Method of Improving Mechanical Performance of Integral Abutment Support Pile Using H-type Concrete Pile

An integral abutment and concrete pile technology, which is applied in sheet pile walls, buildings, and foundation structure engineering, can solve the problems of reduced horizontal thrust stiffness durability, large horizontal thrust stiffness, and pile cracks, etc., and achieves increased Durability, low push resistance flexibility, and reduced push resistance stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

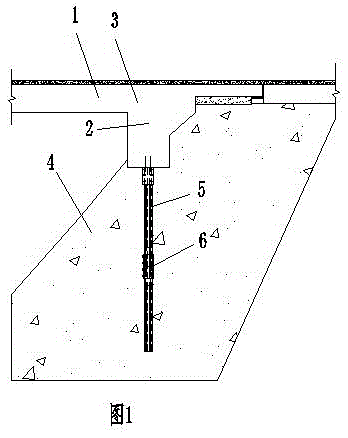

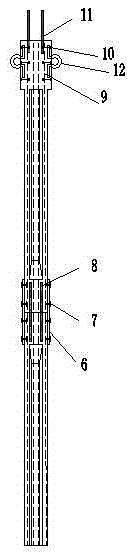

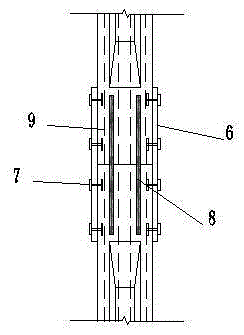

[0034] refer to Figure 1 to Figure 7

[0035] A method for improving the stress of integral abutment support piles with ultra-high toughness concrete piles, comprising the following steps:

[0036] 1) The support pile is simulated by finite element software and compared with the experimental pile. If the two are consistent, the support pile section is designed as an H-shaped section with the best mechanical performance of the pile body. The strength and weakness axes of the H-shaped section are clear;

[0037] 2) Preparation of ultra-high toughness concrete;

[0038] 3) Formwork, reinforcement, and ultra-high toughness concrete support piles are divided into multi-unit prefabrication, and the end section of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com