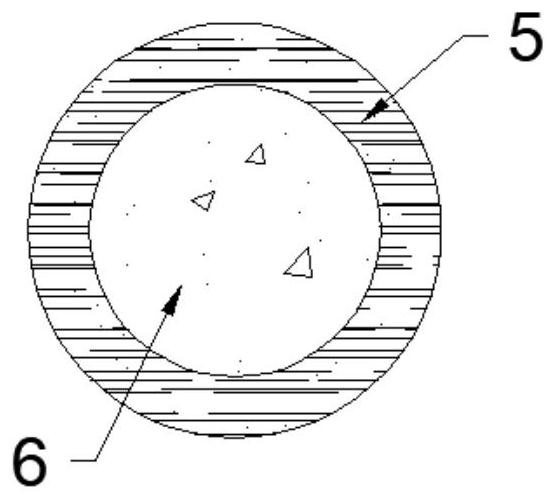

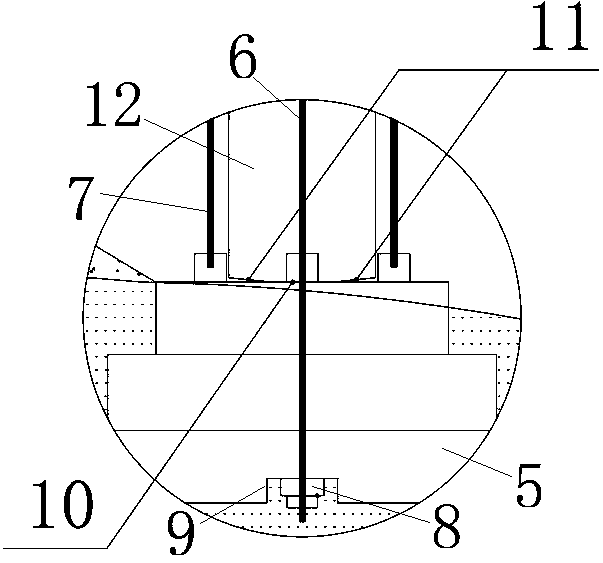

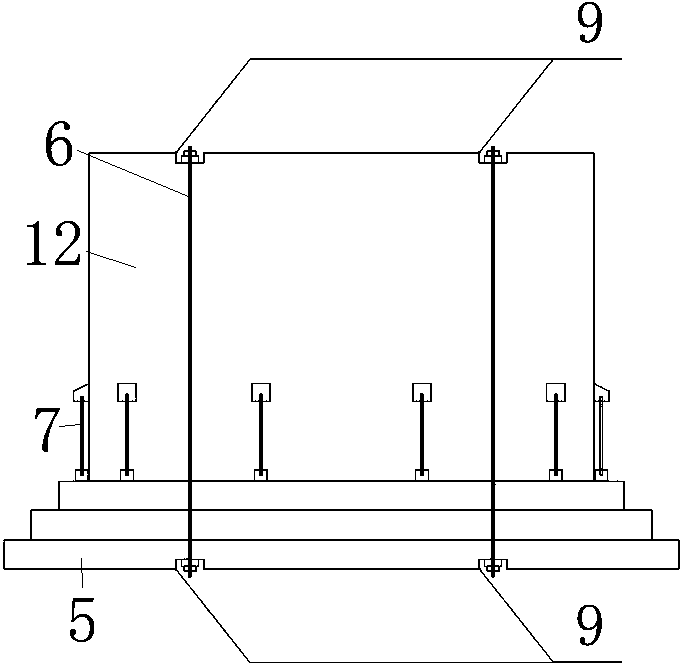

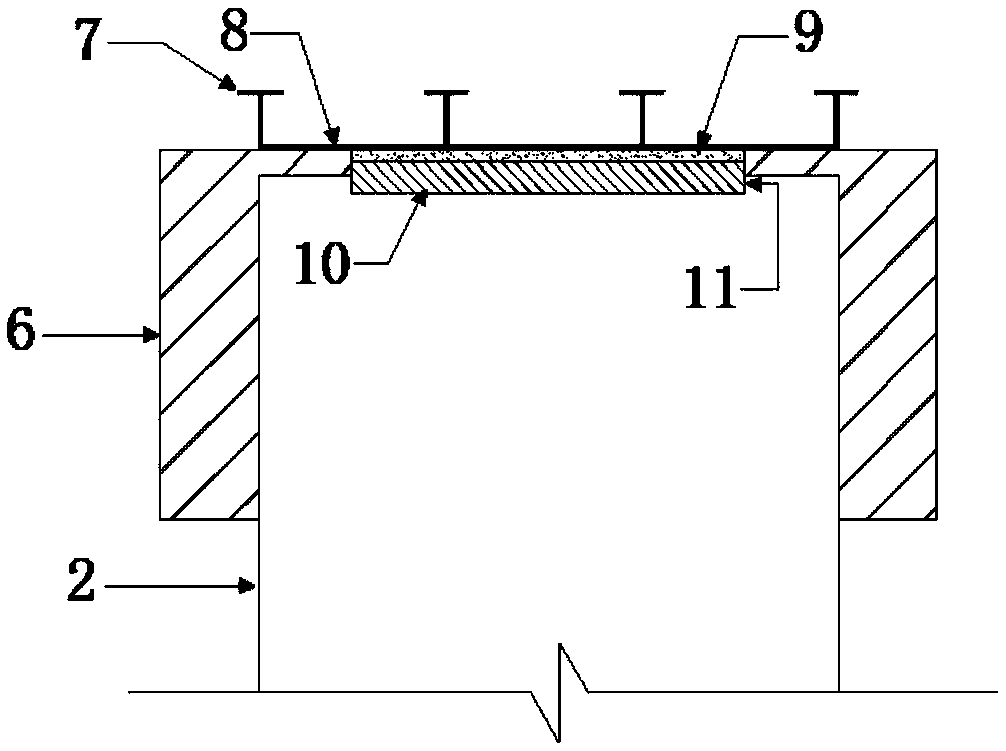

Integral abutment-concrete filled steel tube pile joint with laminated rubber and construction method

PendingCN110886192AImprove mechanical performanceReduce stiffnessBridge structural detailsBulkheads/pilesAbutmentRubber sheet

The invention relates to an integral abutment-concrete filled steel tube pile joint with laminated rubber. The integral abutment-concrete filled steel tube pile joint comprises a concrete bridge abutment and a concrete-filled steel tube pile, and is characterized in that a laminated rubber device is arranged at the top of the concrete-filled steel tube pile; the laminated rubber device comprises laminated rubber; and the laminated rubber is formed by alternately laminating rubber sheets and stiffening steel plates layer by layer. The invention further provides a construction method of the integral abutment-concrete filled steel tube pile joint. The integral abutment-concrete filled steel tube pile joint can improve the lateral displacement capacity of the abutment-pile joint.

Owner:TIANJIN UNIV

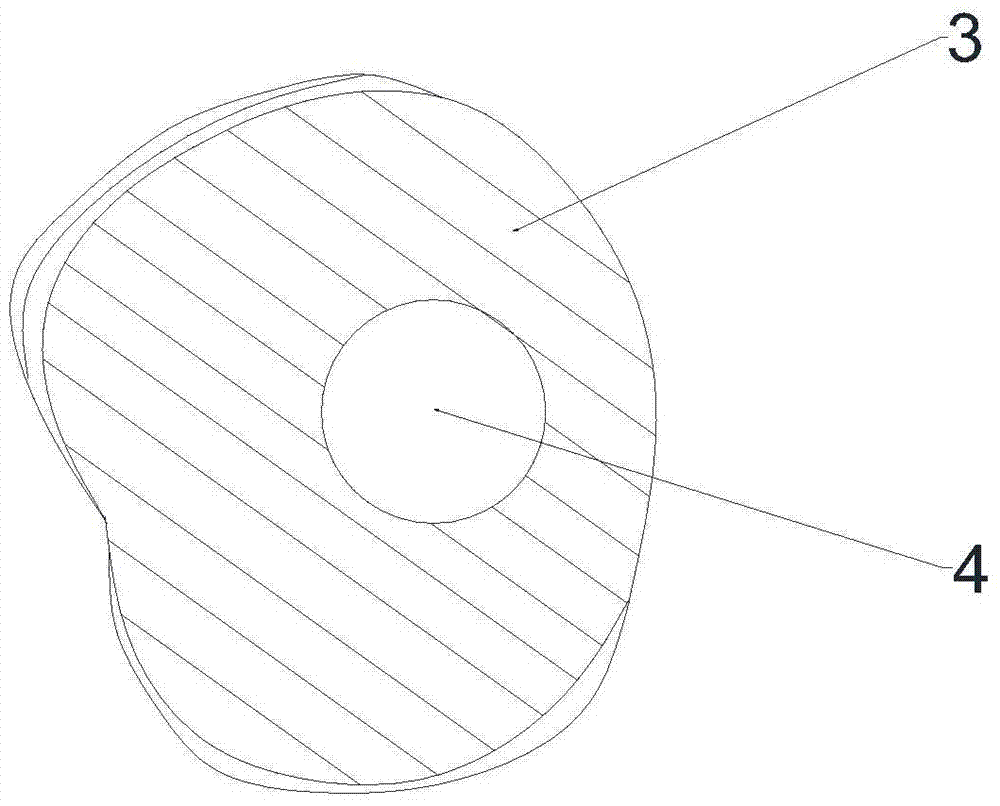

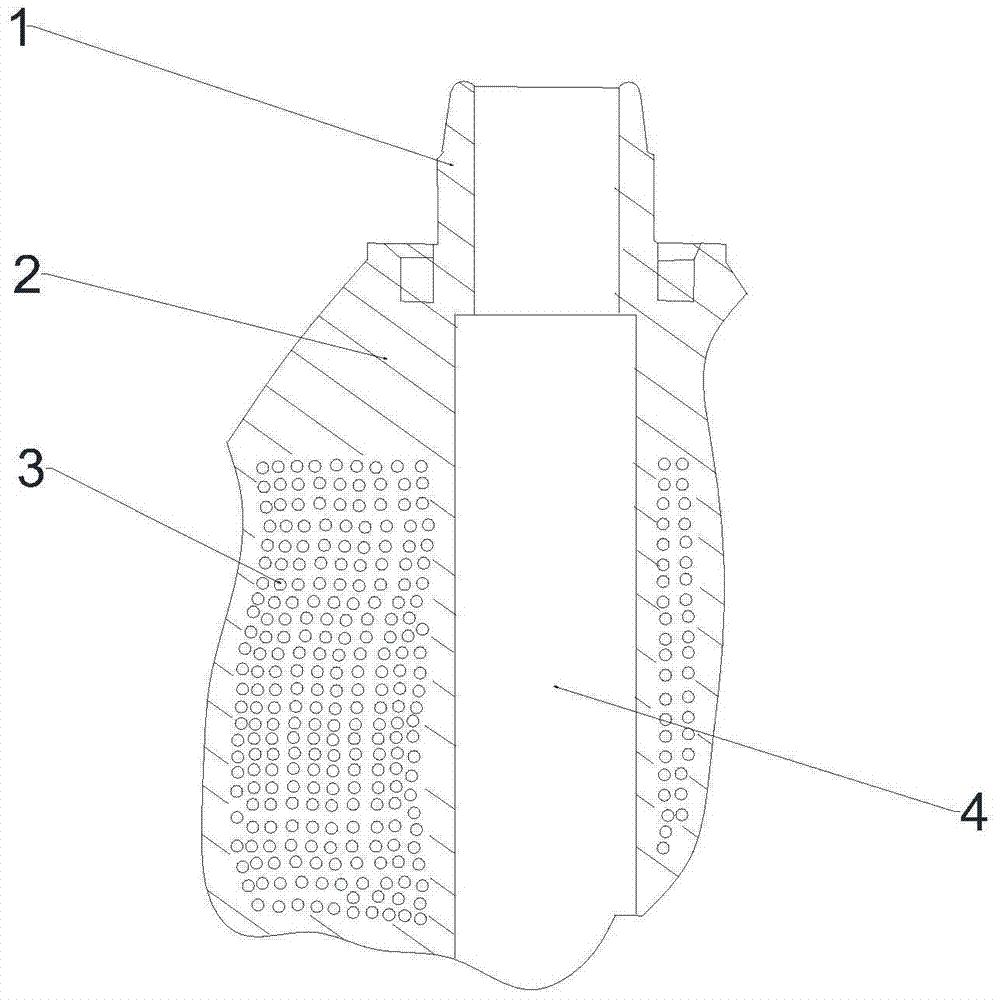

One-piece abutment and methods of making and using the same

ActiveCN104970893BImprove manufacturing precisionReduce scrap rateDental implantsDenturesEngineering

The invention relates to an integrated abutment, which comprises three parts from top to bottom: an implant connecting section for connecting implants, a gingival section, and a crown body for ceramics. The implant connecting section, The gingival segment and the crown body are integrally formed of the same material, and the one-piece abutment also includes screw holes that run through the implant connecting segment, the gingival segment, and the crown body. The shape and size of the crown body are close to or the same as those of the patient tooth. The interior of the crown body is a porous structure, and the porous structure extends from a space at a certain distance from the surface of the crown body to a certain distance from the inner hole surface of the screw hole. This invention overcomes the defect that the existing implant abutment cannot ensure the complete close contact between the metal crown cap and the connecting section of the crown and denture, so it has a simple structure and is easy to use, and can be directly placed on the crown body of the abutment Porcelain is used to realize the personalized customization of the abutment, which can effectively save costs.

Owner:FUJIAN CTRUE MATERIALS TECH

A monolithic abutment jointless bridge suitable for concrete rigid piles

PendingCN108978429AImprove deformation abilitySuitable for old bridge renovationBridge structural detailsCompressible materialSheet steel

A monolithic abutment jointless bridge suitable for concrete rigid piles is characterized in that the lower end of the abutment and the upper end of the pile foundation are slidably connected througha sliding connection structure; The sliding connection structure comprises a compressible material, a cushion block, a sliding layer, a thin steel plate and a stud. A layer of compressible material isadhered on four sides of the top of the pile foundation, and a shallow notch is reserved in the top center of the pile foundation. A cushion block is arranged in the shallow notch, and the length andwidth of the cushion block are consistent with the length and width of the shallow notch; A sliding layer is coated on that cushion block, and the upper surface of the sliding layer and the upper surface of the compressible material are at the same horizontal position; A thin steel plate is arranged above the sliding layer; A plurality of bolts are welded on the upper surface of the thin steel plate. The invention provides an integral abutment seamless bridge suitable for concrete rigid piles, which allows the abutment to slide and rotate on the top of the pile by being provided with a sliding connection configuration at the joint of the abutment and the concrete pile, thereby releasing the restraint.

Owner:ZHEJIANG UNIV OF TECH

An Integral Abutment Seamless Bridge Using Double-layer Concrete Steel Tube Flexible Pile

InactiveCN104060522BHigh compressive strengthImprove toughnessBridge structural detailsBulkheads/pilesEconomic benefitsAbutment

The invention relates to an integrated seamless abutment bridge applying a double-layer flexible concrete-filled steel tube pile. The integrated seamless abutment bridge comprises a main beam of a bridge body and a concrete-filled steel tube pile body inserted into the ground surface, wherein the section of the pile body is of a flat structure; the pile body comprises an inner steel tube and an outer steel tube which sleeves the periphery of the inner steel tube; concrete is poured into a cavity formed between the outer circumferential wall of the inner steel tube and the inner circumferential wall of the outer steel tube; the minor axis direction of the pile body is perpendicular to the length direction of the main beam. According to the integrated seamless abutment bridge applying the double-layer flexible concrete-filled steel tube pile, the compressive strength and the toughness of the concrete are improved; meanwhile, the local buckling of the steel tubes can be avoided or delayed by virtue of the concrete, the vertical bearing capacity is ensured, the lateral push resistance rigidity is low to the greatest extent, the lateral rigidity is reduced, the horizontal longitudinal displacement of the bridge body can be well absorbed, the anti-seismic property and the dissipation property of the pile are improved, the dead weight is reduced, the fire resistance is improved, the construction is simplified, and the integrated seamless abutment bridge has better economic benefits.

Owner:FUZHOU UNIV

Expansion-joint-free bridge and construction method

PendingCN110886197AEliminate bending momentImprove bending abilityBridge structural detailsExpansion jointIntegral abutment

The invention relates to an expansion-joint-free bridge and a construction method. The expansion-joint-free bridge comprises a bridge deck slab, an integral abutment, and a main beam, wherein the integral abutment comprises a first connecting column, a second connecting column, a connecting assembly and a pile foundation; the first end of the first connecting column is fixed to the pile foundation; the second end of the first connecting column and the second end of the second connecting column are connected through the connecting assembly; the connecting assembly comprises an arch part, and the arch part is provided with an arc surface; and the main beam is connected with the second connecting column and the bridge deck slab. The expansion-joint-free bridge construction method comprises the steps that a first connecting column is fixed to a pile foundation; the main beam is fixed to a second connecting column; the second connecting column is connected with the first connecting column through a connecting assembly; the connecting assembly comprises an arch-shaped part, and the arch-shaped part is provided with an arc-shaped face, and the second connecting column can swing along thearc-shaped face relative to the first connecting column; a bridge deck slab is poured; gaps among the first connecting column, the connecting assembly and the second connecting column are sealed and solidified; and the end beam is poured. The expansion-joint-free bridge and the construction method are high in the horizontal deformation resistance.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Method of Improving Mechanical Performance of Integral Abutment Support Pile Using H-type Concrete Pile

The invention relates to a method for improving integral type seamless bridge and bridge abutment pile foundation stress performance by an H-shaped concrete pile, and belongs to the field of bridges. The method comprises the following steps that (1) a sustaining pile is simulated through a finite element software and compared with an experiment pile, under the condition that the sustaining pile is in accordance with the experiment pile, the section of the sustaining is designed to an H-shaped section which enables a pile body to have optimal stress performance, and the strong axis and the weak axis of the H-shaped section are clear; (2) concrete with super high toughness is prepared; (3) moulding and bar laying are carried out, a concrete sustaining pile with super high toughness is divided into multiple units to be prefabricated, the end section of each unit is in a rectangular shape, and the middle section of each unit is in an H shape; (4) the multiple units are connected into a whole through connecting steel plates and bolts, the connecting position gradually changes from the solid rectangular section segment to the H-shaped section segment, and multiple threaded rods stretches out and at least stretches into the one fourth position of the next unit; (5) multiple threaded shearing nails are arranged on the pile head of the sustaining pile, and cast-in-place is carried out on the whole bridge abutment. The method can effectively reduce the horizontal anti-thrust rigidity of the pile, significantly increase the durability of the pile, and save the high maintenance cost.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com